Patents

Literature

7300 results about "Catalyst support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a catalyst support is the material, usually a solid with a high surface area, to which a catalyst is affixed. The activity of heterogeneous catalysts and nanomaterial-based catalysts occurs at the surface atoms. Consequently, great effort is made to maximize the surface area of a catalyst by distributing it over the support. The support may be inert or participate in the catalytic reactions. Typical supports include various kinds of carbon, alumina, and silica.

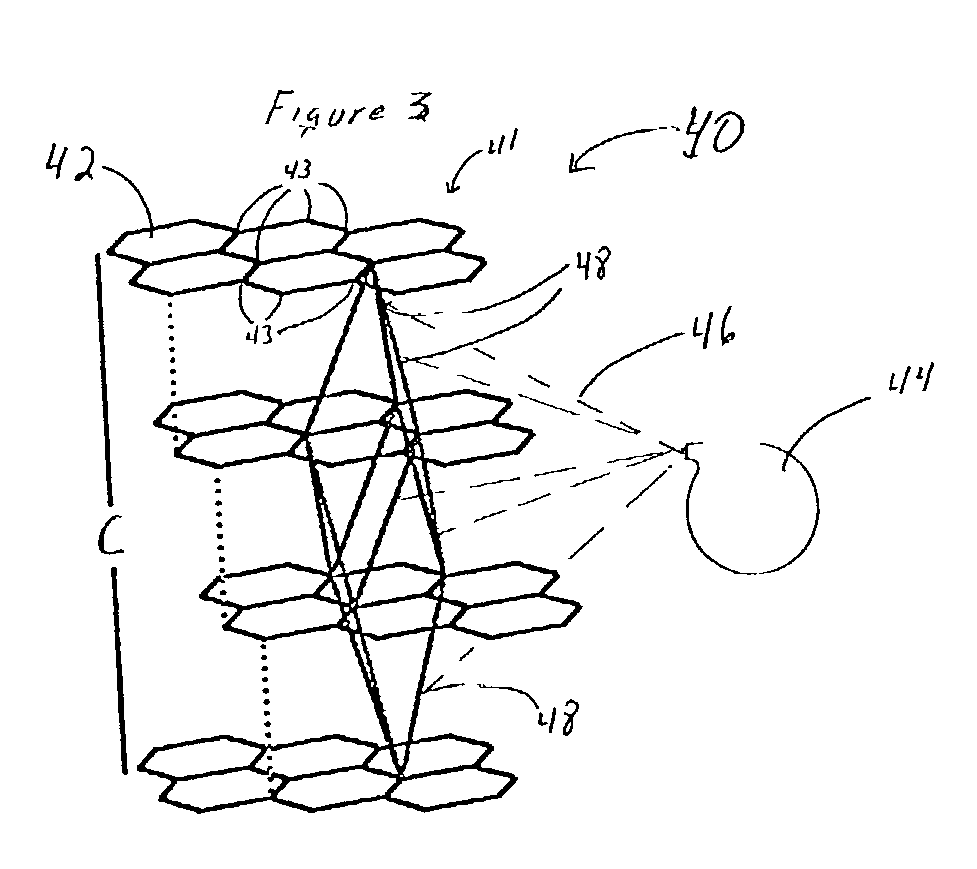

Three dimensionally periodic structural assemblies on nanometer and longer scales

InactiveUS6261469B1Low melting pointEasily de-infiltrateSilicaPaper/cardboard articlesChromatographic separationThermoelectric materials

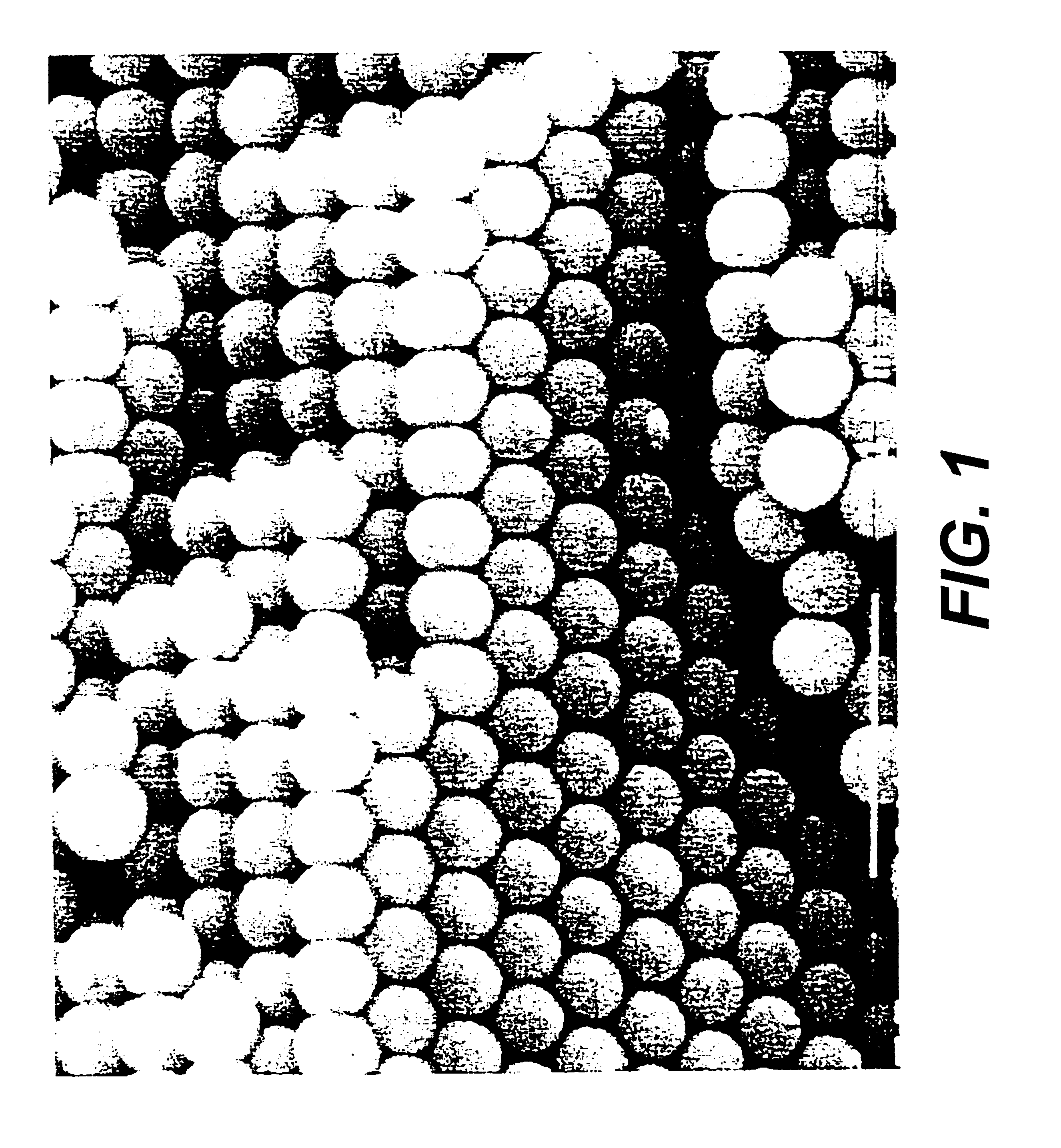

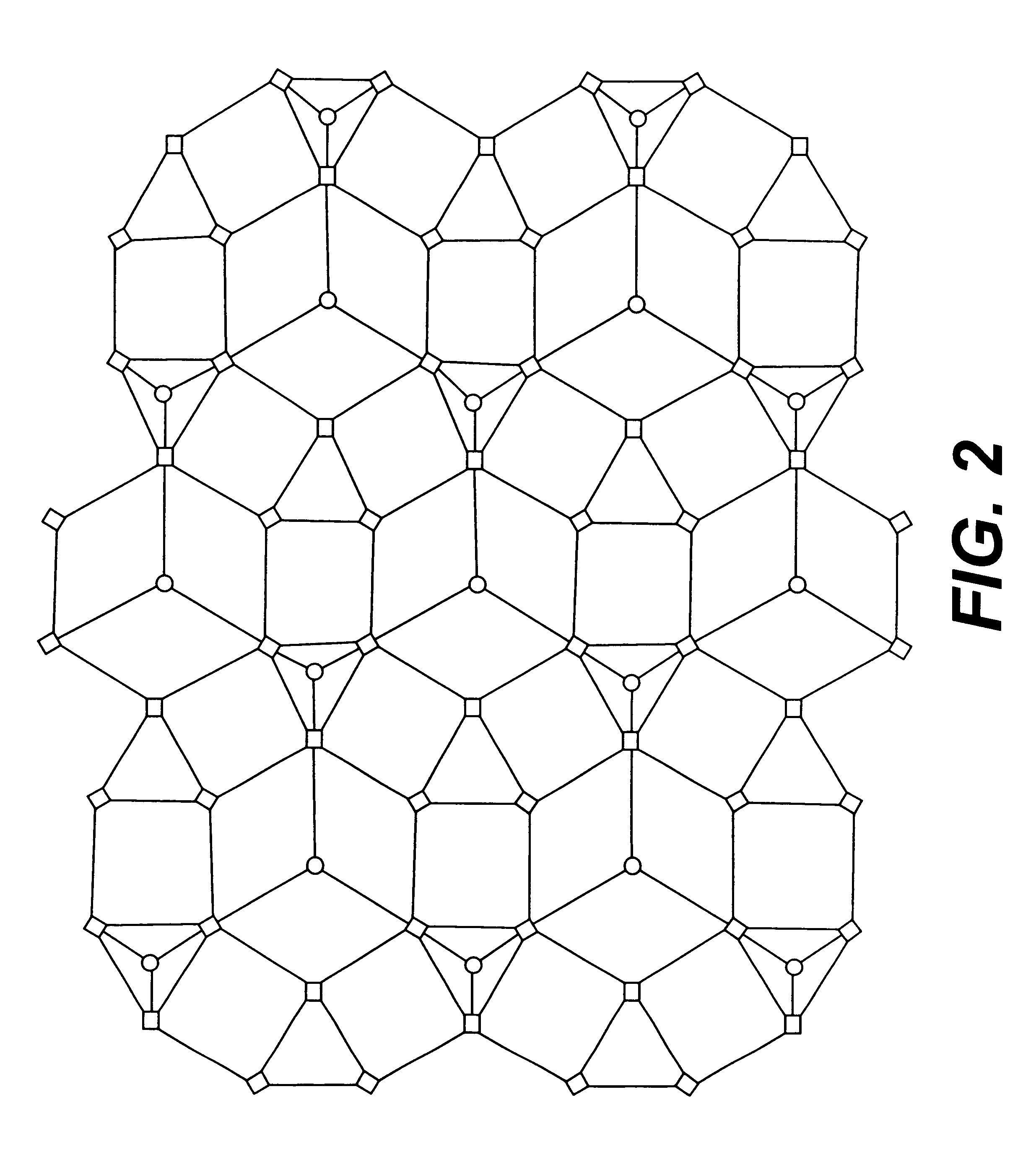

This invention relates to processes for the assembly of three-dimensional structures having periodicities on the scale of optical wavelengths, and at both smaller and larger dimensions, as well as compositions and applications therefore. Invention embodiments involve the self assembly of three-dimensionally periodic arrays of spherical particles, the processing of these arrays so that both infiltration and extraction processes can occur, one or more infiltration steps for these periodic arrays, and, in some instances, extraction steps. The product articles are three-dimensionally periodic on a scale where conventional processing methods cannot be used. Articles and materials made by these processes are useful as thermoelectrics and thermionics, electrochromic display elements, low dielectric constant electronic substrate materials, electron emitters (particularly for displays), piezoelectric sensors and actuators, electrostrictive actuators, piezochromic rubbers, gas storage materials, chromatographic separation materials, catalyst support materials, photonic bandgap materials for optical circuitry, and opalescent colorants for the ultraviolet, visible, and infrared regions.

Owner:ALLIEDSIGNAL INC

Catalytic growth of single-wall carbon nanotubes from metal particles

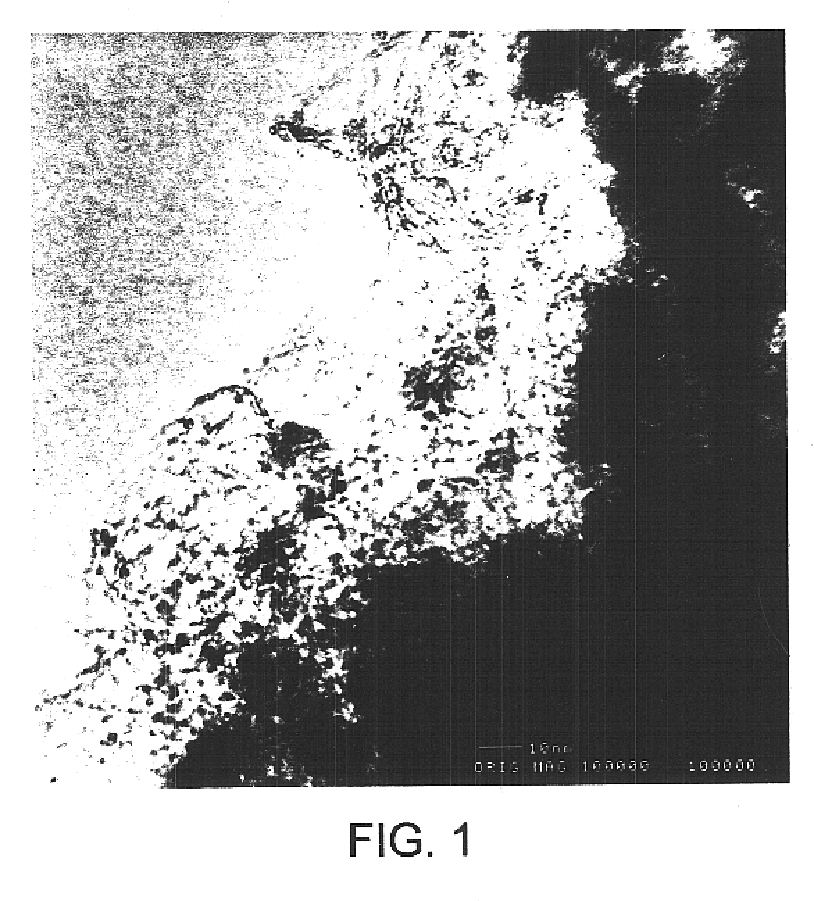

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

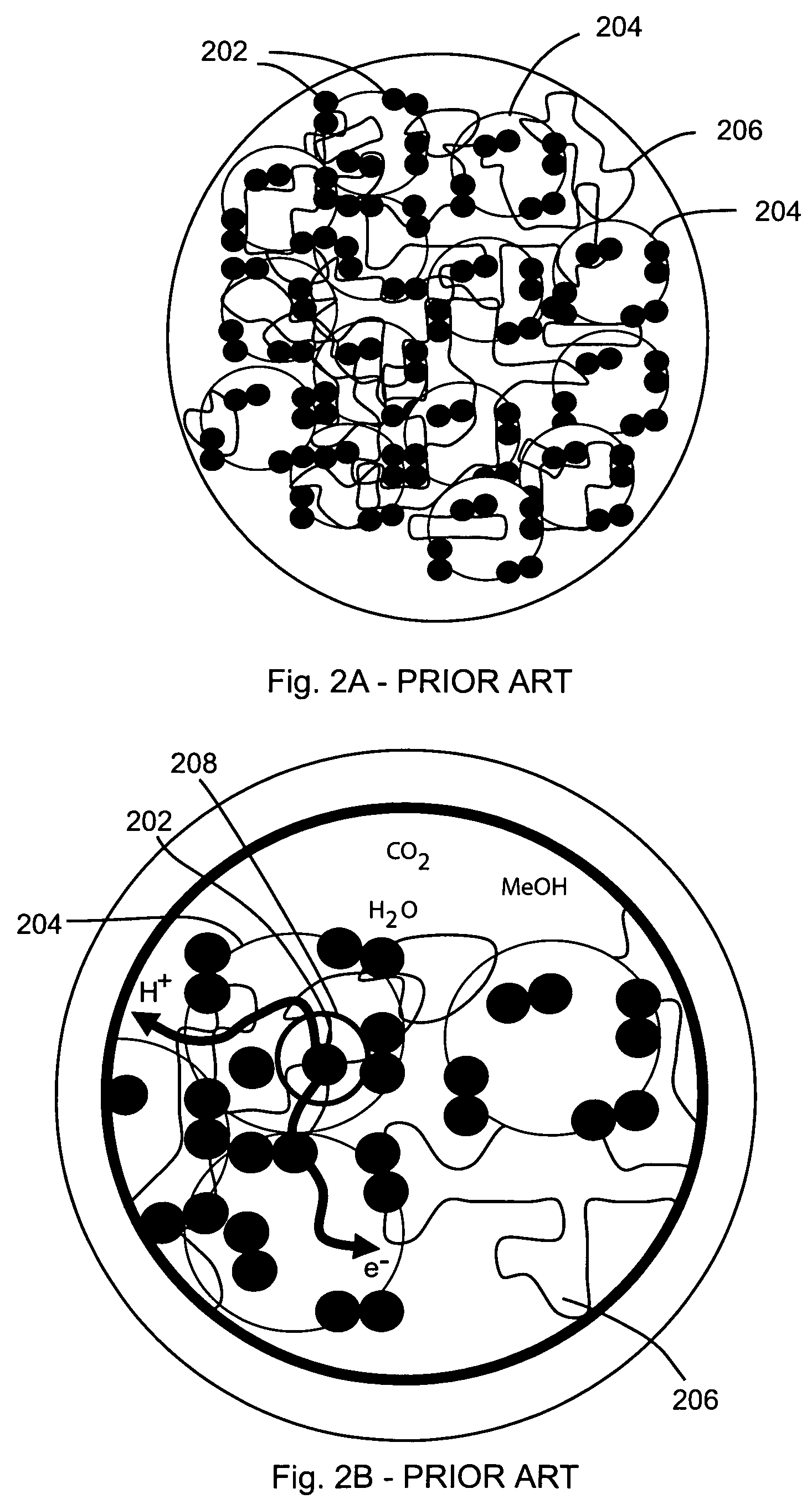

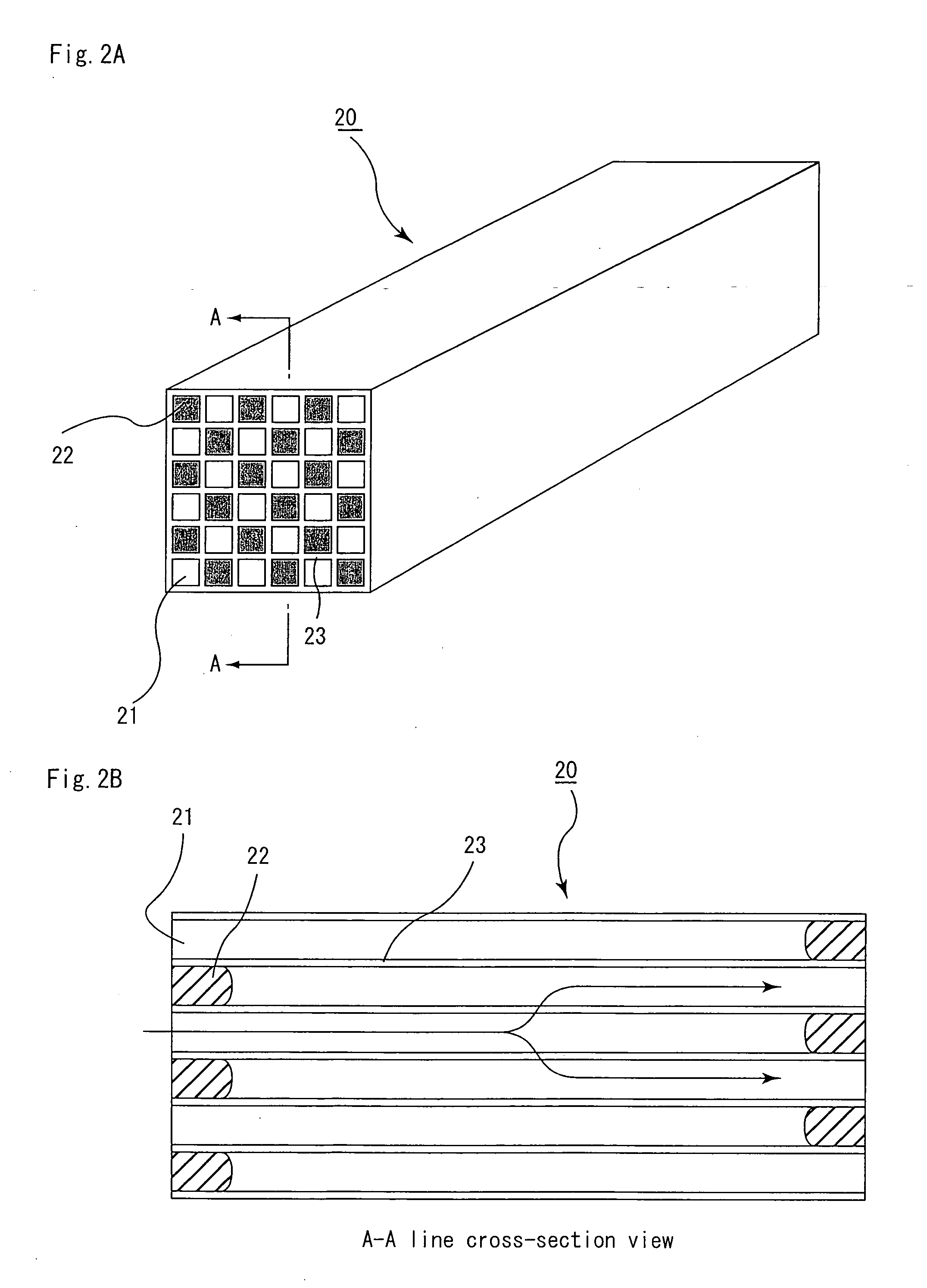

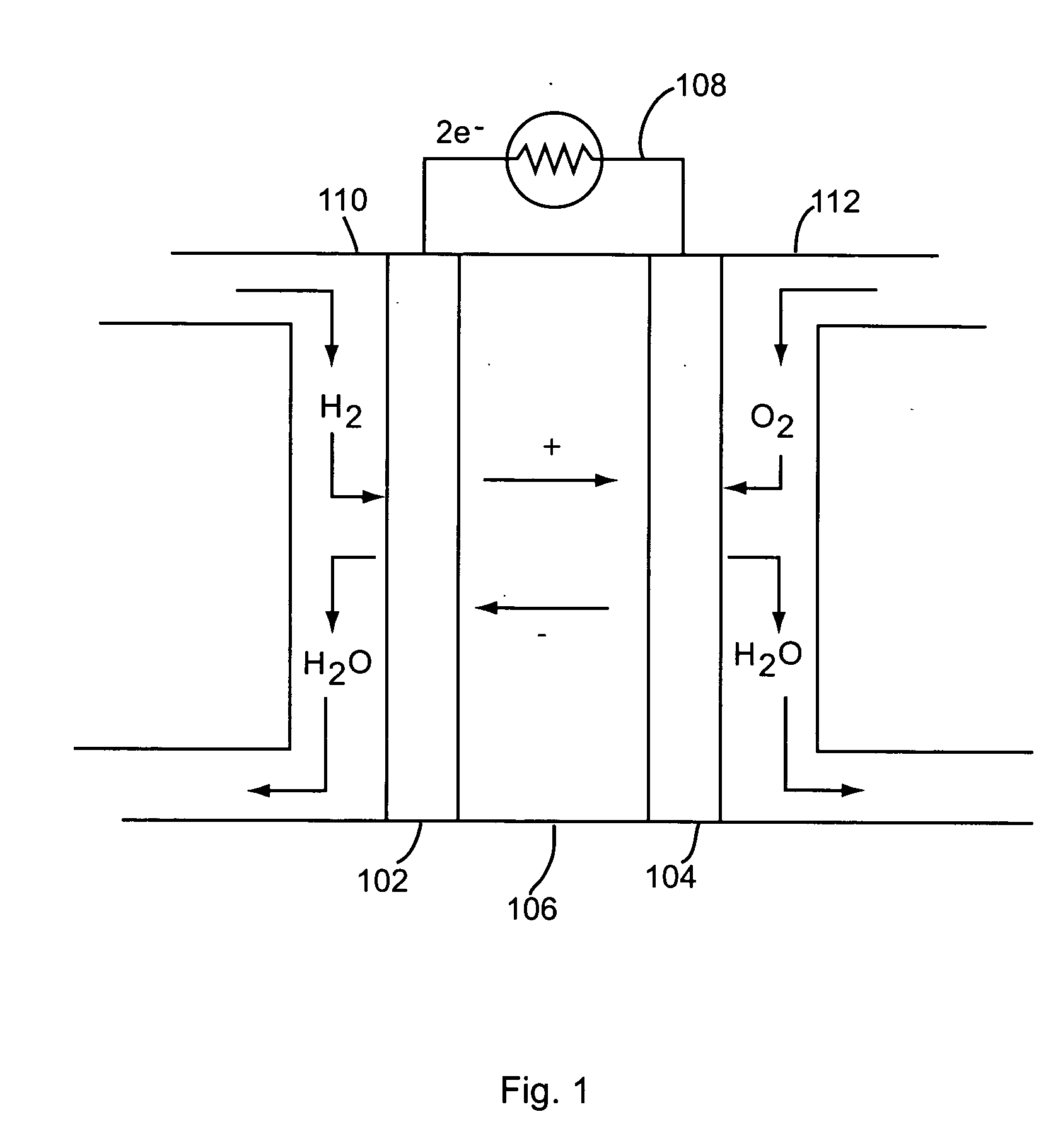

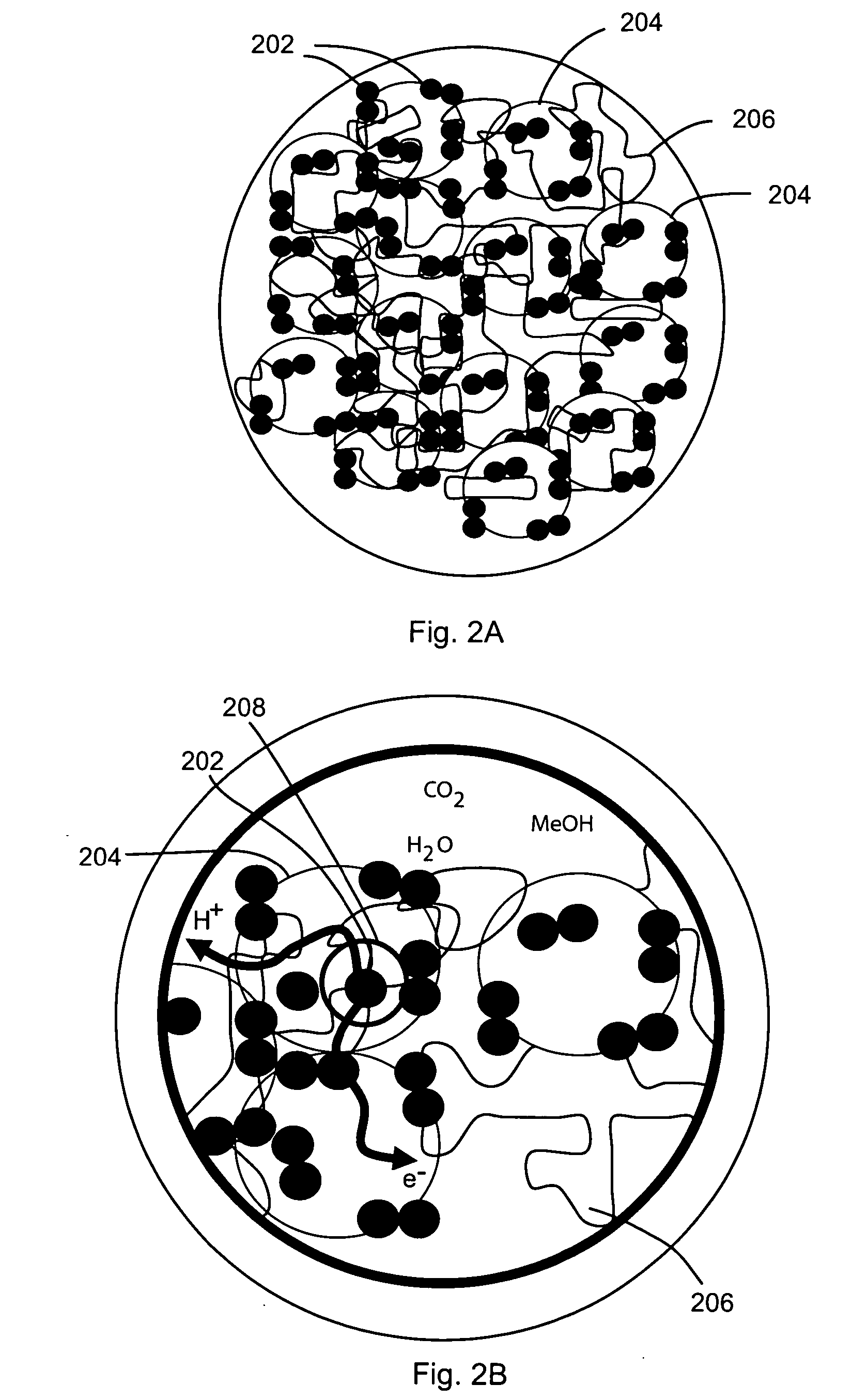

Nanowire-based membrane electrode assemblies for fuel cells

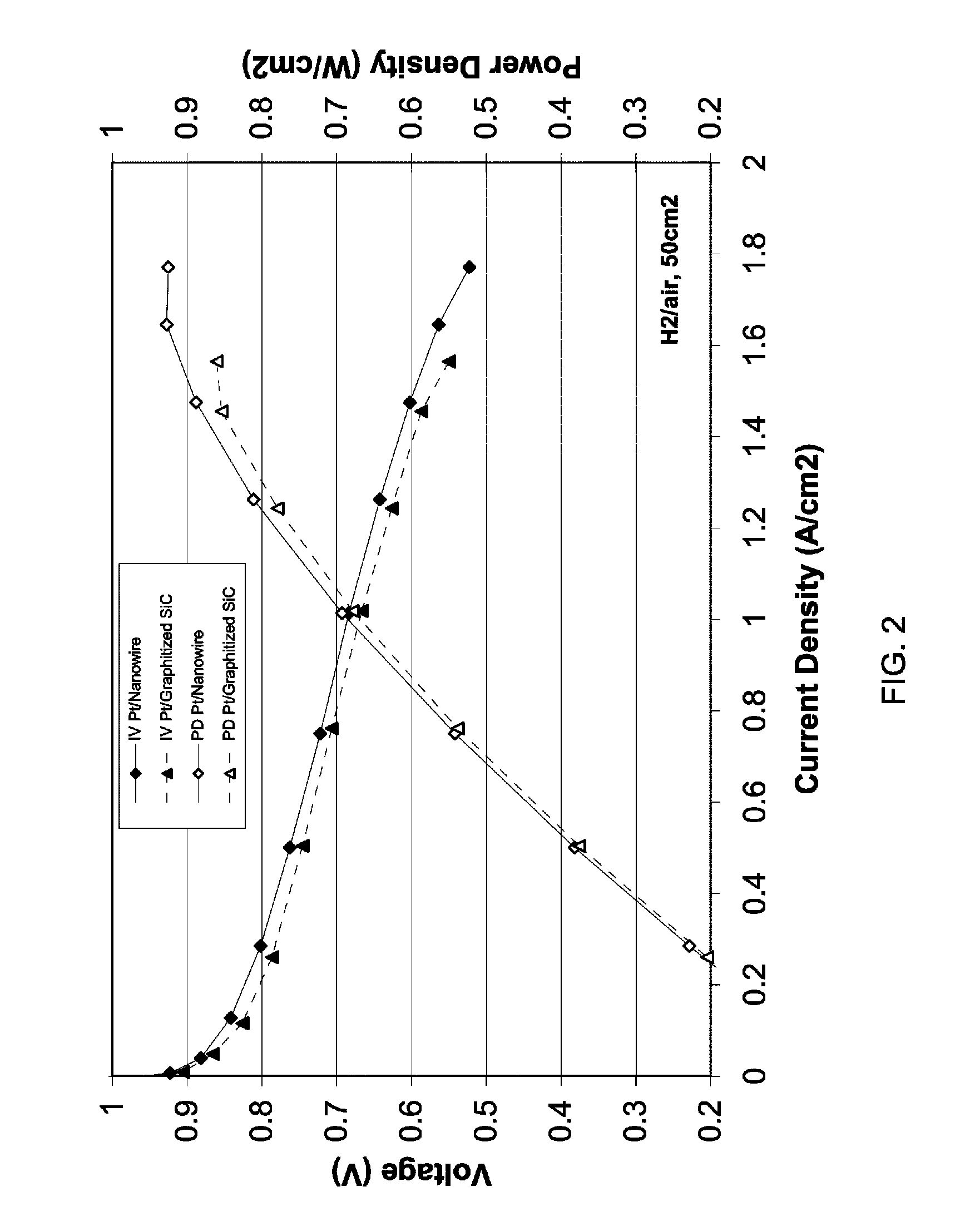

ActiveUS7179561B2High rateLow costMaterial nanotechnologyFinal product manufactureNanowirePtru catalyst

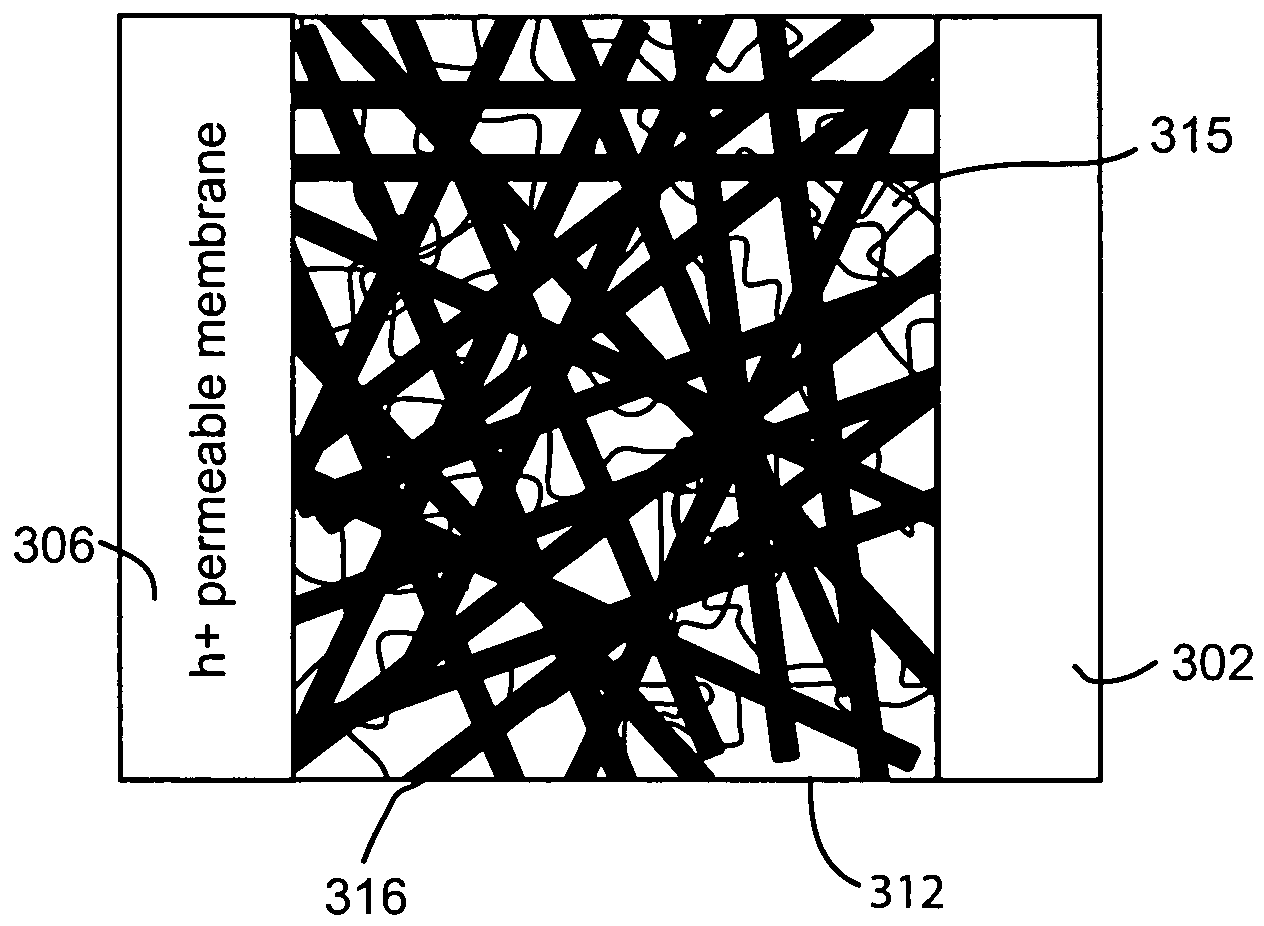

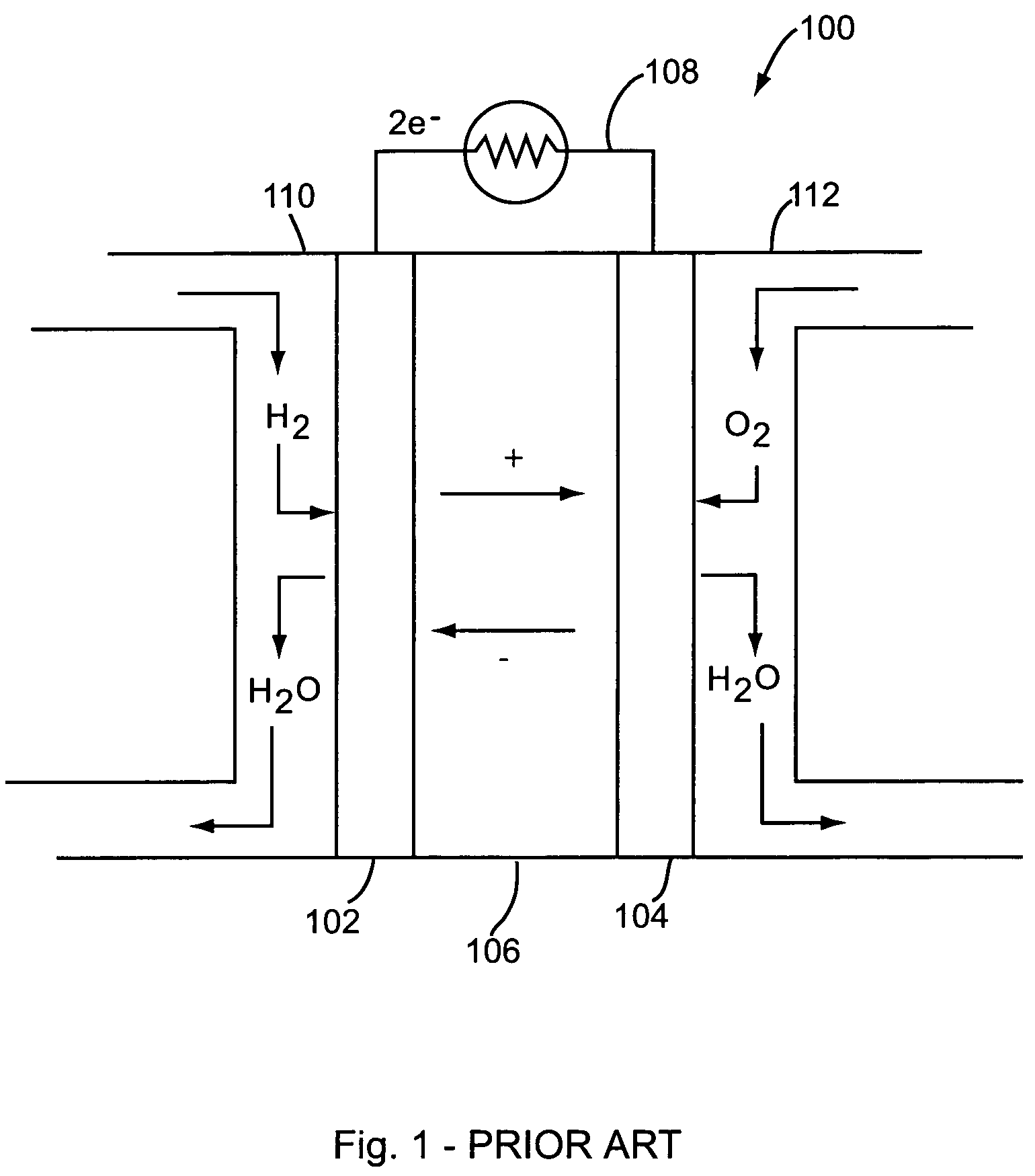

The present invention discloses nanowires for use in a fuel cell comprising a metal catalyst deposited on a surface of the nanowires. A membrane electrode assembly for a fuel cell is disclosed which generally comprises a proton exchange membrane, an anode electrode, and a cathode electrode, wherein at least one or more of the anode electrode and cathode electrode comprise an interconnected network of the catalyst supported nanowires. Methods are also disclosed for preparing a membrane electrode assembly and fuel cell based upon an interconnected network of nanowires.

Owner:ONED MATERIAL INC

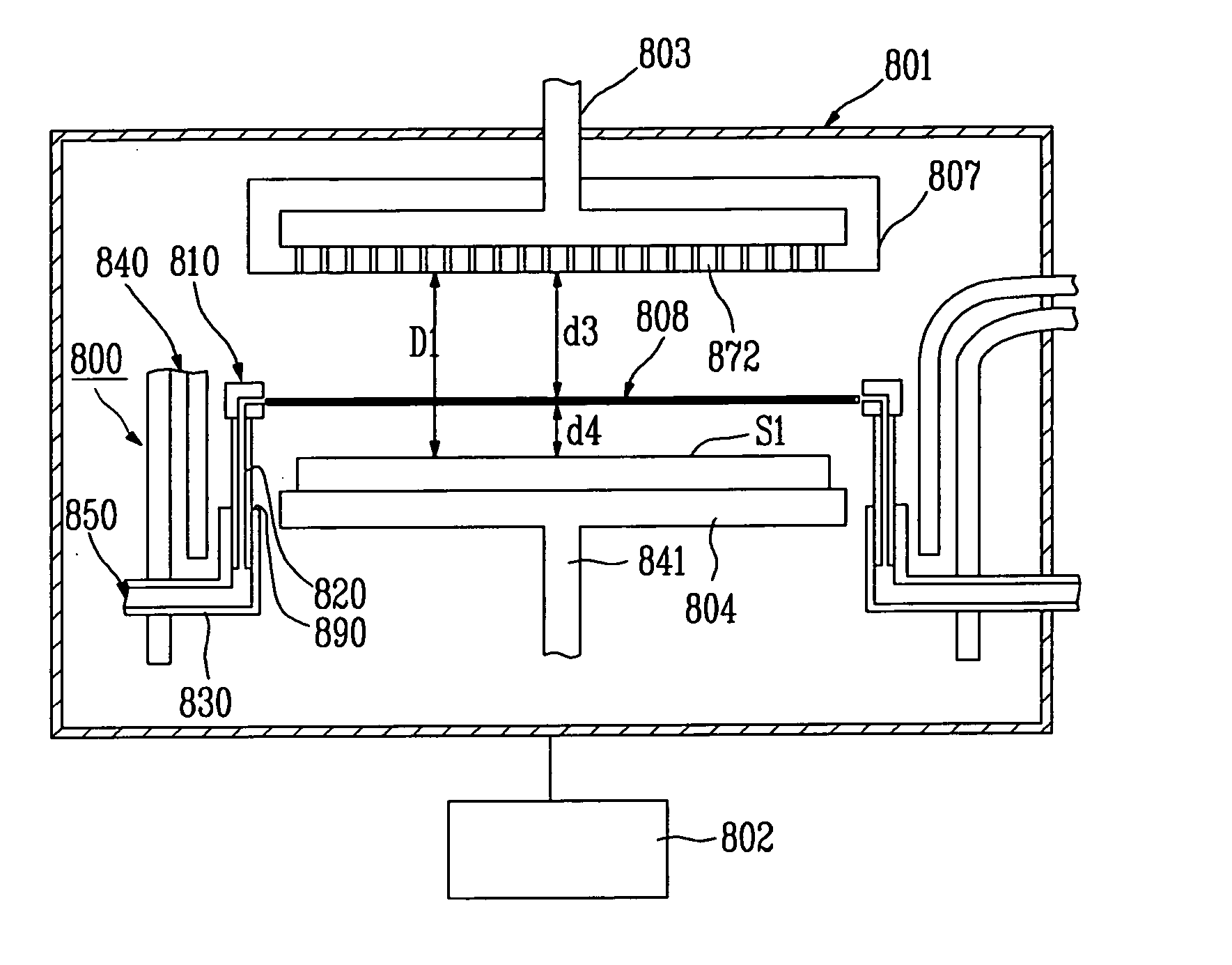

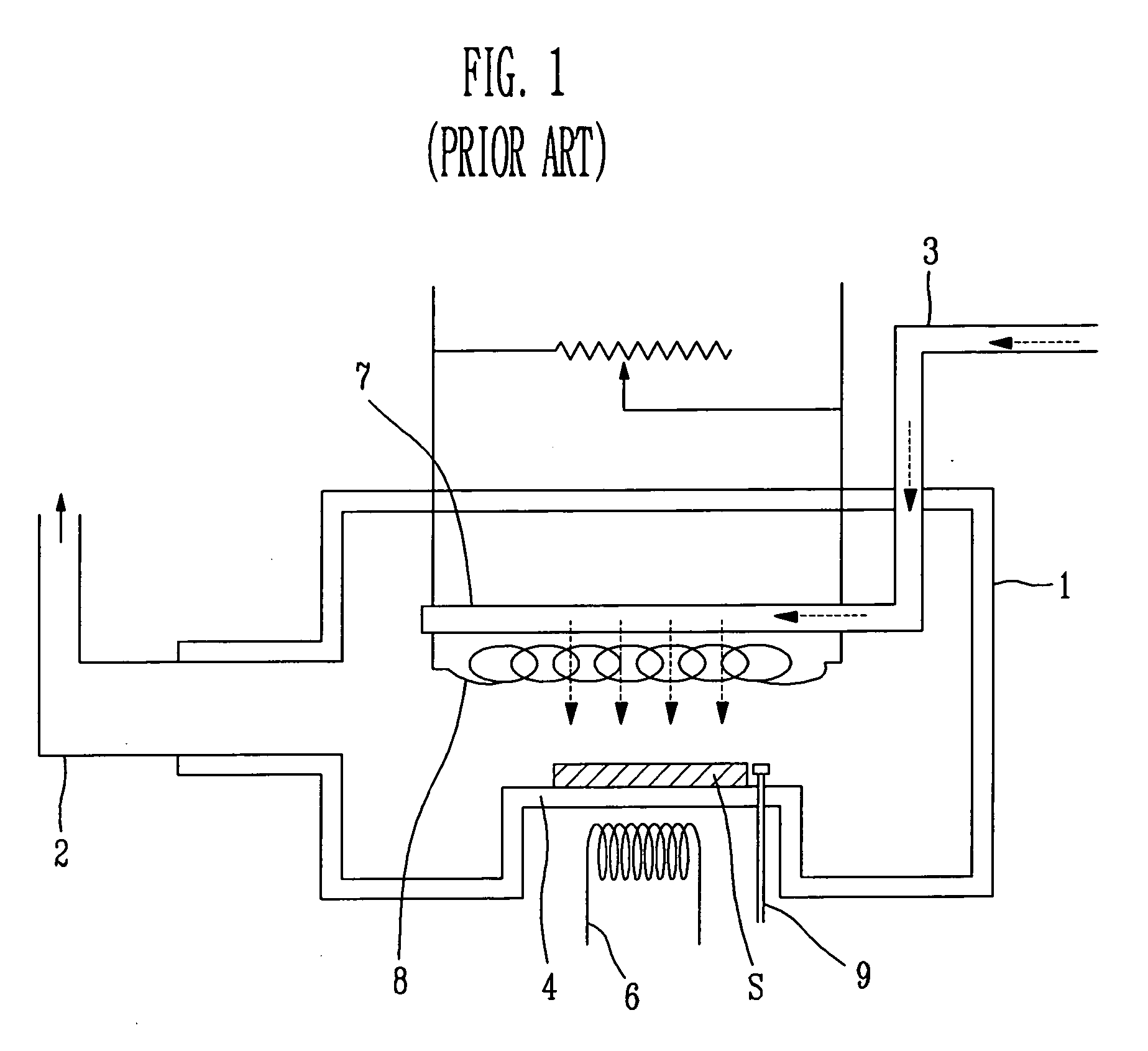

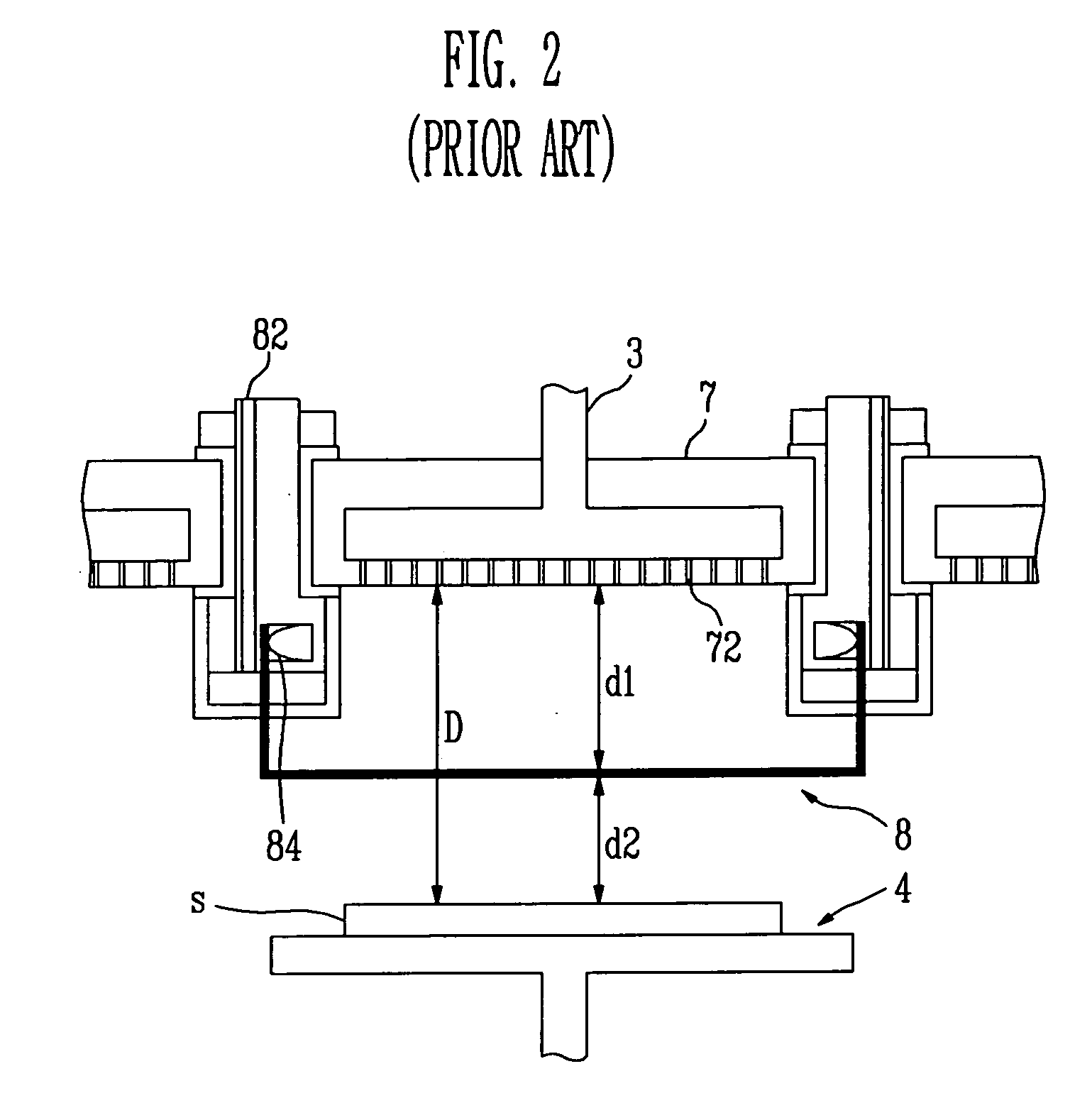

Catalyst enhanced chemical vapor deposition apparatus

InactiveUS20060254514A1Simple structureAvoid formingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseChemical vapor deposition

A catalyst enhanced chemical vapor deposition (CECVD) apparatus is provided in which the showerhead and catalyst support are separated from each other. The CECVD apparatus has excellent spacing between the showerhead, catalyst wire and substrate and can be purged to prevent contaminants from forming on parts functioning at low temperatures. The CECVD apparatus comprises a reaction chamber, a showerhead for introducing reaction gas into the reaction chamber, a catalyst wire for decomposing the reaction gas, a catalyst support for supporting the catalyst wire, a substrate on which the decomposed gas is deposited, and a substrate support for supporting the substrate.

Owner:SAMSUNG DISPLAY CO LTD

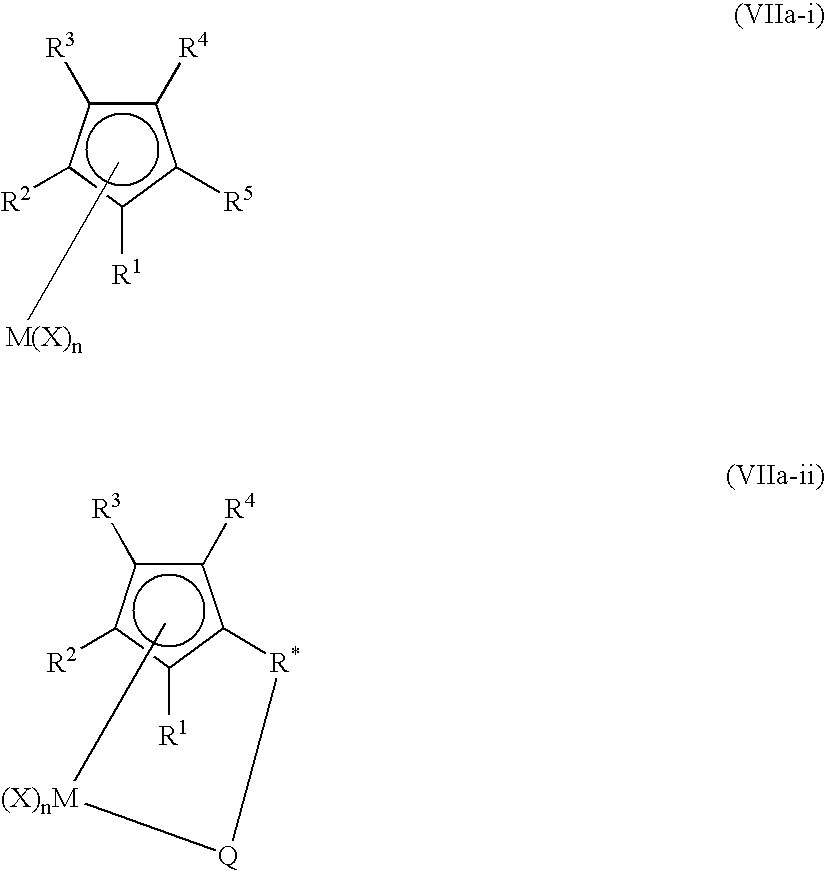

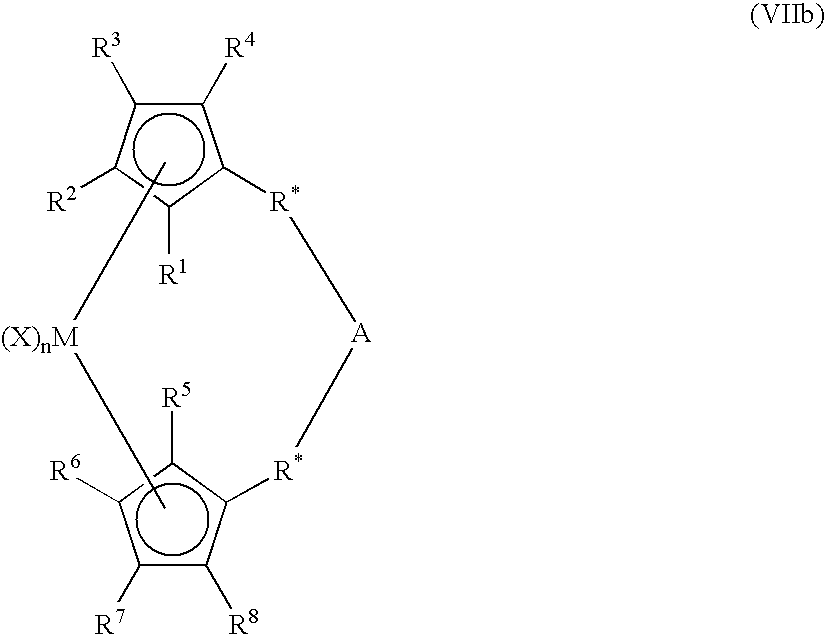

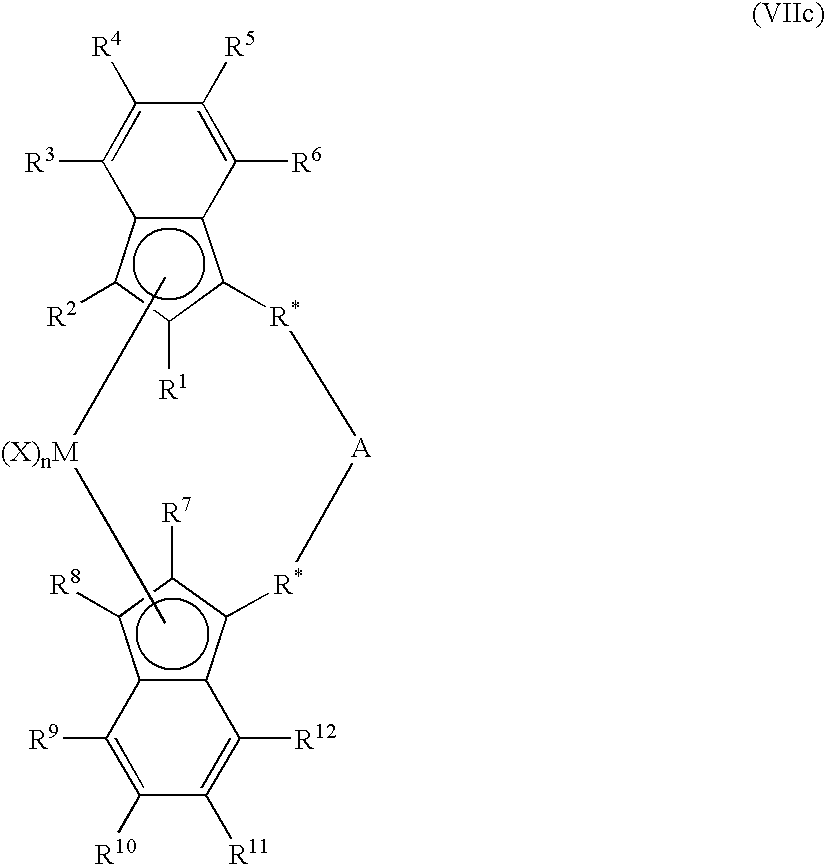

Activated catalyst systems from substituted dialuminoxane complexes

InactiveUS6958306B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylHalogen

A catalyst composition and method for preparing a supported catalyst system for olefin polymerization is provided. In one aspect, the catalyst composition includes a reaction product of a dialuminoxane and a halogen substituted aryl borane, wherein the reaction takes place on a support and at conditions sufficient to exchange one or more ligands on the dialuminoxane for one or more ligands on the halogen substituted aryl borane while on the support. In one embodiment, the method for preparing the supported catalyst system includes combining a dialuminoxane with a support to form a treated catalyst support, and combining a halogen substituted aryl borane with the treated catalyst support at conditions sufficient to exchange one or more ligands on the dialuminoxane for one or more ligands on the halogen substituted aryl borane while on the support to form a supported activator. The method further includes reacting one or more polymerization catalysts with the supported activator.

Owner:UNIVATION TECH LLC

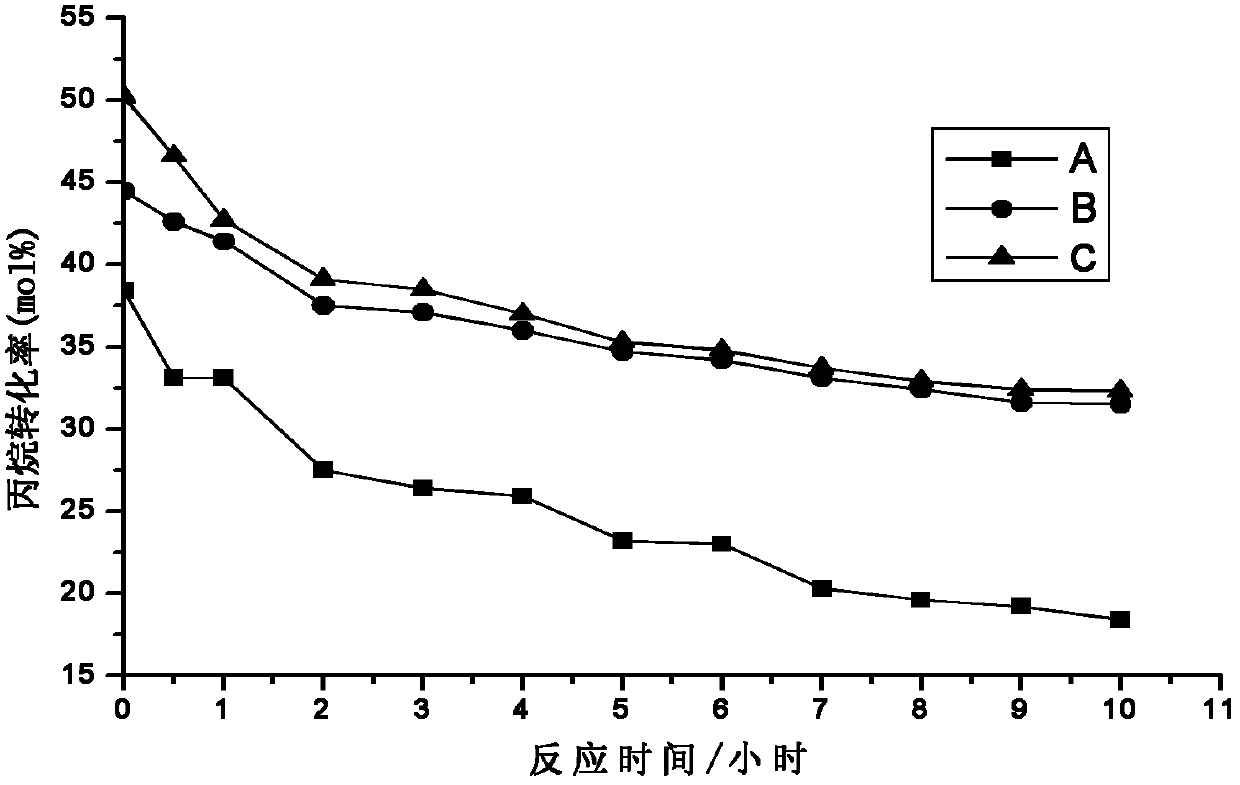

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

Preparation method of mesonic pore molecular sieve carrier material

The present invention belongs to the field of inorganic nanometer material technology, in particular, it relates to a method for preparing mesoporous molecular sieve carrier material by using diblockmacromolecular polymer. It is characterized by that under the acid condition it uses polyoxyethylene-polyoxybutylene diblock macromolecular surfactant as template agent and makes hydrothermal synthesis at 100 deg.C to prepare mesoporous silicon oxide material with two-dimensional hexagonal structure with high degree of order and large specific surface area and laminate silicon oxide material withhigh degree of order. These new material can be used as catalyst, catalyst carrier, adsorption film, organic-inorganic composite material, sensor and chromatographic packing, etc.

Owner:FUDAN UNIV

Method for preparing carbon material with rich mesopores and macropores

The invention relates to a method for preparing a carbon material with rich mesopores and macropores. Inorganic nano-particles are used as pore-forming template agent to be uniformly distributed in a carbon-contained organic precursor and then the carbon-contained organic precursor carries out high-temperature carbonization, template agent washing-out and drying to obtain a porous carbon material. The carbon material prepared by the method has the specific surface area of 50-1,900 m / g and a pore diameter mainly between 2-900 nm, can be conveniently adjusted by the size control of the selected nano-particles, removes a template without using high corrosive HF and has the advantages of simple method, convenient operation, free pore diameter adjustment and control in a mesopore and macropore range, and the like. The carbon material has a wide application prospect in fields of electrochemical energy accumulation, macromolecular adsorption, catalyst carriers, composite materials, and the like.

Owner:NO 63971 TROOPS PLA

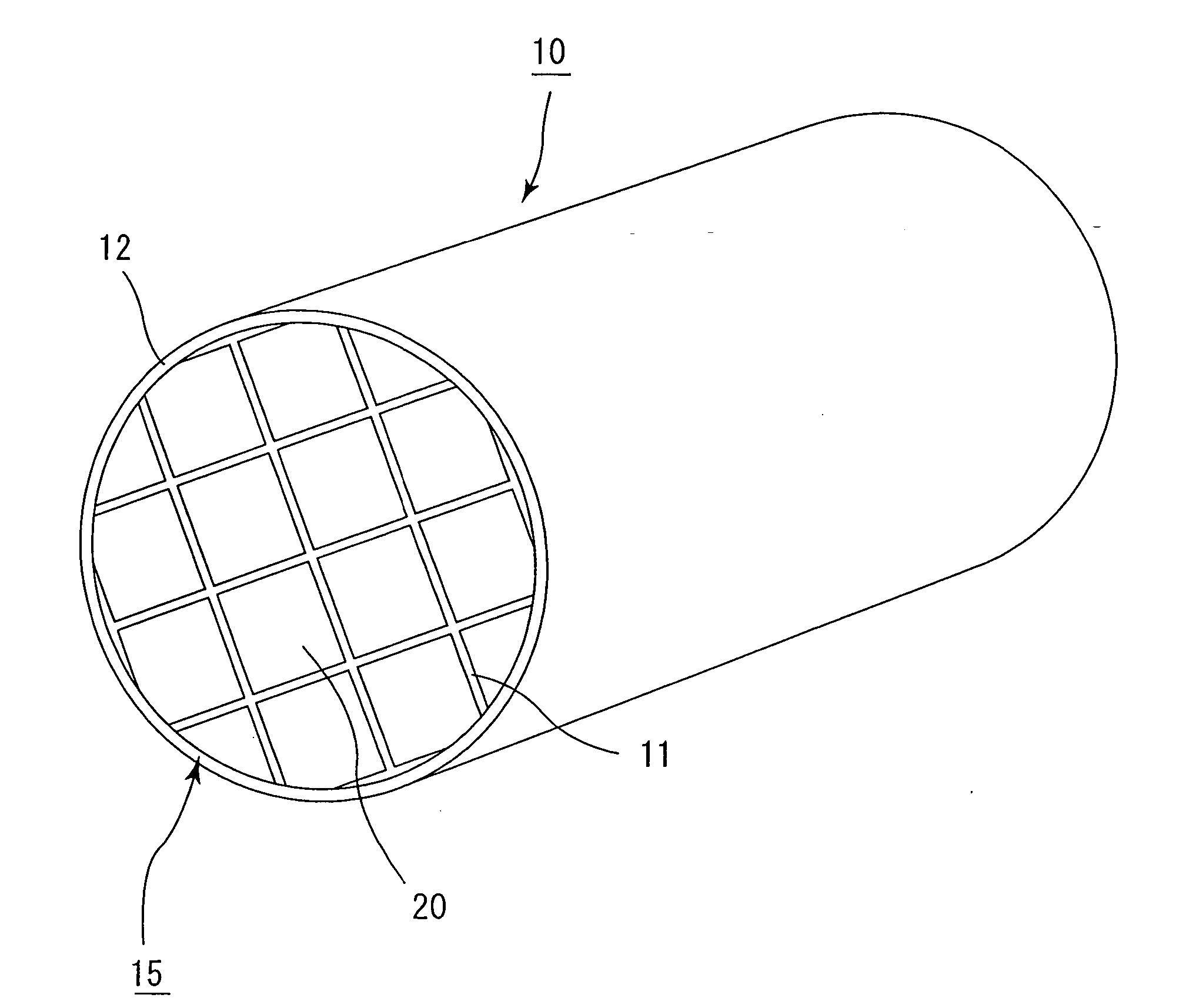

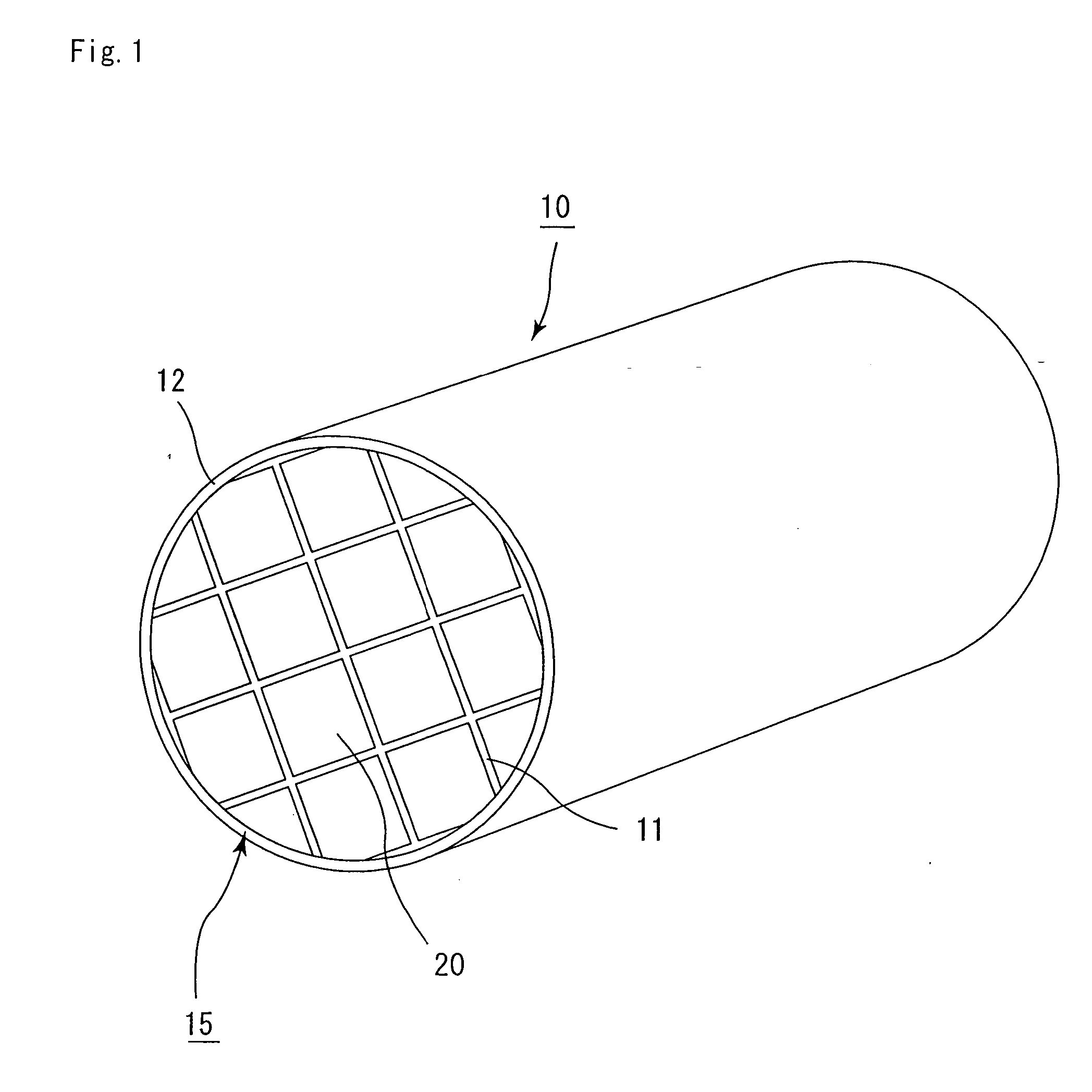

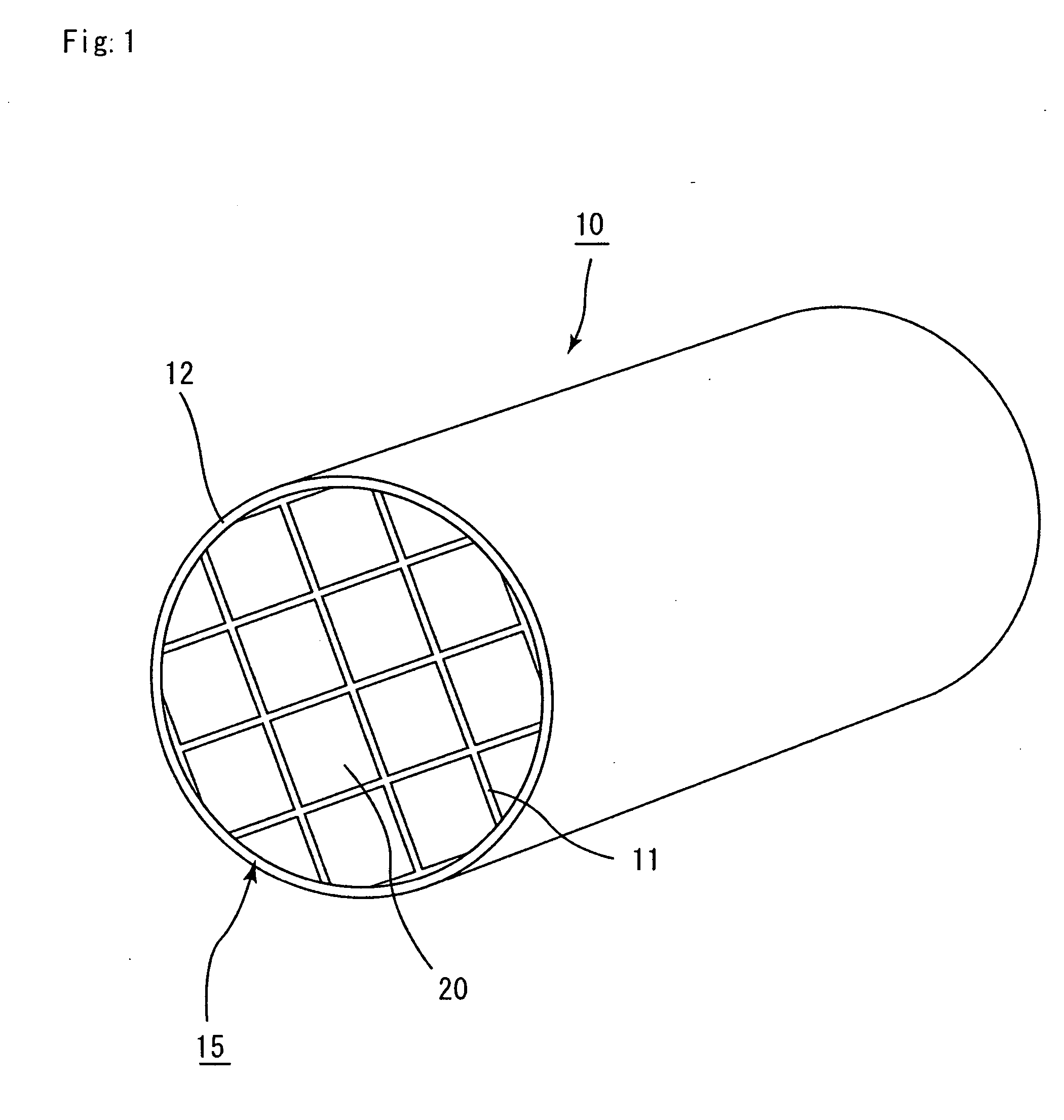

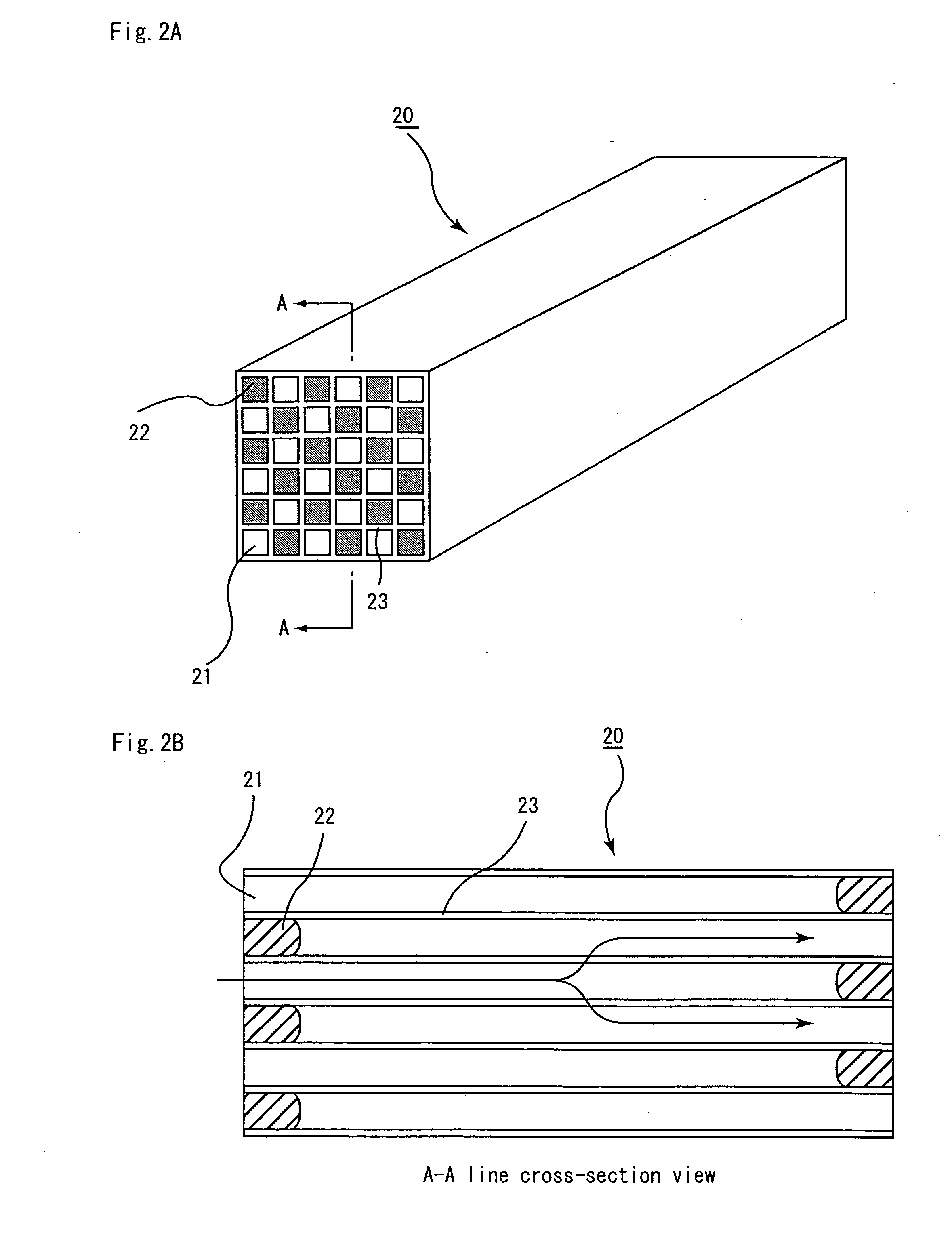

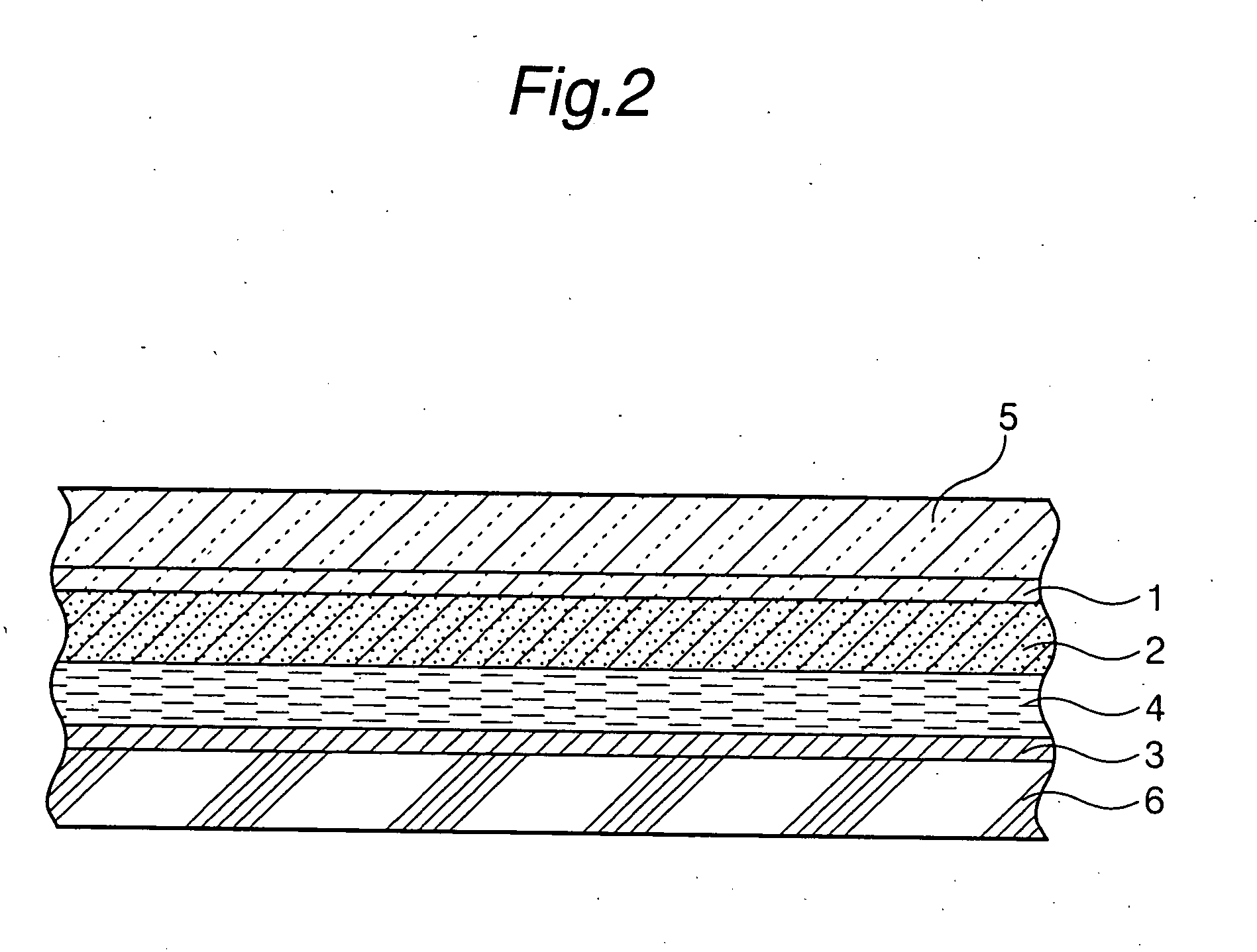

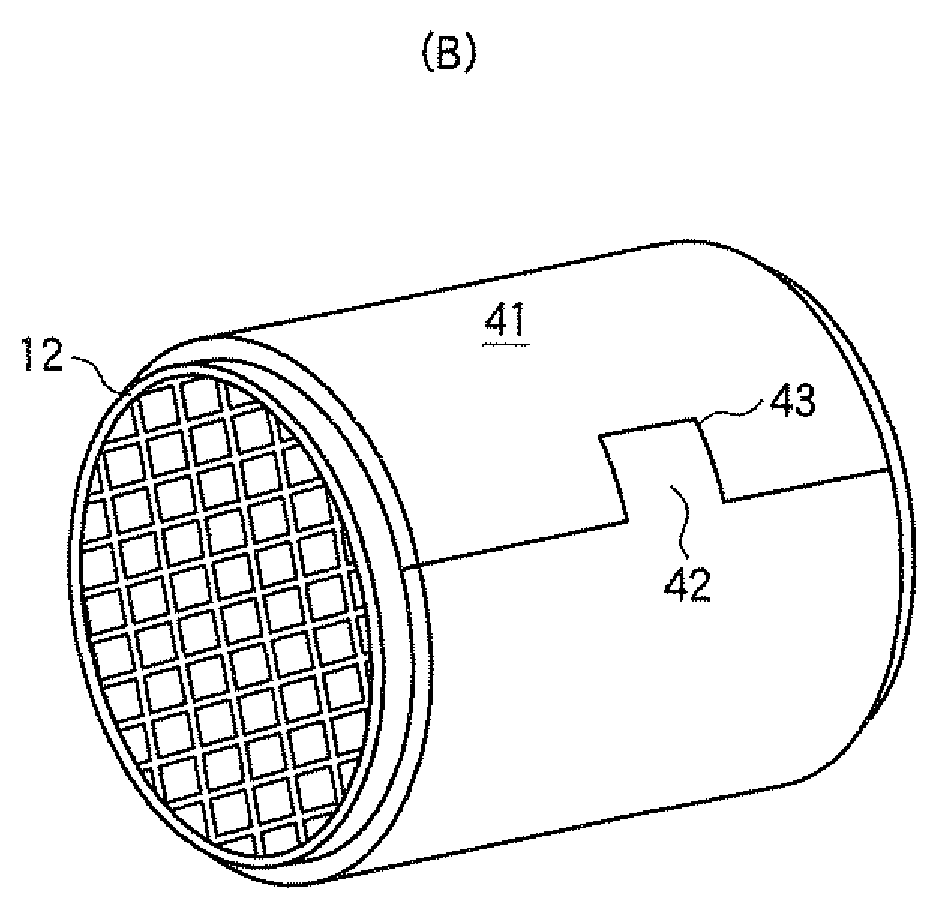

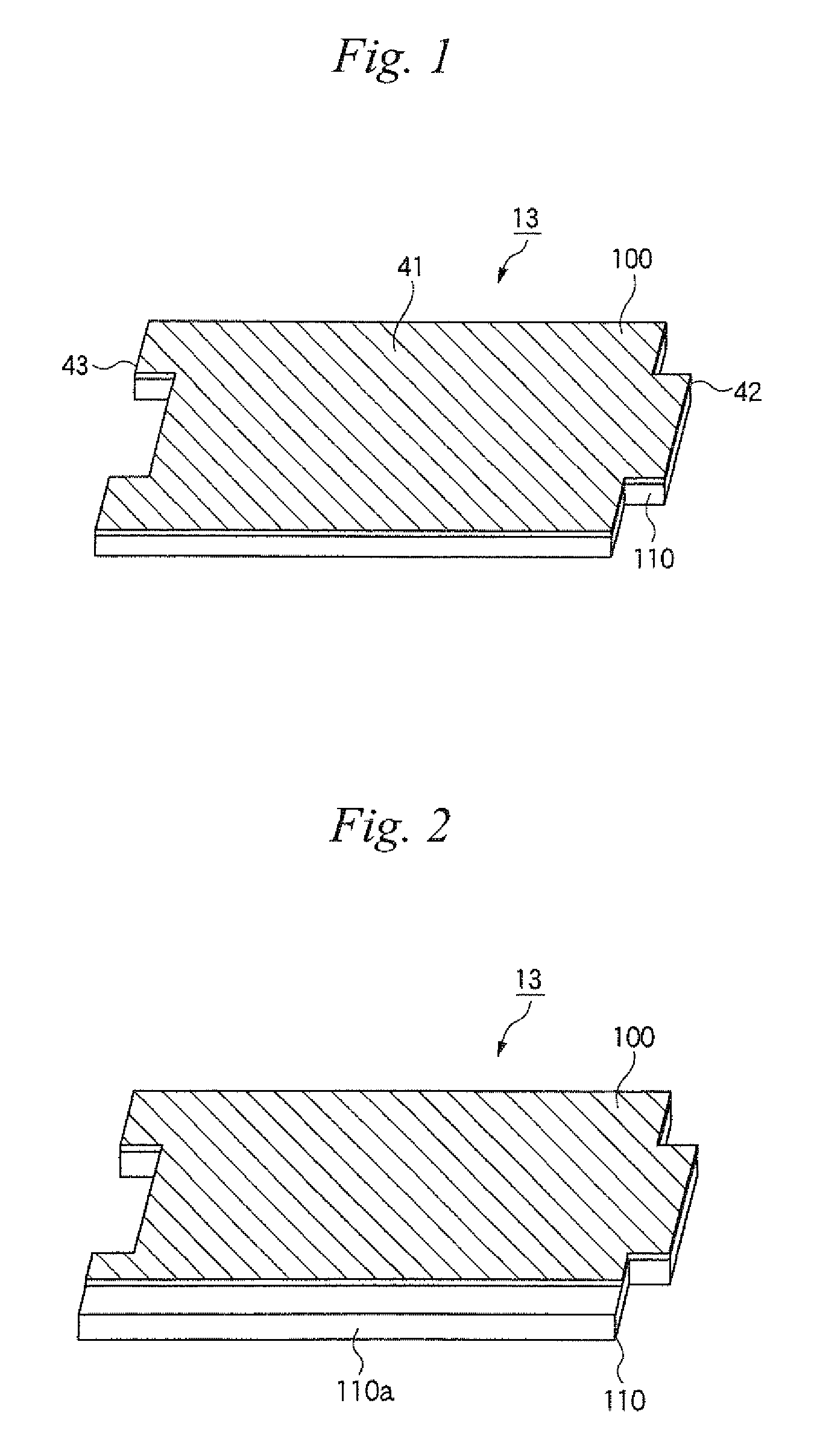

Honeycomb structured body

A honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of porous ceramic members are combined with one another through an adhesive layer, each of the porous ceramic members having a plurality of cells which are allowed to penetrate in a longitudinal direction with a wall portion therebetween and either one end of which is sealed, with a catalyst supporting layer being adhered to the wall portion, wherein, supposing that the rate of the pore volume of pores having a pore diameter of 10 μm or less to the entire pore volume of the porous ceramic member is X1 (%), the porosity is Y1 (%) and the weight of the catalyst supporting layer is Z1 (g / l), these X1, Y1 and Z1 are allowed to satisfy the following expressions (1) and (2): X1≦20−Z1 / 10 (1), and Y1≧35+7Z1 / 40 (2) (where about 20≦Z1≦about 150).

Owner:IBIDEN CO LTD

Nanowire-based membrane electrode assemblies for fuel cells

ActiveUS20060188774A1Higher catalytic metal utilization rateLow costMaterial nanotechnologyFinal product manufactureNanowirePtru catalyst

The present invention discloses nanowires for use in a fuel cell comprising a metal catalyst deposited on a surface of the nanowires. A membrane electrode assembly for a fuel cell is disclosed which generally comprises a proton exchange membrane, an anode electrode, and a cathode electrode, wherein at least one or more of the anode electrode and cathode electrode comprise an interconnected network of the catalyst supported nanowires. Methods are also disclosed for preparing a membrane electrode assembly and fuel cell based upon an interconnected network of nanowires.

Owner:ONED MATERIAL INC

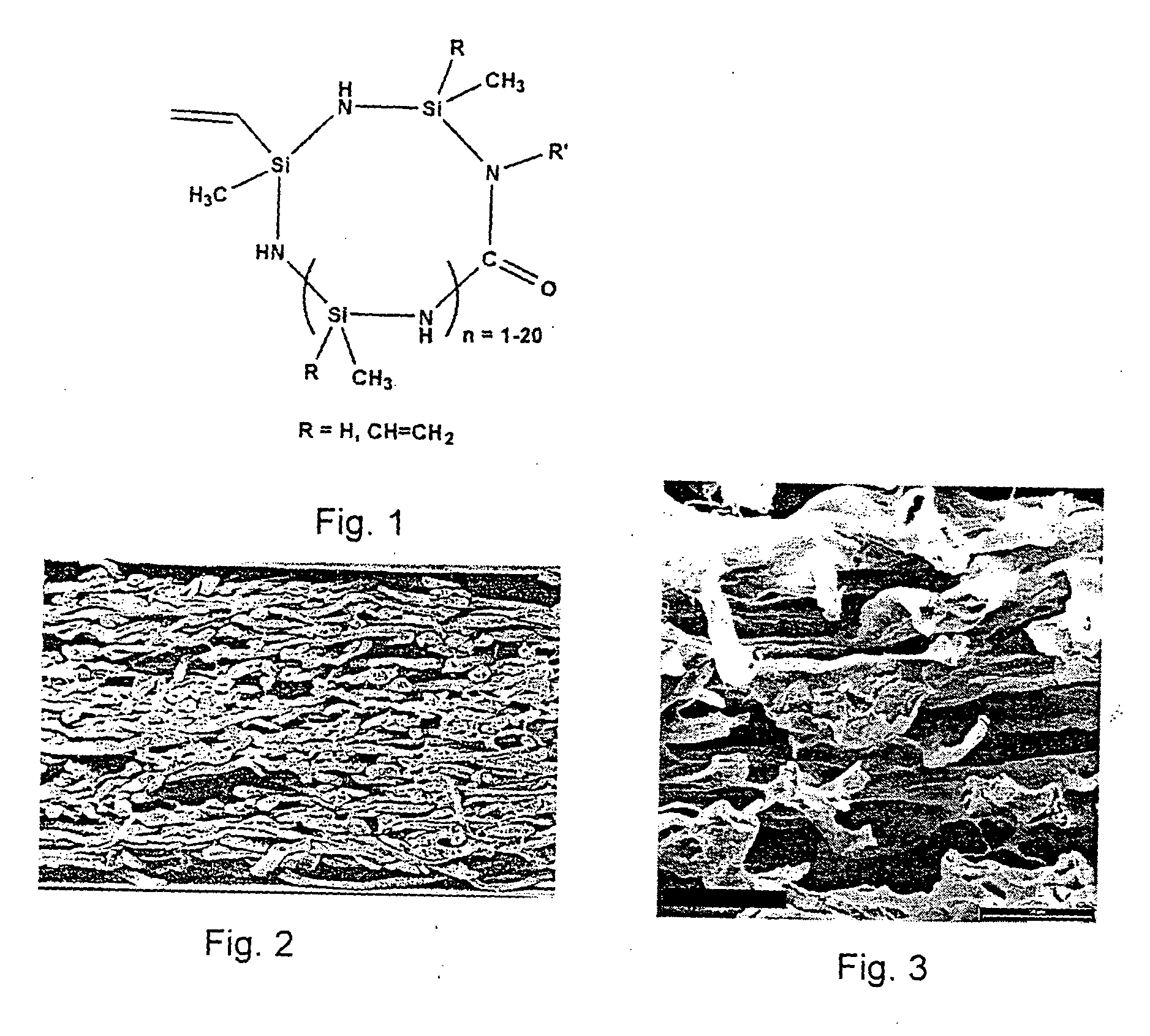

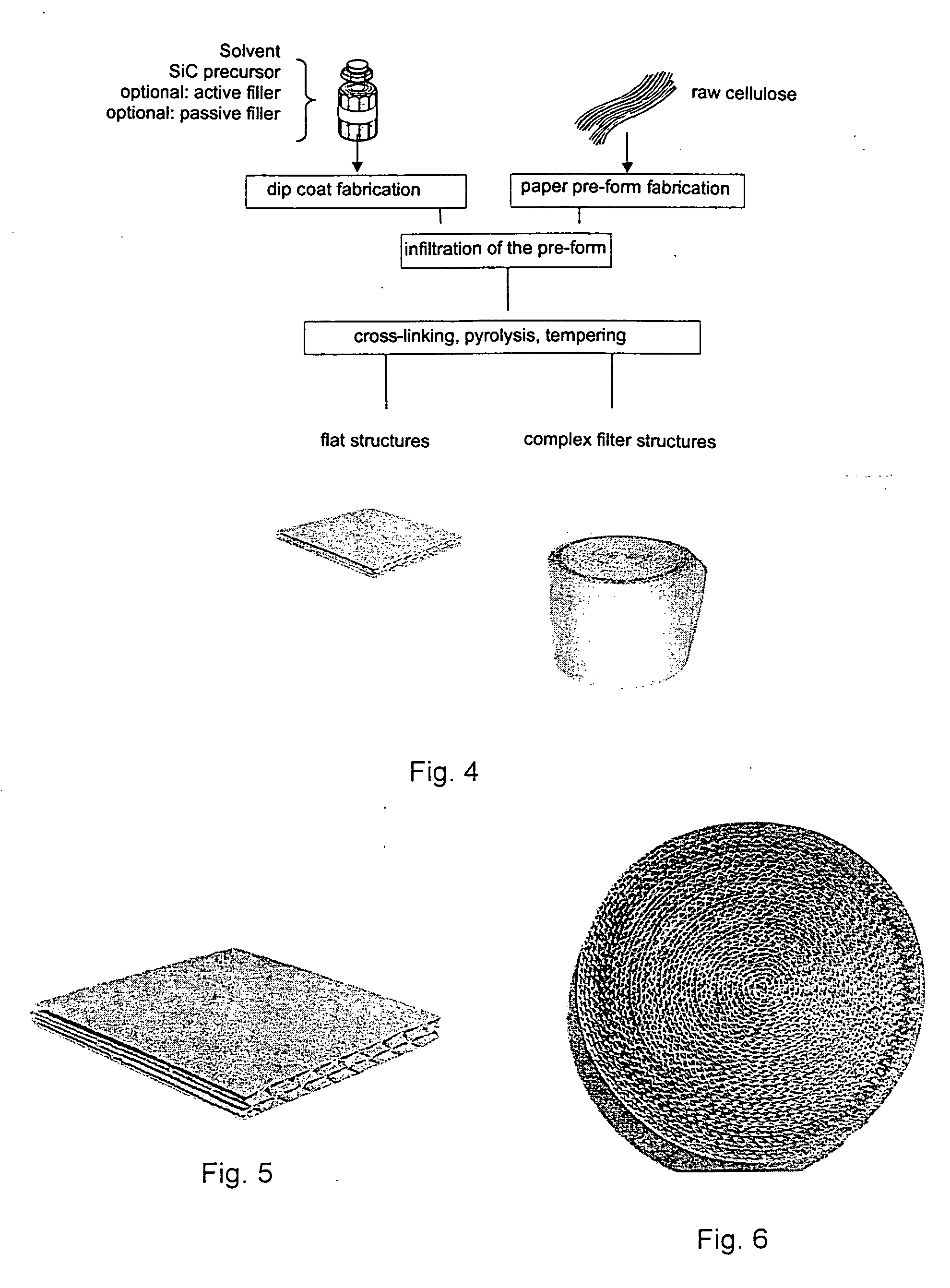

Porous SiC-bodies with micro-channels and process for their fabrication

InactiveUS20060121266A1Large effective internal surface areaImprove filtering effectInternal combustion piston enginesLayered productsParticulatesCellulose

Process for the fabrication of porous bodies mainly constituted by SiC containing ceramic with a microstructure which is interfused with micro-channels which consists of the process steps a) Provision of a pre-body made from cellulose or pulp b) Fabrication of an infiltration solution or a slurry consisting of (A) solvent, polysilazane, polysilane and / or polycarbosilane or (B) solvent, polysilazane and / or polysilane as well as active metallic fillers and / or passive ceramic fillers. c) Infiltrating the body with infiltration solution or slurry d) Cross-linking of the polysilazane, polycarbosilane and / or polysilane while generating a solid green body e) Ceramization through pyrolysis of the green body in an inert-gas atmosphere. f) Removal of residual carbon with an oxidizing thermal process, thereof producible catalyst carriers or carbon particulate filters as well as Porous ceramic which is made from at least 80% SiC in which the porous ceramic features a microstructure with micro-channels consisting mainly of SiC coated micro-channels featuring an average diameter between 1 and 25 μm and webs of SiC located between the micro-channels as well as additional ceramic materials with a content below 20 wt %.

Owner:DAIMLER AG

Silica-alumina catalyst support, catalysts made therefrom and methods of making and using same

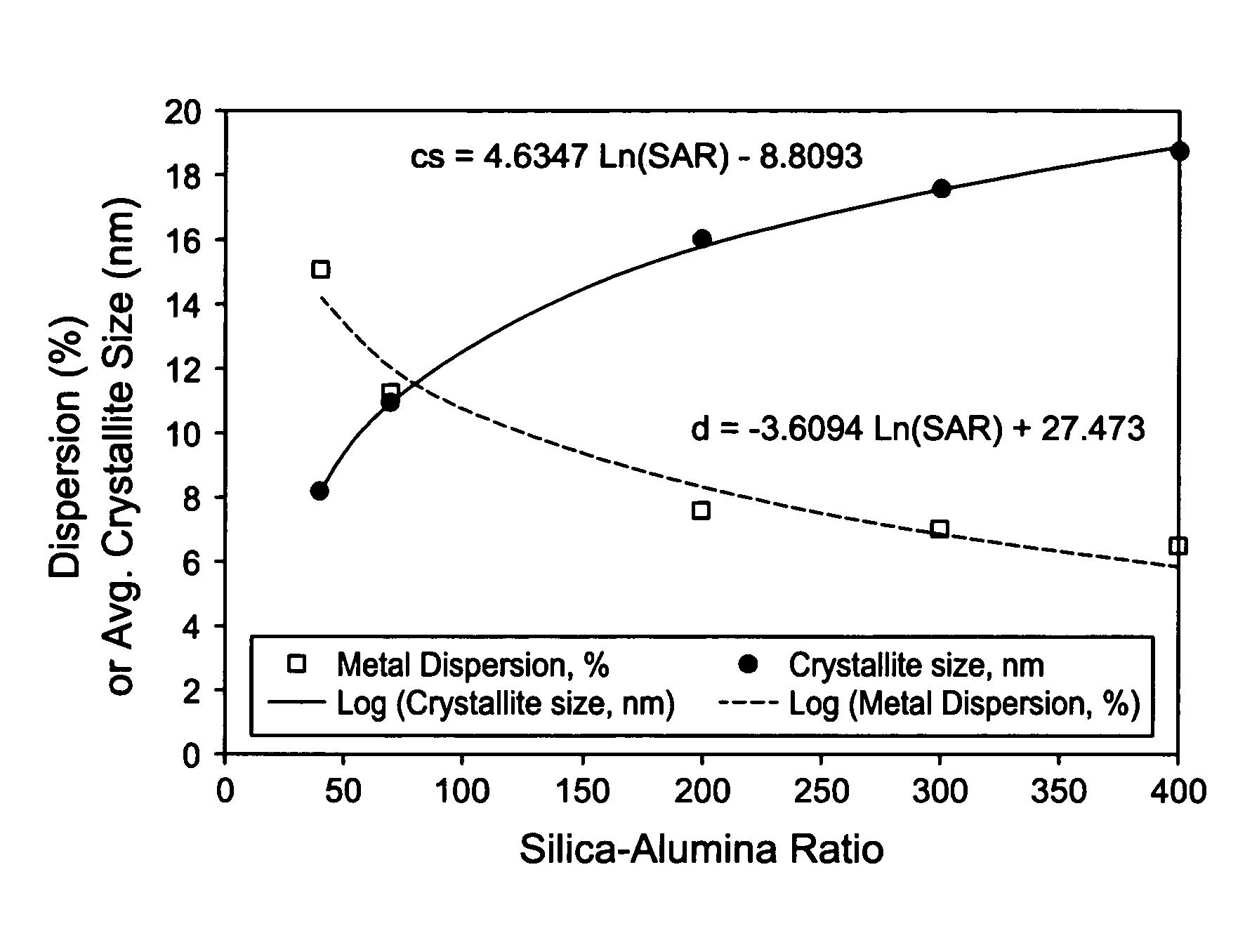

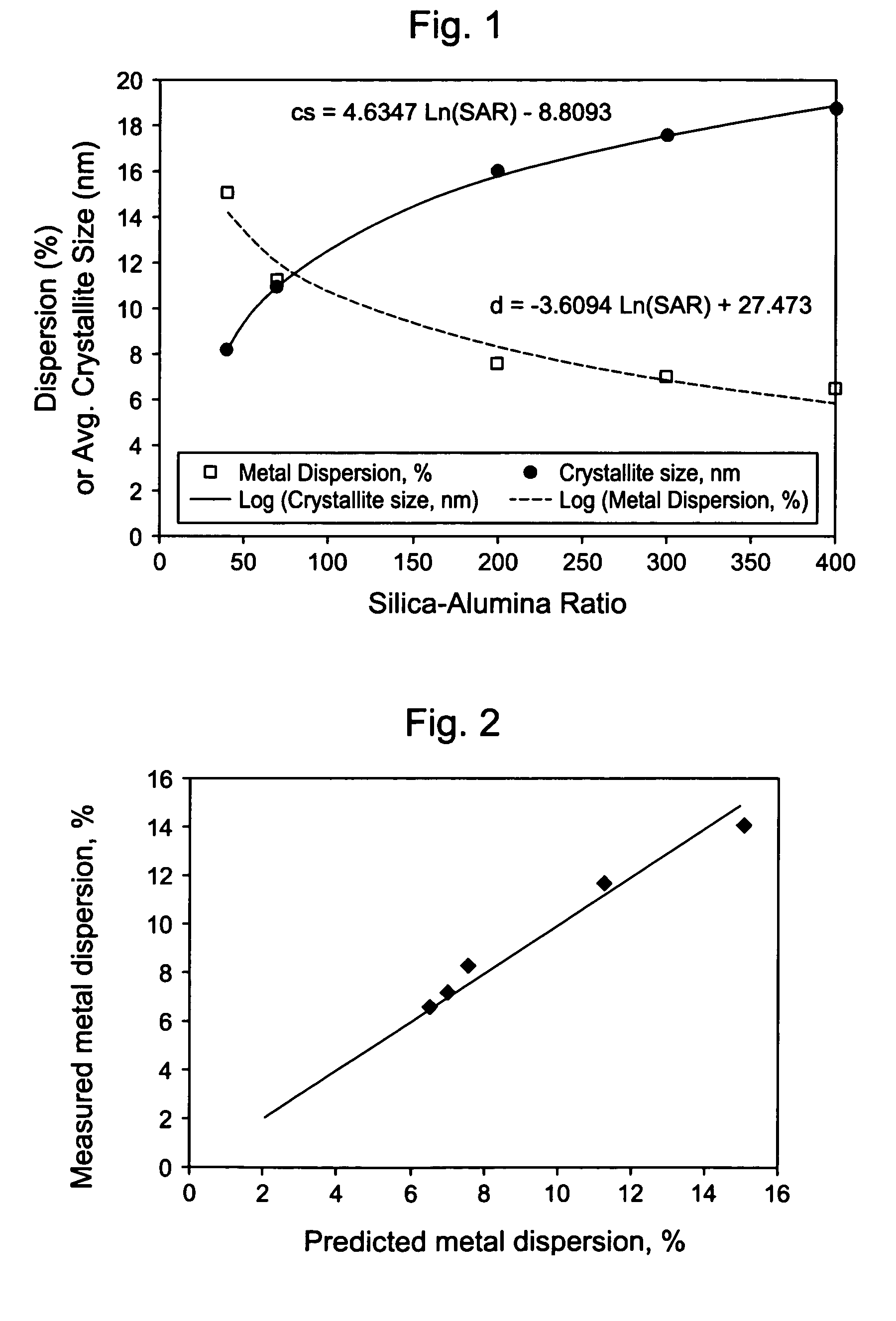

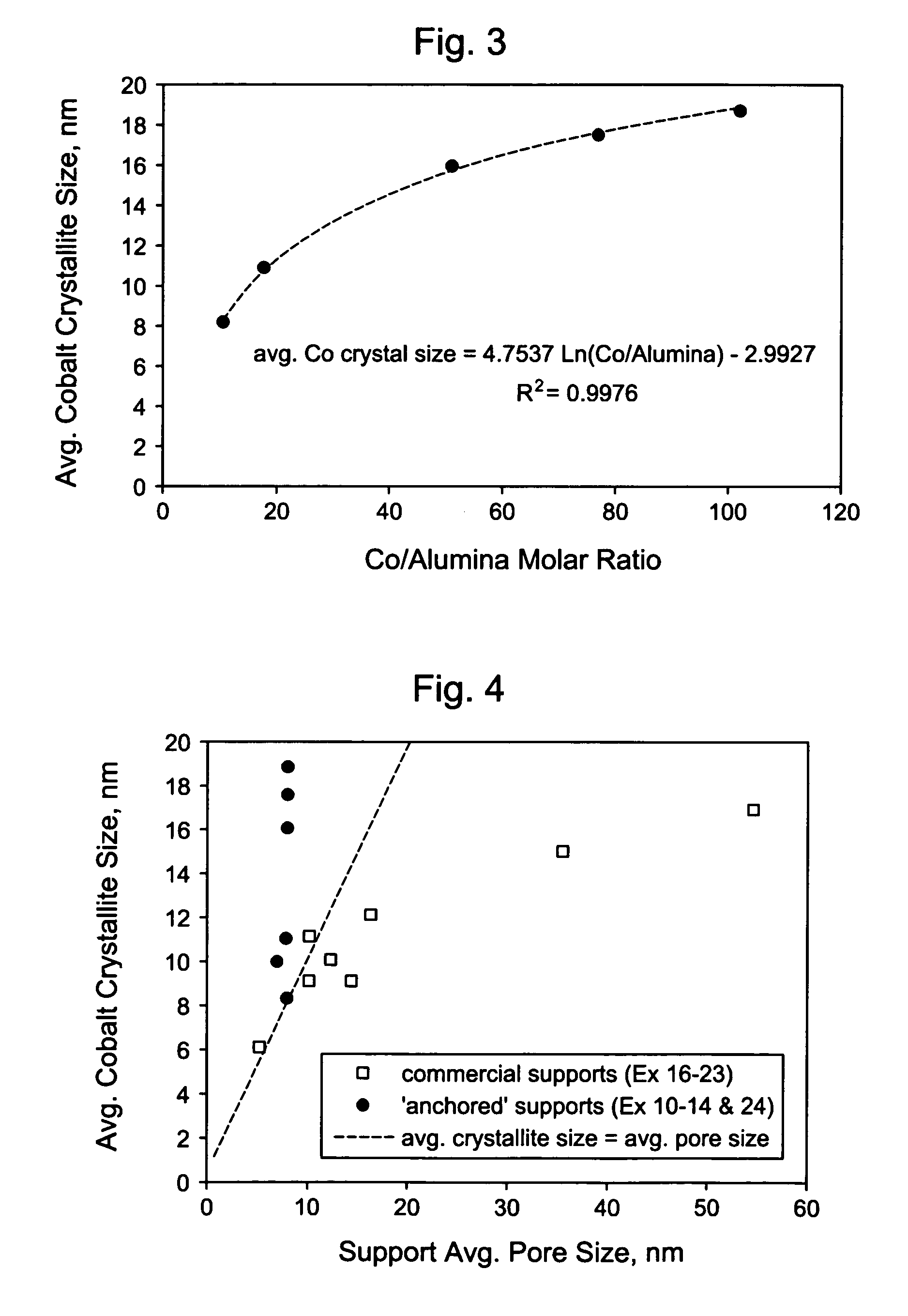

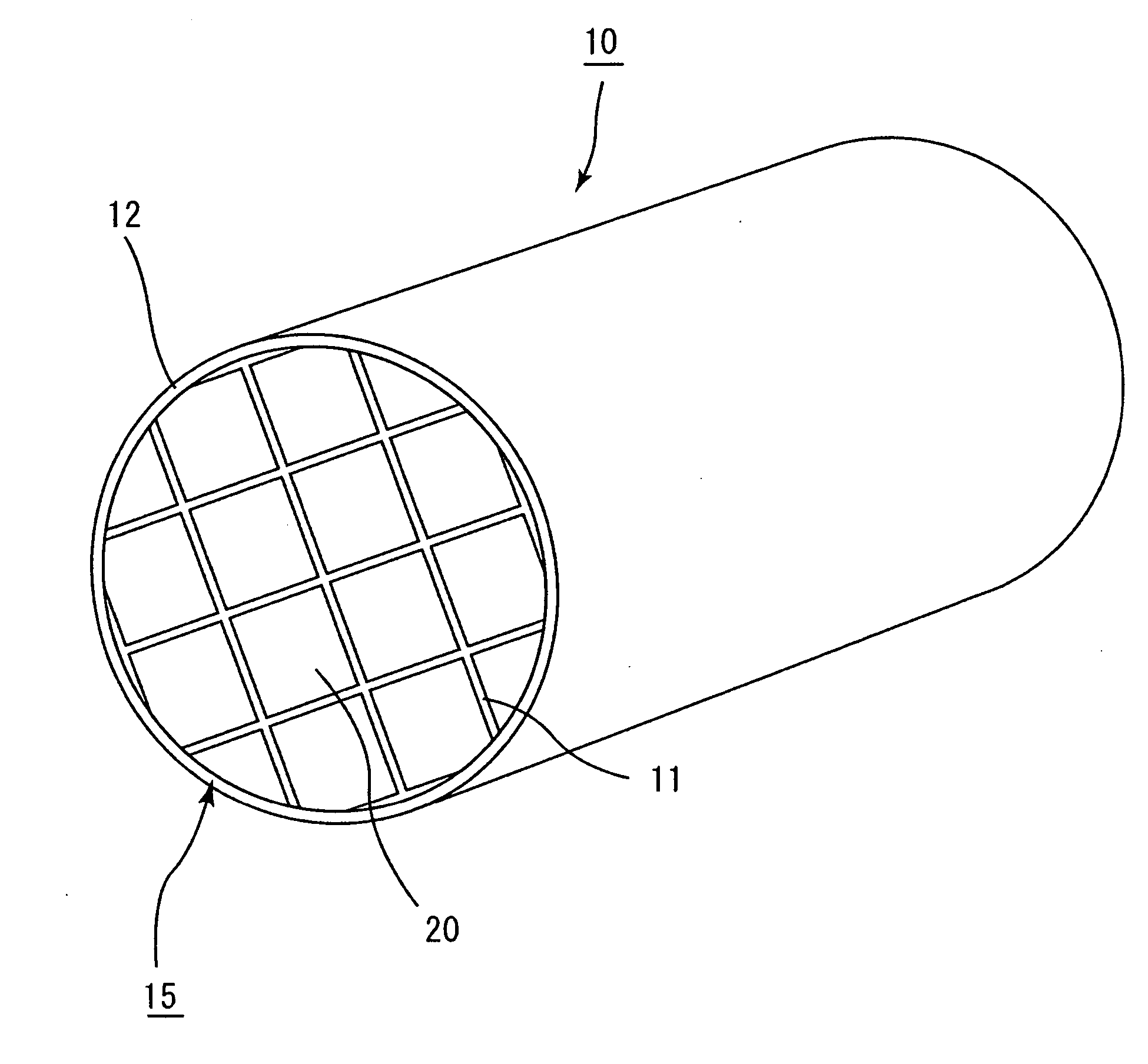

ActiveUS7541310B2High activityHydrocarbon from carbon oxidesMolecular sieve catalystsCompound (substance)Catalytic metal

This invention relates to catalysts comprising a catalytic metal deposited on a composite support with well-dispersed chemical “anchor” species acting as nucleation centers for catalytic metal crystallites growth. The catalysts have the advantage that the average catalytic metal crystallite size can be controlled by the molar ratio of catalytic metal to chemical “anchor,” and is not limited by the porous structure of the support. A preferred embodiment comprises a cobalt-based catalyst on a silica-alumina support made by a co-gel method, wherein its average pore size can be controlled by the pH. The alumina species in the support most likely serve as chemical “anchors” to control the dispersion of cobalt species, such that the average cobalt crystallite size can be greater than the average pore size.

Owner:CLARIANT INT LTD

Honeycomb structured body

Owner:IBIDEN CO LTD

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

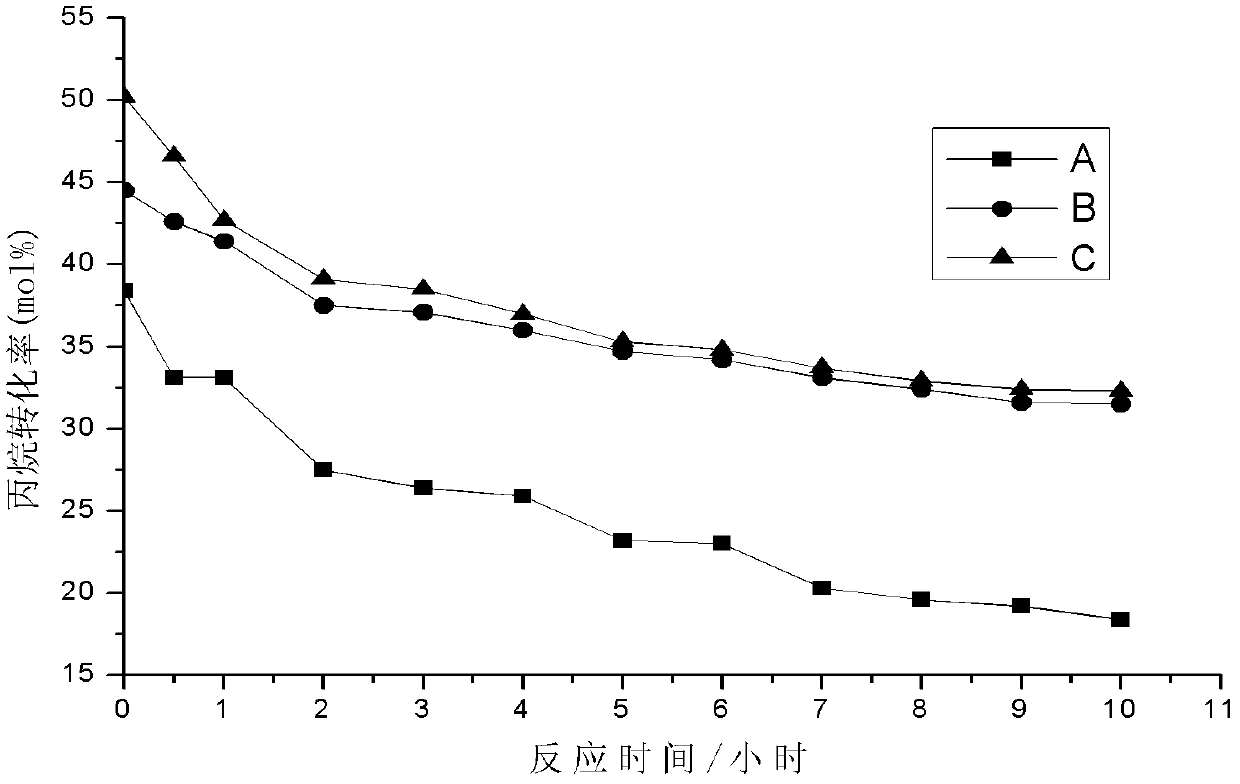

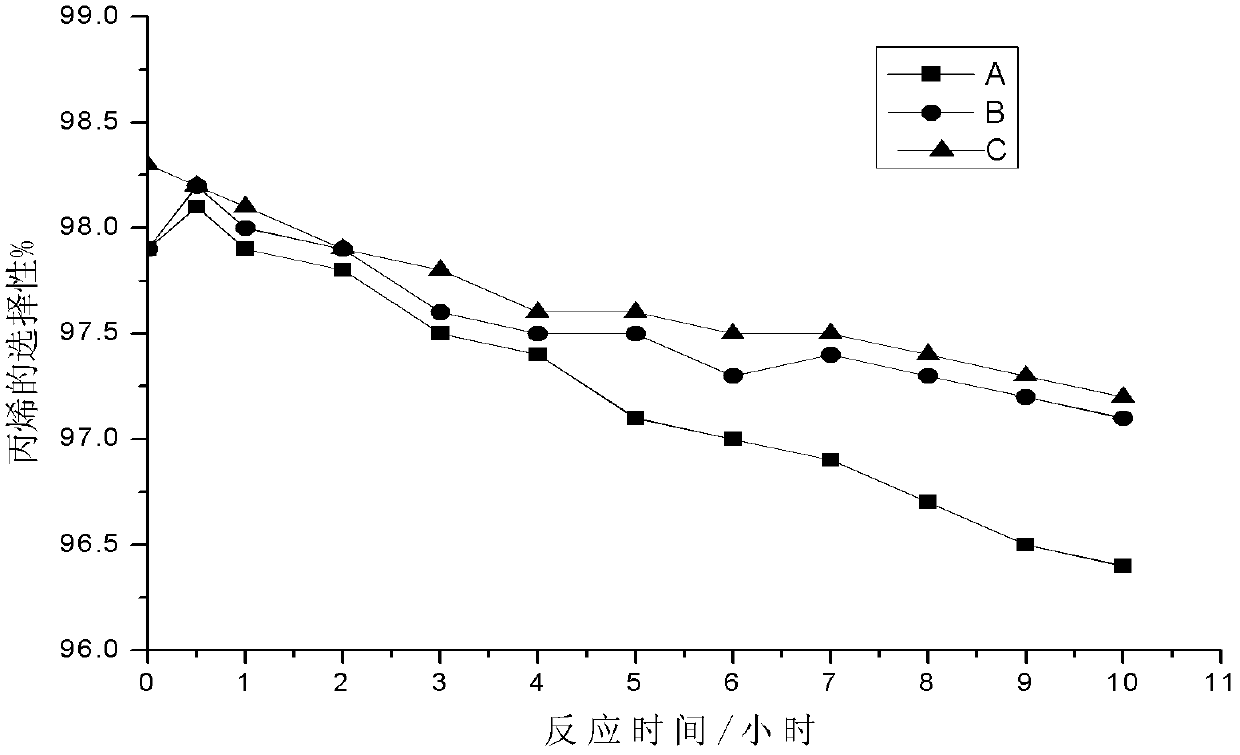

Catalyst for preparing propylene through propane catalytic dehydrogenation and preparation method thereof

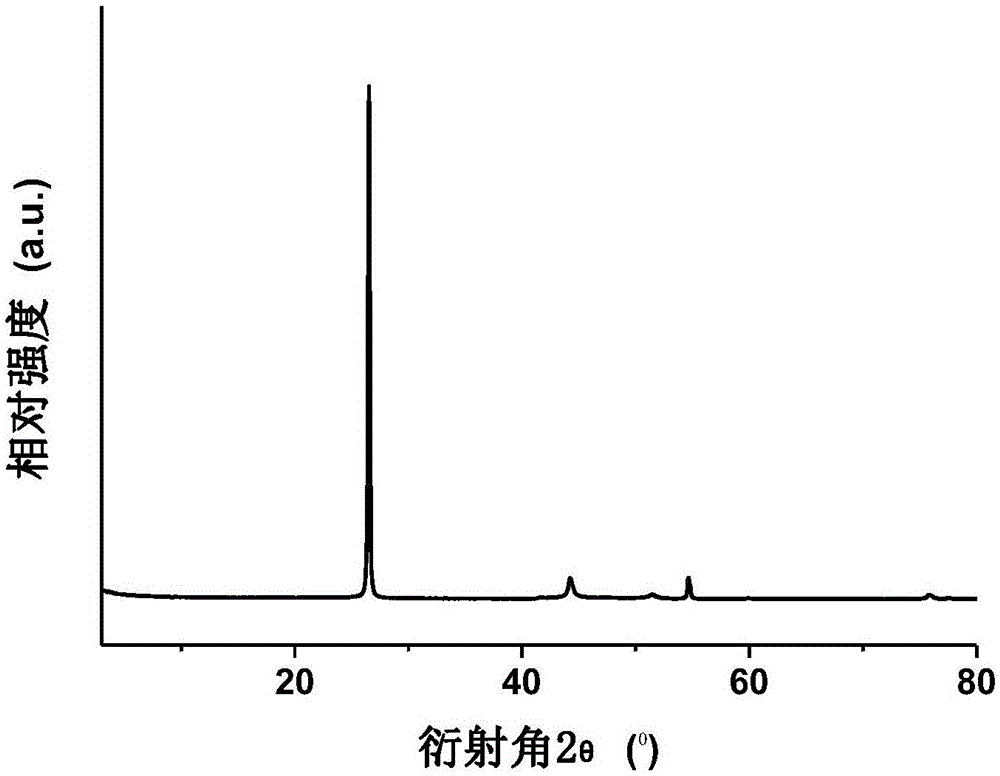

InactiveCN102389831ALarge specific surface areaHigh catalytic activityMolecular sieve catalystsHydrocarbonsDehydrogenationEconomic benefits

The invention relates to a catalyst for preparing propylene through propane catalytic dehydrogenation, which is a load type platinum-based catalyst and is characterized in that home-made mesoporous molecular sieves MCM-41 are used as carriers, metal Pt is used as an active ingredient, and metals Sn, Sn-Ce or Sn-Ce-Ca are used as auxiliary agents. In a preparation method, an isovolumetric continuous immersion method is adopted for preparation. The catalyst and the preparation method have the advantages that the isovolumetric continuous immersion method is adopted for preparing multi-component catalysts, wherein the content of any one component is easy to control, the prepared catalyst has higher specific surface area (700 to 900m<2> / g) and has high catalytic activity, the propane conversion rate is high, the propylene selectivity is good, the one-path stability is good, in addition, the service life is longer, the preparation method of the catalyst carriers is simple and feasible, the economic benefit is obvious, and good industrial development and application prospects are realized.

Owner:NANKAI UNIV

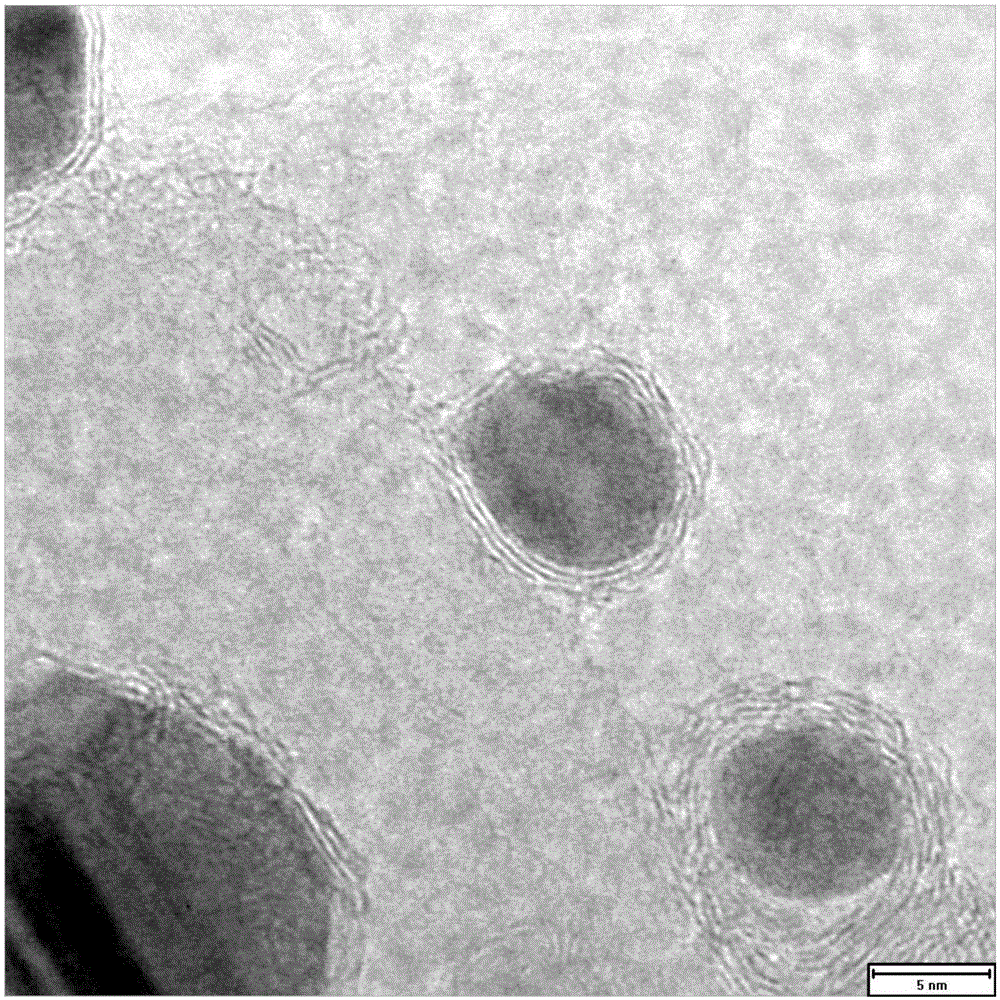

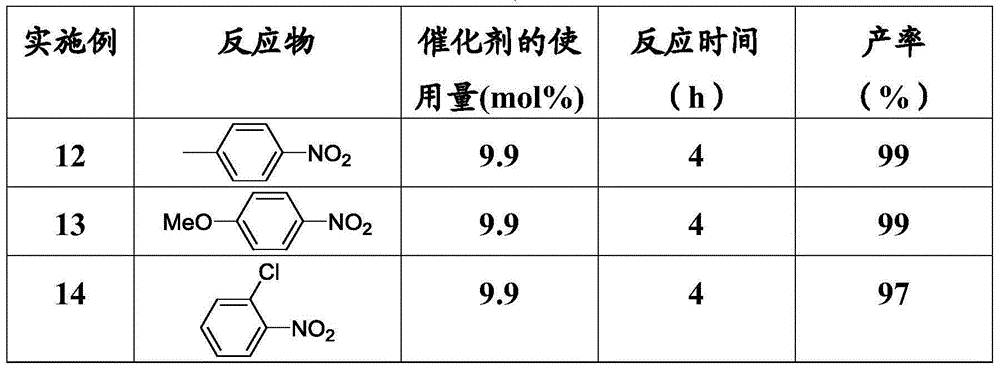

Catalyst for selective hydrogenation reaction of aromatic nitrocompound and preparation method of catalyst

InactiveCN105032424AEasy to storeLow costCarboxylic acid nitrile preparationOrganic compound preparationNitro compoundAlcohol

The invention relates to a catalyst for selective hydrogenation reaction of an aromatic nitrocompound and a preparation method of the catalyst. The catalyst consists of a catalyst carrier and active metal coated with carbon, wherein the catalyst carrier includes a carbon-base carrier, SiO2, TiO2 or Al2O3; the active metal is selected from Co, Fe, Ni or Cu and other poor and noble metals. The catalyst is prepared by adopting a Pechini type sol-gel process which comprises the steps of dispersing an active metal precursor to water containing a coordination compound, adding a polyhydric alcohol solution and a macromolecule auxiliary, then adding the carrier, stirring for dispersion, carrying out hydrothermal reaction, separating out solid on the lower layer, and calcining in the inert atmosphere to obtain the catalyst in which carbon coats the active metal. Compared with the prior art, the catalyst can realize the hydrogenation reaction of a substituted aromatic nitrocompound in the mild condition; substrate conversion rate and production selectivity are high; the catalyst has recyclable economy and good application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

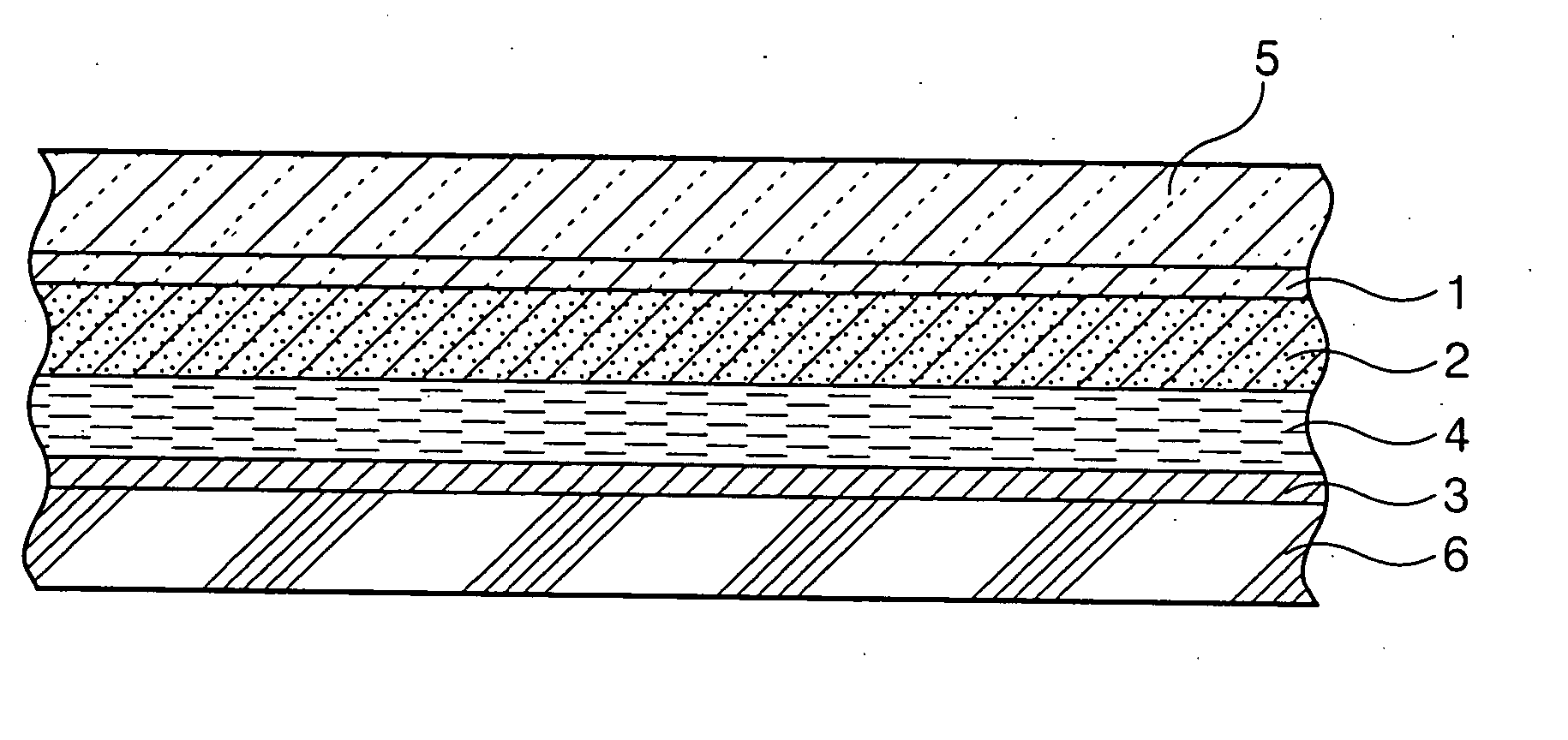

Catalytic converter, holding material for catalytic converter and production method thereof

ActiveUS20090022633A1Improve insulation performanceImprove exhaust gas purification performanceCombination devicesLamination ancillary operationsPorous substrateCatalyst support

The present invention relates to a holding material for a catalytic converter including a catalyst carrier, a metal casing for receiving the catalyst carrier, and the holding material wound around the catalyst carrier and interposed in a gap between the catalyst carrier and the metal casing, the holding material including a low thermal conductivity layer, in which the low thermal conductivity layer includes: a molded material containing an inorganic powder; or a composite material of a porous substrate with an aerogel.

Owner:NICHIAS CORP

Hydrogenating and pour point depressing catalyst and its preparing method

ActiveCN101143333AControl contentUnobstructed channelMolecular sieve catalystsRefining to eliminate hetero atomsPartial oxidationAdhesive

Owner:CHINA PETROLEUM & CHEM CORP +1

Reduction catalysts

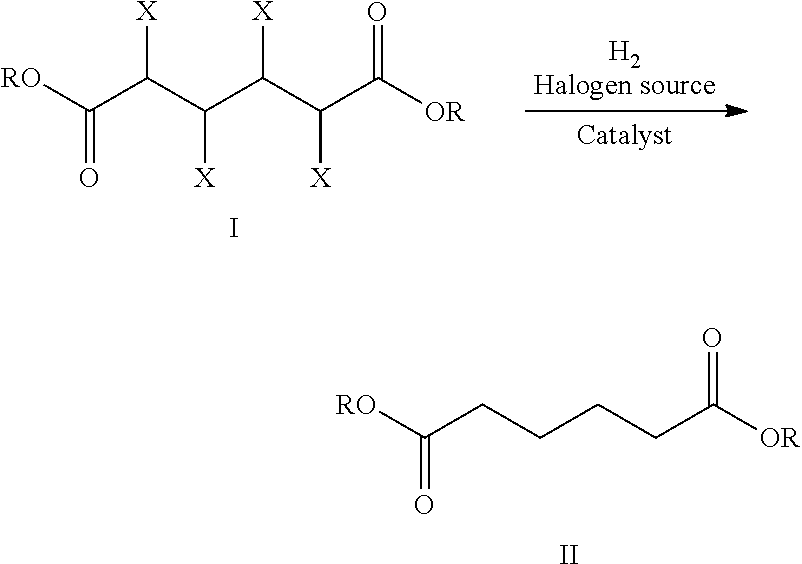

Disclosed are catalysts comprised of platinum and rhodium on a support selected from the group of zirconia, stabilized (doped) zirconia, zirconia-metal oxide composites, and mixtures thereof, wherein the outer surfaces of the support are selected from the group of zirconia, stabilized zirconia, and mixtures thereof. More particularly, the supported catalysts comprise platinum and rhodium, wherein the molar ratio of platinum to rhodium is in the range of about 3:1 to about 1:2. The average pore diameter of the catalyst supports is in the range of about 5 nm to about 70 nm and the surface area is in the range of about 15 m2 / g to about 200 m2 / g. Also disclosed are methods for the hydrodeoxygenation of carboxylic acids, mono- and / or di-lactones thereof having at least one hydroxyl group on the backbone thereof to corresponding acids where the backbone hydroxyl group has been reduced in the presence of the catalyst.

Owner:ARCHER DANIELS MIDLAND CO

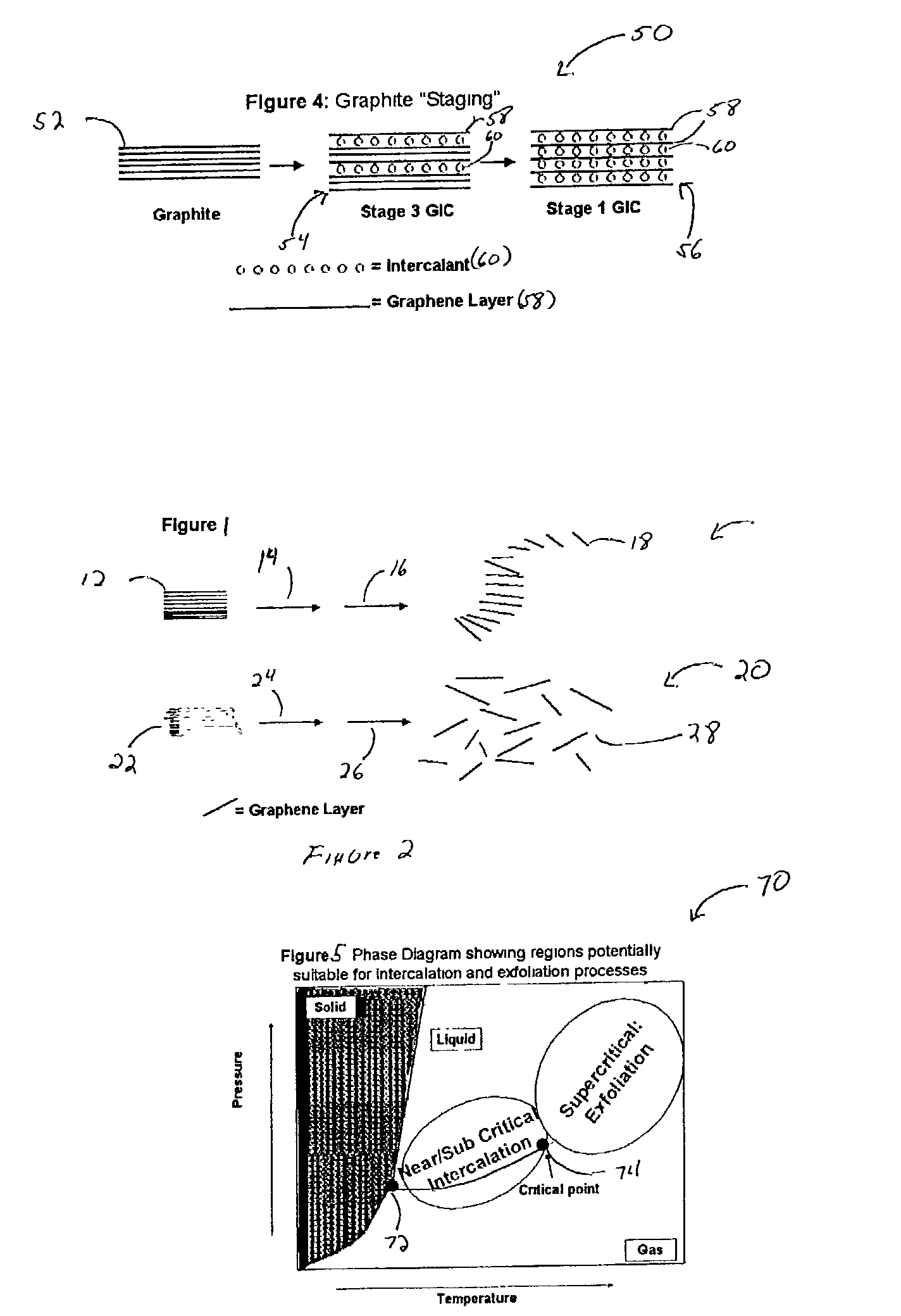

Graphite intercalation and exfoliation process

InactiveUS7105108B2Improve volume expansionReduce needMaterial nanotechnologyGraphiteConductive polymerGraphite particle

The invention relates to expanded graphite and methods of making the graphite and products that can be made from the graphite made from the inventive process. The invention includes the step of introducing a fluid into at least one of a plurality of interstices of graphite flake, wherein the fluid comprises at least one of a sub-critical point fluid, a near critical point fluid, or a supercritical fluid. The graphite flake is also intercalated with an intercalant and optionally an oxidizing agent. The invention may further include novel techniques of exfoliating the graphite. The invention may be practiced to make nano-sized graphite particles and also graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites.

Owner:GRAFTECH INT HLDG INC

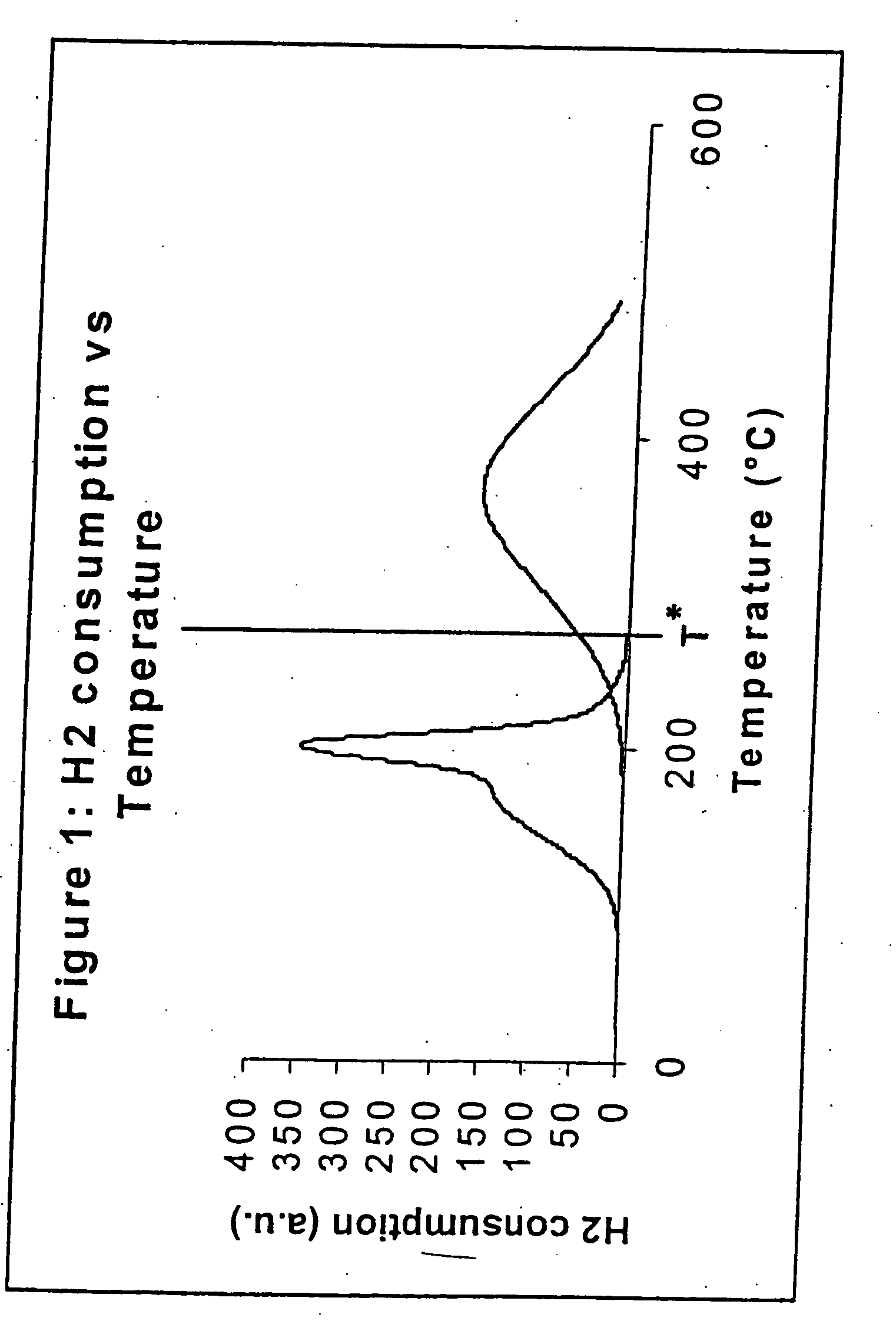

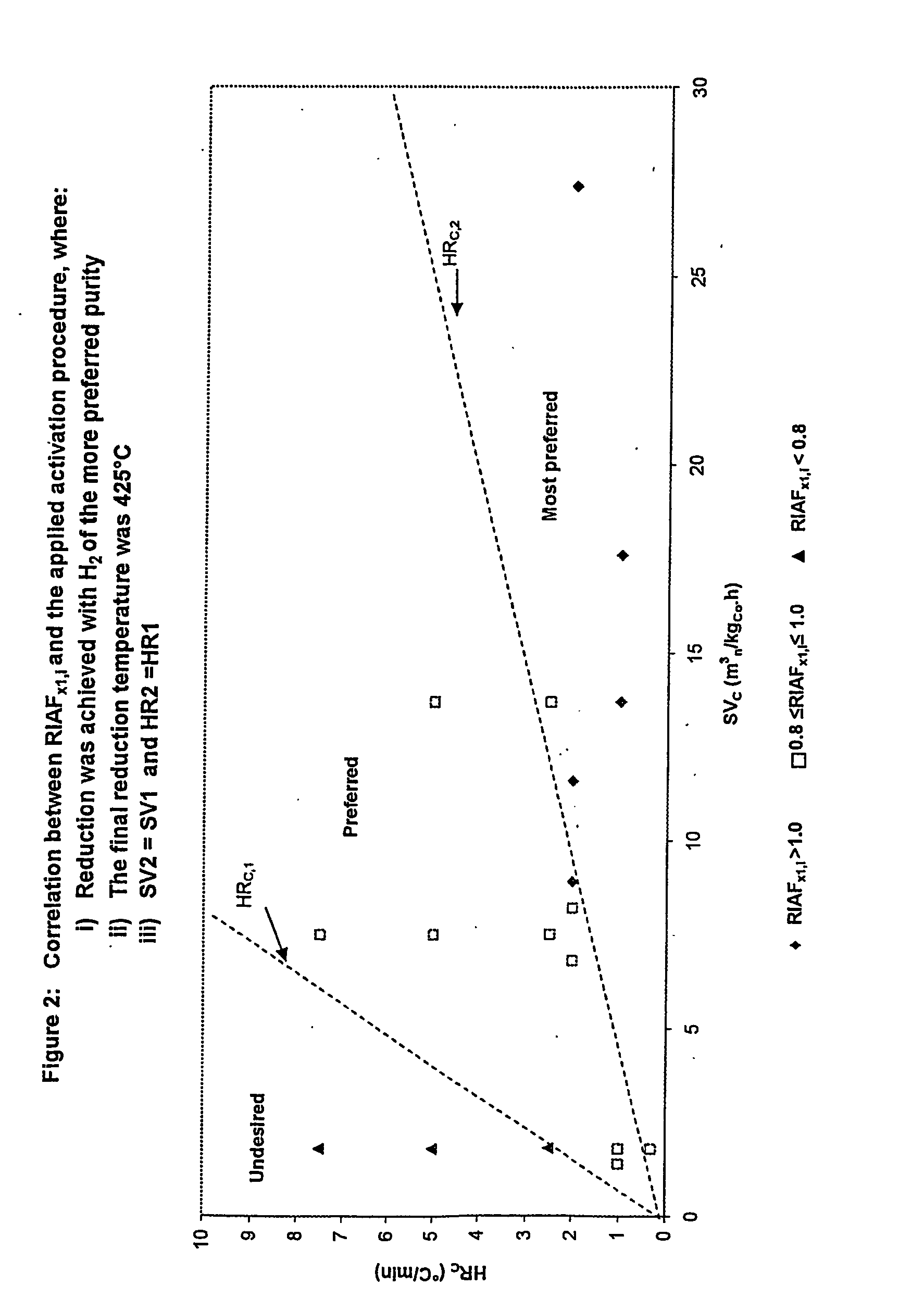

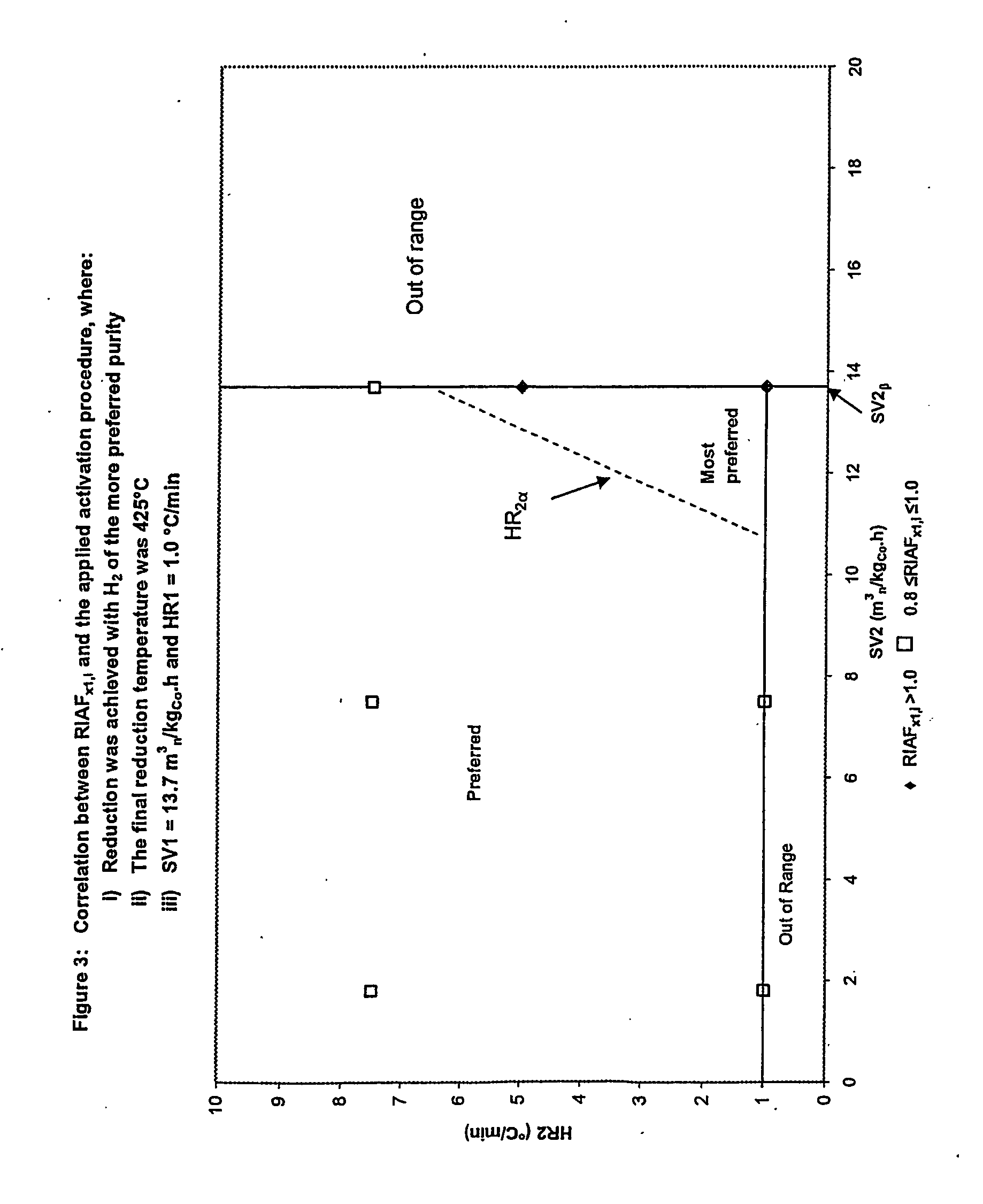

Process for activating cobalt catalysts

InactiveUS20050227866A1Improve reducibilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsParticulatesHydrogen

A particulate pre-reduction cobalt supported Fischer-Tropsch synthesis catalyst precursor which comprises a catalyst support impregnated with cobalt, is treated with a pure hydrogen reducing gas, at a first specific feed gas space velocity, SV1, and at a first heating rate, HR1, to obtain a partially reduced precursor. The support contains reducible cobalt oxide in a calcined state and having a formula-unit in which each mole of cobalt atoms is associated with more than 4 / 3 moles of oxygen atoms and displaying a reducible cobalt oxide specific surface area at least equal to that of Co3O4 spinel. The partially reduced precursor is then treated with a pure hydrogen reducing gas, at a second specific feed gas space velocity, SV2, and at a second heating rate, HR2, to obtain an activated supported Fischer-Tropsch catalyst, with SV2≦SV1 and / or HR2≧HR1; however, when SV2=SV1, HR2≠HR1 and when HR2=HR1, SV2≠SV1.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

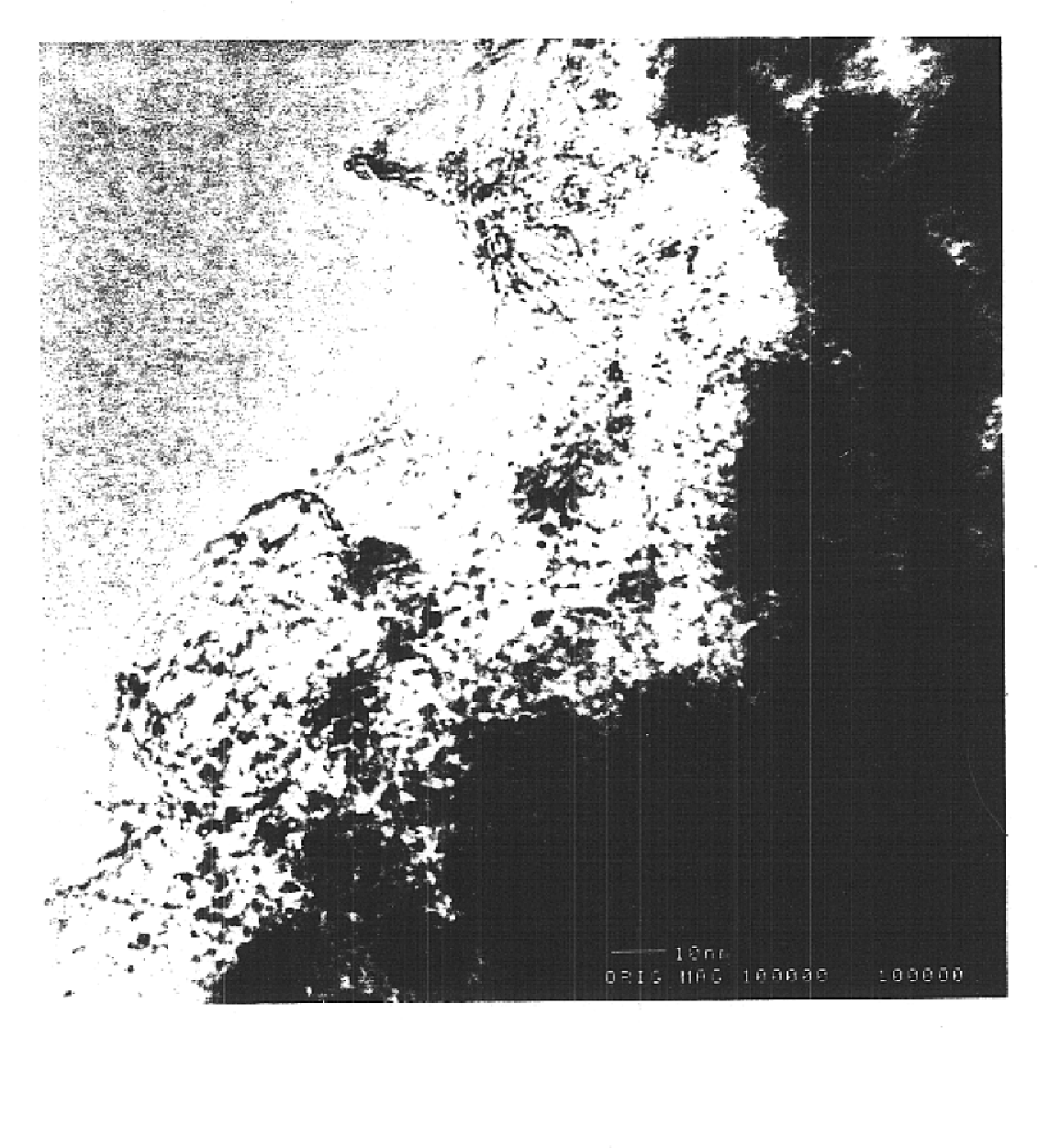

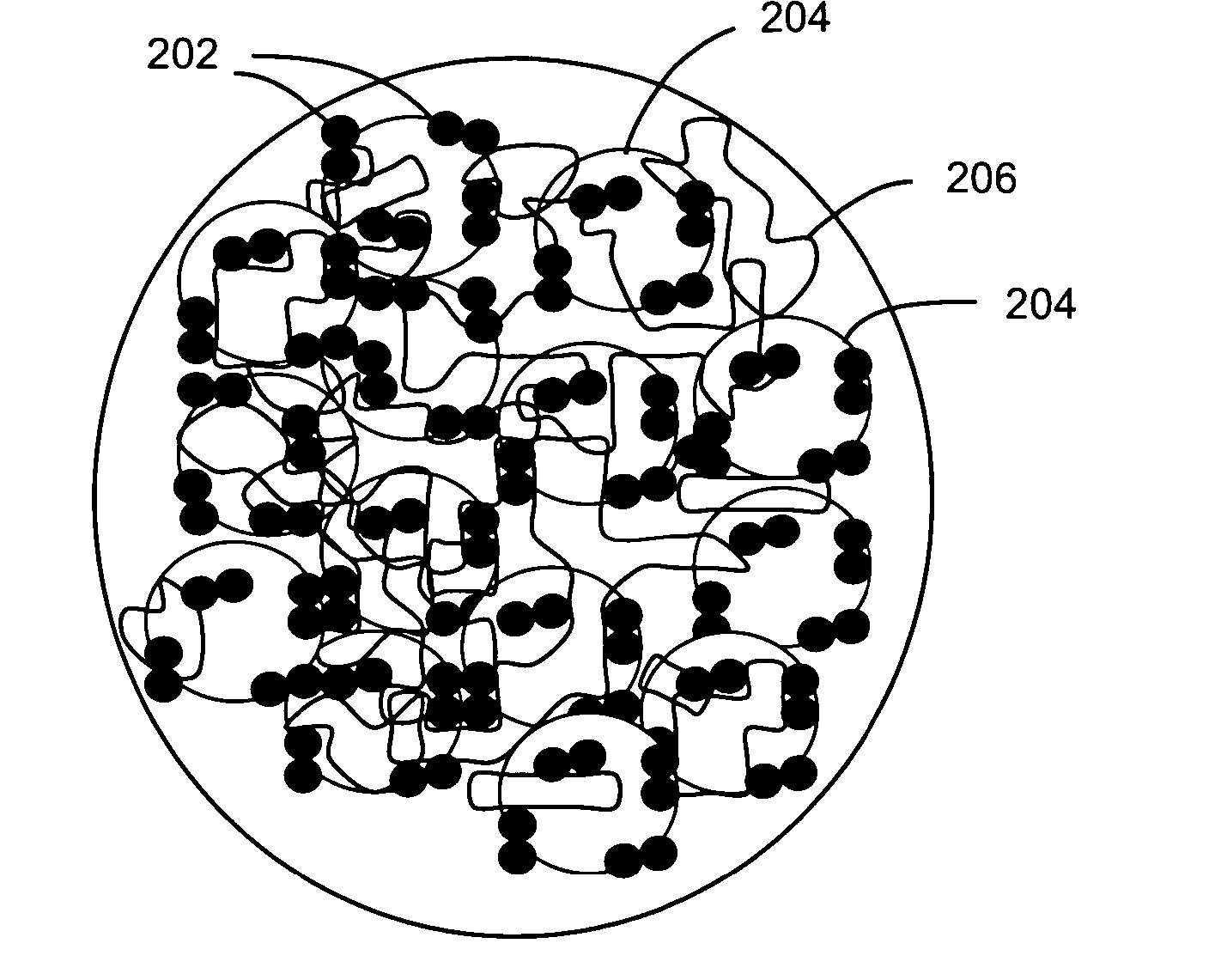

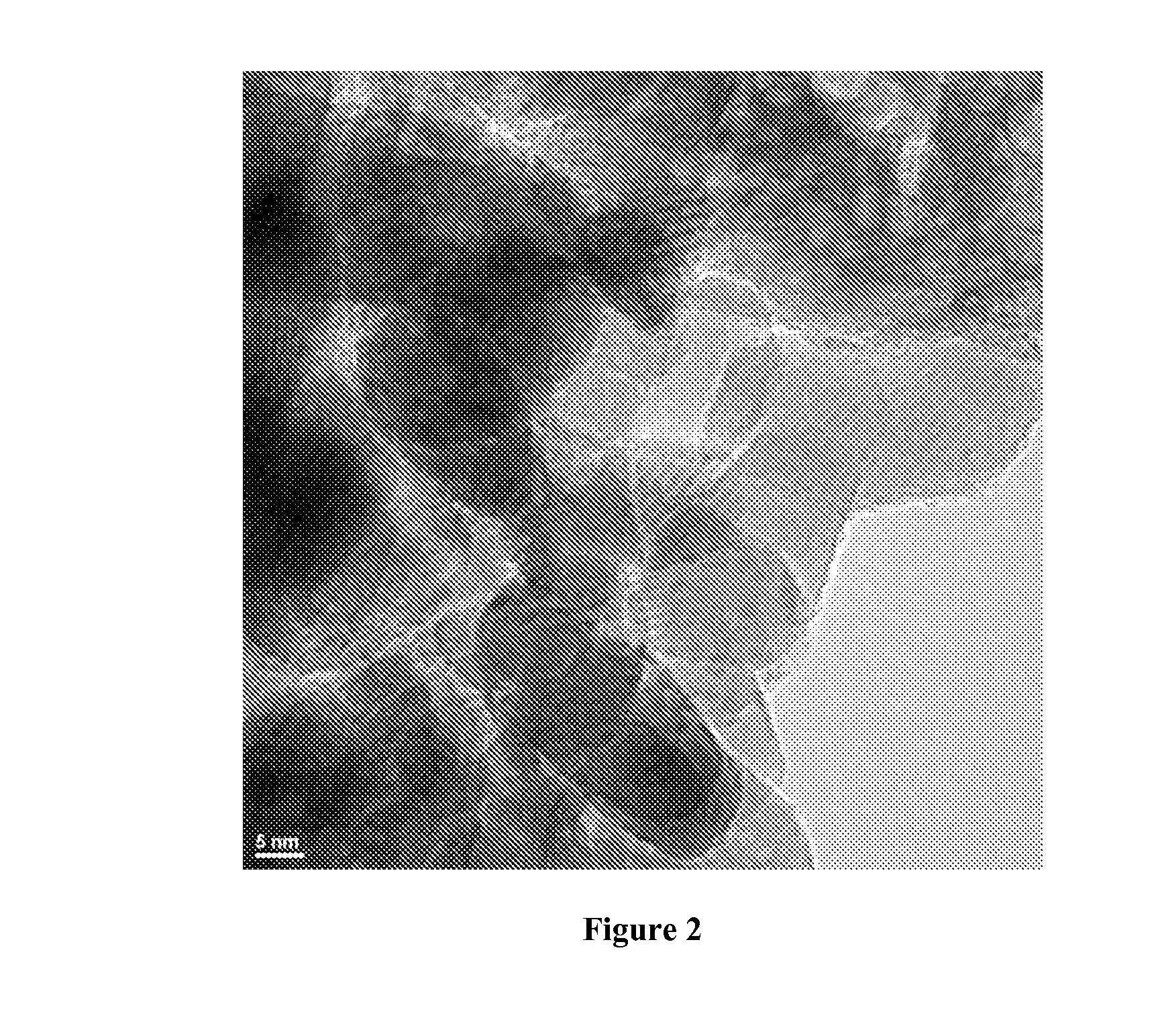

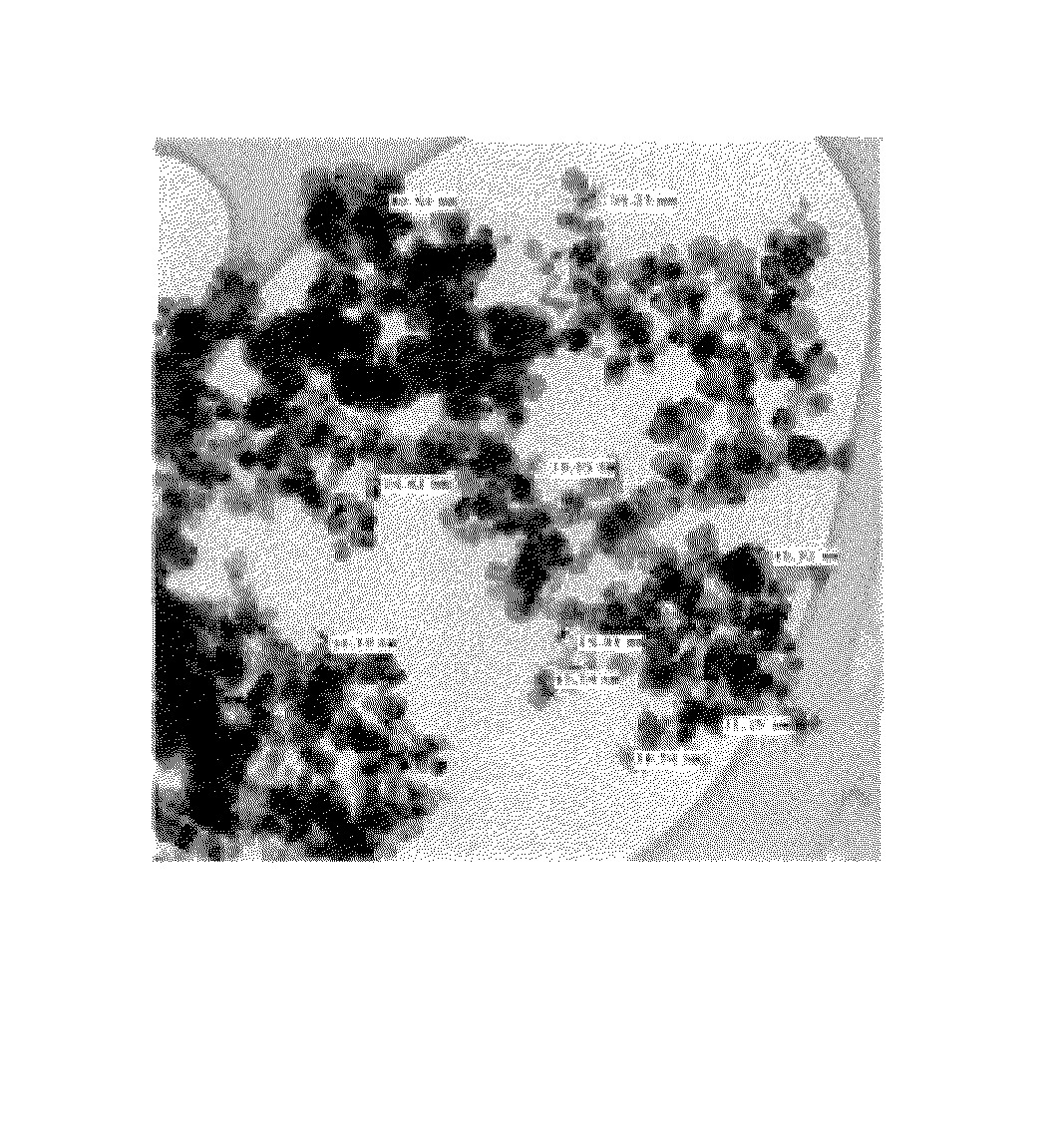

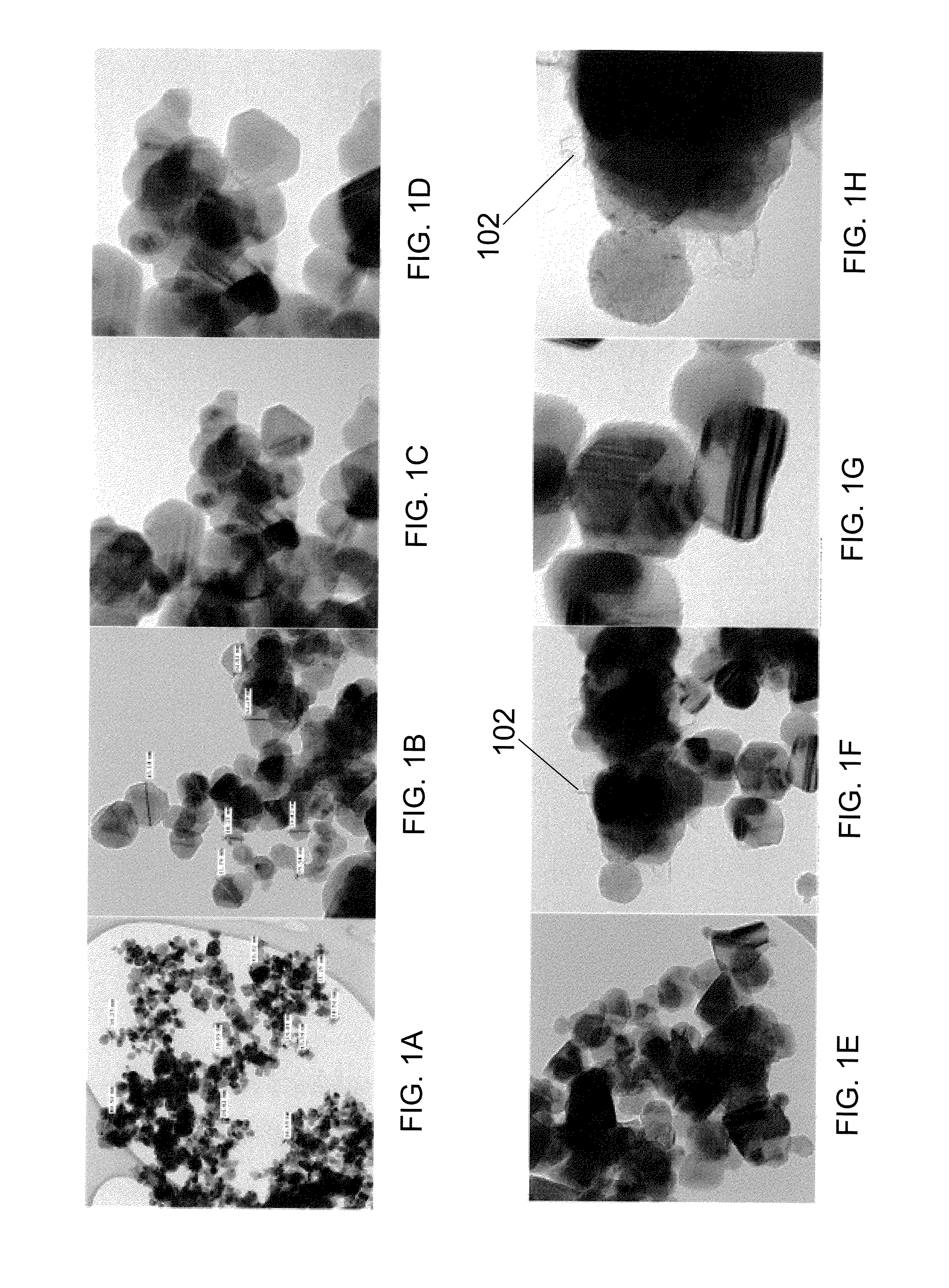

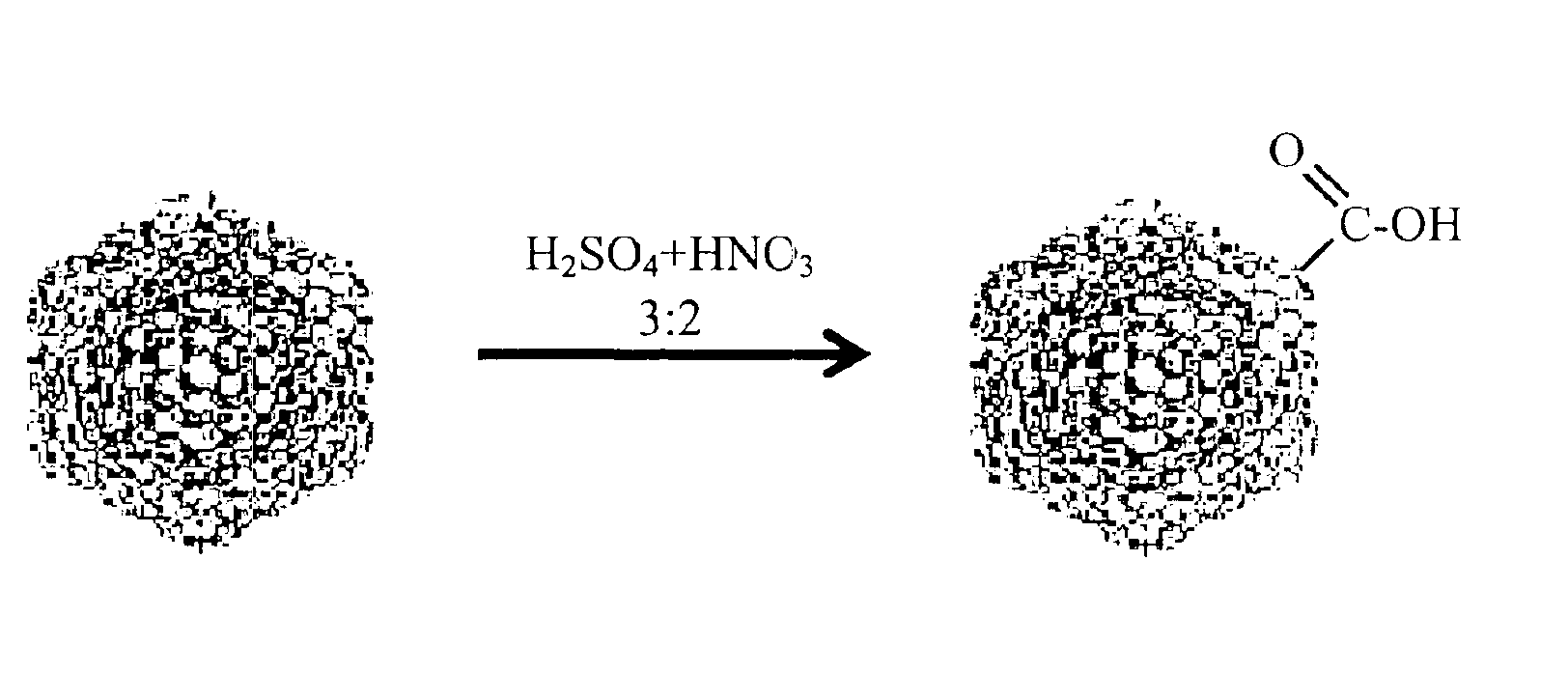

Nanostructured catalyst supports

The present invention relates to SiC nanostructures, including SiC nanopowder, SiC nanowires, and composites of SiC nanopowder and nanowires, which can be used as catalyst supports in membrane electrode assemblies and in fuel cells. The present invention also relates to composite catalyst supports comprising nanopowder and one or more inorganic nanowires for a membrane electrode assembly.

Owner:ONED MATERIAL INC

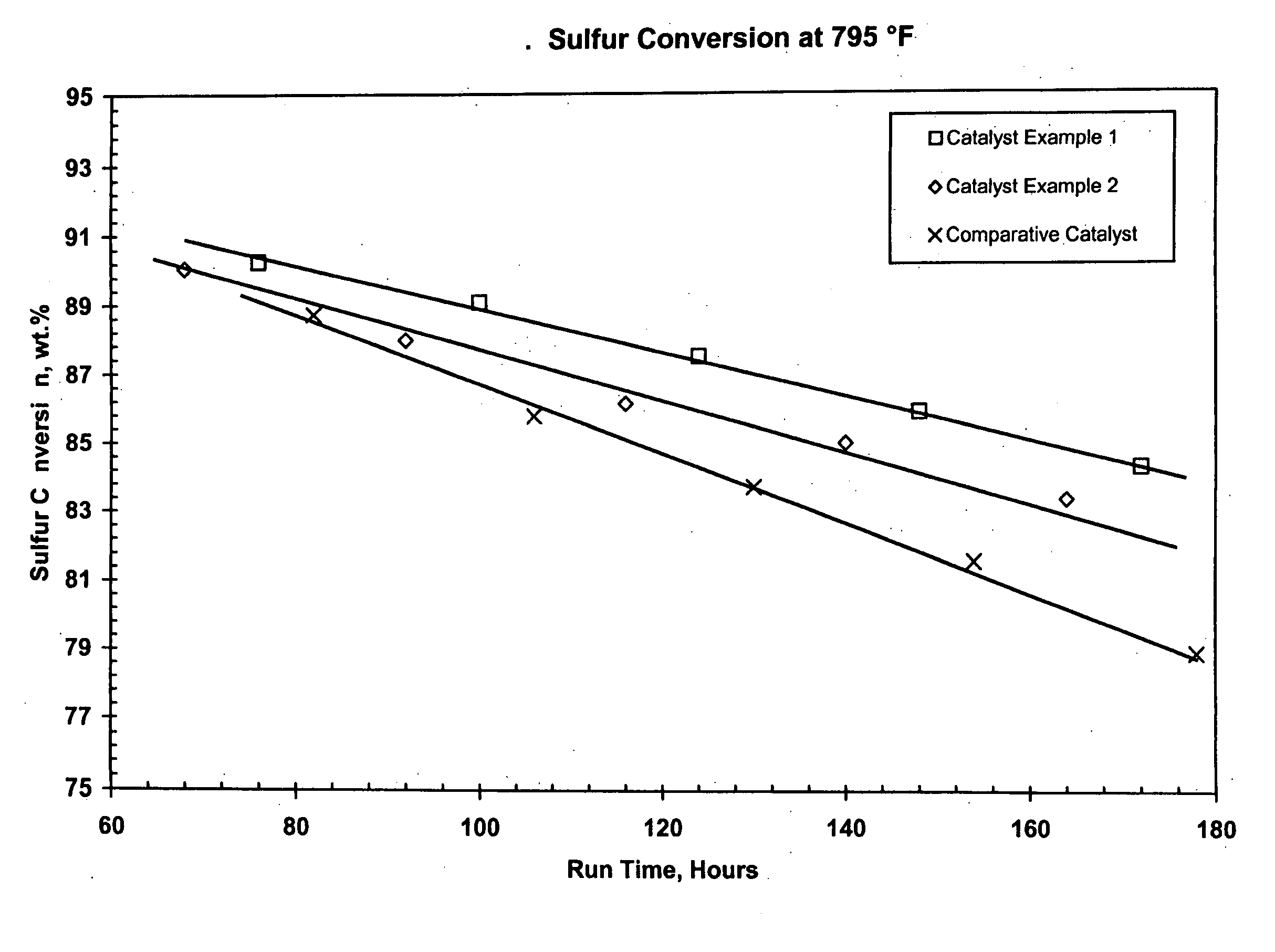

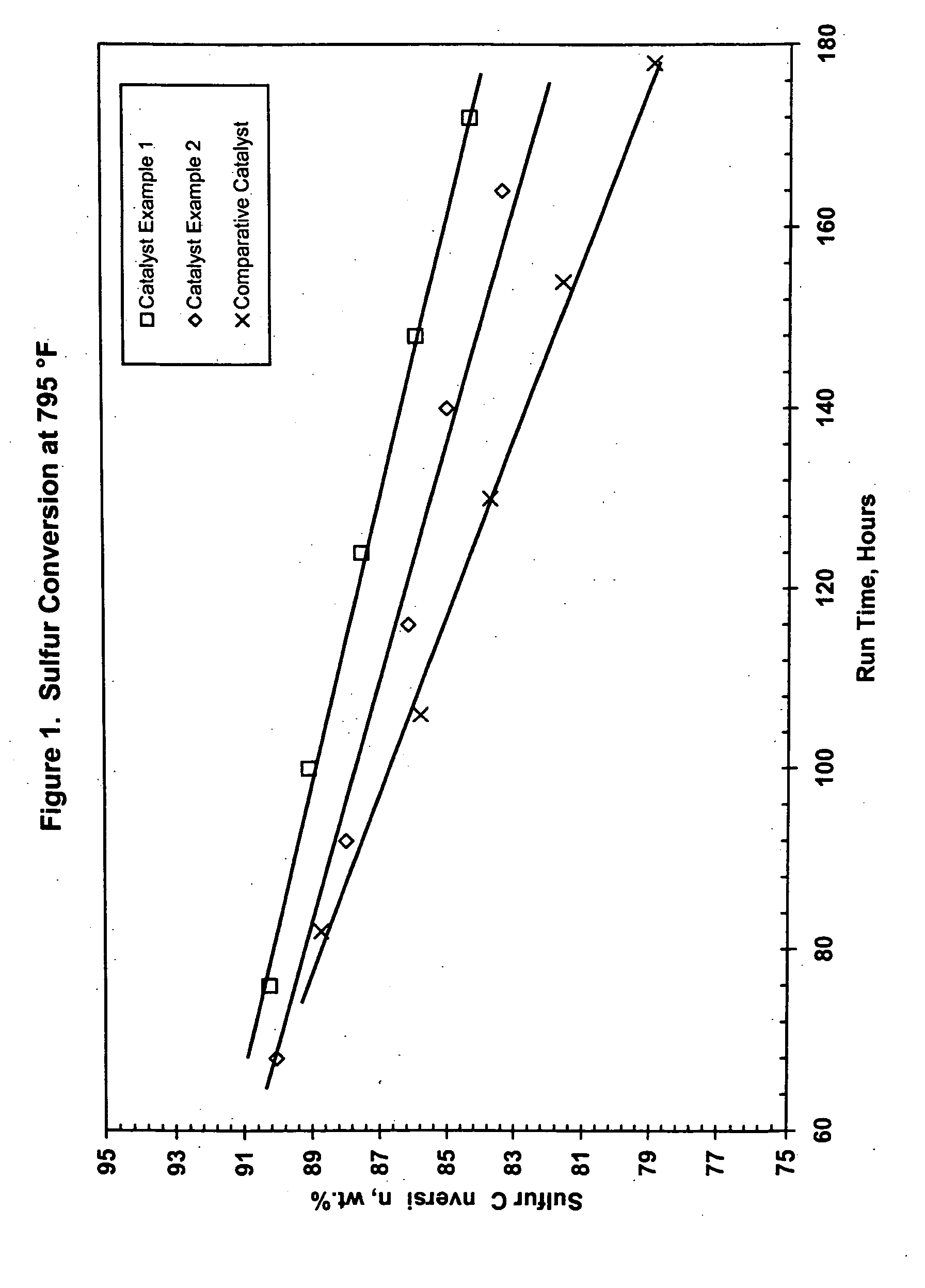

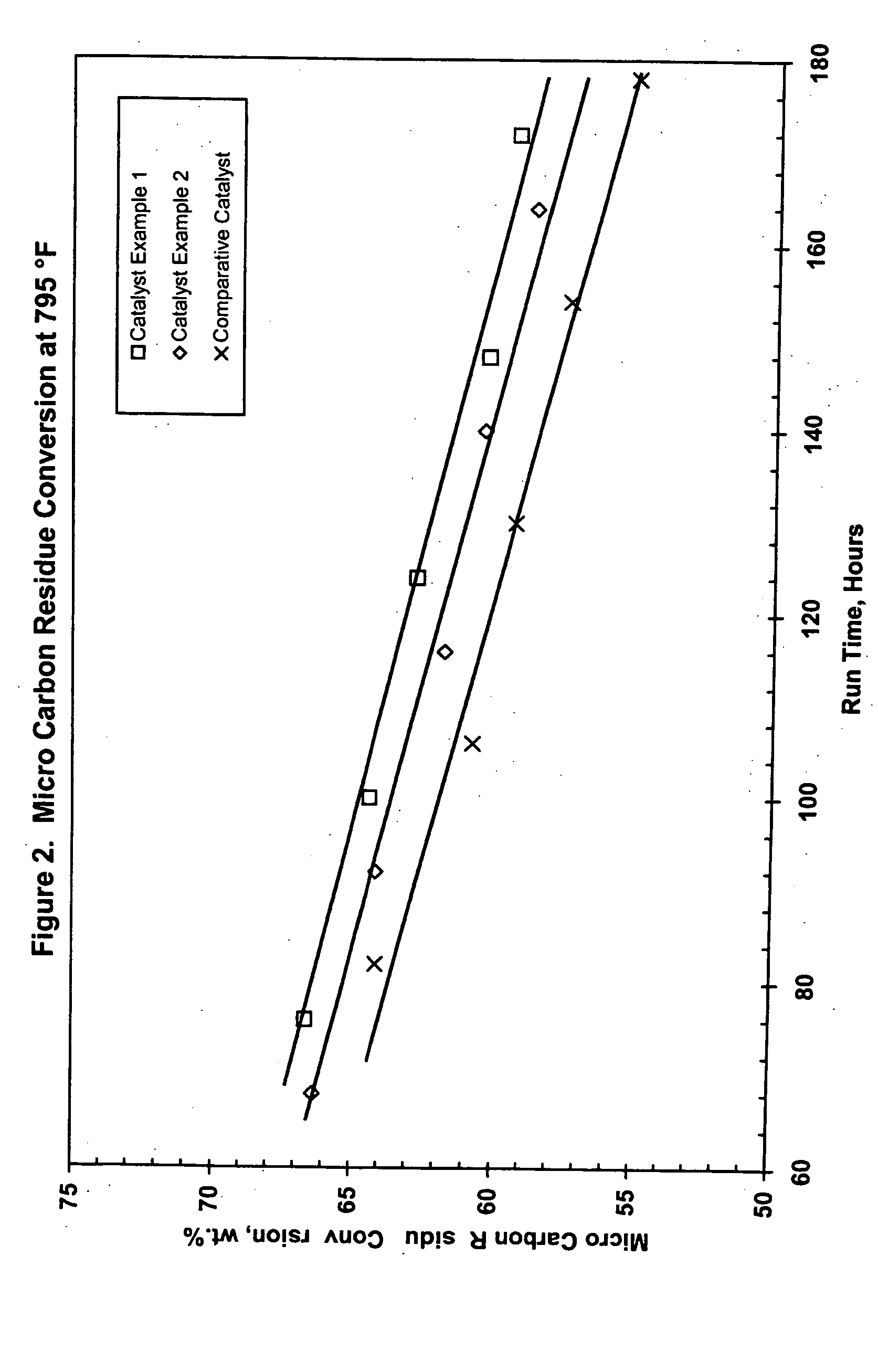

Hydroconversion catalysts and methods of making and using same

InactiveUS20050109674A1Improve the level ofImprove performanceCatalyst activation/preparationHydrocarbon oil crackingHigh concentrationO-Phosphoric Acid

Stable catalyst carrier impregnating solutions can be prepared using a component of a Group VIB metal, e.g., molybdenum, at high concentration, a component of a Group VIII metal, e.g., nickel, at low concentration, and a phosphorous component, e.g., phosphoric acid, at low concentration, provided that the Group VIII metal is in a substantially water-insoluble form and a particular sequence of addition of the components is followed, even when a substantially water-insoluble form of the Group VIB component is used. The resulting stabilized impregnating solution can be supplemented with additional Group VIII metal in water-soluble form to achieve increased levels of such metal in the final catalyst. Furthermore, uncalcined catalyst carriers impregnated with stable solution and subsequently shaped, dried and calcined, have unexpectedly improved performance when used in the hydroprocessing of heavy hydrocarbon feedstocks. High conversion can be achieved at reduced levels of sediment, especially in comparison to standard commercial catalysts.

Owner:ADVANCED REFINING TECH

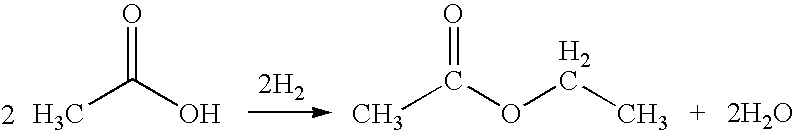

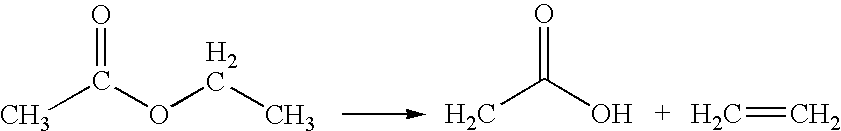

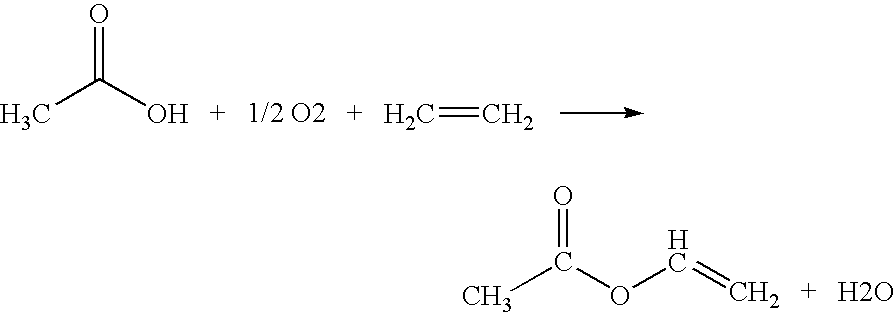

Integrated process for the production of viny acetate from acetic acid via ethy acetate

This invention provides an integrated three step economical process for the production of vinyl acetate monomer (VAM) from acetic acid in the vapor phase. First, acetic acid is selectively hydrogenated over a hydrogenating catalyst composition to form ethyl acetate which is cracked to form ethylene and acetic acid in the second step and in a subsequent step so formed ethylene and acetic acid is reacted with molecular oxygen over a suitable catalyst to form VAM. In an embodiment of this invention reaction of acetic acid and hydrogen over platinum and copper supported on silica selectively produces ethyl acetate in a vapor phase at a temperature of about 250° C., which is cracked over a NAFION catalyst to form ethylene and acetic acid at a temperature of about 185° C., which is mixed with molecular oxygen and reacted over a palladium / gold / potassium catalyst supported on titania to form VAM at a temperature of about 150° C. to 170° C.

Owner:CELANESE INT CORP

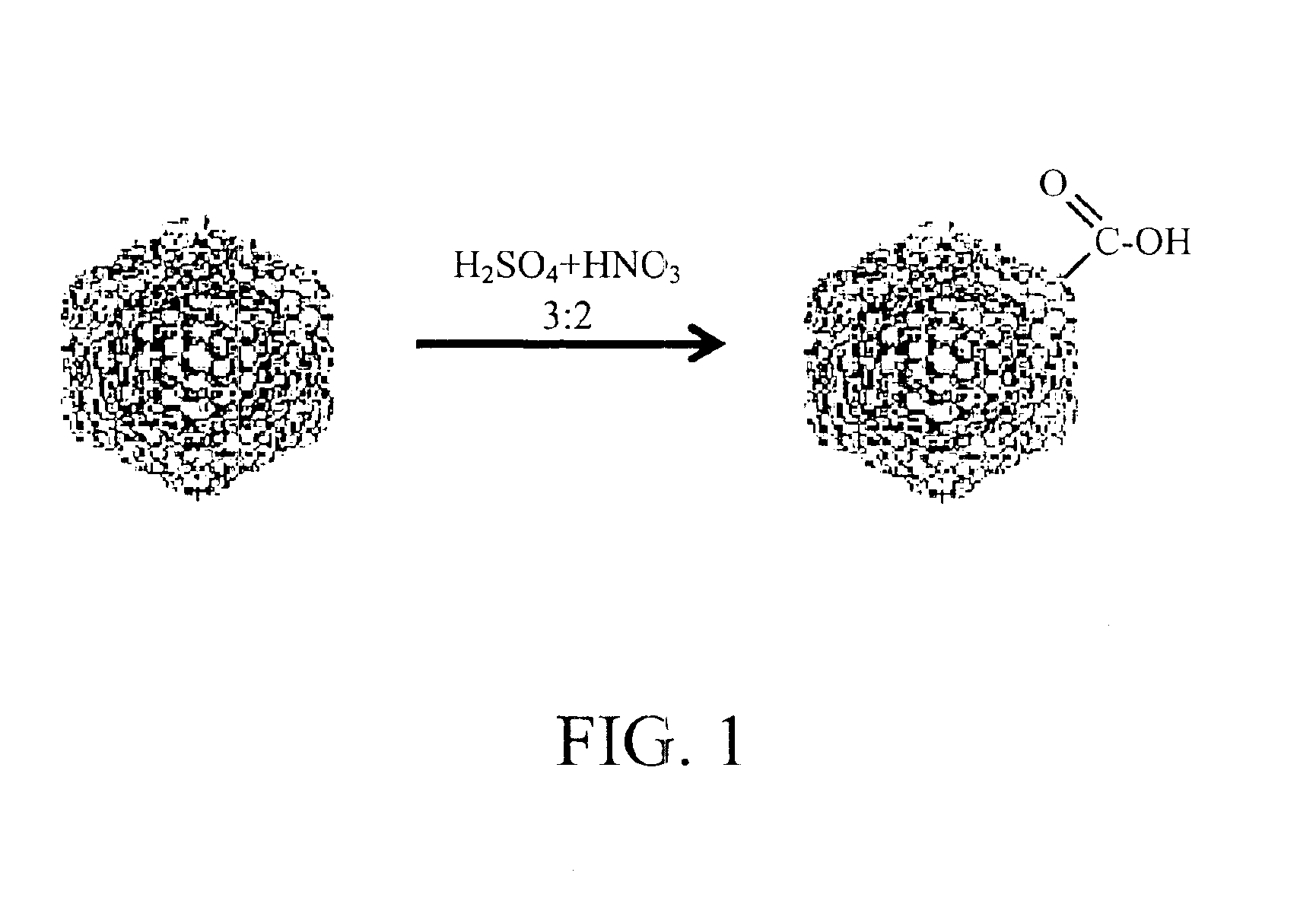

Carbon nanocapsule supported catalysts

ActiveUS6841509B1Improve developmentEasy to modifyNanotechSynthetic resin layered productsCatalytic metalCatalytic effect

A carbon nanocapsule supported catalysts. At least one kind of catalytic metal particle is deposited to a carbon nanocapsule, wherein the carbon nanocapsule has the following formula: F(−M)n, in which F is the carbon nanocapsule, M is the catalytic metal particle, and n is the number of the catalytic metal particle. By applying the carbon nanocapsule as a catalyst support, the catalytic behavior of the catalytic metal particle is specialized, the dispersion is improved, and the catalytic effect is enhanced.

Owner:IND TECH RES INST

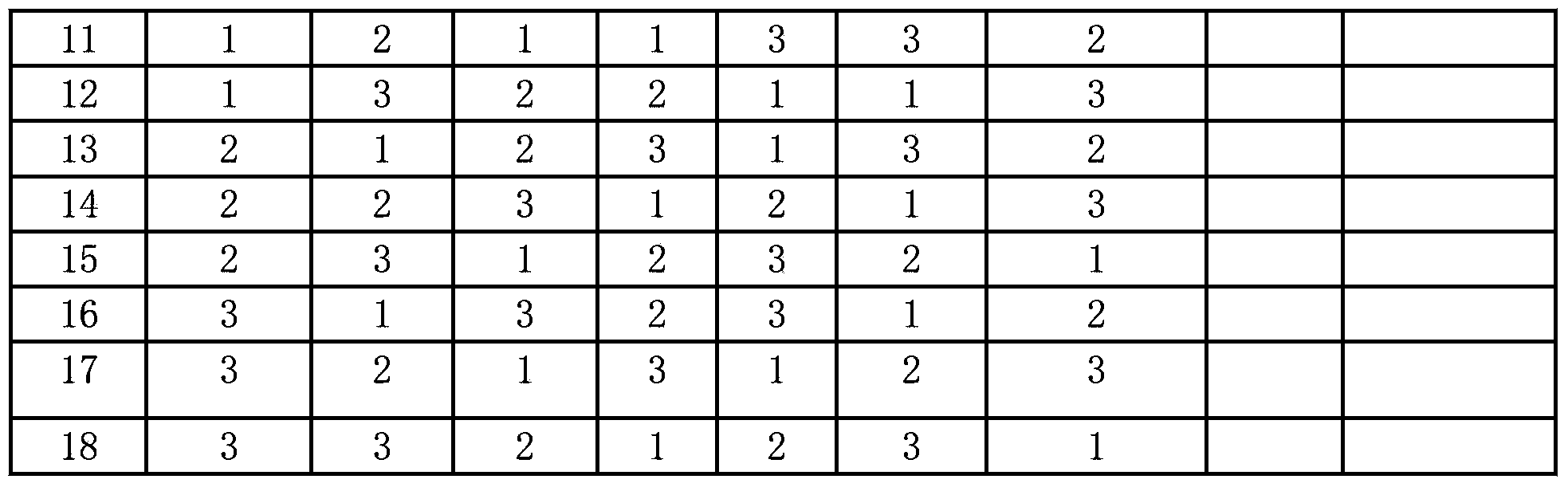

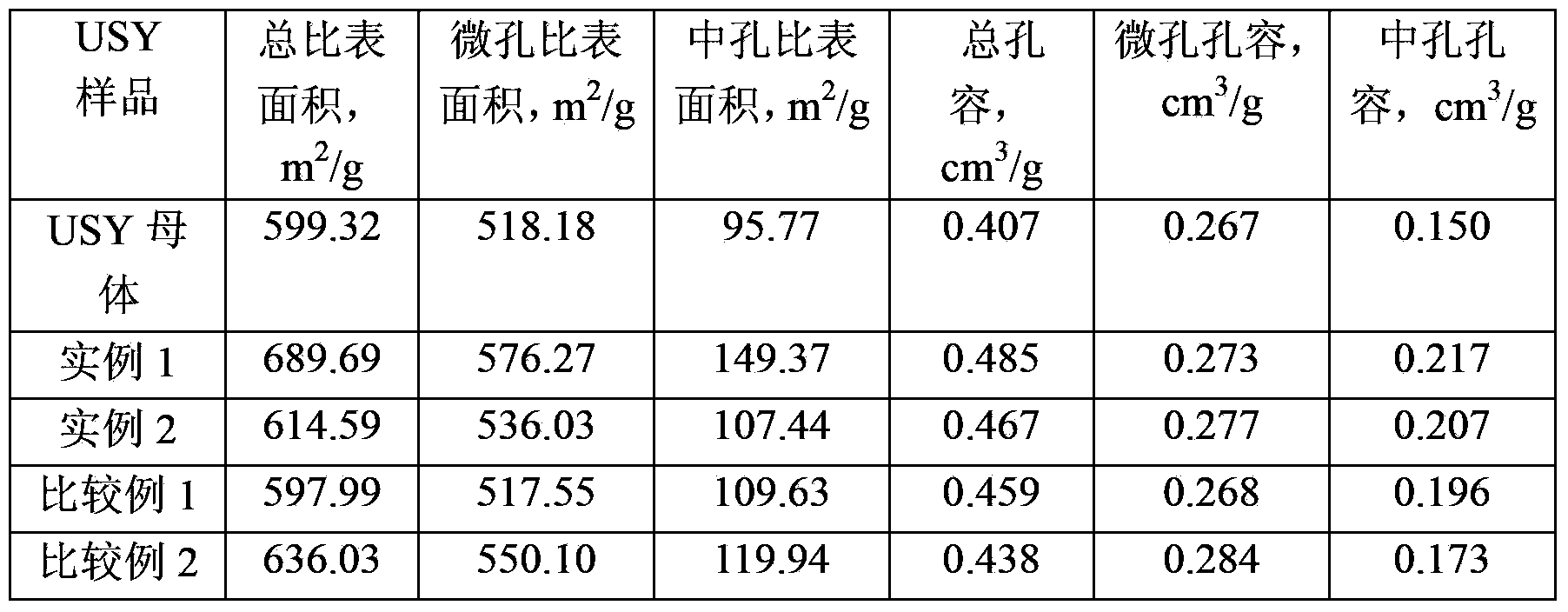

Method for modifying mesoporous-rich USY (Ultra-Stable Y) molecular sieve in combined manner

InactiveCN104229823ASmall cell constantIncreased secondary pore contentFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

The invention relates to a method for modifying a USY (Ultra-Stable Y) molecular sieve. The method is characterized in that organic acid and an inorganic salt dealuminizing reagent are simultaneously added in a modifying process for organic acid-inorganic salt combined modification, and optimum process conditions, namely optimum concentration, volume ratio, reaction time, reaction temperature and the like, of an organic acid and an inorganic salt solution are determined by virtue of an orthogonal test. Compared with an industrial USY molecular sieve, the USY molecular sieve obtained by adopting the method disclosed by the invention is obviously increased in secondary pore content, can be kept at higher crystallinity and is enhanced in silica-alumina ratio, reduced in lattice constant and suitable for high-medium oil type hydrocracking catalyst carriers.

Owner:PETROCHINA CO LTD +1

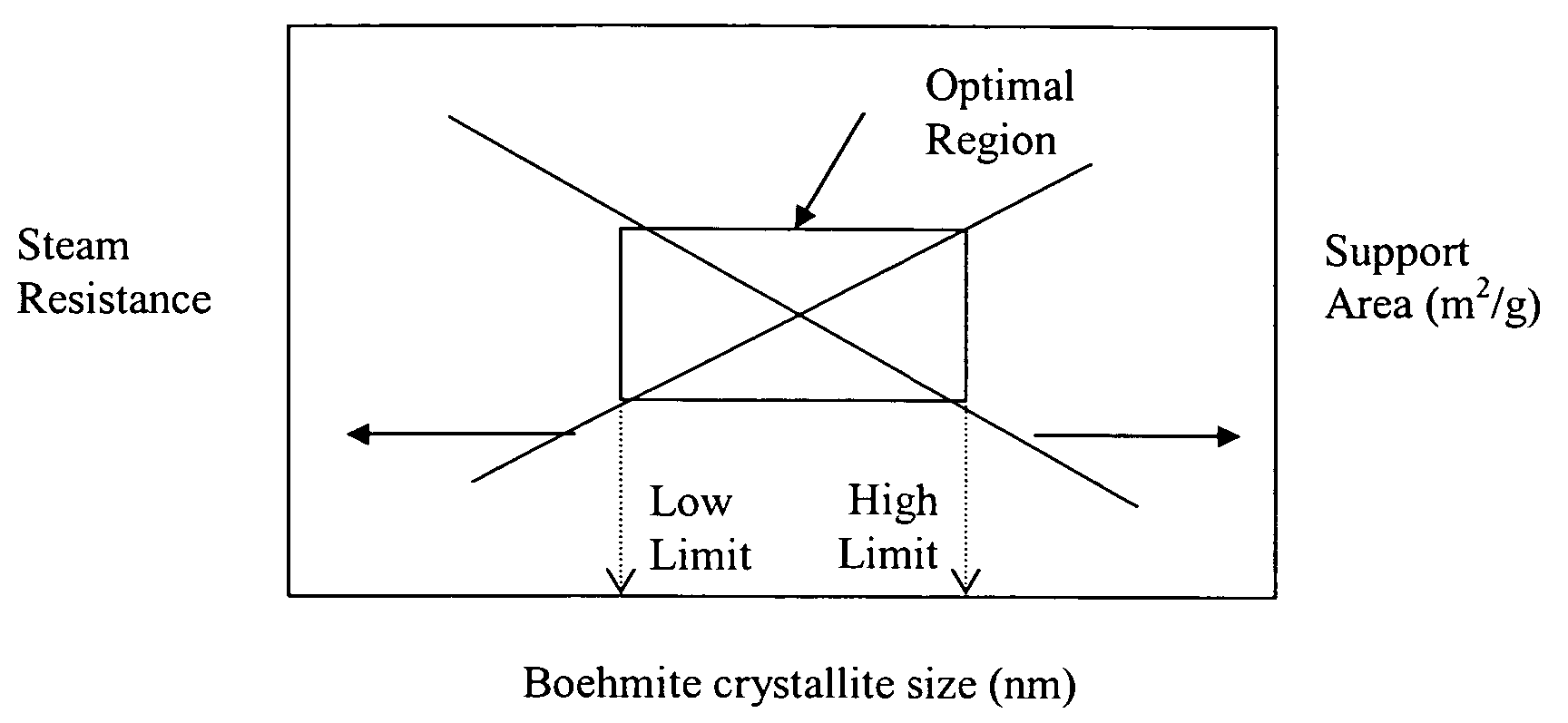

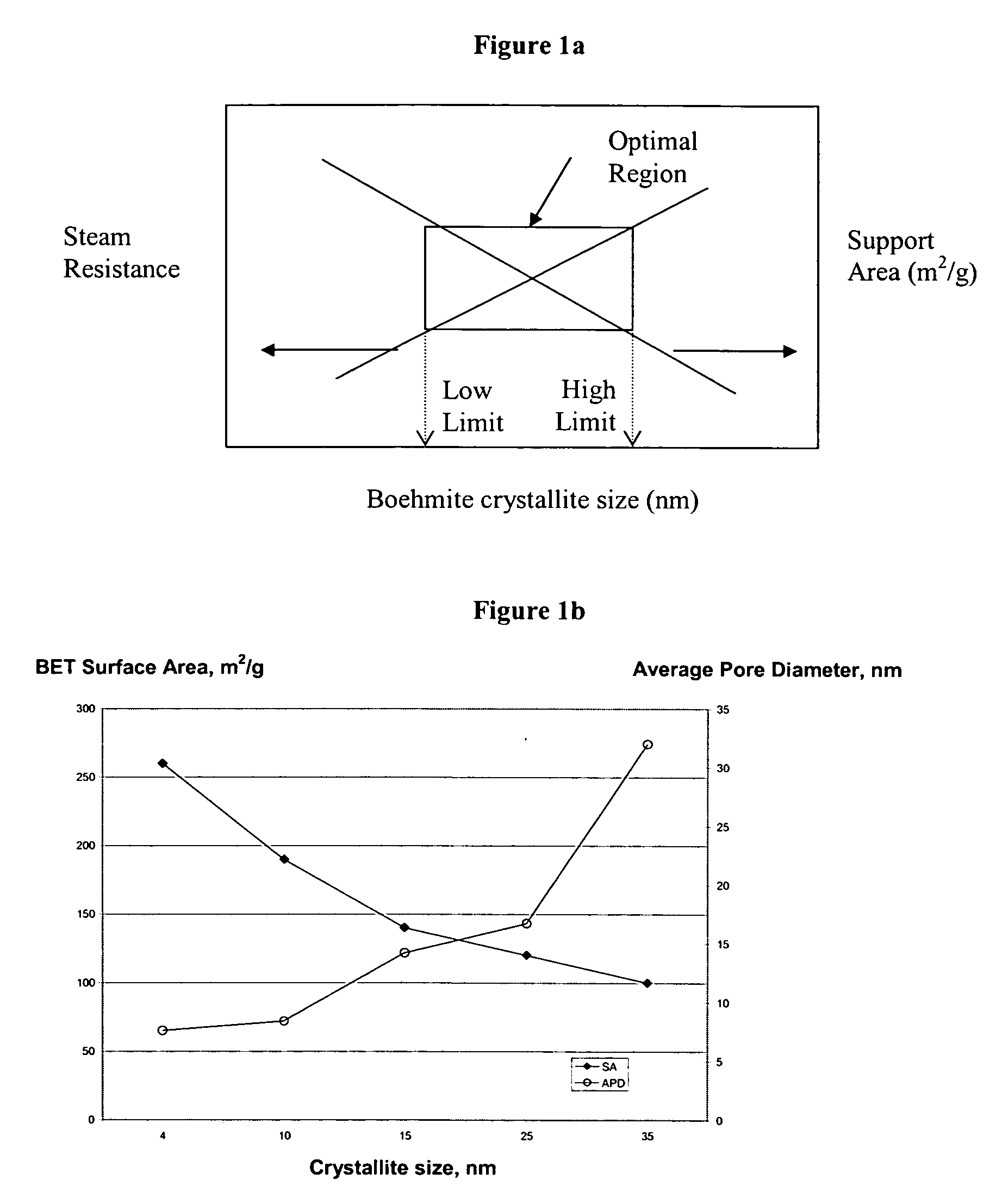

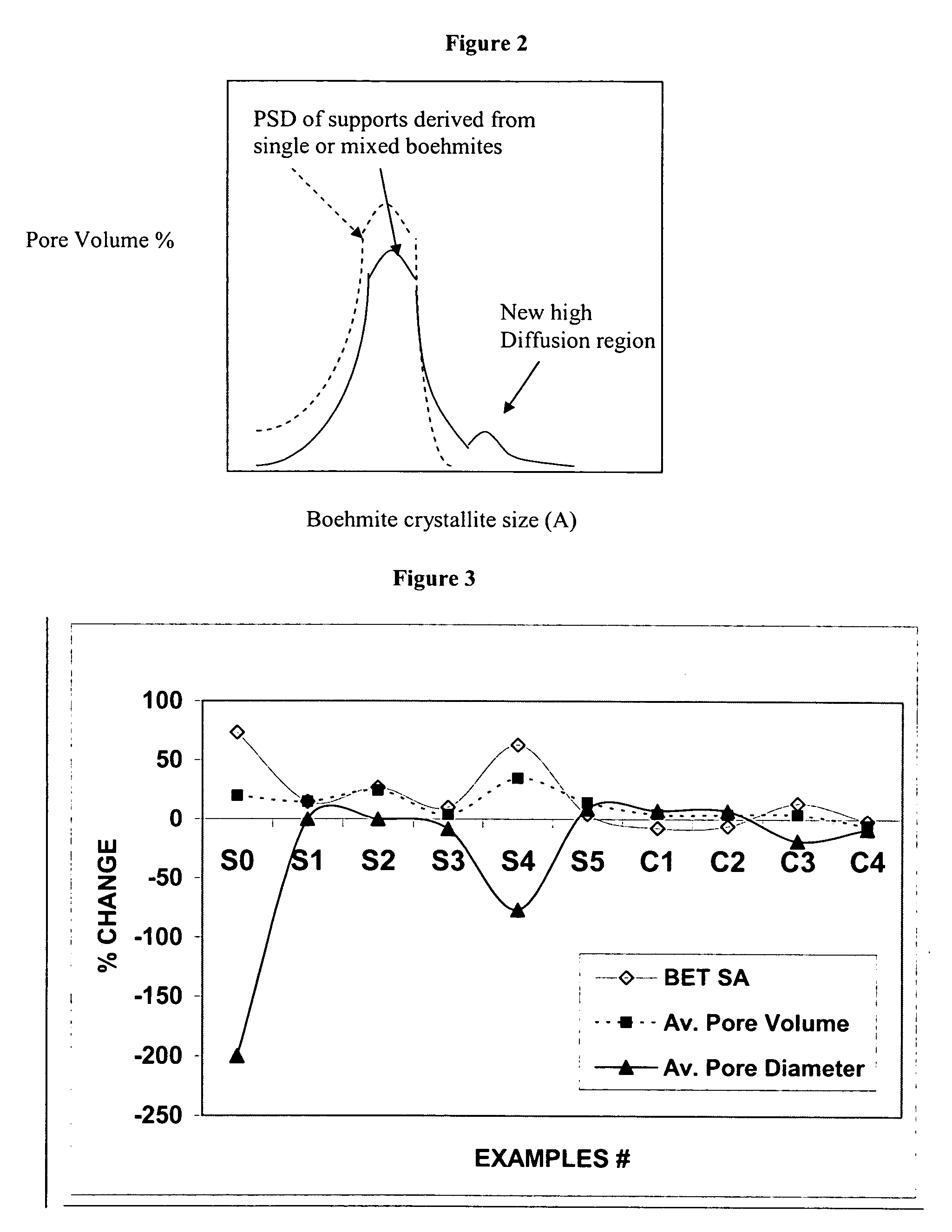

Stabilized boehmite-derived catalyst supports, catalysts, methods of making and using

ActiveUS20050234137A1Good hydrothermal stabilityImprove stabilityMaterial nanotechnologyCatalyst carriersPorosityAluminium hydroxide

A stabilized catalyst support having improved hydrothermal stability, catalyst made therefrom, and method for producing hydrocarbons from synthesis gas using said catalyst. The stabilized support is made by a method comprising treating a crystalline hydrous alumina precursor in contact with at least one structural stabilizer or compound thereof. The crystalline hydrous alumina precursor preferably includes an average crystallite size selected from an optimum range delimited by desired hydrothermal resistance and desired porosity. The crystalline hydrous alumina precursor preferably includes an alumina hydroxide, such as crystalline boehmite, crystalline bayerite, or a plurality thereof differing in average crystallite sizes by at least about 1 nm. The crystalline hydrous alumina precursor may be shaped before or after contact with the structural stabilizer or compound thereof. The treating includes calcining at 450° C. or more. Preferred structural stabilizers can include cobalt, magnesium, manganese, manganese, zirconium, boron, aluminum, barium, silicon, lanthanum, oxides thereof, or combinations thereof.

Owner:CLARIANT INT LTD

Regeneration fluid for SCR denitration catalyst

InactiveCN101574671AHigh activityEasy to cleanDispersed particle separationCatalyst regeneration/reactivationAdditive ingredientAmmonium paratungstate

The invention discloses a regeneration fluid for an SCR denitration catalyst, which comprises the following components: 0.001 to 1 weight percent of penetration enhancer JFC, 0.001 to 1 weight percent of surfactant OP-10, 0 to 1 weight percent of peregal, 0.6 to 4 weight percent of ammonium metavanadate, 5.5 to 12.5 weight percent of ammonium paratungstate, 0 to 6.5 weight percent of ammonium paramolybdate, and the balance of deionized water and acid. The regeneration fluid has the advantages that the regeneration fluid can also supplement active ingredients during the washing, and the activity recovery of the catalyst after the regeneration is up to between 90 and 105 percent; a nonionic surfactant is added into the regeneration fluid, so that the regeneration fluid improves the cleaning capability on the catalyst and cannot cause the damage to a catalyst carrier and other effective ingredients; and the regenerated catalyst fully can continue to be normally used, and the service life can reach more than 95 percent of that of a new catalyst.

Owner:COUNTRY JIANGSU CATALYST REGENERATION TECH

Process for desulfurizing hydrocarbon fuels and fuel components

InactiveUS20050098478A1Substantial sulfur removalLow costCatalytic crackingHydrocarbon oils refiningHydrodesulfurizationSorbent

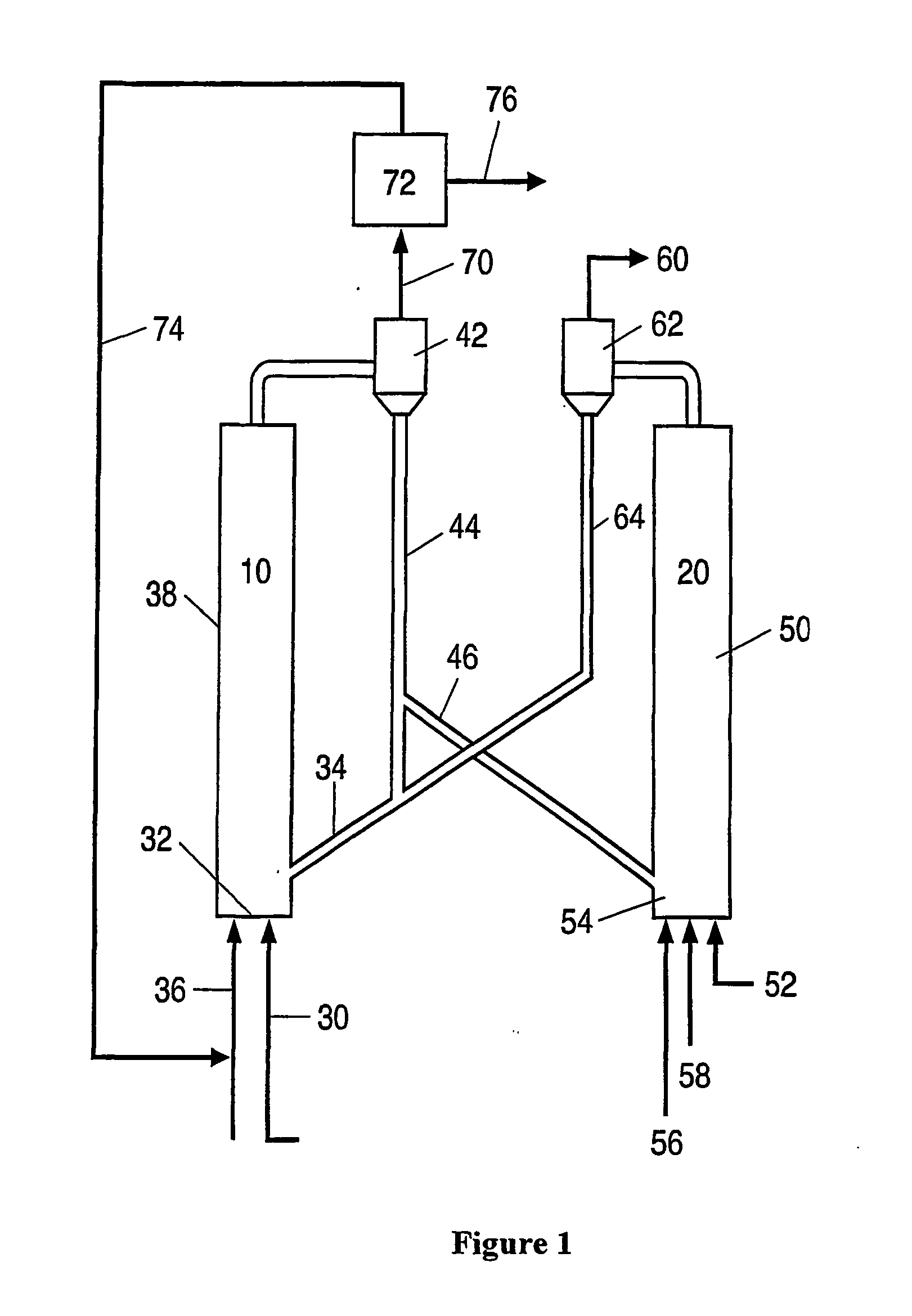

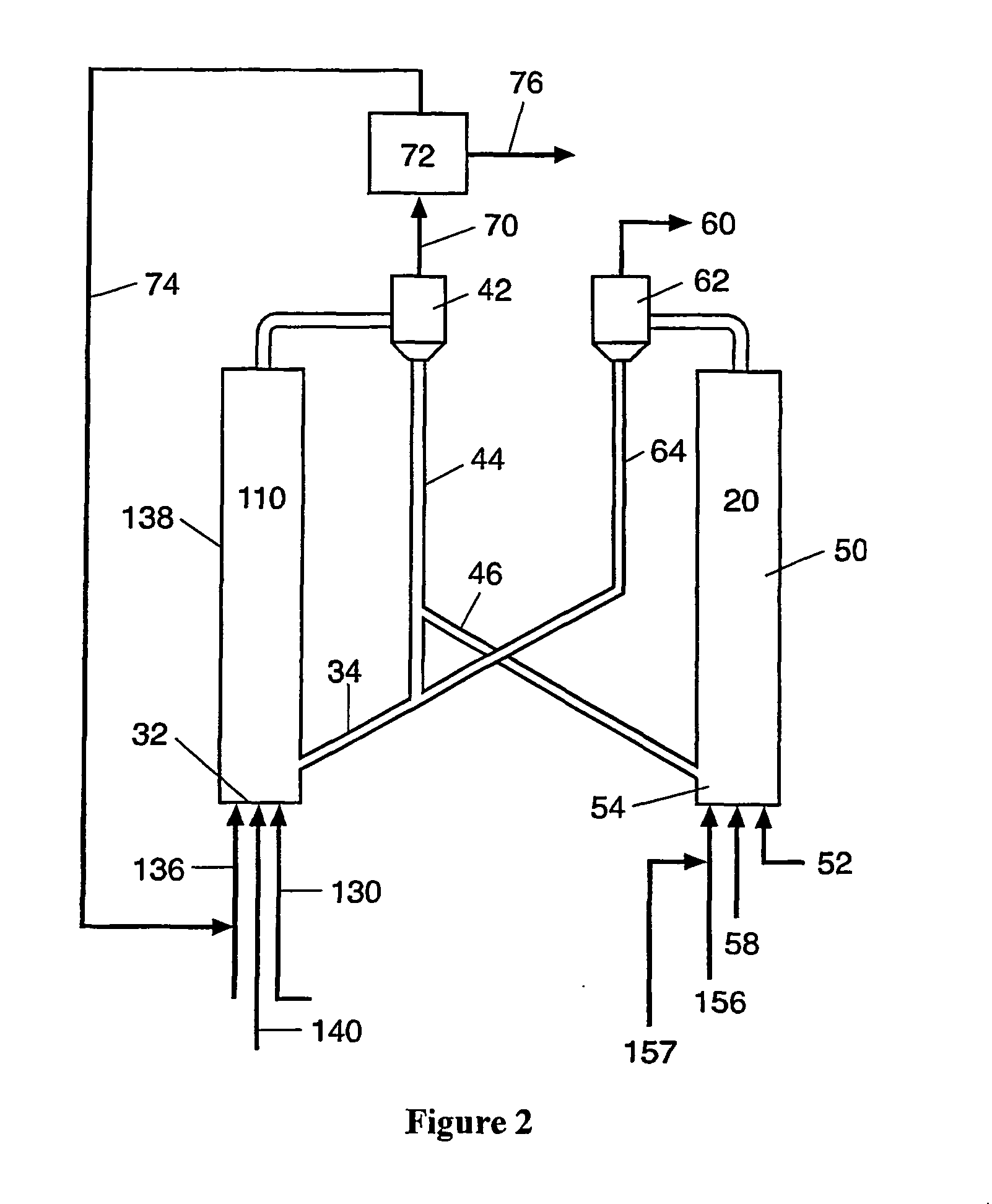

Processes are disclosed for removing sulfur, including cyclic and polycyclic organic sulfur components such as thiophenes and benzothiophenes, from a hydrocarbon feedstock including fuels and fuel components. The feedstock is contacted with a regenerable sorbent material capable of selectively adsorbing the sulfur compounds present in the hydrocarbon feedstock in the absence of a hydrodesulfurization catalyst. In one embodiment, the sorbent can be an active metal oxide sulfur sorbent in combination with a refractory inorganic oxide cracking catalyst support. In another embodiment, the sorbent can be a metal-substituted refractory inorganic oxide cracking catalyst wherein the metal is a metal which is capable in its oxide form, of adsorption of reduced sulfur compounds by conversion of the metal oxide to a metal sulfide. The processes are preferably carried out in a transport bed reactor.

Owner:RES TRIANGLE INST

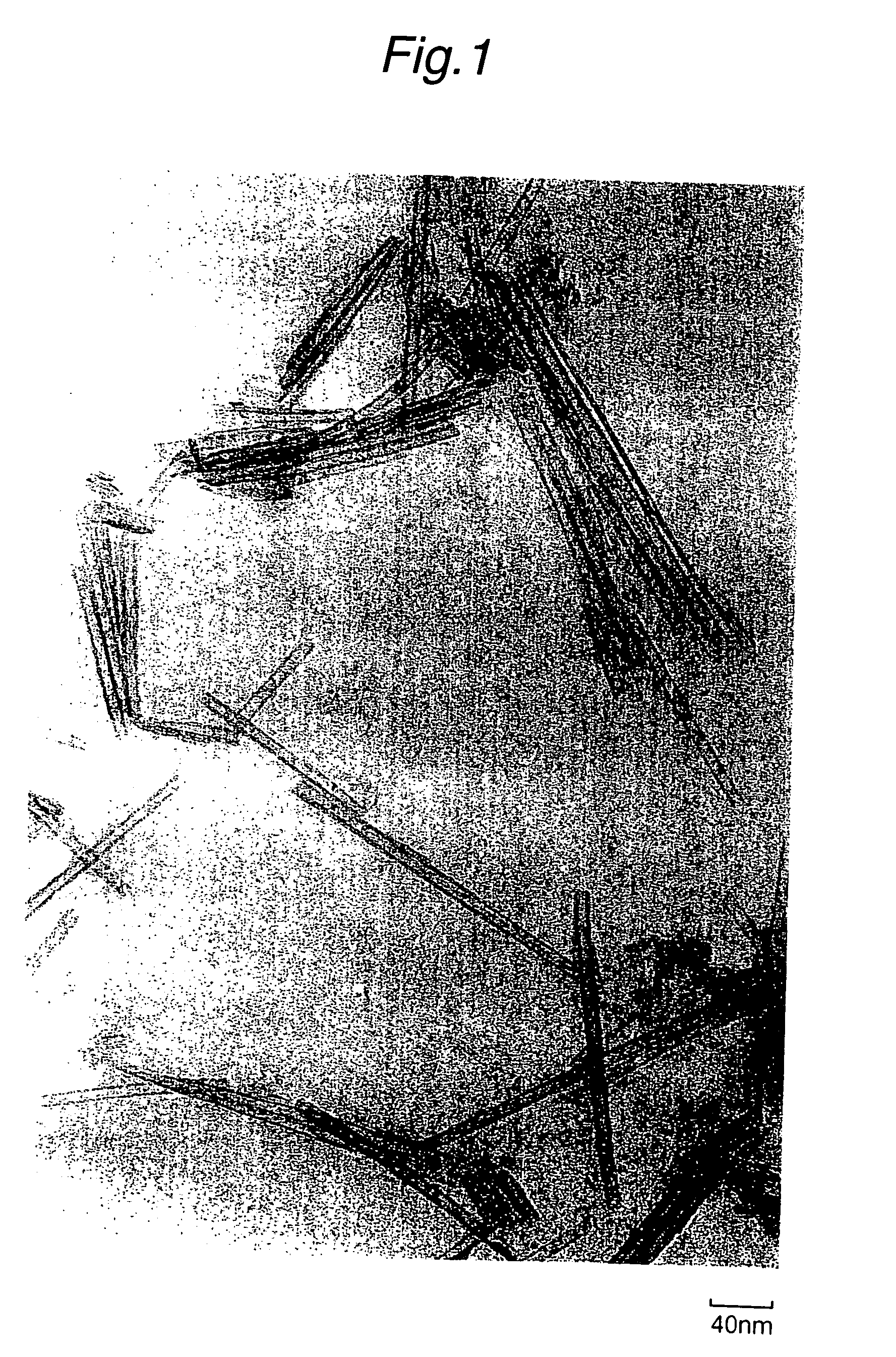

Catalytic growth of single- and double-wall carbon nanotubes from metal particles

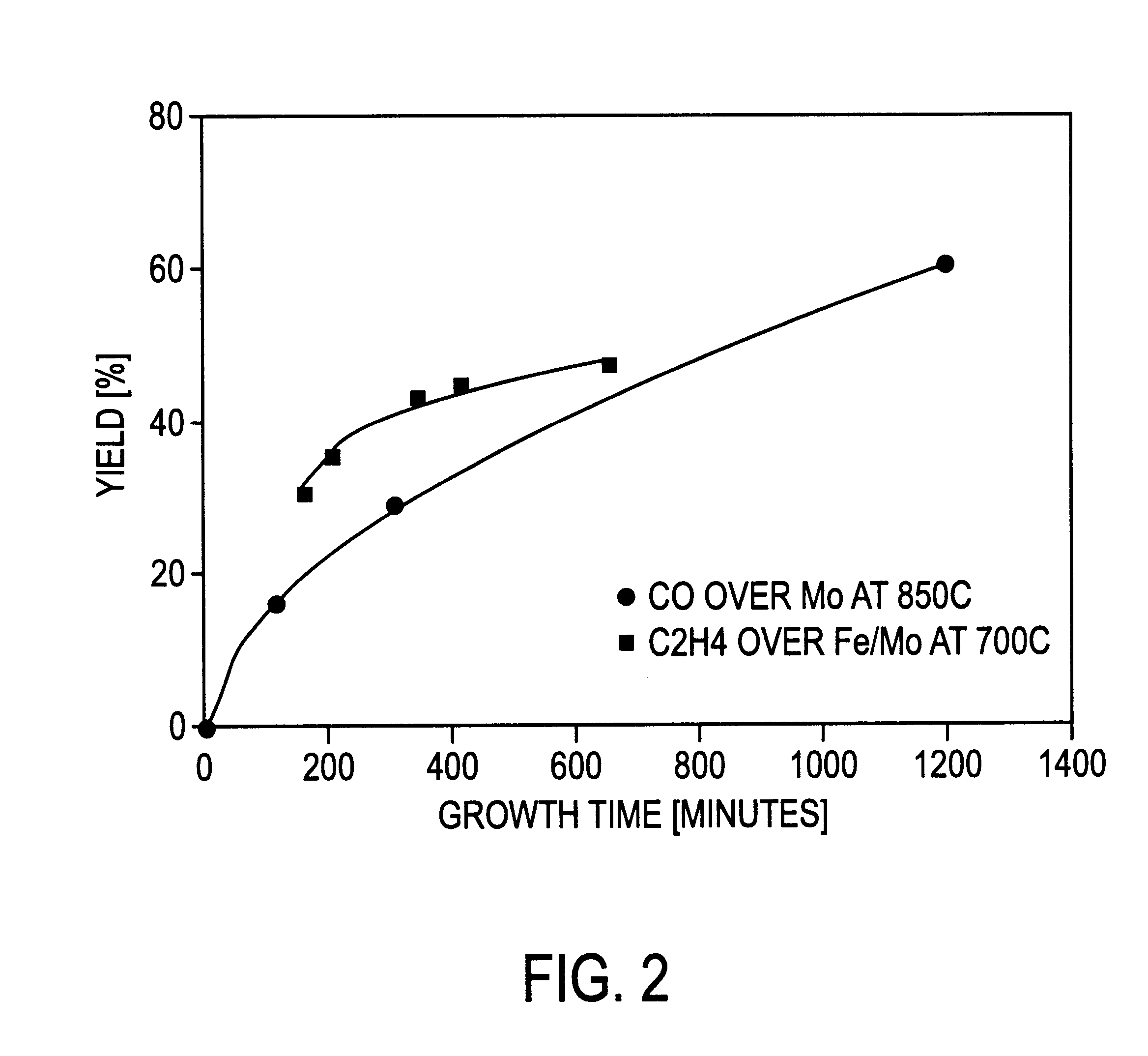

InactiveUS7125534B1Improve productivityImprove scalabilityMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

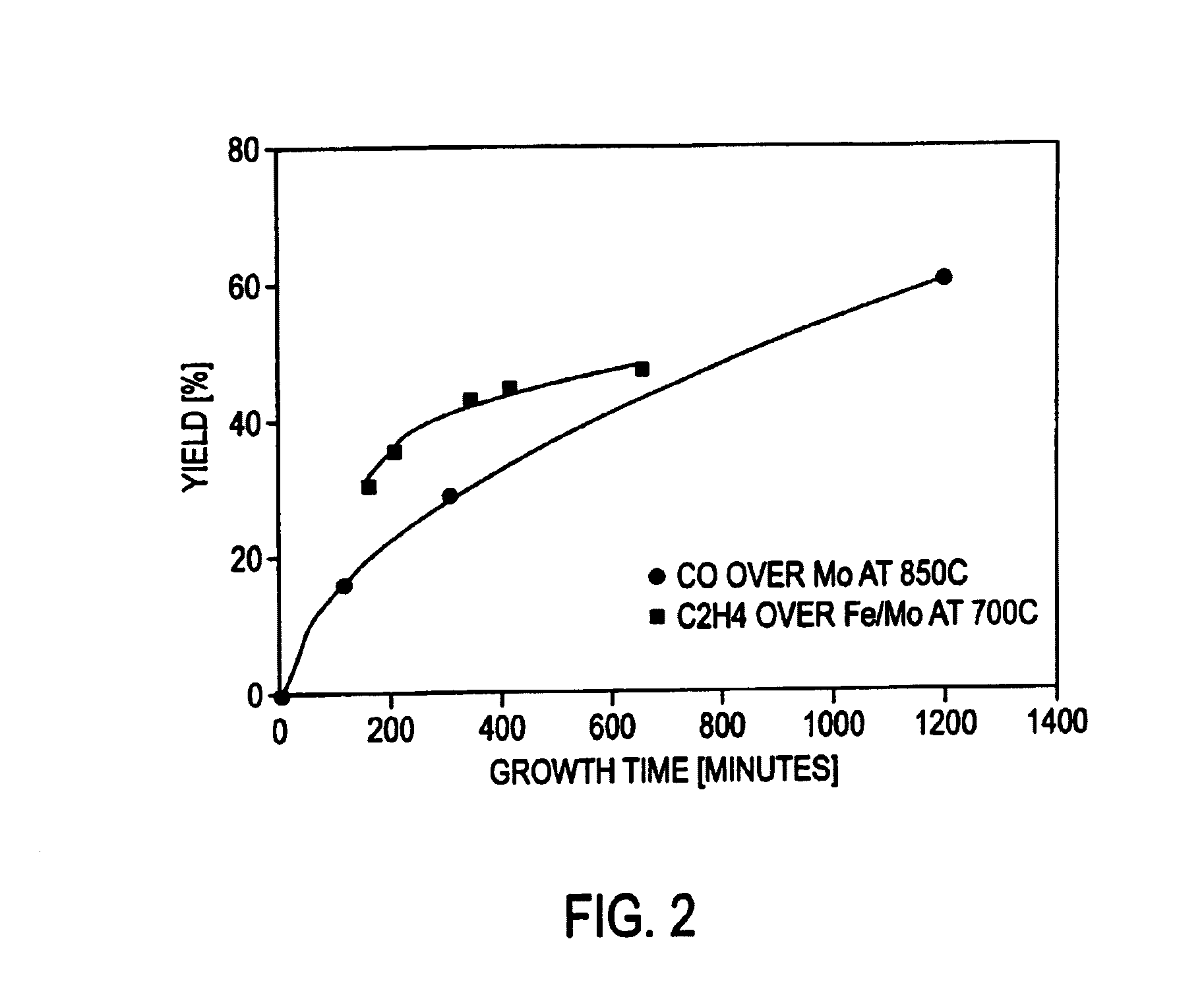

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst. The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com