Preparation method for potash fertilizer particles

A potash fertilizer and granule technology, applied in the directions of potash fertilizer, inorganic fertilizer, fertilization device, etc., can solve the problems of low production efficiency of the roller extrusion method, high cost of melt spray granulation, difficult drying operation, etc., and achieves low production cost, The effect of high degree of equipment automation and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

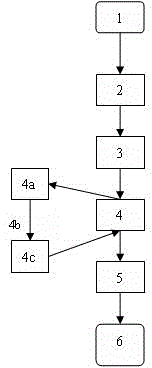

Image

Examples

Embodiment 1

[0037] 1) Weigh 93kg of potassium chloride, 5kg of sodium lignosulfonate, and 2kg of water into a high mixer and mix for 15 minutes to obtain a mixed material.

[0038] 2) Send the mixed material into the two-stage mixing and extruding unit. The first-stage twin-screw kneading machine: the screw diameter is 35mm, the length-diameter ratio is 24:1, the compression section is equipped with 2 sets of compression screw blocks, and the melting section There are 2 sets of forward kneading blocks; the second-stage single-screw extruder: the diameter of the screw is 100mm, the ratio of length to diameter is 7:1, and the diameter of the die is 3mm.

[0039] 3) The temperature of each section of the barrel of the first-stage twin-screw kneader is set as follows: the feeding section is 100°C, the compression section is 110°C, the melting section is 120°C, the exhaust section is 120°C, and the screw speed is set to 500 r / min; The temperature of each section of the barrel of the second-sta...

Embodiment 2

[0042] 1) Weigh 94kg of potassium sulfate, 4kg of sodium laurate sulfate, and 2kg of water into a high-mixer for 20 minutes to obtain a mixed material.

[0043] 2) Send the mixed material into the two-stage mixing and extruding unit. The first-stage twin-screw kneader: the screw diameter is 45mm, the length-to-diameter ratio is 26:1, and the compression section is equipped with 2 sets of compression screw blocks, and the melting section There are 2 sets of forward kneading blocks; the second-stage single-screw extruder: the diameter of the screw is 120mm, the ratio of length to diameter is 10:1, and the diameter of the die is 4mm.

[0044] 3) The temperature of each section of the barrel of the first-stage twin-screw kneader is set as follows: the feeding section is 110°C, the compression section is 120°C, the melting section is 130°C, the exhaust section is 120°C, and the screw speed is set to 400 r / min; The temperature of each section of the barrel of the second-stage single...

Embodiment 3

[0047] 1) Weigh 96kg of potassium chloride, 3kg of fatty alcohol polyoxyethylene ether sodium sulfate, and 1kg of water into a high-mixer for 20 minutes to obtain a mixed material.

[0048] 2) Send the mixed material into the two-stage mixing and extruding unit. The first-stage twin-screw kneading machine: the screw diameter is 55mm, the length-to-diameter ratio is 28:1, and the compression section is equipped with 2 sets of compression screw blocks, and the melting section There are 3 sets of forward kneading blocks; the second-stage single-screw extruder: the diameter of the screw is 150mm, the ratio of length to diameter is 7:1, and the diameter of the die is 3mm.

[0049] 3) The temperature of each section of the barrel of the first-stage twin-screw kneader is set as follows: the feeding section is 120°C, the compression section is 130°C, the melting section is 140°C, the exhaust section is 120°C, and the screw speed is set to 300 r / min; The temperature of each section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com