Patents

Literature

548results about How to "Morphological rules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

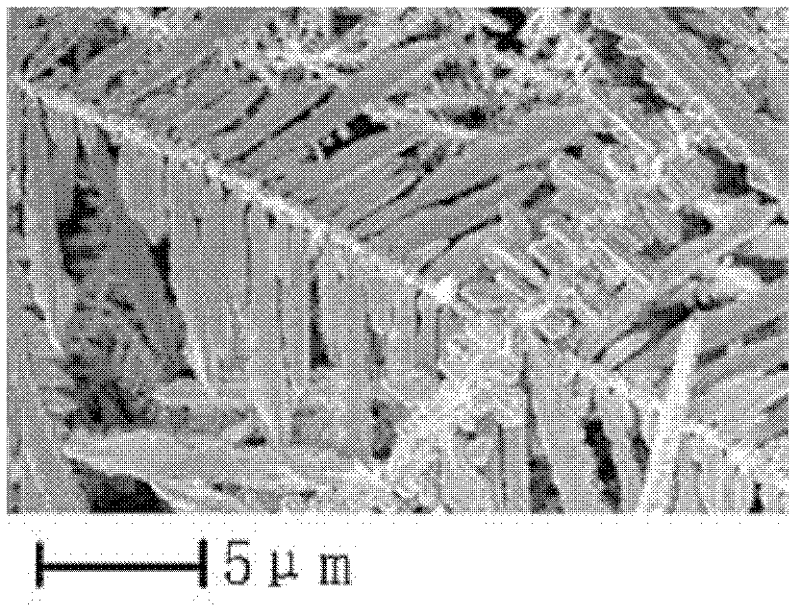

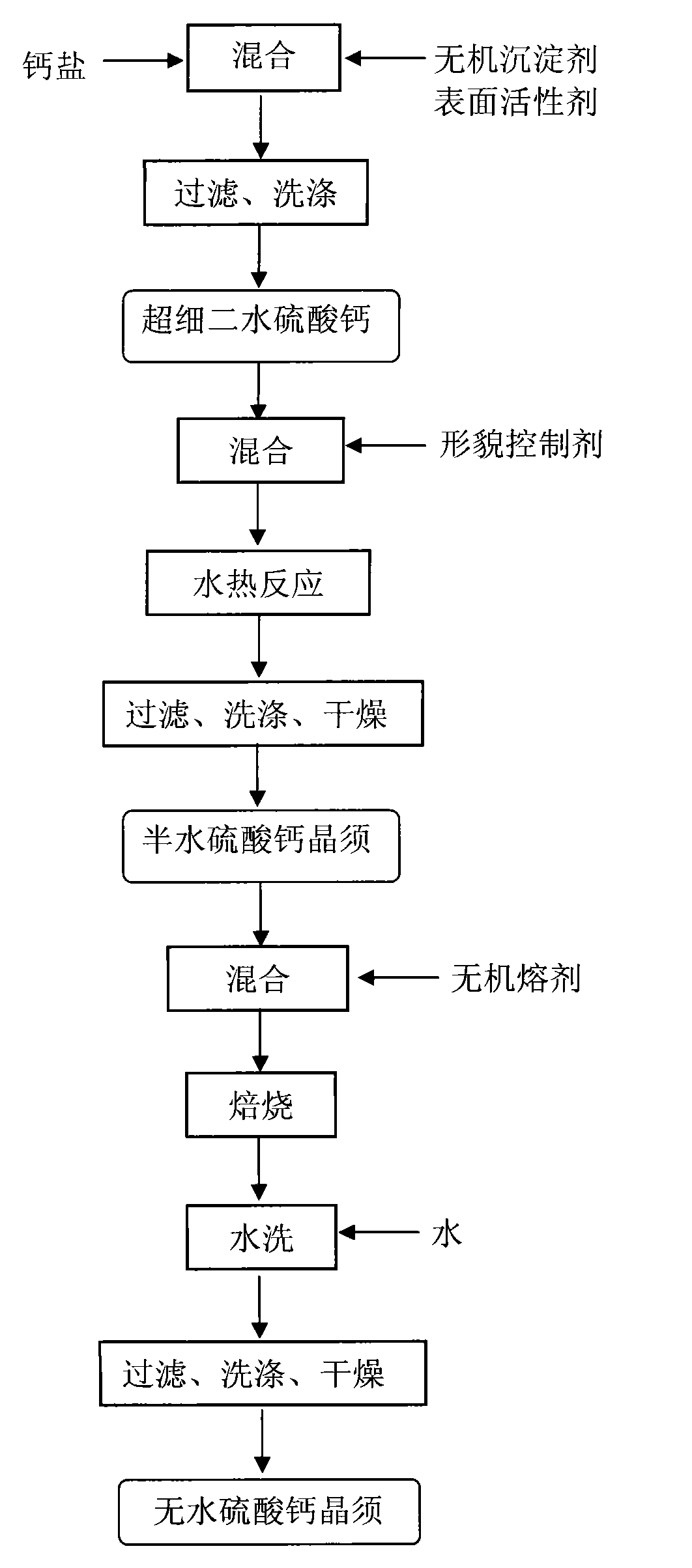

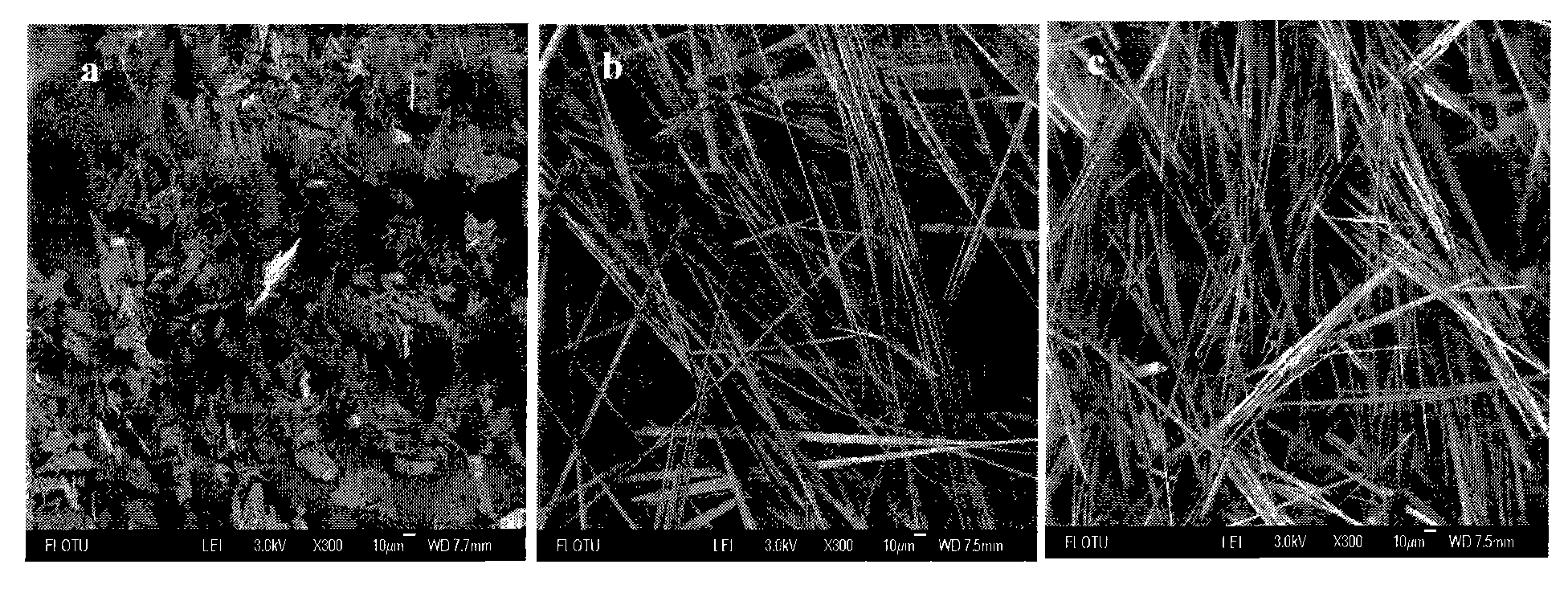

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

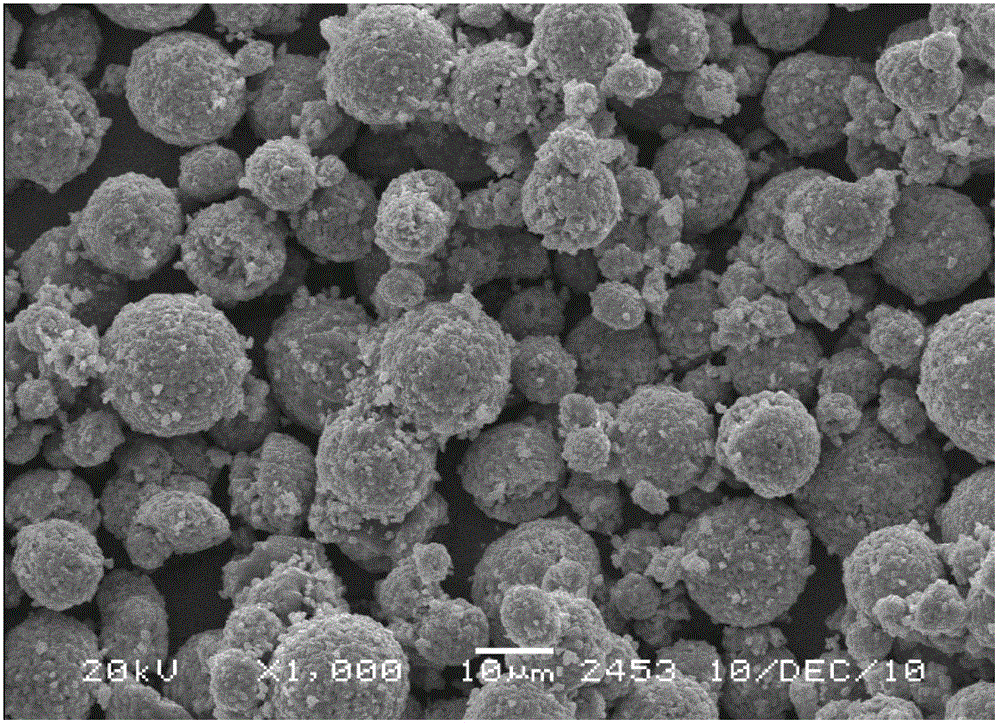

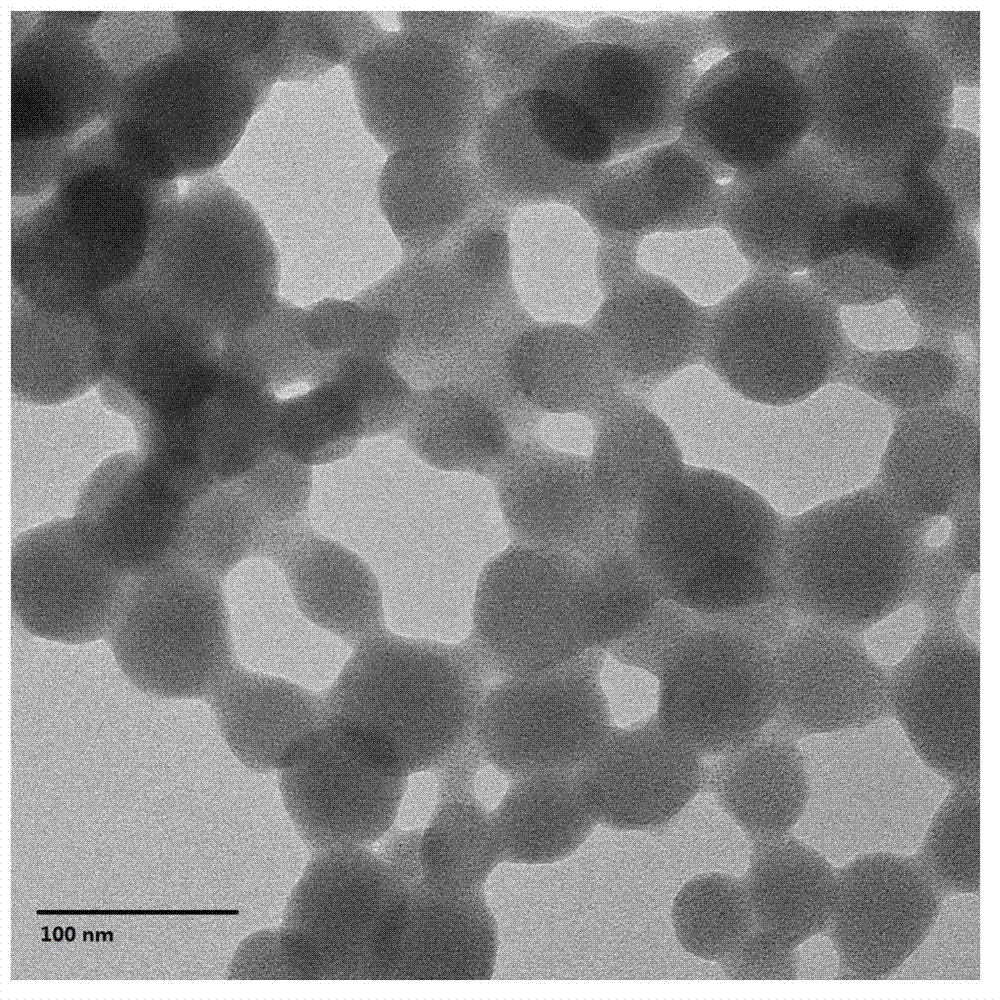

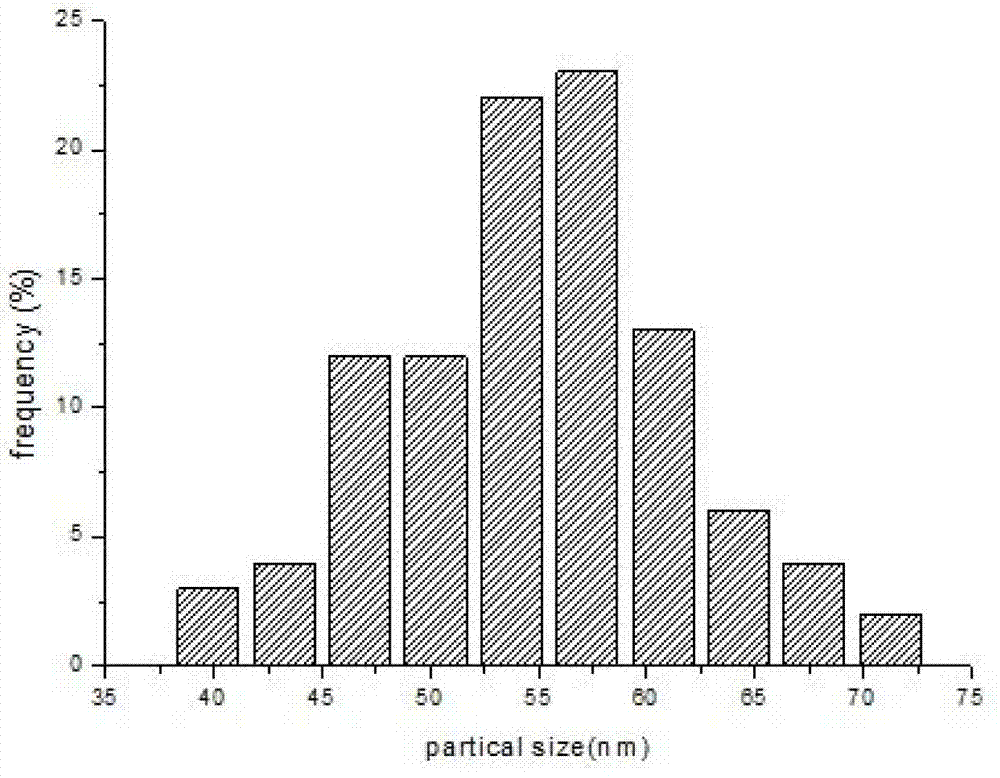

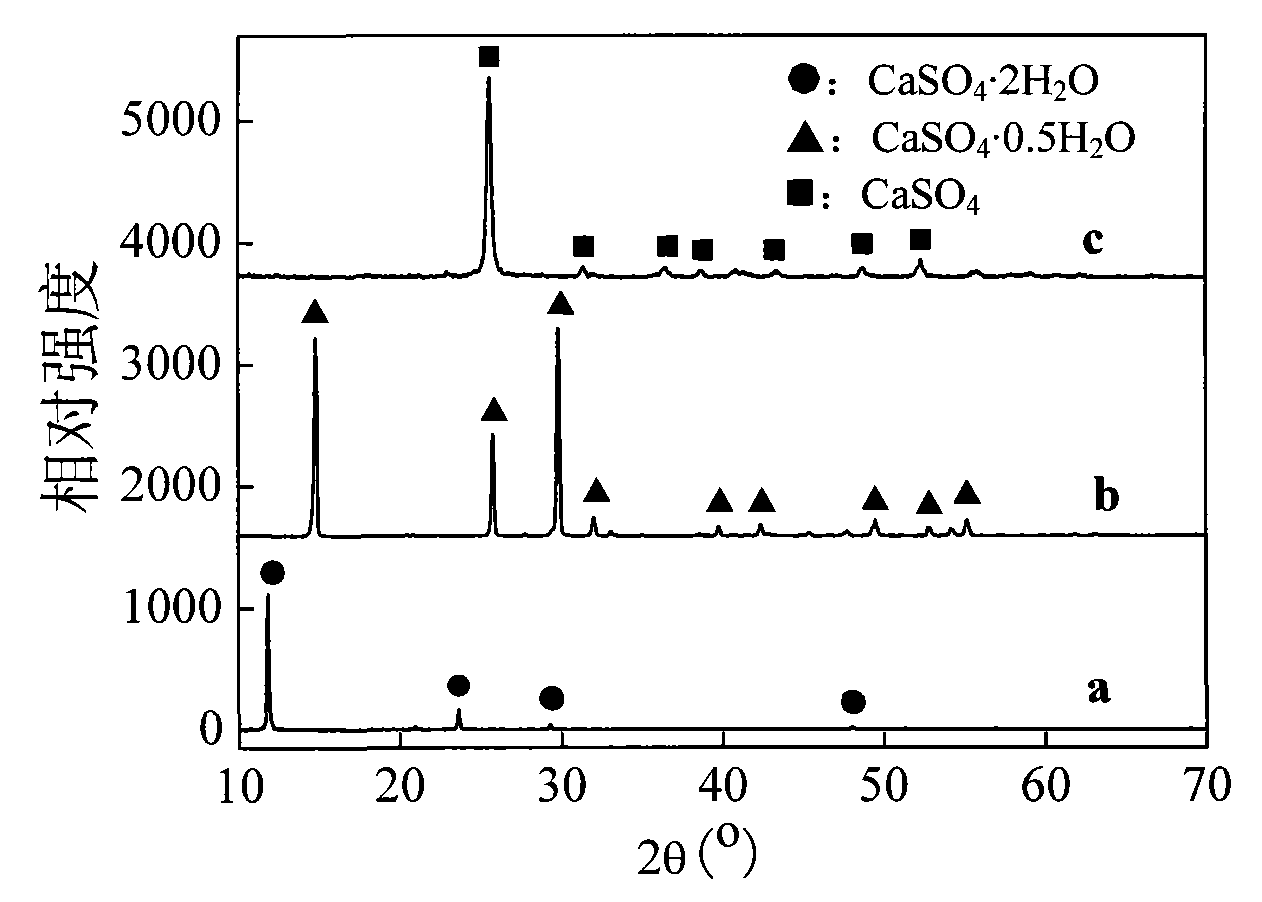

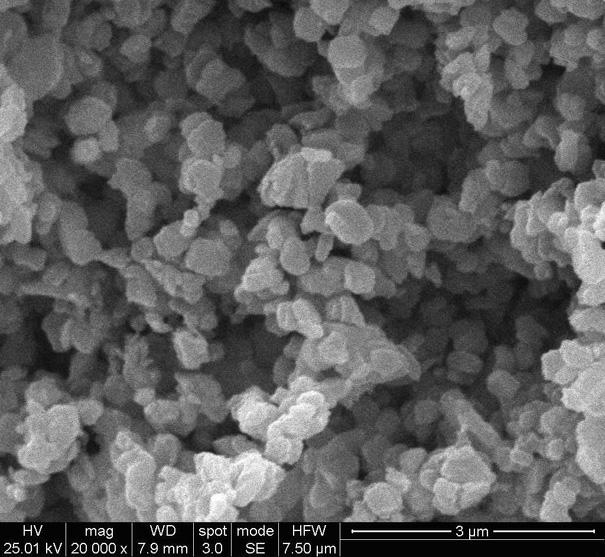

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

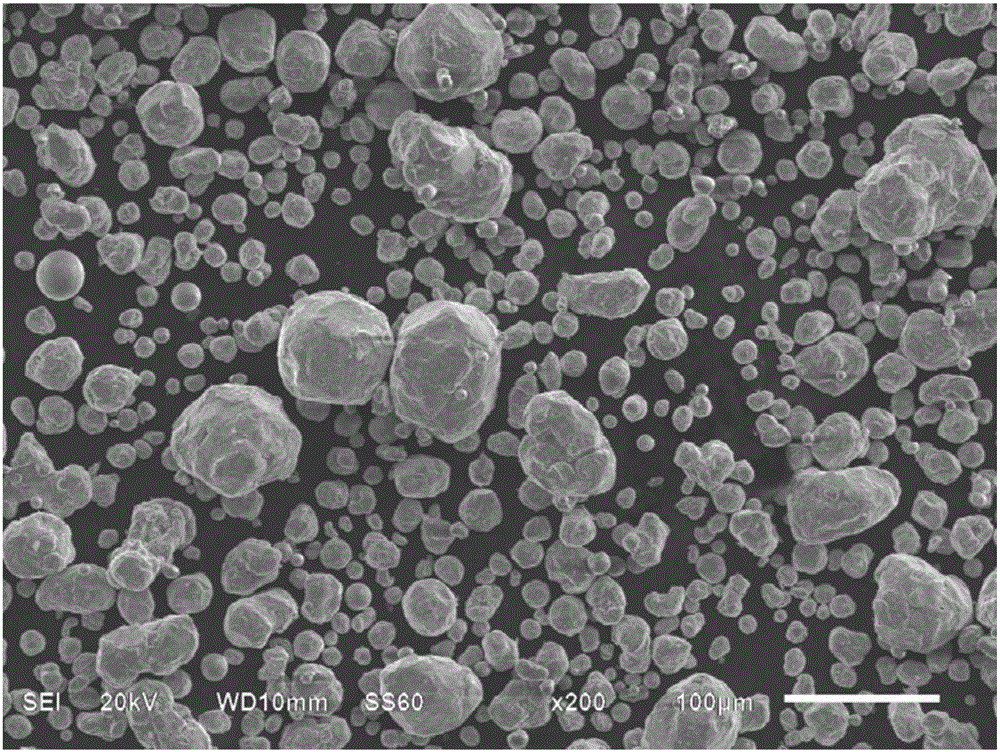

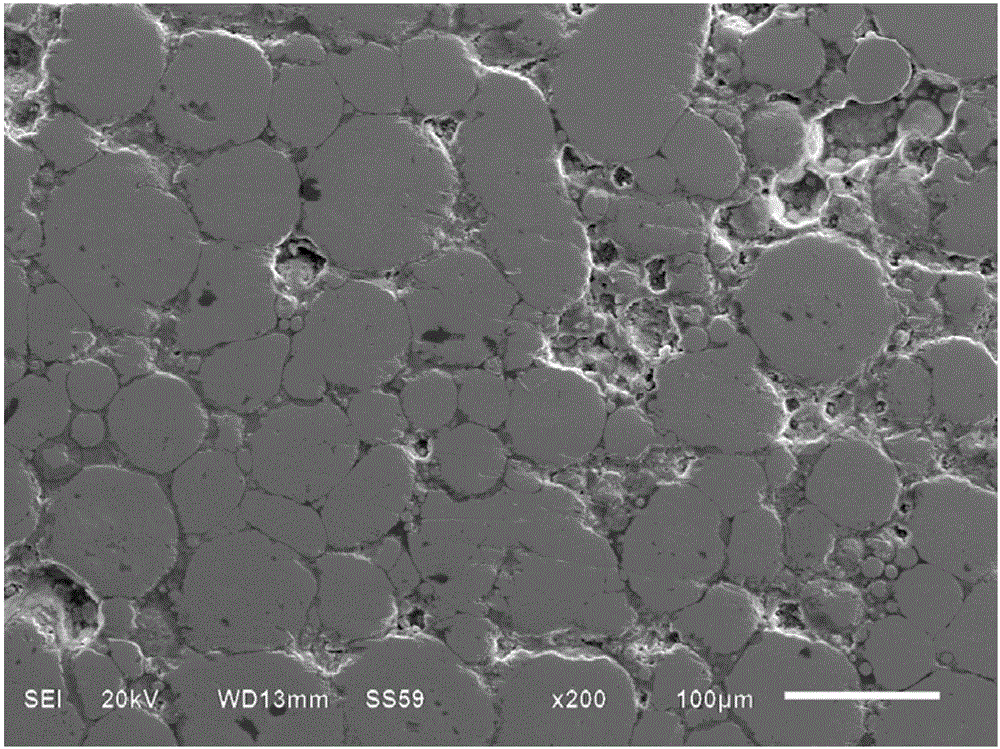

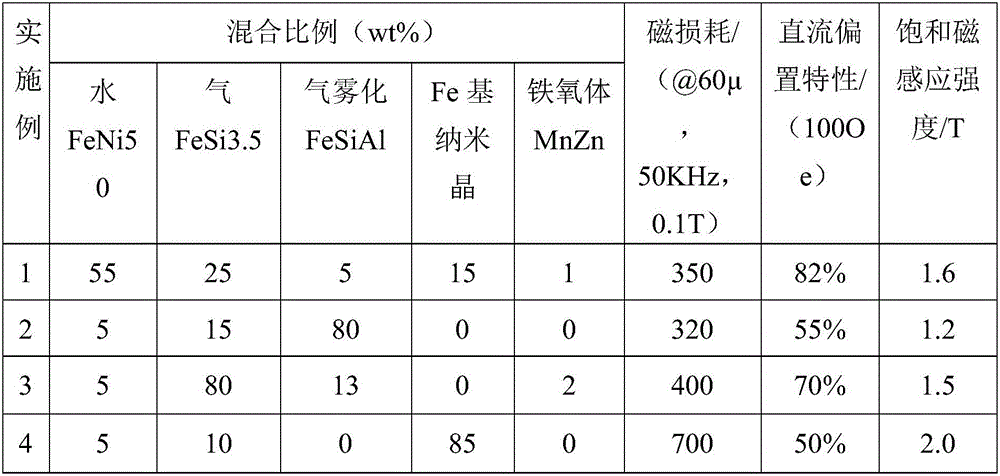

Soft magnetic composite powder and magnetic powder core preparation method thereof

InactiveCN106229104AHigh bulk densityCost-effectiveTransportation and packagingMetal-working apparatusPowder metallurgyMagnetic powder

The invention relates to soft magnetic composite powder and a magnetic powder core preparation method thereof, and belongs to the technical field of powder metallurgy and magnetic materials. According to different magnetic performance characteristics of metal soft magnetic powder, amorphous and nano-crystalline powder and ferrite powder, magnetic performances are linearly calculated and optimally designed, so that the requirements of different magnetic properties are met. Besides, powder sizes are calculated and coordinately designed, the powder is shaped, screened, annealed, coated in an insulated manner and mixed, and the powder with different components is respectively passivated and insulated, weighed according to weight ratio and uniformly mixed to form the composite powder. The prepared soft magnetic composite powder is regular in morphology and good in dispersity and has good apparent density and flowability. In addition, the magnetic performance of a magnetic powder core prepared from the soft magnetic composite powder can be calculated and designed as required, the magnetic powder core has high cost performance and good comprehensive magnetic performance, and the blank of the performance and application of an existing magnetic powder core is effectively filled in.

Owner:BEIJING COMPO ADVANCED TECH

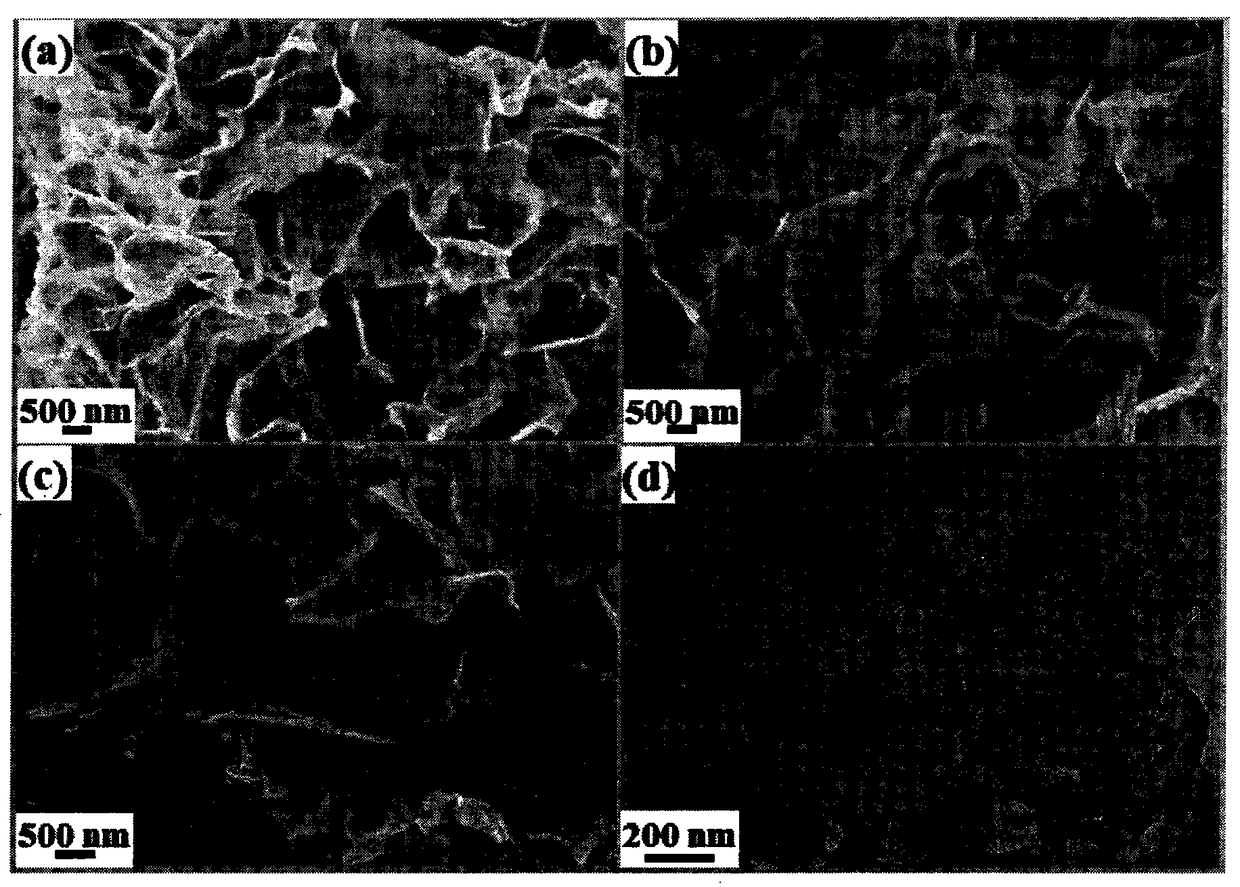

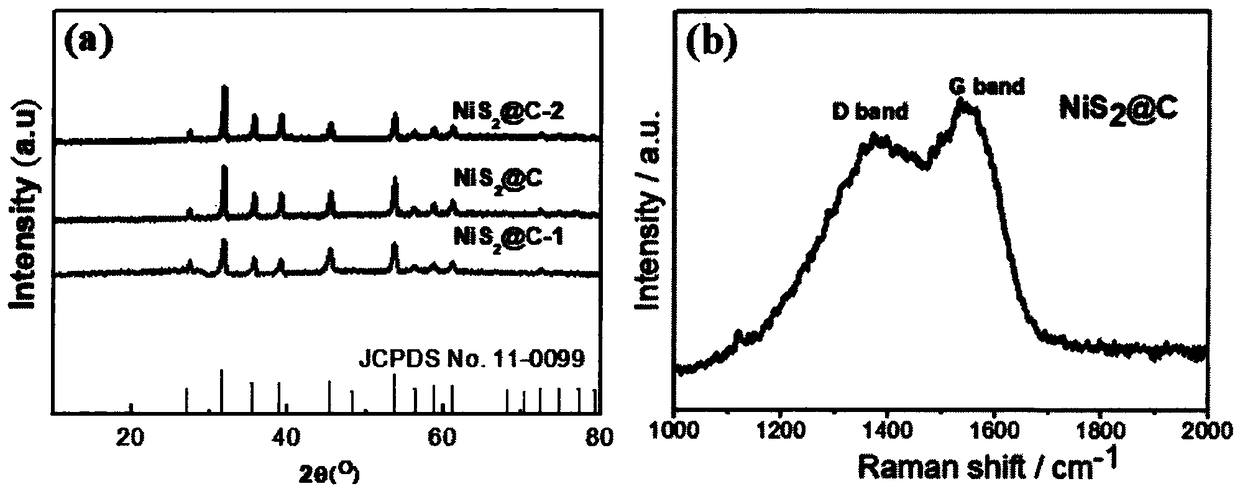

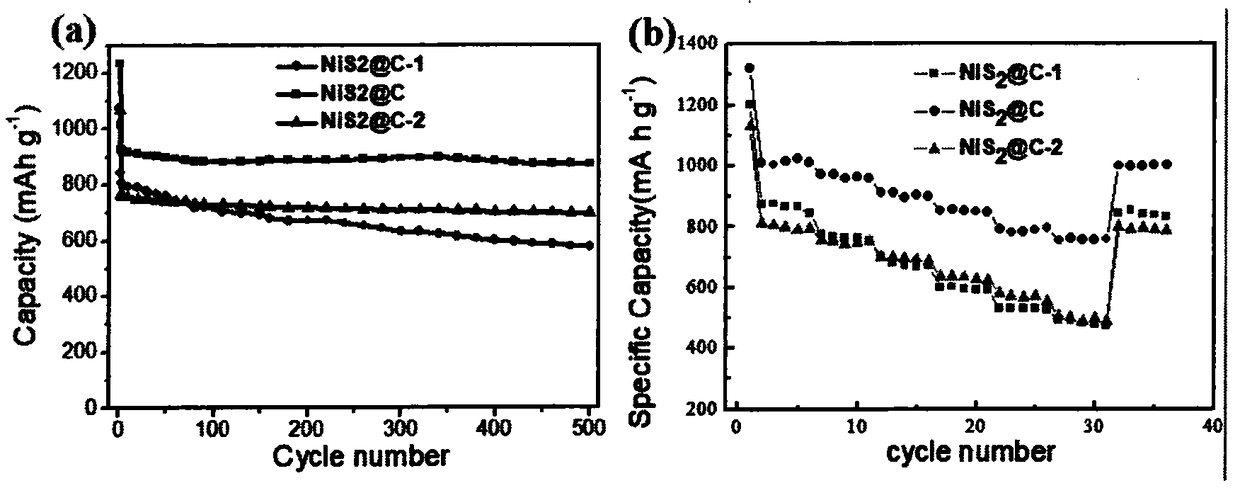

Nickel disulfide carbon nano composite material and preparation method and application thereof

InactiveCN108832097AGood biocompatibilityStrong adhesionMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesCarbon layer

The invention relates to a nickel disulfide carbon nano composite material and a preparation method and an application thereof, wherein the composite material is formed by coating a nickel disulfide nanosheet with a carbon layer. The preparation method comprises the following steps of preparing a nickel hydroxide nanosheet precursor by a hydrothermal method, performing magnetic stirring and dispersing in deionized water to obtain a uniform dispersion liquid of the nickel hydroxide nanosheet precursor, adding a buffering agent tris(hydroxymethyl) aminomethane hydrochloride, and adjusting the pHvalue to be 8.5 by adopting an alkali solution with the pH value of 13, adding dopamine hydrochloride, and magnetically stirring at room temperature for in-situ polymerization, and carrying out washing and centrifugally drying to obtain a nickel hydroxide nanosheet precursor / polydopamine composite material, and carrying out heat treatment and vulcanization with sublimed sulfur powder in a tubularfurnace in nitrogen atmosphere at a certain temperature to obtain the composite material. The preparation process is simple, easy to operate, green and non-toxic and friendly in material preparationprocess; and the prepared nickel disulfide carbon nano composite material is stable in structure, uniform in morphology and high in dispersion. The obtained nickel disulfide carbon nano composite material can be an ideal electrode material of a high-performance lithium ion battery, a supercapacitor and other new energy devices.

Owner:DONGHUA UNIV

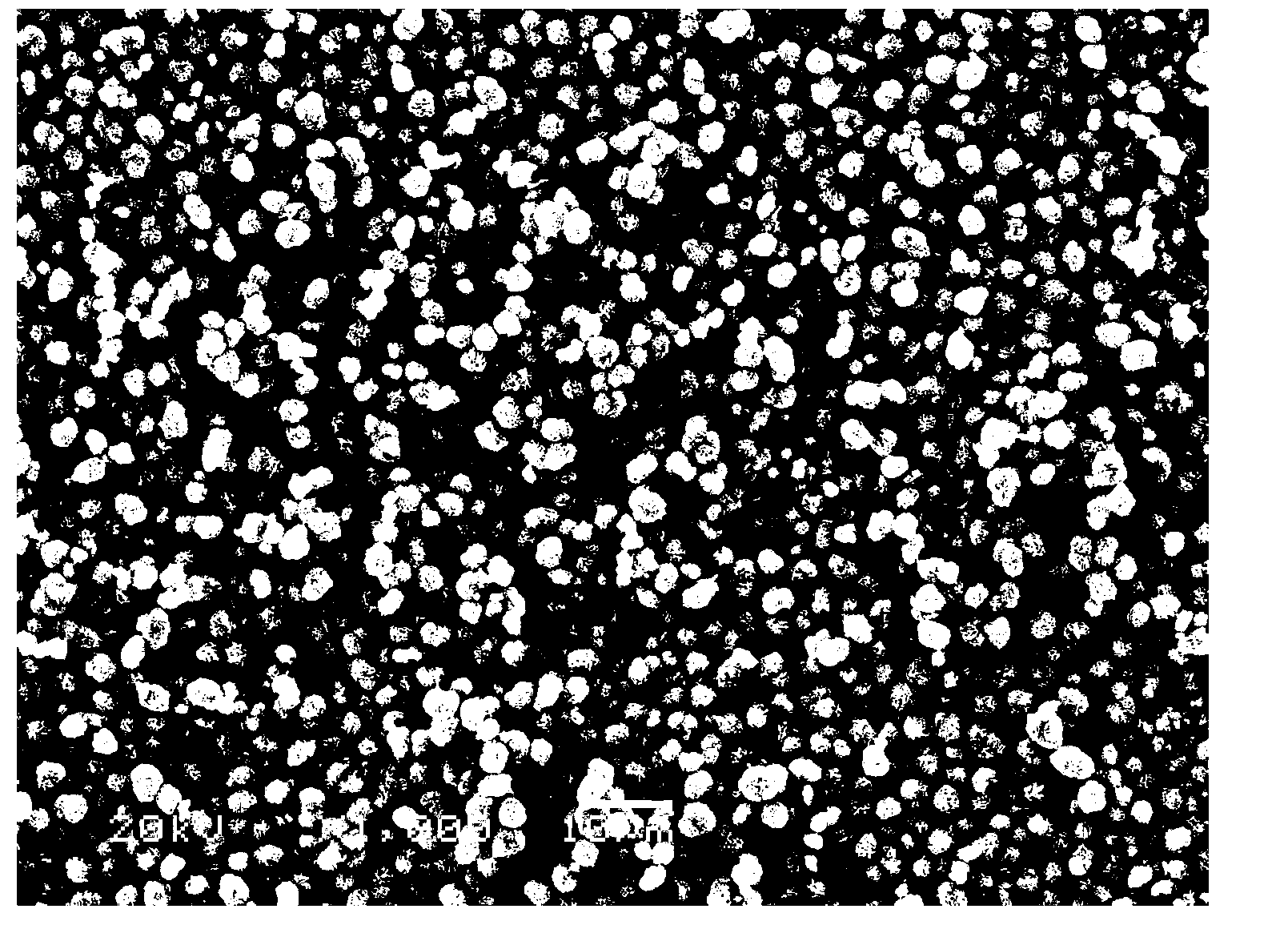

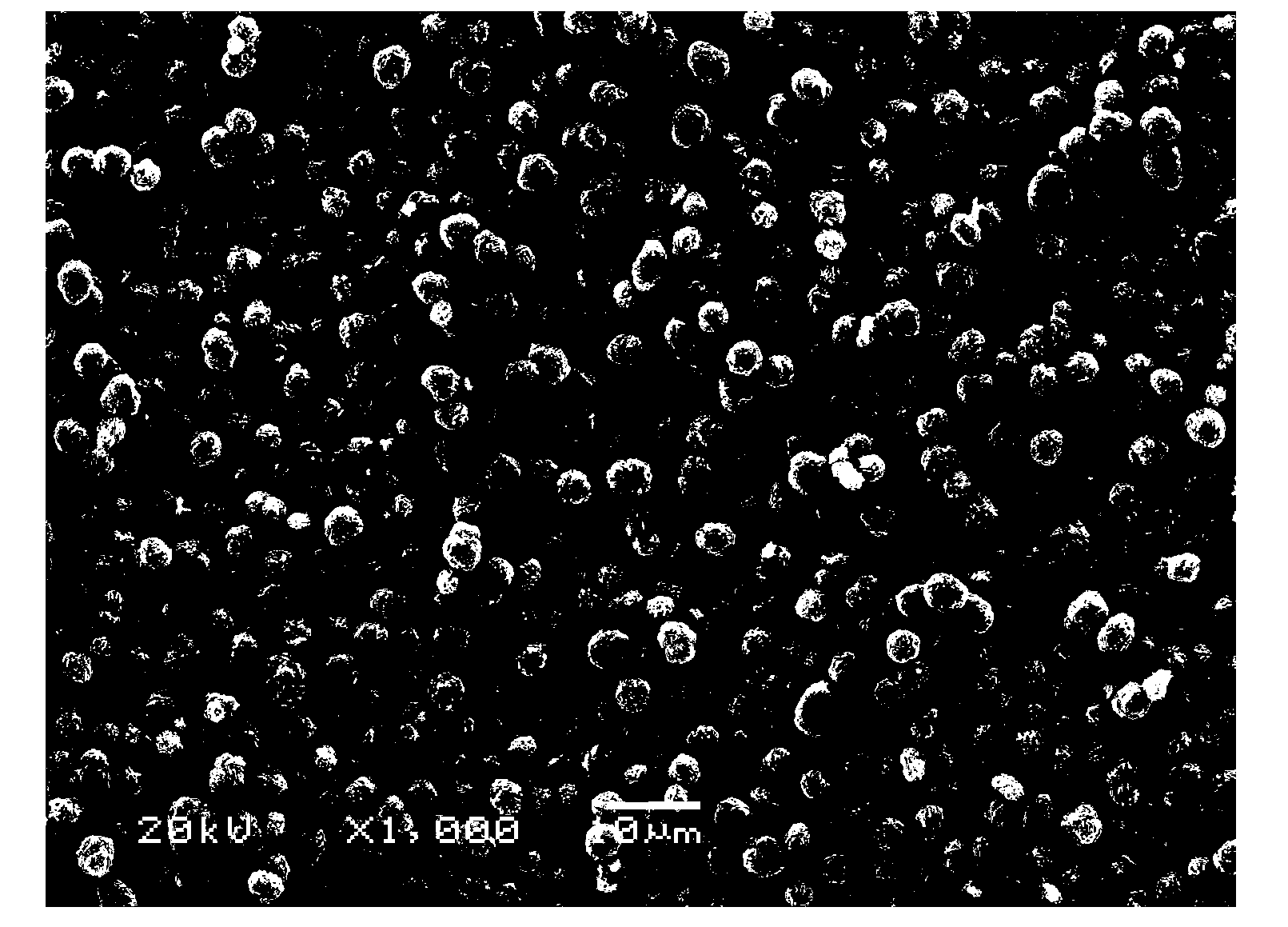

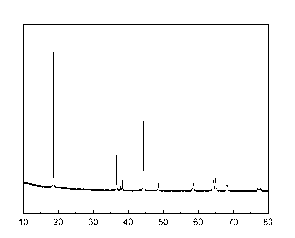

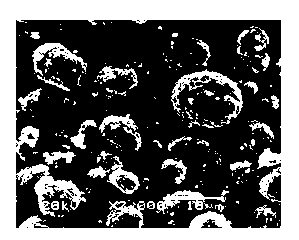

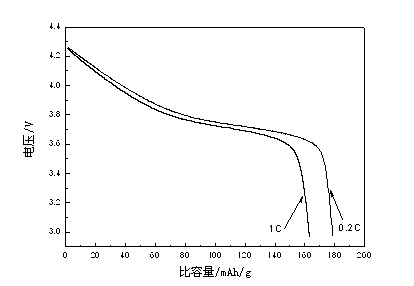

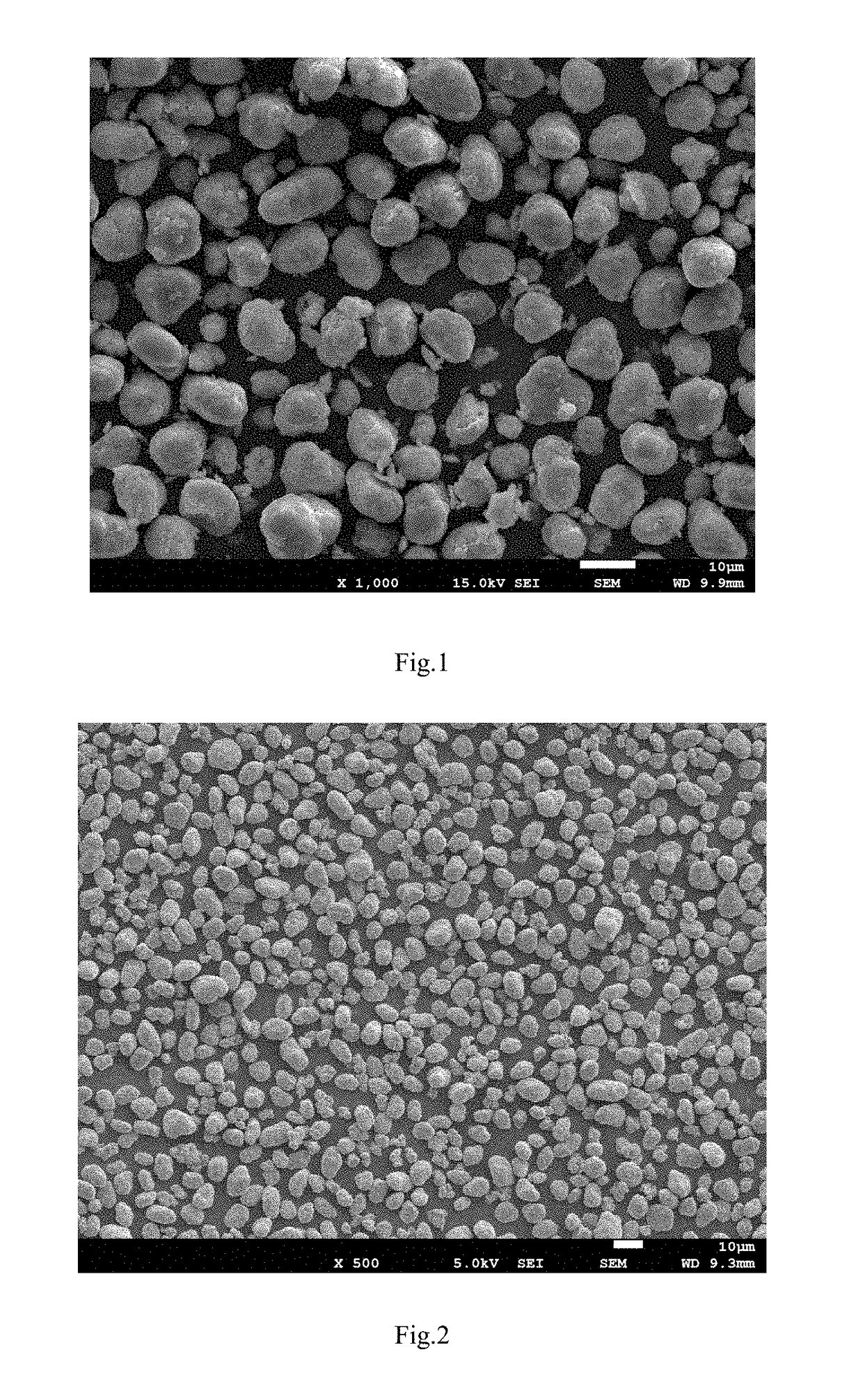

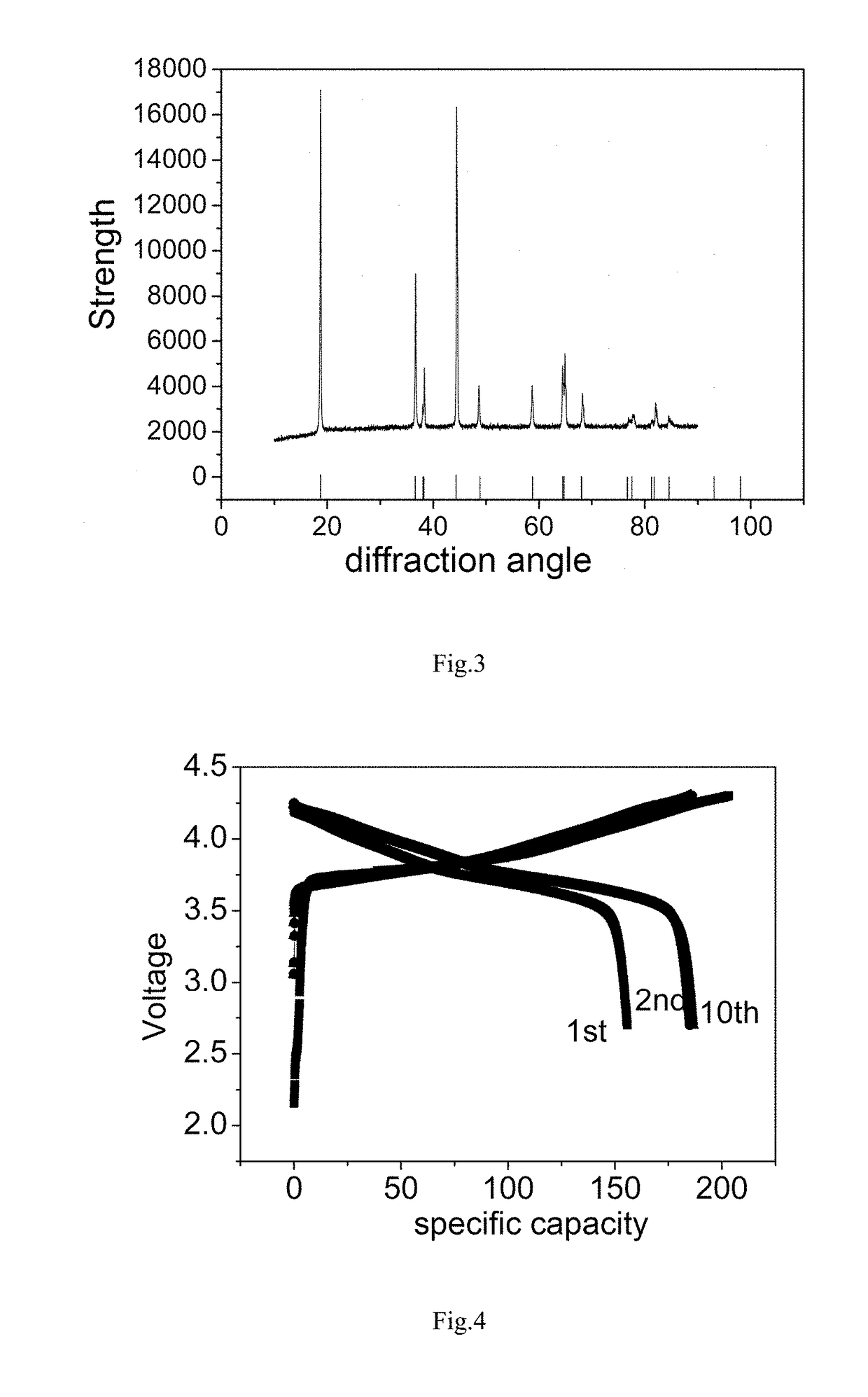

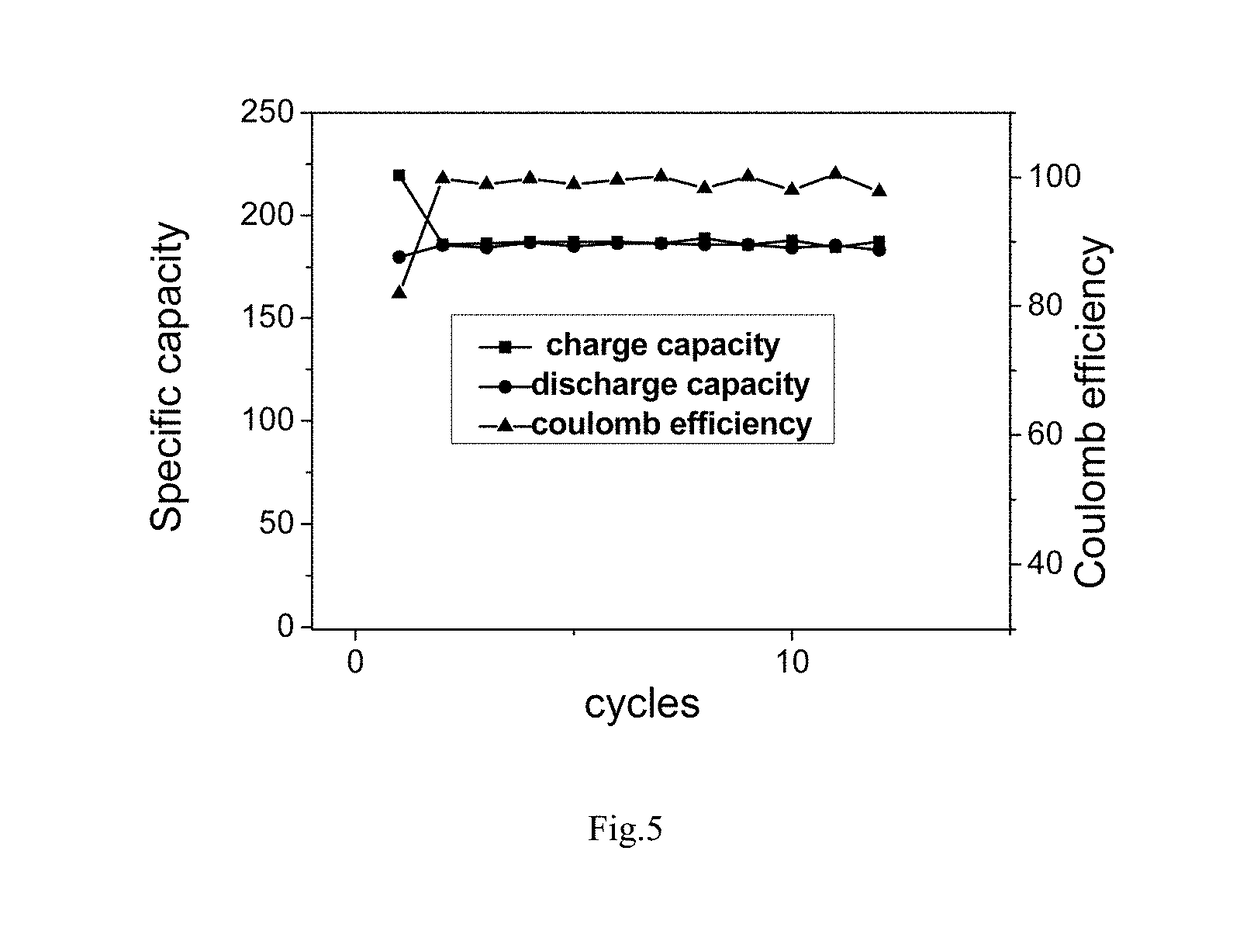

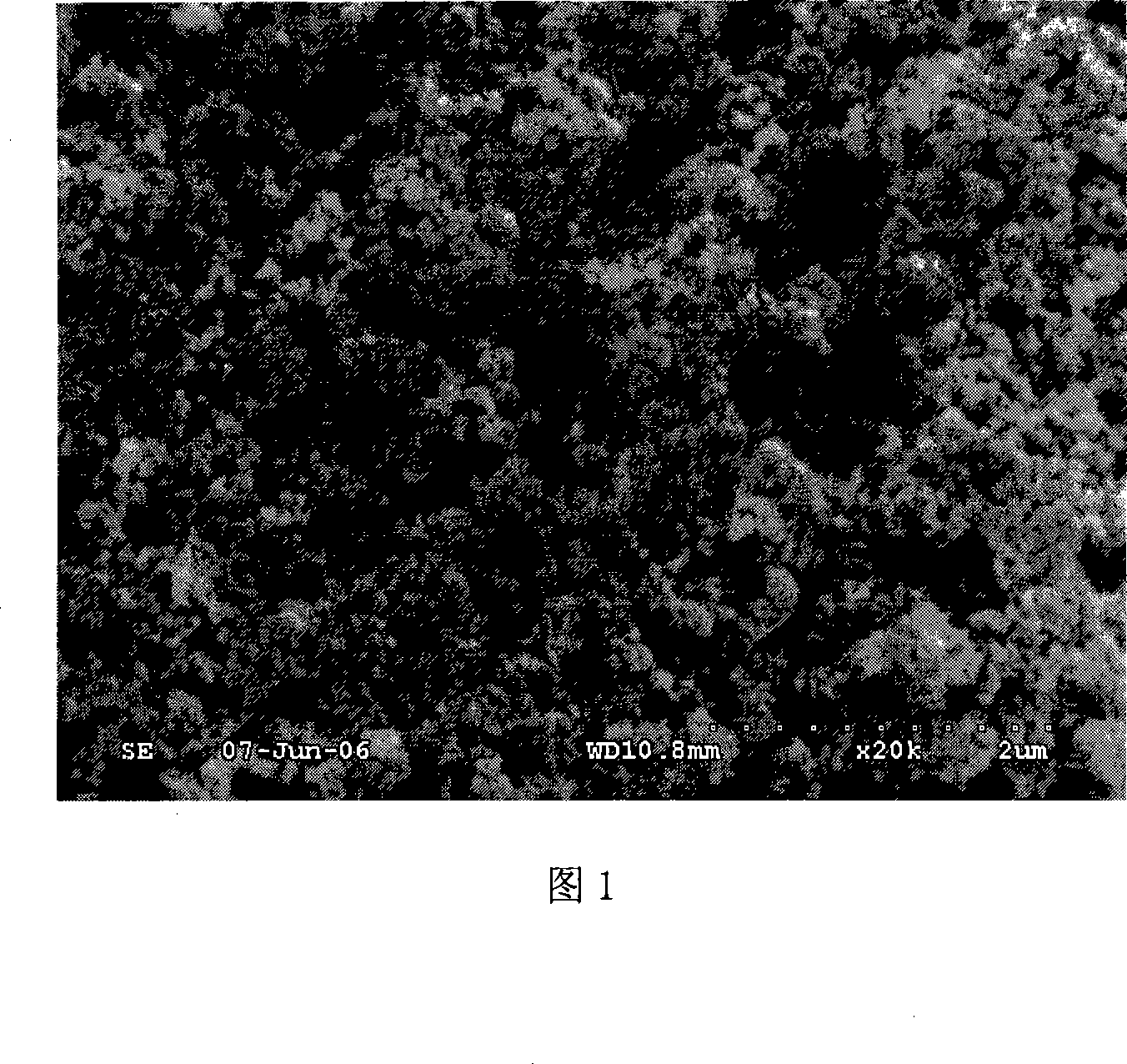

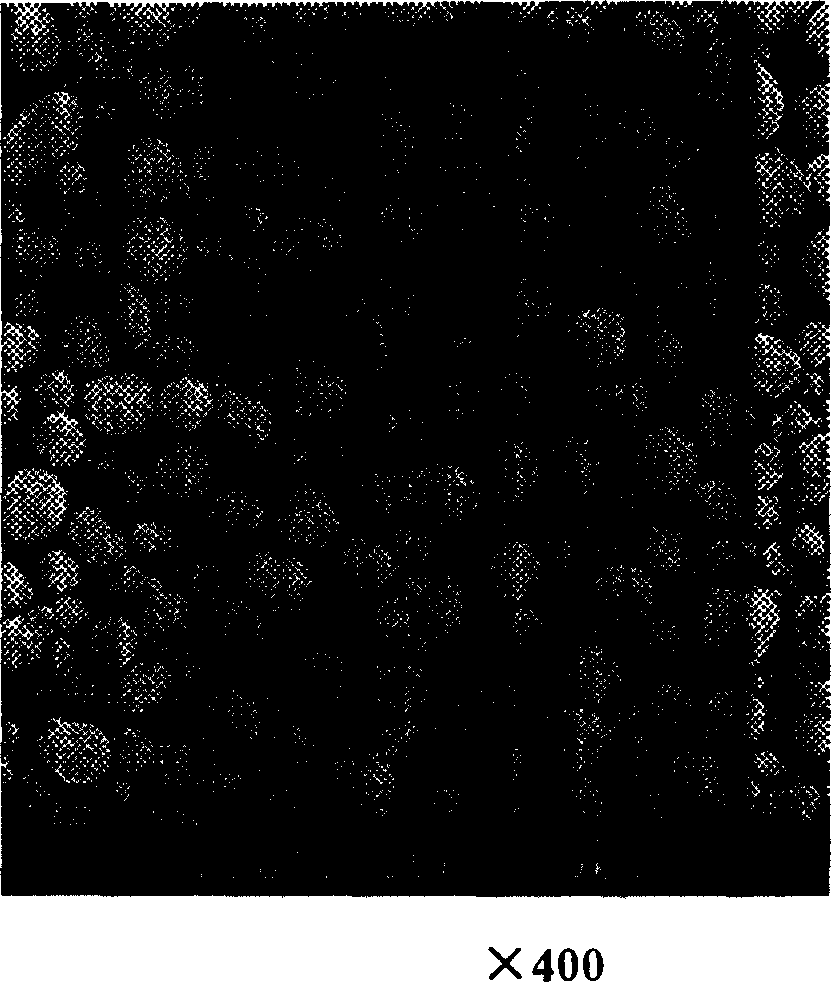

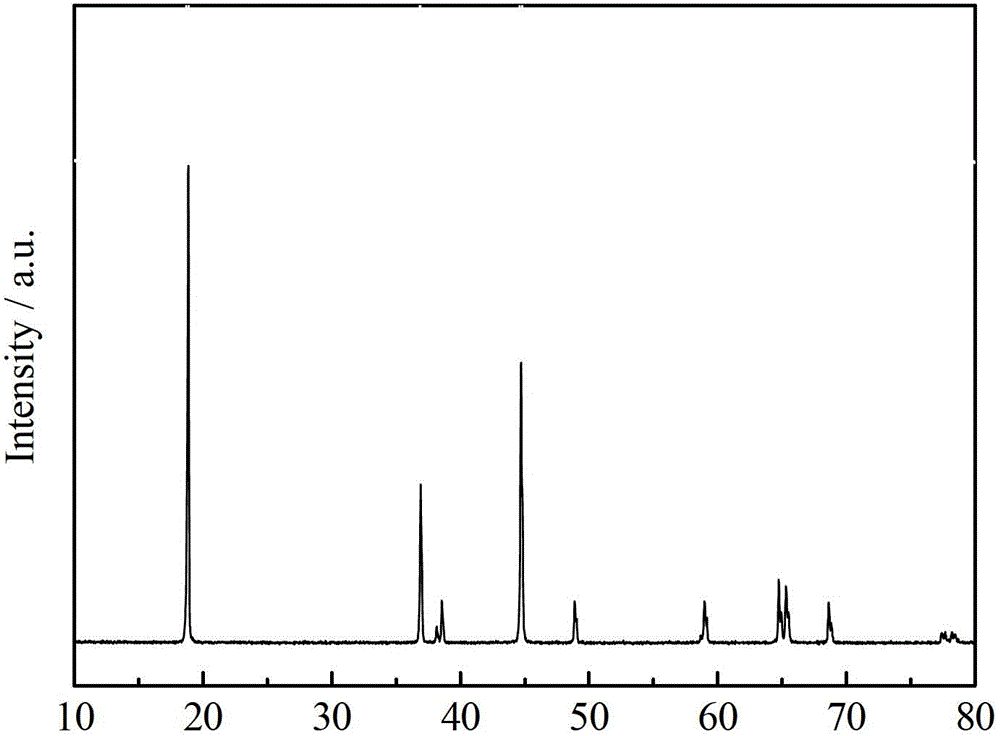

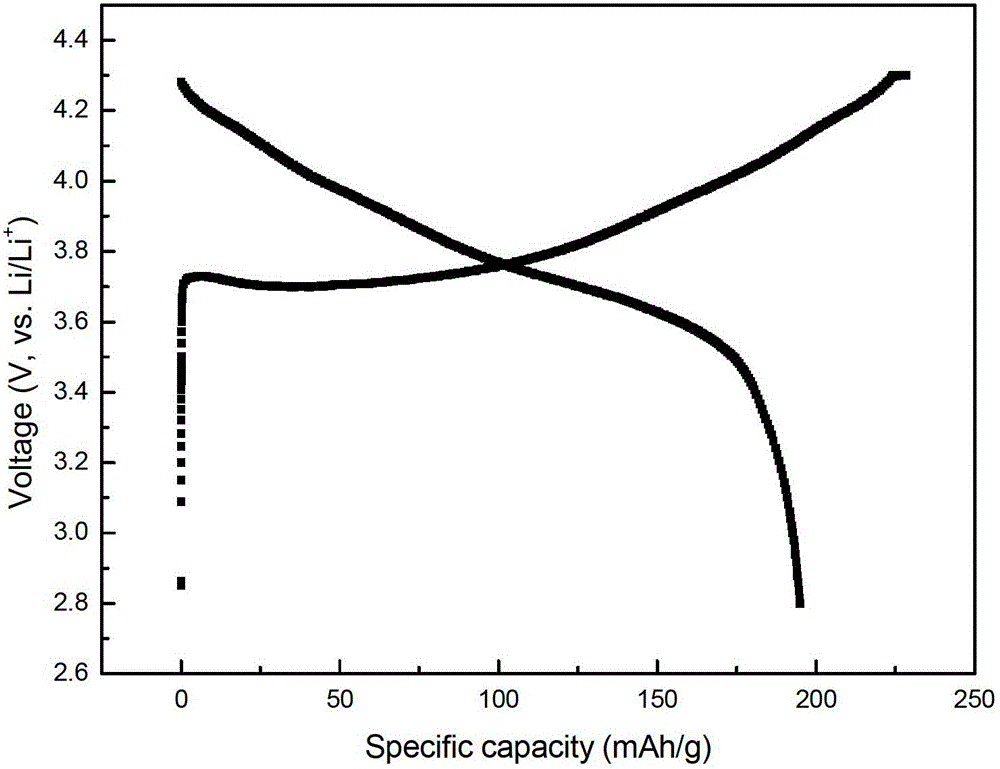

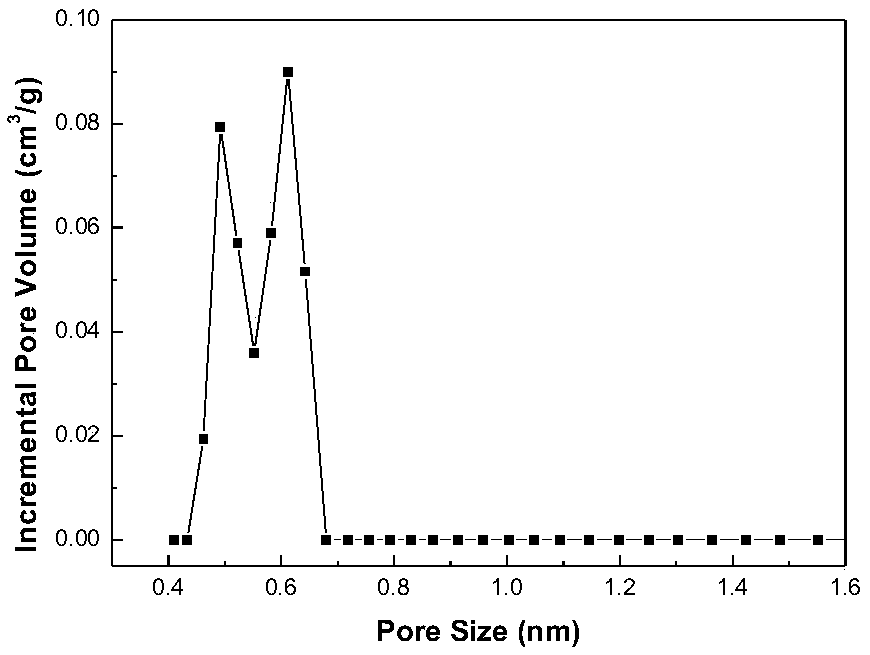

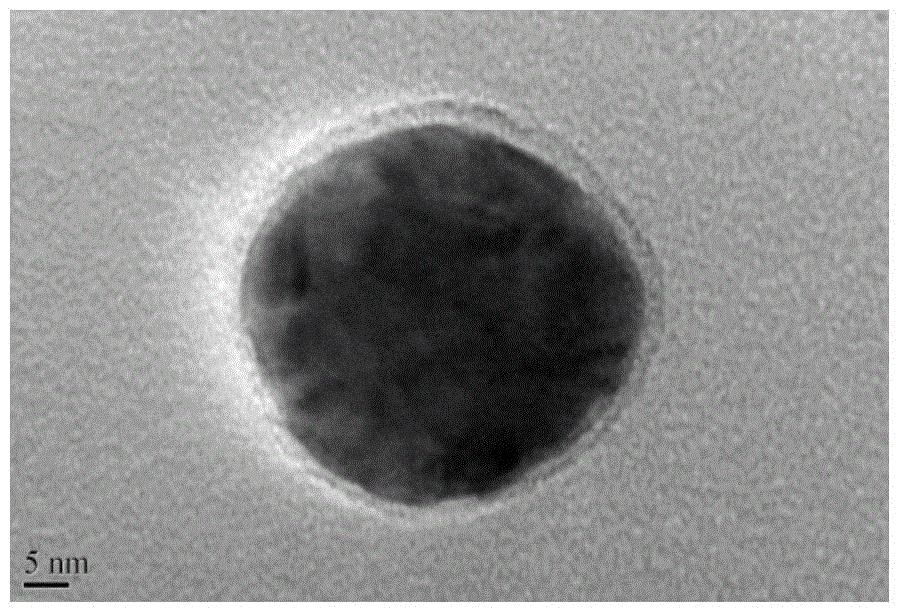

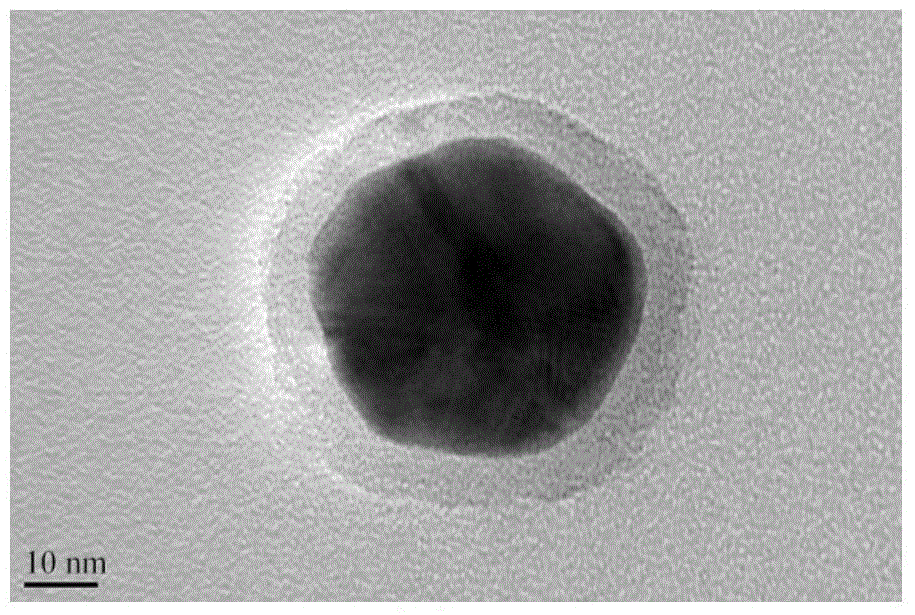

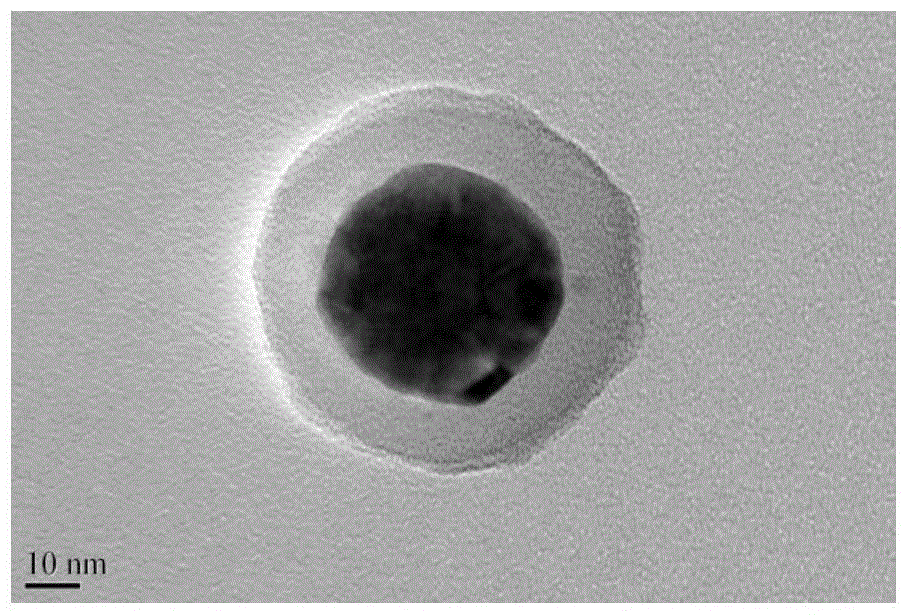

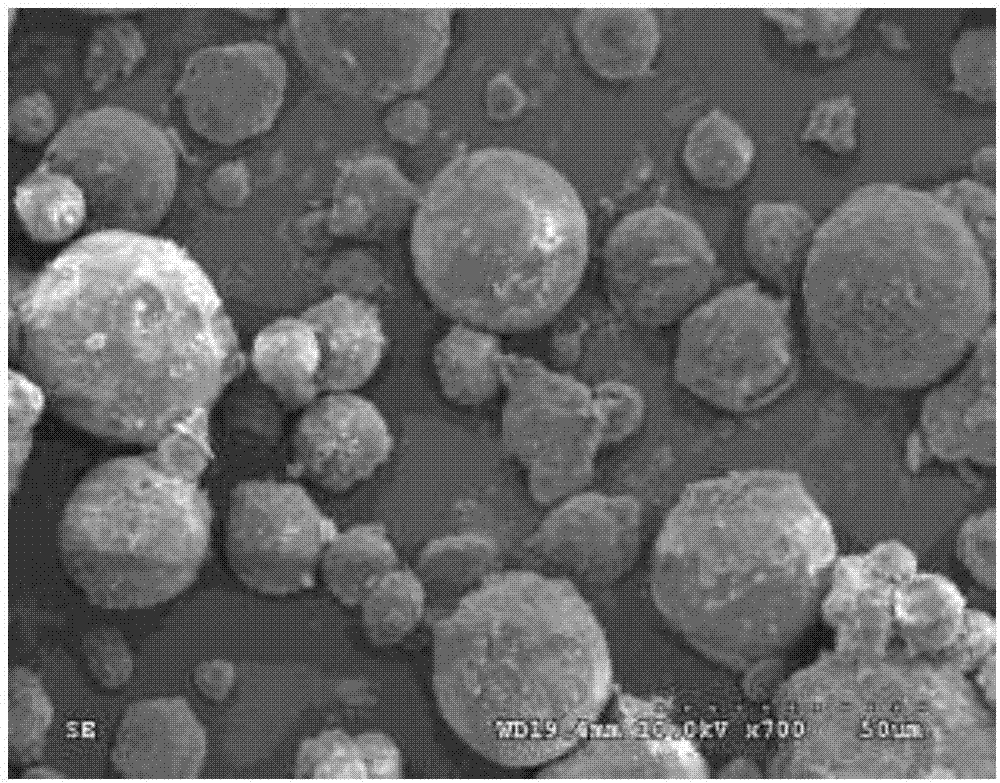

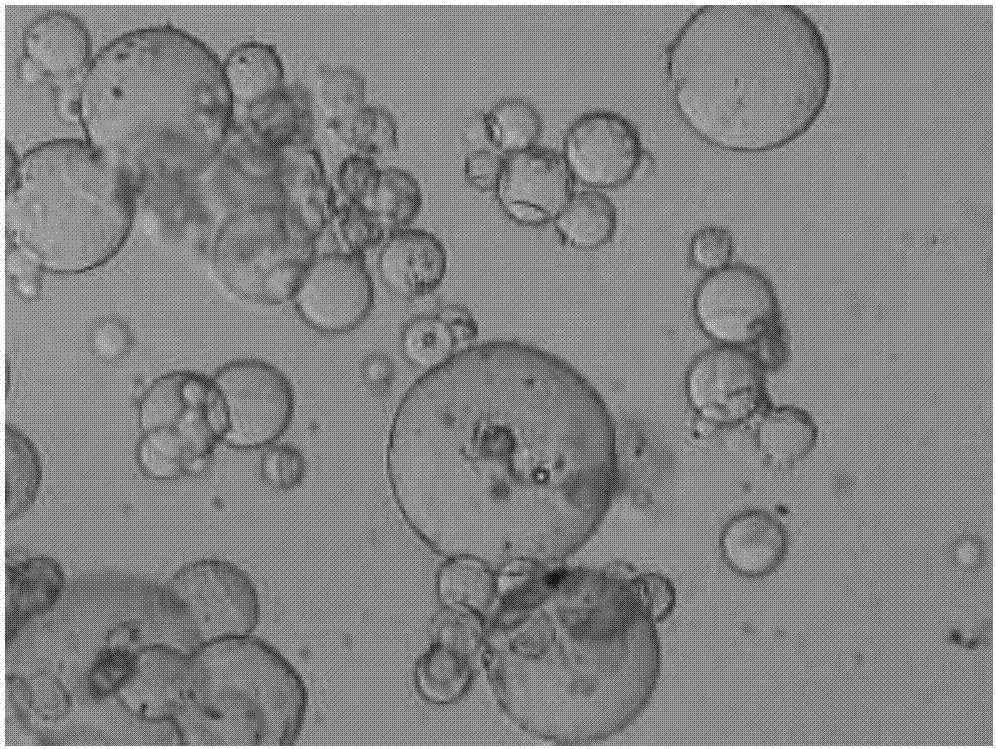

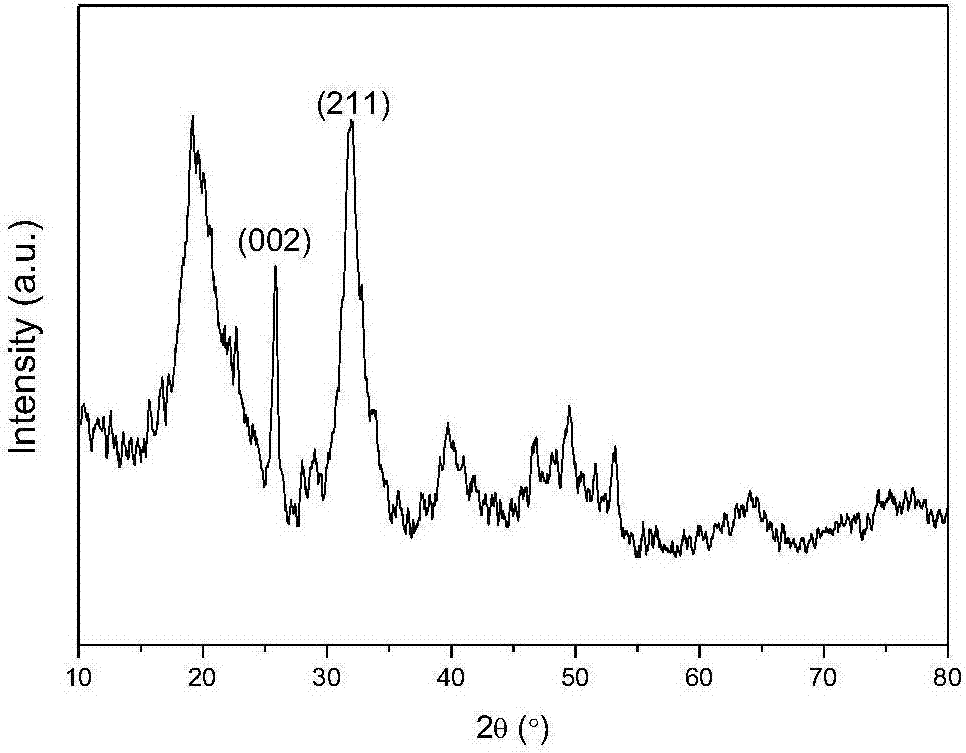

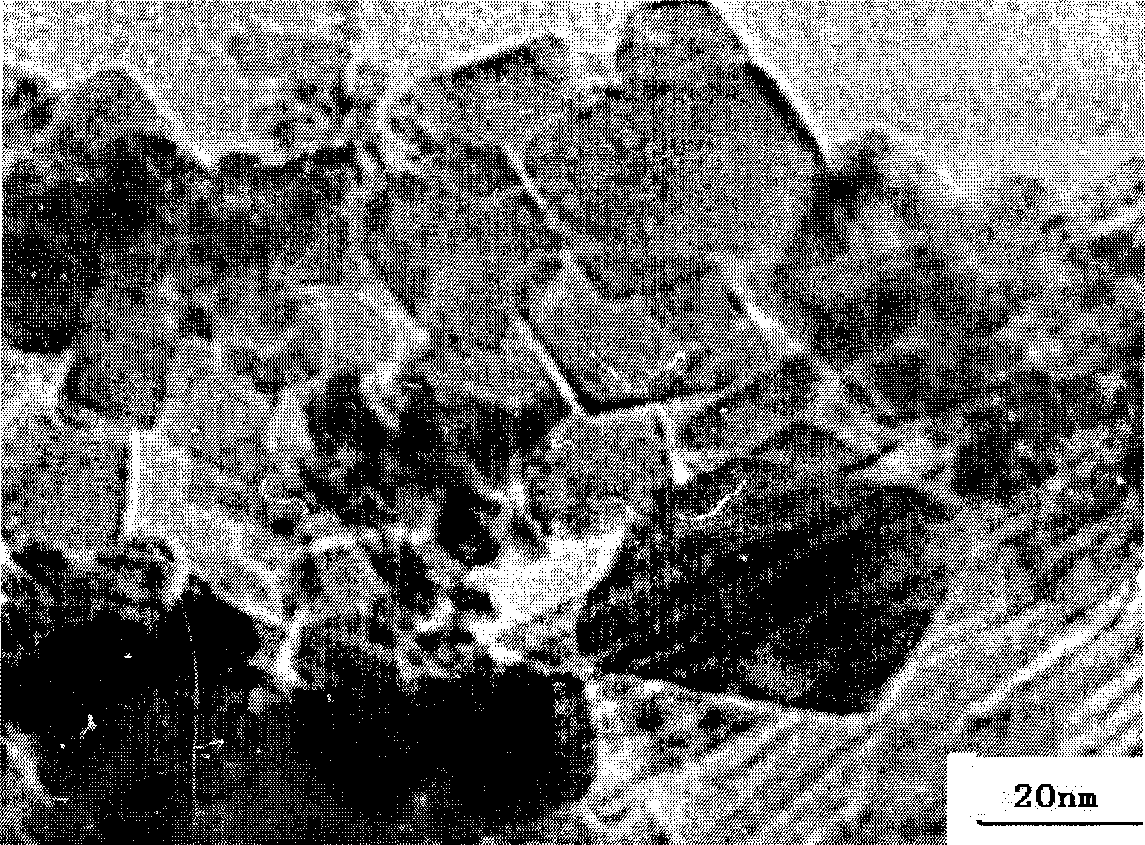

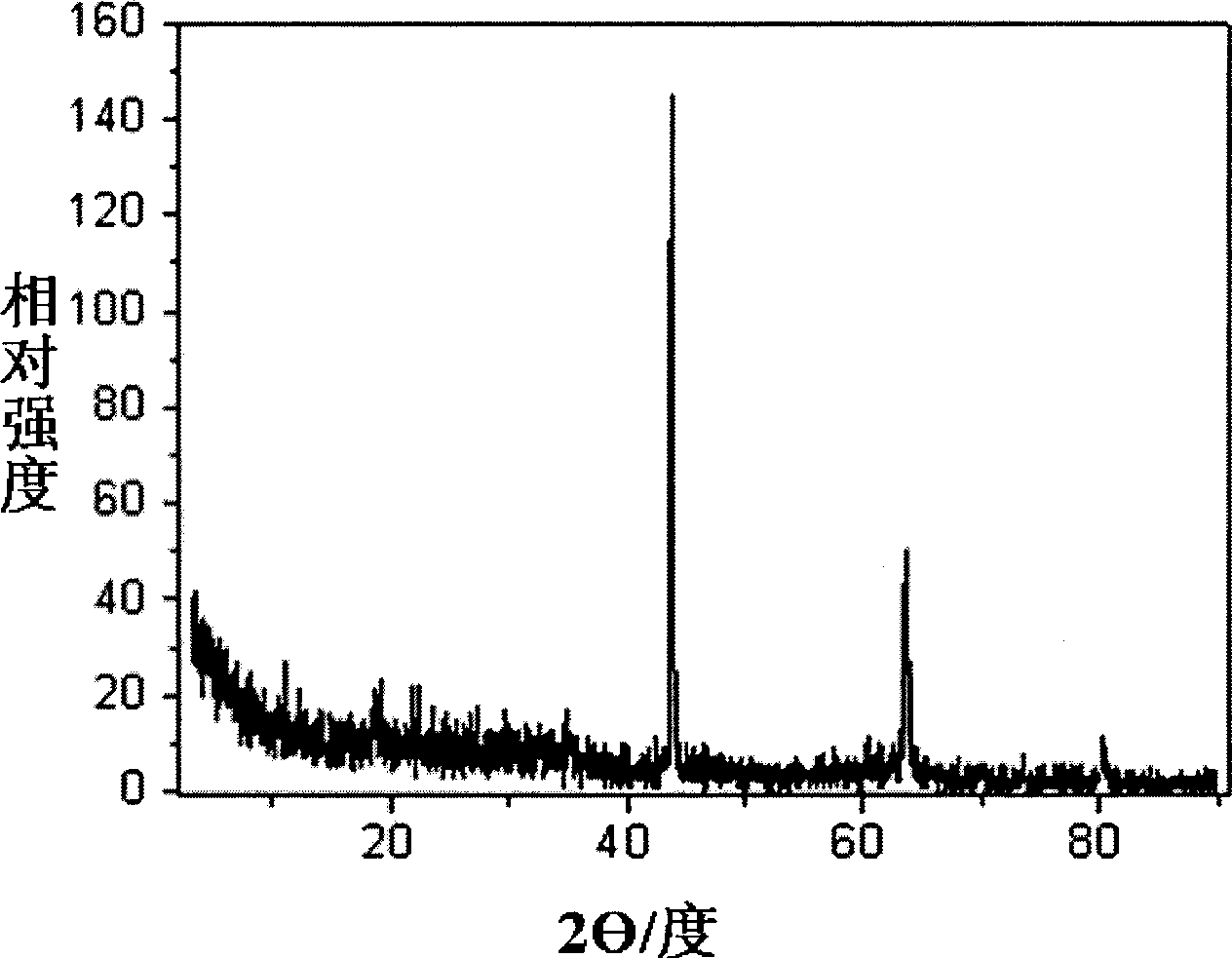

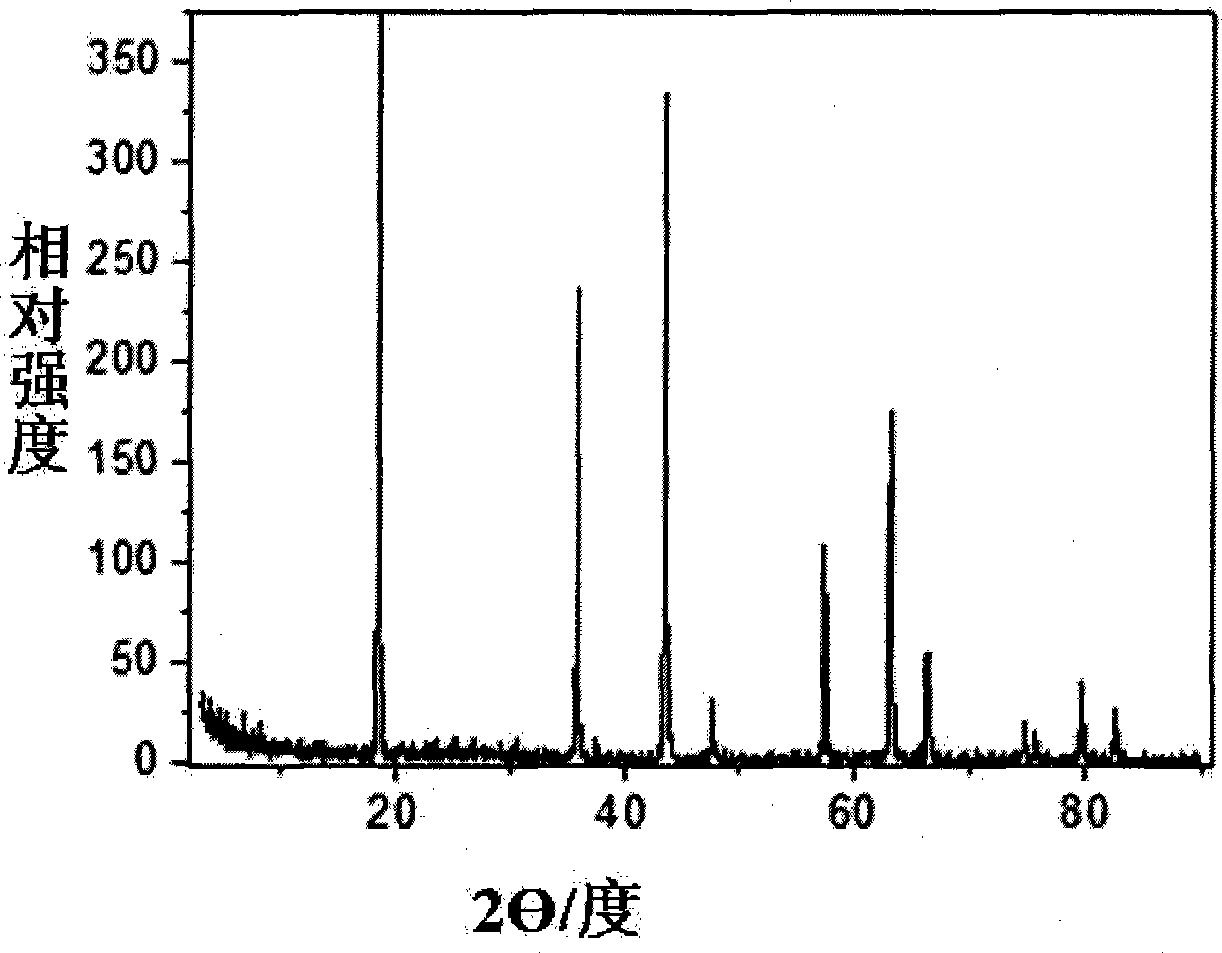

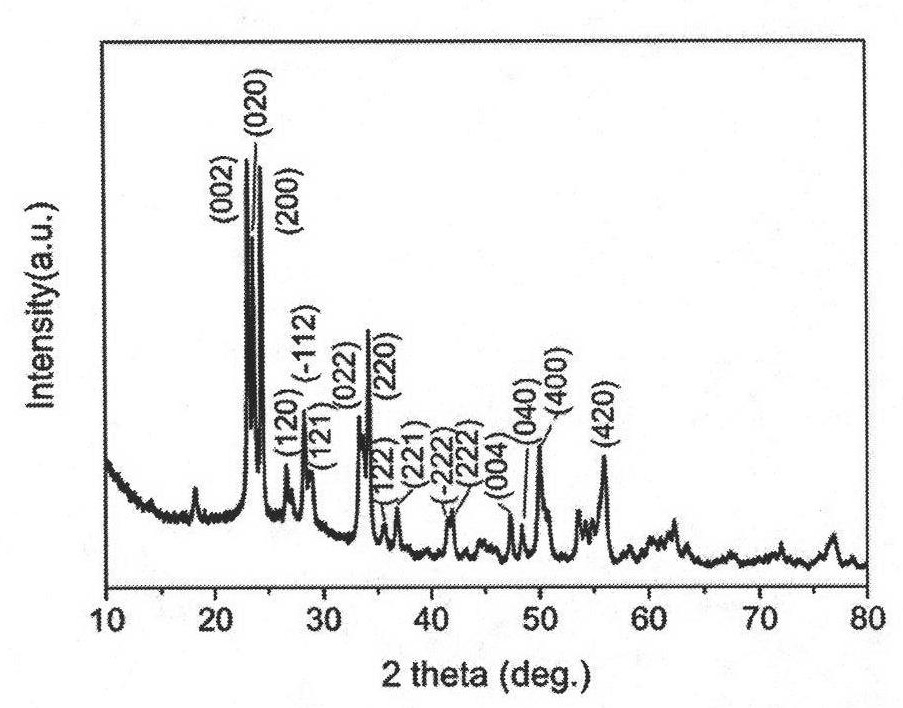

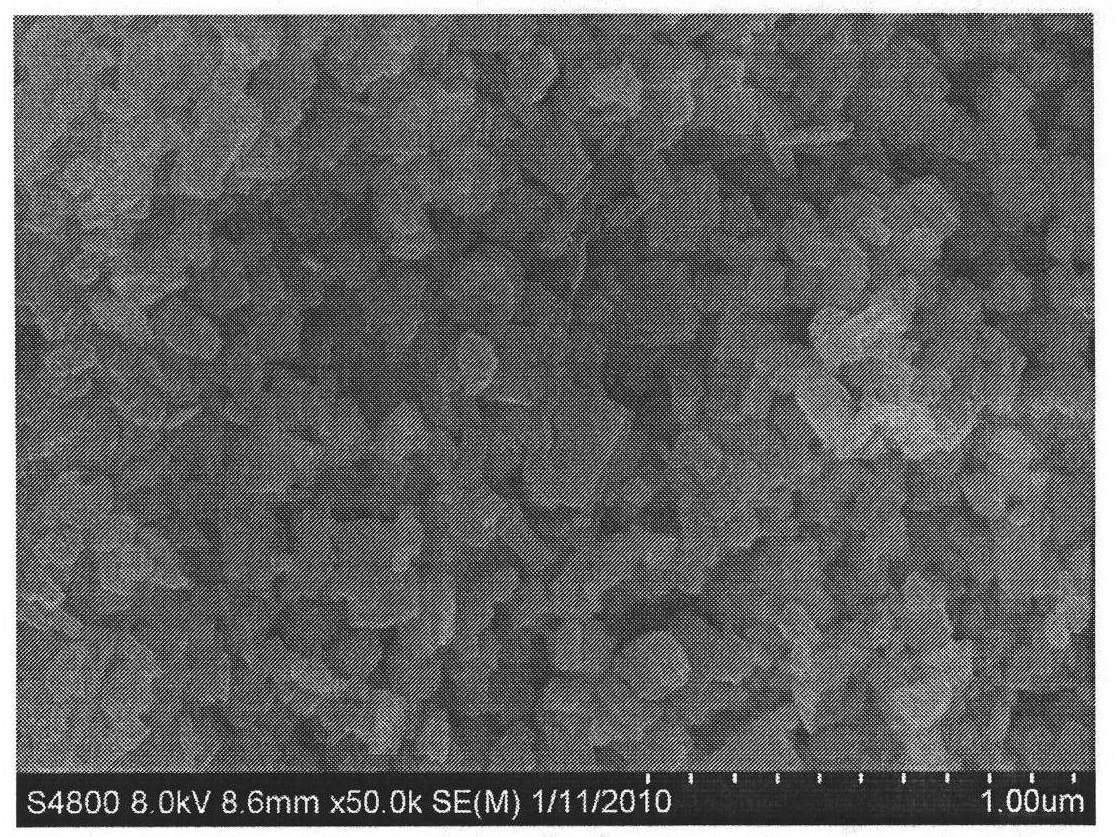

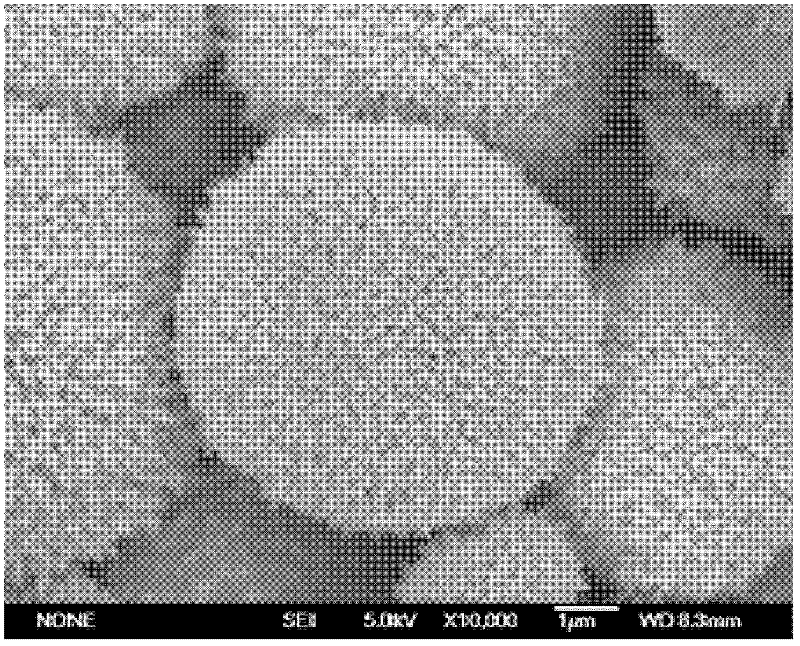

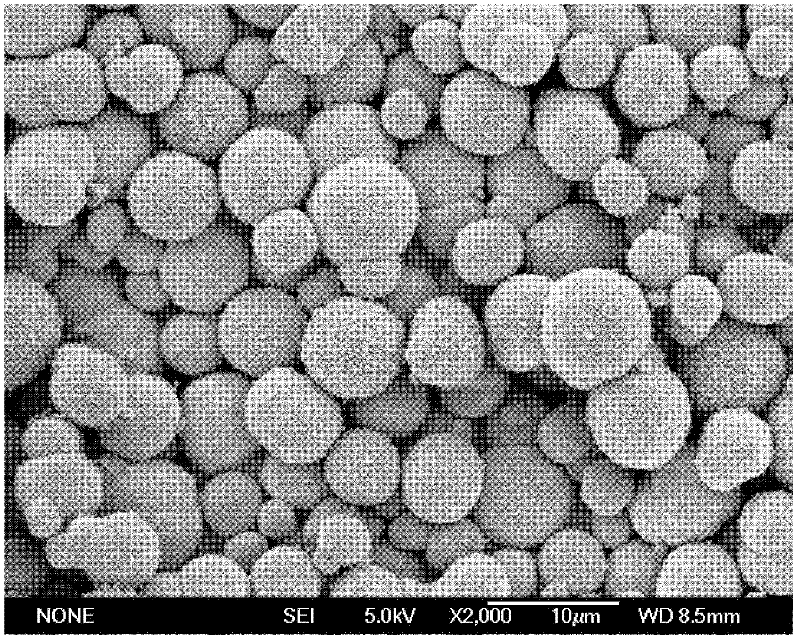

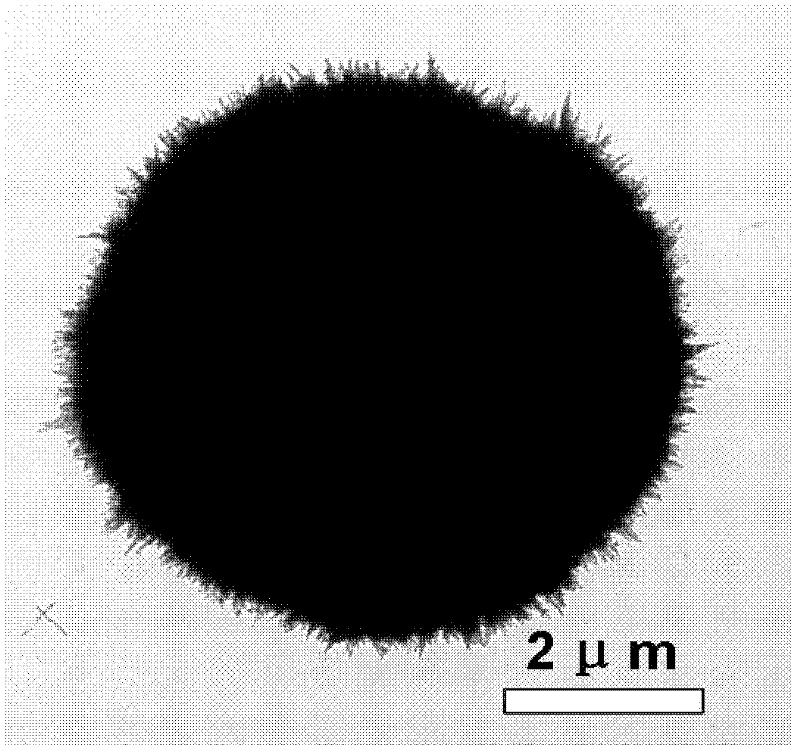

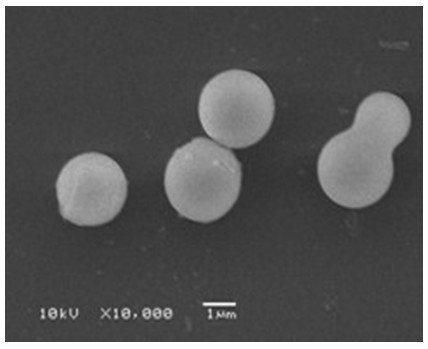

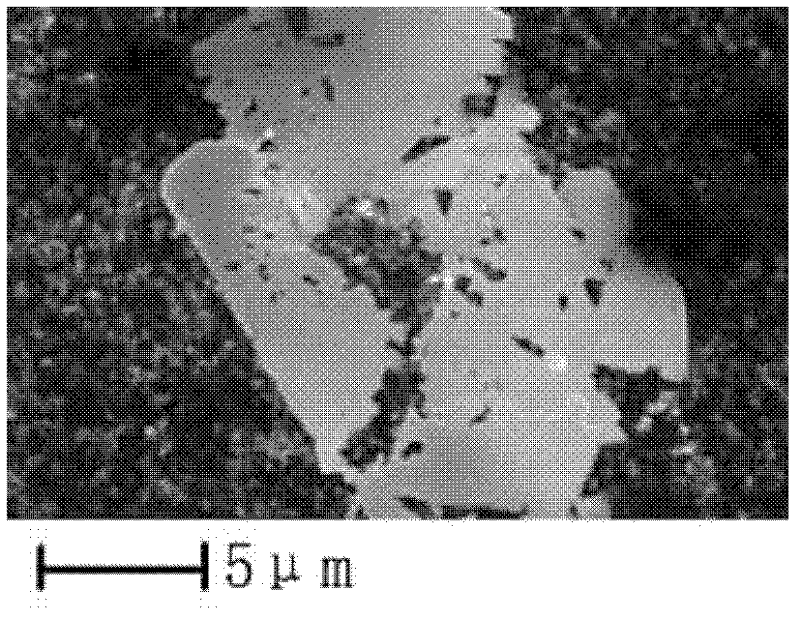

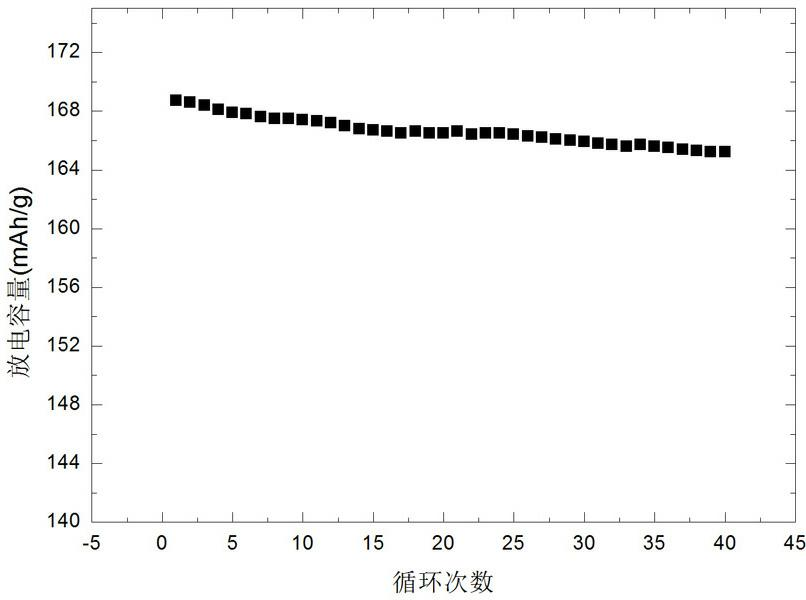

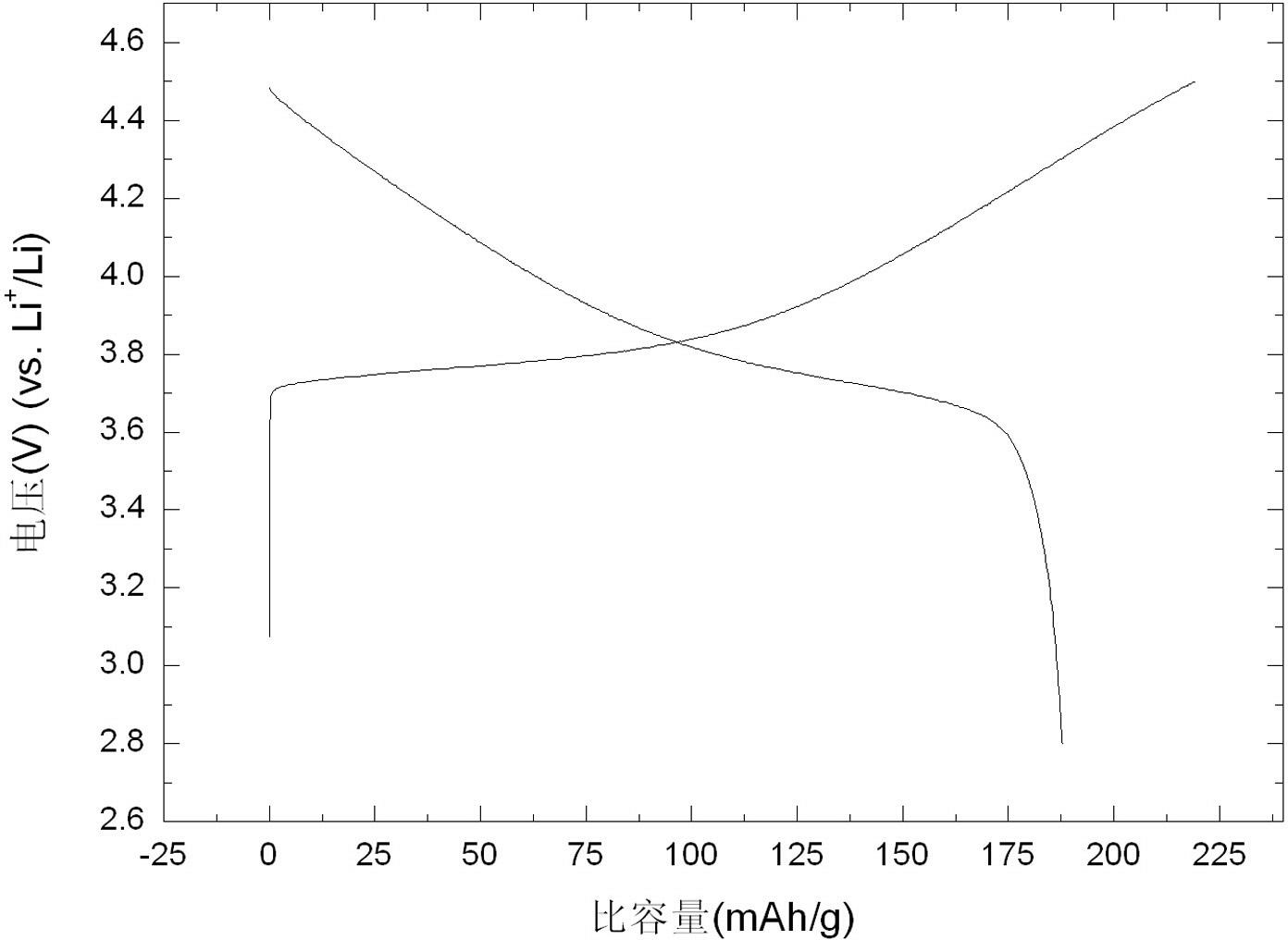

Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material

InactiveCN102013475AEasy to processImprove performanceCell electrodesNanotechnologyLithium iron phosphatePhosphor

The invention discloses a method for preparing a porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y] / 3) / C material, comprising the specific steps of: dissolving a lithium-containing compound, an iron-containing compound, a phosphor-containing compound and a element-doped compound additive in a dispersing agent to form a sizing agent; dispersing a mixture of a pore-forming agent, a cladding agent and a stabilizer in a dispersing agent through ultrasound, then adding into the sizing agent and mixing to form a new sizing agent; carrying out a physical method or a chemical method on the new sizing agent to obtain a sizing agent with the primary particles in nano grade; carrying out spraying drying and granulating on the obtained sizing agent with the primary particles in nano scale to obtain a dry mixed material with secondary particles with spherical appearances; then carrying out a sintering process on the dry mixed material to obtain the product of the invention. The method has the advantages that besides that the primary particles reach the nano scale, the particle diameters are more uniform in distribution and more regular in appearance, an iron phosphate product synthesized from the material has the particle diameters with uniform distribution, and the material has favorable processability, good electric conductivity, excellent power multiplication performance and higher actual capacity.

Owner:秦波

Method for preparing small-size nickel-cobalt lithium manganate precursor

ActiveCN103253717ARealize industrial productionConcentrated particle size distributionManganese oxides/hydroxidesNickel oxides/hydroxidesManganateManganese

The invention relates to a method for preparing a small-size nickel-cobalt lithium manganate precursor. The method is characterized by comprising the following steps of: (1) preparing a solution from soluble salts of nickel, cobalt and manganese as materials, adopting a sodium hydroxide water solution as a precipitator, and adopting ammonia water or ammonium salt as a complexing agent; (2) merging and adding the obtained three solutions into a reaction kettle which contains bottom water and includes stirring and temperature control devices; leading in nitrogen to protect in a reaction process, and continuously carrying out reaction; and (3) stirring and aging for 4-6 hours after a temporary kettle is full, putting the aged material into washing and press filtering equipment to wash; removing moisture in a filter pressing manner; and then mixing and sieving by a 200mesh screen after baking and crushing. By adopting the method disclosed by the invention, industrialized production of the small-size nickel-cobalt lithium manganate precursor can be conveniently achieved; and the method is stable to control the particle size, and convenient to achieve requirements of the materials and equipment.

Owner:宁夏中色金辉新能源有限公司

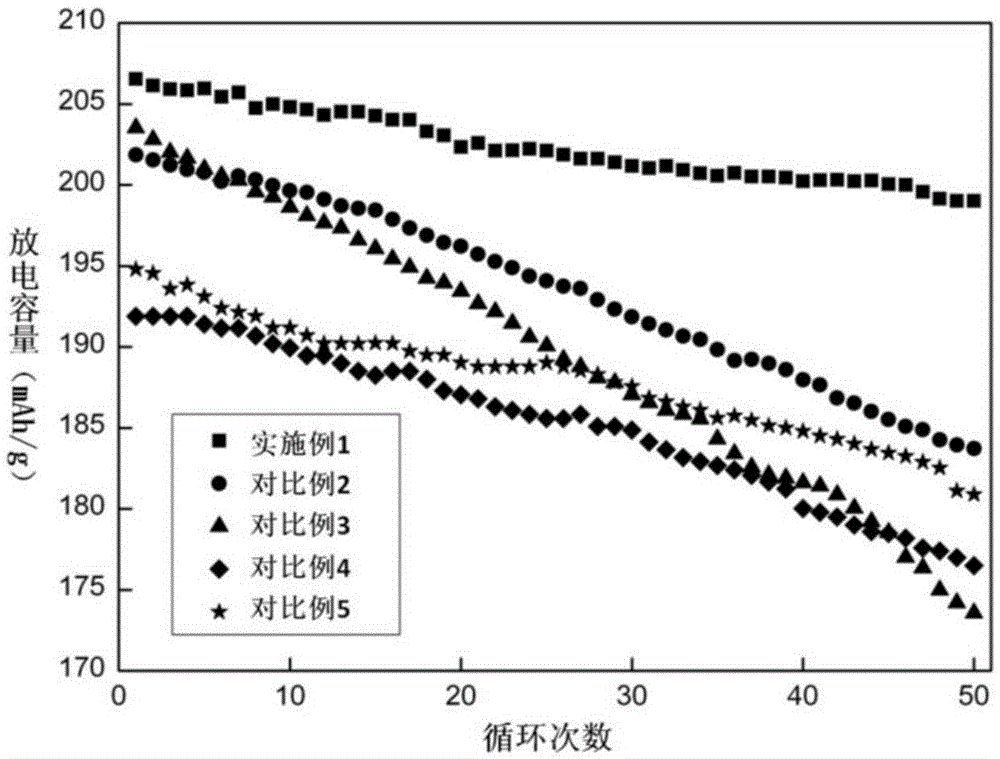

Nickel cobalt lithium manganate composite cathode material and preparation method of nickel cobalt lithium manganate composite cathode material

The invention relates to a nickel cobalt lithium manganate composite cathode material and a preparation method of the nickel cobalt lithium manganate composite cathode material. The nickel cobalt lithium manganate composite cathode material has the chemical formula of Li(NixCoyMn<1-x-y>)O2. The preparation method comprises the steps that after soluble nickel salts, cobalt salts, manganese salts and complexing agents are uniformly mixed, sodium hydroxide precipitating agents are added, the reaction is carried out in a stirring reactor with an ultrasonic device, composite hydroxides of nickel cobalt manganate are obtained, then, the composite hydroxides, water soluble macromolecular compounds and lithium source compounds are placed in the stirring reactor with the ultrasonic device, the spray drying is carried out in the ultrasonic reinforced stirring mixing process, and nickel cobalt lithium manganate precursors are obtained, the precursors are subjected to primary sintering under the certain atmosphere protection, and nickel cobalt lithium manganate products are obtained. When the nickel cobalt lithium manganate composite cathode material and the preparation method are adopted, the prepared product particles are uniform, the morphology is regular, the specific surface area is small, the tap density is high, the electrochemical performance is excellent, the processing performance is good, the cost is low, the environment-friendly effect is realized, and the environment pollution is avoided.

Owner:CENT SOUTH UNIV

Nickel lithium ion battery positive electrode material having concentration gradient, and preparation method therefor

ActiveUS20170317344A1Improve securityImprove cycle capabilitySecondary cellsPositive electrodesElectrical batteryPhysical chemistry

A nickel lithium ion battery positive electrode material having a concentration gradient, and a preparation method therefor. The material is a core-shell material having a concentration gradient, the core material is a material having a high content of nickel, and the shell material is a ternary material having a low content of nickel. The method comprises: synthesizing a material precursor having a high content of nickel by means of co-precipitation, co-precipitating a ternary material solution having a low content of nickel outside the material precursor having a high content of nickel, aging, washing, and drying to form a composite precursor in which the low nickel material coats the high nickel material, adding a lithium source, grinding, mixing, calcining, and cooling to prepare a high nickel lithium ion battery positive electrode material. The obtained material has regular morphology, uniform coating, narrow particle size distribution range, gradient distribution of the concentration of the nickel element, high content of the nickel element in the core, and low content of the nickel element in the shell; the nickel element in the core guarantees the specific capacity of the material, and the shell coating material maintains the stability of the structure of the material, so as to improve the safety of the material in the charge and discharge process, and improve the cycle and rate performance of the material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

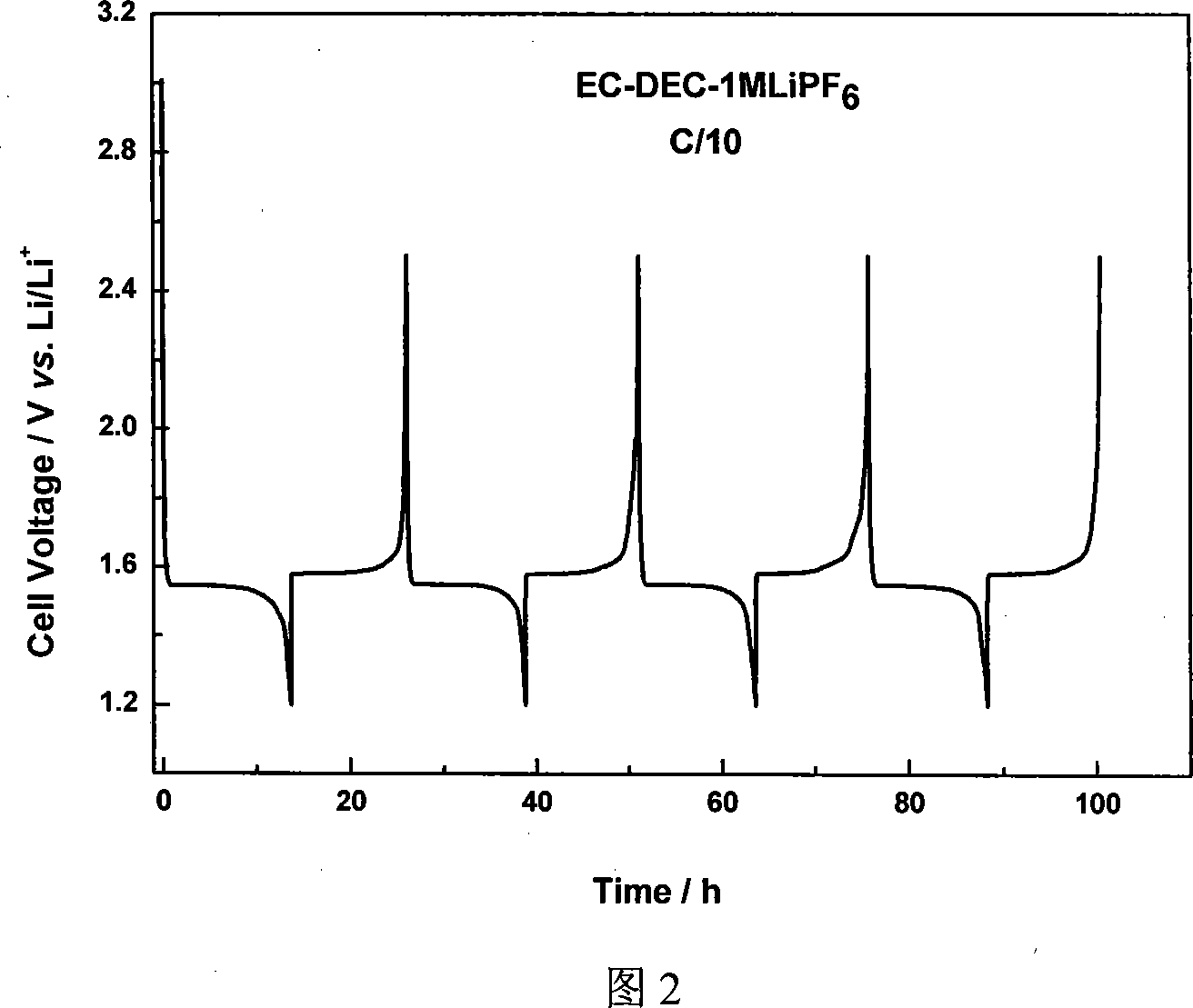

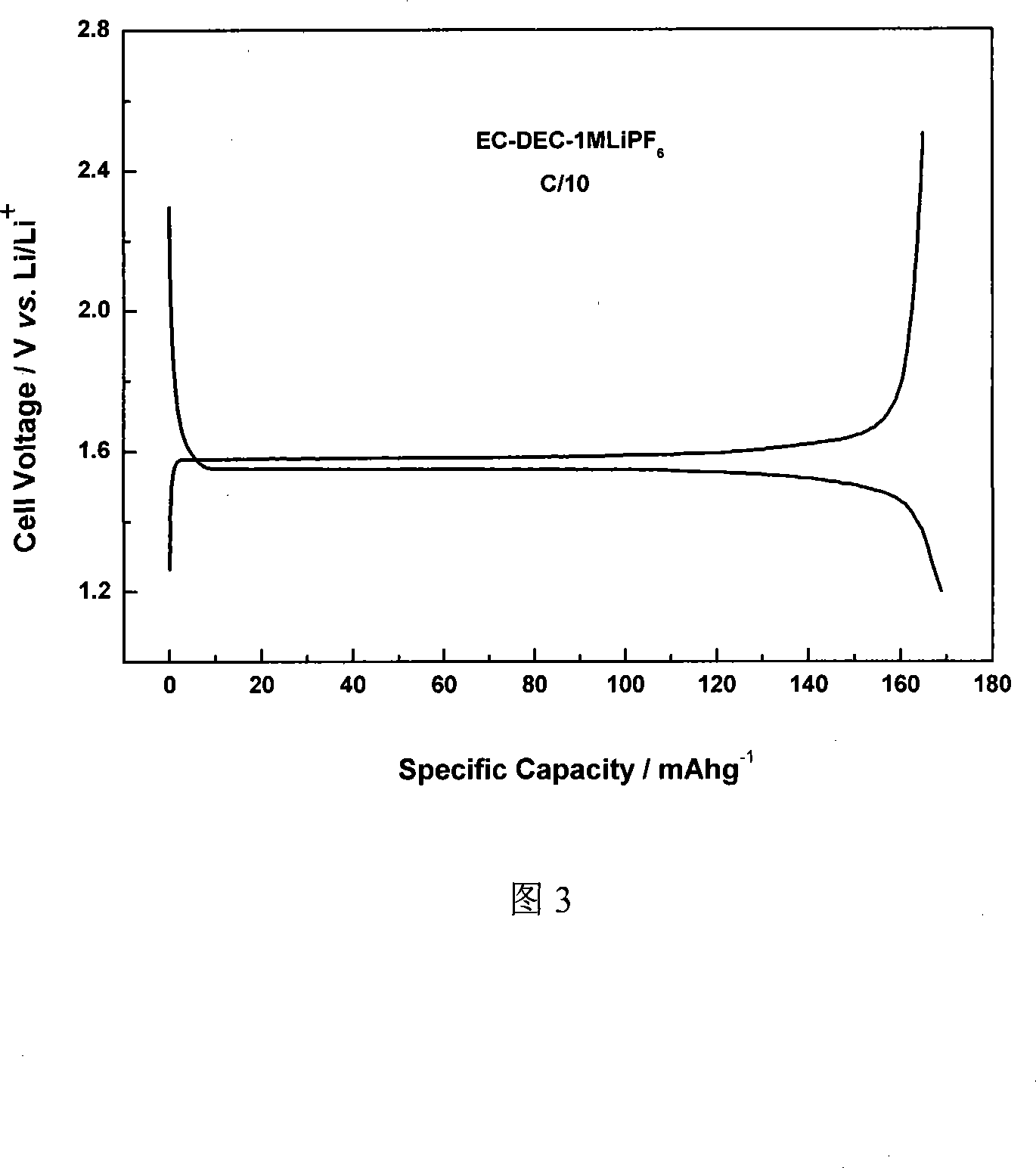

Method for preparing nano-crystal lithium-titanium composite oxide

InactiveCN101058438ARich reservesReserves are cheapNanostructure manufactureCell electrodesCapacitanceWater baths

The invention discloses a making method of nanometer crystal Li-Ti composite oxide, which comprises the following steps: adopting titanium powder or titanium compound as raw material; blending the materials with 30% hydrogen peroxidate under low temperature; adding certain quantity of lithium salt solution and moulder; stirring evenly; reacting under water bath condition at 50-100 deg. c completely; drying the composite system directly to produce predecessor; proceeding heat disposal for the predecessor at 200-400 deg. c for 2-6h; heating to 600-1000 deg. c; sintering 8-36h; cooling; grinding; obtaining the nanometer crystal Li-Ti composite oxide with spinel structure and the content of Li4Ti5O12 over 90%; controlling the even grain size of the product between 15nm and 100nm and specific surface area between 10 and 100m2 / g due to different aperture shape of moulds, sintering time and temperatures; making the reversible specific capacity of the product over 160mAh / g under 0. 1C charging and discharging condition; keeping the capacity maintaining rate between 50% and 70% under discharging condition at 100deg. c as ideal negative electrode material of lithium ion dynamic battery and lithium ion super-capacitance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Positive electrode material of lithium ion battery and preparing method thereof

ActiveCN103151521AReduce the effect of tap densityImprove cycle performanceCell electrodesSodium-ion batteryIron phosphate

The invention relates to a lithium titanate-carbon co-cladded lithium manganese iron phosphate positive electrode material. According to the invention, the characteristic of zero stress of a lithium titanate material is utilized for inhibition of deformation of a positive electrode during charging and discharging so as to improve cycle performance and resistance to over-charge and over-discharge of the positive electrode material, and conductivity and electrochemical properties of the positive electrode material are improved through co-cladding of the lithium titanate material and carbon; meanwhile, tap density of lithium titanate is as high as 1.68 g / cm<3>, which enables influence of carbon cladding on the tap density of the positive electrode material to be reduced. A preparation method for the positive electrode material provided by the invention is simple, is easy to operate and can easily realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Production method of tungsten carbide base ball shaped thermal spray coating powder

A process for preparing the WC-based spherical powder for thermospray coating includes such steps as proportionally mixing WC, Co or mixture of Co and Cr, hexane and paraffin wax, wet grinding, spray drying, granulating, sieving, sintering under protection of H2, and classifying.

Owner:ZIGONG CEMENTED CARBIDE CORP

Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

ActiveCN103066257ASolve the problem of complete oxidationPrevent "cation mixing" phenomenonCell electrodesLithium hydroxideOxygen

The invention provides a preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries. The method comprises: step 1, using a nickel-cobalt-aluminum precursor prepared through a coprecipitation method and doped with mixed ions as raw materials, putting the raw materials into a sealed hearth of a pressure furnace, continuously introducing oxygen until a fixed pressure value is formed, then heating to a pre-burning temperature and keeping warm for a period of time, and cooling to obtain an oxidized precursor; and step 2, adding measured lithium salt or lithium hydroxide into the oxidized precursor, ball milling and uniformly mixing; heating the uniformly mixed raw materials to a certain temperature and keeping warm for a period of time, and meanwhile continuously introducing oxygen to complete a sintering process, thereby obtaining the finish product. According to the invention, through a hyperbaric oxygen atmosphere, the oxygen are enabled to fully infiltrate into particles of the raw materials which has a certain accumulation thickness, thereby preventing situations that only surface materials are oxidized under a normal pressure, and ensuring a full conversion of Ni<2+> to Ni<3+> by a full pre-oxidation.

Owner:GUANGZHOU LIBODE NEW MATERIAL

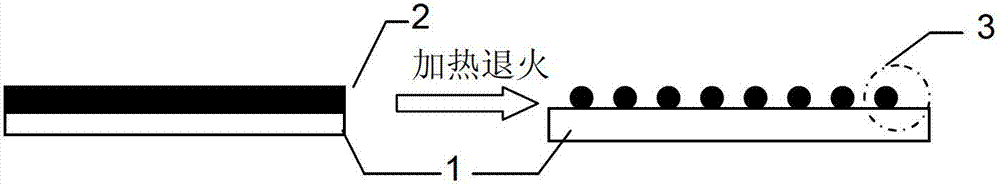

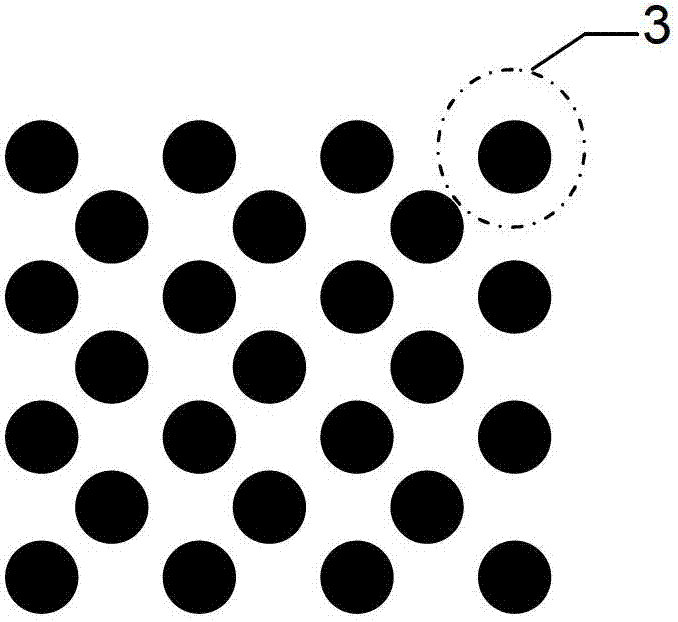

Method for preparing gold nanoparticles by annealing of gold film

InactiveCN102806354AEnables mass productionSimple processVacuum evaporation coatingSputtering coatingGold filmNanoparti cles

The invention discloses a method for preparing gold nanoparticles by annealing of a gold film. The method comprises the following steps: depositing a gold nano film (2) on a base material (1) by a magnetron sputtering method or vacuum evaporation method, wherein the vacuum degree of a magnetron sputtering chamber or a vacuum evaporation chamber is 10<-3>-10<-4>Pa, and the thickness of the deposited gold nano film (2) is 5-20nano; integrally arranging the deposited gold nano film (2) and the base material (1) in an annealing furnace to be heated for 30-120min, wherein the heating temperature is 350-600 DEG C; and cooling to the room temperature, and forming gold nanoparticles (3) on the base material (1). According to the invention, through controlling the thickness of the gold film, the annealing temperature, the annealing time and other parameters, the gold nanoparticles in different sizes and shapes can be obtained. The method disclosed by the invention has the advantages that the preparation is simple, the sizes and the shapes of the nanoparticles can be controlled, the preparation efficiency is high, and the like.

Owner:SOUTHEAST UNIV

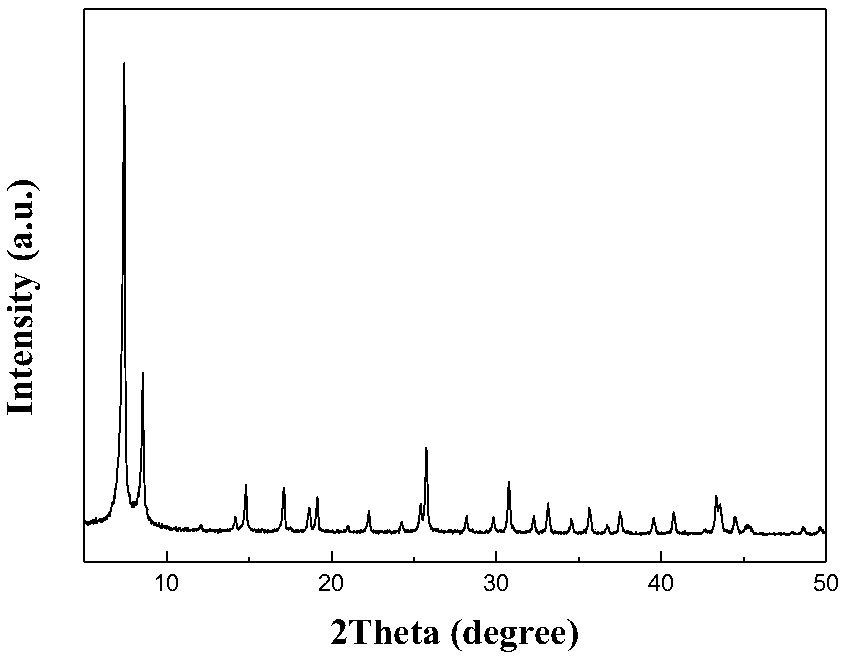

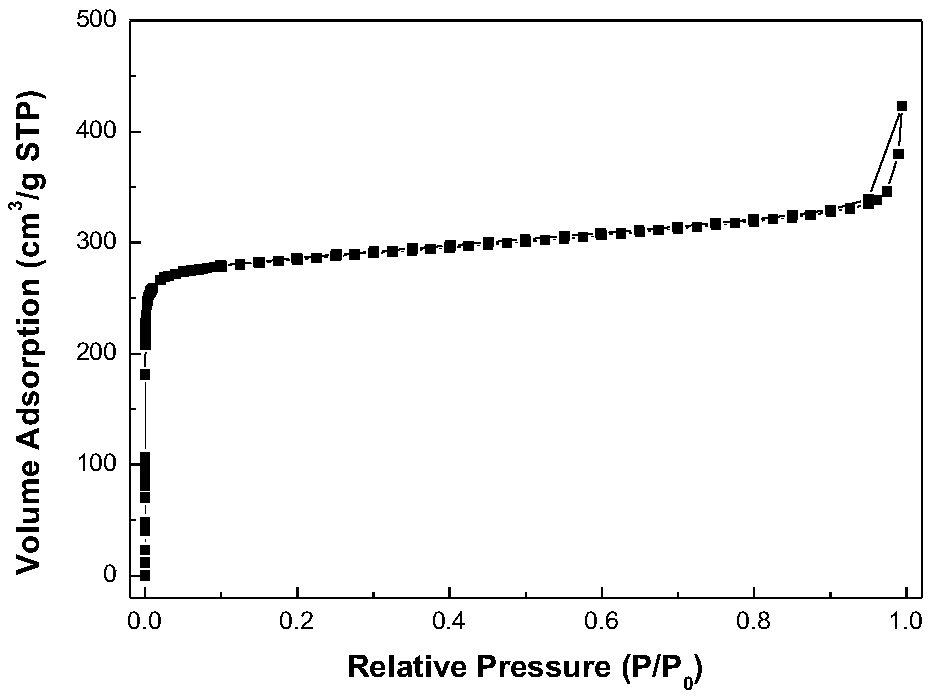

Preparation method for synthesizing metal organic framework UiO-66 adsorbents by aid of mixed ligands

InactiveCN109395698AFacilitated DiffusionImprove adsorption capacityOther chemical processesSorbentMetal-organic framework

The invention provides a preparation method for synthesizing metal organic framework UiO-66 adsorbents by the aid of mixed ligands. The preparation method includes mixing zirconium sources and regulators with one another and then dissolving the zirconium sources and the regulators in solvents to obtain solution A; uniformly dissolving 2-aminoterephthalic acid, terephthalic acid and solvents to obtain mixed ligand solution B; dropwise adding the solution A into the solution B at the constant speed to obtain solution C; injecting the solution C into reaction kettles with polytetrafluoroethylenelinings and carrying out crystallization at the temperatures of 100-160 DEG C for 18-24 h; carrying out reaction, and then carrying out treatment to obtain target products. As proved by XRD (X-ray diffraction) analysis, the obtained products are UiO-66 adsorbent materials. The preparation method for synthesizing the adsorbent materials has the advantages that the preparation method is simple; theUiO-66 adsorbents synthesized by the aid of the mixed ligands are excellent in chemical and thermal stability; the hydrogen adsorption capacity of the metal organic framework UiO-66 adsorbents can beimproved to a great extent, and effective treatment methods and research directions can be provided to hydrogen adsorption separation and storage.

Owner:DALIAN UNIV OF TECH

Method for wrapping gold-silver alloy nanometer particles through silicon dioxide

The invention discloses a method for wrapping gold-silver alloy nanometer particles through silicon dioxide. According to the method, isopropyl alcohol serves as a solvent, tetraethyl orthosilicate serves as a silicon source, a stirring reaction is conducted for 1-3 hours at the temperature of 40-60 DEG C by adjusting the proportion of the tetraethyl orthosilicate and the gold-silver alloy nanometer particles, and then the Au-Ag alloy@SiO2 composite nanometer particles wrapped by SiO2 of different thicknesses can be obtained. The method is simple, the reaction condition is gentle, the reaction time is short, no surface active agents need to be added, the prepared Au-Ag alloy@SiO2 composite nanometer particles are high in dispersity and regular in morphology, the thicknesses of silicon dioxide shell layers are uniform and controllable, quite high plasmon resonance peaks are achieved, and adjustable plasmon resonance peaks can be obtained by changing the thicknesses of the silicon dioxide shell layers.

Owner:SHAANXI NORMAL UNIV

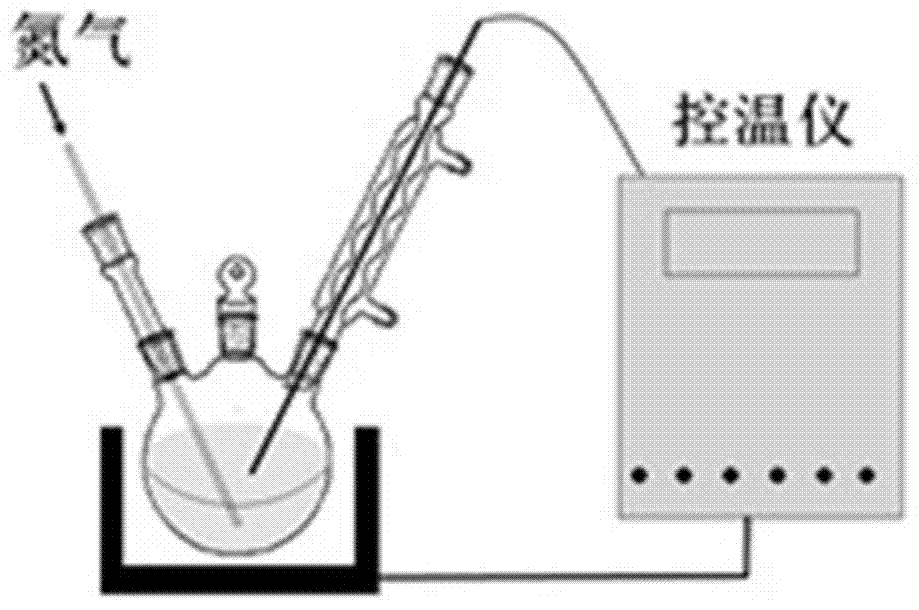

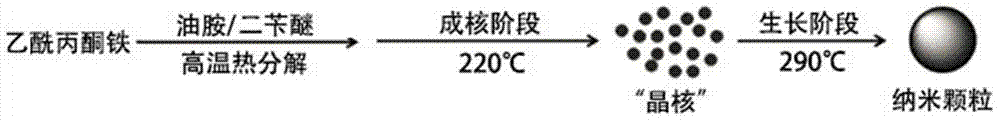

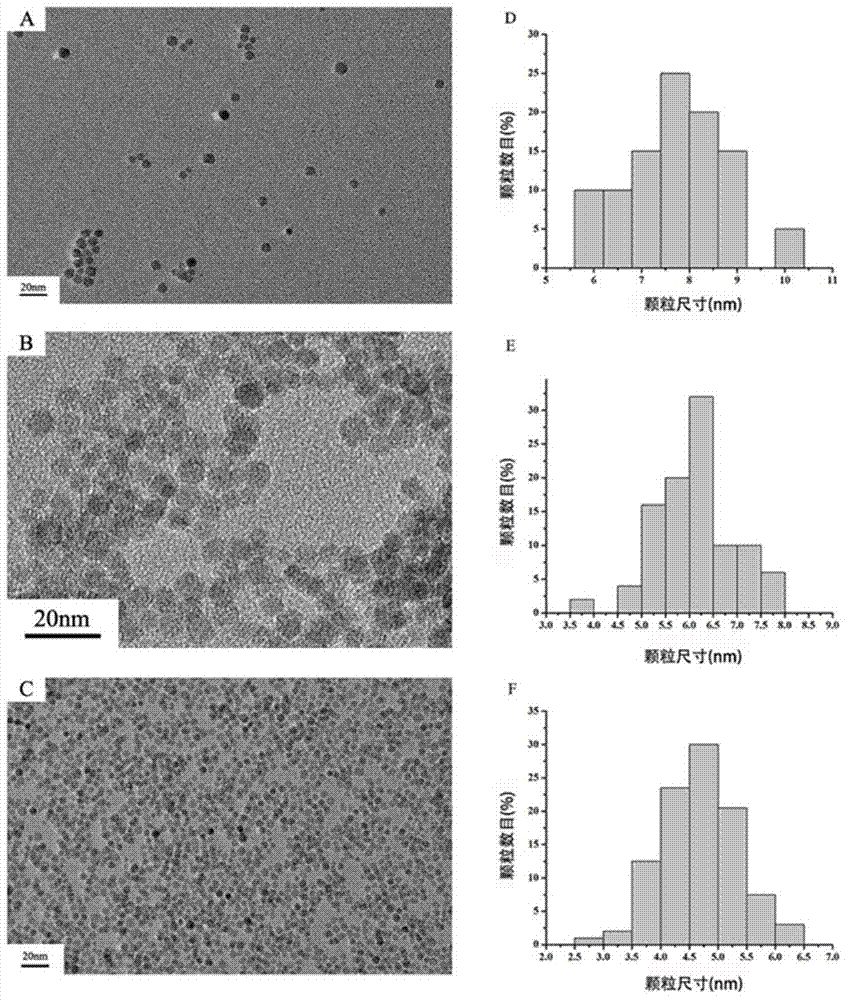

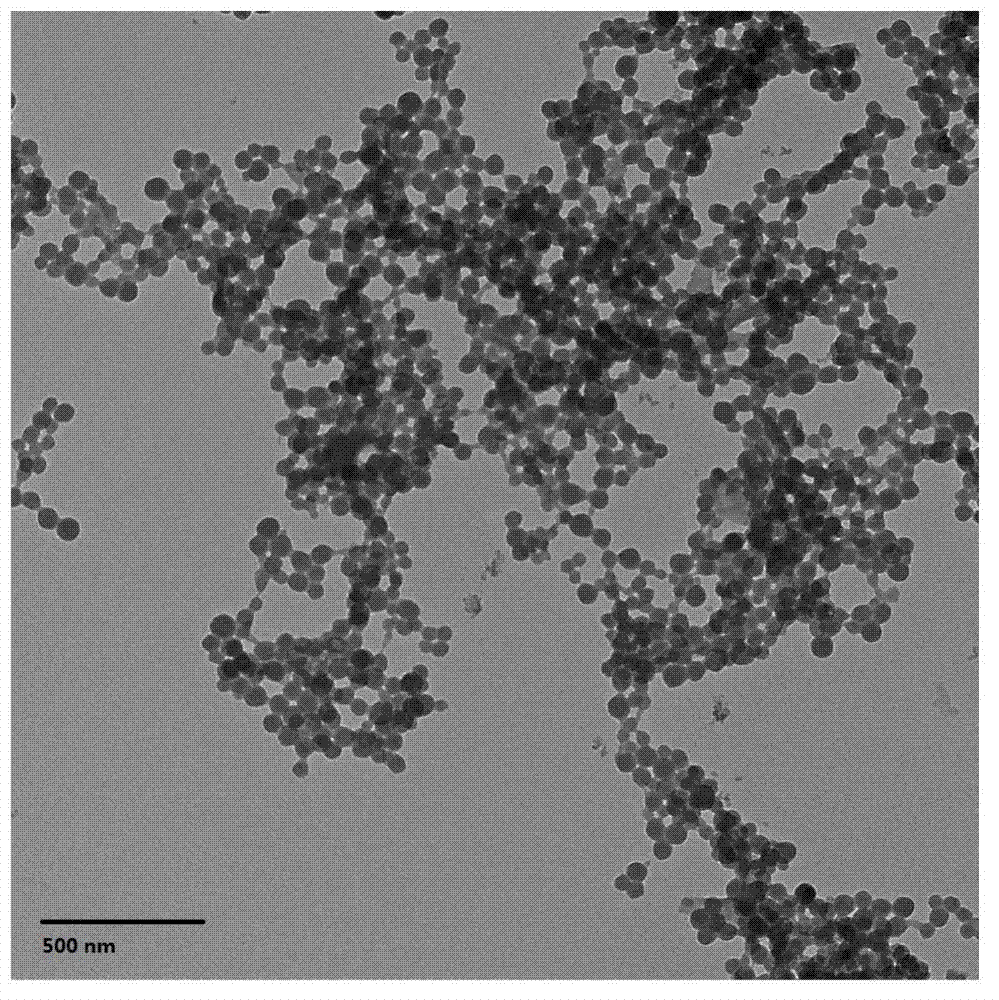

Preparation method and application of RGD-modified ultra-small magnetic iron oxide nanoparticles

ActiveCN104258425AStrong reducing propertiesHigh crystallinityNMR/MRI constrast preparationsEmulsion deliveryCyclic peptideActive agent

The invention discloses a preparation method of RGD-modified ultra-small magnetic iron oxide nanoparticles. The preparation method comprises the following steps: preparing ultra-small magnetic iron oxide nanoparticles by taking ferric acetylacetonate as a reaction raw material and a precursor, taking oleylamine as a surfactant and a reducing agent and taking dibenzyl ether as a solvent; replacing oleylamine molecules wrapped on the surfaces of the nanoparticles by utilizing dopamine-modified HOOC-PEG-COOH to realize PEG-modification of the surfaces of the nanoparticles; and finally, chemically coupling RGD cyclic peptide by virtue of free carboxyl at the tail end of the PEG to obtain the RGD-modified ultra-small magnetic iron oxide nanoparticles. The method of synthesizing the ultra-small magnetic iron oxide nanoparticles has the characteristics of a simple process, a high raw material conversion ratio, strong repeatability and the like. The synthesized magnetic iron oxide nanoparticles have the characteristics of a regular morphology, an ultra-small dimension, good stability, good monodispersity, high biocompatibility, and tumor specific targeting, and the like, and can be used as a T1-weighted imaging high-performance magnetic resonance imaging contrast agent with a tumor active targeting function.

Owner:SOUTHEAST UNIV

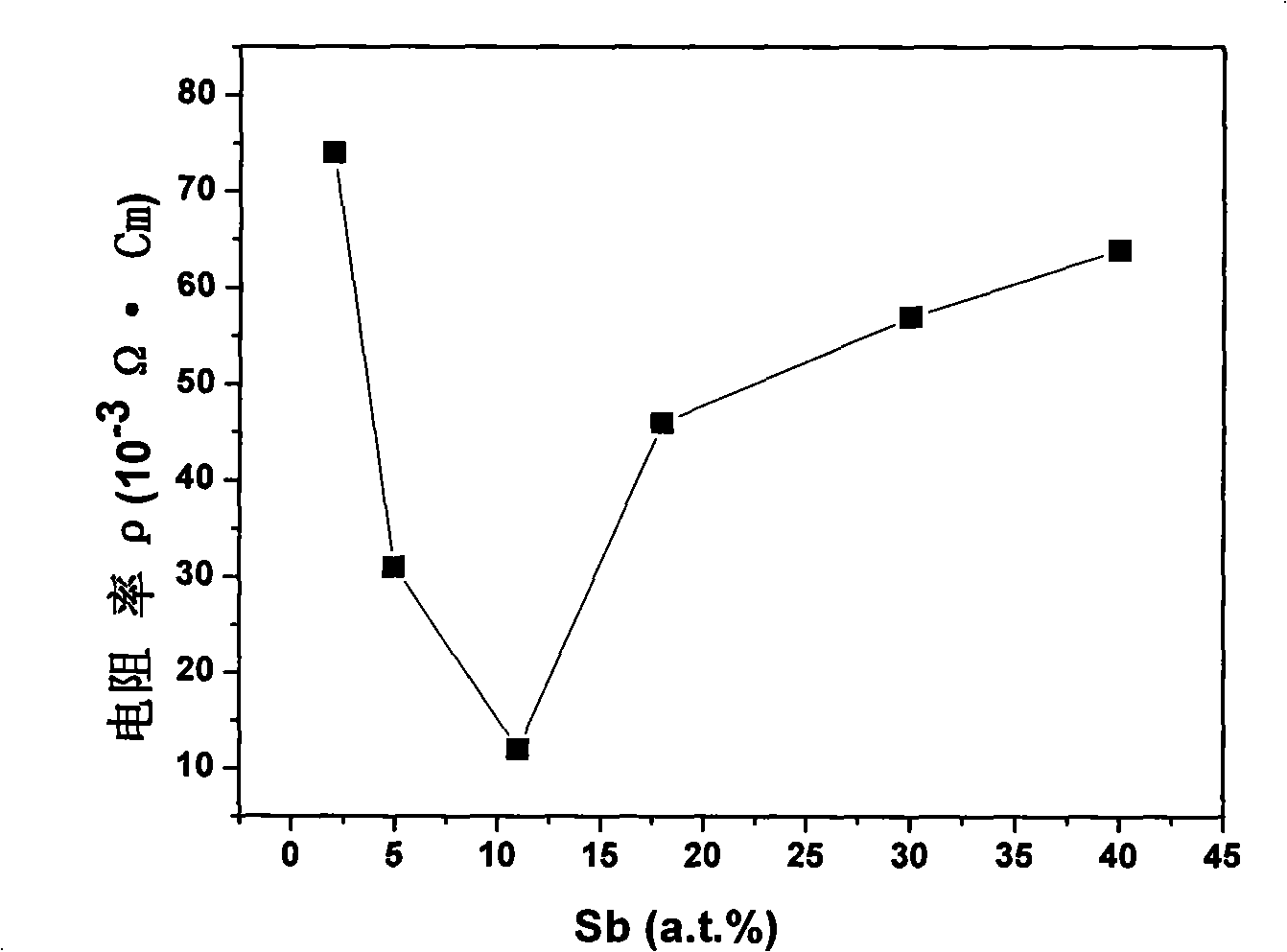

Preparation of stibium doping stannic oxide nanopowder by hydrothermal method

The invention discloses a hydrothermal preparation method of antimony doped tin dioxide nano-powder comprising: respectively preparing a SnCl4 alcohol solution and a SbCl3 alcohol solution, mixing the SnCl4 alcohol solution with the SbCl3 alcohol solution and adding deionized water into the mixture to maintain the concentration of SnCl4 between 0.005 mol / L and 3 mol / L, adjusting the pH value of mixed solution to 8.5-9.5 by ammonia, homogeneously dispersing the mixed solution in a reactor, conducting hydrothermal reaction for 1-2 hours at 100-200 DEG C, centrifugating, washing and drying the products after reaction to obtain powder, heating the powder after the powder is grinded for 0.5-1 hour at 400-700 DEG C, obtaining the antimony doped tin dioxide nano-powder. The powder prepared by the invention has a regular appearance and a narrow granularity distribution. The reaction condition is easy to control for adopting cheap SnCl4.5H2O and SbCl3 as materials, which is suitable for industrial mass production.

Owner:ZHEJIANG UNIV

Preparation method of polyvinyl alcohol/hydroxyapatite (PVA/HA) composite microspheres

InactiveCN107376795AGood dispersionUniform internal structureCosmetic preparationsOther chemical processesFood additiveMicrosphere

A preparation method of polyvinyl alcohol / hydroxyapatite (PVA / HA) composite microspheres belongs to preparation methods of composite water-in-oil emulsion system microspheres. PVA and HA precursors are used as raw materials to prepare a clear and transparent mixed solution; the clear and transparent mixed solution is dispersed into an oil phase containing a surfactant to form a homogeneous water-in-oil microemulsion; and the PVA / HA composite microspheres can be finally obtained by successive crosslinking reaction under acid-catalyzed conditions, HA deposition under alkaline conditions, product centrifugation, washing, drying and other processes. The method has the advantages of simple process, good repeatability, low energy consumption and low cost, and effectively solves the problems that inorganic nanoparticles are easy to agglomerate in the microspheres to cause uneven structures and poor comprehensive performances and the like. The composite microspheres prepared by the method have the advantages of regular morphology, high dispersibility, uniform microstructure, good biocompatibility, biological activity and adsorption performance, and can be used as drug carrier materials, bone repair materials, environmental water treatment materials, cosmetics or food additives and the like.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing lithium ionic cell cathode material spinelle lithium titanate

InactiveCN101462765ASimple preparation processRaw materials are cheap and easy to getCell electrodesTitanium compoundsSolid phasesSol-gel

The invention relates to a method for preparing an anode material of a lithium ion battery of spinel lithium titanate. The invention provides a method for preparing a Li4Ti5O12 material through a low-temperature ionic diffusion reaction, aiming at the drawbacks of a high-temperature solid-phase Li4Ti5O12 synthesis process of high temperature, long time and high energy consumption and the drawbacks of a sol-gel synthesis process of complex process and higher cost. The method adopts a technical proposal that: titanium dioxide or metatitanic acid is uniformly dispersed in 1 to 20mol / L aqueous solution of LiOH, wherein the Lithium to Titanium ratio is (10-100):1; under a condition of uniform stirring, the mixed solution is heated to 60 to 150 DEG C to react for 6 to 72 hours; the obtained products are washed till the pH is equal to 7 to 8, filtered and dried to form a precursor of Lithium-titanium oxide precursor; and the prepared precursor is roasted at 500 to 800 DEG C for 3 to 12 hours to form the final product of Li4Ti5O12.

Owner:万向电动汽车有限公司 +1

Method for preparing tungstic oxide nano-sheets

InactiveCN101805023AMorphological rulesUniform particle sizeNanostructure manufactureTungsten oxides/hydroxidesWater bathsGas detector

The invention provides a method for preparing tungstic oxide nano-sheets, comprising a precursor solution preparation part and a hydro-thermal reaction part, specifically comprising the following steps: carrying out hydrogen peroxide oxidation reaction of metal tungsten powder at the condition of low temperature water bath, back-flowing the obtained peroxy-polytungstic acid solution for 5-15h at the temperature of 50-60 DEG C, dissolving with deionized water after aging at room temperature, adjusting the pH value with hydrochloric acid or nitric acid, mixing with polyethylene glycol to obtain the precursor solution; carrying out the reaction of the precursor solution for 12-24h at the temperature of 150-180 DEG, putting the solution in a drying oven for drying through vacuum leaching, alcohol and distilled water washing after naturally cooling till room temperature so as to obtain tungstic oxide nano-sheets; compared with the prior art, the method has low cost, simple technology, easy operation, high preparation efficiency, good repeatability and convenient industrialization; the tungstic oxide nano-sheets preparaed by the method have regular shape and uniform granularity, and can be widely applied to visible light catalysis, solar battery, intelligent window, gas sensor, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

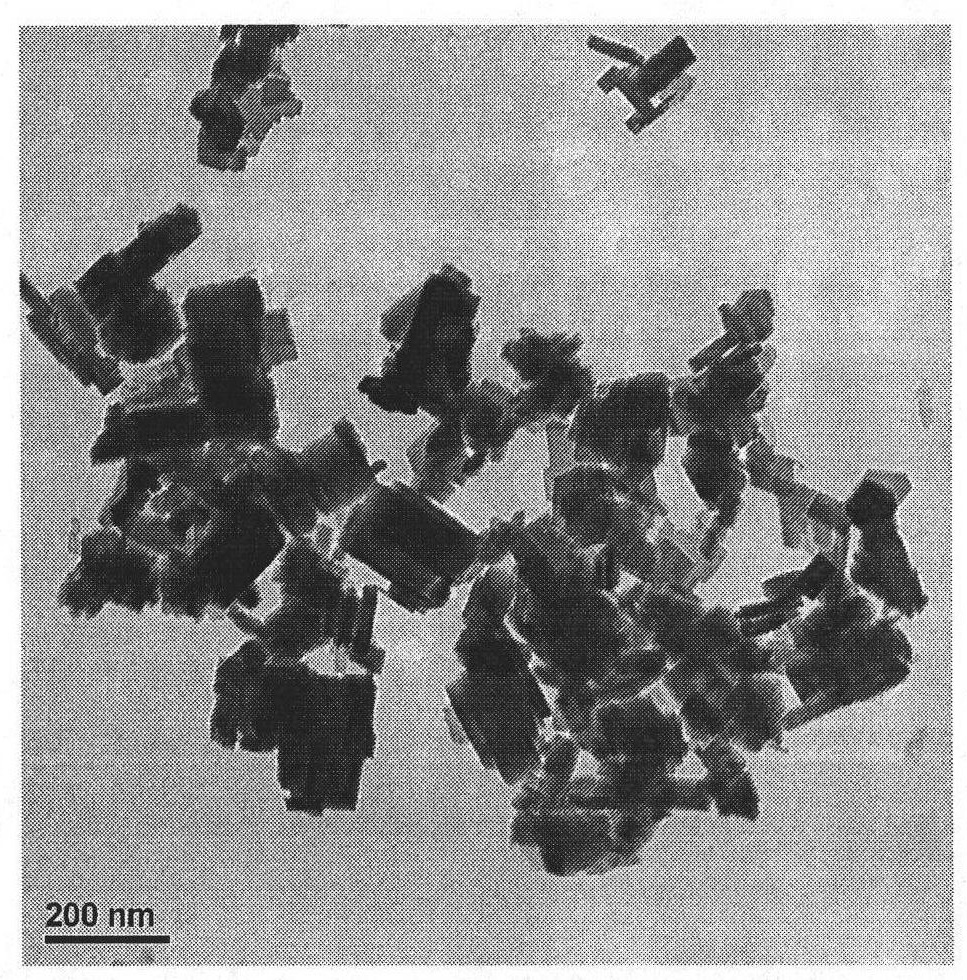

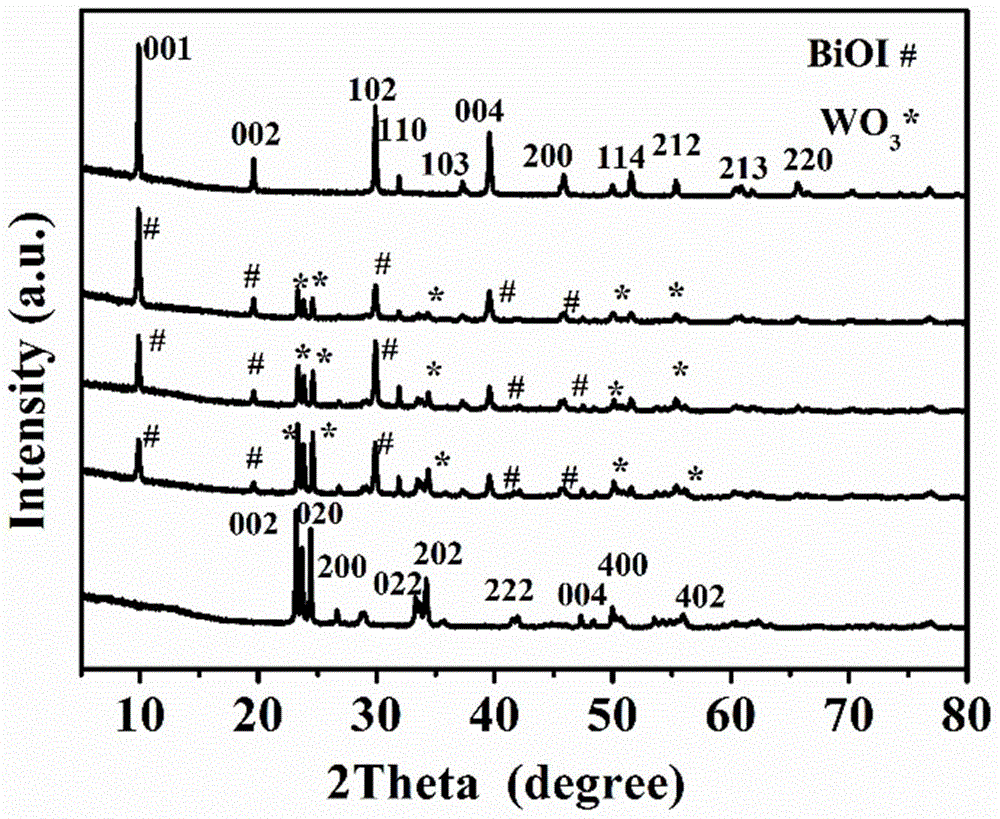

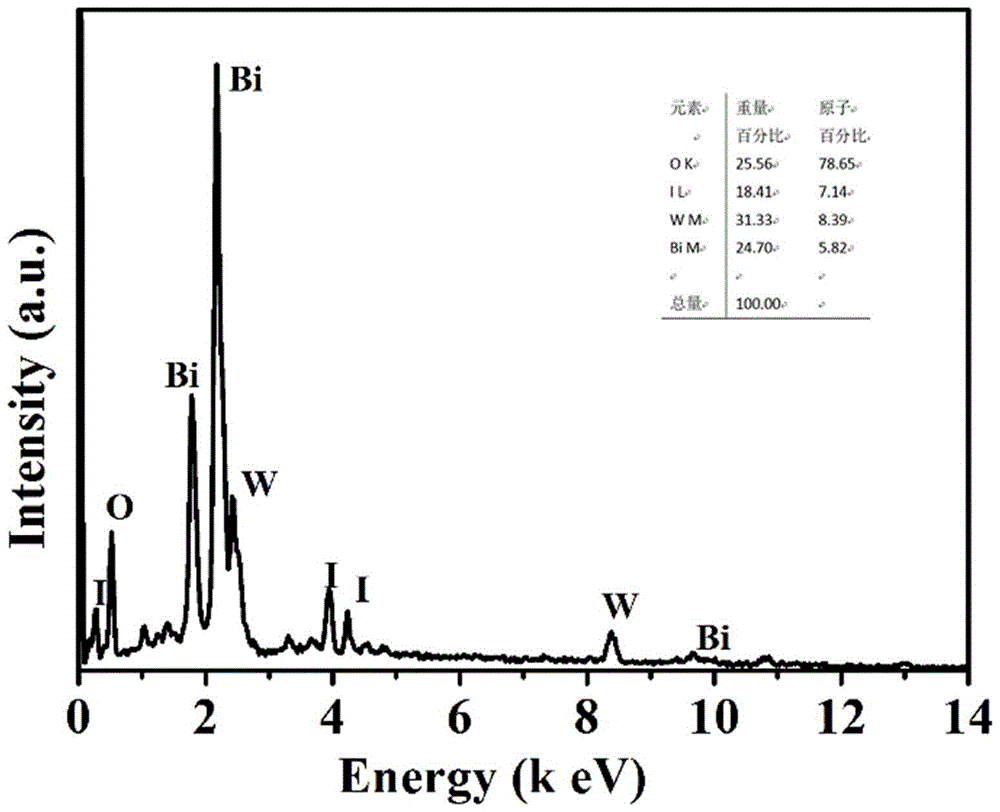

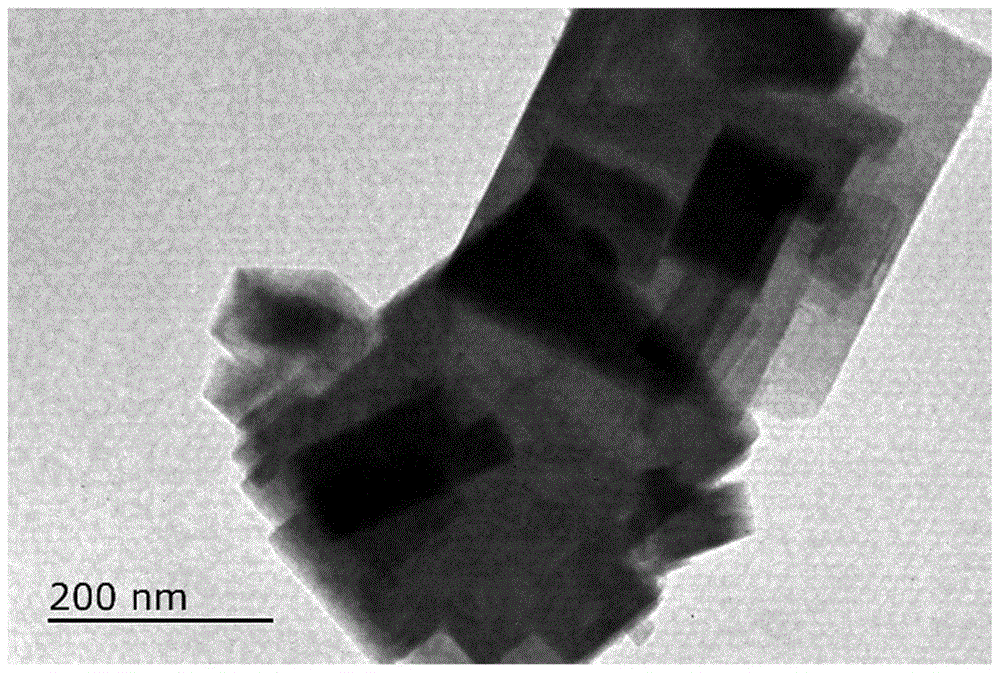

Method for preparing BiOI/WO3 composite heterojunction photocatalyst

InactiveCN105688953AFully crystallizedMorphological rulesPhysical/chemical process catalystsIonPotassium iodine

The invention relates to the technical field of preparation of heterojunction composite photocatalysts, in particular to a method for preparing BiOI / WO 3 A method for heterojunction composite photocatalysts. Disperse tungsten oxide in deionized water, add potassium iodide and bismuth nitrate, stir and mix evenly, filter and wash, and then obtain BiOI / WO 3 Heterojunction composite photocatalysts. The prepared nanocomposite photocatalysts have excellent visible light catalytic activity, especially bismuth nitrate and WO 3 The sample with a molar ratio of 1.0 has the best activity in degrading rhodamine B, and the degradation rate reaches 92% after visible light reaction for 100min, which is higher than that of pure BiOI and WO 3 high degradation activity.

Owner:JIANGSU UNIV

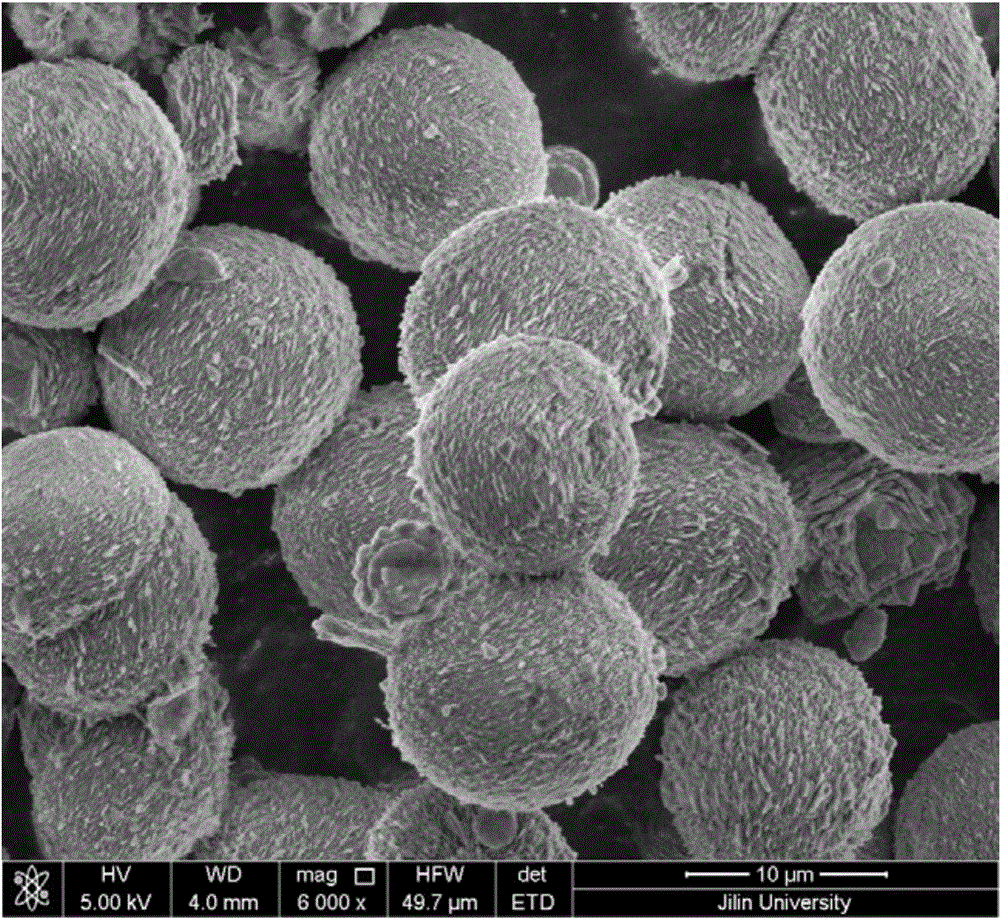

Sea urchin shaped copper oxide catalyst, as well as preparation method and application thereof

InactiveCN102641736ASimple processSimple and fast operationGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsOrganic solventCopper oxide

The invention relates to a sea urchin shaped copper oxide catalyst, as well as a preparation method and application thereof, and belongs to the field of catalysts. The preparation method for the sea urchin shaped copper oxide catalyst comprises the following steps of: dissolving a copper salt and a dispersant into an organic solvent, performing solvent heat reaction in an alkali environment, and thus obtaining the sea urchin shaped copper oxide catalyst. The method for preparing the sea urchin shaped copper oxide is concise, easy and convenient to operate, efficient, low in price and environment-friendly, and realizes large-scale preparation. The sea urchin shaped copper oxide catalyst prepared by the method is controllable in shape and granular size, and can be used for synthesizing organic silicon monomers.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

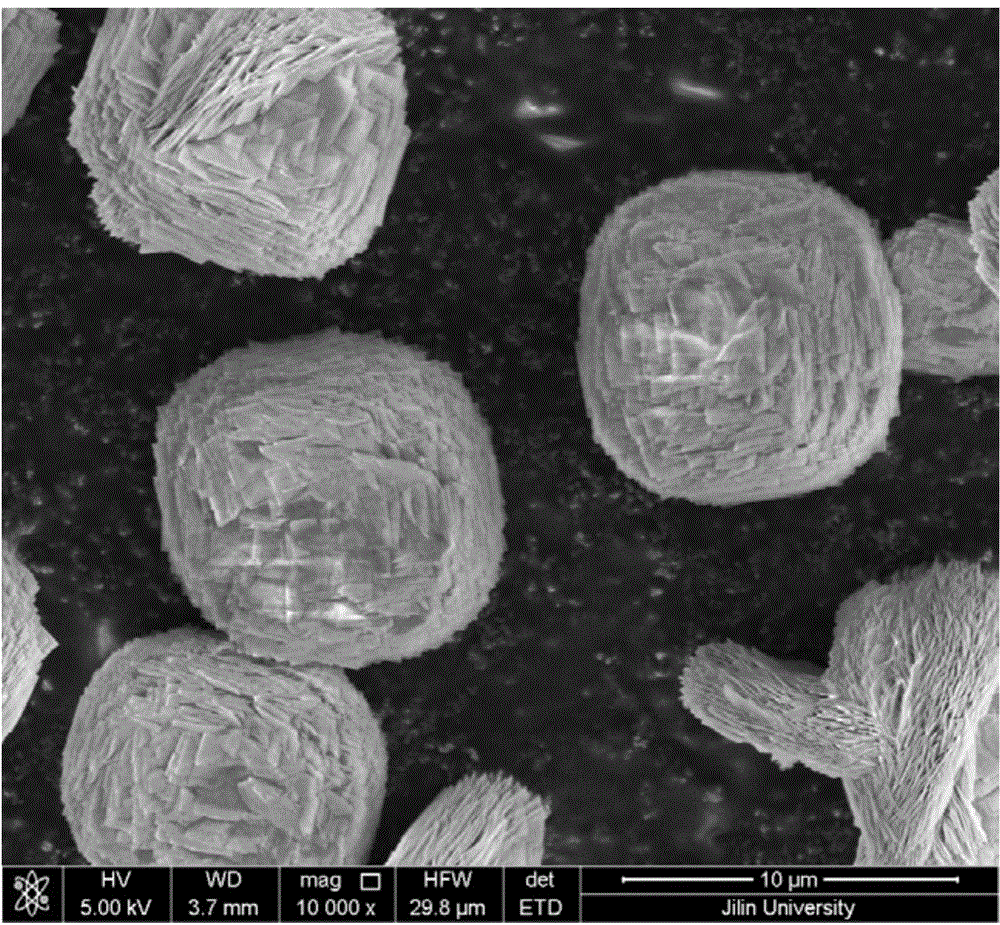

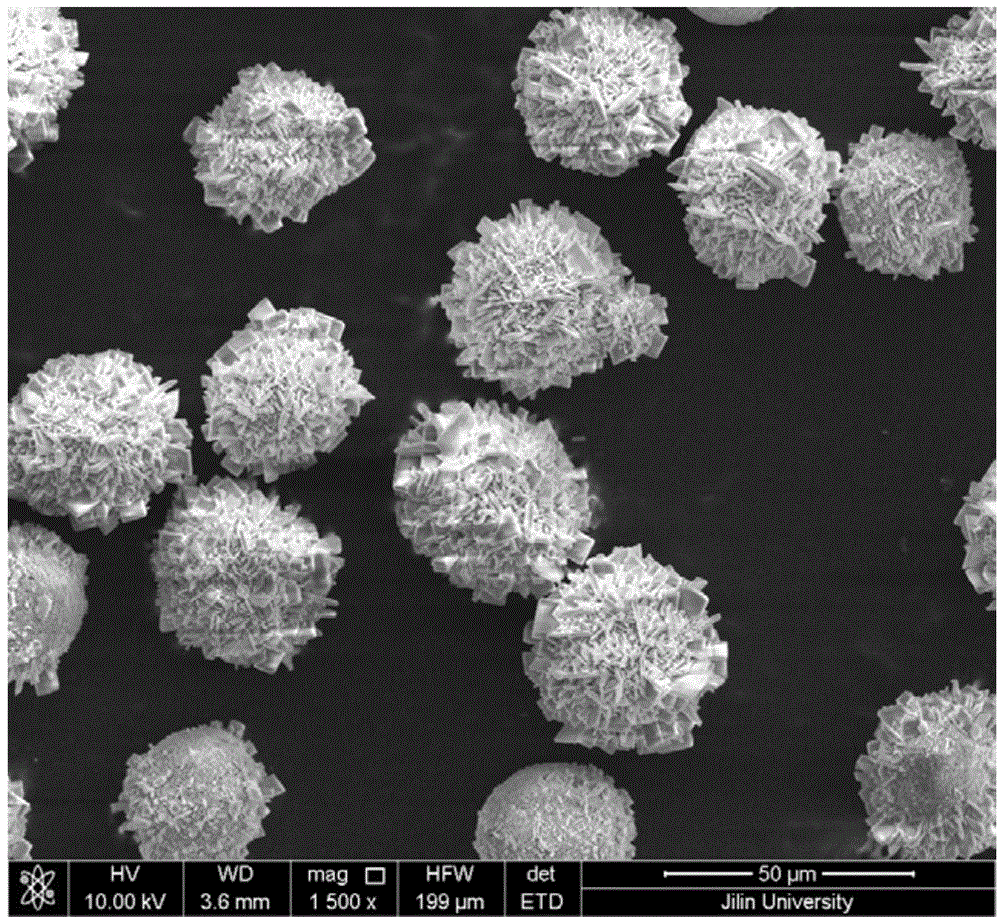

Method for preparing SrCuSi4O10 and BaCuSi4O10 blue pigments through hydrothermal technique

InactiveCN103601202AHigh purityMorphological rulesAlkaline-earth metal silicatesLuminescent compositionsDispersityLevel structure

The invention provides a method for preparing SrCuSi4O10 and BaCuSi4O10 blue pigments through a hydrothermal technique, and belongs to the technical field of hydrothermal chemistry. The method uses copper oxide powder or copper salt, barium salt or strontium salt, and silicate as raw materials, and NH4OH as a mineralizing agent and comprises the following hydrothermal reaction processes: mixing a reactant with distilled water according to a stoichiometric ratio of an objective product, adjusting the pH value of a solution to be greater than 10 and less than 14, putting in a high-pressure reactor so as to enable the filling degree to reach 40%-90%, sealing and reacting for 5-72 hours at the temperature of 230-300 DEG C; and cooling and filtering so as to obtain products. The invention provides a new reaction route and a green preparation method for SrCuSi4O10 and BaCuSi4O10 difficult to prepare. The products are multi-level structure microparticles, have high purity, regular morphology and good dispersity and are uniform in particle size. The preparation method is simple, efficient and high in yield; waste liquid generated in a hydrothermal reaction process can be recycled.

Owner:JILIN UNIV

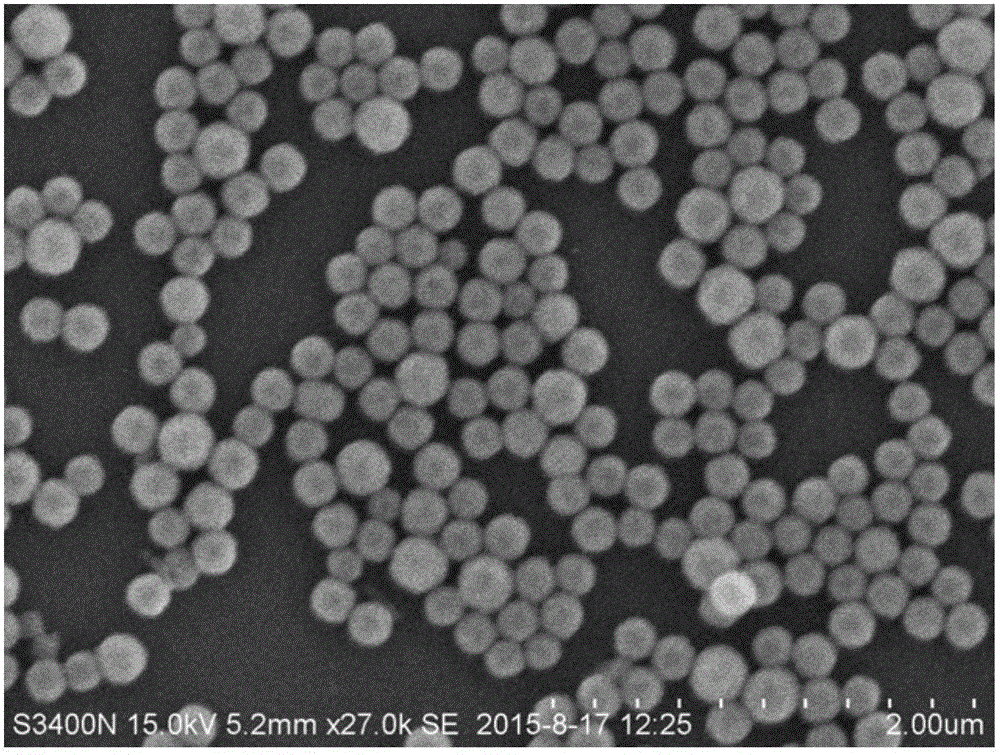

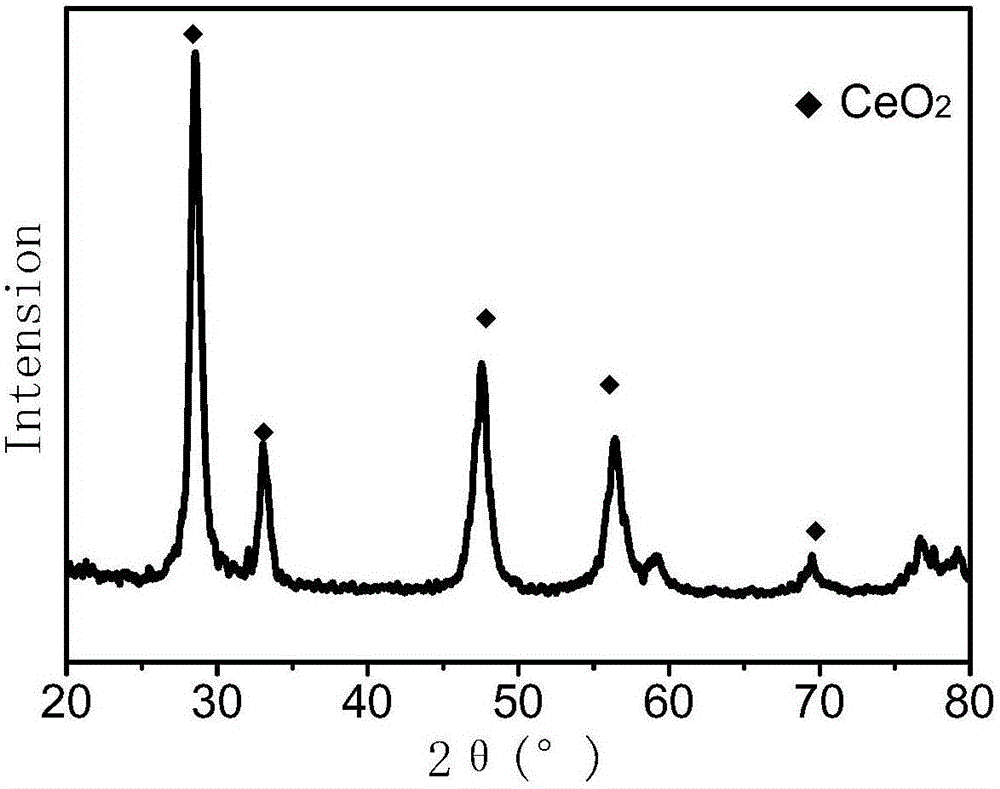

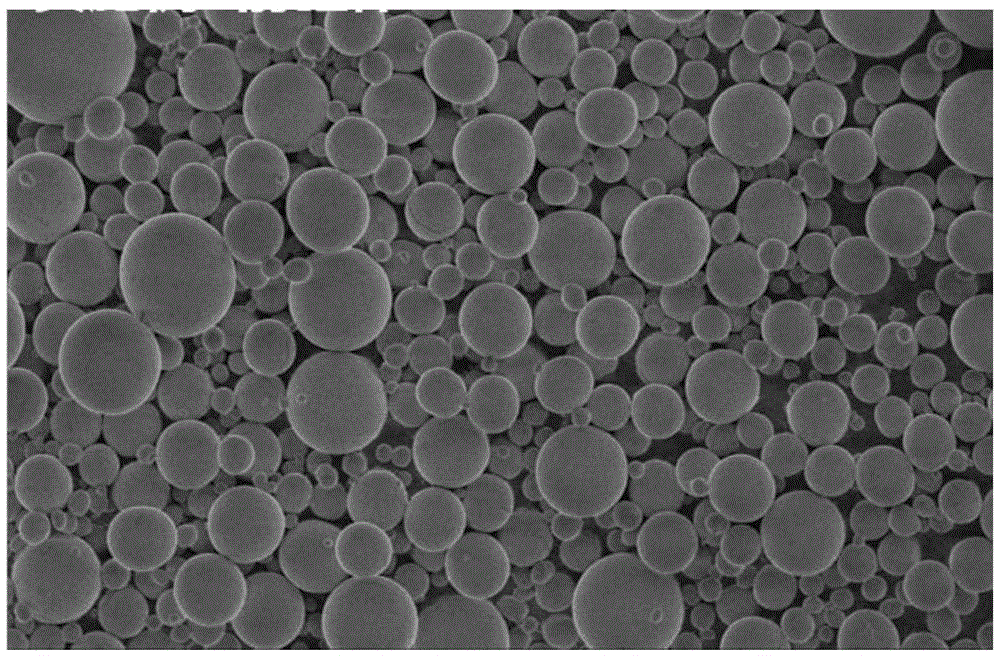

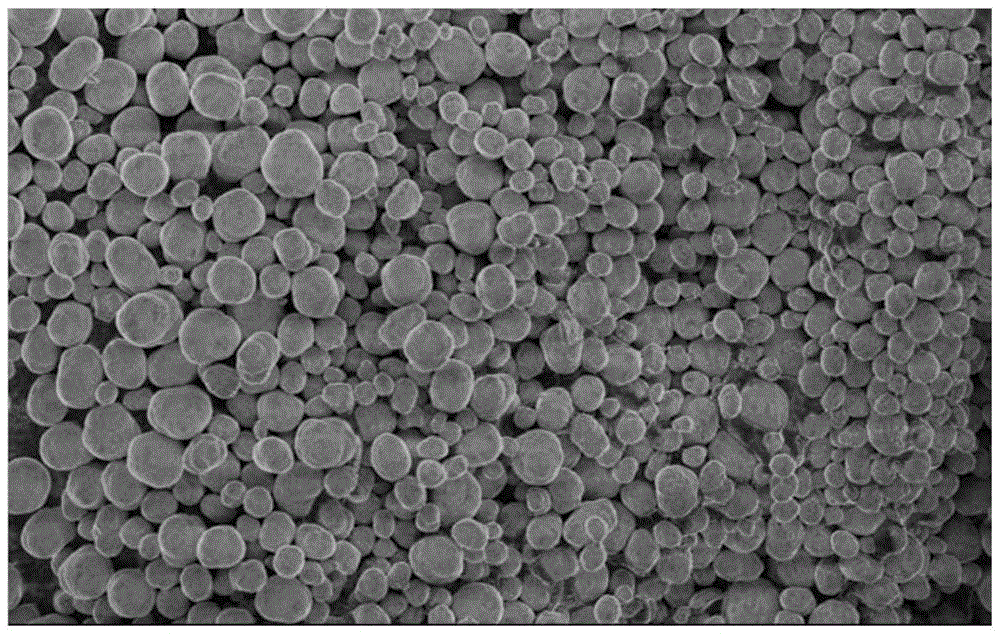

Spherical cerium dioxide

ActiveCN105948097AShort reaction timeSimple and fast operationRare earth metal oxides/hydroxidesCerium(IV) oxideThermal stability

The invention discloses a spherical cerium dioxide. The average particle size of spherical cerium dioxide is 50 nm-300 nm, and the specific surface area after roasting at 1000 DEG C is 1.5-20 m<2> / g, preferably, the specific surface area after roasting at 350 DEG C is 102-153 m<2> / g, and the specific surface area after roasting at 550 DEG C is 80-120 m<2> / g. The preparation method of the spherical cerium dioxide disclosed in the invention has short reaction time and simple operation, and is easy to control. Moreover, the prepared cerium dioxide is spherical and has regular shape, good degree of crystallization, high heat stability, and big specific surface area.

Owner:广州市威格林环保科技有限公司

Preparation method for positive electrode active material, and positive electrode active material

For overcoming the problems of irregular shape, uneven element distribution and partial agglomeration of metal elements of a positive electrode active material prepared by a method in the prior art, the invention provides a preparation method for the positive electrode active material, comprising the steps of S1, mixing a reaction seed crystal with a complexing agent solution, wherein the reaction seed crystal is hydroxide of one or more of nickel, cobalt, manganese or aluminum; and the D50 of the reaction seed crystal is less than or equal to 2-6 [mu]m; S2, under a condition of stirring and ultrasonic processing, adding a metal salt solution and a precipitator solution, regulating PH to 9-13; and then washing and drying to obtain a precursor, wherein the metal salt solution is a solution containing nickel salt, cobalt salt, manganese salt and aluminum salt; and S3, mixing the precursor with a lithium source, performing heat preservation at a temperature of 500-950 DEG C for 2-24h, and cooling. Meanwhile, the invention also discloses the positive electrode active material prepared by the method. The positive electrode active material provided by the invention is regular in shape, high in degree of sphericity, uniform in element distribution and free of partial agglomeration of metal elements; and in addition, the positive electrode active material is high in cycling performance, thermal stability and security.

Owner:BTR NEW MATERIAL GRP CO LTD

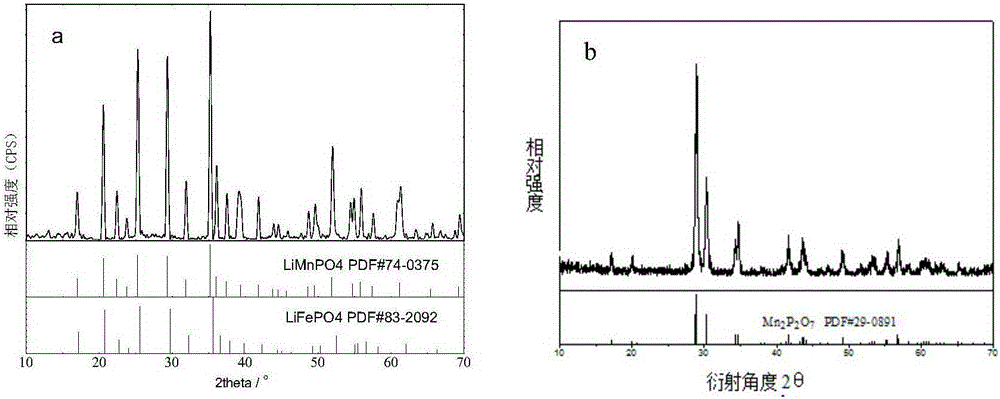

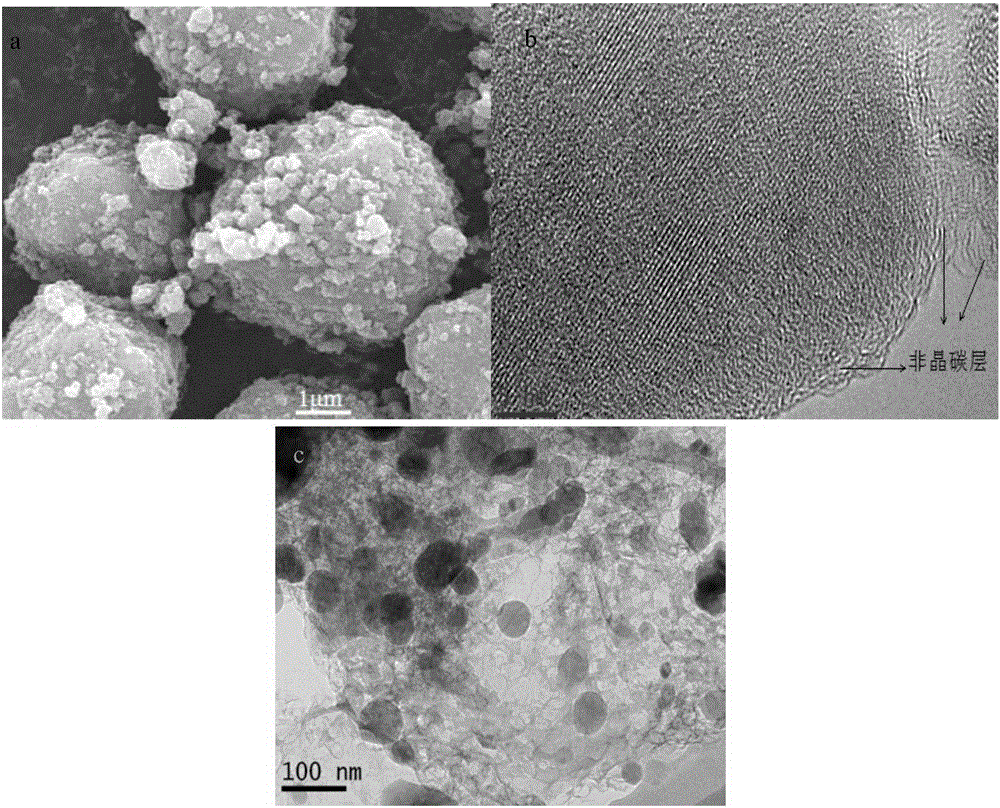

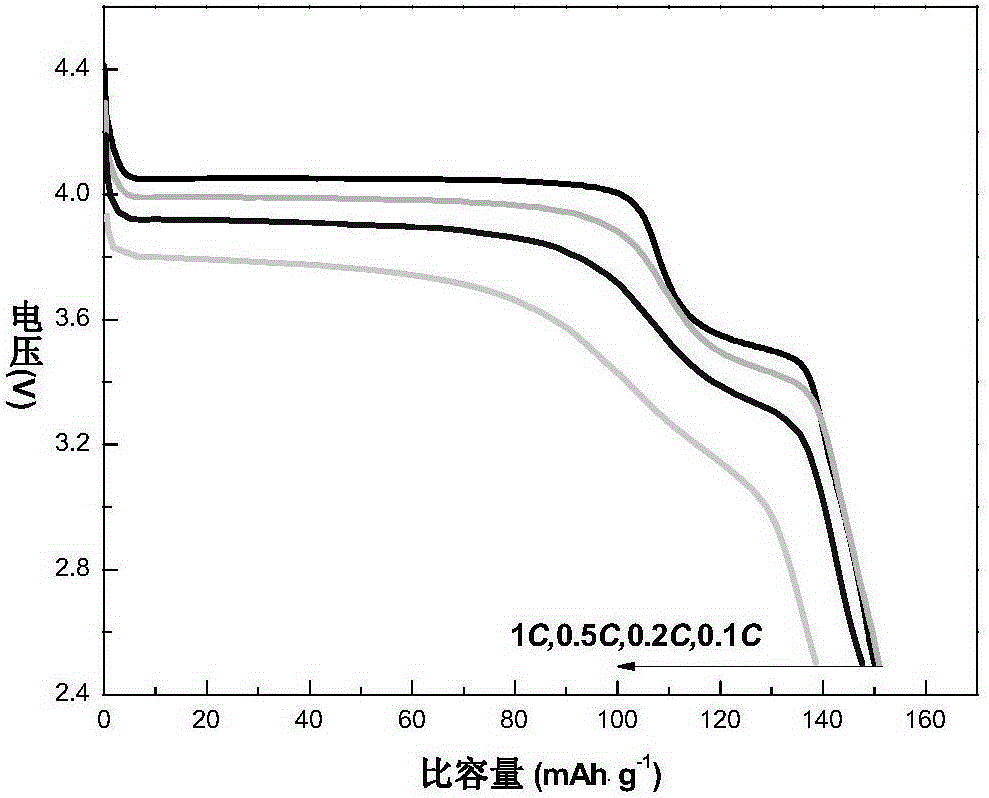

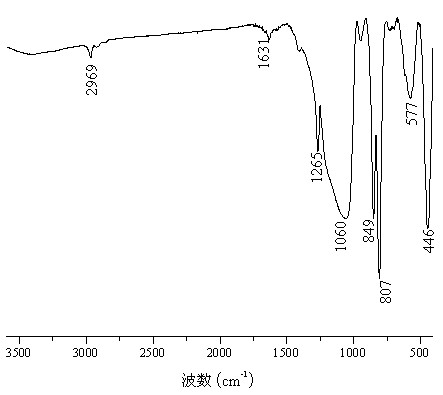

Synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4/C

InactiveCN105355885AUniform controlAdd lessSecondary cellsPositive electrodesHigh rateSynthesis methods

The invention relates to a synthesis method of lithium ion battery composite cathode material LiMn1-xFexPO4 / C. A manganese source, an iron source, a phosphorus source and an organic carbon source are evenly mixed and processed by a high-energy ball mill. Mixtures are subjected to heat treatment at 500-700 DEG C under the protection of inert atmosphere so that (Mn1-xFex)2P2O7 / C can be prepared; then, pyrophosphate / carbon, a lithium source and a carbon source are mixed, heat treatment is performed at 600-750 DEG C under protection of inert atmosphere, and ferromanganese lithium phosphate / carbon anode materials with a composite conductive network are obtained. The synthesis method is suitable for large-scale industrialized production, the prepared materials are composed of secondary particles of primary nano-crystals covered with amorphous carbon, distribution is uniform, and the uniform conductive network is formed on the surfaces of phosphate particles in an in-situ mode. The obtained composite cathode material has high rate capacity and high compaction intensity and has good application prospects in the aspect of high-energy-density lithium ion batteries.

Owner:CENT SOUTH UNIV

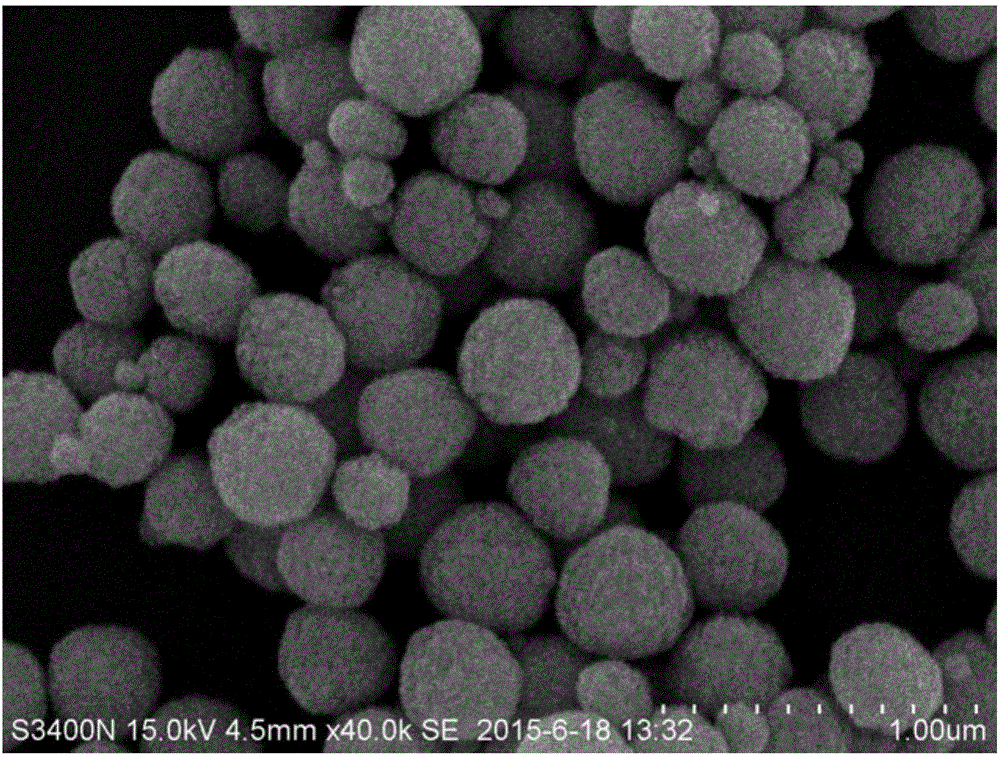

Synthesizing method for organic silicon micro-balls with performances of super hydrophobicity and high temperature resistant

The invention discloses a synthesizing method for organic silicon micro-balls with performances of super hydrophobicity and high temperature resistant, which relates to the synthesizing method of organic silicon. The synthesizing method for the organic silicon micro-balls comprises the following steps: firstly hydrolyzing n-silicate ester of which the structural formula is Si(ORn)4 (n is the number of carbon atom), and then forming a spherical pre-polymer after polycondensation; adding alkylchlorosilane of which the structural formula is Cl2Si(Rn)2 (n is the number of carbon atoms) or alkoxy silane of which the structural formula is (Rn)2Si(ORn)2 (n is the number of carbon atoms), so as to obtain the organic silicon micro-balls of which surfaces are fully provided with alkyls after copolycondensation. The obtained micro-balls have good dispersibility, and have characteristics of super hydrophobicity and high temperature resistant and the range of particle diameter is within 0.5-10 microns. The organic silicon micro-balls are simple in production technology, free form pollution during the production process and convenient for post-treatment technology, and can be widely applied to rubber, plastic and adhesive, so as to improve the temperature resistant performance of basis materials. The organic silicon micro-balls also can be applied to coating and self-prepared hydrophobic self-cleaned coating.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

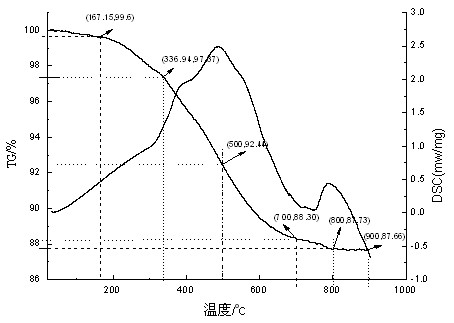

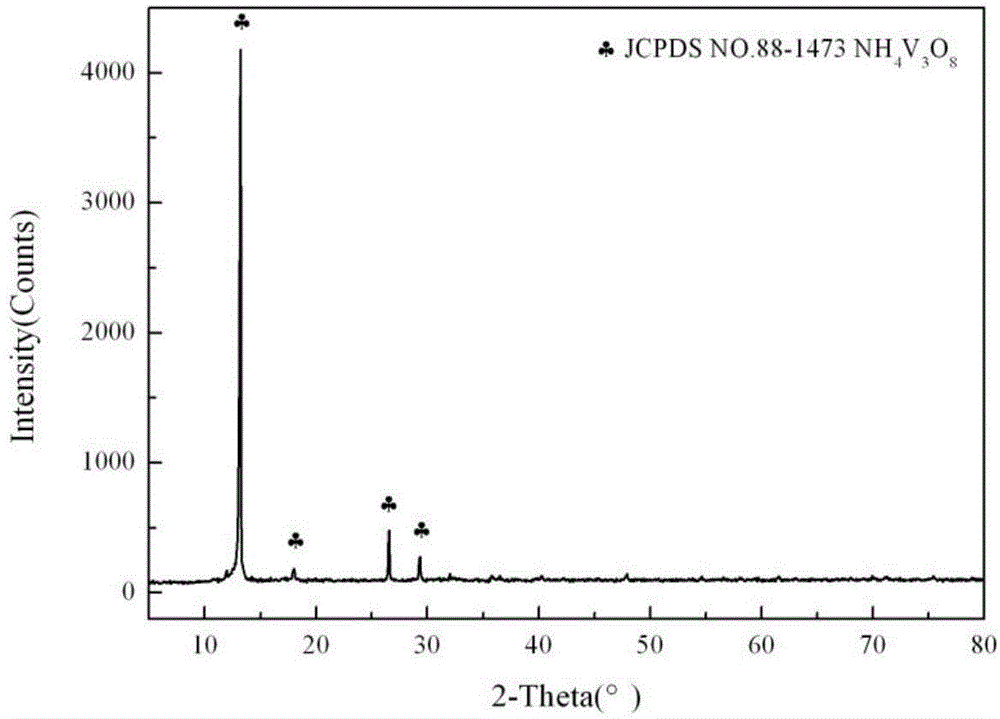

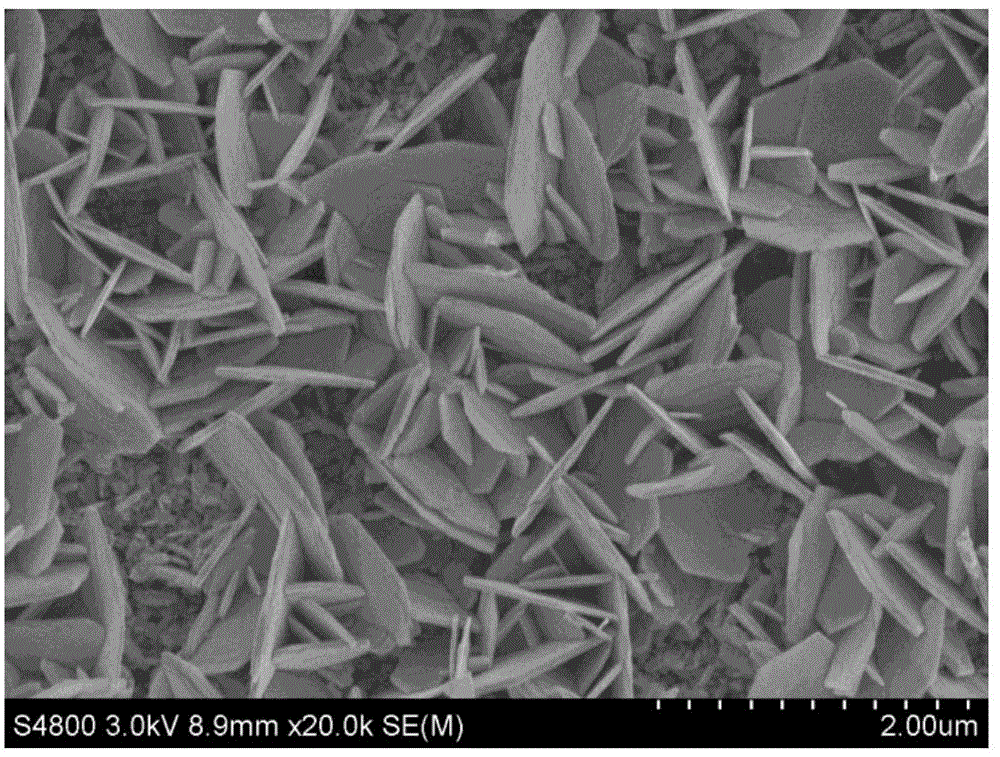

Method for preparing NH4V3O8 anode material for lithium ion battery

ActiveCN104701517APromote absorptionIncrease profitCell electrodesVanadium compoundsFiberCarbon fibers

The invention discloses a method for preparing an NH4V3O8 anode material for a lithium ion battery. The method comprises the steps that ammonium metavanadate is dissolved in deionized water, an NH4VO3 solution is prepared, pre-oxidization short carbon fibers of 1 mm to 3 mm are added, the NH4VO3 solution is transferred into a reaction still after the pH value is adjusted, forced mixing is carried out, after the reaction still is sealed, the reaction still is placed in a water and heat induction heater, and suspension liquid is obtained after a heating reaction; centrifugal separation is carried out on the suspension liquid to obtain a powder product, the powder product is soaked in the deionized water and the absolute ethyl alcohol, repeated washing is carried out, and then drying and grinding are carried out. The NH4V3O8 microcrystal prepared through the method is uniform in chemical component, high in purity and uniform in form, and the electrochemical performance of the material can be effectively improved. The preparation method is simple, low in reaction temperature, short in reaction period, high in productivity, free of any subsequent treatment, environmentally friendly and capable of being suitable for large-scale production.

Owner:安徽翰邦科技咨询有限公司

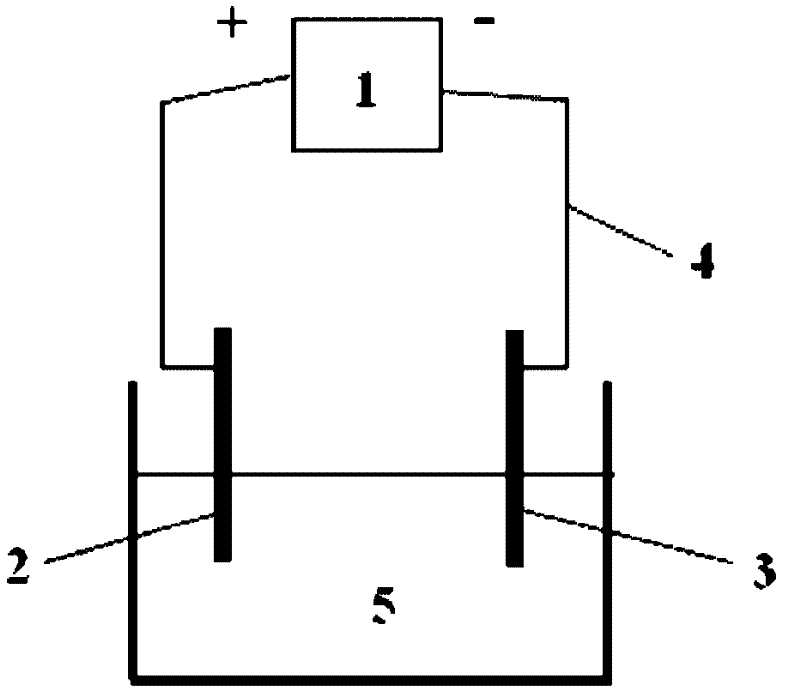

Method for electrochemically aided preparation of silver powder with special form

InactiveCN102418118ASimple preparation processLow costMaterial nanotechnologyElectrochemical responseMetallic electrode

The invention provides a method for electrochemically aided preparation of silver powder with a special form. According to the invention, carbonic or metallic electrodes are used as a working electrode and a counter electrode; after cleaning with ultrasonic wave, the working electrode and the counter electrode are immersed into a solution or sol containing silver ions prepared by using ultra pure deionized water; the working electrode is used as a cathode, the counter electrode is used as an anode, and an electrochemical reaction is carried out under an air-tight condition and the condition of a constant current; after the reaction, a resultant is separated and dried to obtain nanometer silver powder. Through control of the variety of electrodes, the amount of current flowing and the variety of electrolytes, dendritic nanometer silver powder, flake nanometer silver powder, laminated flake nanometer silver powder, fibrous nanometer silver powder, cubic cage nanometer silver powder and tetrahedron cubic cage nanometer silver powder can be prepared. The method provided in the invention enables form control and continuous preparation of nanometer silver particles to be realized without addition of any other chemical reagents; the method has the advantages of a simple process, a widely applicable product, high yield of the powder, greenness, environmental protection and feasibility in industrial production.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for preparing hammer-shaped palladium nanoparticle by utilizing octreotide acetate as template

InactiveCN103203461AExcellent biological templateSimple molecular structureOctreotide acetateSodium borohydride

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000011.PNG)

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000012.PNG)

![Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material Method for preparing porous spherical Li(1-x)MxFe(1-y)Ny(PO4)([3+(alpha-1)x+(beta-2) y]/3)/C material](https://images-eureka.patsnap.com/patent_img/782b61db-f3e4-44d1-8fac-89d25bd2d0b8/HSA00000314482000013.PNG)