Patents

Literature

2283 results about "Palladium catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

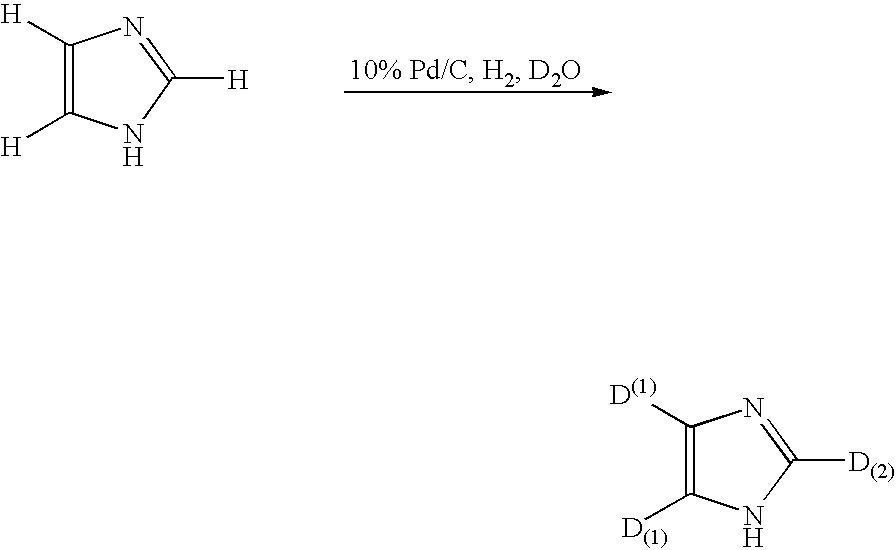

Method for deuteration of a heterocyclic ring

ActiveUS7517990B2Isotope introduction to heterocyclic compoundsSugar derivativesNickel catalystHydrogen atom

The present invention relates to a method for deuteration of a heterocyclic ring, which comprises subjecting a compound having a heterocyclic ring to sealed refluxing state in a deuterated solvent in the presence of an activated catalyst selected form a palladium catalyst, a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst. In accordance with a method of the present invention, a hydrogen atom belonging to a heterocyclic ring of a compound having a heterocyclic ring can be very efficiently deuterated because temperature of deuteration reaction can be maintained at higher than boiling point of the solvent.Further, a method for deuteration of the present invention can be applied widely to deuteration of various compounds having a heterocyclic ring which are liable to decomposition under supercritical conditions or acidic conditions, leading to industrial and efficient deuteration of a compound having a heterocyclic ring.

Owner:FUJIFILM WAKO PURE CHEM CORP

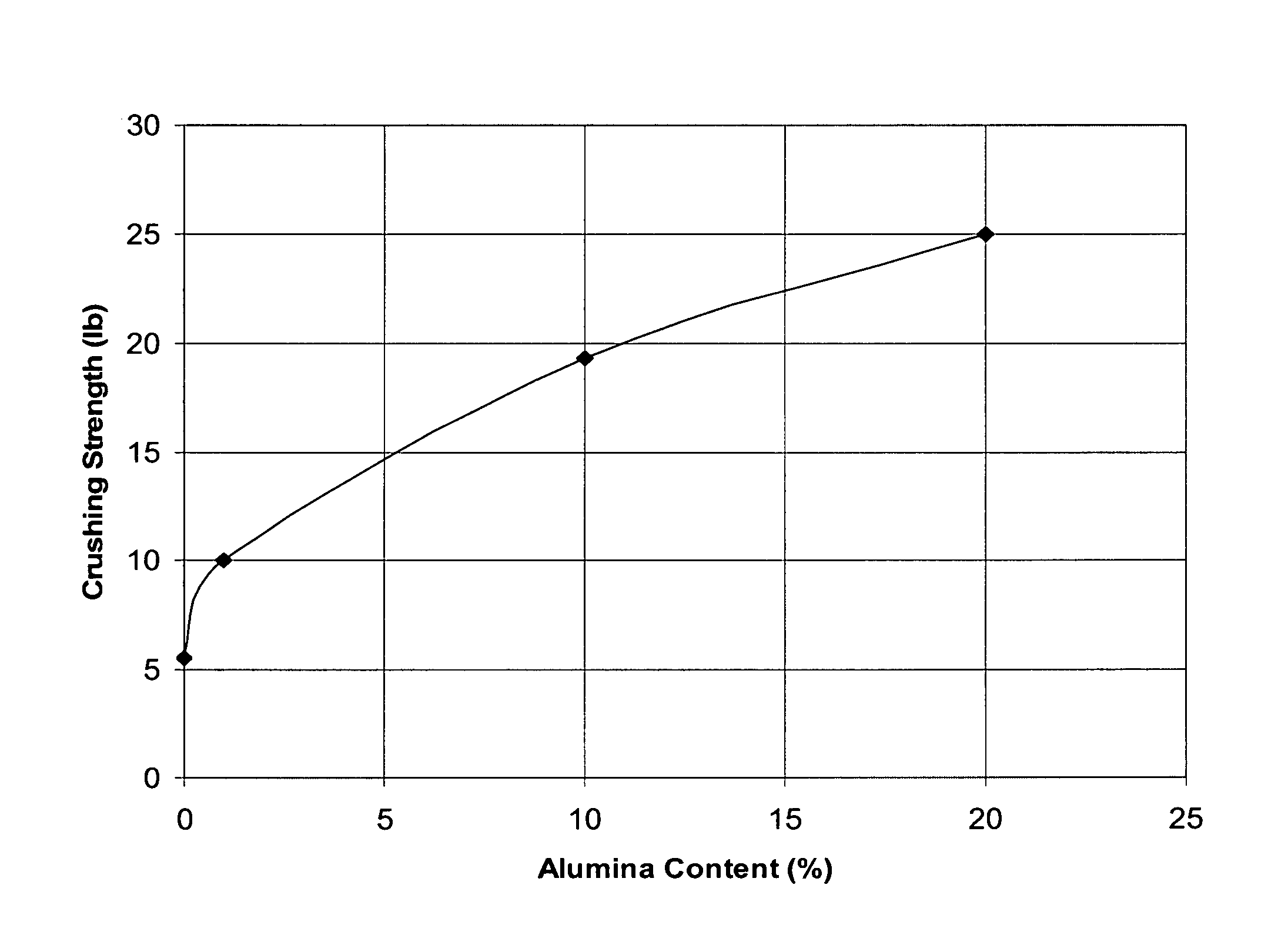

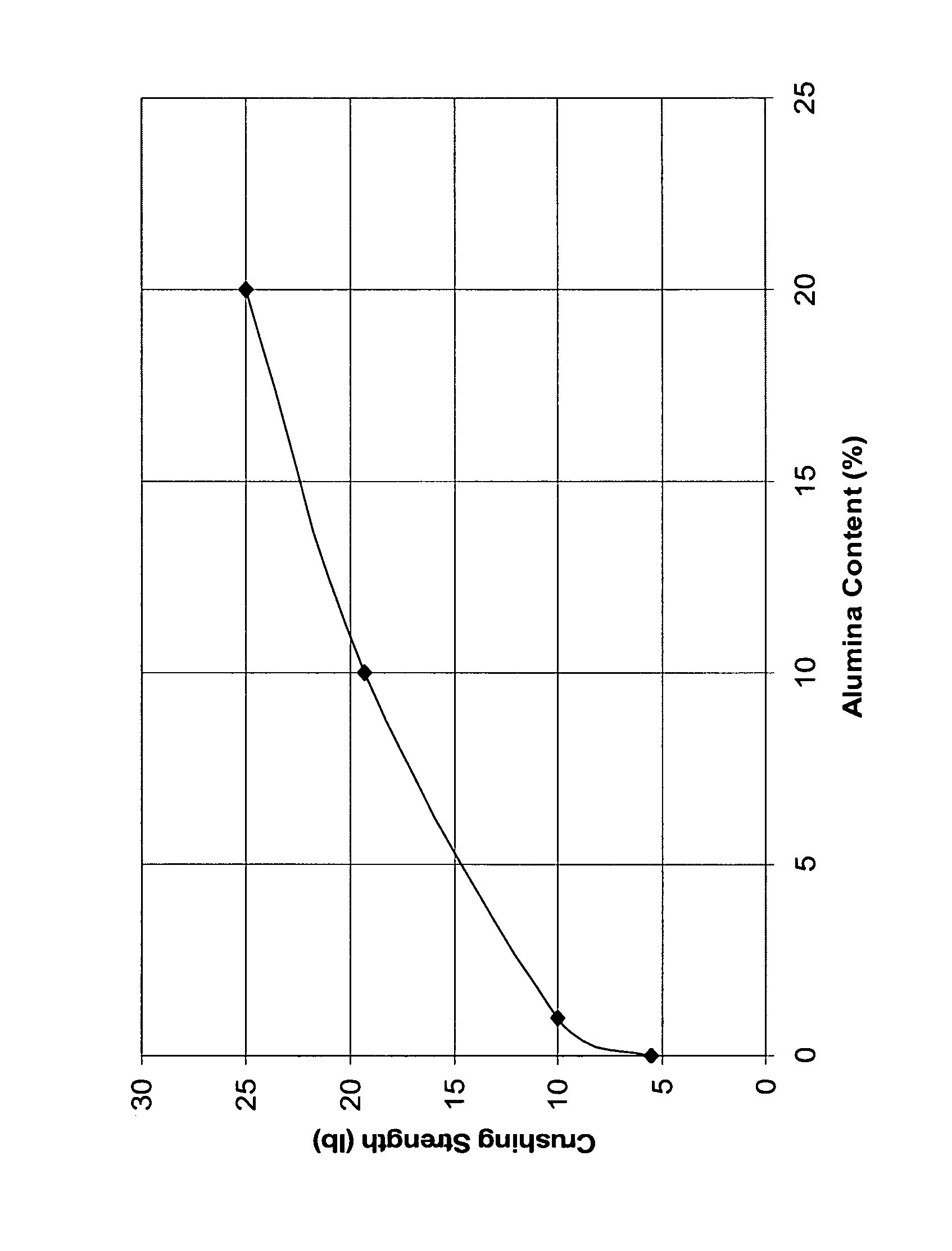

Titania-alumina supported palladium catalyst

InactiveUS8507720B2High activityHigh compressive strengthOther chemical processesOrganic compound preparationPalladium catalystOrganic chemistry

A catalyst comprising palladium supported on a titania-alumina extrudate is disclosed. The extrudate comprises at least 80 wt % titania and 0.1 to 15 wt % alumina. A palladium catalyst prepared from the titania-alumina extrudate has significantly higher crush strength. Its catalytic performance in vinyl acetate production is improved.

Owner:LYONDELLBASELL ACETYLS

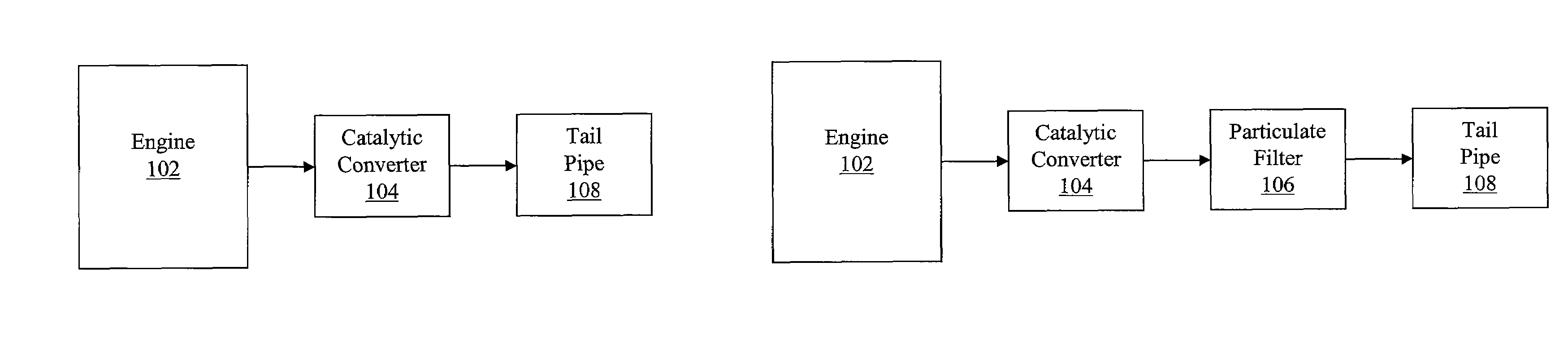

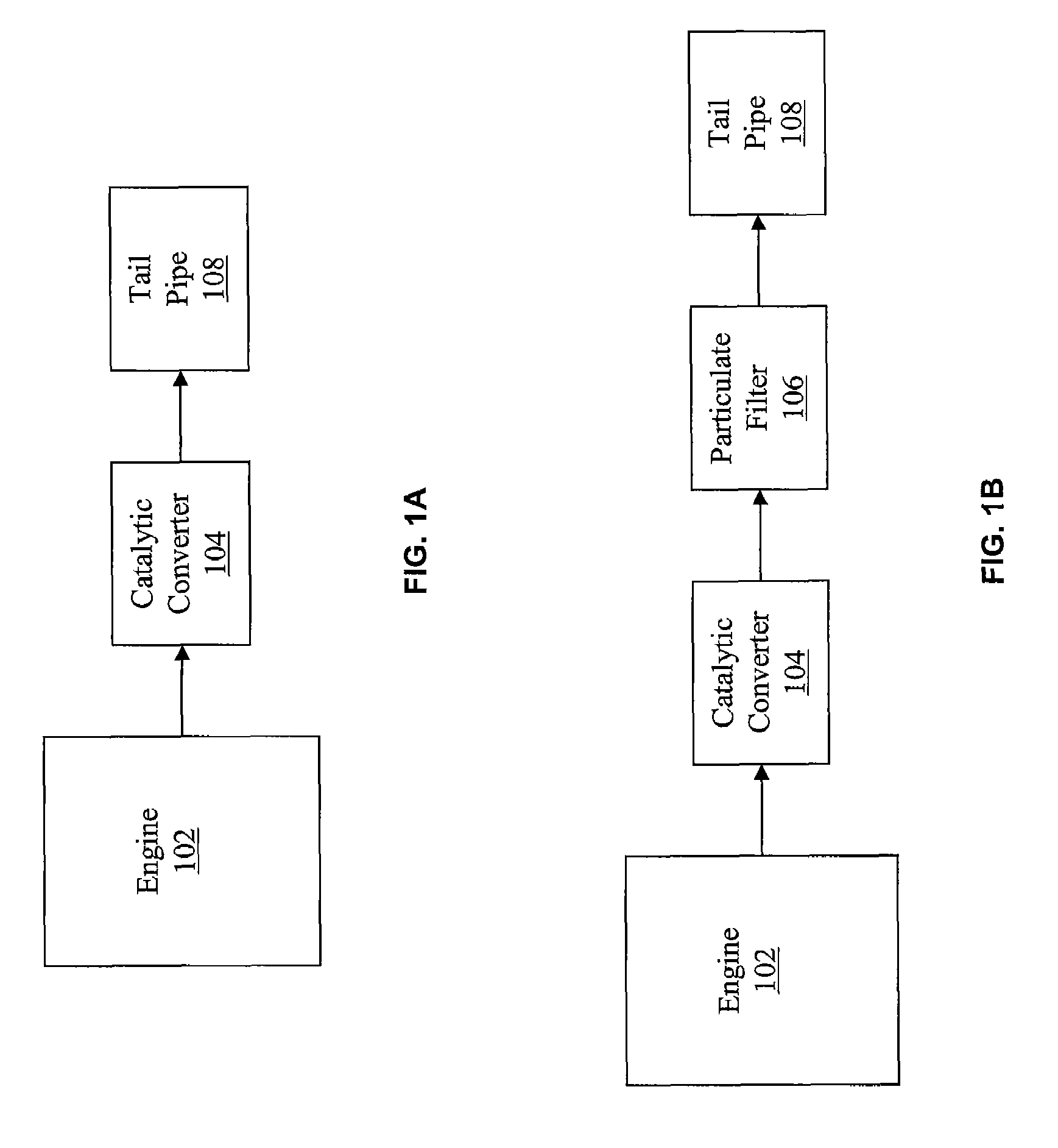

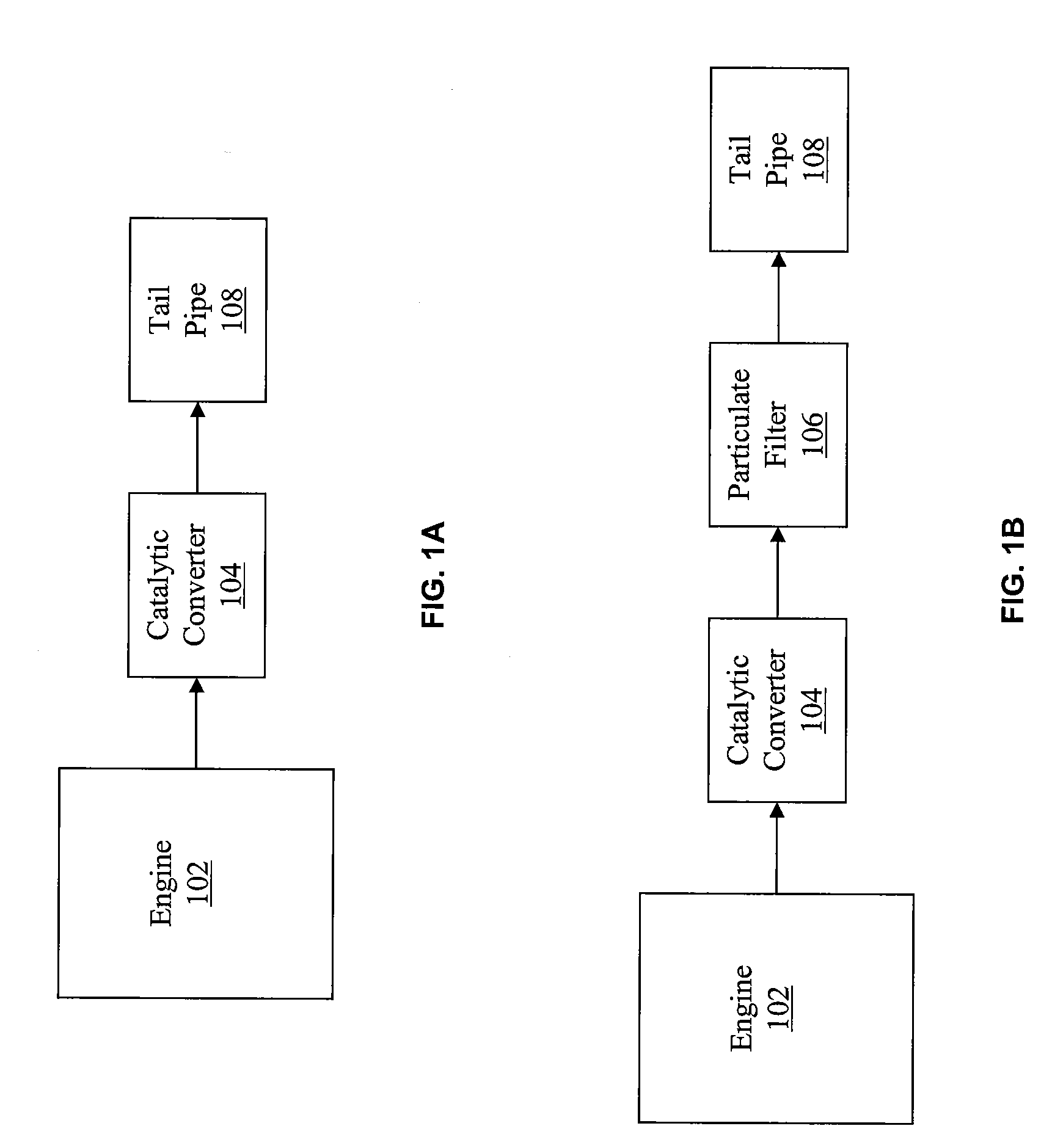

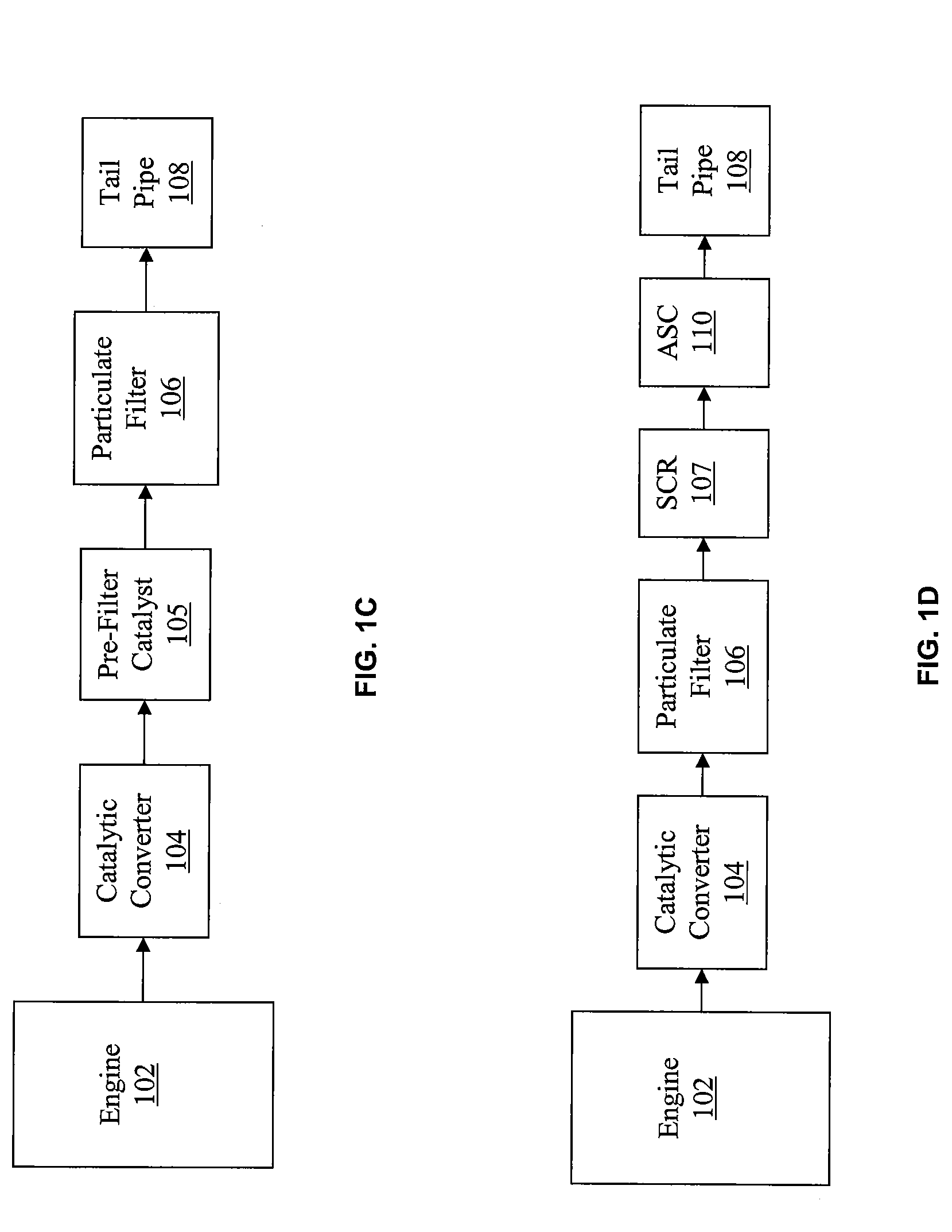

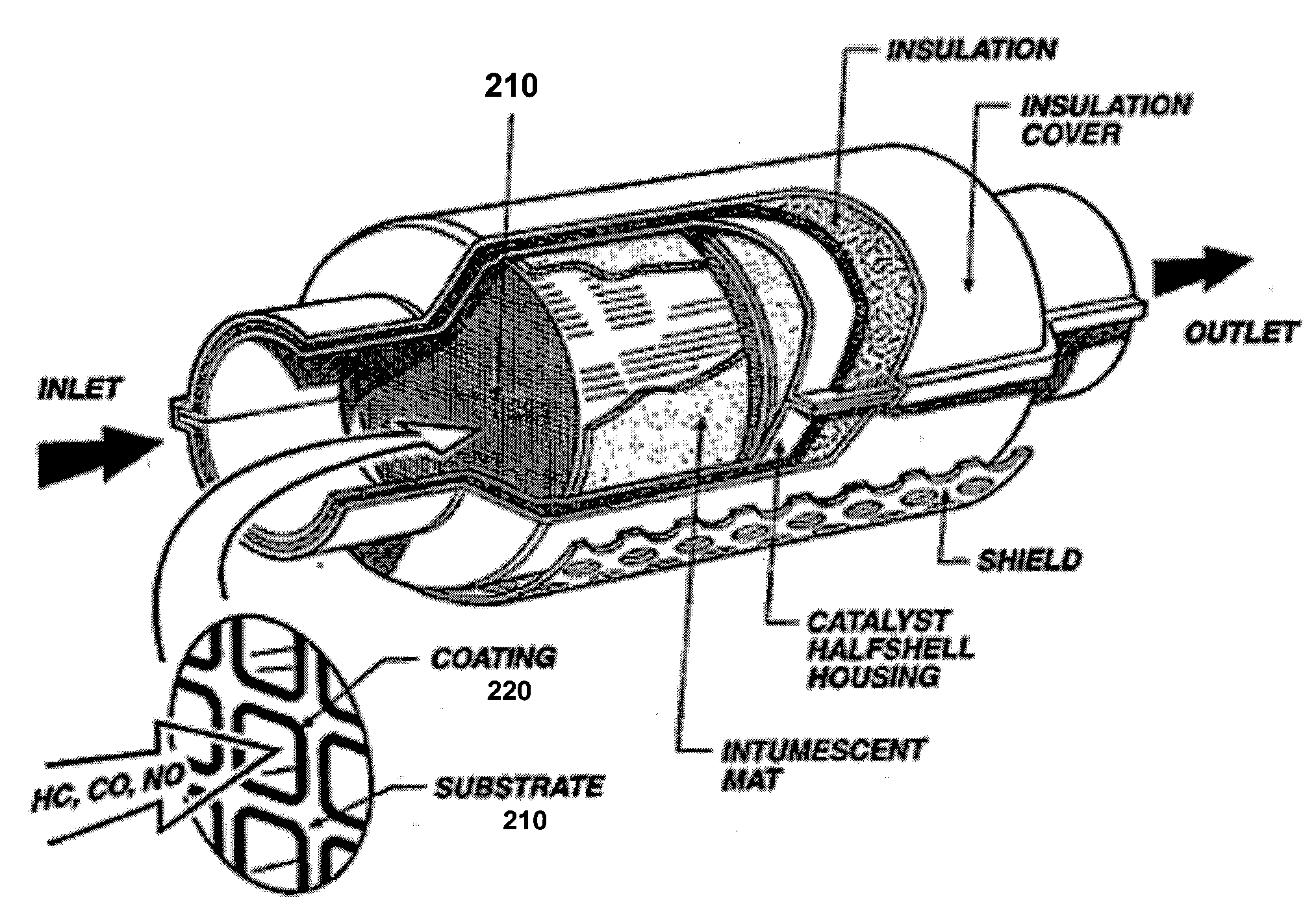

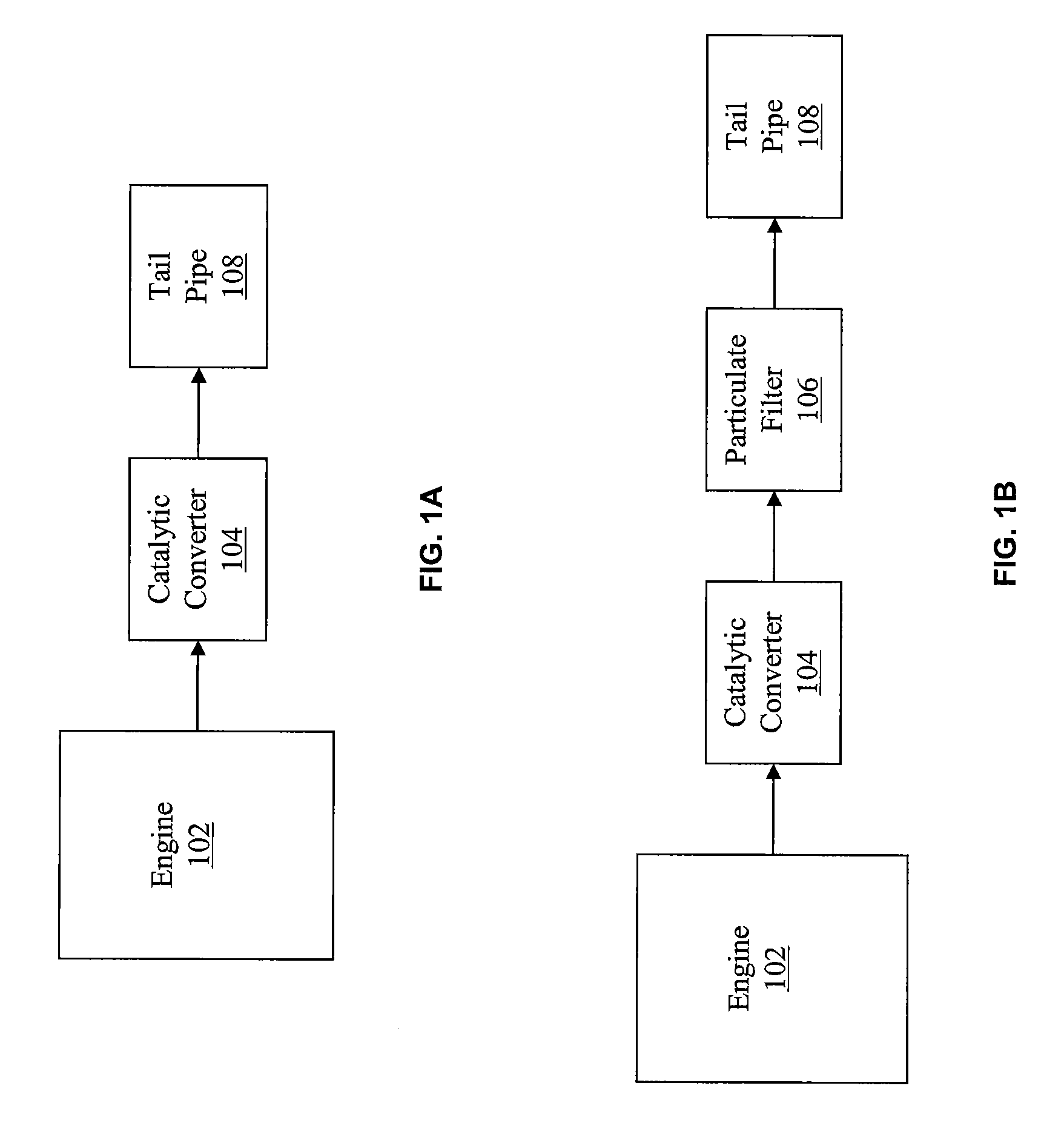

Engine exhaust catalysts containing palladium-gold

ActiveUS7709414B2High activityEmission reductionCombination devicesInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum—palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGC HLDG LTD

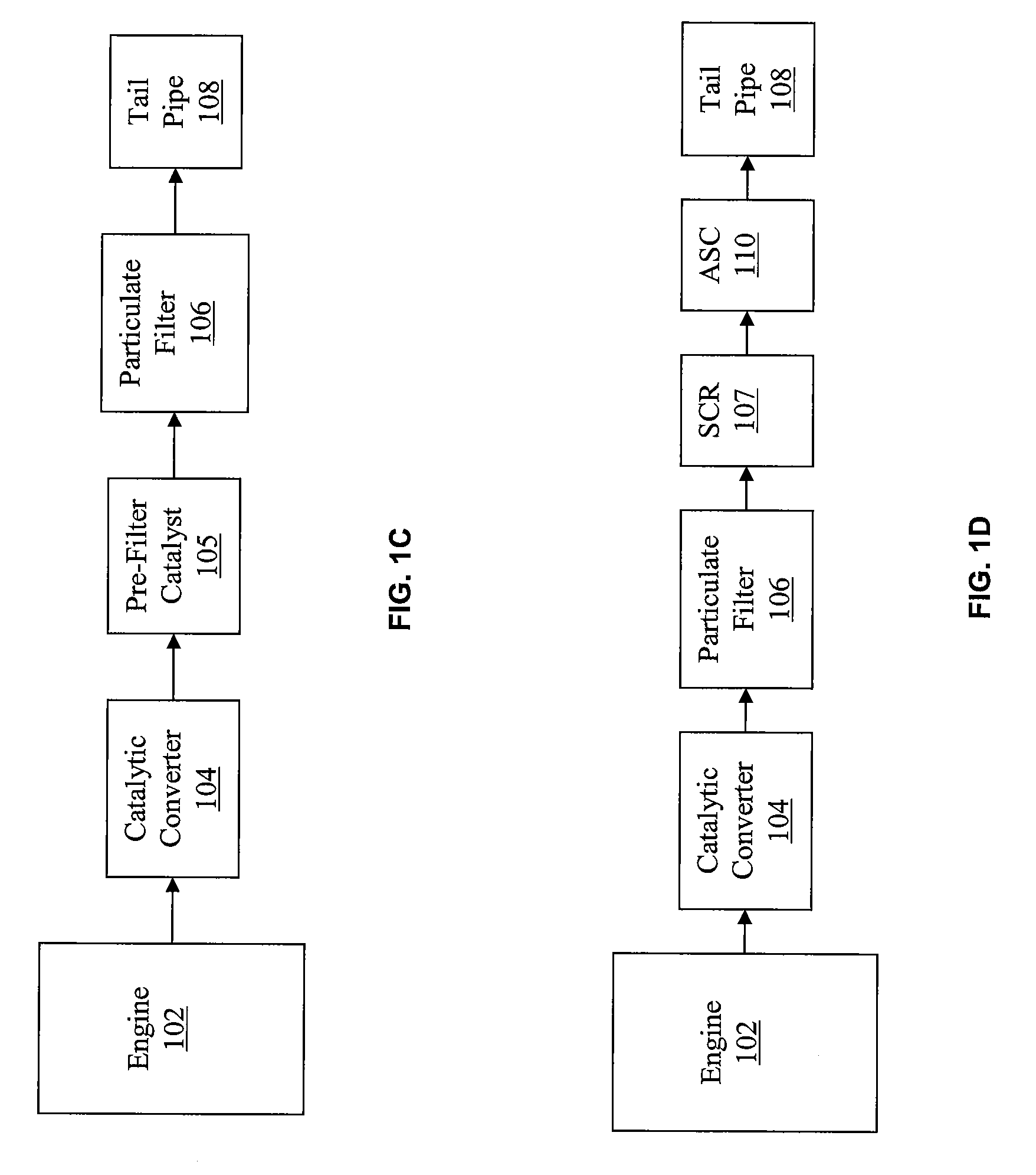

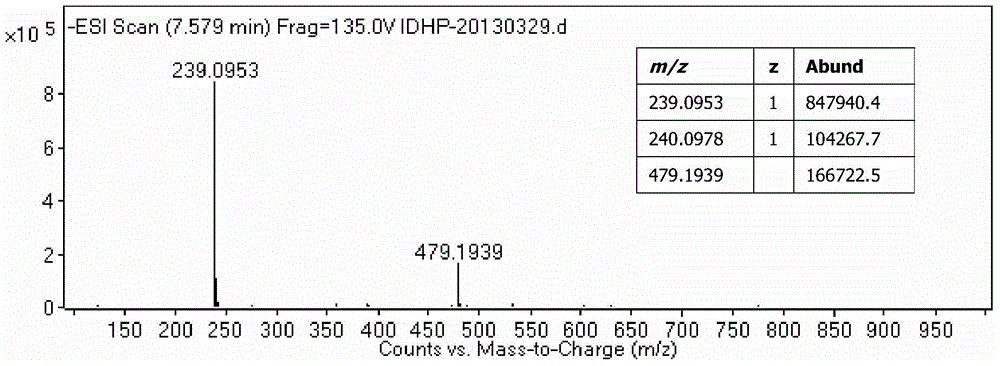

Carbon-intersticed metallic palladium, palladium catalyst and method for preparation thereof, and method for producing alpha,beta-unsaturated carboxylic acid

InactiveUS20060068989A1High yieldOrganic compound preparationCatalyst activation/preparationPalladium catalystMetal

A carbon-insertion-type palladium metal in which an amount of inserted carbon is 0.16 mol or more with respect to 1.0 mol of a palladium metal, and a carbon-insertion-type palladium metal in which a crystal face distance of a (111) face of a palladium metal is 2.270 Å or more are useful as raw materials of a palladium catalyst for use in an α,β-unsaturated carboxylic acid preparation reaction, and the like. The carbon-insertion-type palladium metal can preferably be prepared by reduction of palladium in a palladium compound having a chlorine content of 0 to 300 ppm.

Owner:MITSUBISHI RAYON CO LTD

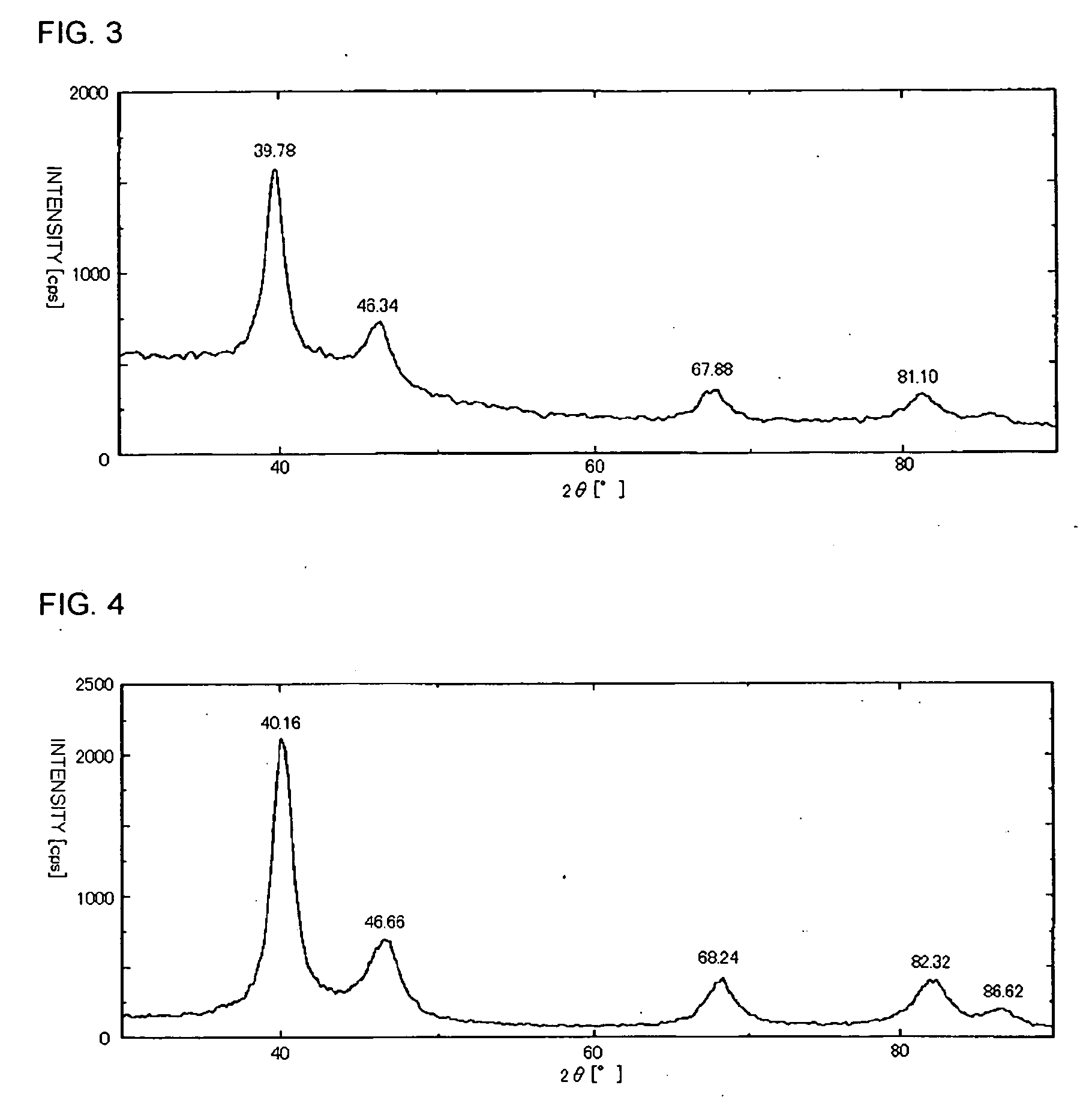

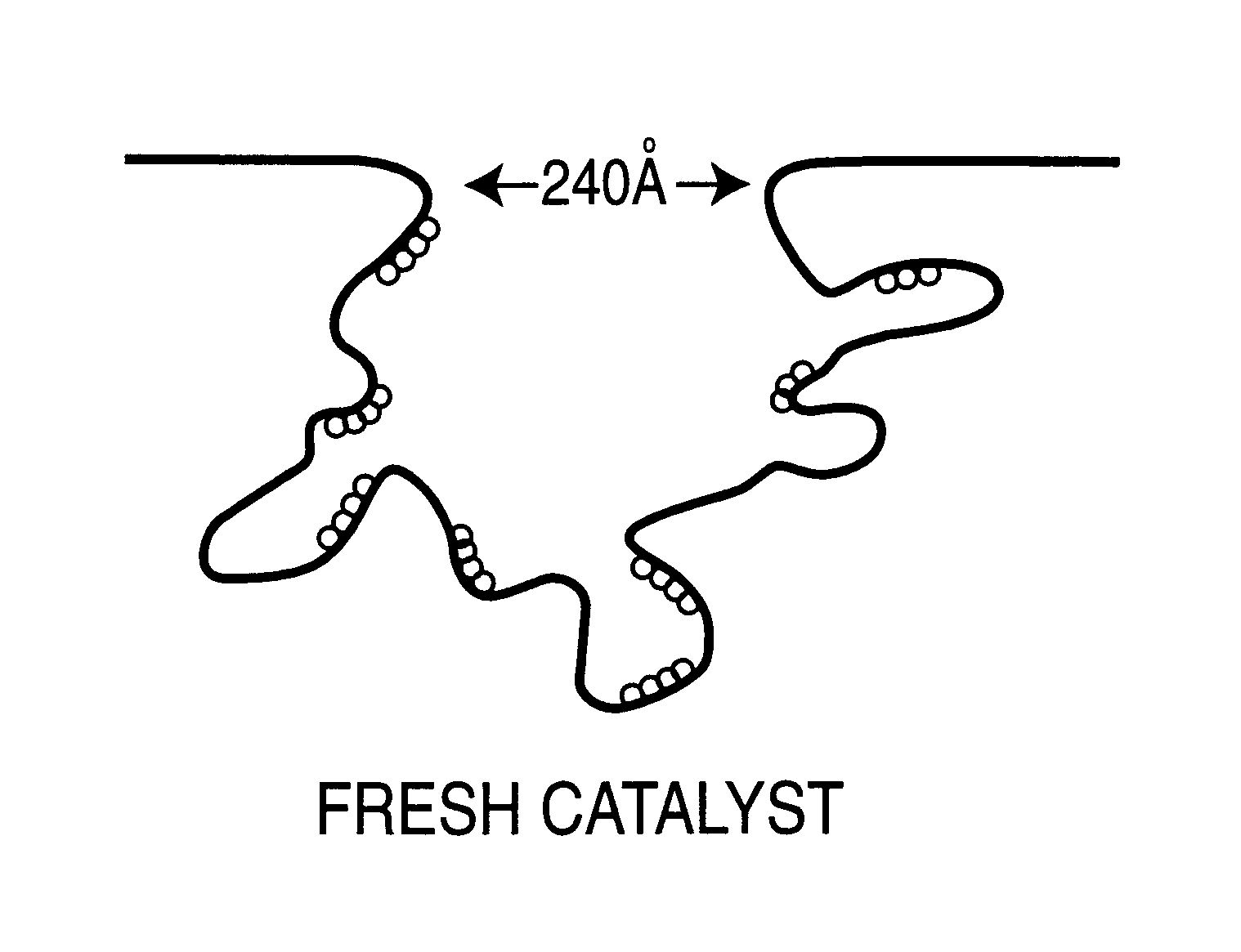

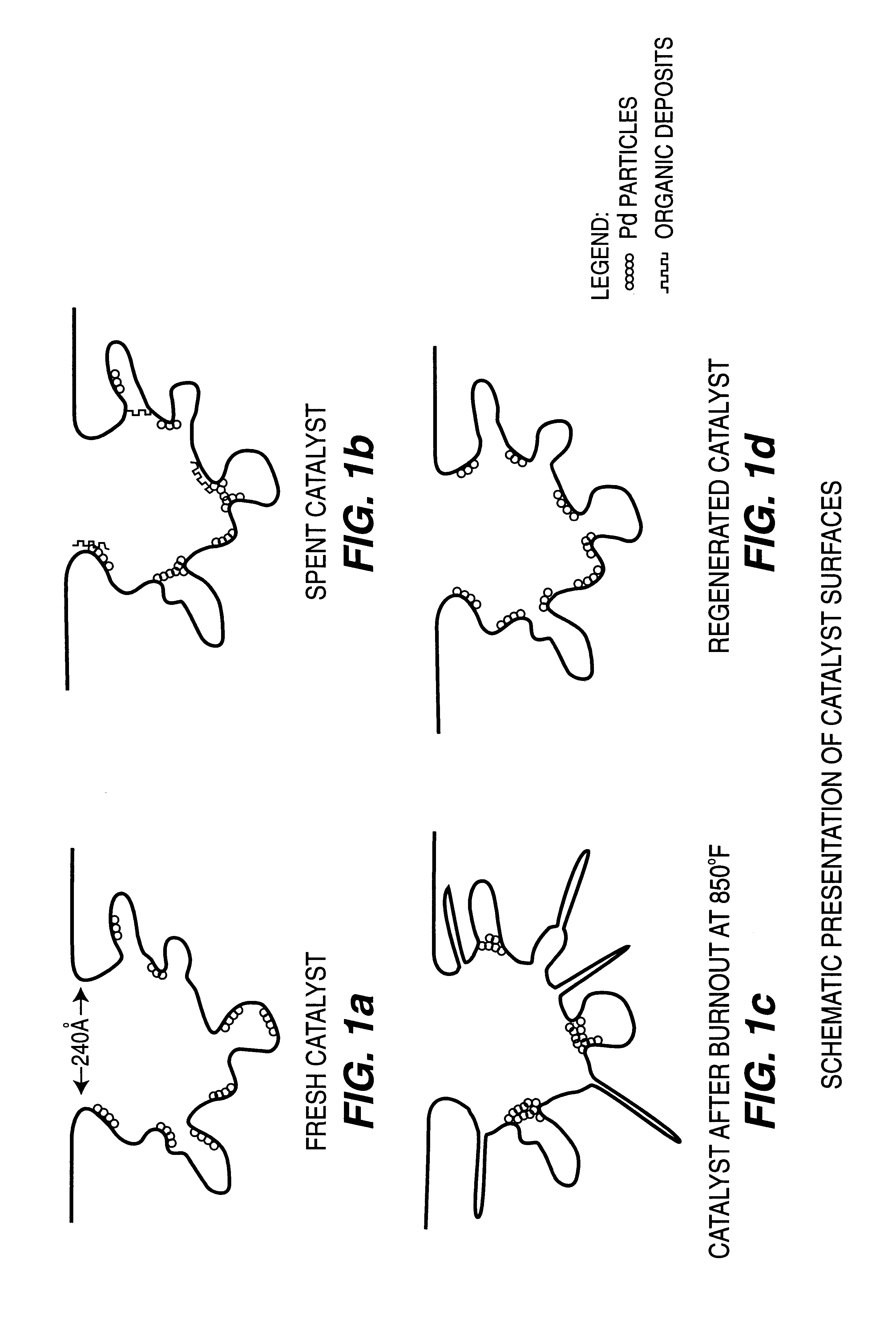

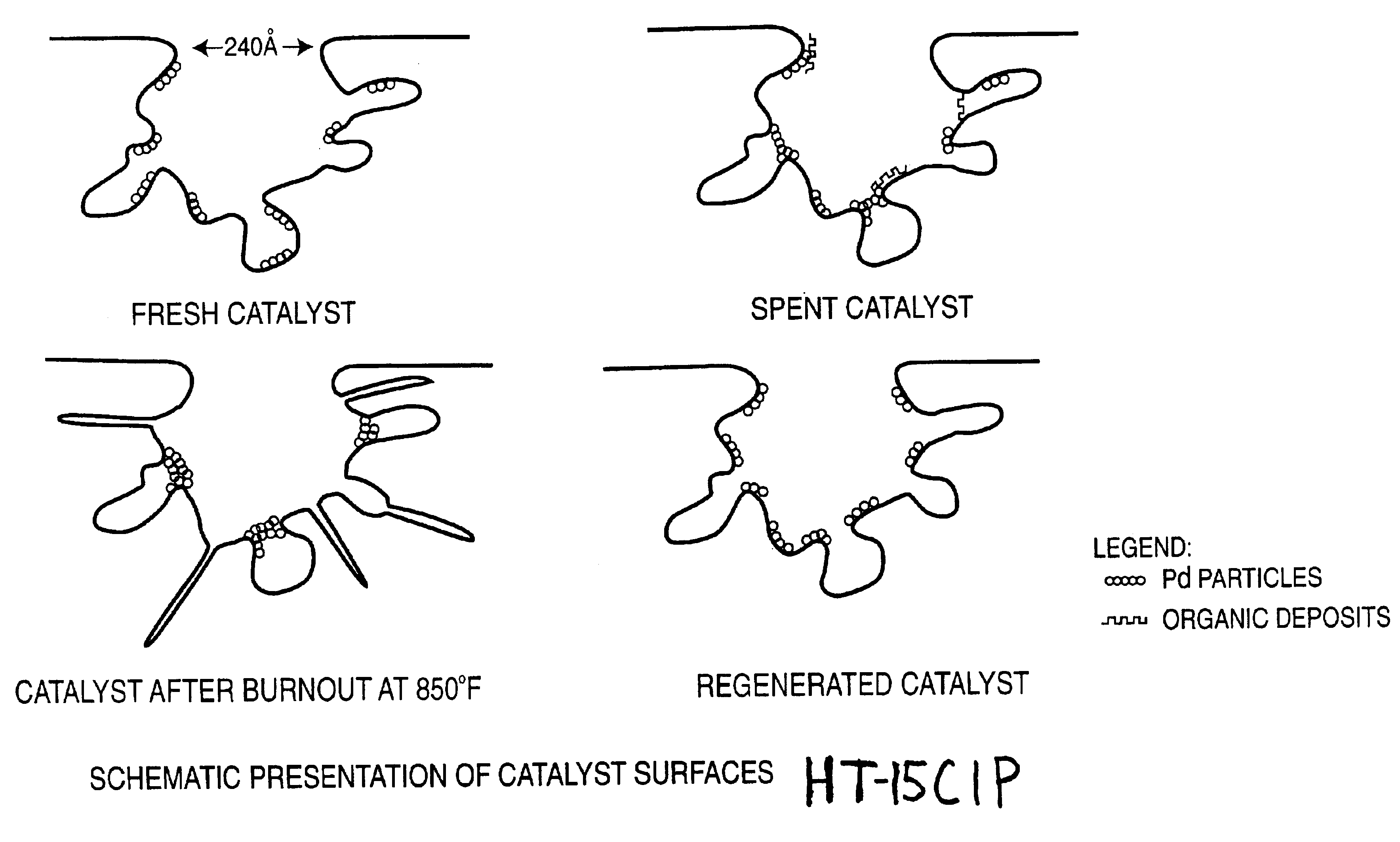

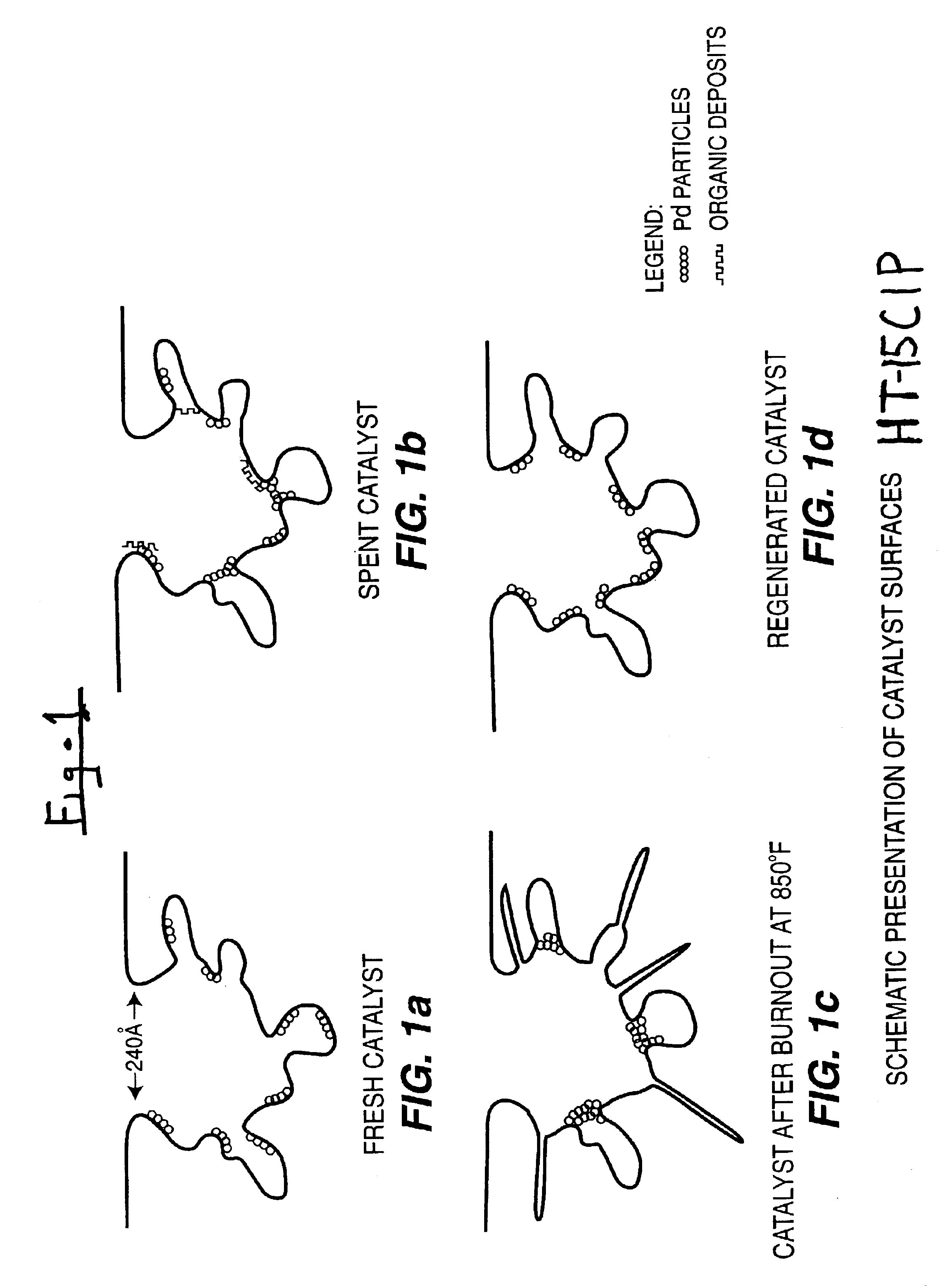

Regeneration of used supported noble metal catalysts

InactiveUS6740615B2Efficient removalImproves expositionHydrogen peroxideOther chemical processesPalladium catalystMetal particle

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

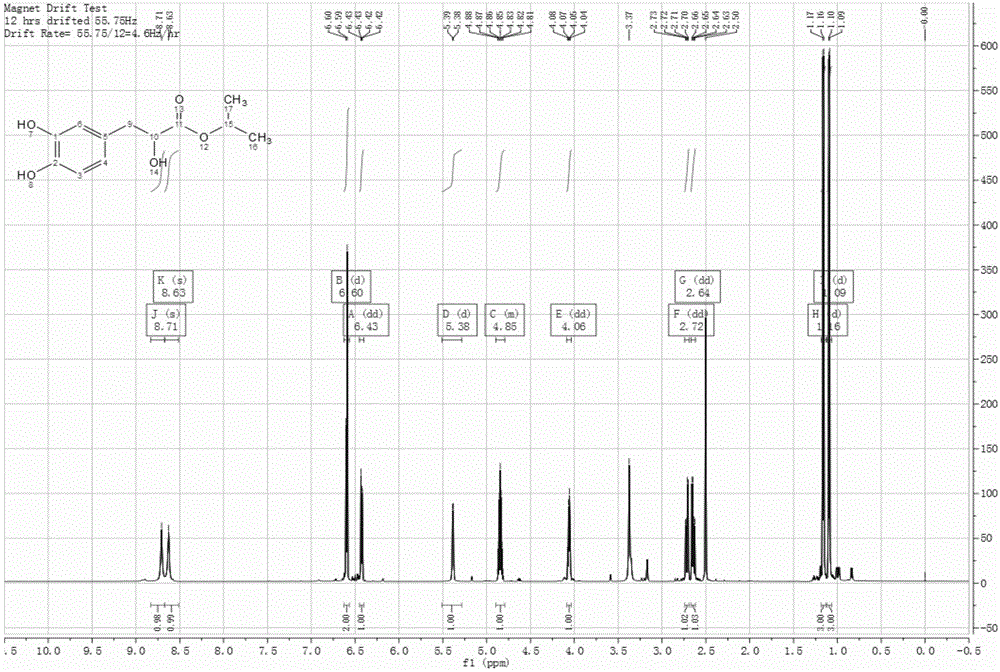

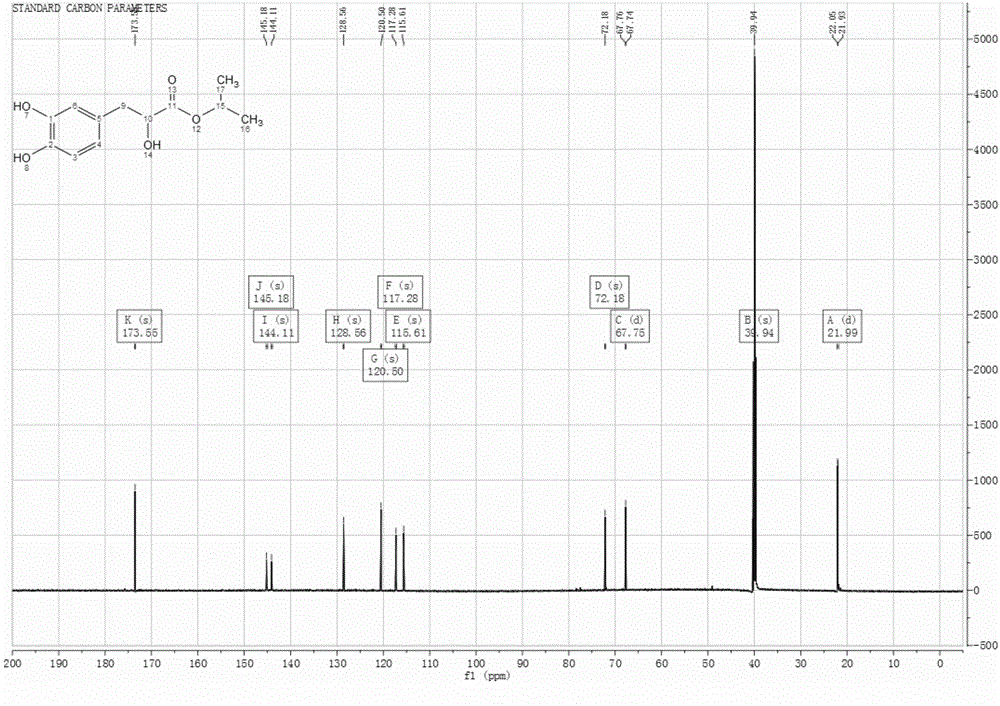

Synthesis method of D,L-danshensu isopropyl ester

ActiveCN103980120ARaw materials are cheap and easy to getShort reaction stepsPreparation from carboxylic acid halidesOrganic compound preparationHydrogenSynthesis methods

The invention relates to a synthesis method of D,L-danshensu isopropyl ester. The method comprises taking protocatechuic aldehyde as an initial raw material, protecting phenolic hydroxyl by benzyl, carrying out Darzens epoxidation, followed by carrying out catalytic reduction with palladium catalyst / hydrogen or Raney nickel / hydrogen, and thus obtaining the D,L-danshensu isopropyl ester. The purity of the product synthesized by the method can reach 98%, and the yield can reach 55%. Moreover, the synthesis method has the advantages of simple and easily obtained raw materials, short routes and high yield, and is suitable for large-scale industrialized production.

Owner:NORTHWEST UNIV

Engine Exhaust Catalysts Containing Palladium-Gold

InactiveUS20080125313A1Reduce inhibitionEmission reductionGas treatmentInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum-palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGCH TECH LIMITED WORLD GOLD COUNCIL

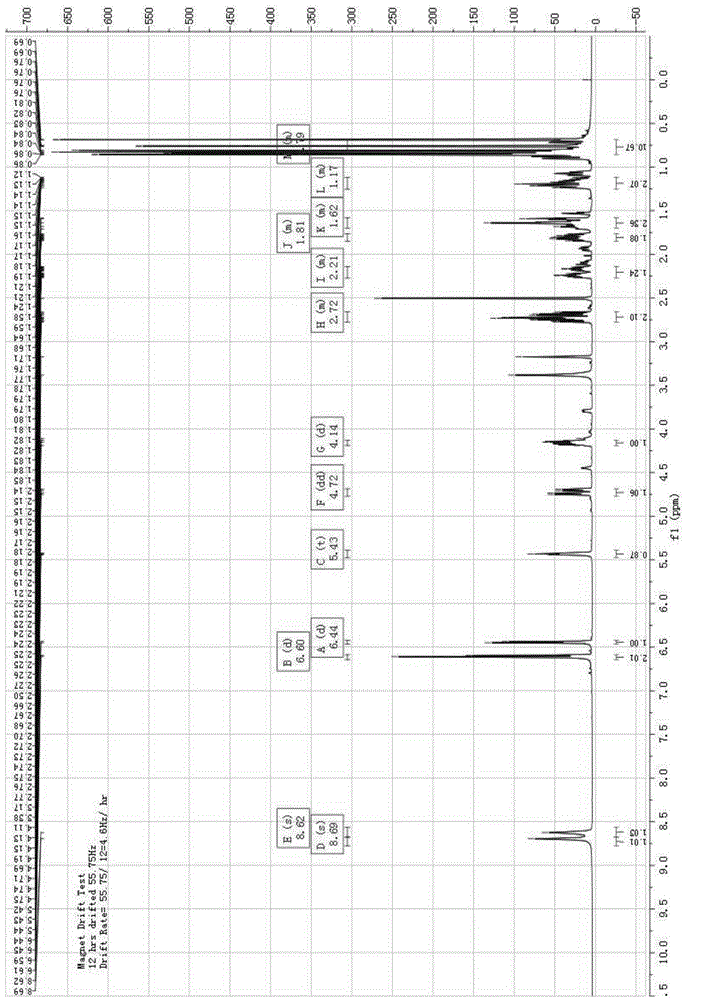

Synthesis method of racemic bornyl beta-(3,4-dihydroxyphenyl)-alpha-hydroxypropionate

ActiveCN104030923ASynthetic Method AdvantagesRaw materials are cheap and easy to getPreparation from carboxylic acid halidesOrganic compound preparationHydrogenSynthesis methods

The invention relates to a synthesis method of racemic bornyl beta-(3,4-dihydroxyphenyl)-alpha-hydroxypropionate. The method comprises the following steps: carrying out Darzens epoxidation on an initial raw material benzyl protected protocatechualdehyde, and carrying out palladium catalyst / hydrogen or Raney nickel / hydrogen catalytic reduction to obtain racemic bornyl beta-(3,4-dihydroxyphenyl)-alpha-hydroxypropionate. The purity and the yield of a product synthesized by adopting the method reach 98% and 48.6% respectively. The synthesis method has the advantages of simple and easily available raw material, short route, high yield, and suitableness for large scale industrialized production.

Owner:NORTHWEST UNIV +1

Engine Exhaust Catalysts Containing Palladium-Gold

ActiveUS20080124514A1Reduce inhibitionEmission reductionCombination devicesInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum-palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGC HLDG LTD

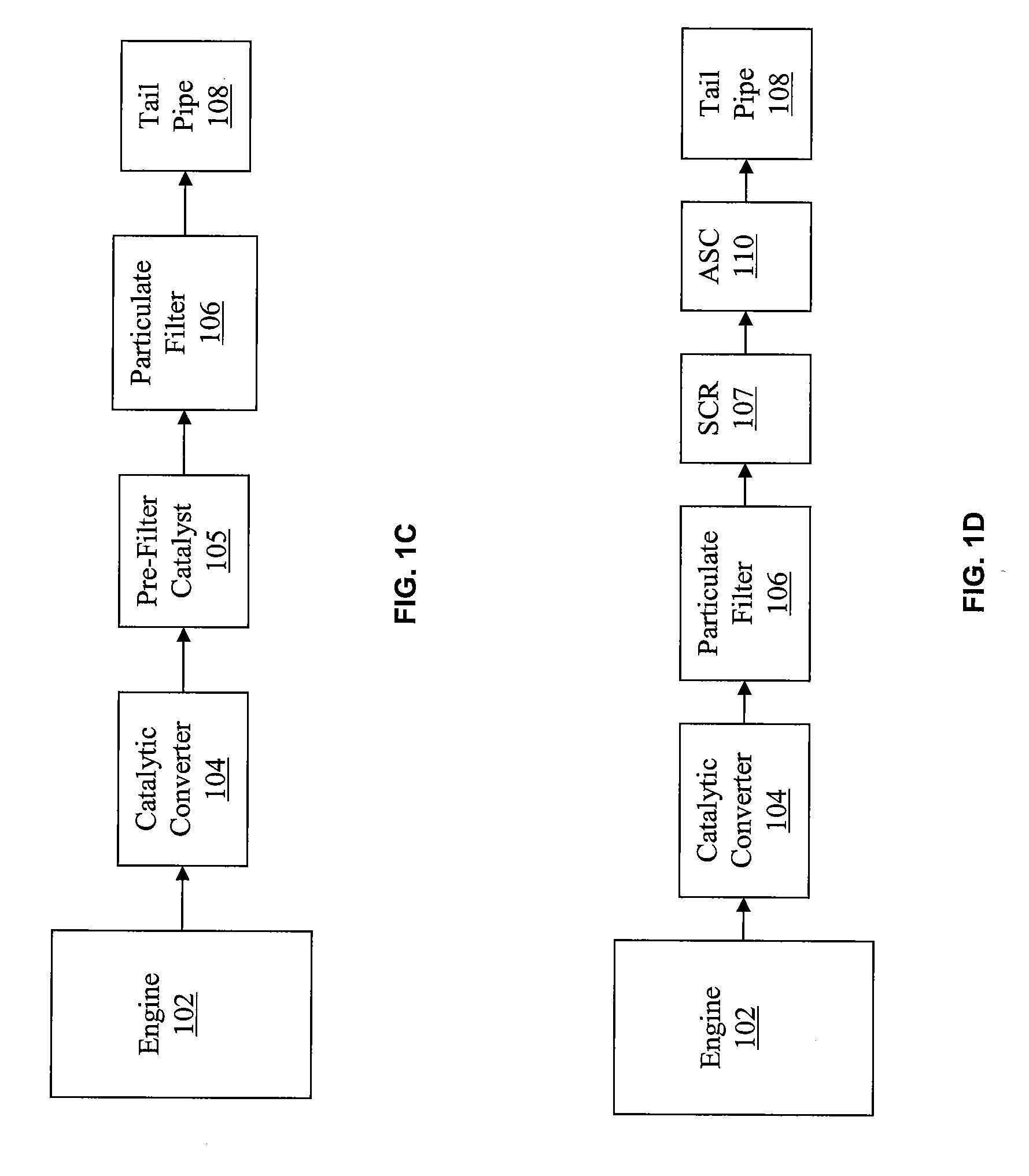

Method of purifying aromatic dicarboxylic acids

InactiveUS6265608B1MinimizationReduce usageOrganic compound preparationCarboxylic compound separation/purificationPalladium catalystCarboxylic acid

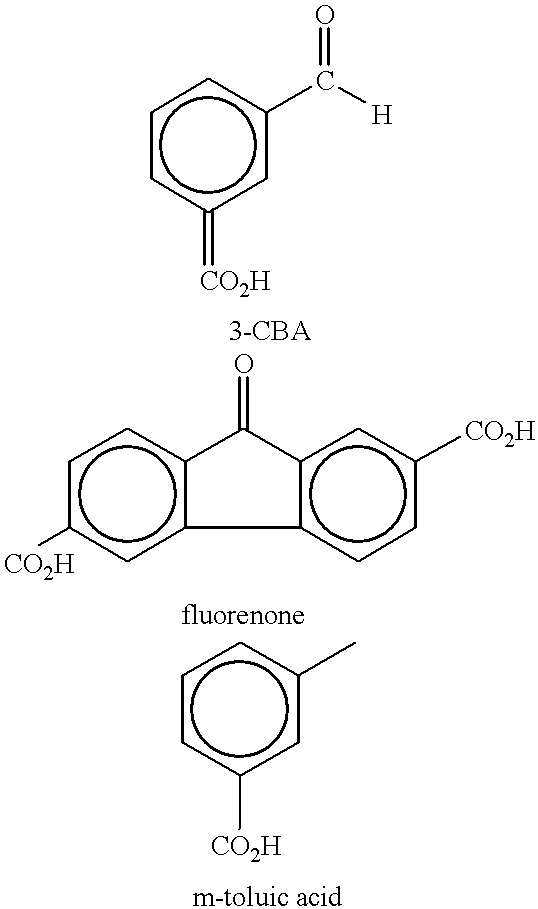

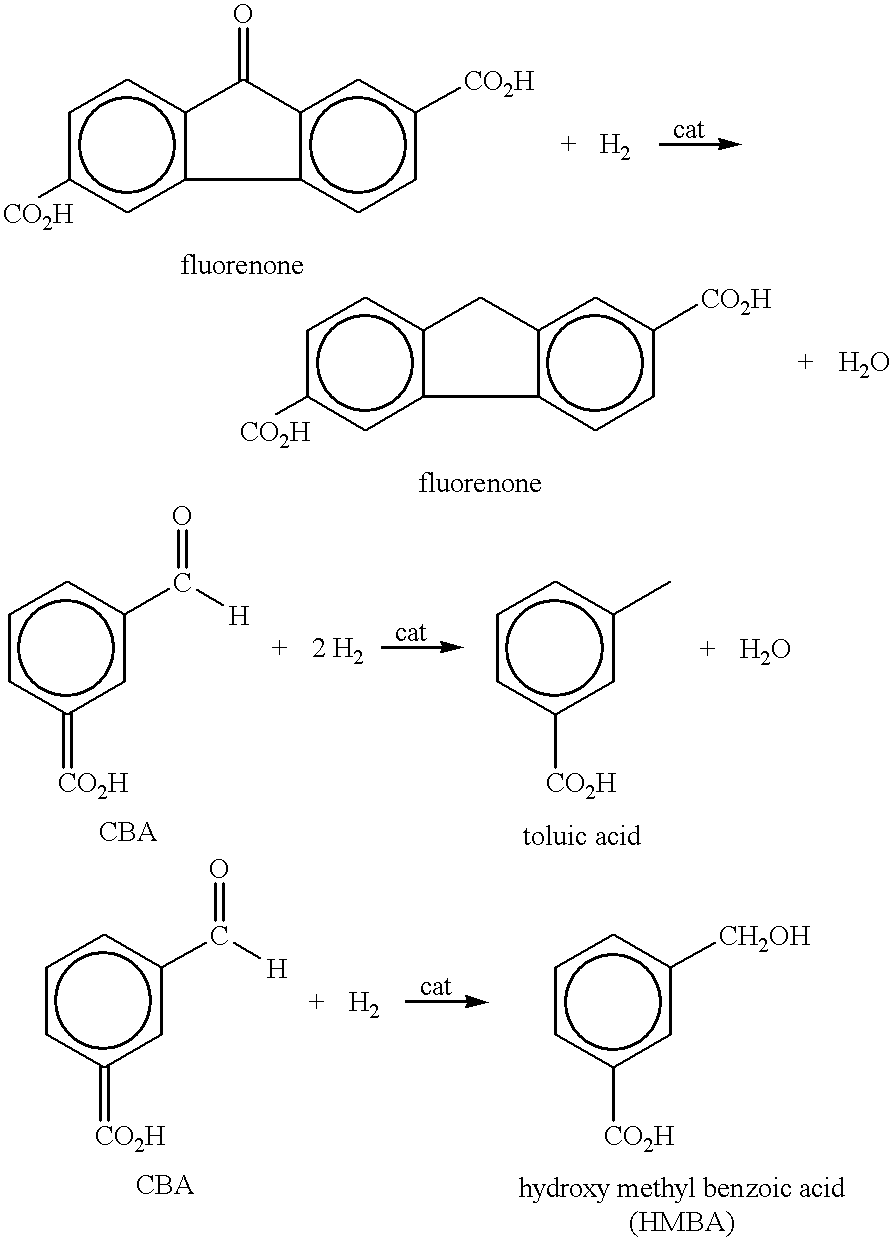

An aromatic dicarboxylic acid is purified by oxidizing m-xylene or p-xylene to produce crude isophthalic acid or crude terephthalic acid, respectively. The products of the oxidizing step are hydrogenated in the presence of a palladium catalyst. Carbon monoxide is introduced during the hydrogenation step. The palladium catalyst is provided on a carbon substrate. The products of the oxidizing step are dissolved in a solvent, which may be water, prior to the hydrogenation step. The products of the oxidizing step may be dissolved at an elevated temperature, above the normal boiling point of the solvent. The oxidation step produces isophthalic acid, 3-carboxybenzaldehyde and fluorenones in the case of oxidizing m-xylene and produces terephthalic acid, 4-carboxybenzaldehyde and fluorenones in the case of oxidizing p-xylene. It may be helpful to monitor the disappearance of 3-carboxybenzaldehyde in the case of oxidizing m-xylene and 4-carboxybenzaldehyde in the case of oxidizing pxylene, and reducing the amount of carbon monoxide when the rate of disappearance is below a predetermined minimum. After the hydrogenation step, the isophthalic acid or terephthalic acid may be crystallized. The carbon monoxide may be maintained at a concentration of 100 to 500 ppm based on added hydrogen and carbon monoxide. Other aromatic dicarboxylic acids may also purified by this procedure.

Owner:GRUPO PETROTEMEX DE C V

Synthesis of unsymmetric anthracene compounds

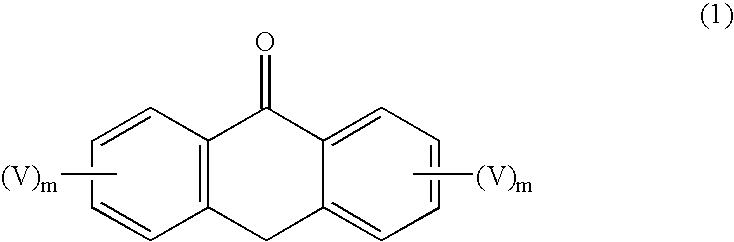

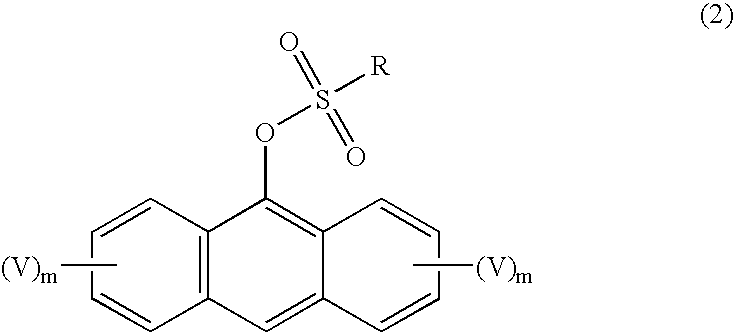

A process for forming an unsymmetric anthracene compound comprises a first step of forming a 9-perfluoroalkylsulfonate derivative of anthrone by reacting the anthrone with a perfluoroalkyl sulfonating agent, followed by a second step of contacting the reaction product with an aryl or heteroaryl boronic acid, ester or anhydride, and a palladium catalyst for a period of time sufficient to form an unsymmetric anthracene compound having at least one 9-position aromatic substituent.

Owner:EASTMAN KODAK CO

Method for preparing carbon supported Au-Pt or Au-Pd catalyst

InactiveCN102553582AHigh activityHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystMicrowave

The invention relates to a method for preparing a carbon supported Au-Pt or Au-Pd catalyst by modifying Au-Pt or Au-Pd bimetal nanoparticles with microwaves, belonging to the technical field of catalytic materials. High pressure and high temperature generated by microwaves in a high-pressure reaction tank are utilized to treat an Au-Pt or Au-Pd composite nano colloid synthesized by a chemical coreduction method so as to induce the modification of the Au-Pt or Au-Pd bimetal nanoparticles; and the microwave-modified bimetal nanoparticles are deposited on the surface of the carbon support, thereby obtaining the carbon supported Au-Pt or Au-Pd catalyst with high activity. The carbon supported Au-Pt or Au-Pd catalyst has high electrocatalytic activity; the supporting rate of the Au-Pt or Au-Pd bimetal is high; the supporting amount of the Au-Pt or Au-Pd is controllable; and the method can be used for preparing the carbon supported Au-Pt or Au-Pd nano catalyst of which the mass ratio of Au-Pt or Au-Pd to carbon is 1-20%. The method provided by the invention has the advantages of low cost, simple technique and low facility request, and has wide industrial application prospects.

Owner:KUNMING UNIV OF SCI & TECH

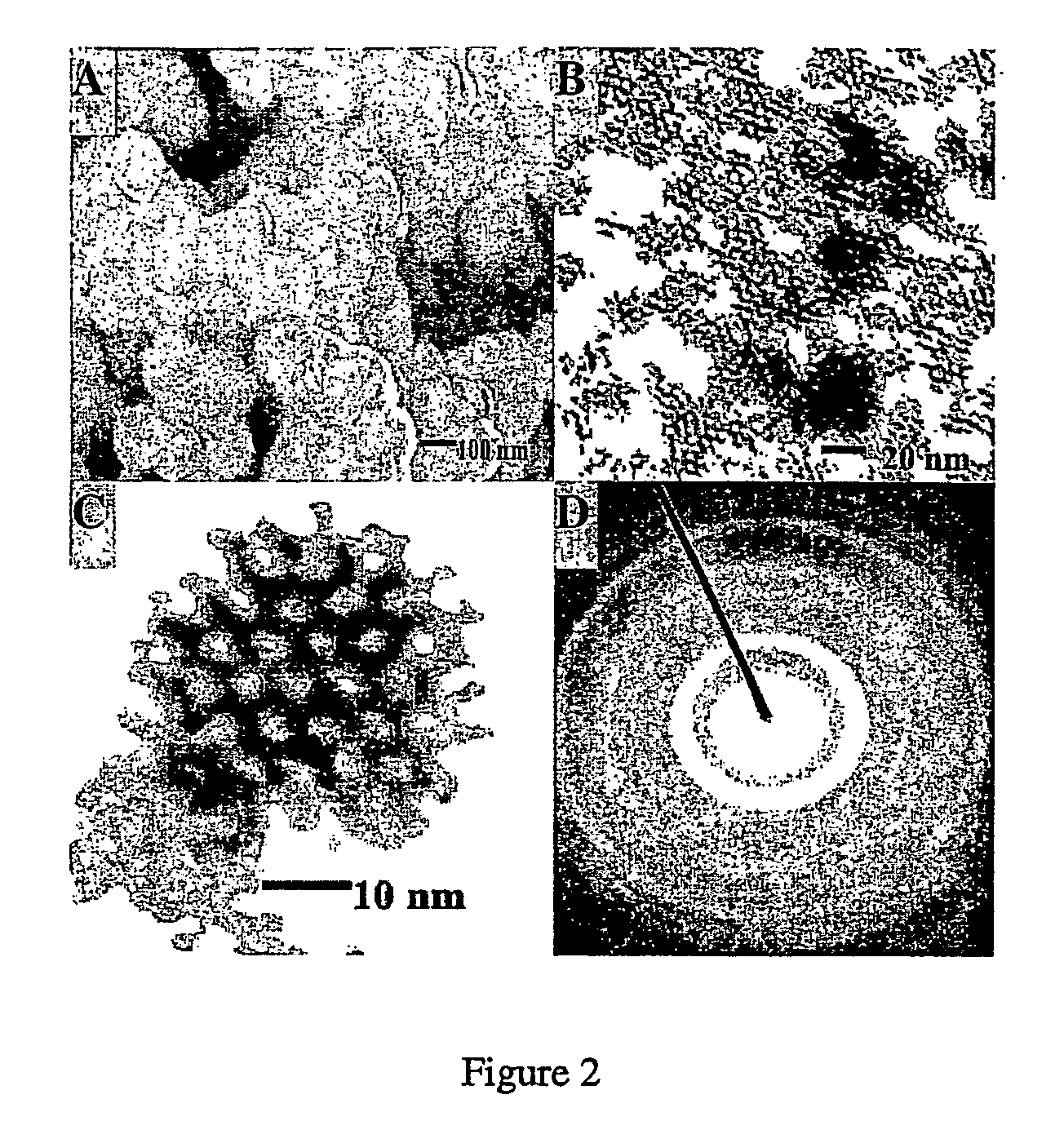

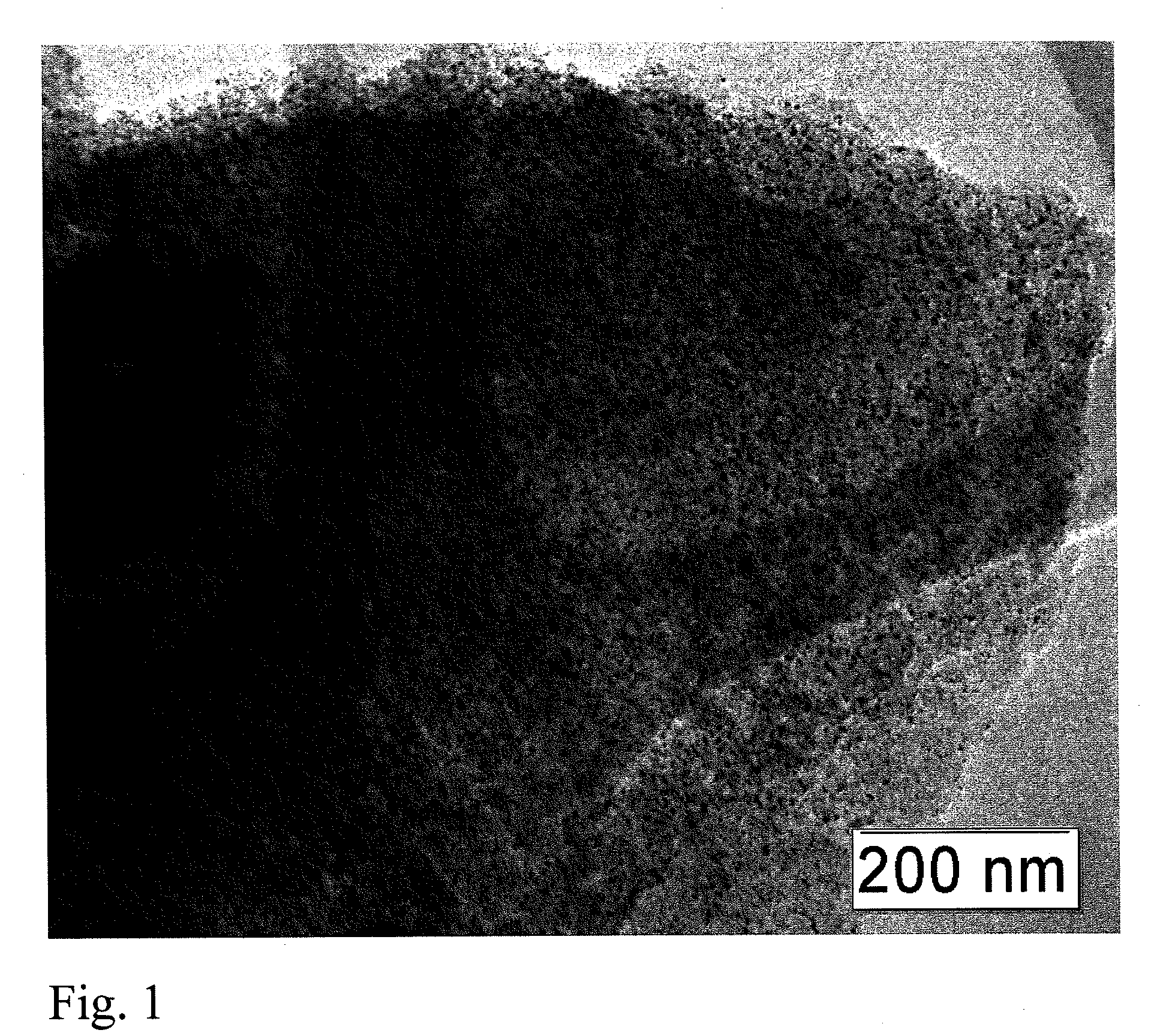

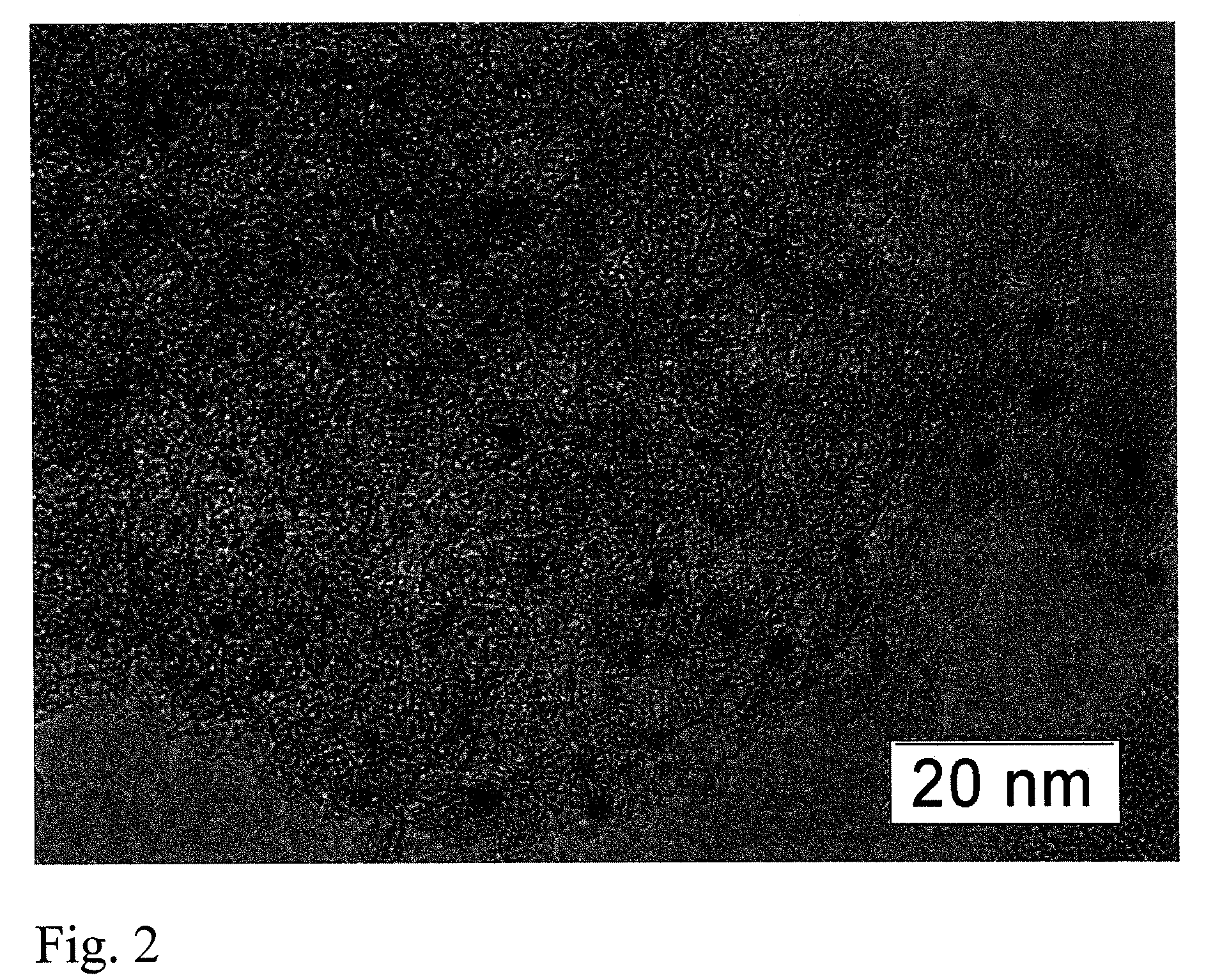

Nanoporous/mesoporous palladium catalyst

InactiveUS20090075139A1Weather/light/corrosion resistanceFinal product manufacturePalladium catalystIon exchange

The present invention provides a catalytic system comprising a catalyst comprising nanoporous or mesoporous palladium and an ion-exchange electrolyte, processes for manufacturing the catalytic system and catalyst, and processes for oxidising or reducing organic and / or inorganic molecules using the catalyst or catalytic system.

Owner:IC INNOVATIONS

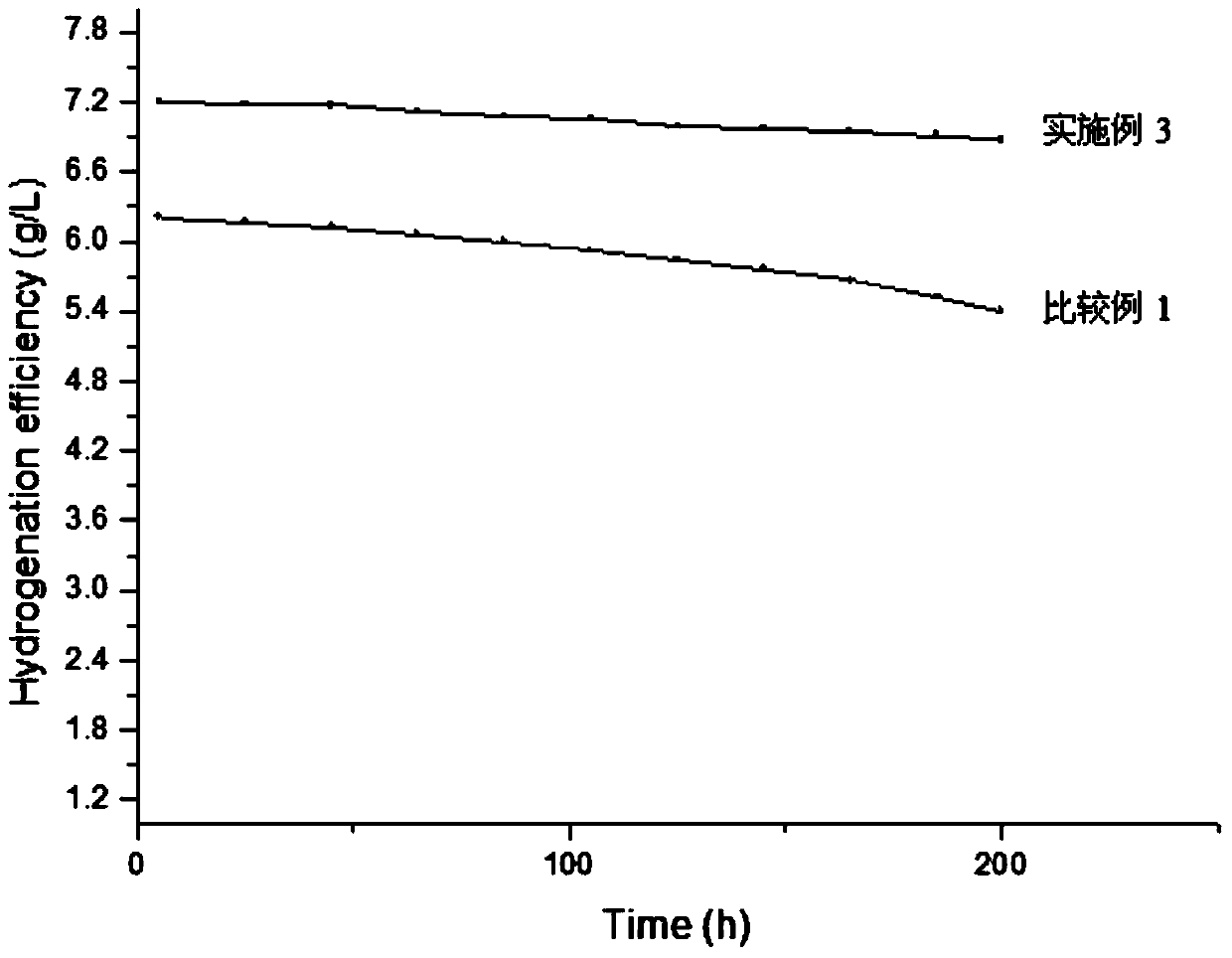

Supported palladium catalyst for producing hydrogen peroxide by anthraquinone process and preparing method thereof

InactiveCN1435277AImprove catalytic performanceImprove overall lifespanPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsPhosphateActive component

A carried Pd-alumina catalyst for preparing hydrogen peroxide by anthraquinone method is prepared from Pd as main active component and Al2O3 as carrier through impregnation. Said Al2O3 has been coated by RE oxide and calcined at 900-1000 deg.C. It has high hydrogenating efficiency of 8-9 gH2O2 / L for 2-ethyl anthraquinone / heavy arene plus trioctyl phosphate or 10-13 gH2O2 / L for (2-tert-butyl anthraquinone plus 2-ethyl anthraquinone) / (heavy arene plus tetrabutyl urea).

Owner:FUZHOU UNIV

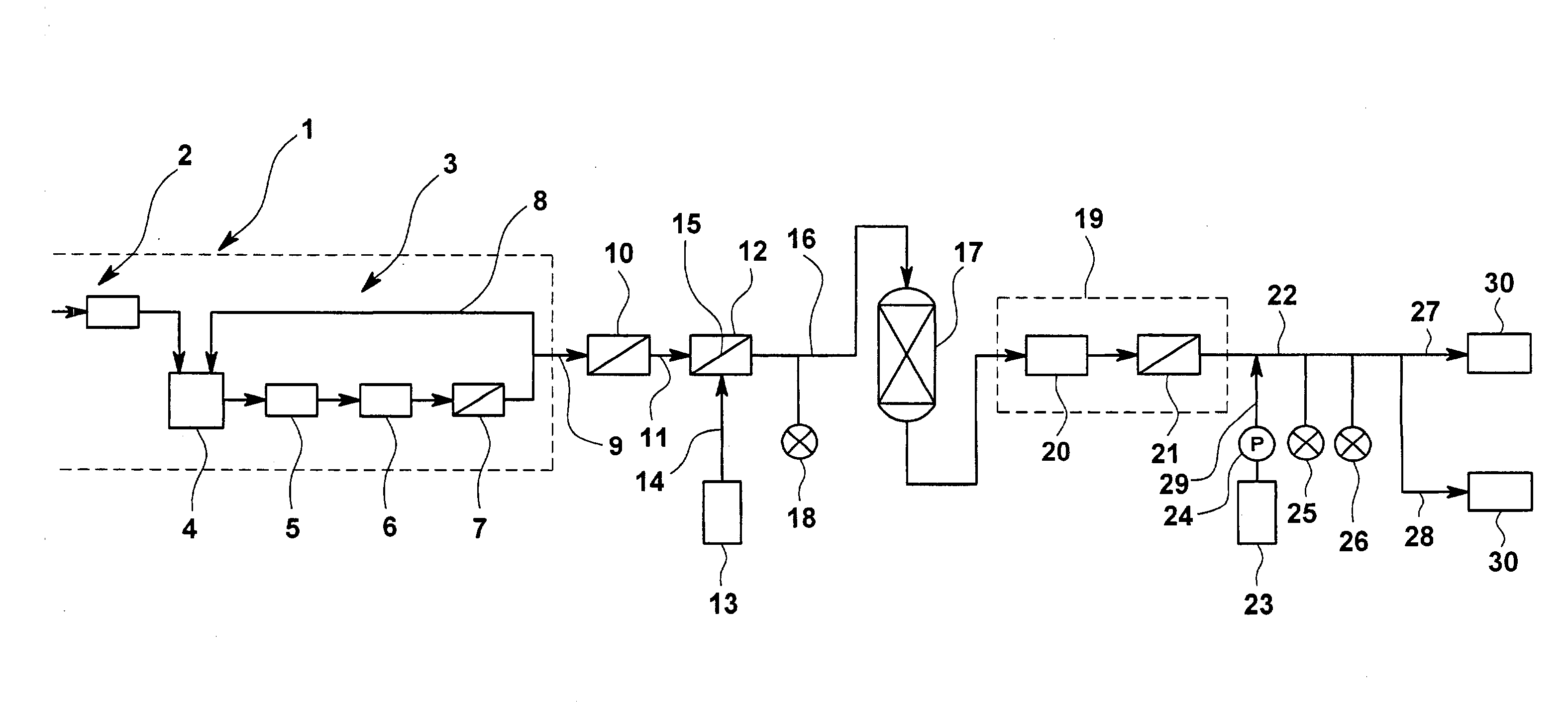

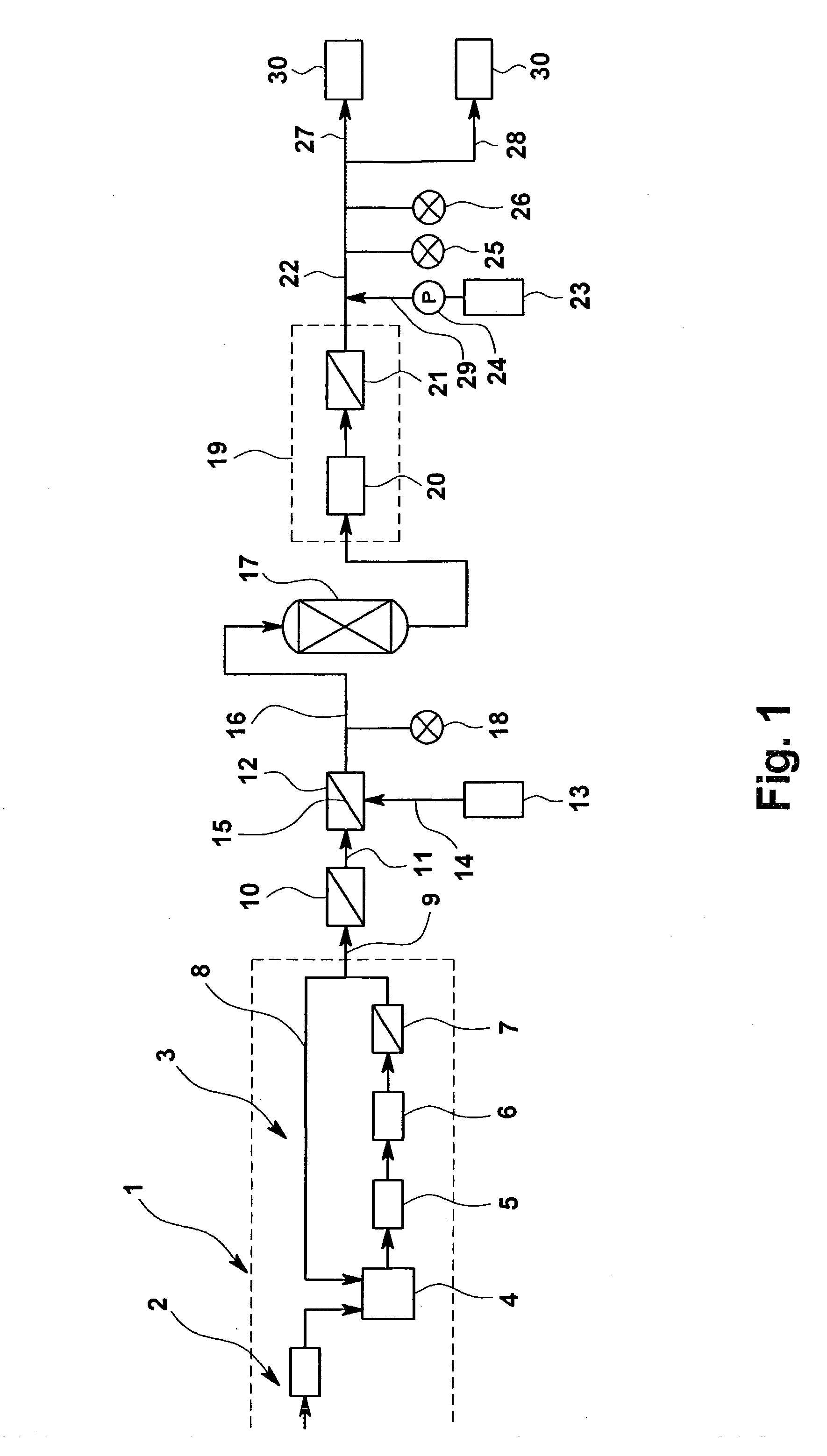

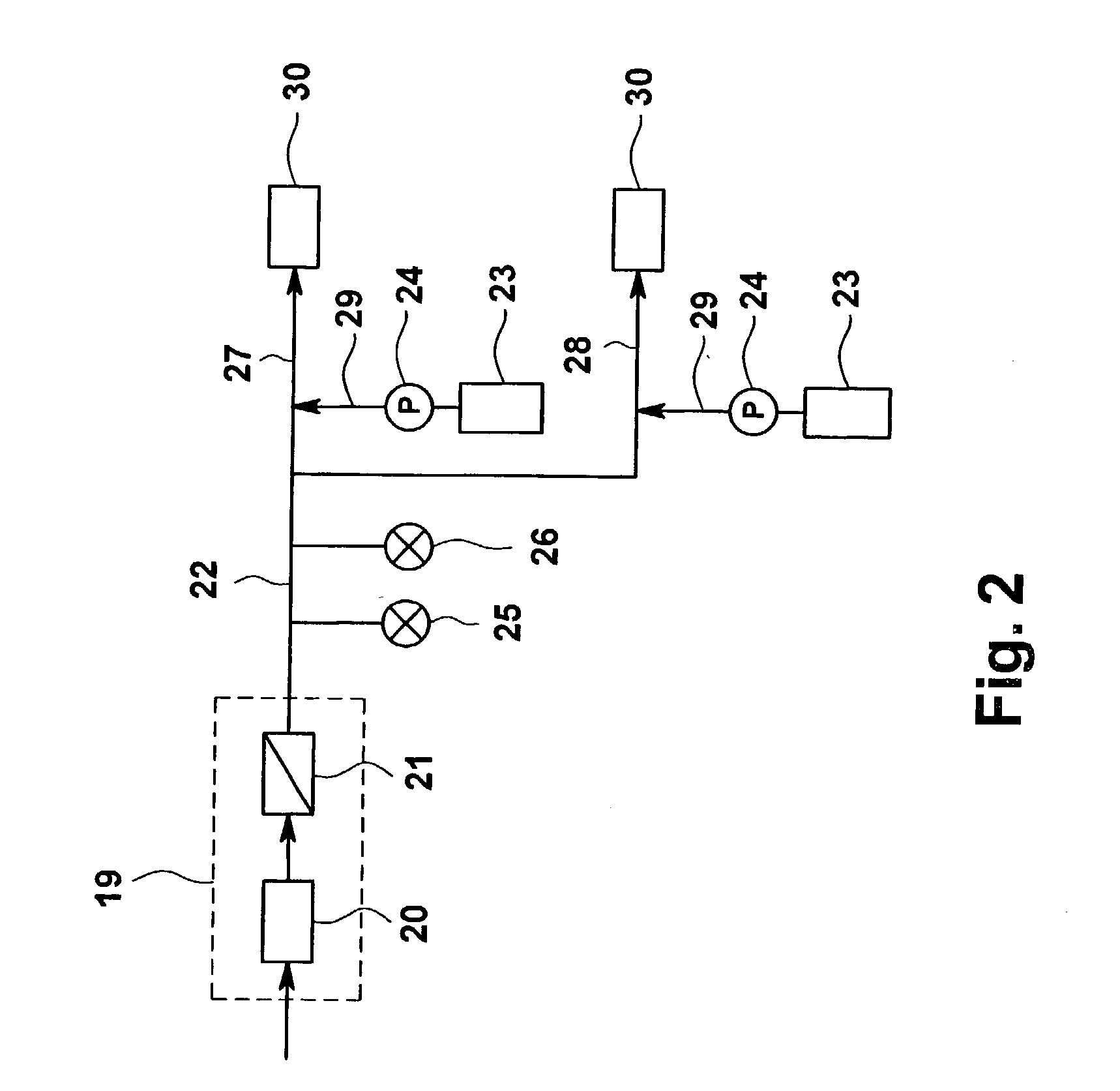

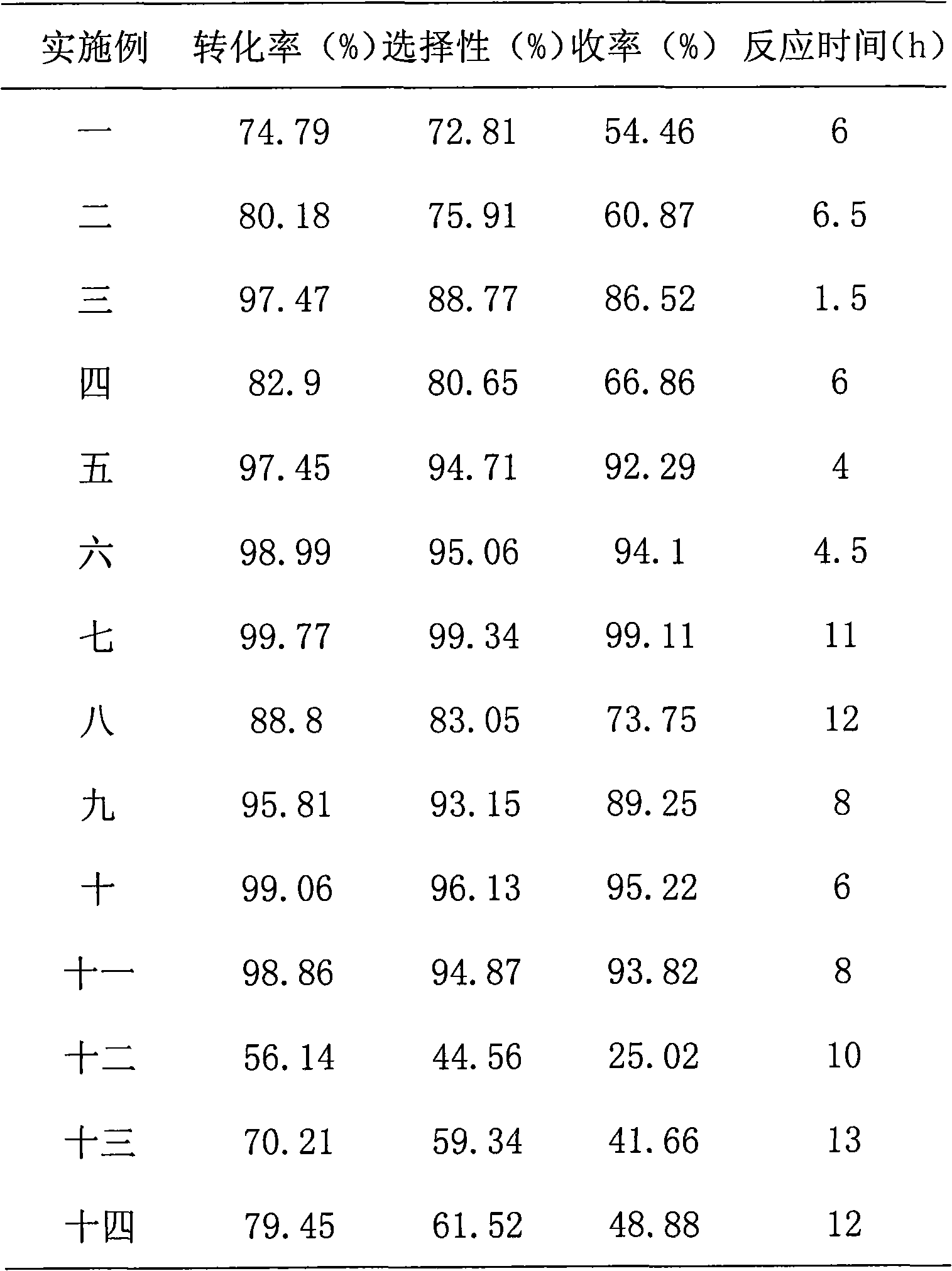

Method for producing oxalic ester with CO coupling

ActiveCN101492370AHigh selectivityImprove conversion ratePreparation by carbon monoxide or formate reactionNitrogen oxidesAlcohol

The invention relates to a method for producing oxalic ester by CO coupling, which mainly solves the problems of the prior art such as low selectivity and low CO single pass conversion in producing the oxalic ester by CO coupling. In the invention, firstly CO and nitrite ester are put into a coupling reactor and then contacted with a catalyst containing Pd; liquid phase reaction effluent II and gas phase reaction effluent III are obtained from effluent I through gas-liquid separation; the gas phase reaction effluent III, O2 and monohydric alcohol of C1-C4 are taken as raw material and put into a regeneration reactor for reaction to generate gas effluent IV containing nitrite ester; the gas effluent IV returns to the coupling reactor for continuous reaction and the mol ratio of nitrogen oxide:O2:monohydric alcohol of C1-C4 is 1:0.3-0.5:1-1.5. The technical proposal of obtaining the oxalic ester product by separating the liquid phase reaction effluent II better solves the problem and can be applicable to the industrial production of oxalic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

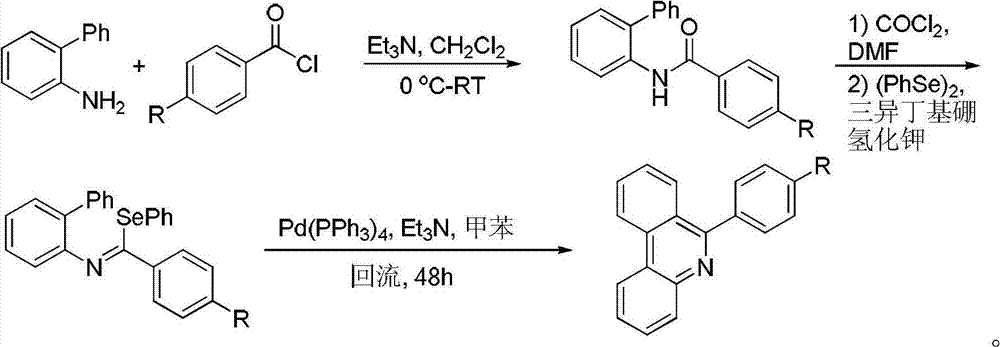

Preparation method for phenanthridine derivative

InactiveCN102827077AStrong designabilityHigh yieldGroup 5/15 element organic compoundsOrganic solventPalladium catalyst

The invention discloses a preparation method for a phenanthridine derivative. The preparation method comprises the following steps of: adding a catalyst, an oxidant, acid, a 2-phenylaniline compound and an olefin compound into organic solvent; after reaction, carrying out post treatment to obtain the phenanthridine derivative, wherein the catalyst is a bivalent palladium catalyst. According to the preparation method for the phenanthridine derivative disclosed by the invention, the adoption of reagents with high toxicity and high corrosiveness is avoided. The preparation method has the advantages of environment friendliness, easiness in operation, higher yield and simplicity and convenience in post treatment. In addition, a substrate obtained by the method is strong in designability and can be used for designing to synthesize a compound with the required structure according to actual requirements, and thus stronger practicability is realized.

Owner:ZHEJIANG UNIV

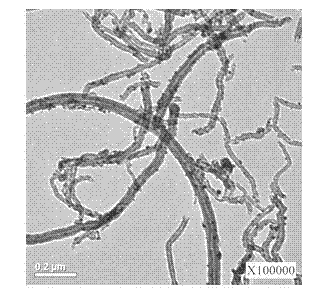

Method for preparing loading type nano Pd/C catalyst from colloidal solution

InactiveCN1966144AAvoid organic pollutionReduce manufacturing costCatalyst carriersNanostructure manufacturePalladium catalystChemical reduction

The invention relates to a method for using colloid solution to prepare carrier nanometer Pd / C catalyst, wherein said method comprises that using chemical reduction to process palladium salt to prepare the nanometer palladium colloid solution with stable surface activity, then using some carrier to absorb it to obtain the palladium colloid, to obtain the nanometer palladium catalyst with different loaded amounts. The inventive catalyst can be used in hydrogenation.

Owner:DALIAN UNIV OF TECH

Regeneration of spent supported metal catalysts

InactiveUS6908873B2Efficient removalImproves expositionOther chemical processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal catalystPalladium catalyst

Owner:EVONIK OPERATIONS GMBH

Scavenging oxygen

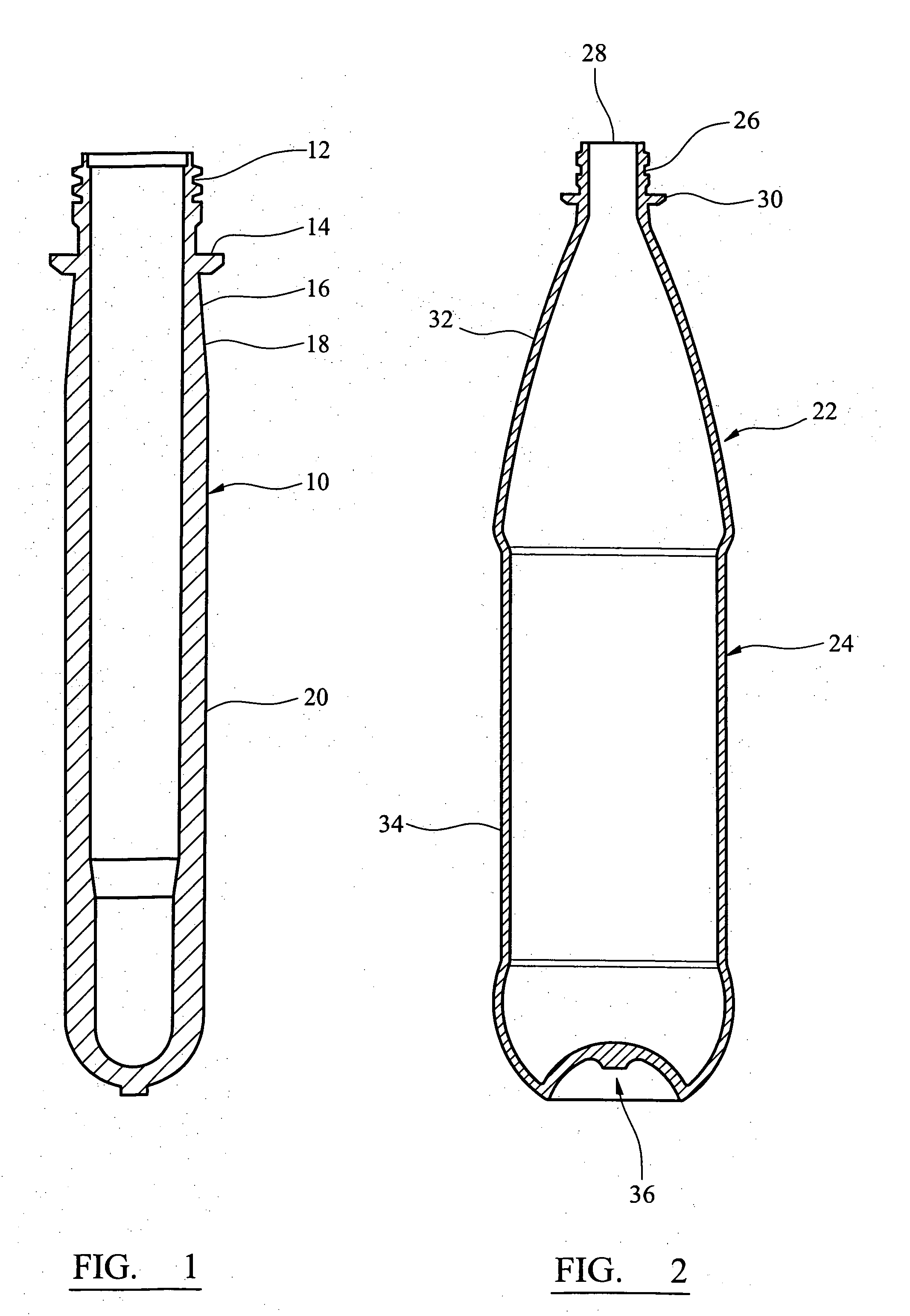

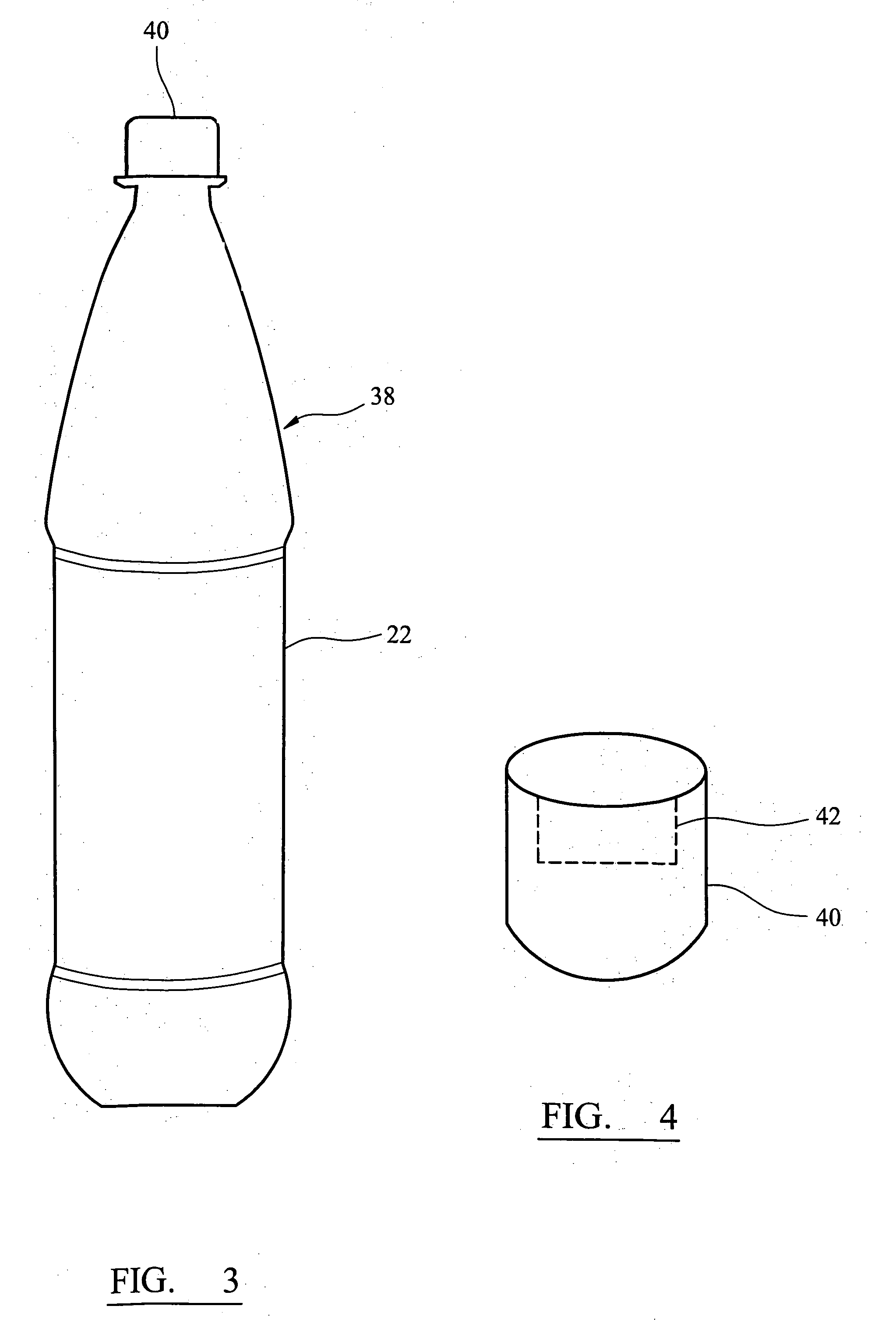

InactiveUS20100028499A1Increase response rateSmall amountClosures with oxygen absorbersFruit and vegetables preservationWater vaporPalladium catalyst

A container (22) includes a shell (24) made from a polymer, for example PET, and incorporating a catalyst, for example a palladium catalyst. A closure (40) incorporates a plug which includes a source of hydrogen, for example a hydride. In use, with container (22) including a beverage and closure (40) in position, the headspace in the container will be saturated with water vapor. This vapor contacts the hydride associated with plug (42) and as a result the hydride produces molecular hydrogen which migrates into the polymer matrix of shell (24) and combines with oxygen which may have entered the container through its permeable walls. A reaction between the hydrogen and oxygen takes place, catalysed by the catalyst, and water is produced. Thus, oxygen which may ingress the container is scavenged and the contents of the container are protected from oxidation.

Owner:COLORMATRIX HLDG

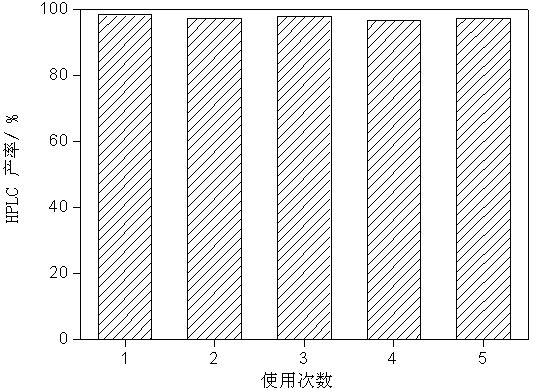

Graphene oxide supported Schiff base palladium catalyst as well as preparation method and application thereof

InactiveCN103447092AAvoid churnAvoid gatheringOrganic compound preparationOrganic chemistry methodsPalladium catalystBULK ACTIVE INGREDIENT

The invention relates to a graphene oxide supported Schiff base palladium catalyst as well as a preparation method and application thereof. A catalyst carrier is a graphene oxide prepared by an improved Hummers process, ligand is Schiff base and an active ingredient is palladium salt; the capacity of the palladium in the active ingredient palladium salt is 5.0%-10.0% of the total mass of the catalyst, the diameter of the graphene oxide is 1 mu m-5 mu m, the thickness of the graphene oxide is 0.8 nm-1.2 nm, and the particle diameter of a palladium nano particle is 3 nm-8 nm. The graphene oxide-supported Schiff base palladium catalyst can be used for preventing the palladium from losing in a catalysis process, meanwhile, the graphene oxide has a unique two-dimensional planar structure and can also be used for improving dispersing performance of the palladium nano particle on the surface of the graphene oxide to prevent the palladium from gathering in the catalysis process, so that the catalytic activity of the supported type catalyst is improved. Therefore, the graphene oxide-supported Schiff base palladium catalyst disclosed by the invention can be used for preventing the palladium from gathering and losing better in a catalytic C-C (Carbon-Carbon) coupling reaction process, and has higher catalytic activity and better recycling performance.

Owner:EAST CHINA UNIV OF TECH

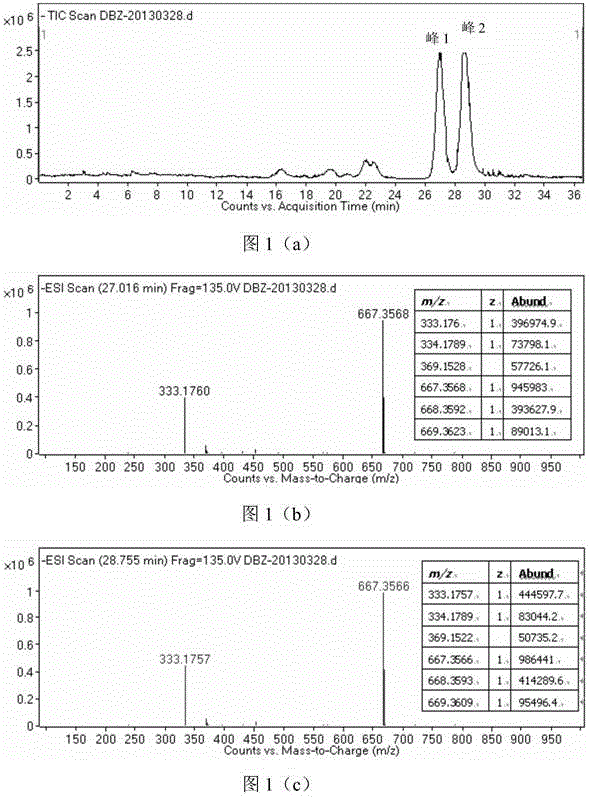

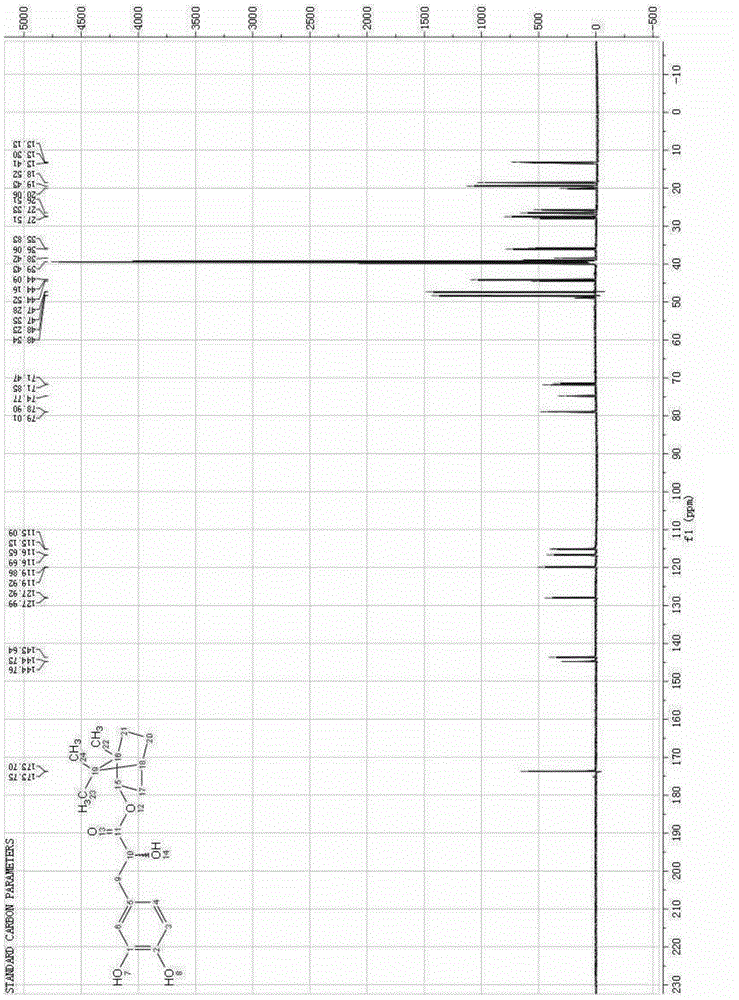

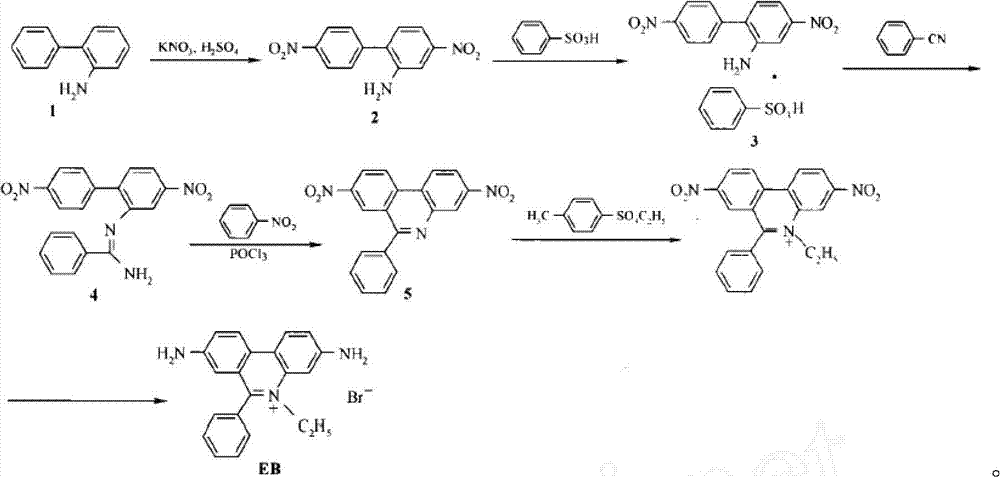

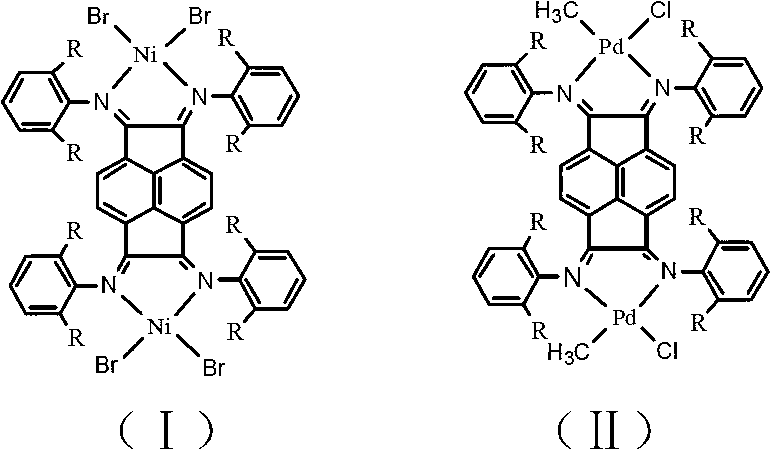

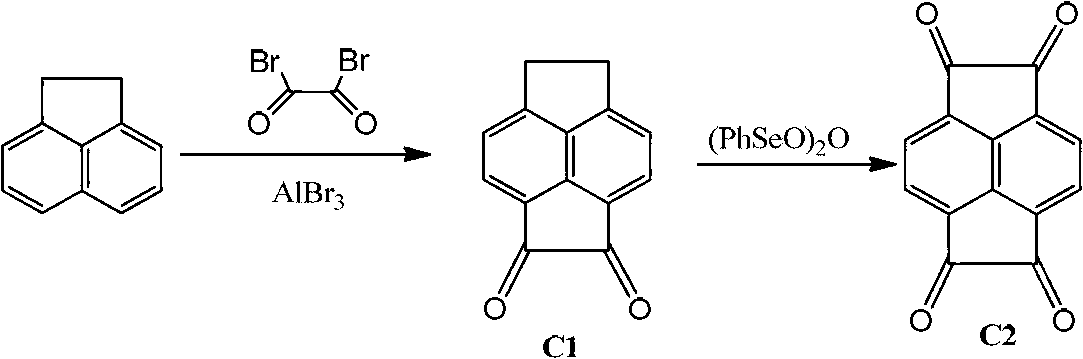

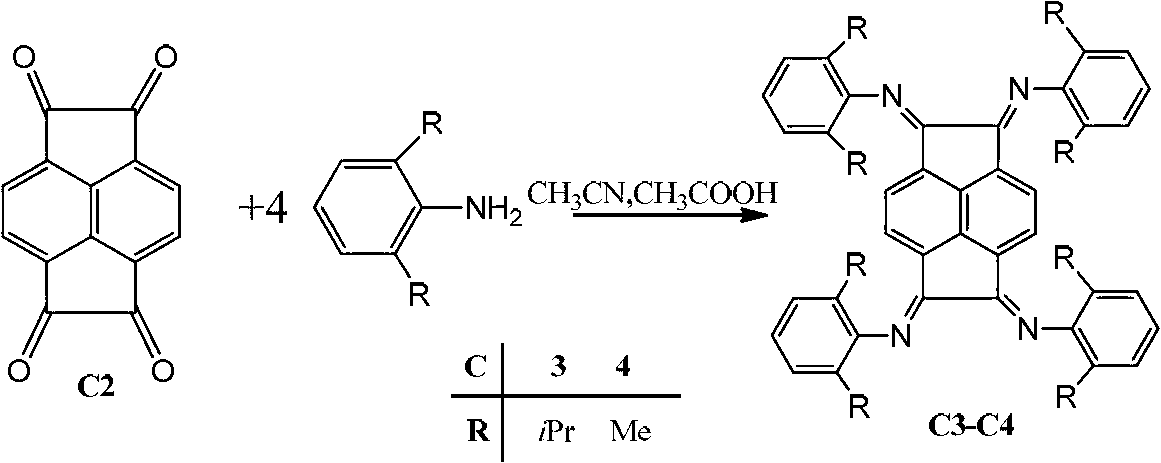

Binuclear acenaphthene (alpha-diimine) nickel/palladium catalysts for olefins, and preparation method and application thereof

ActiveCN102827311AHigh activityImprove stabilityNickel organic compoundsBulk chemical productionNickel catalystDiimine

The invention discloses a preparation method for binuclear acenaphthene (alpha-diimine) nickel / palladium catalysts for olefins and application of the catalysts in catalysis of polymerization of olefins. The binuclear acenaphthene (alpha-diimine) nickel / palladium catalysts for olefins in the invention have structural formulas as represented by formula (I) and formula (II) in the specification. The binuclear acenaphthene (alpha-diimine) palladium catalyst for polymerization of olefins has high activity and good stability and can be used for preparing high-molecular-weight hyperbranched polyethylene with bimodal distribution; the binuclear acenaphthene (alpha-diimine) nickel catalyst for polymerization of olefins has high activity and good stability and can be used for preparing polypropylene with a weight-average molecular weight of more than 100,000 and thermoplastic elastomers with elasticity and a high molecular weight. The preparation method for the synthesized catalysts used for polymerization of olefins has the advantages of a simple process, a short synthetic route, low cost, high yield and easy industrialization.

Owner:ZHEJIANG UNIV

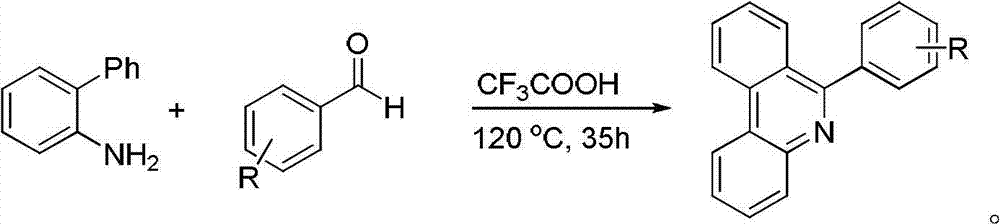

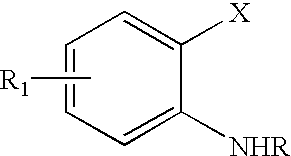

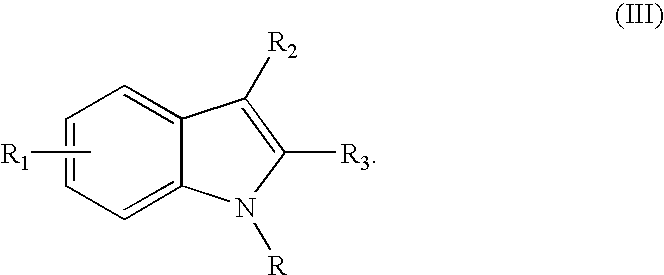

Palladium catalyzed indolization of 2-bromo or chloroanilines

The present invention provides a method for making substituted indole compounds of general formula III comprising the step of: (a) reacting a 2-bromoaniline or 2-chloroaniline of general formula (I) (I) wherein: X, R and R1 are defined herein with a substituted acetylene of formula (II) wherein R2 and R3 in the presence of a palladium catalyst, a ligand, and a base in a solvent at a suitable temperature to give a compound of formula (III);

Owner:BOEHRINGER INGELHEIM INT GMBH

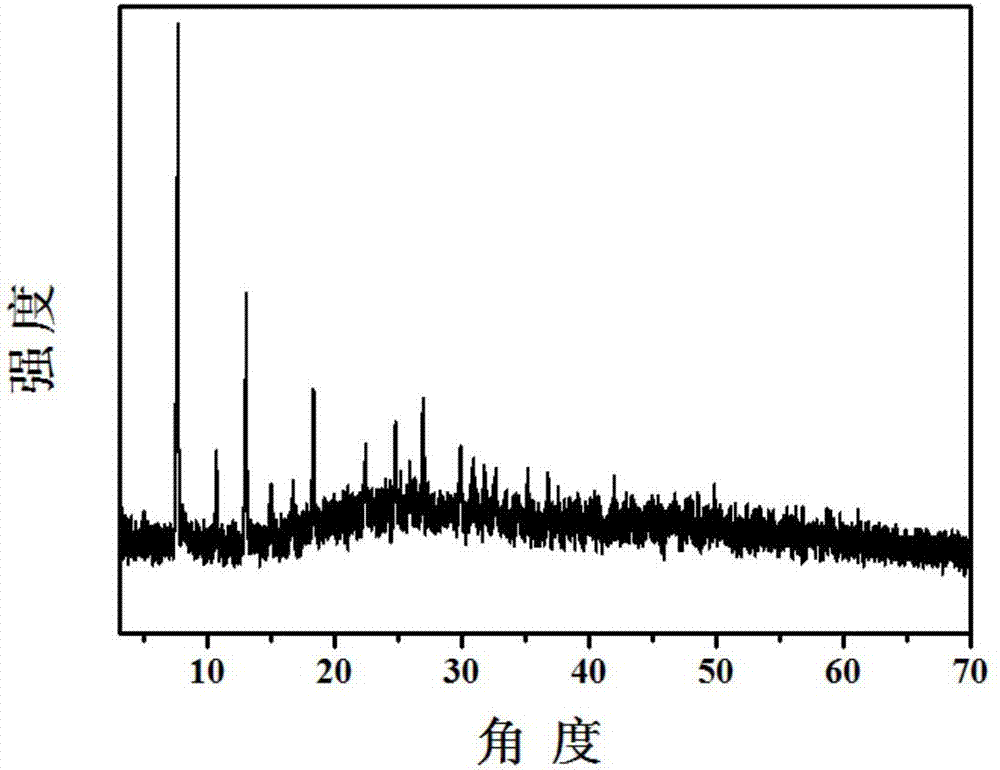

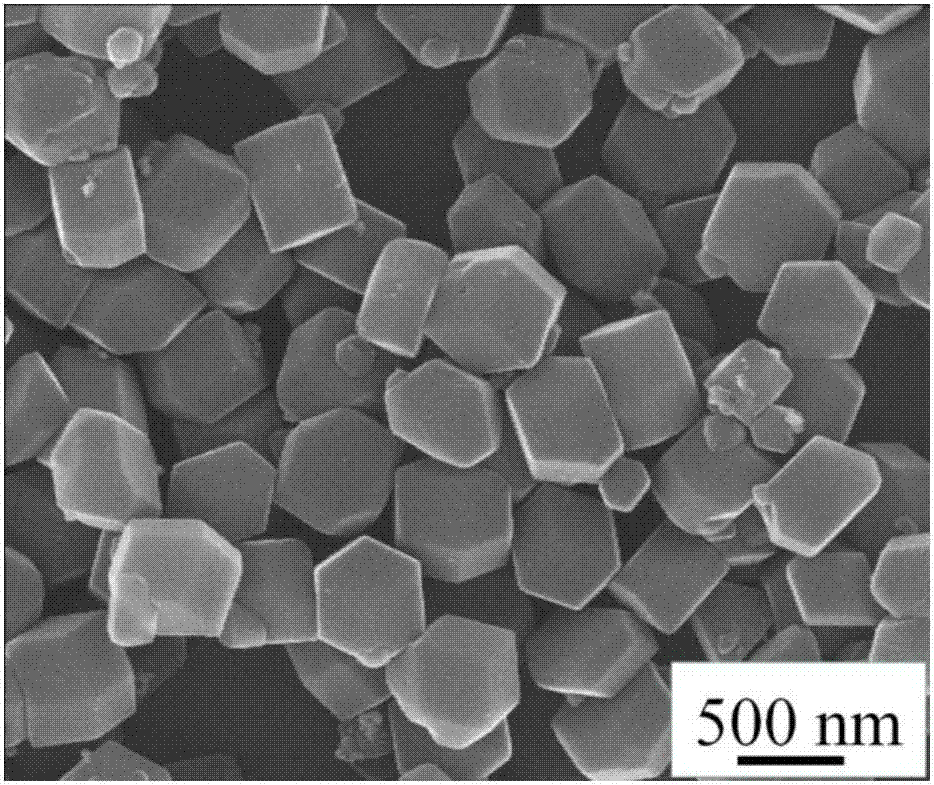

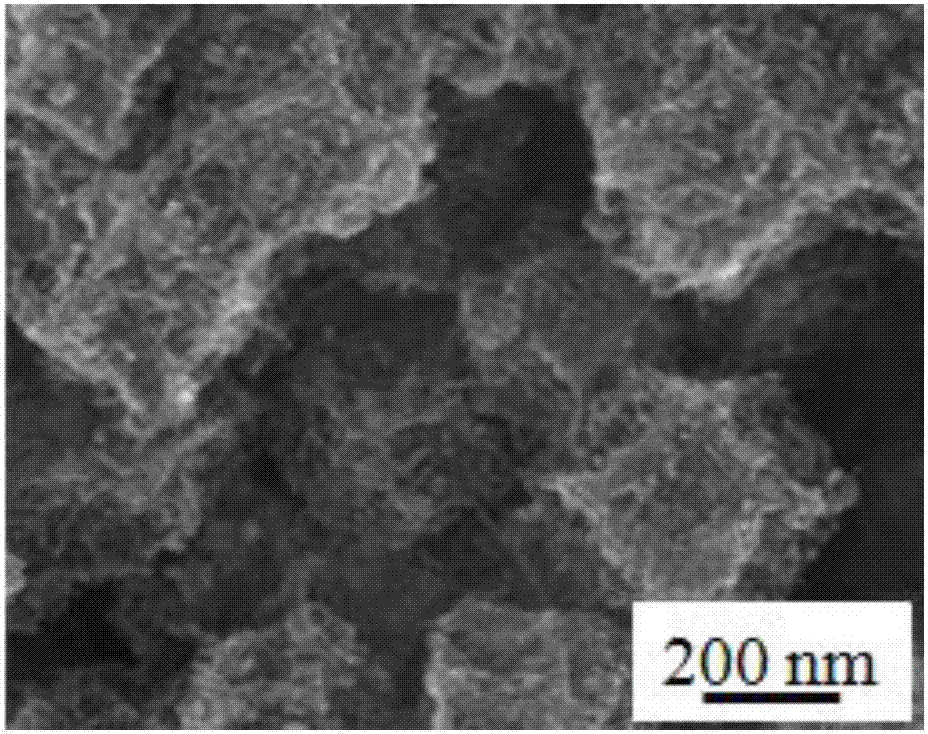

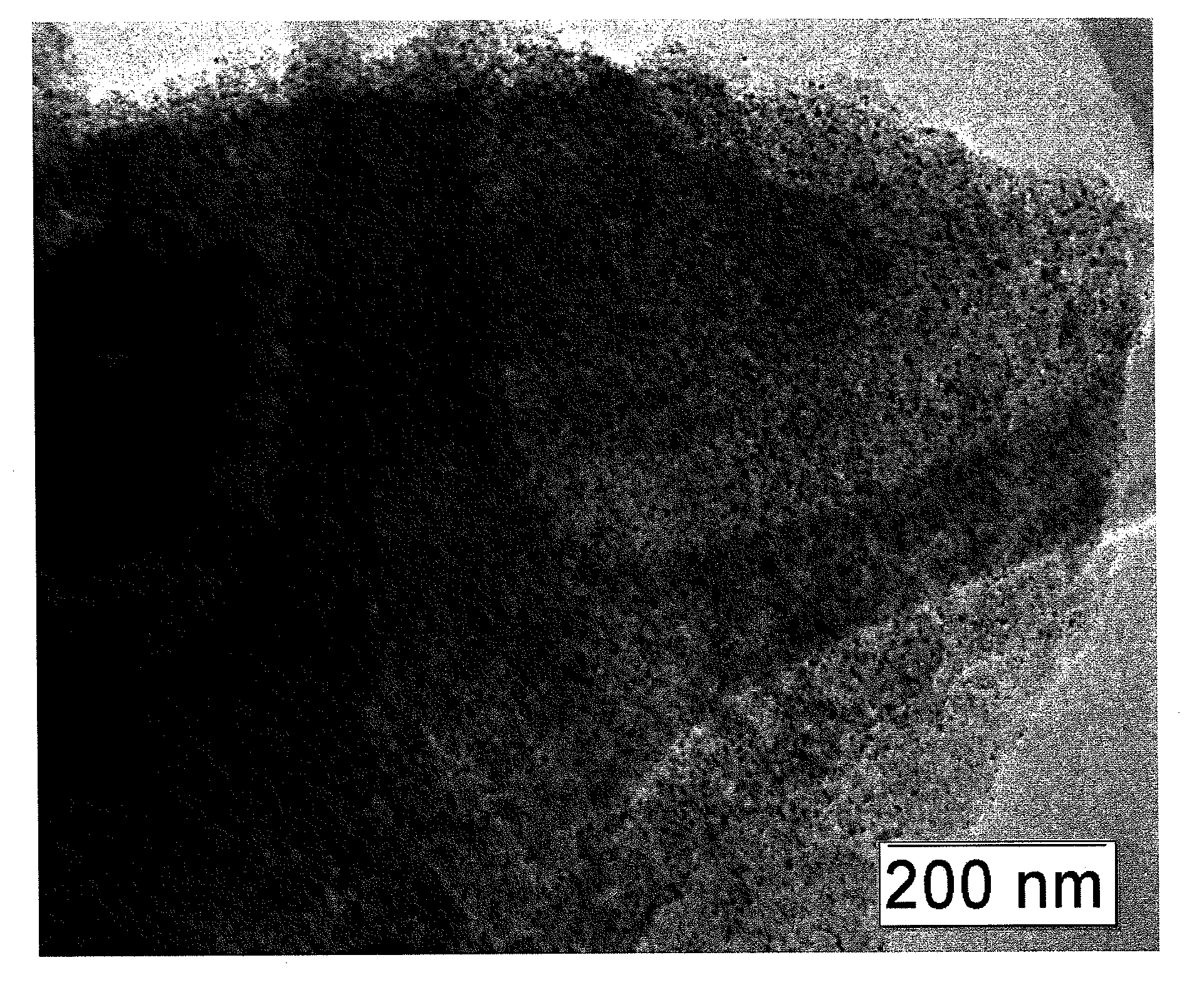

Preparation and applications of supported palladium catalyst using MOFs derived carbon-based material as carrier

InactiveCN106902842AEvenly dispersedGood dispersionCatalystsHydrocarbon preparation catalystsMaterials preparationNanoparticle

The invention discloses preparation and applications of a supported palladium catalyst using a MOFs derived carbon-based material as a carrier, and belongs to the technical field of catalyst material preparation. According to the present invention, ZIF-67 is adopted as a template, reduced palladium nanoparticles are uniformly supported in the pore channels in the ZIF-67 during a ZIF-67 synthesis process, and under a nitrogen protection condition, the carbon-based nanometer material supported palladium catalyst having excellent catalysis performance is constructed through high temperature carbonation; the preparation method of the invention is simple and easy to perform; and the prepared catalyst maintains the high specific surface area and the abundant pore structure characteristics of the precursor ZIF-67 to a large extent, such that the uniform dispersion and the stabilization of the palladium nanoparticles are easily achieved, and the excellent catalytic activity is provided.

Owner:BEIJING UNIV OF TECH

Hydrogen-dissolved water production apparatus

InactiveUS20030132104A1Avoid quality lossQuality improvementUltrafiltrationReverse osmosisParticulatesHydrogen

A degassing device (10), a hydrogen dissolving device (12), and a palladium catalyst column (17) are provided in that order downstream of a high-purity water production device (1), and an impurity removal device (19) is connected to the exit side of treated water of the palladium catalyst column (17). The impurity removal device (19) removes impurity ions which are eluted into the water to be treated or impurity particulates which mix in with the water to be treated during the treatment in the palladium catalyst column (17). The impurity removal device (19) comprises an ion exchange device (20) and a membrane treatment device (21) such as a ultrafiltration membrane device, a reverse osmosis membrane device or the like. By providing an impurity removal device (19) in this manner, it is possible to remove impurities generated during hydrogen peroxide removal treatment by the palladium catalyst and to prevent degradation in quality of hydrogen-dissolved water.

Owner:ORGANO CORP

Method for preparing diaminonaphthalene by catalytic hydrogenation of dinitronaphthalene

InactiveCN101575295AImprove conversion rateHigh selectivityOrganic compound preparationAmino compound preparationPalladium catalystReaction temperature

A method for preparing diaminonaphthalene by catalytic hydrogenation of dinitronaphthalene relates to a preparation technology of the diaminonaphthalene, which comprises the following steps: adding a palladium catalyst comprising active components and a carrier and adding the dinitronaphthalene and solvent to a stainless steel high-pressure reactor with an agitator, closing the reactor, replacing air in the reactor with nitrogen for at least three times and then replacing the nitrogen in the reactor with hydrogen for at least three times, and then filling the hydrogen in the reactor so that the reaction pressure in the reactor reaches 0.4-4.0MPa, heating the reactor so that the reaction temperature reaches 30-150 DEG C so as to carry out catalytic hydrogenation to prepare the diaminonaphthalene. The method adopts the hydrogenation reaction technology in the stainless steel high-pressure reactor with the agitator; a catalyst carrier is pretreated to improve the activity of the catalyst and reduce the consumption of the catalyst. By optimizing the technological conditions, the rate of conversion from the dinitronaphthalene to the diaminonaphthalene is effectively improved and high selectivity of the product diaminonaphthalene is maintained.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

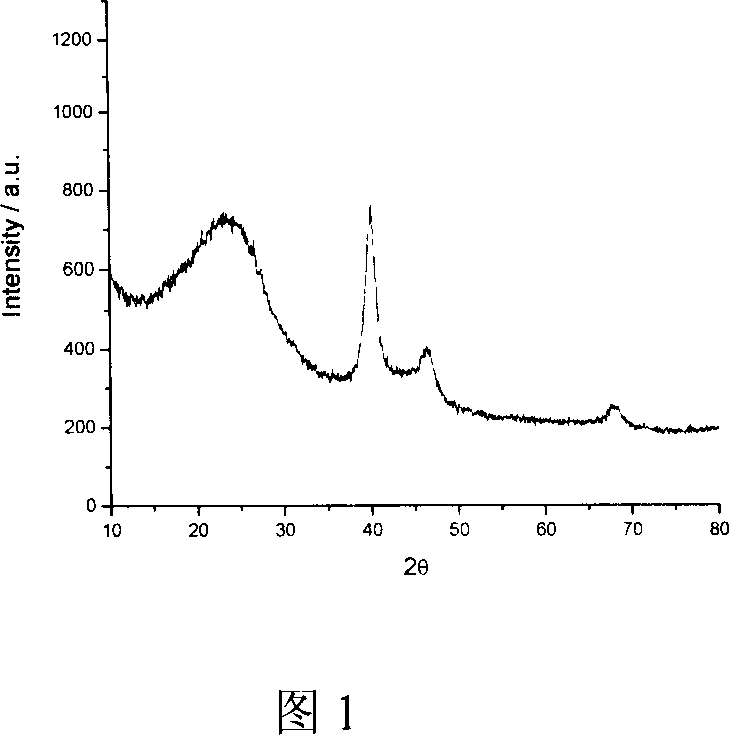

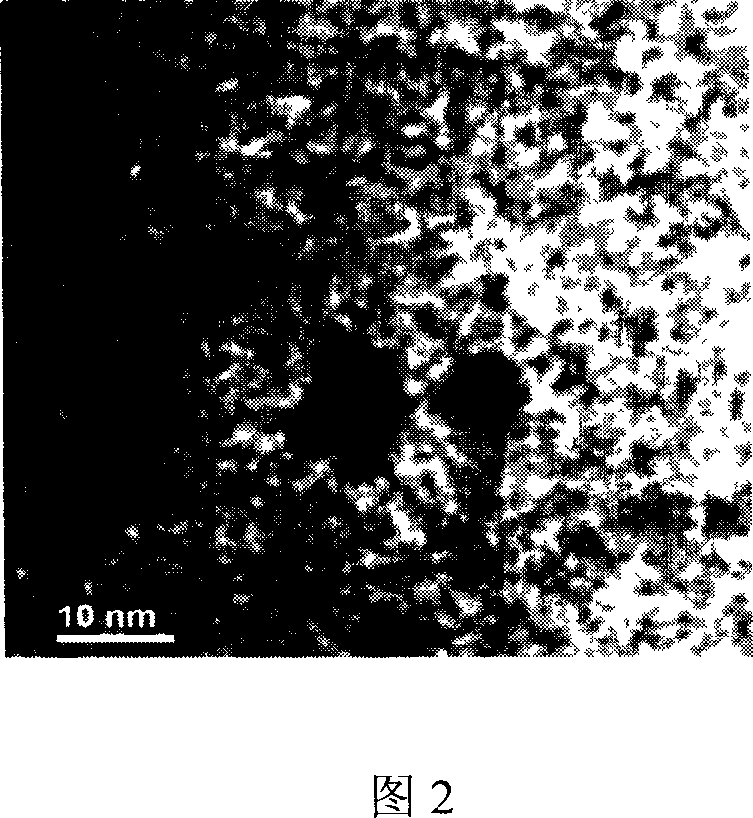

High Dispersing palladium catalyst prepared by lamellar precursor and preparation method thererof

InactiveCN1483512AHigh activityGood choicePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationAnthraquinonesPtru catalyst

The present invention provides a new palladium catalyst and its preparation method. Said method includes the following steps: firstly, in situ synthesizing hydrotalcite lamellar precursor body containing palladium in carrier surface layer hole, then roasting at higher temp. to convert the lamellar precursor body into correspondent composite metal oxide, and using hydrogen gas to make reduction treatment so as to obtain the loaded type high-dispersion catalyst in which the palladium is highly dispersed into the surface of internal hole of the carrier. Said catalyst mainly is used in antraquinone hydrogenation process for preparing hydrogen peroxide by means of antraquinone method.

Owner:BEIJING UNIV OF CHEM TECH

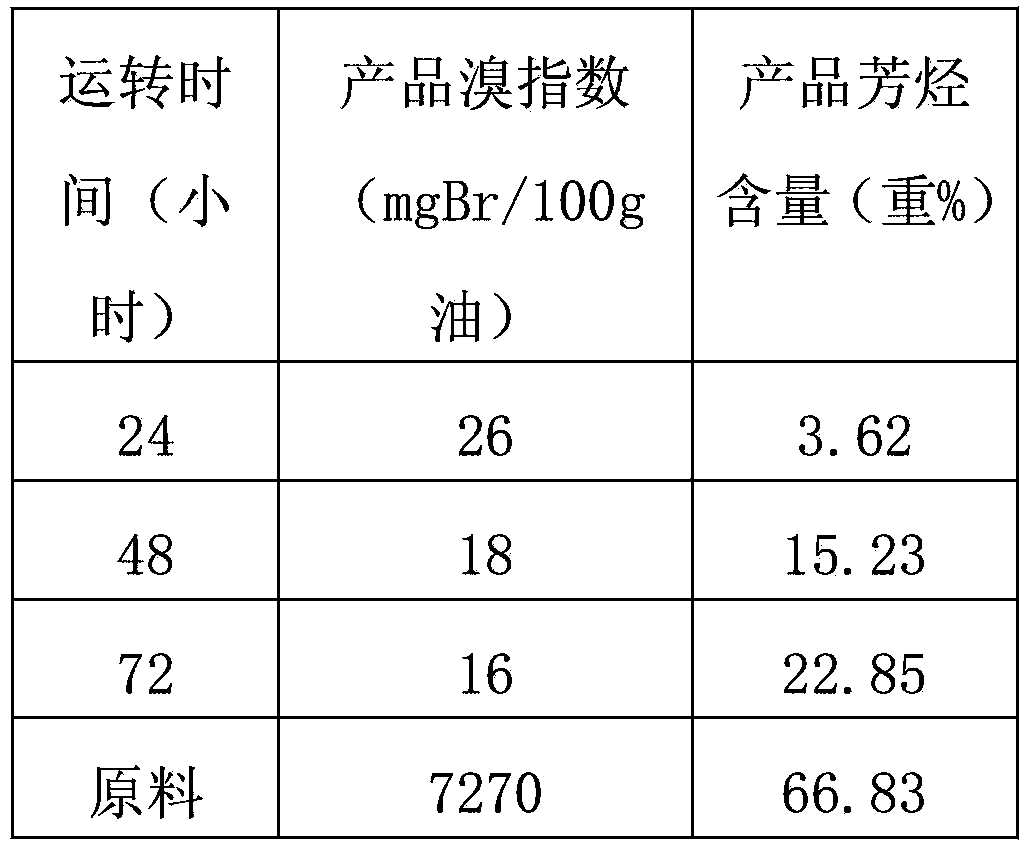

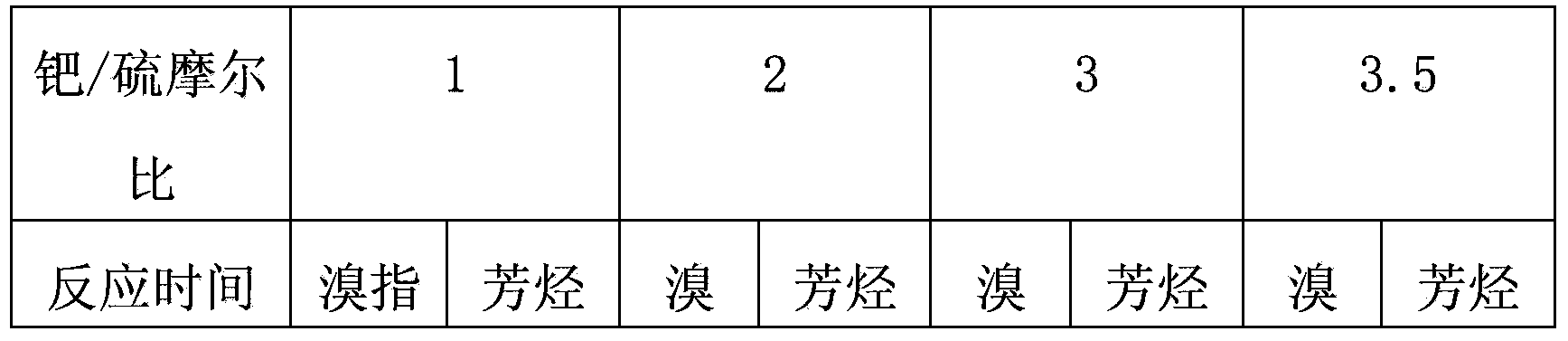

Method for selective hydrogenation of reforming generated oil

ActiveCN104342200AReduce pollutionLow costRefining by selective hydrogenationHydrocarbon oils treatment productsReaction temperaturePalladium catalyst

The invention relates to a method for selective hydrogenation of reforming generated oil. According to the reforming generated oil, the bromine index is 7270mgBr / 100g oil, and the weight of arene is 66.83%; the reaction conditions are as follows: the reaction temperature is 170 DEG C, the hydrogen partial pressure is 1.6MPa, the speed of liquid is 4h<-1> and the volume ratio between hydrogen and oil is 200. The method is characterized in that the used catalyst is Pd / gamma-Al2O3 containing 0.3wt% of palladium, and is passivated by a dry method with sulfur-containing compounds such as dimethyl disulfide, methyl thioether, butyl mercaptan or hydrogen sulfide before being filled; the added amount of the sulfide for passivation is as follows: the molar ratio of the palladium and the sulfur is 1-3.5; and the passivation temperature ranges from normal temperature to 230 DEG C. The method has the advantages that the pollution can be reduced, the investment can be reduced, convenience is brought for starting operation; after the palladium catalyst is passivated by the sulfide, the loss of arene of a hydrorefined product is lower than 0.5% (weight); after short-time reaction, the bromine index of the product is lower than 100 and the requirement of arene extraction for the raw materials can be met.

Owner:PETROCHINA CO LTD +1

Supported platinum and palladium catalysts and preparation method thereof

InactiveUS20080182745A1Small sizeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsParticulatesPlatinum

A method of preparing a supported platinum and / or palladium electrocatalyst and the electrocatalyst produced thereby. The method comprises the contacting of an electrically conductive particulate support which comprises adsorbed polynuclear hydroxo complexes of platinum and / or palladium with a reducing agent. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:MORE ENERGY

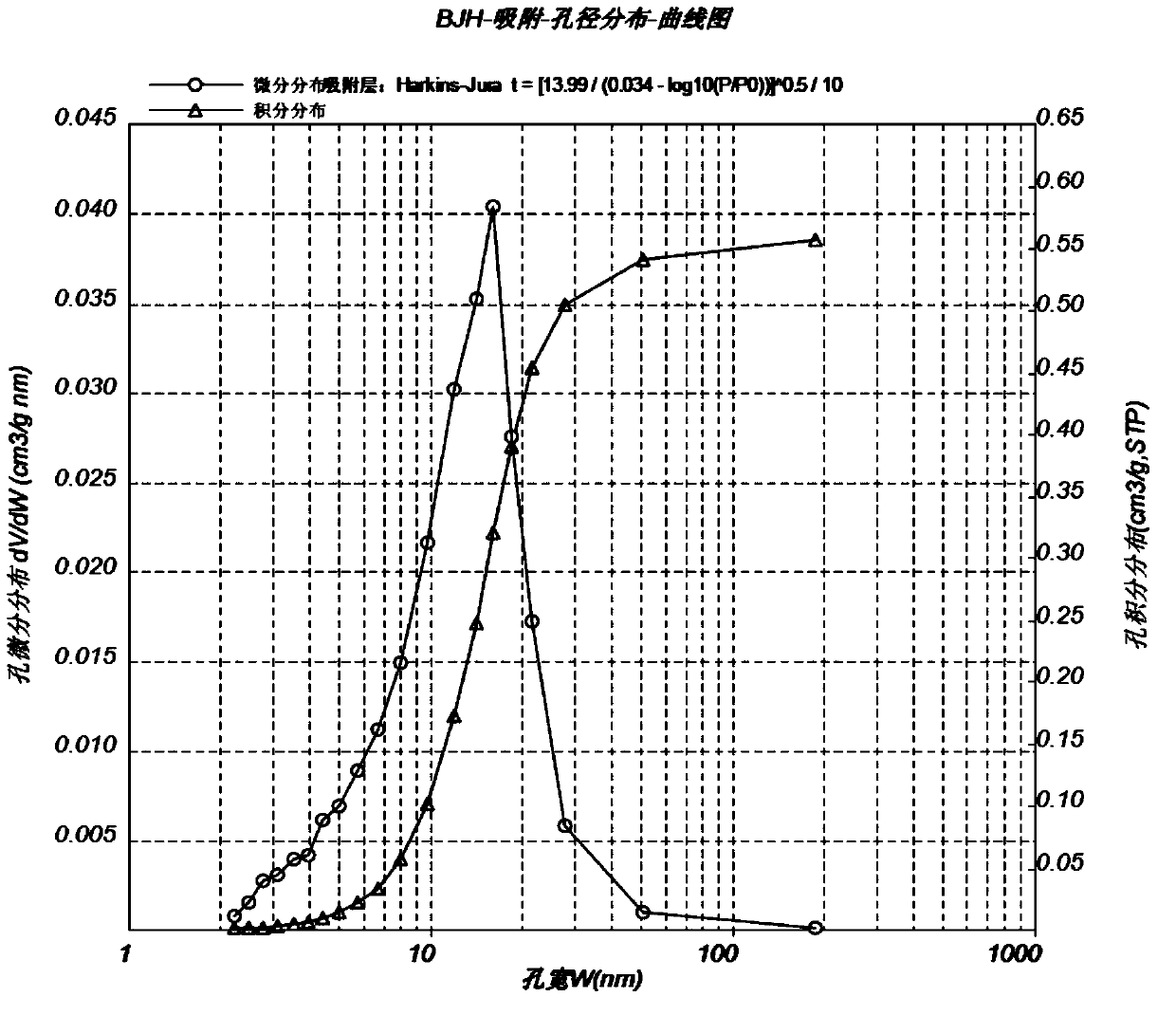

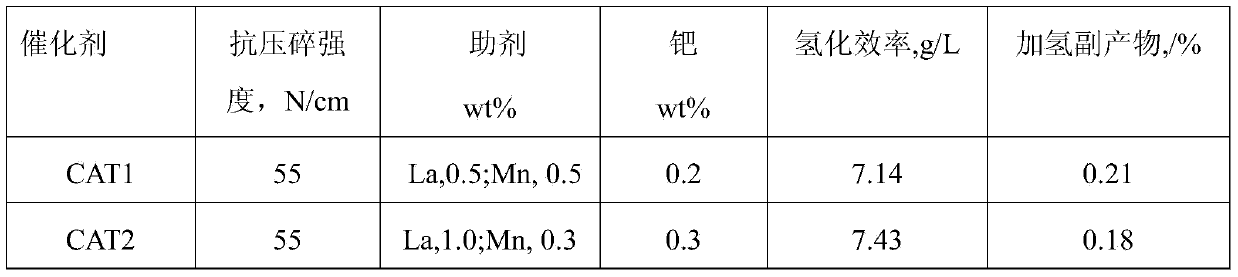

Supported palladium catalyst and preparation method thereof

InactiveCN103691437AUniform pore size distributionHigh mechanical strengthCatalyst carriersPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDispersityManganese

The invention discloses a supported palladium catalyst and a preparation method thereof. The catalyst comprises a carrier, aid ingredients and an active ingredient, wherein the carrier is gamma-aluminum oxide, the aid ingredients are lanthanum and manganese or lanthanum and cobalt, and the active ingredient is palladium; the palladium load capacity is 0.2 wt% to 0.8 wt%, the lanthanum load capacity is 0.5 wt% to 1.5 wt%, and the manganese or cobalt load capacity is 0.2 wt% to 0.5 wt%. According to the catalyst, the carrier is modified with aids subjected to vacuum adsorption drying, and a proper amount of the manganese or the cobalt is added, so that the growth of Al2O3 crystal particles during high-temperature treatment can be inhibited, the specific surface area of the catalyst is enlarged, the Pd dispersity is improved, the alkalinity of the carrier surface is enhanced, the Pd concentration of the catalyst surface is increased, the Pd layer thickness is reduced, and the hydrogenation activity and selectivity of the catalyst are improved; meanwhile, the prepared catalyst is high in mechanical strength, uniform in aperture distribution and low in impurity content.

Owner:JIANGSU GOLD BRIDGE SALT & CHEM GRP +1

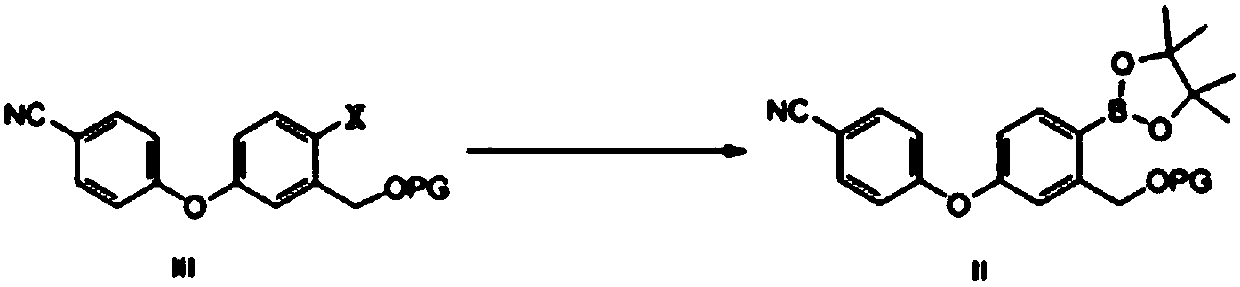

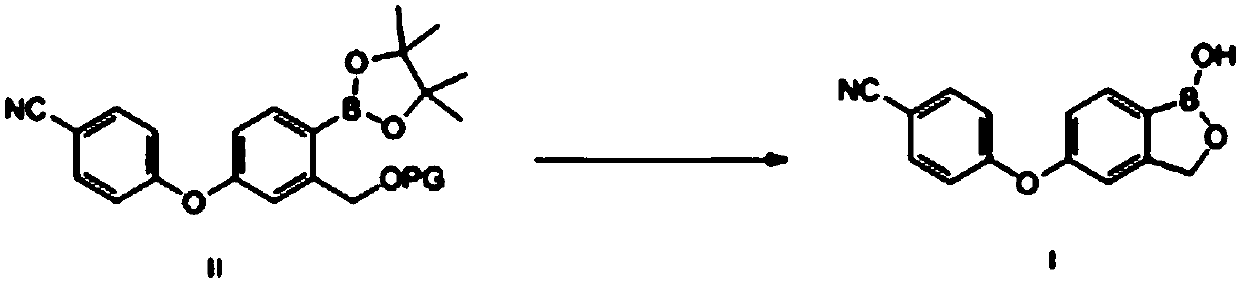

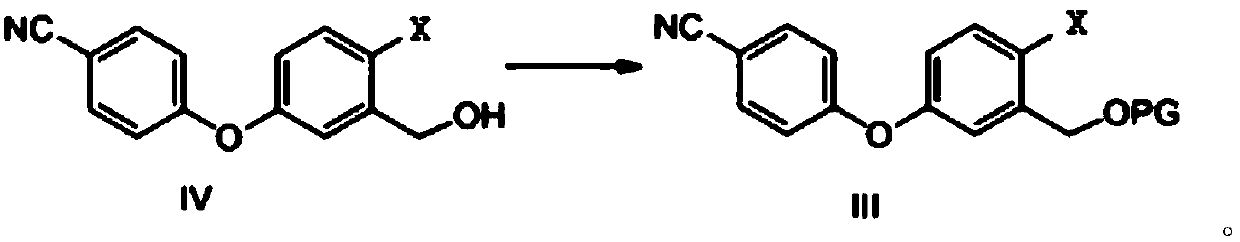

Method for preparing crisaborole

ActiveCN108047261AMild reaction conditionsEasy to operateGroup 3/13 element organic compoundsBulk chemical productionPhenylboronic acidOrganic solvent

The invention discloses a method for preparing crisaborole and an intermediate for preparing crisaborole. The method comprises the following steps: (1) enabling components such as 2-halogen-5-(4-cyanphenoxy) benzyl acetate and bis(pinacolato)diboron to react in the presence of an organic solvent and a palladium catalyst under an alkali condition so as to obtain components such as 2-acetoxyl methyl-4-(4-cyan phenoxy) phenylboronic acid pinacol ester; (2) enabling components such as the 2-acetoxyl methyl-4-(4-cyan phenoxy) phenylboronic acid pinacol ester to react in a solvent under an acid oralkali condition, thereby obtaining crisaborole. The method is gentle in reaction condition, easy to operate, high in reaction yield, simple in aftertreatment, relatively low in cost and applicable toindustrial production.

Owner:SUZHOU VIGONVITA LIFE SCIENCES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com