Numerically controlled continuous steam explosion machine

A technology of steam explosion machine and numerical control system, which is applied in chemical instruments and methods, methods of chemically changing substances by using atmospheric pressure, chemical/physical processes, etc. Due to the limited opening speed of the high-pressure valve, it can meet the requirements of process consistency, improve the blasting energy density, and save steam energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

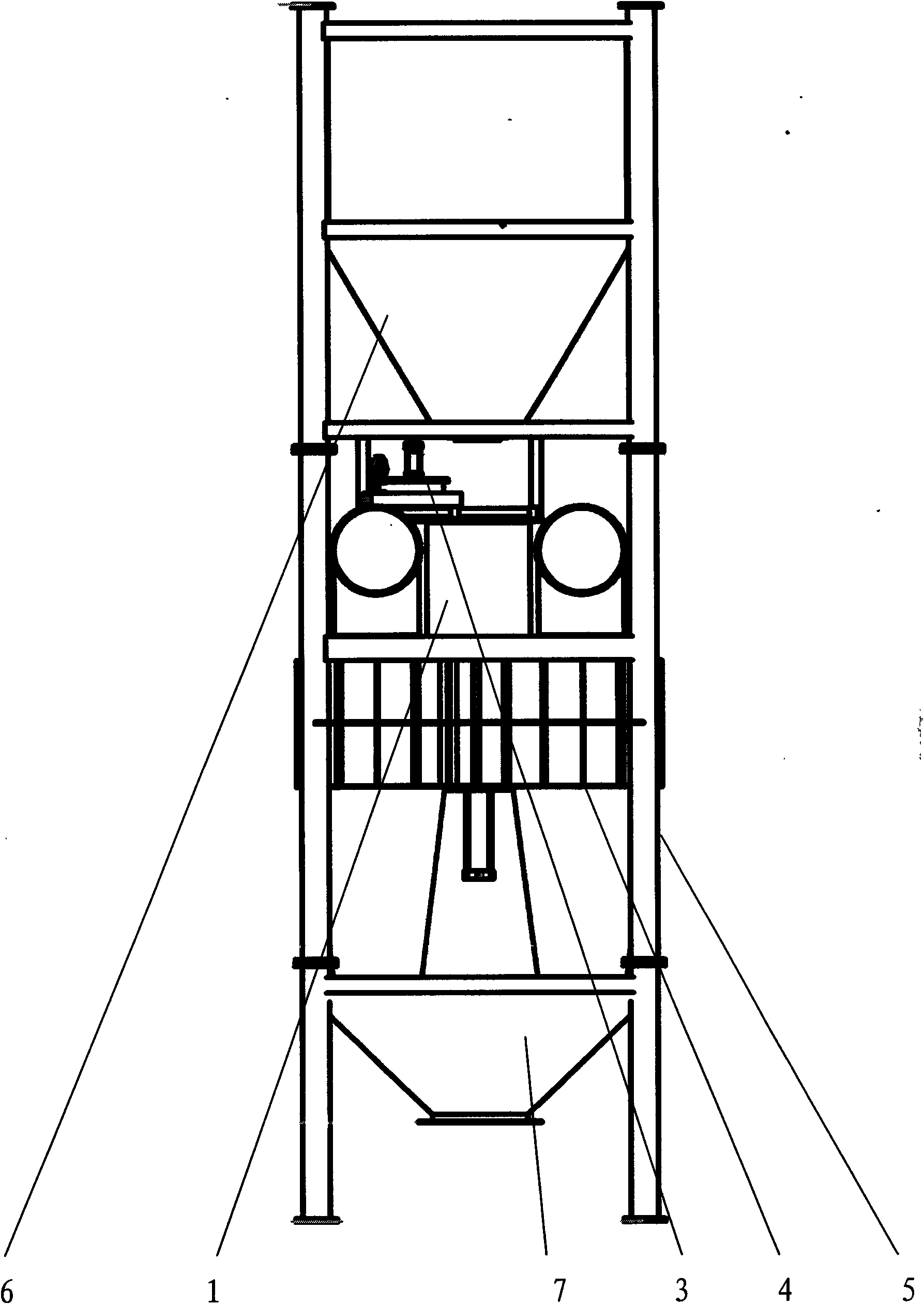

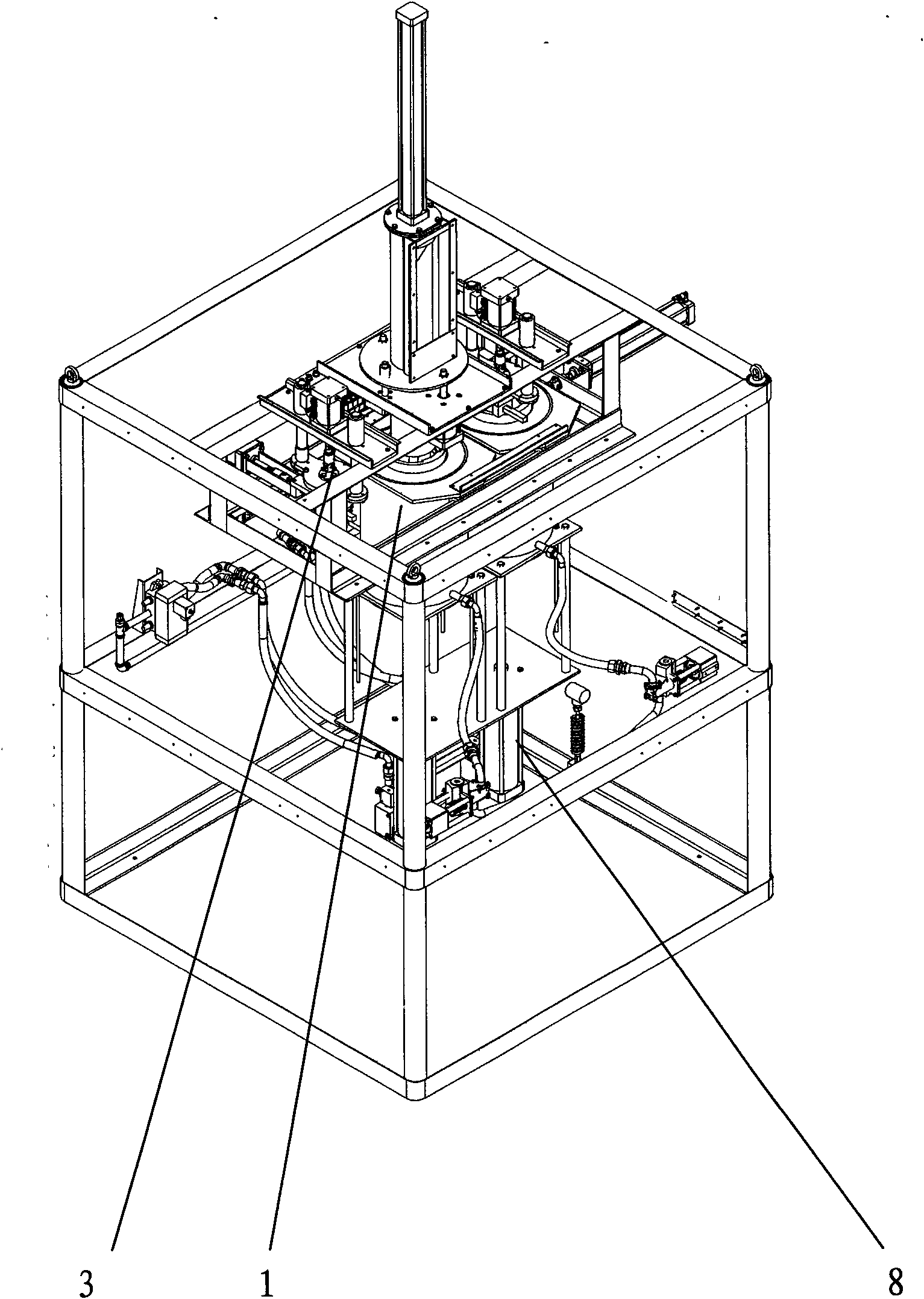

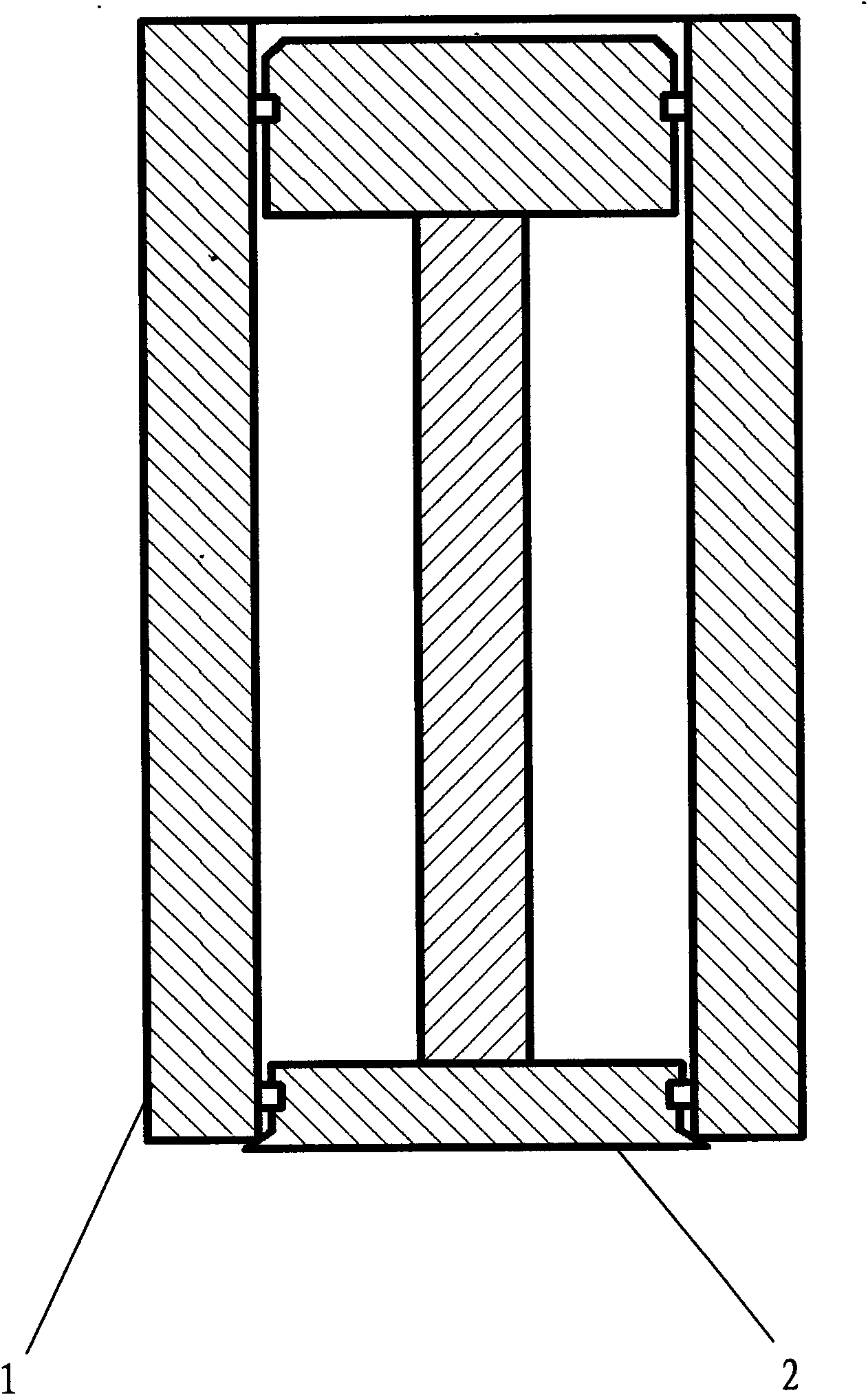

[0021] The LB-6 numerical control continuous steam explosion machine is the specific implementation of the above-mentioned invention. Each high-pressure cylinder of this type of steam explosion machine has a volume of 300 liters and a working pressure of 2.5Mpa. Each cylinder can process an average of 1 ton of straw or 3 tons of grain per hour. It is a medium-sized steam explosion machine and is generally designed to operate in parallel with multiple cylinders. It provides industrialized continuous steam explosion pretreatment equipment for the production of biochemical, brewing, papermaking and other industries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com