Method for preparing carbon supported Au-Pt or Au-Pd catalyst

A platinum catalyst and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem of local sintering of metal nanoparticles, shedding, and agglomeration and growth of nanoparticles and other problems, to achieve the effect of good industrial application prospects, improved catalytic activity, and low method cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The specific preparation steps of carbon-supported high-activity gold-platinum catalyst include as follows:

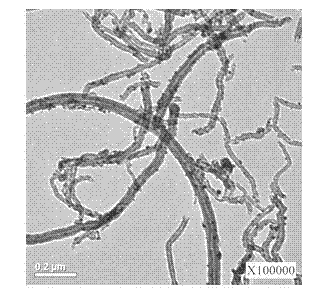

[0024] (1) In the mixed aqueous solution of Au(Ⅲ) content of 0.01wt% chloroauric acid and Pt(Ⅳ) content of 0.01wt% chloroplatinic acid, the mass ratio of gold: platinum is 1:0.25, and then in this solution Add polyvinylpyrrolidone (PVP) with a concentration of 1wt% as a protective agent, and then add sodium borohydride with a concentration of 0.1wt%, wherein the mass ratio of Au(Ⅲ):polyvinylpyrrolidone: sodium borohydride is 1:2: 0.1, Pt(Ⅳ): The mass ratio of polyvinylpyrrolidone: sodium borohydride is 0.25:2:0.1, stir at a speed of 60 rpm for 1 hour, and the reaction temperature is 10°C to obtain gold and platinum with a particle size of 3 to 10 nanometers Complex colloid solutions (such as figure 1 shown);

[0025] (2) Heat the gold-platinum composite colloid solution obtained in step (1) to 100oC under 2 standard atmospheric pressure (atm) and...

Embodiment 2

[0028] The specific preparation steps of the carbon-supported high-activity gold-platinum catalyst include as follows:

[0029](1) In the mixed aqueous solution of Au(Ⅲ) content of 0.03wt% chloroauric acid and Pt(Ⅳ) content of 0.02wt% chloroplatinic acid, the mass ratio of gold: platinum is 1:2, and then in this solution Add polyvinylpyrrolidone (PVP) with a concentration of 1wt% as a protective agent, and then add potassium borohydride with a concentration of 0.1wt%, wherein the mass ratio of Au(Ⅲ): polyvinylpyrrolidone: potassium borohydride is 1:4: 0.2, Pt (Ⅳ): polyvinylpyrrolidone: potassium borohydride mass ratio is 2:4:0.2, stirred at 100 rpm for 0.8h, the reaction temperature is 40°C, and the particle size is 3-8 nanometer gold Platinum complex colloidal solution;

[0030] (2) Heat the gold-platinum composite colloid solution obtained in step (1) to 200oC under the condition of 3 standard atmospheric pressure (atm) and a microwave frequency of 2000MHz, and keep it for ...

Embodiment 3

[0033] The specific preparation steps of the carbon-supported high-activity gold-platinum catalyst include as follows:

[0034] (1) In a mixed ethanol solution (95% concentration) with Au(Ⅲ) content of 0.04wt% chloroauric acid and Pt(Ⅳ) content of 0.01wt% chloroplatinic acid, the mass ratio of gold: platinum is 1: 4. Then add polyvinylpyrrolidone (PVP) with a concentration of 1wt% to this solution as a protective agent, and then add formaldehyde with a concentration of 0.1wt%, wherein the mass ratio of Au(III): polyvinylpyrrolidone: formaldehyde is 1: 5:0.5, Pt (Ⅳ): polyvinylpyrrolidone: formaldehyde mass ratio is 4:5:0.5, stirred at a speed of 300 rpm for 0.8h, the reaction temperature is 40°C, and the particle size is 3-7 nanometer gold Platinum complex colloidal solution;

[0035] (2) Heat the gold-platinum composite colloid solution obtained in step (1) to 250oC at 6 standard atmospheric pressure (atm) and a microwave frequency of 915MHz, and keep it for 6 minutes to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com