Patents

Literature

1323results about How to "Control content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

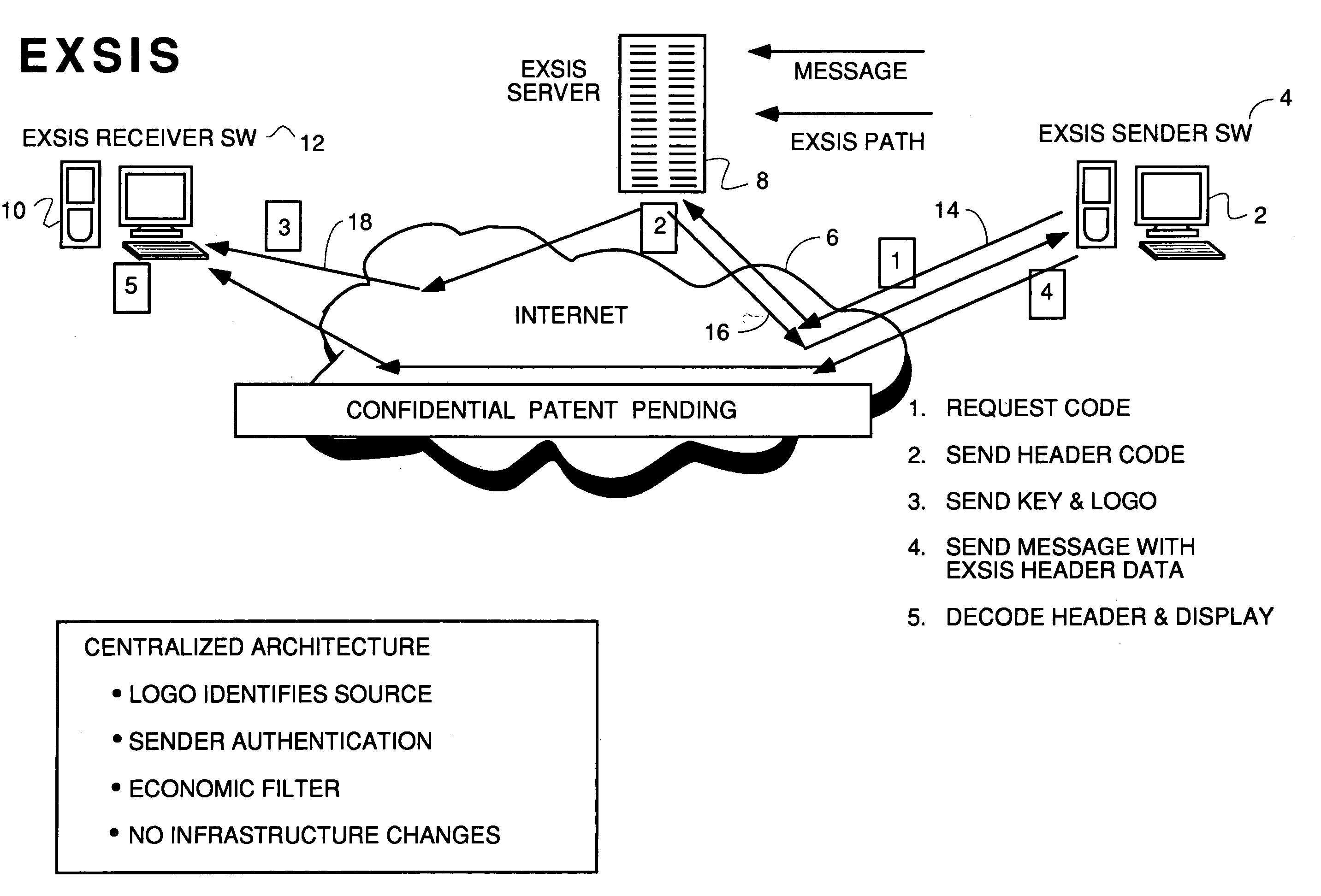

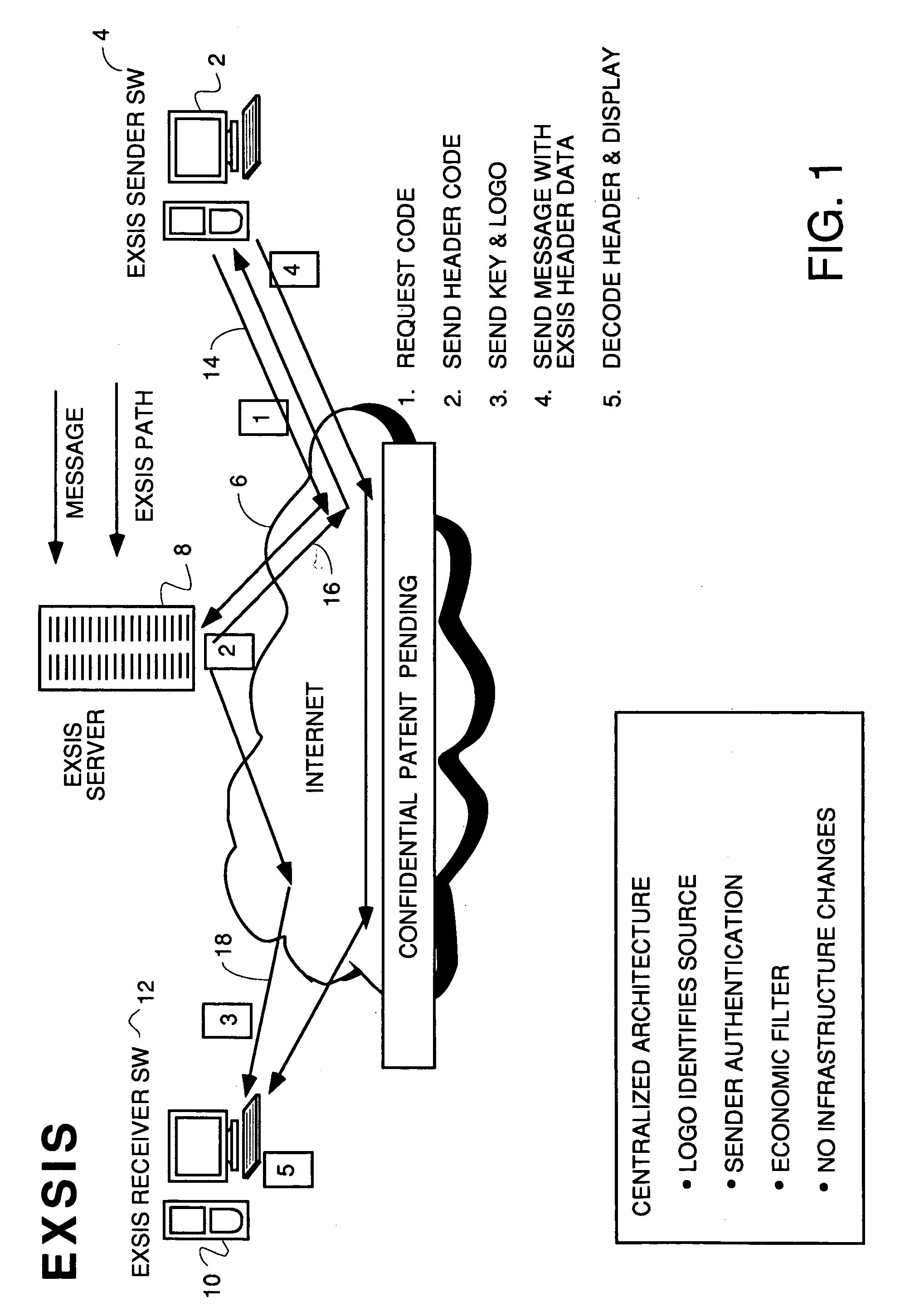

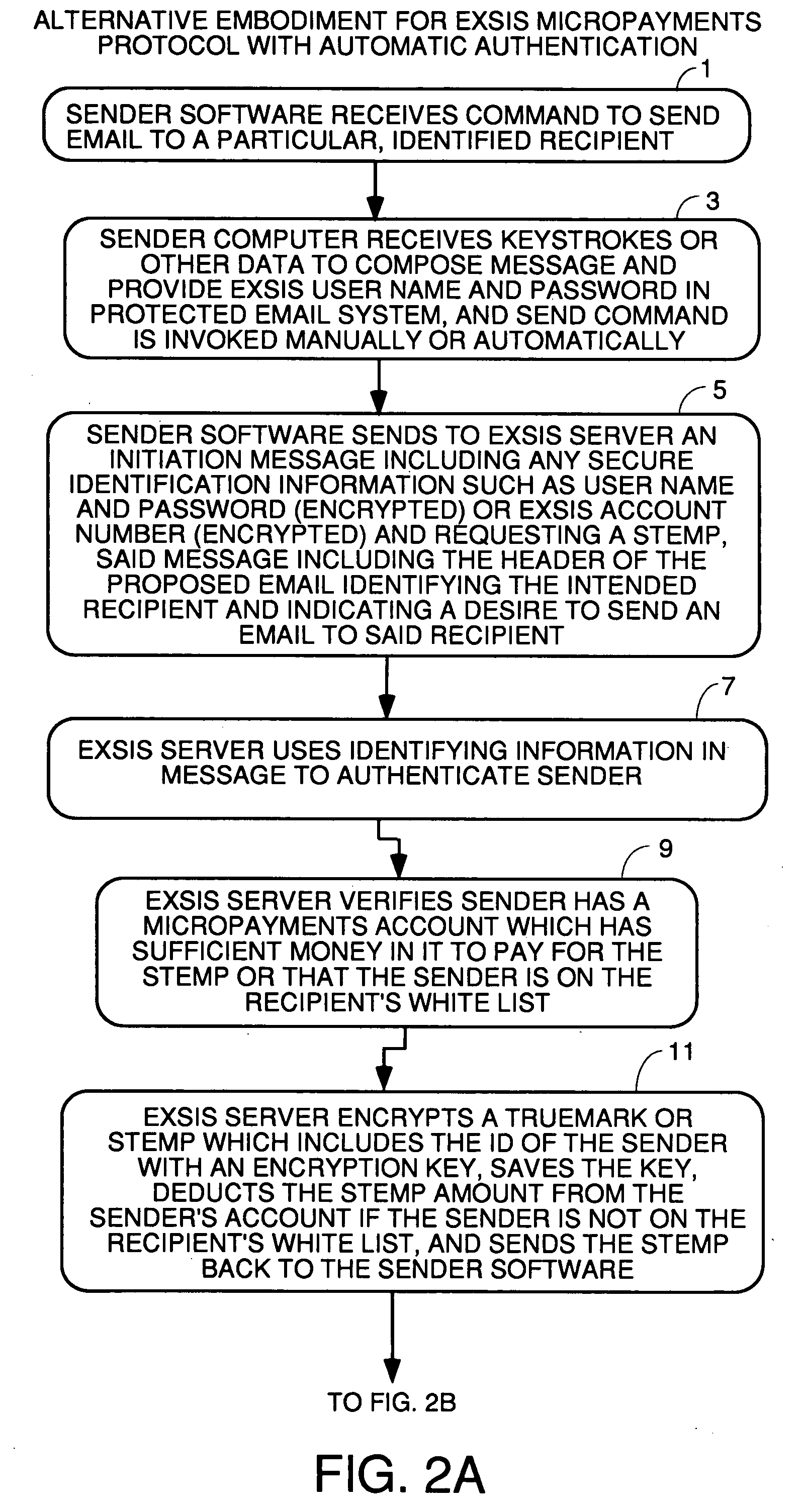

User interface and anti-phishing functions for an anti-spam micropayments system

ActiveUS20060053293A1Control contentEffective controlMetering/charging/biilling arrangementsUser identity/authority verificationTrademarkPhishing

Owner:ICONIX INC

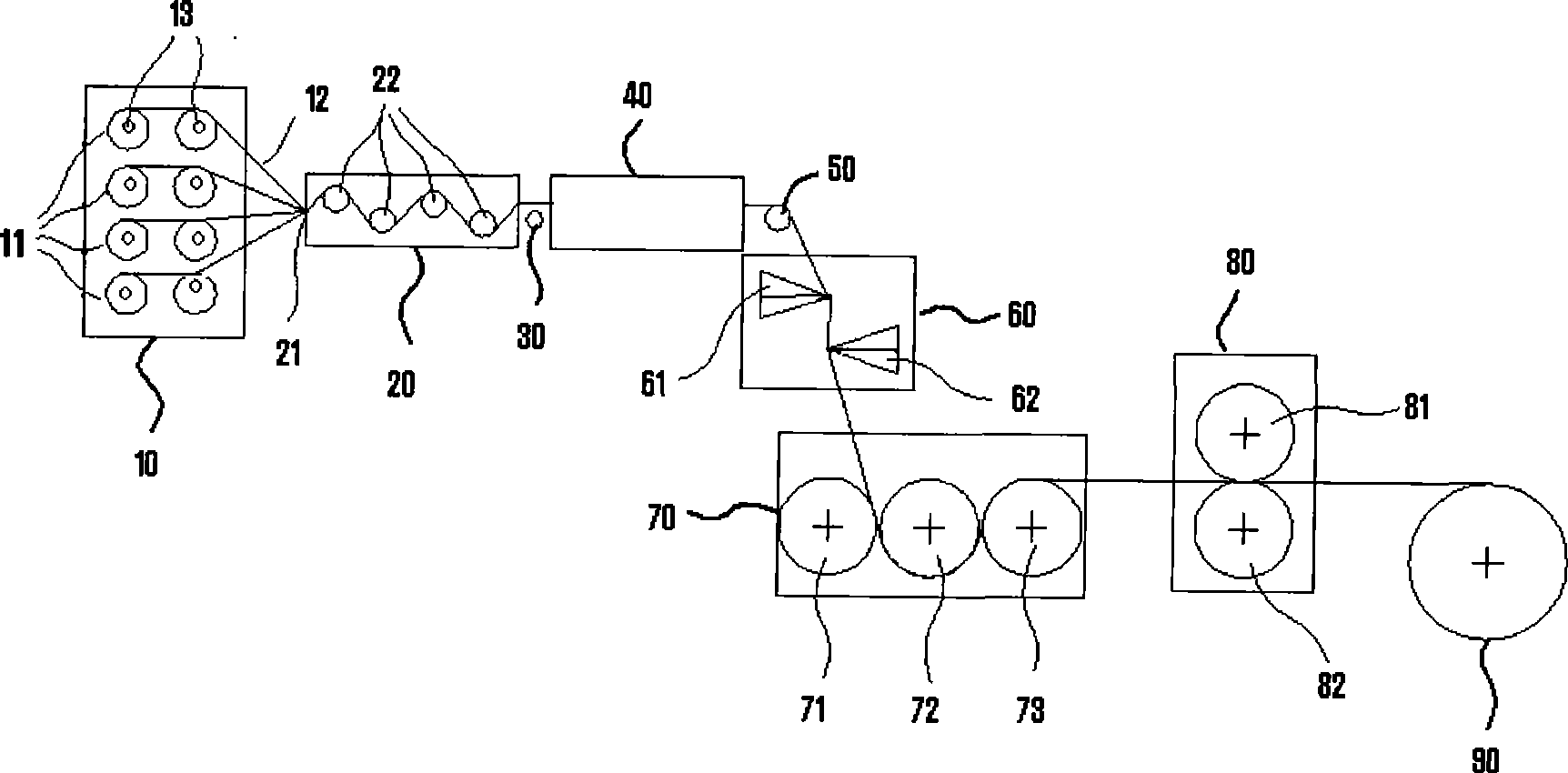

Equipment for preparing continuous fiber reinforced thermoplastic resin composite material presoaked belt and use thereof

The invention relates to an apparatus for preparing a continuous filament reinforced thermoplastic resin composite material prepreg tape, which comprises a yarn stand (10), a tension adjusting device (20), an electrostatic eliminating device (30), a preheating oven (40), a tension adjusting device (50), a dual-extruding die head (60), a three-roller dipping device (70), a cooling roll-in device (80) and a traction and winding device (90). The apparatus adopts the staggered dual-extruding die head (60) to pre-dip the continuous filament tape. Compared with the prior art, the apparatus has the advantages that the apparatus is simple, the continuous filament reinforced thermoplastic resin composite material prepreg tape prepared by the apparatus has low cost, the filament is dipped completely and the void ratio is kept to be not higher than 0.2 percent.

Owner:LIAONING LIAOJIE SCI & TECH

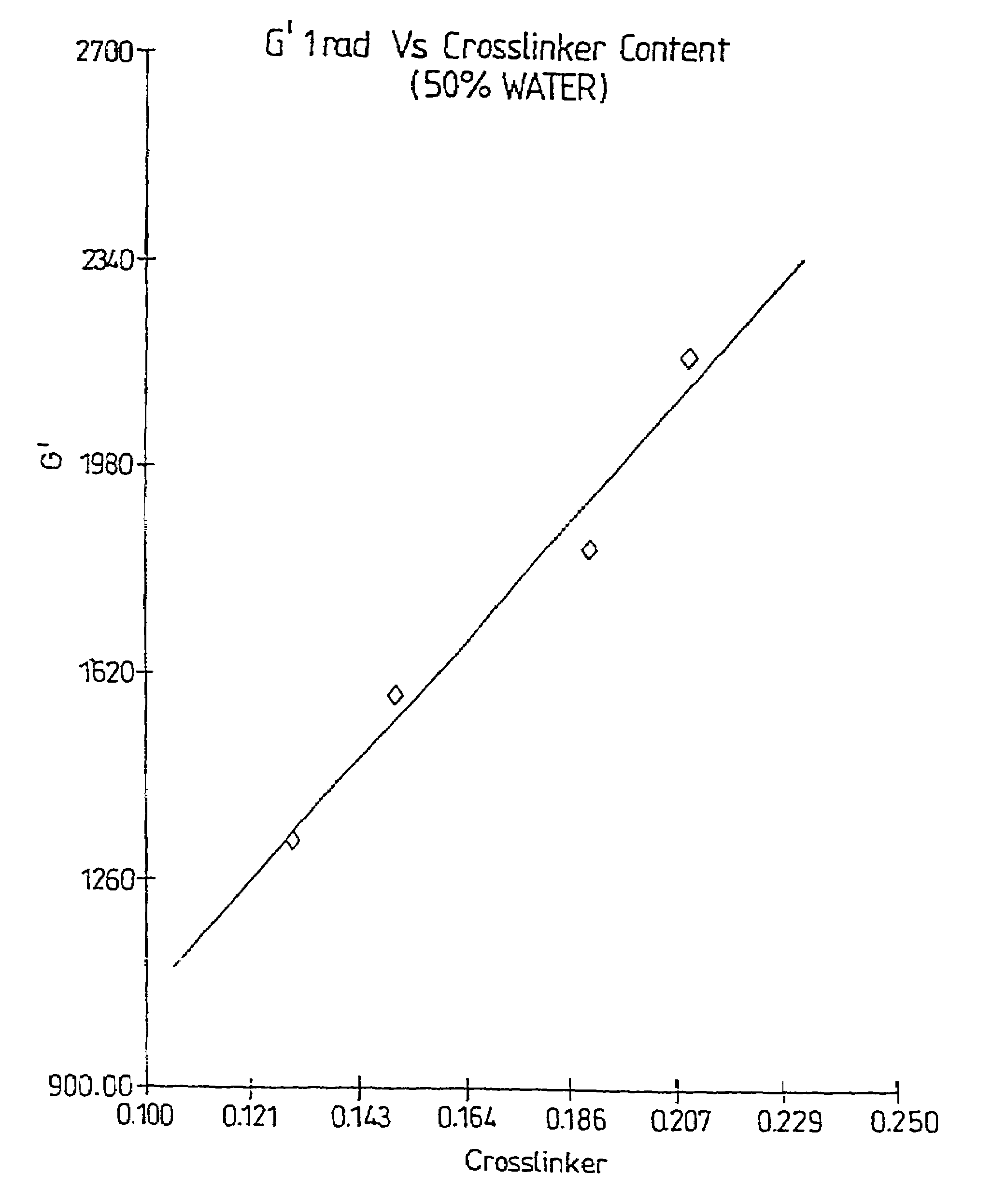

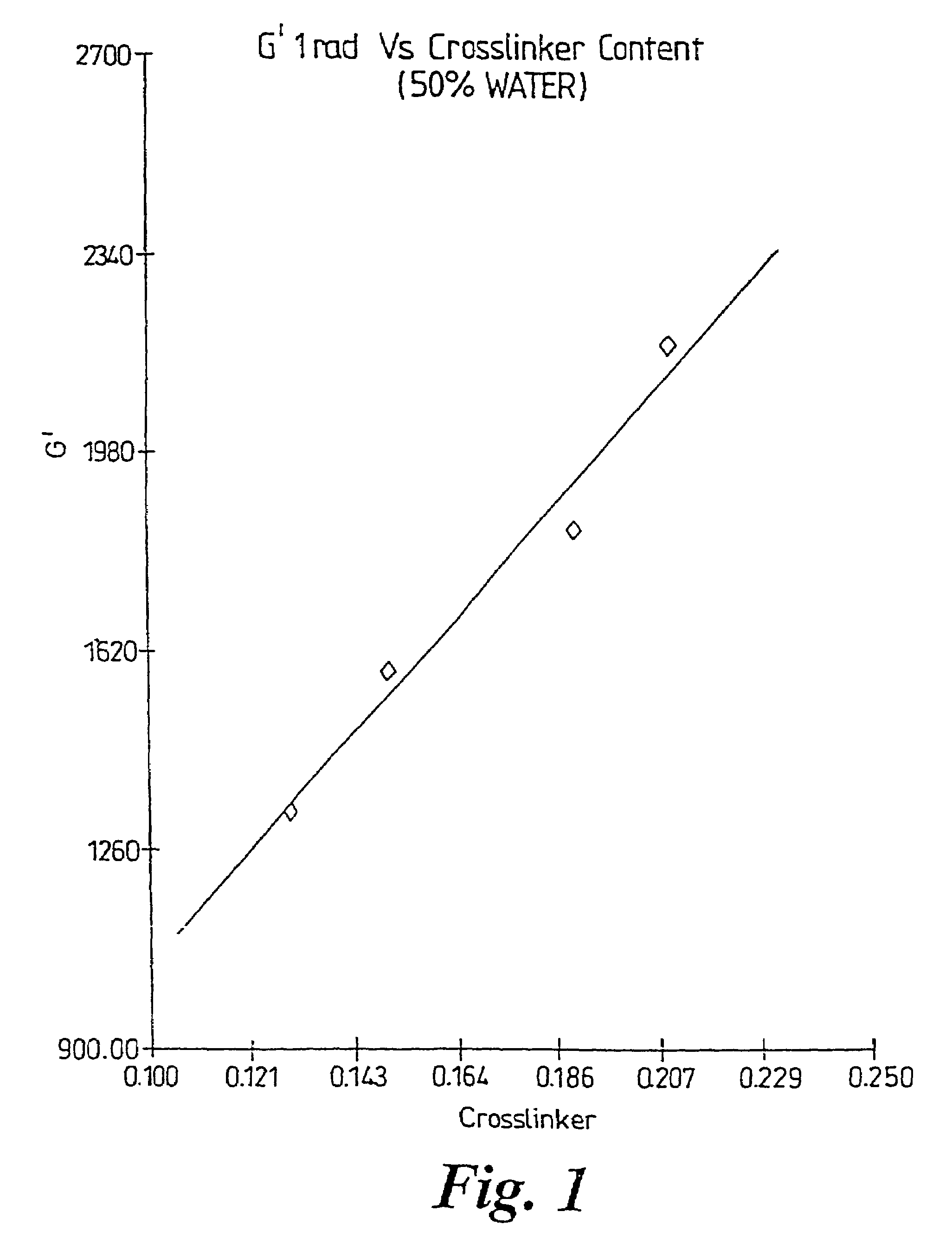

Bioadhesive compositions and biomedical electrodes containing them

InactiveUS7076282B2Good bioadhesionHigh mechanical strengthElectrocardiographySurgical adhesivesWound dressingHydrophobic polymer

Owner:FIRST WATER

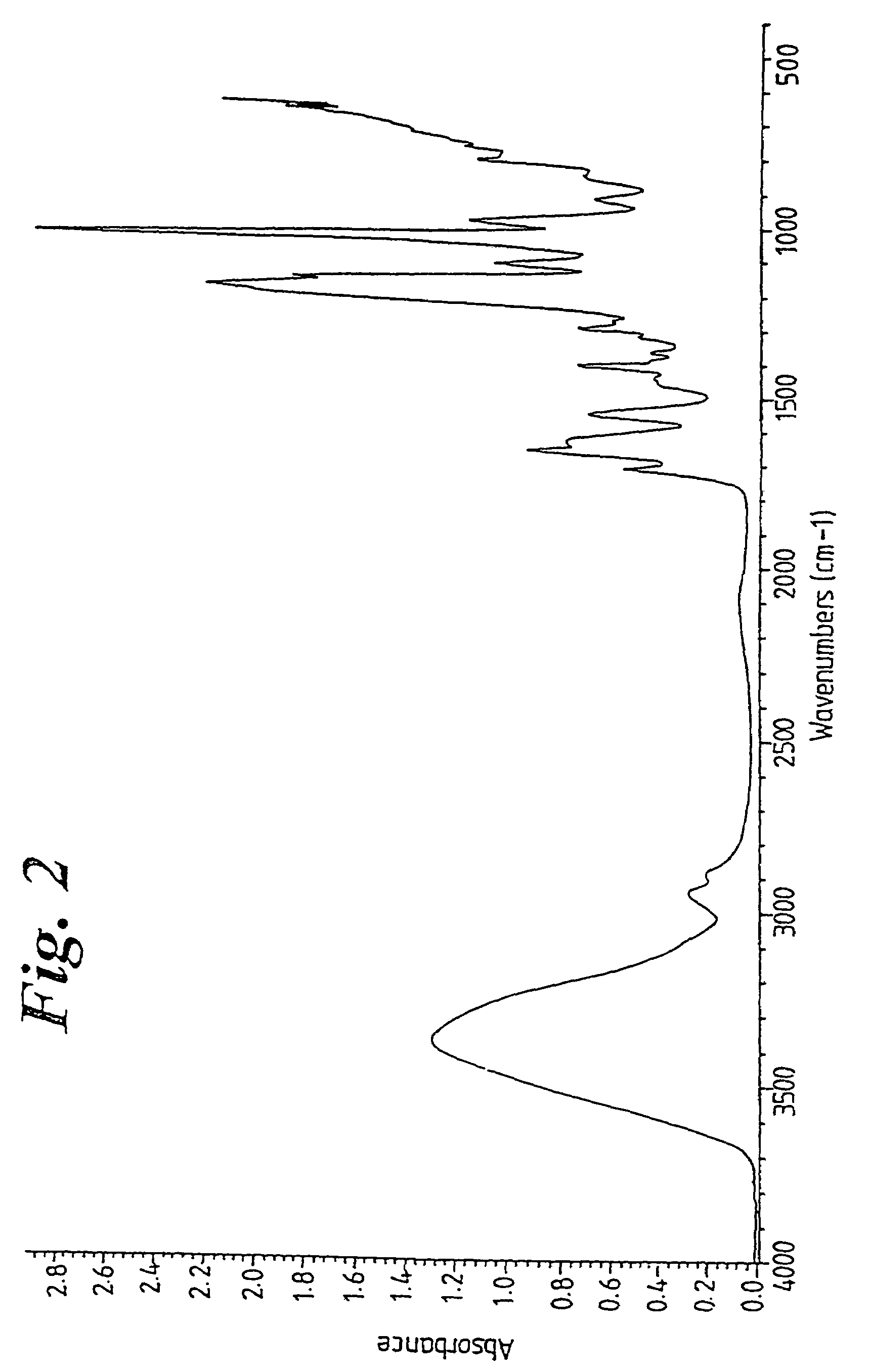

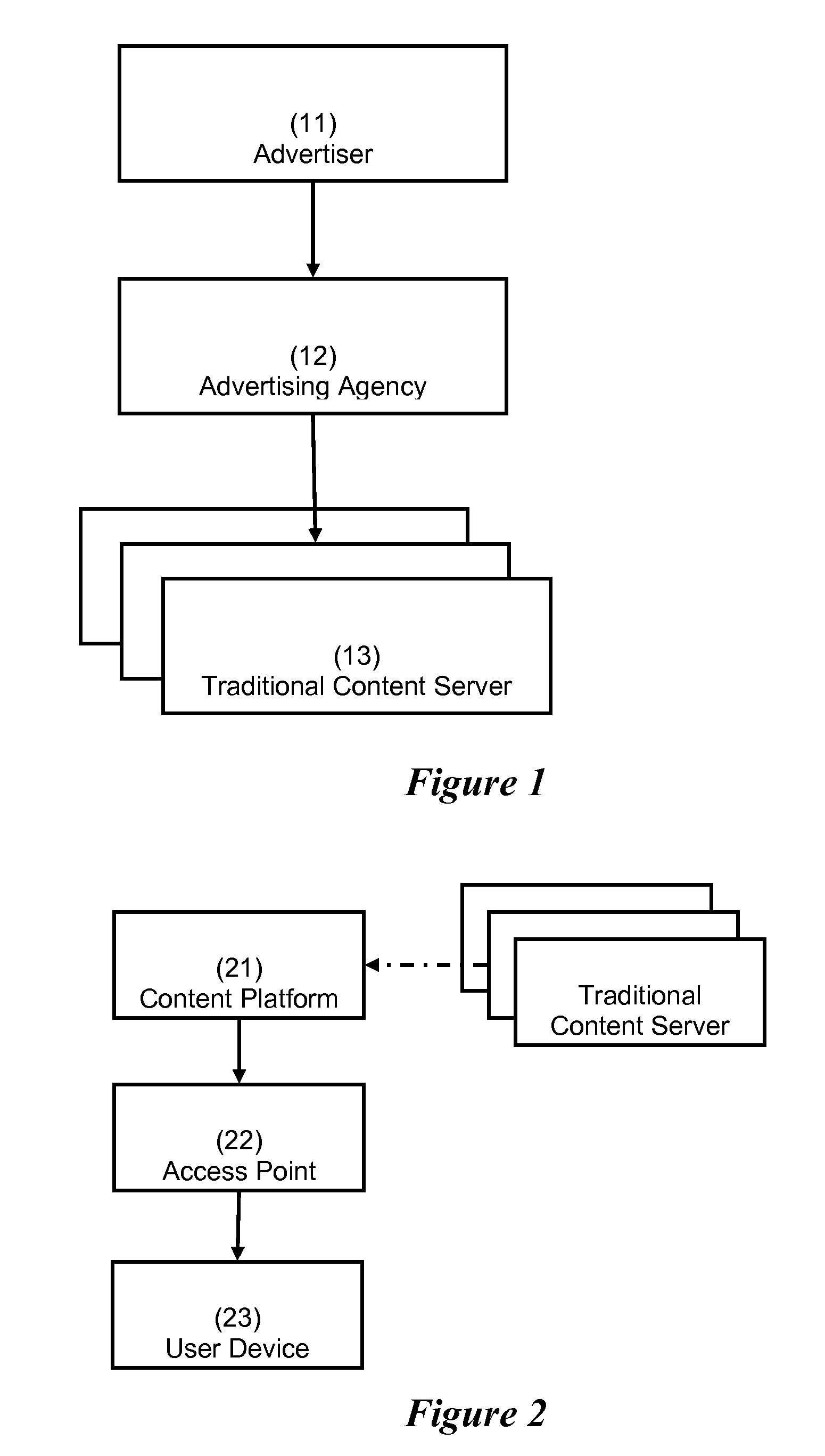

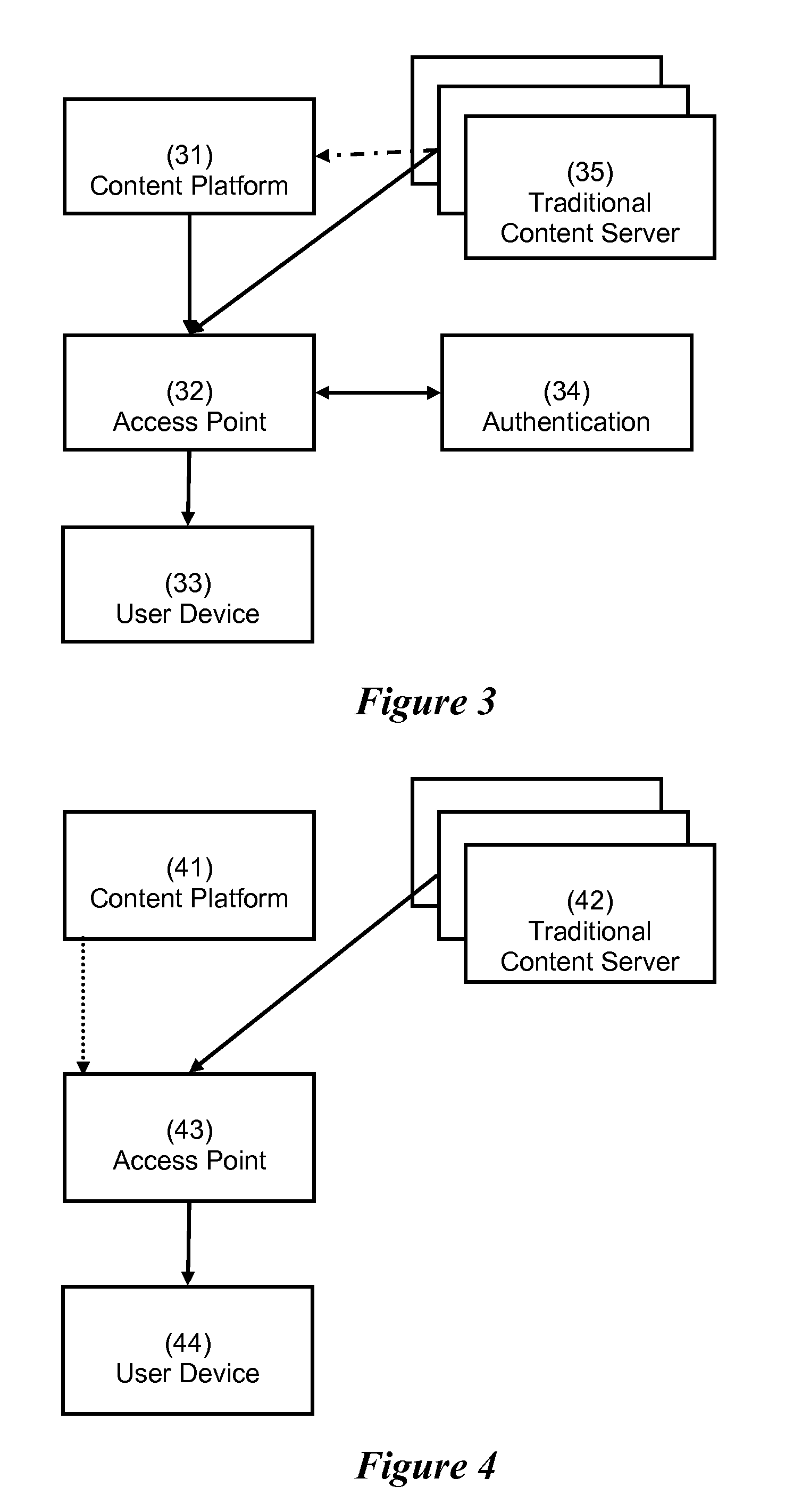

Network Pre-Authentication

InactiveUS20080271120A1Control contentDigital data processing detailsMultiple digital computer combinationsThe InternetA domain

A method of dynamic pre-authentication includes receiving at an access point from one or more content platforms a white-list of internet domains that are to be deemed valid for serving content to a non-authenticated user. Updates to the white list are dynamically received from the one or more content platforms which are each responsible for a particular promotional campaign that features specific content. A request is received at the access point from a non-authenticated user for certain of the specific content, which is allowed such that a domain of the content platform responsible for the certain specific content is accessed by the user.

Owner:1020 INC

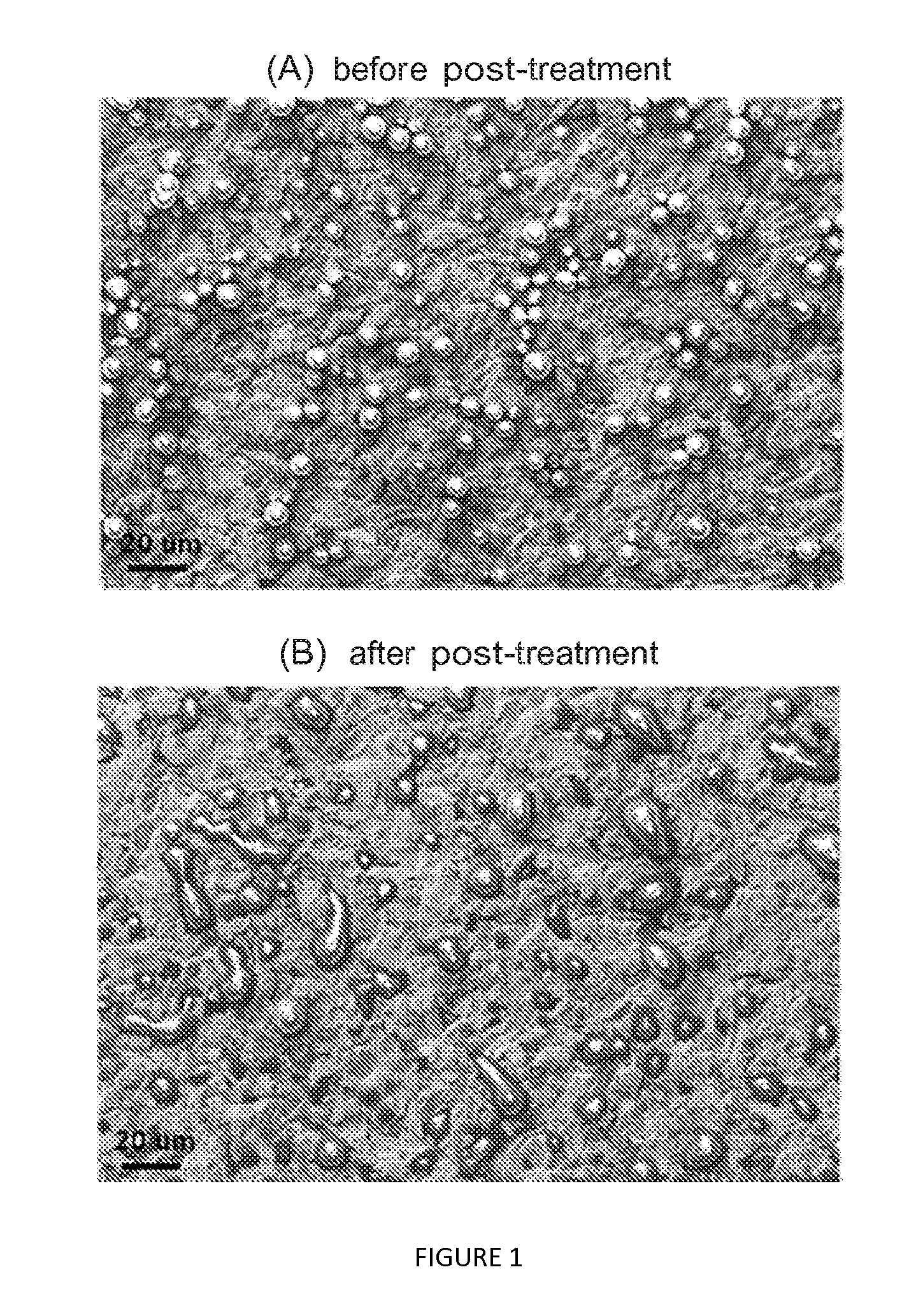

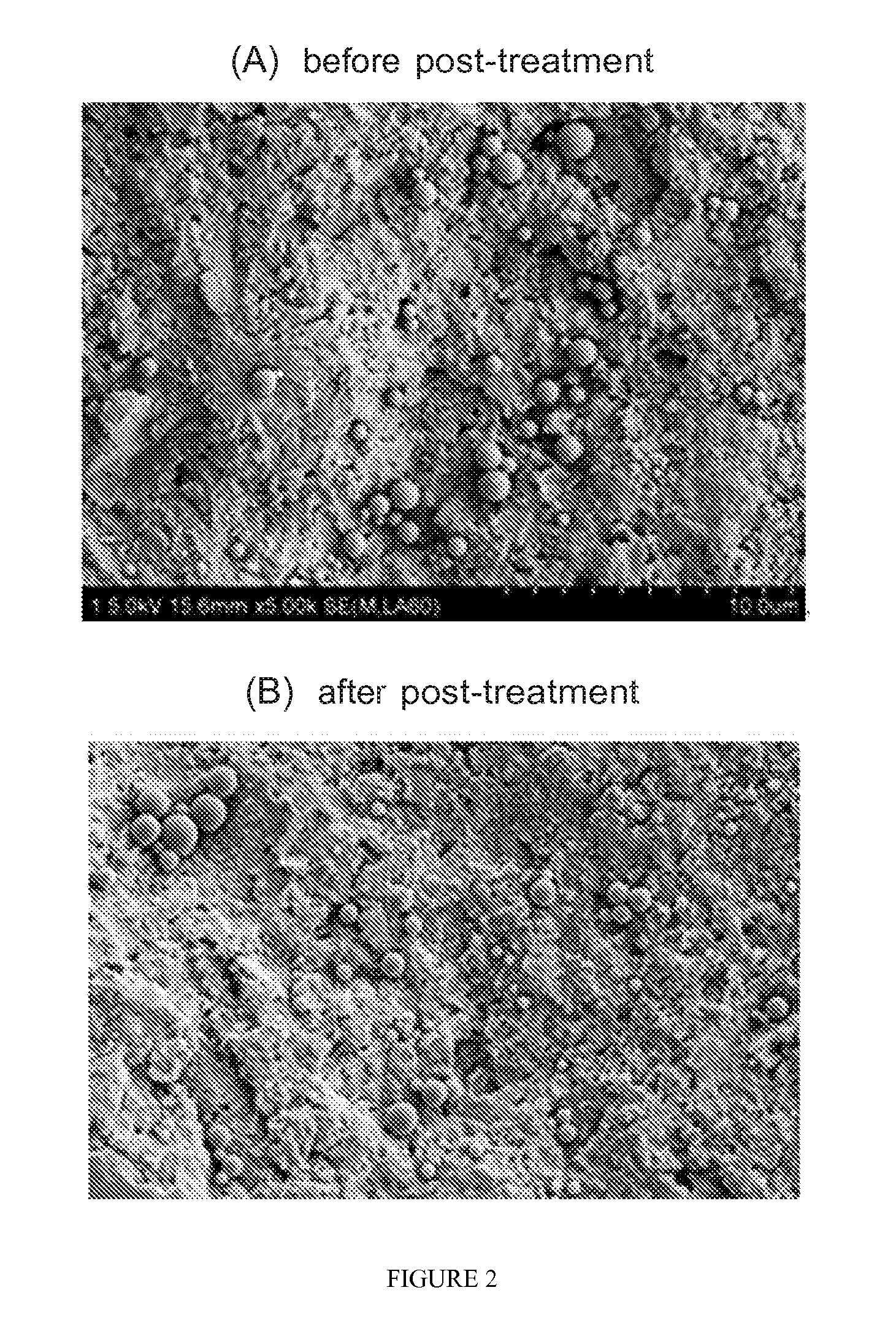

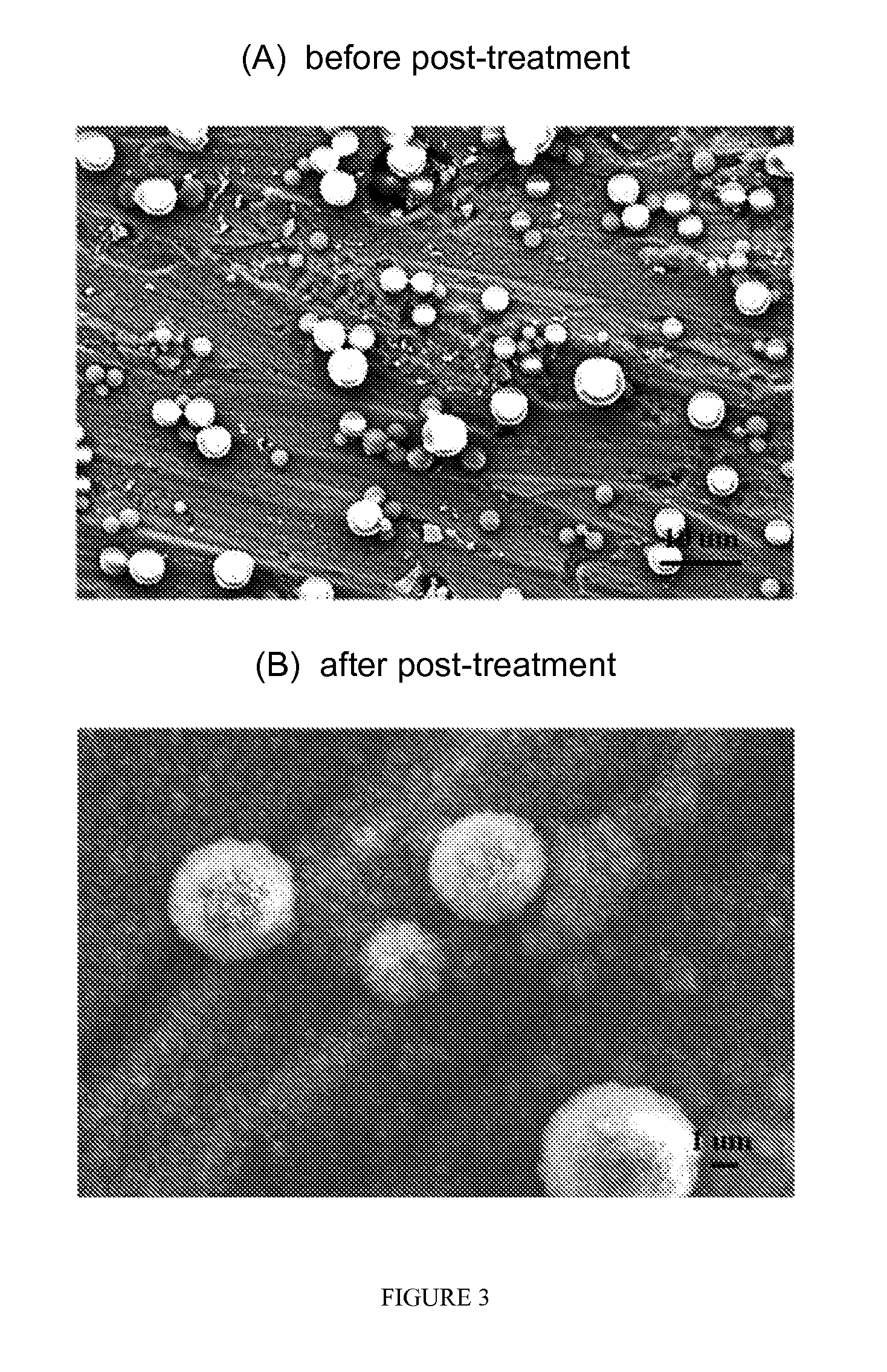

Method for preparing biomedical metal alloy material with multi-drug delivery system

InactiveUS20130164346A1Good biocompatibilityImprove adhesionInorganic non-active ingredientsSurgeryMetal alloyPharmaceutical drug

The present invention provides a method for preparing a biomedical metal alloy material with a multi-drug delivery system. A biomedical metal alloy material with a multi-drug delivery system according to the present invention is prepared by incorporating a therapeutic agent into a biodegradable material to prepare particles containing the therapeutic agent, treating the surface of the particles containing the therapeutic agent to have a charge opposite to the surface charge of a metal alloy material, and inducing an electrostatic interaction between the surface charges of the particles containing the therapeutic agent and the metal alloy material to immobilize the surface-treated particles containing the therapeutic agent on the surface of the metal alloy material.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

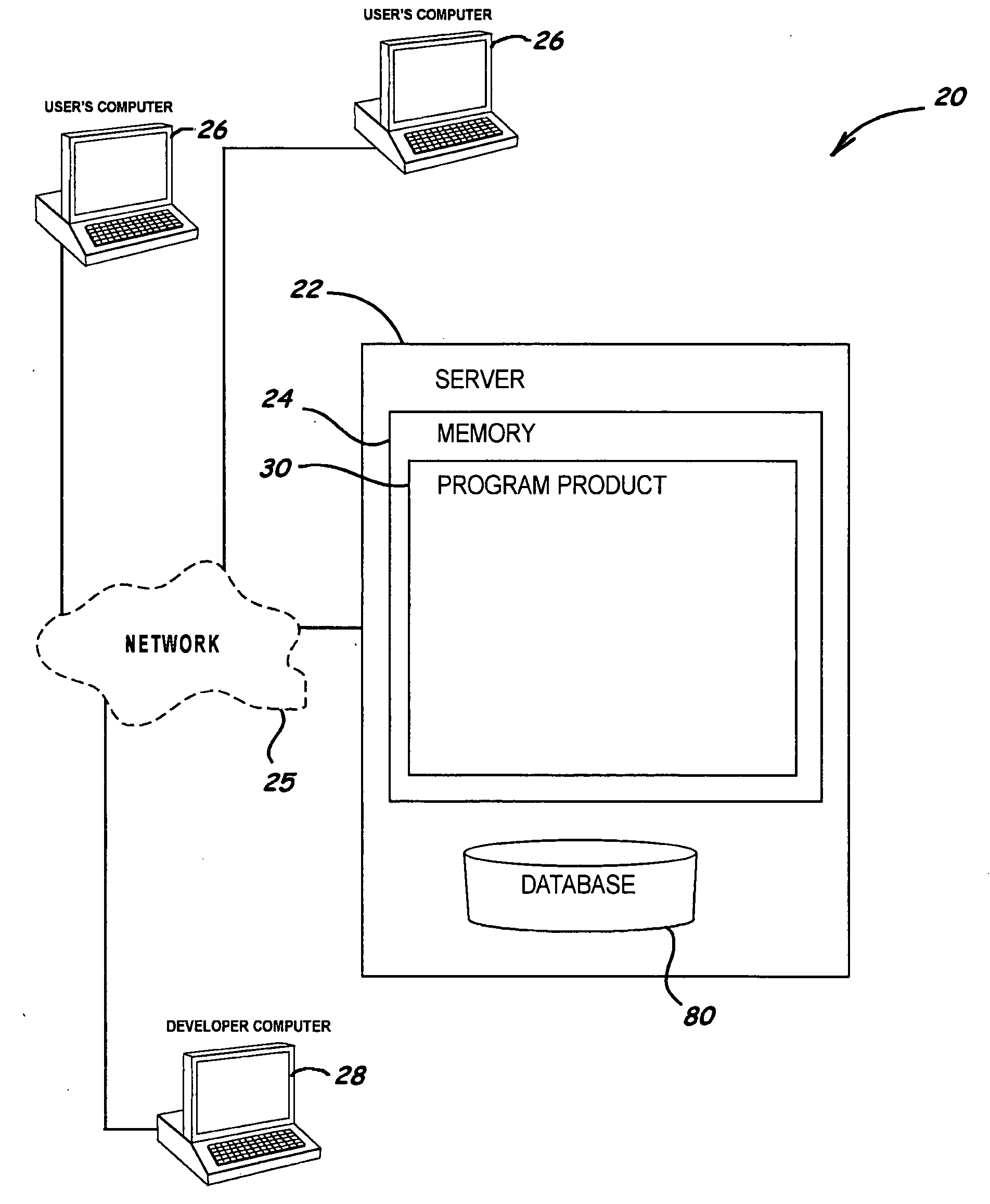

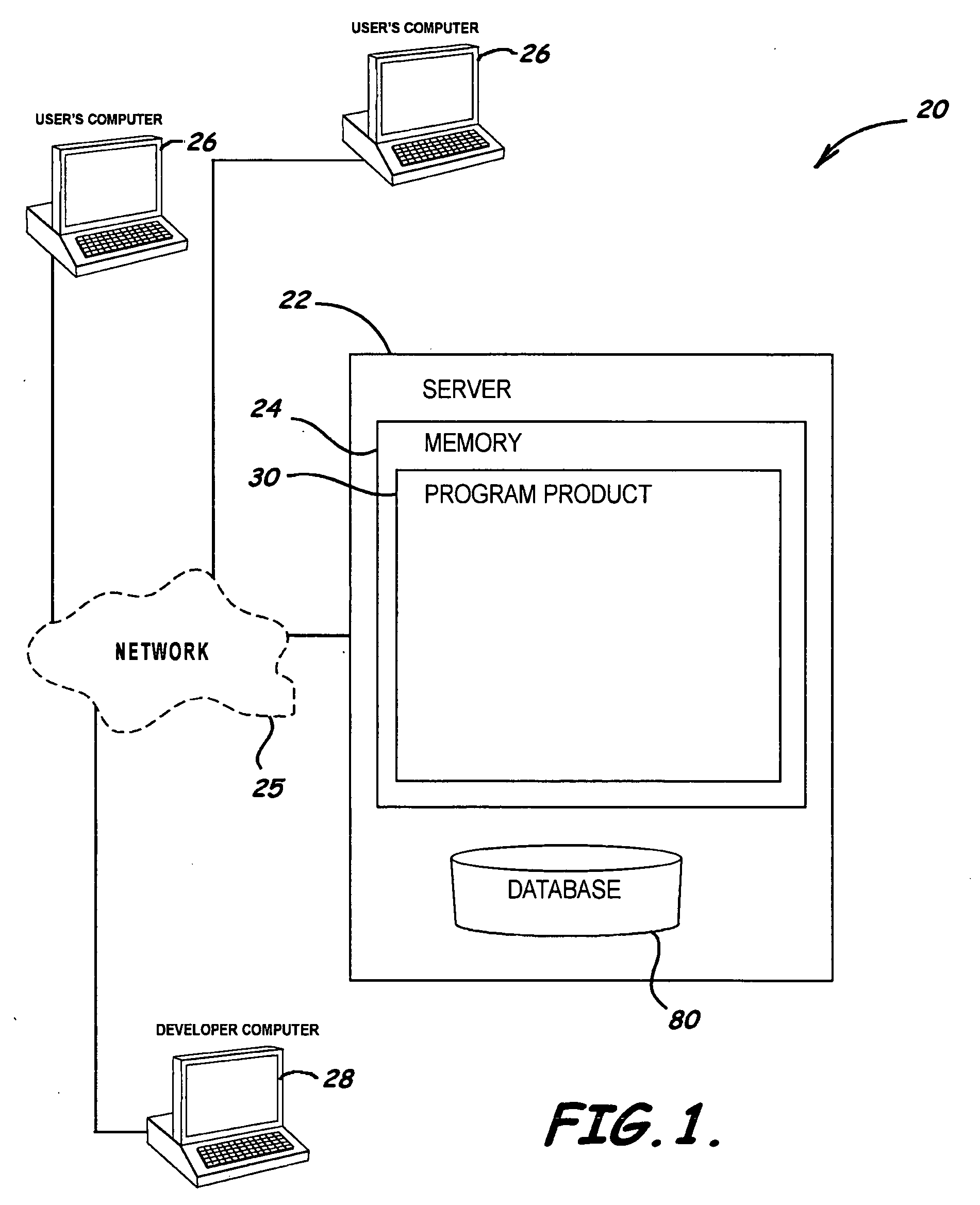

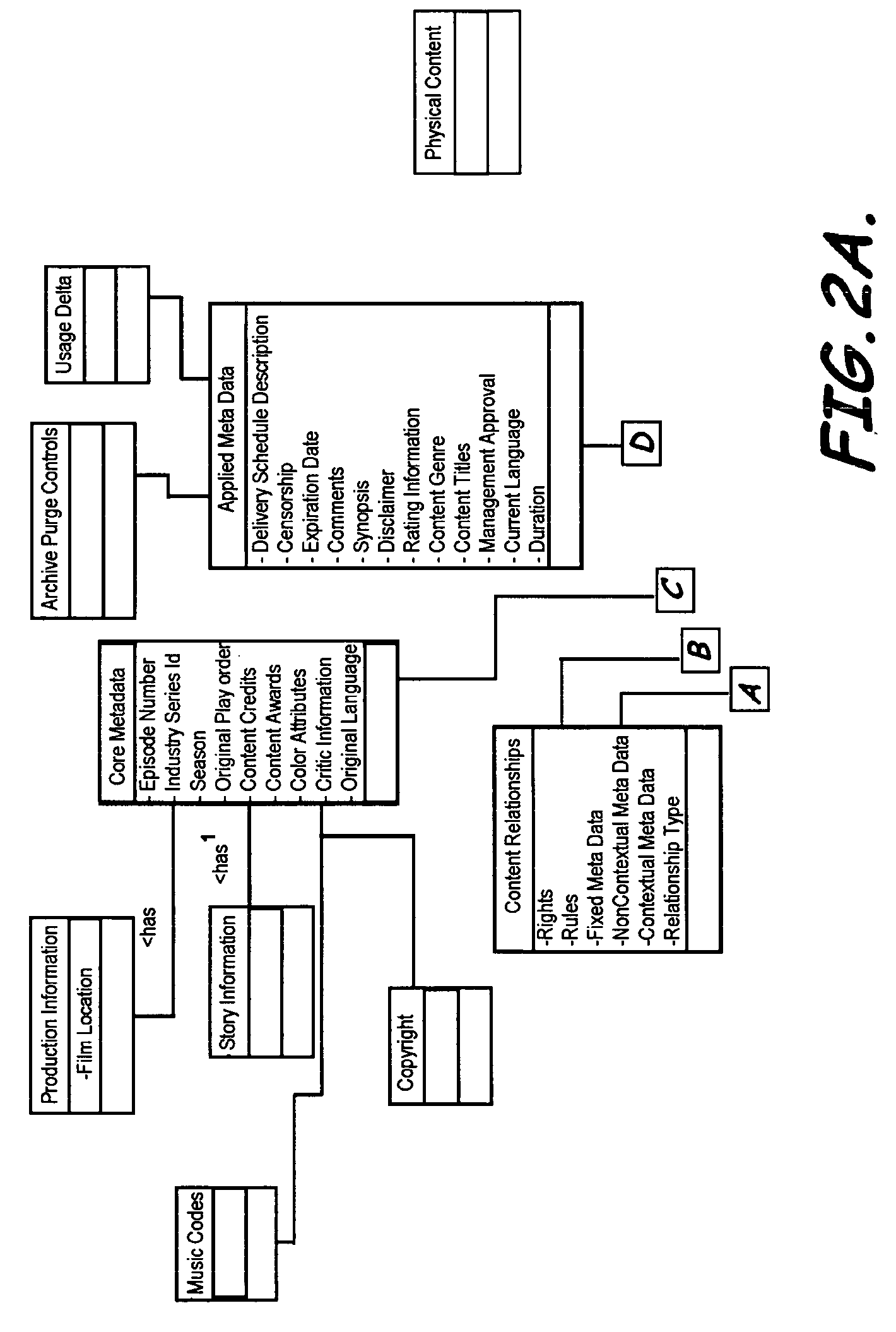

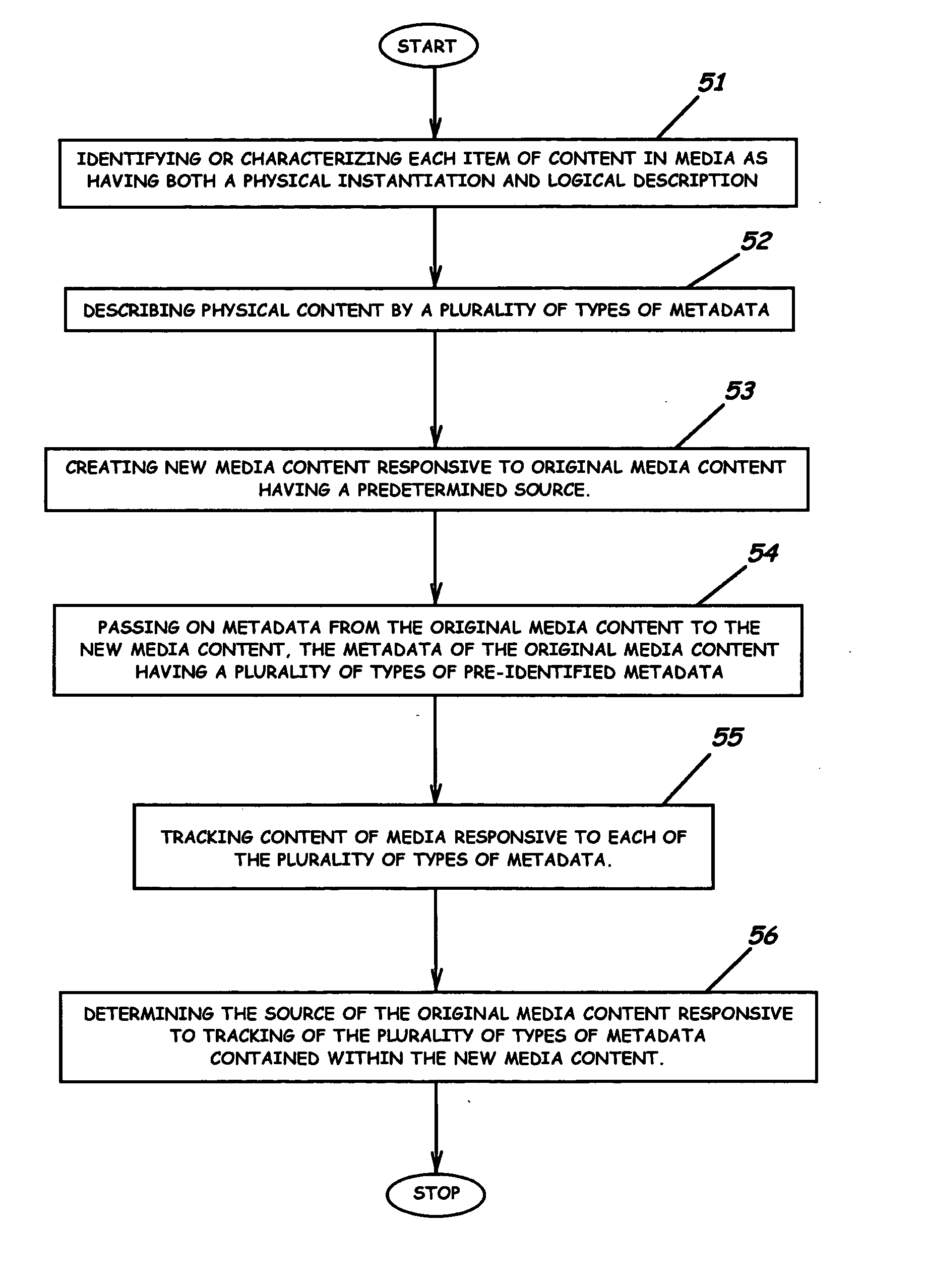

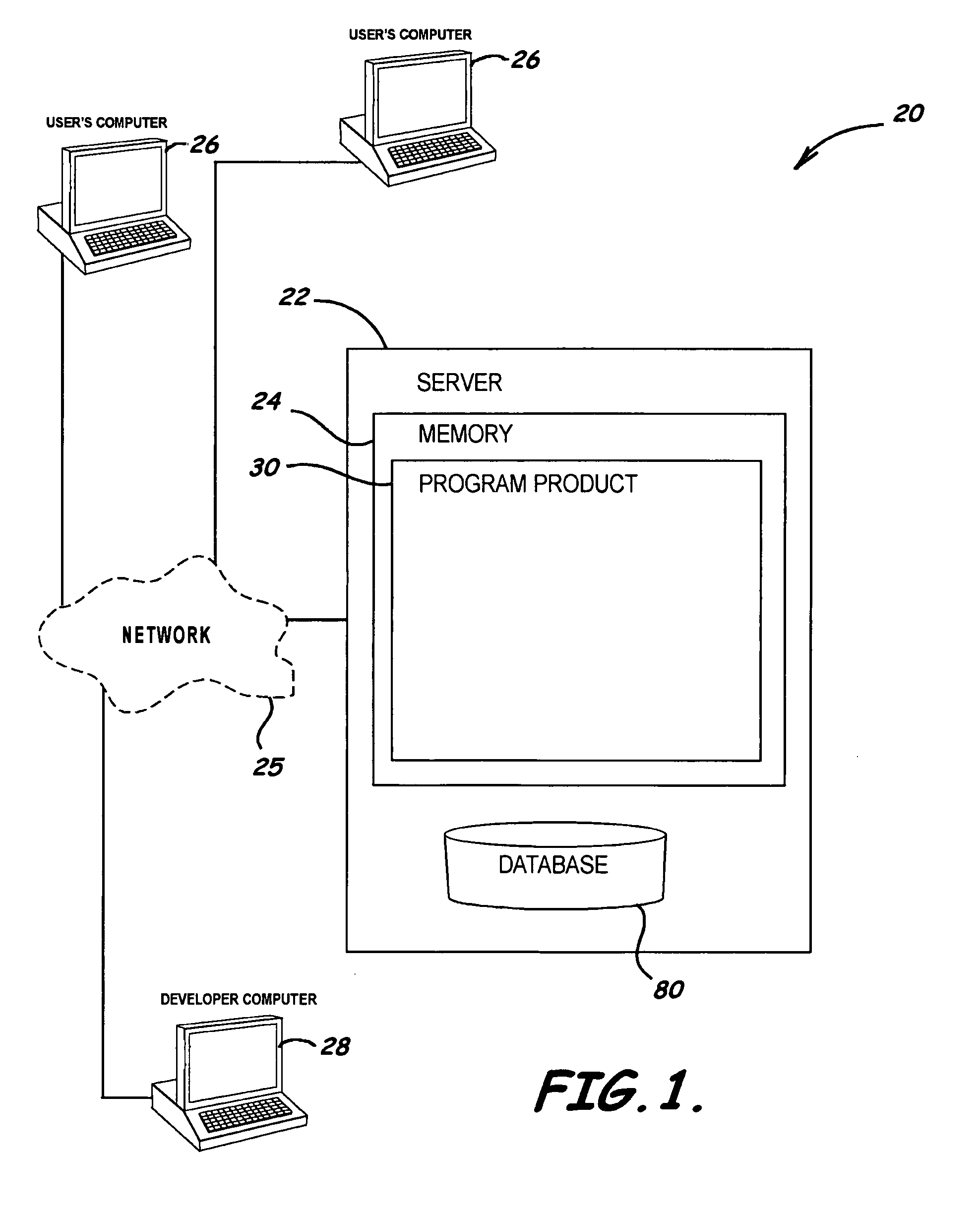

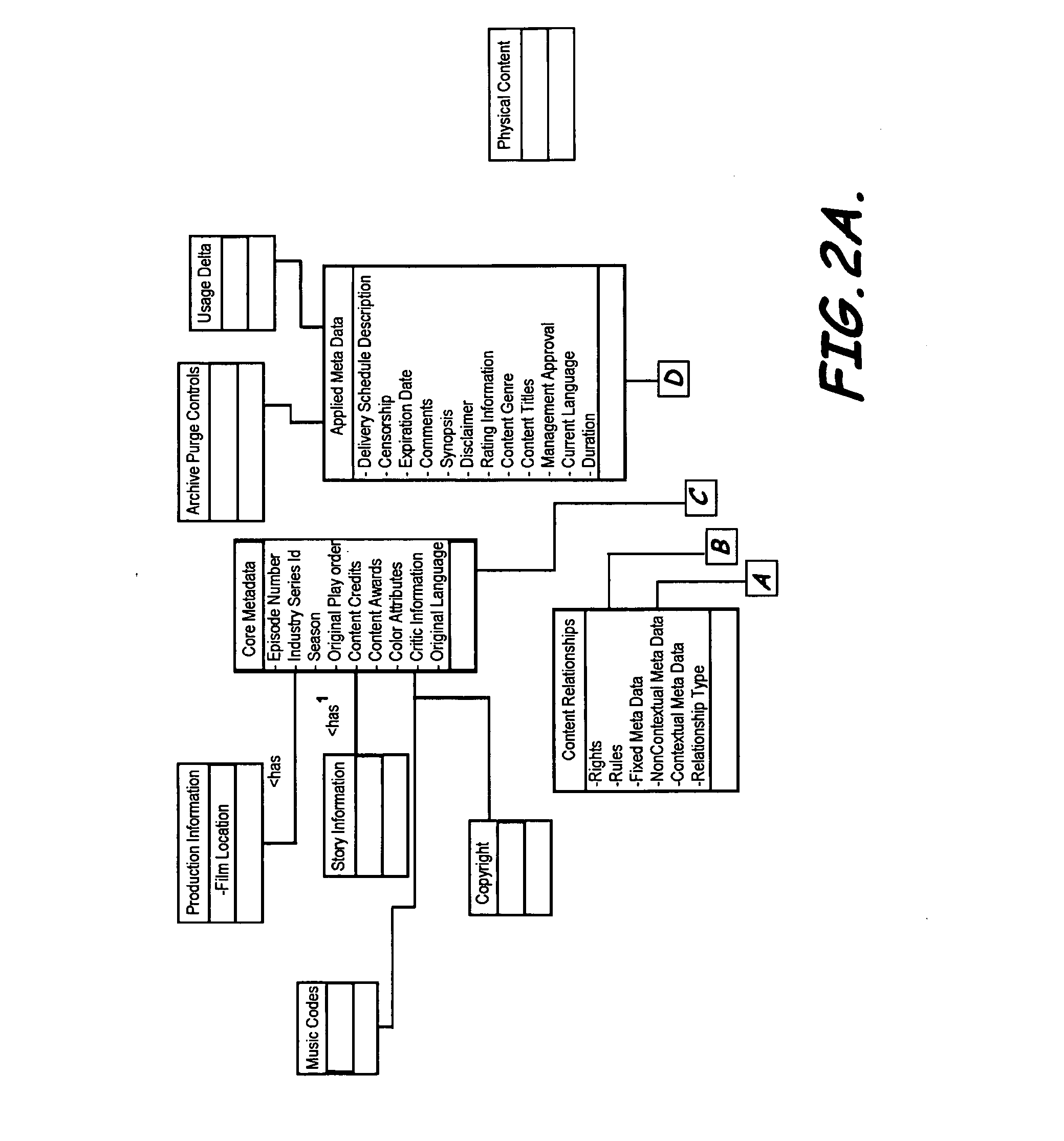

System, methods, and program product to trace content genealogy

ActiveUS20070050409A1Low costCreating new revenue opportunityDigital data processing detailsMetadata multimedia retrievalData recordingSystems approaches

Embodiments of systems, program products, and methods to manage content and distribution of media are provided. An embodiment of a system, for example, can include a communication network for transmitting media files, a content management server having a processor and memory coupled to the processor, a database accessible to the processor of the content management server and including media files associated with metadata records, a plurality of content management developer computers to provide content management developers with online access over the communication network to the media files and associated metadata records to thereby edit the metadata records, a plurality of user computers accessible to the communication network to provide the users with access to the media files over the communication network to thereby view and edit at least portions of respective metadata records. The system also includes content management program product stored in the memory of the content management server to manage content and distribution of media.

Owner:IMAGINE COMM

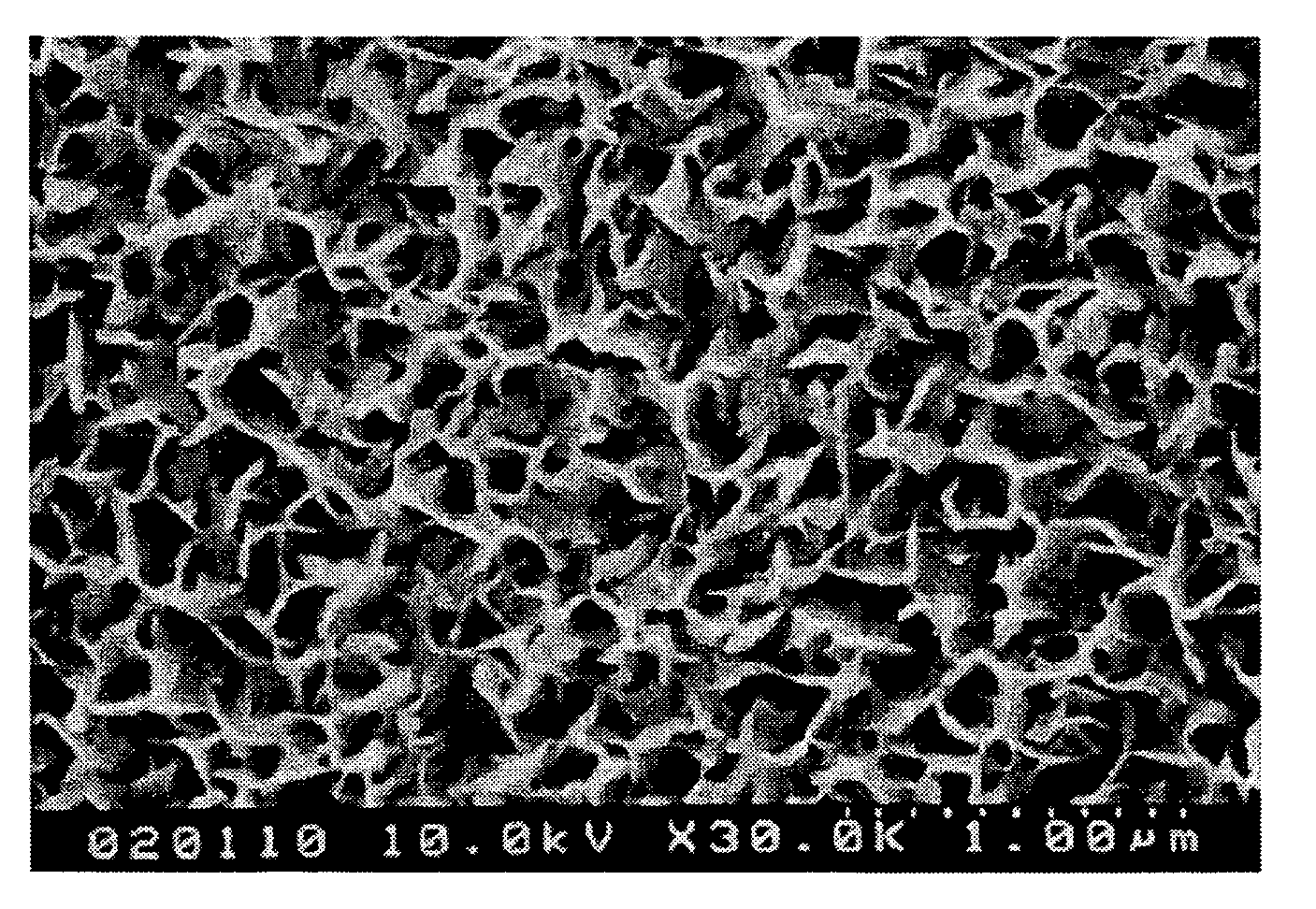

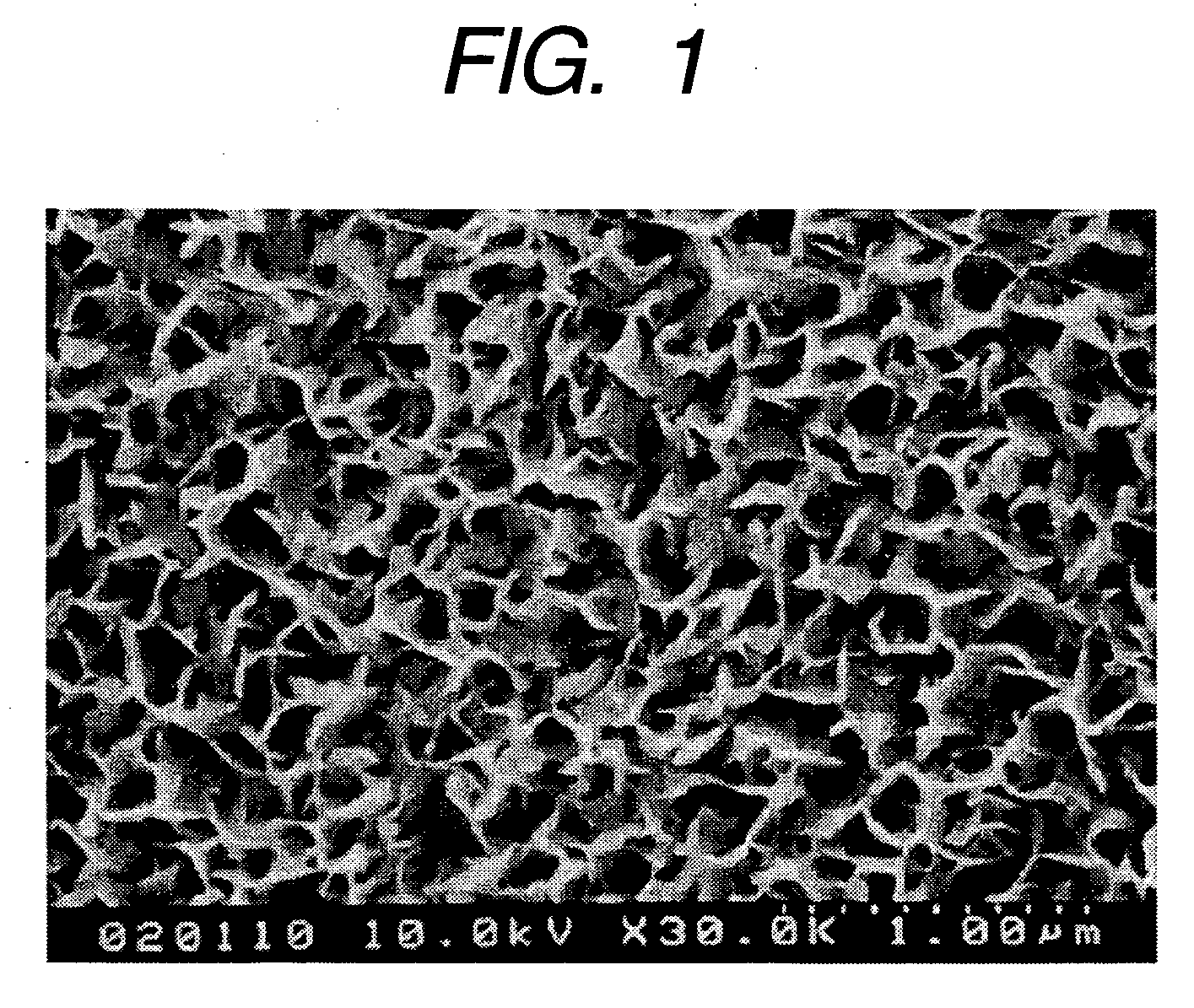

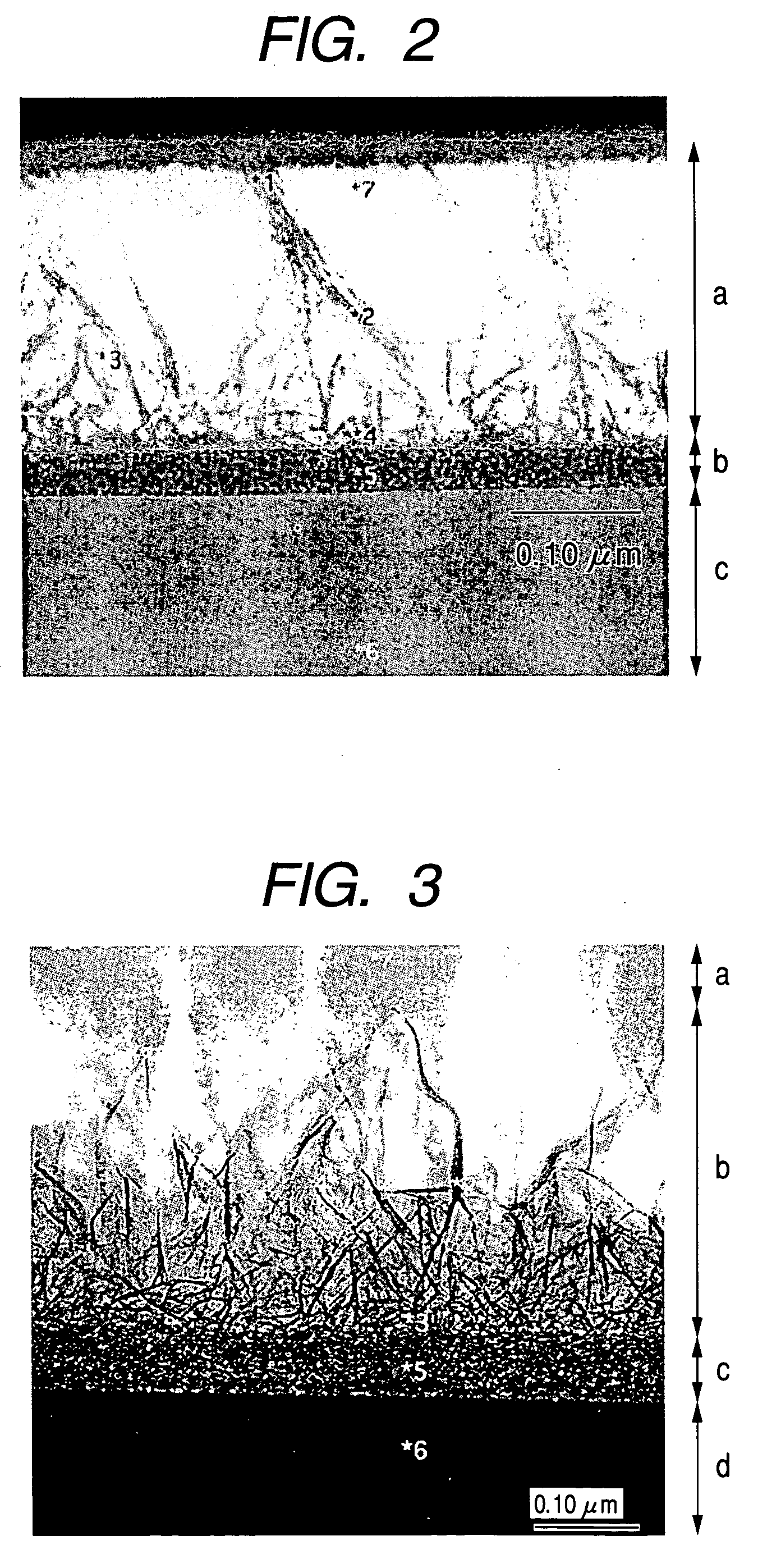

Film and antireflection film having fine irregularities on surface, production method for the same, and optical member using the same

InactiveUS20050233113A1Improve anti-reflection effectReduce reflectionDiffusing elementsLayered productsZirconia silicaZinc compounds

A transparent antireflection film, including fine irregularities mainly composed of alumina, and a transparent thin film layer supporting the fine irregularities, in which the transparent thin film layer contains at least one selected from the group consisting of zirconia, silica, titania, and zinc oxide. A production method for the aforementioned transparent antireflection film, including: forming a multicomponent film using an application liquid containing at least one compound selected from the group consisting of a zirconium compound, a silicon compound, a titanium compound, and a zinc compound, and at least an aluminum compound; and subjecting the multicomponent film to warm water treatment.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

Personal care composition

InactiveUS20060246027A1Good rinsing characteristicGood characteristicCosmetic preparationsHair cosmeticsPersonal careWater soluble

Stable personal care composition comprising hydrophobic modified silica, a particulate material and a dermatologically-acceptable carrier, said carrier comprising about 70% or greater, by weight of the carrier, of at least one water-soluble polyol, said water-soluble polyol having a solubility parameter of from about 11 to about 17.

Owner:TANNER PAUL ROBERT

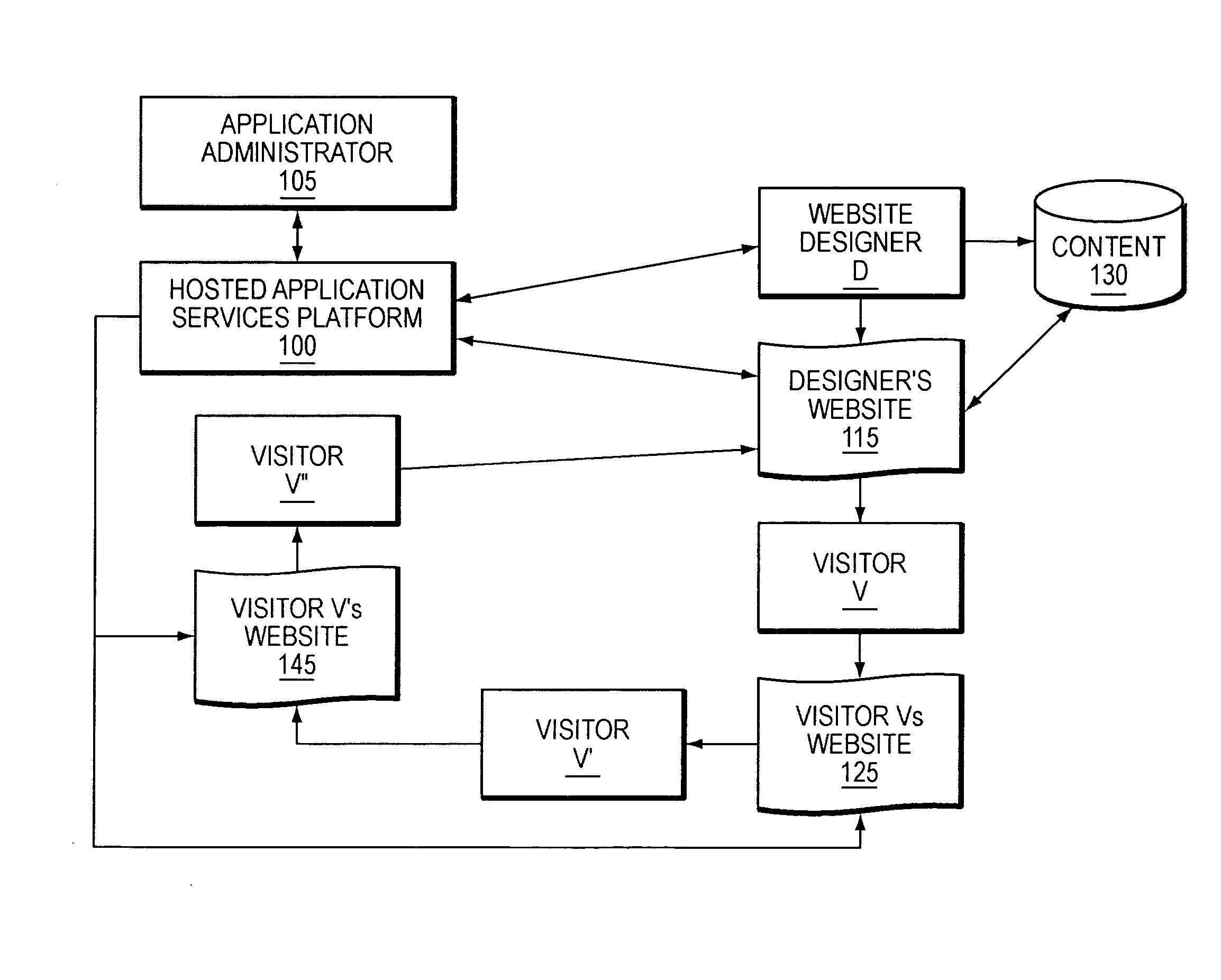

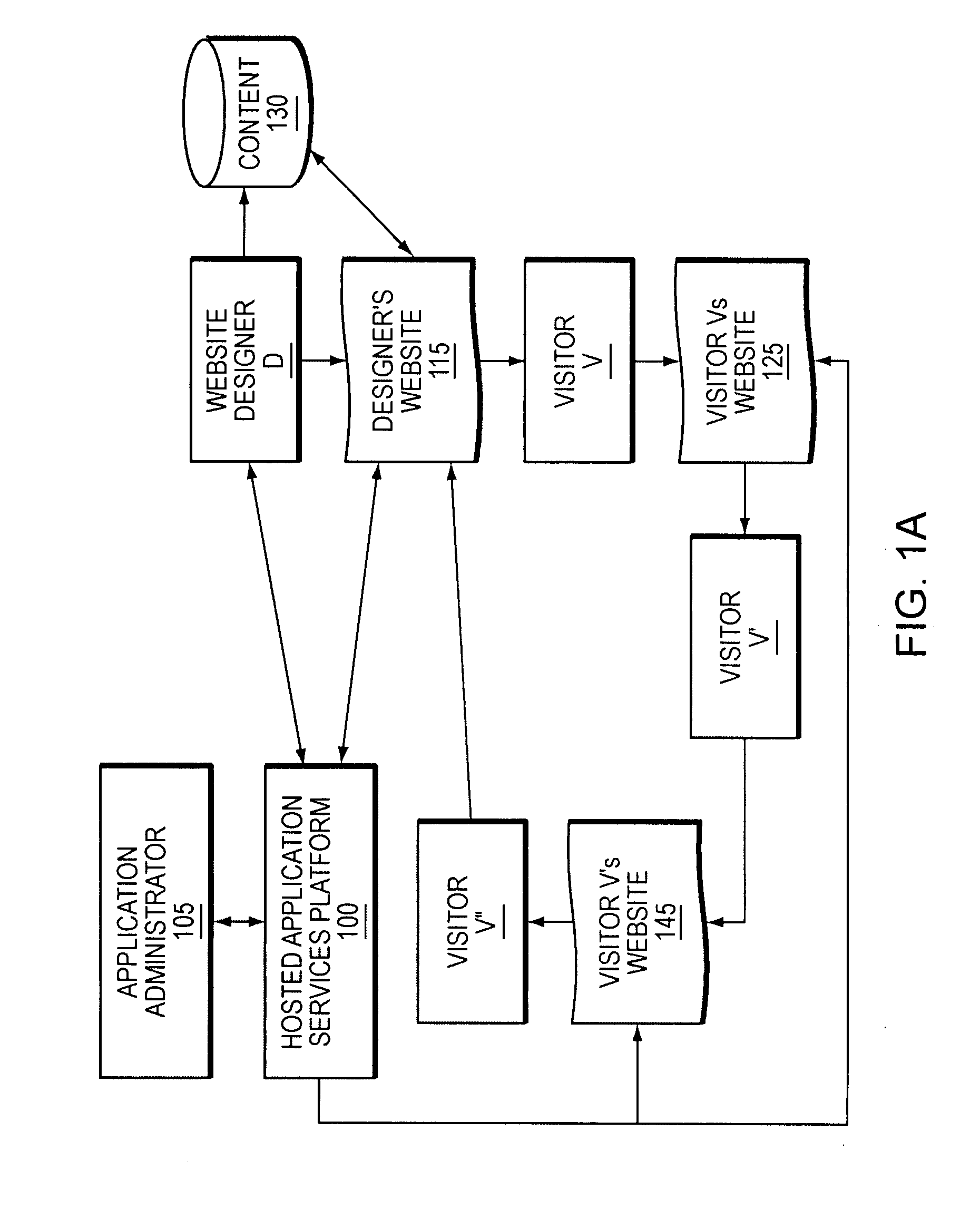

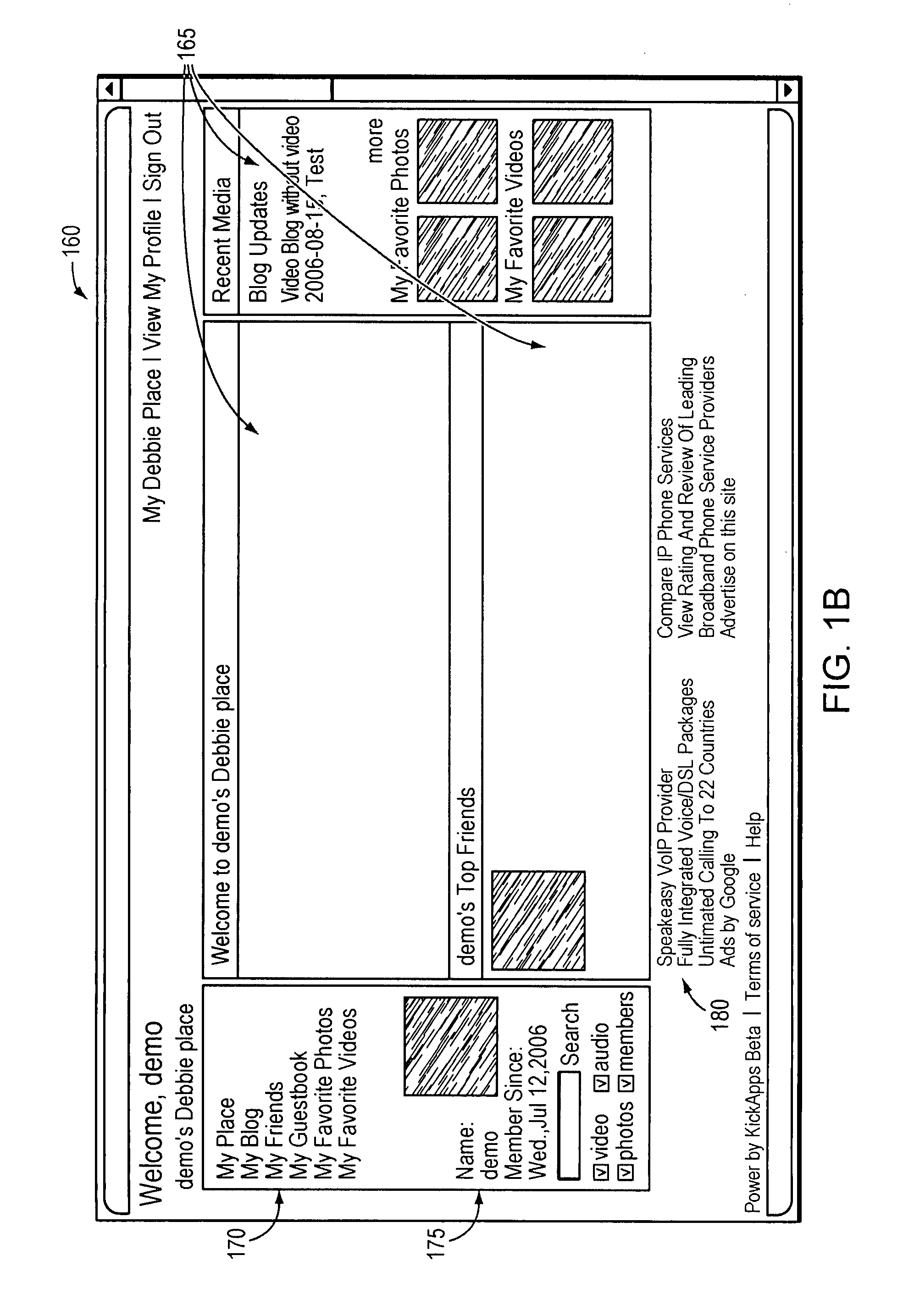

Method and Apparatus for Proliferating Adoption of Web Components

InactiveUS20080071883A1Facilitated DiffusionFacilitate viral proliferationMultiple digital computer combinationsExecution for user interfacesWeb siteWeb page

The invention provides a hosted application services platform and method its use that facilitates the proliferation of web-based components. The components include features, attributes and control objects that can be modified during design and after deployment. Instructions are provided that facilitate the expression of the features, attributes and control objects on web pages, and further allow for the copying of the components from website to website such that modifications to the features and / or attributes are automatically incorporated into the copied component whenever the component is expressed.

Owner:KICKAPPS

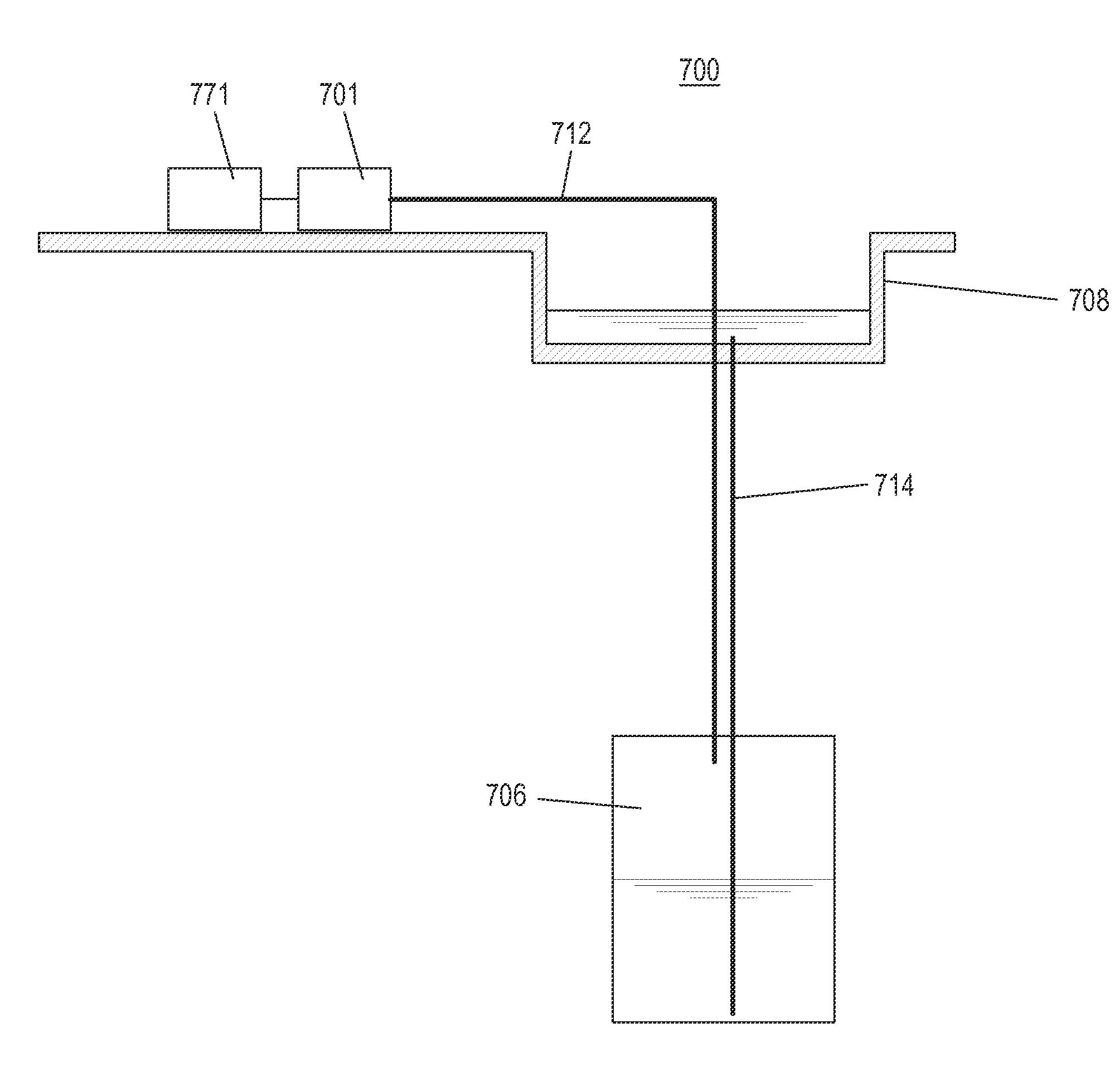

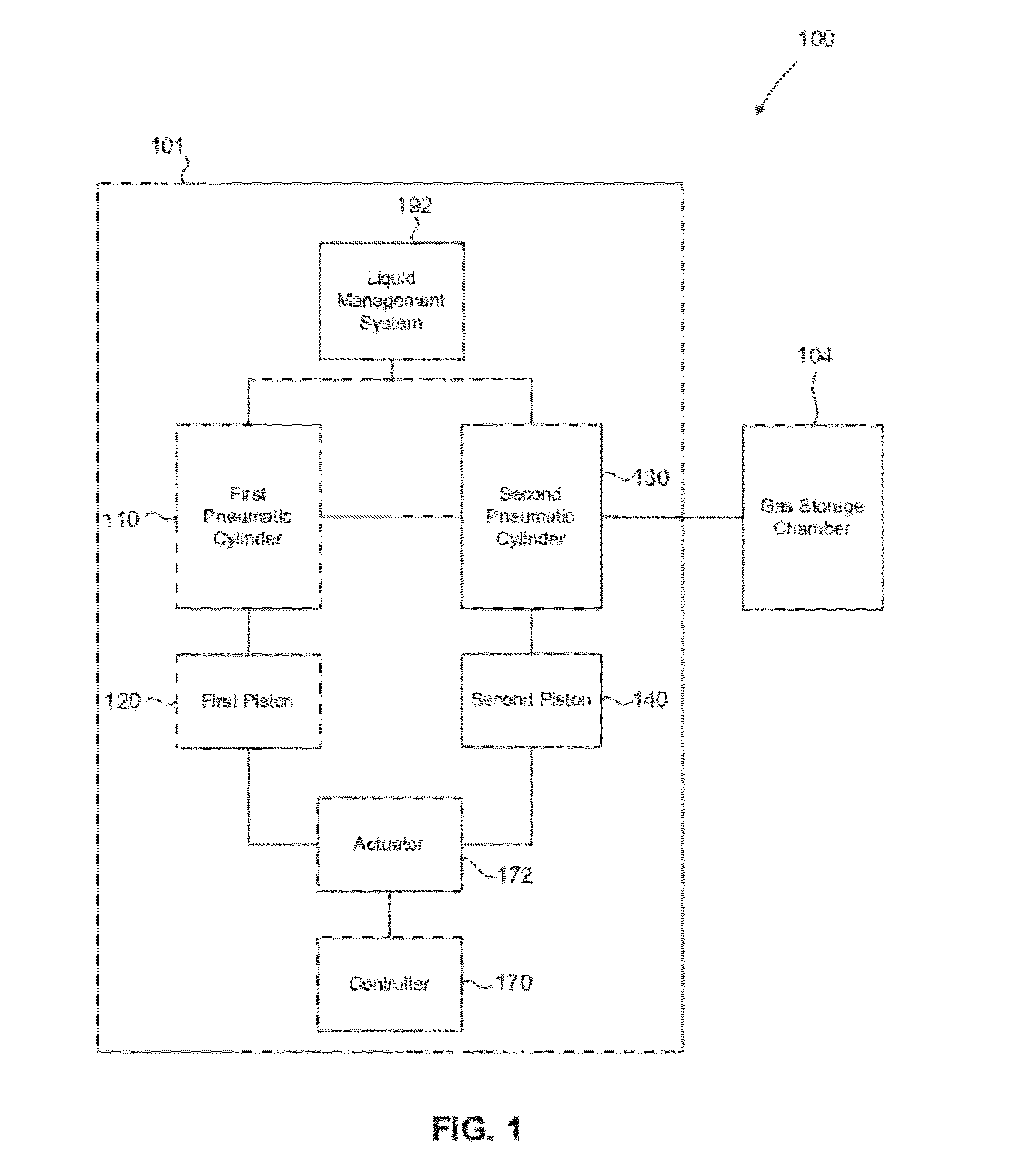

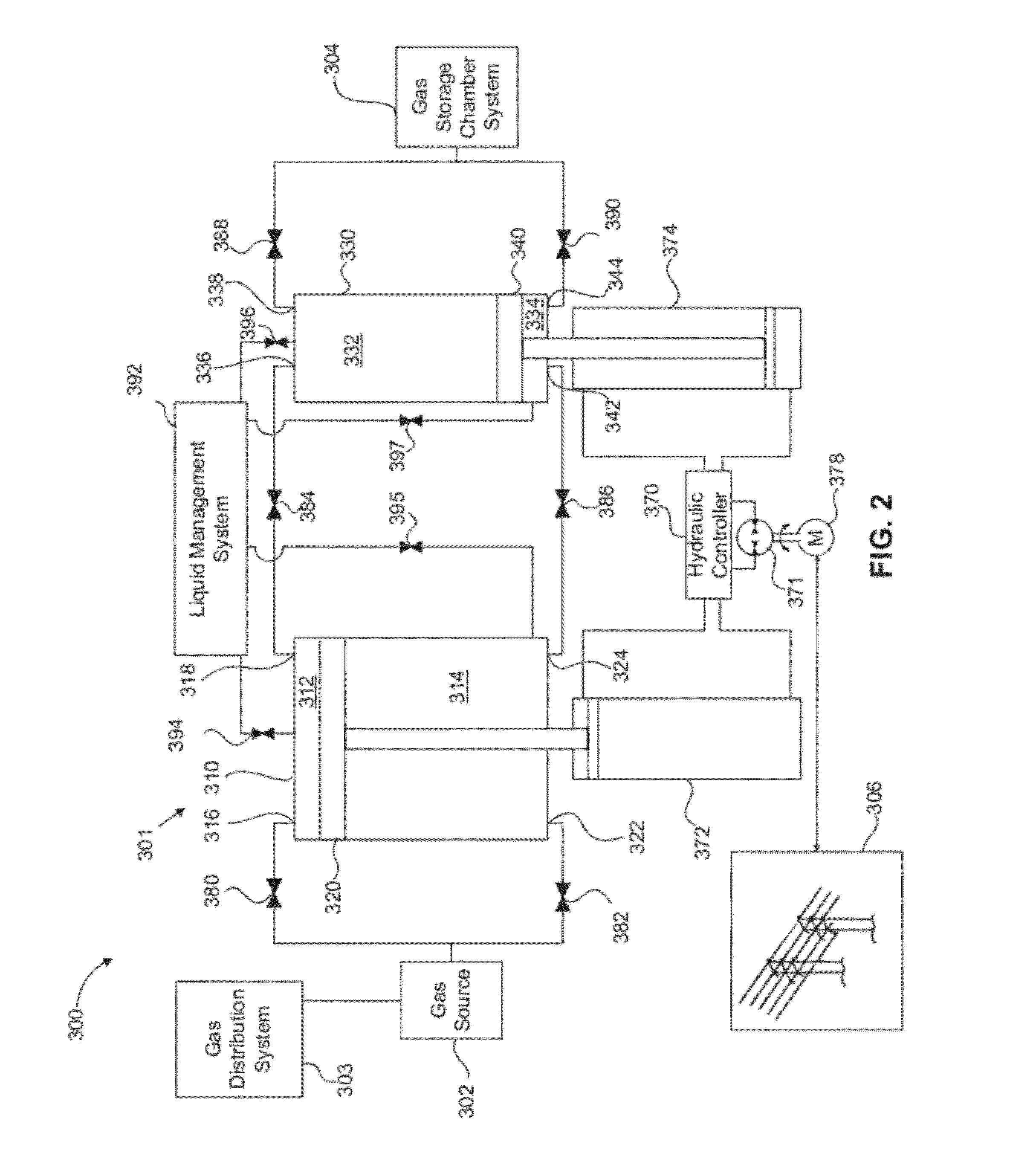

Compensated compressed gas storage systems

ActiveUS20120174569A1Optimize efficiencyEfficiently control temperature and water contentElectrical storage systemRotary clutchesPistonPneumatic cylinder

Systems, devices and methods for the compression, expansion, and / or storage of a gas are described herein. An apparatus suitable for use in a compressed gas-based energy storage and recovery system includes a pneumatic cylinder having a working piston disposed therein for reciprocating movement in the pneumatic cylinder, a hydraulic actuator coupled to the working piston, and a hydraulic controller fluidically coupleable to the hydraulic actuator. The apparatus is fluidically coupleable to a compressed gas storage chamber which includes a first storage chamber fluidically coupleable to the pneumatic chamber, and a second storage chamber is fluidically coupleable to the first storage chamber. The first storage chamber is disposed at a first elevation and is configured to contain a liquid and a gas. The second storage chamber is disposed at a second elevation greater than the first elevation, and is configured to contain a volume of liquid.

Owner:HYDROSTOR

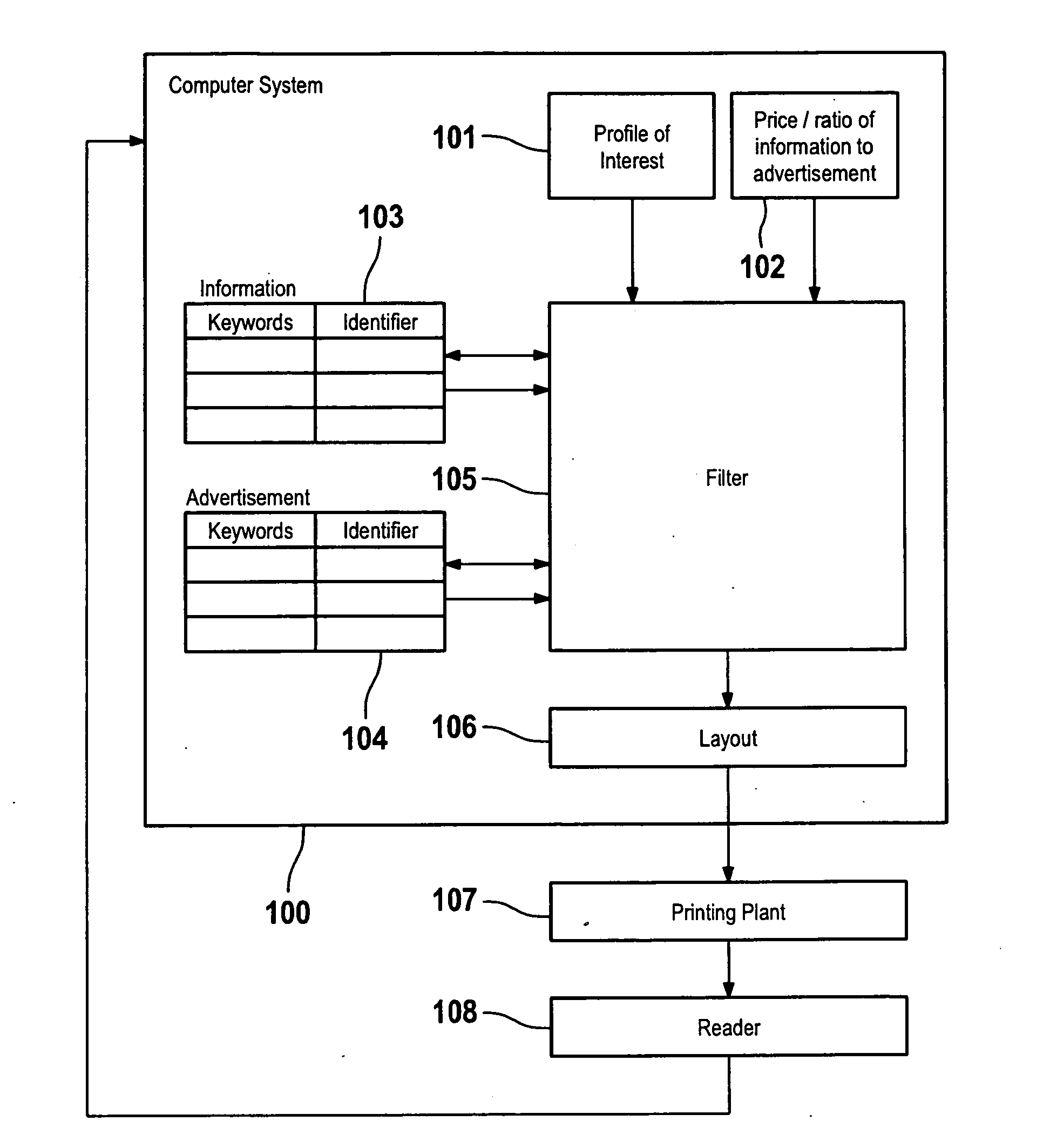

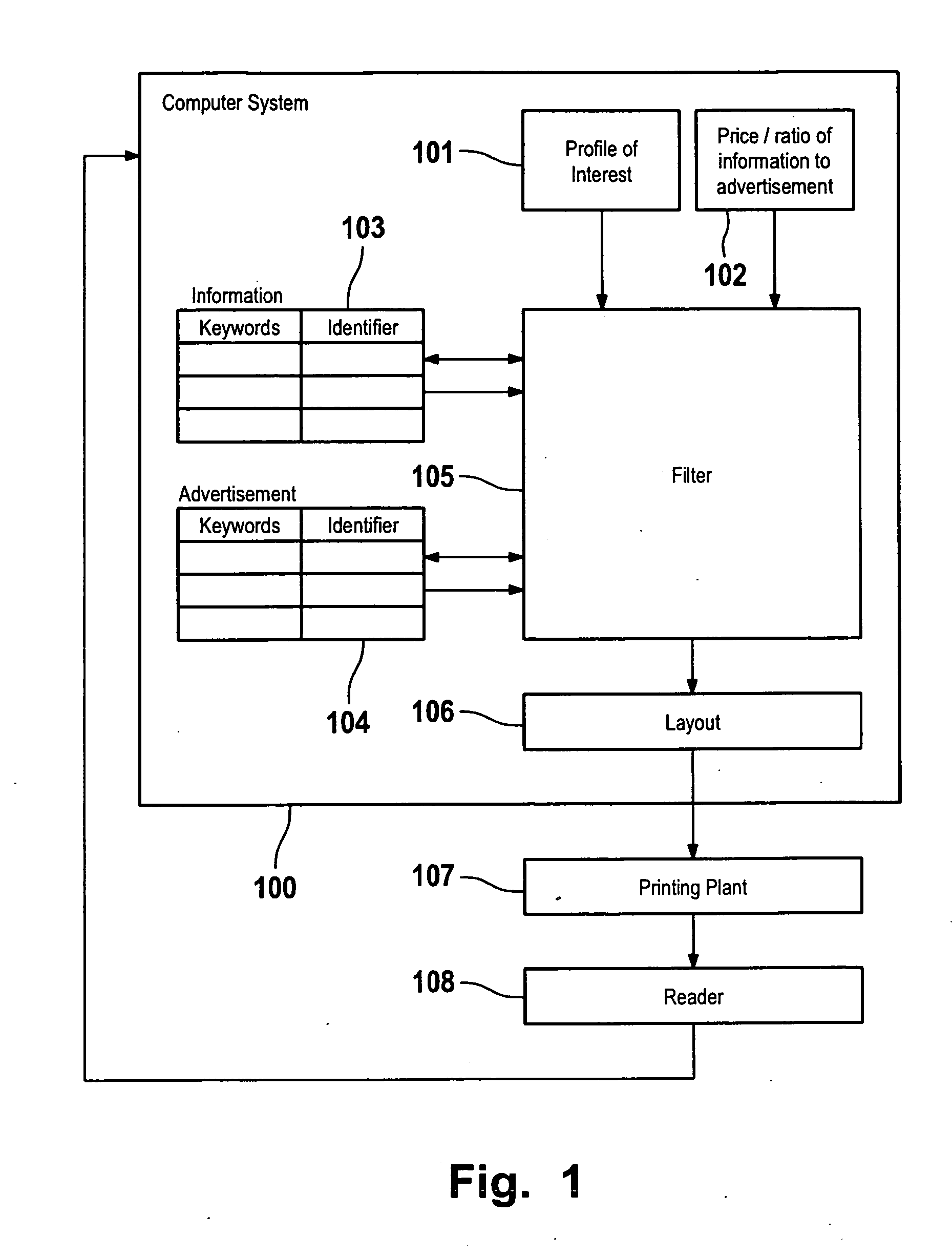

System and process for the production of a customer individualized print product

ActiveUS20050021404A1Avoid wastingLong-lasting protectionMarket predictionsSpecial data processing applicationsPaymentPrint media

A system and method for production of a printed product individualized for the customer, which offers the customer a selection of information content, depending on the variable payment (price) and the profile of interests thereof. Based on the price decision of the customer, a customer-specific relationship of optionally edited information content to customer-specific advertisement is generated. A dynamic matching of the profile of interests is carried out by feedback. The form of the printed product is determined by the selection of the information and the advertisements and the combination thereof according to the customer-specific relationship and profile of interests by means of an inventive layout. The printed product produced is suitable for traditional processing by print media, customer-specific in price, quality and quantity, achieves the interests of the advertisers with targeted advertising and the interests of the producers of the printed product with regard to achievable margins by providing a highly-attractive customer-specific product.

Owner:SCHODER DETLEF +1

System, methods, and program product to trace content genealogy

InactiveUS20070067427A1Low costCreating new revenue opportunityDigital computer detailsProgram/content distribution protectionData recordingSystems approaches

Embodiments of systems, program products, and methods to manage content and distribution of media are provided. An embodiment of a system, for example, can include a communication network for transmitting media files, a content management server having a processor and memory coupled to the processor, a database accessible to the processor of the content management server and including media files associated with metadata records, a plurality of content management developer computers to provide content management developers with online access over the communication network to the media files and associated metadata records to thereby edit the metadata records, a plurality of user computers accessible to the communication network to provide the users with access to the media files over the communication network to thereby view and edit at least portions of respective metadata records. The system also includes content management program product stored in the memory of the content management server to manage content and distribution of media.

Owner:IMAGINE COMM

Camellia facial soap

InactiveCN102517174AAvoid harmModerate glycerin contentCosmetic preparationsToilet preparationsWater bathsOil and grease

The invention relates to camellia facial soap, which belongs to the field of washing products. The camellia facial soap is mainly and technically characterized by comprising the following main raw materials: 24-32g of camellia oil, 12-15g of coconut oil, 12-15g of palm oil, 12-15g of sweet almond oil, 20-23g of deionized water, 9-11g of NaOH and 2-3g of floral essential oil. A preparation method for the camellia facial soap comprises the following steps of: (1) putting the raw materials in a water bath container and stirring and mixing into liquid mixed oil; (2) slowly and completely dissolving the NaOH by using the deionized water; (3) slowly adding the liquid mixed oil into NaOH solution and completely mixing the liquid mixed oil with the NaOH solution; (4) adding the essential oil, andevenly stirring; (5) pouring into a mould and standing for 24-48 hours; and (6) demoulding after liquid soap is solidified, and putting in a cool ventilated place for 4-8 weeks for use. The camellia facial soap manufactured by the preparation method disclosed by the invention has proper glycerol content and good molding performance, has a face cleaning effect, a face protection effect, a disinfecting effect and a sterilization effect, has low requirements on production conditions and is low in production cost.

Owner:郴州邦尔泰苏仙油脂有限公司

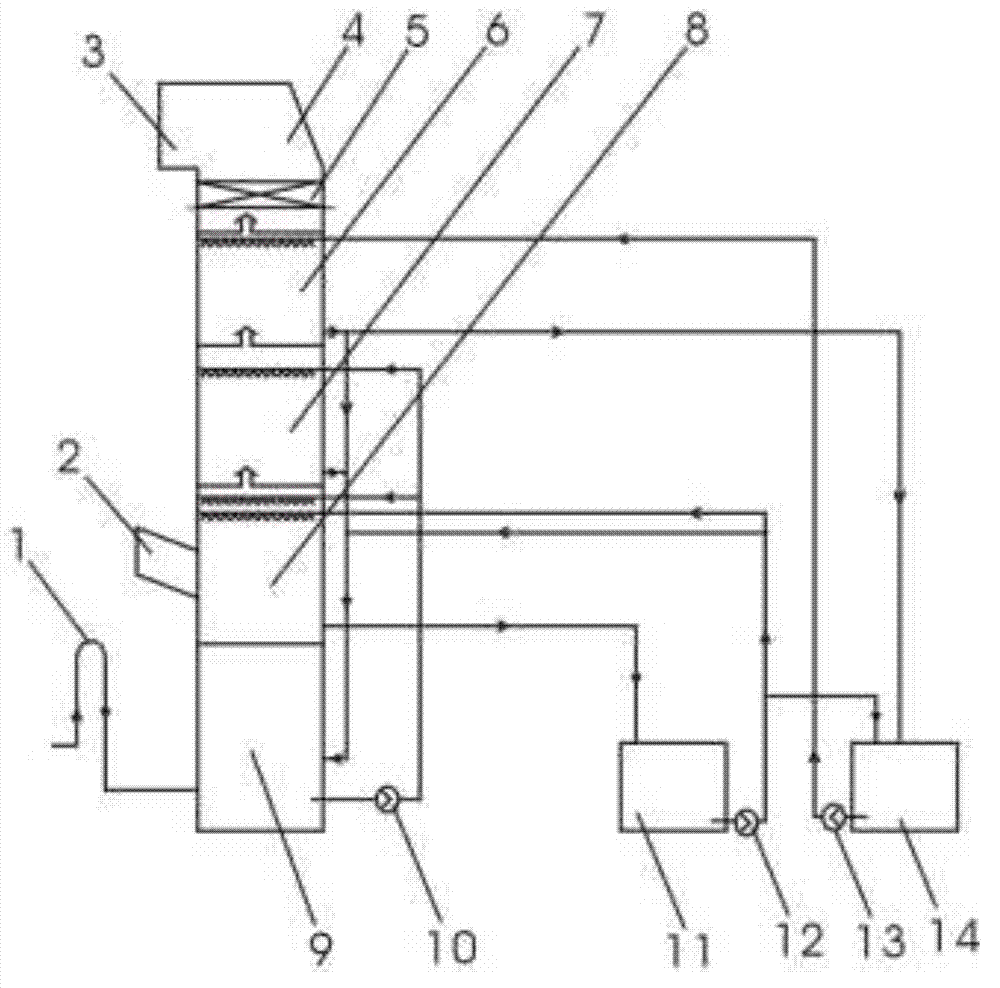

Ammonia escape prevention device in desulfurization and denitrification of flue gas by using ammonia process

ActiveCN103301736AReduce contentControl contentDispersed particle separationAir quality improvementFlue gasTower

The invention relates to an ammonia escape prevention device in desulfurization and denitrification of flue gas by using an ammonia process. The ammonia escape prevention device comprises an oxidized air and original flue gas inlet, a purified flue gas outlet, a desulfurization tower, a mist eliminator, an ammonia washing section, an absorption section, a concentration section, an oxidation section, a circulating ammonia washing pump and a circulating ammonia washing tank, wherein the concentration section is connected upwards to the absorption section, the absorption section is connected upwards to the ammonia washing section, the ammonia washing section is connected upwards to the mist eliminator, the mist eliminator is connected upwards to the desulfurization tower, the purified flue gas outlet is connected and formed in the desulfurization tower, the ammonia washing section is connected to the circulating ammonia washing tank through a pipeline, the circulating ammonia washing pump is arranged on the pipeline which is connected from the ammonia washing section to the circulating ammonia washing tank, the oxidation section is connected to the absorption section and the concentration section through pipelines, a primary circulating pump is arranged on the pipelines which is connected from the oxidation section to the absorption section and the concentration section, the ammonia washing section is connected to the circulating ammonia washing tank through the pipeline and meanwhile connected to the absorption section and the oxidation section through the pipelines, and one ammonia washing section is arranged in front of the mist eliminator. The ammonia escape prevention device is simple in overall structure, convenient to operate and use, good in stability and high in reliability.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

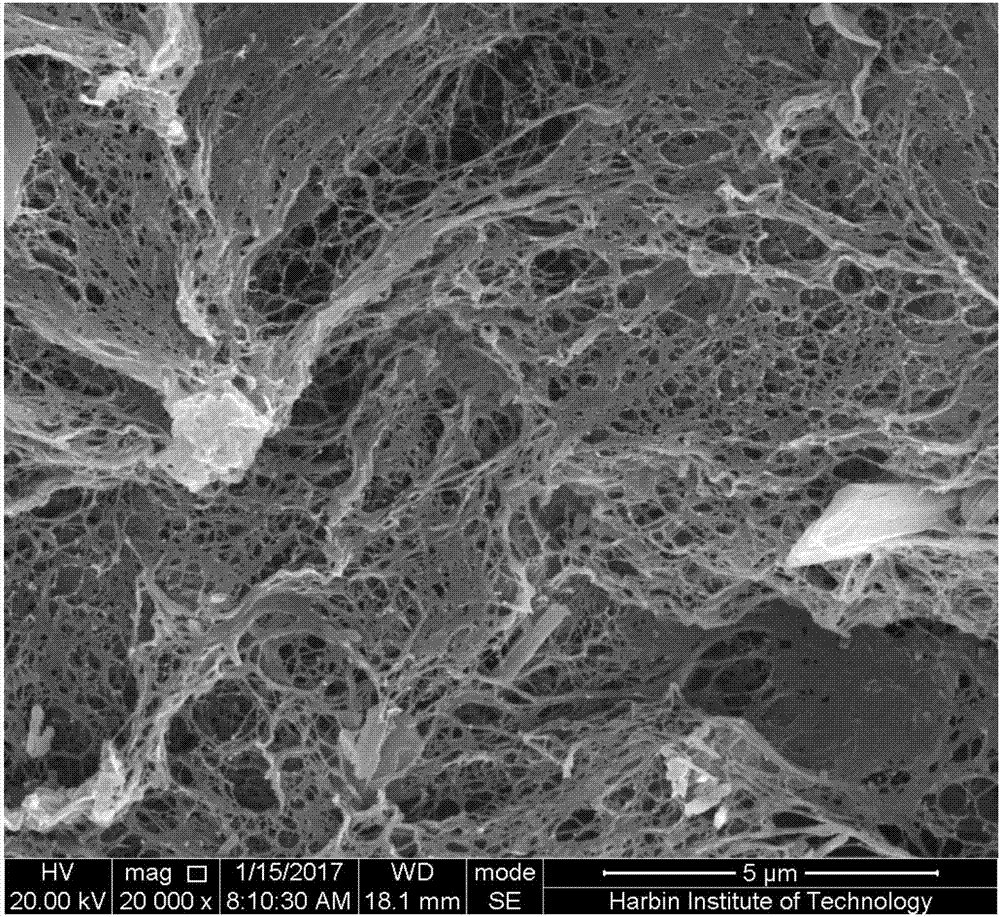

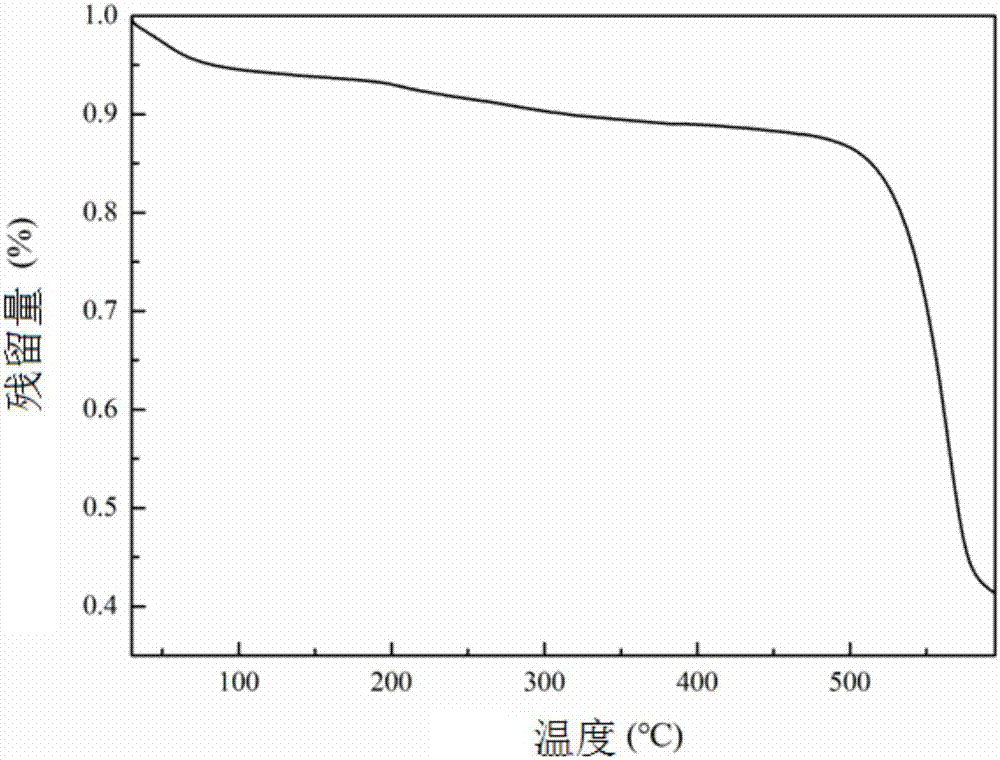

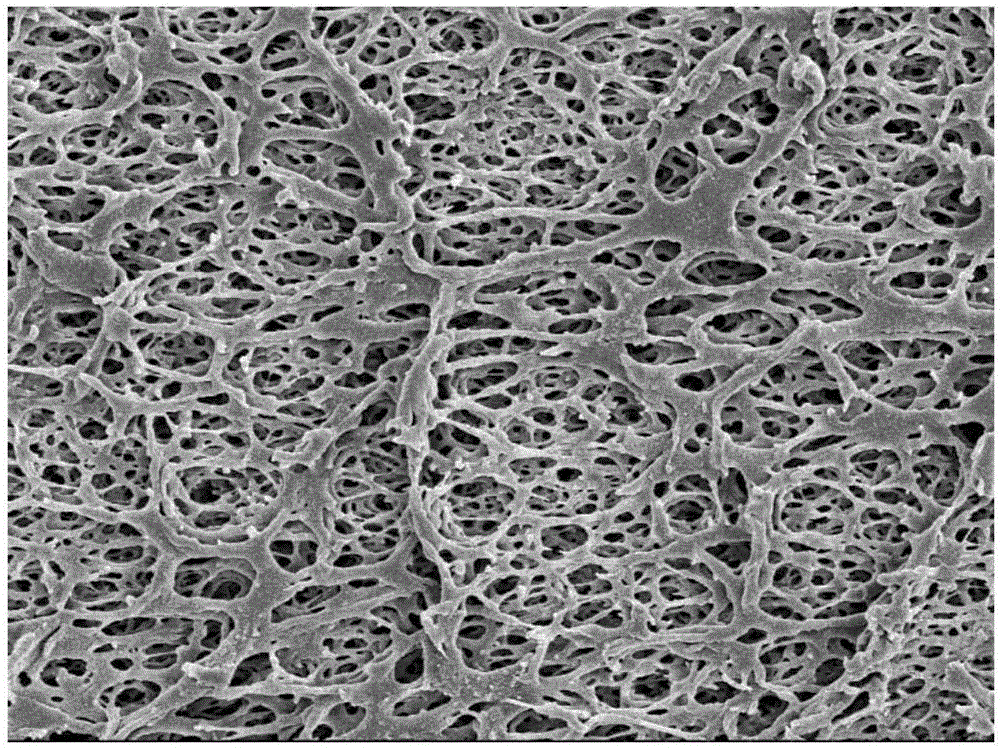

Preparation method of aramid fiber nanofiber aerogel

The invention relates to a preparation method of an aramid fiber nanofiber aerogel, in particular to a preparation method of the aerogel. The invention aims to solve the problems of poor mechanical strength and poor heat resistance of an existing aerogel. The preparation method comprises the steps of (1) extracting; (2) preparing a dark red aramid fiber nanofiber solution; (3) preparing an aramid fiber nanofiber hydrogel; (4) carrying out vacuum filtration and cleaning; (5) freeze drying to obtain the aramid fiber nanofiber aerogel. According to the aramid fiber nanofiber aerogel prepared through the preparation method provided by the invention, the temperature of primary thermal decomposition is 500 DEG C, so that the aramid fiber nanofiber aerogel can be used in a temperature interval ranging from 200 DEG C to 500 DEG C for a long time; the tensile strength of the aramid fiber nanofiber aerogel prepared through the preparation method provided by the invention reaches to 230 MPa. The invention discloses the preparation method of the aramid fiber nanofiber aerogel.

Owner:HARBIN INST OF TECH

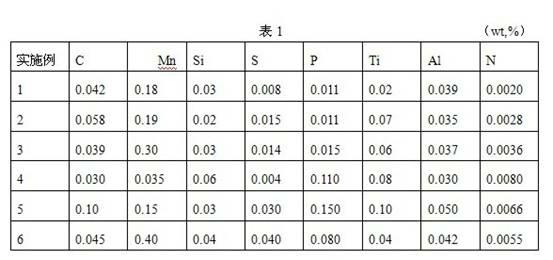

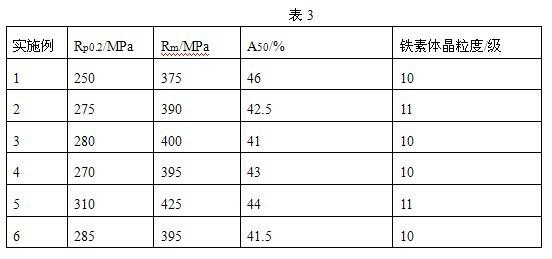

Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

ActiveCN102181805AStable recoveryExcellent anti-scale explosion performanceRoll mill control devicesMetal rolling arrangementsThin slabManganese

The invention relates to a steel plate and a process method thereof used for producing water heater linear enamel by a flexible thin slab rolling line (FTSR), belonging to the production field of enamel steel plates. The steel plate comprises the following chemical components in percentage by weight: 0.03-0.10wt% of carbon, 0.15-0.40wt% of manganese, less than or equal to 0.06wt% of silicon, 0.004-0.040wt% of sulphur, less than or equal to 0.15wt% of phosphorus, 0.03-0.05wt% of aluminum, 0.002-0.008wt% of nitrogen, 0.02-0.10wt% of titanium and the balance of ferrum and inevitable impurities. The tissue of the water heater linear enamel contains fine grain ferrite and a small quantity of pearlite tissues, and the granularity level of the water heater linear enamel is more than or equal to 10 levels. According to reasonable ingredient design and the FTSR process, steel for manufacturing water-storage water heater linear enamel for home appliances is produced; the steel plate has good enamel adhesion and scaling resistance, and also has the characteristics of few added alloy elements, few production working procedures, low production cost and the like; and a hot rolling scouring plate is used for replacing a cold rolling annealing plate.

Owner:HEBEI IRON AND STEEL

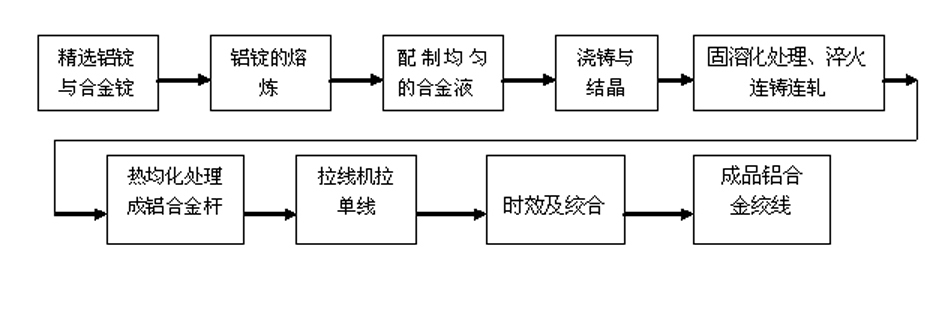

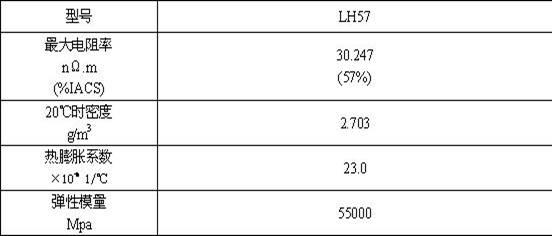

Method for manufacturing moderate intensity aluminium alloy wire with 57% electric conductivity

ActiveCN102041418AQuick checkControl contentSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthIngot

The invention provides a method for manufacturing a moderate intensity aluminium alloy wire with 57% electric conductivity, and relates to a method for manufacturing a moderate intensity aluminium alloy wire of which the electric conductivity reaches 57% (IACS), which comprises the following steps of: (1) selecting aluminum matrixes and aluminum moderate alloy ingots; (2) carrying out on-the-spot sample analysis and regulation; placing the selected aluminum ingots into a shaft furnace to be melted to obtain an aluminum liquid; and refining with a refining agent; (3) casting and crystallizing: enabling the aluminium alloy liquid in a tilting holding furnace to pass through a trough, and filtering with a ceramic filter plate, and adding a rear earth to ensure the rear earth content to be 0.05-0.15%; continuously casting in an aluminium alloy continuous casting machine to form the aluminium alloy ingots; and rolling the aluminium alloy ingots to obtain moderate intensity aluminium alloy rods by an aluminium alloy continuous mill; (4) solutionizing and quenching: carrying out homogenizing heat treatment on the aluminium alloy rods; and (5) drawing, ageing and twisting: drawing the aluminium alloy rods treated by the former process into the aluminium alloy wires with the required diameter on an aluminium alloy drawing machine, and twisting the aluminium alloy wires by using a frame-type wire twisting machine to manufacture the moderate intensity aluminium alloy wires with 57% electric conductivity in IACS.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

High-voltage charge type nonaqueous electrolyte secondary cell

ActiveUS20090181311A1Improve cycle performanceInhibit reduction in cycle propertyOrganic electrolyte cellsLi-accumulatorsNickel compoundsSolvent

The preservation performance of a nonaqueous electrolyte secondary cell charged to high potential is improved while the initial capacity and the cycle property of the cell are also improved. The nonaqueous electrolyte secondary cell includes: a positive electrode having lithium phosphate and a positive electrode active material containing lithium cobalt compound oxide and lithium manganese nickel compound oxide having a layer structure, the lithium cobalt compound oxide having at least zirconium and magnesium added in LiCoO2; a negative electrode having a negative electrode active material; and a nonaqueous electrolyte having a nonaqueous solvent and an electrolytic salt. The potential of the positive electrode is more than 4.3 V and 5.1 V or less based on lithium. The nonaqueous electrolyte contains vinylene carbonate as the nonaqueous solvent and, as the electrolytic salt, at least one of lithium bis(pentafluoroethane sulfonyl)imide and lithium bis(trifluoromethane sulfonyl)imide at 0.1 M or more and 0.5 M or less. The nonaqueous electrolyte contains 1,3-dioxane.

Owner:PANASONIC ENERGY CO LTD

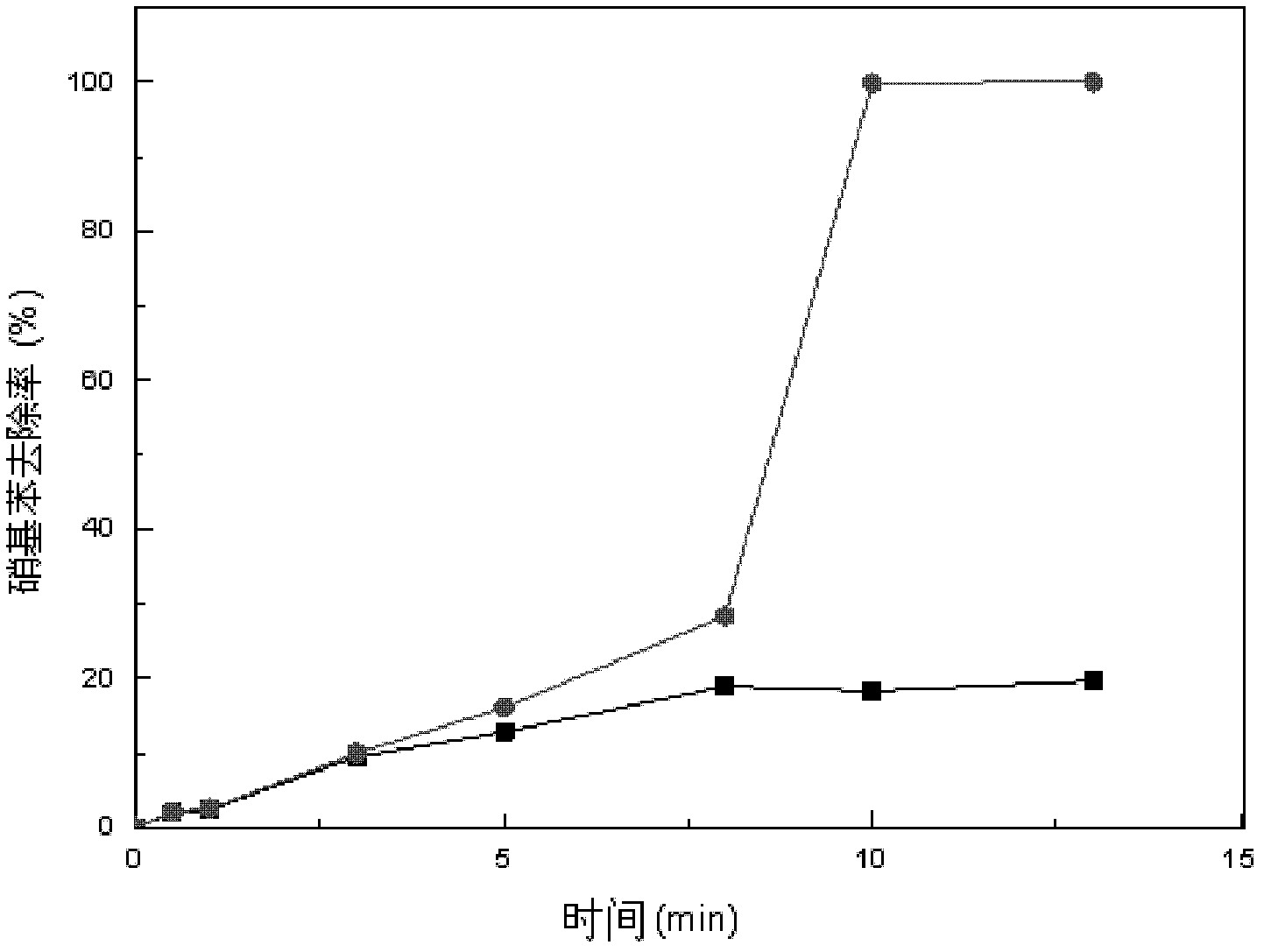

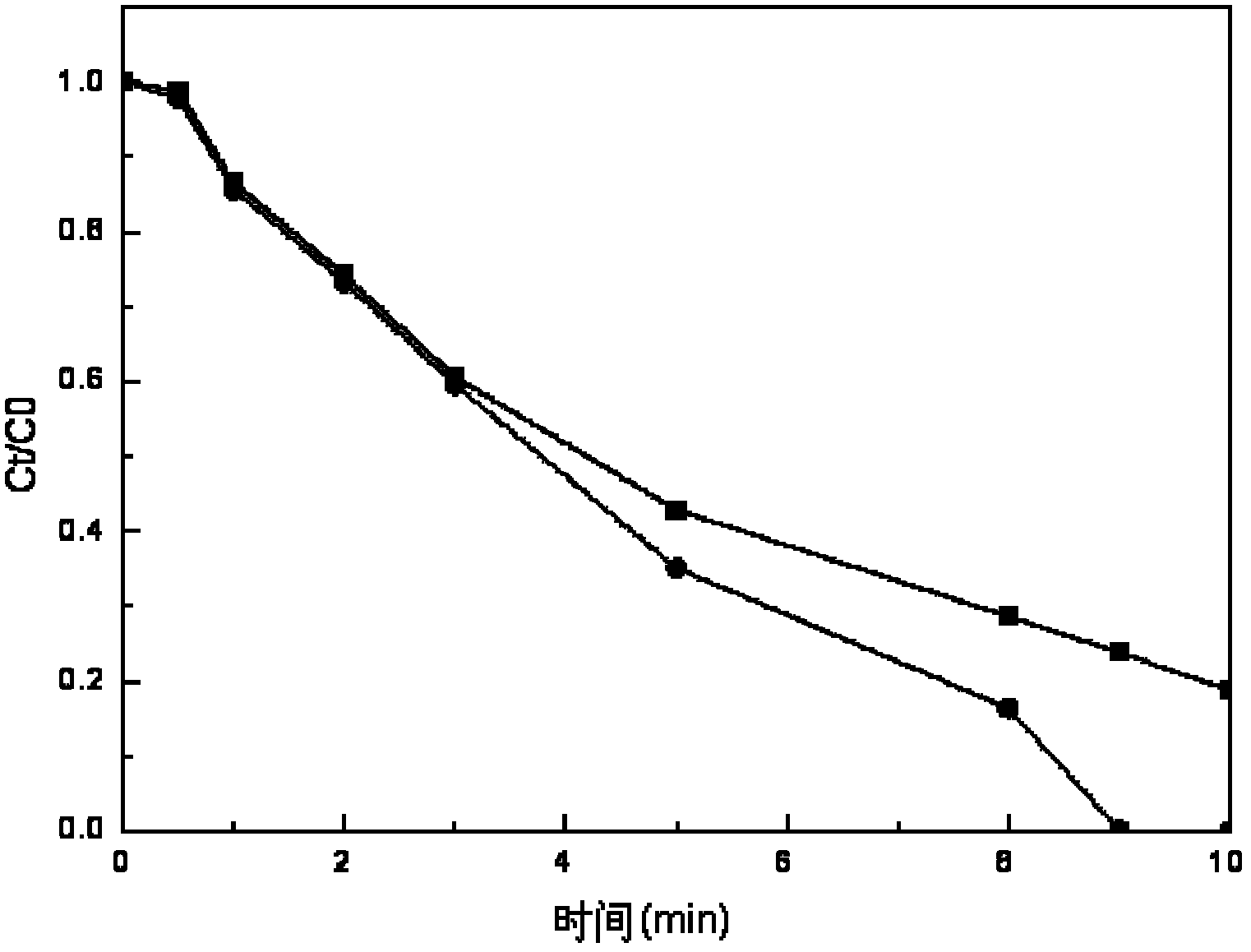

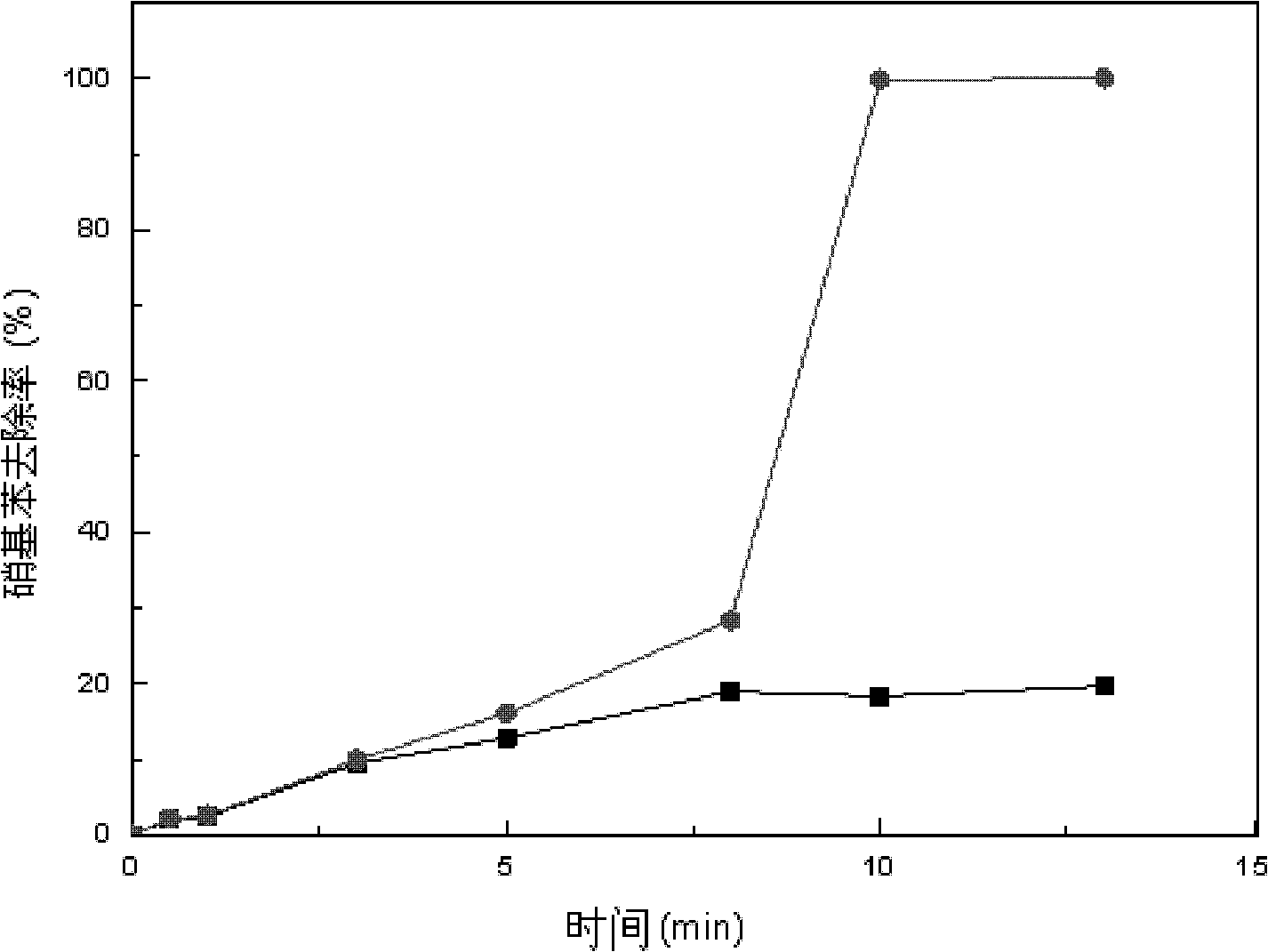

Gradient Ozone Catalytic Oxidation Method for Degrading Organic Pollutants in Water

ActiveCN102276095AAchieving Gradient OxidationControl contentMultistage water/sewage treatmentWater/sewage treatment by oxidationNitrosoCatalytic oxidation

The invention relates to a method for degrading organic pollutants in water by gradient ozone catalytic oxidation, and relates to a gradient ozone catalytic oxidation combination method for degrading organic pollutants in water. By the method, the problem that the conventional advanced oxidation technology has defects during individual use, the problem that the organic pollutants in the water cannot be removed efficiently, the problem that the influence of the pH value and temperature of the water on the method is large, and the problem that high-toxicity byproducts are formed are solved. In the method, water treatment is realized by combining two or three of a process for treating O3 individually, an enhanced catalytic oxidation process for O3 and an O3 / ultraviolet (UV) process sequentially. By the reasonable optimizing and gradient combination of the three treatment modes, the method is suitable for wide pH values and a wide temperature range, the pollutants with intermediate toxicity are controlled to be formed, the toxicity of the pollutants is reduced, the pollutants in the water is degraded efficiently and completely, and the content of oxidative species in effluent is controlled. An efficient oxidation treatment effect is kept at low temperature, and the generation of bromate, nitroso dimethylamine, chlorate, perchlorate, iodate and periodate can be controlled greatly.

Owner:哈尔滨工投环保产业有限公司

Preparation method of nano-silver alginate fiber

ActiveCN103147167ASmall particle sizeUniform particle size distributionAlginate artificial filamentsWet spinning methodsFiberBiocompatibility Testing

The invention discloses a preparation method of a nano-silver alginate fiber. The preparation method comprises the following steps of: preparing an alginic acid silver complex which is a precursor of nano-silver by using algal polysaccharides and soluble silver salts, and then preparing a sodium alginate based nano-silver colloid system through a chemical reduction method; then adding fiber-grade sodium alginate into the sodium alginate based nano-silver colloid system to obtain a nano-silver algae spinning solution; and finally, obtaining a nano-silver algae primary fiber through wet spinning, and carrying out stretching, sizing, drying and oiling treatments to obtain the nano-silver alginate fiber. The prepared nano-silver alginate fiber integrates the excellent performances of the nano-silver and the alginate fiber, so that the novel fiber has excellent flame retardance, biocompatibility, moisture absorption permeability and the like, also has excellent antimicrobial performance, antistatic performance and irradiation resistance and can be widely used in medical treatment, the fire-fighting field, the military field, the aerospace field, the health textile field and the like.

Owner:QINGDAO UNIV

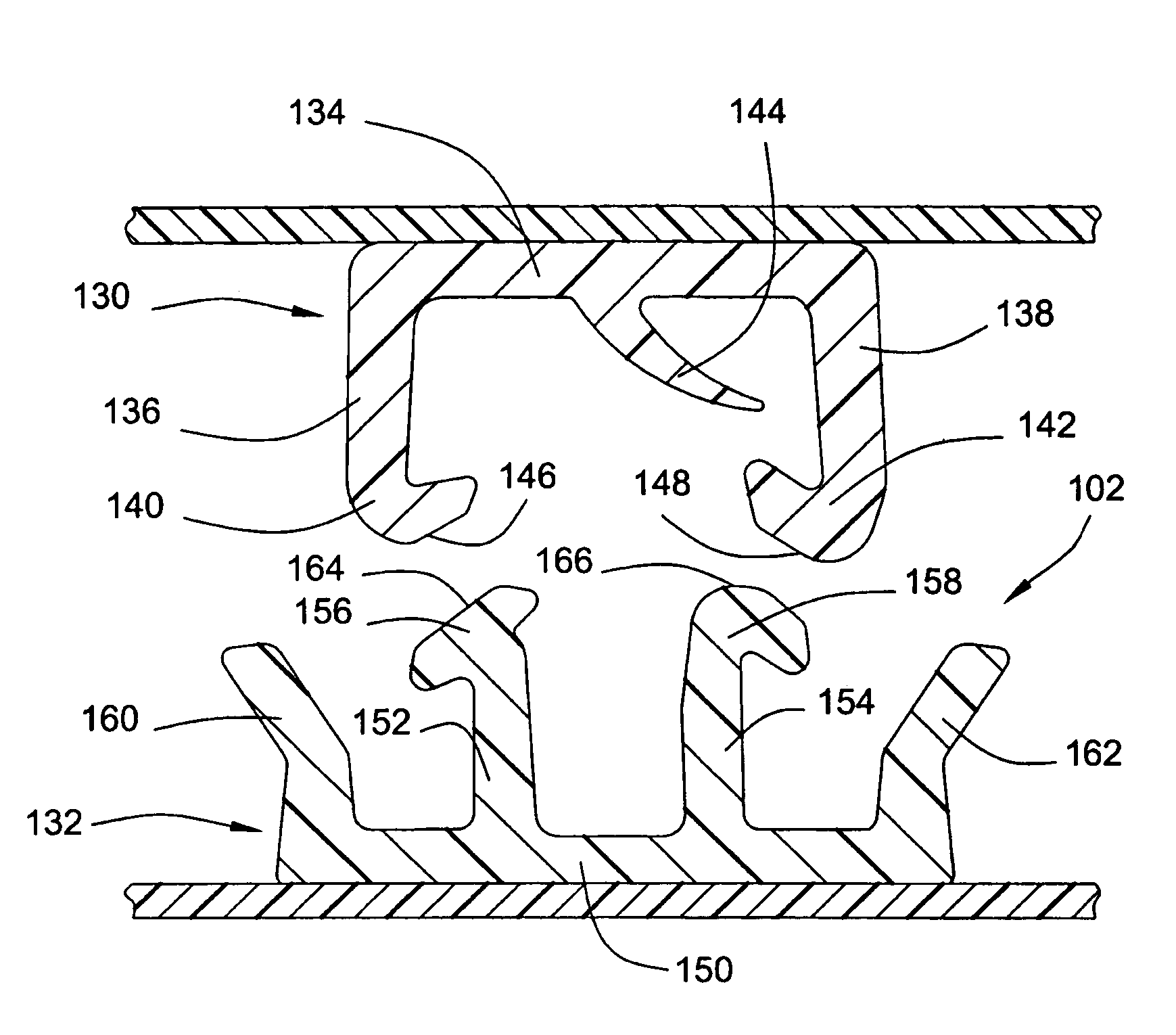

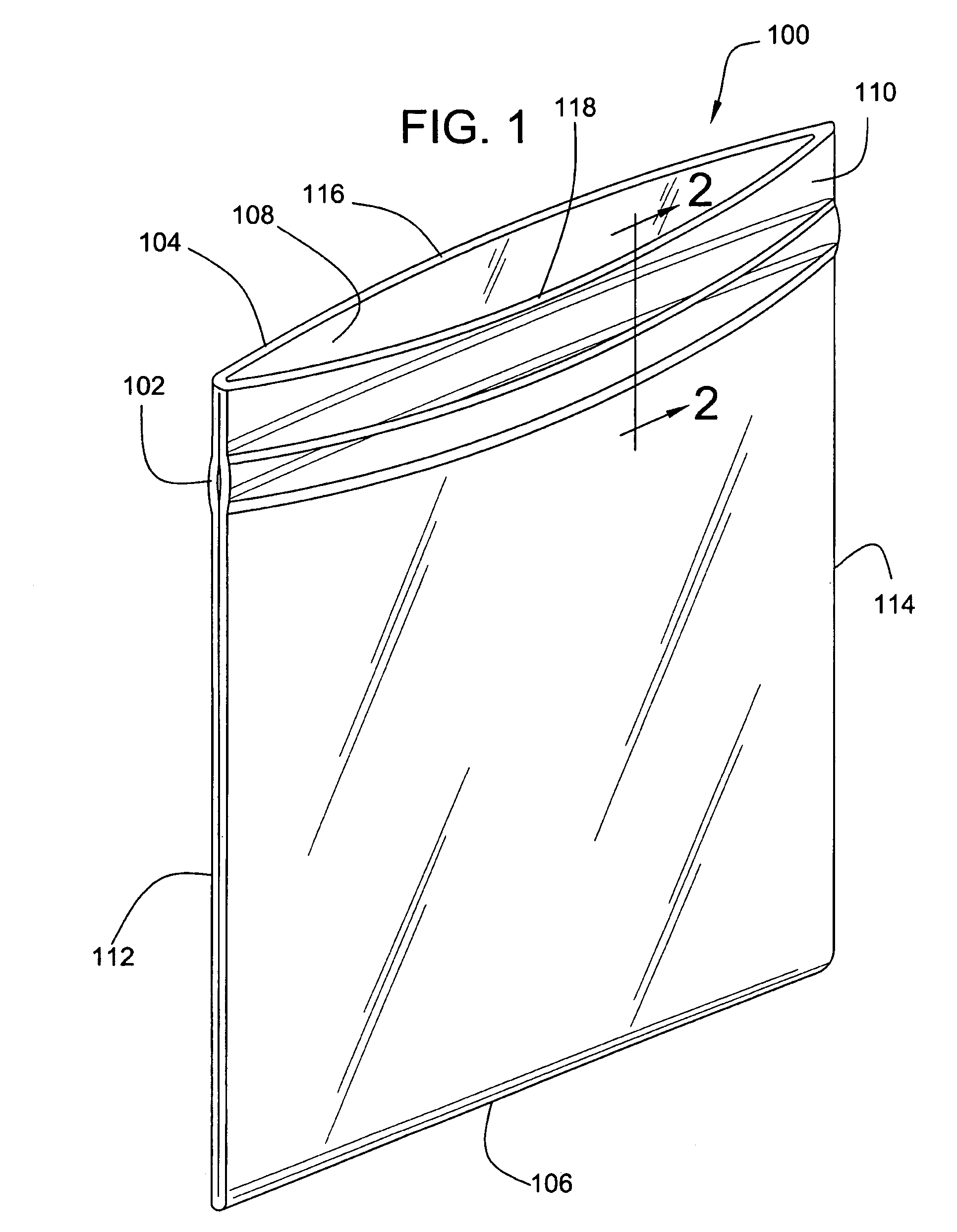

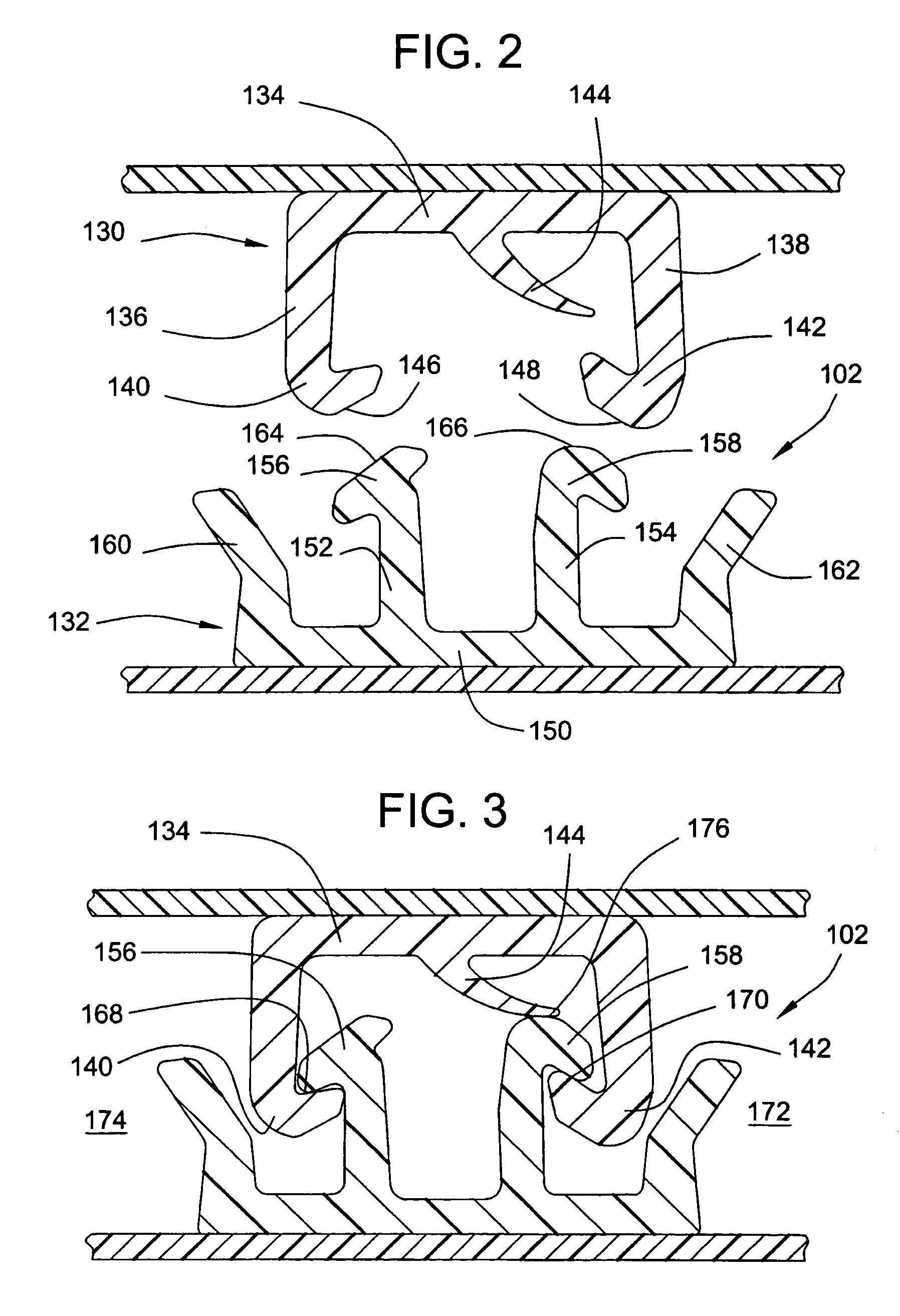

Leak proof closure device with spring member

InactiveUS7322747B2Facilitate interlocking engagementImprove sealingSnap fastenersSlide fastenersEngineeringMechanical engineering

Owner:THE GLAD PROD CO

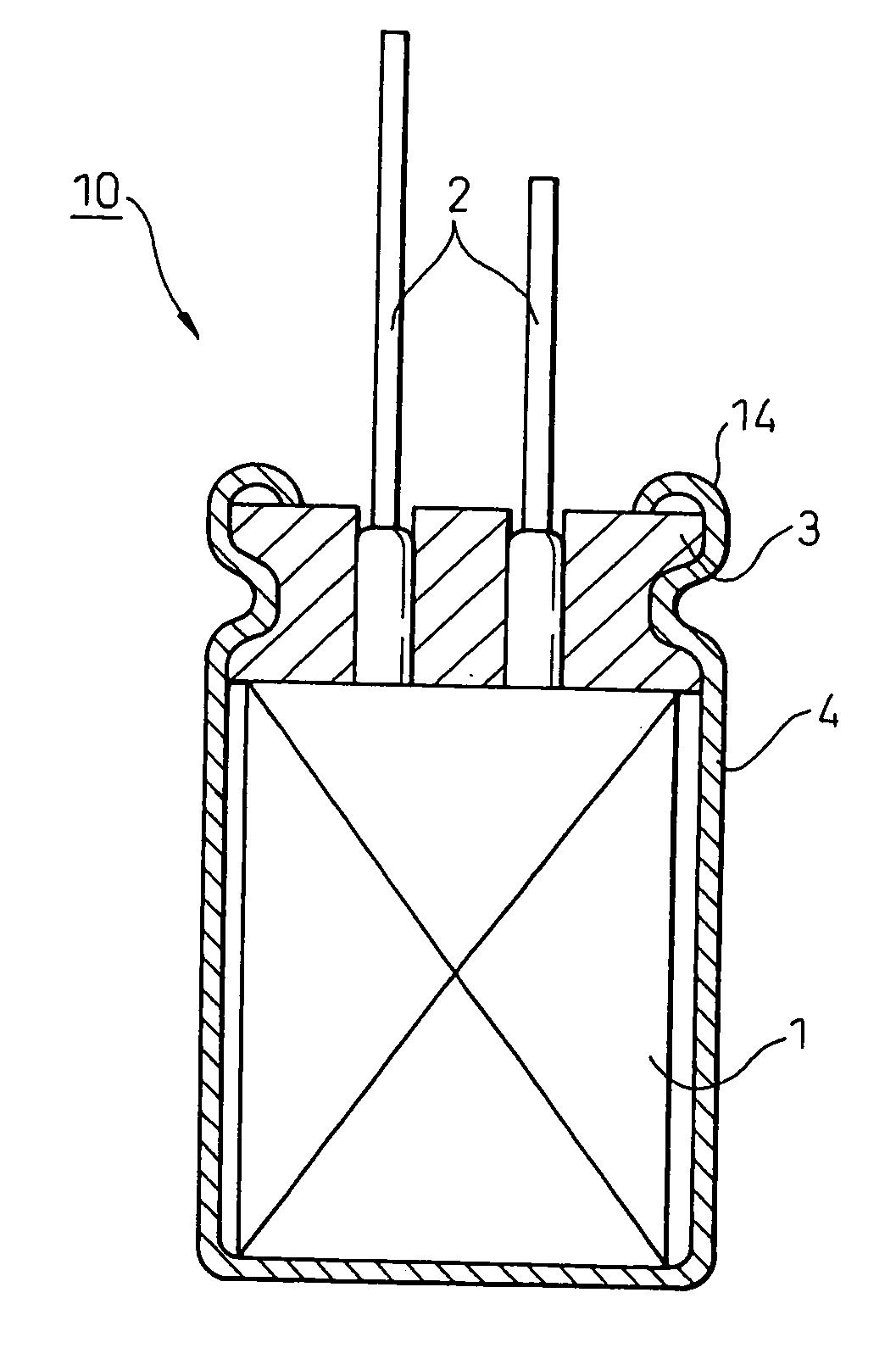

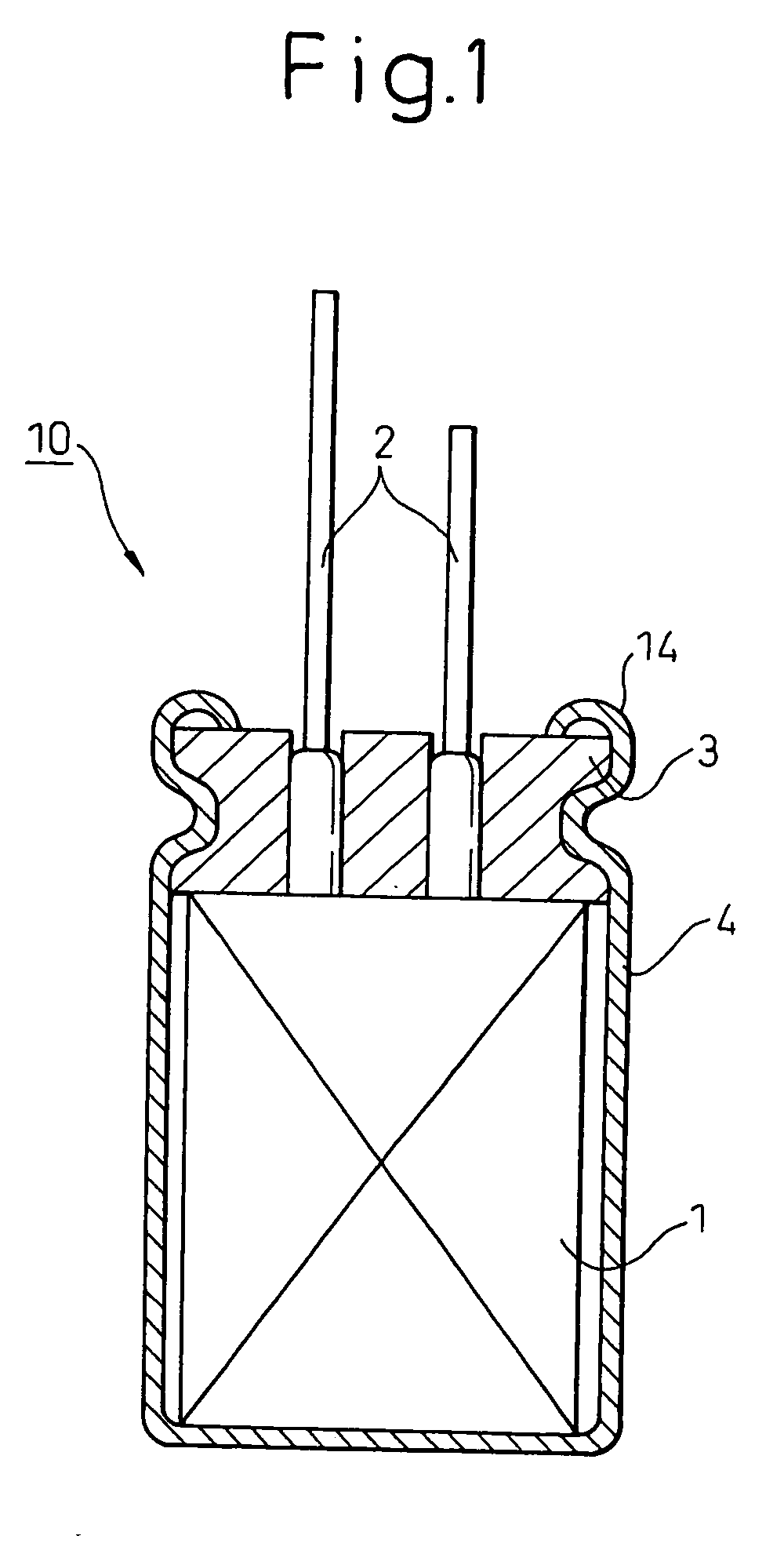

Electrolytic solution for use in electrolytic capacitor, and electrolytic capacitor

ActiveUS20070121276A1Excellent in noise removing abilityImprove discharge efficiencyHybrid capacitor separatorsHybrid capacitor electrolytesDielectricElectrolysis

An electrolytic solution, for use in an electrolytic capacitor, comprising a solvent and a solute wherein water accounts for 20 to 100% by weight of the solvent and the total solute content is from 1.5 to 44% by weight, and an electrolytic capacitor comprising a capacitor element, a case containing the capacitor element, and a sealant with which the case is sealed, the capacitor element comprising a pair of electrode foils each comprising a dielectric, a separator for isolating the electrode foils from each other, and the above electrolytic solution filled between the electrode foils.

Owner:RUBYCON CORPORATION

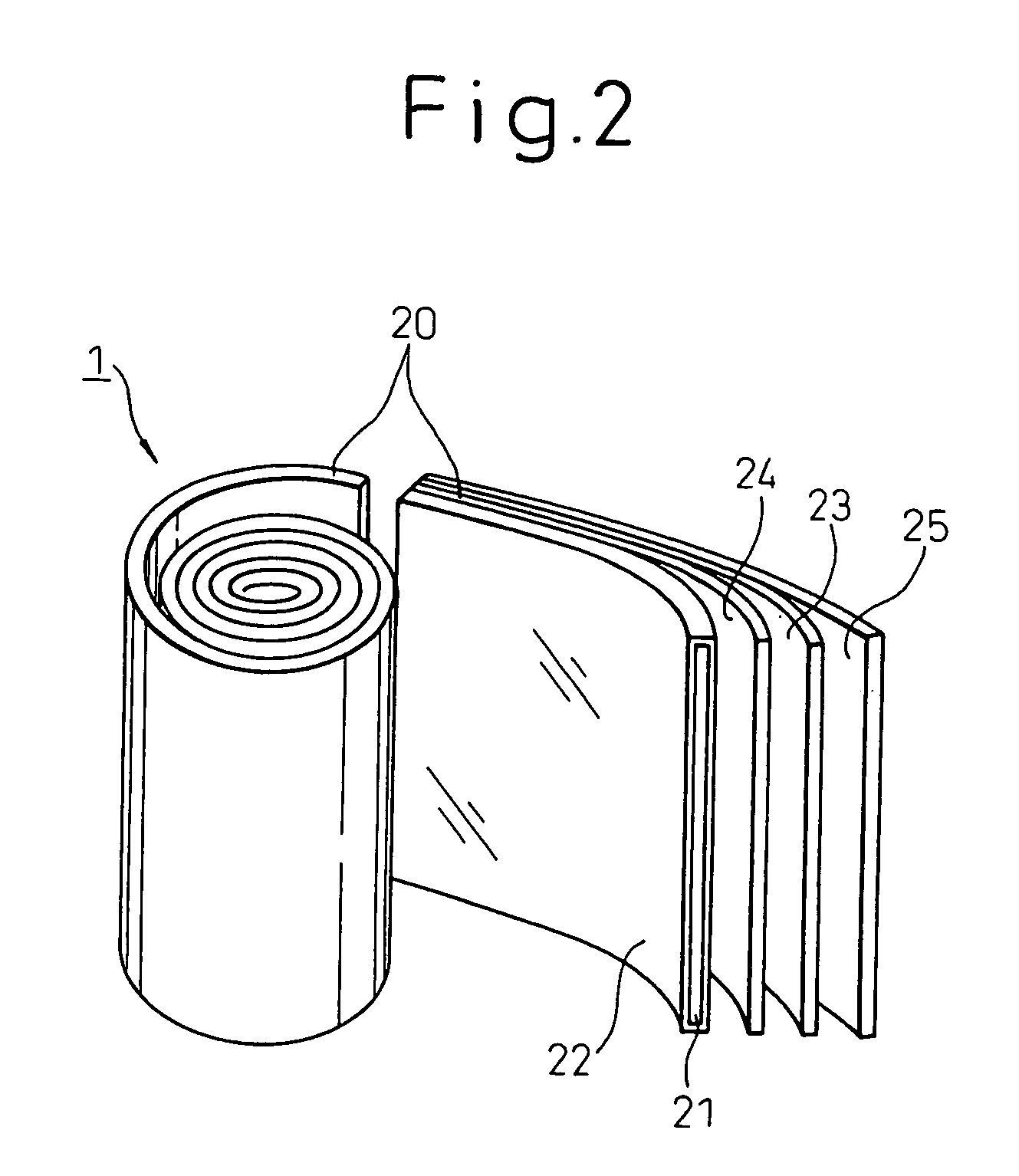

Bisulfate clopidogrel solid preparation, particles and preparation method thereof

InactiveCN101690719AGood stabilityImprove stabilityPowder deliveryOrganic active ingredientsCross-linked polyethylenePharmaceutical preservatives

The invention relates to a bisulfate clopidogrel solid preparation, particles and a preparation method thereof. Particles contained by the solid preparation are solid mixture formed from bisulfate clopidogrel, cellulose excipients and molten adhesive with the melting point between 50 and 86 DEG, and an additionally added excipient of the particles contains weak alkaline lubricants and crosslinked polyvinylpyrrolidone. The solid preparation and the particles thereof are prepared by a melting-granulating method. The solid preparation has the advantages of solving sticking-picking problems existing in the preparation process, effectively reducing the degradation of clopidogrel during storage, reducing the incidence of transforming clopidogrel dextroisomer into clopidogrel levisomer and increasing the stability and security of the solid preparation.

Owner:SHENZHEN SALUBRIS PHARMA

Silicon-carbon composite negative electrode material and preparation method thereof

ActiveCN107768625AIncrease transfer rateImprove transmission efficiencyMaterial nanotechnologyCell electrodesCarbon compositesLithium

The invention relates to a silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has a core-shell structure and comprises an inner core part and a shell part coated on the inner core part, wherein the inner core part is nano silicon, and the shell part is a composite structure containing a porous carbon material and a lithium salt. The invention further provides a preparation method of the silicon-carbon composite negative electrode material.

Owner:乌兰察布市大盛石墨新材料股份有限公司

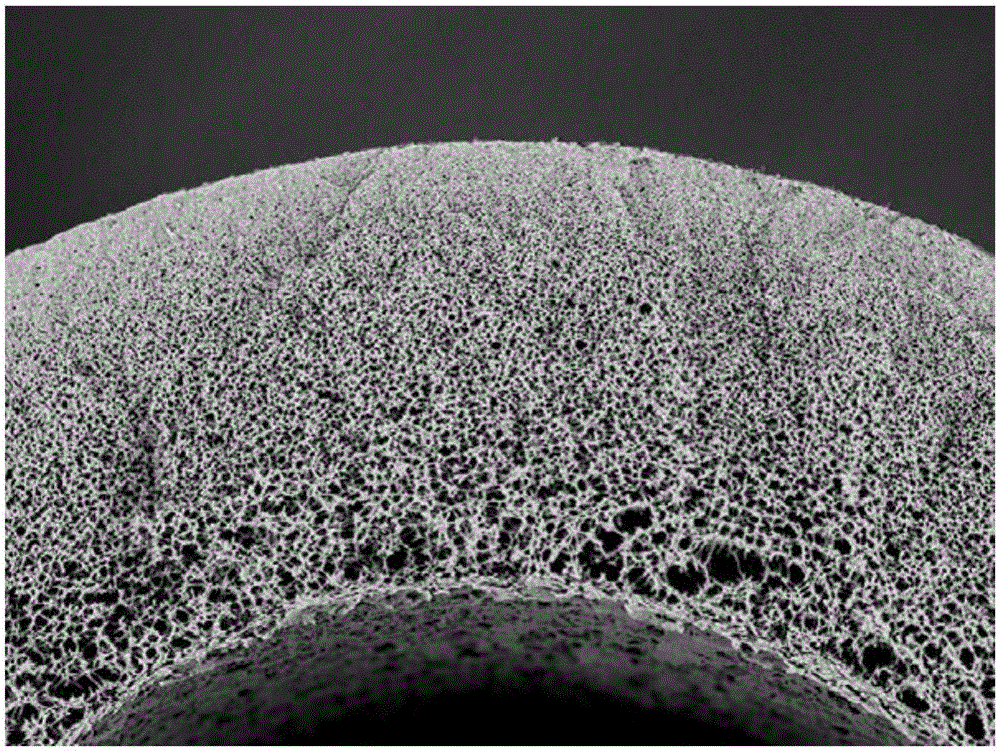

Organic/inorganic hybrid hydrophilic modified hollow fiber polymer film and preparation method thereof

The invention discloses an organic / inorganic hybrid hydrophilic modified hollow fiber polymer film and a preparation method thereof. According to the preparation method, a cross-linked network in which organic macromolecular chains and inorganic SiO2 nano particles are mutually crossed is generated on a porous surface of a film through the utilization of hydrolysis of a silane coupling agent and silicate ester, an organic / inorganic hybrid modified silicon layer with a micro-nano composite structure is formed on the micro-porous surface of the polymer hollow fiber film, and finally, the novel polymer hollow fiber film with super hydrophilic-underwater super lipophobicity is obtained. According to the invention, the content ratio of the silane coupling agent to the silicate ester is adjusted, so that the interface cross-linking degree of the cross-linked network of the film surface can be controlled, and further, the controllable adjustment of nano-scale micropores in the film surface can be realized. The organic / inorganic hybrid hydrophilic modified hollow fiber polymer film has long-lasting hydrophilicity, hydrophilic stability, ultrahigh water flux and ultrahigh anti-pollution performance, and can be widely applied to the fields of drinking water deep purification, industrial sewage treatment, condensation separation and oil-water separation of edible drinks, and the like.

Owner:江苏巨之澜科技有限公司

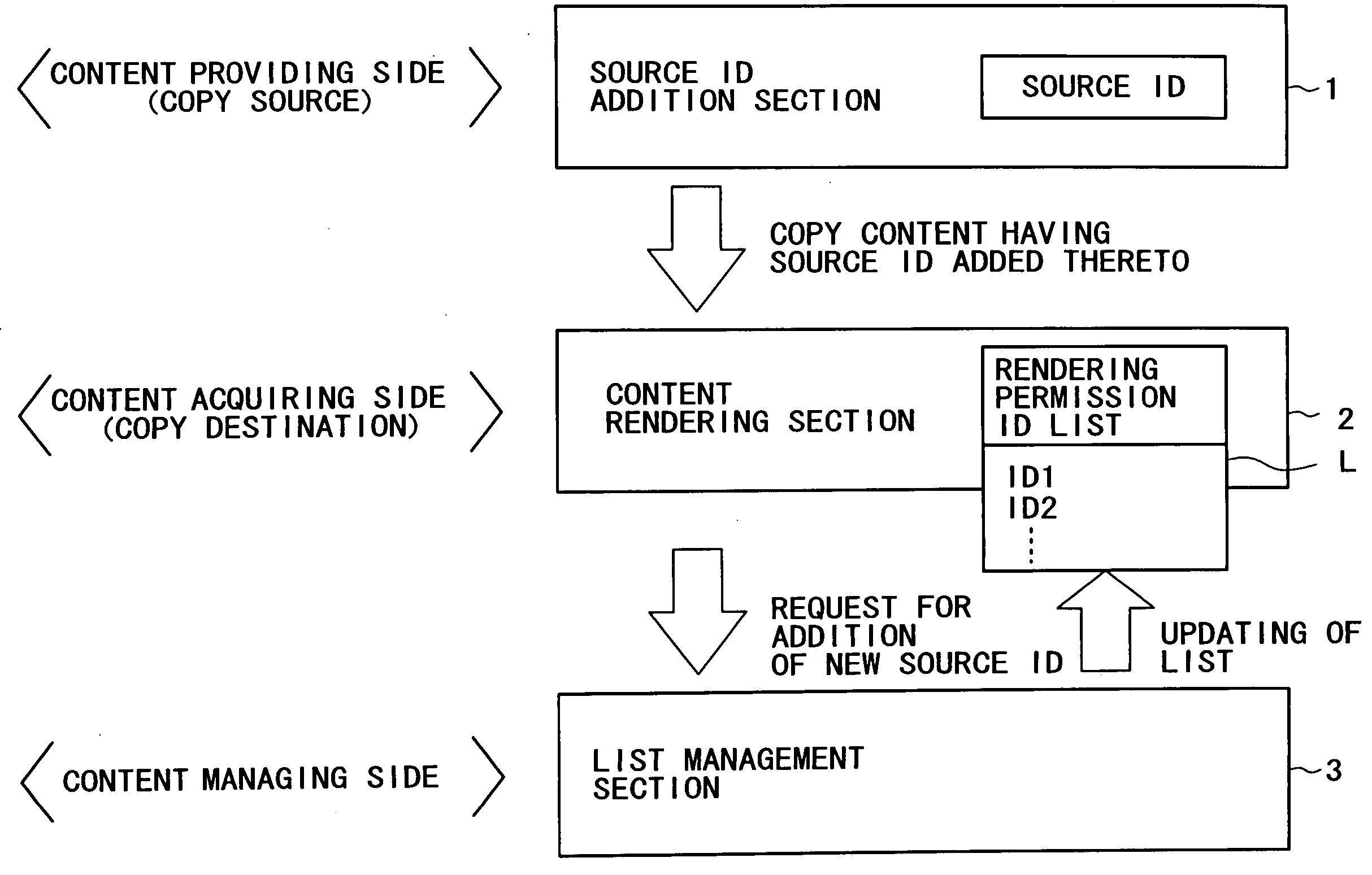

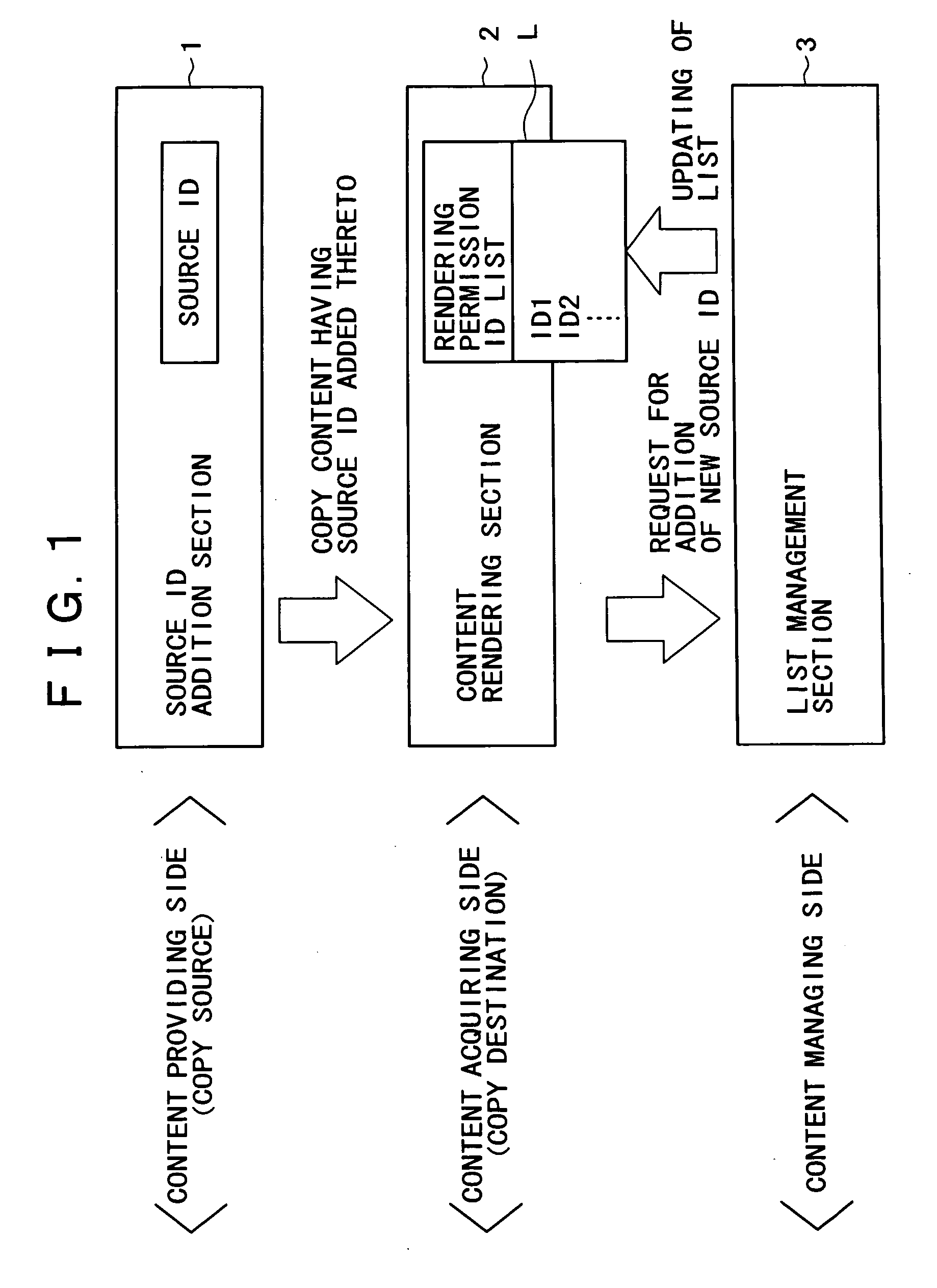

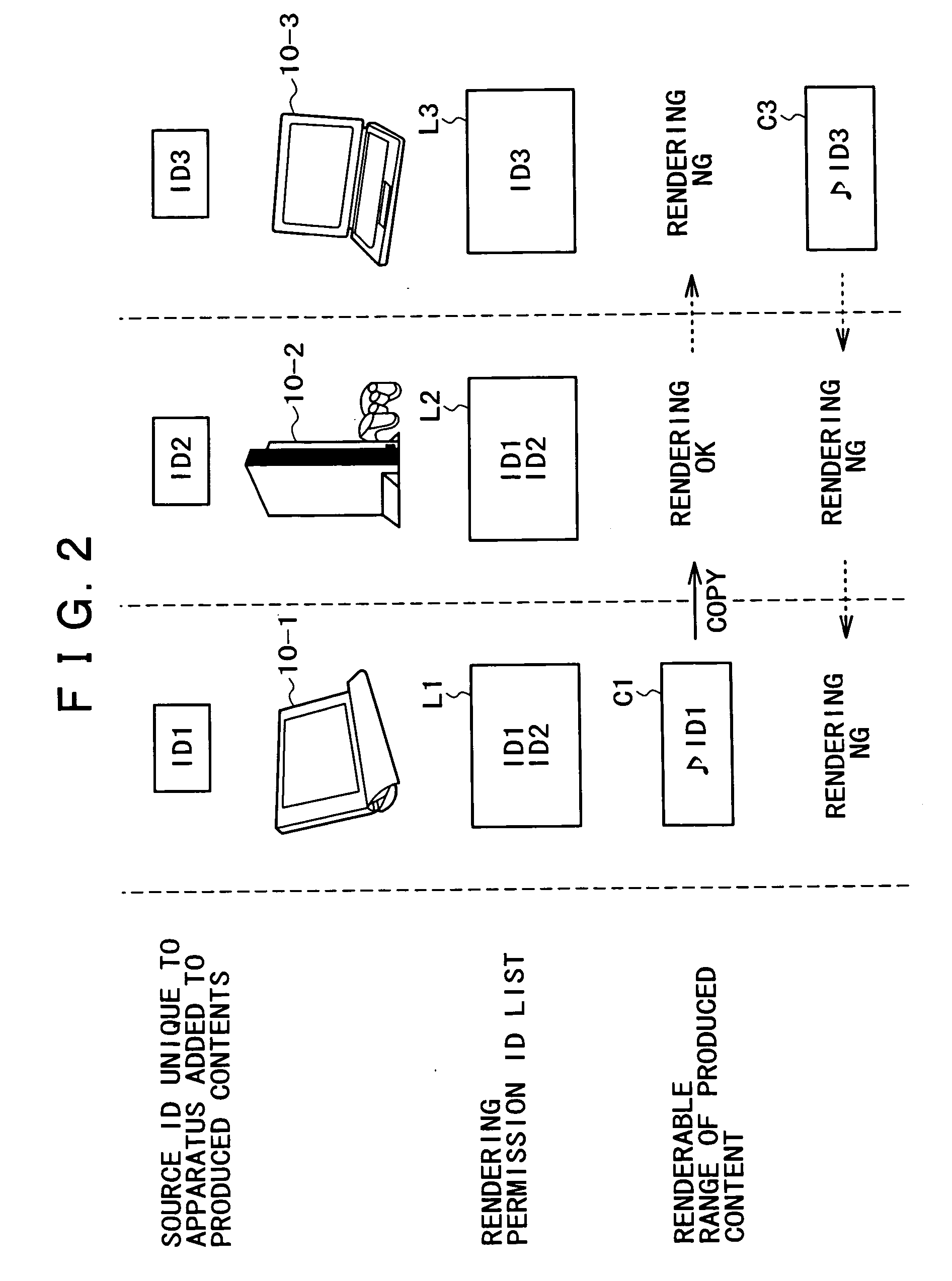

Content sharing system; content processing apparatus; information processing apparatus; program; recording medium; and content sharing method

InactiveUS20050114333A1Efficient executionDegree of freedom is promotedDigital data processing detailsUnauthorized memory use protectionInformation processingComputer graphics (images)

A content sharing system is disclosed that can efficiently execute copyright management for limiting illegal utilization of content, and can promote the degree of freedom in utilization of content within a legal range of private utilization. In the content sharing system, a content processing apparatus on the content providing side includes a source ID addition section for adding, to the content data, a source ID for specifying a providing source of content data. Meanwhile, another content processing apparatus on the content acquiring side includes a content rendering section having a rendering permission ID list including source IDs, added to content data whose rendering is permitted, for limiting, based on the source ID added to the acquired content data and the rendering permission ID list, rendering of acquired content data rendering. The content sharing system further includes a list management section for permitting updating of the rendering permission ID list.

Owner:SONY CORP

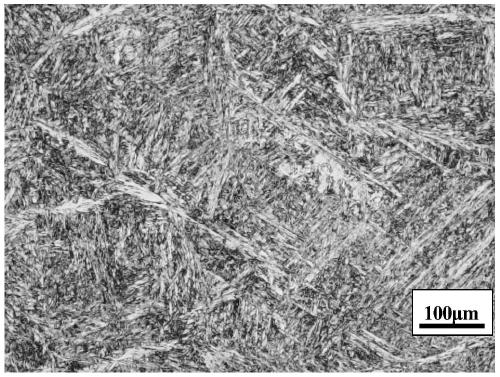

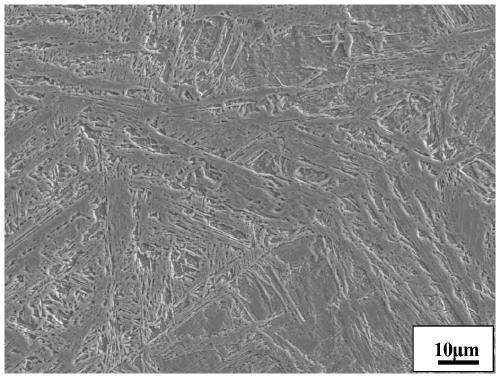

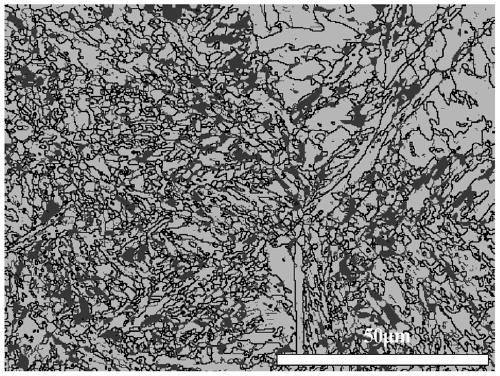

Precipitation-hardened martensite stainless steel and preparation method thereof

InactiveCN110358983APromote formationImprove stabilityChemical compositionMartensitic stainless steel

The invention relates to precipitation-hardened martensite stainless steel and a preparation method thereof, and belongs to the technical field of materials. The precipitation-hardened martensite stainless steel comprises, by weight, 0.14%-0.20% of C, 13.0%-16.0% of Cr, 12.0%-15.0% of Co, 4.5%-5.5% of Mo, 0.5%-2.0% of Ni, 0.40%-0.60% of V, no more than 0.5% of Mn, no more than 0.1% of Si, less than 0.01% of P, less than 0.01% of S, less than 0.01% of O, no more than 0.1% of N, and the balance ferrum. The preparation method of the precipitation-hardened martensite stainless steel comprises thesteps of material proportioning, smelting, molding by casting, forging and heat treatment. According to the precipitation-hardened martensite stainless steel and the preparation method thereof, the contents of Ni and N in the precipitation-hardened martensite stainless steel are optimized, and the content of reverted austenite is controlled through the heat treatment process, so that the best matching between the strength and tenacity of the precipitation-hardened martensite stainless steel is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

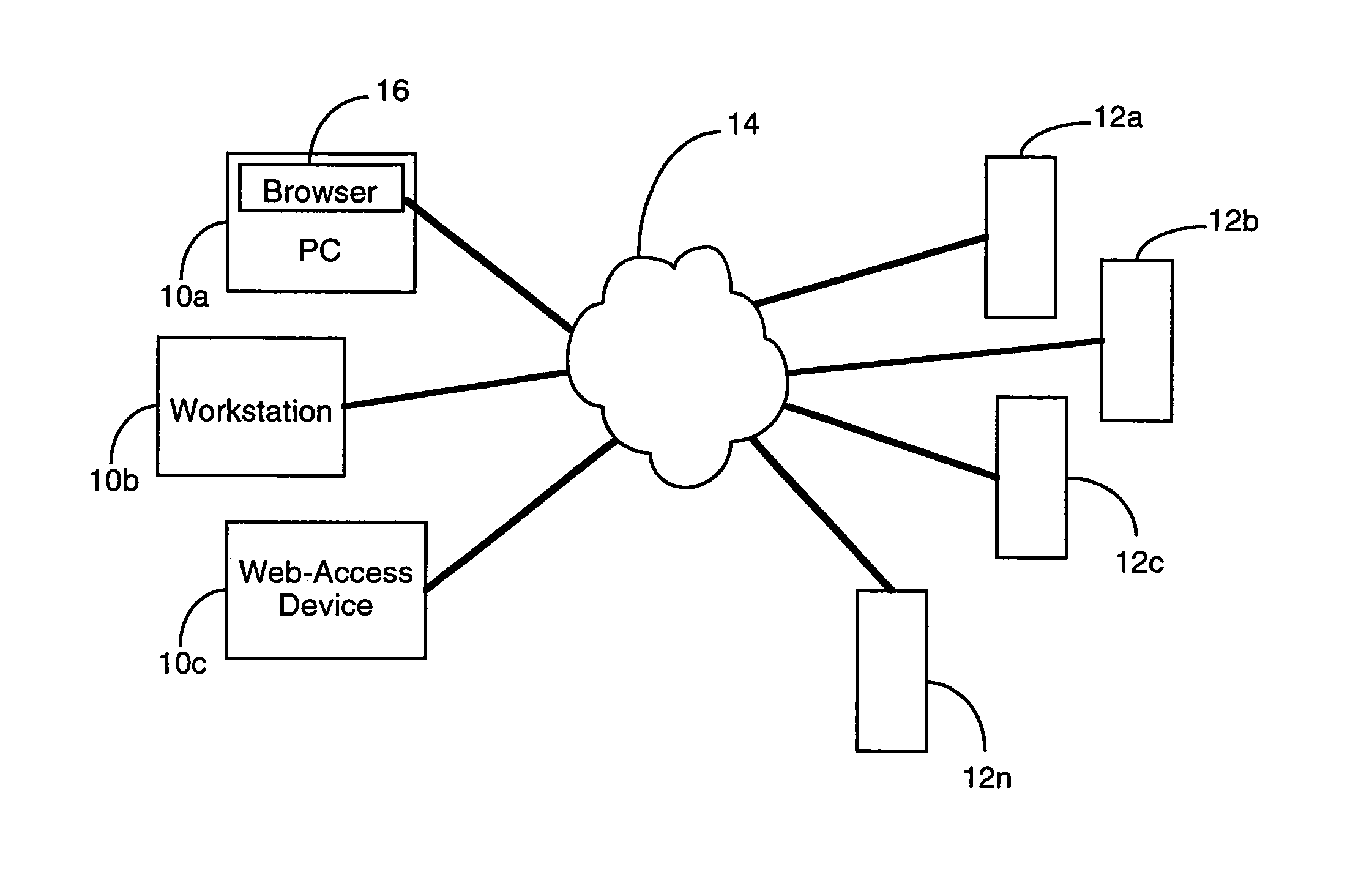

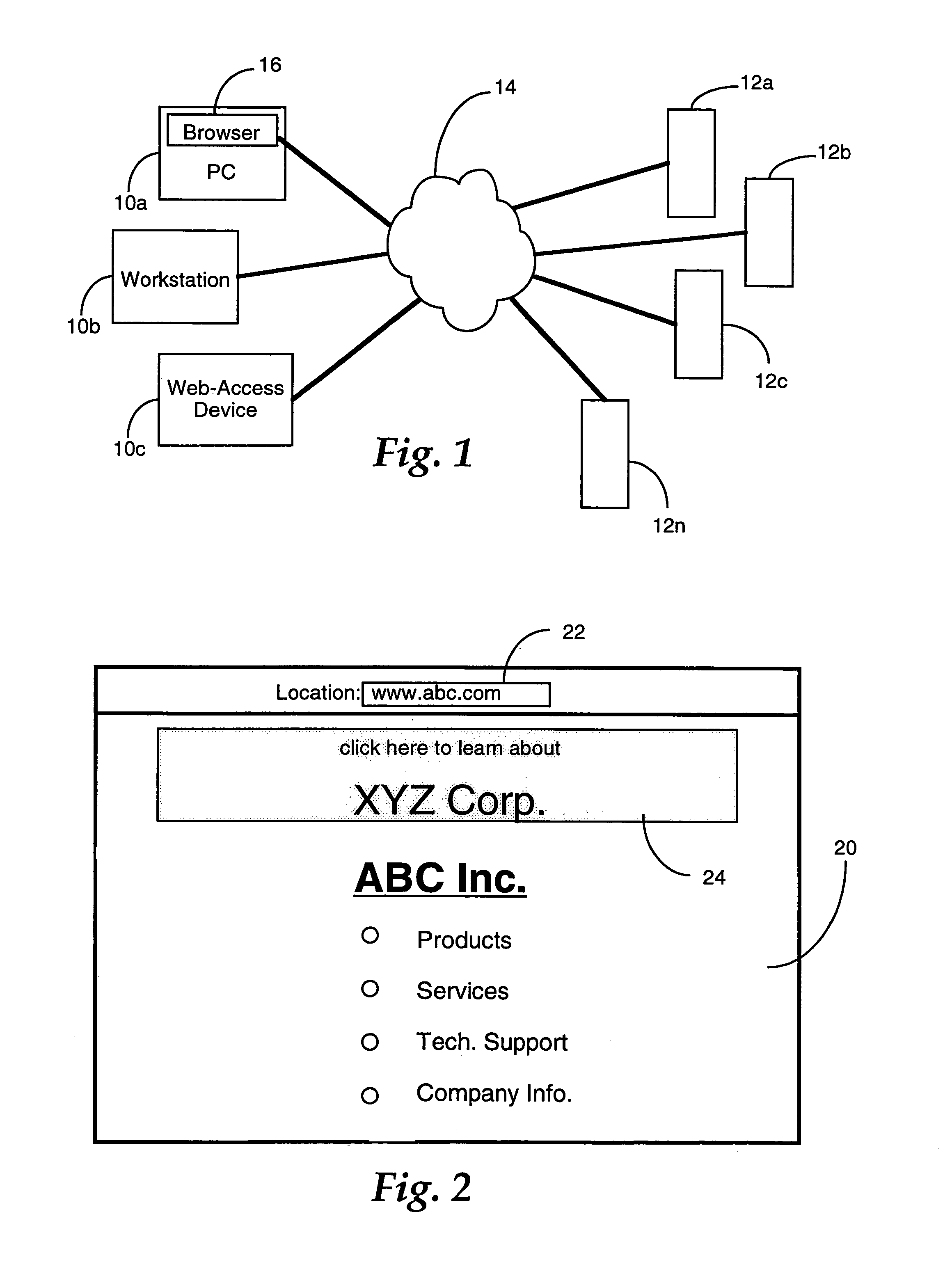

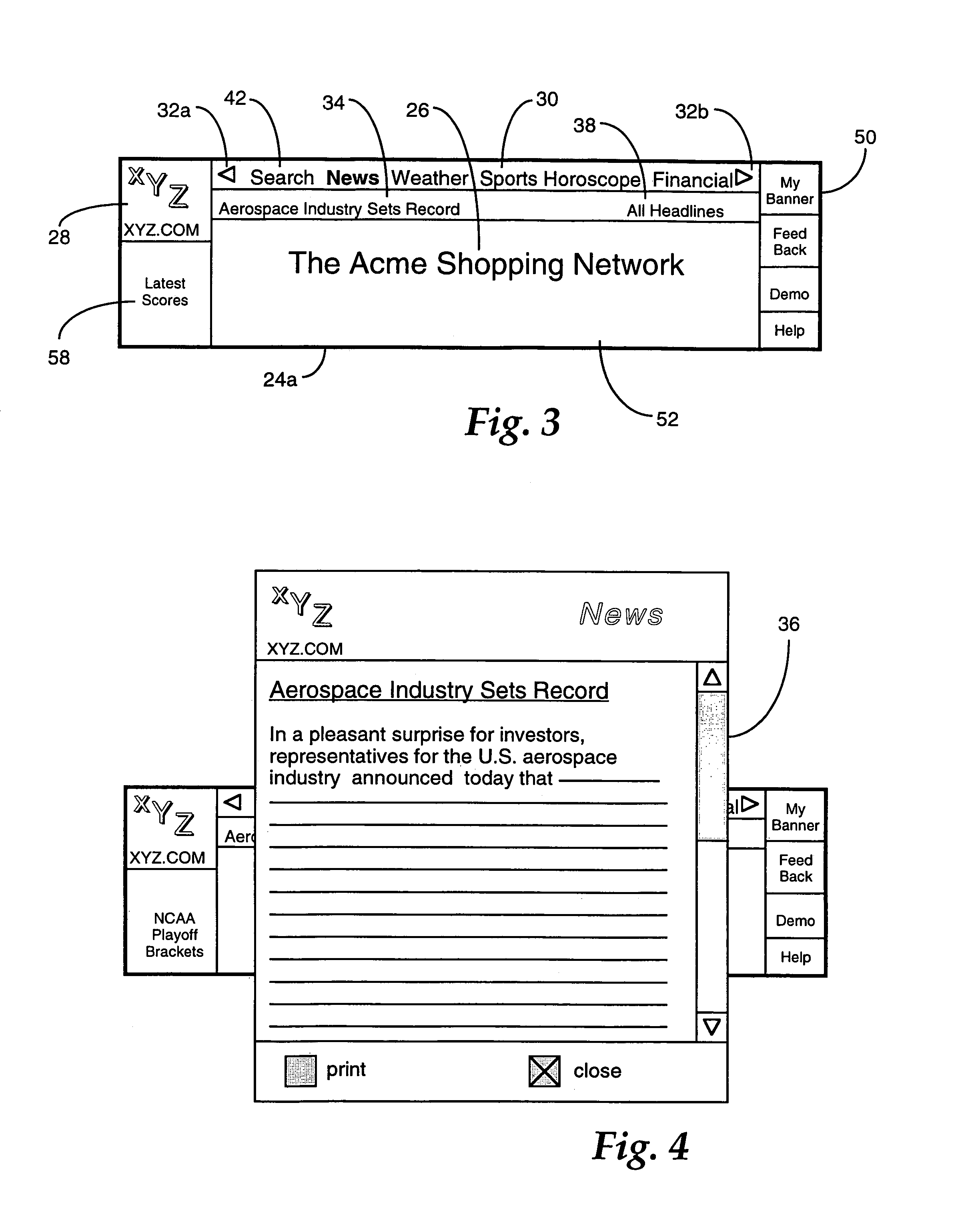

System and method of consistent internet web site banners that provide portal-like functionality

In a continual and integrated approach to Internet banner display rights, a party acquires long-term banner display rights on published web sites of other entities, in a manner so as to ensure full and continual control over the content, look and functionality of the acquired banner space. A variety of different forms of compensation can be provided to the entities which publish the web sites, in exchange for the acquisition of the banner space. The Internet banner is multifunctional, utilizing menus, links and similar user interface items, to operate as a portal to a variety of informational content and services, such as e-commerce, search engines, and the like. These services might be provided by the party which owns the banner space, or by third parties. The banners which appear in the spaces acquired from multiple publishing sites are organized into a networked system, to provide users with integrated and consistent access to the available services. The entity which provides the content and services through the banners can enter into arrangements with end users, to provide incentives for users to access the banners as well as enhance the users' experience.

Owner:ZAP COM CORP

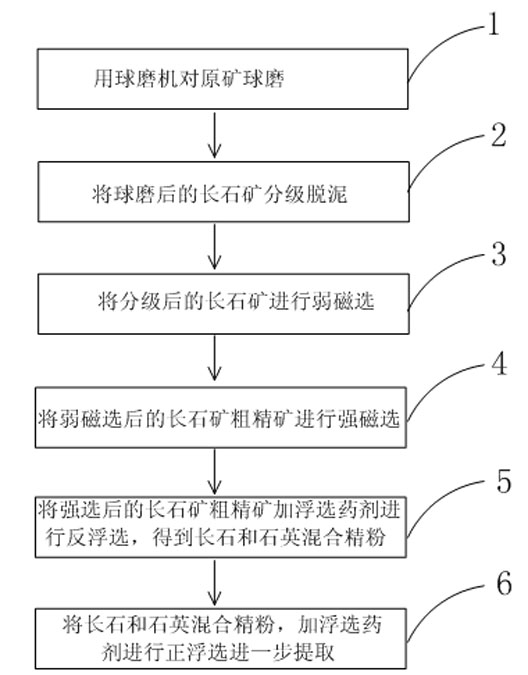

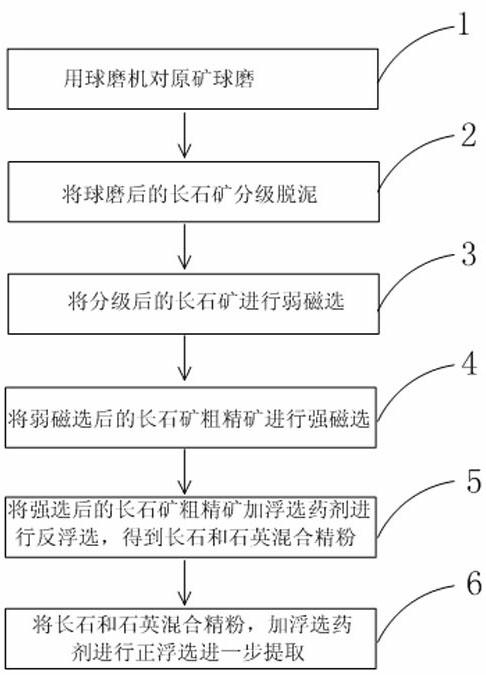

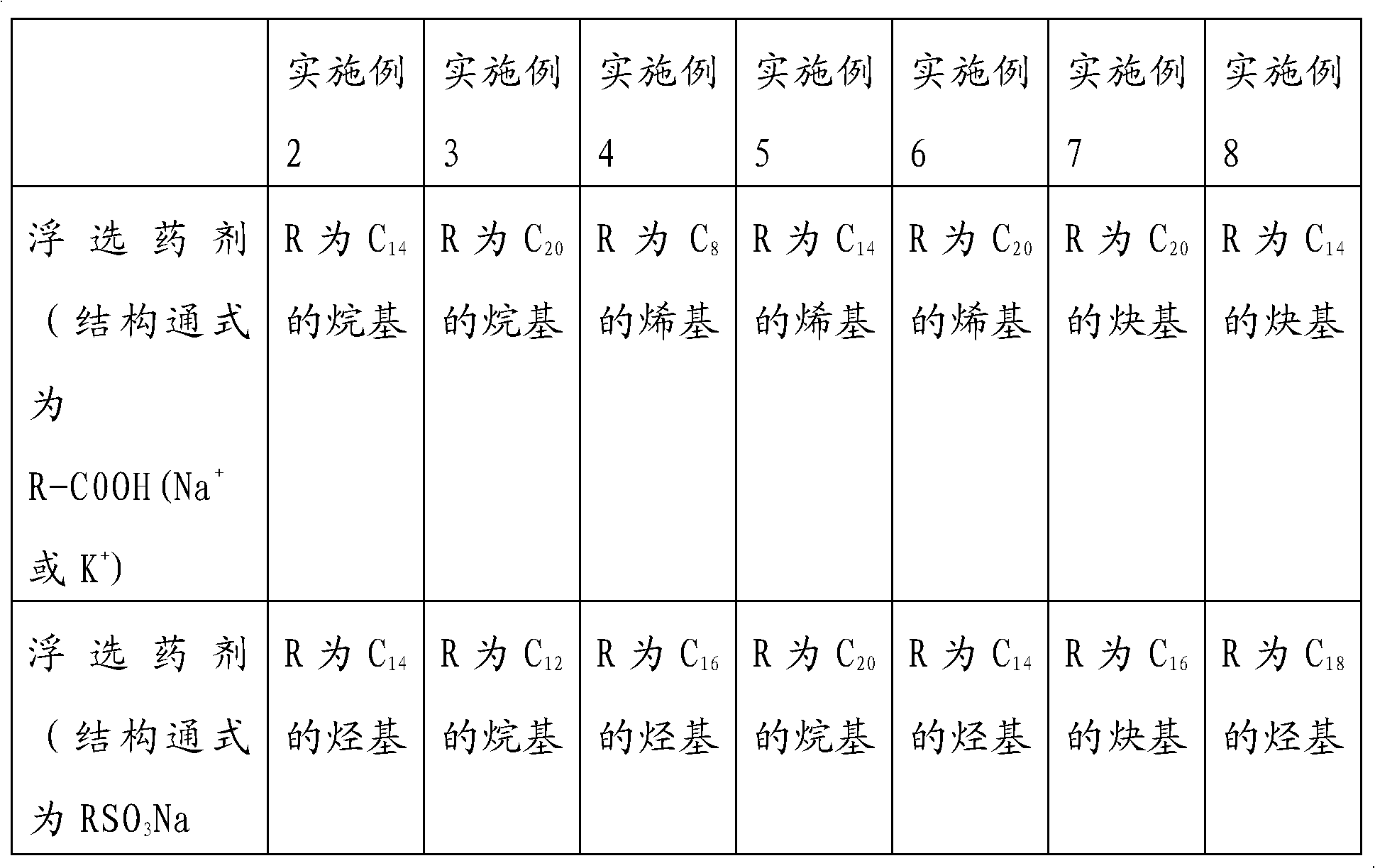

Method for separating and extracting feldspar ore with complex impurity components

InactiveCN102069033AEfficient removalImprove burnt board whitenessWet separationHigh intensityReverse flotation

The invention relates to a method for separating and extracting feldspar ore with complex impurity components, which comprises the following steps of: 1) performing ball milling on the feldspar ore with complex impurity components through a ball mill; 2) performing classification and de-sliming on the milled feldspar ore by using an improved hydraulic classifier; 3) performing low-intensity magnetic separation on the classified feldspar ore through a low-intensity magnetic separator to obtain high-intensity magnetic substances and rough feldspar concentrate for high-intensity magnetic separation; 4) performing high-intensity magnetic separation on the rough feldspar concentrate obtained by the low-intensity magnetic separation through a high-intensity magnetic separator to obtain low-intensity magnetic substances and rough feldspar concentrate for flotation; and 5) performing size mixing and segmentation on the rough feldspar concentrate obtained by the high-intensity magnetic separation, adding a flotation agent, and performing reverse flotation, impurity removal and dehydration through a flotation machine to remove impurities and obtain fine feldspar and quartz mixed powder and flotation water.

Owner:烟台宜陶矿业有限公司

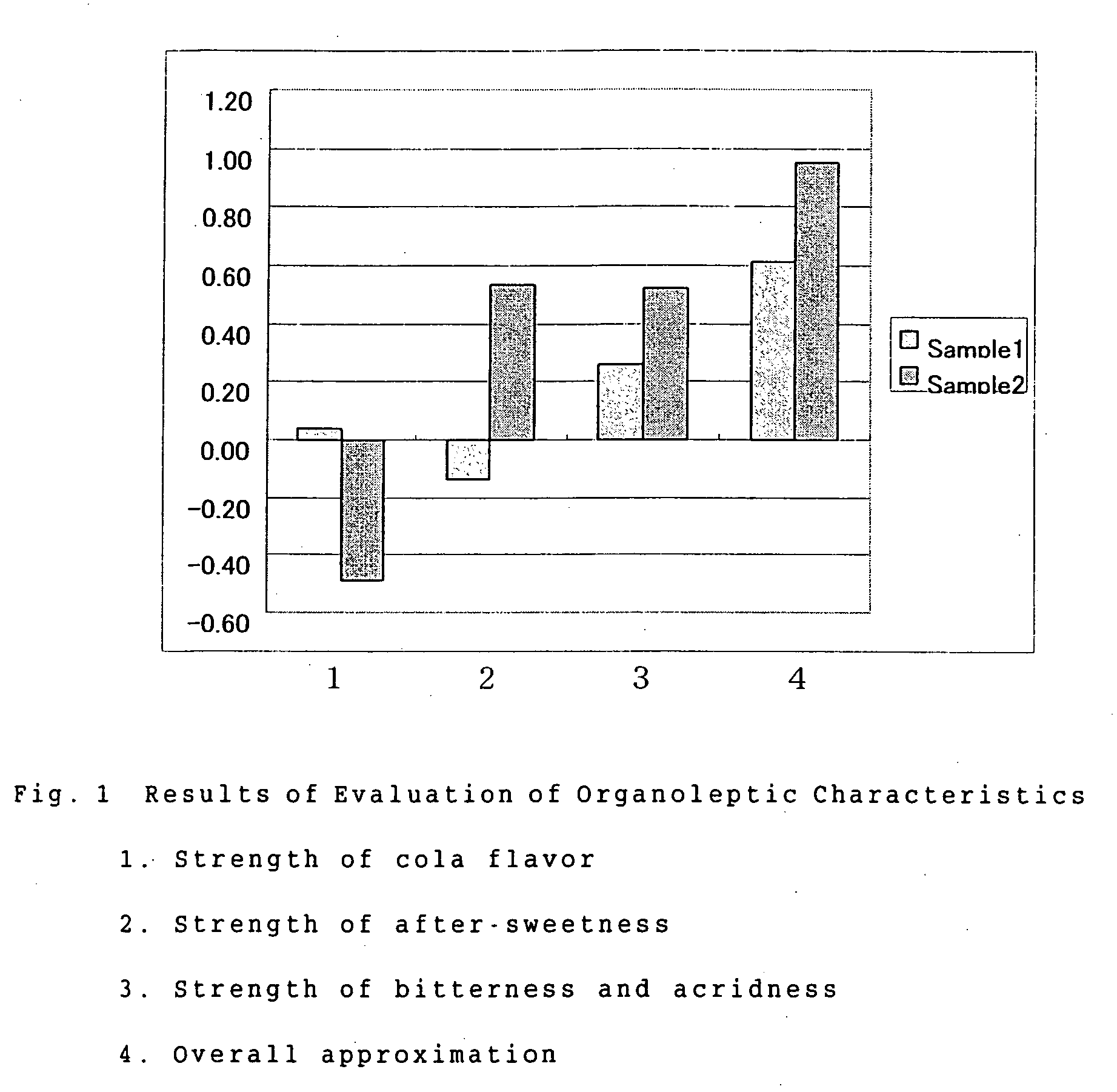

Low-calorie beverages and sweetener composition with improved palatability

InactiveUS20050238779A1Improve palatabilityLimited in calorieFood ingredient functionsFood preparationLow calorieLarge Calorie

The invention described herein provide beverages which have excellent palatability and are limited in calorie content and a sweetener composition having the same characteristics, which contain sucralose and acesulfame K.

Owner:AJINOMOTO CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com