Patents

Literature

236results about How to "Shorten holding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

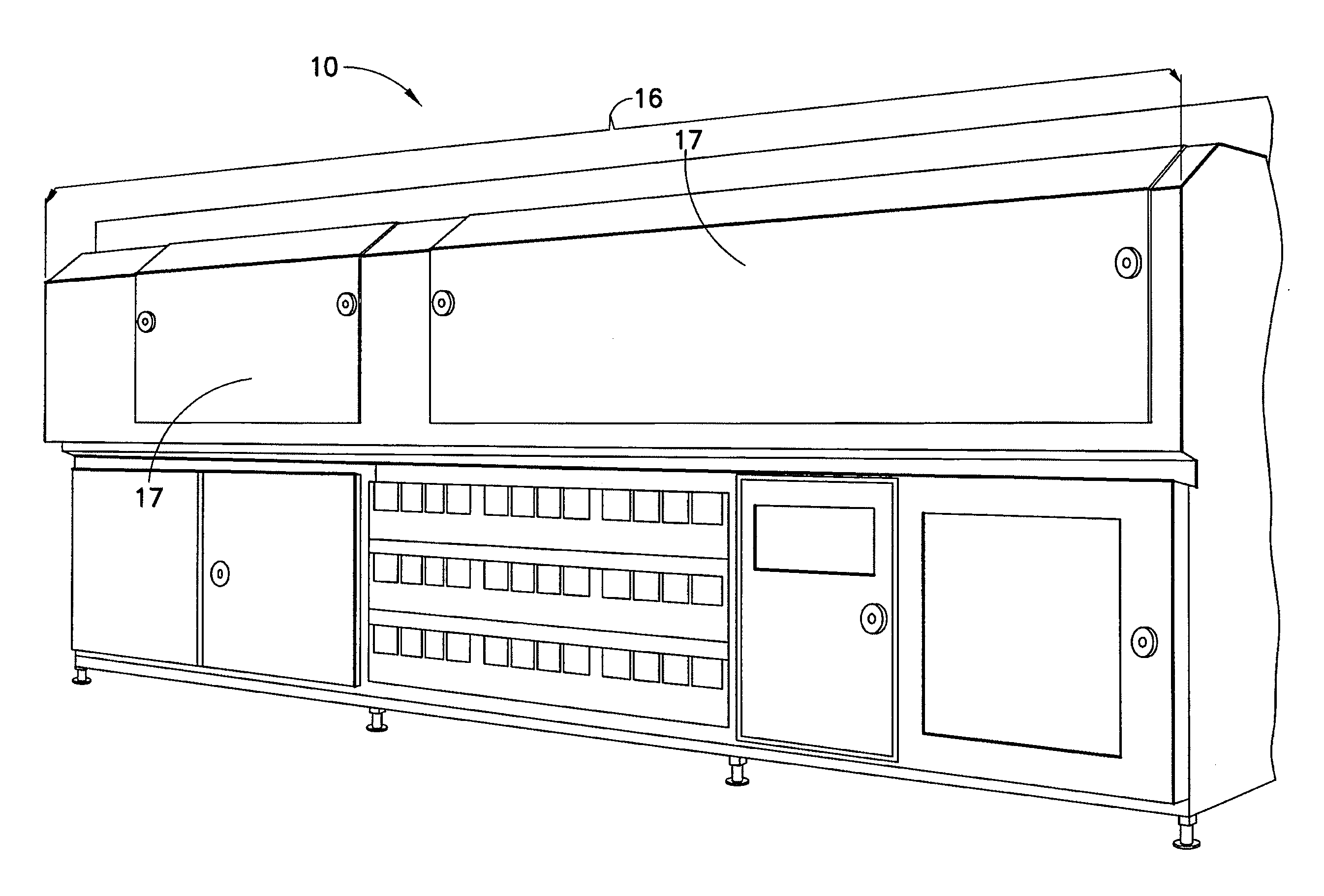

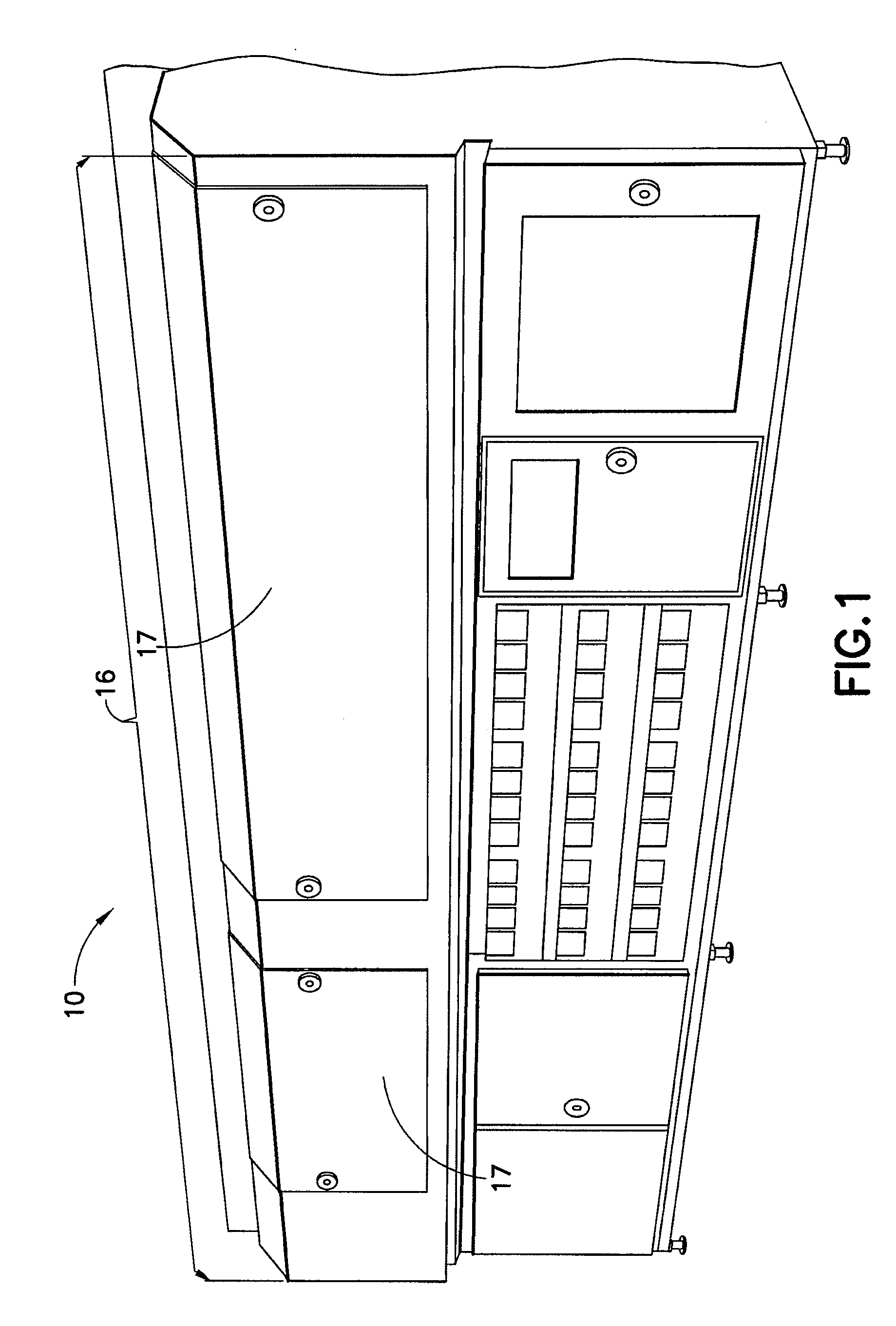

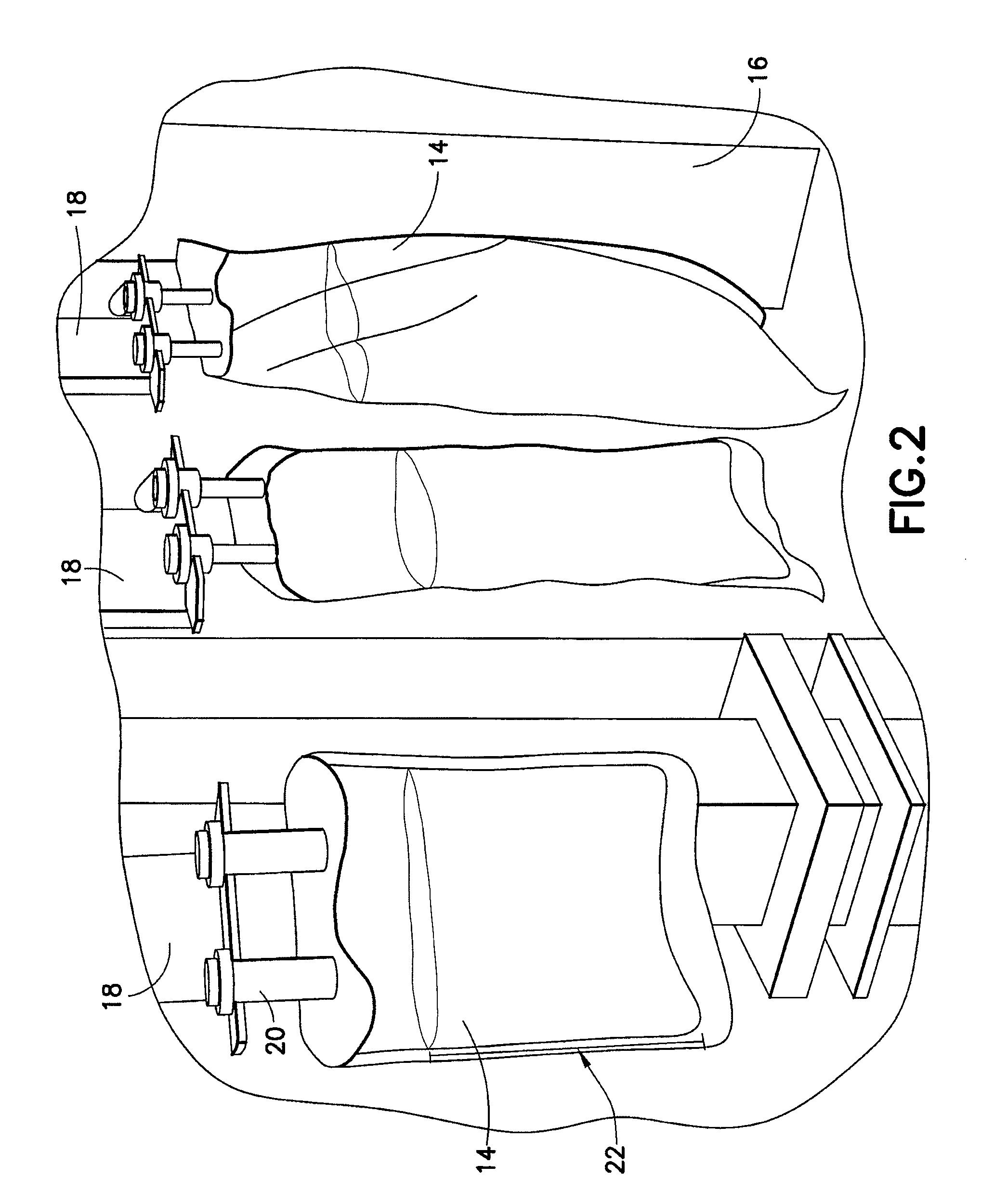

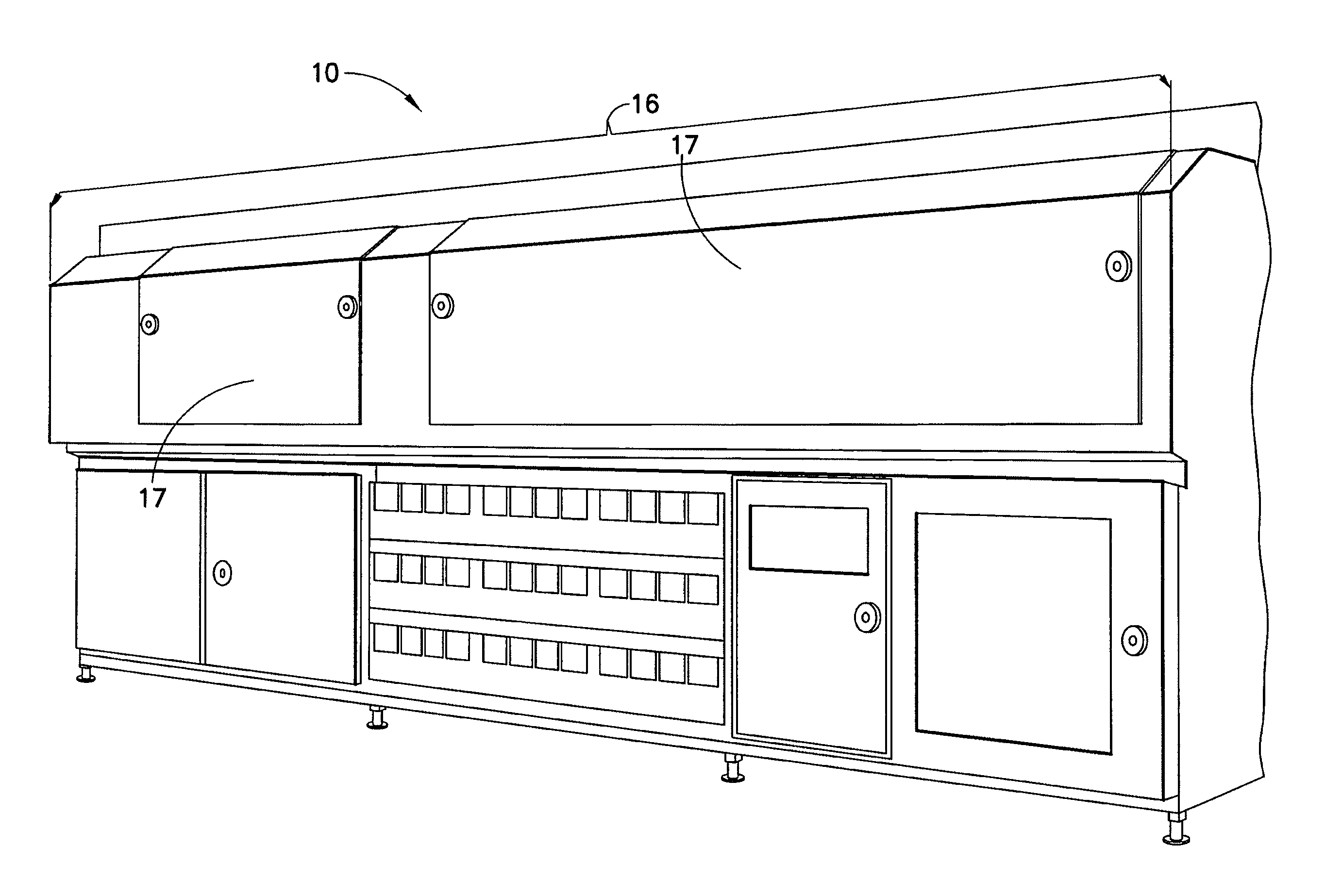

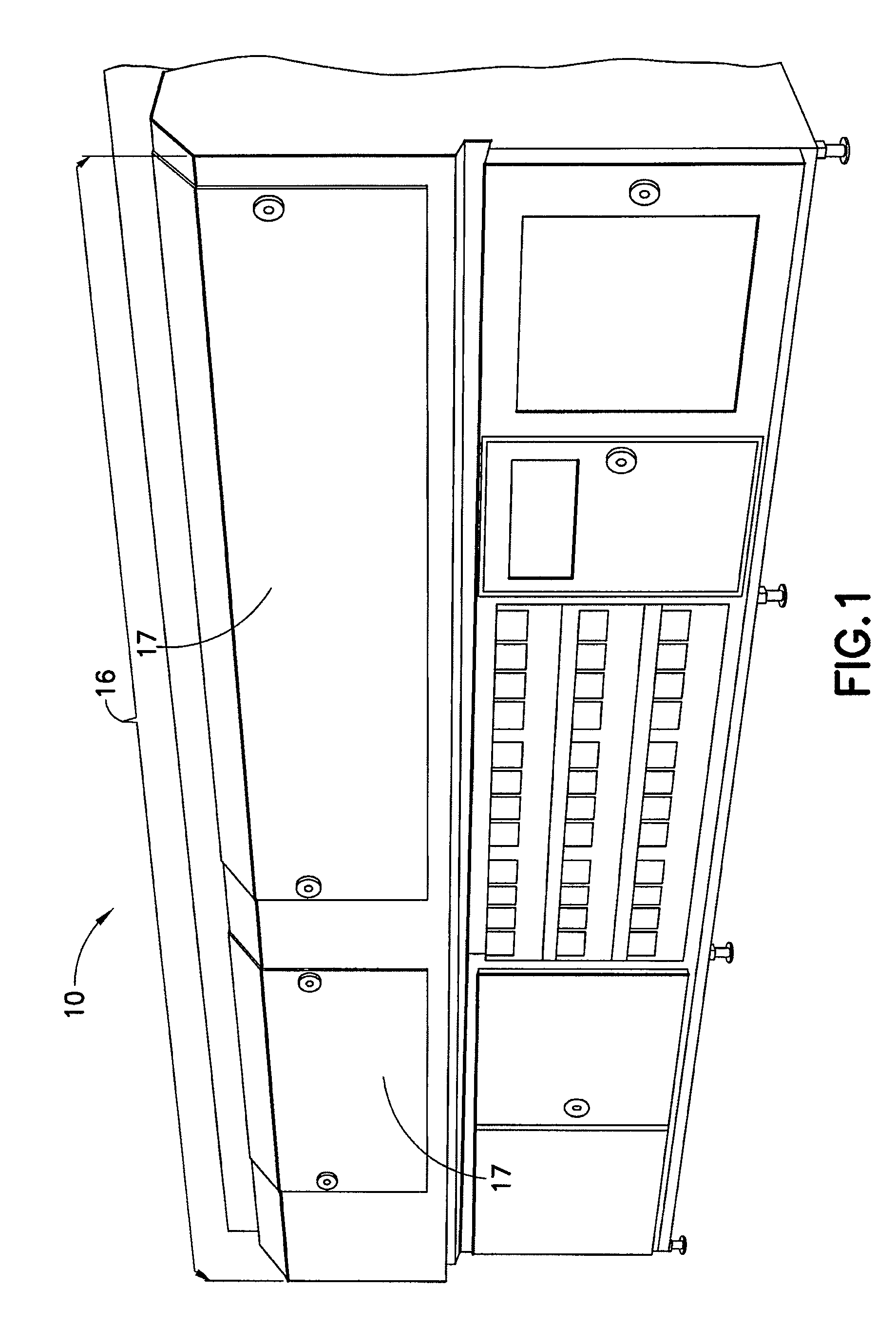

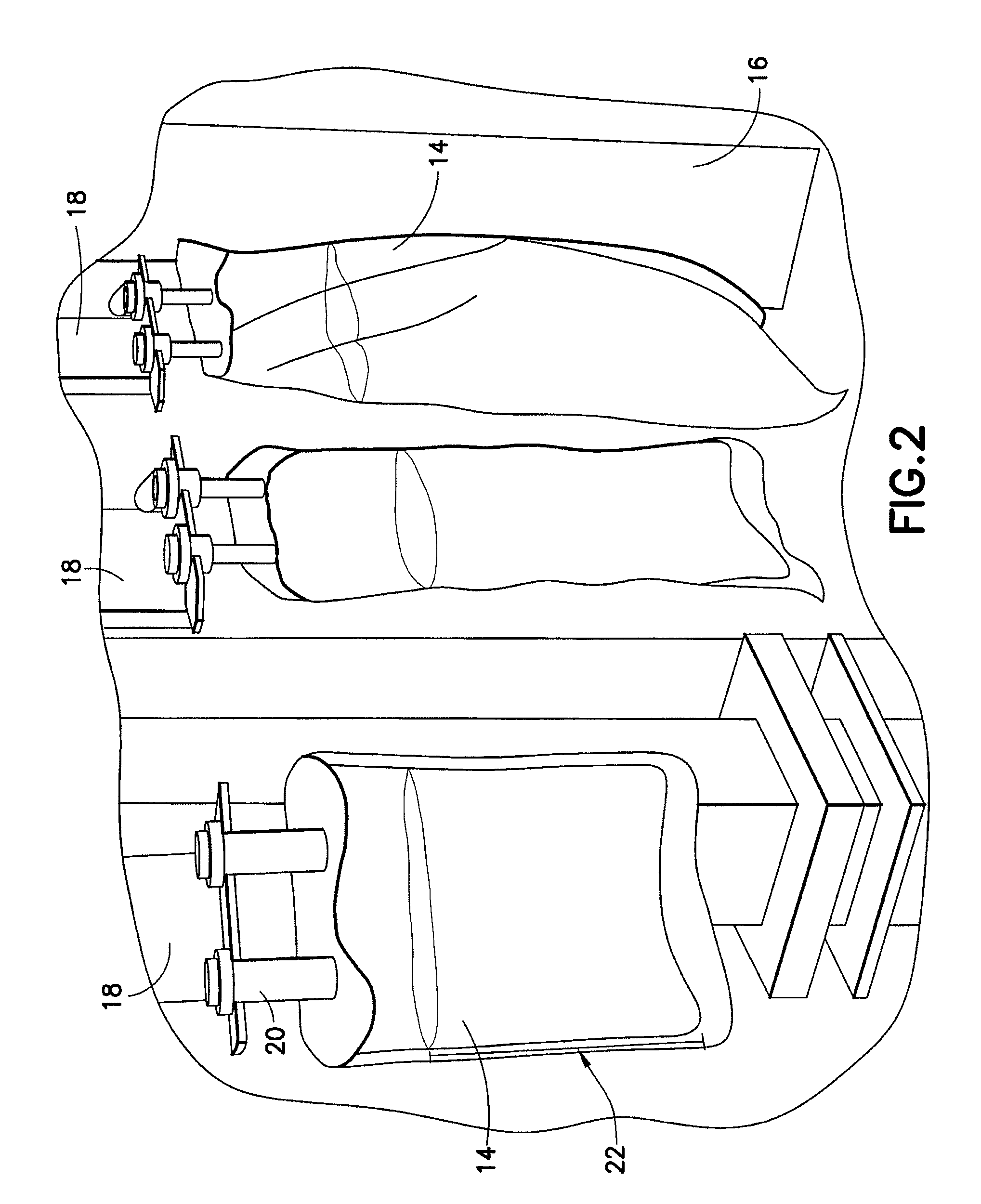

Methods, Systems and Apparatus For Monochromatic UV Light Sterilization

ActiveUS20100007492A1Minimize and eliminate shadowing effectShorten holding timeDough treatmentPackage sterilisationSolid massRegimen

The present disclosure provides for methods, systems and apparatus for monochromatic UV light sterilization of container systems and / or container-packaged products. More particularly, the present disclosure provides for improved methods, systems and apparatus for monochromatic UV light sterilization of liquid and / or solid products / solutions and / or packaging / container systems for liquid and / or solid products / solutions (e.g., parenteral pharmaceutical products / solutions and / or packaging / container systems for parenteral pharmaceutical products / solutions). In exemplary embodiments, the present disclosure provides for improved systems and methods for the sterilization of container systems and / or container-packaged products using monochromatic, continuous wave, high-intensity, incoherent light in multiple light source configurations, wherein such sterilization regimen achieves a desired sterilization level without negatively affecting the physical properties of the package / container systems and / or the efficacy of the underlying products / systems.

Owner:TRITON THALASSIC TECH

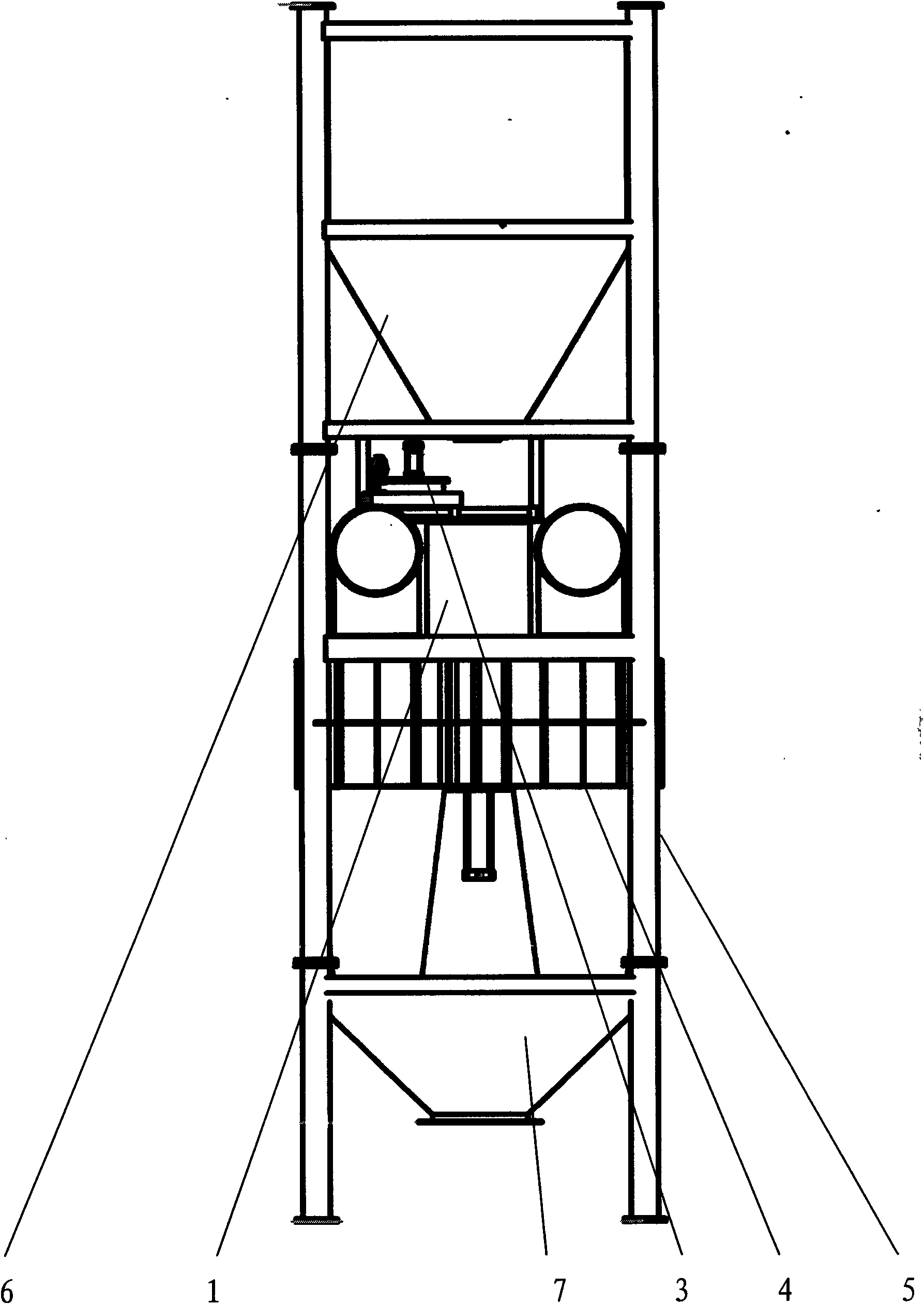

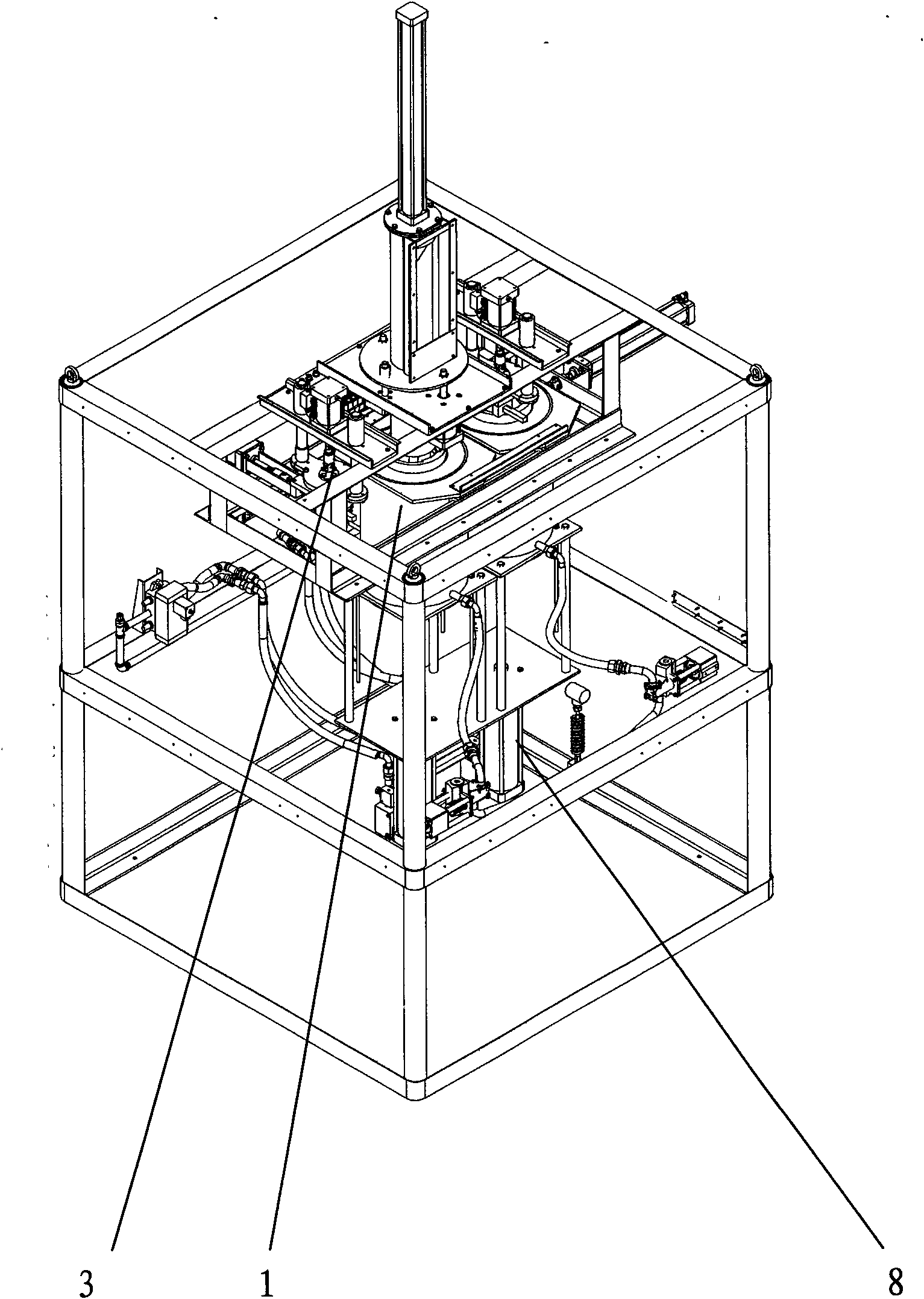

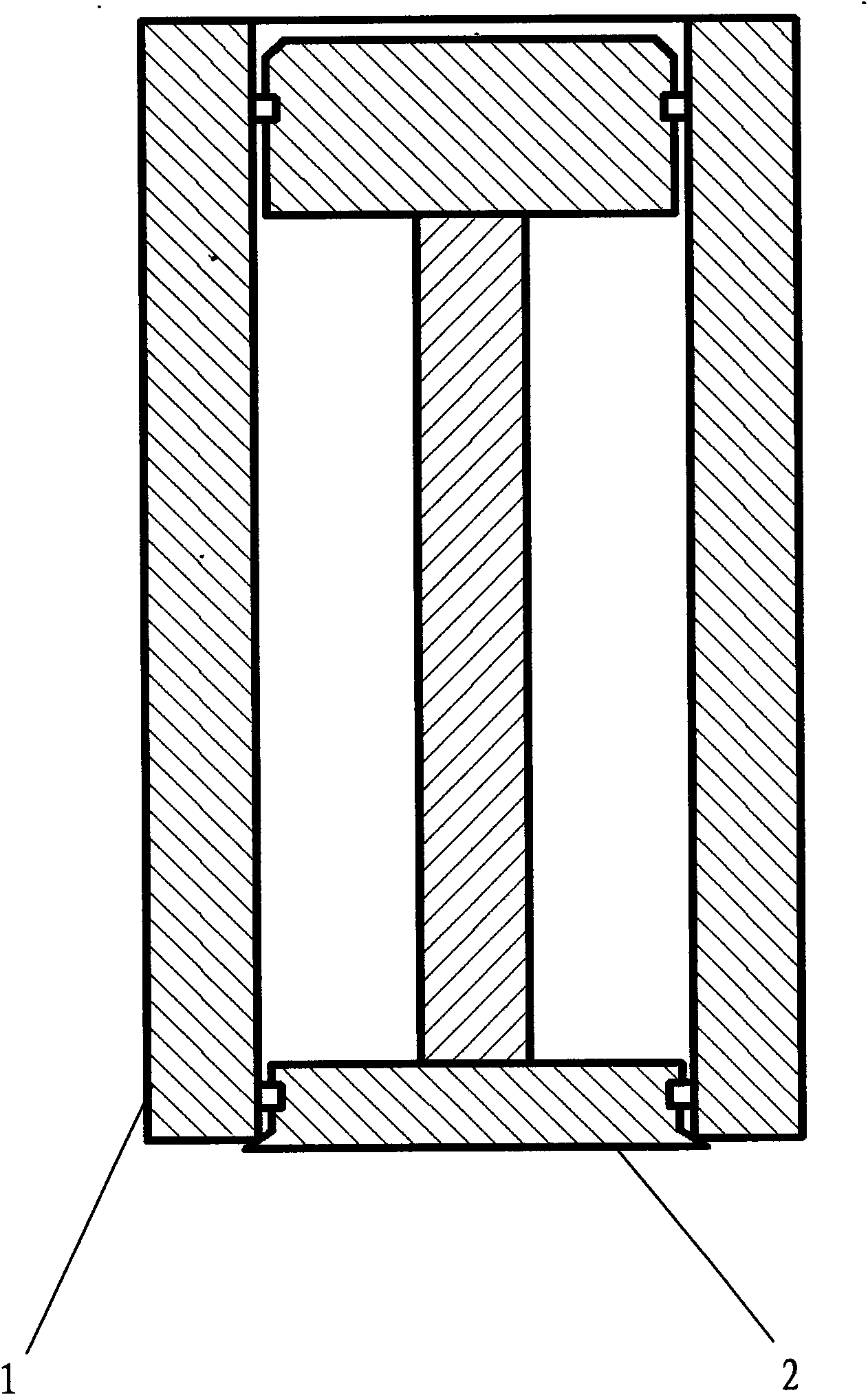

Numerically controlled continuous steam explosion machine

InactiveCN102600763AAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processFixed ratioEngineering

The invention relates to a production device for steam explosion pretreatment of biomass, in particular to a pretreatment device for the industry of biomass utilization, and provides a numerically controlled continuous steam explosion machine, which can complete supersonic steam explosion in milliseconds (0.00875s) based on the principle of a sliding cover. Since the cross-sectional area of the steam explosion machine for gas discharging, i.e. the cross-sectional area of the sliding cover, is equal to the cross-sectional area of a high-pressure cylinder, the cross-sectional area of the steam explosion machine for gas discharging and the steam explosion treatment volume form a fixed ratio, the problem that the gas discharging time is prolonged along with increase in the treatment volume in the traditional hot blowing process can be solved, and the power and density of steam explosion can be increased by three orders of magnitude. Moreover, the 'rawness and maturity' of materials which are subjected to batch treatment can be kept identical, and a foundation is laid for the consistency of industrial biochemical treatment. Meanwhile, the machine has the function of feeding and discharging materials automatically and the continuous steam explosion production can be realized.

Owner:于政道

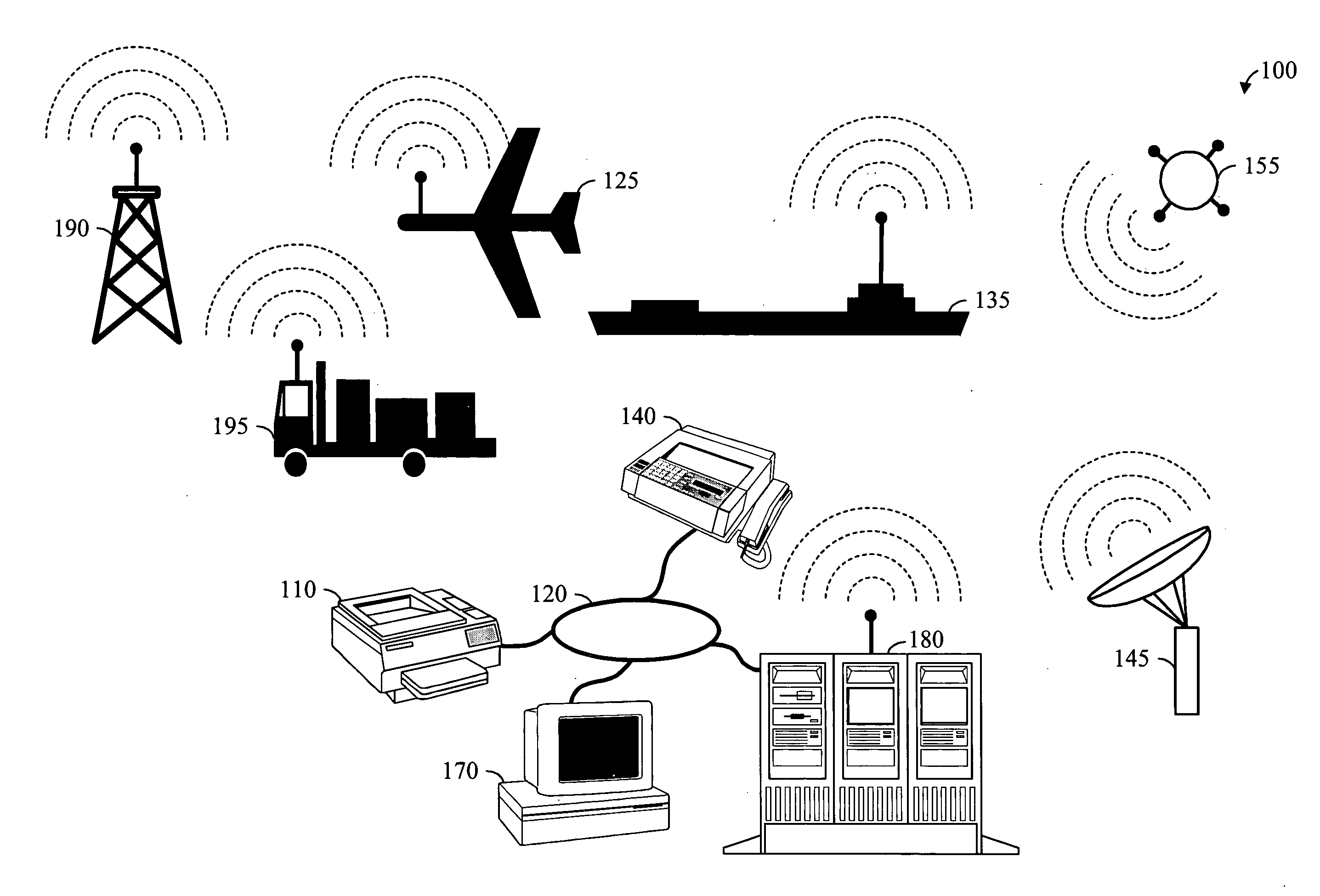

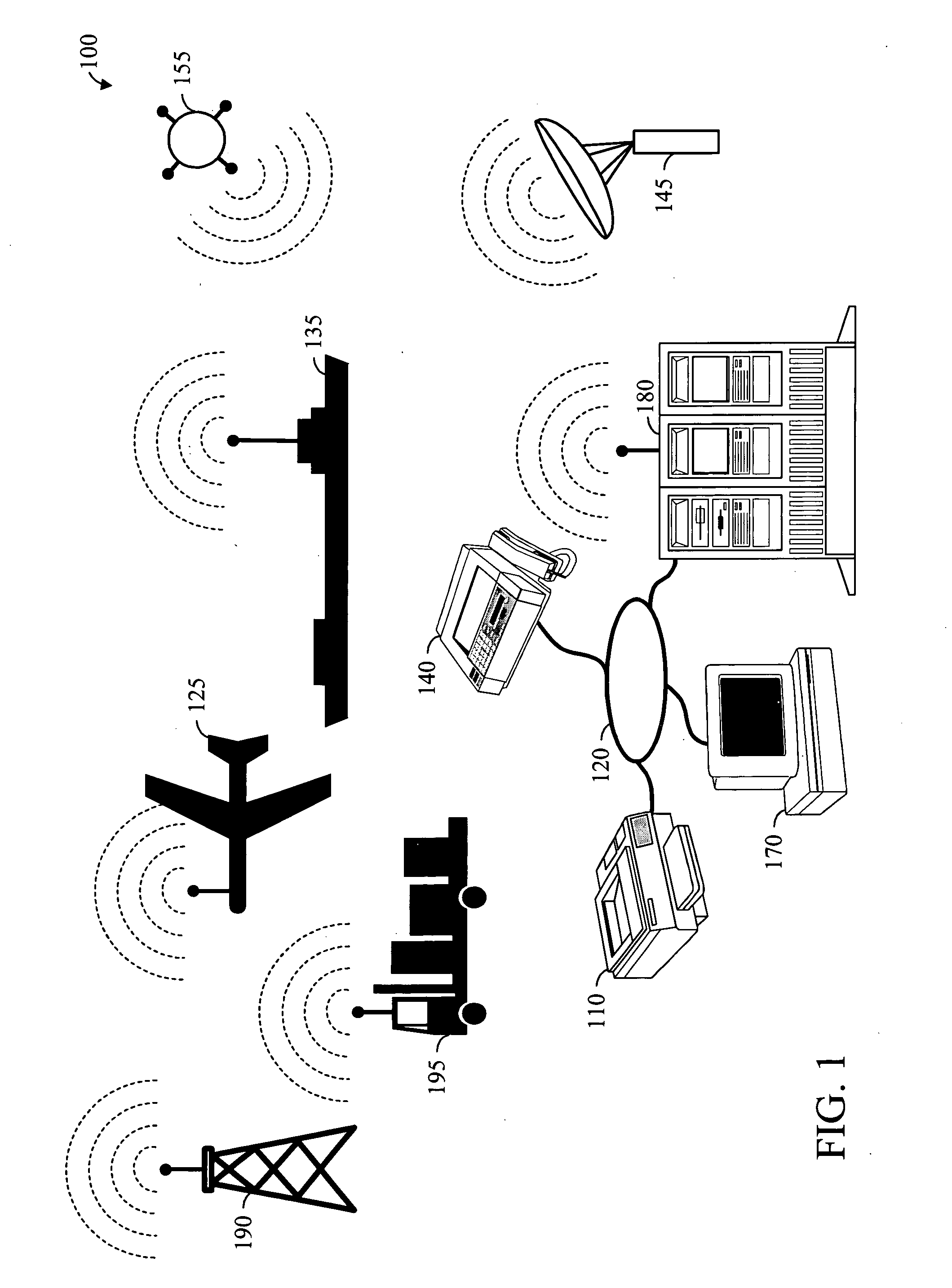

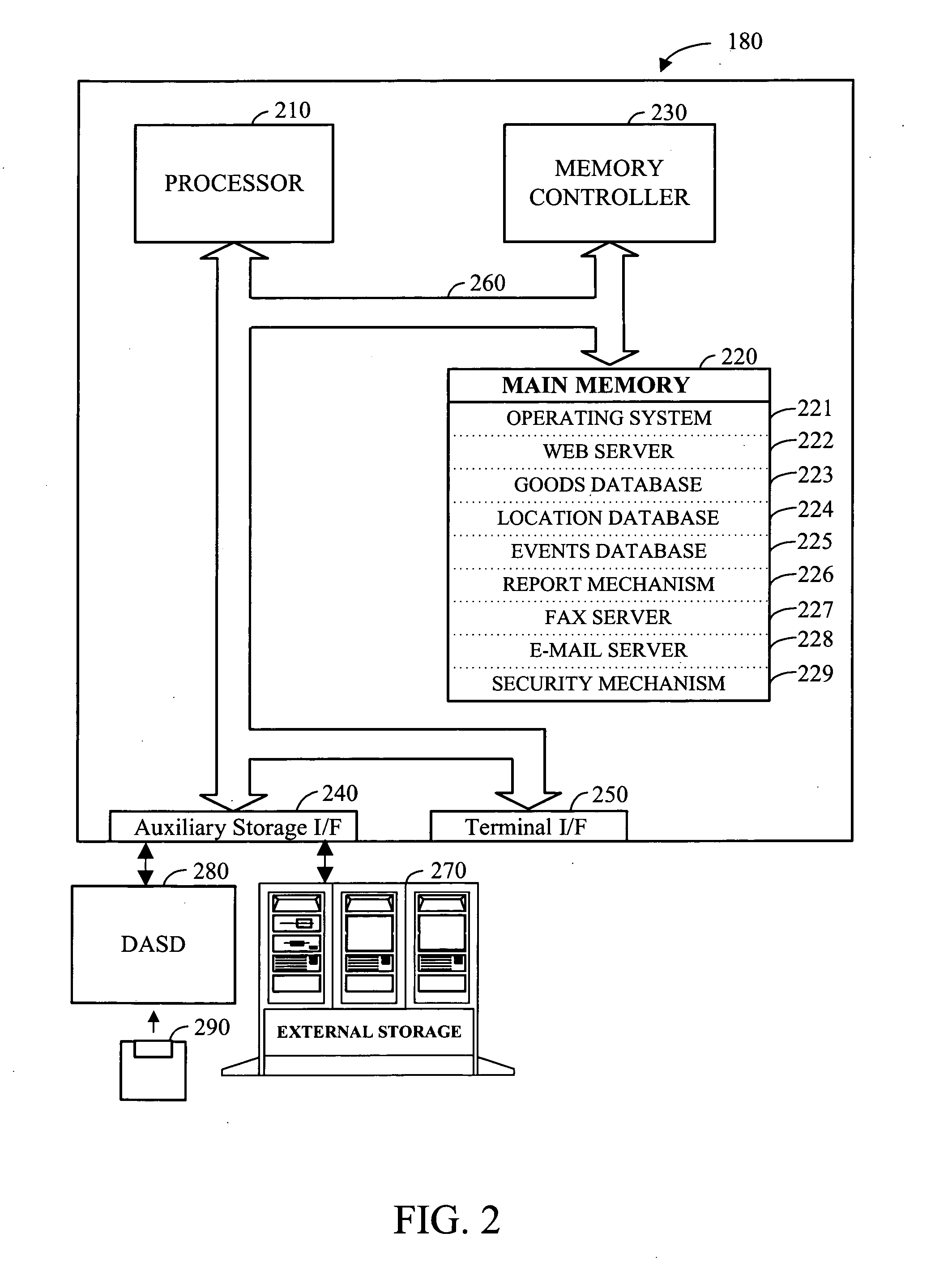

Apparatus and method for monitoring in-transit shipments

InactiveUS20070056369A1Less in-transit damageShorten holding timeAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTransceiverEngineering

By employing a one or more sensors or monitors, environmental conditions and exceptions noted during the shipment of the goods and products can be monitored, stored, and eventually reported. The information about the in-transit goods and products being tracked may also be collected and transmitted by one or more wireless communication devices such as radios, transceivers, and Global Positioning System (GPS) satellites in conjunction with RF communication and / or RFID technology. Once collected, the environmental condition data may be used to assign liability for any damage that occurred to the in-transit goods and products.

Owner:RFID MICRO

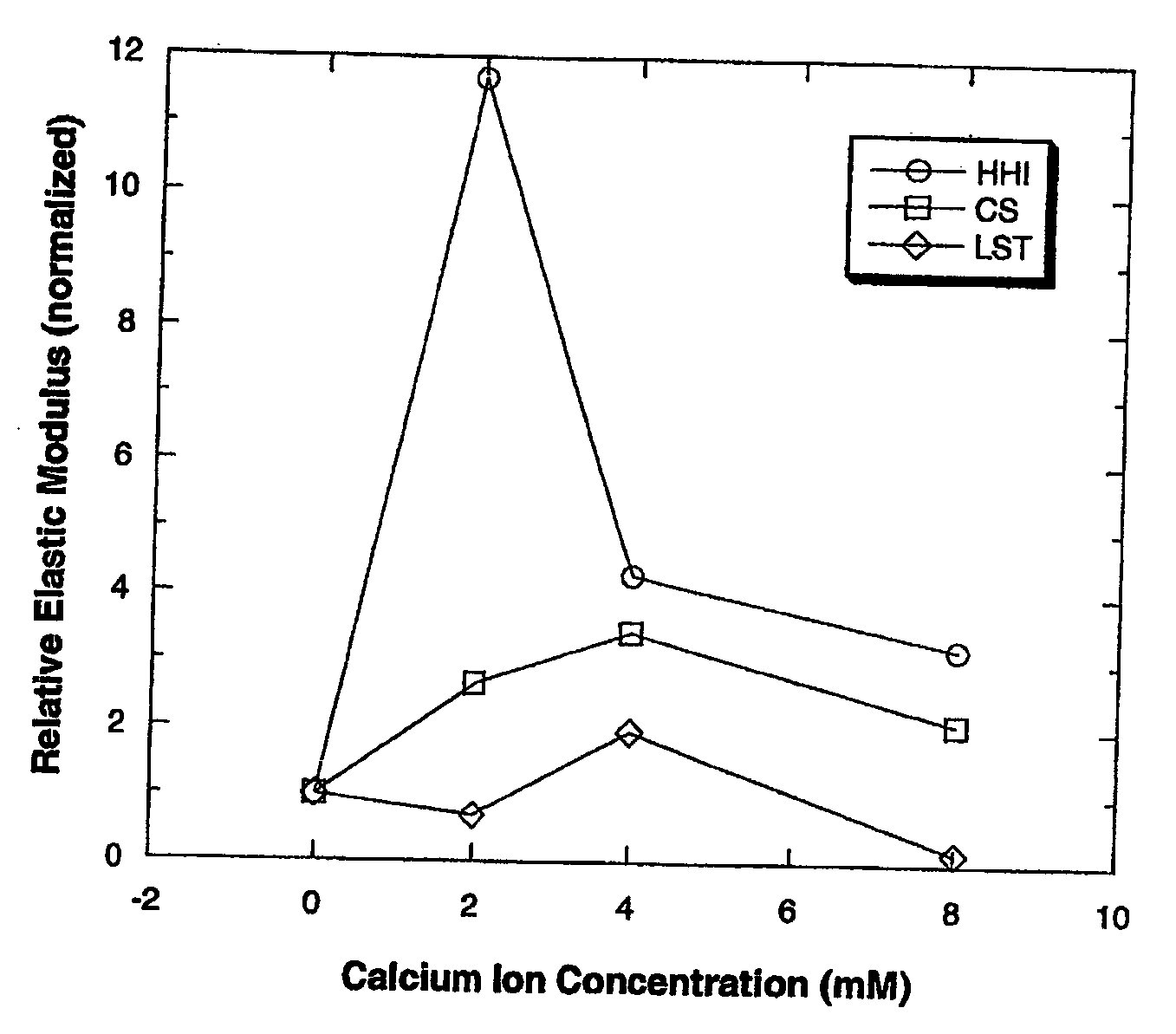

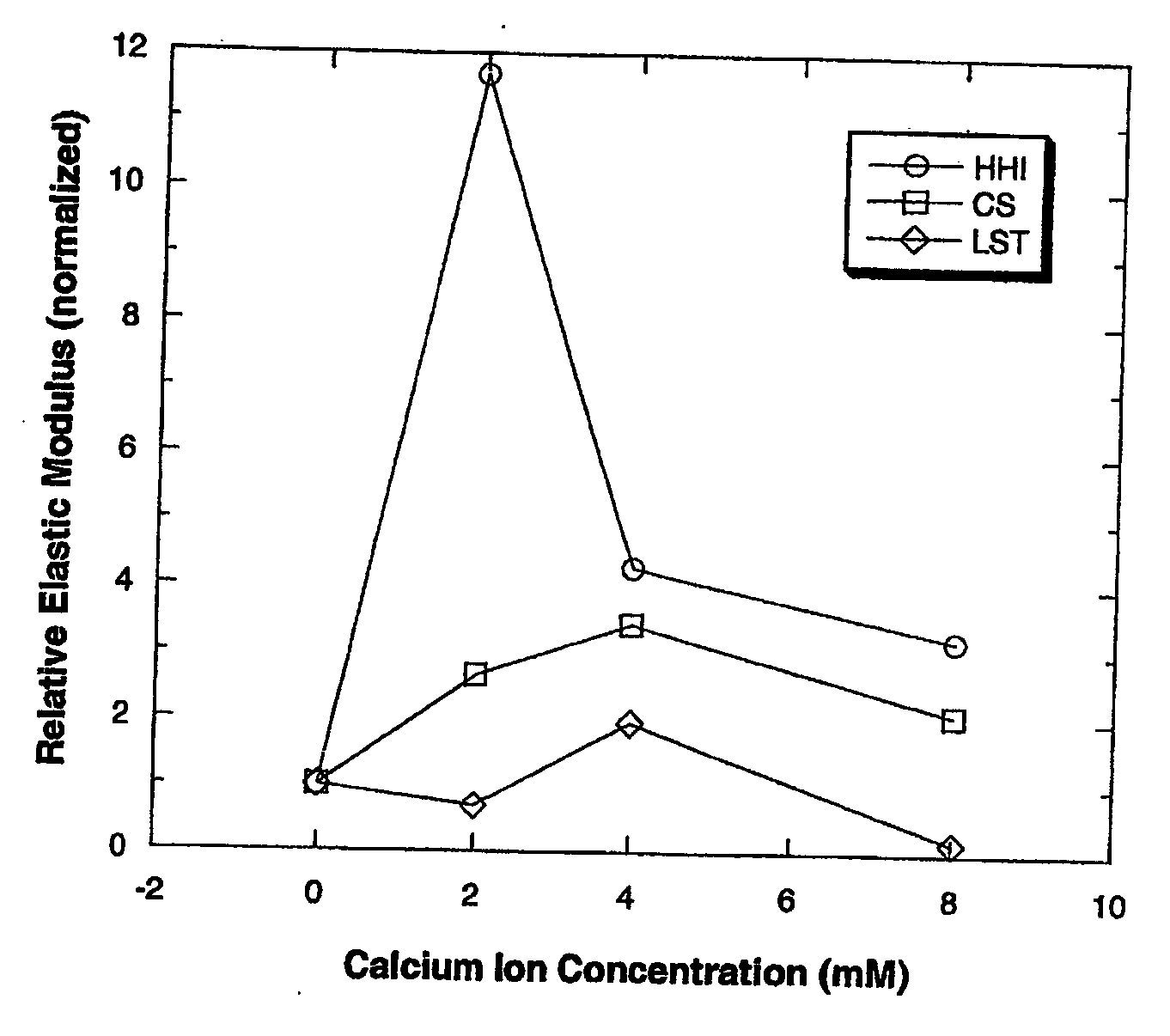

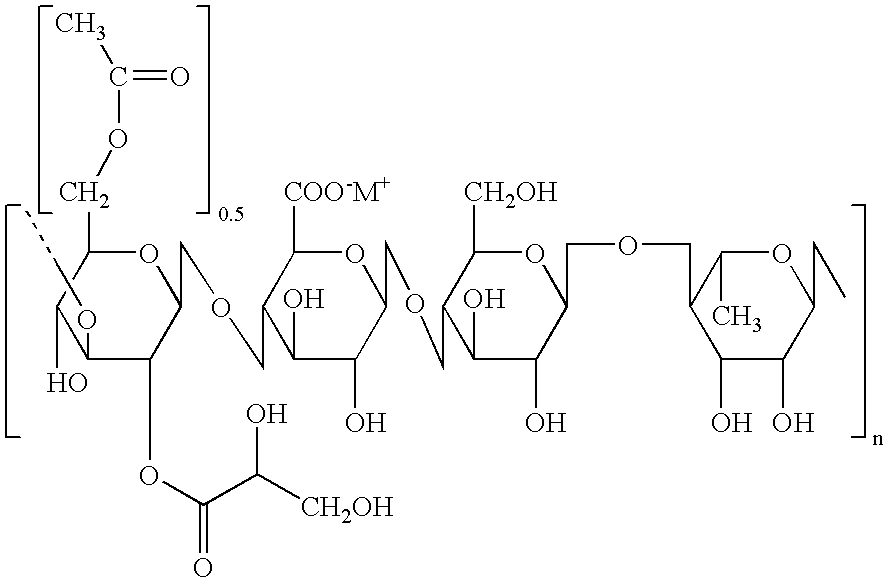

Calcium stable high acyl gellan gum for enhanced colloidal stability in beverages

ActiveUS20050266138A1Improve colloidal stabilityGood particle suspensionSugar derivativesOther chemical processesGellan gumSphingomonas elodea

A low calcium sensitive (calcium stable) high acyl gellan gum is prepared for enhanced colloidal stability in beverages. The low calcium sensitive high acyl gellan gum has superior suspension performance for colloidal stability compared to other high acyl gellan gums. The low calcium sensitive high acyl gellan gum is prepared by adjusting the pH of a gellan fermentation broth (polymer solution) prior to pasteurization and reducing the pasteurization hold time compared to conventional pH levels and hold times.

Owner:CP KELCO U S INC

Prepared high hardness pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089290AReduce dosageReduce manufacturing costDigestersPulping with acid salts/anhydridesKappa numberHardness

The present invention discloses a method for preparing high-hardness pulp by using graminoid plant as raw material and its cooking process. The hardness of said high-hardness pulp is equal to Kappa number 24-50. The described cooking method includes the following steps: preparing graminoid plant raw material, soaking said raw material, feeding said raw material into a cooker, adding cooking liquor into said cooker, introducing steam to make heating operation to attain the requird pressure, then heat-insulating to the required time.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Grain-refined extruded aluminum alloy tubular product with large wall thickness and preparation method thereof

The invention discloses a grain-refined extruded aluminum alloy tubular product with large wall thickness and a preparation method thereof. The tubular product comprises the following metallic substances in percentage by weight: 1.0-1.15% of Mg, 0.60-0.75% of Si, 0.20-0.35% of Cu, 0.35% of Fe, 0.10% of Mn, 0.05-0.08% of Cr, 0.15% of Zn, 0.10% of Ti and the balance of aluminum. The invention further discloses a preparation method of the grain-refined extruded aluminum alloy tubular product with large wall thickness. The grain-refined extruded aluminum alloy tubular product with large wall thickness provided by the invention solves the problem that the grains of the base and surface of a 6061 alloy extruded aluminum alloy tubular product with great wall thickness are thick and big, the deficiency of bulky crystal spots generated after anodic oxidation can be eliminated and indexes of the final product, such as inner welding quality and mechanical performance, can satisfy the GB / T6892-2006 standard requirement.

Owner:龙口市丛林铝材有限公司

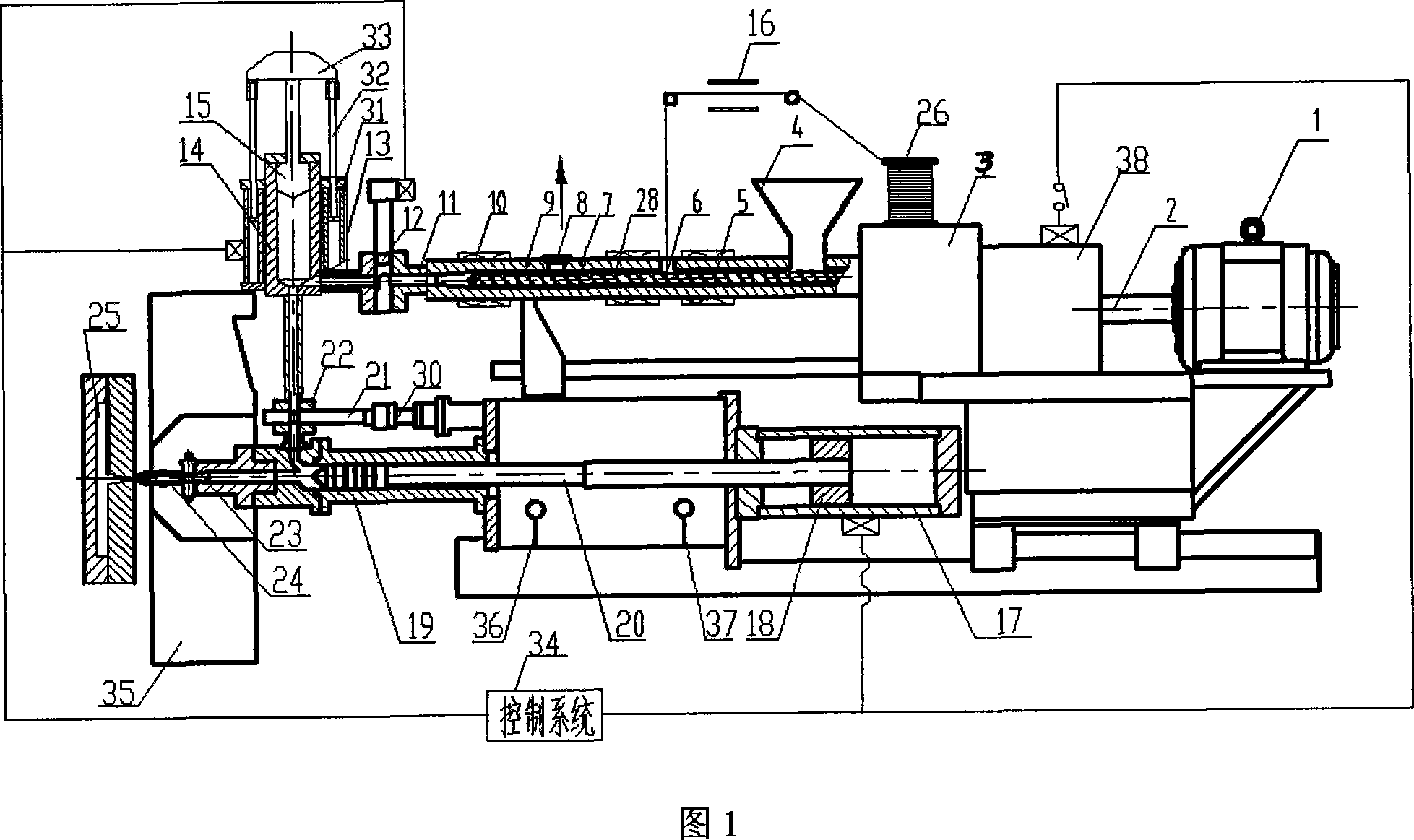

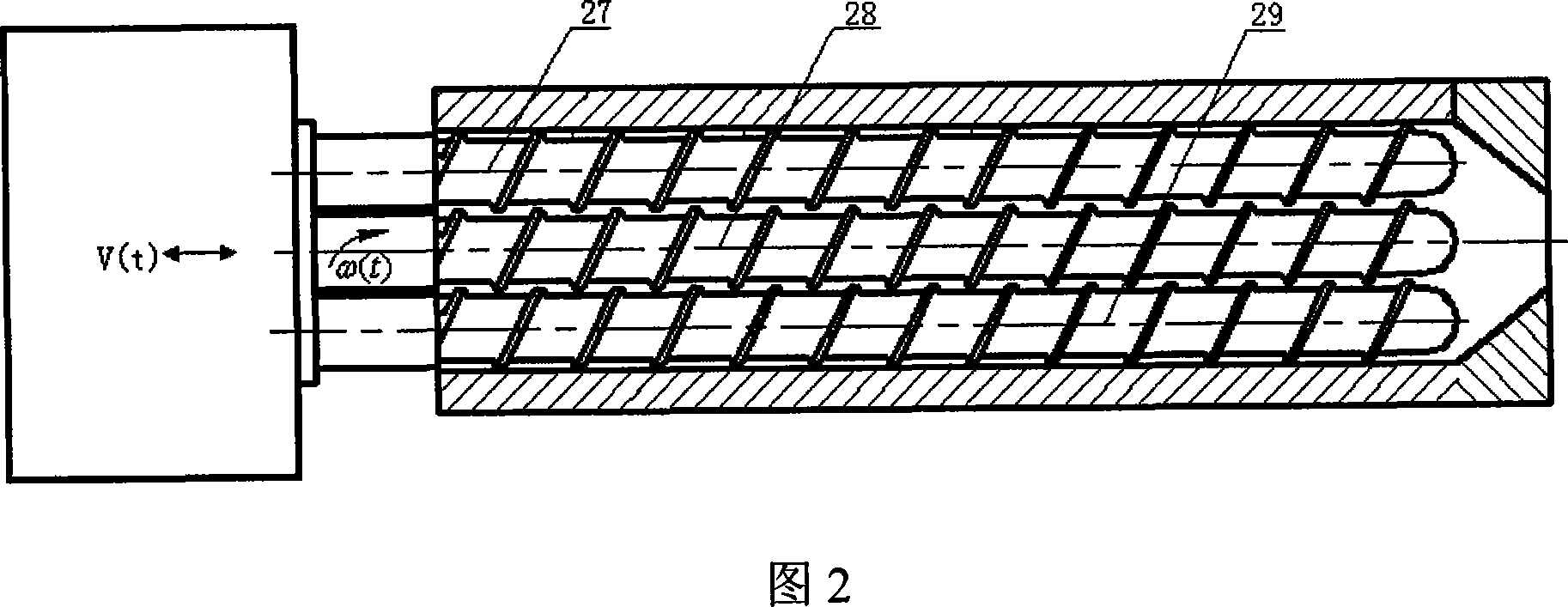

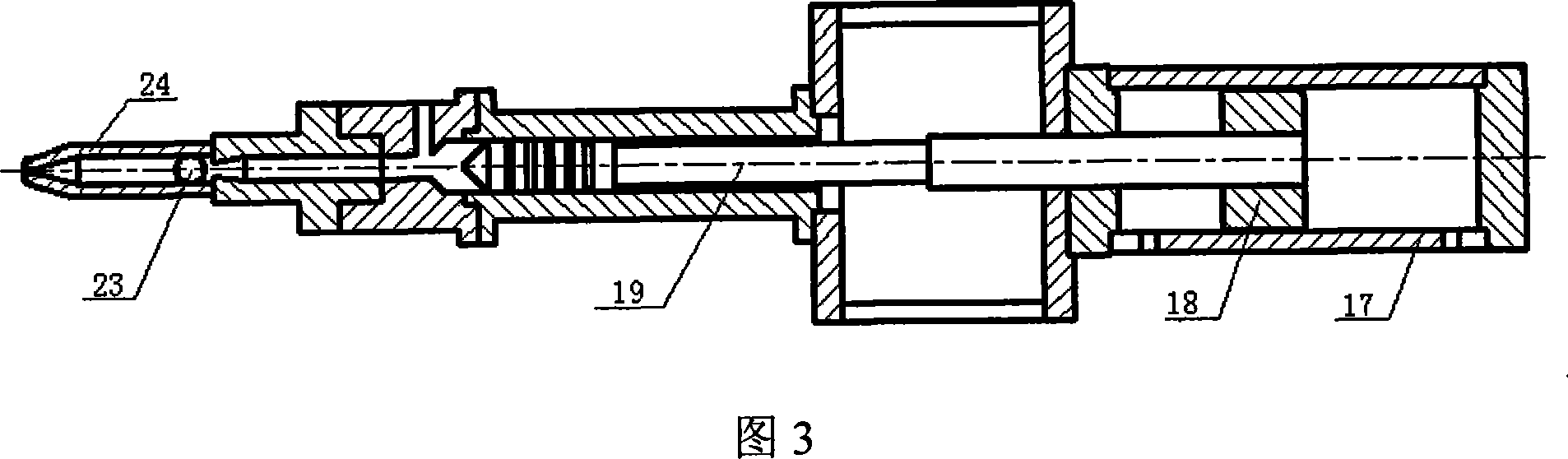

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

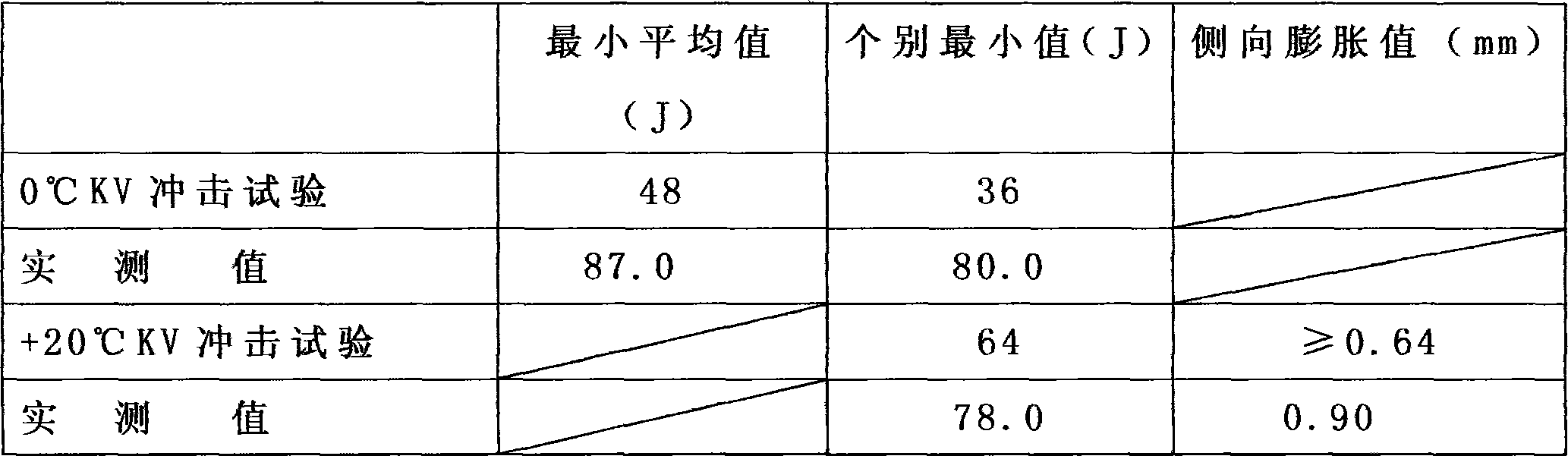

Million - kilowatts class nuclear power station reactor main bolt production process

ActiveCN101169150AUniform tissueFully heatedNuclear energy generationScrewsNuclear engineeringNuclear power

The invention discloses a pile main bolt manufacturing technique of a million kilowatt grade nuclear power station. The manufacturing technique includes material-selecting, melting, heating, forging, cooling, after-forging heat treatment, defect-detecting, and forging capability heat treating. When selecting the material, the microelement content of the materials is controlled, the heat preserving duration in the intermediate temperature stage is prolonged, the heat raising and the heat preserving duration in the high temperature stage are reduced, the distortion volume in the course of the forging is controlled between 30 percent and 70 percent, the forging rate reaches 5 above; after-forging heat treatment, ultrasonic defect detecting, and forging capacity heat treating are conducted when the forging is finished. The main bolt produced according to the manufacturing technique of the invention can improve the impact value under the circumstance that the intensity keeps unchanged, theproduct can meet the RCC-M standard requirements completely, and the reliability and the safety of the pile pressure container using the main bolt of the million kilowatt grade nuclear power station can be ensured.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

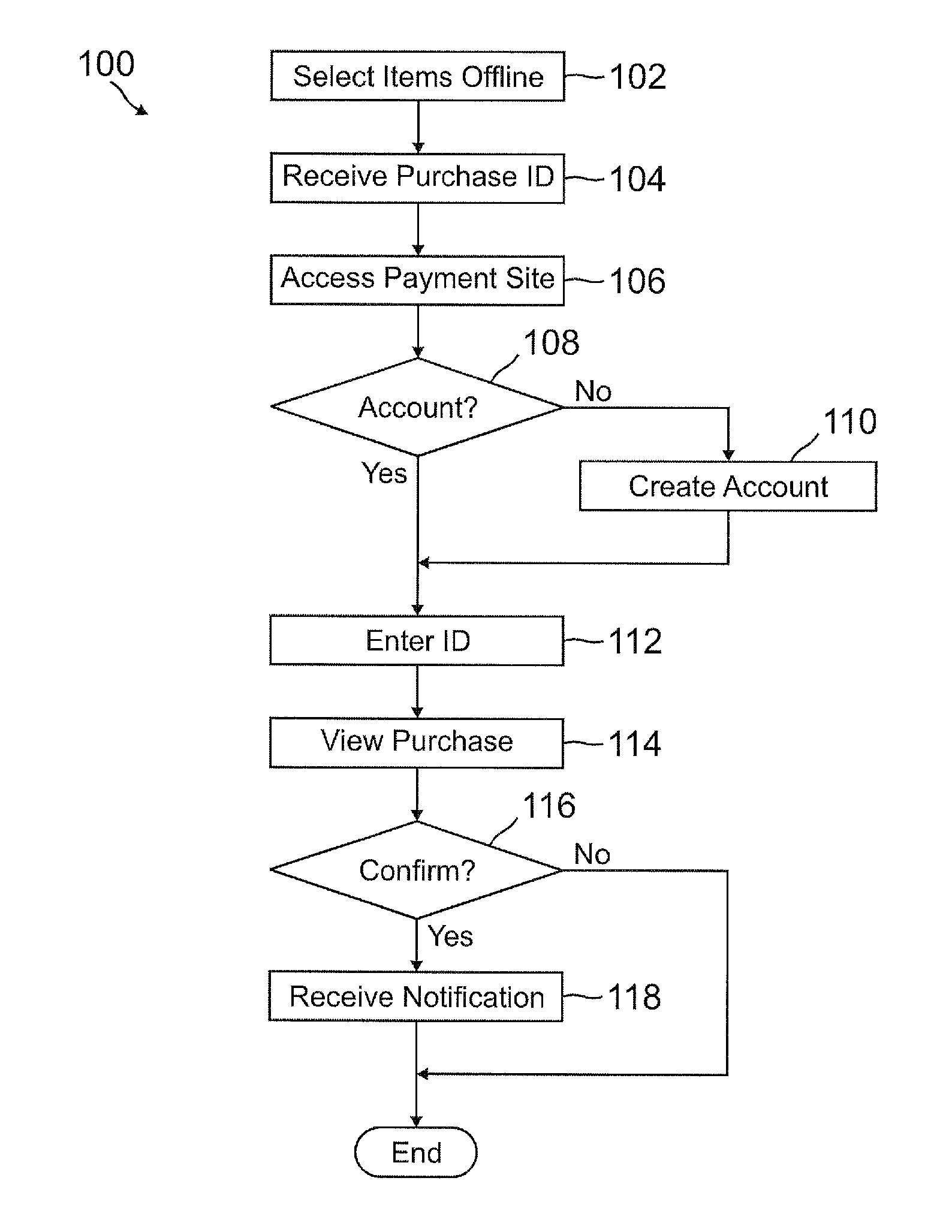

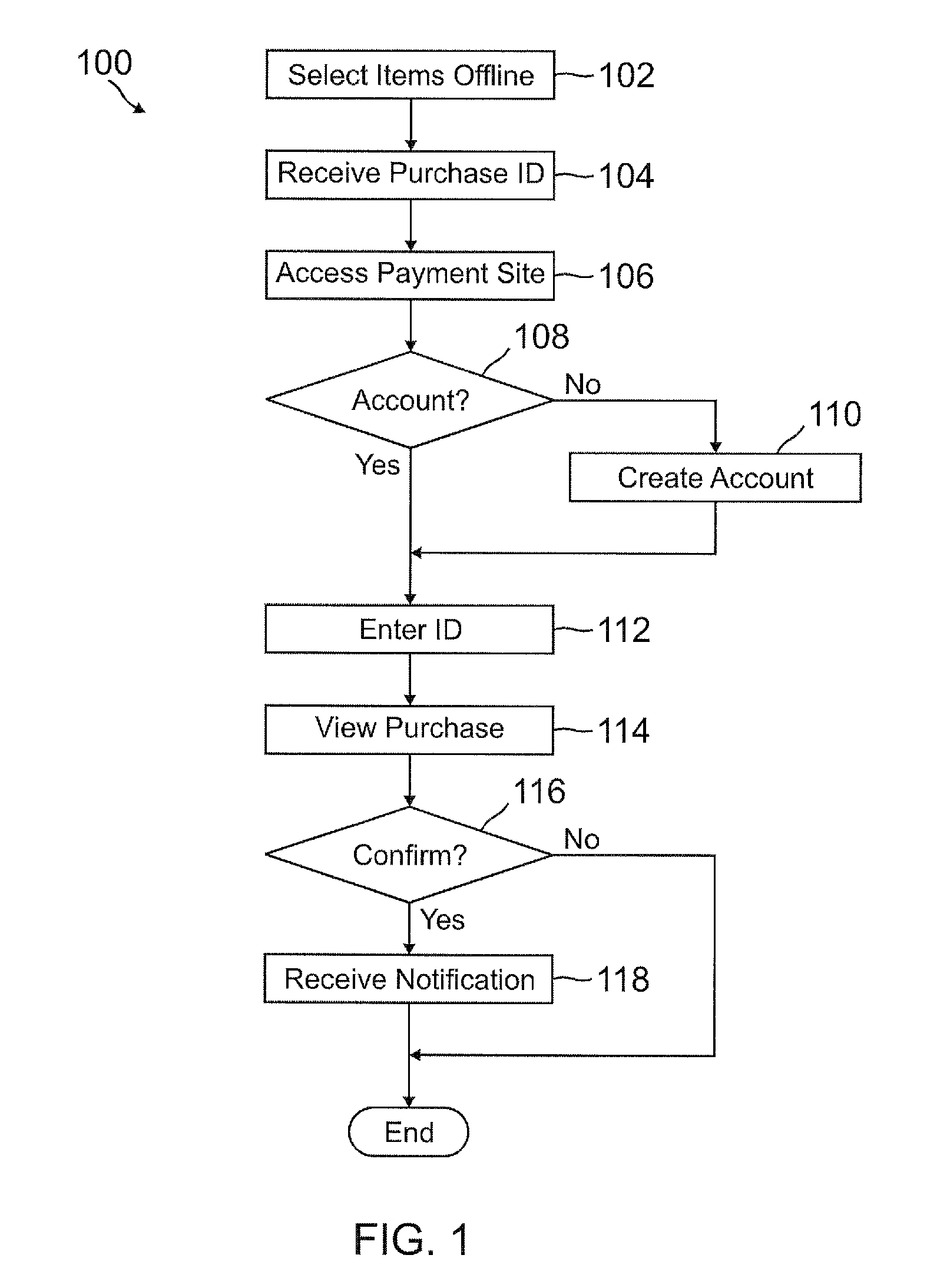

Online payment for offline purchase

InactiveUS20120191610A1Reduce disadvantagesShorten holding timeFinanceCredit schemesPayment service providerLibrary science

A user receives a unique purchase identifier from a merchant during an offline purchase transaction. The merchant holds the purchase. The user makes an online payment at a later time by entering the purchase identifier through a payment provider, who retrieves details of the purchase and processes the payment if the user approves of the payment. The merchant is notified and releases or ships the purchase to the user.

Owner:PAYPAL INC

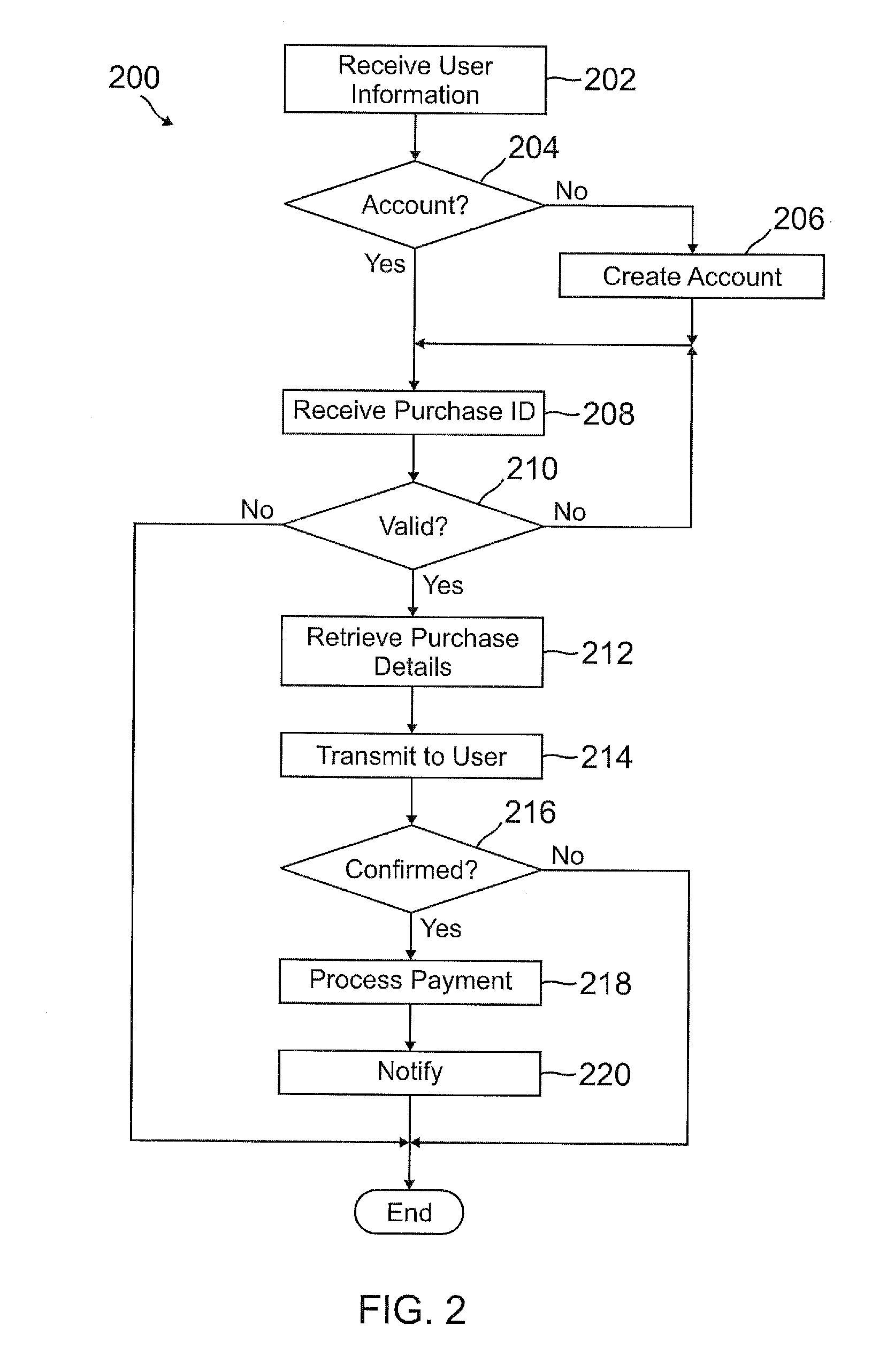

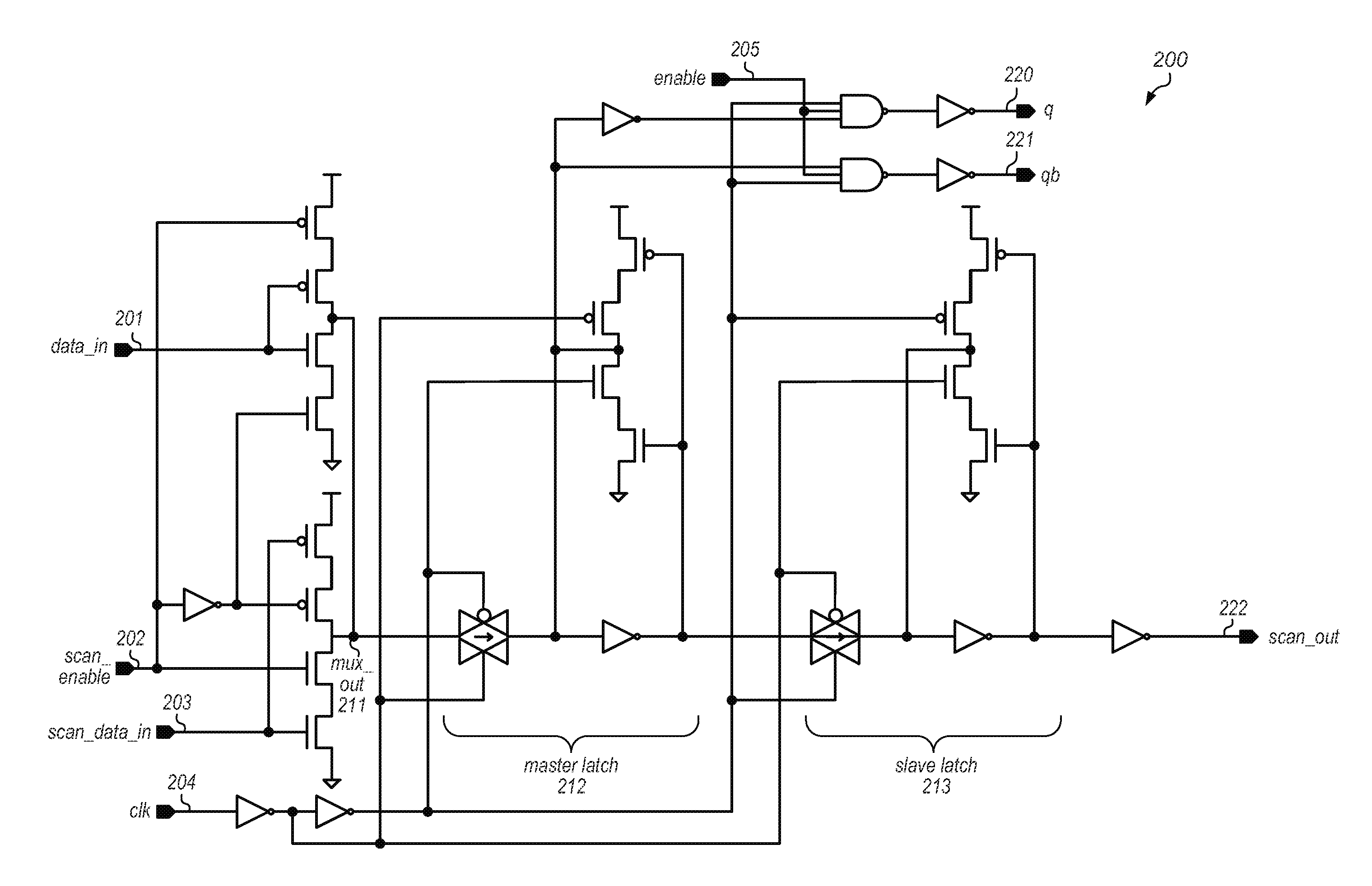

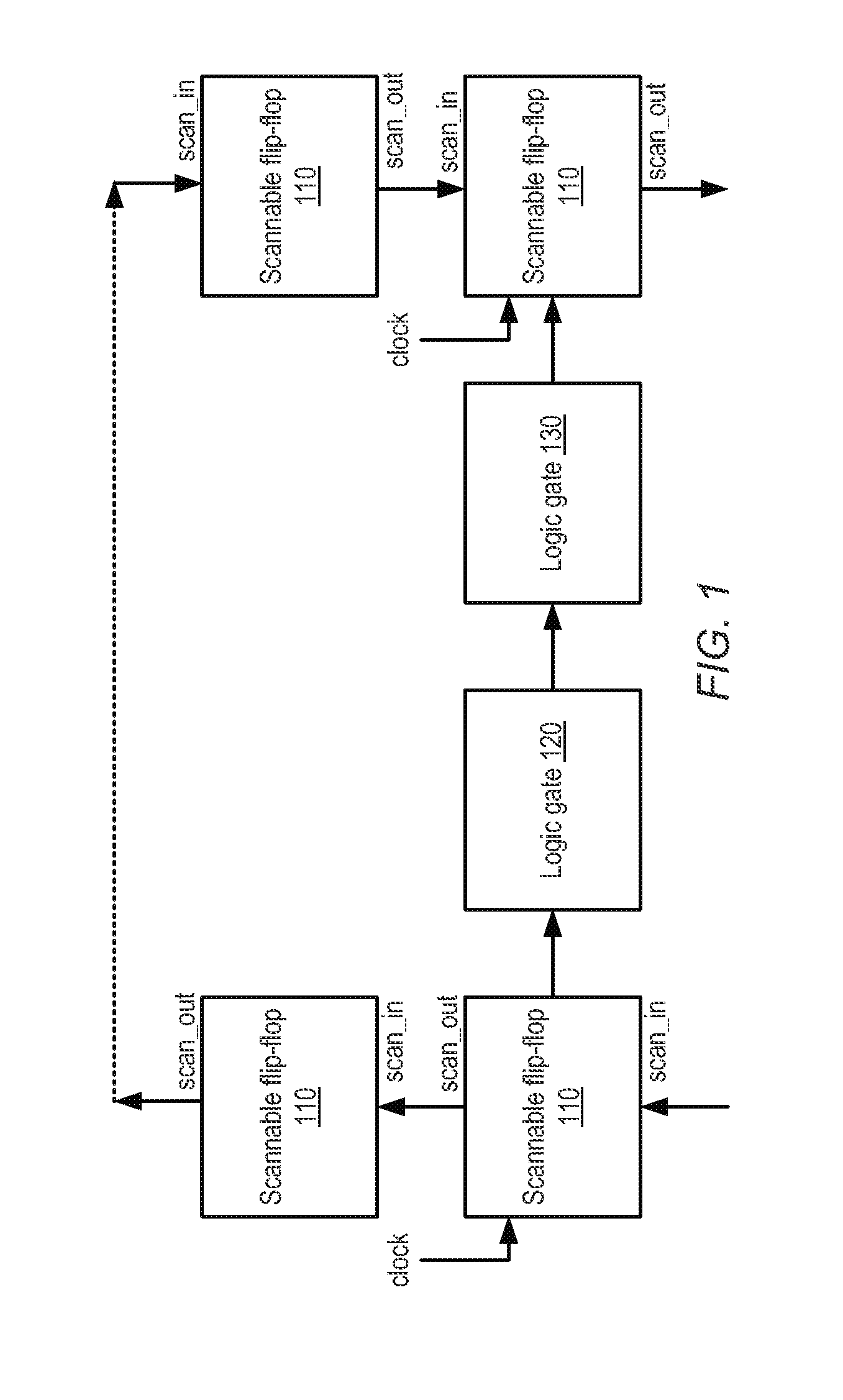

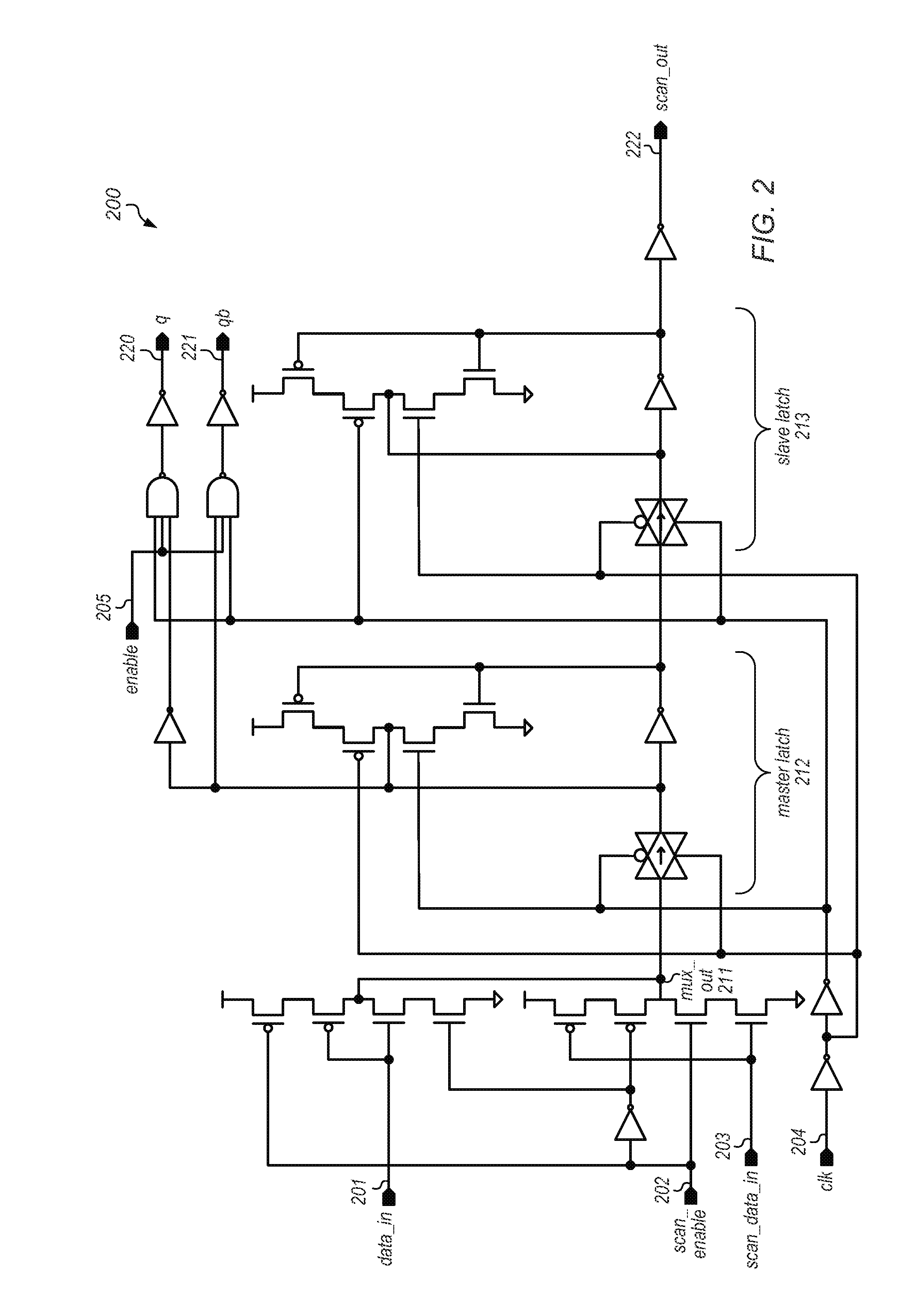

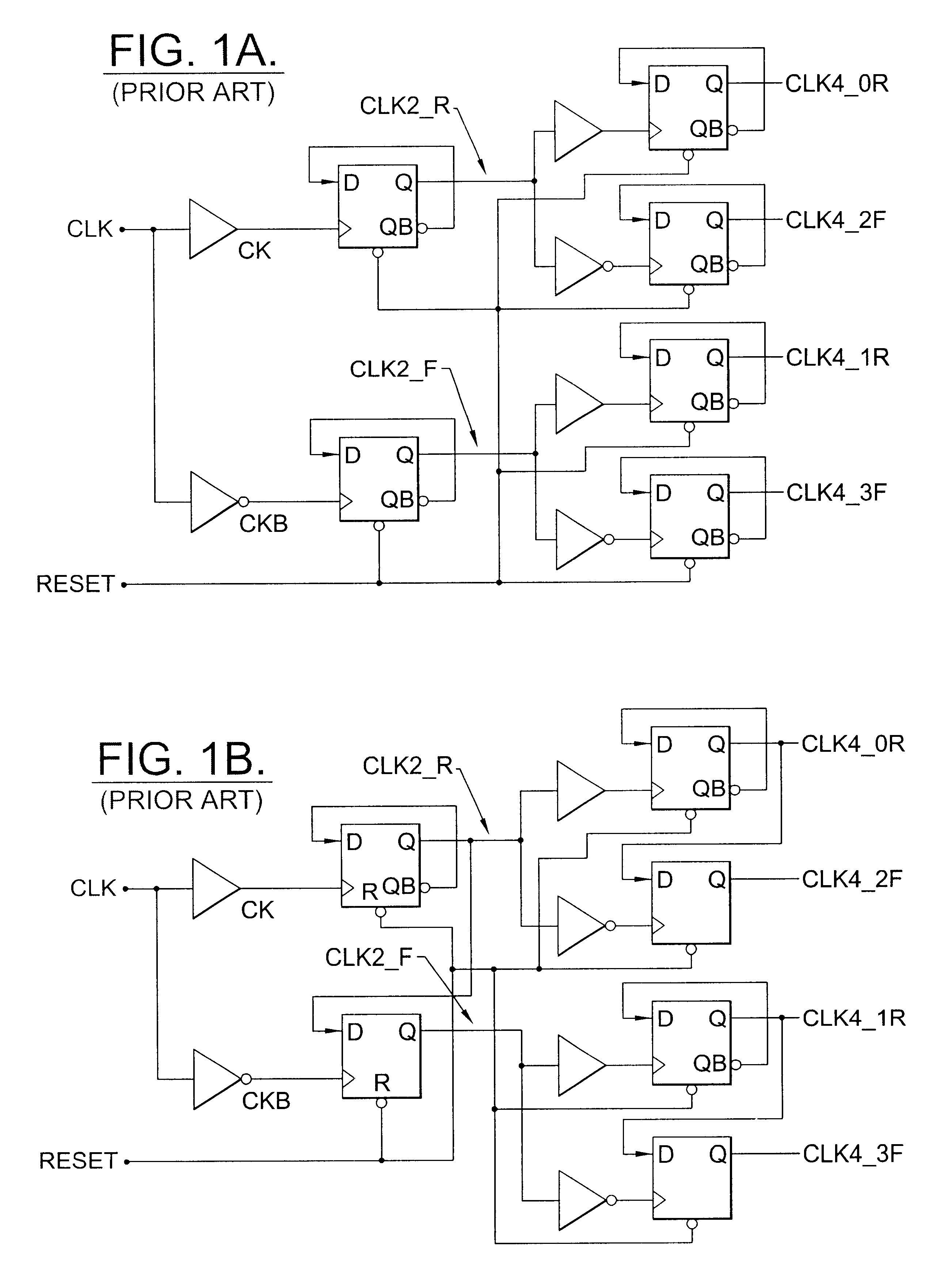

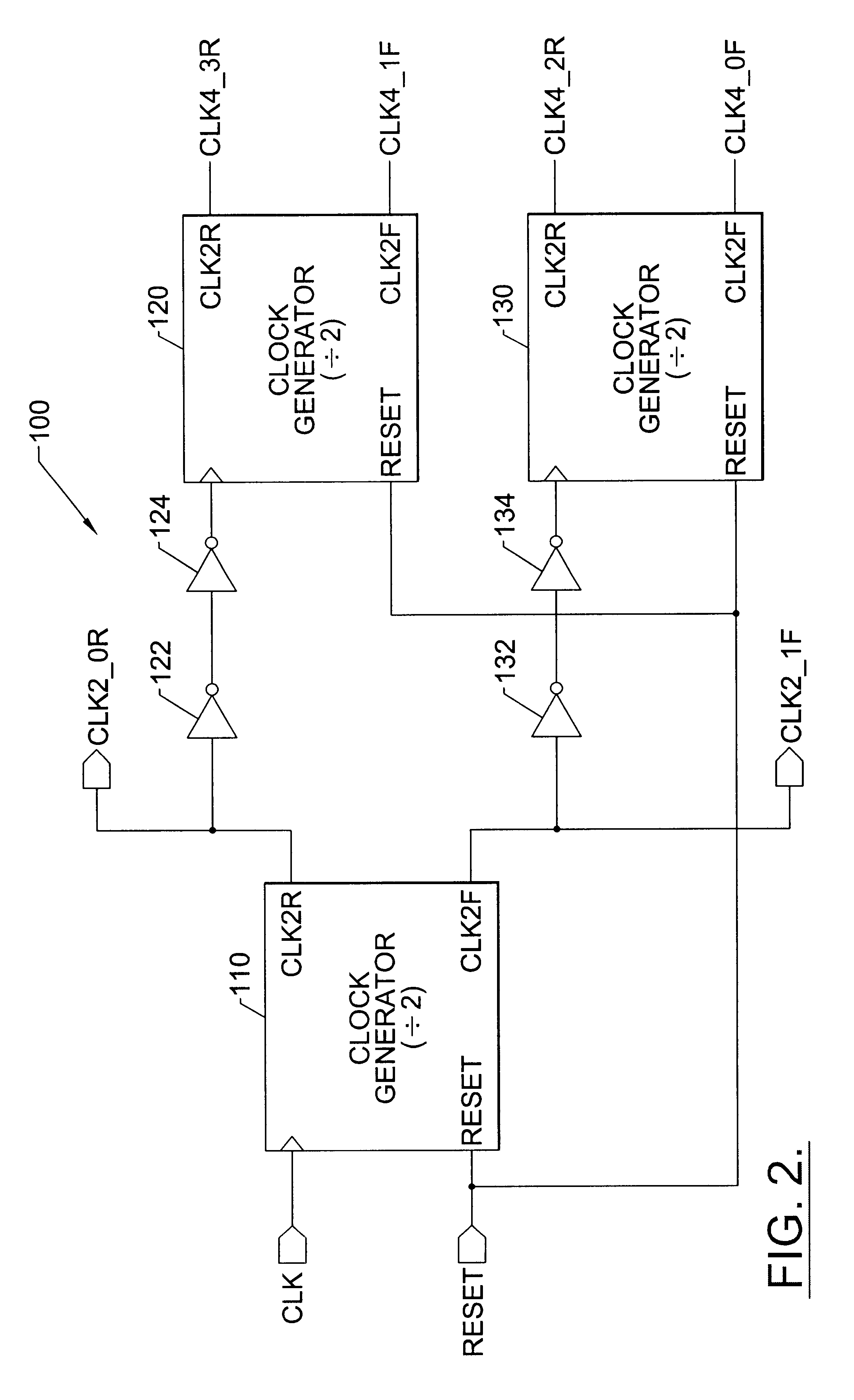

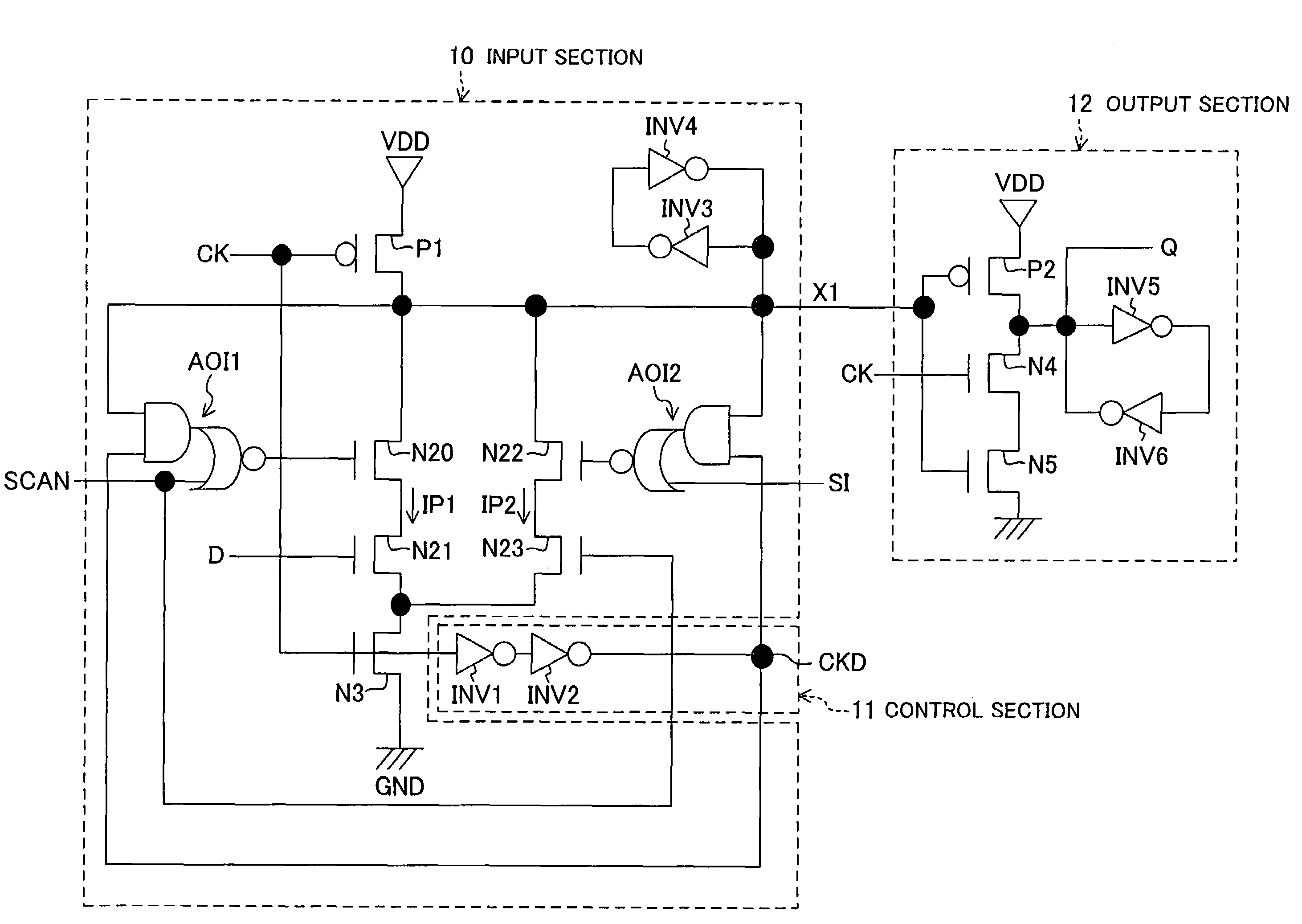

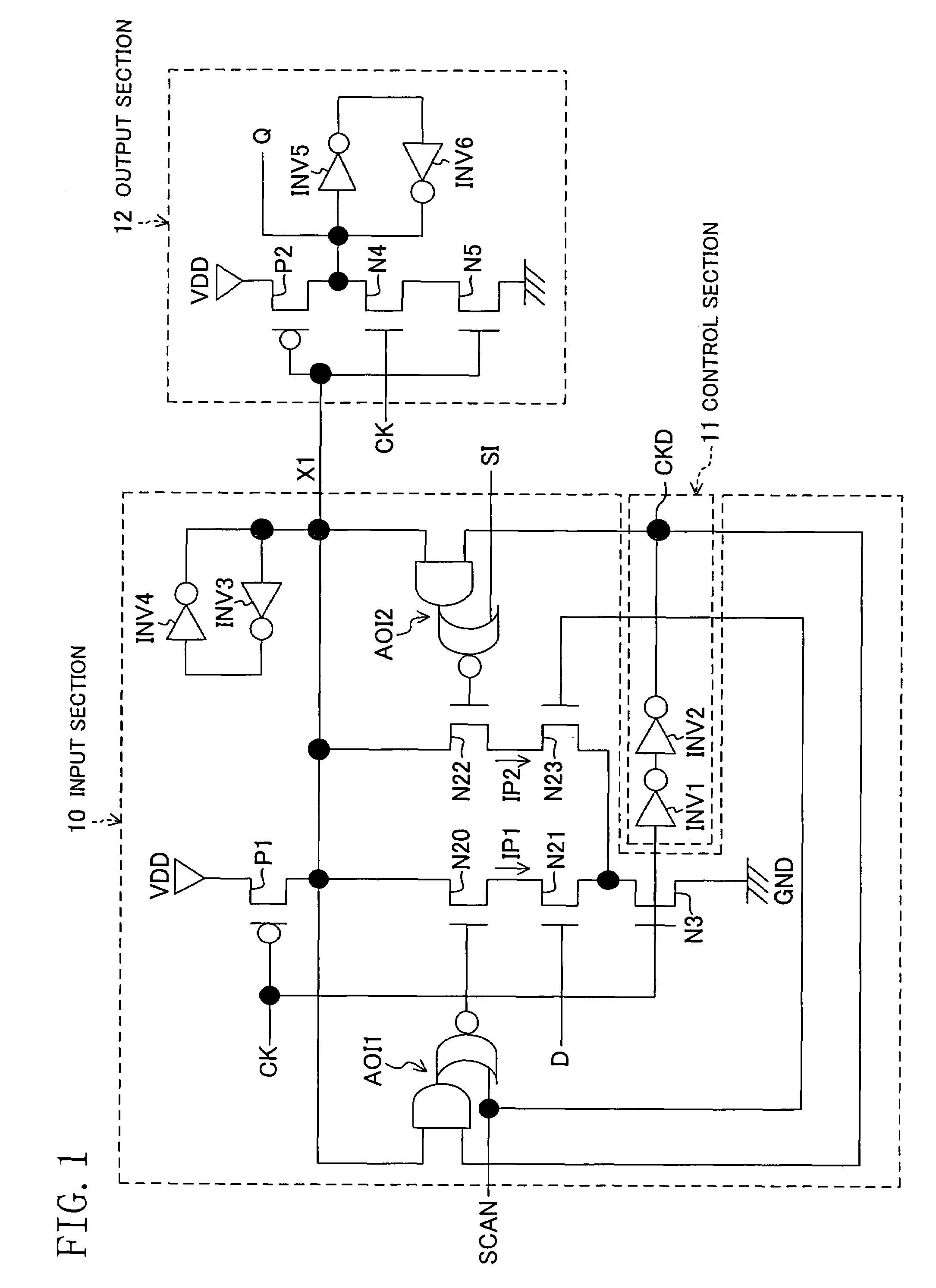

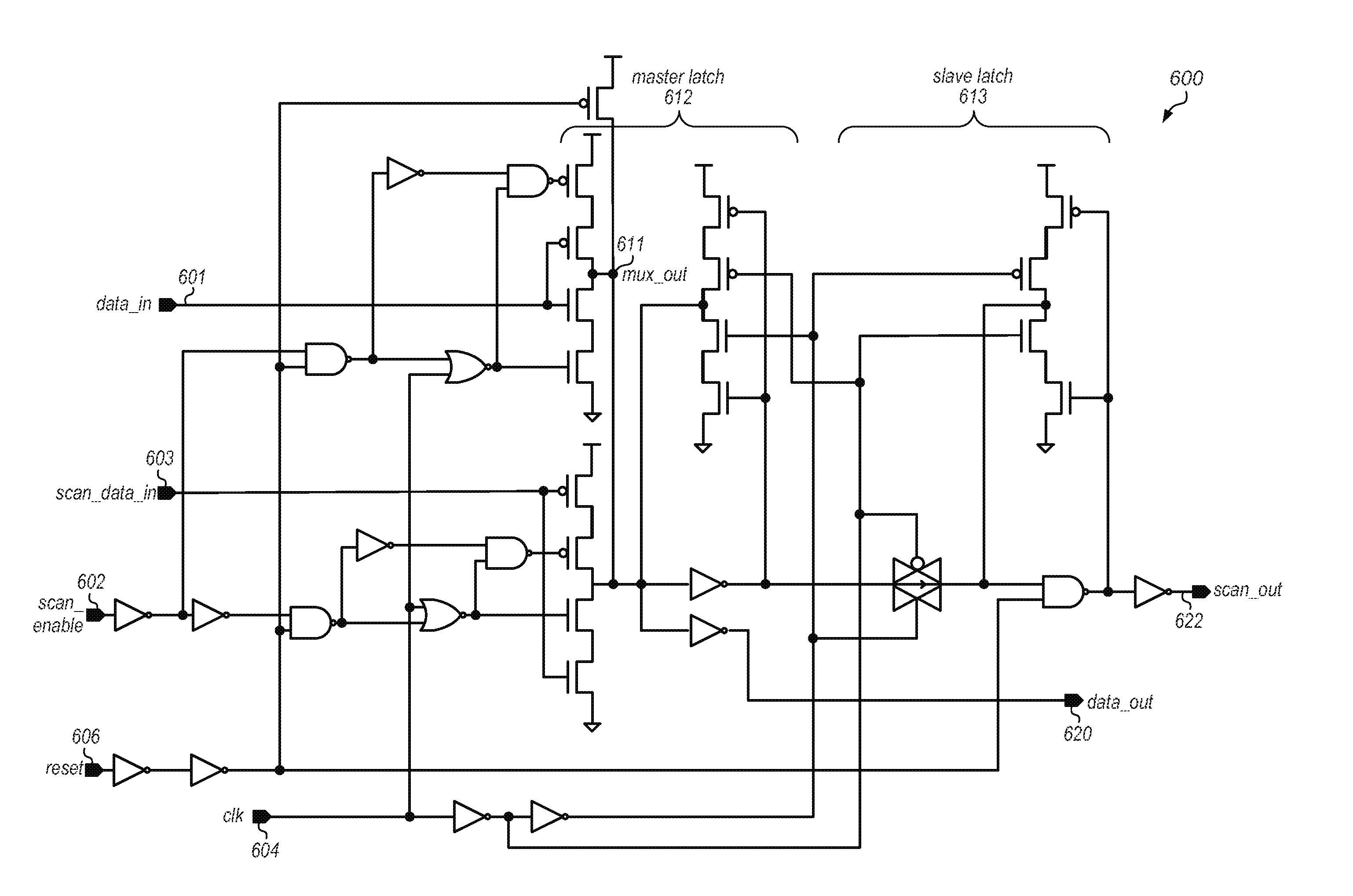

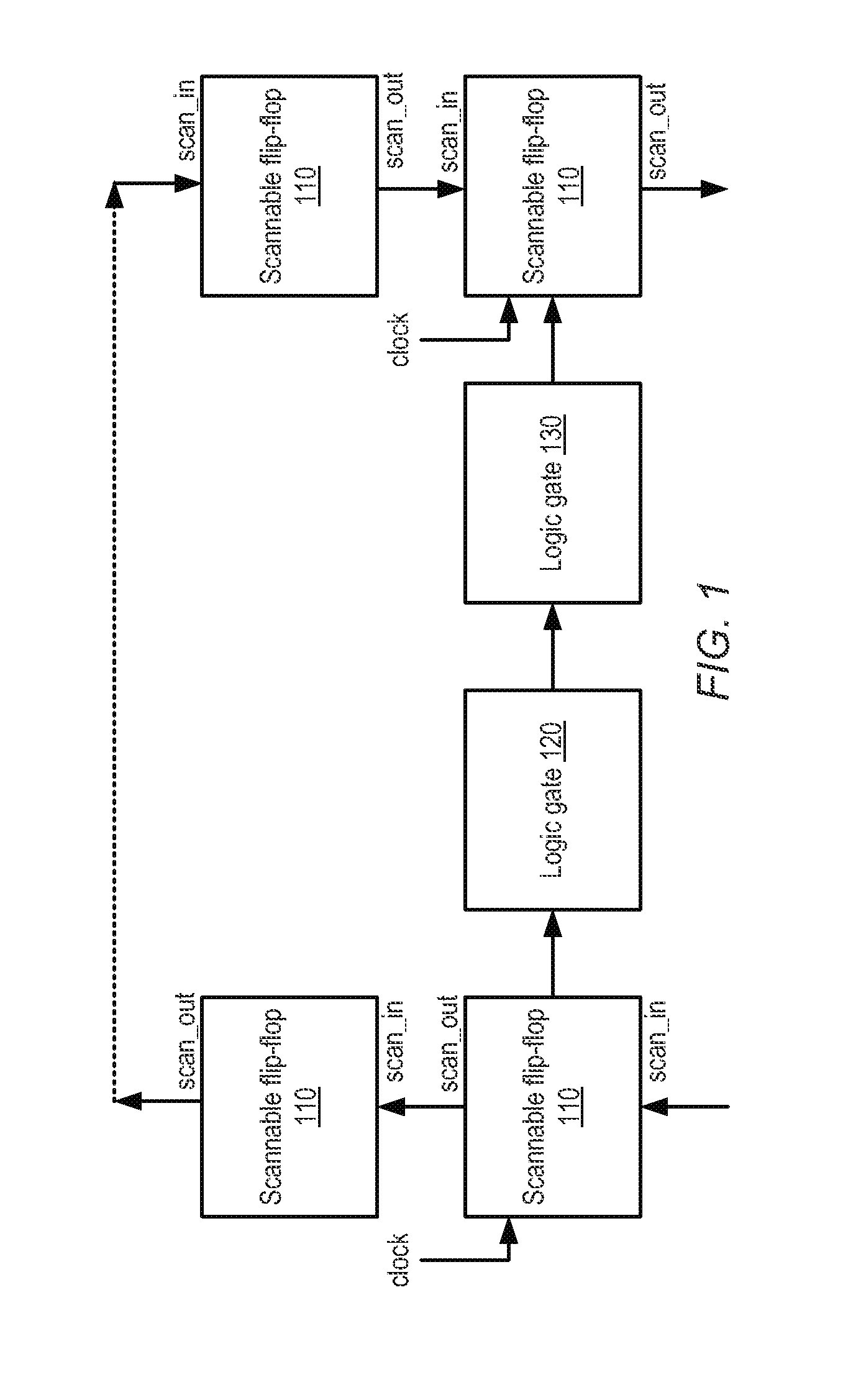

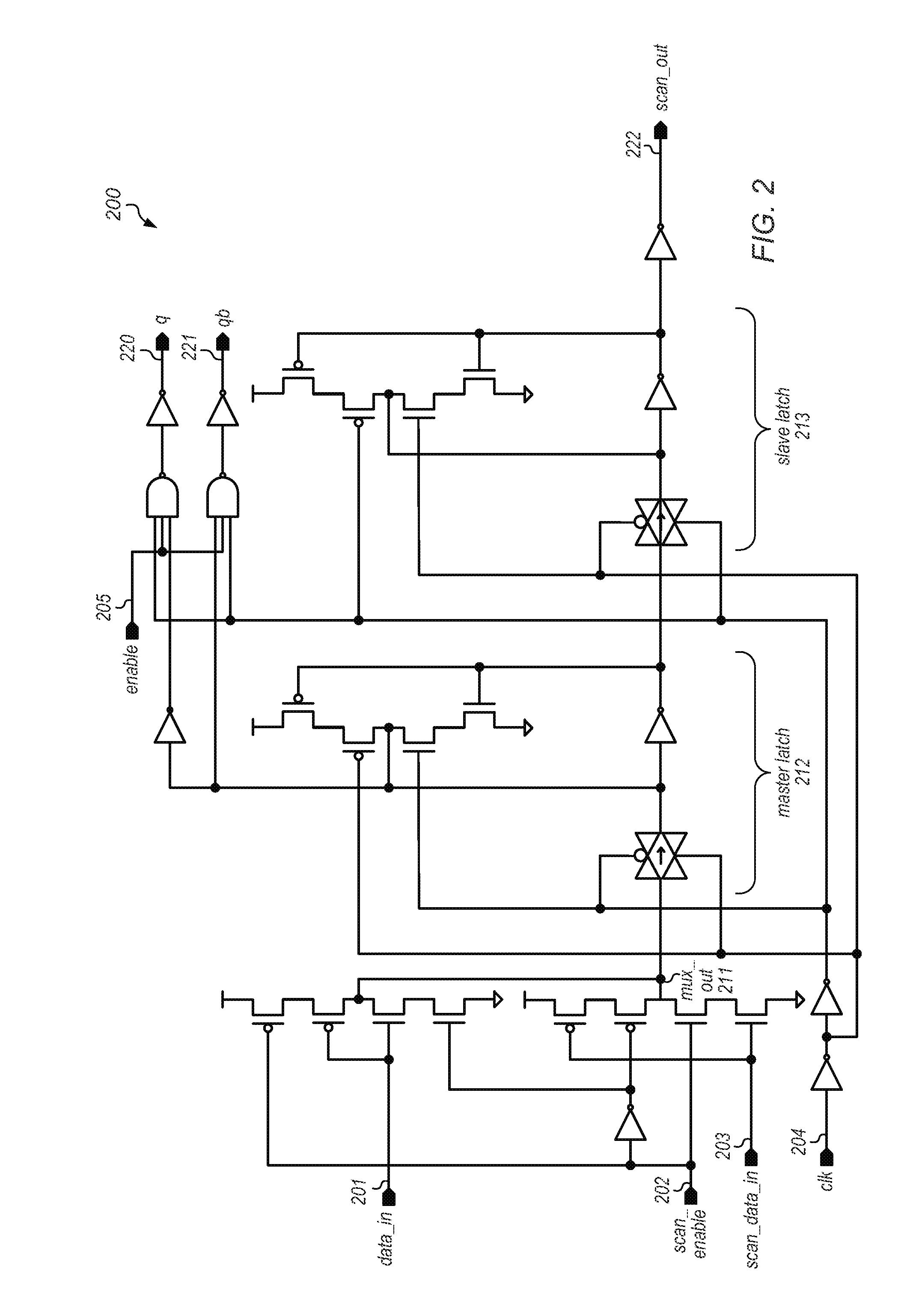

Scannable flip-flop with hold time improvements

InactiveUS20120146697A1Reduce data hold timeImprove circuit performanceElectric pulse generatorMultiplexerControl signal

Embodiments of a scannable flip-flop are disclosed that may reduce data hold time, which may in turn improve the performance of circuits incorporating the scannable flip-flop. The scannable flip-flop may include a slave latch and a master latch including an input multiplexer. The multiplexer may include a number of input ports, for example to receive normal operating mode data as well as scan operating mode data, and the multiplexer may be operable to controllably select one of the input ports and pass the value of the selected port to an output of the multiplexer. For example, the multiplexer may generate individual control signals for the various ports dependent upon both the clock signal and a select signal, such that each of the ports is qualified with the select signal and the clock signal before the multiplexer presents the input data of the selected port as the output of the multiplexer.

Owner:APPLE INC

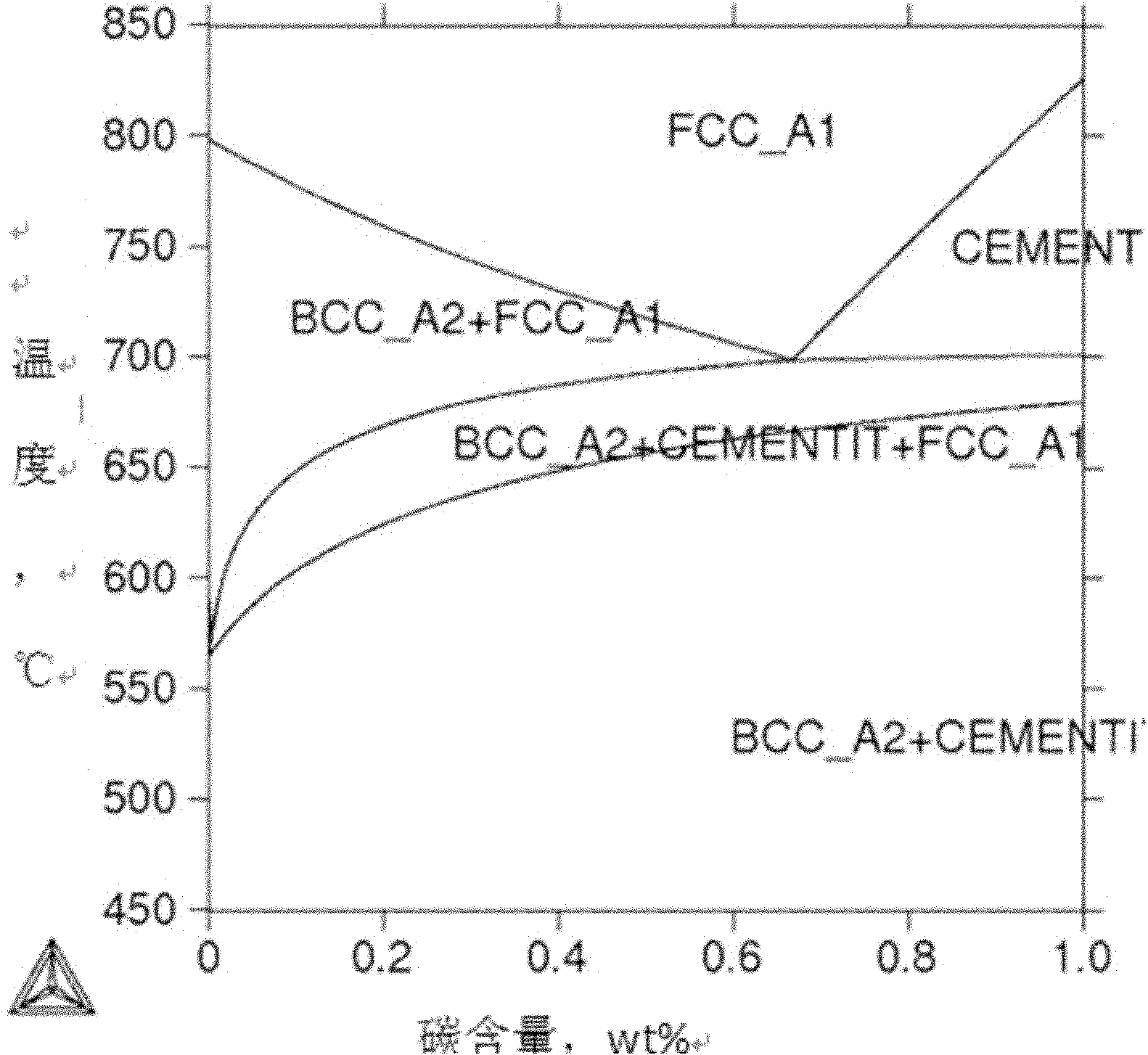

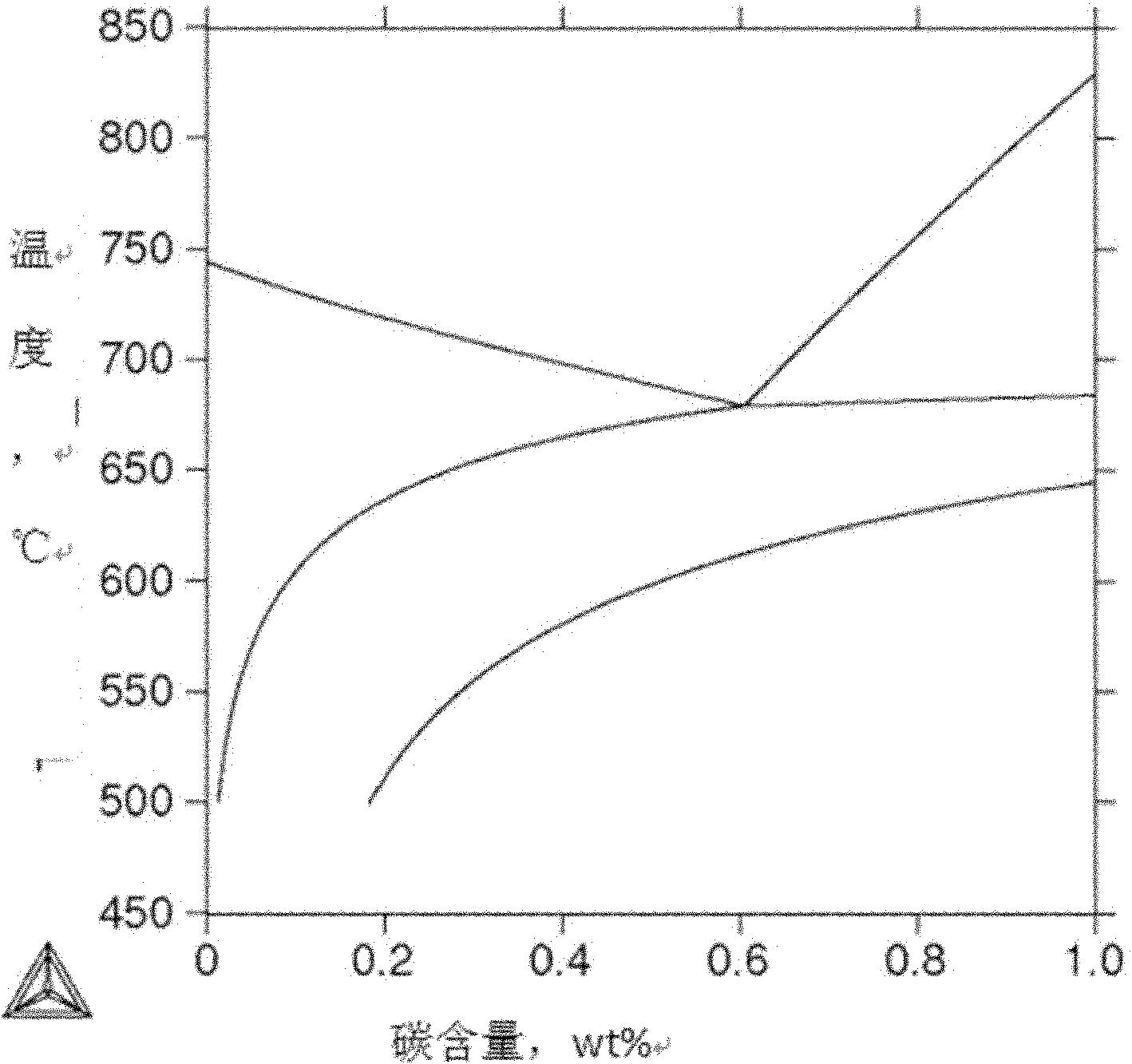

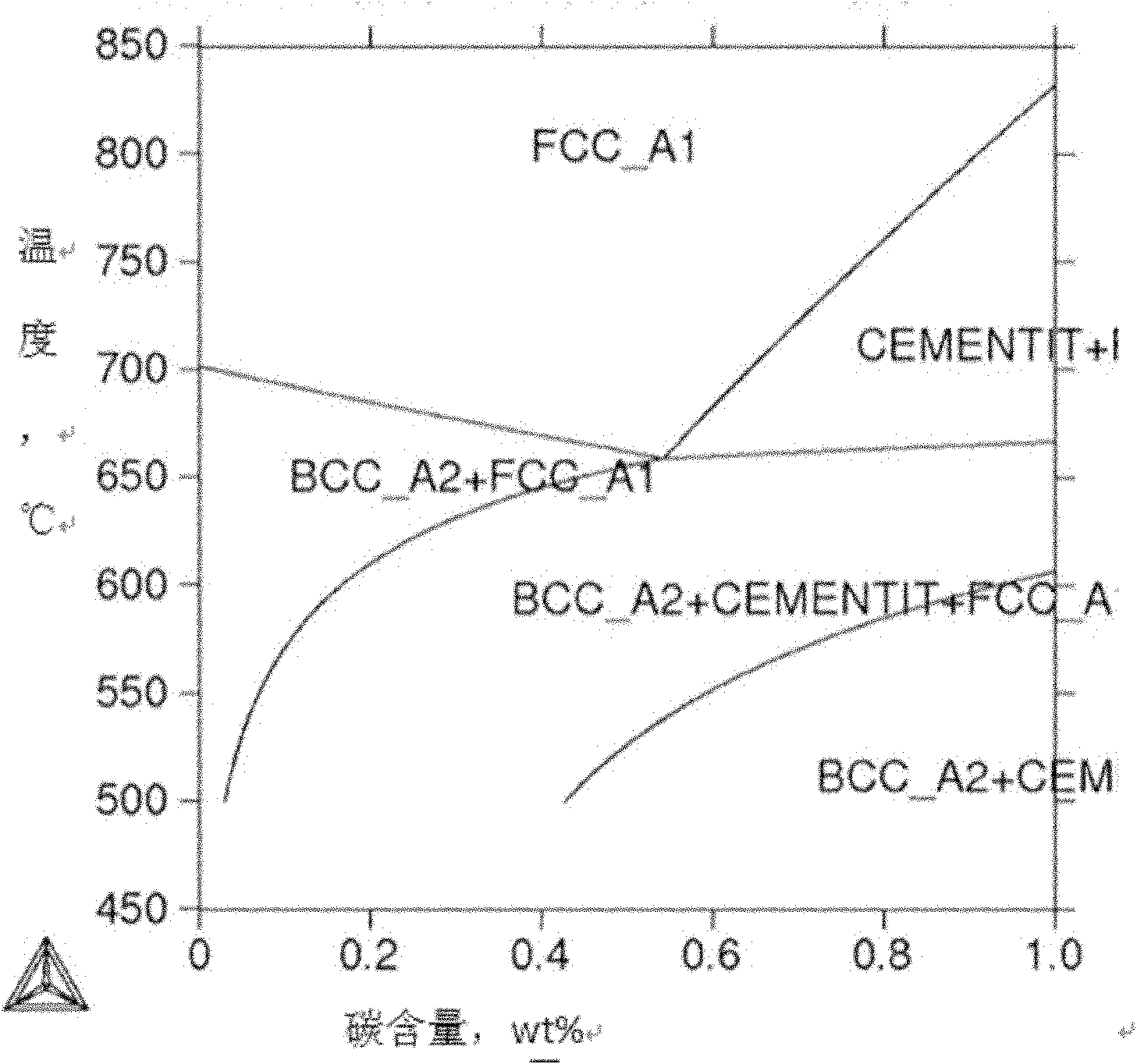

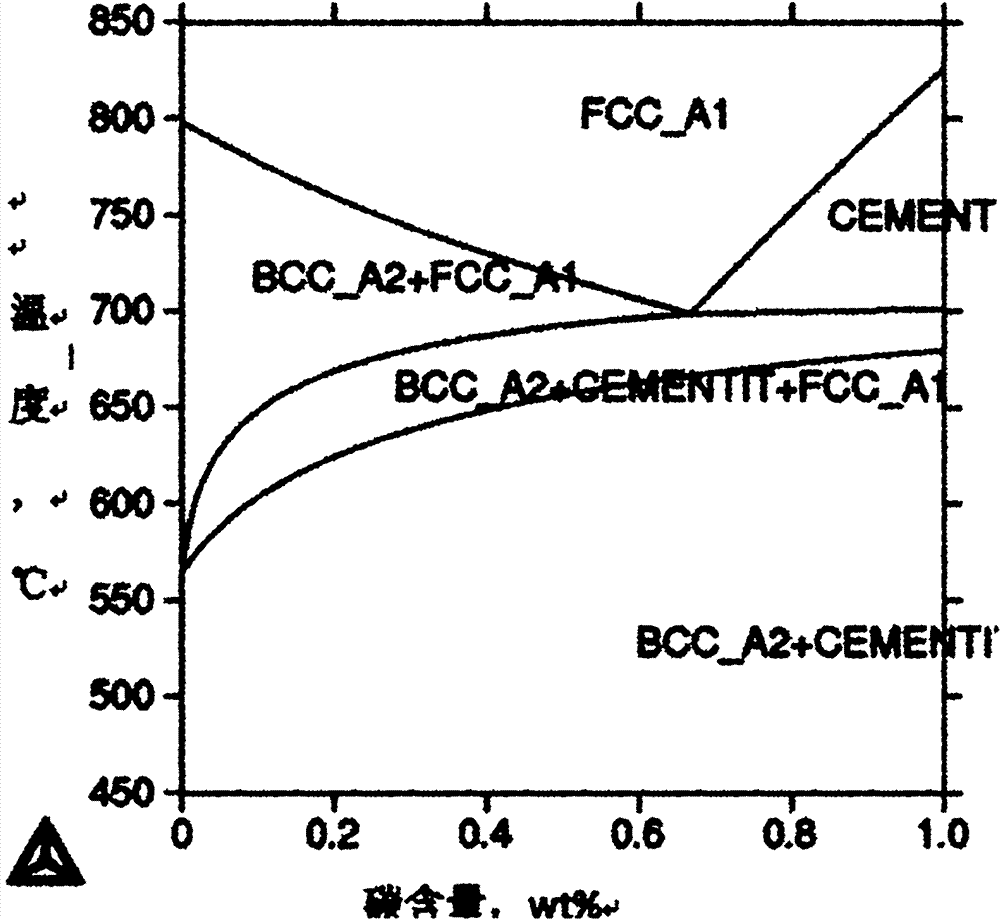

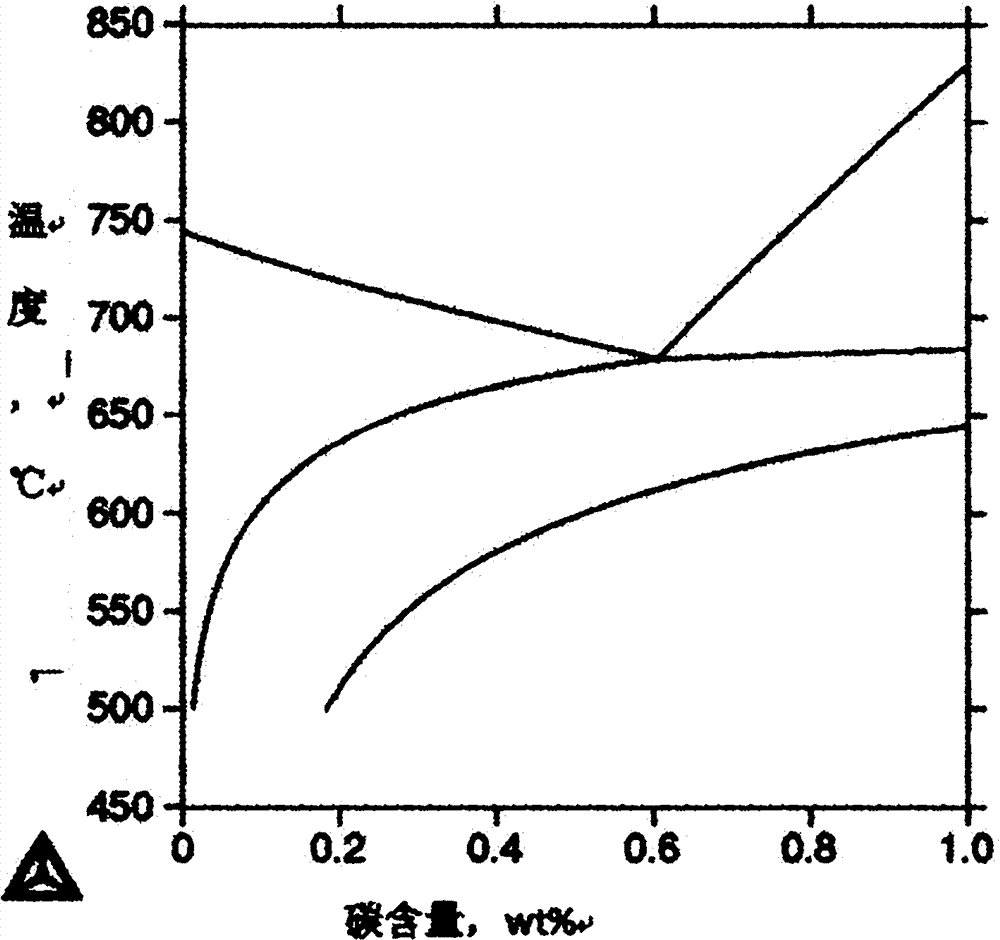

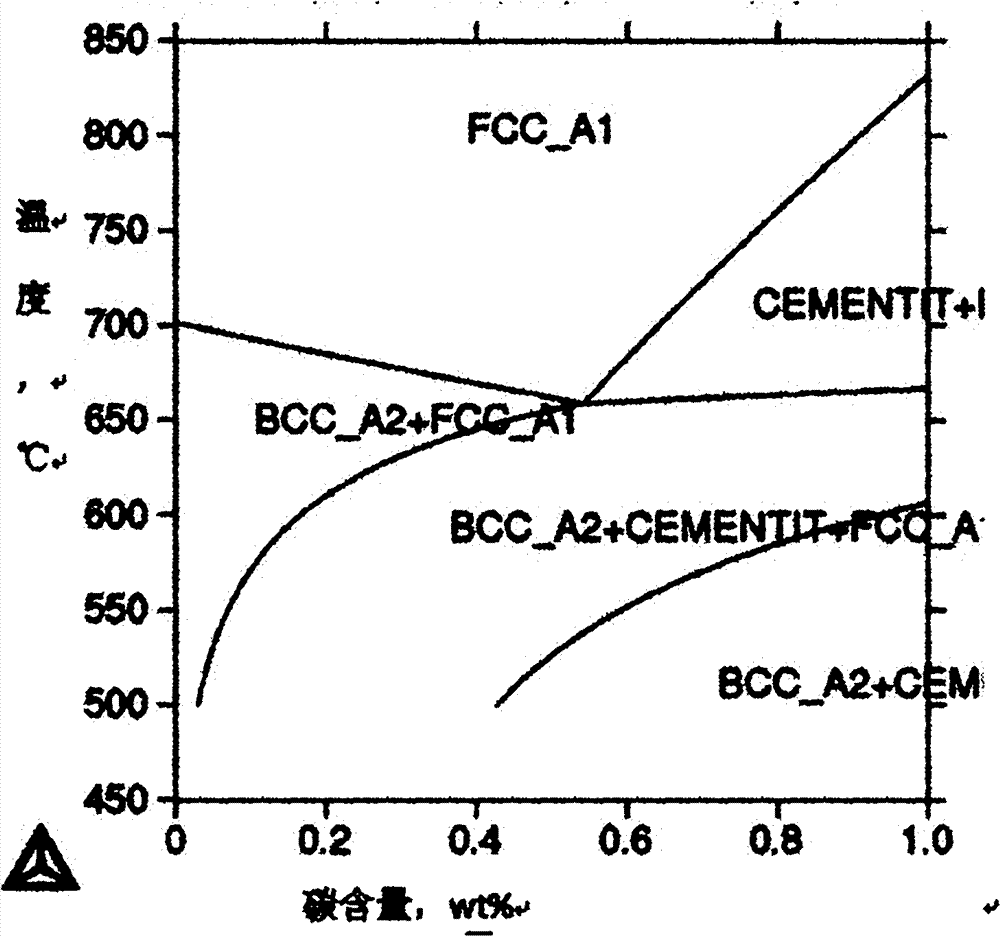

Steel plate warm formed parts with high efficiency, low energy consumption and high quality and production method thereof

The invention relates to steel plate warm formed parts with high efficiency, low energy consumption and high quality and a production method thereof, belonging to the technical field of part forming. The steel plate for producing parts comprises the following components in percent by weight: 0.02-0.45% of C, 3.50-9.0% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. On the basis of these components, one or more of the following components (in percent by weight) are additionally added: 0.1-3.0% of Ni, 0.2-3.0% of Cr, 0.1-0.8% of Mo, 0.3-2.3% of Si, 0.5-2.0% of Cu, 0.0005-0.0050 of B, 0.02-0.30% of Nb, 0.002-0.250% of [N], 0.05-0.25% of Ti, 0.02-0.25% of V, 0.015-3.0% of Al, 0.002-0.005% of RE, and 0.005-0.03% of Ca. The production method comprises the following steps: steel plate heating, steel plate transferring, steel plate precooling, part forming, part cooling, and part temperature control treatment. The production method provided by the invention has the advantages of low cost and high efficiency, and improves the forming rate and final mechanical properties of workpieces.

Owner:CENT IRON & STEEL RES INST

Methods, systems and apparatus for monochromatic UV light sterilization

ActiveUS8125333B2Shorten holding timeEasier on the container/closure systemOptical radiation measurementDough treatmentRegimenContinuous wave

The present disclosure provides for methods, systems and apparatus for monochromatic UV light sterilization of container systems and / or container-packaged products. More particularly, the present disclosure provides for improved methods, systems and apparatus for monochromatic UV light sterilization of liquid and / or solid products / solutions and / or packaging / container systems for liquid and / or solid products / solutions (e.g., parenteral pharmaceutical products / solutions and / or packaging / container systems for parenteral pharmaceutical products / solutions). In exemplary embodiments, the present disclosure provides for improved systems and methods for the sterilization of container systems and / or container-packaged products using monochromatic, continuous wave, high-intensity, incoherent light in multiple light source configurations, wherein such sterilization regimen achieves a desired sterilization level without negatively affecting the physical properties of the package / container systems and / or the efficacy of the underlying products / systems.

Owner:TRITON THALASSIC TECH

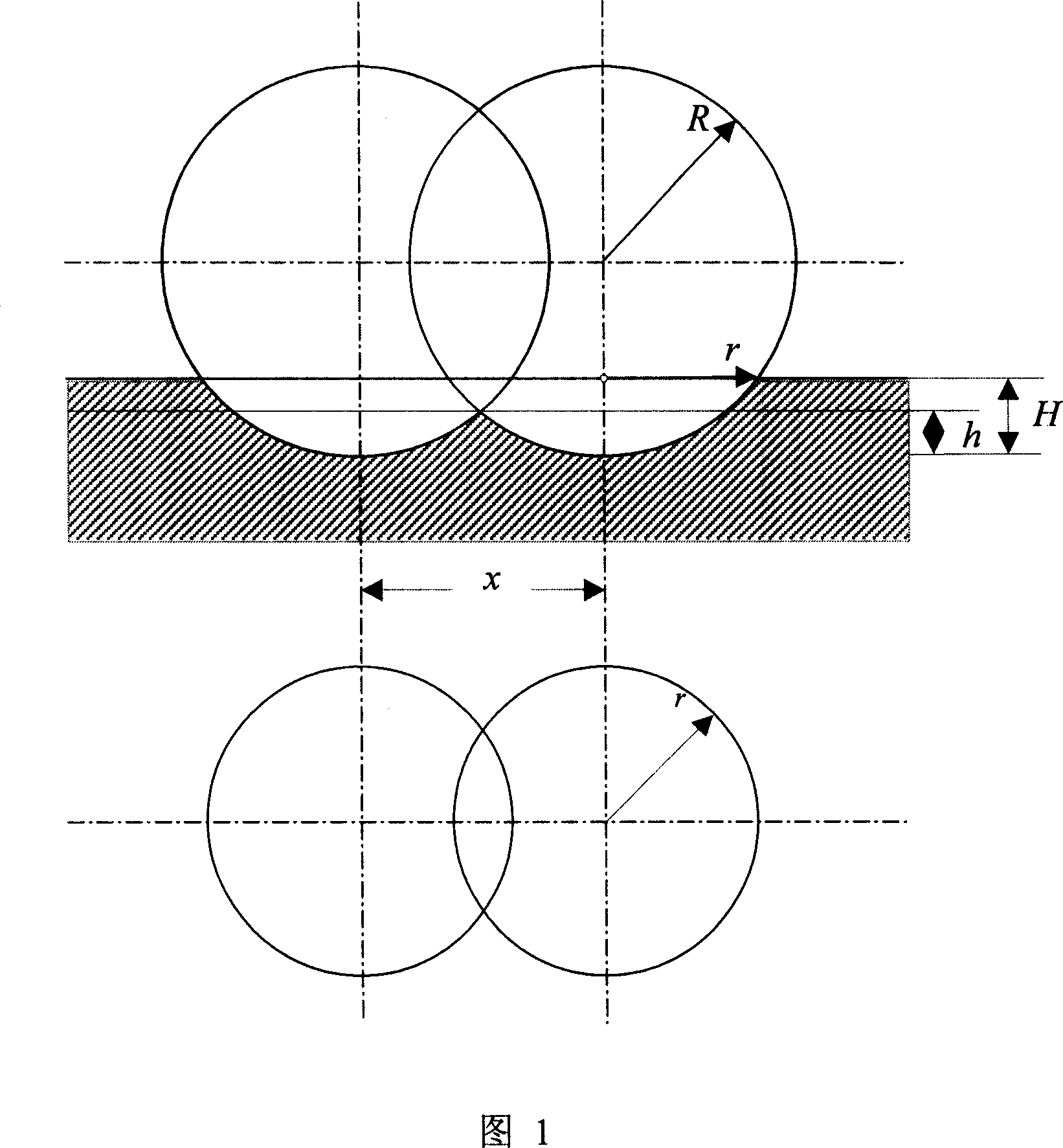

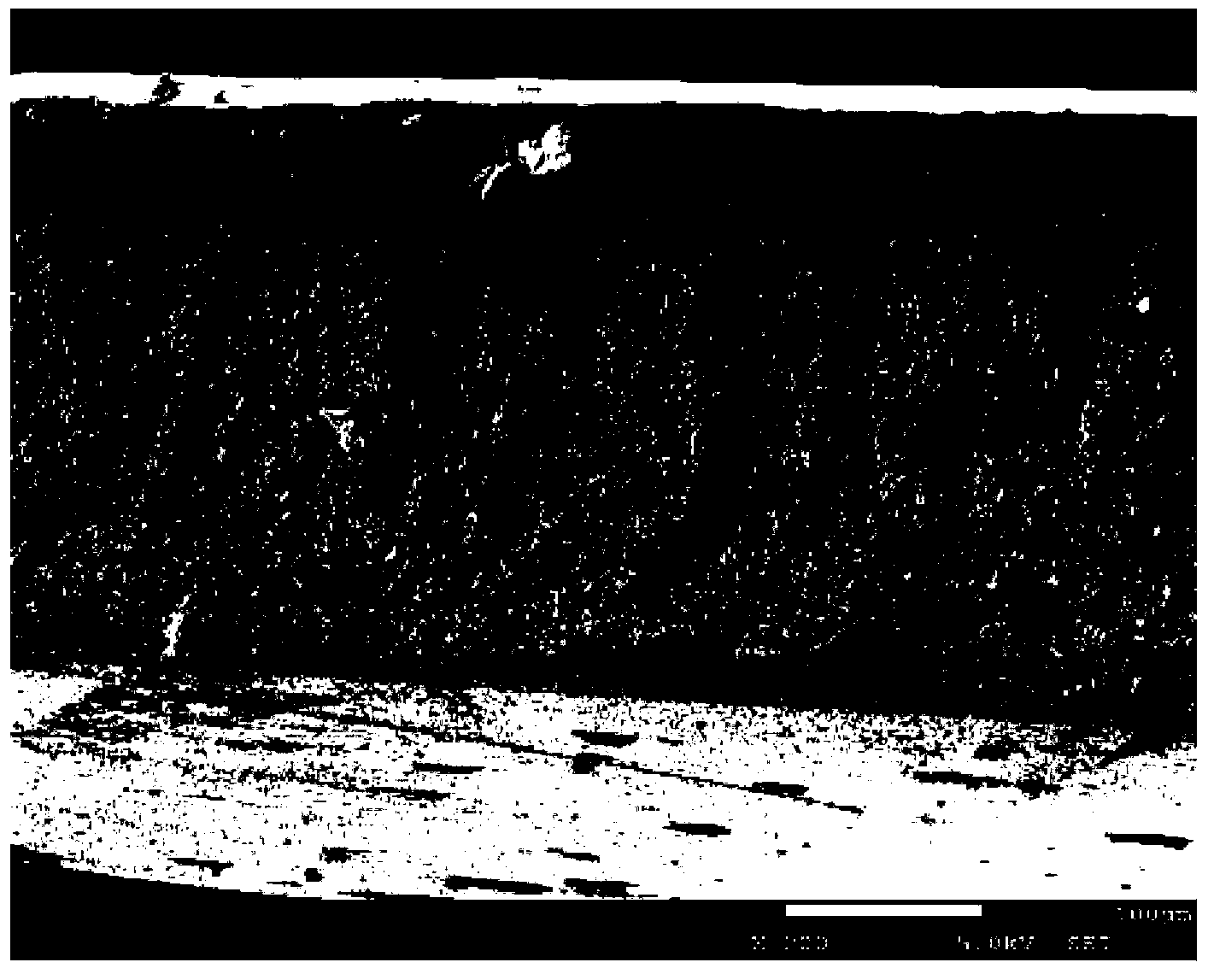

Metal surface nanolizing method of supersonic wave high-energy surface machinery processing

the invention discloses a realizing method of nanometer metal non-coating surface through ultrasonic mechanic manufacturing, which is characterized by the following: contacting plunger chip on the ultrasonic energy exchanger with metal sample directly; controlling the relative position, relative moving pattern and speed of ultrasonic exchanger and metal sample; selecting or controlling the geometrical shape, amplitude, ultrasonic frequency and power of plunger chip; inputting the ultrasonic vibrating energy into the metal piece; deforming local metal surface to obtain the product.

Owner:BAOSHAN IRON & STEEL CO LTD

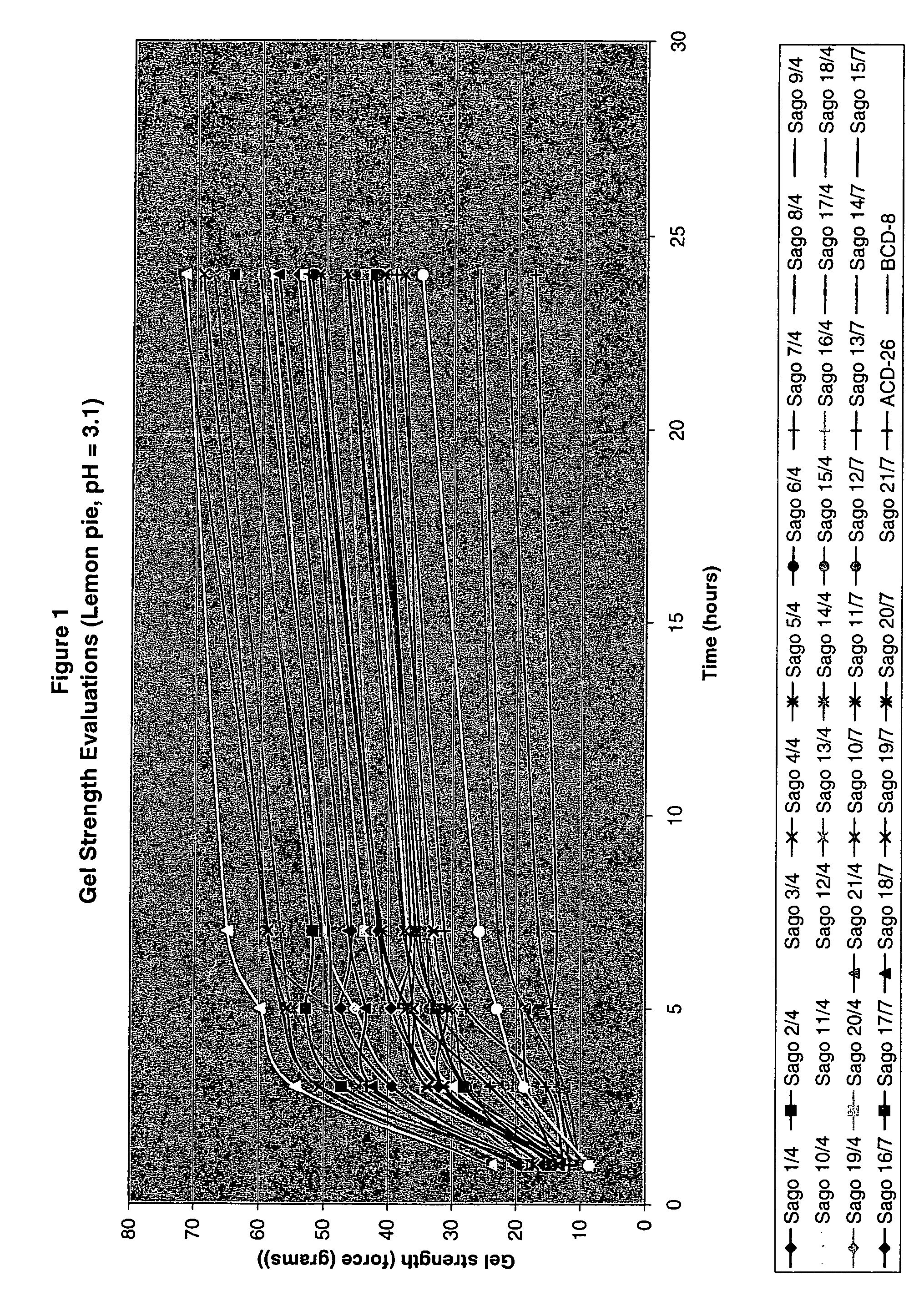

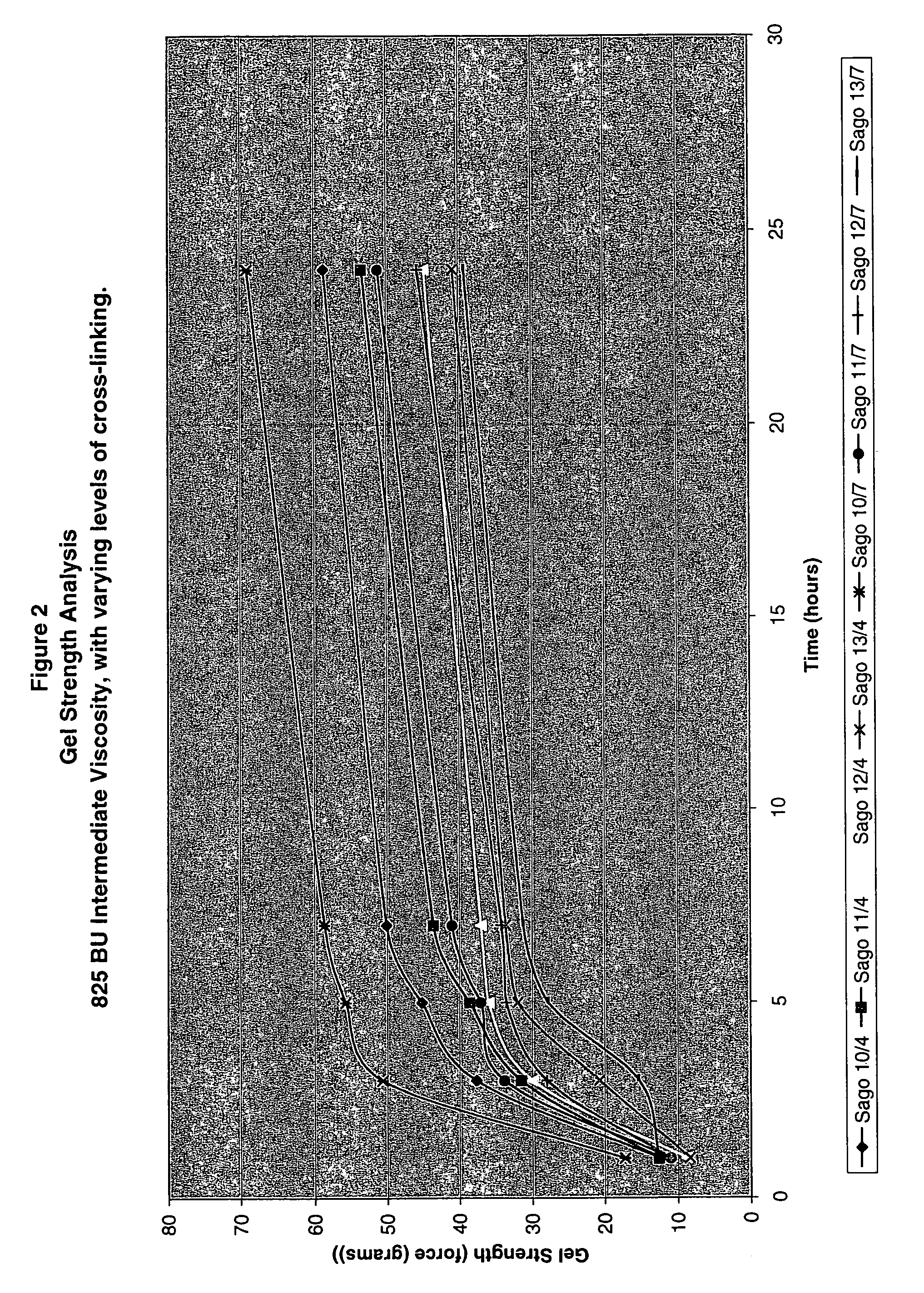

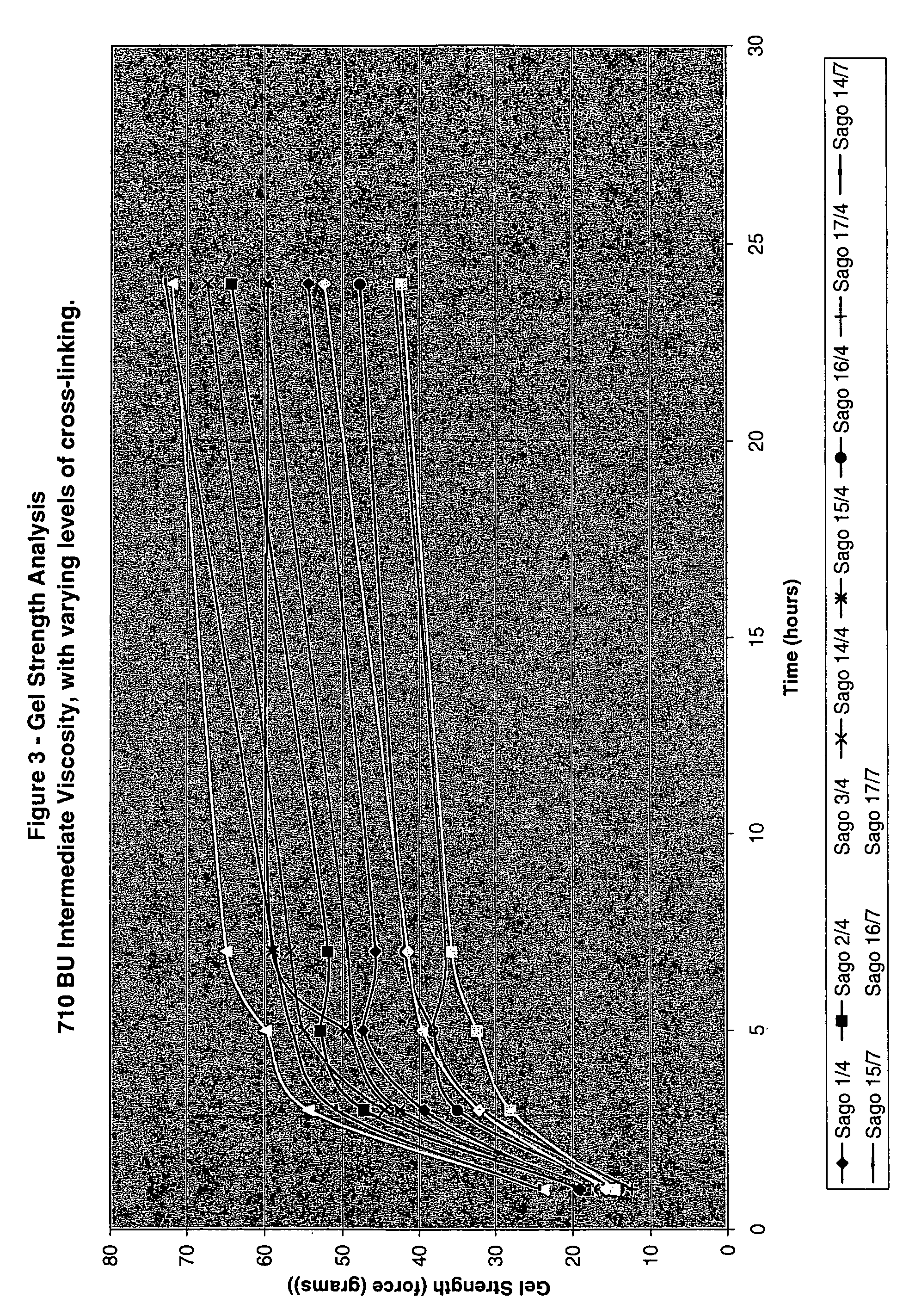

Sago-based gelling starches

InactiveUS7422638B2Fast gelling propertyHigh gel strengthBakery productsFood preparationUltimate tensile strengthFood item

Sago-based gelling starches and the use thereof. Such modified starches exhibit exceptionally fast gelling properties, high gel strengths, and exceptional elasticity. These properties allow for significantly reduced processing times, including reduced hold times. Further, the higher gel strength allows for reduced starch levels without loss of final product gel strength integrity or texture. The instant gelling starches are particularly useful in food systems of the type that gel upon standing, such as pie and cream fillings, puddings, spreads, and jellies.

Owner:CORN PROD DEV INC

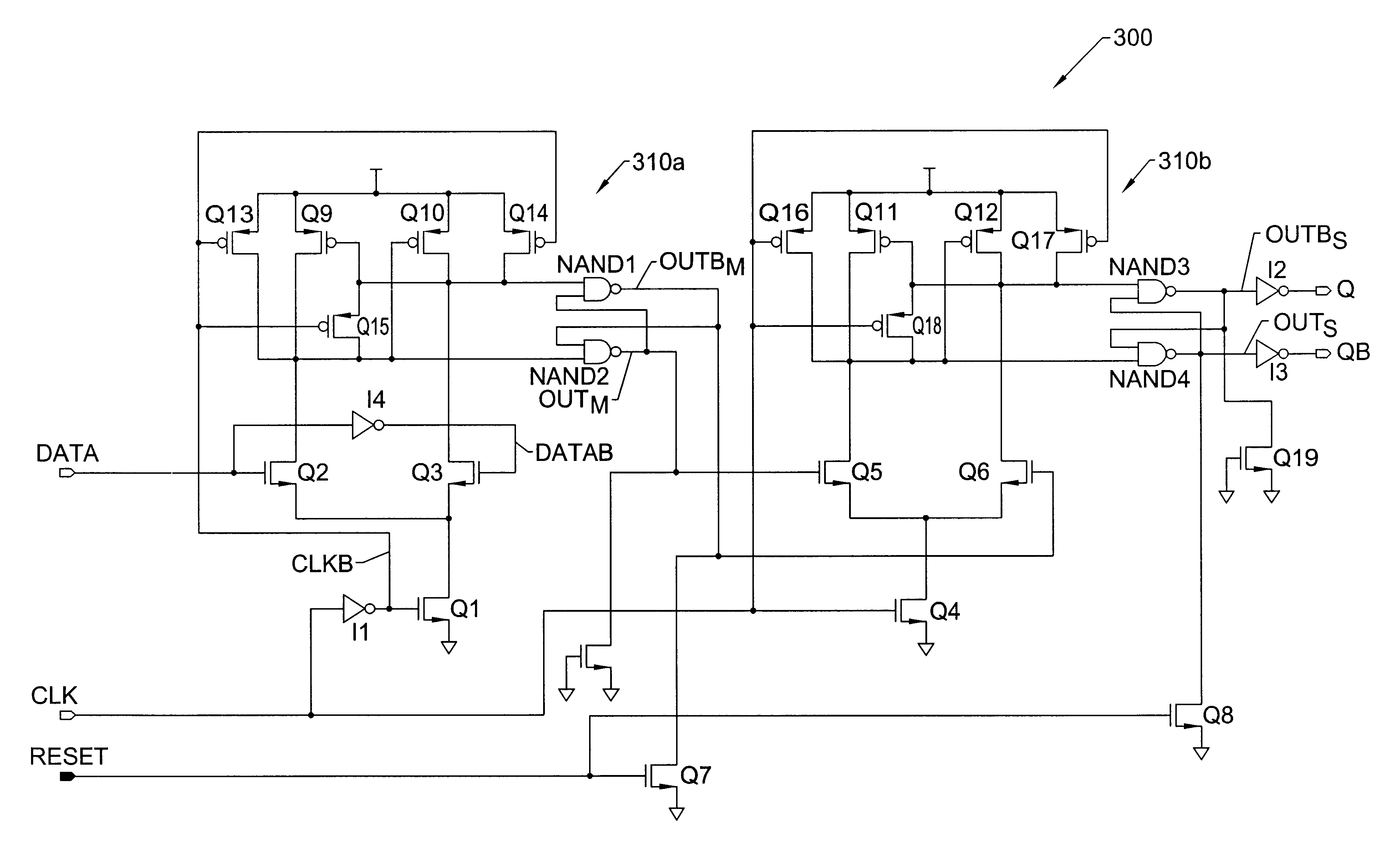

Integrated circuit flip-flops that utilize master and slave latched sense amplifiers

InactiveUS6573775B2Minimal characteristicConvenient timeElectric pulse generatorManipulation for frequency changeSense amplifierIntegrated circuit

Flip-flops include a master stage and a slave stage. The master stage is responsive to a first clock signal and has a first pair of differential inputs and a first pair of differential outputs. The slave stage is responsive to a second clock signal and has a second pair of differential inputs coupled to the first pair of differential outputs and a second pair of differential outputs from which true and complementary outputs (Q, QB) of the flip-flop are derived. If the flip-flop is a D-type flip-flop, the first pair of differential inputs receive true and complementary data signals (DATA, DATAB). If the flip-flop is a set-reset (S-R) flip-flop, the first pair of differential inputs receive set and reset signals (SET, RESET).

Owner:INTEGRATED DEVICE TECH INC

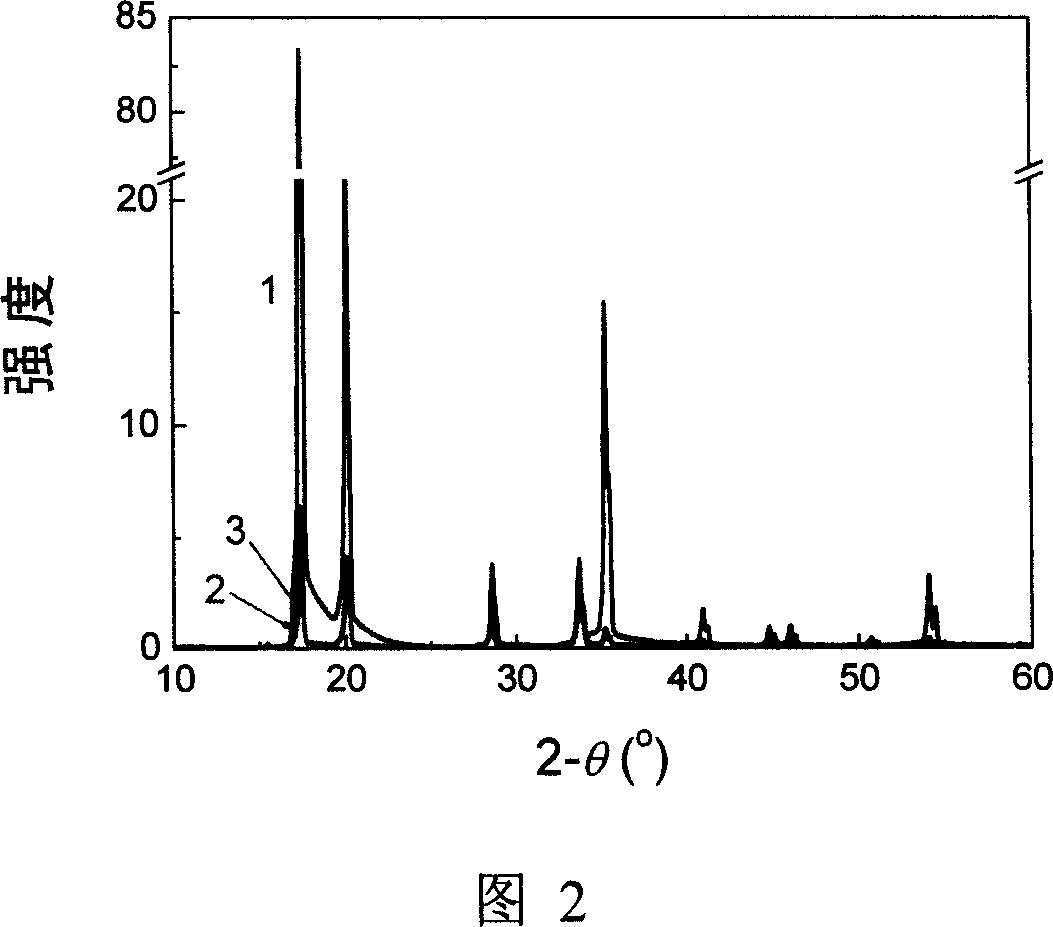

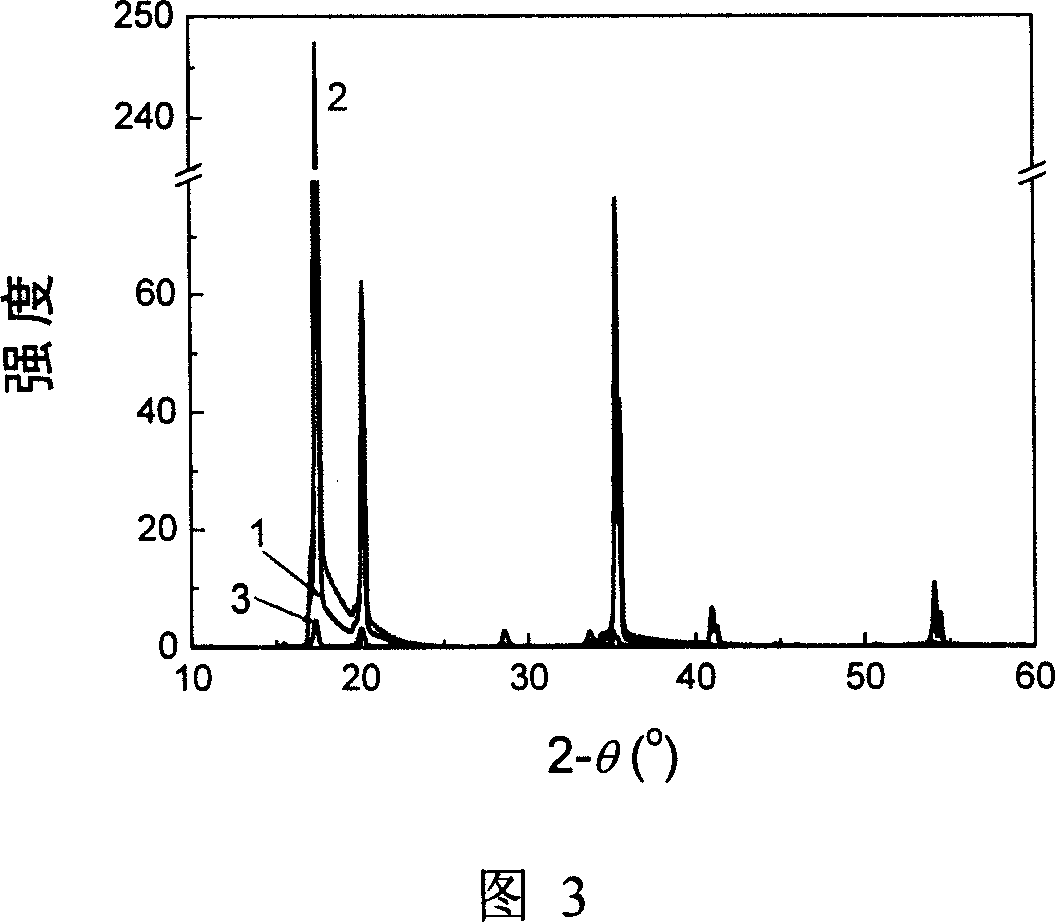

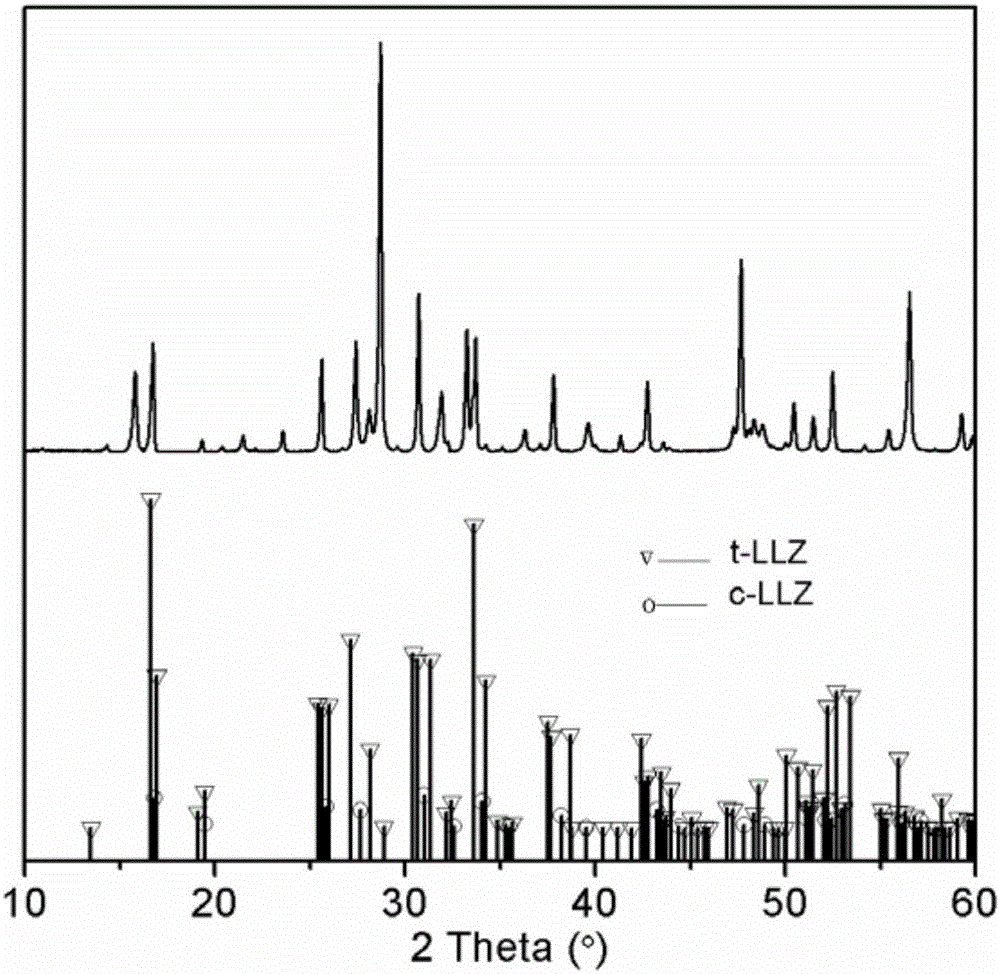

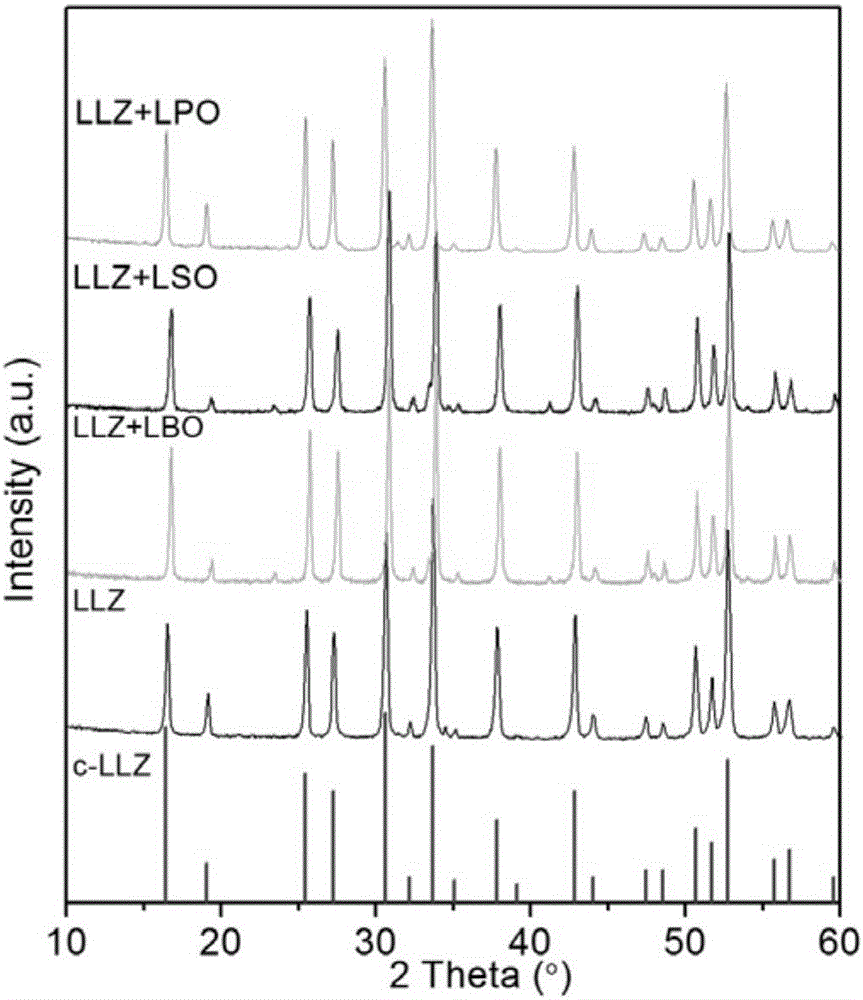

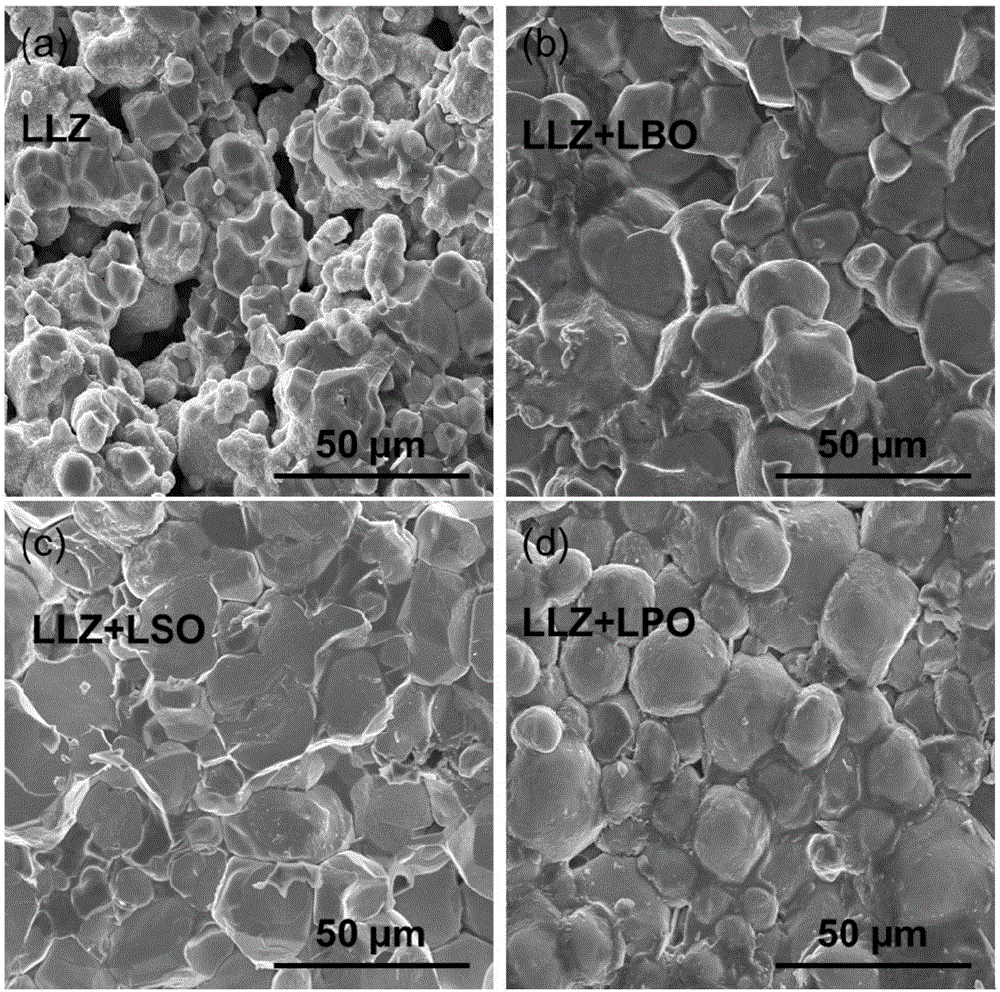

Solid electrolyte for inhibiting lithium dendrites growth in full-solid-state battery, and preparation method thereof

InactiveCN106848392AImprove microstructureImprove sintering performanceSecondary cellsSolid state electrolyteIonic conductance

The invention relates to a solid electrolyte for inhibiting lithium dendrites growth in a full-solid-state battery, and a preparation method thereof. The solid electrolyte is prepared from lithium-lanthanum-zirconium oxide ceramic and 0.1 to 10 weight percent of low-melting-point sintering aid. The preparation method comprises the following steps of dry grinding and uniformly mixing stoichiometric lithium carbonate, lanthanum oxide and zirconium oxide, and then presintering in a muffle furnace at the temperature of 900 DEG C to form a phase; adding the low-melting-point sintering aid into presintering powder, and dry grinding and mixing to obtain a manual pressed sheet sample; densifying during a further high-temperature sintering process to form the solid electrolyte with high ionic conductance, stable performance and high repeatability. Compared with the prior art, without influencing a conductive property of a lithium-contained garnet lithium ion, a low-cost second phase is used so that the conductive property of the lithium ion at a crystal boundary part is improved, the solid electrolyte can better realize lithium ion transmission and plays a role in inhibiting the lithium dendrites growth in the full-solid-state battery, and the safety of the lithium battery is improved.

Owner:SHANGHAI JIAO TONG UNIV

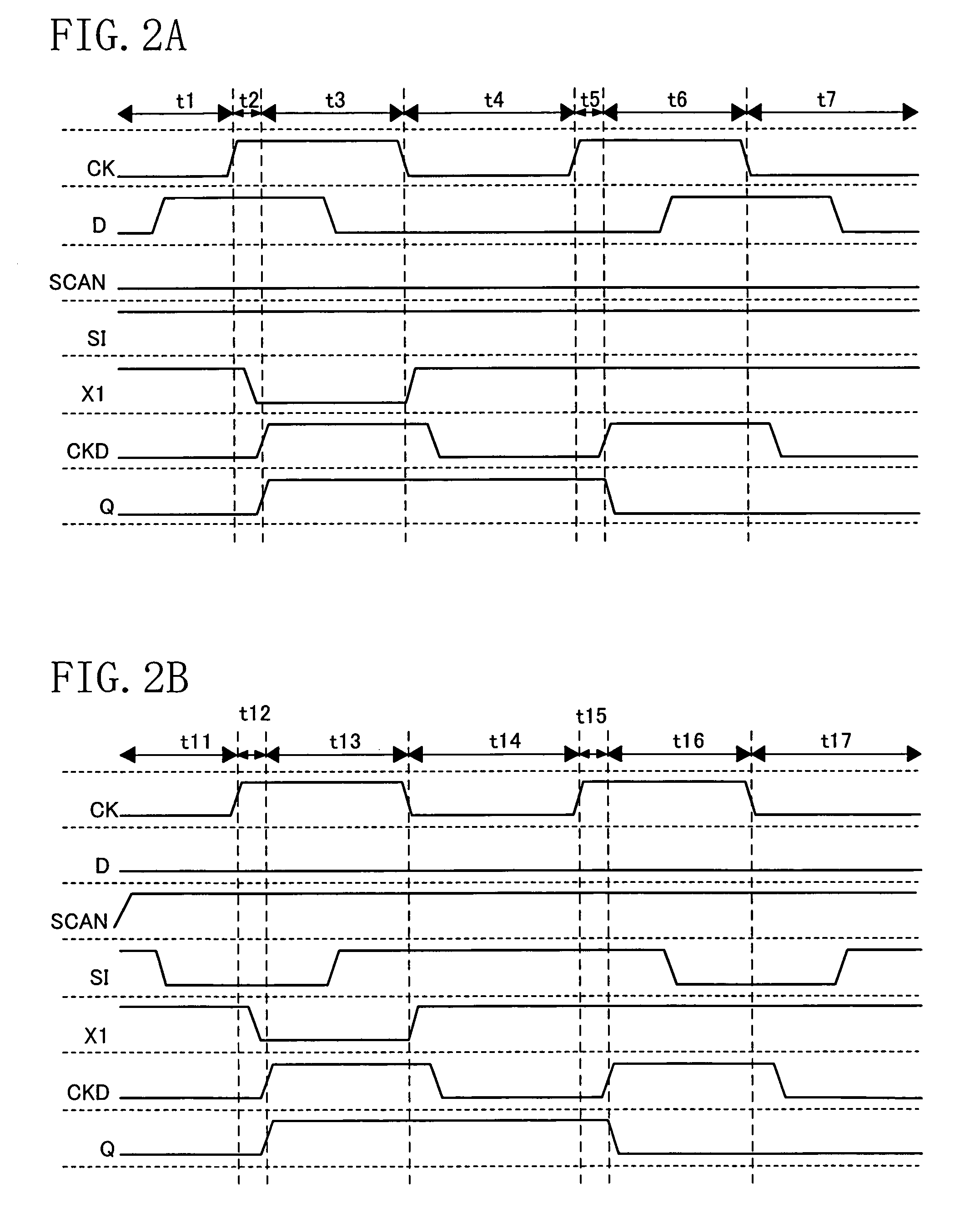

Flip-flop circuit

InactiveUS7345519B2High speedReduce in quantityElectrical testingElectric pulse generatorTest inputControl signal

A scan flip-flop circuit including an input section employing a dynamic circuit and an output section employing a static circuit, capable of latching in data within a period of a pulse width that is shorter than the clock cycle, wherein only three N-type transistors are connected in series in the input section employing a dynamic circuit. A data signal is input directly to one of the three N-type transistors. On the other hand, a test input signal is input to an AND / OR inverter circuit. The AND / OR inverter circuit receives, as a control signal, the potential of the node obtained as the clock signal passes through two inverter circuits. Therefore, there is required only a short hold time for the test input signal.

Owner:PANASONIC CORP

Method for making automotive headliners

InactiveUS8133419B2Less susceptible to degassingFaster demold timeLamination ancillary operationsSynthetic resin layered productsFiberPolyol

Vehicle headliners are prepared with a core layer of a fiber-reinforced polyurethane foam. The polyurethane foam is prepared from a polyurethane-forming composition that uses water as a blowing agent and polyol or polyol mixture that has a high functionality and an average hydroxyl equivalent weight of 100-130. The selection of polyols permits cycle times to be reduced by allowing for faster demolding and shortened aging times before post-molding heat lamination steps can be performed.

Owner:THE DOW CHEM CO

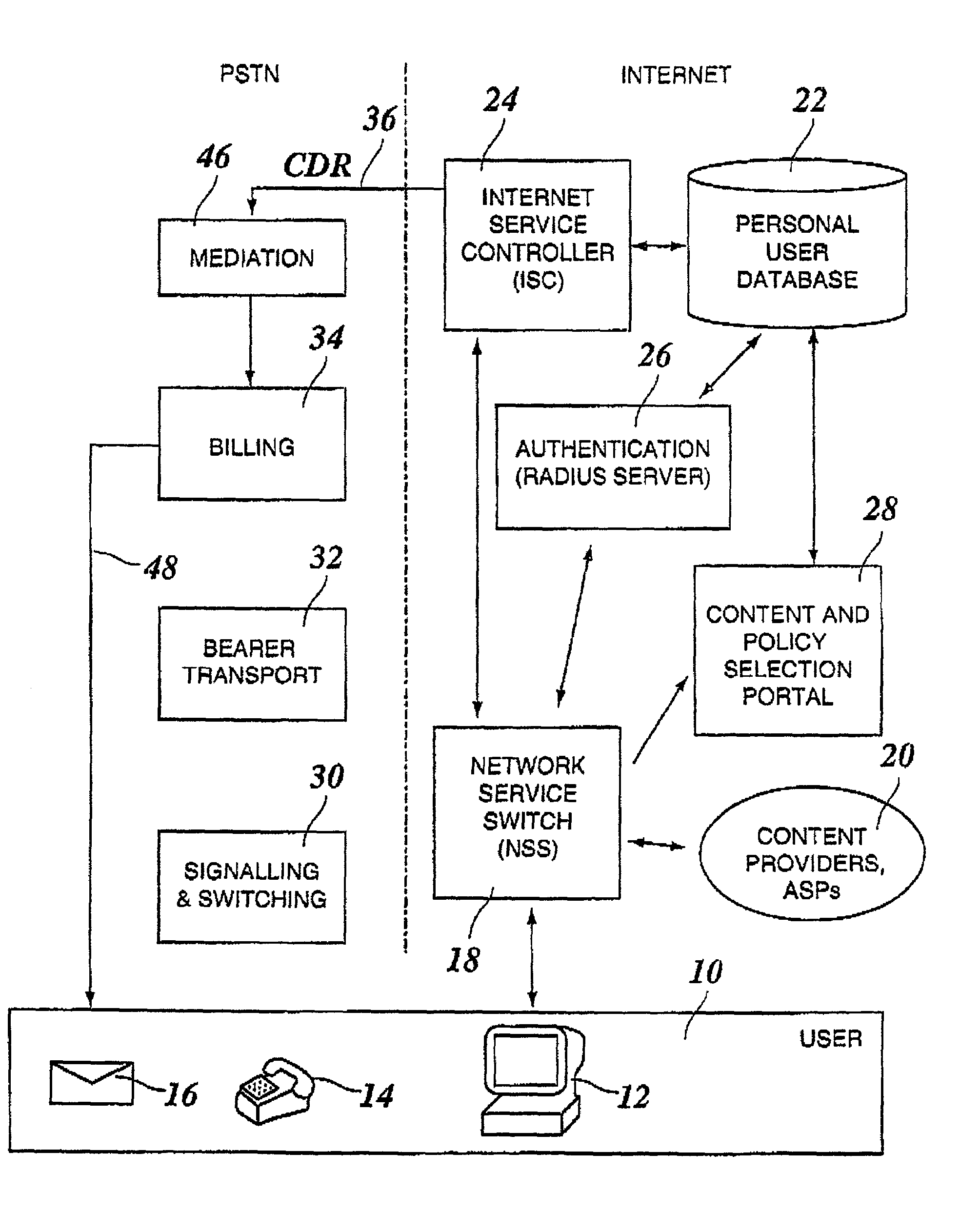

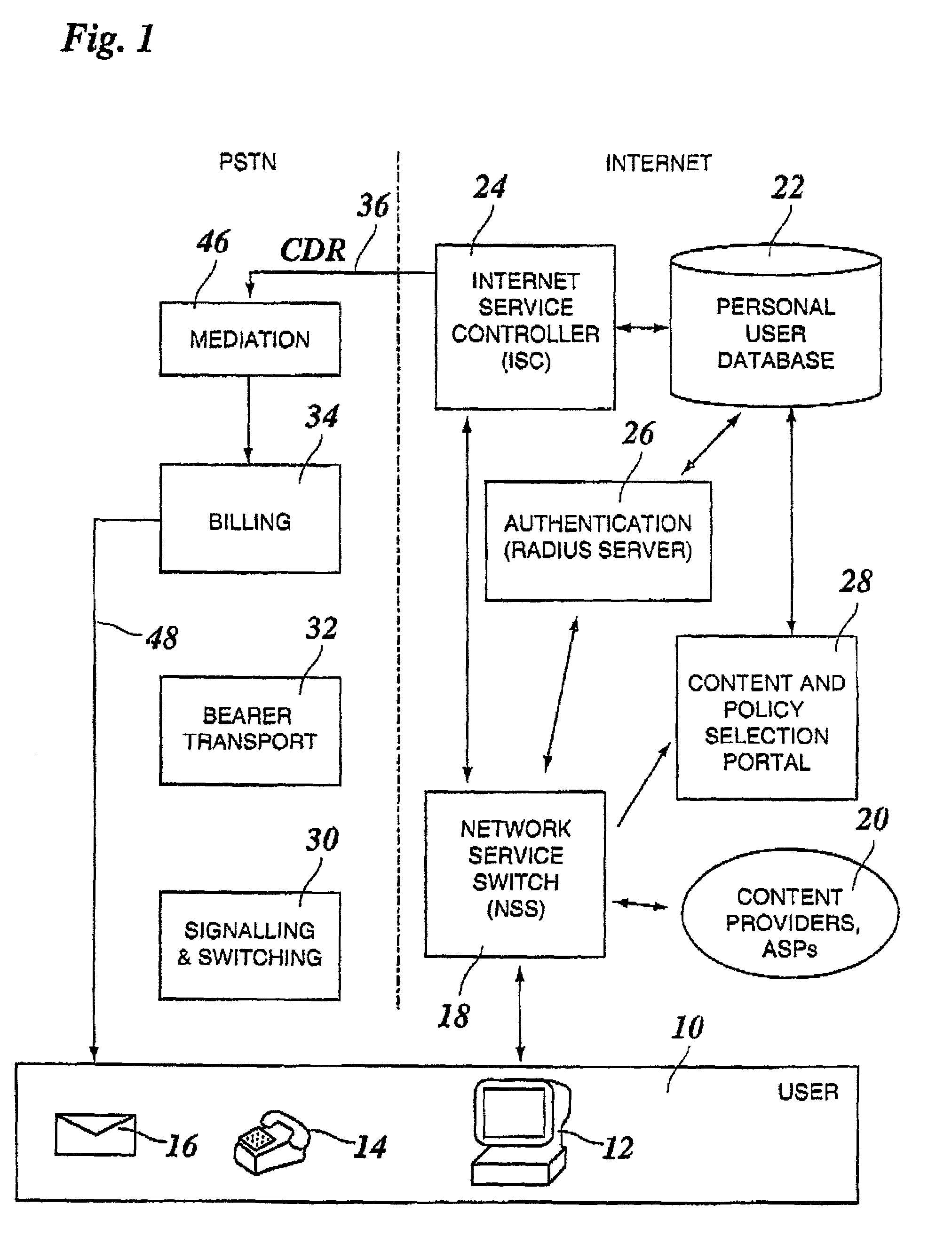

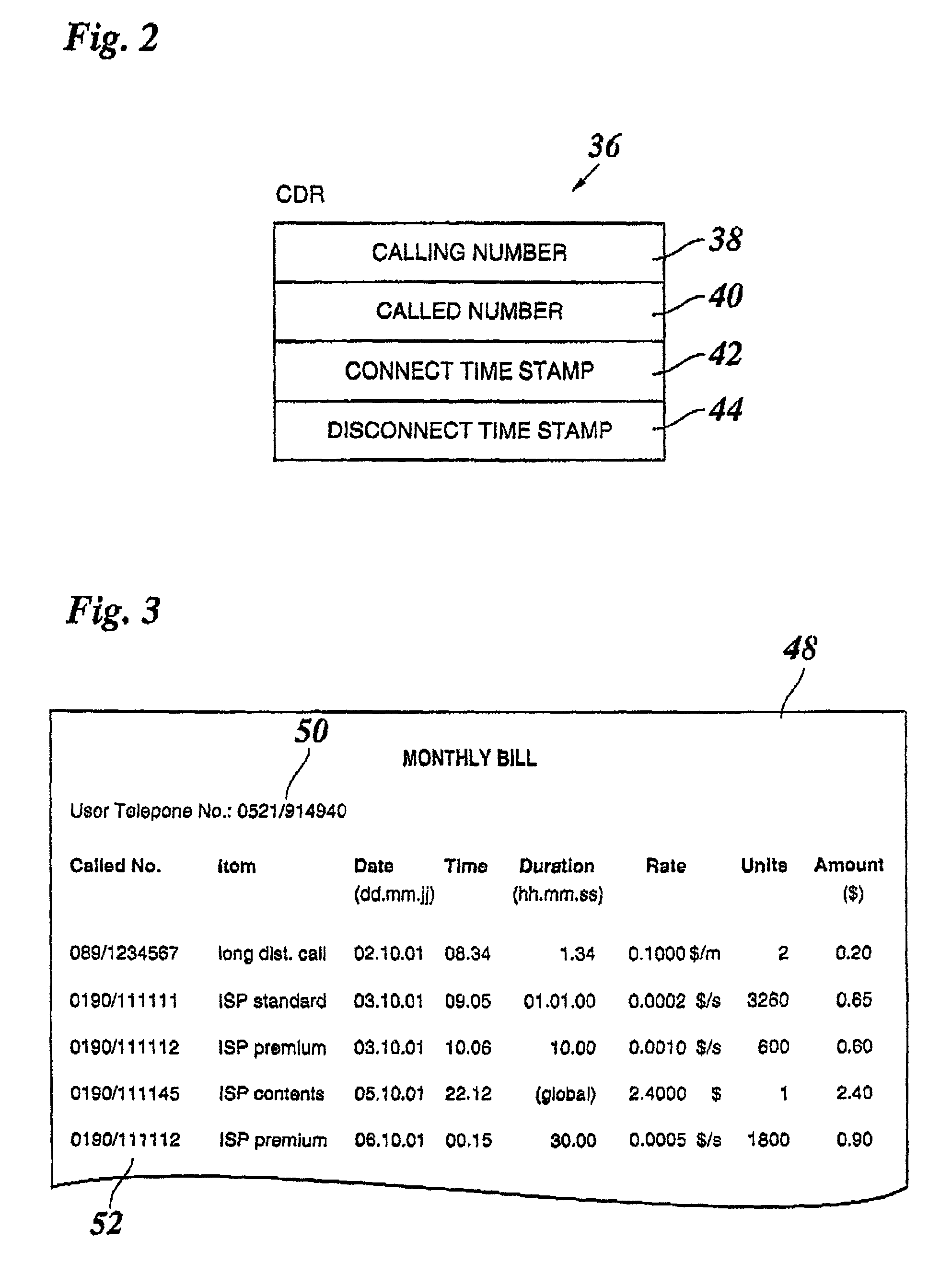

Method and system for providing and billing internet services

InactiveUS7529711B2Efficient and easy to implementBilling system is comprehensive and transparent for the userFinancePayment architectureService profileTelephone network

The present invention relates to systems and methods for providing and billing Internet services that allow a user to select a service profile among a plurality of service profiles. The present invention assigns a service telephone number to each of the service profiles, such that each service profile is uniquely identified by its service telephone number. When the user selects and logs on to one of the service profiles, the present invention checks whether the user has subscribed for being billed on a user telephone number through a telephone network operator, and, if this is the case, the present invention allows access to the selected service profile. When access is allowed, the present invention creates a call detail record including the user telephone number as calling number and the service telephone number of the selected service profile as called number. The present invention then transmits the call detail record to a billing system of the telephone network operator.

Owner:RPX CLEARINGHOUSE

Technique for preparing transparent aluminum oxynitride ceramic

InactiveCN101033139AReduce equipment conditionLow reaction temperatureNitrogen gasAluminum oxynitride

This invention relates to a preparation method for transparent nitrogen alumina ceramics including mixing raw materials, molding blanks and sintering characterizing in mixing Al2O3 in the weight ratio of 80-95% and AlN of 5-20%, adding sintering aids in 0.1-9% of the mixture weight to be ball-milled and dried then pressed and molded, then to get the blank in equal static pressure, then biscuit firing the blank by rising the temperature to 800-1200deg.C for 0.5-3h, then lowering the temperature and firing the second time by sintering at normal pressure under N atmosphere and rises the temperature to 1800-1900deg.C for 0.5-8h to get a transparent nitrogen alumina ceramic material.

Owner:SHANDONG UNIV OF TECH

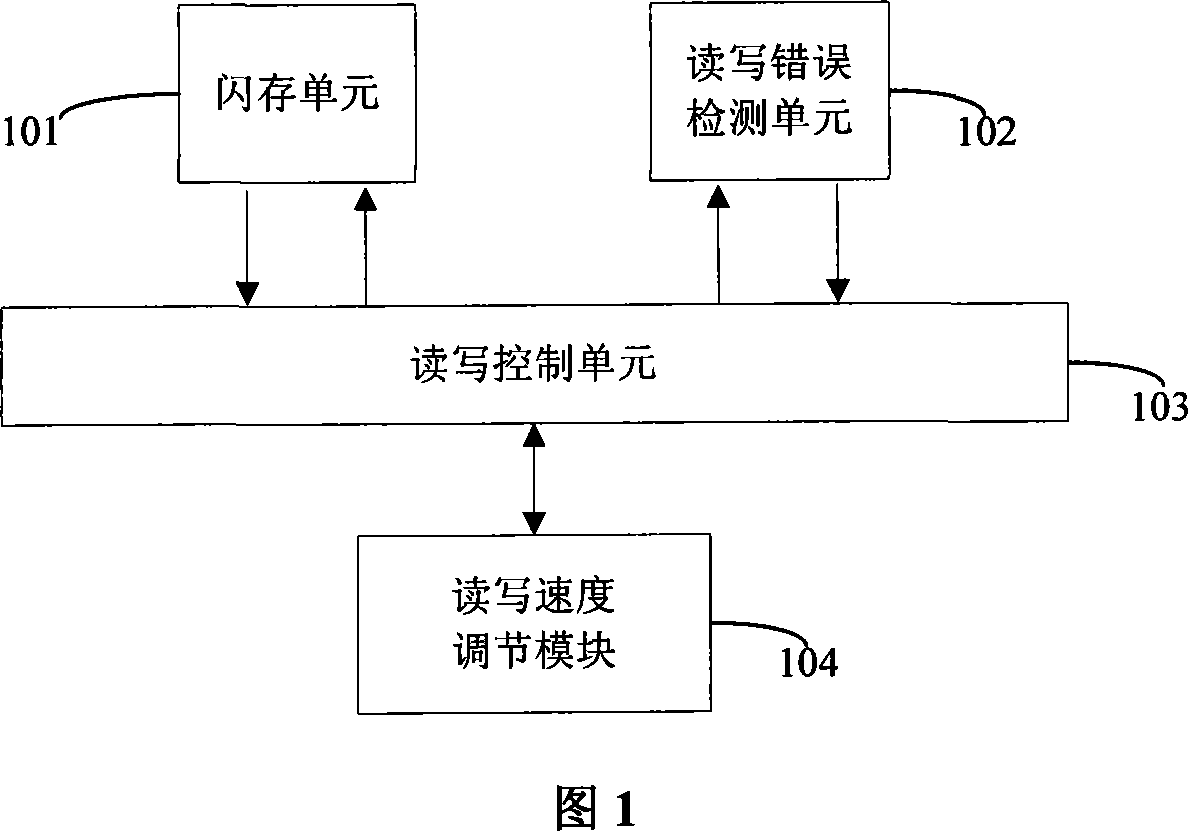

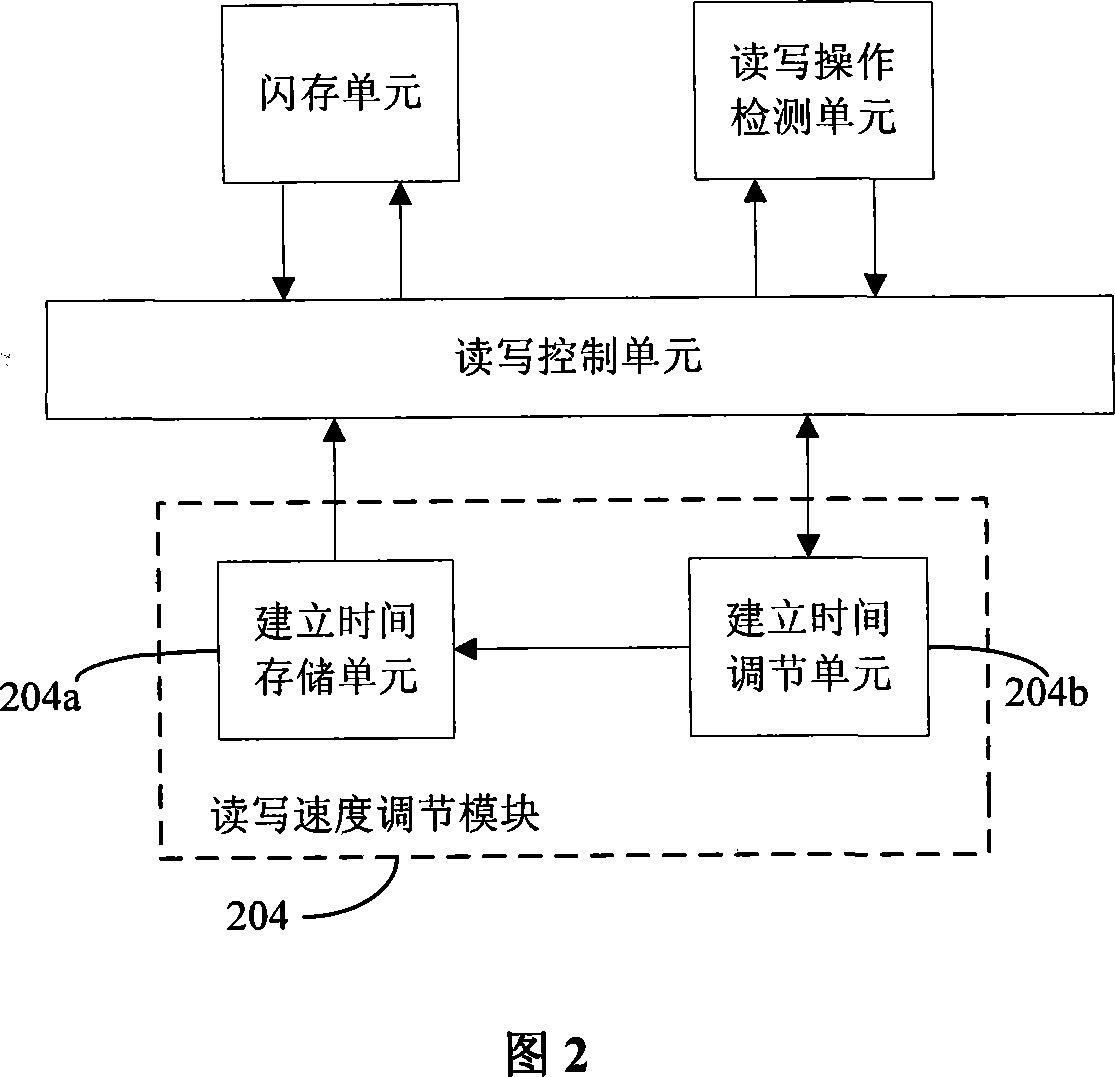

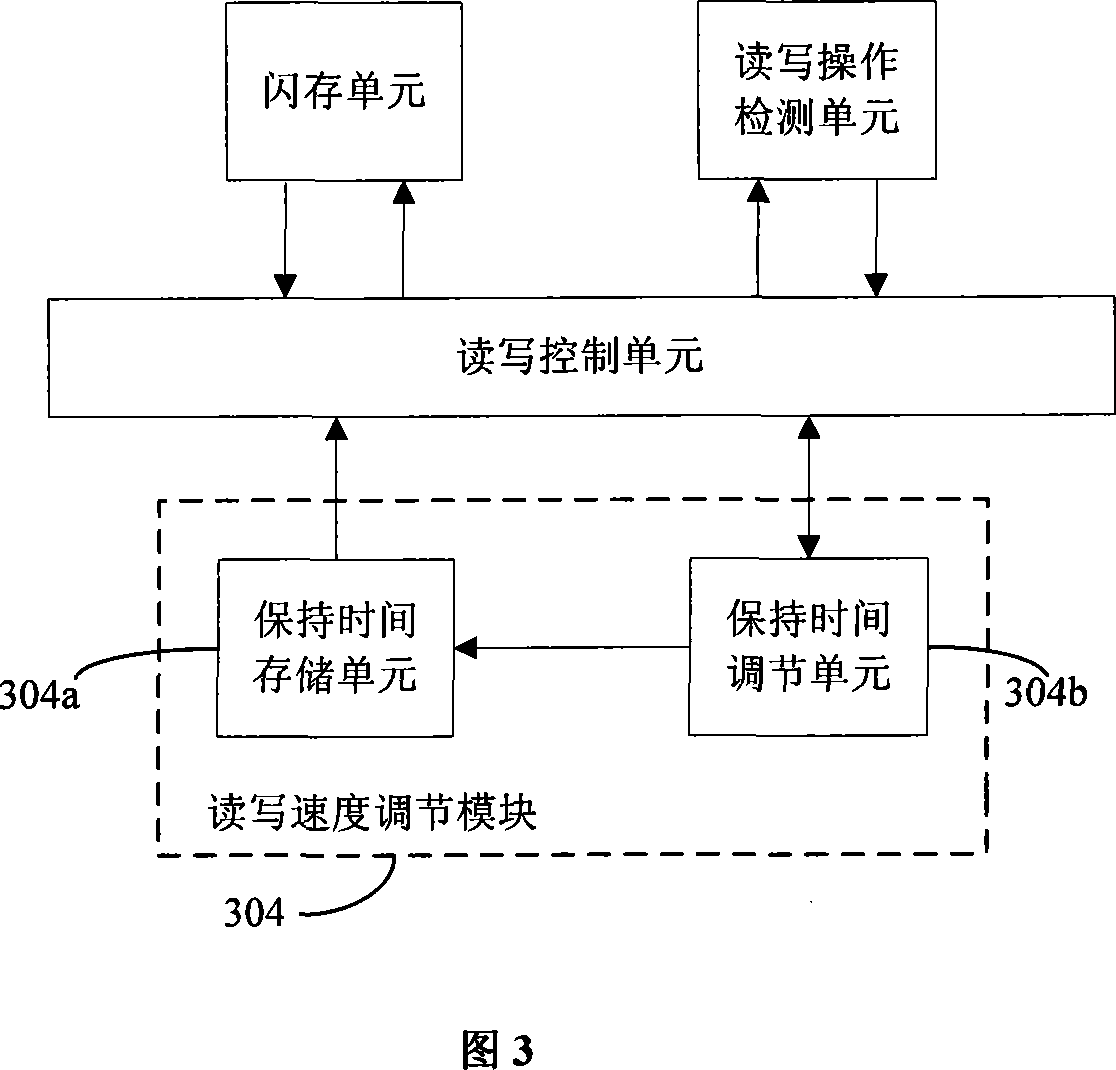

Apparatus and method for adaptive controlling flash storage interface reading and writing speed

InactiveCN101067968AImprove read and write speedReduced settling timeRead-only memoriesSelf adaptiveAdaptive control

Owner:VIMICRO CORP

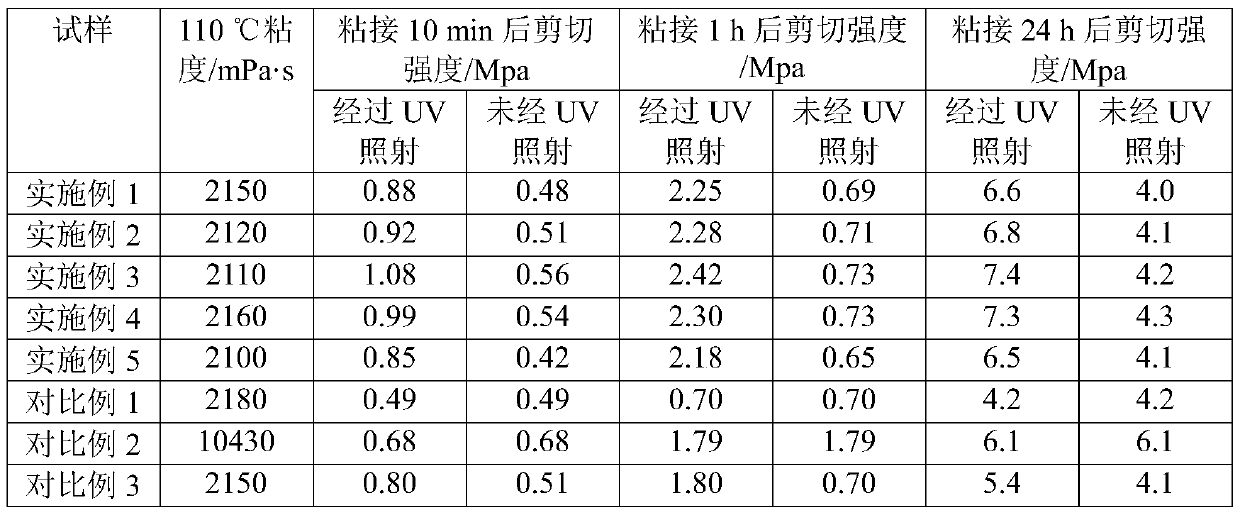

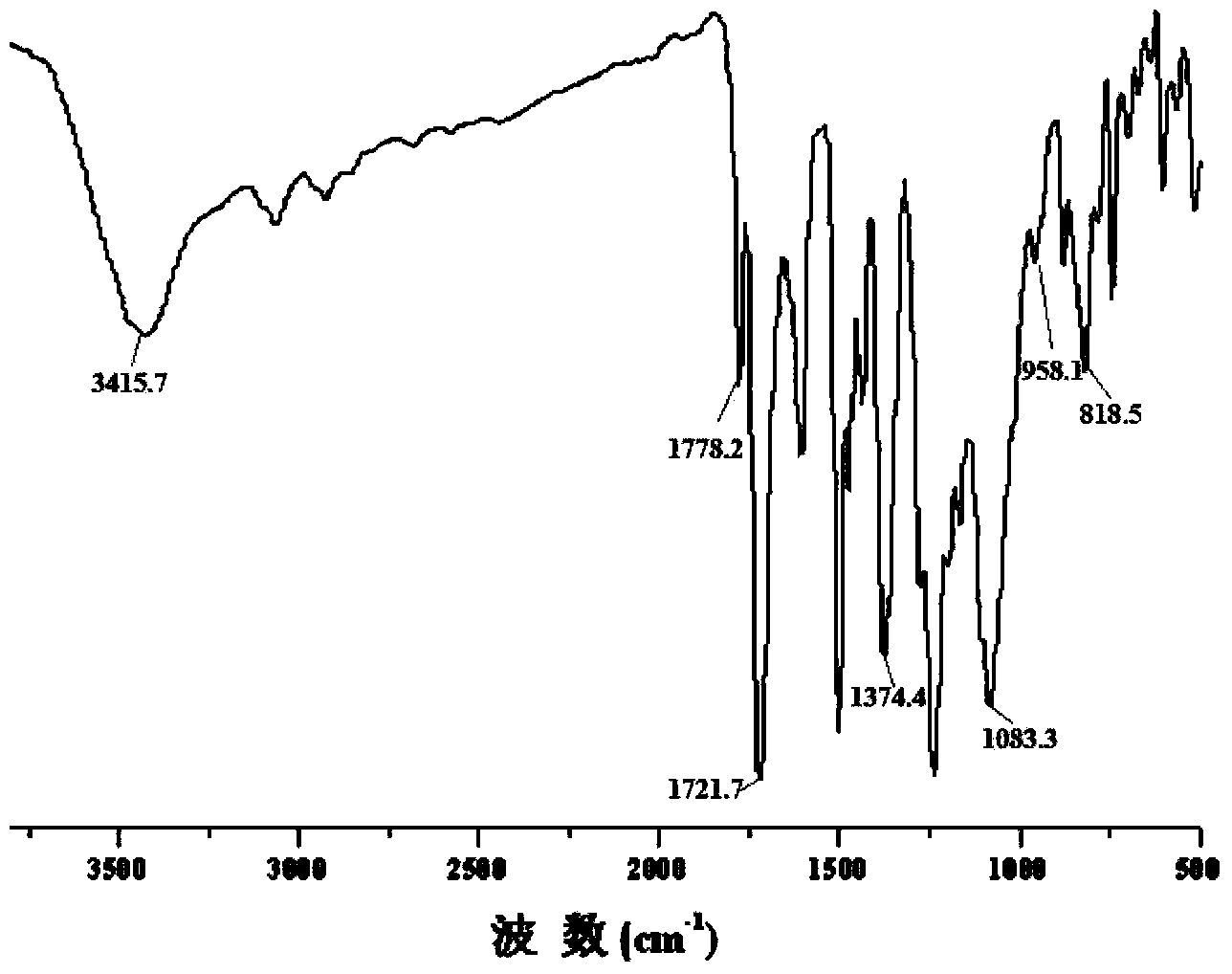

Low viscosity UV/moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

ActiveCN109705794ALow viscosityStrong initial adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention relates to a low viscosity UV / moisture dual-curing polyurethane hot melt adhesive and a preparation method thereof, belonging to the technical field of photocuring adhesives. The low viscosity UV / moisture dual-curing polyurethane hot melt adhesive comprises the following components in parts by weight: 95-97 parts of UV / moisture dual-curing polyester polyether polyurethane, 1-3 partsof free radical photoinitiator, 0.25-2 parts of cationic photoinitiator, 0.25-1 part of photosensitizer, 0.06-0.35 part of polyurethane catalyst, 0.01-0.02 part of water reducing agent, and 0.05-0.2 part of antioxidant. The hot melt adhesive can be used for the bonding of opaque substrates. The viscosity of the adhesive at the sizing temperature 110 DEG C is in the range of 2000-2500 mPa.s, the viscosity is low, the construction is convenient, the initial viscosity is strong, the positioning is fast, the holding time is shortened, even the holding pressure is not needed. The hot melt adhesivedoes not contain small molecular active diluent and is environmentally friendly. The preparation process is simple, easy to operate and suitable for industrial production.

Owner:重庆中科力泰高分子材料有限公司

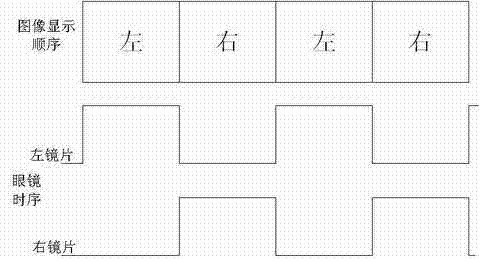

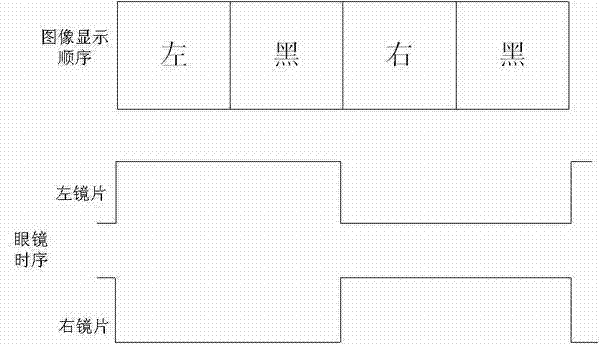

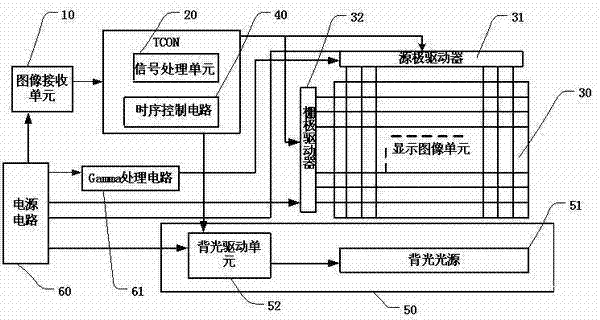

3D (three-dimensional) image display method, 3D image display device and television

InactiveCN103051914ARefresh fastShorten holding timeSteroscopic systemsStandards conversionPattern recognitionComputer graphics (images)

The application provides a 3D image display method, a 3D image display device and a television. A frame of 3D image is received and displayed as four fields of images; when the first field of left-eye image is displayed, the displayed image is rapidly refreshed in a cycle T1, and in a display cycle t1, the left-eye image is then kept; when the second field of dark-field image is displayed, the displayed dark-field image is rapidly refreshed in a cycle T2, and in a display cycle t2, the dark-field image is then kept; likewise, when the third field of right-eye image is displayed, the displayed image is rapidly refreshed in a cycle T3, and in a display cycle t3, the right-eye image is then kept; when the fourth field of dark-field image is displayed, the displayed dark-field image is rapidly refreshed in a cycle T4, and in a display cycle t4, the dark-field image is then kept. Compared with the prior art, the invention optimizes the problem of 3D crosstalk by increasing the image-refreshing speed, thus further increasing the brightness of 3D display.

Owner:HISENSE VISUAL TECH CO LTD

High-performance niobium oxide target material and preparation method thereof

ActiveCN103572236AImprove conductivityUniform densityVacuum evaporation coatingSputtering coatingVolumetric Mass DensityMaterials science

The invention relates to a high-performance niobium oxide target material, which is prepared from the following raw materials in percentage by mass: 89-98.8% of niobium oxide powder, 0.2-1% of activator carbon powder, and 1-10% of a reductant, wherein the reductant is selected from niobium powder or tantalum powder. The invention also provides a preparation method of the niobium oxide target material. The high-performance niobium oxide target material and preparation method thereof disclosed by the invention have the following advantages that (1) the preparation method is high in efficiency: the sintering cycle of the target material is short, only 10-15 hours; and (2) the target optimal is good in performance: the density is high, and can reach more than 99.95% of the relative density; the electrical conductivity is good, and the electrical resistivity is 3*10<-3>-9*10<-3> omega.cm; the target material is uniform in compactness, and has no pit.

Owner:河北东同光电科技有限公司

Writing paper and preparation method thereof

InactiveCN101787660AIncreased fiber lengthIncrease dosagePulp de-wateringReinforcing agents additionPollutant emissionsPulp and paper industry

The invention provides writing paper made of slurry comprising the following components by percentage: 20% to 100% of unbleached straw pulp and 0% to 80% of wood pulp. According to the ISO (International Standardization Organization), the whiteness of the writing paper is 35% to 75%; the opacity thereof is higher than or equal to 75%; and the basis weight thereof is 45.0g / m<2> to 80.0g / m<2>. The production process of the writing paper is energy-saving and cost-saving; and the pollutant emission can be greatly reduced.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Scannable flip-flop with hold time improvements

InactiveUS8493119B2Improve circuit performanceShorten holding timeElectric pulse generatorMultiplexerControl signal

Embodiments of a scannable flip-flop are disclosed that may reduce data hold time, which may in turn improve the performance of circuits incorporating the scannable flip-flop. The scannable flip-flop may include a slave latch and a master latch including an input multiplexer. The multiplexer may include a number of input ports, for example to receive normal operating mode data as well as scan operating mode data, and the multiplexer may be operable to controllably select one of the input ports and pass the value of the selected port to an output of the multiplexer. For example, the multiplexer may generate individual control signals for the various ports dependent upon both the clock signal and a select signal, such that each of the ports is qualified with the select signal and the clock signal before the multiplexer presents the input data of the selected port as the output of the multiplexer.

Owner:APPLE INC

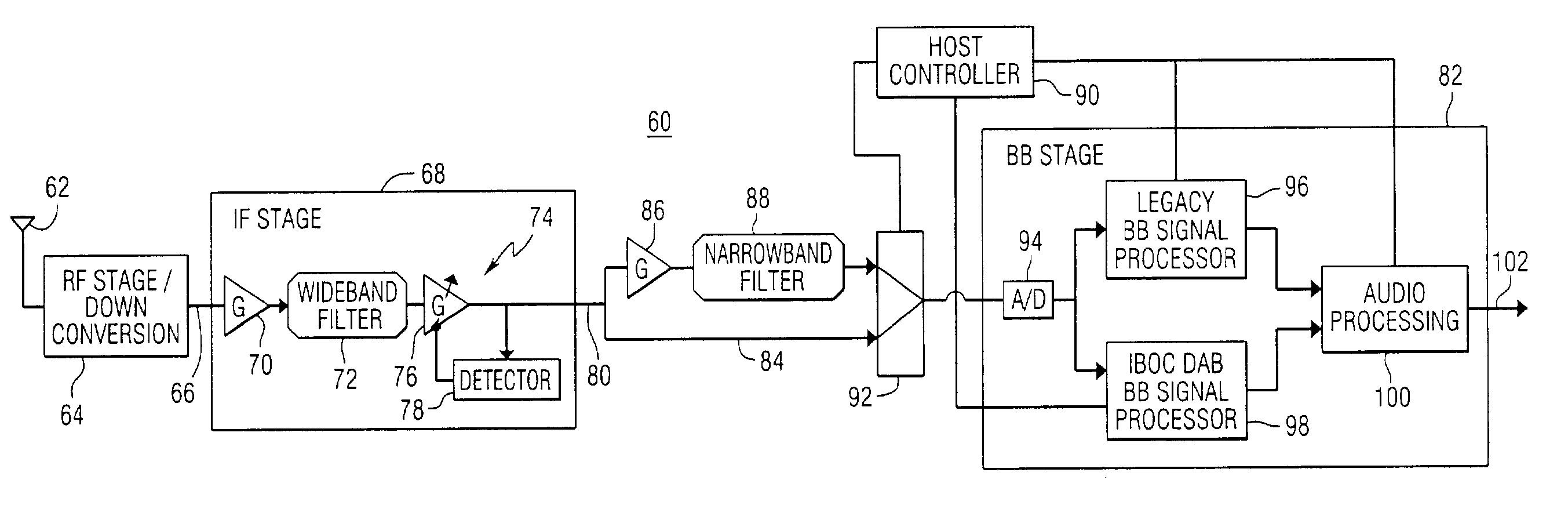

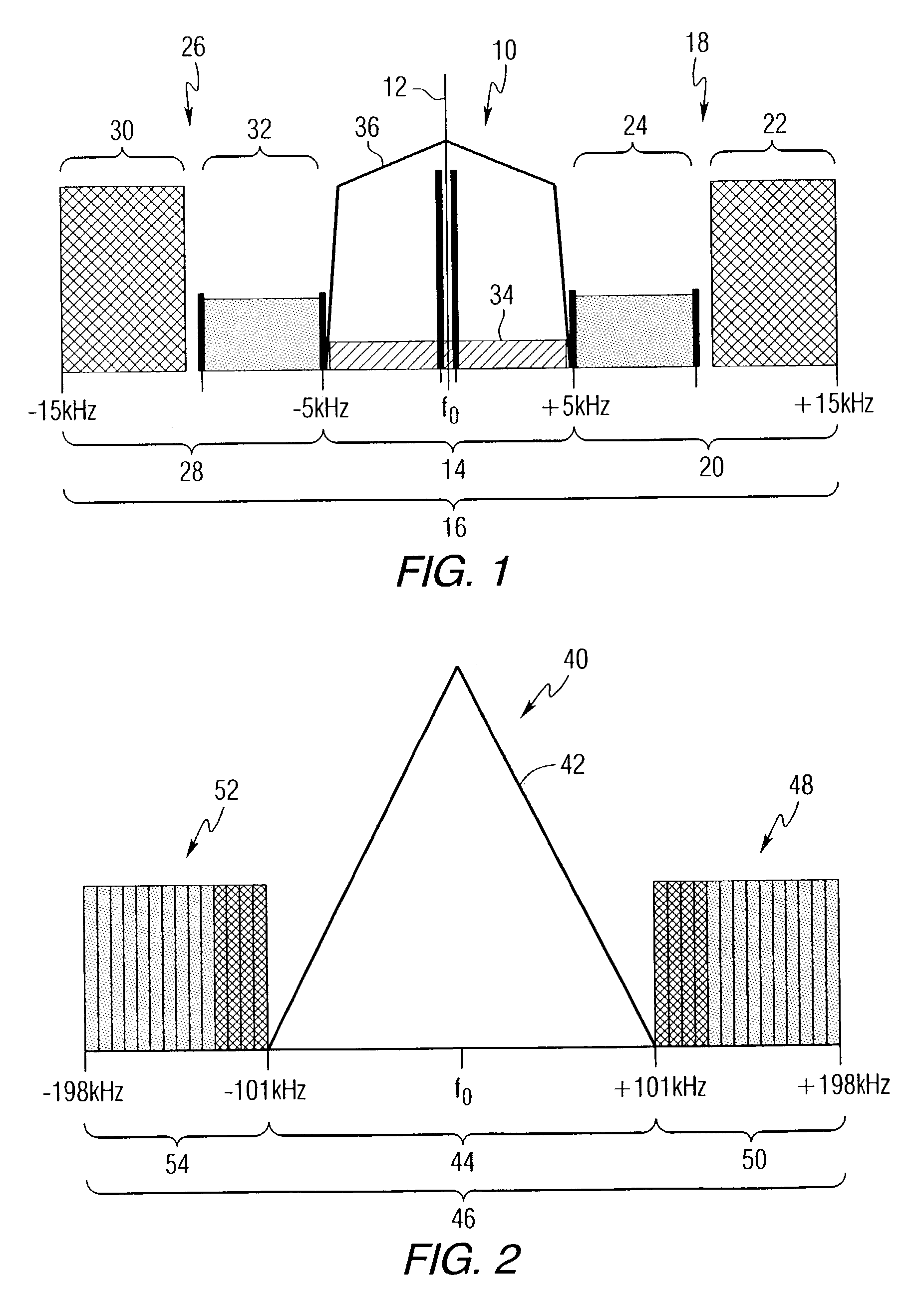

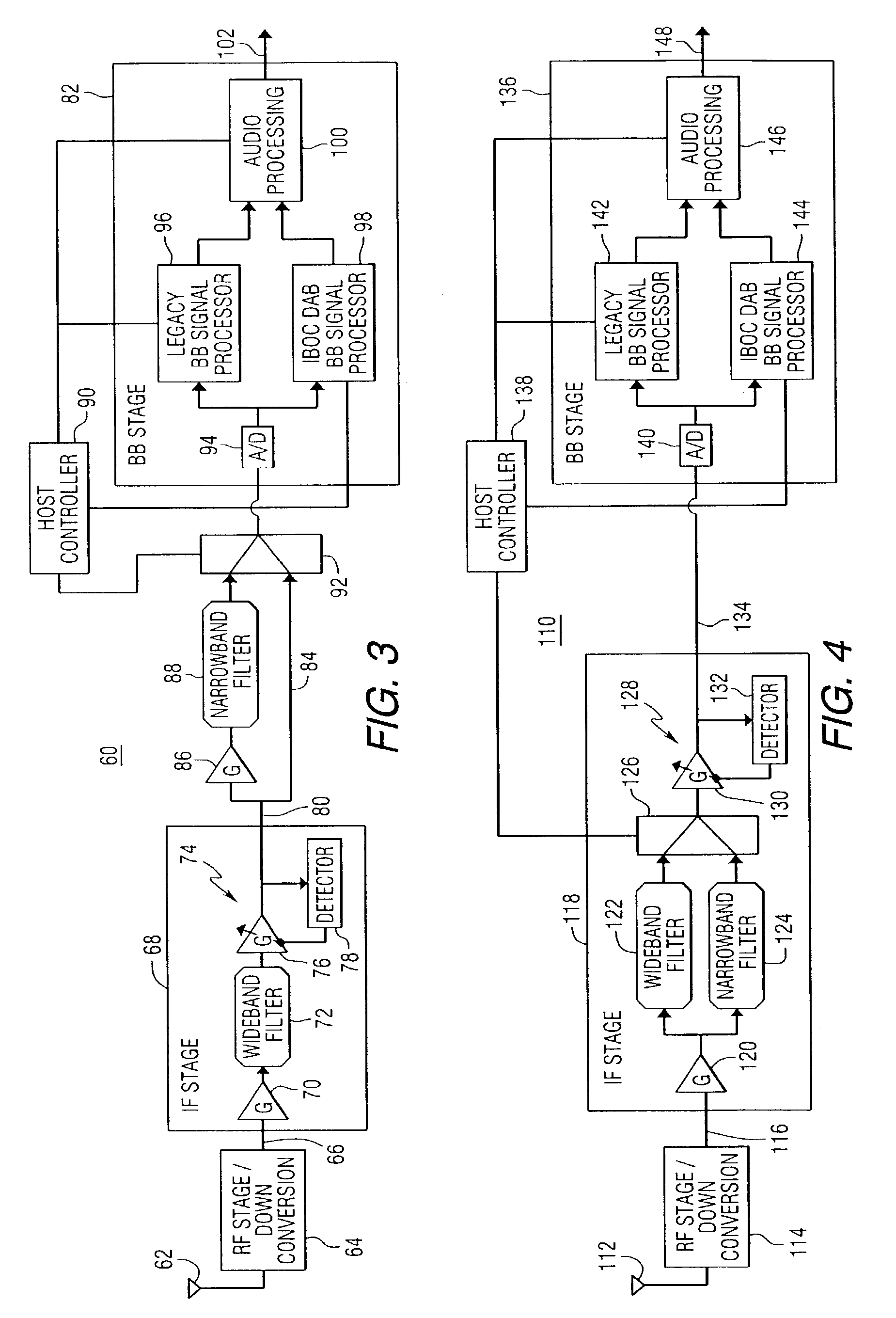

Method and apparatus for dynamic filter selection in radio receivers

ActiveUS6970685B2Shorten holding timeExtended hold timePlural information simultaneous broadcastRadio transmissionRadio receiver designRadio receiver

A method for processing a radio signal which may include a narrowband signal or a wideband signal or both, comprises the steps of receiving the radio signal, initially processing the radio signal using a narrowband filter, switching to a wideband filter for further processing of the radio signal, determining if the wideband signal is acquired, and if the wideband signal is not acquired, alternating between narrowband filter processing for a narrowband filter hold time and wideband filter processing for a wideband filter hold time, where the narrowband filter hold time is gradually increased until a predetermined maximum time limit is reached. If the wideband signal is acquired, the narrowband filter hold time can be set to a predetermined minimum time limit. Receivers which implement the method are also provided.

Owner:IBIQUITY DIGITAL CORP

Production method of steel plate warm formed parts with high efficiency, low energy consumption and high quality

The invention relates to steel plate warm formed parts with high efficiency, low energy consumption and high quality and a production method thereof, belonging to the technical field of part forming. The steel plate for producing parts comprises the following components in percent by weight: 0.02-0.45% of C, 3.50-9.0% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. On the basis of these components, one or more of the following components (in percent by weight) are additionally added: 0.1-3.0% of Ni, 0.2-3.0% of Cr,0.1-0.8% of Mo, 0.3-2.3% of Si, 0.5-2.0% of Cu, 0.0005-0.0050 of B, 0.02-0.30% of Nb, 0.002-0.250% of [N], 0.05-0.25% of Ti, 0.02-0.25% of V, 0.015-3.0% of Al, 0.002-0.005% of RE, and 0.005-0.03% of Ca. The production method comprises the following steps: steel plate heating, steel plate transferring, steel plate precooling, part forming, part cooling, and part temperature control treatment. The production method provided by the invention has the advantages of low cost and high efficiency, and improves the forming rate and final mechanical properties of workpieces.

Owner:CENT IRON & STEEL RES INST

Porous polyimide nanometer composite film and preparation method thereof

The invention discloses a porous polyimide nanometer composite film and a preparation method of the film. The preparation method is characterized by comprising the following steps of: preparing the polyimide composite film by using a sol-gel method, an in-situ polymerization method, a solution direct doping method, and an intercalation hybrid method, placing the composite film into a high-pressure kettle filled with inert gas, and dissolving the gas into the composite film in the presence of the inert gas while keeping the temperature at 30-150 DEG C and the pressure of 5-60MPA for 0.5-12 hours; and rapidly releasing the pressure to the normal pressure to form a lot of foam nuclei on the polyimide / inorganic nanometer particle composite film, and foaming the foam nuclei at the temperature of 150-330 DEG C for 1-60 seconds to obtain the porous polyimide nanometer composite film. The inorganic nanometer particles function as the nucleating agent in the polyimide substrate, not only is the nucleation barrier of the gas reduced, but also the number of the nucleation points is increased, as well as the nucleation points are distributed in the polyimide substrate more uniformly and more stably, so that the obtained micro-pores are smaller in size and more uniform in distribution.

Owner:SICHUAN UNIV

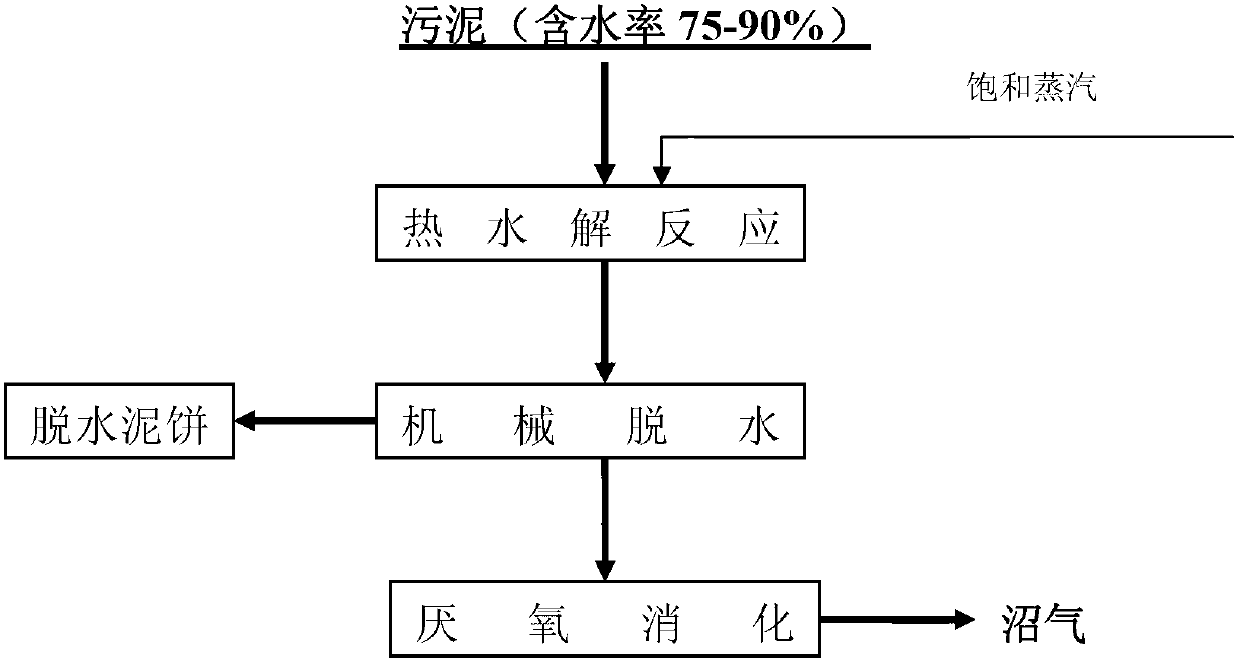

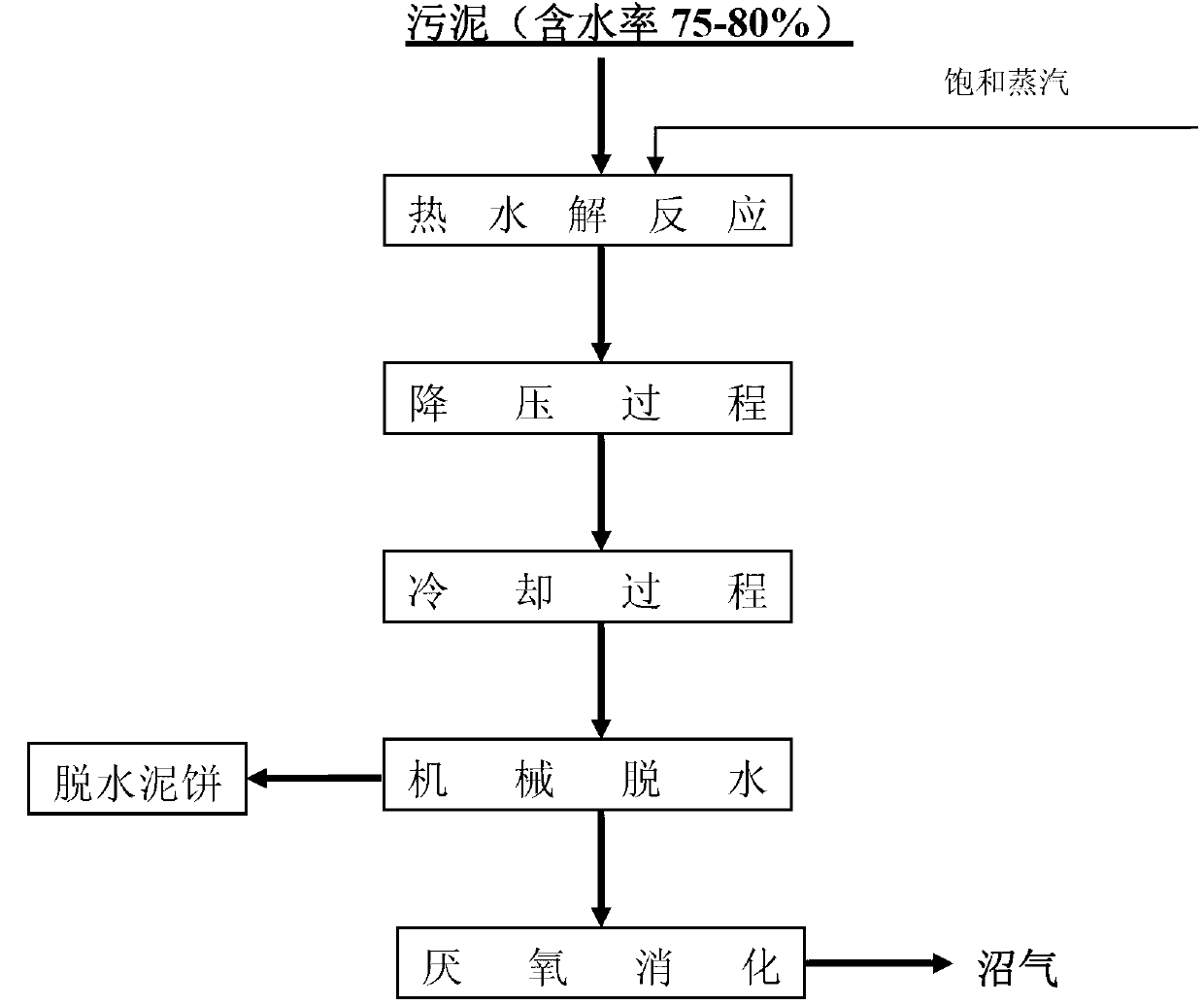

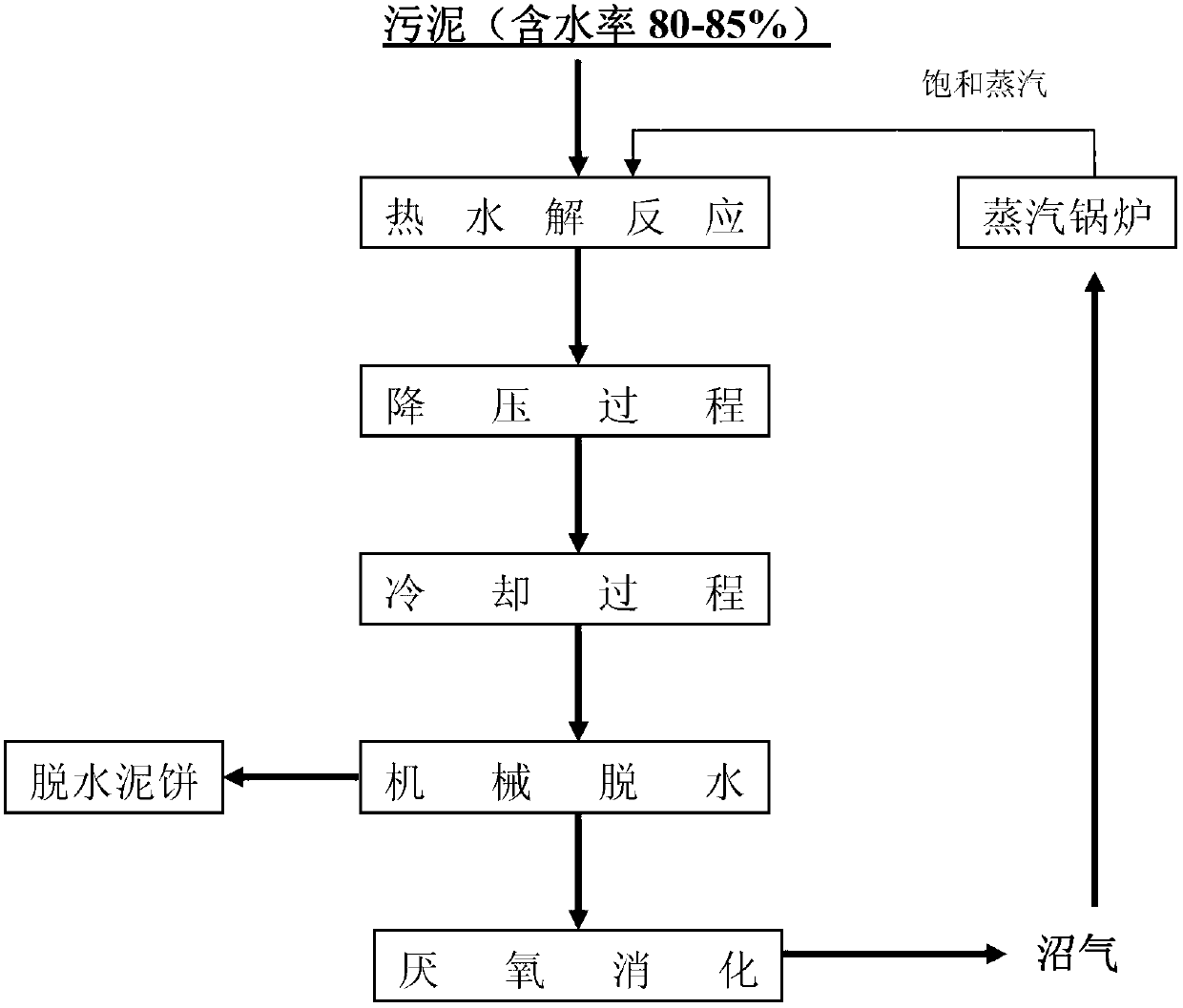

Sludge treatment and resource utilization method based on pyrohydrolysis and application thereof

ActiveCN103130388AHarmlessImproved Anaerobic Digestion PerformanceBio-organic fraction processingSolid waste disposalResource utilizationDesorption

The invention belongs to the technical field of sludge treatment, and discloses a sludge treatment and resource utilization method based on pyrohydrolysis and application of the sludge treatment and resource utilization method based on the pyrohydrolysis. The sludge treatment and resource utilization method based on the pyrohydrolysis comprises injecting sludge with moisture content of 75%-90% into a reaction kettle, then injecting saturated steam with pressure of 1.5MPa-2.5MPa into the reaction kettle, stopping injecting the saturated steam when the temperature of the sludge reaches 150DEG C-185DEG C, maintaining the state for 0-25min, and obtaining slurry of the pyrohydrolysis; carrying out mechanical dehydration on the slurry, and obtaining desorption liquid and dehydration mud cakes; and carrying out an anaerobic digestion reaction on the desorption liquid, and obtaining methane. Processing temperature of the pyrohydrolysis is low, heating time of the sludge and total processing time of the sludge treatment and resource utilization method can remarkably reduced, processing efficiency is improved, energy consumption is reduced, and cost is saved. The dehydration mud cakes obtained by the sludge treatment and resource utilization method can serve as raw materials of organic fertilizer, the obtained methane can be used for fuel of a boiler system, and finally reduction, harmless performance and recycling of the sludge are achieved.

Owner:SHENZHEN ECO SOLUTION TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com