UV resin capable of being dried by heating, a preparing process thereof and applications of the resin

A resin and drying technology, used in sustainable manufacturing/processing, chemical industry, coating, etc., can solve the problems of not being suitable for products with curved corners, affecting the surface protection performance of products, and not having soft properties, and achieving production and processing. Cost reduction, emission reduction, high economic value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The polyester resin used as the raw material for the preparation of the above UV resin is polyester polyol, and the hydroxyl value ranges from 1% to 2.8%.

[0034] The preparation process conditions of the above-mentioned UV resin capable of "heating and drying" are as follows: add a measured amount of isocyanate into the reaction kettle, add a measured amount of solvent butyl acetate and a polymerization inhibitor p-hydroxyanisole, and then add a measured amount of methacrylic acid Hydroxyethyl ester, the reaction time is 1-5 hours, the reaction temperature is 50-90°C, then add the measured polyester resin, continue the reaction for 1-5 hours, cool down and discharge the material, and add a photosensitizer at an appropriate time, that is, a paintable UV resin that can print "heat drying".

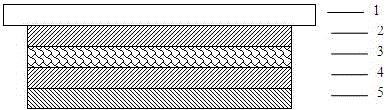

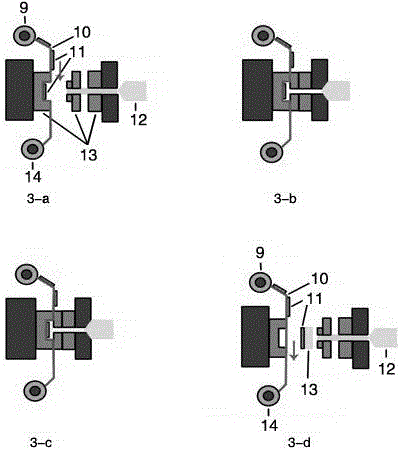

[0035] The heat transfer film of UV resin protection layer of the present invention is first coated with the UV resin layer of the present invention by coating processes such as gra...

Embodiment 1

[0040] Example 1: Preparation of UV resin applied to heat transfer and preparation of heat transfer film thereof

[0041]Take: 45 kg of isocyanate, 30 kg of hydroxyethyl methacrylate, 25 kg of polyester resin, 4.5 kg of photosensitizer, and 0.1 kg of p-hydroxymethyl anisole as polymerization inhibitor. Add the measured amount of isocyanate into the reaction bottle, add the polymerization inhibitor p-hydroxyanisole and the remaining solvent butyl acetate, then add the measured amount of hydroxyethyl methacrylate, the reaction time is 3 hours, the reaction temperature is 70 ° C, and then add The measured polyester resin continues to react for 2 hours, and the temperature is lowered to discharge, which is the resin with the property of "heat drying and winding". The prepared resin material with the performance of "heat drying and winding" is stored in a certain 40°C environment for 40 hours and left to stand.

[0042] Using PET film, coated with common acrylic release agent, and...

Embodiment 2

[0045] 40 kg of isocyanate, 25 kg of hydroxyethyl methacrylate, 31.5 kg of polyester polyol with a hydroxyl value range of 2.0%, 3 kg of photosensitizer, and 0.5 kg of p-hydroxymethyl anisole, a polymerization inhibitor. Add the measured isocyanate into the reaction bottle, add the measured polymerization inhibitor p-hydroxyanisole and the remaining solvent butyl acetate, and then add the measured hydroxyethyl methacrylate, the reaction time is 5 hours, and the reaction temperature is 50 ° C. Then add the measured polyester resin, continue to react for 3 hours, cool down and discharge, which is the post-UV curing resin. The raw materials for preparing the resin with the performance of "heat drying and winding" are stored in a certain 40°C environment for 40 hours and left to stand.

[0046] Use the PET film coated with polyethylene wax layer, print on the gravure printing machine according to the pattern requirements, and leave it for 40 hours to have the performance of "heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com