Preparation of stibium doping stannic oxide nanopowder by hydrothermal method

A technology of tin dioxide and nano-powder, which is applied in the direction of tin oxide, etc., can solve the problems of small control margin and poor stability, and achieve the effects of easy control of reaction conditions, excellent electrical conductivity, and regular powder morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

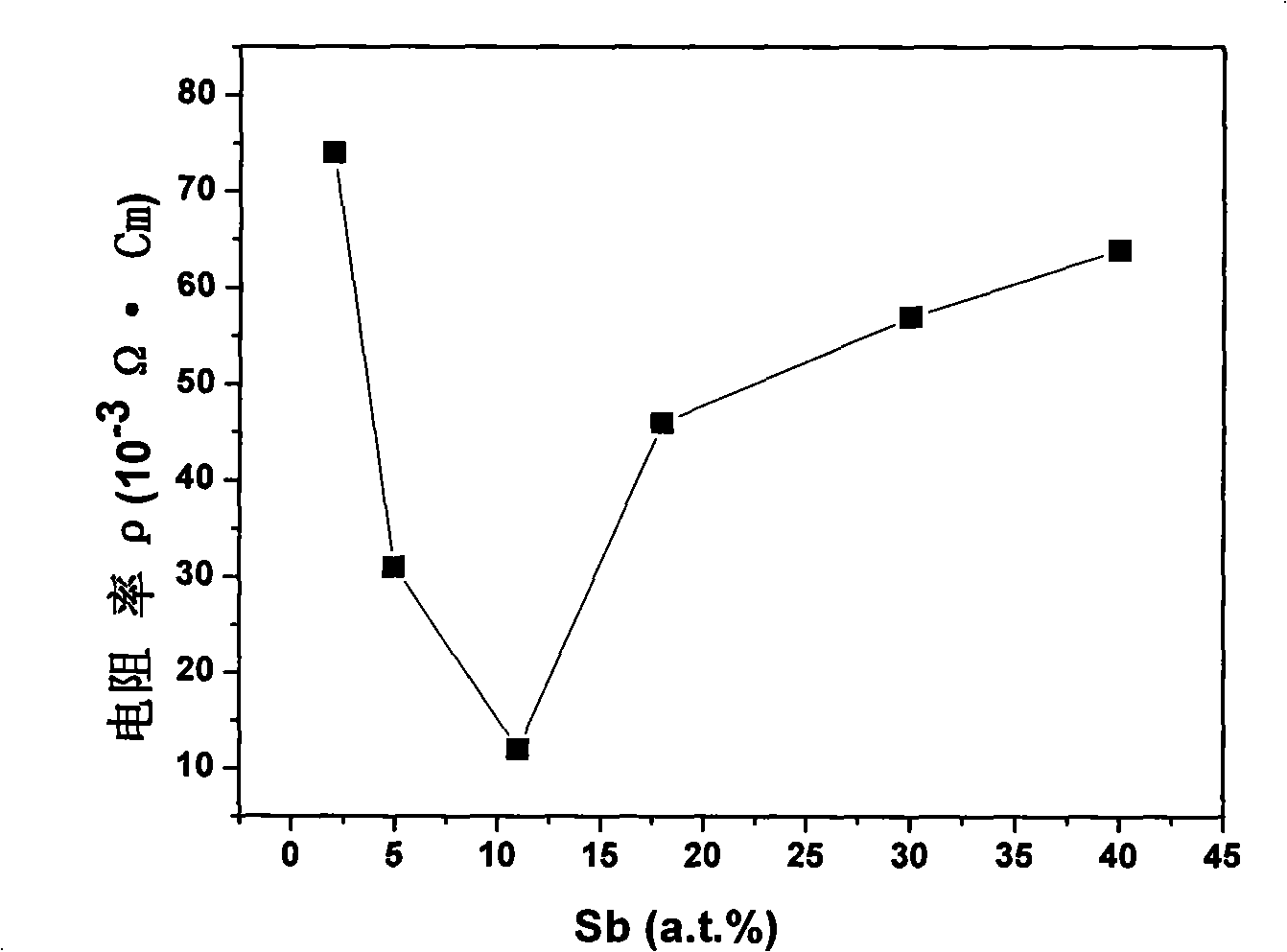

Embodiment 1

[0017] SnCl 4 ·5H 2 O(A.R.) and SbCl 3 (A.R.) were prepared into ethanol solutions of 1mol / L and 0.2mol / L respectively. Take SnCl 4 ·5H 2 O ethanol solution, add SbCl according to the doping ratio Sb / Sn=1:50 (mol / mol) 3 ethanol solution, adding deionized water to dilute the SnCl 4 The concentration is 0.5mol / L, stir and mix evenly, adjust the pH value to 9 with ammonia water, take 80mL of the mixed solution and inject it into a 100mL stainless steel autoclave with a polytetrafluoroethylene lining and electromagnetic stirring, at a hydrothermal temperature of 150°C React with a pressure of 18MPa for 2h. The product was washed with deionized water, dried, ground, and treated at 600° C. for 30 minutes to obtain Sb-doped tin dioxide nanopowder.

Embodiment 2

[0019] SnCl 4 ·5H 2 O(A.R.) and SbCl 3 (A.R.) were prepared into ethanol solutions of 1mol / L and 0.2mol / L respectively. Take SnCl 4 ·5H 2 O ethanol solution, add SbCl according to the doping ratio Sb / Sn=11:100 (mol / mol) 3 ethanol solution, adding deionized water to dilute the SnCl 4 The concentration is 0.5mol / L, stir and mix evenly, adjust the pH value to 9 with ammonia water, take 80mL of the mixed solution and inject it into a 100mL stainless steel autoclave with a polytetrafluoroethylene lining and electromagnetic stirring, at a hydrothermal temperature of 150°C React with a pressure of 18MPa for 2h. The product was washed with deionized water, dried, ground, and treated at 600° C. for 30 minutes to obtain Sb-doped tin dioxide nanopowder.

Embodiment 3

[0021] SnCl 4 ·5H 2 O(A.R.) and SbCl 3 (A.R.) were prepared into ethanol solutions of 1mol / L and 0.2mol / L respectively. Take SnCl 4 ·5H 2 O ethanol solution, add SbCl according to the doping ratio Sb / Sn=9:50 (mol / mol) 3 ethanol solution, adding deionized water to dilute the SnCl 4 The concentration is 0.5mol / L, stir and mix evenly, adjust the pH value to 9 with ammonia water, take 80mL of the mixed solution and inject it into a 100mL stainless steel autoclave with a polytetrafluoroethylene lining and electromagnetic stirring, at a hydrothermal temperature of 150°C React with a pressure of 18MPa for 2h. The product was washed with deionized water, dried, ground, and treated at 600° C. for 30 minutes to obtain Sb-doped tin dioxide nanopowder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com