Apparatus and method for processing chlorine-containing organic wastewater by electrochemical reduction and oxidation

An electrochemical, horizontal placement technology, applied in the field of electrochemistry and environment, can solve the problem of not taking too much consideration, and achieve the effect of avoiding incomplete dechlorination and detoxification, reducing secondary pollution and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

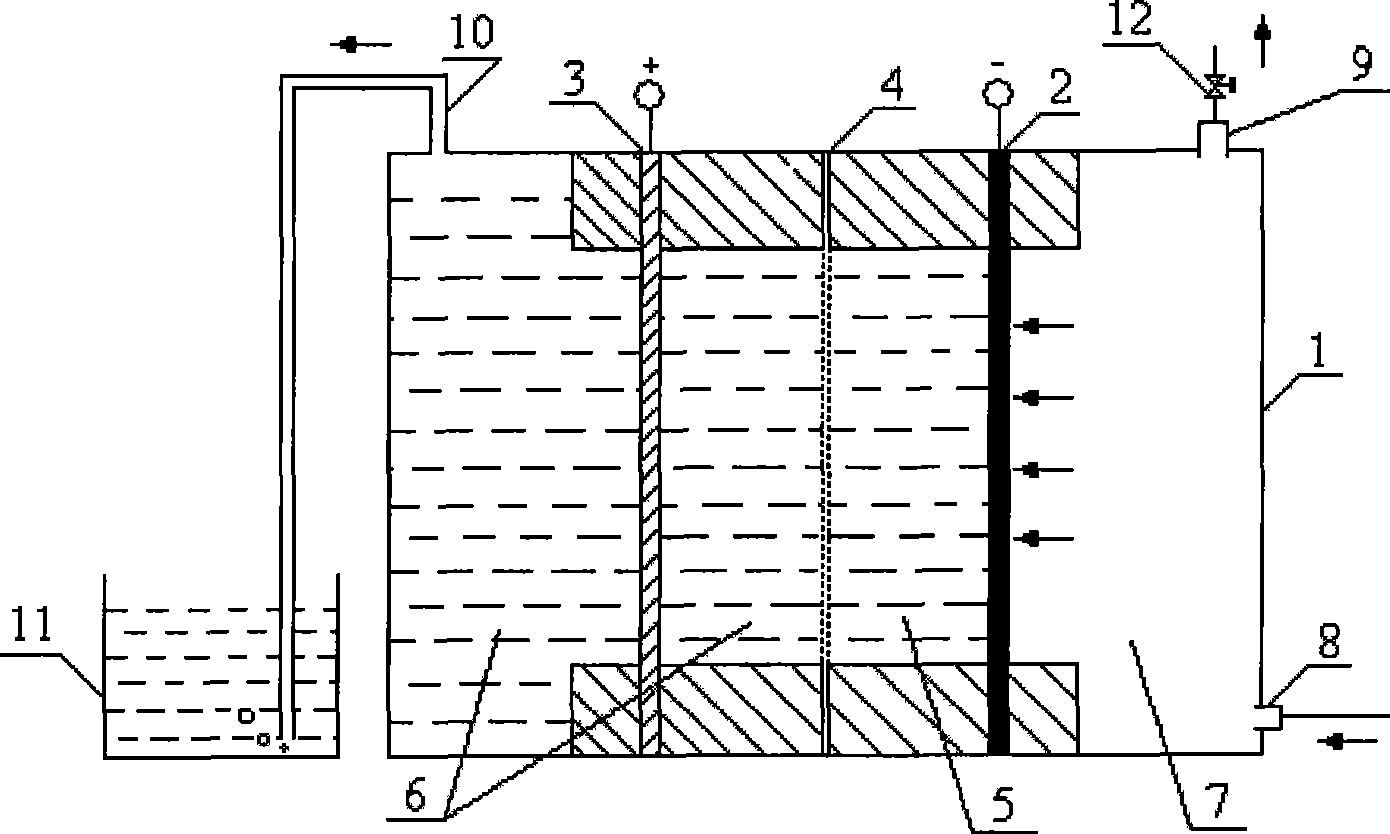

Method used

Image

Examples

Embodiment 1

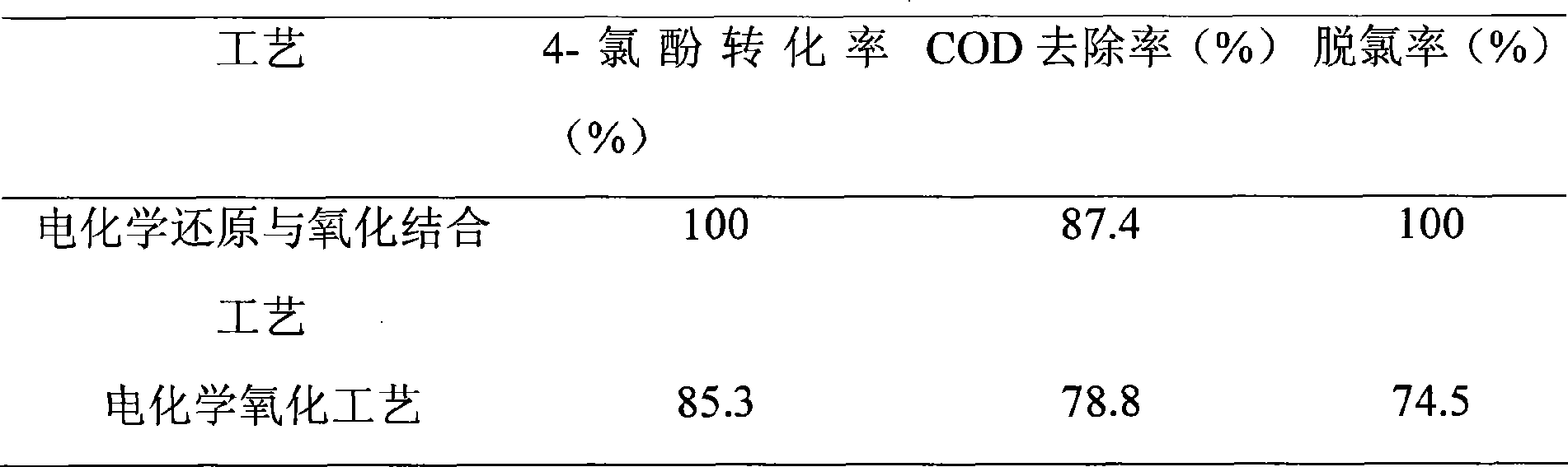

[0043] The experiment compared the difference of 4-chlorophenol conversion rate, COD removal effect and dechlorination rate under the combination of electrochemical reduction and oxidation, and electrochemical oxidation.

[0044] Ti / IrO is used in both processes 2 / RuO 2 For the anode, an organic synthetic filter membrane is placed in the electrolytic cell as a diaphragm, and the waste water degradation effect is sampled and measured in batches in batches. The treatment conditions are that the waste water contains 100 mg / L of 4-chlorophenol concentration, the volume of the waste water is 100 mL, the current is 1.1 A, and the electrolyte ( Na 2 SO 4 ) concentration is 0.1mol / L, and the aeration rate is 25mL / s.

[0045] (1) In the combined process of electrochemical reduction and oxidation, the palladium-loaded gas diffusion electrode is used as the cathode for degradation tests. Hydrogen gas is fed in the early stage of electrolysis, and air is fed in the later stage of elec...

Embodiment 2

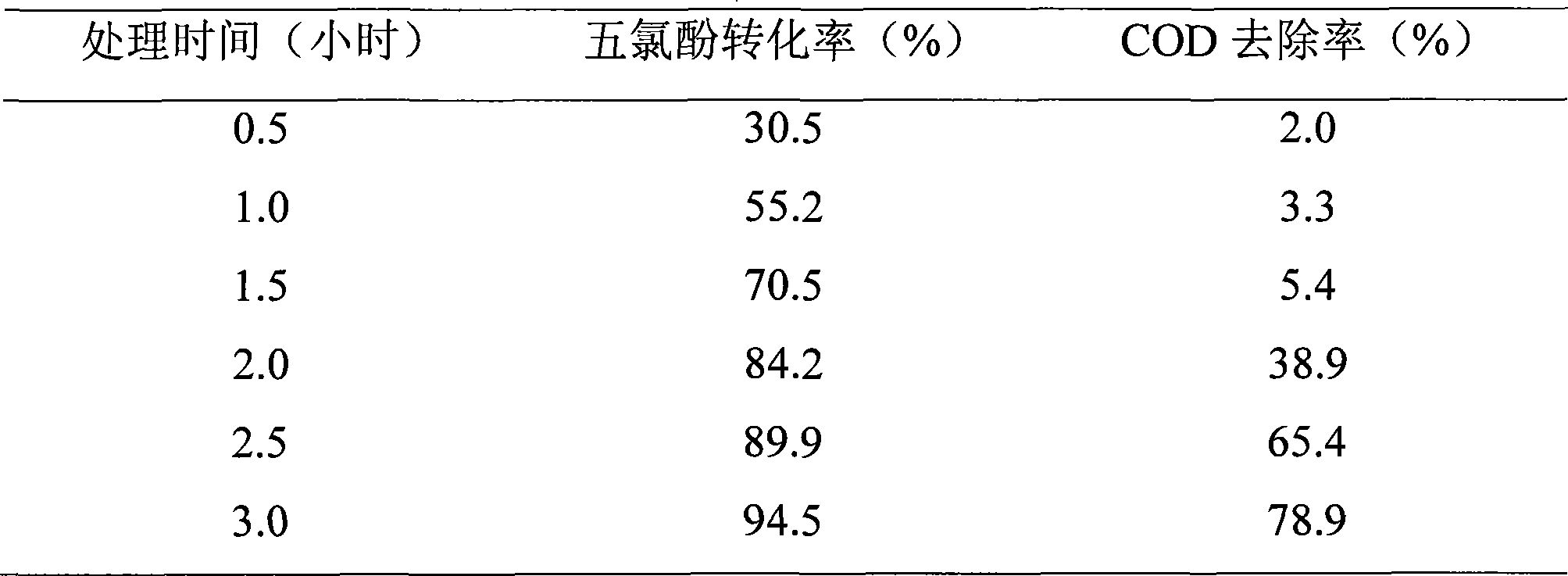

[0052] Press the reactor of example 1, adopt electrochemical reduction and oxidation to combine treatment pentachlorophenol waste water, adopt Ti / IrO 2 / RuO 2 The anode and the palladium-loaded gas diffusion electrode are used as the cathode, and an organic synthetic filter membrane is placed in the electrolytic cell as a diaphragm for degradation tests. The degradation effect of wastewater is sampled and measured in batches. Wastewater volume 100mL, current 1.1A, electrolyte (Na 2 SO 4 ) concentration of 0.1mol / L, hydrogen was introduced in the early stage of electrolysis, air was introduced in the later stage of electrolysis, and the aeration rate was 25mL / s. The results are shown in Table 2.

[0053] Table 2 Combined electrochemical reduction and oxidation treatment of pentachlorophenol wastewater

[0054]

[0055] It can be seen that the combined process of electrochemical reduction and oxidation has a better effect on treating pentachlorophenol wastewater. After 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com