Flexible lead-acid battery core easy to recycle, and preparation method of flexible lead-acid battery core

A technology that is easy to recycle lead-acid batteries, applied in the direction of lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc. The surface of the large plate and the electrolyte and other problems can be improved to improve the stability of product quality, facilitate penetration and diffusion, and improve labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

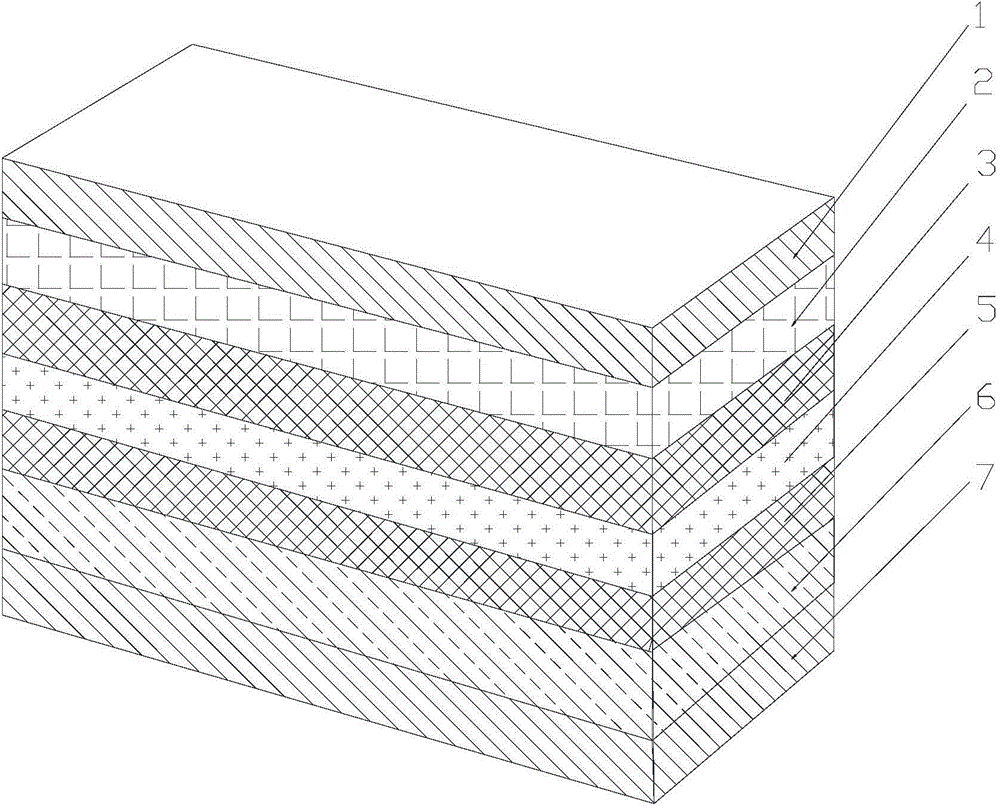

Image

Examples

Embodiment 1

[0072] Step 1: The alginate fiber and the porous glass fiber are respectively opened and removed, and then mixed according to a mass ratio of 1:9 to form a uniform fiber layer. It is combed into a thin web composed of single fibers by a carding machine. Using 1% sodium alginate solution by mass as a binder, spray it into the thin fiber net made above, and roll it to reinforce and shape it to obtain the desired porous glass fiber fabric composited with alginate fibers.

[0073] Step 2: Preheat the porous glass fiber fabric of composite alginate fiber prepared above, and then Pb-Ca(0.06%~0.08%)-Sn(1.2%~1.5%)-Al(0.02%) quaternary alloy Heating and evaporating in the evaporation source makes it join the gas phase space in the form of atoms (or molecules). The porous glass fiber fabric of the composite alginate fiber prepared above is introduced into a vacuum evaporation coating machine, so that the current collector material is deposited on both sides of the fabric and formed int...

Embodiment 2

[0078] Step 1: Open the alginate fiber and the porous glass fiber separately, remove impurities and mix them according to the mass ratio of 9:1 to form a uniform fiber layer. It is combed into a thin web composed of single fibers by a carding machine. The ammonium alginate solution is used as a binder, sprayed into the thin fiber net made above, and rolled and consolidated to obtain the desired porous glass fiber fabric composited with alginate fibers.

[0079] Step 2: preheating the porous glass fiber fabric of the composite alginate fiber prepared above. The above-mentioned Pb-Sn(1.7%)-Cd(1.7%) low-antimony alloy alloy used as the positive and negative current collectors is used as the target material, and is bombarded by charged particles to escape in the form of atoms (or molecules), adding gas space. The porous glass fiber fabric of the composite alginate fiber prepared above is introduced into a vacuum sputtering coating machine, so that the current collector material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com