Patents

Literature

2710 results about "Phenolic aldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

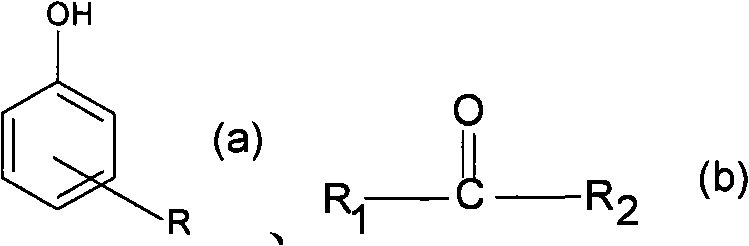

Phenolic aldehydes are derivatives of phenol. Phenolic aldehydes can be found in wines and cognacs.

Particulate material having multiple curable coatings and methods for making and using same

InactiveUS7153575B2Retain it curabilityCurability potentialLiquid surface applicatorsSynthetic resin layered productsFuranPolymer science

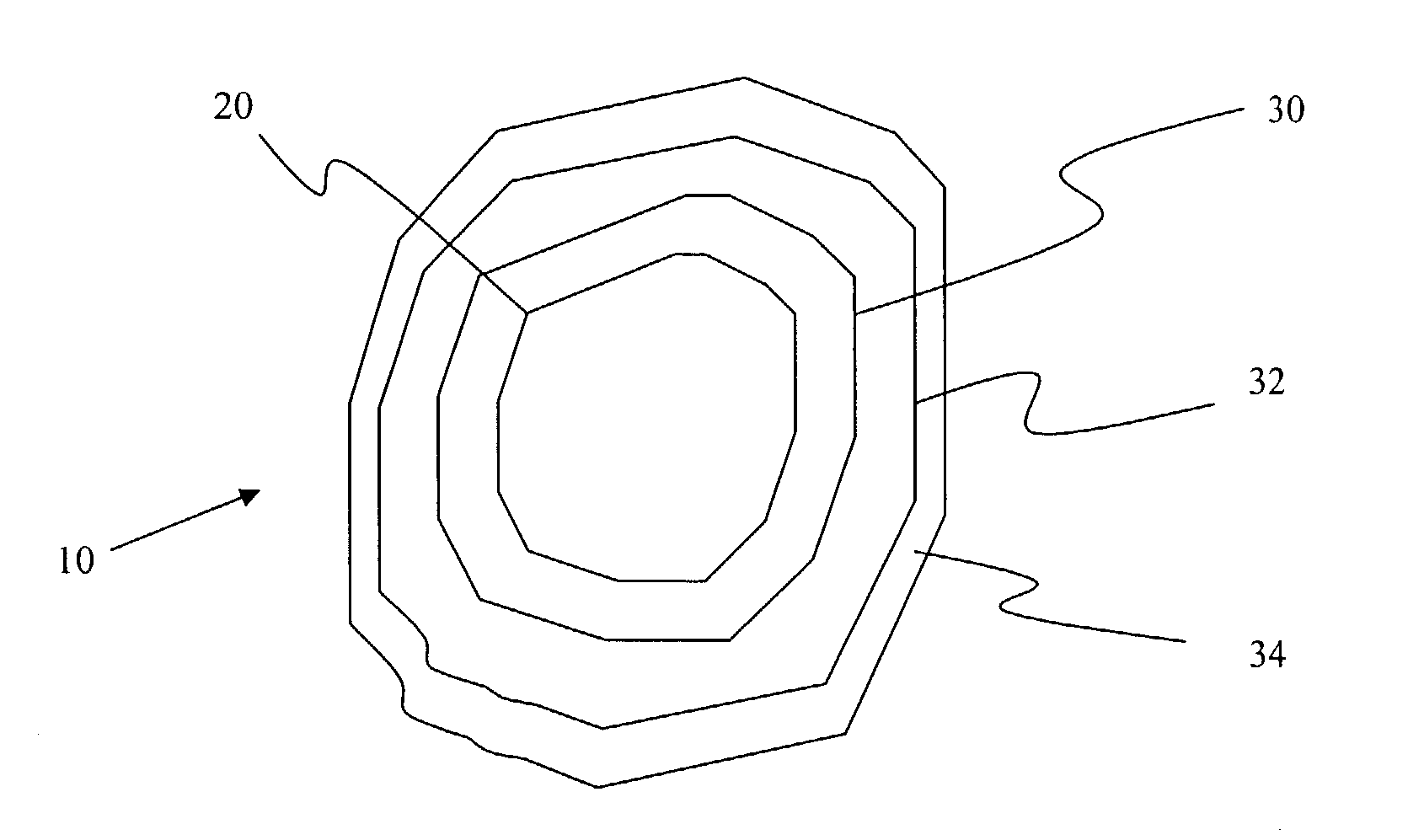

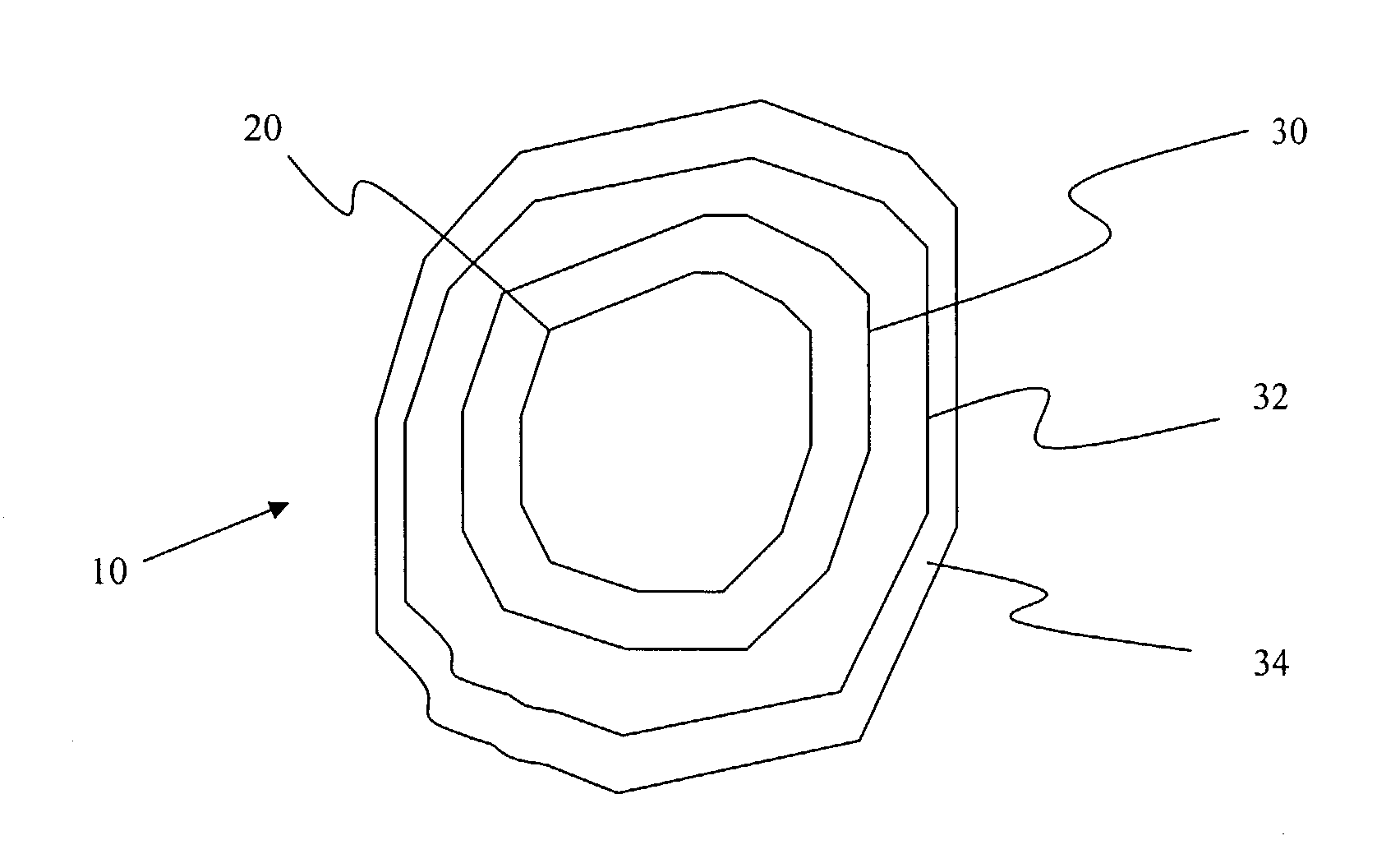

The present invention relates to coated particulate matter wherein the particles are individually coated with a first set of one or more layers of a curable resin, for example, a combination of phenolic / furan resin or furan resin or phenolic-furan-formaldehyde terpolymer, on a proppant such as sand, and the first set of layers is coated with a second set of one or more layers of a curable resin, for example, a novolac resin with curative. Methods for making and using this coated product as a proppant, gravel pack and for sand control are also disclosed.

Owner:HEXION INC

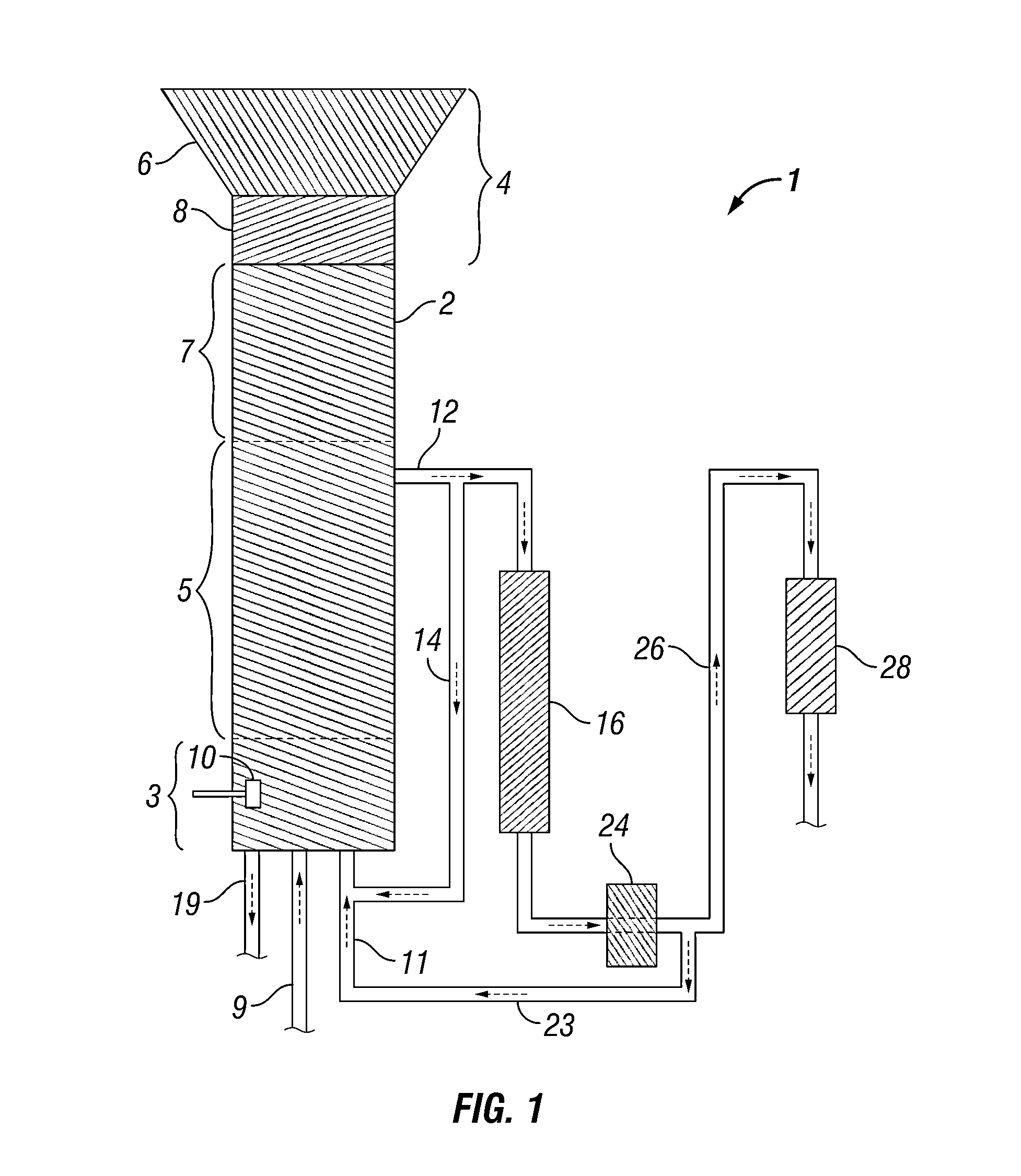

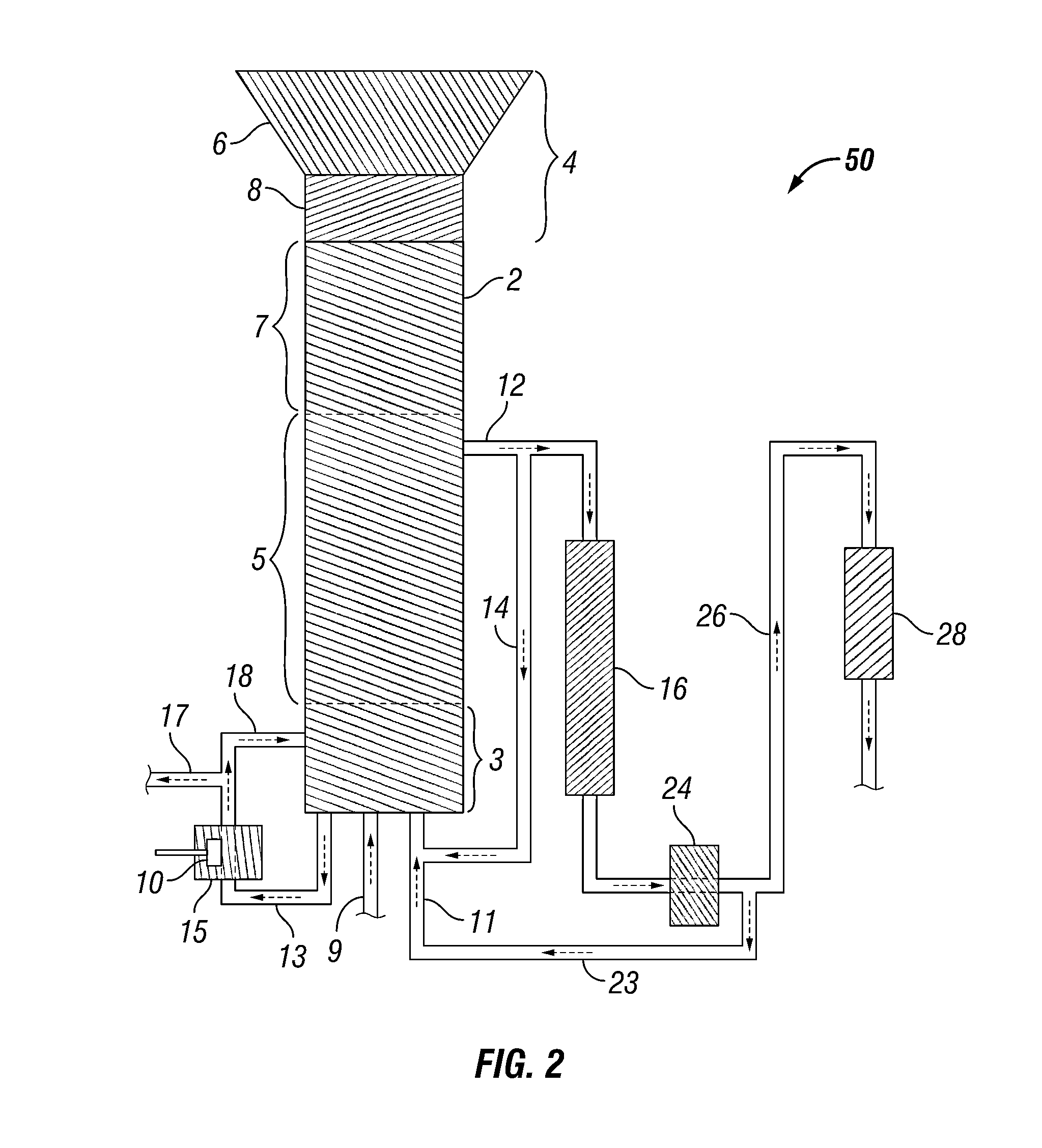

Methods and systems for processing lignin during hydrothermal digestion of cellulosic biomass solids

InactiveUS20140117275A1Low viscosityCellulosic pulp after-treatmentOther chemical processesCelluloseFluid phase

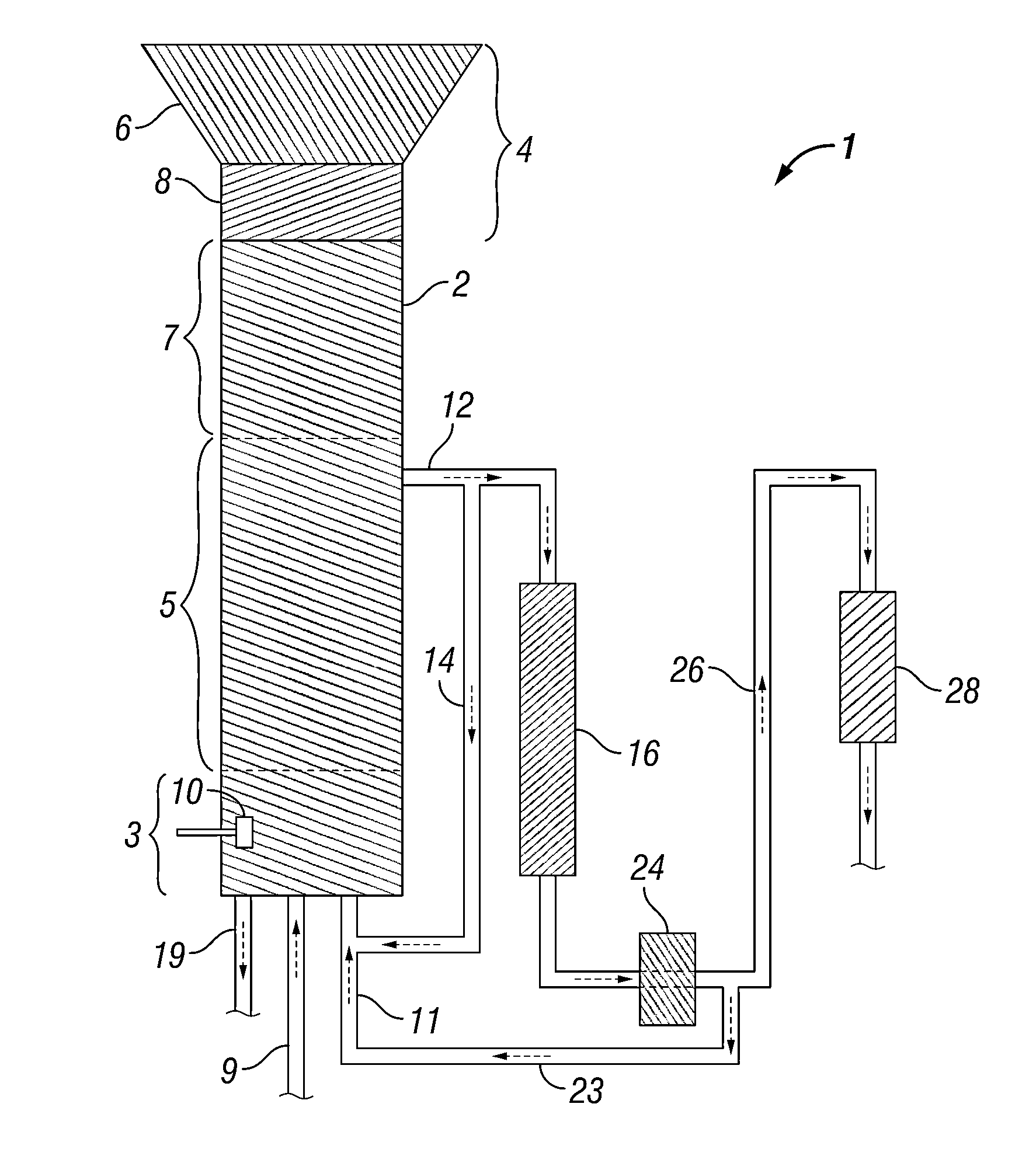

Digestion of cellulosic biomass solids may be complicated by lignin release therefrom, which can produce a highly viscous phenolics liquid phase comprising lignin polymer. Methods for digesting cellulosic biomass solids may comprise: providing cellulosic biomass solids in the presence of a digestion solvent, molecular hydrogen, and a slurry catalyst capable of activating molecular hydrogen; at least partially converting the cellulosic biomass solids into a phenolics liquid phase comprising lignin, an aqueous phase comprising an alcoholic component derived from the cellulosic biomass solids, and an optional light organics phase; wherein at least a portion of the slurry catalyst accumulates in the phenolics liquid phase as it forms; and reducing the viscosity of the phenolics liquid phase.

Owner:SHELL OIL CO

Novel fast-set anticorrosion and wear-resistant epoxy powder coating and preparation process thereof

InactiveCN102492353AImprove anti-corrosion performanceSimple preparation processAnti-corrosive paintsPowdery paintsWear resistantWear resistance

The invention relates to the field of chemical coating, in particular to epoxy powder coating applied to material conveying steel belts in oilfield oil pumping pipelines or coal transportation in the oil industry. In a formula, the coating comprises the following components in percentage by weight: 32-56% of epoxy resin, 8-14% of curing agent, 30-50% of pigments and fillers, 2-10% of resin modifier and 2-6% of assistant, wherein the epoxy resin in the formula is bisphenol A type epoxy resin, a mixture of the bisphenol A type epoxy resin and phenolic aldehyde modified epoxy resin, and phenolic aldehyde modified epoxy resin, and the curing agent is phenolic hydroxyl resin. The epoxy powder coating disclosed by the invention belongs to fast-set anticorrosion and wear-resistant epoxy powder coating, has the granularity being 10-125 mu m, is applied under general curing conditions that the curing temperature is 180-200 DEG C and the curing time is 3-10min, can be regulated according to user needs and is superior to like products in anticorrosion performance, coating film mechanical performance and wear resistance, a preparation process is simple, the labour productivity can be obviously increased, and the epoxy powder coating is suitable for industrialized production.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

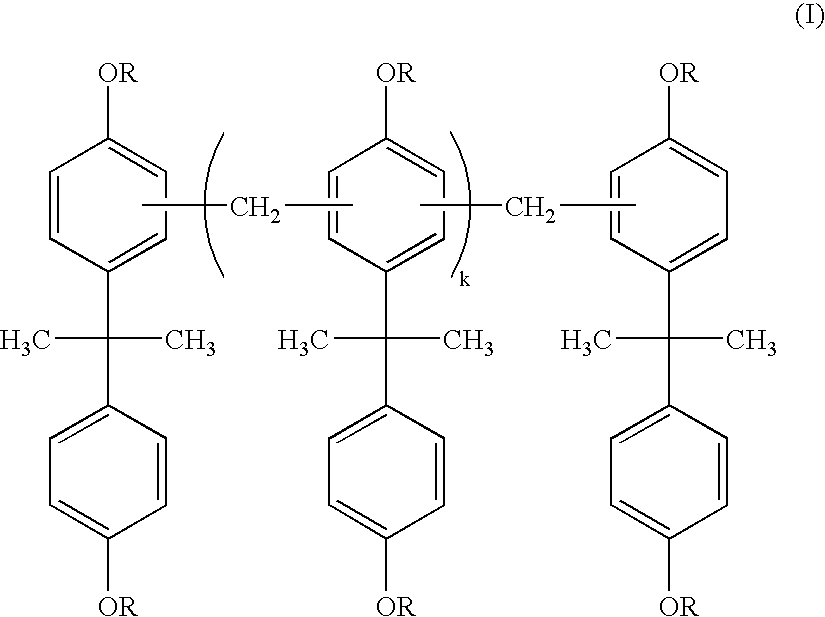

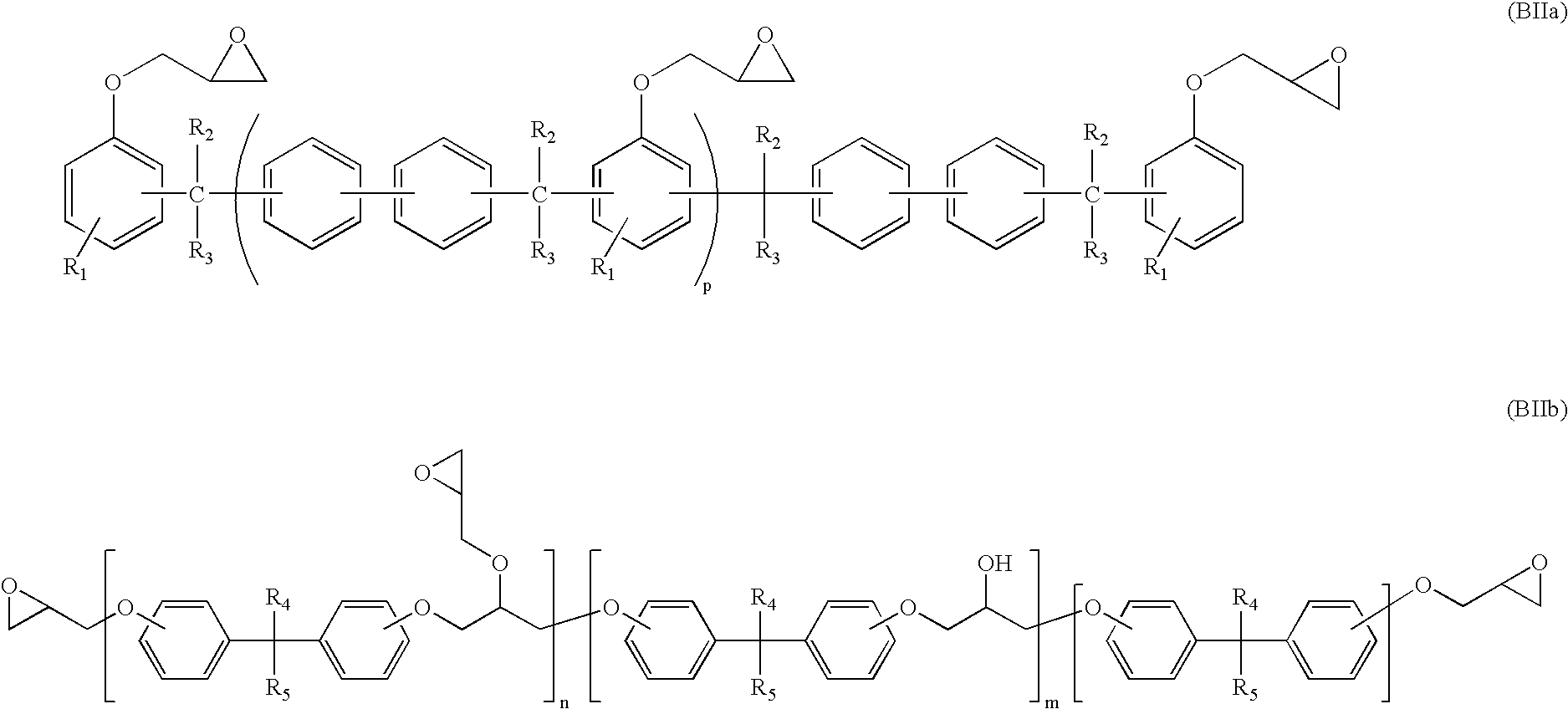

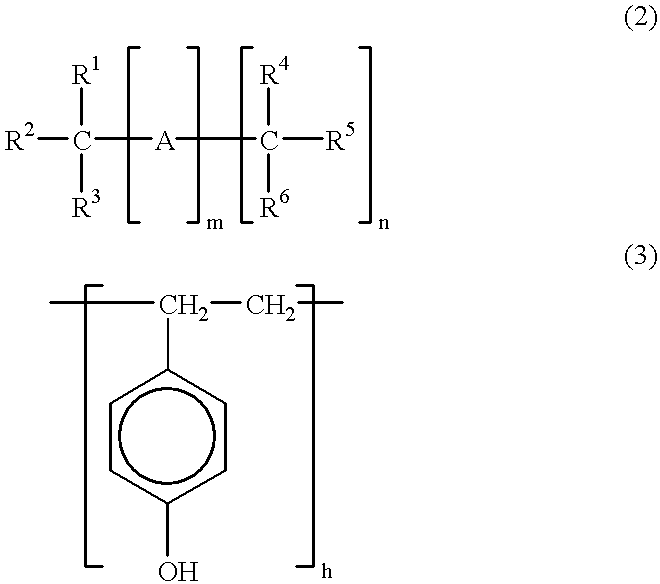

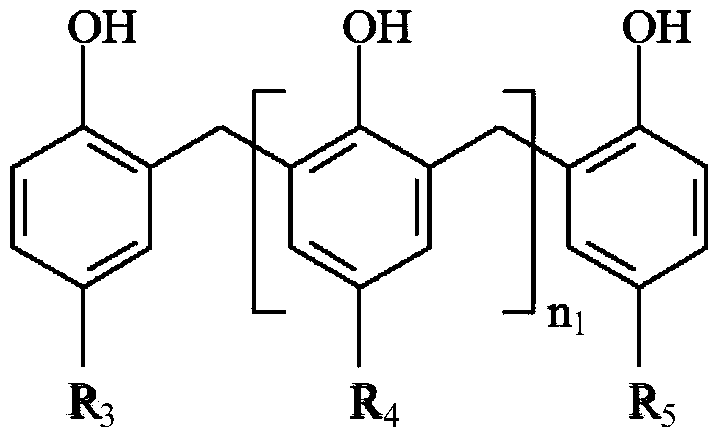

Permanent resist composition, cured product thereof, and use thereof

InactiveUS20050260522A1High densityImprove film adhesionNanoinformaticsPhotomechanical apparatusPolymer sciencePhotoacid generator

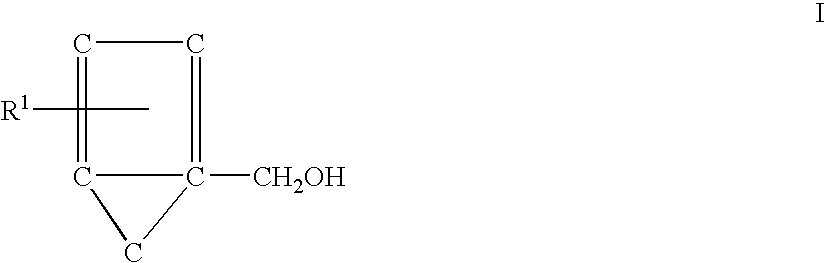

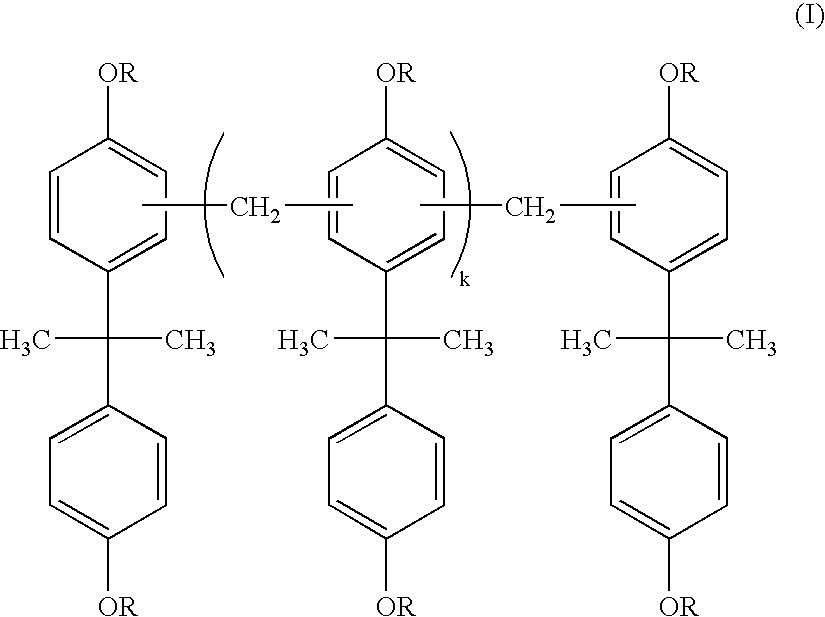

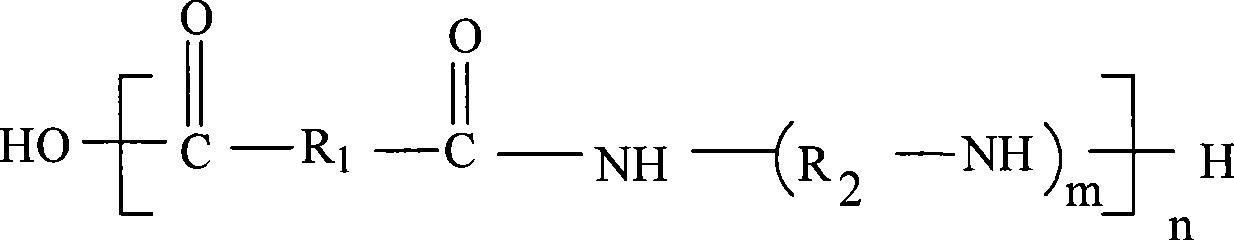

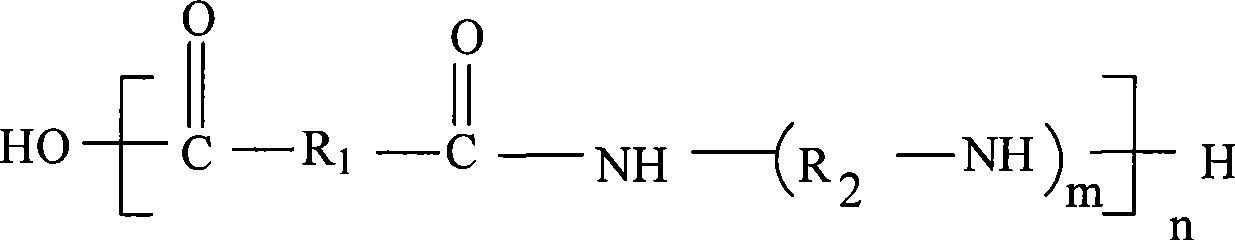

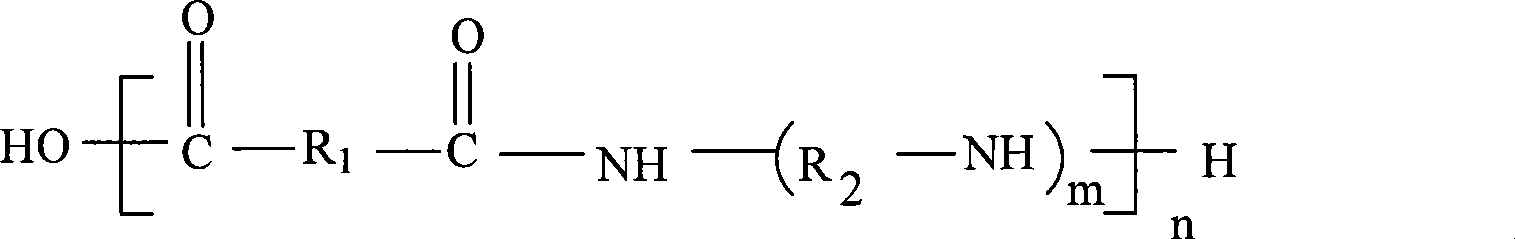

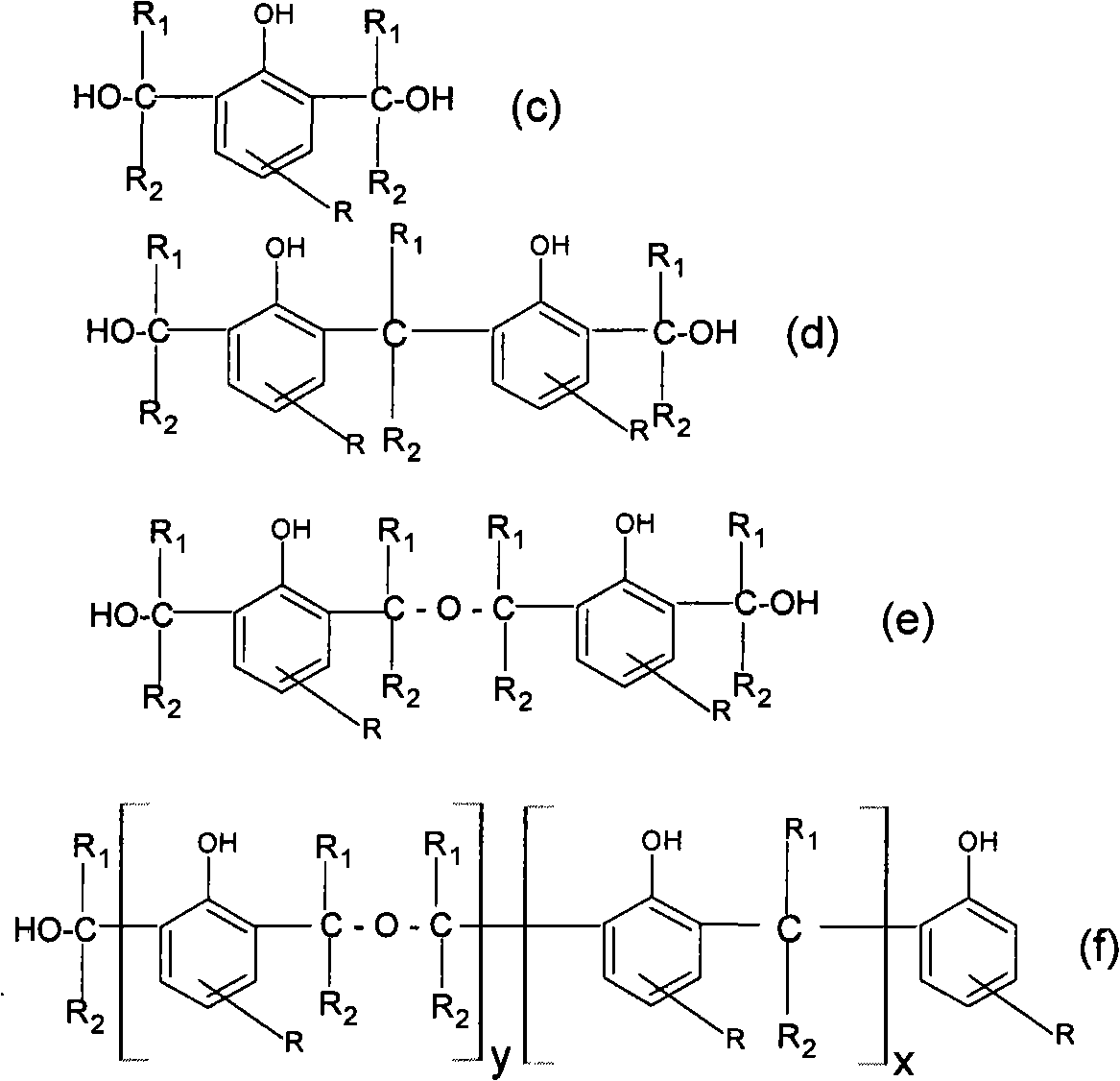

A permanent photoresist composition comprising: (A) one or more bisphenol A-novolac epoxy resins according to Formula I; wherein each group R in Formula I is individually selected from glycidyl or hydrogen and k in Formula I is a real number ranging from 0 to about 30; (B) one or more epoxy resins selected from the group represented by Formulas BIIa and BIIb; wherein each R1, R2 and R3 in Formula BIIa are independently selected from the group consisting of hydrogen or alkyl groups having 1 to 4 carbon atoms and the value of p in Formula BIIa is a real number ranging from 1 to 30; the values of n and m in Formula BIIb are independently real numbers ranging from 1 to 30 and each R4 and R5 in Formula BIIb are independently selected from hydrogen, alkyl groups having 1 to 4 carbon atoms, or trifluoromethyl; (C) one or more cationic photoinitiators (also known as photoacid generators or PAGs); and (D) one or more solvents.

Owner:MICROCHEM CORP +1

Novel non-formaldehyde wood adhesive and preparation thereof

ActiveCN101412898AImprove water resistanceLow priceProtein adhesivesGlue/gelatin preparationLignosulfonatesChemistry

The invention provides a novel aldehyde-free wood adhesive and a preparation method thereof. A mixture of plant protein and lignin sulphonate is used as a base material, and then high water resisting property is obtained through modifying the protein self. Dry strength of the real aldehyde-free wood adhesive is nearly that of urea-formaldehyde glue and phenol glue, the water resisting property of the aldehyde-free wood adhesive is far higher than that of the urea-formaldehyde glue and approximates to that of the phenol glue, the adhesive fully reaches the usage standard of class II glue, and the adhesive has the advantages of low cost, excellent performance and easy coating.

Owner:宁波朝露新材料科技有限公司

Epoxy coating and preparation method and application thereof

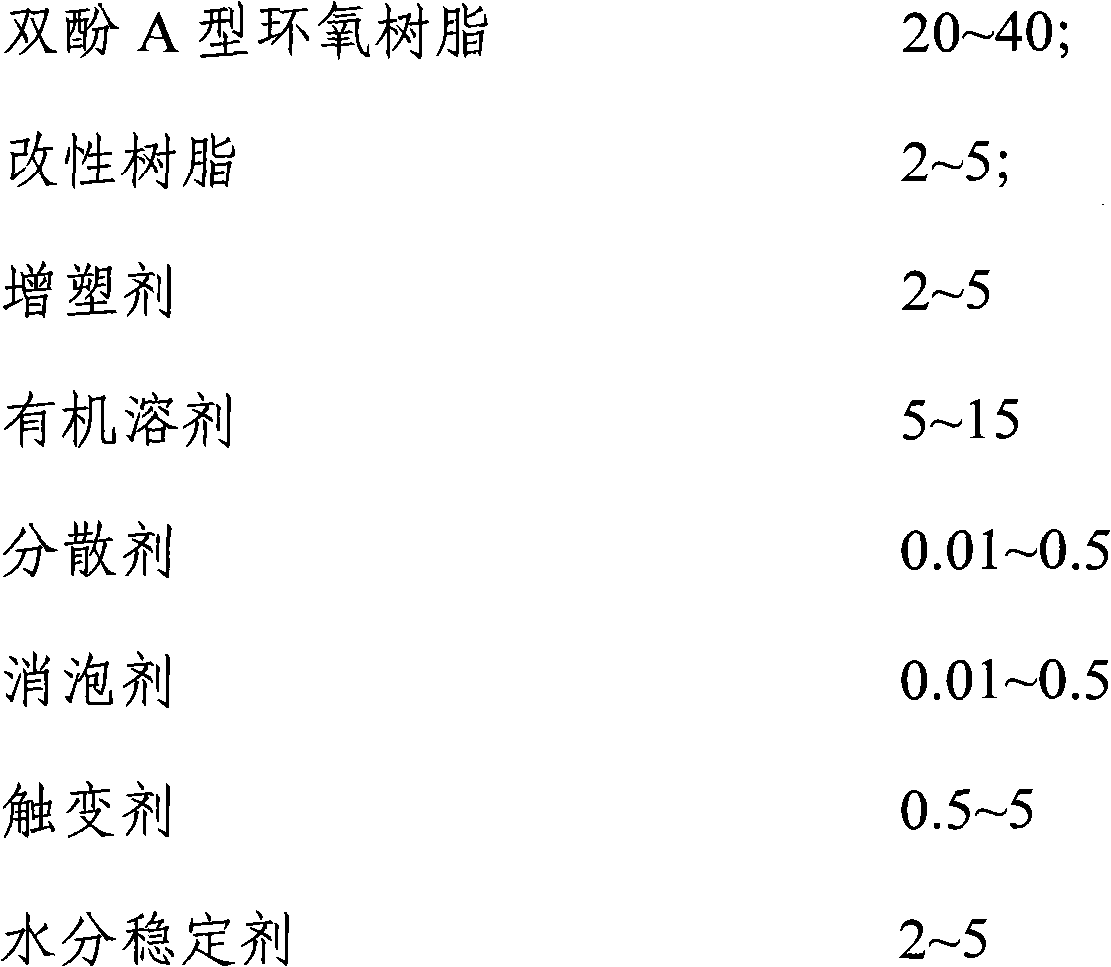

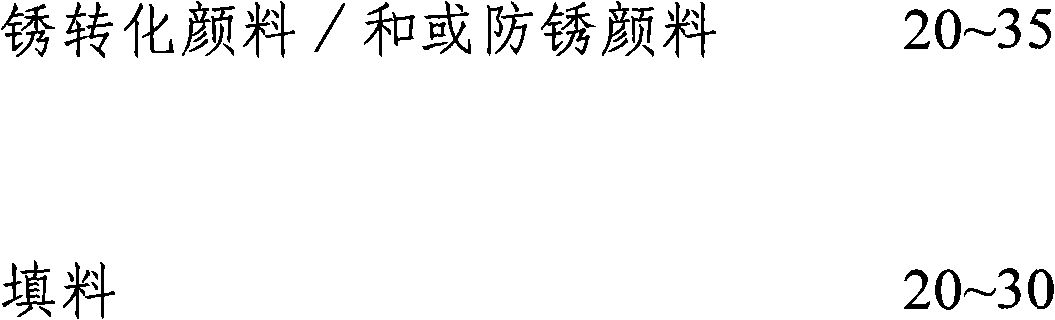

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

Chromium-free environment-friendly epoxy anticorrosion primer

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

Metal base material corrosion-resistant coating and preparation method thereof

InactiveCN102391779AWeather resistantAnti-corrosionAnti-corrosive paintsEpoxy resin coatingsVinyl esterBis epoxide

The invention discloses metal base material corrosion-resistant coating and a preparation method thereof. The metal base material corrosion-resistant coating comprises the following components in parts by weight: 25 to 30 pats of epoxy modified organic silicon resin, 15 to 20 parts of modified vinyl resin, 1 to 2 parts of nano material, 1 to 3 parts of corrosion-resistant particulate filler, 15 to 18.5 percent of pigment and filler, 1 to 2 parts of antisettling agent, 0.3 to 0.5 part of dispersing agent, 0.5 to 0.8 part of stabilizing agent, 3 to 4 parts of aid and 23 to 26 parts of solvent, wherein the modified vinyl resin comprises according to the weight percentage 50 to 70 % of phenolic aldehyde epoxy vinyl ester resin and 30 to 50 % of flexible vinyl ester resin. The metal base material corrosion-resistant coating is prepared by multiple flows of weighing the raw materials in parts by weight, mixing the raw materials according to certain sequence, dispersing, grinding and the like. The metal base material corrosion-resistant coating has high temperature tolerance, wet resistance, corrosion resistance, weldability and constructability and can be applied in the technical fieldsof processing of various different metals.

Owner:资阳赛特化工有限公司

Dark blue organic light-emitting material and preparation method and application thereof

InactiveCN110790782AHigh color purityImprove stabilitySilicon organic compoundsSolid-state devicesBond energyULTRAMARINE BLUE

The invention discloses a dark blue organic light-emitting material and a preparation method and application thereof. The dark blue organic light-emitting material contains a structural unit disclosedin the invention, wherein, M is B or Bi; X is O, S or NR4; R1-R4 are independently selected from connecting bonds or groups obtained from H-H, H-F, H-O-H, H-S-H, H-CN, saturated hydrocarbons, unsaturated hydrocarbons, fluorinated hydrocarbons, heterocyclic compounds, organoboron, organosilicone, alcohols, mercaptans, ethers, thioethers, phenols, thiophenol, aldehydes, ketones, amines, amides, nitriles or sulfones losing one or more H; R1-R3 are located at any substitution position on rings of the structural unit where R1-R3 are located, and the bond energy between the ring where R3 is locatedand M is greater than or equal to the bond energy between the ring where R2 is located and M. The dark blue organic light-emitting material containing the B / Bi-N main body structure has very narrow light-emitting spectrum and TADF properties; the color purity is high, and the stability is good.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Method for preparing phenolic aldehyde adhesive based on lignin phenolized liquid and application thereof

InactiveCN101260283AImprove liquidityGood storage stabilityAldehyde/ketone condensation polymer adhesivesThermal insulationResin adhesive

The invention provides a preparation method for phenolic adhesive based on lignin phenolization liquid and application thereof. Under the condition of normal pressure heating or thermalcatalysis, phenol is taken as liquefaction reagent, lignin is added, the temperature is raised to 90 to 150 DEG C, the thermal insulation liquefaction reaction is made to cool to obtain a lignin liquefaction product; basic catalyst and formaldehyde are directly added into the liquefaction liquid, the temperature is raised to 70 to 97 DEG C under normal pressure to react for 1 to 3 hours, the reaction is terminated when the viscosity is measured to meet the preset requirement, and low-free formaldehyde environmental protection type phenolic adhesive based on lignin phenolization liquid is obtained. The adhesive obtained by the invention has lower cost and lower content of free formaldehyde than the prior phenolic resin adhesive. The plywood pressed by using the adhesive obtained by the invention has good bonding performance.

Owner:HUANGSHAN UNIV

Modified phenolic tackifying resins for rubber compounding applications

This invention is related to modified alkylphenol aldehyde resins and a method for preparing them from the reactions of alkylphenols, aldehydes, amines, rosins and fatty acids. When used in rubber compounds, these modified alkylphenol aldehyde resins provide much improved tack properties.

Owner:SINO LEGEND CHINA CHEM

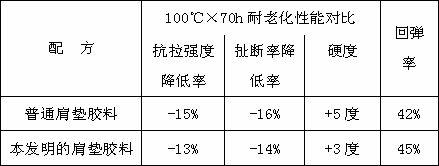

Tyre crown rubber material and mixing method thereof

InactiveCN102604170AGood physical and mechanical propertiesIncrease elasticitySpecial tyresRolling resistance optimizationRubber materialPolymer science

The invention discloses a tyre crown rubber material. The tyre crown rubber material comprises the following raw materials in parts by weight: 60-80 of natural rubber, 20-40 of butadiene rubber BR9000, 0-0.4 of peptizer, 10-30 of intermediate super abrasion furnace black, 25-45 of white carbon black, 3-7 of silane coupling agent, 3-5 of zinc oxide, 1-4 of stearic acid, 1-3 of antiager 6PPD, 0-2 of antiager RD, 1-3 of microcrystalline paraffin, 1-3 of sulfur, 1.5-2.5 of accelerator, 4-6 of fatty acid salt processing agent, 0-1 of anti-reversion agent, 2-5 of environment-friendly arene oil TDAE (Treated Distillate Aromatic Extract), 1-3 of octyl phenolic aldehyde tackifying resin and 0-0.3 of scorch retarder. When mixing is carried out in three sections, partial formula raw materials are subjected to rubber material mixing, and then other formula materials are added for rubber material mixing. The tyre crown rubber material produced by using the tyre crown rubber material formula is good in comprehensive processing property, has the characteristics of low thermogenesis, ageing resistance and tearing resistance and is environment-friendly and can be used for producing green full-steel radial tyre crown.

Owner:安徽大瑞橡胶有限公司

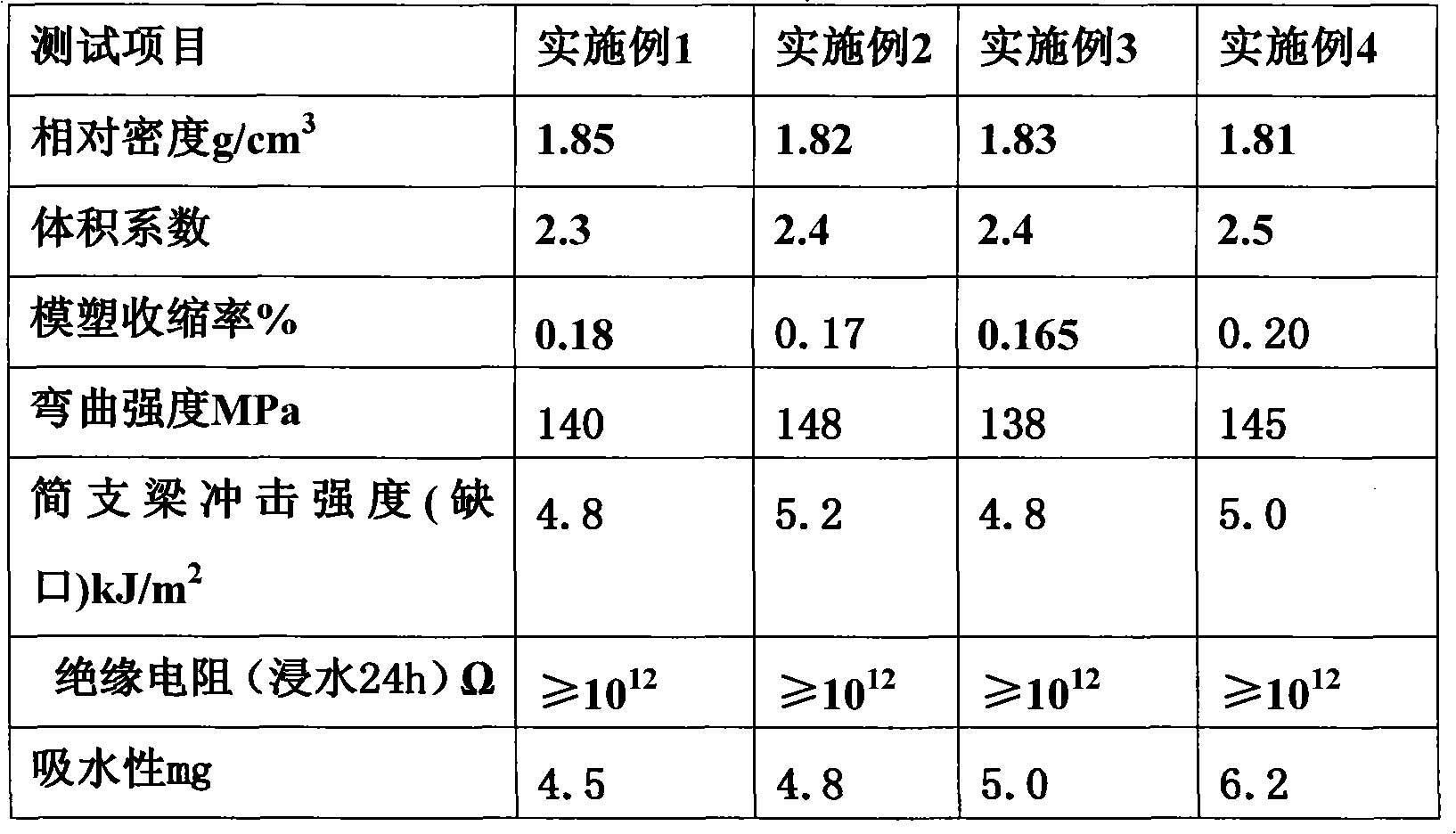

Low-shrinkage phenolic moulding compound

The invention discloses a low-shrinkage phenolic moulding compound, belonging to the technical field of thermosetting plastics. The low-shrinkage phenolic aldehyde moulding compound comprises the following raw materials in parts by weight: 20.0-35.0 parts of phenolic resin, 2.0-10.0 parts of thermosetting resin, 1.0-8.0 parts of curing agent, 0.2-2.0 parts of curing accelerator, 1.0-3.0 parts of lubricant, 30.0-50.0 parts of glass fiber, 1.0-10.0 parts of cotton fiber, 15.0-25.0 parts of nanoscale inorganic filler, 0.5-2.0 parts of coupling agent, and 0.5-4.0 parts of low shrinkage agent. In the technical scheme of the invention, the glass fibers and the cotton fibers are combined to improve mechanical strength, the strength and the shrinkage resistance of a material is improved completely by adopting the nanoscale inorganic filler and the adding the coupling agent and the low shrinkage agent, and the invention can meet the usage requirements of the industries of vehicles, electrical appliances, machineries and textiles on plastic products.

Owner:常熟东南塑料有限公司

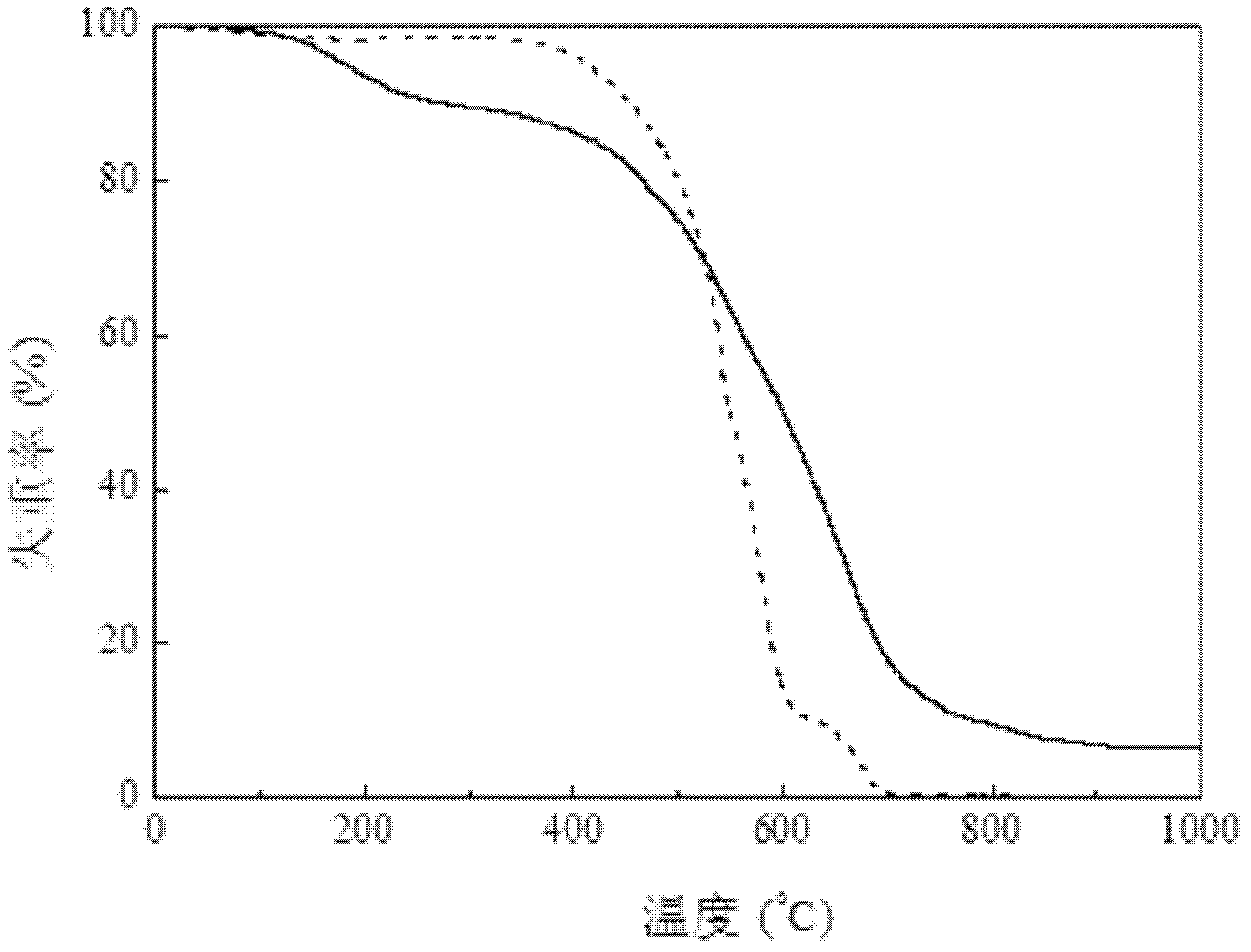

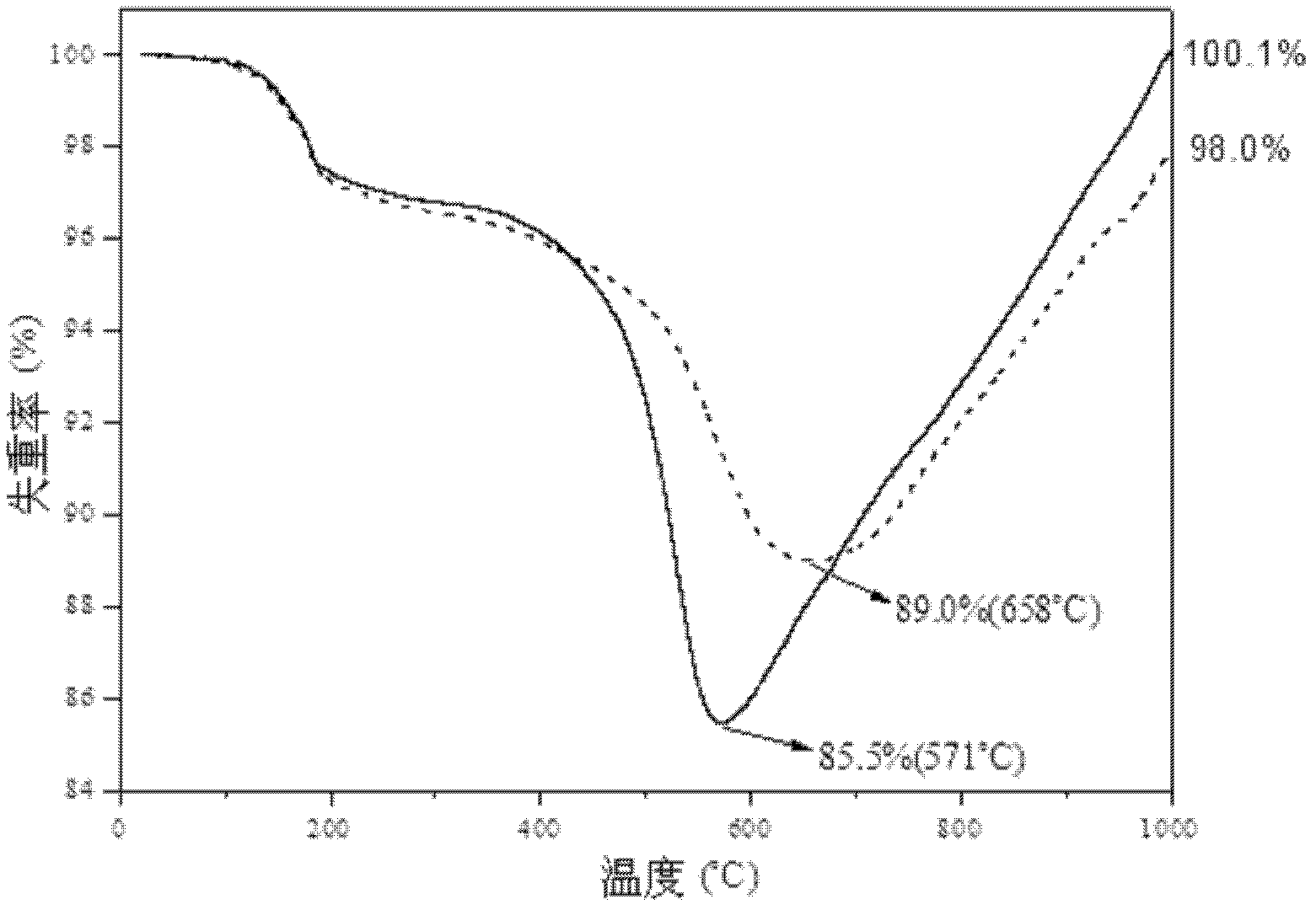

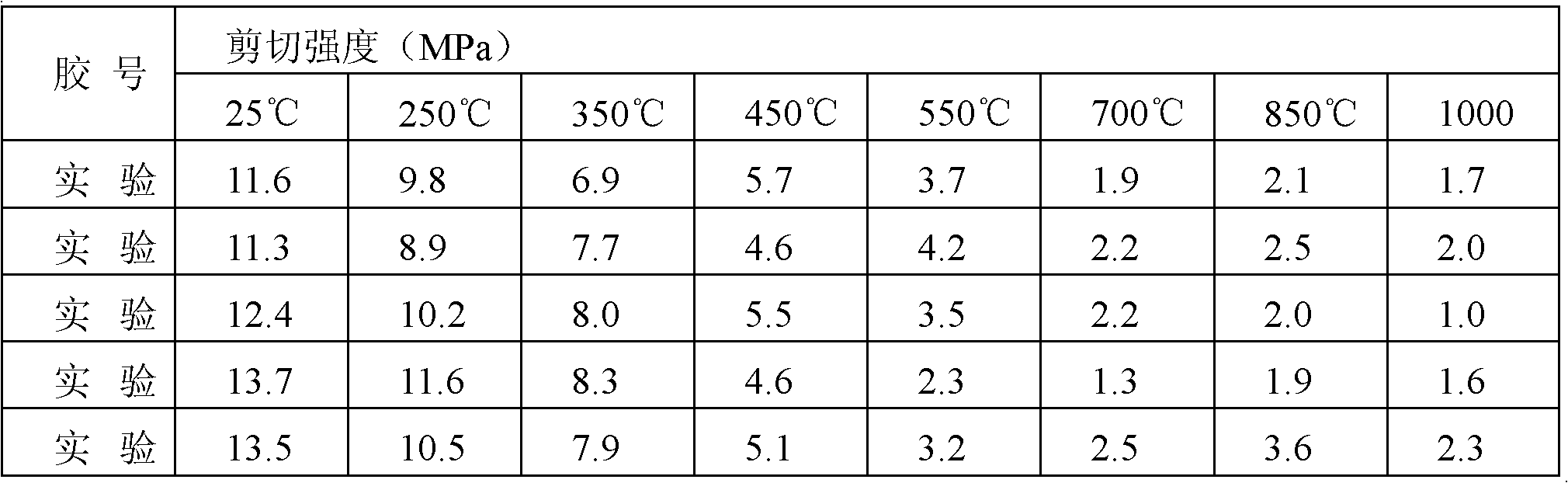

Medium temperature curing high temperature resistant phenolic adhesive

InactiveCN102627927AExcellent bonding strengthHigh bonding strengthAldehyde/ketone condensation polymer adhesivesChemistryAdhesive

A medium temperature curing high temperature resistant phenolic adhesive relates to an adhesive. The invention solves technical problems of phenolic high curing temperature and weak temperature tolerance of adhesive. The adhesive of the present invention consists of modified phenolic resin solution, toughening agent, curing agent, heat-resistant reinforced resin and filler. The adhesive of the invention has a low curing temperature, can be cured at 100 DEG C and obtain good adhesive strength. Curing at 100 DEG C for 6 hours, the adhesive can reach shear strength of 13.5MP and still have shear strength of 2.3MPa at 1000 DEG C. The adhesive further conducts complex reaction in high temperature usage environment and generates product with better heat resistance, thereby realizing the echelon curing and echelon temperature resistance, which are difficult for other type of high temperature resistant glue to achieve.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

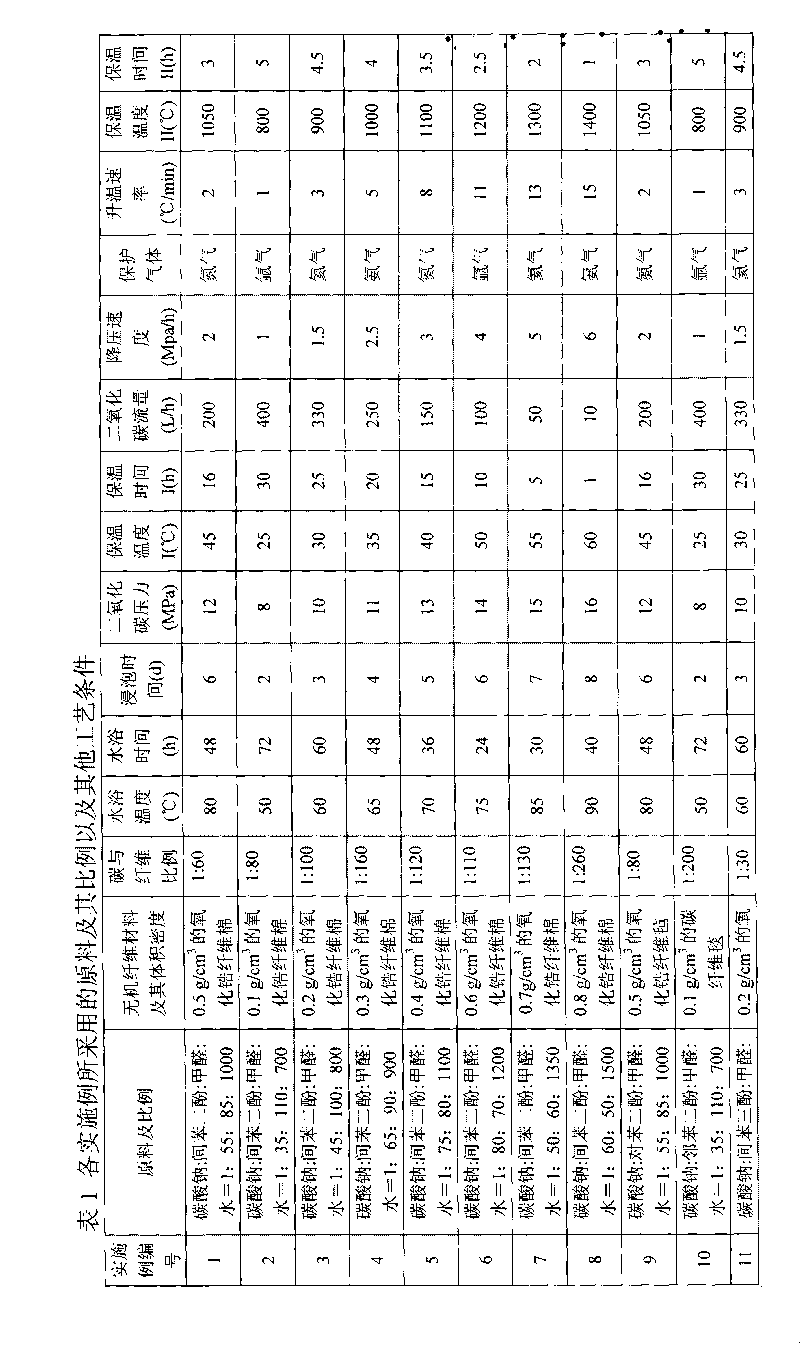

Fiber composite carbon aerogel material and preparation method thereof

The invention provides a fiber composite carbon aerogel material which comprises carbon aerogel and an inorganic fiber material, wherein the mass ratio of the carbon element to the inorganic fiber material in the carbon aerogel is 1:1-300. The invention also provides a method for preparing the fiber composite carbon aerogel material, which comprises the following steps: preparation of phenolic aldehyde solution, preparation of fiber composite phenolic aldehyde gel, aging of the fiber composite phenolic aldehyde gel, drying of supercritical fluid, reaction in an atmosphere cracking furnace, and the like. The fiber composite carbon aerogel material has the advantages of favorable moldability, good high temperature resistance, outstanding high-temperature heat-insulating property, low density and high compressive resistance; and the fiber composite carbon aerogel material can conduct electricity, be used as a catalyst carrier material, electrode material or high-temperature heat-insulating material, meet the special requirements for aviation, spaceflight, military affairs and other aspects, and be used in the civil field having high requirements for high-temperature heat-insulating property.

Owner:海鹰空天材料研究院(苏州)有限责任公司

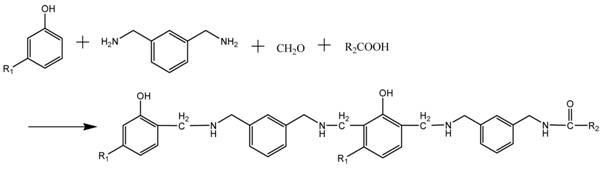

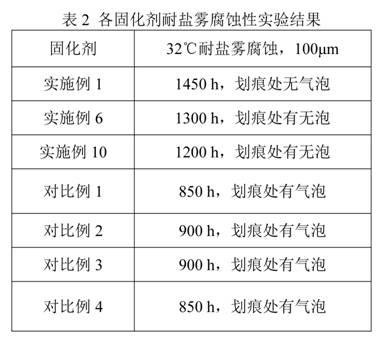

Alkylphenol modified phenolic amide curing agent and preparation method thereof

ActiveCN102633991AStrong resistance to salt spray corrosionHigh impact strengthOrganic compound preparationCarboxylic acid amides preparationAlkylphenolPerylene derivatives

The invention discloses an alkylphenol modified phenolic amide curing agent and a preparation method thereof. The alkylphenol modified phenolic amide curing agent comprises the raw components including phenol or phenol derivatives, methanal or paraformaldehyde, polyamine and fatty acid or fatty acid polymer. The preparation method comprises the following steps of: uniformly mixing the fatty acid or the fatty acid polymer and the polyamine, heating the mixture, cooling the mixture, adding the phenol or the phenol derivatives in the mixture, uniformly mixing the methanal or the paraformaldehyde with the mixture, heating the new mixture, and performing dehydration on the new mixture to obtain the product; or the preparation method comprises the following steps of: uniformly mixing the phenol or the phenol derivatives, the polyamine and the methanal or the paraformaldehyde, heating the mixture, adding the fatty acid or the fatty acid polymer into the mixture, heating the new mixture, and performing the dehydration on the new mixture to obtain the product. The curing agent disclosed by the invention is very strong in salt spray corrosion resistance, is superior to polyamide curing agent and curing agent products of modified phenolic aldehyde amide resin and mixtures of the modified phenolic aldehyde amide resin, and has good impact strength and flexibility as well as excellent water tolerance.

Owner:CARDOLITE CHEM ZHUHAI

High-density polyethylene glued board producing method

InactiveCN101284384AReduce CooldownSave energyWood veneer joiningLow-density polyethyleneWeather resistance

A method for manufacturing a HDPE wood plywood mainly includes: rolling dense pin holes on the cementing surface of a veneer; replacing urea formaldehyde, phenolic aldehyde and other adhesives with HDPE plastic film; laying up in the common conventional plywood lay-up method and only laying the HDPE film instead of the adhesives; heating and pressuring the lay-up on a hot press machine and then pressuring and cooling on a cold press machine. The problems that the HDPE is immiscible with the wood, and can not be taken for the adhesive of the wood are solved by applying the principle of mechanical locking; The heat loss and the time consumption of the hot press machine can be avoided when the lay-up is cooled, for pressing is carried out on the hot press machine and the cold press machine respectively. The plywood product has formaldehyde-pollution-free production, high strength, durability, weather resistance, acid and alkali resistance, high water resistance, good appearance and low price. The manufacturing process has no pollution, and is environment-friendly, energy-saving, efficient and simple.

Owner:林群祥

Method for preparing polyurethane/phenolic aldehyde foam thermal insulation material

InactiveCN101565541ASolve the shortcoming of crispnessImprove flammability disadvantagesThermal insulationRaw material

The invention provides a method for preparing a polyurethane / phenolic aldehyde foam thermal insulation material and belongs to the field of the foam thermal insulation material. The invention aims to solve the problems of poor fire resistant property and strong brittleness in the prior polyurethane foam and phenolic aldehyde foam respectively. The method comprises the following steps that: a prepolymer of alkali phenolic resin, isocyanate and polyether glycol are used as raw materials, and the prepolymer is added with a surfactant and a foaming agent for free foaming at room temperature to prepare the polyurethane / phenolic aldehyde foam thermal insulation material, wherein the weight ratio of the isocyanate to the alkali phenolic resin is 3-1:1, the consumption of the polyether glycol is 20 to 50 percent of the weight of the isocyanate, the consumption of the surface active agent is 4 to 10 percent of the weight of the alkali phenolic resin, and the consumption of the foaming agent is 1 to 10 percent of the weight of the alkali phenolic resin. The method has the advantages of the suitability for places where the foaming-in-place insulation is necessary, stable process reaction, good operability and easily bought raw materials; and the foam thermal insulation material prepared by the method has the advantages of little surface pulverization, good toughness, good fire resistant property, and the like.

Owner:BEIJING UNIV OF CHEM TECH

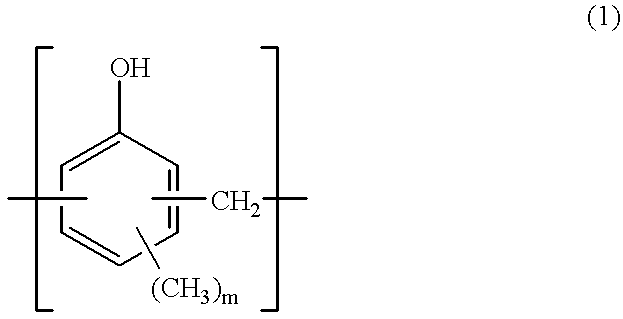

Positive resist composition suitable for lift-off technique and pattern forming method

InactiveUS6210855B1High working precision and reliabilitySolve the lack of resistanceSemiconductor/solid-state device manufacturingDiazo compound compositionsBenzeneResist

A positive resist composition contains (A) a novolak resin having a weight average molecular weight calculated as polystyrene of 2,000-20,000 wherein 2.5-27 mol % of the hydrogen atom of a hydroxyl group is replaced by a 1,2-naphthoquinonediazidosulfonyl group and (B) a low molecular aromatic compound having phenolic hydroxyl groups and 2-20 benzene rings wherein the ratio of the number of phenolic hydroxyl groups to the number of benzene rings is between 0.5 and 2.5. By forming a resist layer on a substrate from the positive resist composition and baking the resist layer at 90-130° C., followed by exposure and development, there is formed a resist pattern having an undercut of desired configuration. Owing to high resolution and improved dimensional control, heat resistance and film retention, the resist pattern lends itself to a lift-off technique.

Owner:SHIN ETSU CHEM IND CO LTD

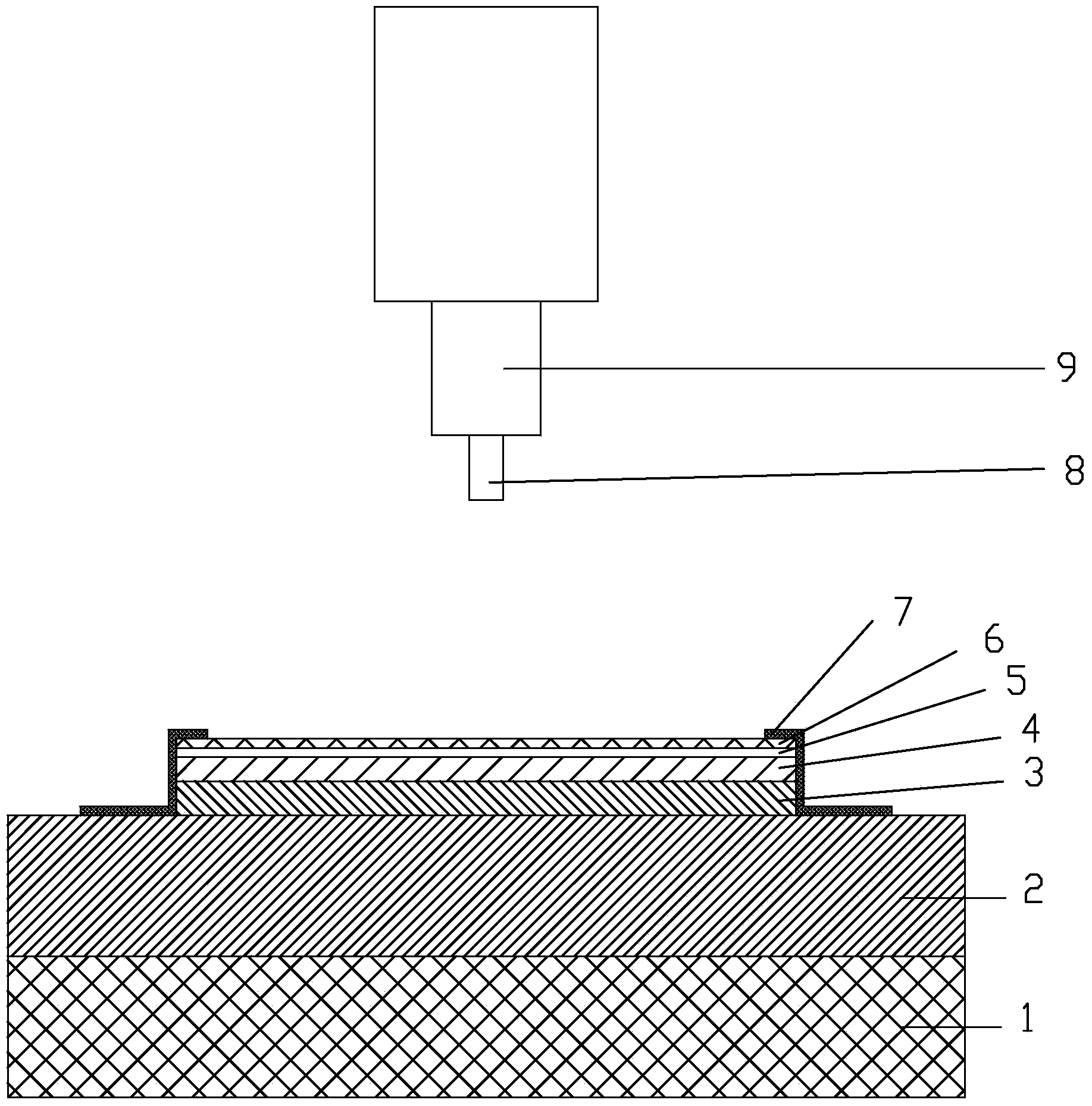

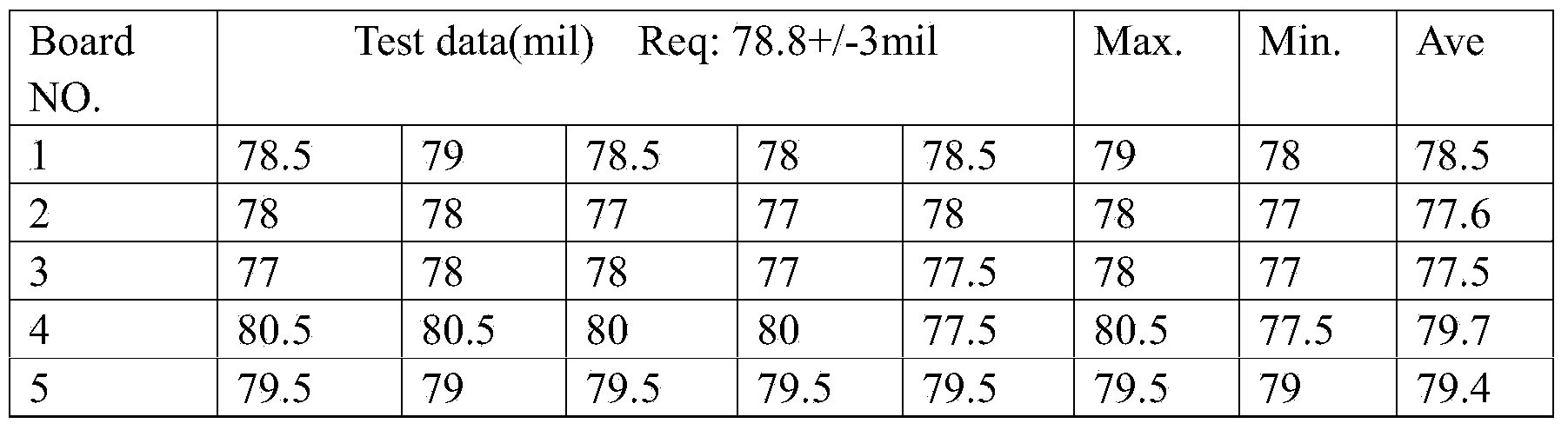

Manufacturing method for improving accuracy of PCB (printed circuit board) back drilling hole

ActiveCN103533761AAffect accuracyHigh precisionPrinted circuit manufactureWell drillingPrinted circuit board

The invention discloses a manufacturing method for improving accuracy of a PCB back drilling hole. The manufacturing method comprises the steps as follows: A), a circuit board substrate is subjected to front procedure processing, through-hole drilling, copper deposition, board electroplating, outer circuit pattern transferring, pattern electroplating and the like; B), back drilling is performed on a PCB 4, and whether the depth of the back drilling hole is qualified is detected; and C), a well drilled back drilling hole is subjected to alkaline etching and photosensitive welding resistance, and finally a finished product is manufactured. The technical scheme is characterized in that drill file coefficients used in a through-hole drilling procedure are correspondingly corrected according to expansion and contraction data obtained in a technological process from the through-hole drilling procedure to the drilling procedure of the PCB 4 during back drilling, and the drill file data is maintained to be consistent with actual expansion and contraction; a drilling-in surface in the through-hole drilling procedure is consistent with that during the back drilling; and a phenolic aldehyde base plate 6 is additionally paved on the top surface of the PCB 4. With the adoption of the manufacturing method, the depth accuracy and the position accuracy of a back drilling hole of a conventional PCB 4 can be effectively improved, so that the completeness of signal transmission of the PCB 4 is guaranteed.

Owner:广东依顿电子科技股份有限公司

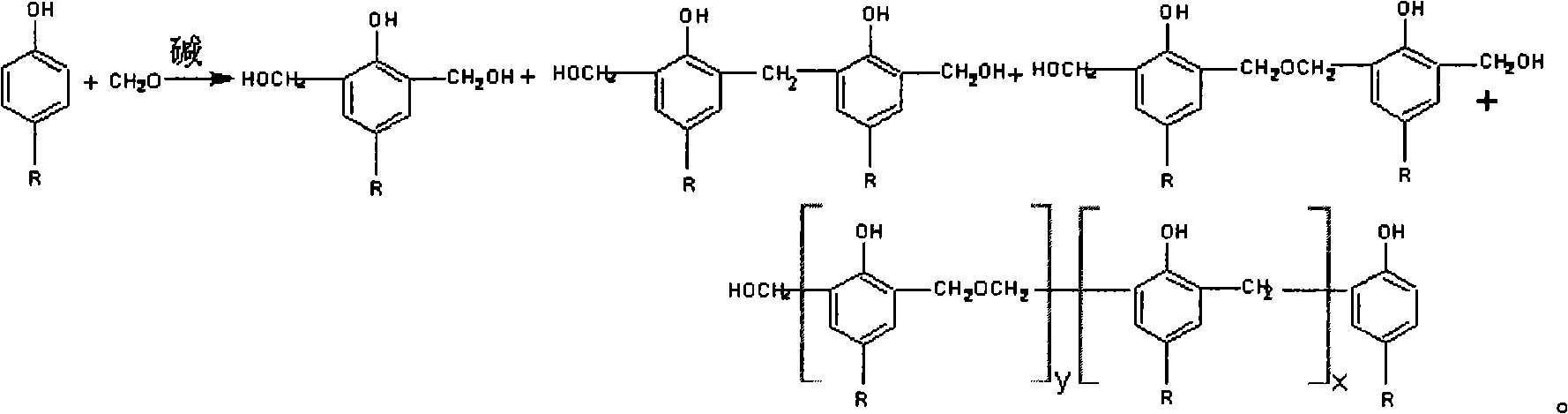

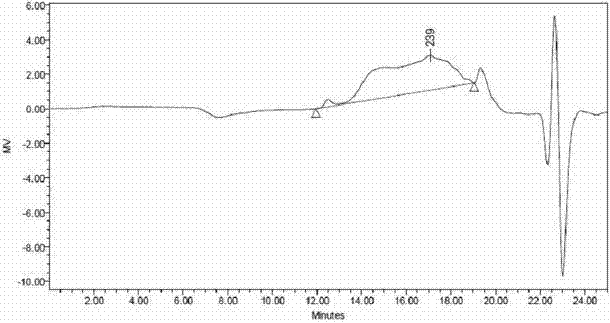

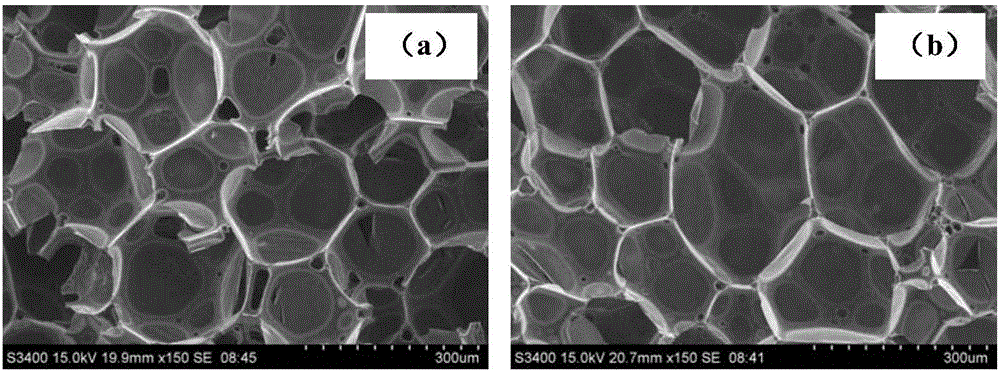

Foaming phenolic resin preparation method and phenolic resin foam

The invention discloses a foaming phenolic resin preparation method. The method comprises the following steps: A, phenol, aldehyde and alkali catalyst are added into a reactor, the mole ratio is 1 : 1-3 : 0.01-0.1, and the components are stirred for 5 to 8 hours at 70 to 90 degrees centigrade; B, the temperature of reaction liquid in step A is reduced to 50 to 60 degrees centigrade, acid is added and stirred until the pH value is 6.0 to 8.0; and C, the reaction liquid in step B is decompressed and dehydrated to 60 to 70 degrees centigrade and 2500 to 7000 m Pa.s viscosity. The invention further discloses phenolic resin foam made of the phenolic resin. The invention makes the foaming phenolic resin which can gel quickly have low free monomer content and high curing activity through controlling the synthesis technology condition accurately. The aperture of the prepared phenolic foam body is only 50 to 60 microns. The structure of the micro holes of the foam body is regular and the foam holes are fine and compact. The prepared phenolic foam body does not need any toughening modifier and no residue falls.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

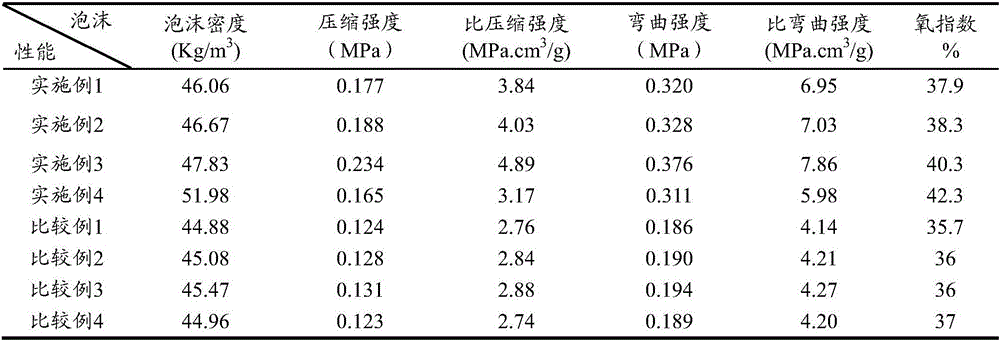

Phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and preparation method thereof

The invention relates to a phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and a preparation method thereof. The preparation method comprises the following steps: synthesizing cardanol glycidol ether from cardanol and epoxy chloropropane under alkaline conditions, and hydrolyzing under acidic conditions to generate cardanol-base dibasic alcohol; by using the cardanol-base dibasic alcohol as the raw material, dropwisely adding oxydol to react under acidic conditions to obtain the epoxy cardanol-base dibasic alcohol, carrying out reaction on the epoxy cardanol-base dibasic alcohol and a phosphorus-containing flame retardant to obtain phosphorus-containing cardanol-base polylol; carrying out reaction on the phosphorus-containing cardanol-base polylol and isocyanate to obtain a phosphorus-containing cardanol-base polyurethane prepolymer; and mixing the phosphorus-containing cardanol-base polyurethane prepolymer with a phenolic resin, and sequentially adding a surfactant, a foaming agent and a curing agent, thereby obtaining the phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam thermal-insulation material. The mechanical properties of the phenolic foam thermal-insulation material are obviously enhanced. The flame-retardant element phosphorus is introduced into the polyurethane prepolymer, thereby solving the problem of degradation of foam flame retardancy due to the carbamate introduced into the phenolic foam.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

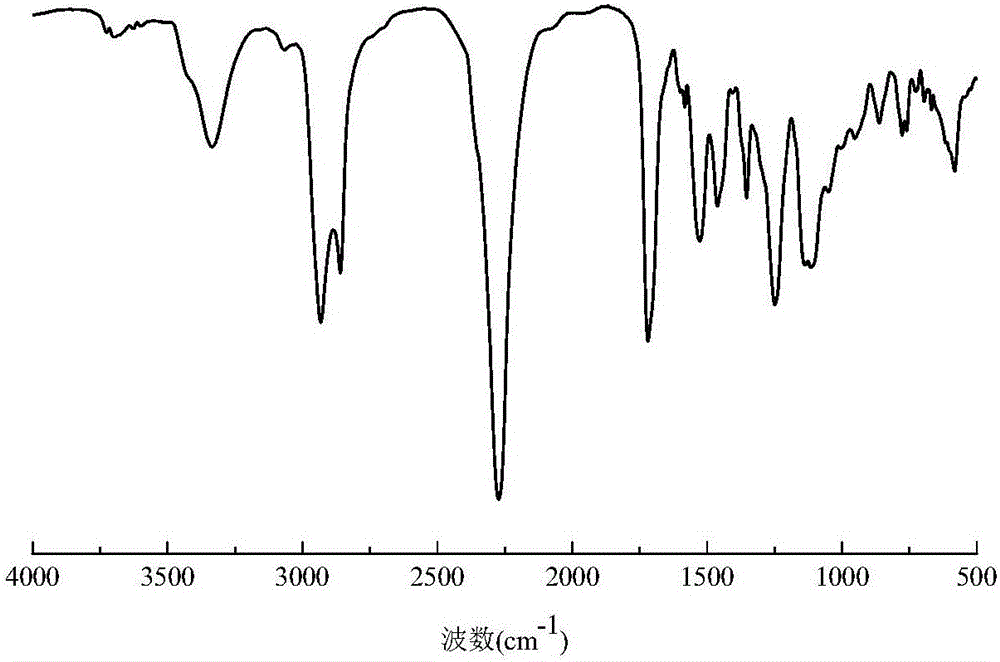

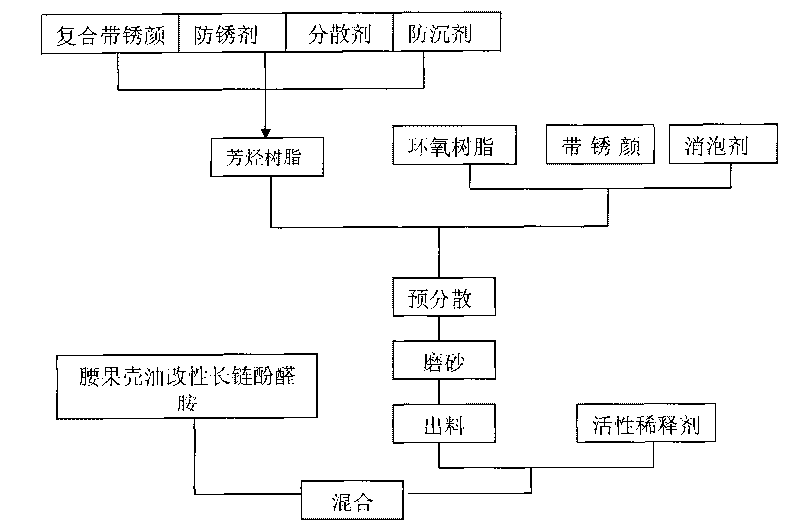

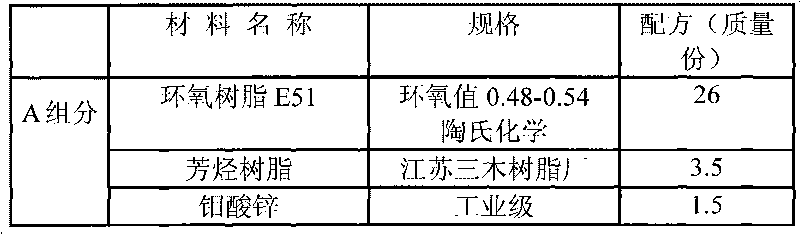

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

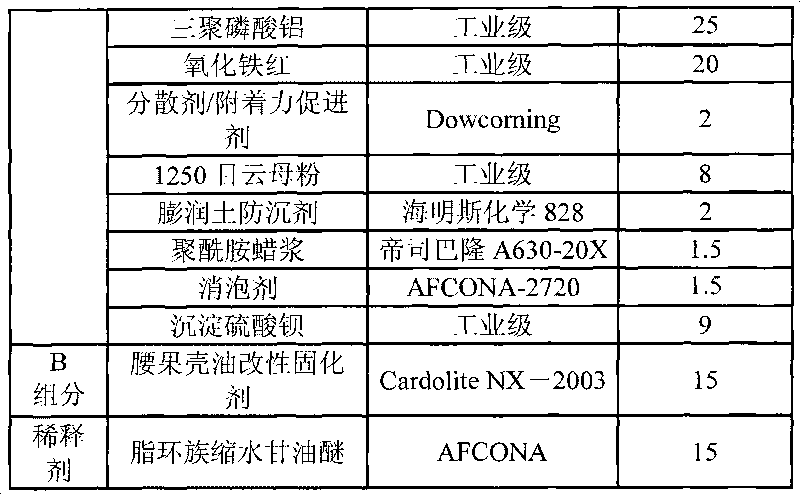

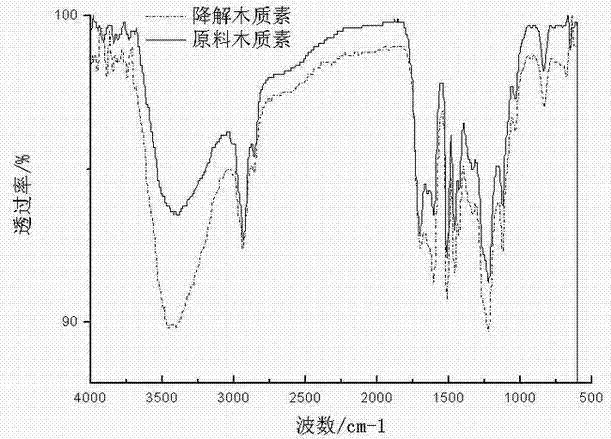

Lignin-modified phenolic foam and preparation method thereof

The invention relates to a preparation method of lignin modified phenolic foam, comprising the following steps: modifying high molecular weight lignin in order to degrade into low molecular weight lignin, wherein the activity is improved, replacing the phenol by the degraded lignin, preparing lignin modified resol, mixing with curing agent, foaming agent and surfactant, foaming at room temperature (25-30 DEG C) or in an oven of temperature 40-80 DEG C, finally the modified phenolic foam plastic is obtained after the curing process. The preparation method of the invention has the following advantages: the cost of the phenolic foam is greatly reduced, the toughness of the foam is increased and the brittles is decreased, thus the foam of the lignin modified phenolic foam has good market prospect; the preparation method of the invention provides a high-addition way to the abundant pulp paper-making waste liquid and forestry and agricultural residues, and reduces the dependency of phenolic foam industry on petrochemical raw material phenol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of polyurethane prepolymer-toughened modified phenolic foam plastic

The invention relates to a preparation method of polyurethane-prepolymer-toughened modified phenolic foam plastic, which comprises the following steps: vacuumizing and dehydrating polyalcohol, dropwisely adding the polyalcohol into isocyanate to react in a nitrogen atmosphere, and adding a chain extender to react; regulating an alkaline A-stage phenol formaldehyde resin with acid according to parts by mass, adding a toughener polyurethane prepolymer, a surfactant, a foaming agent 1 and a curing agent into the resin to obtain a foamed system; and stirring uniformly the foamed system at room temperature, and heating to cure and form to obtain the polyurethane-prepolymer-modified flame-retardant phenol formaldehyde foam thermal-insulation material. The phenol formaldehyde foam has the advantages of less shedding, high toughness and the like; and the adopted phenol formaldehyde resin has the advantages of low viscosity and favorable compatibility with the polyurethane prepolymer, and can be easily mixed uniformly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Polyacetal resin composition and process for producing the same

ActiveUS7186766B2Improve thermal stabilityQuality improvementSuture equipmentsOrganic chemistryPhenolPolymer chemistry

About 0.001 to 1 part by weight of a phenol component (B1) and / or about 0.001 to 10 parts by weight of an amino acid (B2) are added relative to 100 parts by weight of a polyacetal resin (A) to prepare a polyacetal resin composition. The phenol component (B1) may be a novolak phenol-series resin, a phenol aralkyl-series resin, a polyvinyl phenol-series resin, a polyhydric phenol, a polyphenol, a catechin compound, or a lignin. The amino acid (B2) may be an α-amino acid, a β-amino acid, a γ-amino acid, a δ-amino acid, or a derivative of an amino acid. The polyacetal resin composition may further contain an antioxidant, a heat stabilizer, a processing stabilizer, a weather (light)-resistant stabilizer, or a coloring agent. The polyacetal resin composition ensures marked inhibition of formaldehyde emission.

Owner:POLYPLASTICS CO LTD

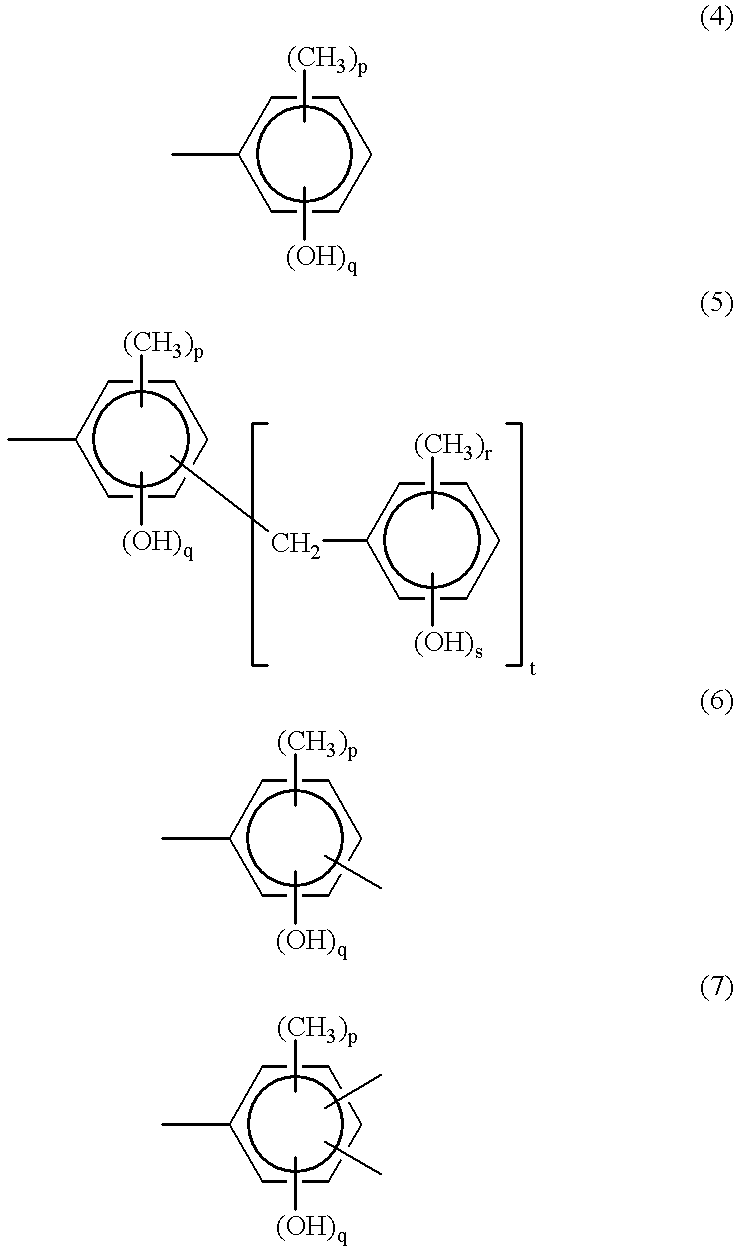

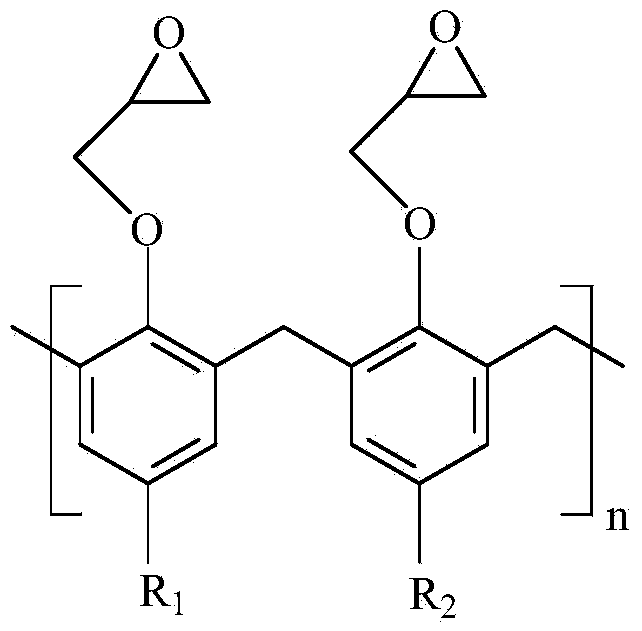

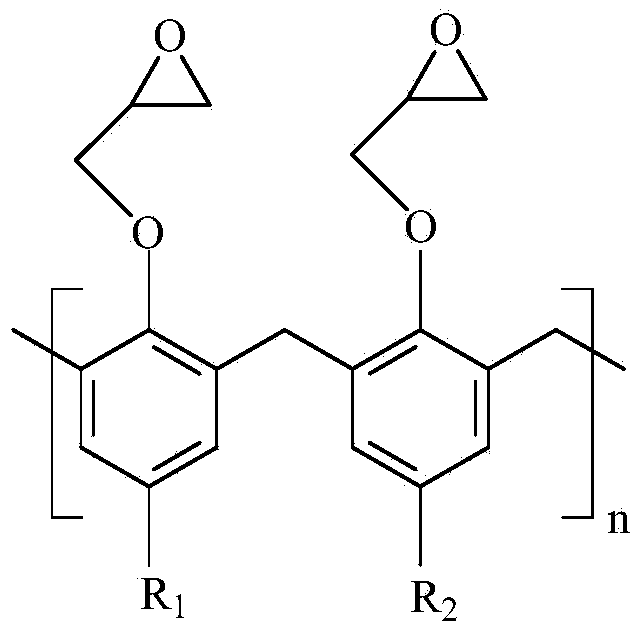

Halogen-free resin composition, prepreg prepared from halogen-free resin composition and laminated board prepared from halogen-free resin composition and used for printed circuit

ActiveCN103992622ALow dielectric constantReduce lossSynthetic resin layered productsCircuit susbtrate materialsAlkylphenolAbsorption rate

The invention discloses a halogen-free resin composition, a prepreg prepared from the halogen-free resin composition and a laminated board prepared from the halogen-free resin composition and used for a printed circuit. The halogen-free resin composition comprises alkylphenol epoxy resin, benzoxazine resin, an alkylphenol aldehyde curing agent and a phosphorus-contained flame retardant. The molecular structure of alkylphenol epoxy resin adopted in the halogen-free resin composition contains more branched alkyls, so that the halogen-free resin composition is relatively high in glass transition temperature, low in water absorption rate, favorable in heat resistance and excellent in dielectric performance; benzoxazine resin is mixed, so that the dielectric constant, dielectric loss value and water absorption rate of a solid can be further reduced; alkylphenol aldehyde is used as a curing agent, so that the advantages of excellent dielectric performance and low water absorption rate generated by more alkyls in the structure are sufficiently exerted. The prepreg prepared from the halogen-free resin composition and the laminated board prepared from the halogen-free resin composition and used for the printed circuit have the advantages of low dielectric constant, low dielectric loss factor, low water absorption rate, high size stability, high heat resistance, and favorable flame retardance, processability and chemical resistance.

Owner:江西生益科技有限公司

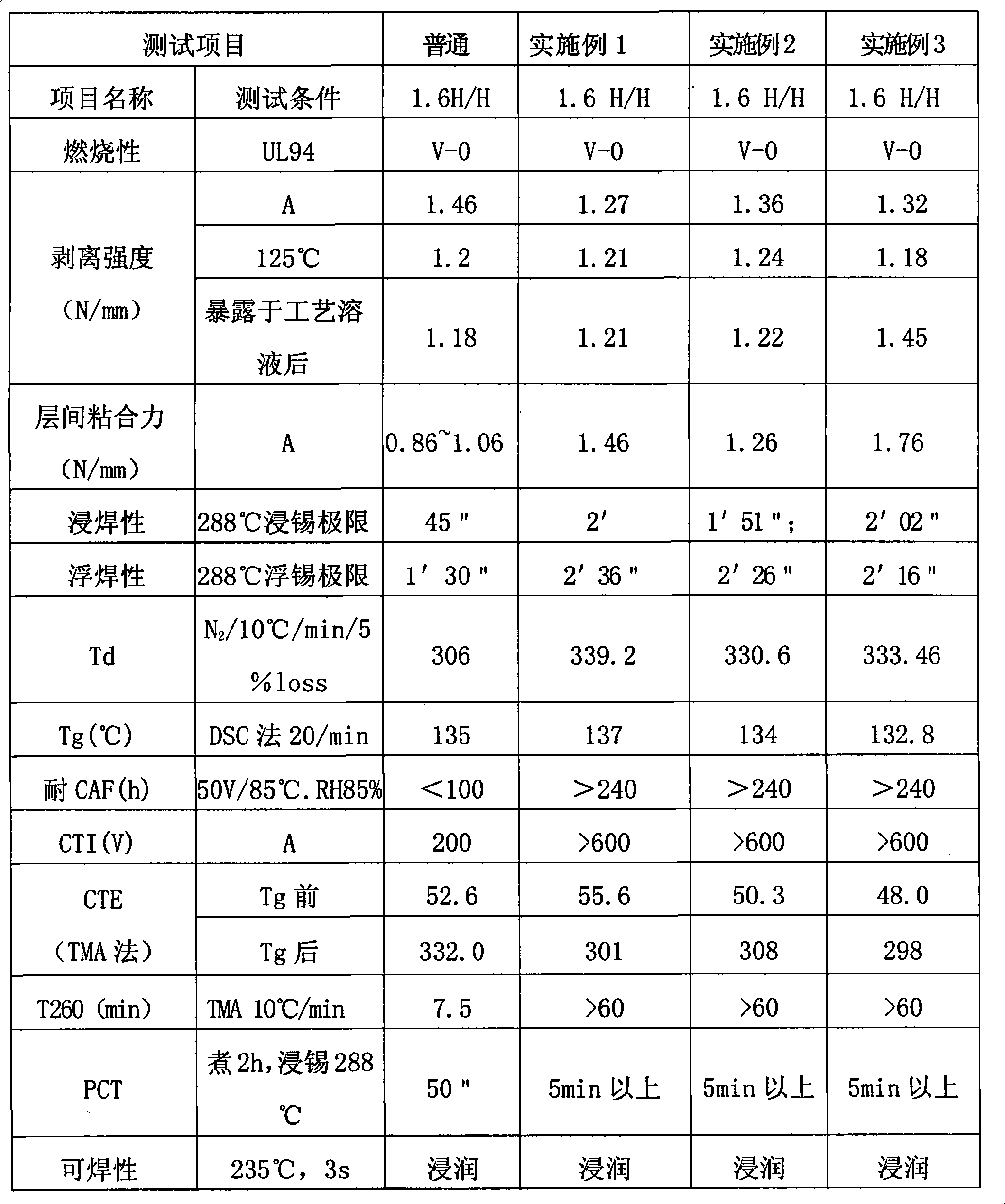

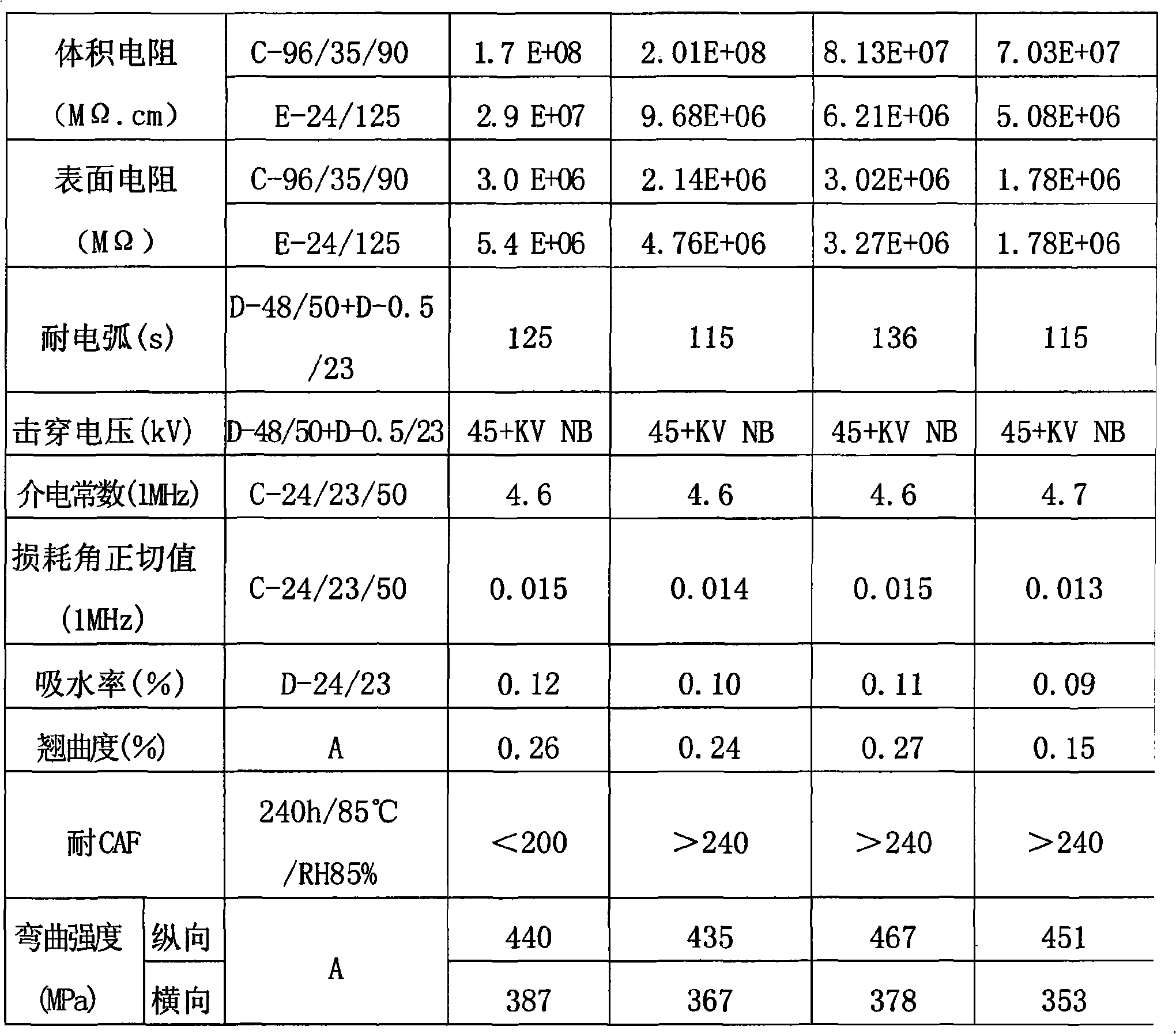

Method for preparing high phase ratio electric leakage resistant tracking index leadless compatible CEM-3 copper-clad laminate

ActiveCN101578010AImprove heat resistanceGood resistance to CAFNon-macromolecular adhesive additivesLamination ancillary operationsGlass fiberBromine

The invention discloses a method for preparing a high phase ratio electric leakage resistant tracking index leadless compatible composite base copper-clad laminate CEM-3, which comprises the following process steps: using low brominated epoxy resin / phenolic aldehyde as a main curing agent, adding a filling material to prepare core material glue impregnated glass fiber paper, and preparing a core material by making the glass fiber paper in a semi-solidified state at a temperature of between 130 and 210 DEG C; adding aluminum hydroxide or magnesium hydroxide as the filling material into the epoxy resin / phenolic aldehyde to prepare a plus material glue impregnated glass fiber cloth, and preparing the plus material by making the glass fiber cloth in a semi-solidified state at a temperature of between 130 and 210 DEG C; and superposing 1 to 20 sheets of the core material, pasting the plus material on the surface of the core material, cladding a copper foil on the plus material, and performing hot press molding at a temperature of between 80 and 200 DEG C, a pressure of between 10 and 60 Kg / cm and a vacuum degree of -60 mmHg. The CEM-3 copper-clad laminate prepared by the method simultaneously has CT1 more than or equal to 600V, higher heat resistance and excellent CAF resistance, and overcomes the defects that a CEM-3 plate prepared by the prior art has the CT1 between 175 and 249 V and poor heat resistance and CAF resistance, thus the CEM-3 copper-clad laminate is more adaptive to long-term operations under wet conditions and has high heat resistance and electric reliability.

Owner:SHAANXI SHENGYI TECH

Bi-component corrosion-proof dope

InactiveCN101100578AGood oil resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

A titanium-nickel nanometer alloy powder contains A and B components; A components consist of epoxy-resin, titanium-nickel nanometer alloy powder, antirust pigment, filler corrosion stabilizer and anti-sagging accessory; B components consist of composite curing agent with cashew nut shell modified phenolic amine curing agent and polyamide epoxy curing agent; the proportion of A and B is 10:1. It has excellent adhesion and physical performance and better oil, water, acid-alkali and salt fog resistances and mating ability. It can be used as universal base coat and used for various substrate materials such as steel, aluminum and stainless steel etc.

Owner:中国人民解放军海军装备技术研究所

Modified epoxy resin and modified epoxy resin composition

InactiveCN104497271AHigh glass transition temperatureImprove impact toughnessGlass transitionBisphenol A

The application belongs to the field of synthetic resin and particularly relates to modified epoxy resin and a modified epoxy resin composition. The modified epoxy resin composition provided by the invention comprises the following components in parts by weight: 50-60 parts of modified epoxy resin, 10-30 parts of polyfunctional epoxy resin, 20-30 parts of a phosphorus-containing curing agent, 1-5 parts of a nitrogen-containing curing agent and 0.1-1 part of a curing accelerator, wherein the polyfunctional epoxy resin is one or more of o-cresol formaldehyde epoxy resin, phenol phenolic aldehyde epoxy resin, bisphenol A formaldehyde phenolic aldehyde epoxy resin, biphenyl type epoxy resin, triphenol hydroxyl methane phenolic aldehyde epoxy resin, tetraphenol hydroxyl methane phenolic aldehyde epoxy resin, tetraphenol ethane epoxy resin and phenoxy resin. Experimental results show that the modified epoxy resin composition provided by the invention has a glass-transition temperature higher than 165 DEG C and good impact toughness and meanwhile, UL-94 V0 level halogen-free flame retardancy is achieved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com