Patents

Literature

378results about How to "Reduce efflux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet coke-quenching aerial fog processing method and device based on non-thermal plasma injection

InactiveCN101486017AReduce the amount of pollutantsPrevent diverted emissionsCombination devicesCoke quenchingWater vaporHigh pressure

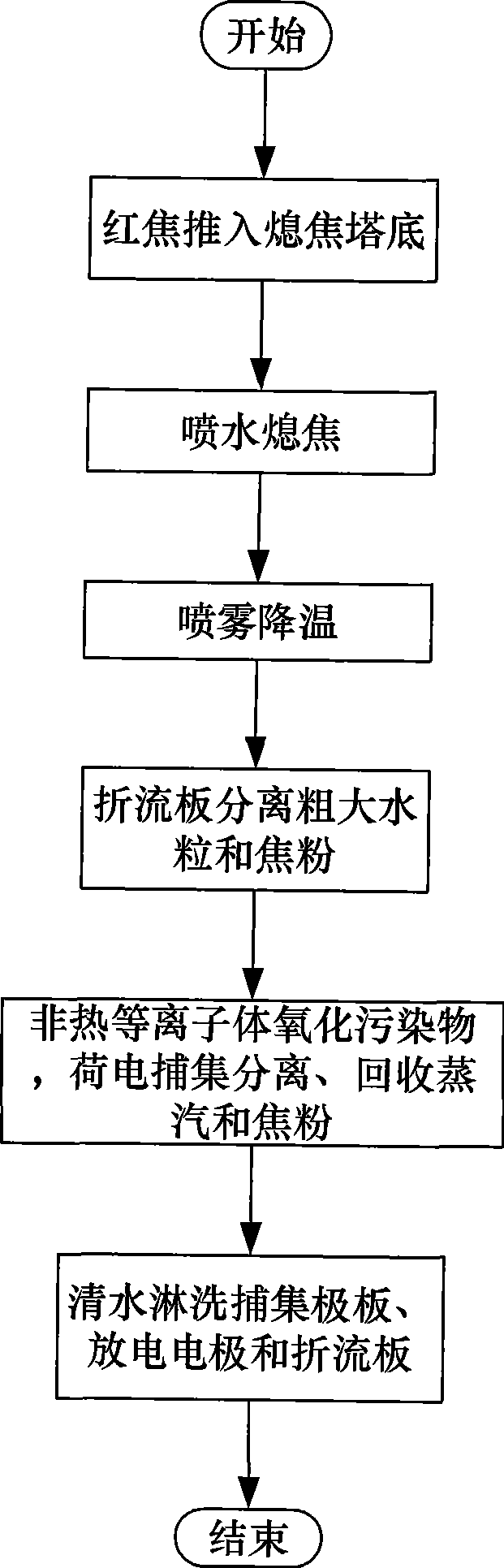

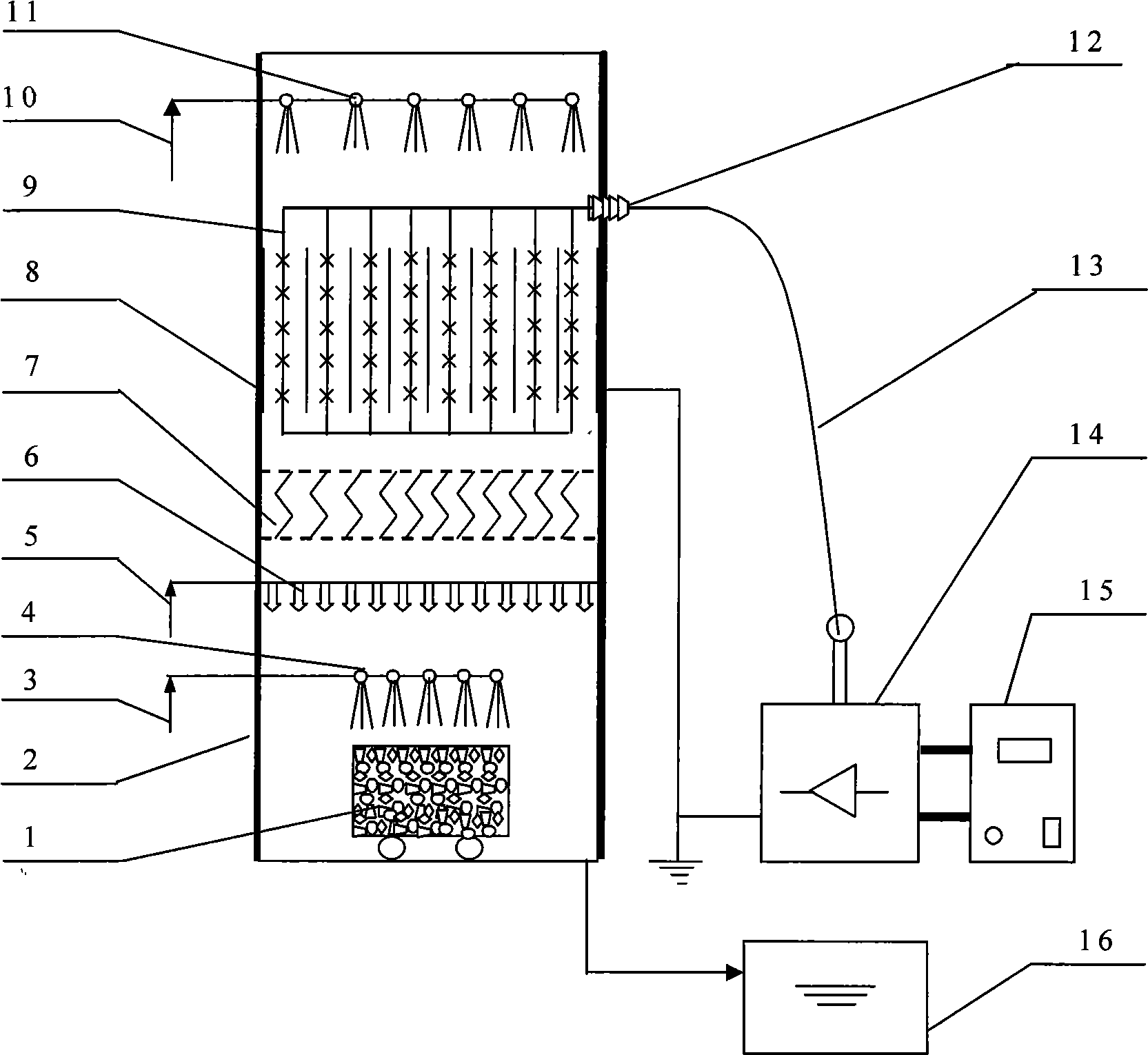

The invention discloses a method and a device for processing wet quenching coke gas fog on the basis of athermal plasma injection. The method comprises the following steps that: in the ascending process, the hot gas fog generated by wet quenching coke sequentially passes through three processing steps including spray cooling, pre-dedusting on a baffle plate and athermal plasma purification, and is cooled in a spray cooling area; the cooled gas fog enters a pre-dedusting area on the baffle plate where the thicker and bigger water particles and coke powder in the gas fog are separated from the gas fog and impact to the baffle plate under the action of inertia; the remaining gas fog continues to ascend and enter an athermal plasma purification area where organic components, ammonia nitrogen and cyanide in the gas fog are oxidized by the athermal plasma; the water particles and the coke powder are charged and are transferred to a trapping pole plate directionally under the action of a high voltage electric field; and then the gas flow after subjected to the athermal plasma purification area continuous to ascend to the top of a coke quenching tower to be discharged. After the processing steps, the contents of water vapor and the coke powder discharged outside after one ton of coke is produced are controlled to be less than 0.05 ton and 5 grams respectively, and the removal rate of the organic components, the ammonia nitrogen and the cyanide can reach more than 80 percent.

Owner:BEIHANG UNIV

Use of nano structured lipid carrier drug feeding system

InactiveCN101129335AIncrease intakeGood curative effectPowder deliveryOrganic active ingredientsLipid formationMonoglyceride

The invention discloses an application of nanometer structure lipid carrier administration system in the antineoplastic drug to reverse the multiple-drug tolerance of tumour cell, which comprises the following parts: solid lipid material, liquid lipid material and antineoplastic drug, wherein the rate of the liquid lipid (such as oleic acid) is 0-30wt%; the solid lipid is selected from monoglyceride; the liquid lipid is oleic acid; the antineoplastic drug is Paclitaxel or adriablastina. The invention has highly effective cell uptaking and cytolymph condensing function with packing molecular target in the antineoplastic drug of cell, which avoids P-glucoprotein in the drug tolerant cytolymph from identifying the antineoplastic drug to reduce exclusion.

Owner:ZHEJIANG UNIV

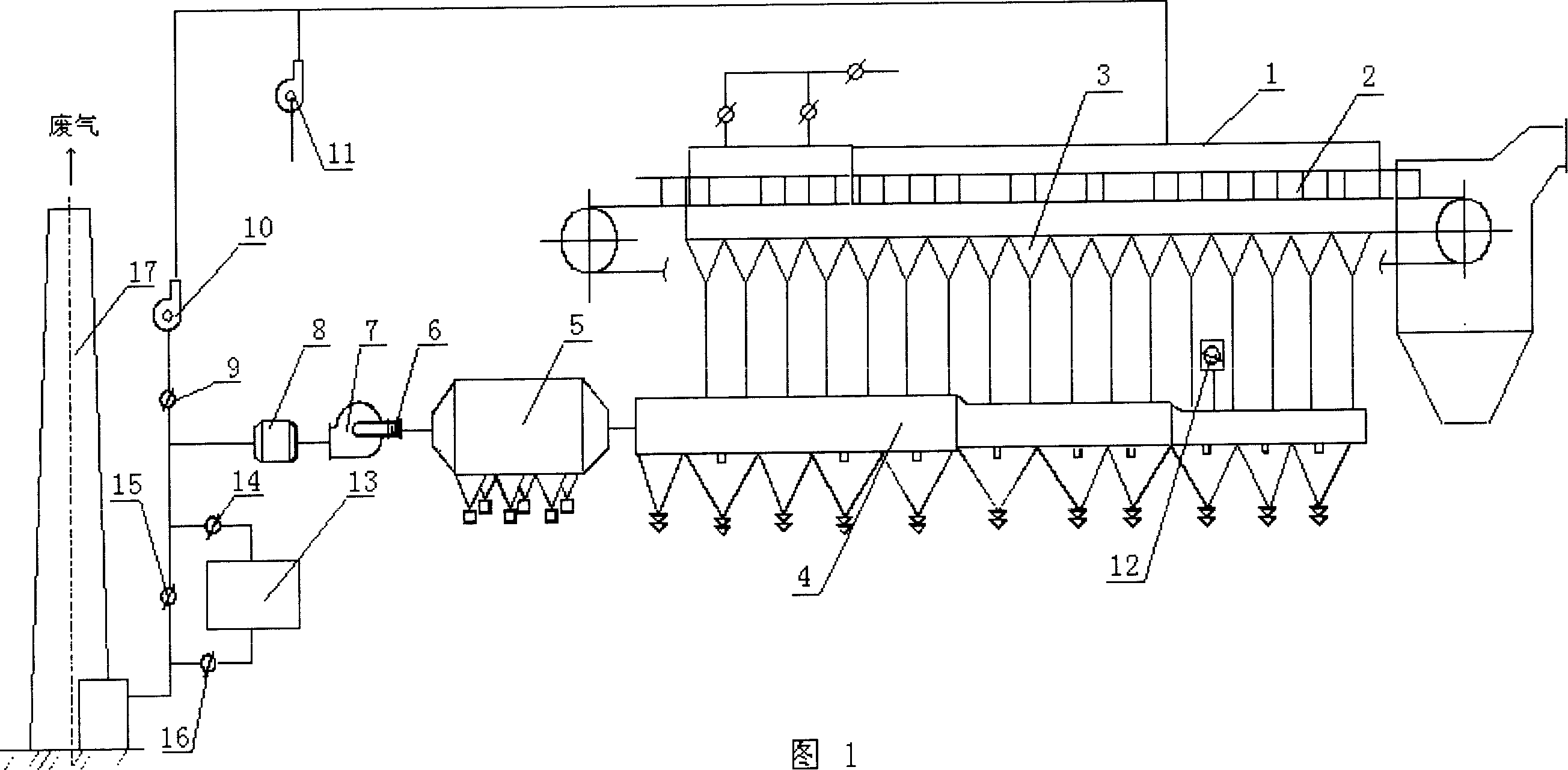

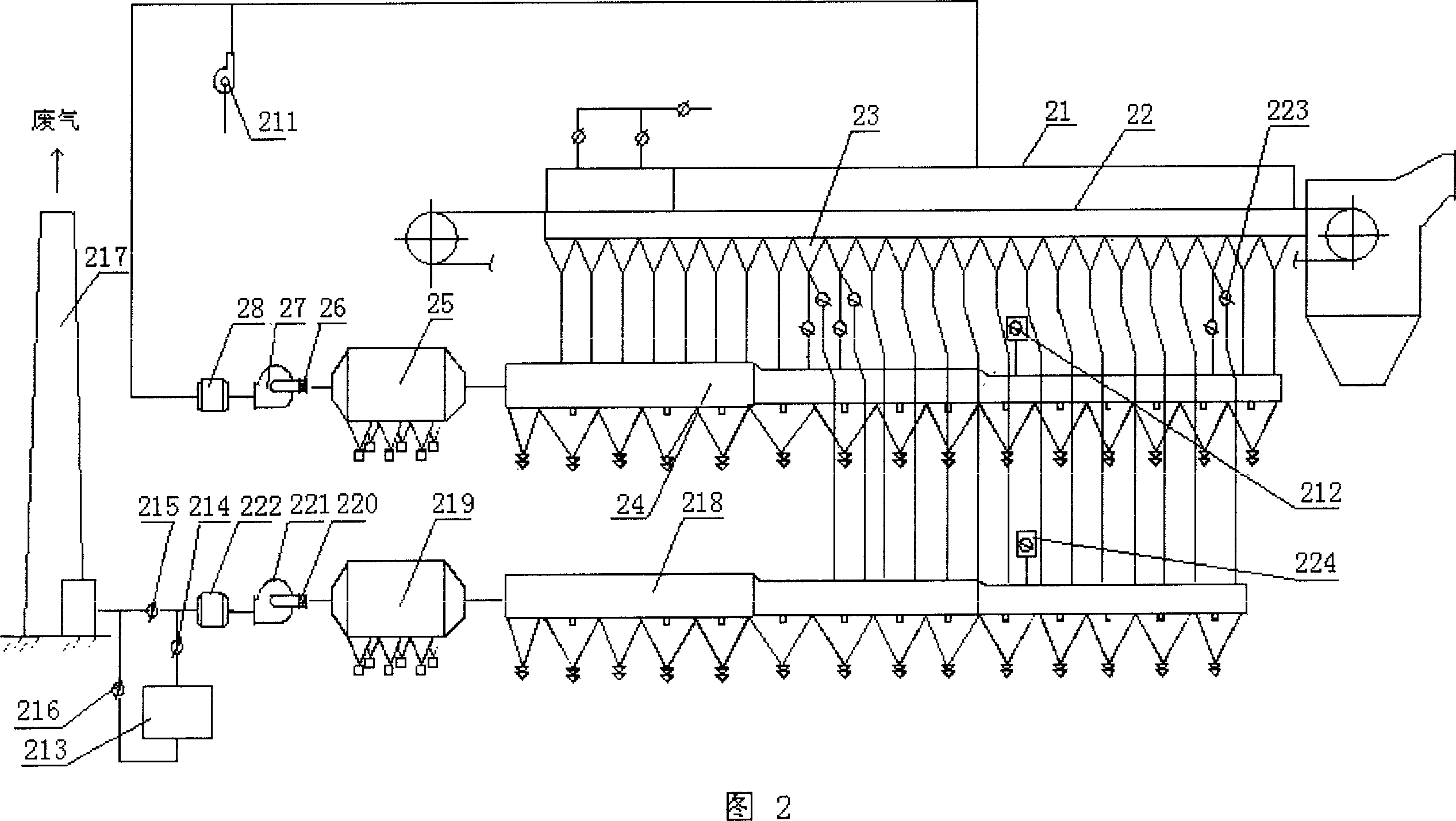

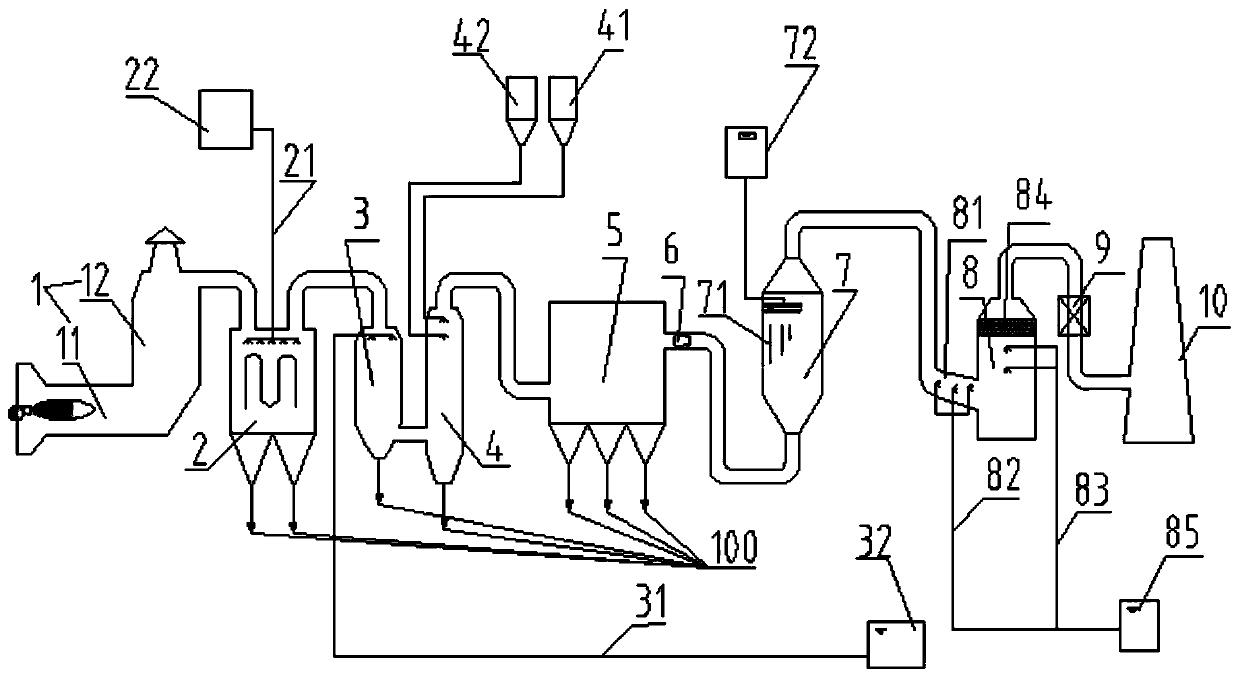

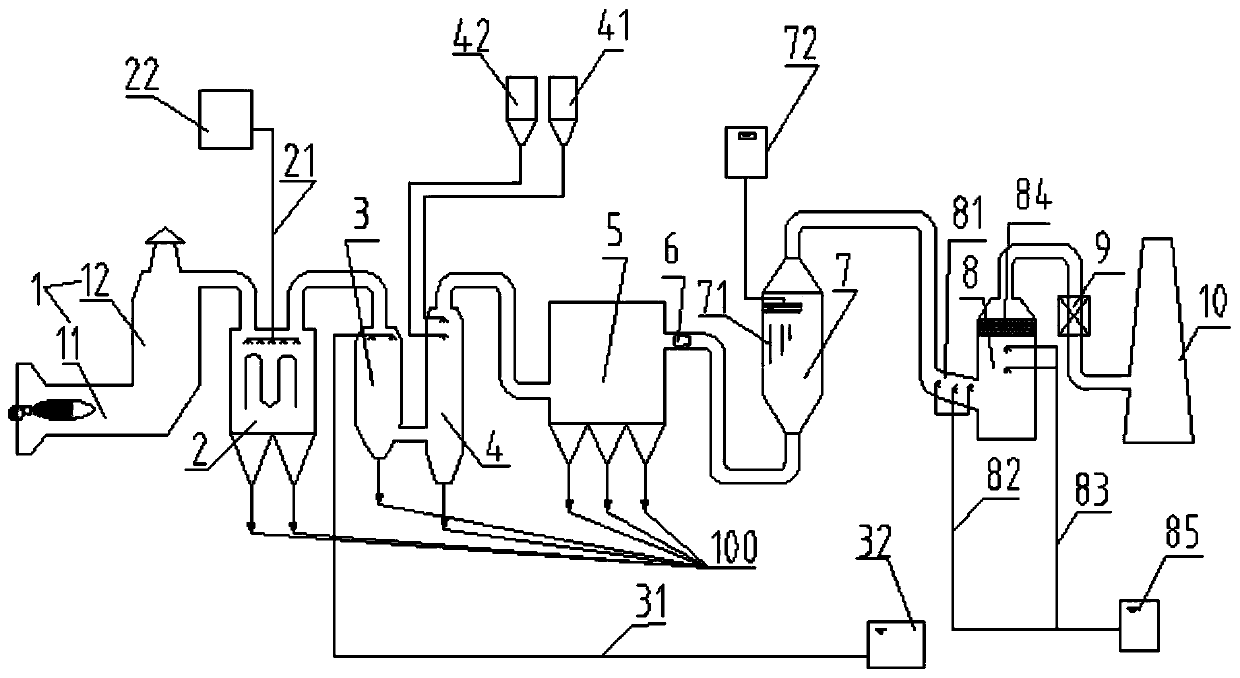

Sinter-smoke circulation collected desulfurizing method and apparatus

InactiveCN101024143AEmission reductionReduce effluxDispersed particle separationFurnace typesFlue gasEnrichment methods

The invention discloses a sintering flue gas desulfurization cycle enrichment methods and device, the described method from the sintering machine take part gas return to the top of sintering machine sealed enclosures within cycle, while complementing sintering machine burning need oxygen, the remaining part of the flue gas discharge after desulfurization. In devices, including dedusting device of flue gases between the chimney and flue, in the road before the desulfurization setup a branch pipeline to connect sintering machine sealed enclosures, in the branches of pipe setup cycle fan and supplement device. This invention due to sintered exhaust gas partly return to the seal trolley of sintering machine to reduce the displacement of gas, thereby reducing the total of dust and exhaust gas, while the SO2 of the sintering process play a enrichment role, to increase desulfurization efficiency, and reduce release total of burning exhaust gas, reducing the processing load of desulfurization device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

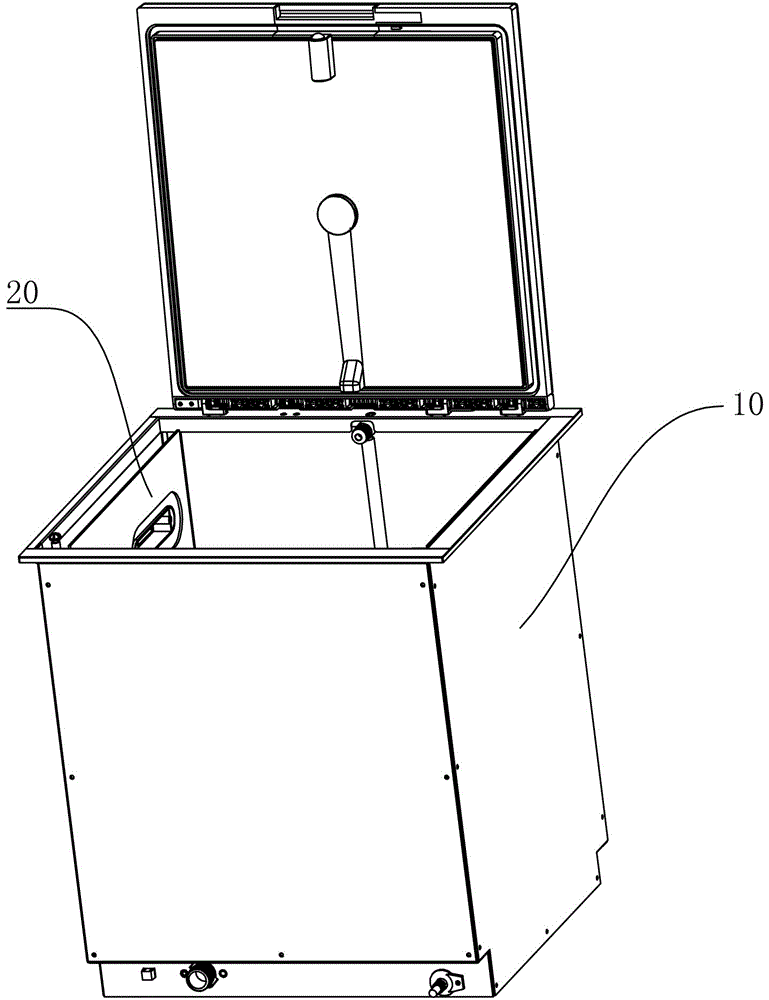

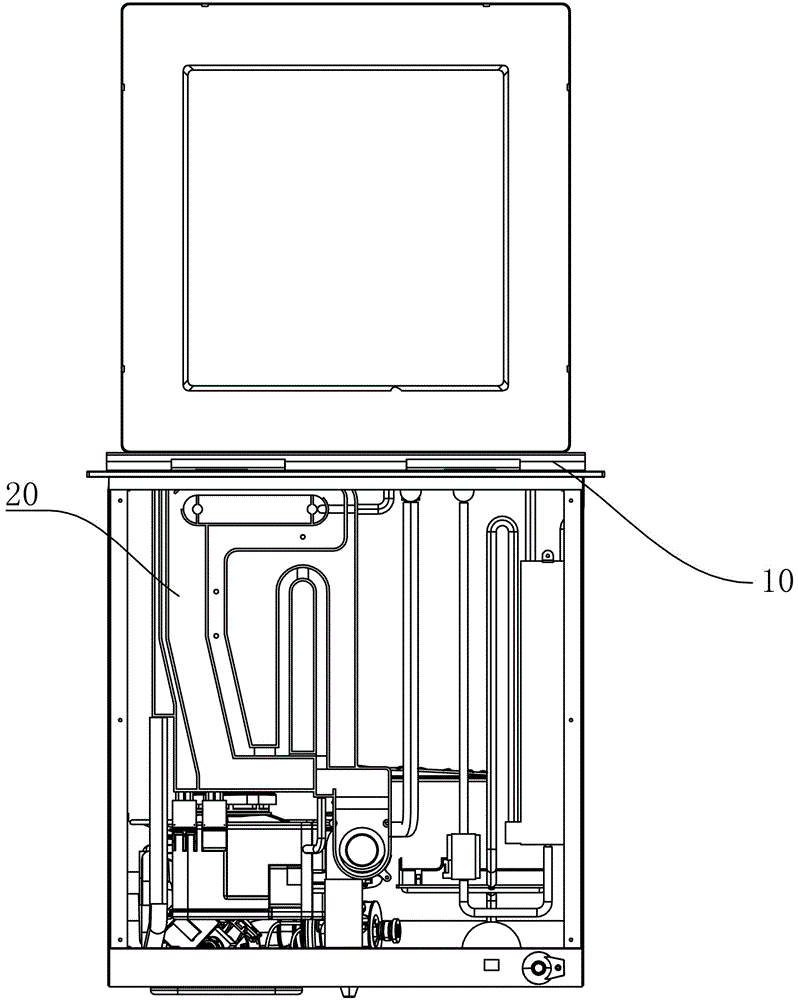

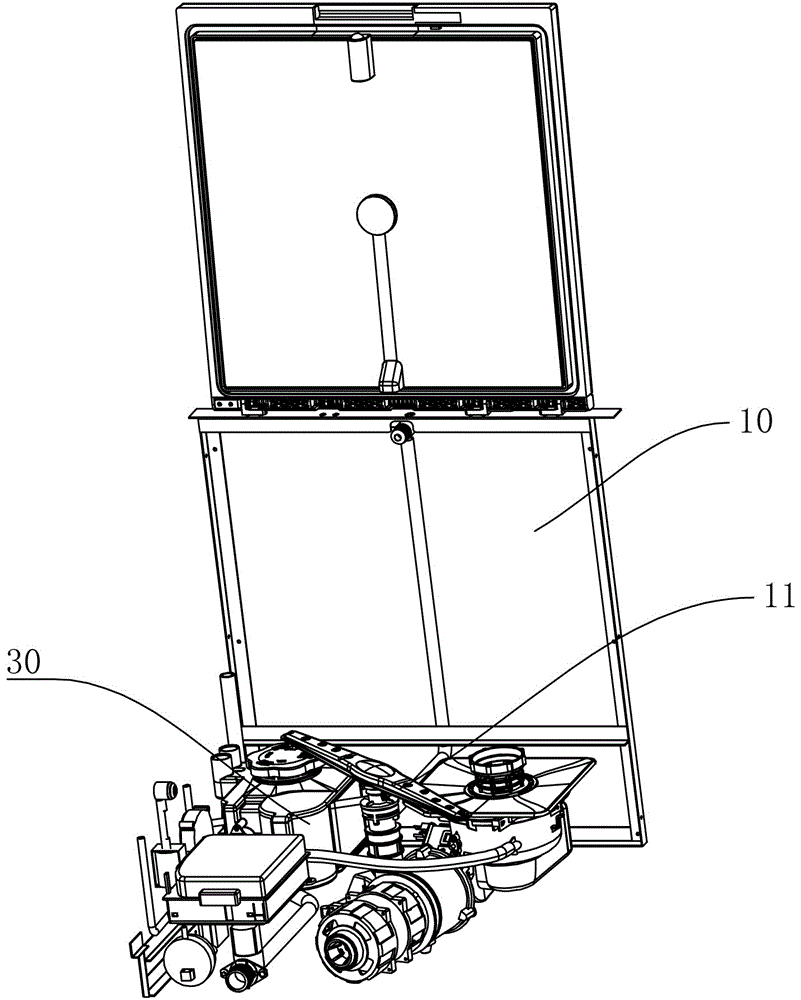

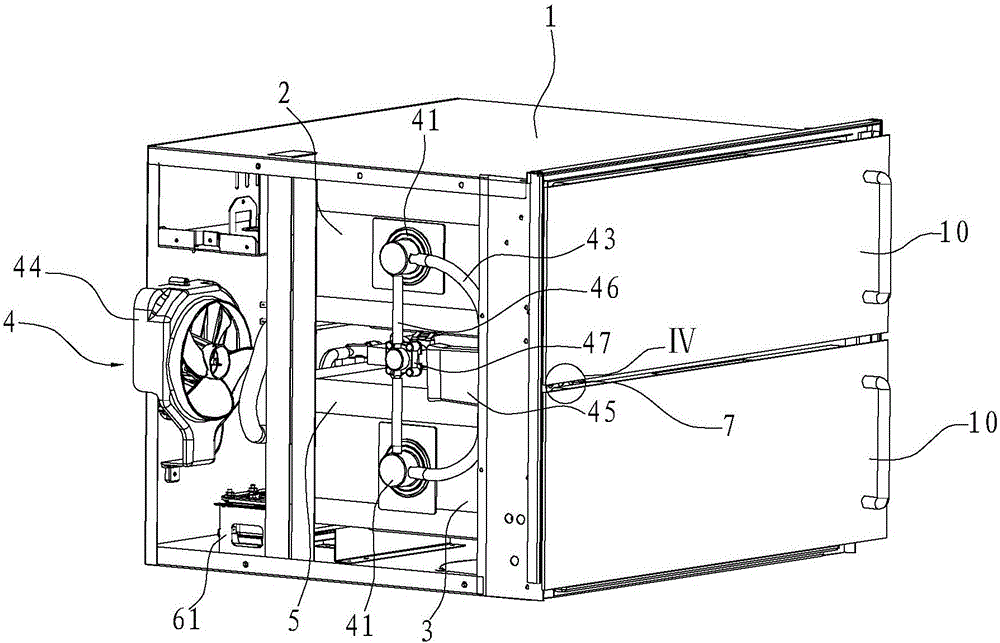

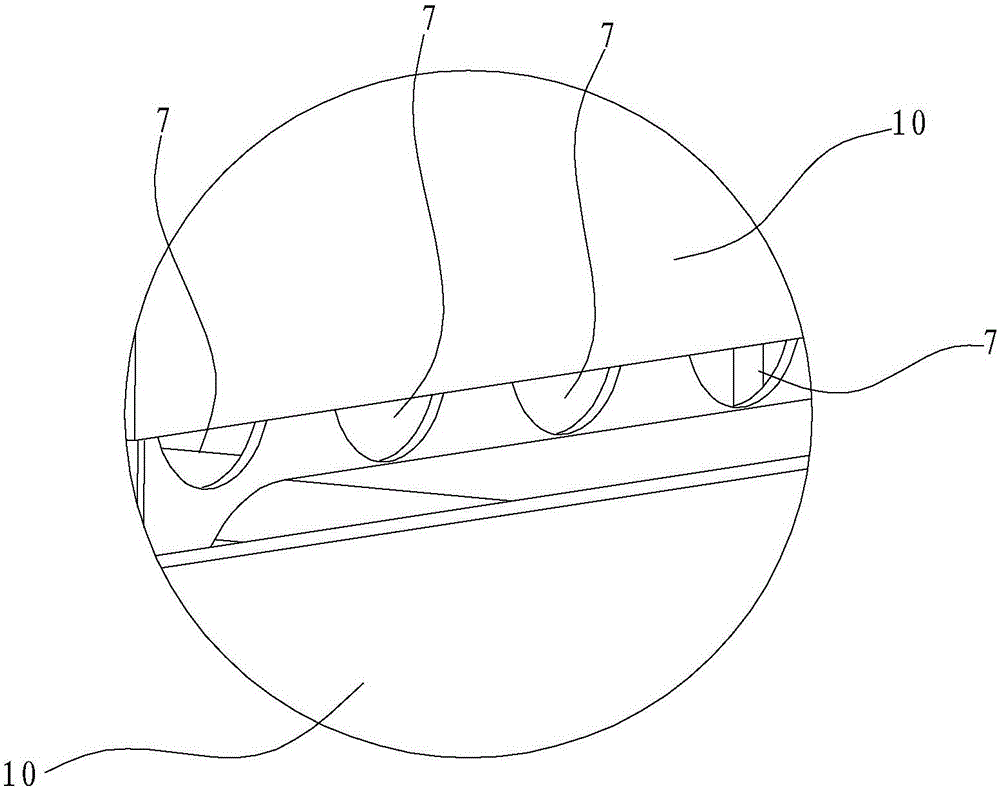

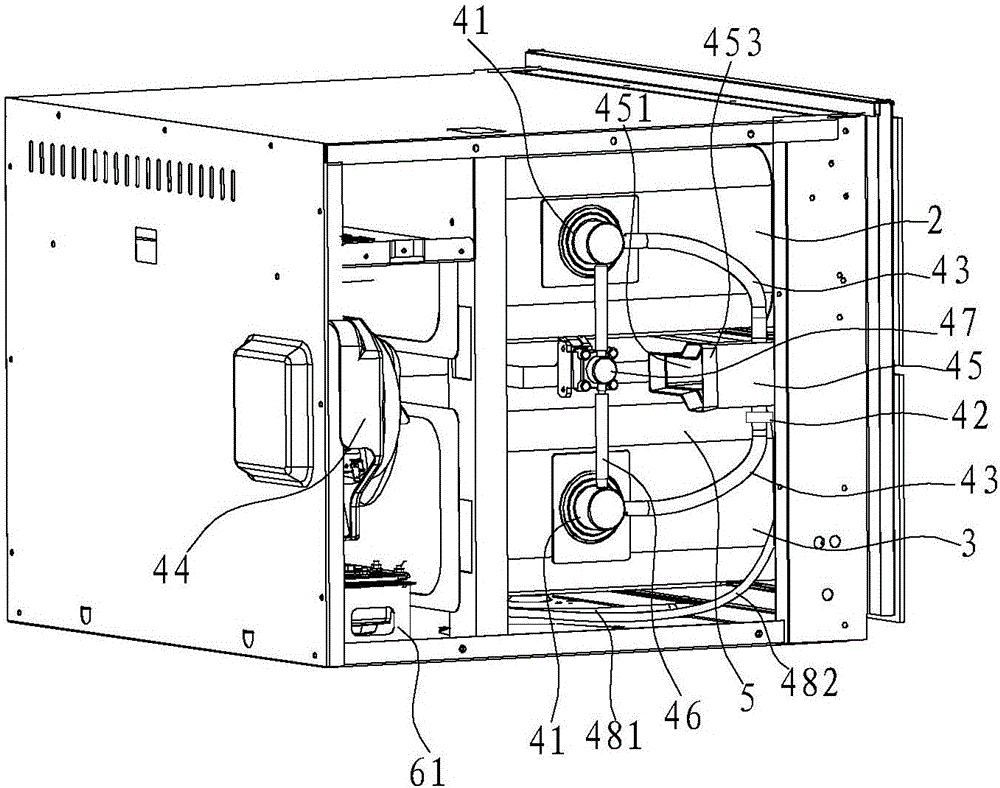

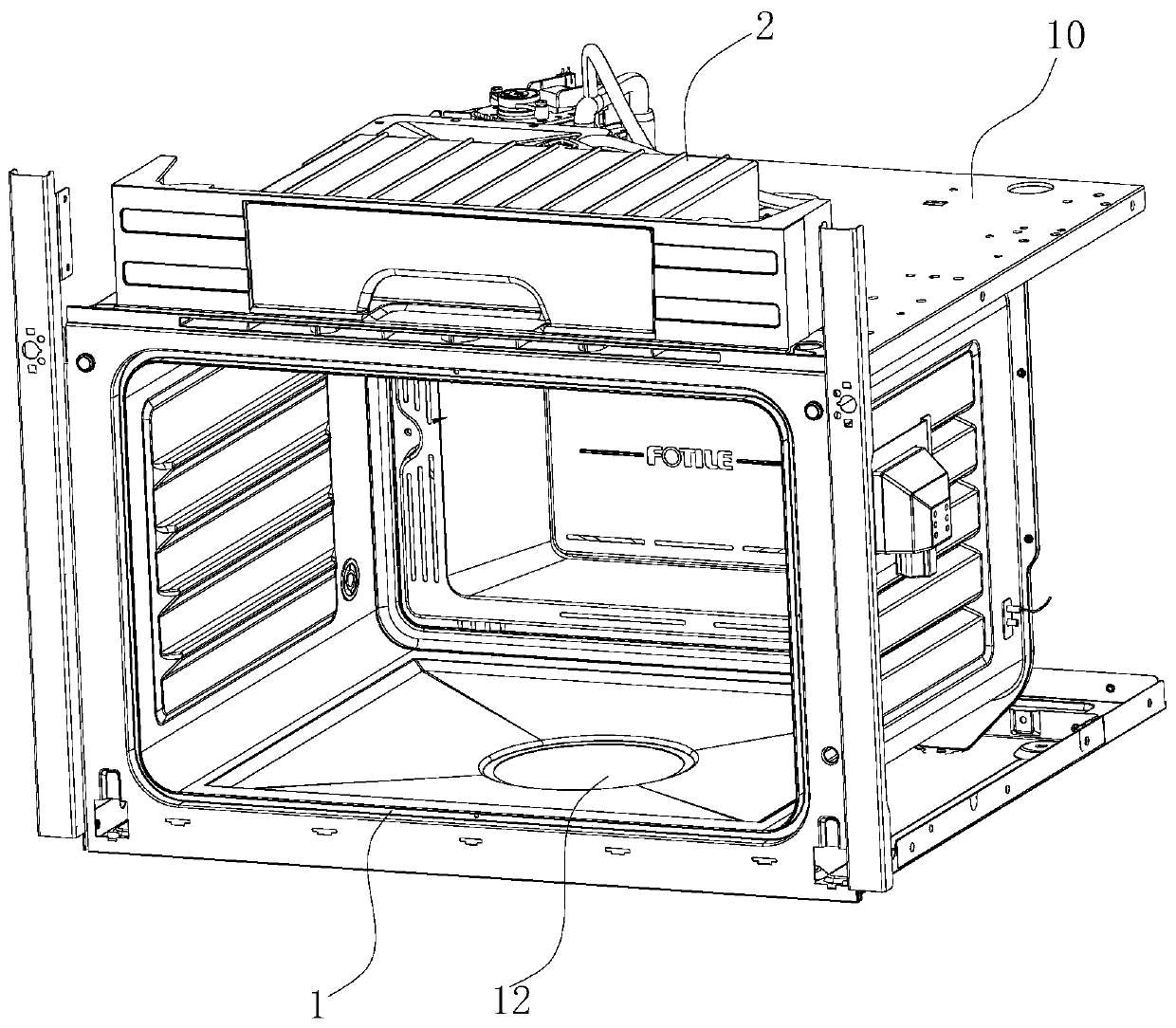

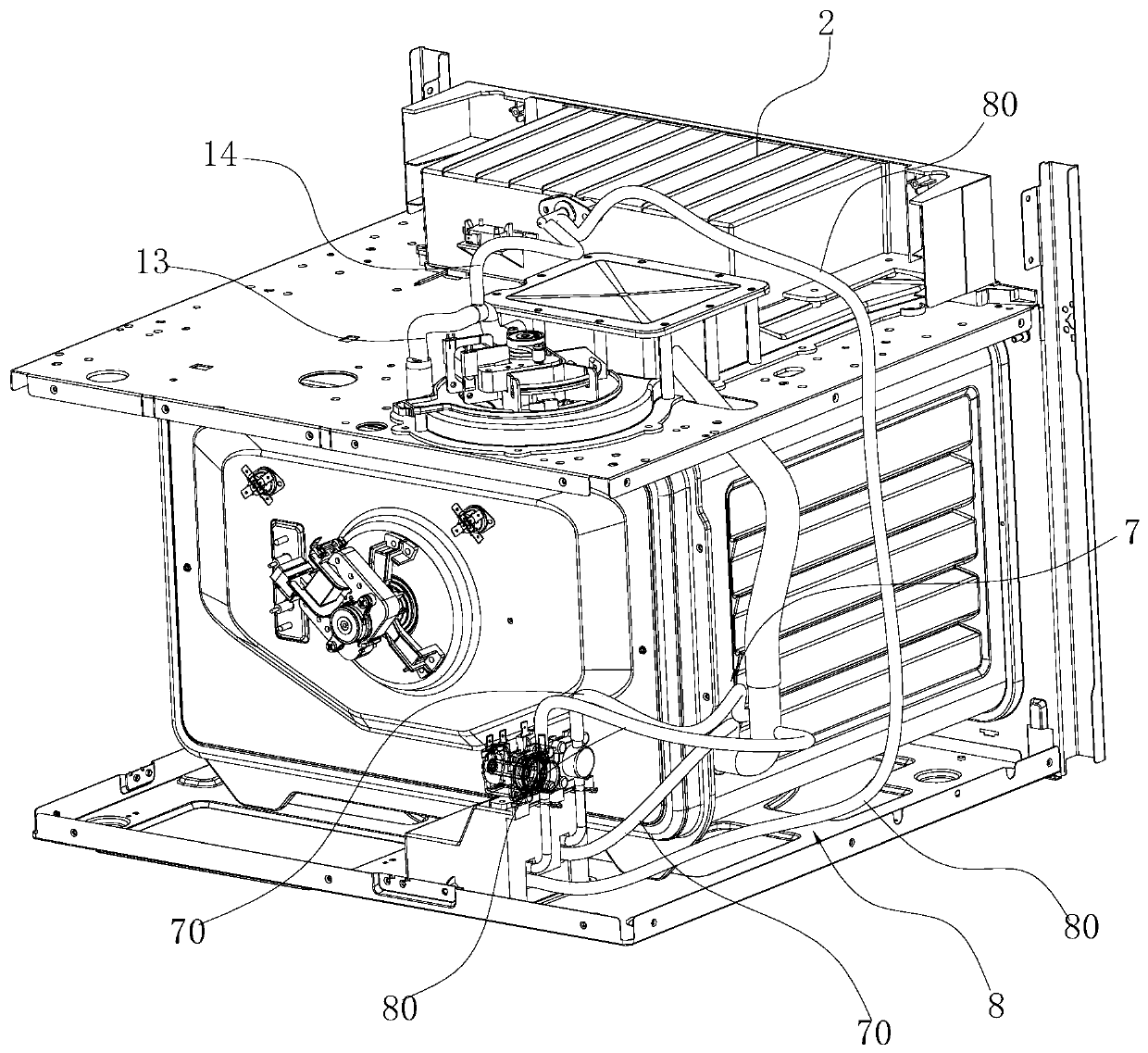

Respirator with condensing and drying functions and dish-washing machine using same

PendingCN106821265AStable jobSafe and reliable workTableware washing/rinsing machine detailsWater savingWater storage

The invention discloses a respirator with condensing and drying functions. The respirator comprises a box body and a cover body which are mutually buckled, wherein the box body is provided with a steam inlet communicated with an inner container of a dish-washing machine and a steam outlet communicated with the outside; the box body is provided with a water diversion port and a water draining outlet; a water storing chamber is formed between the water diversion port and the water draining outlet in the box body; a condensation channel is arranged between the steam inlet and the steam outlet in the box body and arranged in the water storing chamber; a condensation water draining opening is formed below the condensation channel; a fan is arranged at the tail end of the condensation channel. According to the respirator disclosed by the invention, siphon can be prevented, condensation water generated by condensing steam can be drained and repeatedly utilized, and uncondensed steam is exhausted by the fan, so that tableware in the dish-washing machine can be quickly dried. The invention also provides the dish-washing machine using the respirator with the condensing and drying functions; the exhaust quantity of the steam can be reduced, and steam condensation water generated in the respirator can be repeatedly utilized, so that the dish-washing machine realizes better water-saving and energy-saving functions.

Owner:FENGHUA EAGURT MACHINERY MFR

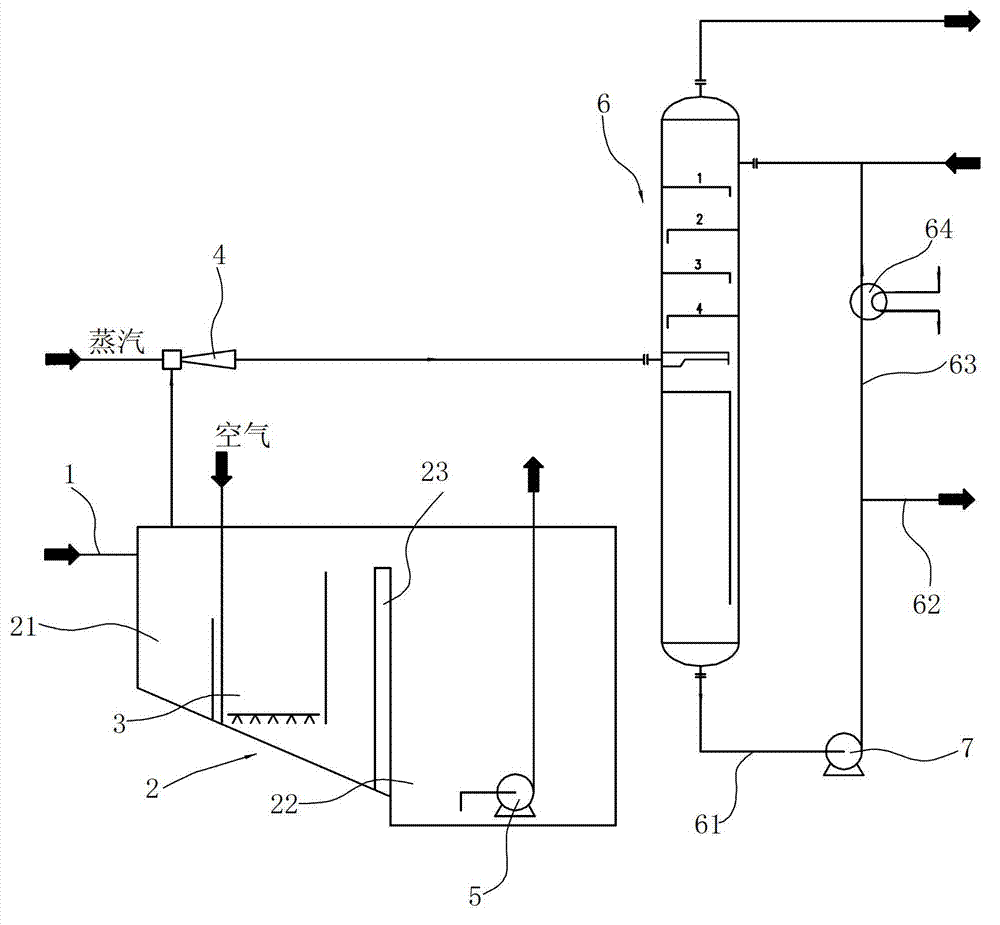

Liquid sulphur degassing device and liquid sulphur degassing method

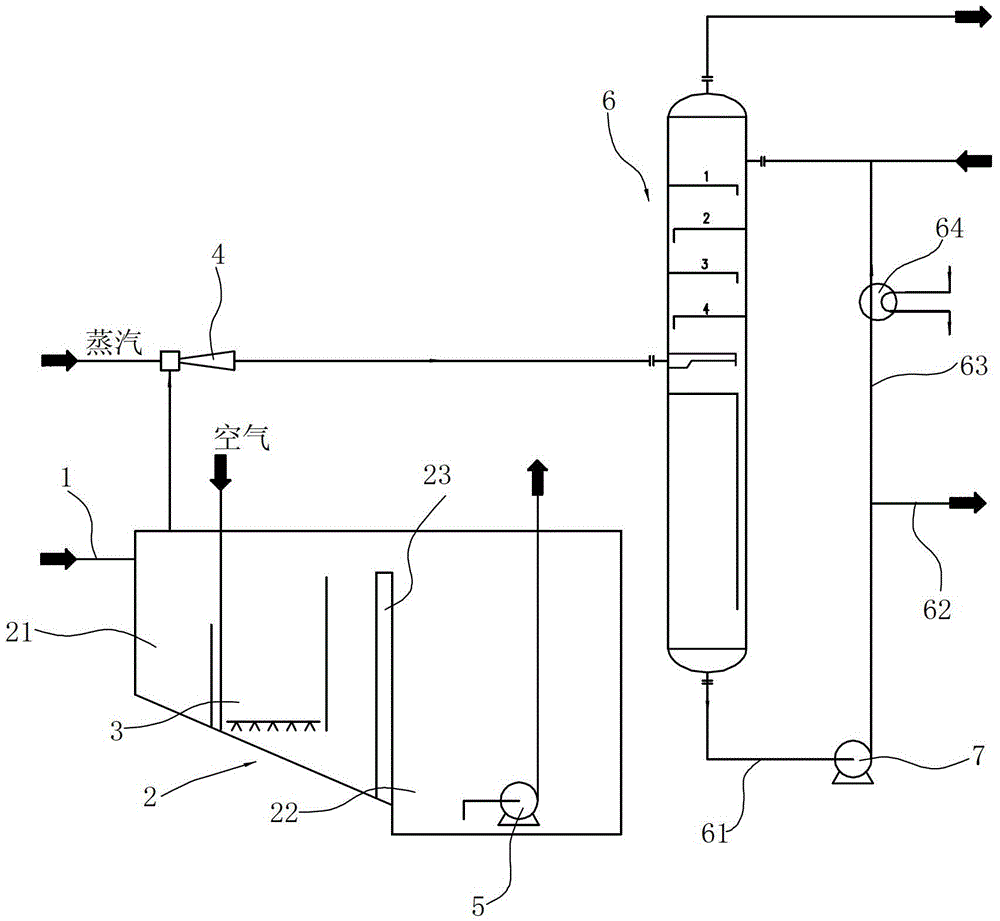

The invention relates to a liquid sulphur degassing device and a liquid sulphur degassing method. The liquid sulphur degassing device comprises a liquid sulphur tank communicated with a liquid sulphur pipeline, wherein the liquid sulphur tank is internally provided with gas stripping equipment which can strip hydrogen sulphide gas in liquid sulphur, and the upper part of the liquid sulphur tank is provided with gas pumping equipment which can pump the hydrogen sulphide gas with other gases in the liquid sulphur tank out of the liquid sulphur tank; and the liquid sulphur degassing device is characterized in that the liquid sulphur tank comprises a gas stripping tank and a finished product tank, wherein an overflow dam is arranged between the gas stripping tank and the finished product tank; the liquid sulphur pipeline is communicated with the gas stripping tank; the suction inlet of the liquid sulphur pump is connected with the bottom of the finished product tank; the outlet of the gas pumping equipment is connected with the material inlet of an absorption tower; and the top of the absorption tower is provided with a waste gas outlet, the upper part of the absorption tower is provided with an absorption liquid inlet, a liquid outlet arranged at the bottom of the absorption tower is connected with a main pipeline, and the main pipeline is provided with a pressure pump which pumps out, pressurizes and conveys the liquid in the absorption tower. The liquid sulphur degassing device provided by the invention is simple in process, low in equipment investment and good in degassing effect.

Owner:ZHENHAI PETROCHEMICAL ENG CO LTD

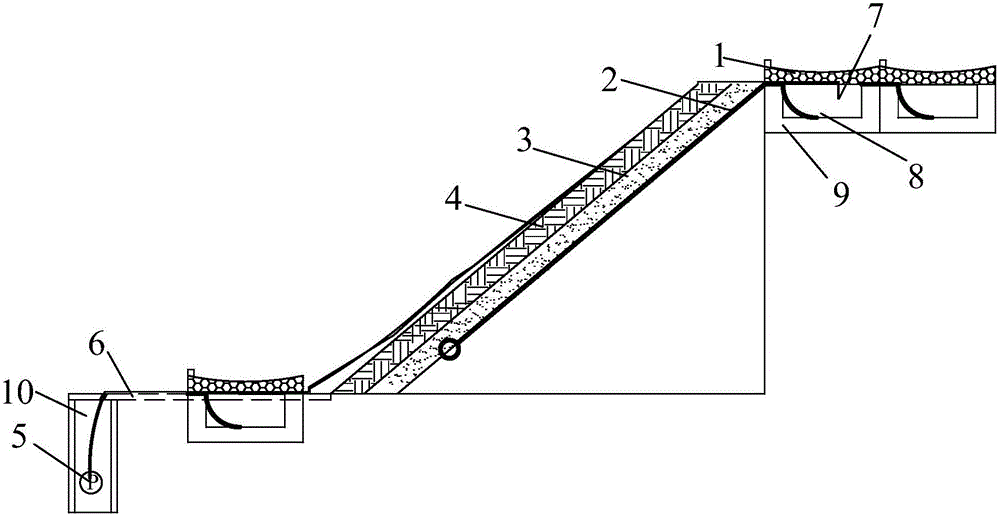

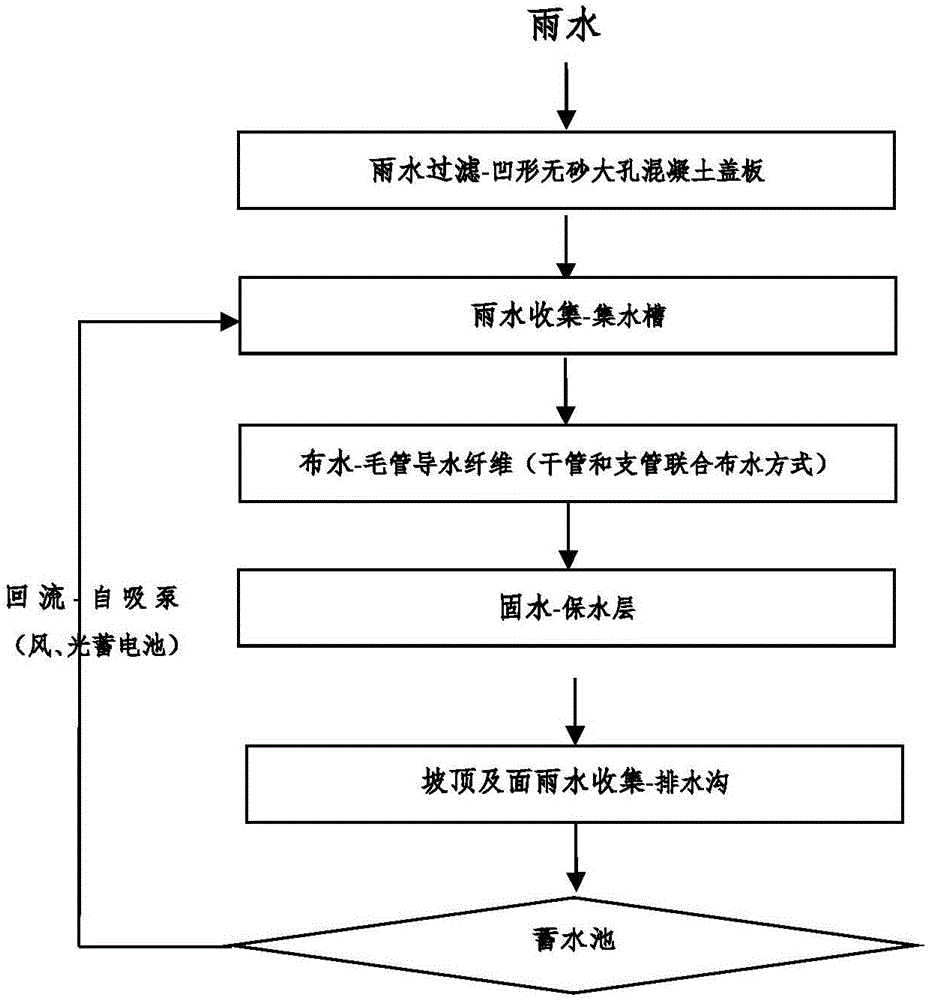

Semi-arid area ecological slope protection structure and construction method thereof

InactiveCN105696606AReduce soil erosionExtended service lifeGeneral water supply conservationExcavationsWater diversionPipe water

The invention relates to the technical field of ecological slope protection and in particular to a semi-arid area ecological slope protection structure and a construction method thereof. The semi-arid area ecological slope protection structure comprises a slope top, a slope surface and a slope bottom, wherein a plurality of water collection grooves are formed in the edge of the slope top; a water diversion groove which can carry out diversion to the slope bottom is formed in the side surface of each water collection groove; a body of each water collection groove is formed by stacking biological stacking bags, a bentonite waterproof blanket with the thickness to be 5-10mm wraps the outer layer of the body of each water collection groove; the slope surface is composed of a planting layer and a water retention layer arranged under the planting layer; the water collection grooves are communicated with the water retention layer of the slope surface through multiple strands of capillary pipe water diversion fibers; a reservoir is formed in the slope bottom; and a self sucking pump is arranged in the reservoir and pours collected seeped water into the water collection grooves through return pipes. When collecting collected water on the slope top and flowing water on the slope surface and constructing and designing the slope surface, the semi-arid area ecological slope protection structure realizes water retention and irrigation of roots of green plants on the slope surface by virtue of the water diversion capacity of the capillary pipe water diversion fibers.

Owner:LINGNAN XINKE ECOLOGICAL TECH RES INST BEIJING CO LTD

Steaming case

ActiveCN106473589AFunctional DiversificationSmooth functionSteam cooking vesselsWarming devicesSolenoid valveEngineering

The invention relates to a steaming case comprising a case body. At least one first liner and a second liner are disposed in the case body; the case body is further provided with a steam exhausting system; a steam returning pipe is arranged between steam exhausting joints of the first and second liners; the steam returning pipe is provided with a first solenoid valve controlling on-off of the steam returning pipe; a steam exhausting pipe of the second liner is provided with a second solenoid valve controlling on-off of the steam exhausting pipe; a wind guide cover is arranged on the inner side of a steam exhausting port and a wind guiding channel formed by the same is opposite to the steam exhausting port; discharged steam of steam discharging ports of each steam exhausting pipe are all accumulated in the wind guide channel of the wind guide cover; and an air outlet of a heat radiating fan is orderly opposite to the wind guide channel and the steam exhausting ports. Compared with the prior art, steam exhausting can be smoothly guaranteed and stagnation in the steaming case can be avoided; part steam can condensate on the wind guide cover, and steam external discharging amount can be reduced; liquid drops due to condensation of the steam in a furnace door part can be avoided, so user use experience can be improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

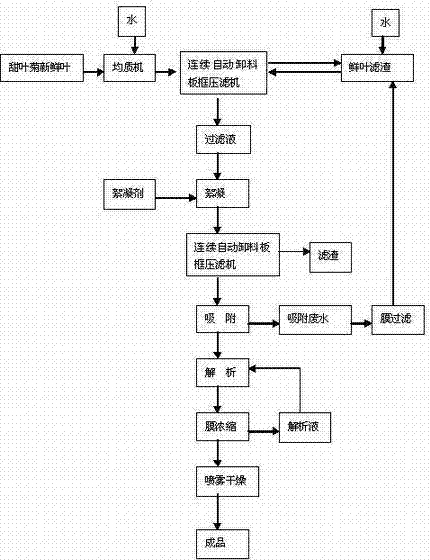

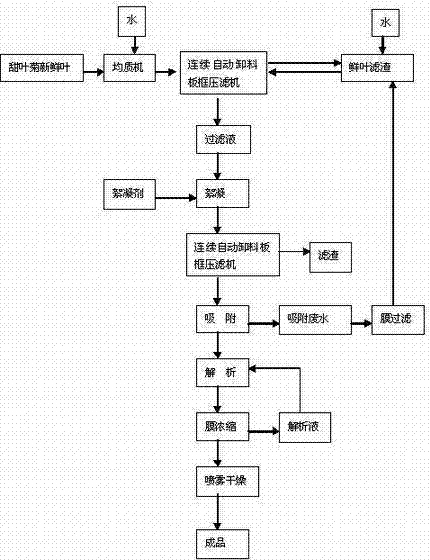

Method for extracting stevioside from fresh stevia rebaudiana leaves

InactiveCN102127129AReduce drying processLow costSugar derivativesSugar derivatives preparationFlocculationEngineering

The invention discloses a method for extracting stevioside from fresh stevia rebaudiana leaves, which comprises: crushing fresh stevia rebaudiana leaves with homogenizing crushing equipment under a condition of water, performing pressure filtration in continuous automatic discharge filtering equipment, subjecting the filtrate to flocculation by mixed flocculating agent; and absorbing by resin, analyzing, desalting and decolorizing by resin, concentrating and spray drying to obtain the stevioside product. In the invention, time and working procedures are saved, a long-distance transport process is avoided, raw material cost is lowered, discharge of waste water is reduced greatly, and clean production can be realized basically.

Owner:LIAONING QIANQIAN BIOLOGICAL TECH

Method for recycling silicon carbide and co-producing white carbon black from waste mortar for wire cutting

The invention discloses a method for recycling silicon carbide and co-producing white carbon black from waste mortar produced by cutting and machining monocrystalline silicon or polysilicon into silicon wafers, which comprises the following steps: utilizing organic and inorganic solvents to dissolve cutting solution molecules in the mortar; removing iron from solid-state sand through mixed acid for acid cleaning and a chelating agent; adding the high-concentration aqueous solution of sodium hydroxide in the solid-state sand so that the aqueous solution of the sodium hydroxide is reacted with silicon in the mortar to produce sodium silicate, and performing filtering to obtain the pure silicon carbide; adding a little amount of high modulus water glass into the aqueous solution of the sodium silicate; and finally performing acid precipitation to separate flocculent sediment out, and drying the flocculent sediment to obtain the white carbon black product, wherein dilute sodium chloride solution can be recycled as a diluent. The method in the invention is simple in process and moderate in reaction conditions, can effectively recycle the silicon carbide, effectively reduce the cost on recycling the waste mortar and preparing the white carbon black by utilizing wastewater, is the practicable technology which can make waste profitable, greatly reduce the discharge of the wastewater and create remarkable economic and social benefits.

Owner:滕州市产品质量监督检验所

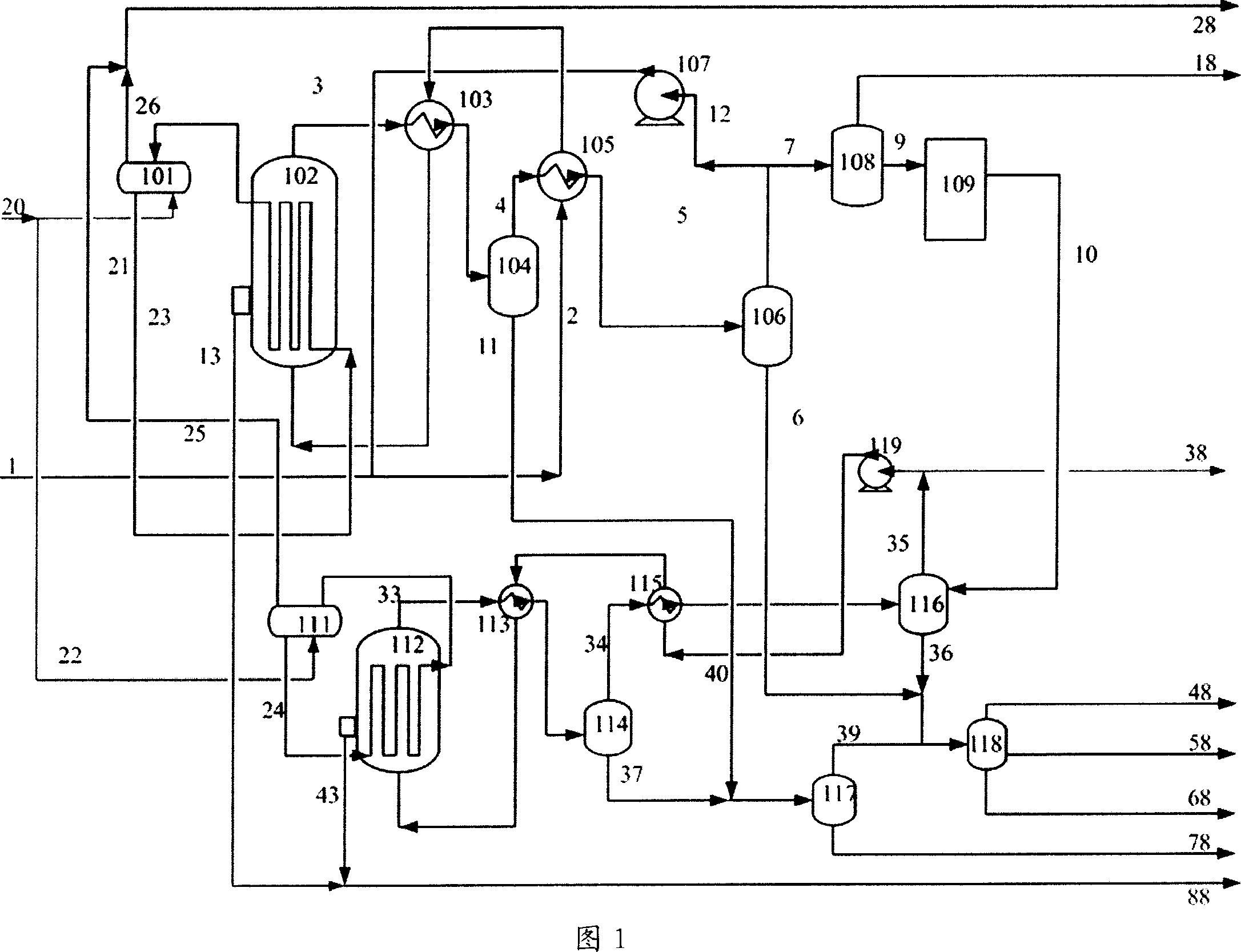

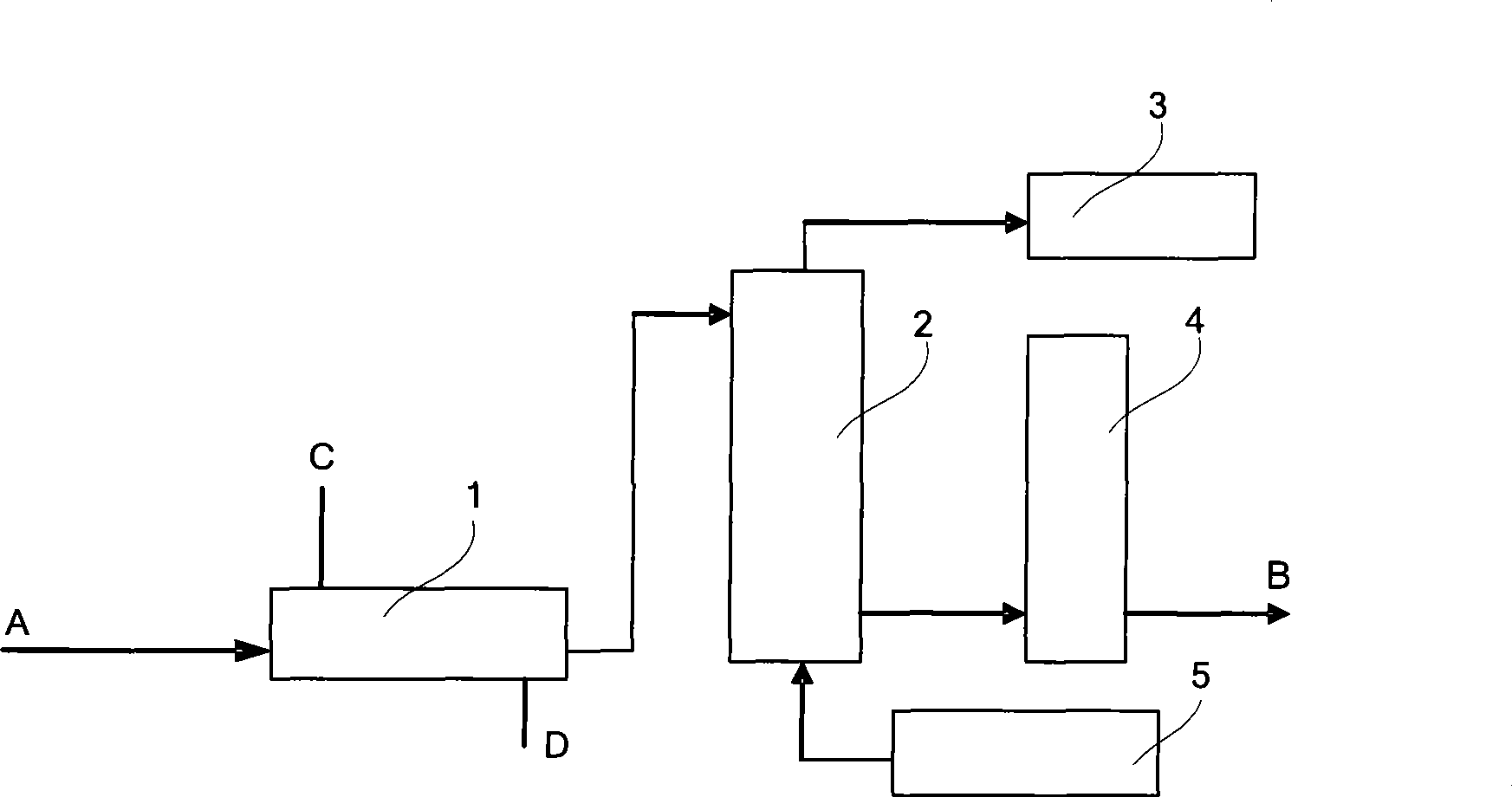

Two stage Fischer-Tropsch synthesis method

ActiveCN1948438AHigh yieldSeverity GuaranteeLiquid hydrocarbon mixture recoveryAlkaneSynthesis methods

This invention relates to a synthesis method of fischer-tropsch. Its preparation includes (a) Synthesis gas material enters into the first fischer-tropsch synthesis reactor to conduct fischer-tropsch synthesis reaction under the action of accelerant, (b) Segregating the first grade reaction product and letting parts of end gas return to the first fischer-tropsch reactor for recycling, and then letting C1-C4 alkanes containing in other surplus end gas to transform into synthetic gas.(c) Mixing the end gas transformed at step (b) and the second fischer-tropsch synthesis reaction circulation gas, and then entering the second fischer-tropsch synthesis reactor to conduct fischer-tropsch synthesis reaction under accelerant. (d) Segregating the second fischer-tropsch synthesis reaction product, and most of the gas returning to the second fischer-tropsch synthesis reactor for circulating reaction, and then evacuating other end gas. The transformation efficiency of CO+H2 is higher than 96% and the yield of methyl hydride is lower than 3%, and the yield of unit space-time of accelerant reaches 185 g / kg*h.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Mining method of nearly horizontal mineral deposit of opencast coal field by casting and internally dumping

InactiveCN103470262AReduce effluxShort distanceUnderground miningSurface miningOpen-pit miningCoal field

The invention relates to a mining method of a nearly horizontal mineral deposit of an opencast coal field by casting and internally dumping and belongs to the mining method of the opencast coal field. The mining method comprises the following steps: (1) dividing a strip mine into a plurality of mining regions, mining overburdened materials of a first strip region, and stacking the overburdened materials outside an opencast mining limit; (2) dividing an overburdening table into one or more tables to be mined; (3) discharging the overburdened materials of a second strip region into a worked-out section of the first strip region after a mineral deposit exposed in the first strip region is mined, and transporting mined mineral products out of a mining field through entering-exiting channel transporting passages arranged on two sides of a channel or the middles of the strip regions. The mining method has the advantages that as the overburdened materials can be discharged and abandoned in the worked-out section, the occupied land of an externally-dumped soil site can be saved; the mining method is environment-friendly and is capable of restoring the land influenced by the mining operation during mining; abandoned and unserviceable lands in barren and mountainous mines can be changed into usable lands.

Owner:CHINA UNIV OF MINING & TECH

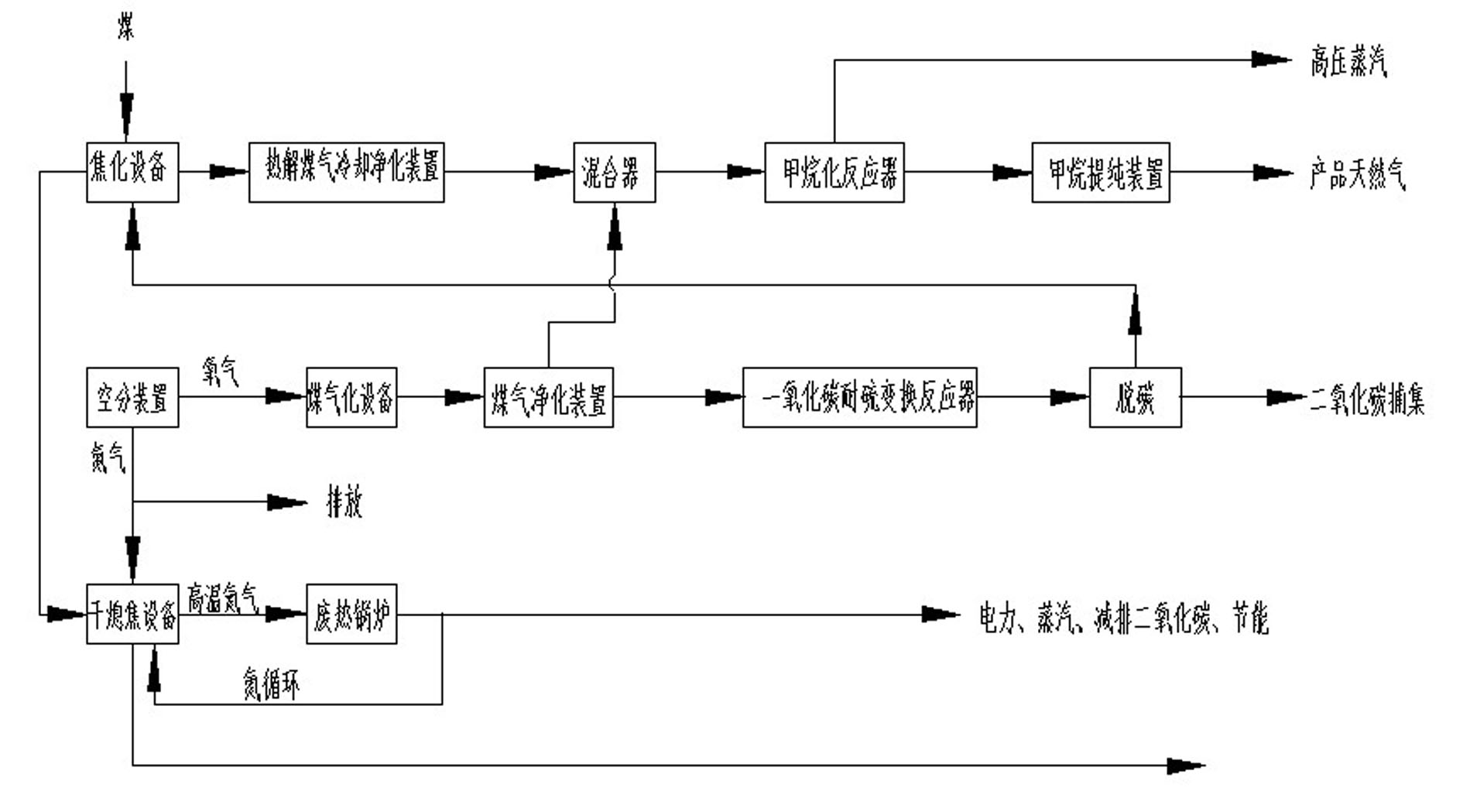

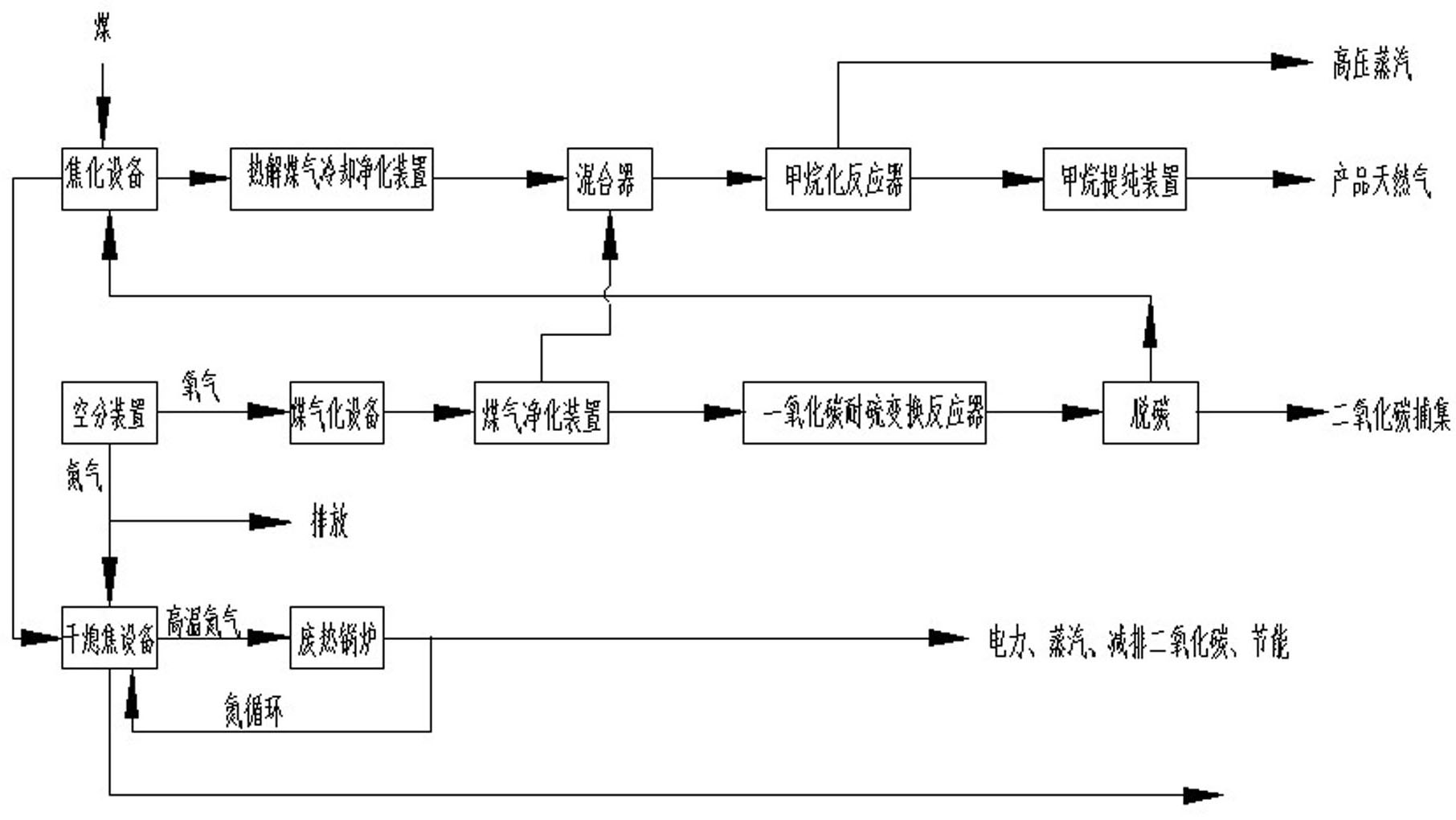

Process for producing natural gas by coal coking and pyrolysis coal gas thereof

InactiveCN102181315AAchieve emission reduction targetsQuality improvementCoke quenchingCombustible gas coke oven heatingHeat carrierMethanation

The invention relates to a process for producing natural gas by coal coking and pyrolysis coal gas thereof, in the process, raw coal gas generated by a coke oven taking H2 as fuel is purified and then completely sent to a mixer for being directly mixed with part of clean gasified coal gas for regulating hydrogen-carbon ratio, and then methanation reaction is performed under the action of a catalyst so as to prepare a product, namely the natural gas; and transformation and decarburization are performed on the other part of the clean gasified coal gas, then carbon dioxide is enriched and caught, and produced hydrogen is sent to the coke oven for burning and supplying heat. In the process, coal gasification and coke dry quenching are simultaneously performed, and a set of air separation device is realized for providing a heat carrier, namely N2, and a gasifying agent, namely O2, for the coke dry quenching and the coal gasification respectively, thereby enabling the air separation processeffect to be higher. Coke making by hydrogen burning, air separation, the coke dry quenching, the coal gasification and methanation of the coal gas of the coke oven are organically integrated, and the clean production in the coking industry and the economic and high-efficient utilization of the pyrolysis coal gas are realized, thereby having great application value in the aspects of energy utilization, CO2 emission reduction and environmental protection.

Owner:TAIYUAN UNIV OF TECH

Bayer process red mud processing method

The invention discloses a treatment method of Bayer method red mud, comprising the following steps: (a) the red mud is sorted by a beneficiation method and divided into three parts, namely, rough sand, fine sand and soil mortar; (b) milling grinding and settling separation are carried out to the rough sand in the step (a) to obtain rough sand one and tailing ore slurry one; (c) after the rough sand one in the step (b) and the fine sand in the step (a) are mixed, magnetic separation is carried out to obtain iron powder and quartz powder; (d) the iron powder obtained in the step (c) is refined and sorted by a magnetic separator to obtain fine iron powder F and fine iron powder P; and (e) the soil mortar in step (a) is pulse magnetic separated to obtain tailing ore slurry and fine iron powder PI. The method can reduce 35-40 percent of red mud discharge, the iron element effective utilization rate can reach more than 70 percent, and the monomer quartz extraction yield can reach 80 percent. The method optimizes the production flow of alumina by using a combination method, reduces the red mud discharge, protects the environment, reduces the production cost of alumina and improves the alumina production capacity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

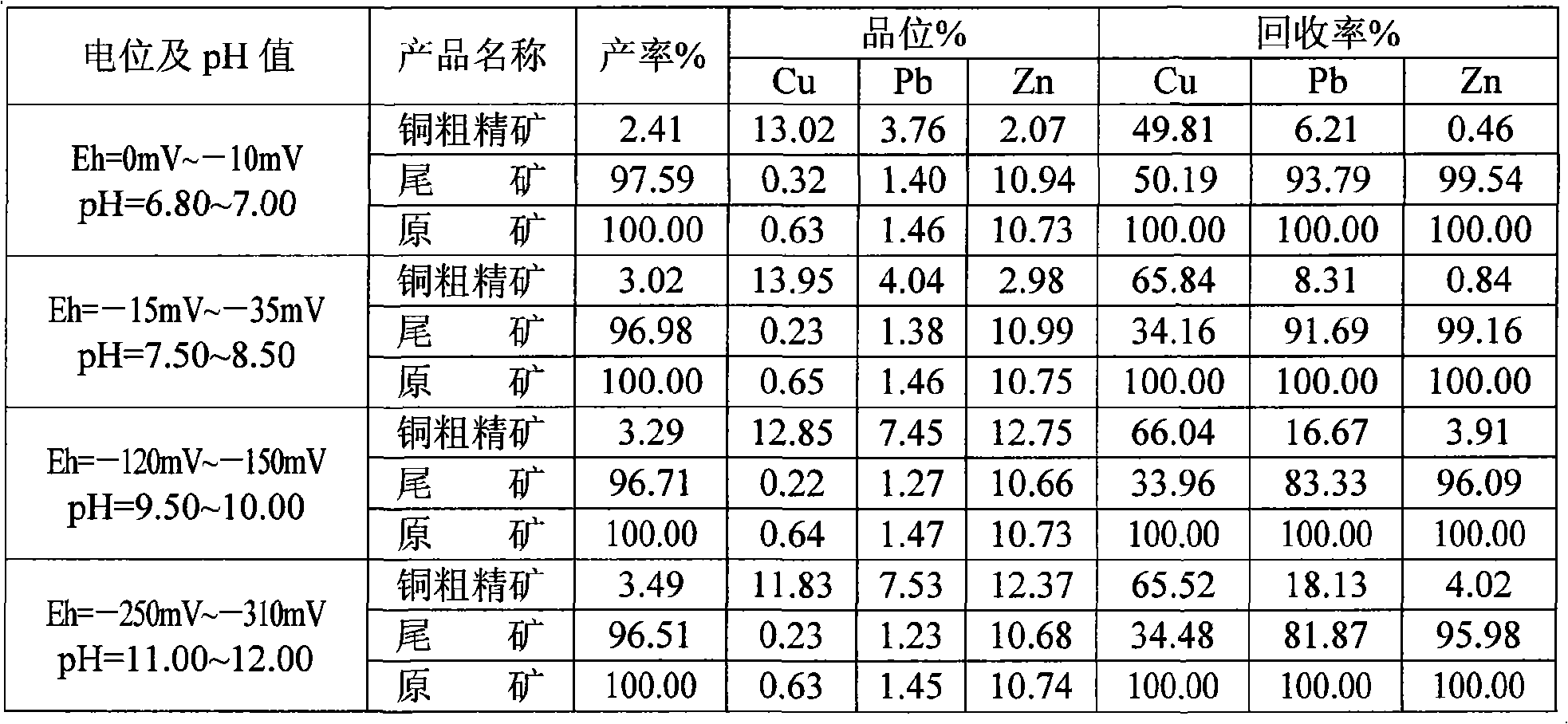

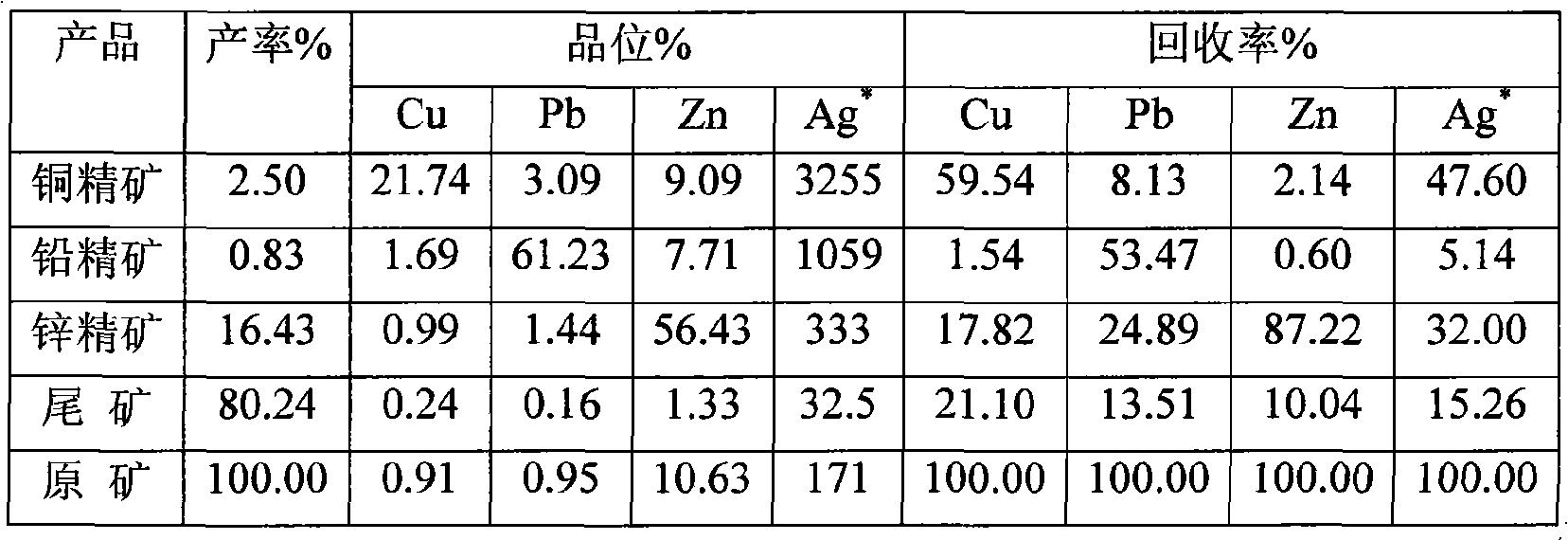

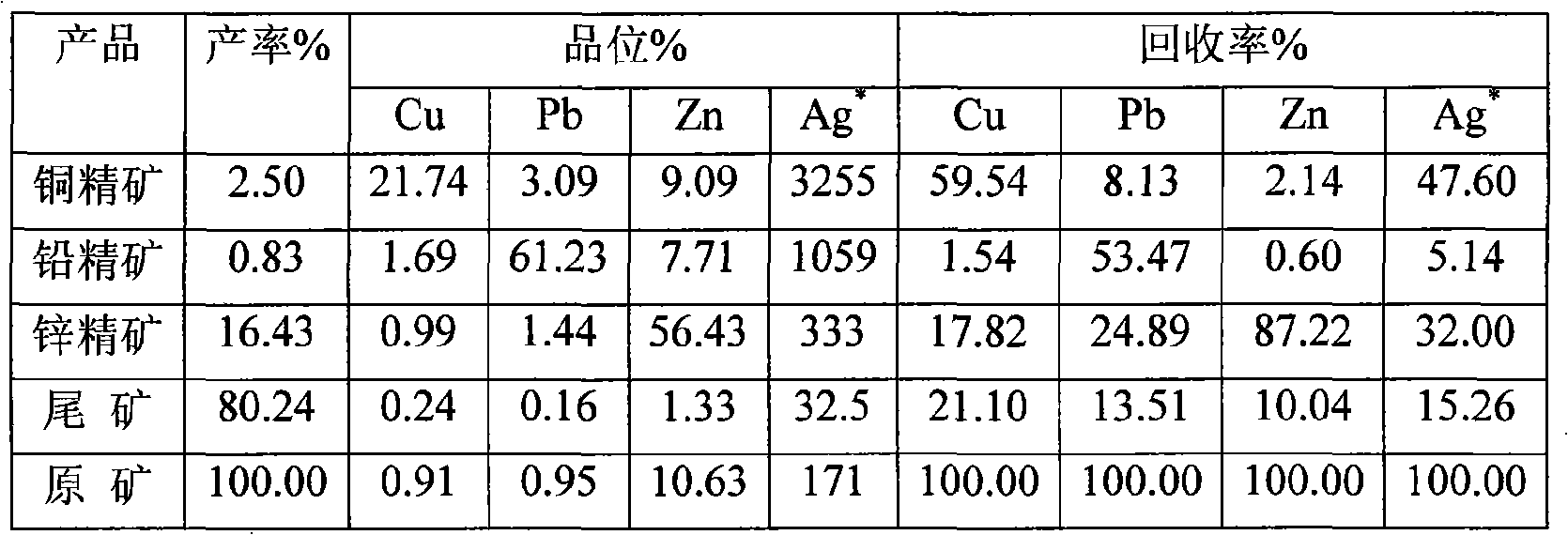

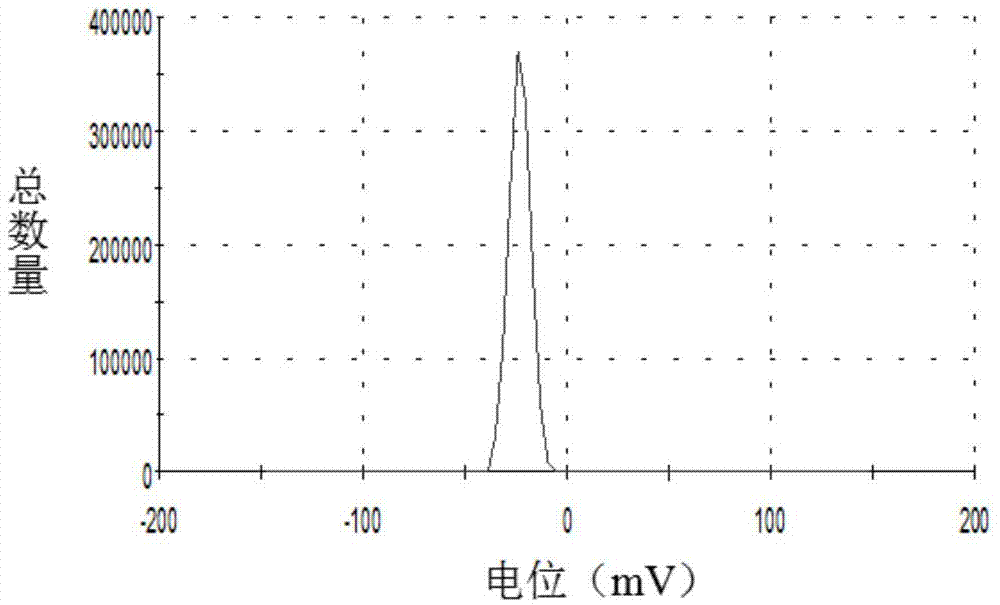

Electric potential regulating and controling differential flotation process for copper-plumbum-zinc vulcanizing mine

InactiveCN101402071AAdaptableAvoid defects that are difficult to grasp with precisionMultistage water/sewage treatmentFlotationSlurryCopper

The invention relates to an ore dressing technology for separating copper, lead and zinc in complex polymetallic sulphide ores, in particular to an electric potential modulation and preferential flotation process for copper-lead-zinc sulphide ores, which comprises the steps of copper, lead and zinc selection; copper is preferentially floated; the electric potential Eh of an ore slurry is between 35 below zero and 15 below zero mV; the PH value of the ore slurry is between 7.50 and 8.50; LP-01 is used as a collecting agent; and YN and ZnSO4 are used as inhibitors. The process has the advantages of solving the problems that the prior flotation process has large difficulty in separating the copper and lead and the copper and zinc, poor quality of concentrated ore and higher cost.

Owner:罗仙平

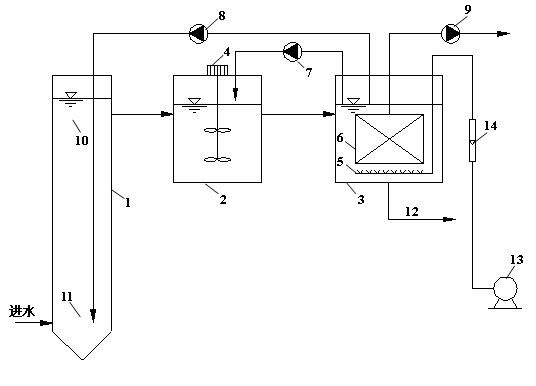

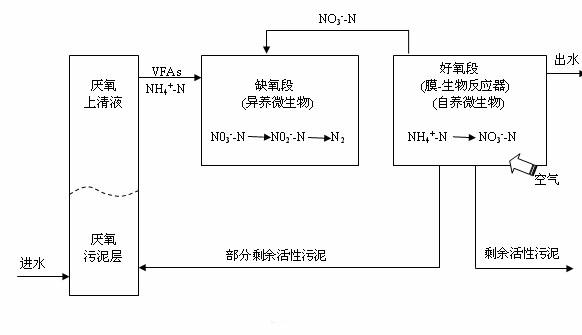

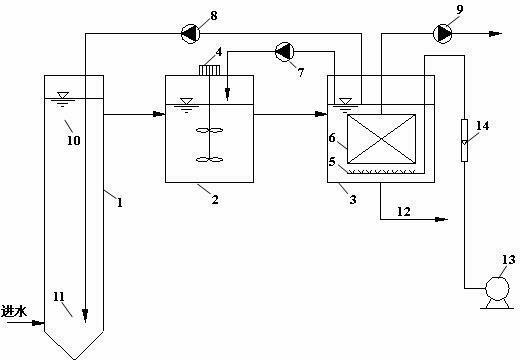

Process for enhancing denitrogenation of membrane bioreactor by anaerobic fermentation acid production

InactiveCN102502959APromote denitrificationAchieve reductionTreatment with anaerobic digestion processesActivated sludgeFiltration

The invention relates to a process for enhancing denitrogenation of a membrane bioreactor by anaerobic fermentation acid production. The process adopts an enhanced anaerobic tank, an anoxic tank and an aerobic tank. After entering the process, the sewage undergoes biochemical treatments including anaerobic fermentation, anaerobic denitrification and aerobic nitrification under the action of different kinds of microorganisms, and finally the effluent is sucked and collected by membrane filtration. By optimizing the growth environment of microorganisms in the anaerobic section, the process, on the one hand, promotes hydrolysis acidification of particle-stage organic matters (including colloid-state organic matters), slowly-degradable organic matters and hardly-degradable organic matters in the raw sewage, and on the other hand, produces acids from the excessive activated sludge which is discharged to the anaerobic tank to provide high-quality carbon sources for anaerobic denitrification. Besides, the process enhances the biological denitrification process by increasing sludge concentration, solves the problem of insufficient carbon source in biological denitrification process, and achieves the purpose of removing total nitrogen from the sewage with high efficiency by virtue of high-efficiency cut-off and separation characteristics of the membrane. The process can supplement carbon sources to the denitrification section for enhanced denitrogenation by fully utilizing converted carbon sources in the incoming water and carbon sources generated by sludge fermentation in the process without needing extra carbon sources. The process is simple and flexible in control, and the total nitrogen in the effluent can reach or exceed the first-class (A-class) discharge standard.

Owner:TONGJI UNIV

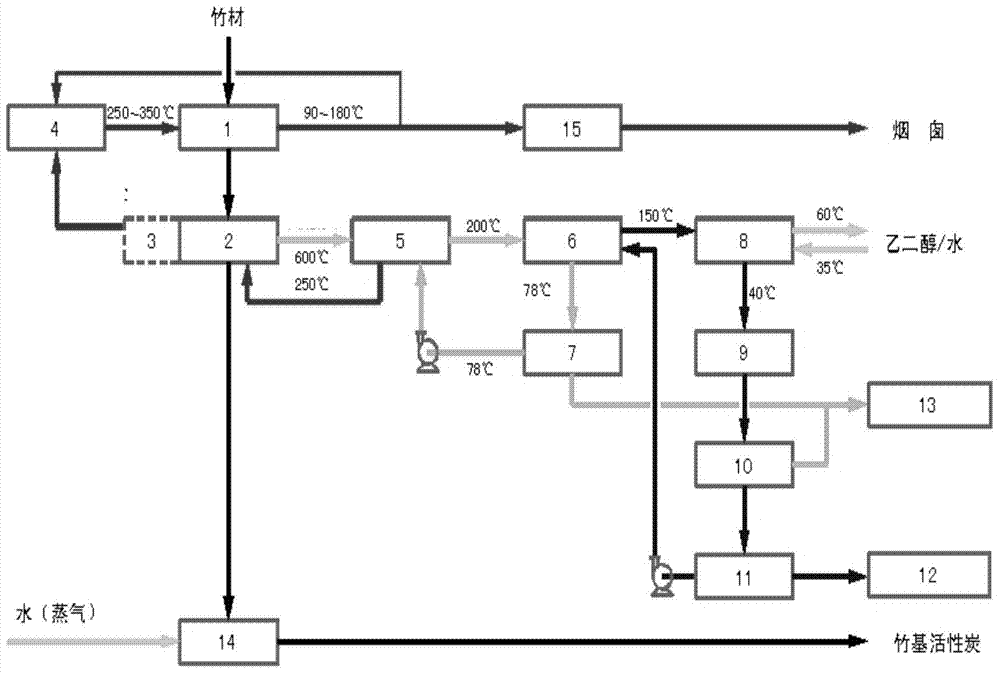

Method for preparing bamboo-based activated carbon and production device thereof

The invention provides a method for preparing a bamboo-based activated carbon and a preparation device thereof. The method comprises the following steps: A, drying, namely crushing bamboo materials at 250-350 DEG G and drying the crushed bamboo materials by drying air; B charring, namely charring the dry bamboo materials under the oxygen deficit condition by using 550-700 DEG C pyrolysis gas as thermal supports; C activating, namely spraying water steam to the charred bamboo materials, activating the bamboo carbon under the oxygen deficit condition at the activating temperature of 900-1000 DEG C, and cooling the activated bamboo carbon to obtain the bamboo-based activated carbon. The reaction is uniform and complete, the water steam in the activating process is completely contacted with the charred material, the generated activated carbon does not easily head and scale in the furnace, and the stability of product quality and the rate of carbon are improved. Moreover, the charring dry-distillation residual heat is completely utilized, the energy consumption is reduced, the charring dry-distillation by-products are recovered, the fume emission is reduced, the pollution to environment is reduced, and the comprehensive utilization rate of the bamboo materials is improved.

Owner:HUNAN HUAYIN ENERGY TECH

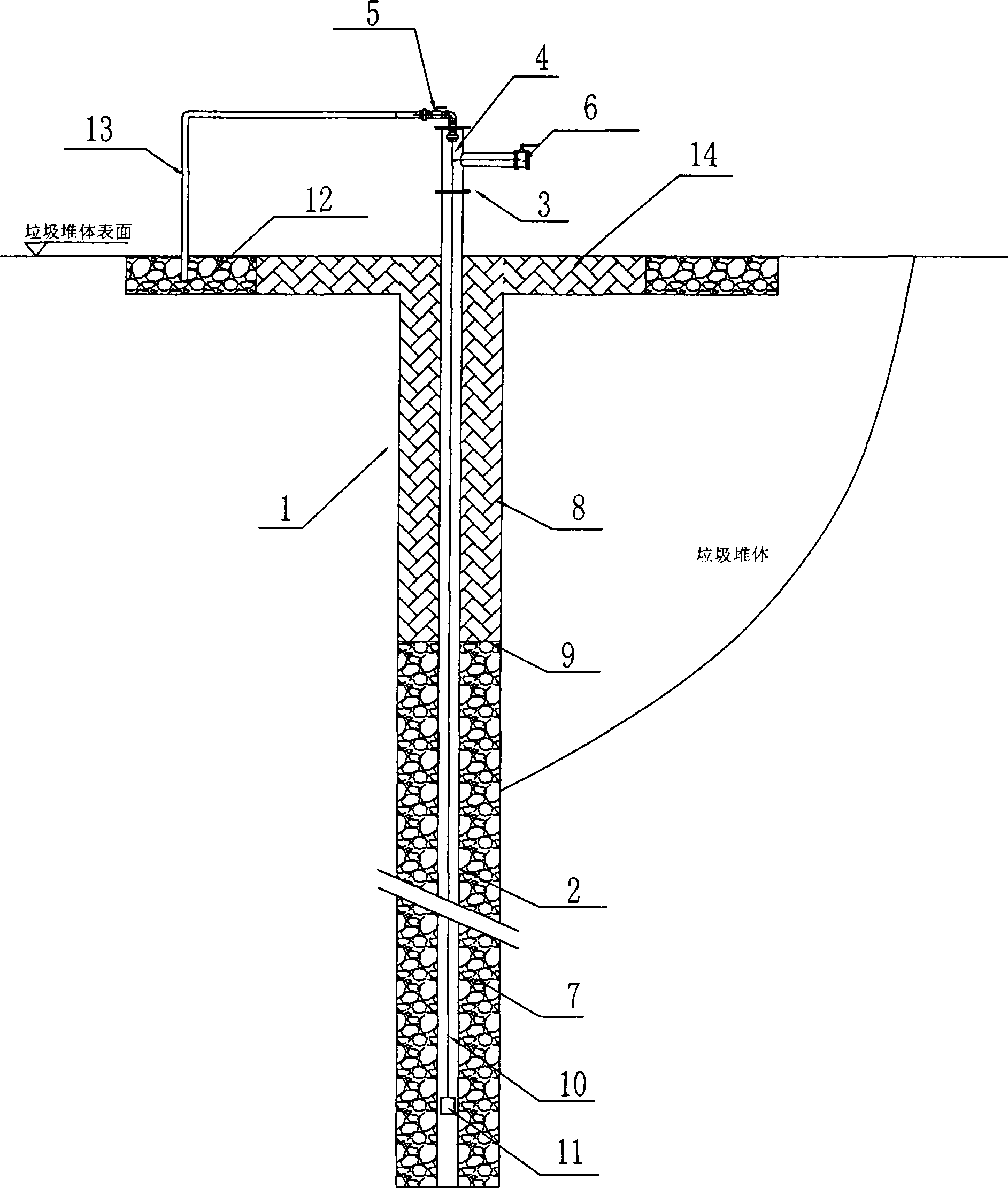

Refuse landfill extraction well and leachate in-situ recharging composite system

InactiveCN101480656AReduce effluxIncrease productionSolid waste disposalEnvironmental engineeringCompound system

The invention relates to an air suction well and percolating liquid original-position recharging compounding system for a refuse landfill field, which is characterized by comprising an air suction drilled shaft, an air suction pipe, a columnar gravel or cobble backfilling layer, a columnar clay backfilling layer, a non-woven fabric layer, a well-internal water discharge pipe, a percolating liquid recharging layer, a recharging pipe, a clay layer for preventing direct recharging. Furthermore, the air suction well and percolating liquid original-position recharging compounding system sucks the percolating liquid through a water discharge pump arranged in the air suction well and recharges the percolating liquid on the spot, thereby not only preventing the refuse landfill field being paved with multiple percolating liquid recharging pipes, but also being beneficial to the degradation of the refuse landfill field and to the increase of the output of landfill gas and the using quantity of the landfill gas of the refuse landfill and effectively decreasing the discharge quantity of the percolating liquid. The invention has the advantages of simple structure, convenient construction, good back percolation effect and low maintenance cost.

Owner:NANJING UNIV

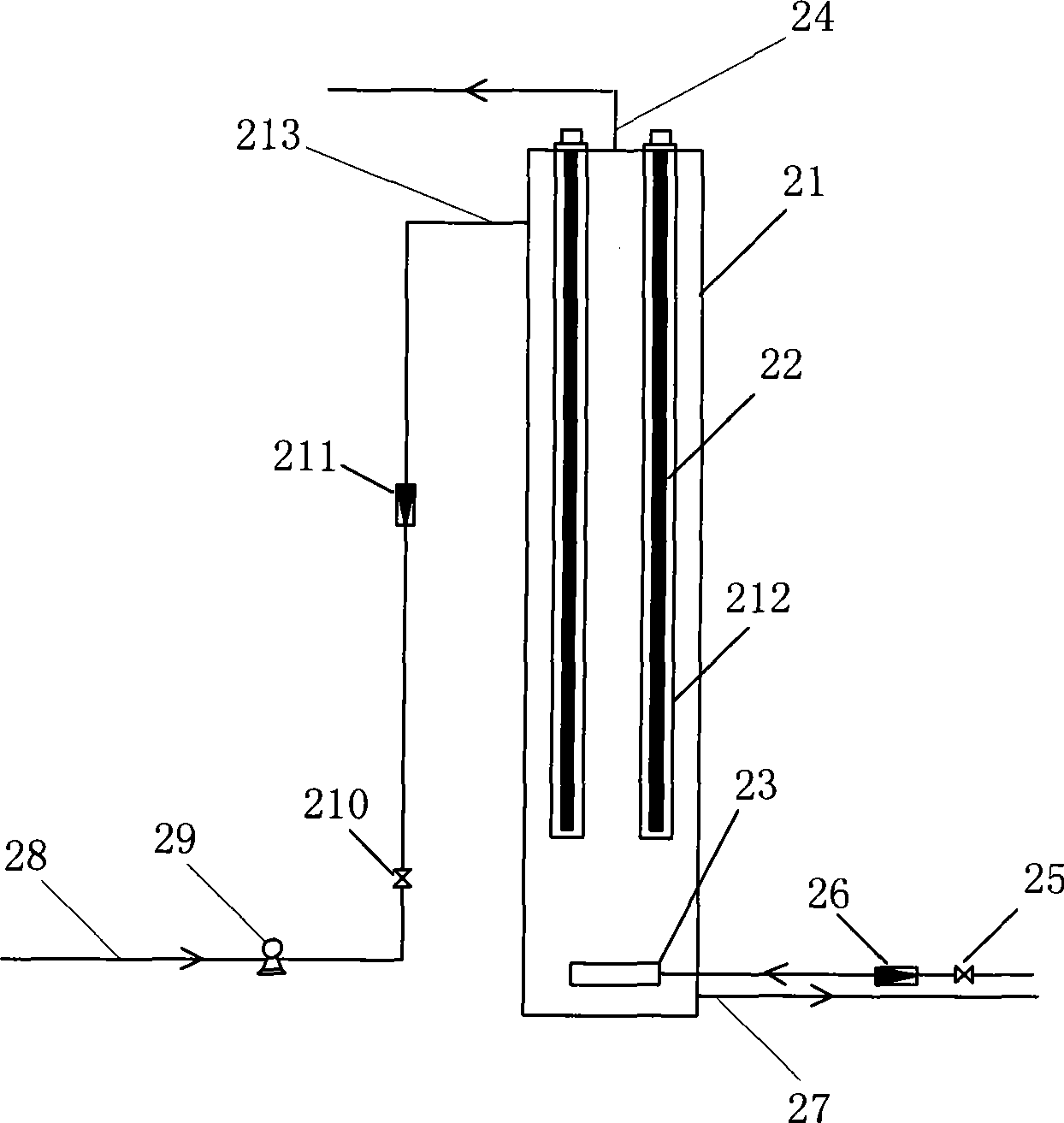

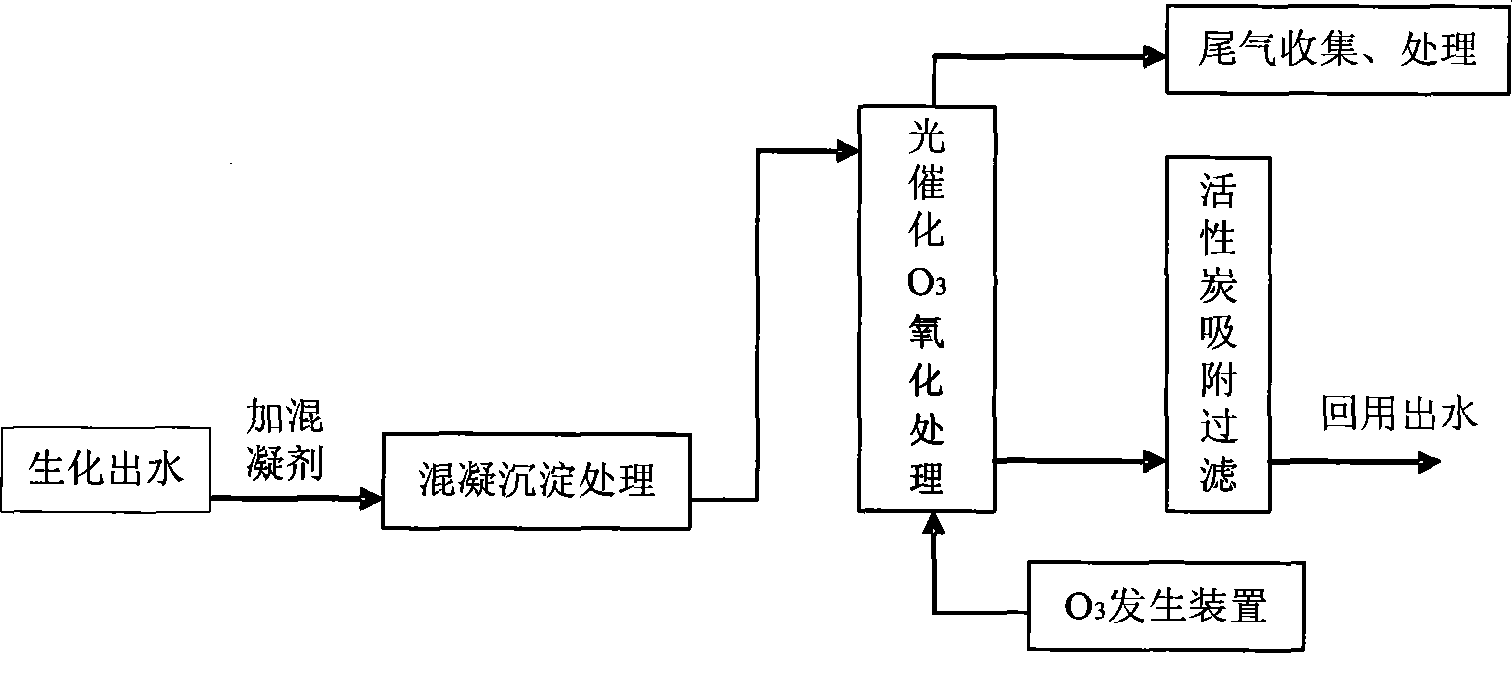

Processing system for implementing coking waste water reuse and processing method

InactiveCN101386461AReduce the concentration of ammonia nitrogenSimple equipmentWaste water treatment from metallurgical processMultistage water/sewage treatmentOrganic compoundThree stage

The invention discloses a treatment system and a treatment method that can realize the reuse of coking wastewater. The treatment system comprises a coagulating sedimentation tank, a photocatalytic O3 oxidation device and a filtration device; wherein the coagulating sedimentation tank is provided with a water inlet for introducing biochemical effluent and a sediment discharge port, the water outlet of the coagulating sedimentation tank is connected with the water inlet of the photocatalytic O3 oxidation device, the water outlet of the photocatalytic O3 oxidation device is connected with the water inlet of the filtration device, and the filtration device is provided with a water outlet connected with a recycled pipe. The invention can finish three stages of treatment, namely the coagulation, photocatalytic O3 oxidation and filtration of coking wastewater, and can decompose the harmful complex polymeric organic compounds in the coking wastewater into micro-molecular compounds or directly mineralize the harmful complex polymeric organic compounds by the organic combination of the coagulating sedimentation tank, the photocatalytic O3 oxidation device and the filtration device; therefore, the treatment system and the treatment method of the invention can ensure that the COD satisfies the standard of the production reuse water, further reduces the concentration of ammonia nitrogen, and has the functions of discolorization, deodorization and sterilization at the same time.

Owner:BEIJING SOUND ENVIRONMENTAL ENG

Liquid sulphur degassing device and liquid sulphur degassing method

Owner:ZHENHAI PETROCHEMICAL ENG CO LTD

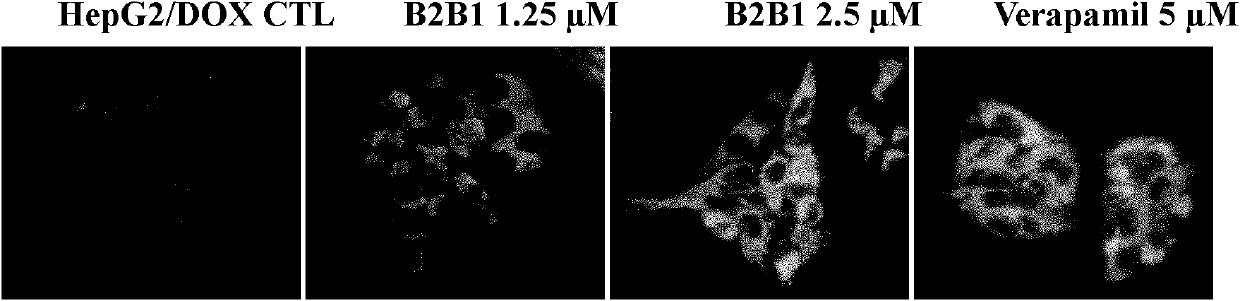

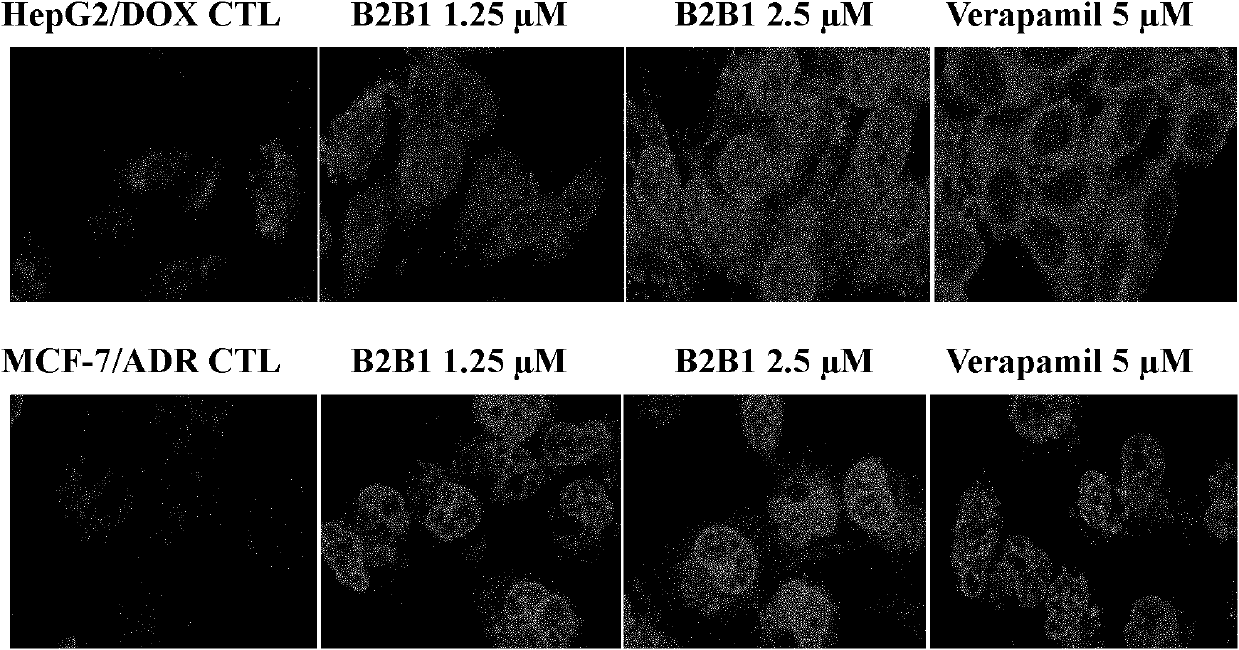

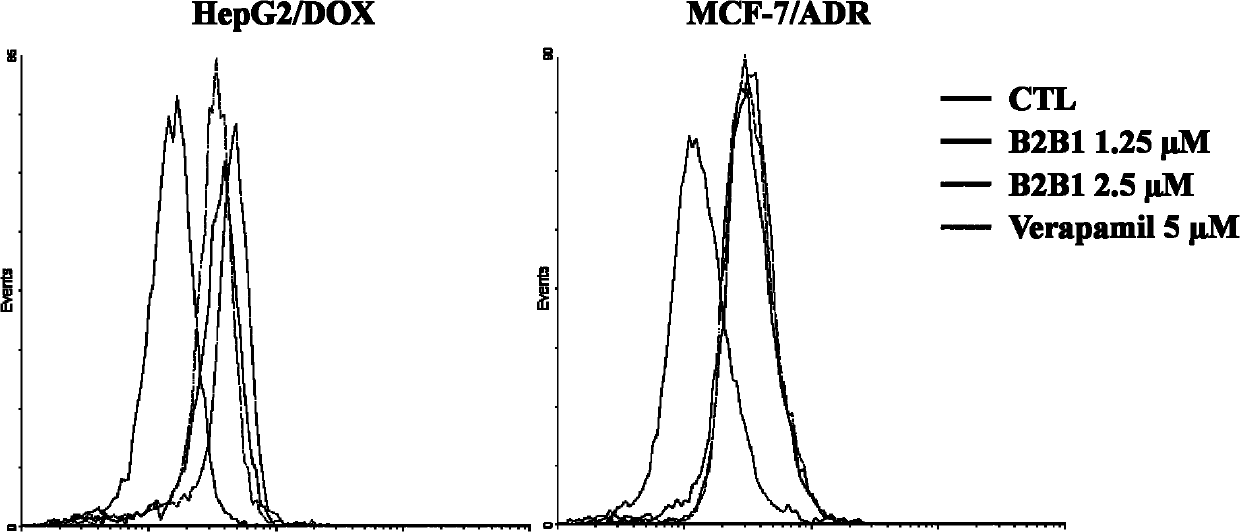

23-hydroxy betulinic acid derivative as well as preparation method and application thereof

ActiveCN102108092APrevent proliferationInhibitory activityOrganic active ingredientsSteroidsNon toxicityAcid derivative

The invention discloses a 23-hydroxy betulinic acid derivative as well as a preparation method and application thereof. The derivative has a structure as shown in a formula (I). The 23-hydroxy betulinic acid derivative can be used for resisting tumors and used as a tumor medicament resistance reversal agent. The 23-hydroxy betulinic acid derivative can be used for effectively inhibiting the proliferation of tumor cells and also can be used for obviously increasing the antipersonnel force of DOX (doxorubicin) on a P-glycoprotein overexpression cell strain HepG2 / ADM under the condition of non-toxicity dosage.

Owner:JINAN UNIVERSITY

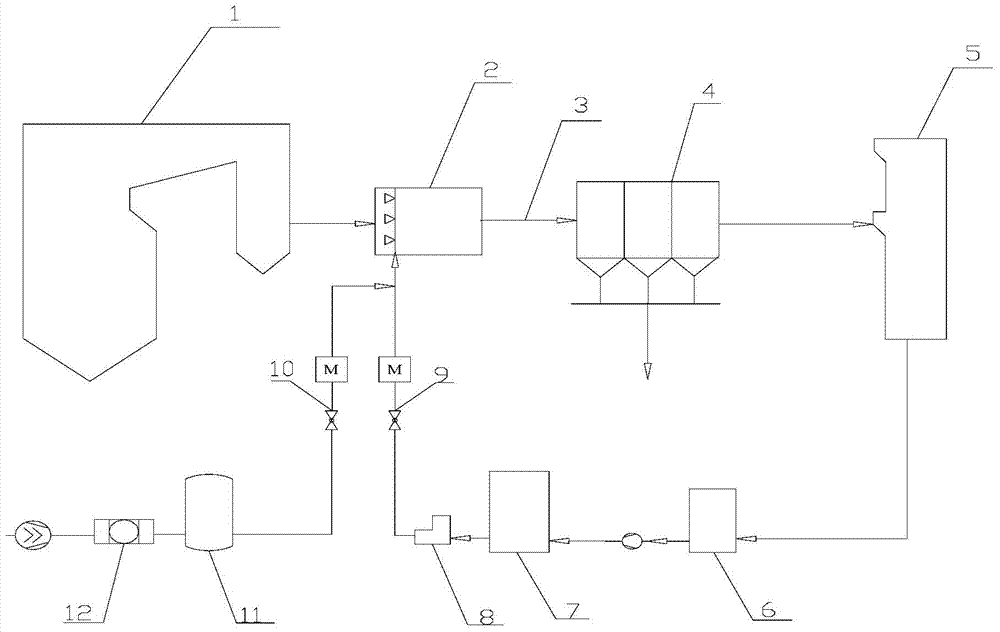

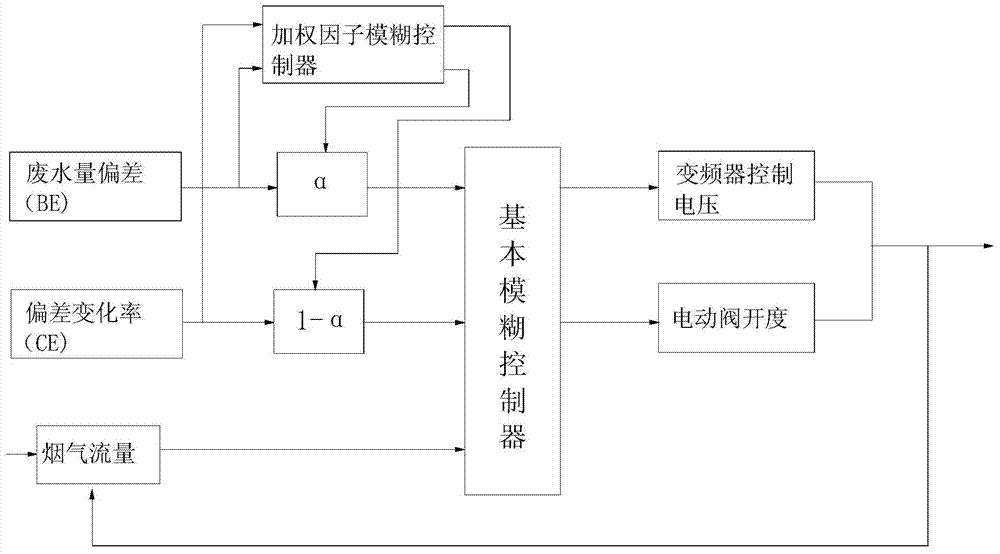

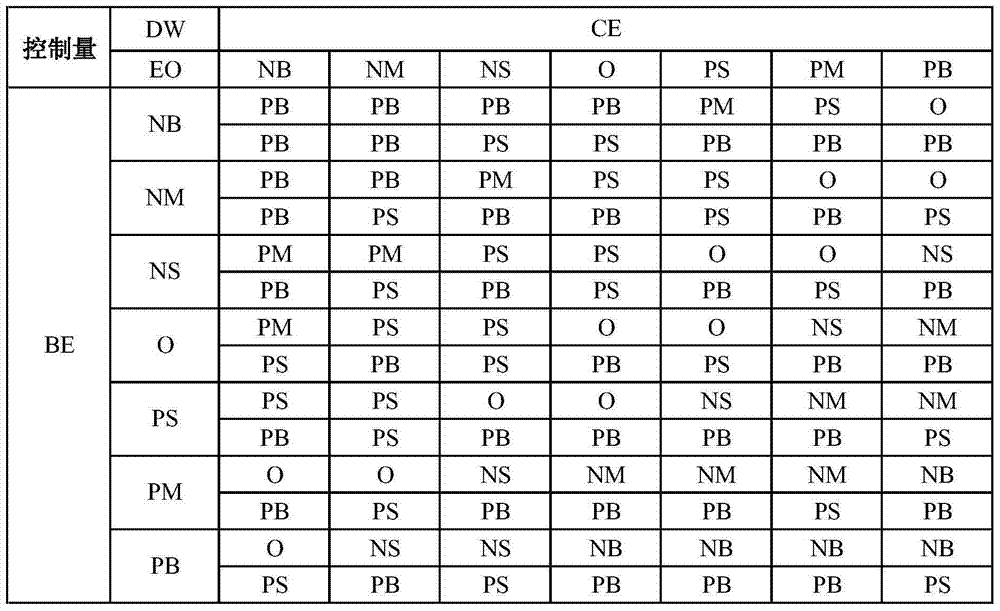

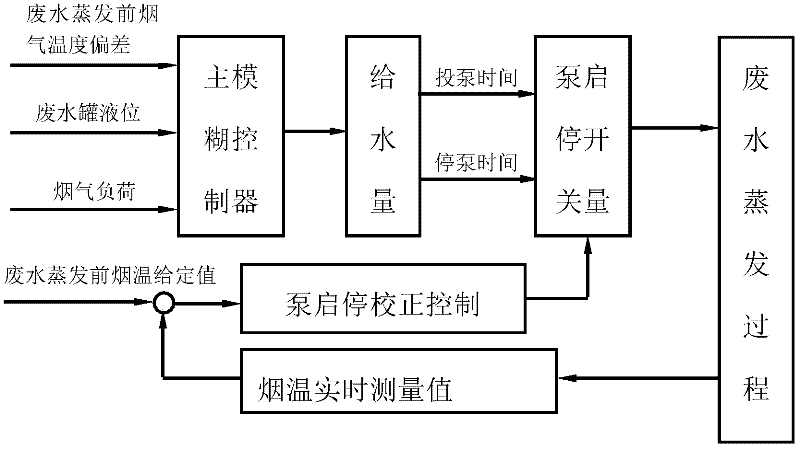

Self-adaptive fuzzy control method for evaporation treatment of wet-method smoke desulphurization waste water

ActiveCN103771553AIncrease credibilityReduce malfunctionWater/sewage treatmentWaste water treatment from gaseous effluentsAutomatic controlA-weighting

The invention relates to a self-adaptive fuzzy control method for evaporation treatment of wet-method smoke desulphurization waste water. The flow rate of the desulphurization waste water is used as a control target to be automatically controlled, the smoke flow rate, the waste flow rate deviation value and the waste water flow rate deviation variation rate are used as fuzzy control input parameters, the waste water pump frequency and the openness of an adjusting valve are used as control output quantity, and a three-input two-output fuzzy controller is established in a control system; the establishment of a control rule table is described by adopting the mathematical explanation method with a weighting factor. The self-adaptive fuzzy control method has the beneficial effects that the automatic control of the desulphurization waste water evaporation process is favored, so that the reliability of parameters can be improved, the possibility of the malfunction caused by the single flow rate deviation adjustment can be reduced, and the reliability of the control method can be improved.

Owner:大连森雅能源环保设备有限公司

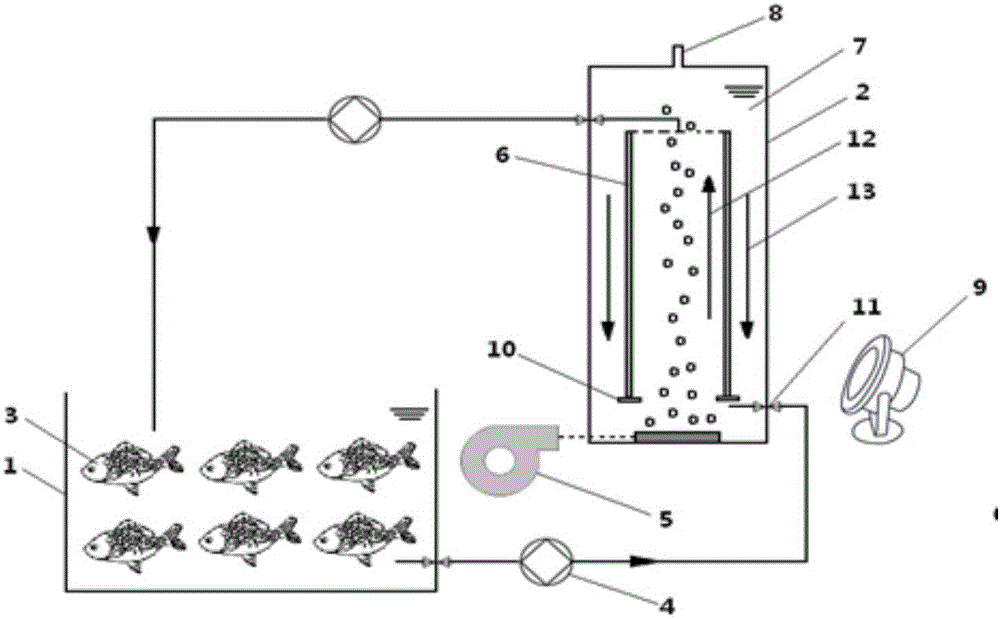

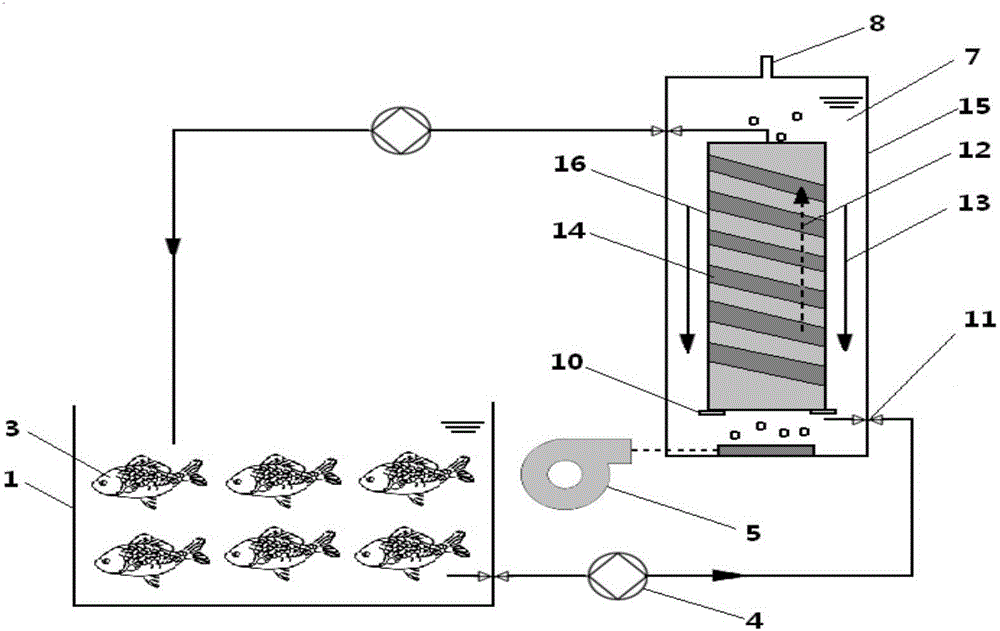

Fish-bacterium-algae-symbiotic ecological breeding system and running method thereof

ActiveCN105961303AImprove utilization efficiencyImprove purification effectClimate change adaptationPisciculture and aquariaOxygenWater processing

The invention discloses a fish-bacterium-algae-symbiotic ecological breeding system and a running method thereof. The fish-bacterium-algae-symbiotic ecological breeding system and the running method mainly aim at reducing aerating cost, improving the use efficiency of nitrogen and organisms and improving purification of breeding waste water. The system is composed of a fishpond, a photobioreactor, a membrane assembly, a light source and an aerating system, and is characterized in that aquaculture is combined with a bacterium-algae-symbiotic system and the membrane technology, the photosynthesis of microalgae continues, the dissolved oxygen concentration of processed waste water is high, healthy breeding of fishes is guaranteed, and aerating cost is reduced; due to excellent organism degradation and absorption of bacteria, the organism recycling capacity of the system is improved; due to the comprehensive synergistic effect of microalgae and microorganisms, waste water processing efficiency is improved; as microalgae absorb nitrogen substances, the nitrogen use efficiency of the system is improved; in addition, due to the adoption of the membrane technology, microalgae can be more easily harvested.

Owner:SHANDONG UNIV

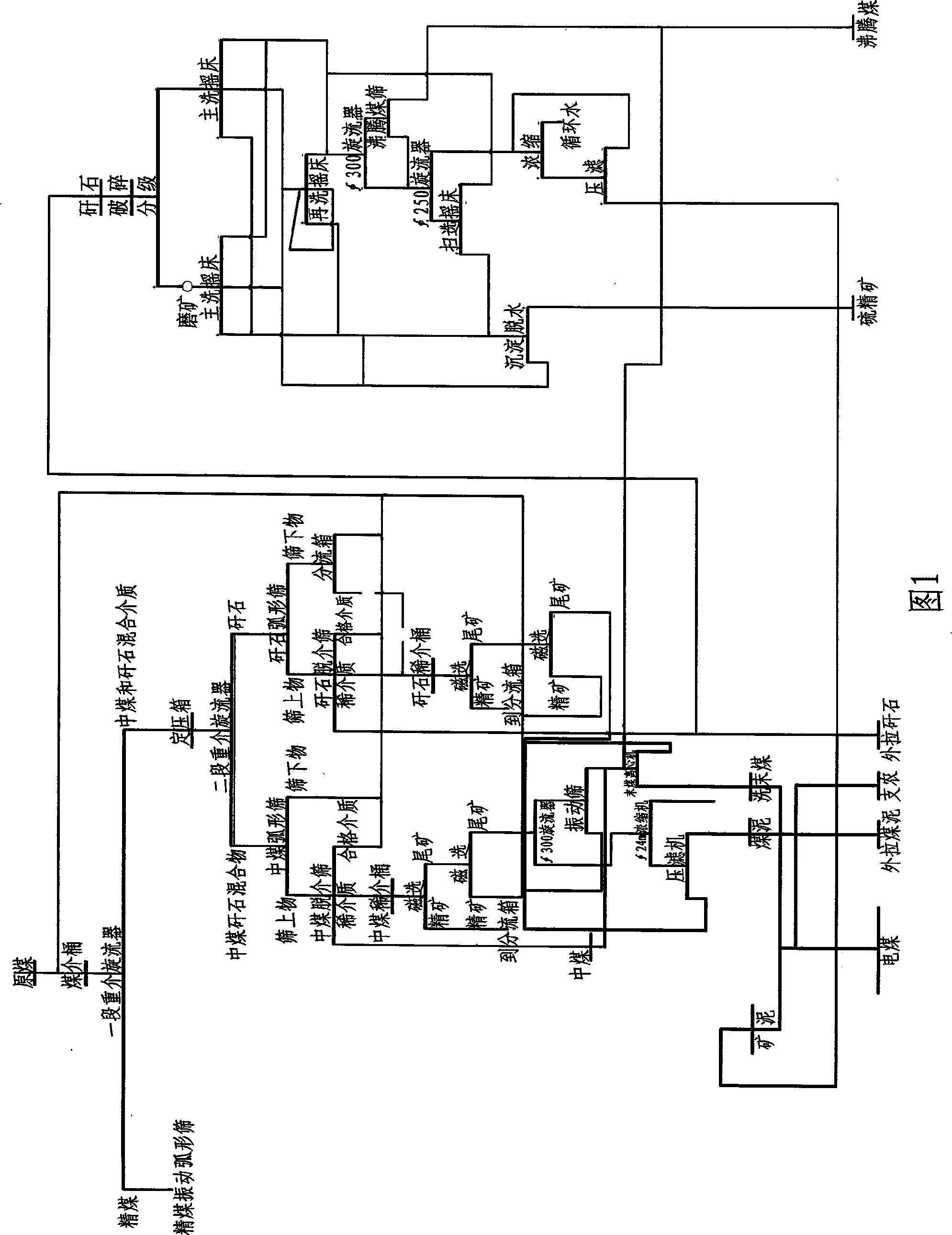

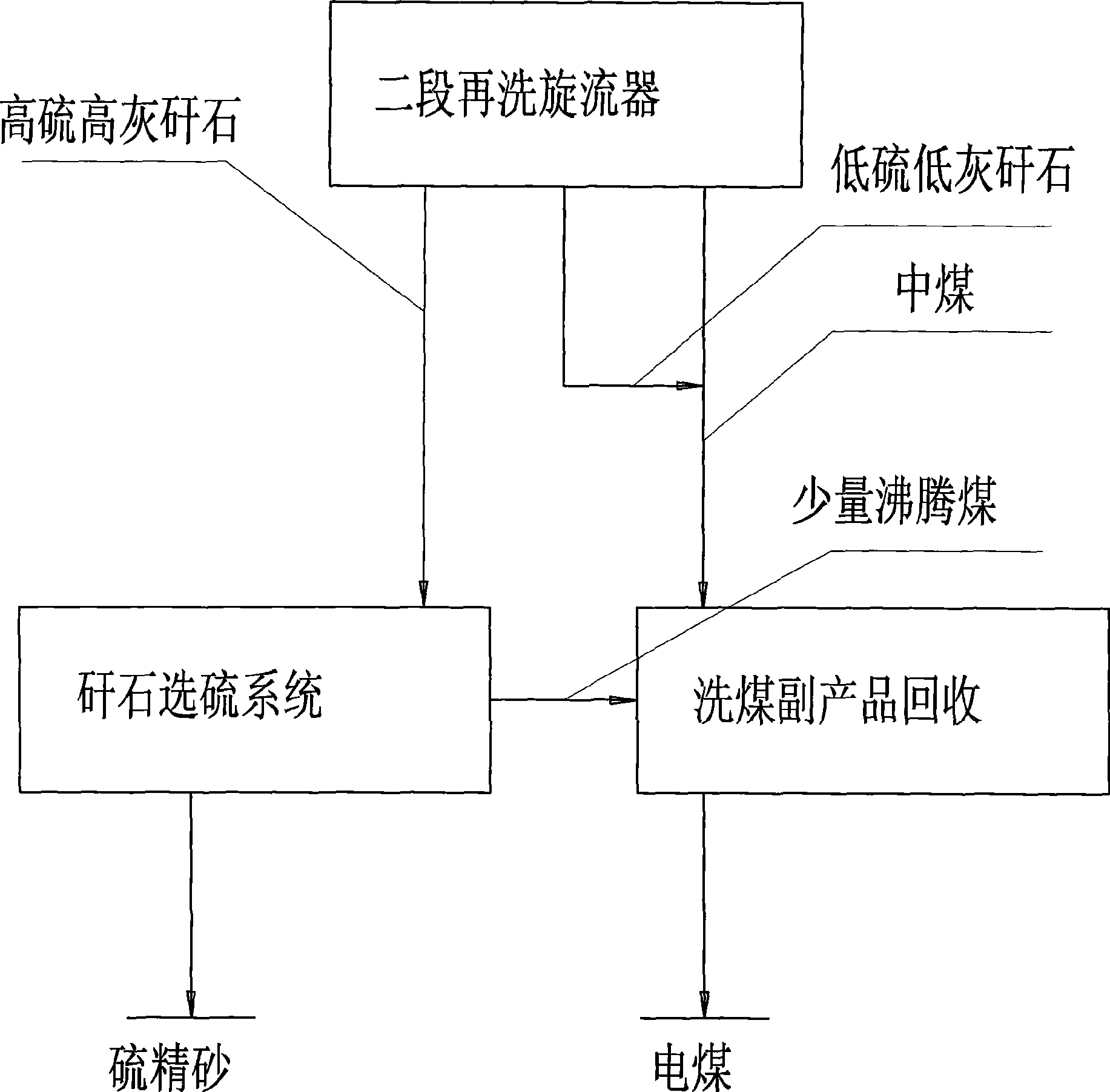

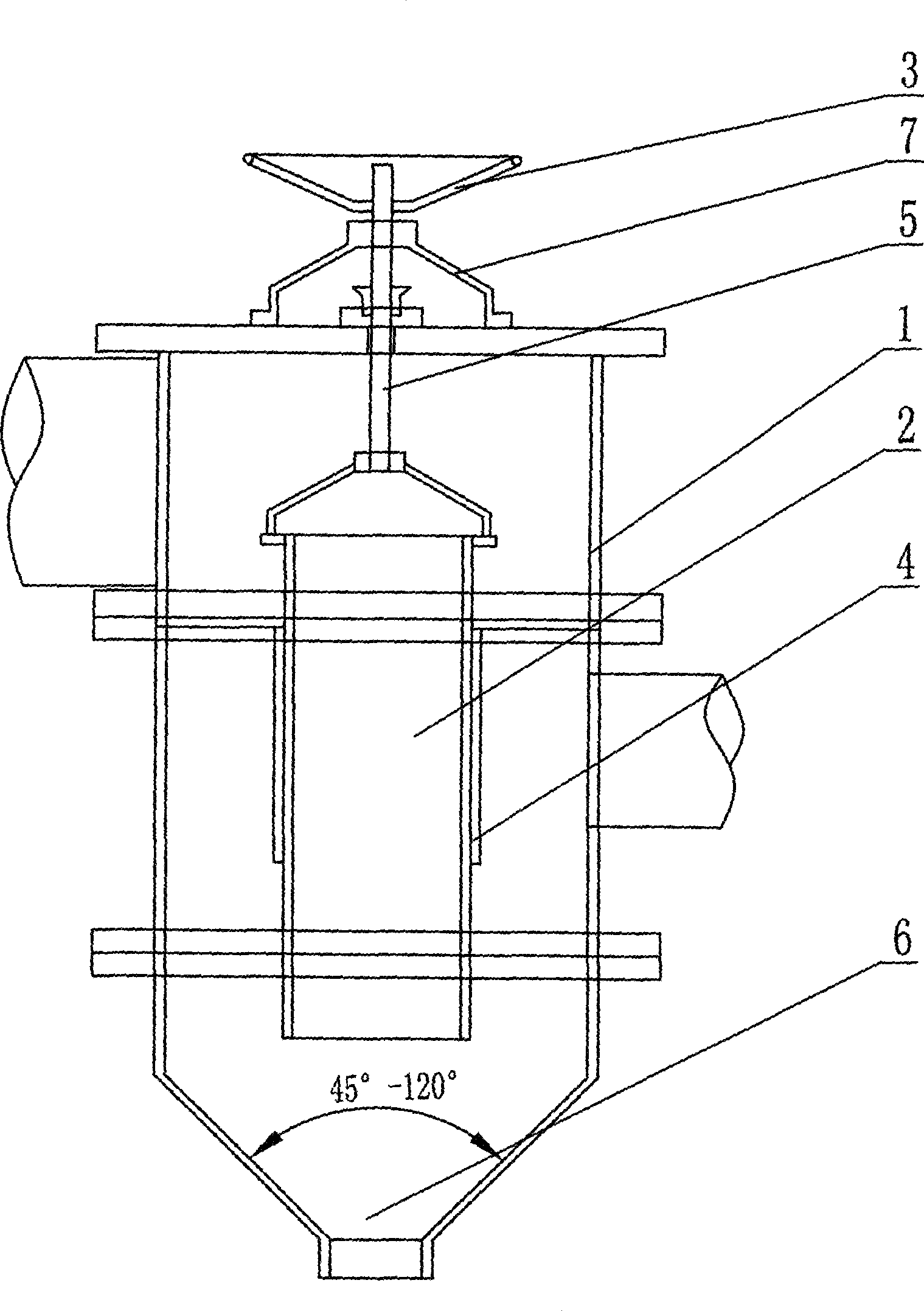

Power coal and sulfur concentrate sorting method and special device thereof

InactiveCN101455992AReduce entryReduce production pressureSievingReversed direction vortexSulfurVolumetric Mass Density

The invention discloses a method and a special device for separating thermal coal and sulfur concentrate. The method comprises: subjecting a mixture of raw coal and heavy medium suspension to the separation of a heavy medium cyclone, wherein a mixture of middlings and waste rocks separated by the heavy medium cyclone are placed into the heavy medium cyclone again to separate the middlings and the waste rocks. The process and the special device can separate middlings with a density of less than 1.8g / cm<3>, waste rocks with a density of less than 2.5g / cm<3> and waste rocks with a density with a density more than 2.5g / cm<3> at the same time, thereby preventing low-sulfur low-ash waste rocks from entering a sulfur separating system to a maximum degree and reducing the production pressure of the sulfur separating system.

Owner:重庆南桐矿业有限责任公司选煤厂

Curcumin solid lipid nanoparticle with P-gp inhibiting effect and preparation method thereof

InactiveCN103655519AImprove bioavailabilityImprove stabilityMetabolism disorderAntipyreticLipid formationSolubility

The invention relates to a curcumin solid lipid nanoparticle with a P-gp inhibiting effect, and a preparation method and application thereof. The curcumin solid lipid nanoparticle comprises the following components according to mass ratio: 0.05-1% of curcumin, 5-15% of lipid material, 5-15% of an emulgator and the balance of water. According to the invention, the solid lipid nanoparticle technology is adopted to encapsulate curcumin, so that the stability of medicine is increased, the solubility of medicine is improved, the excretion function of small intestines is reduced, and the bioavailability of curcumin is improved. In addition, the preparation method of the curcumin solid lipid nanoparticle, disclosed by the invention, is the emulsification evaporation and low temperature solidification method which is simple and convenient and suitable for being used in a laboratory, and has low requirements for an apparatus.

Owner:HARBIN MEDICAL UNIVERSITY

Hazardous waste incineration flue gas purification system and process

PendingCN110006050AReduce effluxAvoid synthetic temperature zonesCombustion technology mitigationIncinerator apparatusFlueActivated carbon

The invention discloses a hazardous waste incineration flue gas purification system and process. The hazardous waste incineration flue gas purification system comprises a rotary kiln, a waste heat boiler, a quench tower, a deacidifying tower, a bag-type dust remover, a low-temperature plasma reaction device and an absorption tower which are sequentially connected, the inlet of the waste heat boiler is provided with an SNCR denitration agent atomization jetting device, the quench tower is internally provided with an emergency cooling spraying device; an activated carbon jetting device and a drypowder jetting device are arranged on the upper part of the deacidification tower, a pre-cooling spraying device is arranged on the flue at the inlet of the absorption tower, a circulating spraying device and a demisting device are arranged in the absorbing tower. According to the method, the removal performance of SO2, NoX, smoke, HCl, HF and dioxin in the dangerous waste incineration flue gas are stable, particularly, the removal of the nitrogen oxides in the flue gas is high in efficiency, the concentration of the nitrogen oxides can be controlled to be 100 mg / Nm3, the operation stabilityis good; the system has the advantages of being simple in structure and low in investment operation cost.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

Steam low-displacement steam box

ActiveCN111557587AAchieve condensationShorten warm-up timeSteam cooking vesselsThermodynamicsInlet valve

The invention relates to a low-displacement steam box. The low-displacement steam box comprises an inner container, a water tank and an exhaust channel, and an exhaust port and a water inlet are formed in the side wall of the inner container. The water tank is provided with a water outlet connector and a water return connector. The low-displacement steam box also comprises a water inlet pipeline and an exhaust pipeline. The water inlet pipeline and the exhaust pipeline are adjacent to each other. One end of the water inlet pipeline is communicated with the water outlet interface. The other endof the exhaust pipeline is provided with a first water inlet branch and a second water inlet branch, a water inlet valve is arranged on the first water inlet branch, a water return valve is arrangedon the second water inlet branch, one end of the exhaust pipeline is communicated with the water return connector, the other end of the exhaust pipeline is communicated with an air inlet of the exhaust channel, and water in the water inlet pipeline can exchange heat with steam in the exhaust pipeline. Compared with the prior art, the amount of discharged steam can be reduced, the use experience ofa user is improved, meanwhile, the water in the water inlet pipeline can be preheated through the steam, and therefore the preheating time of the steam box is shortened, the time for heating water through a heating disc to generate steam is shortened, and the energy consumption of the steam box is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

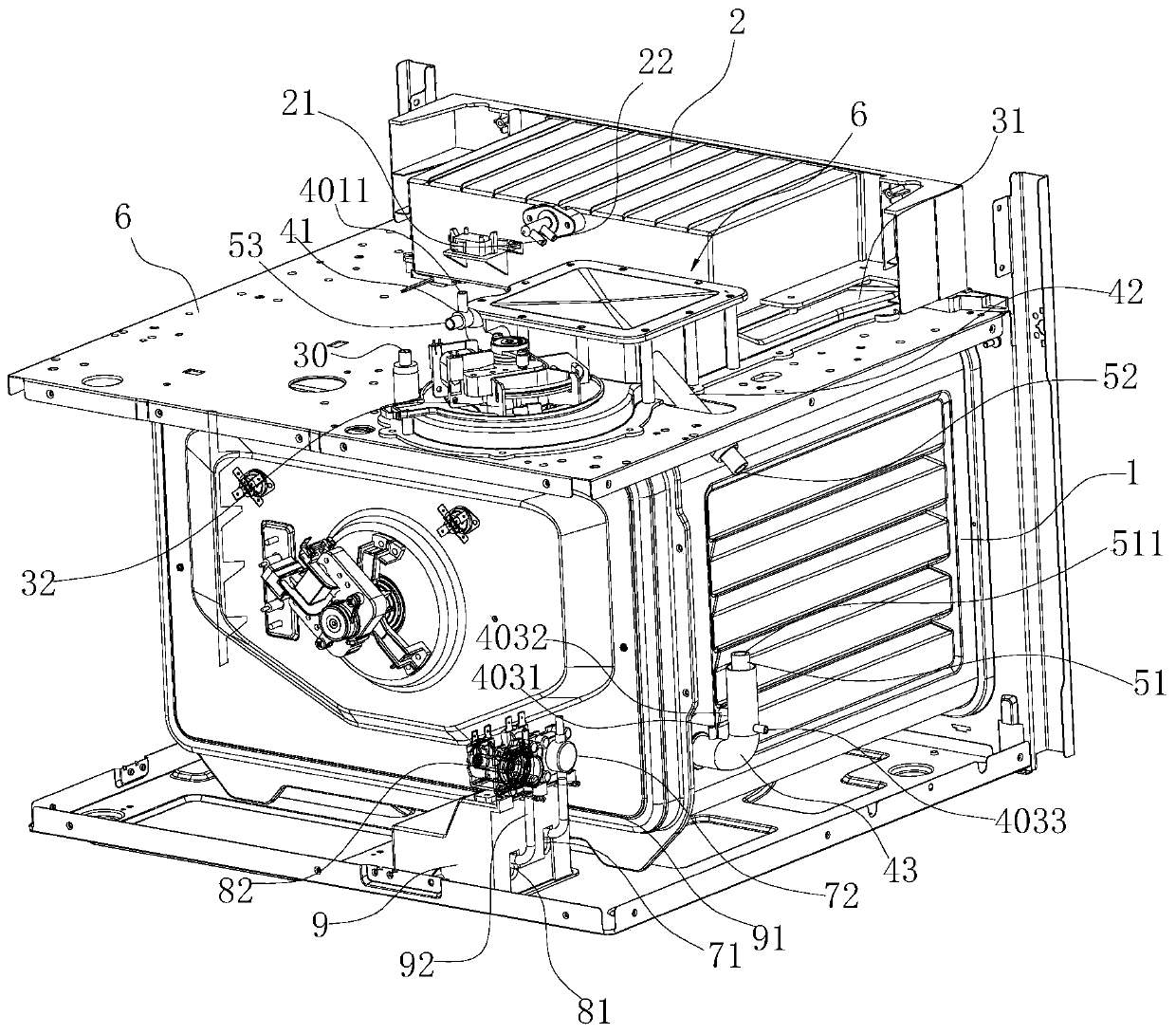

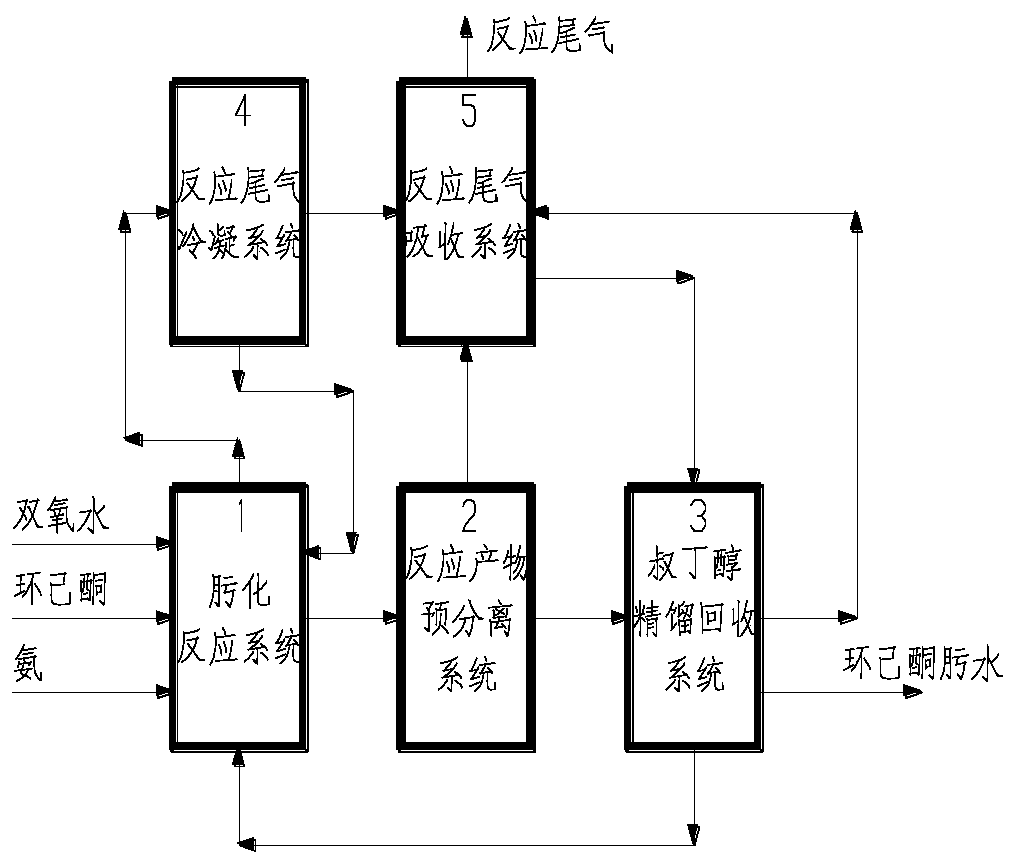

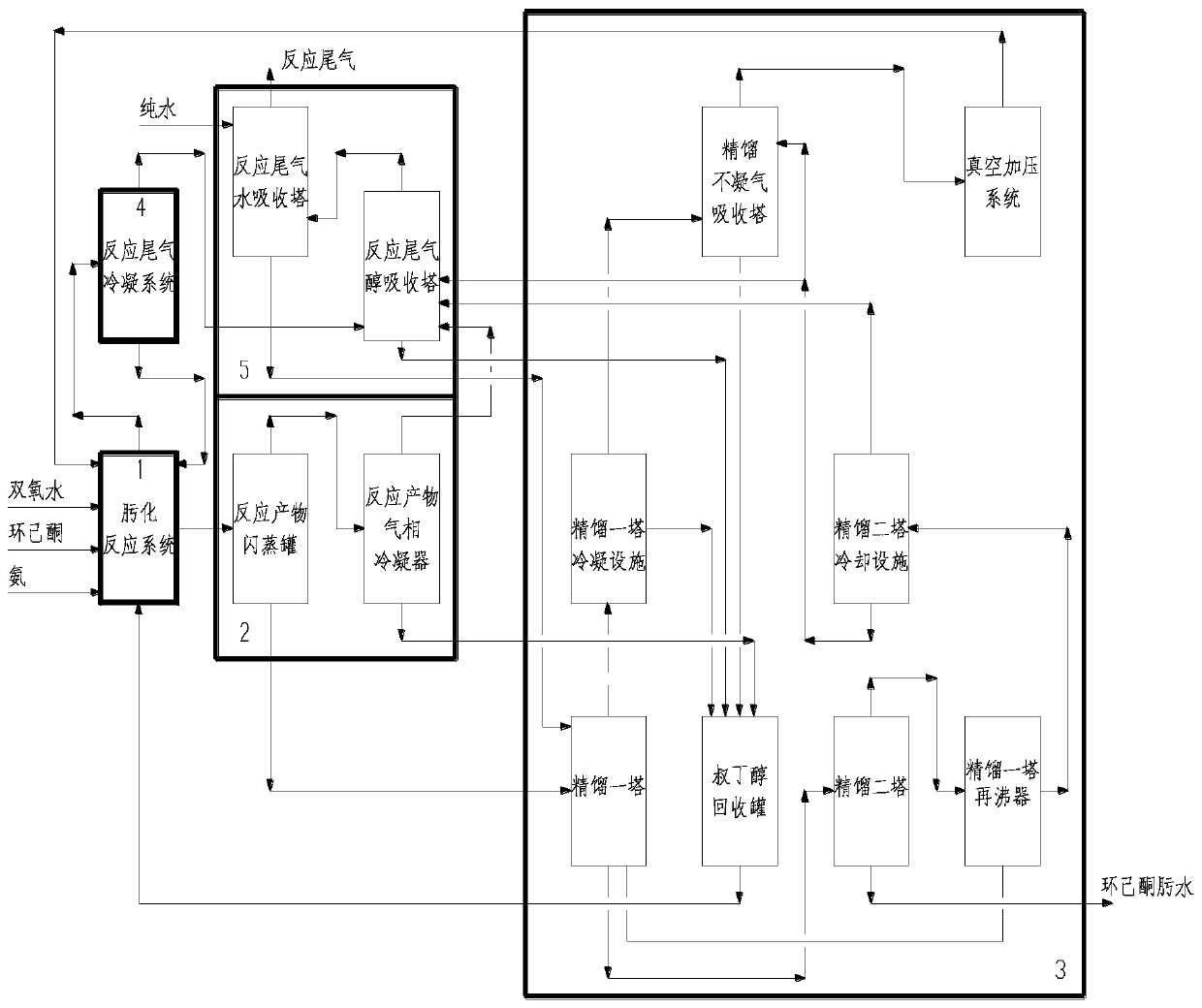

Device and method for recovering ammonia and tert-butyl alcohol in cyclohexanone ammoximation production process

PendingCN111302899AReduce dosageEasy to handleGas treatmentGeneral water supply conservationCyclohexanone oximeChilled water

The invention discloses a device and a method for recovering ammonia and tert-butyl alcohol in a cyclohexanone ammoximation production process. The device consists of an oximation reaction system, a reaction product pre-separation system, a tert-butyl alcohol rectification recovery system, a reaction tail gas condensation system and a reaction tail gas absorption system. According to the invention, the reaction tail gas absorption system adopts two-stage absorption of tert-butyl alcohol and water, so that the desalted water amount for absorption is greatly reduced, the ammonia, tert-butyl alcohol and water amount to the tert-butyl alcohol rectification recovery system are reduced, the water amount in the cyclohexanone-oxime aqueous solution is reduced, and the toluene circulation amount and energy consumption of a downstream cyclohexanone-oxime refining system are favorably reduced; the reaction product pretreatment system is arranged, so that the treatment load of the tert-butyl alcohol rectification recovery system can be reduced, and the condensation effect of the rectification tower I is improved; double-effect rectification is adopted in the rectification recovery system, anda condensation, absorption and vacuum pressurization combined process is adopted in rectification of non-condensable gas, so that the vacuum load and chilled water consumption are reduced; and the steam consumption can be saved by 40-50%, the cooling water consumption can be reduced by 35-50%, the chilled water consumption can be reduced by 10%, the desalted water consumption can be reduced by more than 50%, the treatment load of related facilities can be reduced, and the energy can be saved.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

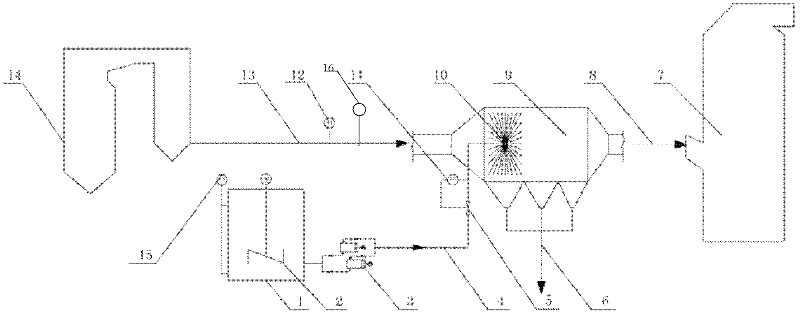

Automatic control method for evaporation treatment of wet flue gas desulphurization wastewater

InactiveCN102515297AImprove reliabilityReduce effluxUsing liquid separation agentWater/sewage treatmentAutomatic controlFlue gas

The invention provides an automatic control method for evaporation treatment of wet flue gas desulphurization wastewater. According to the invention, smoke load, deviation of smoke temperature before wastewater evaporation and a set temperature and a liquid level of a wastewater tank are used as fuzzy control input parameters, and the starting lasting time of a wastewater metering pump and the stopping time of the wastewater metering pump are used as control output quantities, so as to establish a three-input two-output fuzzy controller used for evaporation control of desulphurization wastewater. The invention provides an intelligent control method for an evaporation process of desulphurization wastewater. The intelligent control method is suitable for the automatic control process of a desulphurization wastewater evaporation process; and by using the intelligent control method, the credibility of the input parameters is improved, the possibility of malfunction brought by single-flow deviation adjustment is reduced, and the reliability of the control method is enhanced.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

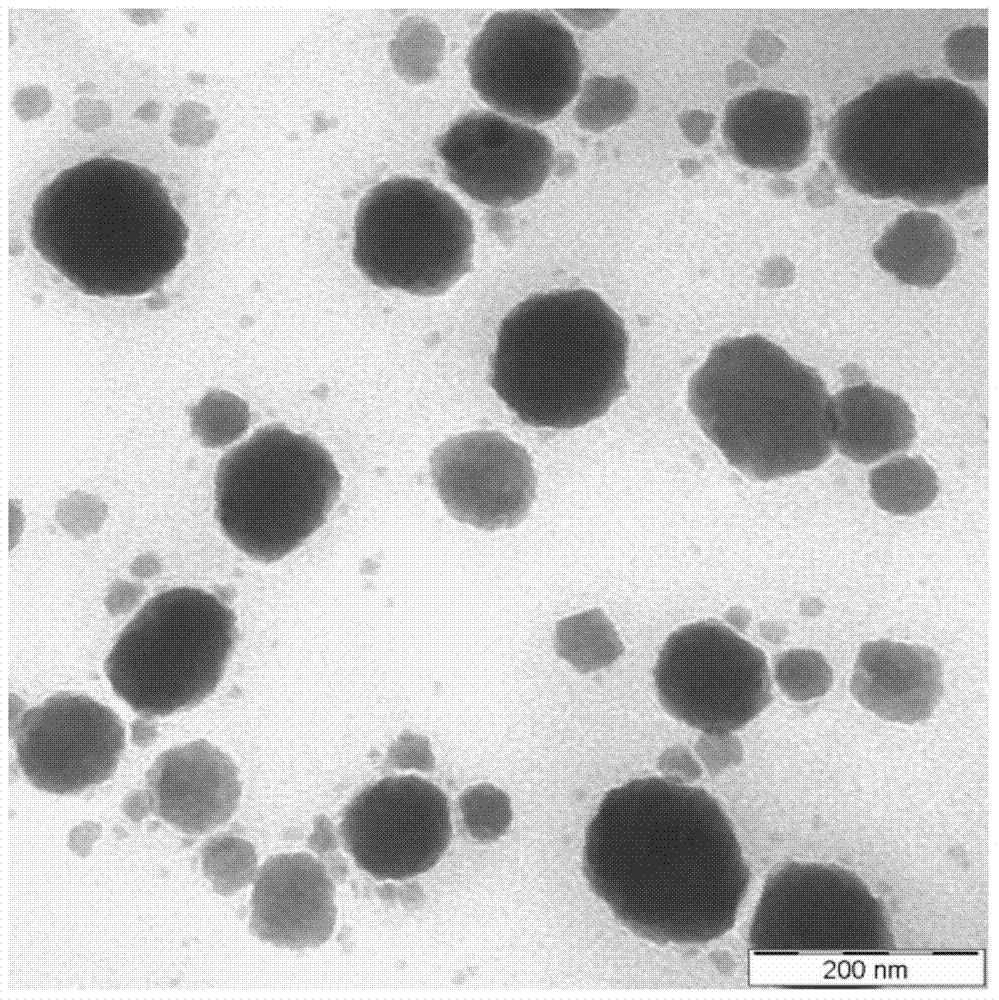

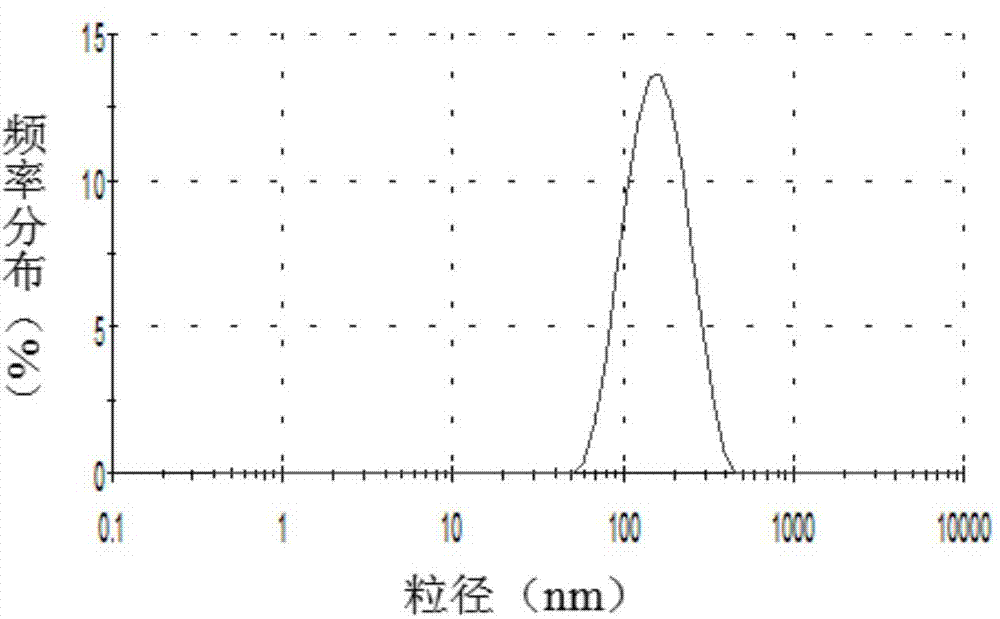

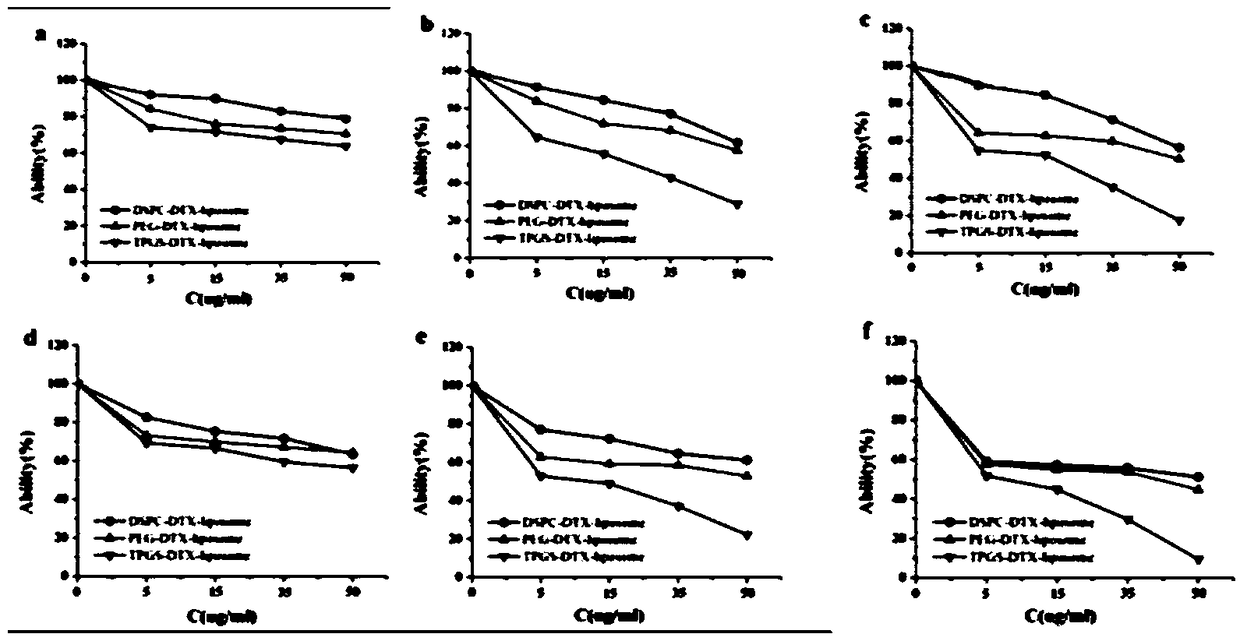

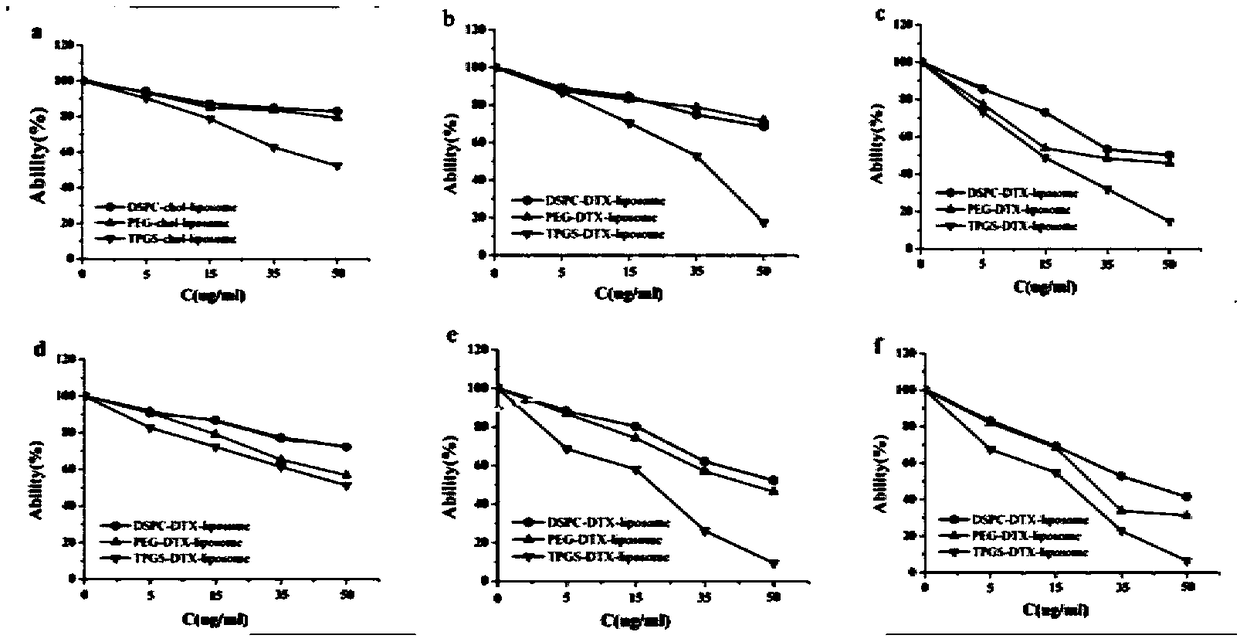

TPGS modified docetaxel liposome nano-drug delivery system and preparation method thereof, and application thereof

InactiveCN109224084AReduce systemic toxicityImprove solubilityOrganic active ingredientsPharmaceutical non-active ingredientsZeta potentialCholesterol

The invention relates to a TPGS modified docetaxel liposome nano-drug delivery system, a preparation method and an application thereof. The TPGS modified docetaxel liposome nano-drug delivery system uses phospholipid and cholesterol as membrane materials, Surfactant TPGS modified liposomes and docetaxel (DTX) as anticancer drug were prepared by membrane dispersion ethanol injection ultrasonic dispersion reverse evaporation and freeze drying. The particle size of nano-doxetaxel liposomes modified by TPGS is 80-200 nm, the zeta potential is 0+30 mV or 0-30 mV, the encapsulation efficiency is 75-99%, with a drug loading of 3-15%. The in vitro cell experiment and in vivo pharmacodynamic experiment of the TPGS modified docetaxel liposome nano-drug delivery system prepared by the invention showthat the nano-drug delivery system can inhibit P. Overexpression of gp, decrease of drug efflux, increase of drug enrichment in tumor cells, increase of cytotoxicity and apoptosis rate, increase of tumor therapeutic effect and reversal of multidrug resistance.

Owner:NINGXIA MEDICAL UNIV

Method for managing, circulating and utilizing nitronic oxide during golden smelting process

ActiveCN101029357AReduce the amount addedReduce manufacturing costProcess efficiency improvementNitrogen oxidesIron oxide

Method for treating and circulation utilizing nitro-oxide during gold smelting process is carried out by refining for gold mud by high-pressure reactor, nitric-acid reacting to obtain nitro-oxide yellow smoke, enclosing it into reactor, adding oxygen into reactor, oxidizing by nitric oxide while converting into nitric acid, metal oxidation and leaching-out reacting, removing nitric acid and purifying gold. It's cheap, circulated utilizes NOx, has less nitric acid, waste-gas discharge and no environmental pollution.

Owner:贵州金兴黄金矿业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com