Patents

Literature

251results about "Alkali metal halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Free-standing and aligned carbon nanotubes and synthesis thereof

One or more highly-oriented, multi-walled carbon nanotubes are grown on an outer surface of a substrate initially disposed with a catalyst film or catalyst nano-dot by plasma enhanced hot filament chemical vapor deposition of a carbon source gas and a catalyst gas at temperatures between 300° C. and 3000° C. The carbon nanotubes range from 4 to 500 nm in diameter and 0.1 to 50 μm in length depending on growth conditions. Carbon nanotube density can exceed 104 nanotubes / mm2. Acetylene is used as the carbon source gas, and ammonia is used as the catalyst gas. Plasma intensity, carbon source gas to catalyst gas ratio and their flow rates, catalyst film thickness, and temperature of chemical vapor deposition affect the lengths, diameters, density, and uniformity of the carbon nanotubes. The carbon nanotubes of the present invention are useful in electrochemical applications as well as in electron emission, structural composite, material storage, and microelectrode applications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

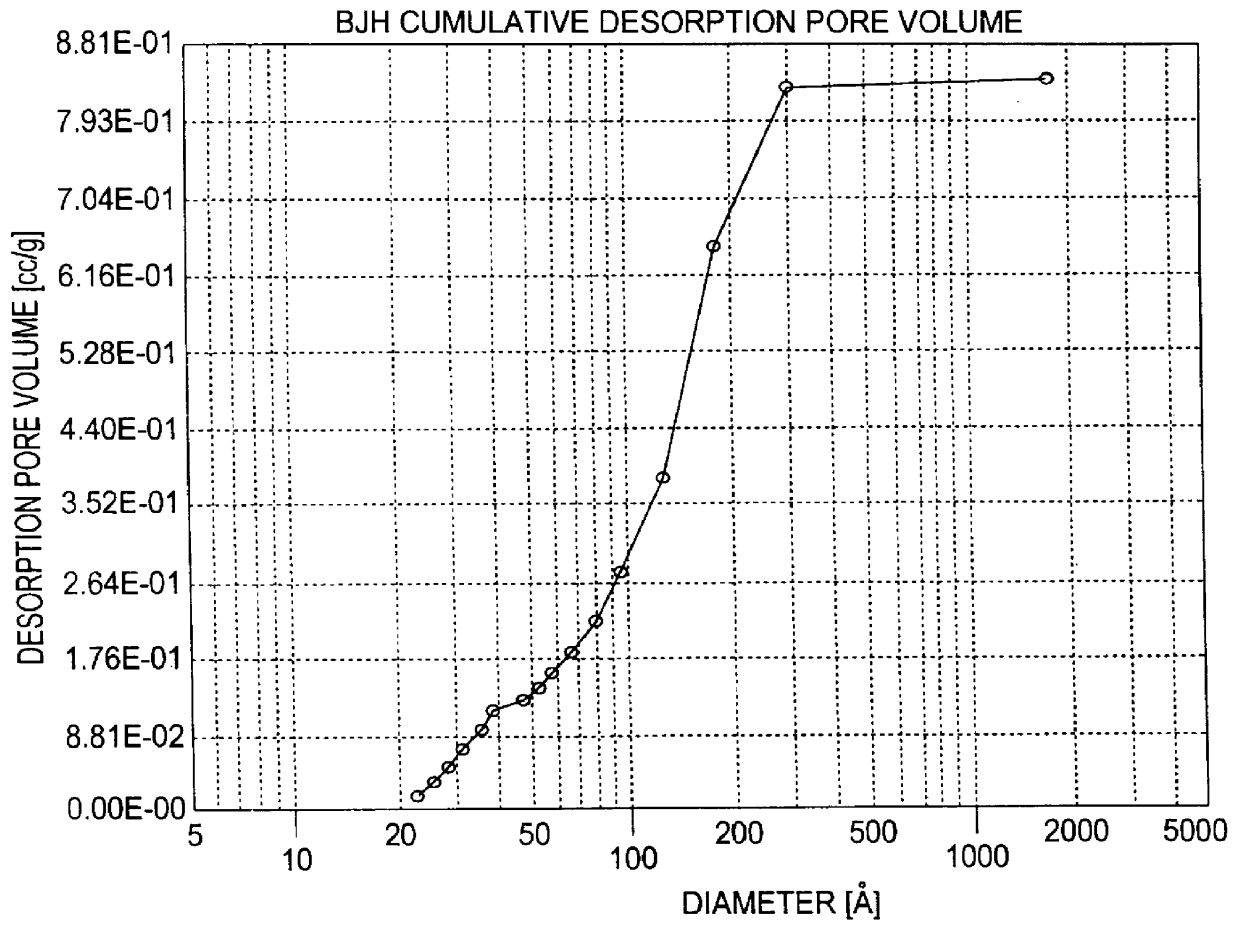

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

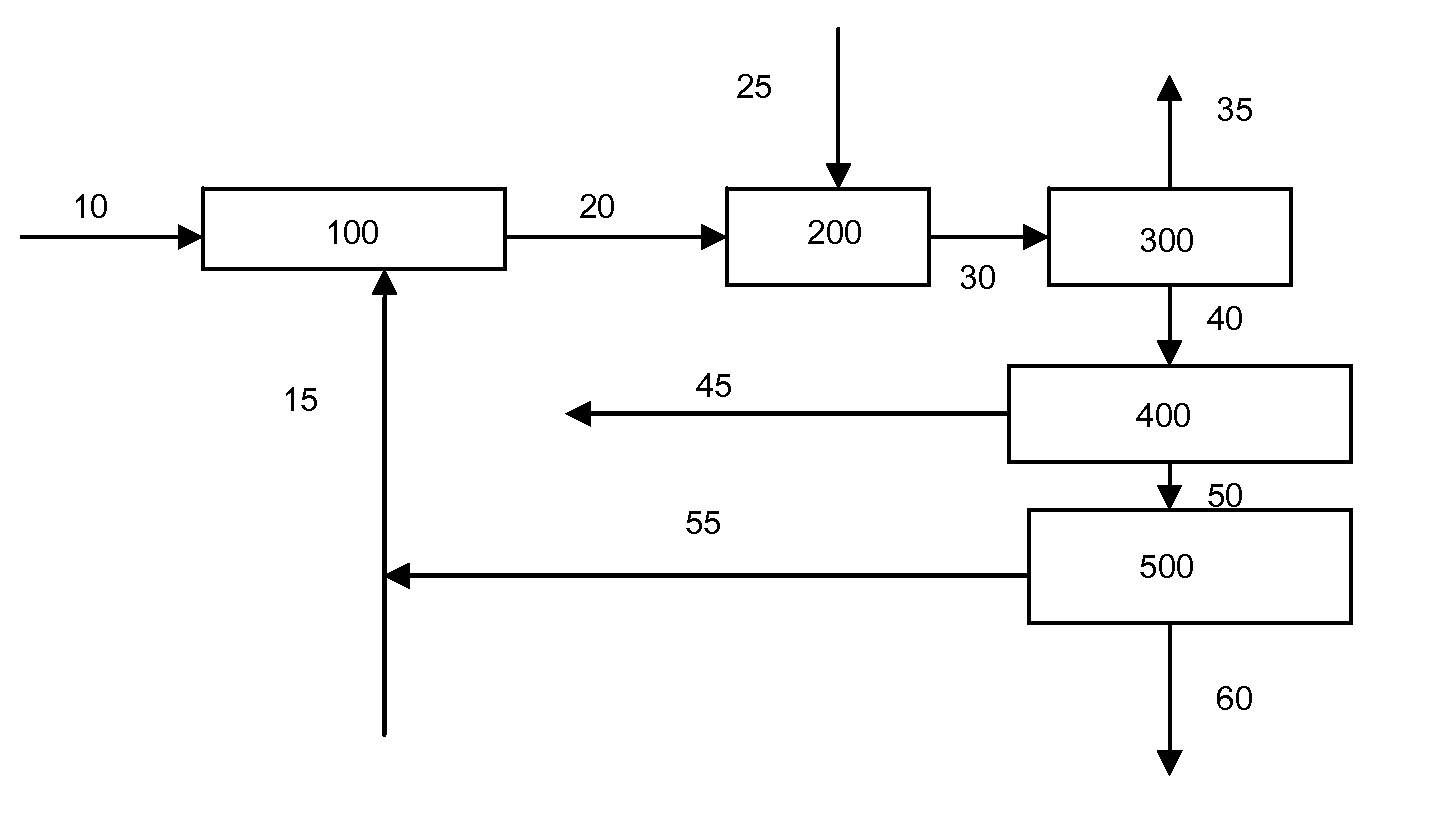

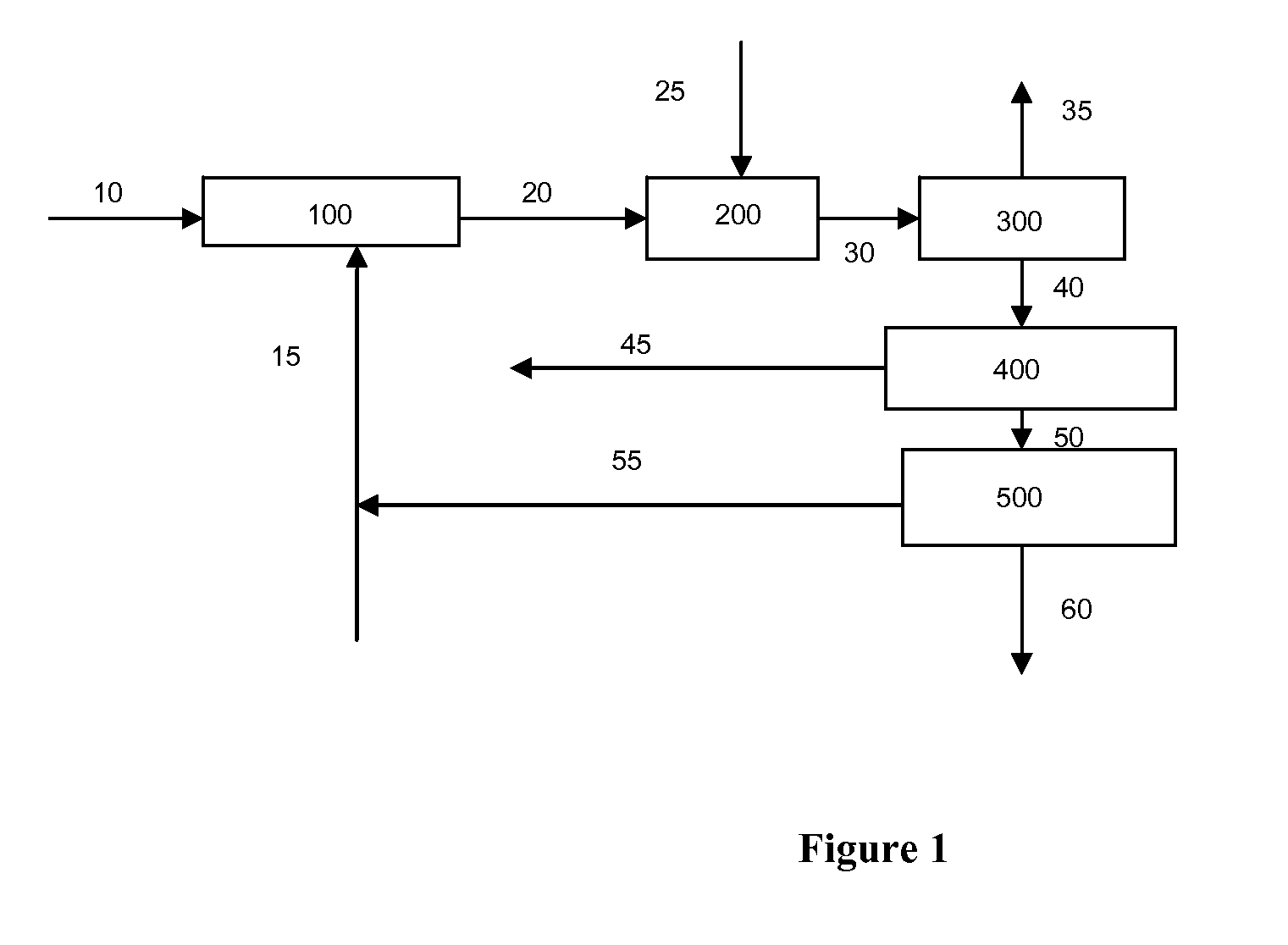

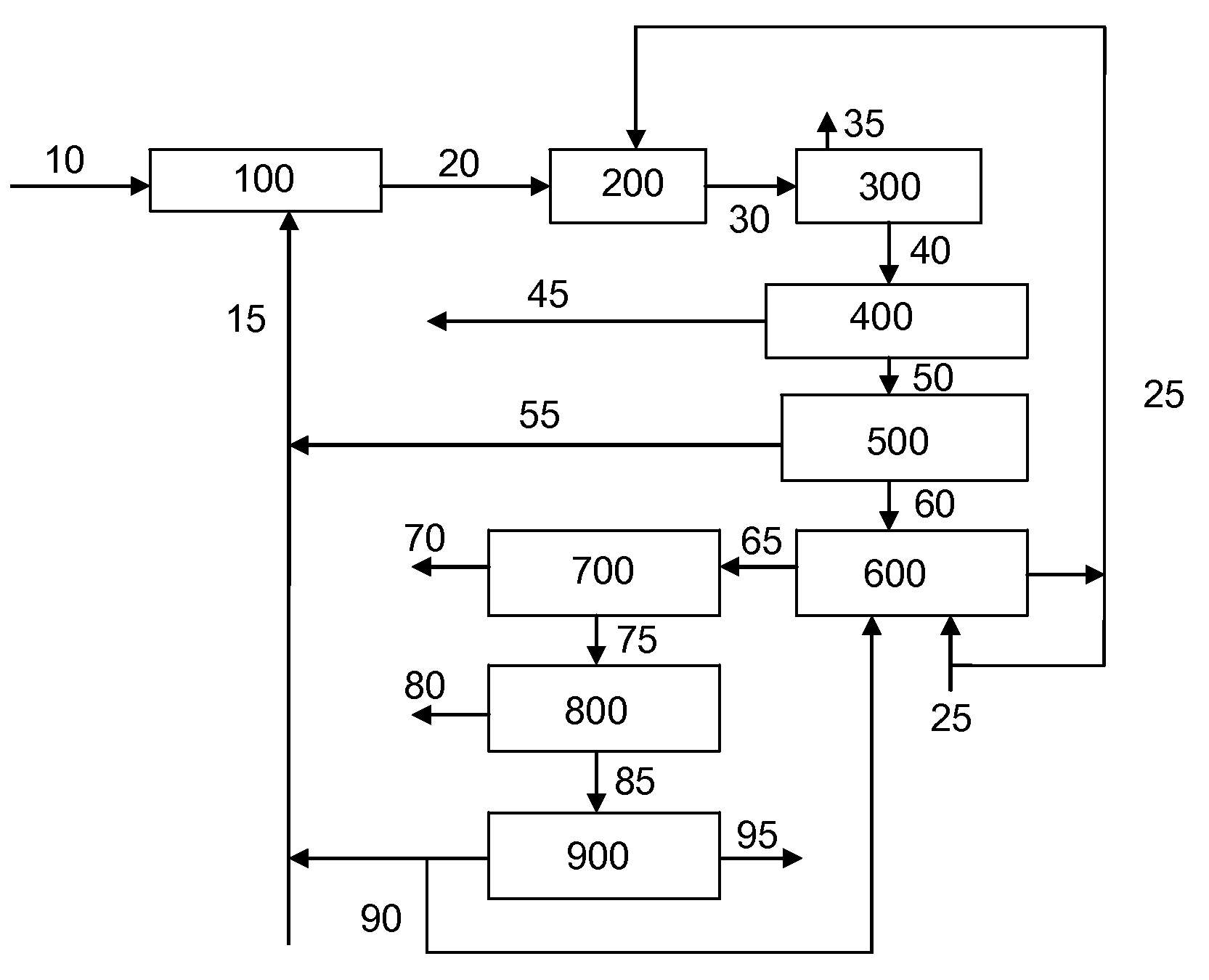

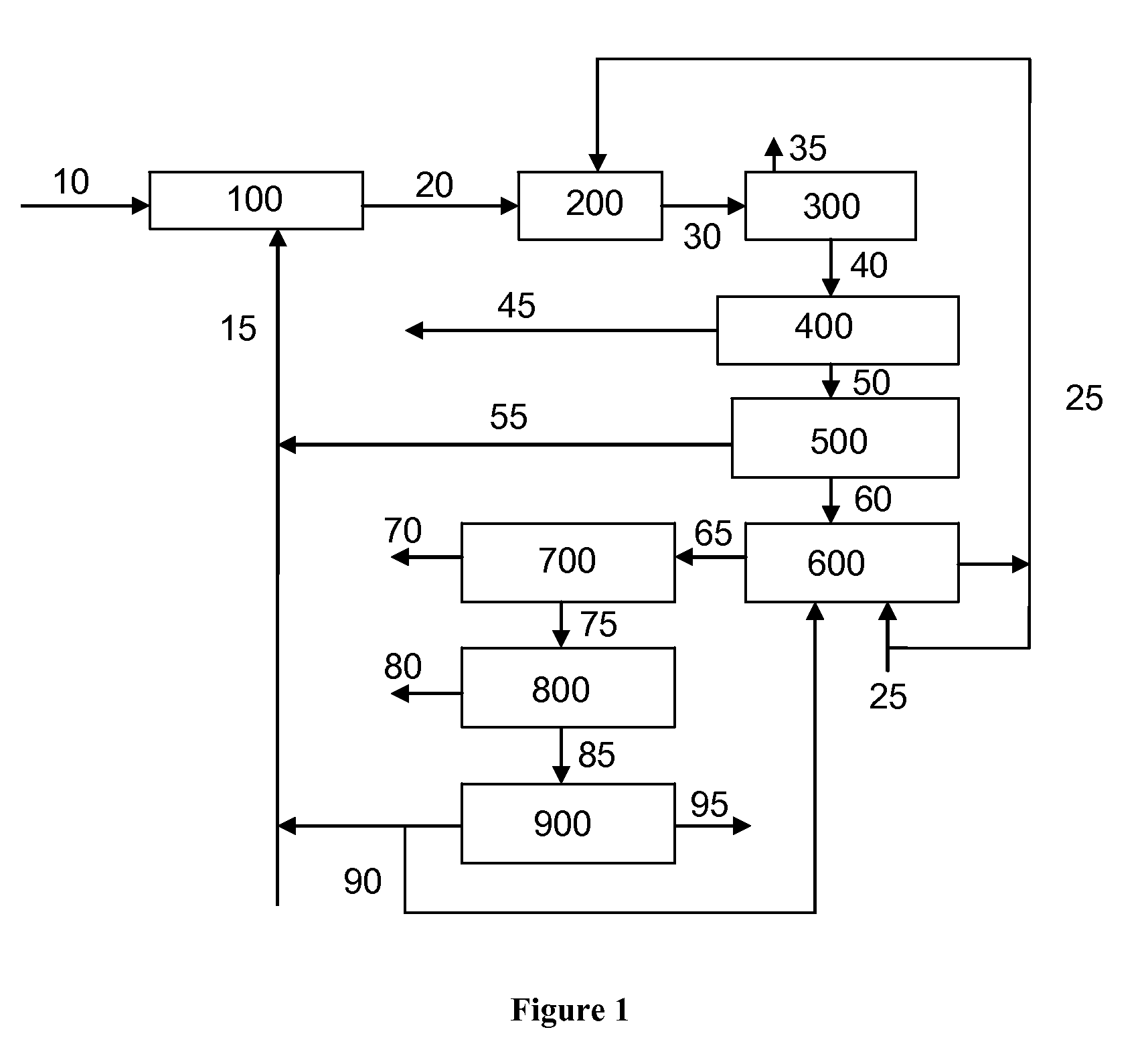

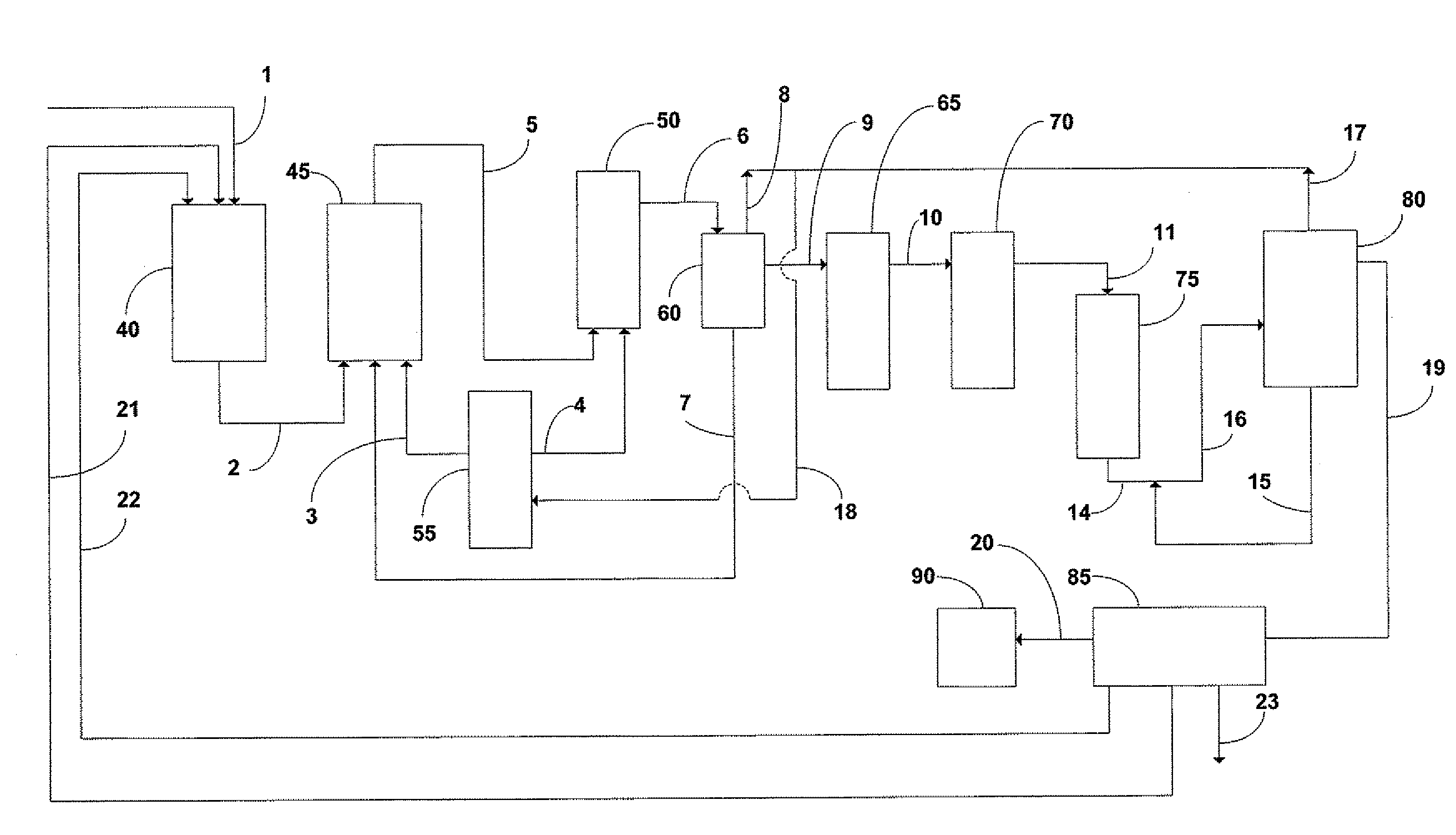

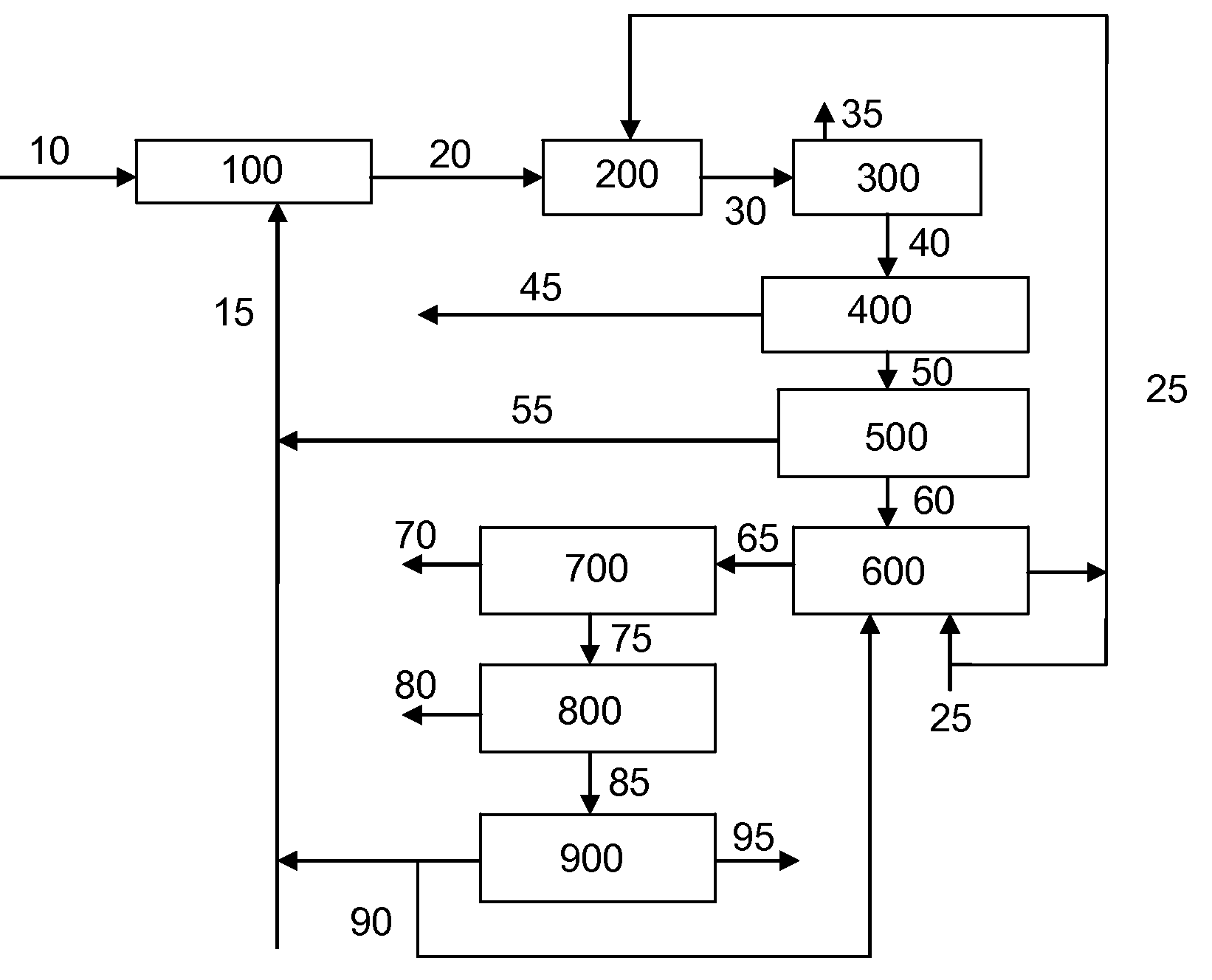

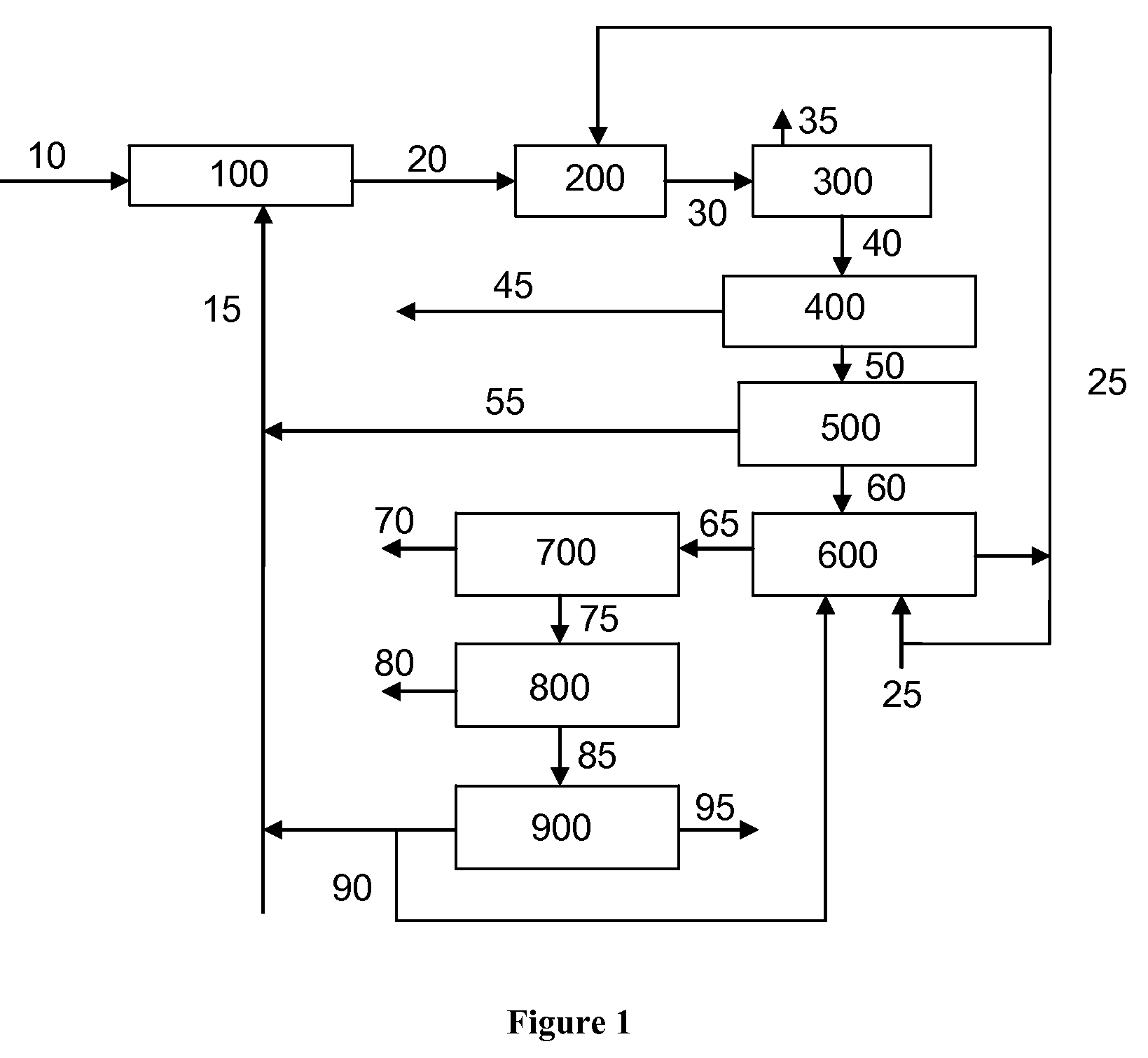

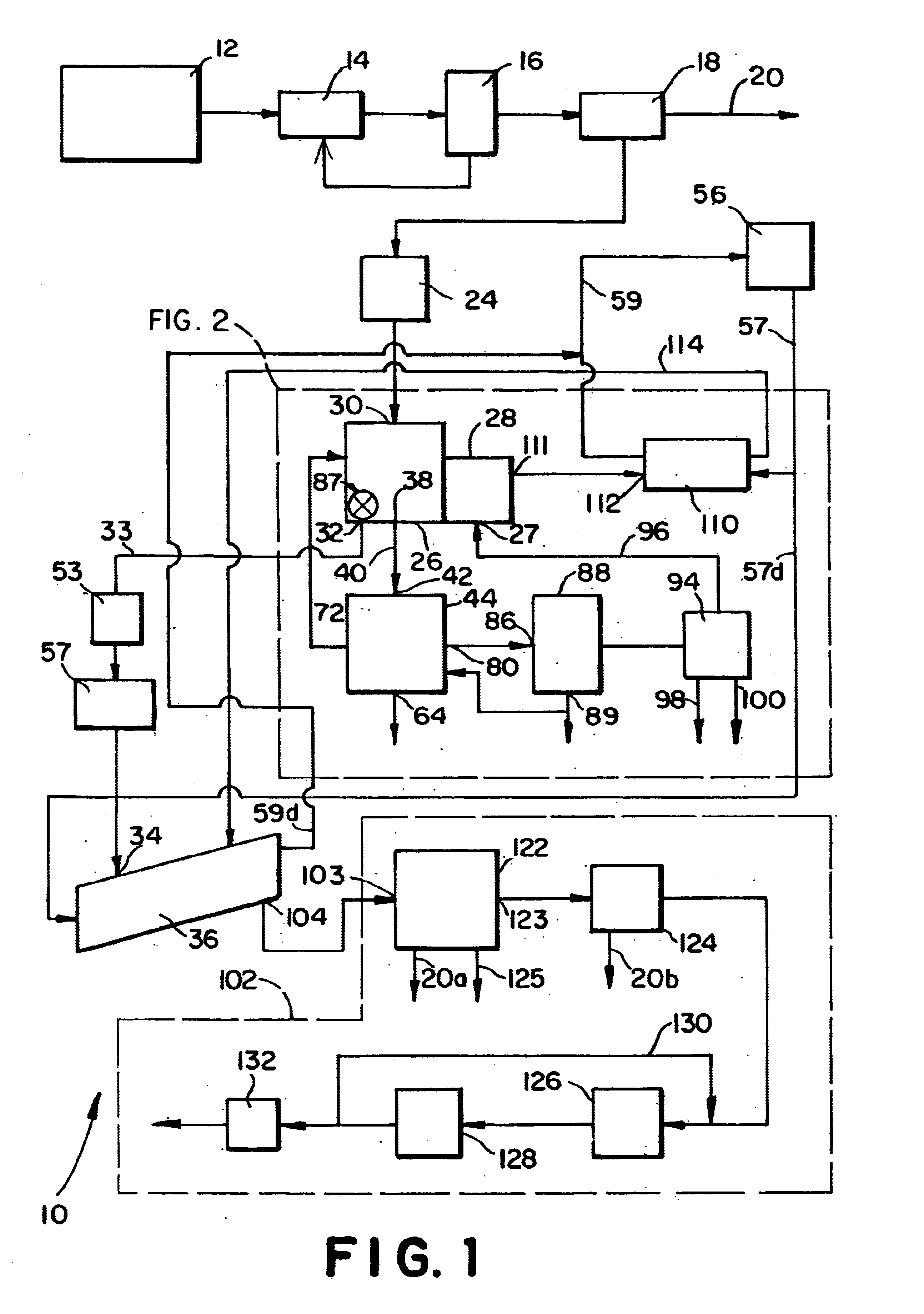

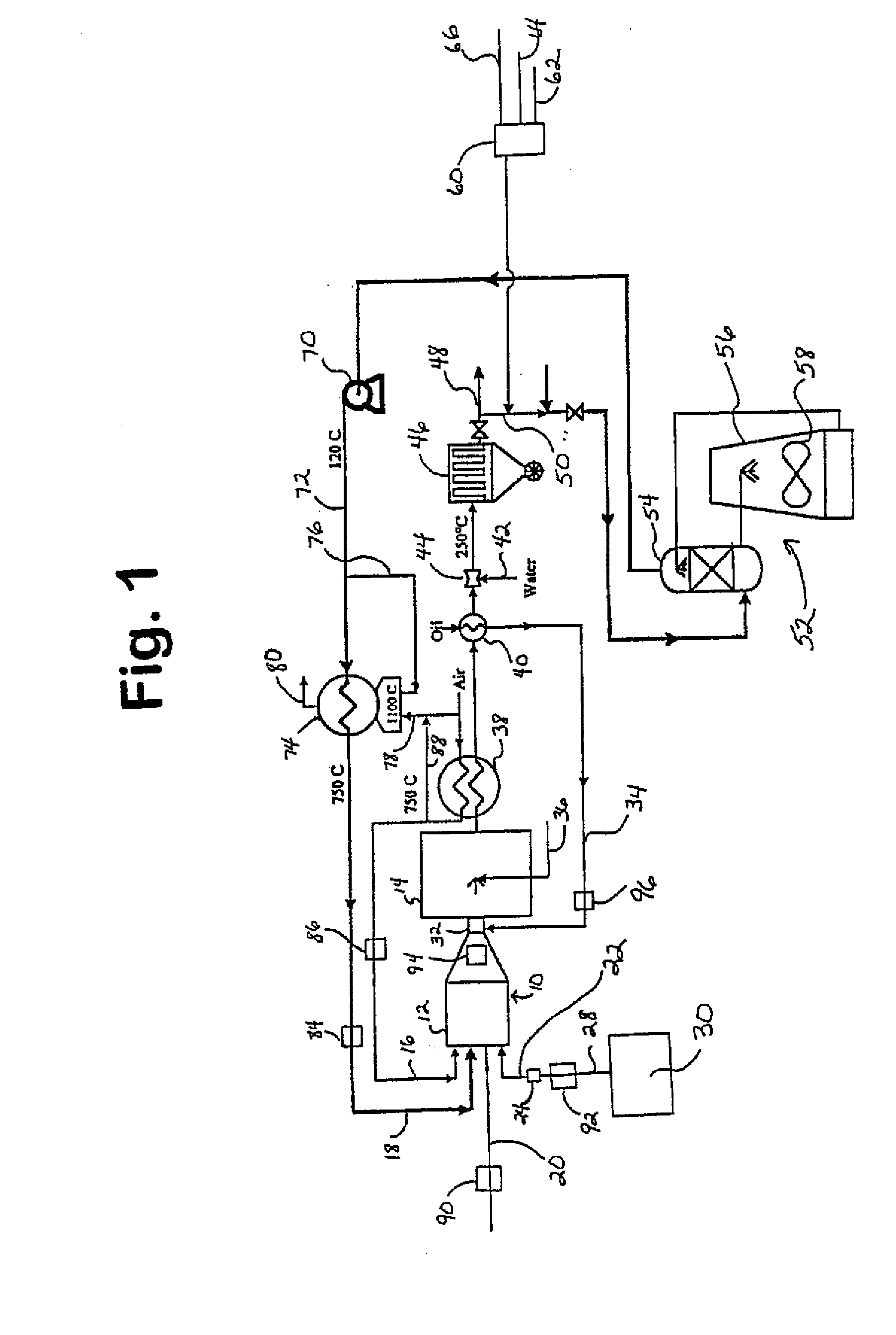

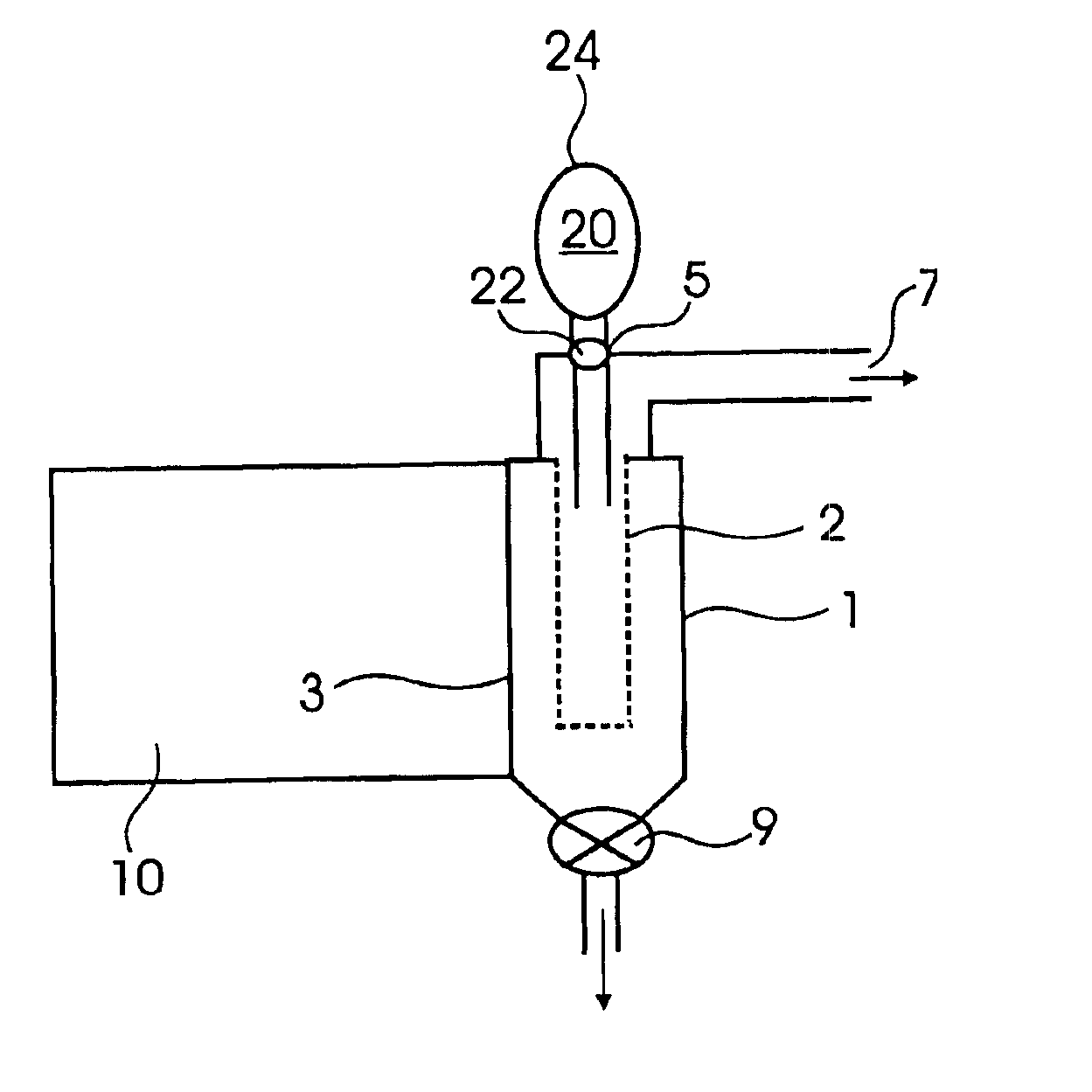

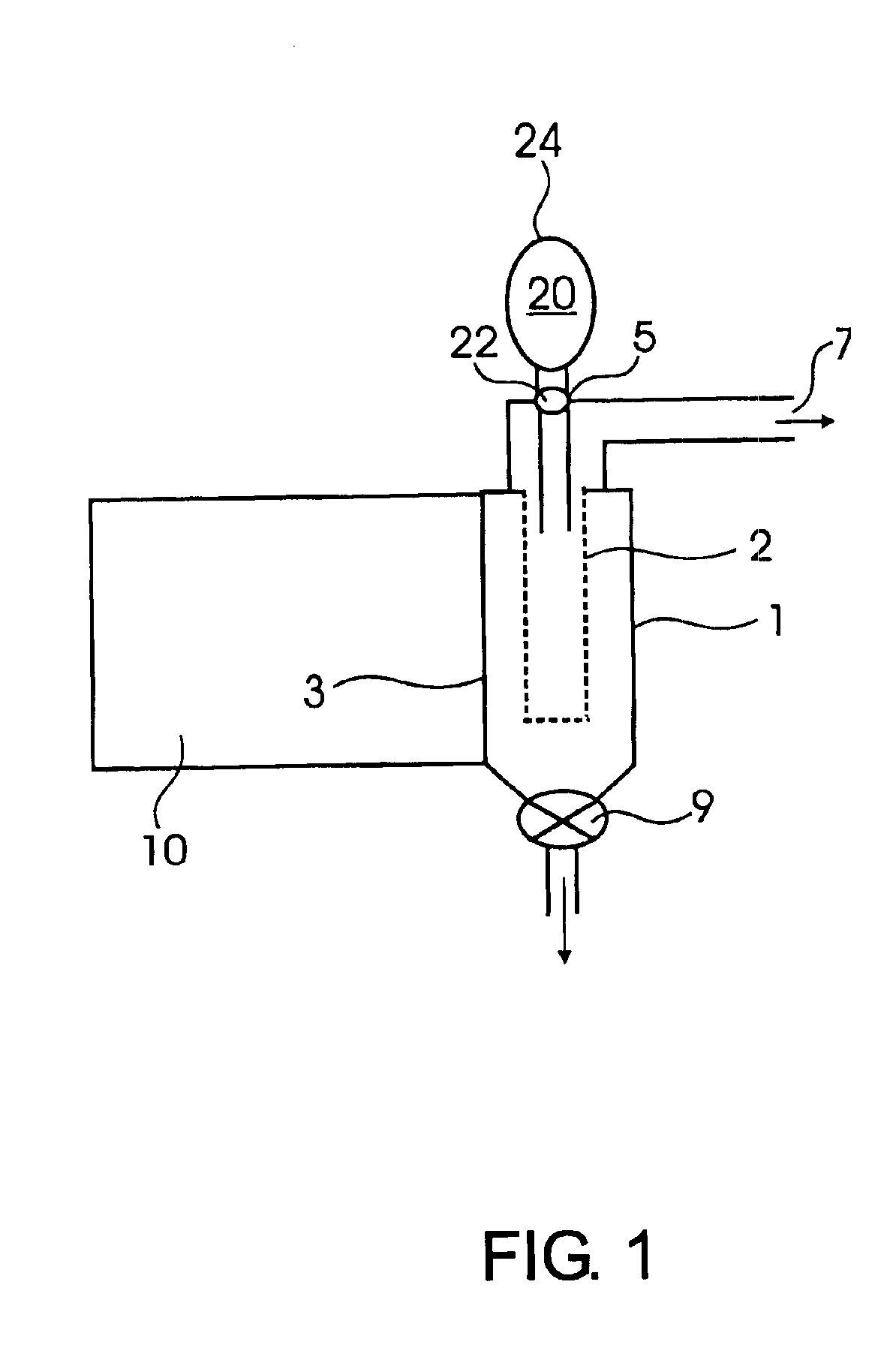

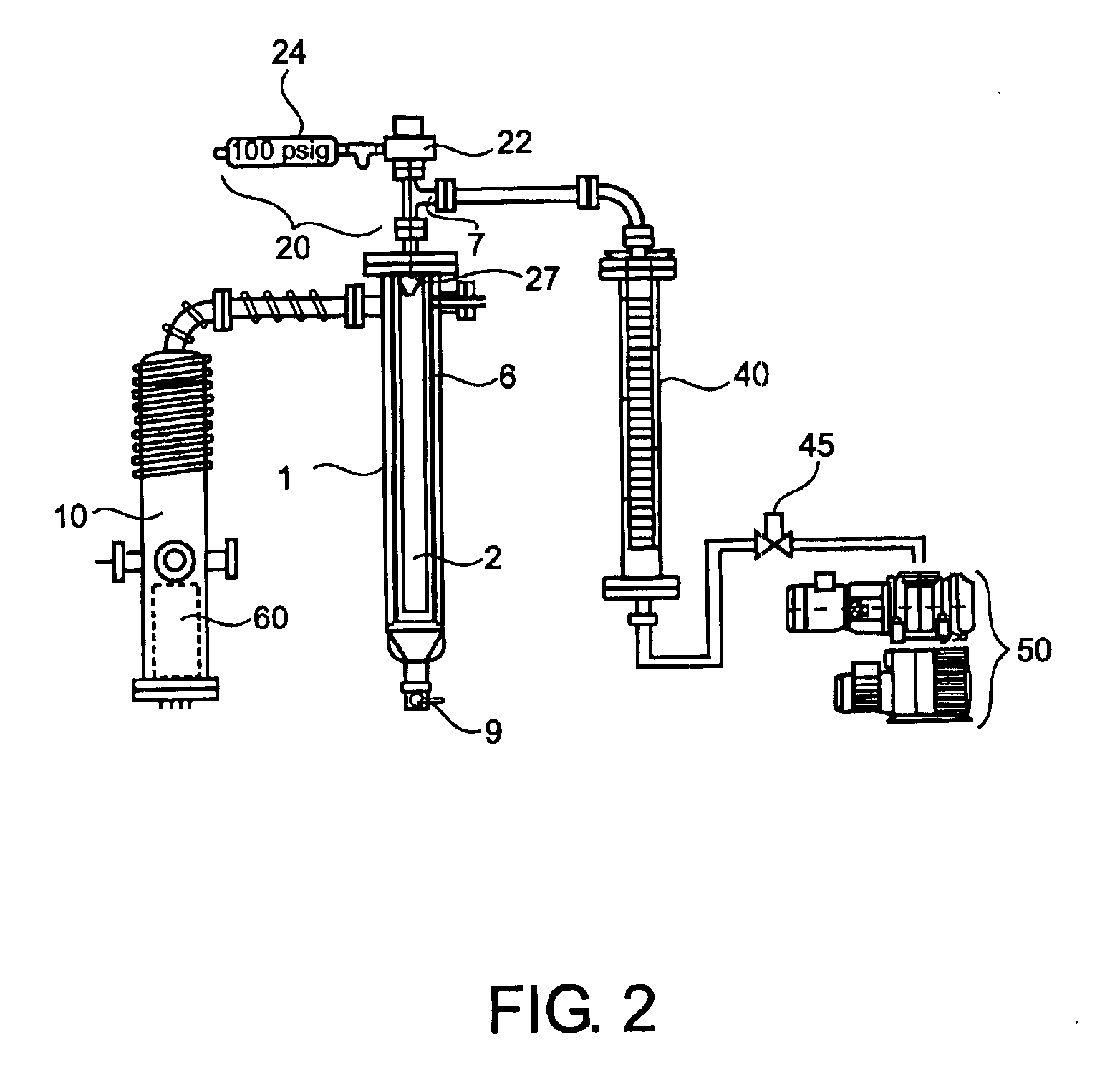

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169448A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesPhysical chemistryAlkali metal

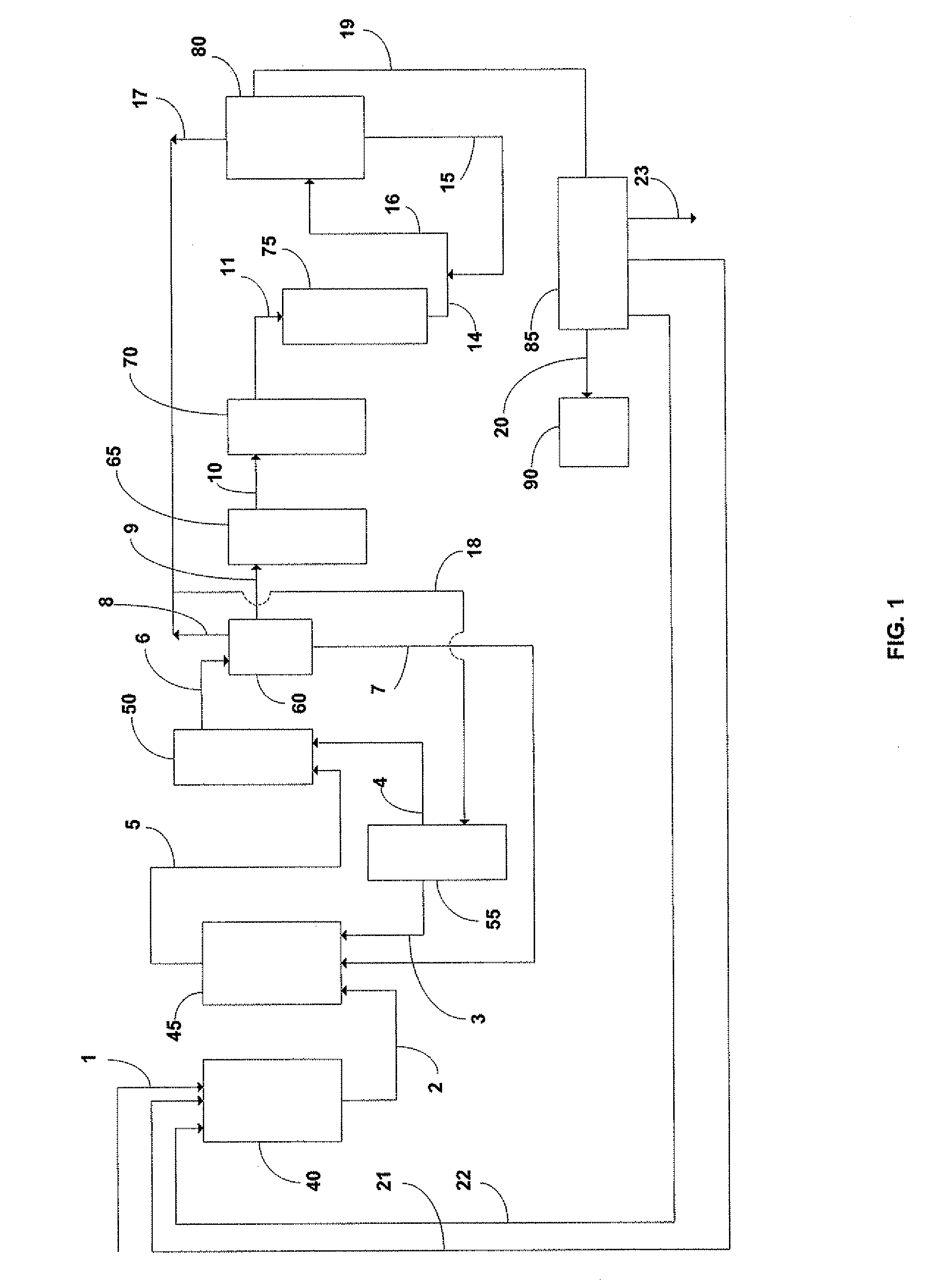

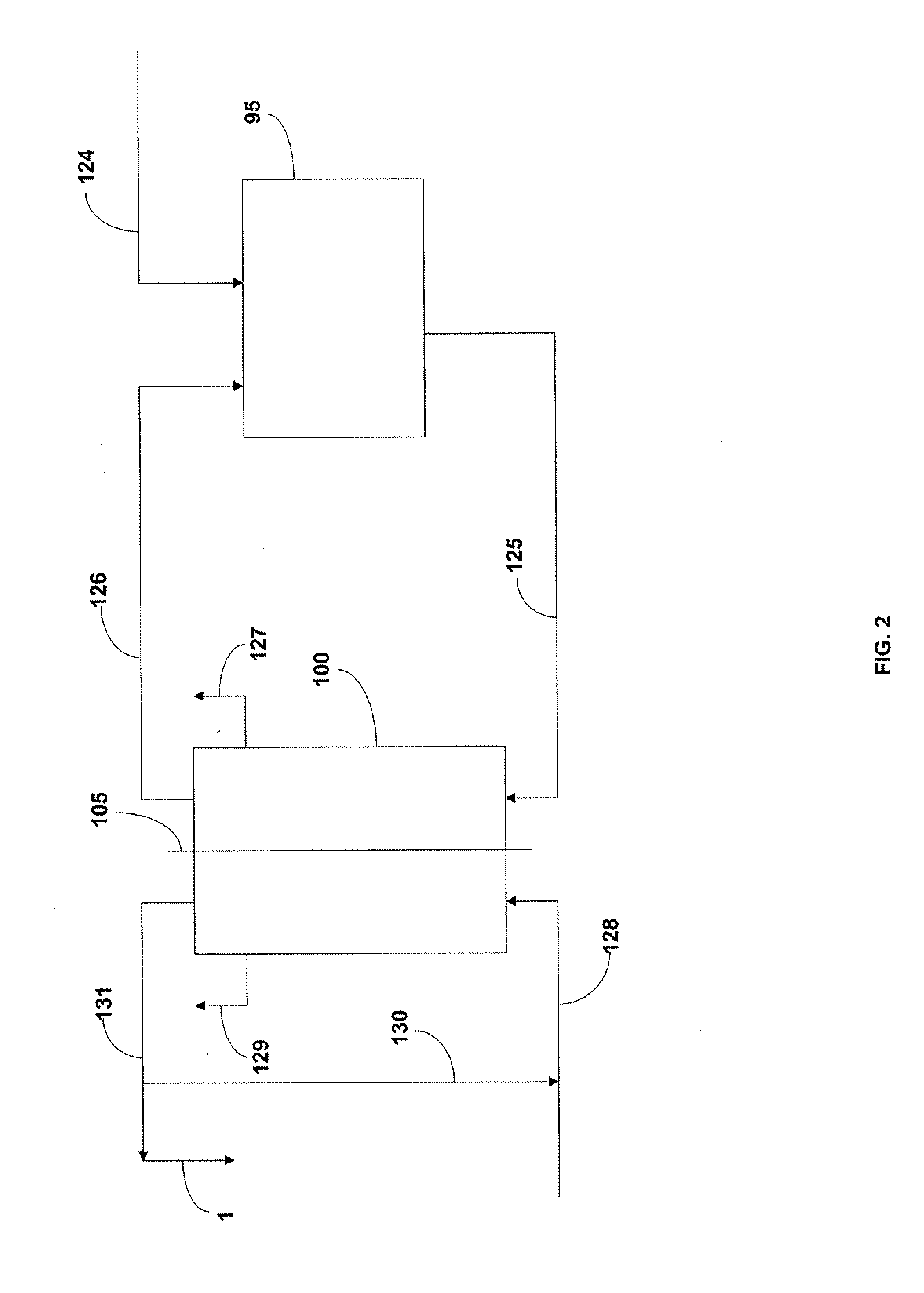

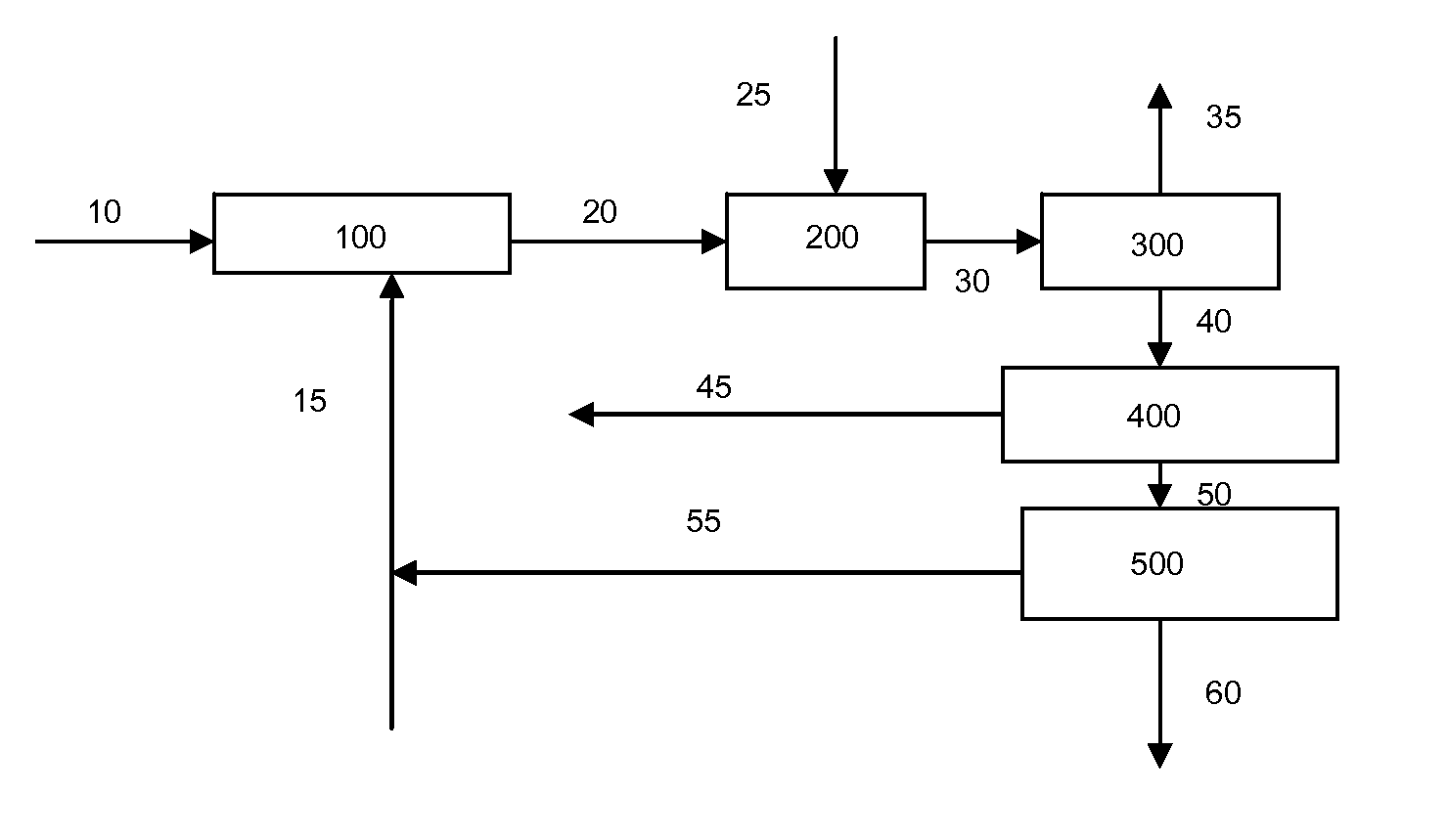

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

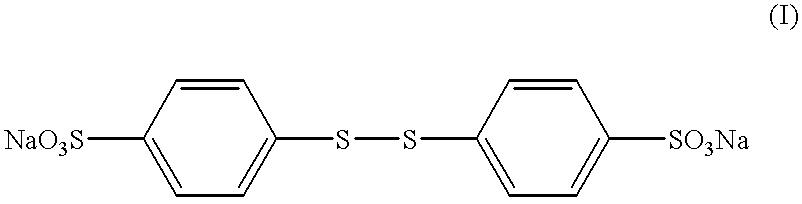

Carbon black

A carbon black with organic groups in which the organic groups are linked to the black via a sulfide- and / or polysulfide bridge. Furthermore, a method of producing the black of the invention is described in which carbon black and compounds of the general formula R-Sy-R are reacted. The carbon blacks of the invention can be used as filler, UV stabilizer, conductivity black and pigment.

Owner:DEGUSSA AG

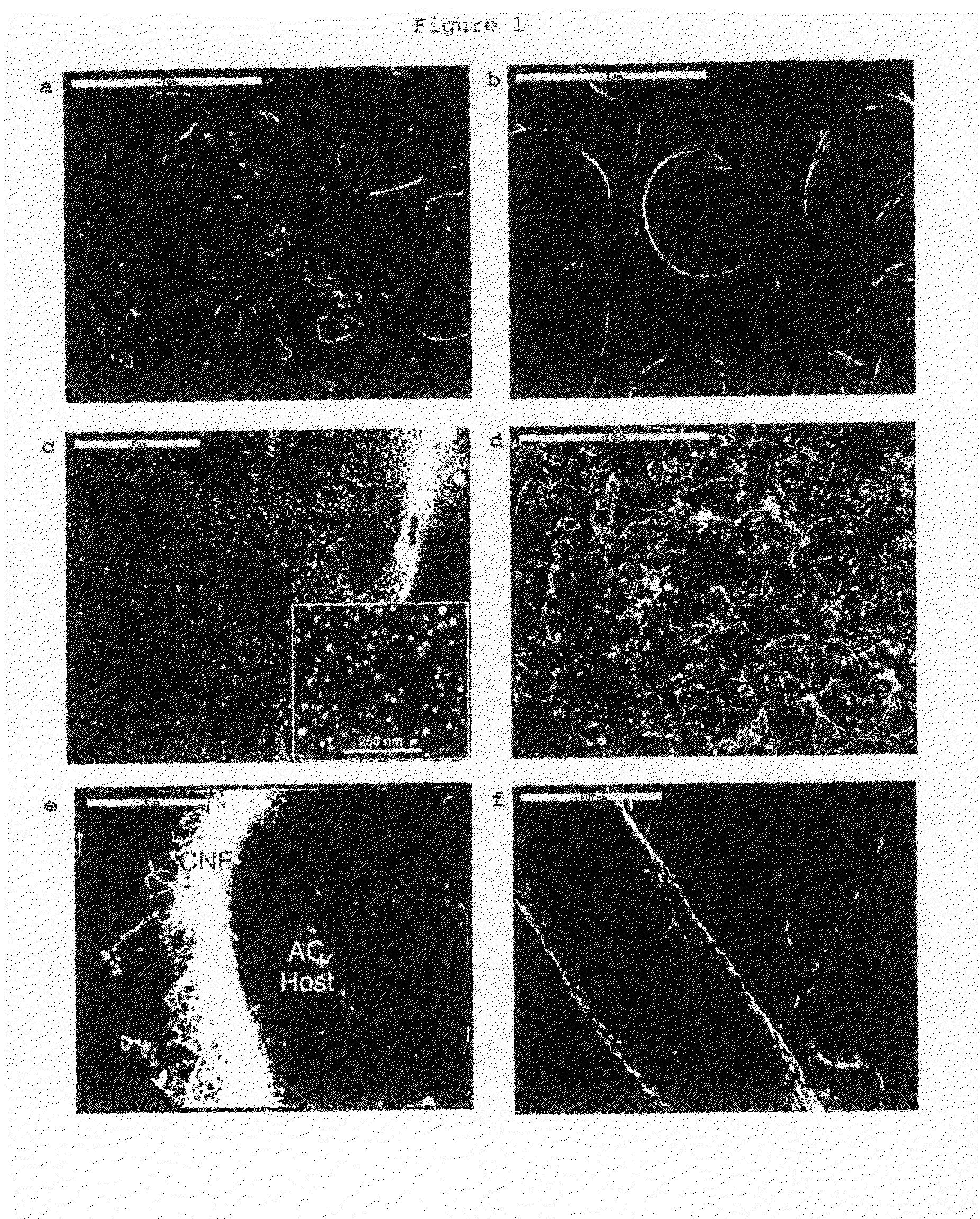

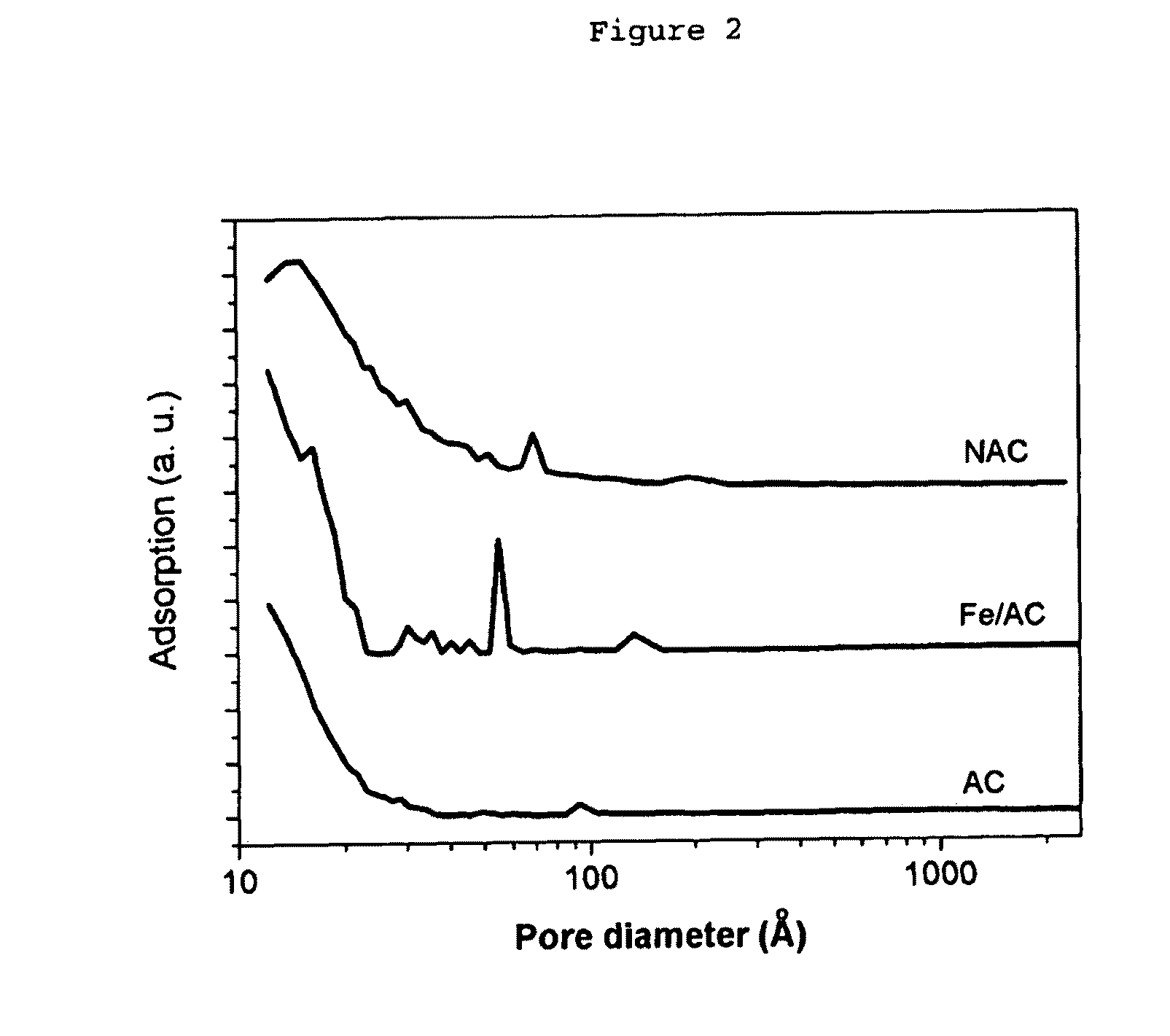

Nanocarbon-activated carbon composite

InactiveUS20090220767A1Percolation limitAvoid combiningPigmenting treatmentMaterial nanotechnologyCarbon compositesPorosity

The present invention relates to carbon-carbon composite material comprising a carbonaceous carrier and nanosize carbon structures (e.g. CNT or CNF), wherein the nanosize carbon structures are grown on the carbonaceous carrier. The carrier may be porous, as in activated carbon or consists of carbon black particles. In accordance with the invention, nanocarbon growth in the pores of porous carriers can be realized. The process for the manufacture of a this carbon-carbon-composite material comprises the steps of treating a carbonaceous carrier material with a metal-containing catalyst material, said metal being capable of forming nanosize carbon structures, and growing nanosize carbon structures by means of a CVD (chemical vapour deposition) method on the treated carrier in a gas atmosphere comprising a carbon-containing gas, followed by an optional surface modification step. This process allows optimising porosity, hydrodynamical properties and surface chemistry independently from each other, which is particularly beneficial in respect of the use of the composite for water purification. Carbon black-based composites are particularly useful for filler applications.

Owner:SUD CHEM IP GMBH & CO KG

Cable semiconducting shields

A semiconducting composition comprising (i) an olefinic polymer and (ii) about 25 to about 45 percent by weight, based on the weight of the composition, of a carbon black having the following properties: (a) a particle size of at least about 29 nanometers; (b) a tint strength of less than about 100 percent; (c) a loss of volatiles at 950 degrees C in a nitrogen atmosphere of less than about 1 weight percent based on the weight of the carbon black; (d) a DBP oil absorption of about 80 to about 300 cubic centimeters per 100 grams; (e) a nitrogen surface adsorption area of about 30 to about 300 square meters per gram or an iodine adsorption number of about 30 to about 300 grams per kilogram; (f) a CTAB surface area of about 30 to about 150 square meters per gram; and (g) a ratio of property (e) to property (f) of greater than about 1.1.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

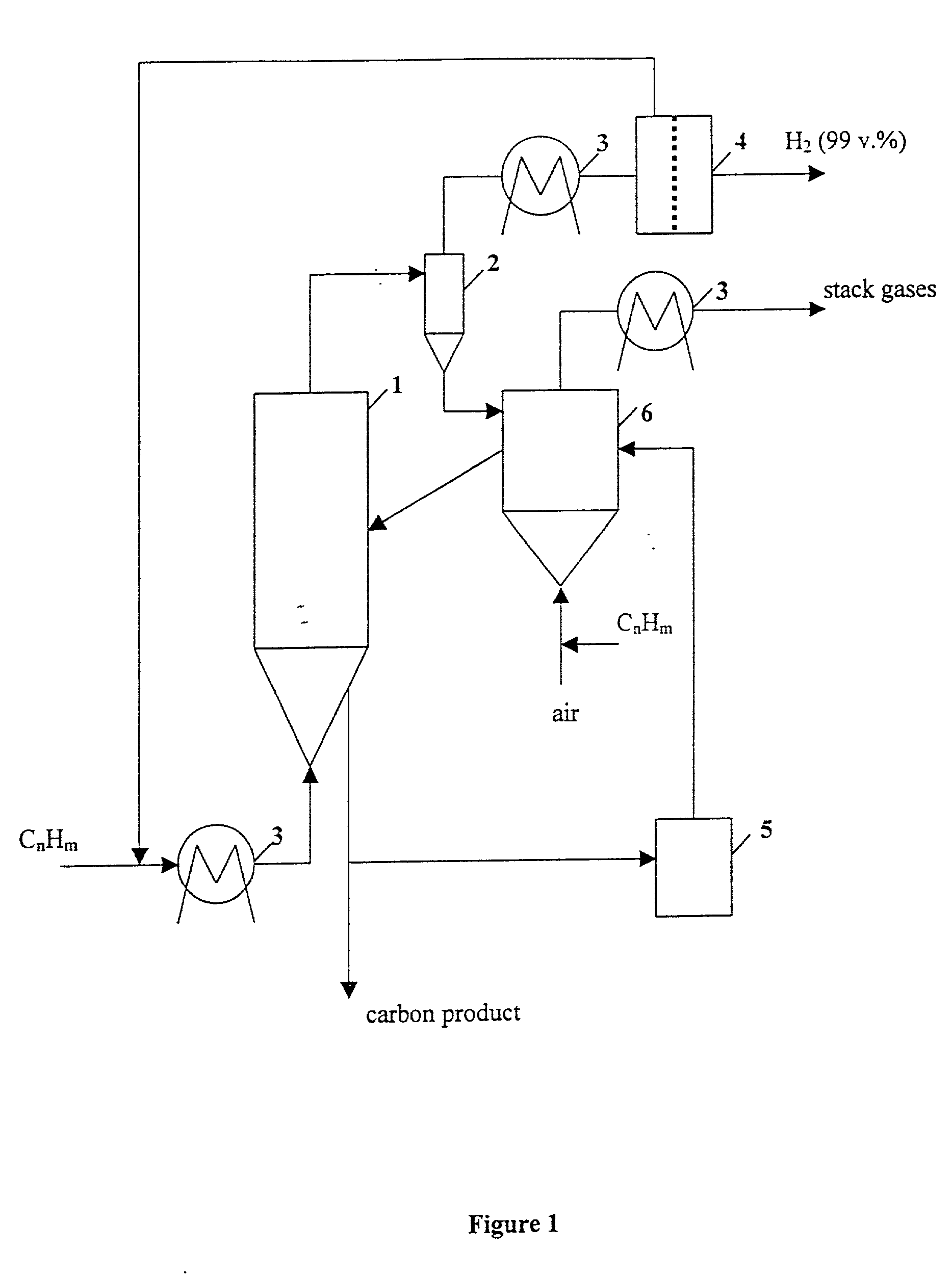

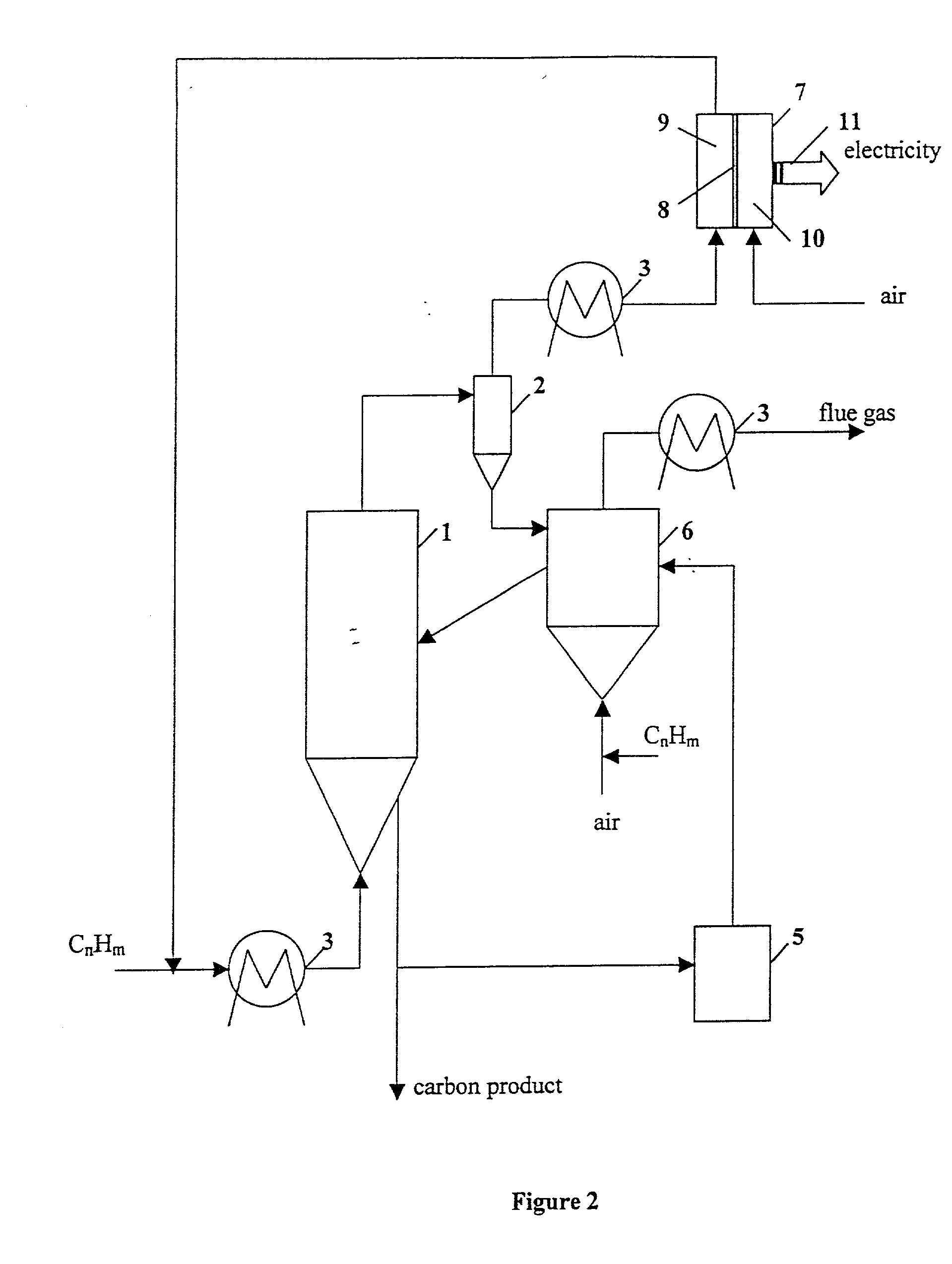

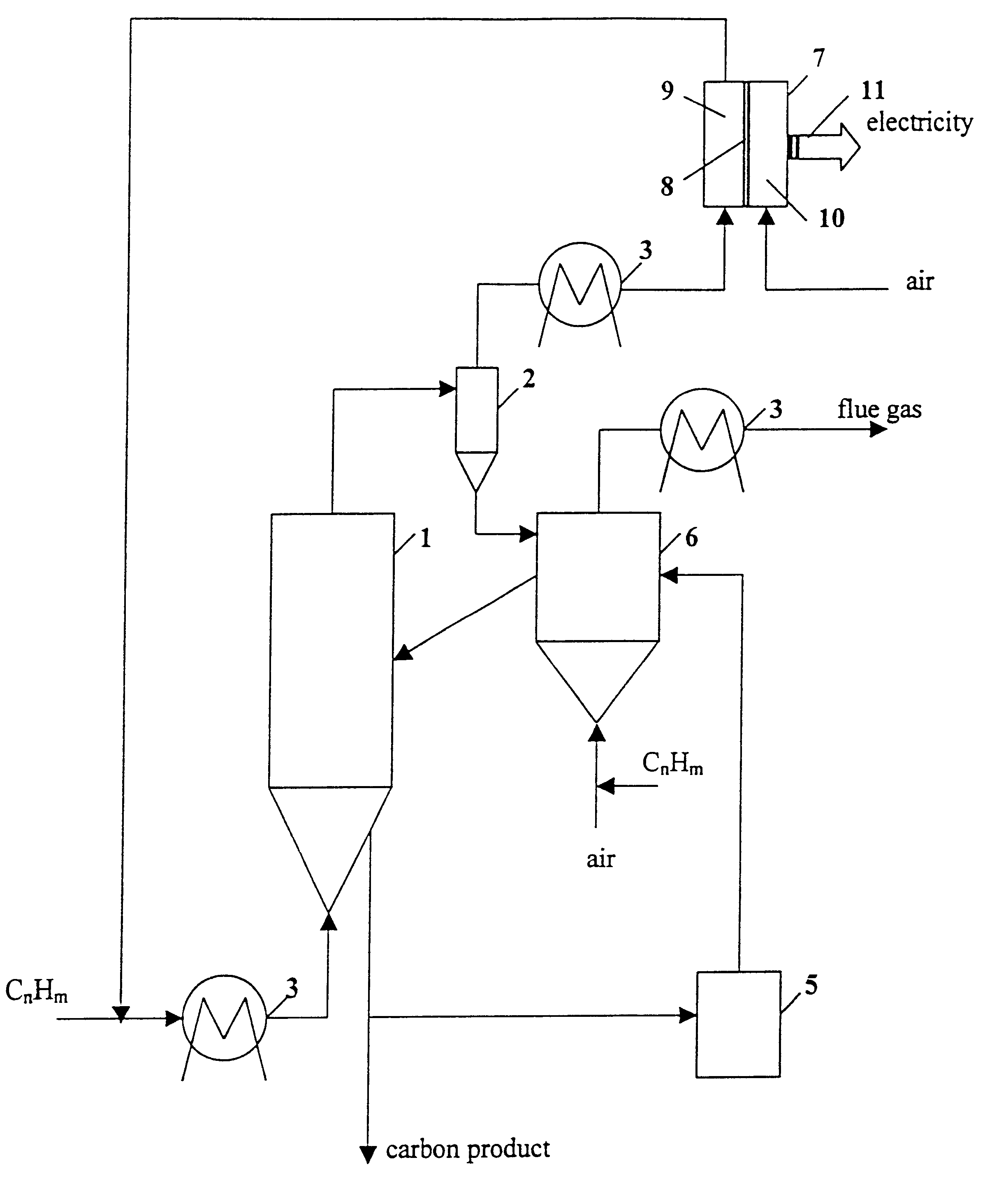

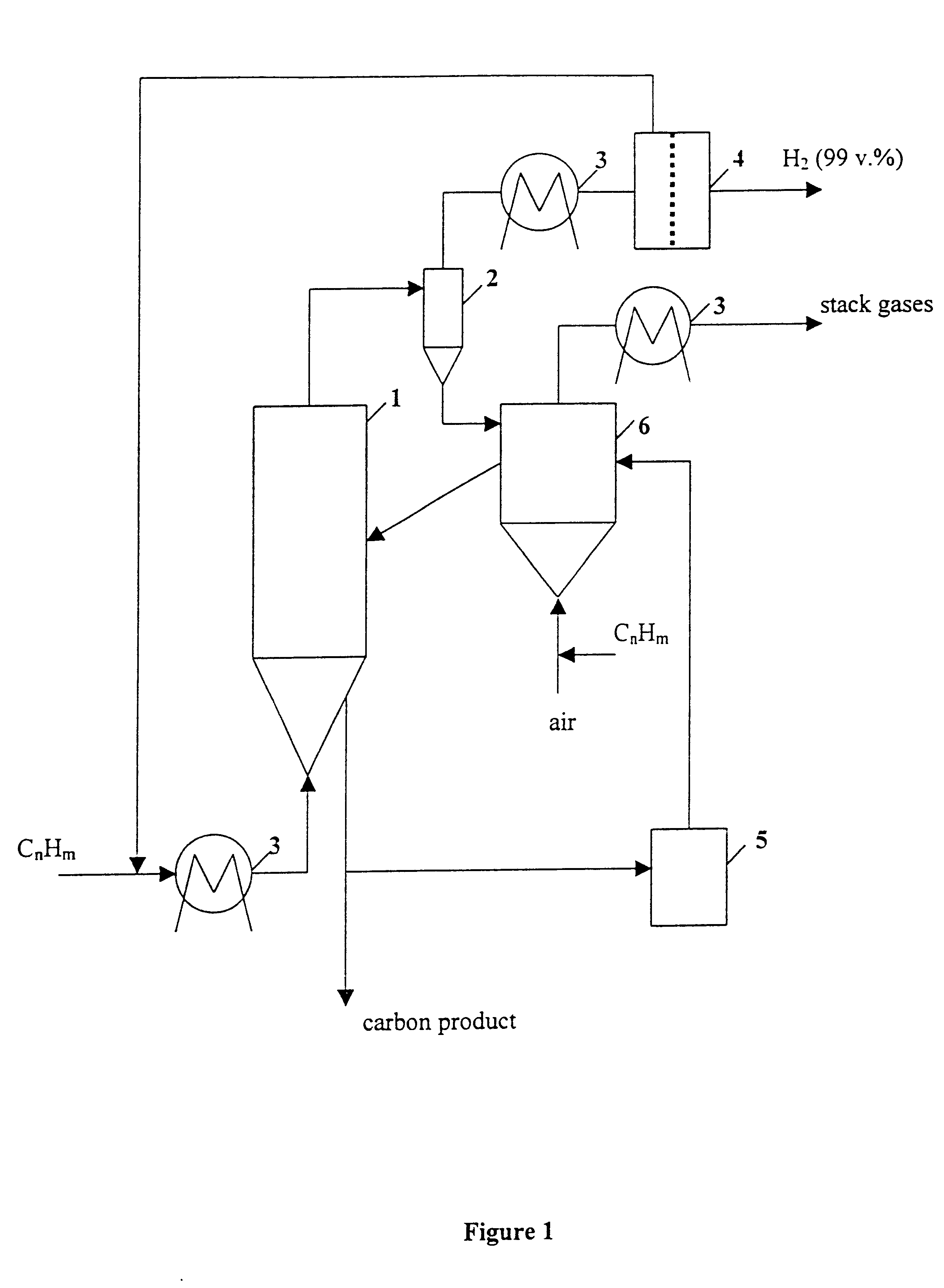

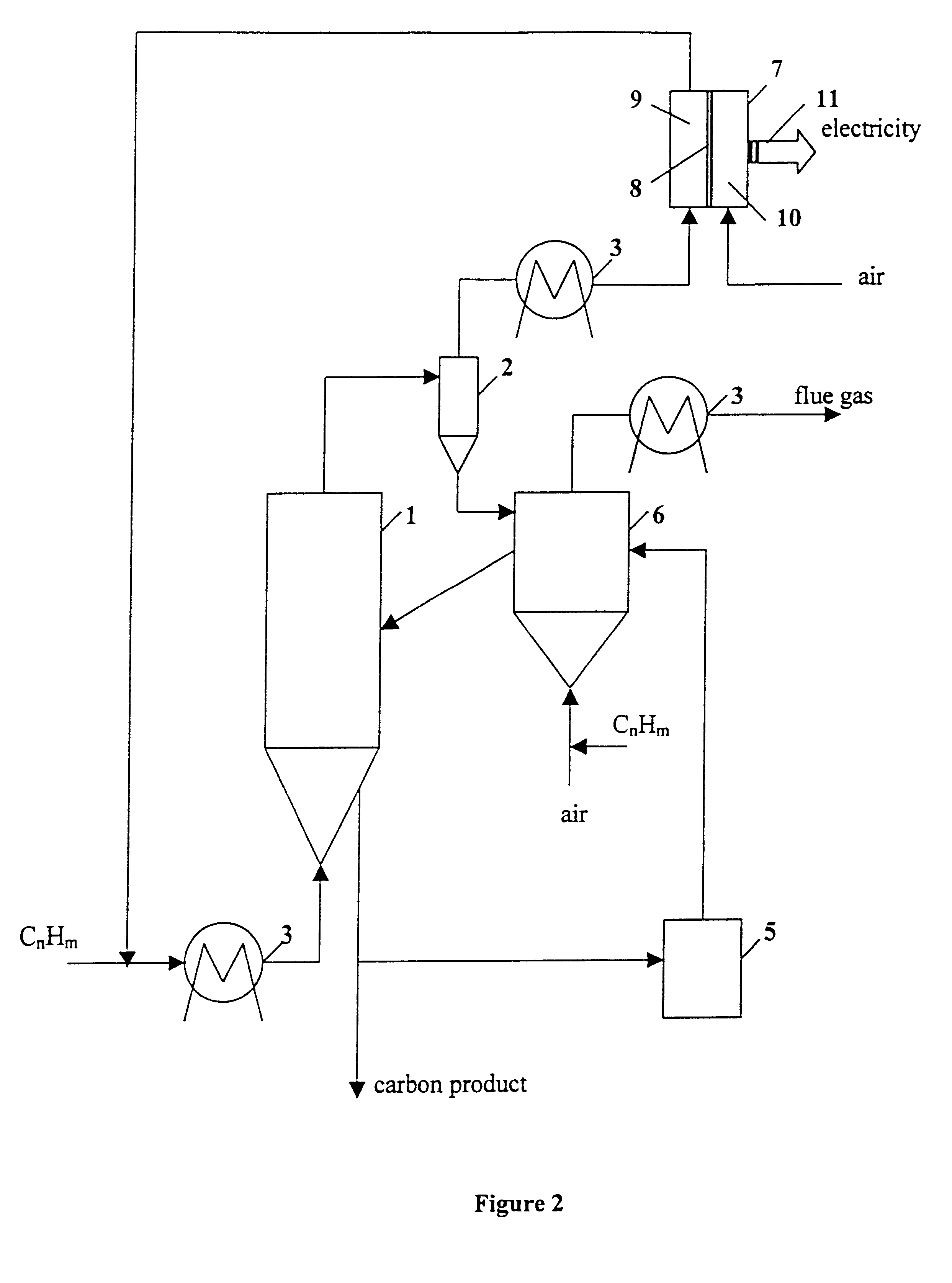

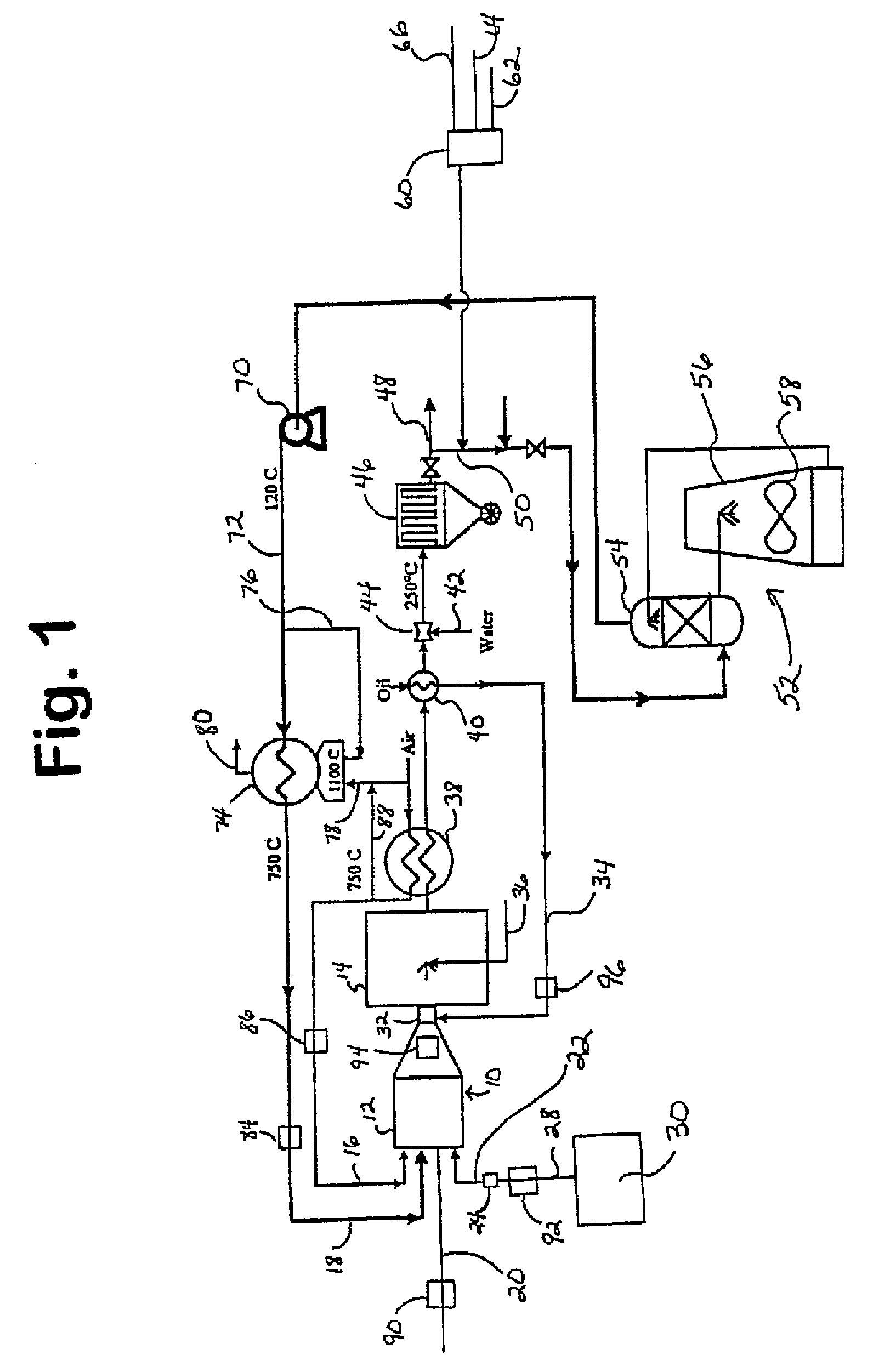

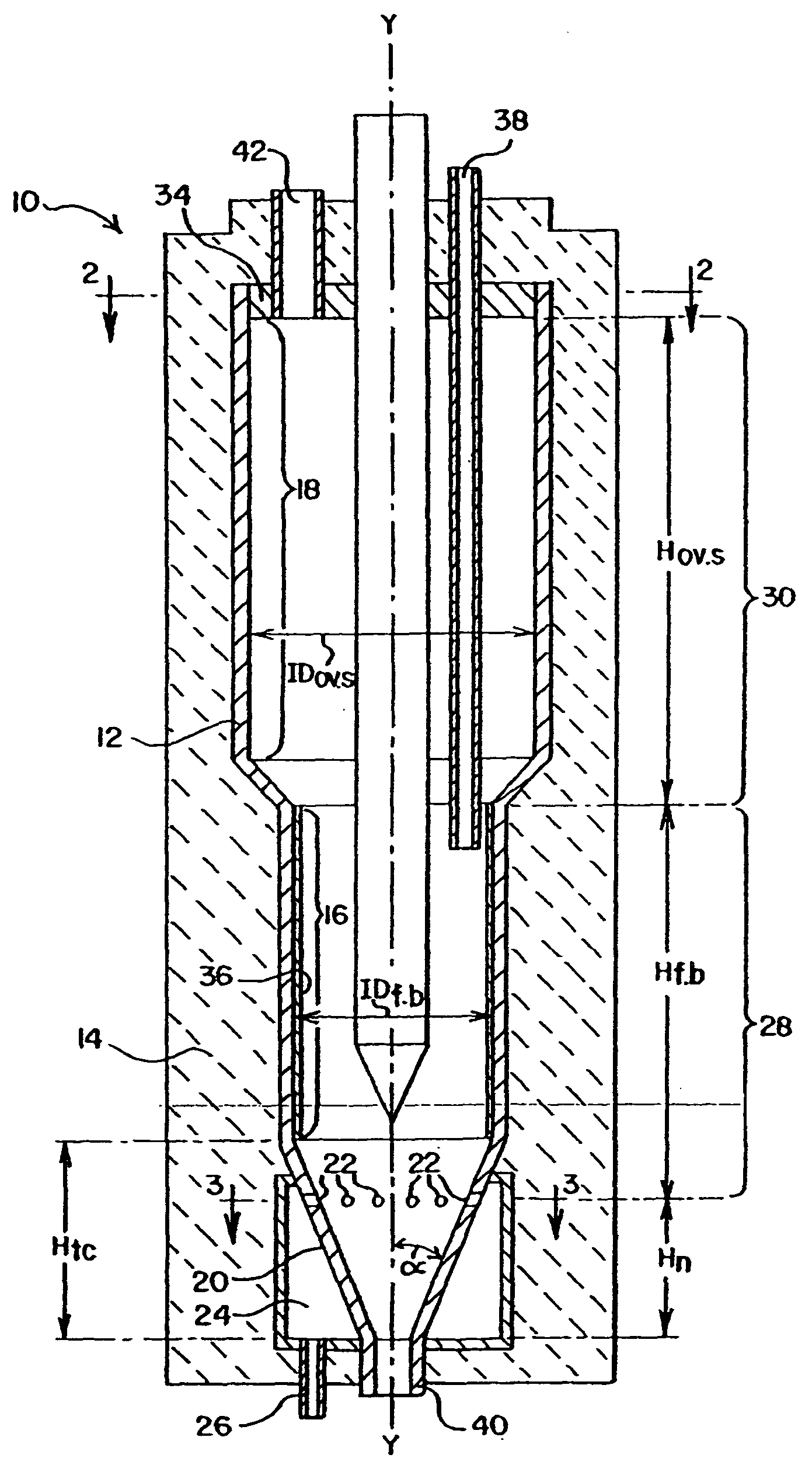

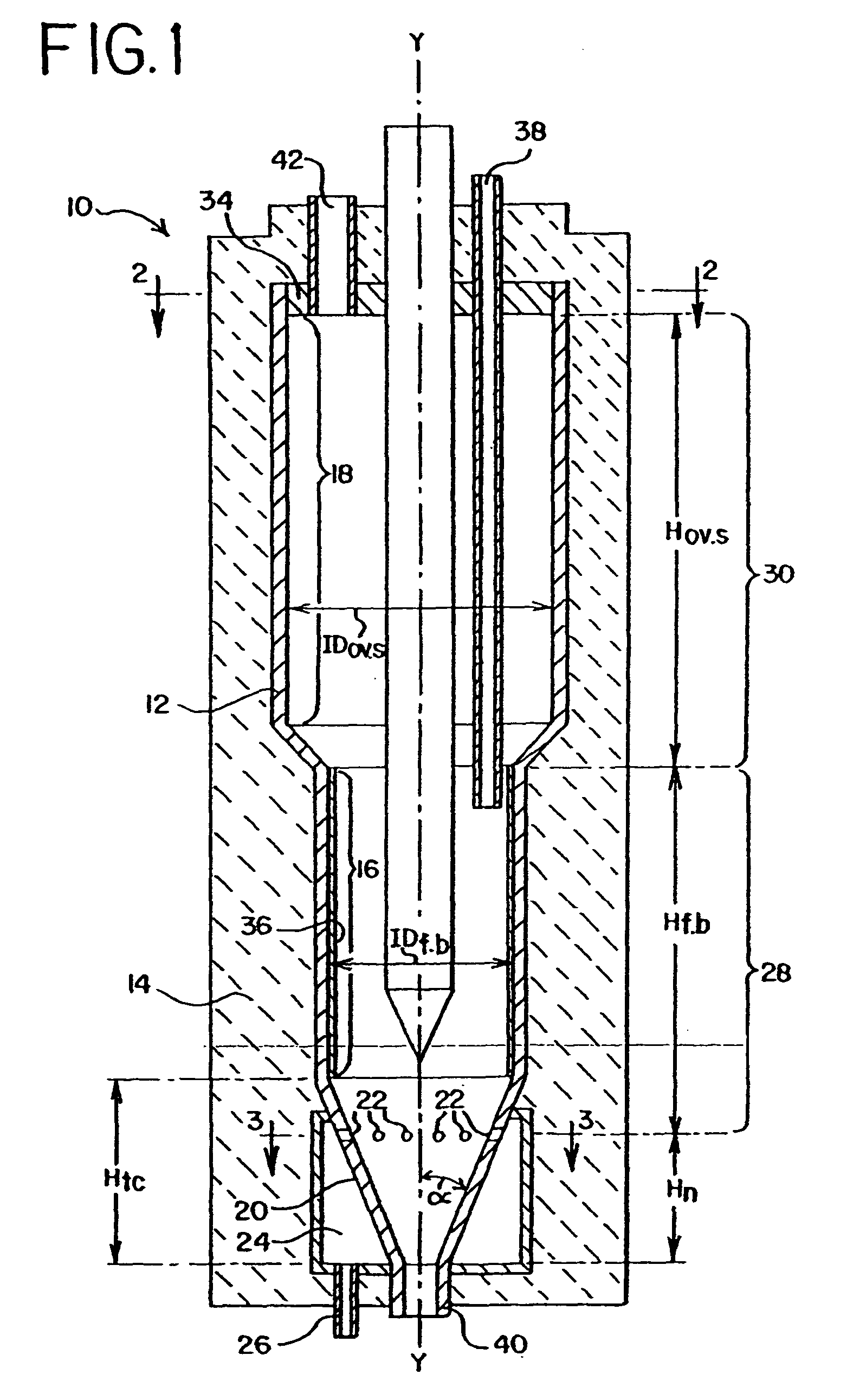

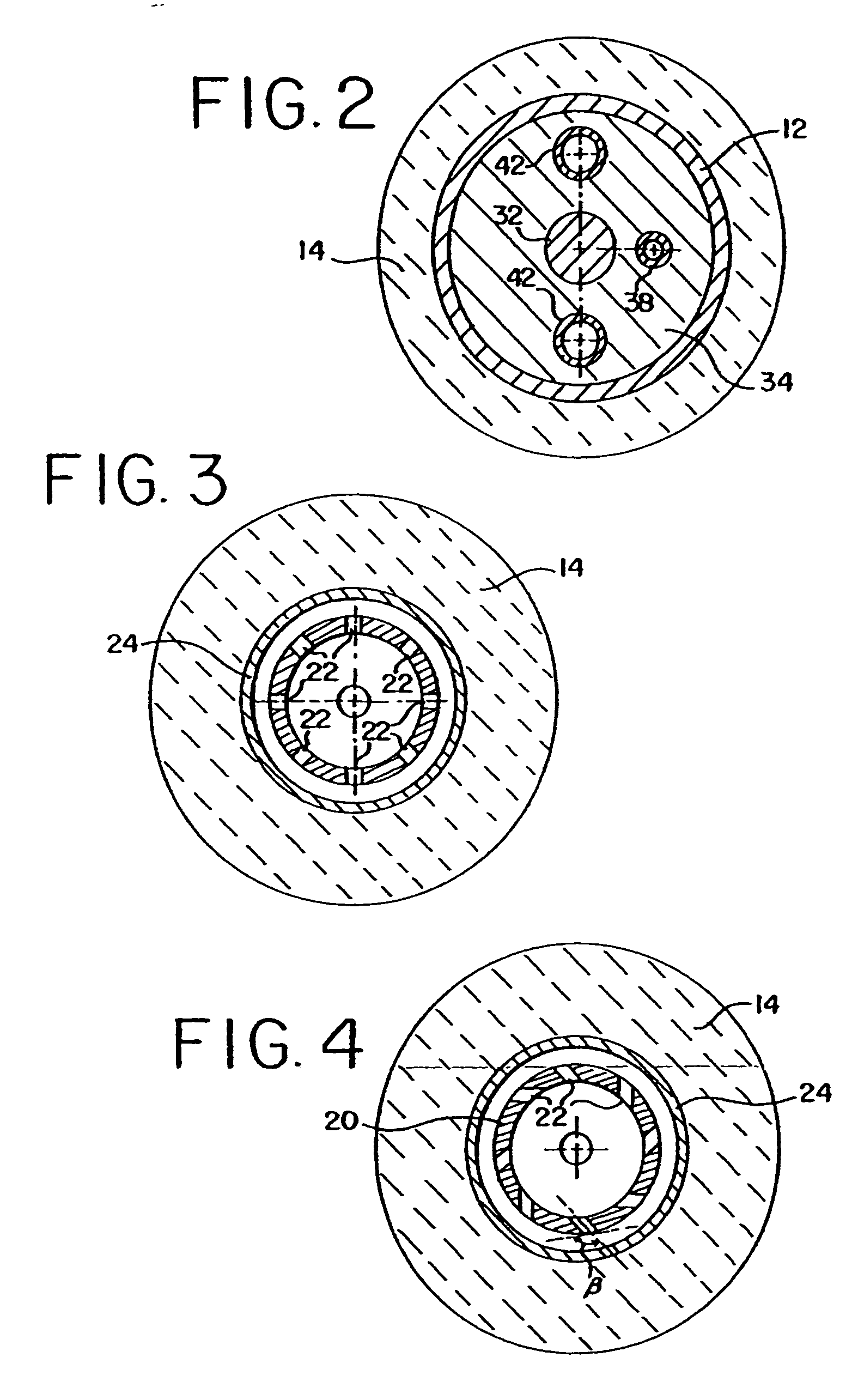

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Processes for preparing highly pure lithium carbonate and other highly pure lithium containing compounds

ActiveUS20110200508A1Electrolysis componentsLithium organic compoundsLithium carbonateLithium hydroxide

Owner:TERRALITHIUM LLC

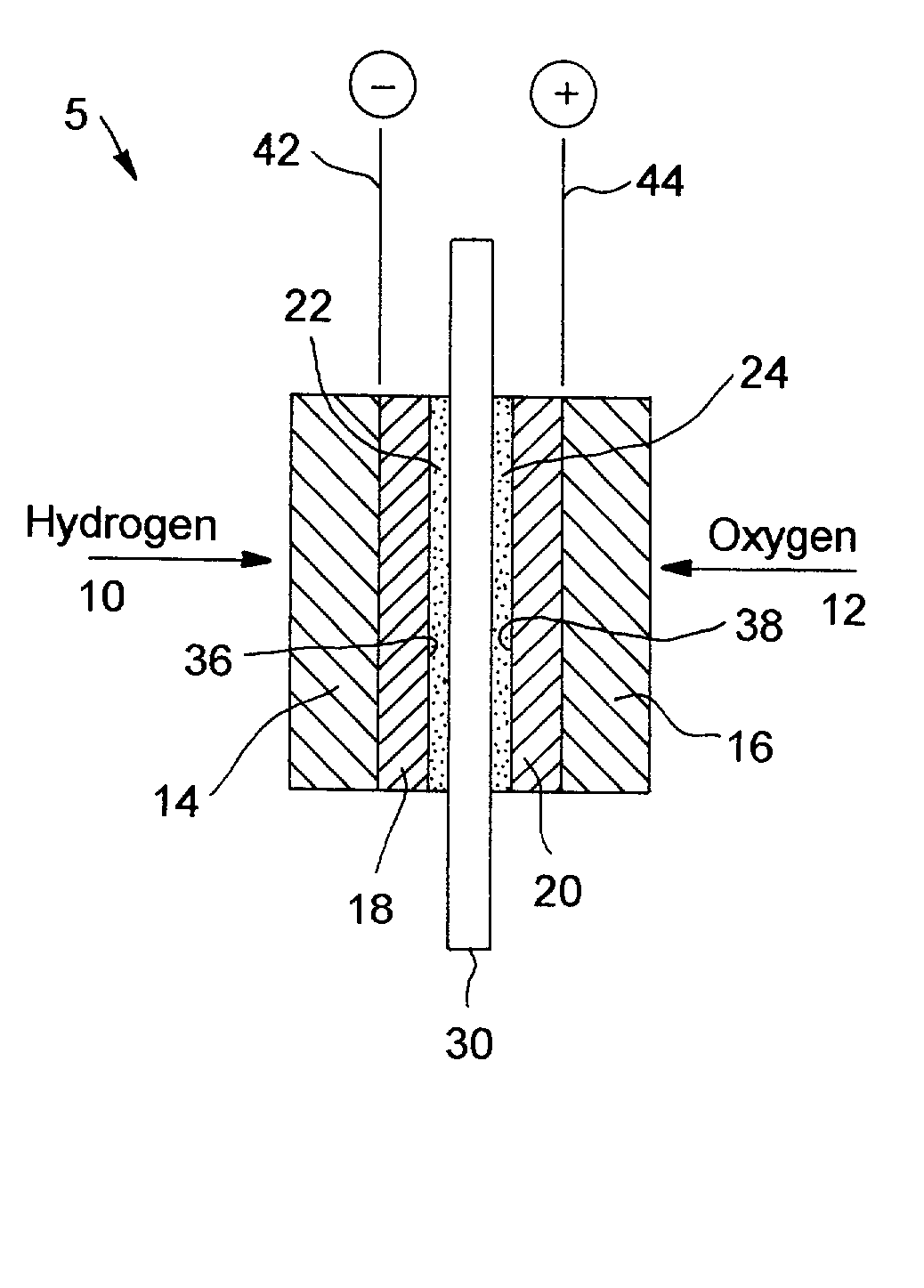

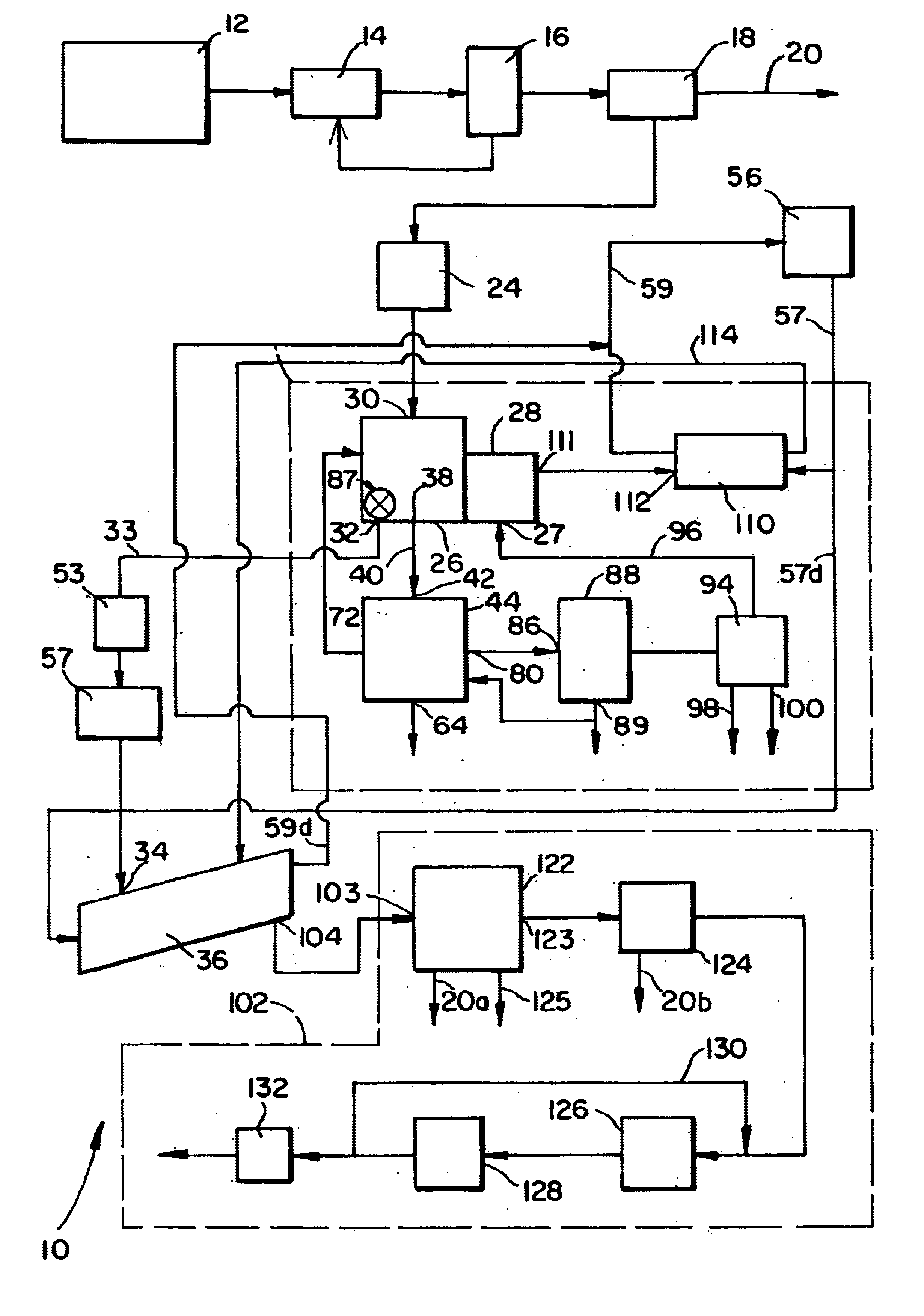

Fuel cells and other products containing modified carbon products

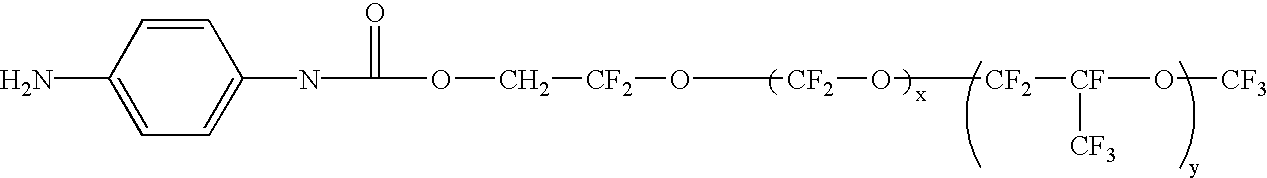

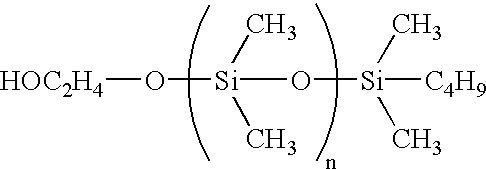

InactiveUS20030017379A1Decrease electrode performanceReduction of gas mass transport efficiencyOrganic diaphragmsAlkali metal halidesFuel cellsModified carbon

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Silica coated carbon blacks

InactiveUS6197274B1Alkali metal halidesPigment treatment with organosilicon compoundsElastomerOrganic group

Silica coated carbon blacks are disclosed and can be prepared by coating a fine dispersion of carbon black, such as a carbon black having an attached organic group(s). Compositions and articles of manufacture, including elastomeric compositions, containing such carbon black are also disclosed.

Owner:CABOT CORP

Reinforcement additives

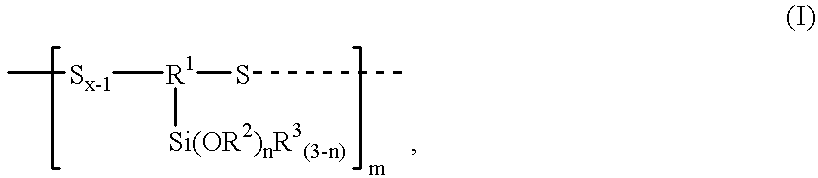

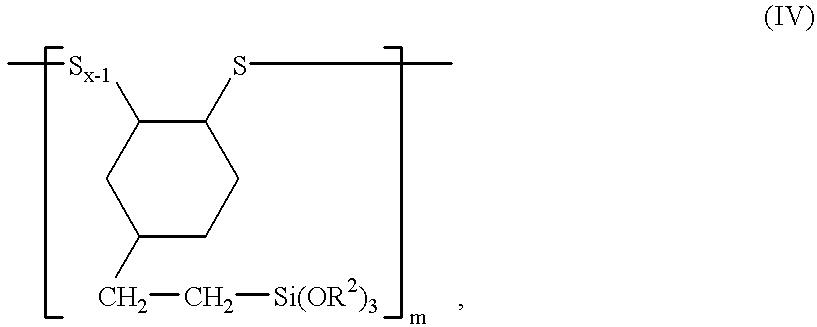

InactiveUS6268421B1Simple methodImprove the overall coefficientAlkali metal halidesSpecial tyresUnsaturated hydrocarbonSulfur containing

The invention concerns reinforcement additives consisting of oligomeric and / or polymeric sulfur-containing organoorganooxysilanes, perhaps other unsaturated hydrocarbon-containing organoorganooxysilanes and reinforcing semiactive, active, and / or highly active carbon blacks, common in rubber, their production, and the use of the additives in perhaps silicatically filled vulcanizable rubber mixtures and compositions and in plastic mixtures or in carbon black dispersions.

Owner:DEGUSSA AG

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7897126B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7901644B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Carbonaceous material for forming electrically conductive matrail and use thereof

ActiveUS20060035081A1Improve conductivityLow resistance anisotropyMaterial nanotechnologyNon-insulated conductorsFiberCarbon fibers

(1) A carbonaceous material for forming an electrically conductive composition, comprising a vapor grown carbon fiber, each fiber filament of the carbon fiber having an outer diameter of 2 to 500 nm and an aspect ratio of 10 to 15,000, or the carbon fiber containing boron in an amount of 0.01 to 5 mass %, and graphitic particles and / or amorphous carbon particles, wherein the amount of the vapor grown carbon fiber is 10 to 90 mass %, the amount of the graphitic particles is 0 to 65 mass %, and the amount of the amorphous carbon particles is 0 to 35 mass %; (2) an electrically conductive composition comprising the carbonaceous material for forming an electrically conductive composition, and a producing method thereof; (3) an electrically conductive coating material comprising, as an electrically conductive material, the electrically conductive composition, and an electrically conductive coating film and electric device using the electrically conductive coating material.

Owner:RESONAC CORP

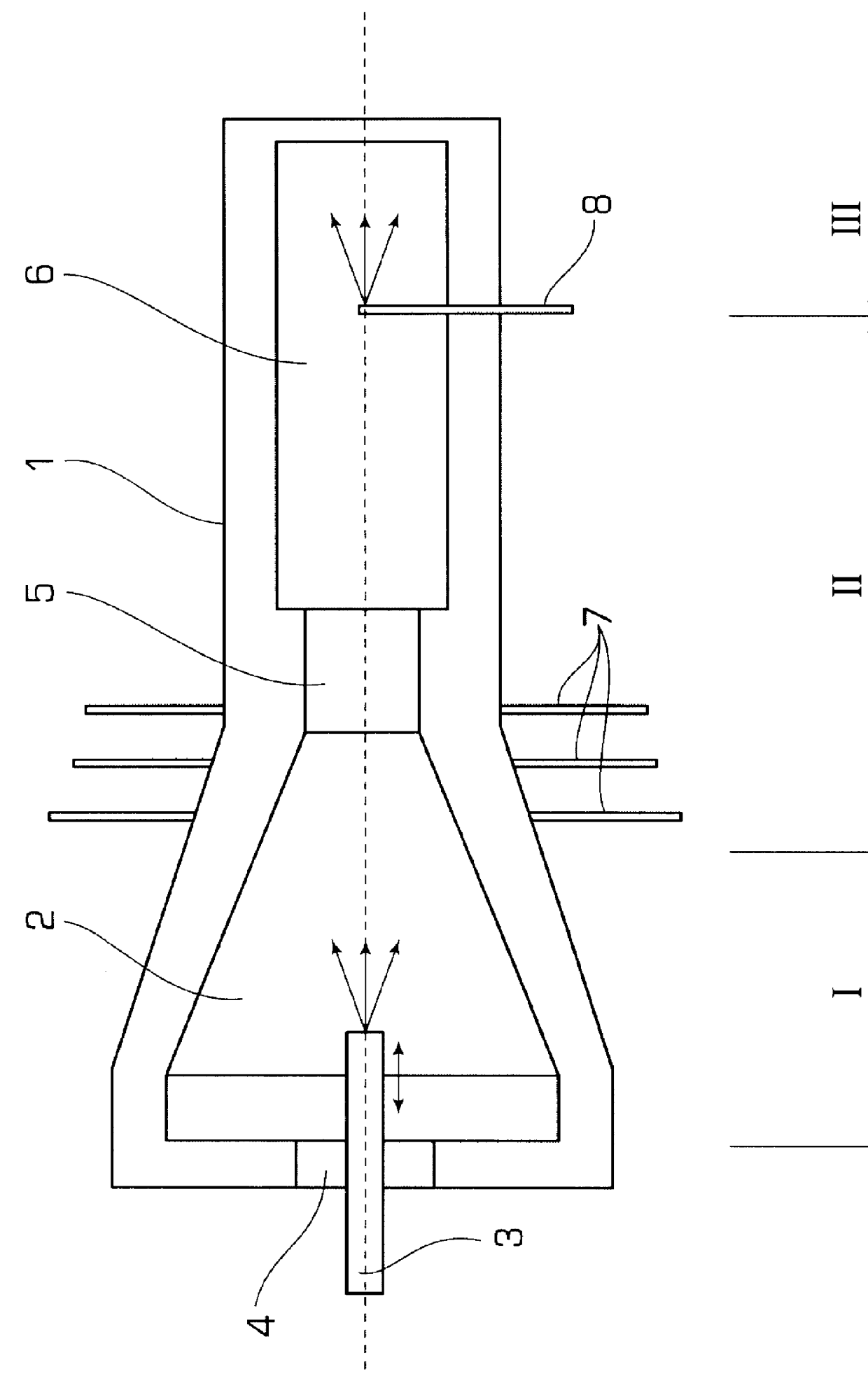

Process for production of carbon black

InactiveUS7655209B2Increase flexibilityLow costProcess control/regulationPigmenting treatmentCombustorProcess engineering

Off-gas from a carbon black furnace is employed as a combustion gas feed stream to the burner or combustion zone of the same or a different carbon black furnace in accordance with certain embodiments, suitable conduit and valving is provided to pass off-gas, from which carbon black has been substantially removed, from any and all of multiple different carbon black furnaces to the burner. The off-gas is heated, preferably by plasma heating, and dewatered. Carbon dioxide stripping or rather stripping of gas components from the dewatered heated off-gas is found to be unnecessary to achieve economically favorable use of off-gas recirculation.

Owner:CABOT CORP

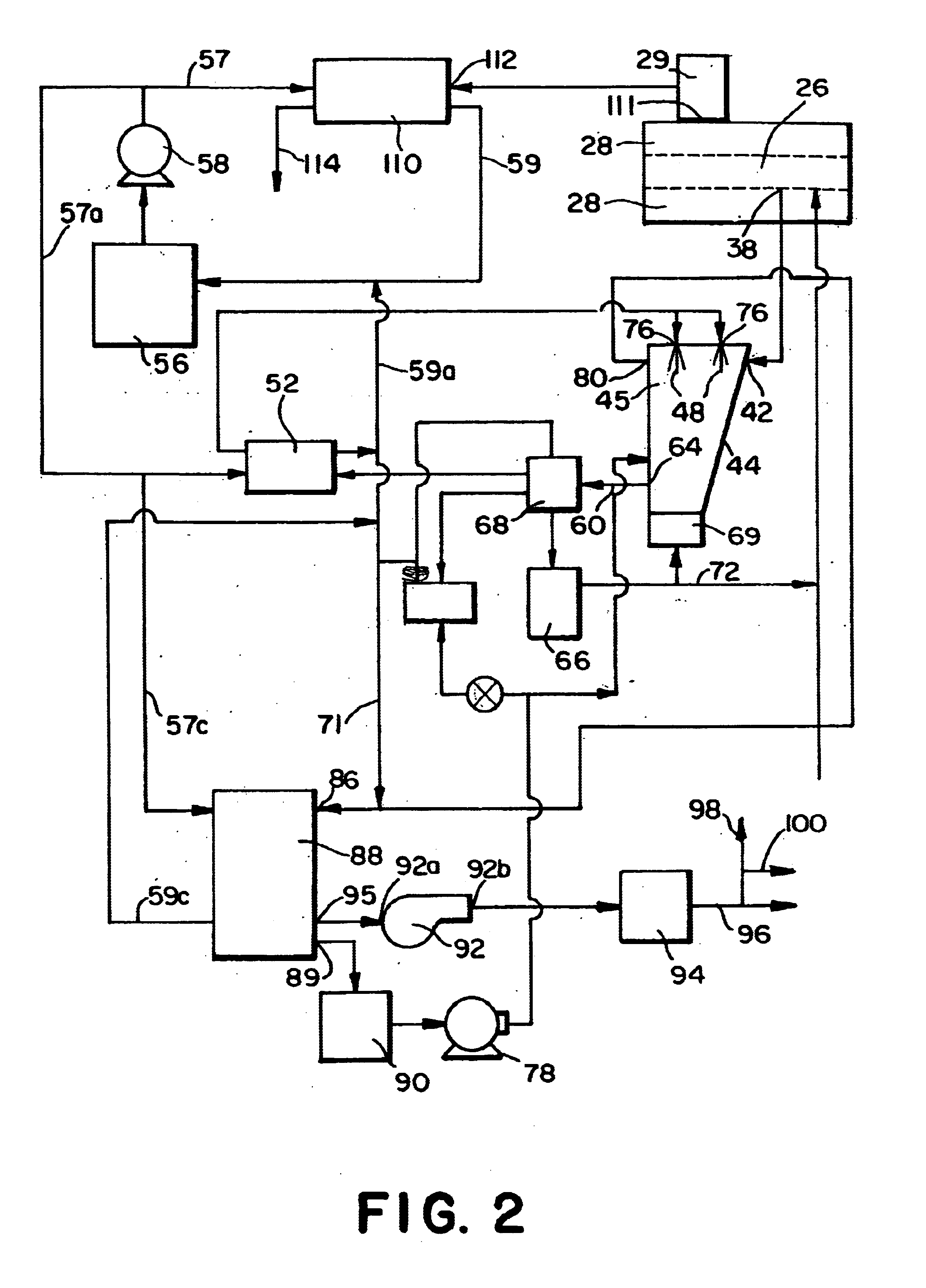

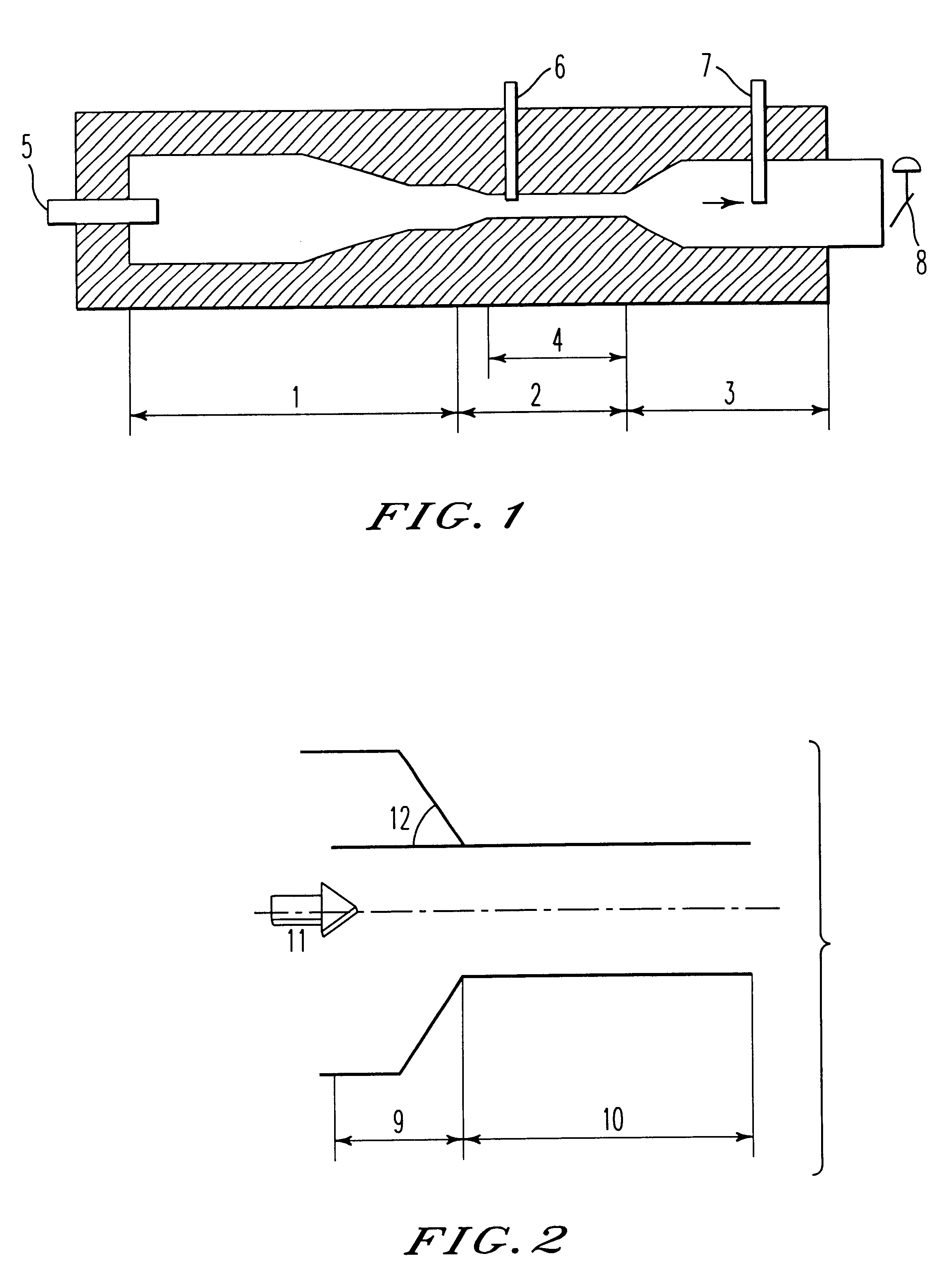

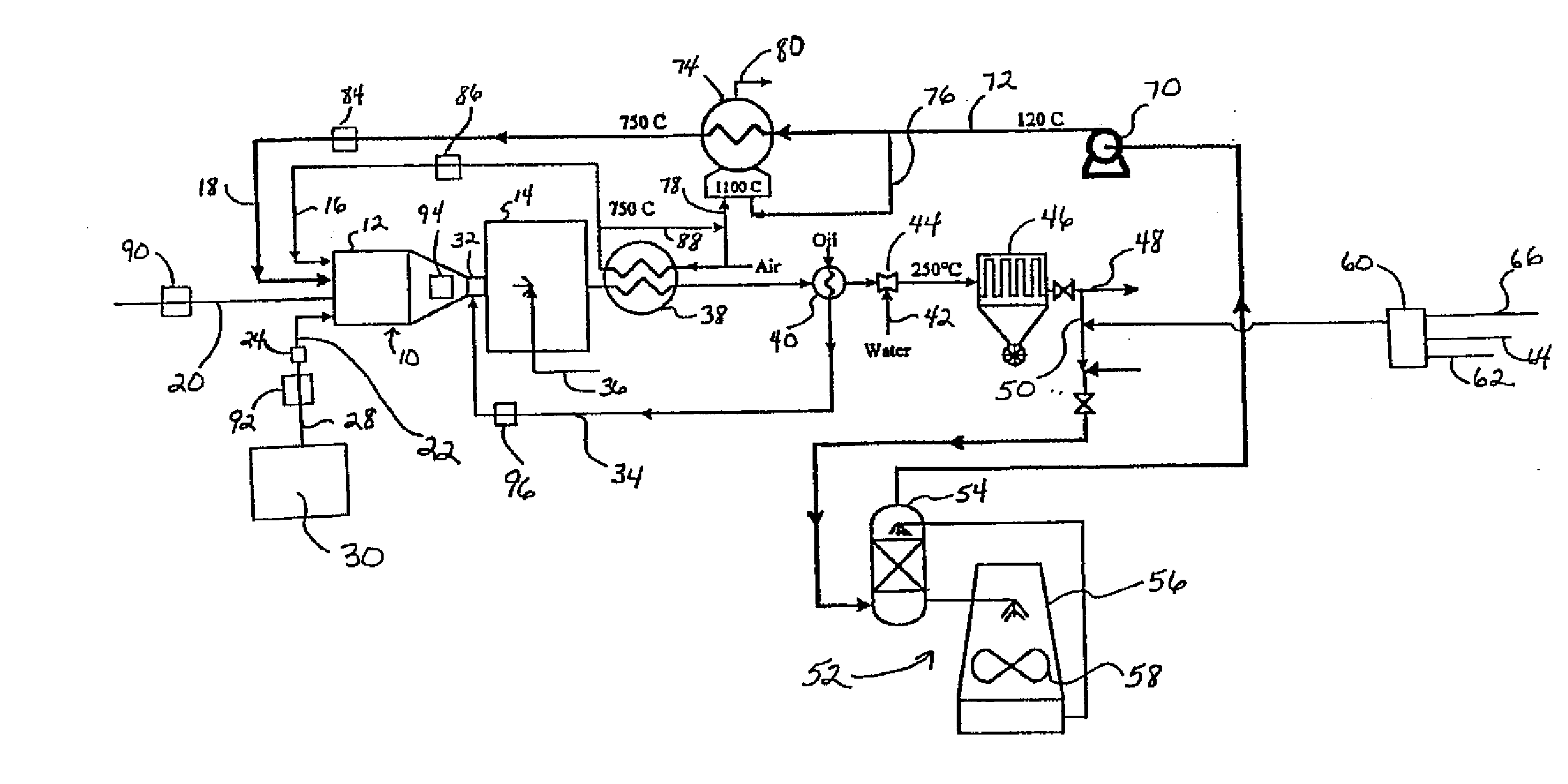

Process for pyrolyzing tire shreds and tire pyrolysis systems

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis reactor, pyrolyzing the shreds in a pyrolysis reactor to produce a hydrocarbon-containing gas stream and carbon-containing solid, removing the carbon-containing solid from the reactor, directing the hydrocarbon-containing gas stream into a separator, contacting the hydrocarbon-containing gas stream with an oil spray in the separator thereby washing particulate from the hydrocarbon-containing gas stream and condensing a portion of the gas stream to oil, removing and cooling the oil from the separator, directing non-condensed gas from the gas stream away from the separator, and directing a portion of the cooled oil removed from the separator to an inlet of the separator for use as the separator oil spray. A process is also provided in which solids from the pyrolysis reactor are directed to an auger having a pressure which is greater than the pressure in the pyrolysis reactor, and in which non-condensed gas from the gas stream after condensing a portion of the gas is directed to at least one burner in heat exchange relation with the pyrolysis reactor, and burned to heat the reactor and generate an effluent flue gas, a portion of which effluent flue gas is cooled and injected into the auger which is a trough auger in one embodiment.

Owner:RENAISSANCE ENERGY GROUP

Carbon black and process for producing the same

InactiveUS6358487B1High blacknessGood dispersionPigmenting treatmentAlkali metal halidesCarbon blackComposite material

A carbon black having an average particle size of at most 13 nm, Dmod of at most 80 nm, a D½ / Dmod ratio of at most 0.6 and at least pH 5.

Owner:MITSUBISHI CHEM CORP

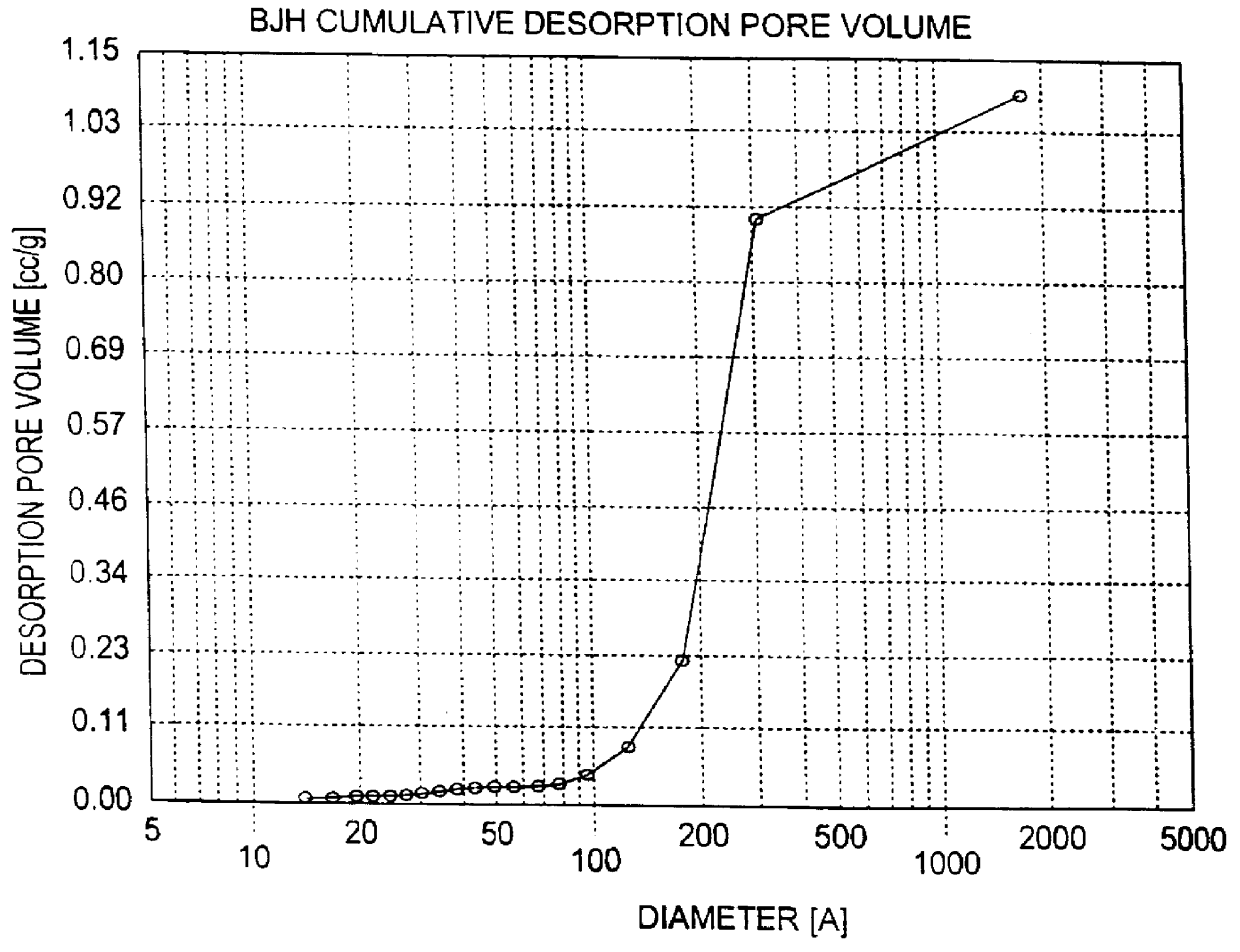

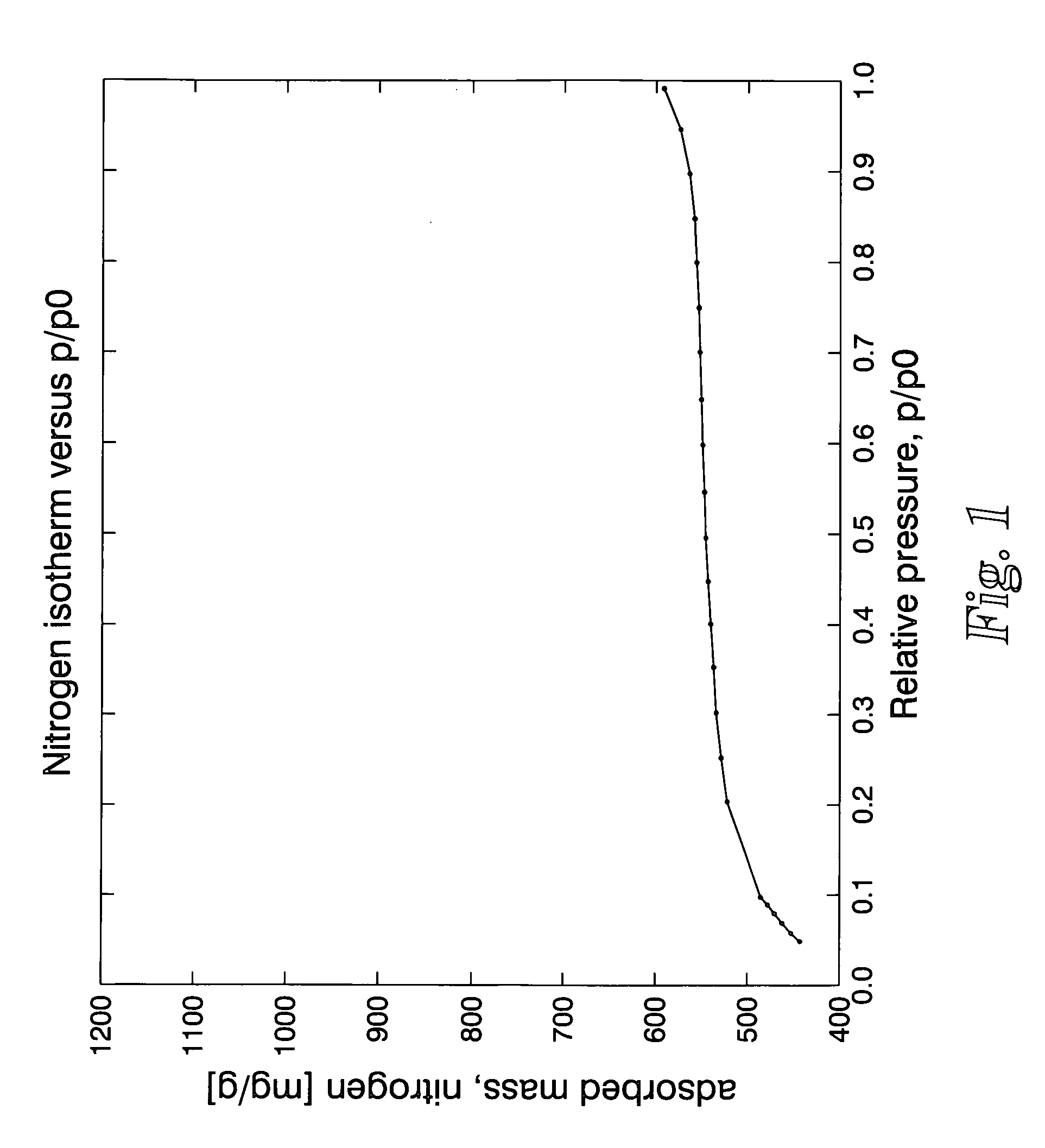

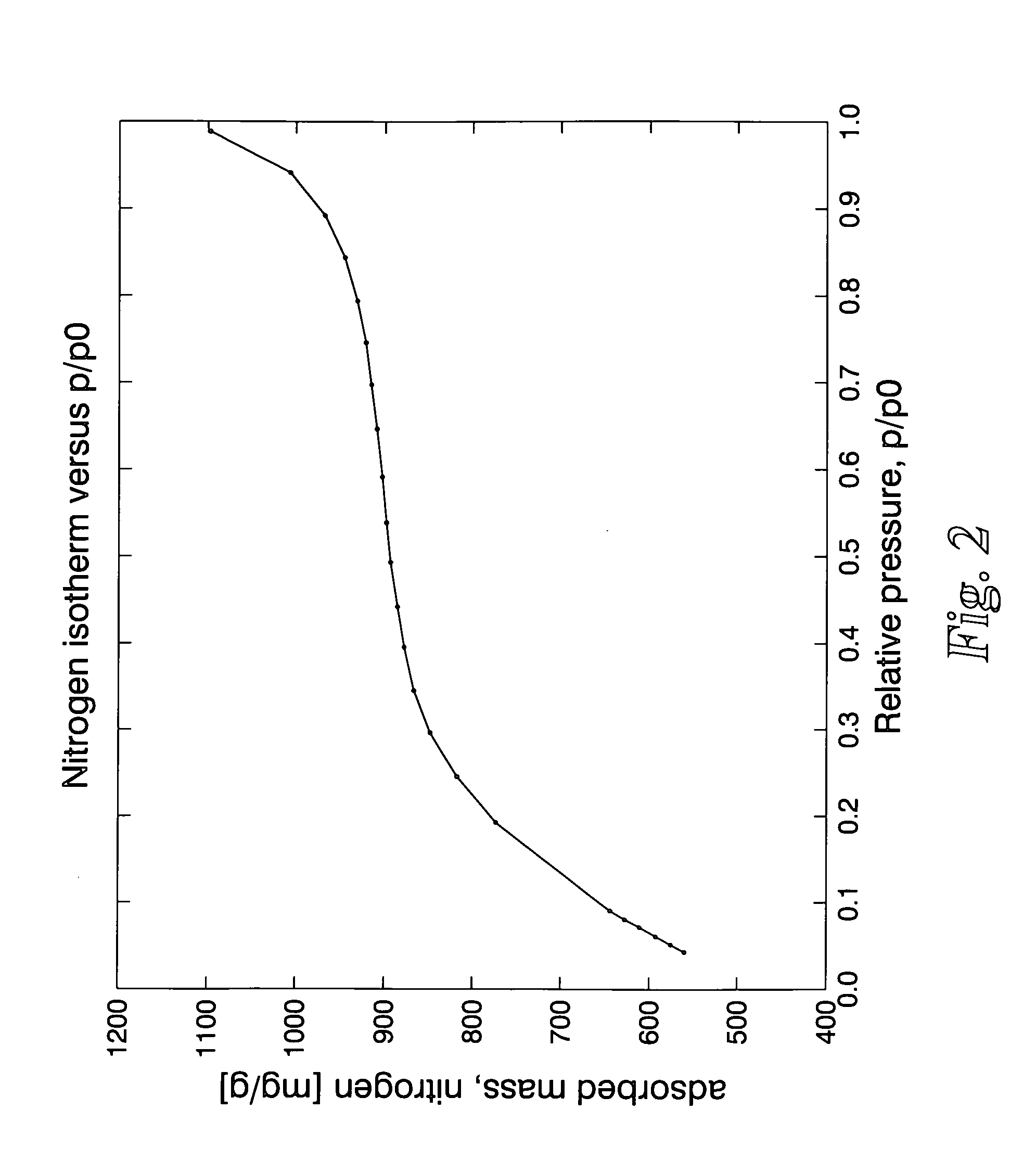

High performance adsorbents based on activated carbon of high Microporosity

The invention concerns high performance adsorbents based on activated carbon of high microporosity which are present in the form of discrete grains of activated carbon, preferably in spherical form, and which are characterized by the following parameters: a Gurvich total pore volume of at least 0.7 cm3 / g, at least 70% of this total pore volume being formed by micropores having pore diameters of ≦20 Å, a measure of central tendency pore diameter of not more than 30 Å, and a BET surface area of at least 1500 m2 / g. These high performance adsorbents are particularly useful for the adsorption of toxins, noxiants and odors, in particular from gas or to be more precise air streams, for purifying or cleaning gases, such as in particular air, for application in medicine or to be more precise pharmacy and as sorptive storage media for gases, in particular hydrogen.

Owner:BLUCHER GMBH

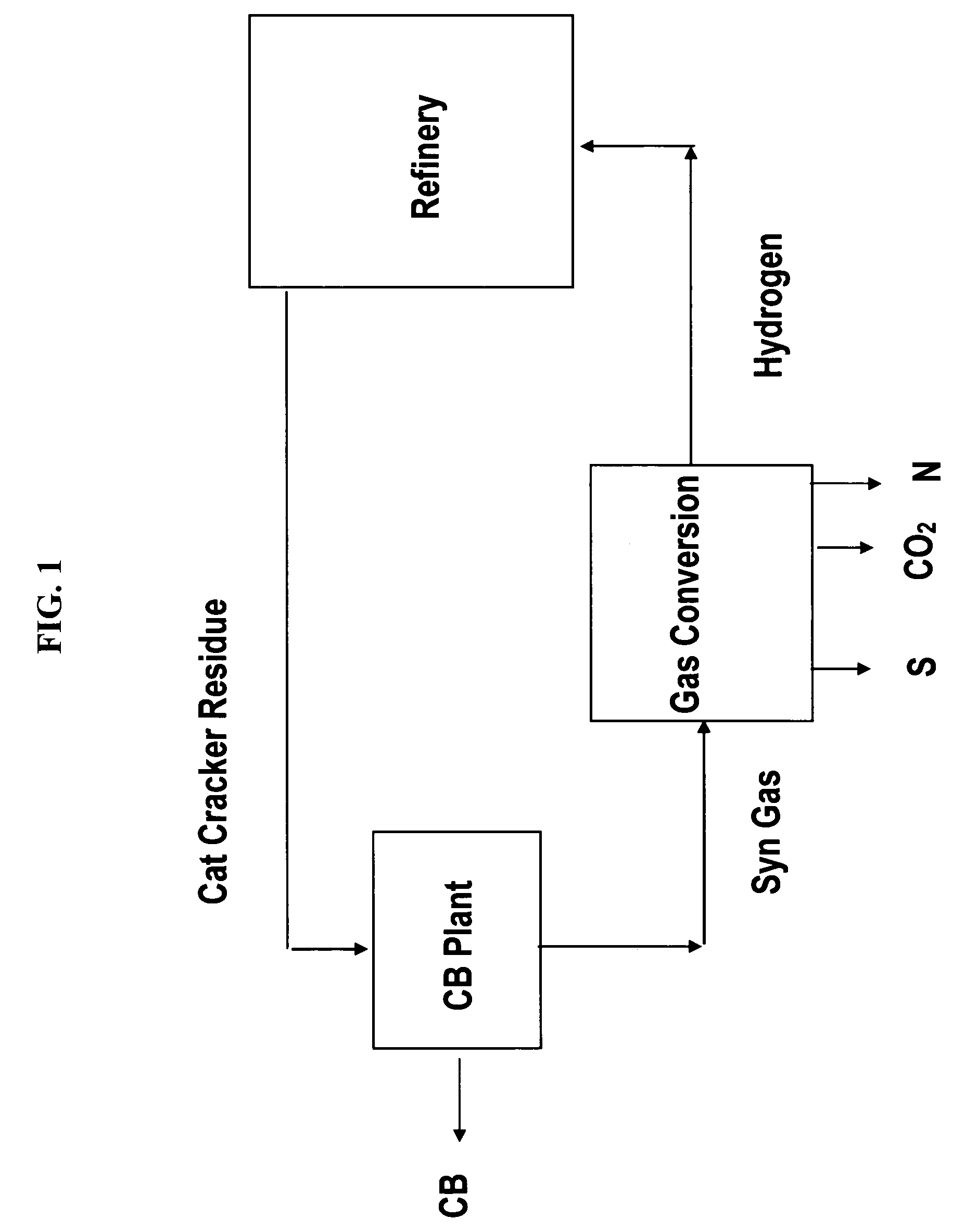

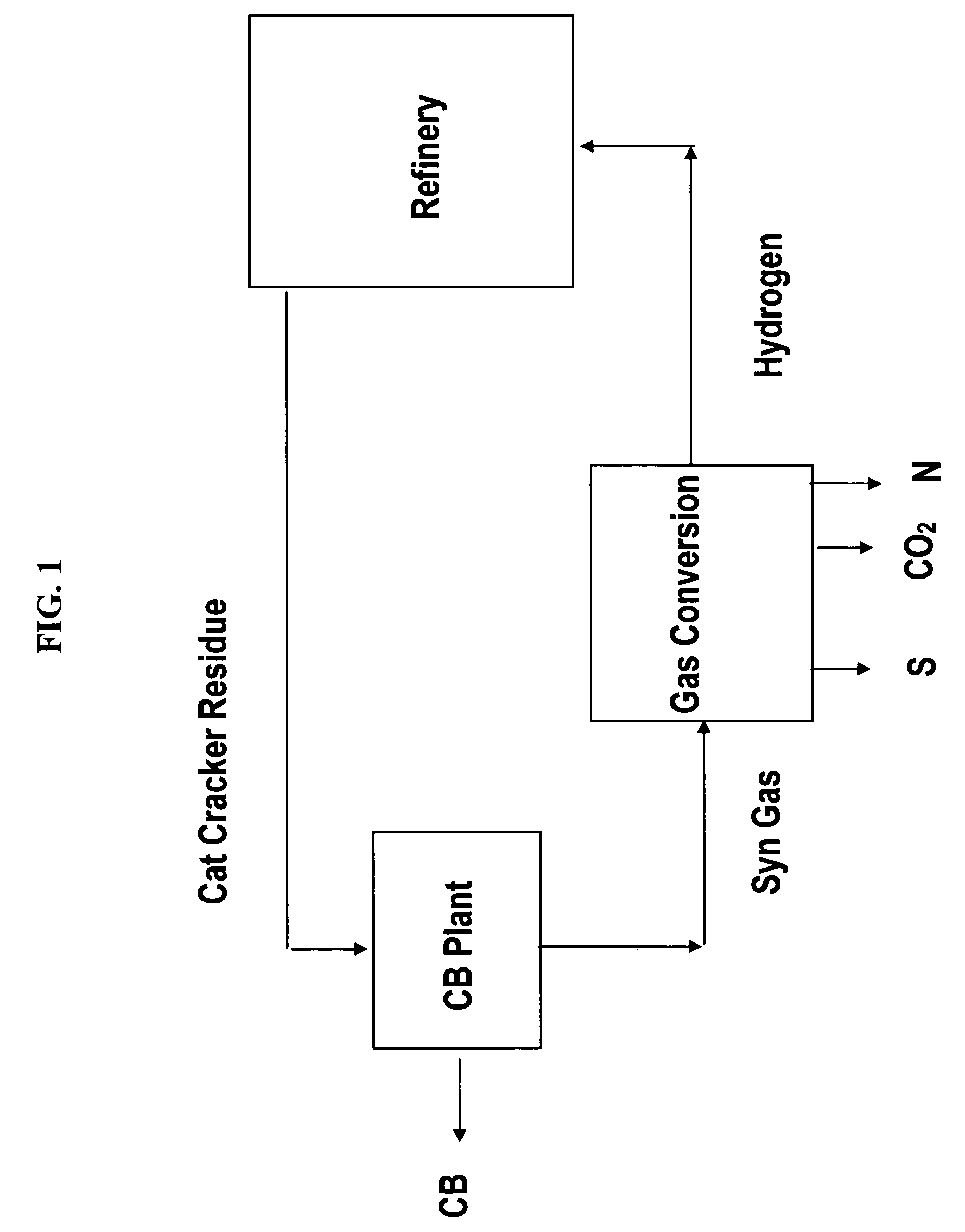

Method to produce hydrogen or synthesis gas and carbon black

InactiveUS7666383B2Emission reductionPigmenting treatmentHydrogen separation using solid contactHydrogenOil refinery

Owner:CABOT CORP

Reaction of carbon black with diazonium salts, resultant carbon black products and their uses

Processes for preparing a carbon black product having an organic group attached to the carbon black. In one process at least one diazonium salt reacts with a carbon black in the absence of an externally applied electric current sufficient to reduce the diazonium salt. In another process at least one diazonium salt reacts with a carbon black in a protic reaction medium. Carbon black products which may be prepared according to process of the invention are described as well as uses of such carbon black products in plastic compositions, rubber compositions, paper compositions, and textile compositions.

Owner:CABOT CORP

Thermally modified carbon blacks for various type applications and a process for producing same

InactiveUS20050063893A1Improve thermal conductivityImprove fatigue performancePigmenting treatmentMaterial nanotechnologyModified carbonFood contact

Owner:COLUMBIAN CHEM CO +1

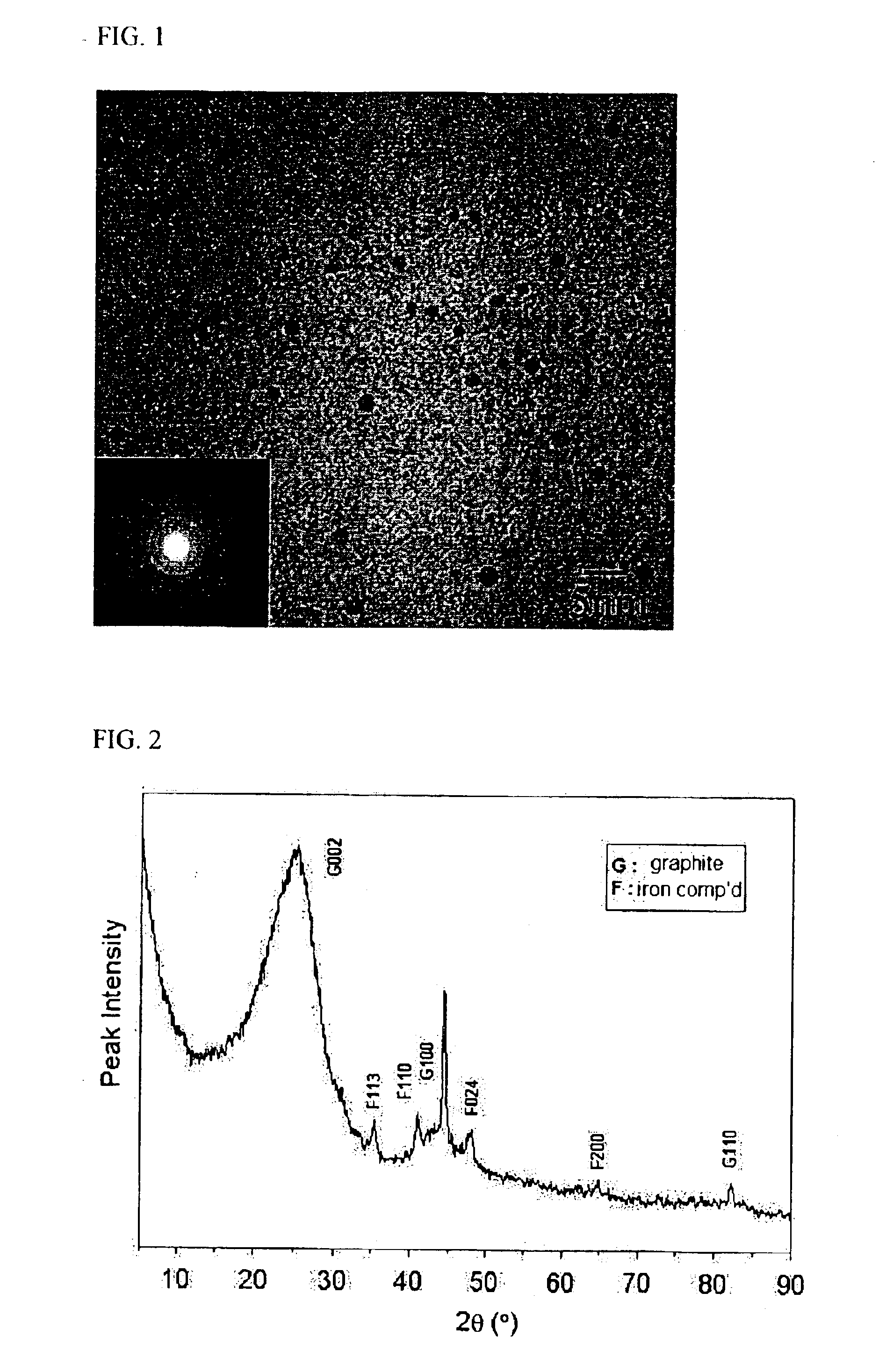

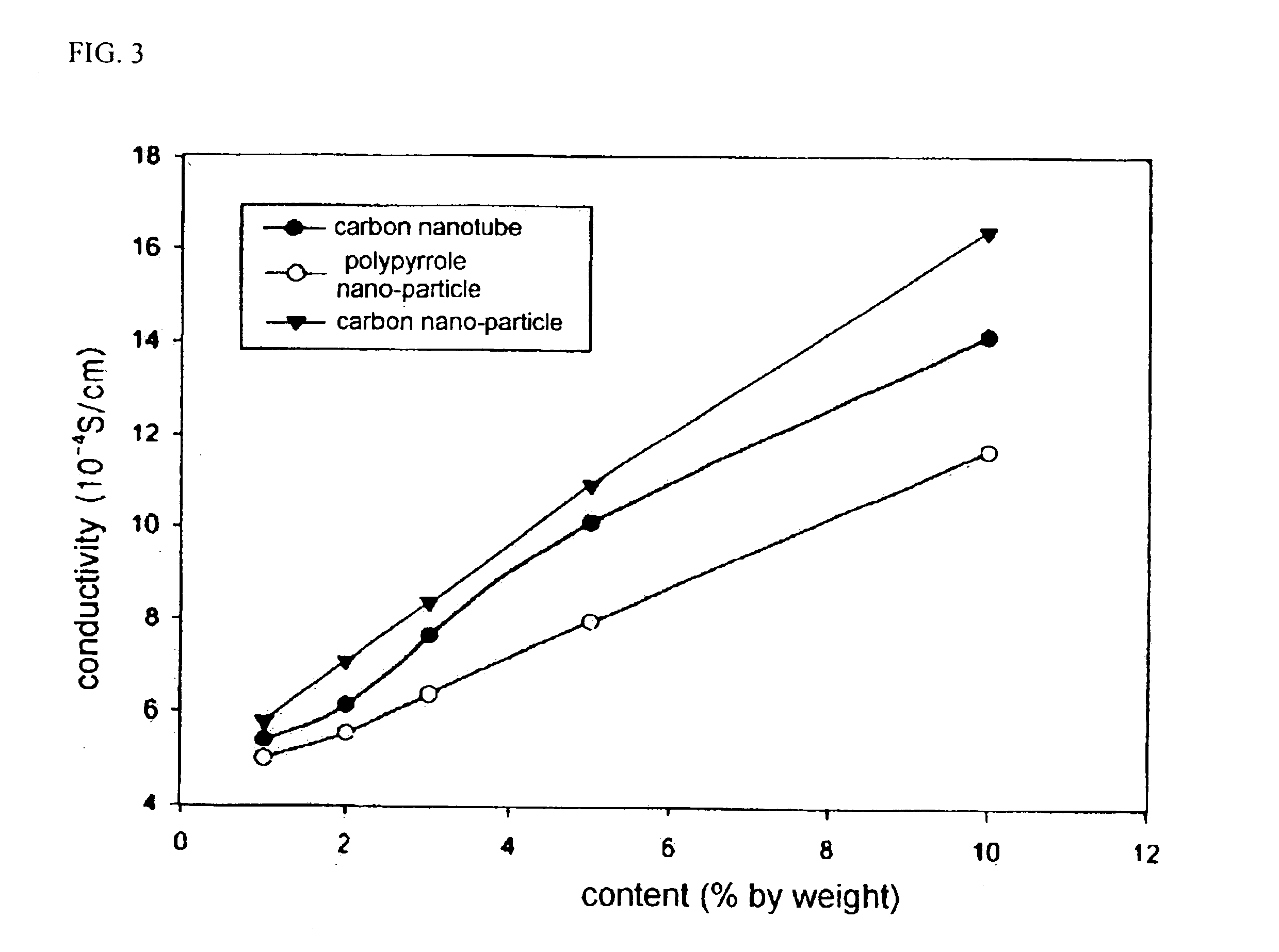

Carbon nano-particle and method of preparing the same and transparent conductive polymer composite containing the same

ActiveUS6919063B2Low costNovel methodMaterial nanotechnologyNanoinformaticsMean diameterConductive polymer composite

The present invention relates to a novel carbon nano-particle and a novel method of preparing the same and a transparent, conductive polymer composite containing the same. The carbon nano-particle has the mean diameter of 1 through 50 nm and the shape of sphere, rod or others, which is a novel material not known in the relevant art. Because of a particle size less than ½ of the shortest wavelength of a visible ray, a transparent resin containing the carbon nano-particle can maintain the transparency. Furthermore, the carbon nano-particle has the excellent electric conductivity and the ferromagnetic property, and can be made by a novel, low cost method entirely different from those of fullerene and carbon nanotube.

Owner:DONG WOON INT

Process For Production of Carbon Black

InactiveUS20080226538A1Increase flexibilityLow costProcess control/regulationPigmenting treatmentCombustorProcess engineering

Off-gas from a carbon black furnace is employed as a combustion gas feed stream to the burner or combustion zone of the same or a different carbon black furnace in accordance with certain embodiments, suitable conduit and valving is provided to pass off-gas, from which carbon black has been substantially removed, from any and all of multiple different carbon black furnaces to the burner. The off-gas is heated, preferably by plasma heating, and dewatered. Carbon dioxide stripping or rather stripping of gas components from the dewatered heated off-gas is found to be unnecessary to achieve economically favorable use of off-gas recirculation.

Owner:CABOT CORP

Thermally modified carbon blacks for various type applications and a process for producing same

InactiveUS20050063892A1Oxidation resistance can be improvedReduced metal and ash contentPigmenting treatmentMaterial nanotechnologyModified carbonOxidation resistant

An electro thermal fluidized bed furnace is adapted to be used in a process for continuously heat treating of fine particulate matter, such as carbon black material, by continuously introducing a non-reactive fluidizing gas through the nozzles of the furnace at a pre-determined rate, continuously introducing untreated carbon black material through the feed pipe of the furnace at a predetermined rate so that it forms a fluidized bed, energizing the electrode so as to heat the fluidized bed, and continuously collecting the treated carbon black from the discharge pipe. The carbon black collected from the discharge pipe exhibits properties of having the PAHs and sulfur removed, the carbon black has been graphitized, the moisture pick-up by the carbon black has been eliminated and the carbon black is more oxidation resistant, Furthermore, the resultant furnace carbon backs have a particle size of 7-100 nm and an oil absorption number of 50-300 ml / 100 g., while the thermal blacks have a particle size of 200-500 nm and an oil absorption number of less than 50 ml / 100 g. All of these properties result in thermally modified carbon blacks having such properties and of such purity so as to provide improved performance properties in food contact type applications, moisture cured polymer systems, zinc-carbon dry cell battery applications, and semi-conductive wire and cable applications.

Owner:COLUMBIAN CHEM CO +1

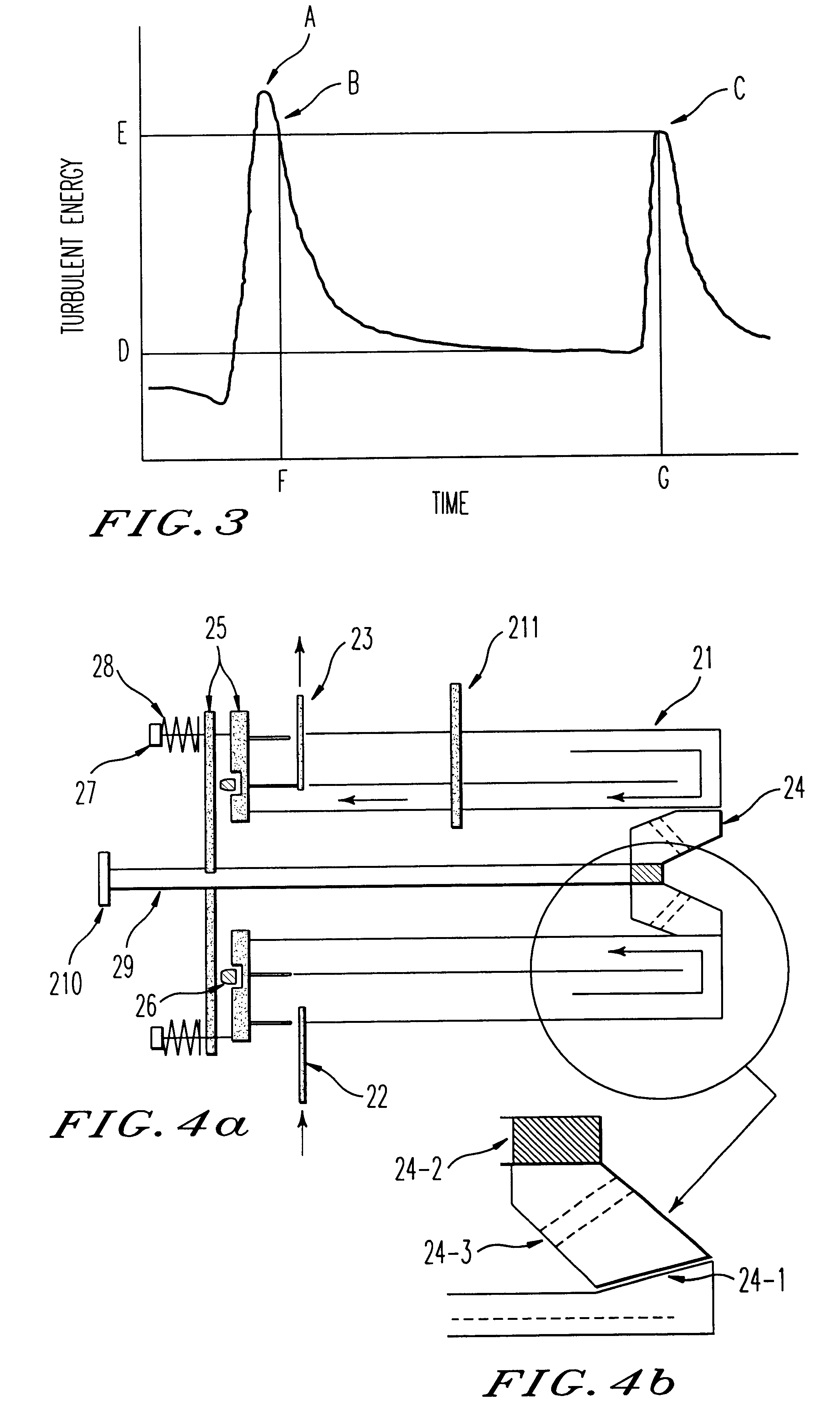

Filter devices and methods for carbon nanomaterial collection

InactiveUS6887291B2Facilitate continuous synthesisEasy to disassembleMaterial nanotechnologyCombination devicesReactor systemCombustion

Filter devices and methods for collection of carbon nanomaterials, including fullerenes, produced in gas phase reactors are provided. The filter devices provide for in situ cleaning of filters to release captured product for collection. Product can be released and removed from the reactor without disrupting continuous synthesis of carbon nanomaterials. The filter devices facilitate increased reactor operation and larger scale production of carbon nanomaterials. The filters are cleaned by application of a motive force and / or a gas flow to the filter. In a specific embodiment filters are cleaned by a reverse flow of gas pulses to the filter provided. The invention also provides reactor systems for gas phase synthesis of carbon nanomaterials that can be operated continuously employing the filter device of this invention. Preferred reactor systems are those which synthesize carbon nanomaterials by combustion. Methods for continuous production of carbon nanomaterials using the filtering devices and methods of this invention are also provided.

Owner:FRONTIER CARBON CORP

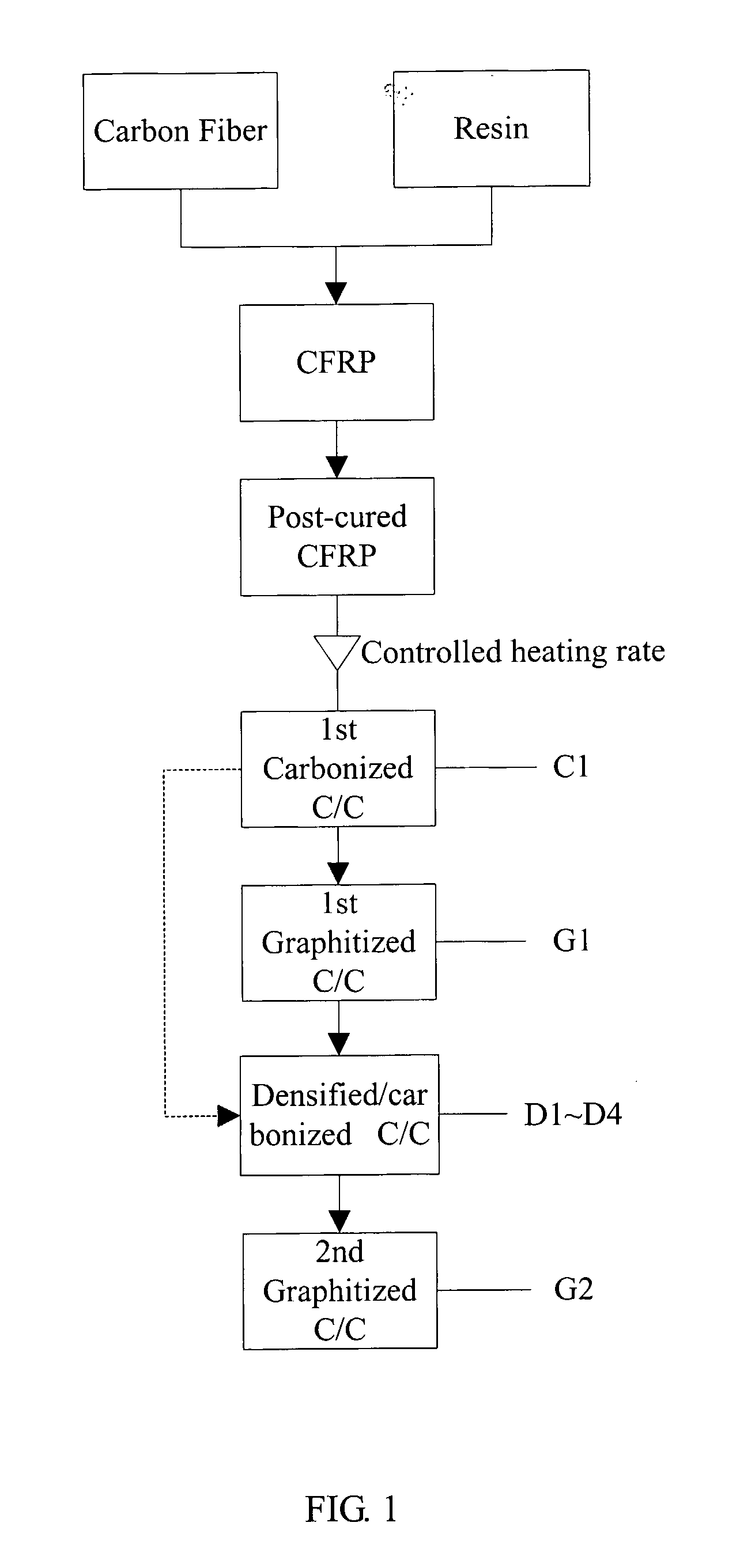

Method for Preparing a Carbon/Carbon Composite

InactiveUS20080025906A1Comparable mechanical propertyAcceptable tribological performanceMaterial nanotechnologyAlkali metal halidesCarbon compositesMaterials science

A method for preparing a carbon / carbon (C / C) composite comprising carbonizing a carbon fiber-reinforced polymer matrix composite precursor by heating the precursor in an inert atmosphere with a heating rate greater than 20° C. / min up to 1500° C. / min.

Owner:NAT CHENG KUNG UNIV

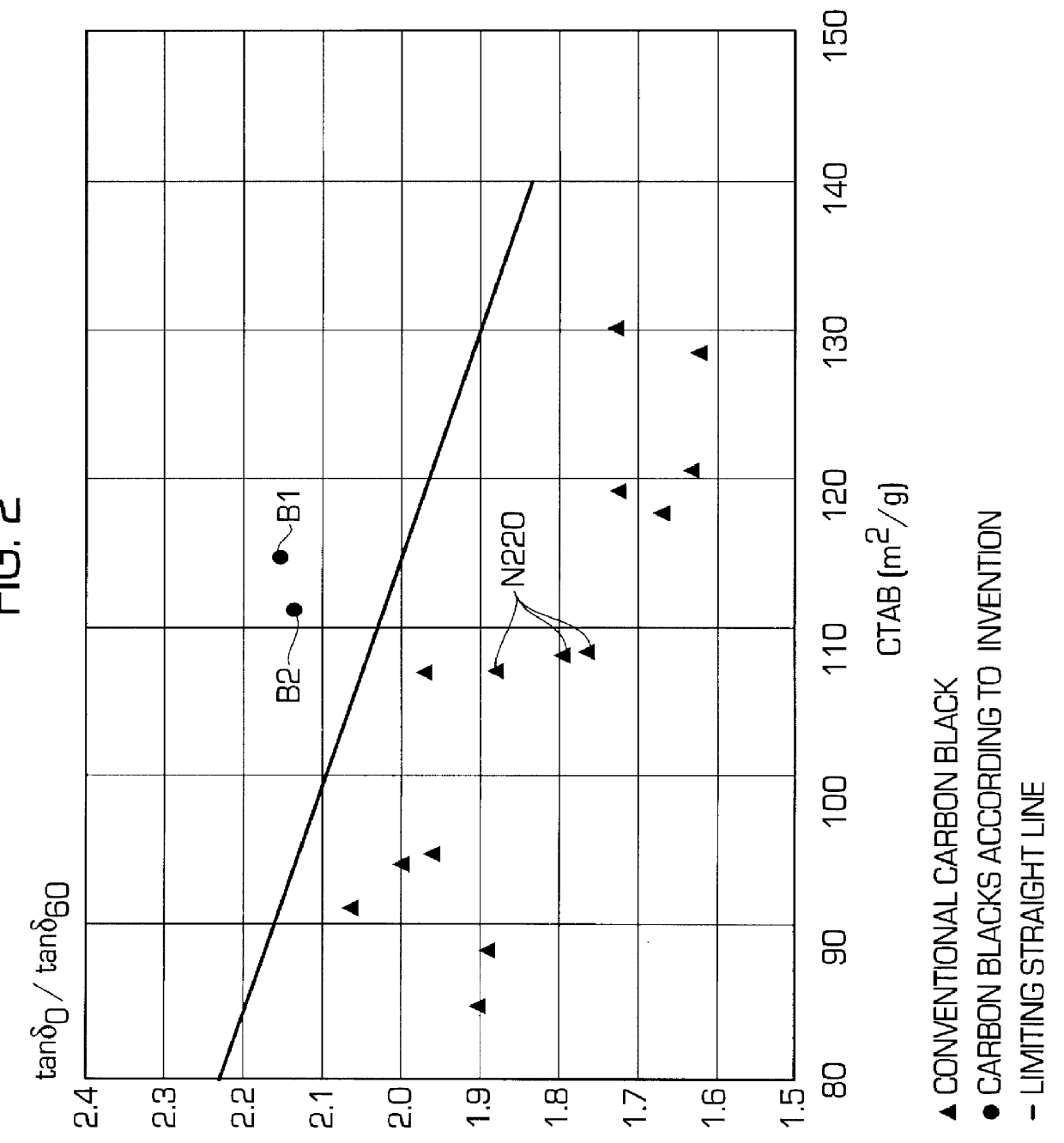

Inversion carbon blacks and method for their manufacture

InactiveUS6056933AIncrease resistanceEasy to wearMaterial nanotechnologyPigmenting treatmentCombustion chamberRolling resistance

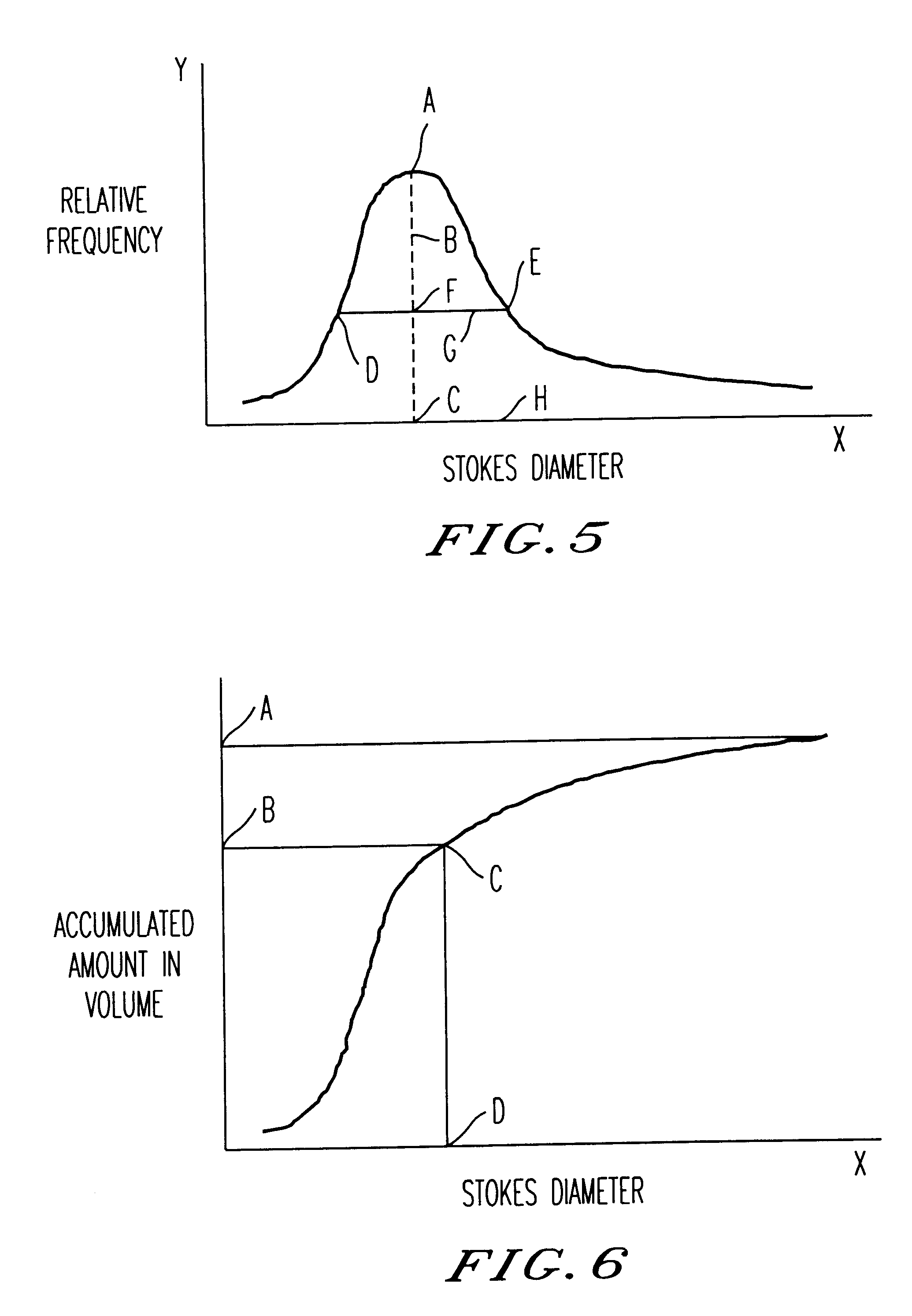

Inversion carbon blacks and a method for their manufacture and disclosed. The inversion carbon blacks have a smaller rolling resistance with identical or improved wet sliding behavior. The particle size distribution contains a smaller proportion of particles with large diameters. This leads to an improved abrasion behavior of rubber compounds which were prepared using these carbon blacks. The inversion carbon blacks can be manufactured in conventional carbon black reactors by controlling the combustion in the combustion chamber in such a manner that carbon black nuclei form, which are immediately brought into contact with the carbon black raw material. The carbon blacks present a lower proportion of larger particles if the additions of combustion air and carbon black raw material are increased in an appropriate manner.

Owner:UBS AG

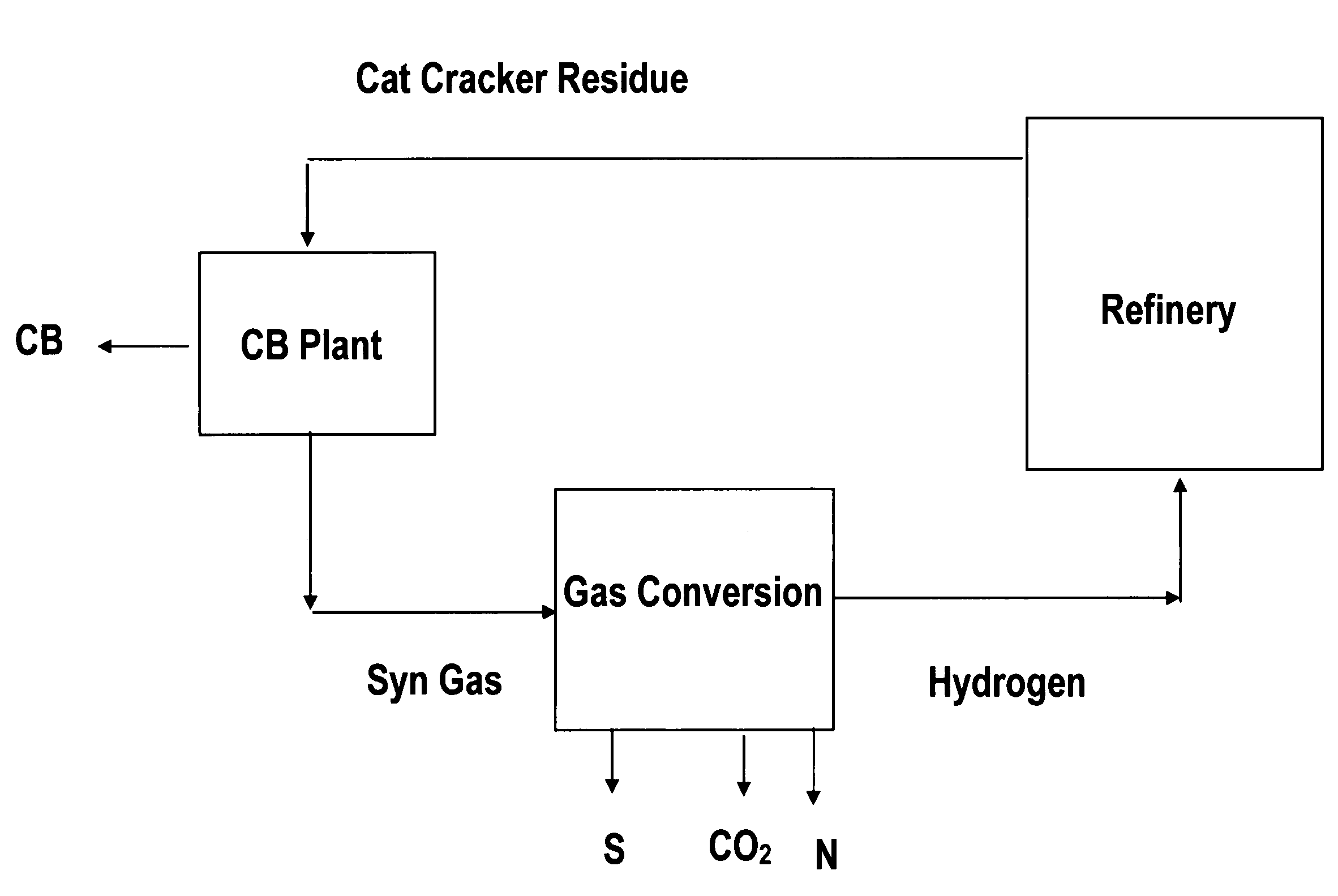

Method to produce hydrogen or synthesis gas

InactiveUS20060228290A1Emission reductionPigmenting treatmentHydrogen separation using solid contactHydrogenChemistry

A method to produce hydrogen gas or synthesis gas is described and involves the use of a staged reactor. The present invention further relates to effectively running a process such that efficient quantities of hydrogen gas are produced, along with economically useful amounts of carbon black. A combined facility utilizing a carbon black manufacturing plant and a refinery plant are further described, as well as products made by the various methods of the present invention.

Owner:CABOT CORP

Popular searches

Cell electrodes Cathode ray/electron stream lamps Fuel cells Tubular articles Discharge tube screens Cathode ray tubes/electron beam tubes From chemically reactive gases Superconductor device manufacture/treatment Energy based chemical/physical/physico-chemical processes Chemical vapor deposition coating

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com