Patents

Literature

692 results about "Gas diffusion electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

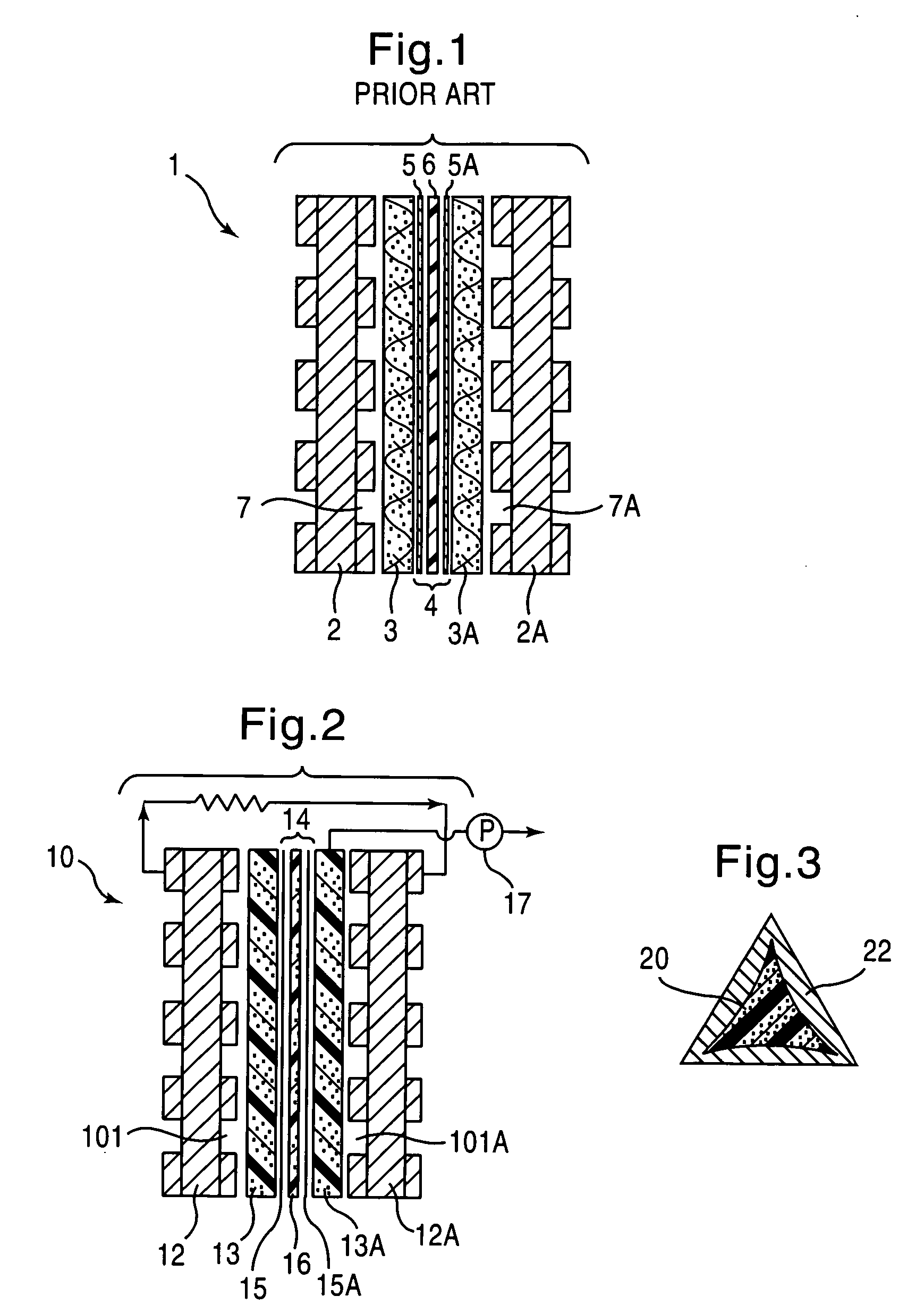

Gas diffusion electrodes (GDE) are electrodes with a conjunction of a solid, liquid and gaseous interface, and an electrical conducting catalyst supporting an electrochemical reaction between the liquid and the gaseous phase.

Low platinum fuel cell catalysts and method for preparing the same

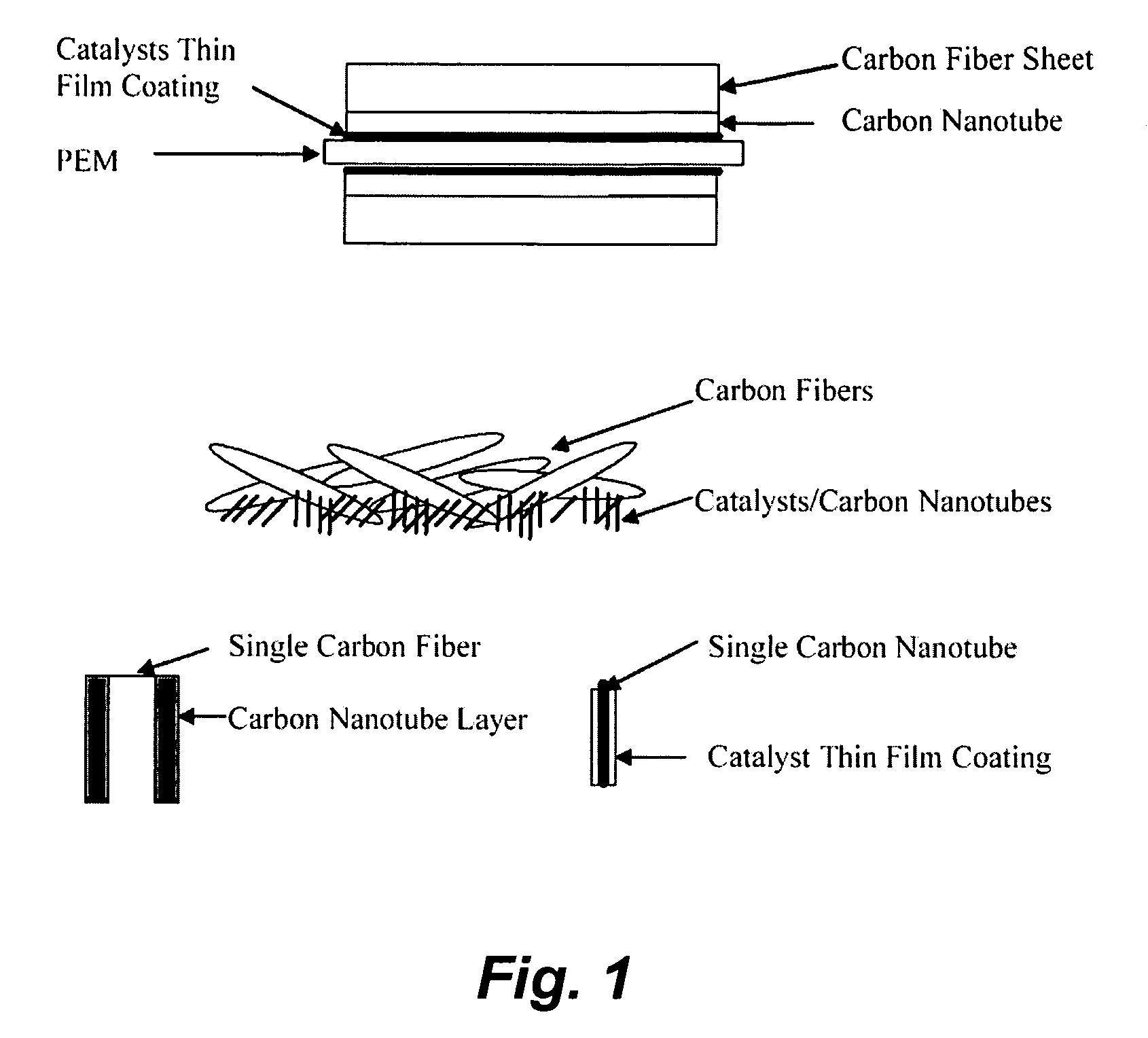

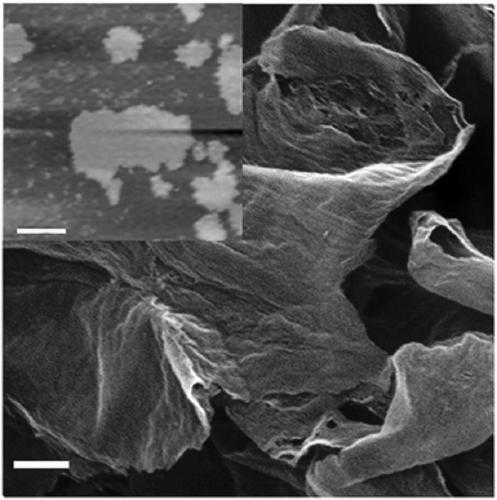

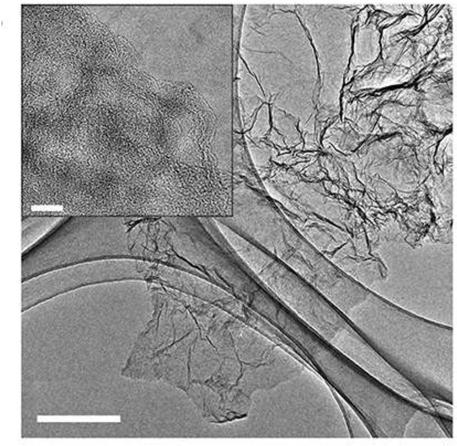

InactiveUS20050053826A1Good dispersionEfficient CatalysisMaterial nanotechnologyConductive materialFiberCarbon fibers

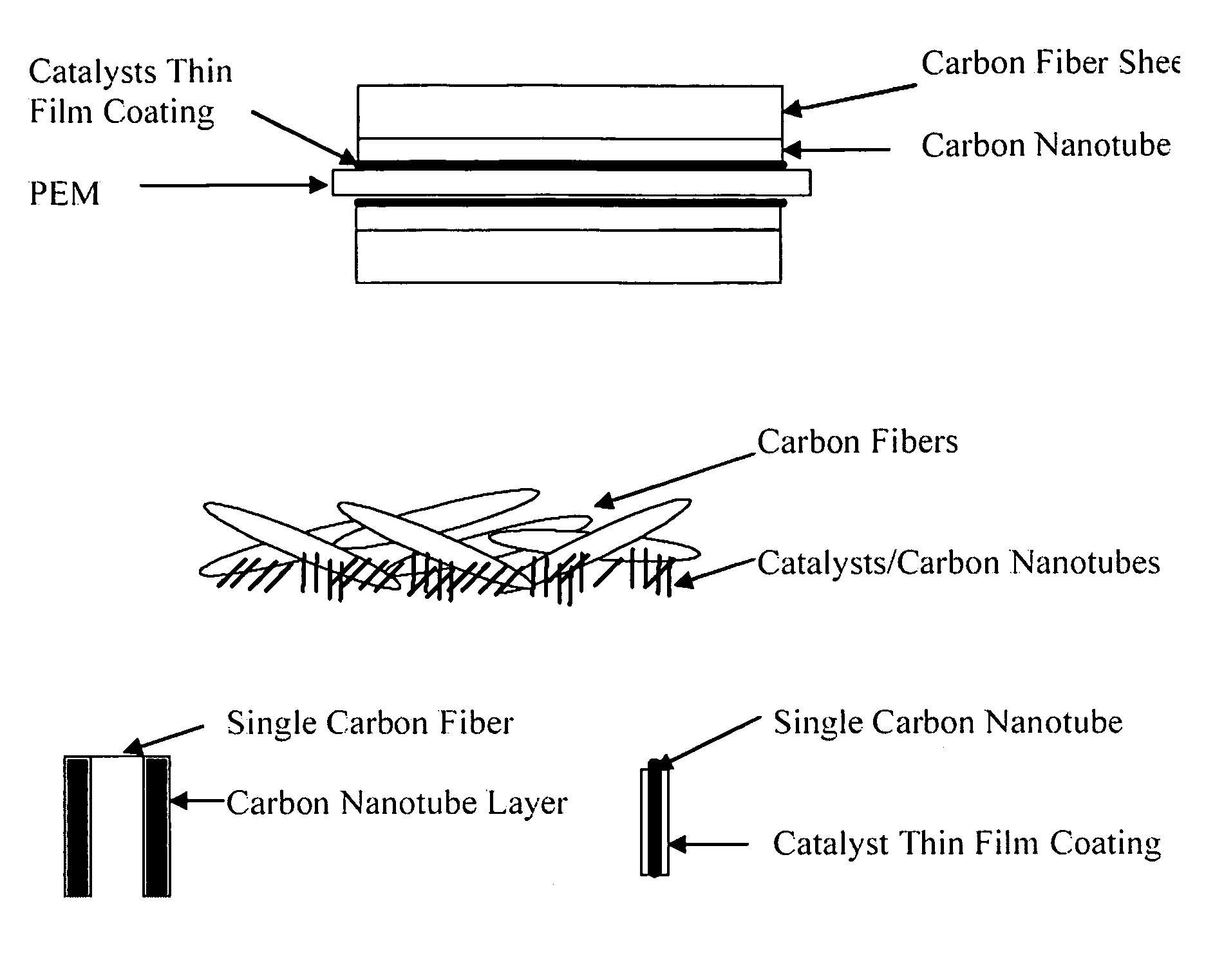

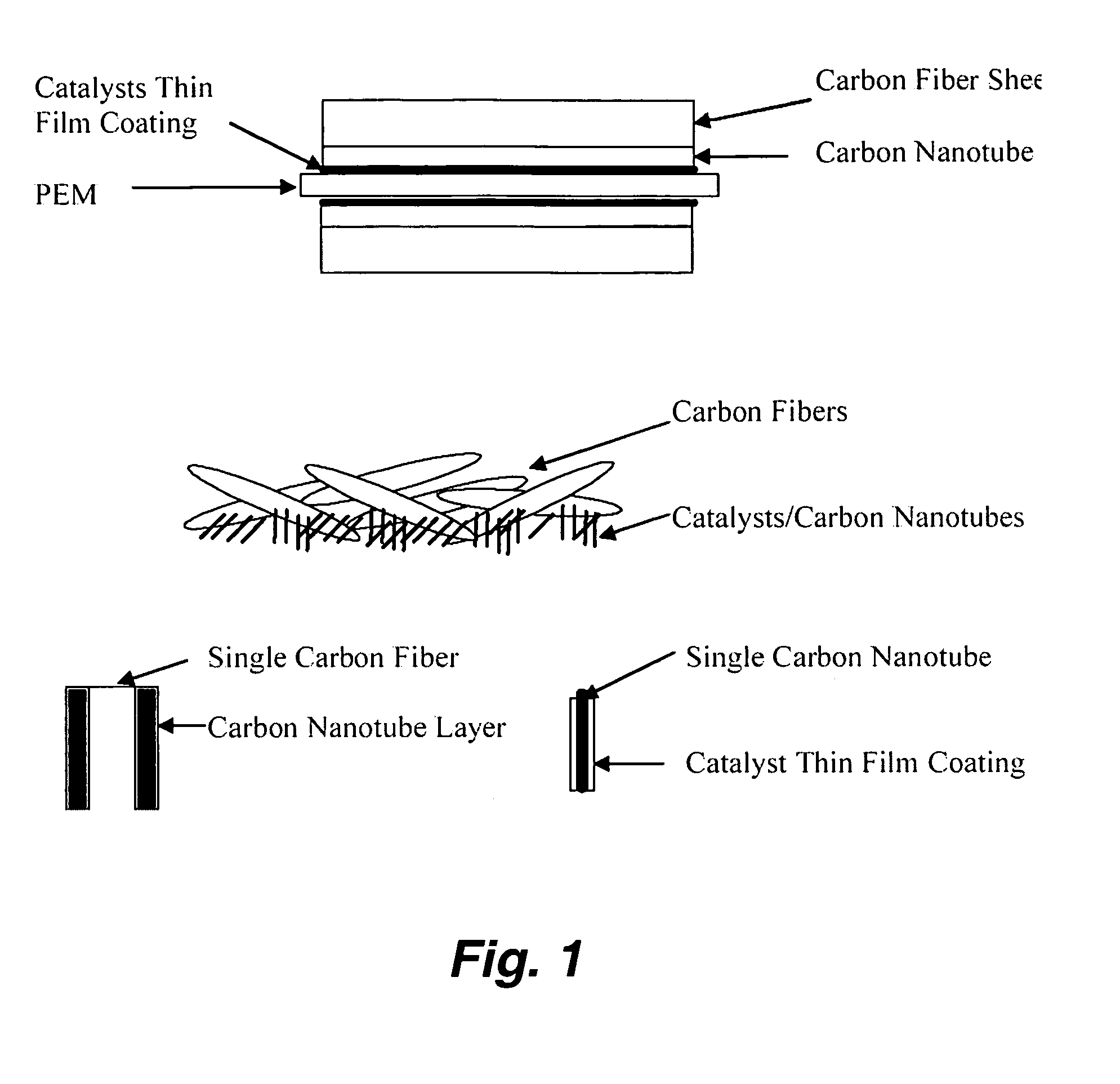

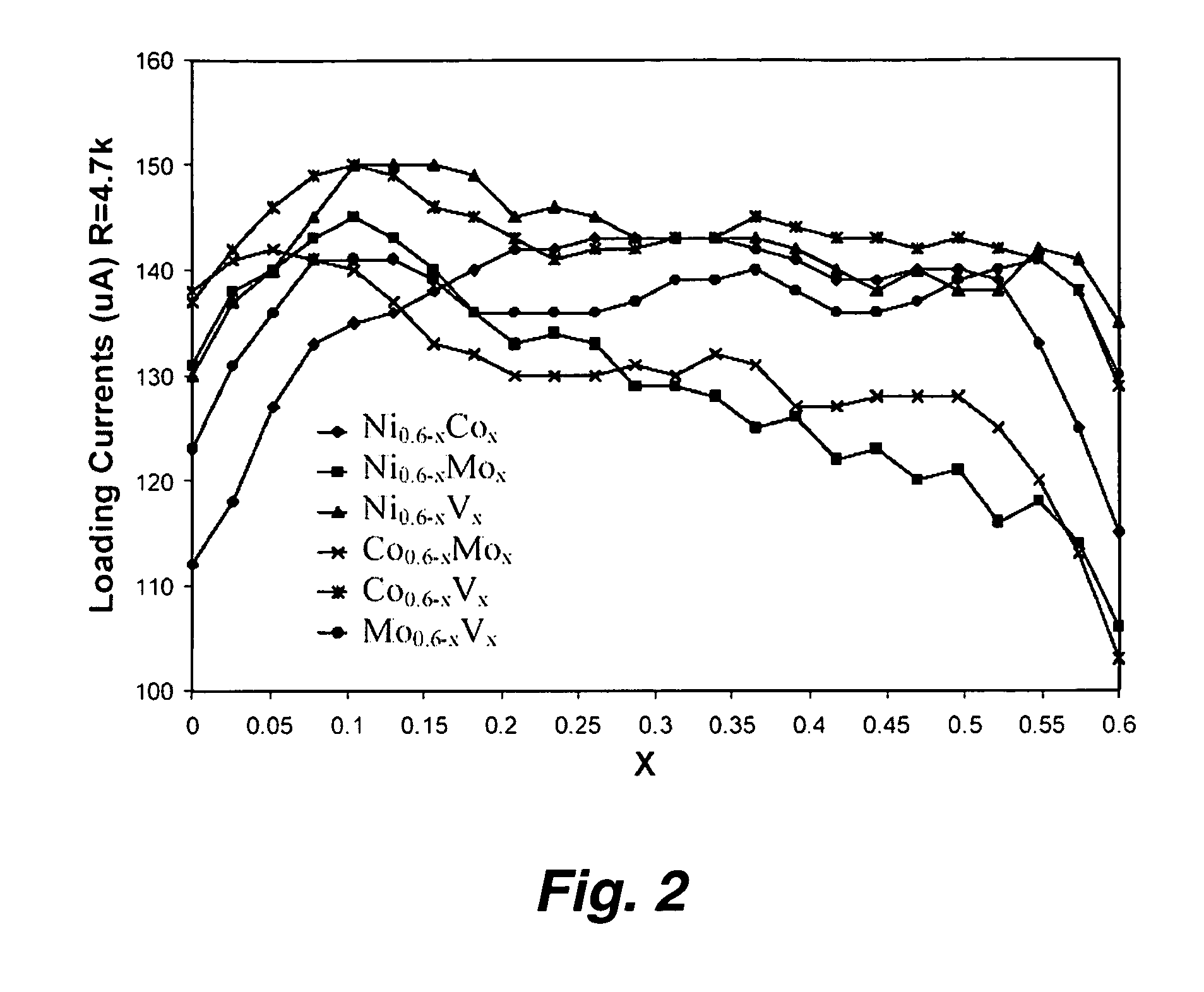

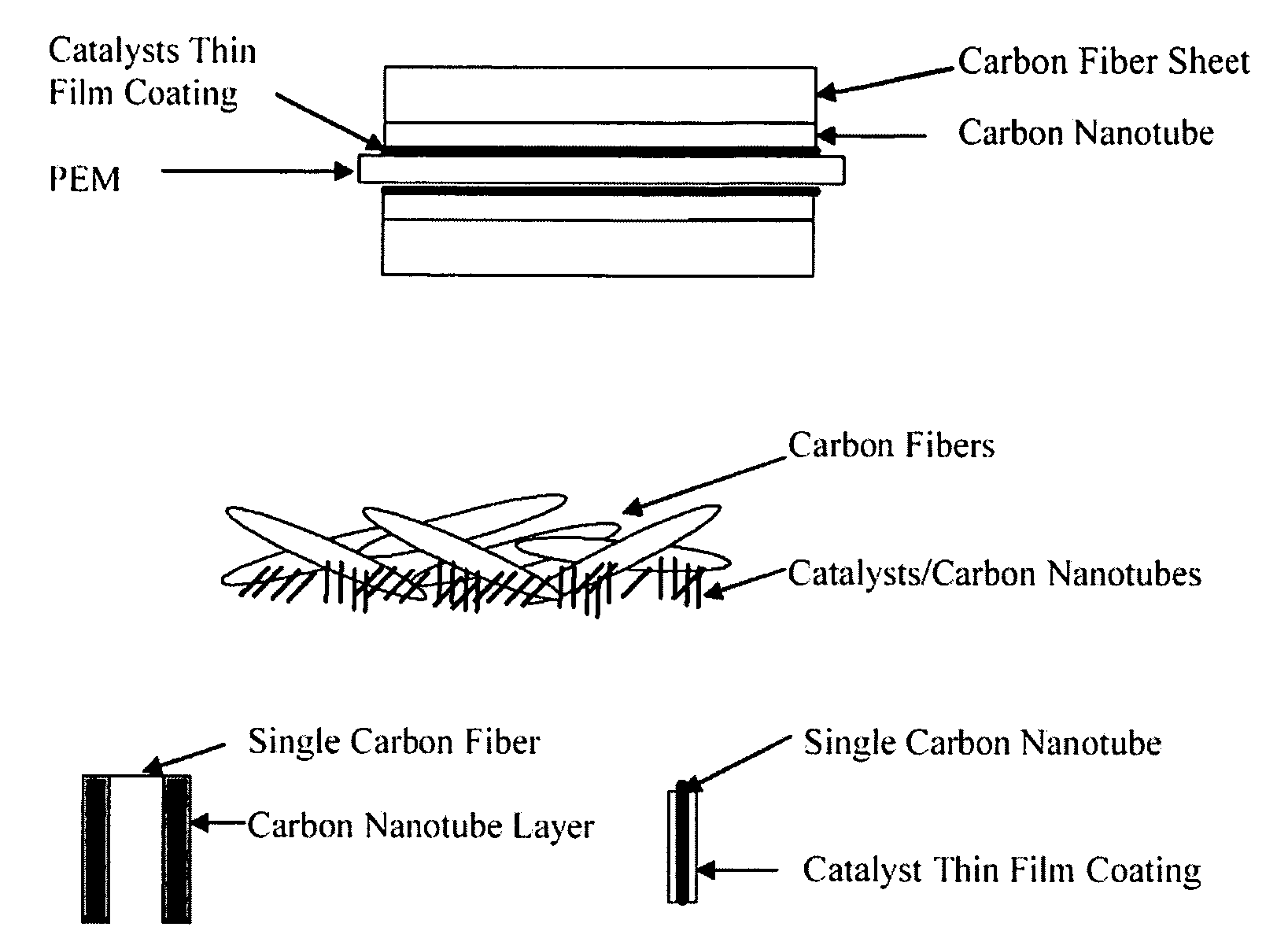

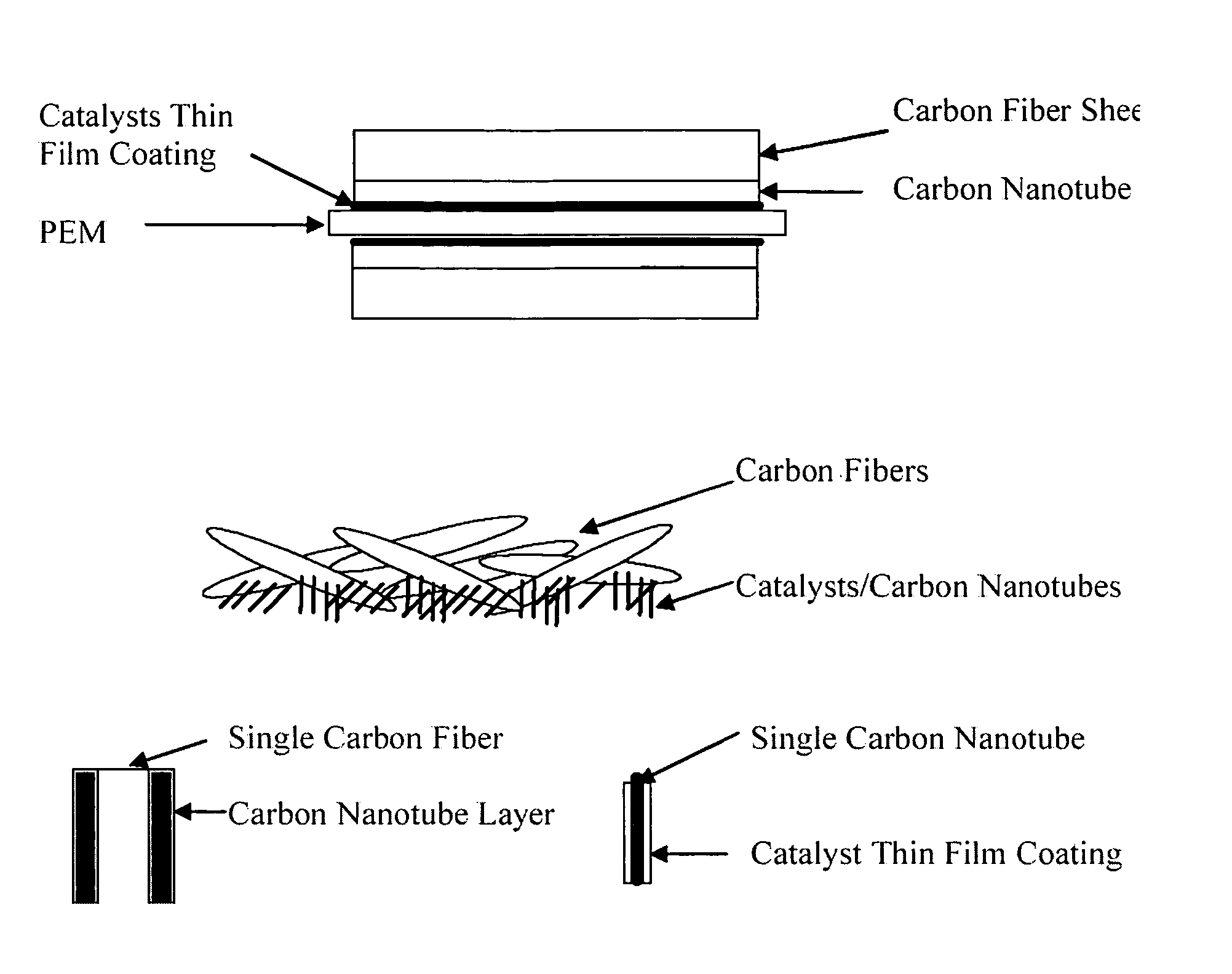

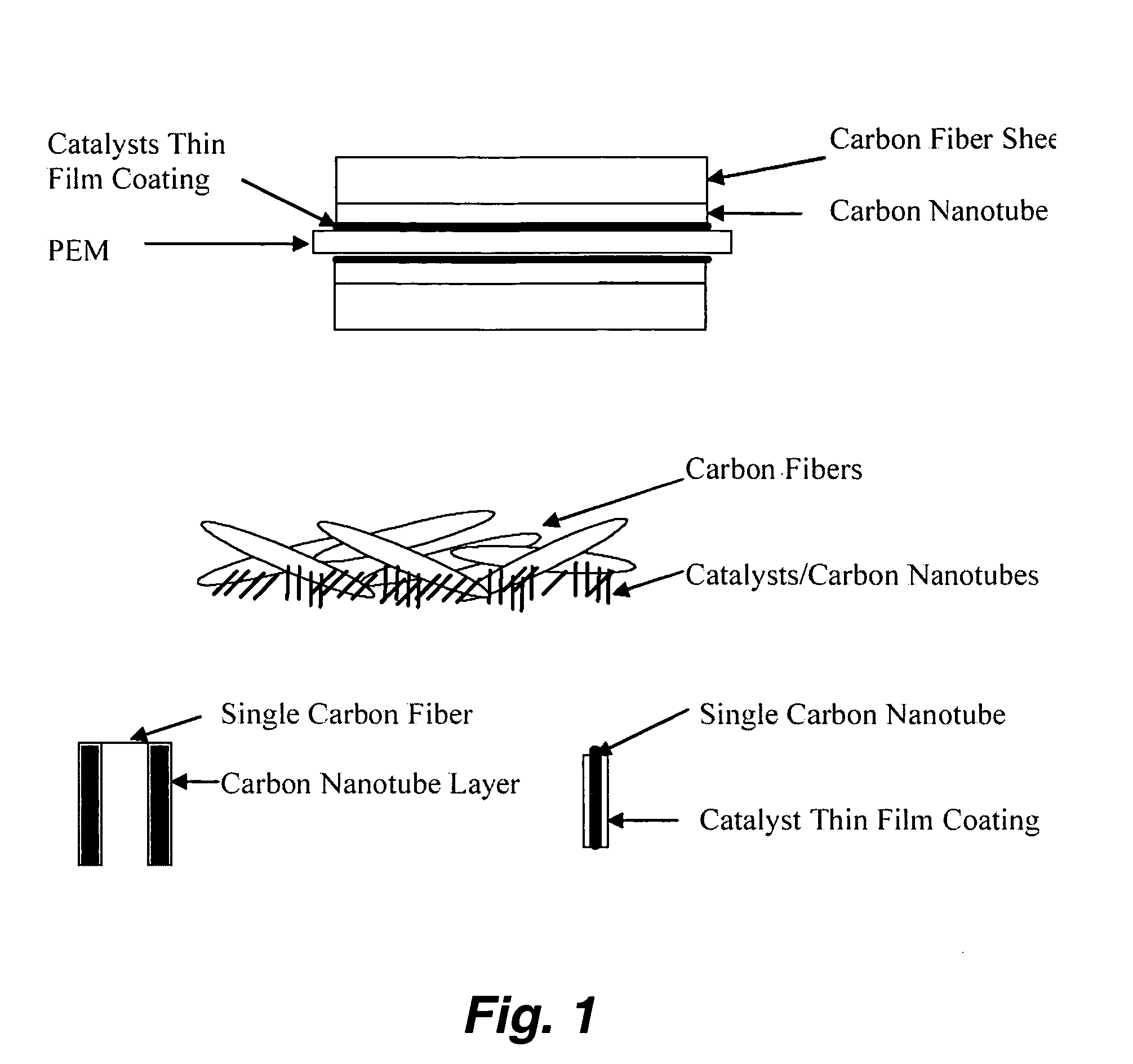

This invention provides novel fuel cell catalysts comprising new series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticales into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

Low platinum fuel cells, catalysts, and method for preparing the same

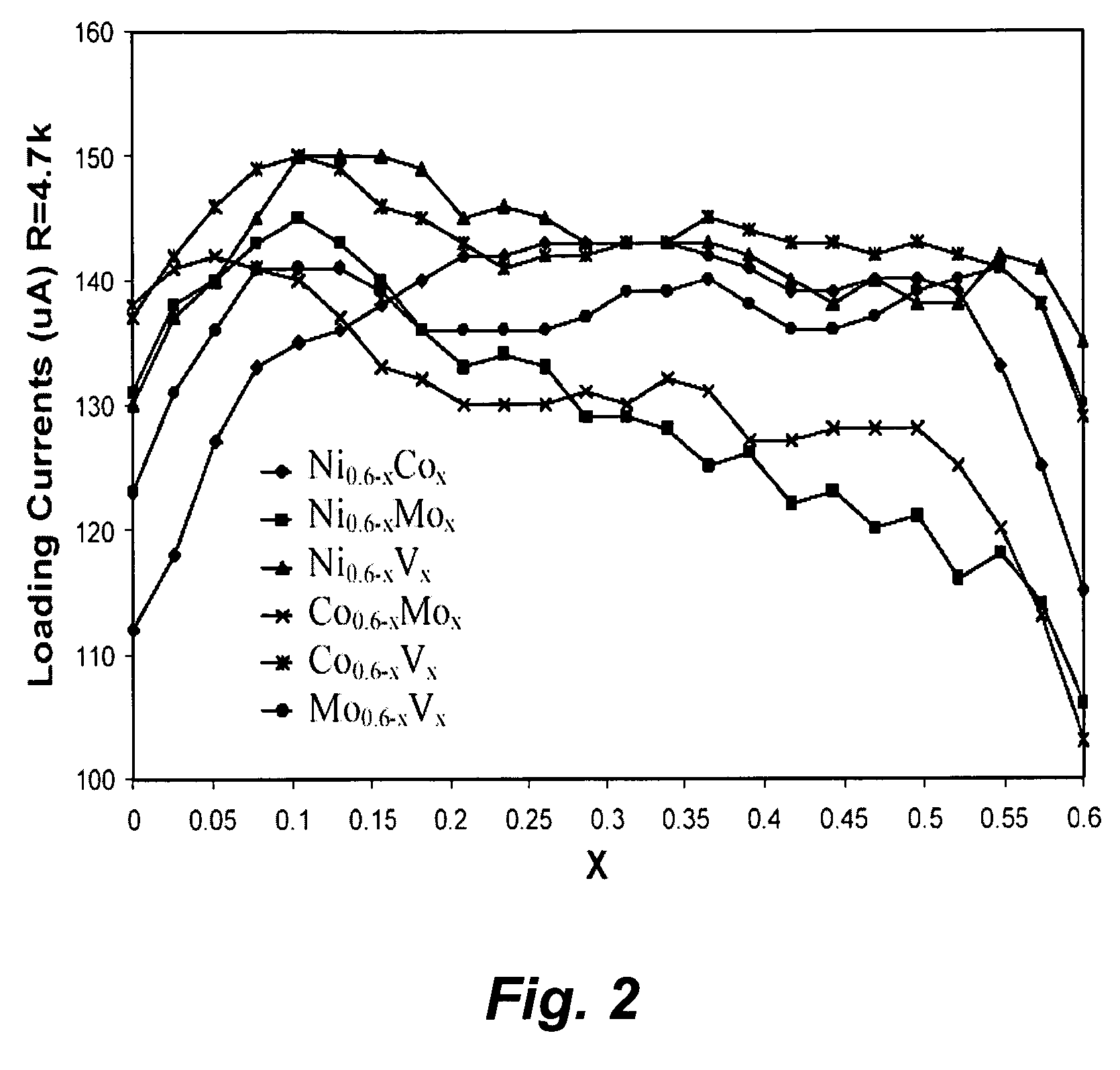

InactiveUS20060172179A1Efficient processingImprove throughputMaterial nanotechnologyConductive materialFiberCarbon fibers

This invention provides novel fuel cell electrodes and catalysts comprising a series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). Processing of the electrodes and catalysts can include electrodeposition methods, and high-pressure coating techniques. In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticles into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

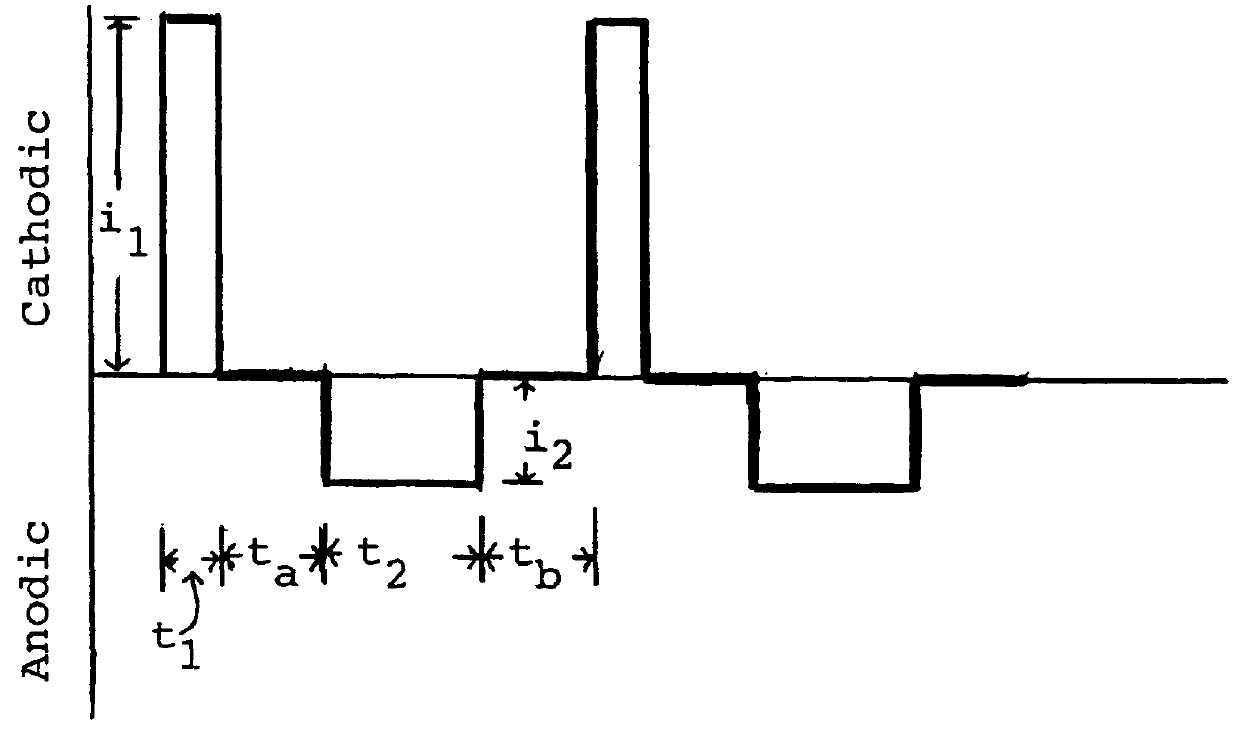

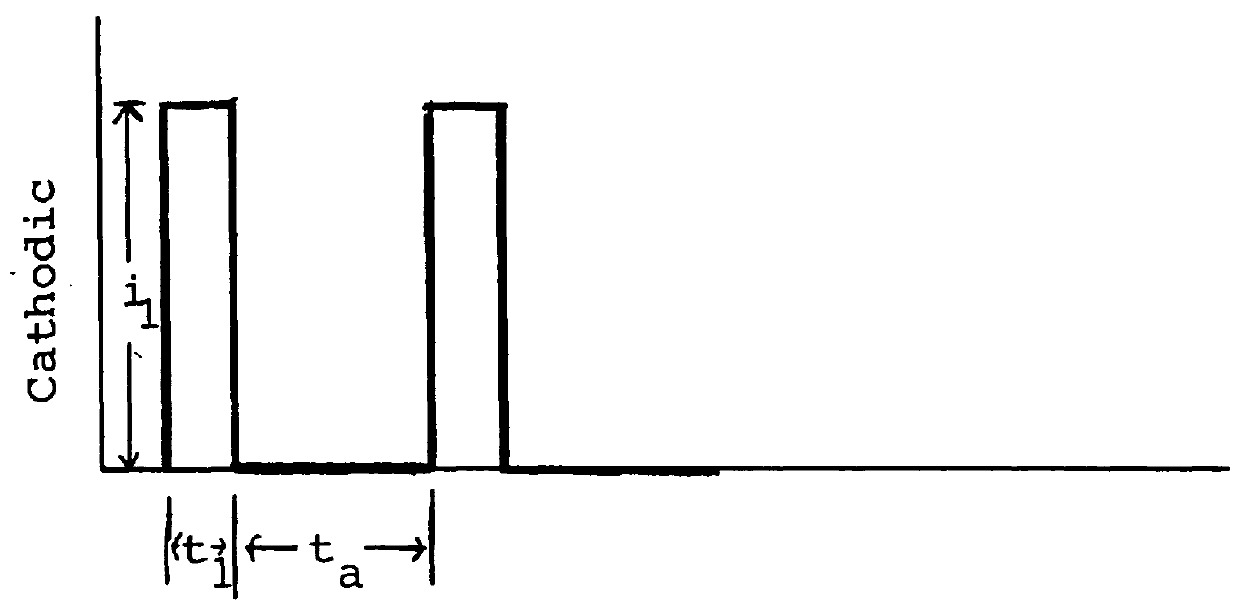

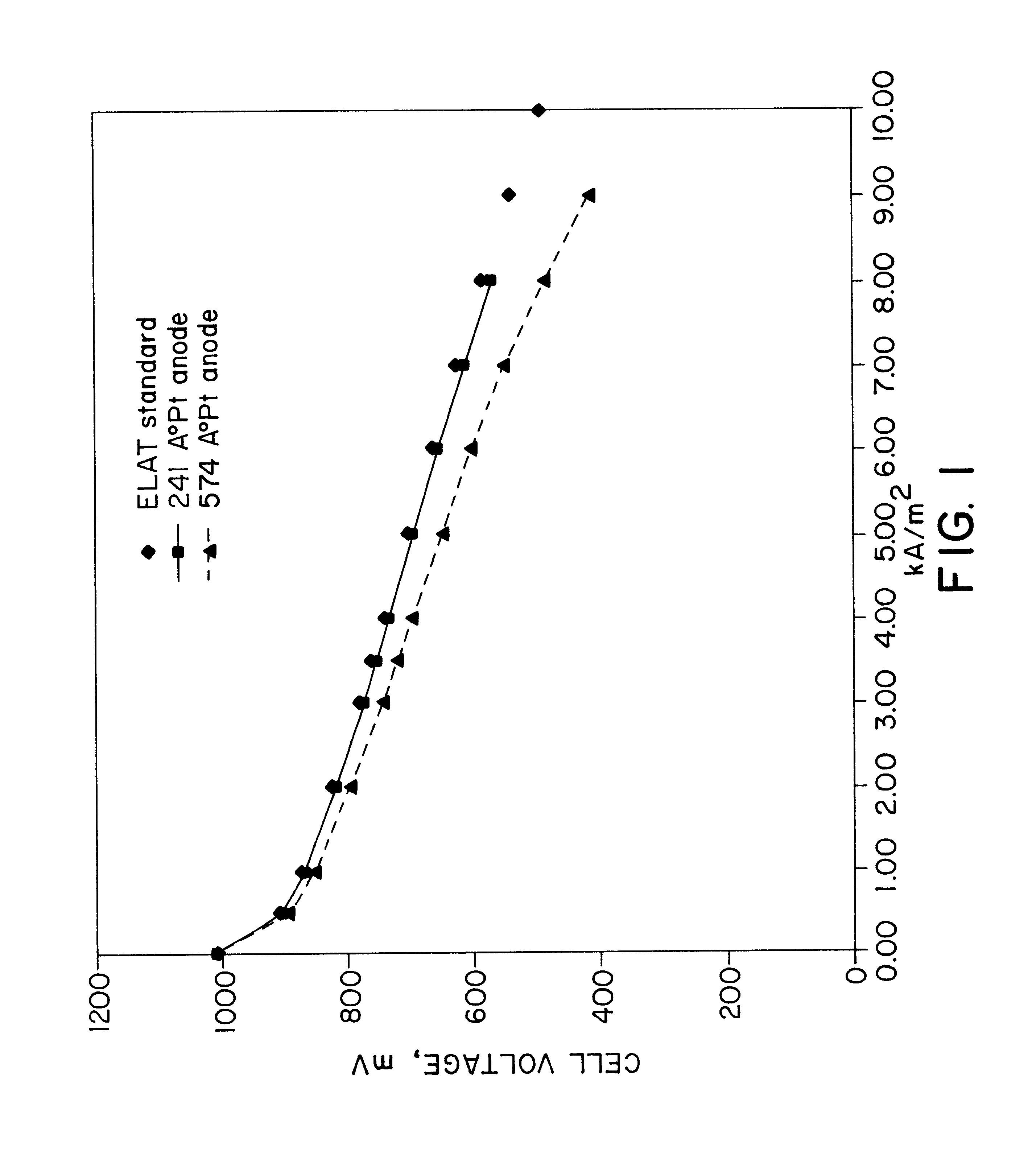

Electrodeposition of catalytic metals using pulsed electric fields

InactiveUS6080504AAdequate power densityEconomical catalyst loadingSolid electrolytesElectrolytic coatingsHertzPulse electric field

A gas diffusion electrode for a proton exchange membrane fuel cell is prepared by electrodeposition of a catalytic metal in nanocrystalline form on a substrate by contacting an electrically conductive substrate and a counterelectrode with a plating bath containing ions of a metal to be deposited on the substrate and passing a pulsed electric current between the substrate and counterelectrode having pulses that are cathodic with respect to the substrate and have a short on-time and / or a short duty cycle with a frequency from about 10 hertz to about 5000 hertz. In a preferred embodiment the electric current is a modulated reversing electric current having pulses that are cathodic with respect to the substrate and pulses that are anodic with respect to the substrate, the cathodic pulses having a short on-time and / or short duty cycle, the charge transfer ratio of the cathodic pulses to the anodic pulses being greater than one, and the frequency of the pulses ranging from about 10 hertz to about 5 kilohertz.

Owner:FARADAY TECH INC

Fuel cells and other products containing modified carbon products

InactiveUS20030017379A1Decrease electrode performanceReduction of gas mass transport efficiencyOrganic diaphragmsAlkali metal halidesFuel cellsModified carbon

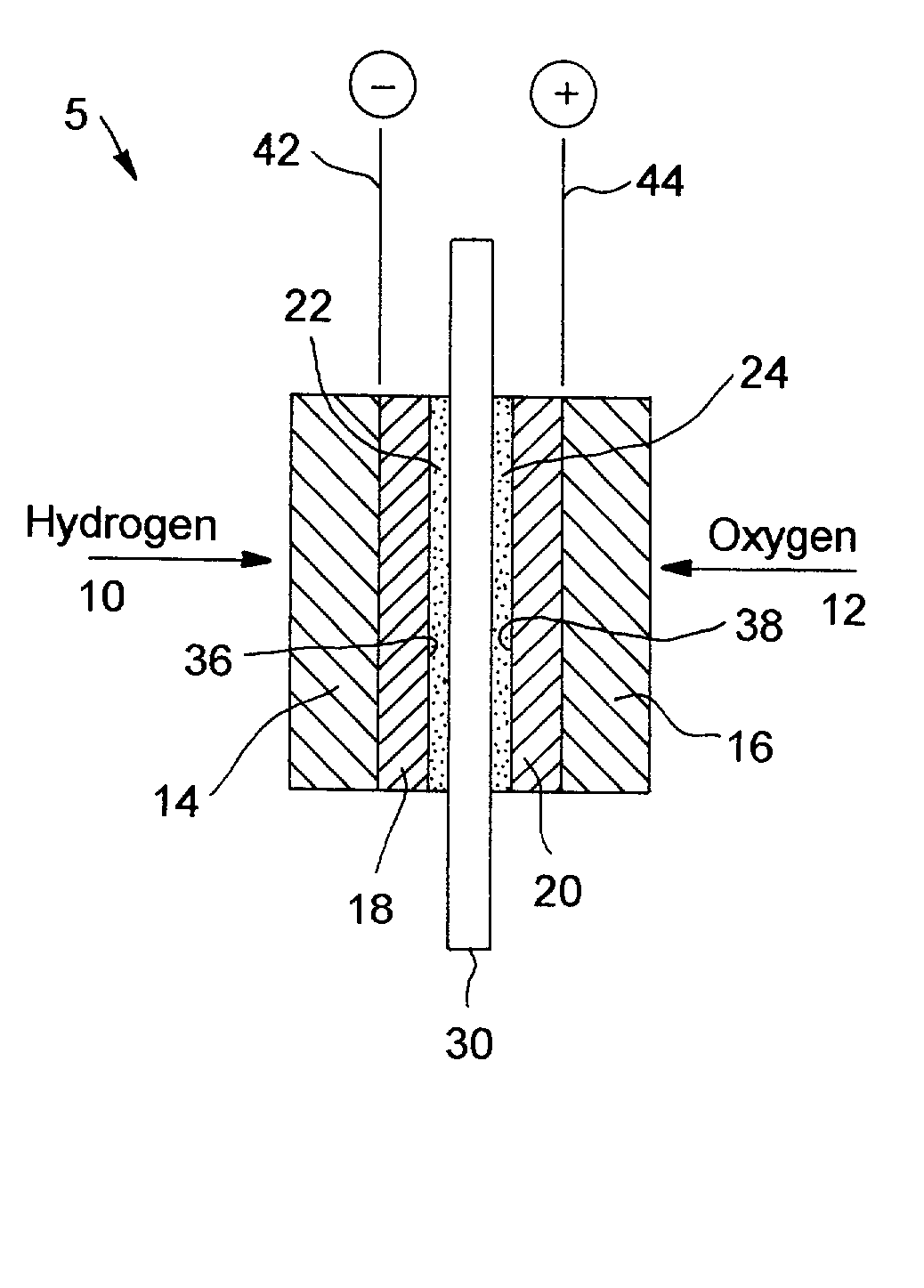

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

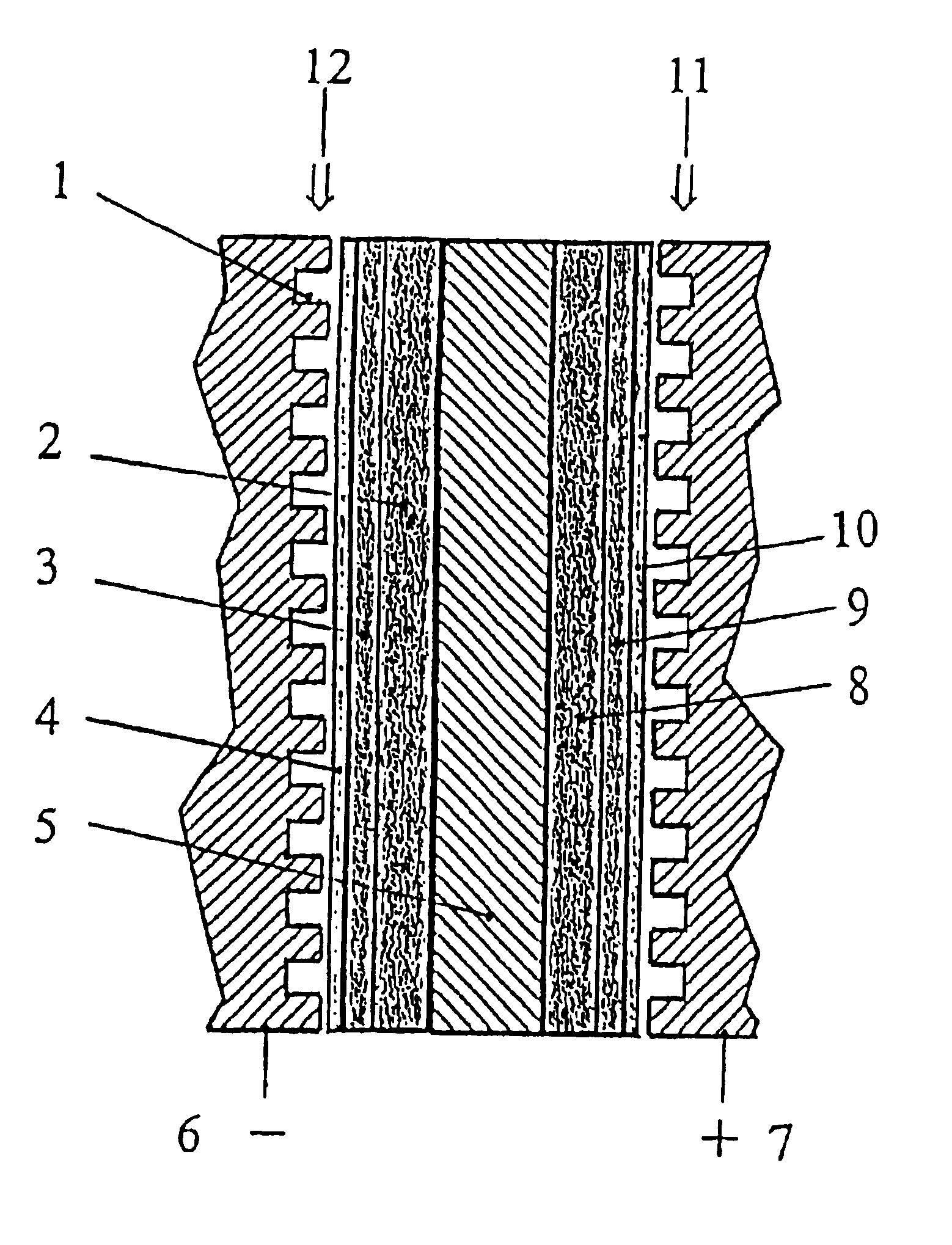

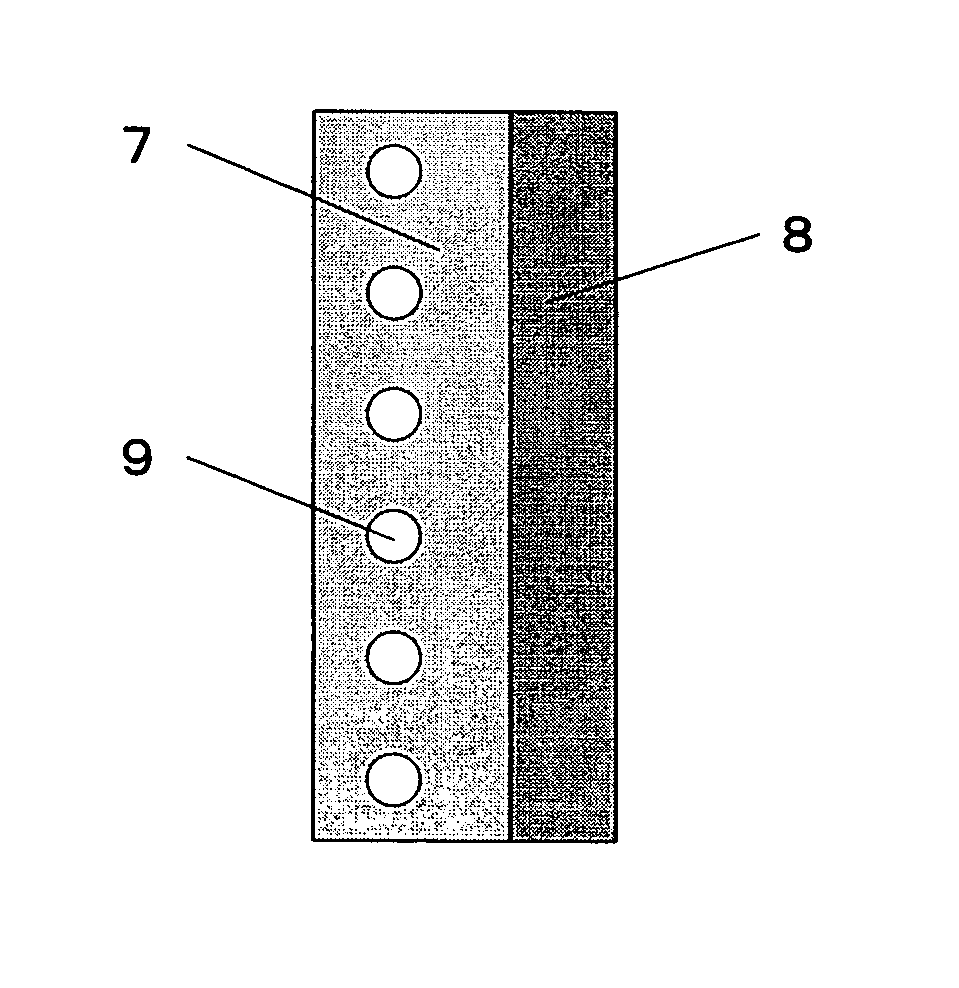

Water management in bipolar electrochemical cell stacks

InactiveUS20060199061A1Reduce probabilityPromote loss of waterFuel cells groupingWater management in fuel cellsPolymer electrolytesLiquid water

A bipolar, filter press-like electrochemical cell stack comprising a plurality of electrochemical cells, where each electrochemical cell is supplied with a gaseous anodic reactant and either supplied with a gaseous cathodic reactant or produces a gaseous cathodic product, and where each electrochemical cell avoids drying out the ion exchange membrane polymer electrolyte, avoids flooding at the cathode, facilitates recovery of liquid water at the anode, and reduces water losses from at least one of the electrodes. A water retention barrier is variously positioned, such as between a gas diffusion electrode and a fluid flow field. The barrier may be either: (i) a thin, gas permeable, liquid water impermeable membrane; (ii) a thin, porous sheet of material; or (iii) a thin, substantially solid sheet of material except for a plurality of small through-holes that penetrate from one side of the sheet to an opposing side of the same sheet. The barrier is advantageously used at the cathode and facilitates air cooling of the cell.

Owner:LYNNTECH

Polymer electrolyte membrane fuel cells

InactiveUS6946211B1Improve performanceImprove toleranceSolid electrolytesPrimary cellsThermoplasticGas diffusion electrode

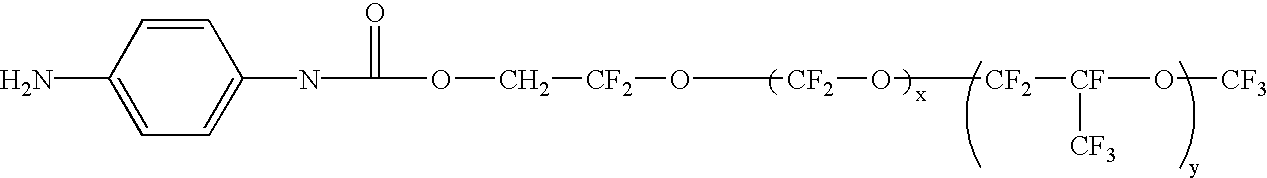

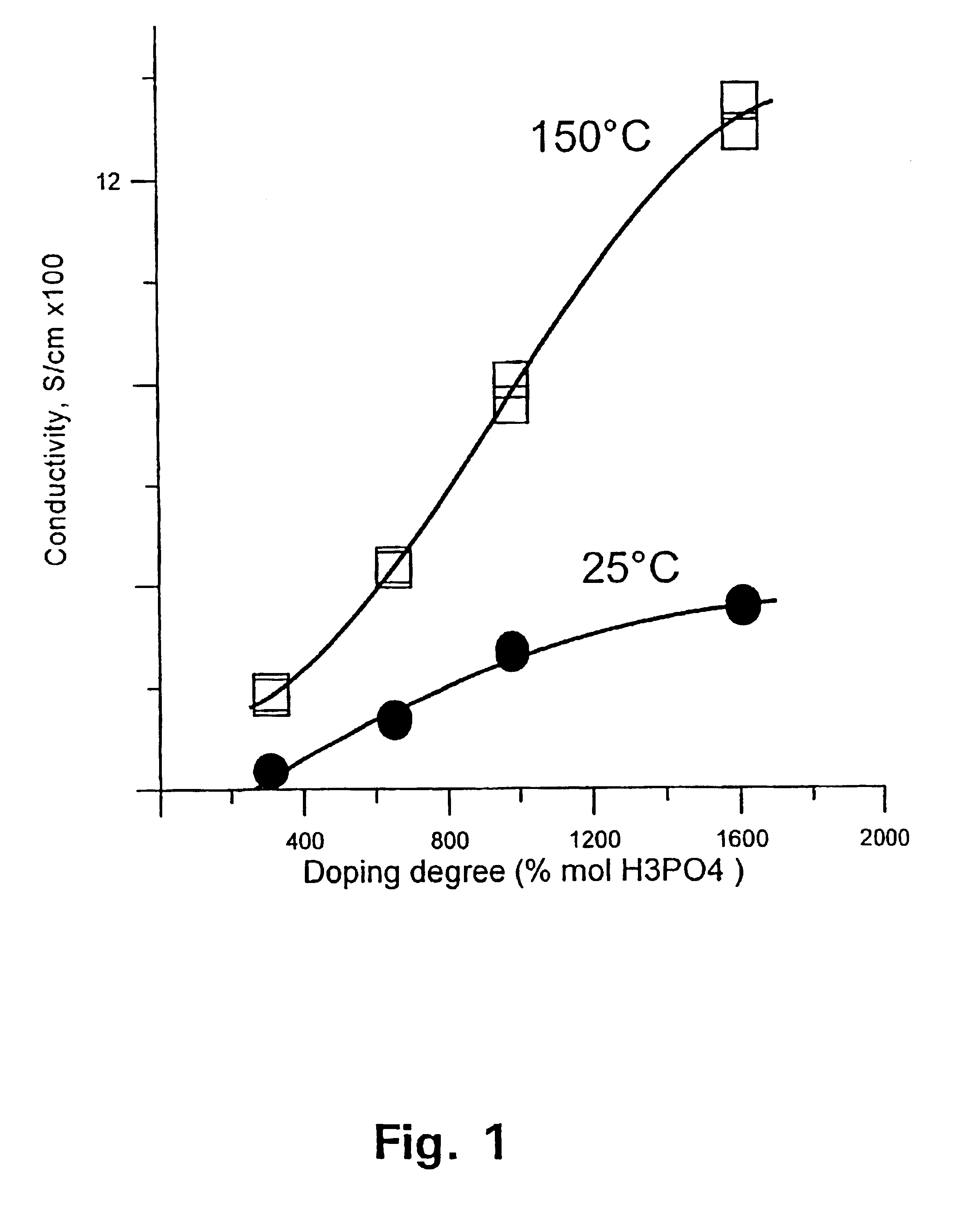

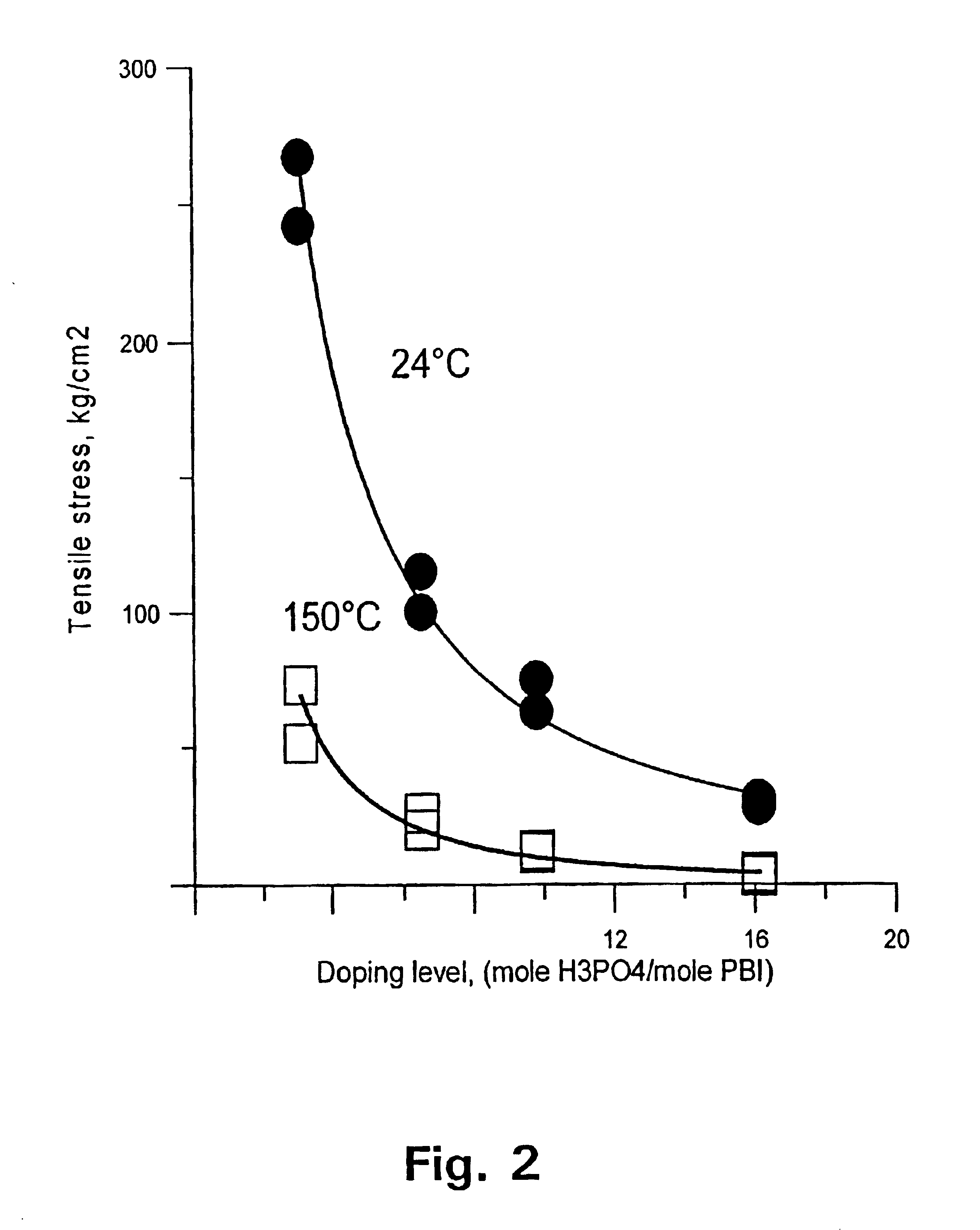

A method for preparing polybenzimidazole or polybenzimidazole blend membranes and fabricating gas diffusion electrodes and membrane-electrode assemblies is provided for a high temperature polymer electrolyte membrane fuel cell. Blend polymer electrolyte membranes based on PBI and various thermoplastc polymers for high temperature polymer electrolyte fuel cells have also been developed. Miscible blends are used for solution casting of polymer membranes (solid electrolytes). High conductivity and enhanced mechanical strength were obtained for the blend polymer solid electrolytes. With the thermally resistant polymer, e.g., polybenzimidazole or a mixture of polybenzimidazole and other thermoplastics as binder, the carbon-supported noble metal catalyst is tape-cast onto a hydrophobic supporting substrate. When doped with an acid mixture, electrodes are assembled with an acid doped solid electrolyte membrane by hot-press. The fuel cell can operate at temperatures up to at least 200° C. with hydrogen-rich fuel containing high ratios of carbon monoxide such as 3 vol % carbon monoxide or more, compared to the carbon monoxide tolerance of 10-20 ppm level for Nafion®-based polymer electrolyte fuel cells.

Owner:DANISH POWER SYST

Gas diffusion electrode manufacture and MEA fabrication

InactiveUS20020134501A1Final product manufactureAdhesive processes with surface pretreatmentTetrafluoroethyleneEmulsion

A method for producing a gas diffusion electrode in which a slurry of carbon black, alcohol, water and a tetrafluoroethylene emulsion is applied as a layer a non-Teflonized carbon cloth substrate, which is then heated to remove water. The dried coated carbon cloth is then rolled followed by heating to remove wetting agents present in the tetrafluoroethylene emulsion. The coated carbon cloth is then cooled and rolled again to produce the final end product.

Owner:GAS TECH INST

Gas diffusion electrode and method of making the same

ActiveUS20060078784A1Porosity adjustableNatural cellulose pulp/paperFinal product manufactureFiberPorous substrate

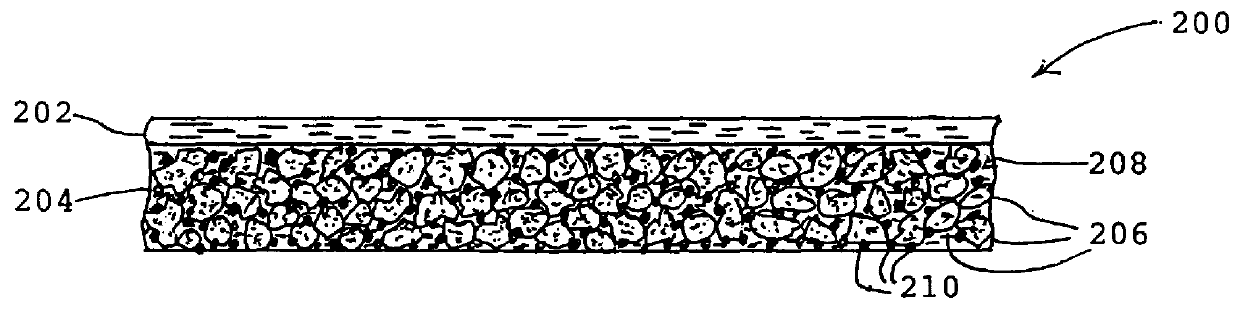

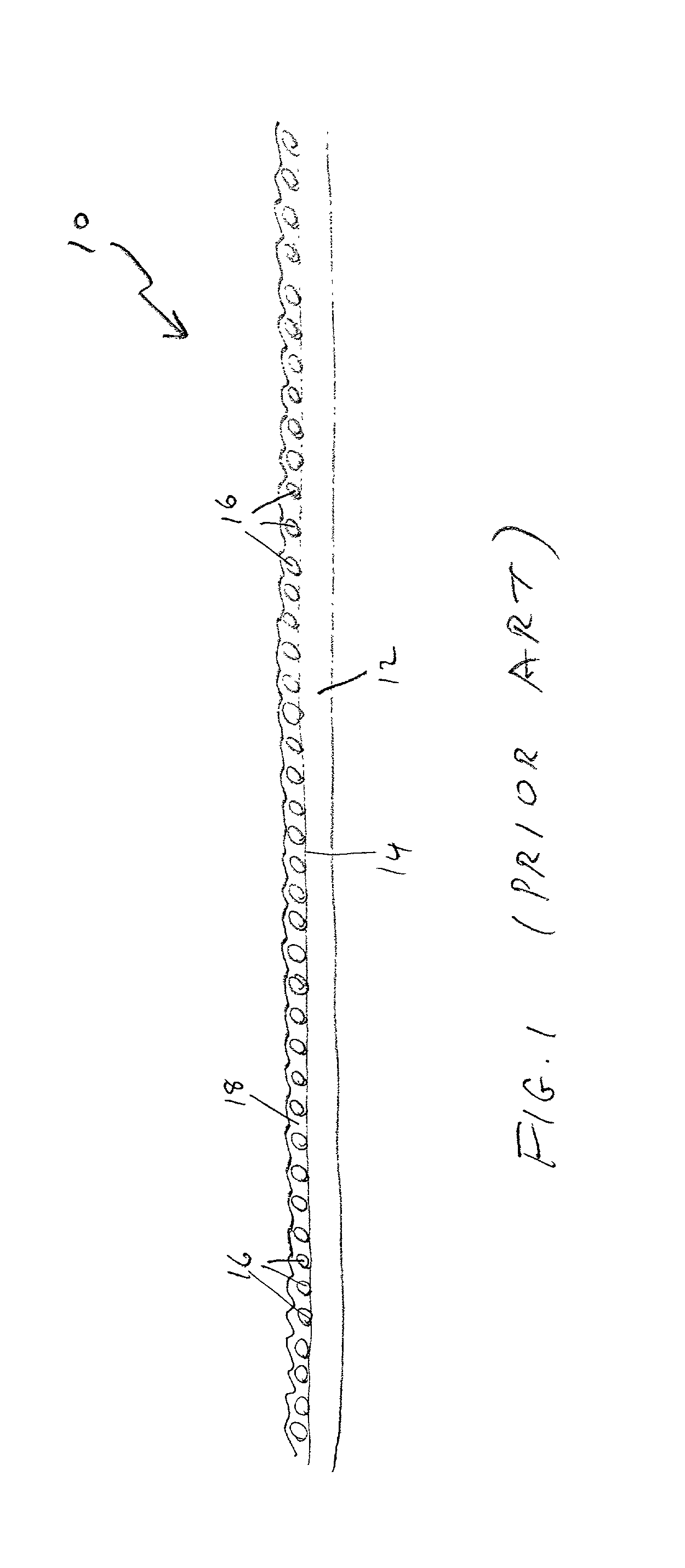

A gas diffusion electrode and method of making the same. According to one embodiment, the electrode comprises a support layer, a first cushioning layer positioned on top of the support layer, a second cushioning layer positioned on top of the first cushioning layer, and a catalyst layer positioned on top of the second cushioning layer. The support layer is a mechanically stable, electrically-conductive, gas porous substrate, such as carbon fiber paper. The first cushioning layer, which is also gas porous, comprises a non-woven mat of electrically-conductive, chemically-inert fibers, preferably carbon nanofibers, bound together with a polymeric binder, such as polytetrafluoroethylene. The second cushioning layer is similar to the first cushioning layer, except that carbon black or a similar electrically-conductive, chemically-inert particulate material is included in addition to or instead of the fibrous material for the purpose of fine-tuning pore size.

Owner:PLUG POWER

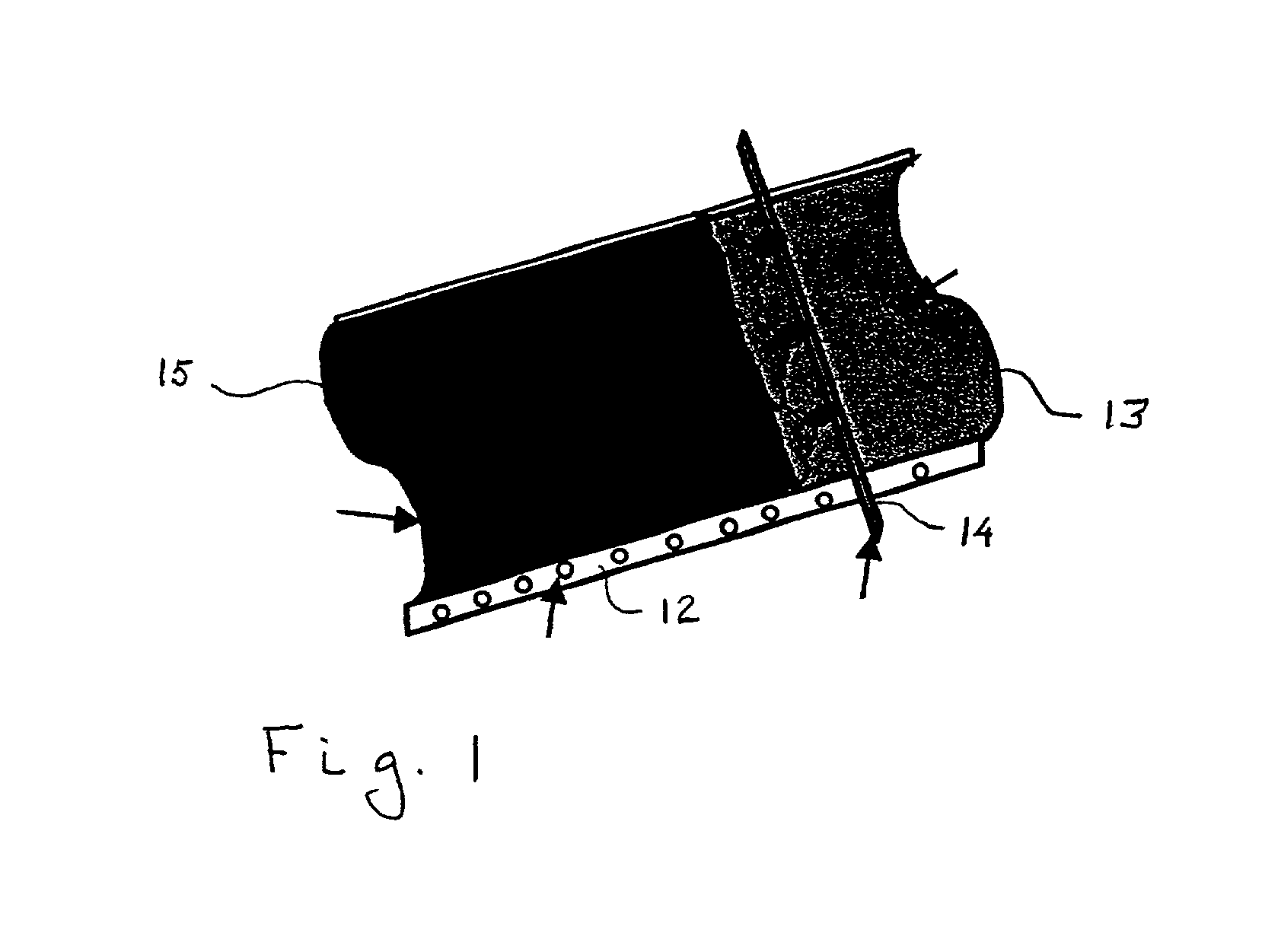

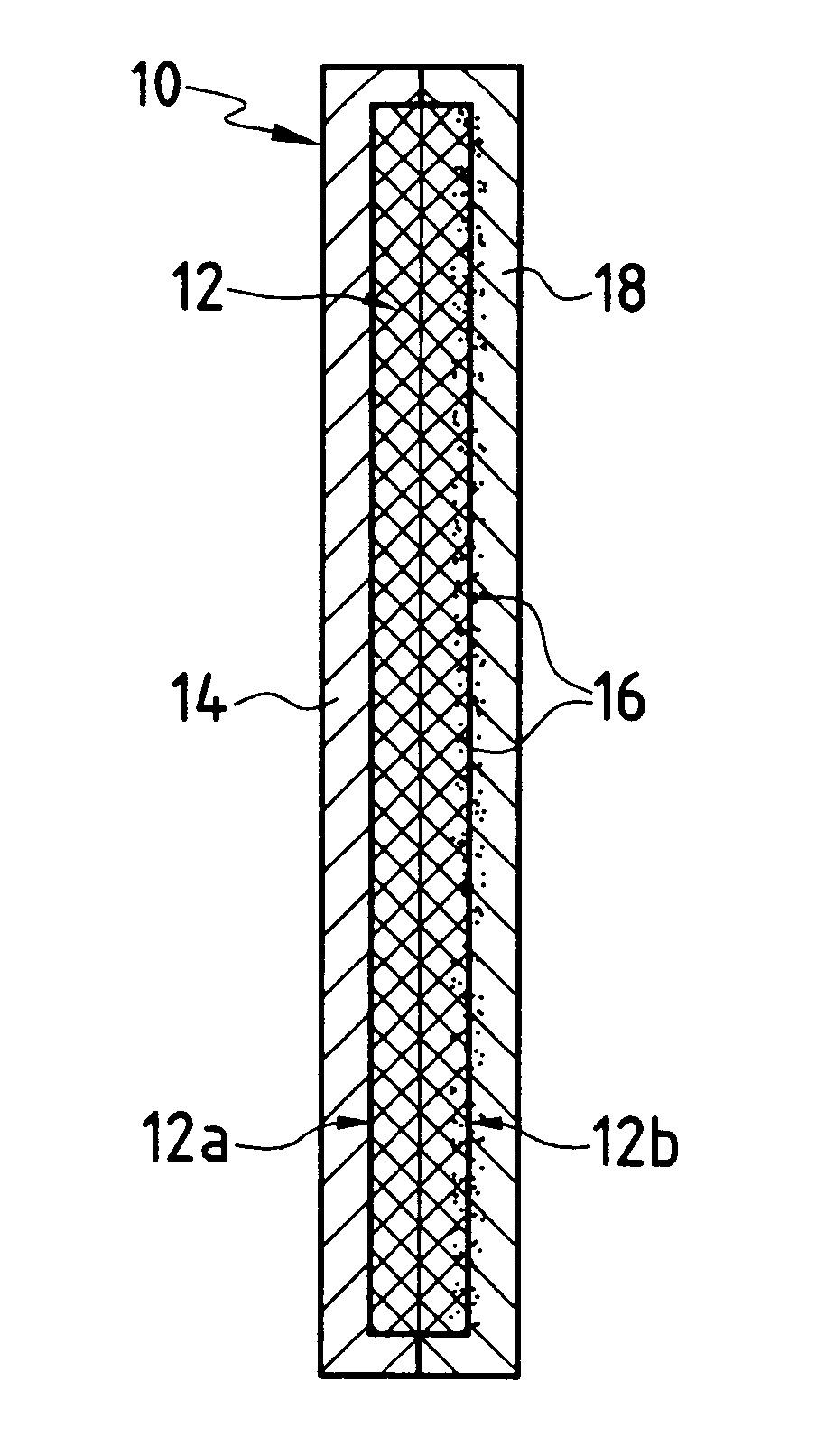

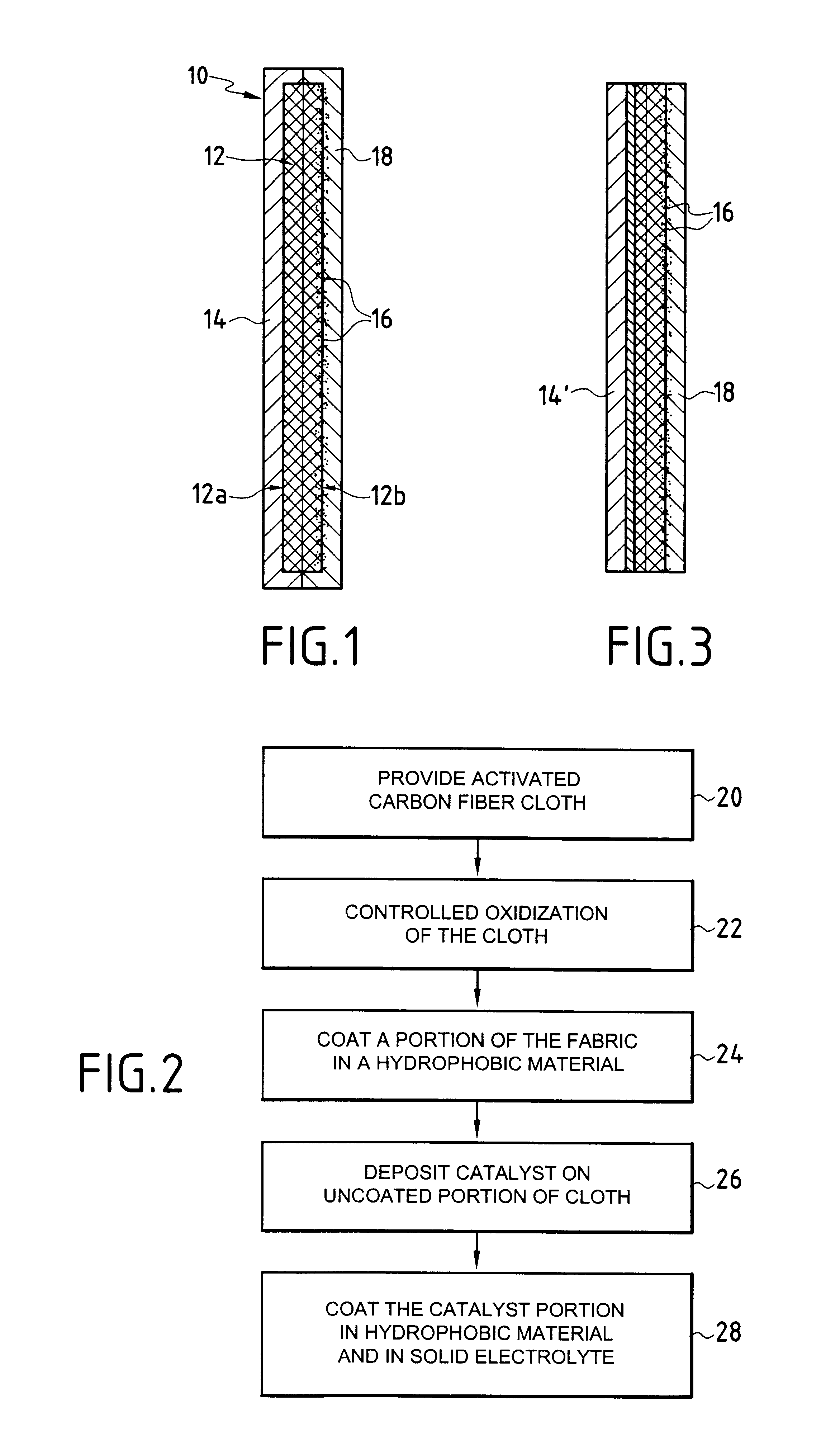

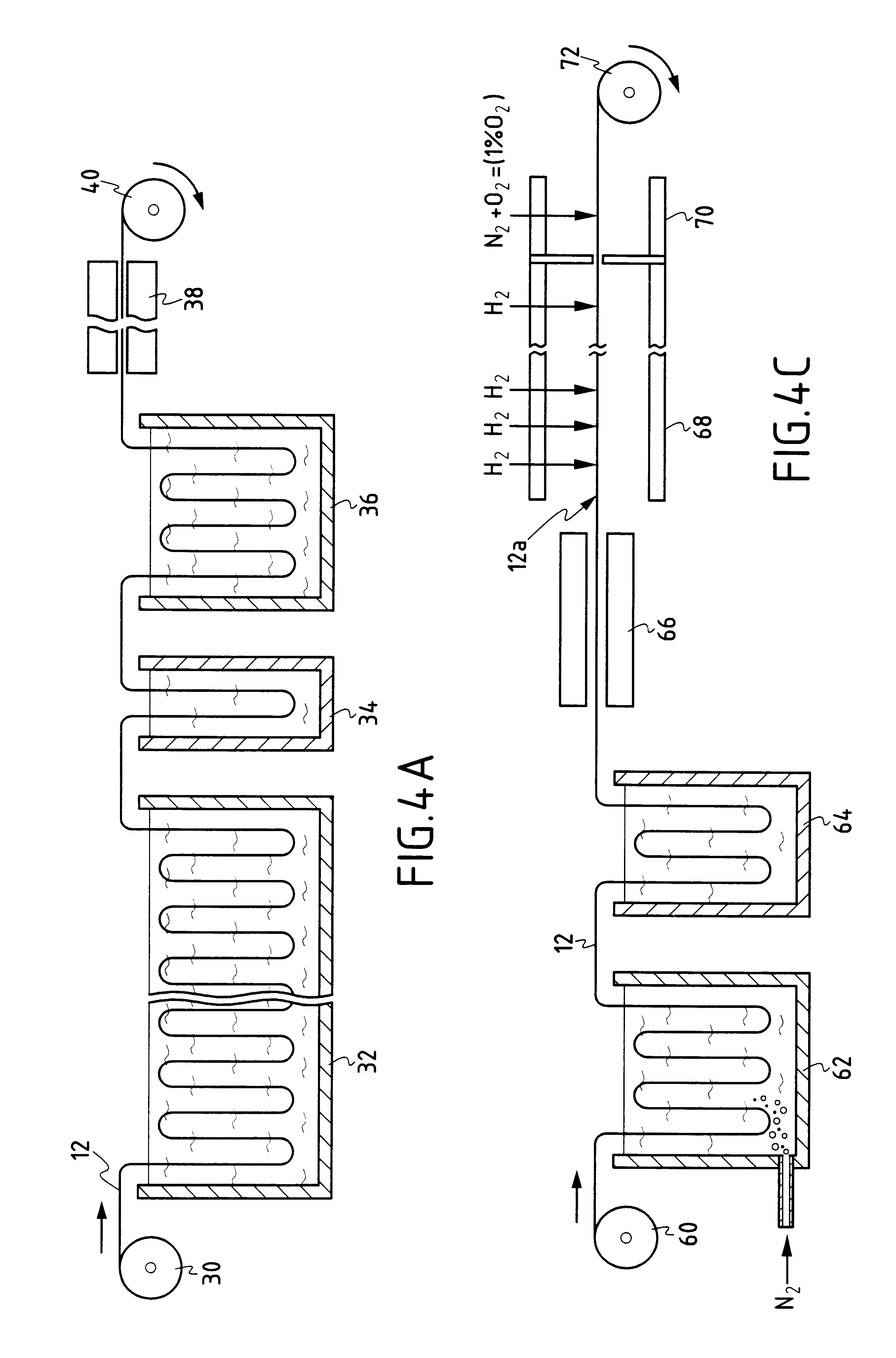

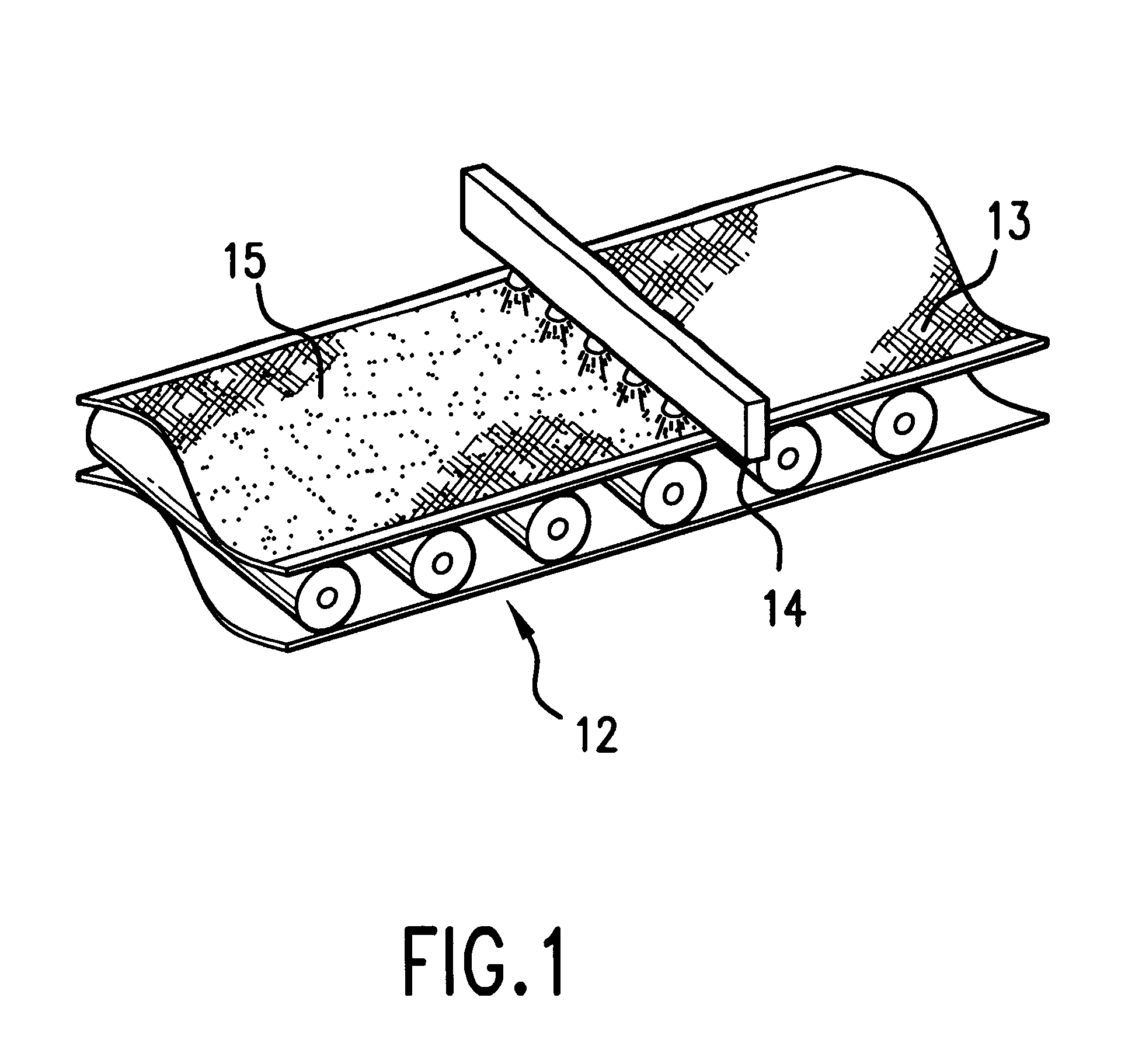

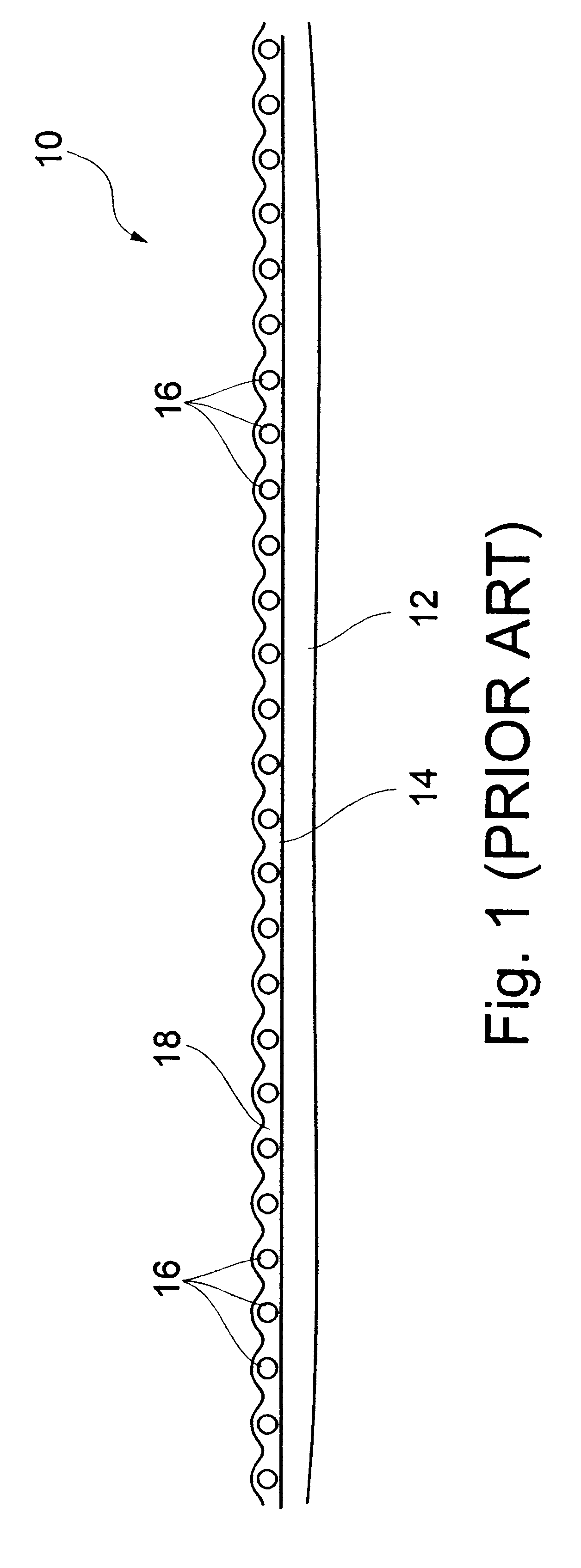

Gas diffusion electrode and application to catalyzed electrochemical processes

InactiveUS6444347B1Easy to operateImprove efficiencyFuel cell auxillariesActive material electrodesFiberElectrochemical response

A gas diffusion electrode comprises a cloth (12) of activated carbon fibers having a first face coated in a hydrophobic material (14) and a second face on which particles of catalyst (16) are fixed directly and are dispersed in substantially uniform manner over the fibers. The electrode can be used in an electrochemical cell of a proton exchange membrane fuel-cell battery, or in an electrochemical reactor, e.g. for making chlorine and caustic soda.

Owner:SNECMA PROPULSION SOLIDE

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

An ion beam-assisted deposition process for preparing a membrane-electrode structure is described wherein a layer of liquid ionomer is applied to the surface of a carbon cloth gas diffusion electrode structure. The coated structure is heated to form an ionomer film on the cloth electrode and the resulting structure is treated with a metal or metal oxide ion-beam having an energy between 500-2000 eV. The process forms a carbon cloth supported metal or a carbon metal oxide ionomer film membrane-electrode structure.

Owner:BASF FUEL CELL

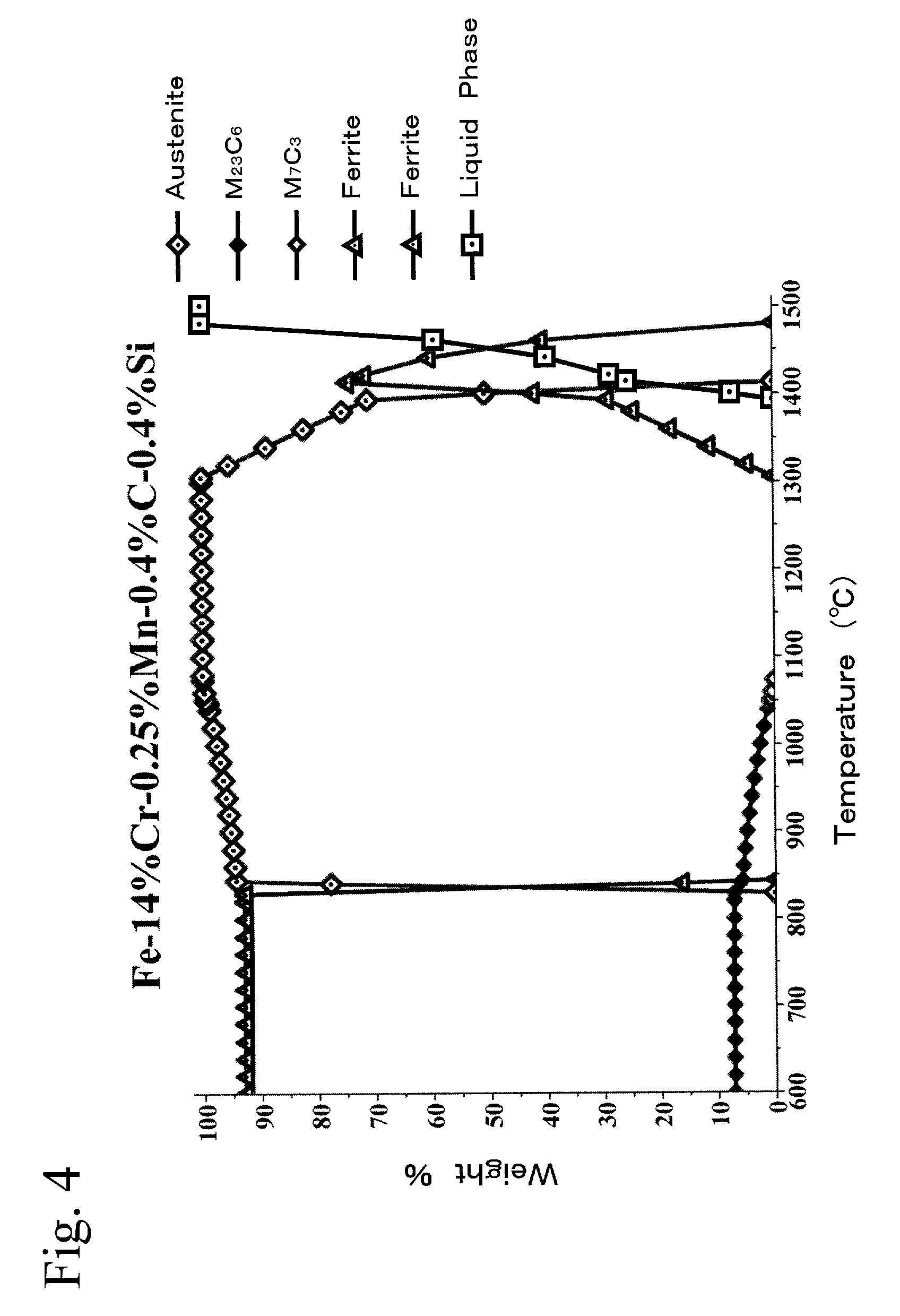

Separator for fuel cell

InactiveUS20020045086A1Lower performance requirementsHigh mechanical strengthFuel cell auxillariesCell component detailsForming gasFuel cells

A separator for a fuel cell comprises a plate-shaped electrode having a pair of gas diffusion electrode plates and an electrolytic layer held by the gas diffusion electrode plates. The separator being layered on both surfaces of the electrode and forming gas passages cooperating with the gas diffusion electrode plate. The separator comprising: a metallic plate; protrusions made from a material of the carbon type, the protrusion having a projected surface projecting from the metallic plate toward the gas diffusion electrode plate so as to contact therewith and to form the gas passages; and intermetallic compounds precipitated on the projected surface of the protrusion. The gas passage is formed by a surface of the metallic plate and a pair of side surfaces of adjoining protrusions.

Owner:HONDA MOTOR CO LTD

Gas diffusion electrode

InactiveUS20060175195A1High gas diffusionHigh densityMachining electrodesActive material electrodesGas diffusion electrodeNanotechnology

The present invention provides a gas diffusion electrode having: an electrode substrate; and a catalyst layer containing a hydrophilic catalyst and a hydrophobic binder, which is carried on the electrode substrate, wherein the electrode substrate contains at least one carbon material selected from a carbon cloth, a carbon paper, a foamed carbon material, and a sintered carbon material.

Owner:DE NORA PERMELEC LTD

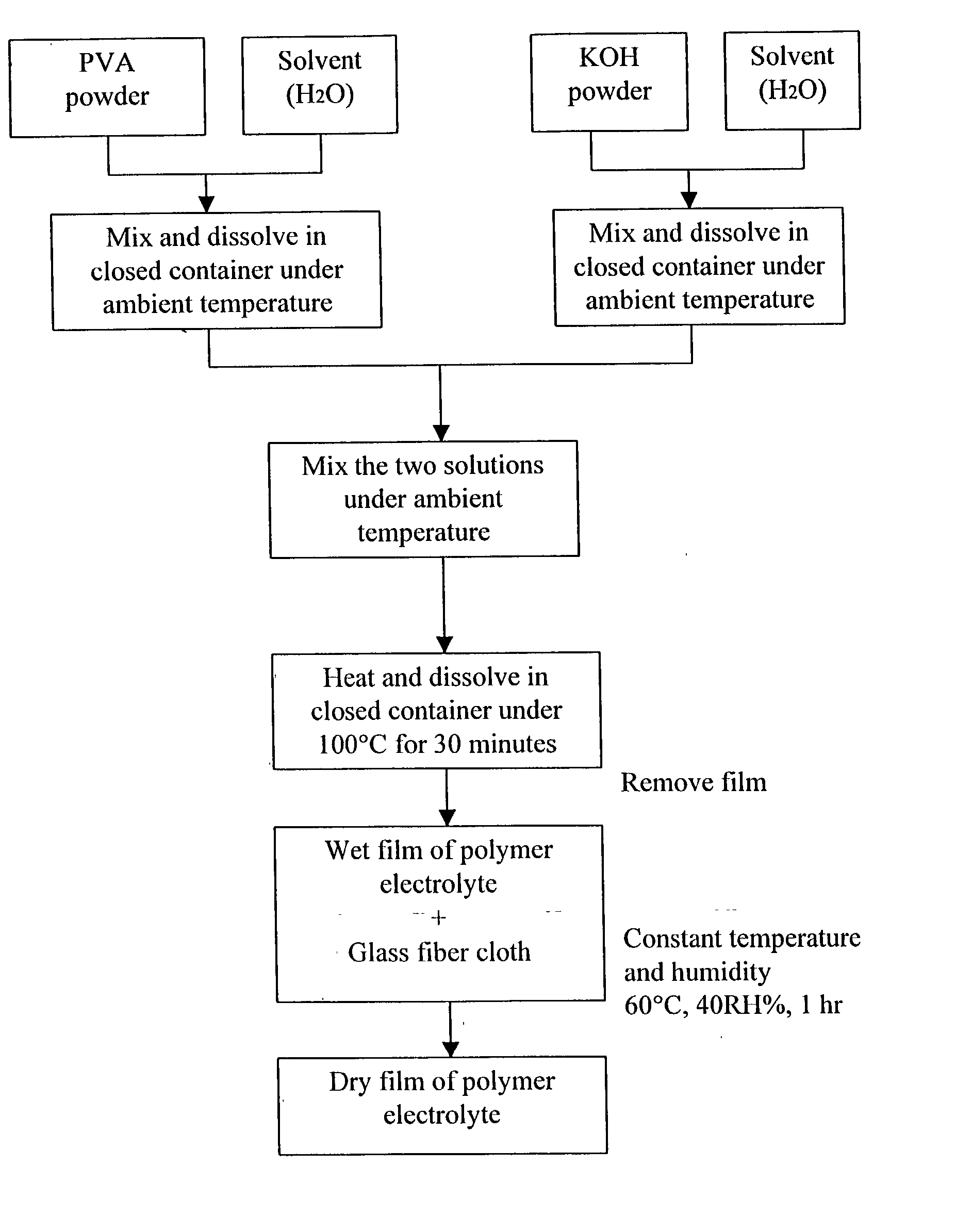

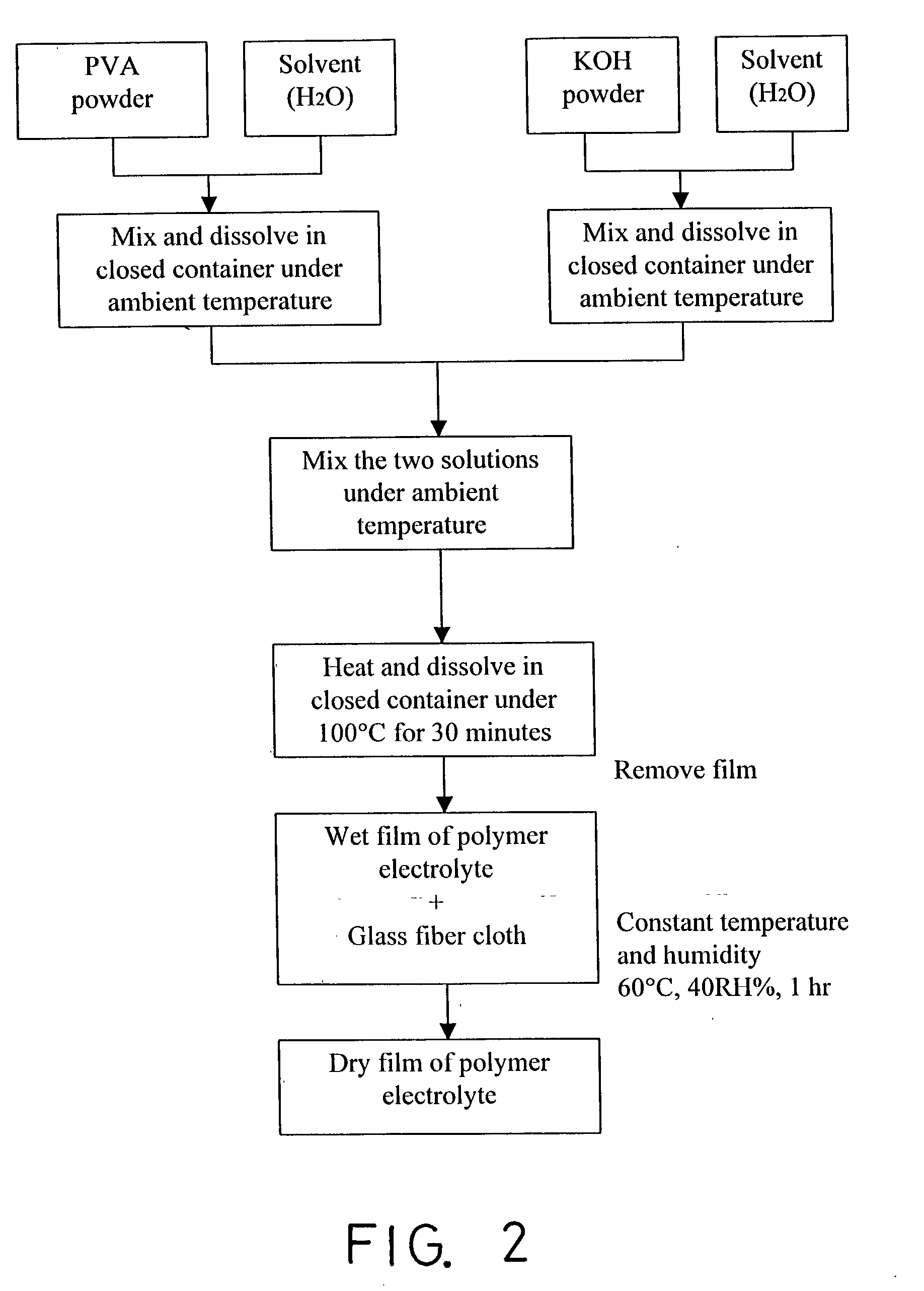

Method for preparing solid-state polymer zinc-air battery

InactiveUS20030228522A1Increase surface areaIncrease motivationFuel and primary cellsAlkaline accumulatorsZinc–air batteryAir cathode

This invention relates to a method for fabricating solid-state alkaline polymer Zn-air battery, which consists of a zinc-gel anode, an air cathode electrode, and alkaline polymer electrolyte. The formulation of said zinc gel anode is similar to that of alkaline Zn-MnO2 battery. The zinc gel anode contains a mixture of electrolytic dendritic zinc powders, KOH electrolyte, gelling agent and small amount of additives. The air cathode electrode is made by carbon gas diffusion electrode, which comprises two layers, namely gas diffusion layer and active layer. The active layer on the electrolyte side uses a high surface area carbon for oxygen reduction reaction and potassium permanganate and MnO2 as catalysts for oxygen reduction. The diffusion layer on the air side has high PTFE content to prevent KOH electrolyte from weeping or climbing. Due to adequate amount of fresh air and oxygen supply, the air cathode electrode can run continuously. Theoretically, the polymer zinc-air battery is an accumulator if the cell has sufficient zinc powder and electrolyte, and the air cathode plays the role of energy transfer.

Owner:MING CHI UNIVERSITY OF TECHNOLOGY

Gas diffusion electrode manufacture and MEA fabrication

InactiveUS6627035B2Increase internal resistanceReduce hydrophobicityFinal product manufactureAdhesive processes with surface pretreatmentTetrafluoroethyleneEmulsion

A method for producing a gas diffusion electrode in which a slurry of carbon black, alcohol, water and a tetrafluoroethylene emulsion is applied as a layer a non-Teflonized carbon cloth substrate, which is then heated to remove water. The dried coated carbon cloth is then rolled followed by heating to remove wetting agents present in the tetrafluoroethylene emulsion. The coated carbon cloth is then cooled and rolled again to produce the final end product.

Owner:GAS TECH INST

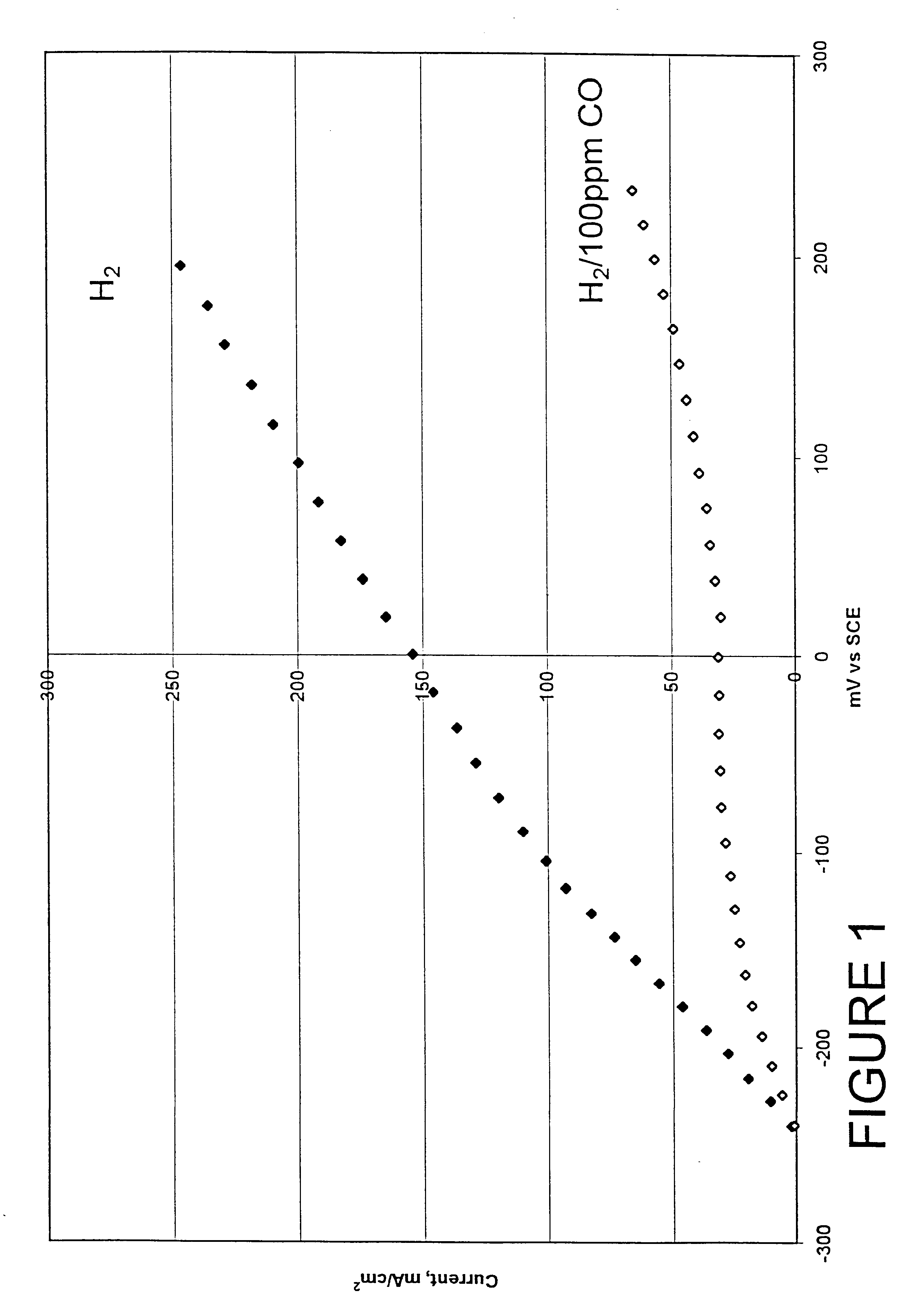

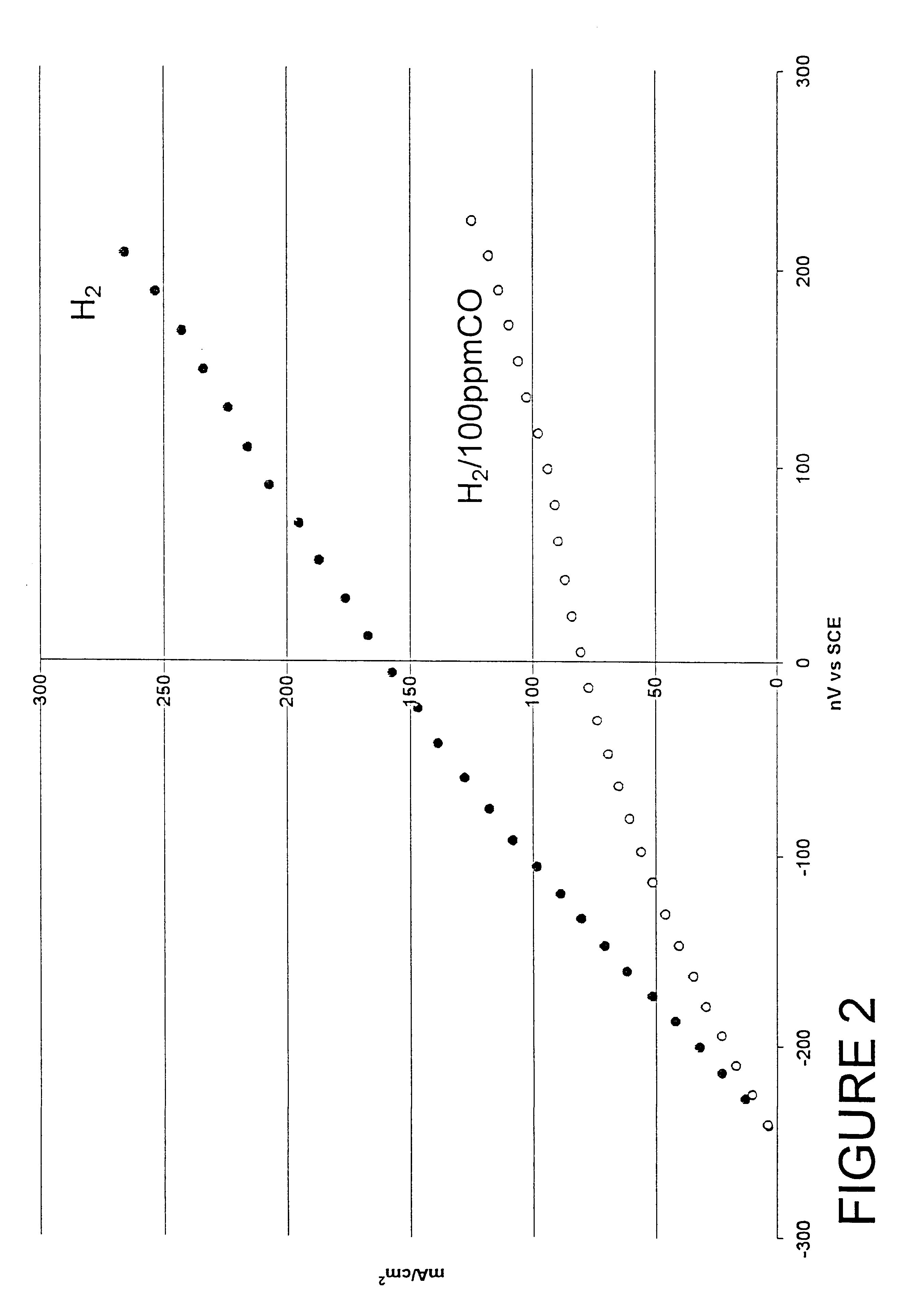

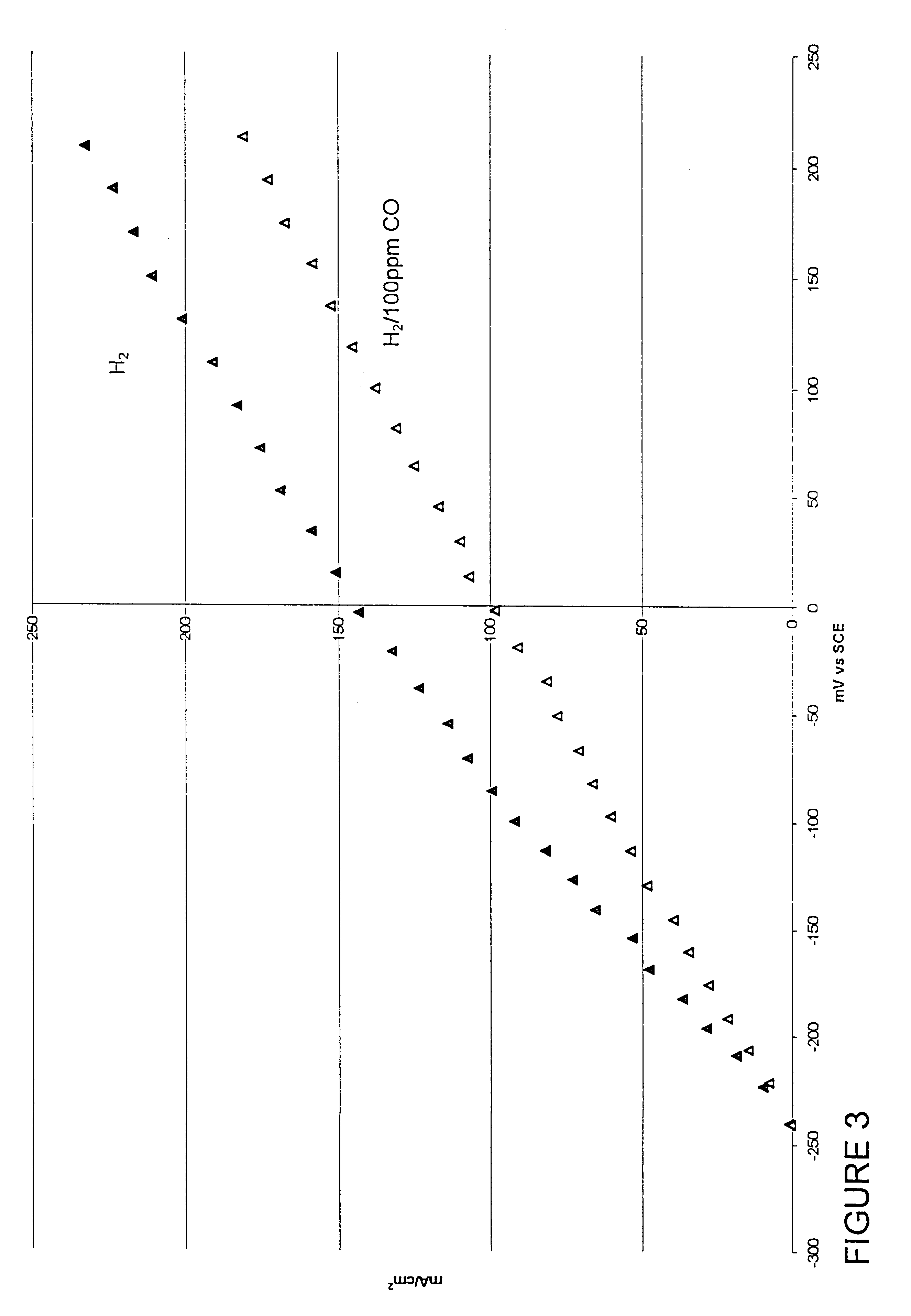

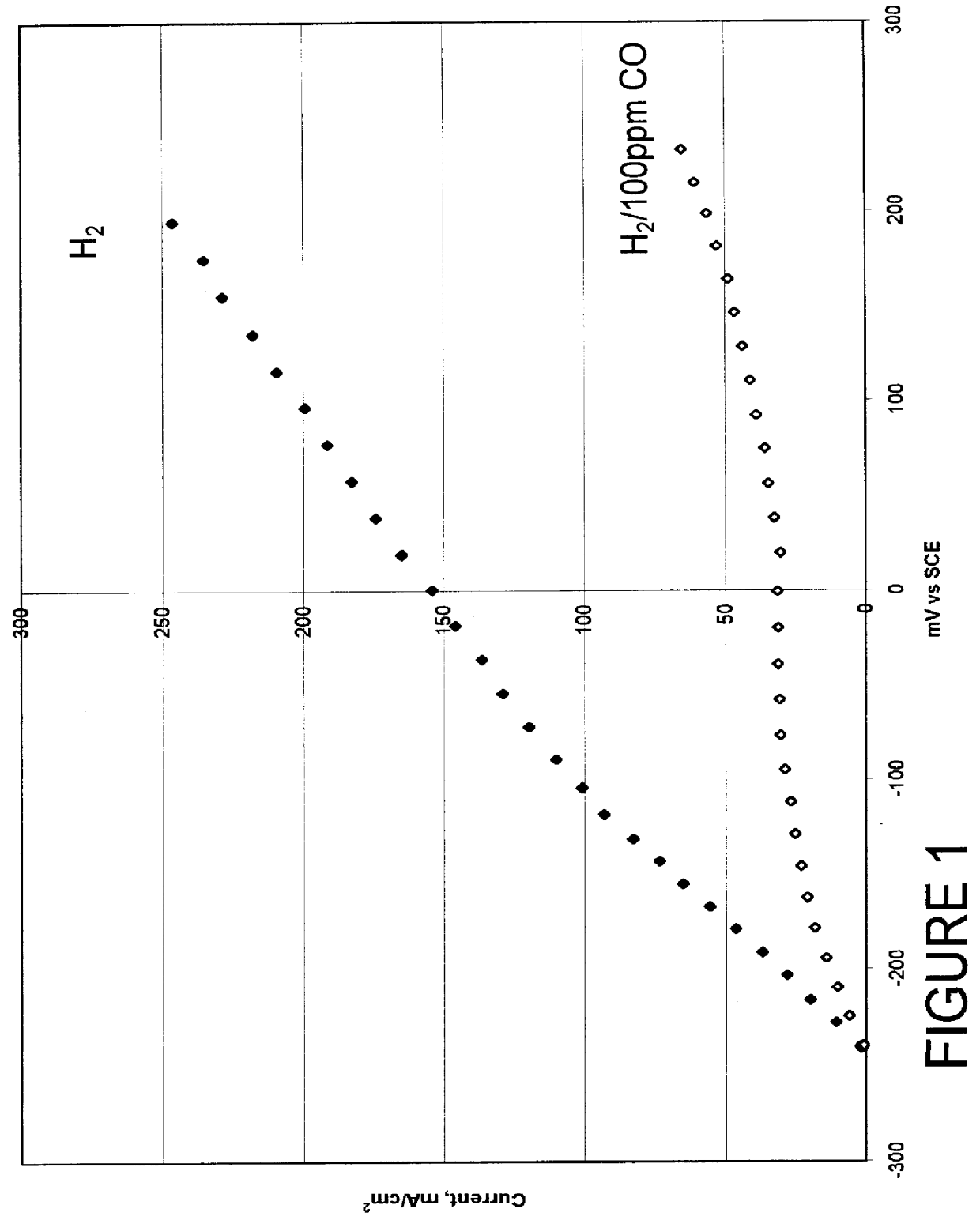

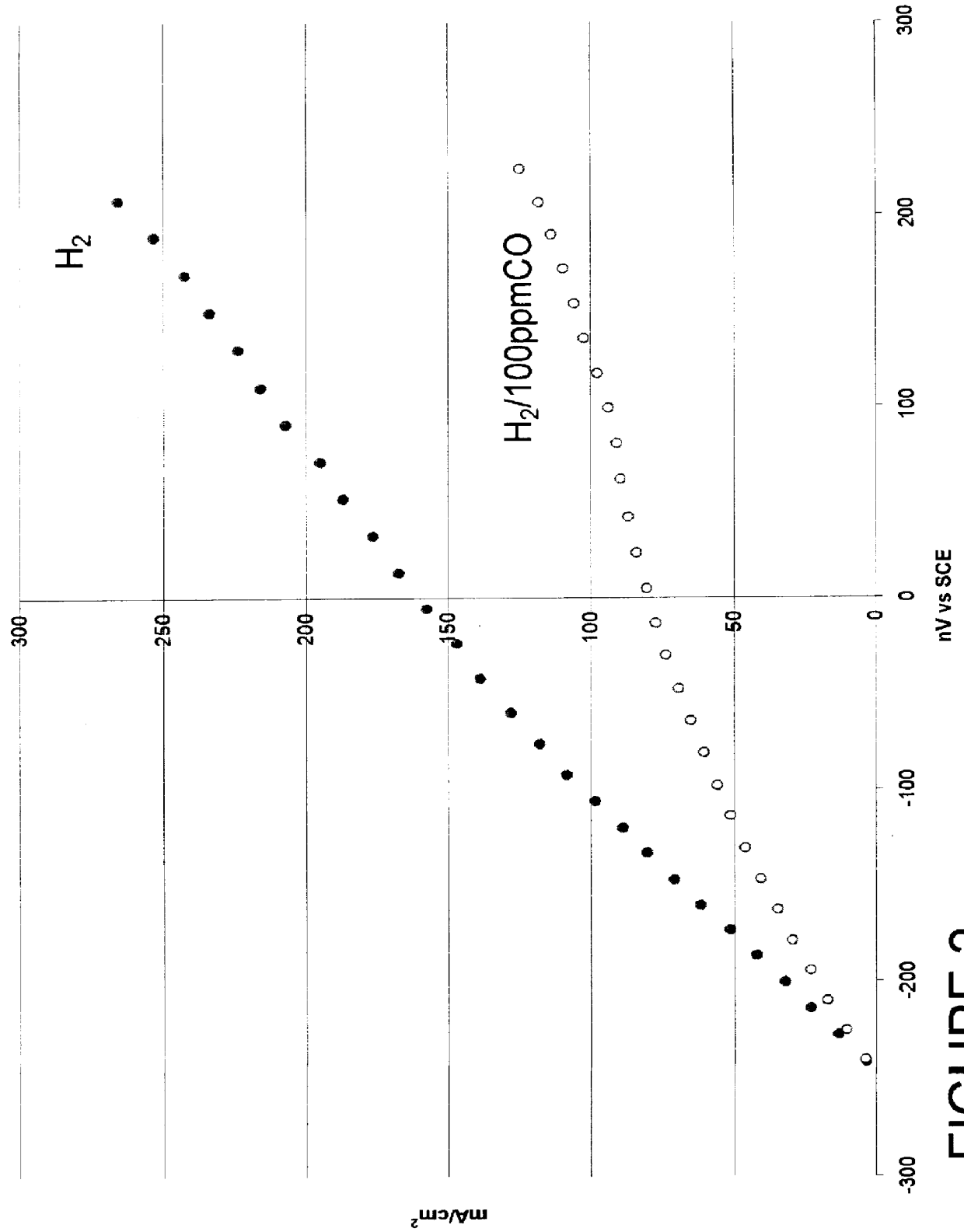

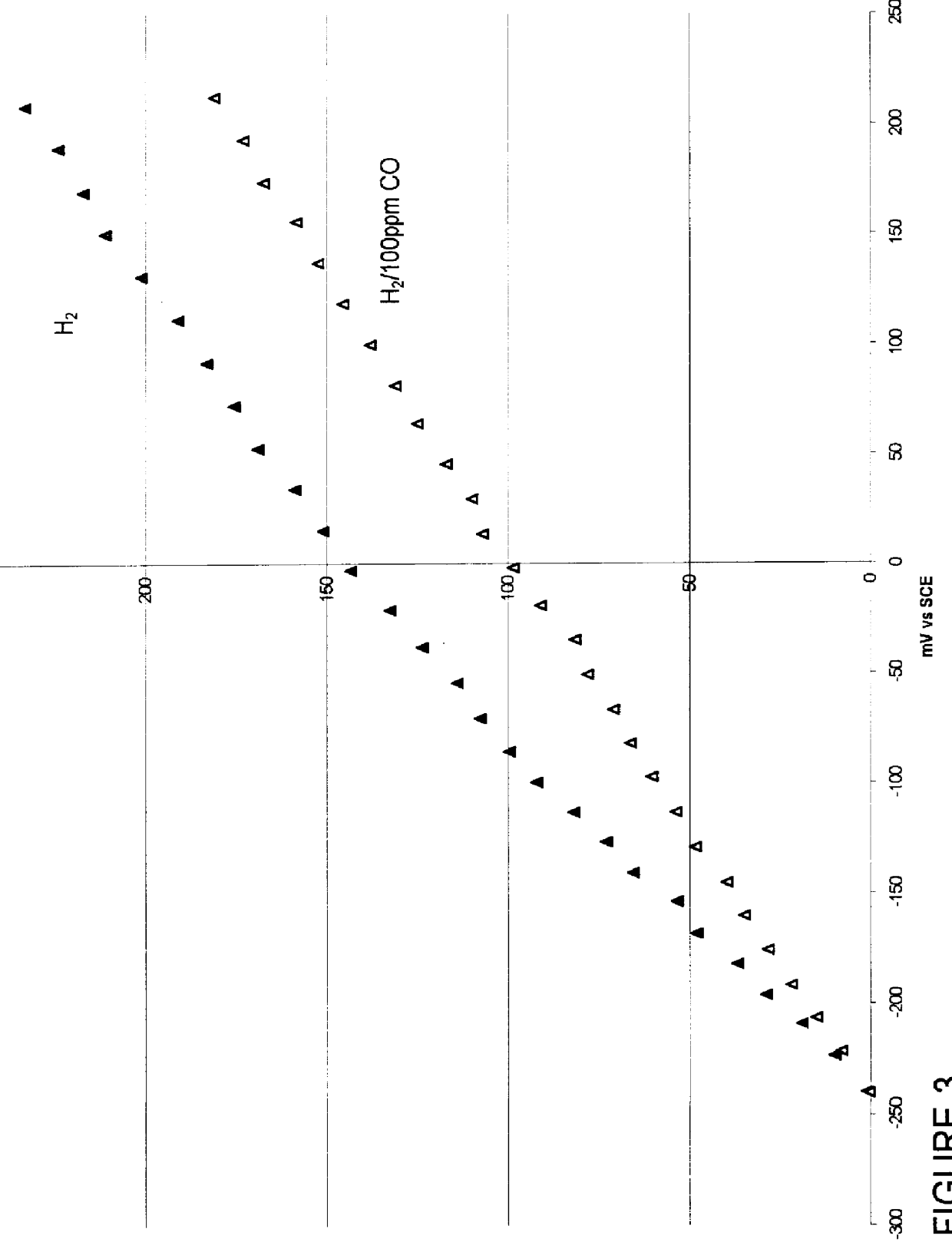

Composition of a selective oxidation catalyst for use in fuel cells

This invention pertains to improved formulations of platinum-molybdenum alloys for use as anode catalysts. These electrocatalysts find utility as a constituent of gas diffusion electrodes for use in fuel cells that operate at less than 180° C. or in applications whereupon hydrogen is oxidized in the presence of carbon monoxide or other platinum inhibiting substances. The new formulations derive unexpected activity through creating highly dispersed alloy particles of up to approximately 300 Å on carbon supports. The desired activity is achieved by carefully controlling the platinum to molybdenum ratio during preparation and judiciously selecting a proper loading of alloy on the carbon support.

Owner:PEMEAS

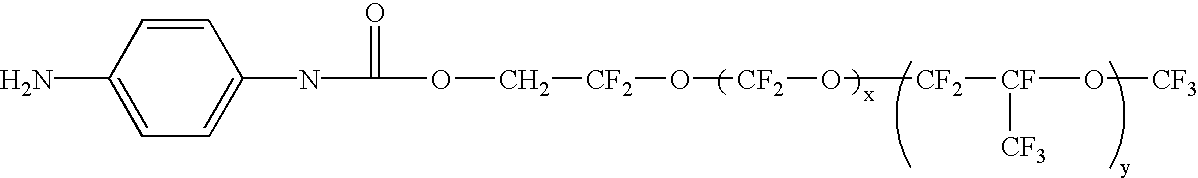

Material for electrode comprising a non-woven fabric composed of a fluorine-containing resin fiber

InactiveUS6416896B1High mechanical strengthImprove the mixing effectSolid electrolytesActive material electrodesFiberFuel cells

A material for electrode which is excellent in electric conductivity, gas permeability, water repellency and chemical resistance and has enhanced handling property, moldability and processability is provided. A gas diffusion electrode for a fuel battery which is obtained by using a non-woven fabric comprising a fluorine-containing resin fiber and electrically conductive fiber as a material for electrode is formed.

Owner:DAIKIN IND LTD

Fuel cells and other products containing modified carbon products

InactiveUS20030022055A1Improve propertiesLess-expensive to manufactureActive material electrodesSolid electrolyte fuel cellsFuel cellsModified carbon

Fuel cells are described and contain a gas diffusion electrode, a gas diffusion counter-electrode, an electrolyte membrane located between the electrode and counter-electrode. The electrode or counter-electrode or both contain at least one modified carbon product. The electrolyte membrane can also or alternatively contain modified carbon products as well. The modified carbon product is a carbon product having attached at least one organic group. Preferably the organic group is a proton conducting group and / or an electron conducting group. The present invention preferably permits the elimination of fluoropolymer binder in the active or catalyst layer and further preferably leads to a thinner active layer and / or a thinner electrolyte membrane. Other uses and advantages are also described.

Owner:CABOT CORP

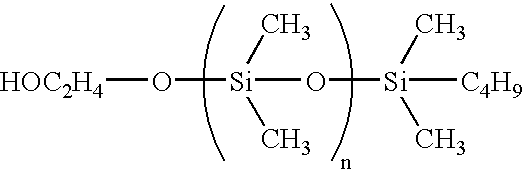

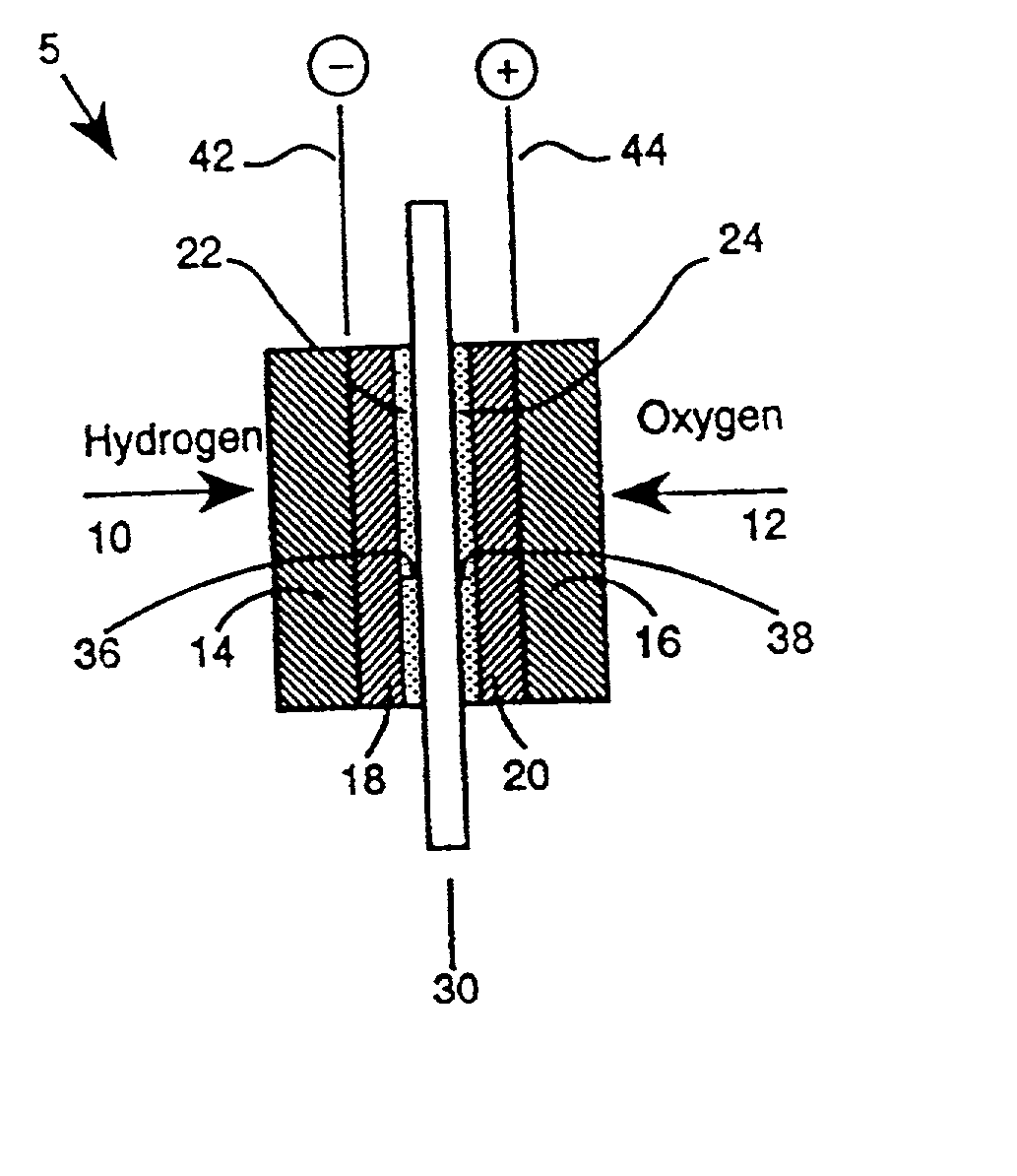

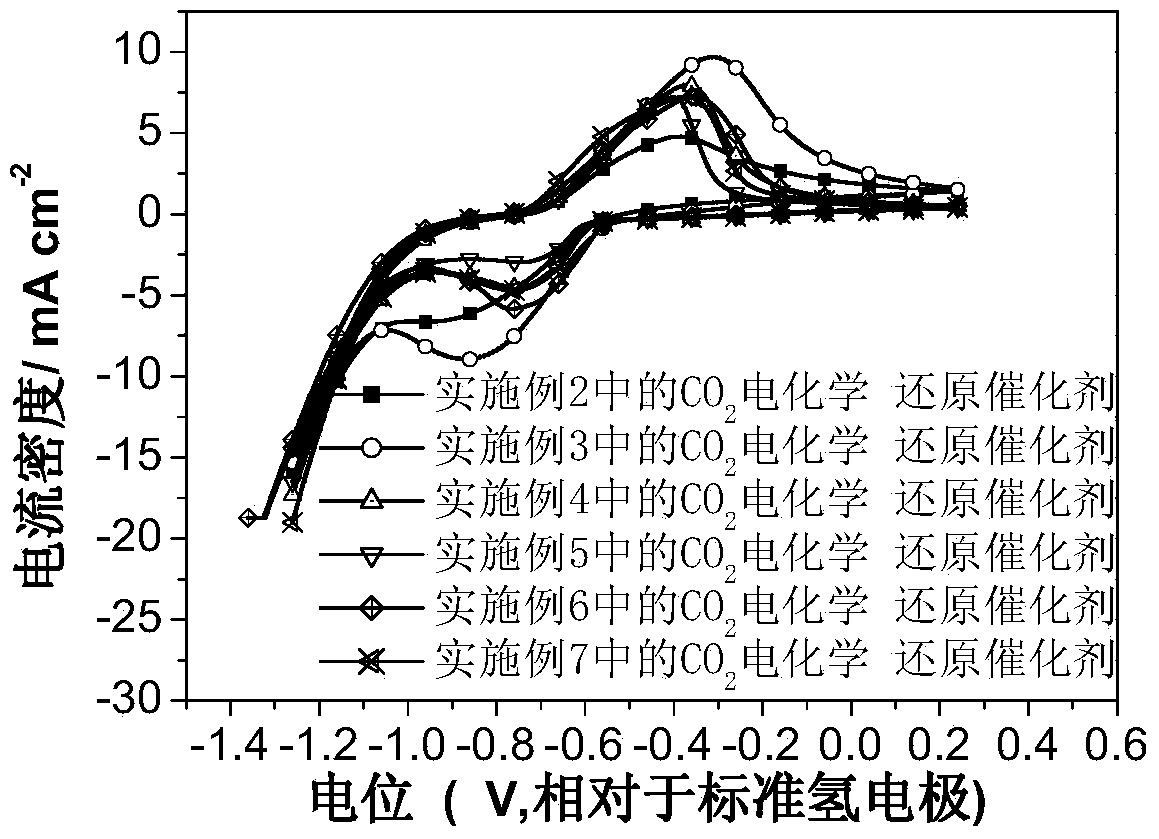

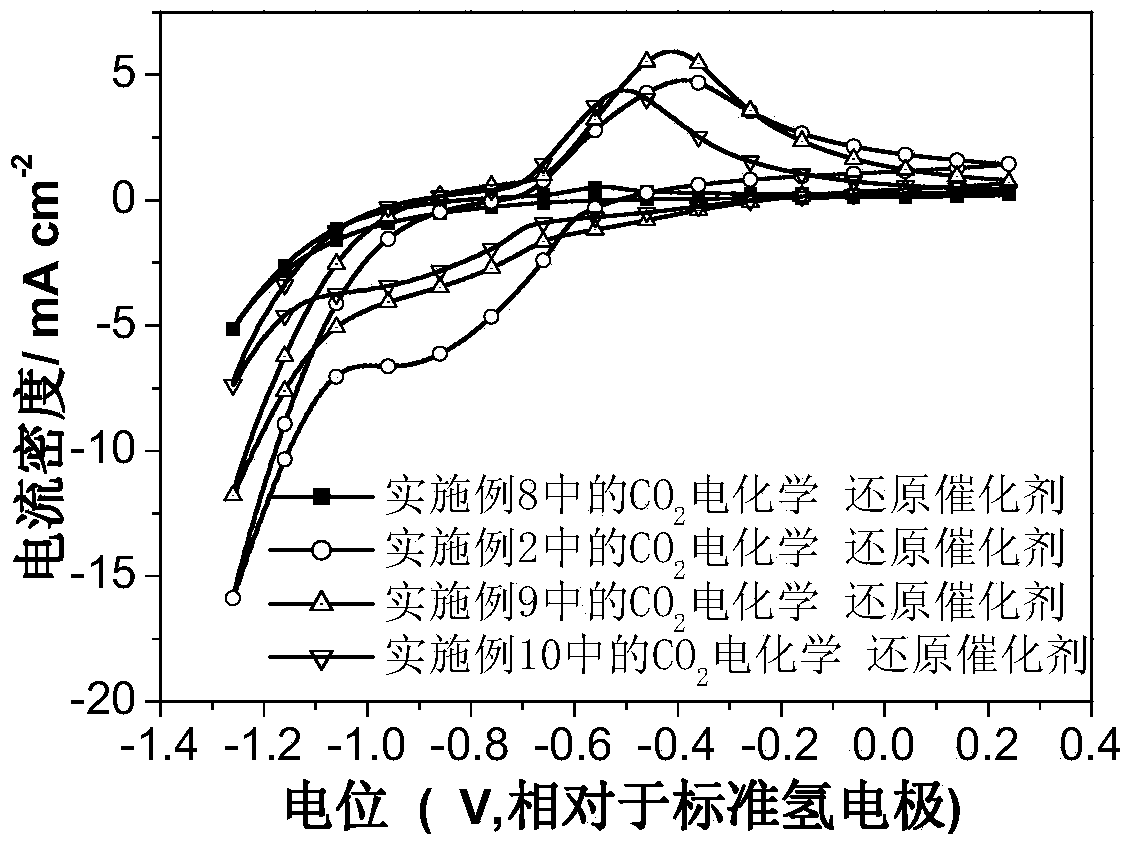

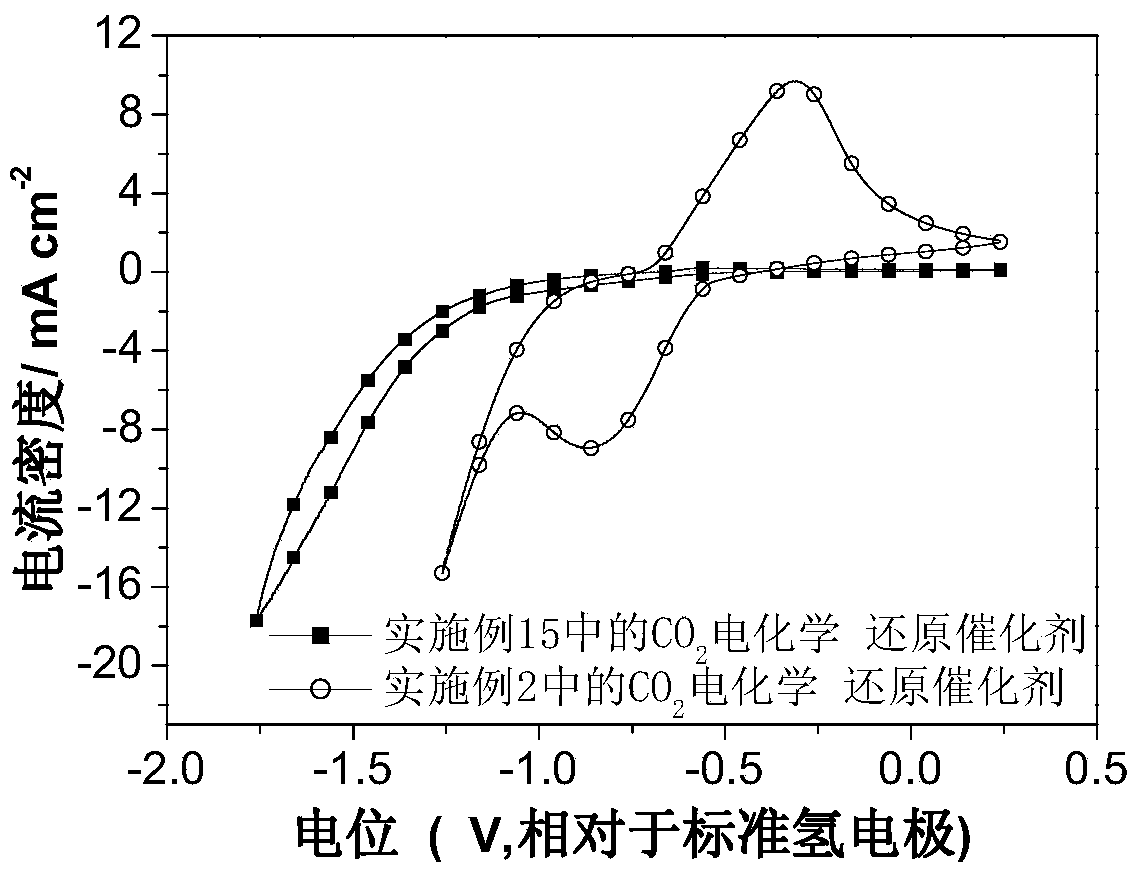

Carbon dioxide electrochemical reduction catalyst as well as preparation method and application thereof

InactiveCN103715436AIncrease the number of active sitesThe synthesis method is simpleMaterial nanotechnologyCell electrodesTin dioxideTrisodium citrate

The invention relates to a carbon dioxide electrochemical reduction catalyst as well as a preparation method and an application thereof. The carbon dioxide electrochemical reduction catalyst comprises tin dioxide nanoflower, wherein the tin dioxide nanoflower is synthesized through hydrothermal reaction and comprises the synthesis raw materials including 0.1-0.5M of tin dioxide, 1-5M of trisodium citrate mixed solution and 0.1-0.5M of sodium hydroxide. The carbon dioxide electrochemical reduction catalyst is applied to a carbon dioxide electrochemical reduction catalyst gas diffusion electrode. The carbon dioxide electrochemical reduction catalyst has the advantages that the specific surface area of the catalyst is enlarged, the electrochemical reduction catalytic activity of the catalyst for carbon dioxide reduction is improved, the hydrogen evolution reaction is effectively inhibited, and the selectivity of formic acid in a product is improved.

Owner:DONGHUA UNIV +1

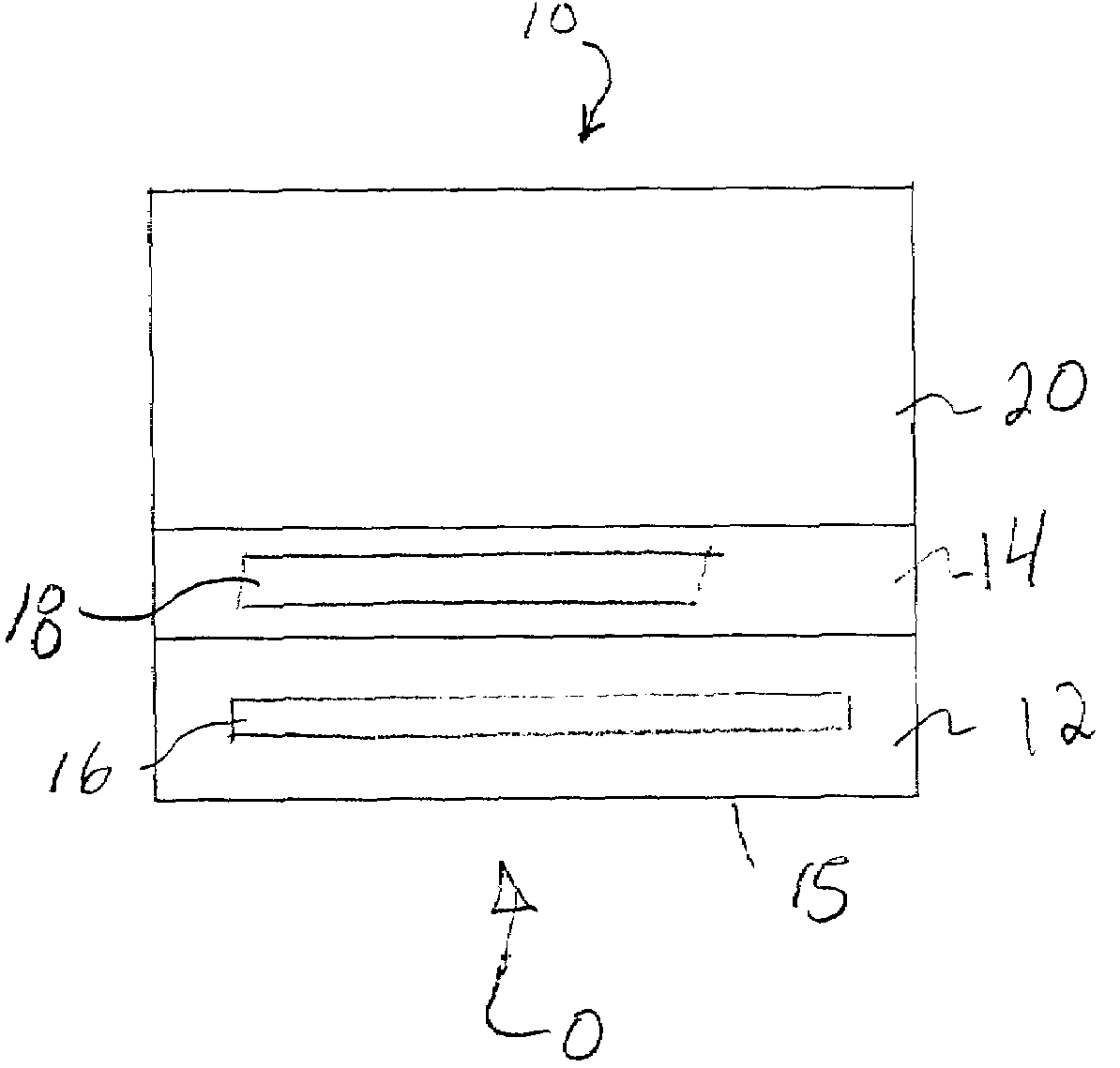

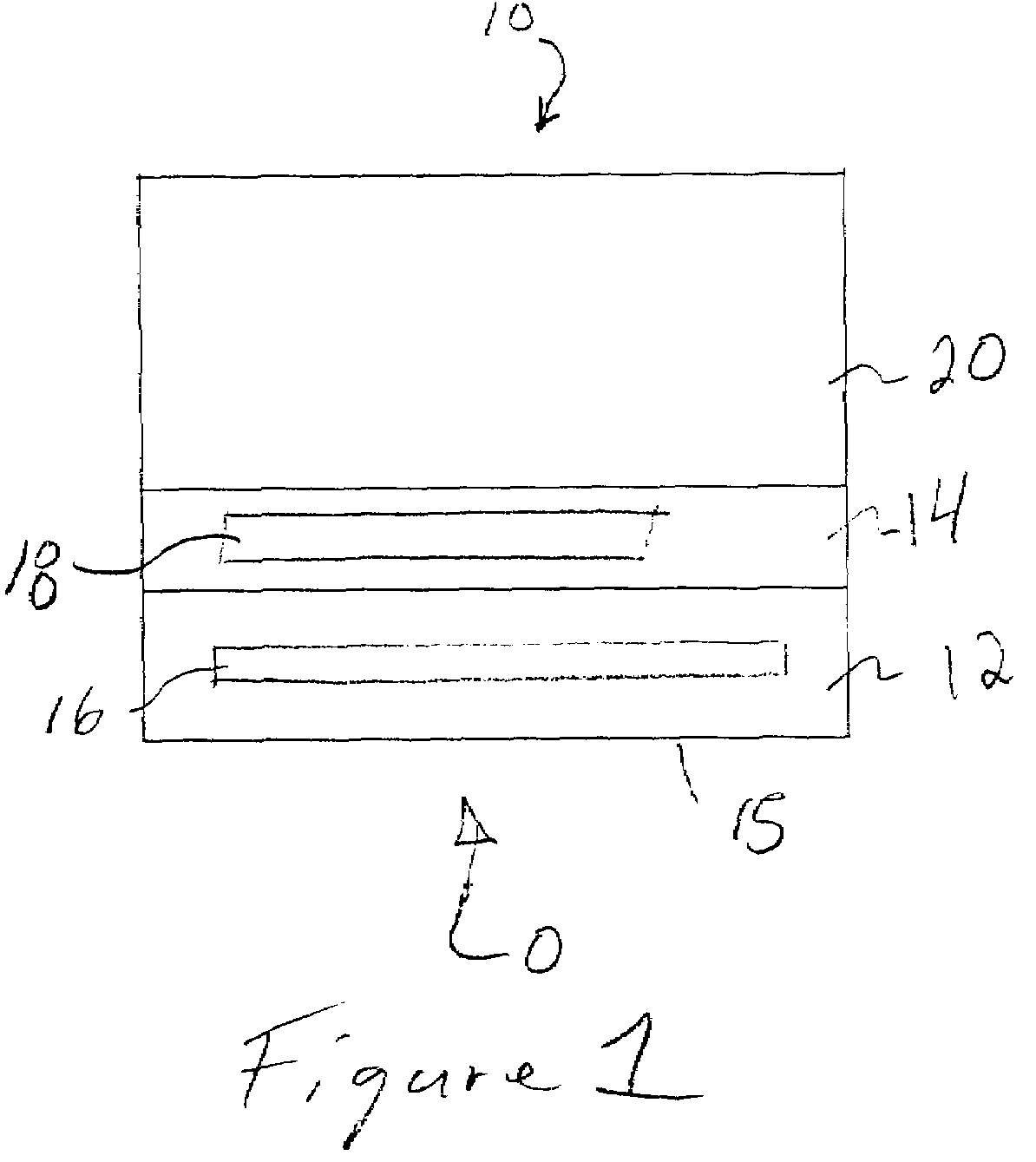

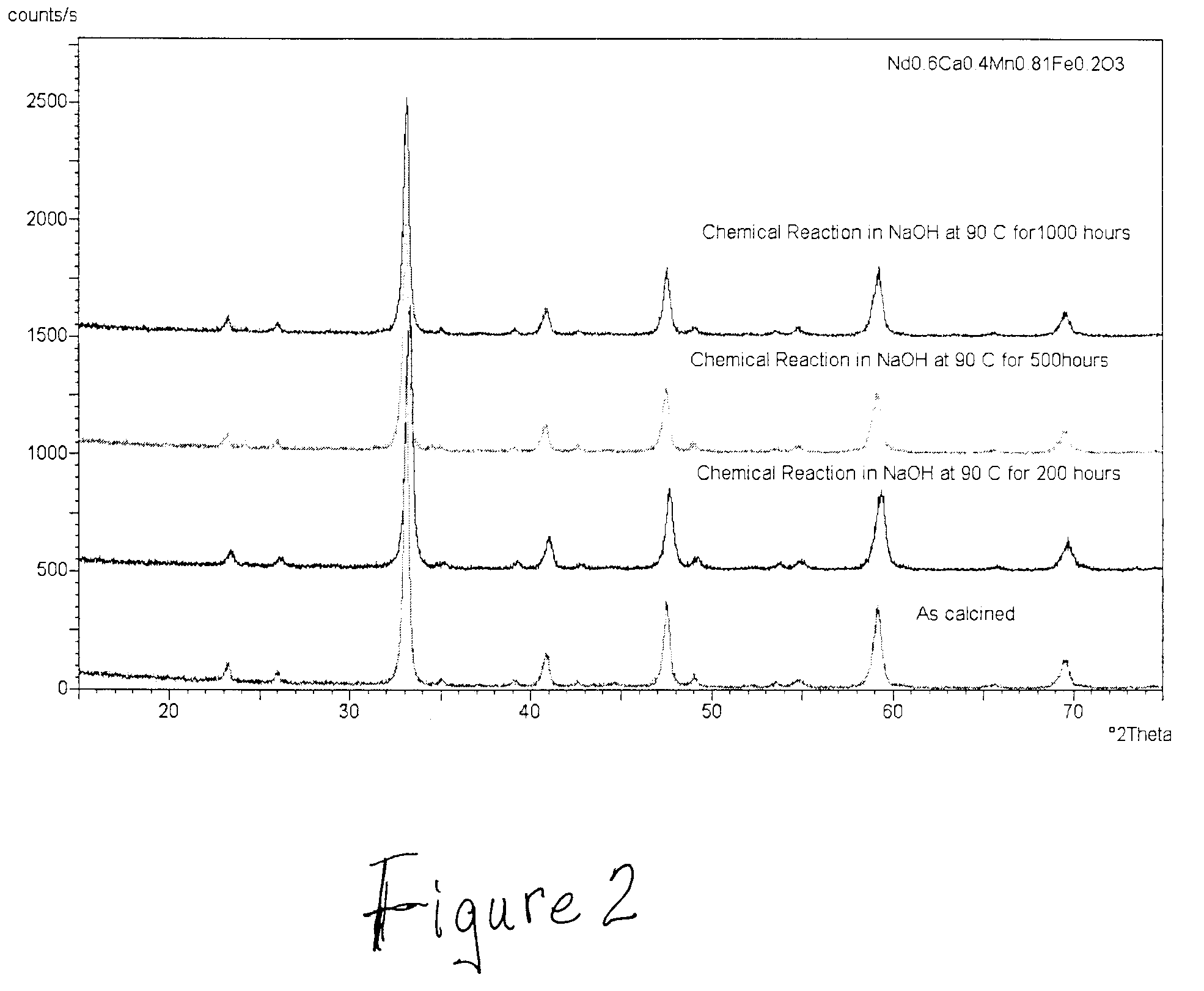

Gas diffusion electrode and catalyst for electrochemical oxygen reduction and method of dispersing the catalyst

An improved gas diffusion electrode composed of a perovskite-type oxide dispersed in a mixture of carbon black and a hydrophobic binder polymer. An improved catalyst for use in the electrochemical reduction of oxygen comprising a perovskite-type compound having alpha and beta sites, and having a greater molar ratio of cations at the beta site. A particularly good reduction catalyst is a neodymium calcium manganite. An improved method of dispersing the catalysts with carbon in a reaction layer of the electrode improves performance of the electrode and the oxygen reduction process. This is provided by adding carbon black to an aqueous solution of metal salts before it is heated to a gel and then to a char and then calcined. Optionally, a quantity of the desired oxide catalyst can be premixed with a portion the carbon before adding the carbon to an aqueous solution of the metal salts to be heated. The amount of premixed metal oxide is chosen in conjunction with the amount of metal salts to provide the desired molar ratio after heating and calcining of the aqueous solution.

Owner:CERAMTEC

Gas diffusion layer having carbon particle mixture

InactiveUS20050130023A1Prevent floodingLong dimensionFuel cells groupingElectrode carriers/collectorsFuel cellsConductive materials

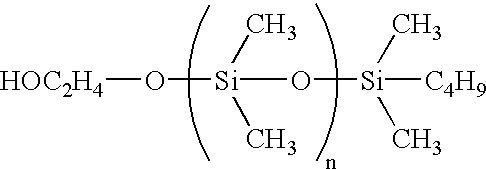

The invention relates to a gas diffusion layer, a device having the gas diffusion layer and a catalyst layer, a fuel cell containing the gas diffusion layer, and a gas diffusion electrode. The gas diffusion layer comprises a flexible, electrically non-conductive, porous material having a solid matrix, interconnected pores or interstices through the solid matrix, at least one external surface and internal surfaces, which internal surfaces are the surfaces of the walls of the pores or interstices, wherein at least a portion of the at least one external surface is coated with one or more layers of an electrically conductive material, the electrically conductive material comprising a mixture of at least two populations of electrically conductive carbon particles of different size, wherein the at least two populations of electrically conductive carbon particles are substantially uniformly mixed in the direction of a plane extending along the at least one external surface.

Owner:FOAMEX LP

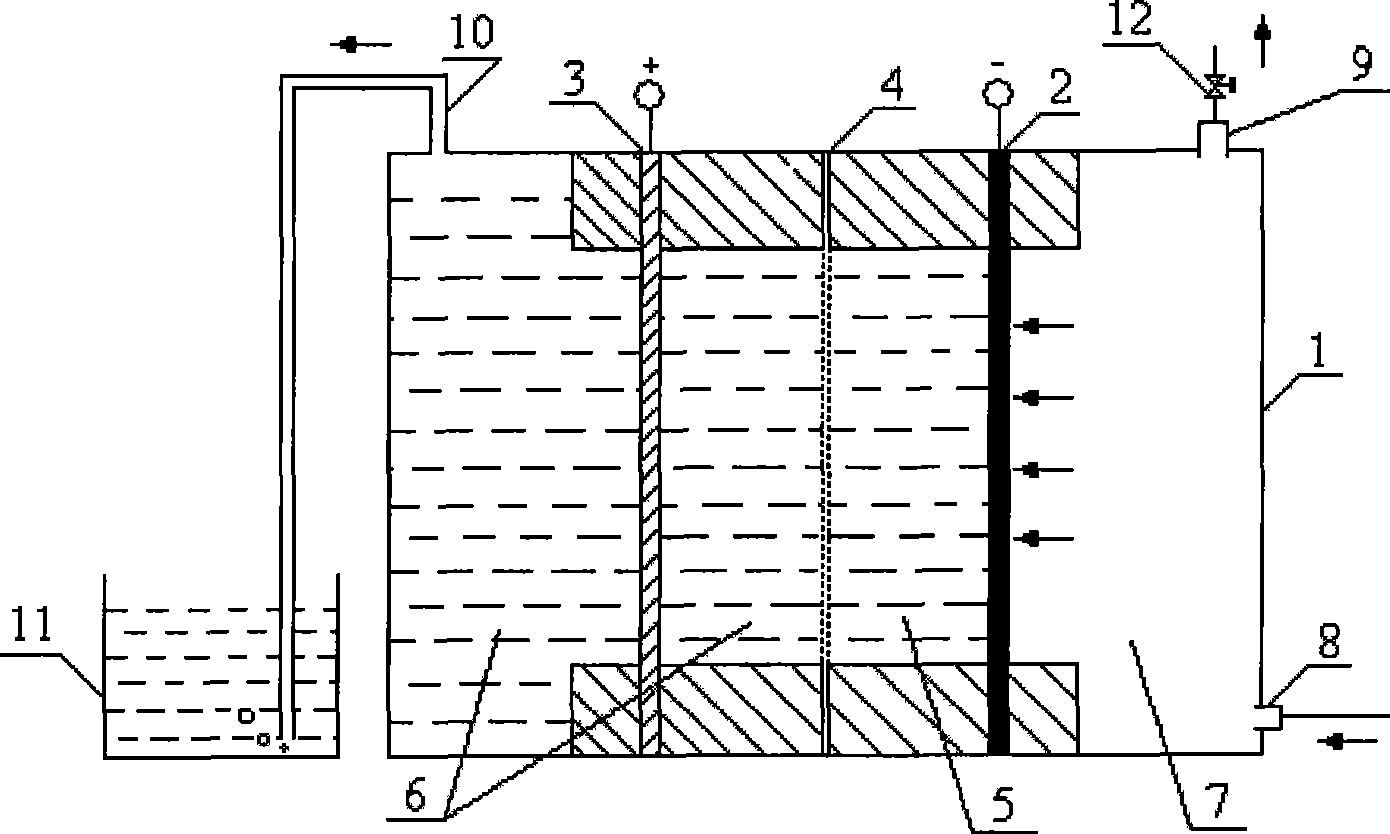

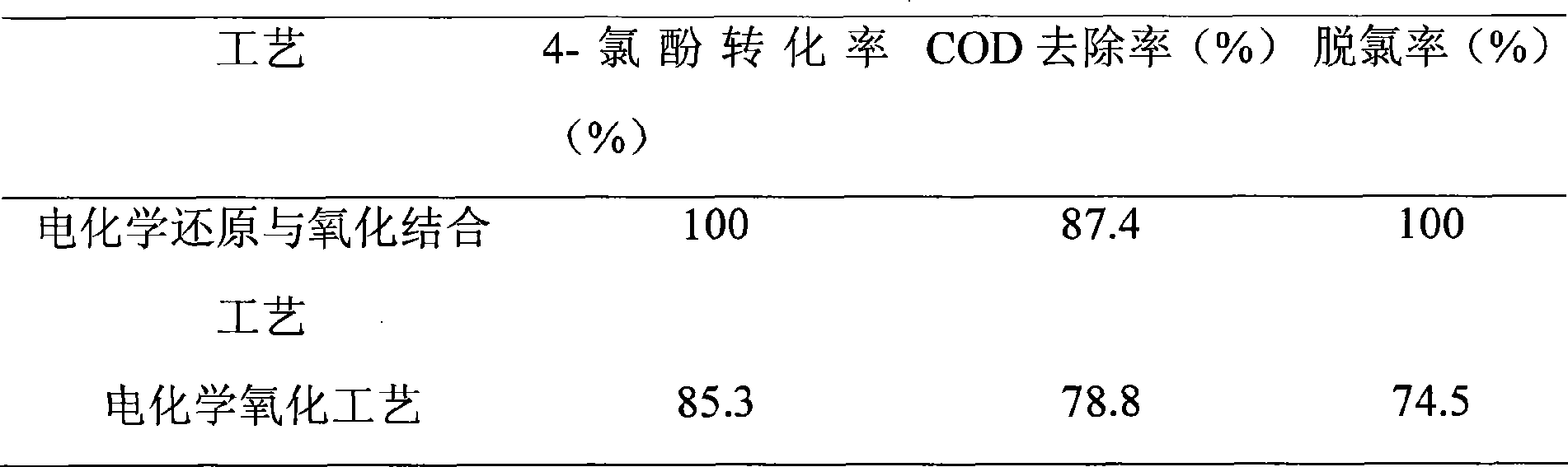

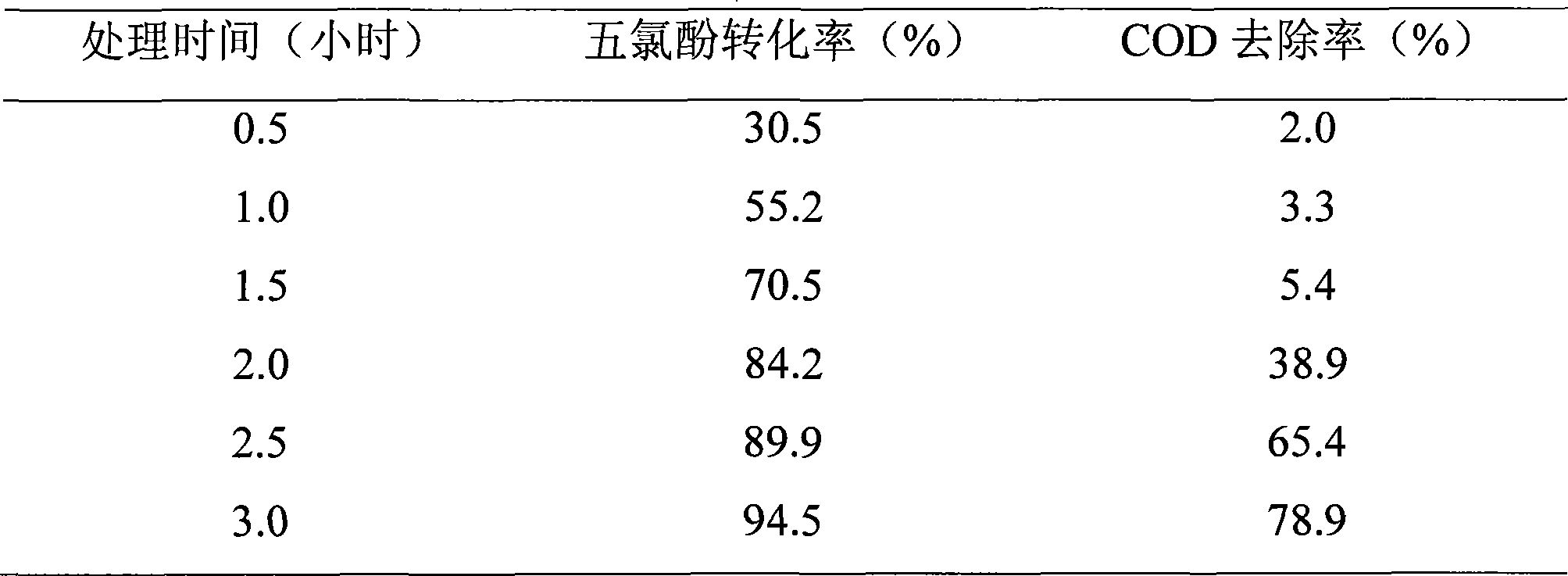

Apparatus and method for processing chlorine-containing organic wastewater by electrochemical reduction and oxidation

InactiveCN101434429AHas reductive dechlorinationReductive dechlorination is fully utilizedWater/sewage treatment by oxidationElectrolysisCatalytic oxidation

The invention discloses a device and a method used for processing chlorine-containing organic wastewater by combining electrochemical reduction with oxidation, which belongs to the electrochemical and environmental technical field. An electrolyzer body is positioned horizontally, the diffusion cathode and the diffusion anode of palladium-loading gas are separately positioned at the two sides of the electrolyzer body, one side of the cathode is connected with a gas compartment, a diaphragm is arranged between the cathode and the anode so as to separate the cathode area and the anode area, an air inlet pipe is arranged at one side of the gas compartment, and the exhaust pipes of the cathode area and the anode area are respectively arranged at the upper parts of the cathode area and the anode area, wherein, the exhaust pipe arranged at the upper part of the anode area is connected with a gas absorption device. The diffusion cathode of the palladium-loading gas not only can electroreduce and dechlorinate chlorinated organic compounds (by pumping in hydrogen), but also can produce hydrogen peroxide by electroreduction (by pumping in air), and also can be decomposed to generate hydroxyl radical. The device has simple structure, processes the chlorine-containing organic wastewater by adopting electrochemical reduction and dechlorination to the cathode and simultaneous adopting electro-catalytic oxidation to both the cathode and the anode, thus achieving the aims of removing pollutants fully, reducing energy consumption and increasing decontamination efficiency.

Owner:TSINGHUA UNIV

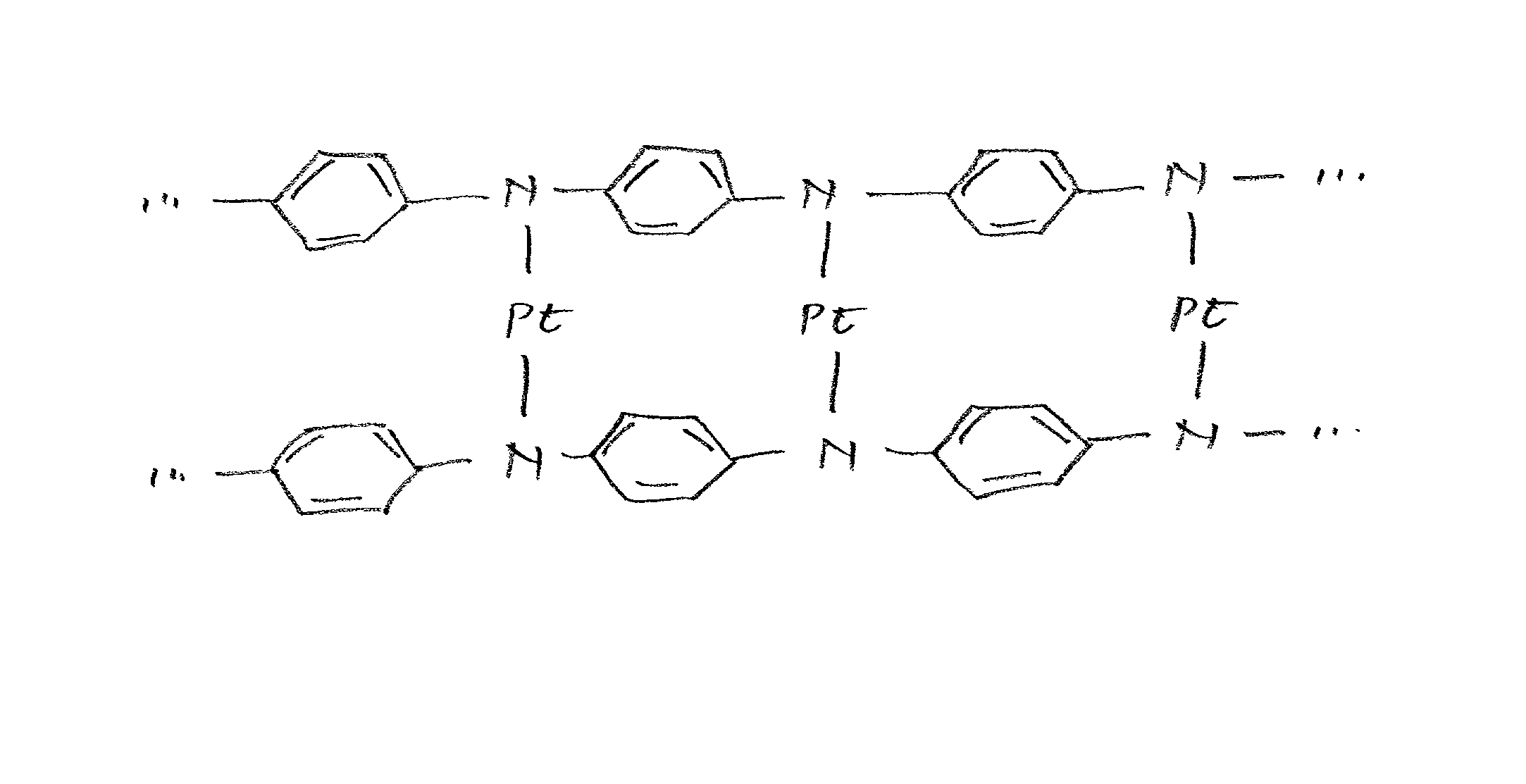

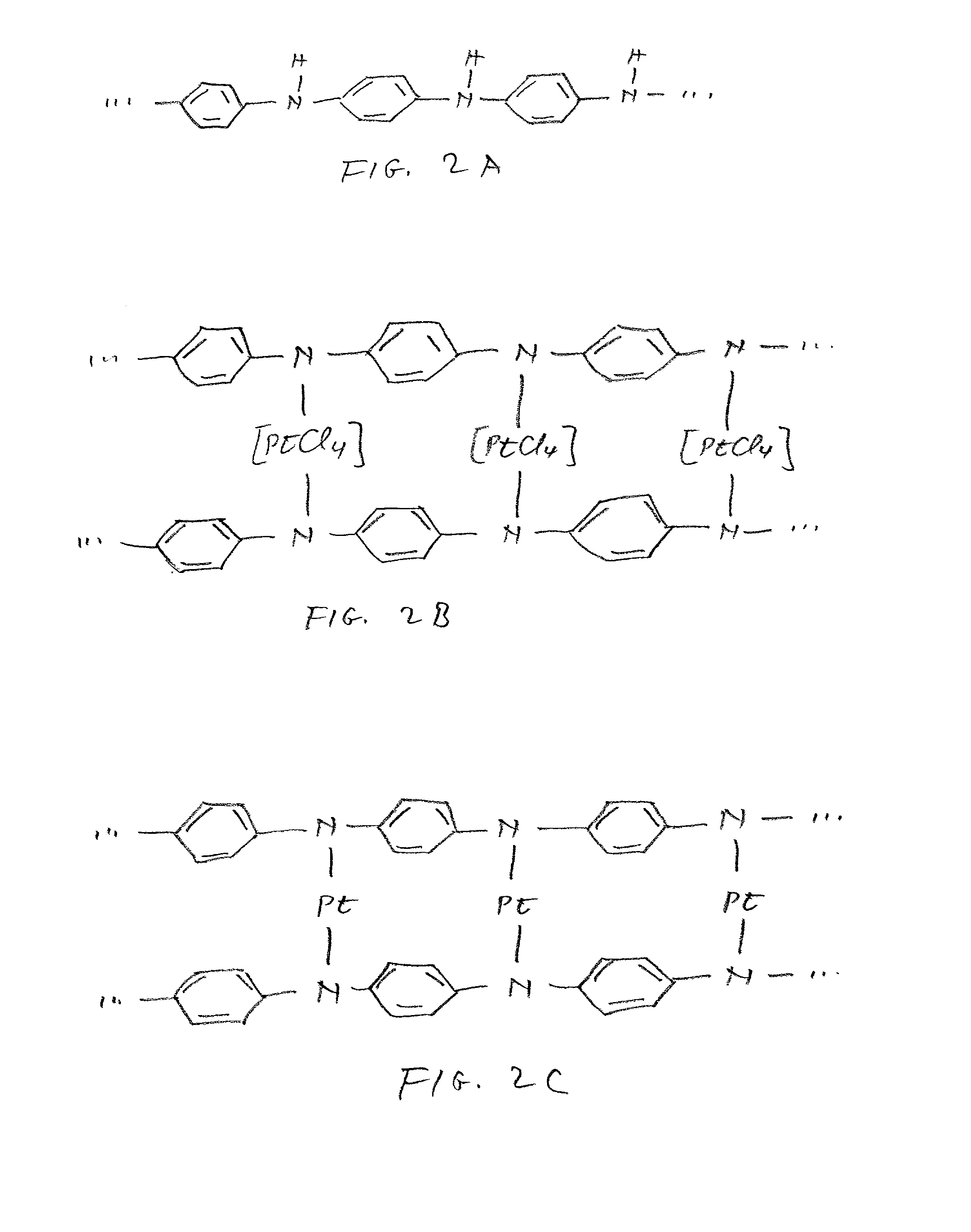

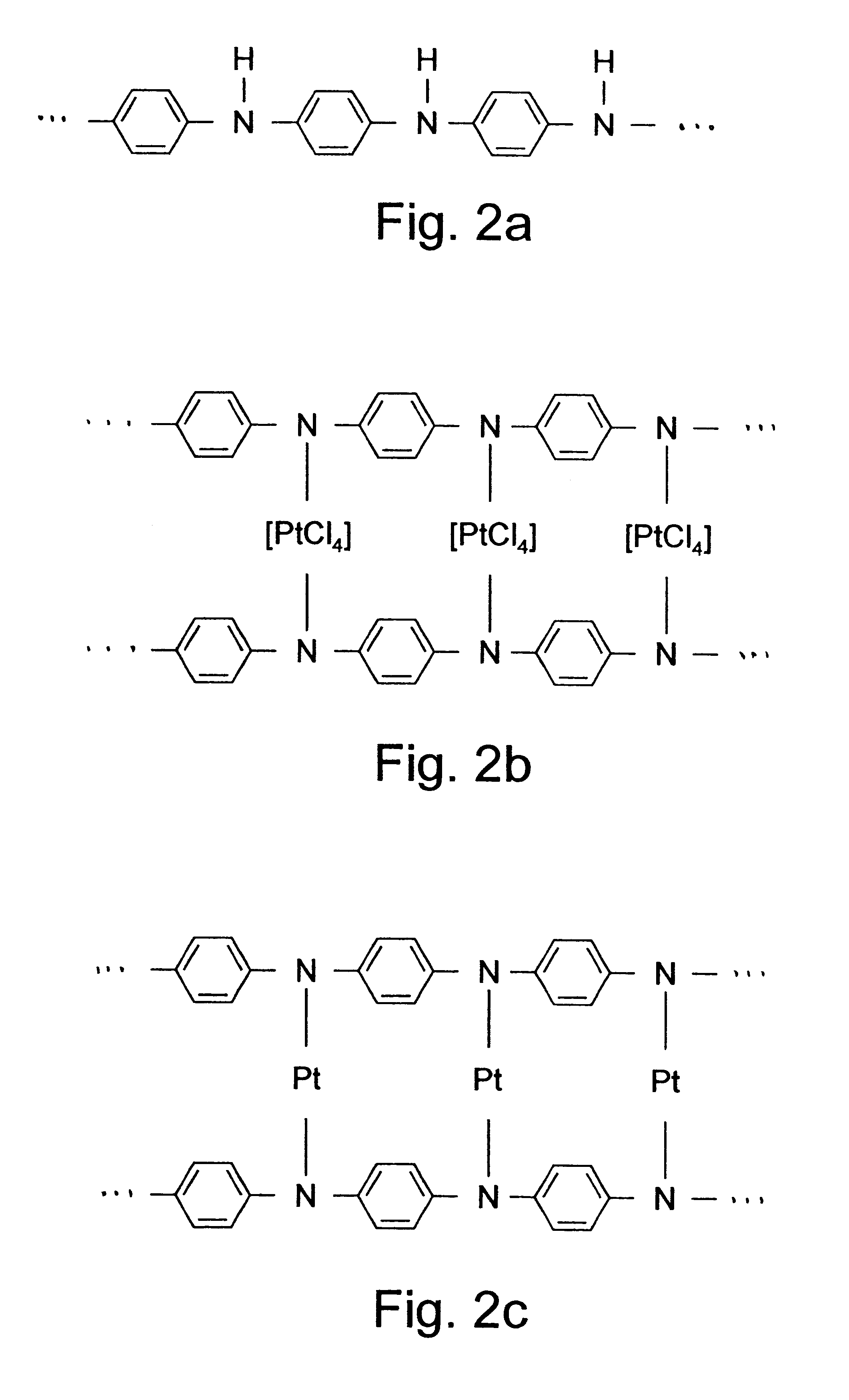

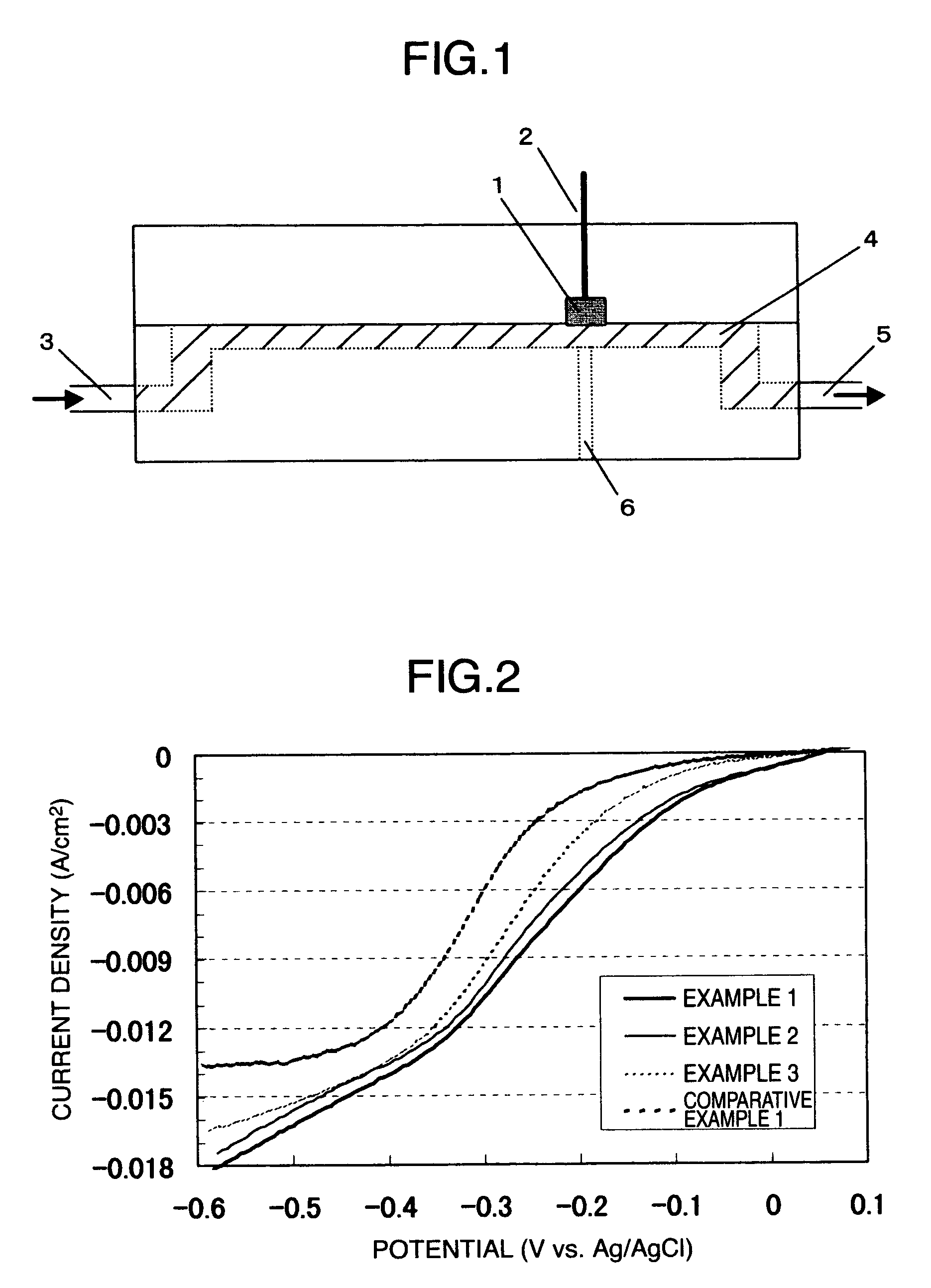

Class of electrocatalysts and a gas diffusion electrode based thereon for fuel cells

InactiveUS20020132157A1Organic-compounds/hydrides/coordination-complexes catalystsConductive materialFuel cellsConductive polymer

An electrocatalyst based on a highly electroconducting polymer and a transition metal, in which transition metal atoms are covalently bonded to heteroatoms of the backbone monomers of the polymer. The covalently bonded transition metal atoms are nucleation sites for catalytically active transition metal particles. The complex is prepared by complexing a highly electroconducting polymer with transition metal coordination ions and then reducing the transition metal ions to neutral atoms. An electrode for a fuel cell is made by impregnating an electrically conducting sheet with the catalytic complex and drying the impregnated sheet. The scope of the present invention includes such electrodes and the fuel cells that incorporate these electrodes.

Owner:MEDIS EL

Class of electrocatalysts and a gas diffusion electrode based thereon for fuel cells

InactiveUS6380126B1Good electrical contactEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsConductive materialFuel cellsConductive polymer

An electrocatalyst based on a highly electroconducting polymer and a transition metal, in which transition metal atoms are covalently bonded to heteroatoms of the backbone monomers of the polymer. The covalently bonded transition metal atoms are nucleation sites for catalytically active transition metal particles. The complex is prepared by complexing a highly electroconducting polymer with transition metal coordination ions and then reducing the transition metal ions to neutral atoms. An electrode for a fuel cell is made by impregnating an electrically conducting sheet with the catalytic complex and drying the impregnated sheet. The scope of the present invention includes such electrodes and the fuel cells that incorporate these electrodes.

Owner:MEDIS EL

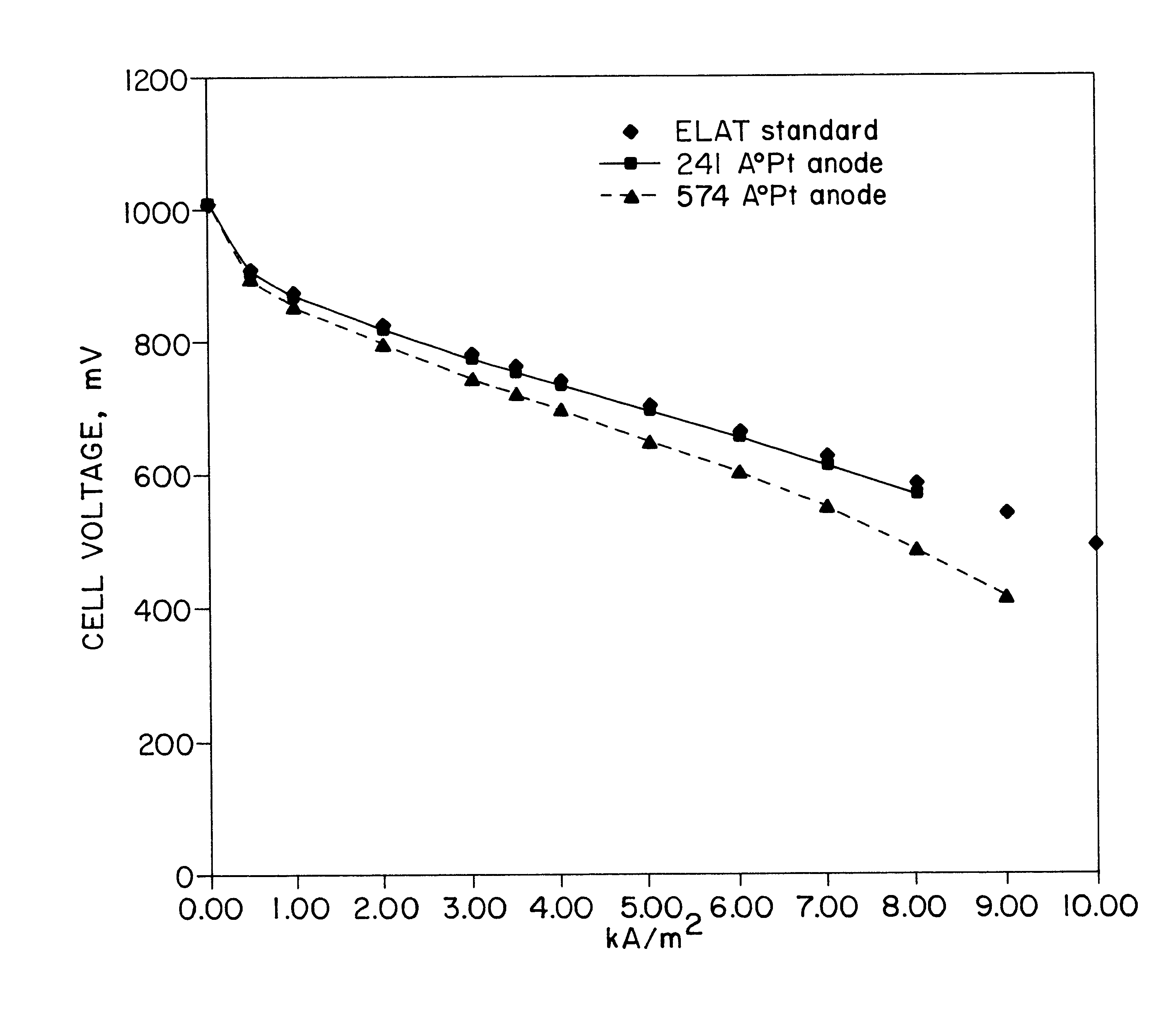

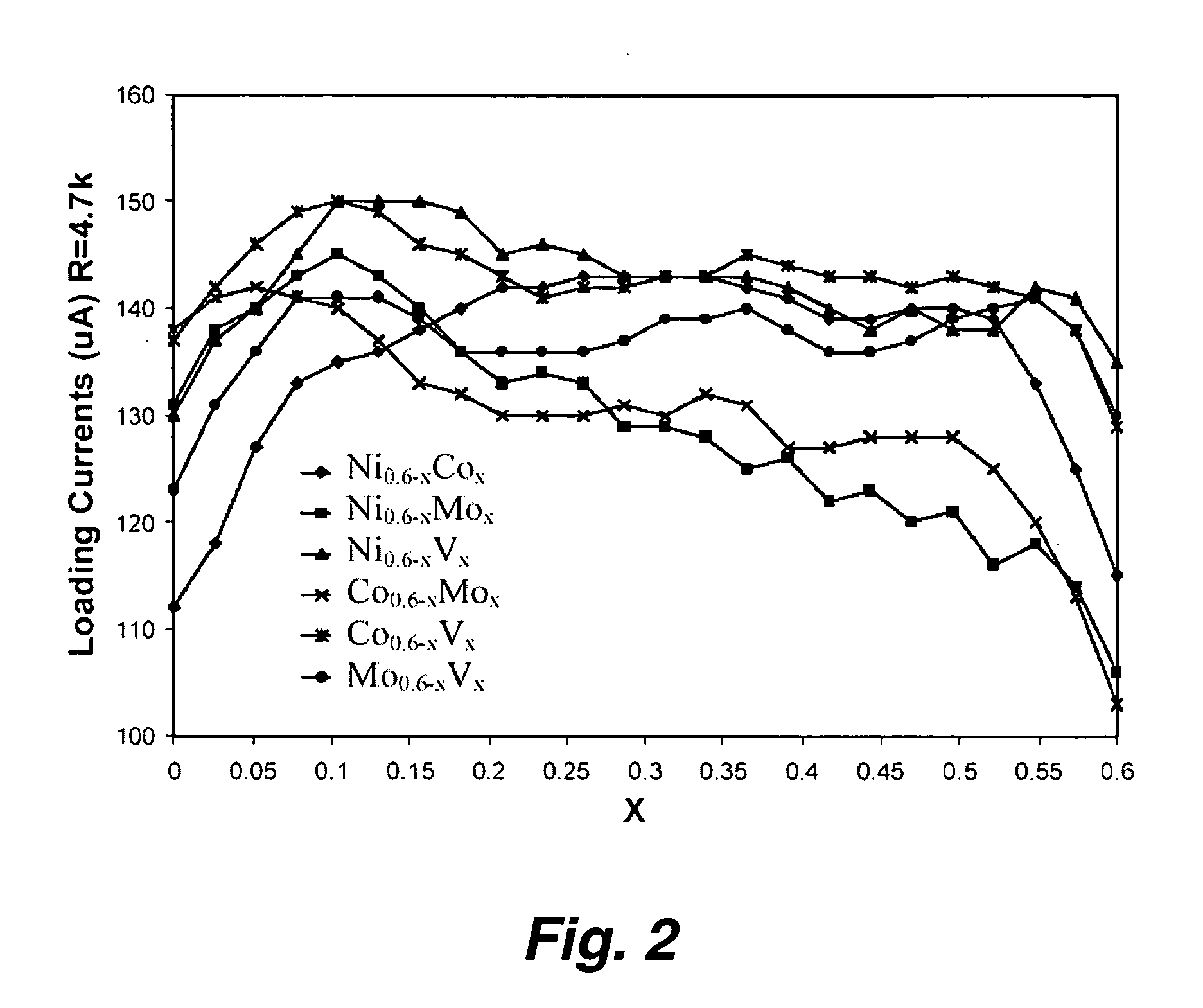

Composition of a selective oxidation catalyst for use in fuel cells

This invention pertains to improved formulations of platinum-molybdenum alloys for use as anode catalysts. These electrocatalysts find utility as a constituent of gas diffusion electrodes for use in fuel cells that operate at less than 180 DEG C. or in applications whereupon hydrogen is oxidized in the presence of carbon monoxide or other platinum inhibiting substances. The new formulations derive unexpected activity through creating highly dispersed alloy particles of up to approximately 300 ANGSTROM on carbon supports. The desired activity is achieved by carefully controlling the platinum to molybdenum ratio during preparation and judiciously selecting a proper loading of alloy on the carbon support.

Owner:PEMEAS +1

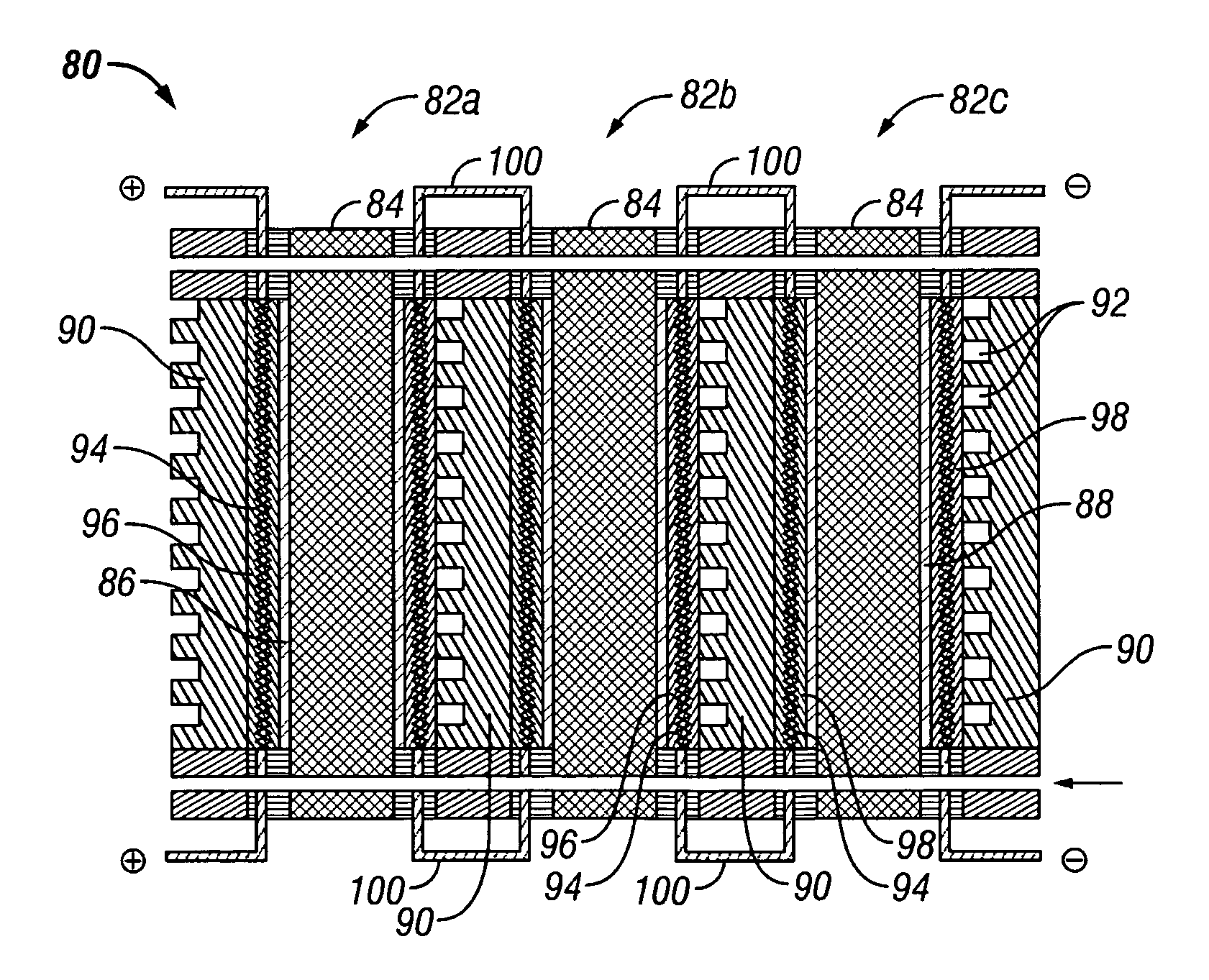

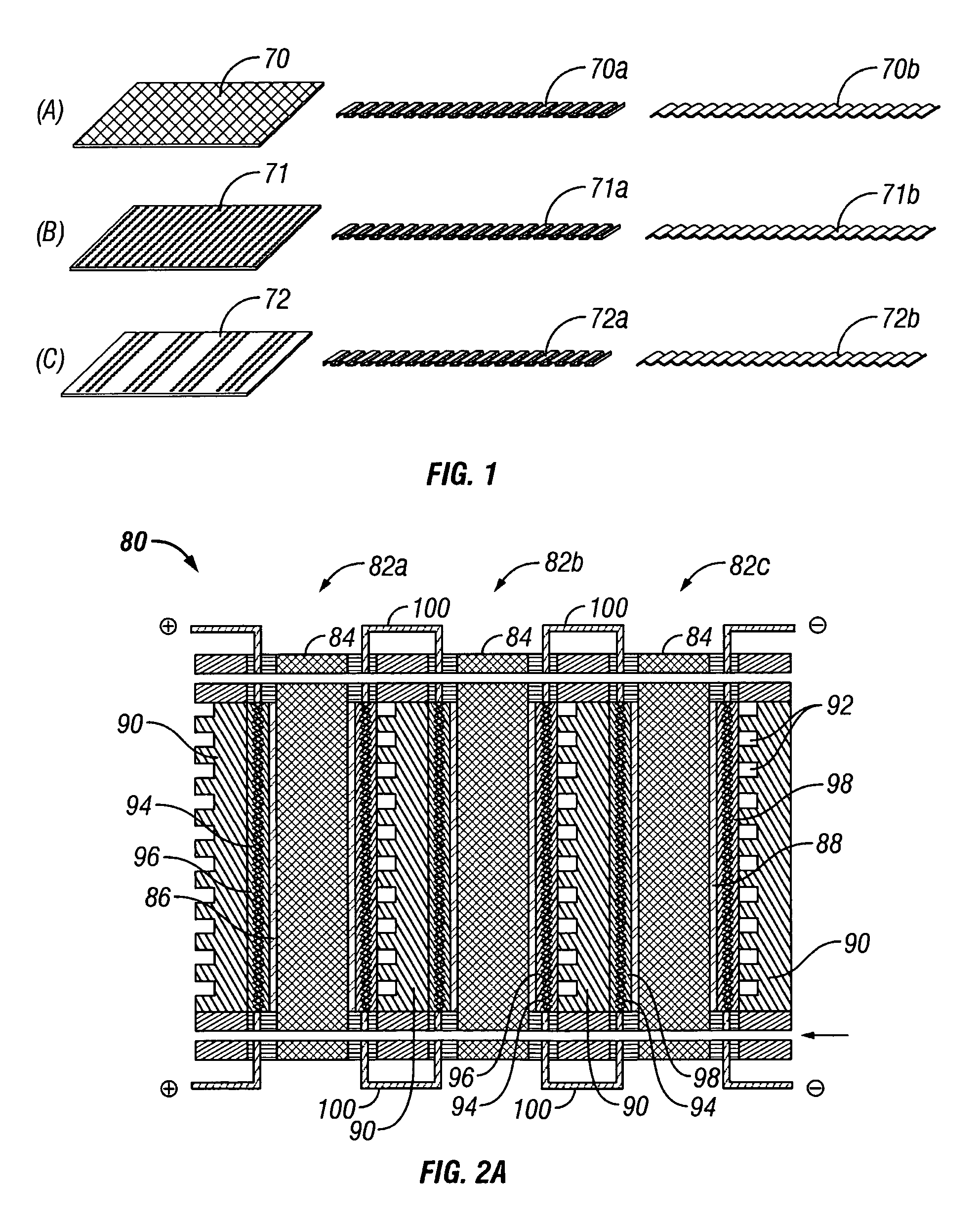

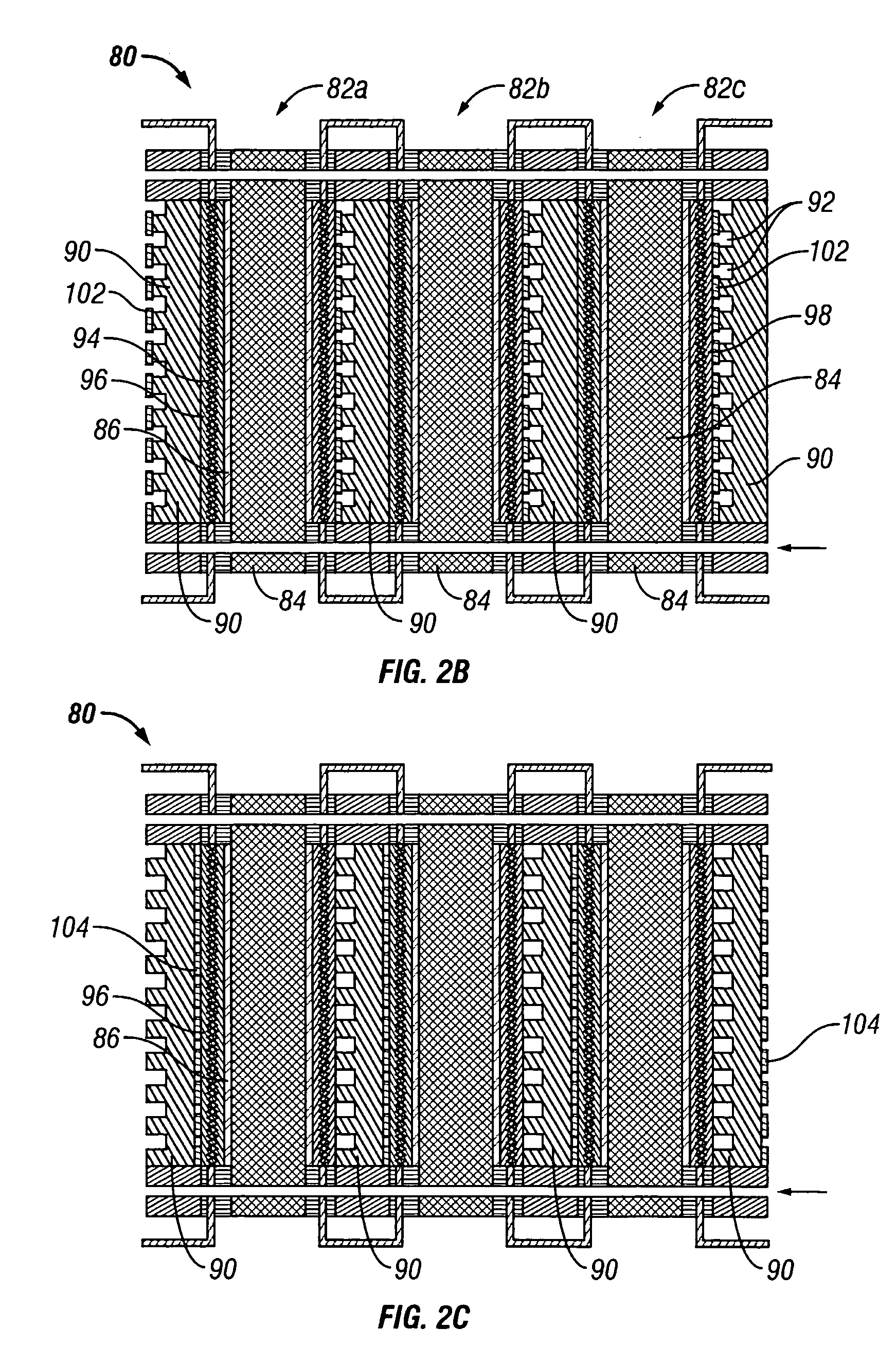

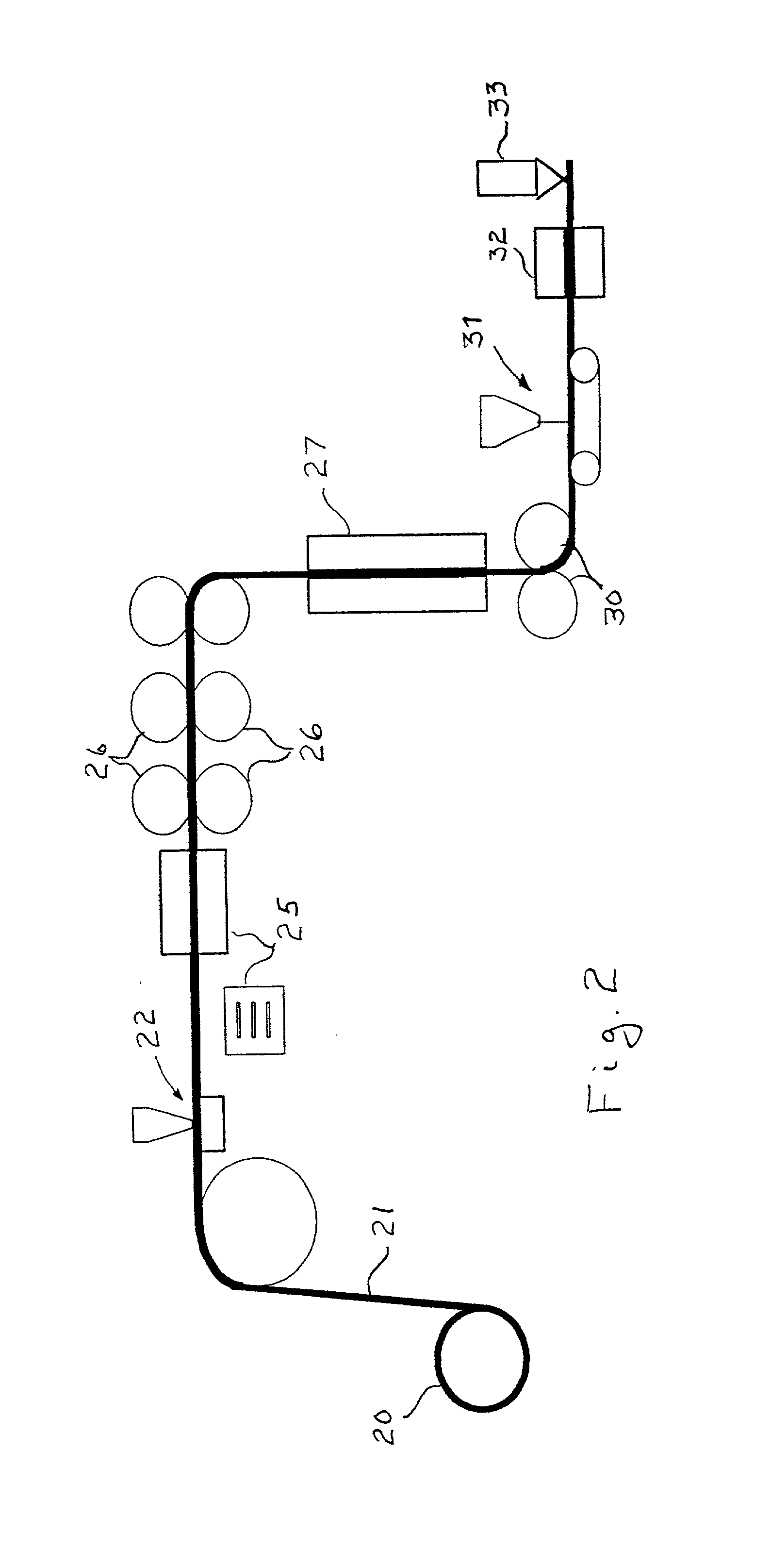

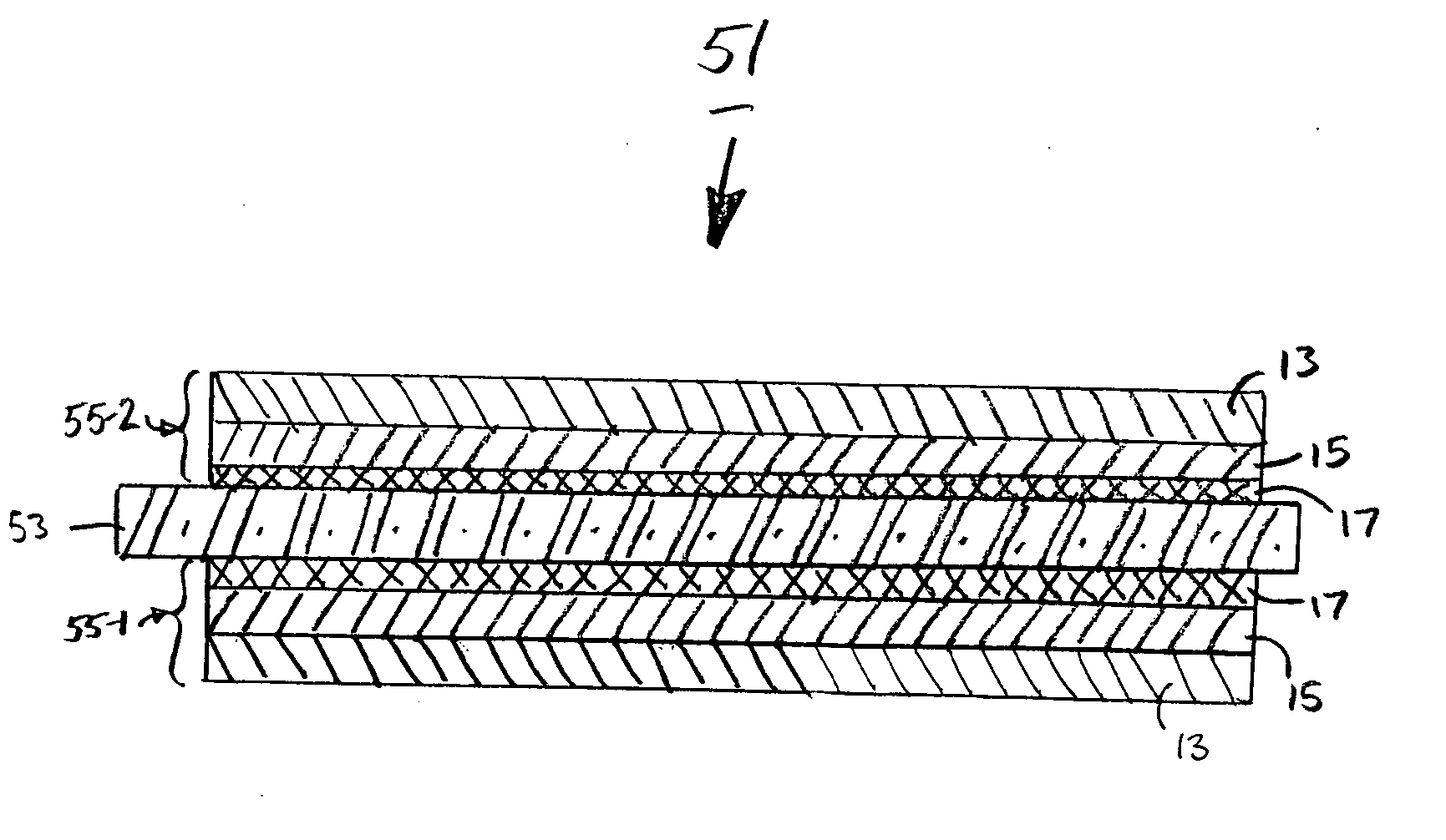

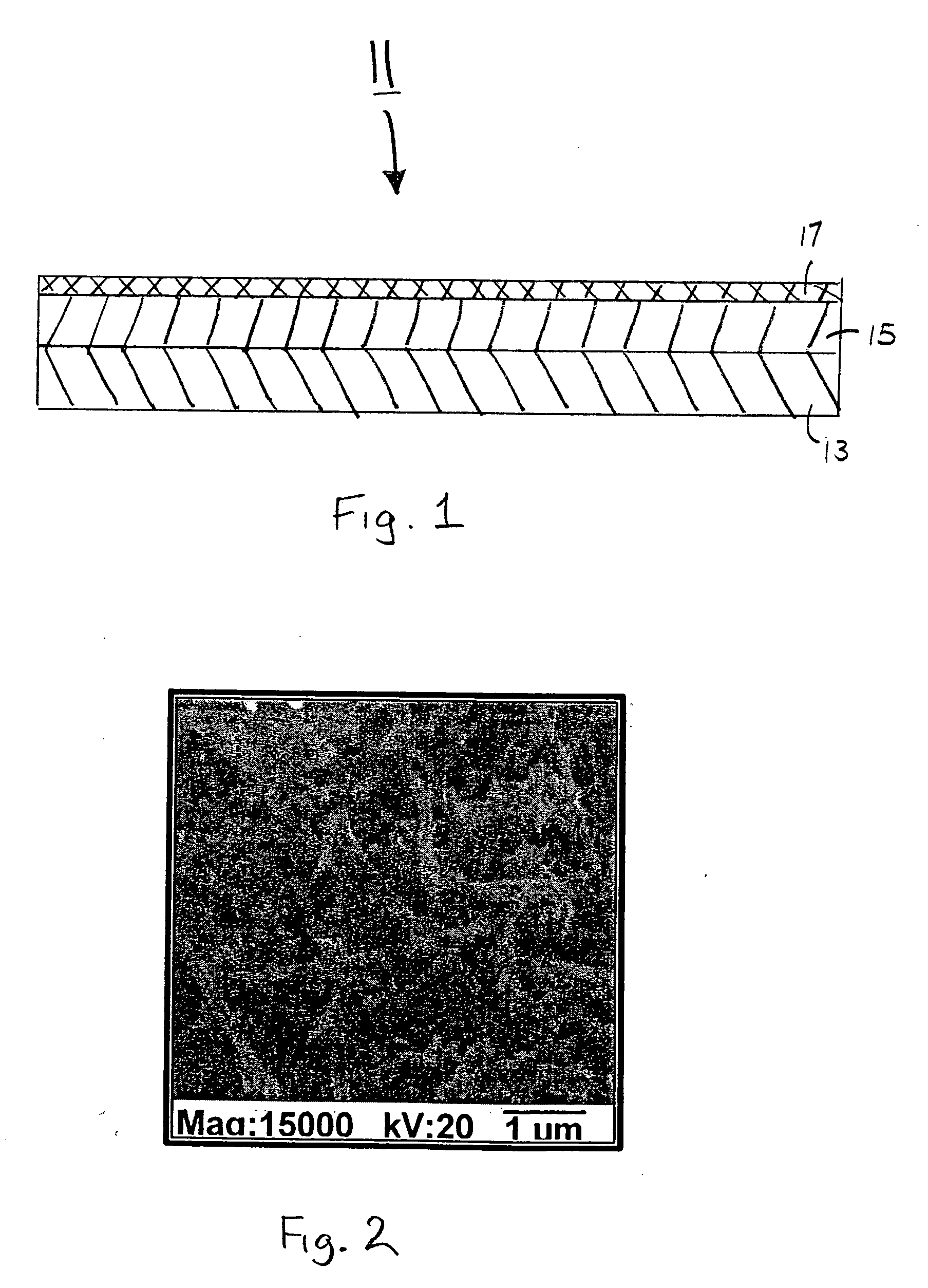

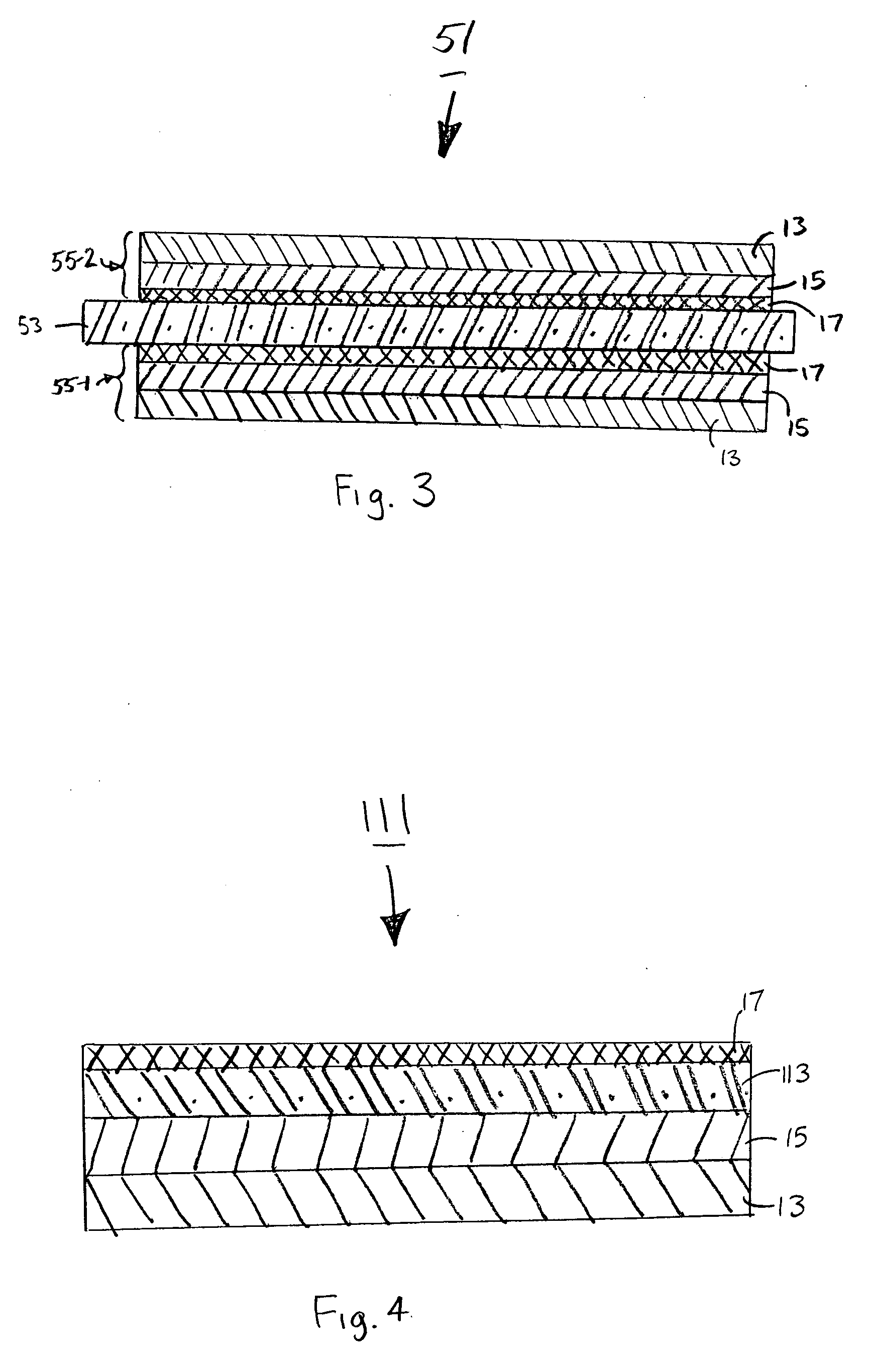

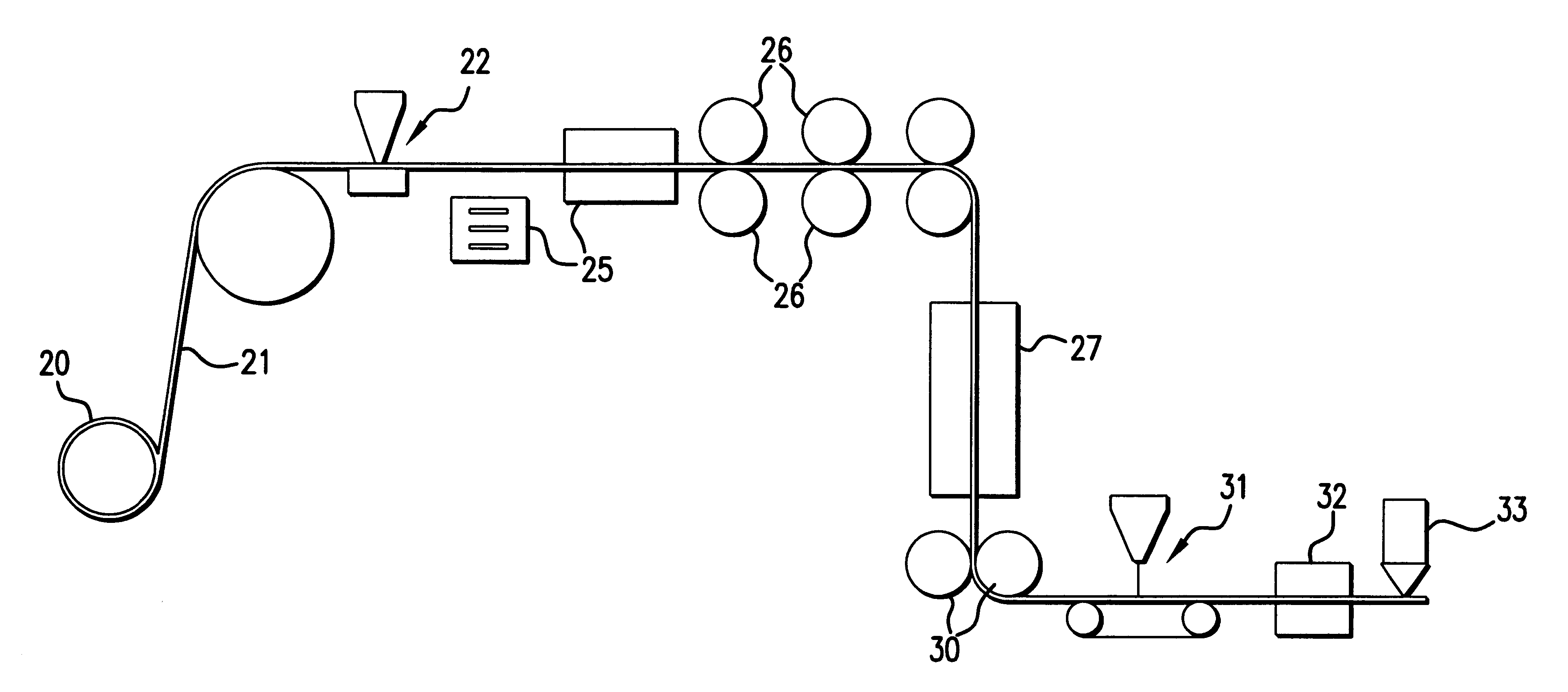

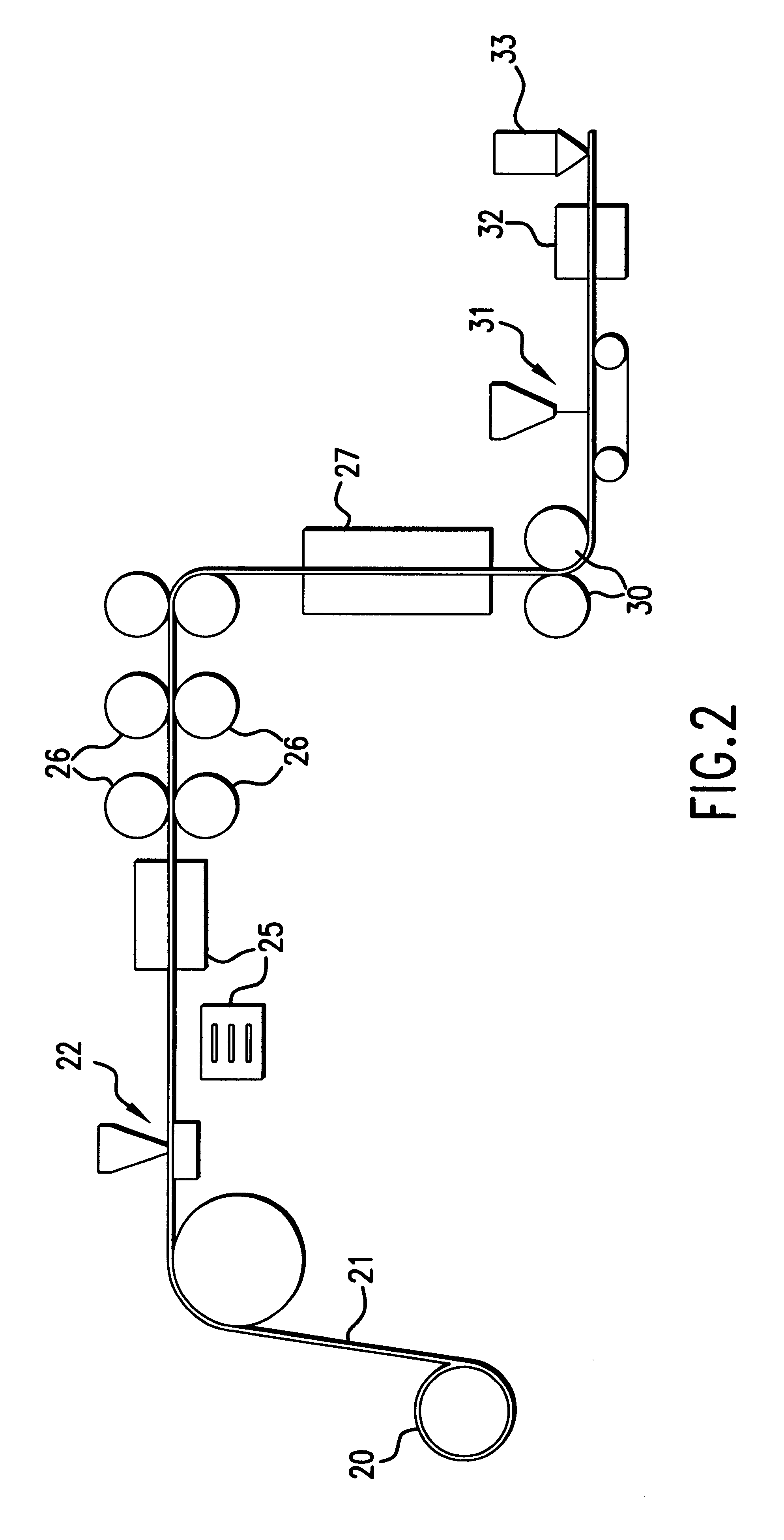

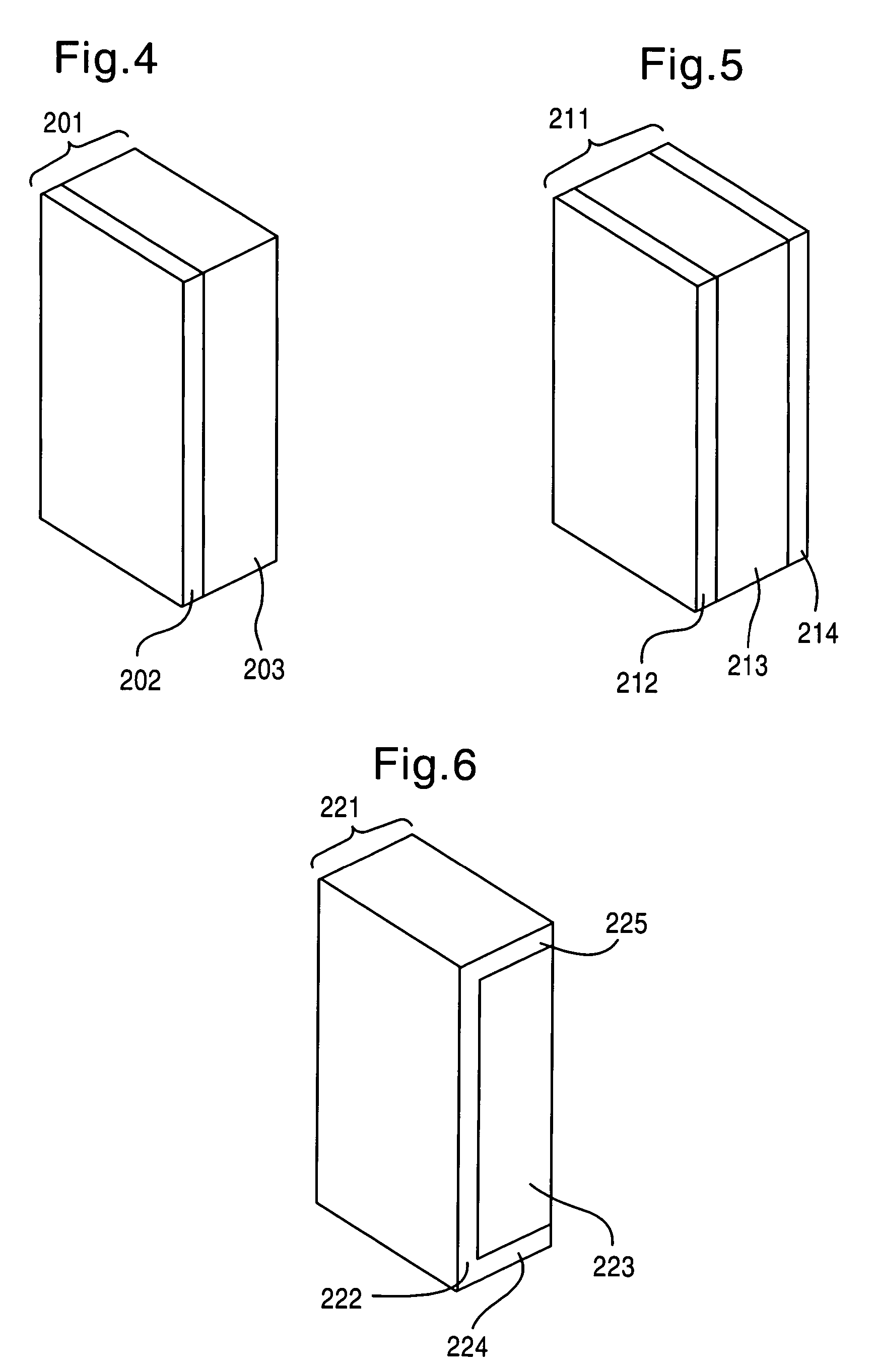

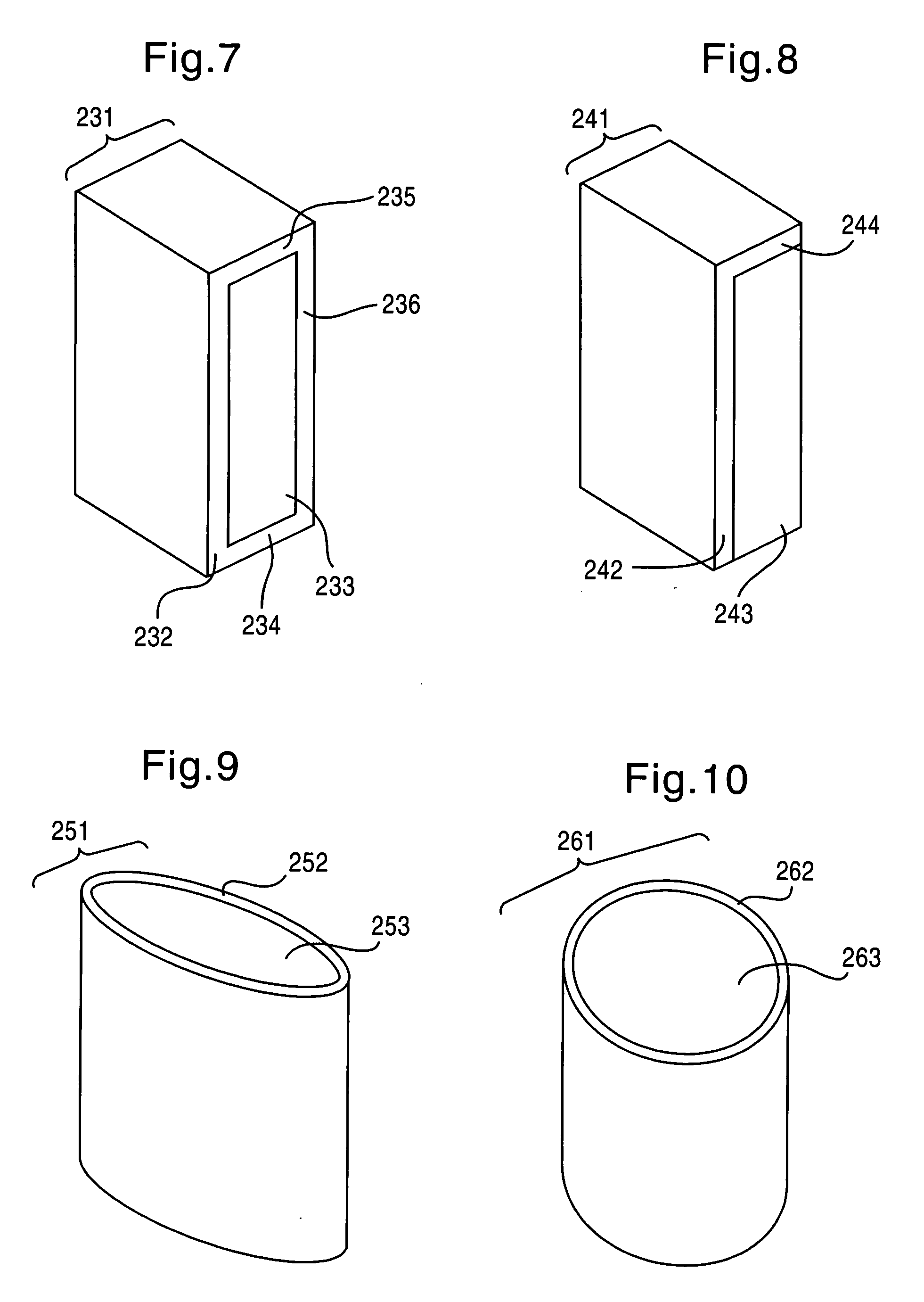

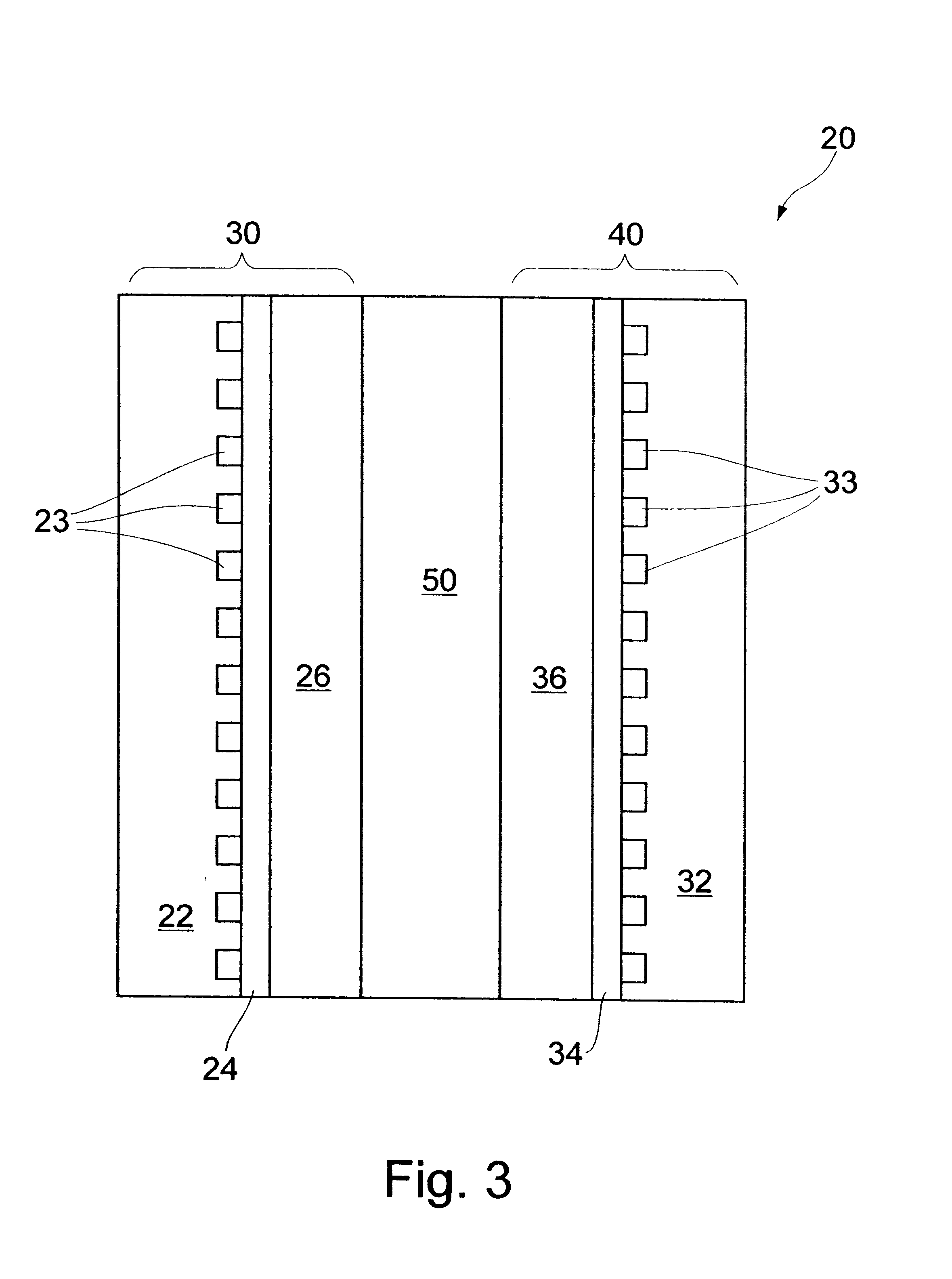

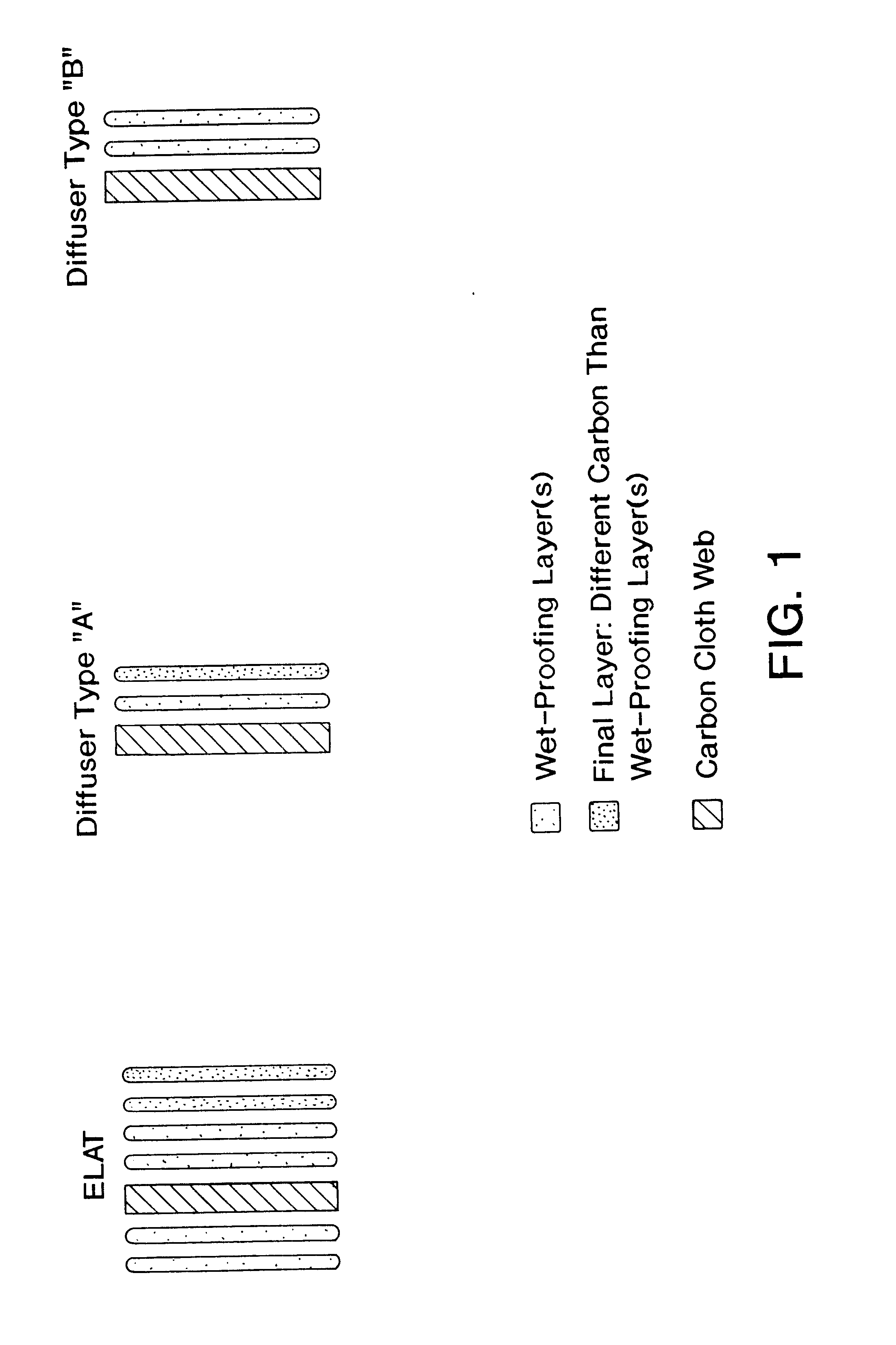

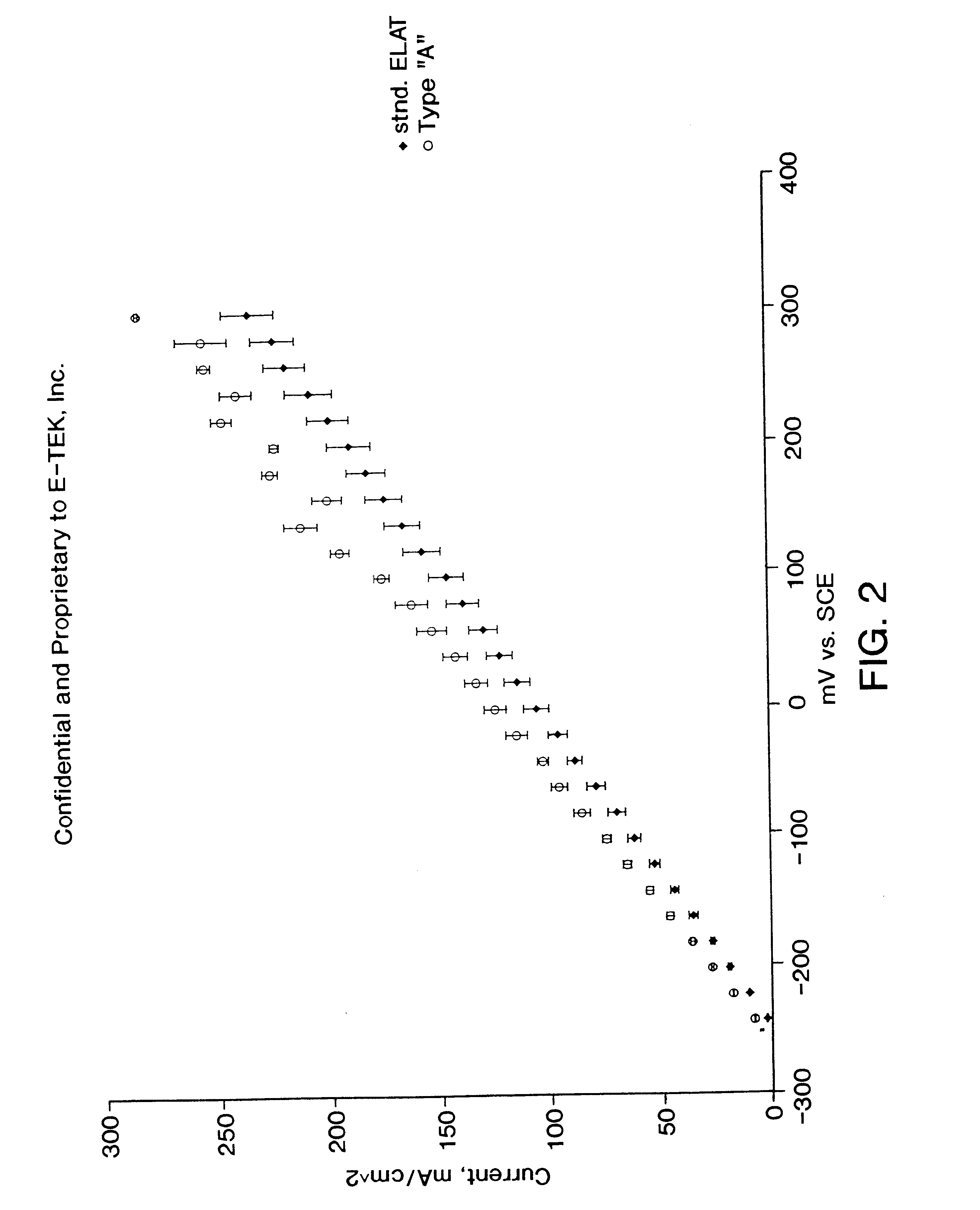

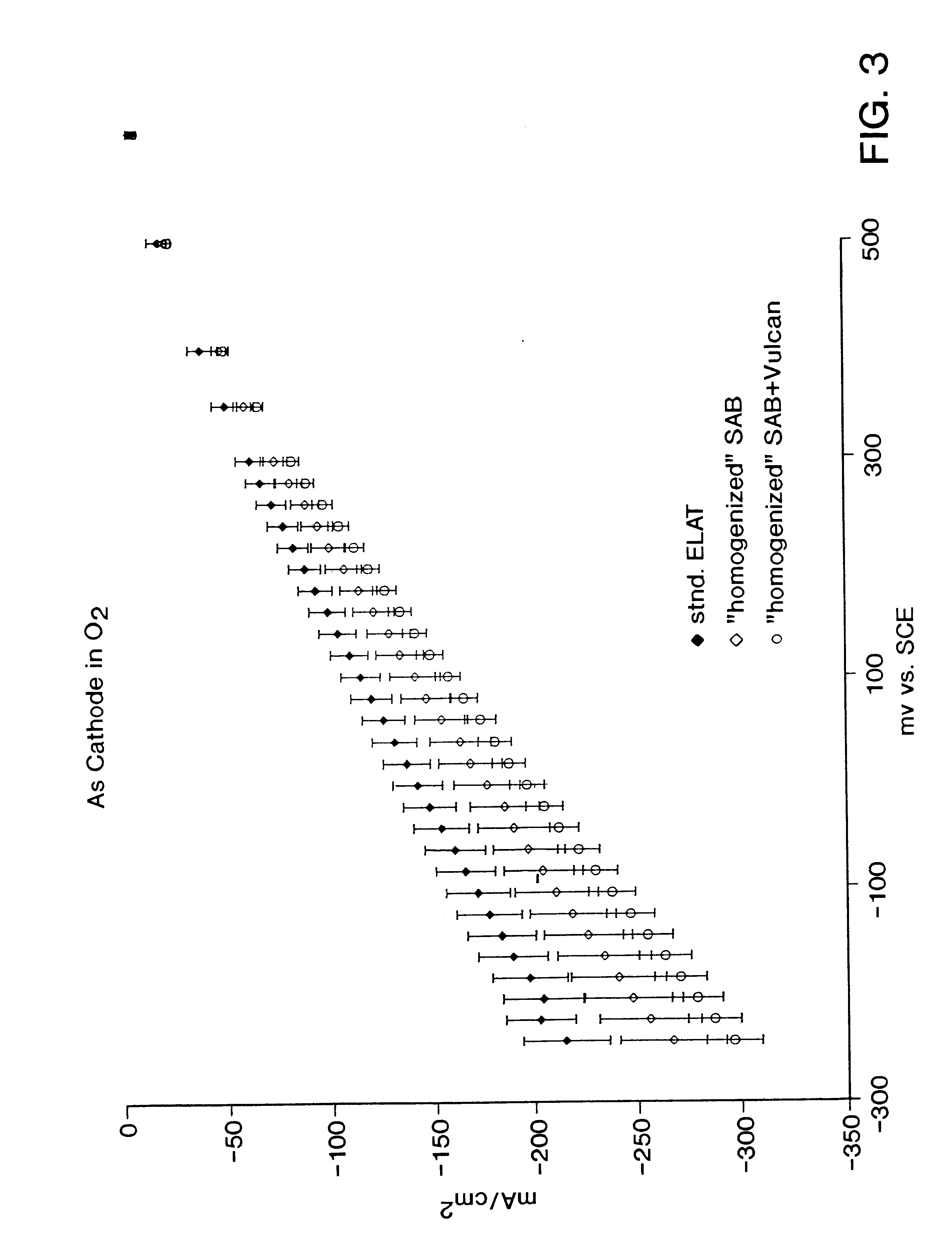

Structures and methods of manufacture for gas diffusion electrodes and electrode components

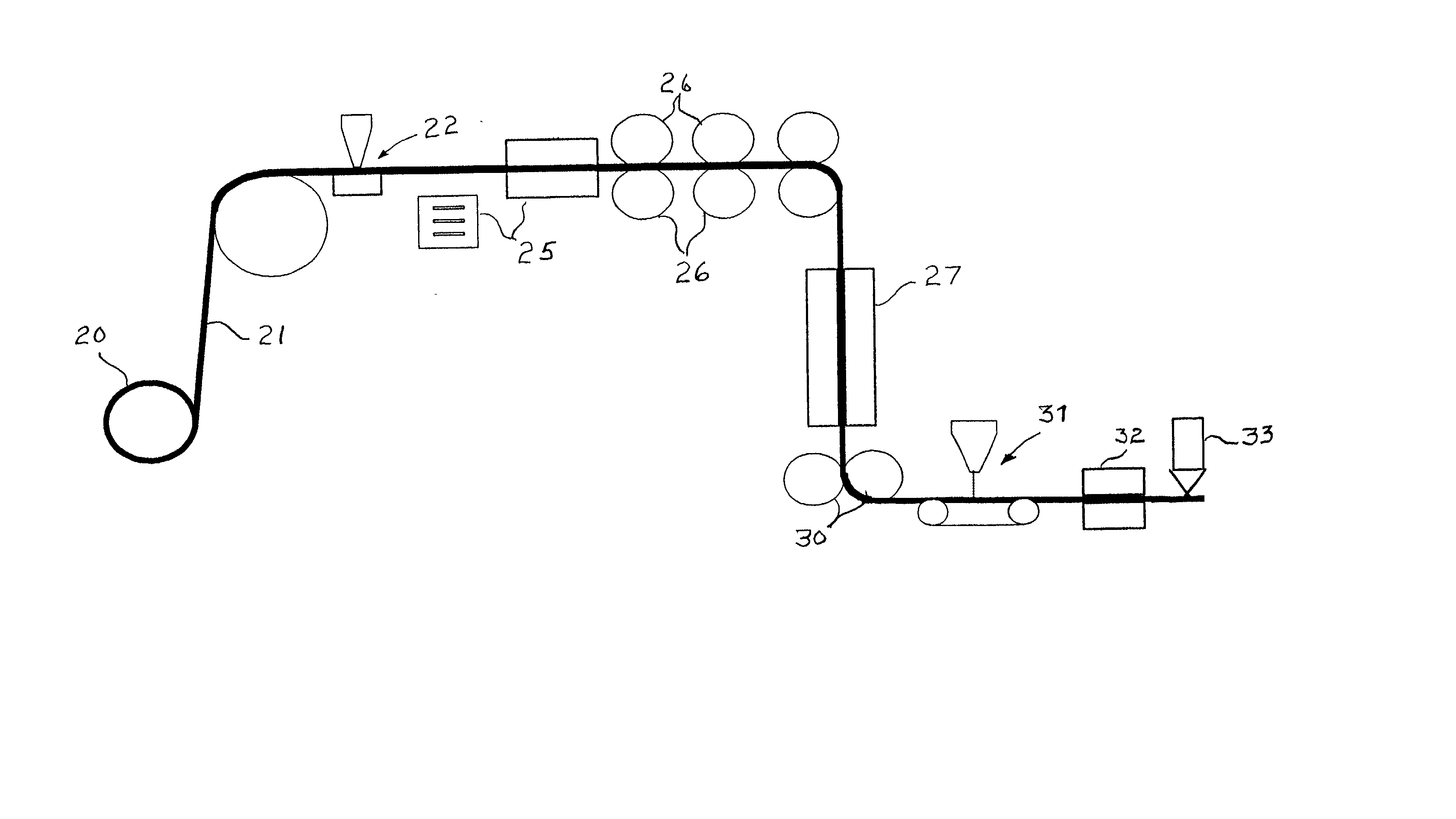

Gas Diffusion Electrodes (GDEs) play a pivotal role in clean energy production as well as in electrochemical processes and sensors. These gas-consuming electrodes are typically designed for liquid electrolyte systems, and are commercially manufactured by hand or in a batch process. However, CDEs using the new electrolytes demand improved electrode structures. This invention pertains to GDEs and gas diffusion media with new structures for systems using membrane electrode assemblies (MEAs), and automated methods of manufacture that lend themselves to continuous mass production. Unexpected improvements in gas and vapor transport through the electrode are realized by incorporating a new dispersion process in the construction, reformulating the applied mix with solution additives, and creating a novel coating structure on a conductive web. Furthermore, combining these changes with a judicious choice in coating methodology allows one to produce these materials in a continuous, automated fashion.

Owner:DEMARINIS MICHAEL +3

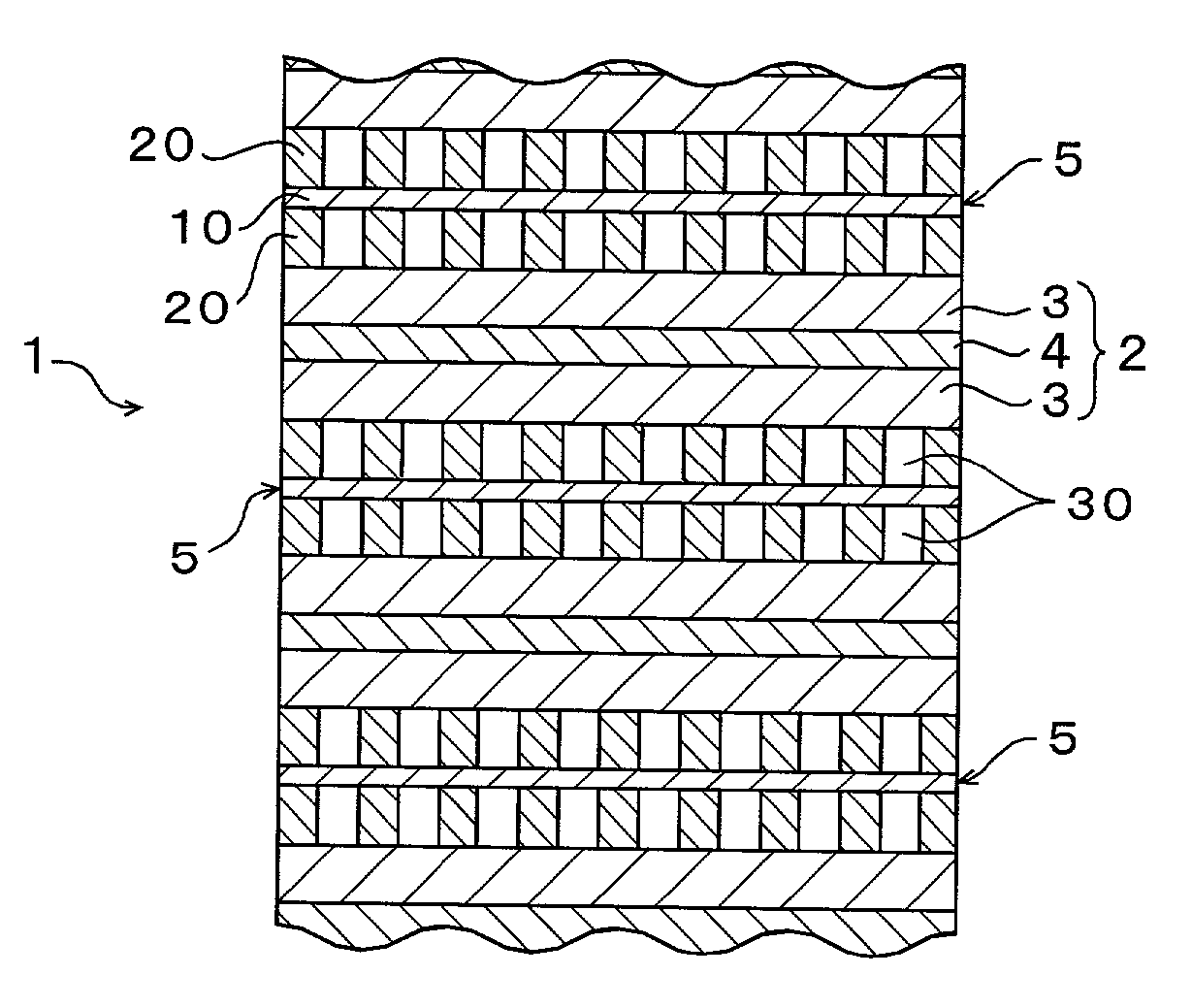

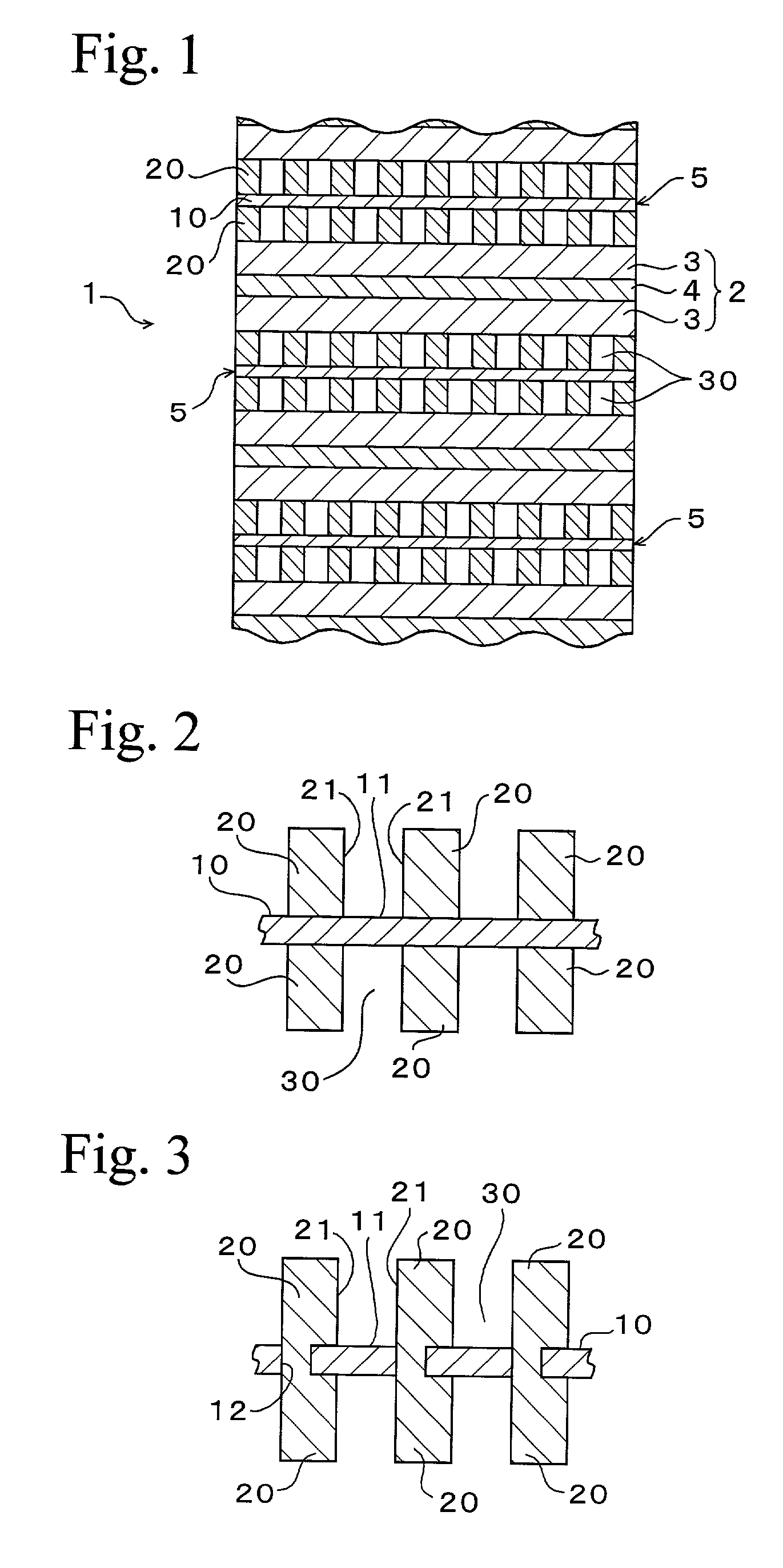

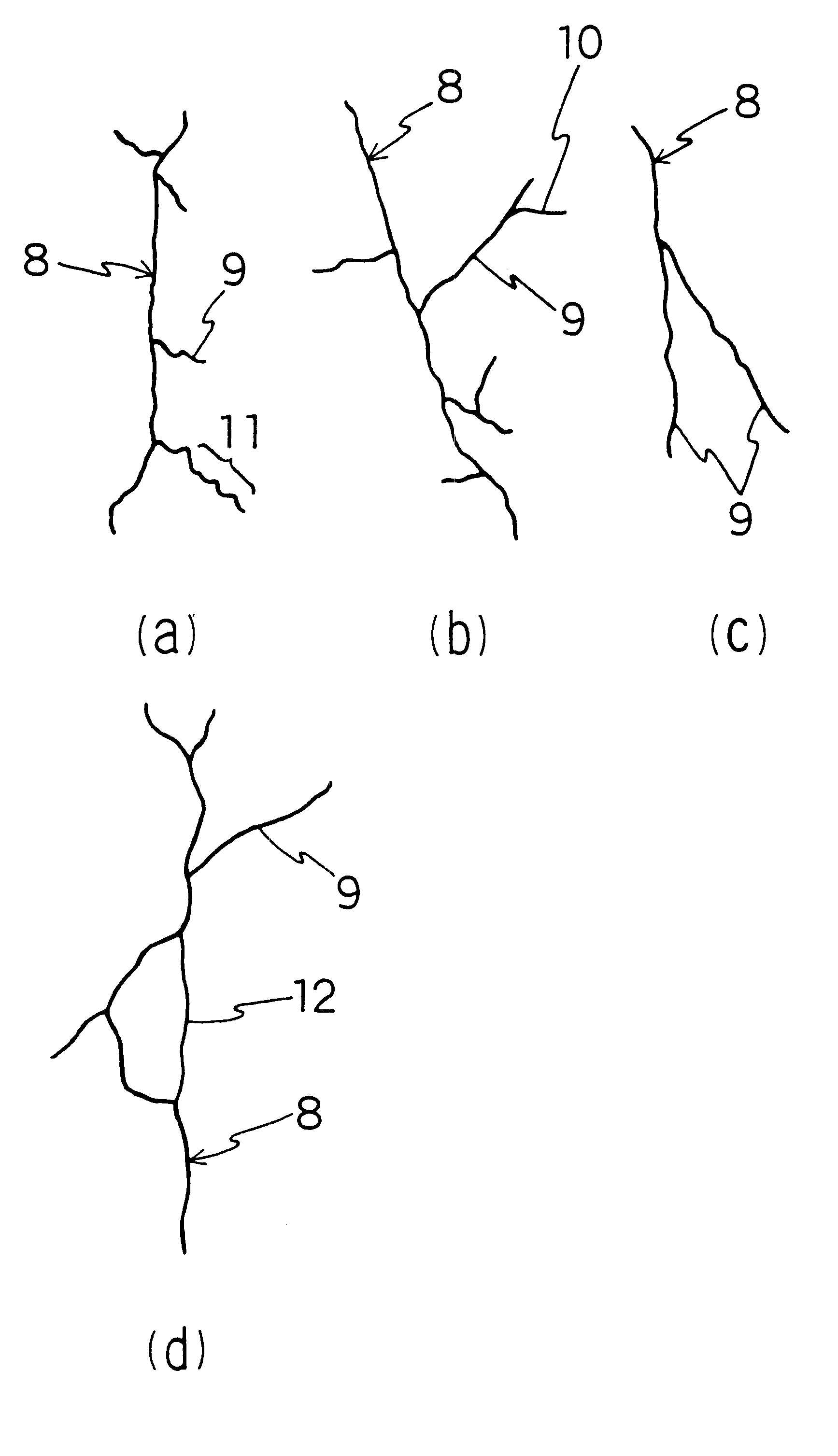

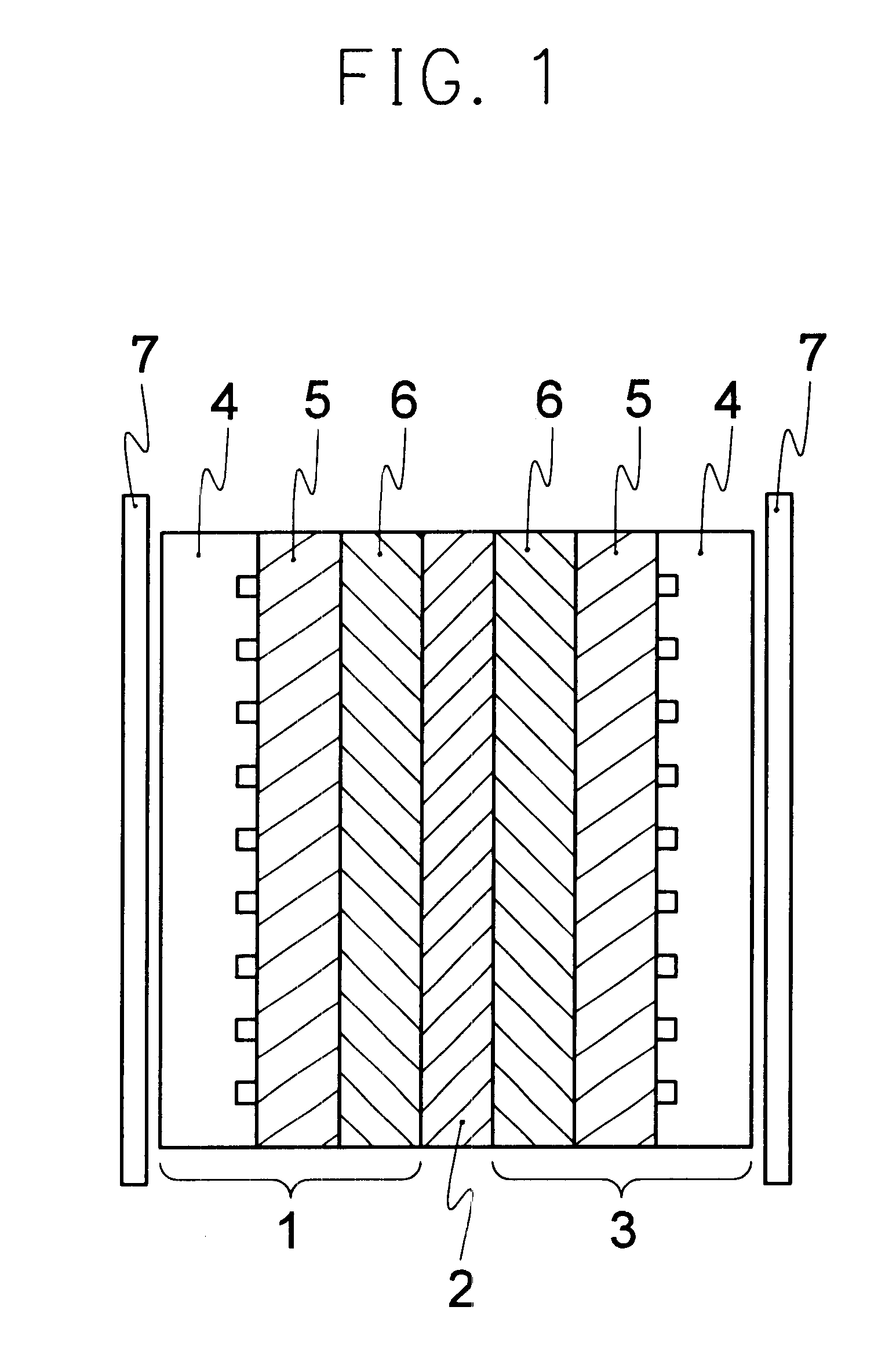

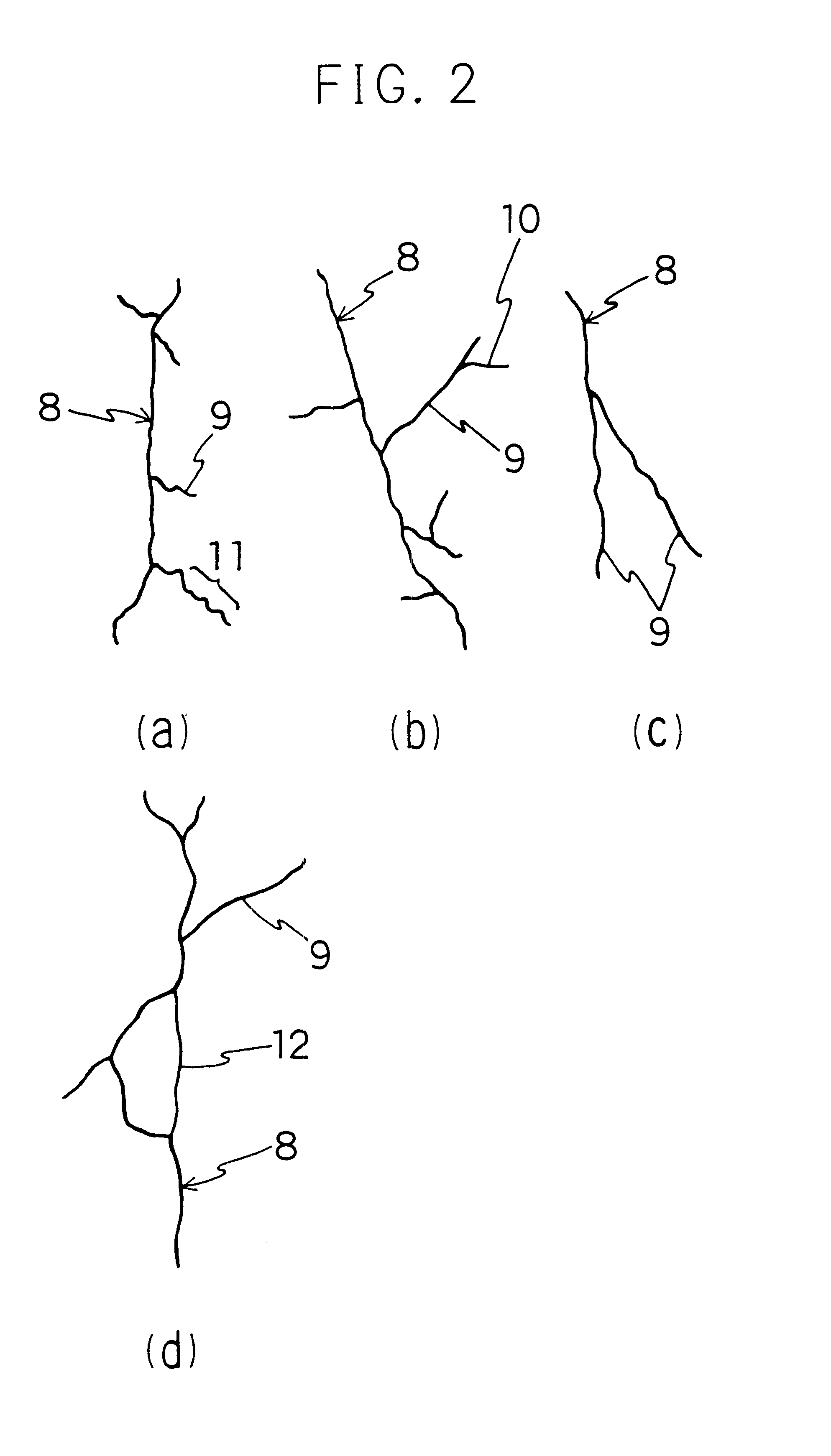

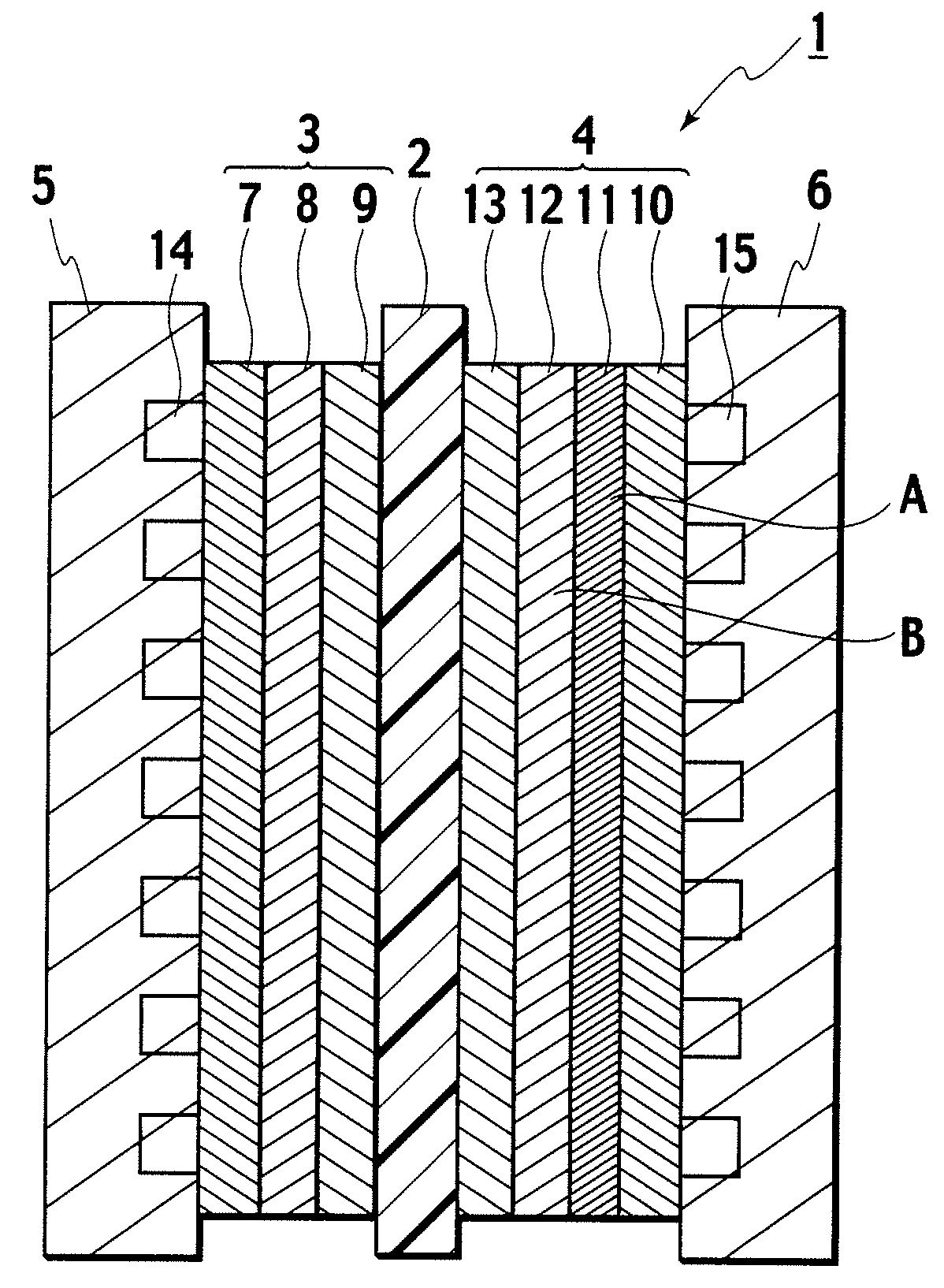

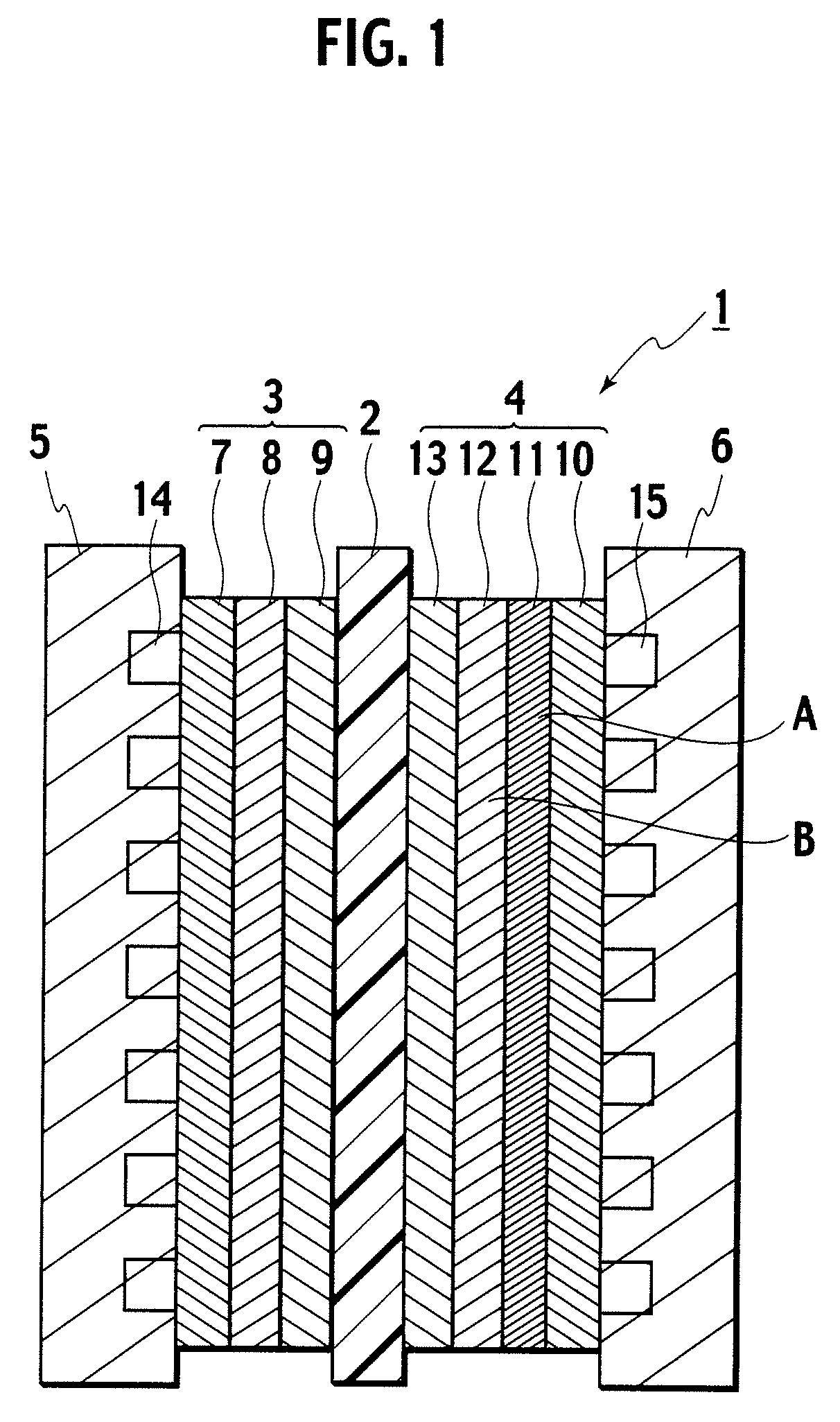

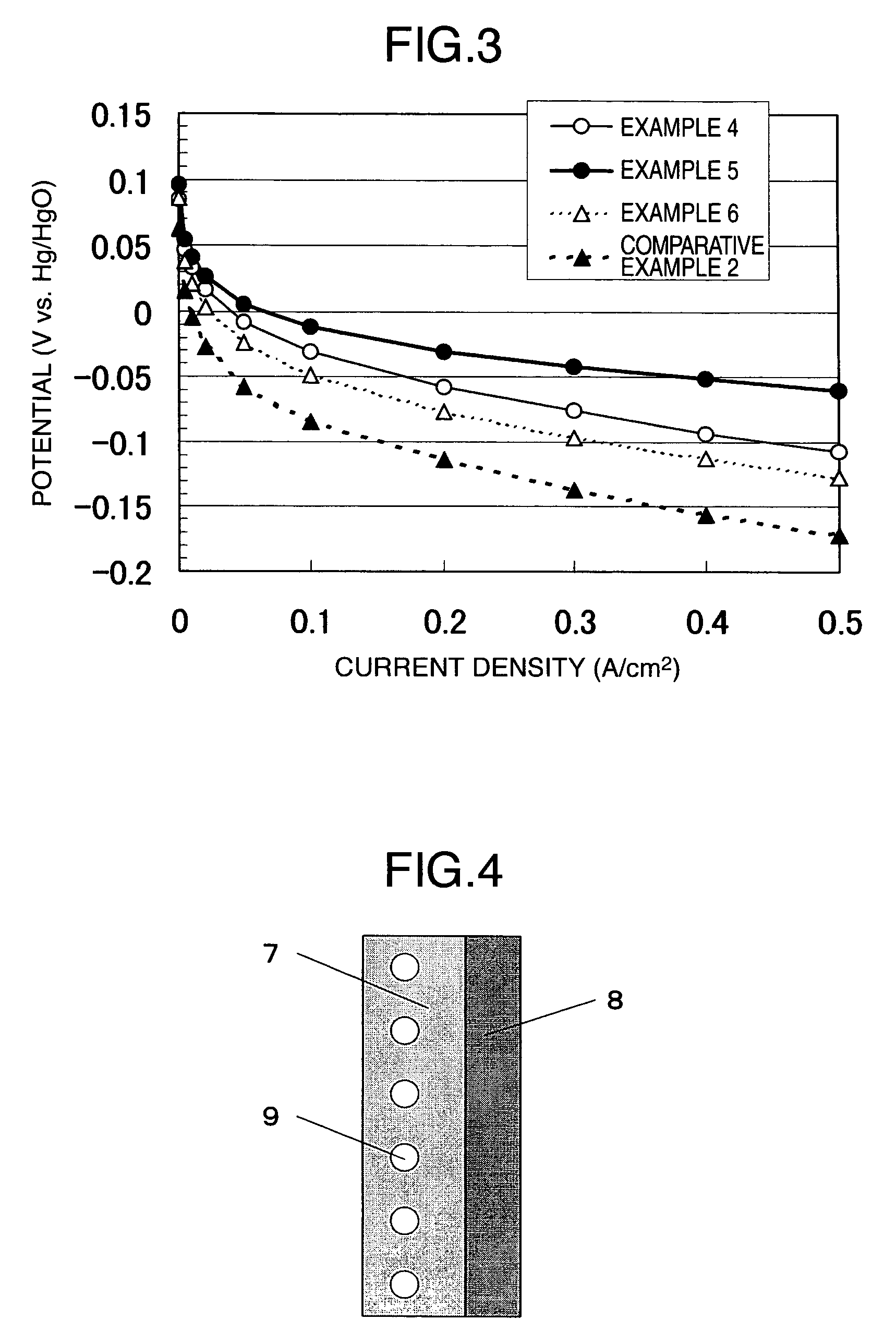

Gas Diffusion Electrode and Solid Polymer Electrolyte Fuel Cell

ActiveUS20080299430A1Suppress power consumptionSave fuel consumptionCell electrodesSolid electrolyte fuel cellsFiberCarbon fibers

A gas diffusion electrode includes: an electrode catalyst layer 13; microporous layers 11 and 12 arranged on the electrode catalyst layer 13 and including at least two layers which are second and first microporous layers 12 and 11 formed of materials having different water repellencies, wherein the second microporous layer 12 disposed on the electrode catalyst layer 13 side is composed to have higher water repellency than the first microporous layer 11; and an oxidant gas diffusion substrate 10 disposed on the microporous layers 11 and 12 and formed of carbon fiber. According to the gas diffusion electrode of the present invention, drainability of generated water from the electrode catalyst layer to the gas diffusion layer and moisture retention and gas diffusibility of the electrode catalyst layer can be enhanced. Moreover, according to a solid polymer electrolyte fuel cell of the present invention, stable power generation characteristics can be obtained even under an operating condition with wide humidity range and current density range.

Owner:NISSAN MOTOR CO LTD

Electrode catalyst for oxygen reduction and gas diffusion electrode

ActiveUS7566388B2Reduced activityMachining electrodesPhotography auxillary processesParticulatesAlkaline earth metal

An electrode catalyst comprising a conductive carrier, and a mixture containing a particulate noble metal and at least one particulate rare-earth oxide, the mixture being supported on the conductive carrier wherein the particulate rare-earth oxide has an alkaline-earth metal as solid solution therein.

Owner:ASAHI KASEI CHEM CORP

Electroreduction carbon dioxide catalytic material, preparation method and applications thereof

ActiveCN109382106ASuitable for industrial applicationsChange the catalytic active siteCell electrodesGrapheneDoped graphenePtru catalyst

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Low platinum fuel cell catalysts and method for preparing the same

InactiveUS20050112450A1Good dispersionEfficient CatalysisMaterial nanotechnologyLayered productsFiberCarbon fibers

This invention provides novel fuel cell catalysts comprising new series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticales into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com