Liquid sulphur degassing device and liquid sulphur degassing method

A liquid sulfur degassing and liquid sulfur technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as increased consumption of additives, impact on product quality, and difficulty in operation, so as to improve recovery and production efficiency. The effect of high, low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

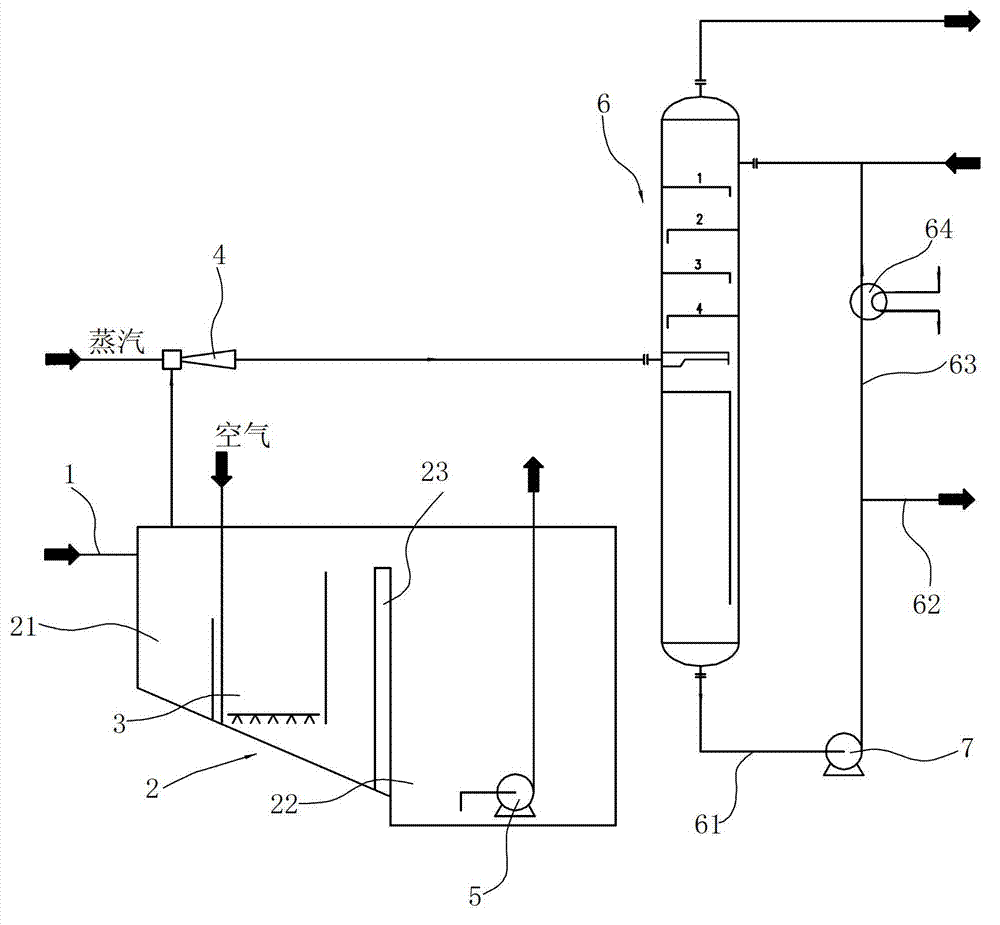

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The liquid sulfur degassing device includes:

[0025] The liquid sulfur pipeline 1 is used to transport the liquid sulfur to be treated, one end of which is connected to the liquid sulfur discharge end of the sulfur recovery device, and the other end is inserted into the gas stripping tank 21 so that its outlet is close to the bottom of the gas stripping tank 21.

[0026] The liquid sulfur pool 2 includes a gas stripping pool 21 and a finished product pool 22 . The depth of the air stripping pool 21 in this embodiment is less than the depth of the finished product pool 22, and the bottom surface of the air stripping pool 21 is an inclined structure, that is, it is inclined downward from the outside of the air stripping pool 21 to the finished product pool 22, so that the liquid sulfur The deposition of solid sulfur in the medium. An o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com