Method for preparing palladium and/or antimony-doping tin oxide nano-powder

A nano-powder, antimony-doped technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of unfavorable long-term large-scale production, affecting the final performance of powder, inconvenient storage and use, etc., to achieve the goal of preparation The effect of short cycle, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

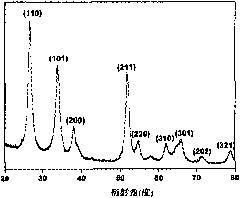

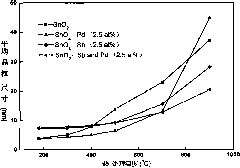

specific Embodiment 1

[0030] Step 1, 2.7078g of SnCl 2 2H 2 O was dissolved in 20mL of ethanol and stirred to form a 0.6mol / L transparent solution; according to Pd 2+ with Sn 2+ The molar ratio is 2.5%, weigh an appropriate amount of PdCl 2 Dissolve in 1.0mol / L hydrochloric acid aqueous solution, and stir to form a 0.3mol / L solution; Dissolve NaOH in a certain amount of deionized water, and stir to form a 1mol / L NaOH solution;

[0031] Step 2, under stirring conditions, the PdCl configured in step 1 2 The solution was evenly added dropwise to the SnCl 2solution, and then stirred for 10 minutes to form a mixed solution;

[0032] Step 3, while stirring, NaOH solution is evenly added dropwise to the mixed solution obtained in Step 2 until the pH value is 12, and then stirred for 1 hour to form a precursor suspension with a large amount of precipitation;

[0033] Step 4, transfer the precursor suspension obtained in step 3 to an autoclave, react at 180° C. for 12 hours, and then naturally cool to...

specific Embodiment 2

[0036] Step 1, 2.7078g of SnCl 2 2H 2 O was dissolved in 20mL of ethanol and stirred to form a 0.6mol / L transparent solution; according to Sb 3+ with Sn 2+ The molar ratio is 2.5%, weigh an appropriate amount of SbCl 3 Dissolve in water and form a 0.3mol / L suspension with white precipitate after stirring; Dissolve NaOH in a certain amount of deionized water and form a 1mol / L NaOH solution after stirring;

[0037] Step 2, under stirring conditions, the SbCl configured in step 1 3 The suspension was evenly added dropwise to the SnCl 2 solution, and then stirred for 20 minutes to form a mixed solution;

[0038] Step 3, while stirring, NaOH solution is evenly added dropwise to the mixed solution described in step 2 until the pH value is 12, and then stirred for 1 hour to form a precursor suspension accompanied by a large amount of precipitation;

[0039] Step 4, transferring the precursor suspension described in step 3 to a high-pressure reactor, reacting at 180° C. for 24 h...

specific Embodiment 3

[0042] Step 1, 2.7078g of SnCl 2 2H 2 O was dissolved in 20mL of ethanol and stirred to form a 0.6mol / L transparent solution; according to Pd 2+ with Sn 2+ The molar ratio is 2.5%, weigh an appropriate amount of PdCl 2 Dissolve in 1.0mol / L hydrochloric acid aqueous solution, and form a 0.3mol / L purplish red solution after stirring; according to Sb 3+ with Sn 2+ The molar ratio is 2.5%, weigh an appropriate amount of SbCl 3 Dissolve in water and form a 0.3mol / L suspension with white precipitate after stirring; Dissolve NaOH in a certain amount of deionized water and form a 1mol / L NaOH solution after stirring;

[0043] Step 2, under agitation conditions, the PdCl configured in step 1 is respectively 2 and SbCl 3 The solution was evenly added dropwise to the SnCl 2 solution, and then stirred for 30 minutes to form a mixed solution;

[0044] Step 3, while stirring, NaOH solution is evenly added dropwise to the mixed solution described in step 2 until the pH value is 12, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com