Patents

Literature

640 results about "Alkaline etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

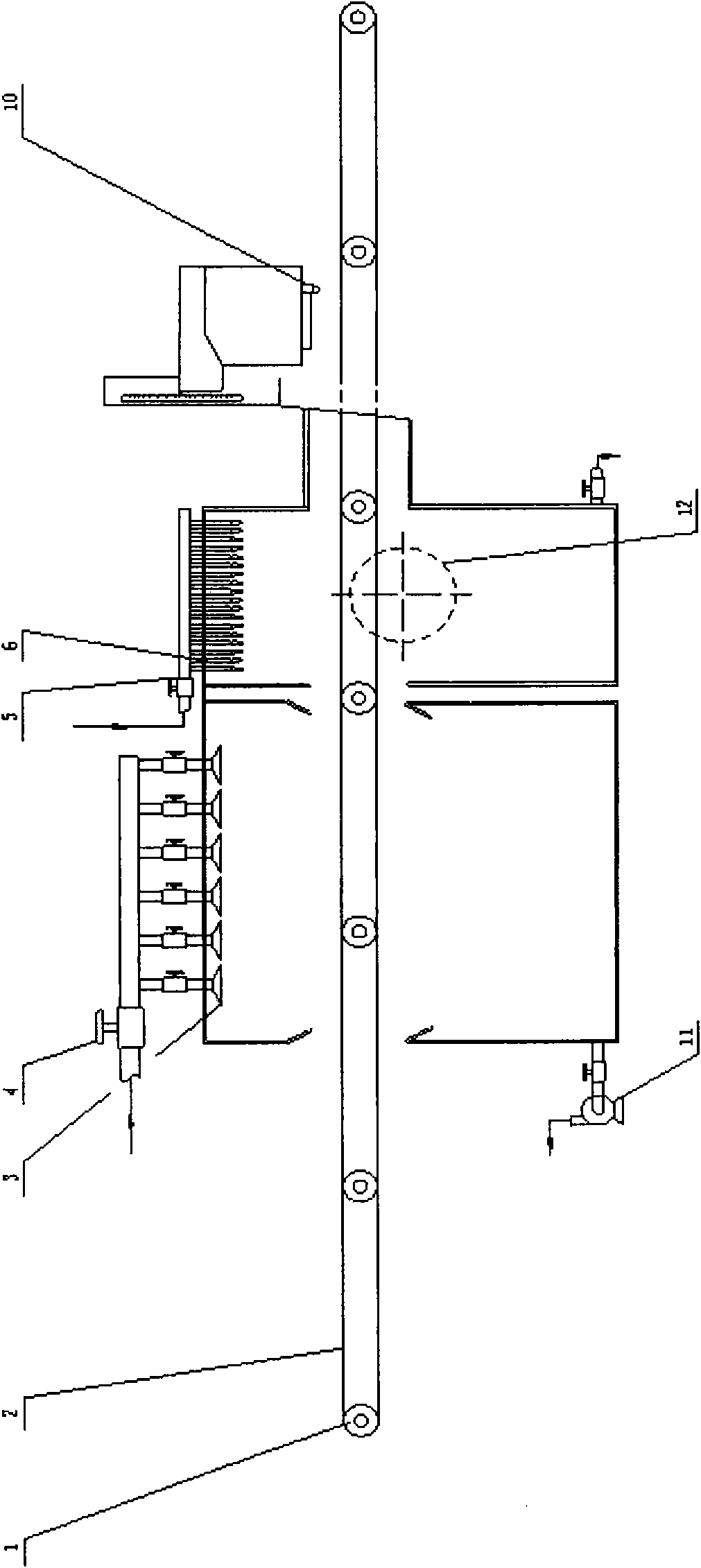

The alkaline etching is the first choice when etching outerlayers. To remove the exposed copper a strong alkaline ammonia-based solution is used. The etching modules have oscillating nozzles, which are arranged either parallel or at right angles to the conveying direction.

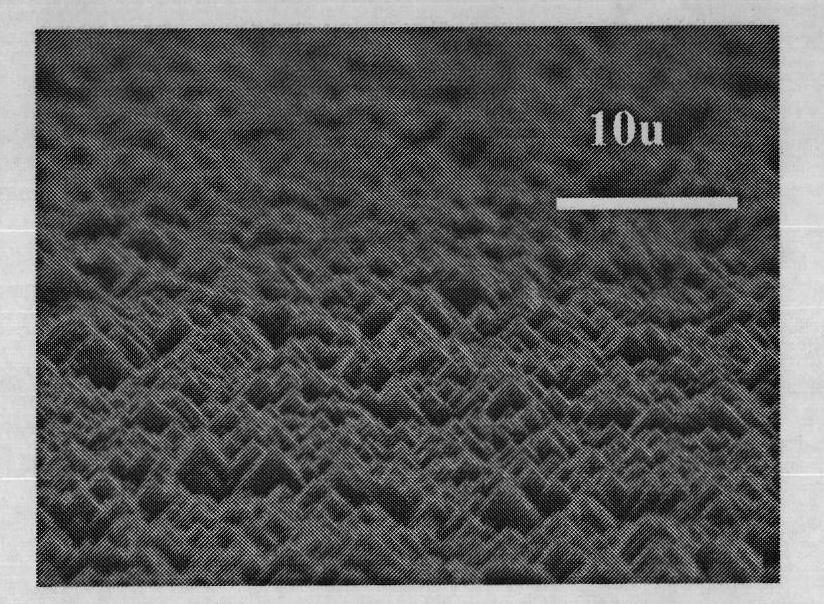

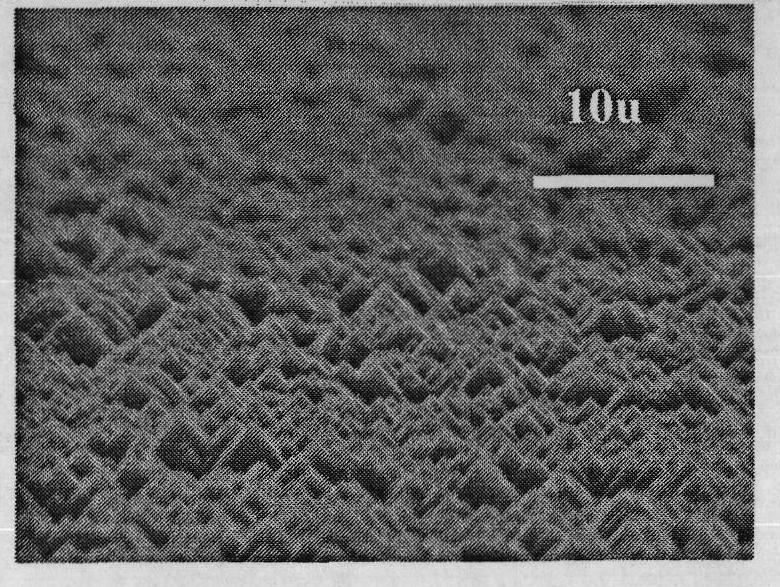

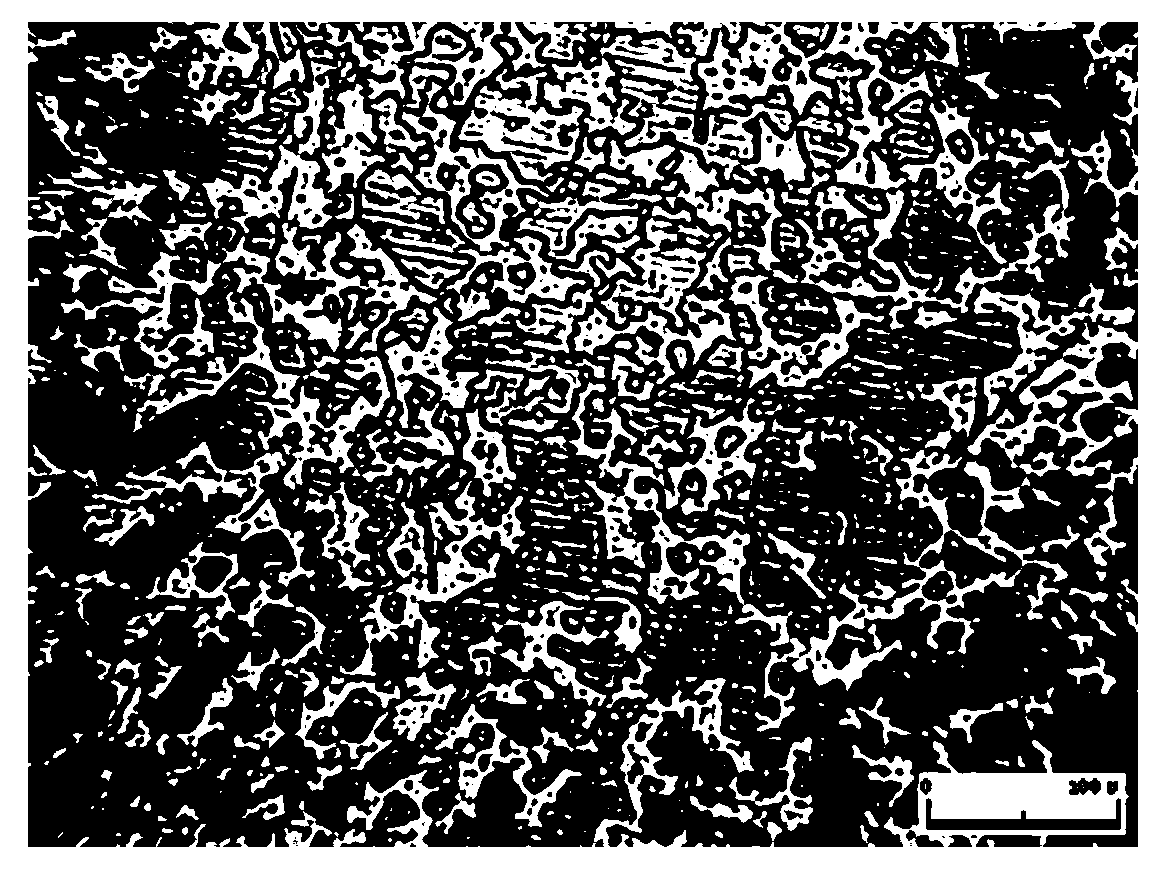

Velvet manufacturing solution of monocrystalline silicon additive

InactiveCN101818378AUniform sizeGuaranteed efficient growthAfter-treatment detailsOrganic acidSurface-active agents

The invention discloses a velvet manufacturing solution of a monocrystalline silicon additive, which comprises an alkaline etching solution, a surface active agent and organic acid or salt, wherein the mass of the surface active agent is 0.05% to 0.5% of the mass or volume of the alkaline etching solution, and the mass of the organic acid or salt is 0.1% to 10.0% of the mass or volume of the alkaline etching solution. The velvet manufacturing solution enables the pyramid size of a velvet surface of monocrystalline silicon to be uniform without blaze or obvious impression. Under a proper temperature condition, the velvet surface is quickly and effectively formed and is matched with traditional production equipment.

Owner:HANWHA SOLARONE QIDONG

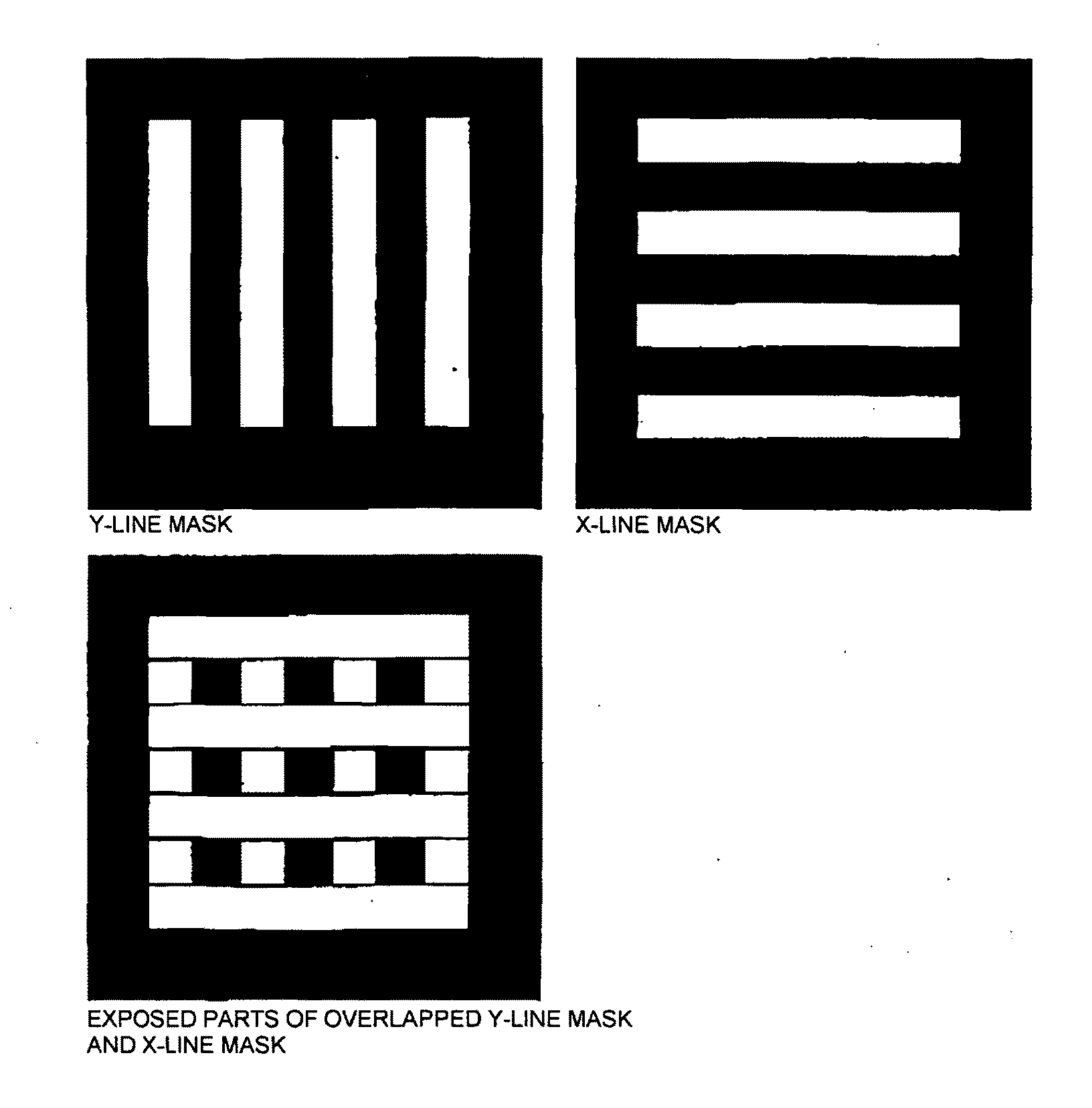

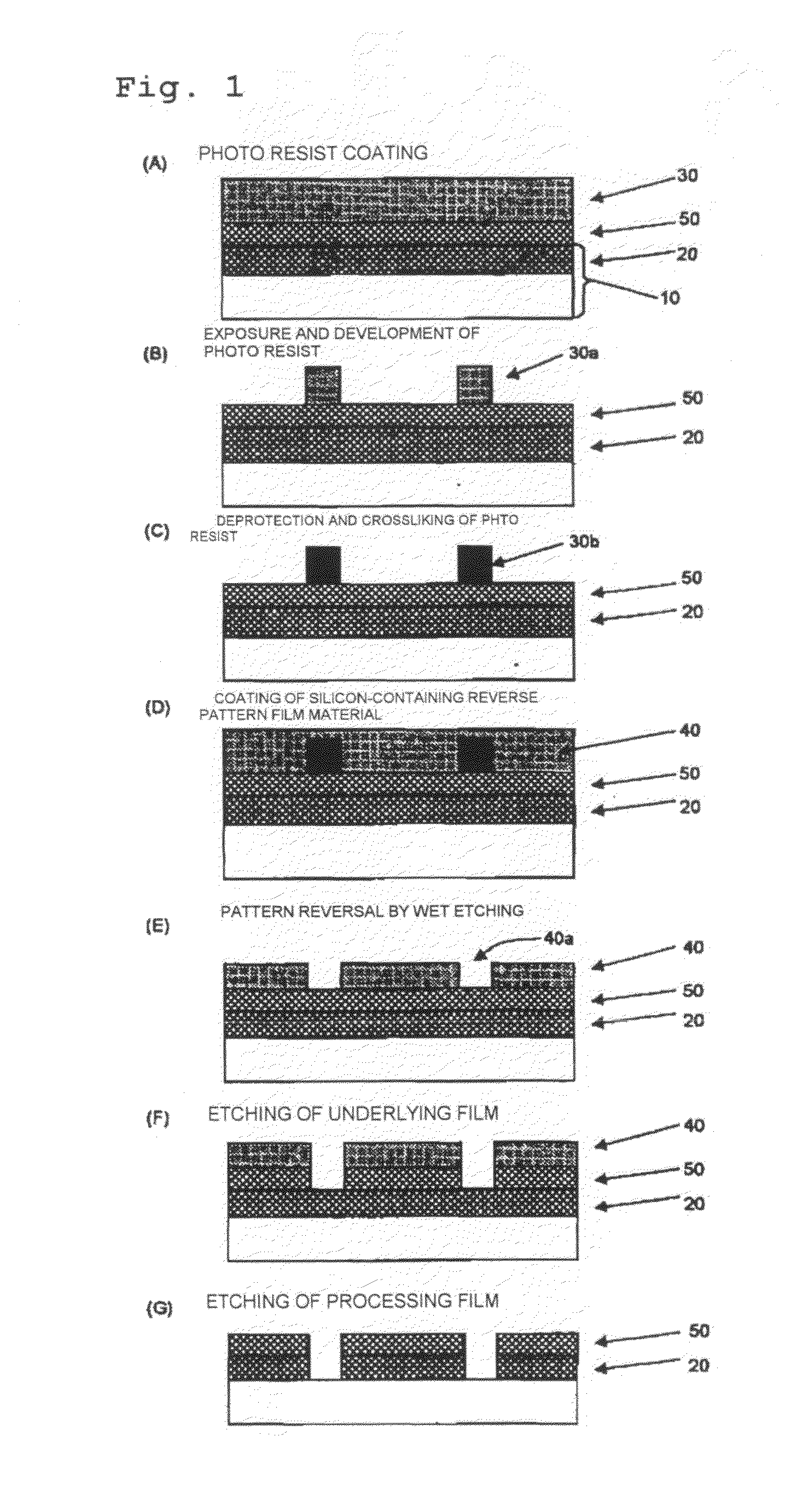

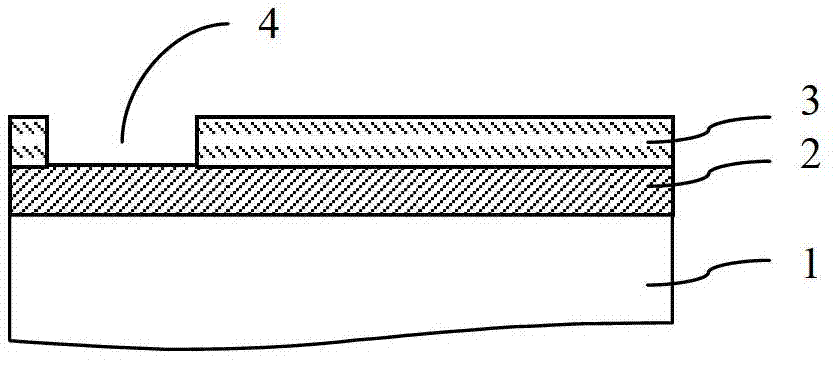

Patterning process

ActiveUS20090286188A1High resolutionSolve the real problemPhotosensitive materialsRadiation applicationsSolubilityOrganic solvent

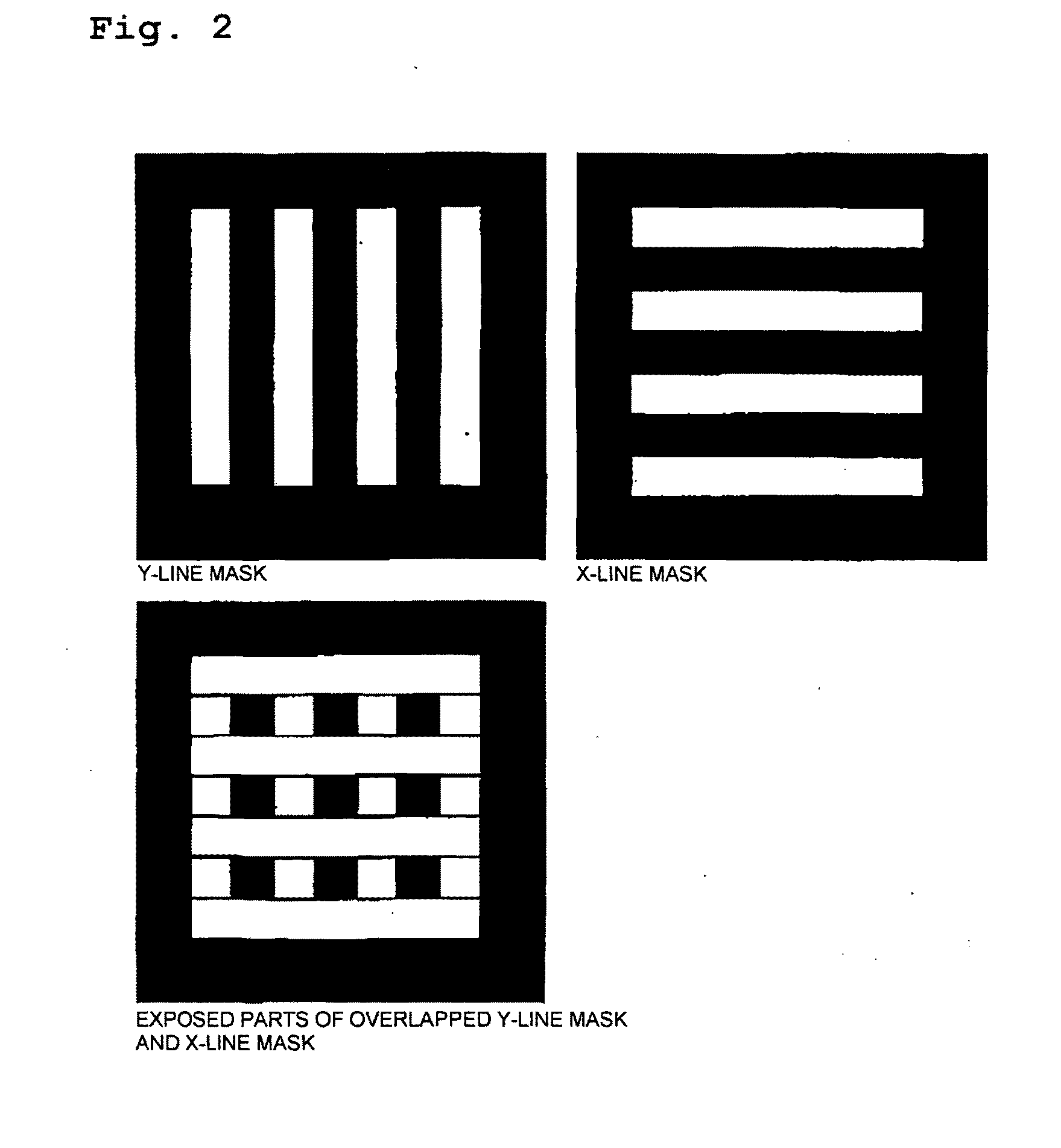

The present invention provides a patterning process, in which a resistance with regard to an organic solvent used for a composition for formation of a reverse film is rendered to a positive pattern to the degree of necessity and yet solubility into an alkaline etching liquid is secured, thereby enabling to finally obtain a negative image by a positive-negative reversal by performing a wet etching using an alkaline etching liquid.A resist patterning process of the present invention using a positive-negative reversal comprises at least a step of forming a resist film by applying a positive resist composition; a step of obtaining a positive pattern by exposing and developing the resist film; a step of crosslinking the positive resist pattern thus obtained; a step of forming a reverse film; and a step of reversing the positive pattern to a negative pattern by dissolving into an alkaline wet-etching liquid for removal.

Owner:SHIN ETSU CHEM IND CO LTD

Novel manufacturing method for back drilling of PCB (Printed Circuit Board)

InactiveCN101998768AImprove the problem of cloakingProtect from being etchedPrinted circuit manufactureBoring/drilling machinesEngineeringFlying probe

The invention discloses a novel manufacturing method for the back drilling of a PCB (Printed Circuit Board), which comprises the steps of: A) drilling the PCB substrate for the first time after the PCB substrate is subjected to cutting, bonding with a dry film, browning the inner layer and treating with a pressing board; B) carrying out the copper-deposition panel electroplating or added-panel electroplating; C) carrying out the back drilling on holes to be subjected to the back drilling; D) carrying out alkaline etching treatment on the board subjected to the back drilling; and E) carrying out solder stripping treatment on the PCB board, detecting the PCB board subjected to the solder stripping treatment through a flying probe tester and obtaining a finished product when the PCB is detected to be qualified. In the manufacturing method, the pattern tin electroplating is carried out after the external layer dry film on the PCB is made, then the back drilling is carried out on the hole to be subjected to the back drilling, and then etching is carried out so that the burr generated in the course of the drilling can be eliminated and the copper in a part of the hole with the copper can be protected from being etched at the same time.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

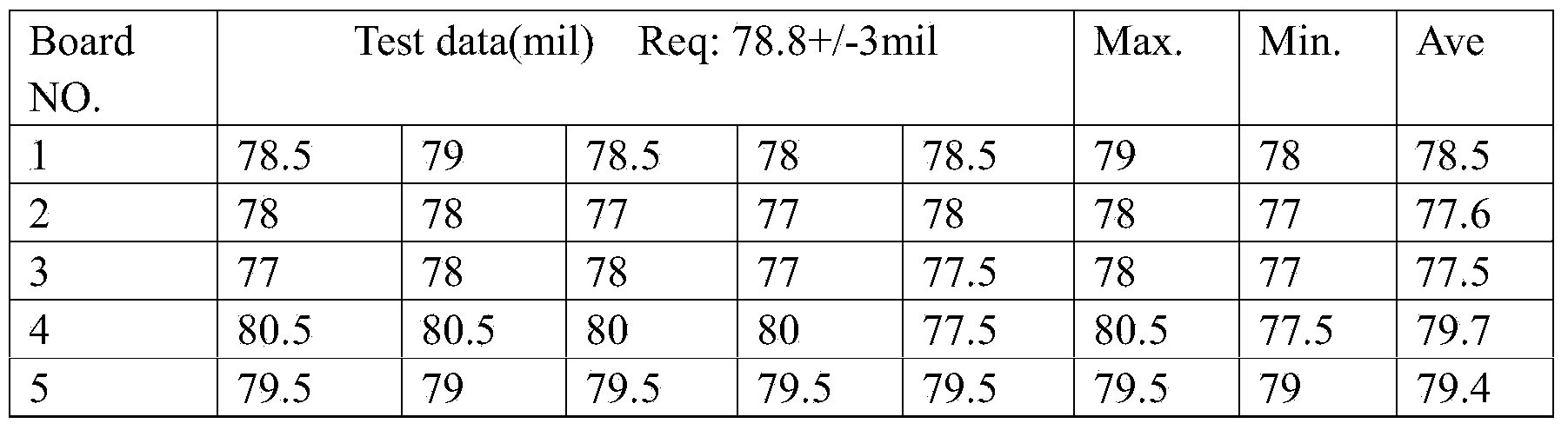

Manufacturing method for improving accuracy of PCB (printed circuit board) back drilling hole

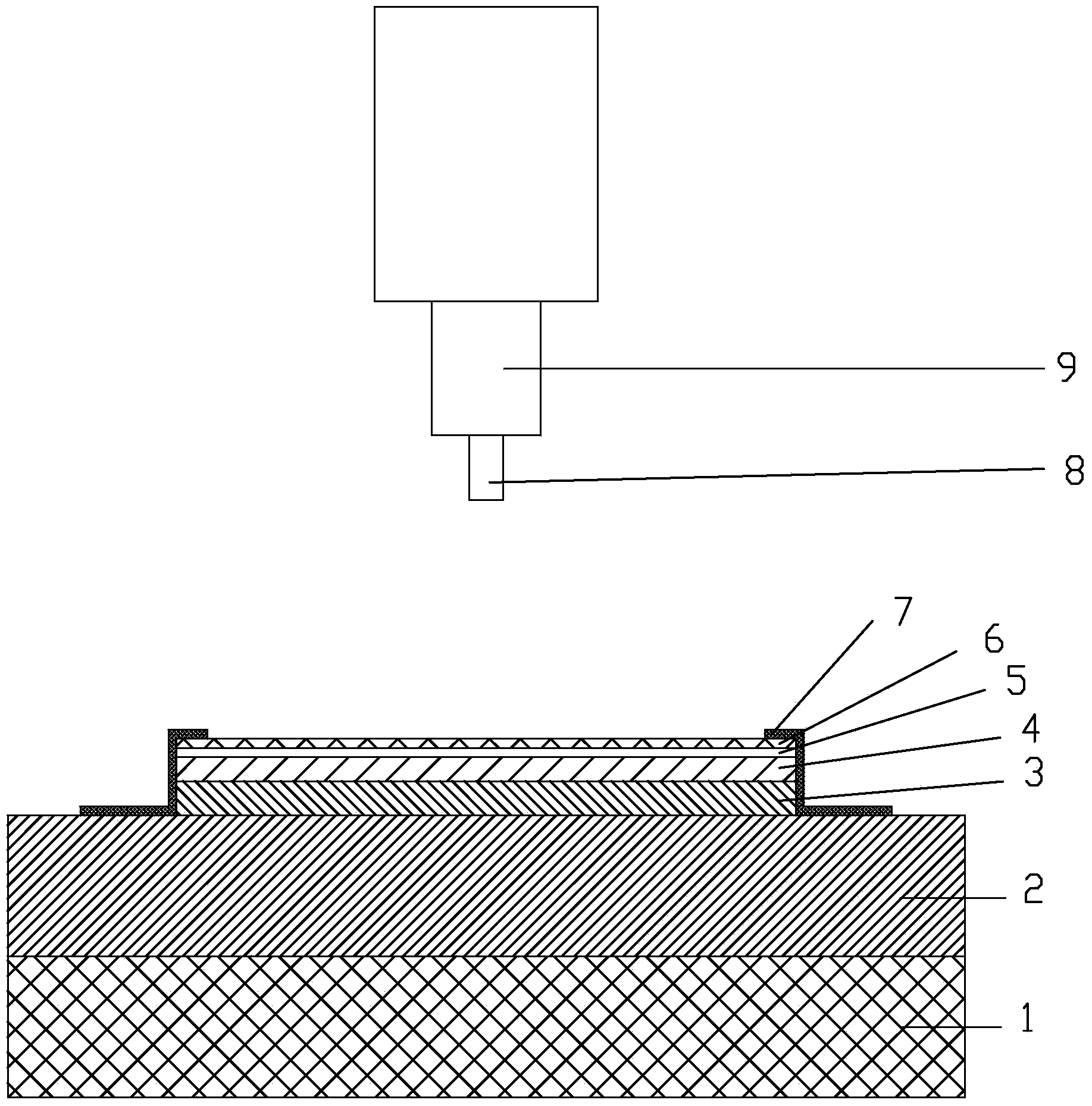

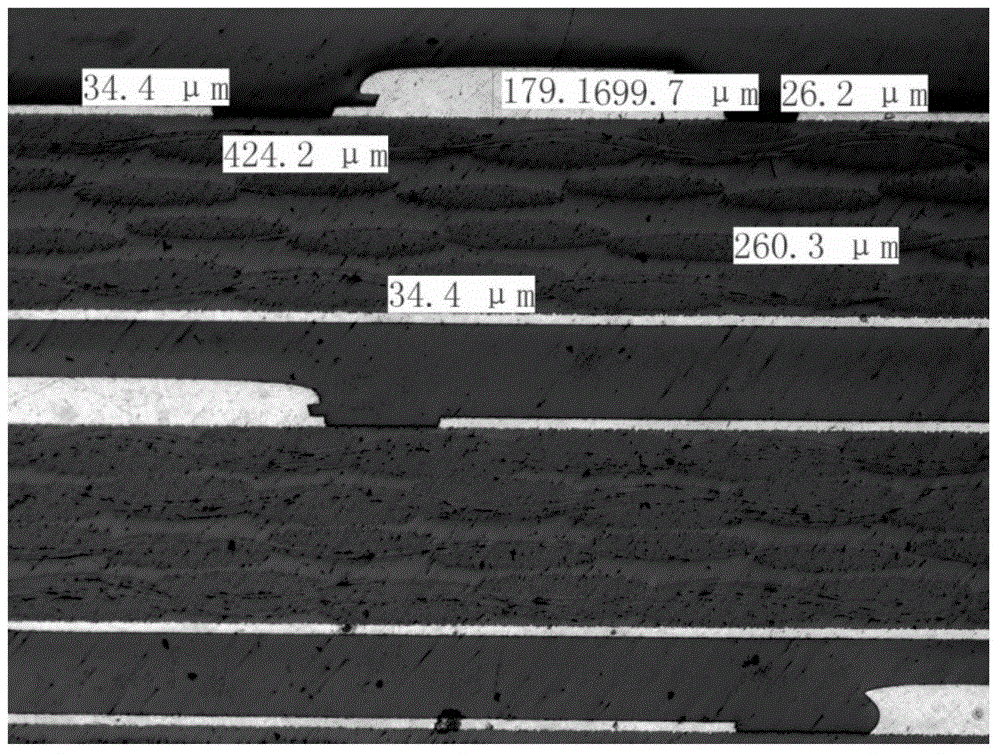

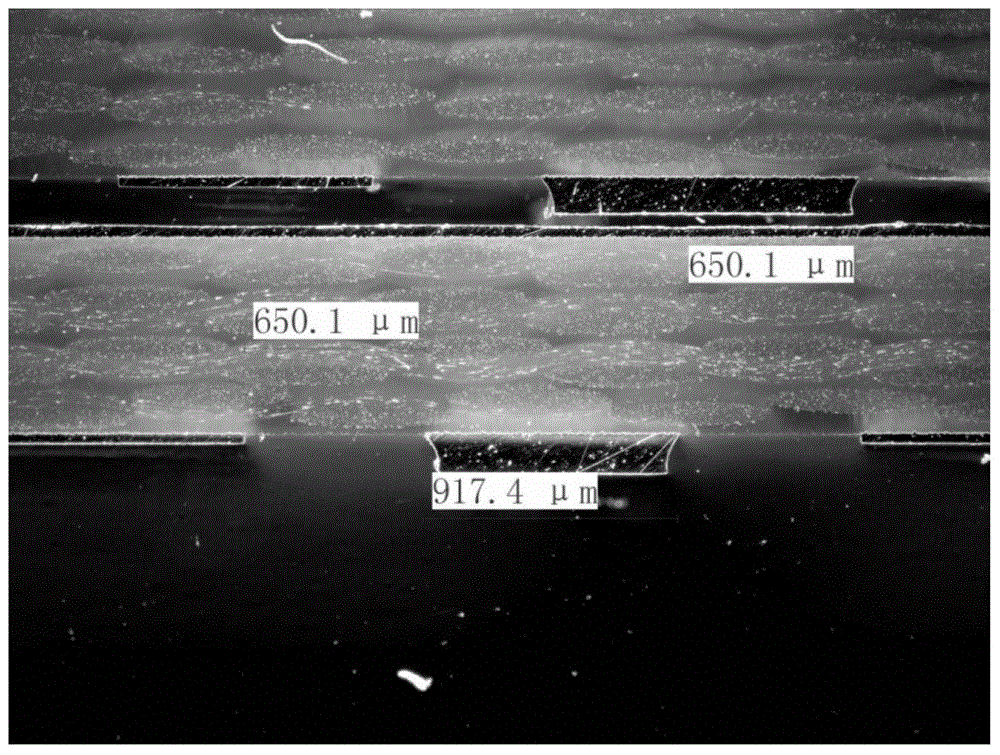

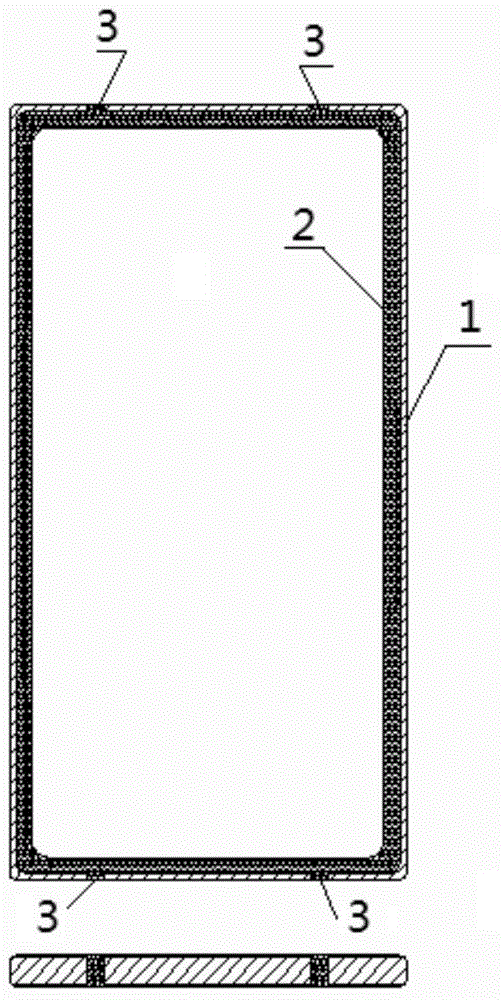

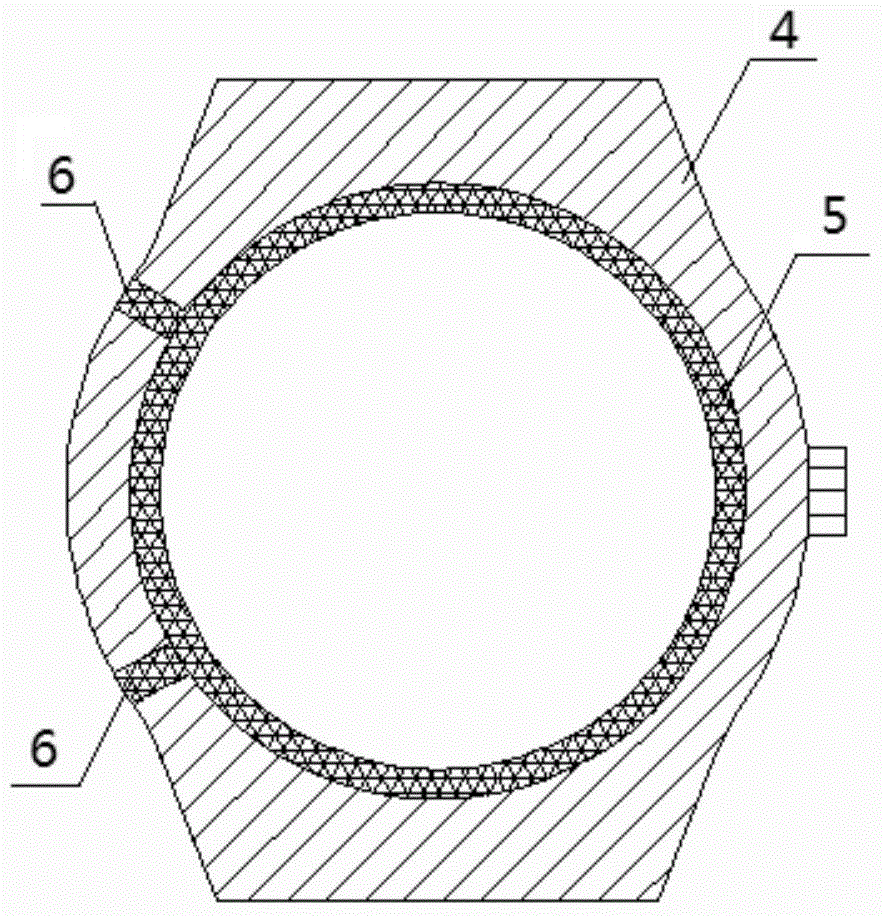

ActiveCN103533761AAffect accuracyHigh precisionPrinted circuit manufactureWell drillingPrinted circuit board

The invention discloses a manufacturing method for improving accuracy of a PCB back drilling hole. The manufacturing method comprises the steps as follows: A), a circuit board substrate is subjected to front procedure processing, through-hole drilling, copper deposition, board electroplating, outer circuit pattern transferring, pattern electroplating and the like; B), back drilling is performed on a PCB 4, and whether the depth of the back drilling hole is qualified is detected; and C), a well drilled back drilling hole is subjected to alkaline etching and photosensitive welding resistance, and finally a finished product is manufactured. The technical scheme is characterized in that drill file coefficients used in a through-hole drilling procedure are correspondingly corrected according to expansion and contraction data obtained in a technological process from the through-hole drilling procedure to the drilling procedure of the PCB 4 during back drilling, and the drill file data is maintained to be consistent with actual expansion and contraction; a drilling-in surface in the through-hole drilling procedure is consistent with that during the back drilling; and a phenolic aldehyde base plate 6 is additionally paved on the top surface of the PCB 4. With the adoption of the manufacturing method, the depth accuracy and the position accuracy of a back drilling hole of a conventional PCB 4 can be effectively improved, so that the completeness of signal transmission of the PCB 4 is guaranteed.

Owner:广东依顿电子科技股份有限公司

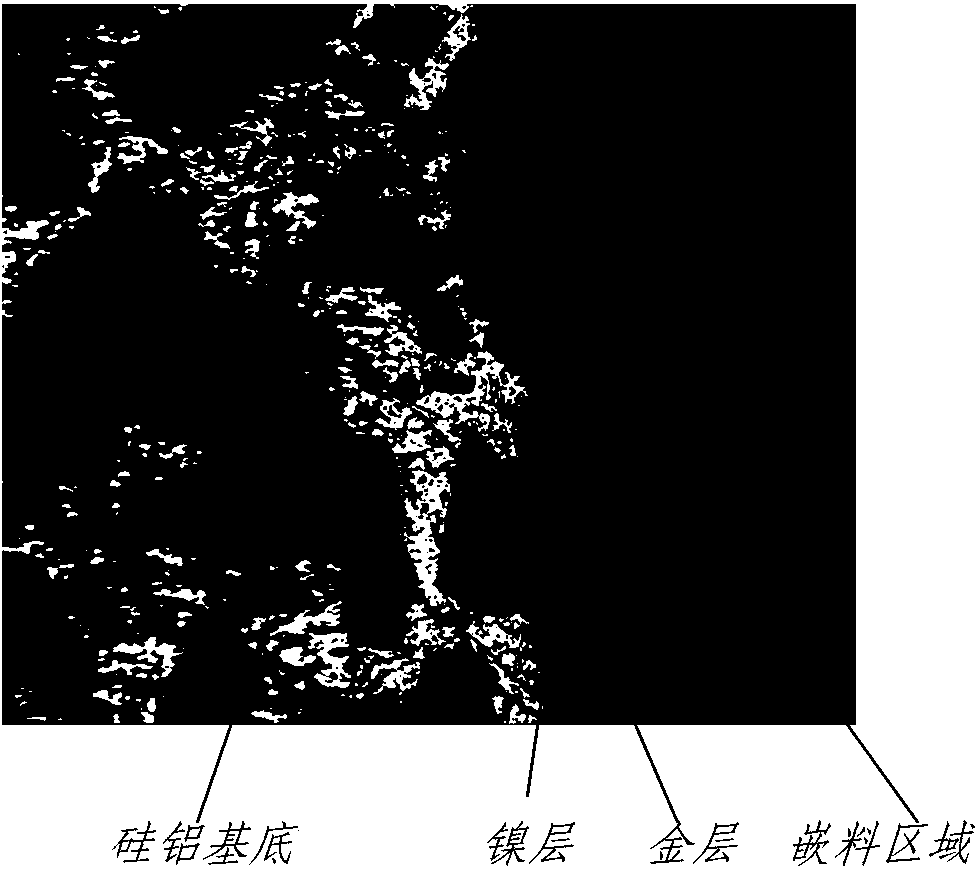

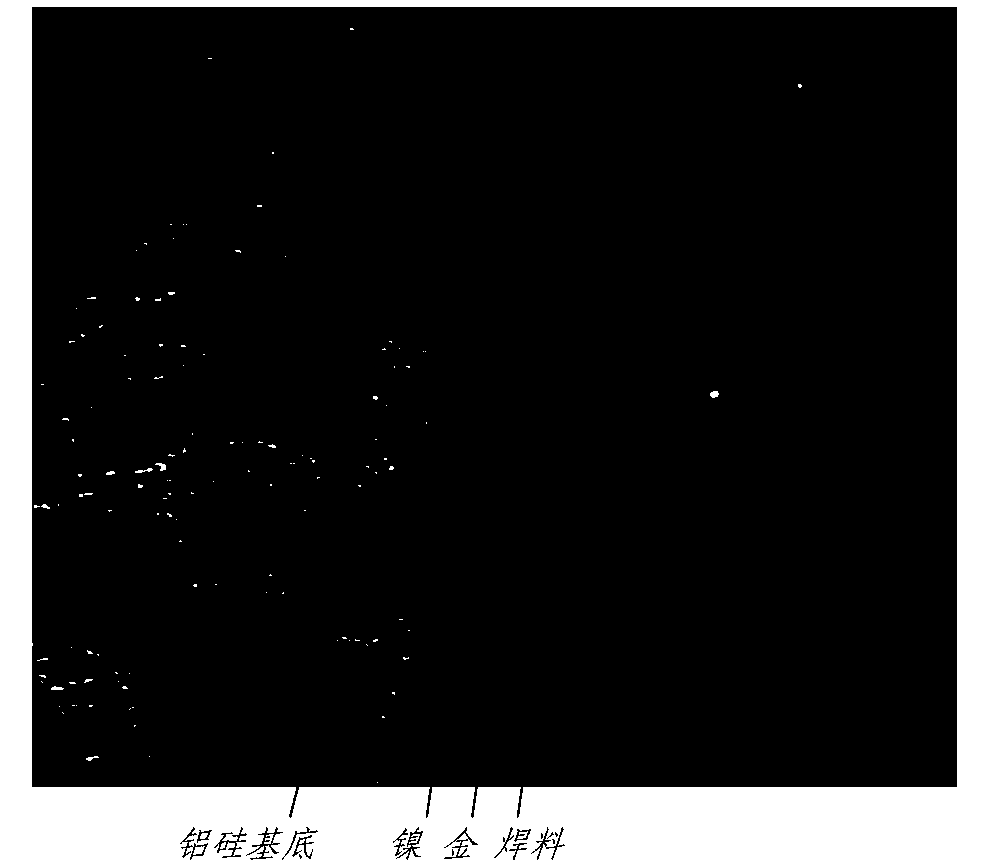

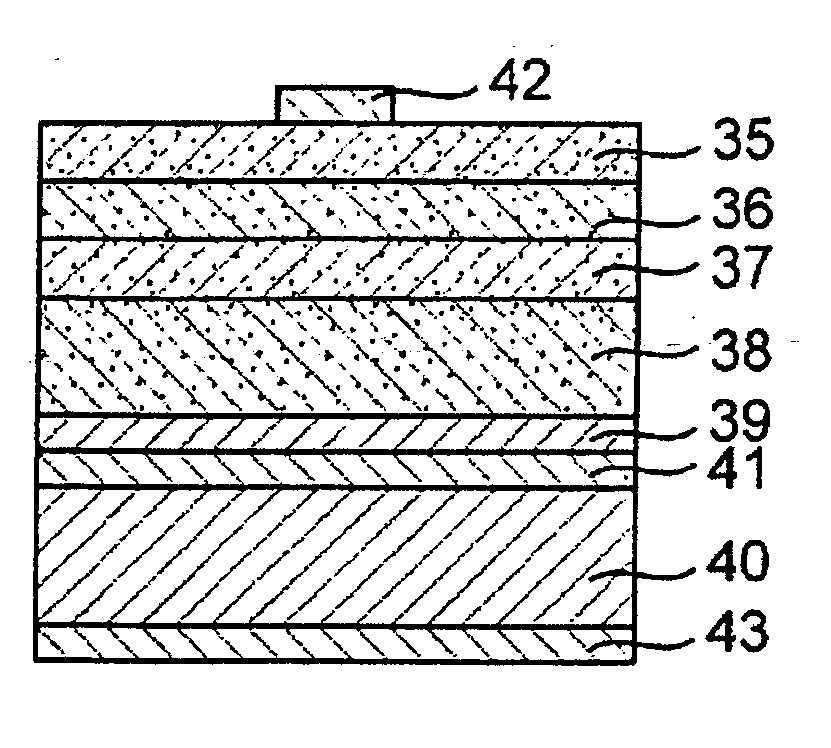

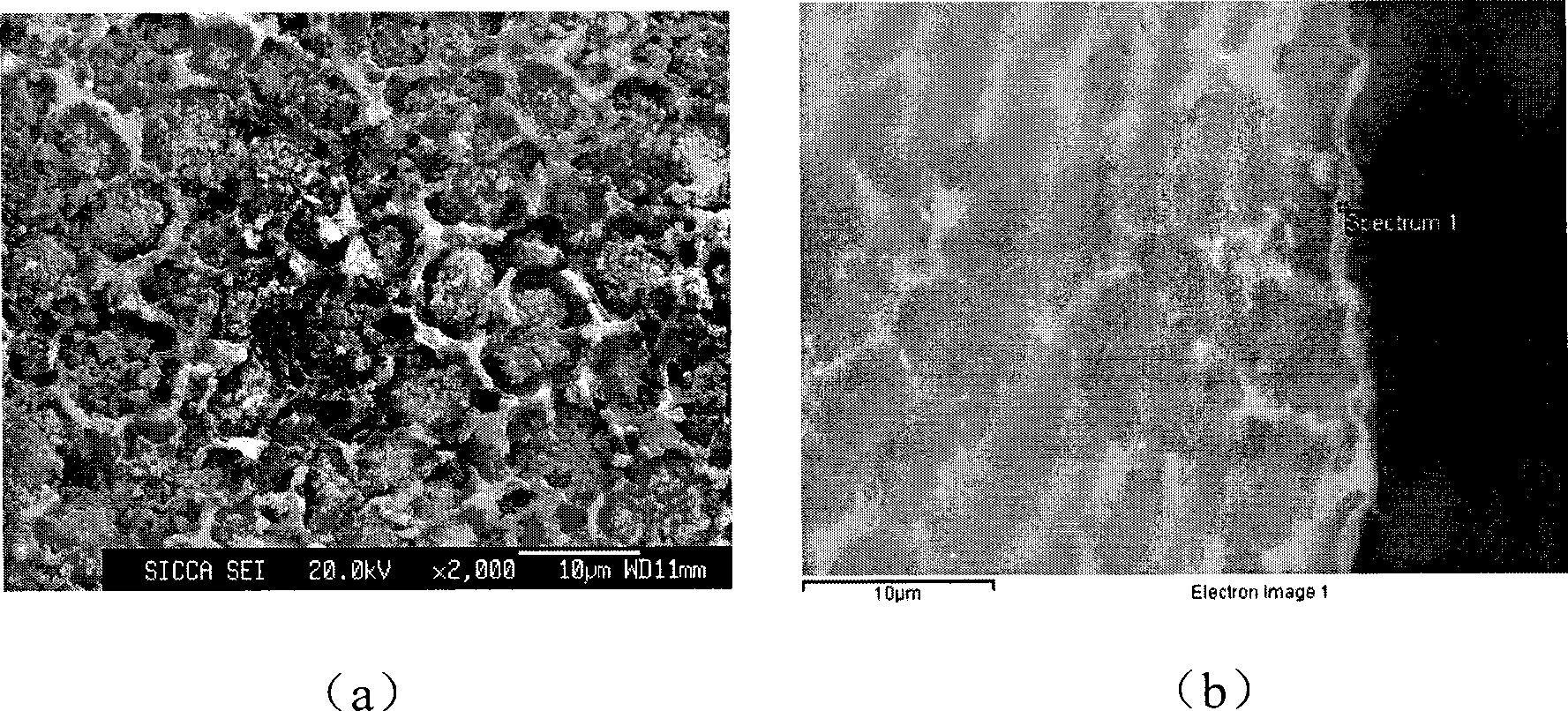

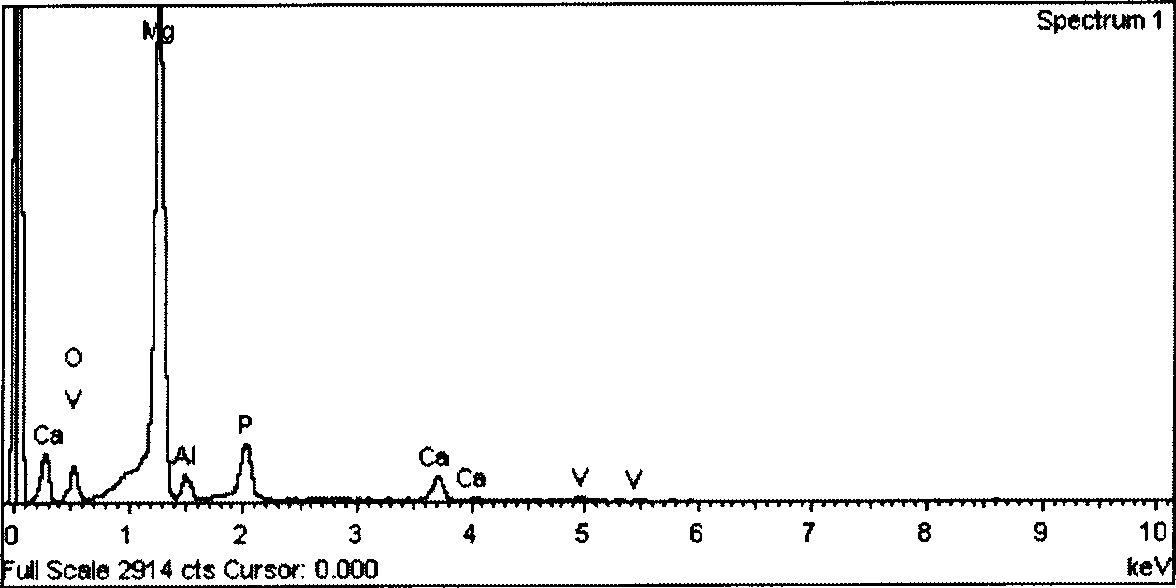

Gold-plating method of high silicon-aluminum composite material

ActiveCN103540935AImprove bindingNo foamingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBinding forceAlkaline etching

The invention relates to a gold-plating method of a high silicon-aluminum composite material. According to a second zinc immersion treatment method of conventional aluminum alloy electroplating, pre-treatment of the method comprises the following six steps: cleaning and oil removing; alkaline etching; bright dipping; primary zinc immersion; zinc annealing; secondary zinc immersion. The gold-plating method subsequently comprises the following steps: I, preplating chemical nickel in a chemical nickel-plating liquid; II, plating nickel for the first time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; III, performing aging treatment; IV, performing activating treatment; V, plating nickel for the second time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; VI, taking a pure gold plate or a platinum titanium mesh as an anode and the high silicon-aluminum composite material as a cathode according to a conventional pure gold-plating method, wherein the gold layer is 2-3 microns thick; VII, detecting the binding force of the plating layer. The plating layer observed under tenfold amplifying glass is free from peeling and bubbling phenomena and good in binding force. The binding force of the gold-plating plating layer and a high silicon-aluminum base material adopted by the method provided by the invention is firm and reaches the standard of appendix A of GJB1420 General Specification of Semiconductor Integrated Circuit Shell.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

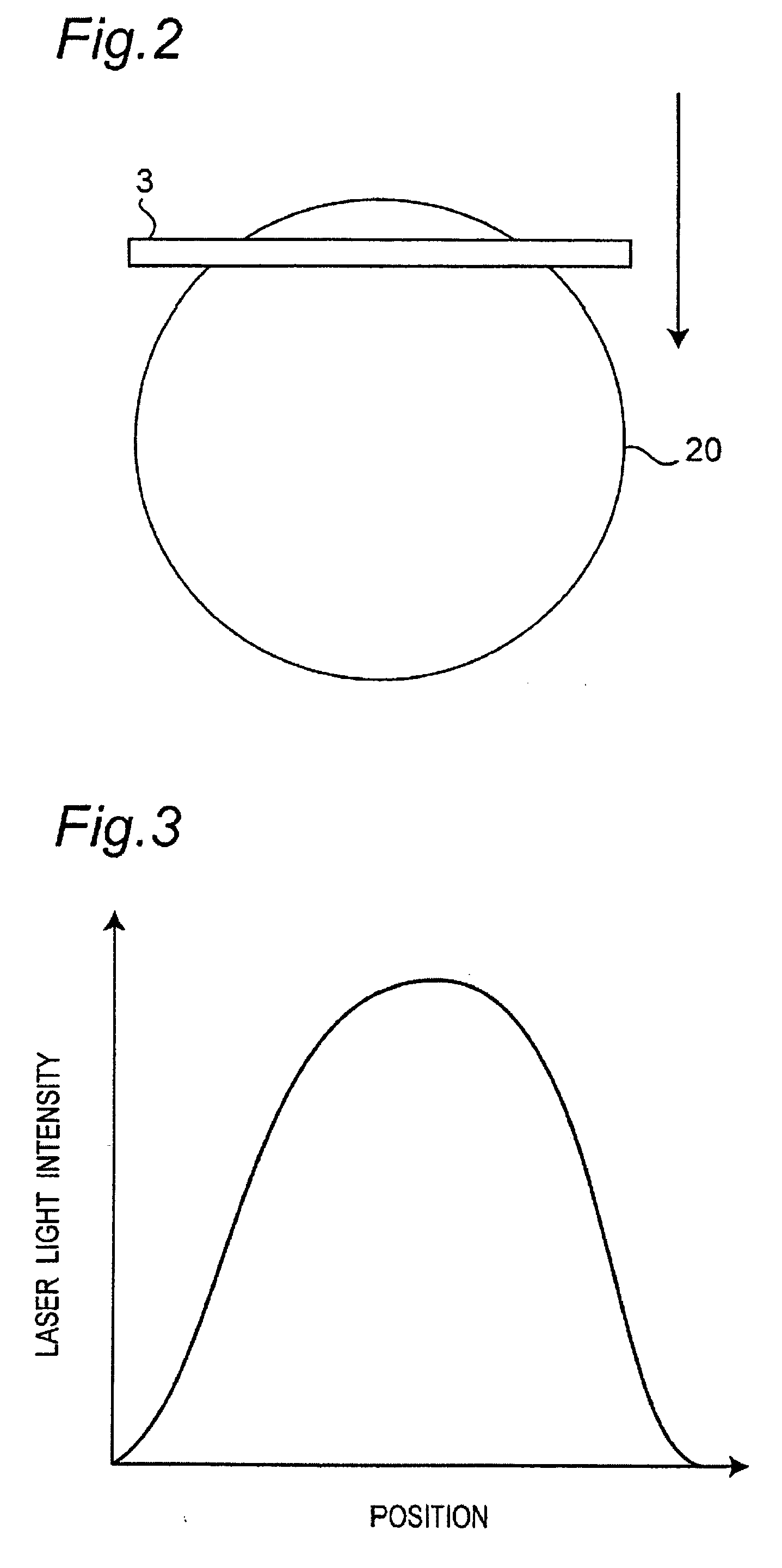

Method for manufacturing nitride semiconductor wafer or nitride semiconductor device; nitride semiconductor wafer or nitride semiconductor device made by the same; and laser irradiating apparatus used for the same

ActiveUS20060189017A1Etching rate of chemical etching becomes very highMirror smoothAfter-treatment apparatusSolid-state devicesWaferingLength wave

To remove the disparate substrate from nitride semiconductor layer grown over the disparate substrate, that is made of a material different from nitride semiconductor, by irradiating the disparate substrate with laser beam having a wavelength shorter than the band gap wavelength of the nitride semiconductor layer, while supplying an acidic or alkaline etching solution to the interface between the disparate substrate and the nitride semiconductor layer.

Owner:NICHIA CORP

Anodic oxidation surface treatment method for aluminum alloy section bar

InactiveCN105401199AImprove decontamination abilityUniform pore size distributionAnodisationHardnessBoric acid

The invention discloses an anodic oxidization surface treatment method for an aluminum alloy section bar. The anodic oxidization surface treatment method comprises the following steps: degreasing, alkaline etching, neutralizing, anodic oxidizing and hole sealing, wherein in the anodic oxidizing process, an anodic oxidizing temperature is 19-21 DEG C, the anodic oxidizing process lasts for25-35 minutes, an anodic oxidizing voltage is 16-18V, the current density is 130-150A / m<2>, and an anodic oxidizing electrolyte is a mixed aqueous solution of sulfuric acid with a concentration being 50-65g / L, boric acid with a concentration being 20-35g / L and citric acid with a concentration being 20-35g / L. The anodic oxidation surface treatment method for the aluminum alloy section bar disclosed by the invention is simple in process, and gentle in condition; and an oxidation film ofthe obtained aluminum alloy material is high in hardness and good in corrosion resistance.

Owner:ANHUI XIN FA ALUMINUM PROD

Method for etching outer circuit of PCB product with high aspect ratio

The invention discloses a method for etching an outer circuit of a PCB (printed circuit board) product with high aspect ratio, which comprises the following steps of: A) cutting a circuit board substrate, sticking a dry film, browning the inner layer, treating a pressing board, and then drilling the circuit board substrate; B) performing copper deposition plating on the full board or adding a board for plating; C) performing first film removal treatment on the pattern plated board; D) performing alkali etching treatment on the outer circuit after development; and E) performing tin removal treatment on the PCB obtained in the step D), inspecting qualification, and obtaining a finished product. The method for etching the outer circuit of the PCB product with the high aspect ratio can manufacture the product with aspect ratio of 15:1 to 30:1 or over by sticking the film again after the pattern plating is finished, using hole covering film exposure, covering the dry film on the hole for protection, adopting alkali etching and then removing the film and the tin; and the method has no defect of the PCB with high aspect ratio manufactured by prolonging the tin plating time or increasing the tin plating current density in the prior art.

Owner:DALIAN CHONGDA CIRCUIT

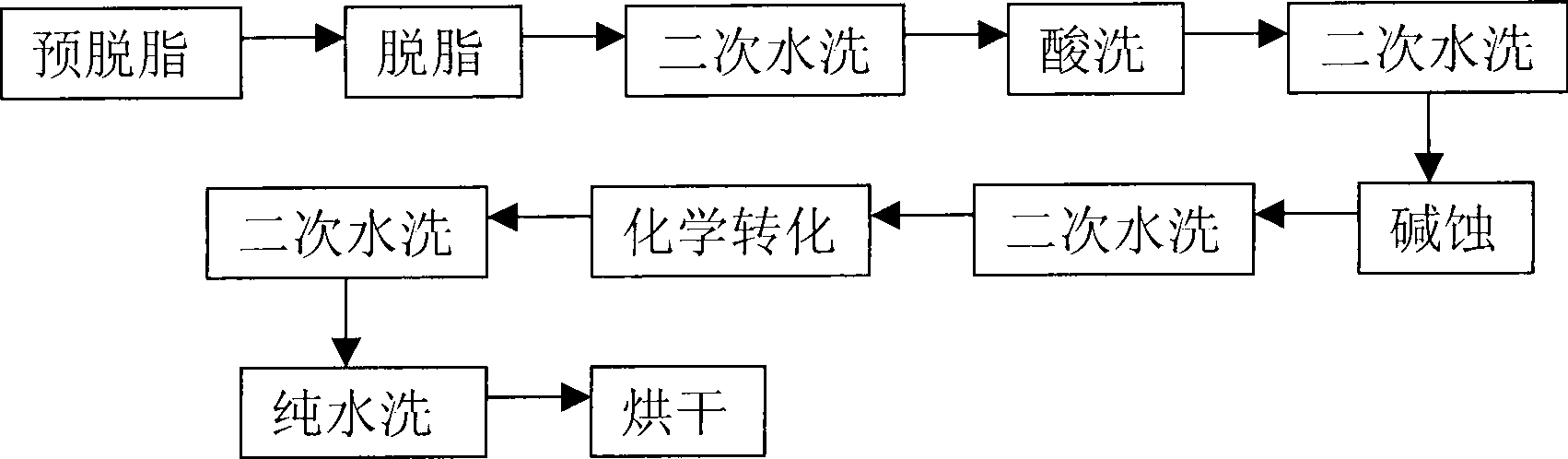

P-Ca-V composite phosphating solution on magnesium alloy surface and chemical conversion processing method

ActiveCN101418441AImprove corrosion resistanceLow resistivityMetallic material coating processesSalt spray testAcid washing

The invention relates to a composite phosphating solution of P-Ca-V on the surface of a magnesium alloy and a method for chemical conversion treatment. The solution is characterized in that each liter of the composite phosphating solution comprises the following compositions: 4 to 20 milliliters of 85 percent phosphoric acid of, 5 to 30 grams of sodium dihydrogen phosphate, 10 to 40 grams of calcium nitrate, 0.5 to 10 grams of benzene sulfonic acid sodium salt, 0.5 to 5 grams of ammonium metavanadate, and the balance being water. The method comprises the following steps: pre-degreasing, degreasing, secondary water washing, acid washing, secondary water washing, alkaline etching, secondary water washing, chemical transformation, secondary water washing, pure water washing, and drying. Taking an AZ91D magnesium alloy as an example, 48 hours after a corrosion resistance salt spray test after the treatment by the method of the invention, the corrosion area of the AZ91D magnesium alloy is less than 1 percent; the paint film adhesive force is at 0 level by a grid method and is obviously superior to the performance of a chromate conversion coating; and the formed chemical conversion coating does not contain crystal water. The composite phosphating solution has the synergistic reaction of Ca and V, as well as the functions of a corrosion inhibitor and a wetting agent of the benzene sulfonic acid sodium salt.

Owner:嘉兴中科亚美合金技术有限责任公司

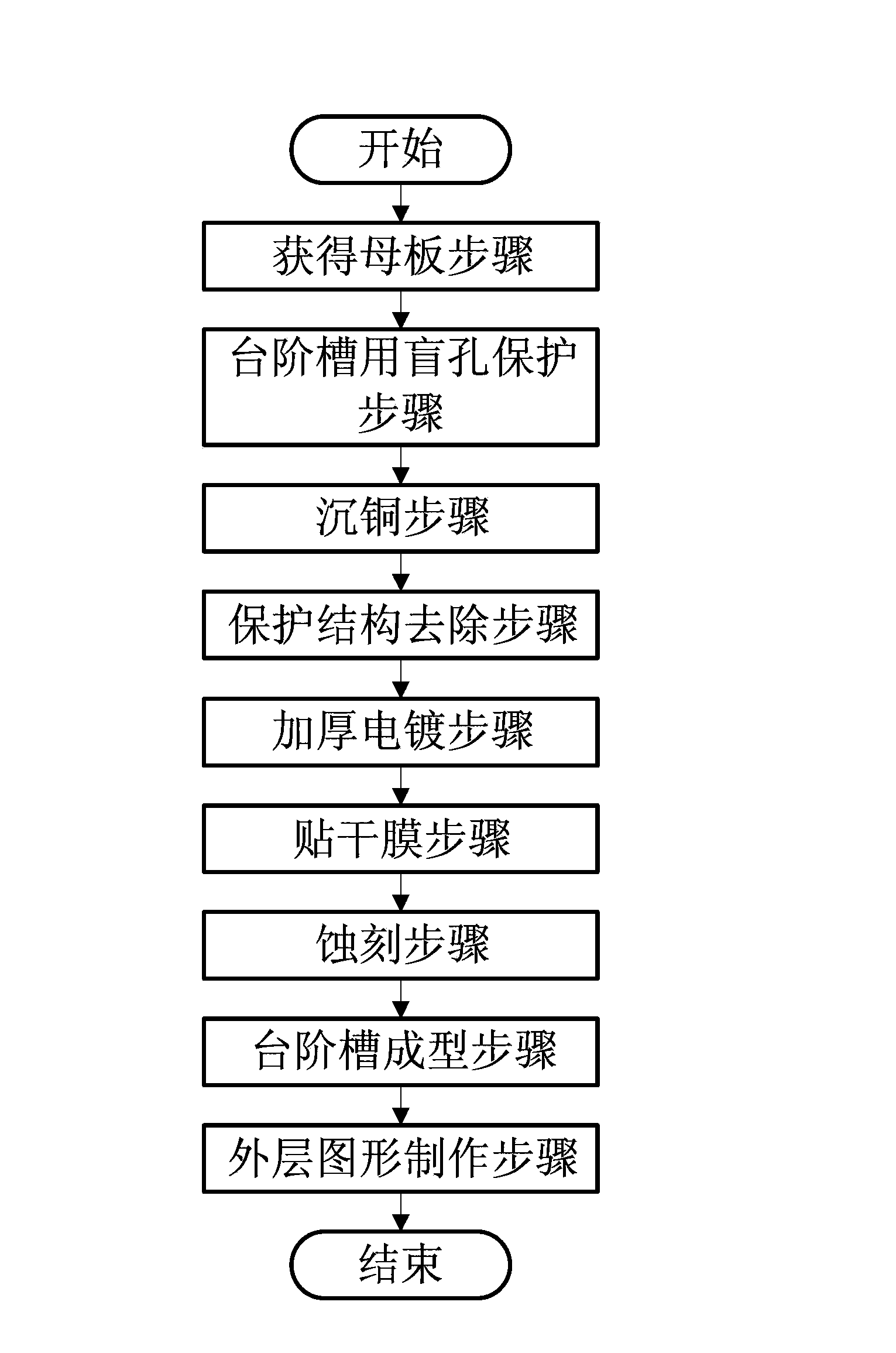

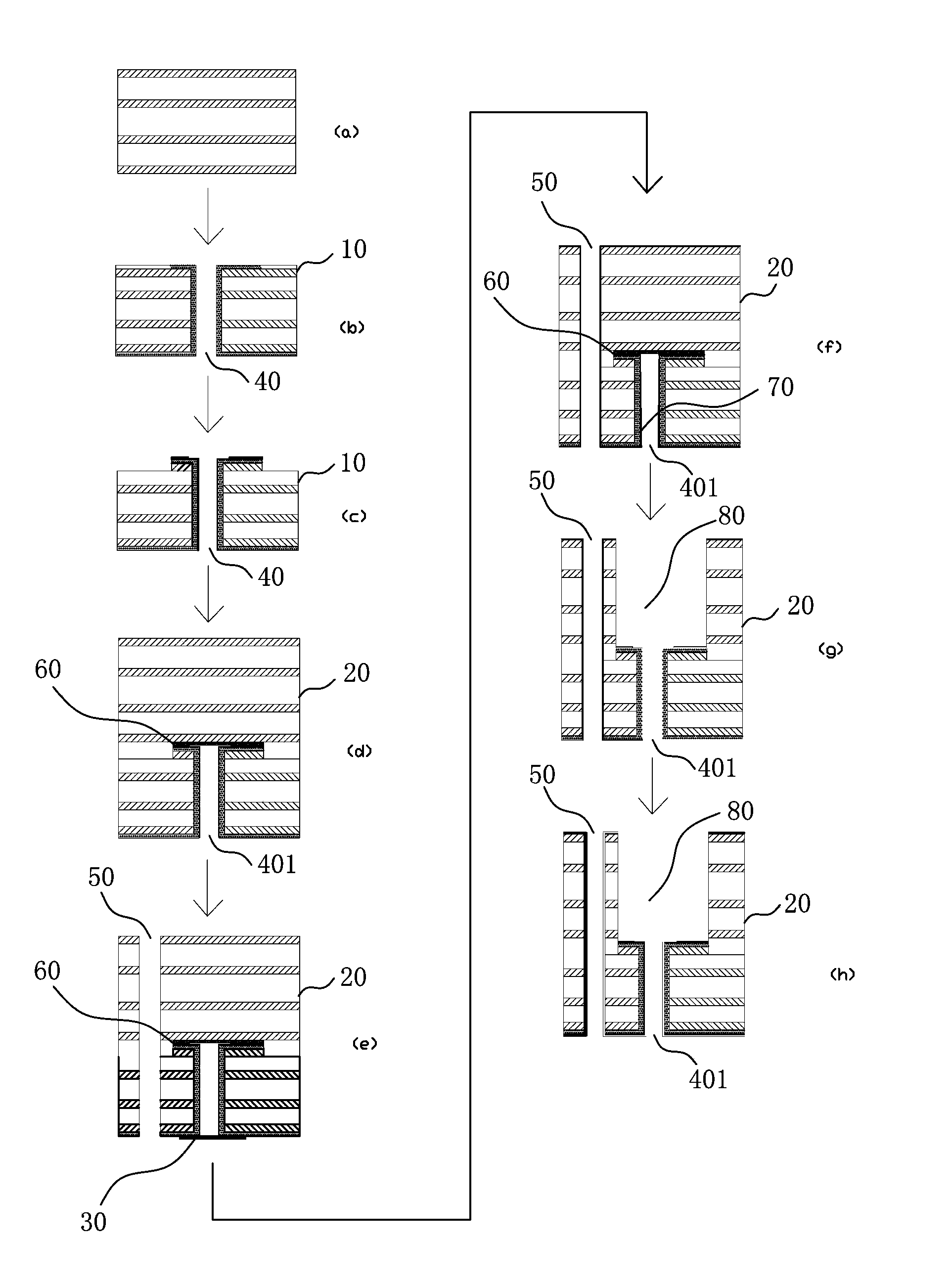

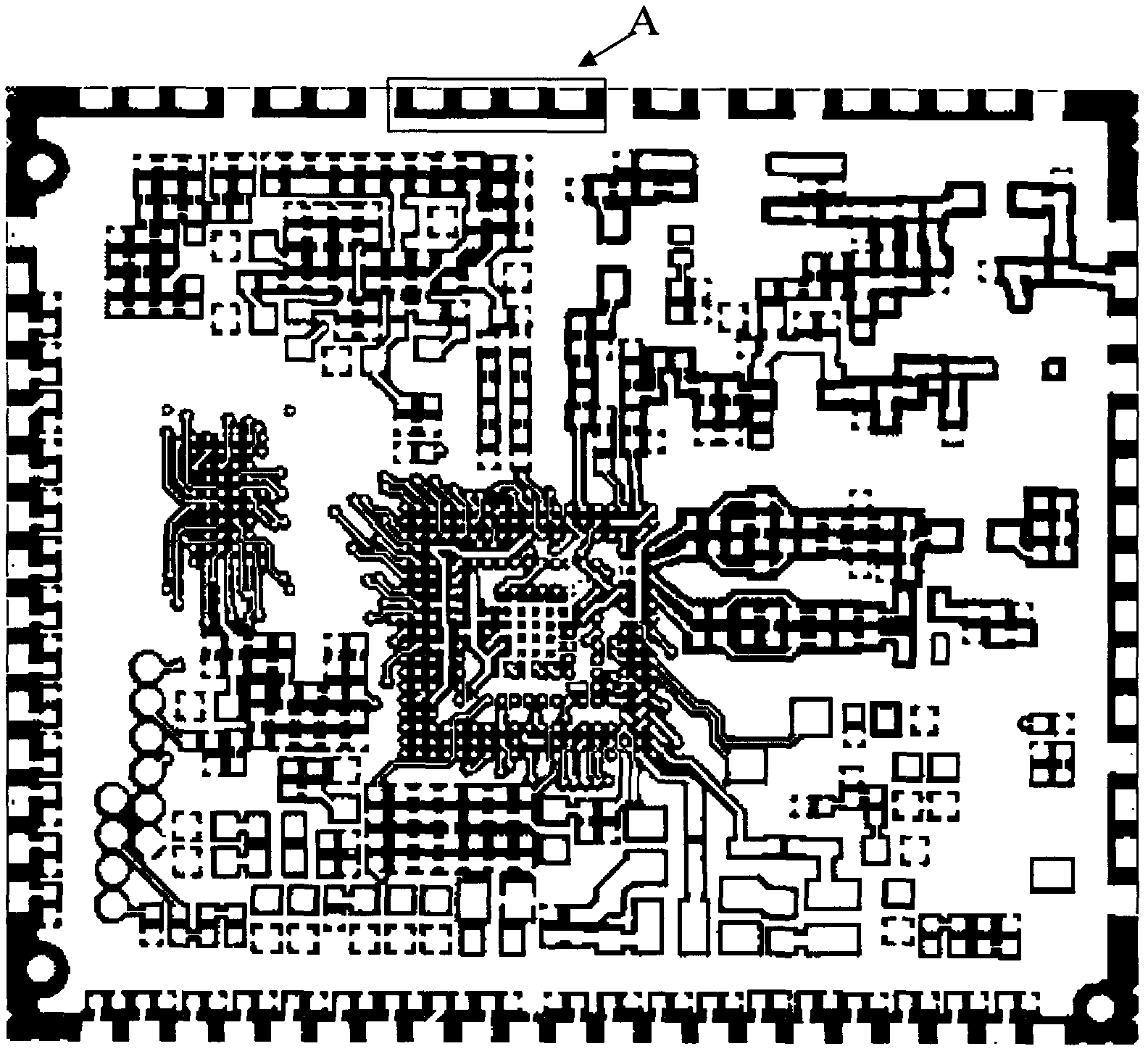

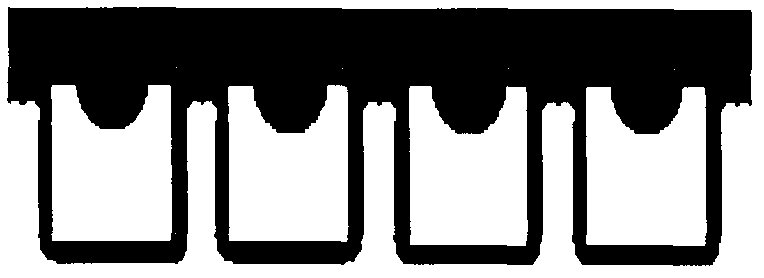

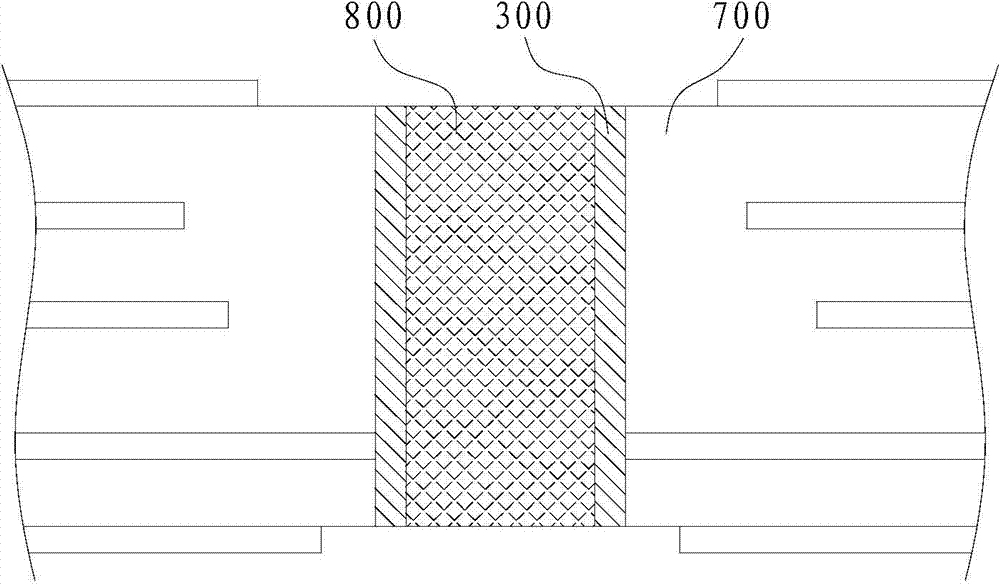

Method for processing PCB with step groove

ActiveCN103391682APrevent infiltrationGuaranteed flatnessPrinted element electric connection formationCopper platingEngineering

The invention discloses a method for processing a PCB with a step groove. The method for processing the PCB with the step groove comprises the step of obtaining of a parent plate, the step of protection of a blind hole for the step groove, the step of copper electroless plating, the step of removal of a protective structure, the step of plating thickening, the step of pasting of dry film, the step of etching and the step of forming of the step groove. Due to the fact that the technological means that a corrosion resistant layer coats the edge of the bottom and the hole wall of the blind hole for the step groove in advance, the protective structure is arranged in a hole opening of the blind hole for the step groove before the copper electroless plating is carried out on the parent plate, the protective structure is removed after the copper electroless plating is finished, etching is carried out on a thickened copper plating layer in the blind hole for the step groove to completely remove the thickened copper plating layer through corrosion resistance of the corrosion resistant layer to alkaline etching liquid, a taper hole is prevented from forming, and finally a compression joint hole applicable to compression joint of an electrical apparatus element is manufactured in the bottom of the step groove is used, damage caused by copper electroless plating chemical liquid is effectively prevented, and the compression joint hole which is applicable to compression joint of the electrical apparatus element is manufactured in the bottom of the step groove. Meanwhile, a graph which is used for circuit connection is arranged at the bottom of the step groove, and the flatness of the plate surface of the parent plate is ensured due to the fact that the protective structure is timely removed.

Owner:SHENNAN CIRCUITS

Metal half hole molding method and manufacture method of printed circuit board

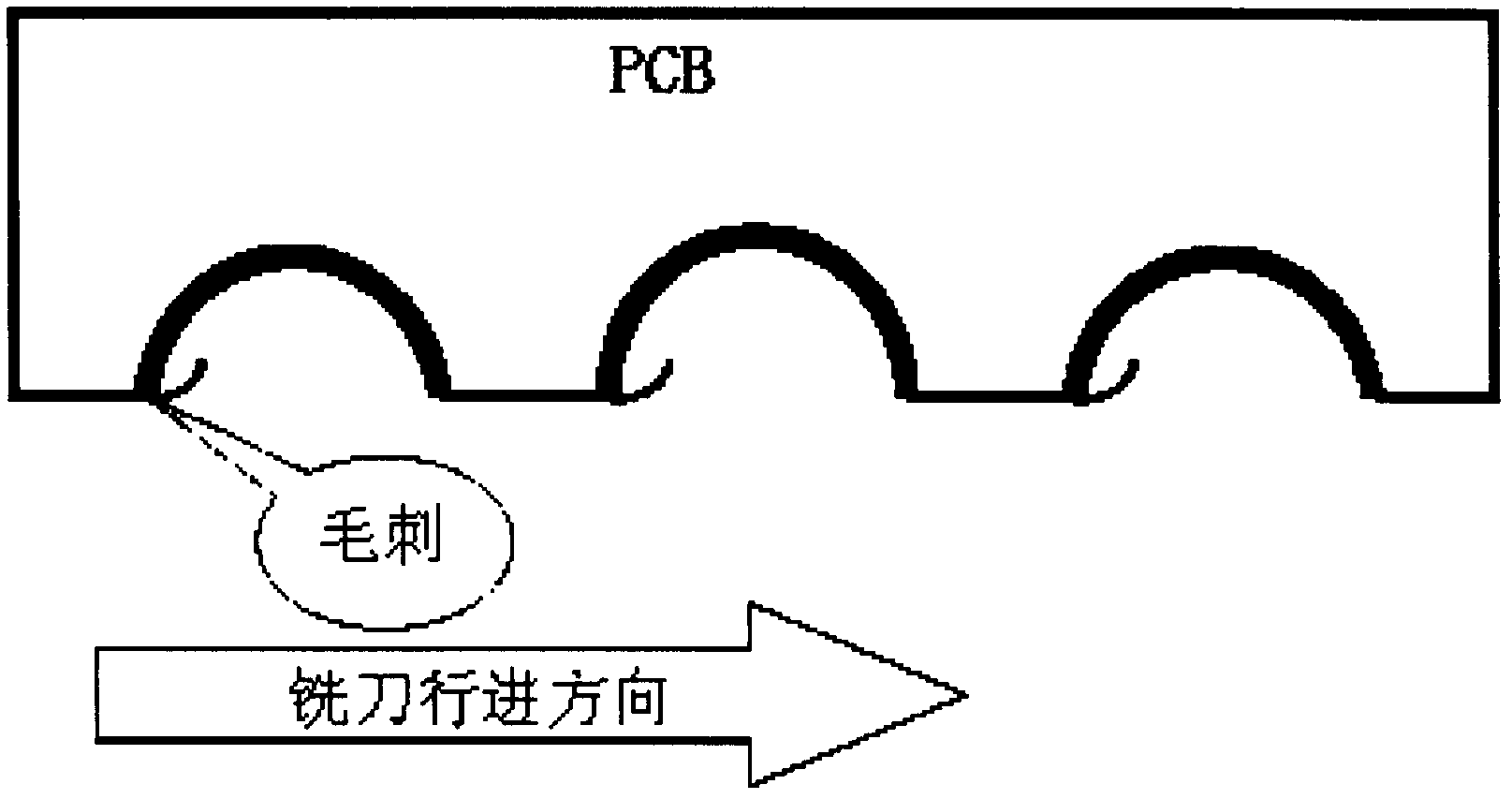

InactiveCN103179805AImprove molding qualityOvercoming the problem of residual copper wire burrsPrinted element electric connection formationCopper wirePrinted circuit board

The invention provides a metal half hole molding method. A metal half hole of a printed circuit board (PCB) is molded through a board milling procedure before the procedures of film removing, alkaline etching and tin removing in the manufacture process of the PCB. A manufacture method of the PCB is further provided. The manufacture method includes the metal half hole molding method which is used for manufacturing the metal half hole of the PCB. By means of the metal half hole molding method and the manufacture method of the PCB, the metal half hole is molded by milling the board before the procedures of film removing, alkaline etching and tin removing, the problem of residual copper wire burr is solved, and the effect of improving molding quality of the metal half hole is achieved.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +1

Heavy-copper step circuit board and preparation method thereof

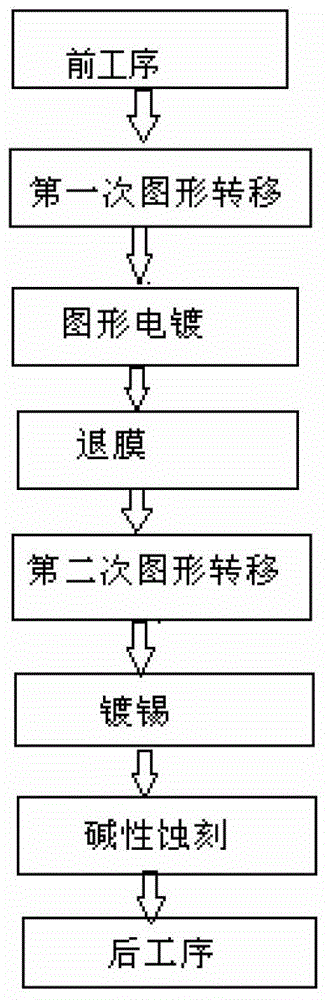

ActiveCN103338595AOptimize grinding plateOptimizing the etch processConductive material chemical/electrolytical removalTinningAlkaline etching

The invention discloses a heavy-copper step circuit board and a preparation method thereof. The preparation method comprises the working procedures of primary pattern transfer, pattern electroplating, film removal, secondary pattern transfer, tinning and alkaline etching. The preparation method solves the quality problem of a clamping film and the quality problems such as circuit nicks and unclean etching due to the fact that an anti-corrosion layer cannot be closely bonded with a circuit by a dry film technology by utilizing the production capacity of the available equipment and optimizing roll film, board grinding and etching processes; the whole preparation process is compatible with the traditional circuit board technology; and the quality and the cost can be compatible effectively.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Production process of metallized semi-pore

InactiveCN101854779AImprove yieldImprove qualityPrinted element electric connection formationCopper platingEngineering

The invention relates to the field of PCB manufacturing, in particular to a production process of a metallized semi-pore on a PCB board, which comprises the following steps: 1) substrate drilling, copper plating, pattern transfer, pattern plating and routing of a round pore into a semi-pore according to design needs; 2) alkaline etching of a PCB board; 3) stripping; 4) secondary alkaline etching; and 5) tin removal. The horizontal moving speed of the routing machine in Step (1) is 0.2-0.5m / min, and the number of stacked plates is 2pnl / gong. The invention adopts the method of alkaline etching without membrane stripping to etch copper burrs produced in routing of the semi-pore, and the other parts of the board surface can not be affected by etching due to dry membrane protection; and then normal membrane stripping, etching (secondary etching) and tin stripping are carried out, thereby ensuring the high quality of the metallized semi-pore.

Owner:惠州威健电路板实业有限公司

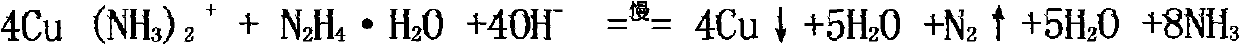

Method for recovering copper from alkaline etching waste liquid and recycling alkaline etching liquid

The invention discloses a method for recovering copper from alkaline etching waste liquid and recycling the alkaline etching liquid, comprising the step of adding a hydrazine hydrate reducing agent and a catalyst into the alkaline etching waste liquid to recover copper powder, wherein the alkaline etching waste liquid can be recycled after the copper powder is recovered. The invention has the optimum conditions of: placing the alkaline etching waste liquid into a reactor; adding hydrazine hydrate with mass percent concentration of 40 percent according to added quantity of 160-200mL / L; adding a solution of various salts of ruthenium, palladium, nickel and cobalt as the catalyst with added quantity of 0.01-0.2g / L (metered by the masses of the ruthenium, the palladium, the nickel and the cobalt), reacting for 30-35 minutes at temperature between 70DEG C and 100DEG C; and separating to obtain the copper powder. The invention has the beneficial effect that after the copper is recovered from the alkaline etching waste liquid, the alkaline etching waste liquid can be regenerated and recycled, therefore, various resources in the alkaline etching waste liquid can be used fully, and the etching cost of a printing plate and the discharge of pollutants can be reduced.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

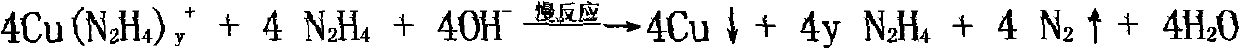

Making method of outer layer patterns of local gold-plating printed plate

ActiveCN103179795AMeet the process requirementsMeet the requirements of partial gold-plated surface treatmentConductive pattern reinforcementTinningResist

The invention provides a making method of outer layer patterns of a local gold-plating printed plate. A printed plate is conducted to conventional plate planting and thickening and is ground to be smooth, so that outer layer etched base copper is in accordance with the requirements on the thickness of a printed plate finished conductor. A gold-plating resistant dry film is bonded on the printed plate, dry film window cutting is performed in a gold-plating pattern area, and then electrogilding treatment and stripping are performed. Tin-plating resistant dry film is bonded on the printed plate, dry film window cutting is performed in an area corresponding to pattern design other than the gold-plating area, patterns exposed after window cutting are conducted to tin plating, so as to be served as a tin plate of an alkaline etching resistant protective layer, and stripping is performed after tin plating. The gold-plating layer and the tin layer are both served as etching resistant layers, and outer layer conductor patterns are prepared through an alkaline etching technology. Peelable blue gel is screen-printed on the outer layer gold-plating conductor patterns and is cured, so that the gold-plating area is protected, and then the tin layer is conducted to tin stripping treatment. Solder resist is prepared and other surface treatment is performed.

Owner:JIANGNAN INST OF COMPUTING TECH

Circuit board manufacturing method

InactiveCN103945651AAchieving Via InsulationEfficient detectionPrinted circuit aspectsPrinted element electric connection formationEngineeringAlkaline etching

The invention discloses a circuit board manufacturing method. The circuit board manufacturing method comprises the following steps of providing a cover plate, correspondingly forming a through hole corresponding to a plated-through hole of a circuit board in the cover plate and enabling the cover plate to cover the electroplated circuit board surface, wherein the through hole is aligned to the plated-through hole of the circuit board; providing a resin material with good copper face wettability and enabling the resin to be fully stirred under the vacuum condition; enabling the stirred resin to be coated on the cover plate surface, enabling the through hole of the cover plate to be full of the resin through a single stroke of a scraper of a silk-screen machine, wherein the rein flows into the plated-through hole through the through hole, and an oil return knife scrapes back the resin left on the cover plate surface; covering a pattern electrotinning layer on a electro-coppering layer required to be reserved, protecting patterns required to be reserved, enabling a copper ring at the hole opening position at at-least one end of the plated-through hole to be exposed, adopting alkaline etching liquid to perform etching to remove the copper ring protected by a tin-free layer, and performing etching for desired depth. The circuit board manufacturing method can remove the copper ring at the hole opening position of the plated-through hole, achieve through hole insulativity of the circuit board and effectively take the place of a backdrill technology.

Owner:DONGGUAN SHENGYI ELECTRONICS

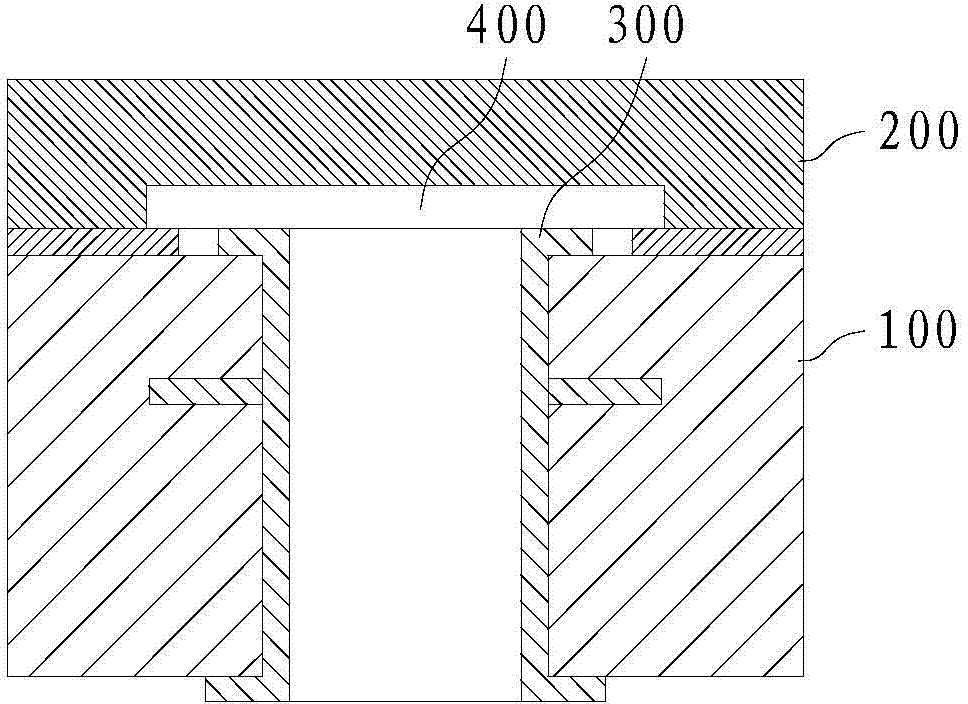

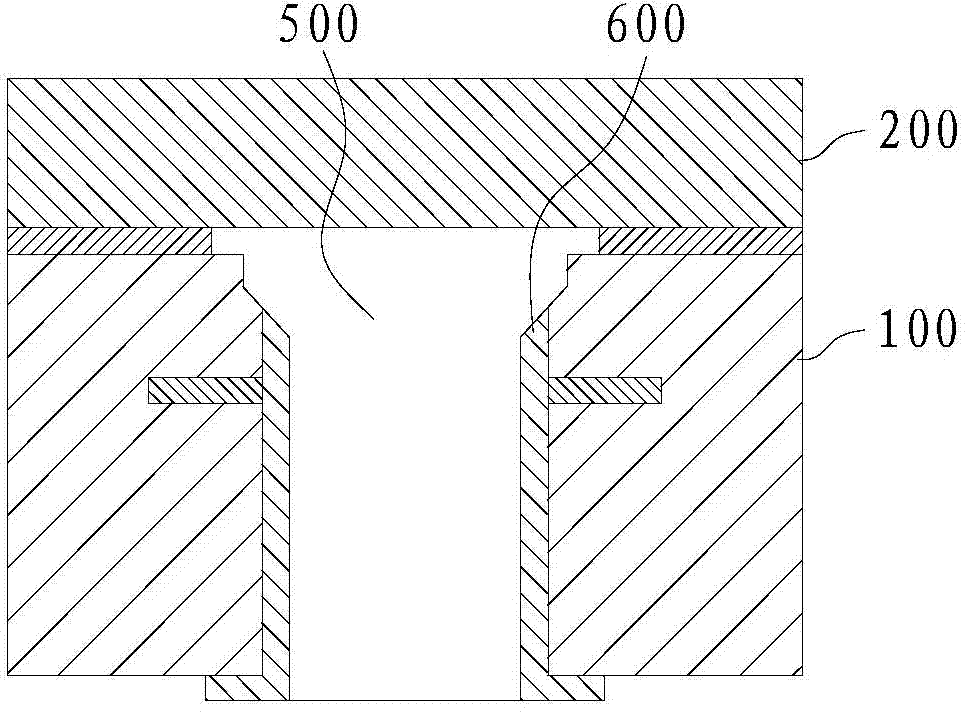

Double-surface pressing connecting through hole structure of printed-circuit board and machining method thereof

ActiveCN103458627AEliminate parasitic capacitanceImprove integrityElectrical connection printed elementsPrinted element electric connection formationTinningCopper plating

The invention discloses a double-surface pressing connecting through hole structure of a printed-circuit board and a machining method of the double-surface pressing connecting through hole structure of the printed-circuit board. The machining method comprises the following steps that a small hole A is drilled in the upper surface of a substrate in a depth-control mode; a pressing connecting hole B is drilled in the same position of the small hole A; the substrate is overturned; a small hole C is drilled in the surface opposite to the small hole A in a depth-control mode and is communicated with the small hole A; a pressing connecting hole D is drilled in the position of the small hole C; electroless copper plating, copper electroplating and tinning are carried out; a hole E is drilled in the position of the small hole A in a depth-control mode; the substrate is overturned; a hole F is drilled in the position of the small hole C in a depth-control mode; alkaline etching and tin stripping are carried out; part of a copper layer at each pressing connecting hole is thickened in a plating mode until the design requirement of a finished product is met, and finally the double-surface pressing connecting through hole structure is obtained. The double-surface pressing connecting through hole structure of the printed-circuit board and the machining method of the double-surface pressing connecting through hole structure of the printed-circuit board completely eliminate the stray capacitance among pressing connecting elements, facilitates the integrality of signal transmission and improves wire distribution density; the process is reasonable, the difficulty that plating layers of the middle small holes are eliminated in a drilling mode is largely lowered, and the diameter of the pressing connecting holes is made to be the smallest; the completeness of the plating layers on the walls of the pressing connecting holes is guaranteed, and the non-metallic middle small holes are achieved; copper wire defects in the holes are avoided.

Owner:SHANTOU ULTRASONIC PRINTED BOARD NO 2 FACTORY +1

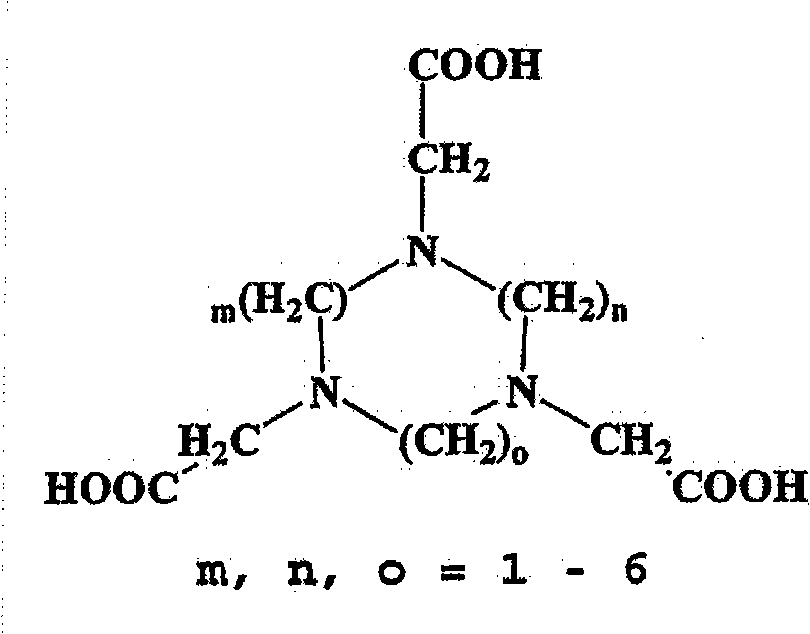

Texturing and cleaning medium for the surface treatment of wafers and use thereof

InactiveCN101952406AFacilitated DiffusionFast etchDetergent mixture composition preparationOrganic non-surface-active detergent compositionsSimple Organic CompoundsWafering

The invention relates to a fluid medium for the surface treatment of monocrystalline wafers, which contains an alkaline etching agent and at least one organic compound with low volatility. Systems of this type can be used either for cleaning, the removal of defects and the texturing of wafer surfaces in a single etching step or, exclusively, for the texturing of silicon wafers having different surface qualities, such as wafers which are cut by a wire saw and exhibit high surface degradation or chemically polished surfaces having a minimal number of defects.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

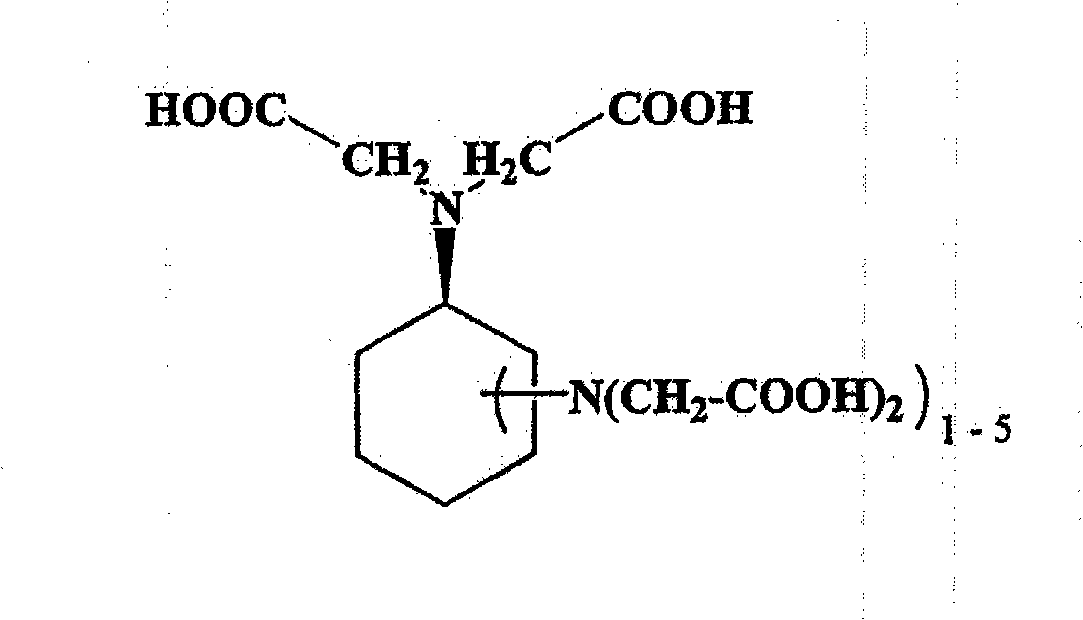

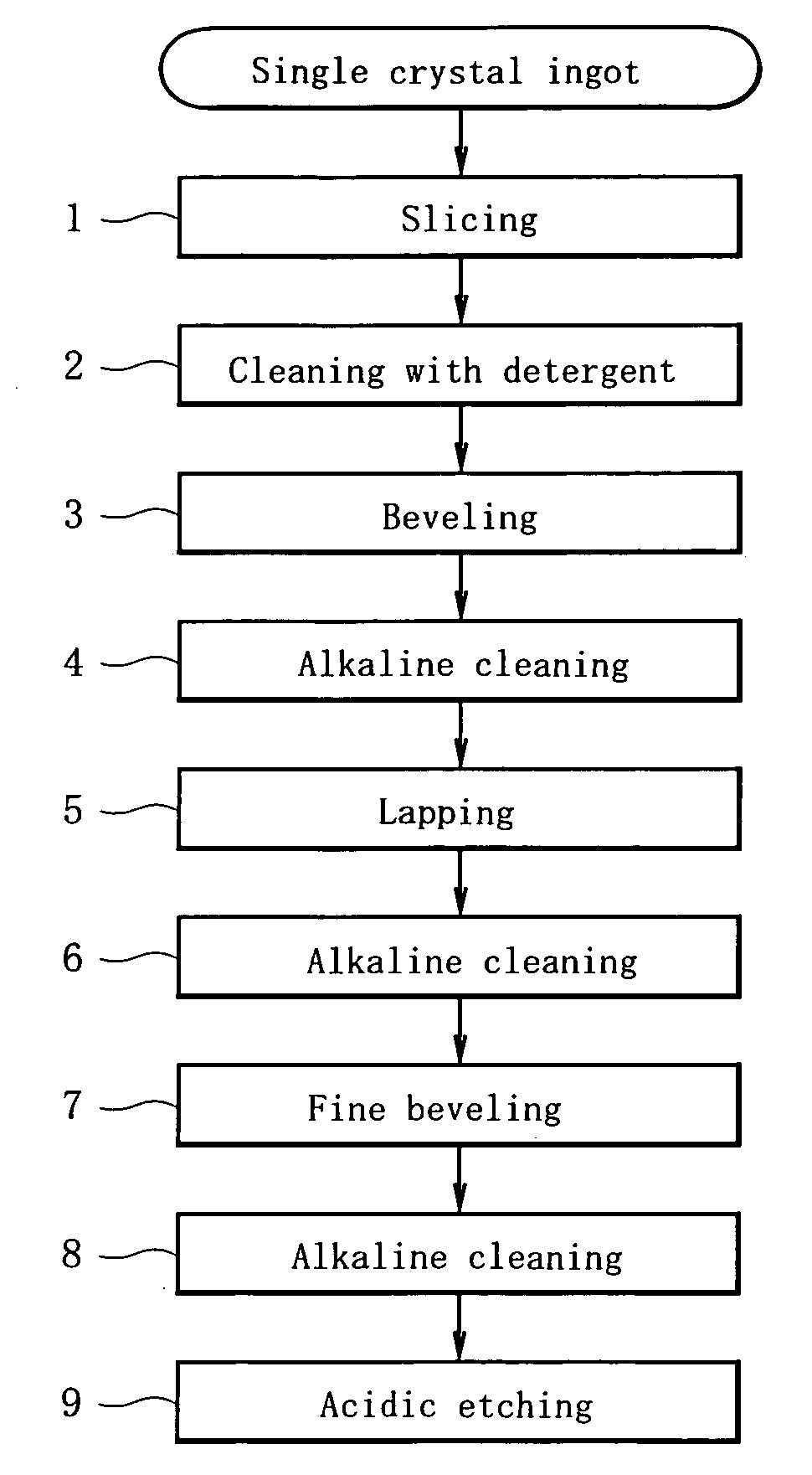

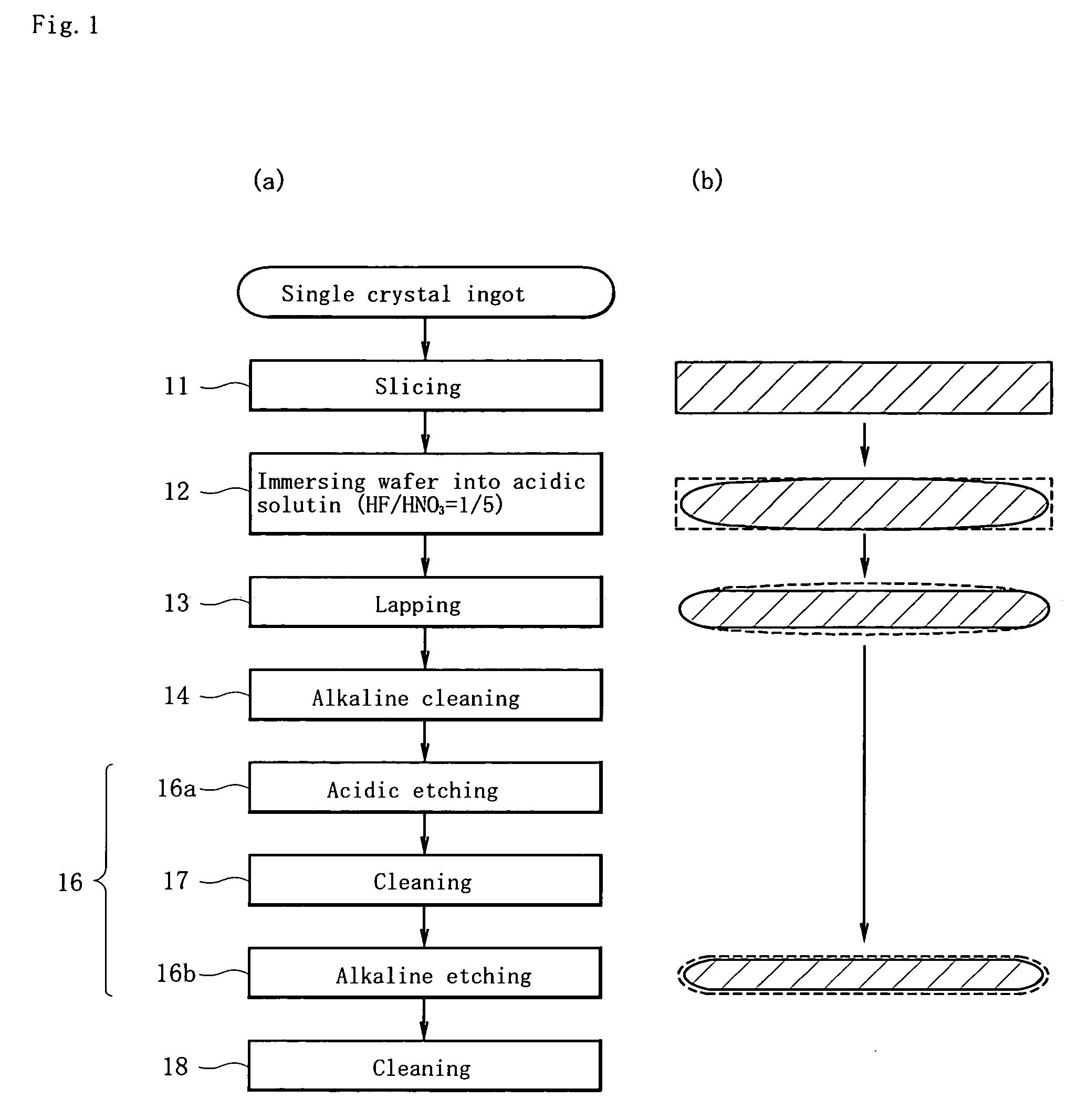

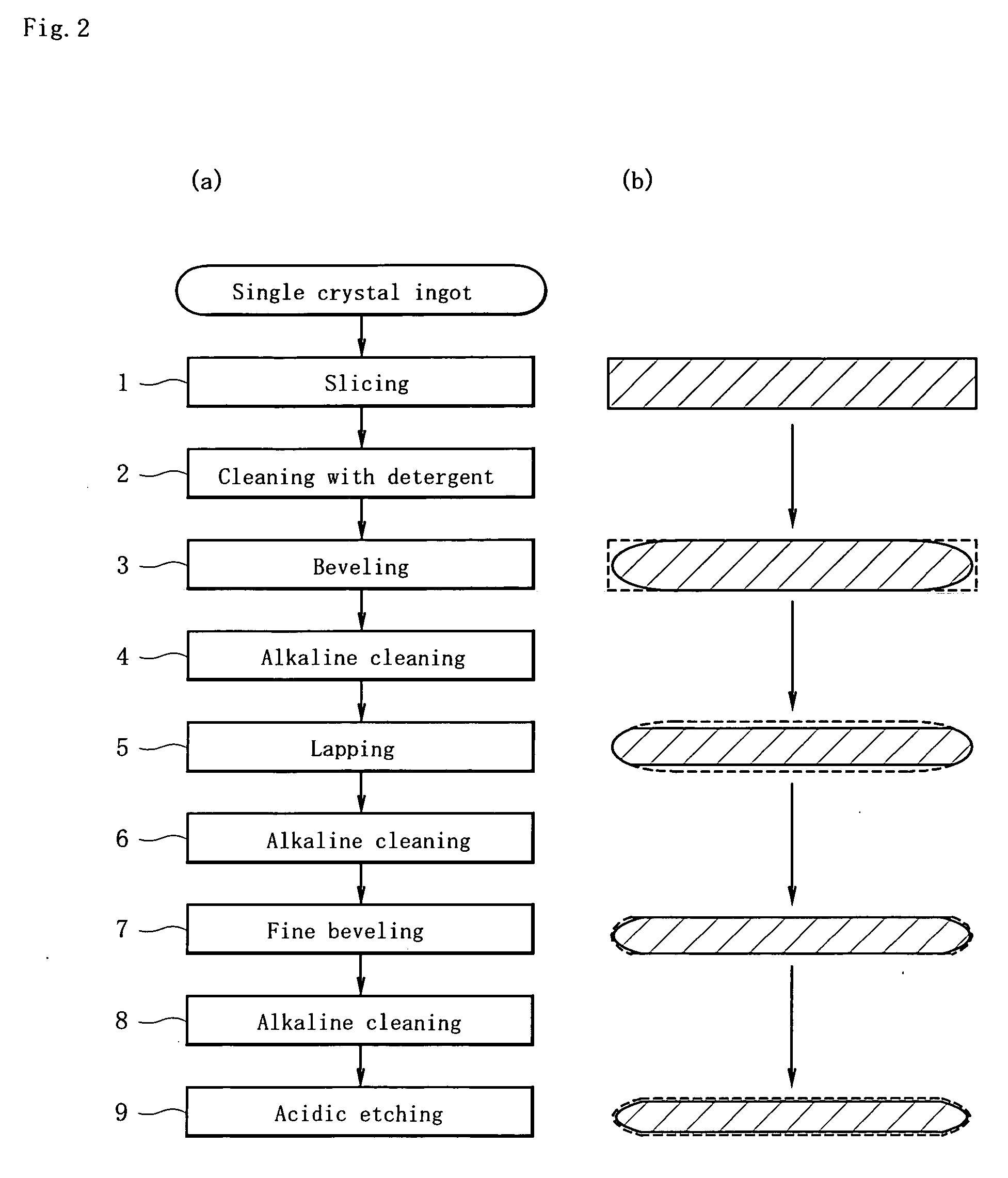

Method of processing silicon wafer

ActiveUS20060252272A1Reduce layeringSimple processDecorative surface effectsSemiconductor/solid-state device manufacturingHydrofluoric acidEdge surface

The inventive method for processing a silicon wafer is a method comprising step 11 in which a single crystal ingot is sliced into thin disc-like wafers; step 13 in which the surface of each wafer is lapped to be planar; step 14 in which the wafer is subjected to alkaline cleaning to be removed of contaminants resulting from preceding machining; and step 16 in which the wafer is alternately transferred between two groups of etching tanks one of which contain acidic etching solutions and the other alkaline etching solutions, wherein an additional step 12 is introduced between step 11 and step 13 in which a wafer is immersed in an acidic solution containing hydrofluoric acid (HF) and nitric acid (HNO3) at a volume ratio of ⅛ to ½ (HF / HNO3) so that degraded superficial layers occurring on the front and rear surfaces of the wafer as a result of machining can be removed and the edge surface of the wafer can be beveled. The inventive method simplifies the steps involved in the processing of a wafer, and reduces the intervention of alkaline cleaning accompanied with mechanical beveling, thereby reducing the risk of contamination due to metal impurities which may result from alkaline cleaning.

Owner:SUMCO CORP

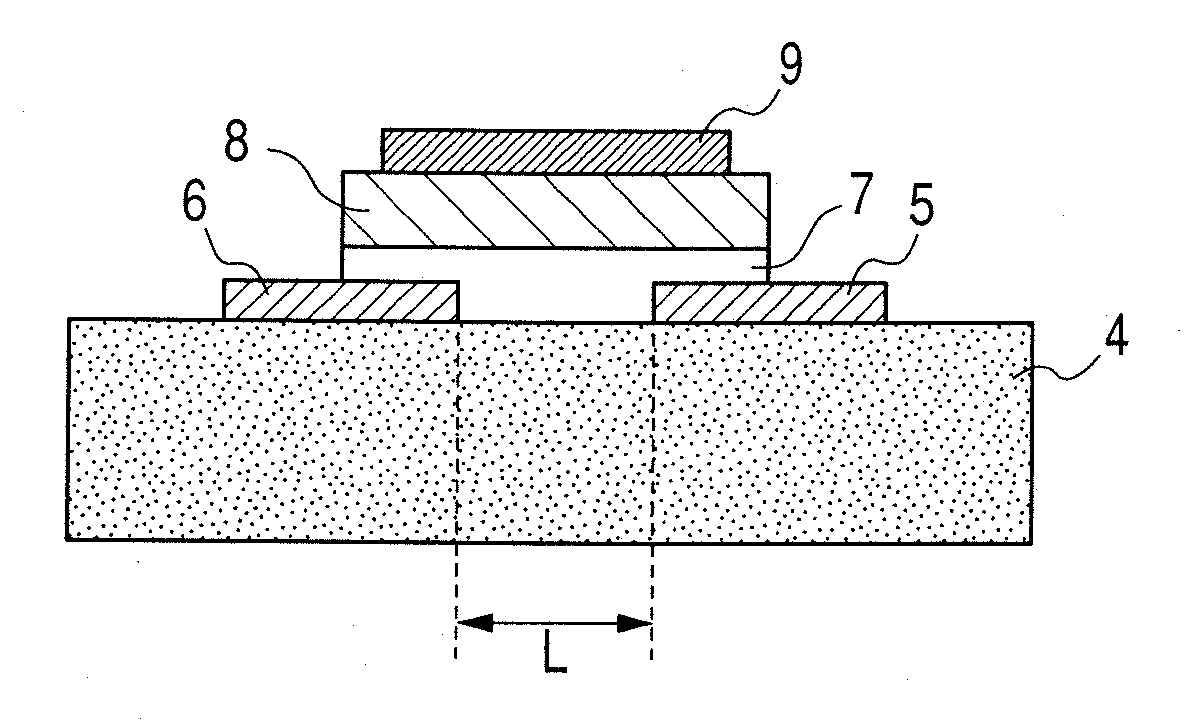

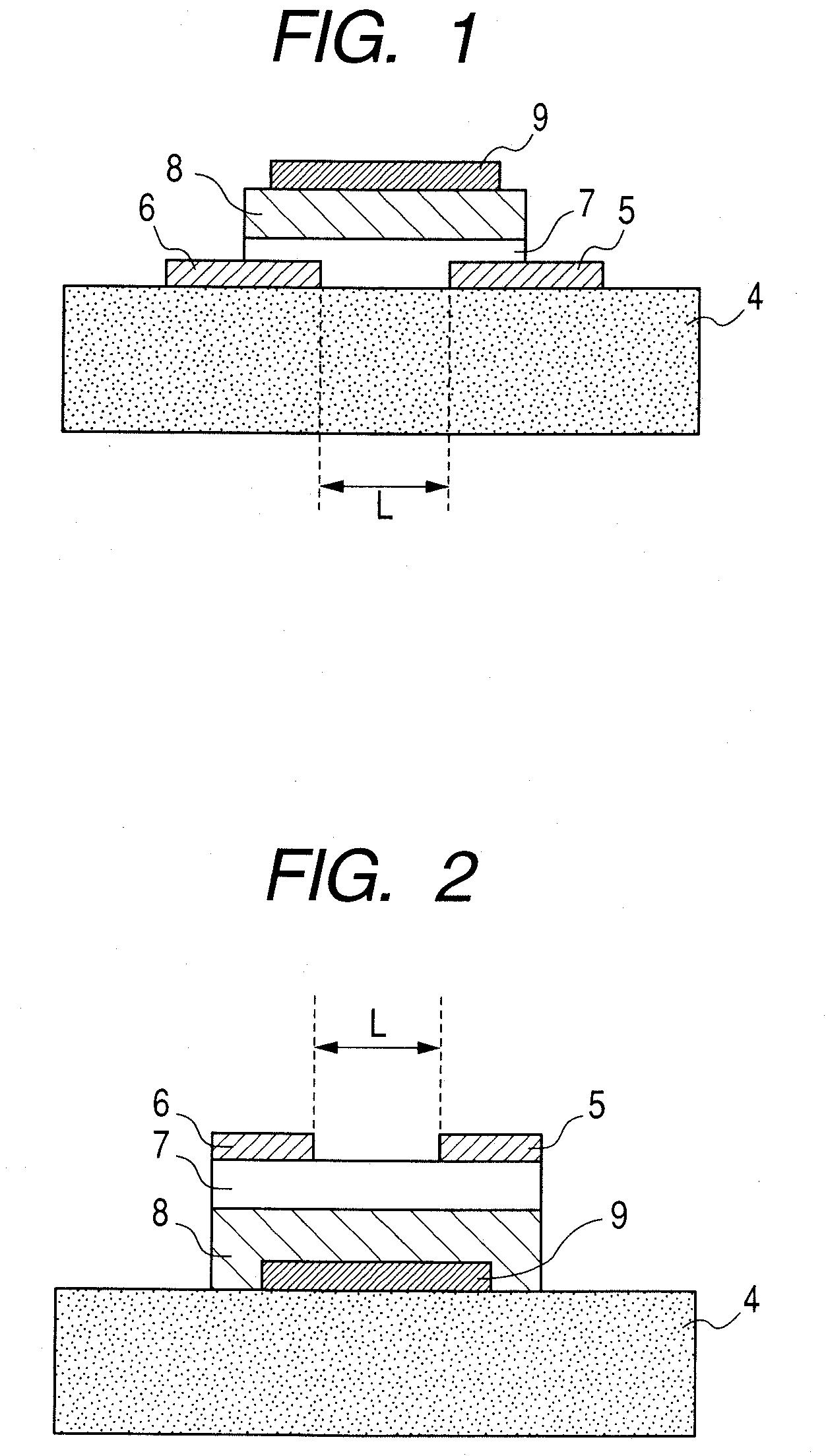

Etching method, pattern forming process, thin-film transistor fabrication process, and etching solution

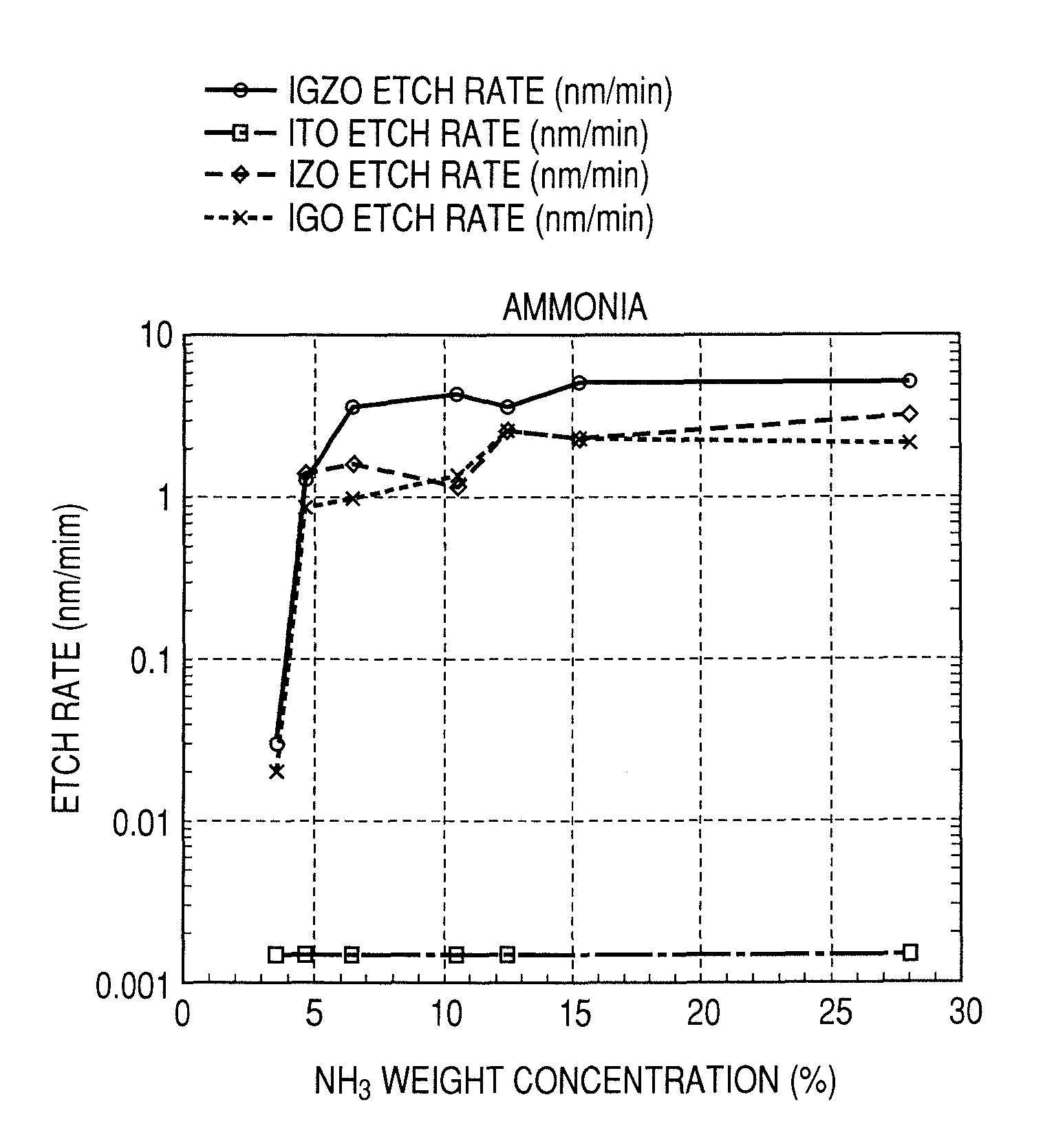

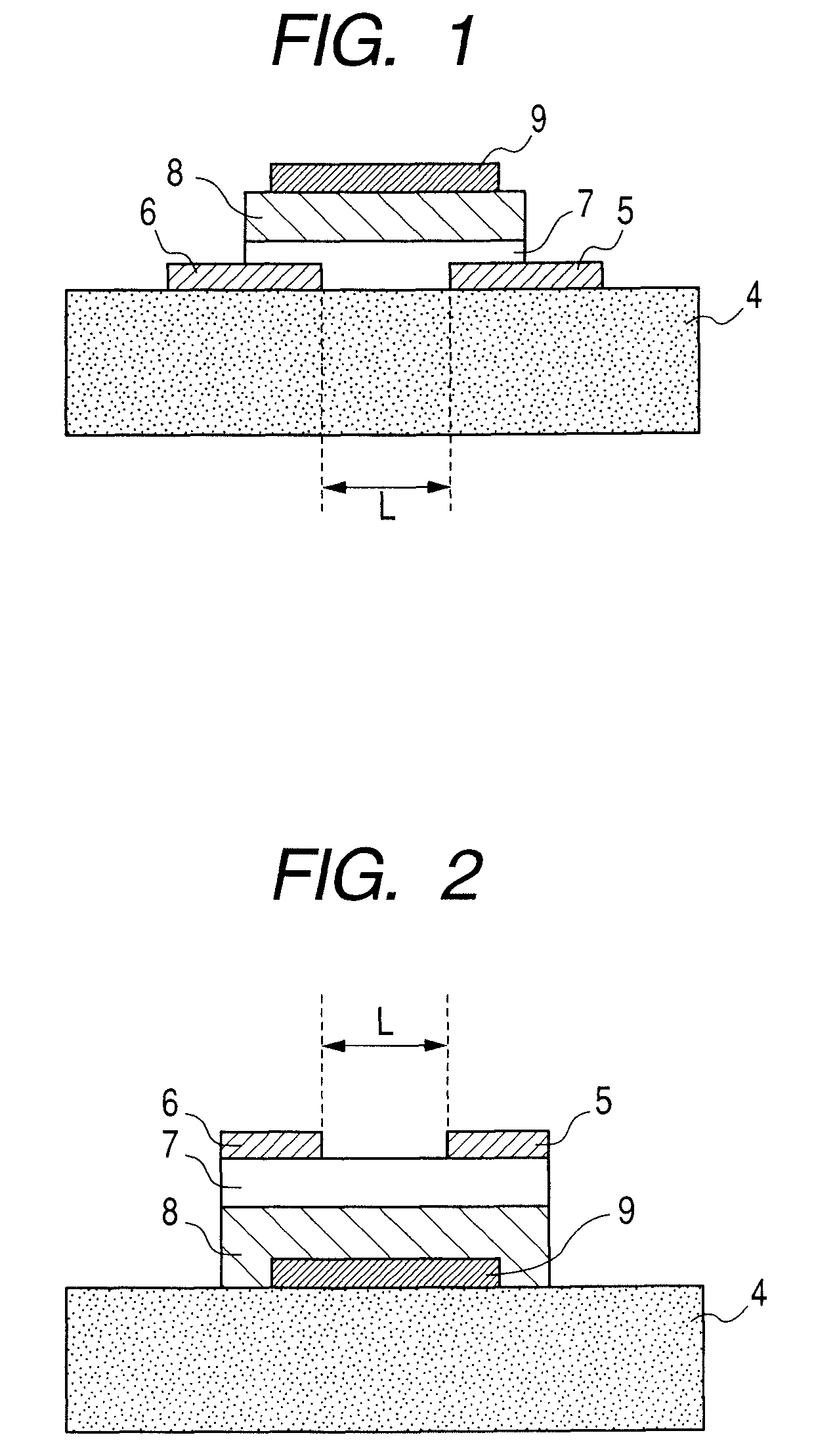

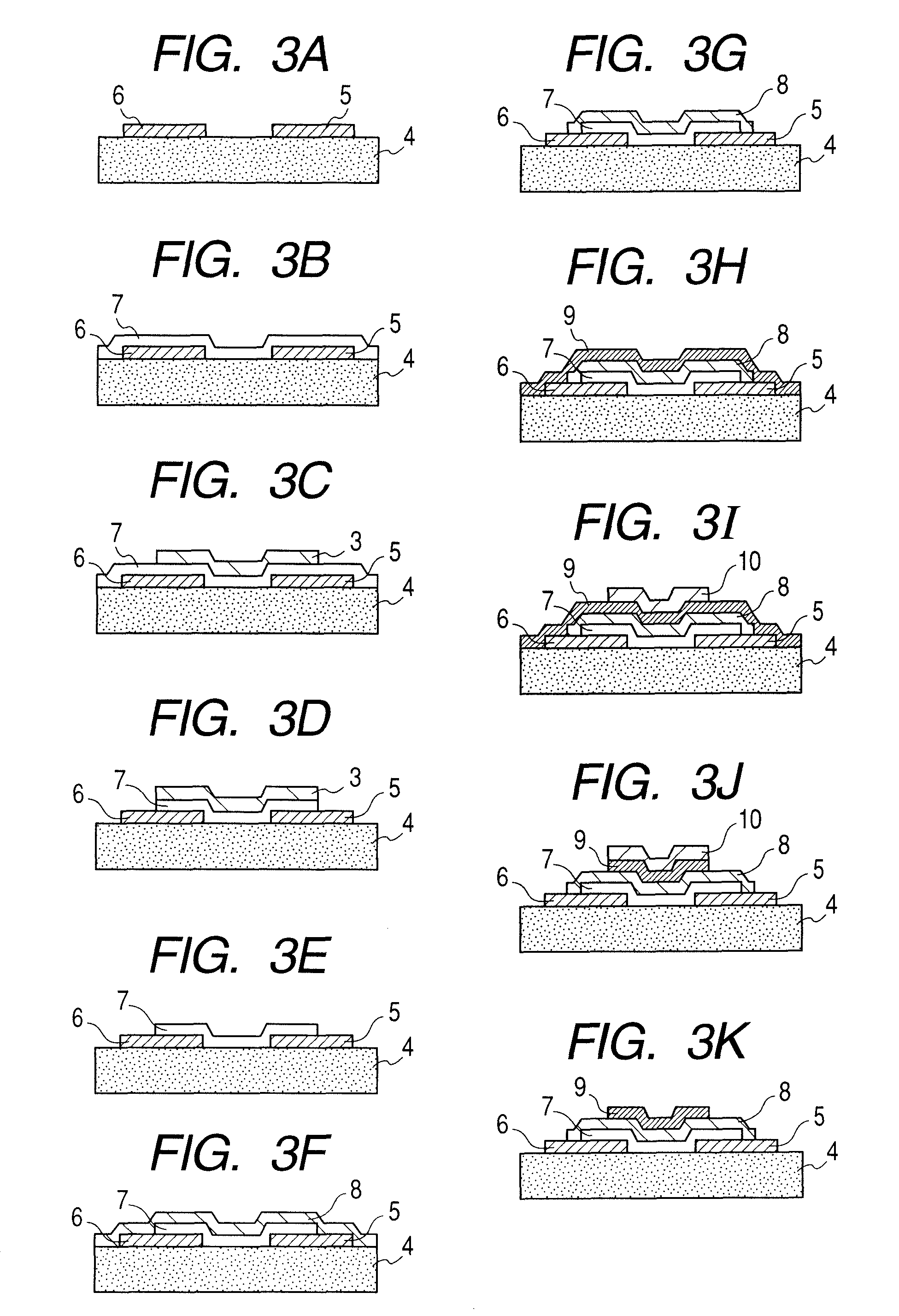

InactiveUS20100035378A1High selectivityImprove stabilitySemiconductor/solid-state device manufacturingSurface treatment compositionsIndiumAmmonia

An etching method is provided in which selective etching can be carried out for an amorphous oxide semiconductor film including at least one of gallium and zinc, and indium. In the etching method, the selective etching is performed using an alkaline etching solution. The alkaline etching solution contains especially ammonia in a specific concentration range.

Owner:CANON KK

Method for cleaning diamond wire-electrode cutting silicon wafer

ActiveCN102225406AReduce reflectivityImprove battery efficiencyCleaning using liquidsIncrease phBiological activation

The invention relates to the technical field of cutting silicon wafer post-treatment, and in particular relates to a method for cleaning a diamond wire-electrode cutting silicon wafer. The method comprises the following steps: coarsely cleaning a degummed silicon wafer in an alkaline cleaning agent and lactic acid respectively, wherein the pH of the alkaline cleaning agent is between 9 and 10, the temperature of the alkaline cleaning agent is between 30 and 50 DEG C, and the temperature of the lactic acid is 60 DEG C; and finely cleaning in the alkaline cleaning agent and purified water respectively, wherein the PH of the alkaline cleaning agent is between 9 and 10, and the temperature of the alkaline cleaning agent is between 70 and 90 DEG C. The cleaning method has the advantages that: the silicon wafer surface is cleaner and the surface damaged layer is better removed by increasing pH of the silicon wafer cleaning solution and increasing the temperature, and the cleaning solution plays a surface activation effect in the alkaline etching process of the silicon wafer. When the silicon wafer is etched, the pyramid etching surface has higher coverage rate, and the etching surface is uniform.

Owner:TRINA SOLAR CO LTD

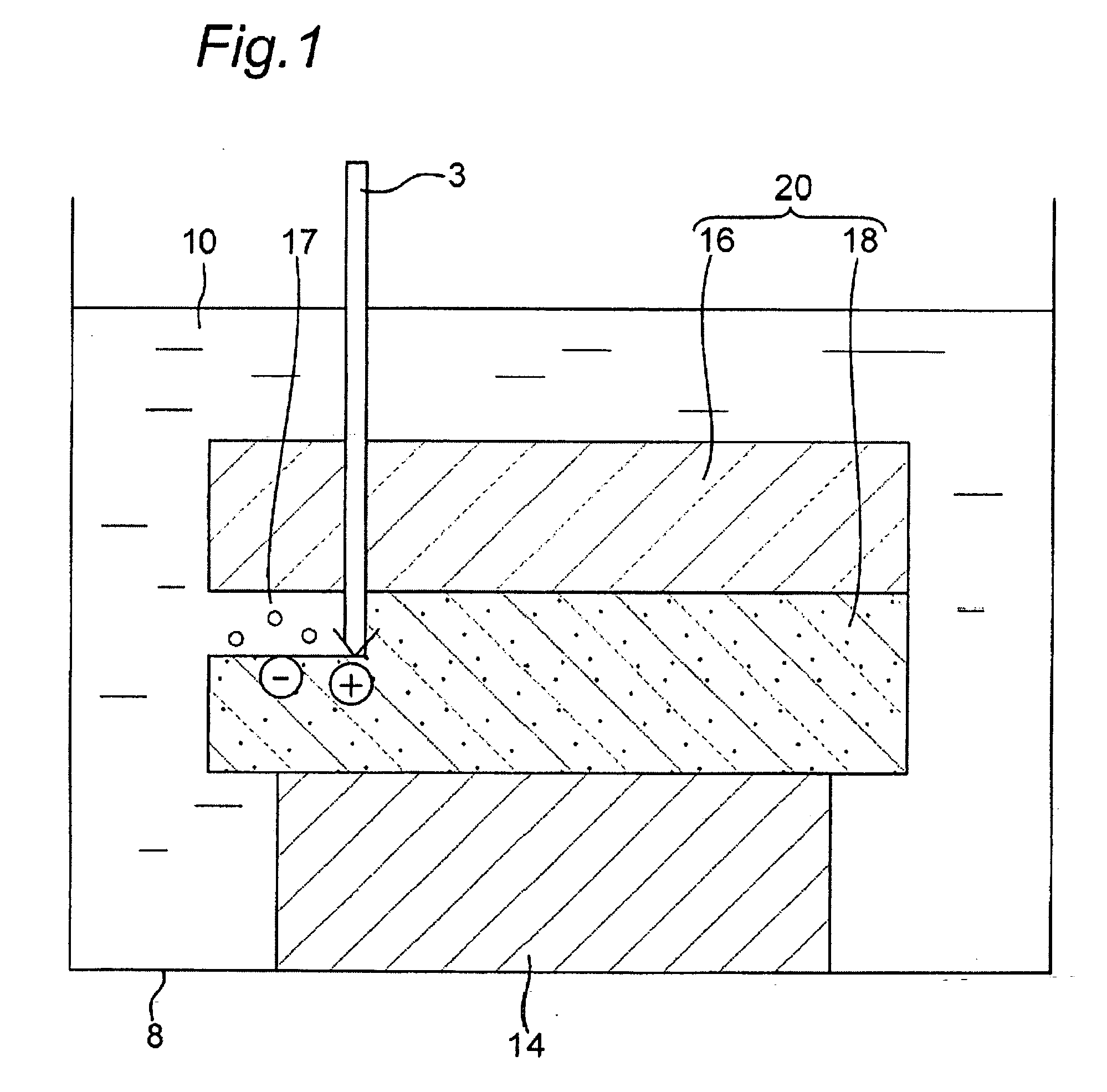

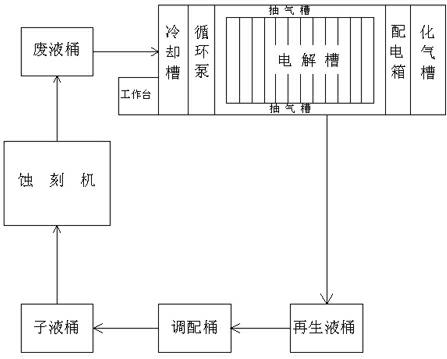

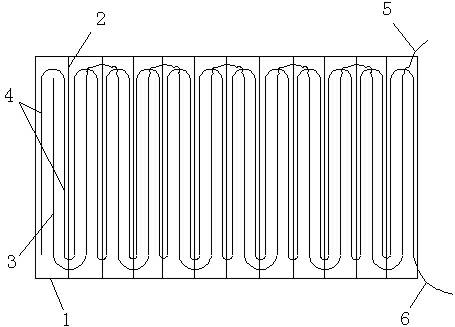

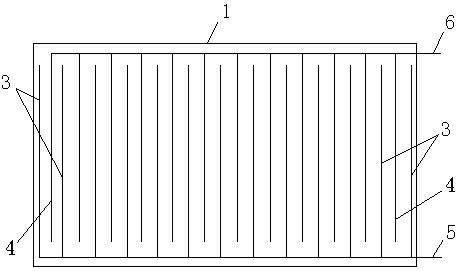

Process for directly electrolyzing waste etching solution to extract copper

InactiveCN102206823ASolve the problem of no effective treatment processImprove performancePhotography auxillary processesProcess efficiency improvementAlkaline etchingWaste management

The invention discloses a process for directly electrolyzing waste etching solution to extract copper; a special electrode connecting mode and matched current and voltage supply are adopted, that is, an acid electrolytic cell and a corresponding current and voltage are adopted for an acid waste etching solution, and a parallel connection for electrodes in the acid electrolytic cell is adopted; an alkaline electrolytic cell and a corresponding current and voltage are adopted for an alkaline waste etching solution, and a series connection for electrodes in the alkaline electrolytic cell is adopted; therefore, the acid waste etching solution and the alkaline waste etching solution can be electrolyzed respectively; when the current decreases to a controlled range, a cathode is removed and electrolytic copper is stripped; the residual waste etching solution is blended to become a regenerated sub-liquid for recycling use in a production line; no substance with other components is mixed into the waste etching solution during the whole process, so the components of the waste etching solution are not destroyed; therefore the regenerated sub-liquid has more stable performance and can be recycled all along, and the cost for the whole process is lower; on the other hand, the invention also solves the problem that currently no effective processing technology exists for acid waste etching solutions.

Owner:DONGGUAN LVHAN ENVIRONMENTAL PROTECTION EQUIPTECH

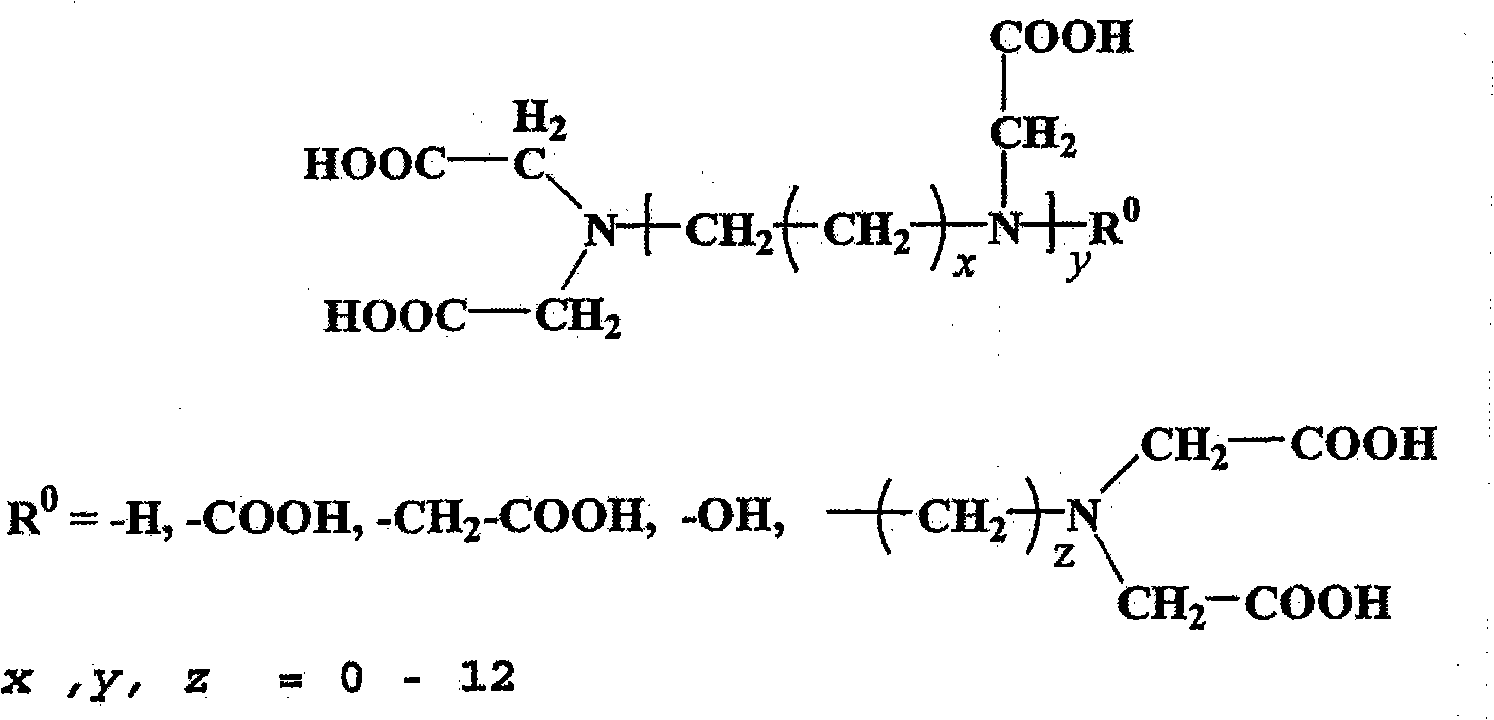

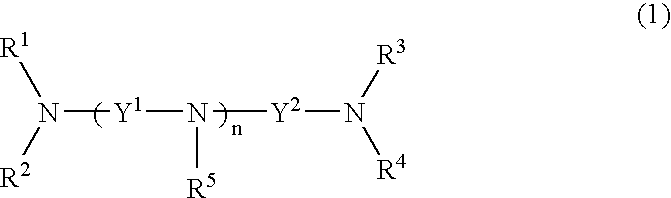

Cleaning composition and method of cleaning therewith

InactiveUS20060154838A1Non-surface-active detergent compositionsDetergent mixture composition preparationCleaning methodsAlkaline etching

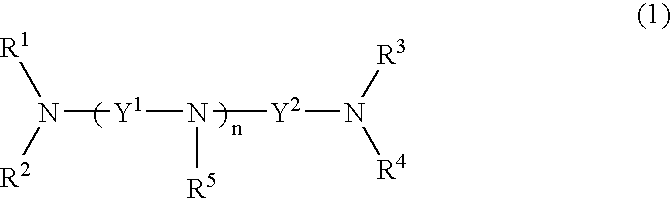

The present invention relates to a liquid cleaner for a semiconductor substrate on which metal wiring may be provided, comprising each component of a chelating agent or a salt thereof shown by the following general formula (1), an alkaline compound and pure water, wherein pH is 8 to 13: (wherein, Y1 and Y2 are lower alkylene groups, n is an integer of 0 to 4, at least 4 of R1 to R4 and n R5s are alkyl groups having phosphonic acid group(s) and the rest are alkyl groups) and a cleaning method using the same. The present invention provides a liquid cleaner which can efficiently remove fine particles or impurities derived from various metals at semiconductor substrate surface, even when used after a process adopting an alkaline polishing agent or alkaline etching liquid, without generating problems of causing difficult-to-remove gelled particles at the substrate surface or easy generation of rough semiconductor substrate surface, and a cleaning method using the same.

Owner:WAKO PURE CHEMICAL INDUSTRIES

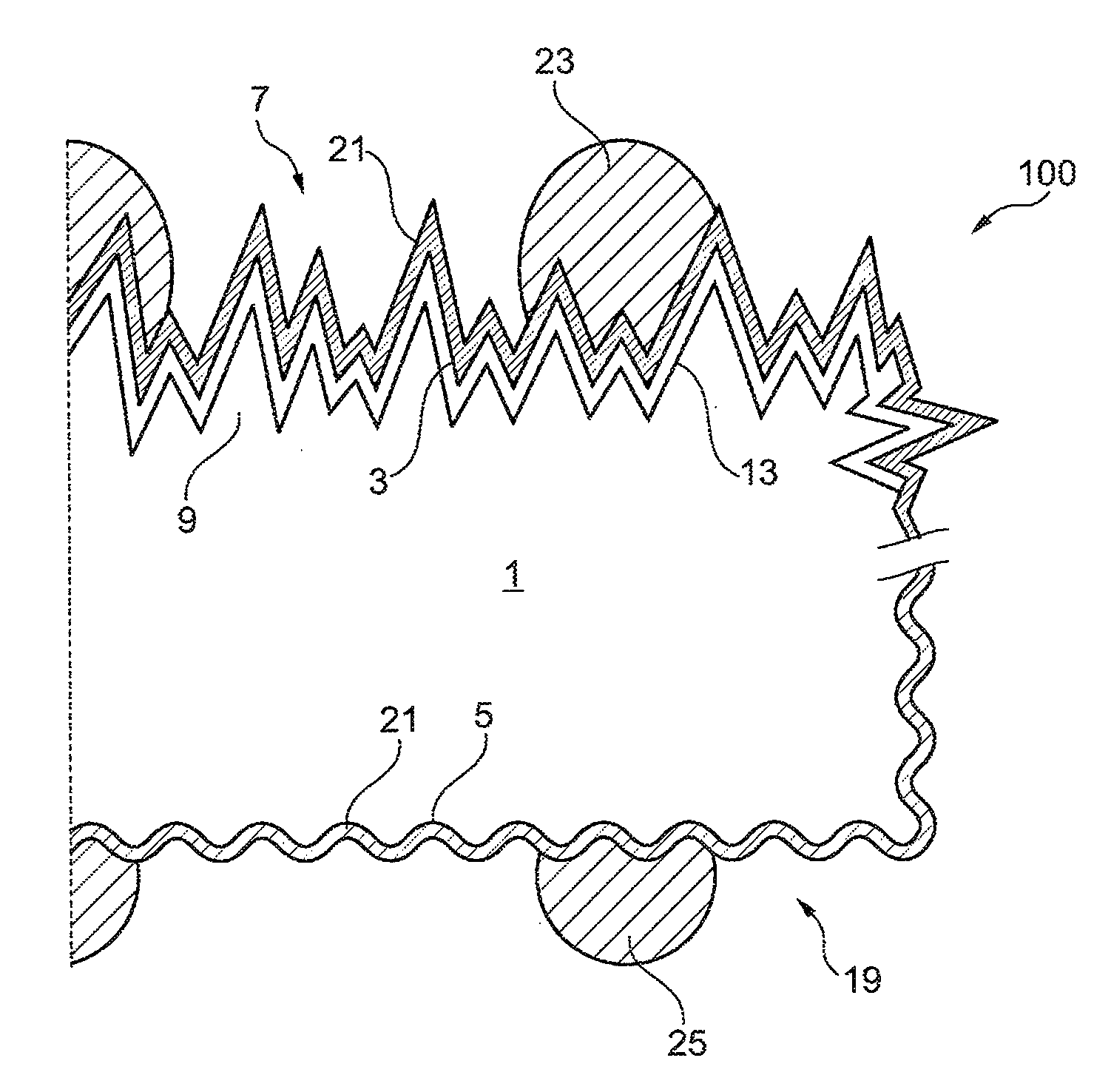

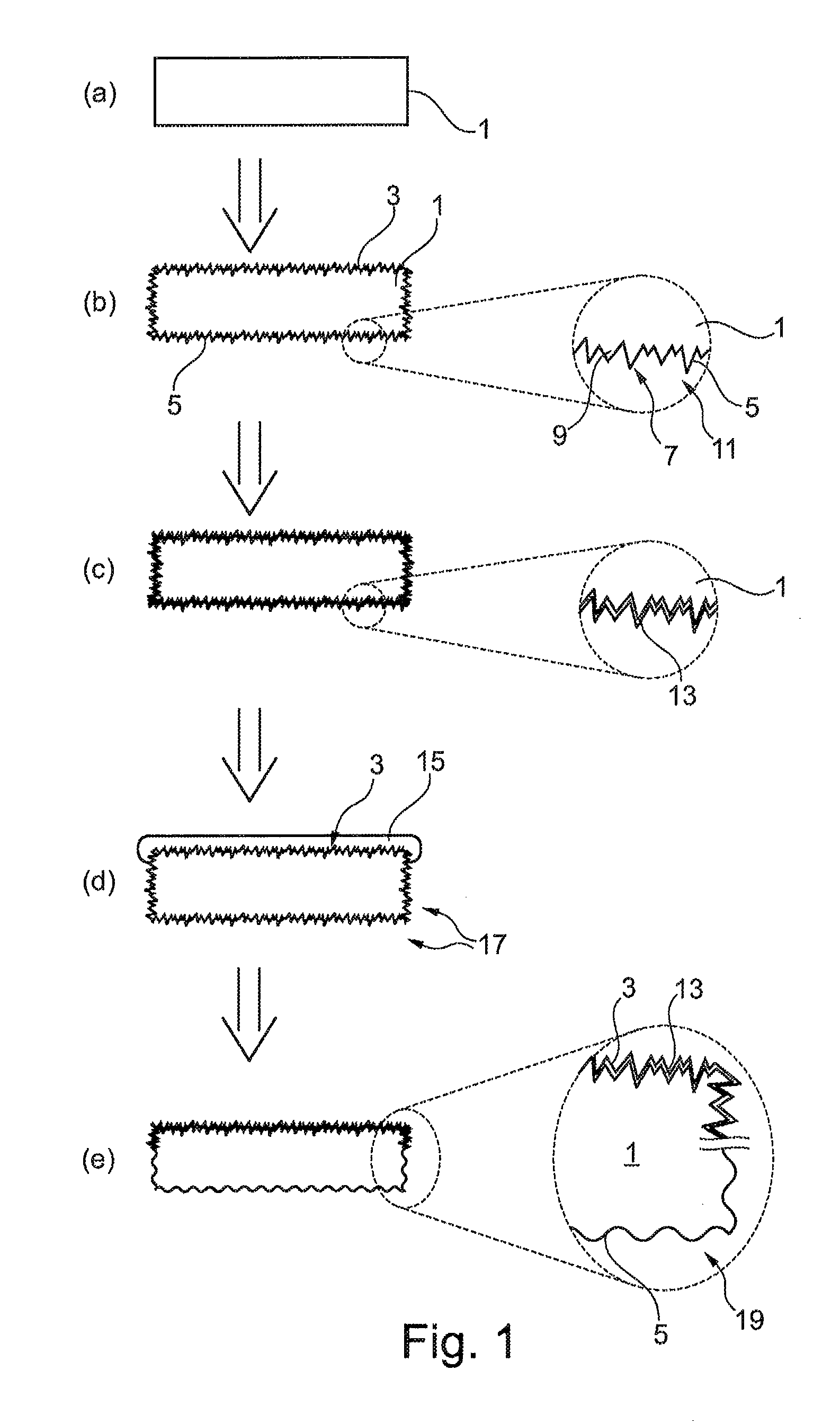

Metal base subjected to surface treatment, metal-resin compound, preparation methods and uses of metal-resin compound and metal base subjected to surface treatment, electronic product housing and preparation method of electronic product housing

InactiveCN105522783ANot easy to fall offImprove structural stabilityAnodisationSynthetic resin layered productsUltimate tensile strengthPolyresin

The invention provides a metal base subjected to surface treatment and a preparation method thereof. The preparation method comprises carrying out anodic oxidation on a metal base to obtain an anodic oxide film on the surface of the metal base and etching the metal base subjected to anodic oxidation orderly through an alkaline etching solution and an acidic etching solution so that etch pits are formed. The invention also provides a metal-resin compound and a preparation method thereof. The metal-resin compound comprises the metal base subjected to surface treatment and a resin layer coating at least one part of the surface of the metal base, wherein a part of resin in the resin layer extends downward and fills the etch pits of the metal base. In the metal-resin compound, bonding strength between the resin and the metal base is high and the resin layer does not easily fall from the metal base surface so that the metal-resin compound has high structural stability, satisfies high structural stability requirements of a use field and can be used as an electronic product housing.

Owner:BYD CO LTD

Etching method, pattern forming process, thin-film transistor fabrication process, and etching solution

InactiveUS7960289B2High selectivityImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesIndiumGallium

An etching method is provided in which selective etching can be carried out for an amorphous oxide semiconductor film including at least one of gallium and zinc, and indium. In the etching method, the selective etching is performed using an alkaline etching solution. The alkaline etching solution contains especially ammonia in a specific concentration range.

Owner:CANON KK

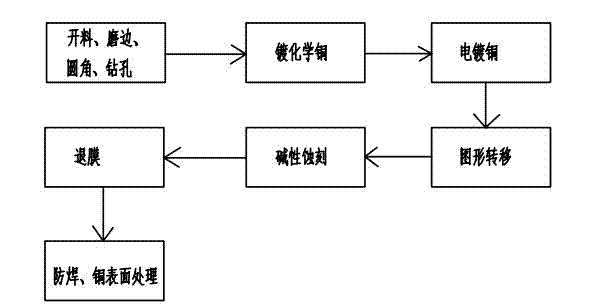

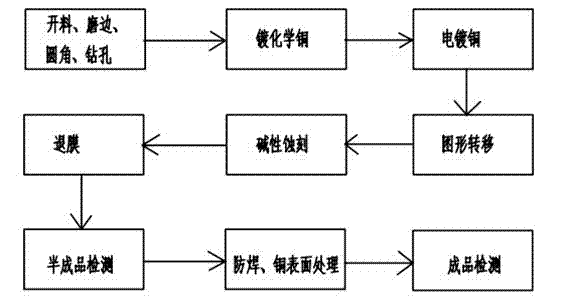

Method for making line in direct negative etching way

ActiveCN103209546AReduce processSave time and costConductive material chemical/electrolytical removalRoundingHigh volume manufacturing

The invention discloses a method for making a line in a direct negative etching way. The method comprises the steps of: cutting, edging, corner rounding and drilling; plating of chemical copper; electroplating of copper; pattern transfer; alkaline etching; film removal; and solder masking and copper surface treatment. Exposure is adopted only once, the technical problem that the conventional negative is required to be exposed and developed twice is solved, production flow time is shortened, and production efficiency is improved; in addition, tin is not required to be plated, so that the treatment of tin waste liquor is eliminated, and cost is saved; and moreover, the method is environment-friendly and applicable to batch production.

Owner:WESKY SUINING ELECTRONICS

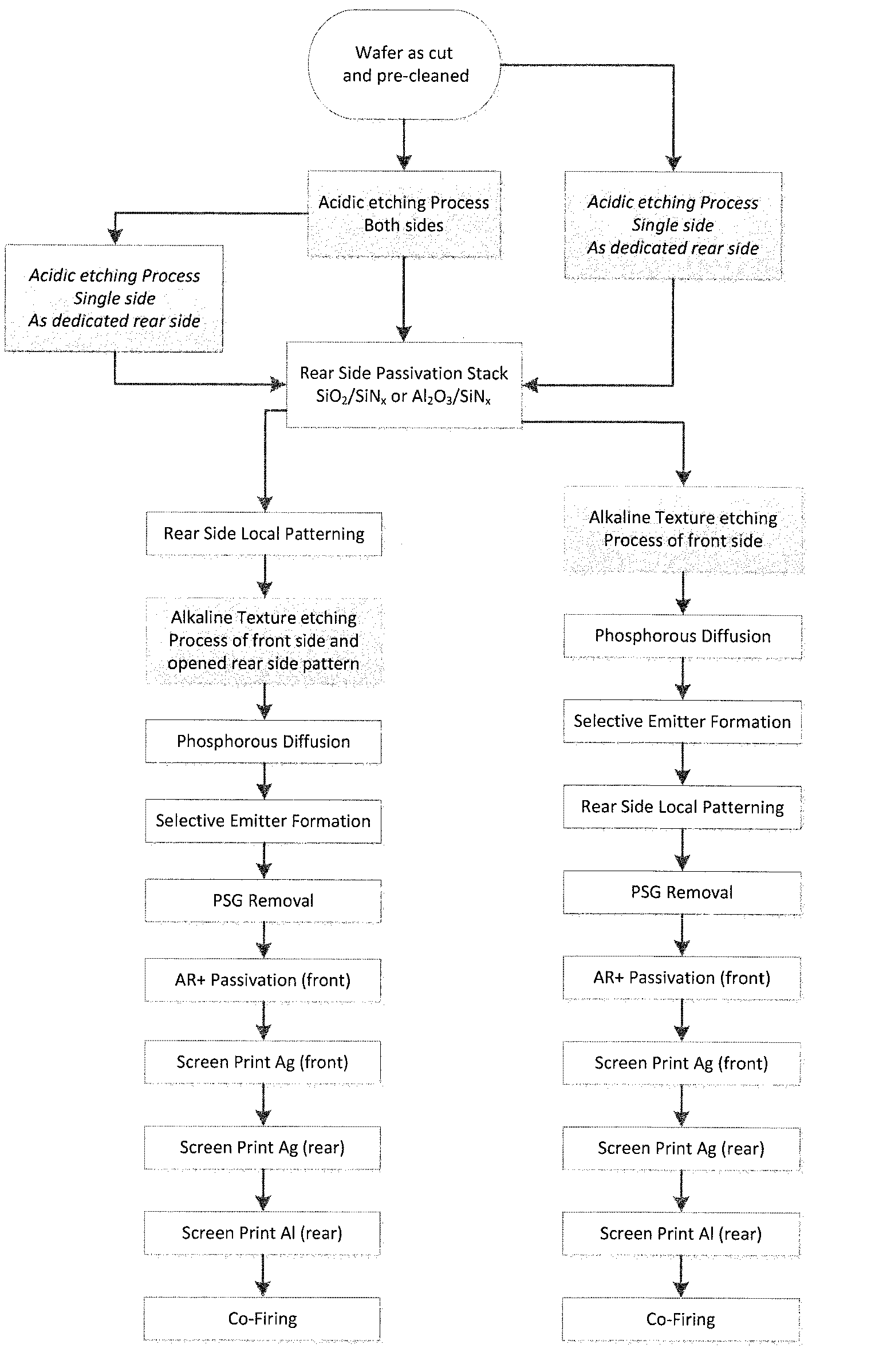

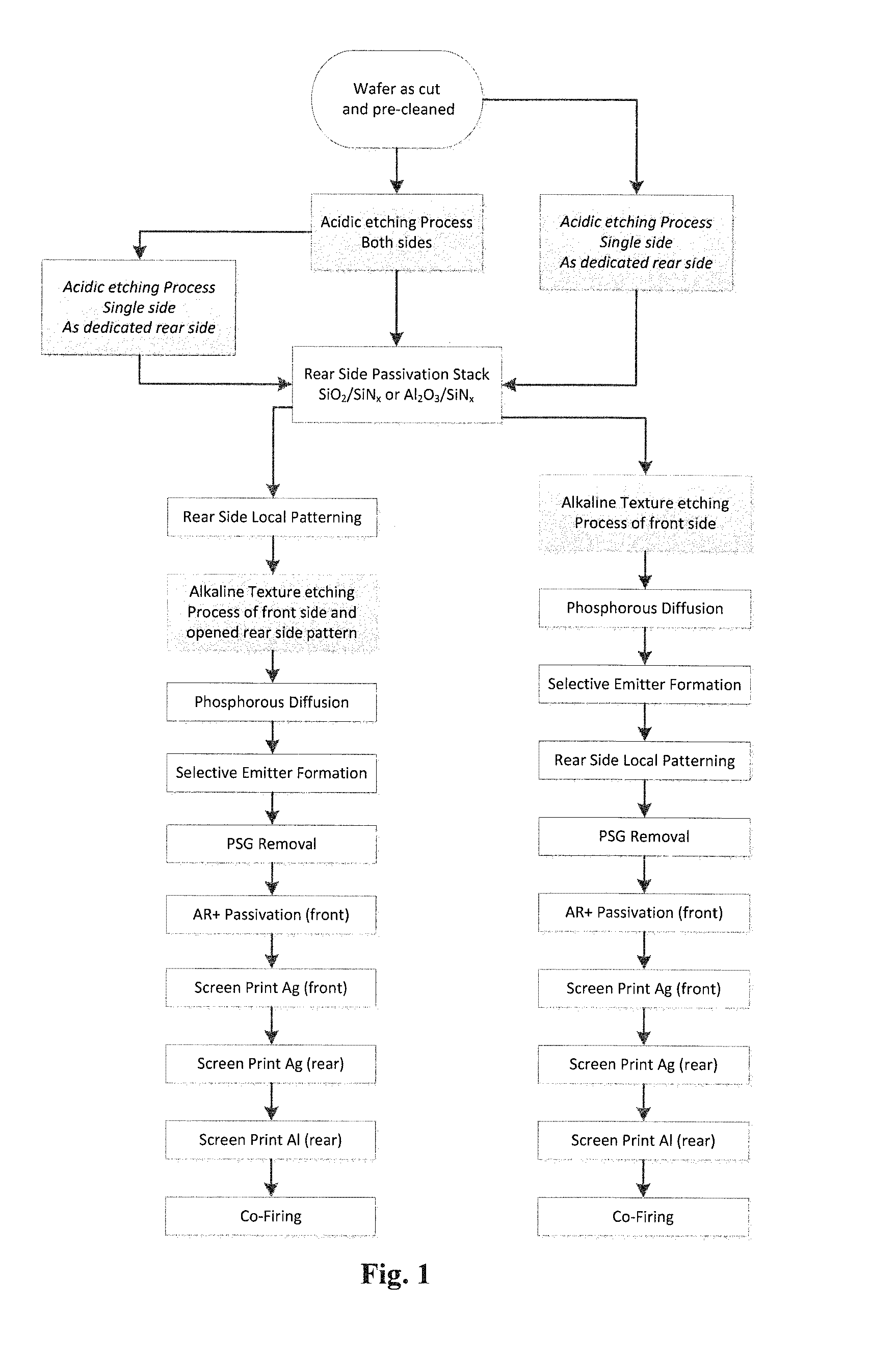

Acidic etching process for si wafers

InactiveUS20150040983A1Improve effectivenessControl roughnessFinal product manufactureSemiconductor/solid-state device detailsAlkaline etchingSilicon

The present invention relates to a method for acidic surface etching of a silicon wafer, such as those used for solar cells, comprising contacting at least one surface of a silicon wafer as cut with an acidic etching agent, provided that the wafer is, prior to the acidic etching, not subjected to an alkaline etching step or process. Further, the present invention is directed to Si wafer, photovoltaic cells, PERC photovoltaic cells and solar modules produced according to the method of the present invention.

Owner:SOLARWORLD AMERICAS

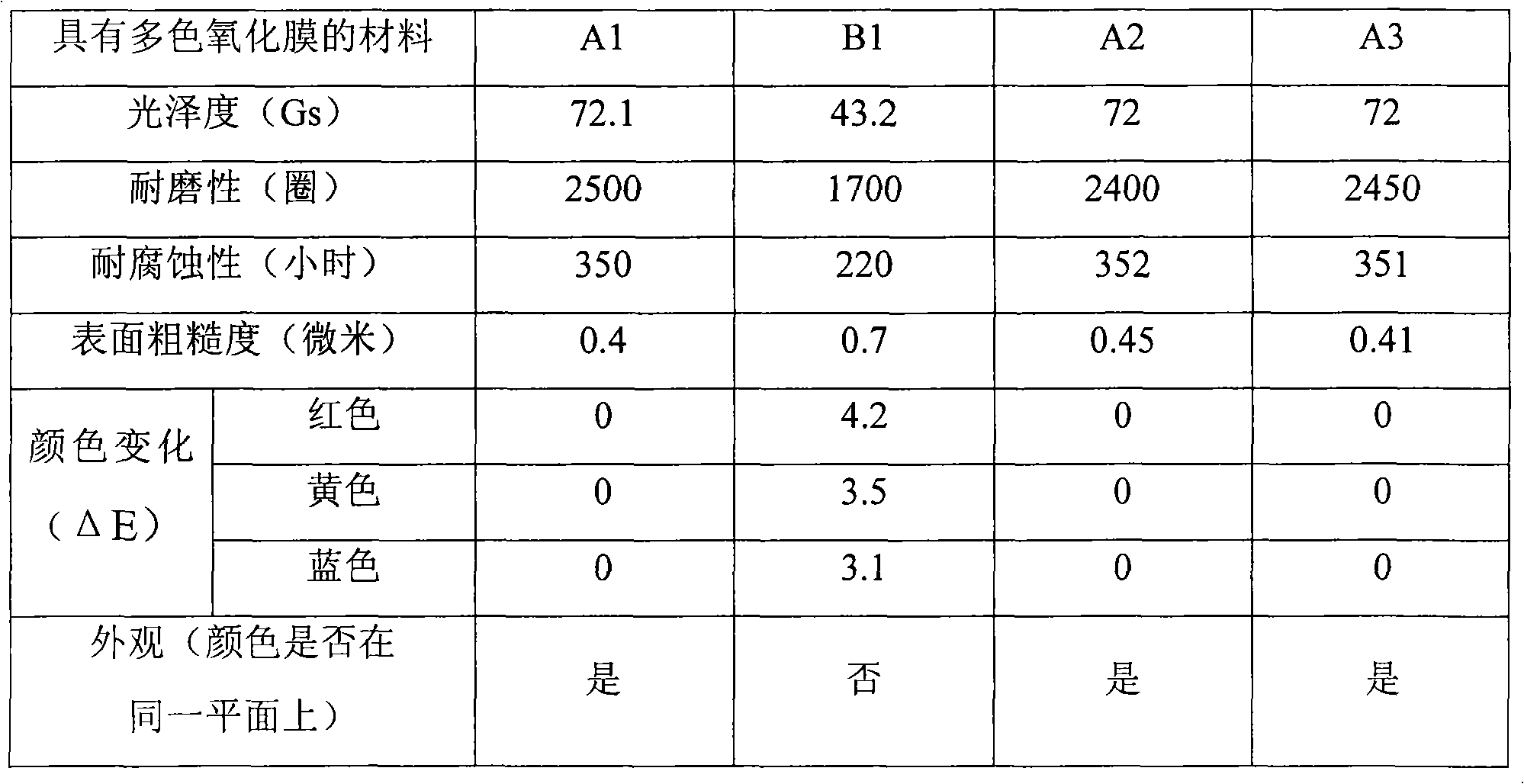

Method and equipment for preparing material with multi-color oxide film on surface

ActiveCN101649478AHigh glossImprove wear resistanceSurface reaction electrolytic coatingColor testColor effect

The invention provides a method for preparing a material with a multi-color oxide film on the surface. The method sequentially comprises the steps of washing, drying and coloring for a base material provided with an anodic oxide film on the surface, wherein the method for coloring adopts printing by a printer. The invention also provides equipment for preparing the material with the multi-color oxide film on the surface. Compared with the prior method needing to etch after a plurality of times of anodic oxidation to obtain the multi-color effect, the method can simply obtain the needed multi-color effect by directly coloring by printing with the printer on a one-time anodic oxide film; moreover, the material with the multi-color oxide film on the surface prepared by the method has better effects on gloss, abrasion resistance, corrosion resistance, surface roughness, color test and appearance than that of the material with the multi-color oxide film on the surface prepared by the priormethod; and in addition, the method of the invention avoids to perform alkaline etching, ink shielding and ink baking, and is friendly to the environment.

Owner:BYD CO LTD

Method for producing a solar cell having a textured front face and corresponding solar cell

InactiveUS20130153025A1Reduce reflectionMinimize reflectionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationElectrical batterySolar battery

The invention relates to a method for producing a solar cell and to a solar cell which can be produced accordingly. On a solar cell substrate, first a ridged texture, which may for example comprise pyramids produced by alkaline etching, is formed both on a front face and on a rear face of the solar cell substrate. Then an etching barrier layer is applied to the front face of the solar cell substrate. Next the texture on the rear face of, the solar cell substrate is smoothed by etching in an isotropically acting etching solution which for example contains acid, wherein the front face is protected by the etching barrier layer. Thus, ridged structures on the rear face can be avoided and in this way reflection can be increased and surface passivation can be improved, both of which can lead to an increased potential efficiency. At the same time an emitter layer formed over the entire surface of the solar cell substrate on the rear face can be removed during etching, so that electrical isolation of the front face contacts and the rear face contacts may be superfluous.

Owner:UNIV KONSTANZ

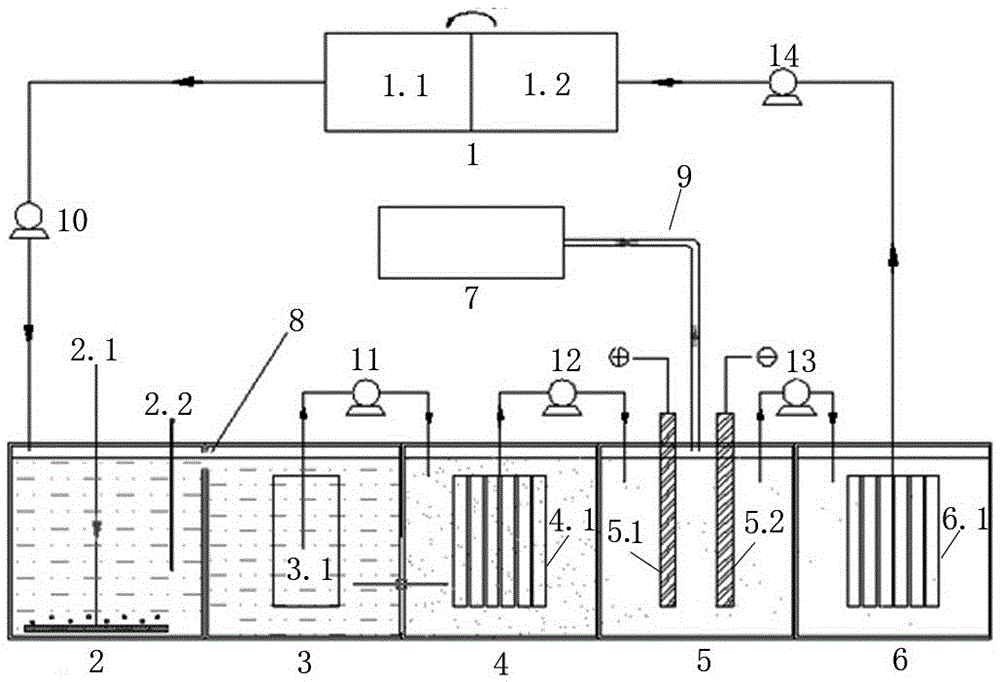

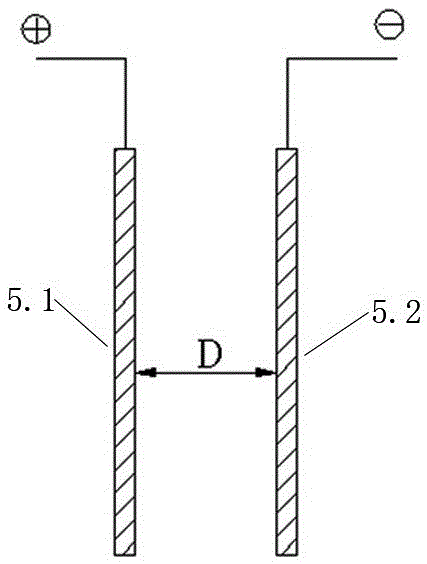

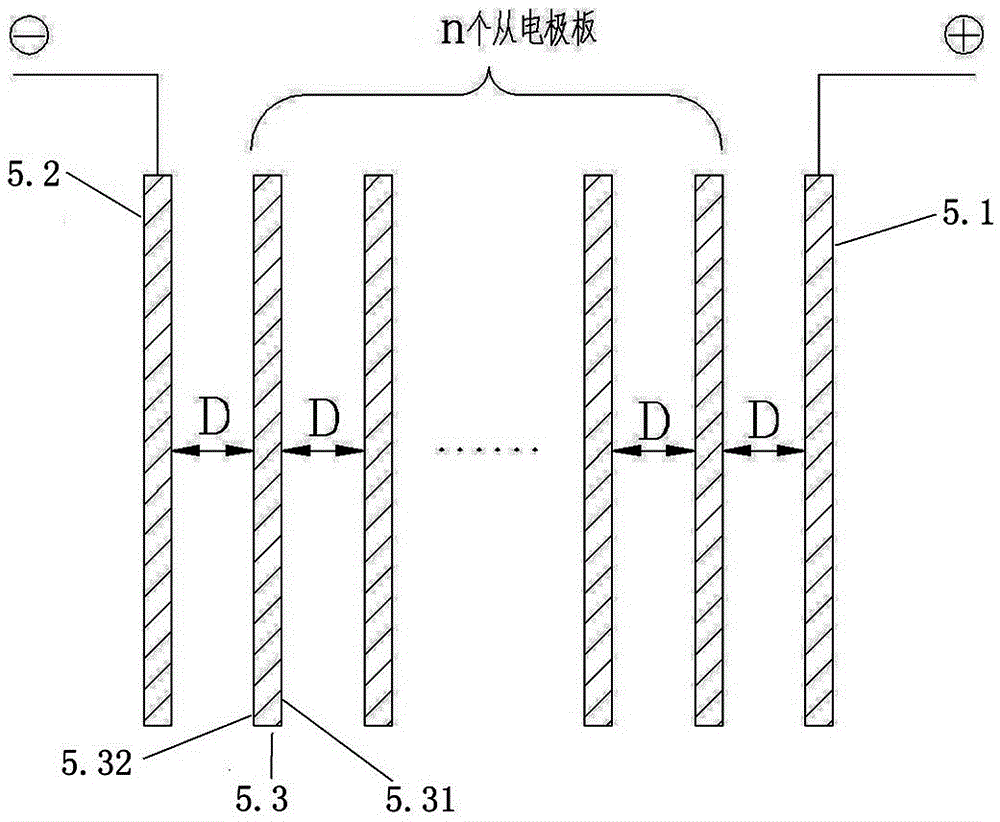

PCB ammonia-nitrogen wastewater zero discharge treatment method and device thereof

ActiveCN105523668AEfficient removalMeet industrial reuse water requirementsDispersed particle separationTreatment involving filtrationElectrolysisUltrafiltration

The invention discloses a PCB ammonia-nitrogen wastewater zero discharge treatment method and a device thereof. The invention is characterized in that the method comprises the following steps: adjusting pH value of etching washing wastewater to 8-11, carrying out rough filtration and ultrafiltration successively, electrolyzing a filtrate I by the use of electrodes with plate electrode distance D being less than or equal to 3 CM and an electrolysis system with electric current density being 1-3 ADS, and adsorbing the generated gas by the use of an alkaline etching liquid; treating the electrolyzed filtrate through a ultrafiltration system so as to obtain a filtrate II, and reusing the filtrate II. Local concentration of the electrolysis product between the plate electrodes is changed by adjusting the distance of the plate electrodes, and chlorine gas generated from the positive electrode escapes in a gaseous state due to too high local concentration so as to synchronously remove ammonia nitrogen and Cl<->. Thus, an effluent obtained after the treatment accords with technical requirements of the etching washing water and satisfies industrial reuse water so as to realize zero discharge.

Owner:珠海市华泰环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com