Patents

Literature

2229 results about "Platinum catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

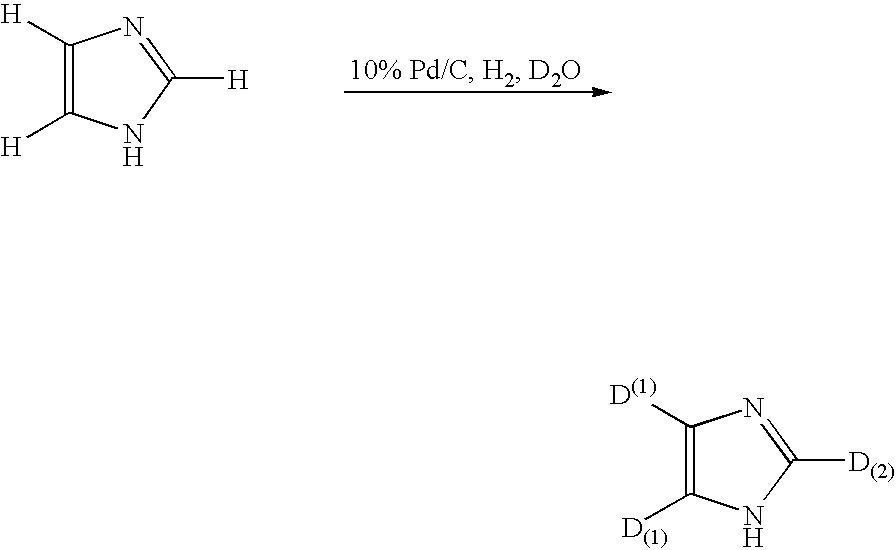

Method for deuteration of a heterocyclic ring

ActiveUS7517990B2Isotope introduction to heterocyclic compoundsSugar derivativesNickel catalystHydrogen atom

The present invention relates to a method for deuteration of a heterocyclic ring, which comprises subjecting a compound having a heterocyclic ring to sealed refluxing state in a deuterated solvent in the presence of an activated catalyst selected form a palladium catalyst, a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst. In accordance with a method of the present invention, a hydrogen atom belonging to a heterocyclic ring of a compound having a heterocyclic ring can be very efficiently deuterated because temperature of deuteration reaction can be maintained at higher than boiling point of the solvent.Further, a method for deuteration of the present invention can be applied widely to deuteration of various compounds having a heterocyclic ring which are liable to decomposition under supercritical conditions or acidic conditions, leading to industrial and efficient deuteration of a compound having a heterocyclic ring.

Owner:FUJIFILM WAKO PURE CHEM CORP

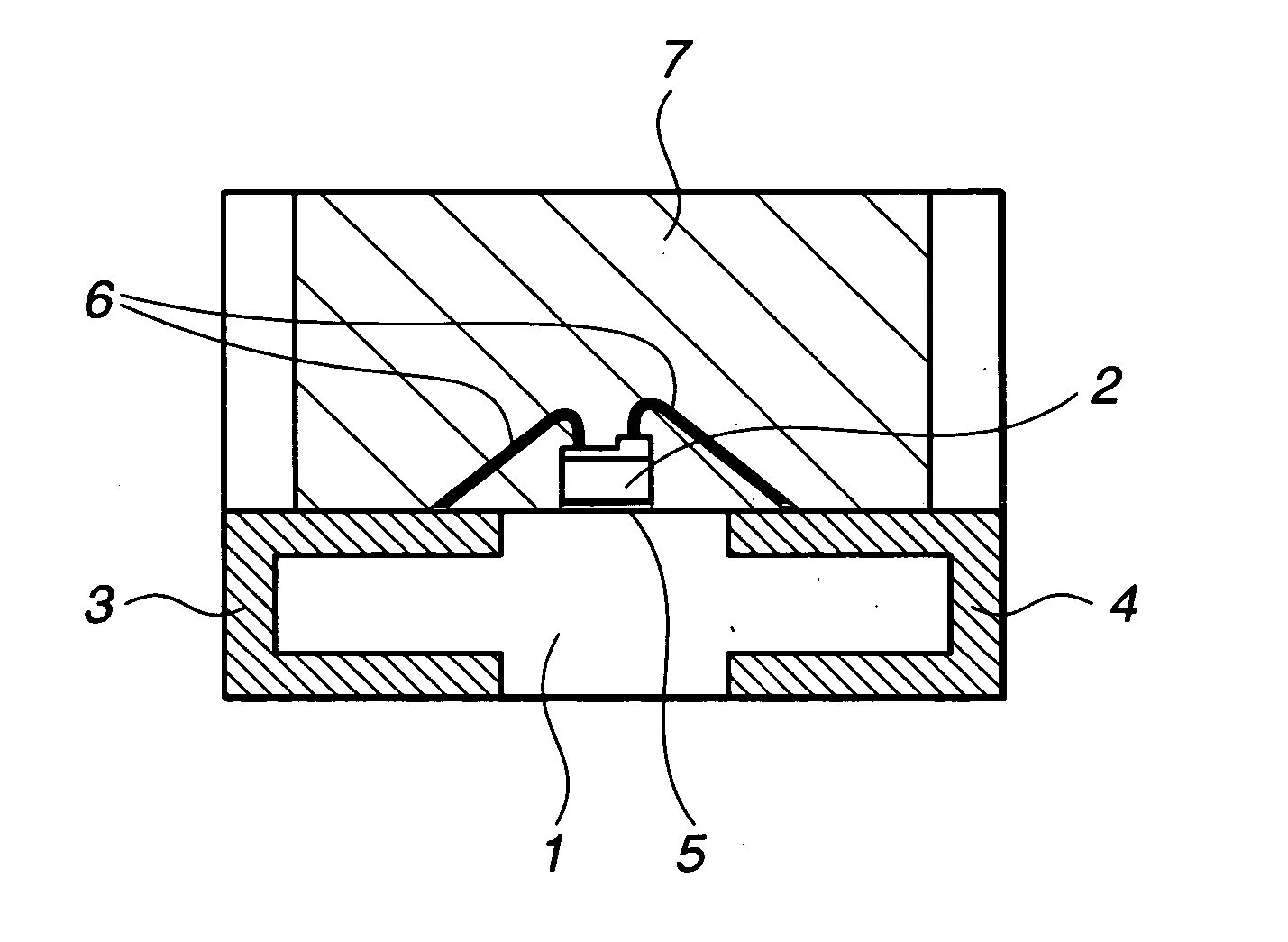

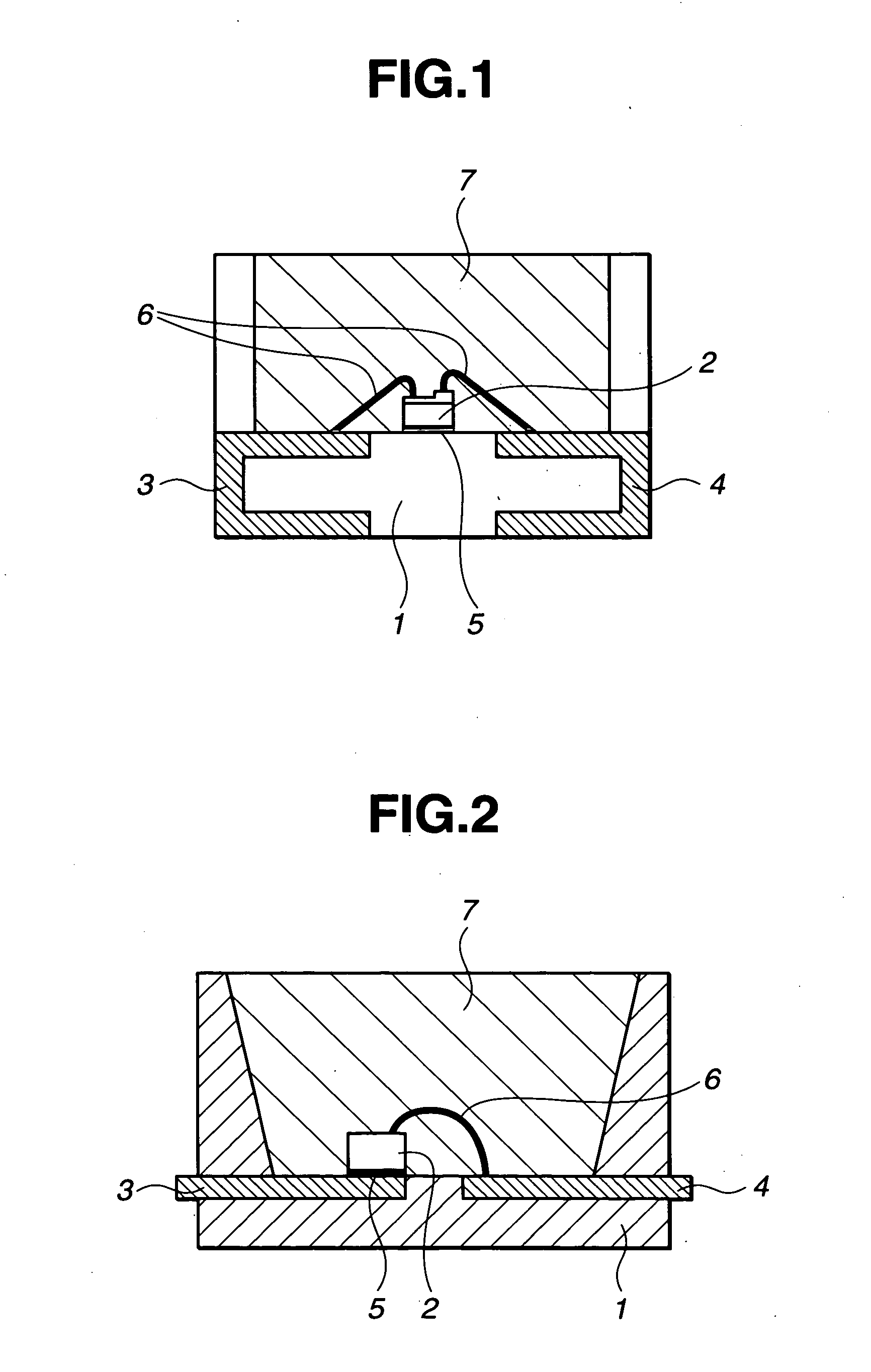

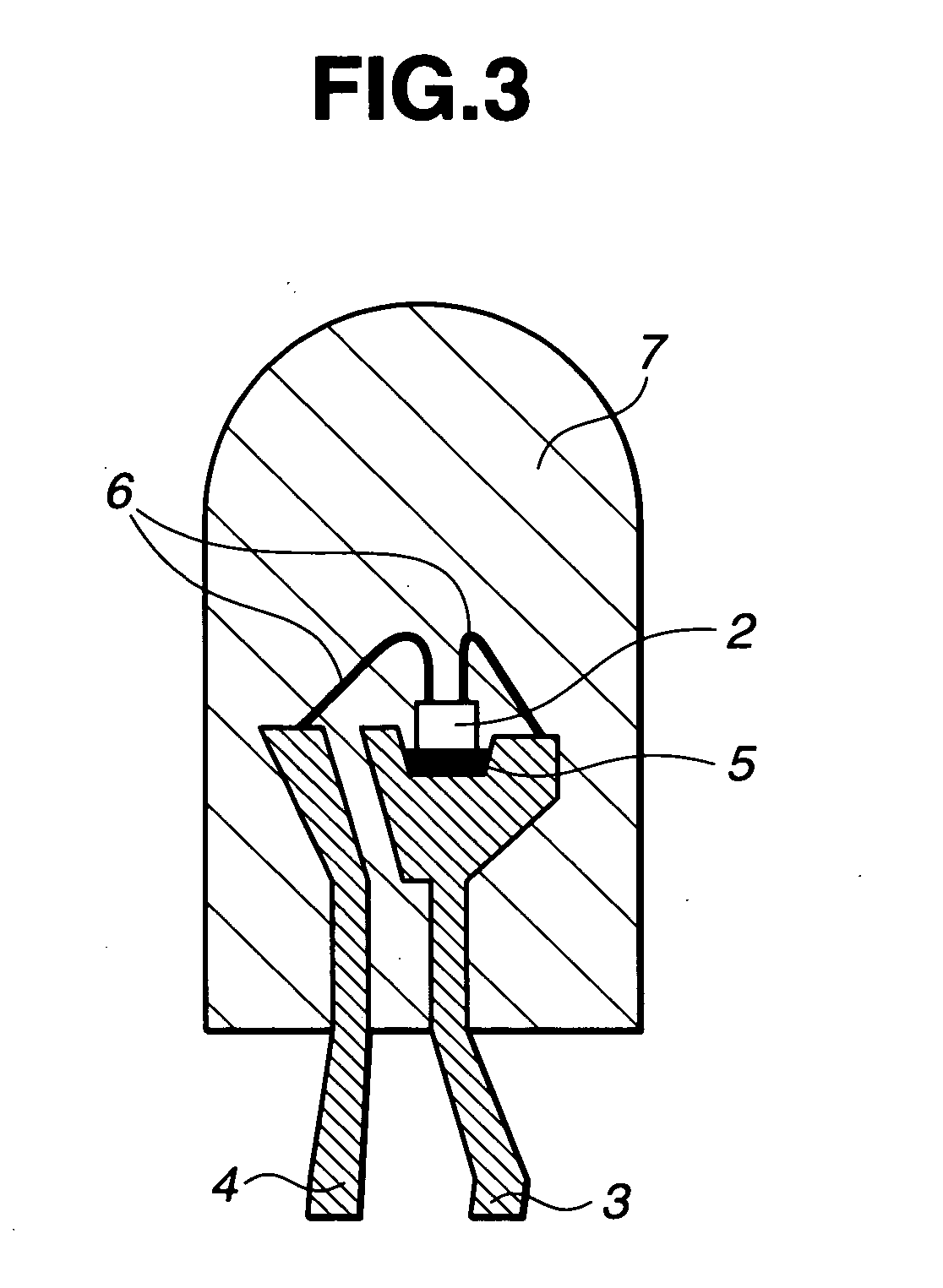

Silicone rubber composition, light-emitting semiconductor embedding/protecting material and light-emitting semiconductor device

ActiveUS20050006794A1Eliminates surface tackSolve low adhesionSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

A silicone rubber composition comprising (A) an organopolysiloxane containing at least two aliphatic unsaturated bonds, (B) an organopolysiloxane of resin structure comprising SiO2 units, R3nR4pSiO0.5 units and R3qR4rSiO0.5 units wherein R3 is vinyl or allyl, R4 is a monovalent hydrocarbon group free of aliphatic unsaturation, n is 2 or 3, p is 0 or 1, n+p=3, q is 0 or 1, r is 2 or 3, q+r=3, (C) an organohydrogenpolysiloxane having at least two SiH groups, and (D) a platinum catalyst cures into a silicone rubber having excellent rubbery and strength properties and little surface tack.

Owner:SHIN ETSU CHEM IND CO LTD

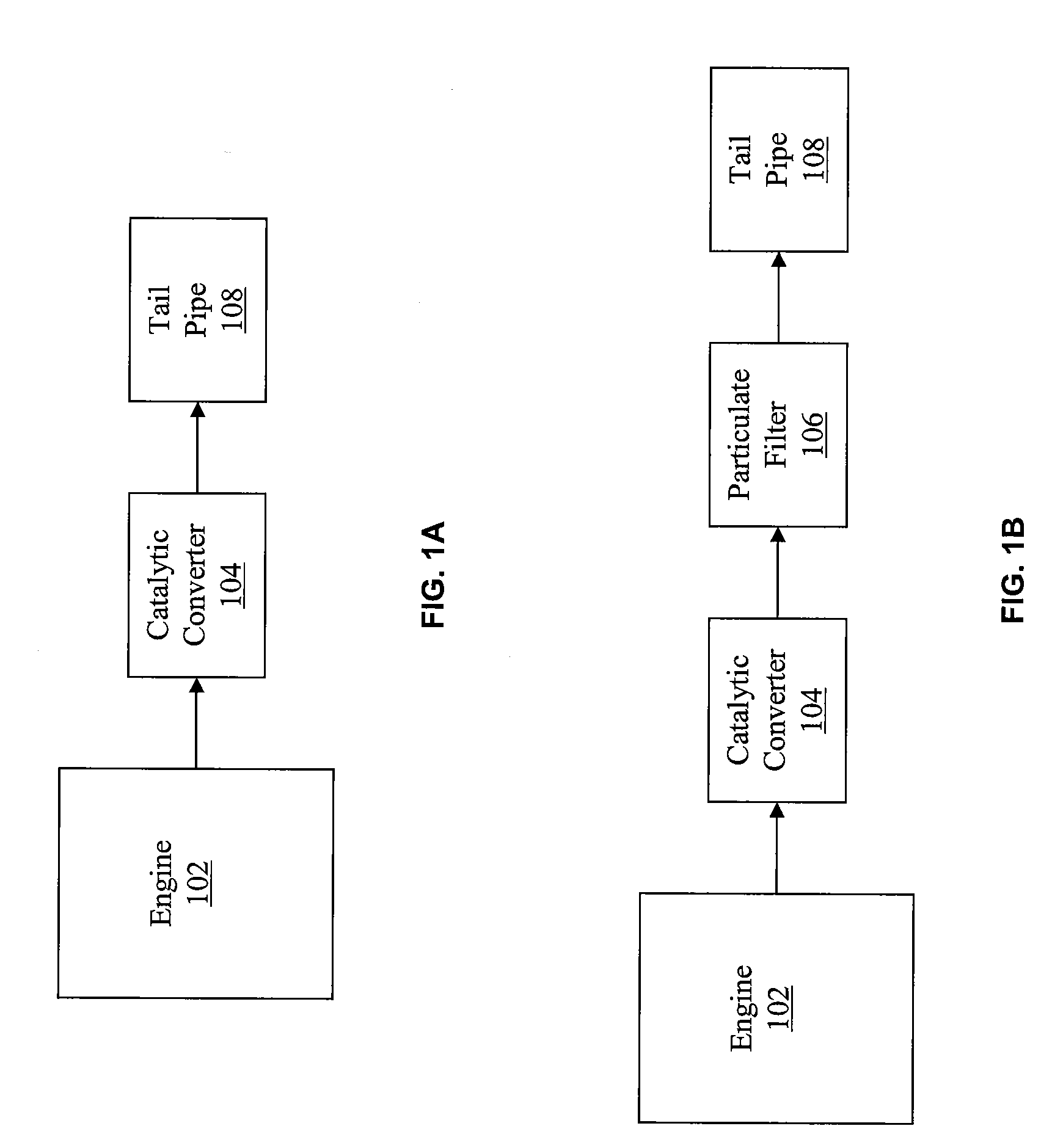

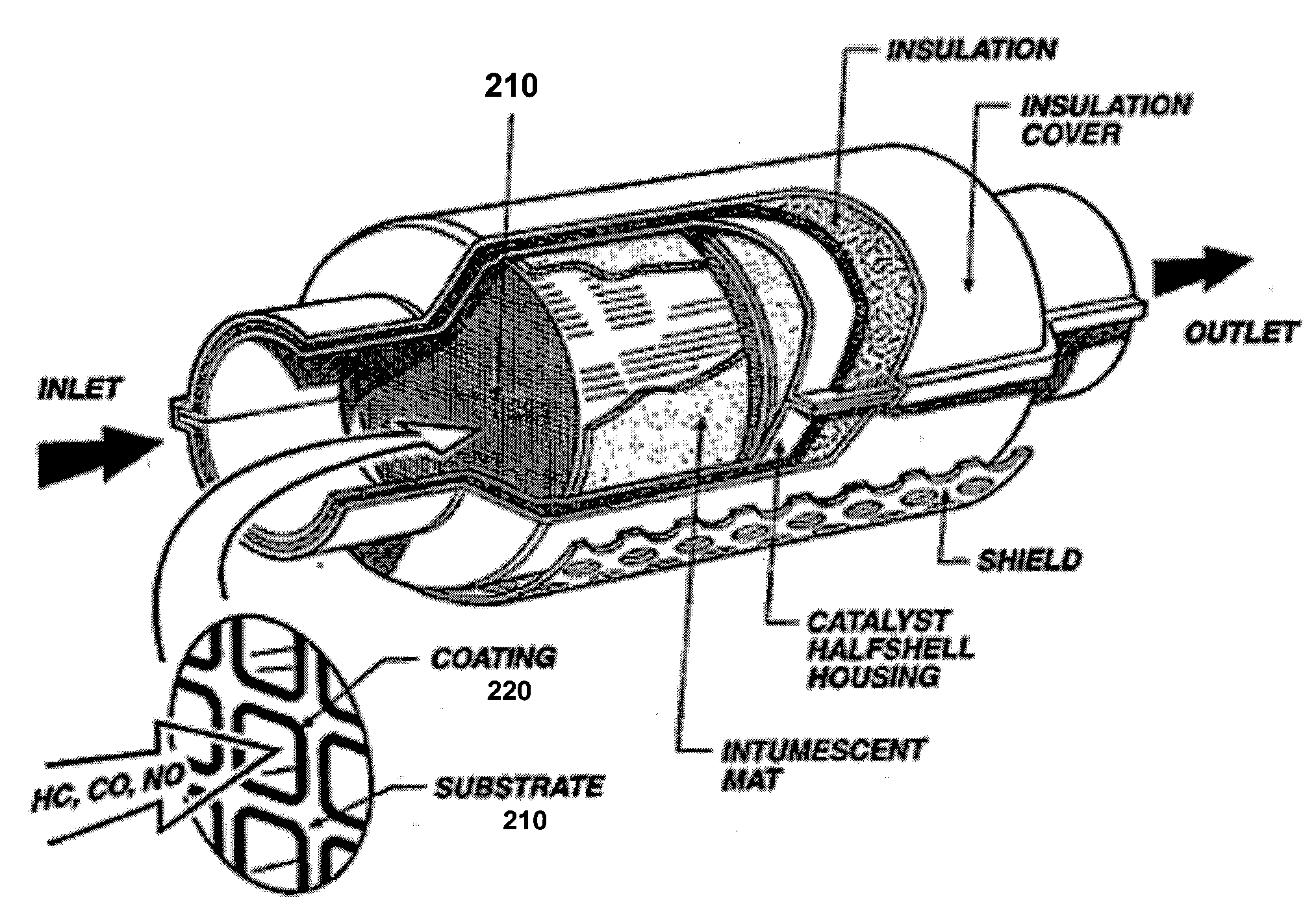

Engine exhaust catalysts containing palladium-gold

ActiveUS7709414B2High activityEmission reductionCombination devicesInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum—palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGC HLDG LTD

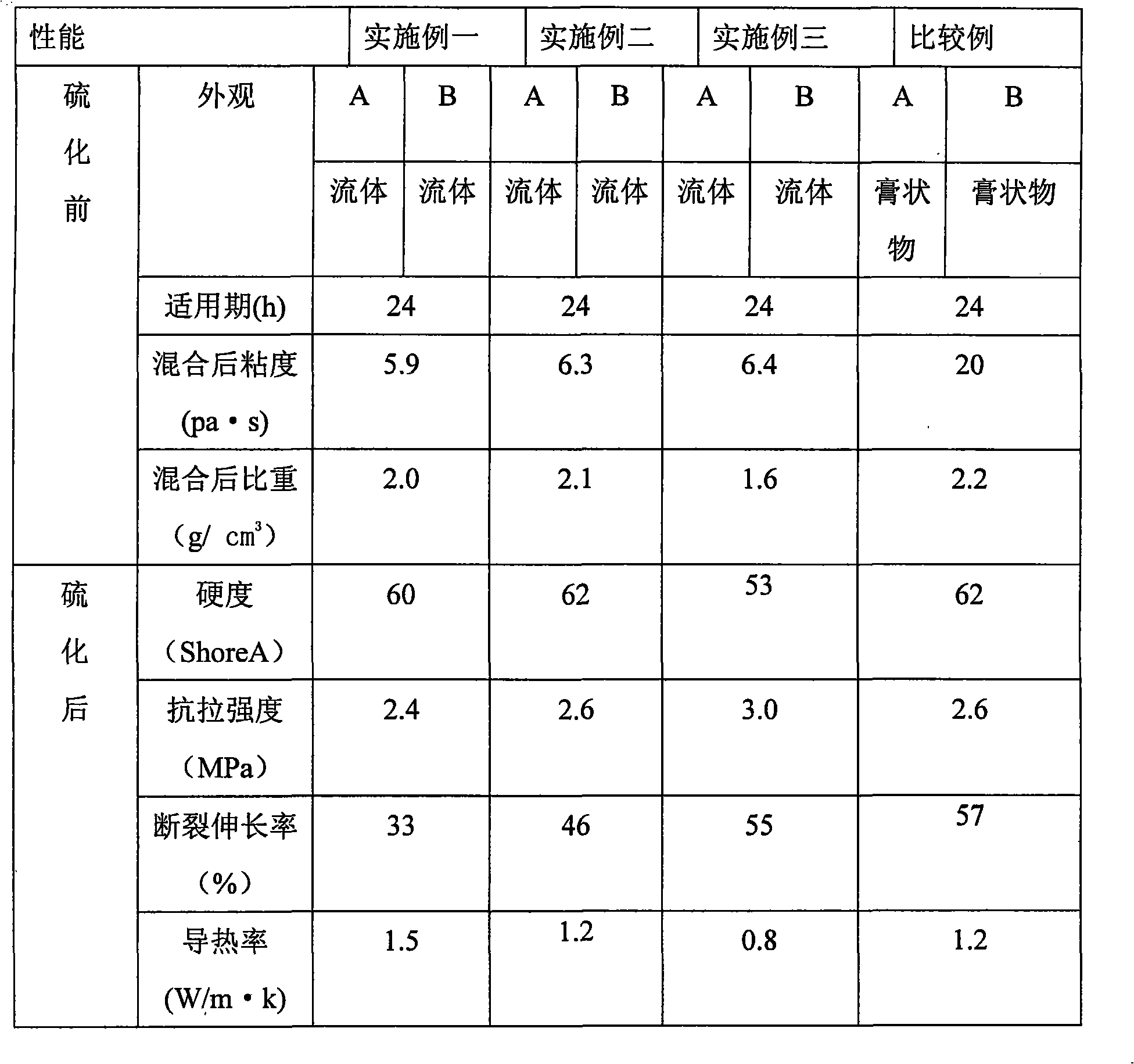

Halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive and preparation method thereof

ActiveCN101735619AExcellent electrical performanceImprove flame retardant performanceOther chemical processesCross-linkHydrogen

The invention discloses a halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive and a preparation method thereof. The preparation method comprises: adding vinyl dimethicone, a reinforcing material, a heat-conducting filling material and a halogen-free flame retardant in a vacuum kneader, dehydrating and blending for 30-120 minutes at 100-150 DEG C and vacuum degree of 0.06-0.1MPa to obtain a base material, adding a cross-linking agent containing hydrogen silicone oil and a cross-linking inhibitor to the base material at the normal temperature, adequately agitating for 10-30 minutes to prepare a component A; adding a platinum catalyst to the base material, adequately agitating for 10-30 minutes to prepare a component B; taking the component A and the component B of the same parts by weight, blending uniformly, and deaerating for 5-10 minutes at the vacuum degree of 0.06-0.1MPa to obtain the halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive. The potting adhesive has good flow properties and convenient use and can be cured at the normal temperature or a high temperature, condensate has excellent flame retardant property and heat-conducting property, and the potting adhesive can be widely applied to the fields of electronic electric appliance, chip encapsulation and LED encapsulation, and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

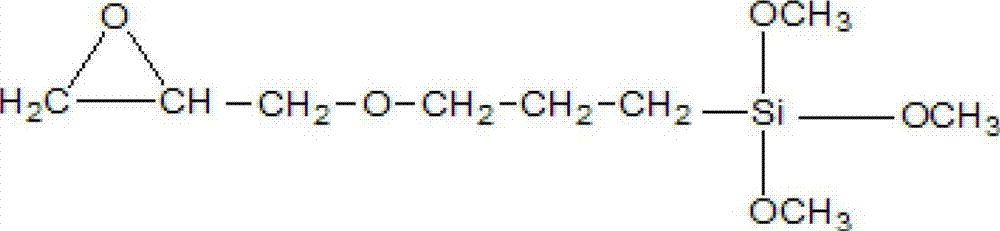

Process for an addition reaction of organic silicon compounds having SiH groups with compounds having olefinic double bonds

ActiveUS7157541B2Silicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilanesUnsaturated hydrocarbon

The invention relates to a process for the preparation of polyorganosiloxanes and polyorganosilanes of high purity by an addition reaction of siloxanes and / or silanes which contain at least one H—Si group with compounds having olefinic double bonds in the presence of a platinum catalyst and optionally further additional components, wherein the reaction is carried out in the presence of a platinum(0) complex catalyst which was dissolved in a solvent before addition to the reaction medium and to whose solution an effective amount of at least one unsaturated hydrocarbon having 2 to 6 carbon atoms was added.

Owner:EVONIK DEGUSSA GMBH

Tin promoted platinum catalyst for carbonylation of lower alkyl alcohols

InactiveUS6903045B2Not volatileLess solubleIsocyanic acid derivatives preparationOrganic compound preparationSolid componentGas phase

A carbonylation catalyst useful for producing esters and carboxylic acids in a vapor phase carbonylation process, wherein the catalyst includes a solid component having a catalytically effective amount of platinum and tin associated with a solid catalyst support material and a vaporous halide promoter component.

Owner:EASTMAN CHEM CO

Engine Exhaust Catalysts Containing Palladium-Gold

InactiveUS20080125313A1Reduce inhibitionEmission reductionGas treatmentInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum-palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGCH TECH LIMITED WORLD GOLD COUNCIL

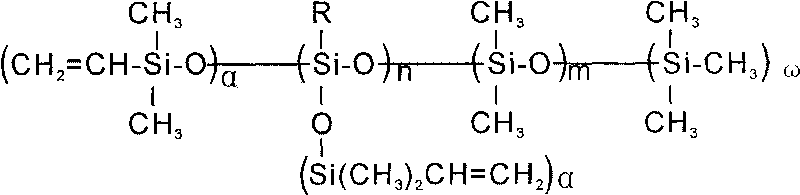

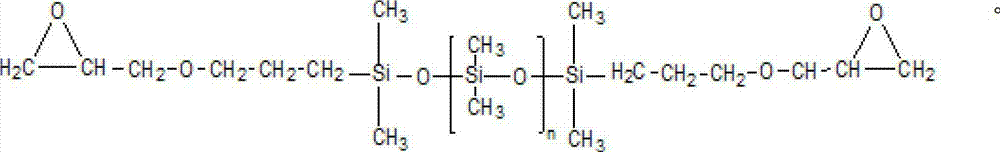

Grafted rubber-like silicone gel with enhanced oil compatibility and its synthetic process

InactiveUS6331604B1Improve compatibilityReduce capacityCosmetic preparationsToilet preparationsSilicone GelsVegetable oil

Fatty alcohol or aliphatic glycol-grafted rubber-like silicone gels with enhanced oil compatibility are synthesized by 1) reacting a fatty alcohol or a aliphatic glycol with methylhydrodimethylsiloxane copolymer in the presence of a platinum catalyst in a reaction medium of a silicone fluid or a cosmetic oil or a mixture thereof, and 2) further reacting the mixture with a vinyl-functional siloxane polymer. The resulting compounds may be used as gelling agents for hydrocarbon oils, vegetable oils and silicone oils. The efficient synthetic process approaches a 100% yield.

Owner:GRANT INDS

Bimetallic platinum catalysts for hydrosilations

A hydrosilation processing a silicon hydride with an unsaturated reactant in the presence of a supported bimetallic catalyst comprising an active hydrosilating metal such as platinum in elemental or compound form, and a surface segregating metal such as copper in elemental or compound form on a support.

Owner:DOW CORNING CORP

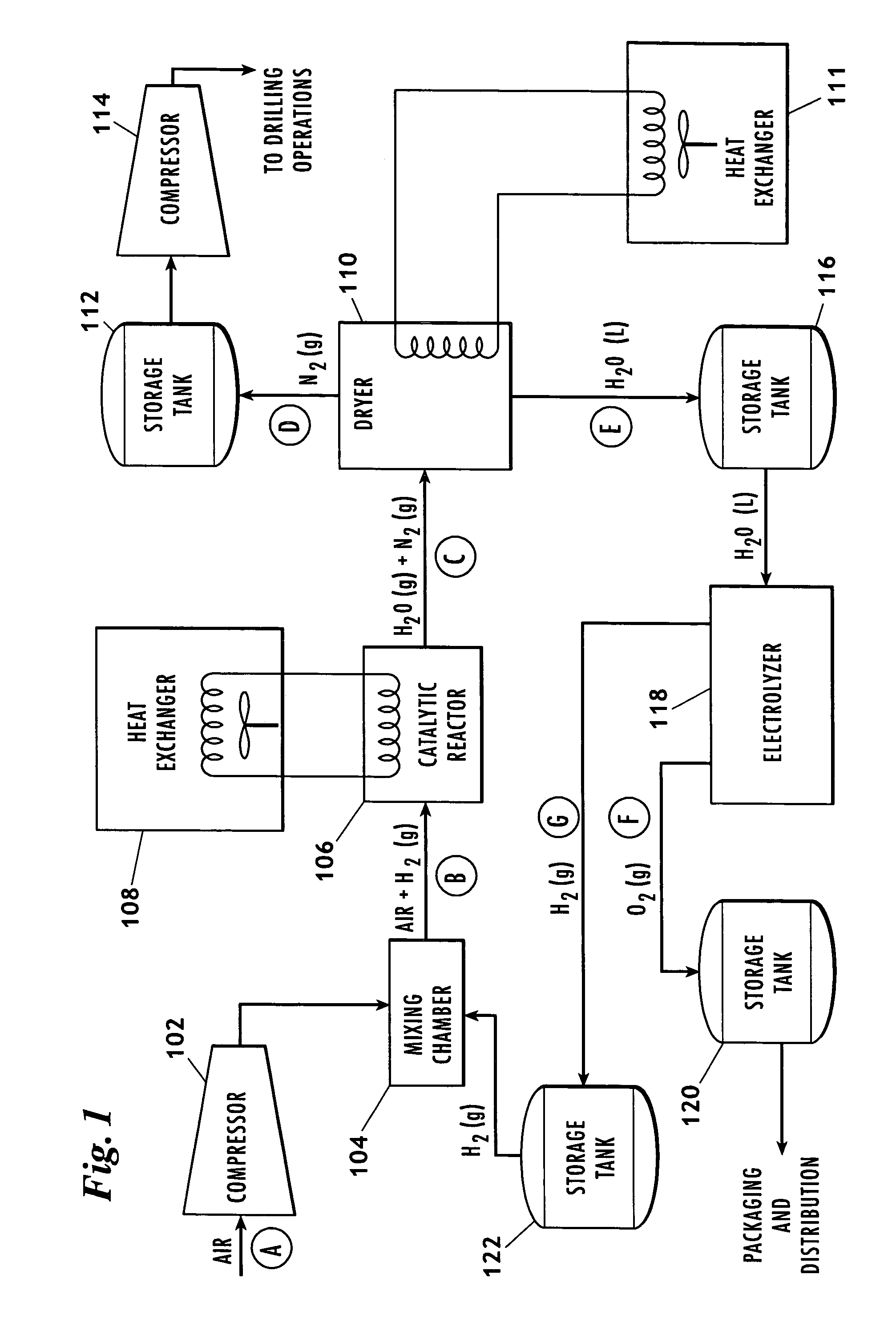

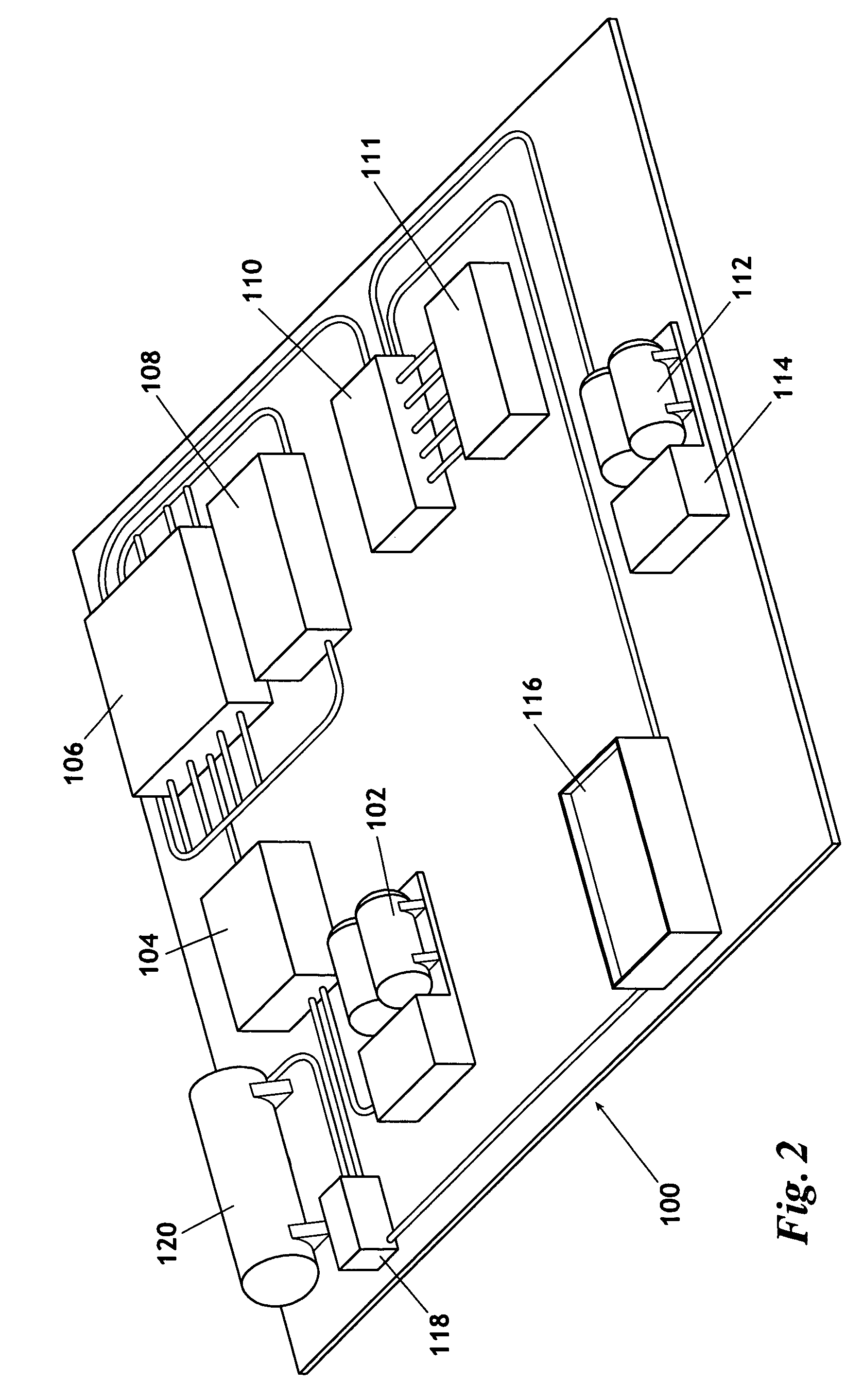

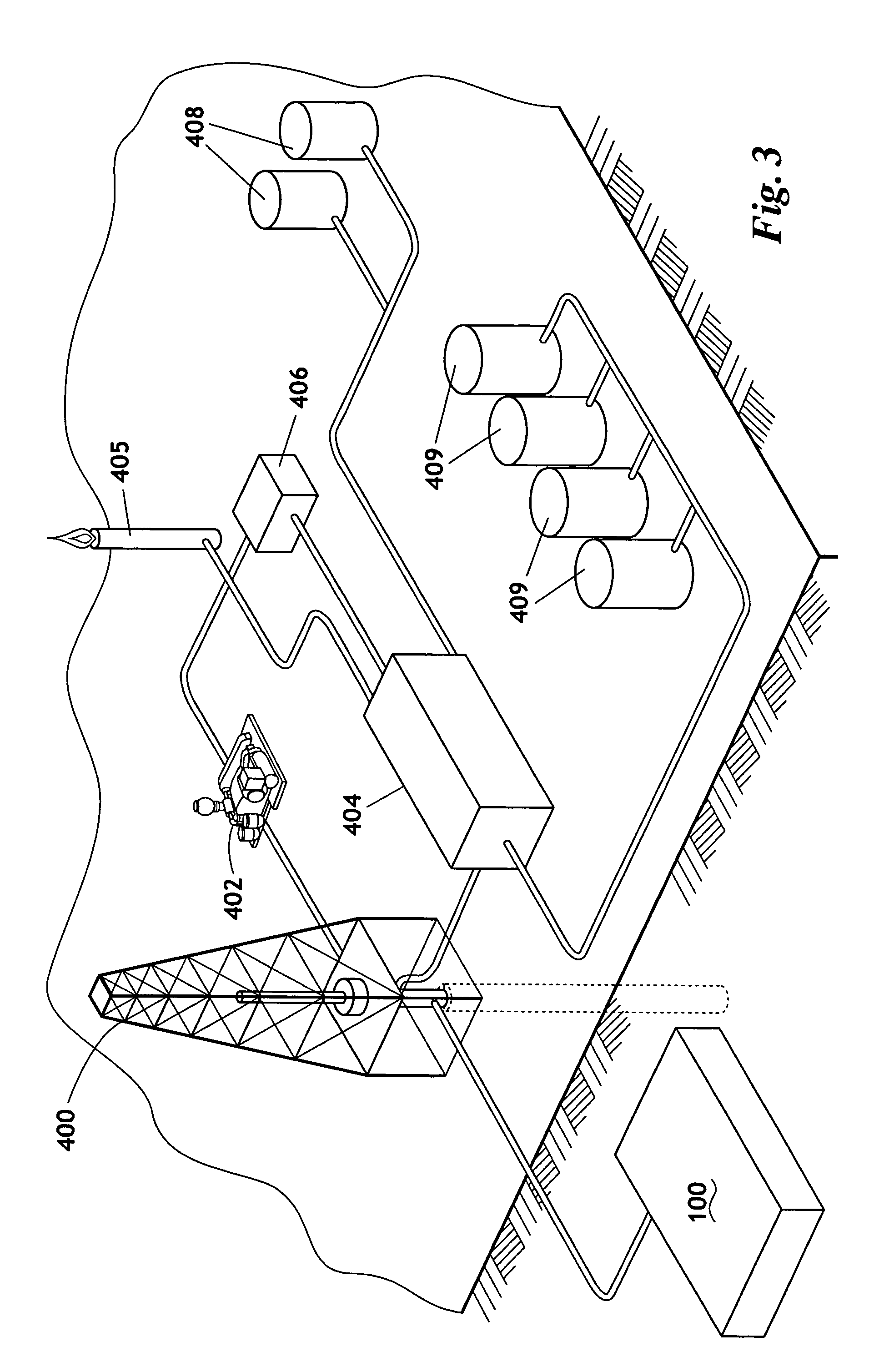

Method for producing nitrogen to use in under balanced drilling, secondary recovery production operations and pipeline maintenance

InactiveUS7468173B2Offsetting costsNitrogen purification/separationDispersed particle separationElectrolysisAtmospheric air

The invention uses a feed of atmospheric air and mixes the air with hydrogen. The hydrogen and air mixture is fed into a catalytic reactor where a deoxygenation reaction occurs. The deoxygenation reaction uses a platinum catalyst to produce water from oxygen and hydrogen. The nitrogen passes through the catalytic reactor without reacting with the hydrogen, the oxygen, or the water. The water is separated from the nitrogen in a dryer. The nitrogen may then be used in drilling and production operations. The water is fed into an electrolyzer where an electrolysis reaction occurs. The electrolyzer passes an electrical current through the water to produce gaseous oxygen and hydrogen. The hydrogen is recycled back to the catalytic reactor and the oxygen may be vented or sold.

Owner:SUNSTONE TECH

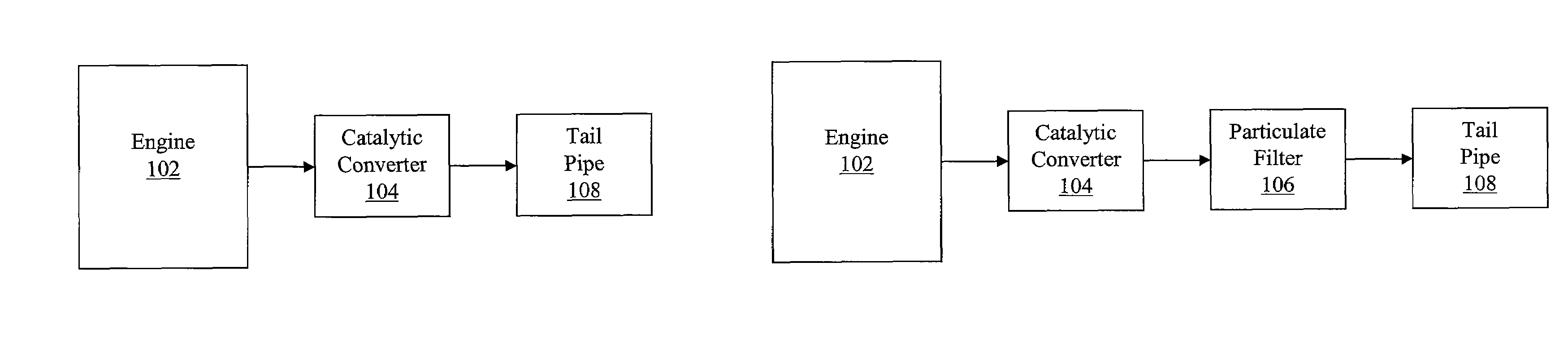

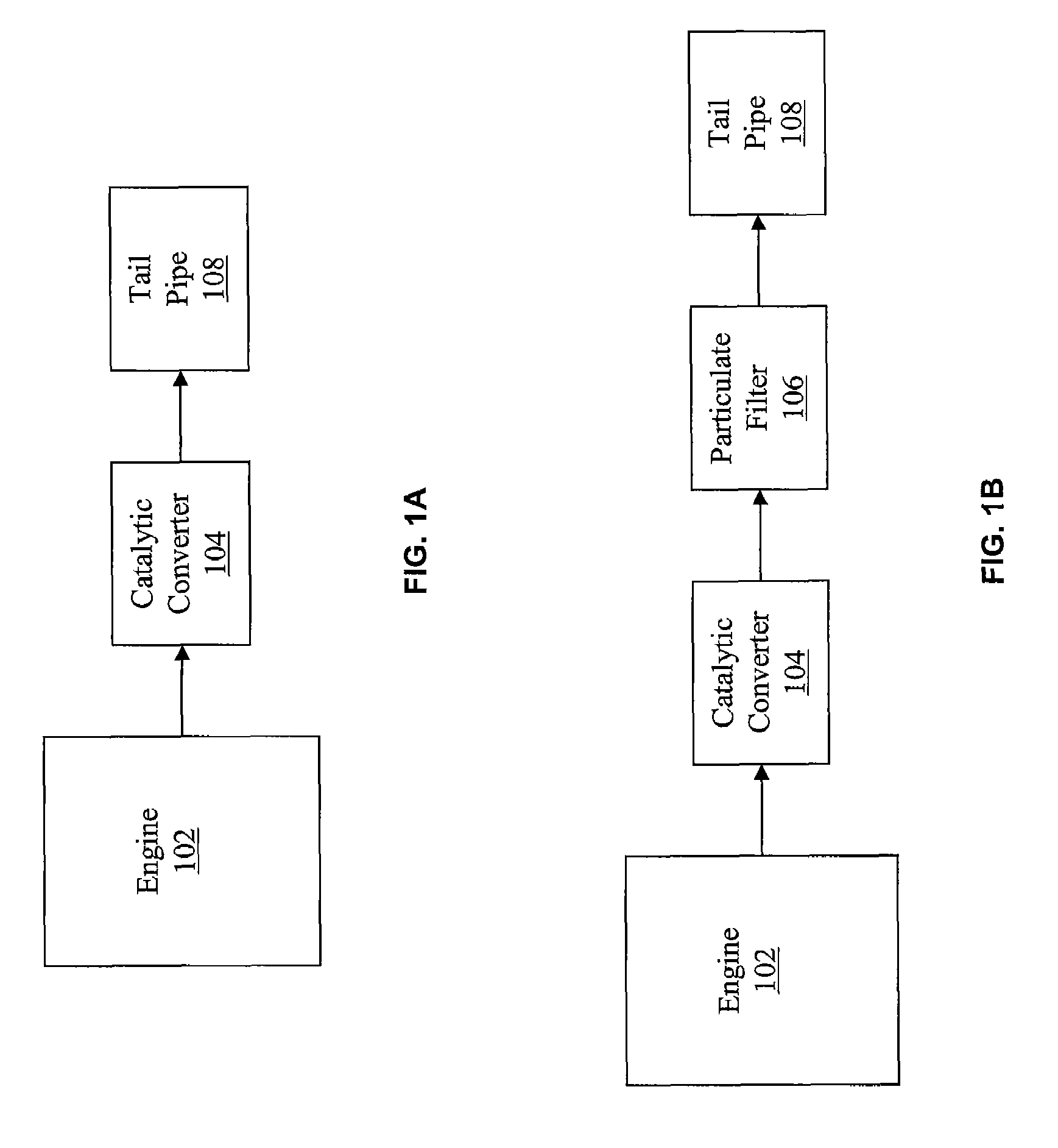

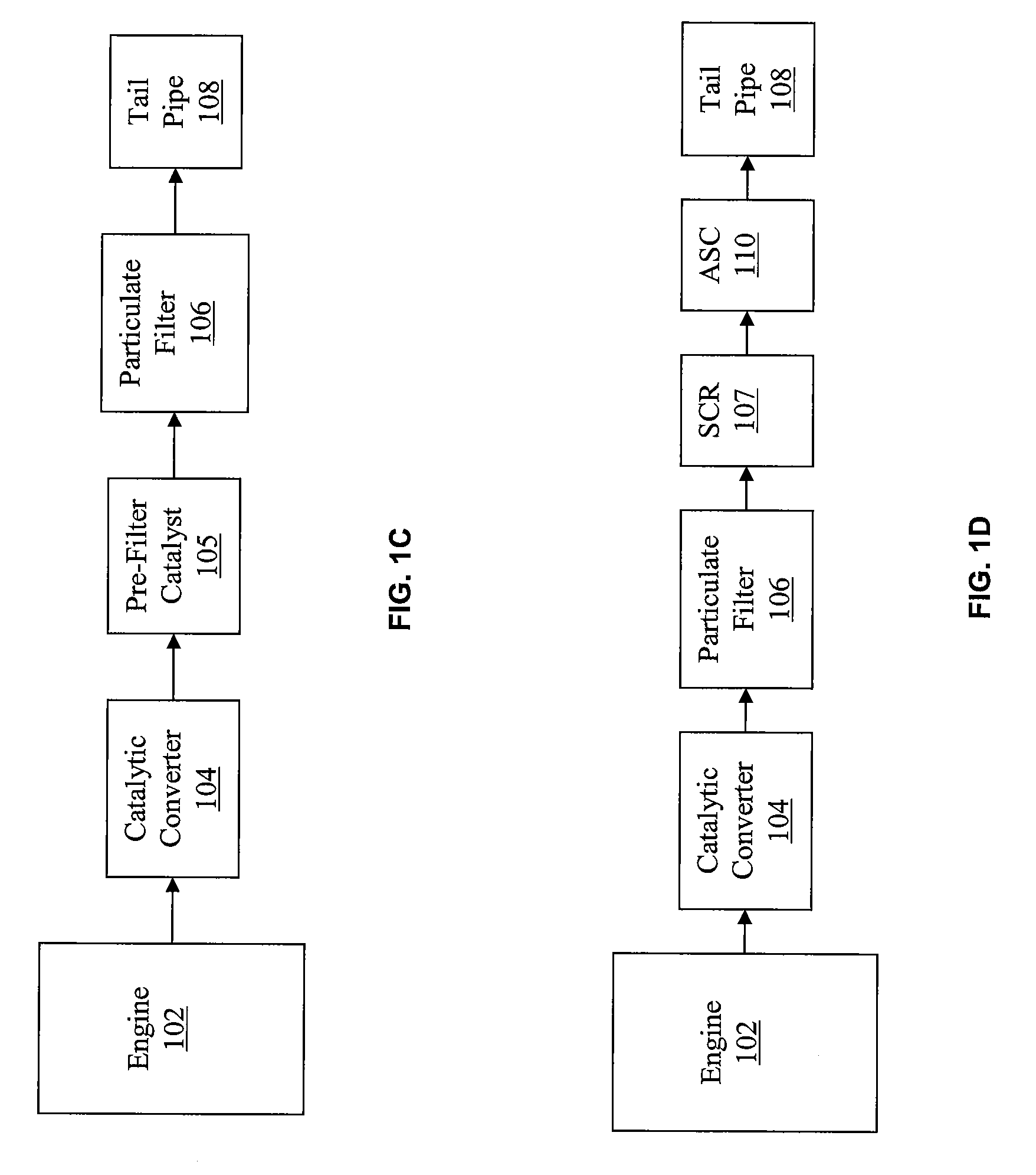

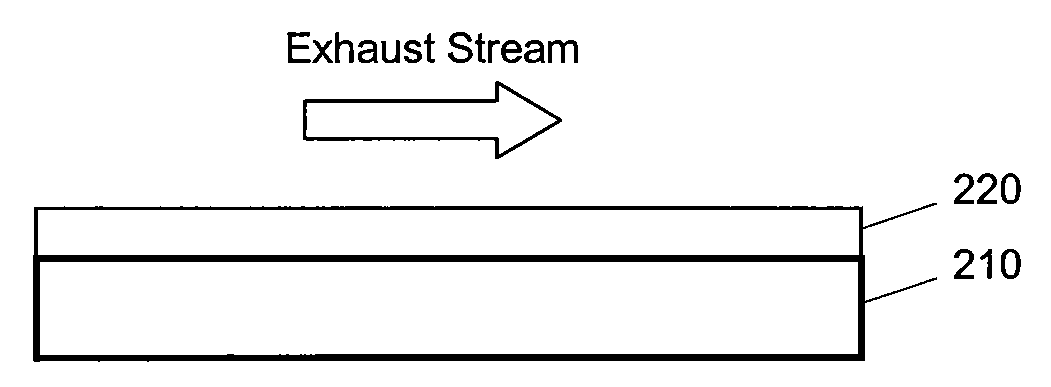

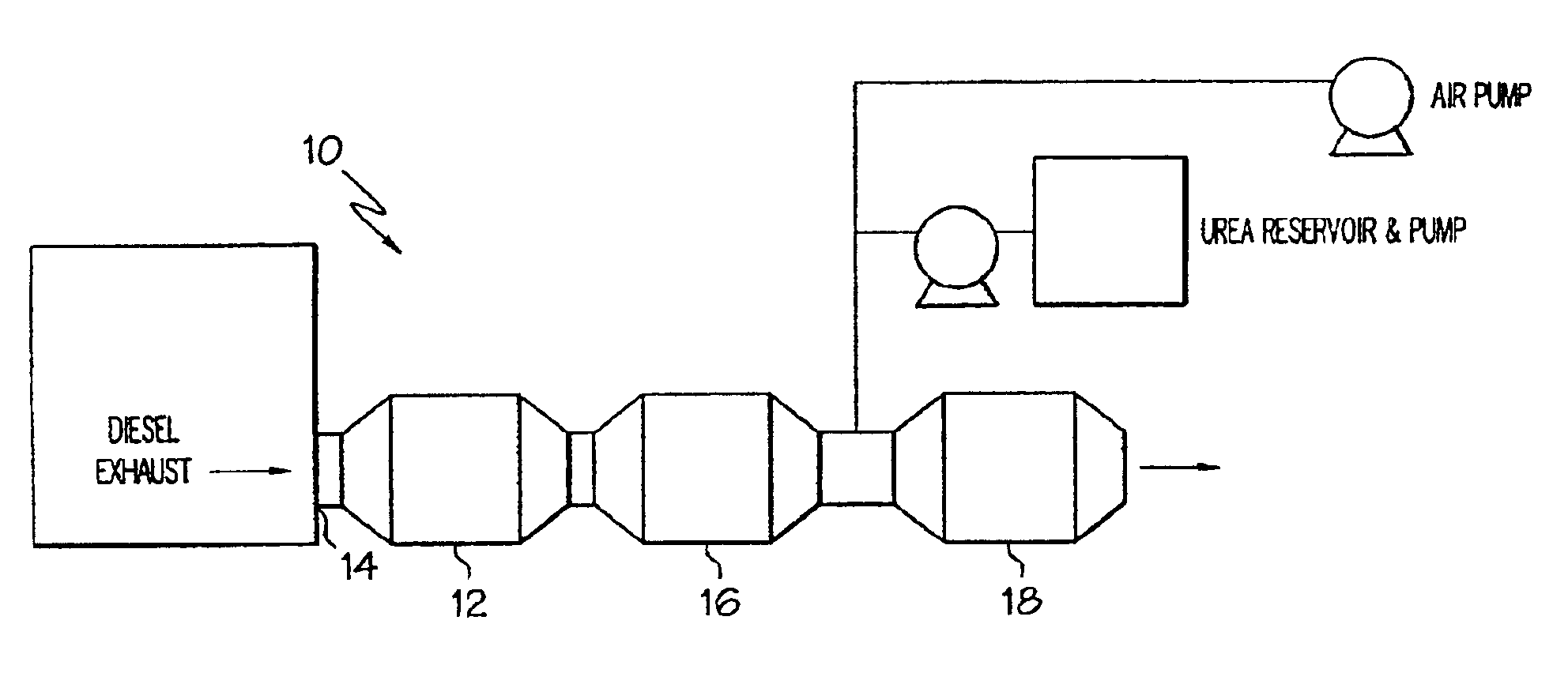

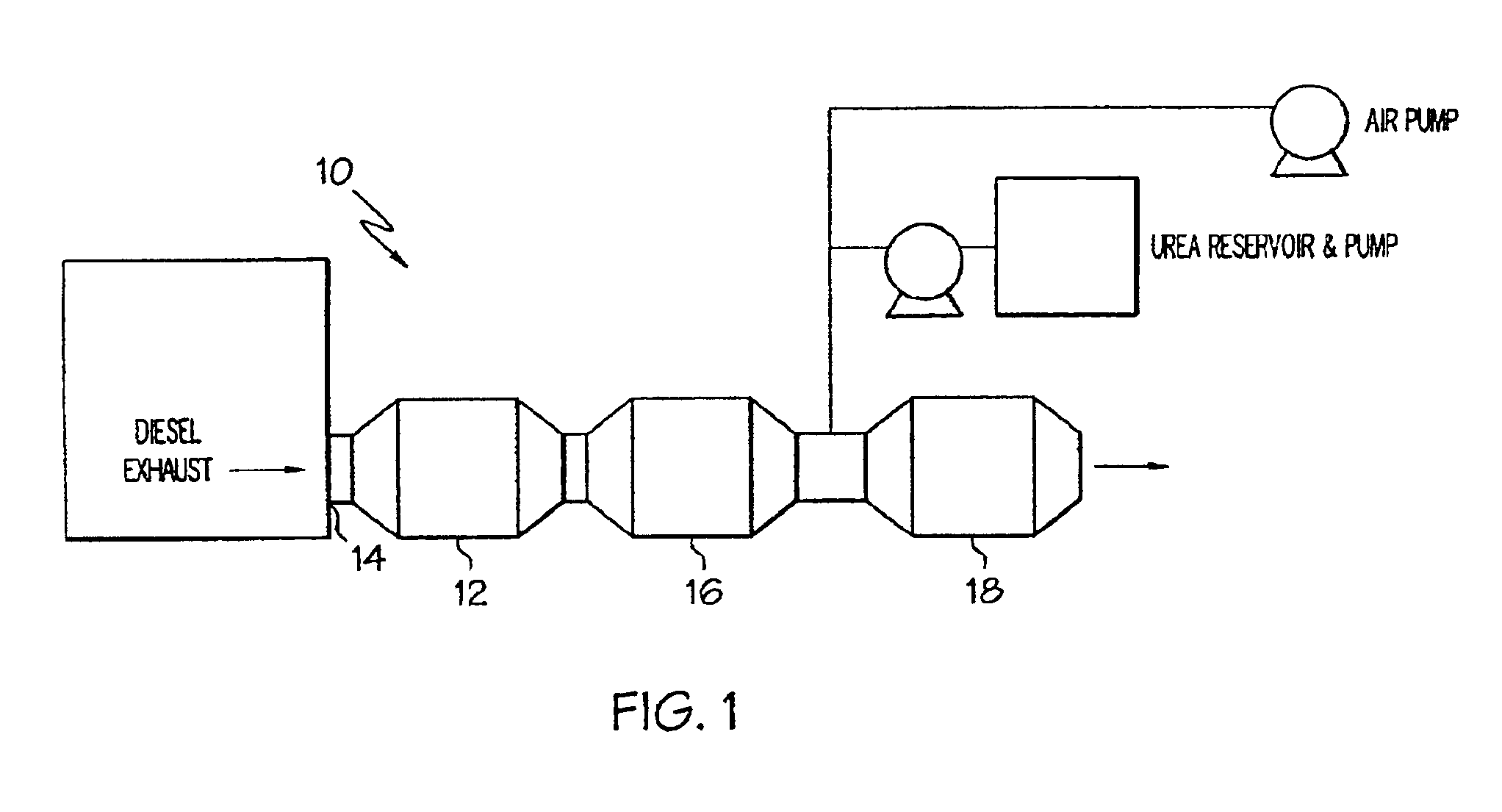

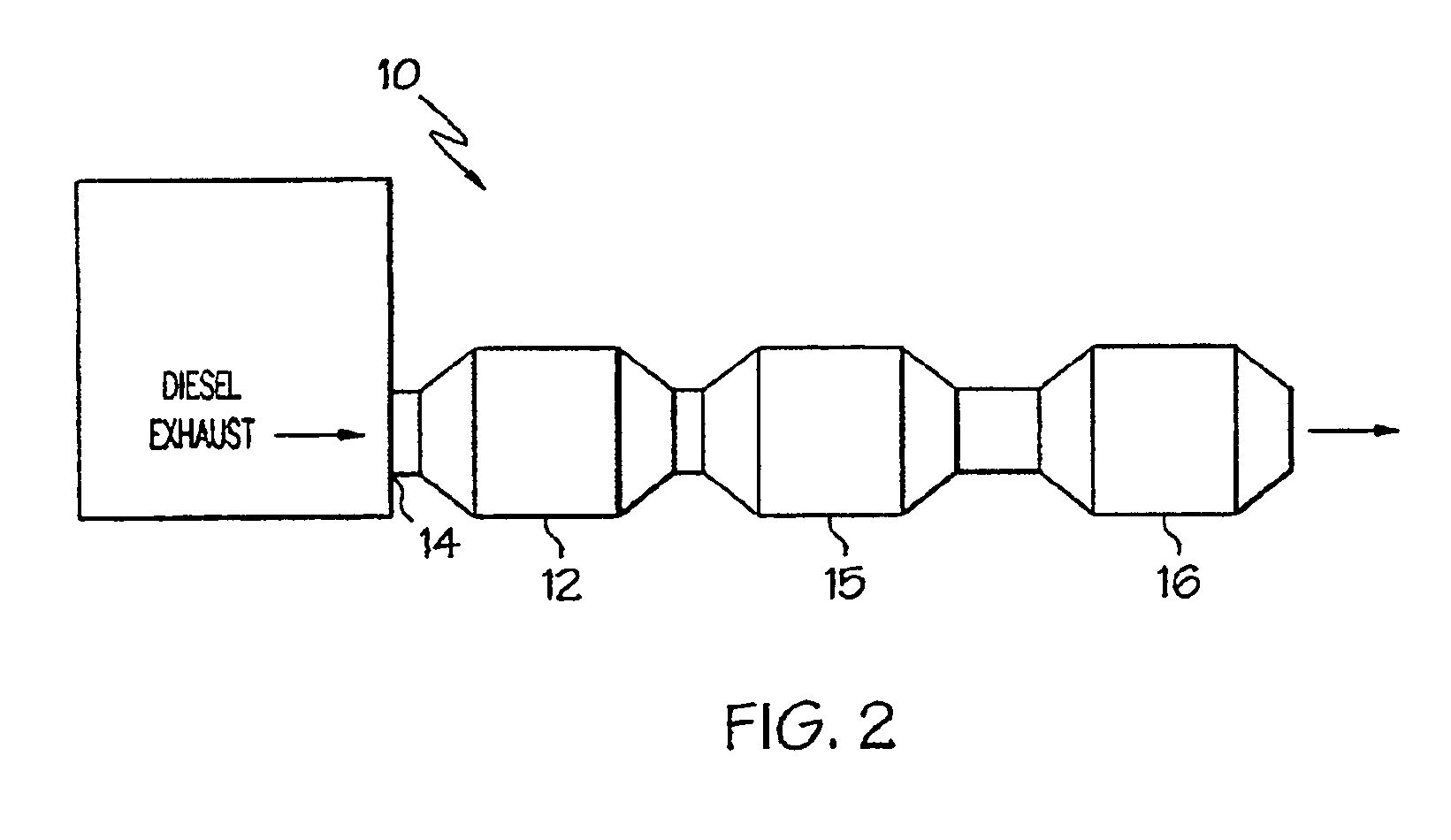

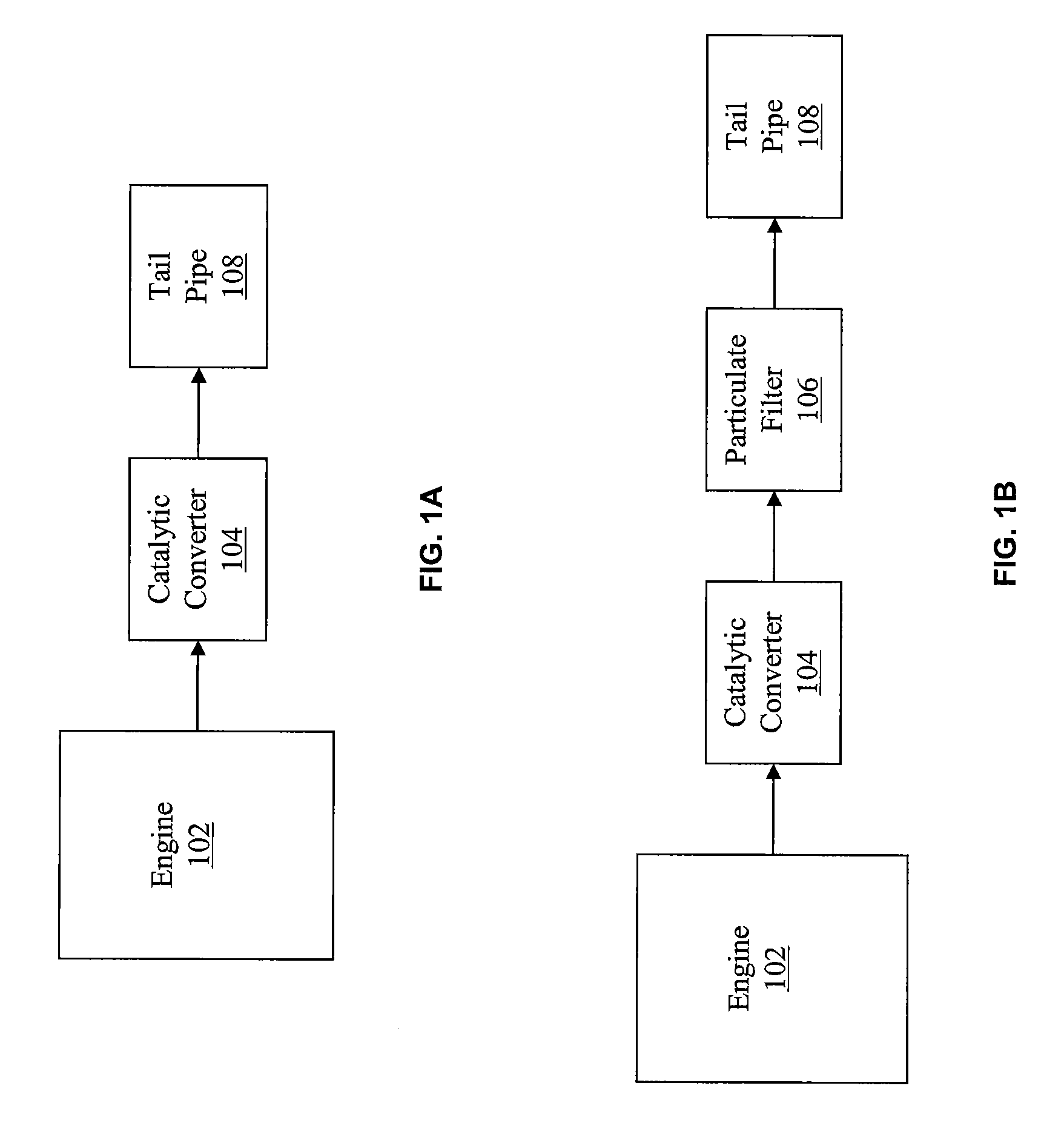

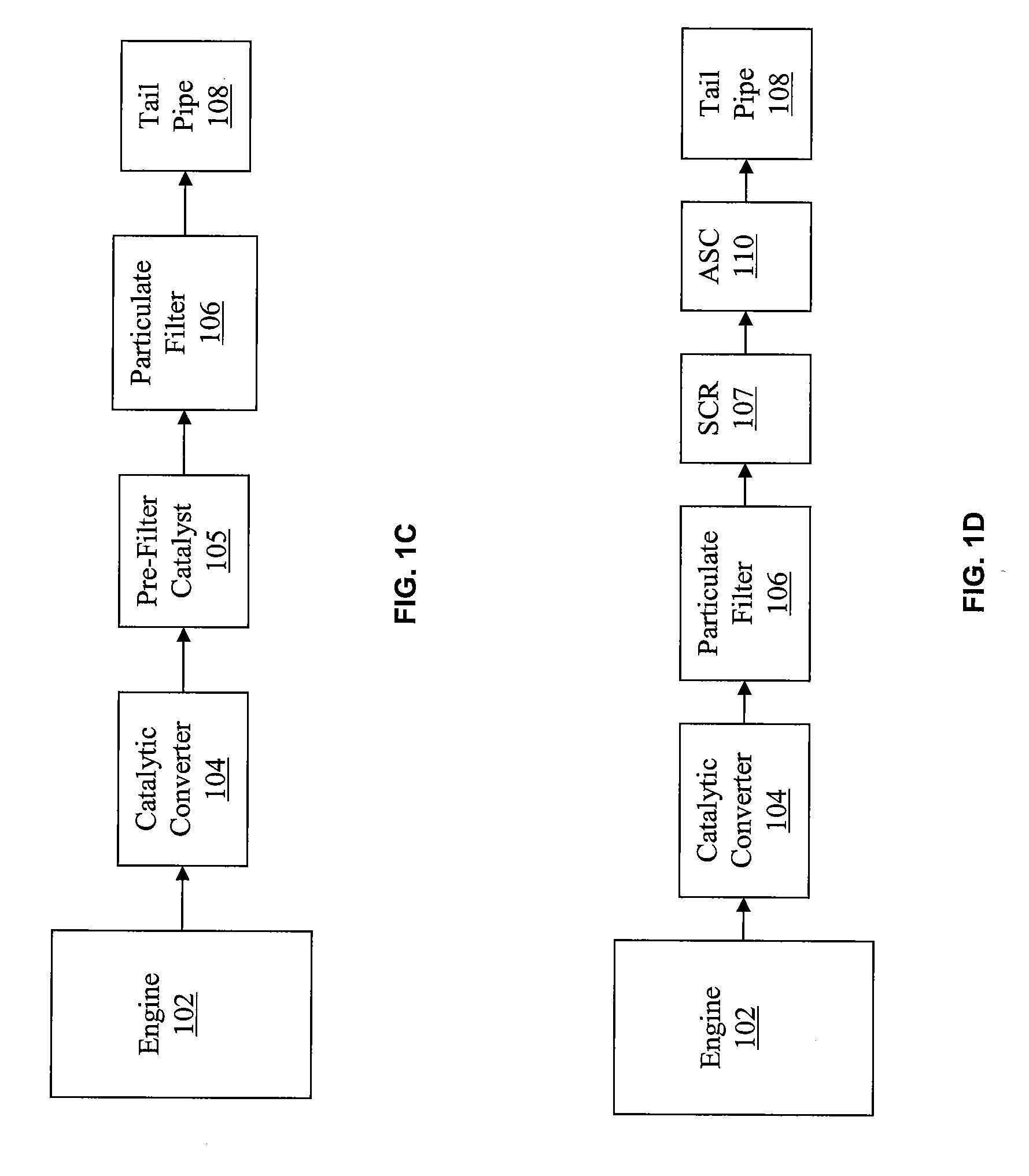

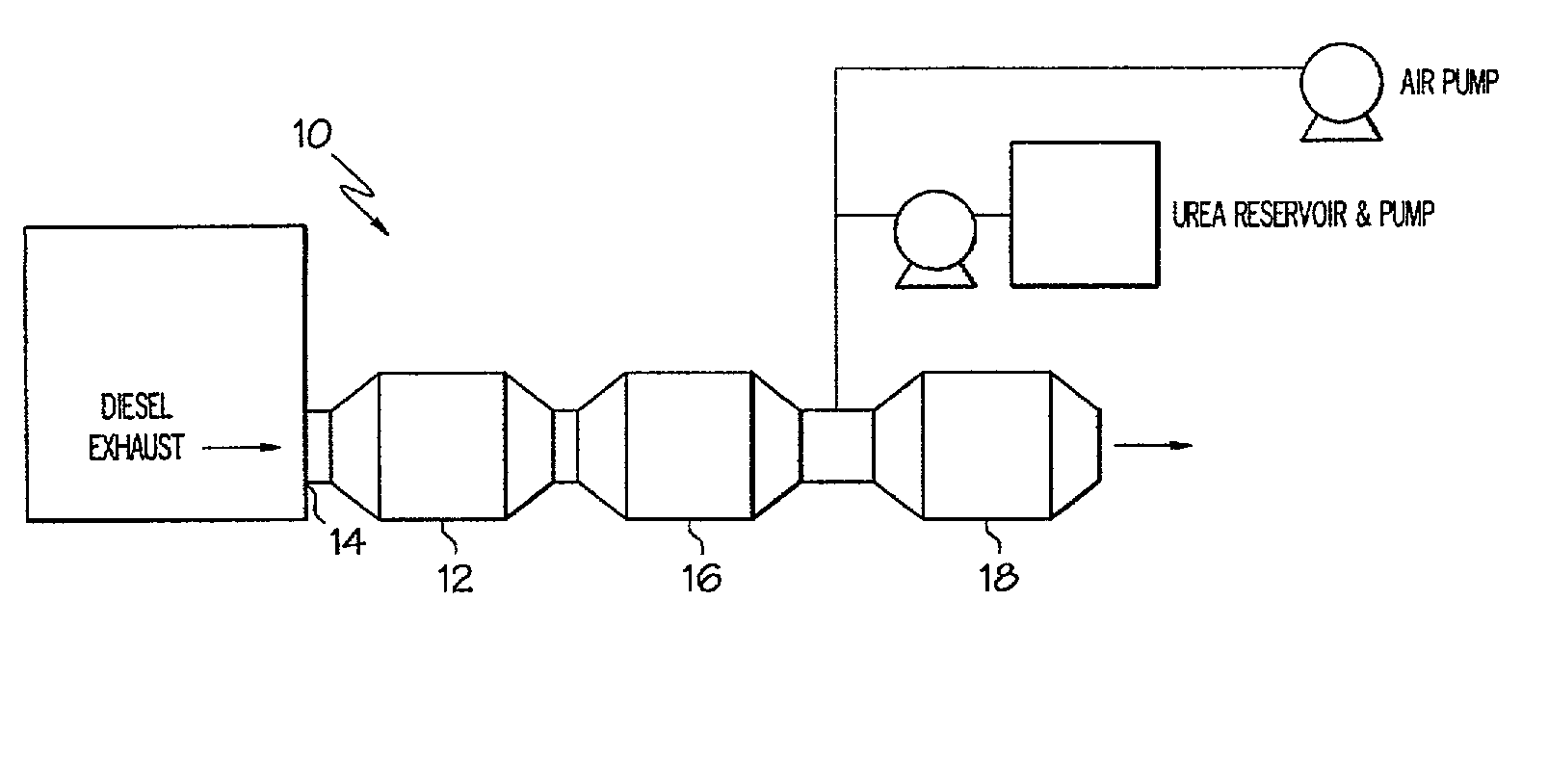

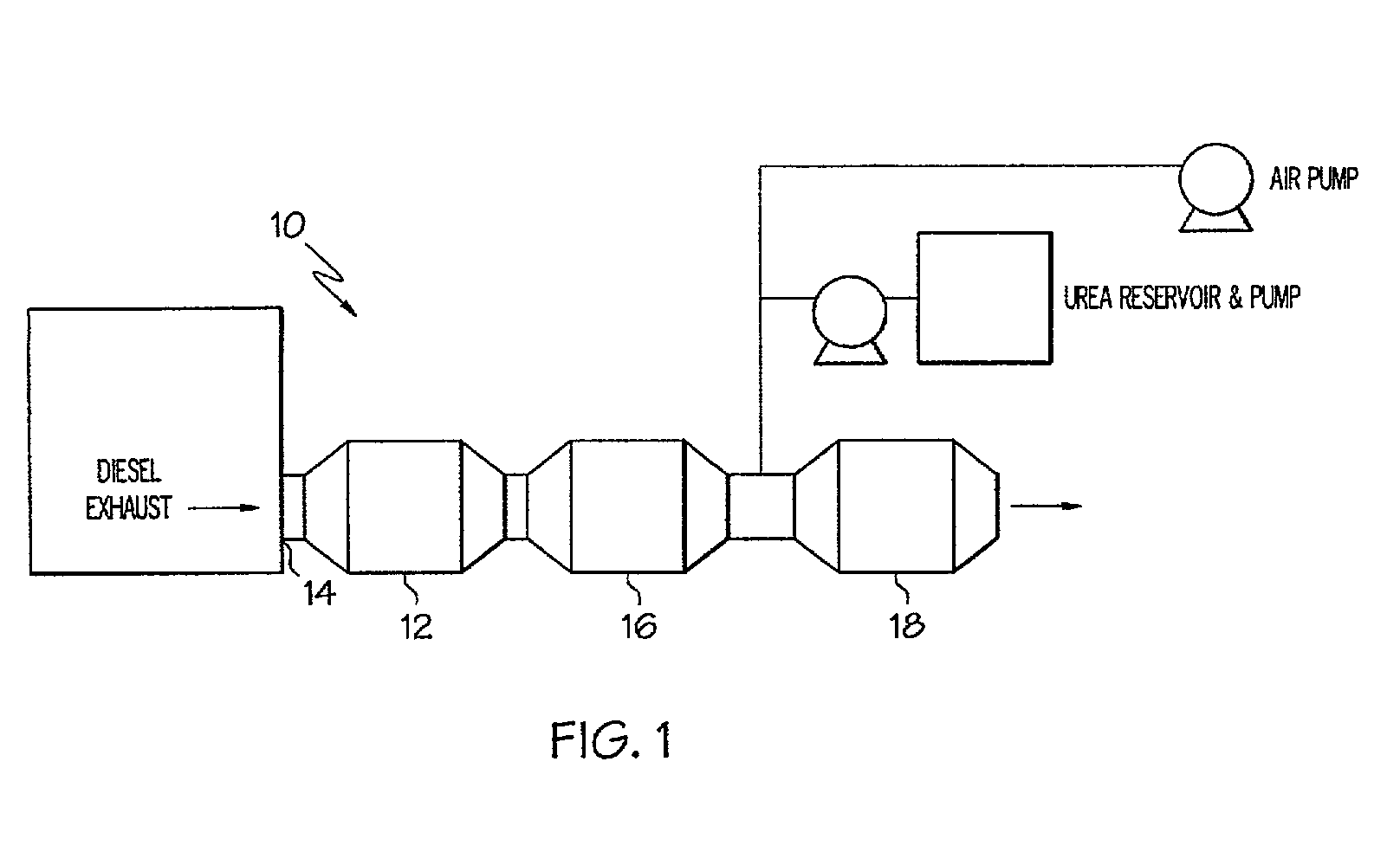

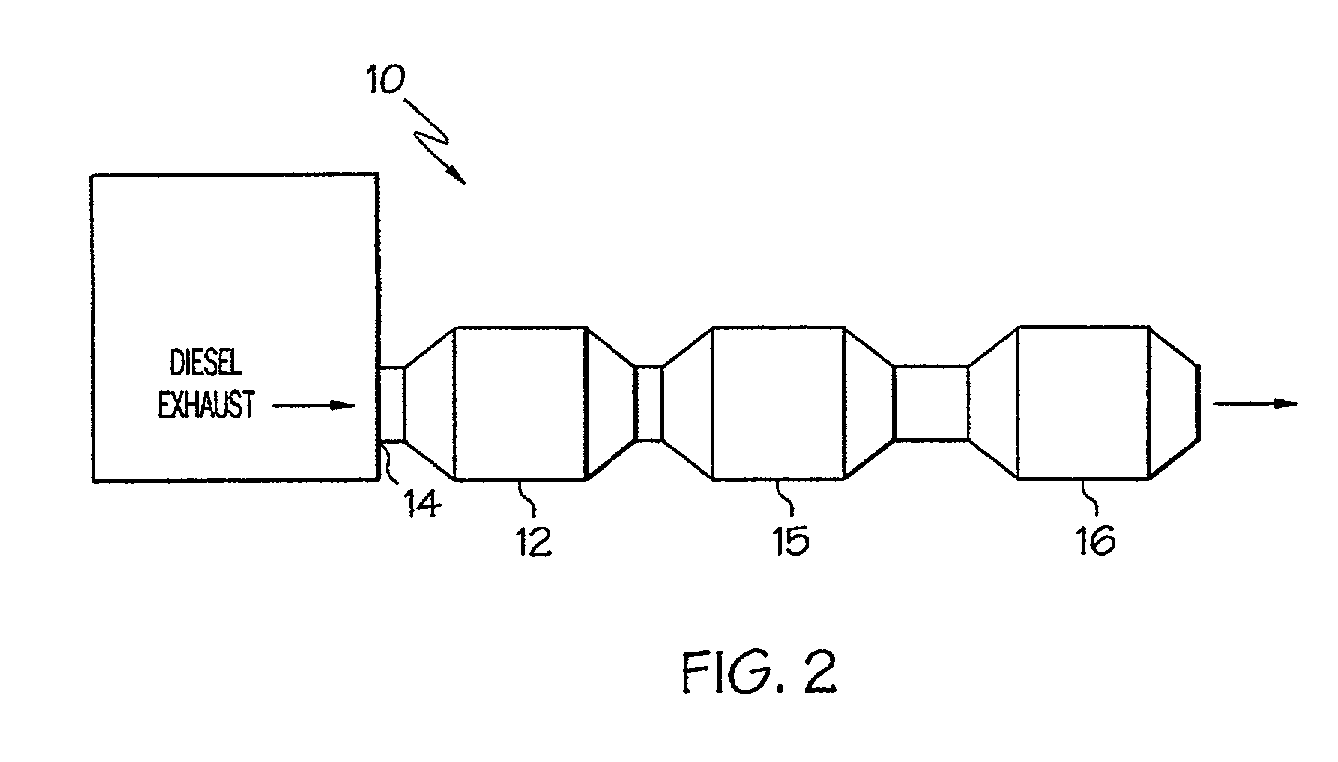

Method of treating diesel exhaust gases

InactiveUS6813884B2Promote regenerationReduce NOxExhaust apparatusDispersed particle separationParticulatesNitrogen

A diesel exhaust treatment system and method of oxidizing NO to NO.sub.2 at low temperatures are provided. The system utilizes a platinum catalyst on a zirconia-stabilized silica support which oxidizes NO in the exhaust gas to NO.sub.2 and uses the NO.sub.2 in an amount sufficient to oxidize particulate trapped on a particulate filter. The catalyst is preferably pre-treated at a temperature of between about 500 to 650.degree. C. in a NO-oxygen-nitrogen mixture to increase conversion at low temperatures. The catalyst preferably includes an additional oxide component selected from the group consisting of TiO.sub.2, P.sub.2 O.sub.5, WO.sub.3, B.sub.2 O.sub.3, and Al.sub.2 O.sub.3. or a heteropolyacid component to further increase activity at low temperatures or to decrease platinum loading at the same level of performance.

Owner:FORD GLOBAL TECH LLC

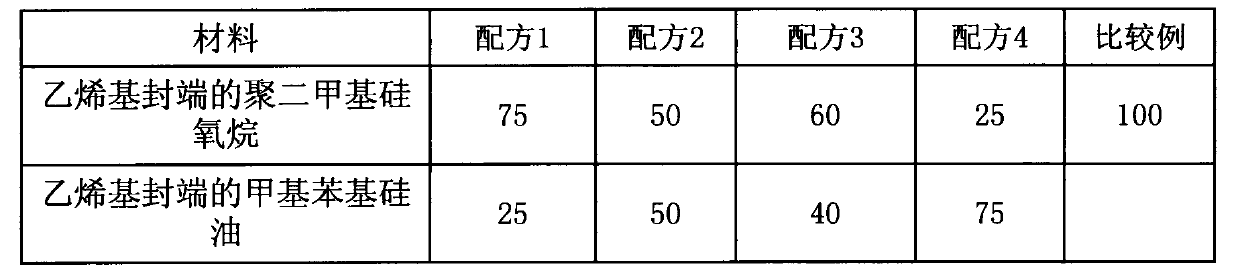

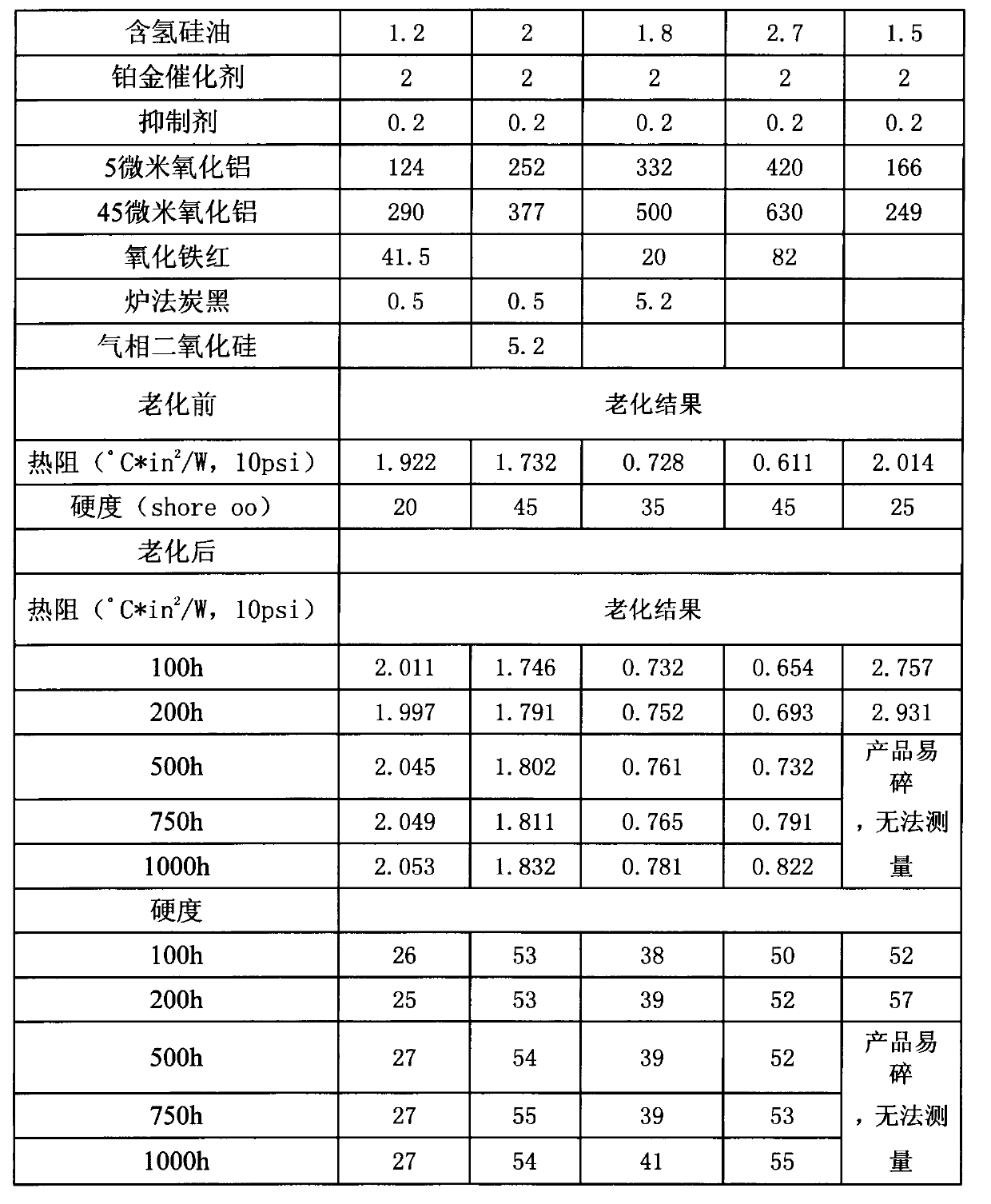

High temperature resistant heat-conducting silica gel sheet and preparation method thereof

The invention discloses a high temperature resistant heat-conducting silica gel sheet and a preparation method thereof. The high temperature resistant heat-conducting silica gel sheet is characterized by comprising the following components in parts by weight: 50-80 parts of vinyl end capped polydimethylsiloxane (PDMS), 20-50 parts of vinyl end capped methyl phenyl silicone oil, 0.3-10 parts of containing hydrogen silicone oil, 2-6 parts of platinum catalyst, 0.2-0.6 parts of inhibitor, 5-100 parts of heat resistant additive and 400-1200 parts of heat-conducting powder. The preparation method of the high temperature resistant heat-conducting silica gel sheet comprises the following steps: firstly, uniformly mixing the vinyl end capped polydimethylsiloxane and the vinyl end capped methyl phenyl silicone oil in a kneading machine; adding the treated or untreated heat-conducting powder and the heat resistant additive which are added in batches, after mixing uniformly, adding the containing hydrogen silicone oil, the inhibitor and the catalyst; and mixing uniformly, and heating and solidifying in a forming machine to form a sheet. The heat resistant silica gel sheet provided by the invention is aged at 250 DEG C for 1000 hours, but still has good usability, and the changes of the hardness and the heat conductivity coefficient are within acceptable ranges.

Owner:SUZHOU TIANMAI THERMAL TECH

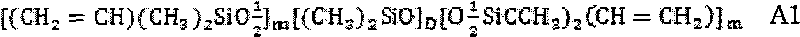

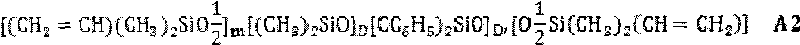

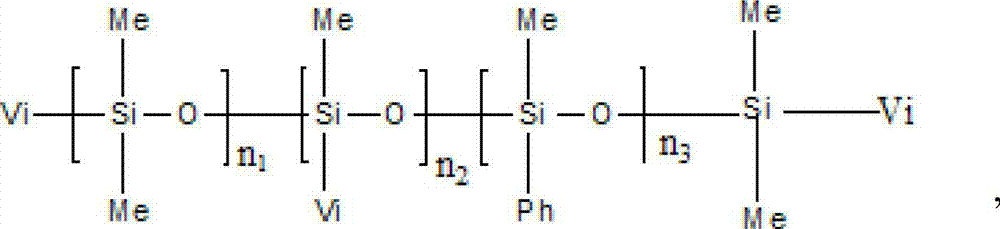

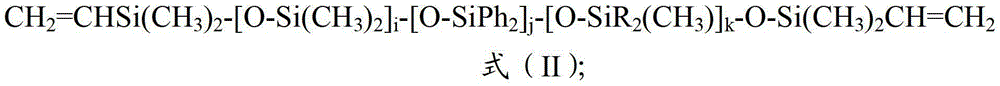

Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

ActiveCN103122149AHigh refractive indexImprove mechanical propertiesSemiconductor devicesHydrogenPolymer science

The invention relates to silicon rubber with high refractive index and high transparency for optical encapsulation and a preparation method thereof. The silicon rubber is prepared from a phenyl vinyl polysiloxane component A, a silicon resin component B containing phenyl vinyl, a phenyl component C containing hydrogen polyoxyalkylene, a platinum catalyst component D, a catalytic inhibitor component E, a modified polysiloxane component F, and a water remover component G in a mixing manner. The silicon rubber not only has over 1.50 of refractive index, but also is good in transparency, excellent in adhesion, and stable in performance, can resist heat and ultraviolet radiation for a long period of time, can meet various requirements of LED (light-emitting diode) encapsulation, and is an ideal encapsulation material of the LED. The silicon rubber can be packaged into a bi-component product; the product has good storage stability; and high transparency is still kept after the product is stored for over 6 months.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Organic silica gel packaging material of large-power LED and preparation method thereof

InactiveCN101717584AHigh heat deformation resistanceReasonable distribution of cross-linking pointsSemiconductor devicesPtru catalystOptical transmittance

The invention relates to organic silica gel for packaging a large-power LED and a preparation method thereof. The gel is prepared by mixing a component A of vinyl-contained polysiloxane, a silicon resin component B, a component C of hydrogen-contained polymethylsiloxane, a platinum catalyst component D, a catalytic inhibiting agent component E and a thickening agent component F, and the obtained packaging gel with different refractive rates of 1.4 grade, 1.5 grade, and the like is used for packaging various types of large-power LEDs or is used as other optical purposes. By adopting the component B as a filling material, the invention solves the problems of temperature resistance, color change, light transmittance and needle penetration reduction of the large-power LED product, can be made into two packaging types of a single component and double components, improves the adaptability on packaging equipment and the manufacture procedure and the efficiency, reduces the cost and is convenient for use.

Owner:陈俊光

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

Preparation method of organic silicon rubber for encapsulating LED being convenient for vacuum defoamation

InactiveCN101880396AReduce surface tensionReduce defective rateOther chemical processesAdhesivesRoom temperatureTransmittance

Owner:HANGZHOU NORMAL UNIVERSITY

Solvent-free organic silicon pressure-sensitive adhesive and preparation method thereof

ActiveCN102174309AReduce or eliminate the generation ofGood compatibilityAdhesivesEnd-groupSolvent free

The invention relates to a solvent-free organic silicon pressure-sensitive adhesive. The organic silicon pressure-sensitive adhesive comprises the following components in part by mass: 100 parts of polydimethylsiloxane of which the end group is alkenyl; 1 to 300 parts of polydimethylsiloxane of which the end group is hydroxyl; 1 to 50 parts of MQ resin, 1 to 30 parts of polyisobutylene, 20 to 200 parts of diluting agent, 0.1 to 5 parts of crosslinking agent and a platinum catalyst capable of curing the organic silicon pressure-sensitive adhesive. The invention also relates to a preparation method of the organic silicon pressure-sensitive adhesive. The organic silicon pressure-sensitive adhesive has the characteristics of high initial tack, long residual action, proper peeling strength, drug penetration and the like, is nontoxic, environmentally-friendly and reusable, and can be prepared into pressure-sensitive adhesive tapes, medical pressure-sensitive adhesive strips and other functional materials requiring the pressure-sensitive performance.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Engine Exhaust Catalysts Containing Palladium-Gold

ActiveUS20080124514A1Reduce inhibitionEmission reductionCombination devicesInternal combustion piston enginesPalladium catalystPt element

An engine exhaust catalyst exhibits improved CO oxidation performance relative to conventional engine exhaust catalysts and includes a first supported catalyst comprising platinum and a second supported catalyst comprising palladium and gold species in close contact. The first supported catalyst may be a platinum catalyst, a platinum-palladium catalyst, or a platinum catalyst promoted with bismuth, and the second supported catalyst preferably has a palladium to gold weight ratio of about 0.85:1.0. To improve aged catalyst performance, the first and second supported catalysts are coated onto different layers, zones, or monoliths of the substrate for the engine exhaust catalyst.

Owner:WGC HLDG LTD

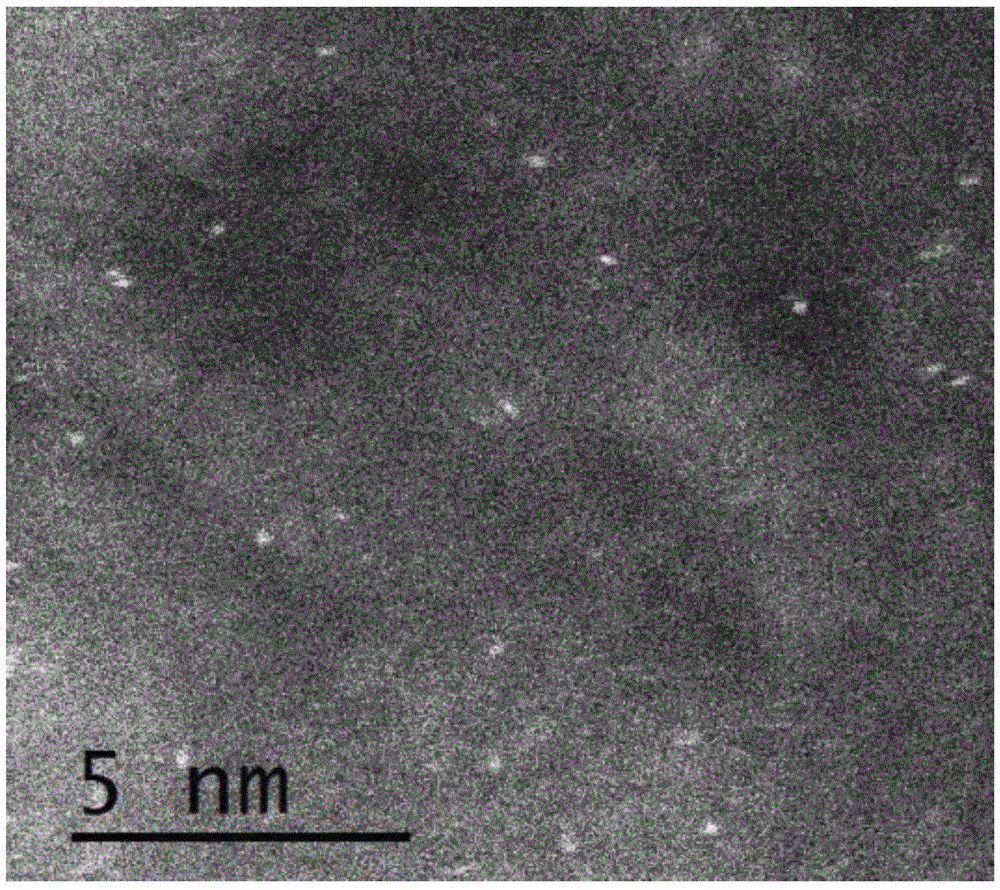

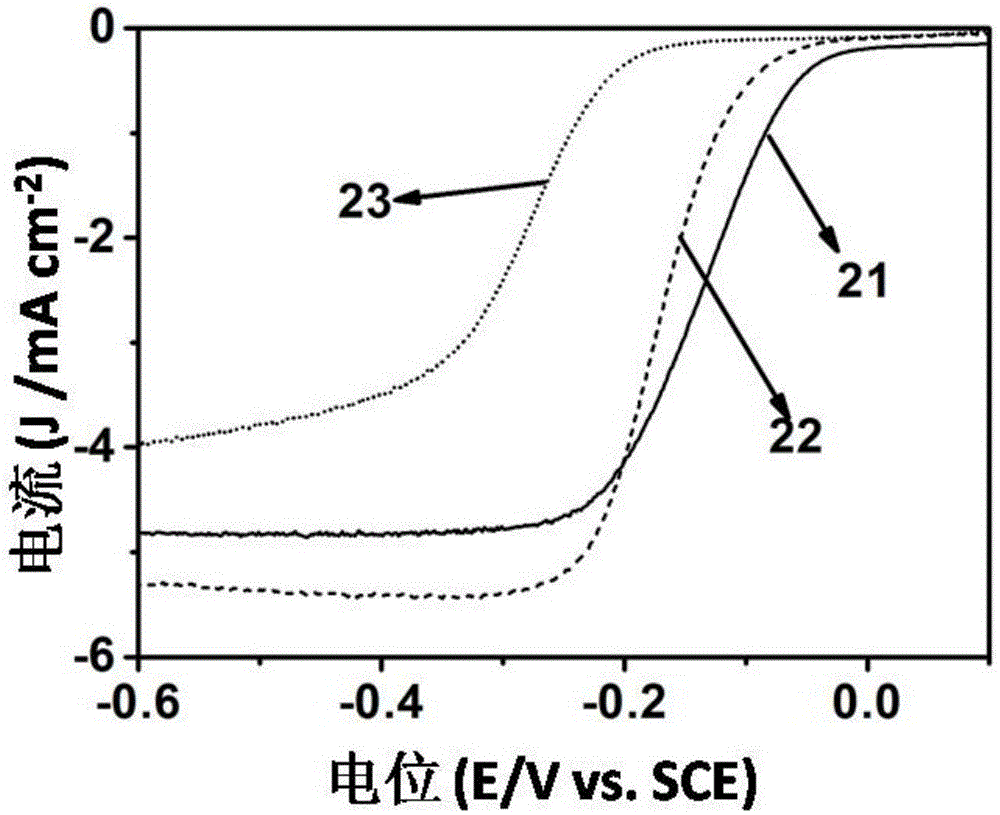

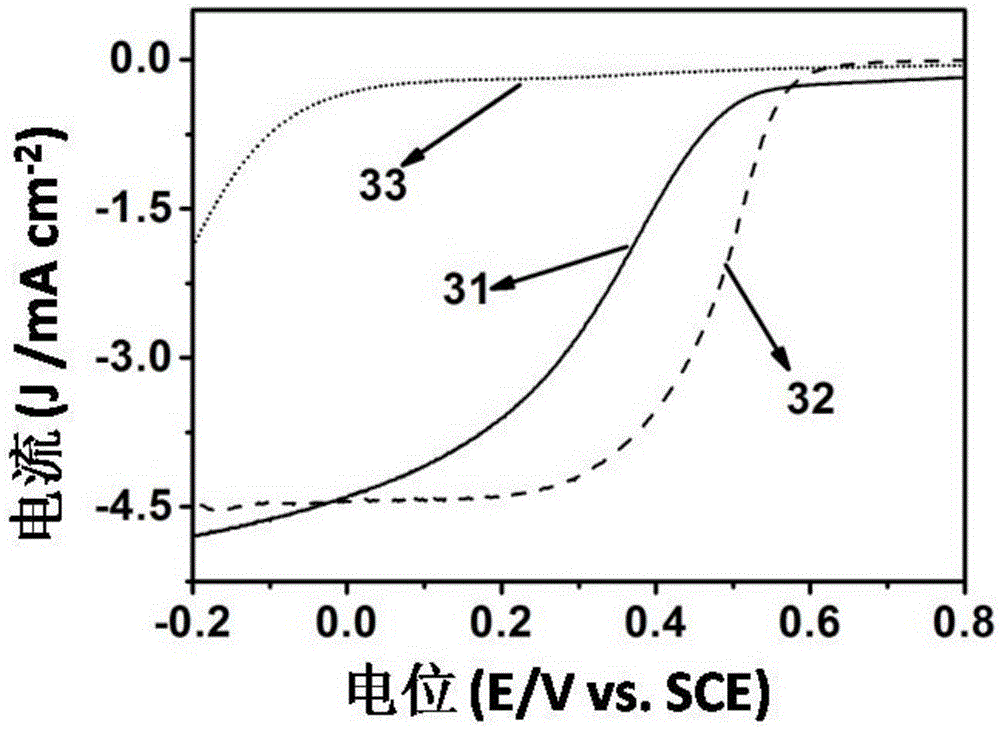

Catalyst with dispersed single platinum atoms and preparation method of catalyst

The invention relates to a catalyst with dispersed single platinum atoms and a preparation method of the catalyst, and aims at solving the technical problems that a precious metal oxygen reduction catalyst is high in preparation cost and low in utilization rate of platinum in the prior art. The catalyst with dispersed single platinum atoms is prepared by stirring, refluxing, evaporating, drying and grinding a carbon support, a nonmetal heteroatom reagent and a platinum compound as raw materials, and carrying out high-temperature treatment and interaction in a sliding rail furnace. A test result shows that the platinum element in the catalyst exists in a form of single atoms platinum; the catalytic activity is high; in acid and alkaline systems, the initial oxygen reduction potential and the half-wave potential are equivalent to those of a commercial carbon-supported platinum catalyst with the platinum content of 20%; other metal impurities are not introduced in the preparation process; and the stability is relatively good. The preparation method of the catalyst provided by the invention is relatively low in cost, simple and feasible. The catalyst is suitable for preparation of a fuel cell; the utilization rate of the platinum is greatly improved; the cost of the catalyst is reduced; and the commercialization process of the fuel cell can be promoted.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

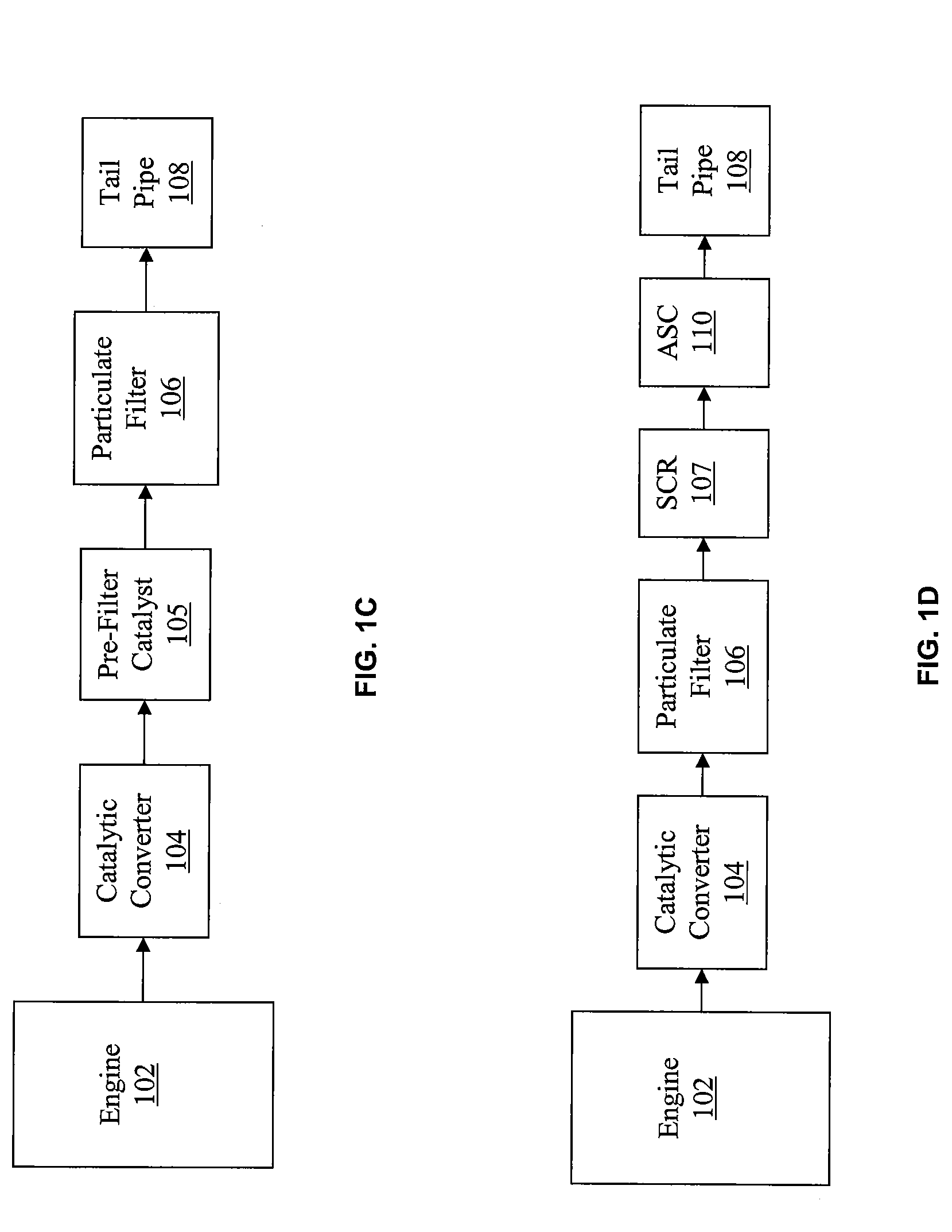

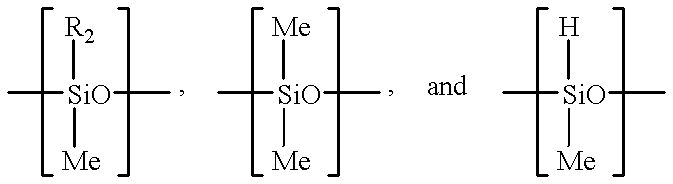

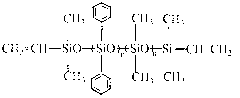

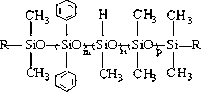

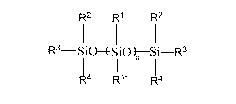

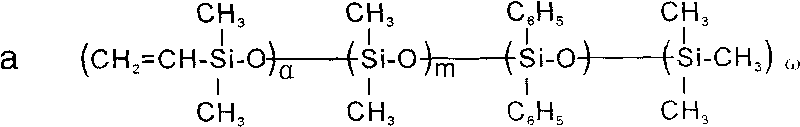

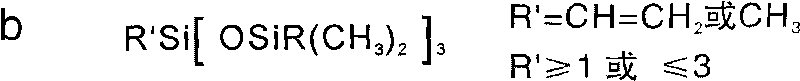

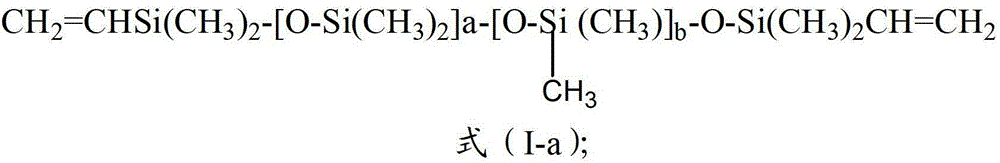

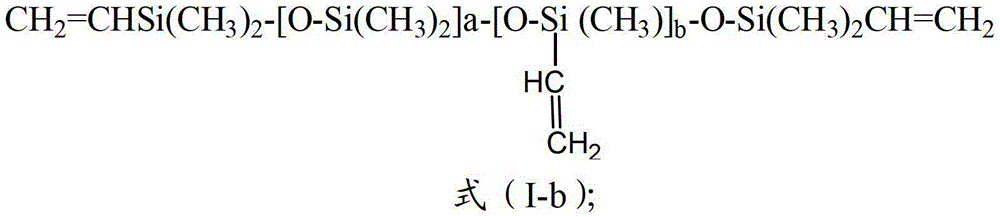

Curable organopolysiloxane materials

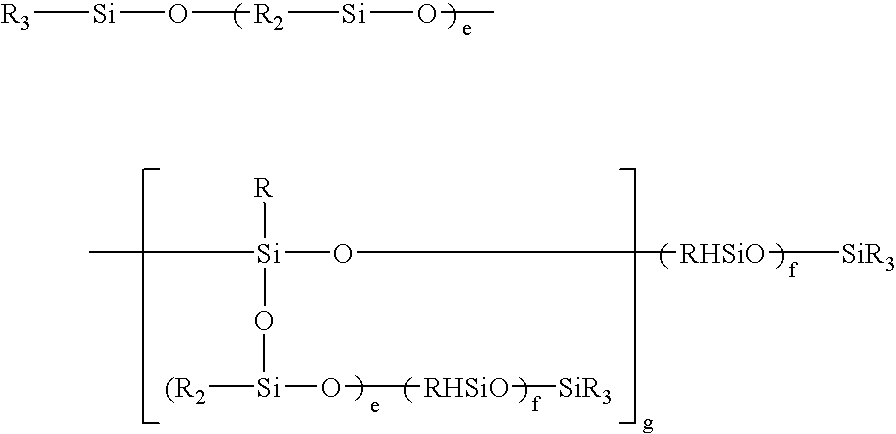

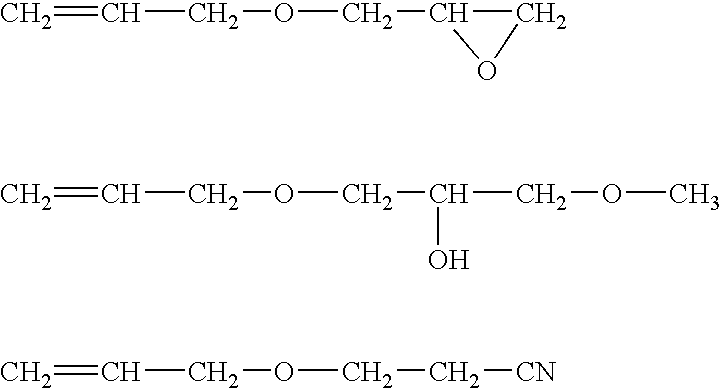

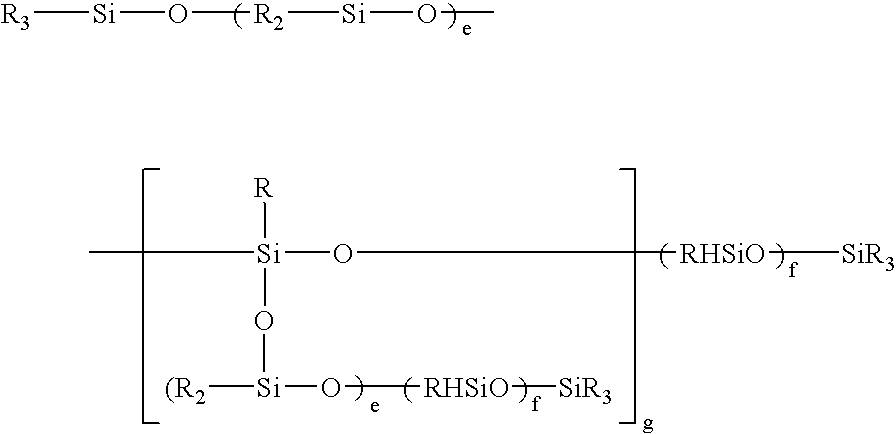

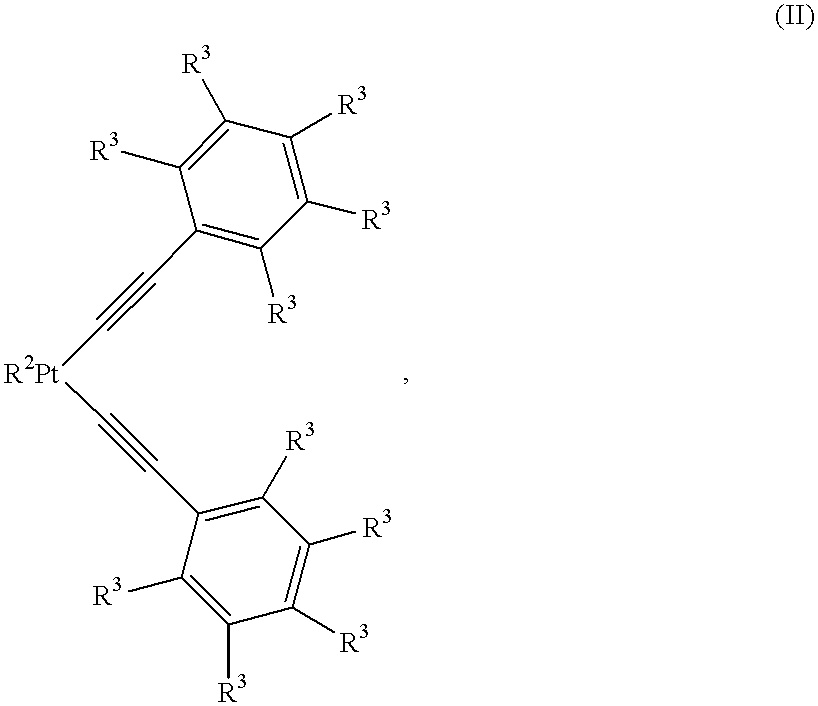

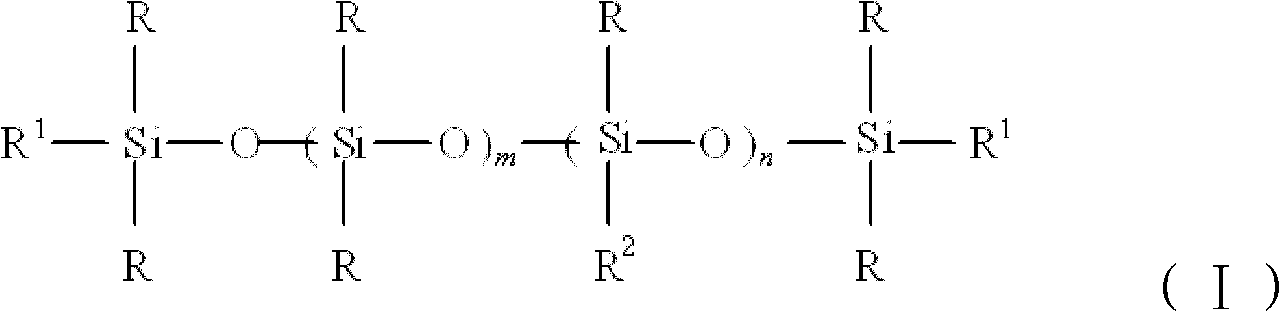

InactiveUS6359098B1Extended shelf lifeCompromising crosslinking rateOrganic-compounds/hydrides/coordination-complexes catalystsPlatinum organic compoundsStructural unitPhysical property

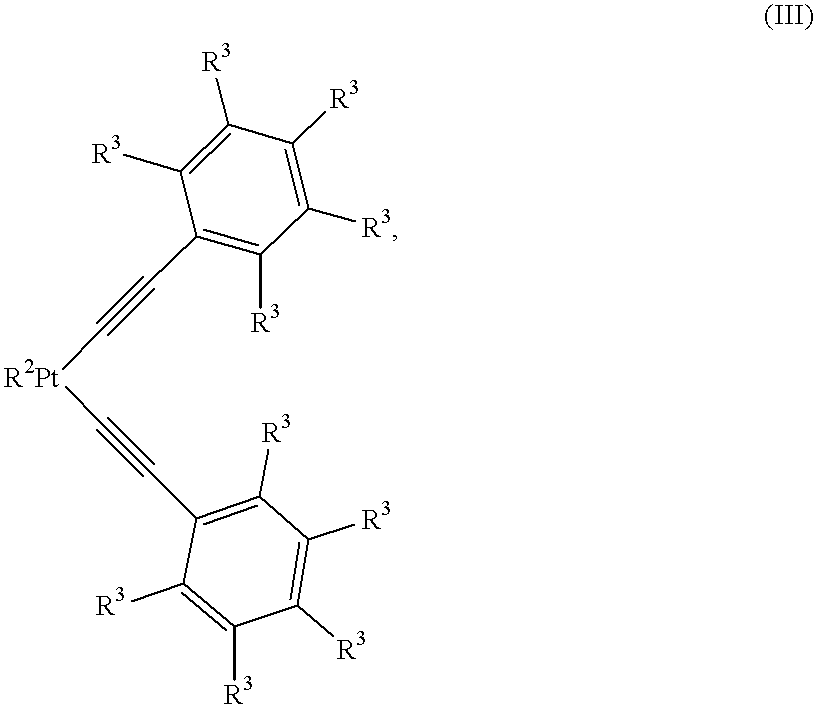

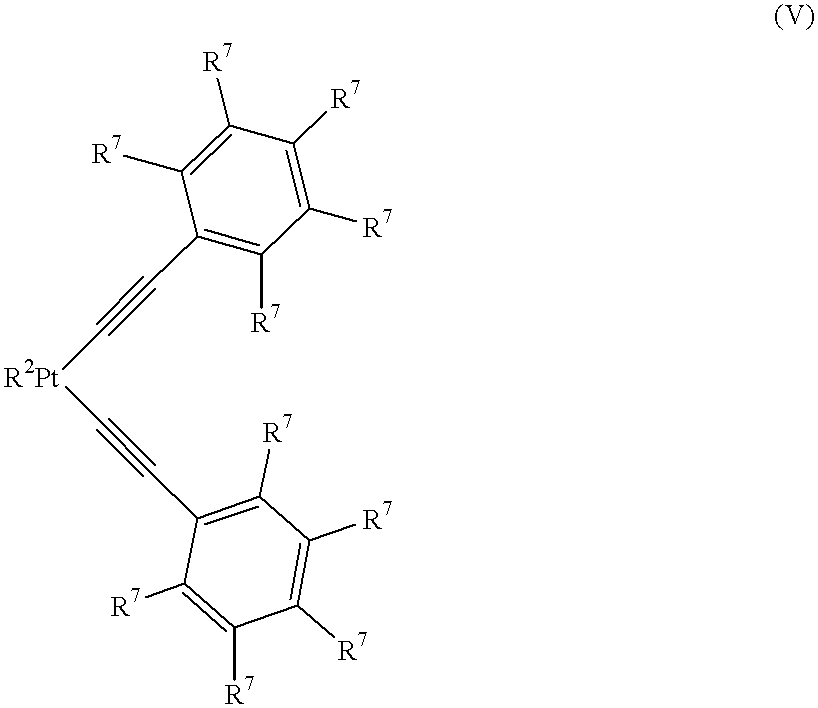

Curable addition crosslinkable organopolysiloxane materials employing a platinum catalyst selected from the group consisting of compounds of the formulaand / or oligomeric or polymeric compounds which are composed of structural units of the general formulaand optionally structural units of the general formulain whichR2, R3, R4, R6, R7, R8, R9, r, s and t have the meanings stated in claim 1, may be prepared as one-component formulations having prolonged shelf life, or as two-component formulations having prolonged pot life, while maintaining desirable chemical and physical properties.

Owner:WACKER CHEM GMBH

Method for Deuteration of an Aromatic Ring

ActiveUS20070255076A1Improve working environmentAmino preparation from aminesOrganic compound preparationNickel catalystHydrogen

The present invention relates to a method for deuteration of a compound having an aromatic ring, using an activated catalyst, and the method comprises reacting a compound having an aromatic ring with heavy hydrogen source in the presence of an activated catalyst selected from a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst.

Owner:FUJIFILM WAKO PURE CHEM CORP

Method of treating diesel exhaust gases

InactiveUS20030140620A1Add supportHigh catalytic activityExhaust apparatusDispersed particle separationParticulatesNitrogen

A diesel exhaust treatment system and method of oxidizing NO to NO2 at low temperatures are provided. The system utilizes a platinum catalyst on a zirconia-stabilized silica support which oxidizes NO in the exhaust gas to NO2 and uses the NO2 in an amount sufficient to oxidize particulate trapped on a particulate filter. The catalyst is preferably pre-treated at a temperature of between about 500 to 650° C. in a NO-oxygen-nitrogen mixture to increase conversion at low temperatures. The catalyst preferably includes an additional oxide component selected from the group consisting of TiO2, P2O5, WO3, B2O3, and Al2O3. or a heteropolyacid component to further increase activity at low temperatures or to decrease platinum loading at the same level of performance.

Owner:FORD GLOBAL TECH LLC

Environmental-friendly synthetic organosilicon leather and method for producing same

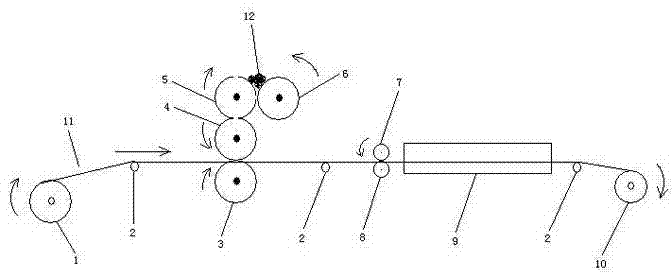

ActiveCN102174262AImprove plasticityEasy to shapeTextile/flexible product manufactureTextiles and paperVulcanizationDecomposition

The invention relates to environmental-friendly synthetic organosilicon leather and a method for producing the same. The synthetic organosilicon leather comprises vinyl polysiloxane gum, white carbon black, a structured treatment agent, a plastifying agent, an inhibitor, hydrogen containing silicone oil, a platinum catalyst and silicone rubber masterbatch. The method for producing the synthetic organosilicon leather comprises the following steps: mixing the raw materials to obtain solid mixed silicone rubber through vulcanization via addition, rolling the solid mixed silicone rubber by a multi-roll rolling machine to fit textile-based fabric, heating and vulcanizing to form the synthetic organosilicon leather. The environmental-friendly synthetic organosilicon leather is efficiently produced with a simple process and can be produced on a large scale. The produced synthetic organosilicon leather has good mechanical properties and excellent characteristics of being resistant to high andlow temperature, weathering aging and physical inertia, is easy to cut and sew and is waterproof and breathable. The combustion and decomposition product of the synthetic organosilicon leather contains no harmful substance, can be recycled and accords with environmental protection requirements.

Owner:东莞市贝特利新材料有限公司

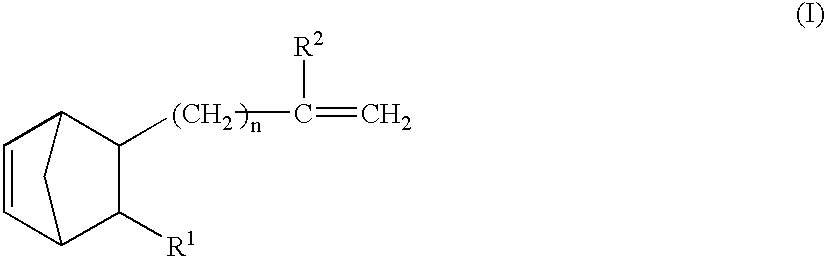

Crosslinkable rubber compositions and uses thereof

The crosslinkable rubber composition is crosslinkable at room temperature, has a gelation time at room temperature of 30 days or less, and can prepare a crosslinked rubber sheet by crosslinking the composition at room temperature, wherein the crosslinked rubber sheet has a tensile elongation of 20% or more, and is free of cracks after treatment at 40° C. in a 50 pphm ozone concentration for 96 hr. Specifically, it comprises an ethylene / alpha-olefin / non-conjugated polyene random copolymer rubber comprising a norbornene compound having a specific vinyl end group, an SiH group-containing compound, which has at least two SiH groups in one molecule, and optionally a platinum catalyst, a reaction inhibitor and / or a silane-coupling agent. The sealing, potting and coating materials and adhesives of the present invention comprise the above rubber composition. The rubber composition has a high crosslinking rate at room temperature and excellent productivity, and can prepare crosslinked rubber molded products (including foamed products) having excellent weathering resistance, ozone resistance, heat aging resistance and compression set at low cost. Further, it is suitable for use of electric and electronic parts, transportation machines, civil engineering and construction materials, medical appliances and goods for leisure activities.

Owner:MITSUI CHEM INC

Addition type heat conducting silicon rubber and manufacturing method thereof

Owner:CHENGDU GUIBAO SCI & TECH

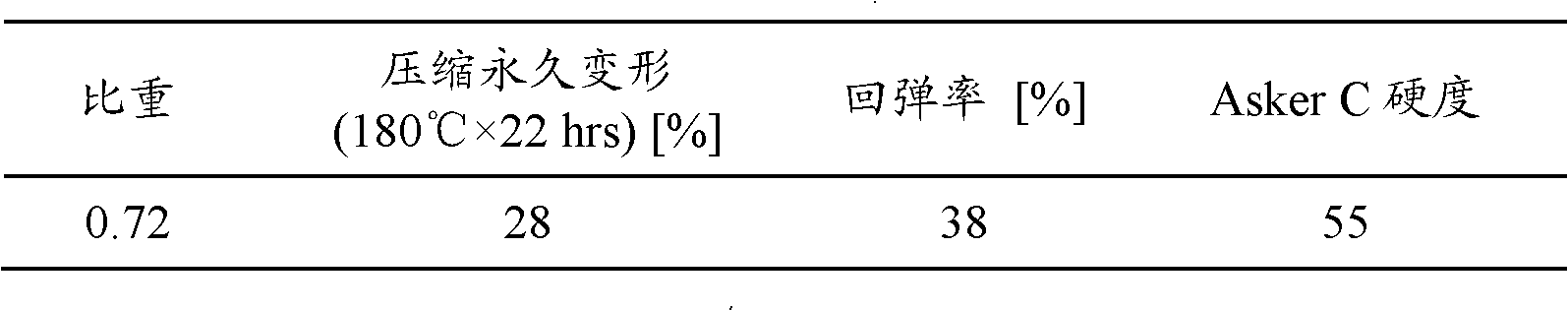

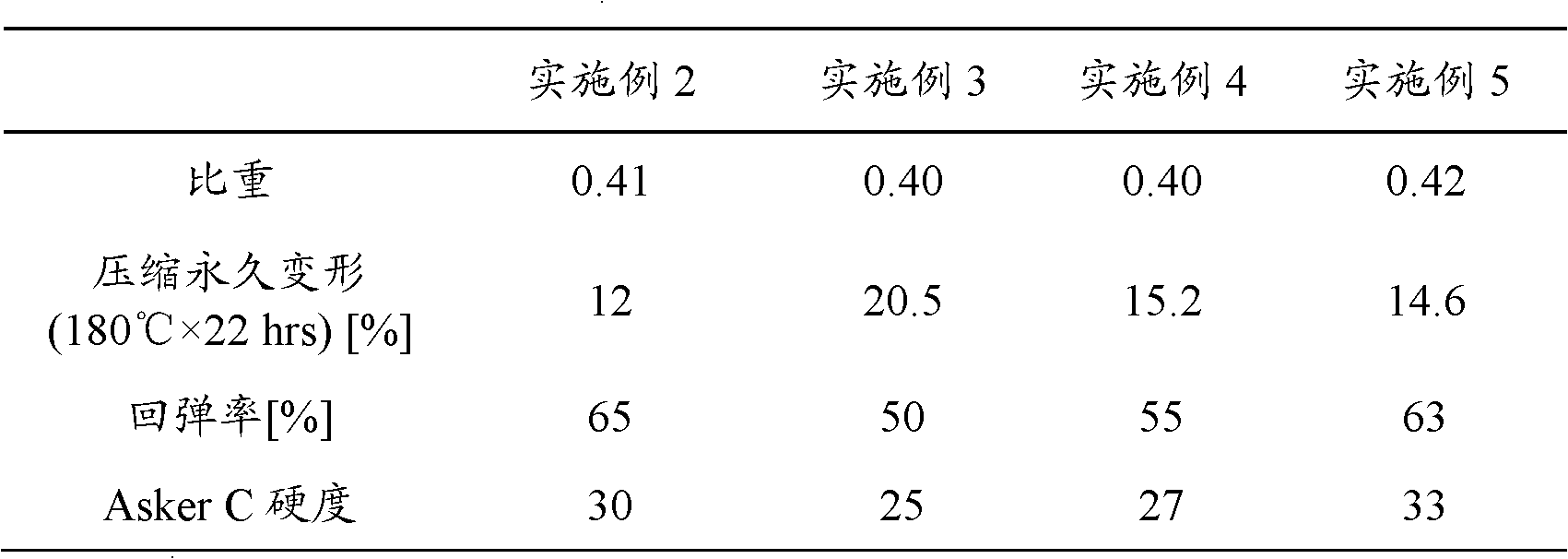

Liquid silicon rubber composition and preparation method thereof

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

Monocomponent addition type silicone rubber packaging glue with strong cohesiveness and preparation method thereof

ActiveCN102492391AHas strong bonding propertiesShorten the timeNon-macromolecular adhesive additivesOther chemical processesHydrogenPolymer science

The invention relates to a monocomponent addition type silicone rubber packaging glue with strong cohesiveness and a preparation method thereof. The packaging glue comprises, by weight, 80-120 parts of vinyl silicone oil, 5-20 parts of vinyl silicone resin, 10-30 parts of hydrogen-containing silicone oil, 1-3 parts of white carbon black, 1-5 parts of titanium dioxide, 0.1-0.5 part of inhibitor and 0.1-0.5 part of platinum catalyst. The preparation method comprises steps of: first mixing vinyl silicone oil, vinyl silicone resin, hydrogen-containing silicone oil, organic polysiloxane adhesion agent, white carbon black and titanium dioxide by high speed stirring; then adding inhibitor and mixing by high speed stirring; finally adding platinum catalyst and mixing by middle speed stirring; and discharging. After sulfuration, the monocomponent addition type silicone rubber packaging glue prepared by the method of the invention has a bonding strength with a base material (copper) higher than 1.86 MPa.

Owner:SHANGHAI RES INST OF CHEM IND

Vulcanization-proof LED (light-emitting diode) packaging silica gel

InactiveCN102965069AStrong adhesionIncrease dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationAdhesive

The invention relates to an LED (light-emitting diode) packaging silica gel, and in particular relates to a vulcanization-proof LED packaging silica gel, belonging to the technical field of adhesives. The vulcanization-proof LED packaging silica gel comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 1: 1; the component A comprises raw materials based on parts by weight: 50-60 parts of methyl phenyl vinyl silicone oil, 30-60 parts of methyl vinyl MQ resin, 0.1-0.3 part of platinum catalyst and 3-5 parts of bonding agent; and the component B comprises raw materials based on parts by weight: 40-50 parts of methyl phenyl vinyl silicone oil, 30-50 parts of methyl vinyl MQ resin, 5-15 parts of cross-linking agent and 0.1-0.3 part of inhibitor. The vulcanization-proof LED packaging silica gel has excellent adhesive force for silver, phenyl-propanolamine (PPA), glass and the like, and has the light transmittance of more than 98%; and phenyl-containing functional groups and branched chain type vinyl are introduced into the LED packaging silica gel, and the dosage of the vinyl MQ resin is increased, so that the crosslinking density and the curing handness are improved, and therefore, the vulcanization resistance of a packaging adhesive layer can be improved.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Single-component addition-type silicone rubber and preparation method thereof

The invention provides a single-component addition-type silicone rubber which is prepared by vulcanizing the following raw materials in parts by mass: 20-50 parts of vinyl polysiloxane, 3-18 parts of vinyl methyl phenyl polysiloxane, 4-20 parts of hydrogen-containing polysiloxane, 0.01-0.1 part of platinum catalyst, 0.3-2.5 parts of inhibitor, 40-60 parts of filler, 2.0-10 parts of additive and 0.5-3 parts of tackifier. The single-component addition-type silicone rubber comprises the heat-resistant additive and the filler, so that the single-component addition-type silicone rubber prepared by vulcanizing has good high temperature resistance and low temperature aging resistance. The single-component addition-type silicone rubber comprises the catalytic inhibitor, so that the single-component addition-type silicone rubber has a higher inhibitory effect, and the storage life of the single-component addition-type silicone rubber is prolonged. When the addition-type silicone rubber is vulcanized, small molecular substances are not produced, and packaging components are not corroded.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Low-oil-permeability super-soft thermally-conductive silica gel composition and thermally-conductive silica gel gasket and preparation method thereof

The present invention relates to a low-oil-permeability super-soft thermally-conductive silica gel composition and a thermally-conductive silica gel gasket, the low-oil-permeability super-soft thermally-conductive silica gel composition comprising a first liquid silica gel, a second liquid silica gel and a thermally-conductive filler, the thermally-conductive silica gel gasket is prepared from the low-oil-permeability super-soft thermally-conductive silica gel composition, the low-oil-permeability super-soft thermally-conductive silica gel composition is prepared from the following components by mass: 7 to 11.9% of a first liquid silica gel and second liquid silica gel mixed liquid, 88 to 92.9% of the thermally-conductive filler, 0.05 to 0.5% of a catalyst and 0.05 to 0.5% of an inhibitor by the preparation method comprising stirring, rolling, vulcanizing and cutting; the low-oil-permeability super-soft thermally-conductive silica gel composition is prepared by mixing the first liquid silica gel, the second liquid silica gel and the thermally-conductive filler, vinyl silicone oil and a platinum catalyst in the first liquid silica gel and vinyl silicone oil and hydrogen-containing silicone oil in the second liquid silica gel can make the prepared plastic material characterized by being low in oil permeability and low in hardness, and the like, the viscosity of the first liquid silica gel and the second liquid silica gel are 3000mPa. s-10000mPa.s, uniform mixing of the material and the thermally-conductive filler during stirring can be guaranteed, and an appropriate crosslinking degree can be achieved during the vulcanizing.

Owner:PINGHU ALLIED IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com