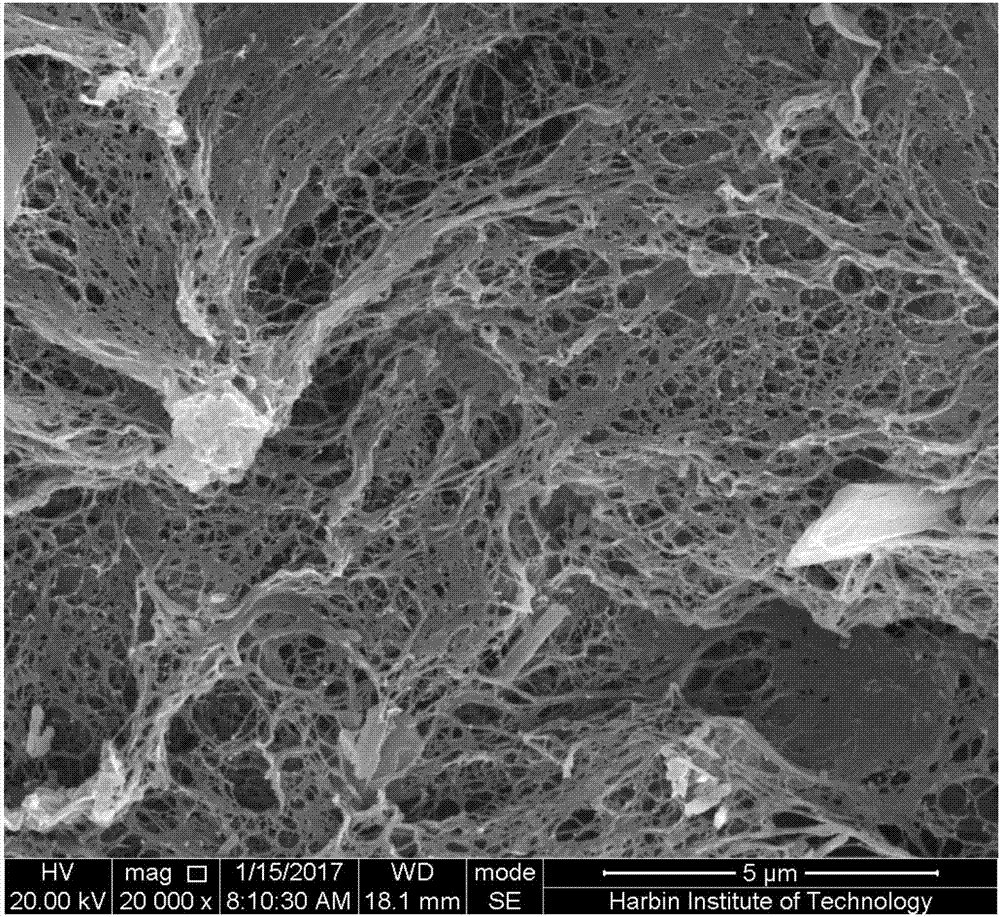

Preparation method of aramid fiber nanofiber aerogel

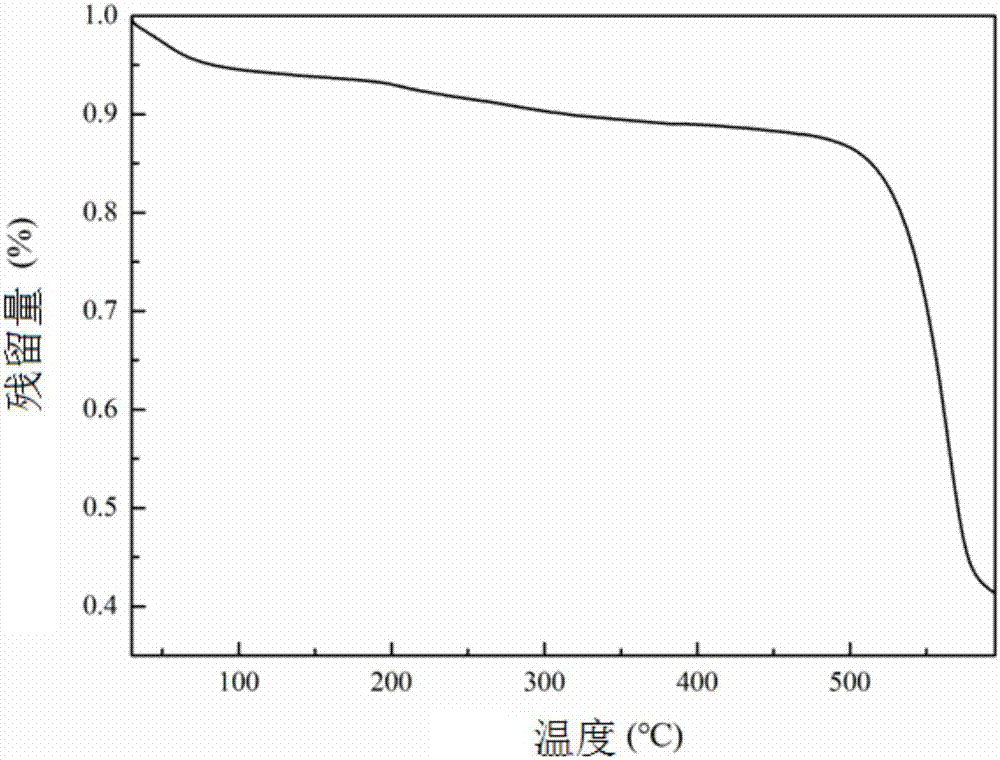

A nanofiber and aramid fiber technology is applied in the field of aerogel preparation, which can solve the problems of poor heat resistance and poor mechanical strength of aerogels, and achieve the effects of ideal heat resistance, ideal mechanical strength and high modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment 1: This embodiment is a preparation method of aramid nanofiber aerogel, which is specifically completed according to the following steps:

[0025] 1. Extraction: Using acetone as the extraction solvent, the aramid fiber is extracted and treated with a Soxhlet extractor for 48h to 72h to obtain the extracted aramid fiber; then the extracted aramid fiber is heated at a temperature of Vacuum drying in a vacuum drying oven at 40℃~90℃ for 12h~72h to obtain dry aramid fibers;

[0026] 2. Use nitrogen to purge the dry three-necked flask for 20min-30min, then add dimethyl sulfoxide, potassium hydroxide and dried aramid fiber to the three-necked flask, and then stir at a stirring speed of 500r / min~1300r / min The reaction is stirred for 3 to 10 days to obtain a dark red aramid nanofiber solution;

[0027] The mass ratio of the dry aramid fiber described in step 2 to the volume ratio of dimethyl sulfoxide is (0.5g~2g): 500mL;

[0028] The quality of potassium ...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the temperature of the extraction process described in step 1 is 50°C to 130°C. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0042]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aramid fiber described in step 1 is one of Kevlar fibers of 50 denier to 1600 denier or a mixed fiber of several of them. . Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com