P-Ca-V composite phosphating solution on magnesium alloy surface and chemical conversion processing method

A chemical conversion treatment and chemical conversion technology, applied in the field of metal surface treatment technology, can solve the problems of difficult to maintain corrosion resistance, loose and porous film layer, containing crystal water, etc., to achieve excellent corrosion resistance, maintain electrical conductivity, and enhance resistance. corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Prepare the magnesium alloy surface P-Ca-V composite phosphating solution according to the following formula.

[0052] 85% phosphoric acid: 8ml / L

[0053] Sodium dihydrogen phosphate: 20g / L

[0054] Calcium nitrate: 15g / L

[0055] Sodium benzenesulfonate: 1g / L

[0056] Ammonium metavanadate: 1g / L

[0057] The balance is water

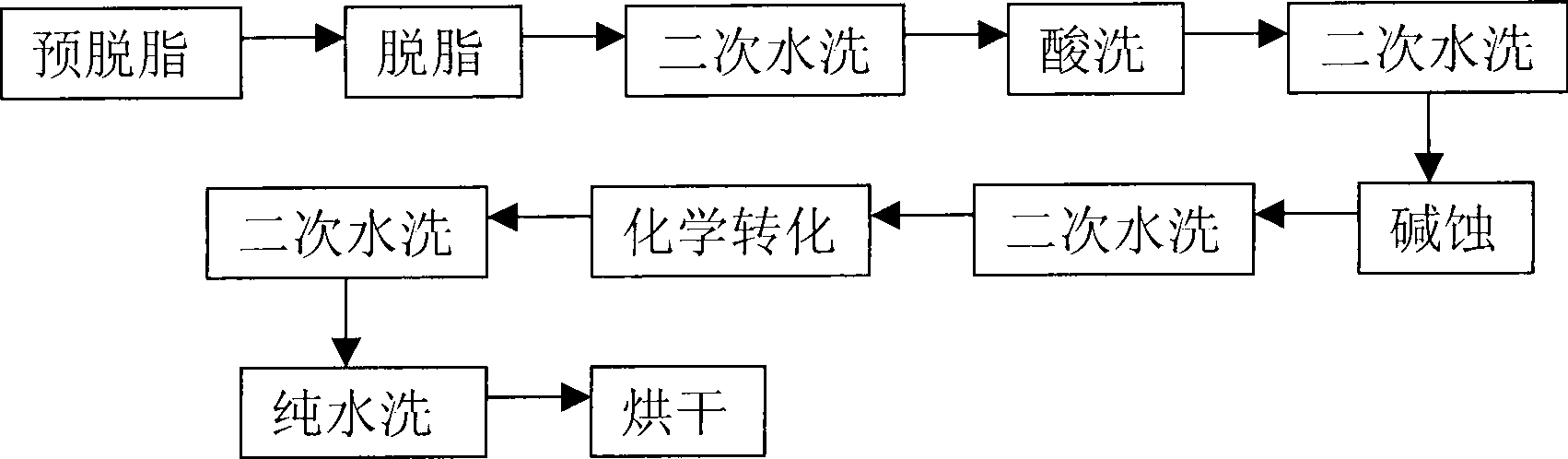

[0058] For AZ91D magnesium alloy samples press figure 1 The process flow and the degreasing, pickling, alkali etching, chemical conversion process and medium that the present invention proposes carry out chemical conversion treatment, wherein degreasing is 60 ℃, 10 minutes; pickling is 50 ℃, 1 minute; alkali etching is 80 ℃ , 5 minutes; chemical conversion to 45°C, 40 seconds. After the sample is washed with water, washed with pure water and dried, a dense and uniform off-white composite phosphate film is formed on the surface.

[0059] Its performance measurement shows (table 1):

[0060] Corrosion resistance: 24 hours salt spray, corros...

Embodiment 2

[0067] Prepare magnesium alloy surface P-Ca-V composite phosphating solution according to the following formula:

[0068] 85% phosphoric acid: 4ml / L

[0069] Sodium dihydrogen phosphate: 25g / L

[0070] Calcium nitrate: 20g / L

[0071] Sodium benzenesulfonate: 1g / L

[0072] Ammonium metavanadate: 1g / L

[0073] The balance is water

[0074] For AZ91D magnesium alloy samples press figure 1 The process flow and the degreasing, pickling, alkali etching, chemical conversion process and medium that the present invention proposes carry out chemical conversion treatment, wherein degreasing is 60 ℃, 10 minutes; pickling is 50 ℃, 30 seconds; alkali etching is 85 ℃ , 7 minutes; chemical transformation at 45°C, 1 minute. After the sample is washed with water, washed with pure water and dried, a dense and uniform off-white composite phosphate film is formed on the surface.

[0075] Its performance has been measured and shown (Table 1): Corrosion resistance: salt spray test, after 48 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com