Patents

Literature

303 results about "Sodium benzenesulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment of barley roots with sodium benzenesulfonate caused loss of potassium (k+), nitrate (no3-) & uv-absorbing material into the surrounding solution. extent of loss depended on lipophilic nature of org acid used & on concn of its undissociated form.

P-Ca-V composite phosphating solution on magnesium alloy surface and chemical conversion processing method

ActiveCN101418441AImprove corrosion resistanceLow resistivityMetallic material coating processesSalt spray testAcid washing

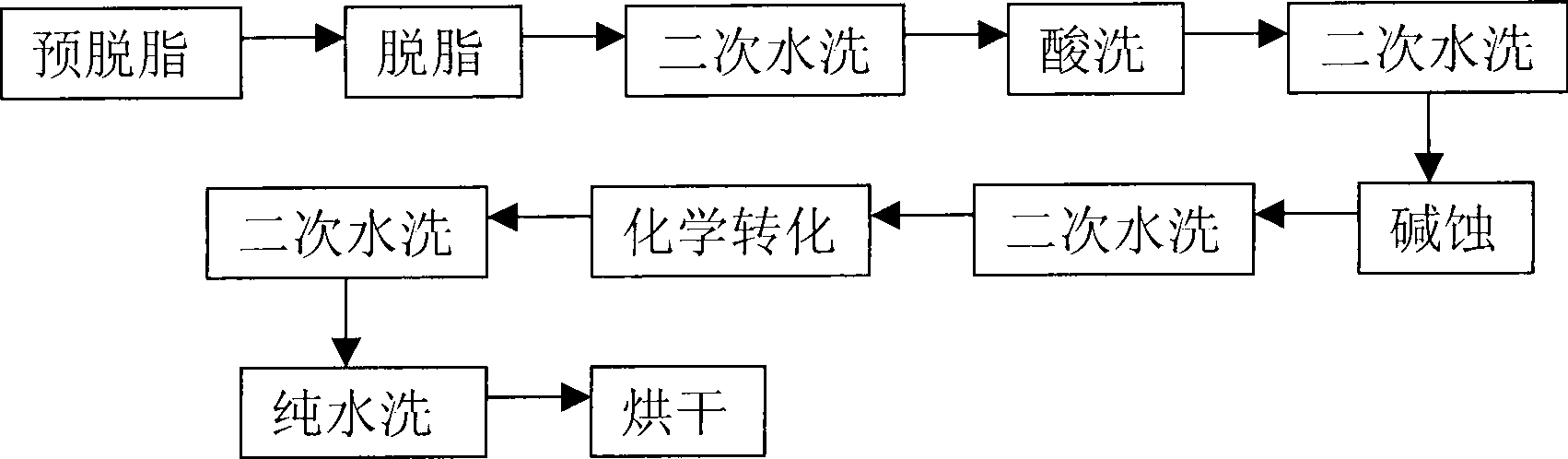

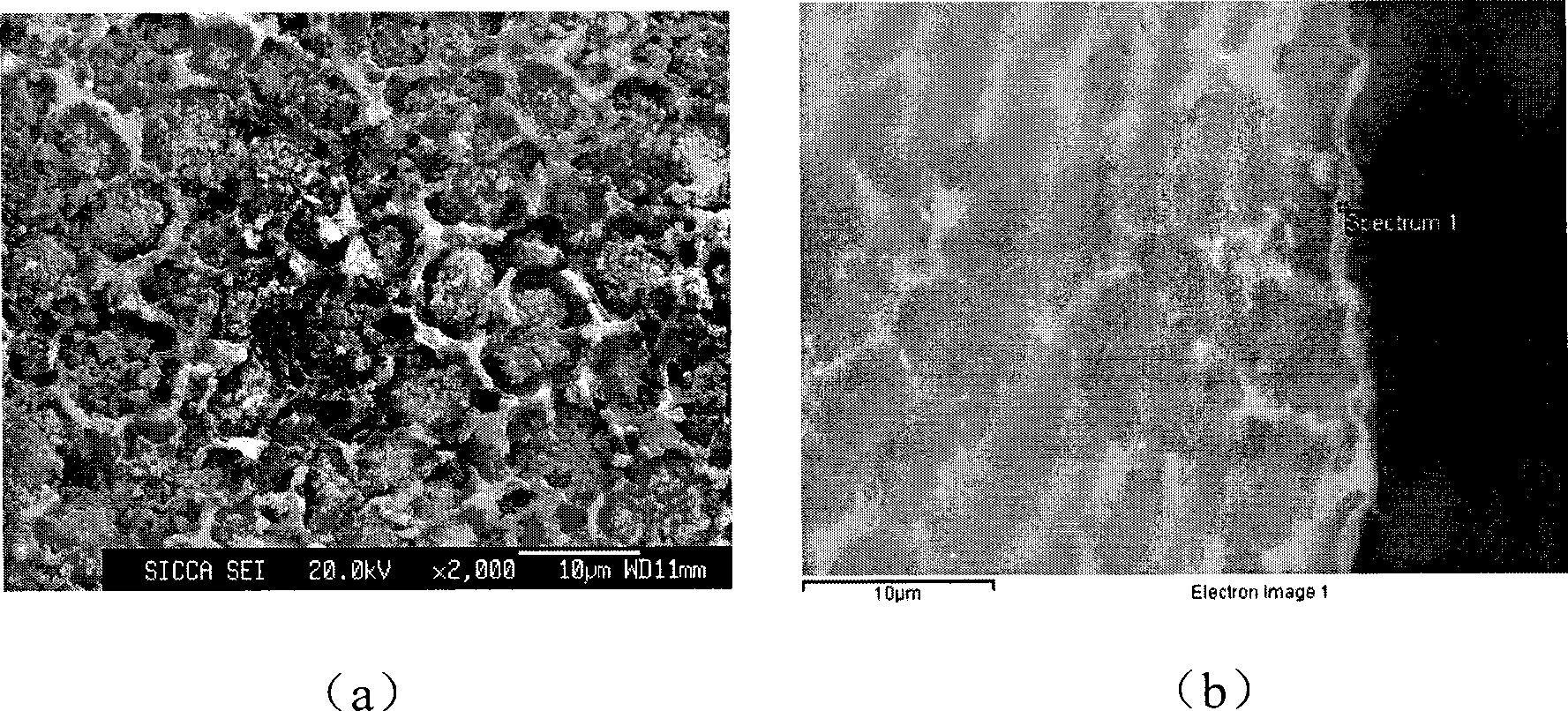

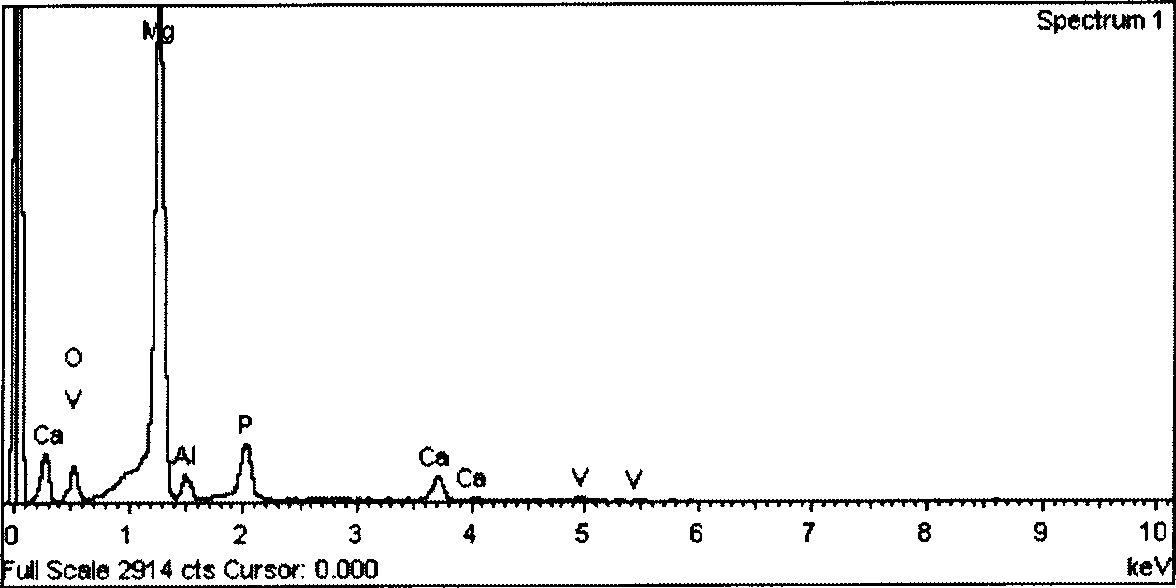

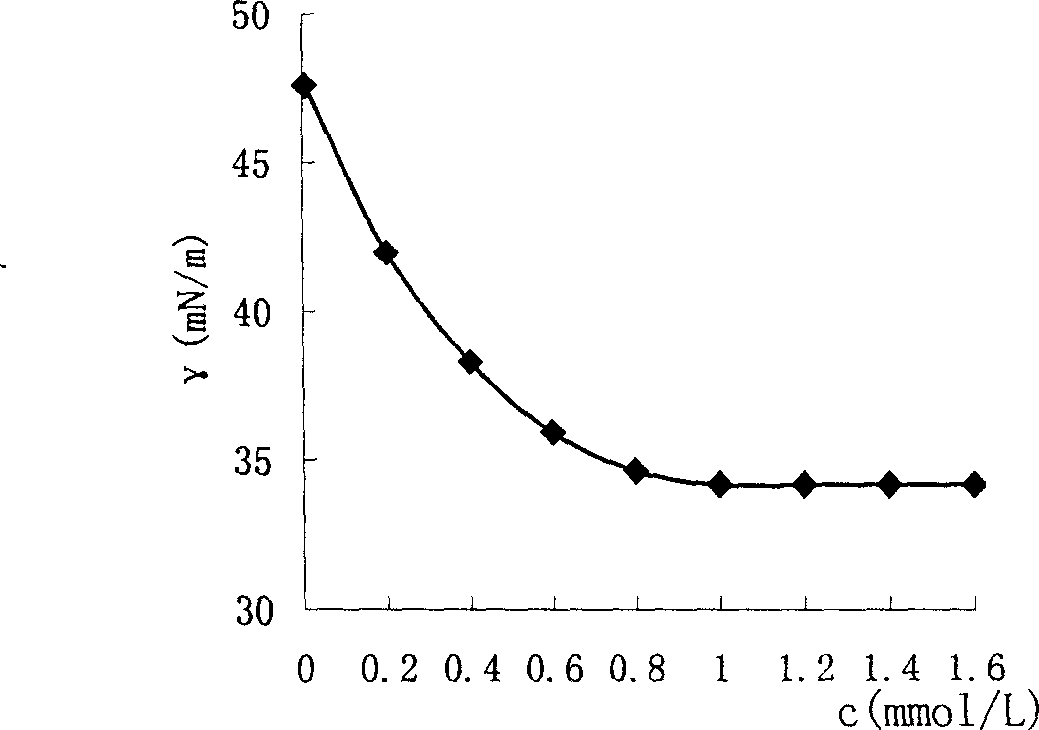

The invention relates to a composite phosphating solution of P-Ca-V on the surface of a magnesium alloy and a method for chemical conversion treatment. The solution is characterized in that each liter of the composite phosphating solution comprises the following compositions: 4 to 20 milliliters of 85 percent phosphoric acid of, 5 to 30 grams of sodium dihydrogen phosphate, 10 to 40 grams of calcium nitrate, 0.5 to 10 grams of benzene sulfonic acid sodium salt, 0.5 to 5 grams of ammonium metavanadate, and the balance being water. The method comprises the following steps: pre-degreasing, degreasing, secondary water washing, acid washing, secondary water washing, alkaline etching, secondary water washing, chemical transformation, secondary water washing, pure water washing, and drying. Taking an AZ91D magnesium alloy as an example, 48 hours after a corrosion resistance salt spray test after the treatment by the method of the invention, the corrosion area of the AZ91D magnesium alloy is less than 1 percent; the paint film adhesive force is at 0 level by a grid method and is obviously superior to the performance of a chromate conversion coating; and the formed chemical conversion coating does not contain crystal water. The composite phosphating solution has the synergistic reaction of Ca and V, as well as the functions of a corrosion inhibitor and a wetting agent of the benzene sulfonic acid sodium salt.

Owner:嘉兴中科亚美合金技术有限责任公司

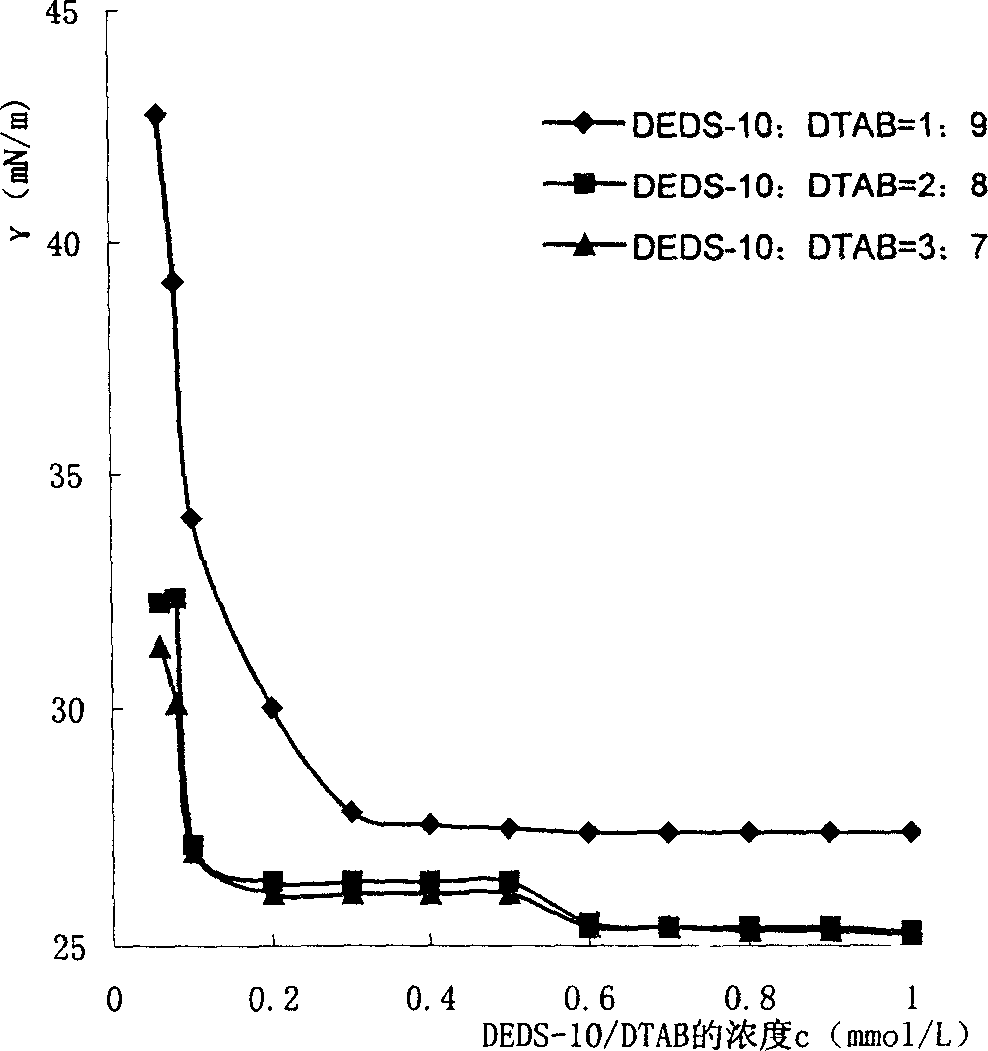

Surface activator with double-ether bisbensulfosalt and double molecule

InactiveCN1817430AMild reaction conditionsSimple and fast operationTransportation and packagingMixingChlorosulfuric acidHigh surface

A dual-component surfactant of biether biphenylsulfonate is 2.2-bis (4-alkoxy-3- sodium phenylsulfonate) propane. Its preparing process includes such steps as adding biphenol A and the aqueous solution of NaOH into reactor, reaction at 50-78 deg.C, sequentially adding absolute alcohol and long-chain alkyl bromine into reactor, reacting at 50-78 deg.C for 12-36 hr, evaporating alcohol, washing the resultant, recrystallizing, drying to obtain biether compound, adding it into reactor, using dichloromethane as solvent, dripping chlorosulfonic acid, reaction at 15-35 deg.C for 1-3 hr, neutralizing resultant, salting out, filtering and drying. Its advantages are high surface activity, and high foam stability.

Owner:SOUTHWEST PETROLEUM UNIV

Prepn process of ferric alkyl aryl sulfonate

The preparation process of ferric alkyl aryl sulfonate includes the following steps: reflux reaction between anhydrous ferric trichloride or ferric trichloride hexahydrate and alkyl aryl sulfonic acid in alcohol solution, eliminating solvent and hydrogen chloride gas at high temperature and low pressure to produce coarse product; washing with ethyl ether to eliminate excessive p-toluene sulfonic acid, and re-crystallizing in mixed solvent of methanol and acetonitrile to obtain purified ferric alkyl aryl sulfonate. The present invention provides also one other process for preparing ferric long chain (benzene) sulfonate. The present invention has low material cost and high product purity, and the product is used in electronic industry.

Owner:湖北赛尔新能源材料有限公司

A kind of chemical nickel plating solution and chemical nickel plating process

InactiveCN102268658AReduce stressImprove toughnessLiquid/solution decomposition chemical coatingElectroless nickelNickel salt

The invention relates to an electroless nickel plating solution and an electroless nickel plating process for a flexible printed circuit board. The electroless nickel plating solution of the present invention comprises the following components: nickel salt, calculated as Ni2+ content, is 4.5-5.5g / L; reducing agent, 15-40g / L; complexing agent, 20-100g / L Stabilizer, 0.01~10mg / L; Accelerator, 0.001~1g / L; Low stress additive, 0.01~10g / L; The low stress additive is sodium naphthalene disulfonate, sodium benzenesulfonate, saccharin, gelatin, One or more of butynediol, acetic acid, coumarin, formaldehyde, and acetaldehyde. In the chemical nickel plating process of the present invention, the temperature of the chemical nickel plating liquid is 75-90 DEG C, the pH value of the chemical nickel plating liquid is 4.5-5.4, and the chemical nickel plating time is 15-30 minutes. The electroless nickel plating solution and the electroless nickel plating process of the present invention can effectively reduce the stress of the nickel layer, improve the toughness of the nickel layer, make the nickel layer have good bending performance, and meet the production and assembly requirements of flexible printed circuit boards , to further improve the yield rate.

Owner:SHENZHEN JINGCHENGDA CIRCUIT TECH

Preparation method and application of liquid selenium-rich fertilizer

InactiveCN106045667AReduce usageEliminate the risk of poisoningBioloigcal waste fertilisersFertilising methodsOrganic fertilizerInorganic selenium

The invention provides a preparation method and application of a liquid selenium-rich fertilizer. The preparation method of the liquid selenium-rich fertilizer comprises the following steps: dissolving sodium selenite in water to form original mother solution, concentration of the sodium selenite being 30-50 g / l; mixing the original mother solution with amino acid solution with a mass concentration of 15%-20%, a volume ratio of the original mother solution to the amino acid solution being 1:(2-3), and shaking and chelating at 35-45 DEG C for 48-72 h to obtain chelate; adding 1-3 g of sodium alkyl benzene sulfonate per liter of the chelate, stirring and secondarily chelating with alcoholic fermentation filtrate at 25-35 DEG C for 36-48 h, the volume ratio of the alcoholic fermentation filtrate to the chelate being 1:(0.8-1.2) to obtain the liquid selenium-rich fertilizer. In the technical scheme of the invention, 90% or more of inorganic selenium is converted into organic selenium such as selenomethionine and selenocystine, toxin and harm risks are eliminated, and materials are saved.

Owner:AGRI RESOURCE & ENVIRONMENT RES INST GUANGXI ACADEMY OF AGRI SCI

Liquid detergent

InactiveCN101100629AShort removal timeConserve waterInorganic/elemental detergent compounding agentsCationic surface-active compoundsFruit juiceFatty acid

A liquid detergent consists of aliphatic alcohol polyethenoxy ether sodium sulfate 5-15 proportion, lauryl sodium benzenesulfonate 2-10 proportion, fatty acid diethanolamine 1-8 proportion, hydrogen peroxide 2-6 proportion, ammonia water 0.5-5 proportion and water 40-92 proportion. It spends 30 s-6 mins in eliminating various mechanical and edible stains, blood stain, ball-pen ink, beverage stain and tea stain. It shortens washing time to 4-8 mins and costs 0.5-0.8 yuan / kg and is economical.

Owner:周正新

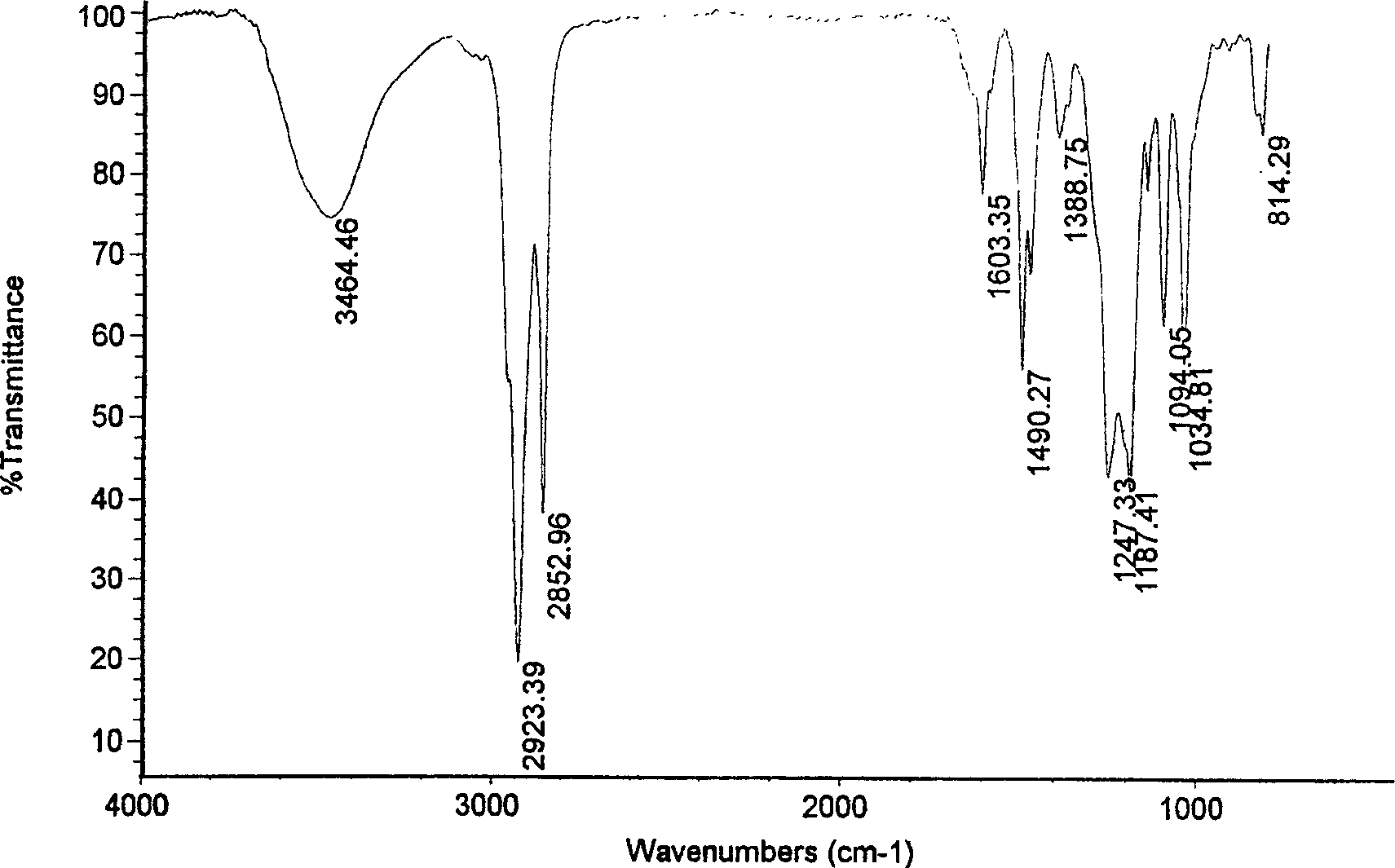

Preparation method for sulfur-doped three-dimensional structured positive electrode material of lithium-sulfur battery

InactiveCN105609773AImprove conductivityImprove cycle lifeCell electrodesLi-accumulatorsDoped grapheneSodium salt

The invention provides a preparation method for a sulfur-doped three-dimensional structured positive electrode material of a lithium-sulfur battery. The preparation method comprises the following steps of (1), adding graphite oxide into water for performing ultrasonic processing to form a graphene oxide suspension liquid; (2), adding benzene sulfonic acid sodium salt to the graphene oxide suspension liquid to obtain three-dimensional sulfur-doped graphene; (3), adding the three-dimensional sulfur-doped graphene obtained in the step (2) and ketjen black into N-methyl pyrrolidone for performing an ultrasonic reaction to form a suspension liquid; (4), adding elemental sulfur to the N-methyl pyrrolidone for performing an ultrasonic reaction until the elemental sulfur is fully dissolved to form a suspension liquid; and (5), mixing the two kinds of suspension liquid obtained in the step (4) and the step (3), uniformly stirring, and slowly adding distilled water while stirring to obtain the three-dimensional structured positive electrode material of the lithium-sulfur battery. Due to sulfur adsorption by sulfur atoms in the sulfur-doped graphene, the shuttle effect can be effectively lowered, so that the cycling life of the lithium-sulfur battery is prolonged.

Owner:钟玲珑

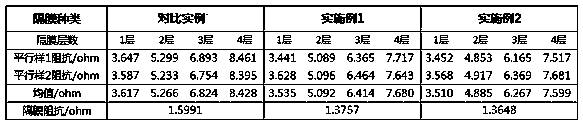

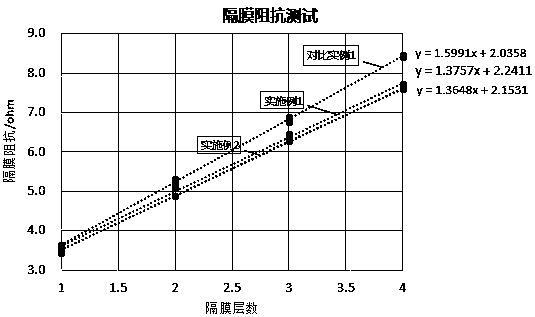

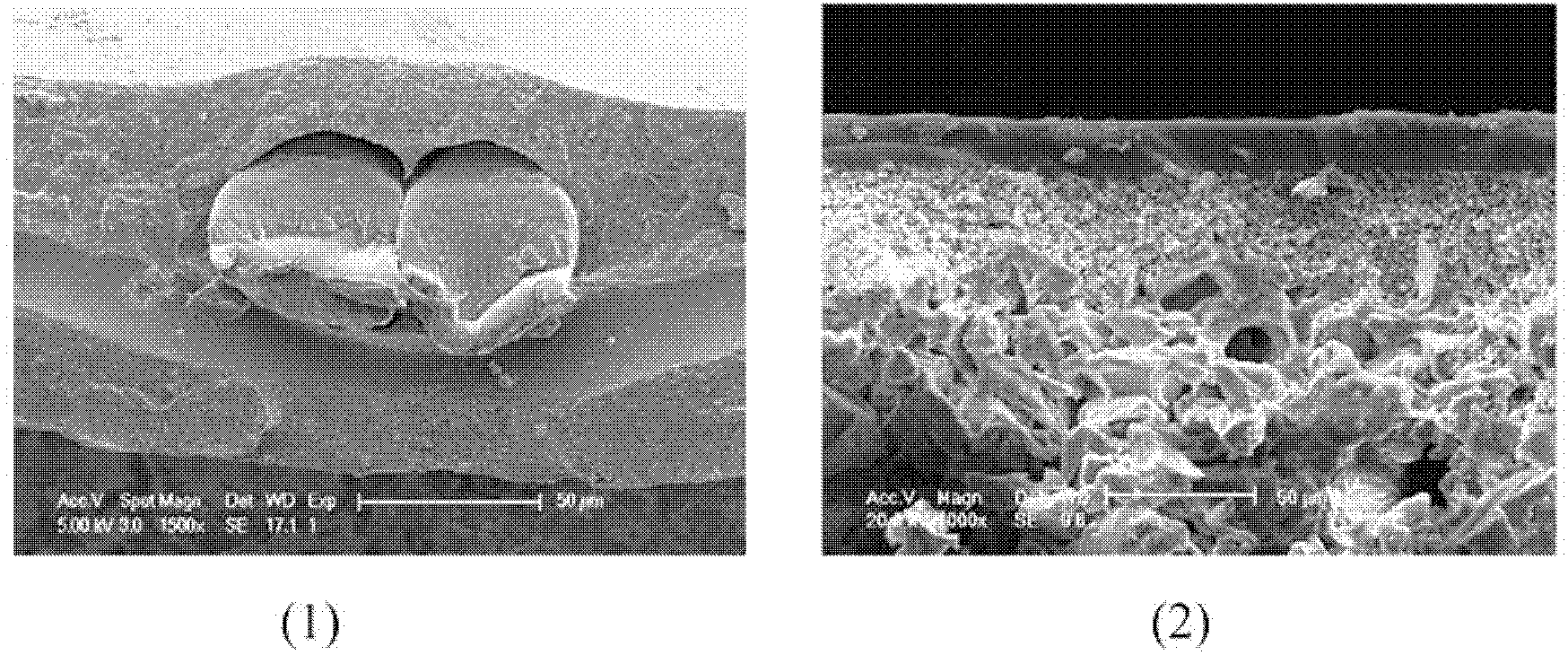

Ceramic diaphragm and preparation method thereof

InactiveCN109713204AIncrease coverageIncrease flexibilitySecondary cellsCell component detailsMethacrylatePolyolefin

The present invention provides a ceramic diaphragm comprising a diaphragm substrate having a surface coated with a polymer-coated functional ceramic powder. The polymer coating the surface of the ceramic powder is polystyrene sulfonic lithium (PSSLi) and a polyethylene glycol methacrylate hydrocarbon microporous diaphragm. The diaphragm substrate is a polyolefin microporous diaphragm. The polyethylene glycol methacrylate (PEGMA) has an average molecular weight of 400 to 5000 g / mol. The method provided by the invention comprises firstly activating the ceramic powder by using a silane coupling agent; then introducing a halogen functional group to graft the ceramic powder with a halogen initiator; adding sodium benzenesulfonate monomer (SSNa) and polyethylene glycol methacrylate (PEGMA) for apolymerization reaction; then adding the mixture to a lithium ion aqueous solution for ion exchange to obtain the polymer-coated functional ceramic powder; and finally stirring the polymer-coated functional ceramic powder to form a ceramic slurry and form the polymer-coated ceramic diaphragm by coating. The method provided by the present invention greatly improves the dispersibility and the functionality of lithium ions.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

Preparation method and application of special rice selenium-enriched leaf fertilizer

InactiveCN106007994AReduce usageEliminate the risk of poisoningBioloigcal waste fertilisersFertilising methodsSilicic acidAqueous solution

The invention provides a preparation method and an application of a special rice selenium-enriched leaf fertilizer. The preparation method of the special rice selenium-enriched leaf fertilizer comprises the following steps: dissolving sodium selenite into water to prepare a primary mother solution, wherein the concentration of sodium selenite is 25 to 50g / l; mixing the primary mother solution with an amino acid solution, wherein the mass concentration of the amino acid solution is 15% to 20%; then vibrating and chelating at the temperature of 35 to 45 DEG C for 48 to 60 hours to obtain a chelation solution; evenly mixing the chelation solution and an aqueous solution of a mono-silicic acid to prepare a mixed solution; adding 1 to 3g of sodium alkyl benzene sulfonate into each liter of the mixed solution, then stirring with an alcoholic fermentation filtrate at the temperature of 25 to 35 DEG C, and performing secondary chelation for 36 to 48 hours, so as to obtain the special rice selenium-enriched leaf fertilizer. With the adoption of the technical scheme of the preparation method, 90% or more of inorganic-form selenium is converted into organic-form selenium in selenomethionine, selenocystine and the like, the risk of poison is eliminated, the absorption and conversion rate of the selenium is increased, the use amount of the sodium selenite is reduced, and the cost is lowered.

Owner:AGRI RESOURCE & ENVIRONMENT RES INST GUANGXI ACADEMY OF AGRI SCI

Aerated brick added with compound attapulgite particles

The invention discloses an aerated brick added with compound attapulgite particles. The aerated brick added with compound attapulgite particles is prepared by the following raw materials by weight: 30-40 parts of the compound attapulgite particles, 20-30 parts of fly ash, 4-6 parts of cement, 2-4 parts of shell powder, 0.1-0.3 part of sodium sulfate, 1-2 parts of hydroxypropyl methyl cellulose, 0.4-0.6 part of sodium sulfite, 0.7-0.9 part of diethylene glycol, 0.01-0.03 part of melamine, 2-4 parts of sodium chloride, 3-5 parts of calcium oxide, 0.3-0.4 part of dimethyl sodium benzenesulfonate and 0.08-0.14 part of zinc powder.

Owner:安徽中龙建材科技有限公司

Method for manufacturing golden finger of soldering-pan of flexible package carrying board

InactiveCN101853789AReduce stressImprove toughnessSemiconductor/solid-state device manufacturingPrinted element electric connection formationElectrical conductorEngineering

The invention relates to a method for manufacturing a flexible carrying board of which the chip is directly packaged on a flexible printed circuit carrying board (COF), in particular to a method for manufacturing a golden finger of a soldering-pan of a flexible carrying board. The COF packaged flexible carrying board is made of a glueless flexible substrate; a basement membrane of the substrate is made of a polyimide material and has the thickness between 12 and 25 micrometers; and a conductor layer is made of copper, and has the thickness between 9 and 36 micrometers. The method for manufacturing the golden finger of the soldering-pan of the flexible carrying board comprises low-stress electroless nickel plating & gold immersion technology; a raw material is nickel sulfate and a reducing agent is sodium hypophosphite; and in order to reduce the stress of a nickel layer, an additive for reducing the stress is added. The low-stress additive is one or more of benzene sulfonic acid sodium salt, coumarin, formaldehyde, aldehyde and naphthalene disulfonic acid, and the concentration is 0.01 to 0.2 mol / liter. The operating temperature of the low-stress electroless nickel plating is between 80 and 85 DEG C and the pH value is between 4.8 and 5.2.

Owner:SHENZHEN DANBOND TECH

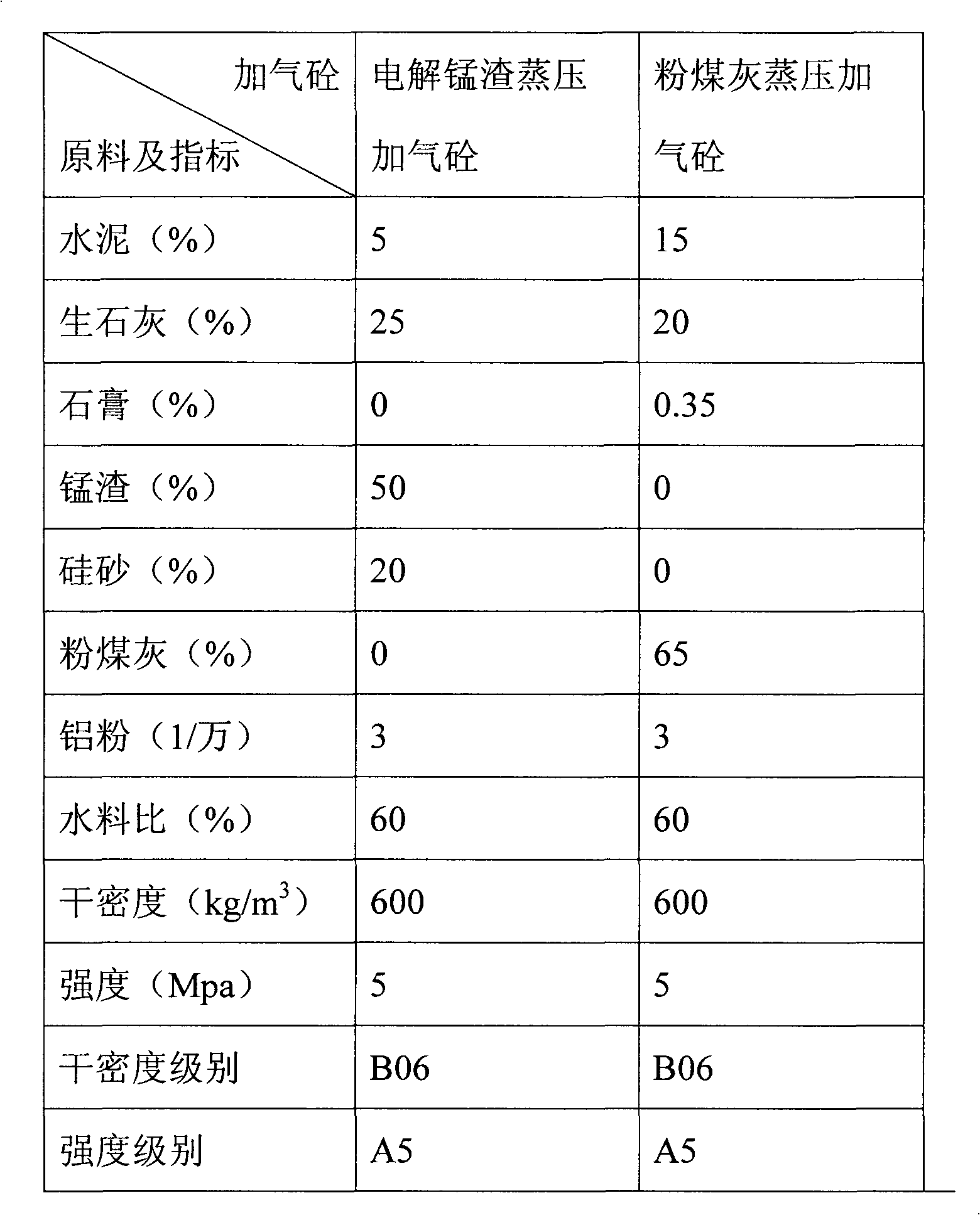

High-strength aerated concrete building block produced by using electrolysis manganese residues and preparation method thereof

InactiveCN102795883AIncrease consumptionSimple processSolid waste managementCeramicwareElectrolysisManganese

The invention discloses a high-strength aerated concrete building block produced by using electrolysis manganese residues and a preparation method thereof. The building block is made of: (1) basic raw materials, (2) additives and (3) a solvent, wherein the basic raw materials include 48-58 percent by weight of electrolysis manganese residues, 20-30 percent by weight of silica sand, 5-10 percent by weight of cement and 15-25 percent by weight of quicklime; based on the total amount of the basic raw materials, the additives include 0.05-0.12 percent by weight of aluminum powder, 1-5 percent by weight of water glass, 0.005-0.01 percent by weight of sodium benzene sulfonate washing powder and 0.1-0.4 percent of an aid; the solvent is water; and the weight ratio of water to a water material of the basic raw materials is 0.6-0.7. The preparation method comprises the following steps of: pretreating the raw materials, and forcibly stirring according to a certain proportion as required to obtain slurry; and standing and performing steam curing with a still kettle to obtain a product. The aerated concrete building block produced with the method has the advantages of low volume weight, high strength, simple process, convenience in operating, freeness from pollution, high electrolysis manganese residue consumption and convenience in mechanical production.

Owner:HUAIHUA YONGGU ENERGY SAVING WALL MATERIAL

Coating liquid, organic-inorganic hybrid cation exchange membrane and preparation method thereof

InactiveCN102658036AImprove uniformityImprove mechanical propertiesSemi-permeable membranesCross-linkMass ratio

The invention discloses a coating liquid, an organic-inorganic hydrid cation exchange membrane and a preparation method thereof. The coating liquid comprises polyvinyl alcohol, water and a multi-silicon cross-linking agent, wherein the mass ratio of the multi-silicon cross-linking agent and the polyvinyl alcohol is (0.75-1.34):1. The multi-silicon cross-linking agent is prepared as the following process: a monomer A, a monomer B, a solvent C and an initiator D are mixed and reacted according to the molar ratio of monomer A containing a sodium benzene sulfonate group: monomer B containing an alkoxy silicon group: solvent C: initiator D = 1: (1-2.34): (38.5-87.7): (0.020-0.036). Then, 60-75% of the solvent C is removed to produce the multi-silicon cross-linking agent solution. The hybrid cation exchange membrane is obtained from the coating liquid of the invention. The membrane has the advantages of high crosslinking degree, homogeneous transparency, good mechanical property, high swelling resistance and thermostability, and can be applied to the field of alkali recovery.

Owner:UNIV OF SCI & TECH OF CHINA

Process for synthesizing specific carboxylic styrene butadiene latex for well cementation of oil-gas field

InactiveCN1544496ALarge particle sizeShort reaction timeSealing/packingFunctional monomerCarboxylic salt

The invention relates to a process for synthesizing single-purpose carboxylic styrene butadiene latex for well cementing in oil and gas field by using butadiene and phenylethene as main monomer, using carboxylates or / and sulfonic acid, sulfonate containing unsaturated bond as functional monomer, and using composite emulsifying agent system. The invention realizes a C8-C20 alkyl sodium sulfate, C8-C20 sodium alkyl benzene sulphonate- non-ionic emulsifier, wherein the polymerization temperature is preferably between 50-90 deg. C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

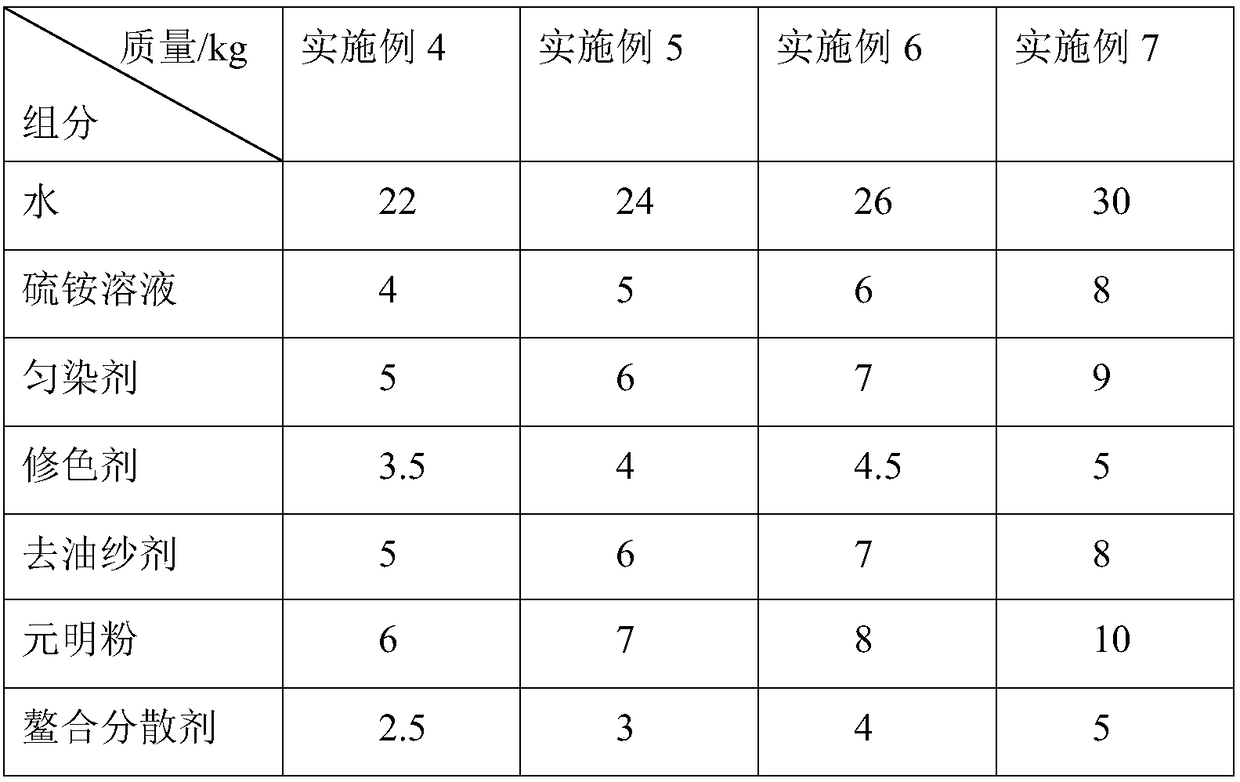

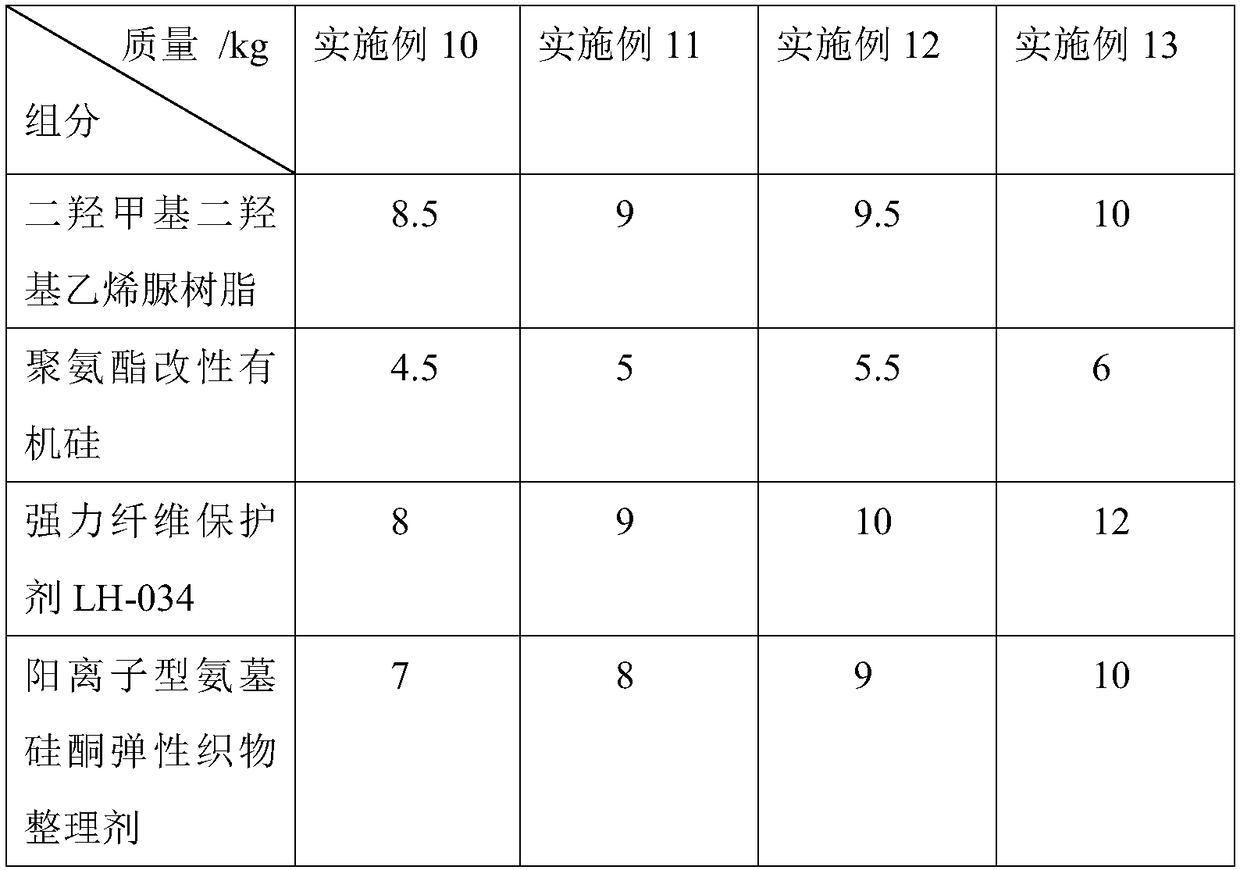

Dyeing production process for full-cotton knitted fabric

InactiveCN109371721AImprove wettability and permeabilityEasy accessWrinkle resistant fibresDyeing processWater bathsEthylenediamine

The invention discloses a dyeing production process for a full-cotton knitted fabric. The dyeing production process comprises the following steps: (1) pretreatment, (2) neutralization, (3) deoxygenization, (4) dyeing, (5) neutralization, (6) soaping, and (7) formation, wherein the step (1) comprises the steps of adding water into a dye vat, heating to 40-50 DEG C, adding pretreatment liquid into the dye vat, uniformly stirring, carrying out temperature-maintenance treatment for 3-5 minutes, adding a gray fabric into the water in a water bath ratio of (1 to 8)-10, heating to 90-100 DEG C, and washing with clean water for 1-2 times; and the pretreatment liquid contains the following substances in parts by weight: 3-5 parts of a penetrating agent, 3-7 parts of hydrogen peroxide, 4-8 parts ofcaustic soda liquid, 4-7 parts of a degreaser, 3-8 parts of a stabilizer, 5-8 parts of tetraacetyl ethylenediamine, 2-8 parts of butyl acetate, 1-3 parts of sodium sulfate, 1-3 parts of 4-(2-nonanoyloxyethoxycarbonyloxy)sodium benzenesulfonate and 1-5 parts of tris(hydroxymethyl)methylglycine. The dyeing production process has the advantages of high dyeing rate and uniformity in dyeing.

Owner:绍兴勇舜印染有限公司

Preparation method of cation dyeable POY (Polyester Pre-Oriented Yarn)

ActiveCN107557902AReduce pressure riseLess impuritiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnTransesterification

The invention relates to a preparation method of cation dyeable POY (Polyester Pre-Oriented Yarn). The method comprises the following steps: firstly, mixing dimethyl isophthalate-5-sodium benzenesulfonate, ethylene glycol, a catalyst and an anti-ether agent, performing transesterification, and adding the ethylene glycol and a complex ion modifier for preparation after the transesterification is ended; secondly, mixing terephthalic acid, the ethylene glycol, the catalyst, a stabilizer and a delustering agent, performing esterification reaction, adding a product obtained by preparation after theesterification reaction into a reaction system already reaching a reaction endpoint of the esterification reaction, and performing condensation polymerization to obtain a spinning melt; finally, metering, extruding, cooling, oiling and winding the spinning melt to obtain the cation dyeable POY. The method reduces the generation of impurities in a production process, thereby reducing pressure riseof a spinning assembly and a filter, prolonging the service life, ensuring the continuity and safety of the whole production flow, and achieving a good economic value and promotion value.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

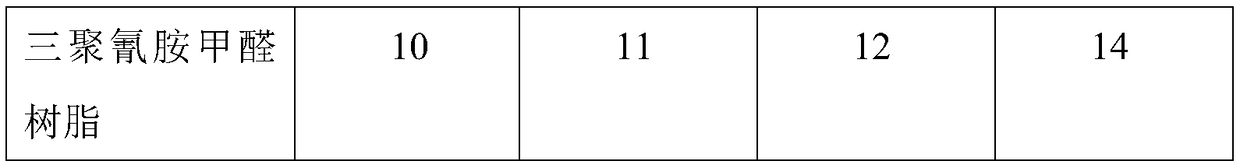

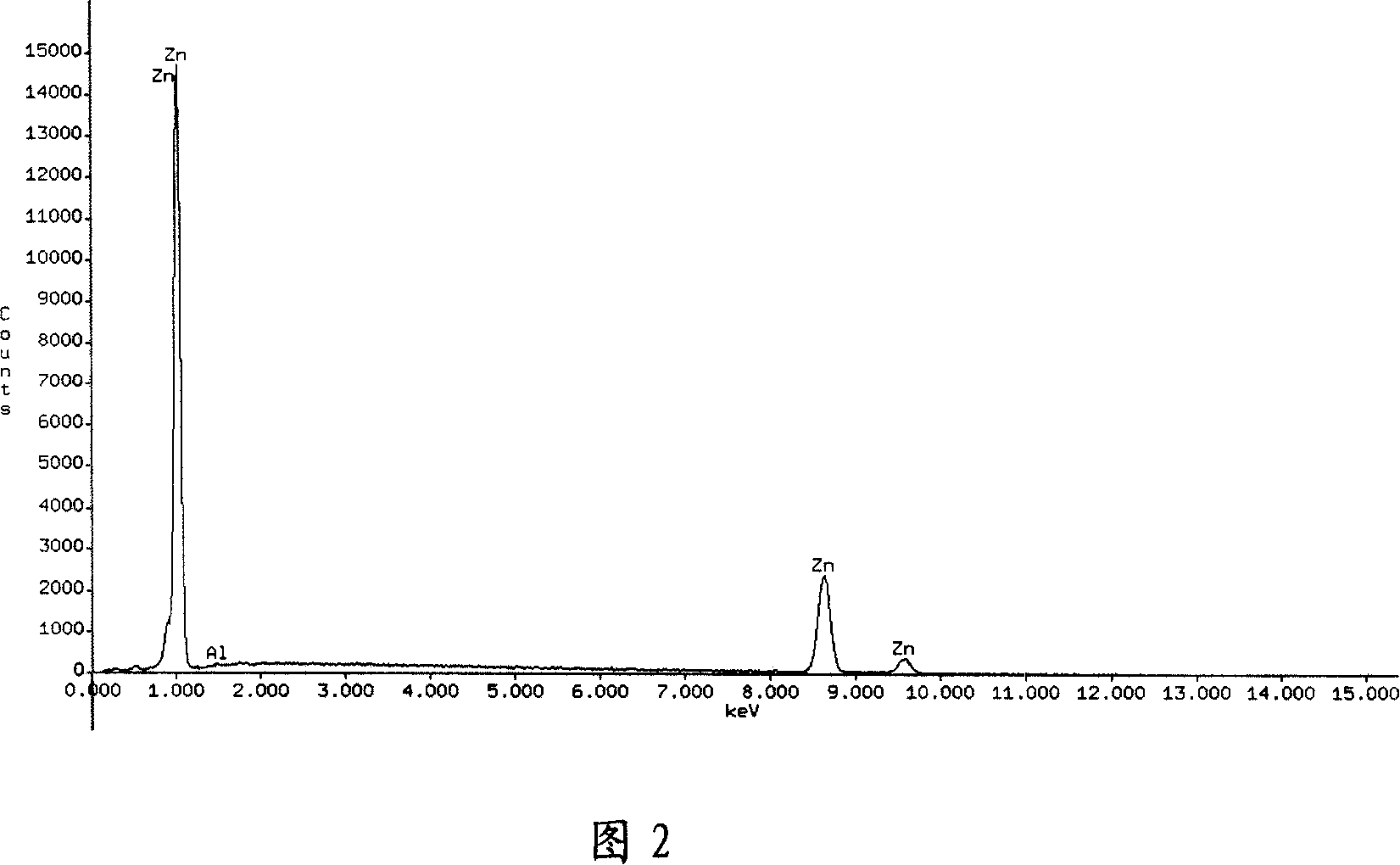

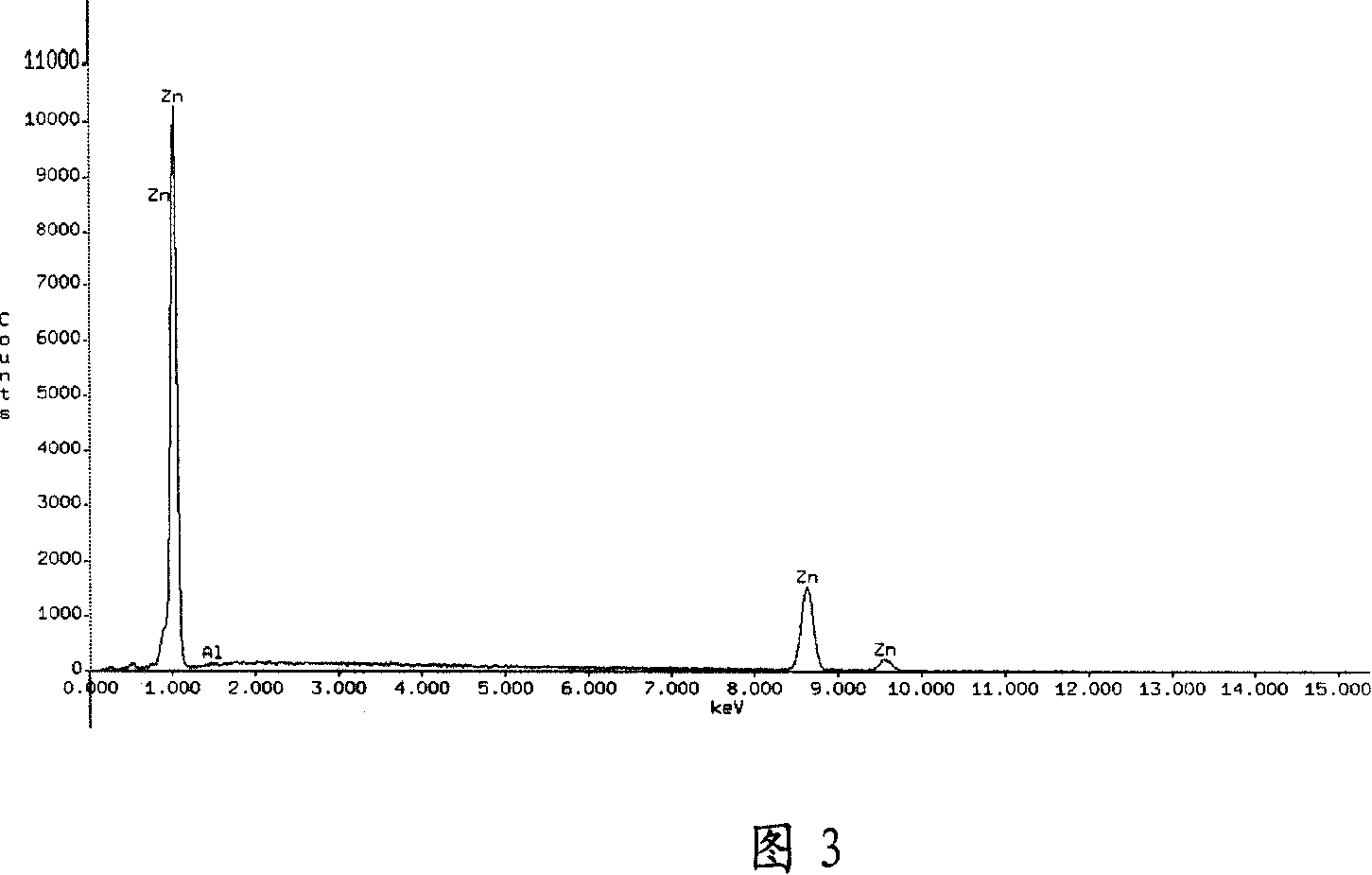

Process for purifying zinc from casting zinc residue

InactiveCN101054686AHigh purityEasy to peelPhotography auxillary processesProcess efficiency improvementElectrolysisMaterials science

The present invention relates to reclaiming of non-ferro metals, especially to a process for extracting high-purity Zn from casting zincilates. The casting zincilates are casted into anode sheets, pure aluminum plates are selected as cathodes, and then they are electrolyzed in electrolysing solution to obtain zincium of high-purity at the cathode plates finally, wherein per litre of said electrolysing solution contains 1-3 mol ammine, 1-3 mol ammonium chloride, 0.075-0.3 g additive agent and 40-60 g zincium ions therein, in which said additive agent in per litre electrolysing solution is a mixture composed of 0.05-0.2 g gelatine and 0.025-0.1 g sodium dodecylbenzene sulfonate. By casting the casting zincilates directly into anode sheets and adopting Zn-NH3-NH4Cl-H2O system for performing electrorefining to prepare high-purity zincium, the process is greatly shortened, the energy consumption is saved, and the cost of investment is depressed. The obtained cathode zincium has a high purity (>=99.9%) and is easy to peel off, with low intensity of labor and reduced attrition of cathode plates. The electrolysing solution my be circle-utilized, without pollutions to the environment.

Owner:ZHEJIANG UNIV OF TECH

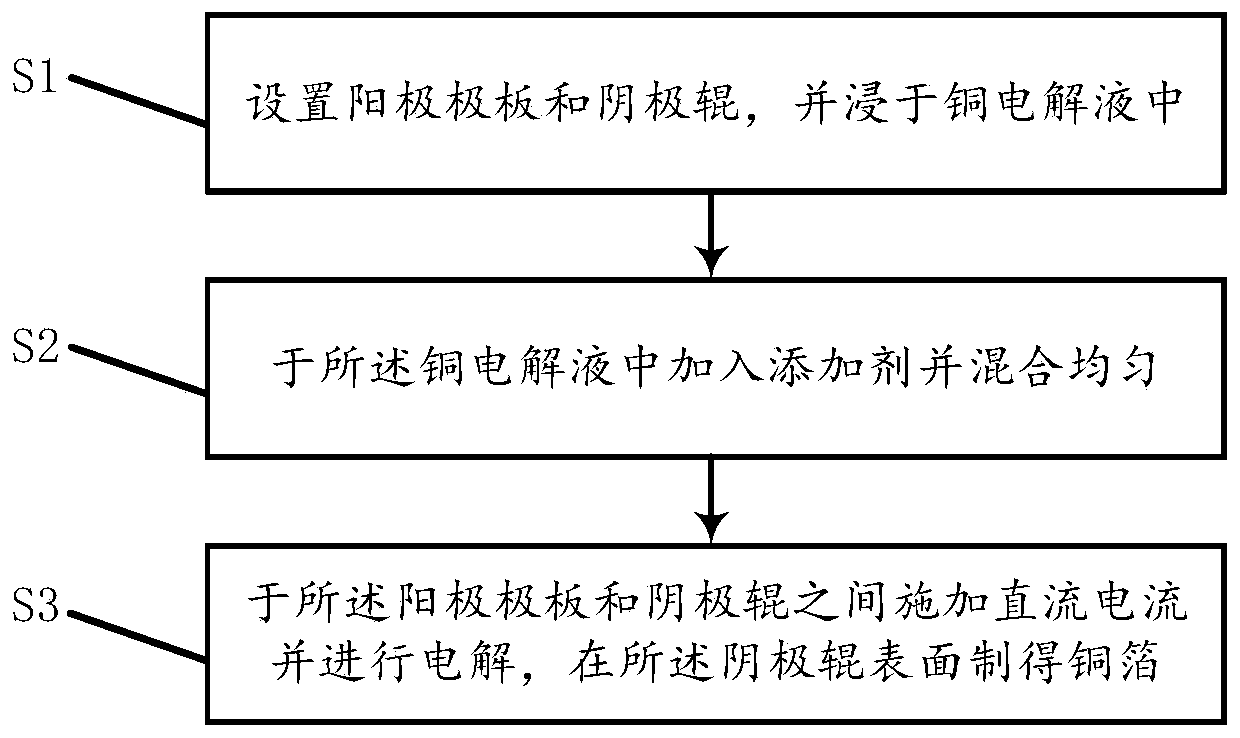

Ultra-thin electrolytic copper foil and preparation method thereof

ActiveCN110396704AHigh tensile strengthImprove flatnessNegative electrodesElectroforming processesElectrolysisCopper foil

The invention discloses an ultra-thin electrolytic copper foil and a preparation method thereof. The method comprises the following steps that an anode plate and a cathode roller are arranged and aresoaked in a copper electrolyte; an additive is added into the copper electrolyte and uniformly mixed; a direct current is exerted between the anode plate and the cathode roller and electrolysis is performed to prepare the copper foil on the surface of the cathode roller; and the additive comprises sodium dodecyl benzene sulfonate, sodium 3-mercaptopropanesulphonateand hydroxyethyl cellulose and collagen, and the concentration of sodium dodecyl benzene sulfonate is 20-70 mg / L, the sodium 3-mercaptopropanesulphonateand hydroxyethyl cellulose with the concentration of 30 -60 mg / L, and the concentration of the hydroxyethyl cellulose is 20-50 mg / L, the concentration of the collagen is 100-180 mg / L, and the molecular weight of the copper foil is 2000-4000. According to the preparation method, through introducing the additive with a specific ratio, crystal grains can be further refined during direct current electrolysis, and the ultra-thin copper foil with the thickness of less than 6 micronscan be prepared while ensuring that the copper foil has good tensile strength and flatness; and the process is simple and convenient, and facilitates the industrial large-scale production.

Owner:HUBEI ZHONGYI TECH

4.5 micrometer electrolytic copper foil for lithium ion battery, preparation method and additive

ActiveCN110644021AInhibition of growth rateRealize industrializationElectrode carriers/collectorsSecondary cellsElectrolysisThiourea

The invention discloses 4.5 micrometer electrolytic copper foil for a lithium ion battery, a preparation method and an additive. The 4.5 micrometer electrolytic copper foil is prepared from polyquaternium-10, polyquaternium-7, polyquaternium-51, dithiobis-1-propanesulfonic acid disodium salt, sodium alcohol mercaptan sulfonate, gelatin, alkaline safranine dye, N-butyl thiourea, mercaptoimidazole sodium benzenesulfonate and polyethylene glycol acetal. The 4.5 micrometer electrolytic copper foil for the lithium ion battery, the preparation method and the additive have the beneficial effects thatby means of the coupling reaction of the additive, nucleating surface energy is reduced, the growth speed of crystal nuclei is restrained, pinholes and micro-defects are removed, the nucleating quantity is increased, grains are refined, the structure of the copper coil is homogenized, and the tensile strength and the ductility are effectively improved; and industrialization of the copper foil which has the tensile strength of 35-40 kgf / mm<2> and the uniform double-face structure (Rz of the smooth and rough faces is 1.0-2.0 micrometers) and is free of defects and ultrathin (the thickness is 4.5 micrometers) is achieved, and industrialization of high-energy-density power battery copper foil products is effectively achieved.

Owner:安徽华创新材料股份有限公司

Treatment material for chemical wastewater

InactiveCN104445566AImprove adsorption capacityEffective neutralizationWater/sewage treatment by neutralisationWater/sewage treatment by sorptionEngineeringPolypropylene

The invention provides a treatment material for chemical wastewater. The treatment material for the chemical wastewater is prepared from the following raw materials in parts by weight: 6 to 11 parts of aluminium oxide, 8 to 14 parts of activated carbon, 3 to 9 parts of hexamine, 2 to 6 parts of camphor, 2 to 6 parts of soyabean protein, 5 to 7 parts of attapulgite, 3 to 9 parts of sodium dihydrogen phosphate, 2 to 7 parts of sodium lignin sulfonate, 4 to 7 parts of benzene sulfonic acid sodium salt, 1 to 5 parts of bagasse, 6 to 10 parts of maleic anhydride grafted polypropylene, 2 to 6 parts of nanometer-grade granular inorganic material, 2 to 7 parts of bentonite, 2 to 8 parts of barium carbonate, and 6 to 9 parts of sodium sulfate. The treatment material for the chemical wastewater has the beneficial effects that the heavy metal ion in water can be effectively neutralized, so that the water can be purified, and meanwhile, suspended matters can be absorbed well, and as a result, the water purifying purpose is reached.

Owner:QINGDAO ZHIGU INNOVATION TECH

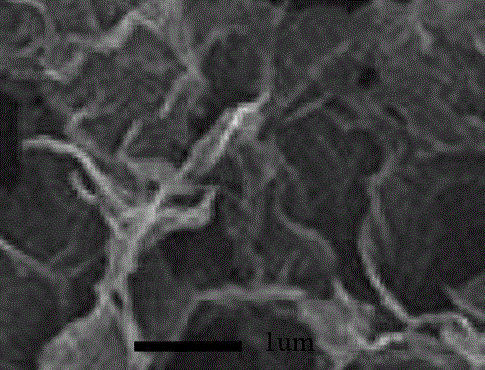

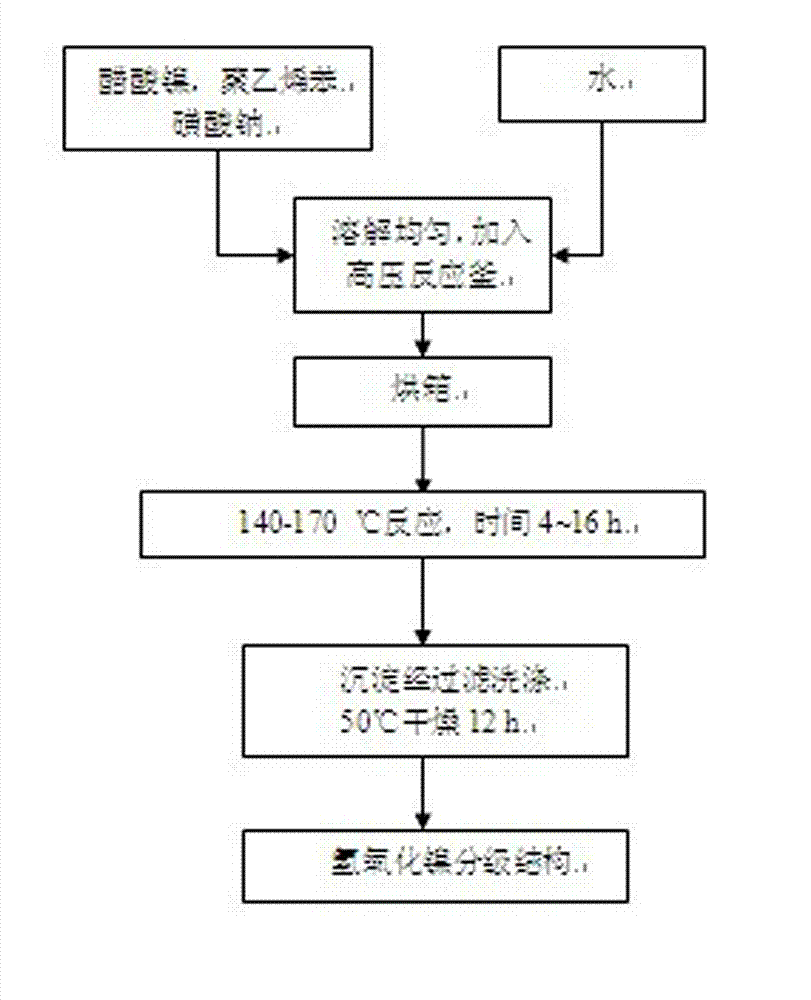

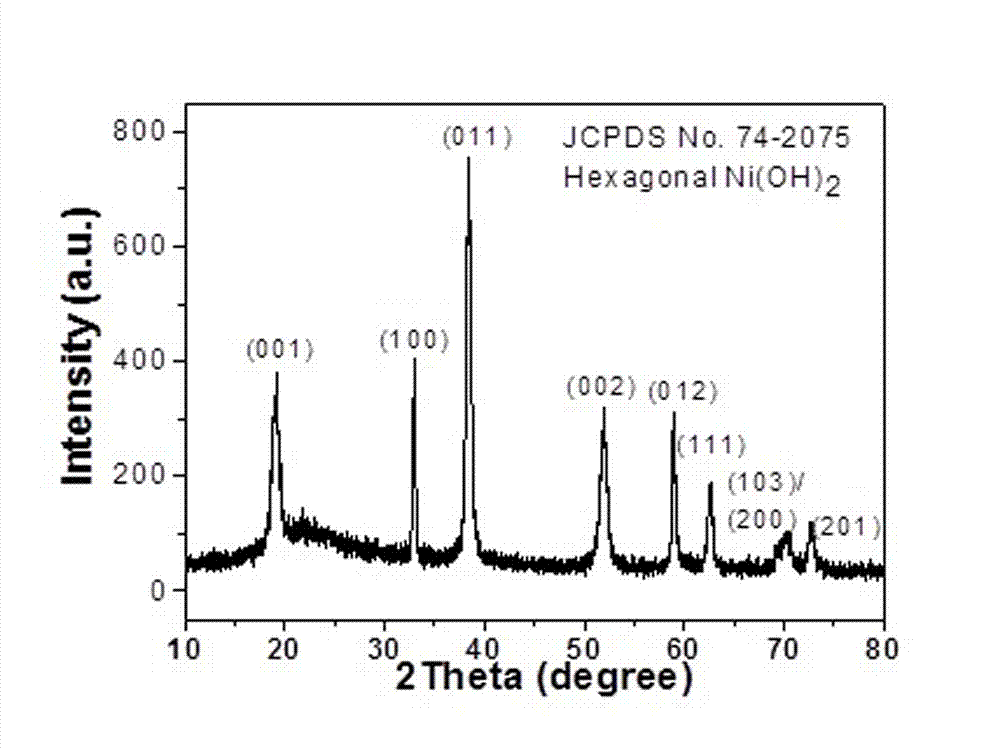

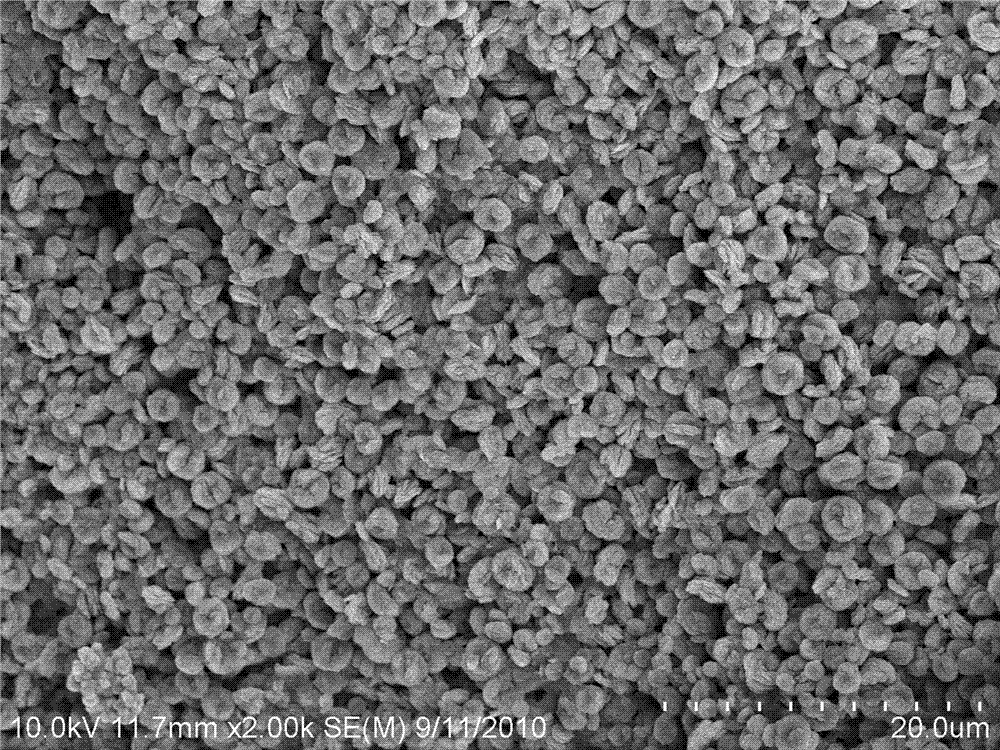

Method for hydrothermal synthesis of nickel hydroxide hierarchical structure microspheres assembled by nano-sheets

InactiveCN102897852ASimple manufacturing processHigh crystallinityNanotechnologyNickel oxides/hydroxidesMicrosphereEthylic acid

The invention belongs to the technical field of preparation of functional nano-materials, relates to a preparation method of nano-hierarchical structure nickel hydroxide and particularly relates to a method for hydrothermal synthesis of nickel hydroxide hierarchical structure microspheres assembled by nano-sheets. The method disclosed by the invention comprises the following steps of: mixing a nickel acetate (Ni(CH3COO)2) water solution with a polyethylene sodium benzenesulfonate water solution, placing in a high-pressure reaction kettle lined with polytetrafluoroethylene to perform hydrothermal reaction, cooling, then performing centrifugal separation, washing with water, washing with ethanol, and then drying. The nickel hydroxide hierarchical structure prepared by the method disclosed by the invention is good in monodispersity and uniform in appearance, the diameter is 1.5-3mu m, and the hierarchical structure is assembled by flaky nano-units in a spiral layer-by-layer superimposition way and belongs to a multi-stage mesoscopic structure. The structure material combines larger surface area and excellent anti-agglomeration stability, and has great application prospects in the fields of battery electrode materials, catalysis, air sensitivity and the like. The method disclosed by the invention has the advantages of simple process, no need of adding a precipitating agent, convenience in operation and good repeatability, and is expected to realize industrial production.

Owner:JIANGSU UNIV

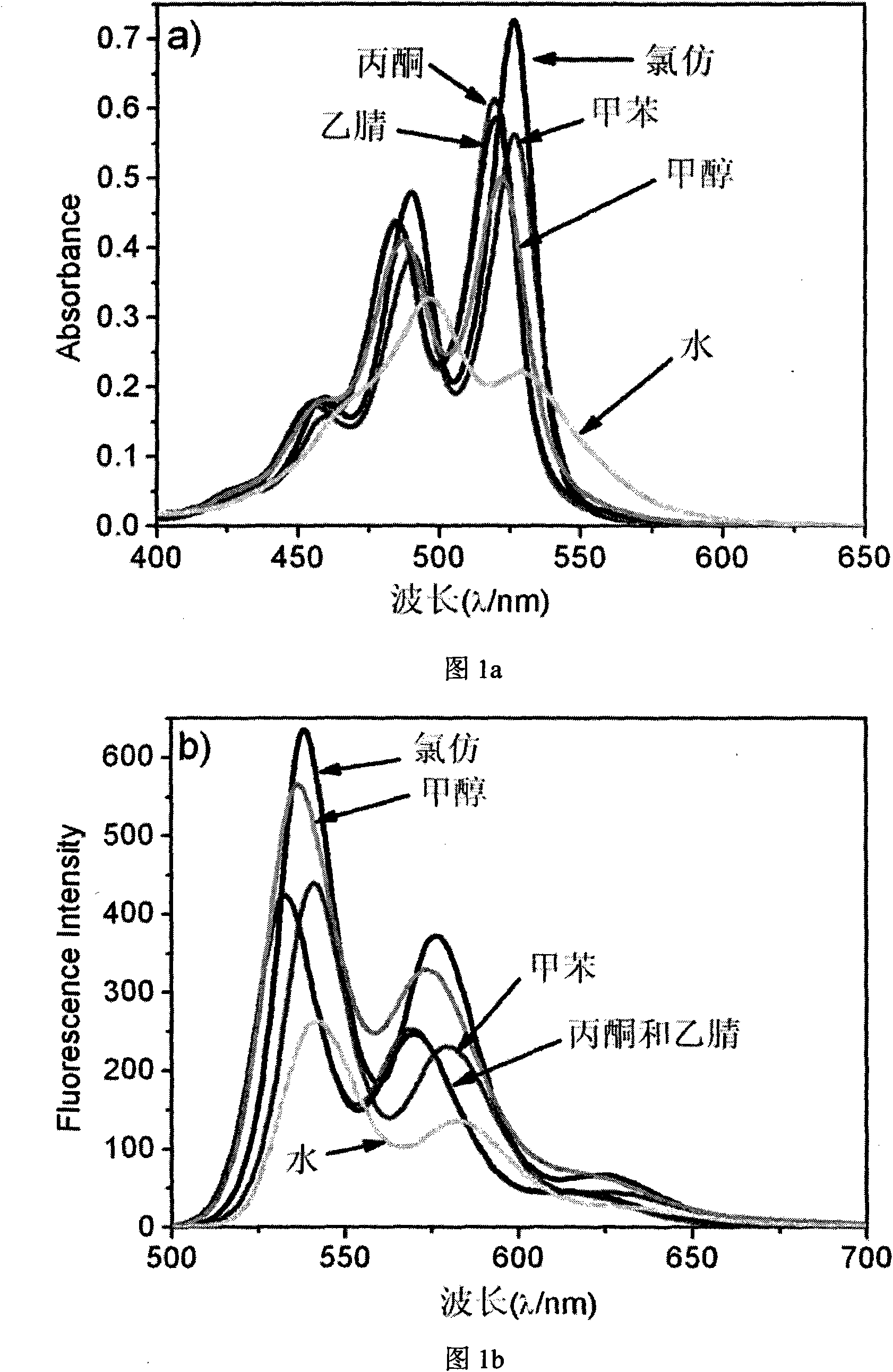

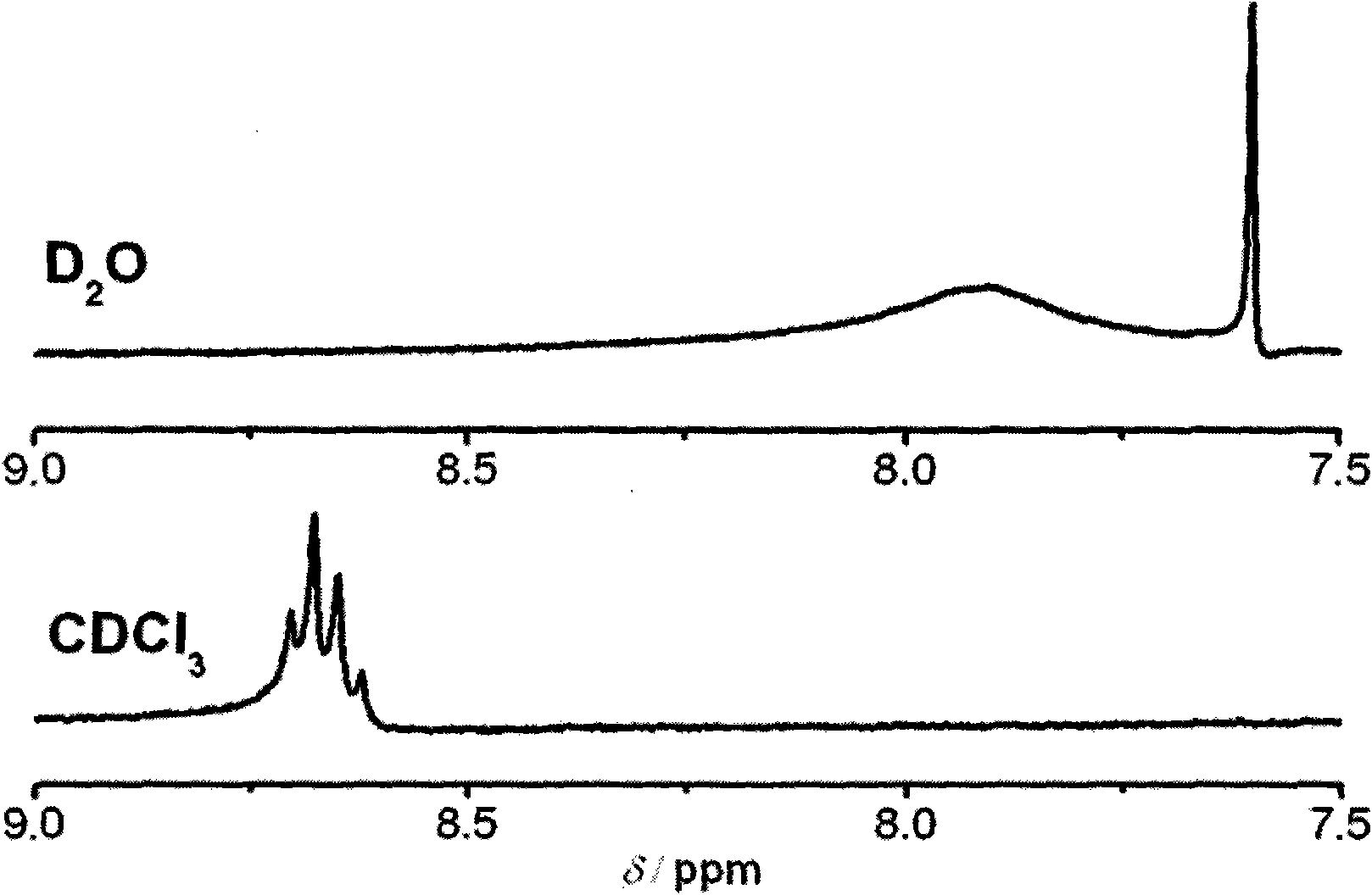

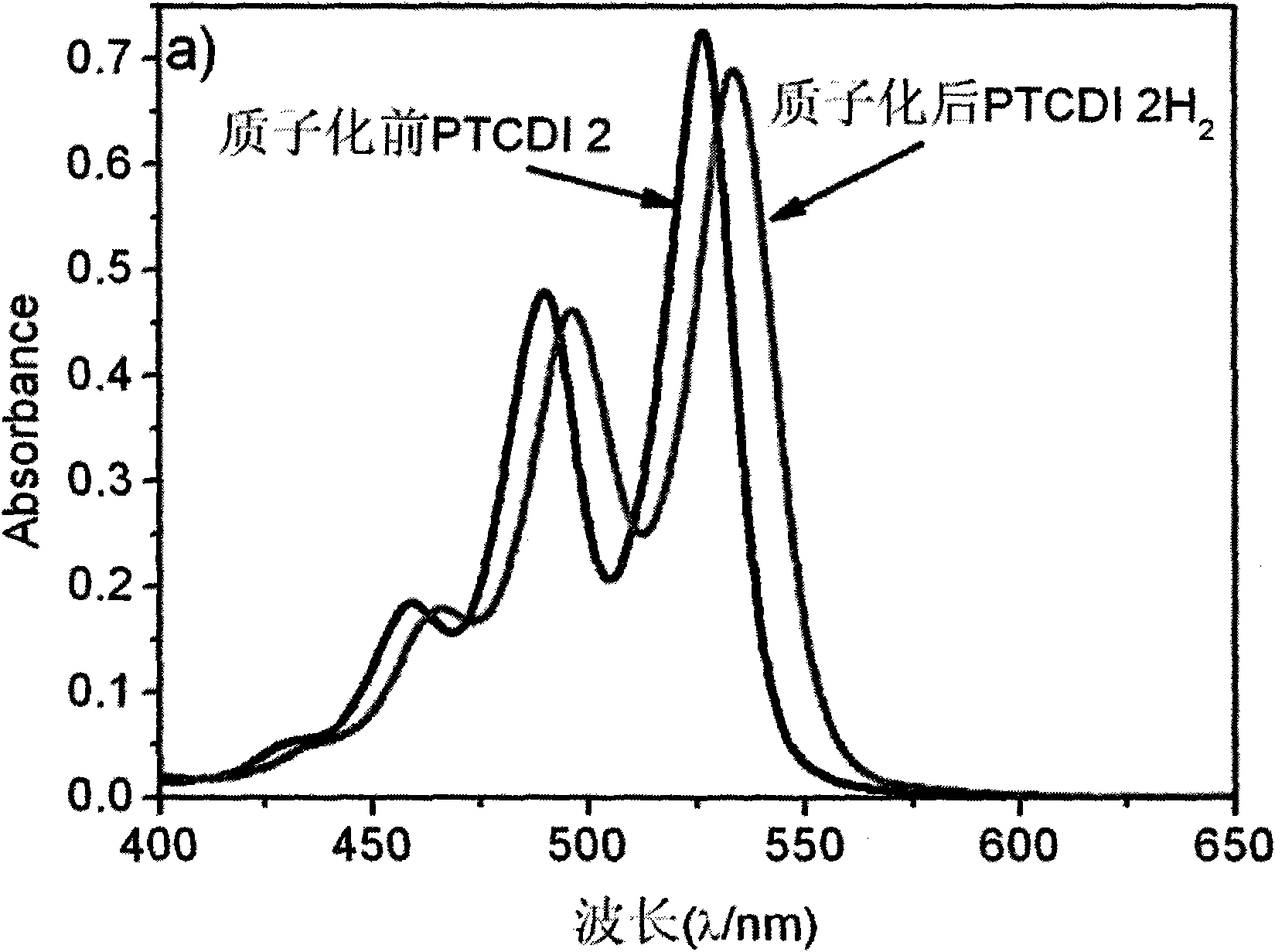

Perylene imide bridge type dimethylate-ethylenediamine-Beta-cyclodextrin derivate, preparation and applications thereof

The invention relates to perylene imide bridge type dimethylate-ethylenediamine-Beta-cyclodextrin derivate, and synthesis. The chemical formula of the derivate is C152H236N4O72, and the structure is shown in an attached drawing. The compound self-assembles into nano spherical aggregates, the electrostatic repulsion between molecules is increased by protonizing imino so as to disaggregate supermolecule aggregates, and simultaneously photoinduced electron transferring process in the molecules is blocked so as to generate strong fluorescence, thereby realizing aggregation behavior of pH value control and change of optical property. In the compound, cyclodextrin is taken as a receiver of specific molecules, the perylene with excellent optical property is taken as a detector which can optically sense water-soluble aromatics guest molecules (benzene sulfonic acid sodium salt, 2-naphthalenesulfonic acid sodium salt, 2-anthroic acid sodium salt and pyrenebutyric acid sodium salt), and the guest molecule module structure is shown in the attached drawing.

Owner:NANKAI UNIV

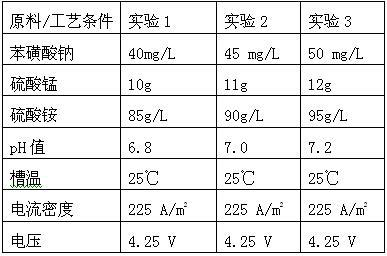

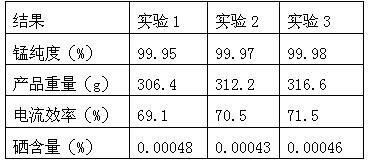

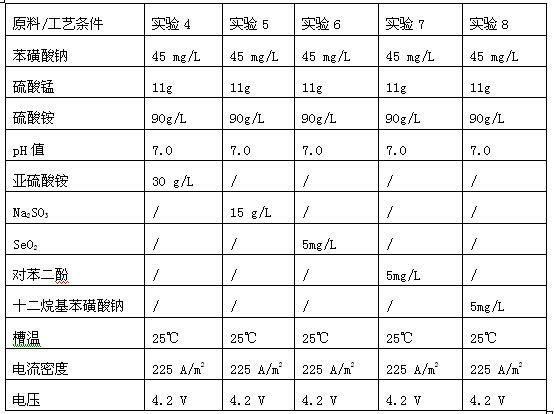

Electrolytic manganese solution containing new additive, and preparation method and application thereof

InactiveCN102492958AReduce interfacial tensionIncrease added valuePhotography auxillary processesElectrolysisManganese

The invention discloses an electrolytic manganese solution containing a new additive, and preparation method and application thereof, and belongs to the technical field of physical chemistry. The electrolytic manganese solution containing the new additive is characterized by adding an additive of benzene sulfonic acid sodium salt into the prior electrolytic manganese solution which contains manganese sulfate, ammonium sulfate and water, thereby replacing toxic selenium dioxide or sulfur dioxide added in the traditional electrolytic manganese solution, and preparing the electrolytic manganese solution containing the benzene sulfonic acid sodium salt, wherein, in the electrolytic manganese solution, the concentration of the benzene sulfonic acid sodium salt is 25-90 mg / L, the concentration of sodium sulfate is 7-35 g / L, the concentration of ammonium sulfate is 68-120 g / L, and the pH is 5.0 to 8.3. The electrolytic manganese solution containing the additive of sulfonic acid sodium salt can be applied to producing electrolytic manganese with purity as high as 99.90% to 99.98%.

Owner:KAILI UNIV +1

Natural pyrethrin water emulsion and its preparation

The pyrethrin water emulsion consists of pyrethrin 1 weight portions, synergist 1-30 weight portions, sodium benzene sulfonate 10-95 weight portions, and water 0-95 weight portions. It is water soluble, light stable and water stable. When used, it can form one air isolating layer in the surface of pest and has high pesticidal effect. It is used in killing pest in vegetable, fruit, flower, tea, Chinese medicine plant, etc. and may be also used for other purpose. It has high pesticidal effect, low residue and other advantages.

Owner:YUNNAN NANBAO BIOTECH

Prepn of water-reducing and surface halide accumulation resisting modifier for magnesite binding material

The water-reducing anti-bleeding modifying agent of magnesite cementing material is made up by using (wt%) water 18-22%, phenol 10-14%, sodium sulfophenylate 6-10%, industrial formaldehyde 8-12% and organic silicon water-resisting agent. It can be added to the magnesite cement, and can raise the resistance to absorb moisture and anti-bleeding property of its product, and also can raise the product strength.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

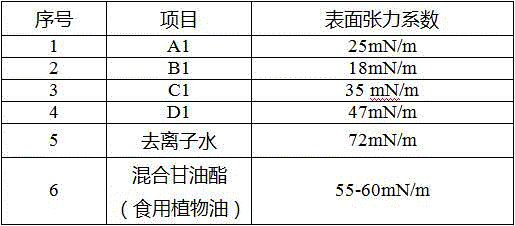

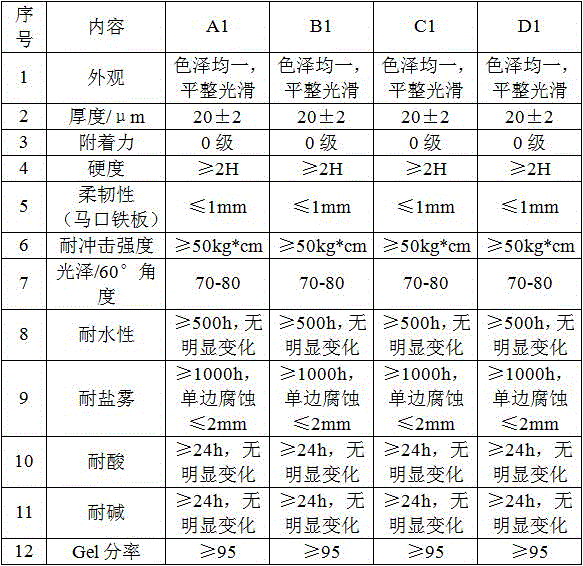

Aqueous epoxy resin emulsion, preparation method thereof, cathode electrophoresis coating

InactiveCN106243311AMaintain surface tensionImprove cleanlinessPolyurea/polyurethane coatingsPaints for electrolytic applicationsEpoxyPolymer modified

The invention discloses an aqueous epoxy resin emulsion. The aqueous epoxy resin emulsion is prepared from, by mass, 5-10% of epoxy resin, 5-10% of diisocyanate, 2-8% of polyether polyol, 0.5-2% of dibutyltin dilaurate, 2-8% of cyclohexanedimethanol, 1-2% of propylene glycol methyl ether acetate, 2-4% of triethylamine, 1-3% of sodium benzenesulfonate, 5-10% of butanone, 1-3% of hydroxyl-terminated polyether modified organosilicon or hydroxyl-terminated fluorine-containing organic polymer and 50-60% of deionized water. Organosilicon and the fluorine-containing organic polymer are adopted to modify the epoxy resin, so the aqueous epoxy resin emulsion keeps the excellent performances of original coatings, has reduced surface tension and stable performances, and can be widely applied. The invention also discloses a preparation method of the aqueous epoxy resin emulsion, and a cathode electrophoresis coating prepared through adopting the aqueous epoxy resin emulsion.

Preparing method for ordinary-pressure positive-ion dyeable polyester fiber

ActiveCN107541803ALess impuritiesReduce pressure riseMonocomponent polyetheresters artificial filamentMelt spinning methodsPressure risePolyethylene glycol

The invention relates to a preparing method for an ordinary-pressure positive-ion dyeable polyester fiber. The preparing method includes the steps that dimethyl isophthalate-5-sodium benzenesulfonate,ethylene glycol, a catalyst and an anti-ether agent are mixed to be subjected to an ester exchange reaction, the reaction is end, then ethylene glycol and sodium ethylene glycol are added, modulationis carried out, then terephthalic acid, ethylene glycol and a catalyst are mixed, and the mixture is subjected to an esterification reaction; the modulated product after the ester exchange reaction is end and polyethylene glycol are added into an esterification reaction system reaching the end point of the esterification reaction, condensation polymerization is carried out, and spinning melt is obtained; the spinning melt is measured, extruded, cooled, subjected to oil applying, stretched, subjected to heat setting and wound, and the ordinary-pressure positive-ion dyeable polyester fiber is prepared. According to preparing method, generation of impurities in the polyester-fiber production process is reduced, pressure rising of a spinning assembly and a filter is reduced accordingly, the service cycle of the polyester fiber is prolonged, the continuity and the safety of the whole production process are guaranteed, and the preparing method has the good economic value and popularizationvalue.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Method for synthesizing surface functional group modified carbon quantum dots and application to nano oil displacement

ActiveCN111234818ALow priceReduce manufacturing costNanoopticsDrilling compositionModified carbonAmidogen

The invention provides a method for synthesizing surface functional group modified carbon quantum dots and an application of the surface functional group modified carbon quantum dots in nano oil displacement, which comprises the following steps: by using anhydrous citric acid as a carbon source, carrying out a hydrothermal method to obtain a carboxyl modified carbon quantum dot solution, and purifying to obtain a carboxyl modified carbon quantum dot solid; reacting the carboxyl modified carbon quantum dots and sodium p-chloromethylbenzenesulfonate in a polytetrafluoroethylene reaction kettle for 3 h after the pH value of the solution is adjusted to be weakly alkaline, and generating sulfonic group modified carbon quantum dots; reacting the carboxyl modified carbon quantum dot with ammoniawater, and purifying to obtain an amido-modified carbon quantum dot; and reacting the amido-modified carbon quantum dot with sodium hypochlorite in an ice-water bath for 3 hours, adding NaOH to reactfor 8 hours, and purifying to obtain the surface amino-modified carbon quantum dot. The obtained surface functional groups (carboxyl, sulfo, acylamino and amino groups) are used for modifying the carbon quantum dots to carry out a rock core displacement experiment, and the oil displacement rate can be greatly improved.

Owner:SOUTHWEST PETROLEUM UNIV

Optical fiber coloring ink capable of being solidified by LED and preparing method thereof

The invention relates to the technical field of communication fiber coloring solidification, in particular to optical fiber coloring ink capable of being solidified by LED. The ink is characterized by being prepared from, epoxy acrylic resin or urethane acrylate, Isopropyl tri(dioctylpyrophosphate) titanate, polyacrylic acid, 3-Aminopropyltriethoxysilane, cellulose nitrate, isopropyl alcohol, 2-Isopropylthioxanthone, sodium benzenesulfonate, benzophenone, oleic acid, a compound photosensitizer, 4-Methoxyphenol, an antifoaming agent BYK088 and a flatting agent BYK344, wherein, the compound photosensitizer is obtained by uniformly mixing a photosensitizer 184, a photosensitizer 1173 and a compound photosensitizer 907 with a mass ratio of (1 to 3):1(1 to 2). The invention further discloses a preparing method of the optical fiber coloring ink capable of being solidified by LED. The optical fiber coloring ink capable of being solidified by LED has the advantages of more energy conservation, faster coloring speed, better environment protection, longer service life of a curing light of a coloring device and lower coloring noise.

Owner:广东昊辉新材料有限公司

Preparation method of reproduced cotton-like polyester fiber capable of being dyed by cationic dye

ActiveCN111088545ASimple processLow costMonocomponent copolyesters artificial filamentPolyesterFiber

The invention relates to the field of polyester synthesis, and discloses a preparation method of a reproduced cotton-like polyester fiber capable of being dyed by cationic dye. The preparation methodcomprises the steps: 1) carrying out an esterification reaction on isophthalic acid sodium pentasulfonate, dimethyl isophthalate-5-sodium benzenesulfonate or a mixture of the isophthalic acid sodium pentasulfonate and the dimethyl isophthalate-5-sodium benzenesulfonate and ethylene glycol, and then adding polyethylene glycol to react, thus acquiring a trimonomer ester; 2) sorting and crushing therecycled polyester; 3) uniformly mixing the recycled polyester with a reaction auxiliary, and then mixing with the trimonomer ester, melting and extruding to prepare a regenerated polyester slice; and4) spinning. According to the method, the recycled polyester does not need to be degraded, the modified trimonomer ester and the reaction auxiliary are ingeniously utilized to directly react with therecycled polyester to prepare the regenerated polyester; the method has the advantages of simple process and low cost; and polyester molecular chains have modified trimonomer ester blocks, so that the fiber has excellent moisture regain and cationic dyeing effect, and achieves the cotton-like effect.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com