Magnet ring winding machine

A technology of winding and winding mechanism, applied in coil manufacturing, electromechanical devices, control of mechanical energy, etc., can solve the problems of high cost, uneven quality and low efficiency of magnetic coils, so as to reduce production costs and improve stability. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

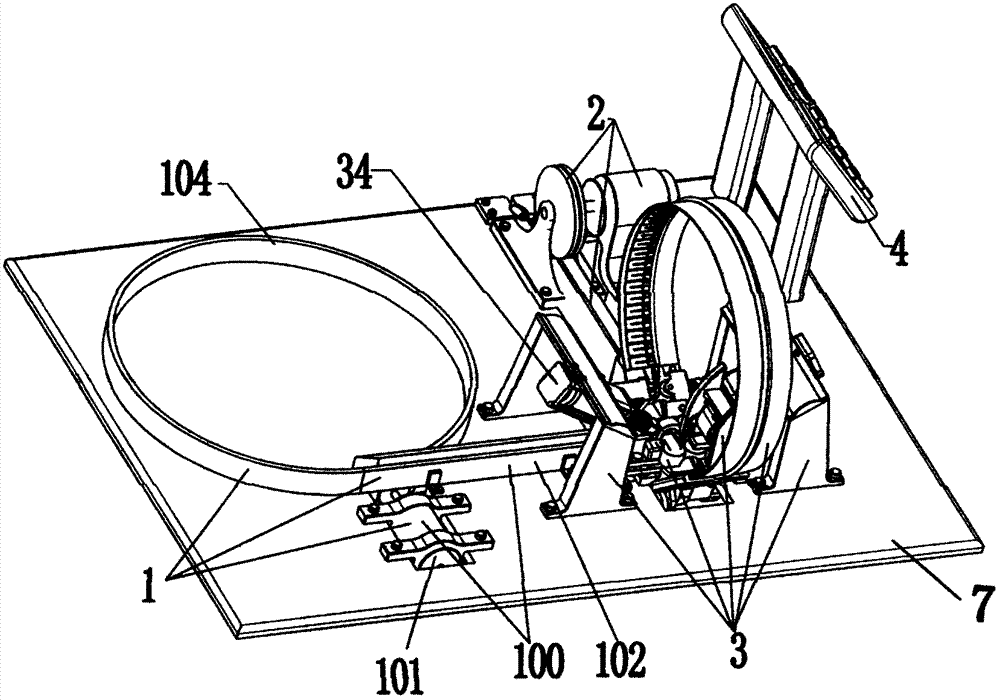

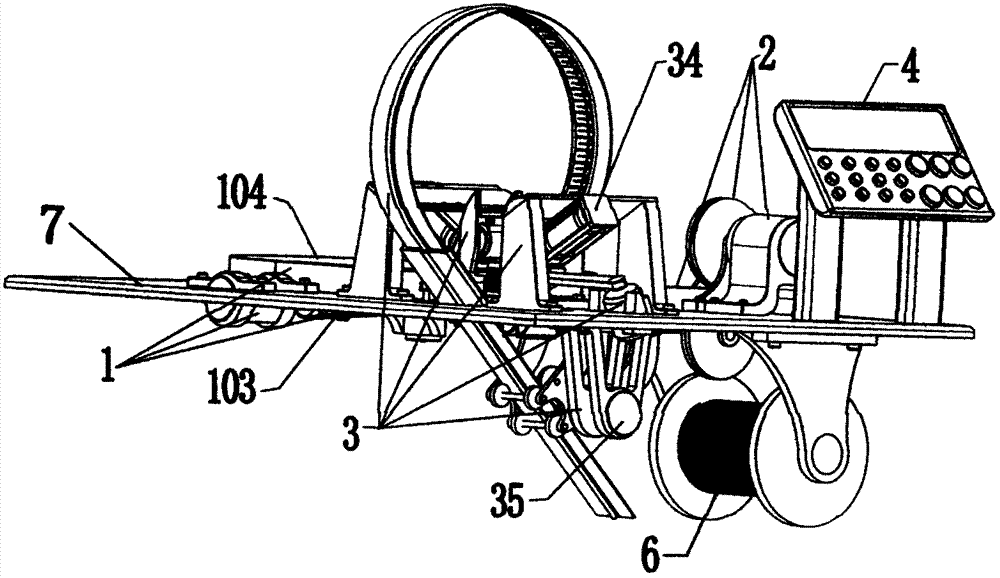

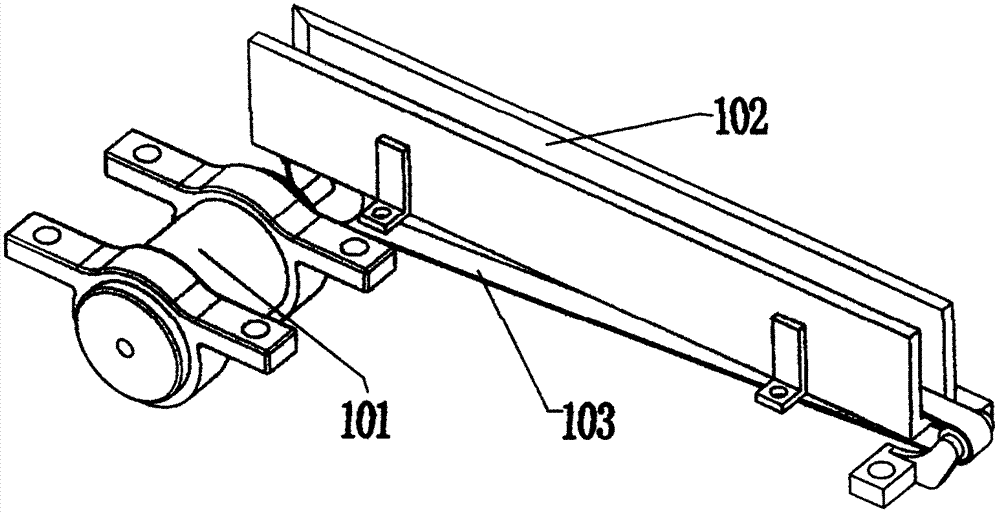

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , under the control of the console 4, the wire driving device 32 in the winding mechanism 3 works, wherein, the stepping motor 32a1 of the wire pulling device 32a on the guide seat 312 rotates, and the belt 32a3 is connected to the pulley 32a2 on the stepping motor 32a1 and The belt pulley 32a4 on the driving wheel 32a5 makes the driving wheel 32a5 run, and the driven wheel 32a6 installed on the support 32a7 of the "H" shape is next to the driving wheel 32a5 under the active force of the spring 32a8 on the support seat 32a9. Under the operation of 32a5, a pulling force is formed; the stepping motor 32b1 of the wire transmission device 32b on the base 311 rotates, and the belt 32b3 connects the pulley 32b2 on the stepping motor 32b1 and the pulley 32b4 on the driving pulley 32b5 to make the driving pulley 32b5 run. The driven whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com