Patents

Literature

37results about How to "Particle rules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EV71virus-like particles as well as preparation method and application thereof

ActiveCN103255163AEfficient expressionGrow fastFungiSsRNA viruses positive-senseIon exchangeHigh pressure

Owner:BEIJING MINHAI BIOTECH +2

High-molecular mPEG-PLGA-mPEG accessory medicine for medicine use, prepu. method and application thereof

InactiveCN1537636AEvade captureAvoid the effect of adsorptionPharmaceutical non-active ingredientsLactidePolyethylene glycol

A high-molecular mPEG-PLGA-mPEG (PELGE) used as the axcessory of injection, oral-applied medicine, and the water-soluble medicine or the medicine difficult to dissolve in water is an amphipathic three-block copolymer, which is prepared from stannous octoate as catalyst, diisocyanate as coupling agent, polyethene glycol with single terminated end, glycollide, and lactide or polylactic acid-glycollic acid copolymer.

Owner:四川大学华西药学院 +1

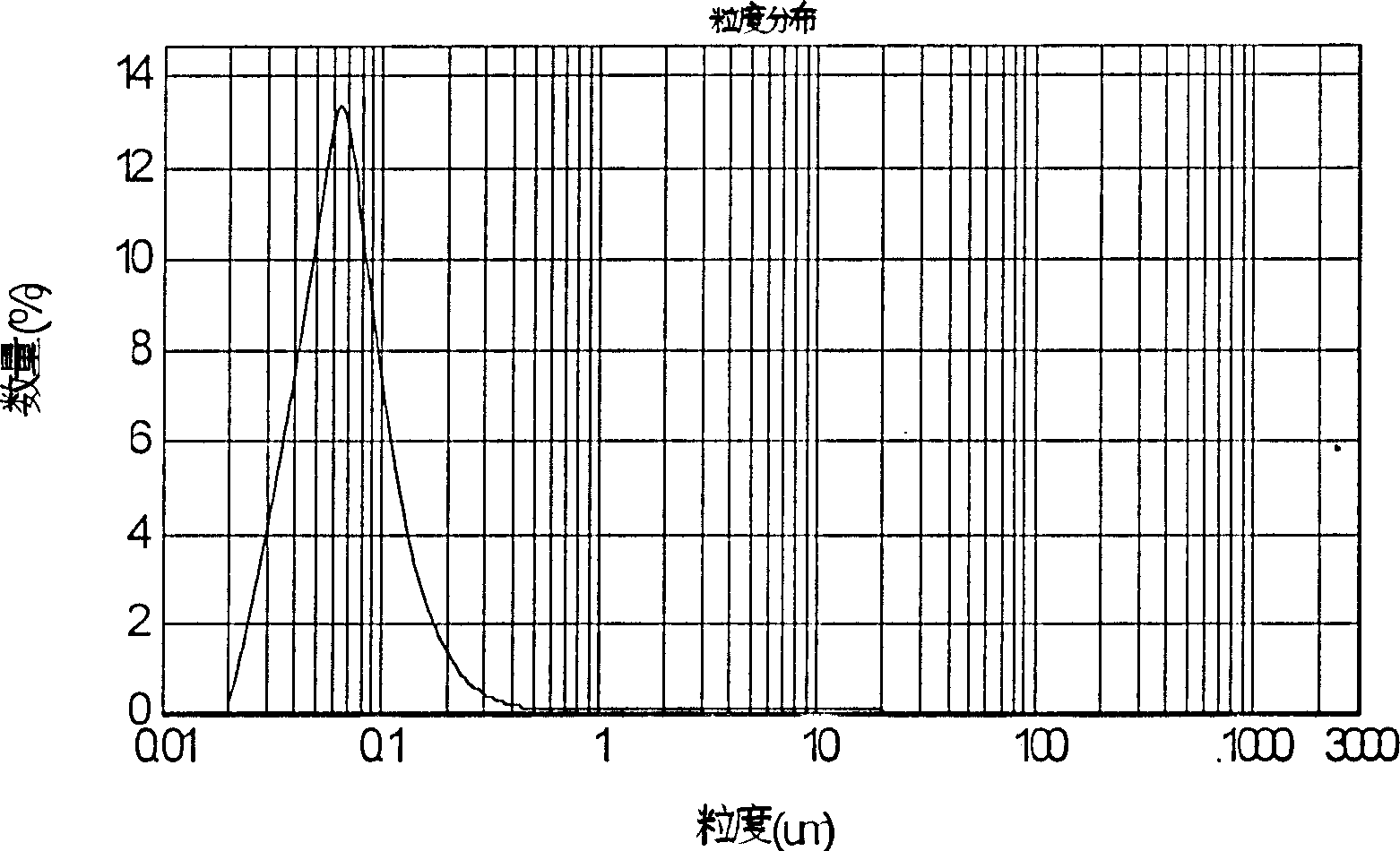

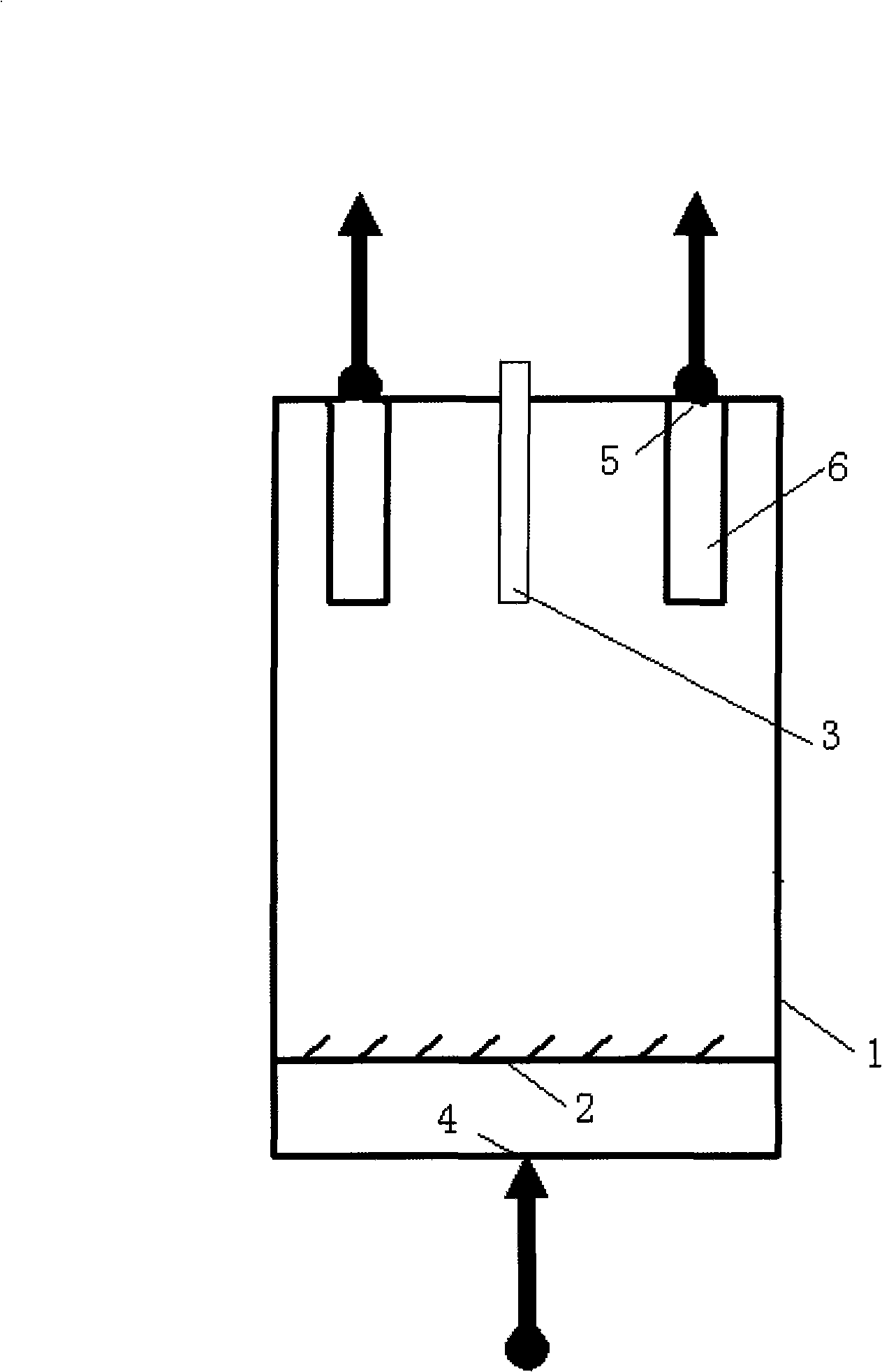

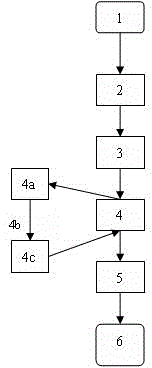

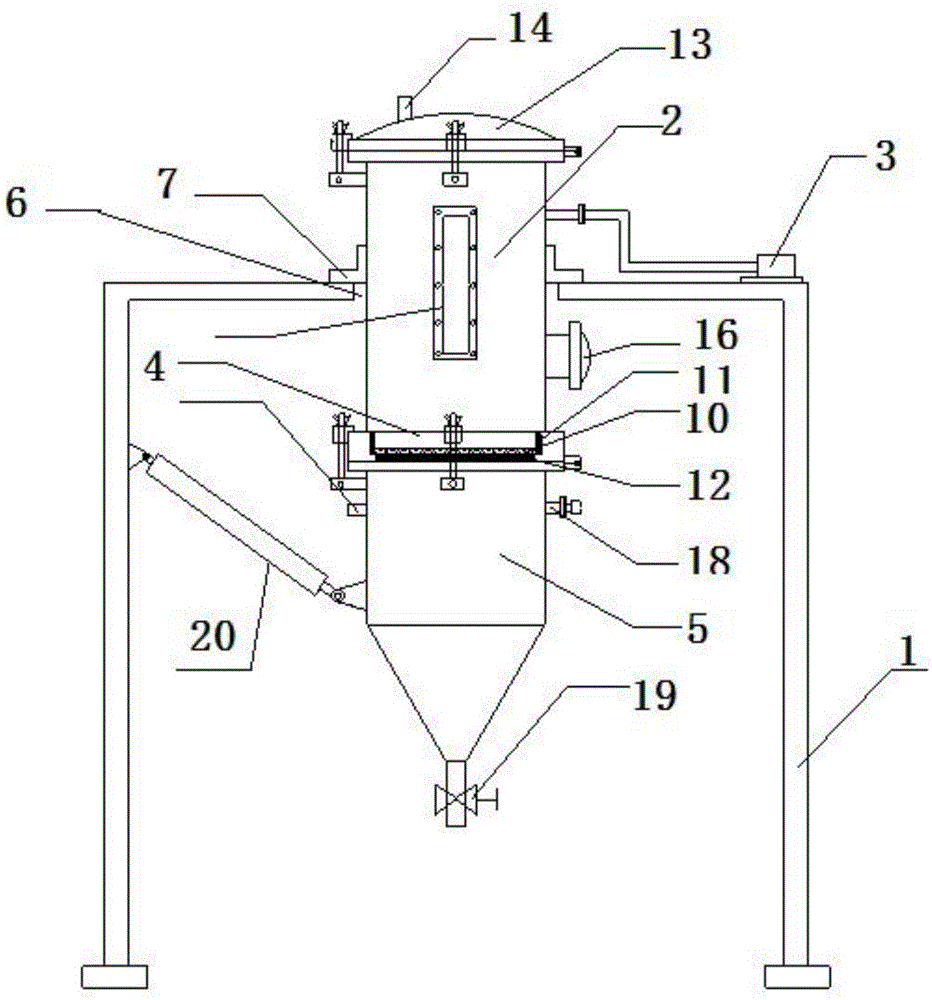

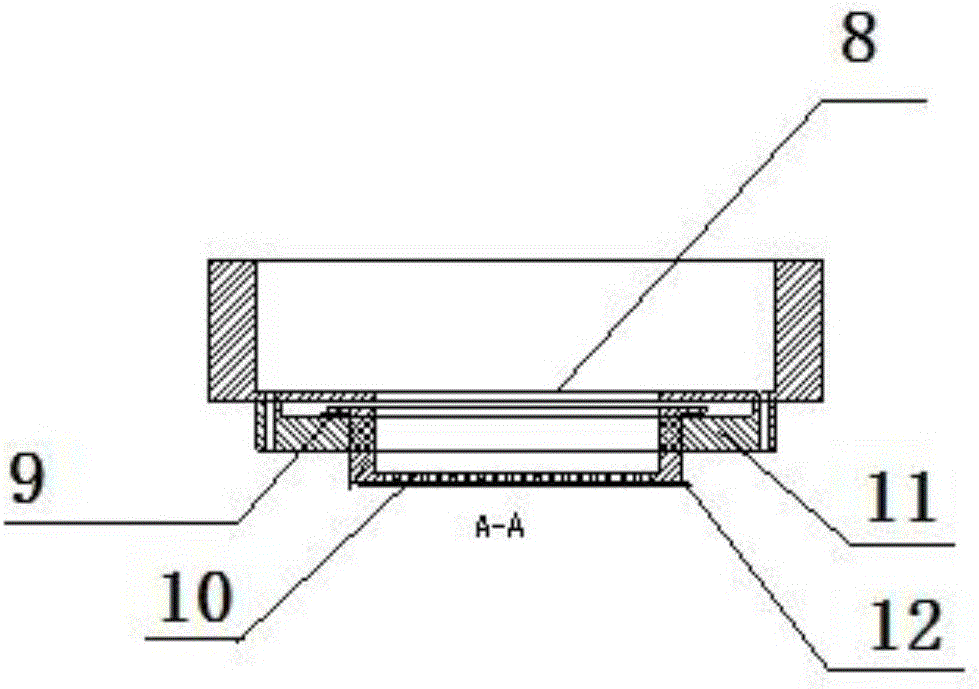

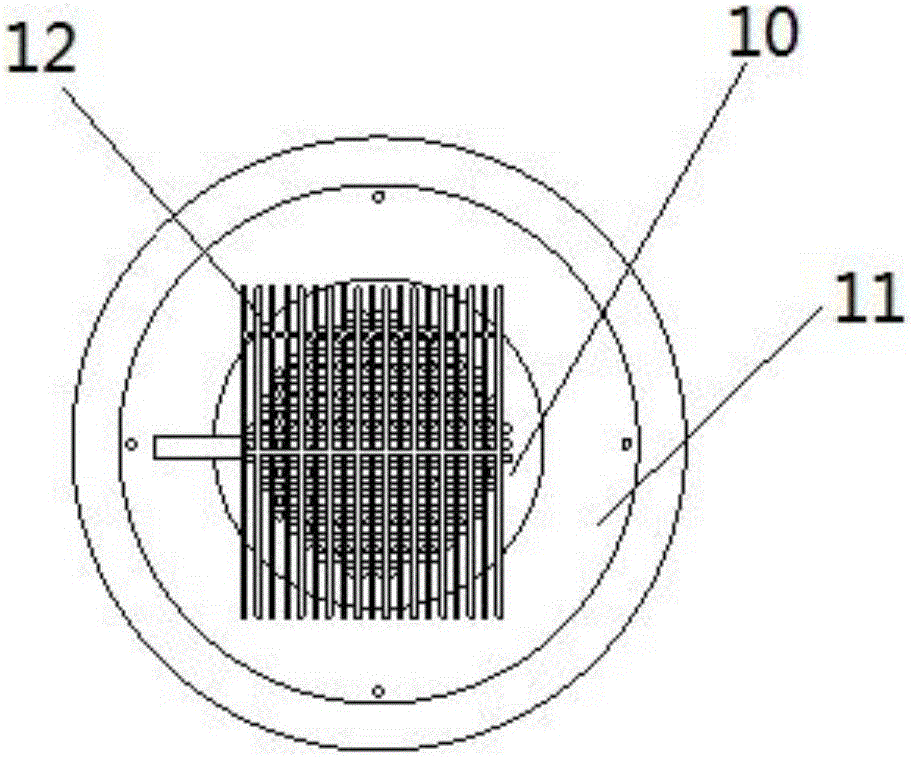

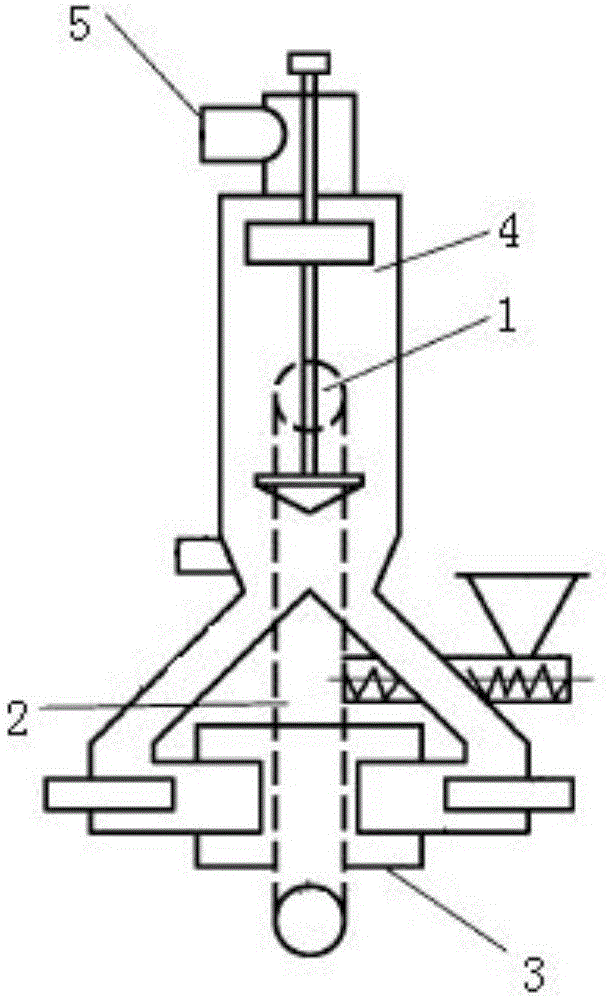

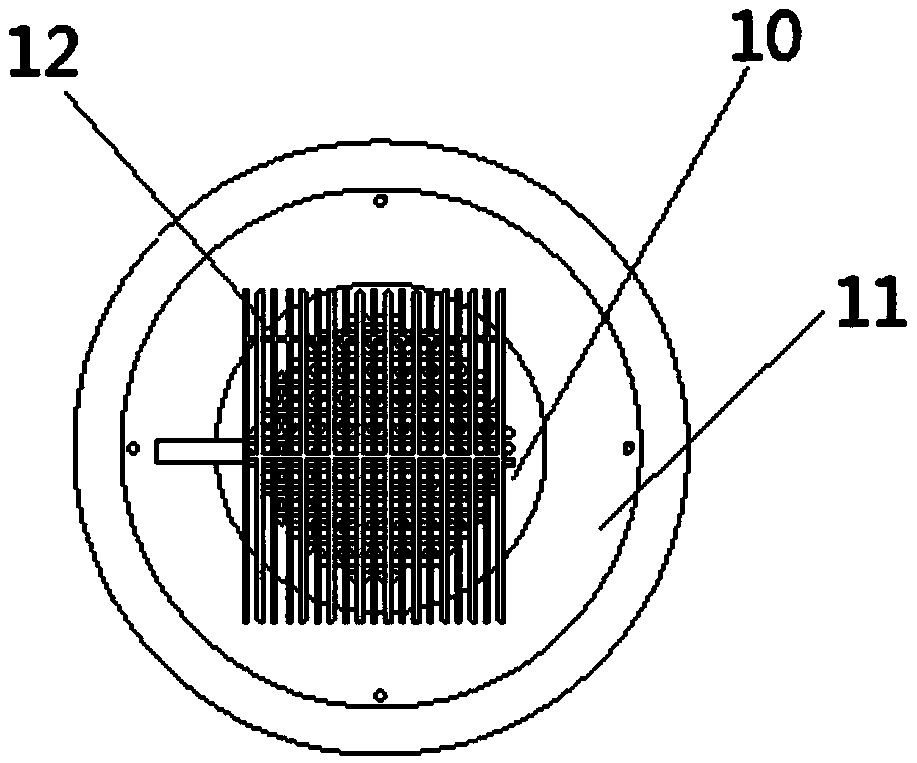

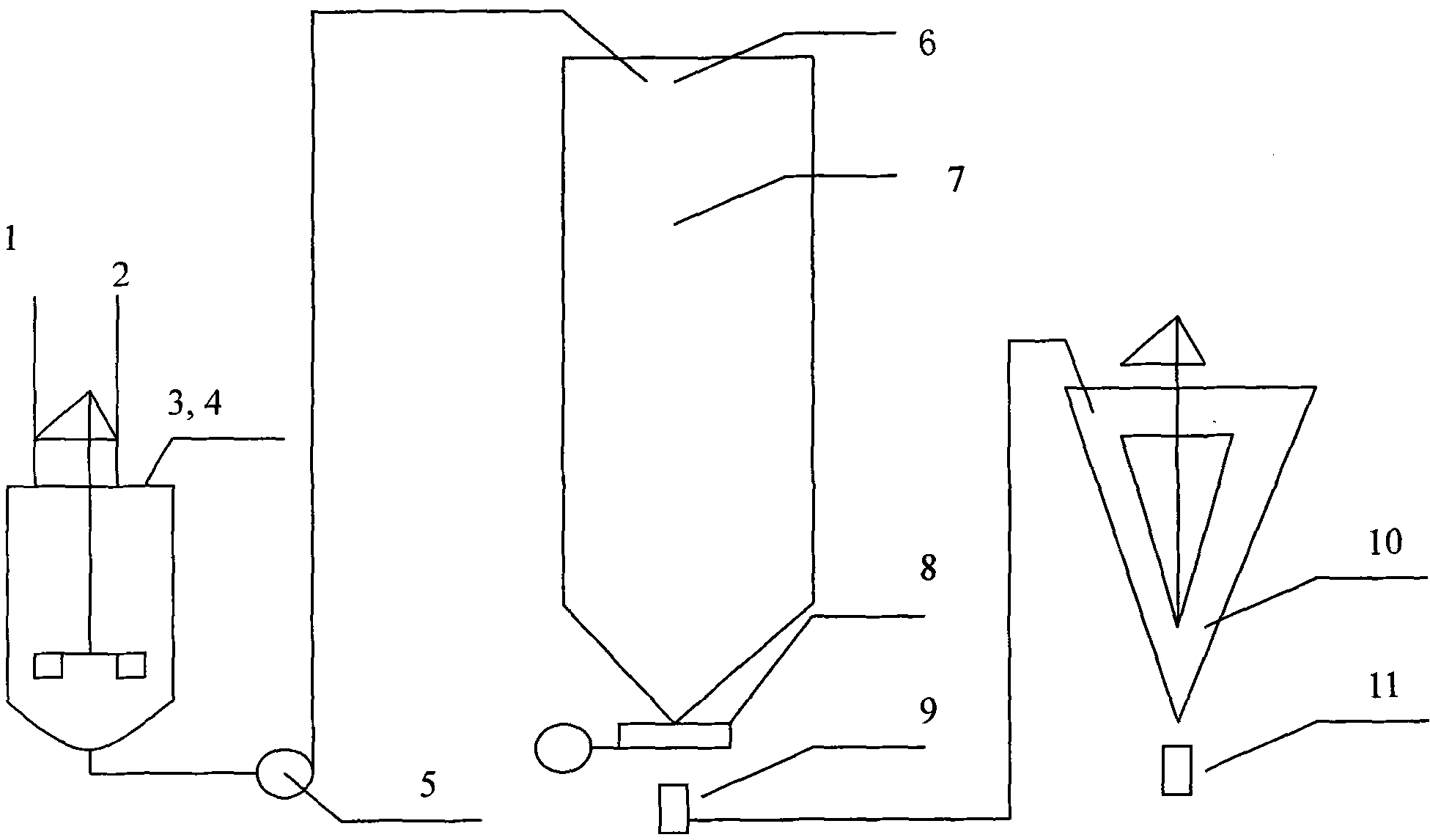

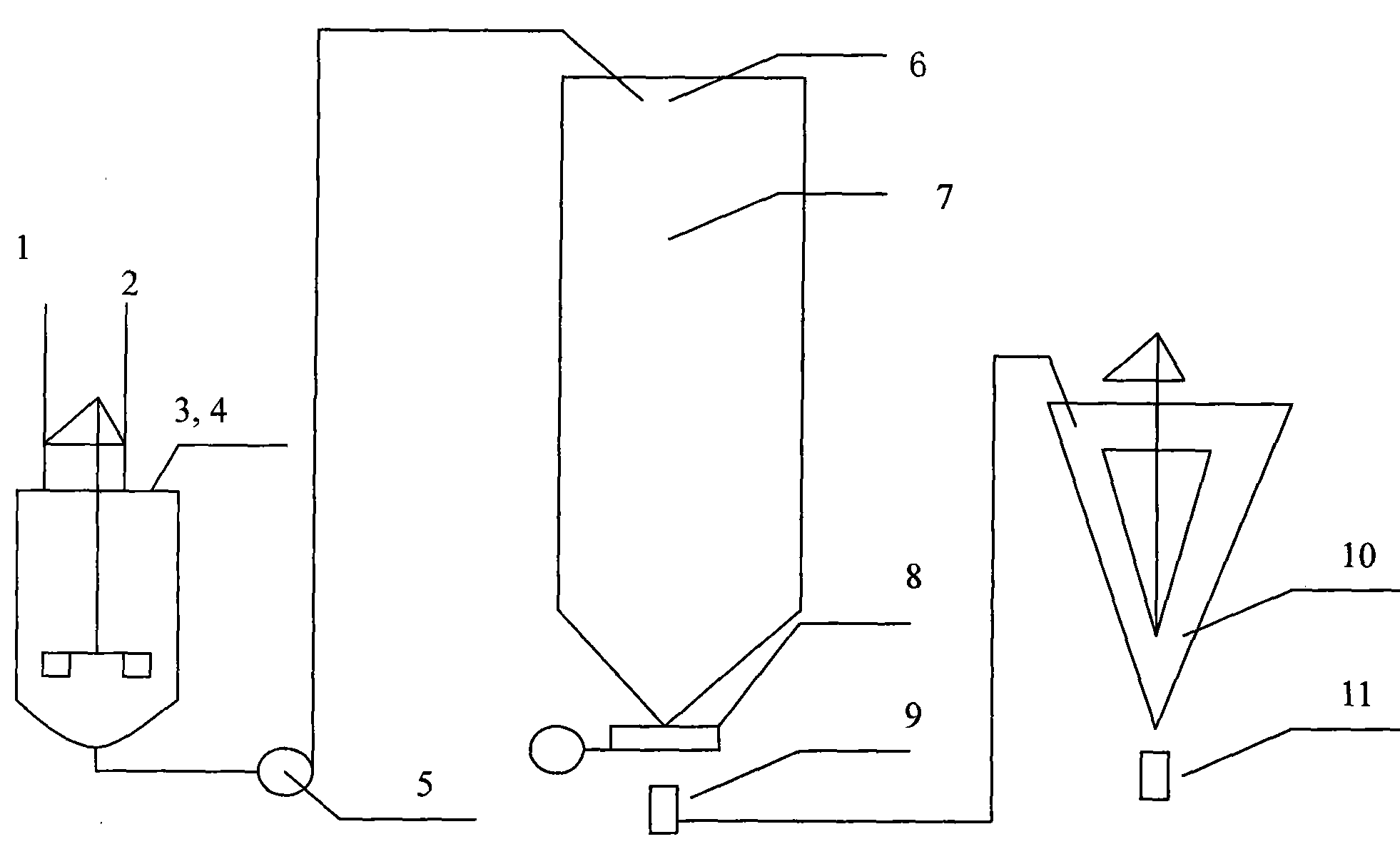

Method and apparatus for atomizing, freezing and drying for powder production by using low-temperature low-dew point gas

InactiveCN101403561AReduce manufacturing costParticle rulesDrying solid materials with heatDrying solid materials without heatComing outFreeze-drying

The invention discloses a method for milling by low temperature low dew point gas spray freeze drying which uses an atomizer for nebulizing liquid to be dried into 1 to 250 micron droplets which are frozen into ice powder in the gas with the low temperature of -60 DEG C and the dew point of -70 to -80 DEG C, then air-intake temperature is adjusted to 2 to 4 DEG C lower than the eutectic temperature of materials, the gas passes through a pore plate of a fluidized bed to lead the ice powder which stays on the fluidized plate to be fluidized, and simultaneously the solvent in the ice powder is sublimated. The sublimation drying process is completed until the dew point of the gas at the gas vent returns to -55 to -60 DEG C. The ice powder is dried for 1 to 2 hours into powder products when the temperature is increased to 30 to 50 DEG C. The gas coming out of the gas vent returns to the place for low temperature low dew point gas preparation for recirculation. The method is characterized by easy operation, continuous duty, and the like, and is especially suitable for the drying of materials such as medicine, food, biochemical product, and the like, guarantees the quality of products and can directly obtain the dried powder products; simultaneously the drying time of the method is greatly shortened compared with the vacuum freeze drying.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

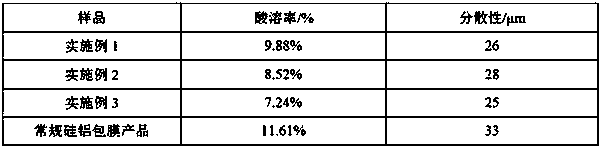

Preparation method for increasing weather fastness of titanium dioxide

InactiveCN109762372AGood weather resistanceAct as a connecting layerInorganic pigment treatmentChemistryTitanium dioxide

The invention belongs to the technical field of titanium dioxide preparation, and discloses a preparation method for increasing the weather fastness of titanium dioxide. The preparation method comprises the following steps: preparing titanium dioxide slurry; rising the temperature of the slurry to 80 to 90 DEG C, regulating pH (Potential of Hydrogen) to be 10.0 to 10.5, adding Na2SiO3 after homogenizing, and then homogenizing; regulating the pH of the slurry to be 4.5 to 5.5, enabling aluminum salt and diluted acid or diluted alkali to be in concurrent flow, keeping the pH of the slurry to be4.5 to 5.5, and then homogenizing; grinding the slurry for 15 to 30 minutes; regulating the pH of the slurry after grinding to be 8.0 to 9.0, homogenizing, then enabling the aluminum salt and the diluted acid or diluted alkali to be in concurrent flow, keeping the pH of the slurry to be 8.0 to 9.0, and then homogenizing; regulating the pH of the slurry to be 5.4 to 5.6, homogenizing, and then carrying out tertiary washing, flash evaporation and jet pulverization, thus obtaining a titanium dioxide finished product. The titanium dioxide prepared by the invention is higher in weather fastness andbetter in dispersity.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

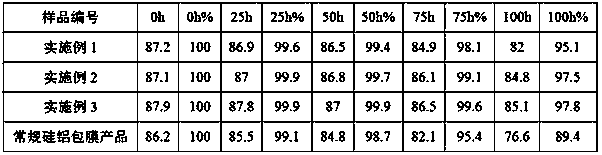

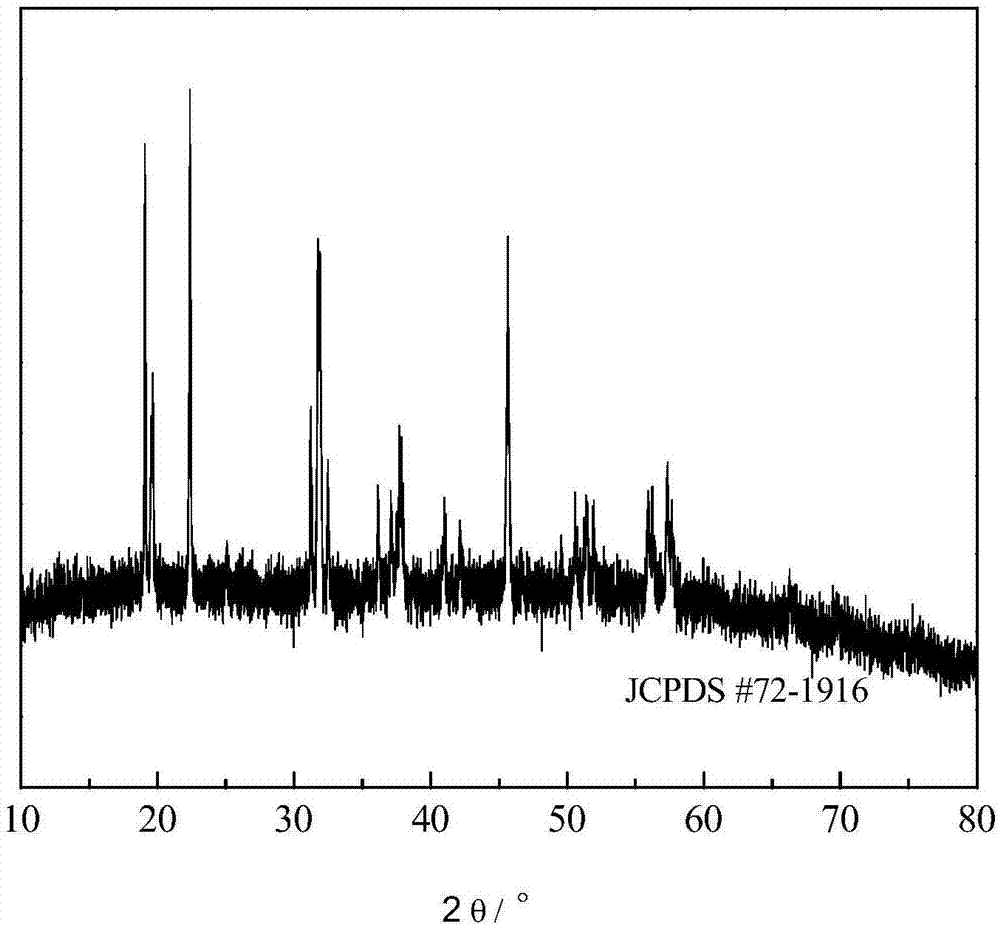

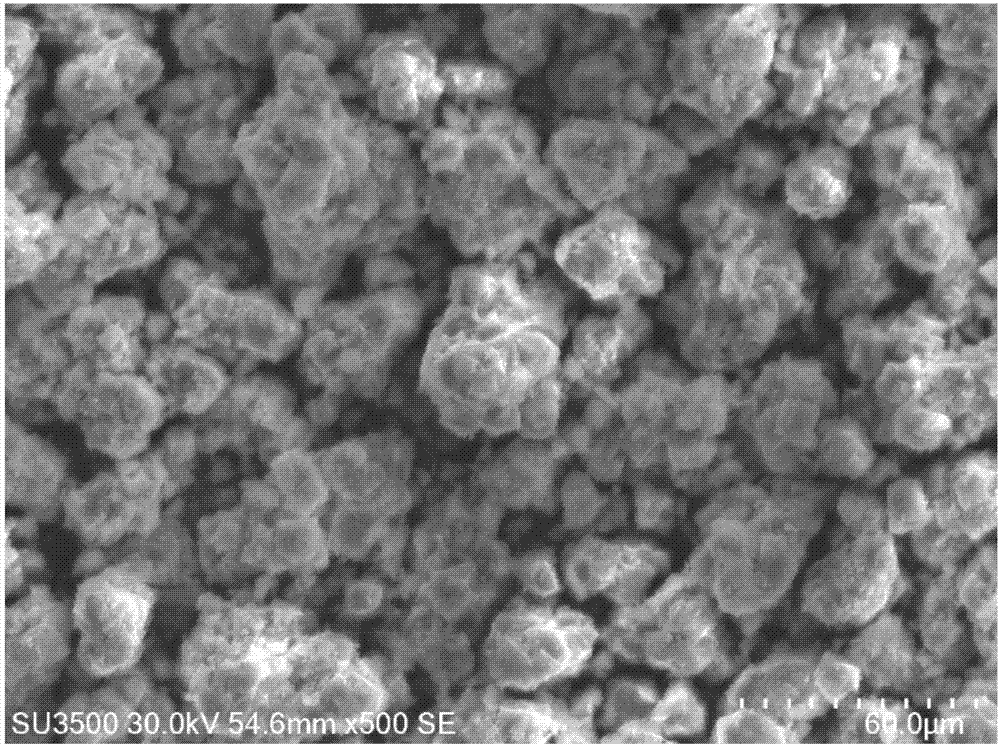

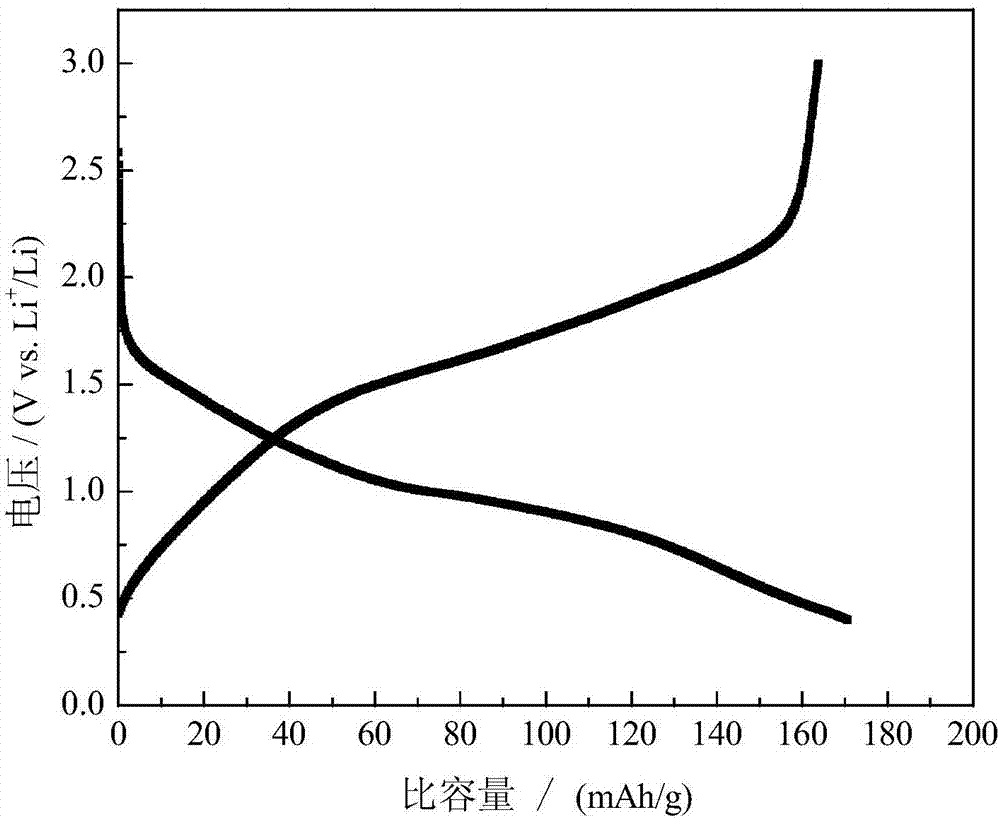

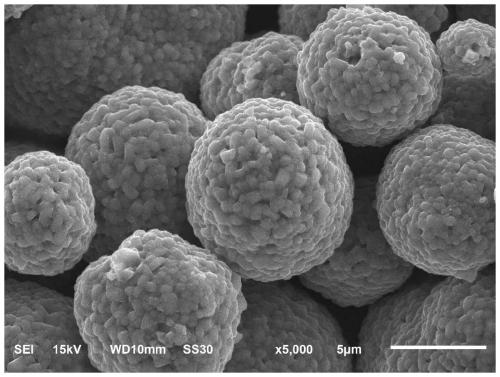

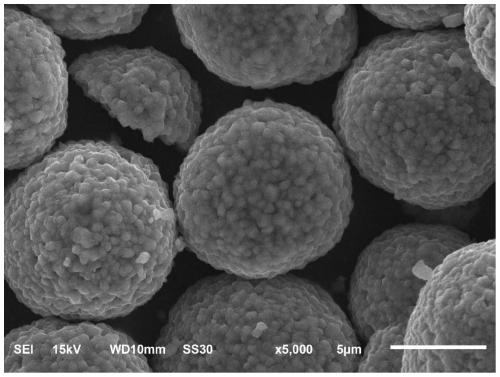

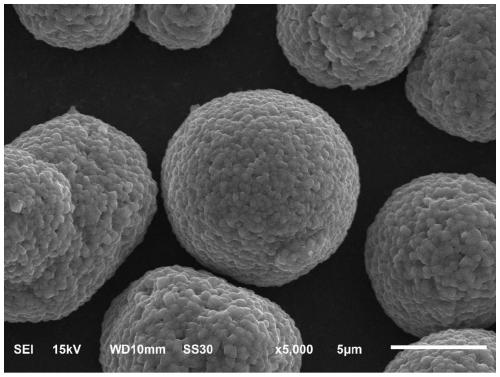

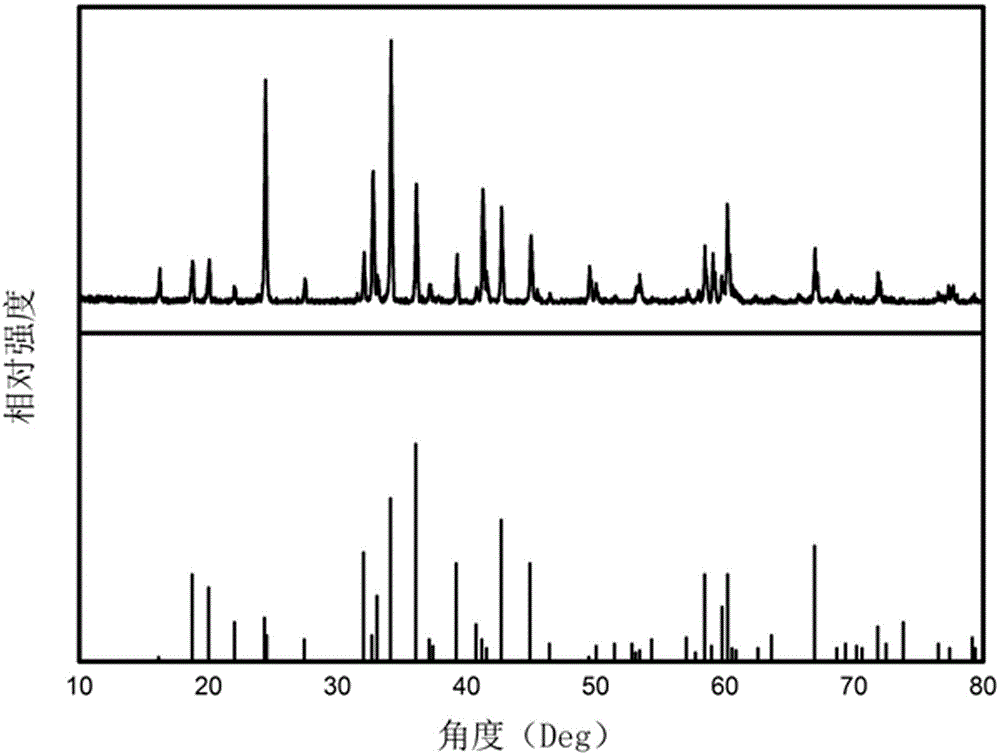

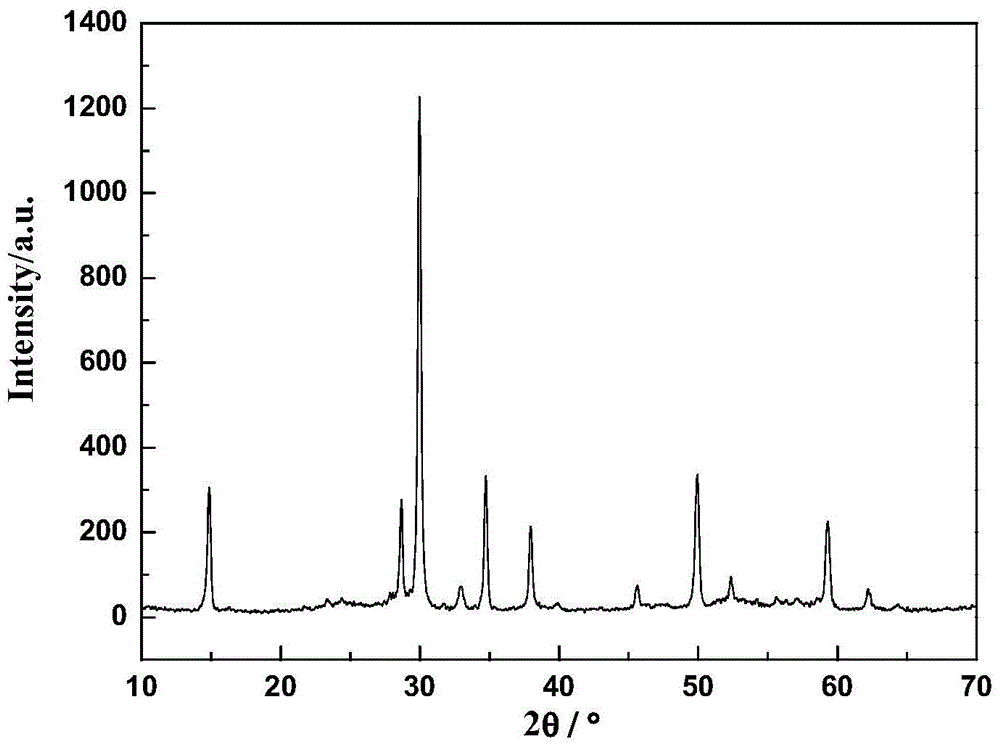

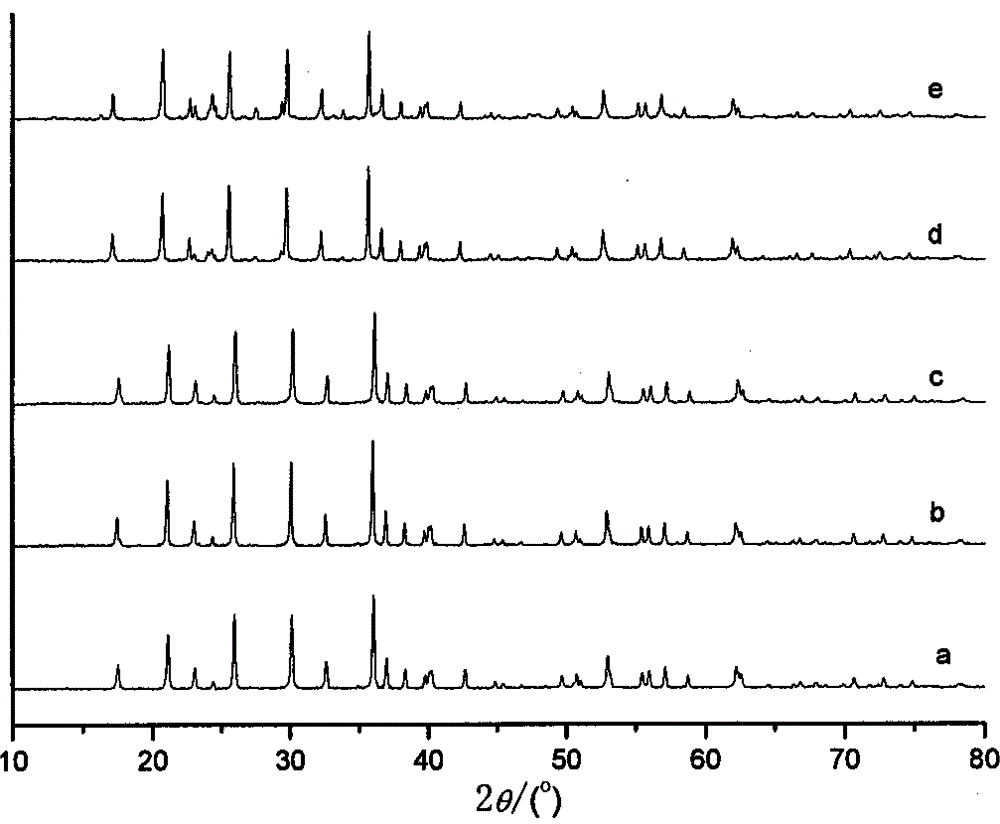

Preparation method of positive material sodium hexafluoroferrate applicable for sodium or lithium ion batteries and clad material thereof

InactiveCN107293712AReduce energy consumptionShort processCell electrodesSecondary cellsIonChemistry

The invention discloses a preparation method of positive material sodium hexafluoroferrate applicable for sodium or lithium ion batteries and a clad material thereof. Sodium hexafluoroferrate sediment is prepared in a water solution by controlling the conditions of synthetic process, the sodium hexafluoroferrate material can be obtained through filtering and drying, and then the sodium hexafluoroferrate is mixed with a clad layer substance or a precursor thereof, so that the sodium hexafluoroferrate clad material is prepared through calcinations under different atmospheres. The sodium hexafluoroferrate material obtained in the invention is good in crystallization property and free of impurity phase; the particle morphology is regular, the particle size is uniform and controllable, and the mobility is good; and the sodium hexafluoroferrate and the clad material thereof are high in specific capacity and high in cycle stability. The preparation method is simple in technology, low in energy consumption, little in pollution and good in product performance, and is extremely applicable for industrial production.

Owner:HUNAN INSTITUTE OF ENGINEERING

High-performance lithium ion battery composite positive electrode material and preparation method thereof

PendingCN111554897AEasy to transportAvoid breakingSecondary cellsPositive electrodesLithium-ion batteryBattery cell

The invention provides a high-performance lithium ion battery composite positive electrode material and a preparation method thereof, wherein the high-performance lithium ion battery composite positive electrode material comprises a high-nickel ternary positive electrode material matrix and a Bi2-aMaWO6 coating layer coating the high-nickel ternary positive electrode material matrix, and a is greater than or equal to 0 and less than 1, and M is any one or a combination of two or more of Zr, Mg, Al, Na, Fe, Ga, Mo, W, Y, Ti and Ce. According to the preparation method, the Bi2-aMaWO6 modified high-nickel ternary positive electrode material is obtained mainly through the high-temperature calcination of Bi2-aMaWO6 and the high-nickel ternary positive electrode material, the preparation methodis simple, and the prepared modified positive electrode material is regular in particle morphology, good in crystallinity and free of impurity phases; the generation and expansion of micro-cracks canbe successfully inhibited in the charging and discharging process, so that the harmful phase change from H2 to H3 is favorably reduced; and meanwhile, the specific discharge capacity, the cycle performance and the thermal stability of the positive electrode material are improved.

Owner:湖南桑瑞新材料有限公司

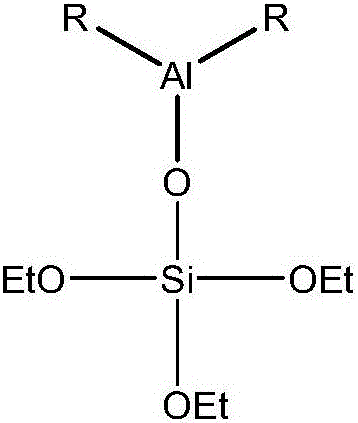

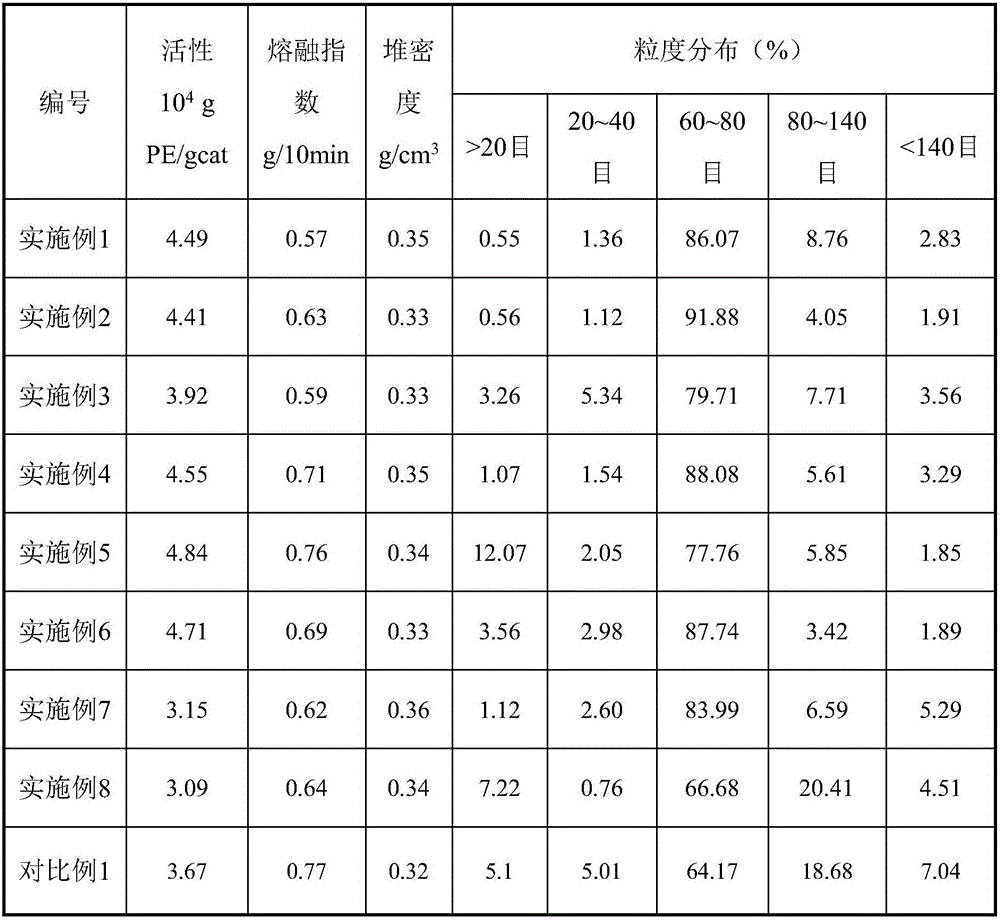

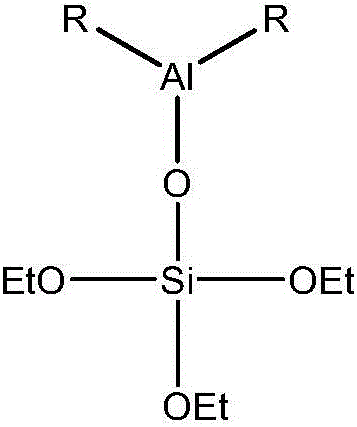

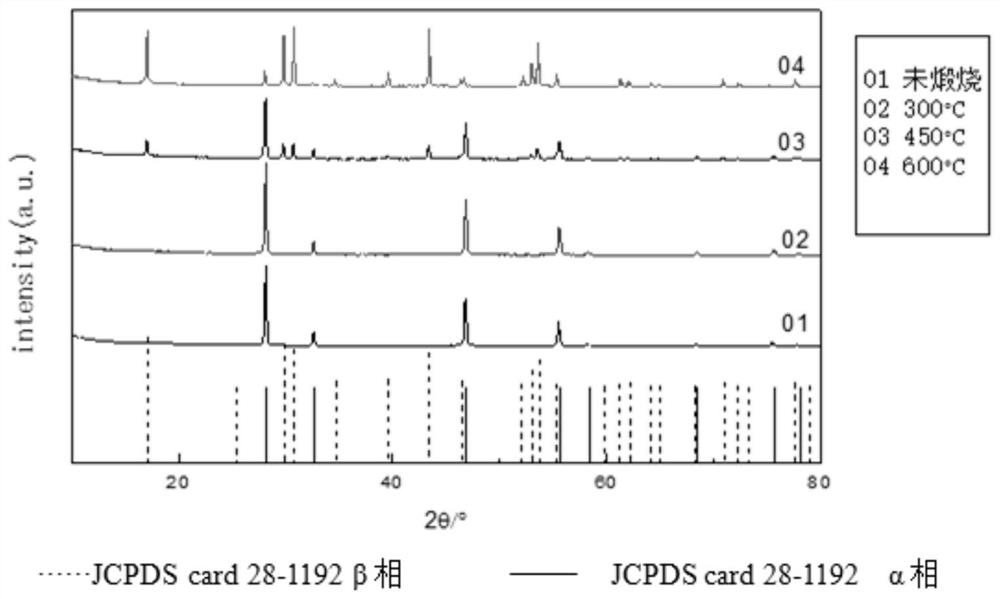

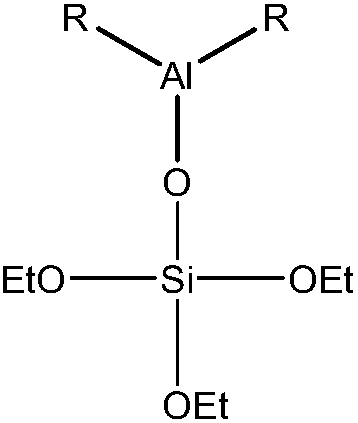

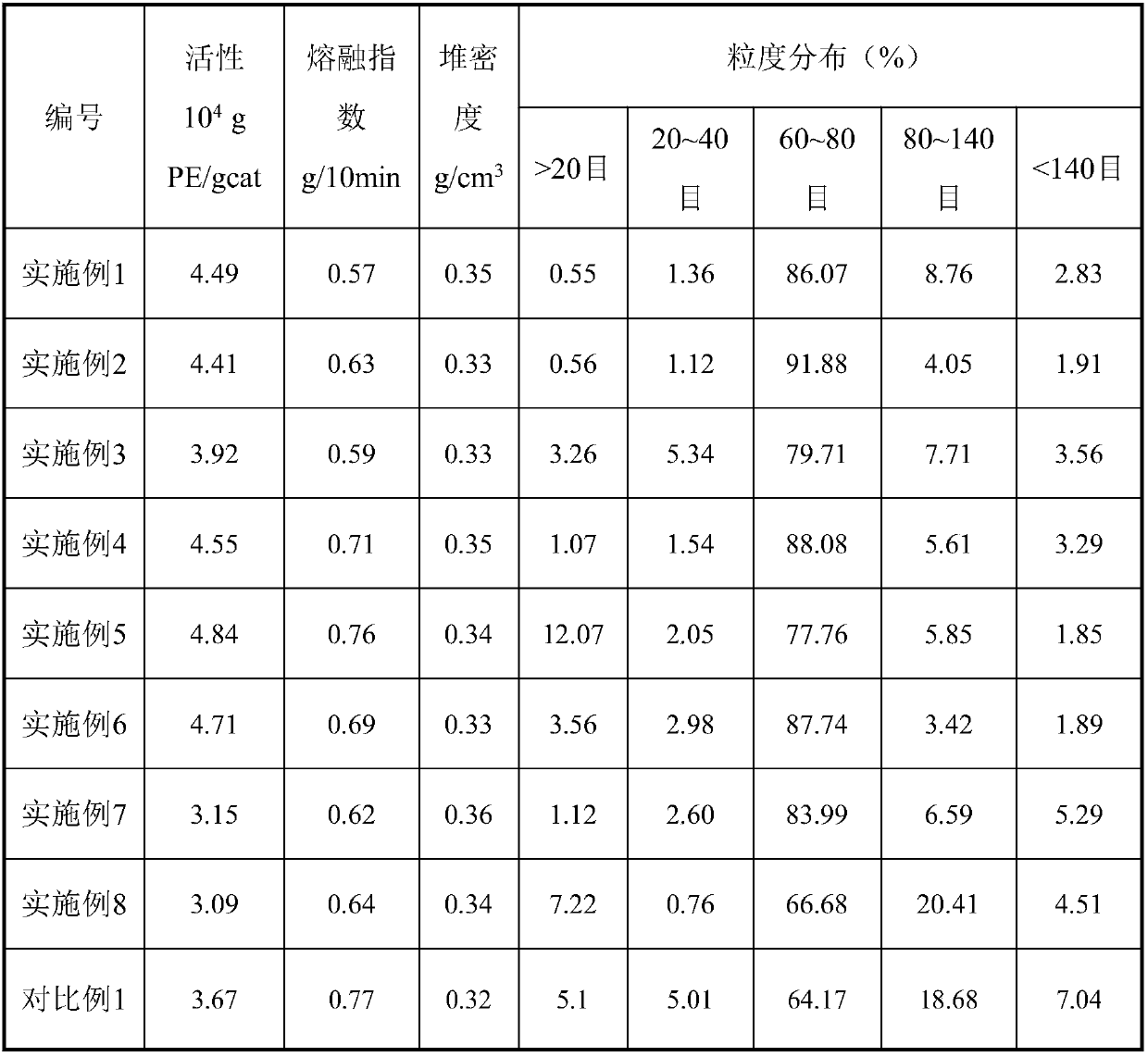

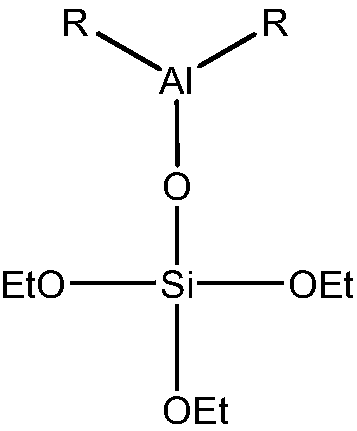

Electron donor of Ziegler-Natta catalyst and application of electron donor in vinyl polymerization

The invention relates to an electron donor of a Ziegler-Natta catalyst, a catalyst component comprising the electron donor and the catalyst. The electron donor adopts a Si-Al ester compound; the catalyst prepared from the Si-Al ester compound serving as the electron donor shows higher catalytic activity, better hydrogen response and better copolymerization performance when applied to vinyl polymerization and copolymerization, and can be used for catalyzing vinyl homopolymerization or production of high-performance polyolefin materials with high bulk density, narrow particle size distribution and small fine grain content through copolymerization of vinyl and other alpha-olefins.

Owner:TIANJIN UNIV OF SCI & TECH

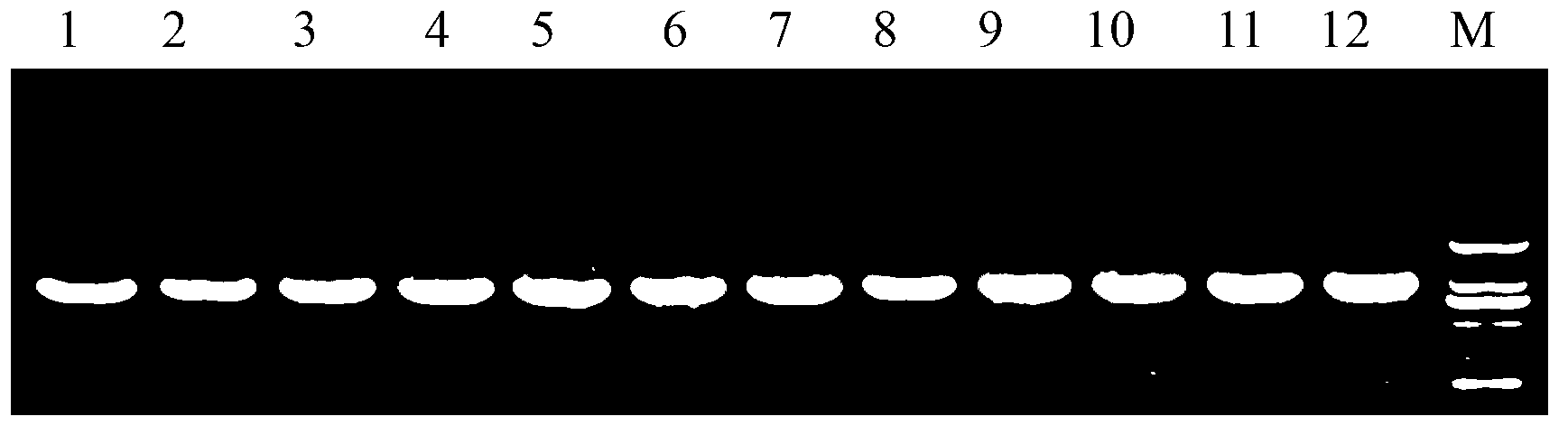

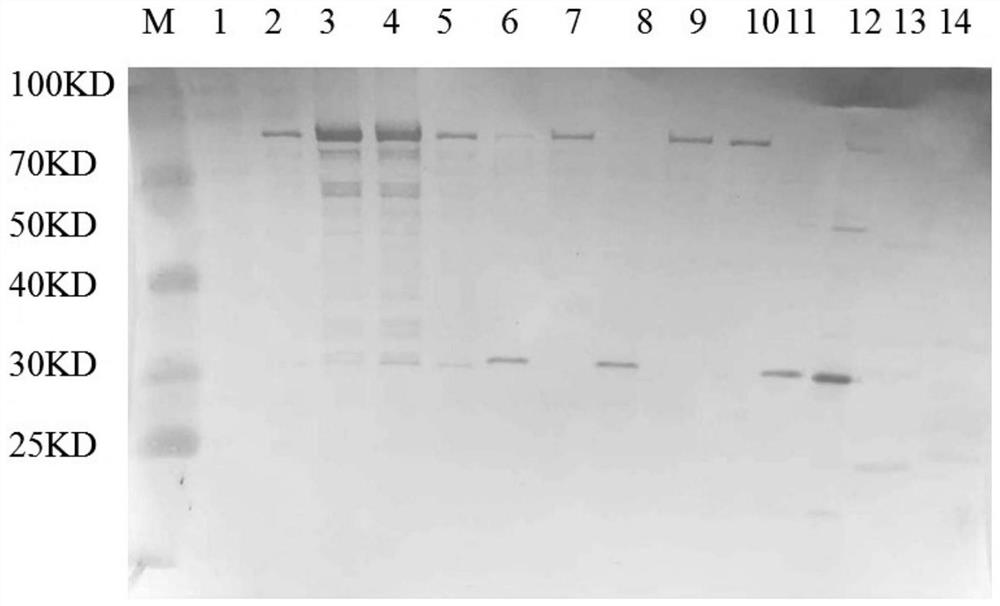

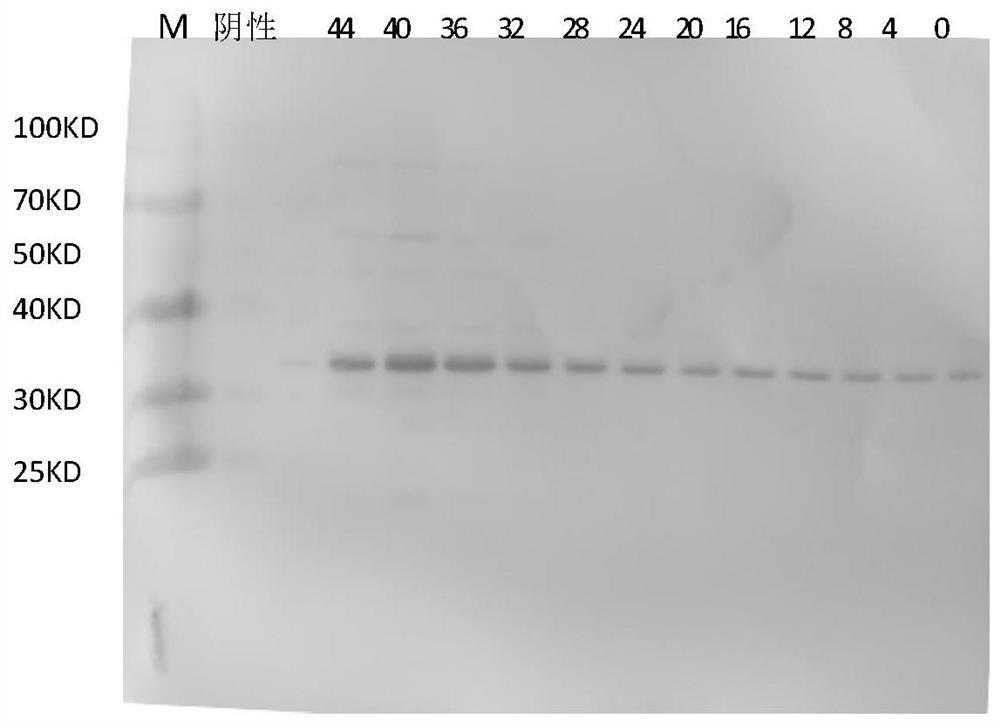

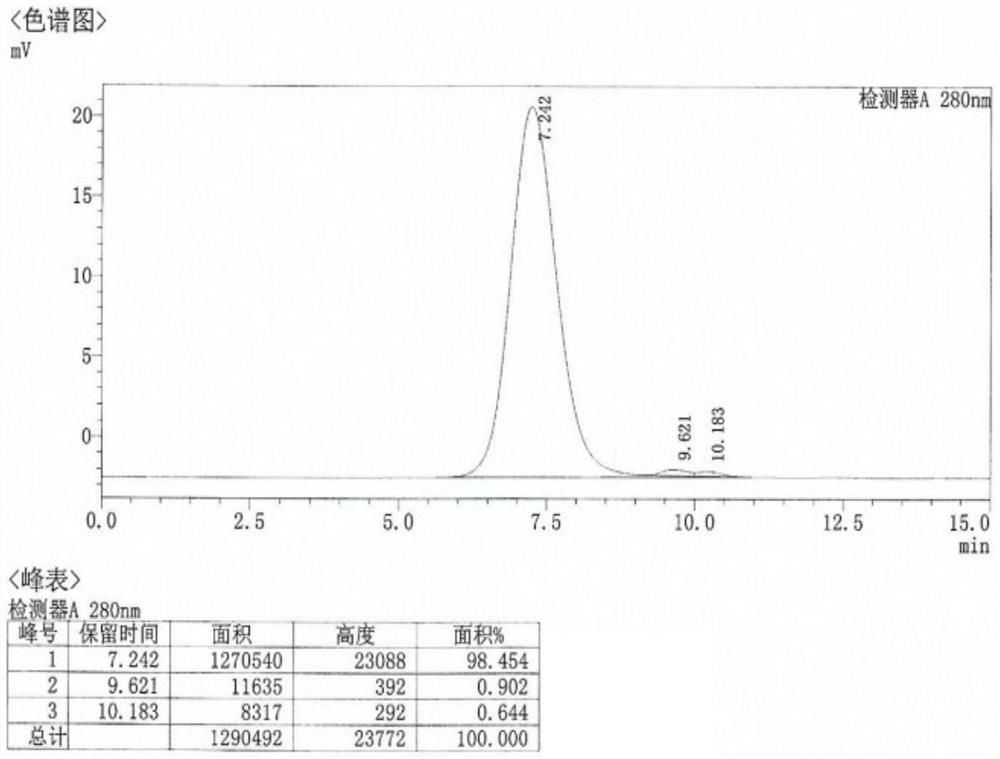

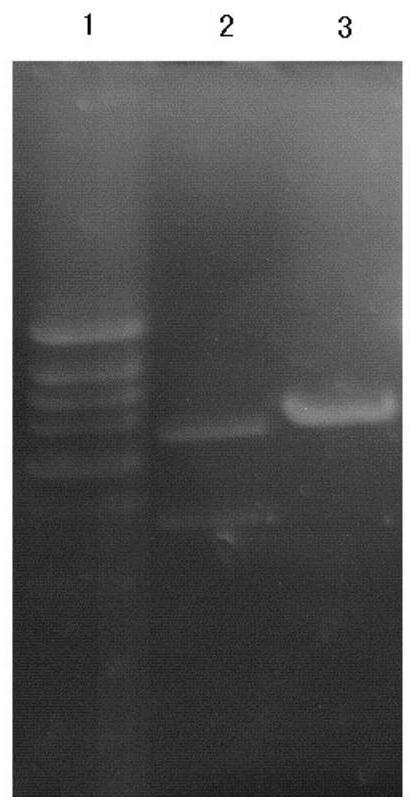

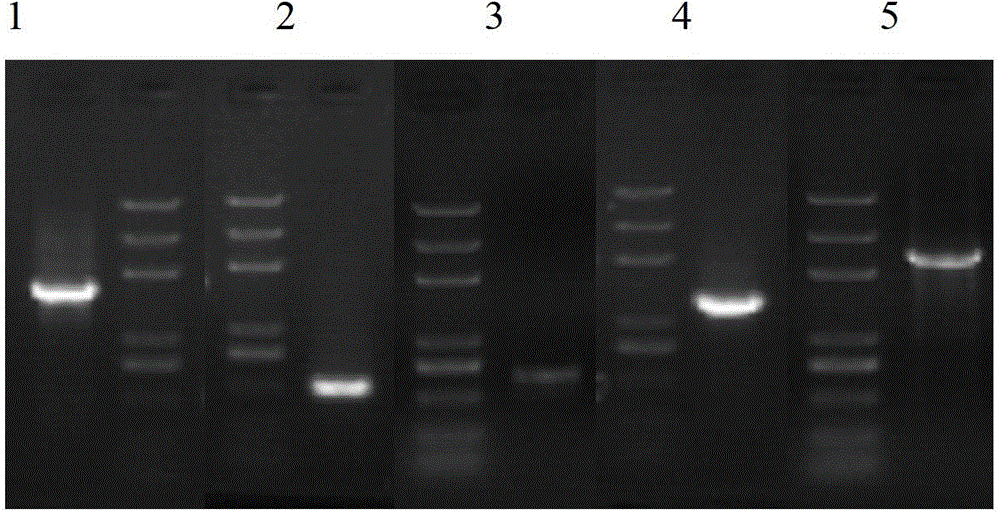

Hansenula polymorpha engineering bacteria for efficiently expressing CA10 virus-like particles and application thereof

ActiveCN111778168AEfficient expressionImprove stabilityFungiSsRNA viruses positive-senseUltrafiltrationVirus-like particle

The invention provides hansenula polymorpha engineering bacteria for efficiently expressing CA10 virus-like particles and application thereof. The engineering bacteria comprise a recombinant vector carrying CA10 virus P1 and 3CD genes, and an original strain of the engineering bacteria is uracil-deficient hansenula polymorpha AU 0501; and the P1 and 3CD genes are optimized according to hansenula polymorpha preferred codons. The invention further provides a preparation method of the CA10 virus-like particles. The preparation method comprises the steps that the engineering bacteria are cultured,the CA10 virus-like particles are expressed, and the virus-like particles are separated and purified by adopting ultrafiltration and three-step chromatography processes. The CA10 virus-like particlesand a vaccine prepared from the CA10 virus-like particles have good immunogenicity, safety and biological activity, the process is simple, purification is conducted by adopting a chromatography method, large-scale preparation and purification can be achieved, a high-purity (greater than 99%) VLP protein stock solution is obtained, and the engineering bacteria can be used for preparing the vaccinefor preventing CA10 infection and have good economic value and application prospects.

Owner:BEIJING MINHAI BIOTECH

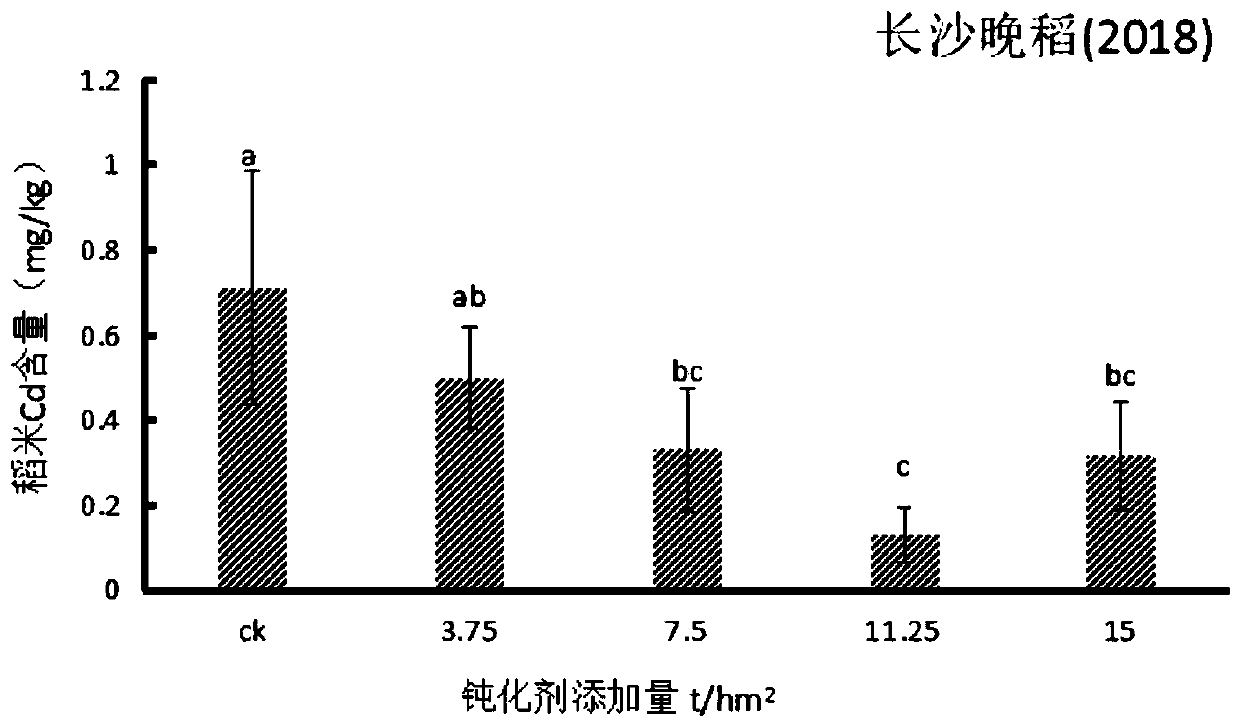

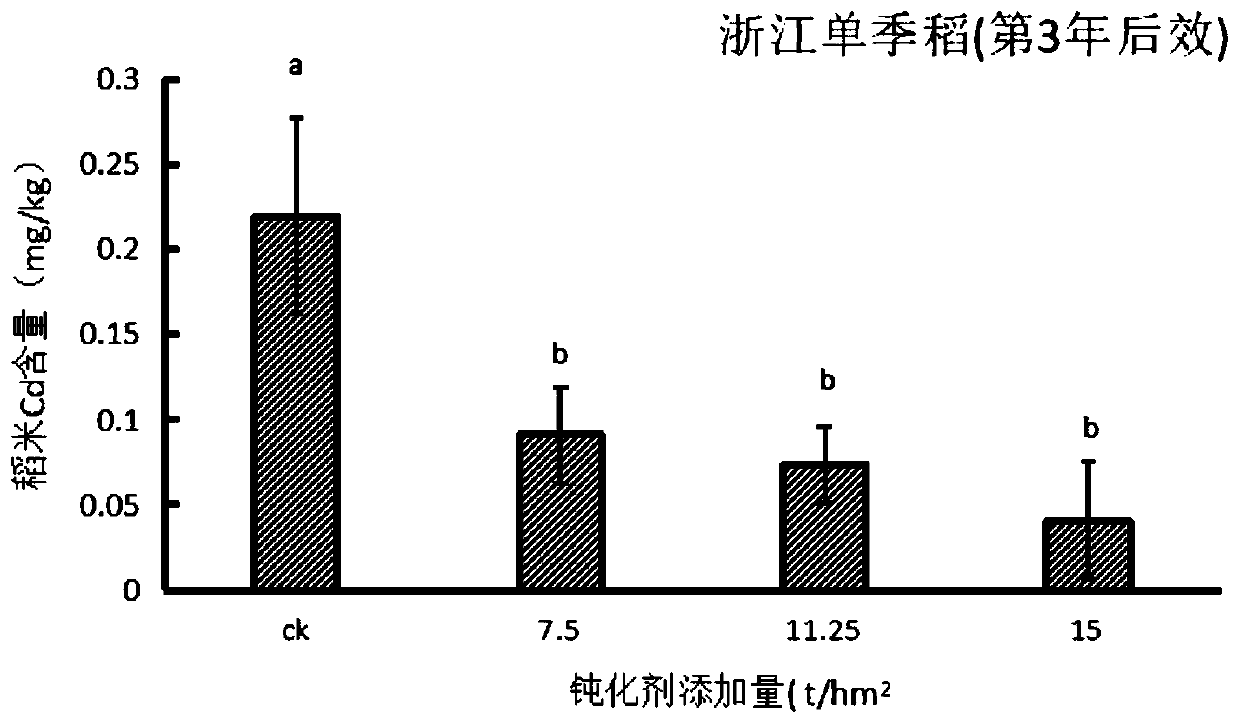

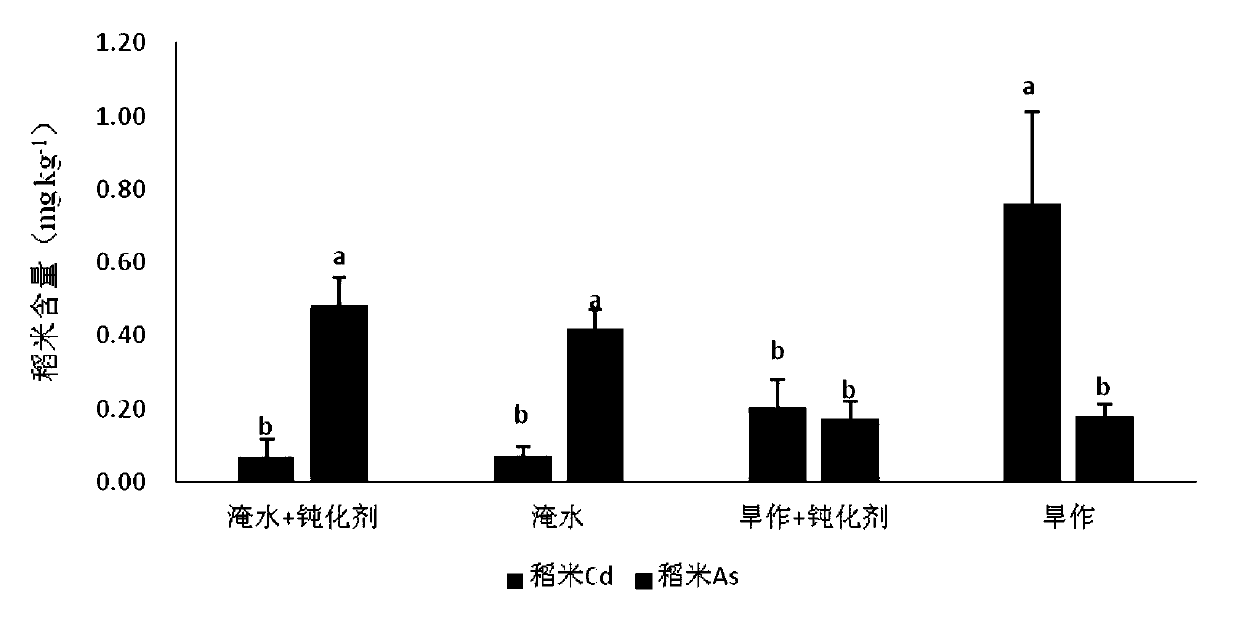

Long-acting passivator for cadmium in soil, and preparation method and application thereof

ActiveCN110938435ARaise the pHImprove the passivation effect of the seasonAgriculture tools and machinesOrganic fertilisersPhysical chemistryCalcite

The invention discloses a long-acting passivator for cadmium in soil, and a preparation method and application thereof. The long-acting passivator for cadmium in soil comprises calcite mineral powder,humic acid and a binder, wherein the mass fraction of humic acid is 1-5%, and the mass fraction of the binder is 3-6%. The preparation method comprises the following steps: putting the calcite mineral powder into a disc granulator; mixing the humic acid and the binder and adding water to form an aqueous solution; and allowing the aqueous solution enter the disc granulator through multi-angle spraying, and enabling the above materials to be agglomerated into particles through granulation. According to the long-acting passivator for cadmium in soil disclosed by the invention, the calcite mineral powder is selected for cooperation with the humic acid, so in-season passivation effect is improved, and good subsequent passivation effect can be maintained; and with the preparation method disclosed by the invention, the obtained passivator is in the form of a regular particle and has high dispersion speed after meeting water.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

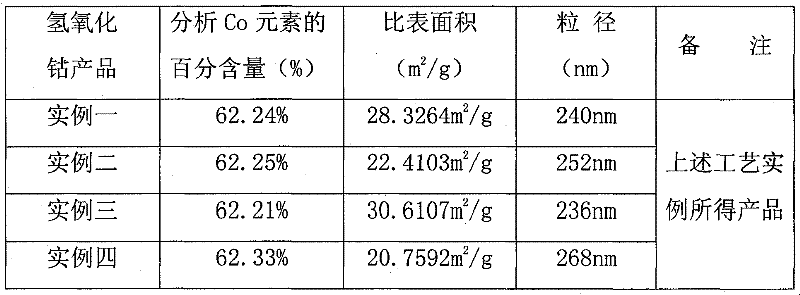

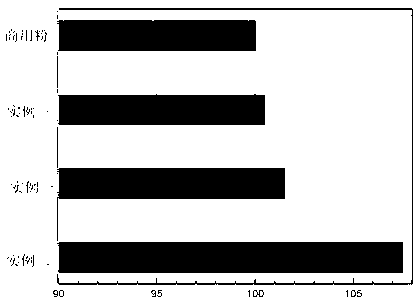

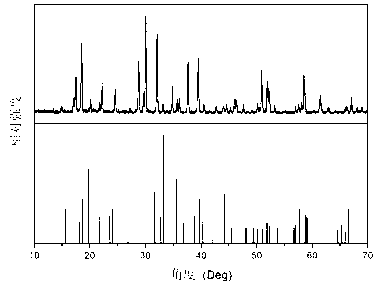

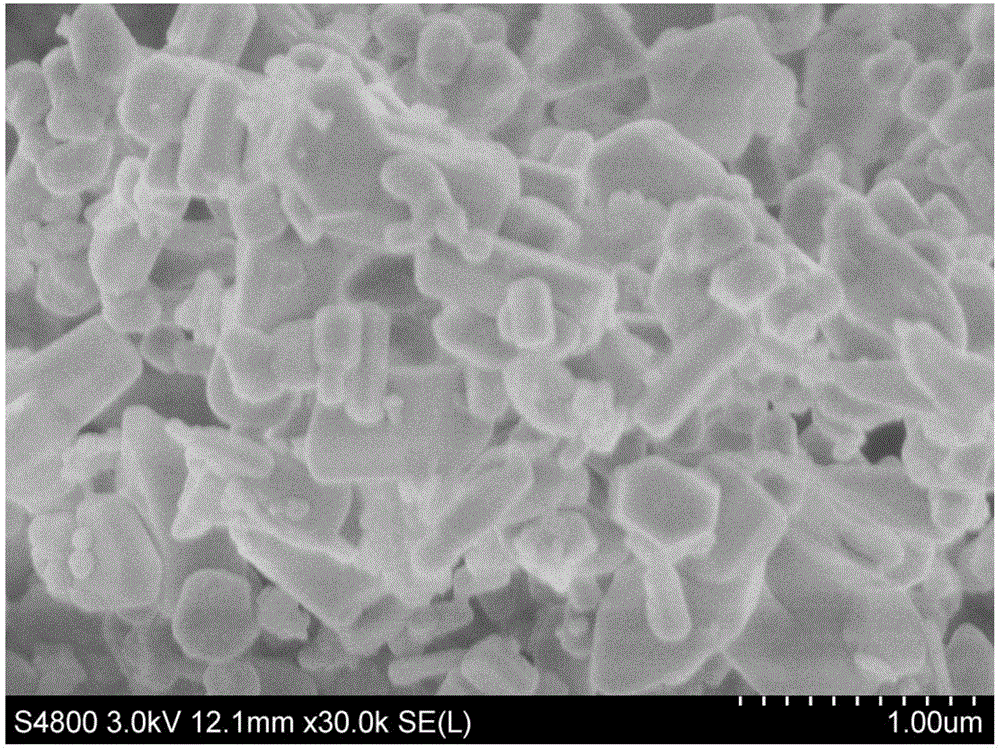

Method for preparing high purity nano cobalt hydroxide

InactiveCN101955234BHigh purityParticle rulesNanostructure manufactureCobalt oxides/hydroxidesDispersityChemical plating

Owner:HAINAN JINYI NEW MATERIALS

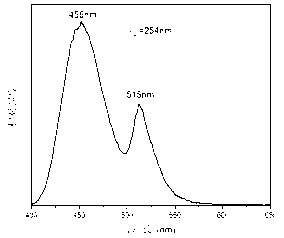

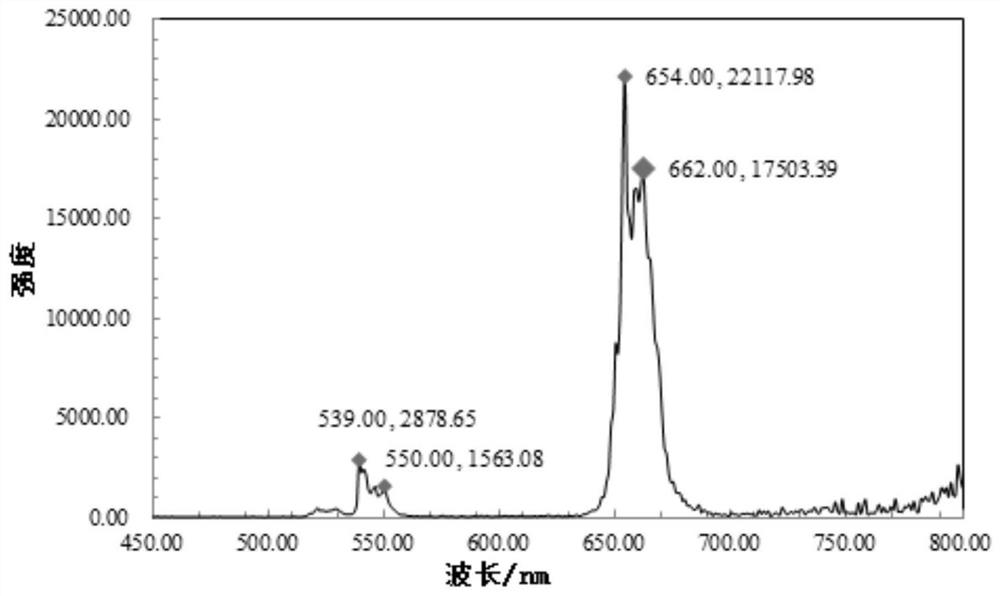

Preparation method of tri-phosphor double-peak blue fluorescent powders for lamp

InactiveCN103013508AHigh Relative Luminous BrightnessImprove thermal stabilityLuminescent compositionsPhysical chemistryHeat stability

Owner:LANZHOU UNIVERSITY

Preparation method for potash fertilizer particles

ActiveCN104311258AHigh strengthReduce intensitySolid/semi-solid fertilisersPotassium fertilisersThermopotashPotash

The invention relates to a preparation method for potash fertilizer particles. The preparation method is characterized in that the potash fertilizer particles are pelletized by a two-stage mixing extruder, potash fertilizer powder and additives are rapidly refined, scattered and mixed due to the strong shear force of the high rotation speed screw of a first-stage twin screw mixing mill, and then enter a second-stage single screw extruder through exhaust, the output end can conduct high pressure stable extrusion at a low rotation speed, and finally, pelleting is carried out by a die surface pelletizer to obtain the potash fertilizer particles. The potash fertilizer particles have high nutrient concentration, are regular in shape and uniform in diameter, and have high strength and good slow release performance. The preparation method is simple to operate, has strong technological adaptability, consumes little energy, has high granulation rate and high yield, and has market application value.

Owner:山东亿田生物肥料科技有限公司

A jujube granule producing method

ActiveCN106942664AReduce primary colorKeep the colorFood ingredient as colourFood ingredient as taste affecting agentPressure differenceControllability

A jujube granule producing method is disclosed. The method includes raw material selecting, cleaning, dehydrating, stoning, sterilizing, enzymolysis, fermentation, low-oxygen low-temperature heat-pump drying, nitrogen charging pressure difference rapid puffing, medium and short wave infrared drying, crushing, grading, packaging, and other steps. The enzymolysis is performed firstly so that jujube viscosity is reduced and jujube flavor is adjusted. Then through progressive multi-stage drying, the color of jujubes is kept, a proper tissue structure is formed, the water content is controlled ingeniously. Through combining a crushing manner, the rotating speed, environment temperature and humidity, and other factors, the problem that jujubes are liable to stick to form clump or liable to be powdered, and the like in granulation is overcome by and objectives of improving uniformity, reducing viscosity, maintaining the original color, increasing the crisp degree, making granulation easy and avoiding powder generation are achieved. The method is simple and convenient to operate, high in controllability and high in mechanization degree. The utilization rate, edibility and healthcare properties of raw materials are improved. A product of the method can be used for snacks, soup making, medicines, tea drinks and stuffing.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

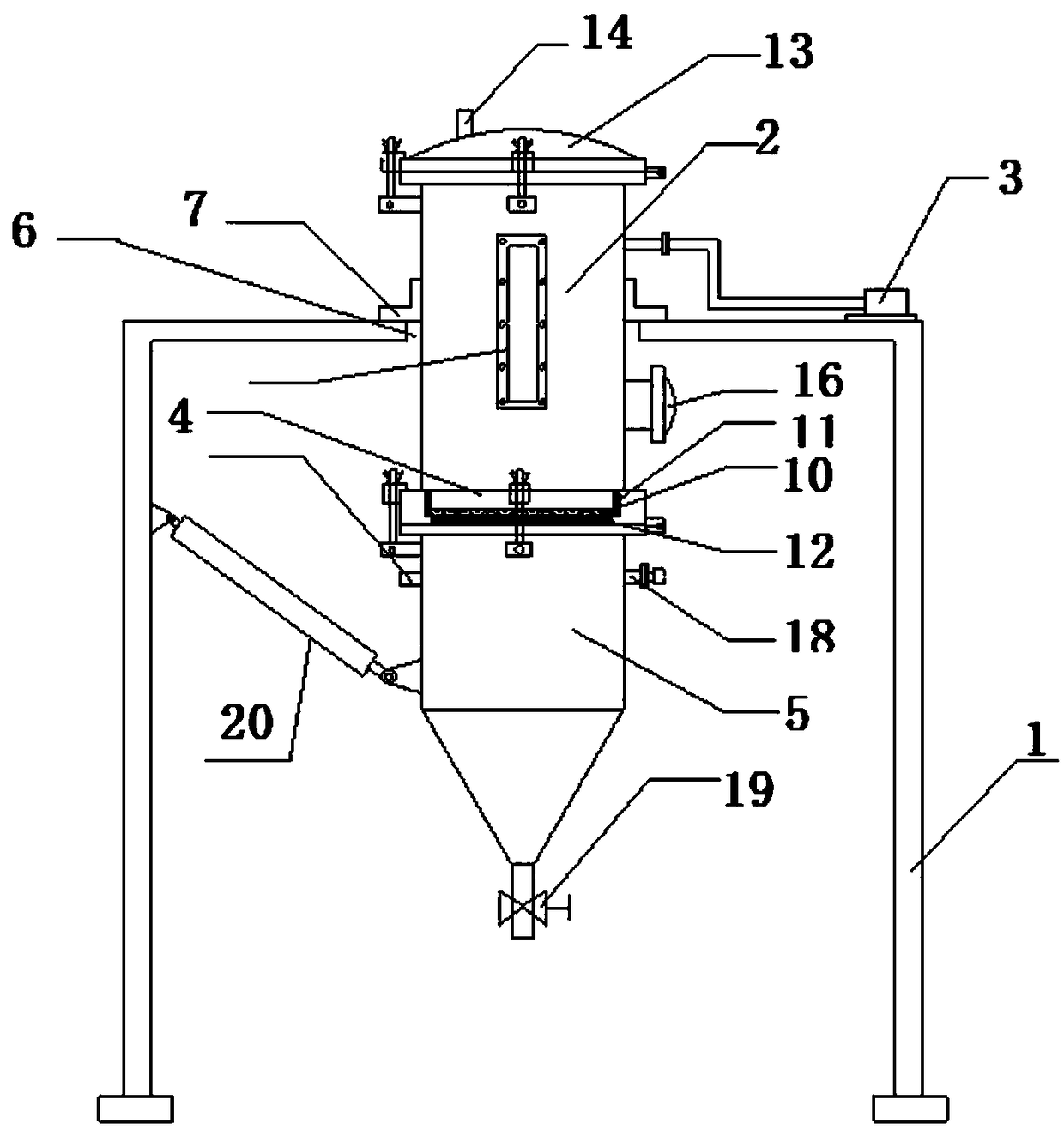

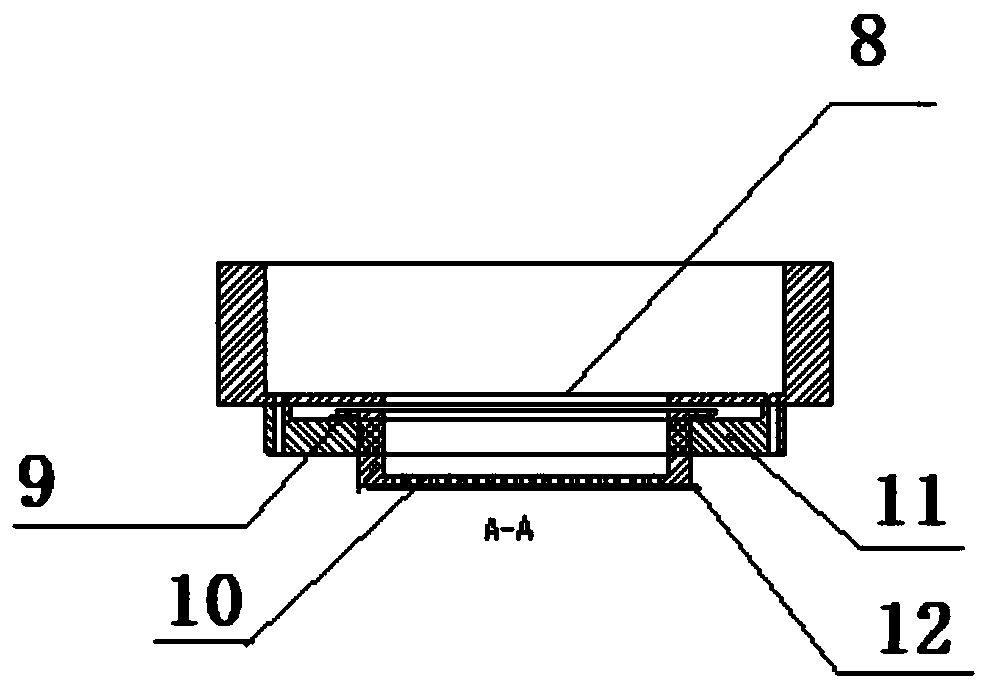

Large plastic part recycling processing device and processing method

ActiveCN106493876AReduce energy consumptionReduce noisePlastic recyclingPulp and paper industrySmall footprint

The invention provides a large plastic part recycling processing device and a processing method. The processing device comprises a fixing support, a drying tank, a vacuum pump, a hot-melting dicing device and a material storage tank, the middle of the fixing support is provided with an opening, and the two sides of the drying tank are each provided with a connecting convex table; and the drying tank is erected at the opening of the fixing support through the connecting convex tables at the two sides, the connecting convex tables are connected with the fixing support through fastening bolts, the bottom of the drying tank is provided with the hot-melting dicing device, the material storage tank is connected to the lower portion of the drying tank, the portions, at the outer side of the joint, of the drying tank and the material storage tank are connected through fastening bolts, the vacuum pump is connected to one side of the drying tank, and the vacuum pump is placed on the fixing support. The large plastic part recycling processing device has the beneficial effects that energy consumption is reduced, noise is small, crushed particles are regular, and the occupied area is small.

Owner:TIANJIN LAIWO VACUUM DRYING EQUIP MFG CO LTD

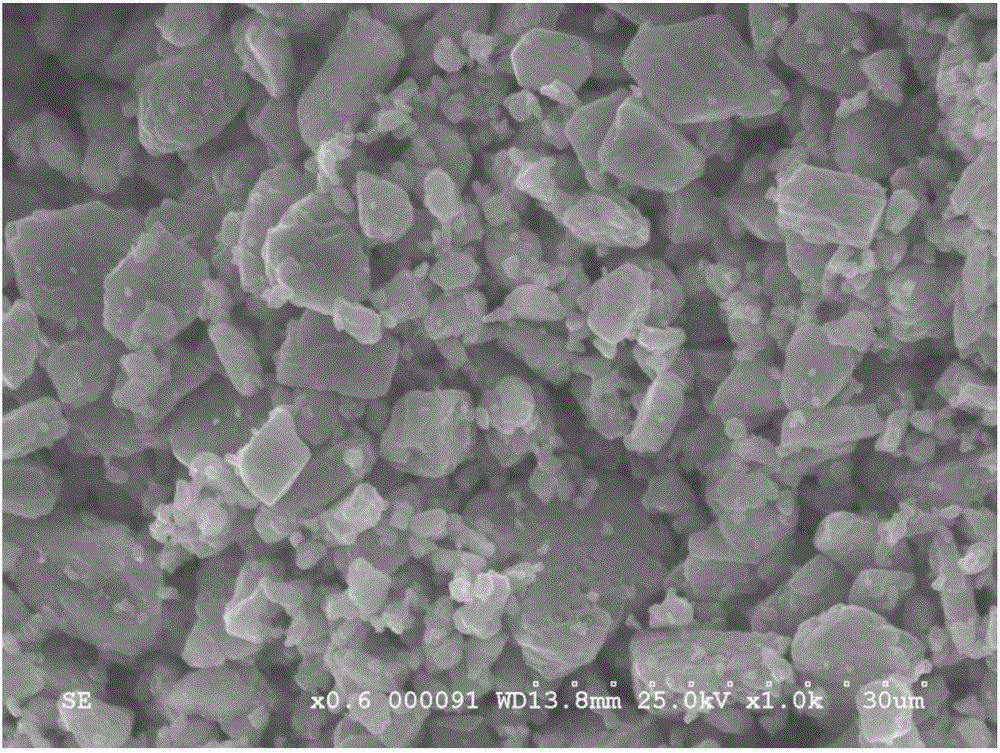

Method for preparing active material calcium zincate of cathode of battery by utilizing airflow mill

ActiveCN106673052AUniform finenessParticle rulesCell electrodesZinc compoundsCalcium hydroxideZincate

The invention discloses a method for preparing an active material calcium zincate of a cathode of a battery by utilizing an airflow mill and belongs to the technical field of an active material of a zinc nickel battery. The method comprises the following steps: 1) uniformly mixing and stirring zinc oxide, calcium hydroxide and deionized water at a weight ratio of (4-6):(4-6):1, and then putting the mixture into a material inlet of the airflow mill and entering into a crushing chamber through an ascending pipe, thereby acquiring a crushed material; 2) putting the crushed material acquired in the step 1) into a classifying chamber for classifying, thereby acquiring classified particles; and 3) returning the classified particles acquired in the step 2), of which the grain size is less than or equal to 1000 meshes, to the crushing chamber for crushing, and discharging the classified particles of which the grain size is more than 1000 meshes from a product outlet, namely, acquiring the active material calcium zincate of the cathode of the battery. The calcium zincate product acquired according to the method is uniform in fineness, regular in particle shape, high in purity and high in material activity. The charging / discharging cycle life can reach above 3000 times.

Owner:秦立新

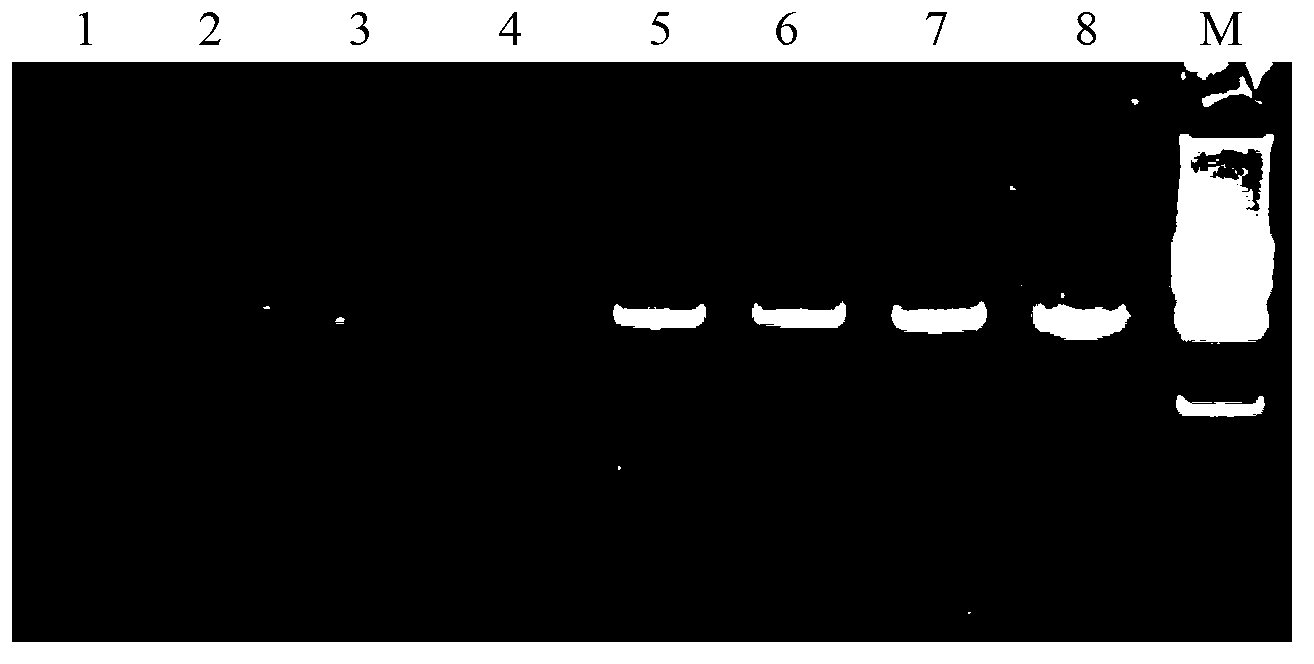

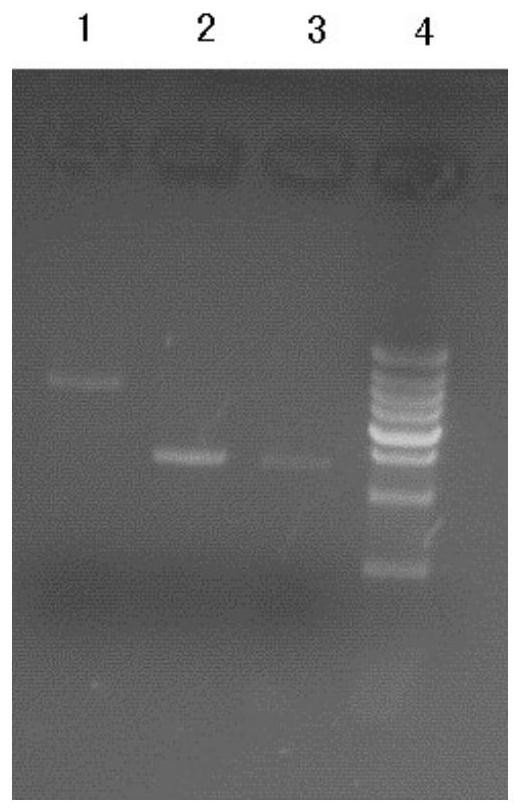

A kind of foot-and-mouth disease virus-like particle vaccine and preparation method thereof

ActiveCN109601007BEliminate potential safety hazardsReduce manufacturing costSsRNA viruses positive-senseVirus peptidesDiseaseTransfer vector

The invention provides a foot-and-mouth disease virus-like particle vaccine and a preparation method thereof. Insert the two ORFs of the codon-optimized FMDV P12A and 3C genes in series into the transfer vector to construct a recombinant expression plasmid; or clone a single ORF containing the P12A3C gene under the promoter SV40 into the vector to construct a recombinant expression plasmid, and transform competent cells to obtain recombinant expression Bacmid‑DNA was transfected into sf9 cells to obtain insect cells capable of expressing foot-and-mouth disease virus-like granule protein. After culturing the cells, the supernatant is collected, concentrated by ultrafiltration, centrifuged, and chromatographically purified to prepare the VLP vaccine.

Owner:GPROAN BIOTECH (SUZHOU) INC

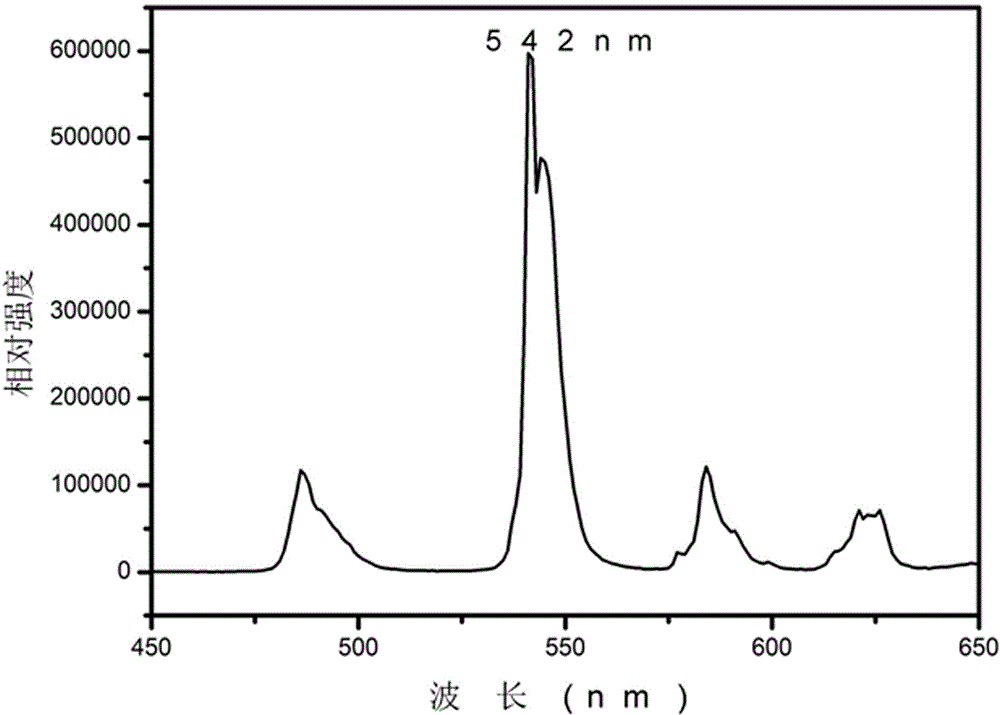

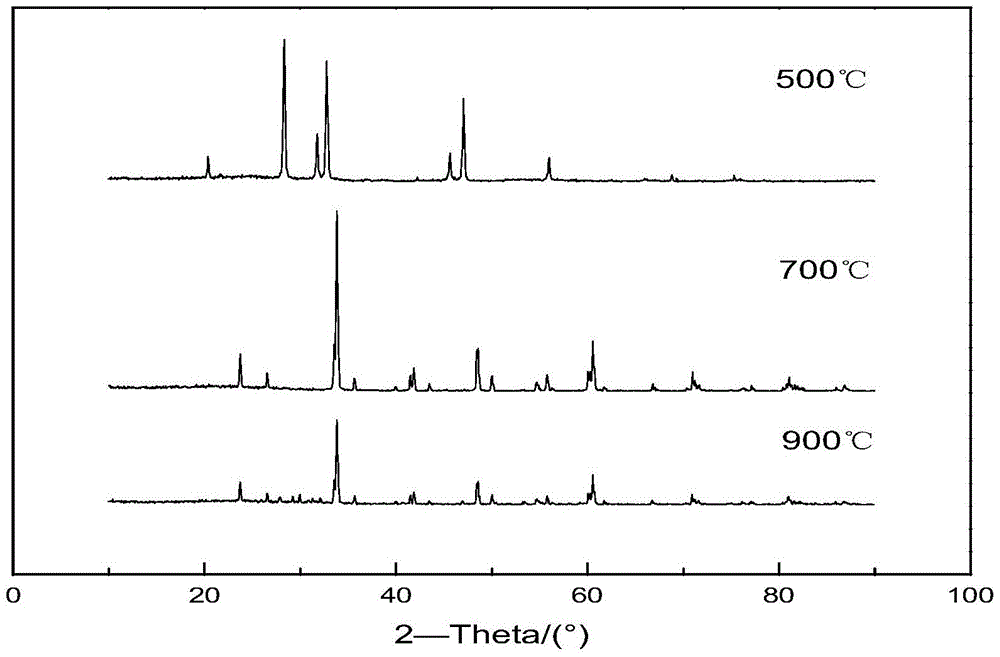

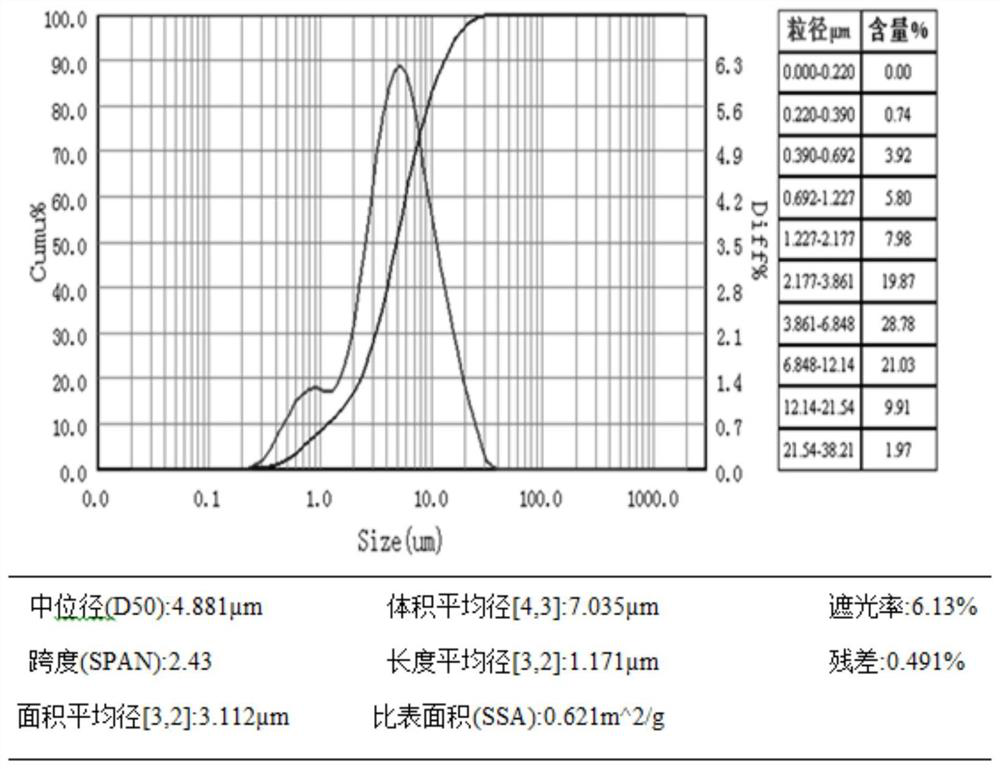

Preparation method for regular particle-shaped aluminate green emitting phosphor

InactiveCN102719247AHigh Relative Luminous BrightnessParticle rulesLuminescent compositionsChemical compositionCrucible

The invention discloses a preparation method for regular particle-shaped aluminate green emitting phosphor. The method comprises the following steps of: weighing raw materials according to the stoichiometric proportion of all chemical components in an expression (Ce0.63Tb0.37)MgAl11019; weighing a H3BO3 fluxing agent, a Li2CO3 fluxing agent and a AlF3 fluxing agent which are used as composite fluxing agents, and adding into raw materials and uniformly mixing; placing raw material powder in a crucible and calcining to obtain a primary calcined product; crushing the primary calcined product, placing in the crucible again, and calcining in the atmosphere of H2 / N2 to obtain a secondary calcined product; and crushing the secondary calcined product, washing, filtering, drying and screening to obtain a final product. According to the preparation method, (Ce,Tb)MgAl11O19 (CMAT) green emitting phosphor which is regular in particle shape, uniform in particle size and high in relative luminance is obtained on the basis of the conventional high-temperature solid phase method by mainly adjusting the proportion of all the fluxing agents in the composite fluxing agents; and the preparation process is simple, so that the green emitting phosphor can be industrially produced on large scale.

Owner:甘肃稀土新材料股份有限公司 +3

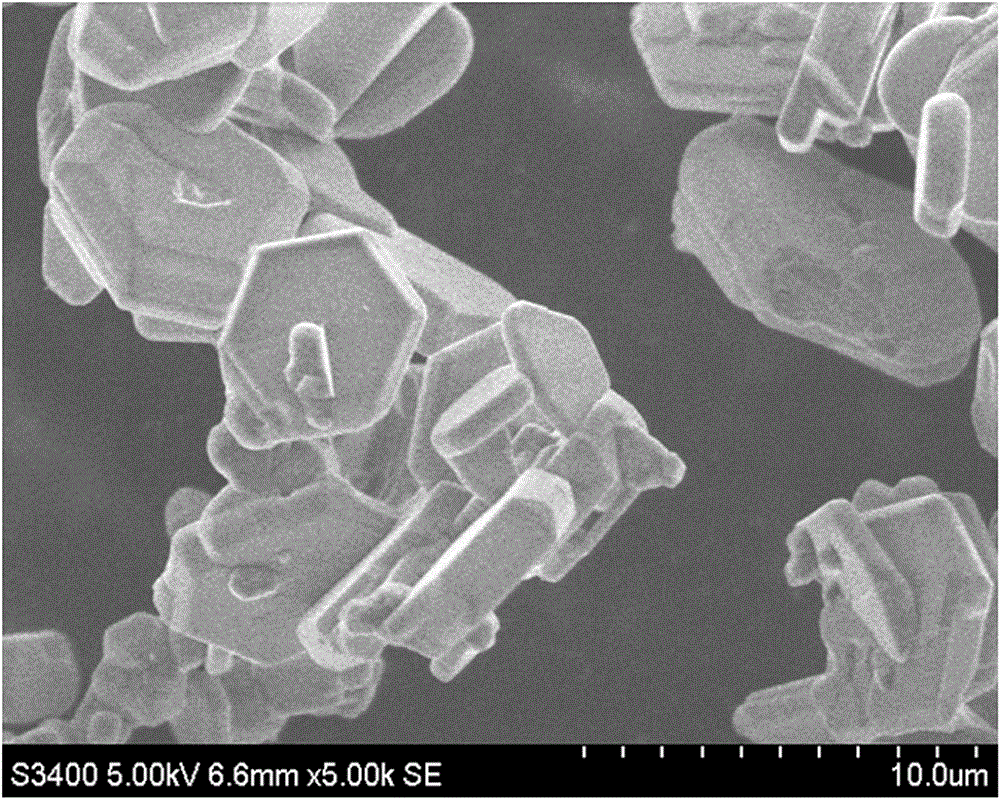

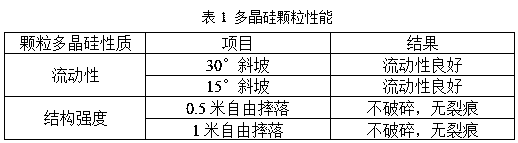

Method for preparing polycrystalline silicon particles from silicon wastes

The invention discloses a method for preparing polycrystalline silicon particles from silicon waste, and belongs to the technical field of photovoltaic products. According to the invention, silicon waste is used as a raw material, and cleaning, granulating, drying, microwave sintering, cooling and the like are performed to obtain polycrystalline silicon particles, wherein the specific physical strength of the polycrystalline silicon particles is that the polycrystalline silicon particles cannot be broken when rolling, falling off and the like within one meter, the purity of the polycrystallinesilicon particles is high (99.9999%-99.99999%), and the particle size of the polycrystalline silicon particles is uniform (300-30 mm); the method can be used in other required processes, increases the one-time charging amount, can also be used as a re-charging material, greatly reduces the production cost of polycrystalline silicon, and recycles resources; and the preparation method is low in cost.

Owner:SICHUAN HOT PULSE MICROWAVE SCI & TECH CO LTD

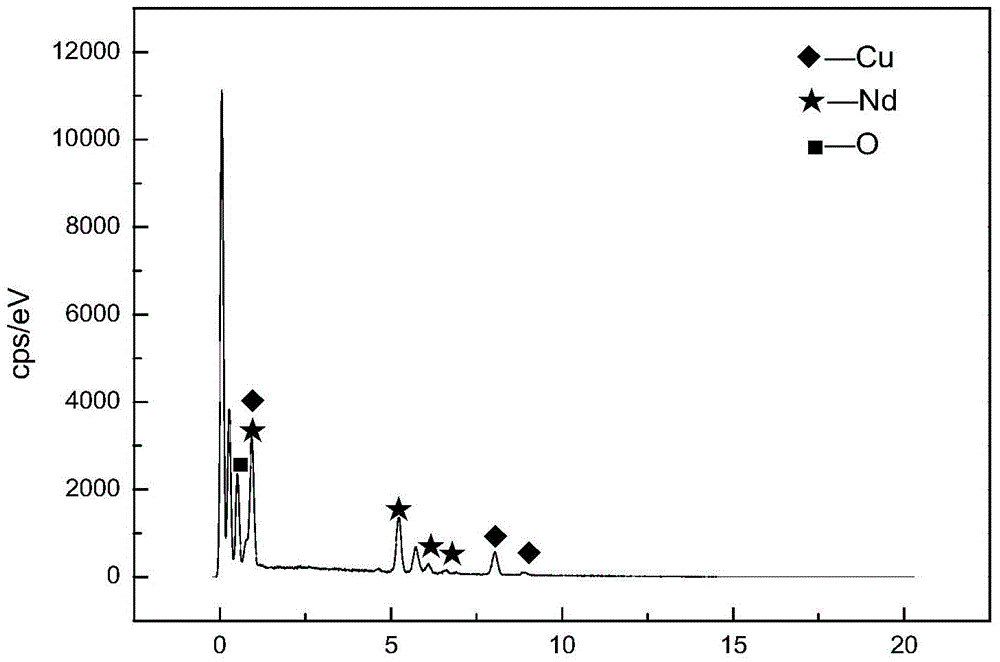

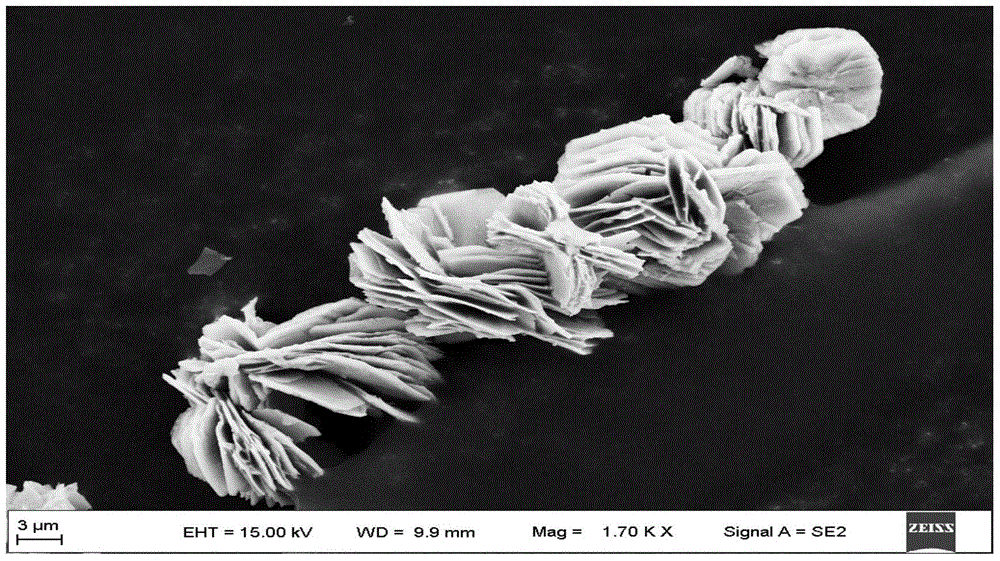

Synthesis method of copper-rare earth nano petal-shaped metal oxide

InactiveCN104108737BAchieve hybridAvoid mismatchMaterial nanotechnologyCopper compoundsRare earthMixed materials

The invention discloses a method for synthesizing copper-rare earth nanometer petal-shaped metal oxides, which comprises: weighing copper and rare earth soluble salt compounds in deionized water according to a molar ratio of 0.3 to 2:1, and dissolving them in deionized water at 0 to 90 Stir at ℃ for 10-90 minutes; add coordination solvent, continue to stir, and let the solution stand for 30-120 minutes to obtain an acidic precursor; add a neutralizing precipitant to the acidic precursor solution to make the solution If stratification occurs, add the coordination solvent again, and repeat the operation from the beginning of stirring to the end of standing until the solution appears stratified; After 3-5 hours, a metal oxide material with a petal-like lamellar structure is obtained. The invention realizes the mixing of materials at the atomic size, and can accurately control the atomic ratio; after low-temperature sintering, a copper-rare earth nano-petal-like sheet structure with high purity and uniform sheets composed of nanoparticles is prepared.

Owner:NORTHEASTERN UNIV LIAONING

A micron-scale up-conversion luminescent material and its preparation method

ActiveCN108913140BMorphological rulesIncrease productionLuminescent compositionsUpconversion luminescenceLuminescent material

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Electron donor of a ziegler-natta catalyst and its application in ethylene polymerization

The invention relates to an electron donor of a Ziegler-Natta catalyst, a catalyst component comprising the electron donor and the catalyst. The electron donor adopts a Si-Al ester compound; the catalyst prepared from the Si-Al ester compound serving as the electron donor shows higher catalytic activity, better hydrogen response and better copolymerization performance when applied to vinyl polymerization and copolymerization, and can be used for catalyzing vinyl homopolymerization or production of high-performance polyolefin materials with high bulk density, narrow particle size distribution and small fine grain content through copolymerization of vinyl and other alpha-olefins.

Owner:TIANJIN UNIV OF SCI & TECH

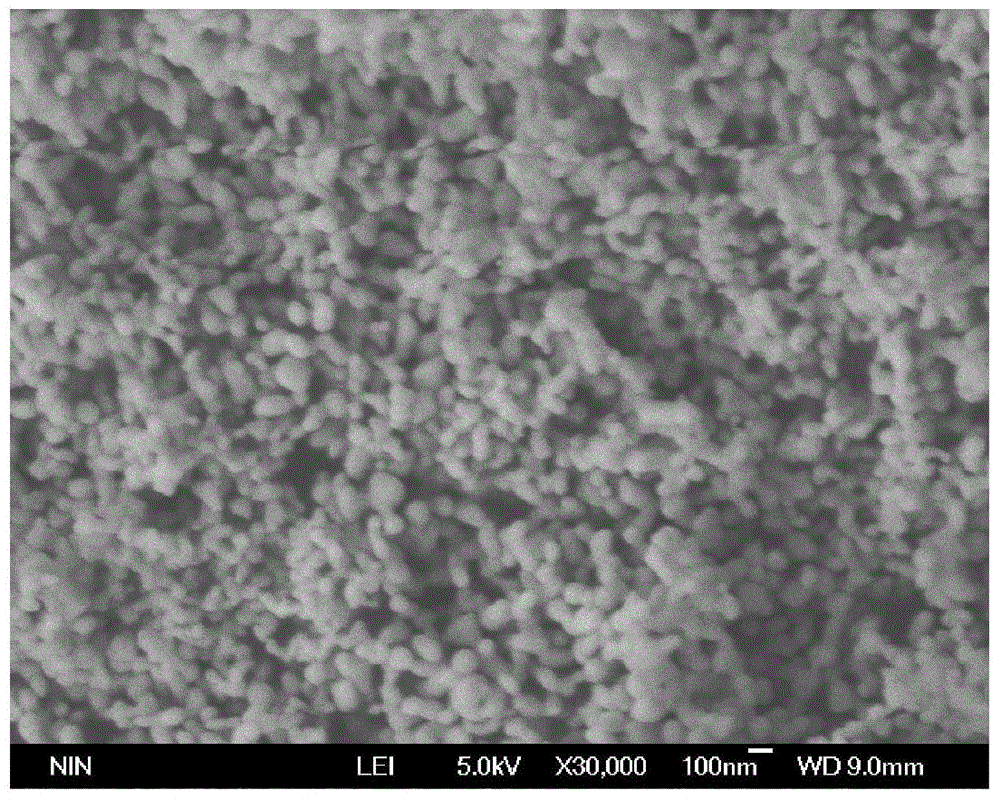

a nanobi 2 ti 2 o 7 Powder preparation method

ActiveCN105036183BSimple processing methodEasy to dopeMaterial nanotechnologyTitanium compoundsAcetic acidCooking & baking

The invention provides a preparation method for nanometer Bi2Ti2O7 powder. The preparation method comprises the following steps: completely dissolving Bi(NO3)3.5H2O and acetic anhydride so as to obtain a solution A; then dissolving tetrabutyl titanate in glycol and adding glacial acetic acid so as to obtain a solution B; mixing the solution A with the solution B and drying the obtained mixture in a baking oven; and carrying out calcining, insulation and cooling so as to obtain the Bi2Ti2O7 powder. The prepared Bi2Ti2O7 powder has improved photocatalytic performance and the characteristics of completely developed powder crystal phase, high purity, regular particle morphology, a size of less than 100 nm, uniformness and fineness.

Owner:SHAANXI UNIV OF SCI & TECH

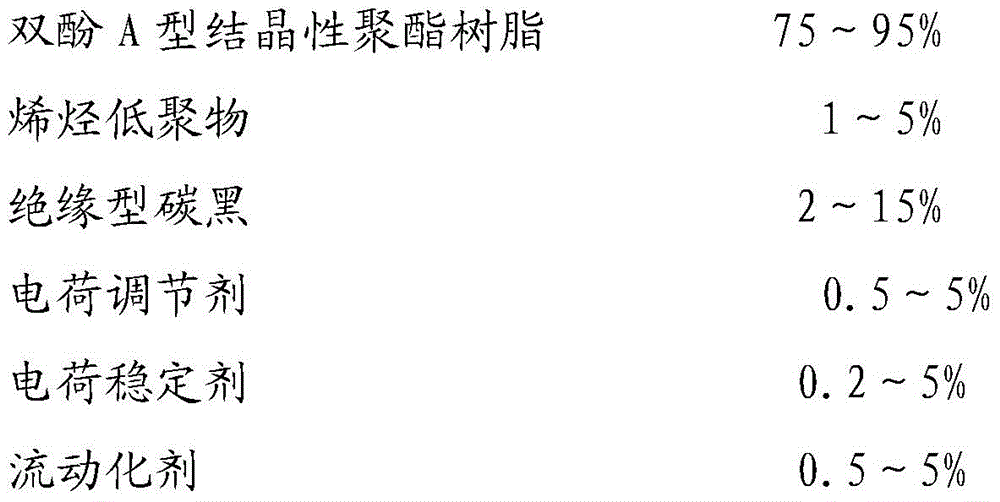

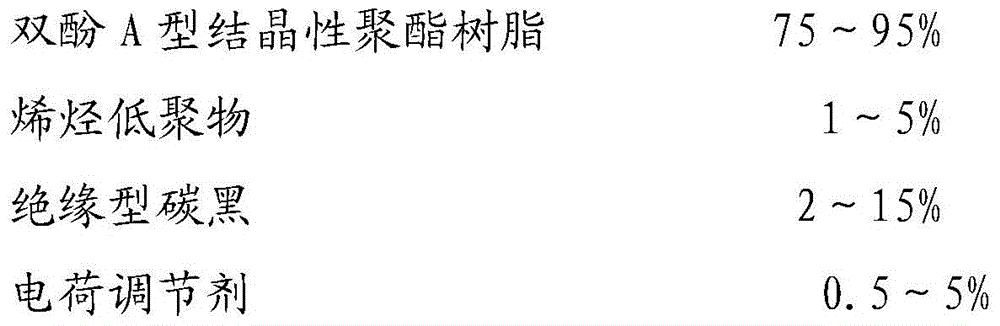

Fine developer for large format development and preparation method thereof

The invention discloses a fine developer for large-format development and a preparation method thereof, which comprises 75-95% by mass of a bisphenol A crystalline polyester resin binder, 2-15% of an inorganic dye, 1-5 % of olefin oligomer, 0.5-5% of charge regulator, 0.2-5% of charge stabilizer, etc. are fully mixed and then added to a twin-screw extruder for high-temperature extrusion dispersion. The extrusion dispersion temperature is 100-150°C. Fine developer particles of 6-8 μm are obtained by pulverization and classification, and then 0.5-5% developer fluidization agent is mixed and distributed on the surface of the fine developer particles to finally produce large-format fine developer materials. The fine developing material particles obtained by the above method are regular, fine and uniform up to 6-8 μm, have high charge and stability at 20-30 μc / g, and good fluidity above 70%.

Owner:天津复印技术研究所有限公司

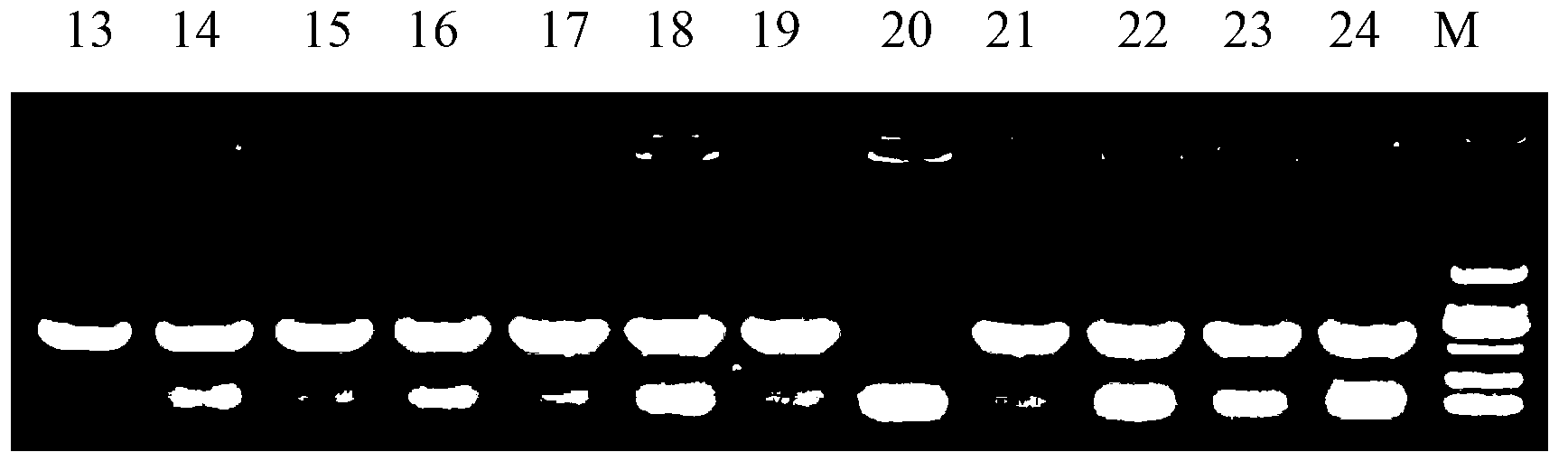

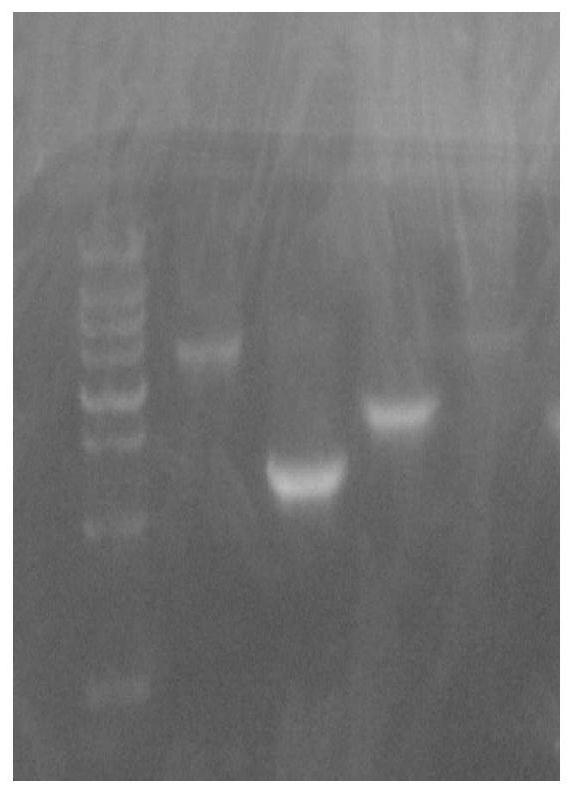

HPV16L1-g protein and coding gene and application thereof

ActiveCN103265627BEfficient and stable expressionParticle integrityFungiViral antigen ingredientsImmunogenicityDrug biological activity

Owner:BEIJING MINHAI BIOTECH

Physical method for preparing low-smoke and halogen-free polyolefin flame retardant, aluminum hydroxide

A physical method for preparing a low-smoke and halogen-free polyolefin flame retardant, aluminum hydroxide is characterized by comprising steps as follows: S1, preparation of a semi-finished product, namely, crude aluminum hydroxide granule powder; S2, preparation of fine aluminum hydroxide granule powder; S3, post-treatment. The steps are concise, the method is energy-saving and environment-friendly, obtained aluminum hydroxide granules are regular in shape and large in yield and are uniformly mixed and distributed, and the yield in every hour exceeds 500 kg.

Owner:JINGJIANG CHENYANG CHEM CO LTD

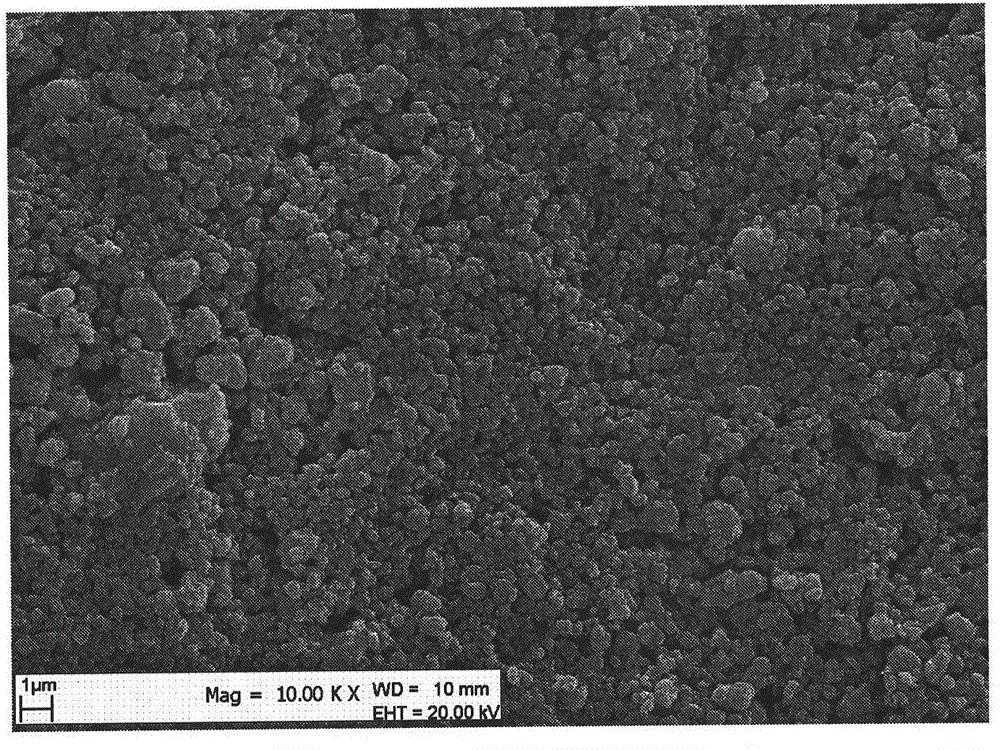

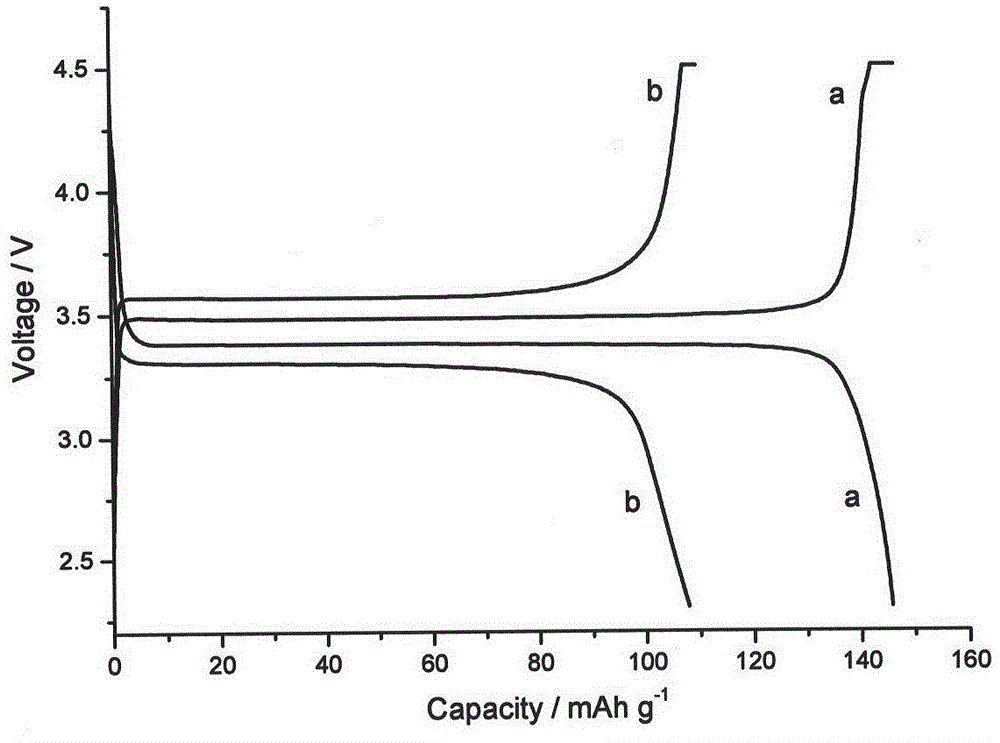

Preparation method of lithium iron phosphate/lithium vanadium phosphate composite material

The invention relates to a preparation method of a lithium iron phosphate / lithium vanadium phosphate composite material. The method comprises the following steps: mixing iron phosphate and vanadium pentoxide which are utilized as raw materials with a lithium salt compound; adding a chelating agent; grinding and mixing; performing heat treatment in an inert atmosphere, and then adding a carbon source material; and heating, roasting and cooling to room temperature to obtain the carbon-coated lithium iron phosphate / lithium vanadium phosphate composite material. The lithium iron phosphate / lithiumvanadium phosphate composite material can be assembled into a testing battery of which the discharge specific capacity can reach 144mAh / g with the current of 150mA / g at room temperature and can reach105mAh / g with the current of 30mA / g at the temperature of minus 20 DEG C, the crystal form is complete, the particle appearance is regular, and excellent normal-temperature and low-temperature electrochemical performances are shown. All the raw materials in the method are bulk industrial chemicals, the cost is low, the process route is simple, the industrial scale production is easy to realize and the application prospect is very broad.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

HPV16L1-h protein and coding gene and application thereof

ActiveCN103265625BEfficient and stable expressionParticle integrityFungiViral antigen ingredientsVaccine ImmunogenicityDrug biological activity

The present invention provides a human papilloma virus 16 type L1 protein HPV16L1-h and a coding gene and application thereof. The amino acid sequence of the HPV16L1-h protein is shown as SEQ ID No. 2, and the coding gene is shown as SEQ ID No. 1 in a sequence table. The present invention also provides an HPV16L1-h recombinant expression vector. The HPV16L1-h protein provided by the present invention has good immunogenicity, no potential carcinogenic risk, has good safety, immunological characteristics and biological activity, can be prepared and purified in a large scale, can be used for preparing a vaccine for preventing cervical cancer and drugs for treating cervical cancer, and has good economic values and application prospects.

Owner:BEIJING MINHAI BIOTECH

A recycling processing device and processing method for large plastic parts

ActiveCN106493876BReduce energy consumptionReduce noisePlastic recyclingSmall footprintPulp and paper industry

The invention provides a large plastic part recycling processing device and a processing method. The processing device comprises a fixing support, a drying tank, a vacuum pump, a hot-melting dicing device and a material storage tank, the middle of the fixing support is provided with an opening, and the two sides of the drying tank are each provided with a connecting convex table; and the drying tank is erected at the opening of the fixing support through the connecting convex tables at the two sides, the connecting convex tables are connected with the fixing support through fastening bolts, the bottom of the drying tank is provided with the hot-melting dicing device, the material storage tank is connected to the lower portion of the drying tank, the portions, at the outer side of the joint, of the drying tank and the material storage tank are connected through fastening bolts, the vacuum pump is connected to one side of the drying tank, and the vacuum pump is placed on the fixing support. The large plastic part recycling processing device has the beneficial effects that energy consumption is reduced, noise is small, crushed particles are regular, and the occupied area is small.

Owner:TIANJIN LAIWO VACUUM DRYING EQUIP MFG CO LTD

Preparation method for salinomycin sodium fine granular formulation

ActiveCN101366461BGuaranteed contentAvoid it happening againAnimal feeding stuffAccessory food factorsPrillSide effect

The invention relates to a method for preparing salinomycin sodium micro-granules, which comprises the steps of feed liquid preparation, spray drying and powder mixing packaging. A feed liquid is prepared by adding sodium hydroxide, calcium carbonate and a small quantity of carboxy methyl cellulose into a zymotic fluid to ensure that the pH value of the zymotic fluid is alkaline and contributes to the stability of the intermediate process and a final product, the feed liquid enters a spraygun through the pressure increase of a screw pump, and only a few seconds are spent to convert liquid drops into granules, thereby avoiding the pasting of materials and the production of substances containing toxic side effect at high temperature for a long time. The salinomycin sodium micro-granules prepared by the method are even and regular, thereby being mixed with feedstuff easily during the application, ensuring that animals have even and effective food intake, and avoiding the phenomenon that beasts and birds fail to intake or intake overmuch.

Owner:山东齐发药业有限公司

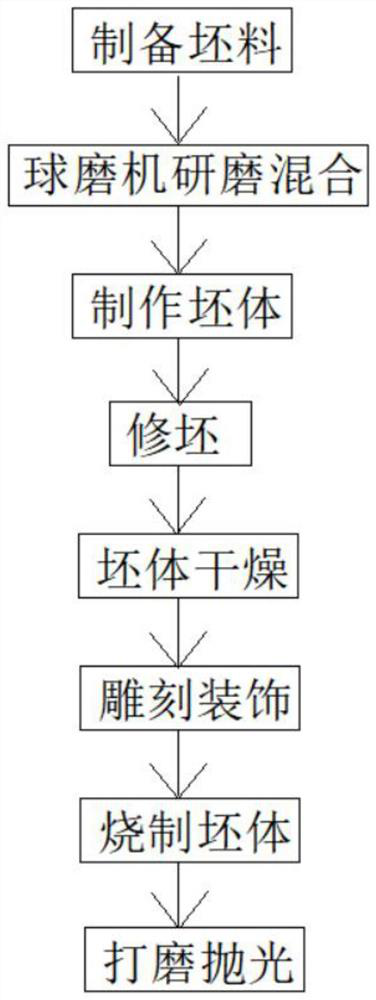

Nixing pottery rapid manufacturing process suitable for dry pressing molding

The invention discloses a Nixing pottery rapid manufacturing process suitable for dry pressing molding, which comprises the following steps: 1, preparing a blank material from the following raw materials in parts by weight: 40-60 parts of east mud, 20-40 parts of west mud, 15-30 parts of kaolin and 5-10 parts of silicon carbide particle by mixing and crushing to obtain pottery clay powder, 2, adding water into the argil powder obtained in the step 1, putting the argil powder and the water into a ball mill, and grinding and mixing to obtain powder with the water content of 10-20%, 3, manufacturing a green body, 4, carrying out fettling, 5, drying the green body, 6, carrying out carving decoration, 7, firing the green body, and 8, carrying out grinding and polishing by placing the Nixing pottery fired in the step 7 stably, rubbing and grinding the surface of the Nixing pottery once by adopting coarse stone, and then rubbing and grinding by adopting soft stone until the surface of the Nixing pottery is smooth as a mirror. The method is simple in process and short in consumed time, and the production efficiency is improved.

Owner:钦州市文承陶业文化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com