Patents

Literature

52 results about "4-Methoxyphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological diesel-oil stabilized additive, its production and use

InactiveCN101029257AImprove oxidation stabilityLiquid carbonaceous fuelsEthylenediamine4-Methoxyphenol

A safe biological diesel-oil consists of main antioxidant, synergist, deoxidant and solvent oil. The main antioxidant is 2-tert-4-methoxyphenol or3-tert-4-methoxyphenol or 2, 6-di-tert mixed phenol or 2-tert-hydroquinone or hemimelitic phenol or two or above substances mixture; synergist is mixture of ethylenediamine tetraacetic acid salt or citric acid, citrate ester or propanediol or poly-phosphoric acid or two or above substances mixture; deoxidant is vitamin E or carotenoid or ascorbic acid or ester ascorbate mixture or two or above substances mixture, main antioxidant is 4-6wt%, synergist is 2-36wt%, deoxidant is 4-6wt% and solvent oil is residue. It has better stability.

Owner:FOSHAN ZHENGHE BIO ENERGY

Thermoplastic fiber-reinforced epoxy composite and applications thereof

ActiveCN102774013AImprove processing and manufacturing speedRealize mass production4-MethoxyphenolEpoxy

The invention discloses a thermoplastic fiber-reinforced epoxy composite and applications thereof. The thermoplastic fiber-reinforced epoxy composite is prepared by taking epoxy resin and crylic acid as raw materials, thermoplastic fiber aramid woven cloths as reinforcing materials, N,N-dimethylaniline as catalyst, 4-methoxyphenol as polymerization inhibitor, trimethylolpropane triacrylate as diluted monomer, isopropylthioxanthone as photoinitiator, silane coupling agent as modifier, and metahanol as solvent, firstly synthesizing epoxy acrylate, diluting with the trimethylolpropane triacrylate, synthesizing photosensitive resin, dipping the thermoplastic fiber aramid woven cloths with the photosensitive resin, and carrying out fast forming of a novel electric car body support frame on photocuring forming equipment. The photocured electric car body support frame prepared by using the method has excellent performances, is environment-friendly, and has no harm influence on human body and ambient environment, and the curing effect meets the national standard.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

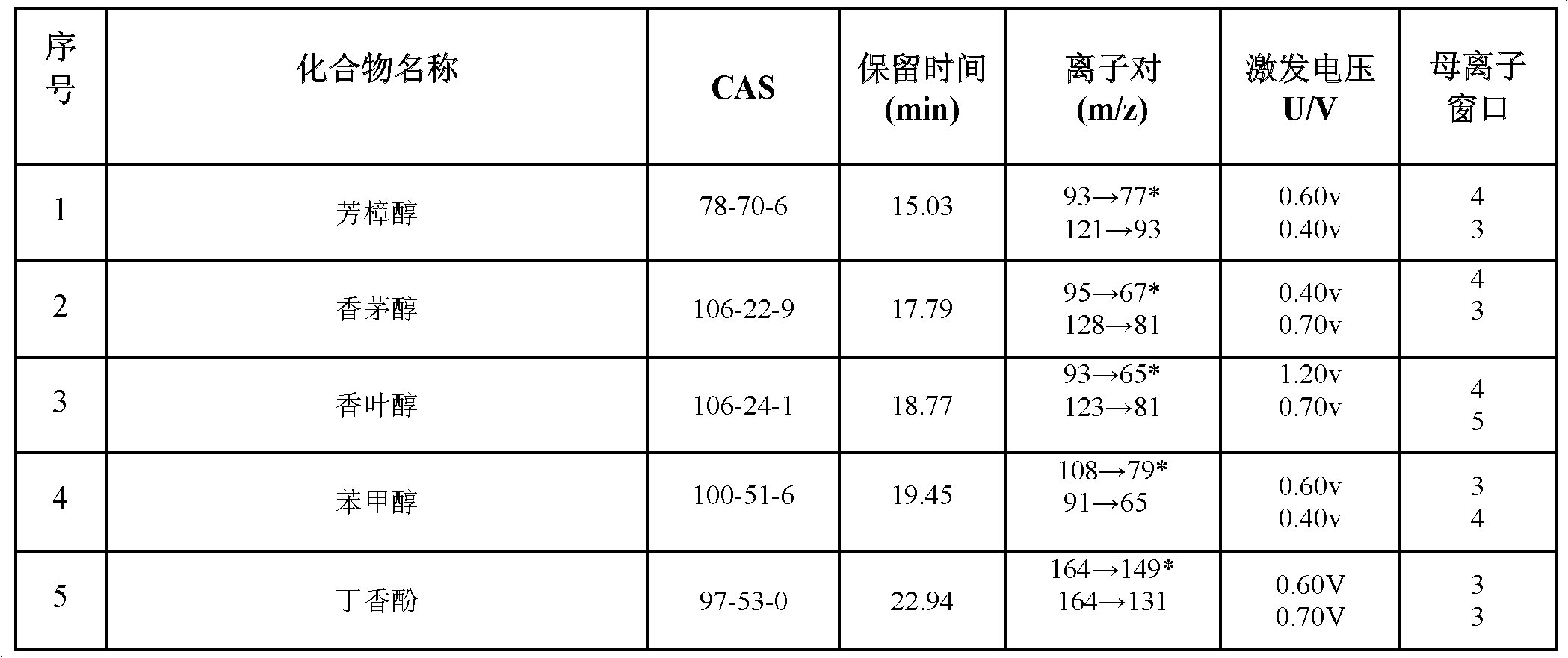

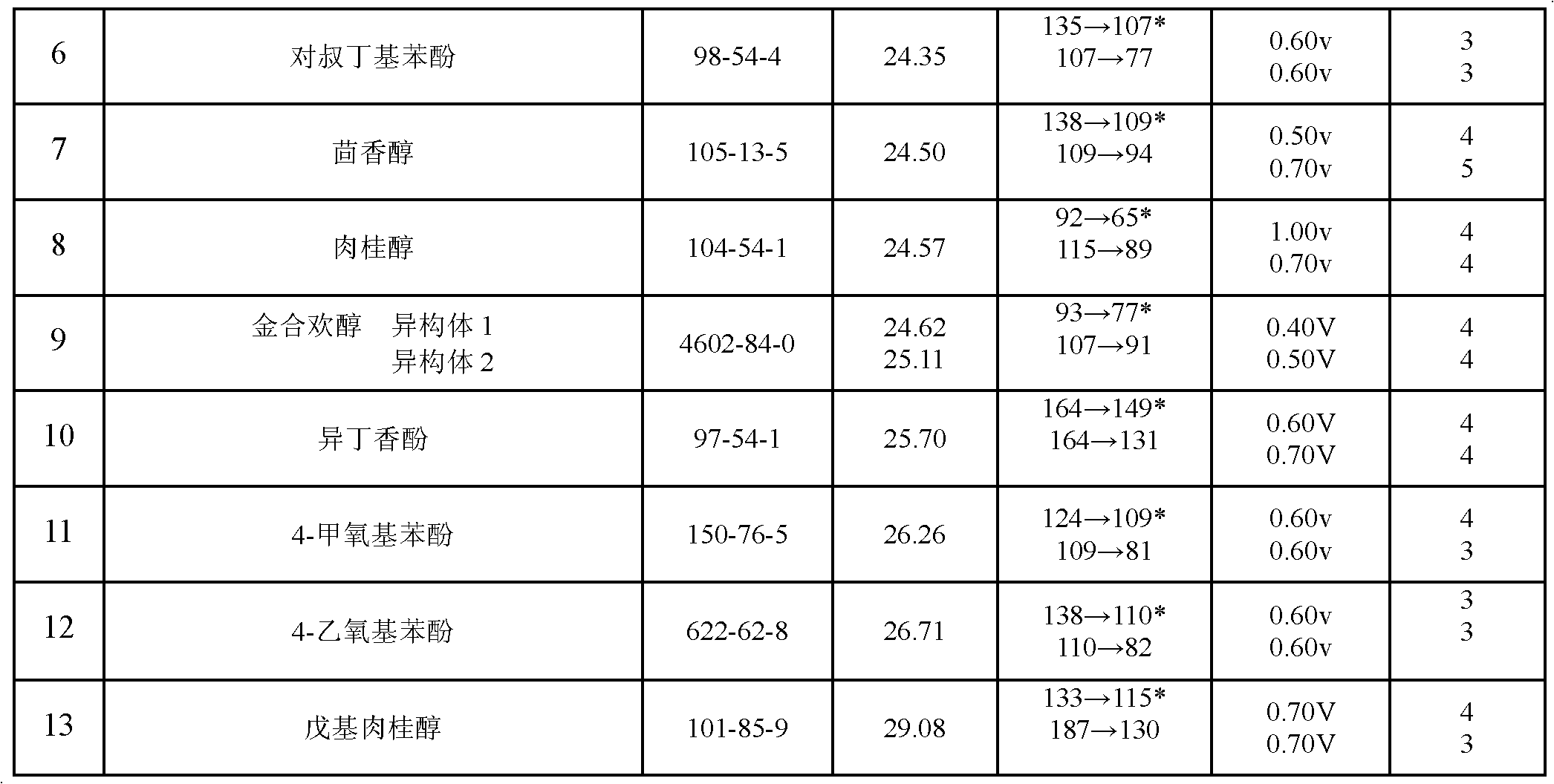

Method for simultaneously detecting residual amounts of 13 phenolic alcohol sensitization aromatics in toy

InactiveCN103105438AApplicable AnalysisHigh sensitivityComponent separation4-MethoxyphenolIsoeugenol

The invention relates to a method for simultaneously detecting residual amounts of 13 phenolic alcohol sensitization aromatics in a toy. The method realizes simultaneous detection of 13 phenolic alcohol sensitization aromatics such as benzyl alcohol, linalool, 4-methoxyphenol, citronellol, geraniol, 4-ethoxyphenol, anise alcohol, p-tert-butylphenol, cinnamyl alcohol, eugenol, isoeugenol, amylcinnamyl alcohol and farnesol in a toy for the first time by the gas chromatography-ion trap tandem mass spectrometry technology, and fills the technical gap. The method can be used for detecting plush toys, paster toys and plastic toys (prepared from ABS, PVC and PS materials), and has a wide application range and strong applicability. The ion trap tandem mass spectrometry realizes qualification and quantification by two-stage mass spectrometry MS / MS and thus the method has good qualification and quantification effects on a toy sample having a complex matrix.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

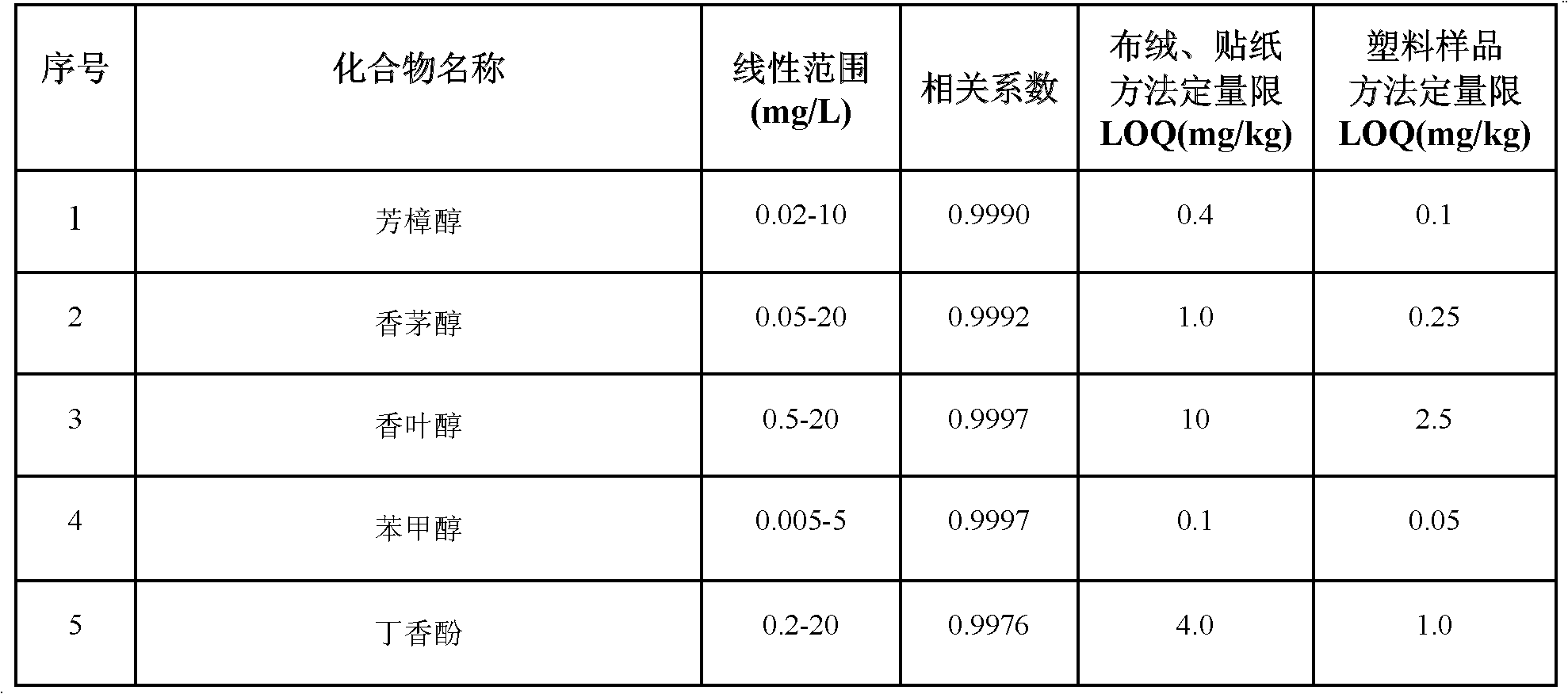

Stabilizer composition suitable for HFC-161 and HFC-161 mixed working medium

InactiveCN103627371AImprove performancePerformance impactHeat-exchange elementsAdditives4-MethoxyphenolBenzophenone

The invention discloses a stabilizer composition suitable for HFC-161 and HFC-161 mixed working medium. The stabilizer composition is composed of two ingredients; a first ingredient is a combination material comprising one, two, or more than three selected from 4-methoxyphenol, 2-hydroxy-4-methoxybenzophenone, 4-tert-butylcatechol, 2, 2-bis(4-Hydroxyphenyl)propane and benzophenone; and the second ingredient is diethylene glycol dimethyl ether and / or 2-(2-Methoxyethoxy)ethanol. The stabilizer composition is capable of ensuring that HFC-161 cycled in a refrigerating system is not decomposed at a high temperature of 175 DEG C.

Owner:SINOCHEM LANTIAN +2

Optical fiber coloring ink capable of being solidified by LED and preparing method thereof

The invention relates to the technical field of communication fiber coloring solidification, in particular to optical fiber coloring ink capable of being solidified by LED. The ink is characterized by being prepared from, epoxy acrylic resin or urethane acrylate, Isopropyl tri(dioctylpyrophosphate) titanate, polyacrylic acid, 3-Aminopropyltriethoxysilane, cellulose nitrate, isopropyl alcohol, 2-Isopropylthioxanthone, sodium benzenesulfonate, benzophenone, oleic acid, a compound photosensitizer, 4-Methoxyphenol, an antifoaming agent BYK088 and a flatting agent BYK344, wherein, the compound photosensitizer is obtained by uniformly mixing a photosensitizer 184, a photosensitizer 1173 and a compound photosensitizer 907 with a mass ratio of (1 to 3):1(1 to 2). The invention further discloses a preparing method of the optical fiber coloring ink capable of being solidified by LED. The optical fiber coloring ink capable of being solidified by LED has the advantages of more energy conservation, faster coloring speed, better environment protection, longer service life of a curing light of a coloring device and lower coloring noise.

Owner:广东昊辉新材料有限公司

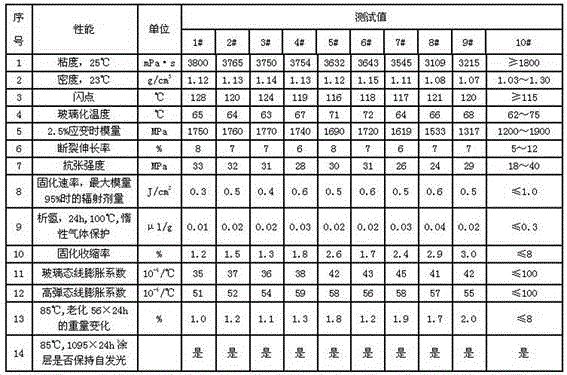

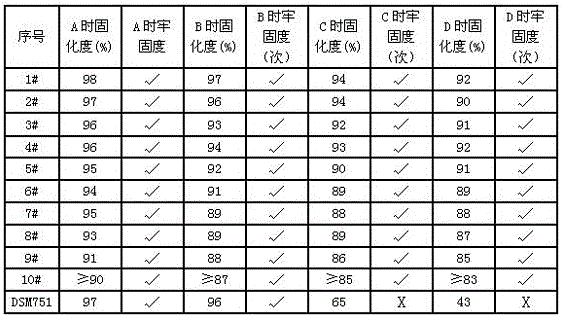

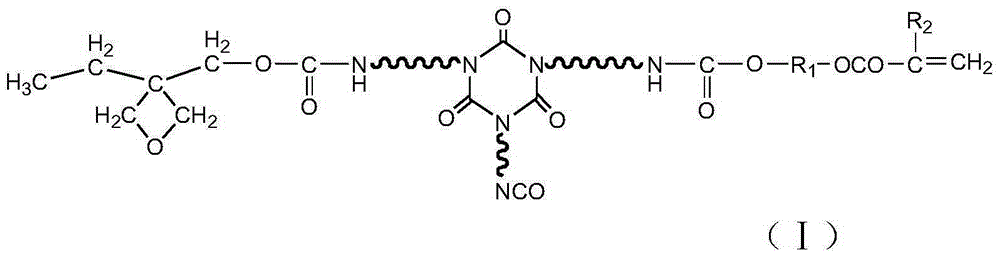

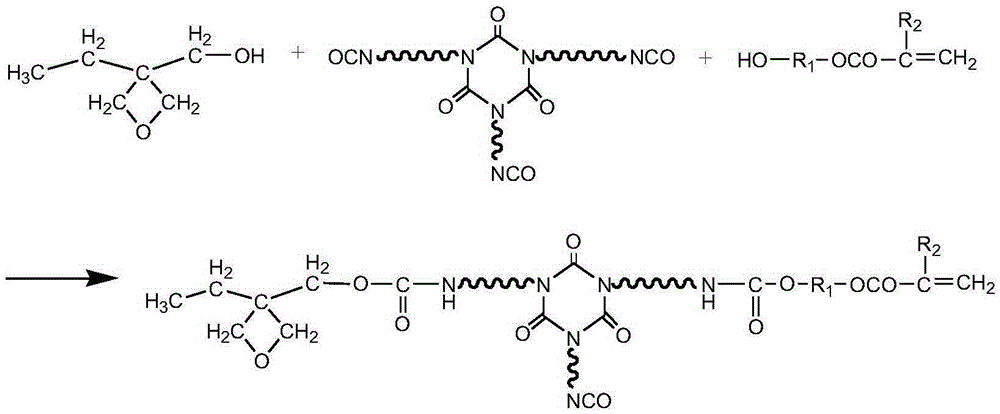

Multi-cured optical resin and synthesizing method thereof

InactiveCN106543154ASpecial chemical structureSolve problems that cannot be curedOrganic chemistryOrganic non-macromolecular adhesive4-MethoxyphenolHydroxybenzoate Ethers

The invention provides a synthesizing method for multi-curing available optical resin. The method comprises the following steps: adding 80-110g of HDI tripolymer, 5-10g of 3-ethyl-3-(hydroxymethyl) oxacyclobutane, 4-10g of hydroxyl acrylate, 0.1g of polymerization inhibitor 4-methoxyphenol and 0.01g of catalyst dibutyltin dilaurate into a three-necked flask with a thermometer, and heating to 65 DEG C; controlling the temperature to be 60-75 DEG C, reacting for 2-3 hours, analyzing NCO group with an infrared infrared spectrometer; and stopping the heat reaction when the NCO peak does not change so as to obtain the multi-cured functional resin capable of free radical+cation+moisture reaction.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

LED chip cleaning solution

InactiveCN106085622AImprove cleaning efficiencyImprove decontamination abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compounds4-MethoxyphenolCleansing Agents

The invention discloses an LED chip cleaning solution. The LED chip cleaning solution comprises the following raw materials by mass: 10 to 15 parts of alkylolamide polyoxyethylene ether, 10 to 15 parts of sorbitan fatty acid ester polyoxyethylene ether, 5 to 8 parts of benzotriazol, 3 to 4 parts of citric acid, 1 to 2 parts of glycerin, 1 to 2 parts of ethanol, 5 to 8 parts of polyoxyethylene ether, 5 to 8 parts of hydrogen peroxide, 2 to 4 parts of ammonium hydroxide, 6 to 10 parts of 1,3-dioxolane, 6 to 8 parts of t-butyl-4-methoxyphenol and 4 to 5 parts of tripropylene glycol methyl ether. The LED chip cleaning solution is high in cleaning efficiency, strong in detergency, good in safety performance, free of pollution to environment, reduced in consumption of energy and low in washing cost; and in the process of washing, the cleaning solution causing no damage to LEDs can form a protection film on the chip, isolate air, prevent water and other molecules in the atmosphere from corroding the chip, resist oxidation and facilitates subsequent operations.

Owner:ANHUI FUN OPTOELECTRONICS TECH

UV curable water-based polyurethane adhesive

InactiveCN109796923AShort curing timeGood mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedPropanoic acid

The invention discloses a UV curable water-based polyurethane adhesive, which is prepared from, by weight, 1-10 parts of polyoxypropylene glycol, 1-10 parts of polypropylene oxide glycol, 5-10 parts of isophorone diisocyanate, 0.5-2 parts of dibutyltin dilaurate, 2-5 parts of 2,2-bis(hydroxymethyl)propionic acid, 2-5 parts of 2-hydroxyethyl acrylate, 0.01-0.2 part of 4-methoxyphenol, 2-5 parts ofpoly(2,2-dimethyltrimethylene carbonate), 1-5 parts of triethylamine, 1-5 parts of KH560, 2-7 parts of nano-magnesium hydroxide, 15-20 parts of absolute ethyl alcohol, 1-5 parts of TPO-L photoinitiator, 1-5 parts of glycerolatedimethacrylate, 1-5 parts of hexanediyl bisacrylate, 1-5 parts of Terpene resin and 20-50 parts of deionized water. The invention further discloses a preparation method of the UV curable water-based polyurethane adhesive. The adhesive, applied to the field of textile, can bring excellent flame retardance and mechanical performance to textile products, and has the advantages of short curing time, good solvent resistance, high bonding strength and being green and environmentally friendly.

Owner:浙江久大纺织科技有限公司

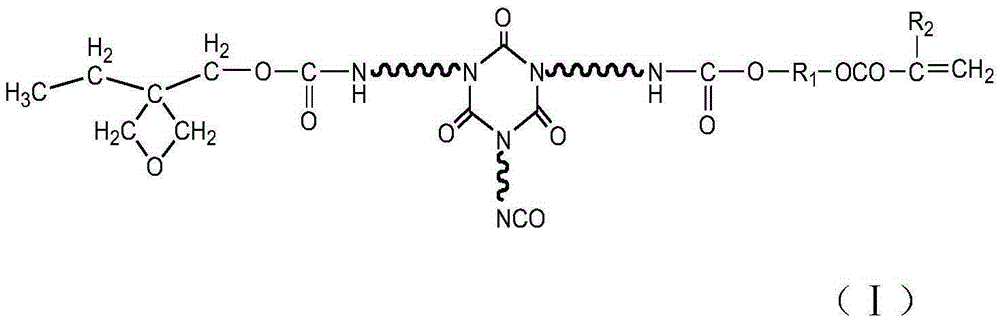

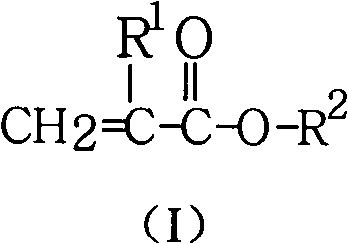

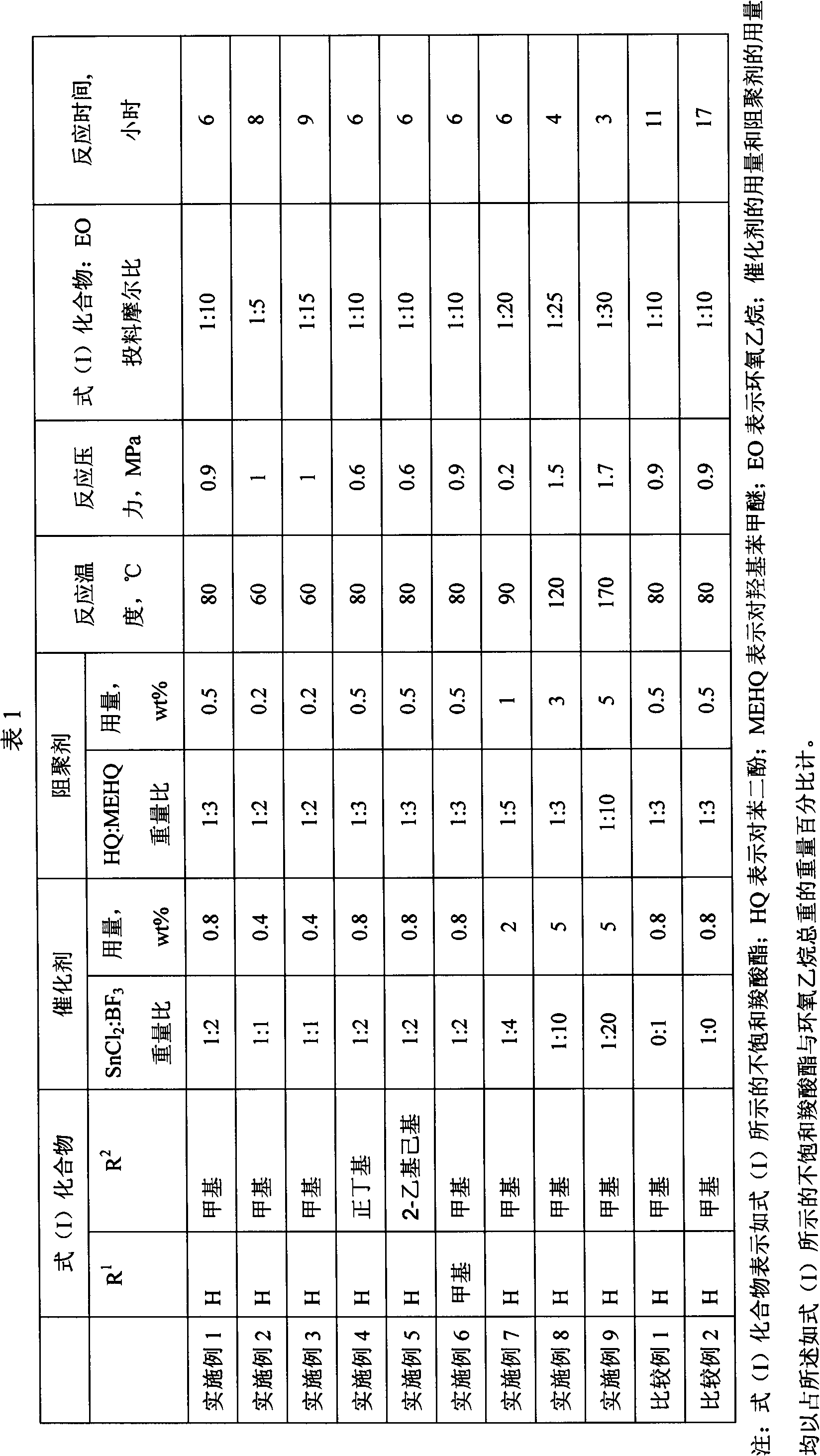

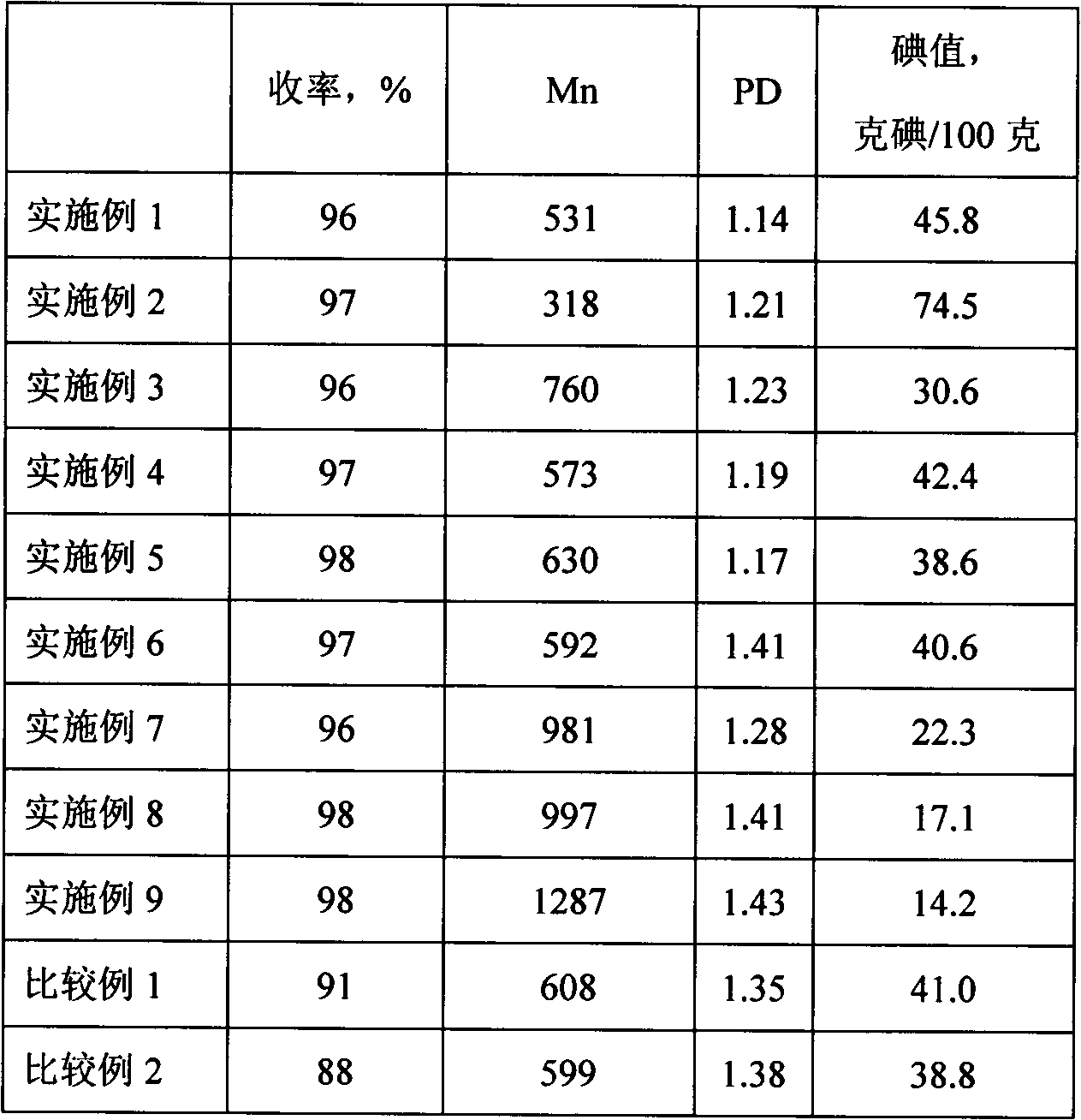

Preparation method for polyethylene glycol mono alkyl ether unsaturated carboxylic ester

ActiveCN102924706ASimple processShort process routeOrganic compound preparationCarboxylic acid esters preparation4-MethoxyphenolHydroxybenzoate Ethers

The present invention relates to a preparation method for polyethylene glycol mono alkyl ether unsaturated carboxylic ester, wherein a purpose of the present invention is to mainly solve the technical problem of long process route of the existing two-step method in the prior art. A technical scheme of the preparation method is that: in the presence of a catalyst, a polymerization inhibitor and an unsaturated carboxylic ester represented by a formula (I), ethylene oxide is added, and a reaction is performed at a reaction temperature of 30-185 DEG C under reaction pressure of -0.01 to 1.9 MPa to obtain the polyethylene glycol mono alkyl ether unsaturated carboxylic ester, wherein the catalyst is SnCl2 and BF3, a weight ratio of SnCl2 to BF3 is 1:0.5-20, the polymerization inhibitor is hydroquinone and / or 4-methoxyphenol, R1 is hydrogen atom or methyl, and R2 is C1-C8 alkyl. With the technical scheme, the technical problem is solved well. The preparation method can be applicable for polyethylene glycol mono alkyl ether unsaturated carboxylic ester production.

Owner:SHANGHAI DUOLUN CHEM

Preparation method of hexa(4-methoxyphenoxyl)cyclotriphosphazene

InactiveCN104311599AMild reaction conditionsEasy to controlGroup 5/15 element organic compounds4-MethoxyphenolHydroxybenzoate Ethers

The invention belongs to the technical field of organic synthesis. An ultrasonic vibration technology is adopted to accelerate the movement of chemical balance to a product direction. The invention relates to a preparation method of hexa(4-methoxyphenoxyl)cyclotriphosphazene. The method comprises a salt forming process, a nucleophilic substitution process and a post-treatment process, and concretely comprises the following steps: adding a 4-methoxyphenol solution into an acid binding agent solution in a dropwise manner under 800-1000W ultrasonic conditions, and reacting at room temperature for 10-30min to obtain a 4-methoxyphenol salt solution; adding a hexachlorocyclotriphosphazene solution into the 4-methoxyphenol salt solution in a dropwise manner under 800-1000W ultrasonic conditions, and reacting at 35-60DEG C for 1-4h; carrying out a refluxing reaction for 8-12h to obtain a hexa(4-methoxyphenoxyl)cyclotriphosphazene solution; and carrying out reduced pressure distillation to evaporate a solvent in the obtained system, dissolving the obtained concentrated in dichloromethane, washing by deionized water, drying, and carrying out reduced pressure distillation to obtain the target product hexa(4-methoxyphenoxyl)cyclotriphosphazene. The preparation method has the advantages of mildness and easy control of reaction conditions, and high yield, and is suitable for preparing hexa(4-methoxyphenoxyl)cyclotriphosphazene.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Flame-retardant smokeless environmentally-friendly glass reinforced plastic coating material and preparation method thereof

InactiveCN103773168AGood physical propertiesImprove mechanical propertiesFireproof paintsEpoxy resin coatings4-MethylimidazoleChloride

The invention discloses a flame-retardant smokeless environmentally-friendly glass reinforced plastic coating material. The flame-retardant smokeless environmentally-friendly glass reinforced plastic coating material is characterized by being prepared from the following raw materials in parts by weight: 29-34 parts of E-12 epoxy resin, 14-18 parts of amino resin, 5-8 parts of dioctyl phthalate, 8-11 parts of nanometer aluminum nitride powder, 1-2 parts of cellulose nitrate, 2-3 parts of bismuthyl chloride, 5-7 parts of magnesium hydroxide, 5-7 parts of ethyl methacrylate, 6-8 parts of 4-methoxyphenol, 3-6 parts of diepoxypropane ethyl ether, 20-23 parts of chopped glass fiber, 2-3 parts of nanometer calcium carbonate, 1-2 parts of zinc stearate, 7-10 parts of 2-ethyl-4 methylimidazole and 1-2 parts of additives. The flame-retardant smokeless environmentally-friendly glass reinforced plastic coating material has good physical performance and mechanical performance by adding the additives and plays a role of reinforcement; the flame-retardant smokeless environmentally-friendly glass reinforced plastic coating material has a good flame-retardant effect by adding the magnesium hydroxide and a smoke suppression effect and is non-toxic and environmentally-friendly, so that a glass reinforced plastic material has a relatively good flame-retardant effect.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Preparation method of heat-resisting transparent heat-insulation UV-curing coating

InactiveCN101747672AHigh visible light transmittanceHigh infrared reflection performanceCoatings4-MethoxyphenolUltraviolet

The invention discloses a preparation method of heat-resisting transparent heat-insulation UV-curing coating, belonging to the technical field of photocureable coating. The preparation method comprises steps of respectively putting the mixed solution of dispersing agent and diluent and different nano-powders into a beaker, adjusting pH to 9.0-10.0, carrying out ultrasonic dispersion after stirred on a magnetic stirrer, and stopping ultrasonic agitation to obtain nano-powder slurry; according to different nano-powder mass ratios, evenly mixing the slurry; putting hydroxy silicone oil, crylic acid and 4-methoxyphenol into the breaker at the temperature of 110 DEG C to react for 5 hours, and preparing UV curing resin; adding nano slurry into the UV curing resin, defoamer, thickening agent and film-forming auxiliary agent, adjusting pH to 9.0-10.0 to obtain heat-resisting transparent heat-insulation UV-curing coating. The invention has simple preparation and construction technology, effectively lowers production cost and is favorable for popularizing to the market. The prepared coat has higher visible light transmittance, infra-red reflectivity, transparent coat, strong hardness, favorable adhesive force, resistance to soiling, ultraviolet ray aging resistance and high temperature resistance.

Owner:JIANGNAN UNIV

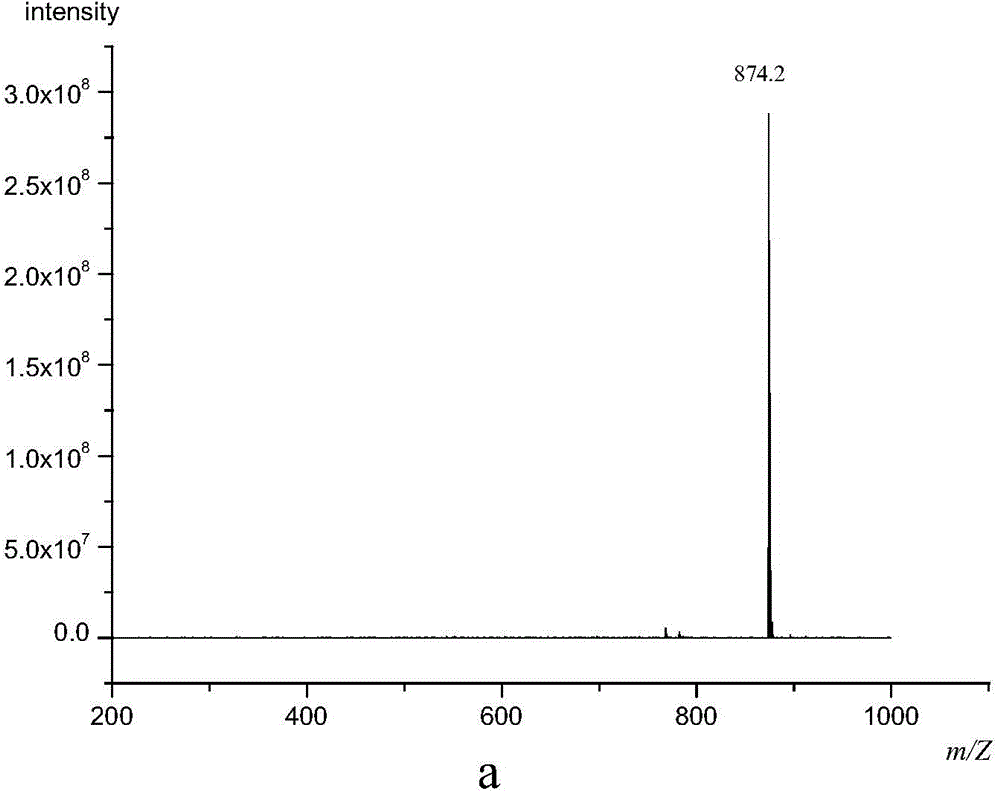

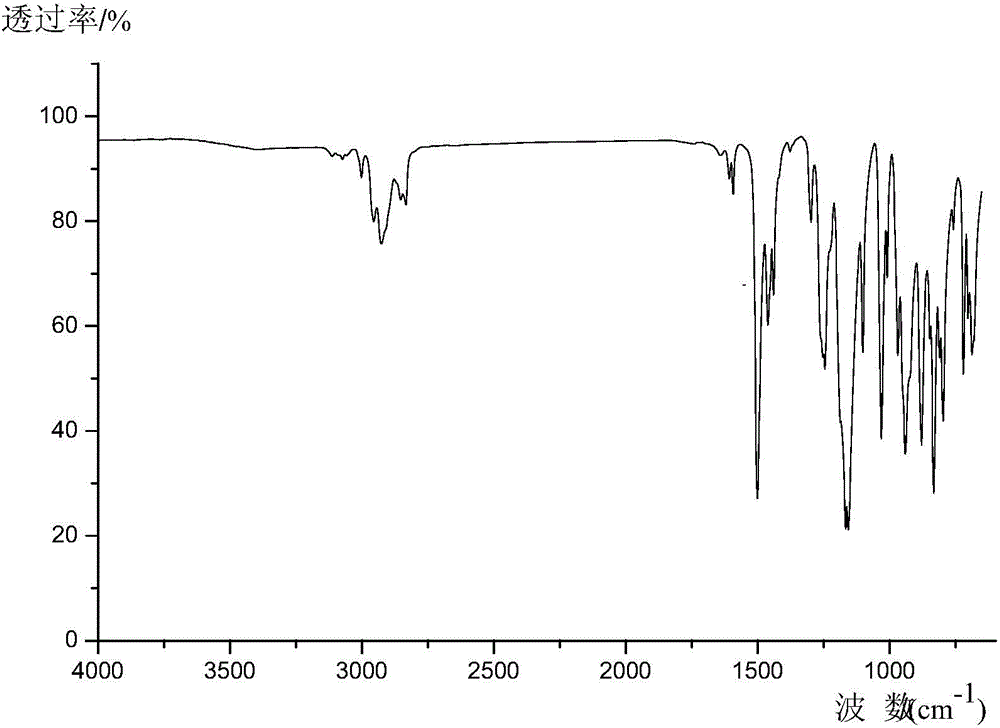

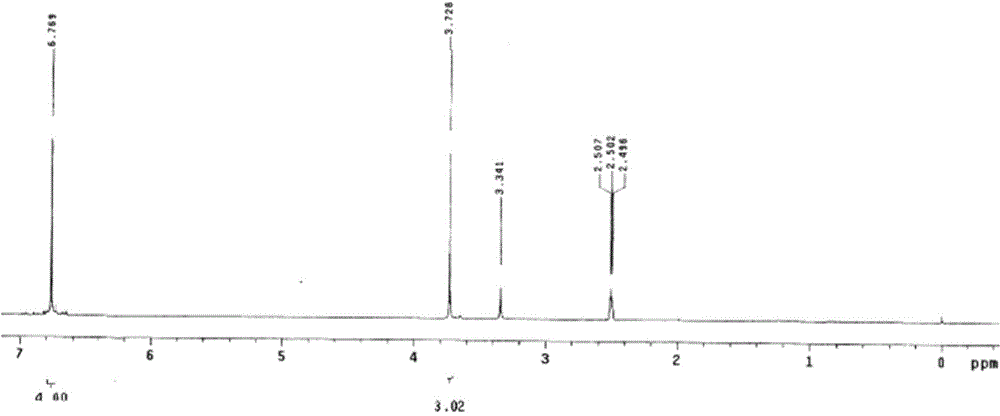

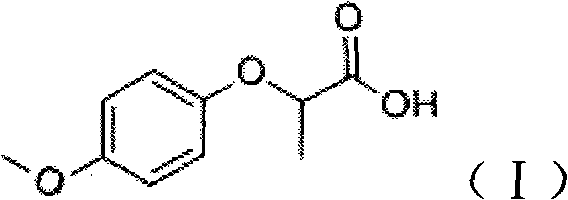

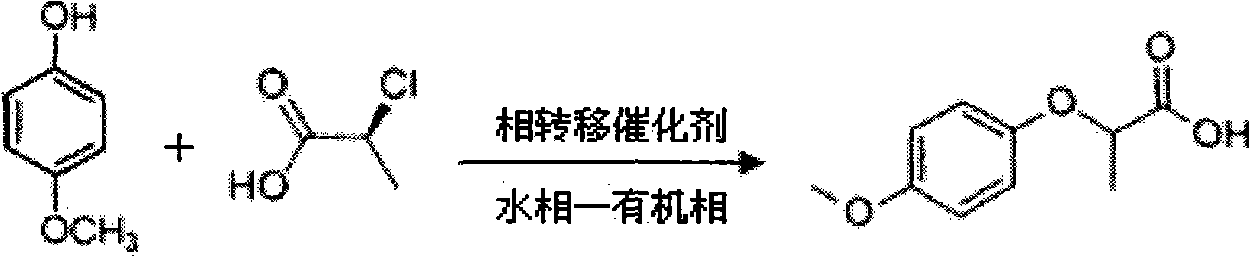

Industrial method for synthesizing 2-(4-methoxyphenoxy)-propionic acid through phase transfer

ActiveCN102010326AImprove conversion efficiencyGuaranteed conversion efficiencyOrganic compound preparationCarboxylic compound preparation4-MethoxyphenolHydroxybenzoate Ethers

The invention discloses an industrial method for synthesizing 2-(4-methoxyphenoxy)-propionic acid through phase transfer, which comprises the following steps of: stirring and mixing 4-Methoxyphenol, sodium hydroxide, a phase transfer catalyst and water, and reacting at normal temperature and normal pressure for 10 to 20 minutes to obtain mixed feed liquid; adding 2-chloro-propanoic acid and an organic phase into the mixed feed liquid, and reacting for 0.5 to 1.5 hours to obtain a product of 2-(4-methoxyphenoxy)-propionic acid; regulating the reaction liquid subjected to reaction to be acid byusing HCl or sulfuric acid solution, and standing to separate a water phase and the organic phase; and evaporating organic phase separation liquid to remove a solvent, and performing acid-base recrystallization to obtain the 2-(4-methoxyphenoxy)-propionic acid. When the reaction is finished, the yield of the 2-(4-methoxyphenoxy)-propionic acid is over 90 percent, the reaction temperature is reduced to 40-60 DEG C, the reaction time is only 0.5 to 1.5 hours, and the content of 2-(4-methoxyphenoxy)-propionic acid in the final product is 99.5 percent.

Owner:SOUTH CHINA UNIV OF TECH

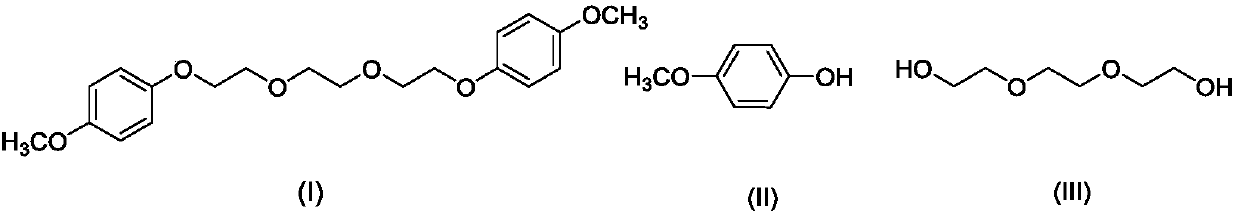

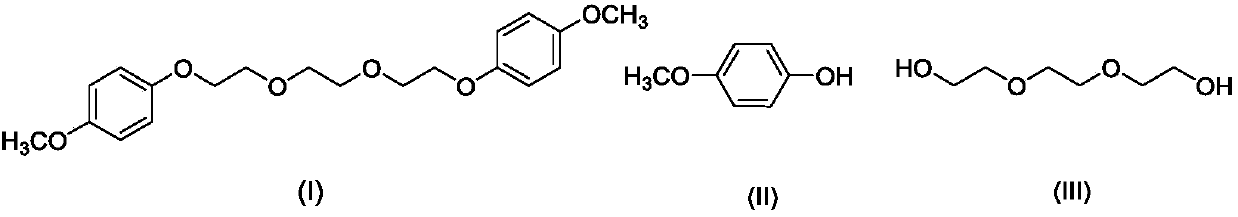

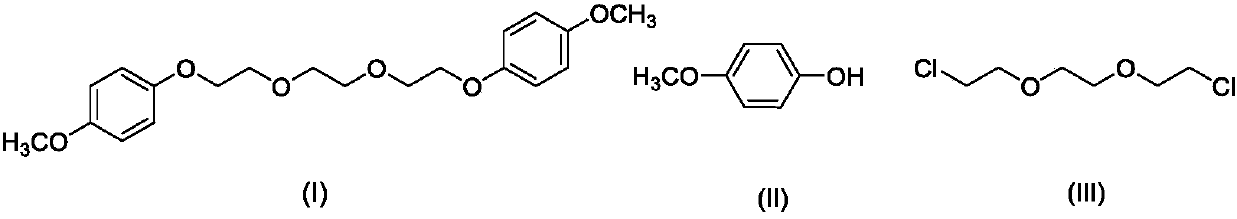

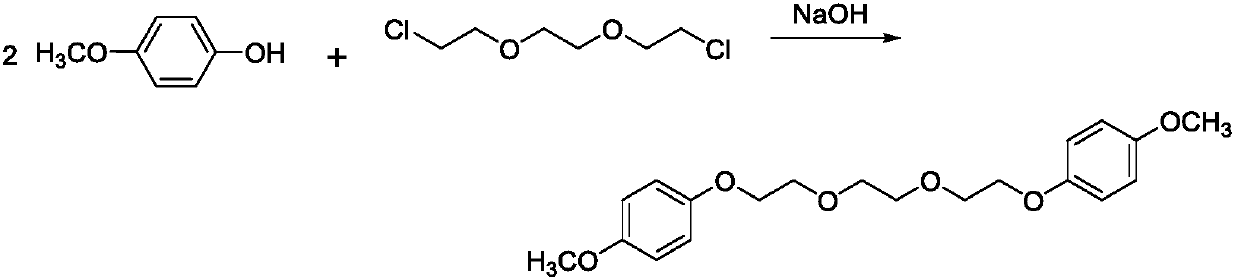

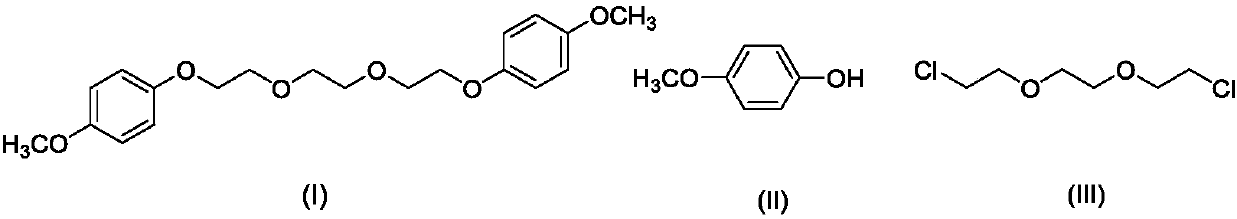

Preparation method of 1, 2-bis (2-(4-methoxyphenoxy)ethoxy)ethane

ActiveCN107935822AReduce usageHigh reaction yieldEther preparation by compound dehydration4-MethoxyphenolSodium hydroxide

The invention discloses a preparation method of 1, 2-bis (2-(4-methoxyphenoxy)ethoxy)ethane, and aims to solve the problems that in the prior art, used reactants are not environmentally friendly, theyield is low and the like. 4-methoxyphenol and triethylene glycol are used as raw materials, and the preparation method comprises the following steps: (1), stirring at 20 DEG C, adding 4-methoxyphenoland triethylene glycol into acetonitrile, adding dicyclohexylcarbodiimide, reacting for 24h at 85 DEG C, and evaporating out acetonitrile to obtain a turbid liquid 1; (2), adding dichloromethane intothe turbid liquid 1, filtering, washing for 3 times with 1M sodium hydroxide, washing twice with saturated sodium chloride, drying by anhydrous magnesium sulfate, and evaporating out dichloromethaneto obtain a yellow powdery solid 2; (3), adding ethyl ether into the yellow powdery solid 2, raising the temperature to 35 DEG C, filtering out insolubles, cooling to -15 DEG C, lowering the temperature for 4 hours, and filtering to obtain a white powdery solid, namely 1, 2-bis (2-(4-methoxyphenoxy)ethoxy)ethane. The method is mainly applied to preparation of 1, 2-bis(2-(4-methoxyphenoxy)ethoxy)ethane.

Owner:XIAN MODERN CHEM RES INST

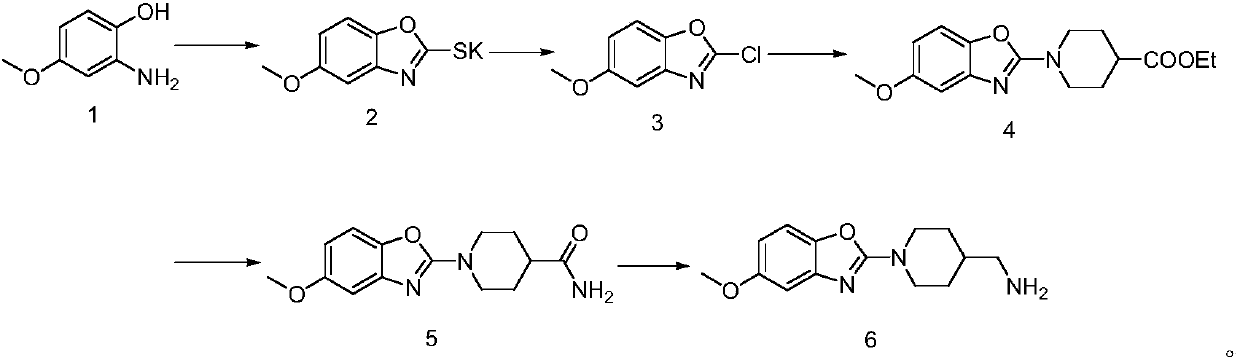

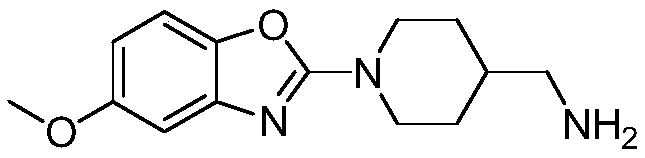

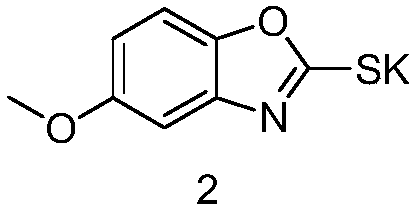

Preparation method of substituted benzoxazole derivative

The invention discloses a preparation method of a substituted benzoxazole derivative, i.e., (1-(5-methoxybenzo[d]oxazole-2-yl)piperidin-4-yl)methylamine. According to the preparation method, 2-amino-4-methoxyphenol is taken as a starting raw material, and a target product is obtained by carrying out ring closing, chlorination, nucleophilic substitution, ammonolysis and reduction. The compound is an important medical intermediate.

Owner:湖南华腾制药有限公司

Green synthesis method of trimethylolpropane triacrylate

InactiveCN108752201ASimple production processQuality improvementOrganic compound preparationCarboxylic acid esters preparation4-MethoxyphenolHydroxybenzoate Ethers

The invention relates to a green synthesis method of trimethylolpropane triacrylate. The green synthesis method comprise following steps: 1, raw materials are introduced into a reactor, heating backflow treatment is carried out until no water is detected in an obtained backflow liquid, and cooling to room temperature is carried out; 2, a water washing phase obtained in a step 4 of a former batch is introduced into a reaction vessel for water washing, an obtained methane sulfonic acid water phase is concentrated, and is recycled back into a step 1 of a next batch; 3, a sodium hydroxide solutionis added to a reaction liquid obtained through water washing for washing, an obtained mixture is allowed to stand for layering, a sulfuric acid solution is added into an obtained alkali washing waterphase for adjusting, and underpressure distillation and rectification are carried out so as to obtain acrylic acid; 4, water is added into a material obtained after alkali washing for washing, 4-methoxyphenol is added, an obtained mixed solution is allowed to stand for layering, an obtained lower layer water washing phase is recycled back into a step 2 of a next batch; and 5, a reaction materialobtained through removing of water phase is introduced into an evaporator, and vacuum pumping is carried out so as to obtain a finished product. The advantages are that: recycling of a catalyst, excess acrylic acid raw material, and a solvent is realized respectively, production cost is reduced, and at the same time waste water emission is reduced.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Corrosion-resistant and fireproof coating

InactiveCN107955514AStrong adhesionHigh hardnessFireproof paintsAnti-corrosive paints4-MethoxyphenolWater based

The invention discloses corrosion-resistant and fireproof coating. The corrosion-resistant and fireproof coating comprises, by mass, 50-60 parts of water-based polyurethane, 3-5 parts of acetone, 15-20 parts of maleic resin, 2-3 parts of nano zinc phosphate, 5-13 parts of polyurethane polymer, 11-13 parts of cellulose acetate, 1-3 parts of ammonium dodecylbenzene sulfonate, 1-2 parts of 4-methoxyphenol, 6-10 parts of polyvinyl alcohol, 1-2 parts of azo dimethyl valeronitrile, 10-15 parts of organic bentonite, 3-6 parts of triethanolamine, 2-7 parts of microgel, 2-4 parts of aluminum dihydrogenphosphate, 1-3 parts of polydimethyl siloxane, 4-7 parts of nano pigment, 2-3 parts of dipentaerythritol, 10-13 parts of filler, 2-4 parts of leveling agent, 2-3 parts of sealing agent, 5-7 parts ofdispersing agent, 2-4 parts of wetting agent, 1-3 parts of stabilizer, 3-5 parts of defoaming agent and 2-4 parts of solvent.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

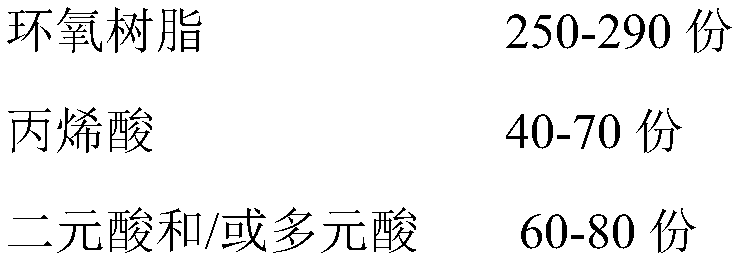

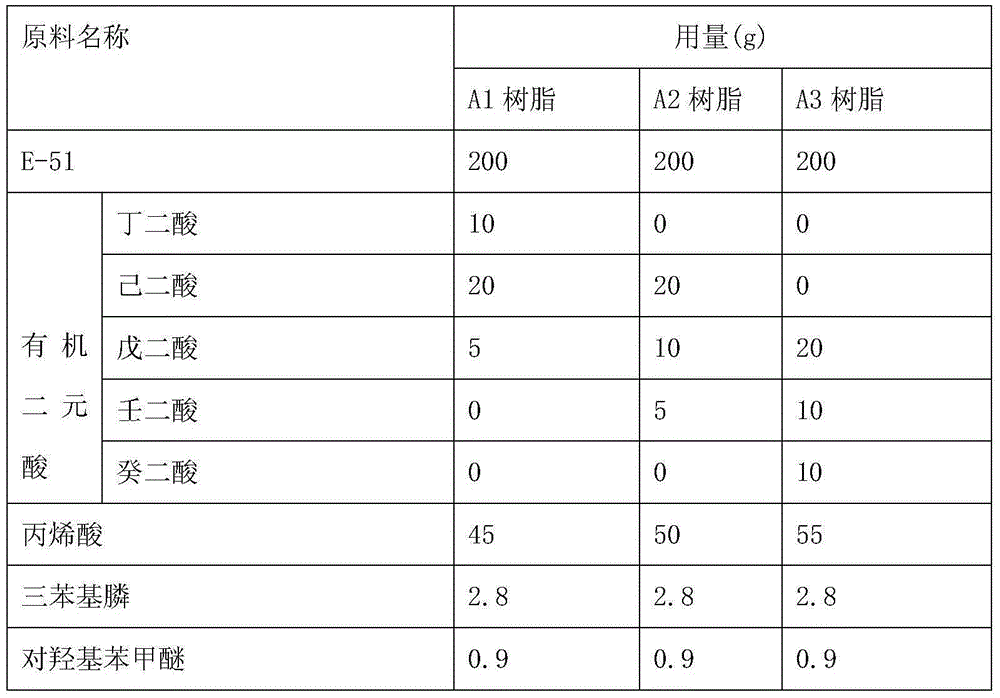

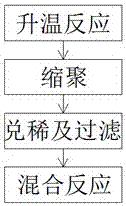

Waterborne UV epoxy acrylic resin and preparation method thereof

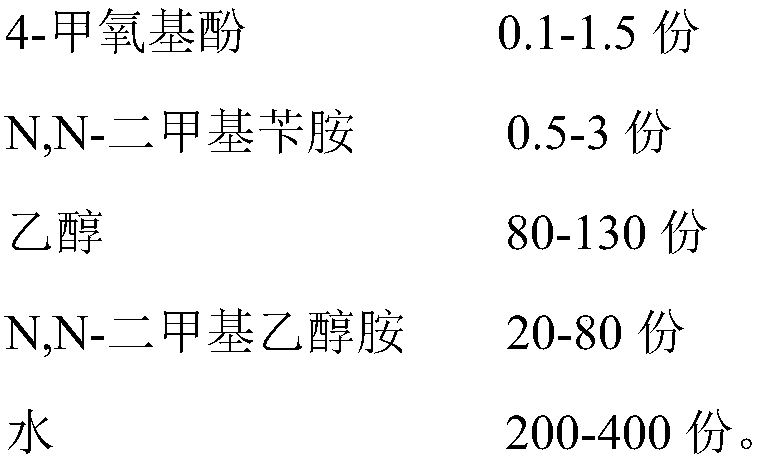

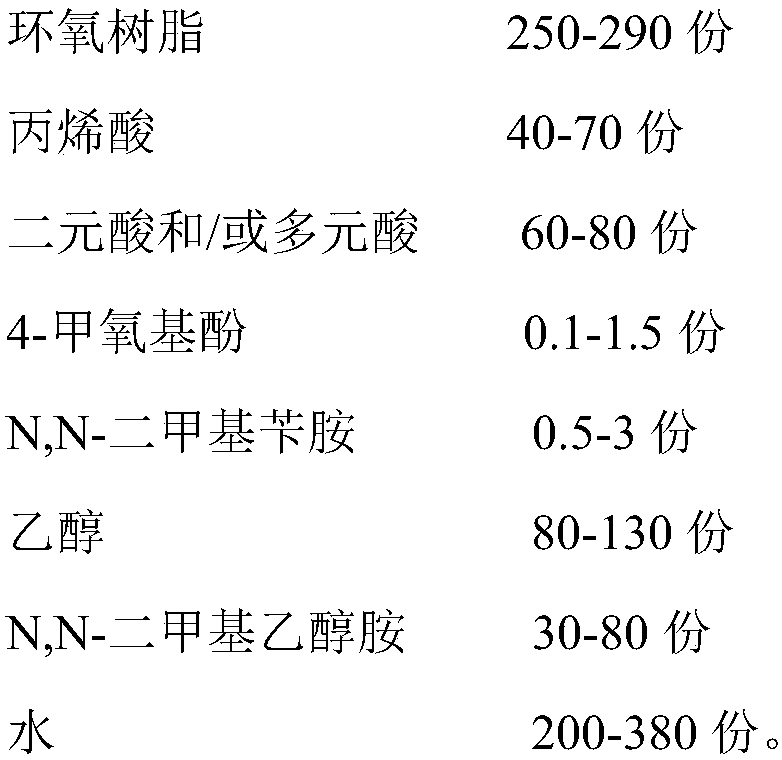

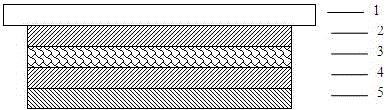

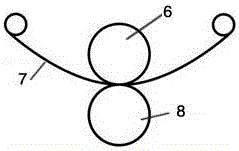

The invention discloses waterborne UV epoxy acrylic resin. The formula comprises the following components (by weight): 250-290 parts of epoxy resin, 40-70 parts of acrylic acid, 60-80 parts of diacidand / or polybasic acid, 0.1-1.5 parts of 4-methoxyphenol, 0.5-3 parts of N,N-dimethyl benzylamine, 80-130 parts of ethanol, 20-80 parts of N, N-dimethylethanolamine, and 200-400 parts of water. With the introduction of itaconic acid for modification of epoxy acrylate, the waterborne UV epoxy acrylic resin has good stability and good hydrophilicity, will not be hydrolyzed or layered after long-termstorage, has fast UV curing rate, and has good adhesion to a base material. The product is convenient and environmentally-friendly to use, and is pollution-free.

Owner:JIANGMEN HENGZHIGUANG ENVIRONMENTAL PROTECTION NEW MATERIAL CO LTD

UV resin capable of being dried by heating, a preparing process thereof and applications of the resin

InactiveCN106397718AHigh economic valueEmission reductionChemical industryPolyurea/polyurethane coatings4-MethoxyphenolUV curing

The invention relates to UV resin. The UV resin has a property of capability of being dried by heating and a property of waiting for UV curing. The UV resin includes, by mass, 40-60% of isocyanate, 25-45% of hydroxyethyl methylacrylate, 30-50% of polyester resin and 0.005-0.01% of a polymerization inhibitor that is 4-methoxyphenol, with the balance being a solvent. A preparing process of the UV resin and applications of the UV resin in preparation of heat transfer membranes waiting for UV curing are also disclosed. Product decoration and surface protection can be finished in one step, thus avoiding a step of spraying of a protective paint layer, saving energy, protecting the environment, and saving labor and materials. Products are beautiful and durable.

Owner:广东东田转印新材料有限公司

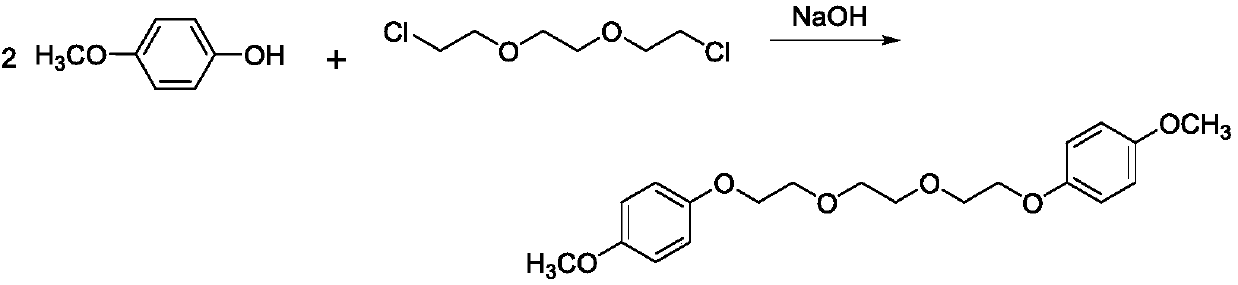

Synthesis method of 1,2-di(2-(4-dimethoxyphenoxy) ethoxy) ethane

InactiveCN107903152ASimple post-processingHigh reaction yieldOrganic compound preparationEther preparation by ester reactions4-MethoxyphenolN dimethylformamide

The invention discloses a synthesis method of 1,2-di(2-(4-methoxyphenoxy) ethoxy) ethane, and aims to solve the problems of long reaction time, complex post-treatment and the like in the prior art. According to the method provided by the invention, 4-methoxyphenol and 1,2-(dichloroethane group) ethane are taken as raw materials, and the method comprises the following steps: (1) carrying out stirring at 20 DEG C, adding 4-methoxyphenol and 1,2-(dichloroethane group) ethane into N,N-dimethylformamide, adding potassium hydroxide to react at 150 DEG C for 12h, and pouring a reaction solution intowater to obtain a brown turbid solution 1; (2) cooling the brown solution 1 to -15 DEG C, keeping the temperature for 4h, filtering the brown solution to obtain a white flaky solid, adding diethyl ether into the white flaky solid, raising the temperature to 35 DEG C, filtering the mixture when the mixture is hot, cooling the mixture to -15 DEG C, keeping the temperature for 4h, and carrying out filtering to obtain white powdery solid 1,2-di(2-(4-dimethoxyphenoxy) ethoxy) ethane. The method provided by the invention is mainly used for synthesizing 1,2-di(2-(4-dimethoxyphenoxy) ethoxy) ethane.

Owner:XIAN MODERN CHEM RES INST

UV curing gloss oil with excellent explosion-proof performance and preparation method thereof

ActiveCN105131677ABenzene ring content decreasedExcellent anti-violence performanceDefoamers additionPaper coatingEpoxy4-Methoxyphenol

The invention discloses UV curing gloss oil with excellent explosion-proof performance. The UV curing gloss oil with the excellent explosion-proof performance is prepared from, by weight, 80-120 parts of organic dibasic acid modified epoxy acrylate active oligomer, 0.2-0.6 part of antifoaming agents, 10-30 parts of tripropylene glycol diacrylate, 10-20 parts of 1,6-hexanediol diacrylate, 4-12 parts of diphenyl ketone, 1-3 parts of 1-hydroxy-cyclohexyl benzene ketone, 4-12 parts of active amine, 0.3-0.9 part of flatting agents and 5-10 parts of water; the organic dibasic acid modified epoxy acrylate active oligomer is prepared from, by weight, 150-250 parts of E-51 epoxy resin, 30-50 parts of organic dibasic acid, 20-30 parts of succinic acid, 0-30 parts of adipic acid, 2-30 parts of glutaric acid, 0-15 parts of azelaic acid, 0-15 parts of sebacic acid, 30-70 parts of acrylic acid, 1.2-4.5 parts of triphenylphosphine, 0.3-1.8 parts of 4-methoxyphenol and 5-10 parts of water. Compared with epoxy-acrylic resin used by ordinary UV gloss oil, the UV curing gloss oil has the excellent explosion-proof performance, and due to the fact that the content of benzene rings in molecules is decreased, the anti-yellowing performance is promoted to some extent.

Owner:BAUHINIA VARIEGATA INK & CHEM (ZHONGSHAN) LTD

Environment-friendly anti-aging glass-reinforced plastic composite coating material and preparation method of coating material

InactiveCN103788842AGood physical propertiesImprove mechanical propertiesPolyester coatingsAlkali freePhysical property

An environment-friendly anti-aging glass-reinforced plastic composite coating material is characterized by comprising the following raw materials in parts by weight: 33-35 parts of an unsaturated polyester resin, 6-10 parts of phenolic resin, 2-3 parts of aluminium hydroxide, 1-2 parts of magnesium oxide, 26-28 parts of alkali free glass fiber, 1-2 parts of ammonium borate, 3-4 parts of cumarone, 2-3 parts of a crosslinking agent TAC, 4-6 parts of dibutyl phthalate, 5-7 parts of methyl ethyl ketone peroxide, 2-3 parts of dibutyltin oxide, 3-4 parts of 4-methoxyphenol, 3-5 parts of n-propyl methacrylate, 1-2 parts of a ceramic powder, and 1-2 parts of an additive. The additive is added, so that the material has good physical property and mechanical performance, so as to exert the effect of reinforcement. The preparation method is simple and reasonable, and the products formed by the preparation method have the characteristics of excellent corrosion resistance, high strength, light quality, equal mechanical performance to part metal materials, low cost, energy source saving, environment protection, and low carbon.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Mobile phone glass screen protective film OCA optical cement

InactiveCN108949044AHigh light transmittanceGood adhesionNon-macromolecular adhesive additivesOrganic non-macromolecular adhesive4-MethoxyphenolEthanol

The invention discloses a mobile phone glass screen protective film OCA optical cement, which contains the following components in parts by weight: 20-40 parts of saturated polyacrylate containing crosslinkable groups, 15-25 parts of isobornyl methacrylate, 10-15 parts of mercaptoacetate resin, 1-5 parts of acetamide, 2-7 parts of hexamethyl phosphoryl diamide, 3-8 parts of 2,3-epoxycyclicarnyl ether, 1-6 parts of tetraethyldiaminobenzophenone, 4-8 parts of aliphatic bis(ethanol) ester, 5-10 parts of triisooctyl 3-mercaptopropionate, 1-5 parts of nanozinc oxide, 2-6 parts of nano-silicon dioxide, 1-7 parts of 4-methoxyphenol, and 0.1-1.0 parts of initiator. The mobile phone glass screen protective film OCA optical cement has the beneficial effects of being high in transmittance, good in adhesion, water resistance, anti-aging property and excellent in release force performance, easy to coat and produce, good in 100% curing environment-friendly effect, and low in price.

Owner:安徽臻荣智能科技有限公司

Preparation method of solvent-free photocuring material

InactiveCN106496434AThe preparation process is simple and environmentally friendlyLow costNon-macromolecular adhesive additivesFilm/foil adhesives4-MethoxyphenolPolyethylene terephthalate glycol

The invention relates to a preparation method of a solvent-free photocuring material. The preparation method includes adding 120 g of double-carbon hydroxyl silicone oil and 17 g of isophorone diisocyanate into a reactor together, adding 0.1 g of dibutyltin dilaurate as a catalyst, reacting for 2.5-5 hours at 75 DEG C, adding 3.5 g of hydroxyethyl acrylate and 0.3 g of 4-methoxyphenol, continuing to react for 2-4 hours at 75 DEG C, adding 30 g of 2-ethylhexyl acrylate with stirring evenly, adding 5 g of 2-hydroxy-methyl-phenyl-propane-1-one as a photoinitiator, mixing to enable system viscosity to be kept at 2,000 mPa-S, applying a mixture on a PET (polyethylene terephthalate) film after even stirring, disposing the PET film 15 centimeters away from a 2 Kw ultraviolet lamp and under the same and curing the PET film for 50 seconds so as to obtain the solvent-free photocuring material.

Owner:山东高洁环保科技有限公司

Aging-resistant flame-retardant ultraviolet-curable optical fiber coating and preparation method thereof

The invention discloses an aging-resistant flame-retardant ultraviolet-curable optical fiber coating. The aging-resistant flame-retardant ultraviolet-curable optical fiber coating is prepared from 50-57 parts by weight of propoxyglycerol triacrylate, 10-14 parts by weight of 1, 1-dimethyl-2, 2, 3, 4, 4, 4-hexafluorobutyl methacrylate, 3-6 parts by weight of ethoxylated trimethylolpropane triacrylate, 3-5 parts by weight of a photoinitiator 1844, 7-10 parts by weight of ethoxylated bisphenol A diacrylate, 5-7 parts by weight of isobornyl methacrylate, 2-4 parts by weight of gamma-aminopropyltriethoxysilane, 1-2 parts by weight of 4-methoxyphenol, 4-6 parts by weight of nano-clay, 1-2 parts by weight of methyl-(butylaminoformyl)-2-benzimidazole carbamate, and 9-13 parts by weight of an aid.The aging-resistant flame-retardant ultraviolet-curable optical fiber coating has high anti-oxidation and anti-aging properties, good leveling properties, a fast curing rate and good adhesion.

Owner:成都市创斯德机电设备有限公司

Waterborne polyester resin coating and preparation method thereof

InactiveCN106905824AImprove hydrolysis resistanceGood dispersionPolyester coatings4-MethoxyphenolAdipic acid

The invention discloses a waterborne polyester resin coating, which includes 6-8% of polyol, polyprotic acid and a catalyst, 2-6% of a curing agent, 4-8% of pigment, 2-6% of a filling material, 12-18% of a cosolvent and 40-80% of water. The polyol comprises 8-12% of trimethylolpropane, 12-24% of neopentylene glycol, 6-12% of glycol and 8-12% of propanediol. The polyprotic acid includes 5-15% of refined terephthalic acid, 12-24% of m-phthalic acid, 6-12% of phthalic acid, 10-18% of trimellitic anhydride, 6-12% of hexahydro-phthalic acid, 10-20% of maleic anhydride, and 5-10% of adipic acid. The waterborne polyester resin coating further includes 0.1-0.3% of 4-methoxyphenol, 6-24% of 2-butoxyethanol, 8-16% of dimethyl ethanolamine and 60-100% of deionized water. The hydrolytic stability of polyester main chains is improved, so that the aqueous insulating properties of the polyester resin coating are improved. The waterborne polyester resin coating can be widely applied to aqueous insulation devices, overcomes the defects in the prior art, and meets the actual use demand.

Owner:滁州市全丰物资有限公司

Efficient cleaning agent for equipment in chemical laboratory and preparing method of efficient cleaning agent

InactiveCN106010843AEfficient removalEasy to rinseAnionic surface-active compoundsDetergent mixture composition preparation4-MethoxyphenolHydroxybenzoate Ethers

The invention discloses an efficient cleaning agent for equipment in a chemical laboratory and a preparing method of the efficient cleaning agent. The efficient cleaning agent is prepared from 1,2,3-propanetriol, polymer with methyloxirane and oxirane, sodium lignosulfonate, soap powder, hydroxypropyl methyl cellulose ether, hydrogen peroxide, midazoline, 4-methoxyphenol, fatty alcohol polyoxyethylen ether, sodium tripolyphosphate, isopropyl alcohol, citric acid and water. Water is heated, sodium lignosulfonate, fatty alcohol polyoxyethylen ether, sodium tripolyphosphate and isopropyl alcohol are added first and stirred and mixed evenly till the mixture is completely dissolved; then, soap powder and citric acid are added and stirred evenly; finally, the rest of the raw materials are added in sequence, heating is carried out under the microwave condition, full stirring is carried out for h, and a finished product is obtained. The cleaning agent can effectively remove residual acid, alkali, oil stains and other chemical substances on the equipment in the chemical laboratory; besides, bleaching is easy, high patience pertinence is achieved, and secondary contamination can be avoided; the preparing method is simple, good in effect and high in speed.

Owner:张小霞

Antibacterial flame-retardant ultraviolet curing optical fiber coating and preparation method thereof

InactiveCN108373730AFlame retardantHas antibacterial propertiesFireproof paintsAntifouling/underwater paints4-MethoxyphenolCarbamate

The invention discloses an antibacterial flame-retardant ultraviolet curing optical fiber coating. The antibacterial flame-retardant ultraviolet curing optical fiber coating is prepared from 50-57 parts by weight of polyethylene glycol acrylate, 10-14 parts by weight of 2, 2, 2-trifluoroethyl methacrylate, 3-6 parts by weight of isobornyl acrylate, 3-5 parts by weight of a photoinitiator 1173, 7-10 parts by weight of ethoxylated bisphenol A diacrylate, 5-7 parts by weight of acrylate phosphate, 2-4 parts by weight of gamma-aminopropyl triethoxysilane, 1-2 parts by weight of 4-methoxyphenol, 4-6 parts by weight of amorphous silica, 1-2 parts by weight of butyl iodopropynyl carbamate and 9-13 parts by weight of an aid. The antibacterial flame-retardant ultraviolet curing optical fiber coating contains safe and non-toxic antibacterial components and has good effects of resisting mildew and oxidation. Through use of zinc oxide, flame retardant and antibacterial effects are obtained and a sealing effect is provided. Through use of the aid, the leveling property is good, a uniform coating is formed, a curing rate is fast, and hardness, wear resistance, toughness and strong adhesion are obtained.

Owner:CHENGDU SHANSHUI TIANXIA TECH CO LTD

Epoxy paint for automobile leaf springs and preparation method thereof

InactiveCN106543854AWell mixedIncrease the degree of cross-linkingAnti-corrosive paintsSodium bicarbonatePolyethylene glycol

The invention discloses epoxy paint for automobile leaf springs. The paint comprises the following raw materials in parts by weight: 0.7-1 part of fatty acid polyethylene glycol ester, 0.4-1 part of triethanolamine, 0.8-1 part of sodium pyrophosphate, 1-2 parts of zinc ricinate, 7-9 parts of 2-hydroxyethyl methacrylate, 0.8-1 part of phosphoric pentoxide, 2-3 parts of 4-methoxyphenol, 0.6-2 parts of tetrabutylammonium bromide, 17-20 parts of acrylic acid, 6-8 parts of methyl methacrylate, 140-150 parts of epoxy resin E-5, 0.07-0.1 part of ammonium persulfate, 2-3 parts of sodium bicarbonate, 0.6-1 part of sodium dodecyl benzene sulfonate, 0.1-0.13 part of N,N-diethylaniline, 1-2 parts of 2-mercapto benzimidazole, 2-3 parts of barium stearate, 4-5 parts of dimethyl nylon acid, and 6-7 parts of bentonite. The paint has low cost, and solves the problems of large 'falling amount' of the automobile leaf springs in the prior art without environmental protection, and bad antirust capability.

Owner:TONGLING SIDE TECH

Synthesis of diphenylether-formaldehyde resin

InactiveCN106811161AThe synthesis reaction process is simpleEasy to controlNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesives4-MethoxyphenolHydroxybenzoate Ethers

The invention relates to synthesis of diphenylether-formaldehyde resin. A process comprises the following steps that 80 to 90g of diphenylether-formaldehyde resin, 32 to 40g of HDI trimers, 5g of 3-ethyl-3-hydroxymethyleneoxetane, 10g of hydroxyethyl methylacrylate, 0.1g of polymerization inhibitors of 4-methoxyphenol and 0.01g of catalysts of dibutyl tin laurate are added into a three-opening flask with a temperature indicator; the temperature is raised to 80 to 90 DEG C; the temperature is controlled to be 80 to 90 DEG C; the reaction is taken for 3 to 6hours; the heating reaction is stopped, and the diphenylether-formaldehyde resin is obtained.

Owner:孙萌萍

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com