Automatic silicon rod bonding production line

A technology of automated production lines and silicon rods, applied in semiconductor devices, electrical components, conveyor objects, etc., can solve the problems of low production efficiency, waste of labor, large operating space, etc., and achieve reasonable design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

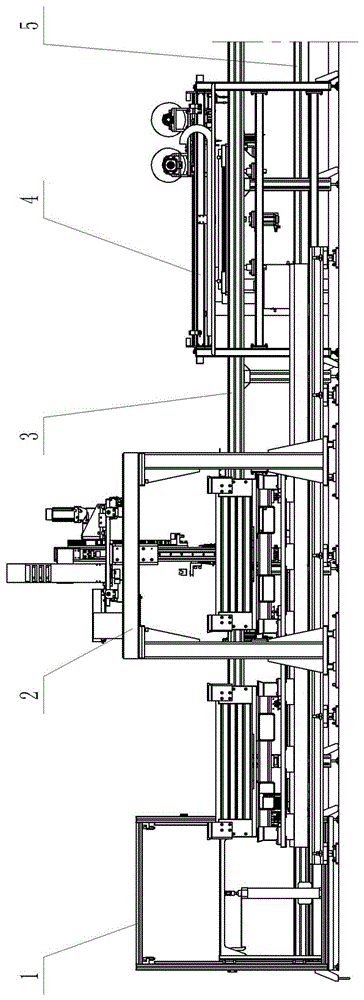

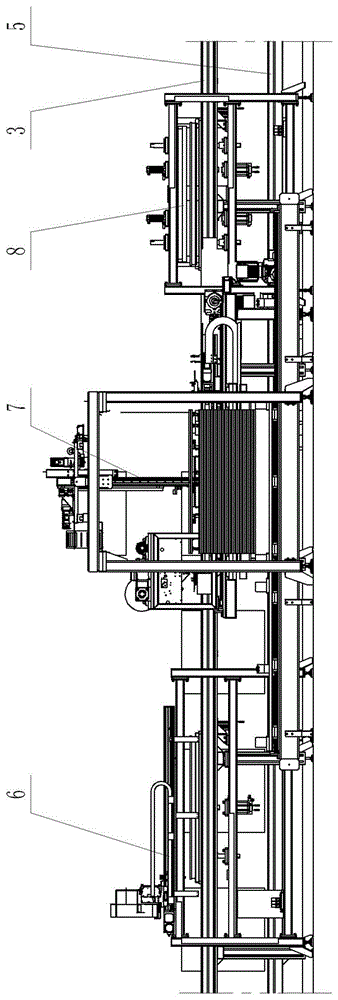

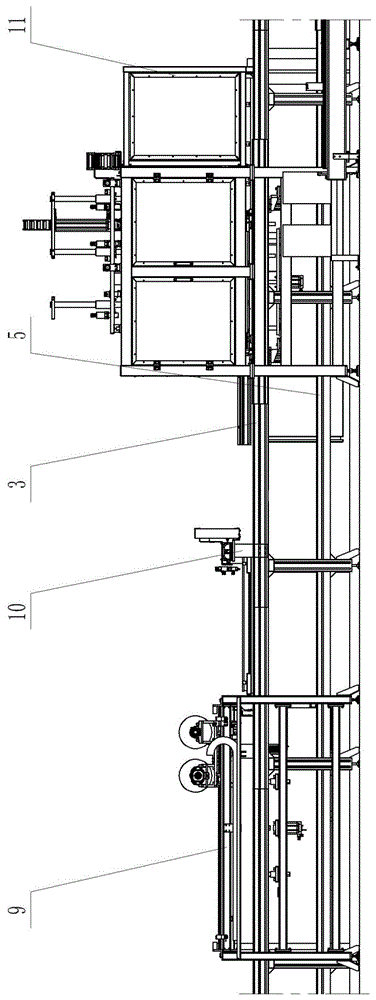

[0046] according to Figure 1-30 The specific structure of the present invention will be described in detail. Such as Figure 1~4 As shown, the silicon rod bonding automatic production line includes a double-layer transmission line composed of an upper transmission line 3 and a lower transmission line 5 arranged in parallel. Tray lifter 1 for trays; along the conveying direction of the transmission line, there are crystal trays 17 automatic feeding unit 2, crystal trays 17 cleaning unit 4, crystal trays 17 gluing unit 6, glass automatic feeding unit 7, and glass pressing unit 8. Glass cleaning unit 9, glass online gluing unit 10, silicon rod automatic loading unit 11 and automatic unloading unit 12.

[0047] Such as Figure 5-9 As shown, the crystal tray 17 automatic feeding unit 2 includes a sliding feeding device 13 and an upper conveying line 3 respectively arranged on both sides of the frame I16, and an intelligent transplanting device 15, wherein the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com