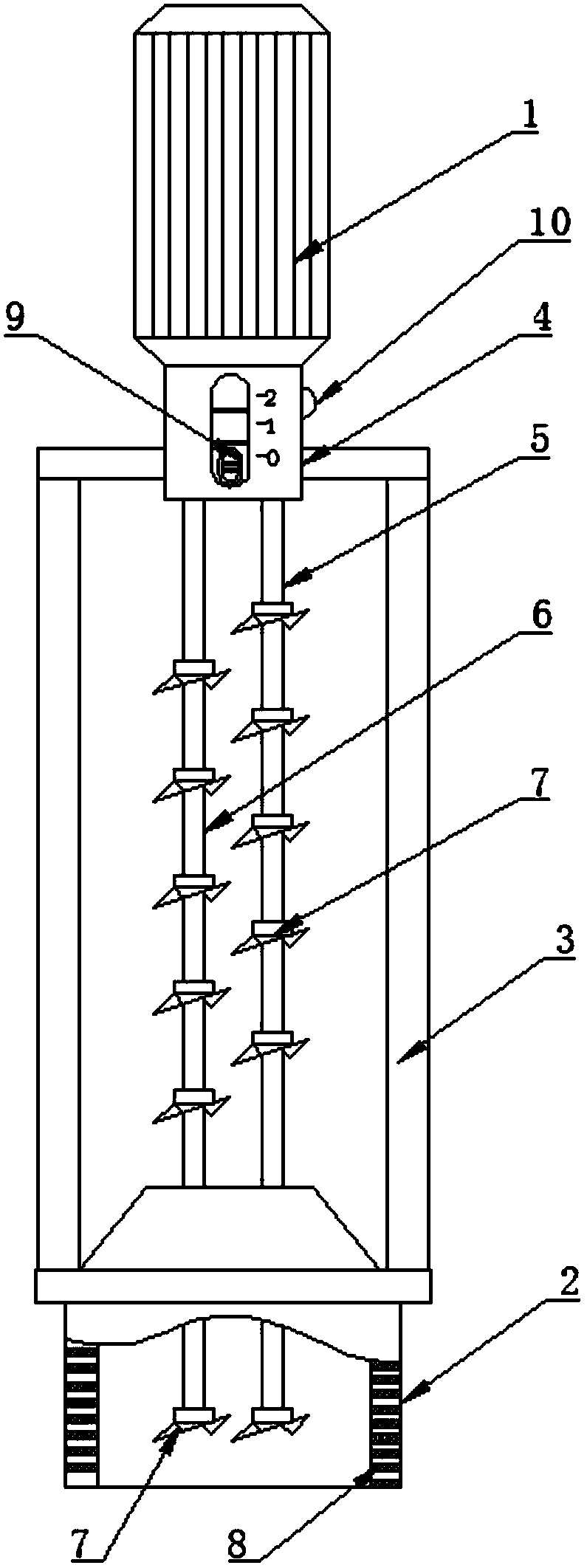

Double-shaft high-shear emulsifying machine

A shearing emulsifier and shaft height technology, applied in the field of emulsifiers, can solve the problems of long working time, low working efficiency and small shearing force, and achieve the effects of reasonable structure, high working efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Such as figure 1 As shown, a biaxial high-shear emulsifier includes a motor 1, a head 2, a connecting rod 3, and a bracket 4. The upper part of the connecting rod 3 is fixedly connected to the lower part of the bracket 4, and the lower part of the connecting rod 3 is fixedly connected to an organic Head 3; the motor 1 is connected to the top of the first main shaft 5 and the second main shaft 6, and the ends of the first main shaft 5 and the second main shaft 6 are respectively provided with a rotating slice 7; the rotating slice 7 extends to the machine head 2; the first main shaft 5 and the second main shaft 6 are alternately provided with several rotating slices 7 . There are four connecting rods 3, and the connection method is more stable, so that the biaxial operation is stable; the emulsification is carried out by using the biaxial to drive the rotating slice, which can better refine and disperse the powder and small particles in the liquid, and emulsify homogeneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com