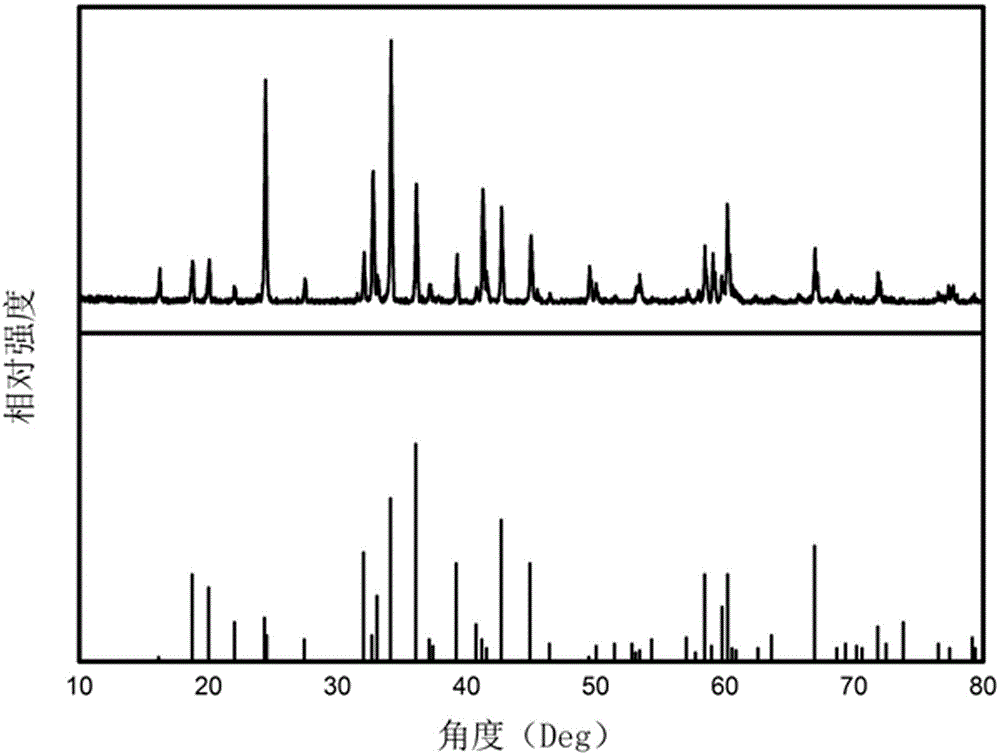

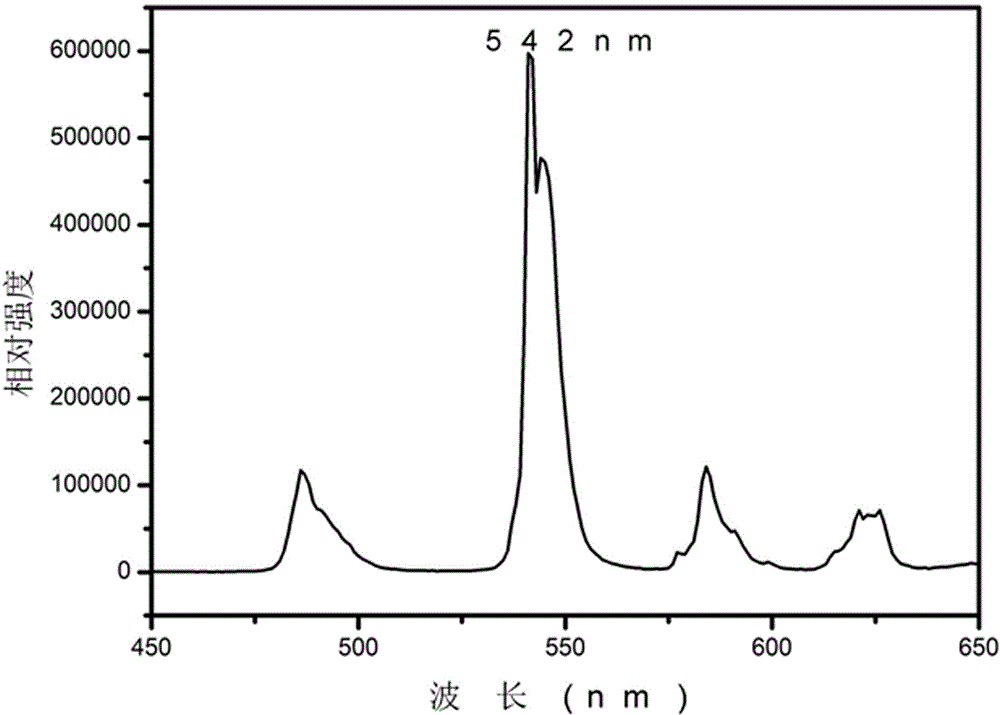

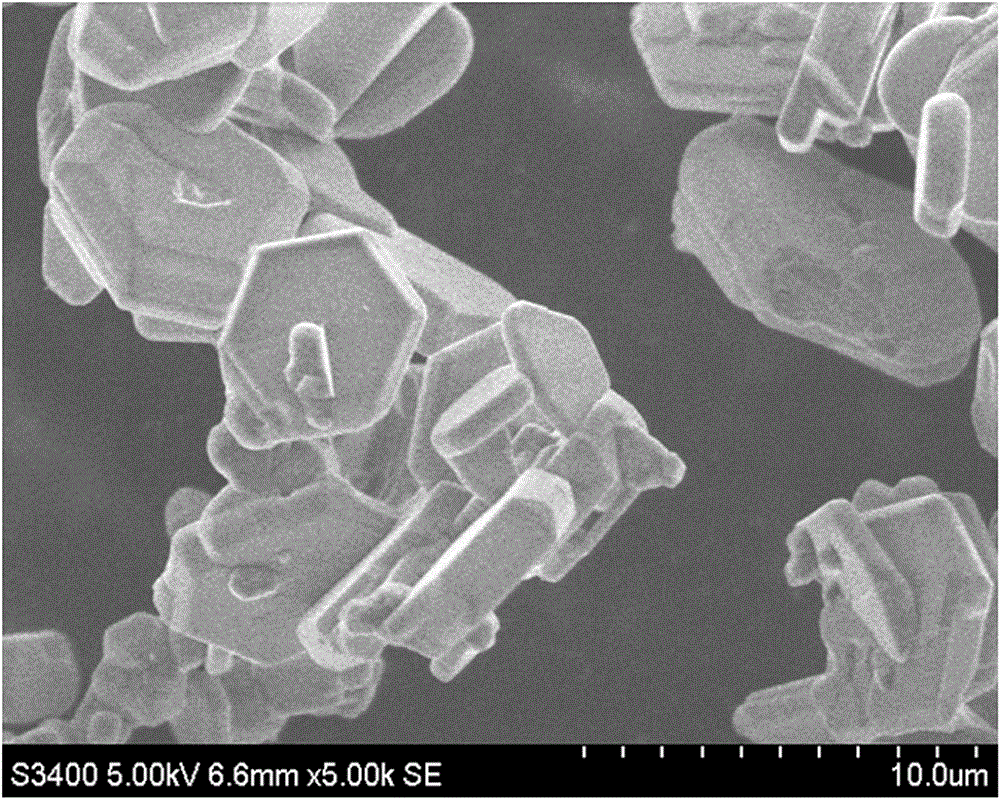

Preparation method for regular particle-shaped aluminate green emitting phosphor

A green phosphor, aluminate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult to achieve industrialization, low brightness of phosphors, low output rate, etc., and achieve regular particle morphology and preparation. Simple process and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to (Ce 0.63 Tb 0.37 )MgAl 11 o 19 Molecular formula weighs 0.4874gCeO respectively 2 , 0.3118gTb 4 o 7 , 0.1814gMgO, 2.5235gAl 2 o 3 , Weigh flux 0.007gH 3 BO 3 , 0.0701gLi 2 CO 3 , 0.1402gAlF 3 , put all the raw materials into an agate mortar and add an appropriate amount of alcohol to grind for 1 h; put the mixed raw materials into a crucible in an air atmosphere at 1500 ° C for 5 h, and cool to room temperature with the furnace to obtain the primary calcined product; grind and pulverize the primary calcined product After being placed in the crucible again, H 2 / N 2 Insulate at 1500°C for 3~5h in reducing atmosphere (reducing atmosphere used is changed from 10%H 2 and 90%N 2 composition), cooled to room temperature with the furnace to obtain the final calcined product; the final calcined product was ground and pulverized, washed, filtered, dried, and sieved (100 mesh) to obtain CMAT green phosphor.

Embodiment 2

[0022] According to (Ce 0.63 Tb 0.37 )MgAl 11 o 19 Molecular formula weighs 0.4874gCeO respectively 2 , 0.3118gTb 4 o 7 , 0.1814gMgO, 2.5235gAl 2 o 3 , Weigh flux 0.021gH 3 BO 3 , 0.0701gLi 2 CO 3 , 0.2102gAlF 3 , put all the raw materials into an agate mortar and add an appropriate amount of alcohol to grind for 1 hour; put the mixed raw materials into a crucible in an air atmosphere at 1550 ° C for 5 hours, and cool to room temperature with the furnace to obtain the primary calcined product; grind and pulverize the primary calcined product Placed in the crucible again, H 2 / N 2 Insulate at 1550°C for 3~5h in a reducing atmosphere (the reducing atmosphere used is changed from 10%H 2 and 90%N 2 composition), cooled to room temperature with the furnace to obtain the final calcined product; the final calcined product was ground and pulverized, washed, filtered, dried, and sieved (100 mesh) to obtain CMAT green phosphor.

Embodiment 3

[0024] According to (Ce 0.63 Tb 0.37 )MgAl 11 o 19 Molecular formula weighs 0.4874gCeO respectively 2 , 0.3118gTb 4 o 7 , 0.1814gMgO, 2.5235gAl 2 o 3 , Weigh flux 0.007gH 3 BO 3 , 0.1402gLi 2 CO 3 , 0.2102gAlF 3 , put all the raw materials into an agate mortar and add an appropriate amount of alcohol to grind for 1 h; put the mixed raw materials into a crucible in an air atmosphere at 1600 ° C for 5 h, and cool to room temperature with the furnace to obtain the primary calcined product; grind and pulverize the primary calcined product Placed in the crucible again, H 2 / N 2 Keep warm at 1600°C for 3~5h in a reducing atmosphere (the reducing atmosphere used is changed from 10%H 2 and 90%N 2 composition), cooled to room temperature with the furnace to obtain the final calcined product; the final calcined product was ground and pulverized, washed, filtered, dried, and sieved (100 mesh) to obtain CMAT green phosphor.

[0025] Table 1, the effect of different flux r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com