Patents

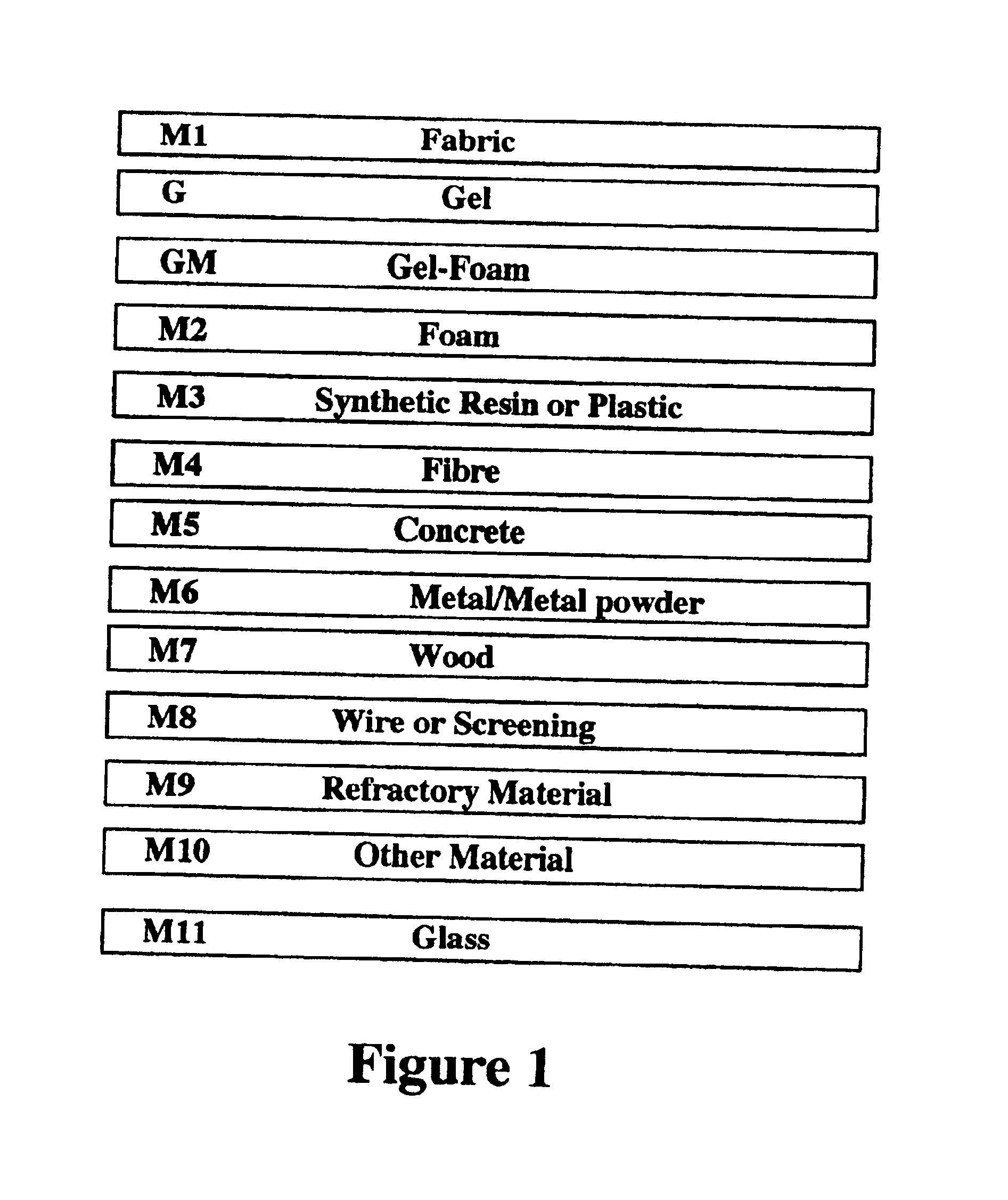

Literature

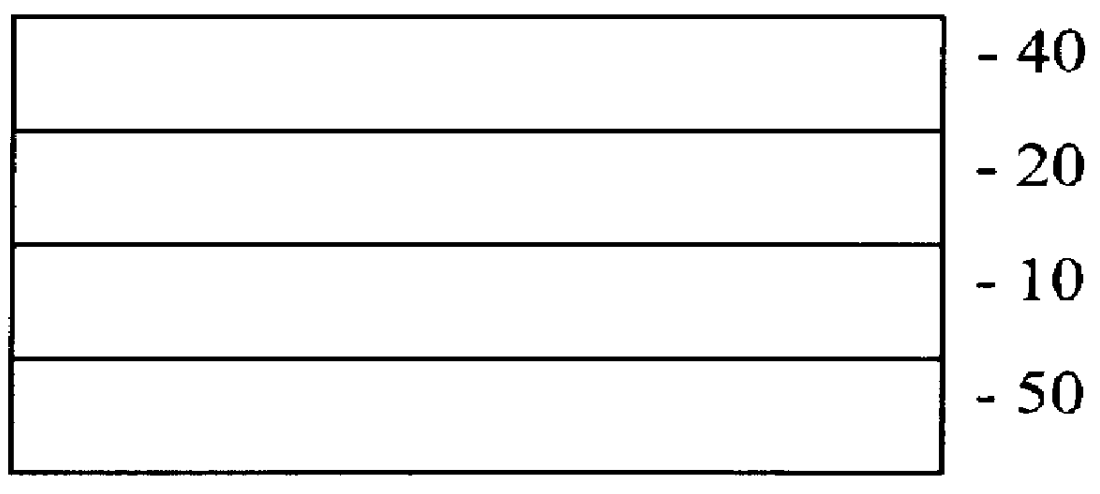

2490 results about "Tear resistance" patented technology

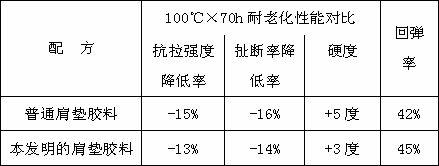

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tear resistance (or tear strength) is a measure of how well a material can withstand the effects of tearing. It is a useful engineering measurement for a wide variety of materials by many different test methods.

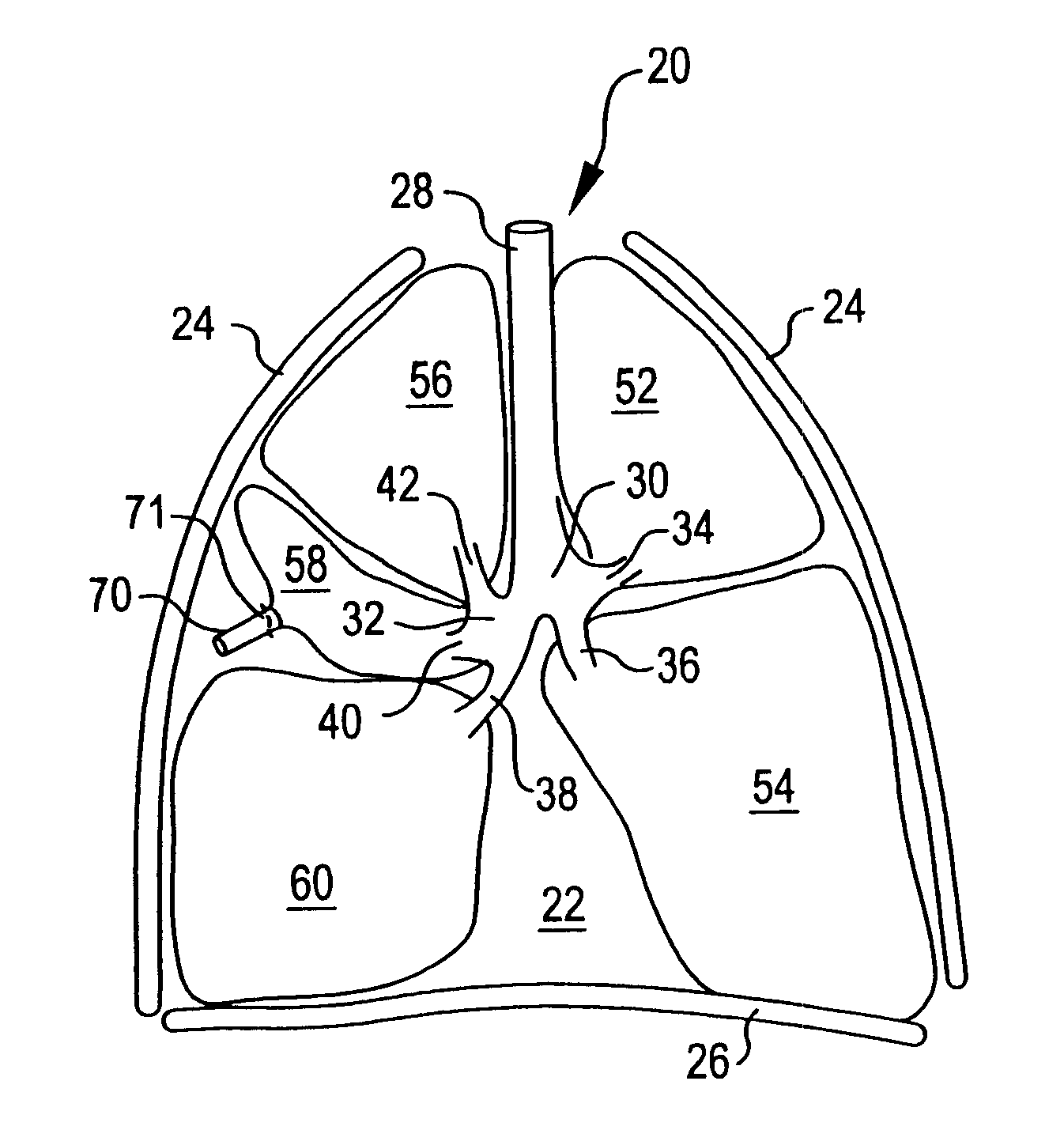

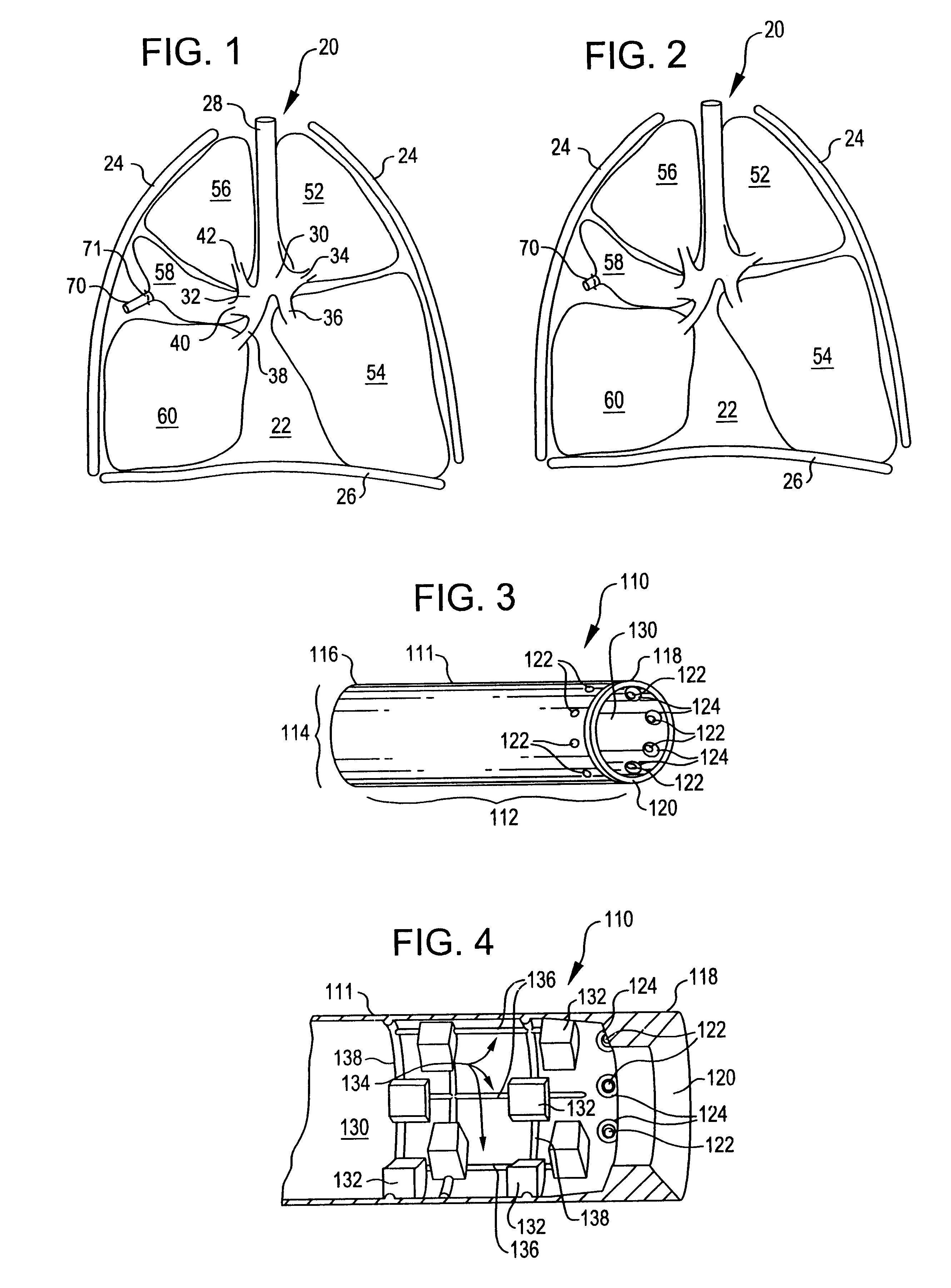

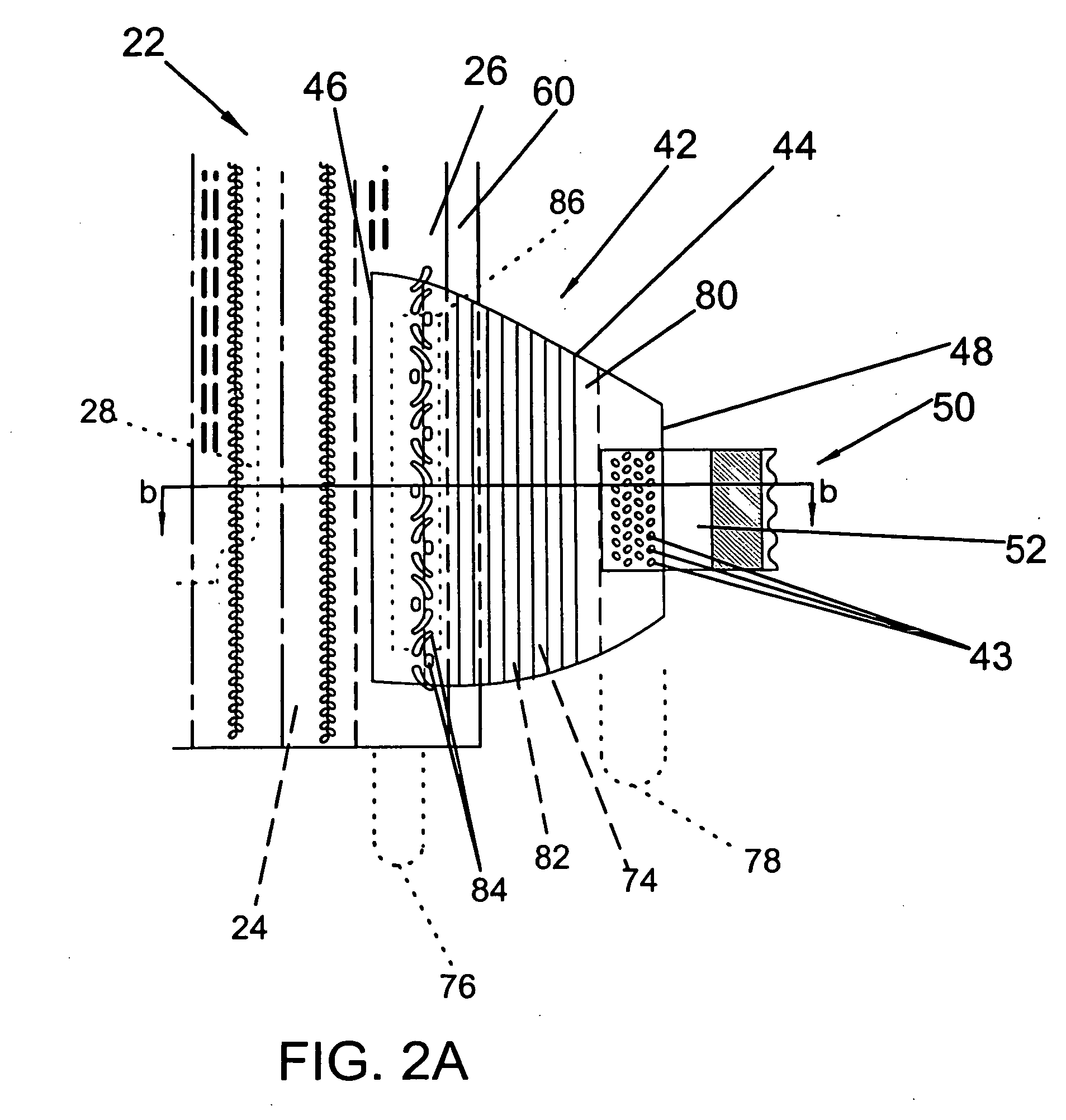

Constriction device including tear resistant structures

InactiveUS6843767B2Prevent tear propagationIncreasing the thicknessBronchiDiagnosticsTear resistanceBody tissue

A constriction device that constricts body tissue and is formed of relatively thin elastic material includes a tear resistance structure to preclude an inadvertent tear in the device from propagating through the device. The tear resistance structure includes a plurality of intersecting ribs formed in the elastic material. The ribs circumscribe the device and define rectangular, square, diamond, wavy, or knurled patterns.

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

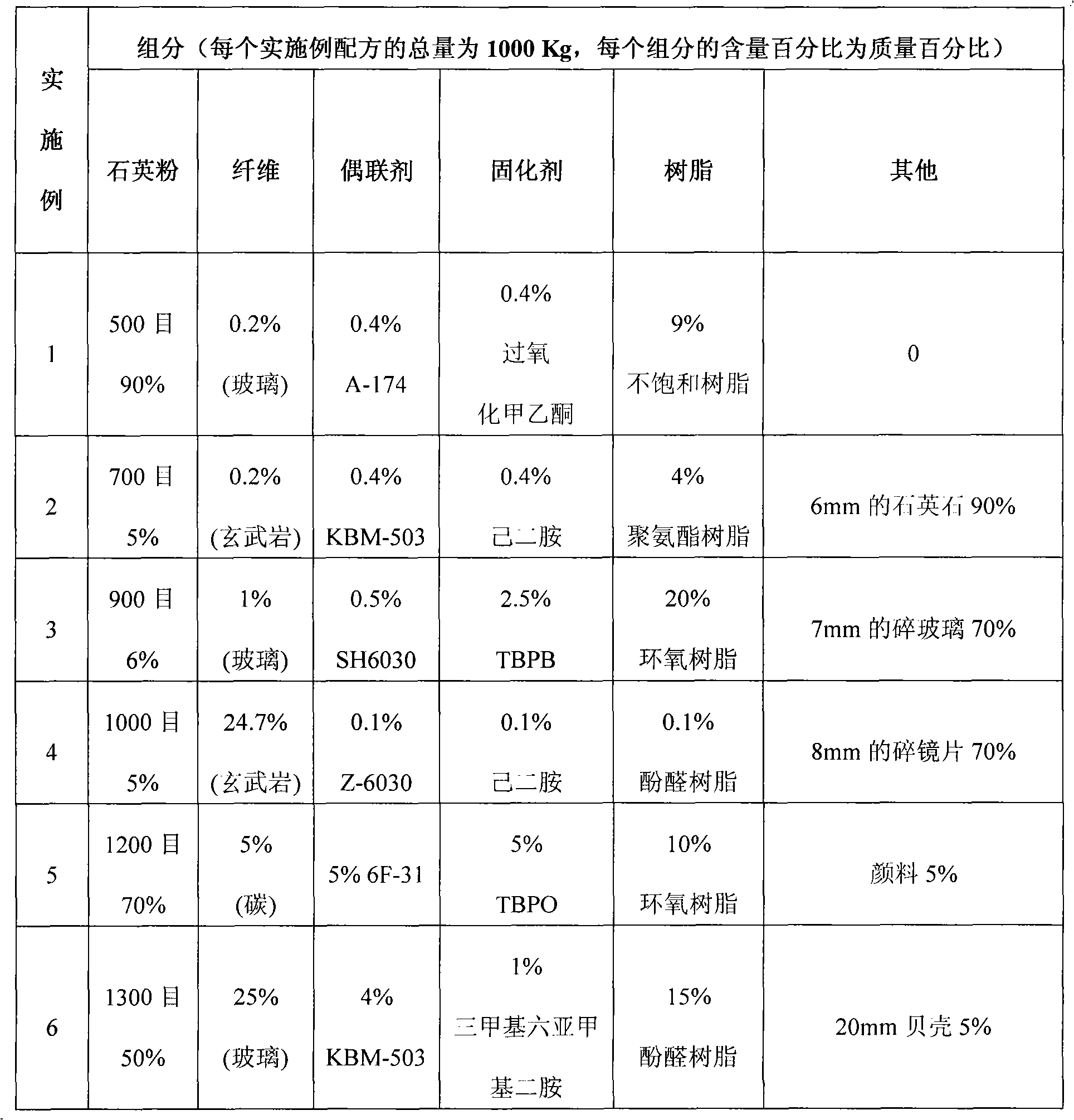

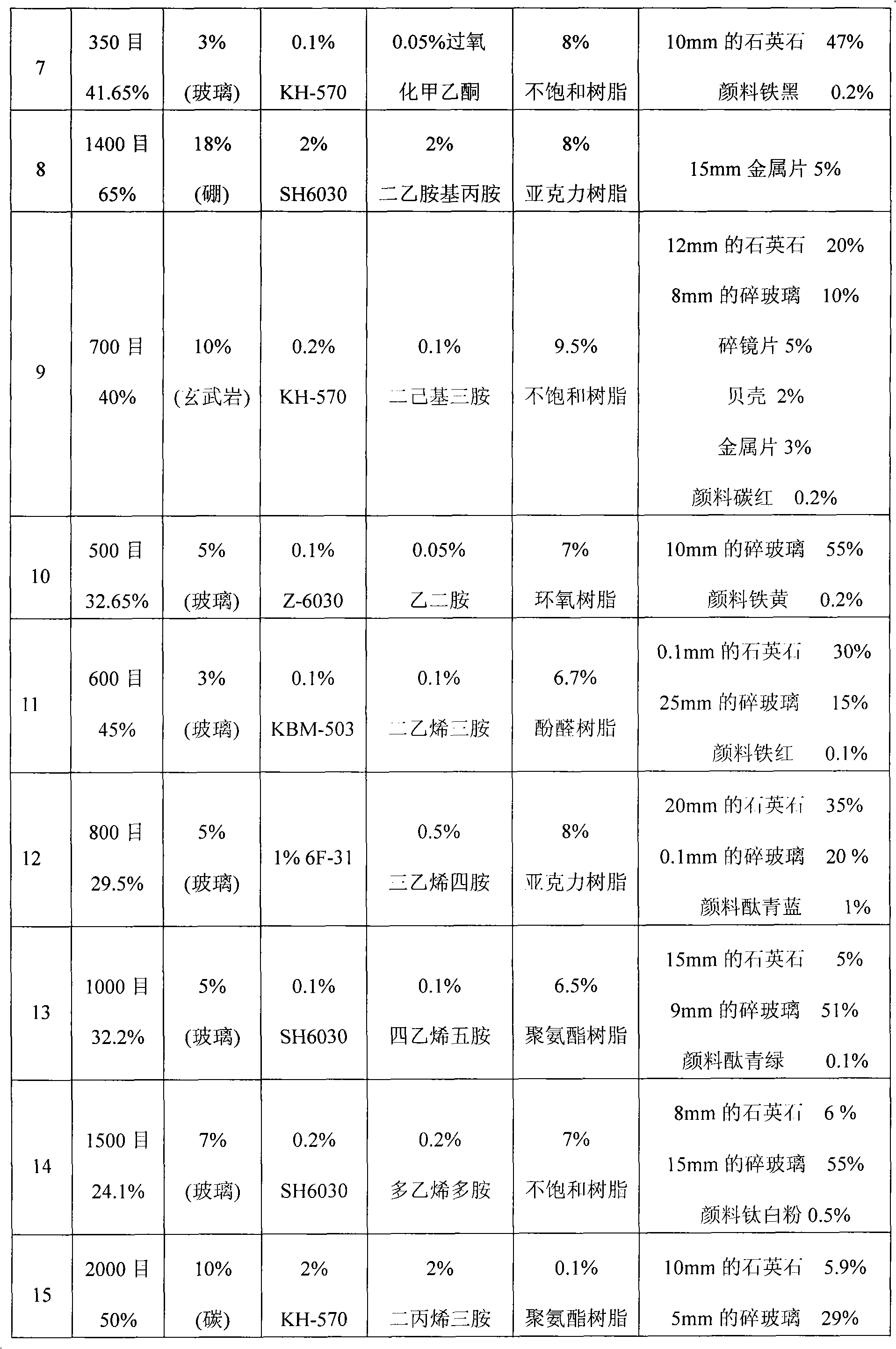

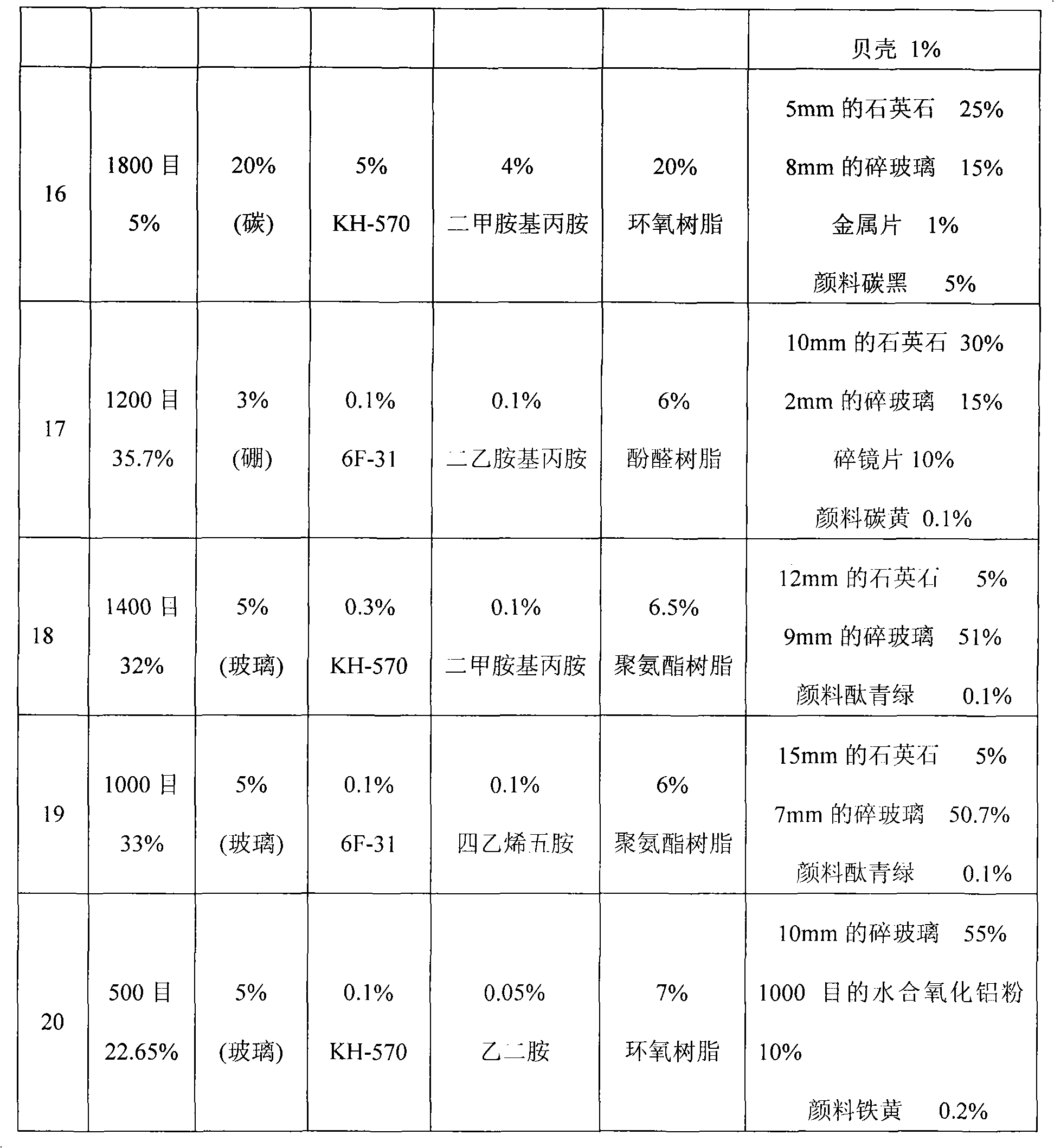

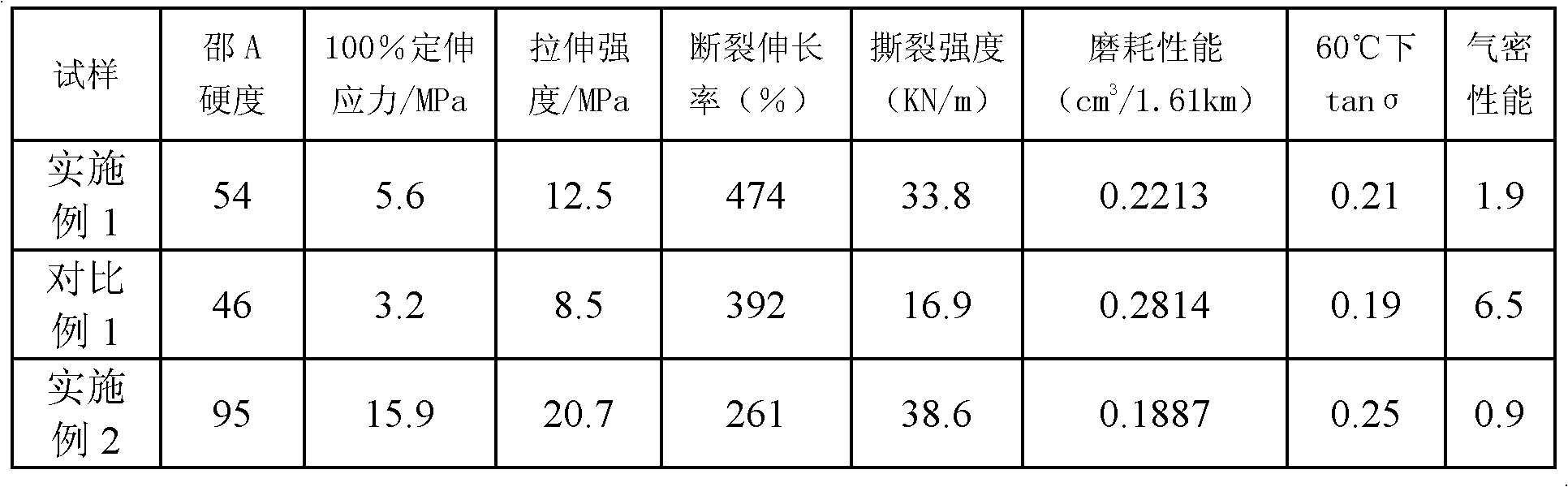

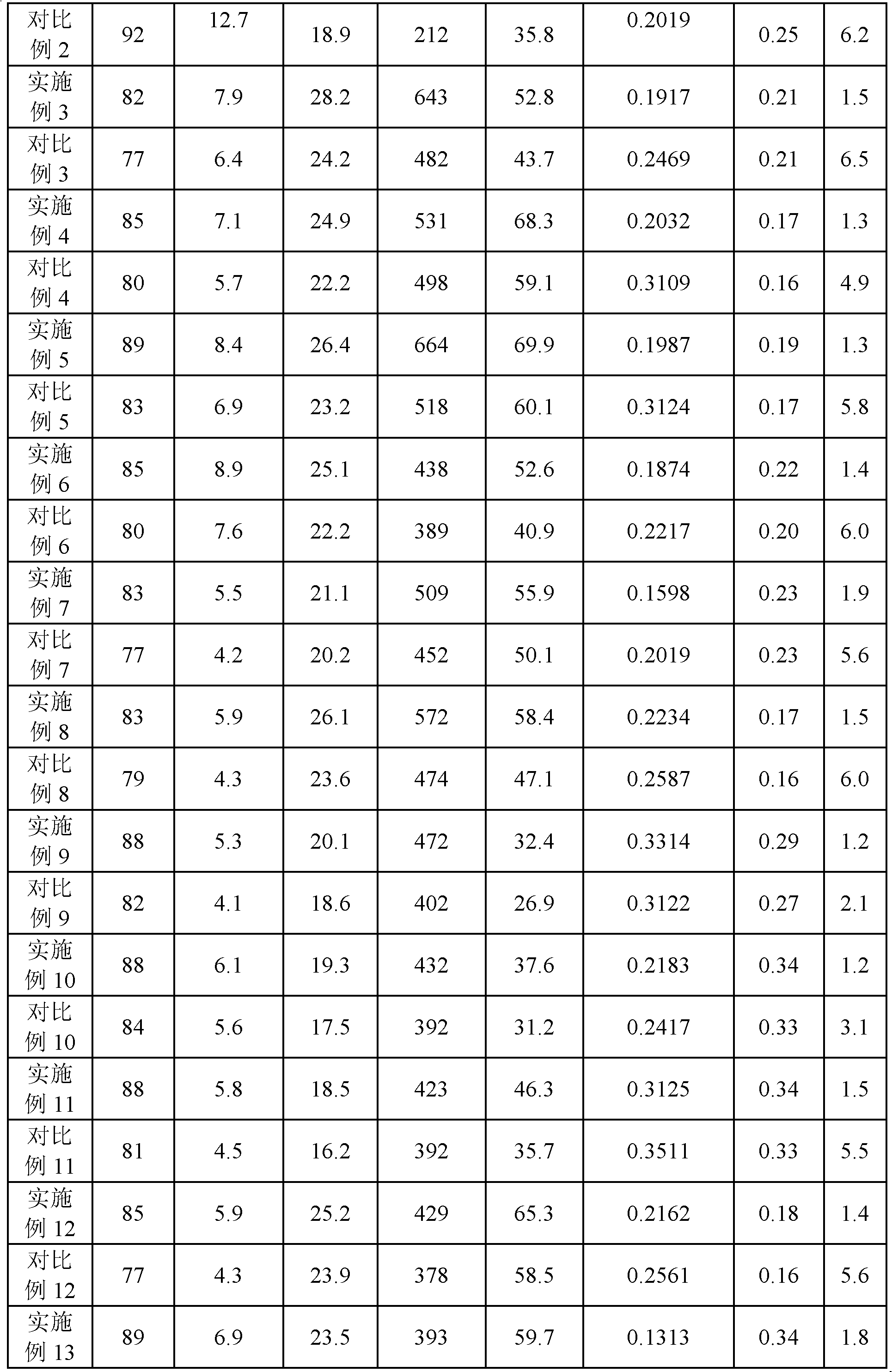

Artificial quartz in lump and fabrication technology thereof

The invention discloses a man-made quartz stone, which comprises 0 to 90 percent of quartz stone, 5 to 90 percent of silica flour, 1 to 25 percent of fiber, 0.1 to 20 percent of resin, 0.1 to 5 percent of a coupling agent, 0.1 to 5 percent of a curing agent, 0 to 70 percent of cullet, 0 to 70 percent of broken glass block, 0 to 5 percent of paint, 0 to 5 percent of shell, 0 to 5 percent of metal sheet by mass. The tear resistance, the compressive strength and the buckling strength of the man-made quartz stone are significantly improved compared with the prior man-made quartz stone. The invention further relates to a manufacturing process for a man-made quartz stone plate or block and vessel.

Owner:张璐 +1

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Stretch wrap films

InactiveUS6093480AImprove clingImproved maximum stretchWrappers shrinkageSynthetic resin layered productsStretch wrapGram

A multilayer, thermoplastic stretch wrap film containing at least three polymeric film layers and comprised of a first layer and a second layer. The first and second layers may comprise a polymer of two or more monomers, wherein a first monomer is ethylene, in a major amount by weight, and a second monomer is an alpha olefin of from about 3 to about 12 carbon atoms, in a minor amount by weight. If the first and second layers are outer layers, they have a cling force to each other of at least about 140 grams / inch. The stretch wrap film also has at least one inner polymeric layer, located between the first and second layers. The inner polymeric layer comprises a low polydispersity polymer having a polydispersity of from about 1 to about 4, a melt index (I.sub.2) of from about 0.5 to about 10 g / 10 min., and a melt flow ratio (I.sub.20 / I.sub.2) of from about 12 to about 22. The inner layer(s) comprise(s) from about 5 wt. % to about 40 wt. % of the stretch wrap film so as to produce a film having a maximum stretch of at least 340%, a F-50 dart drop value of at least about 130 g / mil, a machine directional tear resistance of at least about 125 g / mil and a transverse directional tear resistance of at least about 500 g / mil. It is contemplated that additional outer layers may be added such an outer high cling layer or an outer slip layer, as well as additional inner layers.

Owner:BERRY PLASTICS CORP

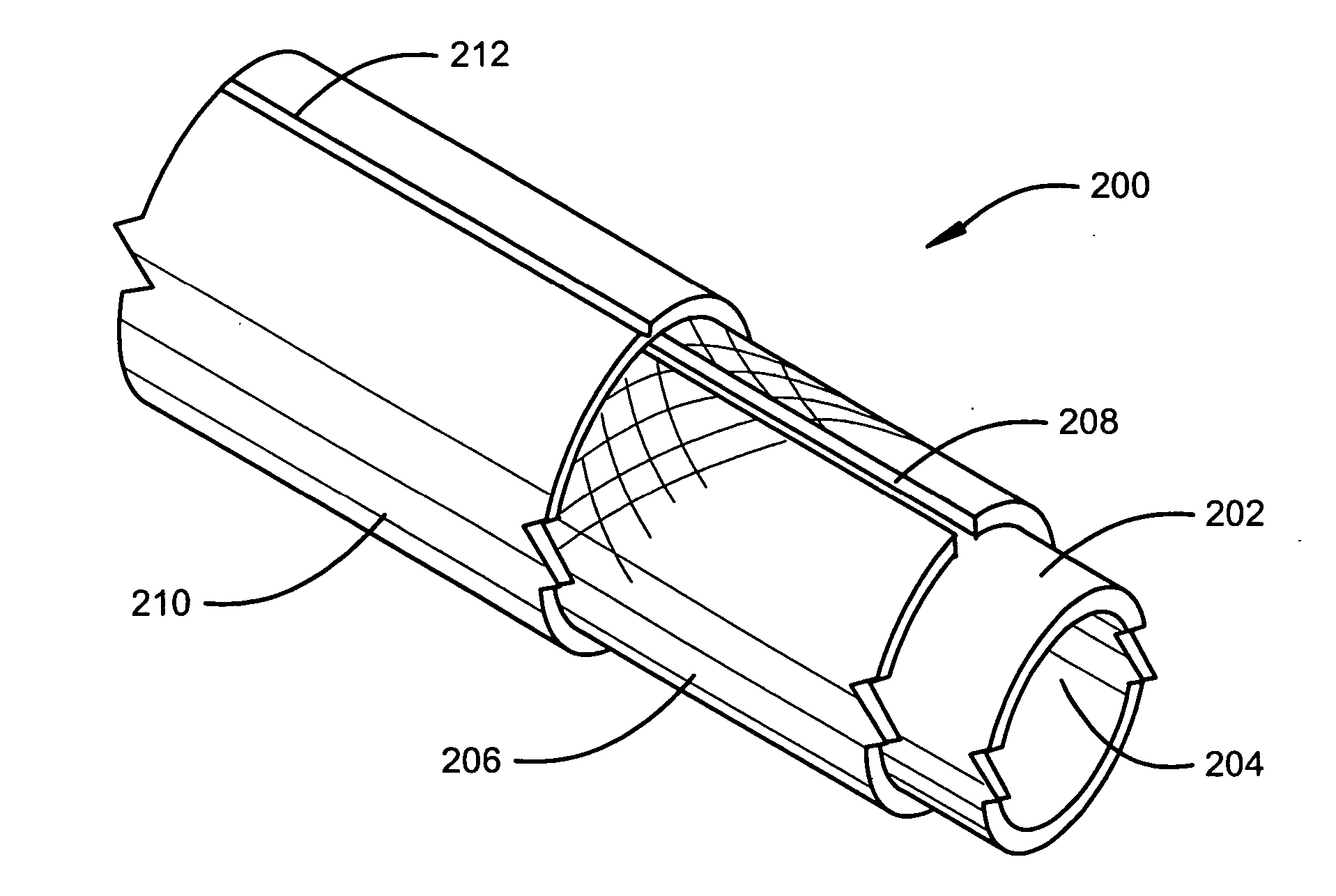

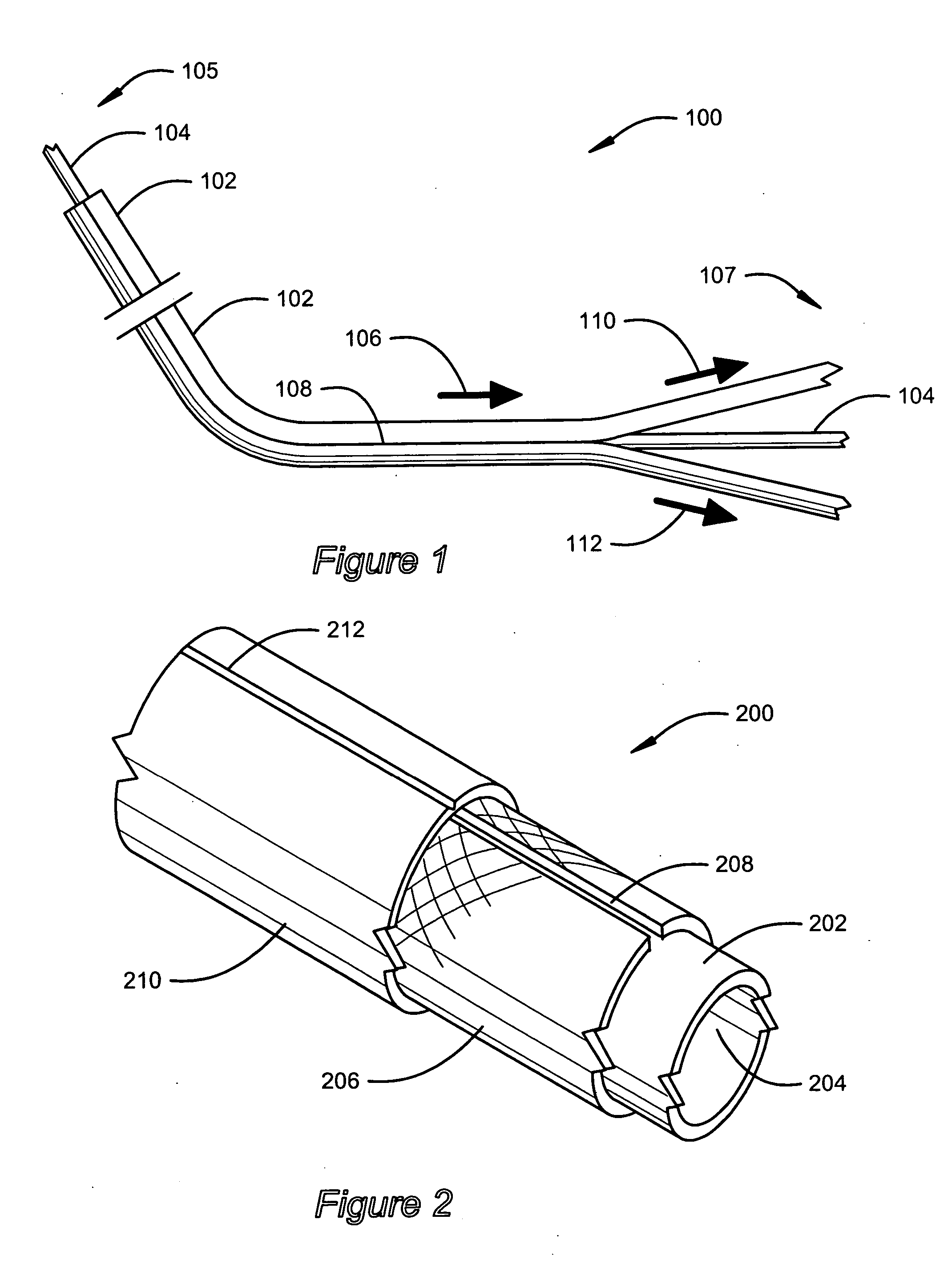

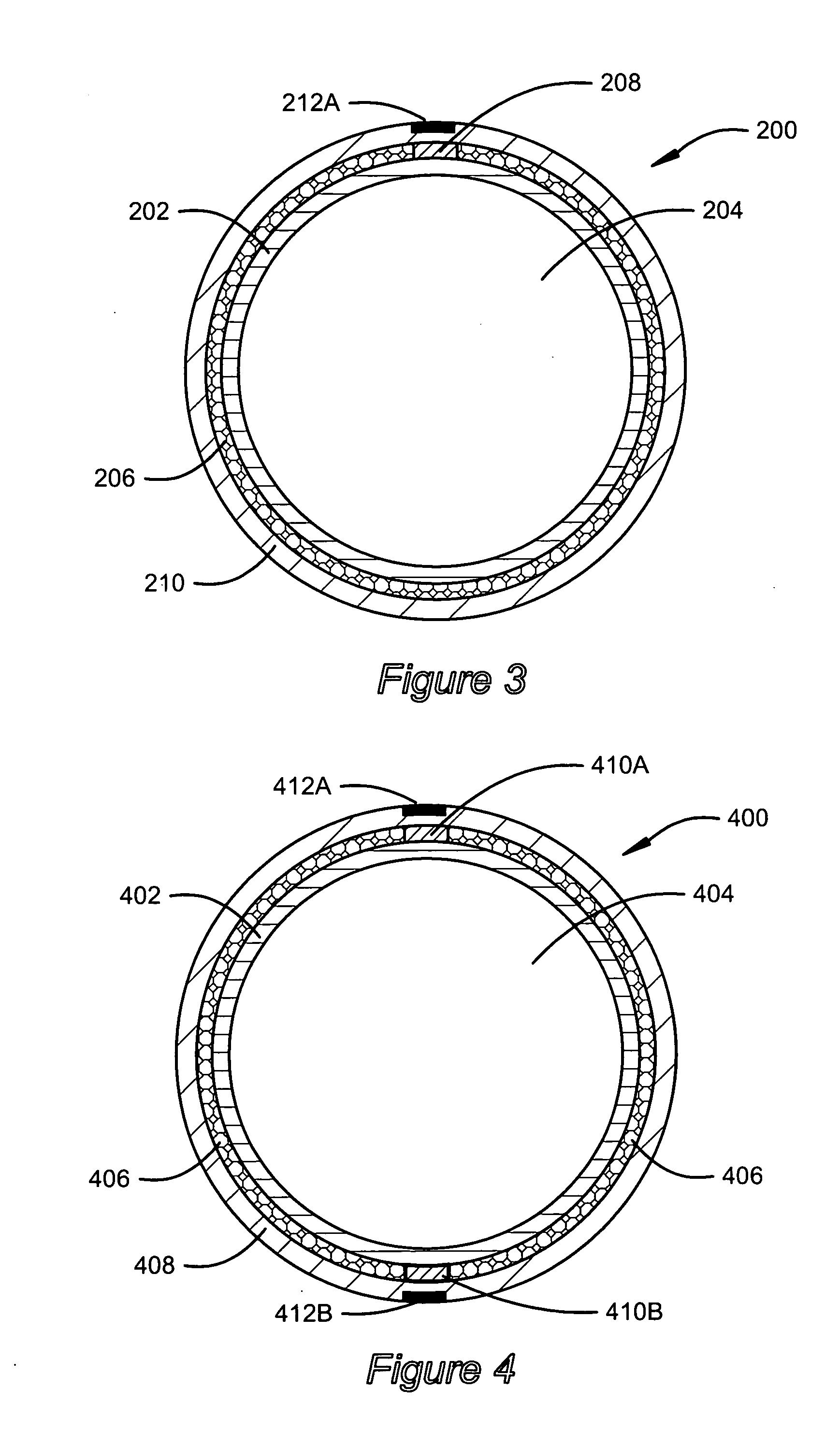

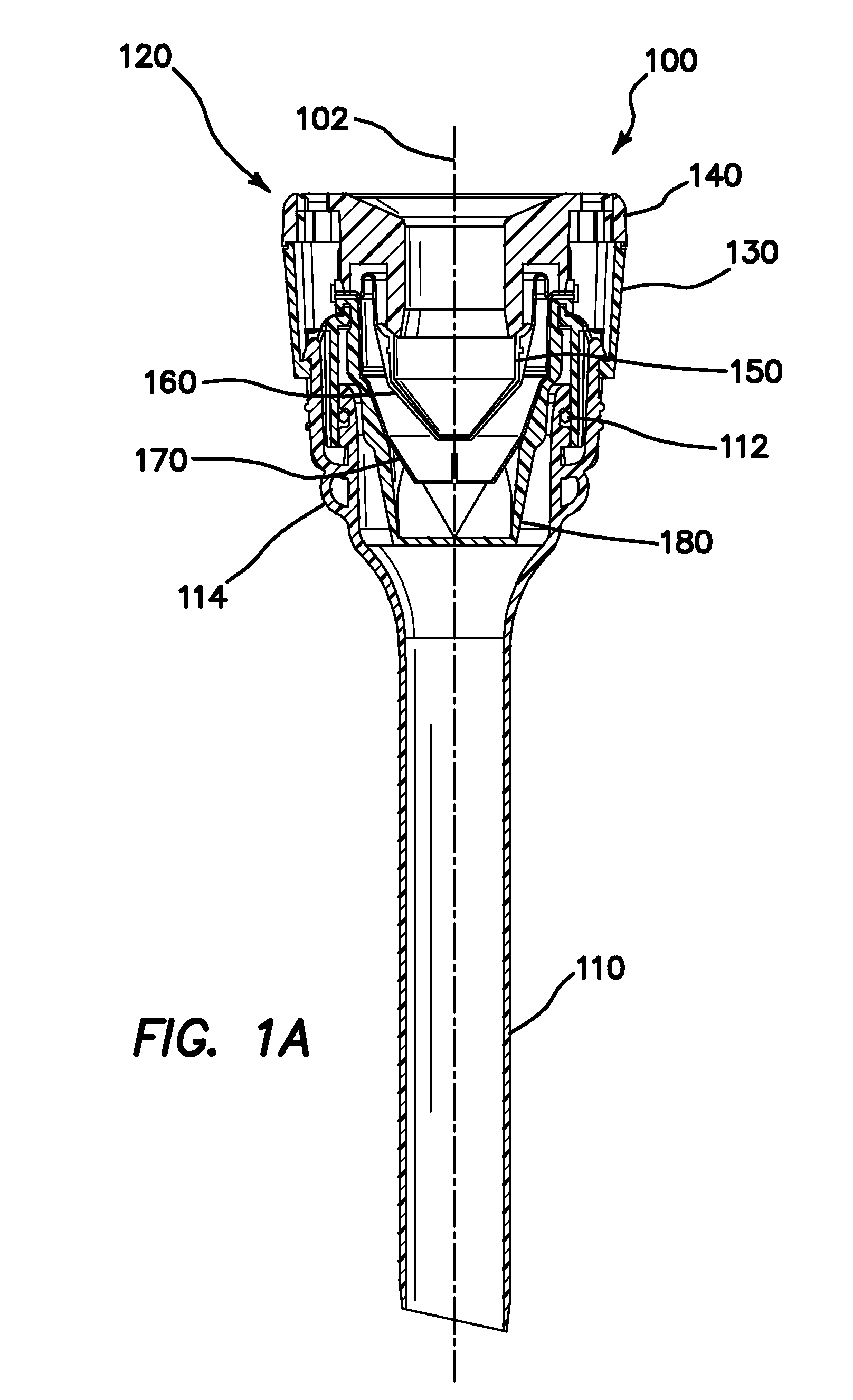

Peel-away catheter shaft

InactiveUS20050182387A1Decrease in tear resistanceReduce resistanceGuide needlesInfusion syringesTear resistanceGuide catheter

A peel-away shaft for a guiding catheter includes a shaft wall defining an open lumen of the catheter shaft. A peel-away region is defined over at least a partial length of the catheter shaft. A braid substantially encompasses the open lumen. The braid includes a region of discontinuity extending along the peel-away region. The region of discontinuity of the braid reduces the tear resistance of the shaft wall along the peel-away region.

Owner:CARDIAC PACEMAKERS INC

High strain tear resistant gels and gel composites for use as artificial muscle actuators

InactiveUS6909220B2Improve propertiesImprove tear resistanceCellsSludge treatmentPolymer sciencePlasticizer

Novel gels and articles are formed from one or more copolymers having at least one poly(ethylene) components and high levels of one or more plasticizers, said gels having an amount of crystallinity, glassy components, and selected plasticizers sufficient to achieve improvements in one or more physical properties including improved crack propagation resistance, improved tear resistance, improved resistance to fatigue, resistance to catastrophic failure, and exhibiting high strain under elongations not obtainable in amorphous gels which high strain making the gel suitable for use as film layers for artificial muscles.

Owner:APPLIED ELASTOMERICS

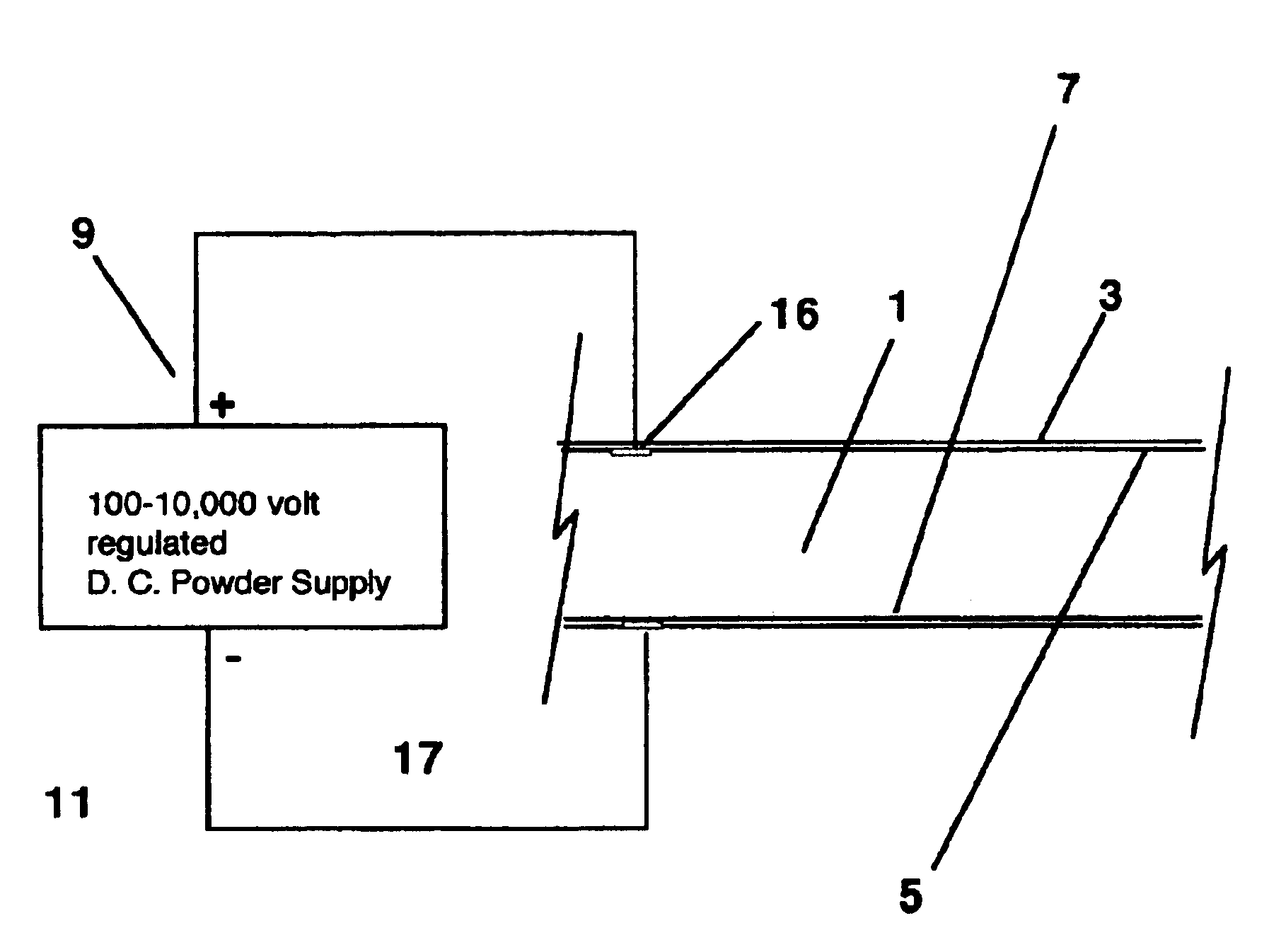

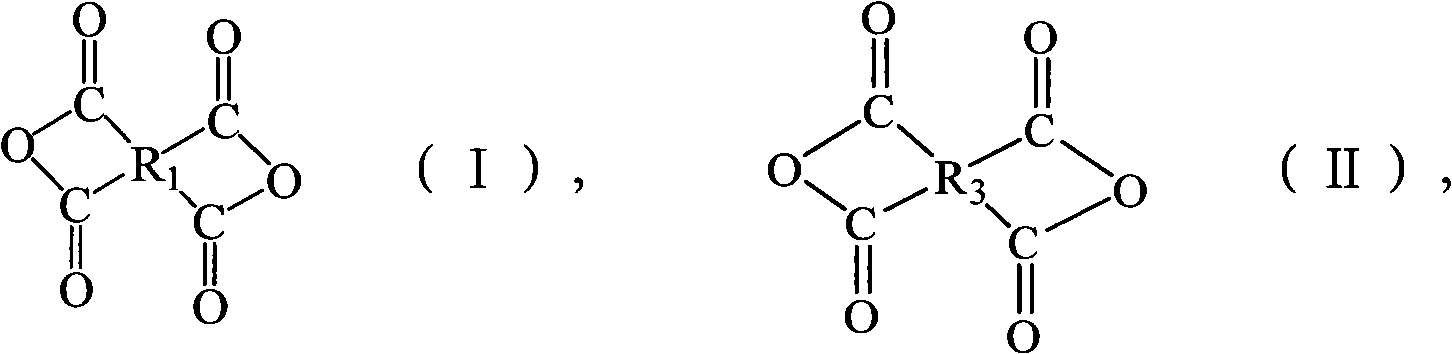

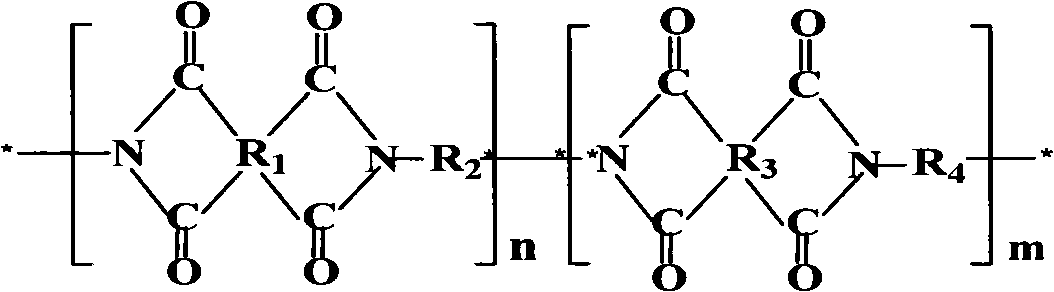

Copolymerized polyimide nanofiber nonwoven and preparation method and application thereof

ActiveCN101974828AHigh mechanical strengthElectrospun copolyimide nanofiber nonwovens with this property are tear-resistantMonocomponent synthetic polymer artificial filamentCell component detailsPorosityTear resistance

The invention relates to a copolymerized polyimide nanofiber nonwoven and a preparation method and application thereof. The preparation method comprises the following steps of: reacting a tetracid dianhydride monomer with a diamine monomer by taking a high-polar solvent as a reaction medium; performing condensation polymerization through mechanical agitation in a reaction kettle to form copolymerized polyimide acid solution; performing electrostatic spinning on the copolymerized polyimide acid solution in a high-voltage electric field so as to obtain the copolymerized polyimide nanofiber nonwoven; performing imidization on the nonwoven at a high temperature to prepare the copolymerized polyimide nanofiber nonwoven which has the characteristics of high tear resistance, high porosity, high temperature and low temperature resistance and high mechanical properties. The copolymerized polyimide nanofiber nonwoven is mainly used for battery diaphragms and capacitor diaphragms.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

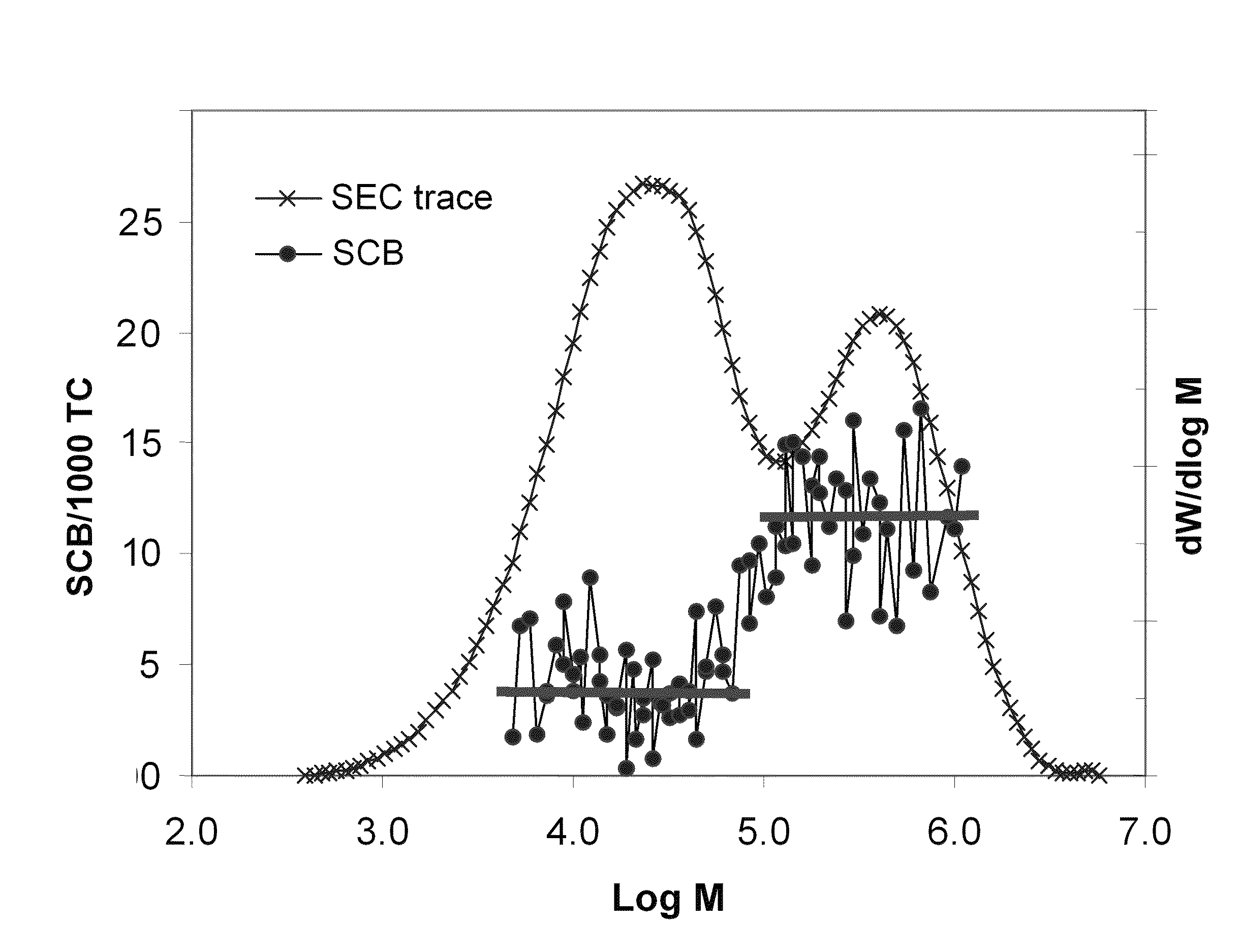

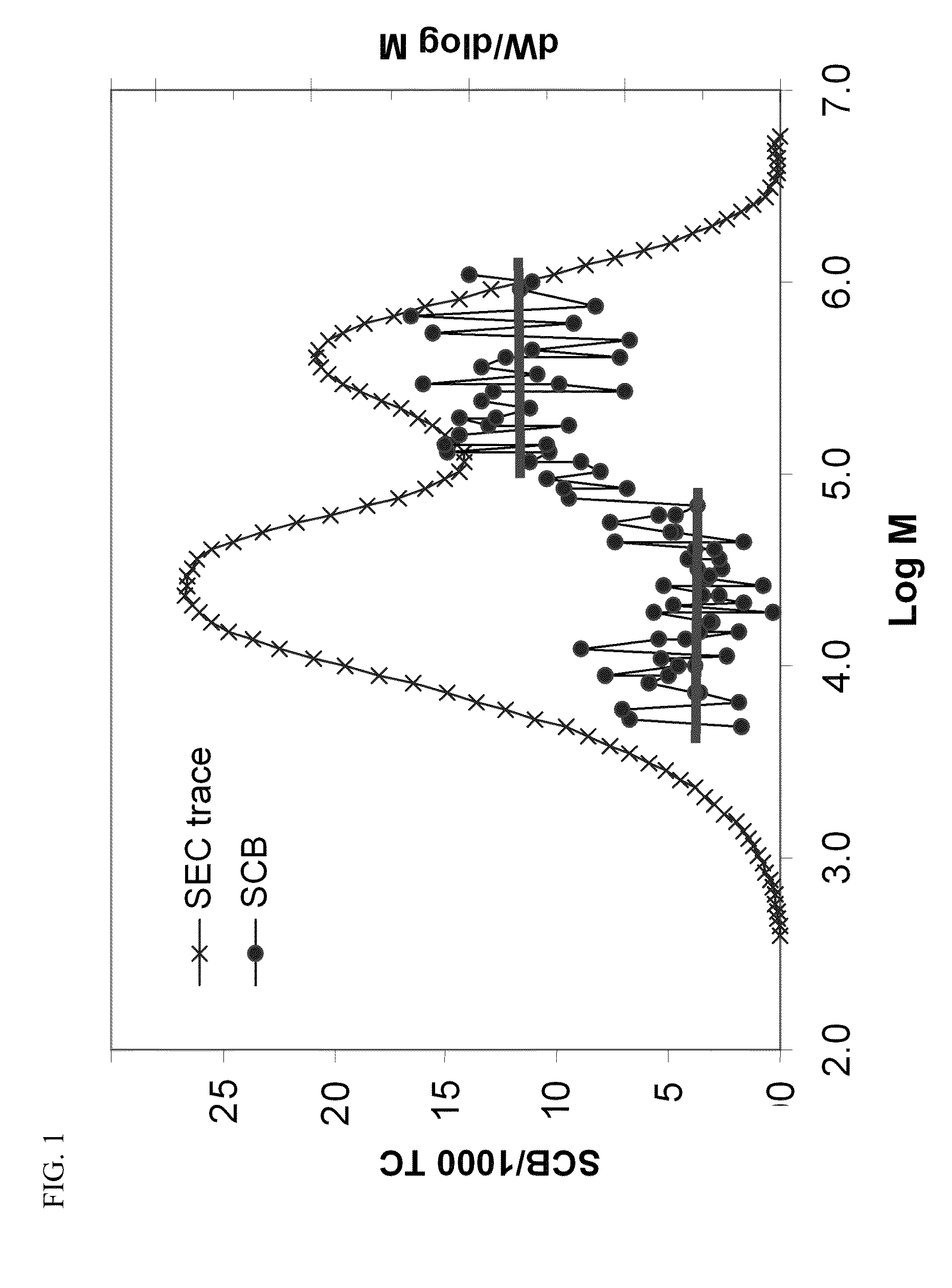

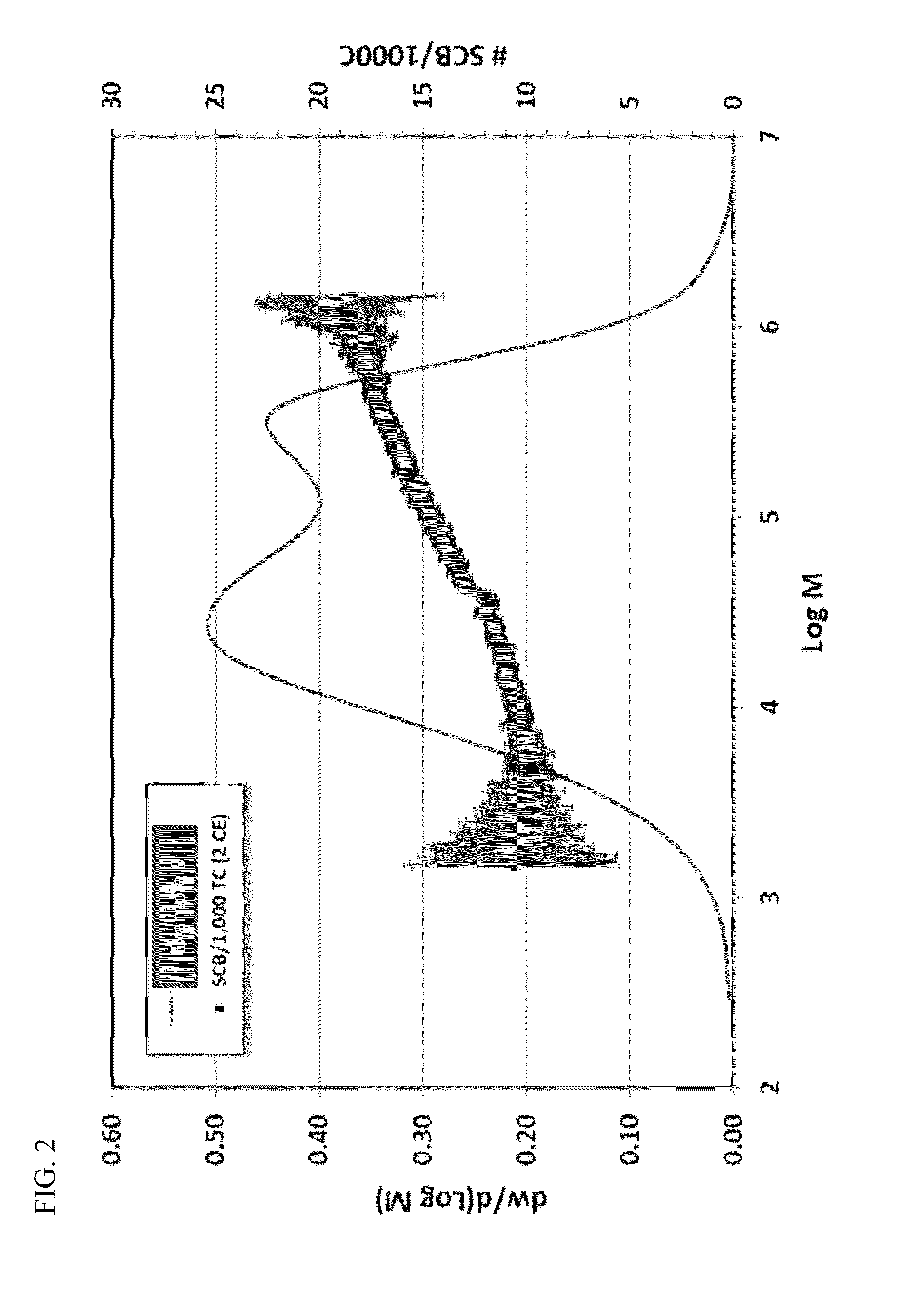

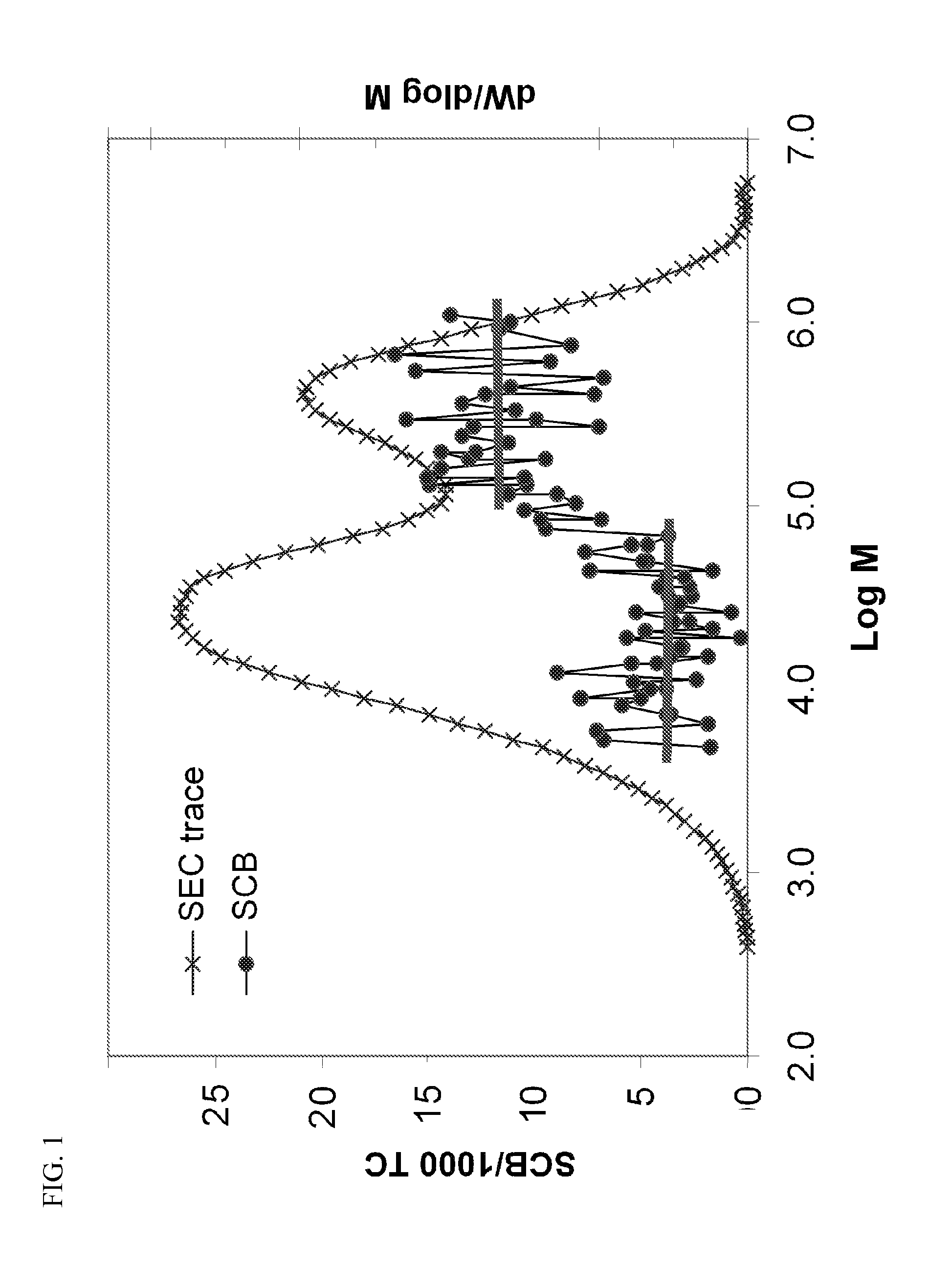

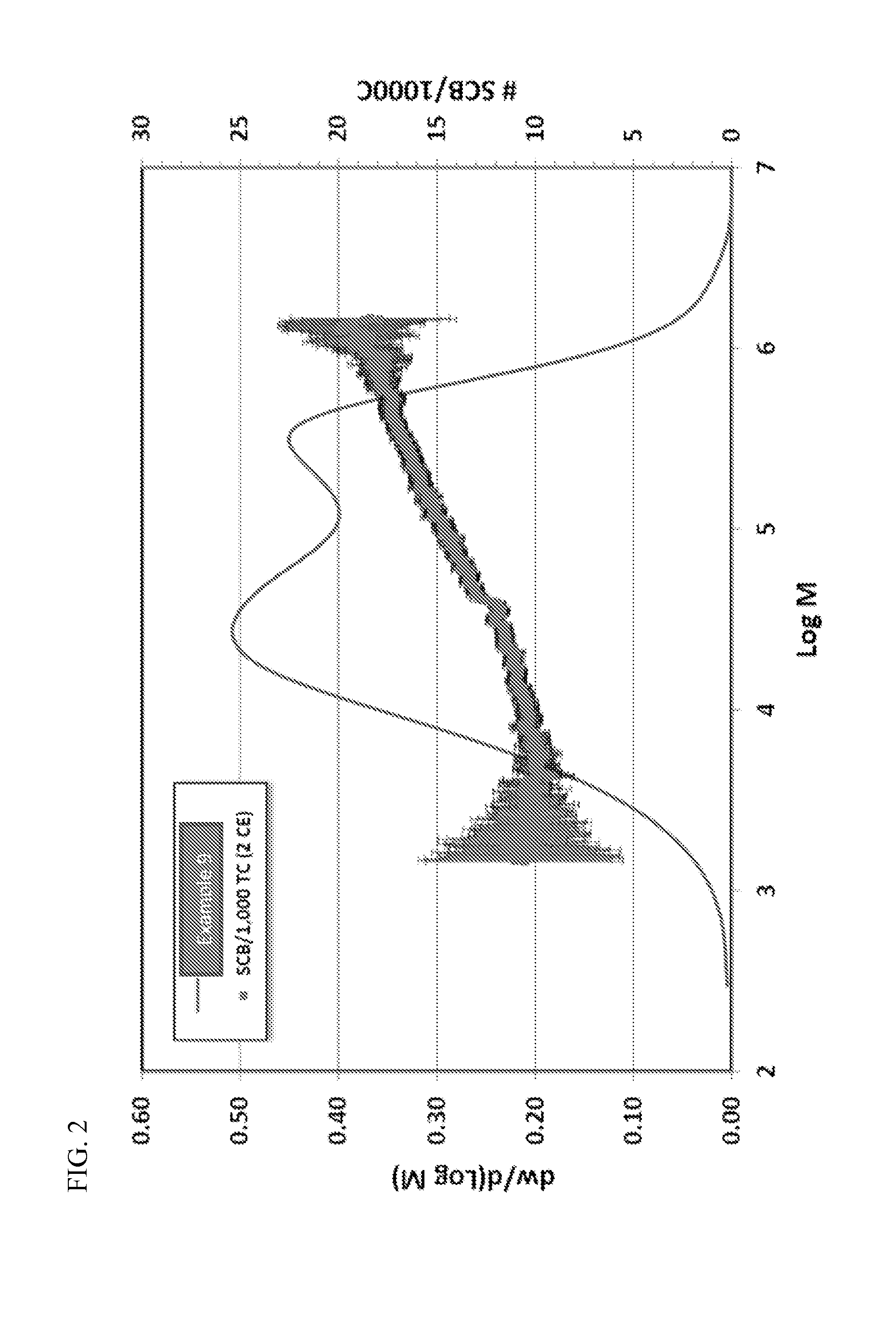

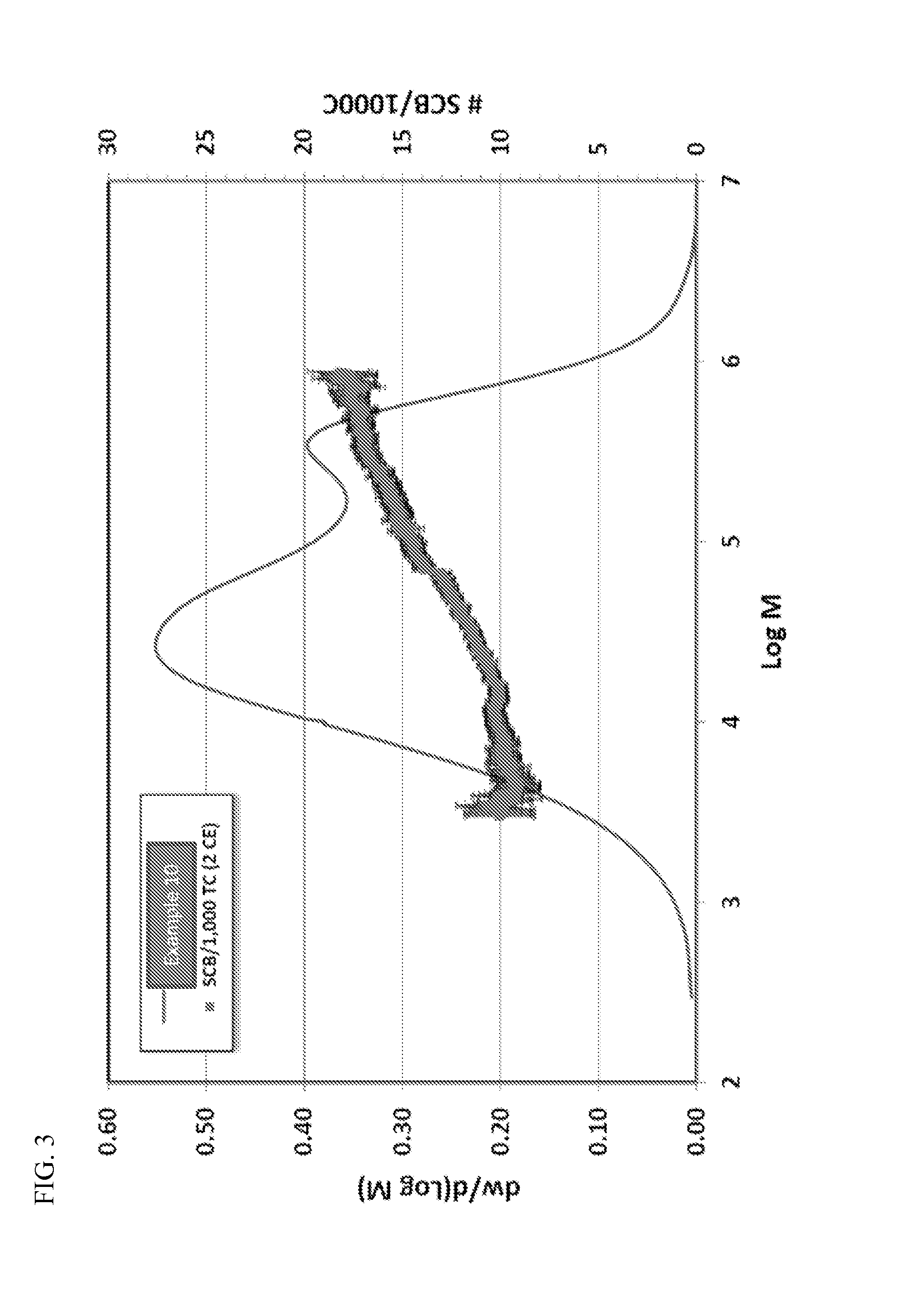

Low density polyolefin resins and films made therefrom

Disclosed herein are broad molecular weight distribution olefin polymers having densities in the 0.895 to 0.930 g / cm3 range, and with improved impact and tear resistance. These polymers can have a ratio of Mw / Mn in the 8 to 35 range, a high load melt index in the 4 to 50 range, less than about 0.008 LCB per 1000 total carbon atoms, and a reverse comonomer distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

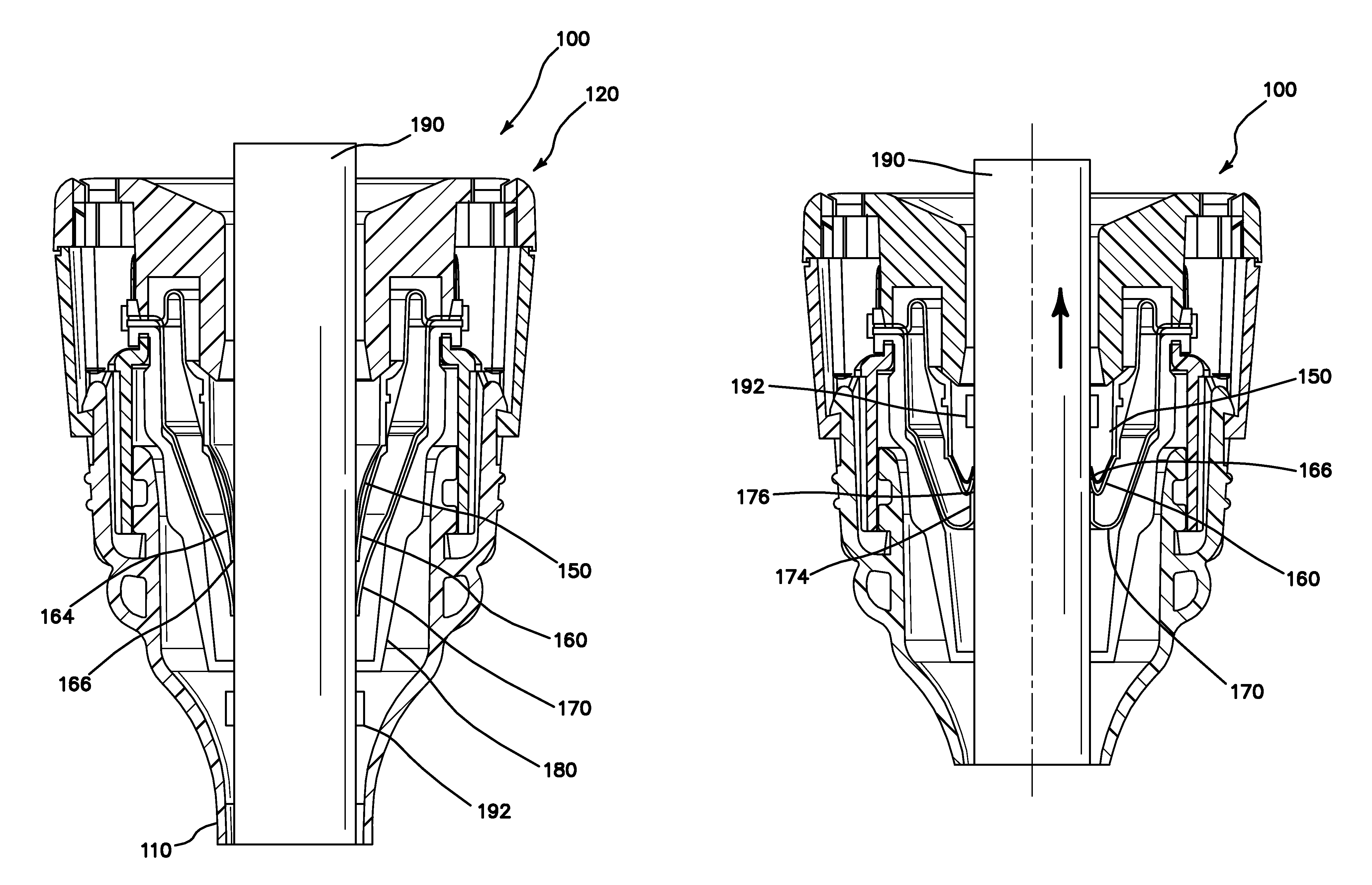

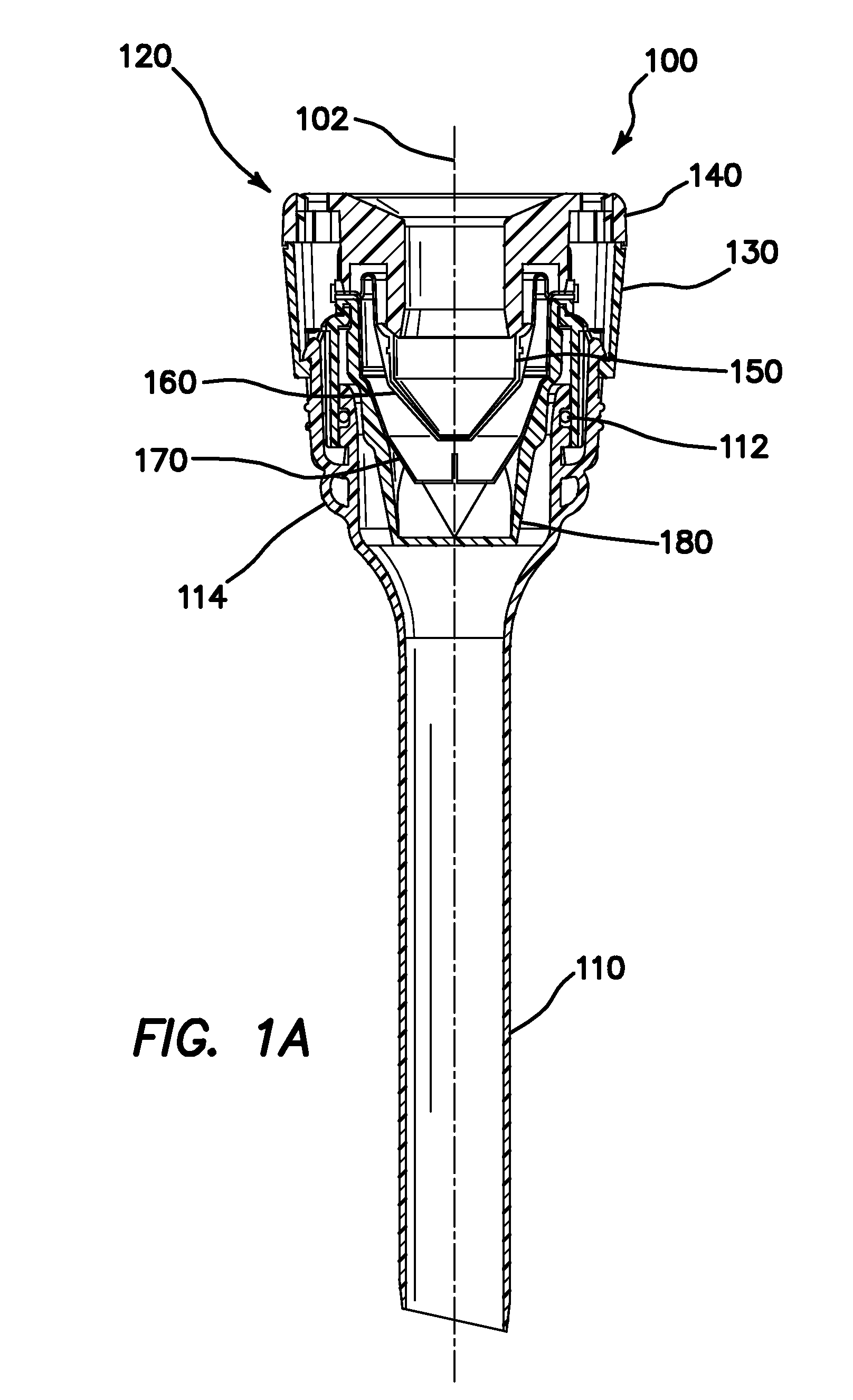

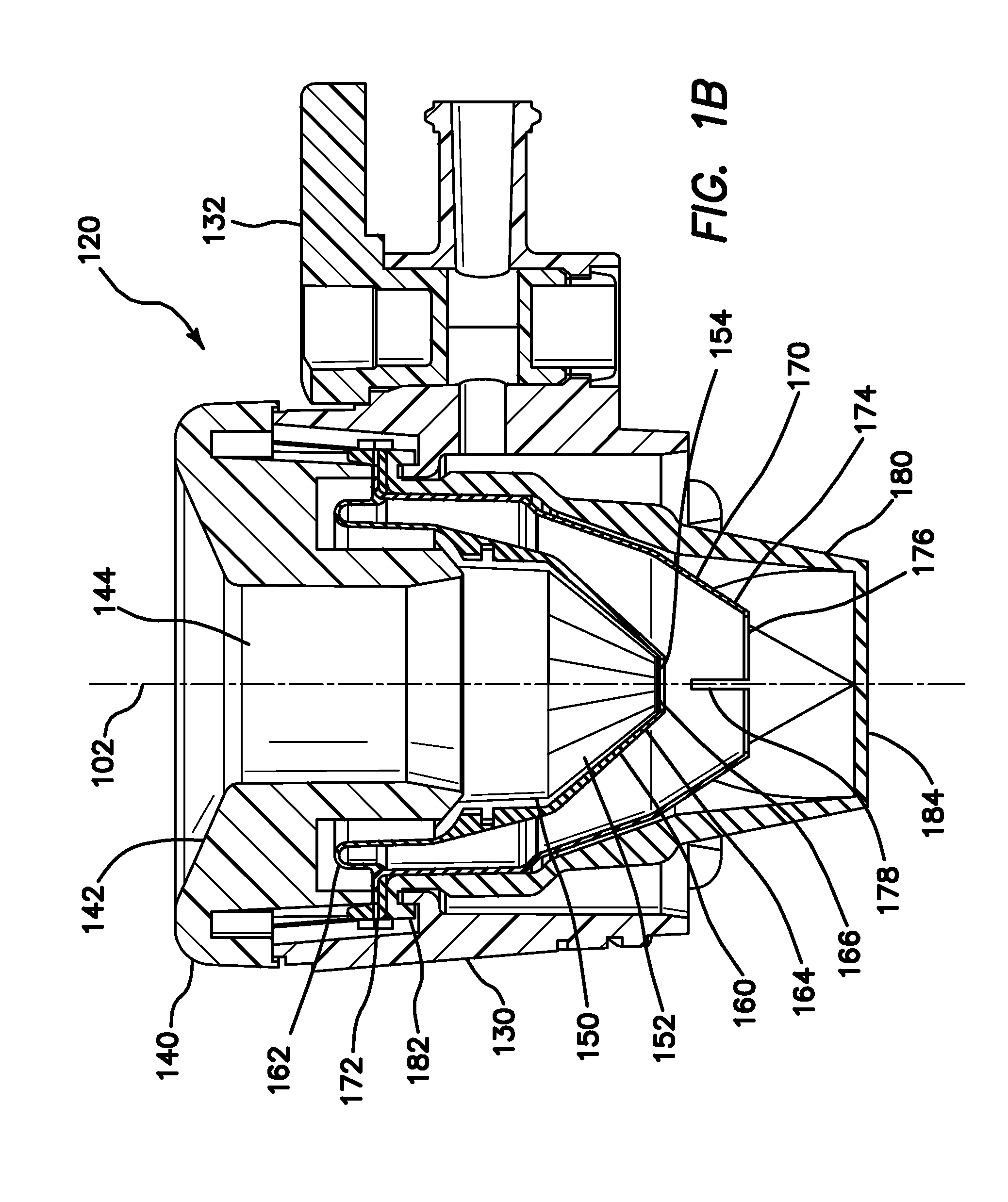

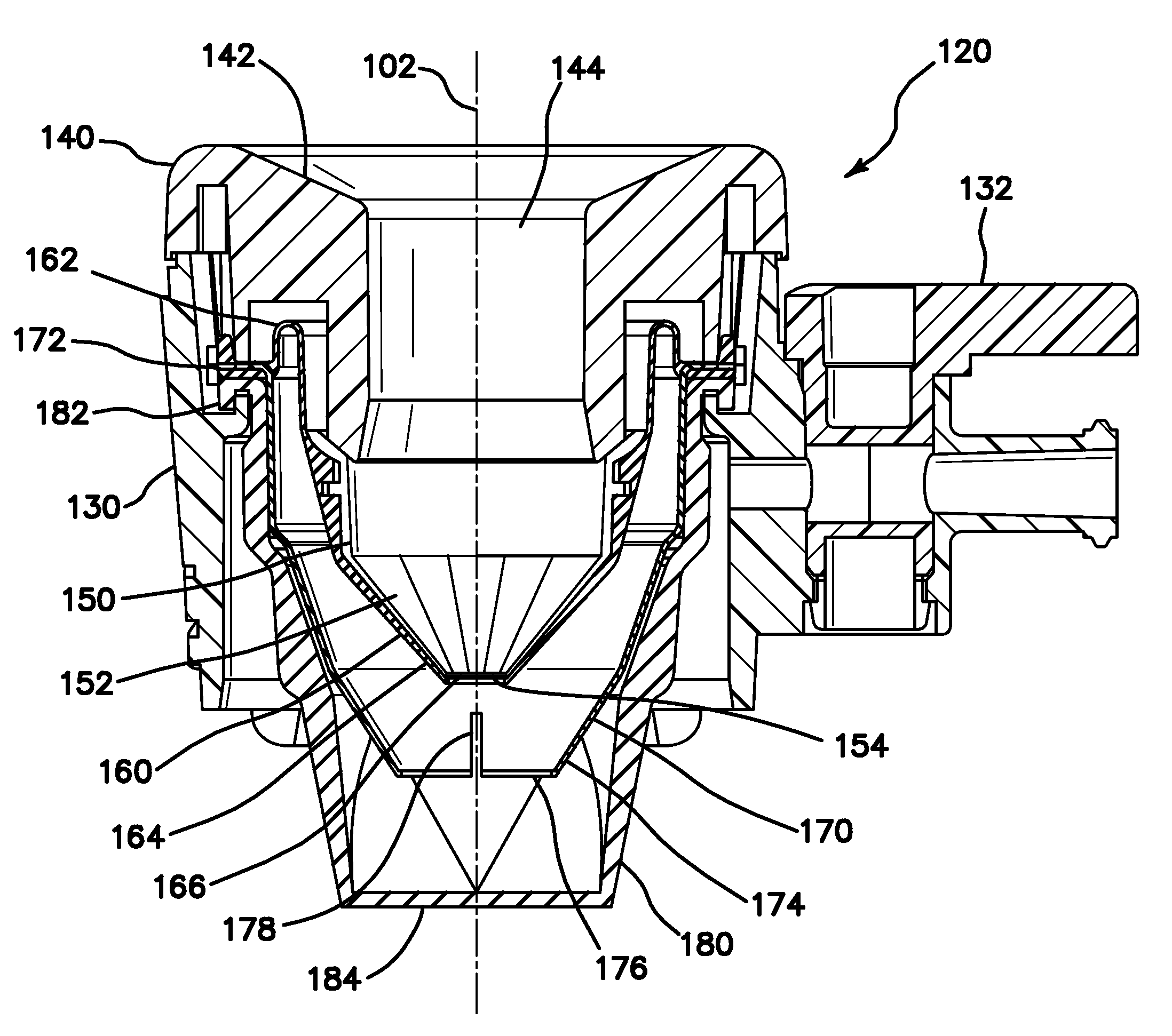

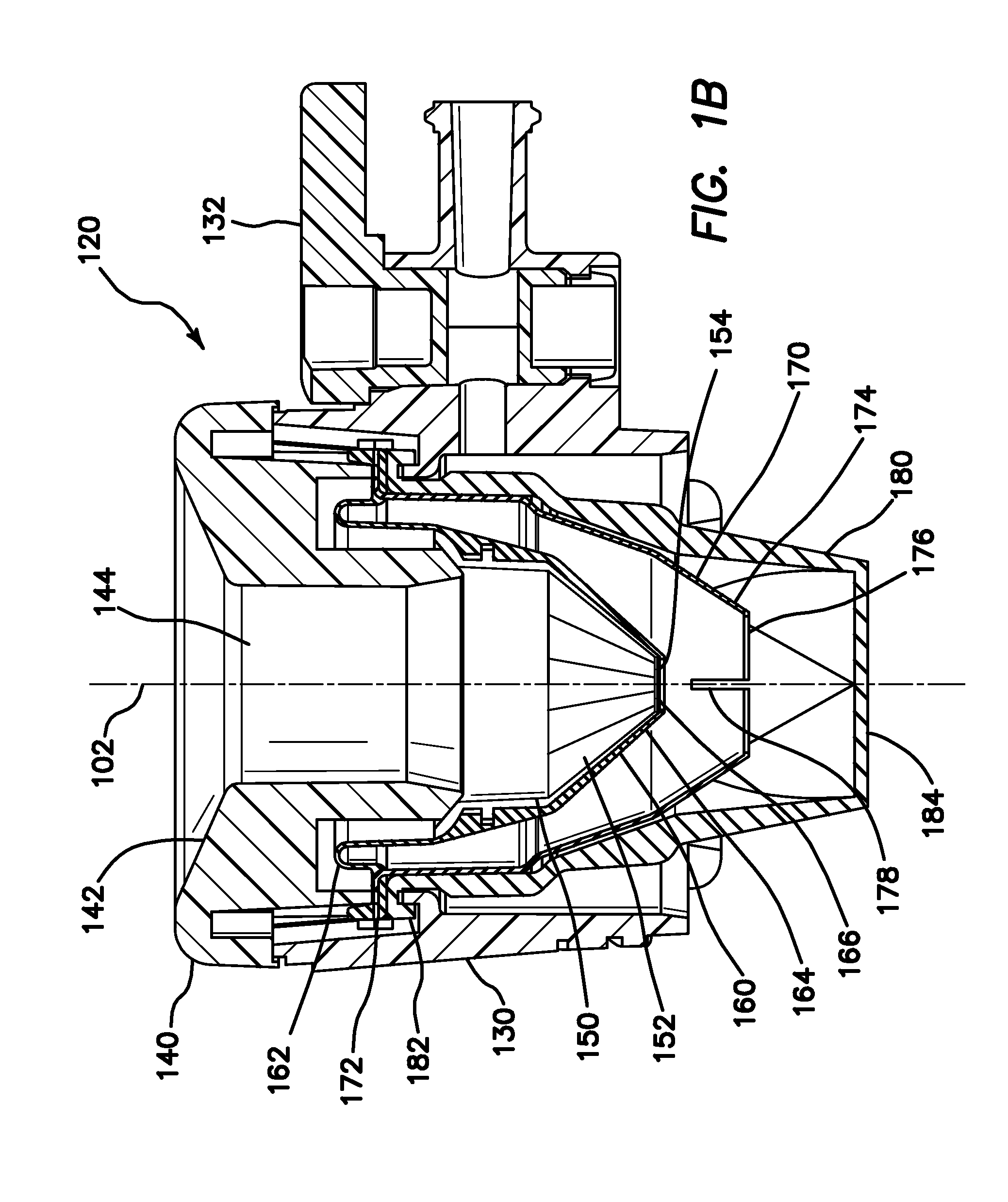

Instrument seal with inverting shroud

A surgical access device comprising an instrument access channel extending through an instrument seal and a shroud comprising an inverting region disposed distally of the instrument seal exhibits improved tear-resistance of the instrument seal from instrument manipulation, for example, instrument withdrawals. Some embodiments of the inverting region invert through the instrument seal on instrument withdrawal. Some embodiments of the inverting region induce at least a portion of the instrument seal itself to invert on instrument withdrawal.

Owner:APPL MEDICAL RESOURCES CORP

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

Low Density Polyolefin Resins and Films Made Therefrom

Disclosed herein are broad molecular weight distribution olefin polymers having densities in the 0.895 to 0.930 g / cm3 range, and with improved impact and tear resistance. These polymers can have a ratio of Mw / Mn in the 8 to 35 range, a high load melt index in the 4 to 50 range, less than about 0.008 LCB per 1000 total carbon atoms, and a reverse comonomer distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

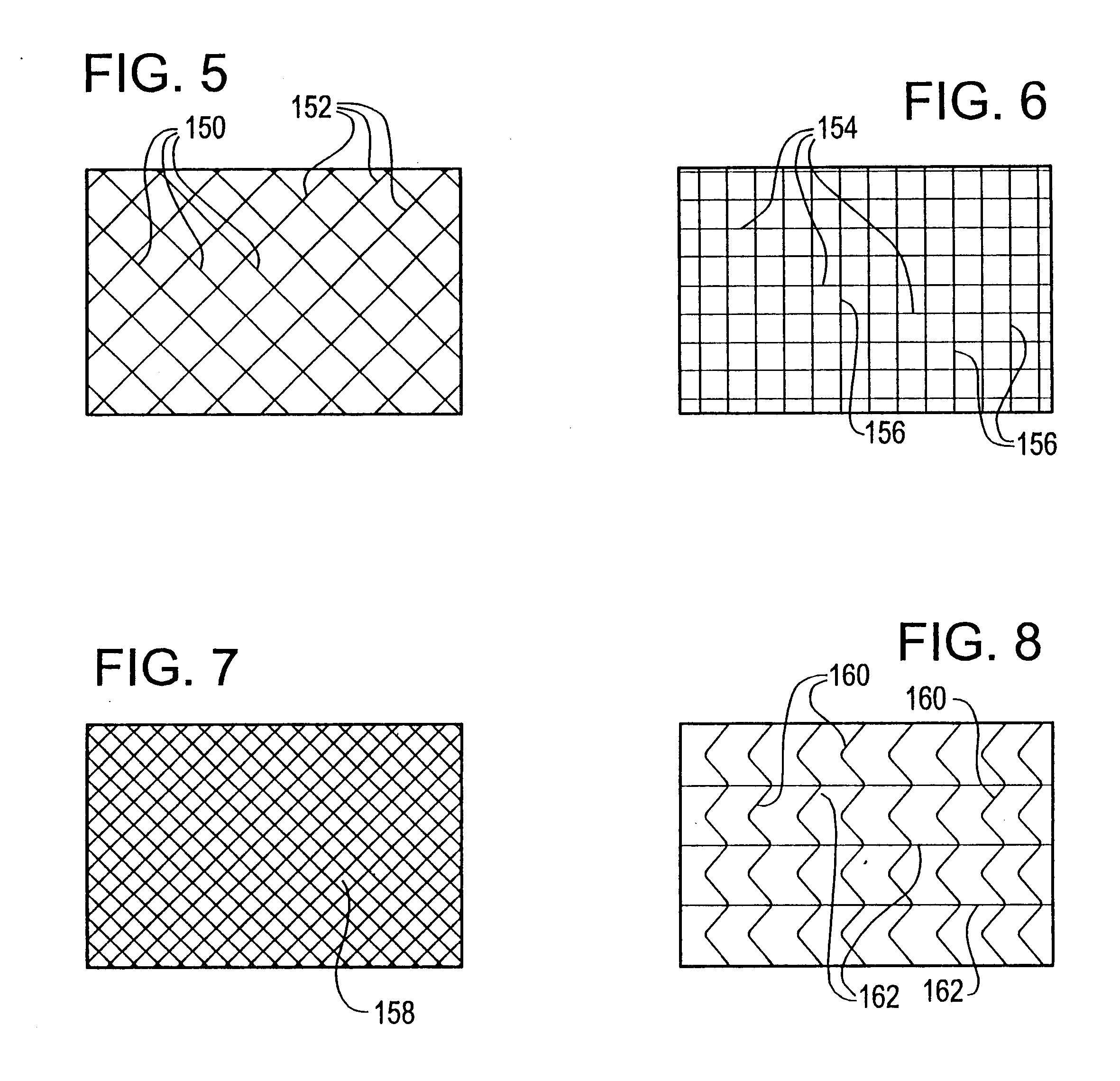

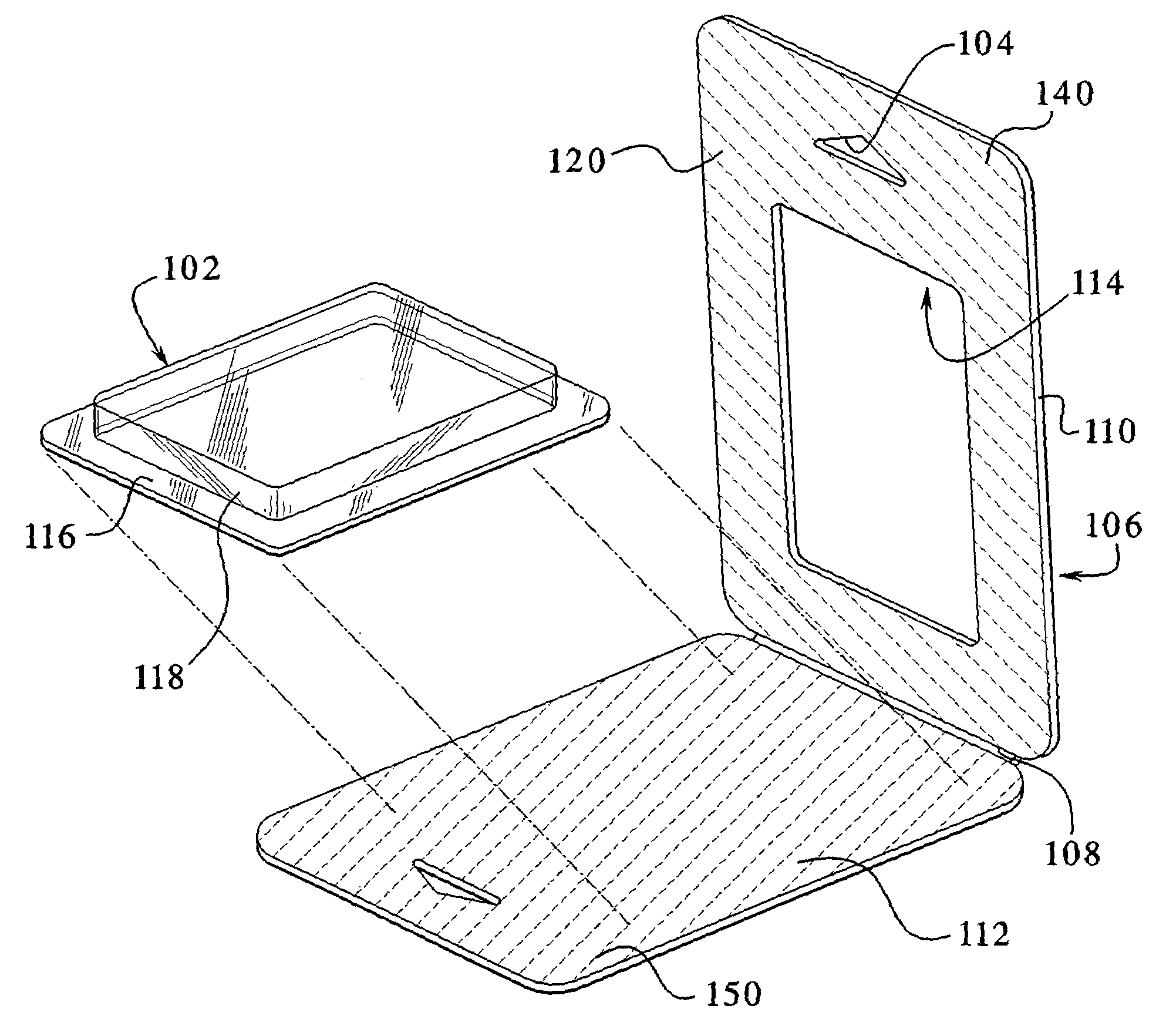

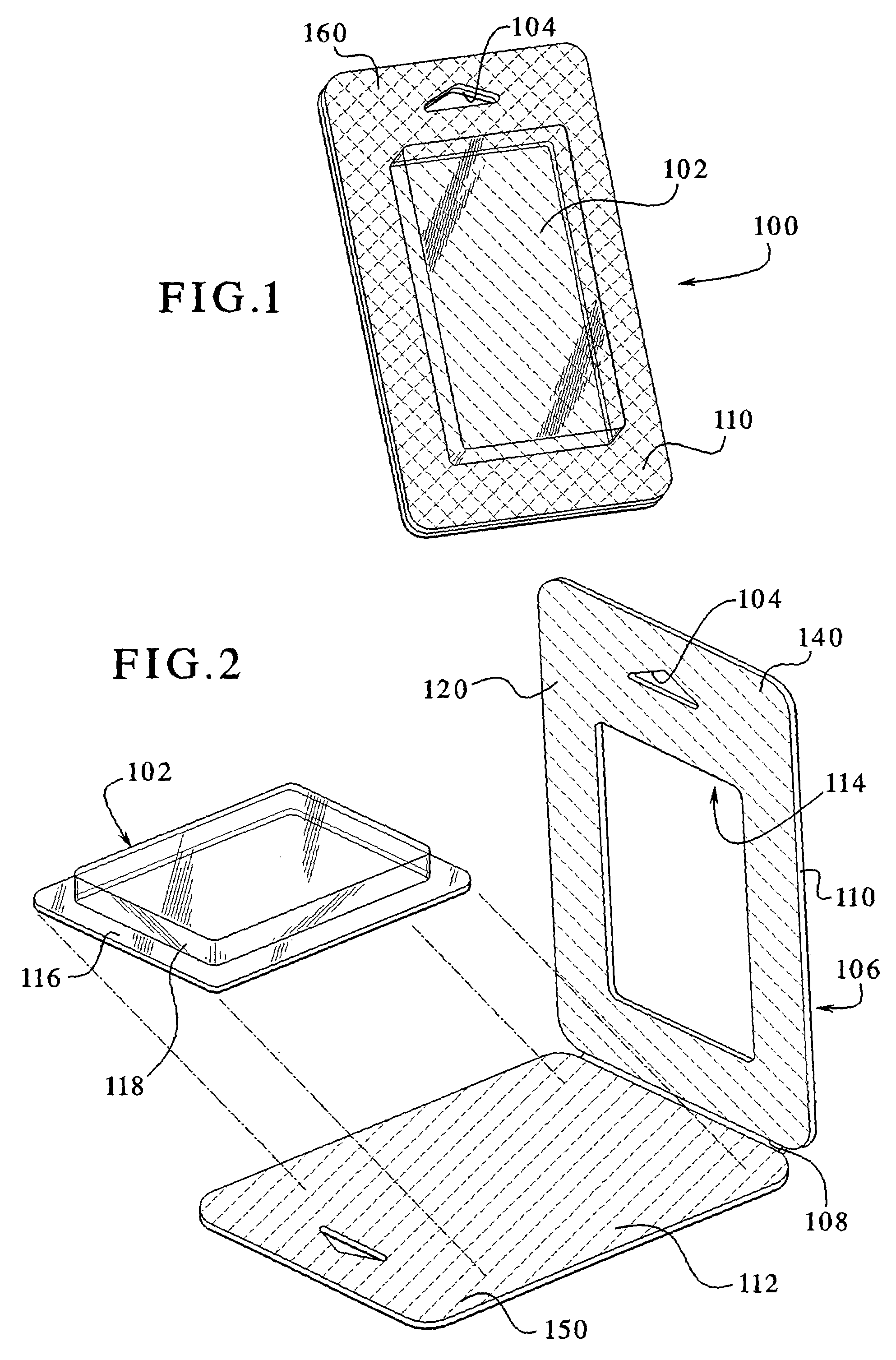

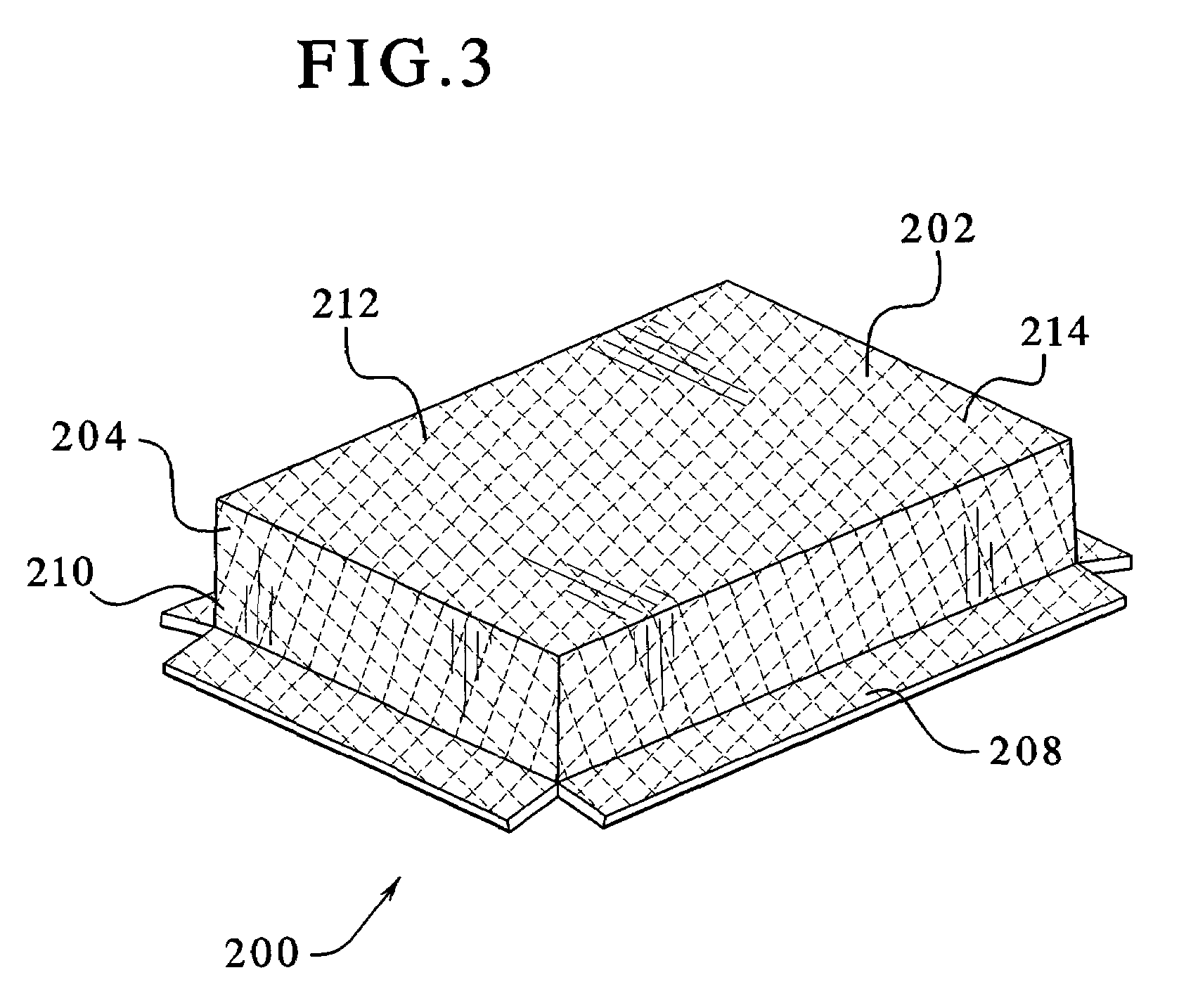

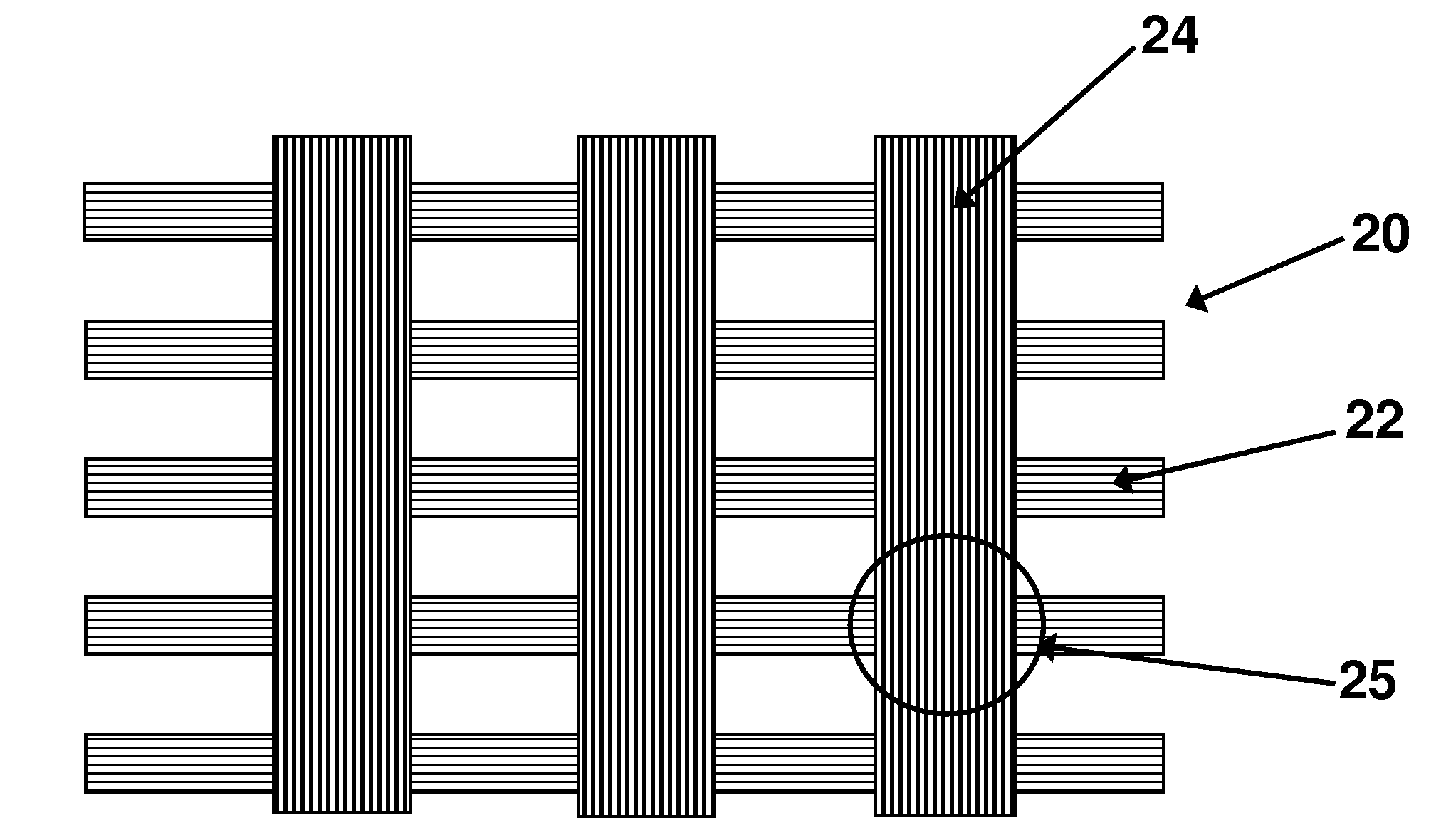

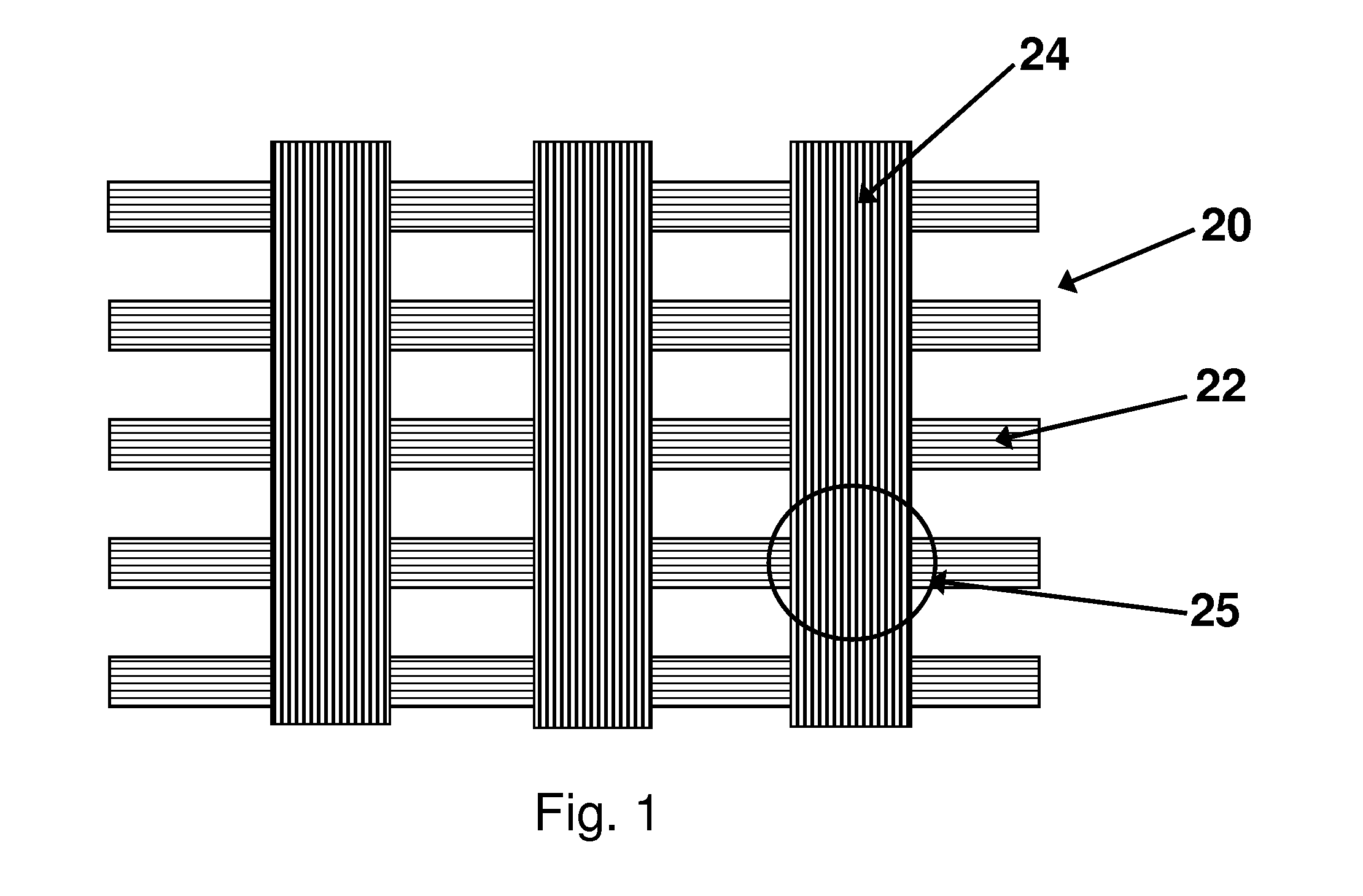

Pilfer-resistant packaging with criss-cross grain pattern

ActiveUS7051876B2Prevent theftEasy and economical to manufactureSmall article dispensingPharmaceutical containersGraphicsTear resistance

A clamshell package for displaying and housing products or other objects that is substantially pilfer-resistant, yet safe to open. The clamshell packaging includes a substantially tear-resistant housing that encloses a display chamber by criss-cross grain material to provide cut or tear resistance in multiple directions. The display chamber of the clamshell package may be either substantially transparent to allow for the product to be displayed or substantially opaque display graphics and / or to prevent the contents from being viewed. The chamber is preferably seamless such that it may not be opened without the use of scissors and, when opened, such opening is readily apparent. Furthermore, when cut open, the material used does not form sharp or jagged edges that may pose a danger to anyone handling the package. In addition to clamshell packages, the tear resistant material may also be used in blister packs and other types of packaging.

Owner:COLBERT PACKAGING CORP

Instrument seal with inverting shroud

ActiveUS20090240204A1Protection from damageImprove tear resistanceCannulasInfusion syringesTear resistanceEngineering

A surgical access device comprising an instrument access channel extending through an instrument seal and a shroud comprising an inverting region disposed distally of the instrument seal exhibits improved tear-resistance of the instrument seal from instrument manipulation, for example, instrument withdrawals. Some embodiments of the inverting region invert through the instrument seal on instrument withdrawal. Some embodiments of the inverting region induce at least a portion of the instrument seal itself to invert on instrument withdrawal.

Owner:APPL MEDICAL RESOURCES CORP

Giant engineering tire tread rubber and giant engineering tyre using the same

InactiveCN101440176ASolve wear resistanceSolve heat resistanceSpecial tyresHeat resistanceTear resistance

The invention discloses tread rubber for a large project tire and the large project tire using the tread rubber. The tread rubber for the large project tire consists of (A) tread cap rubber, (B) tread center rubber and (C) tread base rubber. On one hand, the invention adopts rubber matrixes with three different formulas to well solve the problem that an outer layer is easy to overcure if the tread rubber for the large project tire is thick; and on the other hand, the tread rubber prepared by the three formulas of the rubber matrixes can obtain superior equilibrium between abrasion resistance, heat resistance, tear resistance, low heat generation and curing speed.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

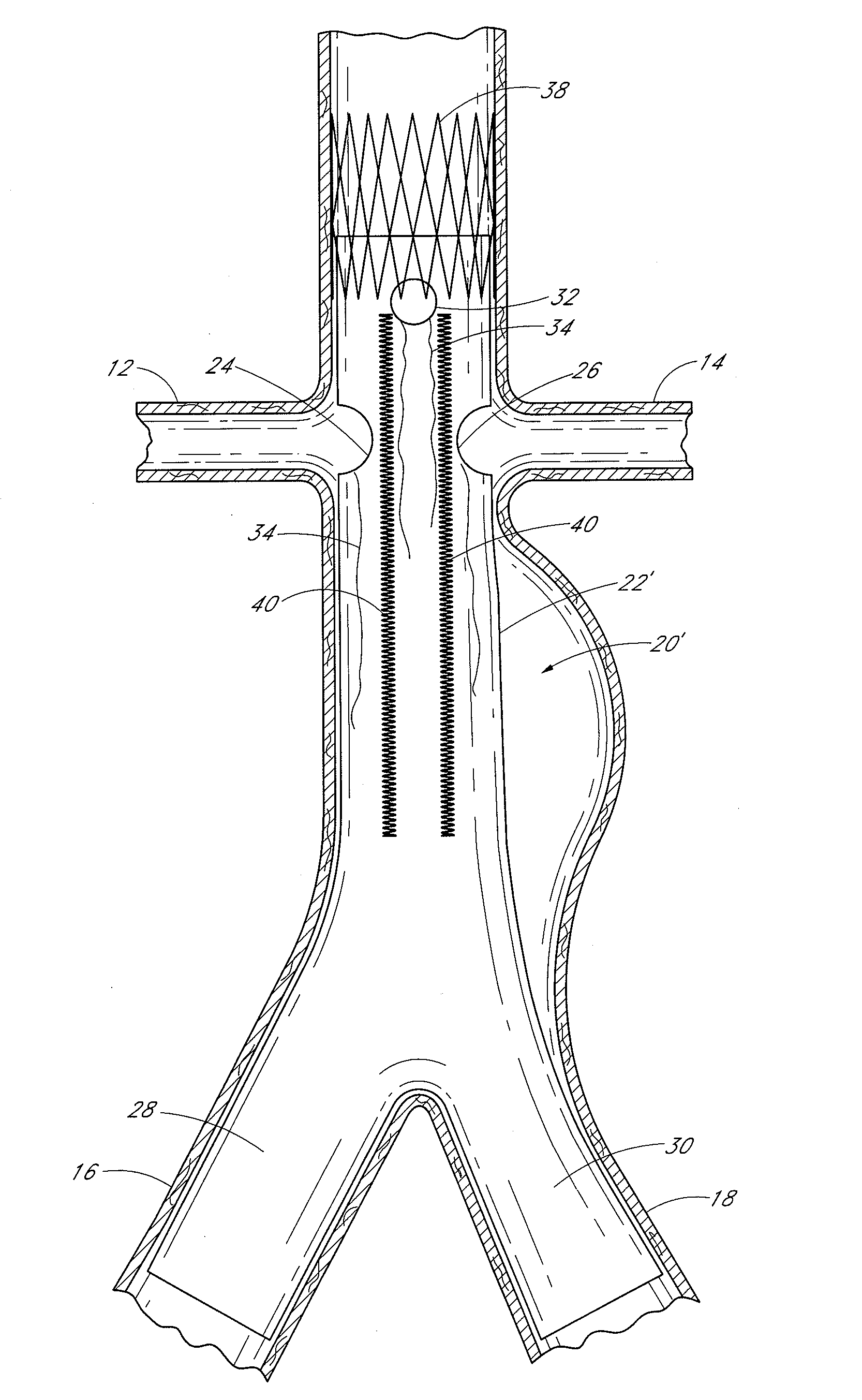

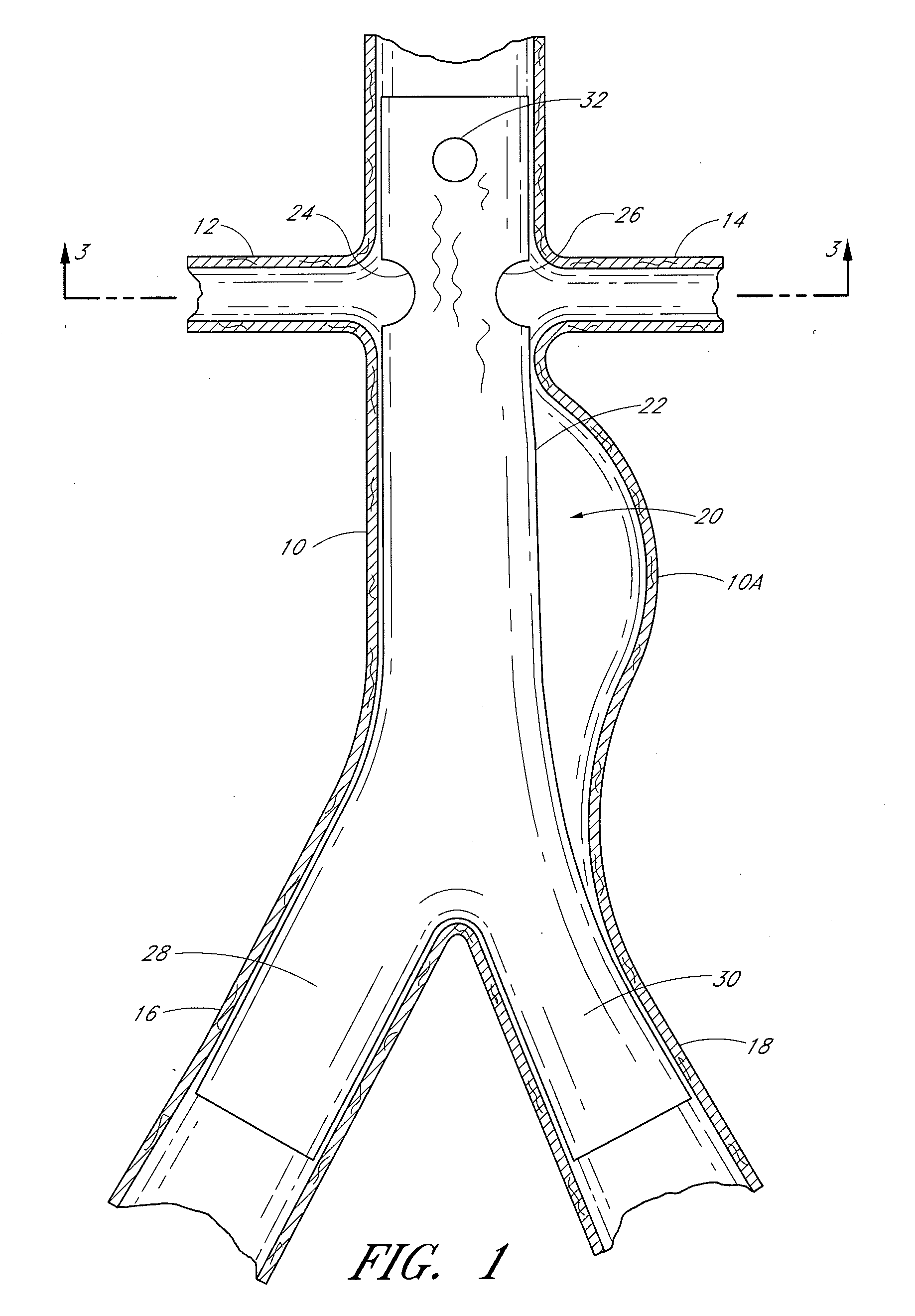

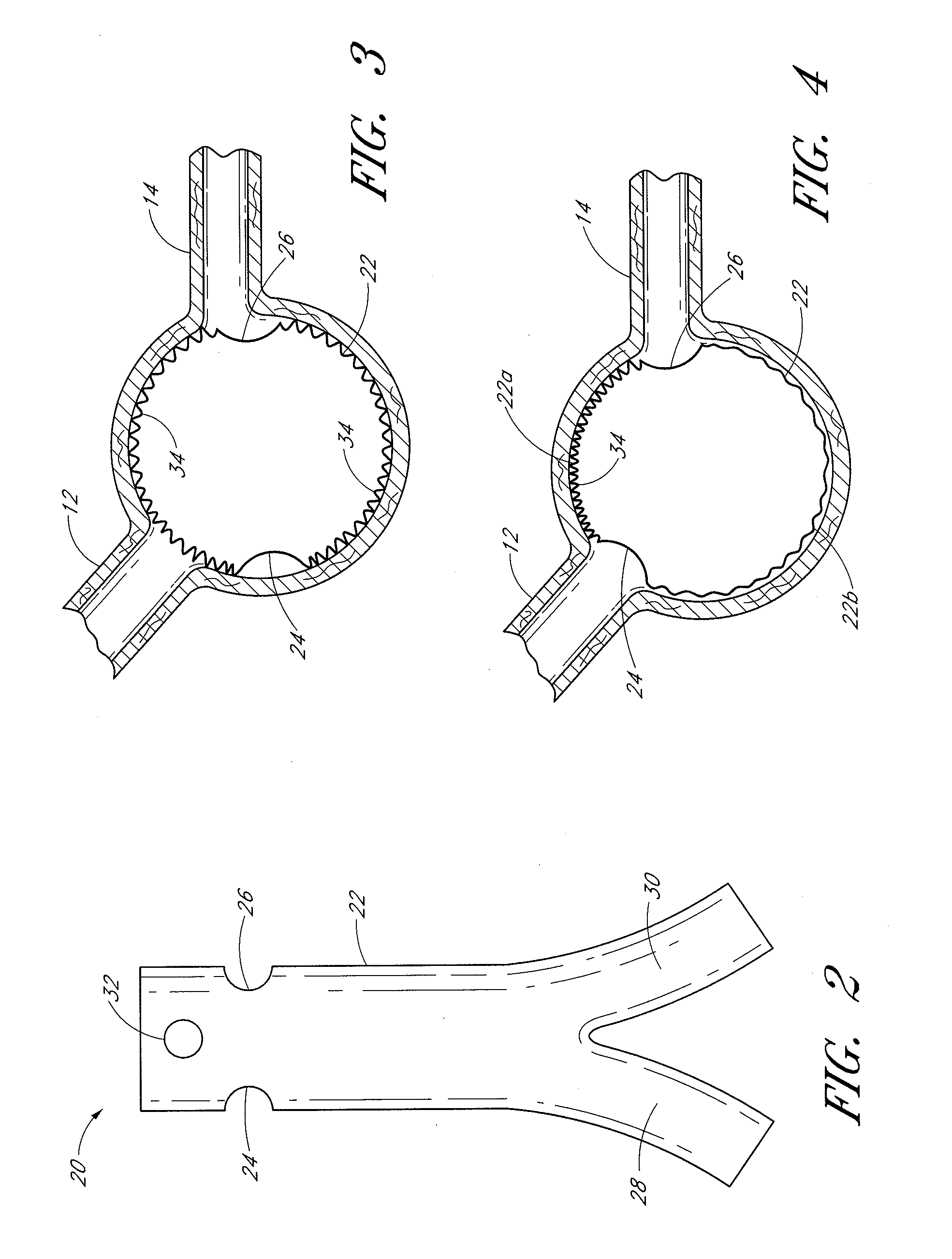

Fenestrated prosthesis

Some embodiments of the present disclosure are directed to endoluminal prostheses having one or more reinforced fenestrations therein. The one or more reinforced fenestrations can have improved sealing capabilities with respect to branch grafts deployed within the fenestrations, improved tear resistance and expandability, and improved pull-out resistance for branch grafts. In some embodiments, the endoluminal prosthesis can have a main graft body defining a flow lumen therethrough, a first opening passing through a wall of the main graft body, and a first support member supported by the main graft body and overlapping an edge of the first opening, the first support member being configured to at least increase the tear resistance of the main graft body adjacent to the first opening. The support member can be stitched or otherwise attached to the main graft adjacent to the fenestration.

Owner:ENDOLOGIX LLC +1

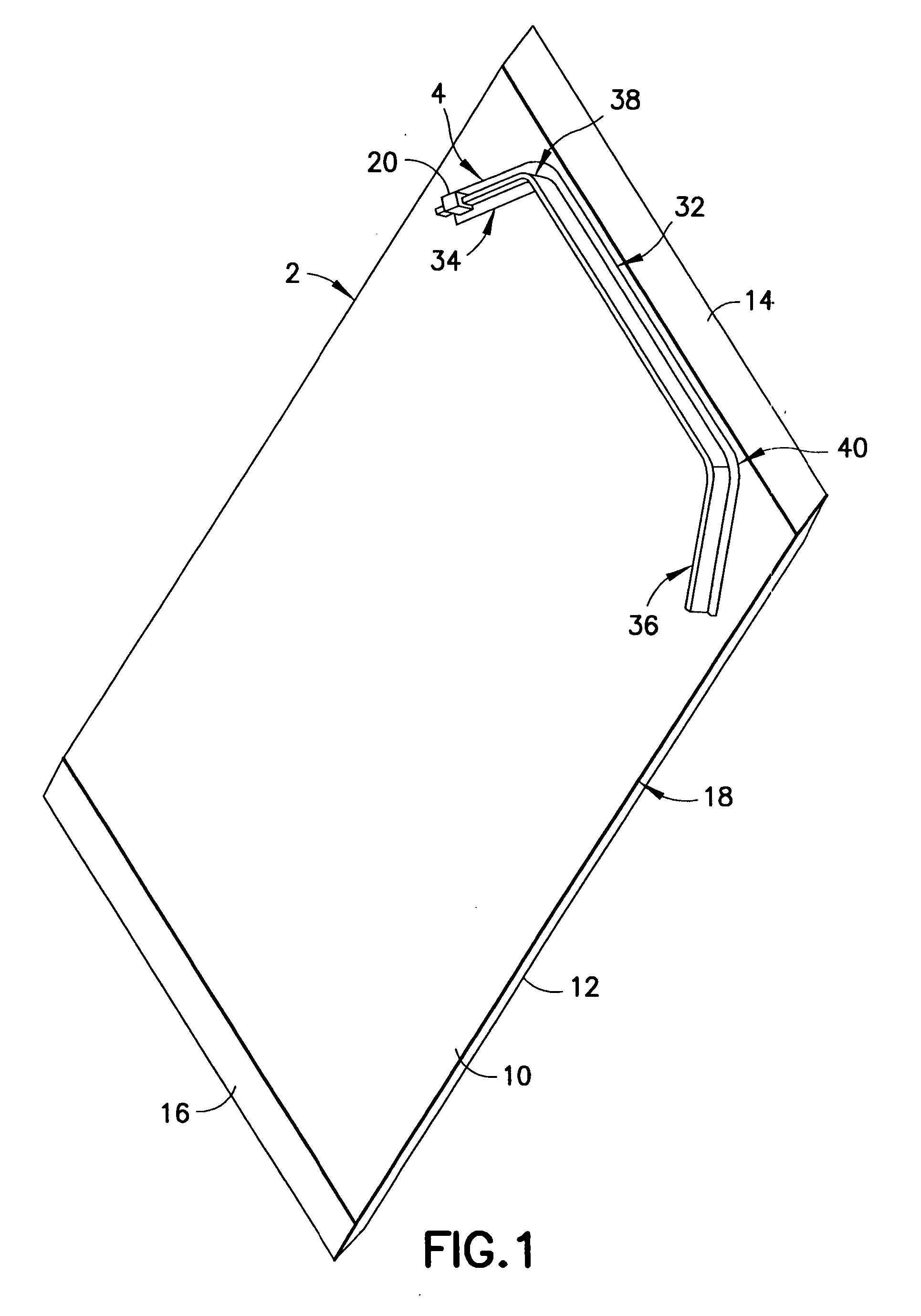

Reclosable packages with two-dimensional zipper attachement

A reclosable package having a two-dimensional zipper attachment on the exterior of one wall. The zipper comprises a pair of zipper strips that have straight central sections and end sections that curve or bend, diverging from the straight central section. Directly below the interface of the zipper profiles, the wall has a line of weakened tear resistance that can be torn open after the zipper has been opened. A flap portion of the wall, with one of the zipper strips attached to its periphery, can then be folded back to provide a wide opening for accessing the package contents.

Owner:ILLINOIS TOOL WORKS INC

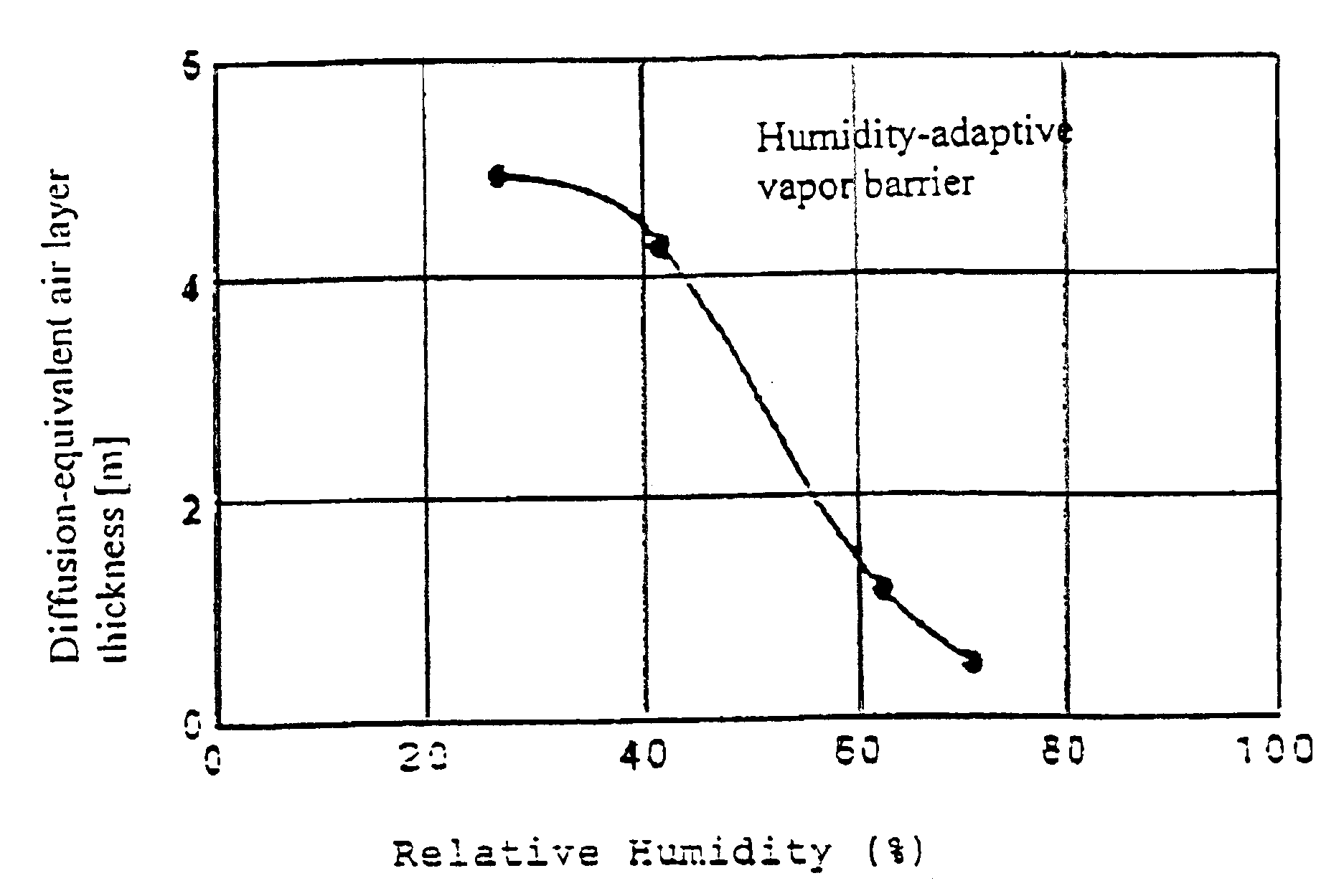

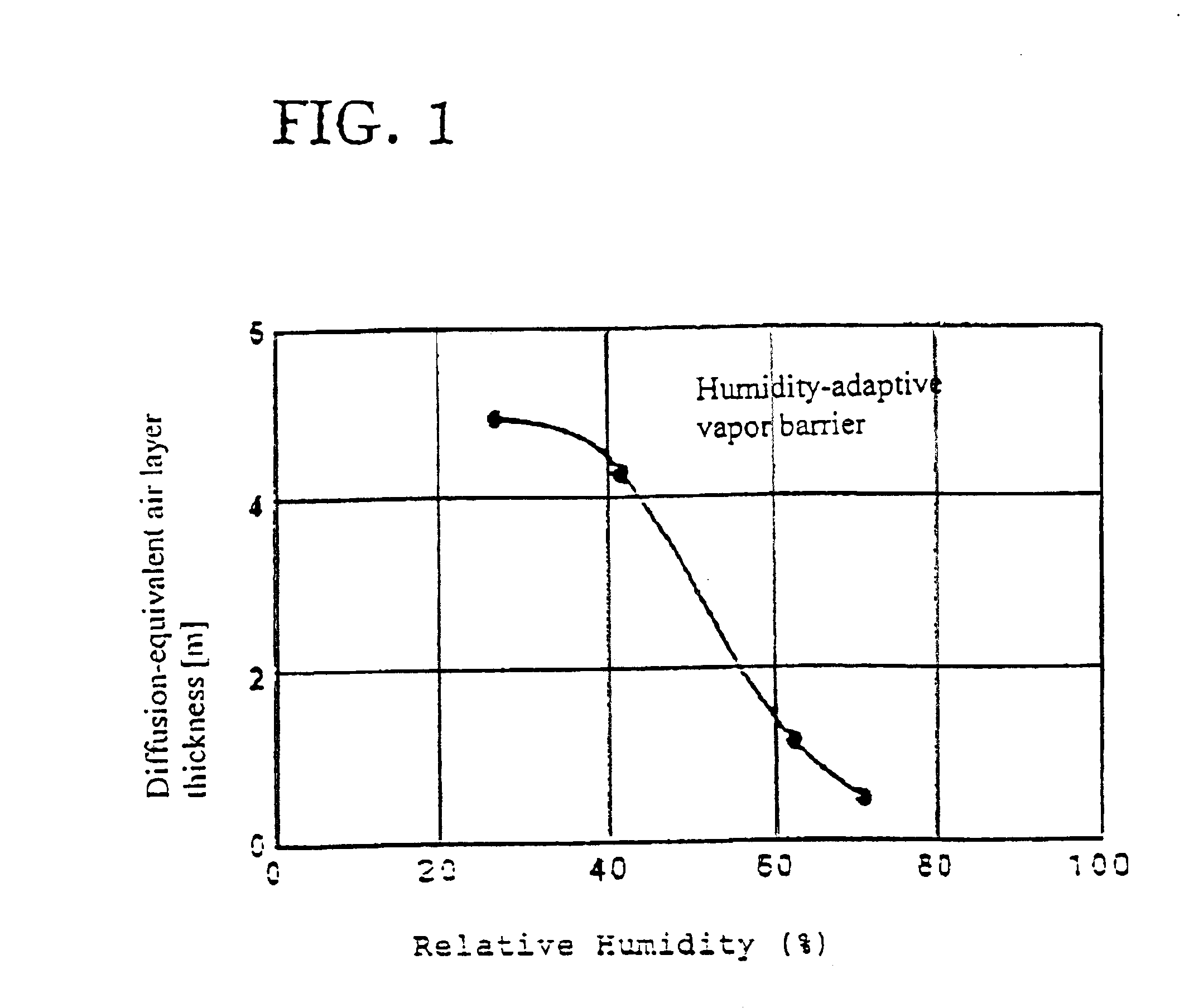

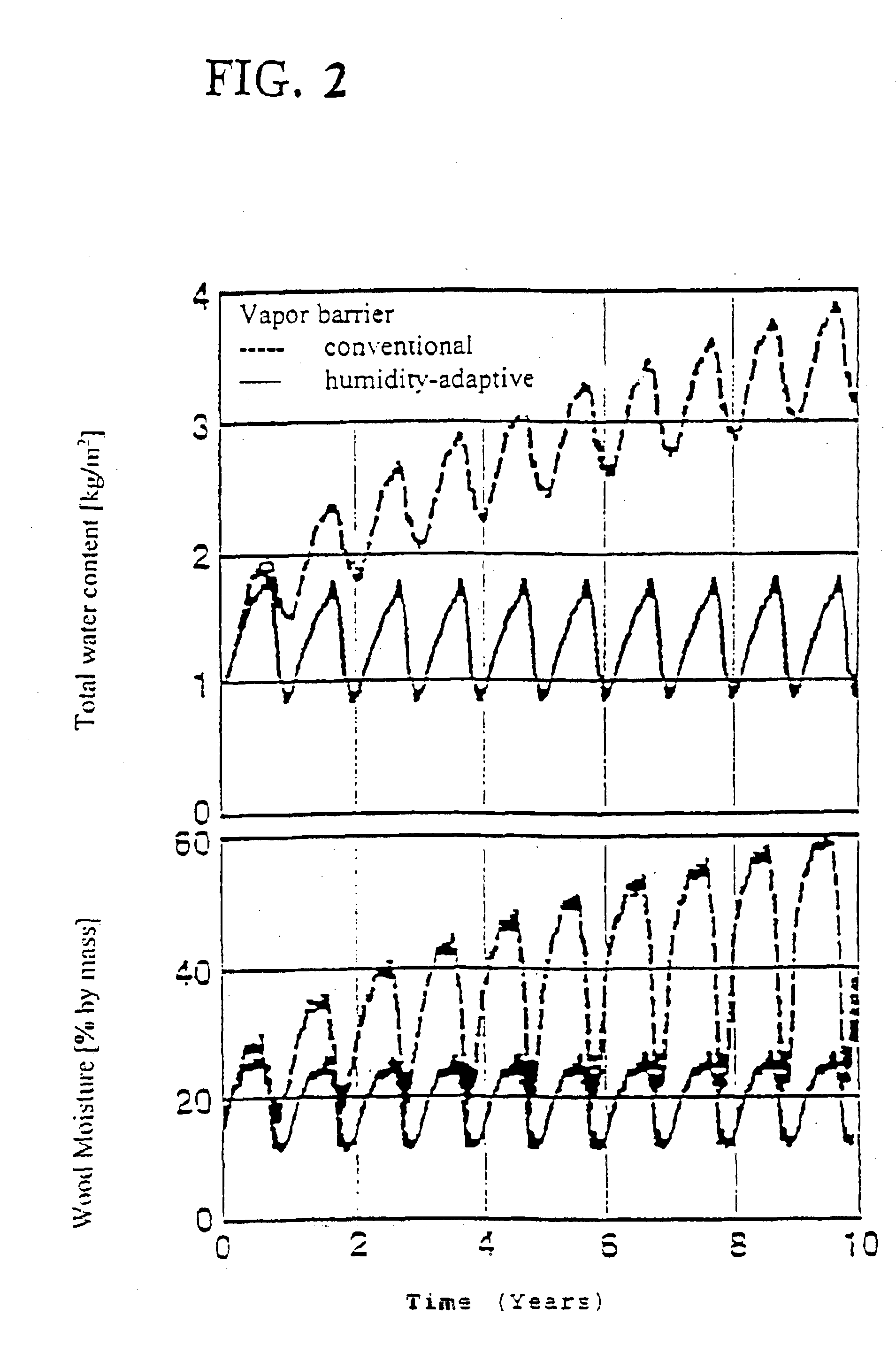

Vapor barrier for use in the heat insulation of buildings

InactiveUS6890666B2Synthetic resin layered productsCellulosic plastic layered productsVapor barrierAmbient humidity

The invention relates to a vapor barrier for use in cthe thermal insulation of buildings which can be used, in particular, for thermal insulation procedures in new buildings or in the renovation of old buildings. The vapor barrier in accordance with the invention is thereby capable of achieving water vapor exchange under different ambient conditions. This is achieved by using a material which has a water vapor diffusion resistance which is dependent on the ambient humidity and which also has adequate tensile strength and tear resistance.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

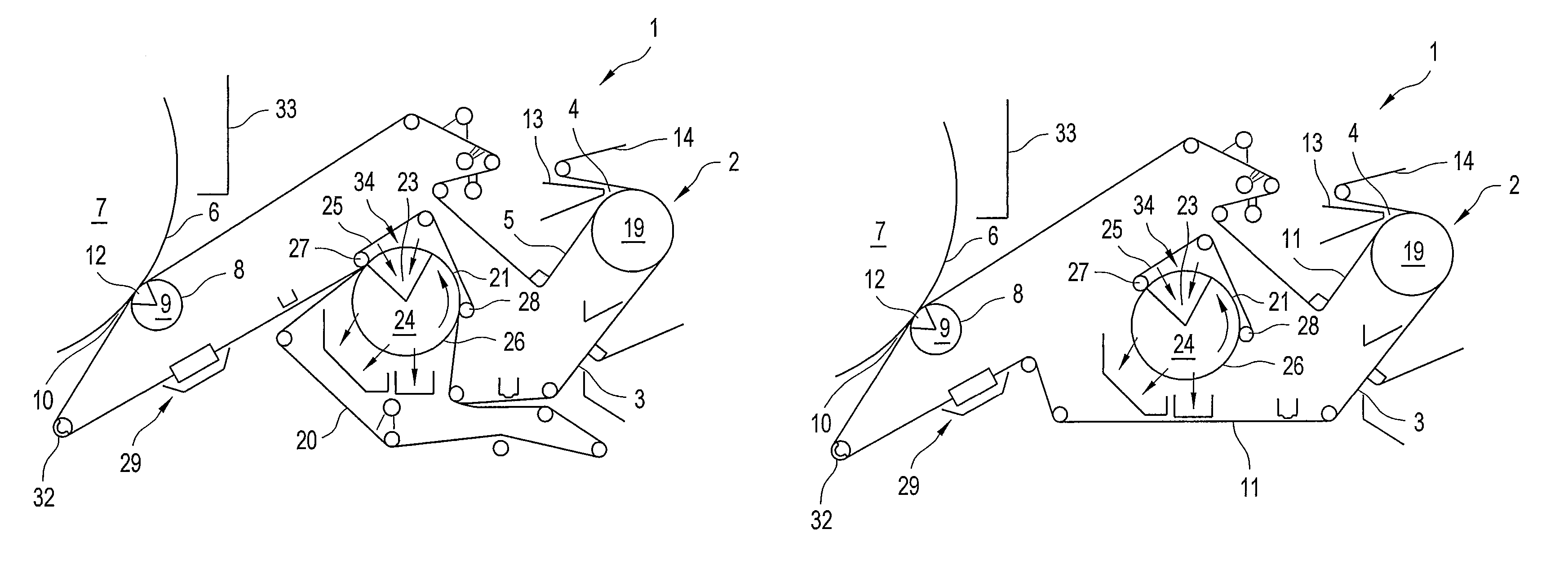

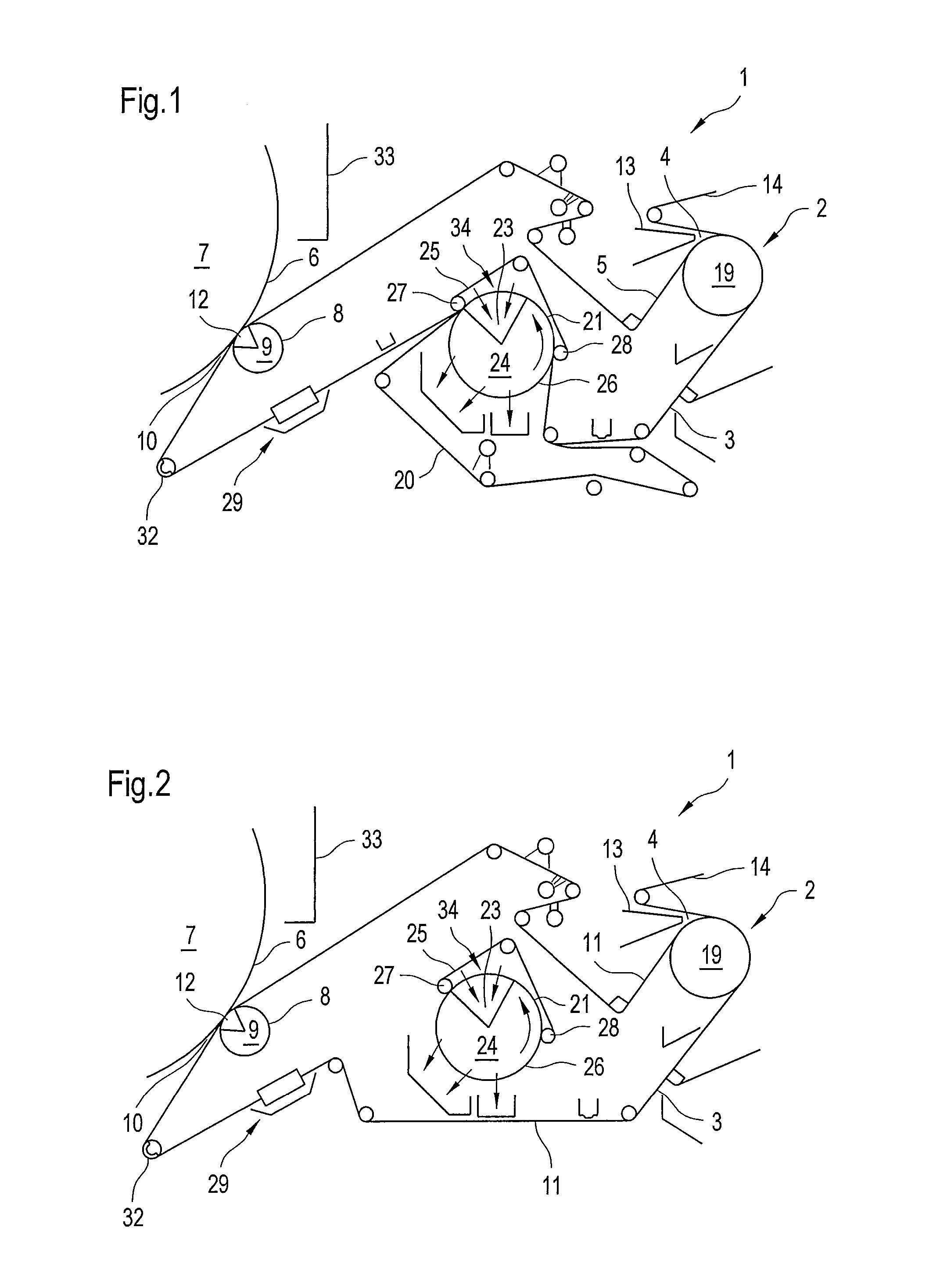

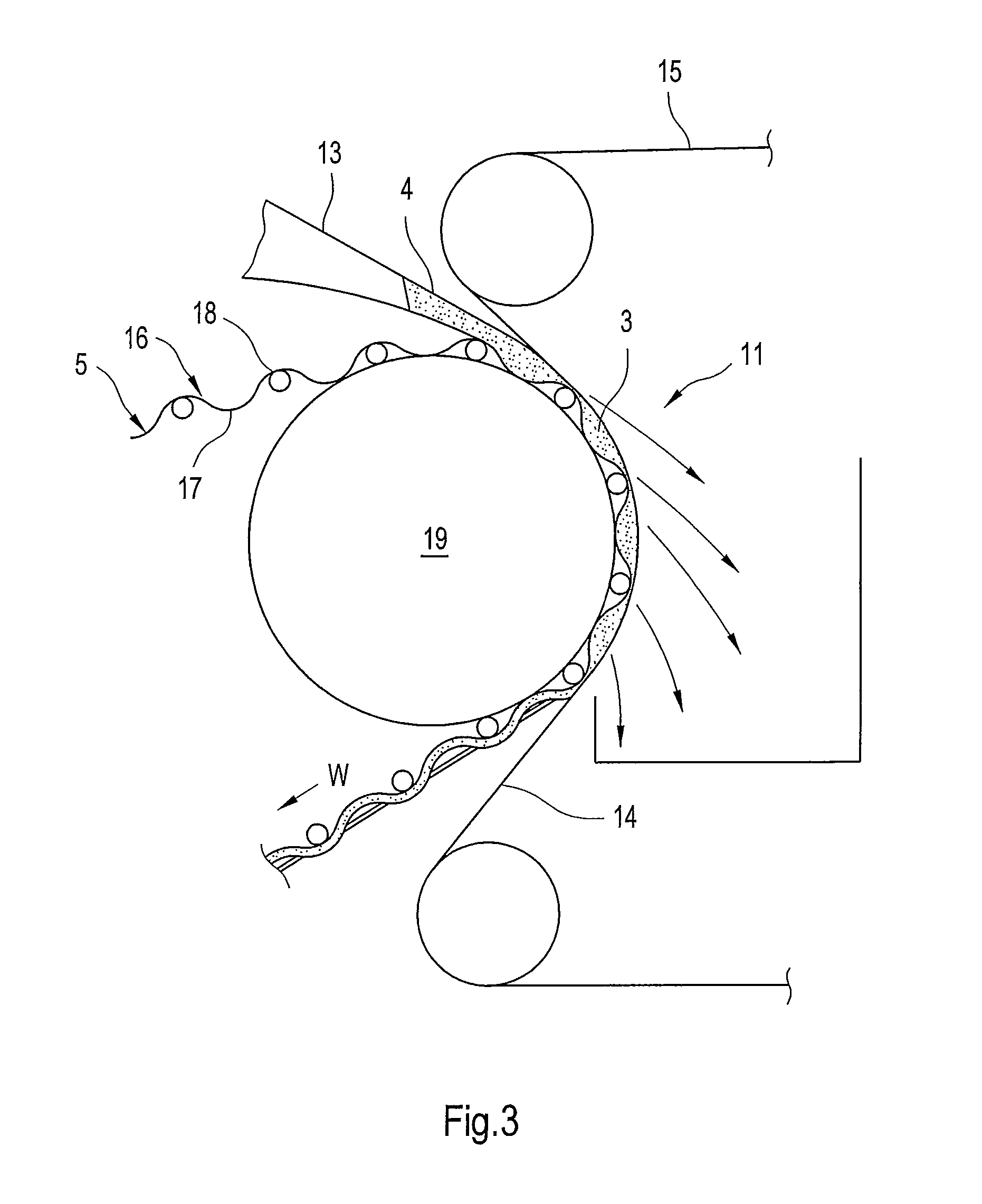

Machine for the production of tissue paper

Owner:VOITH PATENT GMBH

Biological whole degrading film and mfg. process of its material

InactiveCN100999587AImprove heat resistanceExcellent anti-sticking propertySynthetic resin layered productsPolyesterPolymer science

The present invention discloses continuous production process of flexible biodegradable material and film with excellent heat resistance, low stickness and isotropic tear resistance. The production process is completed in a screw extruder mainly with the materials including polylactic acid, aliphatic polyester, plasticizer and assistant.

Owner:刘津平

Method for preparing graphene oxide/white carbon black/rubber nanocomposite material

A method for preparing a graphene oxide / white carbon black / rubber nanocomposite material is described. The prepared graphene oxide / white carbon black / rubber nanocomposite material contains nanoscale graphene oxide and white carbon black that are highly dispersed. The nanocomposite material has a relatively high modulus, excellent wear resistance and tear resistance, a relatively low rolling resistance, and at the same time has a low air-permeability and excellent self-healing capability.

Owner:BEIJING UNIV OF CHEM TECH

X65 pipeline steel for use in acid condition and its making process

ActiveCN1811002AImprove the effect of controlled rollingImproved dynamic tear resistanceManufacturing convertersProcess efficiency improvementMetallurgyTear resistance

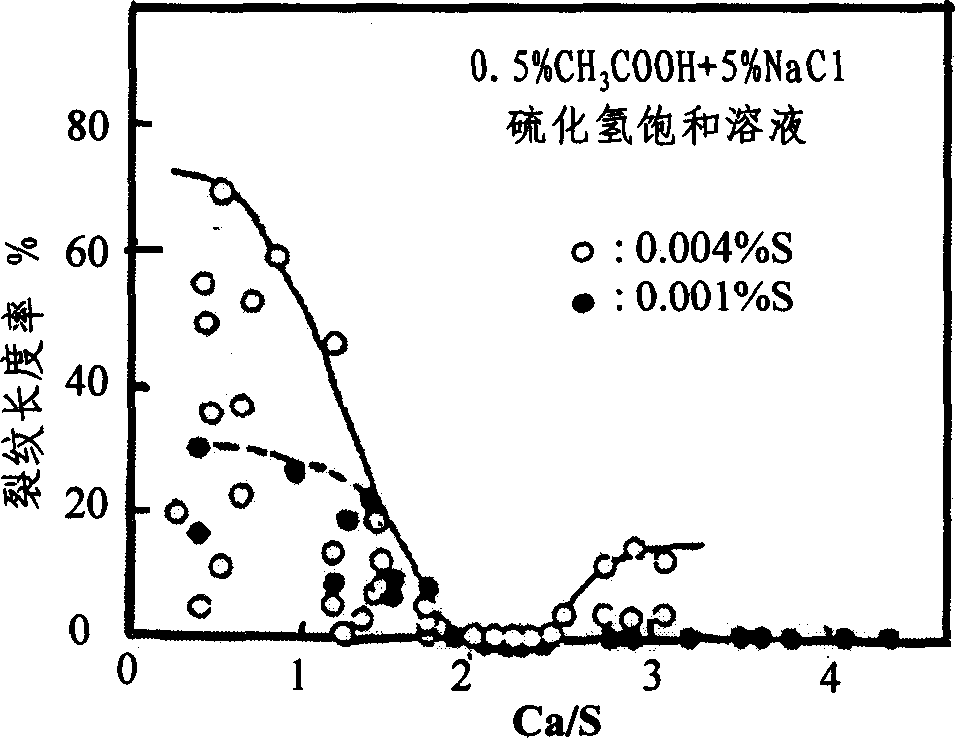

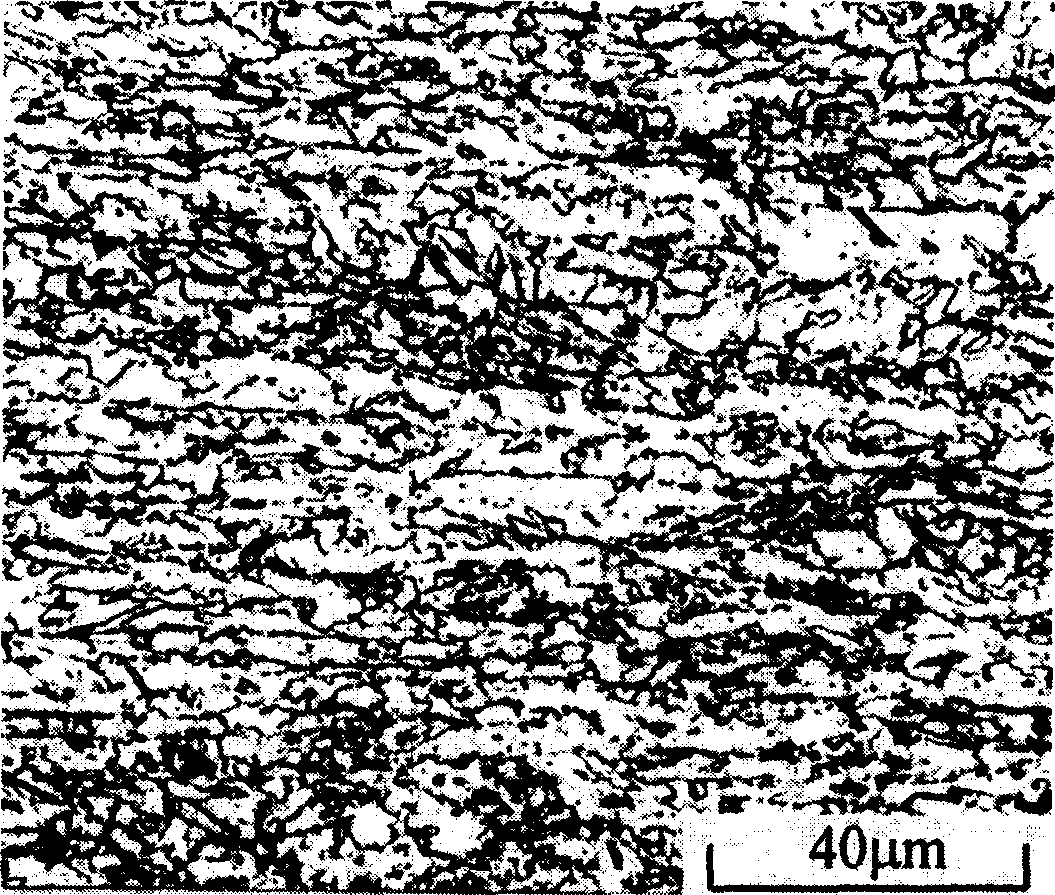

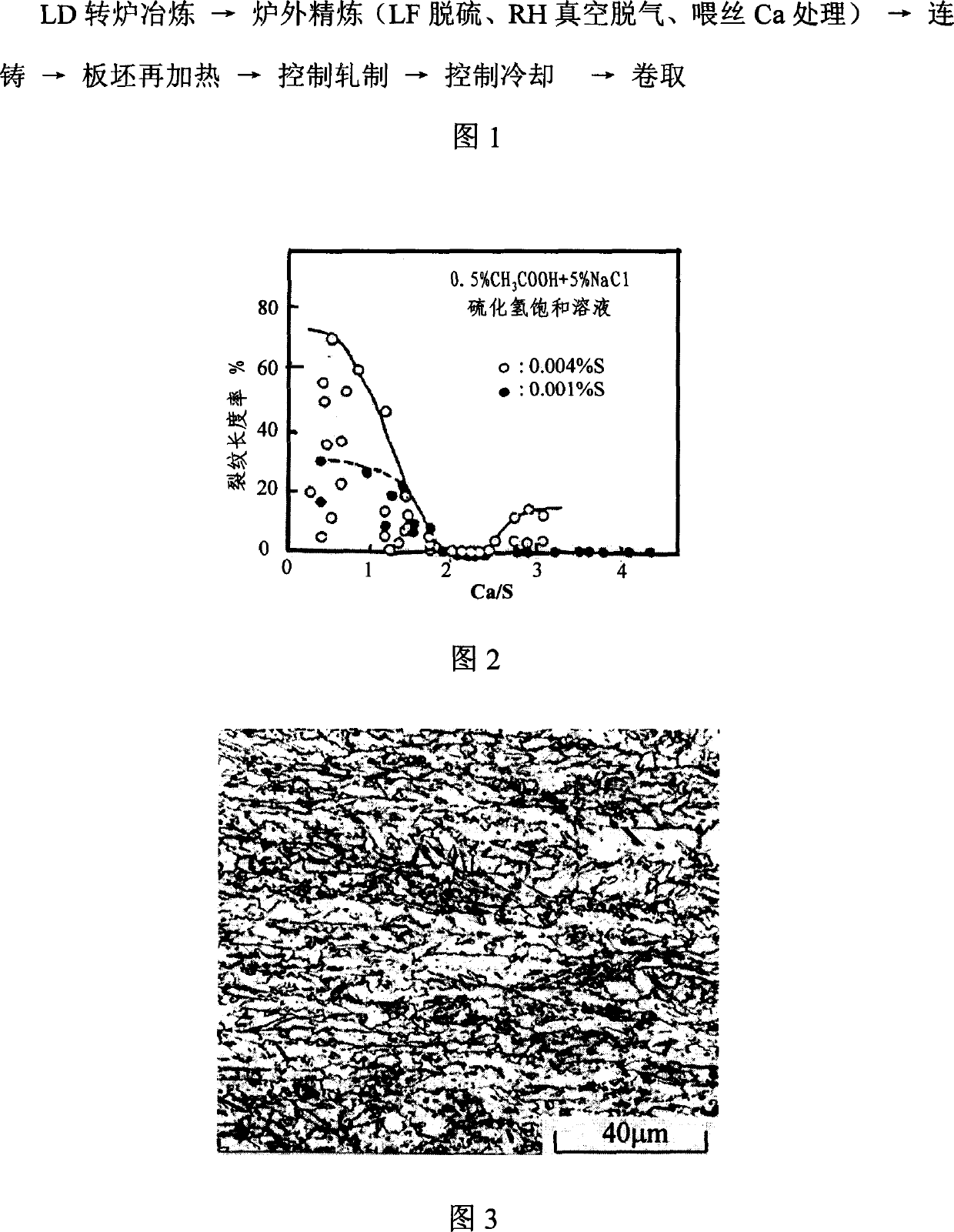

The X65 pipeline steel for use in acid condition consists of C 0.02-0.05 wt%, Mn 1.20-1.50 wt%, Si 0.10-0.50 wt%, S not more than 0.0020 wt%, P 0.004-0.012 wt%, Nb 0.05-0.07 wt%, Ti 0.005-0.025 wt%, Mo 0.050-0.195 wt%, Cu not more than 0.35 wt%, Ni not more than 0.35 wt%, N not more than 0.0080 wt%, Ca 0.0015-0.0045 wt% and Ca / S not less than 2.0 except Fe. Its making process includes the following steps: smelting in a converter or an electric furnace; secondary steel making including LF desulfurizing + RH vacuum deairing and Ca treatment; continuous casting; rolling with initial rolling termination temperature of 940-1020 deg.c and finish rolling termination temperature of 780-840 deg.c; and winding at 500-580 deg.c. The X65 pipeline steel has low manufacture cost, high HIC resistance, high dynamic tear resistance and high impact toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

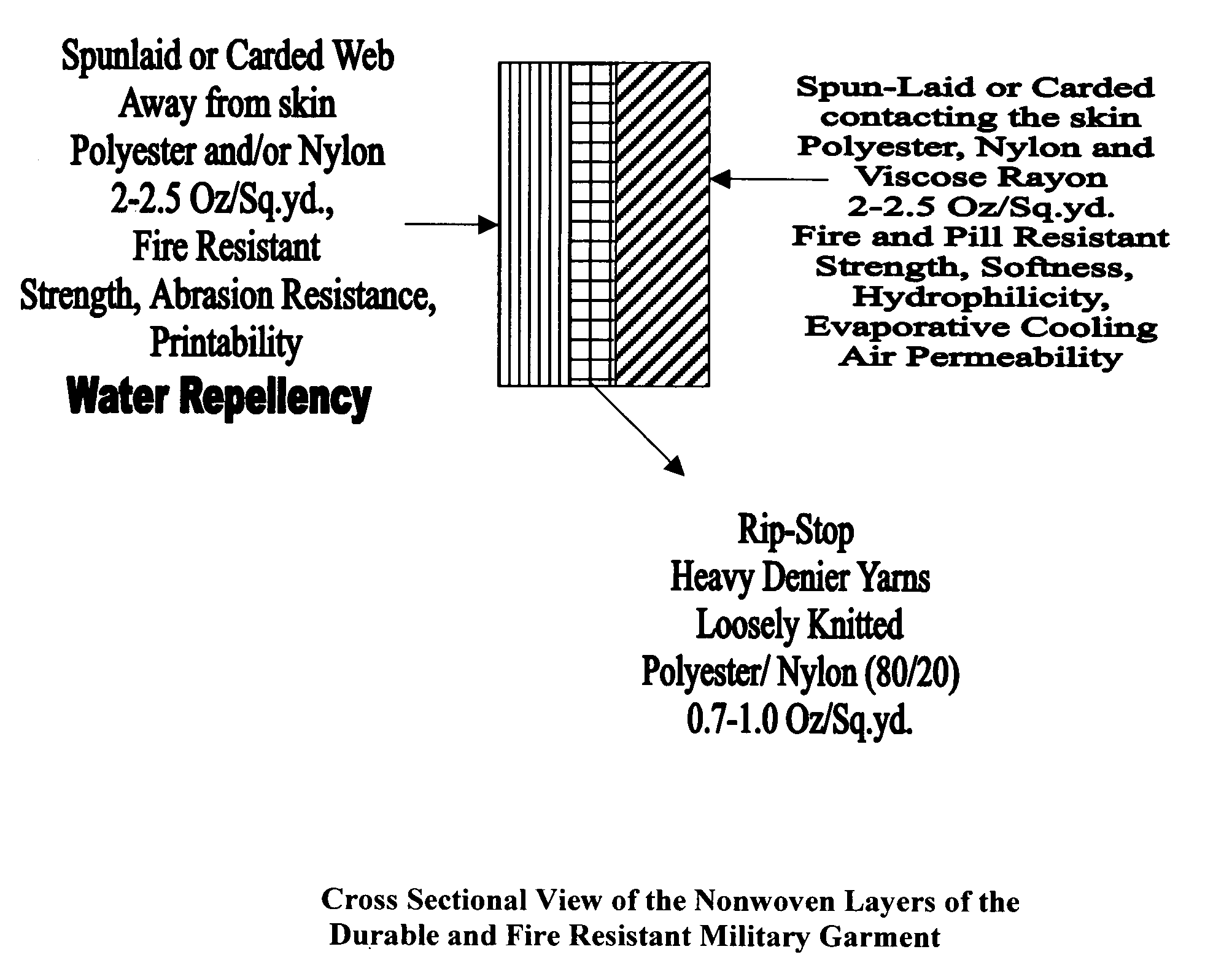

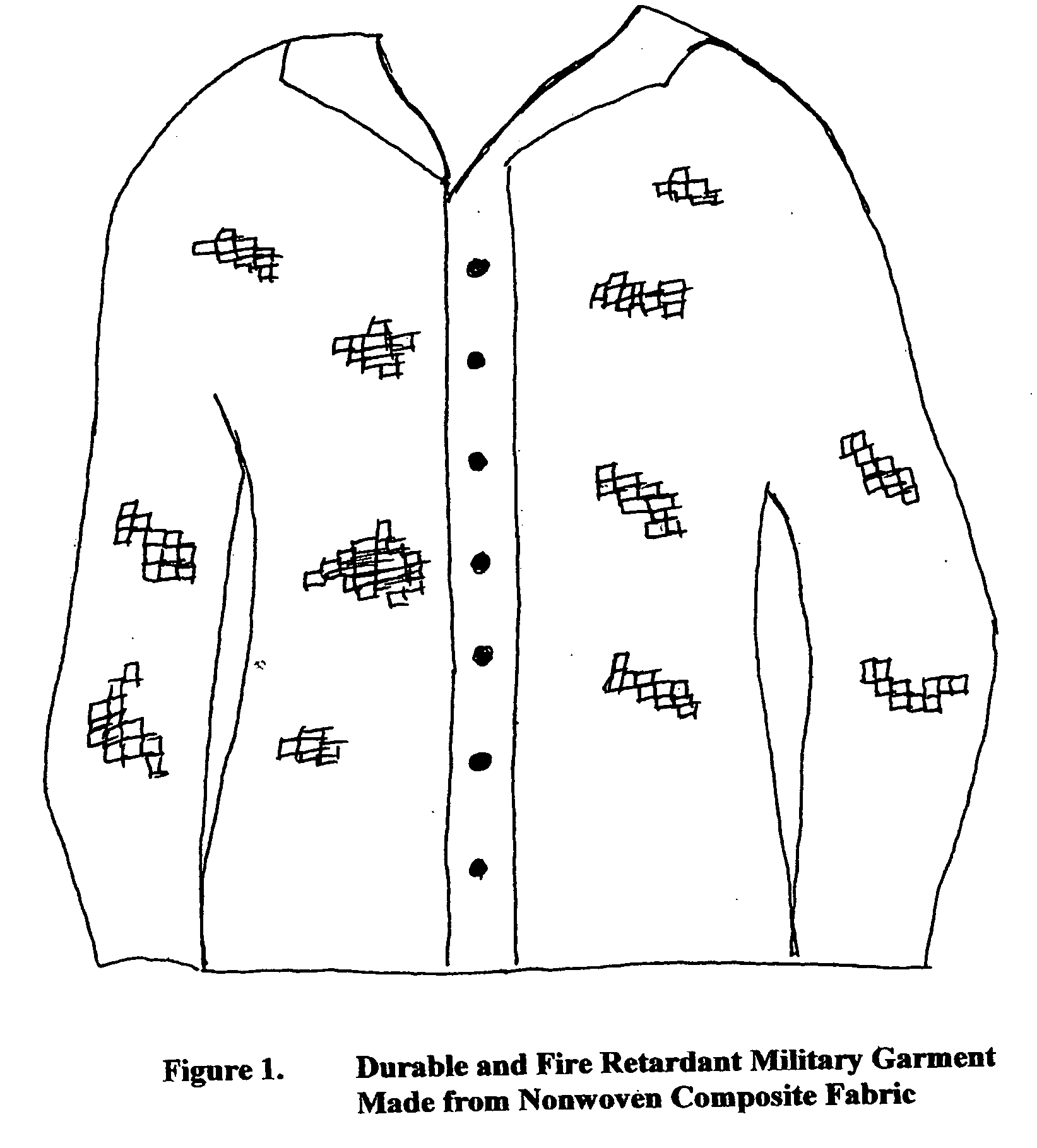

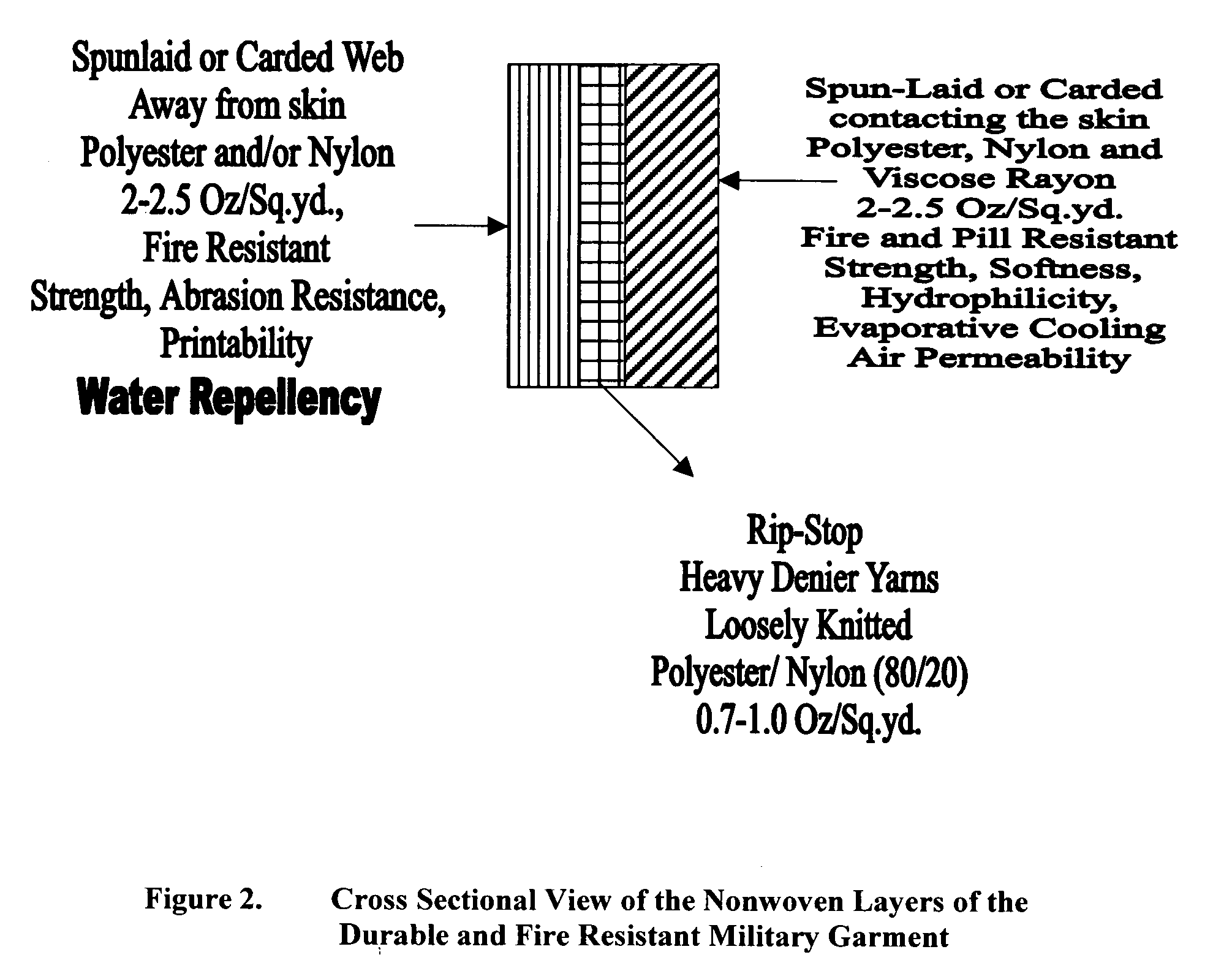

Durable and fire resistant nonwoven composite fabric based military combat uniform garment

InactiveUS20060035555A1Durable/wash resistant fire retardant chemicalImprove wear resistanceProtective equipmentLayered productsPunchingMilitary Uniforms

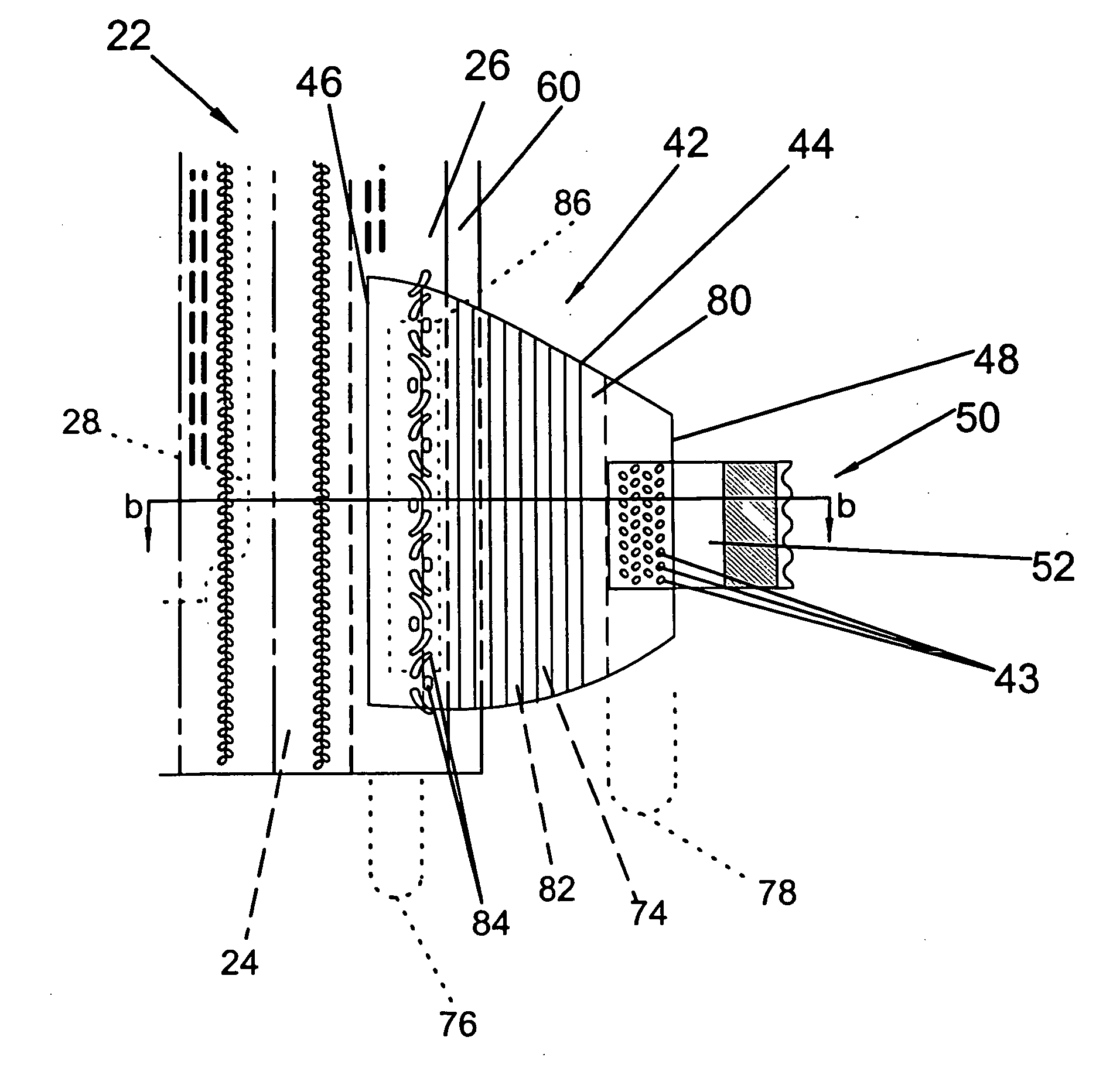

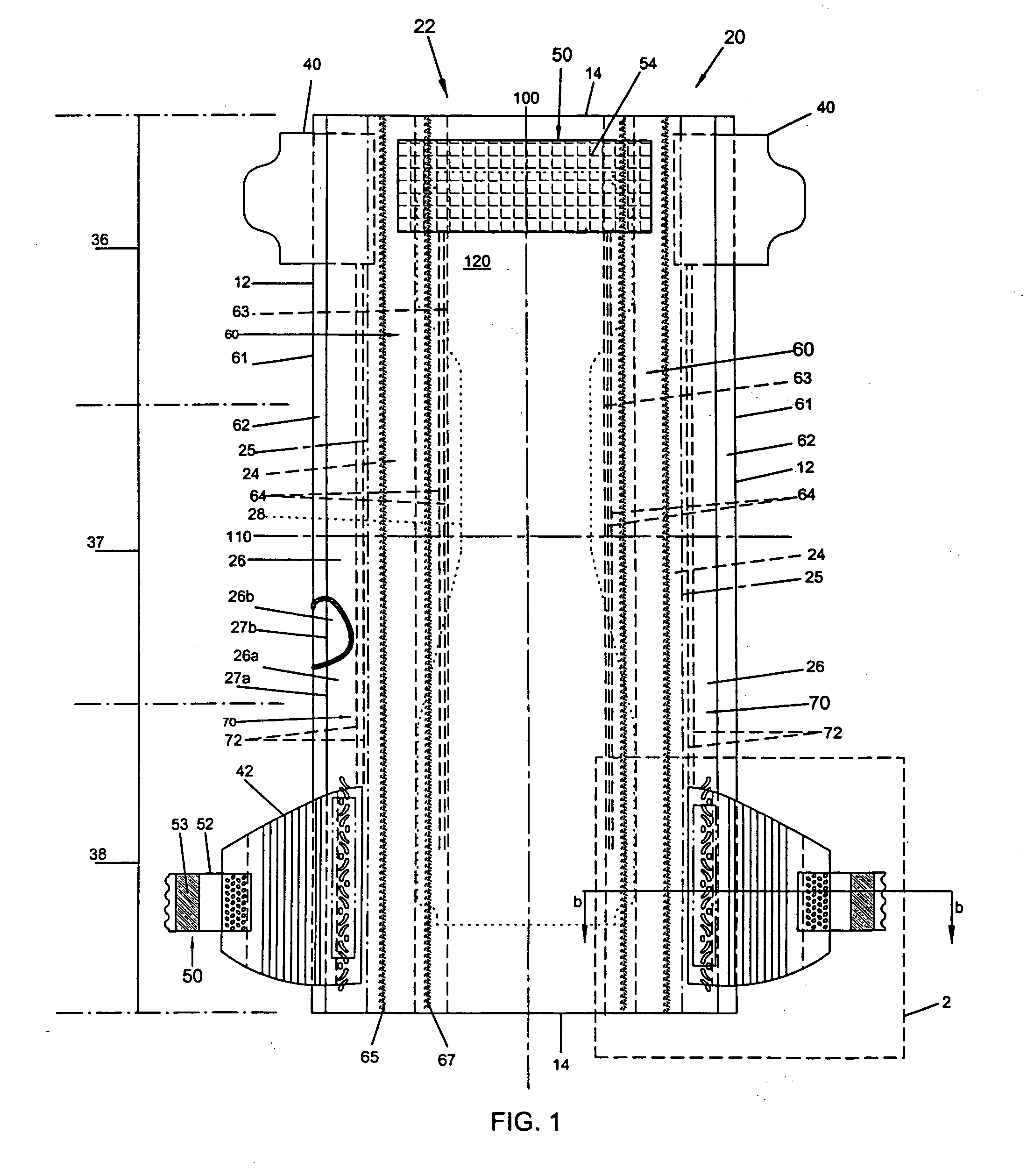

The present invention is directed to the design and manufacture of a durable, fire resistant, comfortable and economical nonwoven composite fabric based garment, which meets the stringent requirements of military combat uniform clothing. The nonwoven based garment is designed to replace the traditional woven textile fabric used in the military and outdoor sporting garments today. The novel garment of the current invention is constructed using a unique nonwoven composite fabric that exhibits mechanical, physical, durability and comfort characteristics similar to or better than that of the current woven military uniform fabric. In particular, the present invention contemplates the nonwoven composite fabric used to make the garment is prepared by combining at least two separate fire resistant nonwoven webs forming the inside and outside layers of the garment. An optional rip-stop element such as a loosely knitted fabric may be sandwiched between the two nonwoven webs to improve the tear resistance of the entire garment. Hydroentangling or needle-punching processes and subsequent thermal calendering / embossing techniques combine the individual nonwoven webs of the garment before dyeing, printing and finishing with traditional textile chemicals to form a composite fabric for stitching to make the garment.

Owner:NARAYANAN VASANTHAKUMAR +2

Engineering tire tread rubber

The invention discloses an engineering tire tread rubber which comprises the following components in parts by weight: 100 parts of rubber, 20-50 parts of hard carbon black, 0-20 parts of white carbon black, 1-8 parts of chemically modified short fiber, 0-3 parts of silane coupling agent, 0.5-2 parts of accelerating agent, 0.2-8 parts of anti-reversion agent, 1-2.8 parts of sulfur, 3-6 parts of anti-aging agent, 0.5-4 parts of microcrystalline protective wax, 3-10 parts of aromatic hydrocarbon oil, 0.5-8 parts of processing aid, 1-10 parts of zinc oxide, 1-6 parts of stearic acid and 0.05-1 part of anti-scorching agent. Compared with the prior art, by introducing the chemically modified short fiber, the invention solves the problem of difficult dispersion of the short fiber in the tread rubber, improves the cutting, chunking and chipping resistant properties and the delaying and heating properties of the tread rubber, and improves the wear resistance, the fatigue resistance, the tearing resistance and the cutting resistance of the rubber, thereby prolonging the service life of the engineering tire.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Absorbent article with improved tear resistance and softness

A disposable absorbent article may comprise a chassis and an ear. The chassis comprises a liquid permeable topsheet, a backsheet, and an absorbent core disposed between the topsheet and backsheet. The ear comprises an elastomeric material and a first substrate joined to the elastomeric material. The ear has a first void region adjacent the proximal edge of the ear. The ear is joined to the chassis by at least one mechanical bond that engages the elastomeric material.

Owner:THE PROCTER & GAMBLE COMPANY

Sheet-Like Building and Construction Materials With High Wet Slip Resistance and High Water Penetration Resistance, and Methods of Making Same

Owner:BERRY FILM PROD CO INC

Tyre crown rubber material and mixing method thereof

InactiveCN102604170AGood physical and mechanical propertiesIncrease elasticitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention discloses a tyre crown rubber material. The tyre crown rubber material comprises the following raw materials in parts by weight: 60-80 of natural rubber, 20-40 of butadiene rubber BR9000, 0-0.4 of peptizer, 10-30 of intermediate super abrasion furnace black, 25-45 of white carbon black, 3-7 of silane coupling agent, 3-5 of zinc oxide, 1-4 of stearic acid, 1-3 of antiager 6PPD, 0-2 of antiager RD, 1-3 of microcrystalline paraffin, 1-3 of sulfur, 1.5-2.5 of accelerator, 4-6 of fatty acid salt processing agent, 0-1 of anti-reversion agent, 2-5 of environment-friendly arene oil TDAE (Treated Distillate Aromatic Extract), 1-3 of octyl phenolic aldehyde tackifying resin and 0-0.3 of scorch retarder. When mixing is carried out in three sections, partial formula raw materials are subjected to rubber material mixing, and then other formula materials are added for rubber material mixing. The tyre crown rubber material produced by using the tyre crown rubber material formula is good in comprehensive processing property, has the characteristics of low thermogenesis, ageing resistance and tearing resistance and is environment-friendly and can be used for producing green full-steel radial tyre crown.

Owner:安徽大瑞橡胶有限公司

Polyester filament woven fabric for air bags

InactiveUS20060252322A1Pedestrian/occupant safety arrangementSynthetic resin layered productsEngineeringFabric structure

A polyester plain weave fabric construction wherein said fabric has a basis weight of between 150 to 300 g / m2 with tongue tear strength equal to or better than nylon fabrics of the same construction and weight. The present invention relates to both coated and uncoated polyester filament woven fabric. The uncoated fabric is useful for industrial purposes wherein the fabric has a warp tongue tear resistance of at least 0.75 N / g / m2, when the fabric basis weight is between 150 to 300 g / m2 The preferred uncoated polyester filament yarn has a linear density of between about 200 to about 800 dtex, a tenacity of at least 65 cN / tex, a tensile index of at least 350. The fabrics can be coated with chloroprene, neoprene, polyurethane, silicone or other organic coatings to reduce air permeability. The fabric of the present invention may also be constructed with the warp and / or filling yarn having an aspect ratio between 1.2 and 6.

Owner:INV PERFORMANCE MATERIALS LLC +1

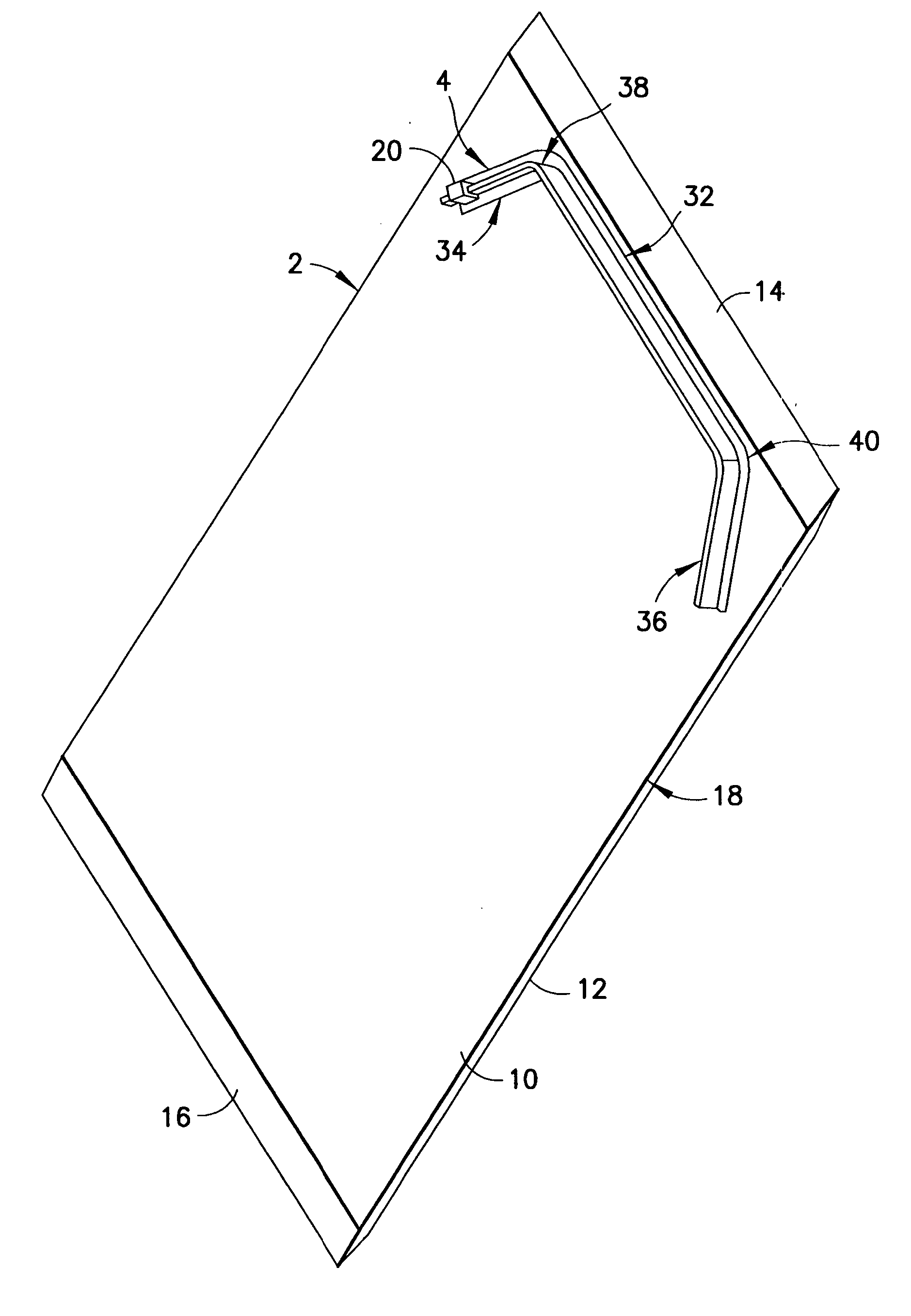

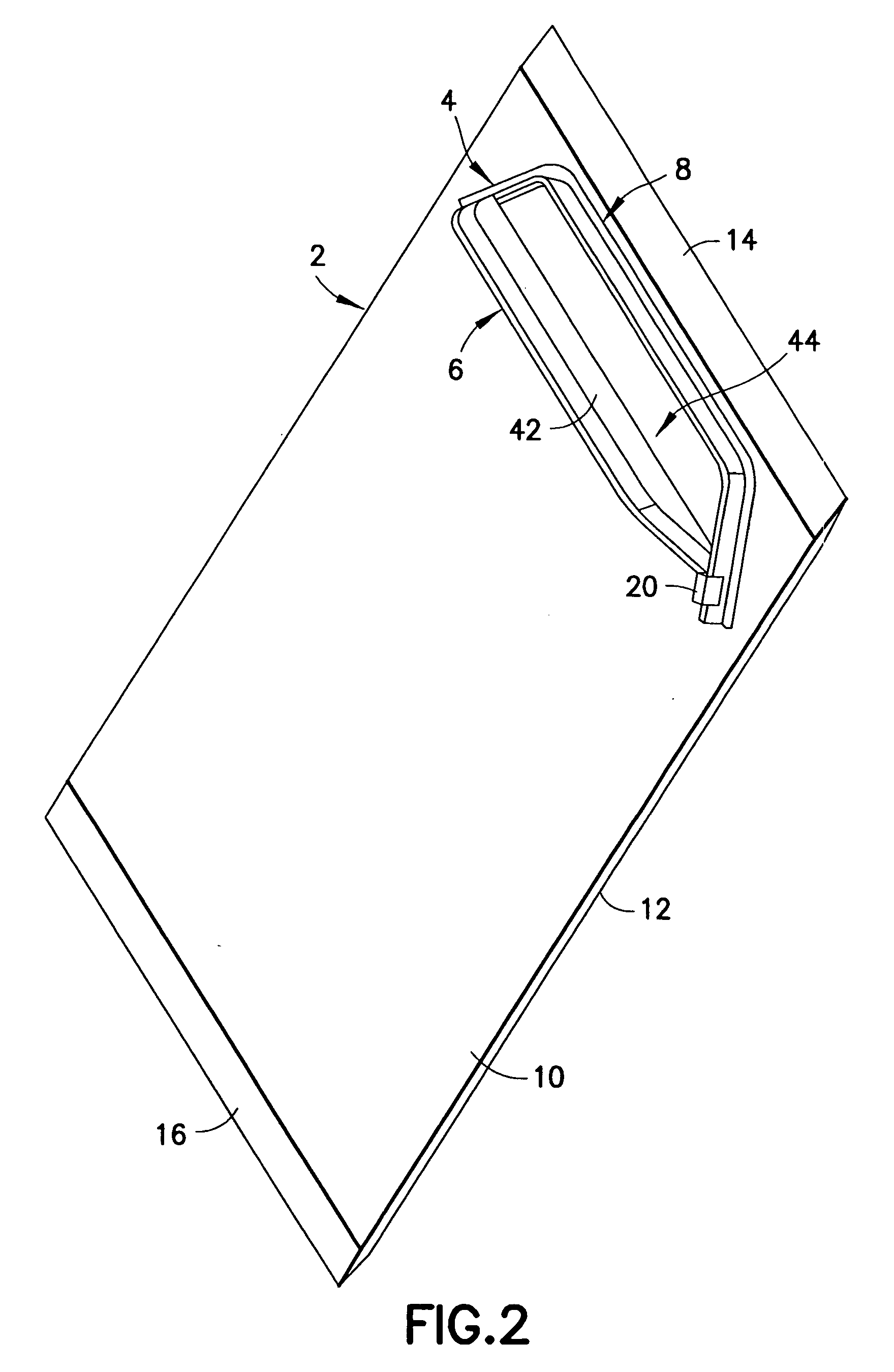

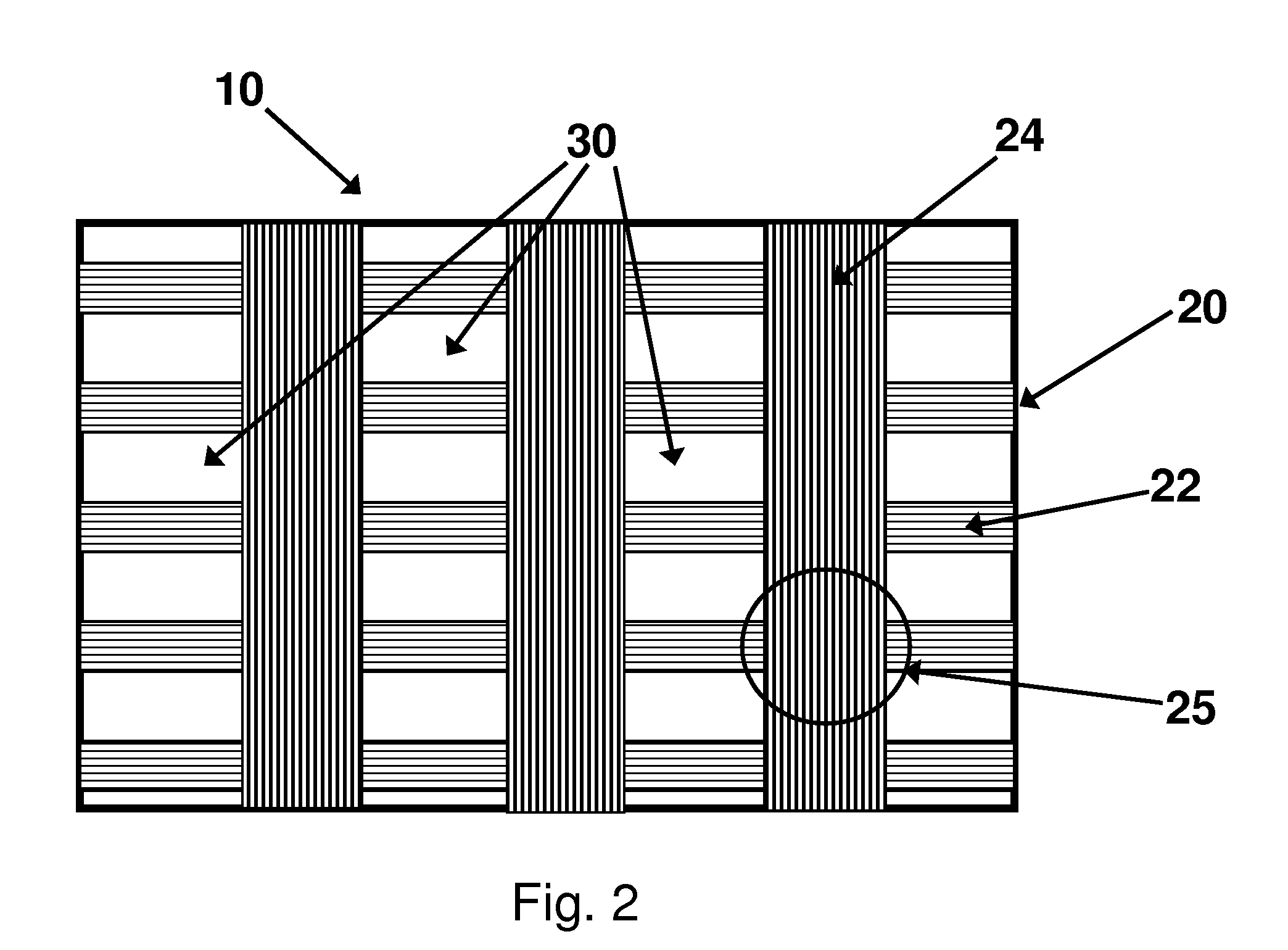

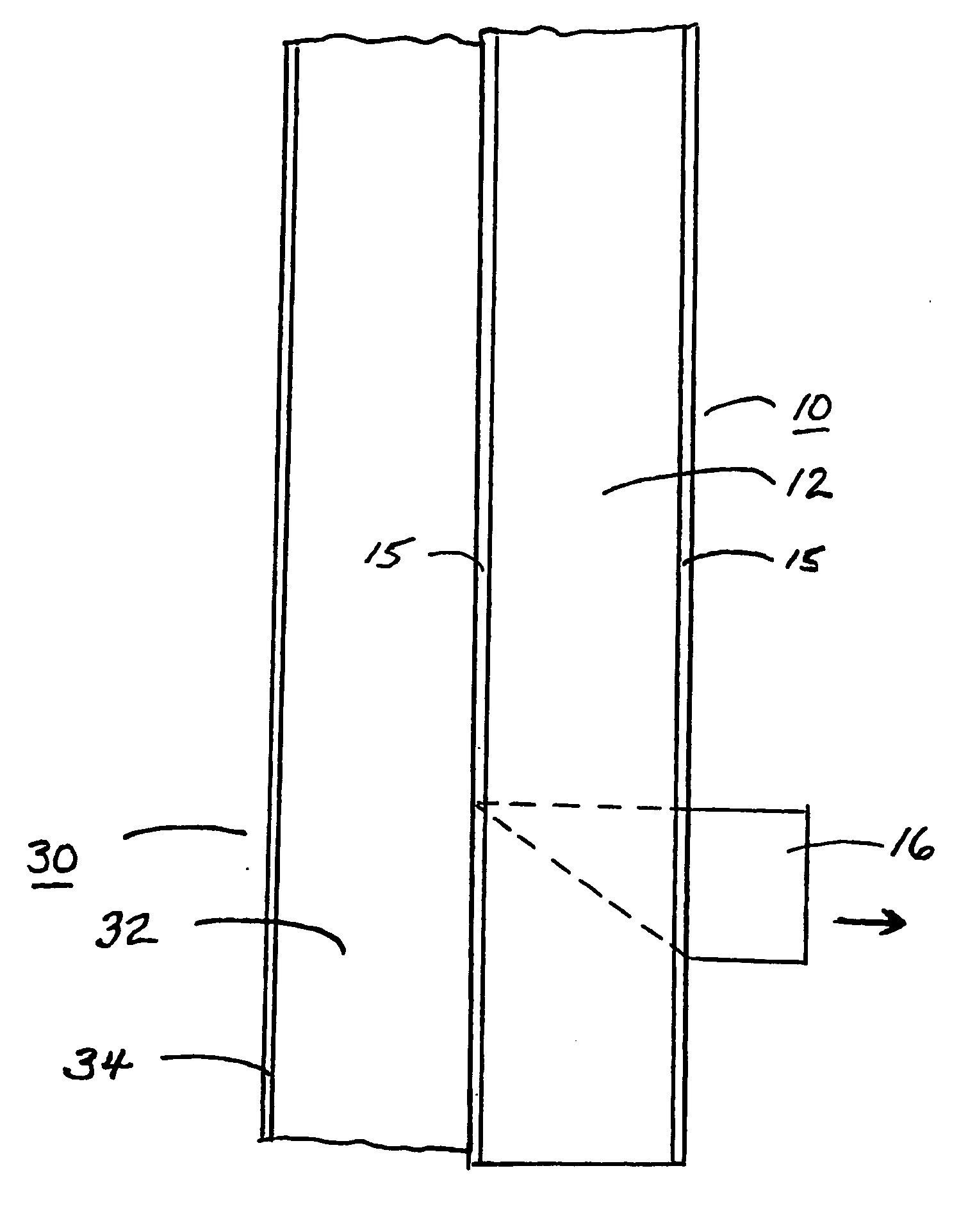

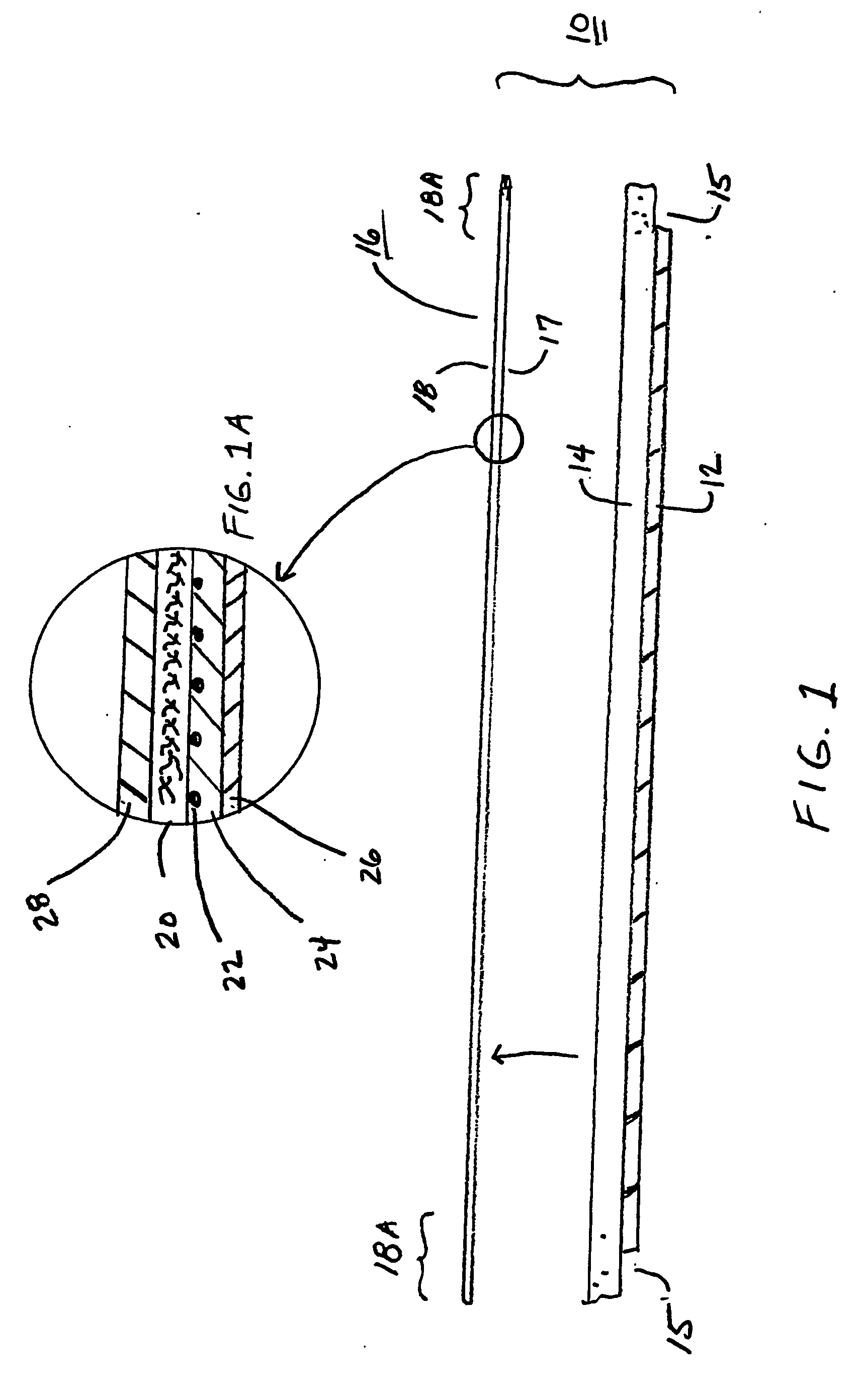

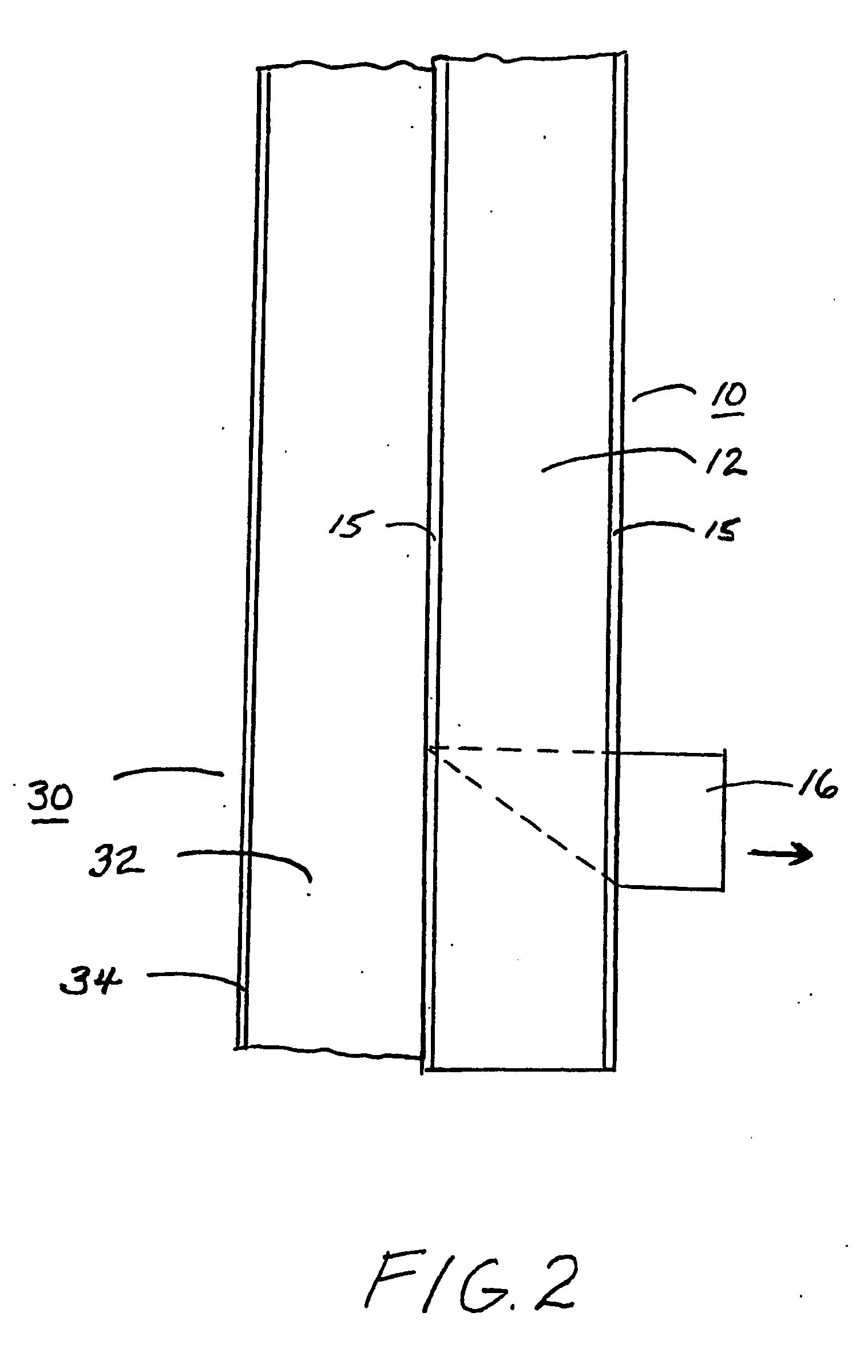

Moisture barrier membrane with tearable release liner composite

ActiveUS20060141191A1Improve economyGreat ecological advantageSynthetic resin layered productsLaminationWaxPolyolefin

An exemplary moisture barrier membrane 10 comprises a waterproof adhesive layer, (14) a carrier support, (12) and a release liner (16) composite having a paper sheet, (20) cutting strings, (22) a polyolefin (24) coating or film for holding the strings against the paper and apart from the waterproof adhesive layer, and a release agent (26) such as silicone or wax over the polyolefin coating or film. This construction allows for relatively thin paper and strings to be used, such that tear resistance is conferred upon the release liner composite as a whole.

Owner:GCP APPL TECH INC

Waterproof coiled material having pre-laid anti-sticking function and preparation method thereof

ActiveCN103358635AHigh tensile strengthImprove tear resistanceSynthetic resin layered productsBasementTear resistance

The invention discloses a waterproof coiled material having a pre-laid anti-sticking function. A preparation method comprises the steps: with a plastic sheet material as a supporter, a hot melt pressure sensitive adhesive is blade-coated on the plastic sheet material, an acrylic acid isolating protection layer is spayed on the hot melt pressure sensitive adhesive layer, and a PET silicon-coated isolating film is coated on a topside layer. The waterproof coiled material disclosed by the invention has high tensile strength and good tear resistance, is non-toxic and odorless, is wide in adaptive temperature range, can be welded or be in self-adhesive lap joint, forms a full bonding with post-poured concrete, can be directly constructed while walking on the coiled material, and is suitable for waterproof of underground waterproof engineering, such as basements, artificial lakes, culverts, tunnels, subways and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

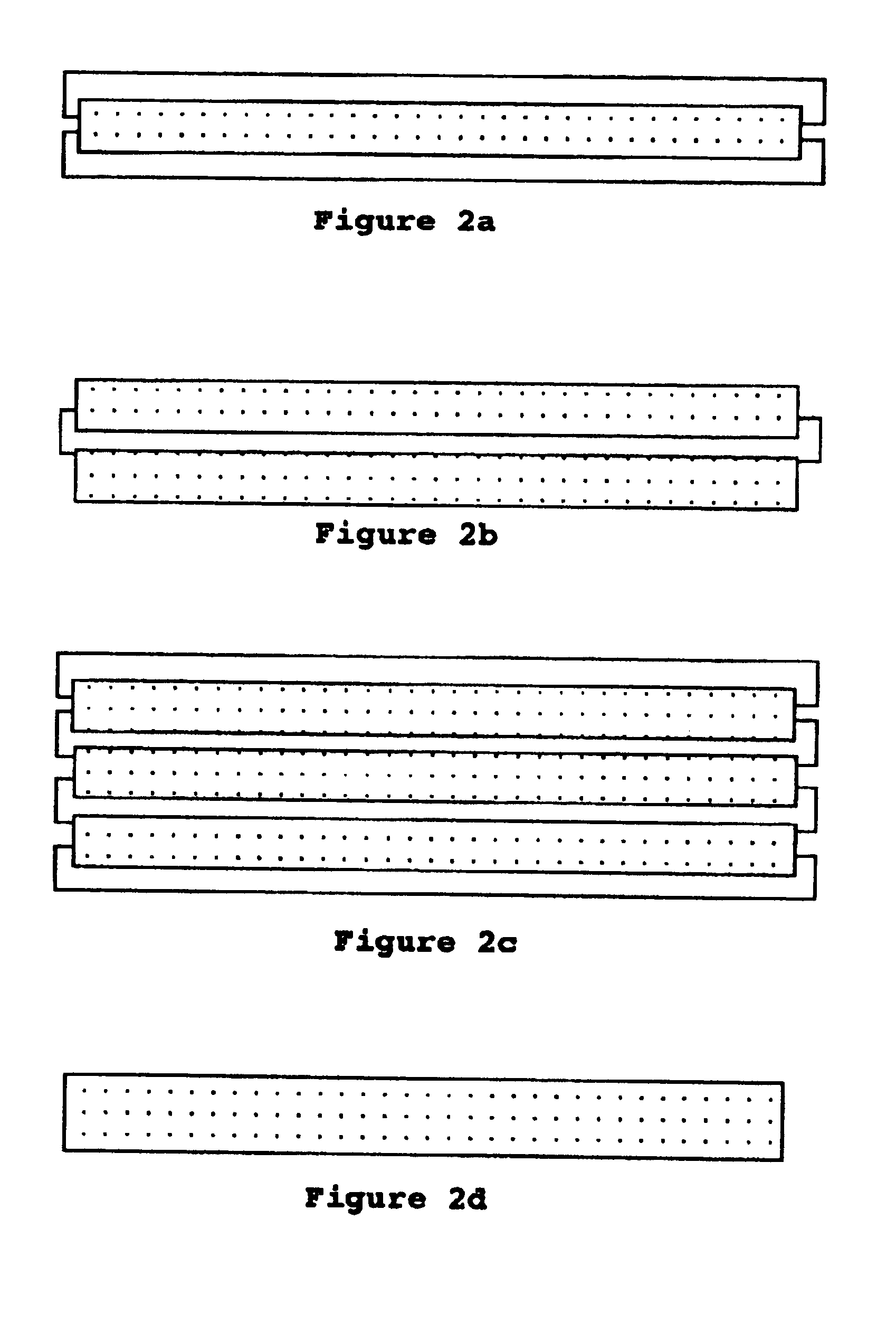

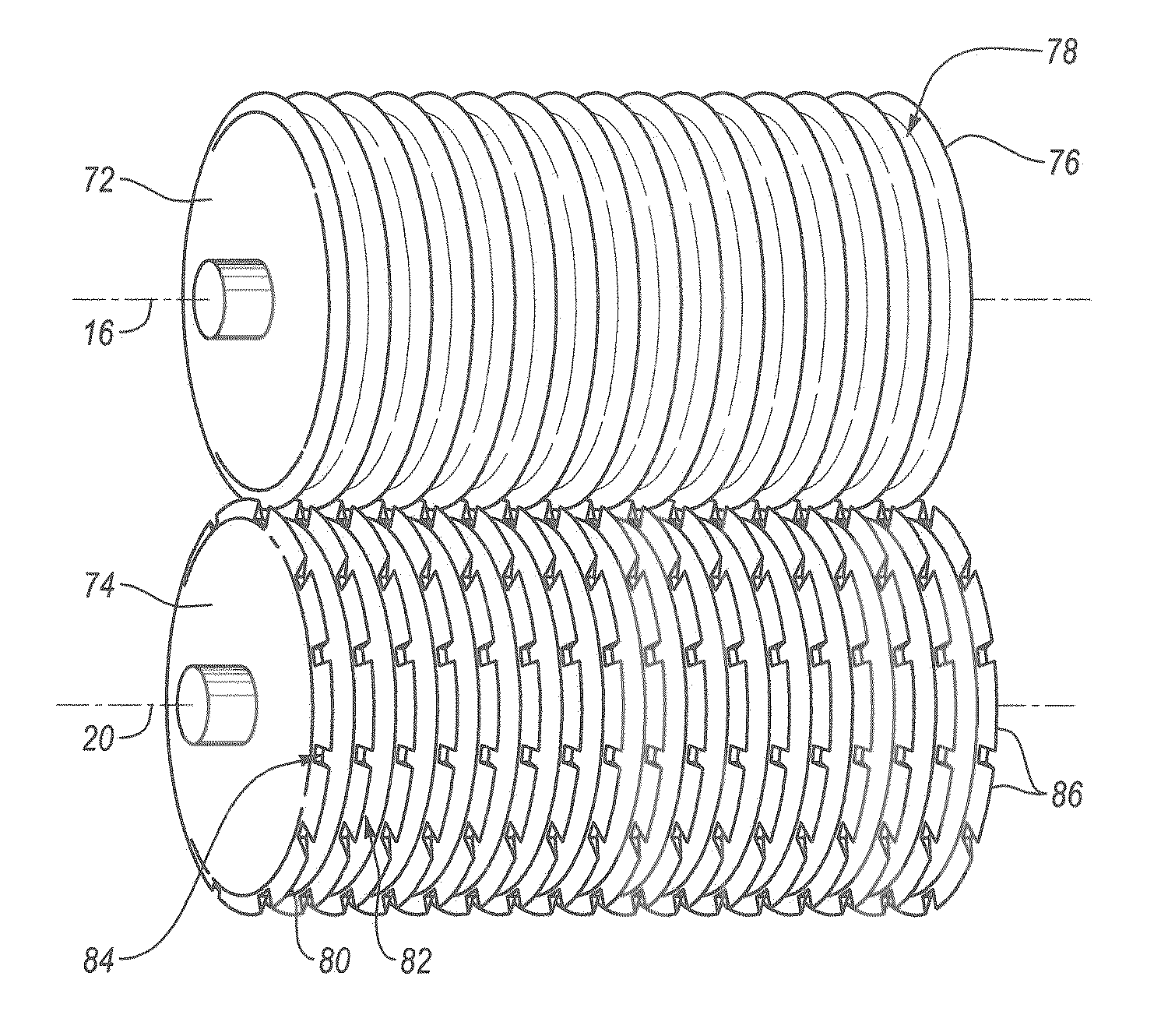

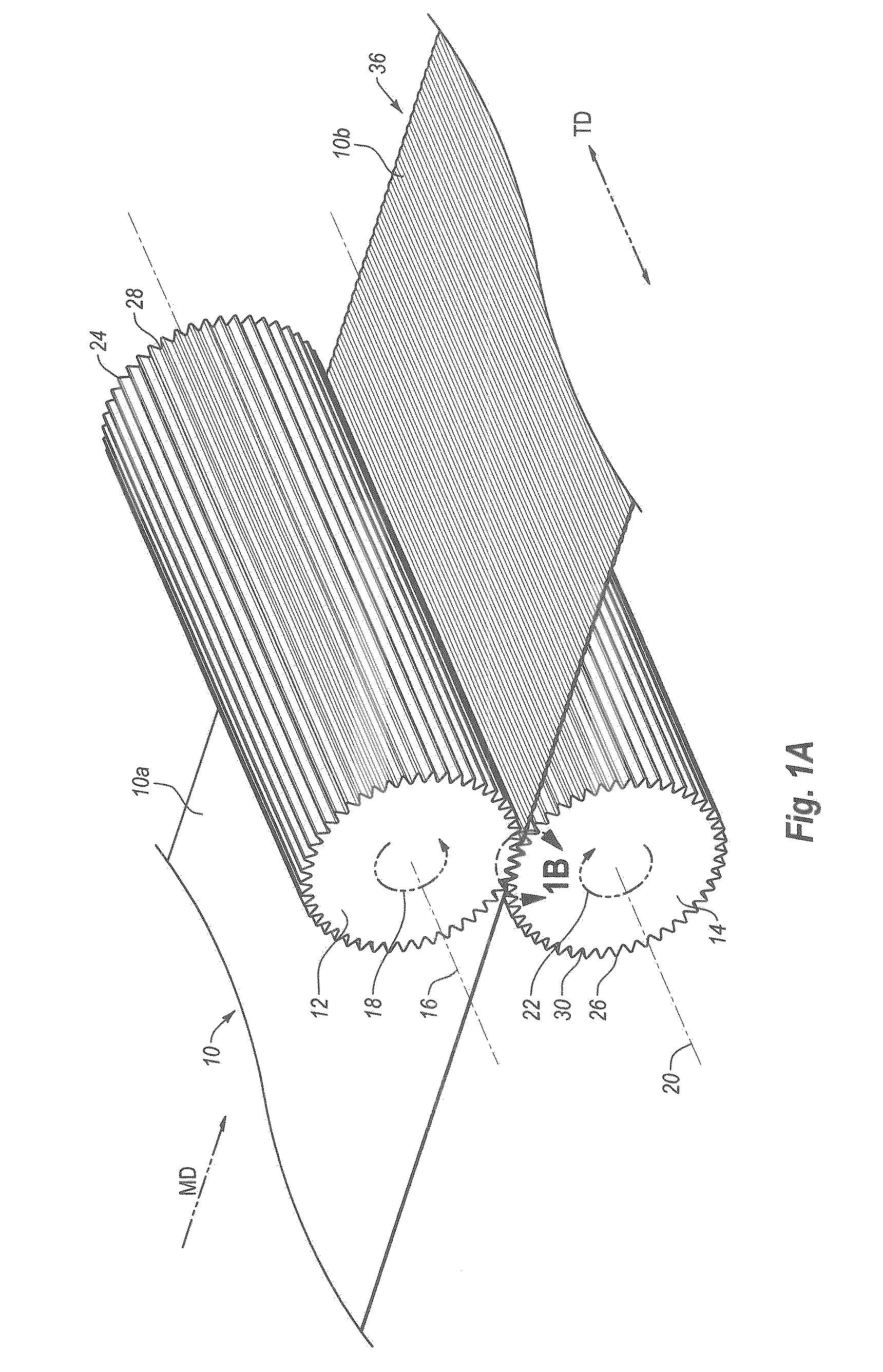

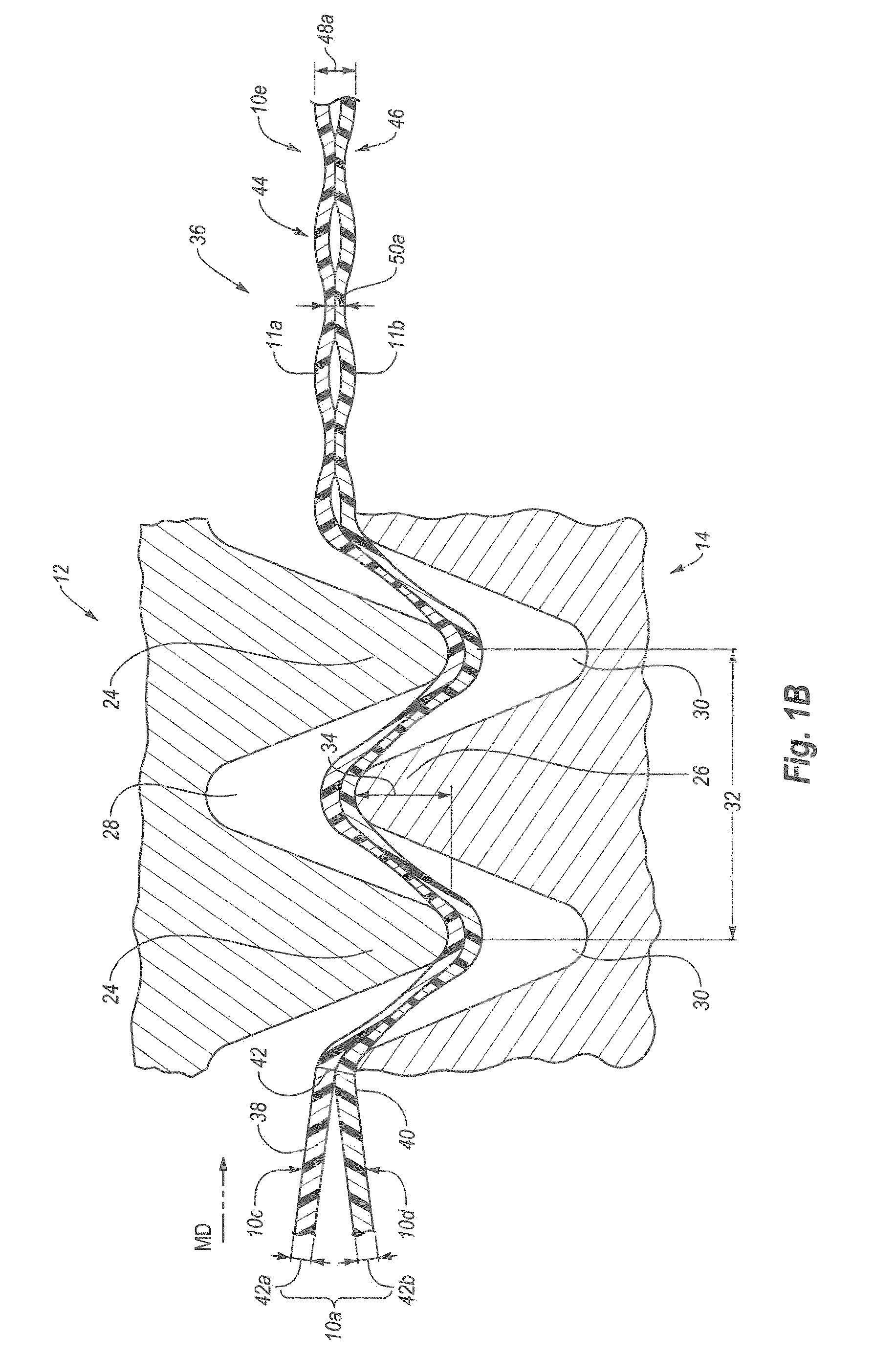

Multi-Layered Lightly-Laminated Films and Methods of Making The Same

ActiveUS20120064271A1High strengthReduce the amount requiredLamination ancillary operationsOrnamental structuresTear resistanceBond strength

Apparatus and methods for creating multi-layered lightly-laminated provide films with increased or maintained strength. An increased level of strength is achieved by bonding adjacent layers of the multi-layer film together in a manner that the bond strength of the laminated layers is less than a strength of a weakest tear resistance of the individual first and second film layers. The inventors have surprisingly found that such a configuration of light bonding provides increased and unexpected strength properties to the multi-layer film as compared to a monolayer film of equal thickness or a multi-layer film in which the plurality of layers are tightly bonded together.

Owner:THE GLAD PROD CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com