Patents

Literature

3911results about How to "Realize continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

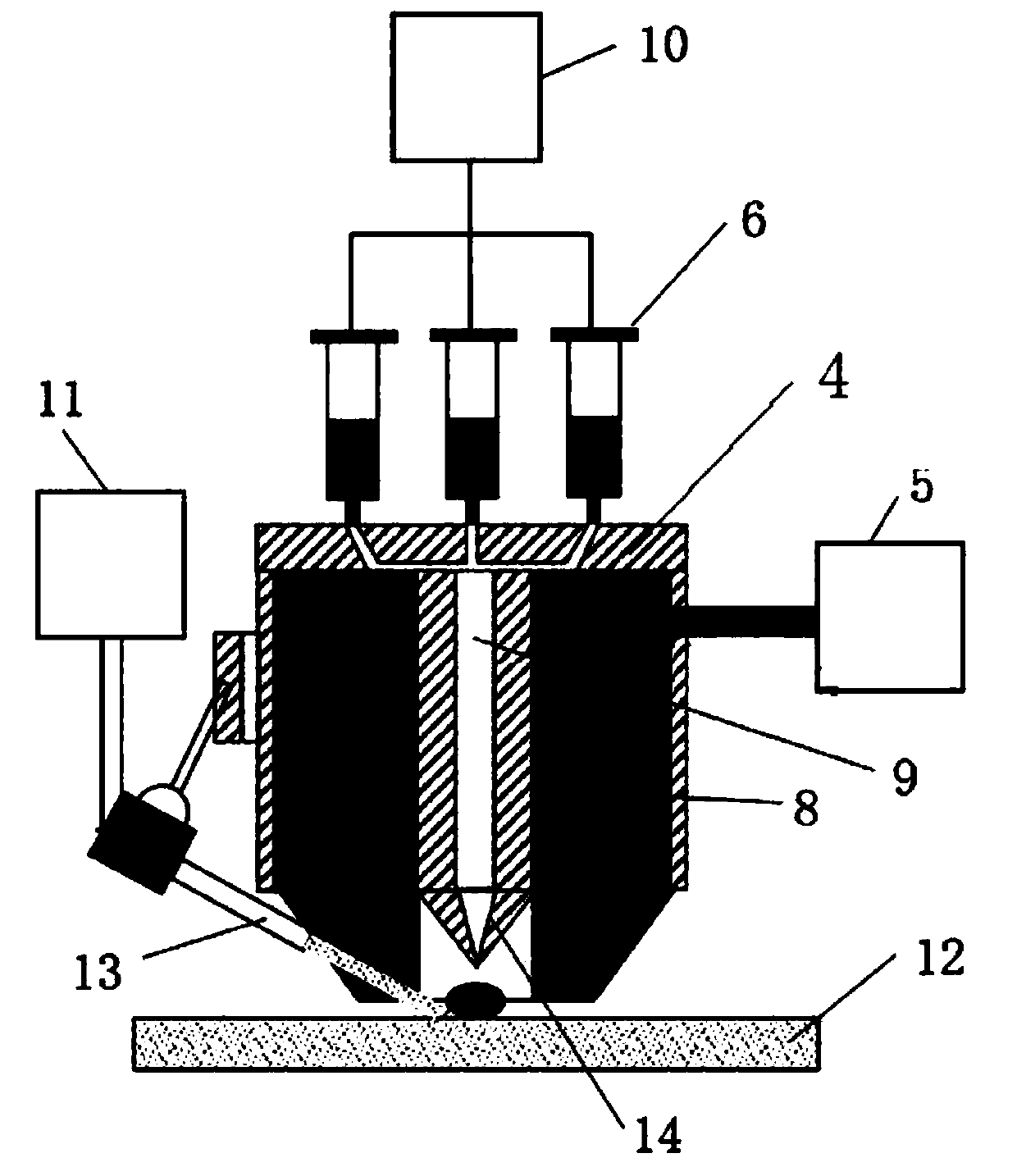

Method for continuously synthesizing precursor of lithium ion battery positive material

InactiveCN102092798AInhibition formationSolve the problem of easy oxidationCell electrodesManganese oxides/hydroxidesSynthesis methodsManganese

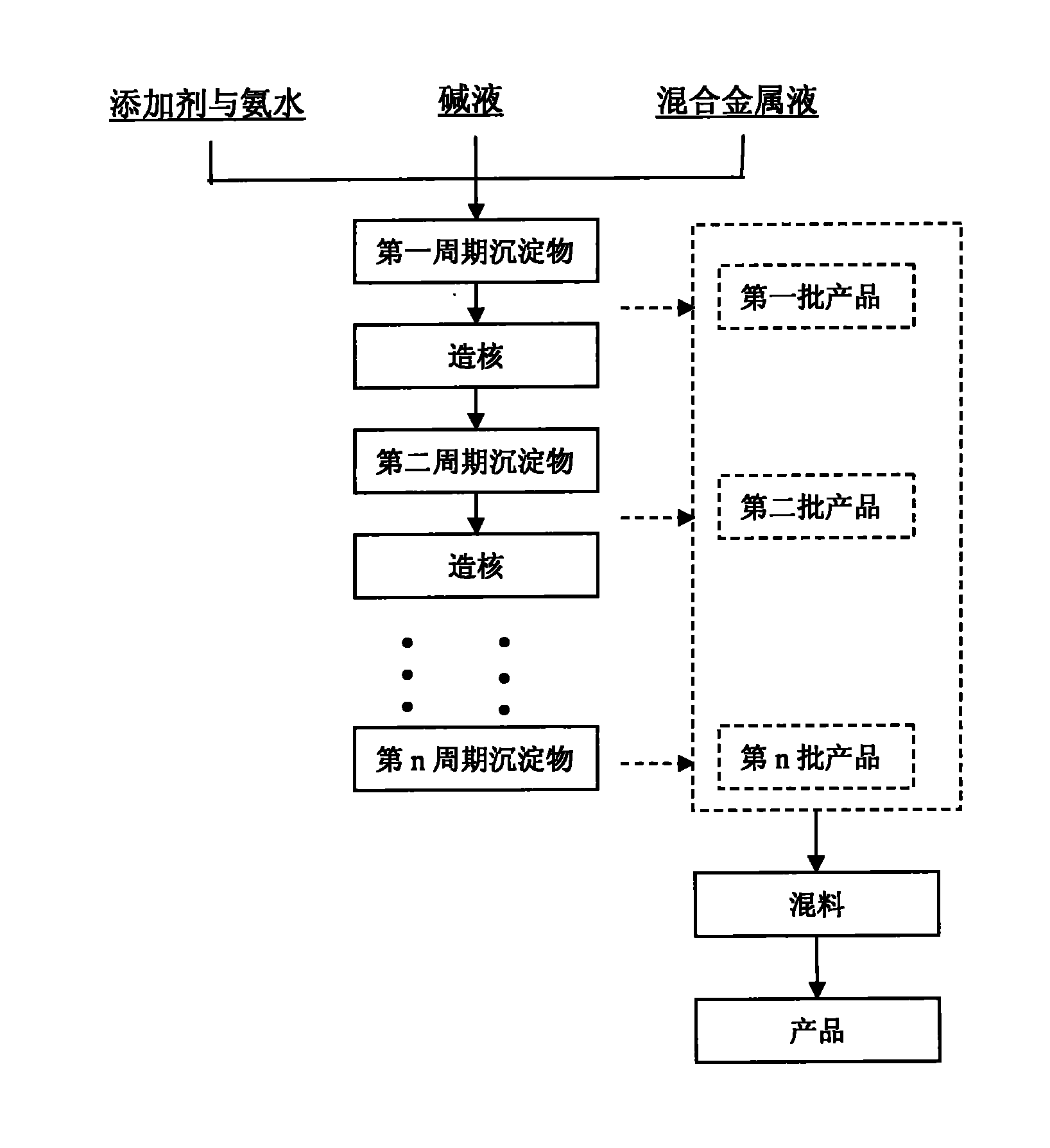

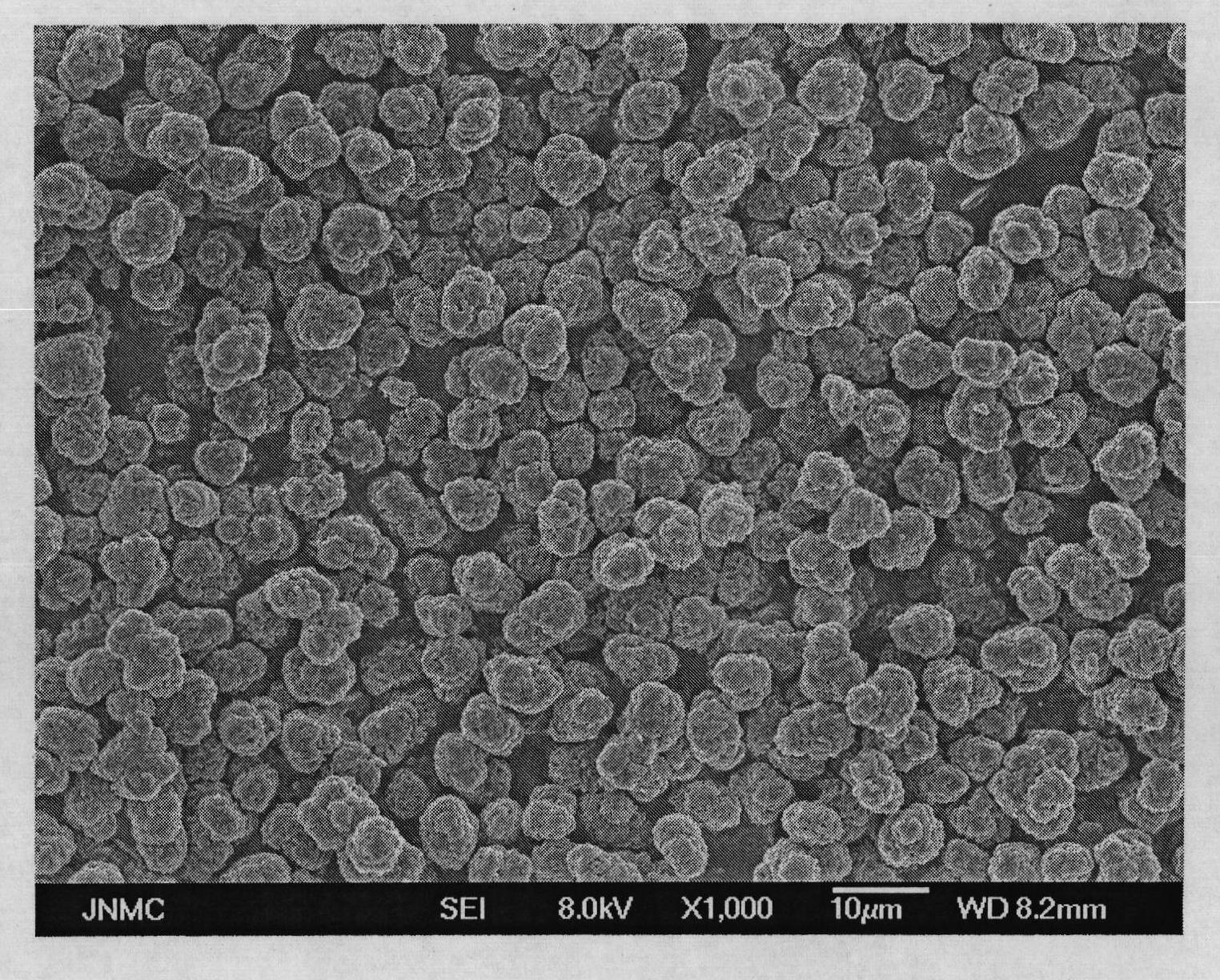

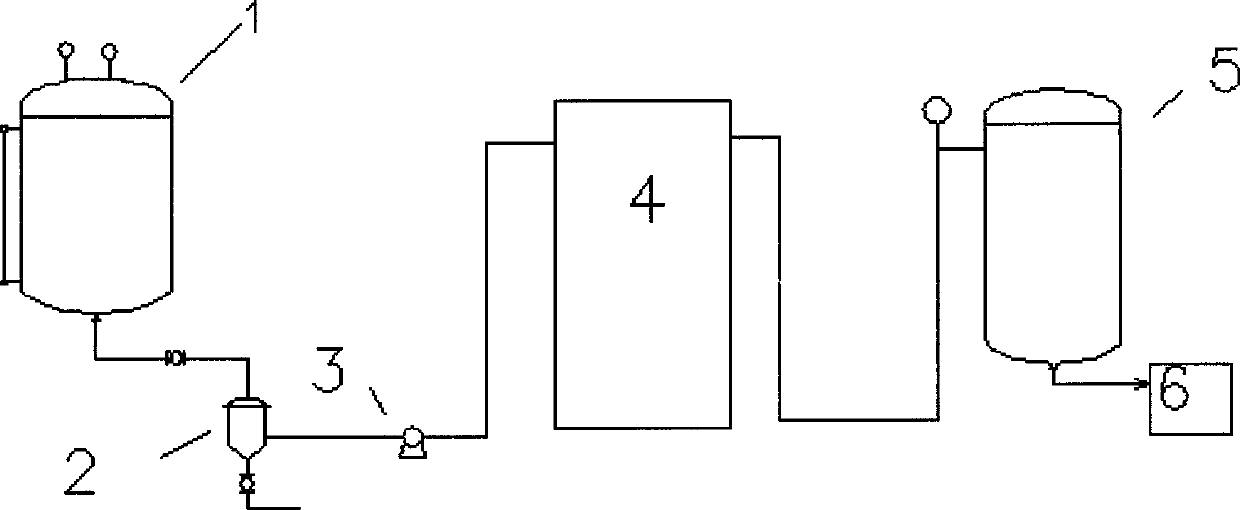

The invention provides a method for continuously synthesizing a precursor of a lithium ion battery positive material, relating to an improvement of a synthesis method of a nickle cobalt manganese termary positive material nickle cobalt lithium manganate of the lithium ion battery positive material. The method is characterized in that the synthesis process is as follows: merging a complexing agent ammonia, an aqueous solution of metal nickle cobalt manganese ions and a precipitator sodium hydroxide solution and then continuously adding the substances into a reaction kettle for a synthesis reaction under the strong stirring condition in the presence of protective gas; and aging, filtering and washing the effluent from the reaction kettle, and then drying to obtain the lithium ion battery positive material precursor spherical nickle cobalt manganese termary hydroxide. The method has the advantages that the preparation process is continuous, the particle size of the prepared nickle cobalt manganese compound hydroxide powder is controlled in a range of 5-20 microns, and the prepared nickle cobalt manganese compound hydroxide powder is even in distribution and excellent in electrochemistry property. The method has the advantages of high production efficiency, low production cost and significant economic and social benefits, and the energy is saved.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH +1

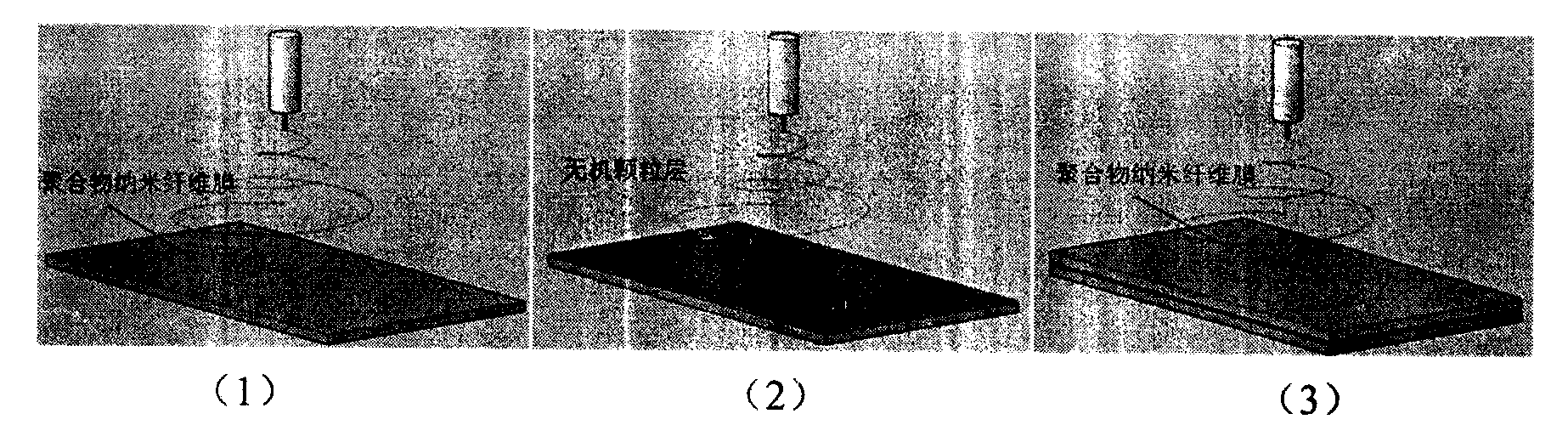

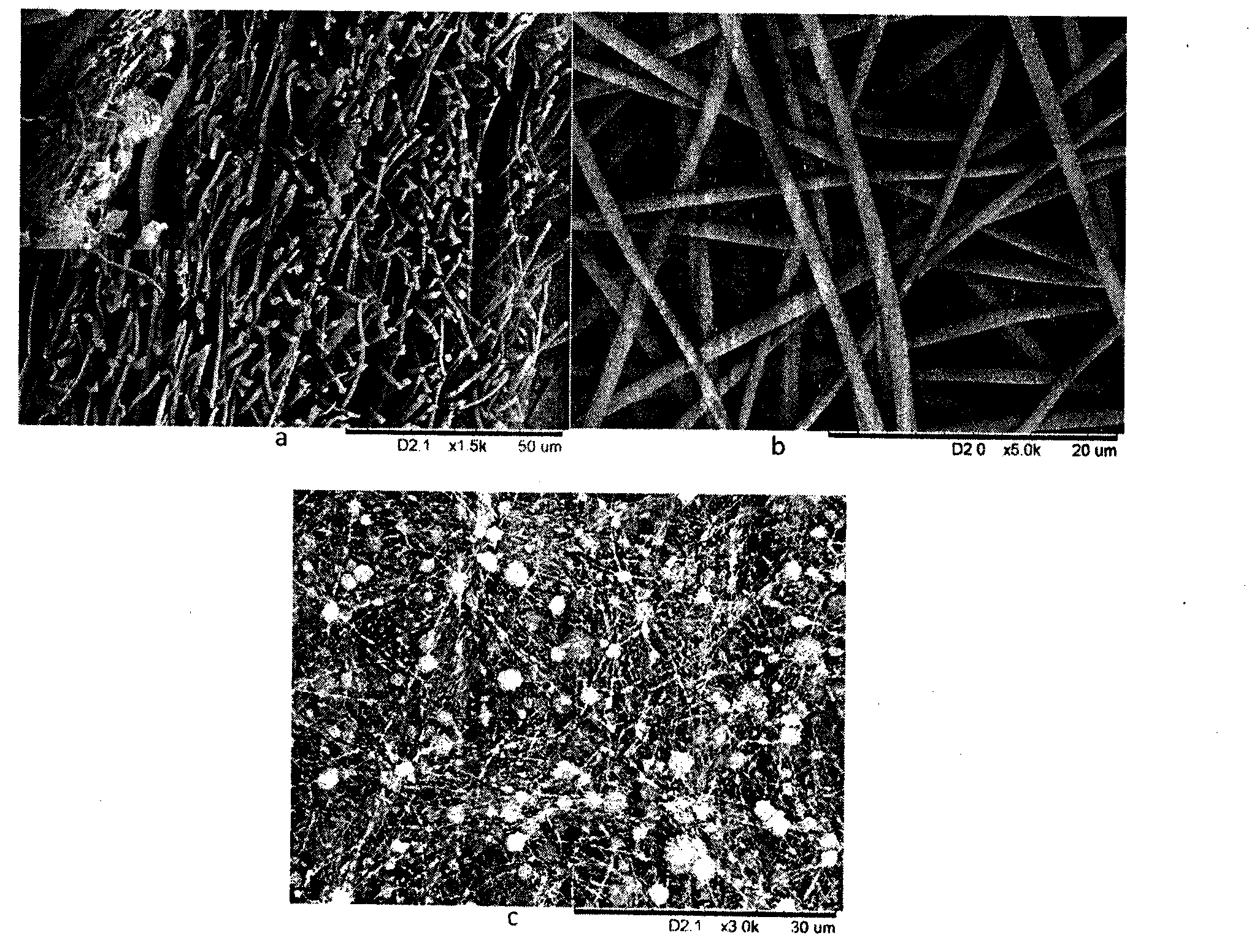

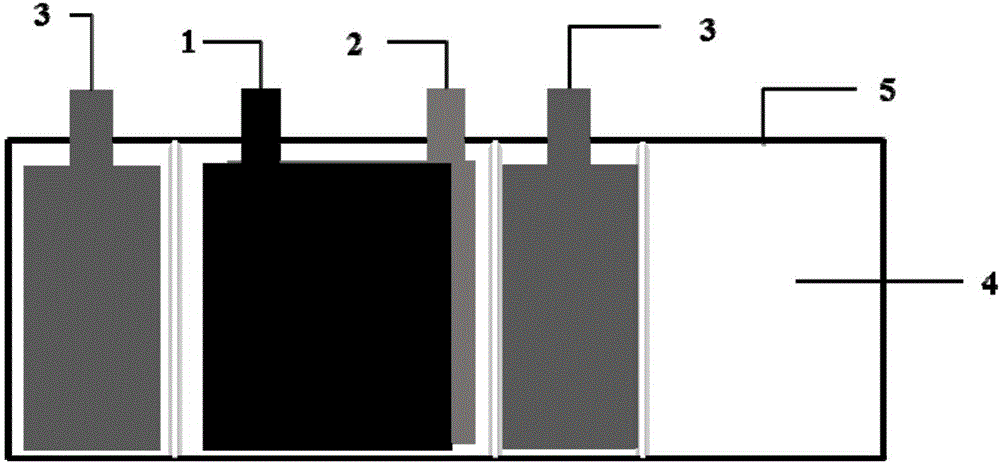

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

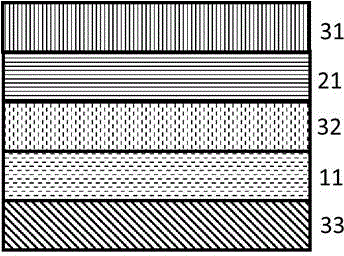

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

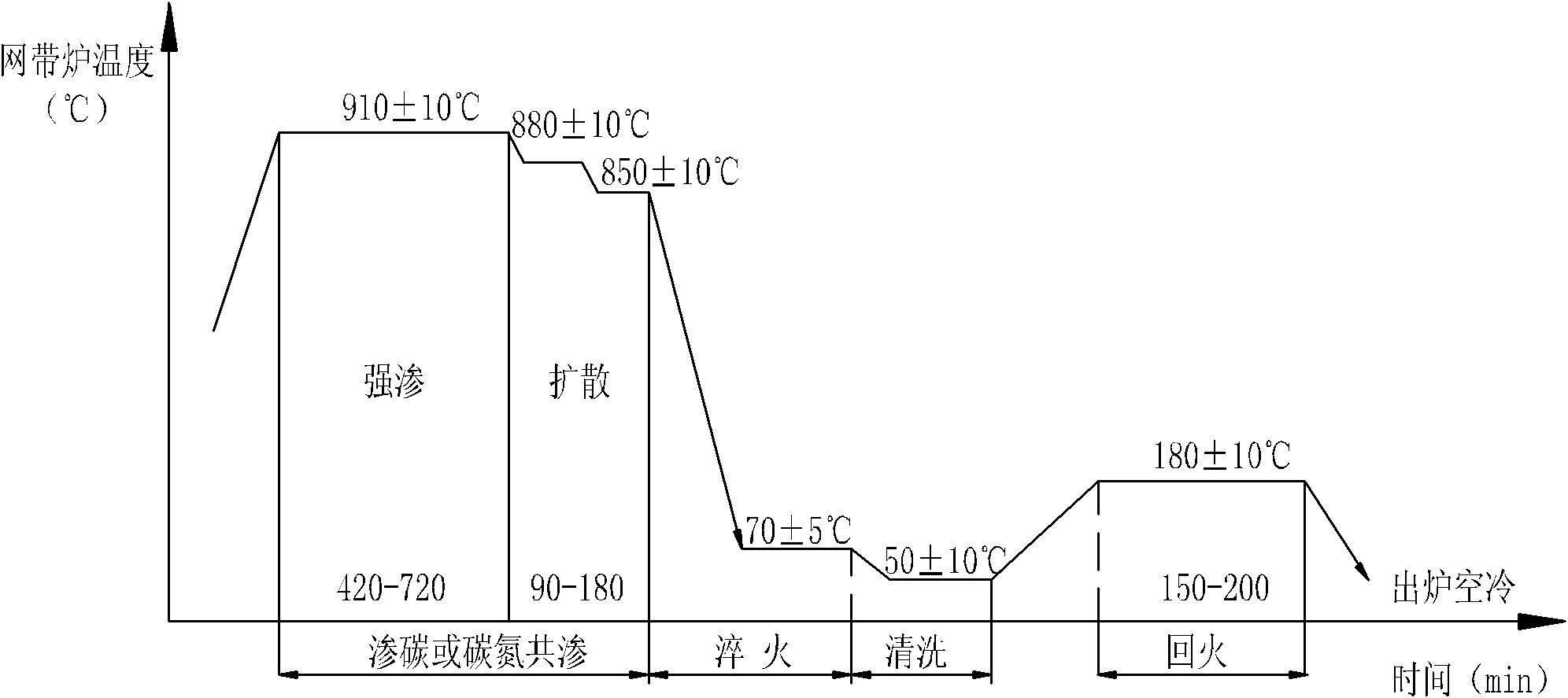

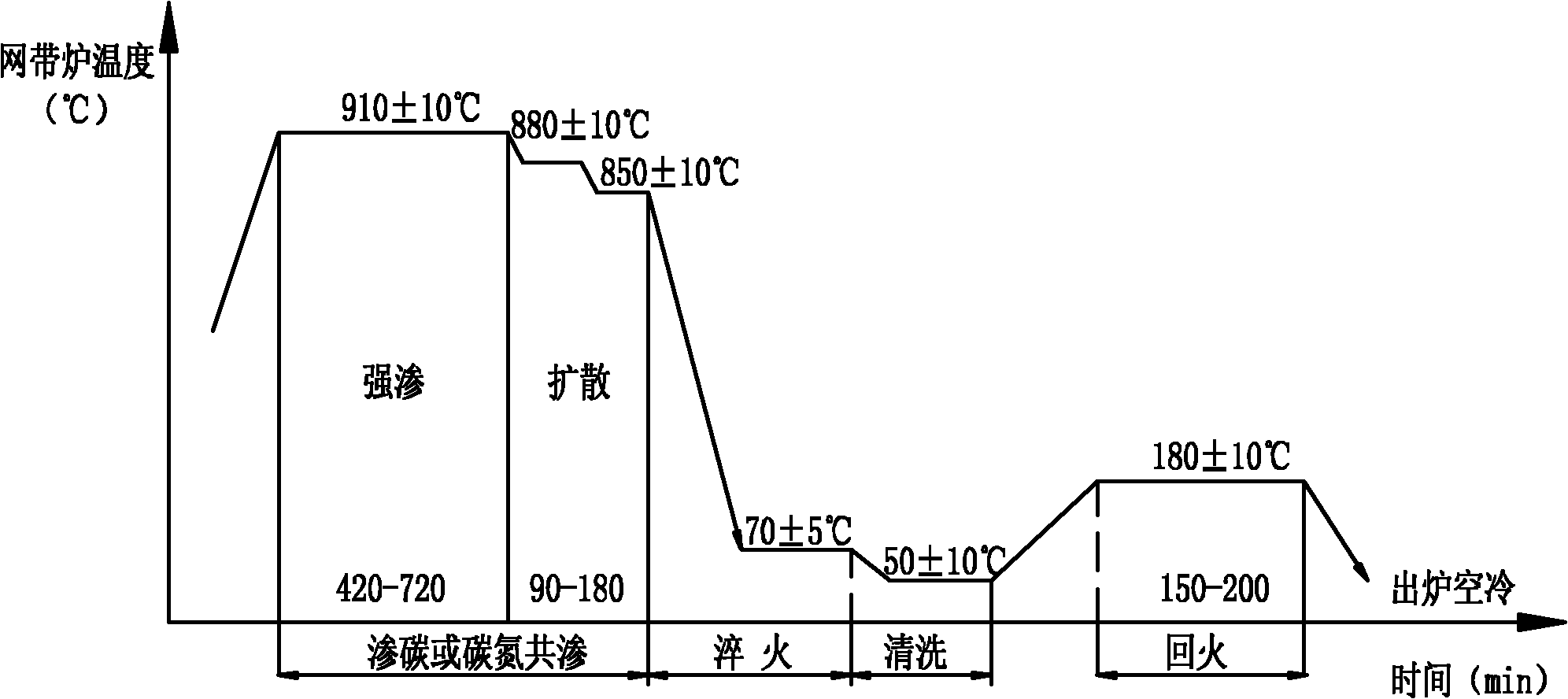

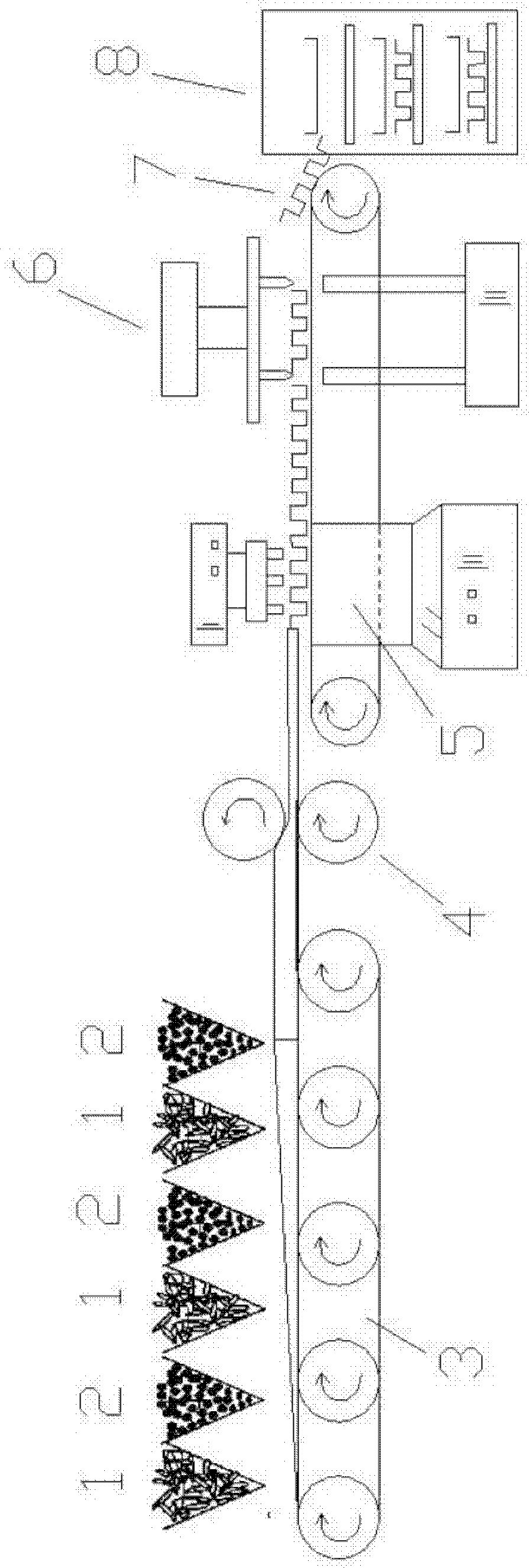

Medium-deep-layer carburization or carbonitriding thermal processing technology for bearings or clutch parts

ActiveCN102154652ALess often openLess closing actionSolid state diffusion coatingFurnace typesProduction lineCarbon potential

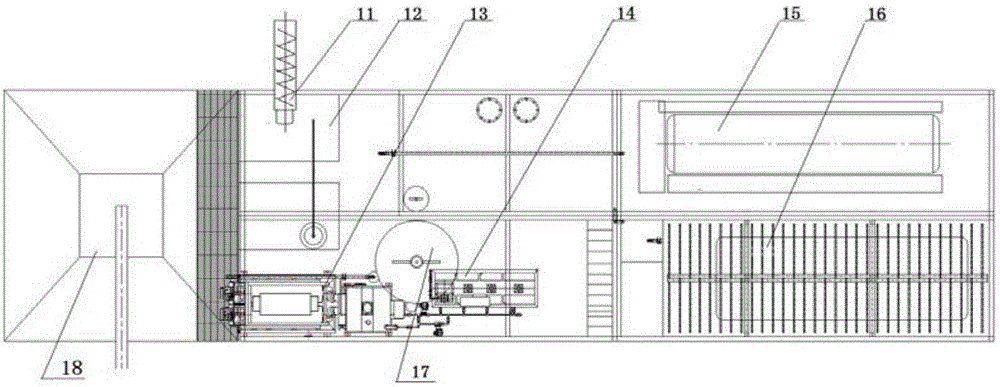

The invention relates to a medium-deep-layer carburization or carbonitriding thermal processing technology for bearings or clutch parts. In the invention, the carburization or carbonitriding is carried on parts by utilizing a continuous production line of a carrier roller type mesh belt furnace with a controllable atmosphere, and the technology comprises the following steps in sequence: strong permeation, diffusion, quenching, cleaning, low-temperature tempering, discharging and air cooling. In the invention, the continuous production line of the carrier roller type mesh belt furnace with the controllable atmosphere is used for carrying out the medium-deep-layer carburization or carbonitriding, thus continuous production is realized, the production efficiency is improved, the productivity is increased, frequent opening and closing actions of a gap furnace can be reduced, non-oxidization treatment is realized, and the labor intensity is reduced; and in addition, carbon potentials in all areas of the mesh belt furnace are respectively controlled so as to guarantee the quality stability.

Owner:JIANG SU NAN FANG BEARING CO LTD

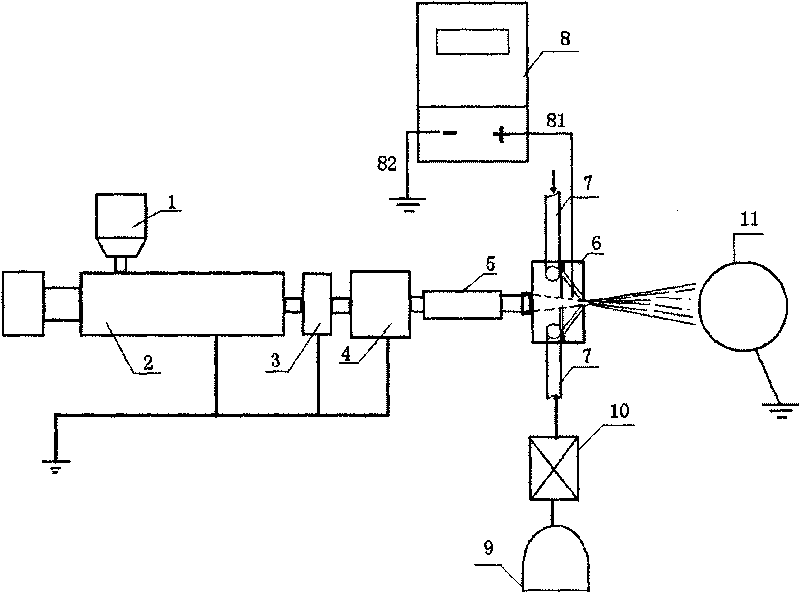

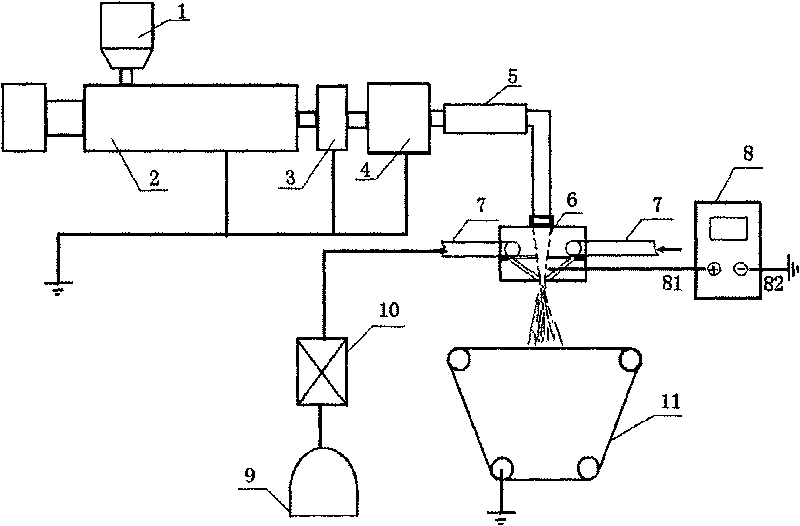

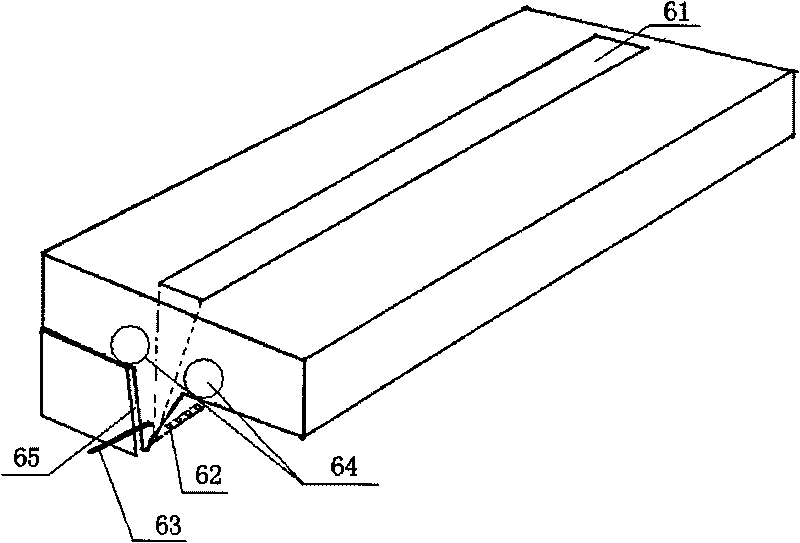

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

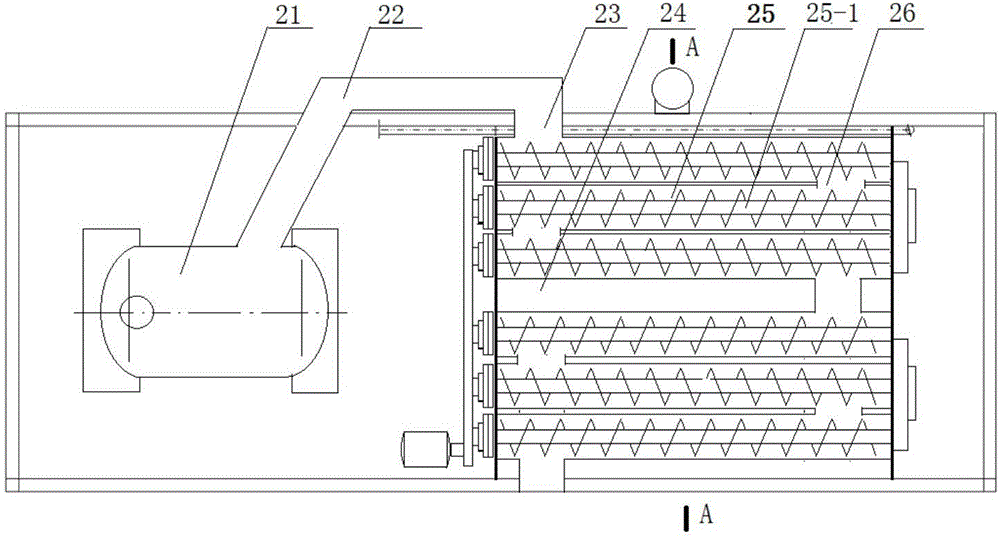

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

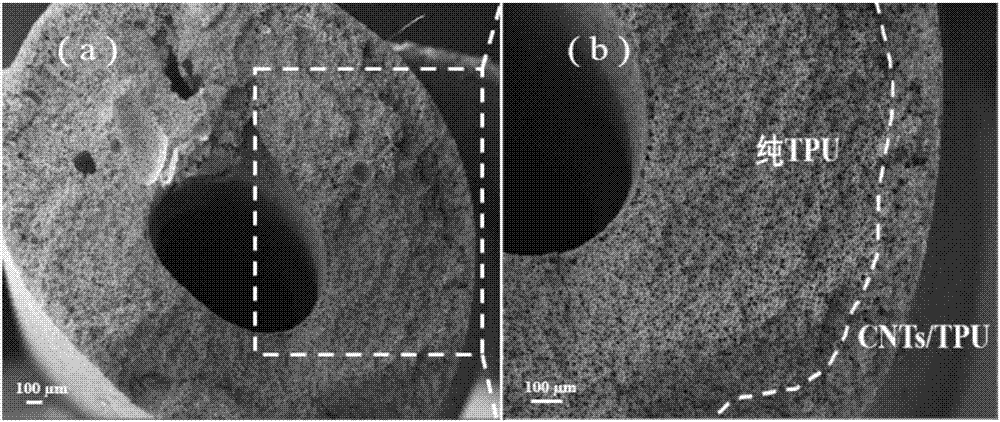

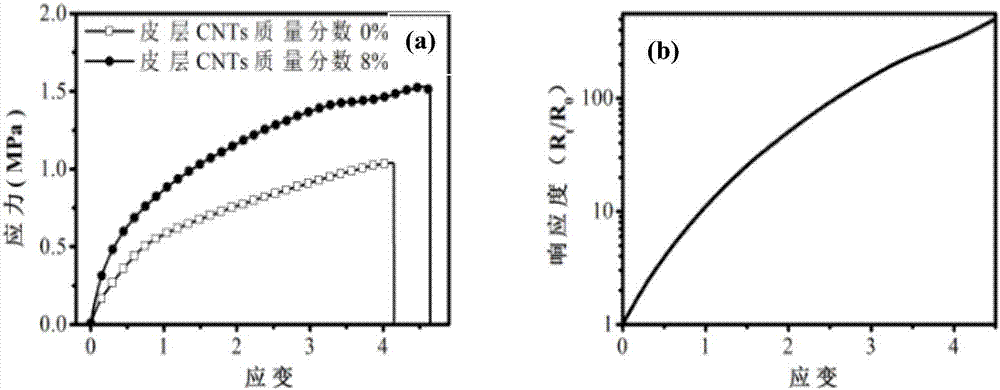

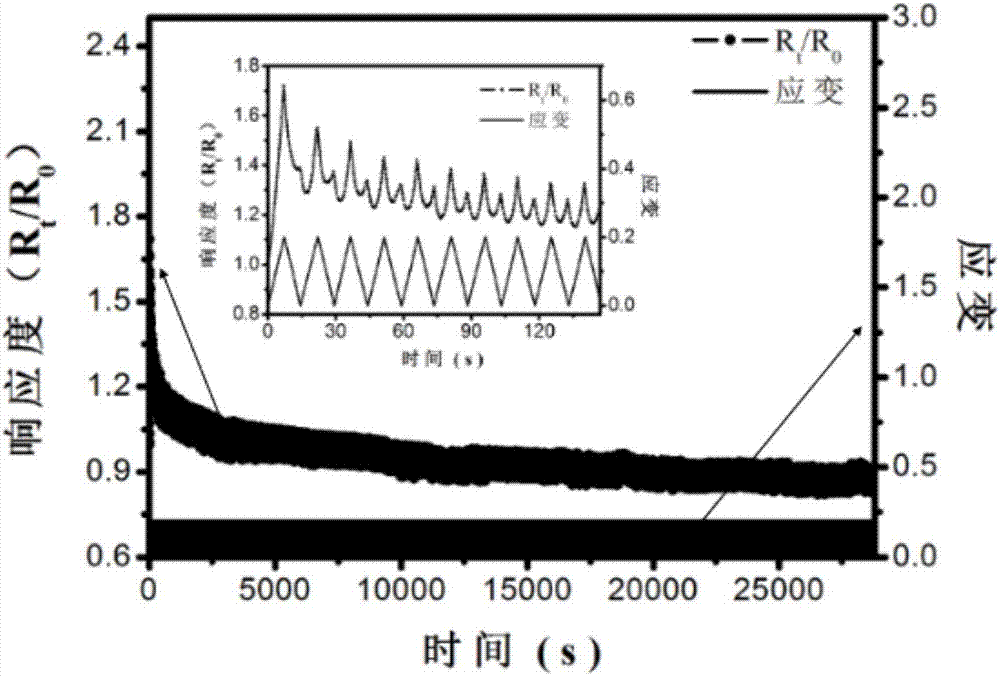

Conductive polymer composite fiber with skin-core structure and preparation method thereof

InactiveCN106968023ALow fiber densityReduce the conductive percolation valueElectroconductive/antistatic filament manufactureFilament/thread formingSkin coreElectrically conductive

The invention belongs to the technical field of wet spinning fiber manufacture, and in particular relates to a conductive polymer composite fiber with a hollow, porous and skin-core structure and a preparation method thereof. The invention provides a conductive polymer composite fiber which has a skin-core structure. The skin-core structure comprises a skin layer and a core layer, wherein the core layer is of a hollow structure; the skin and core layers are porous; at least one of the skin and core layers is conductive; the skin layer and the core layer are prepared from polymer material substrates. By changing the spinning solution-extruding speed of the skin layer and the core layer, the preparation method can conveniently control the thicknesses of the skin layer and the core layer, and further adjust mechanical properties and electrical properties of the fiber. Compared with traditional conductive fibers, the fiber has the advantages of low fiber density, a low conductive percolation value and a big strain-response range ( the maximum strain-response value being over 300%), and can achieve continuous production.

Owner:ZHENGZHOU UNIV

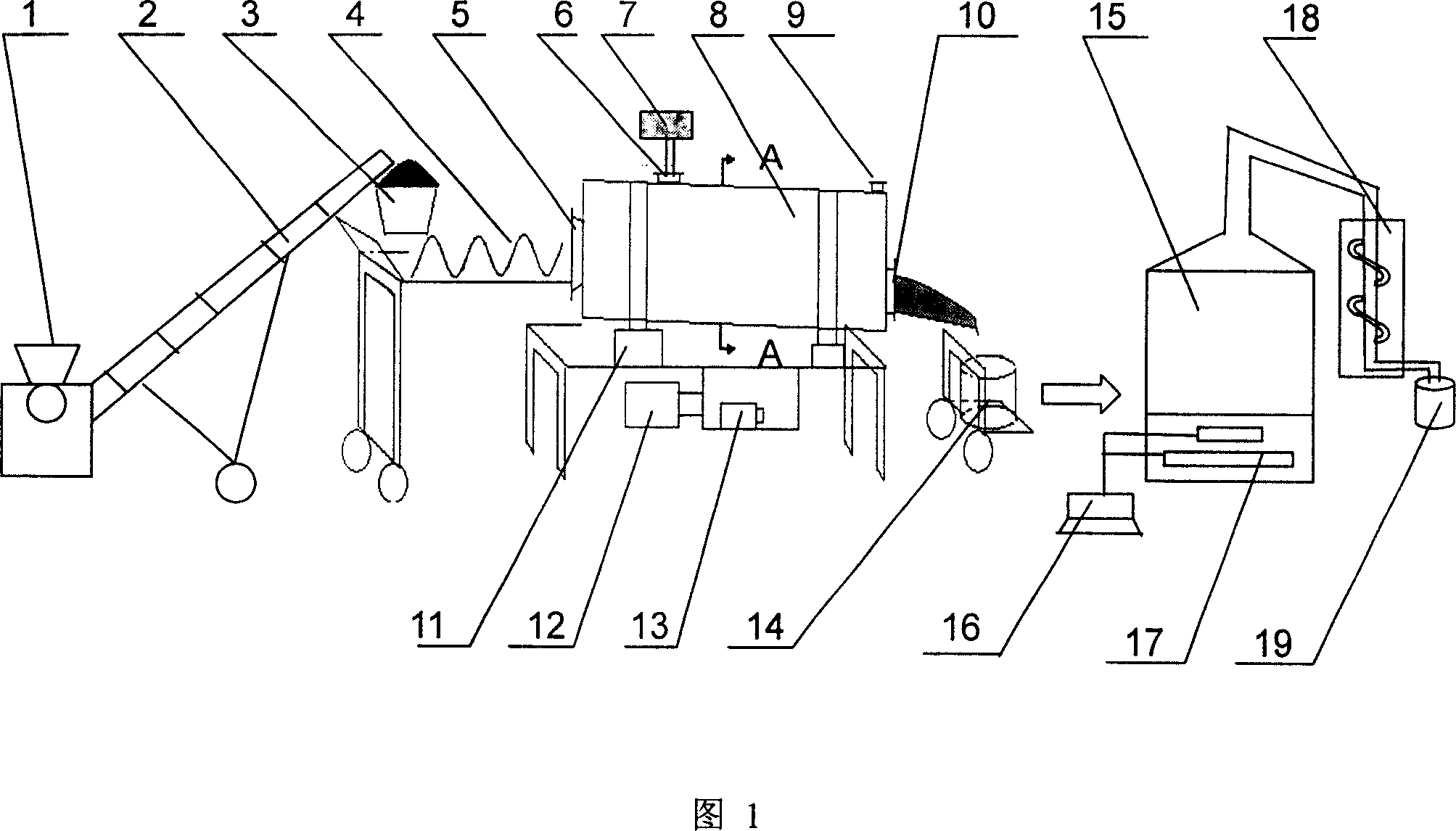

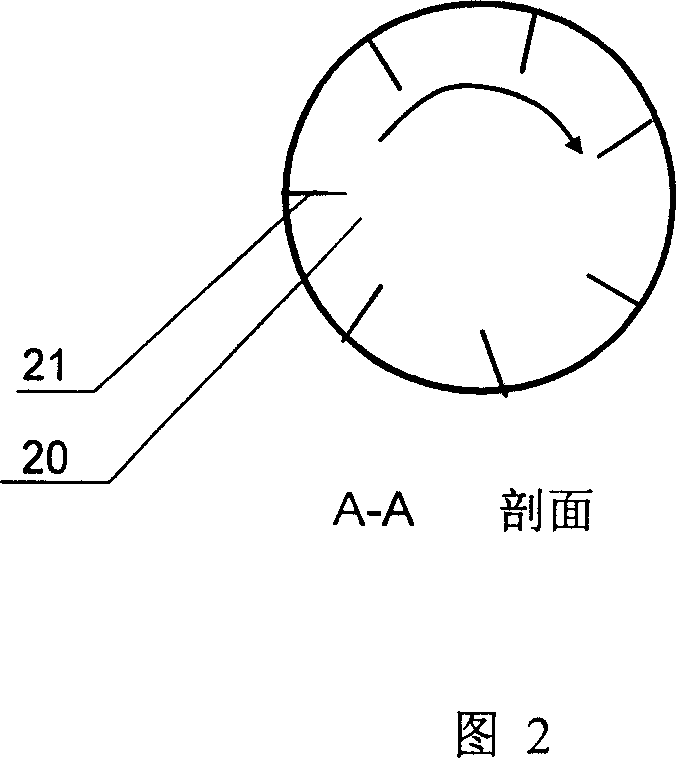

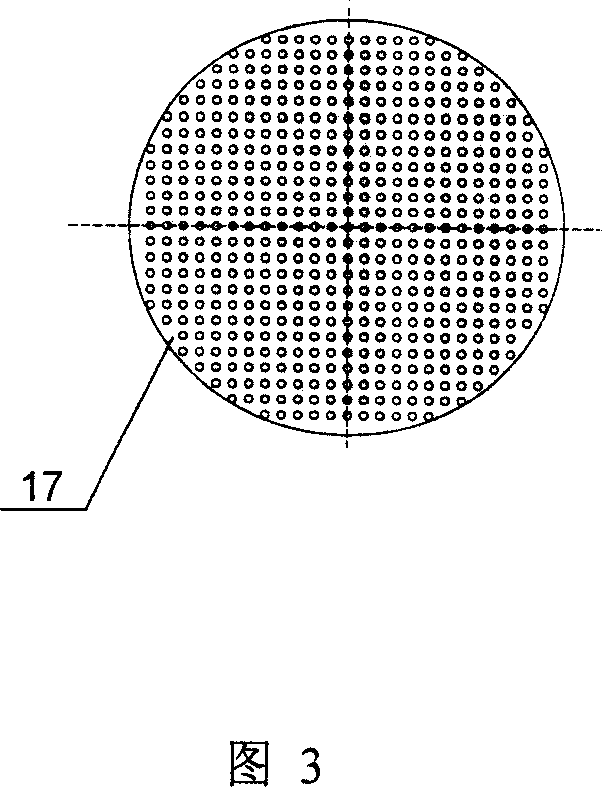

Method and system for preparing ethanol based on sweet broomcorn straw solid fermentation

InactiveCN101033476AImprove conversion efficiencyIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationSweet sorghum

This invention relates to a method and system of preparing ethanol based on the solid state fermentation of sweet sorghum stem, belonging to the ethanol production technology of solid state fermentation. It includes the following key processes and device: raw materials smash is to choose the suitable mill to smash sweet sorghum stalk, strain addition is to add ethanol bacteria at the entrance of solid-state fermentation tank, solid-state fermentation is that the raw materials added bacteria is fermented in the slant rotor solid-state fermentation tank, solid distillation is to distill the solid-state fermented materials to obtain ethanol.

Owner:TSINGHUA UNIV

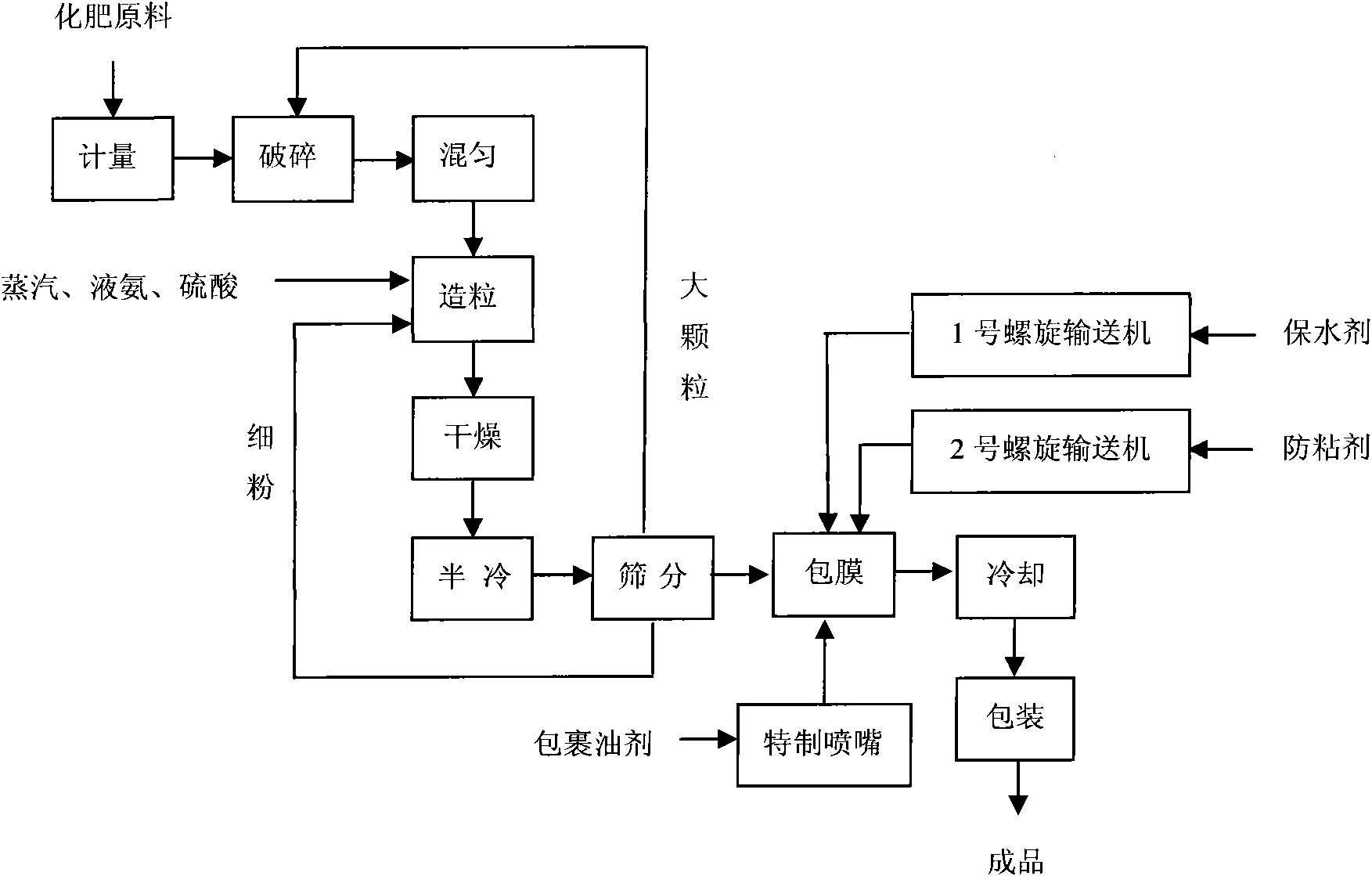

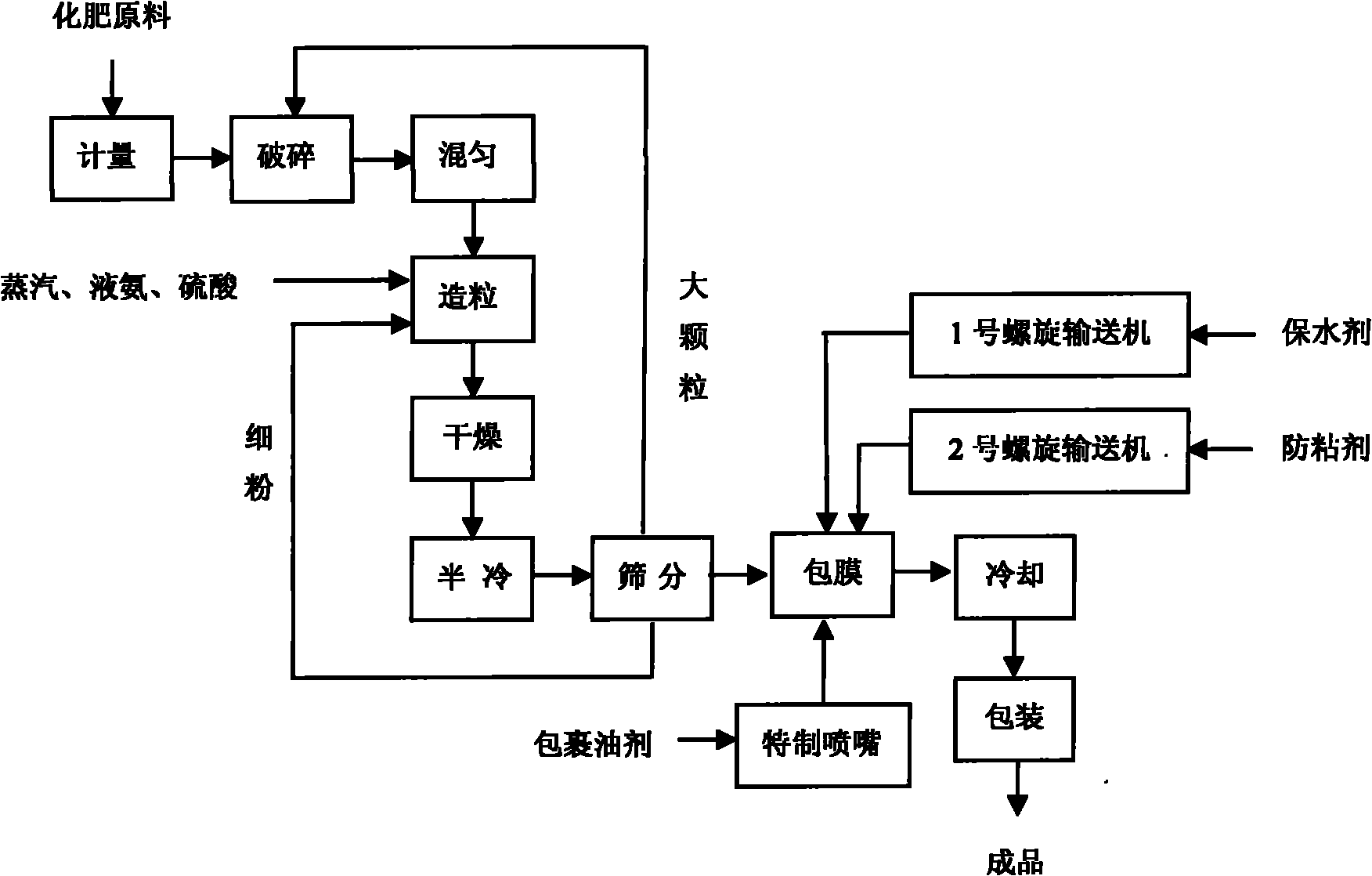

Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

ActiveCN101792354ASimple production methodHigh ball rateFertiliser formsFertilizer mixturesFilm coatingNutrient

The invention discloses a color drought-resistance water-retention sustained-release compound fertilizer and a method for producing the same, wherein the method comprises the followings steps of: measuring, crushing and uniformly mixing fertilizer raw materials, granulating by adopting an ammonia-acid method rotary drum granulating process, performing one-stage drying, semi-cooling and screening of grains, and sending the mixture to a coating machine; adopting a continuous melting rotary drum film-coating method coating process to perform compressed air atomization and uniform coating of color coating oil sprayed by a special nozzle; and adding a water-retaining agent and an anti-adhesive agent by a screw conveyor, and performing full stirring, cooling and packaging to obtain the finishedproducts. The color drought-resistance water-retention sustained-release compound fertilizer has the effects of drought resistance, water retention, nutrient preservation, soil condition improvement and environmental protection, and the appearance of the fertilizer has color marks; and when the fertilizer is applied to crops, the fertilizer has the advantages of increasing yield and incoming, along with simple production method, convenient operation, low cost and high benefits.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

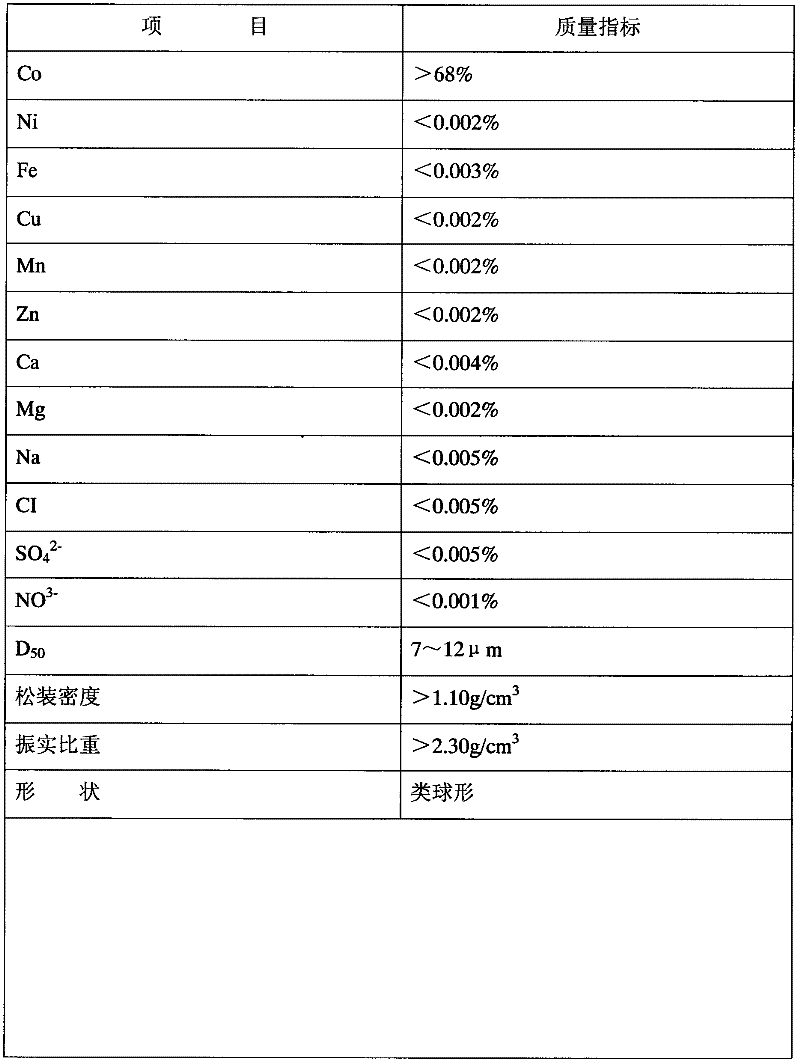

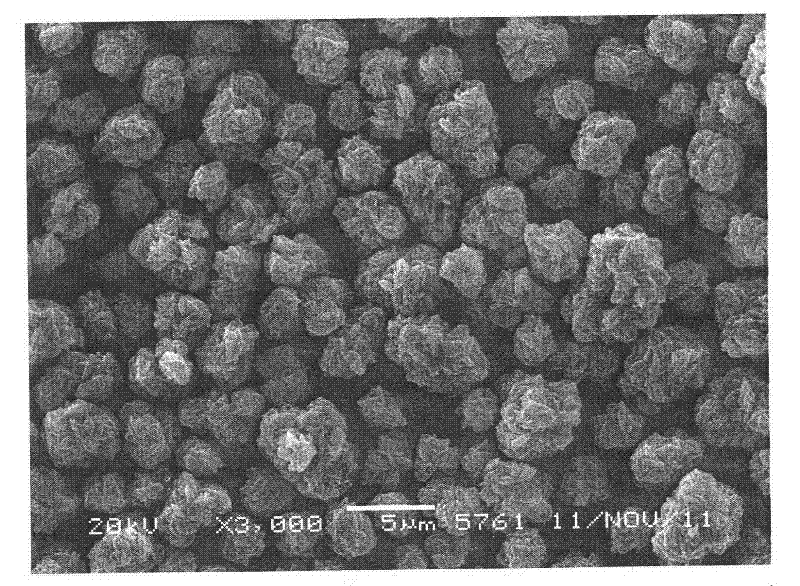

High-density spherical nickel-cobalt-aluminum precursor material and preparation method thereof

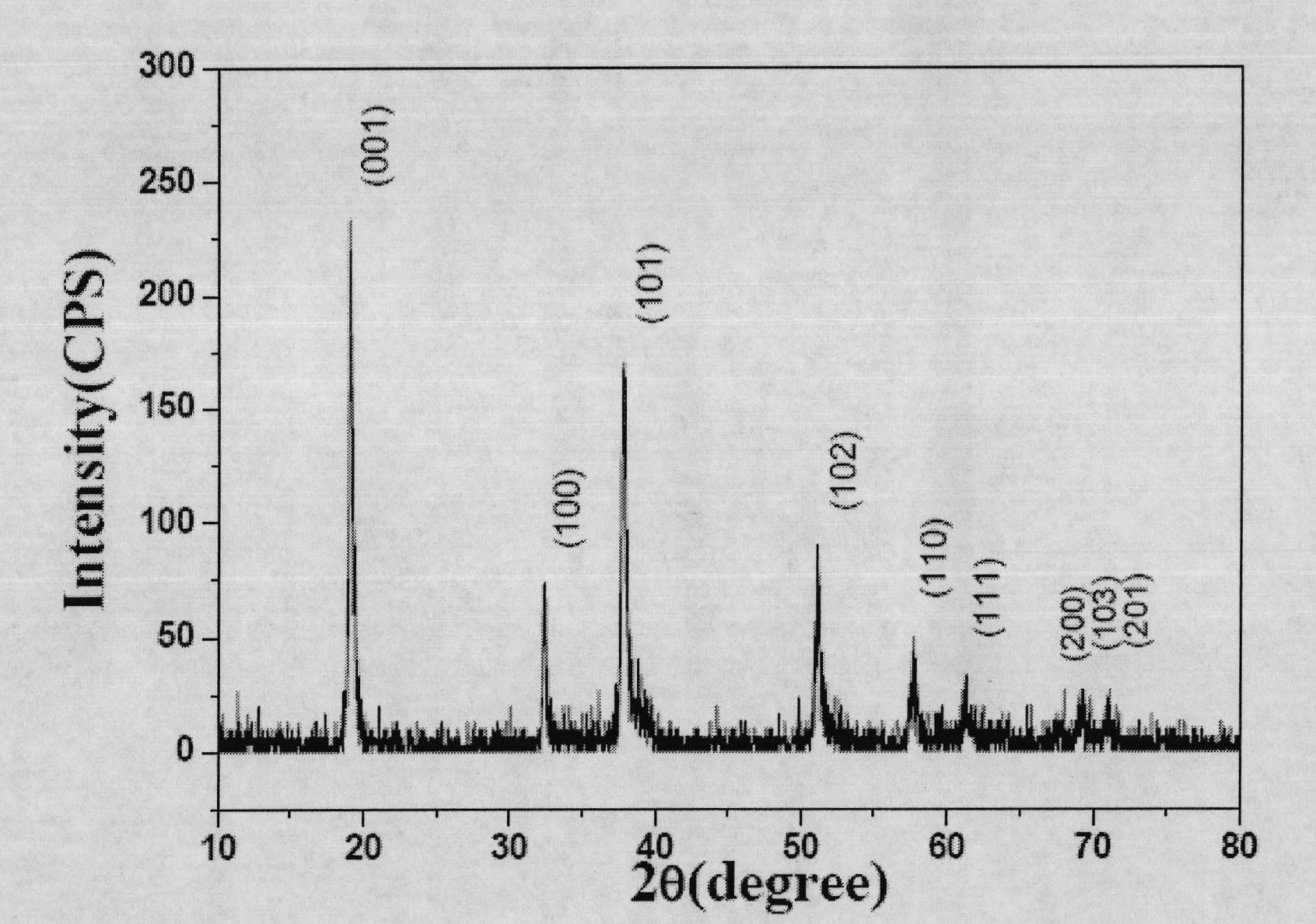

ActiveCN103553152AEffective control of coprecipitation reaction processControl the Co-precipitation Reaction ProcessCell electrodesNickel oxides/hydroxidesNickel saltHigh density

The invention discloses a high-density spherical nickel-cobalt-aluminum precursor material. The chemical molecular formula of the nickel-cobalt-aluminum precursor material is Ni(1-x-y)CoxAly(OH)(2+y); the tap density of the nickel-cobalt-aluminum precursor material is 1.8-2.4 g / cm3; the material is spherically granular; the average particle size of the material ranges from 6 to 17 microns. The invention also discloses a preparation method of the precursor material. The preparation method comprises the following steps of: firstly, evenly mixing an aluminum salt with a complexing agent; secondly, evenly mixing a nickel salt with a cobalt salt solution; adding the mixed solution, the complexing agent and a precipitator solution to a reactor in parallel for continuous coprecipitation reaction, controlling the pH value in the reaction process within the range from 11 to 12, keeping the materials stay in the reactor not more than 20 h, performing solid-liquid separation after stable reaction, and finally, aging, washing and drying the solid material to obtain the high-density spherical nickel-cobalt-aluminum precursor material. The aluminum element in the high-density spherical nickel-cobalt-aluminum precursor material provided by the invention can be combined with nickel and cobalt elements evenly; and the tap density of the high-density spherical nickel-cobalt-aluminum precursor material is higher.

Owner:JINCHI ENERGY MATERIALS CO LTD

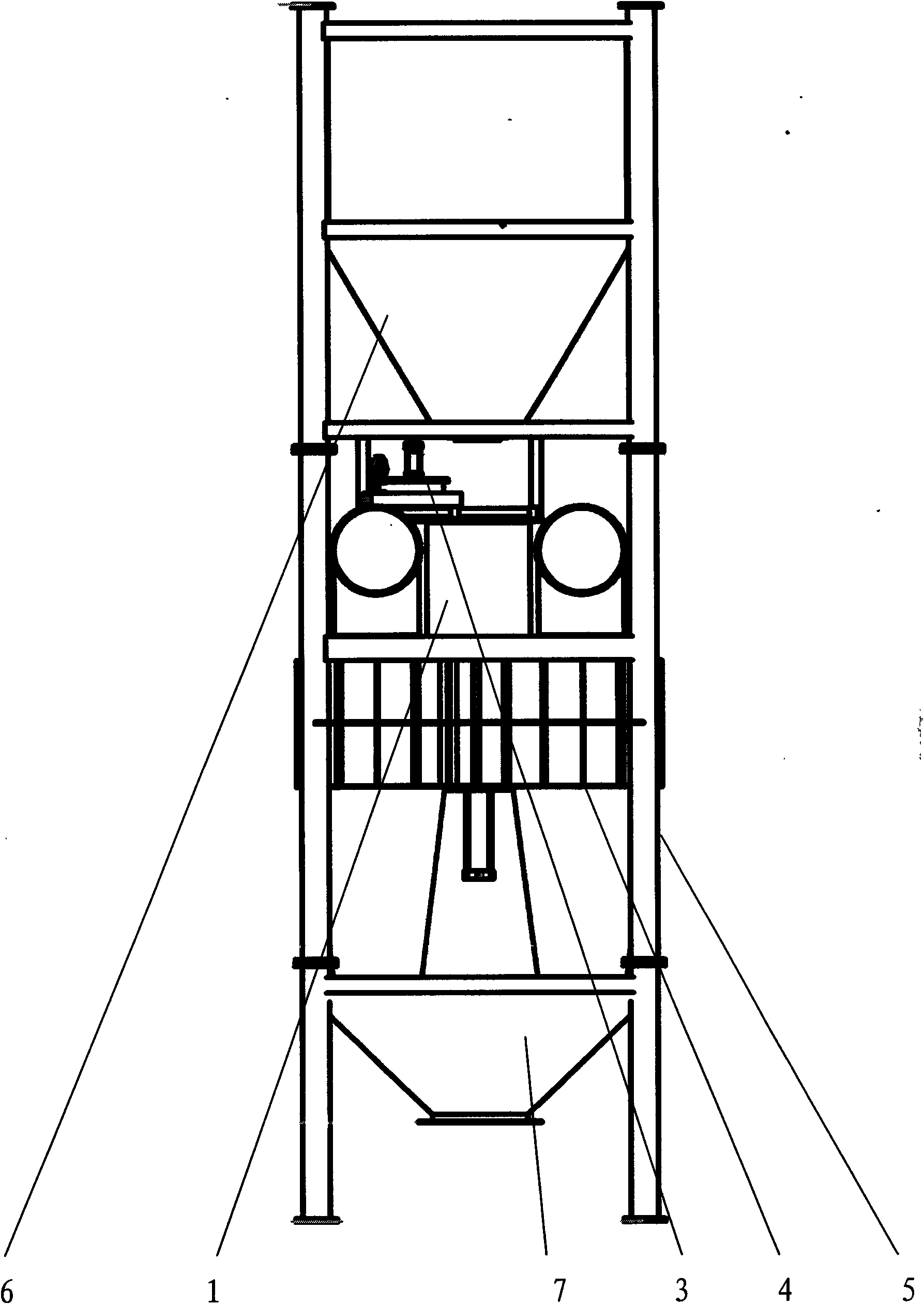

Numerically controlled continuous steam explosion machine

InactiveCN102600763AAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processFixed ratioEngineering

The invention relates to a production device for steam explosion pretreatment of biomass, in particular to a pretreatment device for the industry of biomass utilization, and provides a numerically controlled continuous steam explosion machine, which can complete supersonic steam explosion in milliseconds (0.00875s) based on the principle of a sliding cover. Since the cross-sectional area of the steam explosion machine for gas discharging, i.e. the cross-sectional area of the sliding cover, is equal to the cross-sectional area of a high-pressure cylinder, the cross-sectional area of the steam explosion machine for gas discharging and the steam explosion treatment volume form a fixed ratio, the problem that the gas discharging time is prolonged along with increase in the treatment volume in the traditional hot blowing process can be solved, and the power and density of steam explosion can be increased by three orders of magnitude. Moreover, the 'rawness and maturity' of materials which are subjected to batch treatment can be kept identical, and a foundation is laid for the consistency of industrial biochemical treatment. Meanwhile, the machine has the function of feeding and discharging materials automatically and the continuous steam explosion production can be realized.

Owner:于政道

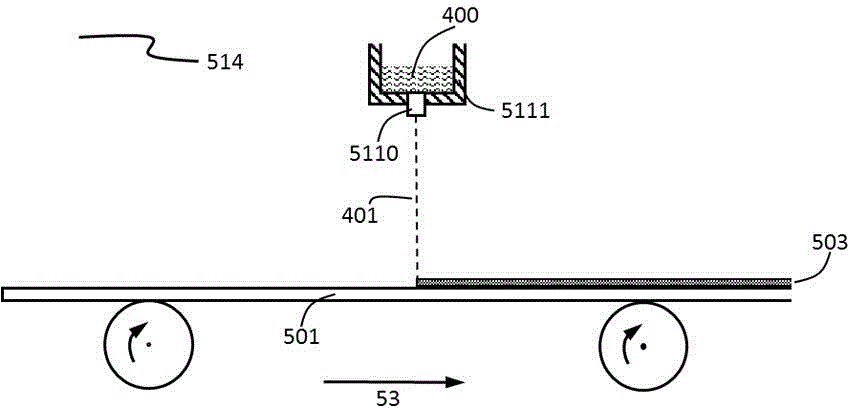

Method for enhancing electrostatic spinning nanofiber membrane

ActiveCN103541149AImprove mechanical propertiesEasy to manufactureElectro-spinningNon-woven fabricsFiberPolymer science

The invention discloses a method for enhancing an electrostatic spinning nanofiber membrane. The blending electrostatic spinning-hot rolling bonding net fixing technology which can effectively improve the strength of the electrostatic spinning nanofiber membrane is provided. The method for enhancing the electrostatic spinning nanofiber membrane is characterized in that interphase blending electrostatic spinning is conducted through multiple types of thermoplastic high polymers with the fusion point at least 20 DEG C lower than that of other components or low-fusion-point thermoplastic high polymers and non-thermoplastic high polymers, electrostatic spinning jet flows of the components are distributed frontwards and backwards in the moving direction of a receiving device, and fibers are distributed randomly in a staggered mode; after hot rolling is conducted on a blending electrostatic spinning fiber membrane, the blending electrostatic spinning fiber membrane is treated, the hot pressing temperature is slightly higher than the fusion starting temperature of the low-fusion-point thermoplastic high polymers, time ranges from 1min to 10min, the pressure ranges from 1MPa to 20MPa, after hot pressing is conducted, part of the low-fusion-point thermoplastic high polymers is fused, point adhesion is generated on the nanofiber intersection portions, and a hole is not blocked. The method for enhancing the electrostatic spinning nanofiber membrane has the advantages that the strength of the prepared enhanced electrostatic spinning nanofiber membrane is far higher than that of a common electrostatic spinning membrane and original good performance of the electrostatic spinning nanofiber membrane can be kept.

Owner:TIANJIN POLYTECHNIC UNIV

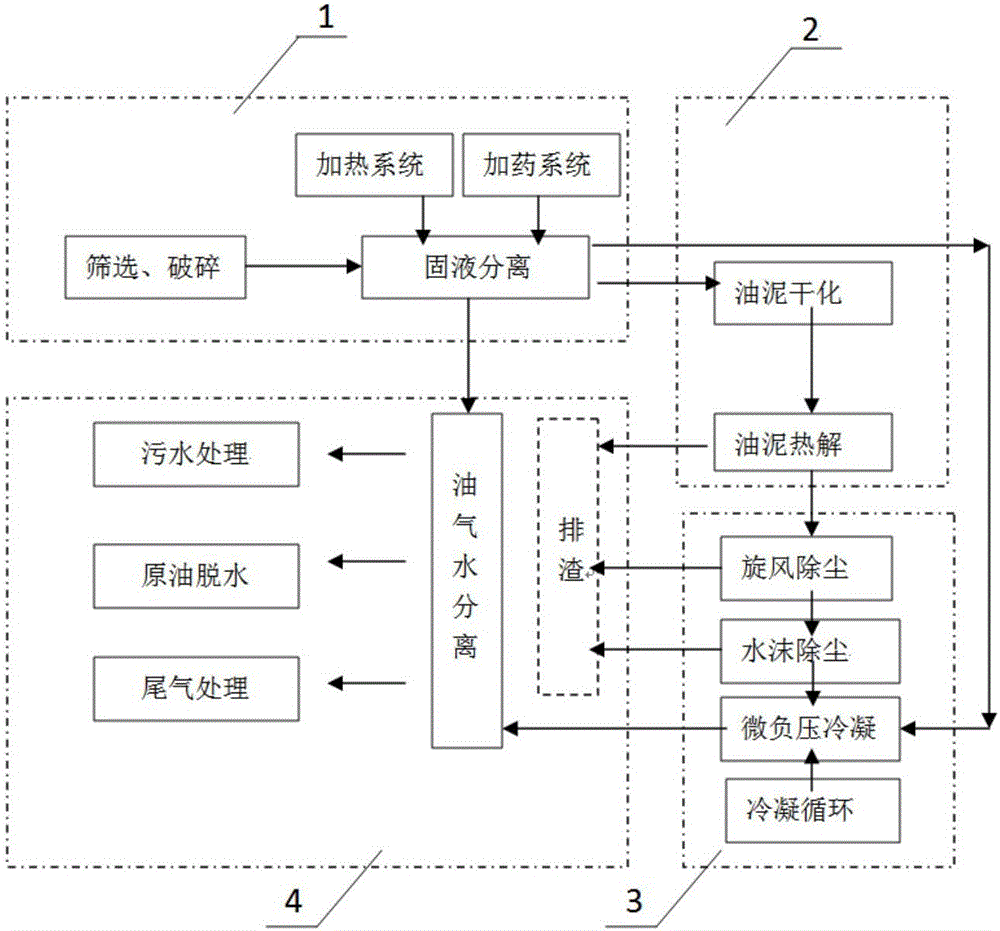

Industrialization scale pyrolysis treatment system and method for oily sludge

InactiveCN106746419ALarge amount of processingEasy to operateCombination devicesSludge treatment by de-watering/drying/thickeningPetroleumPyrolysis

The invention belongs to the field of waste disposal in petroleum industry, and relates to an industrialization scale pyrolysis treatment system for oily sludge. The industrialization scale pyrolysis treatment system comprises a feeding pre-separation unit for performing secondary screening and solid-liquid separation on the oily sludge, a drying pyrolysis unit for performing drying and pyrolysis reaction on the oily sludge, a dust removal and condensation unit for performing dust removal and condensation on a pyrolysis gas mixture generated by the drying pyrolysis unit, and a discharge treatment unit which receives and treats separated substances of the other units respectively. Solid or solid-liquid mixed waste such as the oily sludge can be finally treated to achieve reduction, stabilization, harmlessness and recycling.

Owner:PANJIN NINGTAI ENERGY TECH

Novel electrode material applicable to intelligent liquid crystal dimming film and preparation method thereof

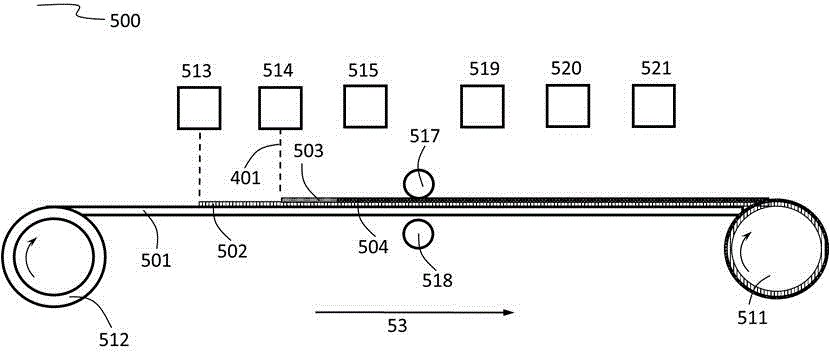

InactiveCN105761774ALow costLow raw material costCarbon-silicon compound conductorsCable/conductor manufactureThin film electrodeThin membrane

The invention relates to a novel electrode material applicable to an intelligent liquid crystal dimming film and a preparation method thereof. A transparent conductive film is at least composed of a substrate and a graphene conductive layer. The transparent conductive film further comprises a functional layer. Graphene sheets are stacked, tiled and connected with one another on a substrate to form the graphene conductive layer. A flexible liquid crystal dimming film device is prepared through the whole wet coating process of the electrodes of a graphene transparent conductive film. The liquid crystal light adjusting layer of the commercialized flexible liquid crystal dimming film is also prepared through the wet coating process. The above two coating processes can be linked up through the roll-to-roll process. Therefore, the preparation of graphene transparent conductive electrodes and the subsequent preparation of the dimming film are ensured to be continuous, low in cost and large-scale in production.

Owner:江苏天贯碳纳米材料有限公司

Preparation method of porous sodium acrylate super absorbent resin

ActiveCN102225981AImprove pass rateRealize continuous productionAbsorbent padsBandagesCross-linkNitrogen gas

The invention relates to a preparation method of a porous sodium acrylate super absorbent resin. The preparation method comprises the following steps: an aqueous solution containing 30 to 45 wt% of acrylic acid monomers with a neutralization rate of 60 to 90 mole%, a cross linking agent, a porogenic agent, and a polymerization initiator are polymerized together under nitrogen protection; and porous particles are prepared through preparing granulums with diameters of 2 to 10 mm from hydrogel prepared through polymerization, and adding the surface cross linking agent and an inorganic filler to carry out surface processing. The preparation method of the invention allows continuous production to be realized, productivity to be improved, manpower to be decreased, a problem of slow imbibition to be solved, drying period to be substantially decreased, product performances to be substantially improved, the qualified rate of products to be high, reaction to be mild, and three wastes to be less.

Owner:浙江卫星新材料科技有限公司

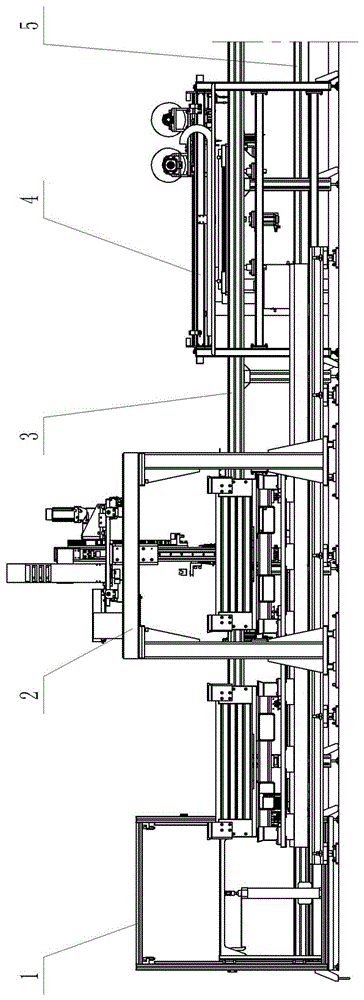

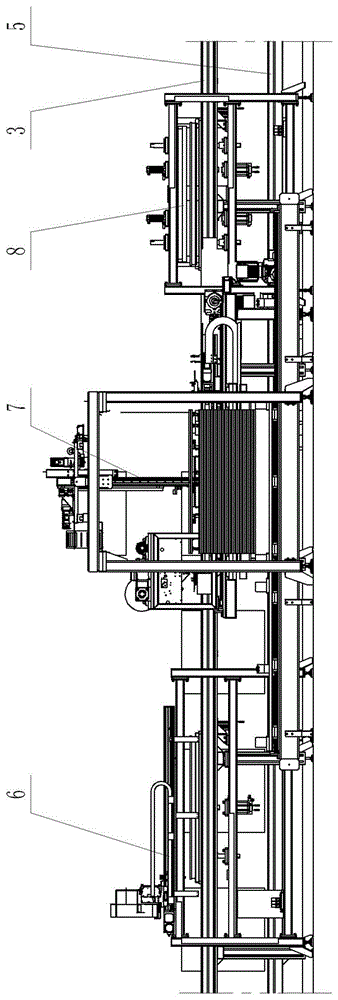

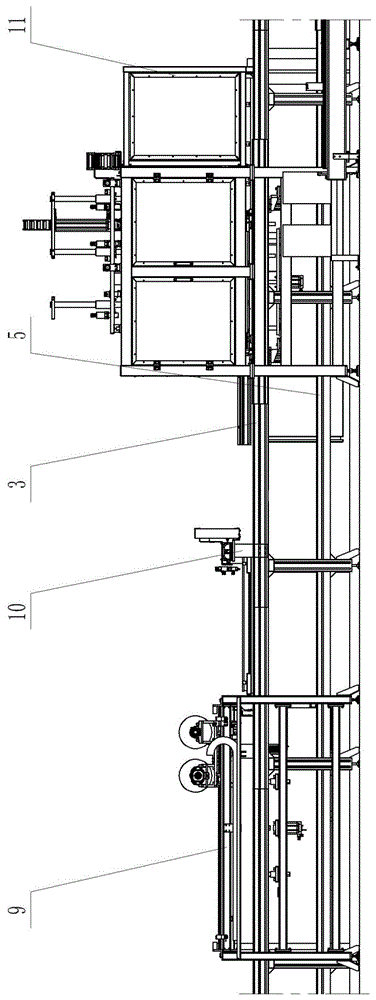

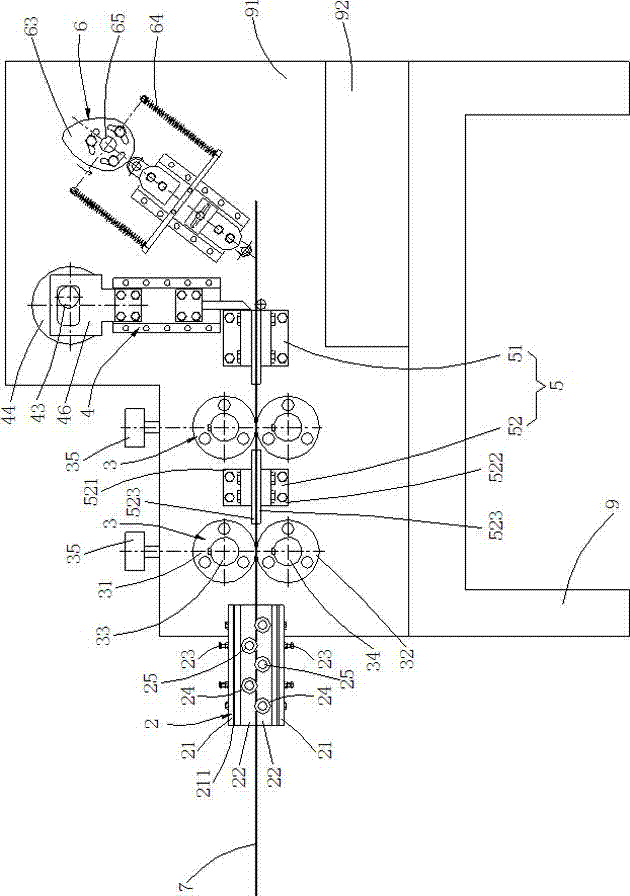

Automatic silicon rod bonding production line

ActiveCN106711067AReasonable designCompact structureSolid-state devicesSemiconductor/solid-state device manufacturingState of artProduction line

The invention relates to an automatic silicon rod bonding production line which solves the problems that the labor intensity of operators is high, the production efficiency is extremely low, the production rhythm cannot be guaranteed, and the continuous production is seriously influenced in the prior art. The automatic silicon rod bonding production line comprises a conveying line and a conveying tray and is characterized in that an automatic crystal support loading unit, a crystal support cleaning unit, a crystal support gluing unit, an automatic glass loading unit, a glass pressurizing unit, a glass cleaning unit, an online glass gluing unit, an automatic silicon rod loading unit and an automatic unloading unit are sequentially along the conveying direction of the conveying line, wherein the automatic crystal support loading unit comprises a sliding loading device and an intelligent transplanting device; the automatic glass loading unit comprises a double-station glass loading device and a loading manipulator; the automatic silicon rod loading unit comprises a loading conveying device and a double-claw transplanting device; and the automatic unloading unit comprises a transplanting platform and a transplanting manipulator. The automatic silicon rod bonding production line reasonable in design, compact in structure, high in degree of automation and capable of realizing full mechanical loading, conveying and unloading and continuous production.

Owner:沈阳昊霖智能装备有限公司

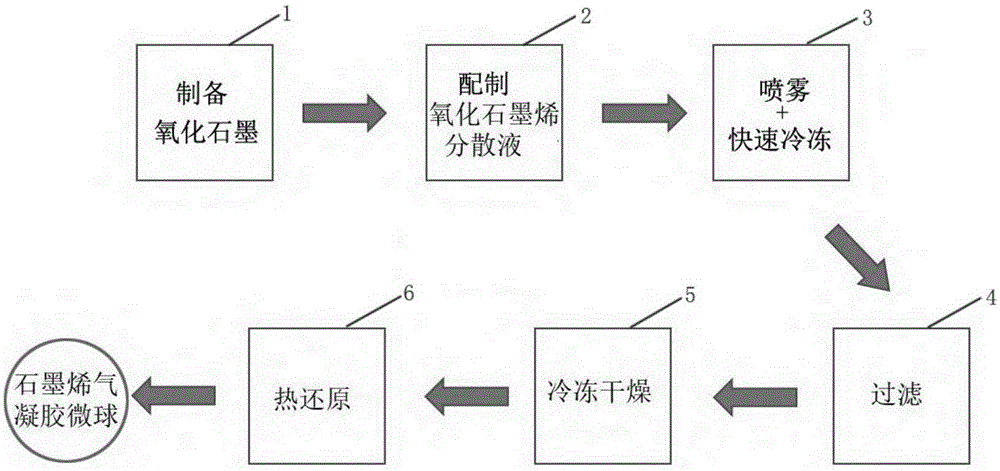

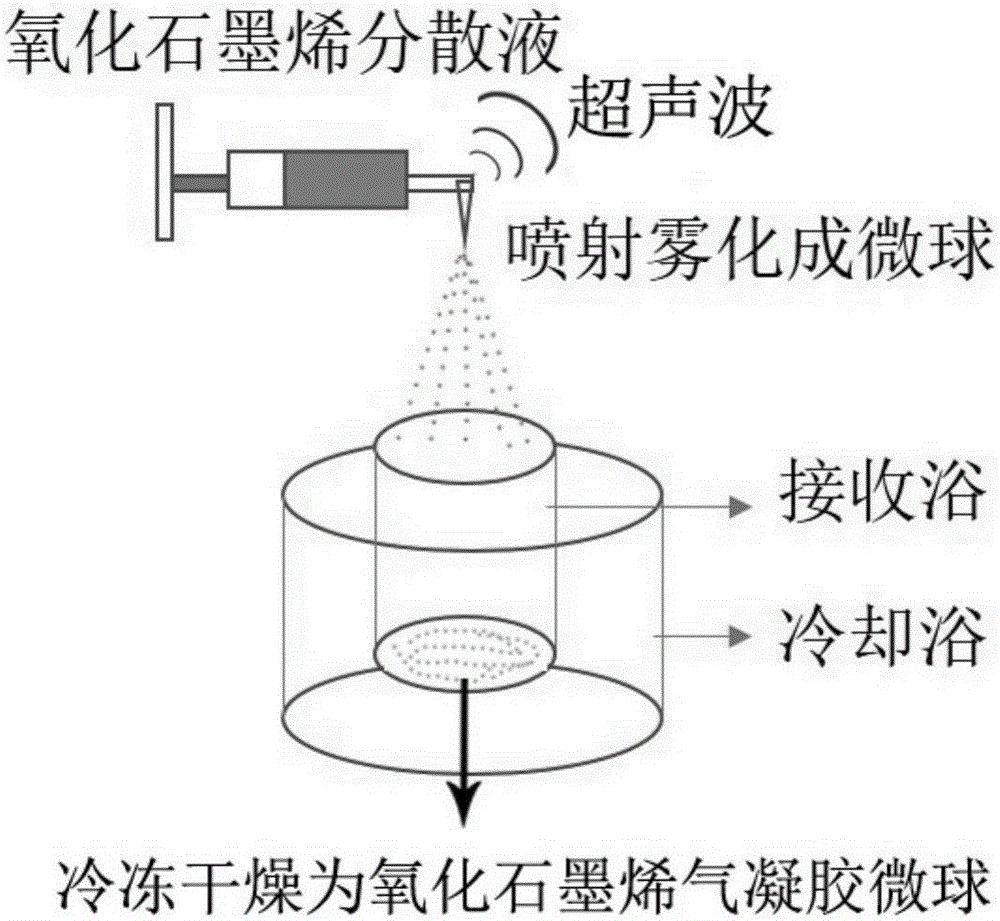

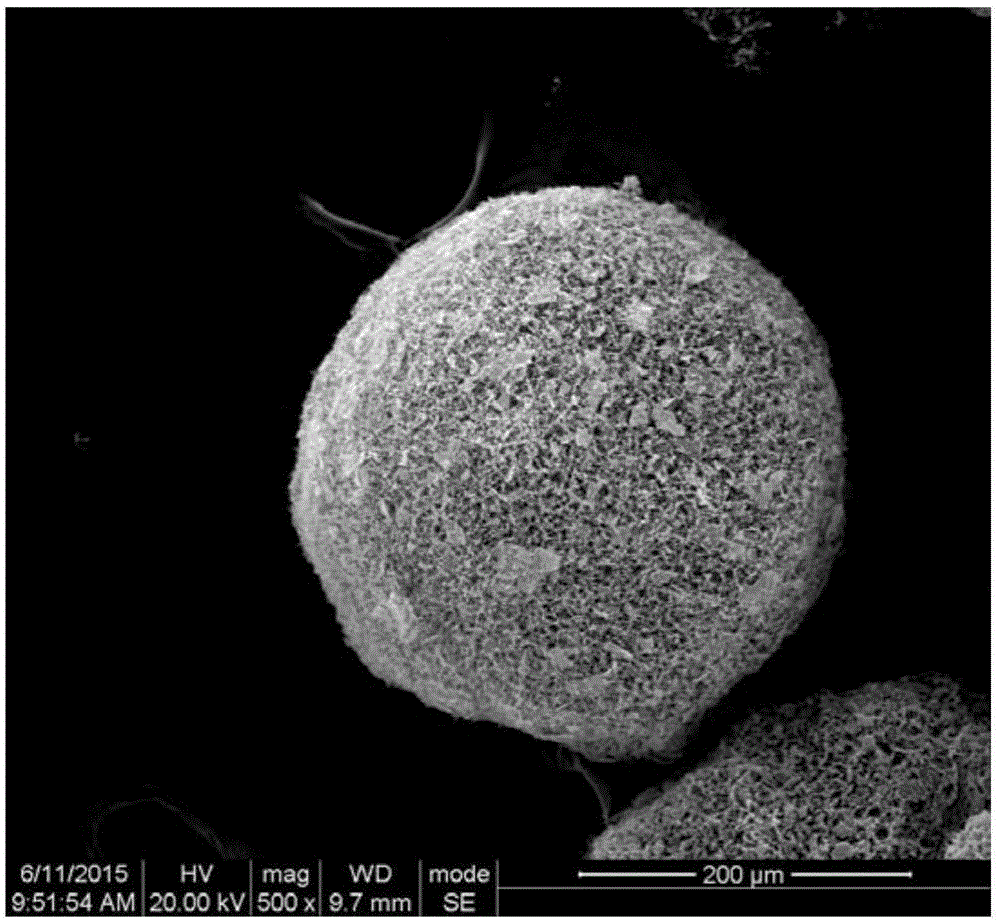

Graphene aerogel microspheres and preparation method and application thereof

ActiveCN105195067AParticle size controllableLarge specific surface areaIon-exchange process apparatusWater cleaningFreeze-dryingMicrosphere

The invention discloses graphene aerogel microspheres and a preparation method and application thereof. The preparation method is characterized in that 1, graphite oxide is prepared; 2, graphene oxide aqueous dispersion is prepared; 3, the graphene oxide aqueous dispersion is atomized through a spraying method into graphene oxide liquid drop microspheres, and meanwhile the microspheres are collected through receiving liquid in a cooling bath; 4, the receiving liquid is filtered to obtain graphene oxide ice microspheres, and then freeze drying is performed on the microspheres to obtain graphene oxide aerogel microspheres; 5, the graphene oxide aerogel microspheres are subjected to thermal reduction to obtain the graphene aerogel microspheres. The preparation method is simple and convenient to implement, no environmental pollution is generated, and the obtained graphene aerogel microspheres are uniform in size and large in specific area, are of a stable center-divergence multi-porous-channel network structure and are used for adsorbing environmental pollutants.

Owner:SICHUAN UNIV

Continuous production technology of three kettle type sodium hydrosulfide

InactiveCN103466559AContinuous productionRealize continuous productionSulfur compoundsContinuous productionSulfur hydride

The invention relates to a continuous production technology of three kettle type sodium hydrosulfide. The continuous production technology comprises the following processing steps: (1) firstly, hydrogen sulfide enters into the bottom of a first reaction kettle and is reacted with a mixed liquid pumped by a second reaction kettle, the unreacted gas at the top of the first reaction kettle enters into the bottom of the second reaction kettle and is reacted with a material from a third reaction kettle, and the reaction temperature is adjusted by cooling water in a jacket; (2) gases which are incompletely reacted at the top of the second reaction kettle and cooled through a gas cooler enter into the bottom of the third reaction kettle and are fully reacted with 48% sodium hydroxide liquor from an alkali liquor tank, and the reaction material on the upper part of the third reaction kettle enters into the second reaction kettle to react due to gravitational flow; (3) the material which is fully reacted at the bottom of the first reaction kettle is pumped into a sodium hydrosulfide product tank through a pump to store and sell. The technology provided by the invention has the beneficial effect that sodium hydrosulfide production units are arranged linearly, so that continuous production of NaHS liquor is realized.

Owner:SHANDONG KENLI PETROCHEM GRP

Method for producing copper alloy coil pipe

ActiveCN101698207AImprove yieldOptimize production methodsTemperature control deviceFurnace typesMetallurgyMethods of production

The invention relates to a method for producing a metal pipe, in particular to a method for producing a copper alloy coil pipe. According to the technical scheme provided by the invention, the method for producing the copper alloy coil pipe comprises the following steps: (a) melting, (b) horizontal and continuous casting, (c) face milling, (d) primary bright annealing, (e) planetary tube rolling, (f) stretching, (g) secondary bright annealing, (h) cleaning, and (i) third bright annealing. The method can improve the comprehensive finished product rate of a pipe material, the labor productivity and the grade of product quality.

Owner:江苏隆达超合金股份有限公司

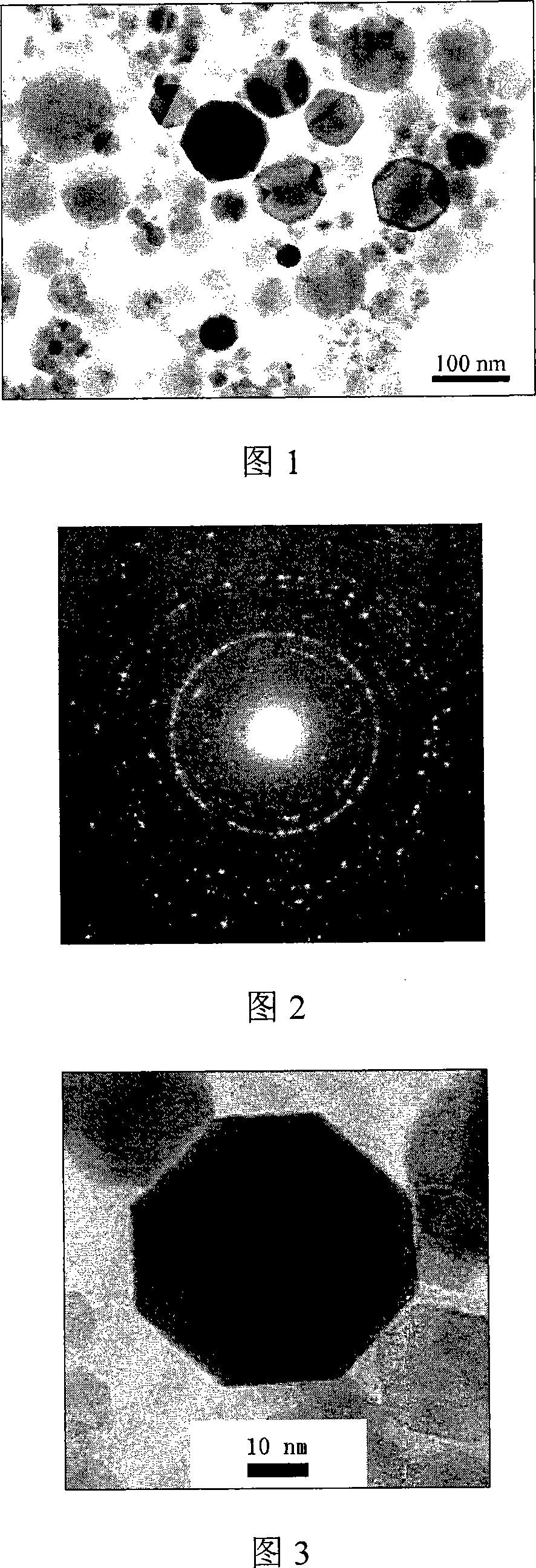

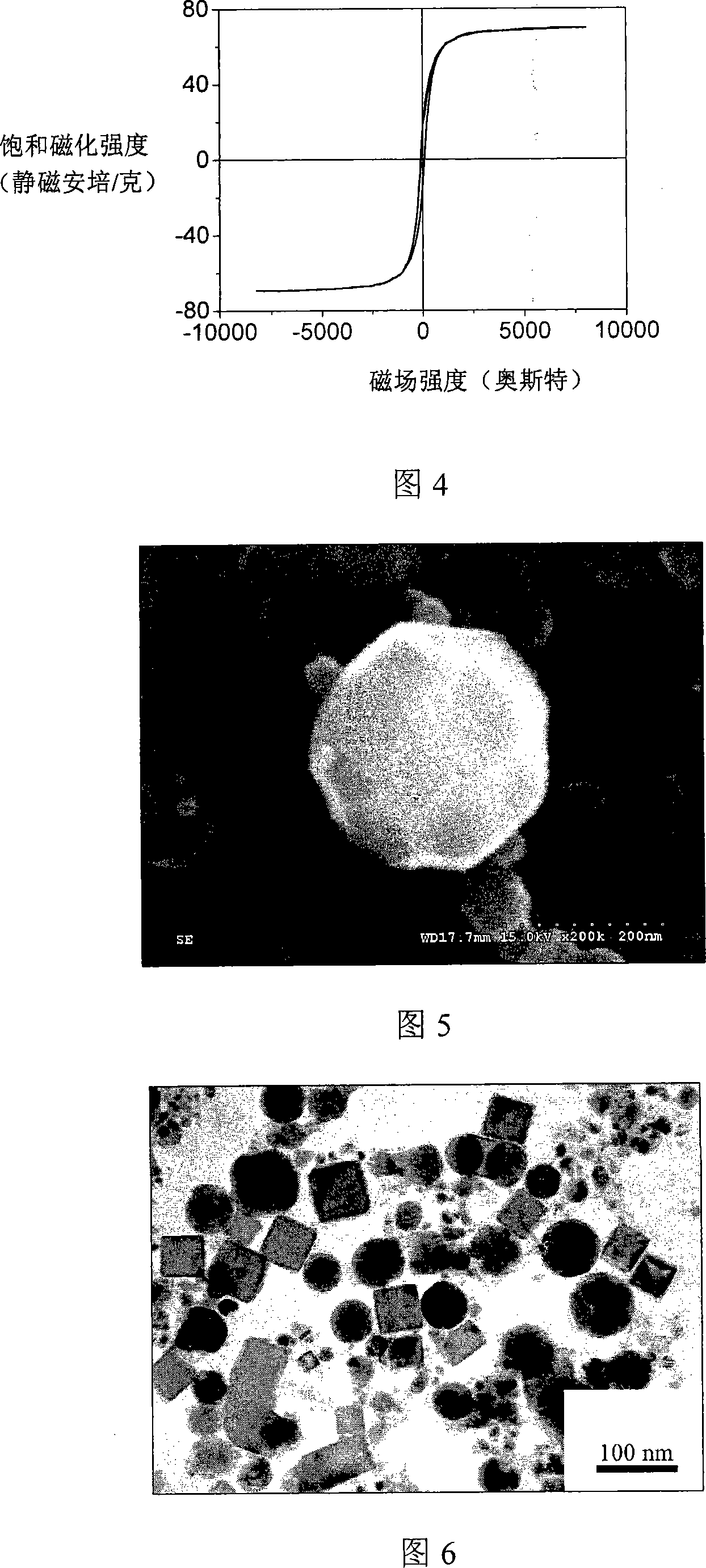

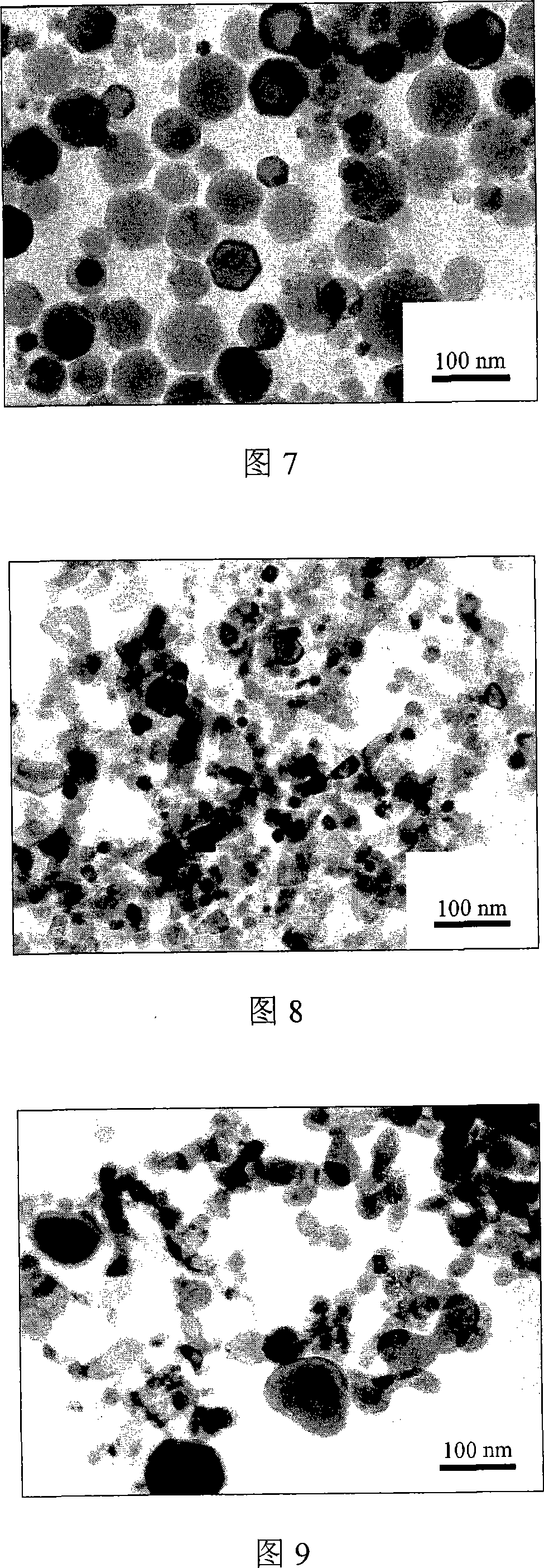

Method for preparing nano material by flame combustion

ActiveCN101234751ARealize continuous productionOxide/hydroxide preparationIron oxides/hydroxidesCombustionOrganic solvent

The invention relates to a direct burning method for preparing high crystallinity metal and oxide nano-particles thereof, metal with carbon shell structure and oxide nano-particles thereof, hollow nano ball of metal oxide, nano-particles with inorganic / inorganic heterogeneous structure and nano carbon pipe of water dispersion. Organic solvent is taken as comburent and carbon providing body; soluble metal compound is taken as metal precursor of nano material; through burning directly the organic solvent of the soluble metal compound precursor in the air, the nano material can be obtained in different positions of flame. The main technical characteristics of the method of the invention are that different kinds and different appearances of nano material can be collected in different positions of the flame; the appearances comprise medicine balls, hollow spheres, polyhedron and one dimensional nano-tube; the structure consists of a catamaran heterogeneous structure and a shell-core structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

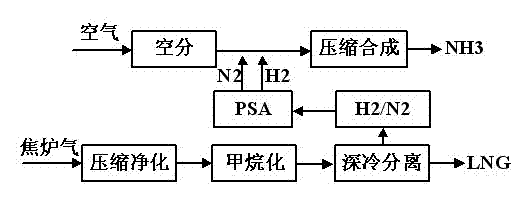

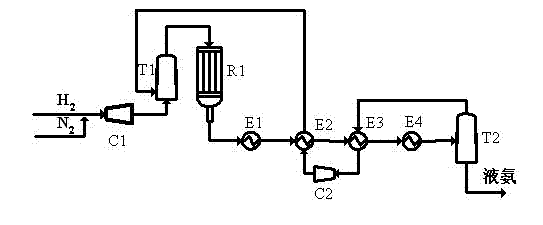

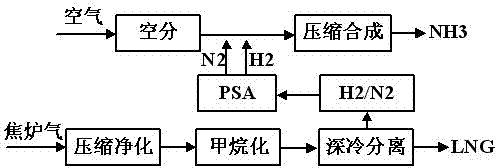

Technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas

InactiveCN102517108AIncrease added valueReduce in quantityGaseous fuelsBulk chemical productionMethanationCoke oven

The invention discloses a technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas. The coke oven gas is subjected to the steps of compression, purification, methanation, cryogenic separation and liquefaction of synthetic natural gas, variable pressure adsorptive separation and liquid ammonia preparation with hydrogen rich gas, so that the liquefied natural gas (LNG) of which methane purity is more than 99 percent and the liquid ammonia reaching national first level standard are obtained. By the technology, the hydrogen byproduct of the coke oven gas for preparing the LNG is fully utilized; effective ingredients of the coke oven gas such as H2, N2, CH4, CO and CO2 are furthest utilized; the CO and the CO2 are methanated, so that the yield of the CH4 is improved by about 1 / 3; the liquefied CH4 is used as the LNG and sold; and the rest nitrogen-containing hydrogen-rich gas is used as a raw material for synthesizing ammonia, so that the additional value of the coke oven gas is improved, and reliable raw material guarantee is provided for developing downstream products with high additional values and prolonging the product chain.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

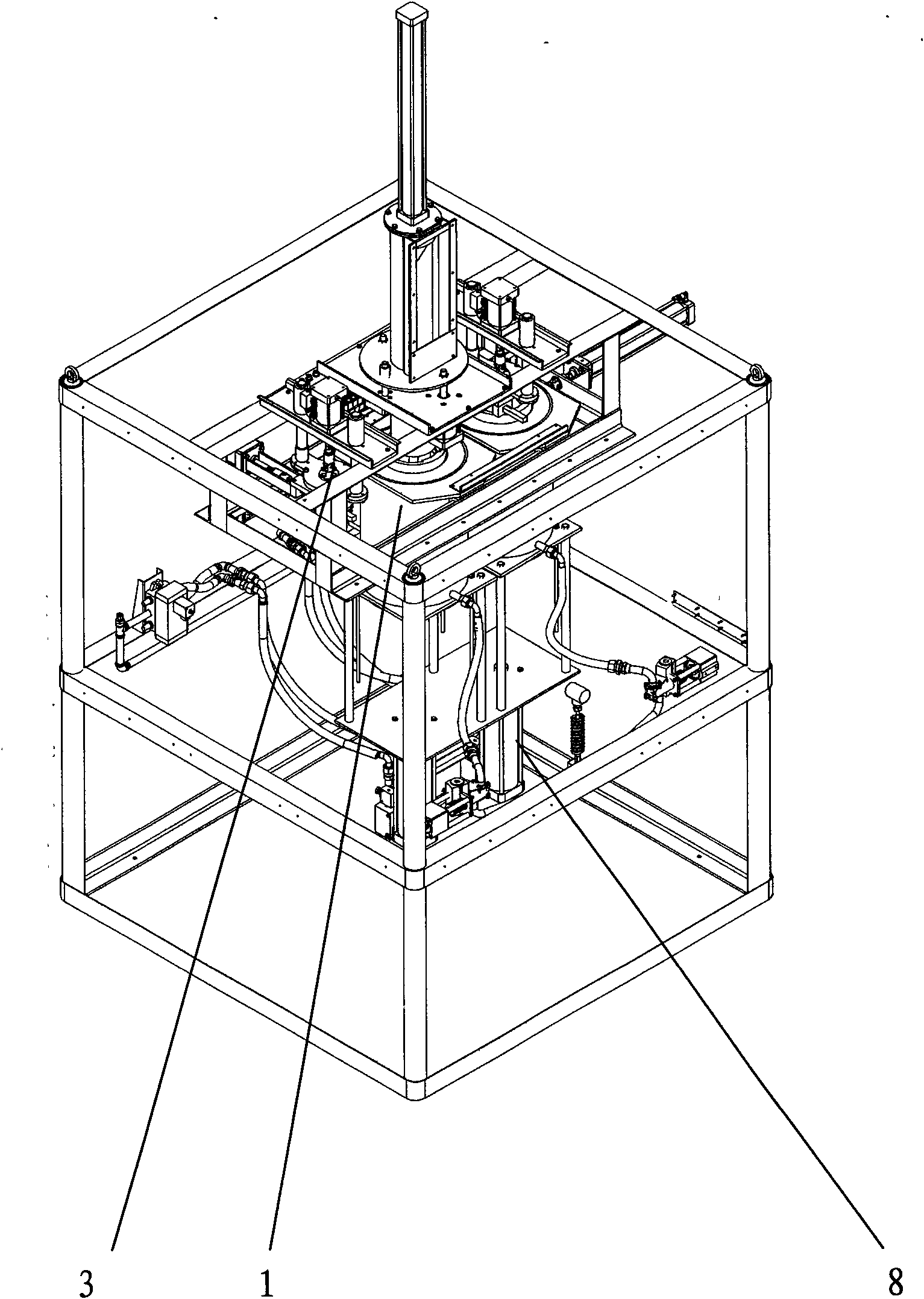

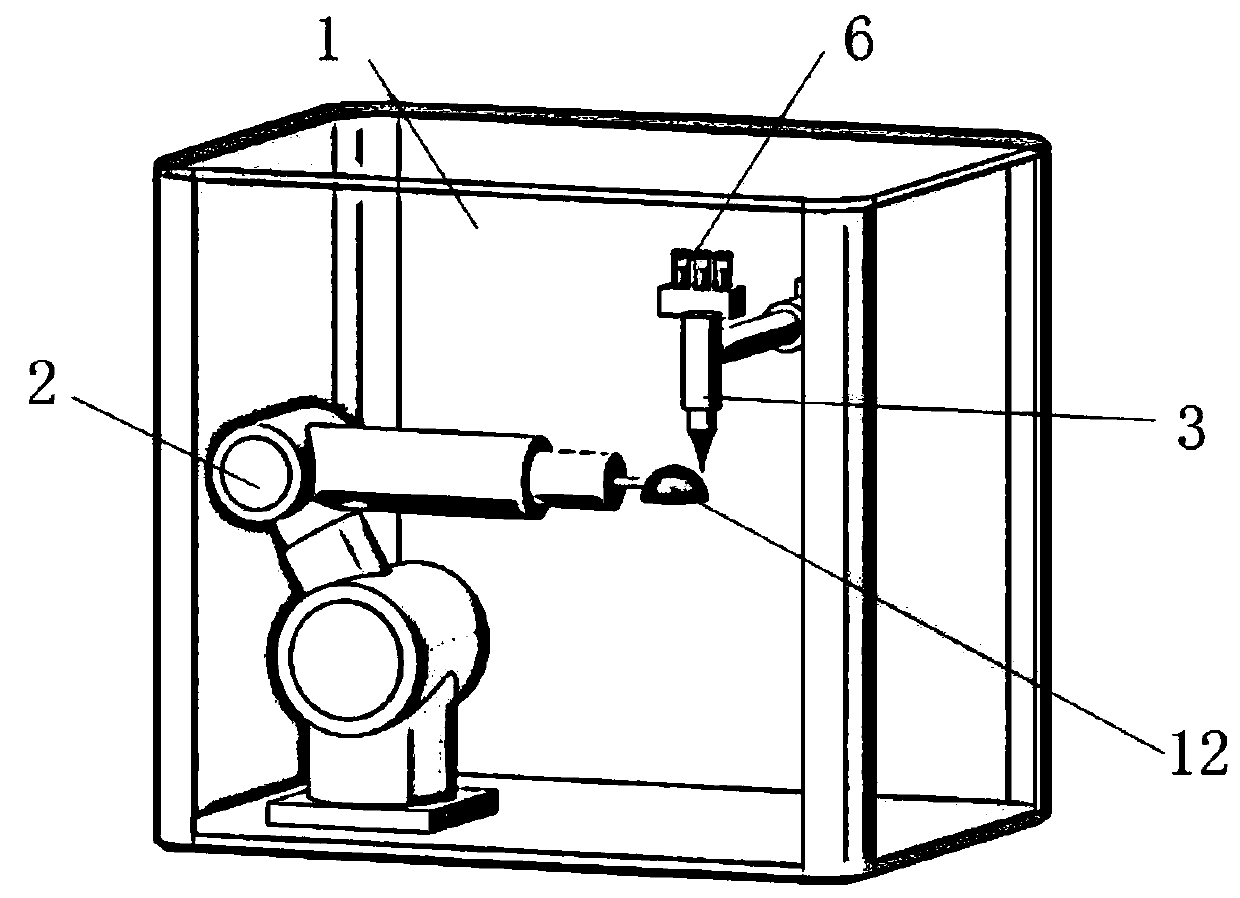

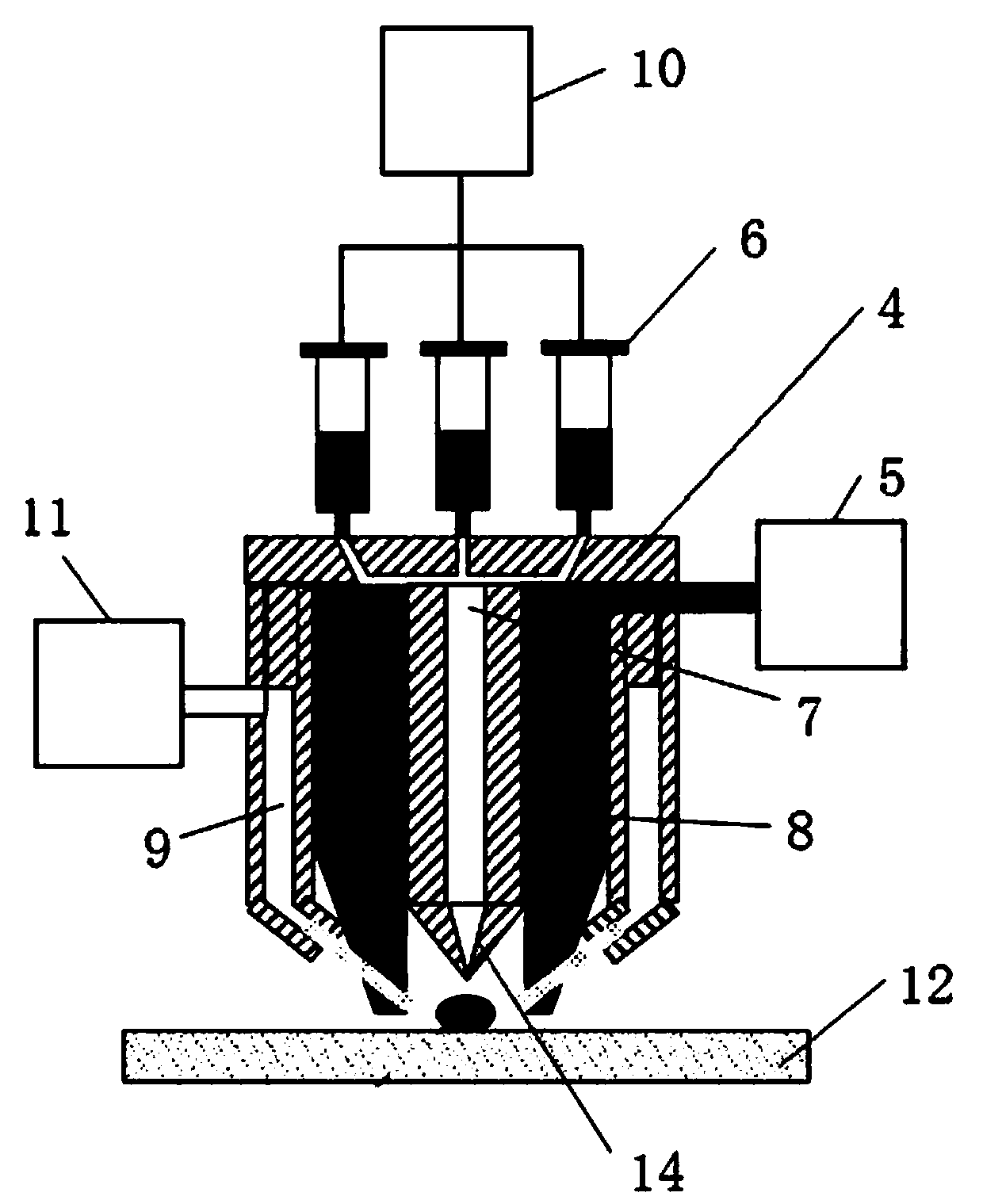

Multi-material laser direct writing conformal system and method

InactiveCN104260360ALarge adjustment rangeHigh repeat positioning accuracyMulti materialControl system

The invention discloses a multi-material laser direct writing conformal system and a method. The system comprises a vacuum seal case, a multi-joint mechanical arm, a multi-material laser direct writing head and a control system for controlling the constituent parts, wherein the mechanical arm and the laser direct writing head are arranged in the vacuum seal case; the laser direct writing head comprises a direct writing head body, a laser and at least two groups of material cylinders; a material channel and a laser focusing channel communicated with the laser and the material cylinders respectively are arranged on the direct writing head body; and the at least two groups of material cylinders are arranged on the direct writing head body in parallel. A particular process is as follows: the mechanical arm drives a workpiece to move along a set path; a material controller selects the corresponding material cylinders; a discharge head delivers and allows materials to be attached to the surface of the workpiece; and at the same time, laser light emitted from the laser focusing channel carries out solidifying or sintering forming on the attached materials. According to the invention, a control process is simple, the forming precision is high, continuous production is achieved, and production efficiency is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

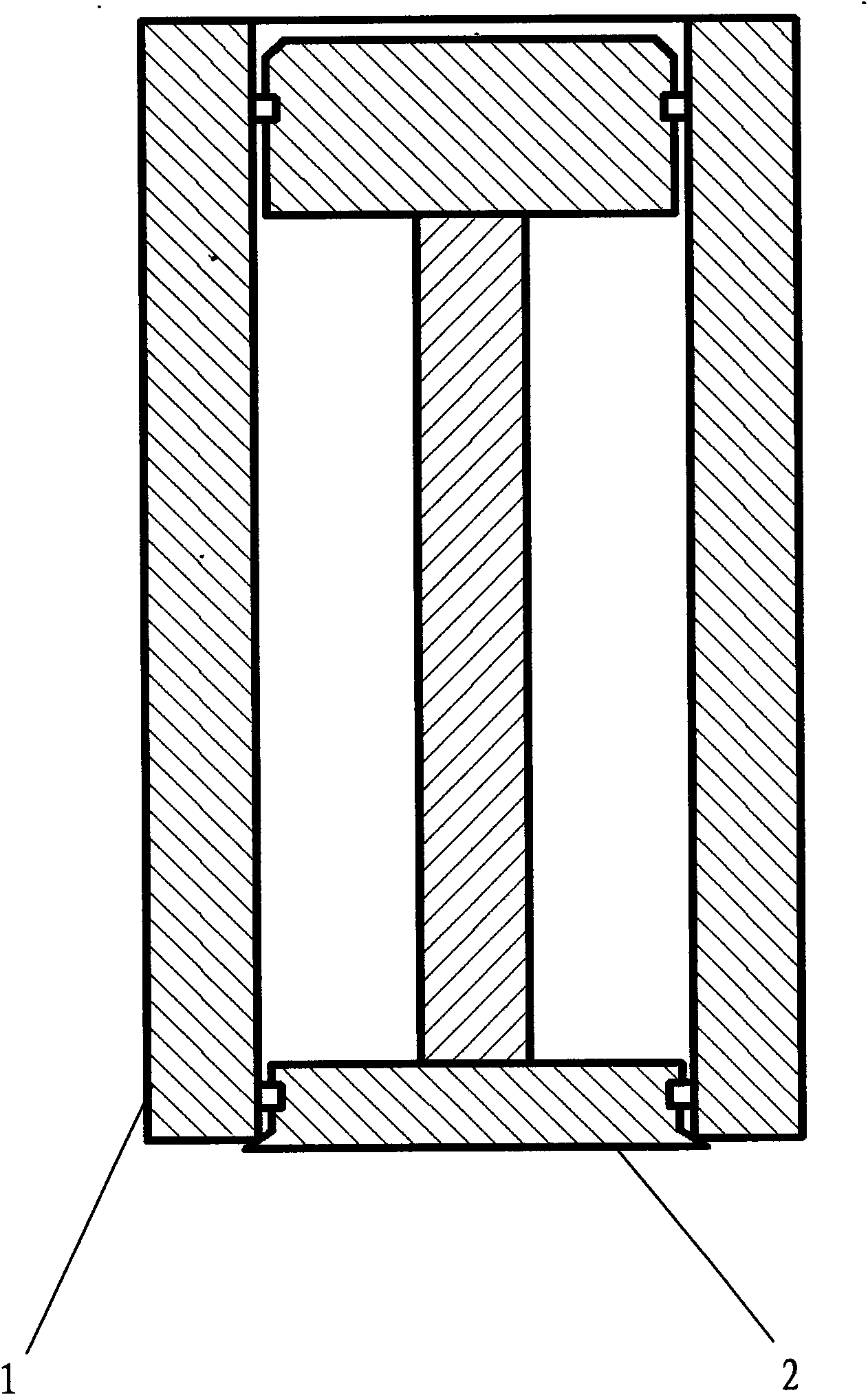

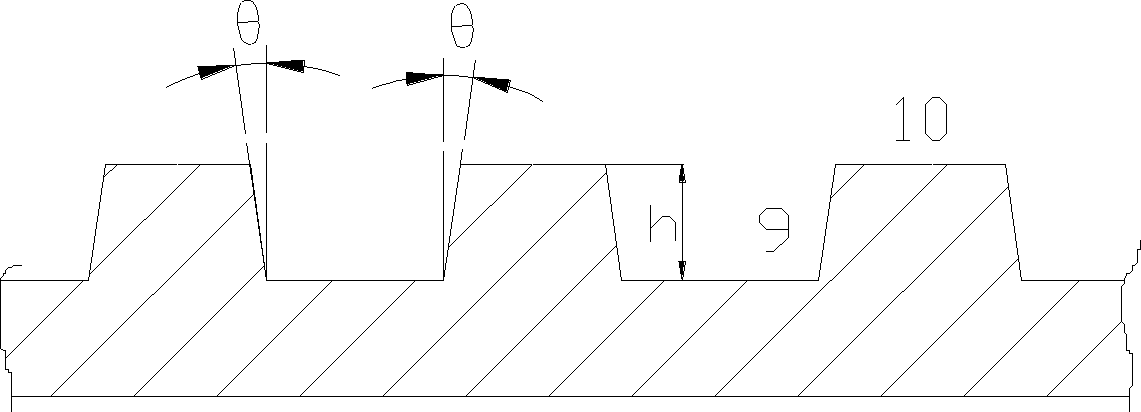

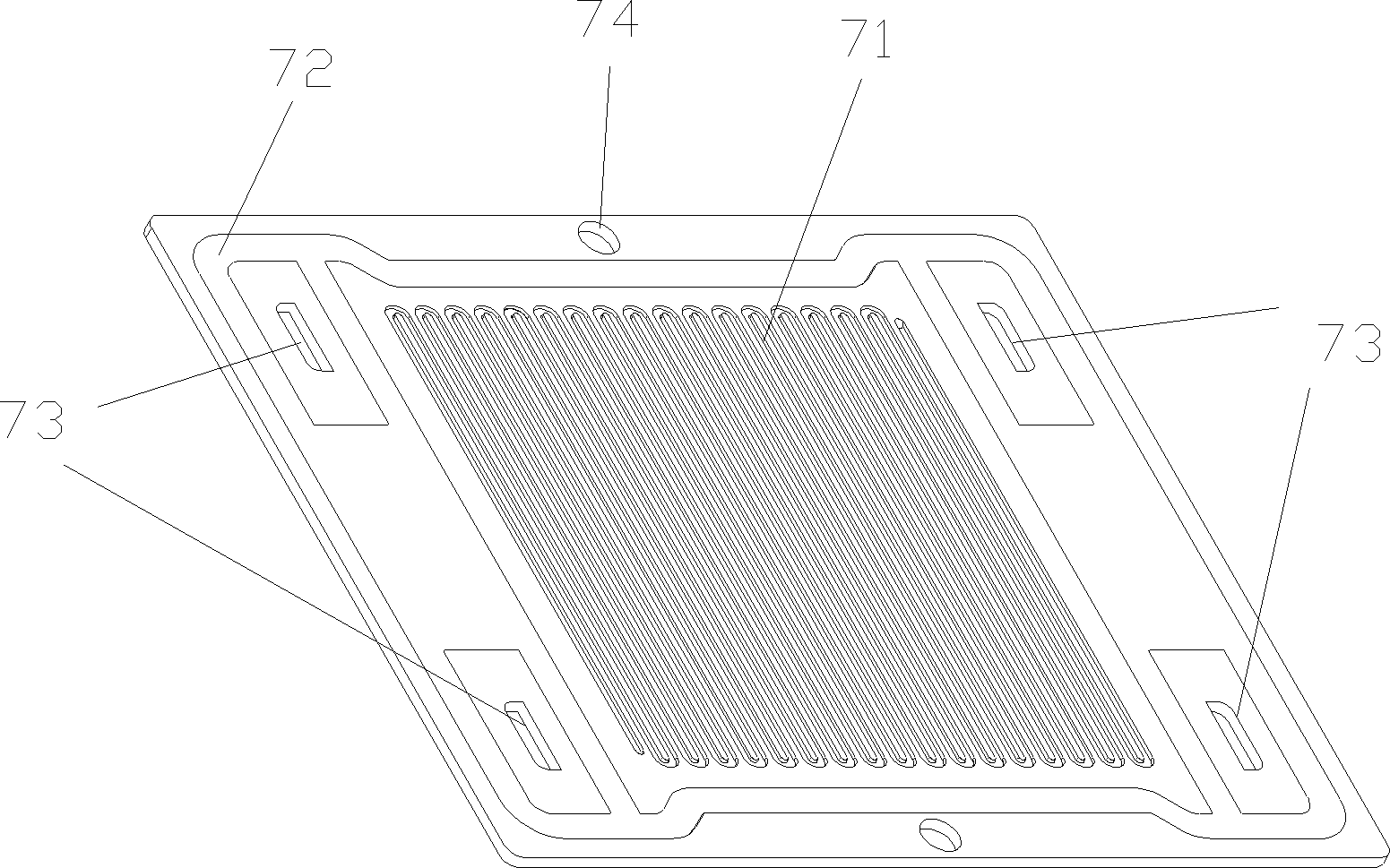

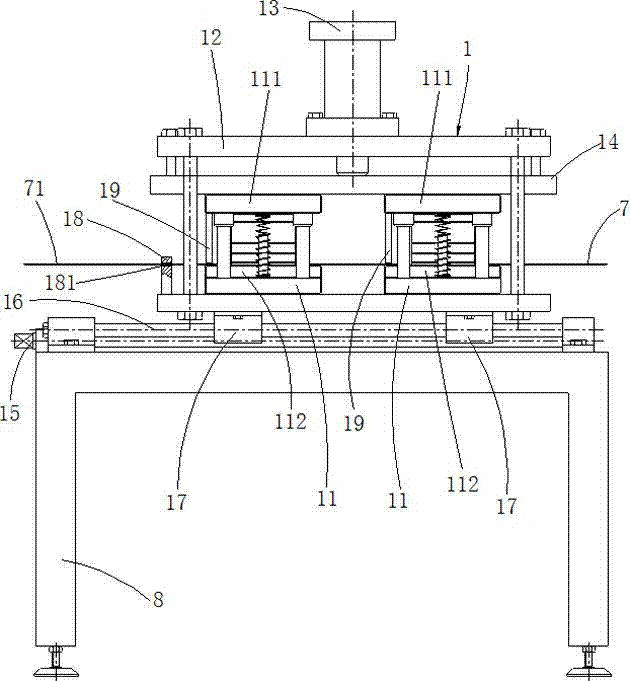

Manufacturing process and device of bipolar plate for fuel cell

InactiveCN102208659AImprove performanceReduce processing costsCell electrodesResin compositeGraphite

A manufacturing process and a device of a bipolar plate for fuel cells. The process comprises the following steps: dry-mixing expanded graphite and resin powder; pressing the mixed materials of expanded graphite and resin powder into a precompressed plate; pressing again to obtain corresponding flow passages on one side or two sides; separating the precompressed plate with pressed flow passages of the bipolar plate to obtain a molded bipolar plate; curing and cooling the molded bipolar plate to obtain the bipolar plate product. The device comprises at least one group of vibrating feeders which are used to feed the expanded graphite and resin powder on a conveyer belt respectively; a conveyer belt for conveying the mixed expanded graphite and resin powder; a roller press for pressing the mixture on the conveyer belt into a precompressed plate; a block press for pressing the precompressed plate again and obtaining corresponding flow passages, and a curing furnace for curing and molding the bipolar plate. The block press comprises a mold for pressing the flow passages of the bipolar plate. The expanded graphite / resin composite bipolar plate of the invention has excellent performance in conductivity, gas-barrier rate, and mechanical strength, and has low price.

Owner:TONGJI UNIV +2

Konjak noodle and processing method thereof

InactiveCN1448069AHigh glutenRealize continuous productionDough treatmentFood preparationFlavorFermentation

The present invention relates to food producing technology and is especially one kind of konjaku noodles and its production process. The material includes starch in 80-99 wt%, konjaku powder 0.1-20 wt%, juice 1-20 wt%, salt 1-2 wt% and soda 0.1-0.2 wt%. The production process includes the steps of: purifying starch, mixing with water, adding konjaku powder and juice while stirring, adding salt and soda while stirring, maturing and fermentation for 0.5-2 hr, rolling into sheet, cutting into noodles and stoving or drying in the sun. the present invention increases the flavors of noodles.

Owner:潘荣华

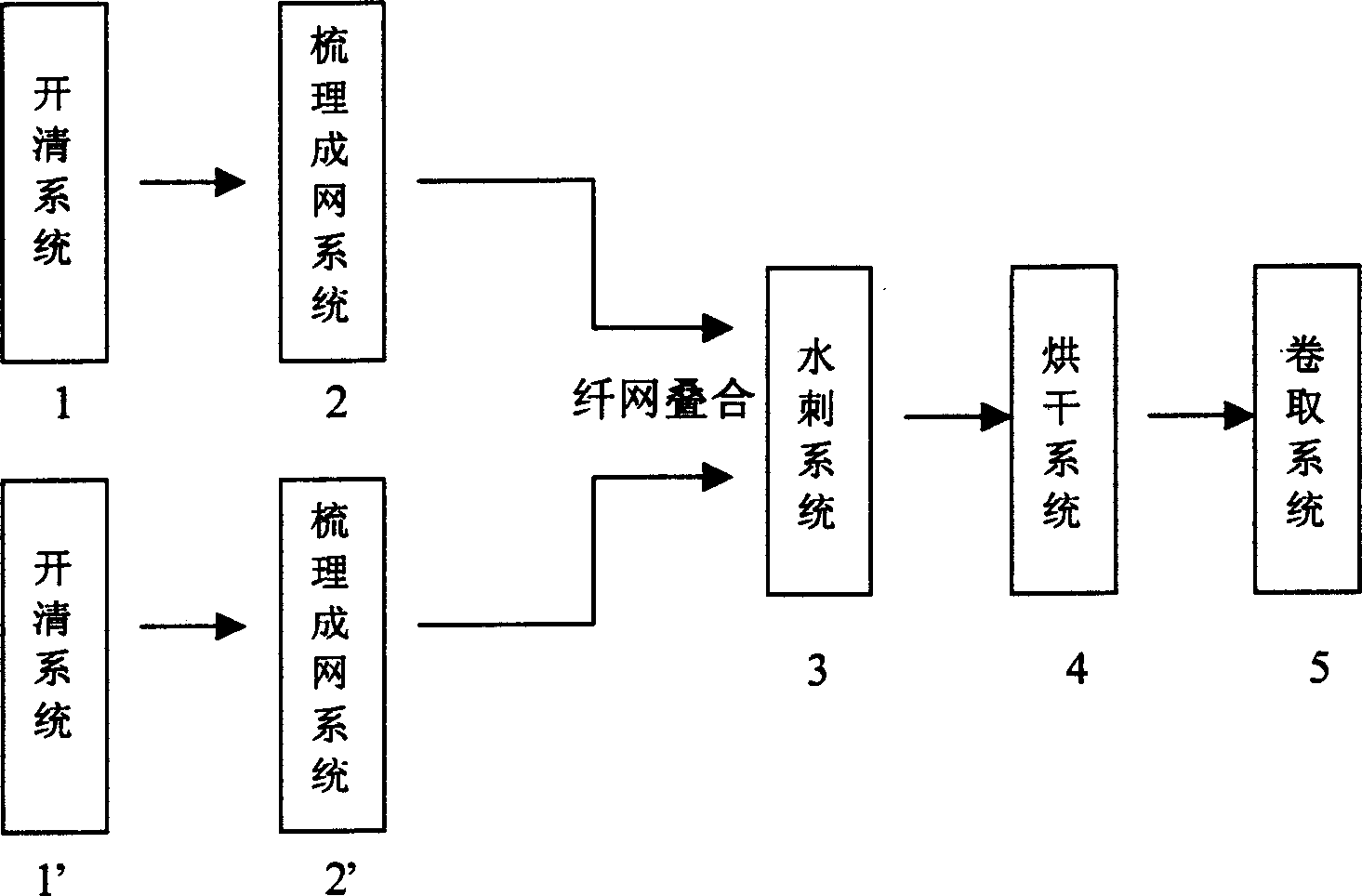

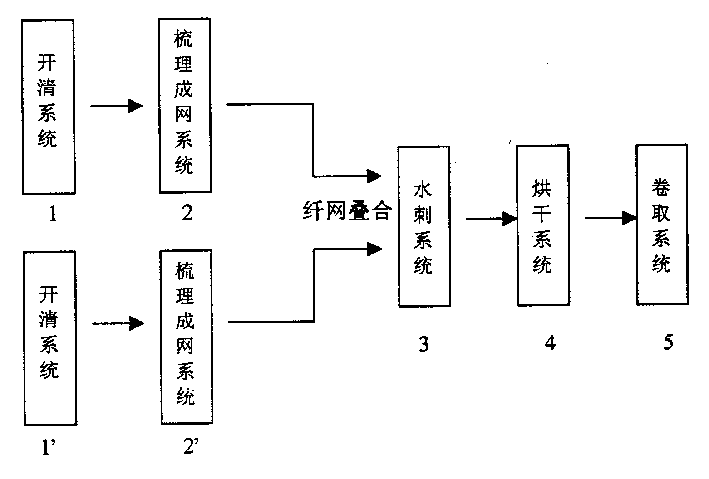

Production process of hydro-entangled composite non-woven fabric

InactiveCN1468995ASimple production processRealize continuous productionNon-woven fabricsNonwoven fabricContinuous production

The production process of hydro-entangled composite non-woven fabric includes fiber opening and carding to form fiber nets and superposing fiber nets in at least two sets of opening system and at least two sets of carding and netting system; twisting and reinforcing fiber inside one hydro-entangling system; and stoving. The production process is simple and high in production efficiency, and can realize continuous production. The product is soft in hand feeling and homogeneous.

Owner:东纶科技实业有限公司

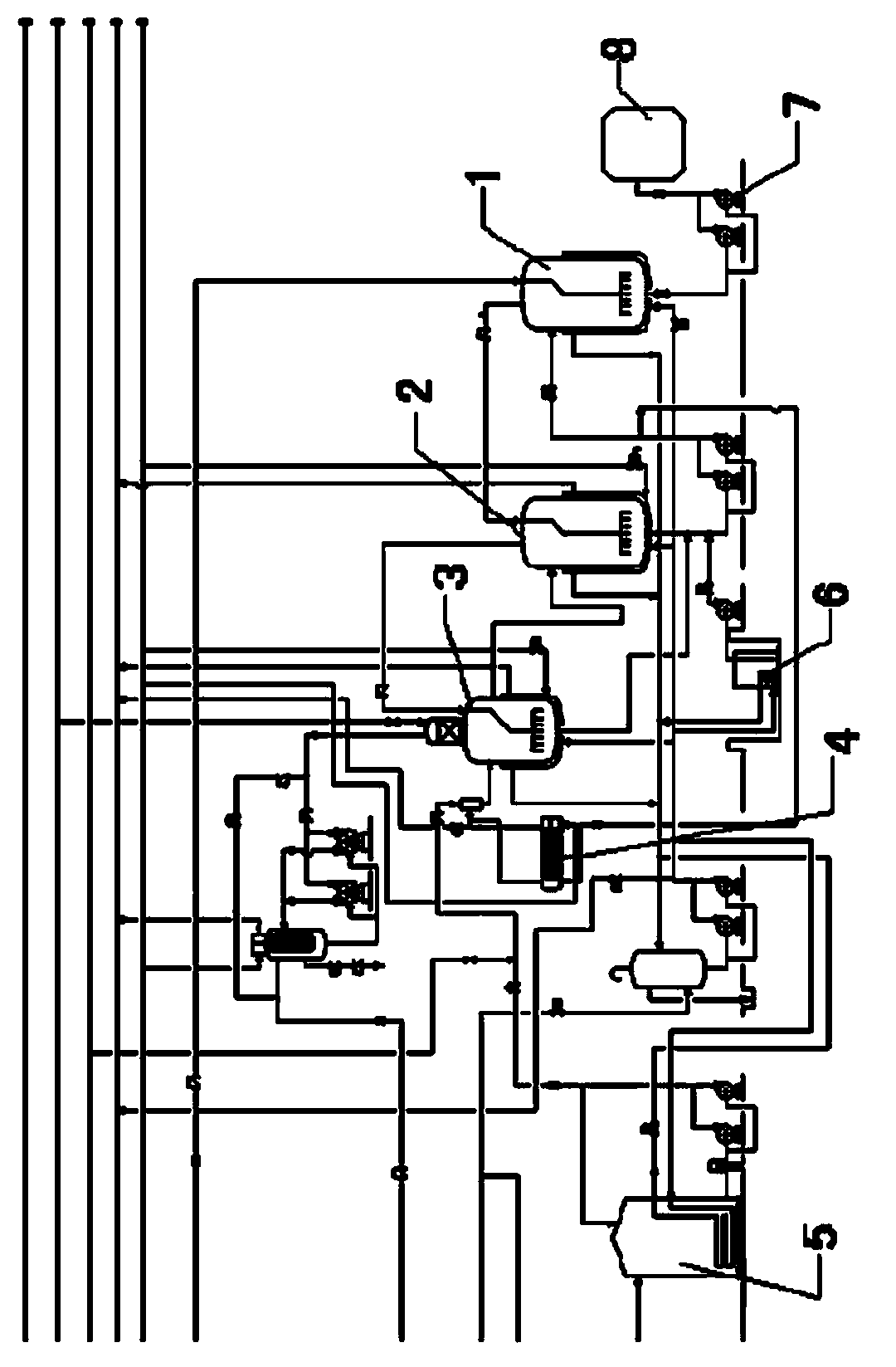

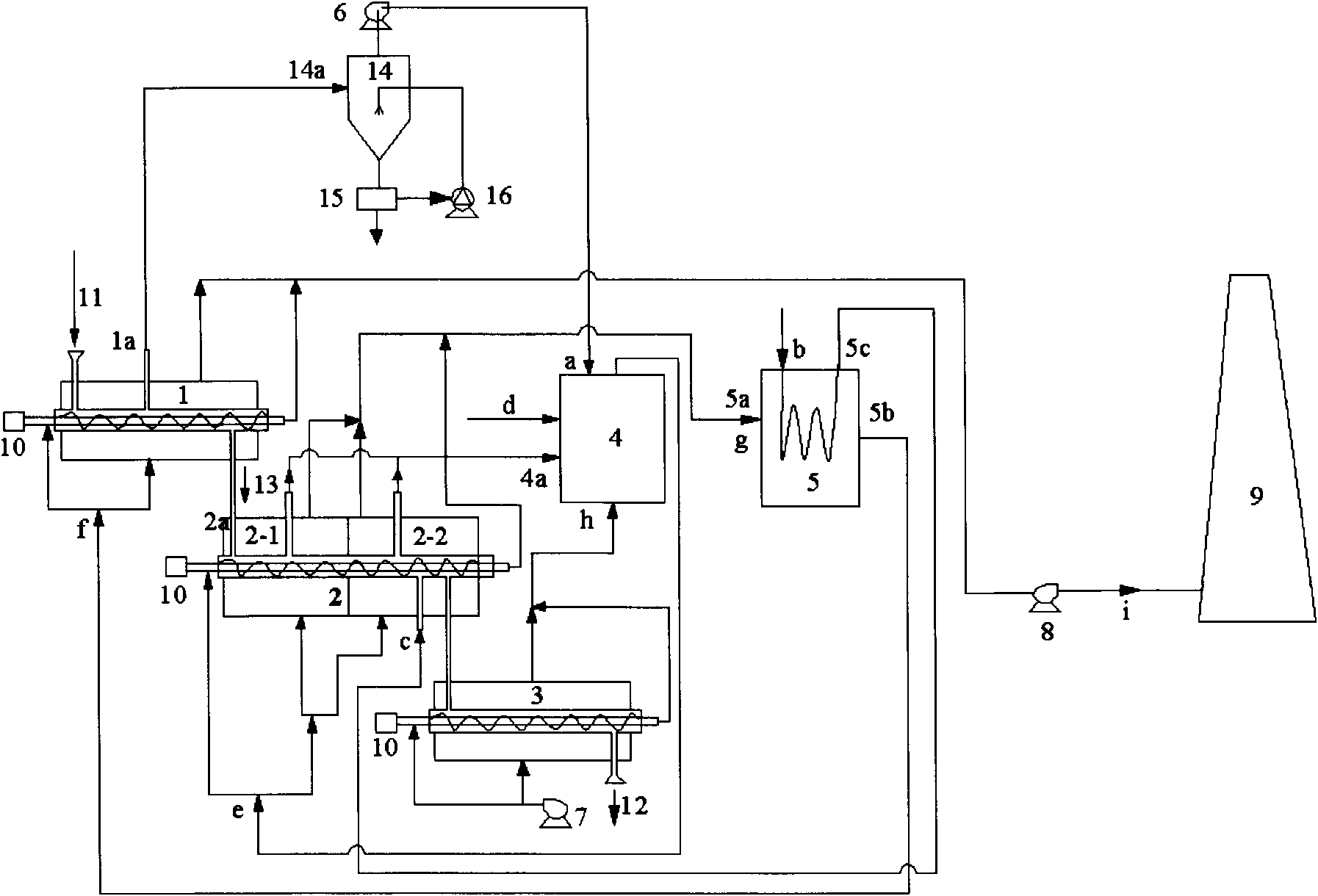

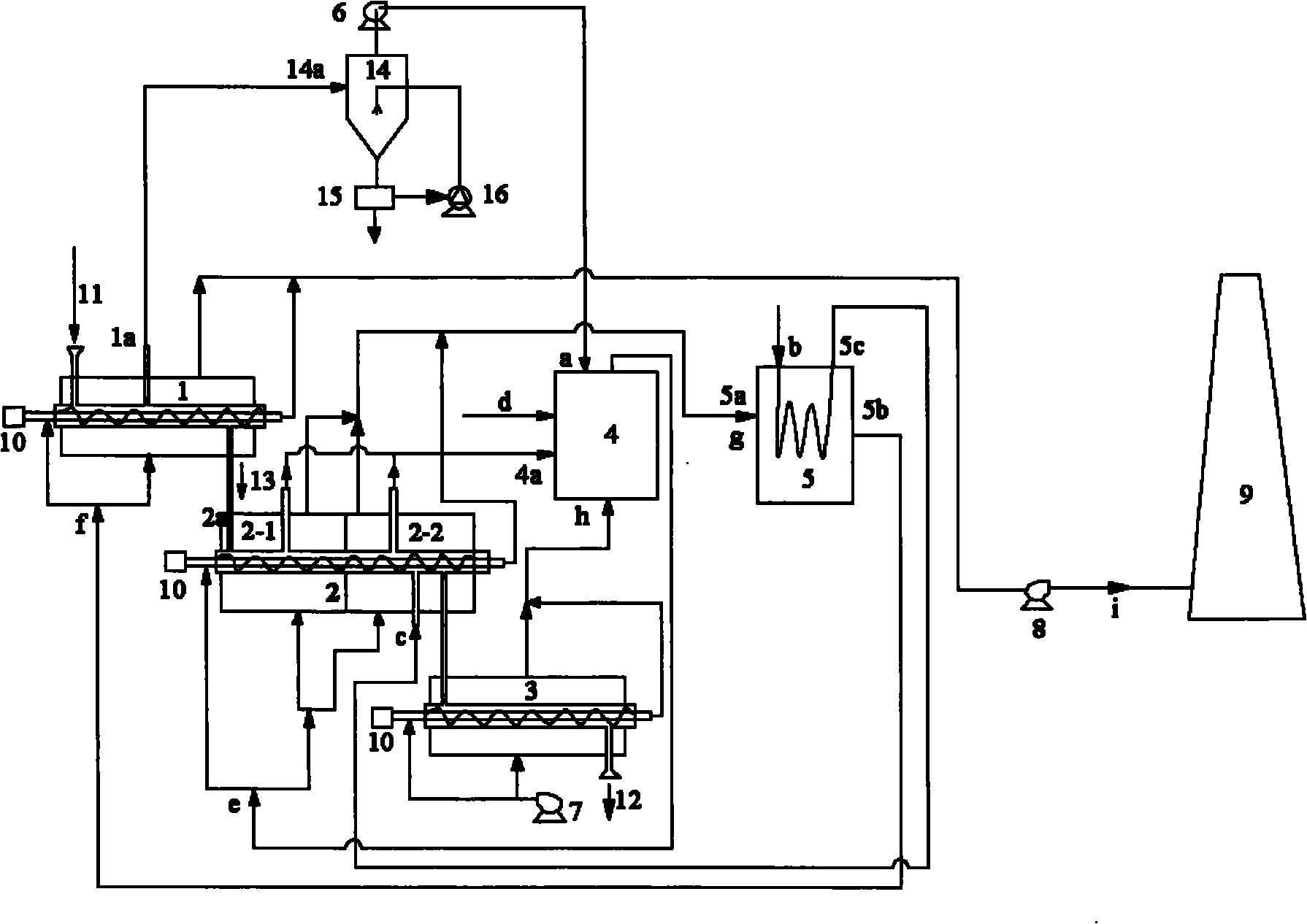

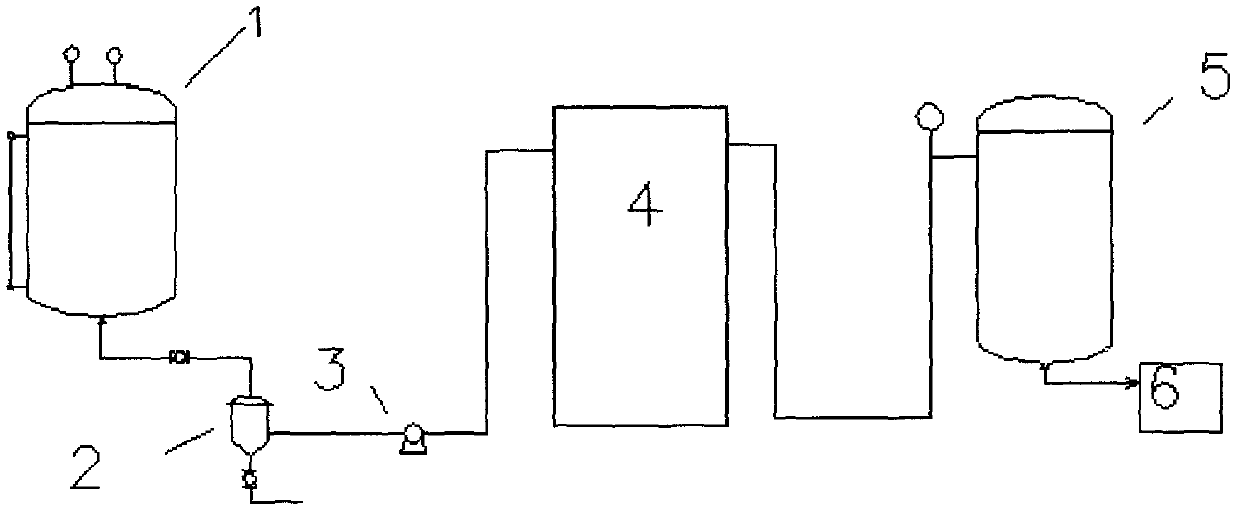

Device and method for continuously preparing active carbon by biomass in bulk

InactiveCN101885487ASolve for uniformityAvoid intermediate manual linksCarbon compoundsEnergy inputCombustionCarbonization

The invention relates to a device and a method for continuously preparing active carbon by a biomass in bulk. The invention is characterized in that the device comprises a spiral dryer (1), a spiral carbonization activation device (2), a spiral cooling device (3), a combustion furnace (4), a waste heat boiler (5), a circulating fan (6), a blower (7), an induced fan (8), a chimney (9), a velocity modulation motor (10), a spray tower (14), a waste liquor circulation pool (15), and a circulation water pump (16), wherein the spiral dryer (1) is provided with a feed port (11), a waste air outlet(1a), a material outlet after drying (13), a coil and a sleeve; and the spiral carbonization activation device (2) comprises a carbonization section (2-1) and an activation section (2-2) communicated with the carbonization section (2-1). By using the invention, the defects of low heat utilization efficiency, low drying / carbonization / activation efficiencies, discontinuous production course and the like in the existing active carbon preparation technology are overcome.

Owner:SOUTHEAST UNIV

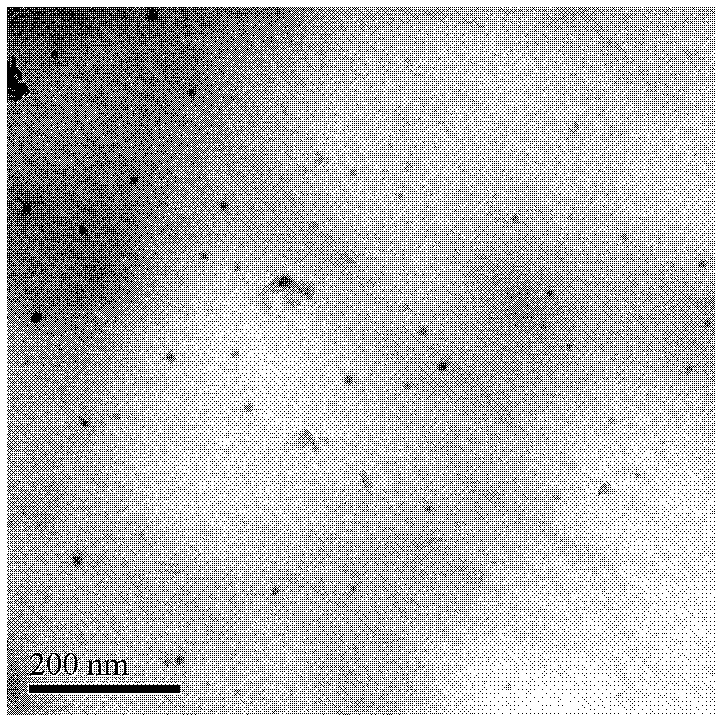

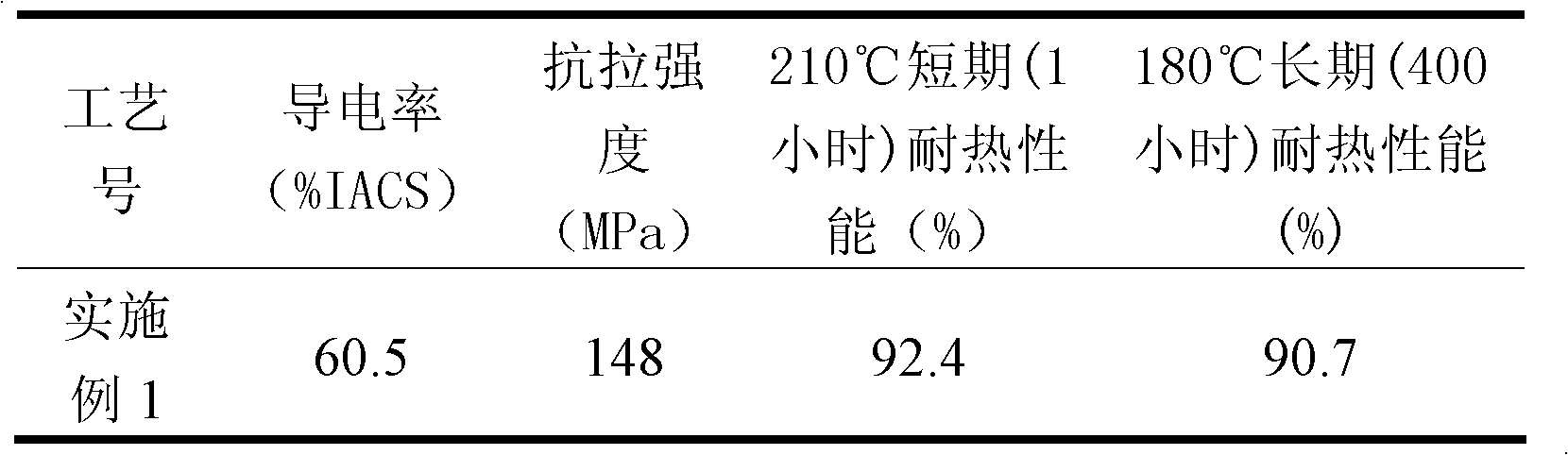

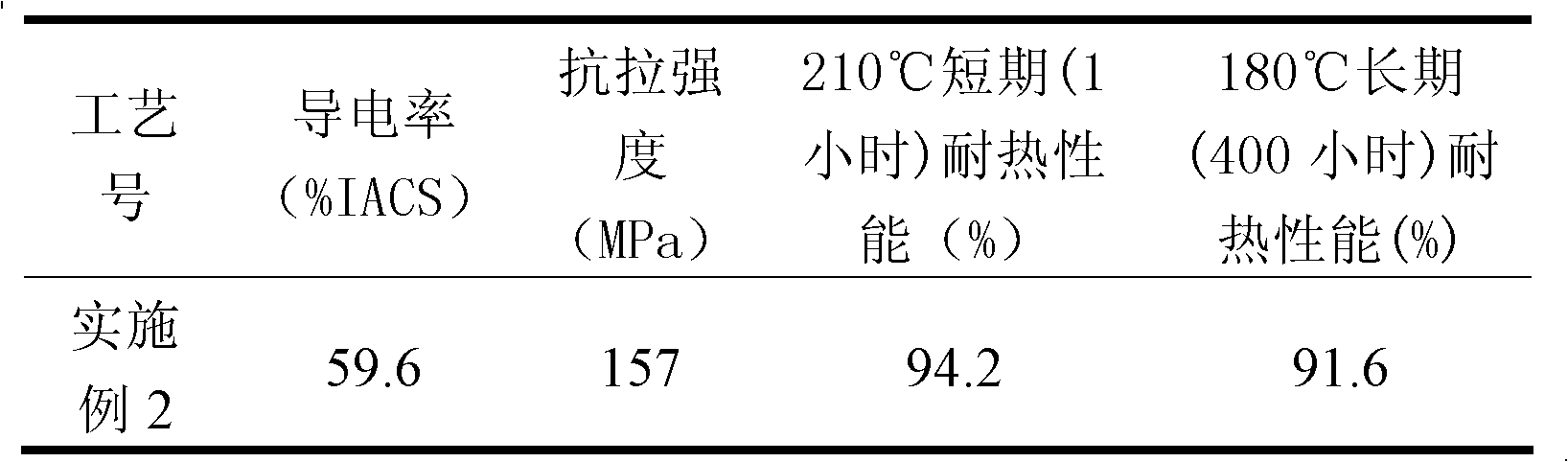

Heat resistant aluminum alloy conductor material and preparation method thereof

ActiveCN102230113AImprove conductivityLow conductivityMetal/alloy conductorsCable/conductor manufactureElectrical conductorManganese

The invention provides a heat resistant aluminum alloy conductor material and a preparation method thereof. The heat resistant aluminum alloy conductor material comprises the following components of 0.06-0.15 % of zirconium, 0.15-0.30 % of erbium, 0.10-0.20 % of iron, less than 0.05 % of silicon, less than 0.01 % of inevitable impurities like titanium, vanadium, chromium, manganese and the like and the balance of aluminum. According to the preparation method, the heat resistant aluminum alloy conductor material is directly rolled after each component is fused and cast. The conductor material can realize that the electric conductivity can reach 59.5-60.5 % IACS (International Association Of Classification Societies), the long-term heat resistance temperature can reach 180 DEG C and the short-term heat resistance temperature can reach 210 DEG C without heat treatment; therefore, the conductor material is an electric wire and cable conductor material with great potential. The conductor material can be widely used for construction and capacity expansion reconstruction of electric power engineering; and by using the conductor material, the transmission line capacity is largely increased, the transmission line loss is reduced, the distance between poles of the transmission line can be increased, the line building cost is reduced, the tense corridor resources are saved and obvious economic benefit and energy-saving and environment-friendly significance are obtained. The heat resistant aluminum alloy conductor material provided by the invention has the advantages of reasonable component mixing ratio, simple preparation process, convenience for realizing continuous production and suitability for industrial application; and the production cost and the energy consumption of the heat resistant aluminum alloy can be effectively reduced.

Owner:CENT SOUTH UNIV

Method for synthesizing ethyl methyl carbonate through ester exchange

ActiveCN103483200AEasy to makeSimple process conditionsPreparation from organic carbonatesMolecular sieveAlcohol

The invention relates to a method for synthesizing ethyl methyl carbonate through ester exchange. The method comprises the following steps: filling a fixed bed reactor with catalysts, pumping dimethyl carbonate and ethyl alcohol into the fixed bed reactor according to the molar ratio of 0.5-2:1 after nitrogen purging is carried out, reacting at the air speed of 0.5-15h-1, the temperature of 100-240DEG C and the reaction operation pressure of 0-1MPa, and finally the ethyl methyl carbonate is obtained. The catalysts are modified molecular sieve based catalysts. The method is simple in technology condition, easy to control, capable of achieving continuous production due to the gas-solid phase reaction and low in cost of the adopted catalysts. The selectivity of the ethyl methyl carbonate can be higher than 90%, and the yield can be higher than 55%.

Owner:HEBEI UNIV OF TECH

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

Method for producing hydroxy cobalt oxide

InactiveCN102689933AThe production process is easy to controlImprove product qualityCobalt oxides/hydroxidesEthylene diamineReaction temperature

The invention discloses a method for producing hydroxy cobalt oxide, comprising the following steps of: firstly, preparing a cobaltous sulfate solution with cobalt content of 75-85g / l; adjusting a pH value of the solution to be 3.0-4.5; adding EDTA (Ethylene Diamine Tetraacetic Acid) into the solution according to the proportion of cobalt to EDTA of 100:(1-3); preparing sodium hydroxide solution with alkali concentration of 7-9mol; performing cocurrent flow on two solutions and flowing into a reaction groove; introducing the air for performing synthetic reaction; controlling the reaction temperature to be between 50 and 70 and a pH value to be between 10.0 and 12.0 for reacting for 15-25 hours; flowing into an aging groove for aging for 50-60 minutes; and finally, filtering, washing and slurrying to prepare a hydroxy cobalt oxide solid product. According to the method, the production process is controllable, particles of the product are uniformly distributed with good consistency, the shape is spherical and the product has good dispersibility; and the production process is free of ammonia nitrogen pollution, so that continuous production is realized, and the equipment utilization rate and the production efficiency are improved.

Owner:湖南红太阳电源新材料股份有限公司

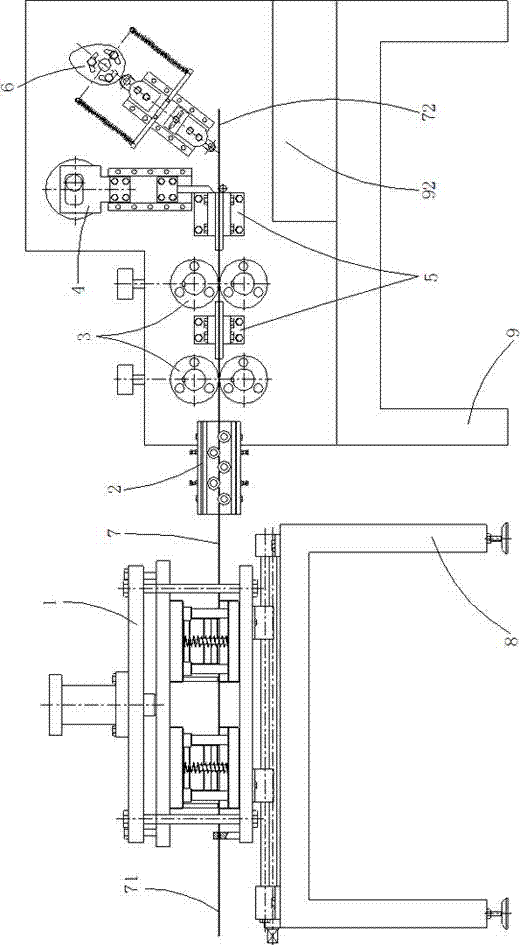

Automatic punching machine for steel strip

ActiveCN102825429ARealize continuous productionIncrease productivityPerforating toolsShearing machinesPunchingEngineering

The invention relates to an automatic punching machine for a steel strip; the automatic punching machine comprises a punching device, a shaping device, a driving device, a cutting device and a bending device; the punching device is arranged close to a steel strip feeding end; the bending device is arranged on a steel strip discharging end; the shaping device is arranged between the punching device and the driving device; the cutting device is arranged between the driving device and the bending device. The automatic punching machine further comprises a machine frame and a machine case; the punching device is fixed on the upper part of the machine frame; the shaping device, the driving device, the cutting device and the bending device are respectively fixed on the same side of the machine case. The automatic punching machine can automatically finish punching, bending and cutting processes of the steel strip, and also can realize continuous production, therefore, production efficiency is enhanced, and production cost is reduced.

Owner:浙江科朗汽车配件有限公司

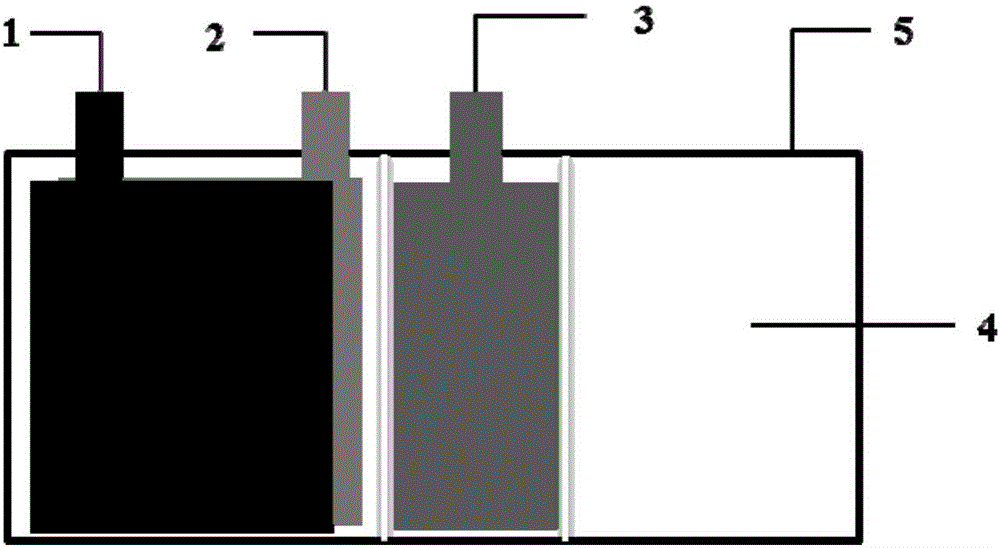

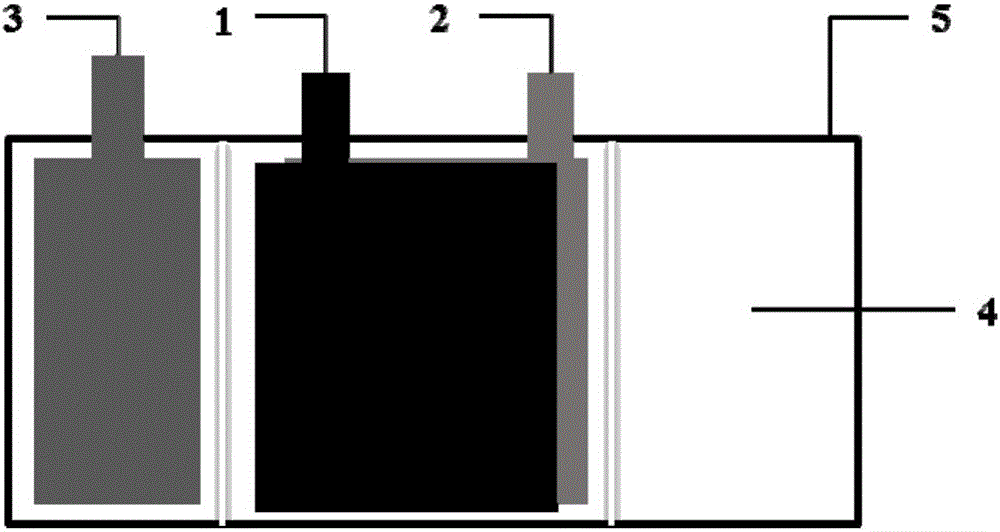

Lithium supplementing method for energy storage device

InactiveCN106450467ADoes not reduce energy densityWide variety of sourcesFinal product manufactureSecondary cells servicing/maintenanceProduct gasEngineering

The invention relates to a lithium supplementing method for an energy storage device. The lithium supplementing method comprises the steps of adopting a device shell which consists of a cavity for placing a core pack, and m other cavities; putting the core pack and a lithium supplementing electrode into the core pack cavity and another cavity respectively, and injecting an electrolyte to enable the cavities where the core pack and the lithium supplementing electrode are located to be rich in electrolyte; performing formation treatment on the core pack, and then performing electrochemical lithium intercalation to obtain an A; or performing electrochemical lithium intercalation firstly, and then performing formation treatment on the core pack to obtain a B; after obtaining the A and B, performing n times of charge-discharge cycling treatment on the obtained A and B, next, extracting gas and redundant electrolyte from the core pack cavity, and sealing connection channels between the core pack cavity and other cavities to obtain a C; and finally, performing cavity-removing treatment on the obtained C to obtain a D, and performing machining and shaping on the D to obtain the finished energy storage device. The lithium supplementing method is simple and convenient to operate without greatly improving the production process of the existing lithium battery, and meanwhile, continuous production can be realized quite easily; and in addition, the lithium supplementing method is remarkable in effect and convenient to realize large-scale industrial application.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com