Patents

Literature

93results about How to "Lower nucleation barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulphoaluminate cement and preparation method thereof

The invention discloses sulphoaluminate cement. The sulphoaluminate cement is characterized by containing 5%-35% by mass of calcium sulphosilicate mineral. The invention further discloses a preparation method of the sulphoaluminate cement. The preparation method is characterized in that the fired clinker contains calcium sulphosilicate, and comprises the following steps of firstly, calcining a raw material according to a proper calcination process in preparation; carrying out secondary calcination according to the set calcination temperature and heat preservation time; and grinding secondarily calcined cement clinker and additive gypsum to prepare the sulphoaluminate cement. The sulphoaluminate cement is simple to prepare, convenient to implement and low in cost; the later strength shrinkage problem of the sulphoaluminate cement can be improved; meanwhile, the calcium sulphate content can be improved; the silicate waste residues with high calcium sulphate content are digested; and the production and application ranges of the sulphoaluminate cement are expanded.

Owner:CHONGQING UNIV

Composite mineral admixture for concrete

The invention discloses a composite mineral admixture for concrete. The admixture is prepared by mixing and grinding the following raw materials in percentage by weight: 40 to 60% of lithium slag, 10 to 30% of mineral slag, 5 to 20% of nickel slag, 5 to 10% of aerated concrete waste, 5 to 10% of sulfoaluminate cement clinker, and 0.1 to 0.5% of super plasticizer powder. The industrial wastes are fully utilized, the concrete production cost is reduced, and the admixture has a high activity, barely influences the early and late strength of concrete, has a shrinkage-compensating function and good anti-permeability property, and can improve the service life of concrete.

Owner:SOUTHEAST UNIV

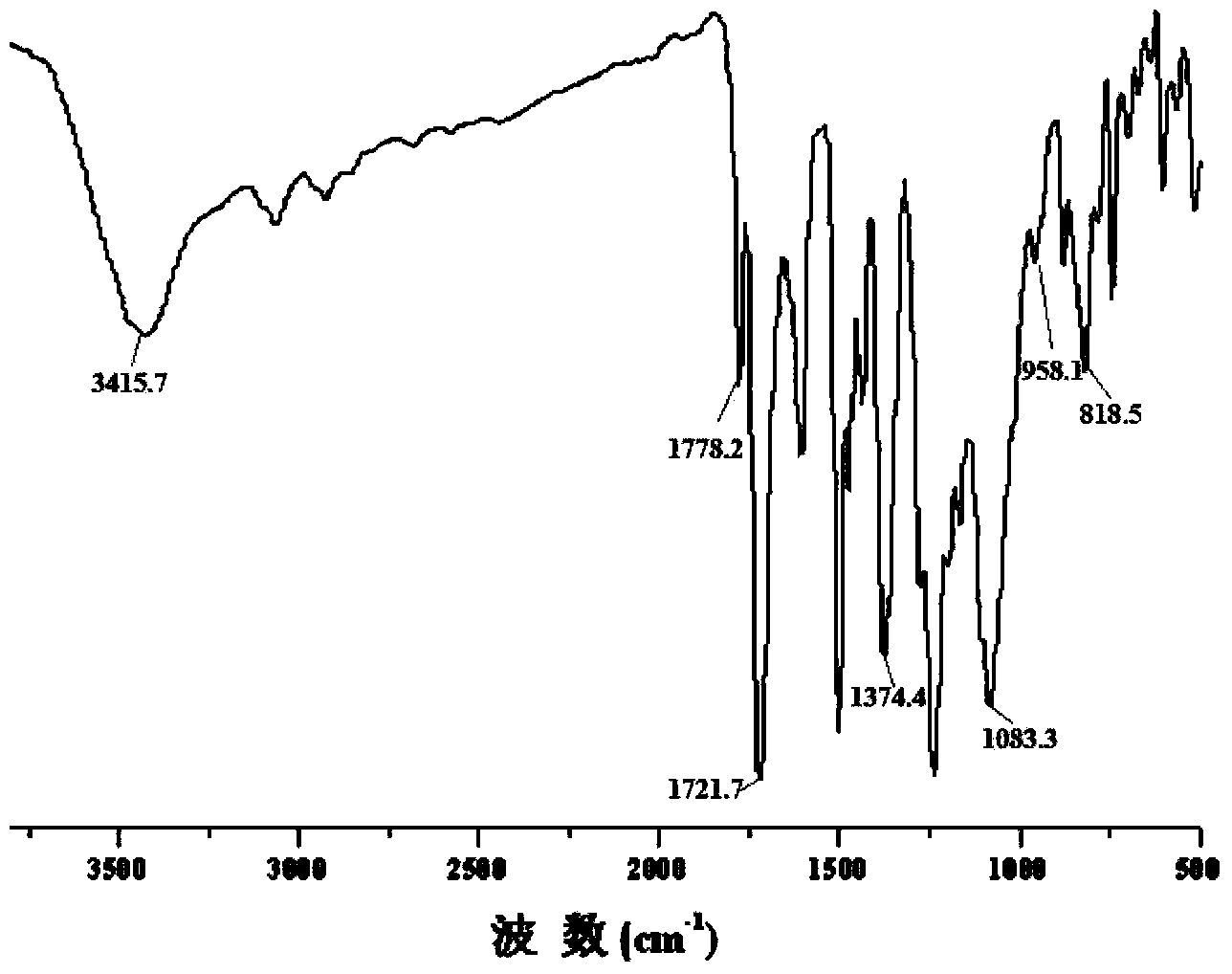

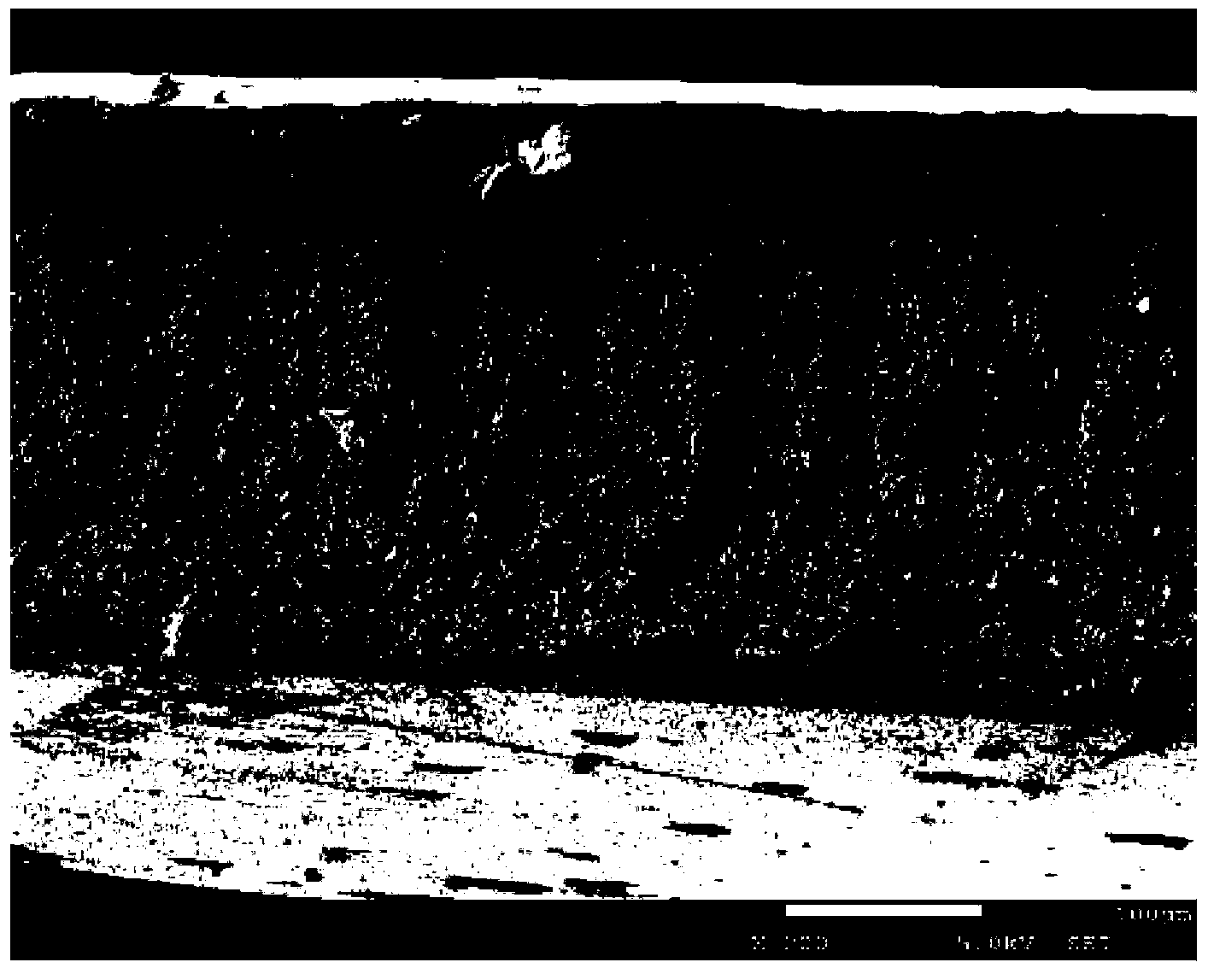

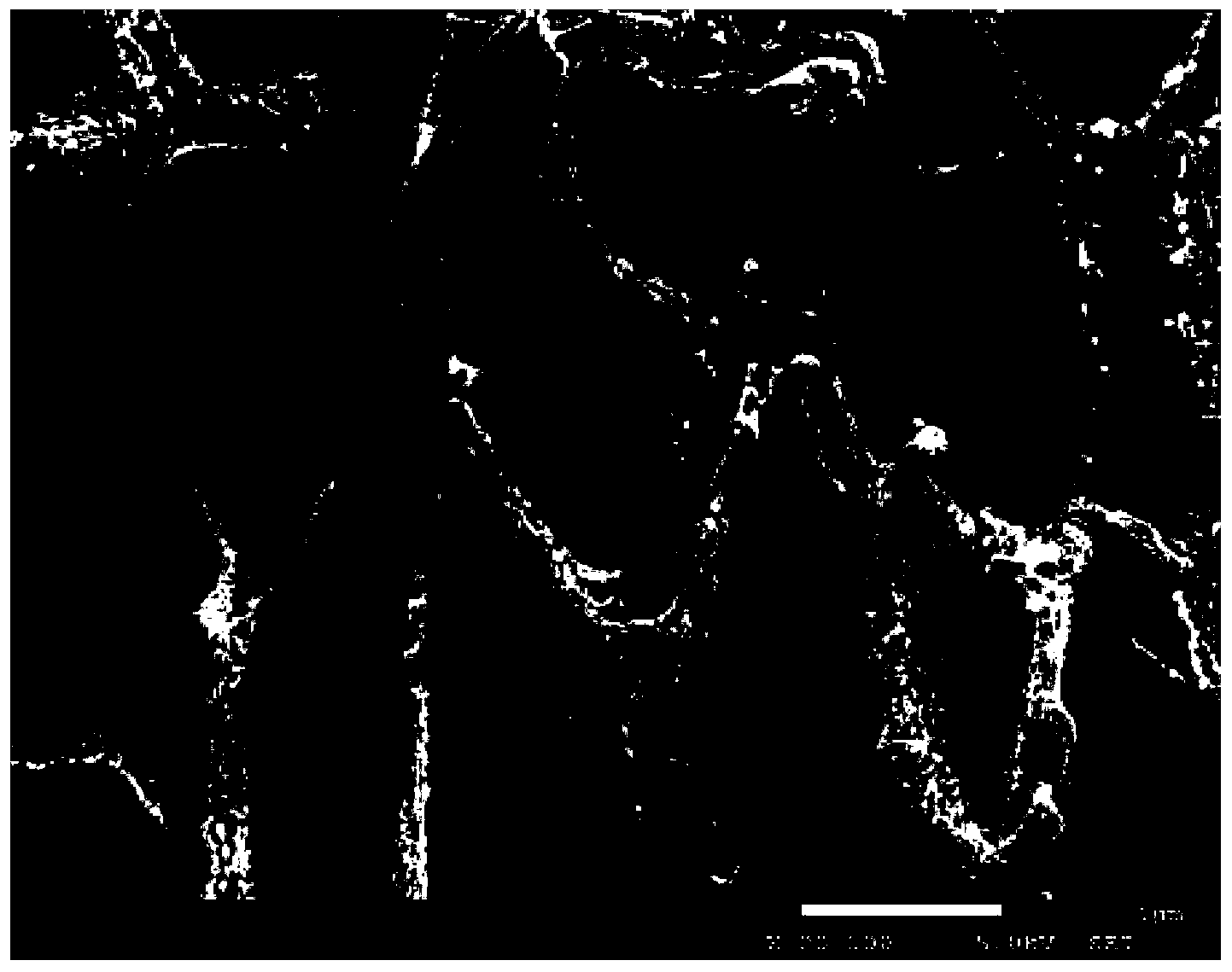

Graphene-base nanocrystal-nucleus early-strength admixture and preparation method thereof

ActiveCN106746834AIncreased dispersionImprove early strengthCarbon compoundsHazardous substanceMaterials science

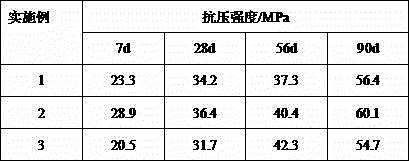

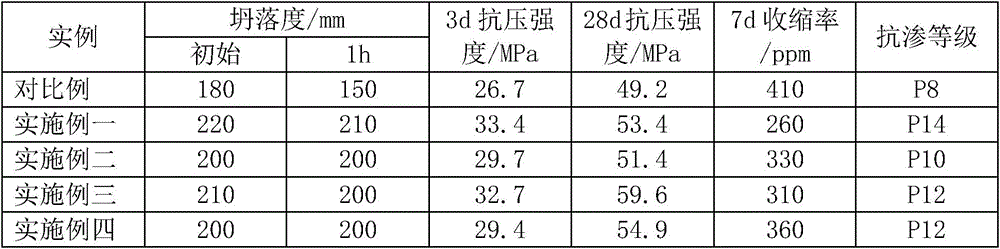

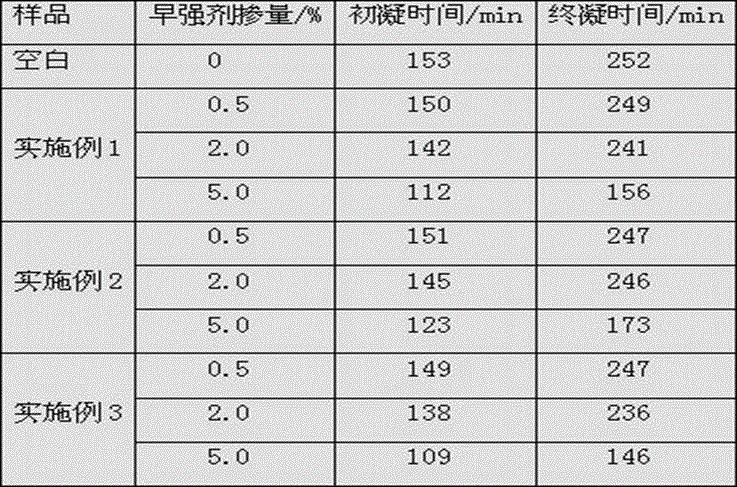

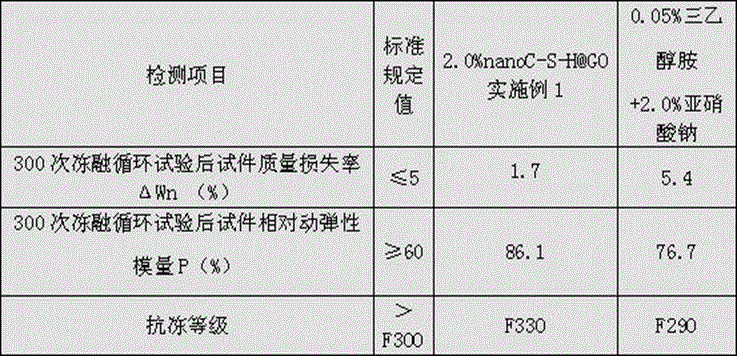

The invention belongs to the technical field of concrete admixtures. In order to solve the problem that many defects in the existing early-strength admixture often causes the problem of degradation of workability and durability, and even water impermeability and corrosion resistance, the invention provides a graphene-base nanocrystal-nucleus early-strength admixture and a preparation method thereof. According to the method, by using calcium nitrate as a Ca source and sodium silicate as a Si source, in-situ precipitation reaction is carried out at room temperature to support the C-S-H nanocrystal nucleus onto graphene oxide (GO), thereby obtaining the nano C-S-H@GO. The introduced GO greatly enhances the dispersion degree of the C-S-H crystal nucleus, exposes more C-S-H active sites, provides a crystal nucleus inducer for the early hydration period of cement, lowers the nucleation barrier of the cement hydration product, and accelerates the hydration process of the hydration product, thereby enhancing the early strength of the cement substrate on the premise of not losing later strength. The method is easy in production technique and simple to operate, and is beneficial to industrial production. The raw materials are free of harmful substances, and thus, the product is green and environment-friendly.

Owner:CHINA RAILWAY 12TH BUREAU GRP +2

Porous polyimide nanometer composite film and preparation method thereof

The invention discloses a porous polyimide nanometer composite film and a preparation method of the film. The preparation method is characterized by comprising the following steps of: preparing the polyimide composite film by using a sol-gel method, an in-situ polymerization method, a solution direct doping method, and an intercalation hybrid method, placing the composite film into a high-pressure kettle filled with inert gas, and dissolving the gas into the composite film in the presence of the inert gas while keeping the temperature at 30-150 DEG C and the pressure of 5-60MPA for 0.5-12 hours; and rapidly releasing the pressure to the normal pressure to form a lot of foam nuclei on the polyimide / inorganic nanometer particle composite film, and foaming the foam nuclei at the temperature of 150-330 DEG C for 1-60 seconds to obtain the porous polyimide nanometer composite film. The inorganic nanometer particles function as the nucleating agent in the polyimide substrate, not only is the nucleation barrier of the gas reduced, but also the number of the nucleation points is increased, as well as the nucleation points are distributed in the polyimide substrate more uniformly and more stably, so that the obtained micro-pores are smaller in size and more uniform in distribution.

Owner:SICHUAN UNIV

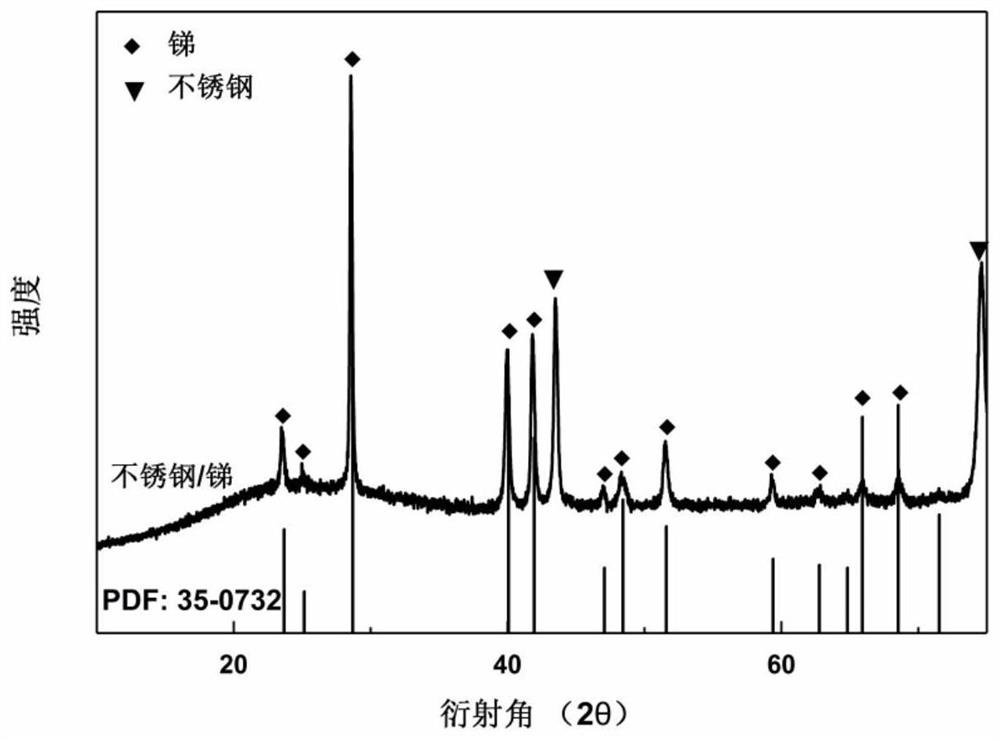

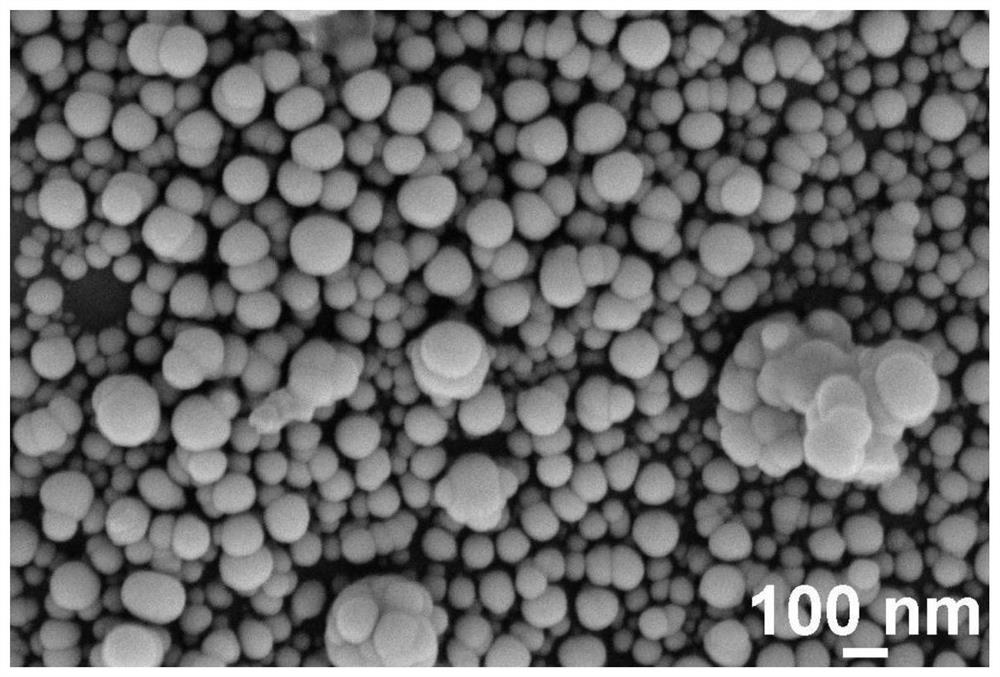

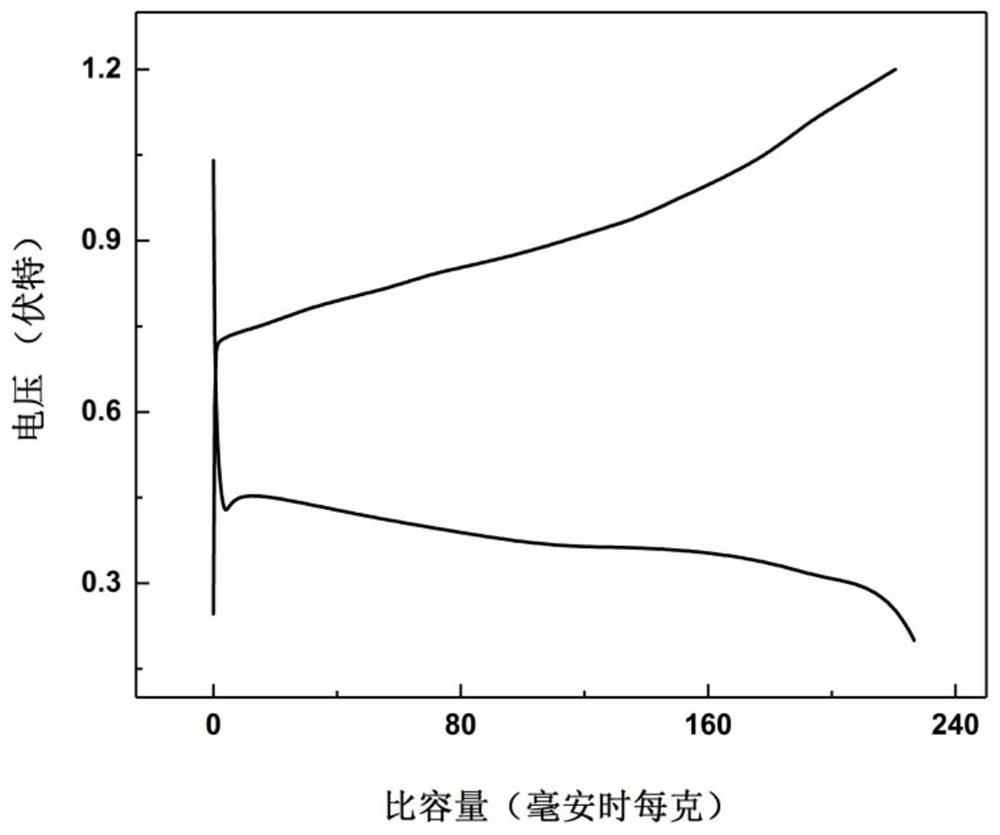

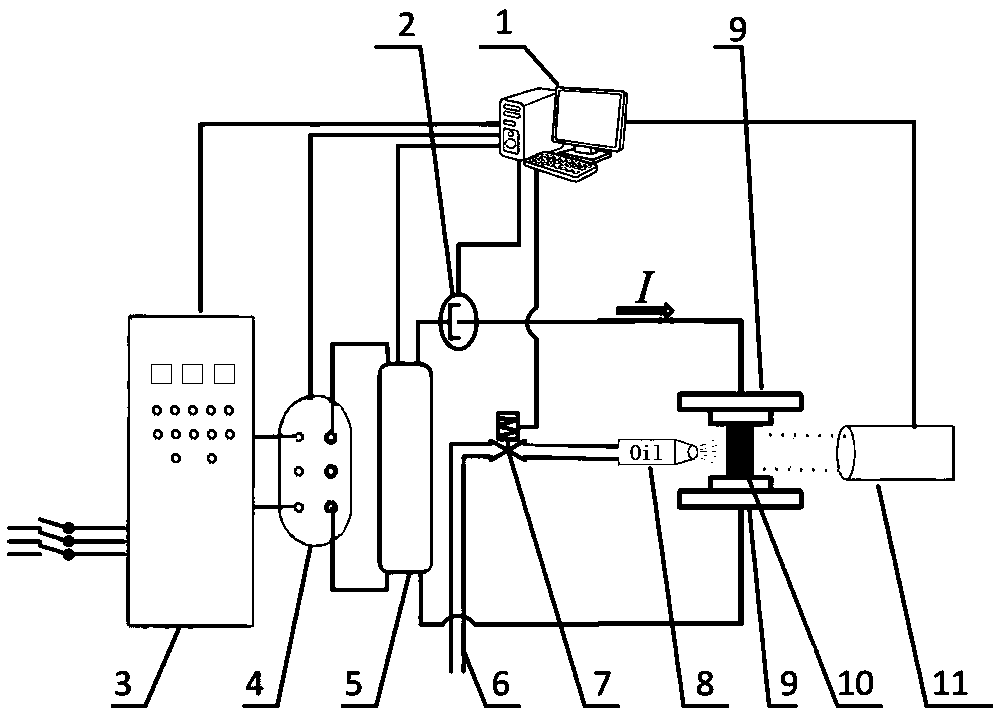

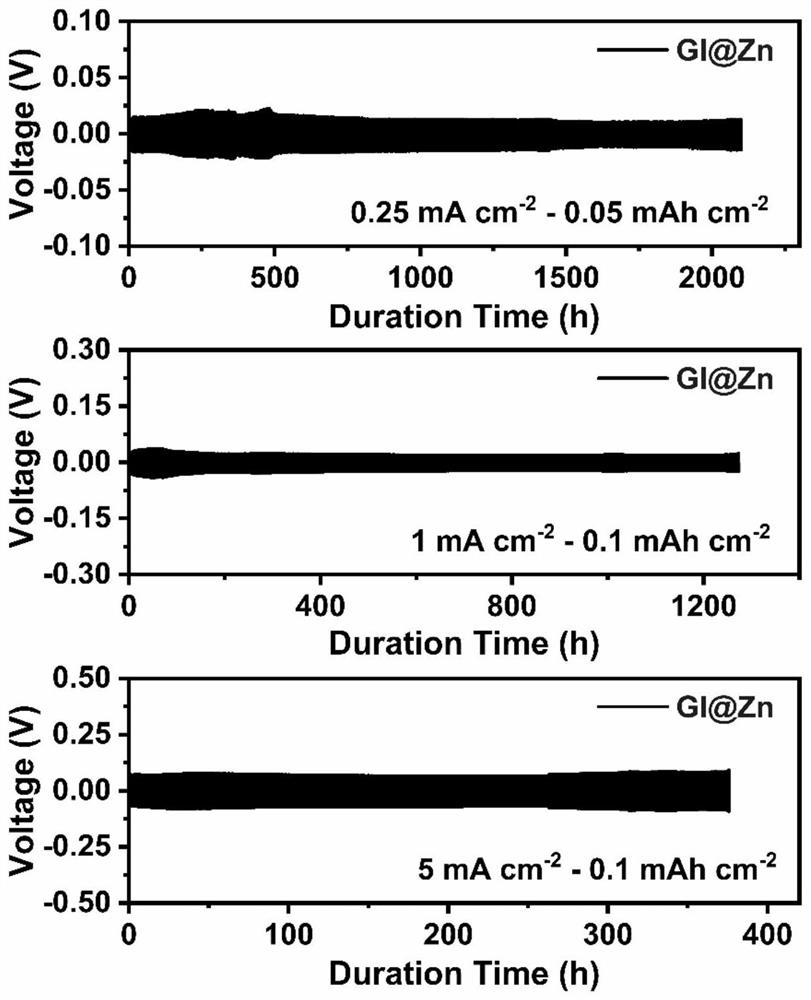

Water-based rechargeable zinc ion battery alloy type negative electrode material and preparation method and application thereof

ActiveCN111916720AImprove bindingImprove cycle stabilityFinal product manufactureElectrode carriers/collectorsElectrical batteryCurrent collector

The invention discloses a water-based rechargeable zinc ion battery alloy type negative electrode material and a preparation method and application thereof, and the preparation method comprises the following steps: electrochemically depositing a particle layer of a specific metal simple substance on a current collector, then performing heating to 50-450 DEG C under a vacuum condition, and treatingfor 0.1-5 hours; wherein the current collector is carbon cloth, carbon fiber paper, graphene paper, MXene, stainless steel foil or titanium foil, and the metal simple substance is antimony, cobalt, nickel, germanium, copper, silver or gold. The material prepared by the invention can be used as a dendritic-crystal-free alloy type negative electrode material and has high theoretical specific capacity; and the deposited metals can be used as nucleation seeds to effectively inhibit zinc dendrites, and the electrode material can reduce nucleation barriers, reduce nucleation overpotential, realizeuniform zinc deposition, effectively inhibit growth of the zinc dendrites and better exert the cycle stability of the zinc dendrites.

Owner:SHANDONG UNIV

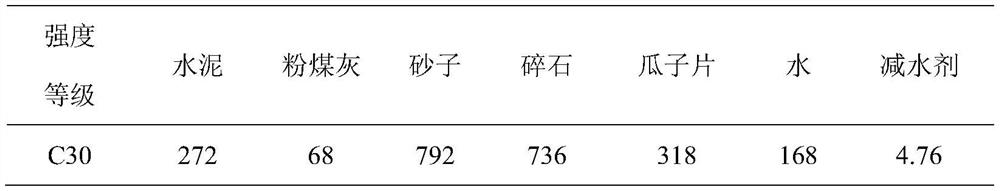

Limestone ultrafine powder concrete with strength grade not higher than C40

The invention relates to the technical field of concrete in building materials and discloses limestone ultrafine powder concrete with a strength grade not higher than C40. The limestone ultrafine powder concrete is prepared from coarse aggregate, fine aggregates, cementing materials, water and an additive, wherein the coarse aggregate is rubble; the fine aggregates comprise river sand and machine-made sand; the cementing materials comprises comprise cement, slag powder, fly ash and limestone ultrafine powder; and the additive is a water reducing agent. In the invention, the limestone ultrafine powder replaces certain amount of cement as part of the cementing materials; the prepared limestone ultrafine powder concrete is superior to traditional concrete in terms of working performance, compressive strength, elasticity modulus, durability and the like; and moreover, the cement is saved, the production cost of concrete is reduced, the energy consumption and CO2 discharge in the cement production process are reduced, and the combination of greenness, energy conservation and environmental protection can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

Method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses

ActiveCN109825689AHigh hardnessImprove toughnessHeat treatment process controlAustenite grainCarbide

The invention discloses a method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses. The method includes the steps that high-speed steel is subjected to conventional austenitizing and then quenched and tempered; then the two ends of the steel are clamped between electrodes of electric pulse equipment, the high-speed steel is discharged in the air environment, the temperature of the material rises to the austenitizing temperature region through pulse currents, austenite grains are ultrafine, and dissolution of carbide is promoted; after electric pulse discharge is completed, quenching is completed through an automatic quenching device; and finally the high-solid-solubility ultrafine grain high-speed steel in a quenched state through electric pulse treatment is tempered three times, and the high-speed steel with excellent comprehensive mechanical performance is obtained. By means of the method, the technical bottleneck that in the traditional heat treatment process, high-speed steel grain refinement and carbide dissolution promotion cannot be taken into account is solved, and the double effects that the high-speed steel austenite grains are ultrafine, and the dissolution quantity of the carbide is increased are achieved. The method is short in technological process, energy saving and high efficiency are achieved, and the hardness and thetoughness of the high-speed steel can be simultaneously improved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

High-activity crystal seed for concrete production and preparation method thereof

InactiveCN101830660AImprove burnabilityLower firing temperatureSolid waste managementSolid waste disposalSlagSeed crystal

Owner:EAST CHINA JIAOTONG UNIVERSITY

Crystalline nucleus early-strength polycarboxylic acid water reducer and preparation method thereof

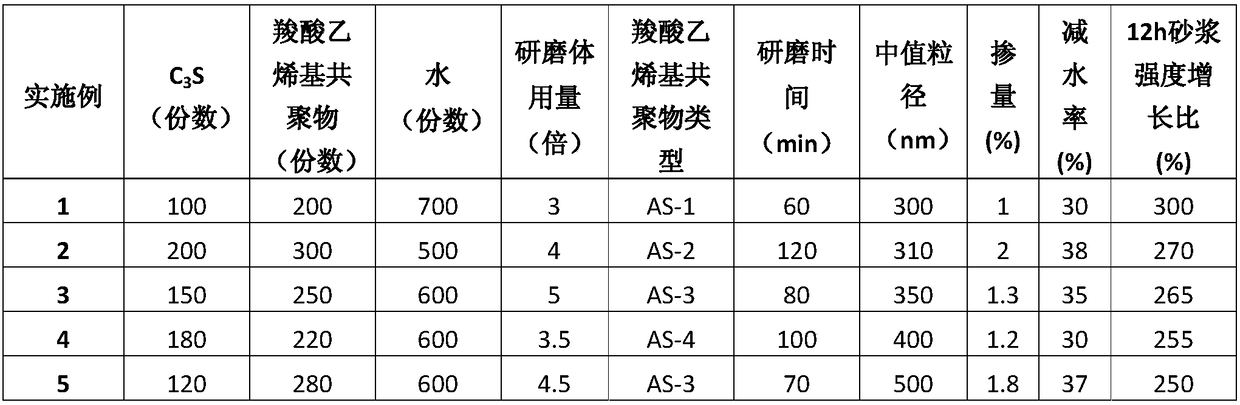

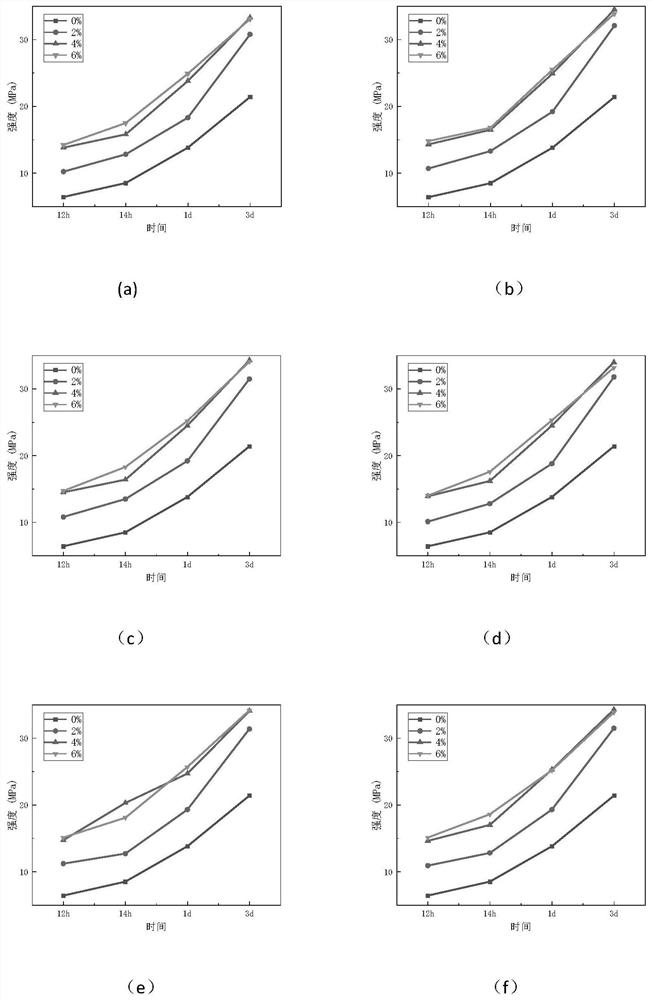

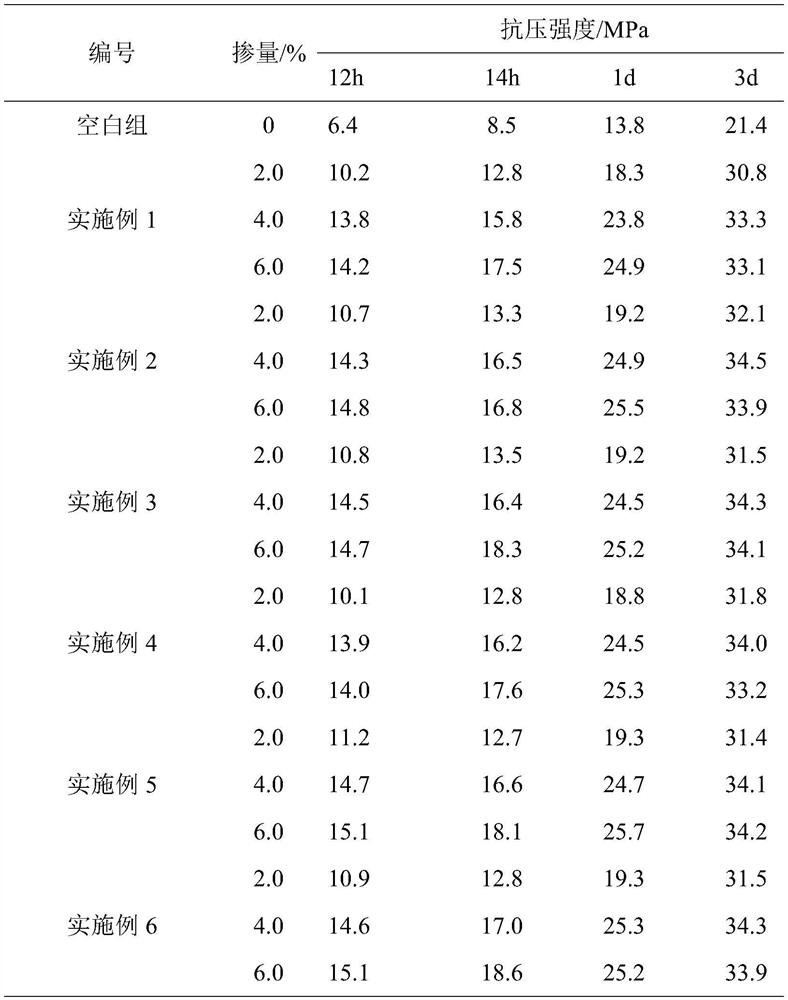

InactiveCN109293267AStrong water reduction effectLower nucleation barrierTricalcium silicateReduction rate

The invention relates to a crystalline nucleus early-strength polycarboxylic acid water reducer and a preparation method thereof. The water reducer comprises the following components in percentage byweight: 10-20% of tricalcium silicate, 20-30% of carboxylic acid vinyl copolymer and 50-70% of deionized water. The preparation method comprises the following steps: adding tricalcium silicate, carboxylic acid vinyl copolymer and deionized water into a ball mill according to proportion, adding zirconia grinding balls, and performing ball milling to obtain the crystalline nucleus early-strength polycarboxylic acid water reducer with a median particle size of less than or equal to 500nm. The crystalline nucleus early-strength polycarboxylic acid water reducer provided by the invention integratesthe advantages of the water reducer and the early-strength agent, the main raw materials are tricalcium silicate and polycarboxylic acid water reducer, which will not cause strength decreasing in thelater stage, the water reducer is mixed into ordinary portland cement mortar according to the mixing amount of 1.0-2.0%, so that the water reduction rate can reach more than 30% and the 12h strengthincrease ratio can reach more than 250%. The preparation method is simple in process, easy to control the process parameters and easy to popularize.

Owner:WUHAN UNIV OF TECH

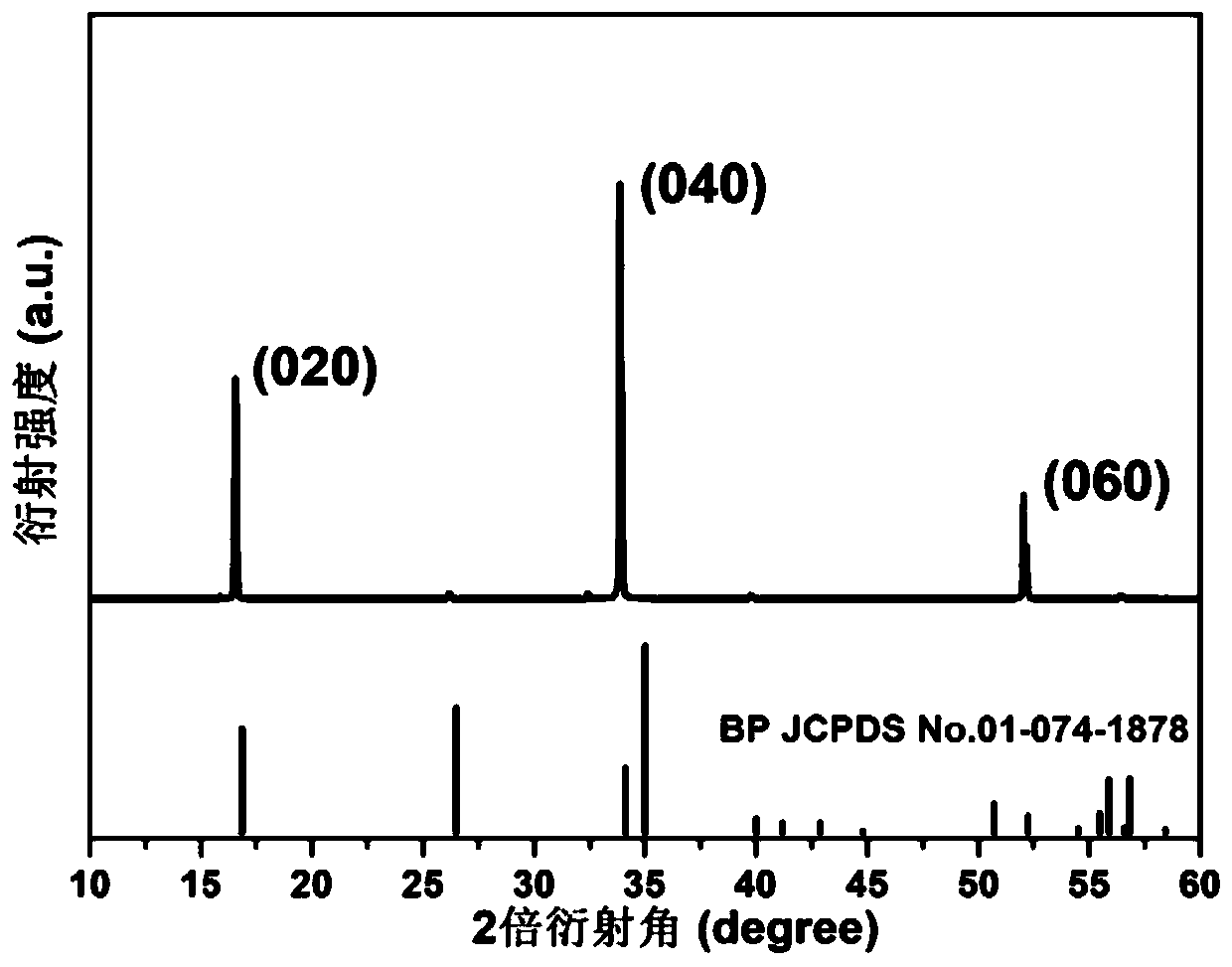

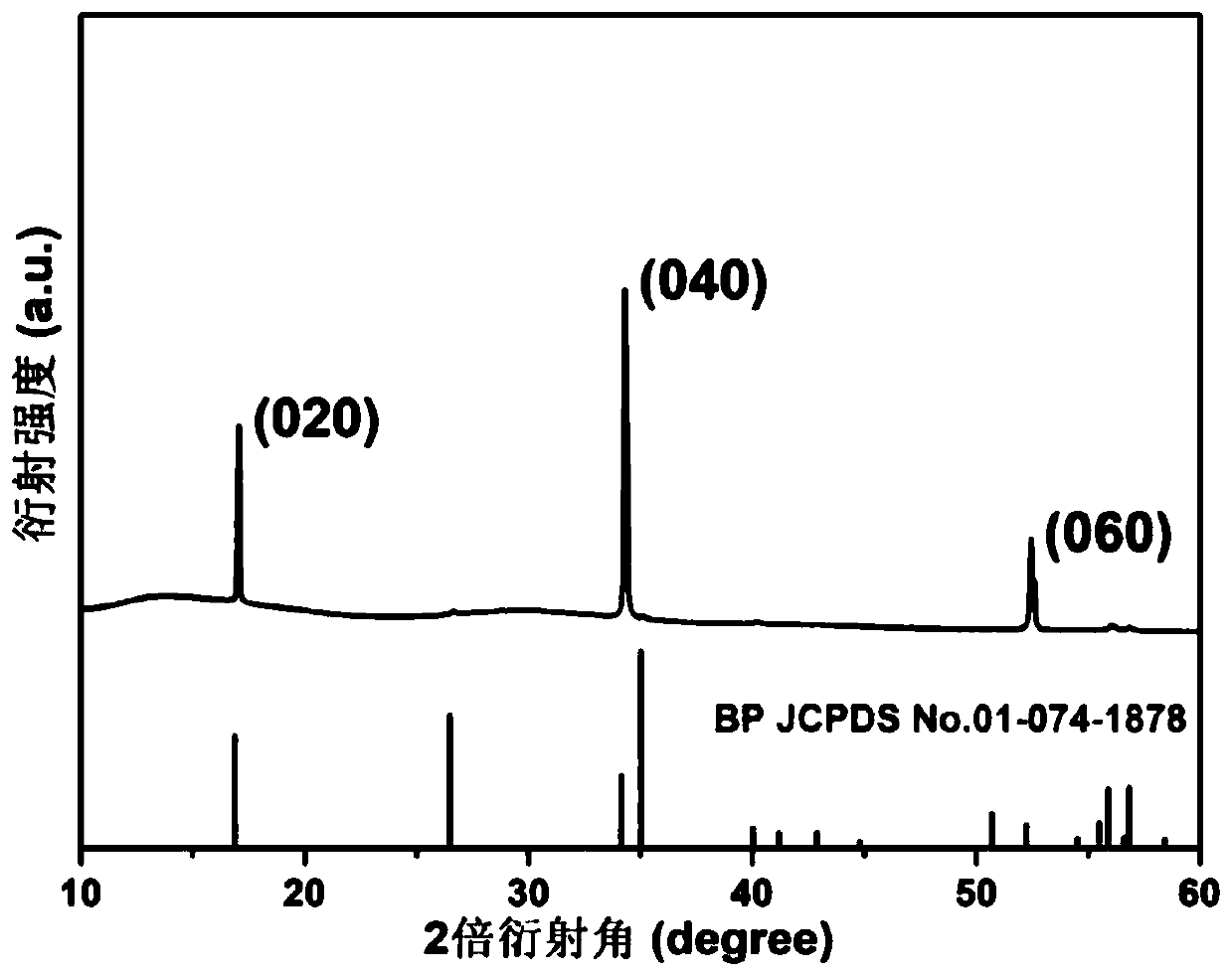

Method for rapidly preparing high-quality two-dimensional black phosphorus crystals through seed crystal induction

InactiveCN110878425AReduce the amount of introductionLower nucleation barrierPolycrystalline material growthPhosphorusCrystallographyPtru catalyst

The invention discloses a method for rapidly preparing high-quality two-dimensional black phosphorus crystals through seed crystal induction. The method comprises the following steps: a red phosphorusraw material, a catalyst and a transport agent are weighed and are placed at the bottom (a raw material end and a hot end) of a single-head sealed quartz tube in an inert atmosphere, the internal ofthe single-head sealed quartz tube is separated by using a porous gasket, a black phosphorus seed crystal is weighed and is placed at the top (a nucleating end and a cold end) of the single-head sealed quartz tube, and the above reaction raw materials are sealed in the quartz tube by using a vacuum tube sealing system; and then the quartz tube is heated through optimized programmed heating and cooling, and the high-purity and high-quality two-dimensional black phosphorus crystal is finally prepared after the reaction is finished. Compared with a traditional preparation method without using crystal seeds, the method of the invention has the advantages of significant reduction of the reaction temperature and the reaction time in the synthesis process, reduction of the energy consumption, effective reduction of the introduction amounts of the catalyst and the transport agent required by the reaction, and cost saving. The black phosphorus crystals synthesized by the method have the advantages of few impurities, high purity, good quality, and facilitation of industrial large-scale preparation of the black phosphorus crystals.

Owner:深圳市中科墨磷科技有限公司 +1

Phosphorus-containing magnesium oxychloride cement preparation method beneficial to improvement of early strength

The invention belongs to the technical field of modification of magnesium oxychloride cement and particularly relates to a phosphorus-containing magnesium oxychloride cement preparation method beneficial to improvement of early strength. The method comprises the steps that firstly, active magnesium oxide, magnesium chloride and water are evenly mixed in the mole ratio being 0.32:1:13, the mixture reacts for 3 days at 80 DEG C, cooling, suction filtration and washing are conducted, and drying is conducted to obtain seed crystals; and then the seed crystals, a phosphorus-containing water repellent agent, magnesium chloride, light calcined magnesium oxide powder and water are mixed, and the magnesium oxychloride cement is prepared. With the method, the seed crystals are added to a magnesium oxychloride cement system, the five-phase production speed and yield can be substantially increased, and the early strength of the cement is obviously improved.

Owner:CHANGZHOU UNIV

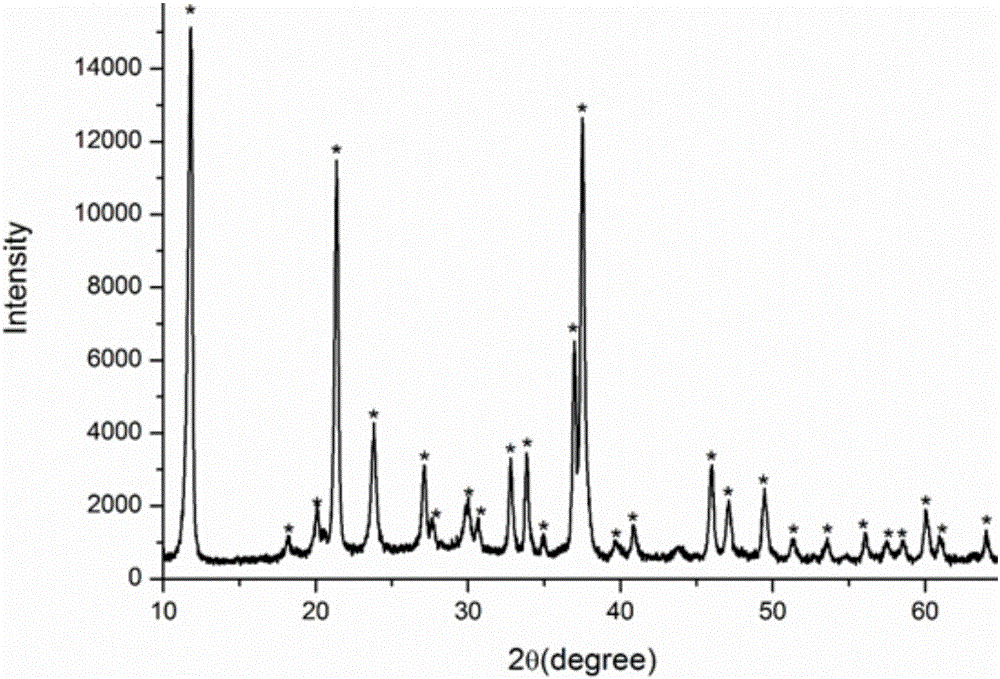

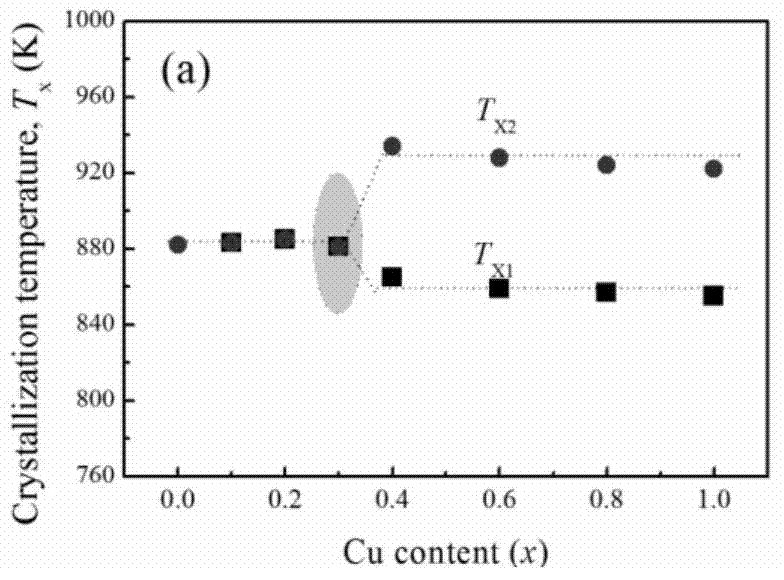

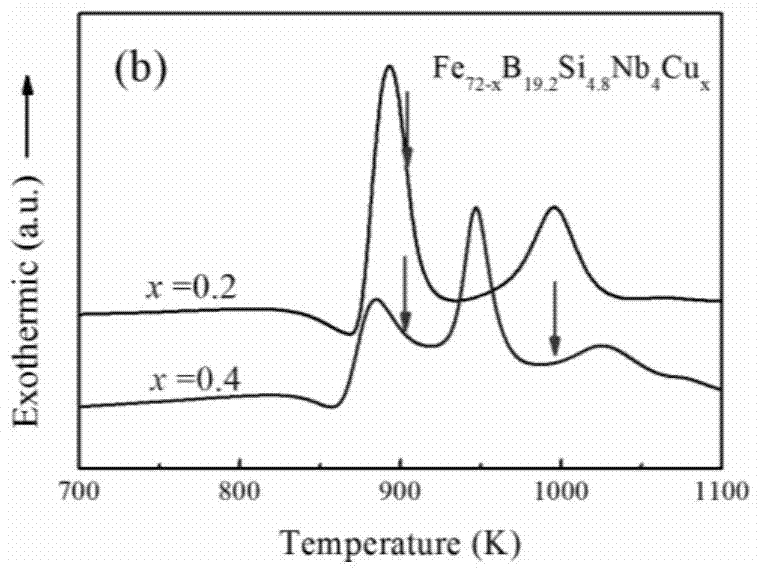

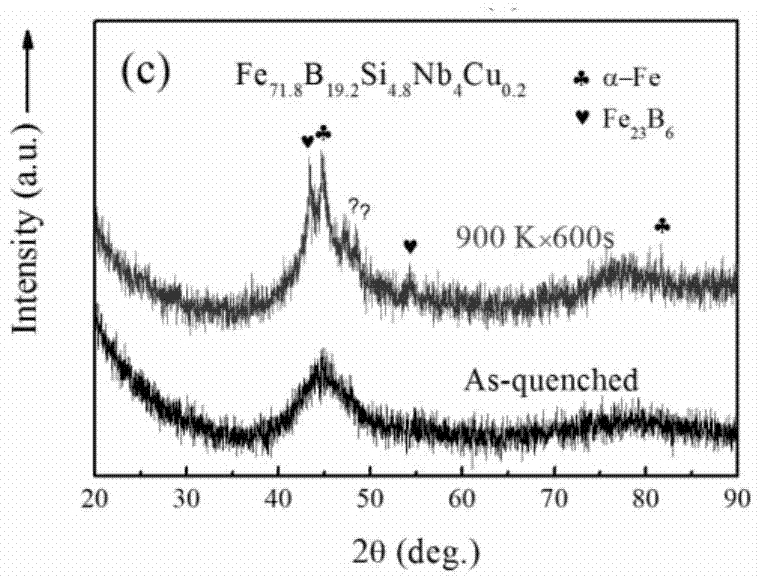

Preparation process for improving forming ability of Fe-base amorphous alloys

ActiveCN104264080ALow costEnhanced Amorphous Formation AbilityFoundry mouldsFoundry coresMagnetizationAlloy

The invention discloses a preparation process for improving the forming ability of Fe-base amorphous alloys, which belongs to the preparation method of Fe-based amorphous alloys. The process is low in cost, and simple and practicable, and can obviously increase the amorphous forming ability under the condition that the saturation magnetization is not reduced. According to the invention, stripped and blocky Fe-base amorphous alloy samples are respectively prepared by using a single-roll rapid quenching or copper mold casting method. The process specially comprises the following steps: under the protection of argon, adding a microelement into a Fe-base amorphous alloy, melting the obtained object in a reacting furnace in stoichiometric ratio, and rapidly cooling and solidifying the obtained product, so that a Fe-base amorphous alloy with high saturation magnetization and large amorphous forming ability is obtained, wherein the added microelement is a copper element, and the microelement accounts for 0.1-1.0% of the Fe-base amorphous alloy by total atomic percent. The process has the advantages that 1, an adopted Fe-base amorphous alloy preparation technology is simple and practicable, and low in cost; 2, the saturation magnetization is reduced while the amorphous forming ability is increased; and 3, the process is applicable to most of primary-phase non-alpha-Fe Fe-base amorphous alloy systems, thereby promoting the popularization and application of the Fe-base amorphous alloys.

Owner:CHINA UNIV OF MINING & TECH

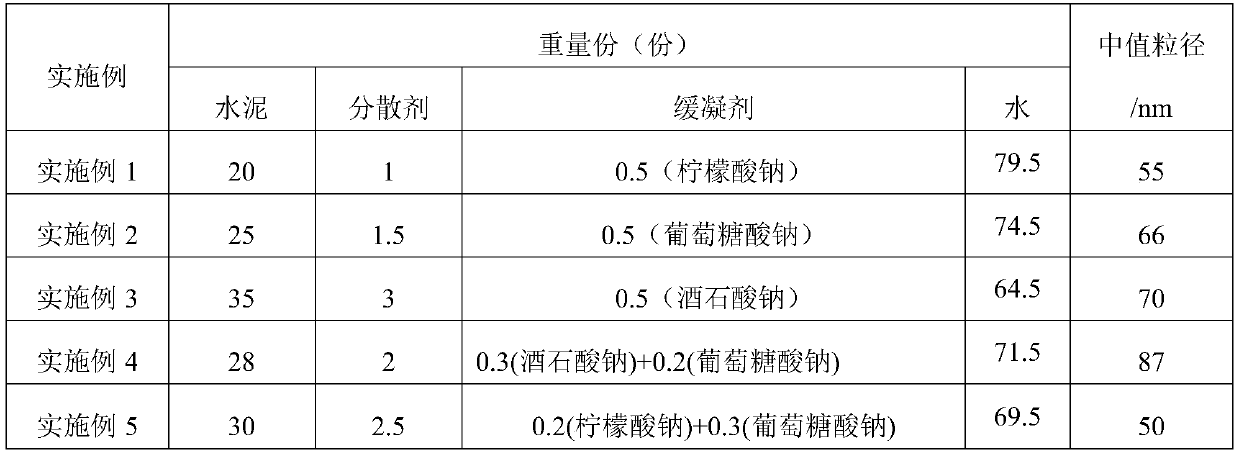

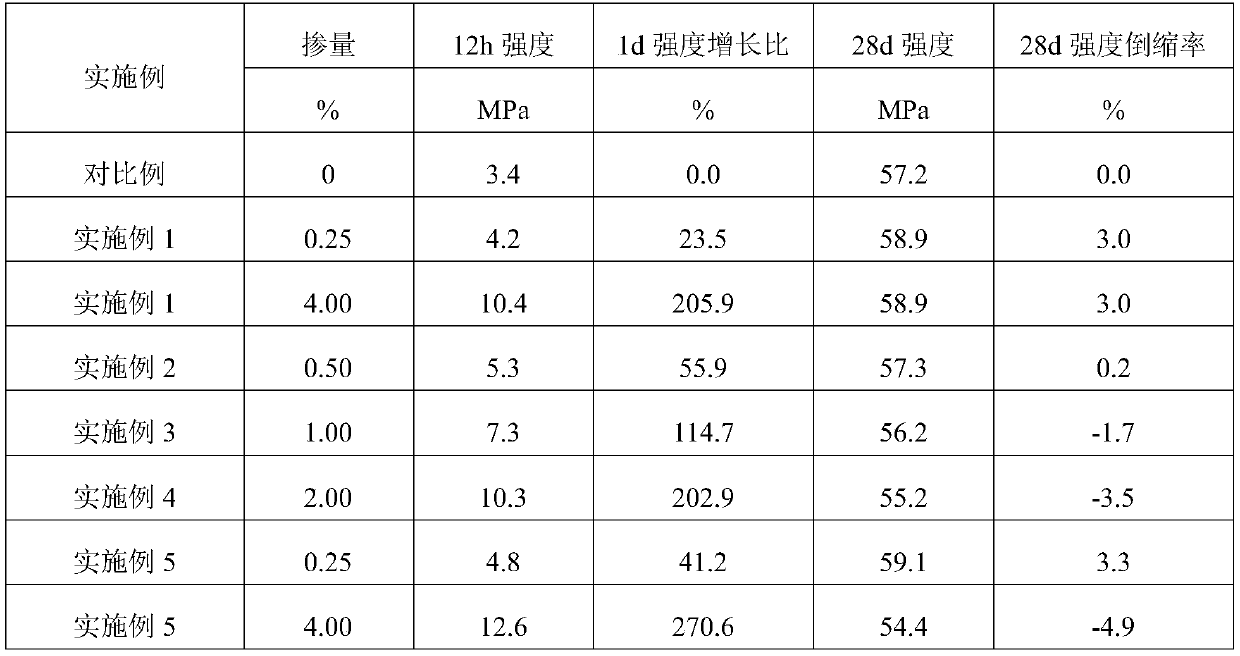

Nano cement-based crystal-nucleated early strength agent and preparation method and application thereof

ActiveCN110304857AAchieve the goal of early strengthGood compatibilityNanotechnologyAlkali–aggregate reaction

The invention provides a nano cement-based crystal-nucleated early strength agent and a preparation method and application thereof. The nano cement-based crystal-nucleated early strength agent mainlycomprises, by weight, 20-35 parts of cement, 1-3 parts of a dispersant, 0.5-1 part of a retarder, and 64.5-79.5 parts of water. Nano cement is used to provide a crystal nucleus for hydrating of the cement-based material herein, the crystal nucleus induces rapid hydration of the cement-based material; after the nano cement is added to the cement-based material, pore structure and induced nucleatingcan be improved to arrive at early strength; in addition, no harmful ions are introduced, the early strength agent herein is well compatible with cement and never causes alkali-aggregate reaction, scumming and the like.

Owner:WUHAN UNIV OF TECH

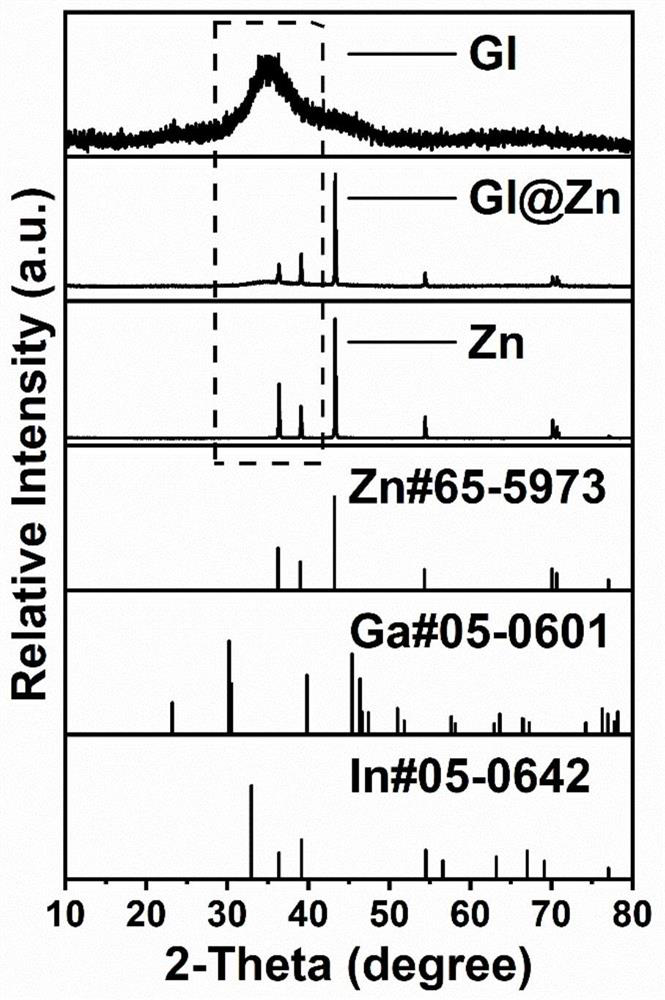

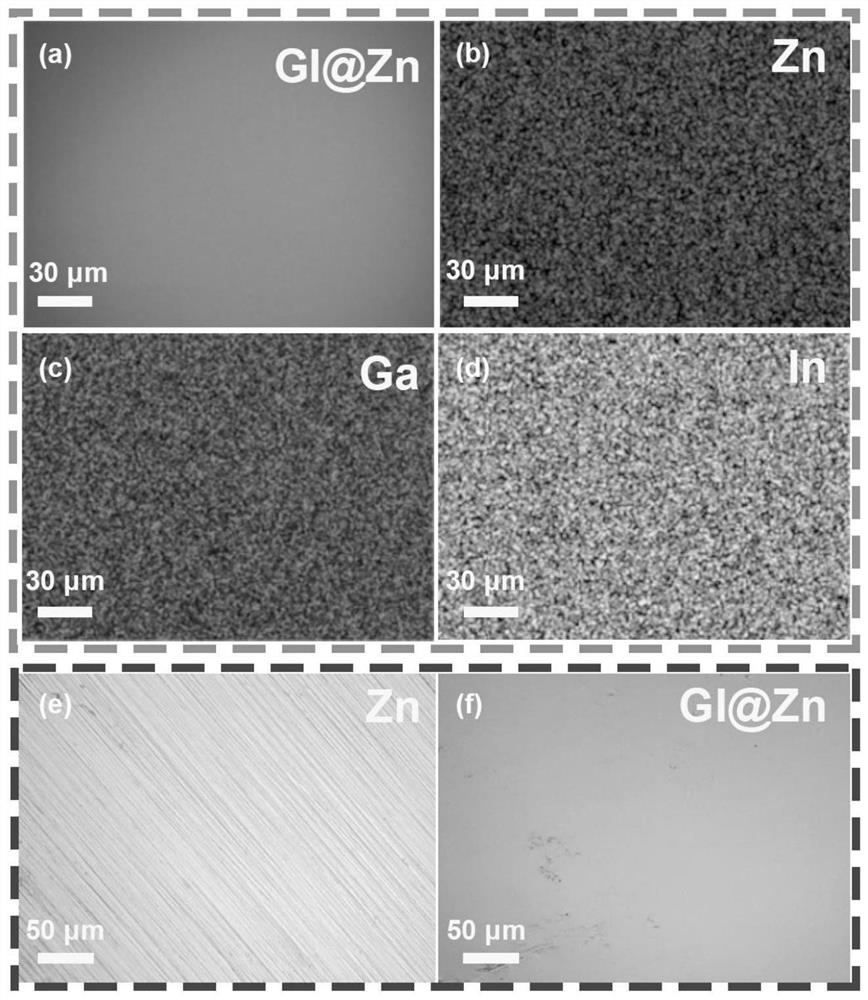

Zinc ion battery liquid metal composite negative electrode and preparation method and application thereof

ActiveCN111916744AImprove corrosion resistanceAvoid corrosionFinal product manufactureCell electrodesElectrolytic agentIndium

The invention discloses a zinc ion battery liquid metal composite negative electrode and a preparation method and application thereof. The composite negative electrode comprises a zinc metal matrix and a liquid alloy layer, and the liquid alloy layer is arranged on the surface of the zinc metal matrix. The characteristic of low solubility of zinc metal in the liquid gallium-based alloy is utilized, the zinc metal can be used as an electrochemically inert liquid coating material, the liquid alloy layer is formed by coating the surface of the zinc metal matrix with the liquid gallium-based alloy, and zinc ion flow, close to the surface of the negative electrode, of electrolyte can be well homogenized. Meanwhile, zinc is in a saturated state in the liquid gallium-based alloy, so zinc in the circulation process finally uniformly nucleates and grows on the surface of the zinc metal matrix, and dendrites are prevented from being formed on the surface of the composite negative electrode. Meanwhile, by compounding with gallium and indium with high hydrogen evolution overpotential, the corrosion resistance of the composite zinc negative electrode can be improved, the problem of side reactions such as negative electrode corrosion hydrogen production in the zinc ion battery is relieved, the cycle life of the zinc ion battery is prolonged, and the use stability and safety of the battery are improved.

Owner:CENT SOUTH UNIV

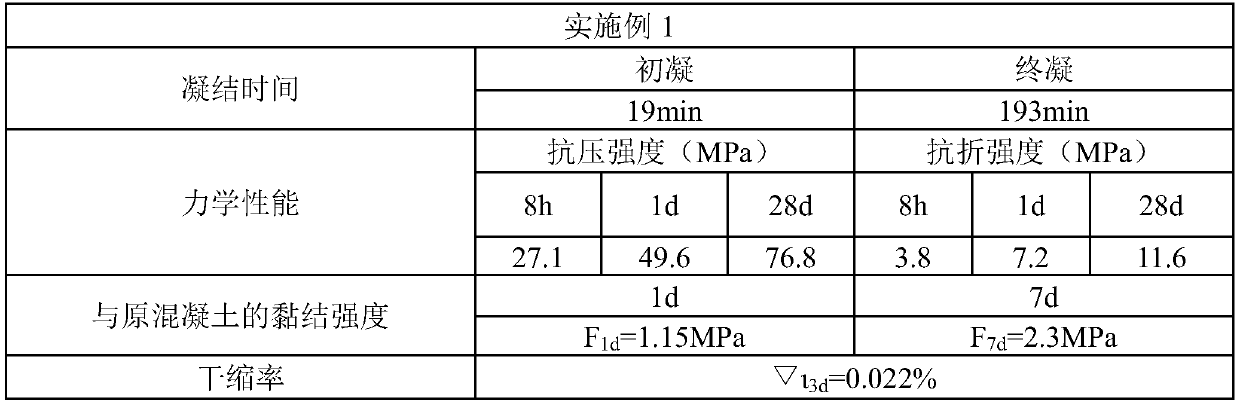

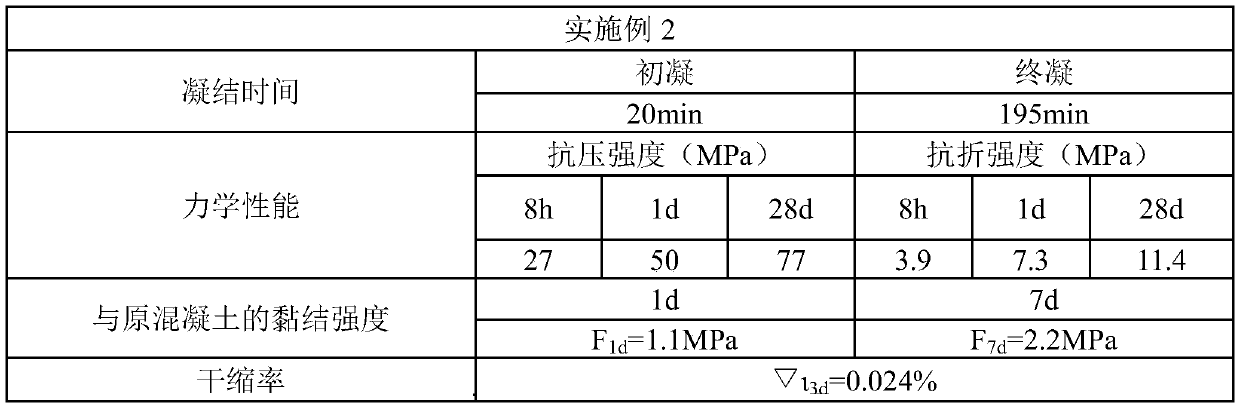

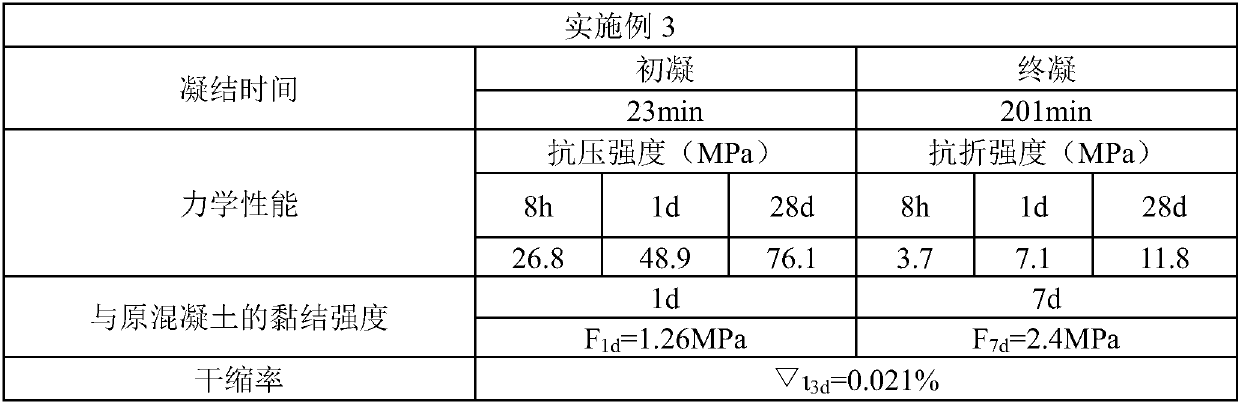

Rapid hardening early strength type composite repair mortar

The invention belongs to the technical field of building materials, and provides rapid hardening early strength type composite repair mortar. The rapid hardening early strength type composite repair mortar comprises, by weight, 5%-10% of water, 20%-30% of cement, 1%-5% of silica fume, 1%-5% of fly ash, 50%-70% of quartz sand, 0.4%-0.5% of composite early strength agents, 0.06%-0.1% of water reducing agents, 1%-5% of gelatin powder and 0.06%-0.8% of hybrid fibers. The composite early strength agents comprise components A and components B, the components A are nanometer calcium carbonate whiskers, the components B are mixtures of triisopropanolamine and aluminum sulfate, the quartz sand comprises coarse sand, medium sand and fine sand, and the hybrid fibers include basalt fibers and polypropylene fibers. The rapid hardening early strength type composite repair mortar has the advantage that the problems of strength decreasing, high dry shrinkage and low bonding strength of repair mortar in the prior art can be solved by the aid of the rapid hardening early strength type composite repair mortar.

Owner:长春昌驰新材料科技有限公司

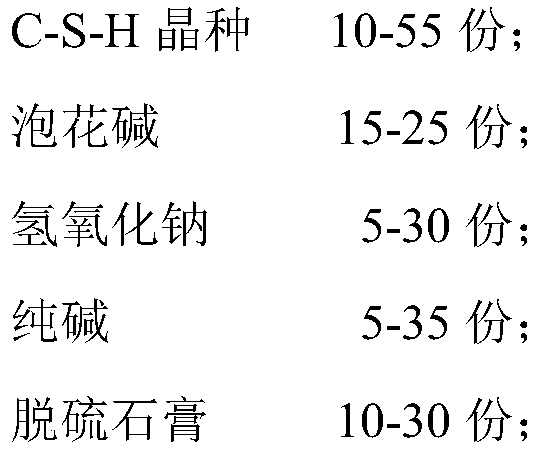

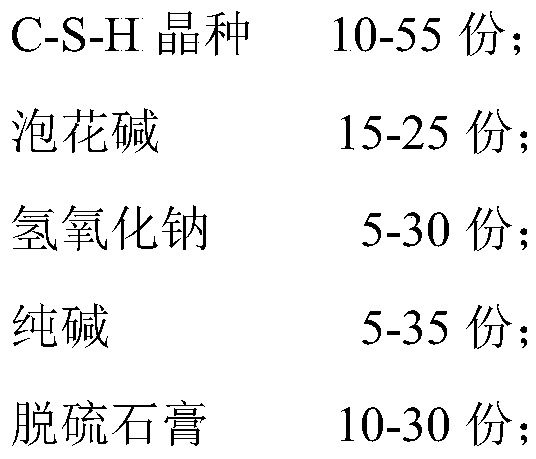

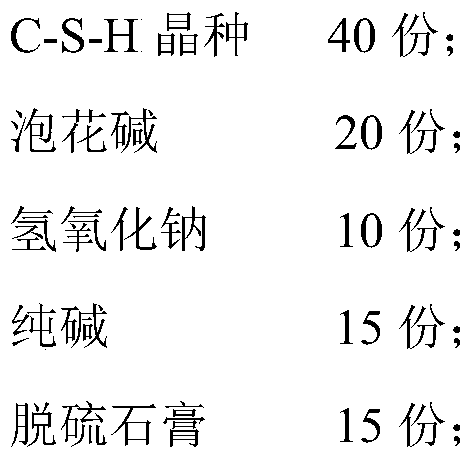

Activity excitant for inorganic solid waste building materials and preparation method thereof

The invention relates to an activity excitant for inorganic solid waste building materials and a preparation method thereof, belonging to the technical field of recycling of solid waste. The activityexcitant is prepared by mixing a C-S-H seed crystal, sodium silicate, sodium hydroxide, sodium carbonate and desulfurized gypsum, wherein the C-S-H seed crystal is prepared from quick lime and amorphous silicon dioxide under hydrothermal conditions, and the sodium silicate, the sodium hydroxide, the sodium carbonate and the desulfurized gypsum play a role in alkali excitation and sulfate excitation so as to promote the conversion of silicon-aluminum-calcium minerals and mineral salts in inorganic solid waste into hydration products. The C-S-H seed crystal promotes the generation of a high-strength crystalline product; and meanwhile, the existence of the seed crystal can also reduce the average voids in a building material product, lower the proportion of harmful pores and slightly-harmfulpores and further improve the strength and performance of a product prepared from the inorganic solid waste building materials.

Owner:上海海顾新材料科技有限公司

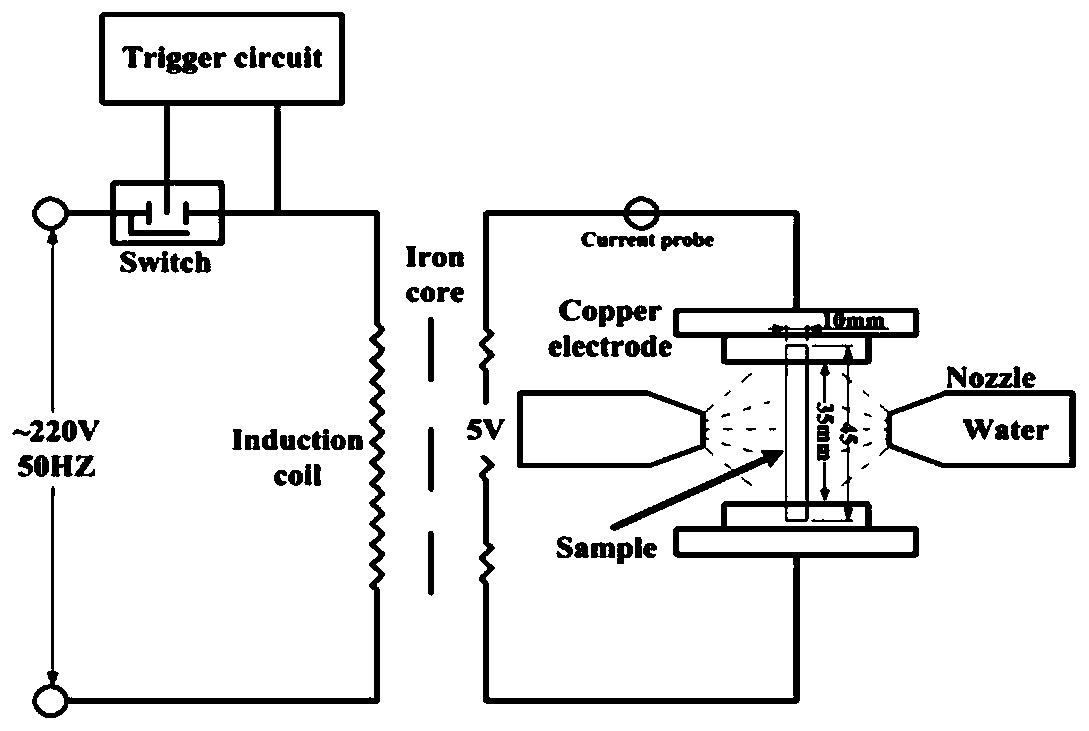

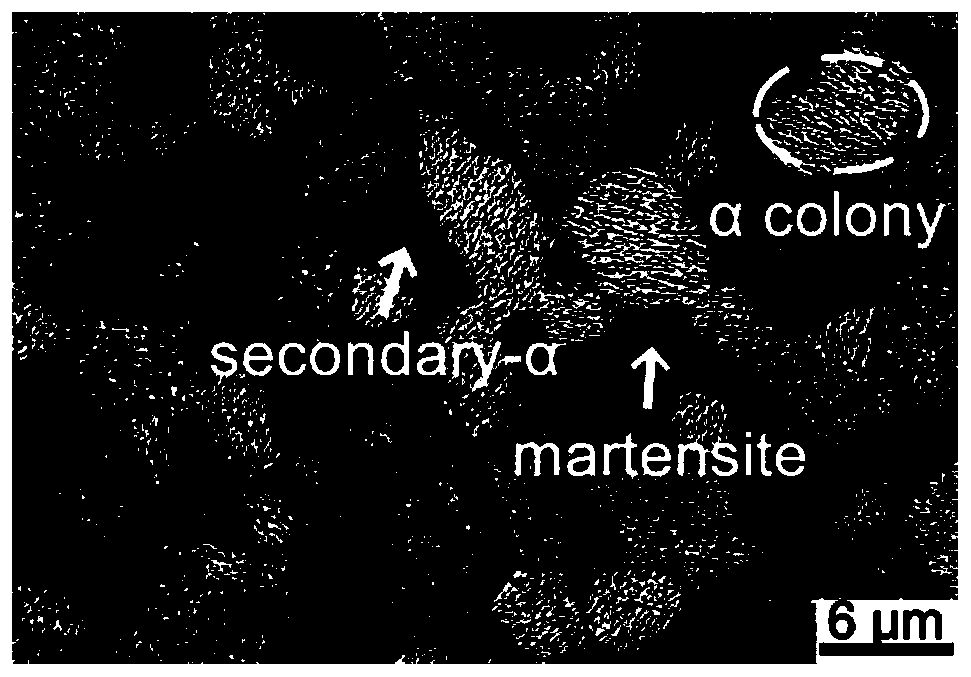

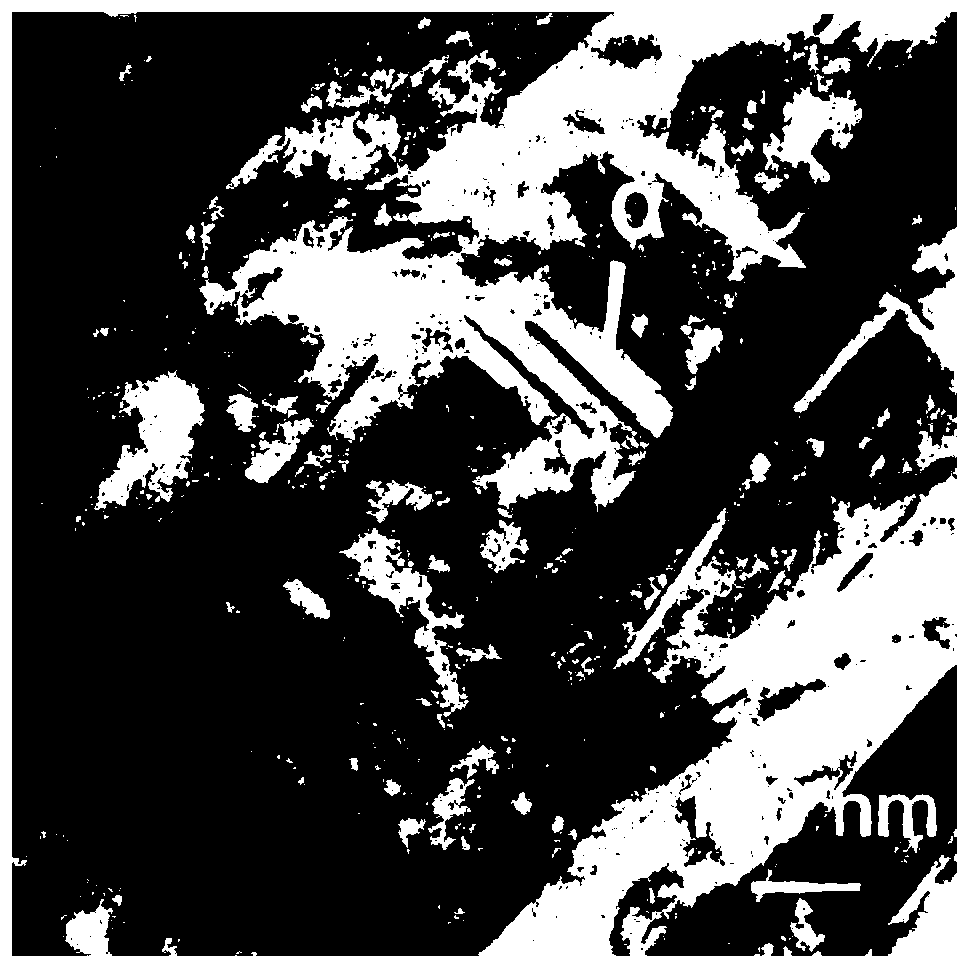

Titanium alloy strong toughening treatment method based on pulse current

The invention discloses a titanium alloy strong toughening treatment method based on pulse current. The treatment method comprises the following steps that (1) the rolled and annealed titanium alloy is cut into the sheet titanium alloy, the sheet titanium alloy is the alpha and beta type titanium alloy; (2) the sheet titanium alloy was polished on the surface to remove surface oxide or foreign matters, and then the sheet titanium alloy is placed in a tubular furnace protected by argon for solution treatment at 850-950 DEG C for 1-1.5 h and then cooled with water to room temperature; (3) the flaky titanium alloy obtained in the step (2) is subjected to pulse current processing by using an electric pulse device, the parameter is 50 HZ, the voltage is 5-6 V, the current density ranges from 5*10<7> to 7*10<7> A / m<2>, the processing time is in milliseconds, the spacing between electrodes was 30-40 mm, and the flaky titanium alloy is cooled with water to room temperature; and (4) the sheet-shaped titanium alloy subjected to pulse current treatment is placed in the tubular furnace protected by argon atmosphere for artificial aging treatment at 510-540 DEG C for 1-1.5 h. The treatment method has the advantages that the strength of the titanium alloy is greatly improved and the plasticity of the titanium alloy is kept under the condition that the titanium alloy component system is not changed.

Owner:JILIN UNIV

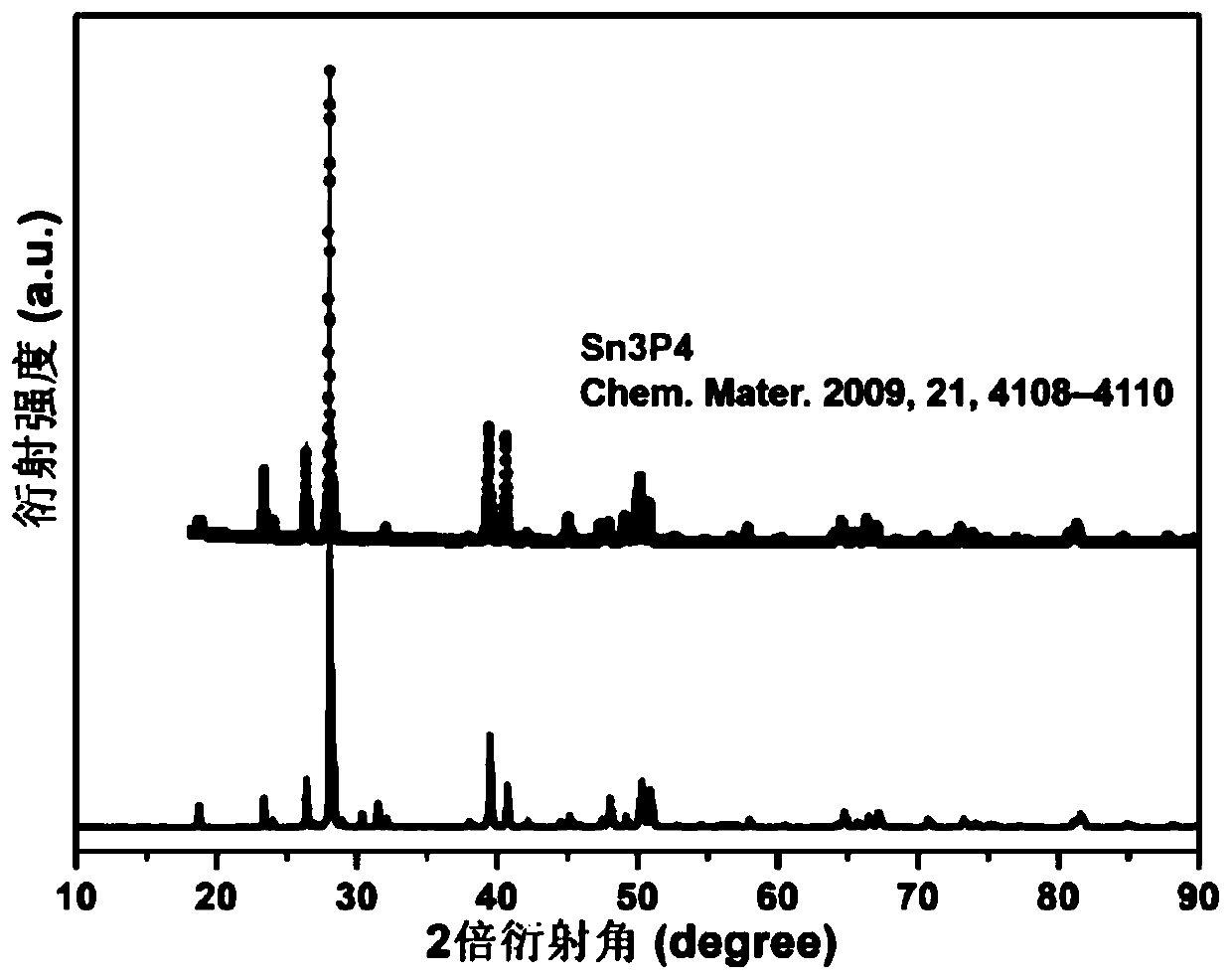

Preparation method of Sn3P4 induced two-dimensional black phosphorus crystals

ActiveCN111285339AHigh purityQuality improvementPhysical/chemical process catalystsPhosphorus preparationPtru catalystBlack phosphorus

The invention discloses a preparation method of Sn3P4 induced two-dimensional black phosphorus crystals. In an inert atmosphere, a red phosphorus raw material and metal elemental tin are placed at thebottom of a single-head sealed quartz tube, a vacuum tube sealing system is used for sealing a reaction raw material in the quartz tube, then the quartz tube is heated through optimized programmed heating and cooling to obtain a block Sn3P4 compound, and the block Sn3P4 compound is ground into powder for standby application. A red phosphorus raw material, the Sn3P4 powder and a transport agent are then weighed and added to the bottom of a single-head sealed quartz tube in an inert atmosphere, the reaction raw material is sealed in the quartz tube by using the vacuum tube sealing system, and the quartz tube is subjected to heating treatment through optimized programmed heating and cooling to prepare the high-purity and high-quality two-dimensional black phosphorus crystals. The intermediate product Sn3P4 of the reaction system is used as the catalyst, so that the nucleation barrier required in the red phosphorus-black phosphorus conversion process can be remarkably reduced, the nucleation and growth processes of the reaction are accelerated, the reaction temperature and reaction time in the synthesis process can be reduced, and the pressure intensity in the tube can be reduced.

Owner:HUBEI MOPHOS TECH CO LTD

Preparation method of lithium-philic carbon nanotube paper and preparation method of composite metal lithium negative electrode

InactiveCN112176771ALower nucleation barrierUniform depositionMaterial nanotechnologySpecial paperMetallic lithiumSolid state electrolyte

The invention provides a preparation method of lithium-philic carbon nanotube paper. The preparation method comprises the following steps of: forming a lithium-philic material coating layer on the surface of a carbon nanotube by adopting an atomic layer deposition method, and manufacturing paper with pulp by adopting a wet papermaking process. The invention further provides a preparation method ofa composite metal lithium negative electrode. The preparation method comprises the steps: heating the solid state lithium to molten state, and then injecting lithium in a high-temperature molten state into the lithium-philic carbon nanotube paper. According to the preparation method, a uniform and compact lithium-philic coating layer is formed on the surface of the carbon nanotube by adopting anatomic layer deposition technology so that the nucleation barrier of lithium deposition is reduced, lithium metal is uniformly deposited in the carbon paper, and the prepared composite lithium metal negative electrode has the effects of inhibiting lithium dendritic crystal growth and modifying the components of a solid electrolyte interface film; meanwhile, space is provided for lithium metal deposition, the cycling stability of the lithium metal negative electrode is remarkably improved, and the cycling life is remarkably prolonged.

Owner:柔电(武汉)科技有限公司 +1

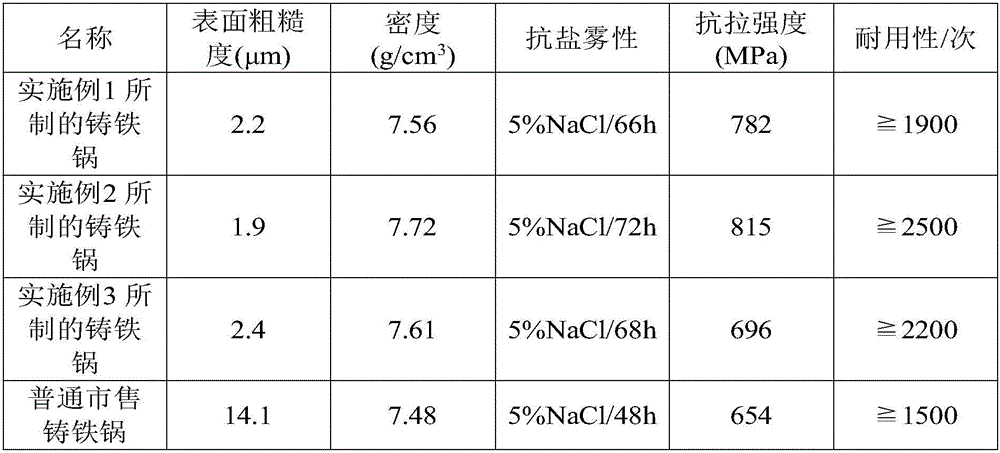

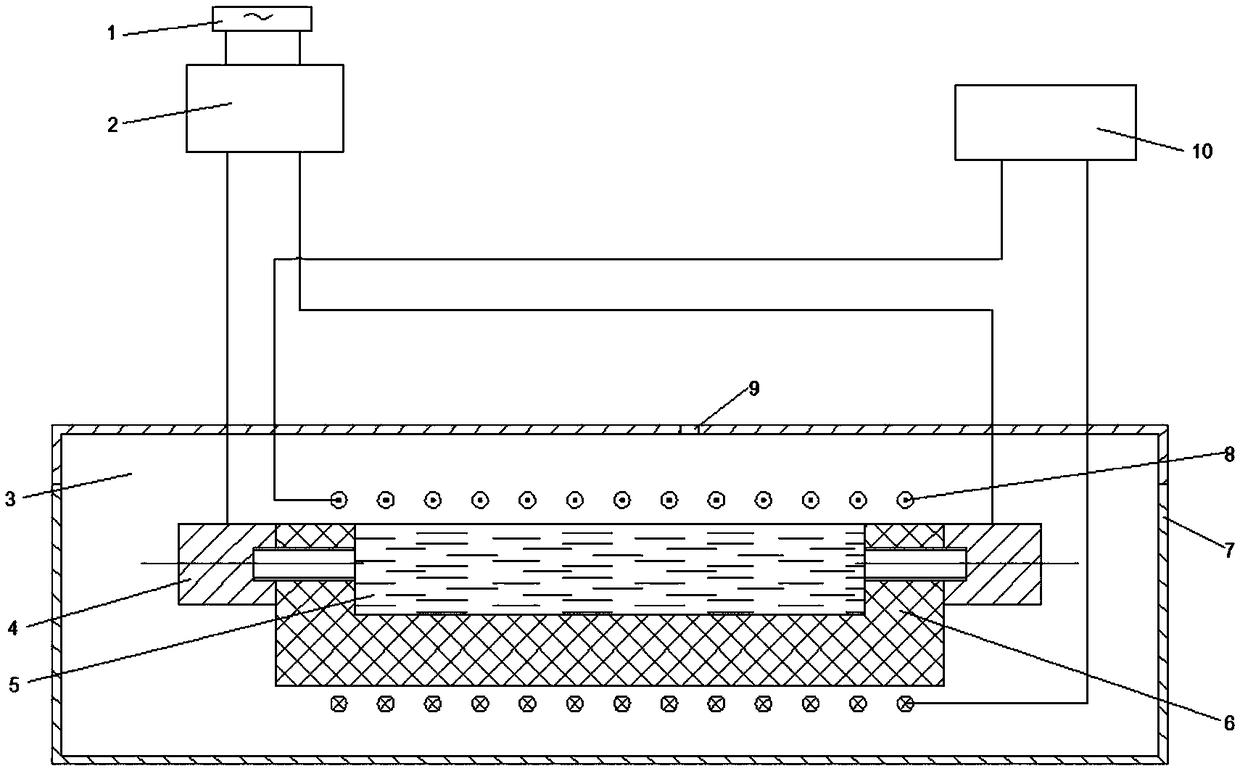

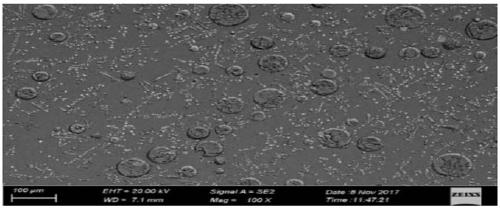

Casting iron pan and casting process thereof

InactiveCN105671235ALower nucleation barrierIncreased crystallization nucleation kineticsCooking-vessel materialsSeed crystalCast iron

The invention discloses a casting iron pan and a casting process thereof.The casting process includes the steps of smashing pig iron, adding samarium and neodymium pure metal into a smelting furnace to be smelted at a high temperature, lowering the temperature of molten iron to be 1250-1350 DEG C, casting the molten iron in a sand mold, preparing a nucleation seed crystal agent, instantly putting in the nucleation seed crystal agent, conducting stirring to evenly disperse the nucleation seed crystal agent in molten iron till small micro-crystals appear, cooling the molten iron containing small micro-crystals till the molten iron is solidified, conducting demolding to obtain a rough product, conducting tempering on the rough product, taking out the product, grinding a tempered casting iron pan till the surface is smooth and presents metal luster to obtain the casting iron pan finished product, putting the finished product in a closed package bag, and storing the casting iron pan in a dry, ventilated and cool place.The casting iron pan is high in strength, plasticity and durability, the problems that the casting iron pan is long in forming time and not stable in performance are solved, and the additional value of the casting iron pan is improved.

Owner:惠州市旲桥科技有限公司

Electrostatic spinning nano-composite fiber mat and preparation method and application thereof

ActiveCN107675361AImprove the defect of poor UV resistanceImprove high temperature resistanceElectroconductive/antistatic filament manufactureMonocomponent cellulose artificial filamentCelluloseBreaking strength

The invention relates to the field of composite materials, in particular to an electrostatic spinning nano-composite fiber mat and a preparation method and application thereof. The preparation methodcomprises the steps that graphene, SiO2 and TiO2 are dissolved in a dimethylacetamide solution and then subjected to ultrasonic dispersion, and a mixed solution is obtained; the mixed solution is added into a polysulfonamide solution and stirred, and a polysulfonamide spinning solution is obtained after ultrasonic dispersion; a natural cellulose / LiCl / DMAC spinning solution and the polysulfonamidespinning solution are subjected to ultrasonic oscillation and mixed, and a spinning nanometer fiber mat is obtained; a PPS fiber non-woven fabric and the nanometer fiber mat are composited through theelectrostatic spinning technology, and the electrostatic spinning nano-composite fiber mat is obtained. The electrical conductivity, the breaking strength and the ultraviolet ray-resistant capacity of the composite fiber mat are remarkably improved, the comprehensive performance of the fiber is greatly improved, and the application field of the composite fiber mat is widened.

Owner:SHANGHAI UNIV OF ENG SCI

Novel magnesium alloy composite material preparation method

The invention relates to a novel magnesium alloy composite material preparation method. The novel magnesium alloy composite material preparation method is characterized in that a novel magnesium alloy composite material is prepared through the steps that aluminum, zinc, manganese, neodymium, cerium and magnesium are proportionally mixed, nickel coated nano-SiC particles are added into a magnesium alloy melt, an electromagnetic field is applied at the same time, the nickel coated nano-SiC particles are evenly scattered in the melt through electromagnetism simulated microgravity, an electric field is applied to a casting ingot after pouring to refine grains, and finally the novel magnesium alloy composite material is subject to equal channel angular pressing. The neodymium element in the novel magnesium alloy composite material has the dispersion strengthening effect, and formed metallic compounds can prevent grain boundary sliding; the cerium element can improve the alloy structure and refine the grains; a microgravity field enables the nickel coated nano-SiC particles to be evenly scattered in the melt; the electric field can increase the degree of supercooling of the melt, nucleation barriers are reduced, and the grains are refined; and the equal channel angular pressing can further refine the grains, and the synthetic mechanical property of the composite material is improved.

Owner:CHANGZHOU UNIV +1

Preparation method of copper and iron immiscible alloy

ActiveCN109175315AThe critical nucleation radius decreasesLower nucleation barrierBoron nitrideRefined grains

The invention provides a preparation method of a copper and iron immiscible alloy, and belongs to the technical field of immiscible alloys. The preparation method is characterized by including the following implementation steps that 1, a boron nitride crucible is put in a vacuum box body of a high-frequency induction furnace, a copper and iron sample with the mass ratio of 85:15 is put in the boron nitride crucible, and the boron nitride crucible is connected with molybdenum electrodes; and the vacuum box body is vacuumized to 2*10<-4> Pa. The preparation method includes the steps that 1, a high-frequency induction heating power source is switched on, heating is carried out until the temperature reaches 1,400 DEG C, the copper and iron sample is completely melted, and heat preservation iscarried out for 10 min; 2, electric pulses are applied to the copper and iron sample obtained after heat preservation, and the acting time is 10 min; and 3, the high-frequency induction heating powersource is switched off, a furnace cooling process is executed, and a pulse power source is switched off after melt of the copper and iron sample is completely solidified. The preparation method has the beneficial effect that the copper and iron immiscible alloy prepared with the method can have a uniform structure and refined grains.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

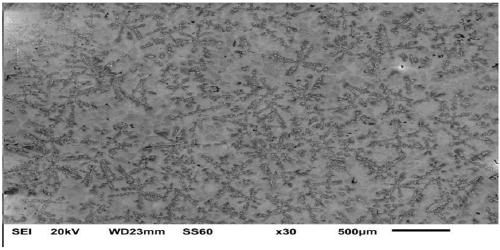

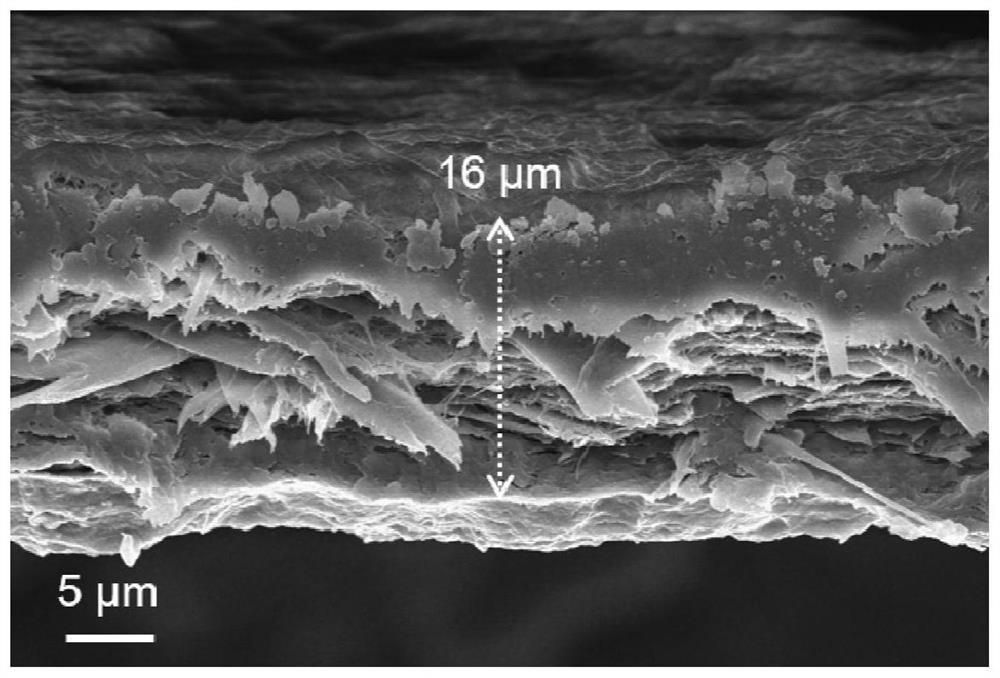

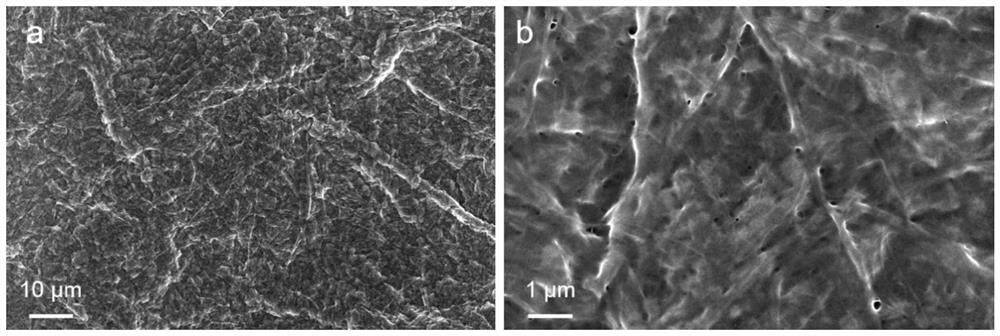

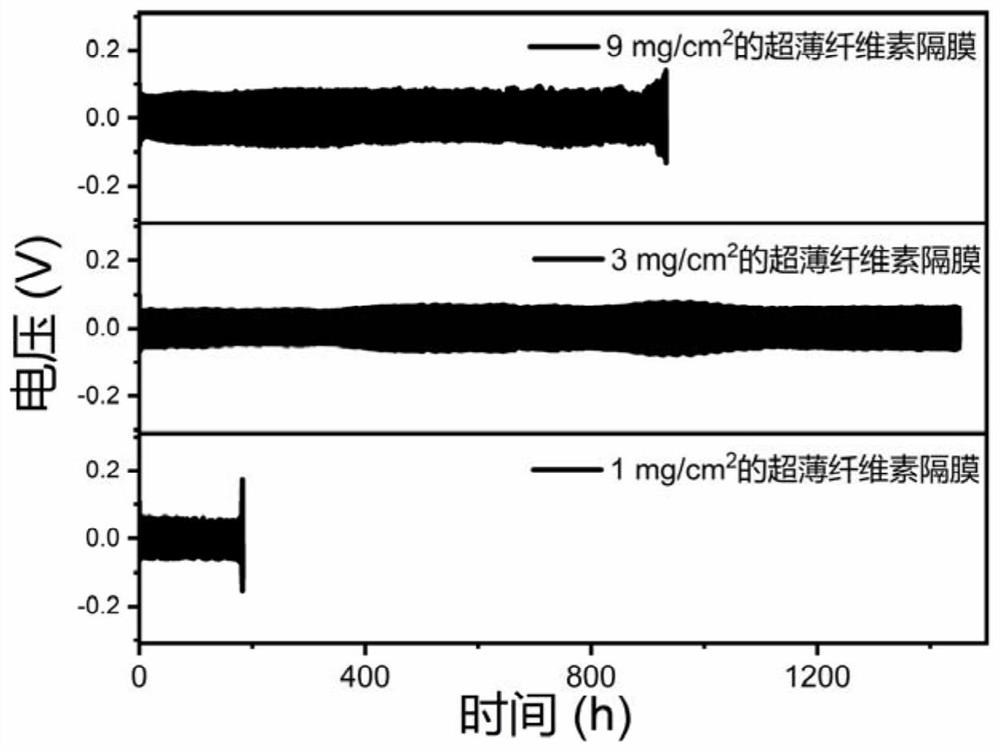

Preparation and application of modified ultrathin cellulose diaphragm

PendingCN114744367AImprove puncture strengthImprove stabilityCell component detailsSecondary cells servicing/maintenanceZinc ionElectrochemistry

The invention belongs to the technical field of electrochemical energy storage, and discloses preparation and application of a modified ultrathin cellulose diaphragm. According to the invention, cellulose or functional material modified cellulose is directly sucked and filtered to a filter membrane substrate by adopting a vacuum suction filtration method, and the filter membrane substrate is peeled off after drying, so that the modified ultrathin cellulose diaphragm is constructed. The modified ultrathin cellulose diaphragm has the effects of high puncture strength, promotion of homogenization of a zinc negative electrode surface electric field and an ion field during zinc ion deposition, optimization of zinc deposition crystal face orientation, reduction of a nucleation barrier and the like, so that the effect of inhibiting growth of zinc dendrites is achieved. Therefore, the water-based zinc-based energy storage system with high stability and long cycle life is realized, and the method has important significance in promoting the practical application of the water-based zinc-based energy storage system.

Owner:JINAN UNIVERSITY

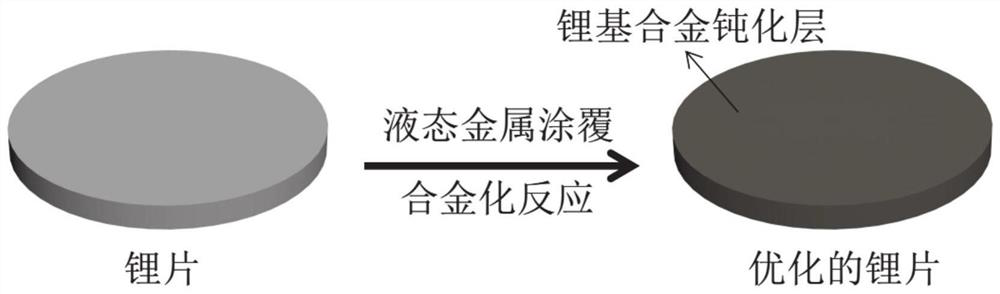

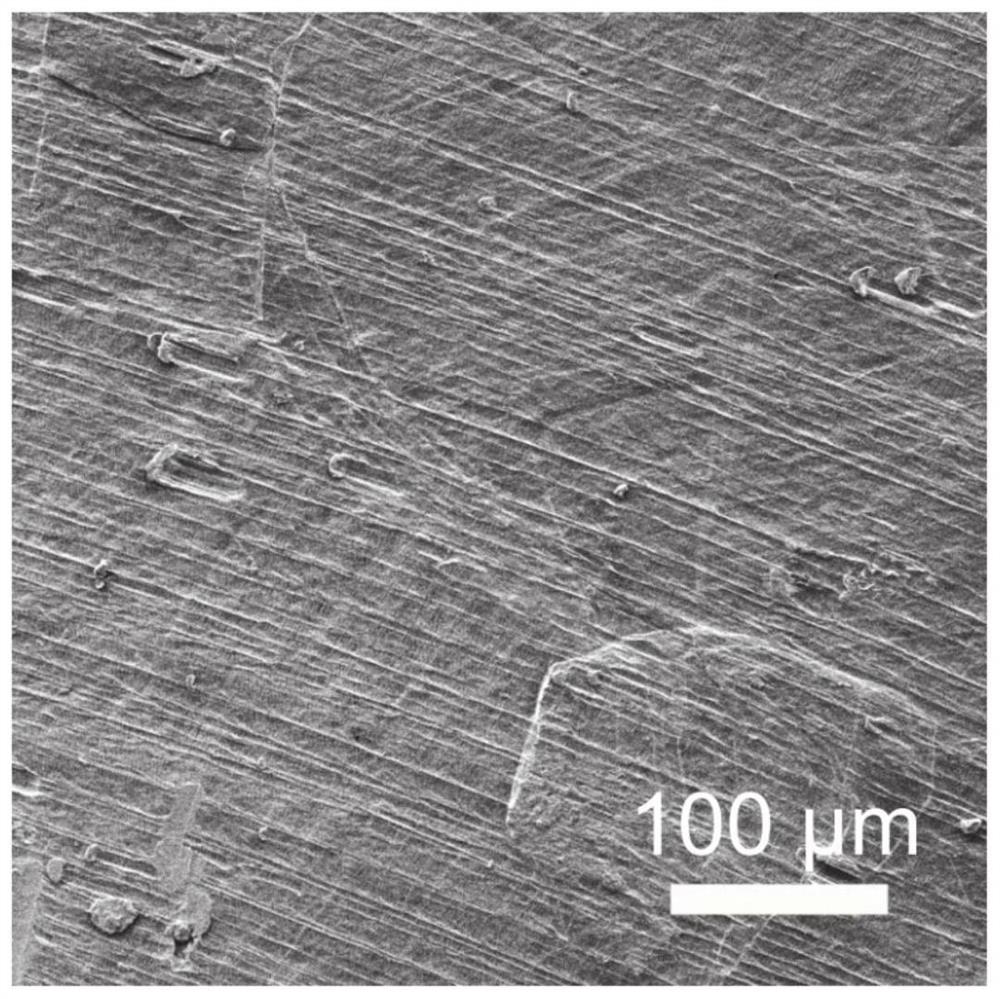

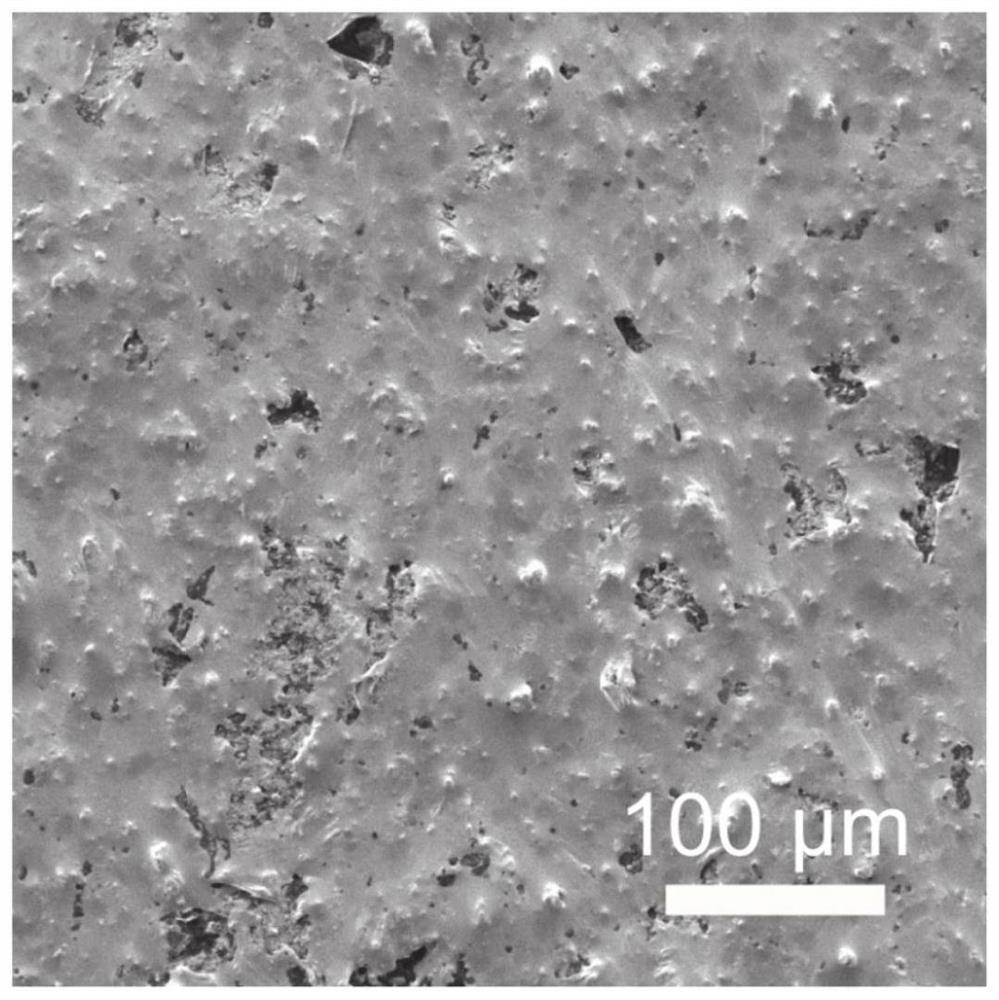

High-stability long-service-life metal lithium negative electrode material as well as preparation method and application thereof

ActiveCN111755699ASolve pollutionEasy to operateSecondary cellsNegative electrodesMetallic lithiumLithium metal

The invention relates to the technical field of lithium ion batteries, and particularly relates to a high-stability long-service-life metal lithium negative electrode material and a preparation methodthereof, and more particularly relates to a method for passivating the surface of metal lithium by utilizing low-temperature gallium-based liquid metal, reducing the reaction activity of the metal lithium and stabilizing a metal lithium negative electrode. The high-stability long-service-life lithium metal negative electrode material is lithium metal with an optimized lithium-based alloy passivation layer. The method comprises the steps of coating the surface of metal lithium with a layer of low-temperature gallium-based liquid metal, and then carrying out alloying reaction in an inert atmosphere so as to obtain the product. The low-temperature gallium-based liquid metal which is low in melting point, good in flowability, good in conductivity, lithium-friendly and non-toxic is used for coating the surface of the metal lithium with high reaction activity; and a lithium-based alloy passivation layer with good lithium affinity, corrosion resistance and high ion diffusion coefficient is formed on the surface of the metal lithium, so that the nucleation barrier of lithium is reduced, the electrochemical dynamics of an electrode interface is accelerated, the cycling stability of the metal lithium is improved, and the service life of the metal lithium is prolonged.

Owner:SHANDONG UNIV

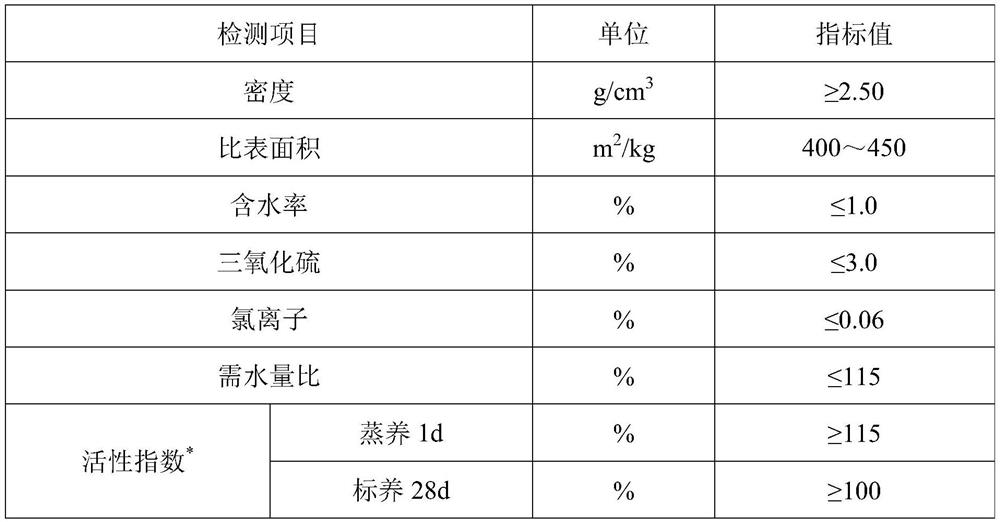

PHC tubular pile non-autoclaved concrete active powder and preparation method thereof

The invention discloses PHC tubular pile non-autoclaved concrete active powder. The PHC tubular pile non-autoclaved concrete active powder comprises, by mass, 35%-65% of granulated blast furnace slagpowder, 20%-45% of fly ash, 5%-15% of silica fume, 5%-35% of microbeads, 5%-20% of gypsum powder, 5%-25% of nickel slag powder and 0.01%-5% of an early strength agent. A preparation method of the active powder comprises the following steps: putting the granulated blast furnace slag powder, the fly ash and the nickel slag powder into a ball mill, grinding for 20-40 minutes until the specific surface area is 400-450 m<2> / kg, and mixing the obtained powder with the silica fume, the microbeads, the gypsum powder and the early strength agent in a mixer for 15-25 minutes. The PHC tubular pile non-autoclaved concrete active powder can ensure the early and later strength of concrete, shorten the steam curing time, improve the production efficiency, enhance the durability of the concrete, and obtain favorable social and economic effects.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

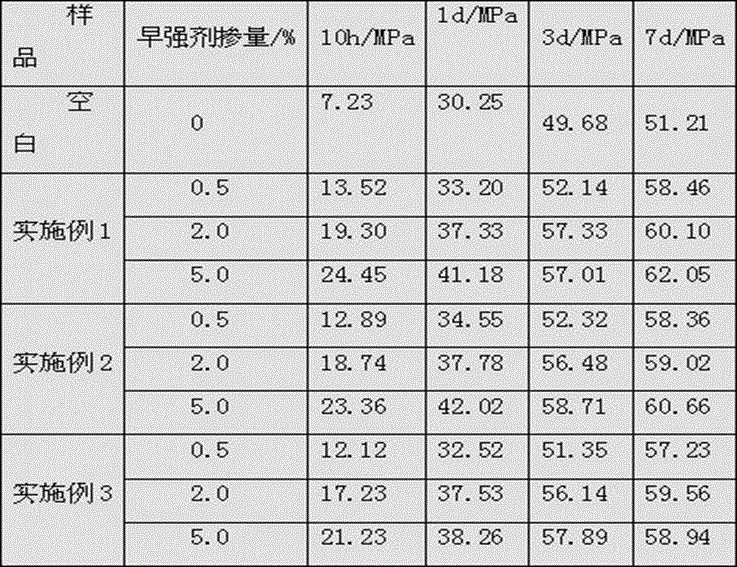

Super high-early-strength concrete early strength agent and preparation method thereof

ActiveCN108101406ALower nucleation barrierPromote hydrationDiethylene glycol monobutyl etherInorganic salts

The invention provides a super high-early-strength concrete early strength agent and a preparation method thereof. The concrete early strength agent comprises the following components by weight: 860-880 parts of water; 70-75 parts of diethylene glycol monobutyl ether; 40-45 parts of polyethylene glycol; 10-20 parts of isopropanol; 1850-1950 parts of a soluble inorganic salt solution; and 5-5.5 parts of an alkaline regulator. The soluble inorganic salt solution is composed of a solution A and a solution B in a ratio of 1:1, the solution A is a soluble calcium salt solution, and the solution B is a soluble silicate solution. Curing of concrete with the early strength agent provided by the invention under the conditions of normal temperature and pressure and a humidity of 95% can make the 8hcompressive strength of concrete reach 60% or more of the design strength, the demoulding time is shortened, the mould turnover velocity is speeded up, and the later strength does not decrease. The preparation method provided by the invention is easy to operate, and all the raw materials just need to be added in different order for stirring and uniform dispersion, the steam curing and autoclavingprocesses in the prior art are eliminated, and energy is saved and consumption is reduced.

Owner:HENAN POLYTECHNIC UNIV

Preparation method for in-situ forming of hexagonal phosphorspath coating on surface of titanium-based nanotube

ActiveCN108070900AReduce internal pressurePromote formationPolycrystalline material growthFrom normal temperature solutionsAnodic oxidationPolyvinyl alcohol

The invention relates to a preparation method for in-situ forming of a hexagonal phosphorspath coating on the surface of a titanium-based nanotube. The preparation method comprises the following steps: firstly, forming a titanium nanotube on the surface of a titanium material by using electrochemical anodic oxidation; secondly, preparing a polyvinyl alcohol aqueous solution of calcium salt, putting a sample into the polyvinyl alcohol aqueous solution of the calcium salt, carrying out vacuum treatment and drying; slowly raising the temperature for sintering and immobilizing calcium in or on thesurface of the titanium nanotube; thirdly, vertically putting the titanium-based nanotube subjected to calcium treatment into a prodromal calcium and phosphorus solution containing urea; adding urease, and controlling temperature and reaction time, to obtain an apatite crystal coating on the surface of the titanium-based nanotube. According to the preparation method for the in-situ forming of thehexagonal phosphorspath coating on the surface of the titanium-based nanotube, disclosed by the invention, the hexagonal phosphorspath coating on the surface of the titanium can be rapidly formed under mild conditions; the preparation process has the advantages of stability, low cost and capability of rapidly realizing mass production. The preparation method for in-situ forming of the hexagonal phosphorspath coating on the surface of the titanium-based nanotube, disclosed by the invention, has broad application value in bone implant materials, surface modification of dental implant, promotionof rapid bone integration and the like.

Owner:TAIYUAN UNIV OF TECH

Concrete early strength agent, early strength concrete and preparation method of early strength concrete

The invention discloses a concrete early strength agent, an early strength type concrete and a preparation method of the early strength concrete. The concrete early strength agent is prepared from, by mass, 70-80% of a component A and 20-30% of a component B, the component A is a liquid mixture and comprises, by weight, 10-24 parts of silica sol dispersion liquid, 10-15 parts of siloxane emulsion, 2-4 parts of a surfactant, 8-15 parts of soluble calcium salt and 4-5 parts of alcamines; the silica sol dispersion liquid is a dispersion liquid of three substances, namely nanoscale silicon dioxide, a dispersing agent and a suspending agent, in water, and the dispersing agent accounts for 0.5-2% of the solvent water; the suspending agent accounts for 0.5-1% of the solvent water, and the nanoscale silicon dioxide accounts for 55-70% of the solvent water; and the component B is a solid mixture and comprises,s by weight, 30-40 parts of meta-aluminate, 20-30 parts of silicate, 20-30 parts of lithium salt, 2-10 parts of calcium tartrate and 0.5-1 part of methyl cellulose ether. The superposition effect of different early strength components can be exerted, the setting and hardening speed of cement is accelerated, the precipitation of hydration products is promoted, and the early strength of concrete can be obviously improved in a low-temperature environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

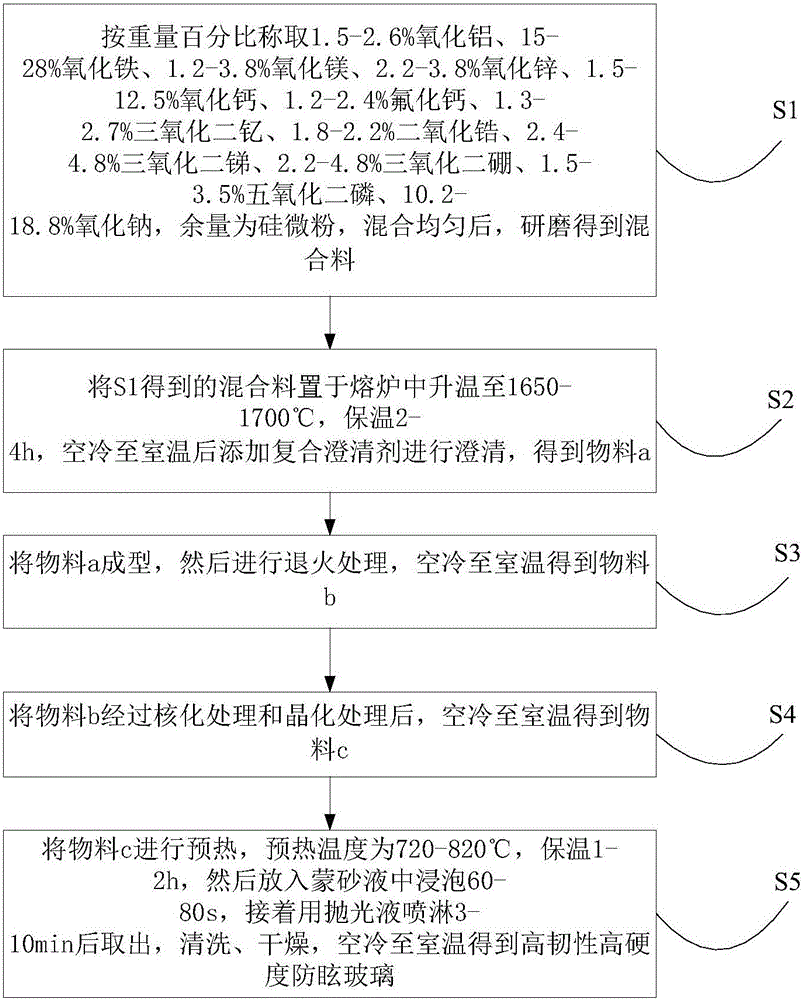

Method for preparing high-tenacity high-hardness anti-dazzle glass

The invention provides a method for preparing high-tenacity high-hardness anti-dazzle glass. The method comprises the steps that firstly, raw materials needed for manufacturing the glass are prepared, then the raw materials are evenly mixed and ground to obtain a mixture, the mixture is placed in a smelting furnace, and then composite clarifying agents are added for clarifying; the mixture is cooled to room temperature, a material a is obtained, the material a is formed, then annealing treatment is carried out, and a material b is obtained; after coring treatment and crystallization treatment are carried out on the material b, a material c is obtained; the material c is preheated, preheating temperature ranges from 720 DEG C to 820 DEG C, and heat preservation is carried out for 1-2 h; then the material c is placed in frosting liquid to be soaked for 60-80 s, a polishing solution is sprayed to the material c for 3-10 min, then the material is taken out to be washed, dried and air-cooled to room temperature, and the high-tenacity high-hardness anti-dazzle glass is obtained.

Owner:徐州高运新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com