Method for preparing bamboo-based activated carbon and production device thereof

A production device and activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of poor quality stability of bamboo-based activated carbon, uneven heating of materials, and many human-influenced factors, etc., to achieve uniform reaction fully, reduce the exhaust of flue gas, and improve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

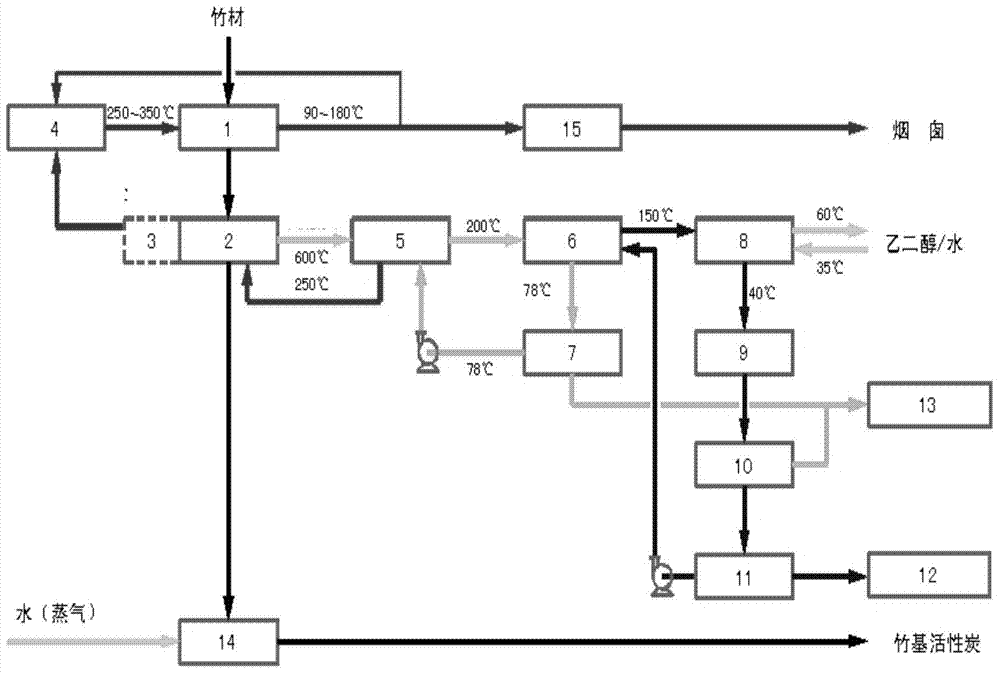

[0039] The preparation method of bamboo-based activated carbon of the present invention and an embodiment of production system are divided into four sections and are specifically as follows:

[0040] 1. Drying section

[0041] After the bamboo is crushed, it first enters the drying equipment (drying room) 1, and the drying room 1 uses a drying gas of 250°C-350°C to dry the broken bamboo, and the drying time is 0.5-2h. The gas mixer 4 is piped to the drying chamber 1, and the drying gas is delivered to the drying chamber 1 by the gas mixer 4 to dry the bamboo.

[0042] Preferably, the drying gas is a mixture of various gas components, mainly including the 900°C-1000°C high-temperature flue gas generated by the combustion of the heat source heating furnace 3 in the carbonization process, the 90°C-180°C drying tail gas and the gas generated by the bamboo during the drying process. The present invention preferably burns low-temperature pyrolysis gas and external fuel in the heati...

Embodiment 1

[0072] The same bamboo will be crushed into 11mm×11mm×5mm, sent to the drying room, and the bamboo will be dried and dehydrated with 300°C dry gas for 0.5h under normal pressure, and the dry tail gas will be recycled. The drying gas is composed of a mixture of high-temperature flue gas at 1000°C generated by the heating furnace and dry tail gas at 150°C.

[0073] Then the dried bamboo is sent to the integrated carbonization and activation furnace, and the pyrolysis gas at 600°C is used as the heat carrier to carbonize the dried bamboo under the condition of anoxic. The carbonization time is 1.5h, and the volatile content of bamboo charcoal reaches below 5%, and the carbonization is completed.

[0074] Spray high-temperature water vapor at the bottom of the carbonization and activation integrated furnace to activate the bamboo charcoal. The activation temperature is 900°C, the weight ratio of water vapor to carbon is 1:6, and the activation time is 2 hours. After cooling by the...

Embodiment 2

[0079] The Taojiang moso bamboo is crushed into 11mm×11mm×5mm, sent into the drying chamber 1, and dried and dehydrated for 0.5h with dry gas at 300°C under normal pressure, and the dried tail gas is recycled. The drying gas is composed of a mixture of high-temperature flue gas at 1000°C generated by the heating furnace and dry tail gas at 150°C.

[0080] Then the dried bamboo is sent to the carbonization and activation unit, and the pyrolysis gas at 600°C is used as the heat carrier to carbonize the dried bamboo under the condition of anoxic. The carbonization time is 1.5h, and the volatile content of bamboo charcoal reaches below 5%, and the carbonization is completed.

[0081] Spray high-temperature water vapor at the bottom of the carbonization and activation integrated furnace to activate the bamboo charcoal. The activation temperature is 900°C, the weight ratio of water vapor to carbon is 1:6, and the activation time is 1.8h. After cooling by the cooling device, the bamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com