Patents

Literature

48results about How to "Fine dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selenium-enriched five-cereal nutritional instant powder and preparation method thereof

ActiveCN106234926AMeet selenium supplement requirementsImprove neurological functionFood scienceAlcoholSoft materials

The invention provides a selenium-enriched five-cereal nutritional instant powder and a preparation method thereof, not only realizes the preparation of instant composite coarse cereal powder under the no addition condition, and has the advantages that the product taste is fine, has the fragrance of puffing coarse cereals, the selenium quantification can be realized, and the product is suitable for demands for selenium supplementation of crowds with selenium deficiency. The five-cereal nutritional instant powder rich in selenium comprises selenium-enriched rice and various cereals as well as auxiliary materials, can be selenium-containing hair nourishing brain strengthening nutrient powder, selenium-containing children's nutrient powder, selenium-containing blood and qi nourishing nutrient powder or selenium-enriched liver nourishing and protecting nutrient powder. The preparation method comprises the steps of soaking fresh five cereals taken as raw materials, mixing the soaked five cereals and water, drying and smashing to obtain five-cereal powder; mixing the five-cereal powder and ethyl alcohol to prepare soft material, then carrying out granulation to obtain five-cereal instant particles; and drying the five-cereal instant particles to obtain the five-cereal instant powder. The preparation method for the five-cereal nutritional instant powder is simple, the obtained five-cereal instant powder is easy to dissolve, the instant time is less than 20 seconds, and the agglomeration probability is low.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

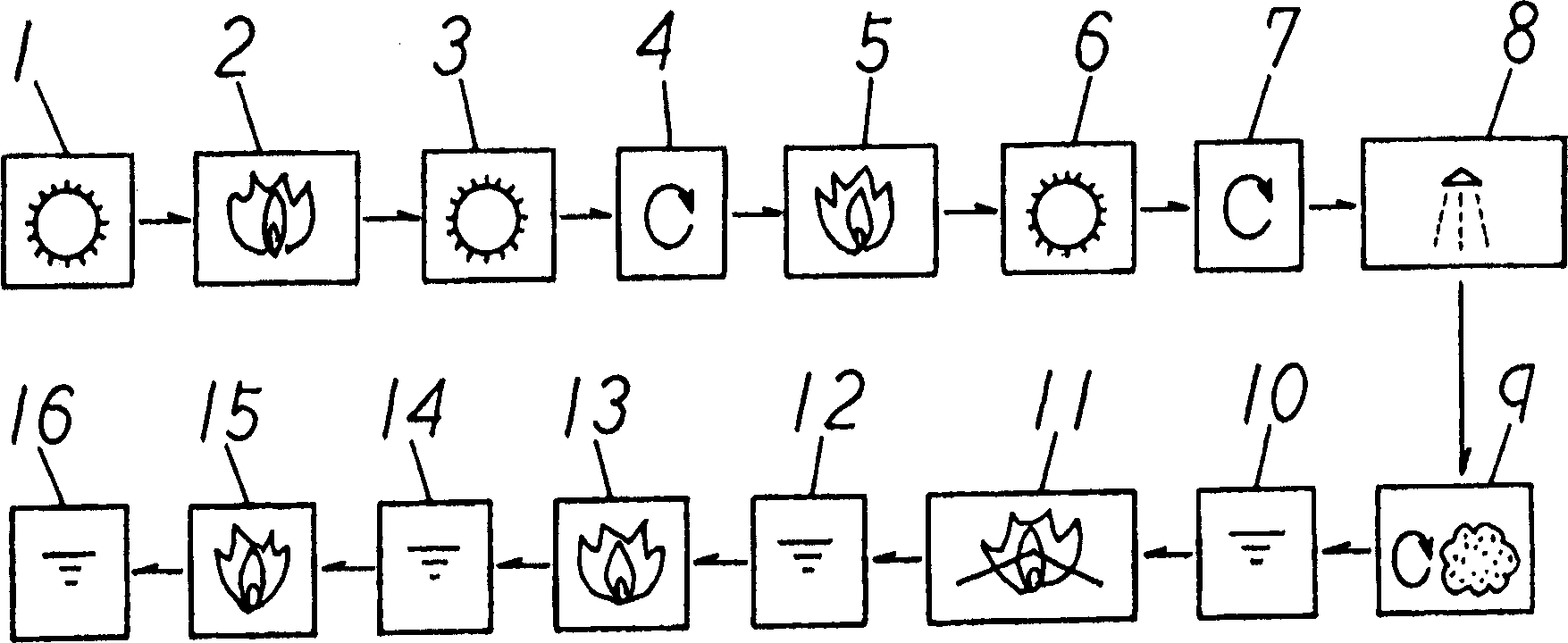

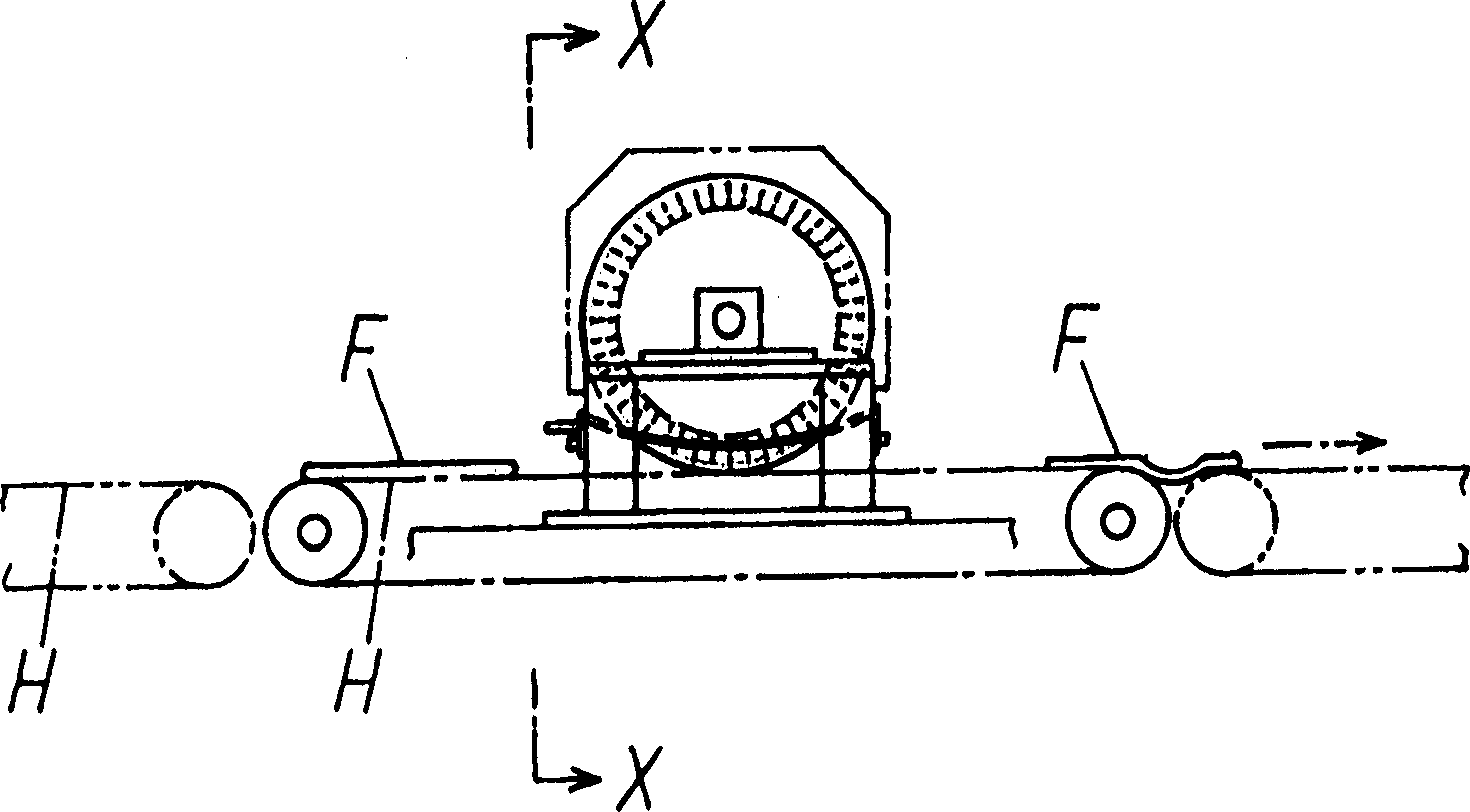

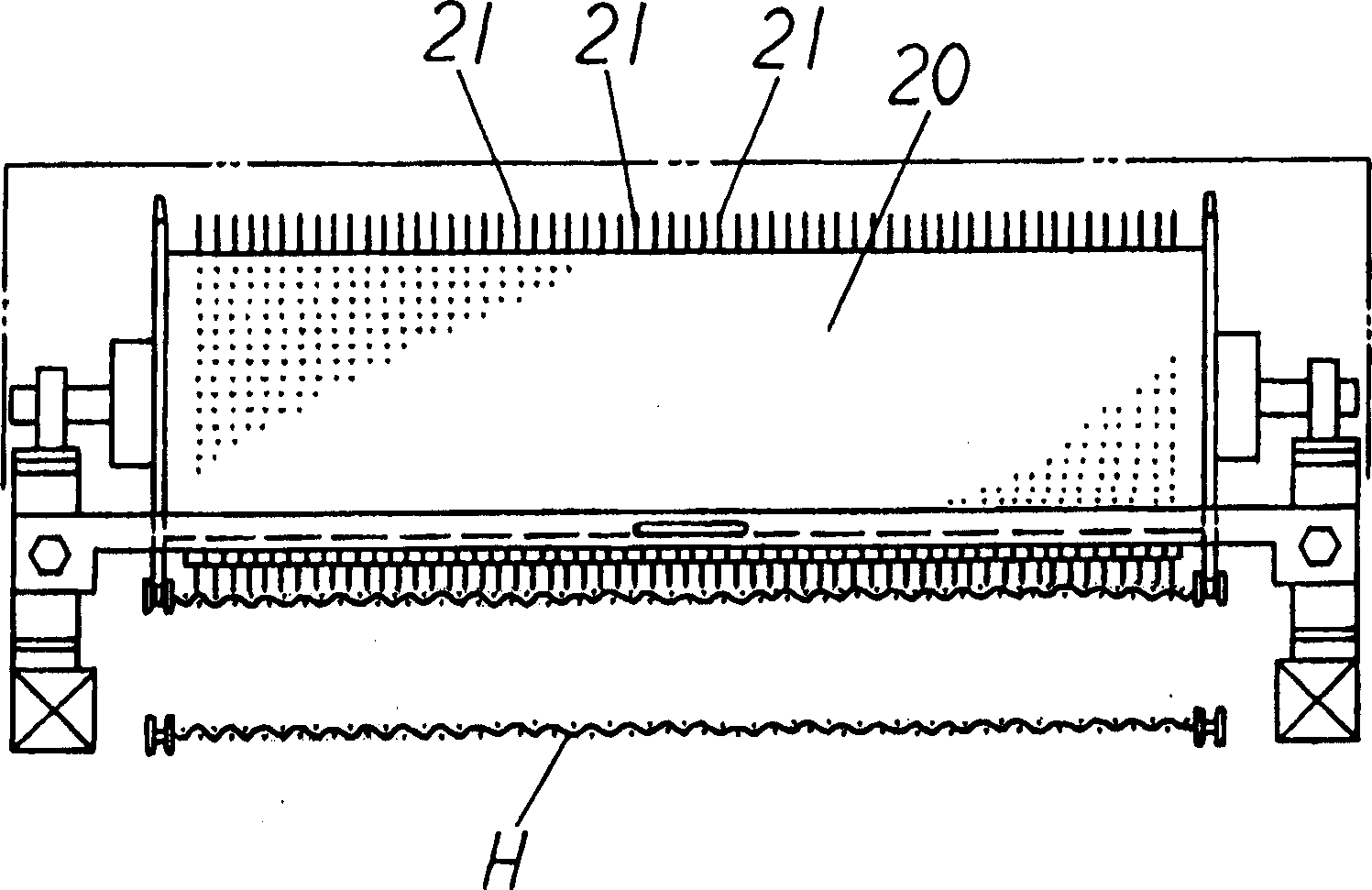

Grilled fish processing method and grilled fish processing device

ActiveCN1903076AAvoid partial sheddingInhibition of local expansionFood preparationAnguilliformesConger

The invention provides a processing method and apparatus for split and broiled fish which makes piercing holes in a food material for broiling. This processing method for the split and broiled fish comprises applying seasoned sauce to a food material of either one of eel, conger eel or loach followed by broiling the food material. The method has a process of making piercing holes in the skin surface of the food material before applying seasoned sauce and broiling, and then broiling the skin surface.

Owner:KYOMARU +2

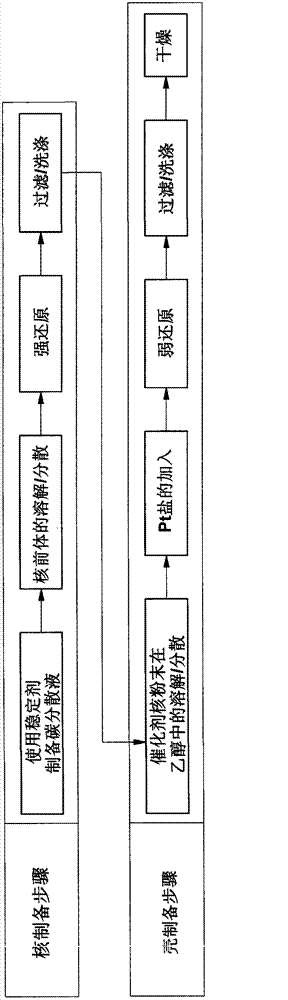

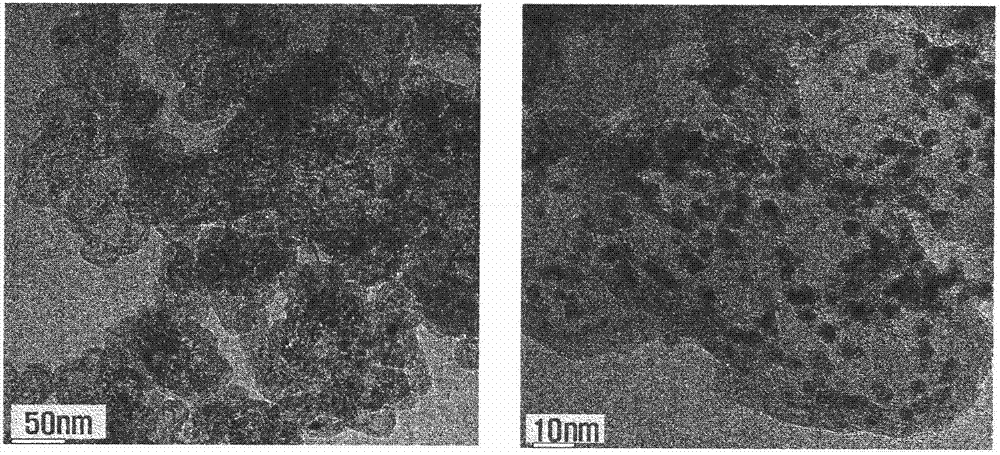

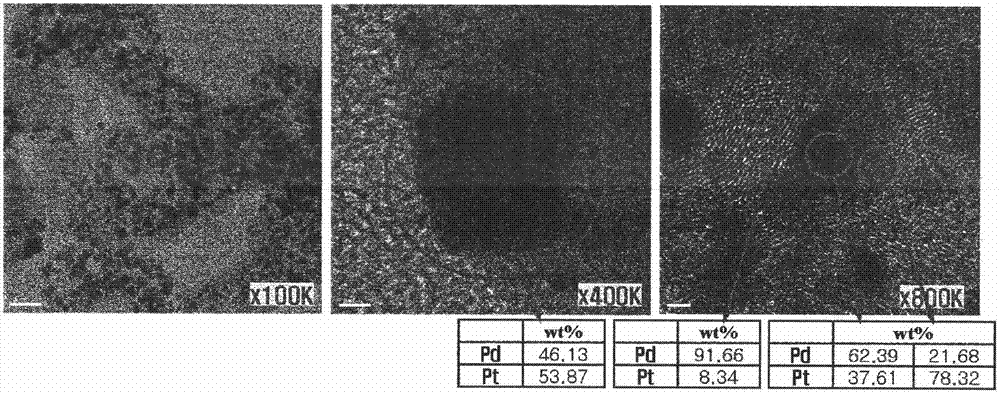

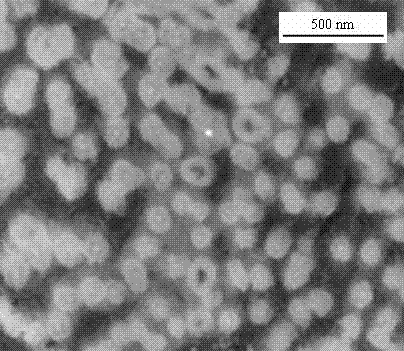

Method for manufacturing core-shell type supported catalysts and core-shell type supported catalysts formed thereby

InactiveCN103157465AEasy loadingShorten flocculation timeCell electrodesMicroballoon preparationAlloySolvent

A method for manufacturing a core-shell type supported catalyst, wherein alloy particles having a core-shell structure with a different interior and exterior are supported on a complex carbon support. The method includes: 1) dissolving and dispersing a carbon support in a solvent using a stabilizer; 2) dissolving a core precursor in the solution, and adding a strong reducing agent to reduce and support a transition metal of the core precursor on a surface of the carbon support; 3) filtering and washing the carbon support on which the transition metal is supported; 4) re-dispersing the filtered and washed carbon support in a shell precursor aqueous solution; and 5) adding a weak reducing agent to the solution of step 4) at 60-80 DEG C. so that metal ions of a shell precursor are selectively reduced and deposited on the transition metal.

Owner:HYUNDAI MOTOR CO LTD +1

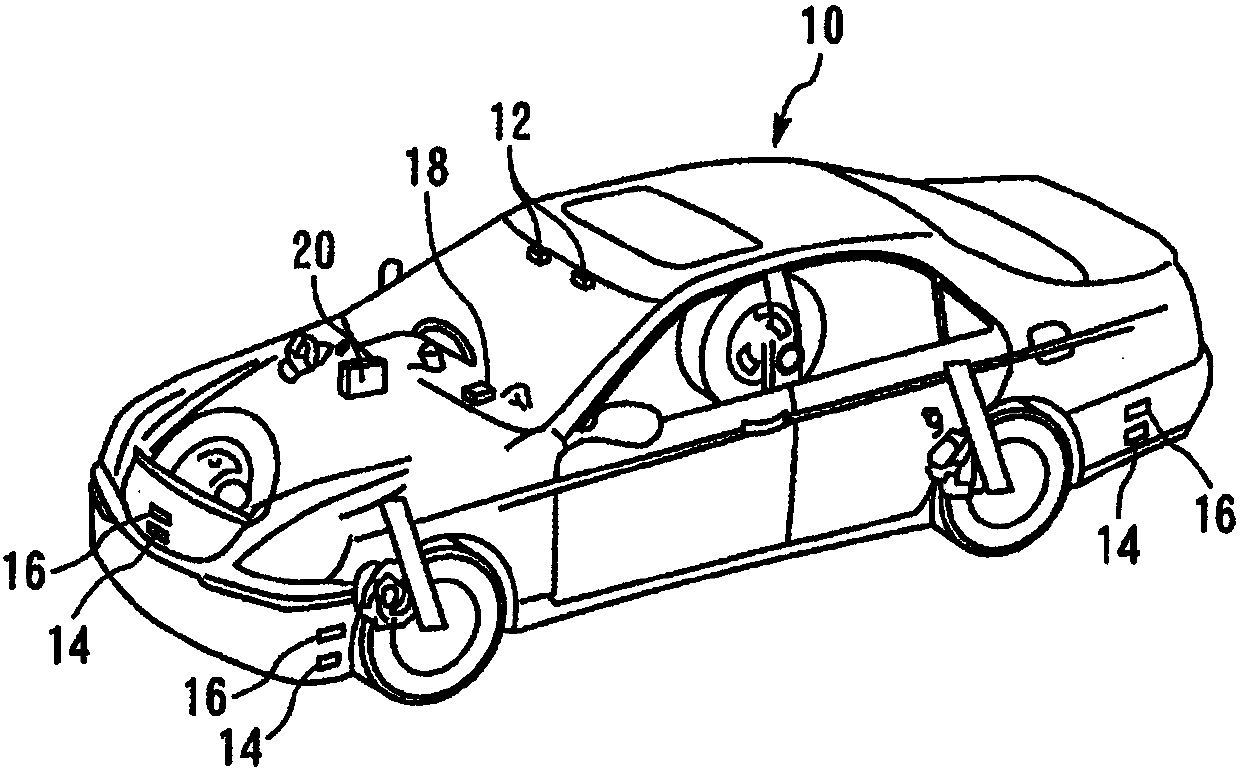

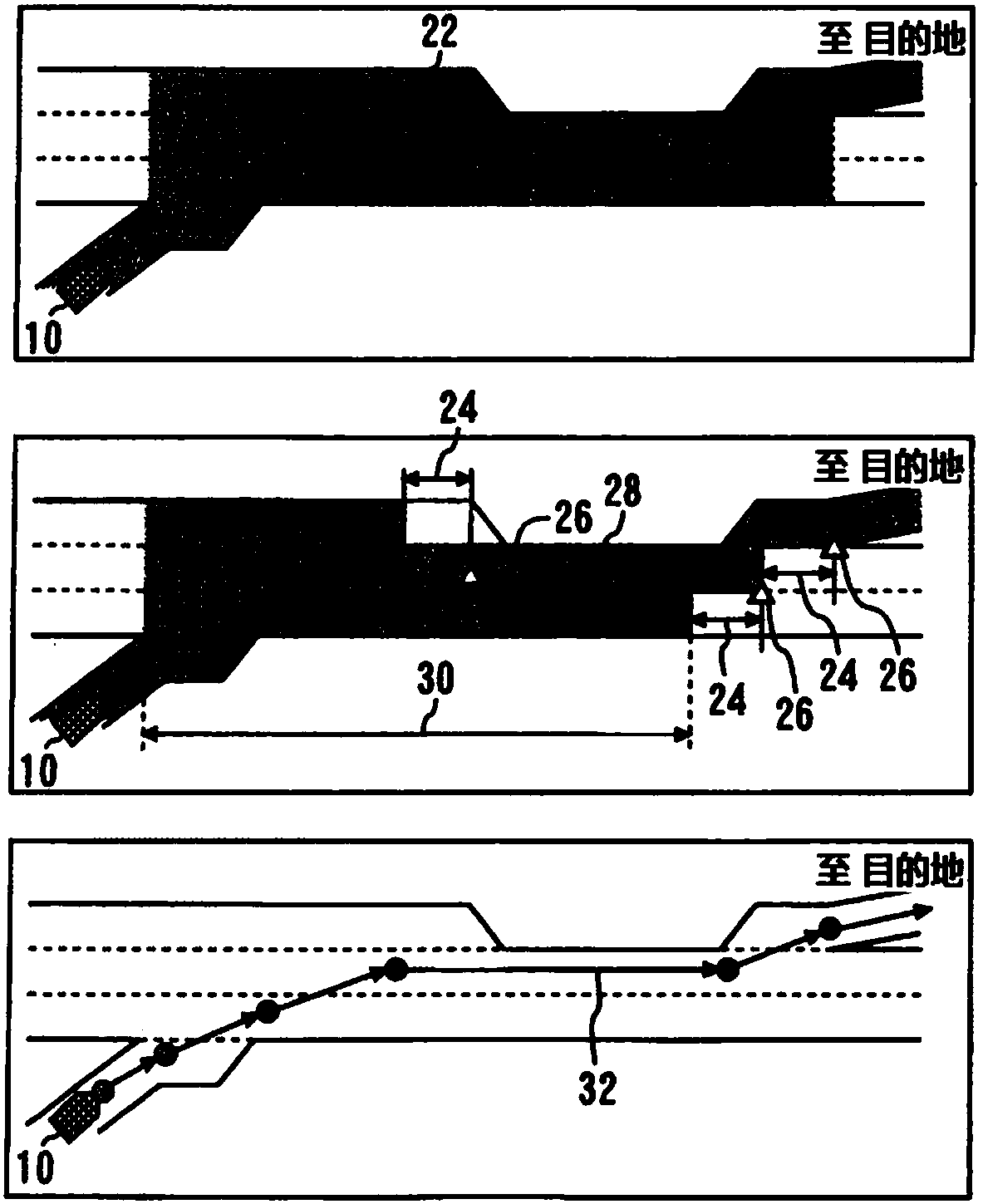

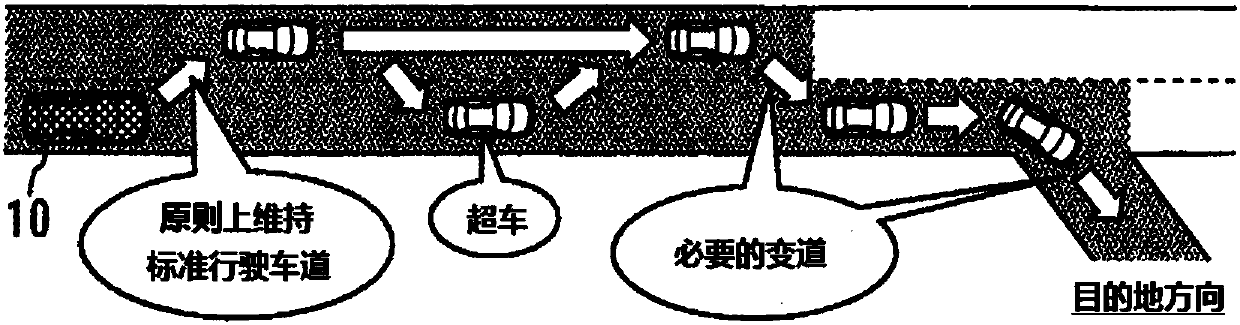

Autonomous driving system and autonomous driving vehicle

ActiveCN107731002AAvoid concentrated lane changesLane change preventionAnti-collision systemsCharacter and pattern recognitionEngineeringAutopilot

The present invention relates to an autonomous driving system and an autonomous driving vehicle, and aims to avoid the local balance in a traffic stream of the pluraltiy of autonomous driving vehicleshaving the line determination functions. The autonomous driving vehicle sets a travelable area in which the autonomous driving vehicle can travel in a process of going to a destination. In a multiple-lane area including two or more lanes in the travelable area, one lane is determined as a standard travel lane. Processing of determining the standard travel lane is configured so that dispersion occurs to standard travel lanes which are determined by a plurality of autonomous driving vehicles in a same multiple-lane area placed under a same environment.

Owner:TOYOTA JIDOSHA KK

High performance battery plate grid alloy

The invented alloy is applied to complete enclosed maintenance free lead acid cell. The ingredient is Cd:1.5%-2.0%, Sb:1.5%-2.0%, RE:0.01-0.05%, Sn:0.01-0.05%; ingredient of RE is Ce, La, Pr, Nd etc. Adding Pb, Cd, mixed rare earths, stannum etc. constitutes alloy of Pb-Cd-Sb-Re-Sn. Features of the alloy are strong corrosion resistance, high deep cycle duty. Method for manufacturing the alloy includes producing Pb-RE intermediate alloy about 660 deg.C by using general crucible furnace or iron-lead pan; adding prepared antimony and stannum to molten lead at 450-500 deg.C; adding the molten fluid into cadmium and Ph-RE. Qualified alloy is casting into ingot for making sheet grating further.

Owner:上海飞轮有色冶炼厂 +1

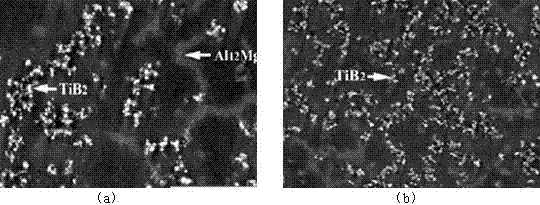

Novel magnesium alloy composite material preparation method

The invention relates to a novel magnesium alloy composite material preparation method. The novel magnesium alloy composite material preparation method is characterized in that a novel magnesium alloy composite material is prepared through the steps that aluminum, zinc, manganese, neodymium, cerium and magnesium are proportionally mixed, nickel coated nano-SiC particles are added into a magnesium alloy melt, an electromagnetic field is applied at the same time, the nickel coated nano-SiC particles are evenly scattered in the melt through electromagnetism simulated microgravity, an electric field is applied to a casting ingot after pouring to refine grains, and finally the novel magnesium alloy composite material is subject to equal channel angular pressing. The neodymium element in the novel magnesium alloy composite material has the dispersion strengthening effect, and formed metallic compounds can prevent grain boundary sliding; the cerium element can improve the alloy structure and refine the grains; a microgravity field enables the nickel coated nano-SiC particles to be evenly scattered in the melt; the electric field can increase the degree of supercooling of the melt, nucleation barriers are reduced, and the grains are refined; and the equal channel angular pressing can further refine the grains, and the synthetic mechanical property of the composite material is improved.

Owner:CHANGZHOU UNIV +1

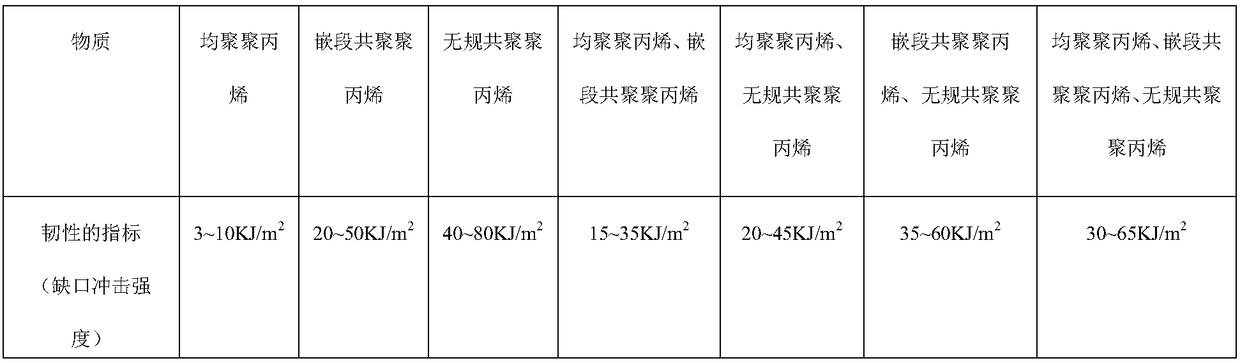

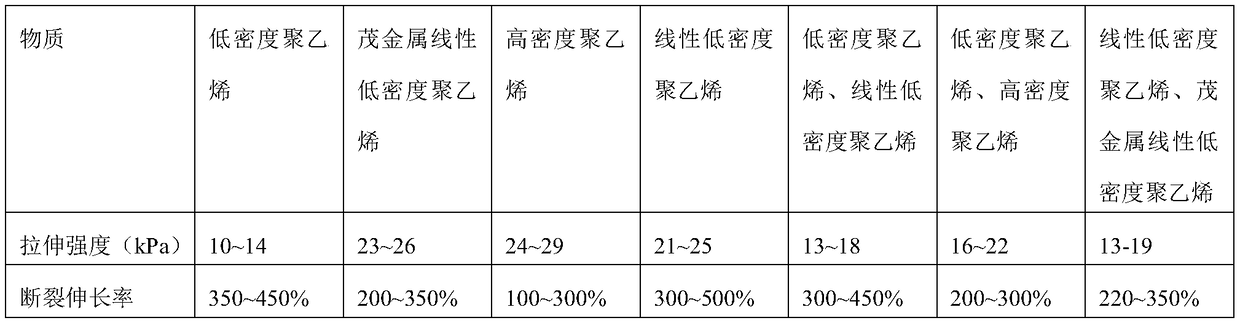

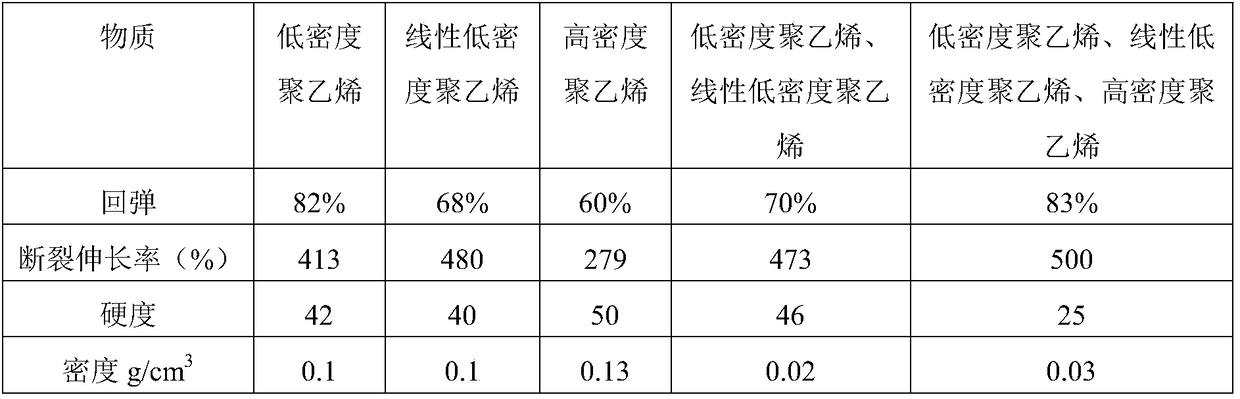

Multilayered compound yoga mat and production process thereof

ActiveCN108976612AImprove distributionEvenly distributedSynthetic resin layered productsMasterbatchFriction force

The invention discloses a multilayered compound yoga mat and a production process thereof. The multilayered compound yoga mat successively comprises a polyethylene foamed layer, a POE foamed layer anda PP / EPDM base plate from top to bottom. The process comprises the following steps: extruding PP / EPDM masterbatch to PP / EPDM sheets through a twin-screw extruder; putting a POE foamed master slice ina foaming furnace to be freely foamed to obtain POE foamed sheets; thermally compounding uncooled PP / EPDM sheets and the POE foamed sheets on a calender bowl to obtain double-layered compound sheets;and finally, foaming the polyethylene foamed master slice freely to obtain the PE foamed sheets, and laminating the PE foamed sheets to the double-layered compound sheets to trim and roll to obtain the multilayered compound yoga mat. By adopting PP / EPDM as the base plate, the friction force of the yoga mat to the ground during use is increased, so that an anti-skid action is played compared withother rubber base plates.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

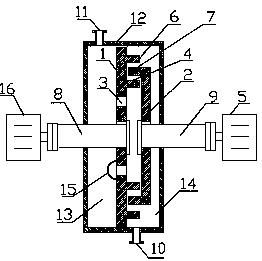

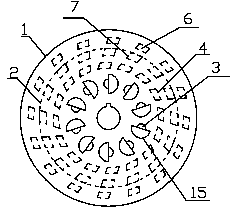

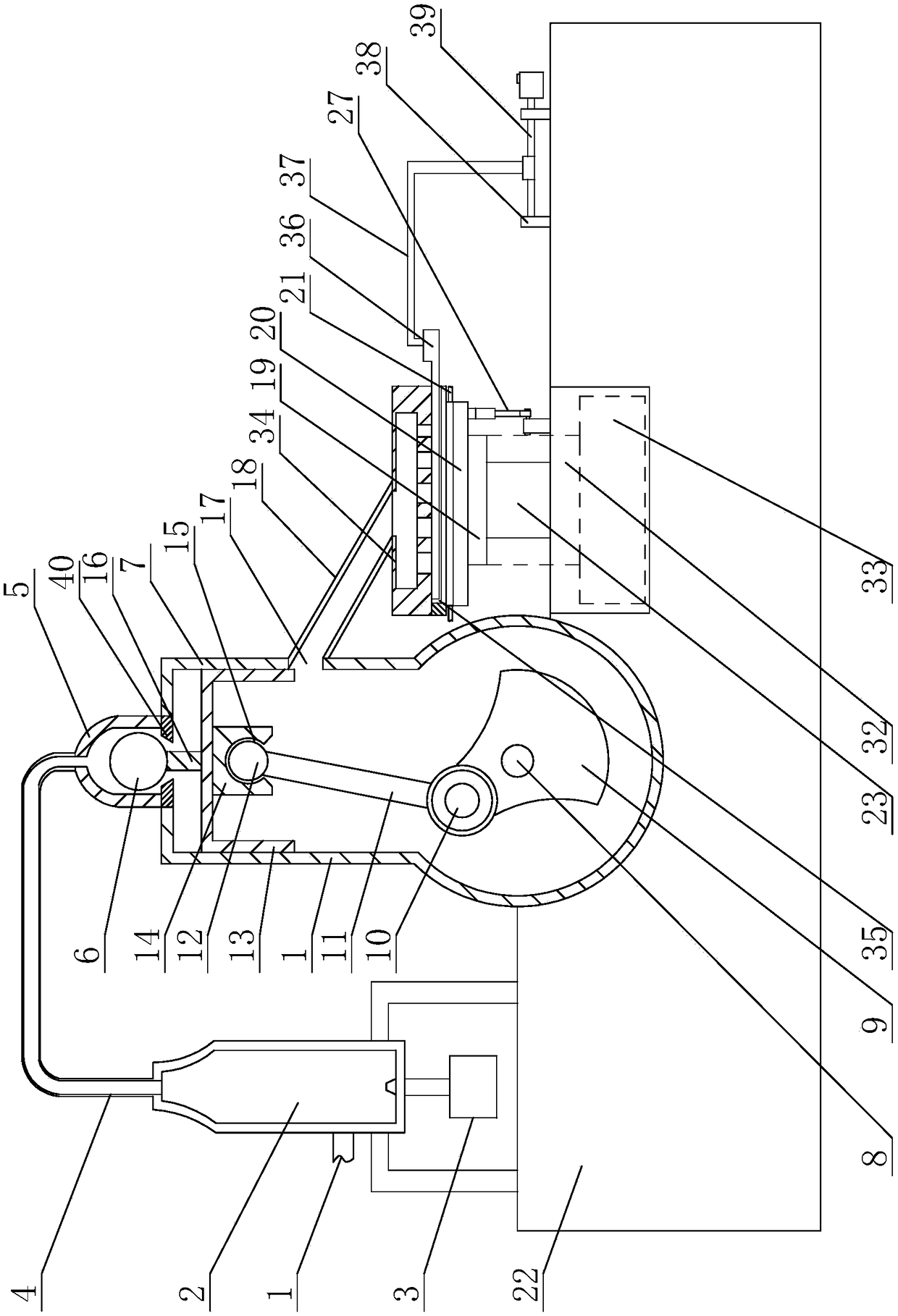

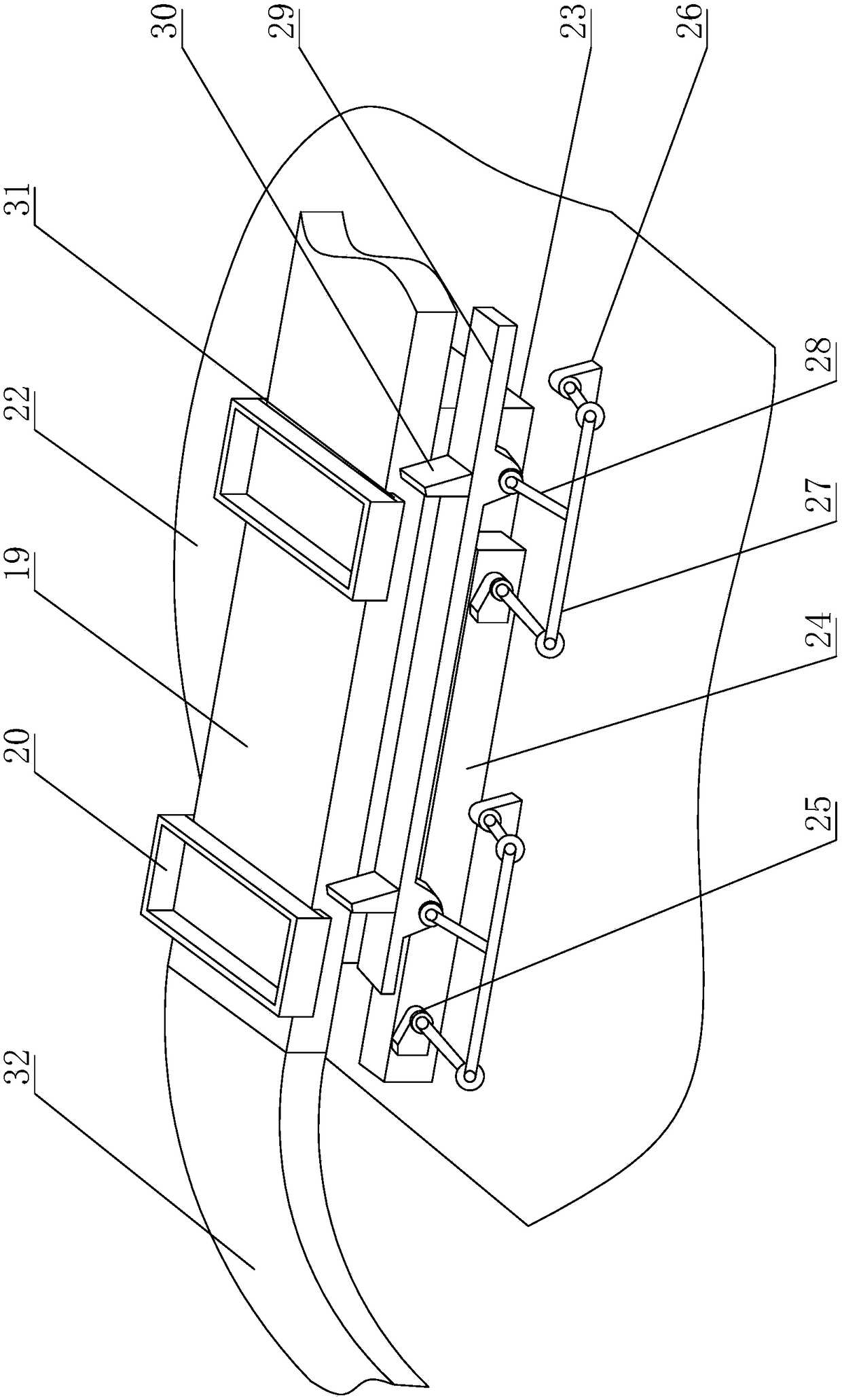

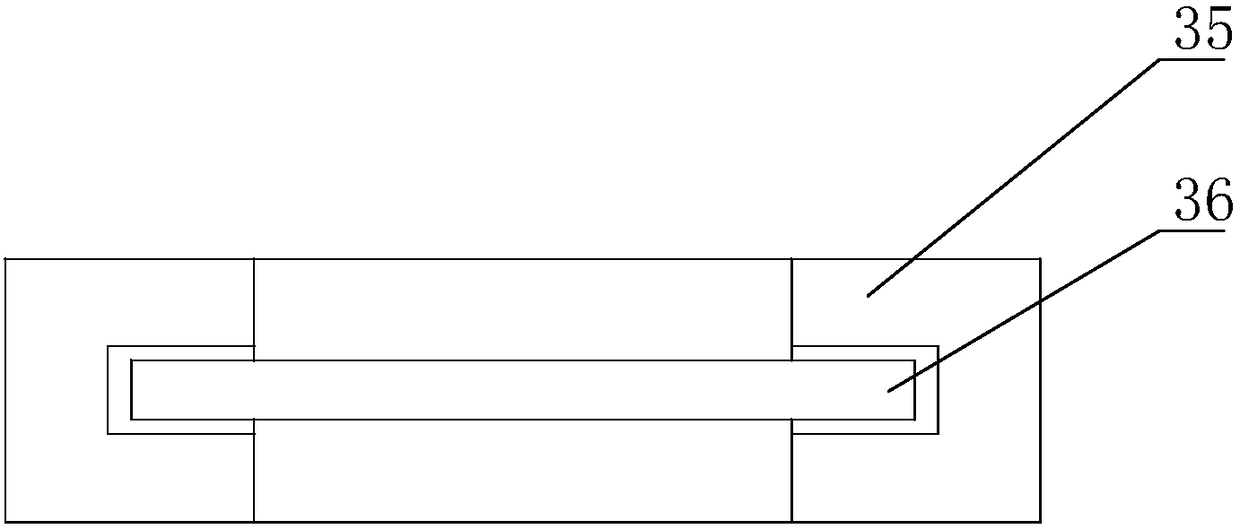

Double-rotor pipeline type emulsifying machine

ActiveCN104801218ACrushed fullyImprove crushing effectTransportation and packagingMixing methodsEngineeringTooth space

The invention discloses a double-rotor pipeline type emulsifying machine which comprises a casing, wherein an inner cavity is formed in the casing; a left rotor and a right rotor are arranged in the inner cavity of the casing; the left rotor comprises a left disc surface, first helical teeth and third helical teeth are arranged on the periphery of the right side surface of the left disc surface, and the first helical teeth are located on the radial outer sides of the third helical teeth; the right rotor comprises a right disc surface, second helical teeth are arranged on the periphery of the left side surface of the right disc surface and face the left side, and second tooth space is formed between every two second helical teeth; after the left rotor and the right rotor are fastened together, the slanting directions of the first helical teeth, the third helical teeth and the second helical teeth are the same, the second helical teeth are located between radial directions of the first helical teeth and the third helical teeth, the rotating direction of the left rotor is opposite to the slanting direction of the first helical teeth, and the rotating direction of the right rotor is the same with the slanting direction of the second helical teeth; the left rotor is provided with feeding through holes formed in the inner radial side of the third helical teeth; the left disc surface divides the inner cavity into a left cavity and the right cavity, a feeding port is formed in the left cavity, and the discharging port is formed in the right cavity. The double-rotor pipeline type emulsifying machine has good emulsifying effect and novel structure.

Owner:刘金辉

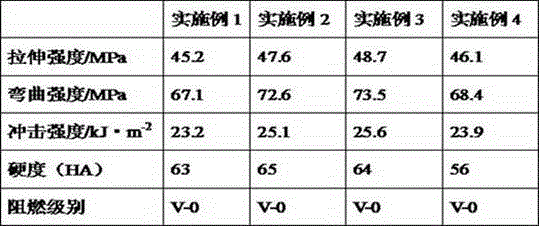

Halogen-free flame-retardant reinforced type ABS (acrylonitrile-butadiene-styrene) composite material and preparation method thereof

The invention relates to a halogen-free flame-retardant reinforced type ABS (acrylonitrile-butadiene-styrene) composite material and a preparation method thereof, and relates to the technical field of plastics. The halogen-free flame-retardant reinforced type ABS composite material adopts the technical scheme that the halogen-free flame-retardant reinforced type ABS composite material consists of an ABS matrix, a main flame-retardant matrix, a synergic matrix, a reinforced matrix, an anti-dripping agent, an antioxidant, a charring agent, paraffin and a color master batch. The halogen-free flame-retardant reinforced type ABS composite material and the preparation method have the advantages that by utilizing the compounding synergic function of the main flame-retardant matrix, the synergic matrix and the reinforced matrix, the flame-retardant property and mechanical property are good; by compounding inorganic components and organic components, the synergic function is formed, the flame-retardant efficiency and mechanical property of the composite material are improved, and the cost of material is reduced; by using the technology to produce, the technology is simple, the operation is convenient, the production efficiency is improved, and the production cost is reduced; while the property of the composite material is reached, the comprehensive cost is lower than the cost of the traditional ABS composite material.

Owner:DONGGUAN POLYTECHNIC

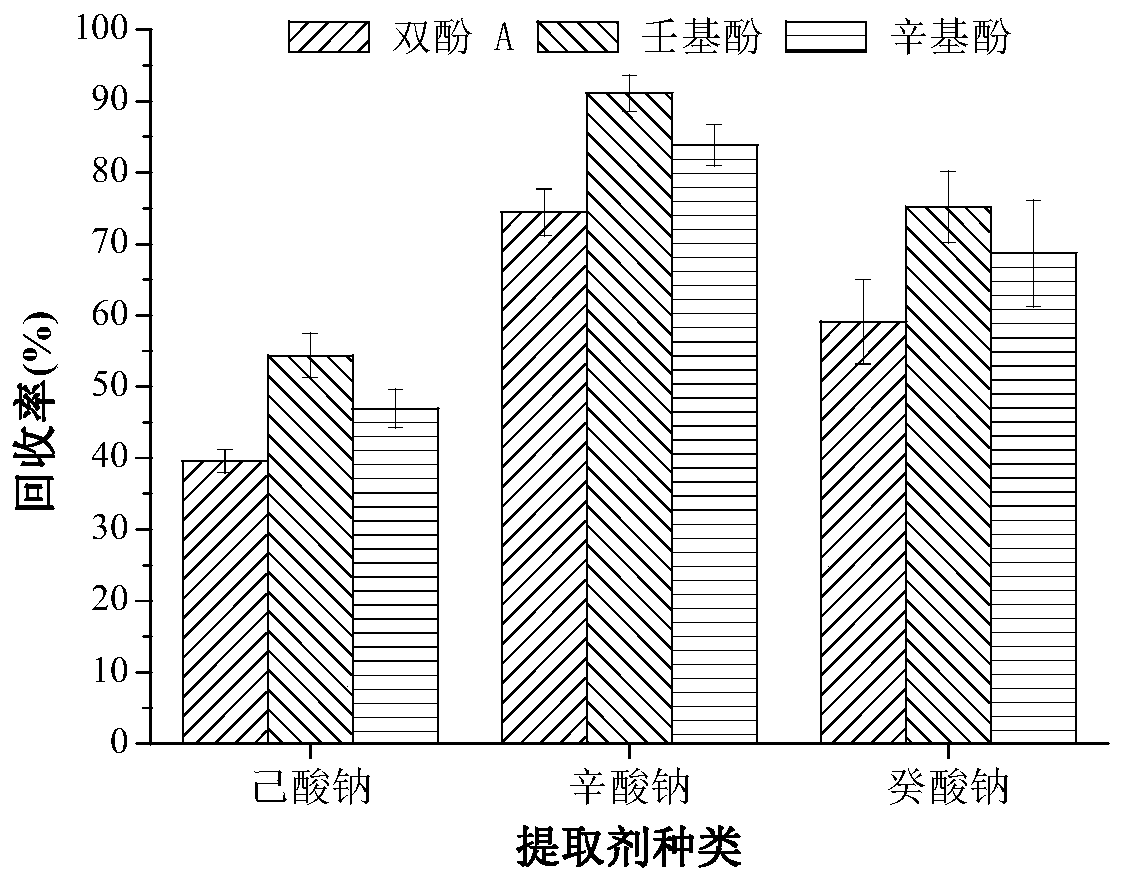

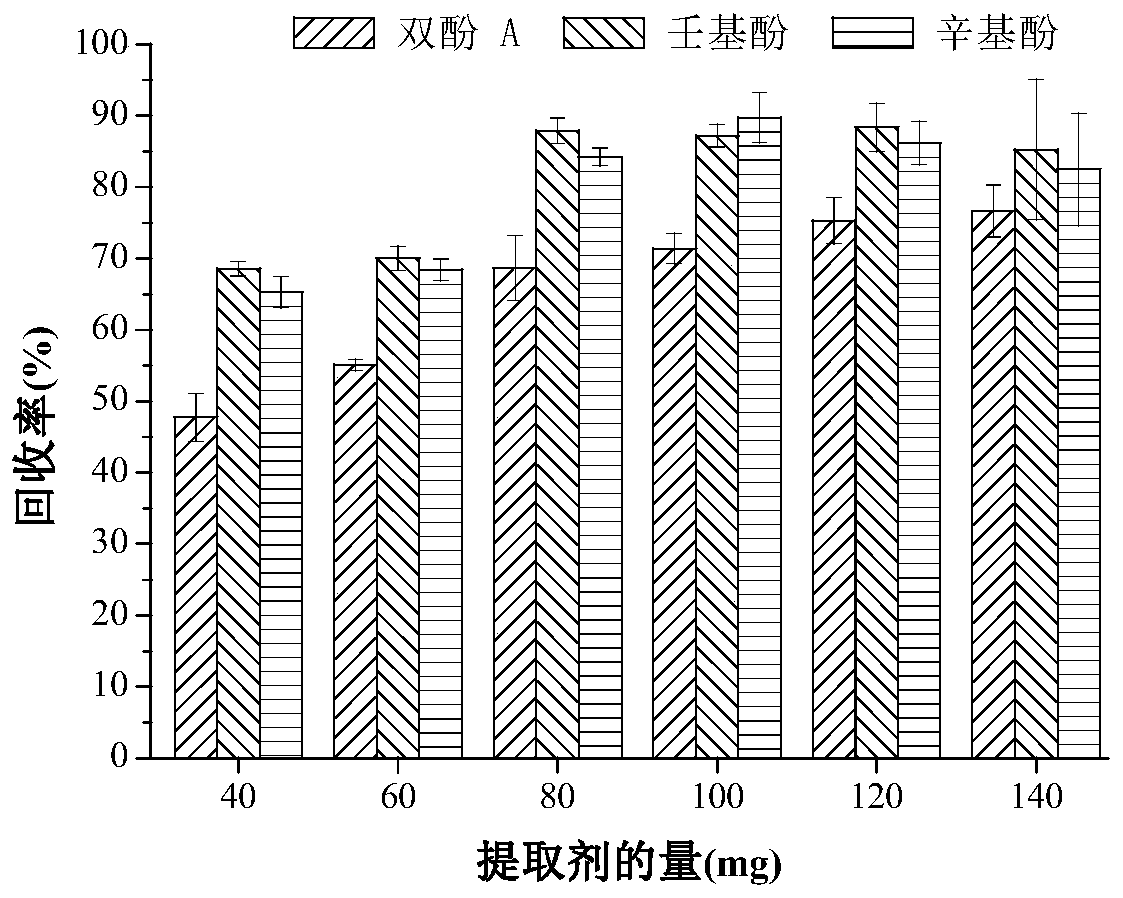

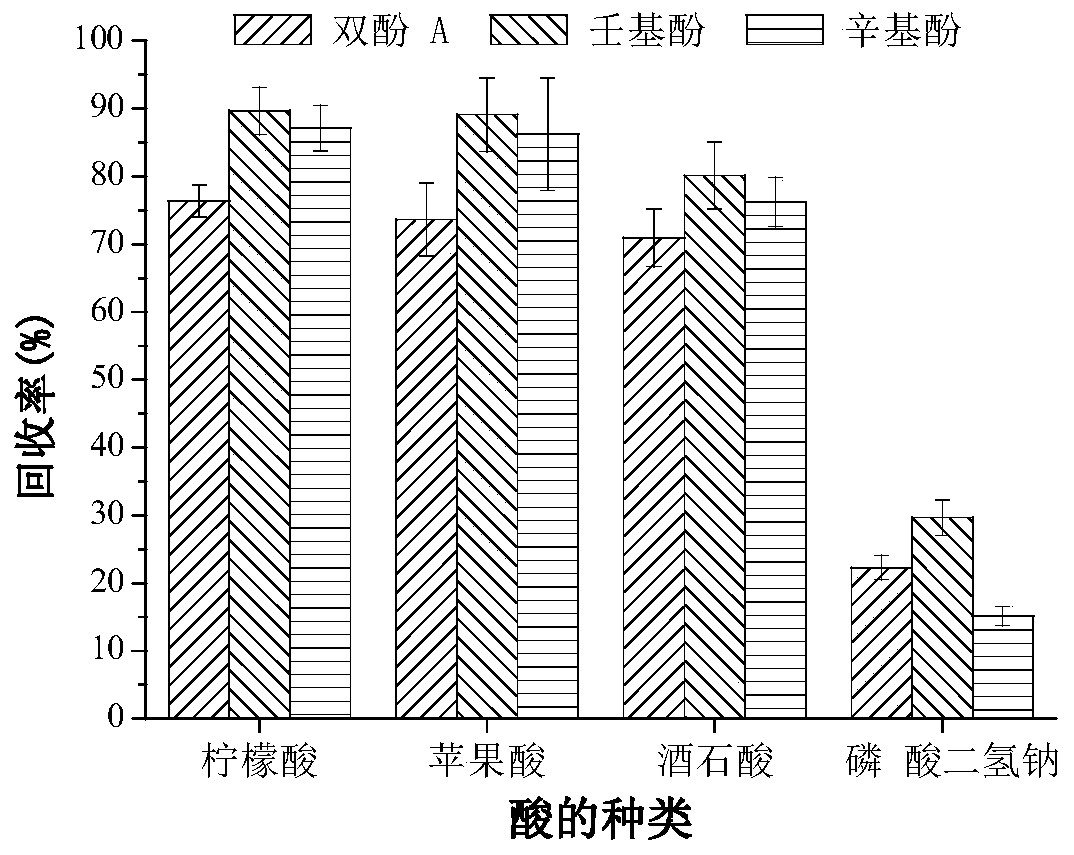

Method for rapidly extracting phenol endocrine disruptor in plastic package beverage

PendingCN110308231AIncrease contact areaImprove extraction efficiencyComponent separationSolventPHENOL LIQUID

The invention discloses a method for rapidly extracting a phenol endocrine disruptor in plastic package beverage, and belongs to the technical field of phenol endocrine disruptor detection. The extraction method comprises the steps of accurately weighing sodium caprylate, citric acid and sodium bicarbonate, and performing pressing formation for use, wherein the mass ratio of the sodium caprylate,the citric acid and the sodium bicarbonate is 1:1:0.4; weighing a to-be-detected sample in a container, placing an effervescent tablet, pressed in advance, in the to-be-detected sampled, and performing centrifugation after reaction is completed; and performing ice-water bath on the to-be-detected sampled after centrifugation so that an upper-layer organic phase is converted to a solid phase, and collecting the organic phase of the solid phase. A green convertible hydrophilic solvent s used as an extraction agent, the extraction agent can be grown in an in-situ way, the dispersion of the extraction agent is helped by CO2 bubbles generated by reaction of the citric acid and sodium bicarbonate, and the extraction agent is fully combined with a target; and a suspension curing method is used for collecting, the recycling rate of the target is greatly improved, and moreover, organic matter separation is very simple and rapid.

Owner:SHANXI AGRI UNIV

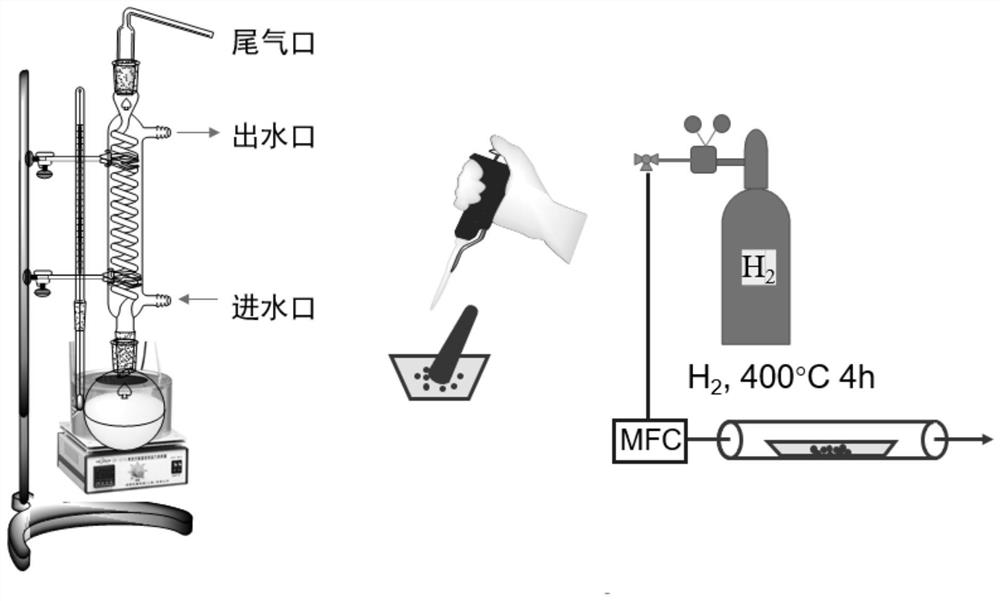

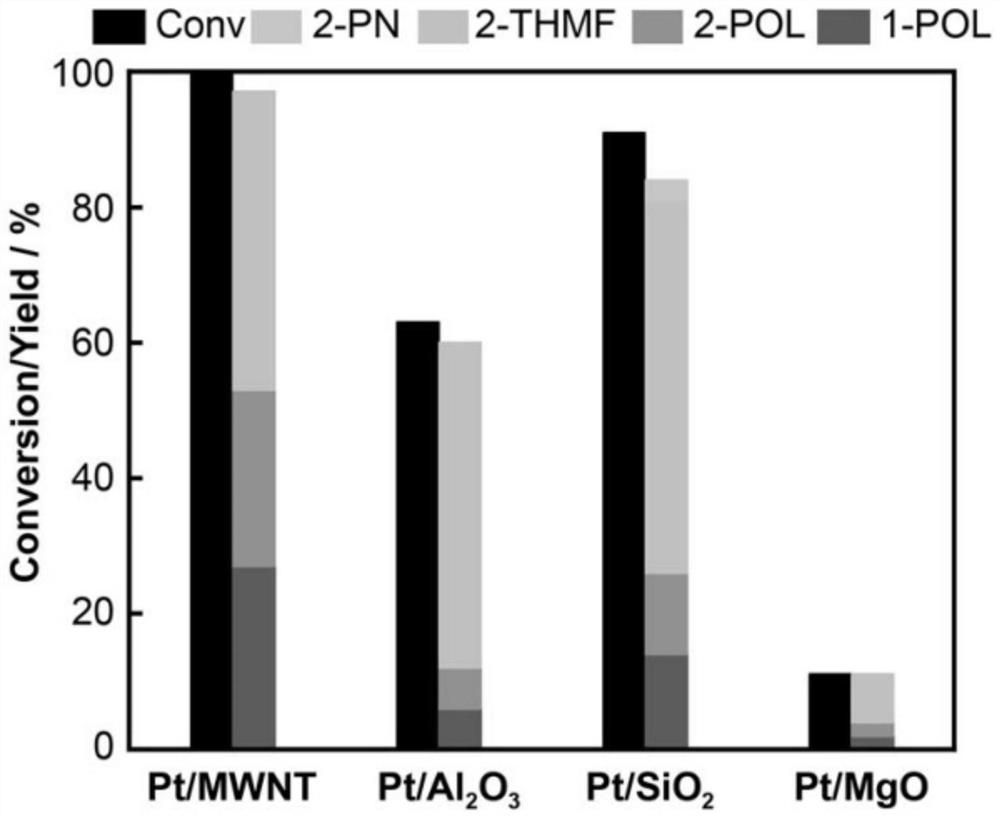

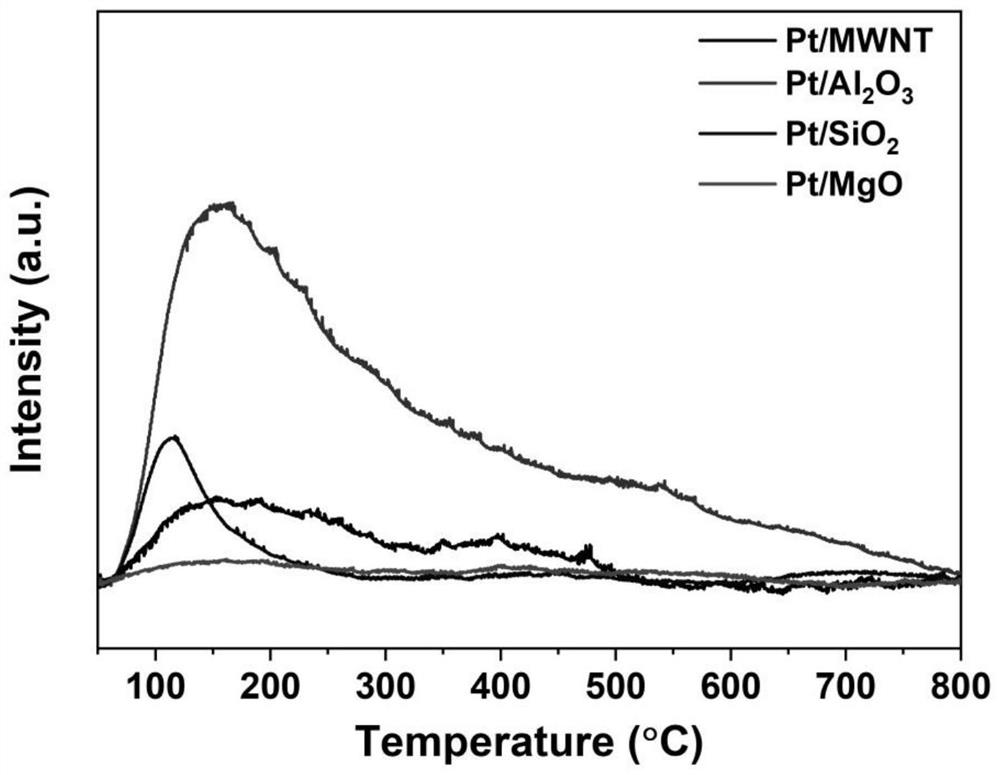

Method for preparing amyl alcohol from 2-methylfuran at room temperature by adopting supported catalyst

InactiveCN113754514AEasy to makeMild reaction conditionsOrganic compound preparationHydroxy compound preparationPtru catalystAmyl alcohol

The invention provides a method for preparing amyl alcohol from 2-methylfuran at room temperature by adopting a supported platinum-based catalyst. Influences of various catalyst carriers, active metals, metal loading capacity and reaction conditions (solvents, time, pressure and the like) are investigated. The acid treatment time of a 5 wt% Pt / MWNT catalyst on MWNT is 4 hours, the catalyst shows excellent activity and selectivity under the H2 pressure of 1 MPa and at the ultralow temperature of 25 DEG C, the 2-MF conversion rate is 100%, and the pentanol (POLs) yield is 53%. A brand new route is provided for synthesis of pentanol, and compared with a traditional synthesis process route, the process route is simple in preparation process, milder in reaction condition, capable of greatly reducing energy consumption and more environmentally friendly. The Pt / MWNT catalyst provided by the invention has good reusability, and shows wide potential in industrial application.

Owner:NANJING UNIV OF TECH

Cordyceps sobolifera buccal tablet and preparation method thereof

The invention belongs to the technical field of health care products, particularly relates to a cordyceps sobolifera buccal tablet, and further discloses a preparation method of the cordyceps sobolifera buccal tablet. Cordyceps sobolifera is a main raw material of the cordyceps sobolifera buccal tablet, and the medical effects of crataegi fructus, lycii fructus, polygonati rhizoma and mulberries are supplemented. The prepared cordyceps sobolifera buccal tablet can effectively improve the immune capability of the human body, has the functions of kidney tonifying, liver nourishing, sleep improving, fatigue resistance and the like, can significantly improve the sub-health state of the human body, and can be used for daily health care. Meanwhile, the buccal tablet is appropriately sweet and sour, free of sucrose, and suitable for diabetics.

Owner:安徽虫草源生物科技有限公司

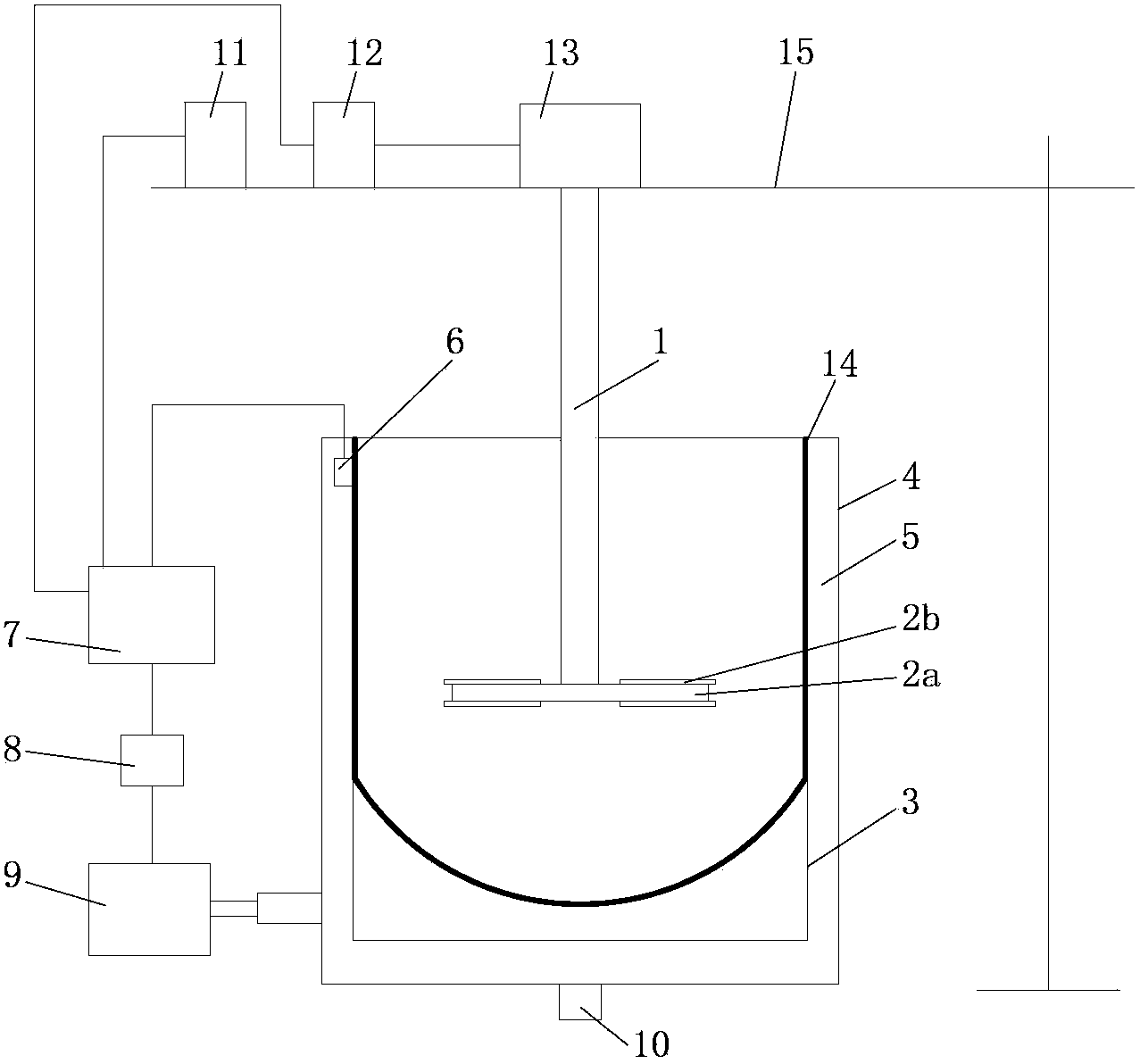

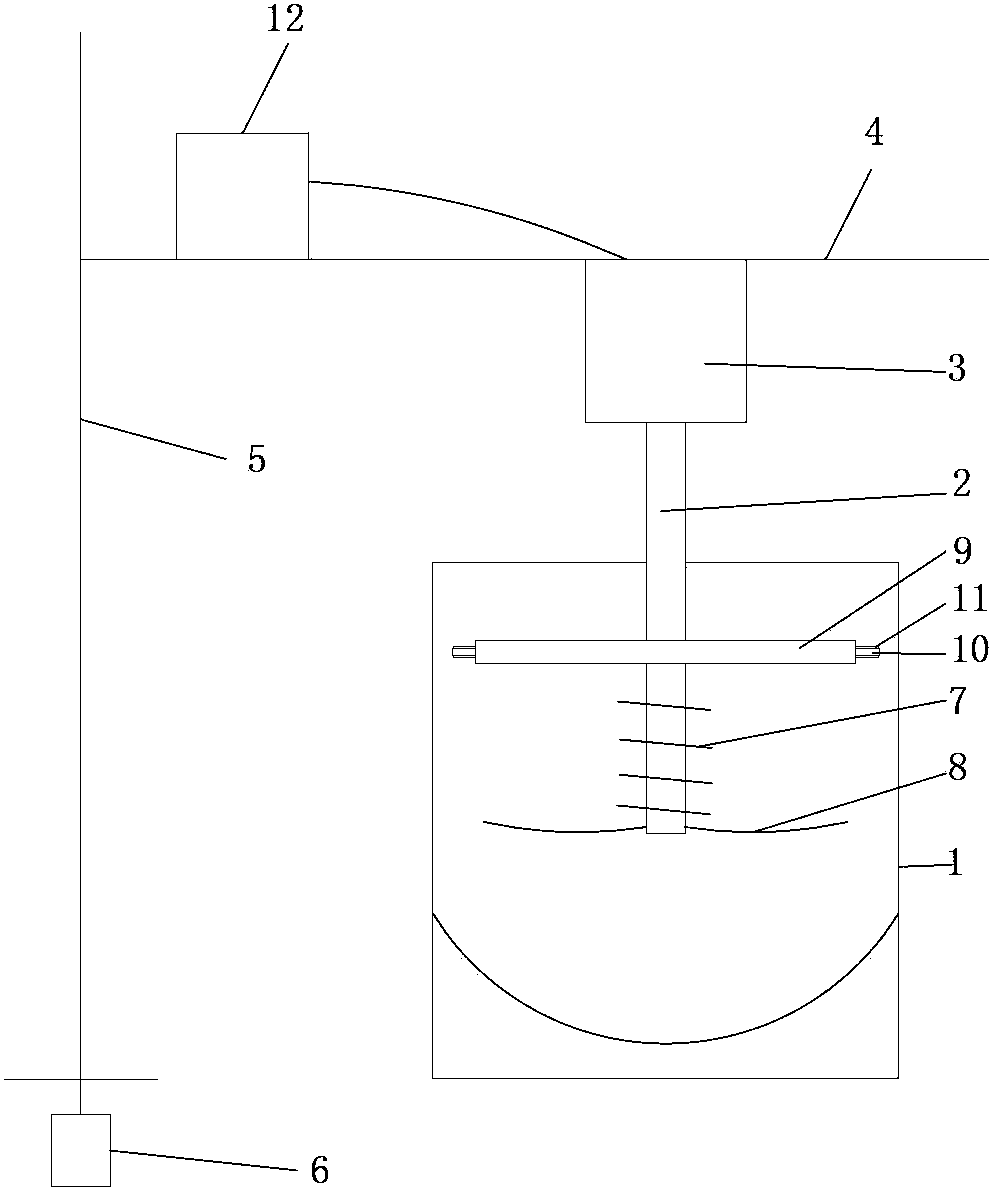

Coating material stirring apparatus with cooling structure

InactiveCN104338455AFine dispersionWell mixedRotary stirring mixersMixer accessoriesElectricityAudio power amplifier

The present invention relates to a coating material stirring apparatus with a cooling structure. According to the apparatus, the tank comprises an inner tank and an outer tank surrounding the inner tank, a cooling space is formed between the inner tank and the outer tank, the outer wall surface of the inner tank is provided with a temperature sensor, the output end of the temperature sensor is connected with a controller, the output end of the controller is connected with the input end of an amplifier, the output end of the amplifier is connected with a water pump, the water pump is communicated with the cooling space through a pipeline, the outer tank is provided with a discharge valve, the discharge valve is communicated with the cooling space, the controller is further electrically connected with a time detection module, the output end of the controller is electrically connected with a motor driving module, the output end of the motor driving module is connected with a motor, and the output end of the motor is electrically connected with a stirring shaft. According to the present invention, the suitable temperature can be provided by adjusting the temperature of the stirring tank when the coating material is stirred, and the stirring is uniform.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

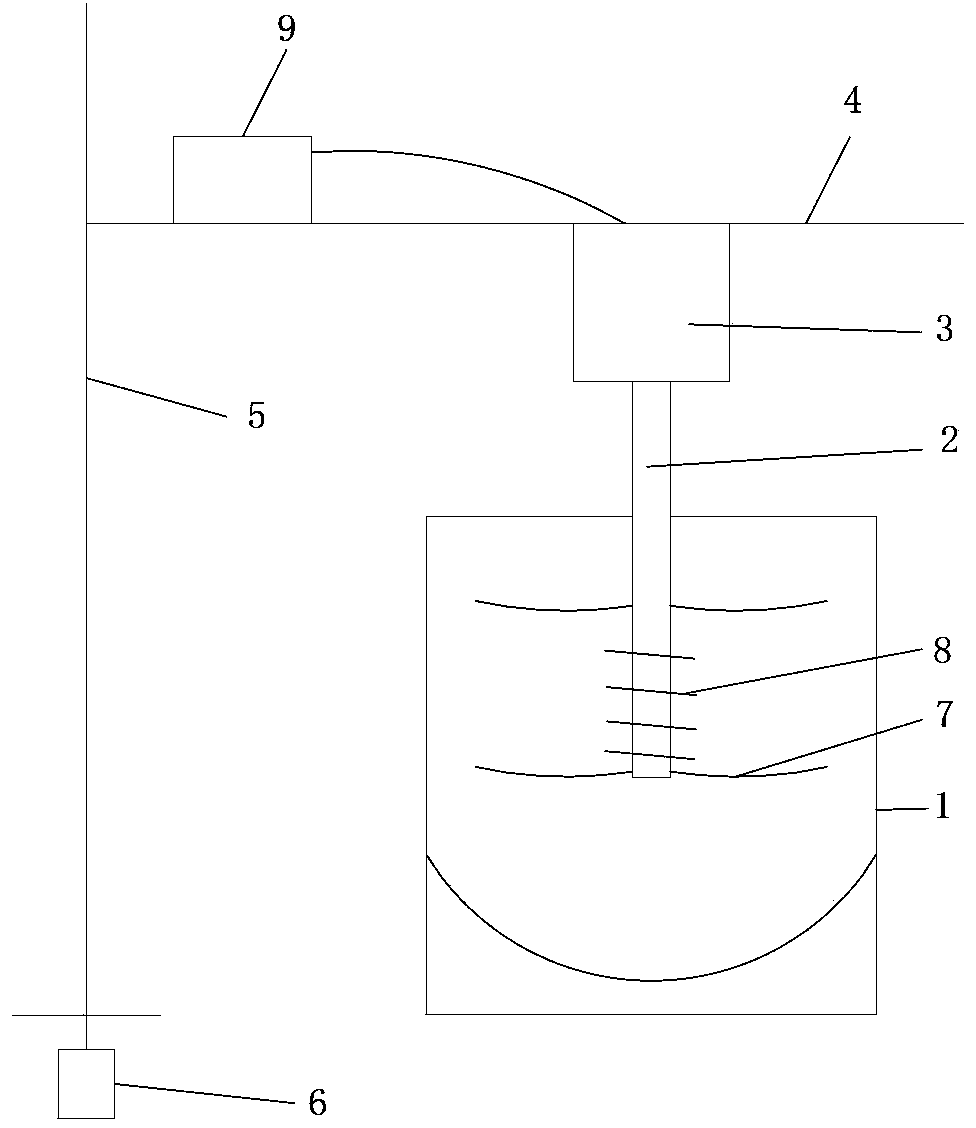

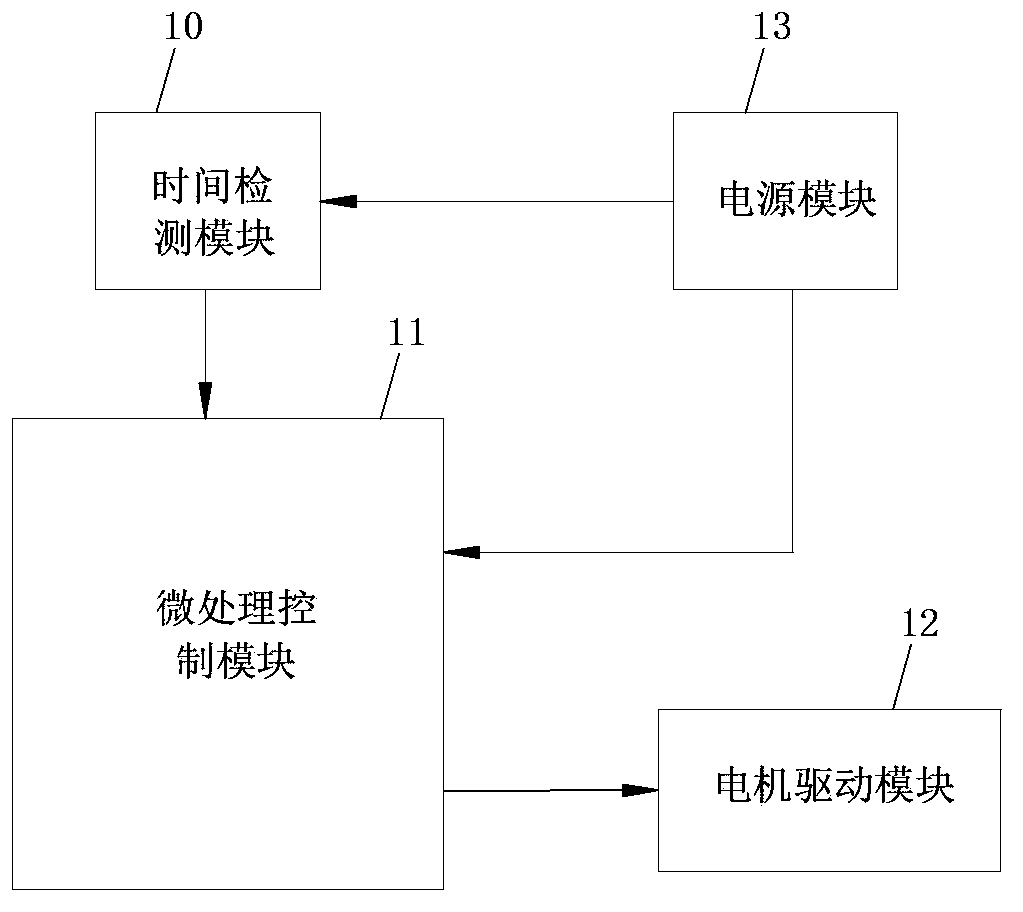

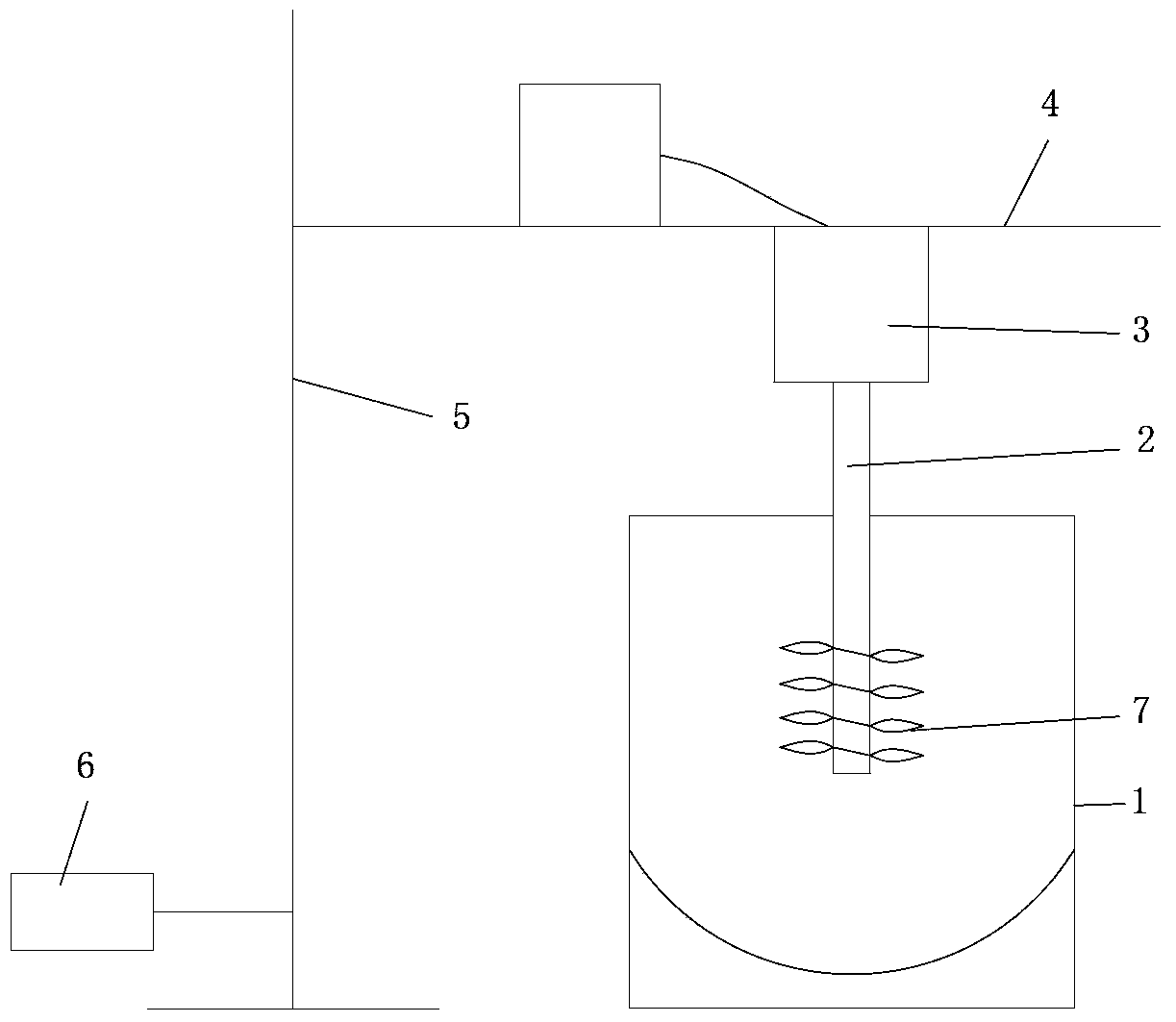

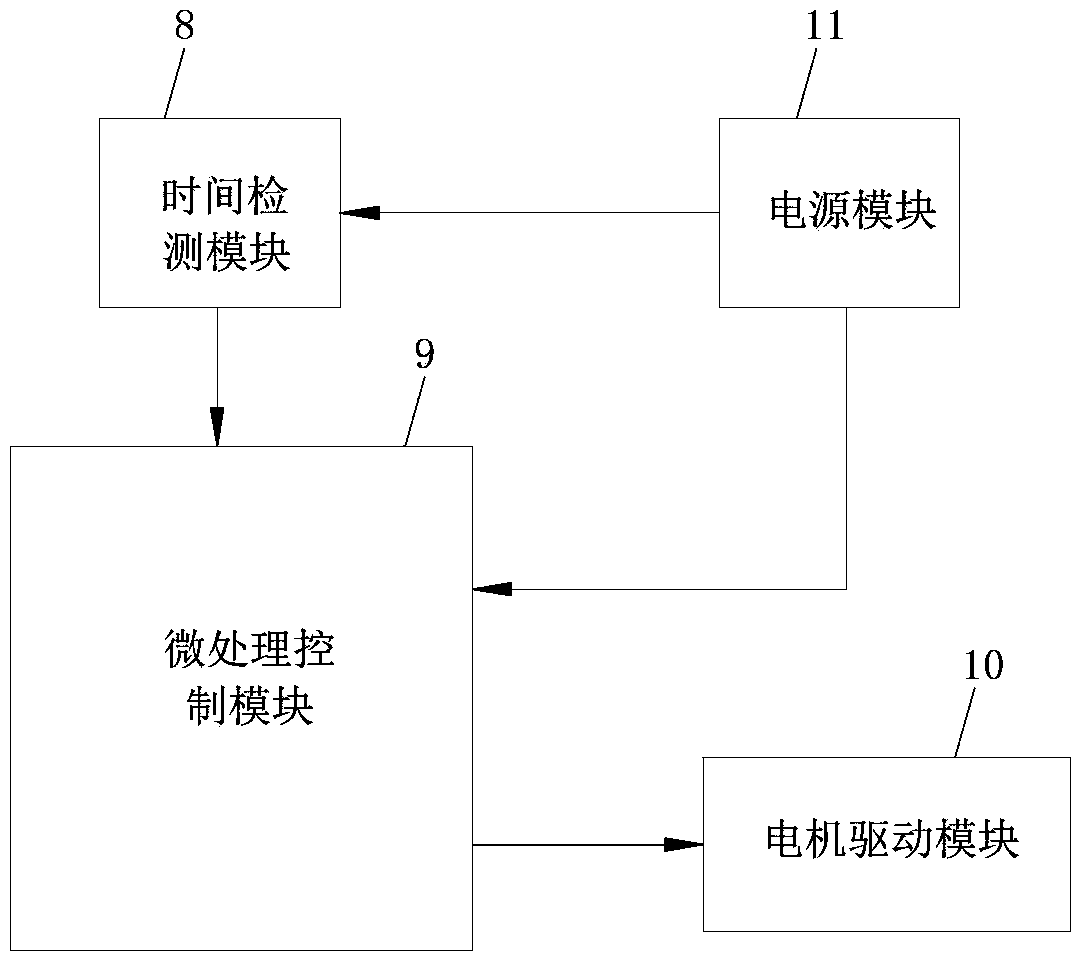

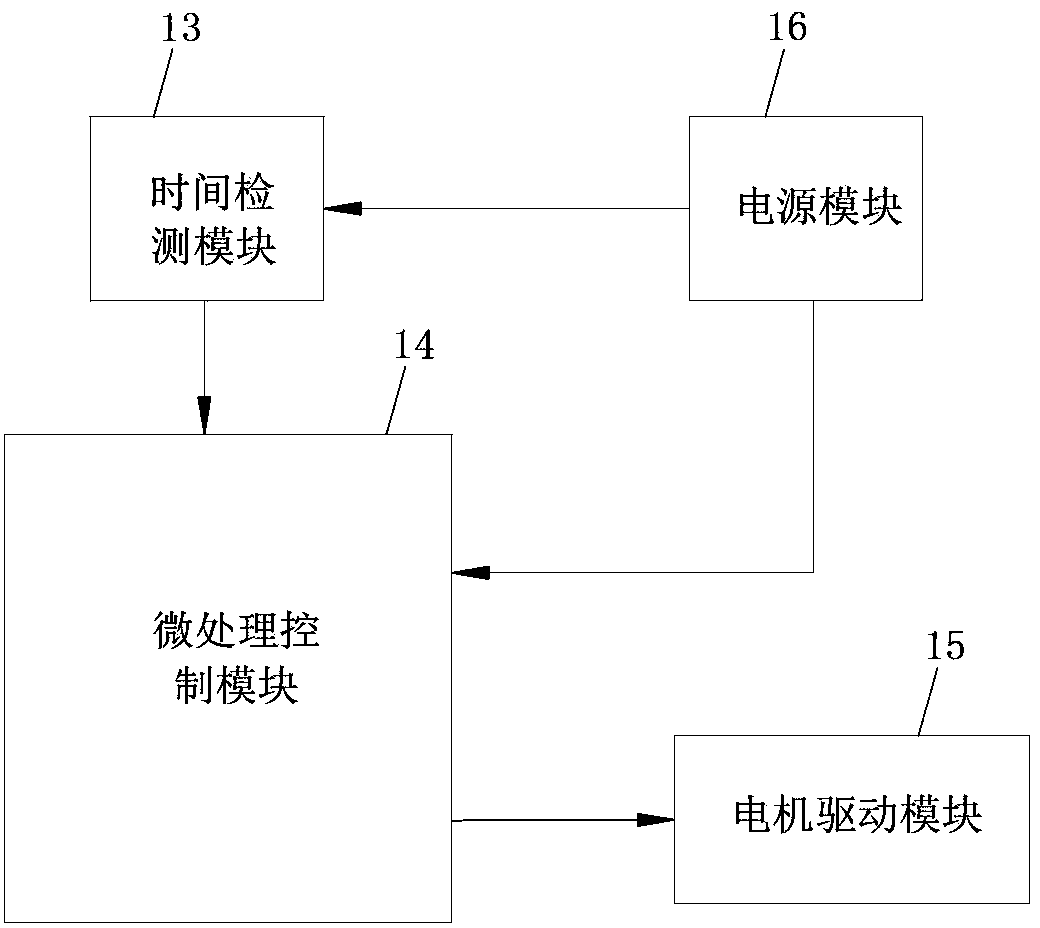

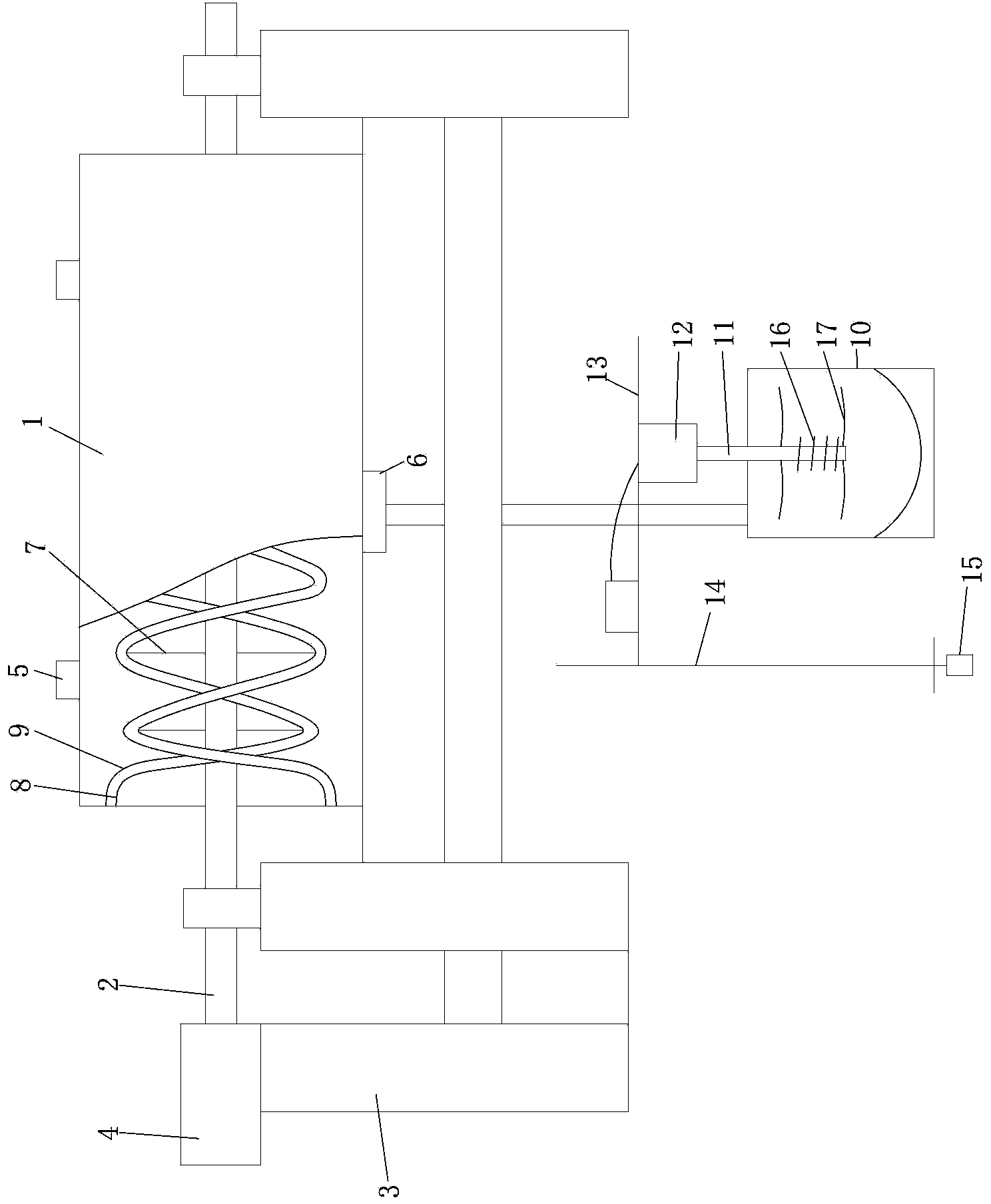

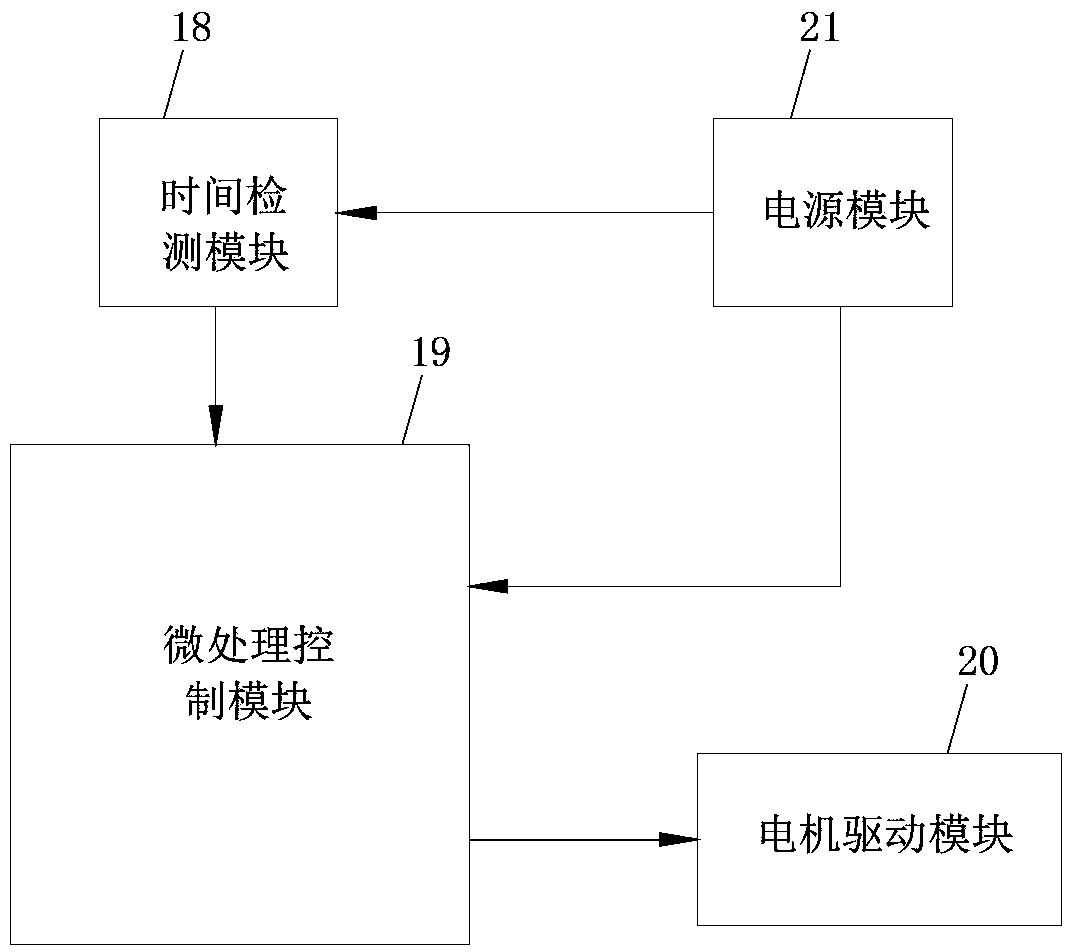

Coating material dispersion apparatus capable of making coating material forward rotate and reverse rotate

InactiveCN104338459AEvenly dispersedFine dispersionRotary stirring mixersMixer accessoriesElectricityMotor drive

The present invention relates to a coating material dispersion apparatus capable of making a coating material forward rotate and reverse rotate. According to the apparatus, a rotation motor is fixed on a support frame, the output end of the rotation motor is connected with a rotation shaft, the lower portion of the rotation shaft is positioned inside a stirring container, the lower portion of the rotation shaft is provided with a spiral cutting blade and further comprises a stirring blade, the stirring blade is fixed on the lower portion of the rotation shaft, the diameter of the stirring blade is larger than the diameter of the spiral cutting blade, a motor control device is provided and comprises a time detection module, a micro-processing control module, a motor driving module and a power supply module, the output end of the time detection module is electrically connected with the output end of the micro-processing control module, the output end of the micro-processing control module is electrically connected with the input end of the motor driving module, the motor driving module is electrically connected with the time detection module, the output end of the motor driving module is electrically connected with the rotation motor, and the power supply module is respectively and electrically connected with the micro-processing control module and the motor driving module. According to the present invention, the material can be uniformly dispersed, and the material thinning degree can be improved.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

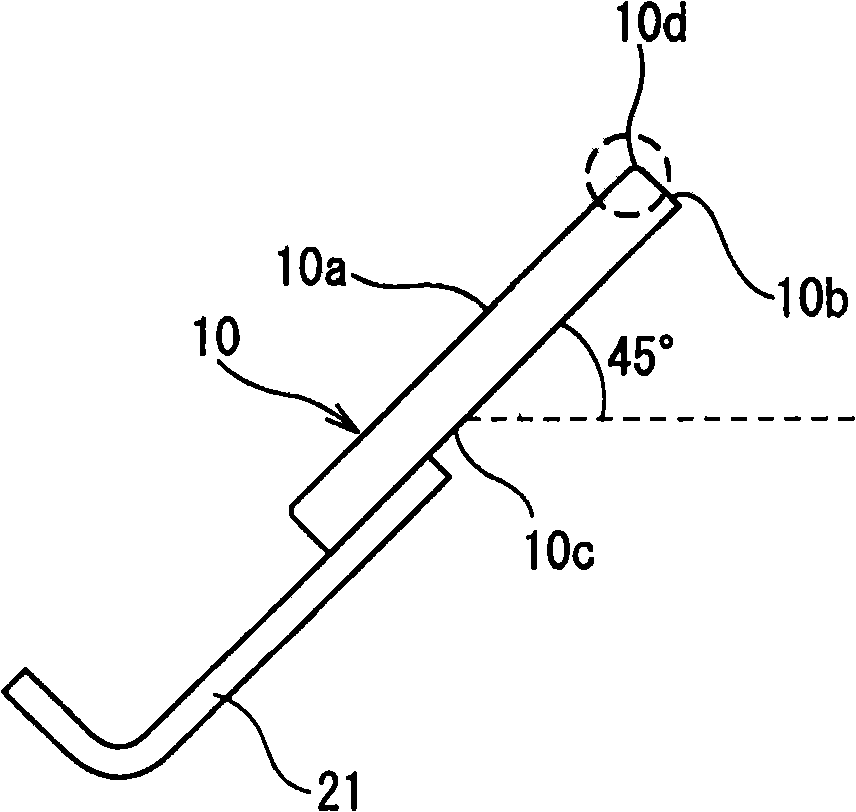

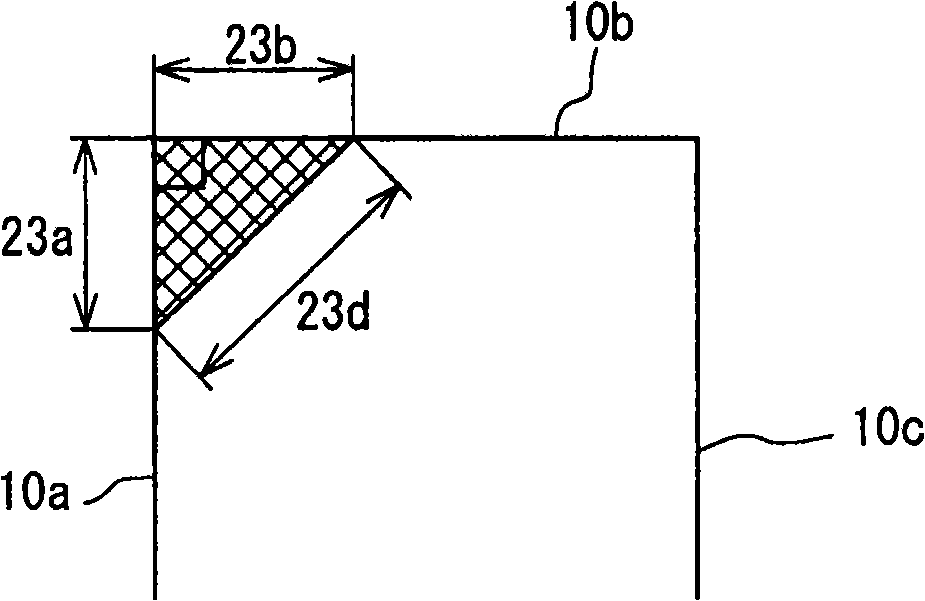

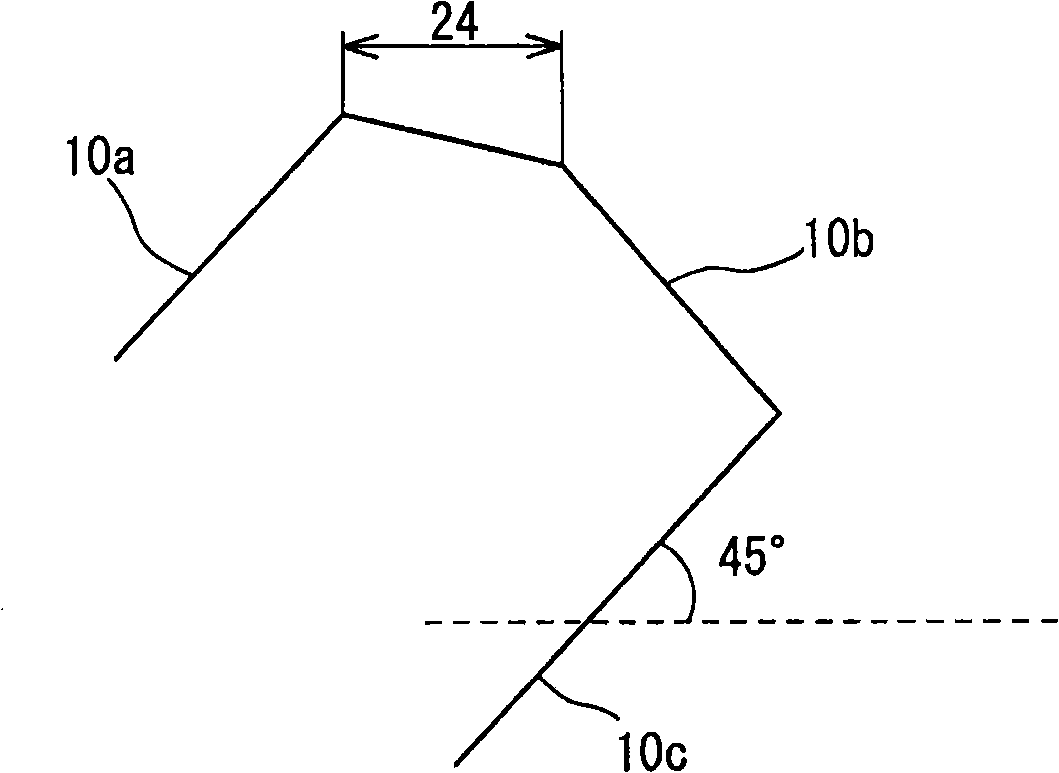

Method for producing cleaning blade for use in image-forming apparatus and cleaning blade

InactiveCN101314245AImprove wear resistanceIncrease contact pressureElectrography/magnetographyDomestic articlesElastomerPolymer science

Owner:SUMITOMO RUBBER IND LTD

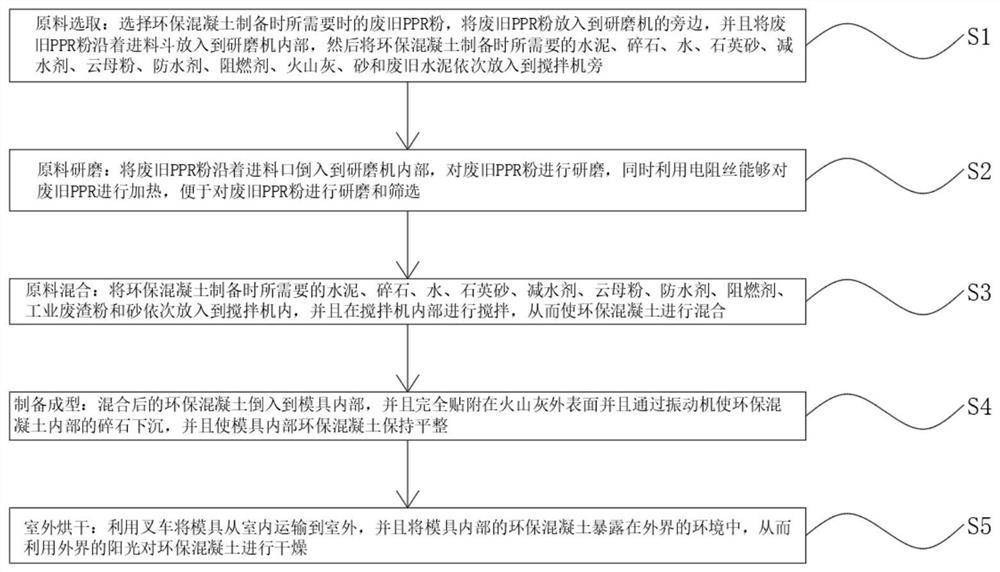

Processing method for high-strength environment-friendly concrete

ActiveCN111822080AReduce usageHigh hardnessSolid waste managementCeramic shaping apparatusSlagCompressive strength

The invention discloses a processing method for high-strength environment-friendly concrete. The environment-friendly concrete consists of the following components in parts by weight: 100-200 parts ofcement, 40-130 parts of water, 23.8-59 parts of quartz sand, 46.2-82.4 parts of broken stones, 1-2 parts of a water reducer, 10-30 parts of mica powder, 5-30 parts of a waterproof agent, 0.5-2 part of a flame retardant, 40-80 parts of cinerite, 10-30 parts of waste PPR powder, 245-490 parts of sand, 60-120 parts of an adhesive and 60-80 parts of industrial waste slag powder. Waste PPR powder andindustrial waste residue powder, which are added into concrete, are poured into a stirrer to stir, so that use amount of cement is reduced, and production cost is reduced; mica powder, quartz sand andcinerite are added, so that hardness, pressure resistance and water seepage resistance of concrete can be improved; and meanwhile, a heat conduction rate of the concrete is reduced, so that the concrete has highest hardness, highest compressive strength, low heat conduction rate and strong water seepage resistance; and meanwhile, production cost is reduced, waste PPR powder and industrial waste residue powder are recycled, so that the environment-friendly purpose is achieved.

Owner:舟山恒尊预拌混凝土有限公司

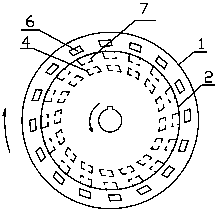

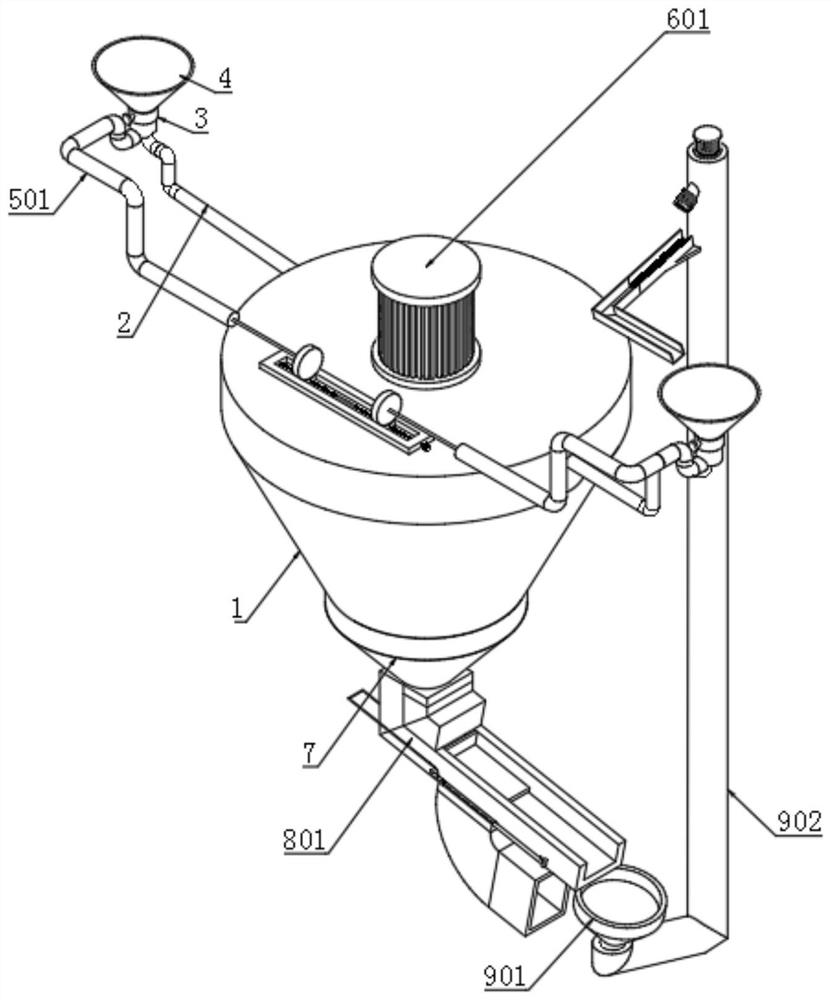

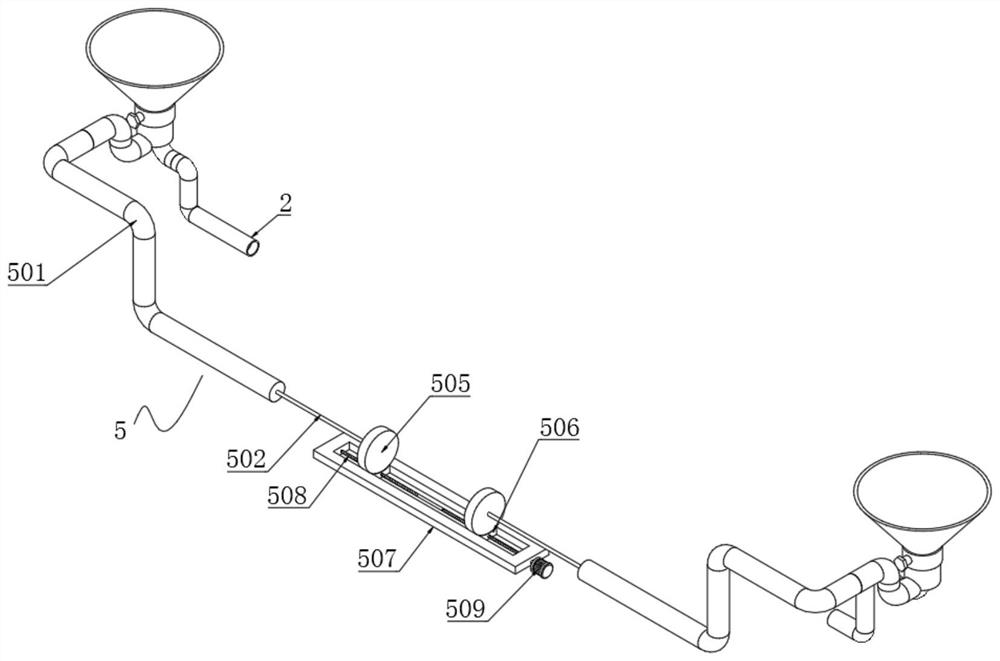

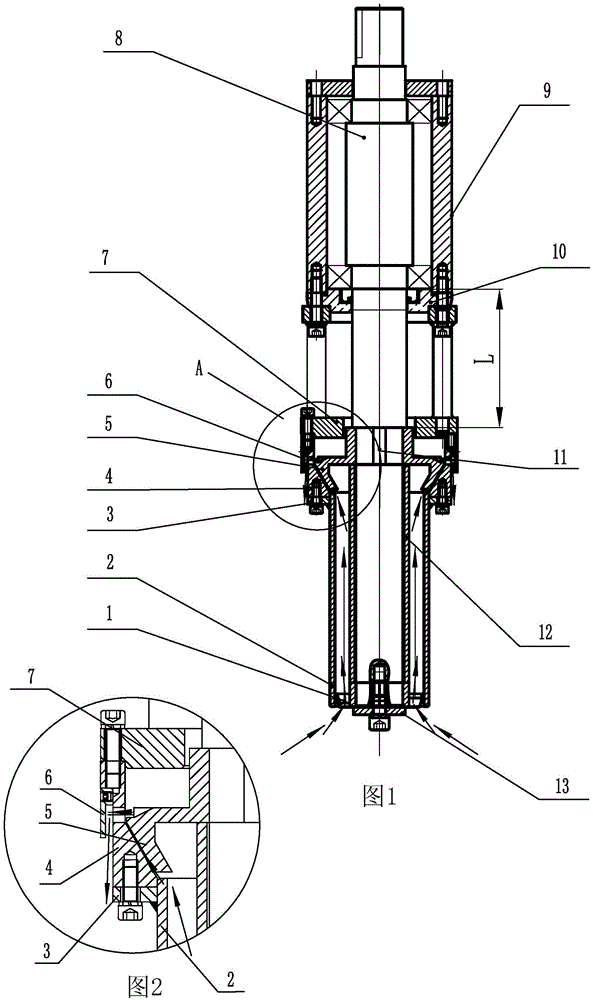

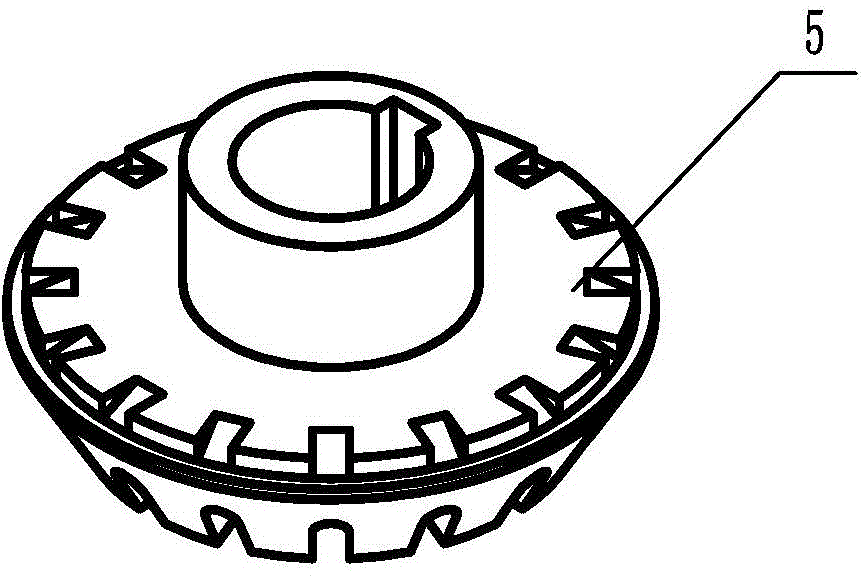

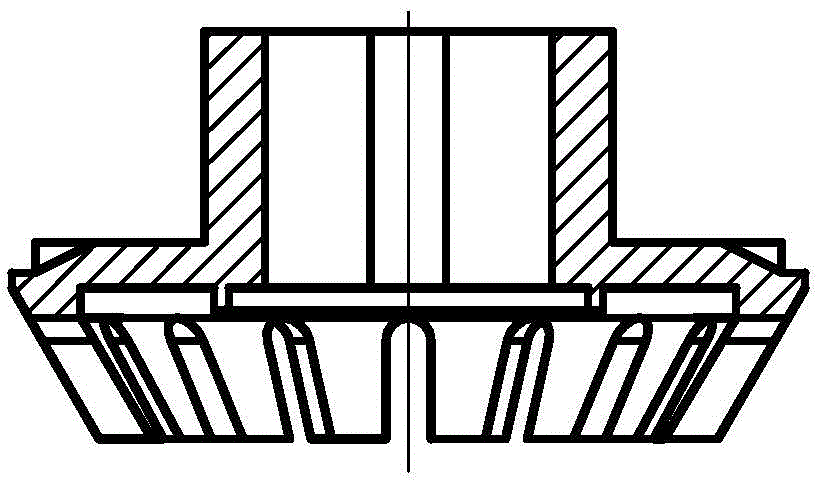

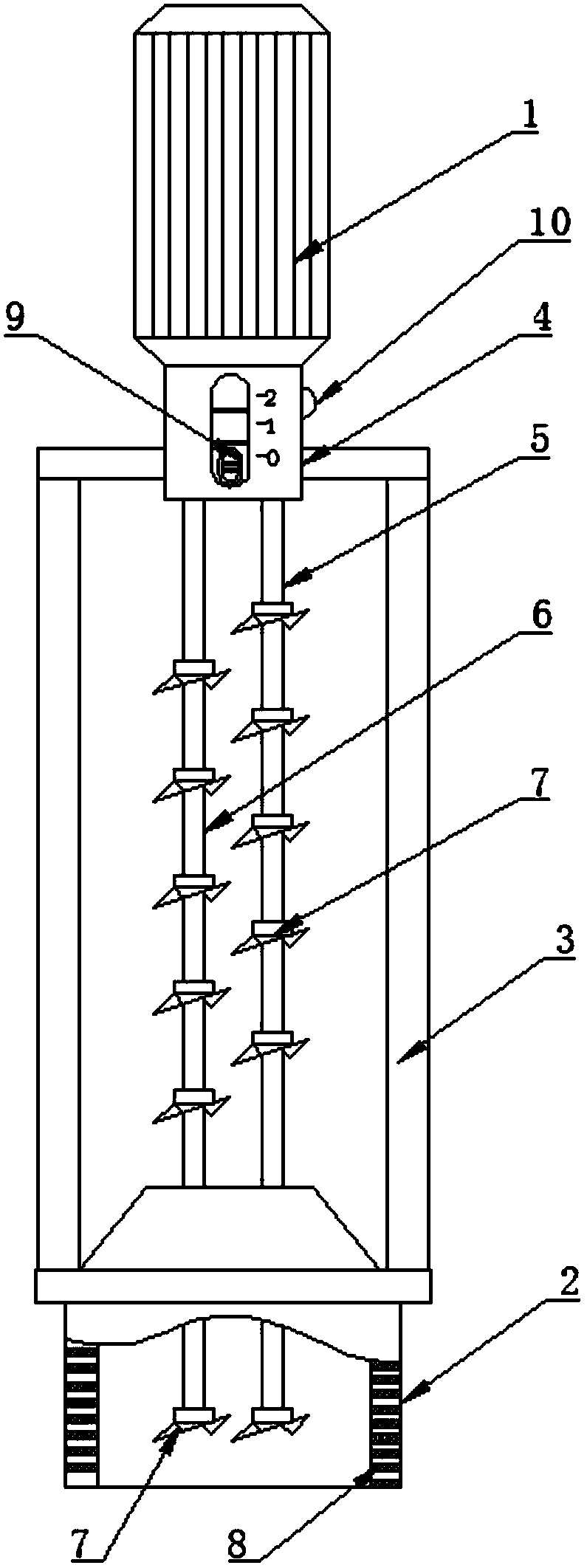

Top-insertion type short-cantilever stator-rotor stirring device

The invention relates to a top-insertion type short-cantilever stator-rotor stirring device comprising a rotation shaft, a bearing seat, a bearing gland, an emulsification support, a rotor, a stator, a sleeve, and an inducer. The bearing seat is connected with the emulsification support. The rotation shaft penetrates through the bearing seat and the emulsification support, and is arranged in the bearing seat through a bearing. The rotor is arranged on the rotation shaft. The stator is positioned on the outer side of the rotor and is connected with the lower end of the emulsification support. A connection plate is arranged on the upper end of the sleeve. The sleeve is sleeved on the outer side of the rotation shaft below the stator, and is connected with the bottom end of the stator through the connection plate. The inducer is arranged on the rotation shaft, and is positioned in the sleeve. The bearing gland penetrates through the rotation shaft, and is arranged between the bearing seat and the emulsification support. According to the invention, cantilever length is greatly shortened, system stiffness is improved, and resonance frequencies of various stages are improved, such that higher rotation speed and lower space between the stator and the rotor are realized. High-quality and high-efficiency mixing of the materials is realized, and equipment reliability can be improved.

Owner:LIUZHOU HUT CHEM MACHINERY

Carbon nano material dispersing device

InactiveCN108246194AGood dispersionEvenly distributedTransportation and packagingMixer accessoriesCamCarbon nanomaterials

The invention discloses a carbon nano material dispersing device, and mainly relates to the technical field of carbon nano materials. The carbon nano material dispersing device comprises an ejector, wherein an end part of the ejector is connected with a gas cavity; the bottom of the gas cavity is provided with a gas inlet device; the top end of the gas cavity is provided with a connecting tube; one end of the connecting tube is provided with a limiting barrel; a separating ball is arranged in the limiting barrel; the limiting barrel is connected with a piston barrel; a cam is arranged on the bottom of the piston barrel; a pushing rod is connected onto the cam; one end of the pushing rod is provided with a positioning ball; a movable plate is arranged in the piston barrel; the bottom of themovable plate is provided with a fixed block; a rotation slot is formed in the fixed block; the pushing rod can stretch into the rotation slot; the movable plate moves upwards along the piston barrelfor pushing the separating ball; a discharge hole is formed in the piston barrel; a discharge tube is arranged at the discharge hole; a placing plate is arranged on the bottom of the discharge tube;an accommodating box is placed on the placing box; and a dispersing agent injecting tube is arranged above the accommodating box. The carbon nano material dispersing device has the beneficial effectsof being capable of dispersing a carbon nano material conveniently, capable of dispersing and containing the material into the container conveniently according to needs, capable of enabling the carbonnano material in the container to be distributed more uniformly, and facilitating taking.

Owner:CHONGQING THREE GORGES UNIV

Preparation method for potash fertilizer particles

ActiveCN104311258AHigh strengthReduce intensitySolid/semi-solid fertilisersPotassium fertilisersThermopotashPotash

The invention relates to a preparation method for potash fertilizer particles. The preparation method is characterized in that the potash fertilizer particles are pelletized by a two-stage mixing extruder, potash fertilizer powder and additives are rapidly refined, scattered and mixed due to the strong shear force of the high rotation speed screw of a first-stage twin screw mixing mill, and then enter a second-stage single screw extruder through exhaust, the output end can conduct high pressure stable extrusion at a low rotation speed, and finally, pelleting is carried out by a die surface pelletizer to obtain the potash fertilizer particles. The potash fertilizer particles have high nutrient concentration, are regular in shape and uniform in diameter, and have high strength and good slow release performance. The preparation method is simple to operate, has strong technological adaptability, consumes little energy, has high granulation rate and high yield, and has market application value.

Owner:山东亿田生物肥料科技有限公司

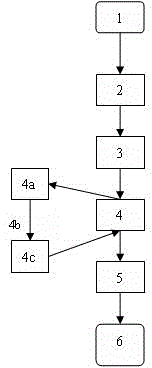

Coating material dispersion machine

The present invention relates to a coating material dispersion machine. According to the coating material dispersion machine, a rotation motor is fixed on one end of an installation plate, the upper portion of a lifting rod is fixed on the other end of the installation plate, the lower end of the rotation motor is connected with a rotation shaft, the lower portion of the rotation shaft is provided with a spiral cutting blade, the lifting rod is connected with a vibration motor, the lower portion of the rotation shaft is positioned inside a stirring container, the coating material dispersion machine further comprises a motor control device, the motor control device comprises a time detection module, a micro-processing control module, a motor driving module and a power supply module, the output end of the time detection module is electrically connected with the output end of the micro-processing control module, the output end of the micro-processing control module is electrically connected with the input end of the motor driving module, the motor driving module is electrically connected with the time detection module, and the power supply module is respectively and electrically connected with the micro-processing control module and the motor driving module. According to the present invention, the dispersion of the coating material can be fine.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

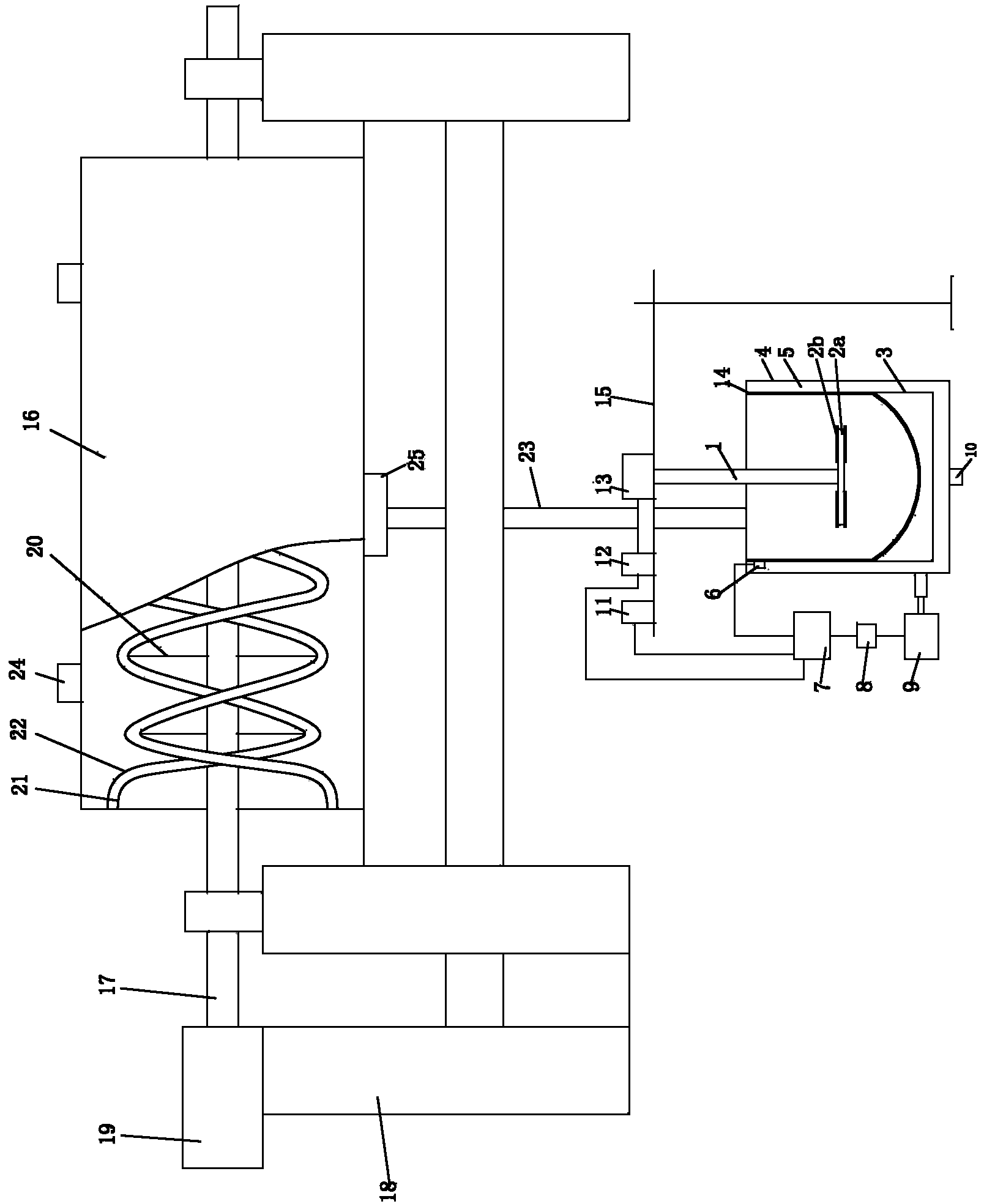

Vertical sand mill capable of feeding back

The invention discloses a vertical sand mill capable of feeding back. The vertical sand mill capable of feeding back comprises a body, a milling drum is connected to one side of the body, dispersing pieces are arranged in the milling drum, a discharge port is arranged on one side of the milling drum, and a feeding pump is arranged at the bottom of the body, connected with the bottom of the milling drum through a feed pipe and connected with the top of the milling drum through a feedback pipe. The vertical sand mill capable of feeding back is simple in structure, convenient to operate, mount and demount and beneficial to transfer. By the aid of the feedback pipe arranged between the feeding pump and the milling drum, materials which do not reach the standard of milling can be fed into the milling drum through the feedback pipe and the feeding pump for multiple milling, and accordingly finer and more uniform and dispersive materials are obtained.

Owner:徐友娟

Super-fine gelatinization method of infant nutritional rice flour

InactiveCN107198230AUniform tasteUniform and delicate tasteMilk preparationFood ingredient as mouthfeel improving agentRice milkNutrient

The invention provides a super-fine gelatinization method of infant nutritional rice flour. The infant nutritional rice flour is prepared from the following raw materials in parts by weight: 40 to 60 parts of rice, 10 to 15 parts of tartary buckwheat flour, 3 to 5 parts of fructus jujubae powder, 5 to 7 parts of rock candy, 3 to 5 parts of milk powder, 1 to 3 parts of beef powder, 1 to 3 parts of chestnut powder, 1 to 3 parts of vegetable powder and 0.5 to 1 part of a compound nutrient. A production method of the infant nutritional rice flour comprises the following steps: a, preparing rice milk; b, preparing primary pulp; c, gelatinizing the primary pulp through a three-step method; d, drying and sheeting through a three-step method; e, preparing the infant nutritional rice flour. According to the super-fine gelatinization method provided by the invention, the steps of gelatinizing the primary pulp through the three-step method and drying and sheeting through the three-step method are adopted and the produced infant nutritional rice flour is uniform, fine and smooth powder and has the advantages that the infant nutritional rice flour has a strong rehydration characteristic and is not caked after being diluted, all the raw materials are uniformly dispersed in a dry-method material mixing process and the infant nutritional rice flour is easily digest and absorb by infants.

Owner:广东金祥食品有限公司

Cordyceps sobolifera oral liquid and preparation method thereof

The invention belongs to the technical field of drugs and healthcare products, particularly relates to a cordyceps sobolifera oral liquid, and further discloses a preparation method of the cordyceps sobolifera oral liquid. Cordyceps sobolifera is a main raw material of the cordyceps sobolifera oral liquid, and the pesticide effects of roses, mulberry leaves, mint, lycii fructus, radix rhizoma glycyrrhizae, mulberries, jujubae fructus and longan arillus are supplemented. The prepared cordyceps sobolifera oral liquid can effectively improve human immune capability and has the functions of sleep improving, fatigue resistance and the like.

Owner:安徽虫草源生物科技有限公司

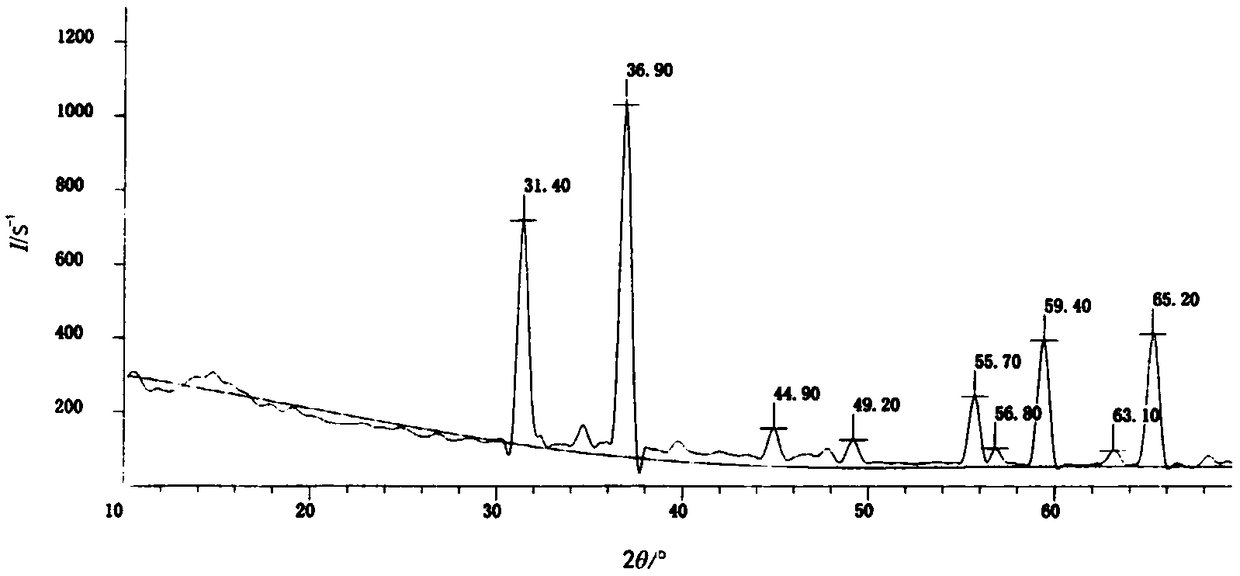

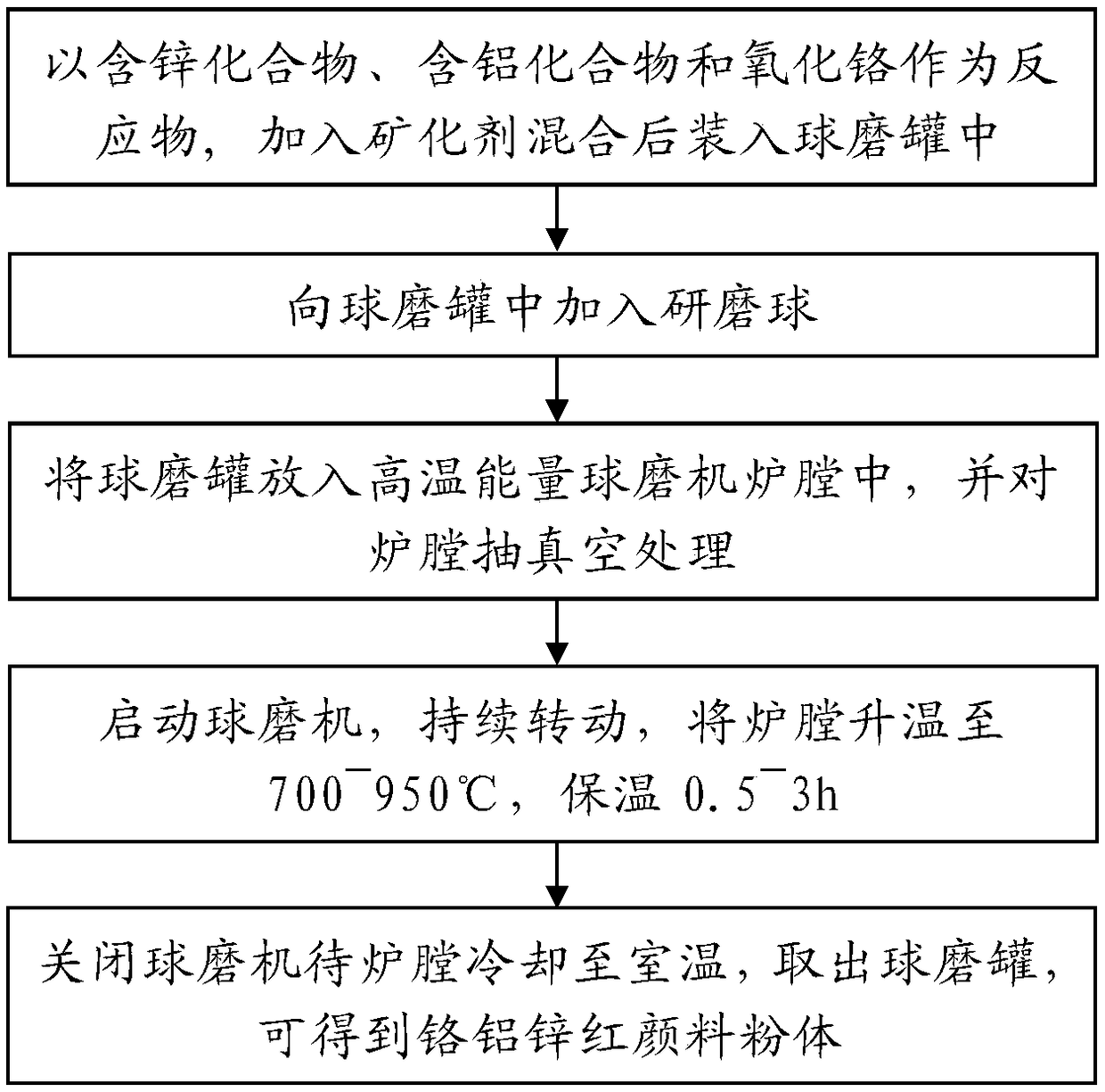

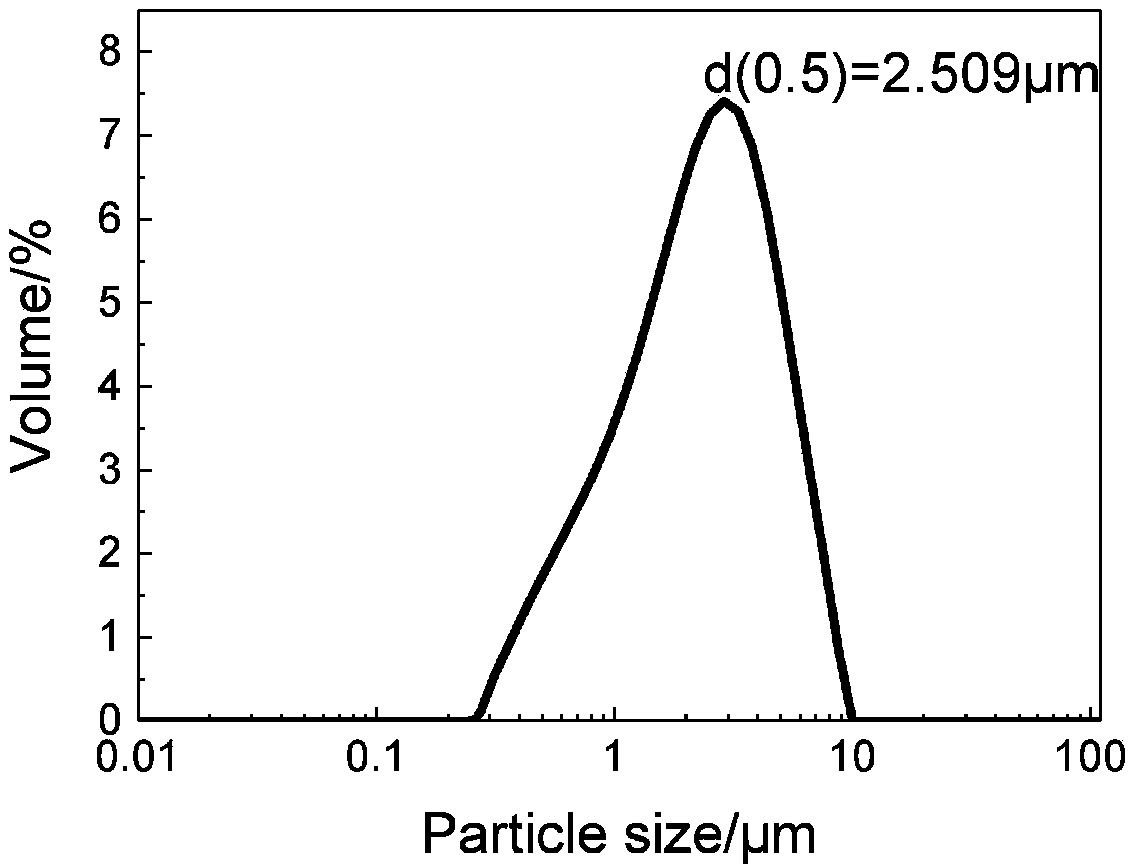

Chromium-aluminum-zinc red pigment preparation method

InactiveCN109135338AFine dispersionRefine and disperse more evenlyPigmenting treatmentRoom temperatureEngineering

The invention provides a chromium-aluminum-zinc red pigment preparation method. The method includes steps: taking a zinc-containing compound, an aluminum-containing compound and chromium oxide as reactants, adding a mineralizing agent, mixing, and adding into a ball milling tank; adding a grinding ball into the ball milling tank; putting the ball milling tank into a chamber of a high-temperature energy ball mill, and subjecting the chamber to vacuumizing treatment; starting the ball mill, keeping continuous rotation, heating the chamber to 700-950 DEG C, and keeping the temperature for 0.5-3h;shutting the ball mill, and taking out the ball milling tank after the chamber is cooled to the room temperature, so that high-quality chromium-aluminum-zinc red pigment powder can be obtained. The chromium-aluminum-zinc red pigment preparation method has advantages that high color uniformity and high quality of products are realized, a production process is simple, and low production cost is realized.

Owner:NORTHEASTERN UNIV

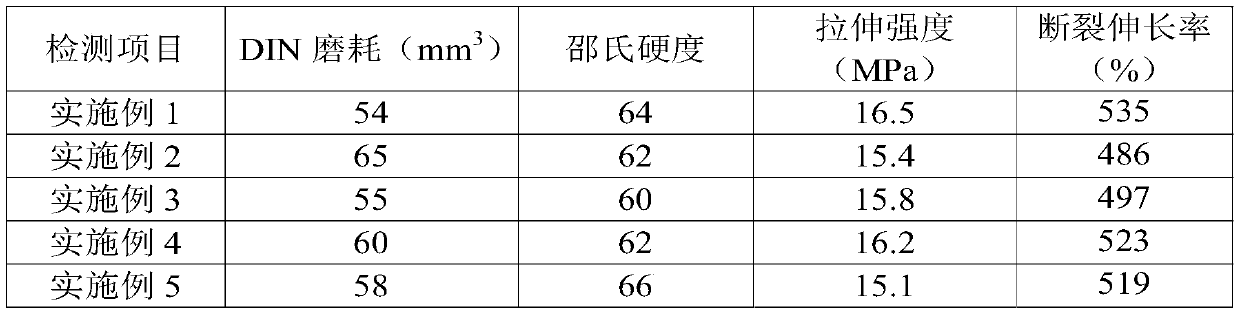

Wear-resistant rare earth rubber material and preparation method thereof

InactiveCN111393727ALarge specific surface areaHigh tensile strengthLanthanum oxide/hydroxidesCerium oxides/hydroxidesRubber materialMicrocrystalline wax

The invention discloses a wear-resistant rare earth rubber material and a preparation method thereof. The wear-resistant rare earth rubber material is prepared from the following raw materials in parts by weight: 100 parts of styrene butadiene rubber, 10-25 parts of natural rubber, 3-8 parts of zinc oxide, 2.5-6.5 parts of stearic acid, 1-4 parts of sulfur, 0.8-2.6 parts of TMTS, 0.6-2.4 parts ofmicrocrystalline wax, 30-50 parts of a filling agent, 0.02-0.05 parts of a silane coupling agent and 0.12-0.24 parts of nano rare earth particles. The prepared wear-resistant rare earth rubber material is high in hardness and tensile strength and excellent in wear resistance, the preparation method is simple, the raw materials are cheap and easy to obtain, economic benefits are high, and the wear-resistant rare earth rubber material has a wide application prospect.

Owner:泉州市华创园智能研究有限公司

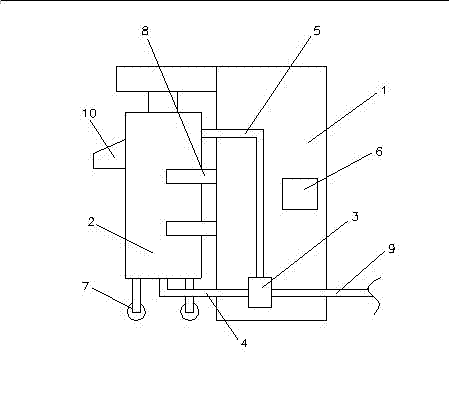

Coating material high-speed dispersion device

InactiveCN104338456AEvenly dispersedFine dispersionTransportation and packagingRotary stirring mixersElectricityMotor drive

The present invention relates to a coating material high-speed dispersion device, which comprises a dispersion disc and a stirring blade, wherein the dispersion disc is fixed on the lower portion of a rotation shaft and is positioned above a spiral cutting blade, the stirring blade is fixed on the rotation shaft and is positioned below the spiral cutting blade, the diameters of the dispersion disc and the stirring blade are larger than the diameter of the spiral cutting blade, the coating material high-speed dispersion device further comprises a motor control device, the motor control device comprises a time detection module, a micro-processing control module, a motor driving module and a power supply module, the output end of the time detection module is electrically connected with the output end of the micro-processing control module, the output end of the micro-processing control module is electrically connected with the input end of the motor driving module, the motor driving module is electrically connected with the time detection module, the output end of the motor driving module is electrically connected with the rotation motor, and the power supply module is respectively and electrically connected with the micro-processing control module and the motor driving module. According to the present invention, the material can be uniformly dispersed, and the material thinning degree can be improved.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

Coating material mixing stirring system with cooling structure

InactiveCN104338472AMix quickly and evenlyFine dispersionMixer accessoriesAudio power amplifierEngineering

The present invention relates to a coating material mixing stirring system with a cooling structure. According to the system, a cooling space is formed between an inner tank and an outer tank, the outer wall surface of the inner tank is provided with a temperature sensor, the output end of the temperature sensor is connected with a controller, the output end of the controller is connected with the input end of an amplifier, the output end of the amplifier is connected with a water pump, the water pump is communicated with the cooling space through a pipeline, a spiral stirring body and a support rod fixed on the rotation shaft are fixedly connected, the spiral stirring body at least comprises the inner layer spiral stirring blade and the outer layer spiral stirring blade, the distance between the top point of the inner layer spiral stirring blade and the rotation shaft is less than the distance between the top point of the outer layer spiral stirring blade and the rotation shaft, the output end of a driving motor is connected with the rotation shaft, and the mixed material output port of a mixing device is communicated with the inner tank through a pipeline. According to the present invention, the suitable temperature can be provided by adjusting the temperature of the stirring tank when the coating material is stirred, and the stirring is uniform.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

Double-shaft high-shear emulsifying machine

InactiveCN107930455AKeep balance and stabilityFine dispersionMixing methodsTransportation and packagingEngineeringMechanical engineering

The invention discloses a double-shaft high-shear emulsifying machine. The emulsifying machine comprises a motor, a head, a connecting rod and a bracket, wherein the upper part of the connecting rod is fixedly connected with the lower part of the bracket; the head is fixedly connected with the lower part of the connecting rod; the motor is connected with the top ends of a first main shaft and a second main shaft; rotary cutting blades are respectively arranged at the tail ends of the first main shaft and the second main shaft; the rotary cutting blades extend into the head; a plurality of rotary cutting blades are arranged on the first main shaft and the second main shaft in a staggered manner. The double shafts of the emulsifying machine drive the rotary cutting blades to perform emulsification, powder and granules in liquid can be refined and dispersed well, and emulsification is homogeneous.

Owner:武汉纤然生物科技有限公司

Coating material mixing dispersion system capable of making coating material forward rotate and reverse rotate

The present invention relates to a coating material mixing dispersion system capable of making a coating material forward rotate and reverse rotate. According to the system, one end of a rotation shaft penetrates through a material cylinder, both ends of the rotation shaft are supported on a bracket through bearings, the rotation shaft body positioned in the material cylinder is symmetrically provided with a pair of spiral stirring bodies, the spiral stirring body and a support rod fixed on the rotation shaft are fixedly connected, the spiral stirring body at least comprises the inner layer spiral stirring blade and the outer layer spiral stirring blade, the distance between the top point of the inner layer spiral stirring blade and the rotation shaft is less than the distance between the top point of the outer layer spiral stirring blade and the rotation shaft, the output end of a driving motor is connected with the rotation shaft, a rotation motor is fixed on the support frame, the output end of the rotation motor is connected with the rotation shaft, the lower portion of the rotation shaft is positioned inside a stirring container, the lower portion of the rotation shaft is provided with a spiral cutting blade, the stirring blade is fixed on the lower portion of the rotation shaft, and the diameter of the stirring blade is larger than the diameter of the spiral cutting blade. According to the present invention, the material can be uniformly dispersed, and the material thinning degree can be improved.

Owner:CHANGZHOU HAOBANG NANO TECH PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com