Patents

Literature

504results about How to "Improve product quality stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

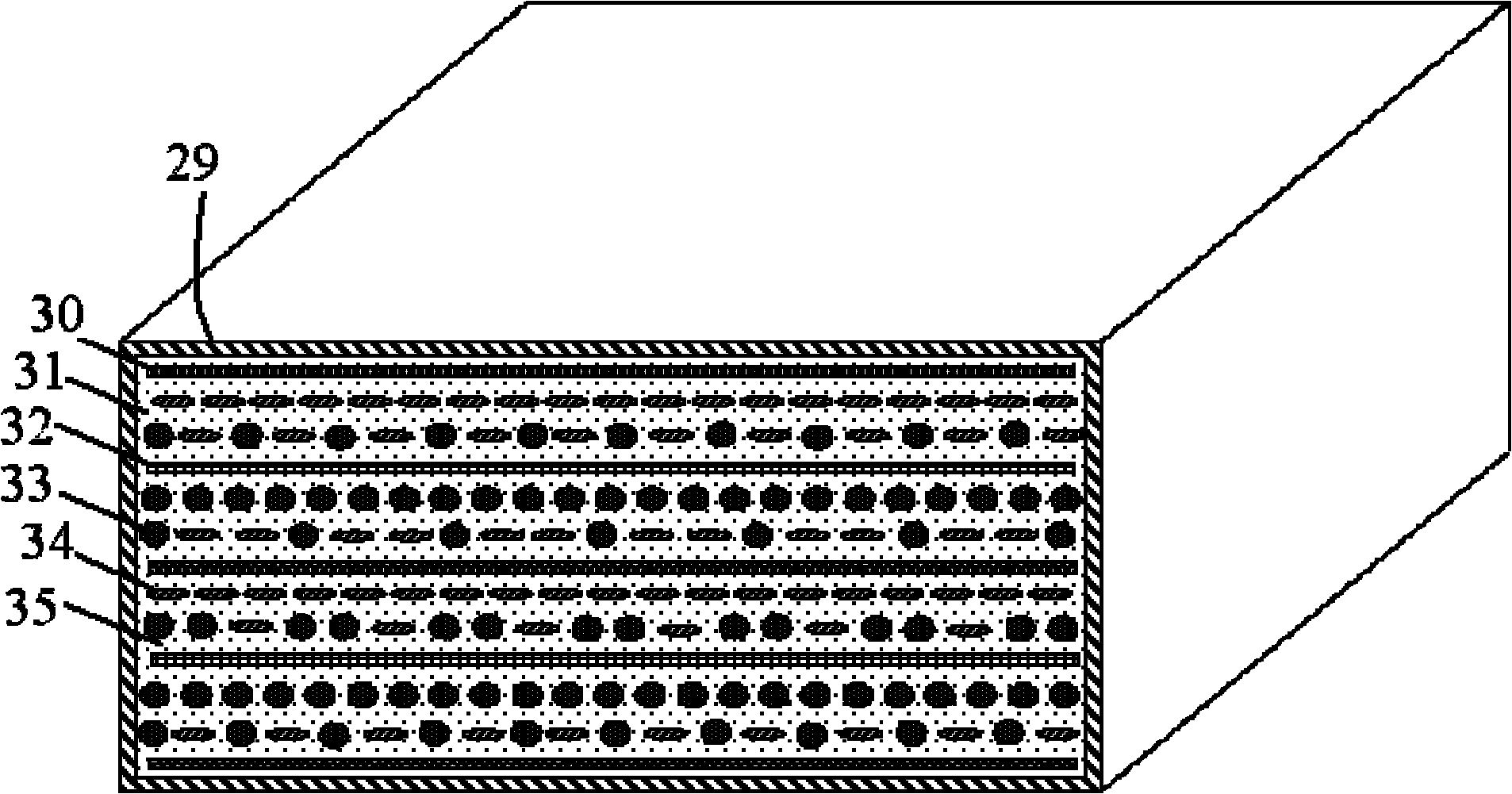

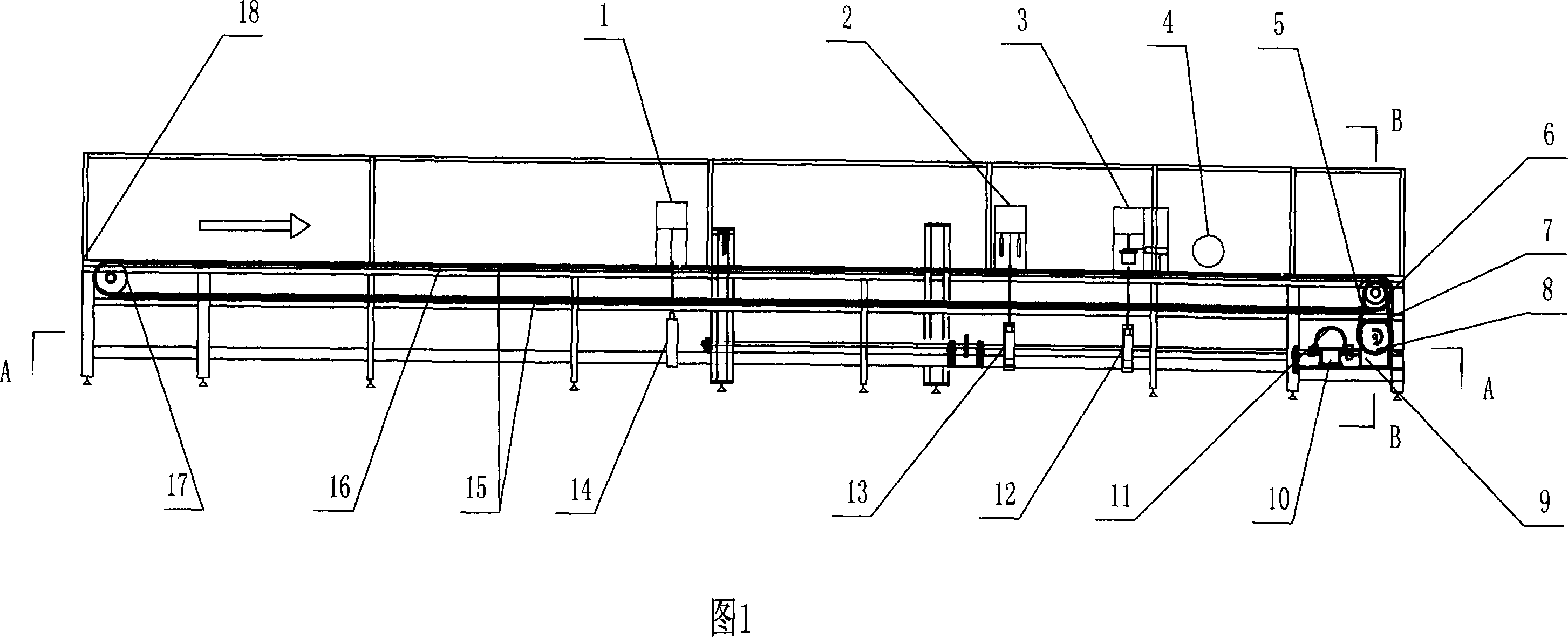

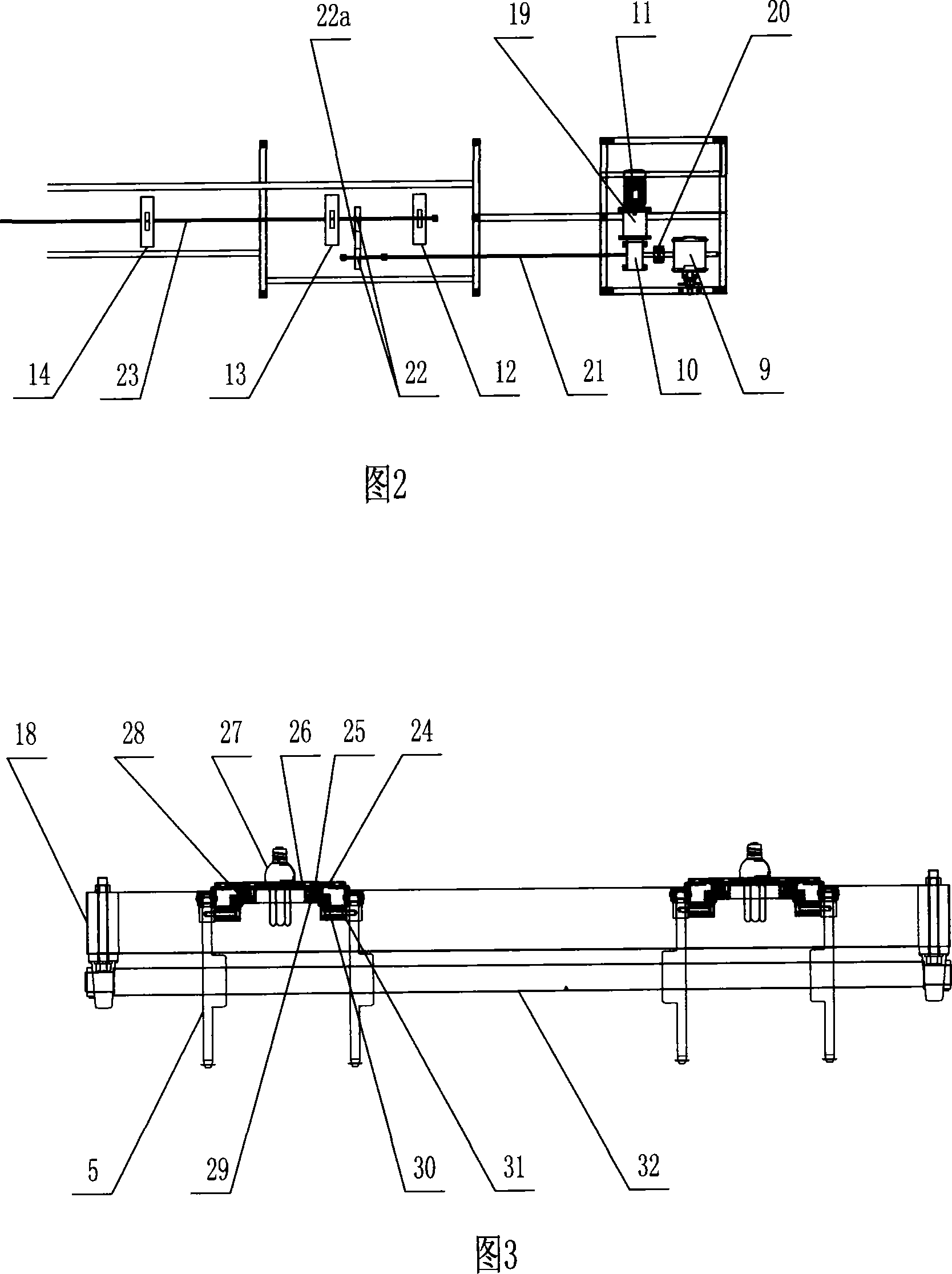

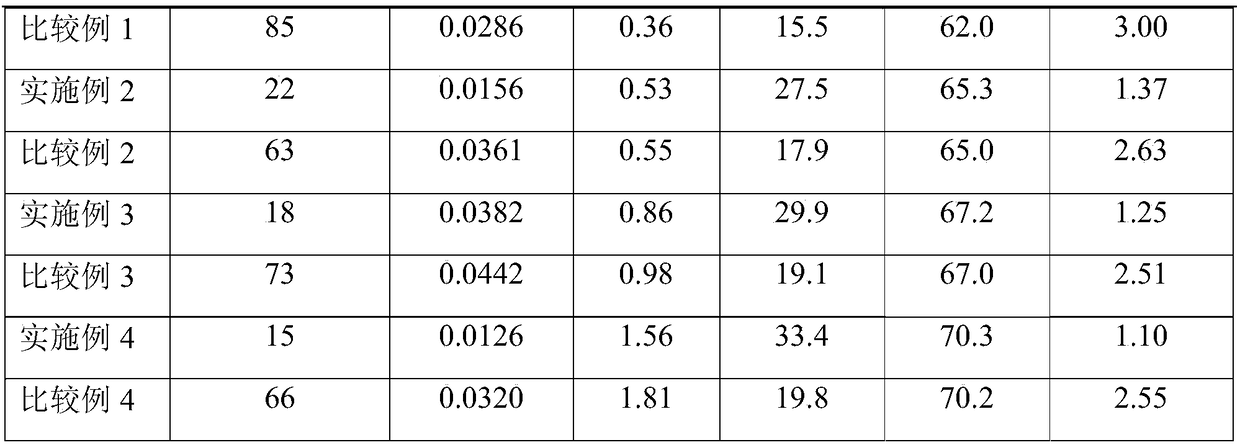

Combined fiber reinforced water-blown polyurethane hard foam composite board, production method and production equipment thereof

ActiveCN102059833AHigh strengthImprove rigiditySynthetic resin layered productsGlass/slag layered productsGlass fiberCarbon fibers

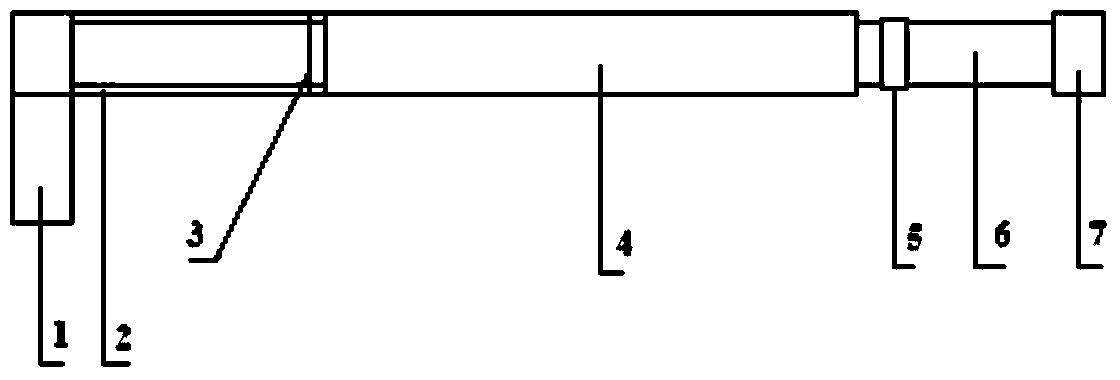

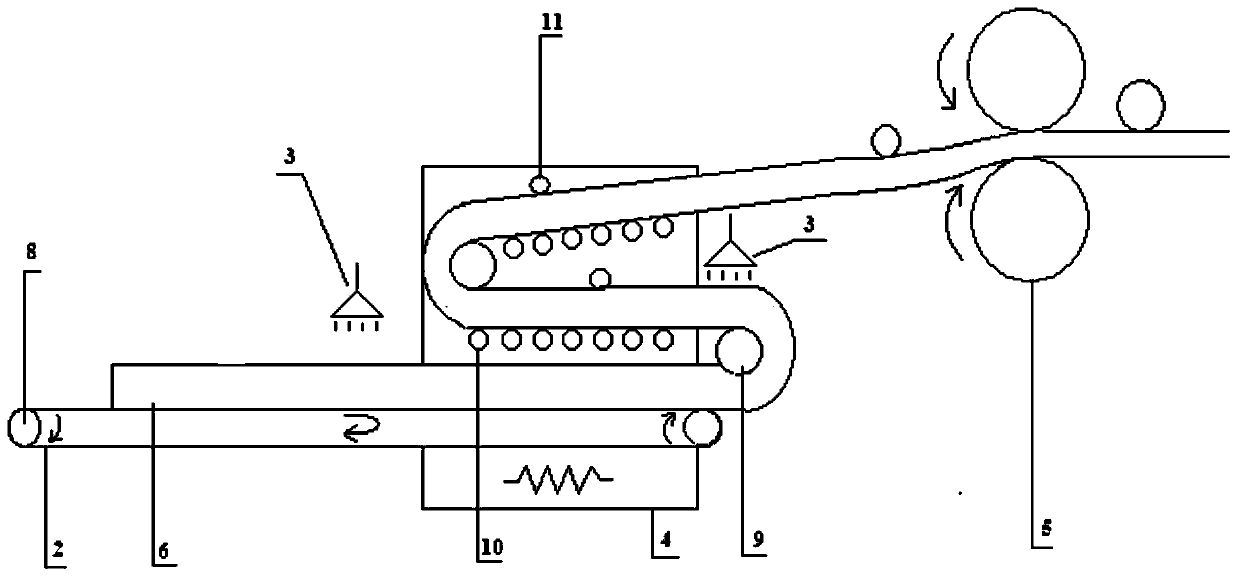

The invention provides a combined fiber reinforced water-blown polyurethane hard foam composite board, a production method and continuous production equipment thereof. In the combined fiber reinforced water-blown polyurethane hard foam composite board, one or mixtures of more of long glass fibers or long glass fibers and carbon fibers, glass fiber cloth, carbon fiber cloth or short-cut glass fibers are used as fiber reinforced bodies which are alternately distributed in a polyurethane foaming raw material matrix in a layered form. The combined fiber reinforced water-blown polyurethane hard foam composite board has the advantages of high strength, good rigidity and better size stability and high-temperature resistance. In the invention, the continuous production equipment is adopted, thereby the production efficiency and the product quality stability are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

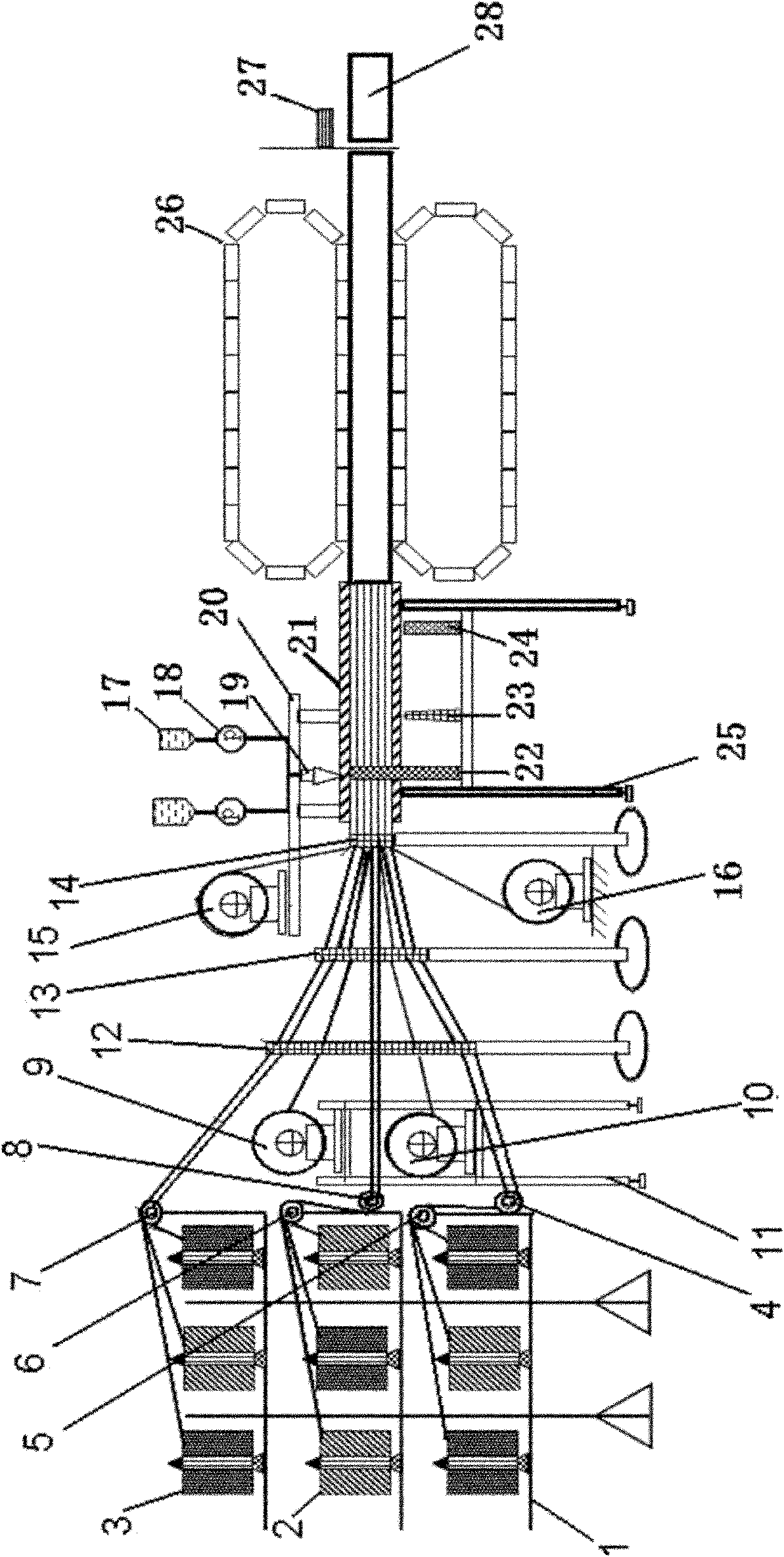

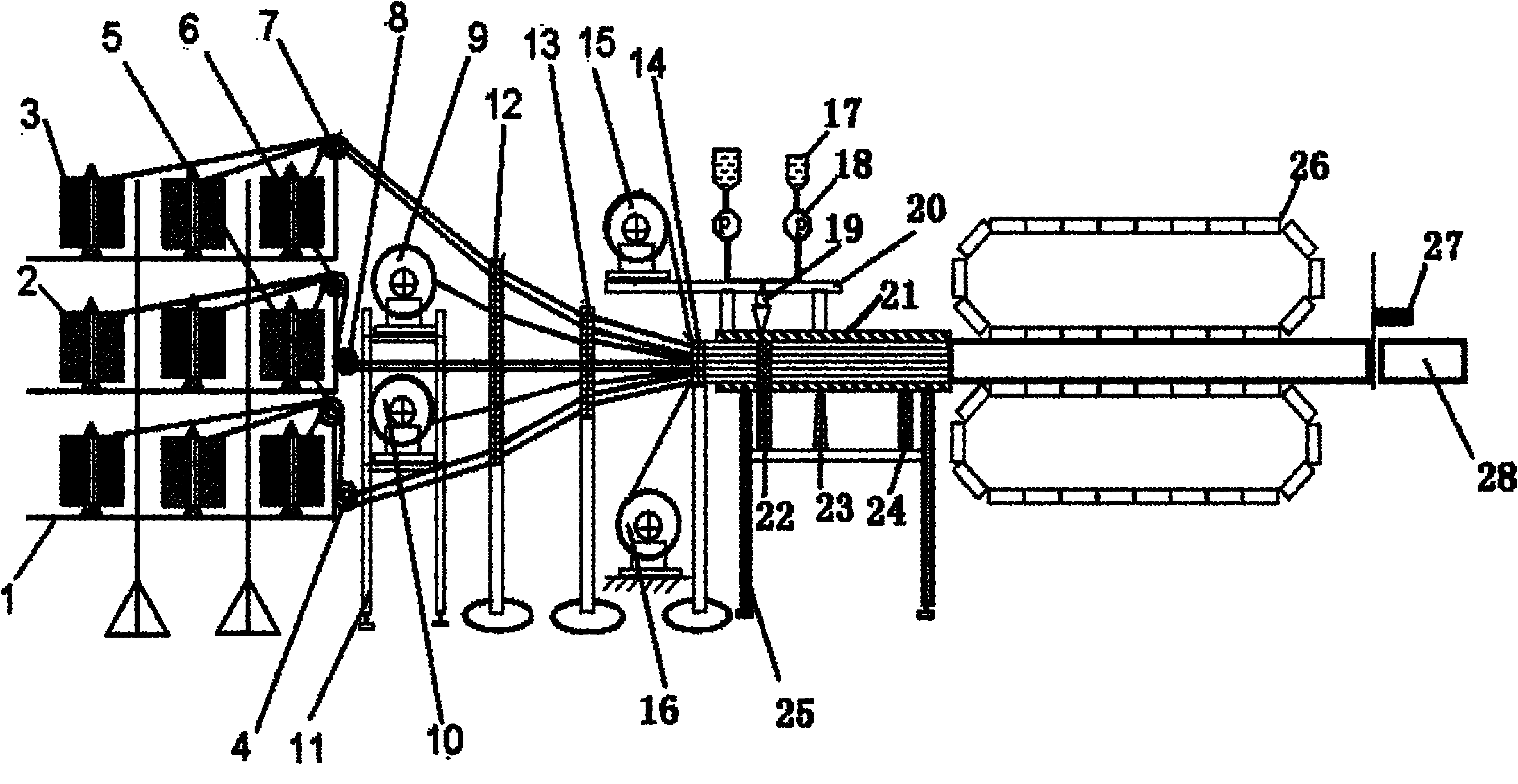

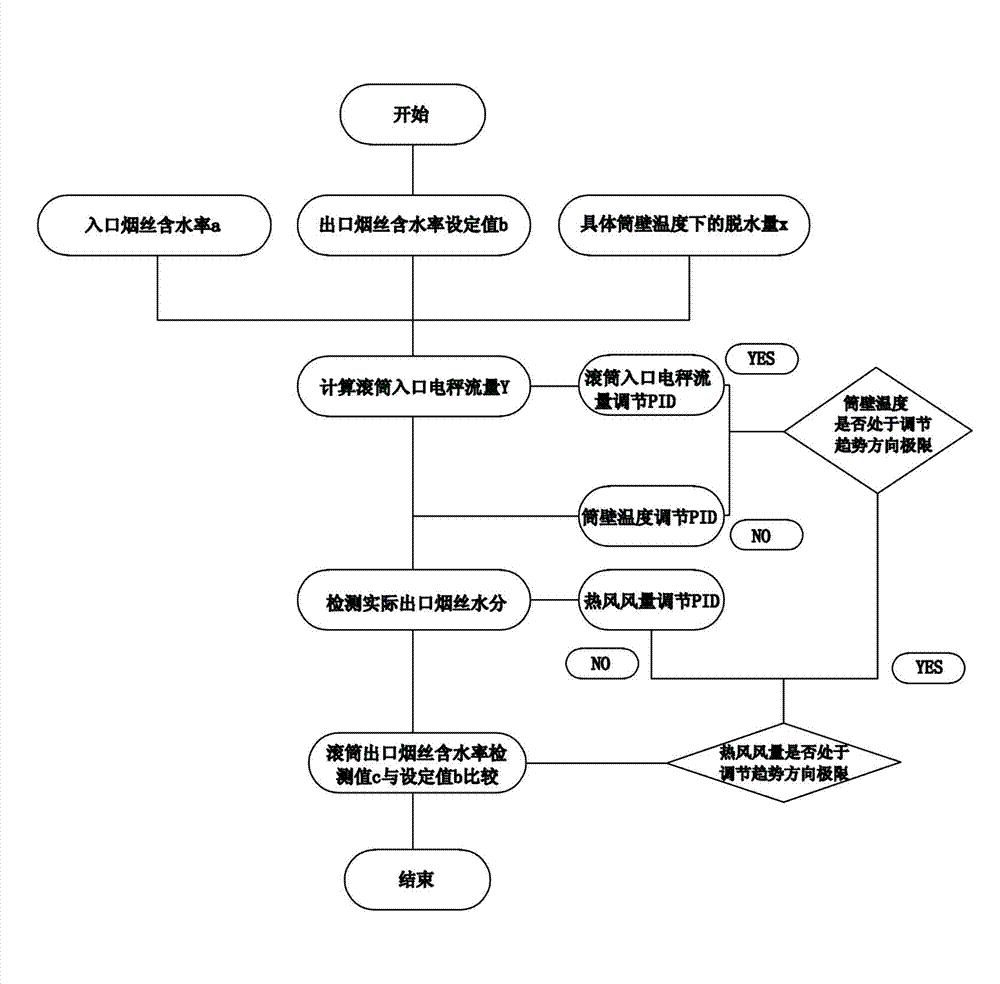

Control method of rotary drum type cut-tobacco drier three-level regulation

ActiveCN103082390AImprove product quality stabilitySmall temperature fluctuationsTobacco preparationThree levelAir volume

Owner:CHINA TOBACCO FUJIAN IND

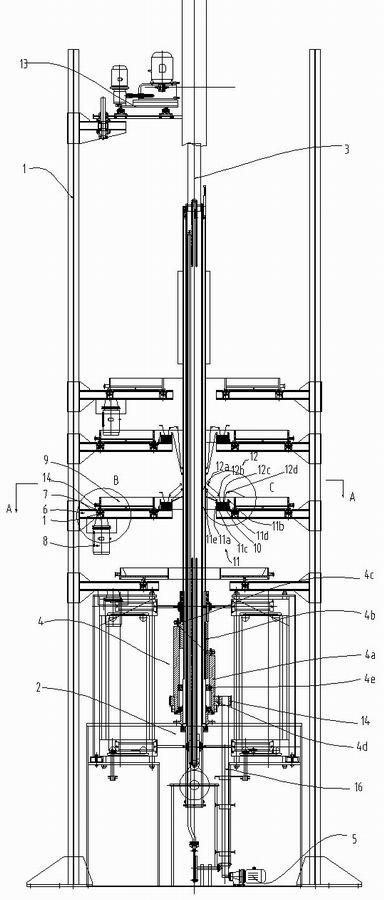

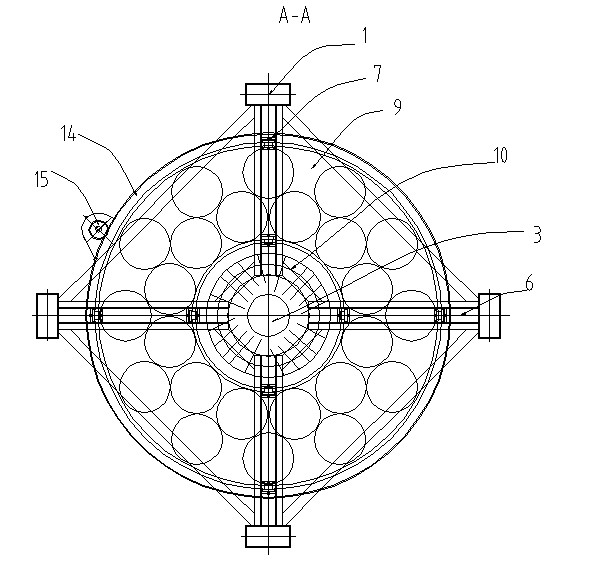

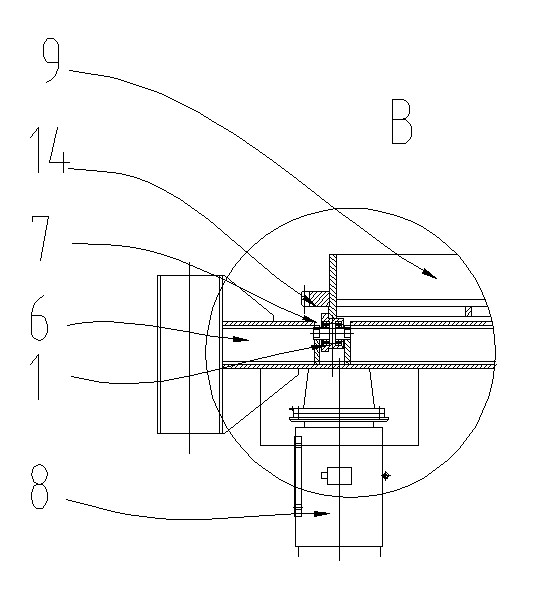

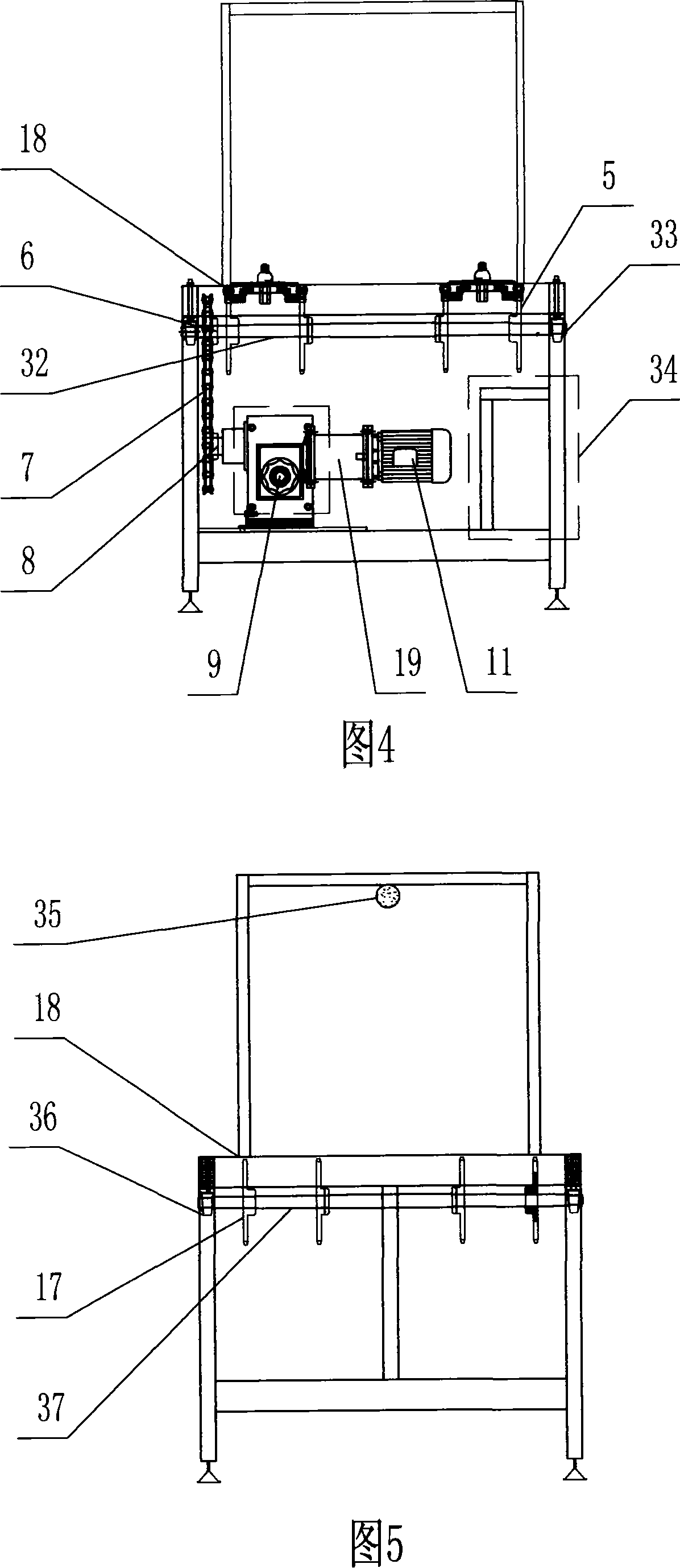

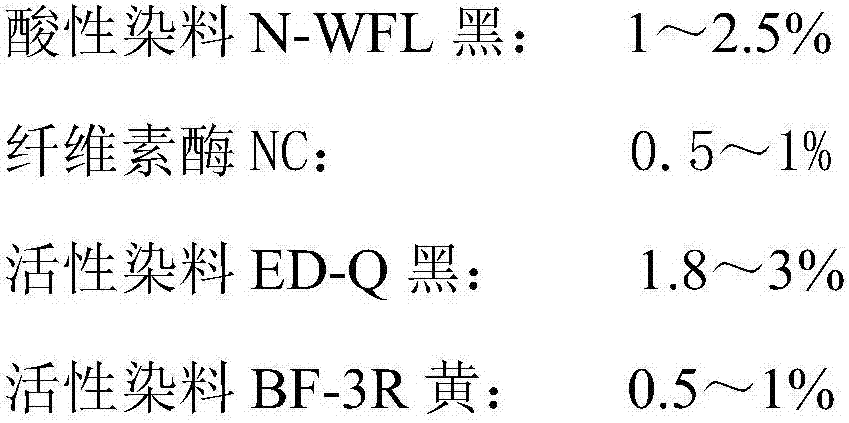

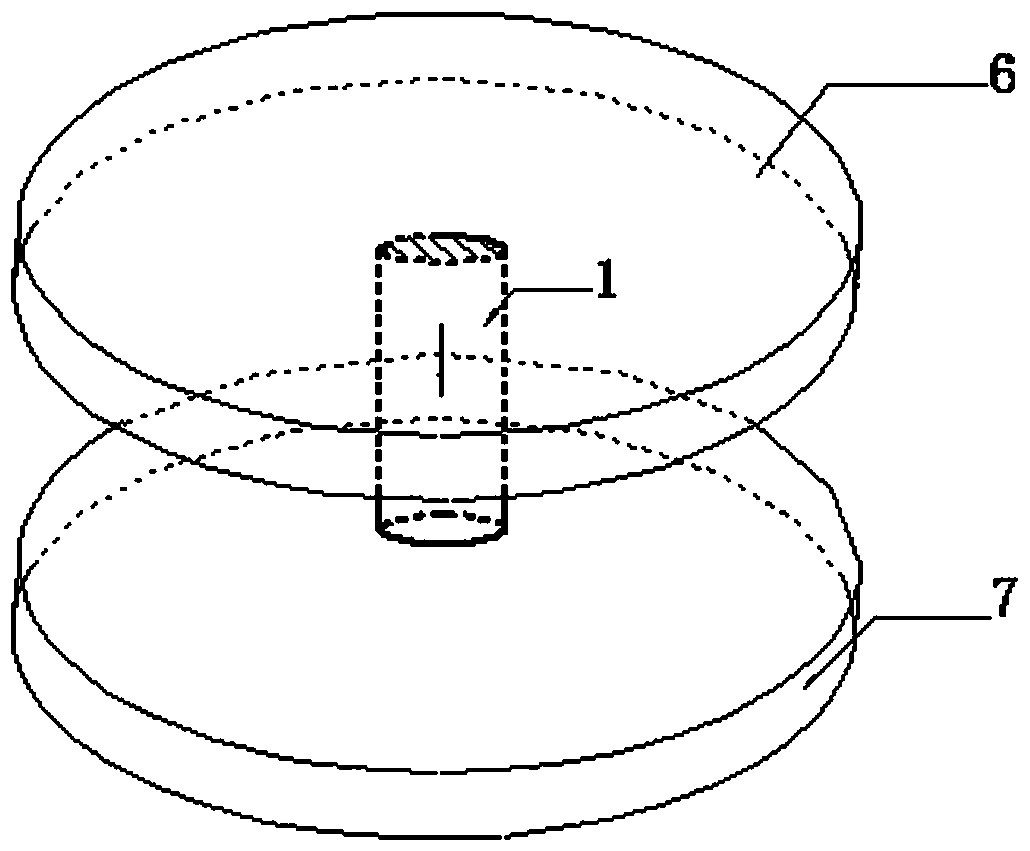

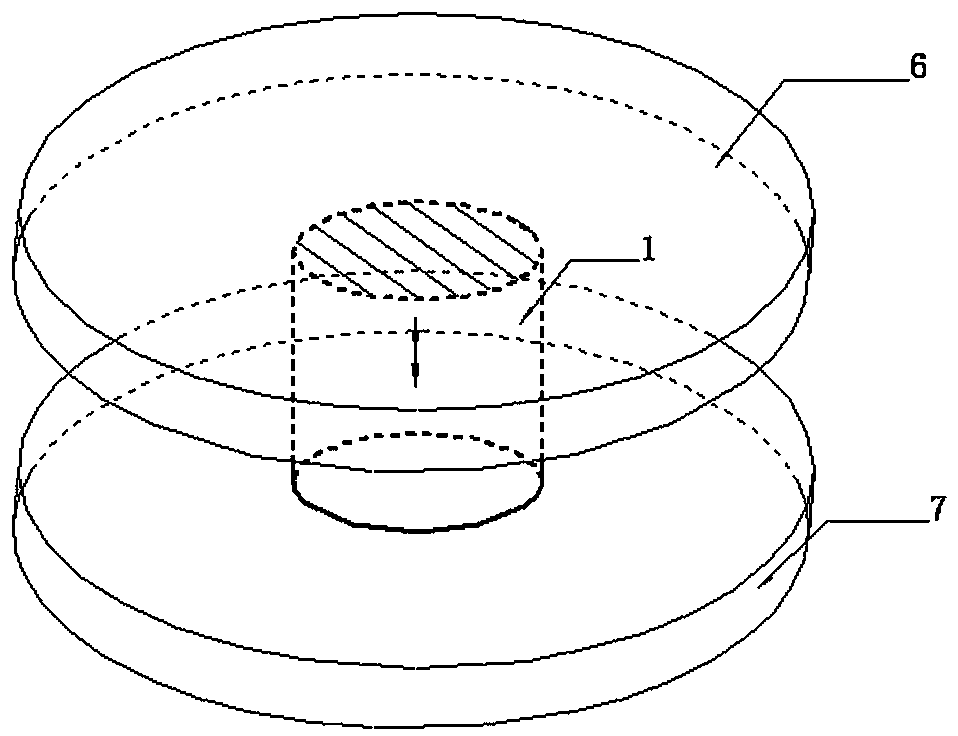

Vertical pipe production line

The invention discloses a vertical pipe production line. The vertical pipe production line is characterized in that: a core shaft support is arranged on a lower portion of a frame, a mold core shaft is erectly fixed on the core shaft support, a propulsion device connected with a first power generator is arranged on a lower portion of the mold core shaft; at least a support frame is fixed on the frame, a circular orbit and a second power generator are arranged on the support frame, the core shaft support is positioned in the center of the circular orbit, a circumferential yarn disk is arrange on the circular orbit and is connected with the second power generator; a circular dipping groove is arranged on the support frame approaching a circumference inside the circular orbit, a axial fiber position frame and a circumferential fiber position frame are distributed on the circular dipping groove; a product synchronization cutting apparatus is fixed on an upper end of the frame, the productsynchronization cutting apparatus is positioned above the mold core shaft. According to the present invention, the vertical pipe production line is adopted, such that circumferential winding of the continuous fibers and axial arrangement of the continuous fibers are combined well so as to improve product quality and processing stability.

Owner:李长城

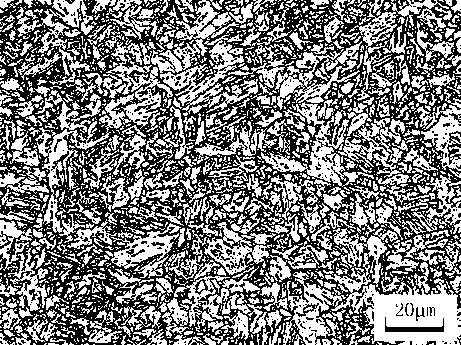

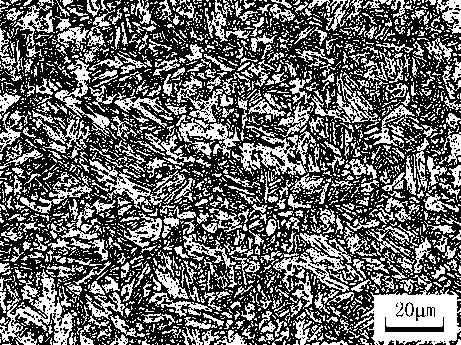

X80 pipeline steel plate with low yield ratio and high toughness and manufacturing method thereof

The invention relates to an X80 pipeline steel plate with low yield ratio and high toughness. The X80 pipeline steel plate contains the following chemical ingredients in percentage by weight: 0.036-0.060% of C, 0.15-0.40% of Si, 1.65-1.90% of Mn, not higher than 0.012% of P, not higher than 0.0015% of S, 0.15-0.40% of Ni, 0.10-0.30% of Mo, 0.30-0.50% of Cr, 0-0.30% of Cu, 0.035-0.055% of Nb, 0.005-0.030% of Ti, 0.020-0.050% of Al and not higher than 0.008% of N. A method for manufacturing the X80 pipeline steel plate comprises the steps of: smelting and continuously casting into blanks; heating the cast blanks; adopting a TMCP (Thermo-Mechanical Control Process); and carrying out quenching and tempering treatment. According to the X80 pipeline steel plate and the method, the temperature and structural homogeneity of a thick-specification pipeline steel plate in thick, longitudinal and transverse directions can be increased remarkably while the high strength, high toughness and low yield ratio of high-grade X80 pipeline steel are realized; and the X80 pipeline steel plate has the advantages that the yield strength (Rt0.5) is not lower than 555 MPa, the tensile strength (Rm) is not lower than 625 MPa, the yield ratio (Rt0.5 / Rm) is not greater than 0.82, the elongation percentage (A50mm) is not lower than 30%, the KV2 at the temperature of -40 DEG C is not lower than 240 J, the DWTTSA at the temperature of -30 DEG C is not lower than 85%, the co-plate strength difference of the steel plate is not higher than 30 MPa.

Owner:武汉钢铁有限公司

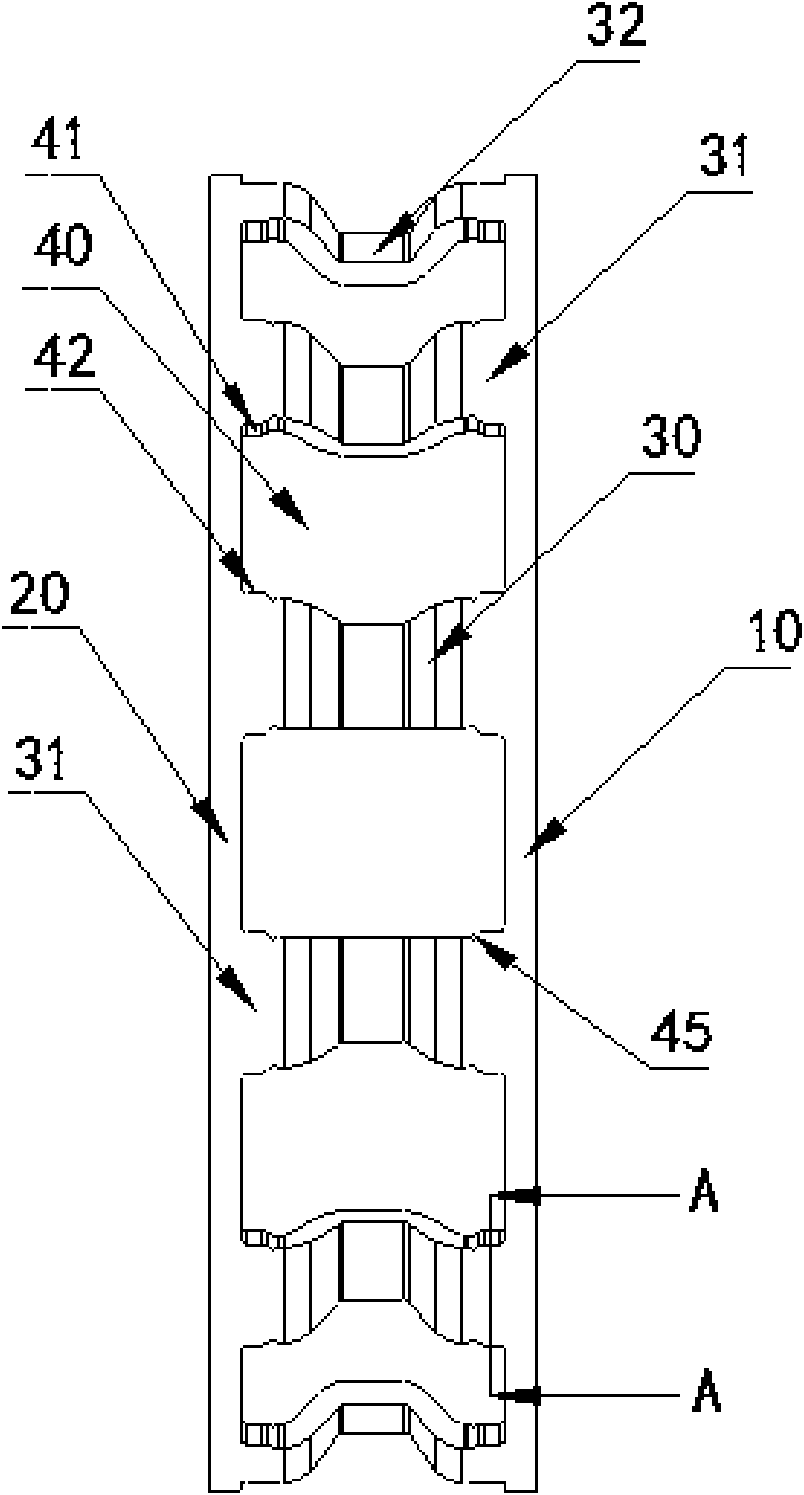

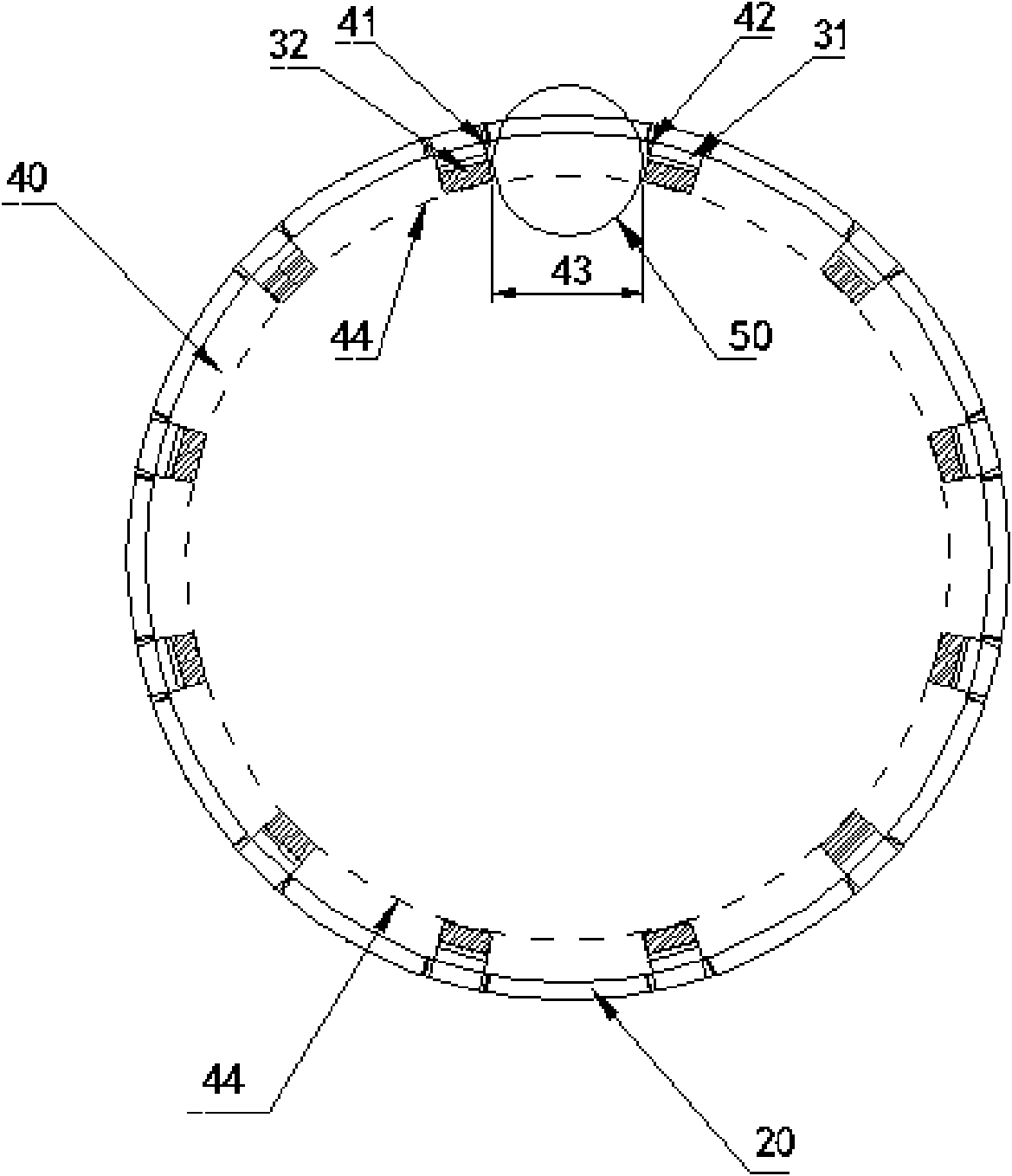

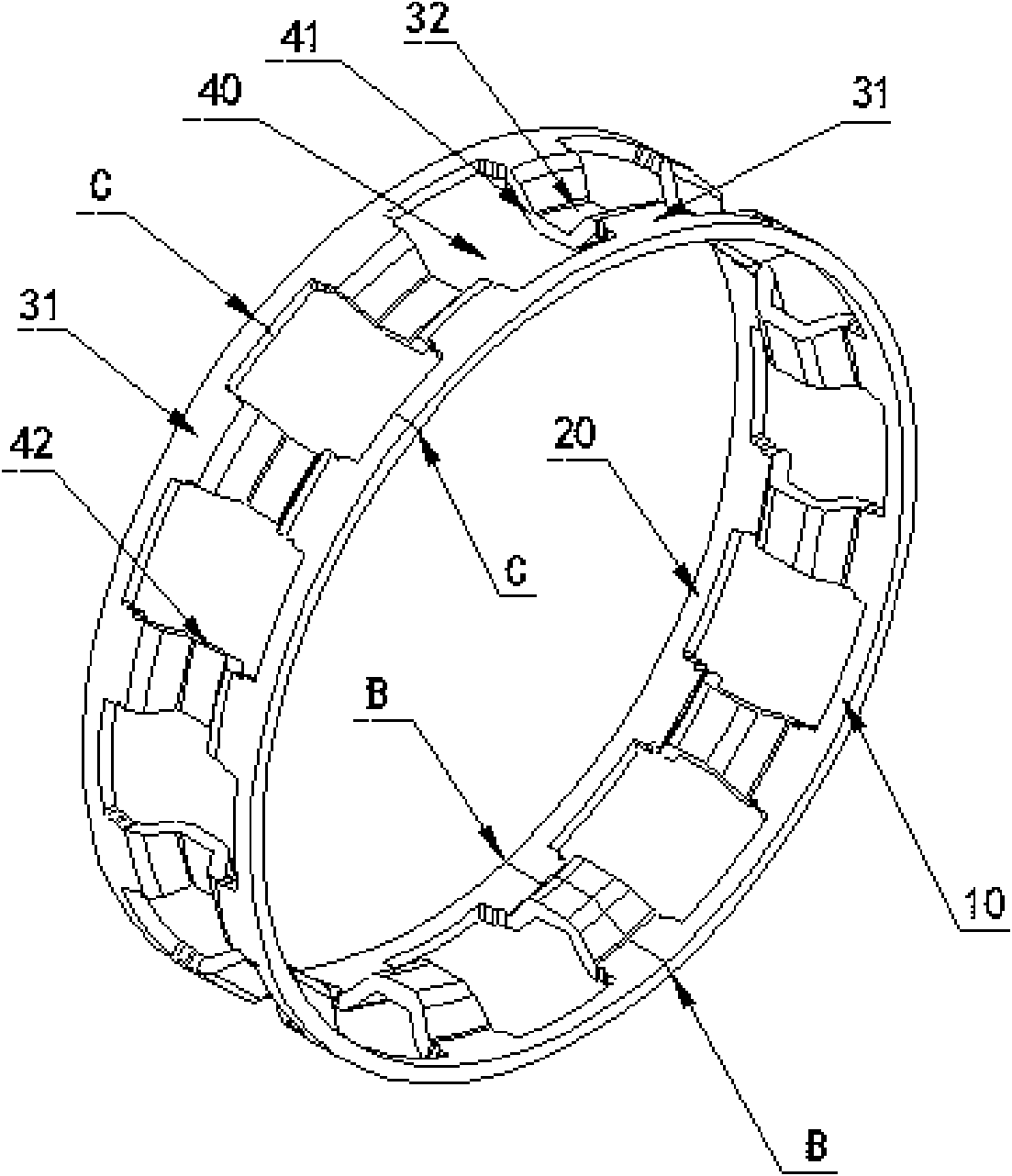

Bearing retainer and machining technique thereof

InactiveCN101672329AReduce waste costsIncrease profitBearing componentsEngineeringStructural engineering

The invention discloses a bearing retainer and a machining technique thereof. The technique mainly comprises: blanking perimeter and height required by the retainer at a time, moulding all cage pocketstructures of the retainer at a time, and punching all the cage pockets into concave cage beams provided with groove structures at a time; circling the retainer bracket with circling mould, and welding the butt ports of two ends of the circle to form an integral bearing retainer structure. The machined bearing retainer bracket is in the integral bearing retainer structure formed by manufacturinginner and outer ring beams, cage pockets, concave cage beams between adjacent cage pockets, and boundary beams for connecting the concave cage beams to the space between the inner and outer ring beamswith the same mild steel plate through the previous technique so that the invention has the advantages of reducing accumulated technique deviations, improving precision and reliablity of products, solving the problem of high cost of material waste in conventional bearing machining technique, fully increasing the utility rate of material, and further improving the production efficiency of the bearing retainer.

Owner:宁波达克轴承有限公司

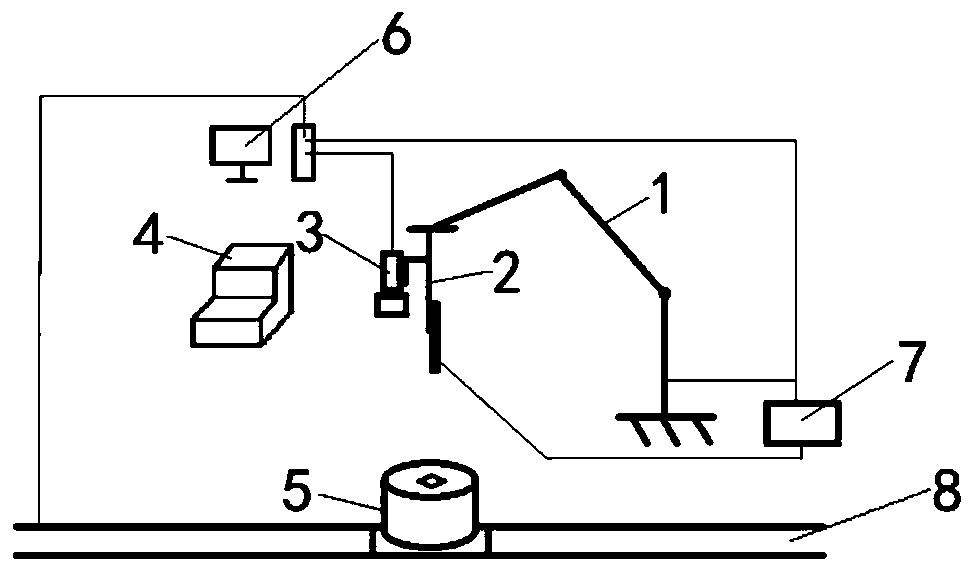

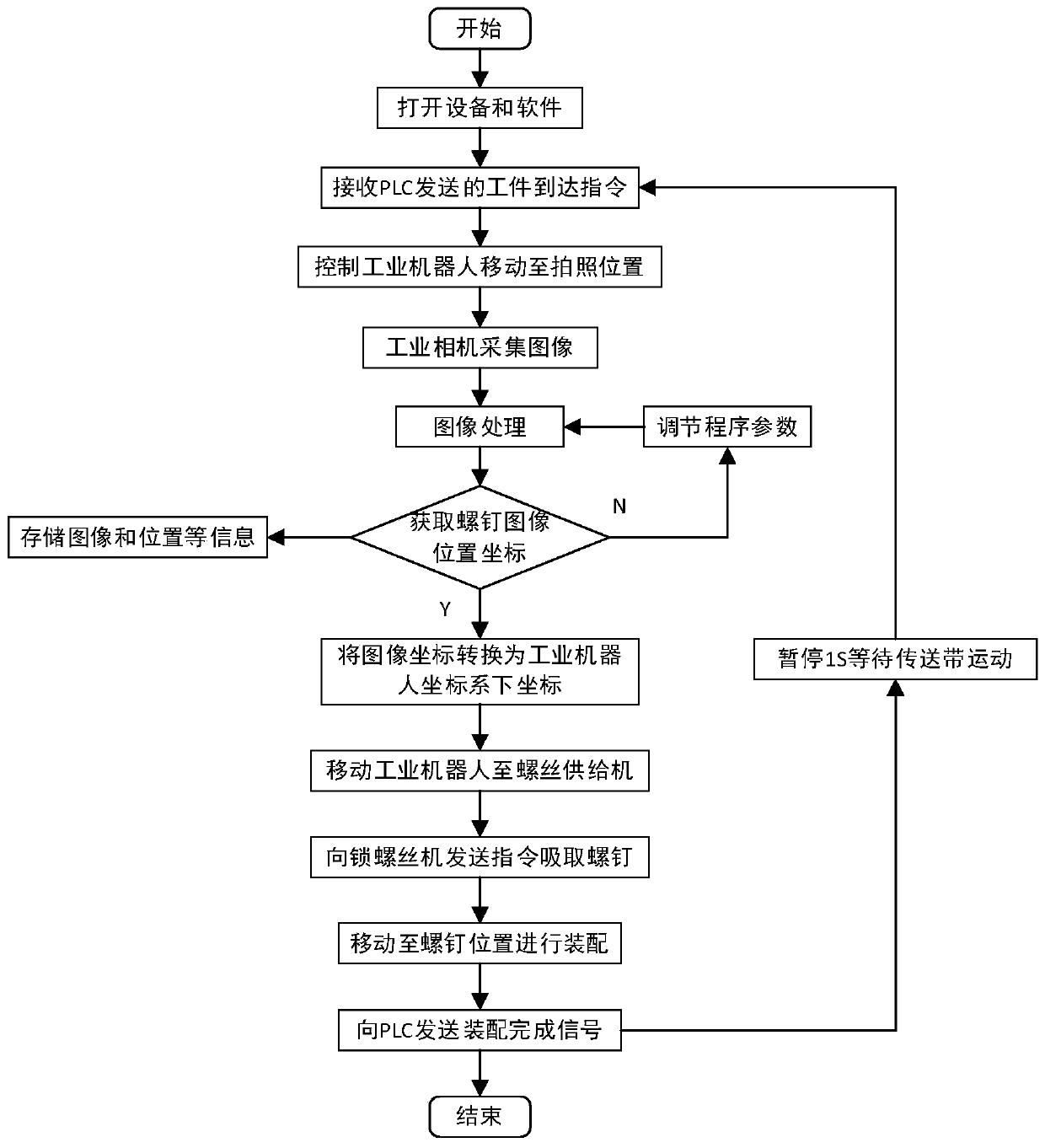

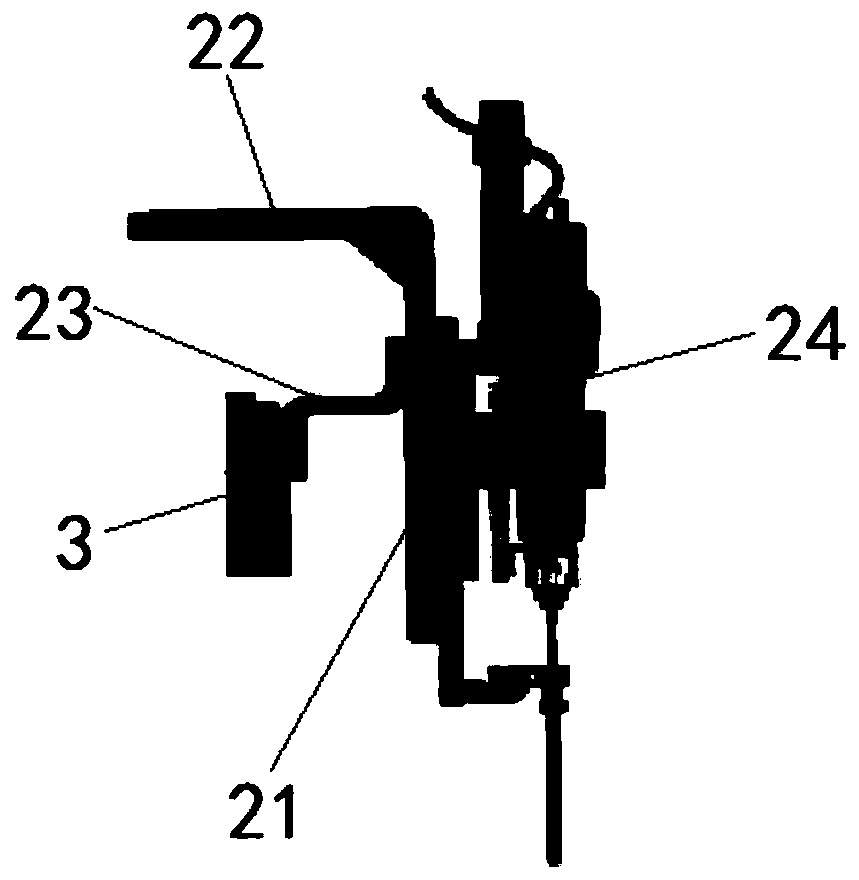

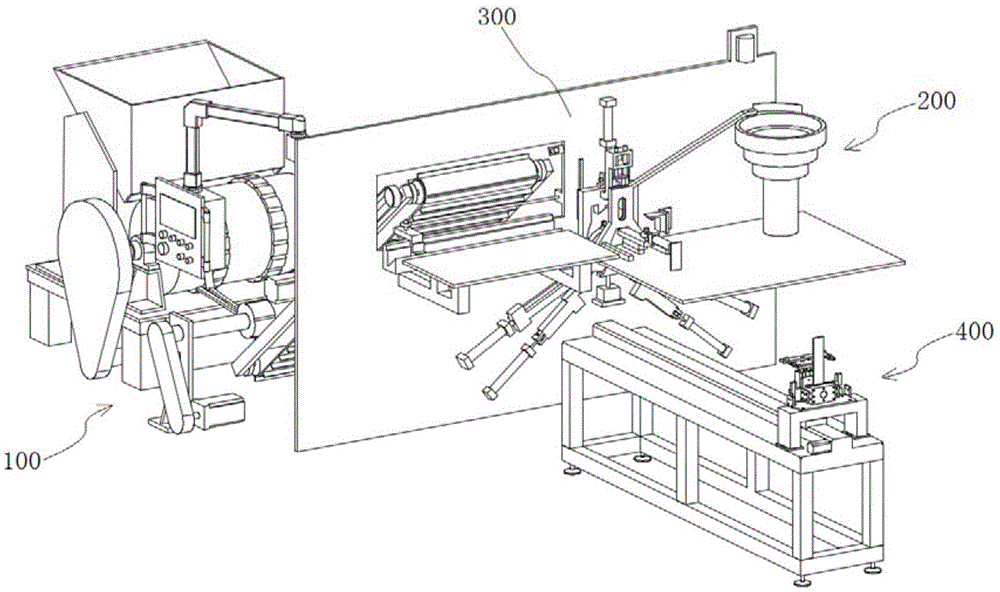

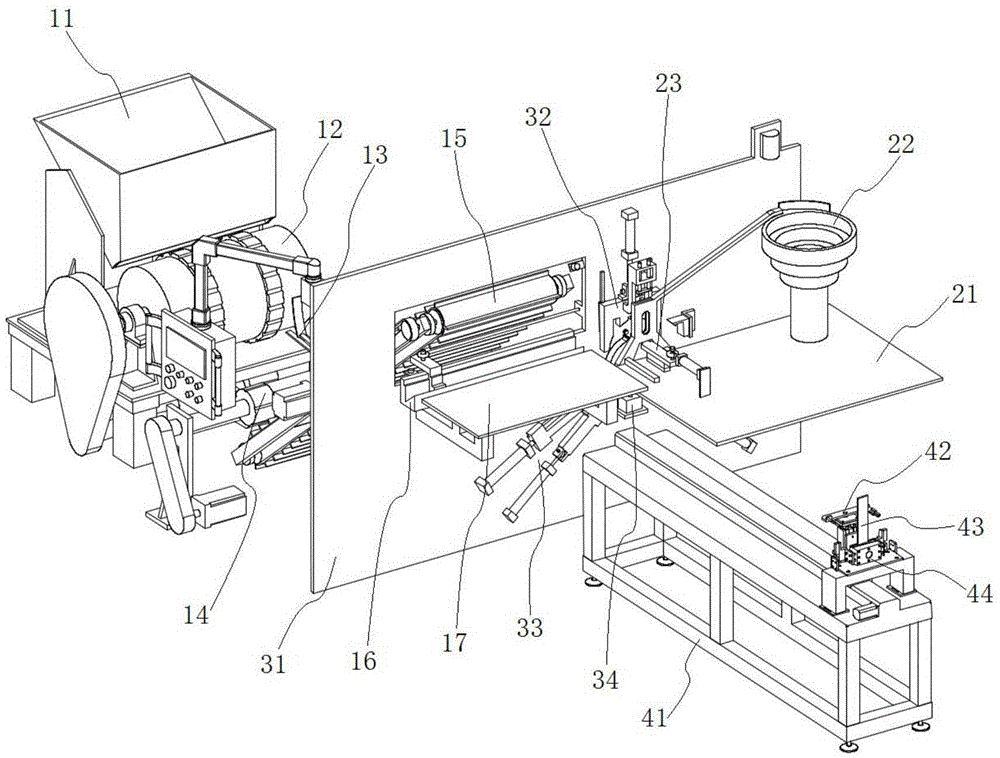

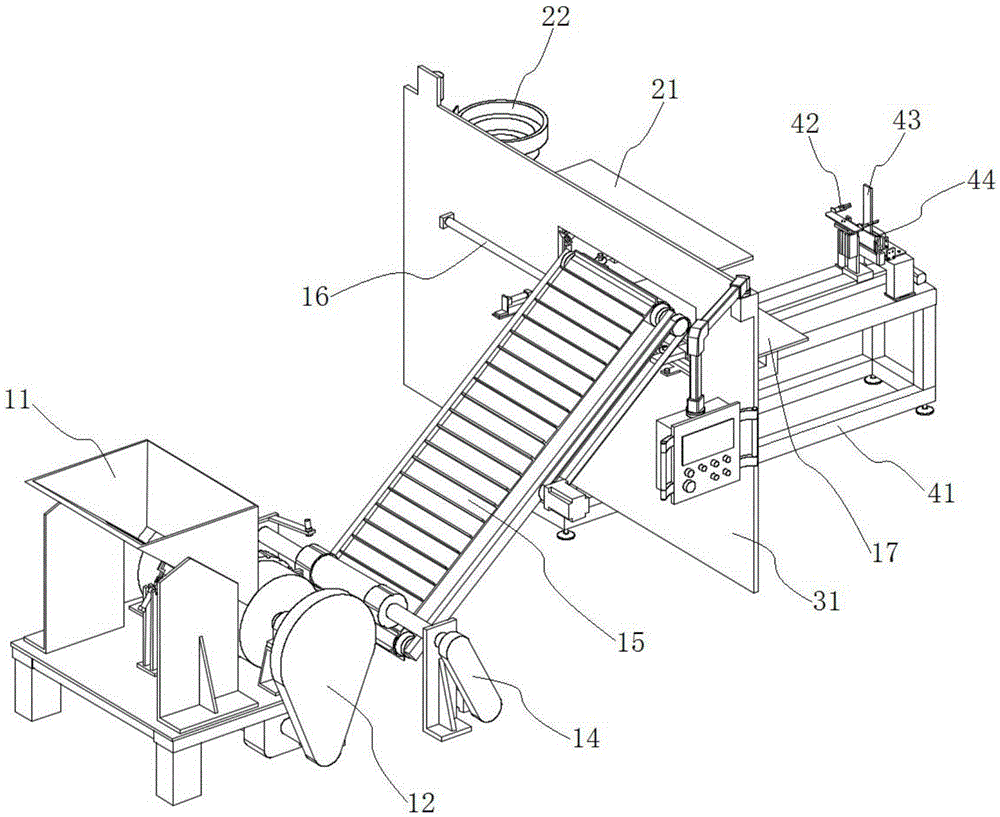

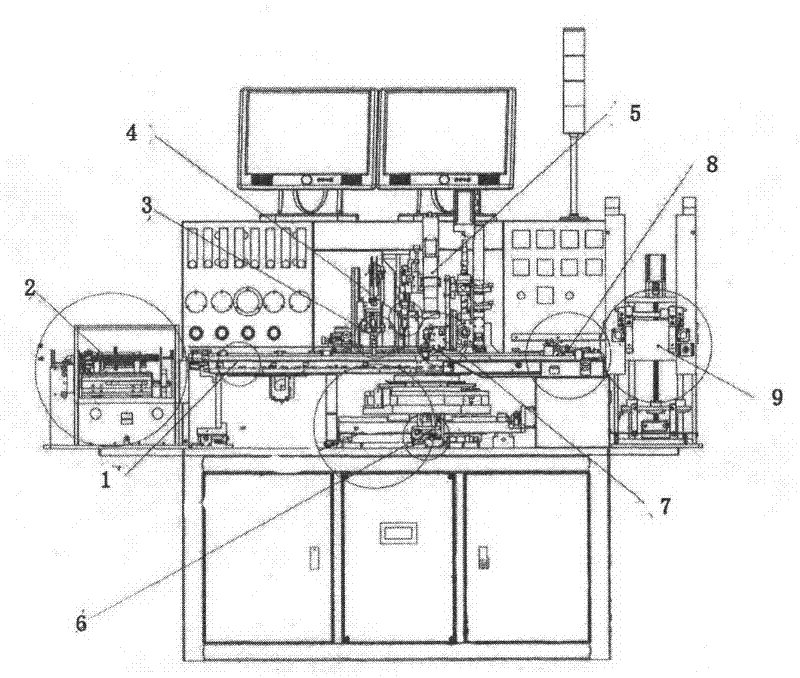

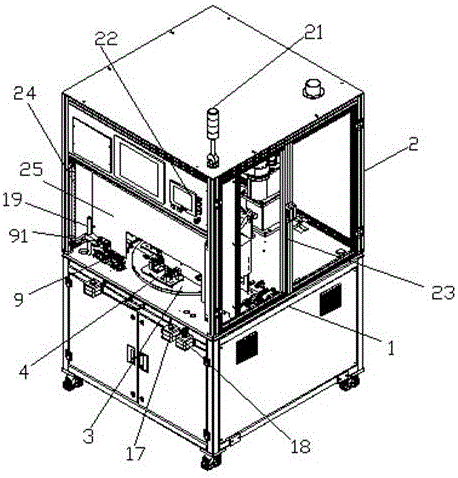

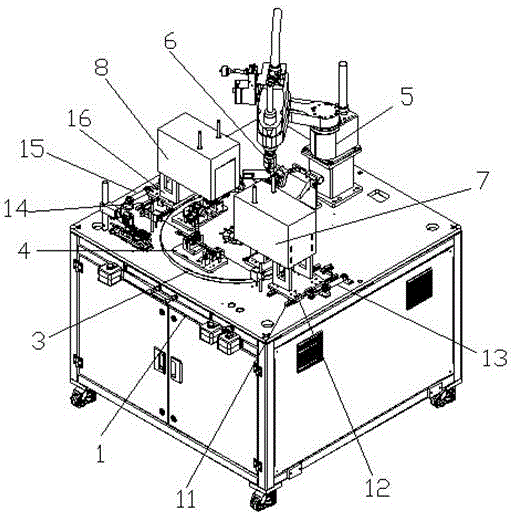

Sunflower module assembling system based on visual guidance

ActiveCN110497187AImprove efficiencyLow costImage enhancementImage analysisManipulatorVisual perception

The invention discloses a sunflower module assembling system based on visual guidance. The module assembly system based on visual guidance comprises a screw feeder, a data processor and a manipulator,wherein an executing mechanism is arranged at the tail end of the mechanical arm, an industrial camera is installed on the tail end executing mechanism, a conveying belt is arranged below the industrial camera, a module tool station is arranged above the conveying belt, and a sunflower module is placed on the module tool station; and a visual guidance assembly technology working method comprisesthe steps that a module workpiece is moved to the tool station through the conveying belt for photographing, the industrial camera transmits an acquired image to the data processor, the data processorperforms image preprocessing and screw hole position detection on the acquired image, the manipulator carries a screw to reach the position of a screw hole for locking screw operation, and the mechanical arm completes the operation and assembly of the locking screw operation. The system and the method has the advantages that the module assembly technology based on visual guidance is used for replacing manual assembly, the quality stability of the assembled product is good, the production efficiency is improved, and the enterprise cost is reduced.

Owner:SHANDONG IND TECH RES INST OF ZHEJIANG UNIV +1

High-purify upper oxygen-free copper rod production method

The invention discloses a method for producing high-purity upward oxygen-free copper rods, which comprises the following steps: uniformly adding copper plates into a melting furnace in batches during melting of copper materials; adopting a Cu-RE intermediate alloy rod to continuously add single rare earth element or mischmetal element, realizing electromagnetic stirring in the melting furnace through induction heating coils, and making the rare earth element uniformly distributed in molten copper; and arranging a ceramic filtration baffle plate on the front of a sluice between the melting furnace and a heat-insulating furnace, making the ceramic filtration baffle plate completely cover the sluice, preventing rare earth oxide from being rolled into upward oxygen-free copper rods, and obtaining the high-purity upward oxygen-free copper rods. The method has the advantages of simple production technique, stable production process, less residual oxide inclusion formed by the rare earth element, good purification effect of the copper materials, and good product quality.

Owner:JIANGSU UNIV +1

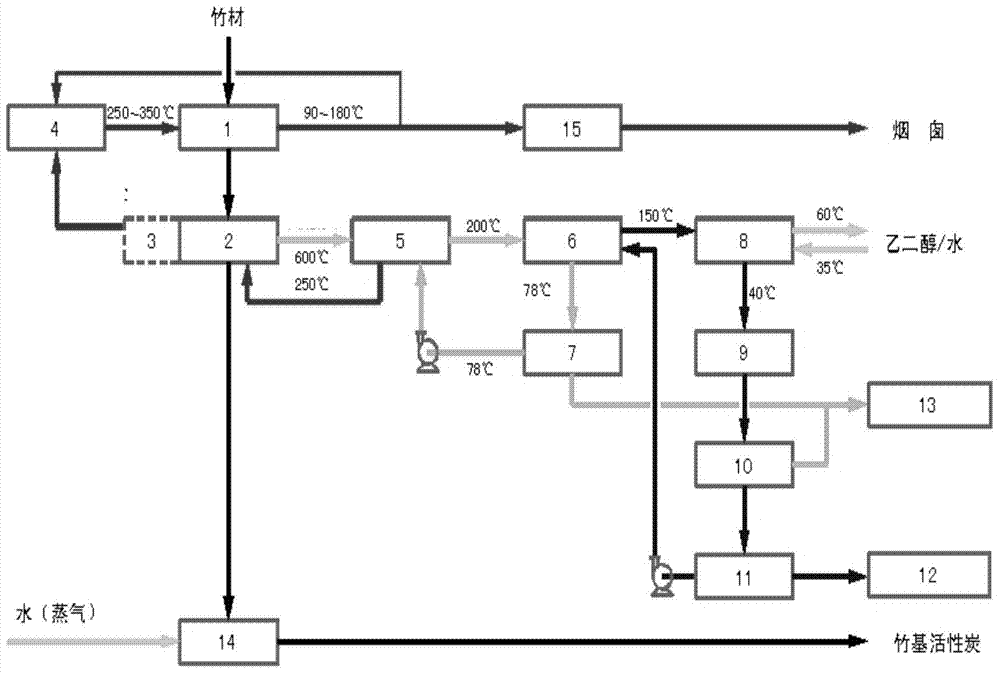

Method for preparing bamboo-based activated carbon and production device thereof

The invention provides a method for preparing a bamboo-based activated carbon and a preparation device thereof. The method comprises the following steps: A, drying, namely crushing bamboo materials at 250-350 DEG G and drying the crushed bamboo materials by drying air; B charring, namely charring the dry bamboo materials under the oxygen deficit condition by using 550-700 DEG C pyrolysis gas as thermal supports; C activating, namely spraying water steam to the charred bamboo materials, activating the bamboo carbon under the oxygen deficit condition at the activating temperature of 900-1000 DEG C, and cooling the activated bamboo carbon to obtain the bamboo-based activated carbon. The reaction is uniform and complete, the water steam in the activating process is completely contacted with the charred material, the generated activated carbon does not easily head and scale in the furnace, and the stability of product quality and the rate of carbon are improved. Moreover, the charring dry-distillation residual heat is completely utilized, the energy consumption is reduced, the charring dry-distillation by-products are recovered, the fume emission is reduced, the pollution to environment is reduced, and the comprehensive utilization rate of the bamboo materials is improved.

Owner:HUNAN HUAYIN ENERGY TECH

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

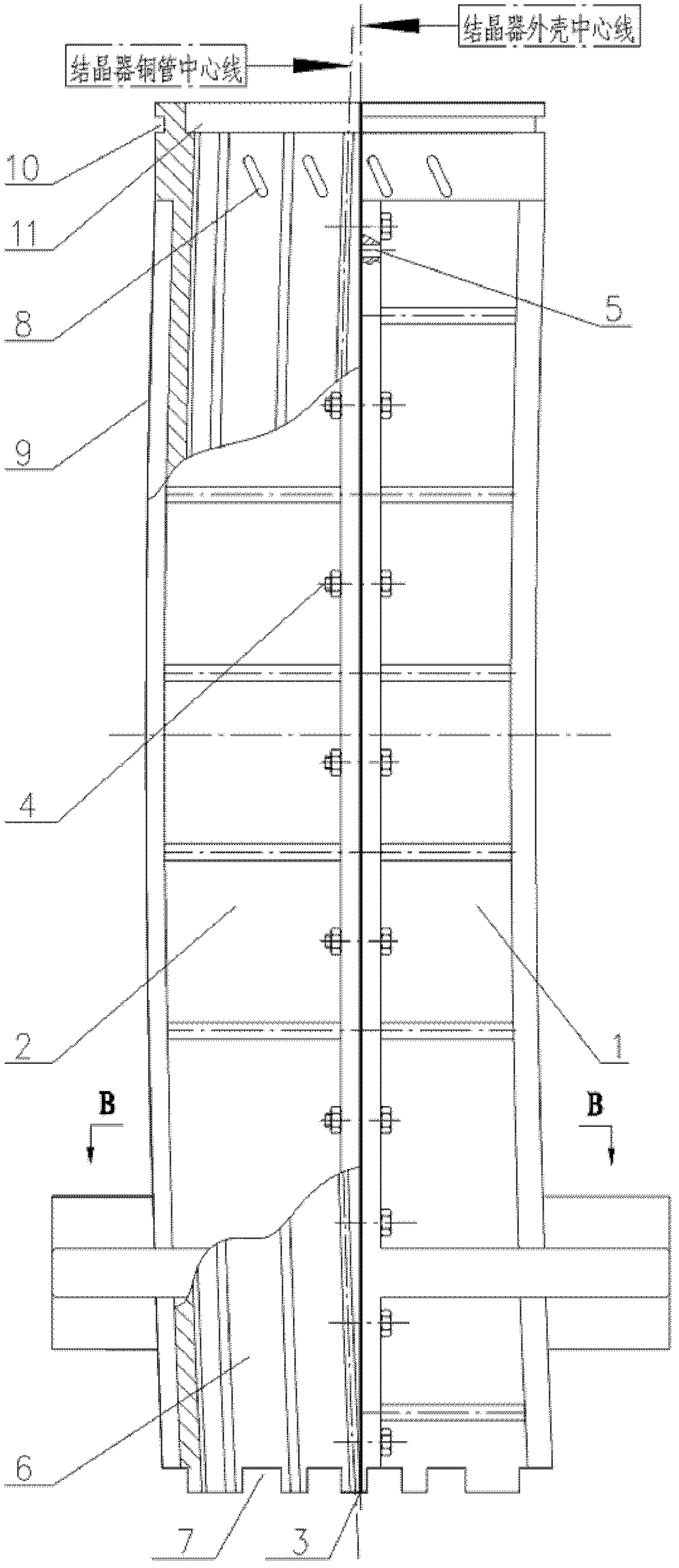

Split type water jacket with diversion water tank and assembly method

The invention provides a split type water jacket with a diversion water tank and an assembly method. The split type water jacket with the diversion water tank comprises an inner arc half water jacket, an outer arc half water jacket, a sealing element, a fastening element and a positioning pin group; wherein the water jacket are two separated bodies by using the centerline of a crystallizer cylinder as a dividing line; an angular water path, a side surface water path and an arc surface water path are arranged in each separated body; an inner cavity of each water jacket is provided with ribs; a diversion water tank is formed between every two adjacent ribs; and crisscross rib plates are distributed at the outer side of the water jackets. When the water sleeves are assembled, the inner arc half water jacket, an outer arc half water jacket are combined according to design dimensions firstly and then are integrally processed; after being processed, the inner arc half water jacket, an outer arc half water jacket are assembled in a crystallizer; combining surfaces are sealed; positioning pins are arranged between the combining surfaces for positioning; and bolts are arranged between the combining surfaces for fastening. According to the split type water jacket, the controllability of cooling water joints is structurally ensured; the deviation between the center of a circle of a copper pipe circular arc and the center of a casting machine can be avoided; the heat exchange effect of the water joints is beneficial for improving; and the production and operation cost is reduced.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

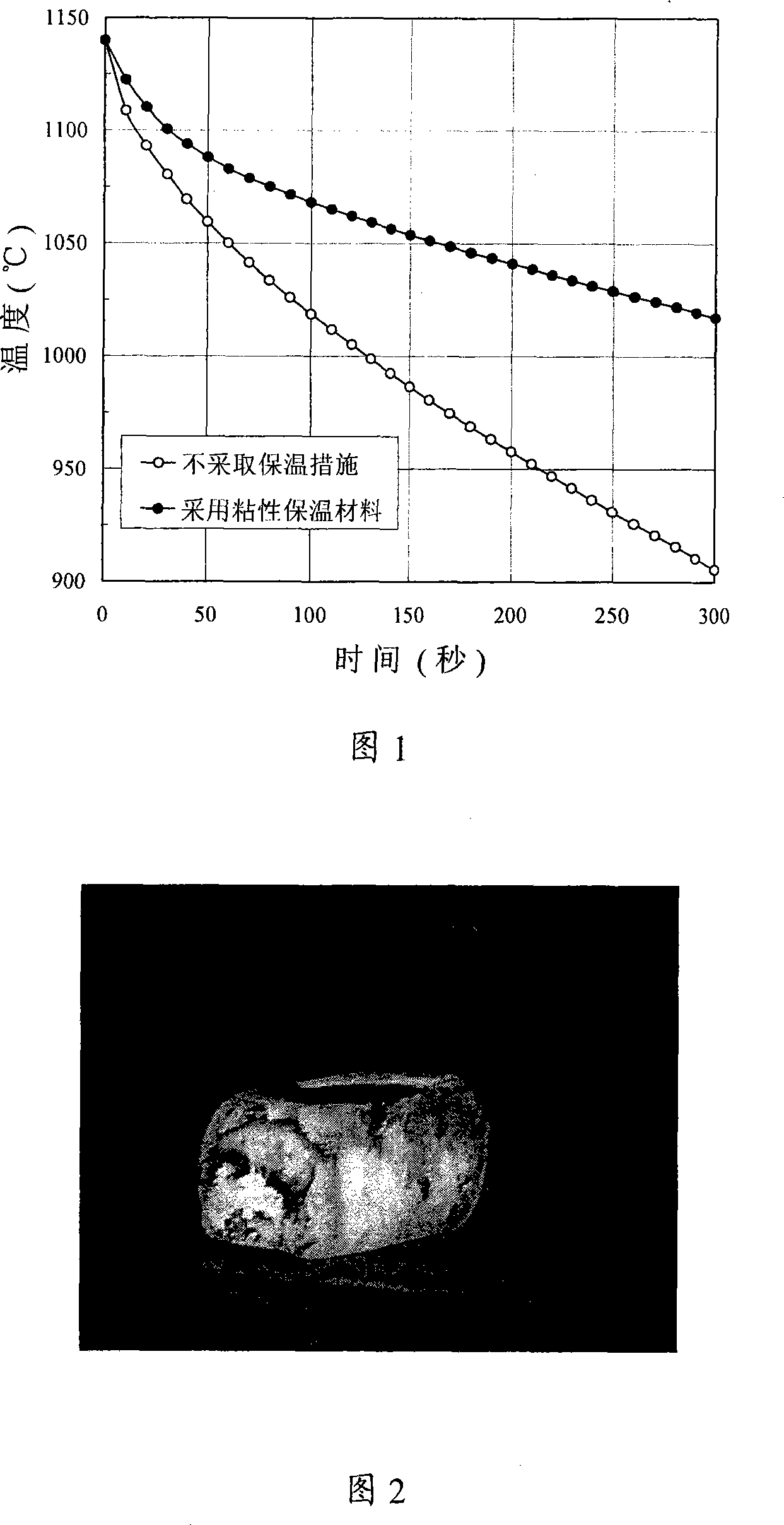

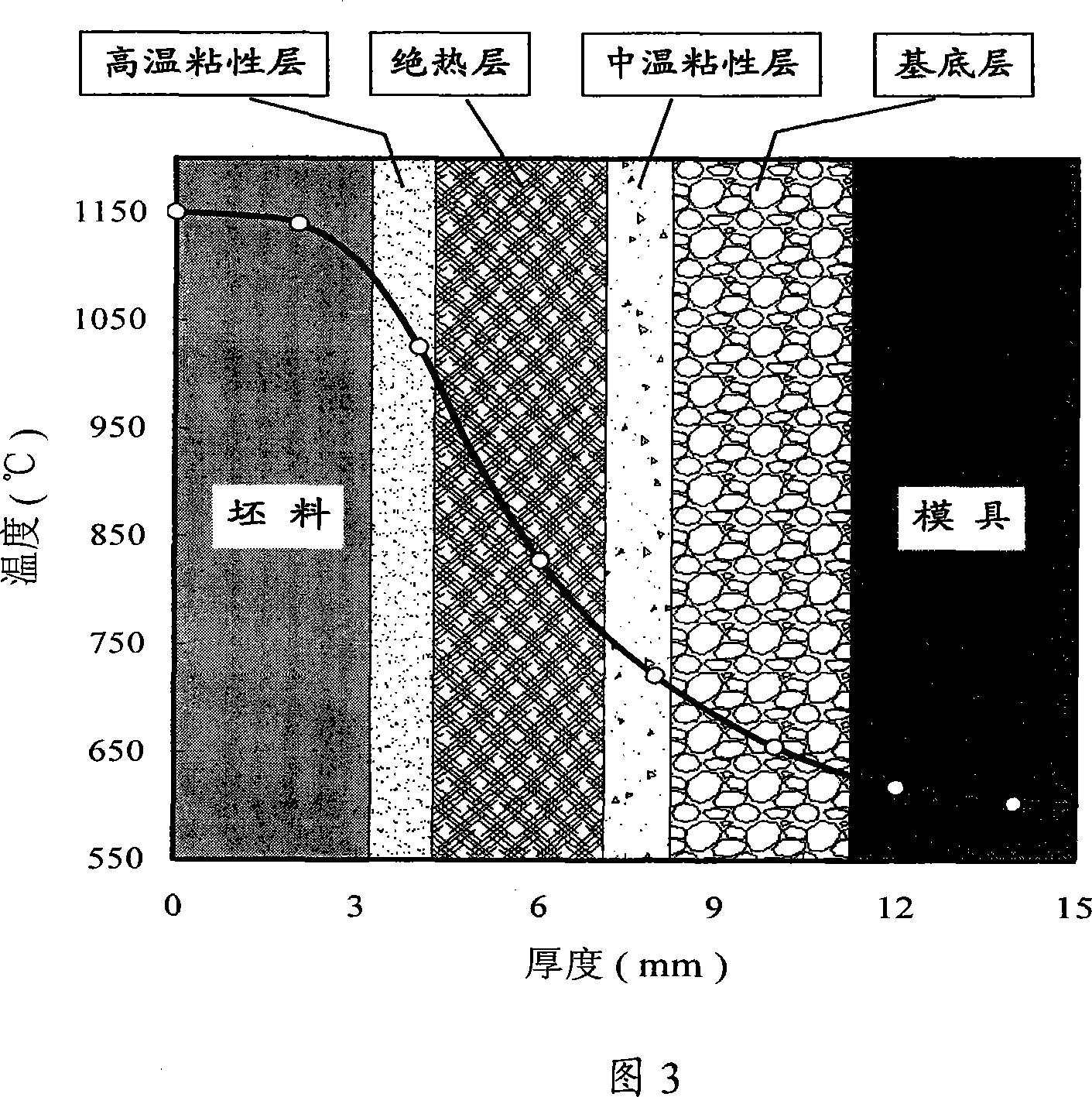

Heat-processing temperature-cntrolled heat-insulation material, its preparing method and use

This invention relates to a temperature-control heat insulating material of the hot working, is oxide of Al2O3 - SiO2 series. According to weight, the components concentration are: 10 to 14% Al2O3, 45 to 52% SiO2, 12 to 16% CaO, 4 to 8%Ca and Na2O, 15 to 22% B2O3. The physics shape of this material under operating conditions is micron order powder or fiber. In the thermo forming process of high-temperature alloy, titanium alloy and so on, this heat insulating material can coat on surface of metal blank to rigidly control deformation temperature, achieve accuracy control, decrease blank heating times, and prolong forge time of each fire.

Owner:CENT IRON & STEEL RES INST +1

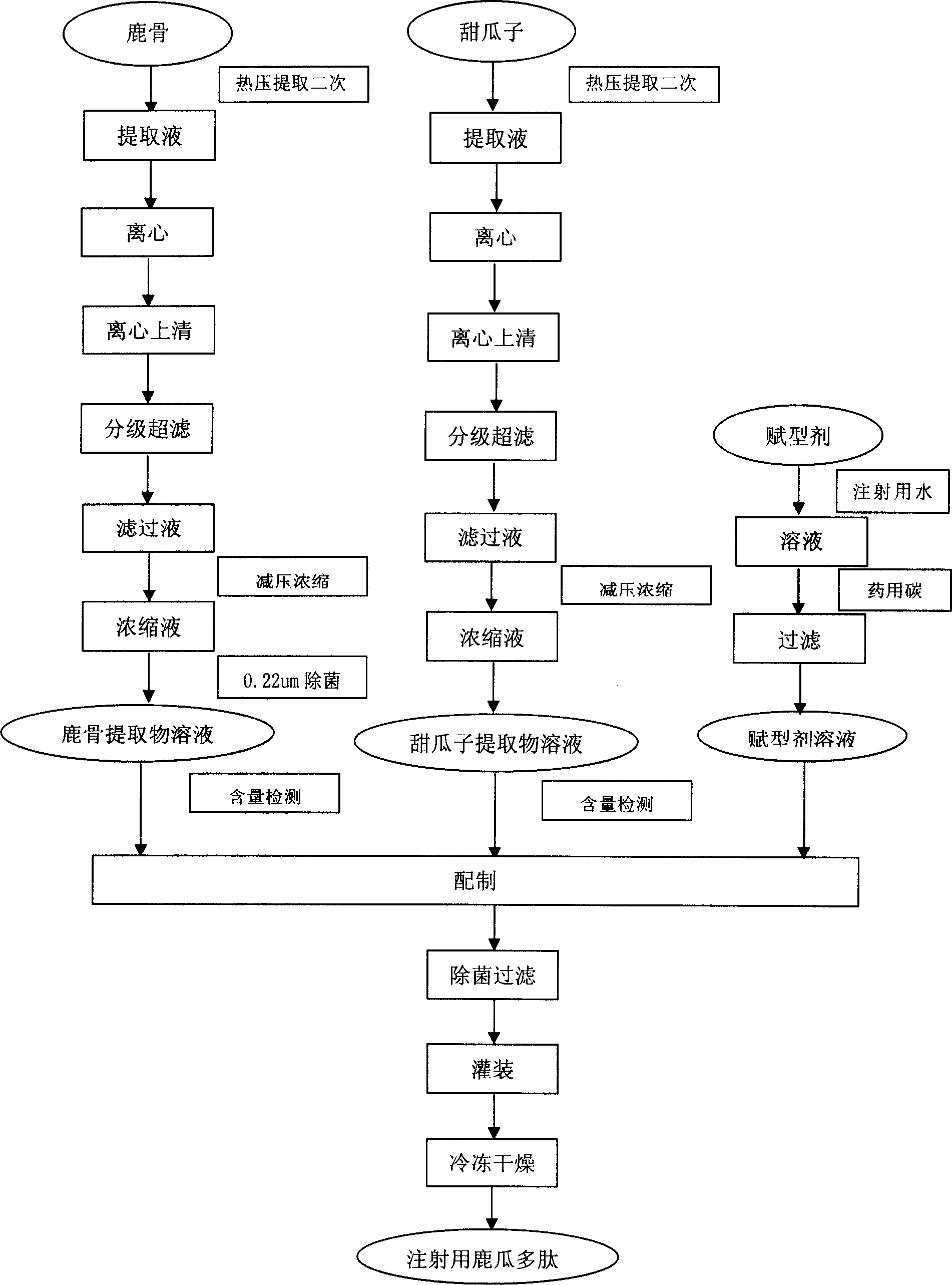

Cervus and cucumis polypeptide injection composition and preparing method

ActiveCN1742778AReduce capillary permeabilityReduce inflammatory exudatePeptide/protein ingredientsAntipyreticBiologyPharmaceutical preservatives

The present invention discloses a deer's bone melon seed polypeptide medicine composite. It is made up by using deer's bone extract, melon seed extract and one or several excipients, in which the weight ratio of deer's bone polypeptide and melon seed polypeptide is 2:1 to 6:1. Said polypeptide medicine composite can be used as injection preparation.

Owner:黑龙江迪龙制药有限公司

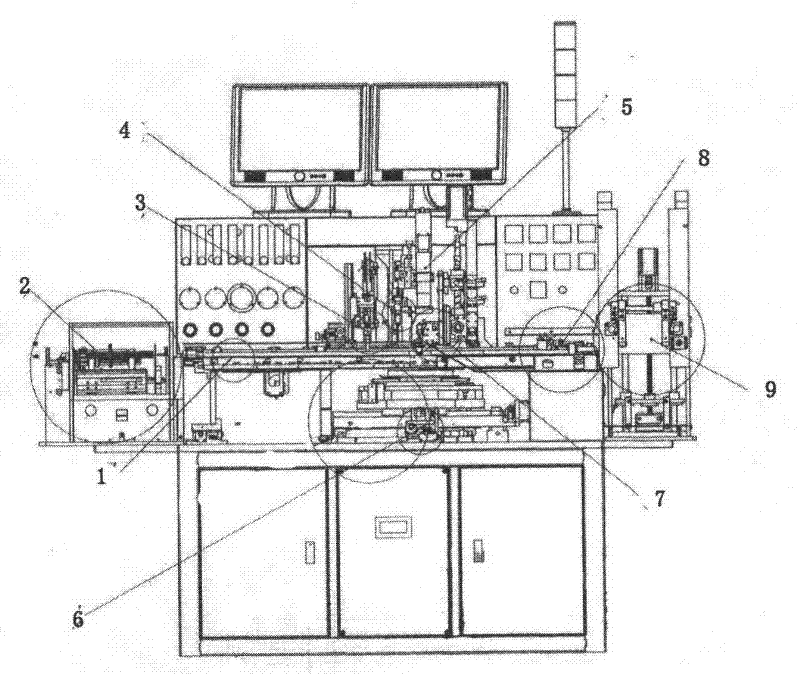

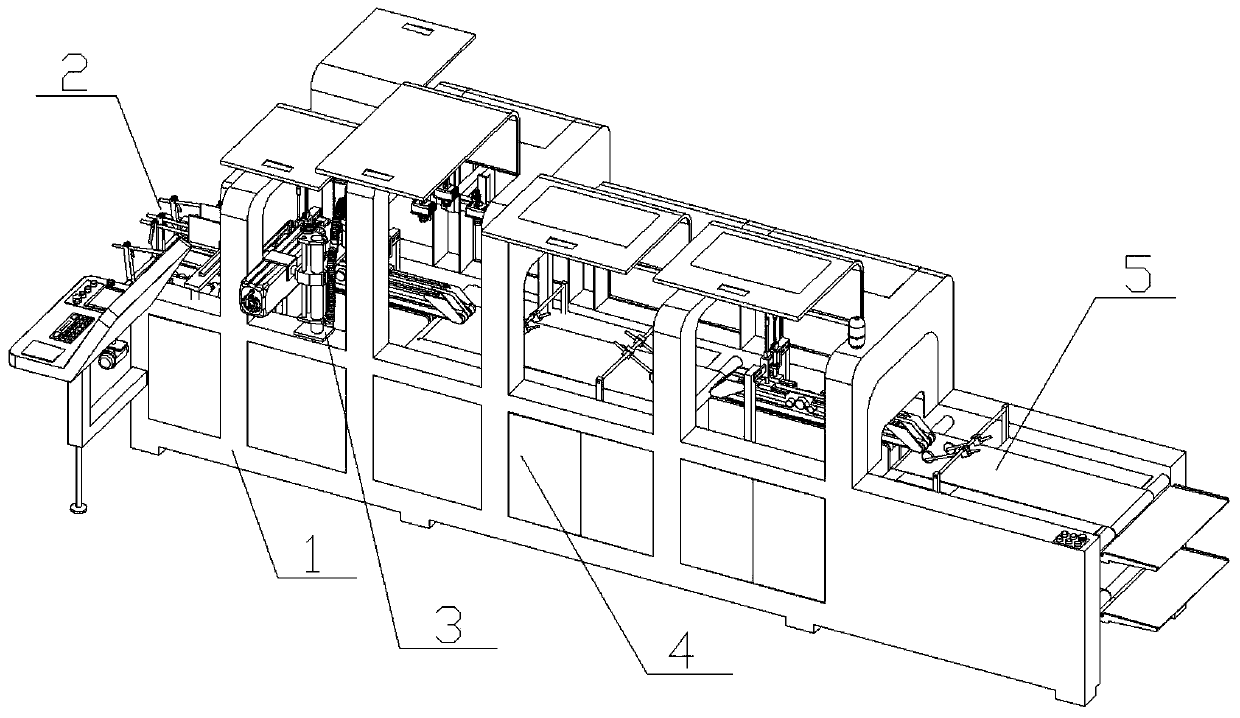

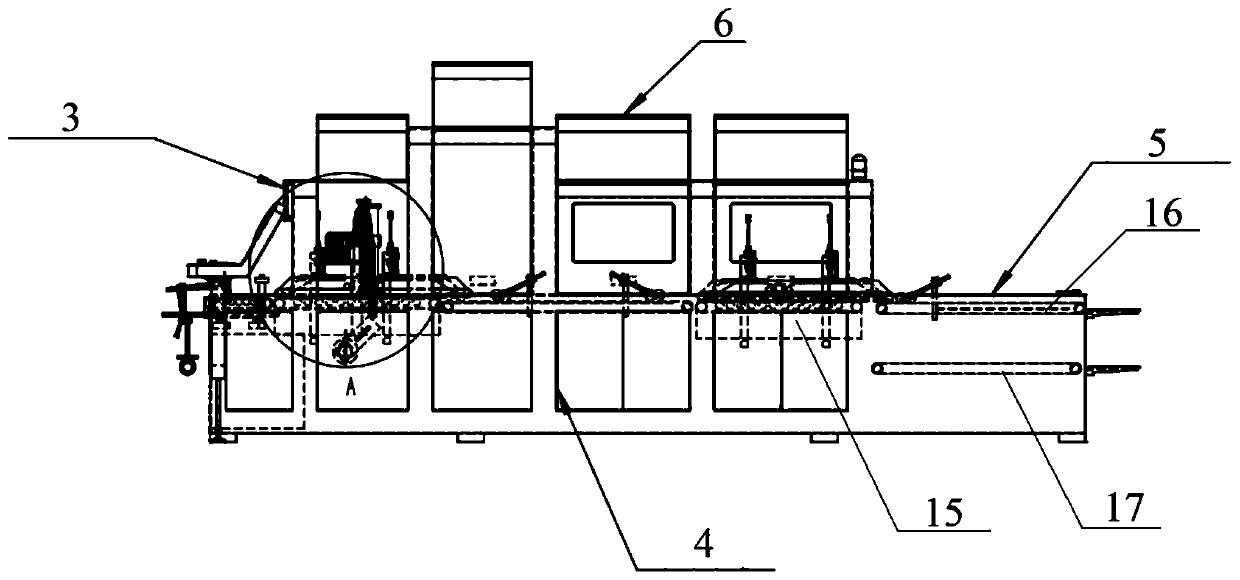

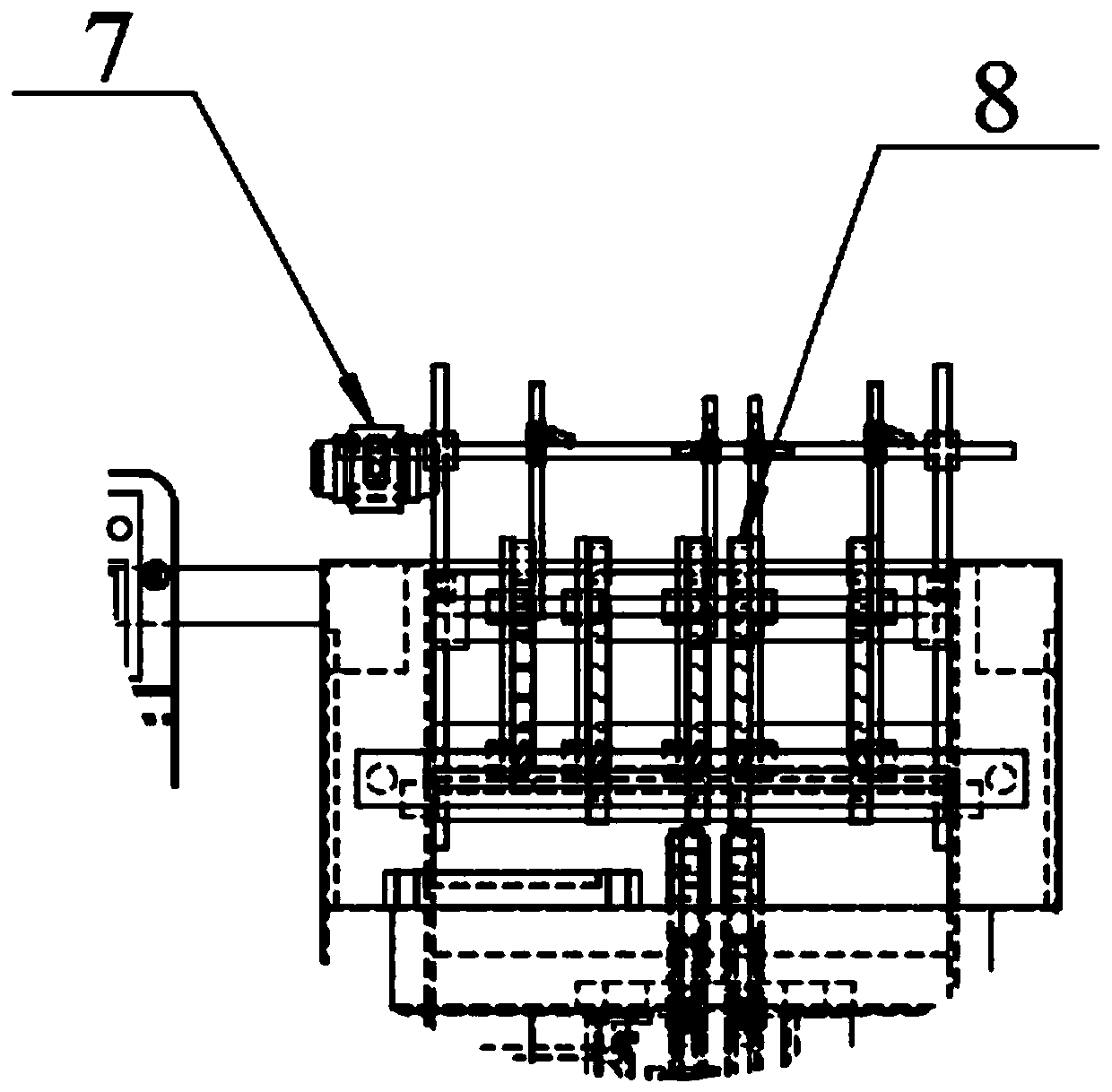

Full-automatic assembly production chain of energy-saving lamp

InactiveCN101083190ANovel ideaReasonable process structure designSequential operation station machinesCold cathode manufactureProduction chainEngineering

The invention relates to the energy-saving lamp full automatic-assembly assembly line. It belongs to the energy-saving lamp manufacture equipment technology area. Its characteristic lies in that the rack intermediate deck coordinate installs the work piece conveying appliance by the transmission chain drive, the one output end of the decelerator which installs on the sublayer of the rack and connects the motor driver connects the dynamic major axis which coordinates the cam major axis driver, another output through the cam dismember coordinates to the work piece conveying appliance, above the work piece conveying appliance fit establishes automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment, compression moulding cam, soldering lamp base cam, dial nail cam which installs on the cam major axis separately connects the automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment. The line flow has rational design, the automation pattern substitutes manual work, reduces the suggestion factor of the quality flaw, enormously raises the production efficiency and the product quality, creates the scale effect, take a foundation for promoting the enterprise brand image.

Owner:王佩诚

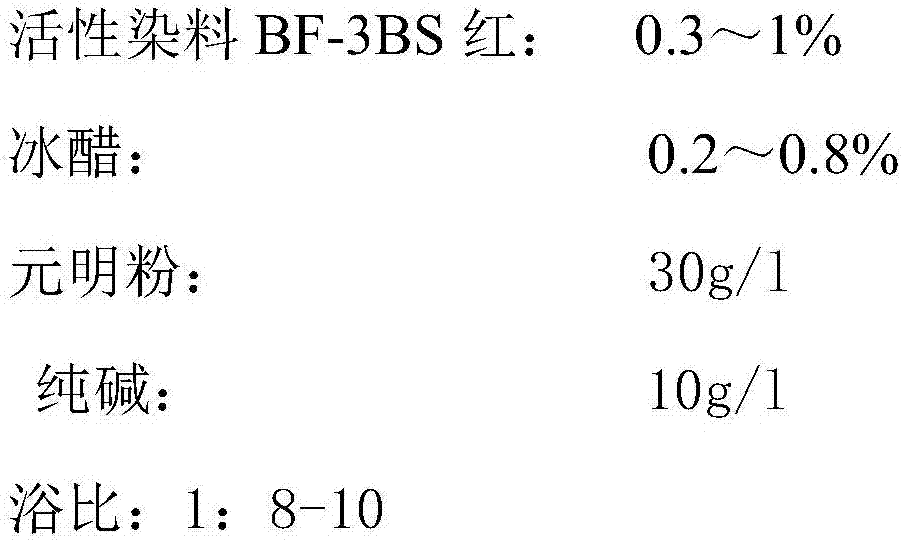

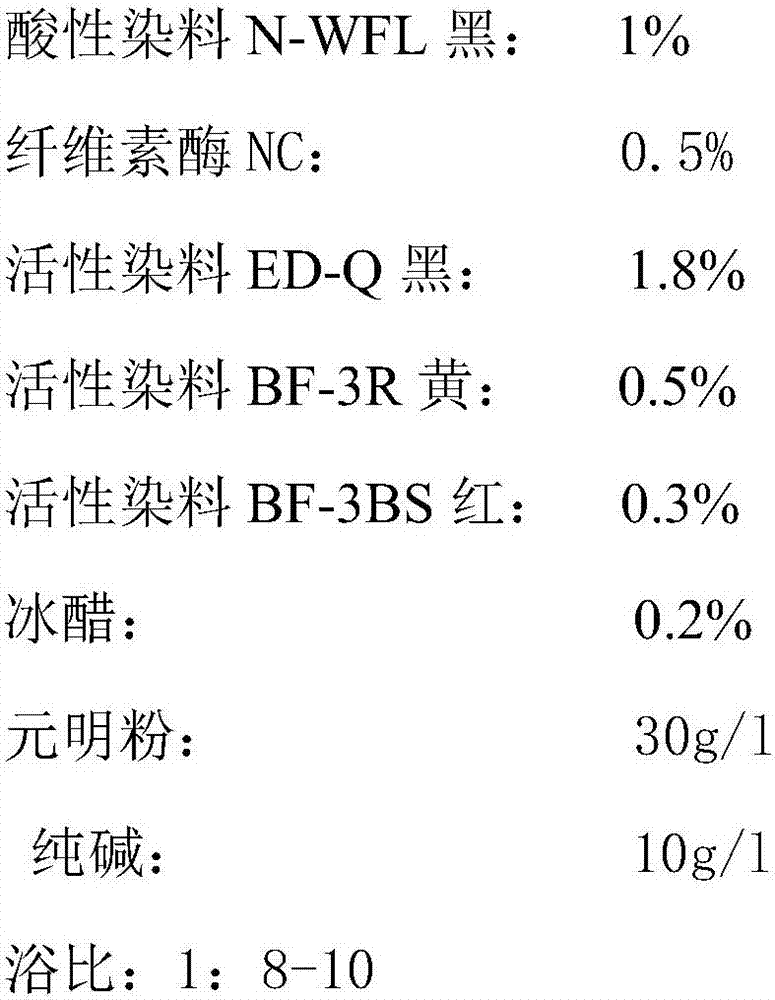

Nylon/cotton fabric hair removal and reactive dye dyeing one-bath process

InactiveCN106958152AReduce consumptionReduce production processShrinkingMercerising of indefinite length fabricsHair removalNylon material

The invention relates to a one-bath dyeing process, in particular to a one-bath process for hair removal and reactive dye dyeing of brocade / cotton fabrics. Follow the steps below: select sample cloth → gray cloth desizing → gray cloth pre-setting → gray cloth mercerizing → dyeing formula design → sample vat dyeing → drying and setting → oiling and setting → pre-shrinking finishing → finished product inspection. A one-bath process of hair removal and reactive dye dyeing of nylon / cotton fabrics, which has obvious energy-saving and emission-reduction effects, and the hand-feel elasticity, color fullness, and various quality internal indicators of the processed fabrics can meet the requirements of different customers.

Owner:HANGZHOU AOMEI PRINTING & DYEING

Continuous technology for producing polycarboxylate superplasticizer monomer polyether through one-step method

InactiveCN105273181ASolve the difficult problem of one-step productionIncrease productivityAlcoholSuperplasticizer

The invention discloses a continuous technology for producing polycarboxylate superplasticizer monomer polyether through a one-step method. The technology includes the steps that with unsaturated alcohol or unsaturated alcohol ether or unsaturated amine as an initiator, epoxide polymerization is performed in a segmented mode in multiple reaction kettles at certain temperature and pressure under the action of a catalyst, and continuous synthesis is performed to obtain the product. The technology has the advantages that for synthesis of the polycarboxylate superplasticizer monomer polyether, by performing epoxide polymerization in the segmented mode in the multiple reaction kettles, the problem that one-step method production of high-molecular-weight products is difficult is solved; the continuous production technology thoroughly changes single intermittent kettle type production of such products, and continuous production improves the product production efficiency and increases the product yield; as the mode of using the special kettles for special purposes is formed, namely, each kettle is used for producing a fixed molecular structure with a fixed molecular weight of the product in a certain step, product quality stability is substantially improved, and technology and operation difficulty is lowered.

Owner:FUSHUN DONGKE FINE CHEM

Steel for wind turbine main shaft bearing and production method of steel

ActiveCN109161658AAvoid crackingImprovement ingredientsShaftsBearing componentsChemical compositionSlow cooling

The invention relates to steel for a wind turbine main shaft bearing and a production method of the steel. The steel comprises the following chemical compositions: 0.10-0.30% of C, 0.10-0.50% of Si, 0.30-0.80% of Mn, 1.30-1.60% of Cr, less than or equal to 0.025% of S, less than or equal to 0.025% of P, 3.25-3.75% of Ni, less than or equal to 0.30% of Cu, 0.15-0.25% of Mo, 0.005-0.05% of Al, 0.005-0.015% of N, less than or equal to 0.0010% of Ca, less than or equal to 0.003% of Ti, less than or equal to 0.0015% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb and the balance of Fe and unavoidable impurities. The production process comprises the following steps: hot metal pretreatment, converter or electric arc furnace smelting, LF refining, RH or VD furnace refining, large section continuous casting CCM large continuous casting slab, continuous rolling and finishing, wherein continuous casting slab and rolling slab are all put into pits for slow cooling and softening annealing; the steel is high in purity, tissue uniformity and density, can replace electroslag steel, and meets the requirements on steel for the wind turbine main shaft bearing.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Processing system and technology for natural fibrous composite felt used for automotive trim plate core layer

The invention discloses a processing system and technology for natural fibrous composite felt used for an automotive trim plate core layer. The system comprises a fiber net generating device. The fiber net generating device is connected with a drying oven through a bottom curtain, the bottom curtain is provided with a driving structure, fiber nets which come out of the drying oven pass through a hot pressing device and extends to a winding device, a cloth guide roller used for winding the fiber nets to be in a S shape and a supporting conveying roller are arranged in the drying oven, the hot pressing device is a pair of heating and compressing rotary rollers, the fiber net generating device comprises an opening device, a carding device and a net paving device, and the opening device, the carding device and the net paving device are connected in sequence. The processing system and technology for the natural fibrous composite felt used for the automotive trim plate core layer are low in cost, high in performance, environmentally friendly and capable of greatly improving the strength and tenacity of the natural fibrous composite felt, and the natural fibrous composite felt can be used as base materials of various automobile trim plates with high strength requirements.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +2

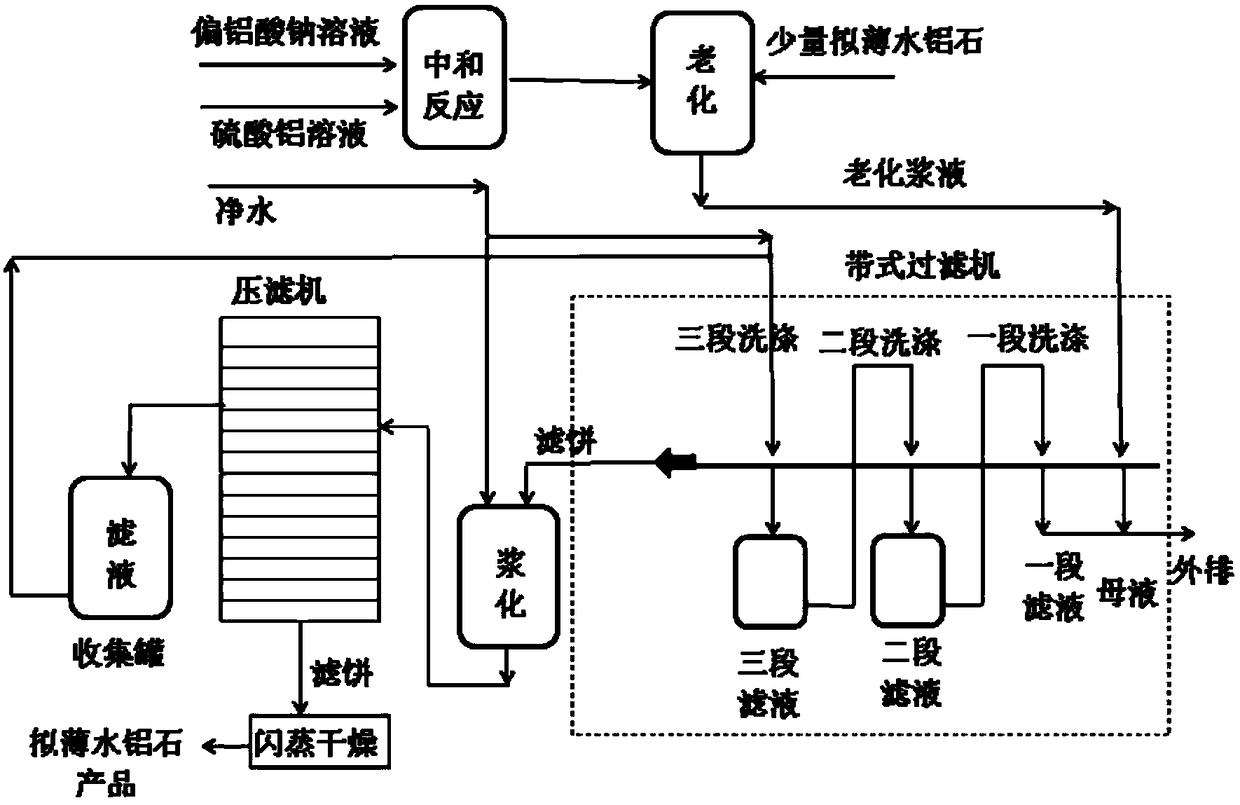

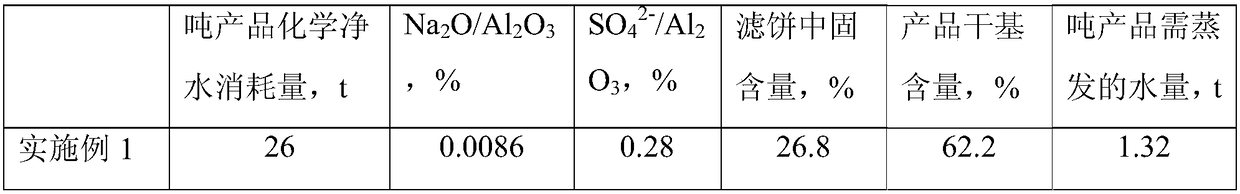

Preparation method of pseudoboehmite

ActiveCN108910925AGood water permeabilityReduce dosageAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPseudoboehmiteEvaporation

The invention discloses a preparation method of pseudoboehmite. The whole process consists of neutralization, aging, washing and drying steps. The process is characterized in that: 0.5%-5% of dried pseudoboehmite is added at the end of aging, the washing process adopts a continuous belt filter and intermittent filter press two-stage combination process, the washing water amount is 10-30 times thatof the pseudoboehmite product, the solid content of a pseudoboehmite filter cake is in the range of 26.0%-35.0%, the washing water amount is reduced by 50% or more, the amount of water needing evaporation for unit product is reduced by 40% or more, and the energy consumption for drying is reduced by 40% or more. The process saves the washing water amount, reduces the energy consumption for dryingand makes the product quality more stable.

Owner:ZIBO QIMAO CATALYST

Flexible lead-acid battery core easy to recycle, and preparation method of flexible lead-acid battery core

ActiveCN103560252AIncrease profitImprove quality ratioCell seperators/membranes/diaphragms/spacersFinal product manufactureCapacitanceFiber

The invention relates to a preparation method of a flexible lead-acid battery core easy to recycle. The preparation method of the flexible lead-acid battery core is characterized by taking porous glass fiber cloth made of compound sodium alginate fiber as a supporting layer, and comprises the following steps: applying metal flow collection layers to two surfaces of the supporting layer by adopting a vacuum sputtering or vacuum evaporation coating method, coating positive and negative electrode active substances respectively, and drying; spraying a sodium alginate solution on the dried surface, so as to form an isolating layer; and drying so as to obtain the flexible lead-acid battery core capable of being wound. The assembling is performed according to required capacitances, shapes and sizes, electrode leading-out terminals are connected and are pressed in a shell, then an electrolyte is filled in the shell, and the sealing is performed, so that the flexible lead-acid battery core easy to recycle is obtained.

Owner:FUJIAN REIDA PRECISION

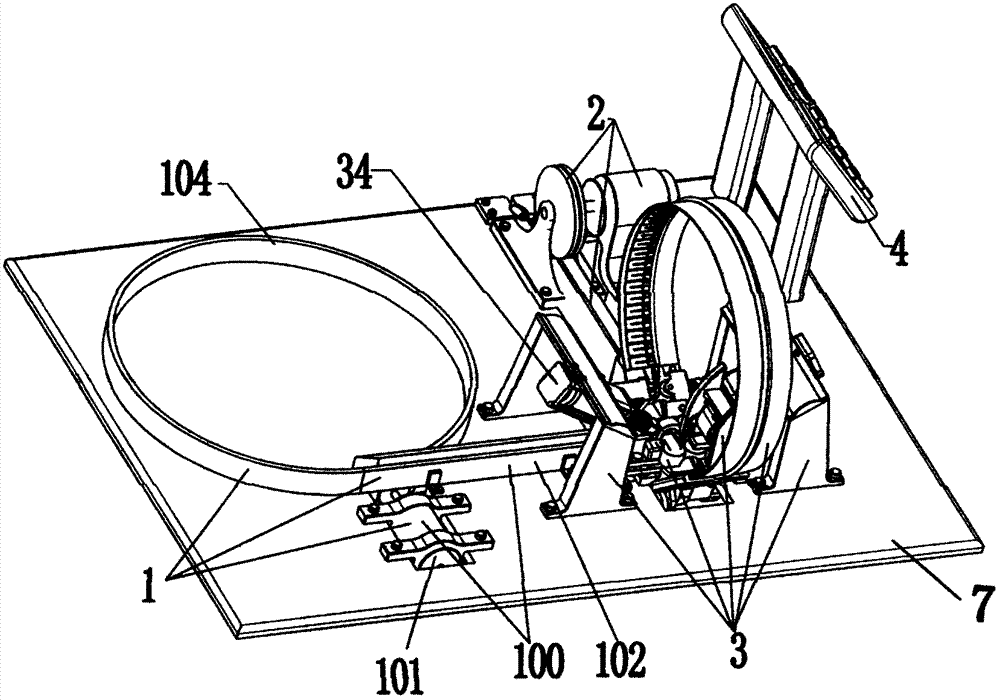

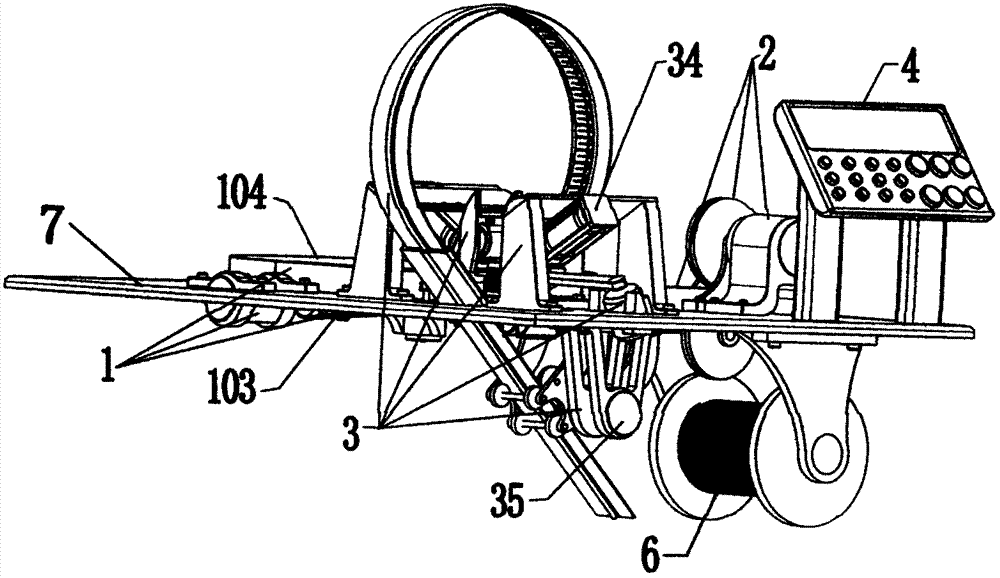

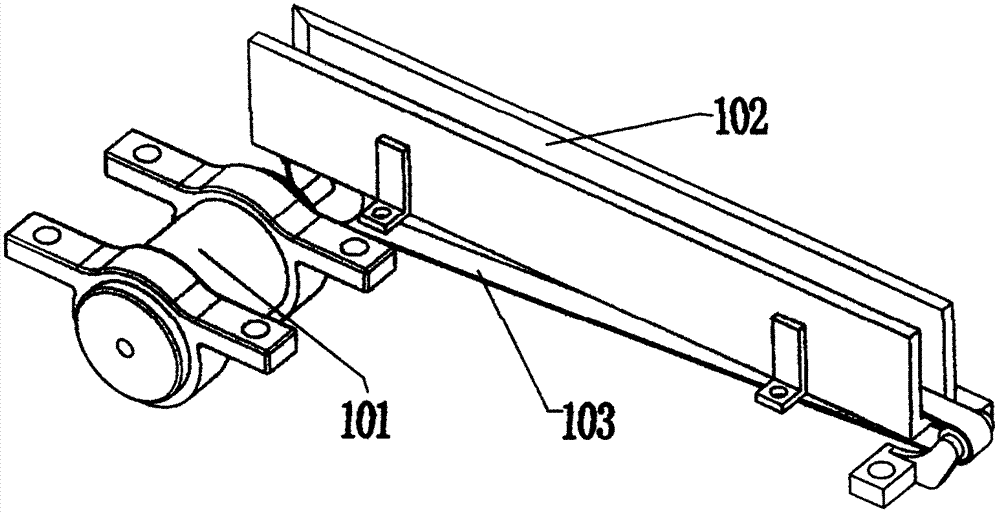

Magnet ring winding machine

InactiveCN103093955AIncrease productivityReduce manufacturing costMechanical energy handlingCoils manufactureWinding machineMagnet

The invention discloses a magnet ring winding machine used for wire rod winding magnet rings with thick wire diameters. The magnet ring winding machine comprises a magnet ring conveying mechanism, a wire feeding mechanism, a winding mechanism and an operating table, wherein the magnet ring conveying mechanism is arranged in the middle of one side of the winding mechanism and comprises a vibration disk and a magnet ring conveying device, and the magnet ring conveying device is arranged between the vibration disk and the winding mechanism; the wire feeding mechanism is arranged behind a base of the winding mechanism and comprises a stepper motor, an upper wire feeding wheel arranged on a rotating shaft of the stepper motor, a lower wire feeding wheel arranged on an internally arranged bearing below the upper wire feeding wheel, a wire horn mouth arranged behind the upper wire feeding wheel and the lower wire feeding wheel, and a wire conduit communicated with a wire hole in the base of the winding mechanism; and the winding mechanism comprises a wire device guiding wire rods to operate, the base mounted on the wire device, a wire driving device mounted on a guide seat, a magnet ring control device fixing and driving a magnet ring to rotate, a wire lifting device arranged on the guide seat, and a wire groove soft belt pulling device arranged below the guide seat.

Owner:陈登儒

Preparation method of high performance halogen free environment-friendly extruded magnetic stripe made of rubber&plastic ferrite and magnetic stripe

InactiveCN102163496AReduce production stepsReduce energy consumptionMagnetsInductances/transformers/magnets manufactureAdhesiveFerrite powder

The invention discloses a preparation method of a high performance halogen free environment-friendly extruded magnetic stripe made of rubber&plastic ferrite. The method is characterized by comprising the following steps: (1) preparing raw material mixture, to be more specific, preparing uniform raw material mixture by mixing ferrite powder, the size of which is between 10 and 200 nanometers, cladding agent and adhesive; (2) extruding a sheet, to be more specific, setting a scope of extrusion thickness for an extruder, feeding the raw material mixture into the extruder, and successively extruding to obtain a plastic magnetic sheet; (3) cutting, to be more specific, cutting the plastic magnetic sheet into predetermined shape and dimension; (4) UV glazing, to be more specific, spraying UV oil polish on a surface of the magnetic sheet, thereby forming a protection film on the surface; (5) magnetizing, to be more specific, magnetizing by placing the magnetic sheet in a magnetic field to obtain a magnetic stripe. The invention also discloses an extruded magnetic stripe of high performance halogen free environment-friendly rubber&plastic ferrite prepared by the method. The invention can be widely applied to the manufacturing field of flexible rubber&plastic magnetic products.

Owner:广州高馨能生物科技有限公司 +1

A method and device for producing high-power tube chip welding

InactiveCN102294526AReduce operating costsSolve production efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDie bonding

The invention discloses a welding method and device for producing high-power tube chips. The purpose of the present invention is to provide a high-power tube chip welding method and device thereof, which have automatic production, high production efficiency, saving enterprise operating costs and stable product quality. The steps of the invention include mold making, material suction, wire feeding, pressing, core welding, heat preservation, cooling, stacking and the like, and the invention is mainly used in chip factories to produce power tube chips.

Owner:JIEYANG HONGGAN ELECTRONICS

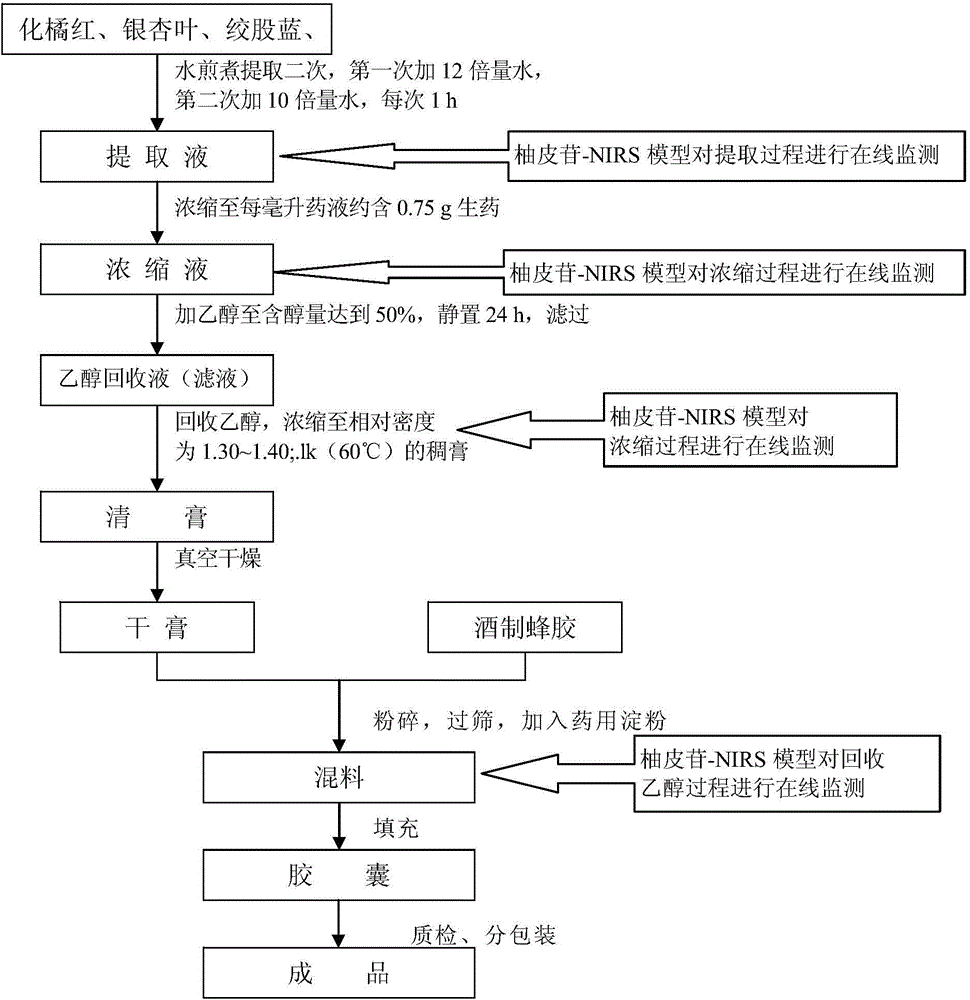

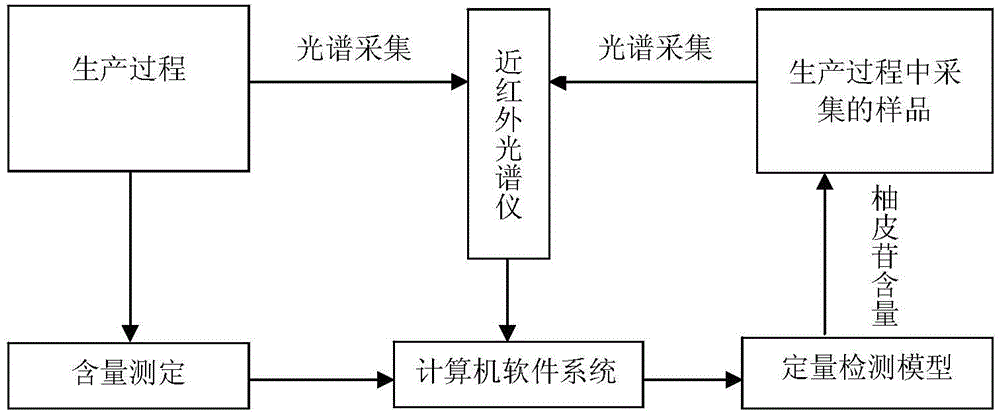

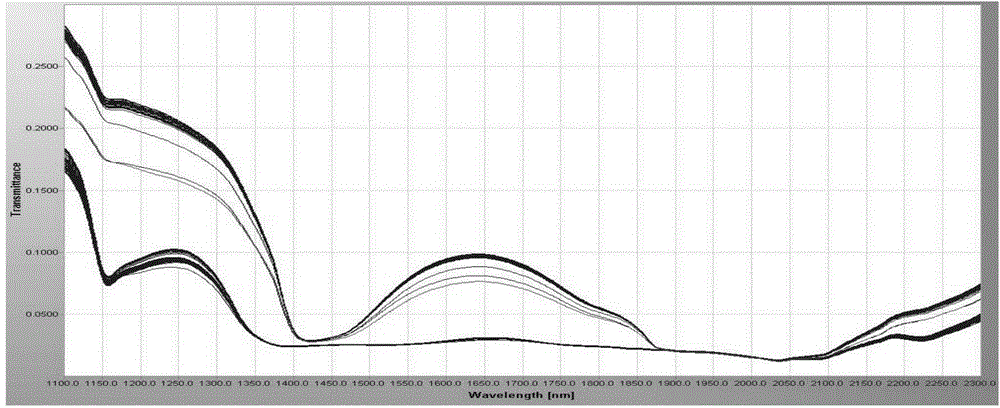

Near-infrared on-line detection method used in production process of traditional Chinese medicine containing naringin

The invention provides a near-infrared on-line detection method used in production process of a traditional Chinese medicine containing naringin. The method comprises the following steps: collecting a sample in the production process of the traditional Chinese medicine containing naringin, and acquiring a near-infrared spectrum of the sample; measuring the content of naringin in the sample by using the existing technology; establishing a detection model by using chemometrics software according to the near-infrared spectrum of the sample and the naringin content measured by using the existing technology, wherein the spectrum range of the near-infrared spectrum of the detection model is 1100-2300nm; and acquiring the sample to be detected, and measuring the content of naringin and the spectrum similarity degree by using the detection model. By adopting the near-infrared on-line detection method used in the production process of the traditional Chinese medicine containing naringin, the problems that a quality analysis method is low in efficiency and too many raw materials are wasted in the production process of the traditional Chinese medicine containing naringin are effectively solved.

Owner:广东省中医药工程技术研究院

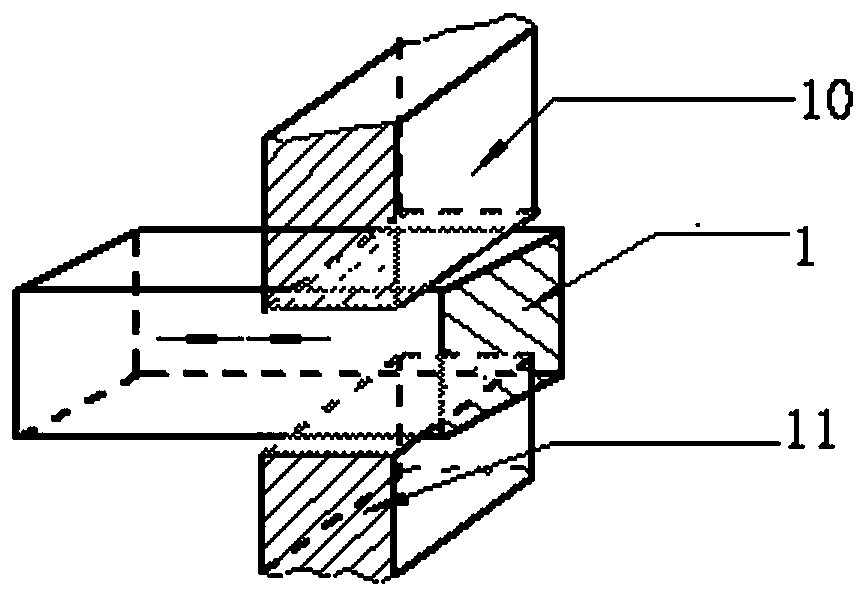

Forging method capable of efficiently, integrally and uniformly compacting deformation

InactiveCN108465762AImprove forgeabilityImprove forging efficiencyMetal-working apparatusIngotDeformation Problem

The invention relates to a forging method capable of efficiently, integrally and uniformly compacting deformation, and the forging method can uniformly refine compacting deformation and the structureof a large forged piece product. The forging method is characterized in that special upper and lower wide plates are adopted for upsetting and forging a forged piece, so that forging main deformationis completed; then, finishing forming is performed on upper and lower anvils; a special wide plate is utilized for integrally forging, so that forging permeability is greatly improved, and the problemthat forging deformation is uneven at positions such as each hammer head, and a joint of the hammer heads during upper and lower anvil forging is also overcome, and therefore, the inner part of the forged piece is forged thoroughly and compacted, and a uniform fine grain structure is obtained; upset electroslag ingots are mainly deformed on upper and lower wide plates, and integral once formationis performed until design dimensions at every pass in a wide plate forging process, and reduction is controlled to be 25%-40%; the electroslag ingots are integrally forged until deformed to the designed dimensions between upper and lower flat plates after being turned over by 90 degrees, and 700mm-wide upper and lower nails are adopted for forging and forming so as to conveniently erecting angles, so that the uneven forging deformation problem of the hammer head during main deformation is avoided, forging permeability is improved, anvil replacing times are reduced, forging time is saved by about 1 / 2, forging production efficiency is improved, production cost is reduced, and product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Laser code spraying, detecting and sorting all-in-one machine and laser code spraying, detecting and sorting method

ActiveCN110052420ARealize the integration of laser marking, detection and sortingEase capacitySortingLaser beam welding apparatusControl systemComputer module

The invention provides a laser code spraying, detecting and sorting all-in-one machine and a laser code spraying, detecting and sorting method, and belongs to the field of packaging equipment. The laser code spraying, detecting and sorting all-in-one machine comprises a laser code sending control system, a laser code spraying device, a laser code spraying control system, a sorting device, a sorting control system and a master control system, wherein the laser code spraying device is controlled by the laser code spraying control system to perform laser code spraying on products, the sorting device is controlled by the sorting control system to sort the products after laser code spraying, the laser code sending control system, the laser code spraying control system and the sorting control system are all connected with the master control system, the linkage control of the three systems is realized through the master control system, and the laser code sending control system comprises a classification module, a code sending module and a screening module. Through the technology, the production efficiency can be improved, the production links can be reduced, linkage control of code spraying and sorting systems can be realized, the quality stability of the whole products can be improved, and the production of the packaging quality inspection and code spraying and sorting links of people can be more automated.

Owner:INT PAPER SHOREWOOD PACKAGING GUANGZHOU

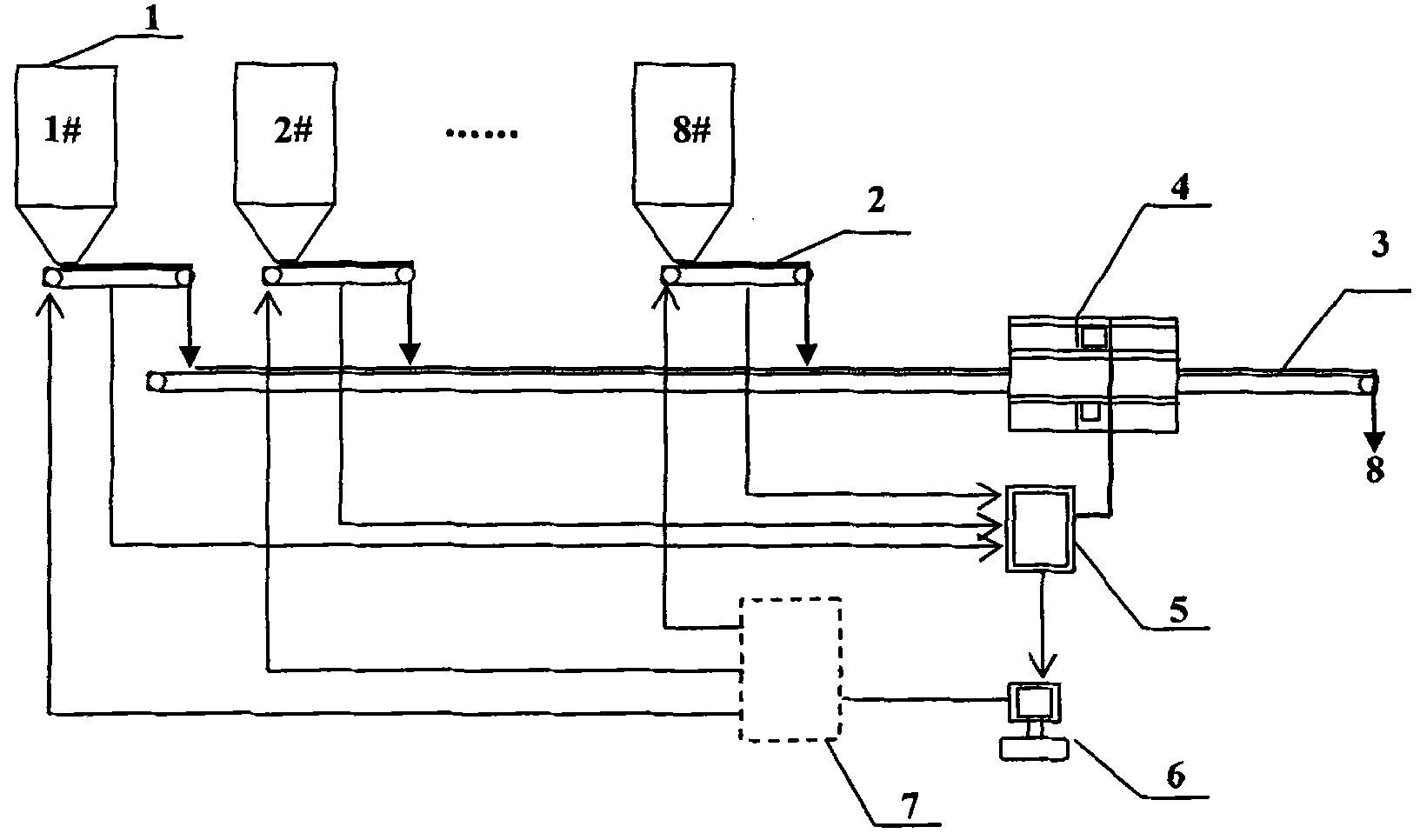

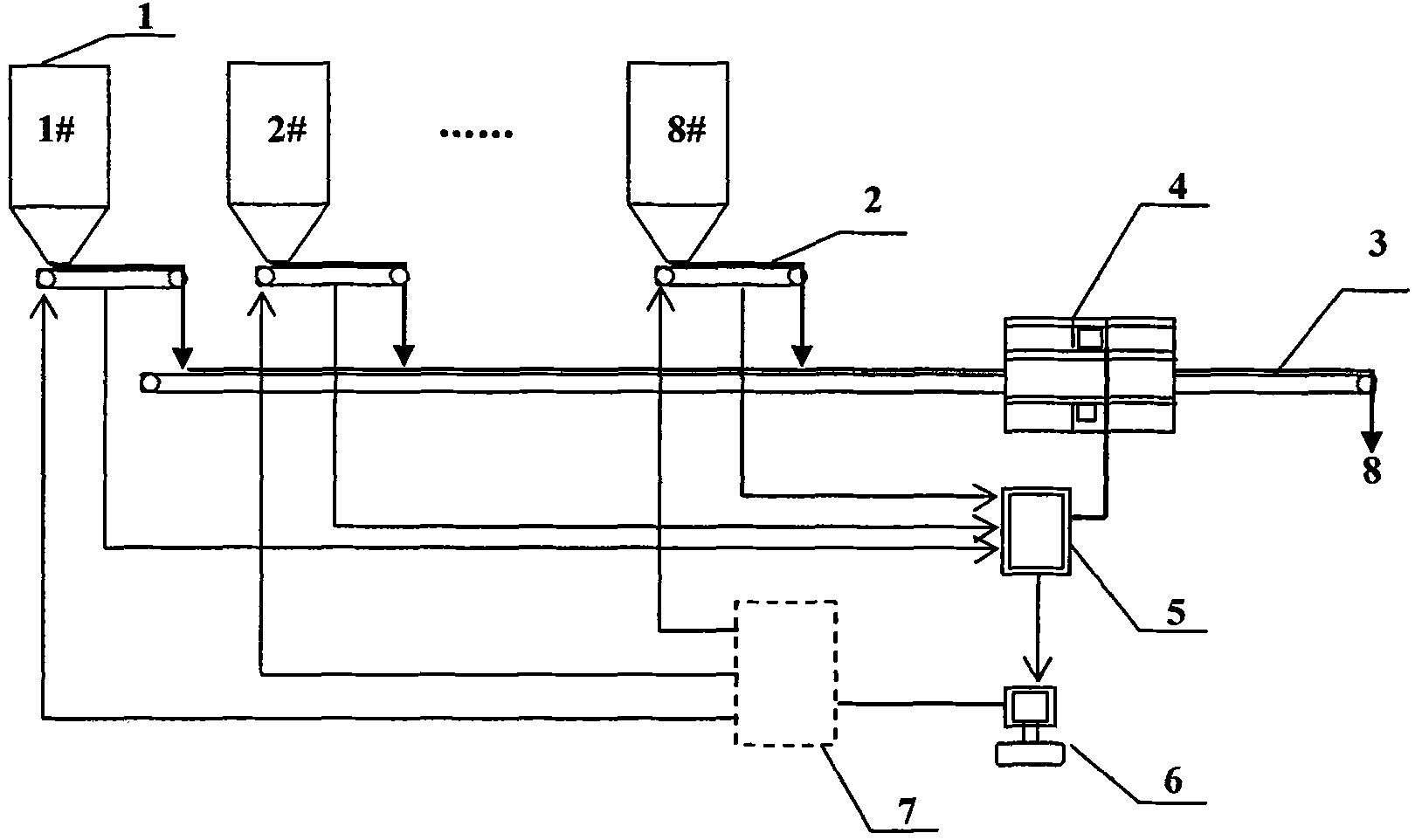

Continuous proportioning system and method for refractory synthesis material

ActiveCN101920530ARealize large-scale productionSimplify Process Control FlowMixing operation control apparatusTraffic volumeLine element

The invention relates to a continuous proportioning system and a method for a refractory synthesized material, belonging to the technical field of refractory materials. The system comprises a proportioning bin, a belt weigher, a belt conveyer, an on-line element analyzer, a data processing control console and proportioning software, wherein, the on-line element analyzer is used for carrying out full-flow component detection on materials before grinding, and analytical software is used for calculating the composition of the materials and controlling the feeding proportion of the materials according to prescription requirements so as to achieving the purpose of on-line continuous proportioning, thereby realizing that the components of the materials to be ground are precise, unified and stable. The invention overcomes the scale limitation of the traditional batch-type proportioning, solves the problem that the traditional continuous proportioning can not ensure the components of the materials to be ground, promotes the mass production of high-quality synthesis refractory materials, simplifies the control flow and saves the cost.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Inactivated type lactic acid bacteria microecological preparation as well as preparation method and application thereof

InactiveCN106307549AImprove securityImprove product quality stabilityUnknown materialsImmunological disordersMicroorganismLactobacillus

The invention relates to an inactivated type lactic acid bacteria microecological preparation as well as a preparation method and application thereof. The inactivated type lactic acid bacteria microecological preparation comprises inactivated bacteria and auxiliary materials, wherein the inactivated bacteria comprise inactivated bifidobacteria and inactivated bacterium lacticum. The inactivated microecological preparation disclosed by the invention is high in safety, resistant to infection by bacteriophages, free from limit of bacterium quantity, and high in product quality stability, and can be matched with an antibiotic for use; besides, the inactivated type lactic acid bacteria have the efficient capacity of being adhered to epithelial cells of intestinal tracts, and are resistant to high temperature, high acid and bile; when the inactivated type lactic acid bacteria and the antibiotic are in synergic use, the problems of a viable bacteria preparation can be safely and effectively solved; and in addition, the inactivated lactic acid bacteria can generate competitive inhibition on harmful microorganisms, adsorb harmful substances and regulate an immune response reaction, so that the immunity of organisms can be enhanced. The preparation method disclosed by the invention has the characteristics of being simple to operate and mild in conditions, and cost reduction, popularization and production are facilitated.

Owner:JIANGSU WECARE BIOTECHNOLOGY CO LTD

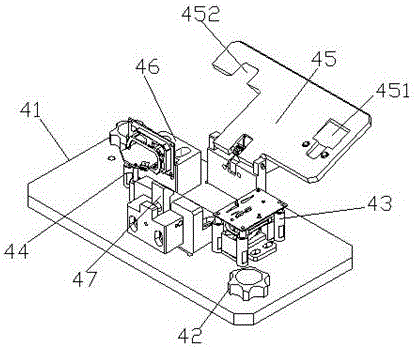

Welding device for automobile antenna PCB product

InactiveCN106392399AEnsure the stability of welding qualityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCircular discEngineering

The invention discloses a welding device for an automobile antenna PCB product. The welding device comprises a lower rack and an upper rack, wherein a rotary disc and a four-shaft robot are arranged on the lower rack; a plurality of PCB jigs are arranged on the rotary disc in ring array; a first detection device and a second detection device, positioned on the two sides of the rotary disc, are symmetrically arranged on the lower rack; and a soldering device which points to the rotary disc below is arranged on the four-shaft robot. According to the welding device for the automobile antenna PCB product, PCBs are placed on the PCB jigs, after fixation, through the anticlockwise rotation of the rotary disc, the PCB jigs are continuously sent to the positions below the soldering device to be welded, the first detection device detects whether the PCB jigs correspond to corresponding welding procedures or not and detects whether missing placing and mistaken placing exist or not, the second detection device detects whether the PCBs are successfully welded or not and whether welding spots are qualified or not, abnormity warning is carried out, and the stability of welding quality is guaranteed.

Owner:苏州德机自动化科技有限公司

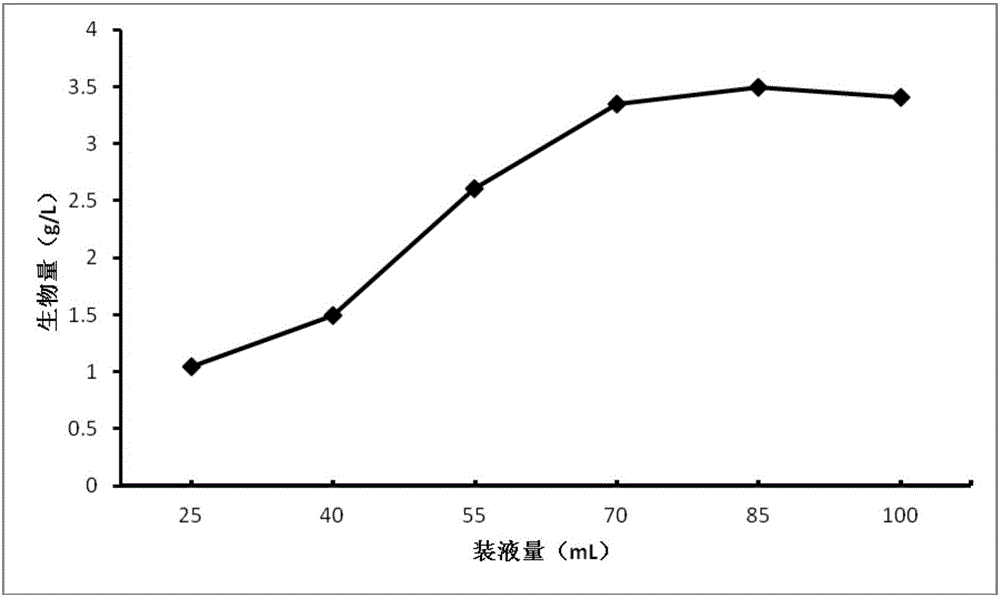

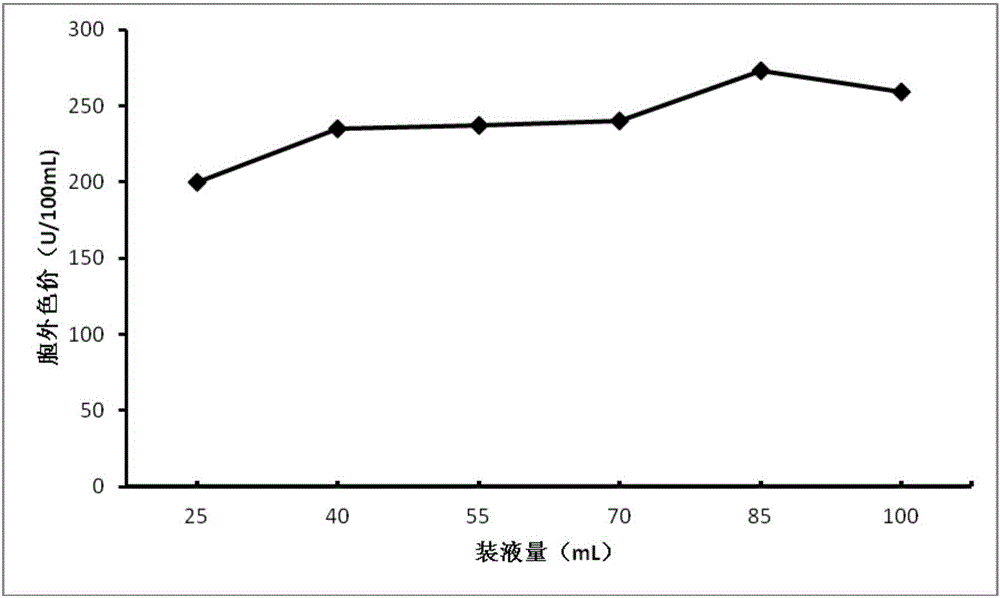

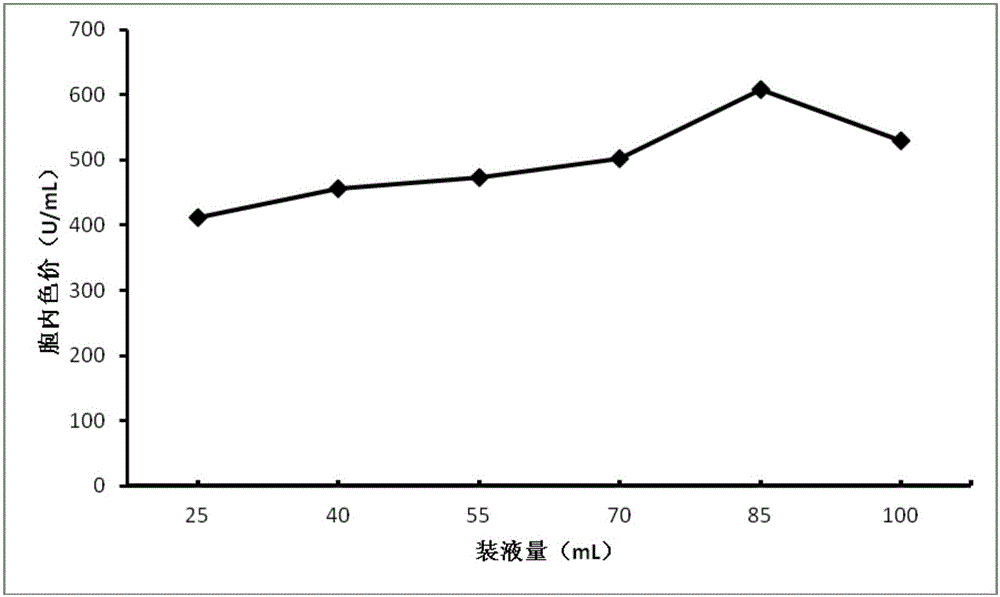

Culture medium applied to monascus fermenting yeast seed, culturing method of culture medium and preparing method of monascus vinegar

The invention relates to the technical field of microbial fermentation, in particular to a culture medium applied to a monascus fermenting yeast seed, a culturing method of the culture medium and a preparing method of monascus vinegar. The culture medium is prepared from a basic culture medium body, a carbon source, a nitrogen source, a growing factor and inorganic salt. The culturing method comprises the steps of taking the basic culture medium body, adding the carbon source, the nitrogen source, the growing factor and the inorganic salt into the basic culture medium body, inoculating monascus spore suspension, adjusting an initial pH value as 4-8 and shaking and culturing to obtain the monascus fermenting yeast seed. The preparing method of the monascus vinegar comprises the following steps of preparing the monascus fermenting yeast seed, saccharifying, fermenting, filtering and sterilizing. The culture medium applied to the monascus fermenting yeast seed, the culturing method of the culture medium and the preparing method of the monascus vinegar are different from an existing culturing method of the culture medium and an existing preparing method of the monascus vinegar. Screening the optimal culture medium and producing the functional monascus vinegar through a solid-liquid fermenting method are innovation and development of the vinegar industry.

Owner:周礼红

High-strength-and-toughness cast iron heavy-duty automobile brake drum and making technology thereof

InactiveCN103866177AImprove thermal fatigue resistanceImprove deformation resistanceBraking drumsThermal fatigueAlloy

The invention discloses a high-strength-and-toughness cast iron heavy-duty automobile brake drum. The brake drum is characterized in that brake drum comprises 3.55-3.85wt% of C, 2.35-2.75wt% of Si, 0.45-0.85wt% of Mn, 0.02-0.06wt% of P, 0.01-0.04wt% of S, 0.06-0.12wt% of Ti, 0.02-0.08wt% of Sn, 0.01-0.04wt% of Sb, 0.008-0.05wt% of Mg, 0.015-0.035wt% of RE, and the balance Fe. The making technology of the brake drum sequentially comprises the following steps: weighing raw materials in proportion, carrying out alloy melting, carrying out creeping and inoculation, carrying out cast molding, cleaning, and machining. Compared with the prior art, the technology has the advantages of best thermal fatigue resistance, good deformation resistance, good cooperation of strength, ductility, hardness and wear resistance, and good casting and machining properties.

Owner:金建平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com