Patents

Literature

654results about How to "Reduce production and processing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

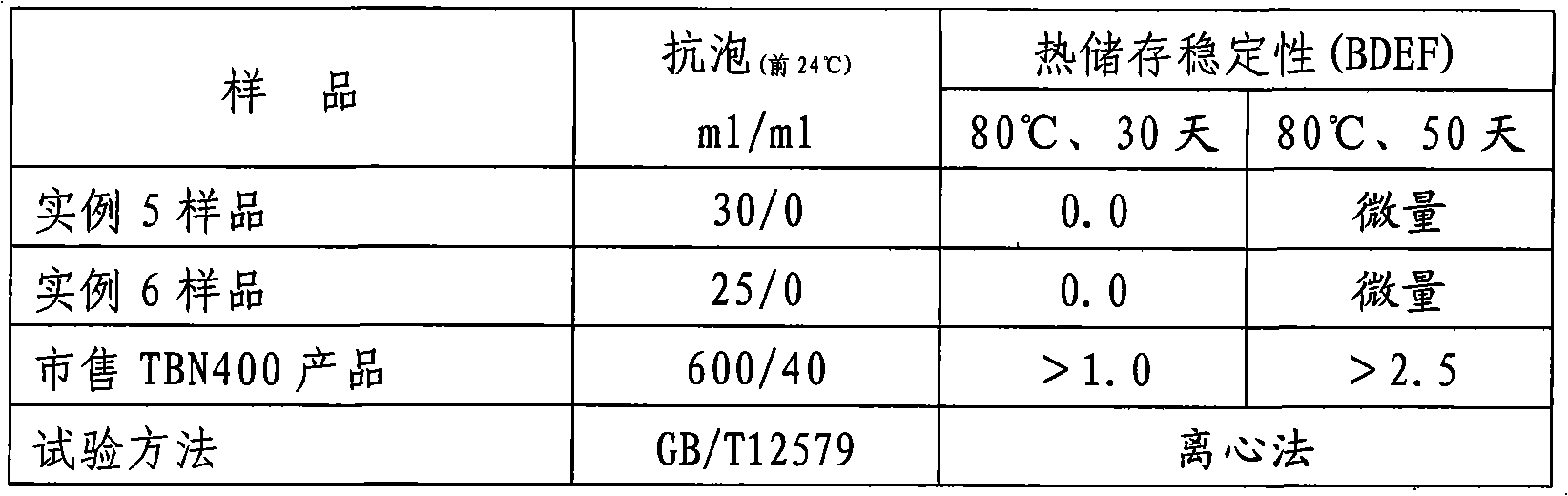

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

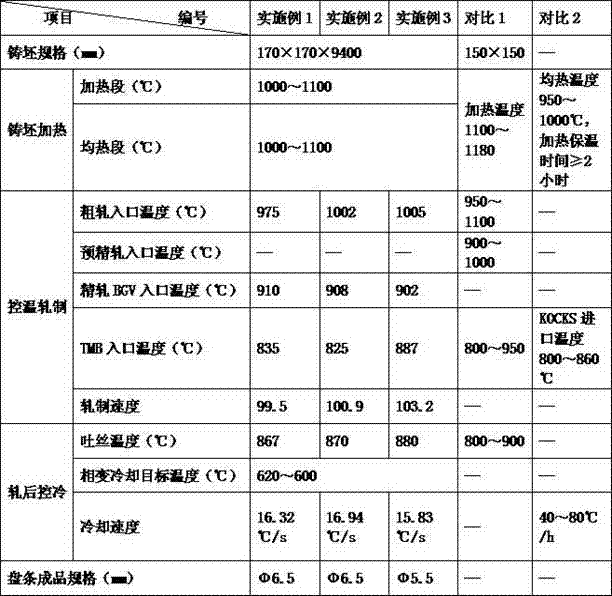

Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

ActiveCN102912101AImprove metallographic structureImprove performanceHeat treatment process controlWire rodSpring steel

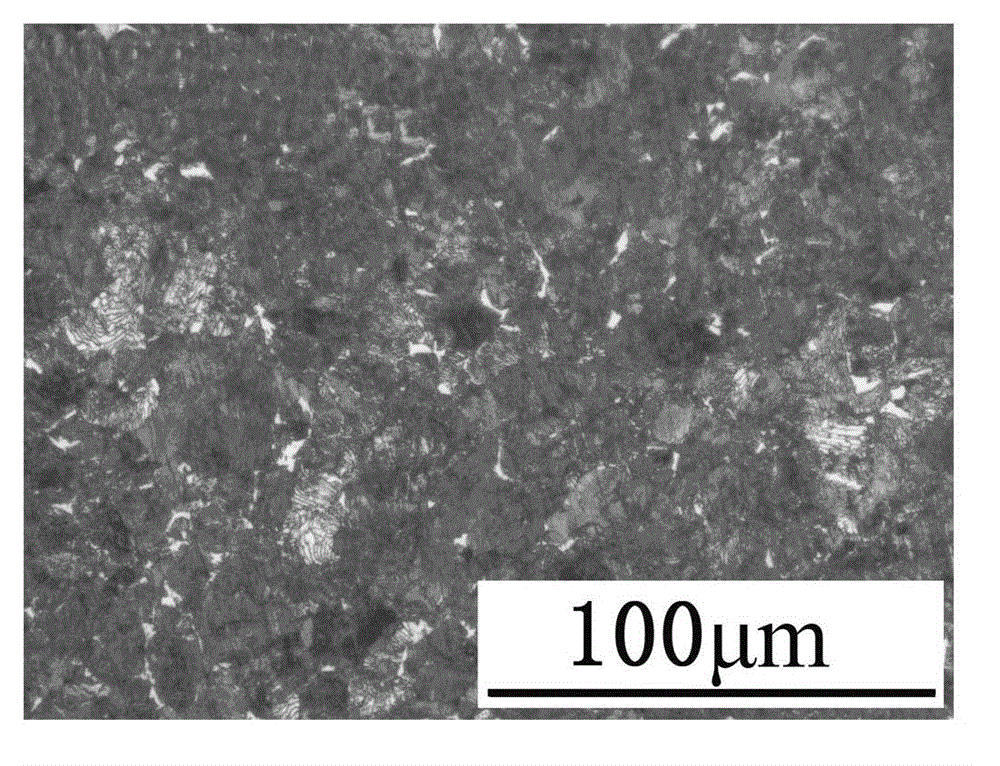

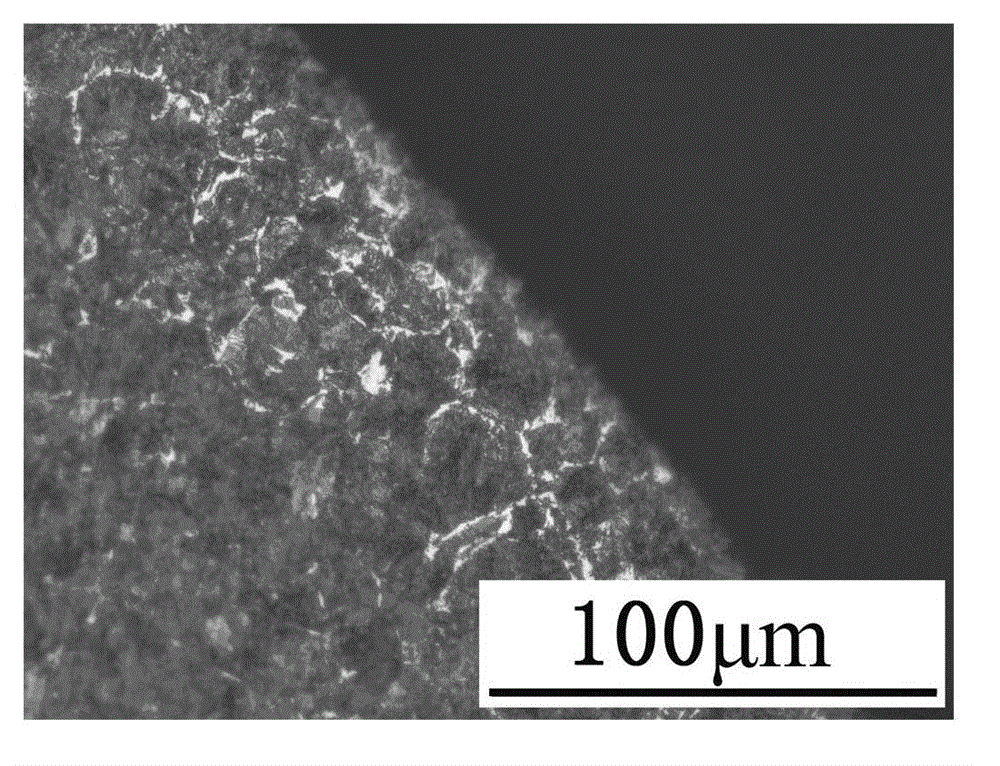

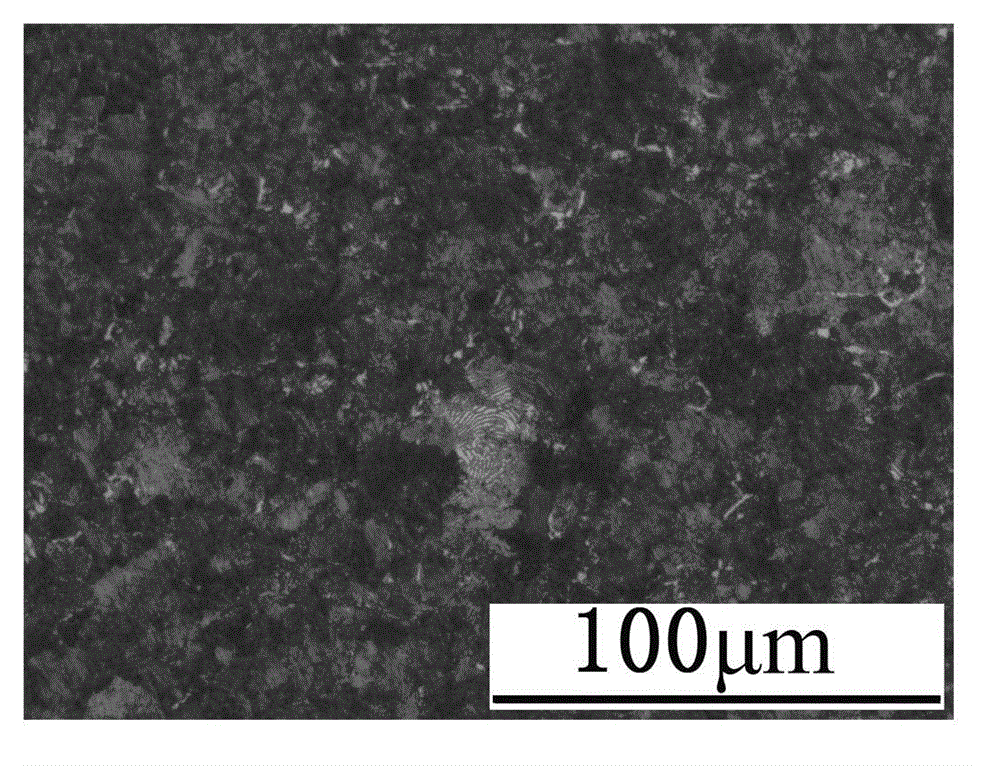

The invention discloses a production process of a 65 Mn spring steel wire rod and a 65 Mn spring steel wire rod. According to the invention, advantages of a device of a high line set are utilized, a finish rolling and reducing-sizing mills adopt 8+4 type, through optimization of a heating cycle process before rolling, a rolling control process and a cooling control process, only 8 front finish rolling machines and 2 reducing-sizing mills are utilized, so that surface decarburization of a spring is reduced and is even removed, and the fatigue life of a finished spring is prolonged; the amount of scales is reduced and the metal yield is improved; a metallographic structure is improved and a high sorbite rate is obtained, so that the production process has conditions to cancel a lead patenting process at the earlier drawing stage, the production processing cost is reduced, and the metallographic structure and the comprehensive performance of a hot-rolled wire rod for the 65 Mn spring steel are optimized. According to the invention, the microstructure quality and the mechanical property of the produced hot-rolled wire rod with phi6.5 mm for the 65 Mn spring steel reach the standard of the conventional 65 Mn spring steel after lead hot-rolled wire rod for the 65 Mn spring steel, the conditions to cancel the lead patenting process at the earlier drawing stage by a downstream user can be satisfied, a processing process is reduced for a user, and the production cost is reduced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

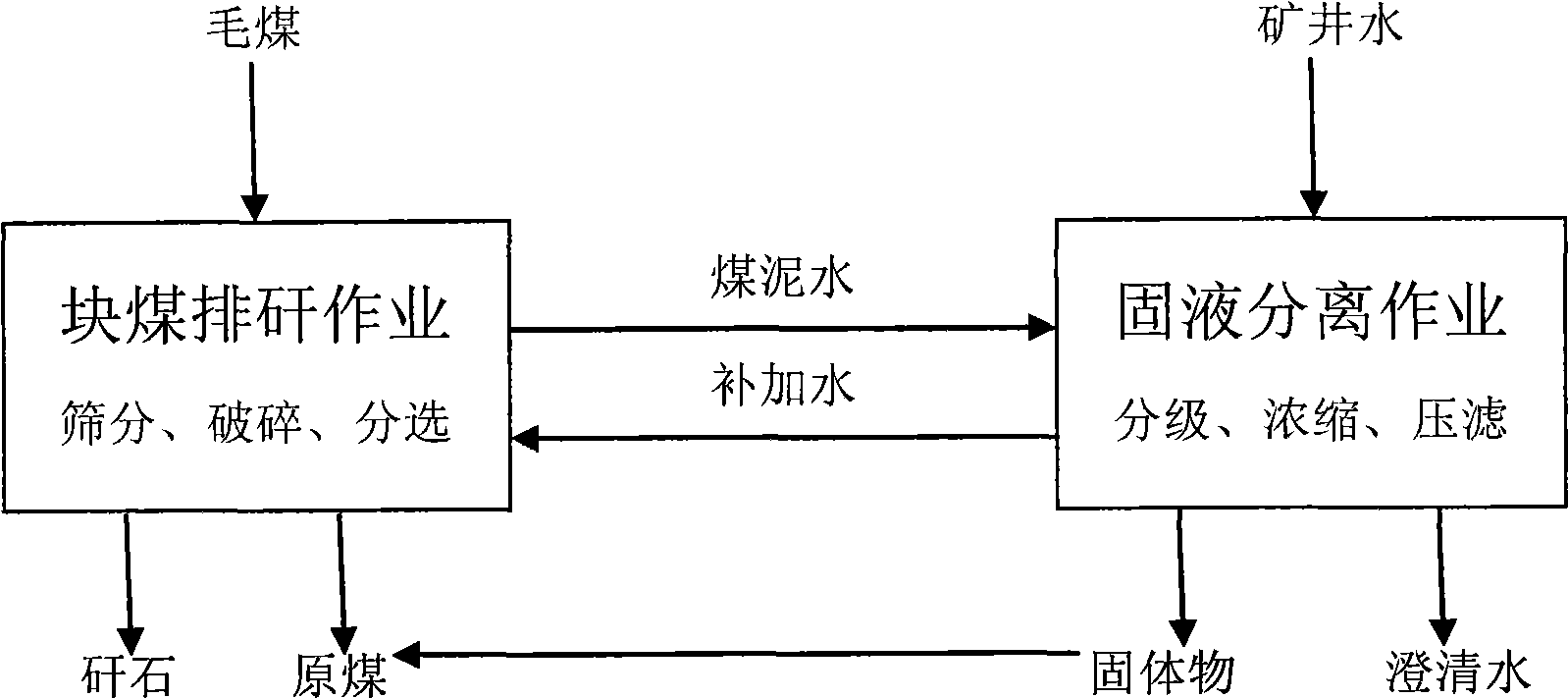

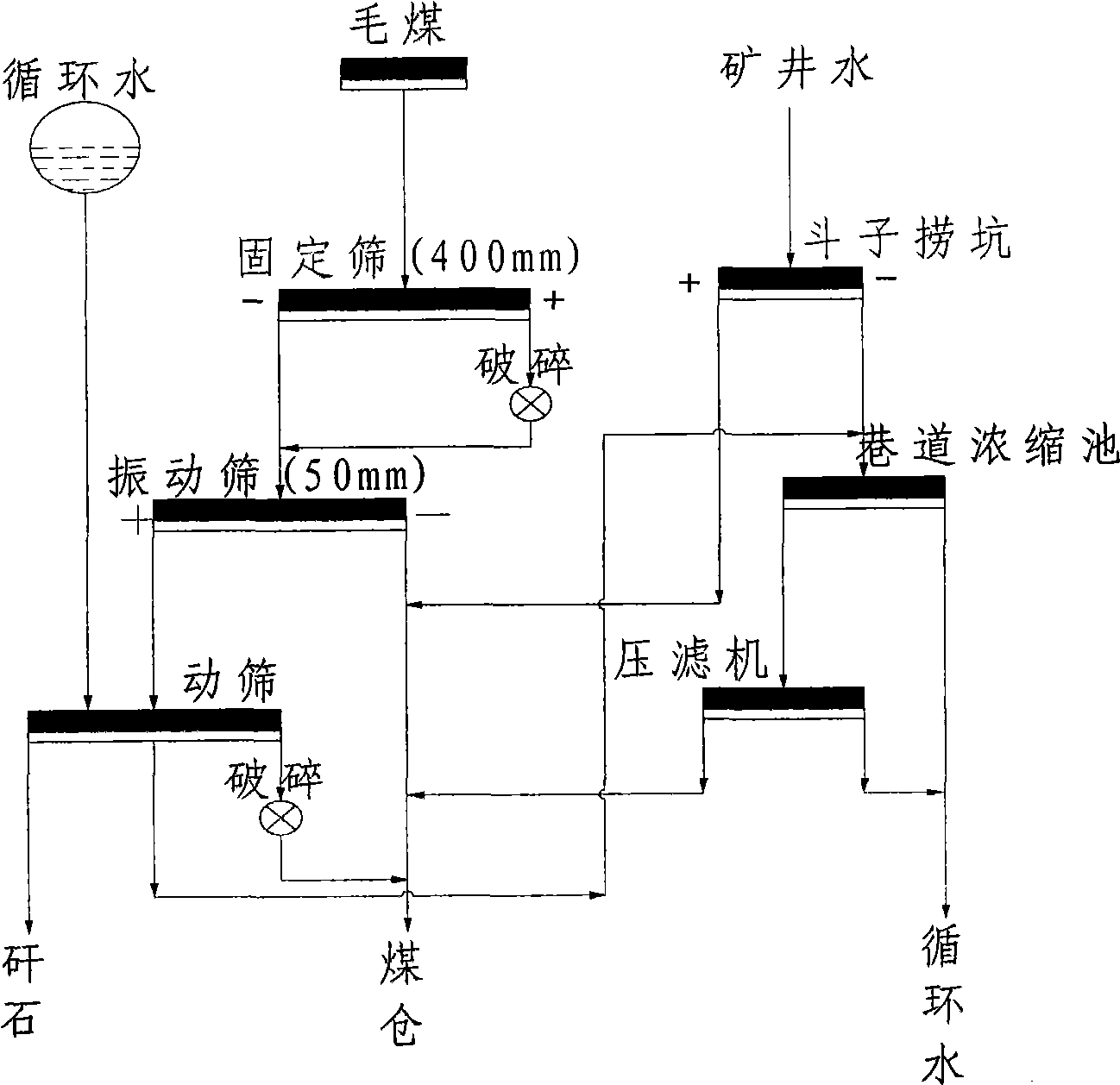

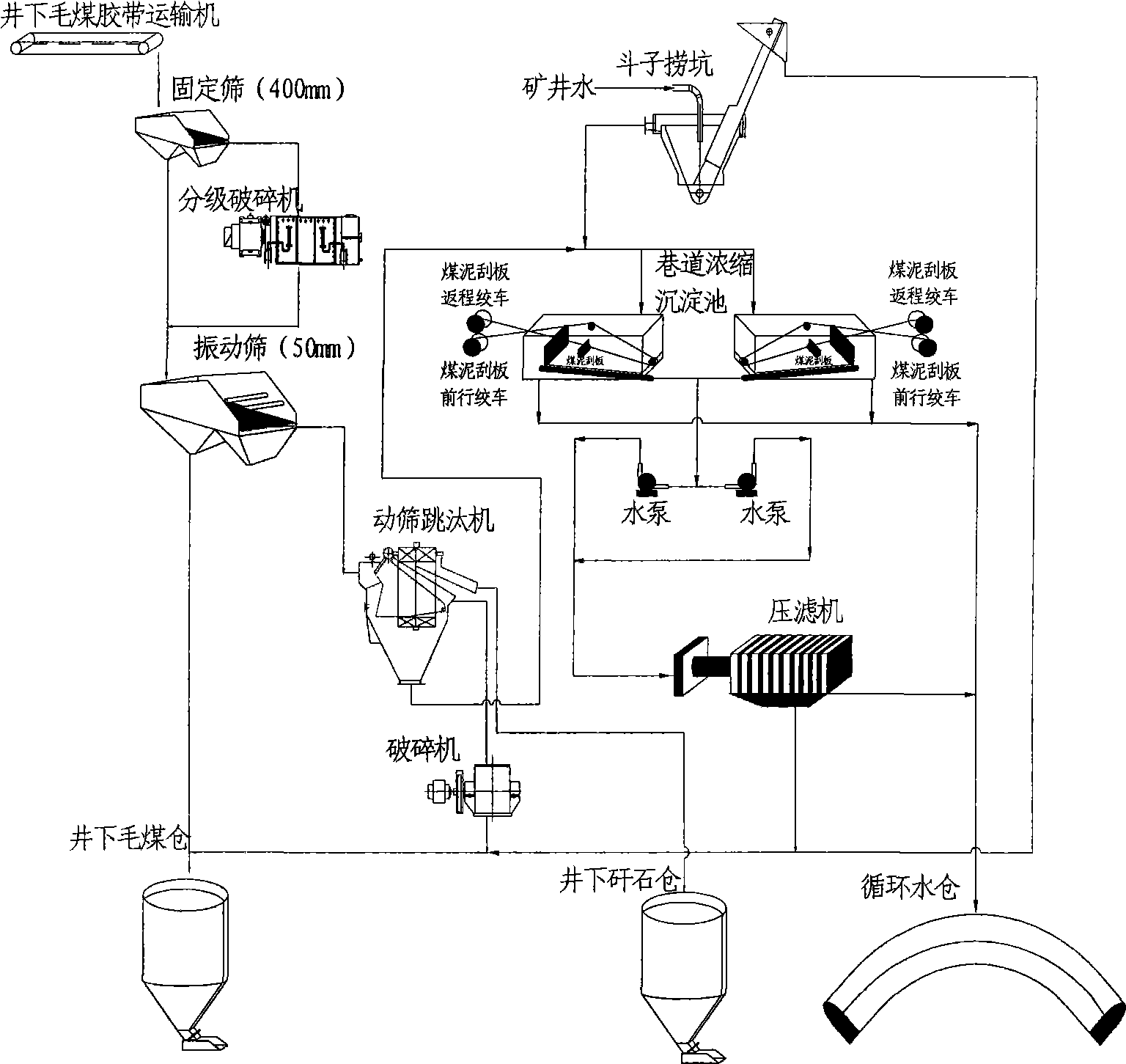

Down-hole gross coal dirt-discharging and mine water treating combined process

An underground gross coal gangue removal and mine water treatment combined process is characterized in that the process comprises two parts: gangue removal operation from lump coal and mine water solid-liquid separation operation, wherein, the gangue removal operation from lump coal comprises screening, crushing and separation steps, and the mine water solid-liquid separation operation comprises hydraulic classification, concentration and pressure filtration steps; by the gangue removal operation from lump coal, chunks of gangues in the gross coal are removed, and simultaneously the large particles thereof are crushed into appropriate size; by the mine water solid-liquid separation operation, the solid substances in the mine water are recycled to a coal streamline, and simultaneously the clear overflow water is delivered to a underground water sump; the coal muddy water generated by the gangue removal operation from lump coal is delivered to a mine water solid-liquid separation system for treatment and the mine water solid-liquid separation system provides water for washing and selection for the gangue removal operation from lump coal, so the coal muddy water and the water for washing and selection are combined into an organic whole.

Owner:HENAN POLYTECHNIC UNIV

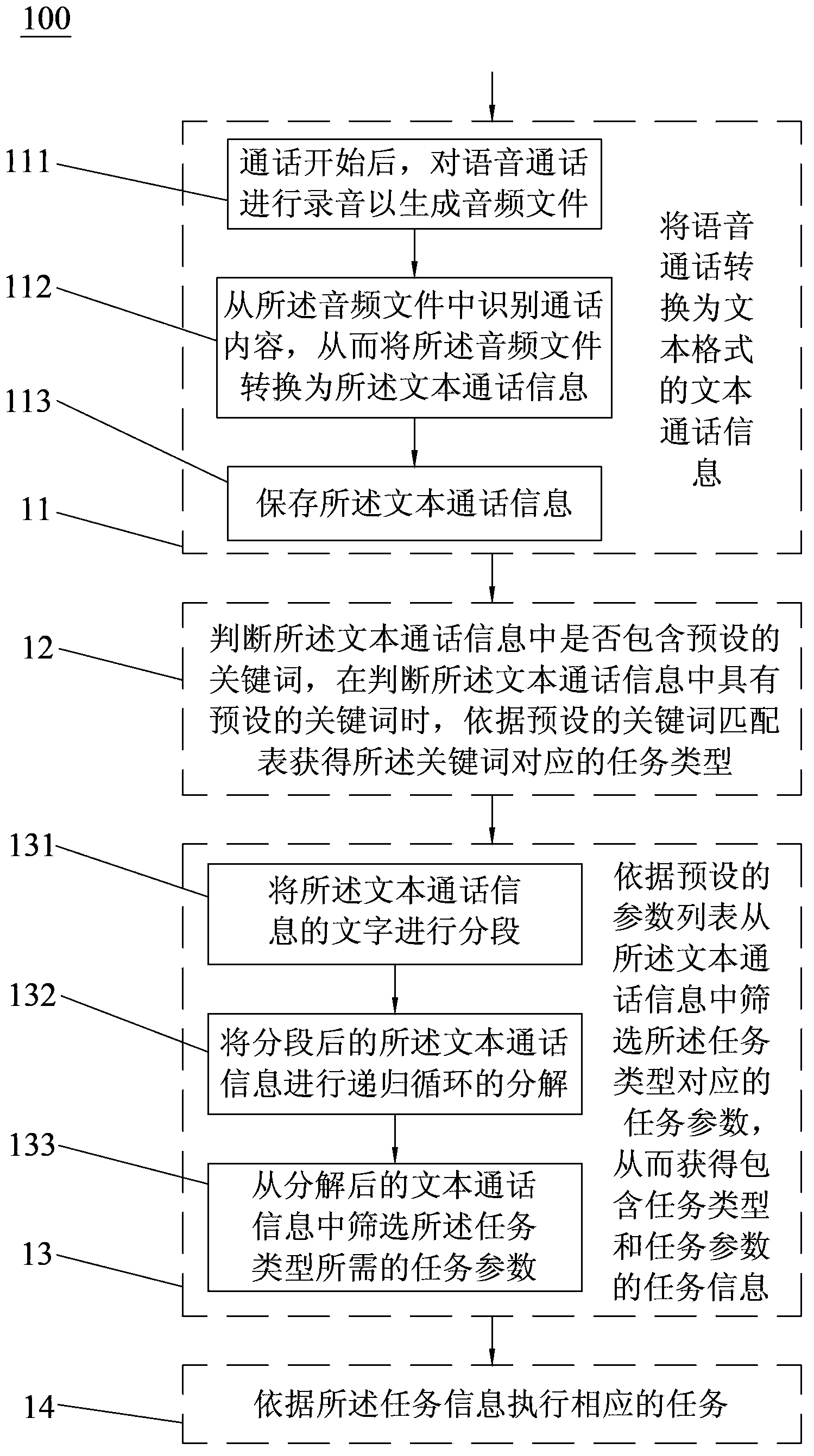

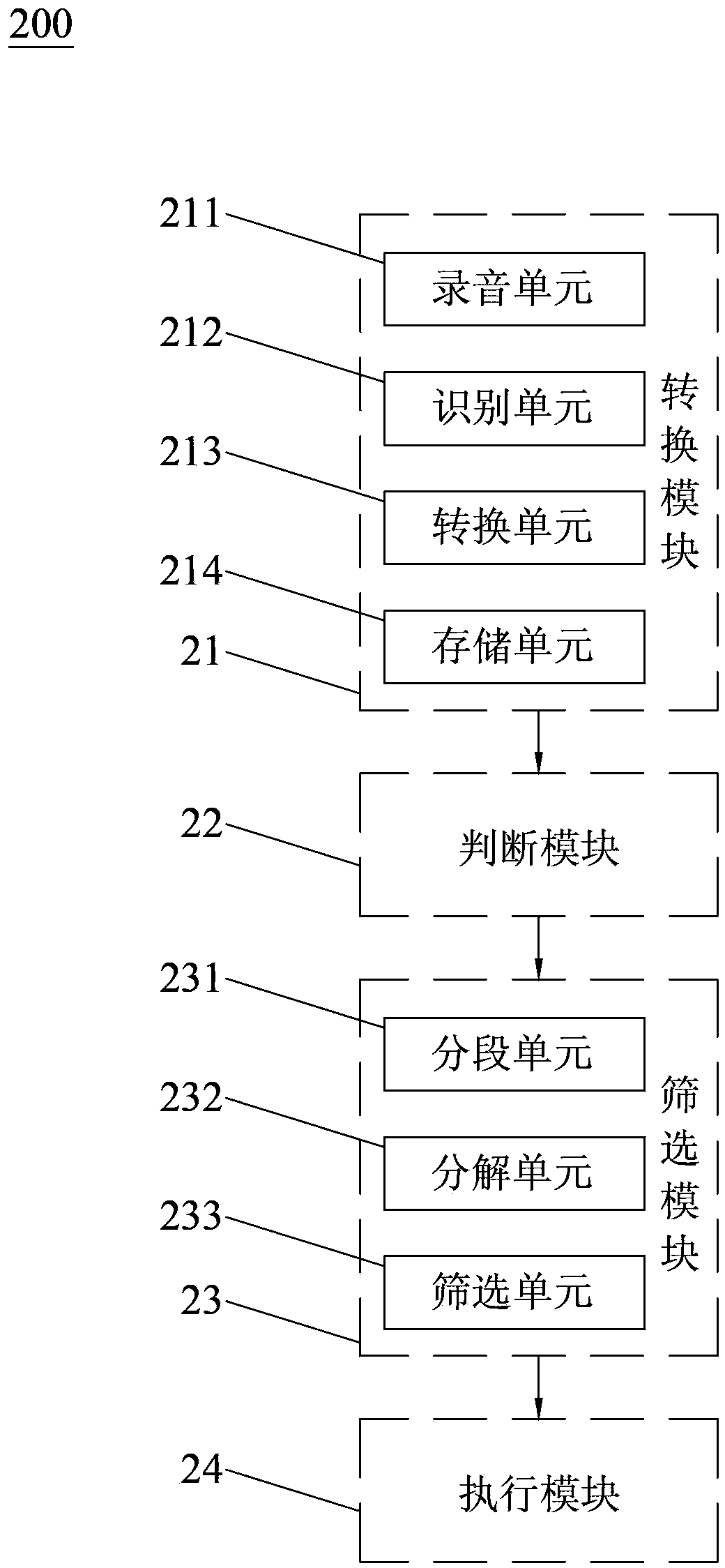

Method and mobile terminal for executing tasks according to communication information

ActiveCN103440866AEasy to recordEasy to view and useSubstation equipmentSpeech recognitionVoice communicationComputer terminal

The invention discloses a method for executing tasks according to communication information. The method for executing tasks according to communication information includes the following steps that firstly, voice communication is converted into text communication information of a text format; secondly, whether the text communication information contains preset key words or not is judged, if yes, a task type corresponding to the key words is obtained according to the preset key words and task parameters corresponding to a task type are screened out from the text communication information according to a preset parameter list so that task information containing the task type and the task parameters can be obtained; thirdly, according to the task information, a corresponding task is executed. According to the method for executing tasks according to communication information, the corresponding task can be automatically executed according to the communication information, so that a user does not need to perform complicated manual operation, the method is more convenient to perform and user-friendly, and the user experiences are greatly improved. In addition, apart from an existing mobile terminal, no extra parts are needed to achieve the function of automatically executing the task according to the communication information and cost in producing and machining the mobile terminal is greatly reduced.

Owner:GUANG DONG MING CHUANG SOFTWARE TECH CORP

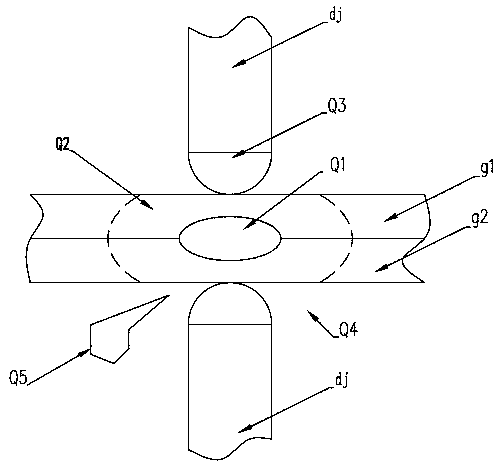

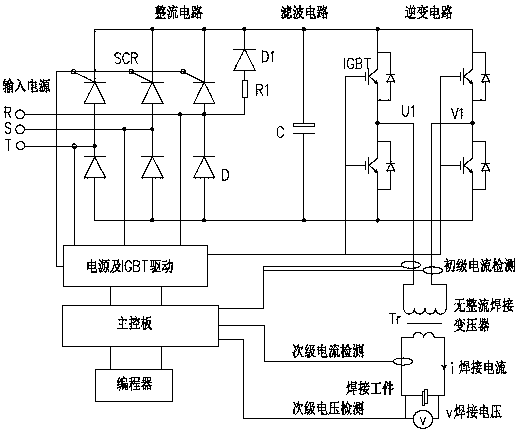

Non-splashing dynamically heating self-adaptive resistance welding method for automobile metal sheets

ActiveCN103394801AShort welding timeNo thermal equilibriumWelding electric supplyTransformerMetallic materials

The invention relates to a non-splashing dynamically heating self-adaptive resistance welding method for automobile metal sheets, which comprises the following implementation steps: firstly, a nugget formation process is enabled to be kept in the state of non-splashing power-on heating fusion and cooling crystallization heat balance in the way that a non-secondary rectification welding transformer and a pulse width adjustable alternate current contravariant power supply are utilized and different metallic materials thermal balance factors are called; the nugget size is controlled through detecting the change rate of dynamic resistances at the two ends of electrodes. According to the invention, as a non-splashing thermal balance factor, namely t+t0, is adopted in the method, the splashing problem in the welding is effectively solved, and the welding quality is improved; the change rate of dynamic resistances at the two ends of the welding electrodes during the welding can be detected to quickly judge the nugget formation process, so that the interference in the measuring is reduced, and the reliability of the detection is improved; besides, the difficult problem that a plenty of splashes are generated in the welding of automobile metal sheets for a long time is effectively solved, the welding quality and the production efficiency are greatly improved, and the production and processing cost is greatly reduced.

Owner:TIANJIN SUNKE DIGITAL CONTROL TECH CO LTD

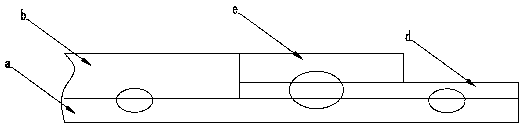

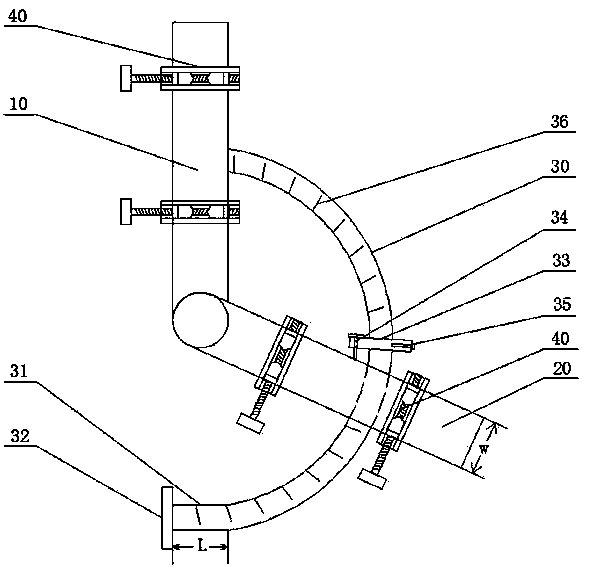

Welding clamp

InactiveCN104002080AMeet welding requirementsSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention relates to a welding clamp. The welding clamp comprises a first supporting plate and a second supporting plate, wherein the first supporting plate and the second supporting plate are connected in a pivoted mode, an arc-shaped angle positioning plate is arranged between the first supporting plate and the second supporting plate, one end of the angle positioning plate is fixed to the first supporting plate, the other end of the angle positioning plate penetrates through the second supporting plate, the radian of the angle positioning plate is 180 degrees, and the first supporting plate and the second supporting plate are respectively connected with a clamping device for locking a workpiece to be welded in a sliding mode. According to the welding clamp, the included angle between two workpieces is adjusted through the first supporting plate capable of rotating relatively or the second supporting plate capable of rotating relatively, angle positioning is carried out through the angle positioning plate, and the included angle between the two workpieces is made to meet the welding requirement; the distance between welding edges of the two workpieces are adjusted through the sliding clamping devices to meet the requirements for the welding angle and the welding joint height; the welding clamp is simple in structure, is easy and convenient to operate and largely reduces production and machining cost.

Owner:上饶市金兴汽车内饰有限公司

Beach sludge composite curing agent as well as preparation method, use method and application thereof

InactiveCN105924109AEnvironmental protection is goodObvious superioritySludge treatment by de-watering/drying/thickeningPortland cementSludge

The invention discloses a beach sludge composite curing agent as well as a preparation method, a use method and an application thereof. The beach sludge composite curing agent is obtained by mixing and grinding of an ordinary Portland cement clinker, a sulphoaluminate cement clinker, phosphogypsum, desulfurization gypsum, mineral waste residues, a naphthalene-based additive and sulfates, wherein the weight percentages of the raw materials are as follows: 40-60% of the ordinary Portland cement clinker, 5-10% of the sulphoaluminate cement clinker, 2-4% of the phosphogypsum, 3-6% of the desulfurization gypsum, 30-50% of the mineral waste residues, 1-3% of the naphthalene-based additive and 3-5% of the sulfates. The beach sludge composite curing agent disclosed by the invention can greatly shorten the curing time of sludge, and is small in doping amount, high in concretion strength, low in construction cost, and good in curing stability.

Owner:天津市三川恒泰科技有限公司

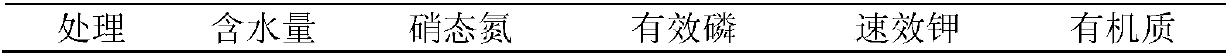

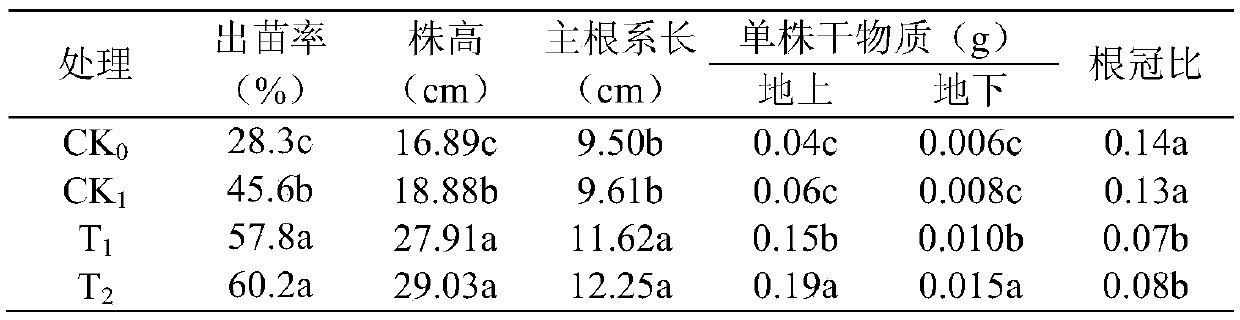

Desertification soil improver as well as preparation method and application thereof

InactiveCN109095996AStrong water absorptionStrong expansion abilityOrganic fertilisersSolid/semi-solid fertilisersMicrobial agentVitamin B6 synthesis

The invention discloses a desertification soil improver as well as a preparation method and application thereof. The desertification soil improver disclosed by the invention is prepared from the following substances in parts by weight: 20-40 parts of bentonite, 50-70 parts of straw, 0.5-1.5 parts of urea, 0.2 part of a microbial agent and 8-9 parts of a vitamin B6 solution. On the basis that the straw and the bentonite are adopted as main raw materials, the vitamin B6, the urea and the microbial agent are compounded and processed into the granulized soil improver, granular structures of desertification soil are increased, soil can be fertilized, the water and fertilizer retention capability of the soil can be improved, in addition, plant growth can be promoted, vegetational cover of the desertification soil is improved, convenience can be brought to production and transportation, and effects of efficient utilization of agricultural wastes and desertification soil improvement and treatment can be achieved.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI +1

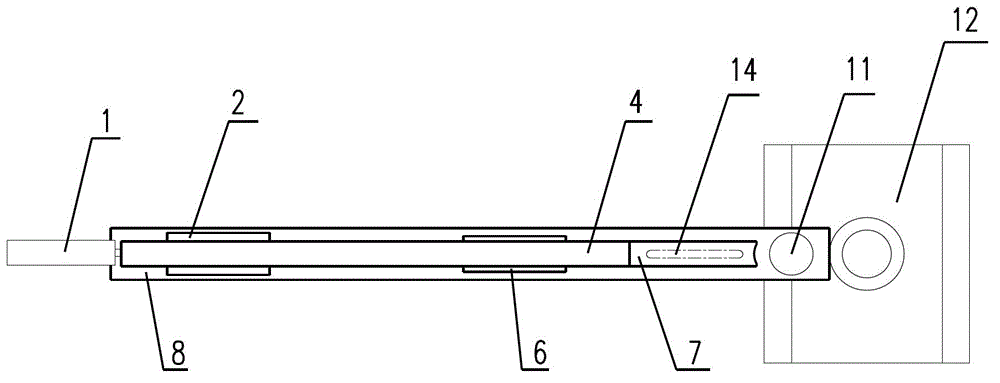

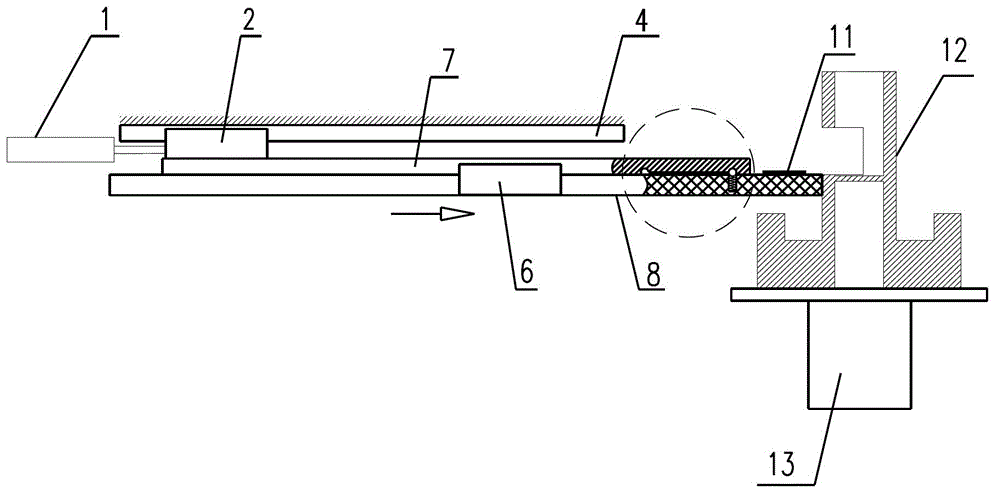

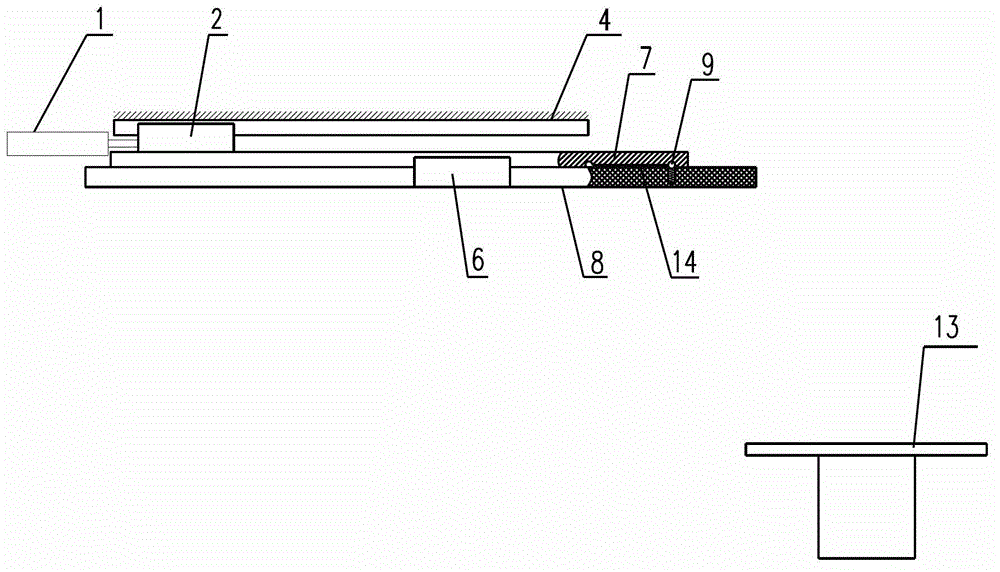

Gasket assembling mechanism

The invention provides a gasket assembling mechanism. The mechanism comprises upper and lower slide rails, which are horizontally and transversely arranged, wherein a first slide rail is fixed on a base; a second slide rail is mounted on the first slide rail by a slide block; a horizontal long bottom plate is placed close to the lower surface of the second slide rail; the bottom plate is mounted on the second slide rail by a slide block; a locating groove and a locating hole matched with each other are respectively formed in the second slide rail and the bottom plate; a spring and a locating block are pressed into the locating hole in sequence; the locating block is impelled upward by the spring; a compression cylinder is placed on one side of the second slide rail; a rack for bearing parts is arranged on the right side of the bottom plate; the rack can lift up and down; and by a double-slide-rail moving mechanism, a gasket is pushed to enter a narrow part recess of a mounting space; full mechanical operation of the whole assembling process can be achieved, manual assembling is not needed and high assembling efficiency is achieved; moreover, the gasket assembling mechanism provided by the invention has the advantages of simple structure, good reliability, accurate assembling position and comparatively low production and machining cost.

Owner:SHANGHAI UNIV OF ENG SCI

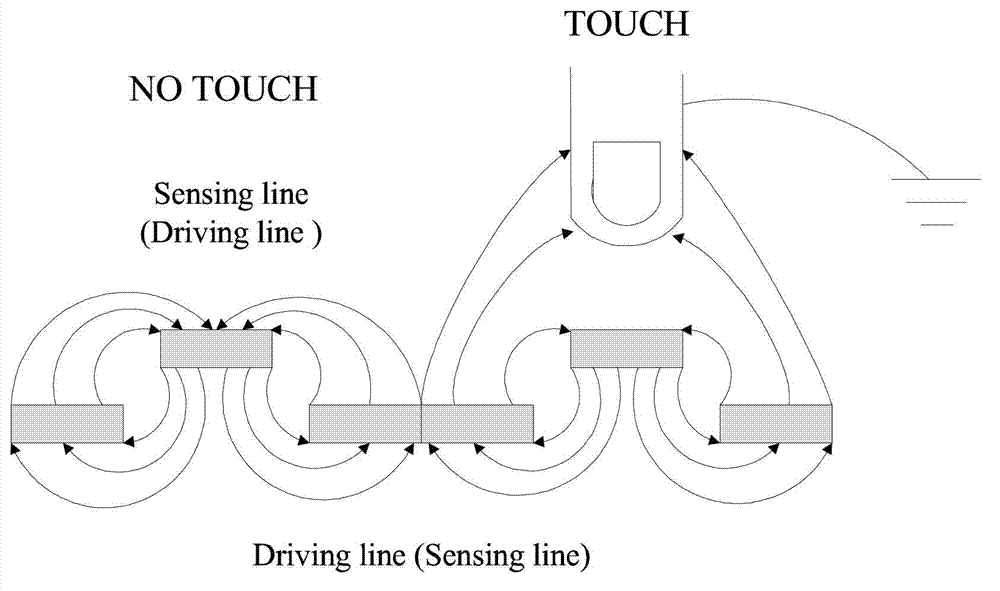

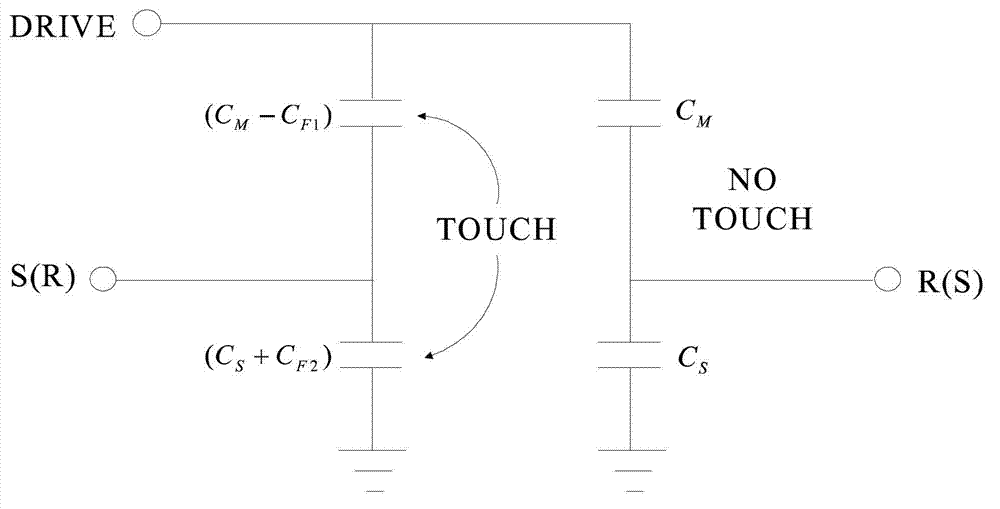

Method of automatic power down protection during contact of terminal mobile with liquid and terminal mobile

ActiveCN103366138AGood protectionReduce production and processing costsInternal/peripheral component protectionBurning outCapacitance

The invention discloses a method of automatic power down protection during contact of a terminal mobile with liquid. The method is applicable to the terminal mobile with a capacitive touch screen, and comprises the following steps that (1) whether capacitance variation values of zones on a touch screen are in a preset range is detected; the preset range is a range of the capacitance variation values the touch screen generated during the contact between the liquid and the touch screen; and a zone with the capacitance variation value in the preset range is called a liquid contact zone; (2) a total area value of the liquid contact zone is calculated; and whether the total area value is greater than or equal to a preset value is judged, if so, then the next step is executed, if not, an initial state is returned; and (3) the terminal mobile is powered down and turned off. According to the method, automatic power down of the terminal mobile can be triggered by the terminal mobile when the liquid contact zone on the touch screen is greater than or equal to a used area of the touch screen; the danger that the terminal mobile is burned-out since the liquid enters the terminal mobile is avoided; and the terminal mobile is well protected.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

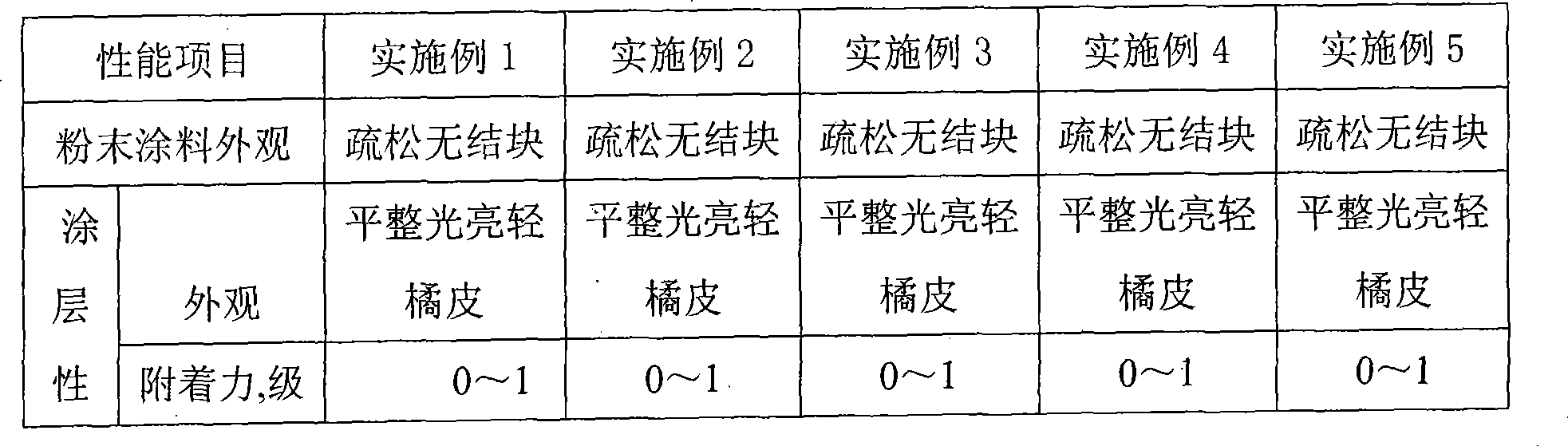

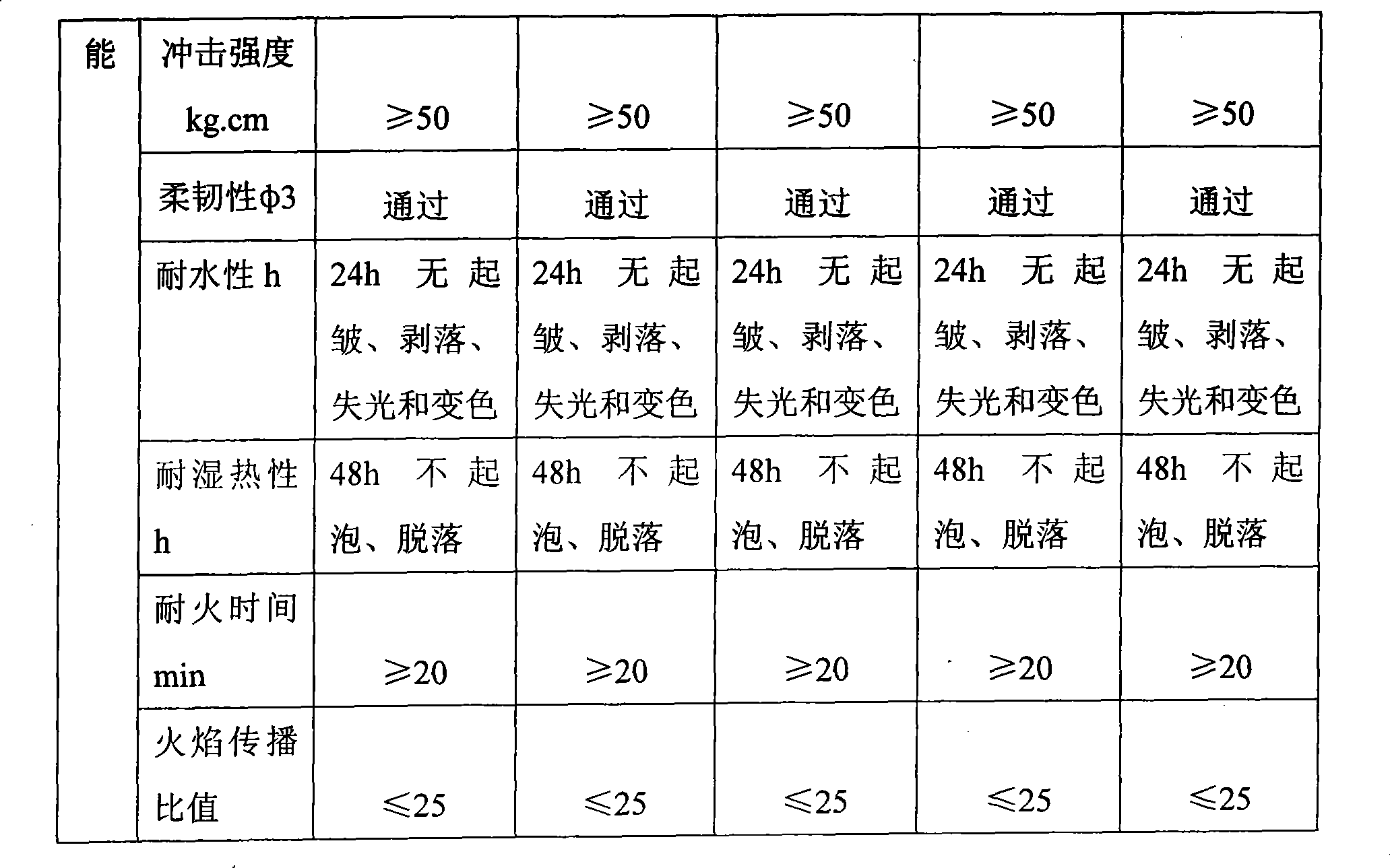

Facing type fireproofing powder paint

InactiveCN101434804AImprove fire performanceImprove the attenuation effectFireproof paintsPowdery paintsEpoxyPentaerythritol

The invention discloses a finishing-typed fireproof powder coating, belonging to the technical field of the powder coating. The coating is prepared by normal production process by taking epoxy resin, brominated epoxy resin, polyester resin, a curing agent, a leveling agent, a degassifying agent, ammonium polyphosphate, melamine, pentaerythritol, pigment, antimony trioxide and a bulking agent as raw materials. The finishing-typed fireproof powder coating has the active effects that compared with the prior art, the coating has better flame-retardant and fireproof effect and better ageing attenuation resistance, lower formula cost and production processing cost and easier practical operation.

Owner:XUZHOU ZENITH COATING

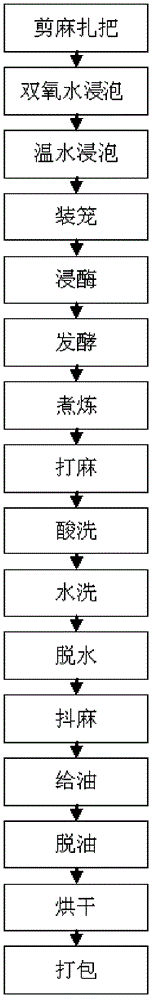

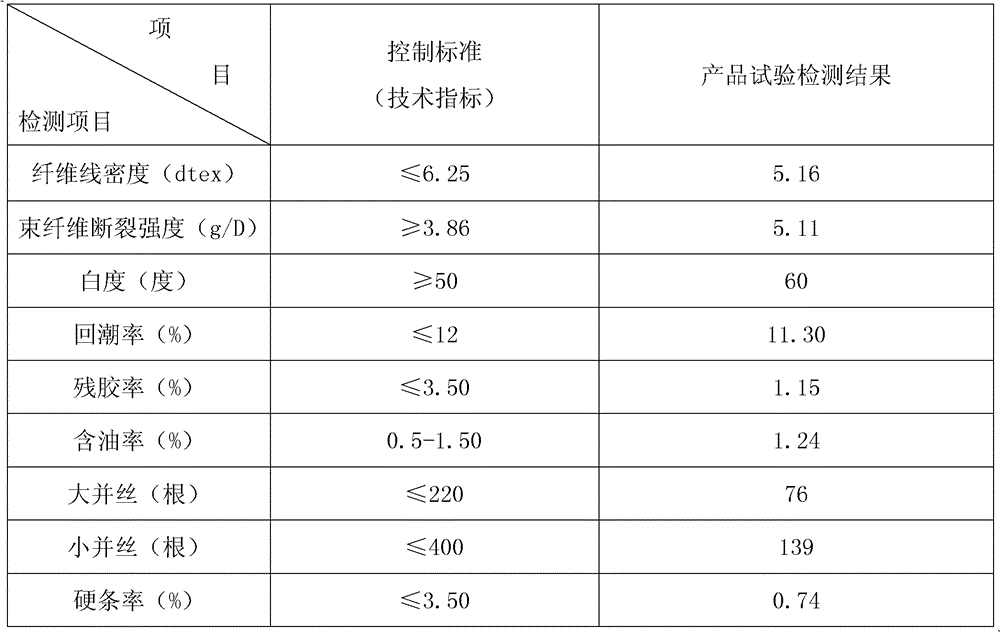

Compound biological enzyme degumming method for ramie

InactiveCN102747434AImprove product qualityReduce manufacturing costVegetable materialChemistryEnzyme

The invention discloses a compound biological enzyme degumming method for ramie. The method mainly comprises: sequentially carrying out treatments of ramie cutting, bundle trussing, soaking with hydrogen peroxide, soaking with warm water, cage filling, immersion in enzyme, fermentation, boiling, ramie bundle beating, pickling, water washing, dehydration, ramie shaking, oil preparing, oiling, deoiling and drying on raw ramie, and carrying out packaging and warehousing on the dried refined ramie. The method of the present invention has the following advantages that: a degumming process is simple, a period is short, the whole process has characteristics of easy control and no pollution, production cost is low, the prepared refined ramie has characteristics of stable and reliable quality, and substantial improvement of combing and spinning performance, wherein a finished product rate is more than 67%.

Owner:安徽省华龙麻业有限公司

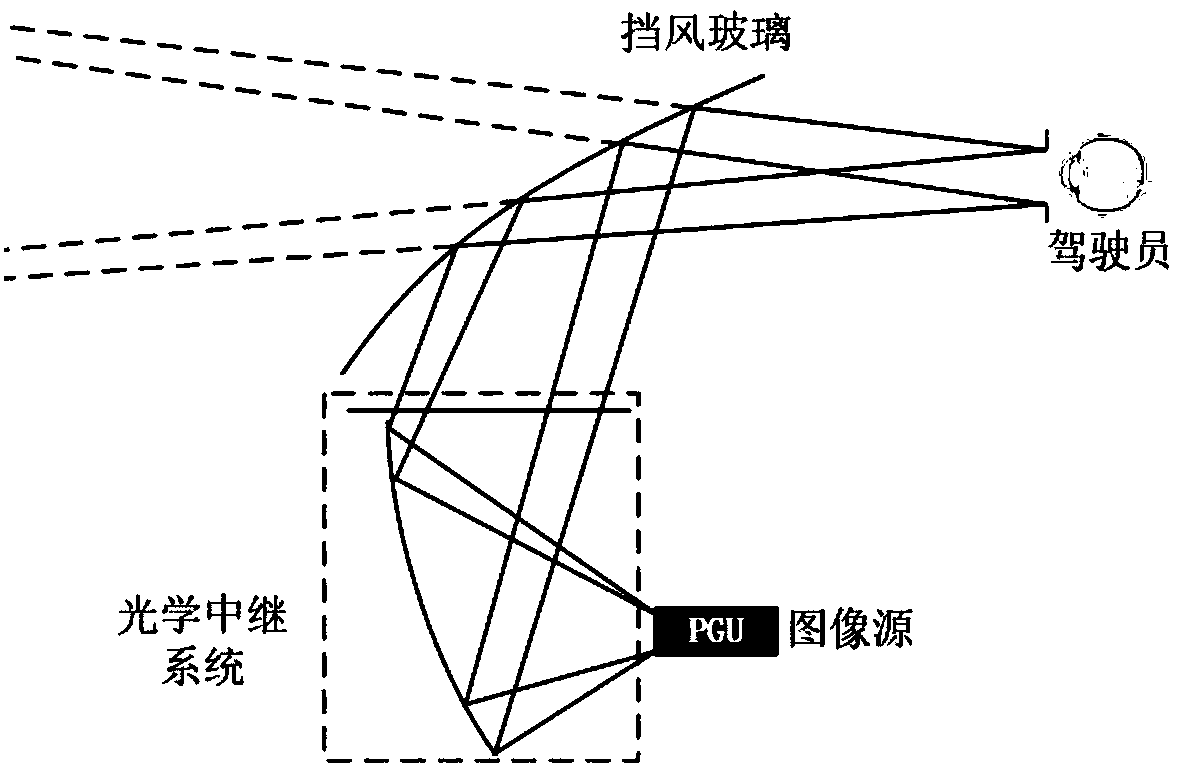

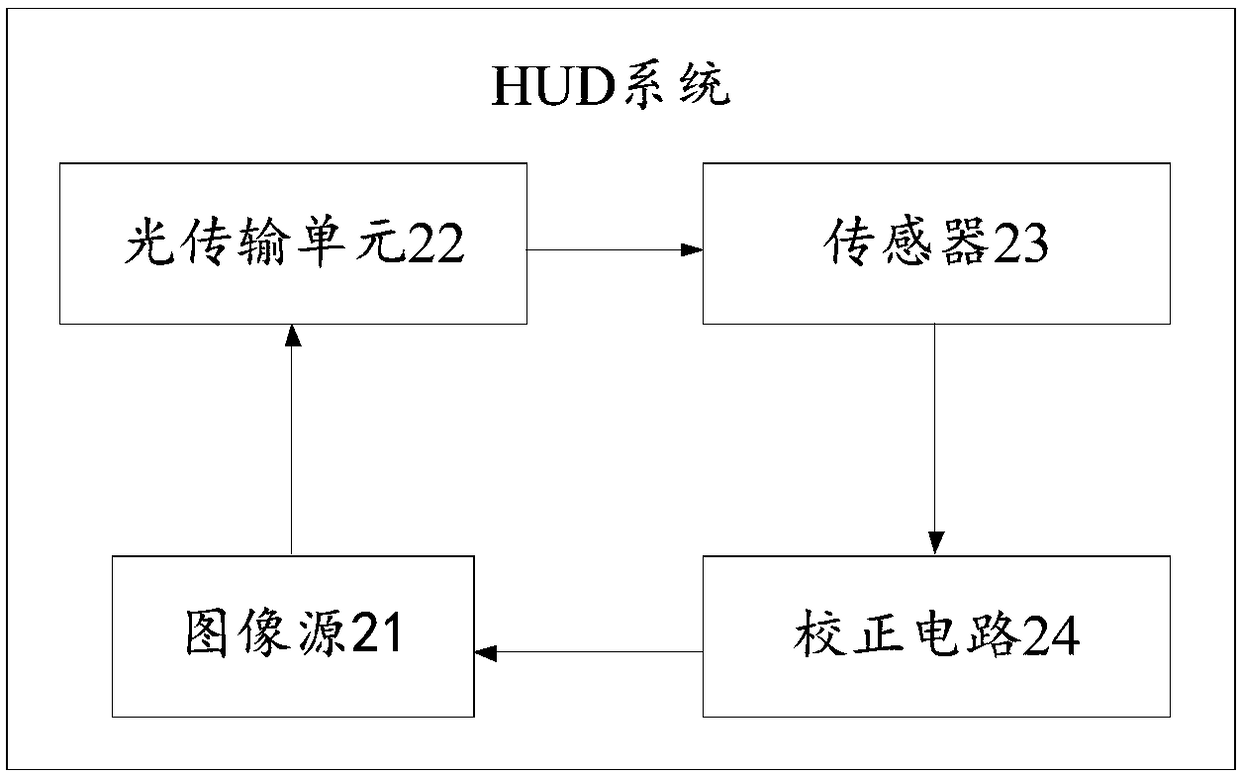

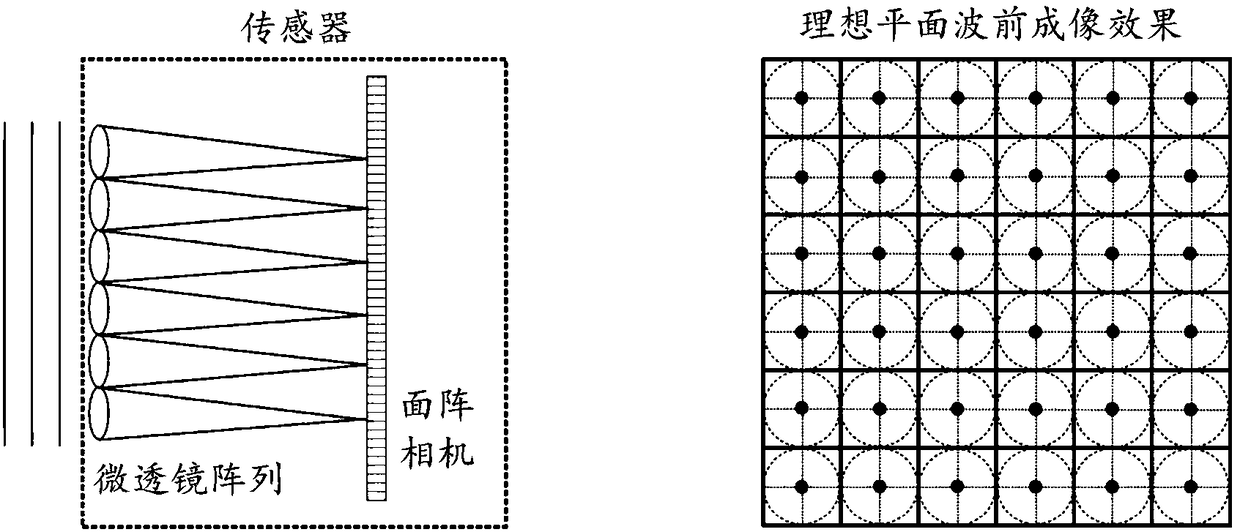

Head up display (HUD) device and display image correction method

ActiveCN108061968AImprove versatilityReduce production and processing costsOptical measurementsVehicle componentsDistortionCorrection method

The invention discloses a head up display (HUD) device and a display image correction method, and relates to the technical field of computers, mainly aiming at improving the versatility of an HUD system by dynamically adjusting the suitability between an optical relay system in the HUD system and windshield of a vehicle by means of an aberration adjustment device. The HUD device is mainly characterized by comprising an image source, an optical transmission unit, a sensor and a correcting circuit, wherein the image source is a light source used for emitting display images; the optical transmission unit is used for transmitting detection light containing imaging distortion information; the sensor is used for receiving the detection light and converting the detection light into a wavefront error image; the correcting circuit is used for receiving the wavefront error image and correcting the display images emitted by the image source according to the wavefront error image.

Owner:BOE TECH GRP CO LTD

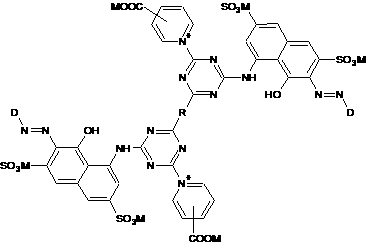

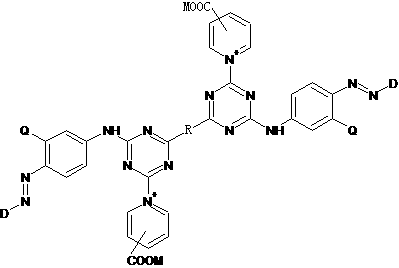

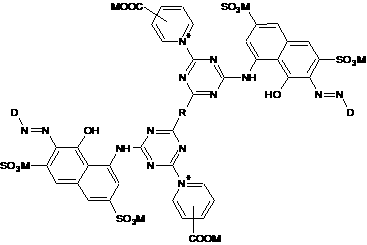

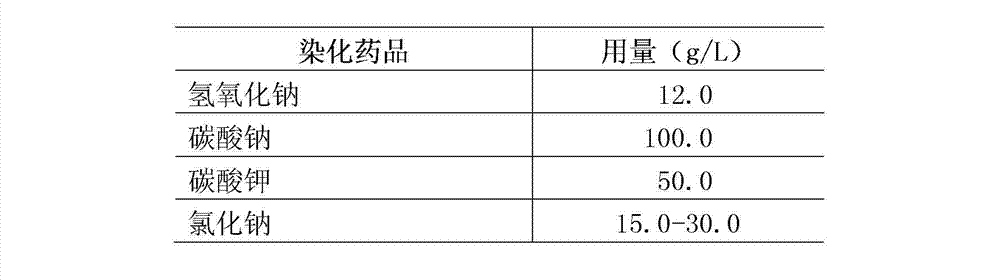

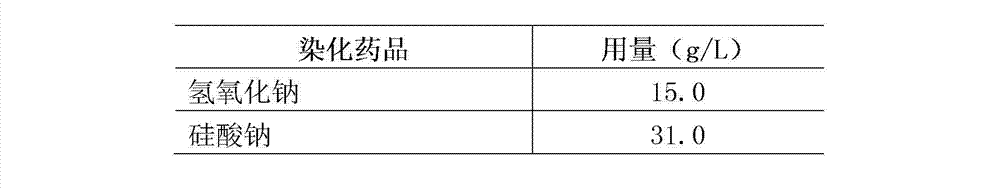

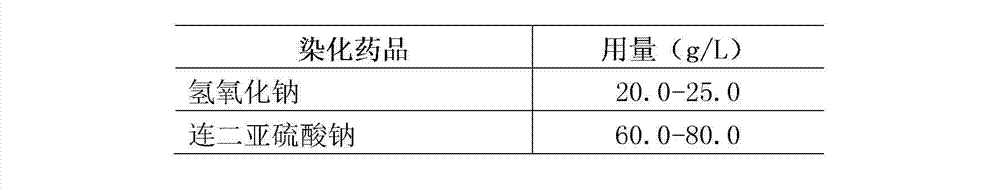

Active dye gravure printing ink and preparation method thereof, and method for applying active dye gravure printing ink for printing

ActiveCN103224729AConducive to fixationReduce production and processing costsDuplicating/marking methodsTransfer printing processTextile printerCellulose

The invention belongs to the technical field of printing and dyeing industry, and particularly relates to an active dye gravure printing ink and a preparation method thereof, and a method for applying the active dye gravure printing ink for printing. The active dye gravure printing ink is prepared from 1-20% by mass of an active dye, 3-25% by mass of an auxiliary solvent, 0.1-5% by mass of a dyeing resistance salt, 1-10% by mass of a viscosity adjusting agent and the balance of water, wherein the active dye comprises one or a plurality of materials selected from a red active dye compound, a yellow active dye compound, an orange active dye compound and a blue active dye compound. The active dye gravure printing ink has the following characteristics that: deterioration can not be generated after storing for a long time, a color fixation rate of the dye is substantially increased after a cellulose fabric is subjected to printing and steaming color fixation.

Owner:ZHEJIANG YIDE CHEM

Multi-color roller gravure printing production method of textile dye

ActiveCN102785495AExtended door widthShorten the printing processDuplicating/marking methodsOther printing apparatusFiberWastewater

The invention relates to a multi-color roller gravure printing production method of a textile dye. According to the traditional printing method, more floating colors exist in the washing process, and the excessive wastewater discharge is easily caused. The invention comprises the following steps that: (1) pre-treatment working solutions are selected according to textiles of different types of fibers; (2) the pre-treatment working solutions of different concentrations are padded under the conditions that the immersion time is 5-30 seconds, the expression is between 50% and 100% and the speed is 10 to 40m / min, and are dried; (3) a special dye ink for gravure printing is selected; (4) through an improved multi-color roller gravure printing machine with adjustable printing thickness, lengthened width, enhanced drying and the like, the special dye ink is printed to the textile which is padded with the pre-treatment working solutions and is dried at a speed of 10-40 m / min and is dried; (5) the printed textile enters steaming equipment for steaming fixation; and (6) after fixation, the printed textile is subjected to washing, drying and other treatment processes to complete the entire printing production process of the textile.

Owner:ZHEJIANG YIDE CHEM

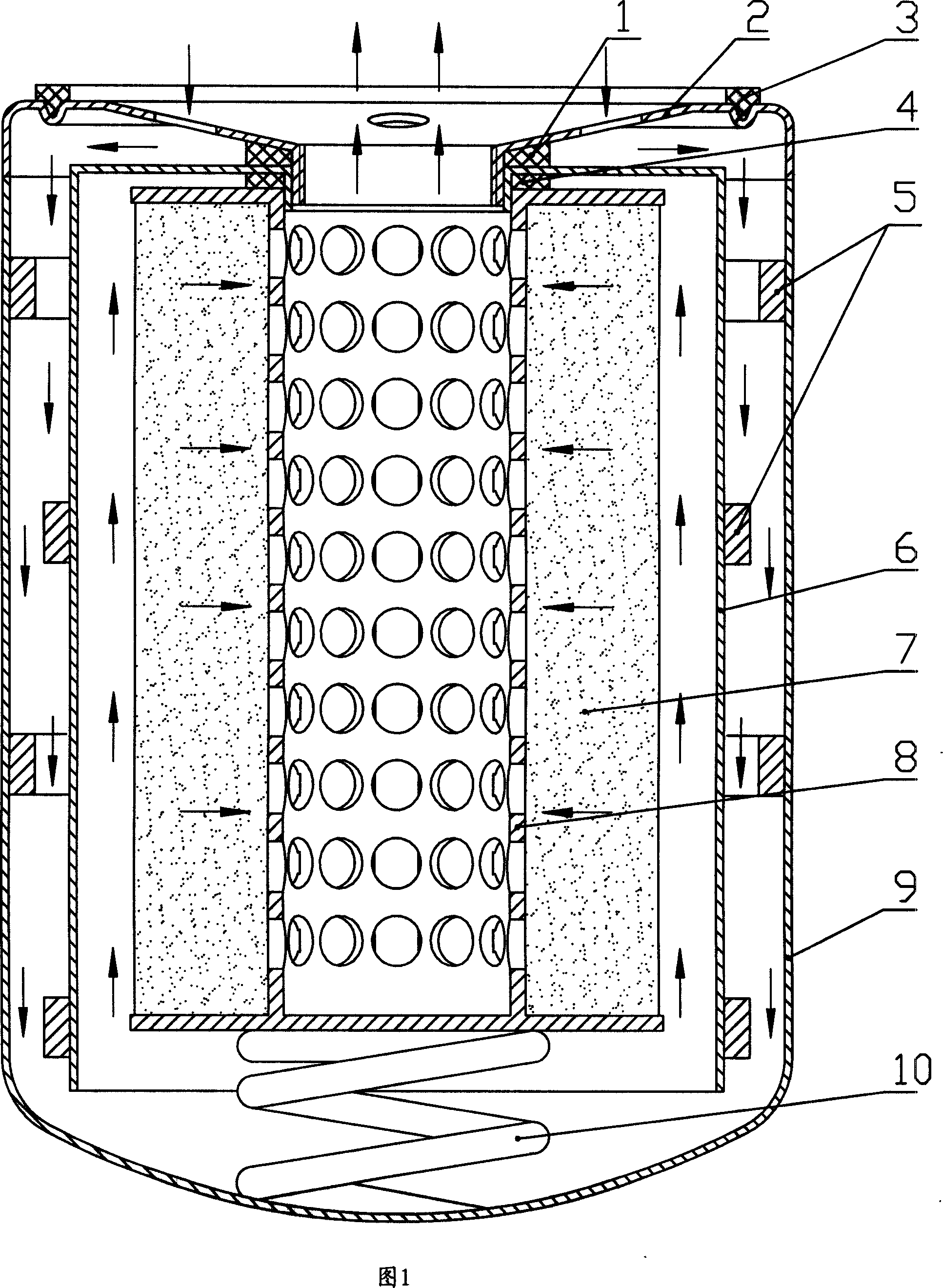

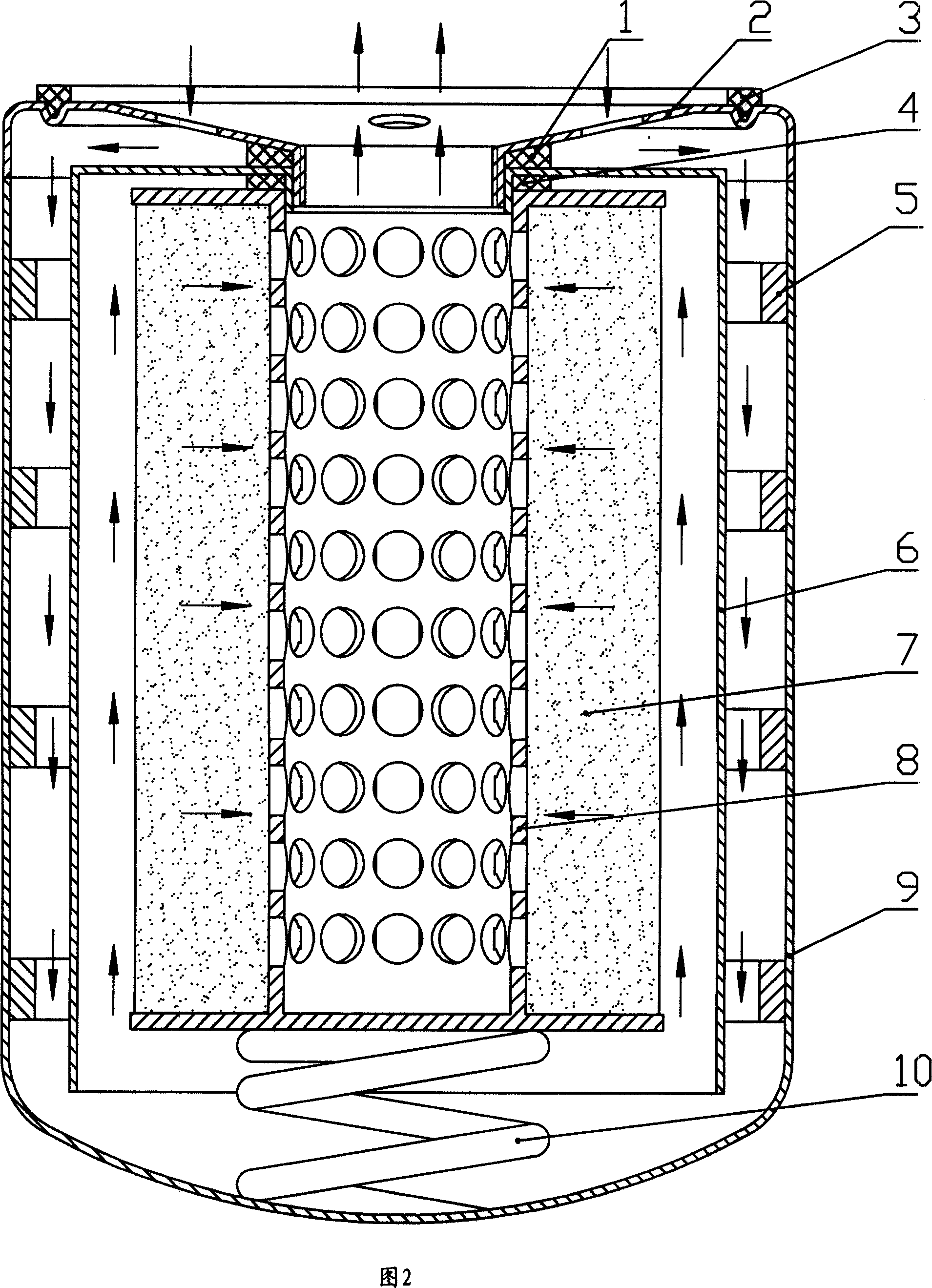

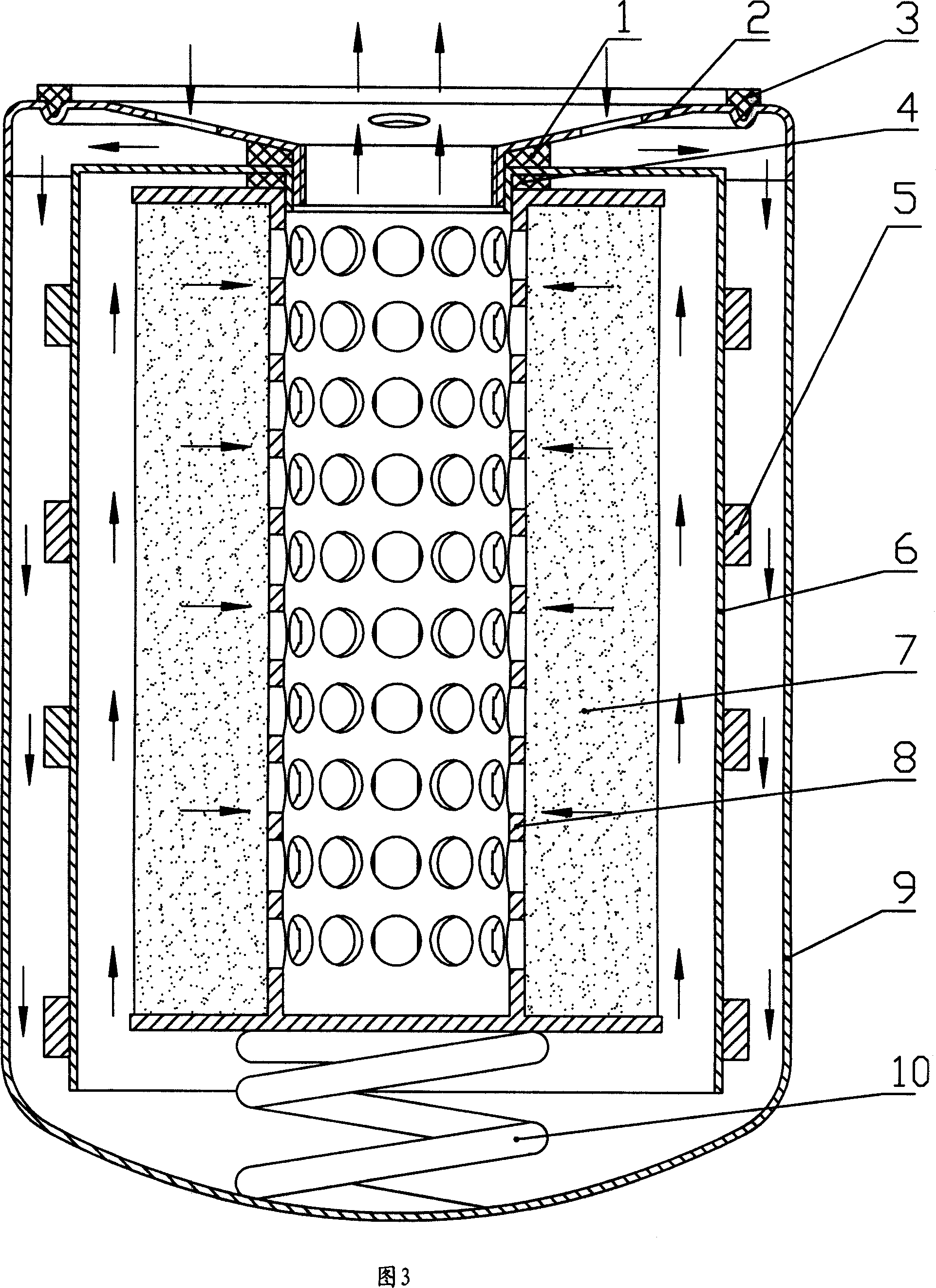

Solar energy water heater

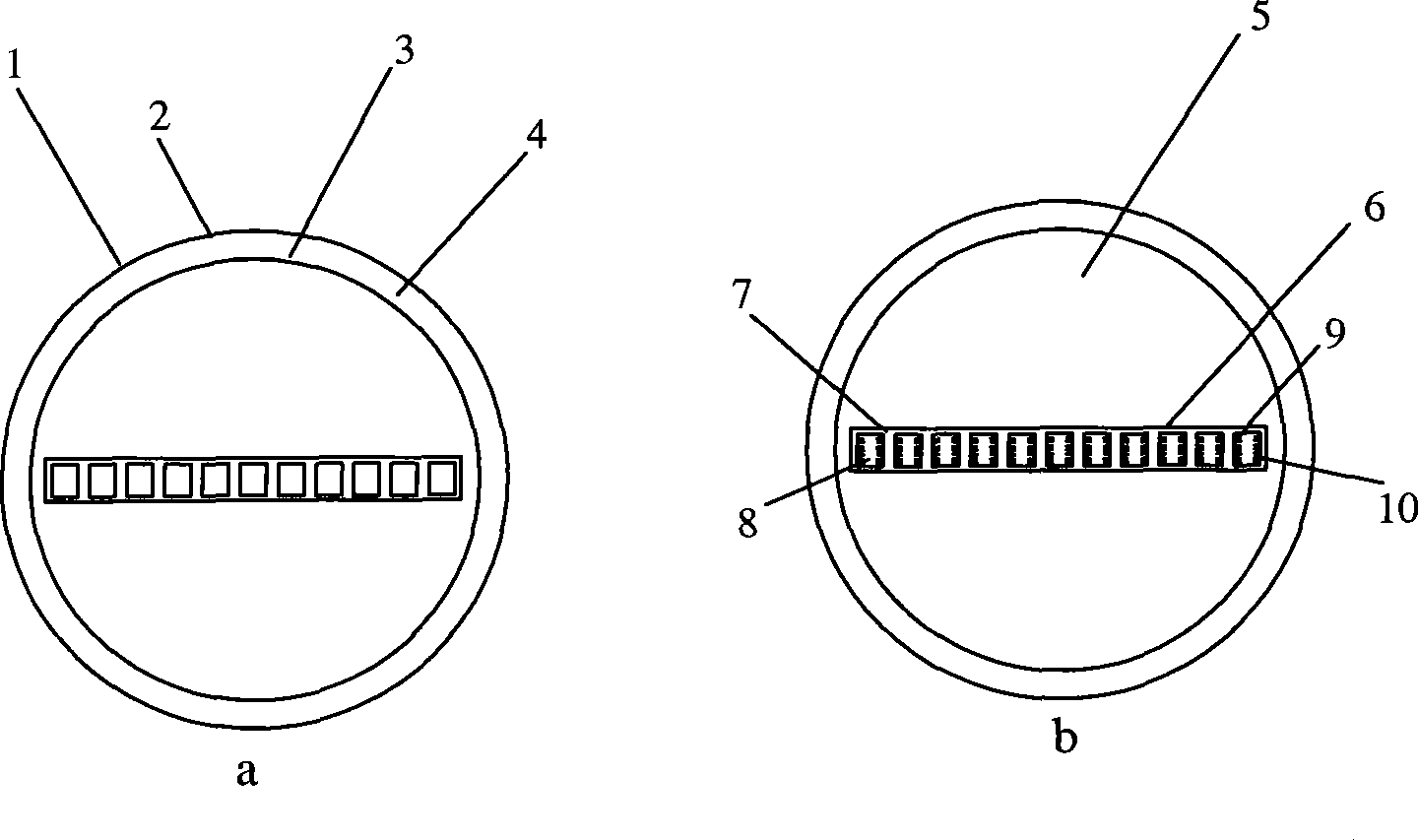

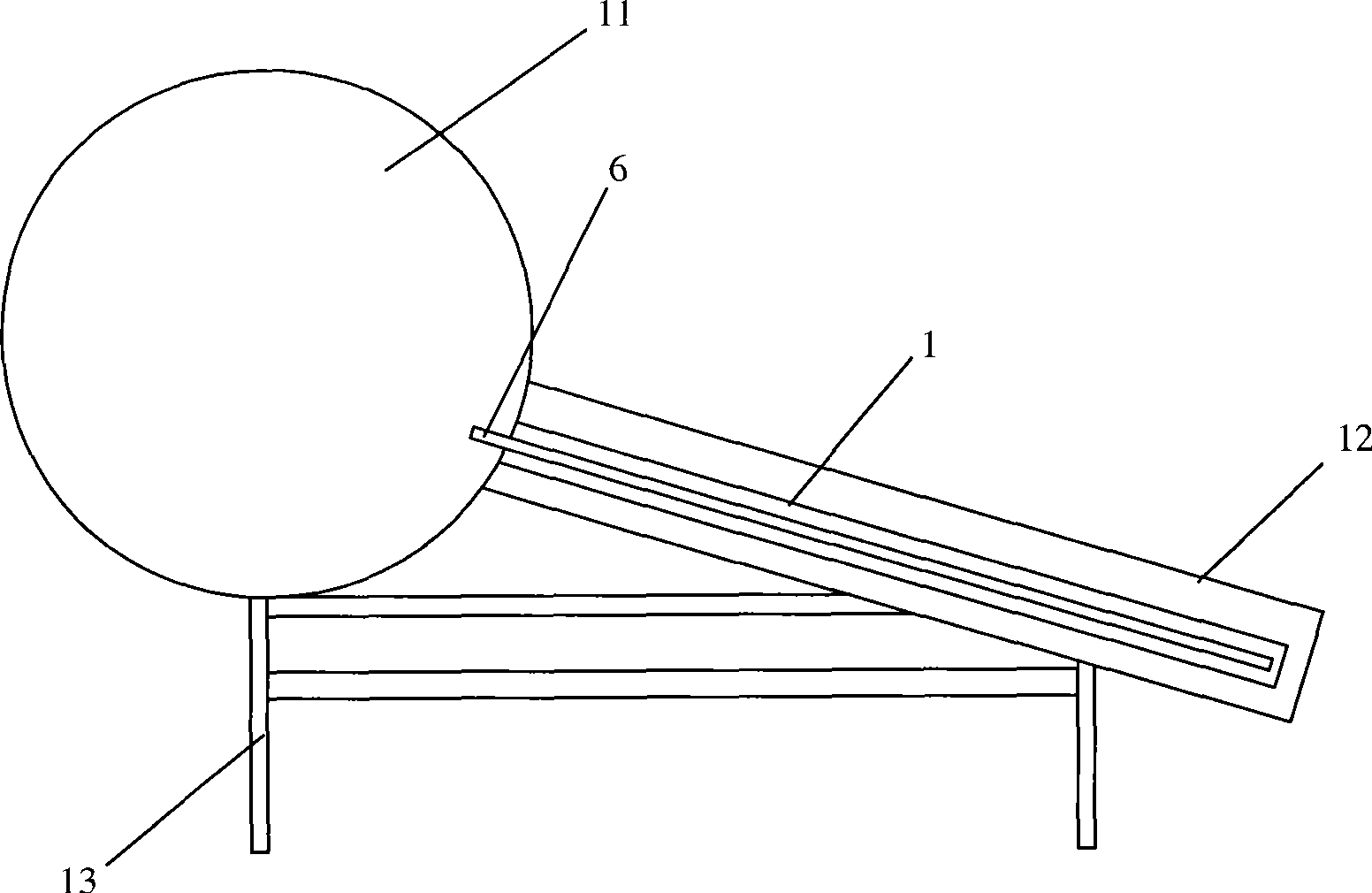

InactiveCN101504197AHigh efficiency in absorbing solar energyImprove heat transfer efficiencySolar heating energySolar heat devicesHeat transmissionSolar water heating system

The invention relates to solar water heating technology, in particular to a novel solar water heating system. The novel solar water heating system comprises a vacuum tube solar collector, and a hot water storage tank, wherein the vacuum tube solar collector comprises a bracket and a group of euphotic tubes which are fixed on the bracket and provided with vacuum interlayers; one end of each of the euphotic tubes is connected with the hot water storage tank; a flat heat pipe is arranged in a middle cavity of the euphotic tubes; one end of the flat heat pipe is inserted in the hot water storage tank or is connected with the hot water storage tank; and the flat heat pipe is provided with a through hole which is filled with working substances, and two ends of the flat heat pipe are sealed to form a heat pipe structure. In the novel solar water heating system, the flat heat pipe provided with a capillary heat pipe is arranged in the conventional vacuum glass tube, thereby greatly improving the absorption efficiency of solar energy and the heat transmission efficiency; and compared with the conventional solar water heating system, the novel solar water heating system greatly improves the absorption efficiency of the solar energy and the heat transmission efficiency, and has simple structure, low cost and application and promotion values .

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

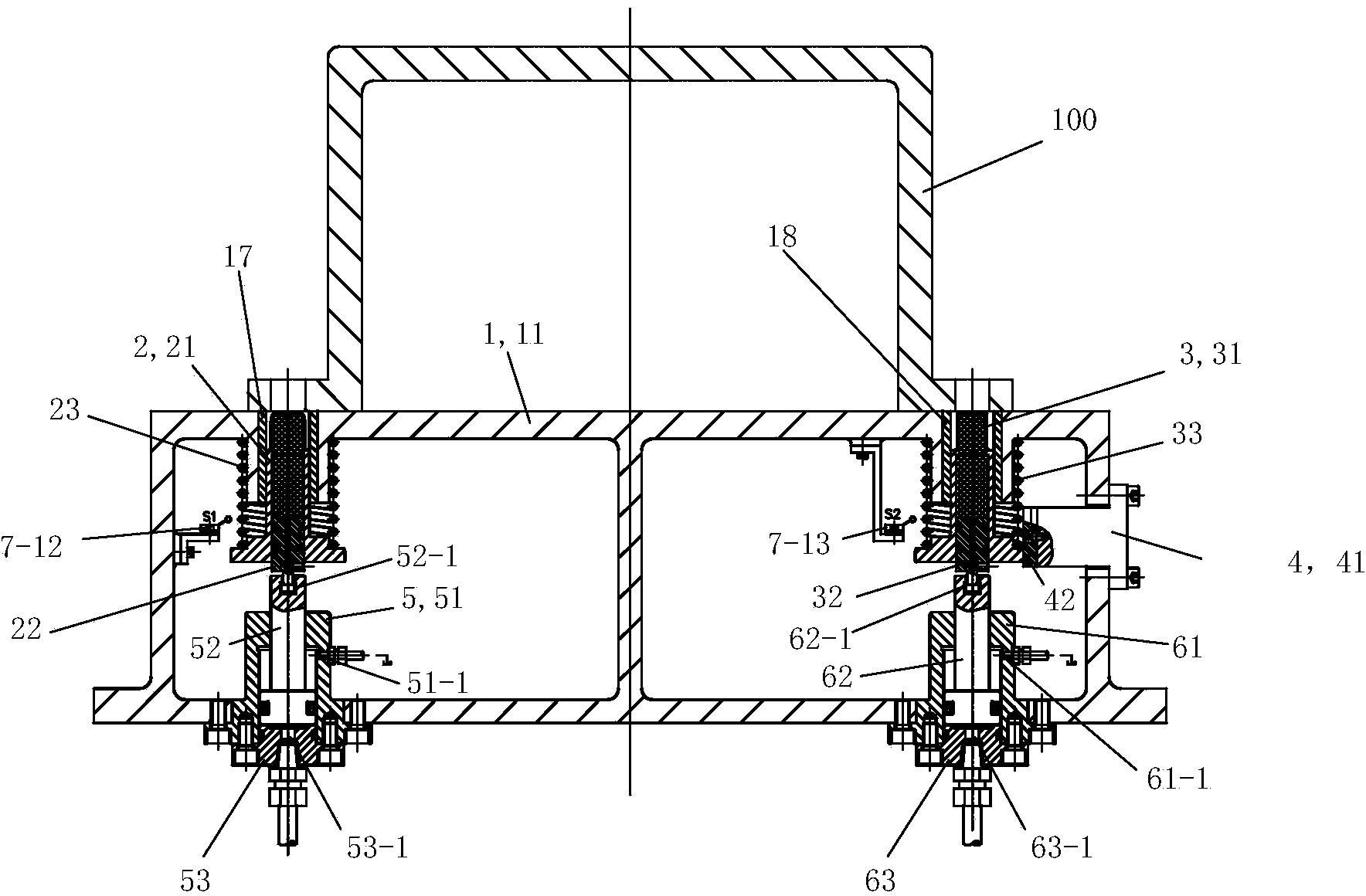

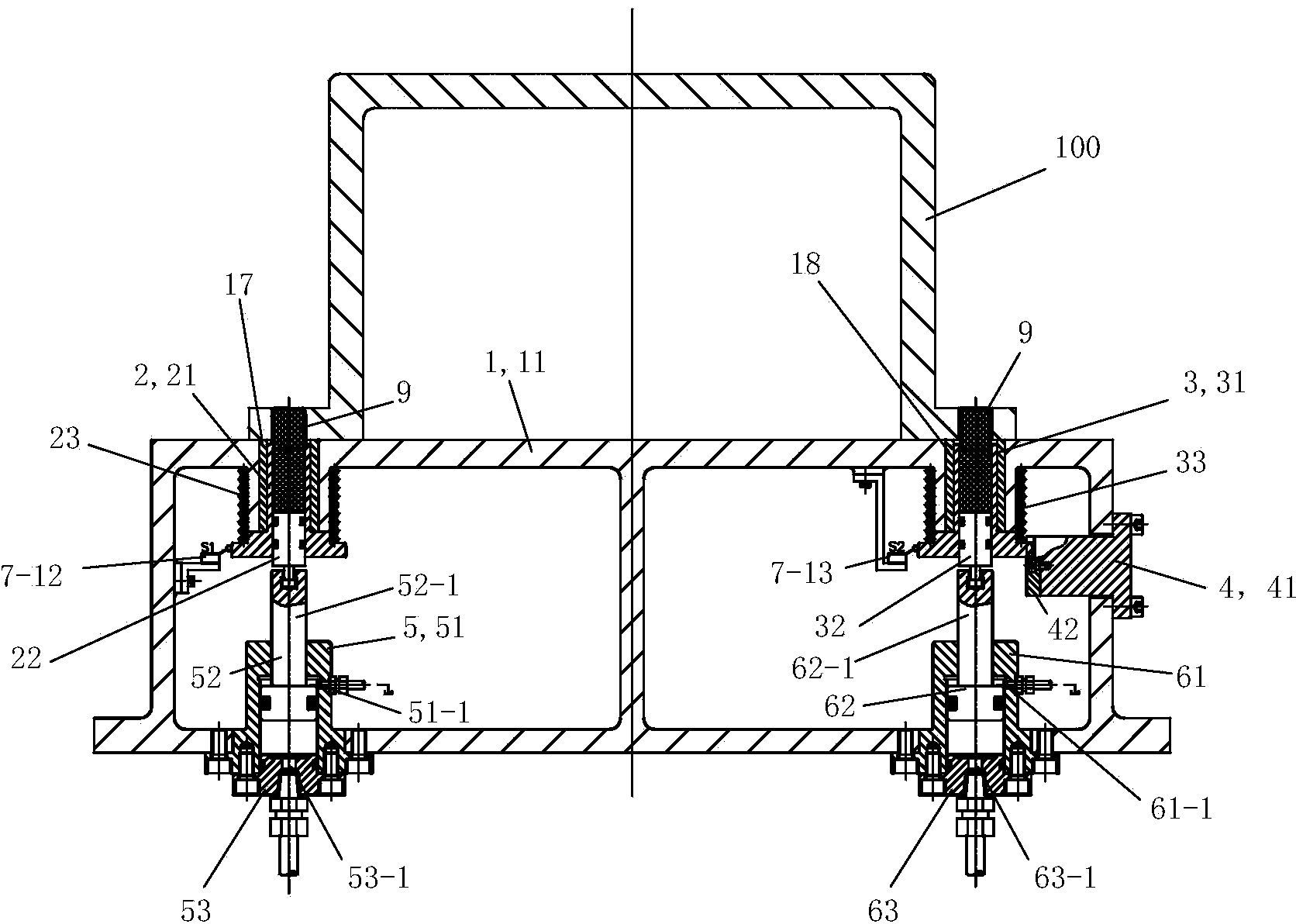

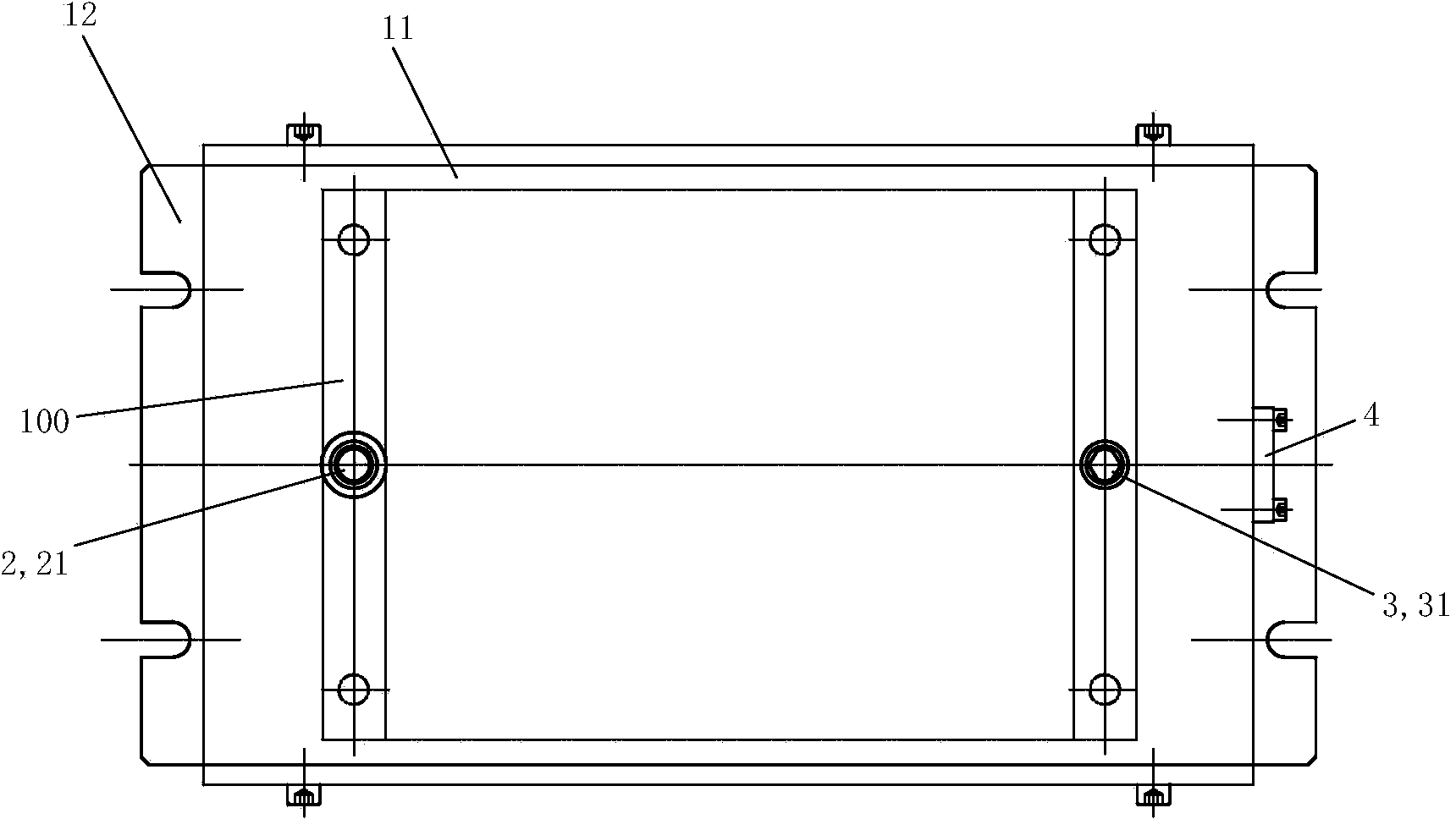

One-face two-pin precise positioning system and control method thereof

InactiveCN103962868AHigh positioning accuracySimple structureWork clamping meansPositioning apparatusControl systemEngineering

The invention discloses a one-face two-pin precise positioning system. The one-face two-pin precise positioning system is characterized by comprising a worktable, a round pin positioning device, a diamond pin positioning device and a control system; the control system comprises a first power device and a second power device, the first power drive drives a first plunger to move in a plunger hole of a round pin, the round pin is driven to move upwards by upwards extruding hydraulic plastics, the positioning portion of the round pin is inserted into a corresponding positioning hole of a workpiece, the positioning portion of the round pin generates corresponding plastic deformation and expands, and the gap between the round pin and the corresponding positioning hole in the workpiece is reduced. The second power device drives a second plunger to move in a plunger hole of a diamond pin, the diamond pin is driven to move upwards by upwards extruding the hydraulic plastics, the positioning portion of the diamond pin is inserted into a corresponding positioning hole of the workpiece, the positioning portion of the diamond pin generates corresponding plastic deformation and expands, and the gap between the diamond pin and the corresponding positioning hole in the workpiece is reduced.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Disposable double stage filtering magnetic machine oil filter

InactiveCN1944969AExtended service lifeImprove filtering effectLubricant mounting/connectionPressure lubricationMetal particleFilter paper

The disposable double stage magnetic machine oil filter has two filtering rooms, including one magnetic filtering room and one filter paper filtering room, formed inside the casing and one isolating cylinder inside the casing to guide the machine oil to pass successively through these two filtering rooms. The present invention has increased area and time for machine oil to contact with the magnet, raised metal particle filtering effect, no jamming in the filter paper, long service life of the filter and excellent protection on the engine.

Owner:周中标

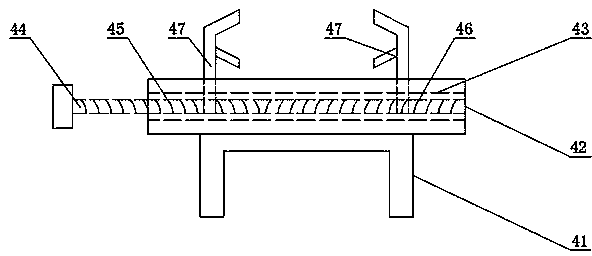

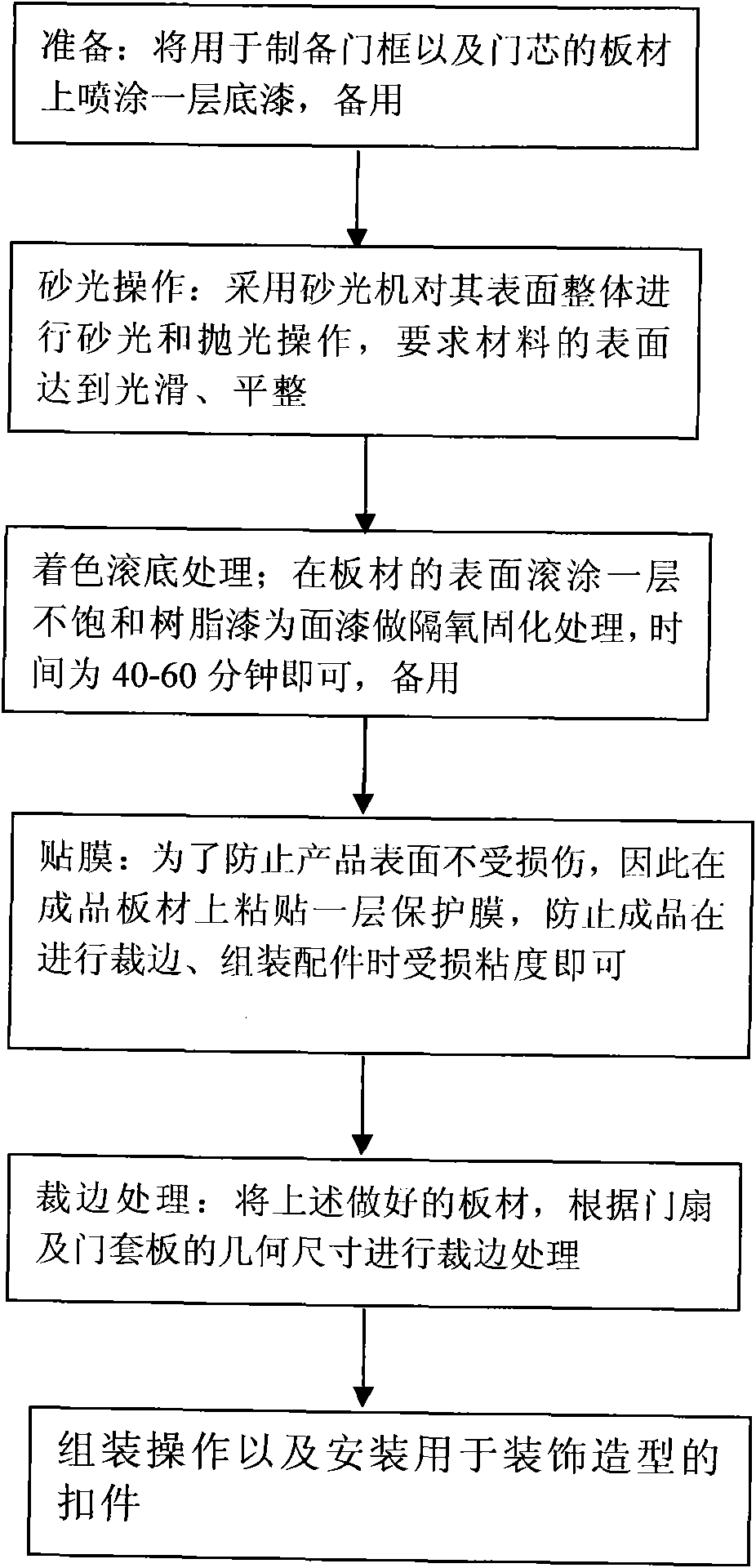

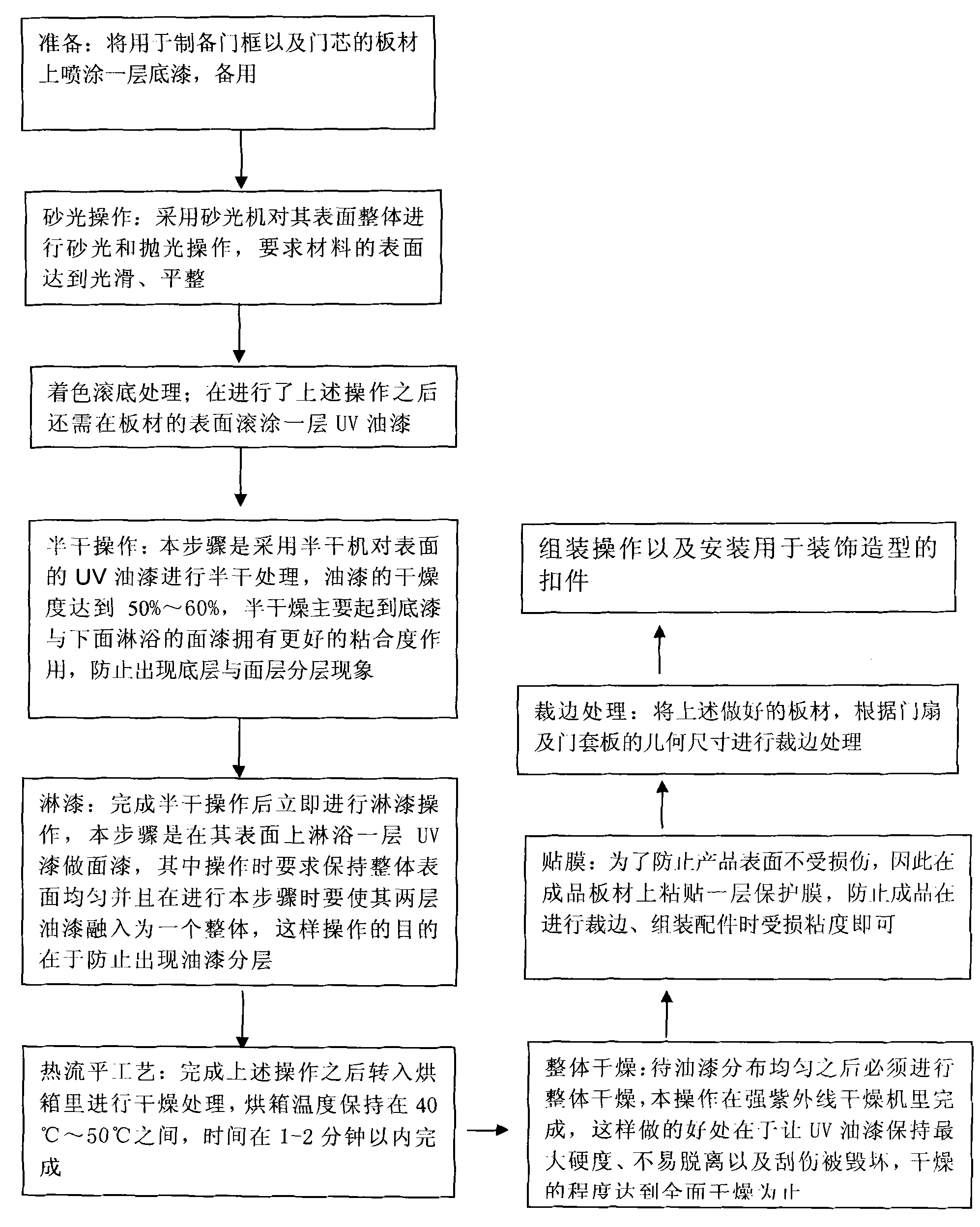

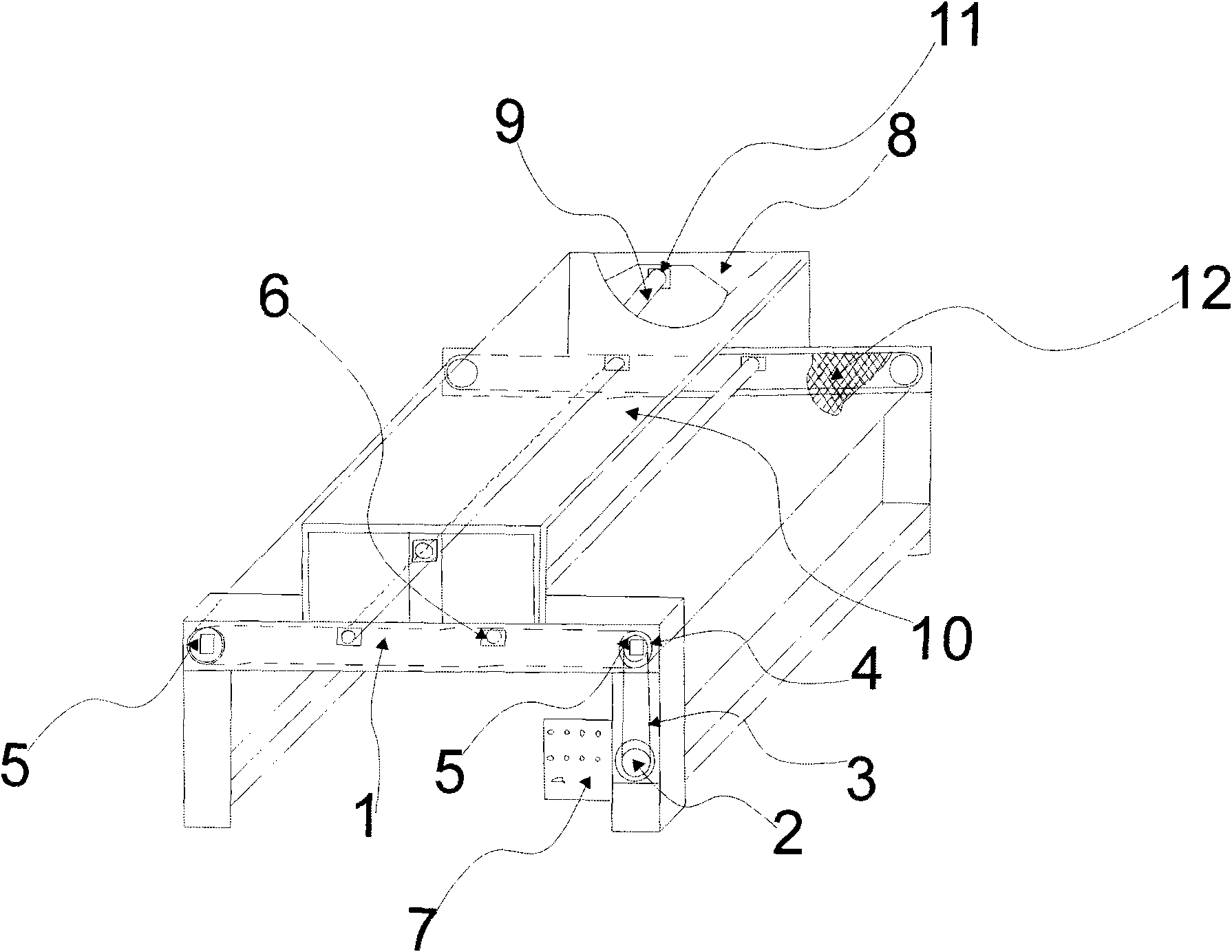

Manufacturing process of wood door and half drying machine

InactiveCN101871307ANot easy to shrinkNot easy to expandPretreated surfacesCoatingsManufacturing engineering

The invention discloses a manufacturing process of a wood door, which is characterized by comprising preparation, sanding operation, colorizing and bottom rolling treatment, lamination, trimming treatment, assembling operation, decorative and shaping fastening piece installation and final entire packaging. The process prevents expansion and contraction in door vertical frame, cross beam and other places. In the invention, the surface oil paint stripping and layering can be prevented by adopting half drying operation, paint spraying, a thermal leveling process and overall drying operation, time is saved and product quality is improved. At the same time, the invention also provides a half drying machine for half drying operation.

Owner:CHENGDU TIANCHENG SHENGMU DOOR

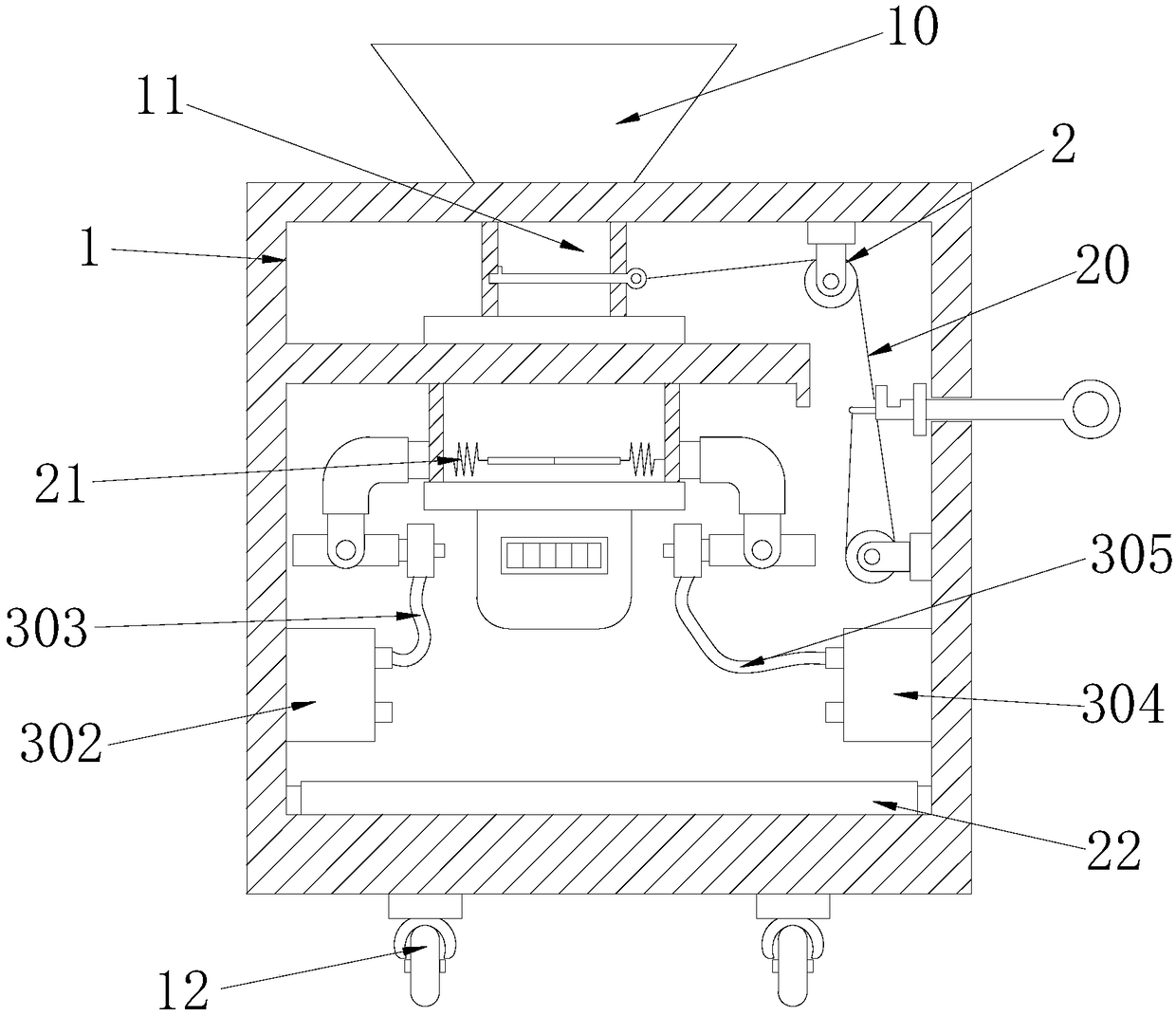

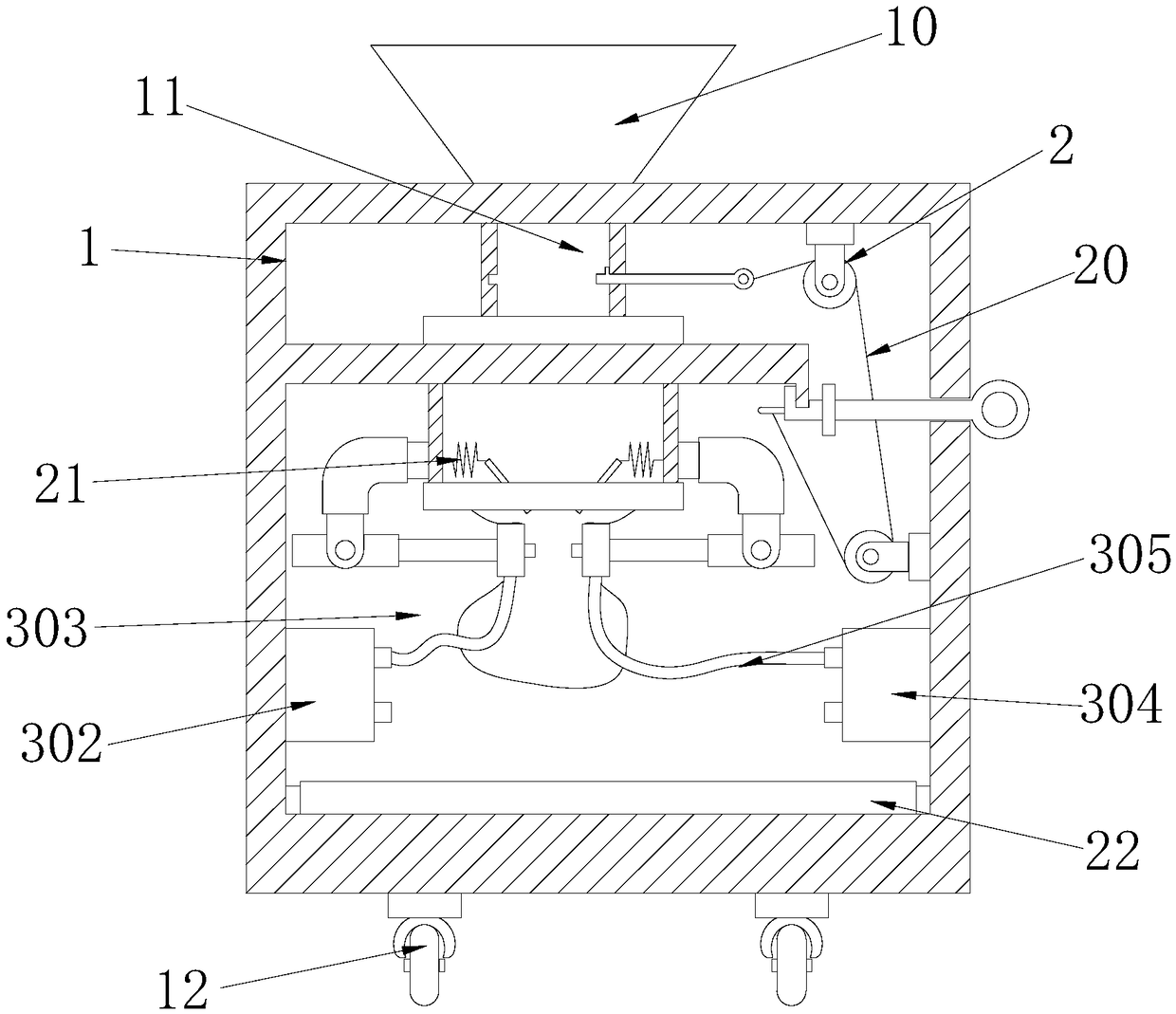

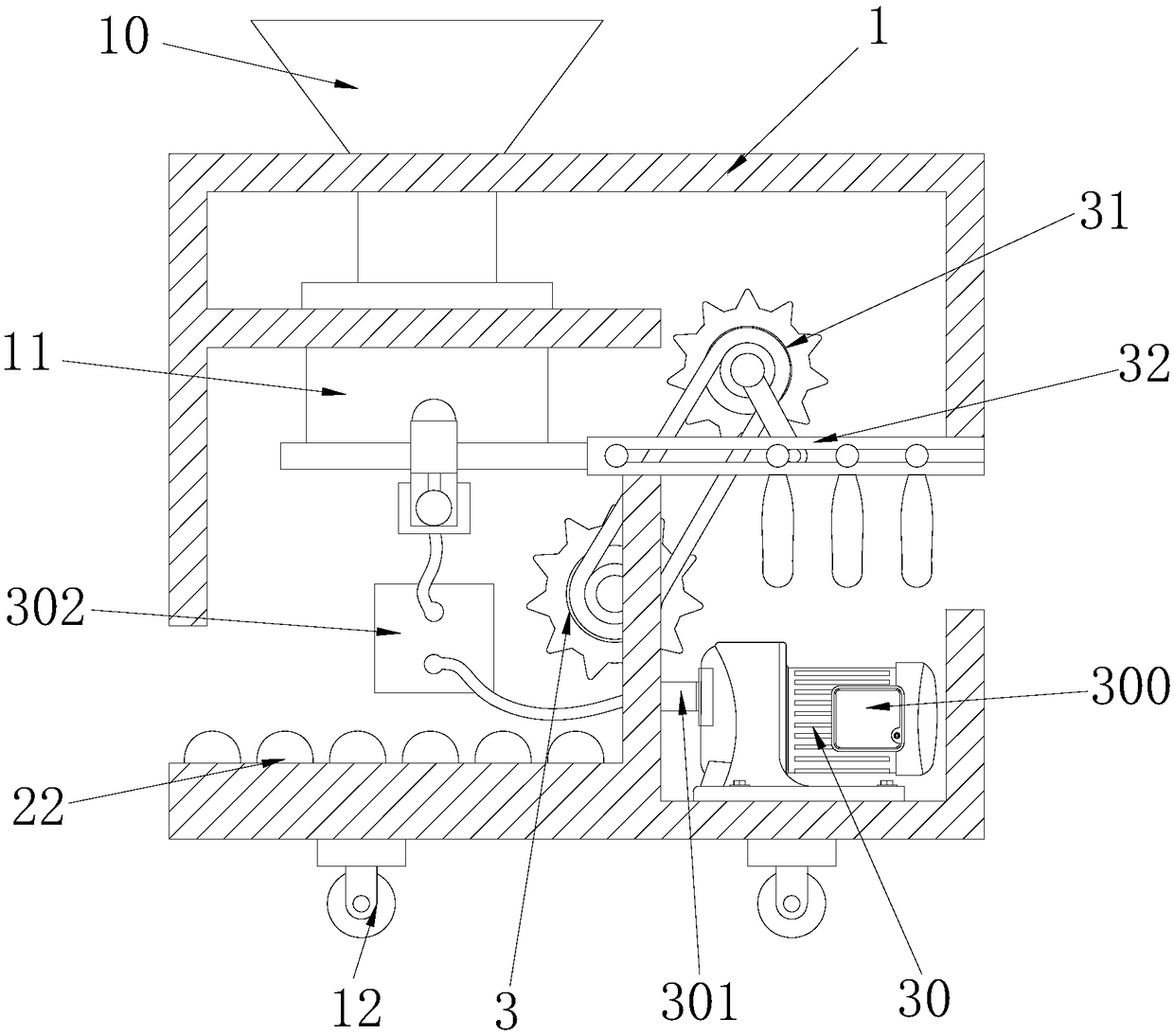

Drug making particle split charging machine with height capable of being adjusted

InactiveCN108715237ACapable of welding operationReduce production and processing costsSolid materialPackaging machinesEngineeringMachining

The invention discloses a drug making particle split charging machine with the height capable of being adjusted. The machine structurally comprises a device protection shell, a split charging transmission mechanism and a packaging bag conveying mechanism; the device protection shell comprises a discharging hopper, a discharging control pipeline and walking universal wheels, the split charging transmission mechanism is provided with a starting trigger mechanism, a packaging transmission mechanism, a material discharging roller and a packaging bag, and the packaging bag conveying mechanism is provided with a power source control device, a transmission gear set device and a packaging bag conveying table. The machine has the beneficial effects that through the simple structure, split chargingand packaging work are integrated, material packaging is carried out, in the process, manual additional packaging work is not needed, only through device starting, discharging, split charging, packaging and discharging integration is finished, production machining cost is saved, and production machining efficiency is improved.

Owner:湖州曜东服饰有限公司

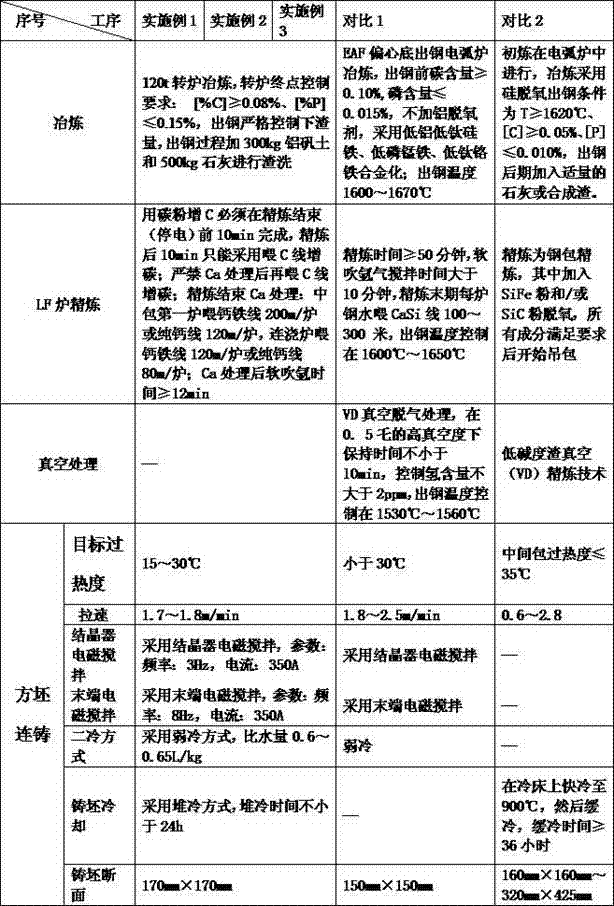

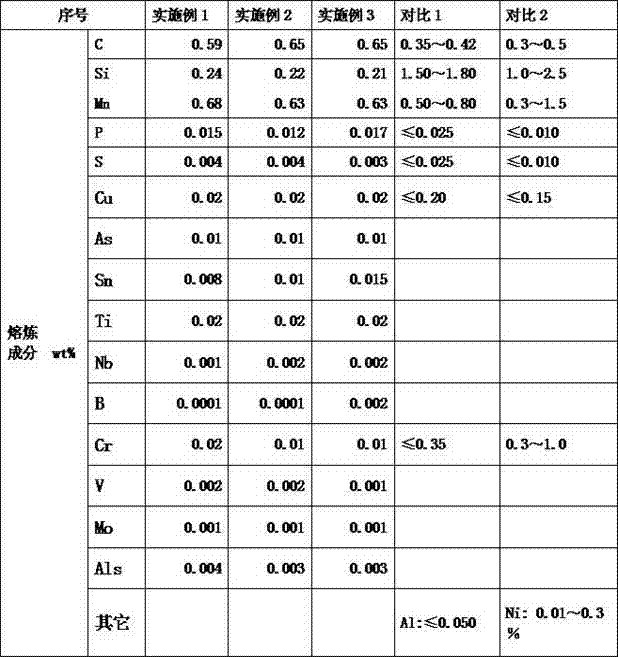

Steel wire rod for furniture spring and production method of steel wire rod

ActiveCN104745958AMeet the requirements of excellent comprehensive performanceReduce production and processing costsProcess efficiency improvementWire rodSpring steel

The invention relates to a steel wire rod for a furniture spring, which comprises the following main components in percentage by weight (wt%): 0.58-0.67 percent of C, 0.19-0.25 percent of Si, 0.60-0.68 percent of Mn and the balance of Fe. The steel wire rod further comprises the following residual components in percentage by weight (wt%): less than 0.027 percent of P, less than 0.012 percent of S, less than 0.04 percent of Cu, less than 0.03 percent of As, less than 0.028 percent of Sn, less than 0.03 percent of Ti, less than 0.005 percent of Nb, less than 0.0005 percent of B, less than 0.097 percent of Cr, less than 0.03 percent of Ni, less than 0.005 percent of V, less than 0.01 percent of Mo and less than 0.005 percent of Als. The steel wire rod has the characteristics of simple production process, low processing cost, excellent comprehensive performance and the like and can meet the requirement of wire rod raw materials of a mattress spring.

Owner:SGIS SONGSHAN CO LTD

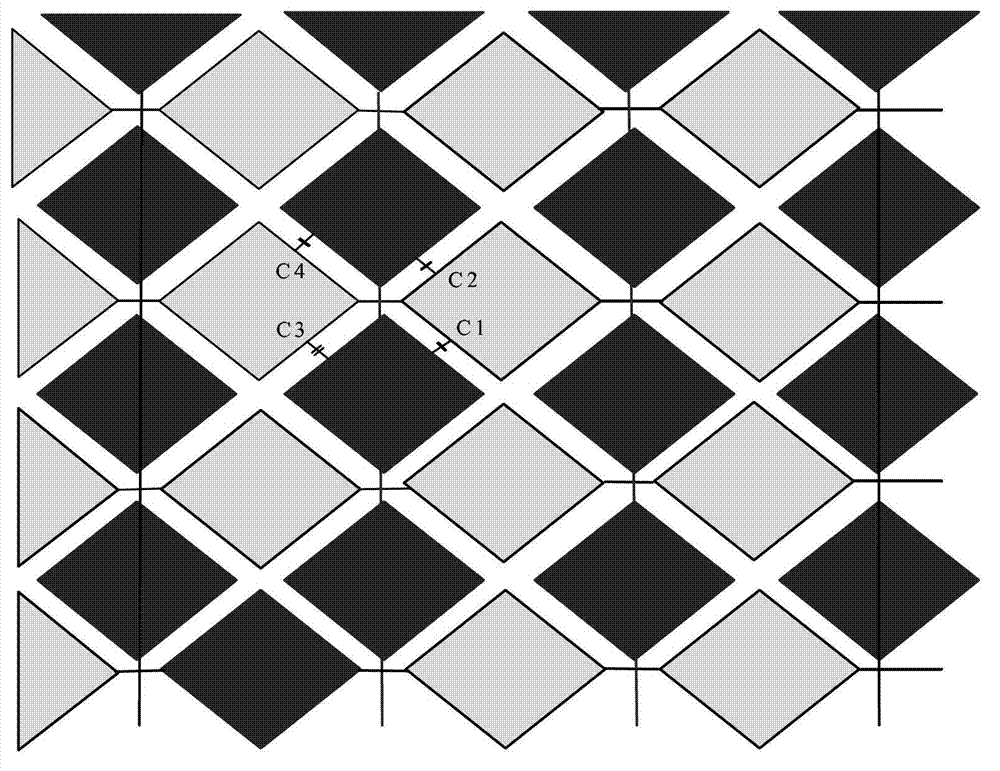

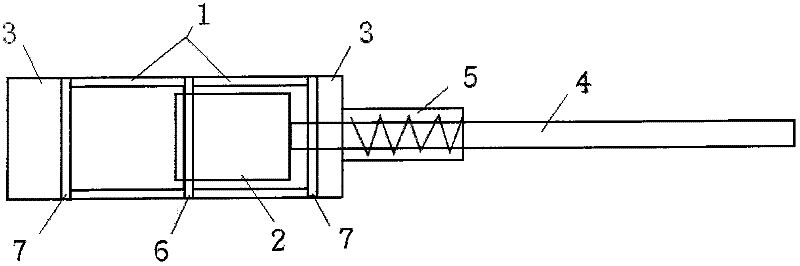

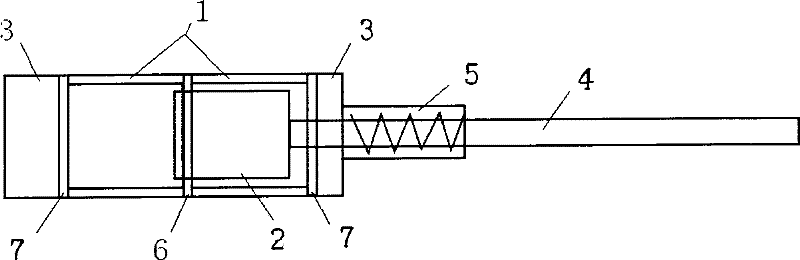

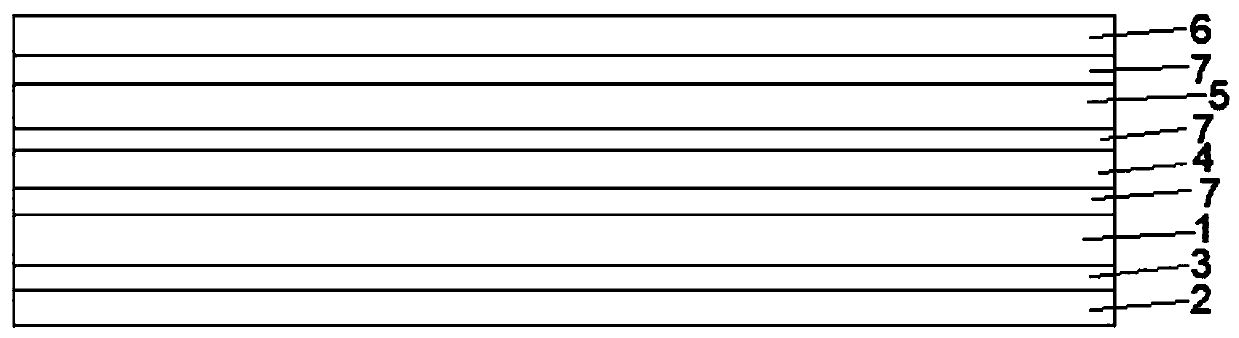

Differential-capacitive length sensor

InactiveCN102359754AReduce production and processing costsSimple processing circuitUsing electrical meansCapacitanceGrating

The invention discloses a differential-capacitive length sensor which adopts a differential-capacitive technology and has the accuracy of higher than 0.1mum. The device comprises a capacitor fixing polar plate, a capacitor movable polar plate, a capacitor polar plate seat, a measuring rod and a spring device. The capacitor fixing polar plate is a cylinder which is separated by two rubber bands; two ends of the capacitor fixing polar plate are respectively connected with a capacitor polar plate seat by the rubber bands; the capacitor movable polar plate is arranged in the cylinder of the capacitor fixing polar plate; the capacitor movable polar plate is a cylinder, the outer radius of which is slightly less than the inner radius of the capacitor fixing polar plate and which can move horizontally in the cylinder of the capacitor fixing polar plate; the capacitor movable polar plate is connected with the measuring rod; and the spring device which is used for controlling the measuring rod to horizontally move is arranged outside the capacitor polar plate seat. As the traditional grating moire fringe technology is not used in the invention, the laser reticle and the processing reforming of moire fringes are not needed, the production and manufacturing cost is greatly reduced, and a backend processing circuit is relatively simple.

Owner:张华建

MIM stainless steel feed for middle frame of mobile phone and preparation method of product made of MIM stainless steel feed

InactiveCN109047753AImprove liquidityAvoid deformationTransportation and packagingMetal-working apparatusWhiskersHardness

The invention relates to MIM stainless steel feed for a middle frame of a mobile phone and a preparation method of a product made of the MIM stainless steel feed. The MIM stainless steel feed comprises the following components: stainless steel mixed powder and a forming agent, wherein the stainless steel mixed powder and the forming agent are combined according to a weight ratio of (90-92):(10-8);the stainless steel mixed powder comprises stainless steel composite powder and silicon carbide crystal whiskers; and the stainless steel composite powder comprises leaf-shaped powder produced through the water atomization process and spherical powder produced through the water atomization process. The MIM stainless steel feed provided by the invention has the advantages that a raw material is combined with metal powder which has different shapes, specifications and components, and a polymer forming agent with reasonable components is matched for the combination, so that the high fluidity, the low deformation possibility, the high glossiness and the high hardness of the MIM stainless steel feed can be achieved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Process method for quickly removing benzopyrene and other harmful substances in tea oil

InactiveCN102160581AReduce production and processing costsKeep the flavorEdible oils/fatsFood gradeHazardous substance

The invention discloses a process method for quickly removing benzopyrene and other harmful substances in tea oil, which is fast, simple and efficient. The process method is technically characterized by comprising the steps of: by application of the object surface absorbing function principle, firstly carrying out pre-filtration on the tea oil, adding a proper amount of food-grade fat treatment agent, fully stirring, after standing, stirring uniformly, then filtering and separating to remove the benzopyrene and other harmful substances in the tea oil. In the method, the benzopyrene in the tea oil can be reduced to be about 21% of the original amount, so that the process method can be widely used for tea oil production of all large, medium and small tea oil production and processing enterprises.

Owner:湖南山润油茶科技发展有限公司

Hot-press-free antibacterial and anti-scraping optical explosion-proof film

InactiveCN109096940AEnhanced interfacial interaction forceGood dispersionFilm/foil adhesivesPolyureas/polyurethane adhesivesOptical transparencyTransmittance

The invention relates to hot-press-free antibacterial and anti-scraping optical explosion-proof film. Konjac glucomannan nanocrystalline is added into a protection layer and modified through chitosan,the interfacial interaction force among molecules in a formula system is greatly increased, the dispersing performance and the compatibility among components are improved, and thus the mechanical performance of the structure of the protection layer is improved; by adding inorganic and organic compound synergistic antibacterial agents, the antibacterial effect of the protection layer is greatly improved, and cross propagation of bacteria after surface contact of the human body is avoided; the antibacterial and anti-scraping optical explosion-proof film is subjected to hot-press-free curing molding, and the processing procedure and the processing cost are reduced; TPU is good in processability and flexibility and resistant to shock, an optical-grade PET base material is good in optical transparency, the requirement of the explosion-proof film for the optical performance is met, and the light transmittance of the explosion-proof film is increased. The explosion-proof film has good lighttransmittance, static resistance, wear resistance, scraping resistance and bacterial resistance; through the arrangement of the explosion-proof structure layer, the safety and stability during use areguaranteed, and meanwhile the requirement for optical-grade appearance is met.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

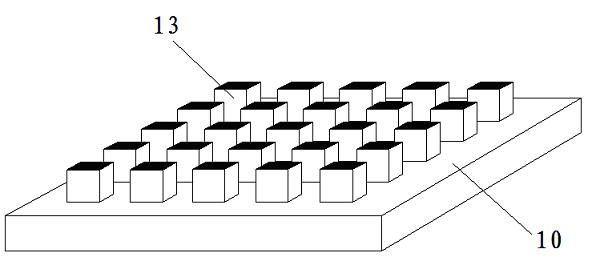

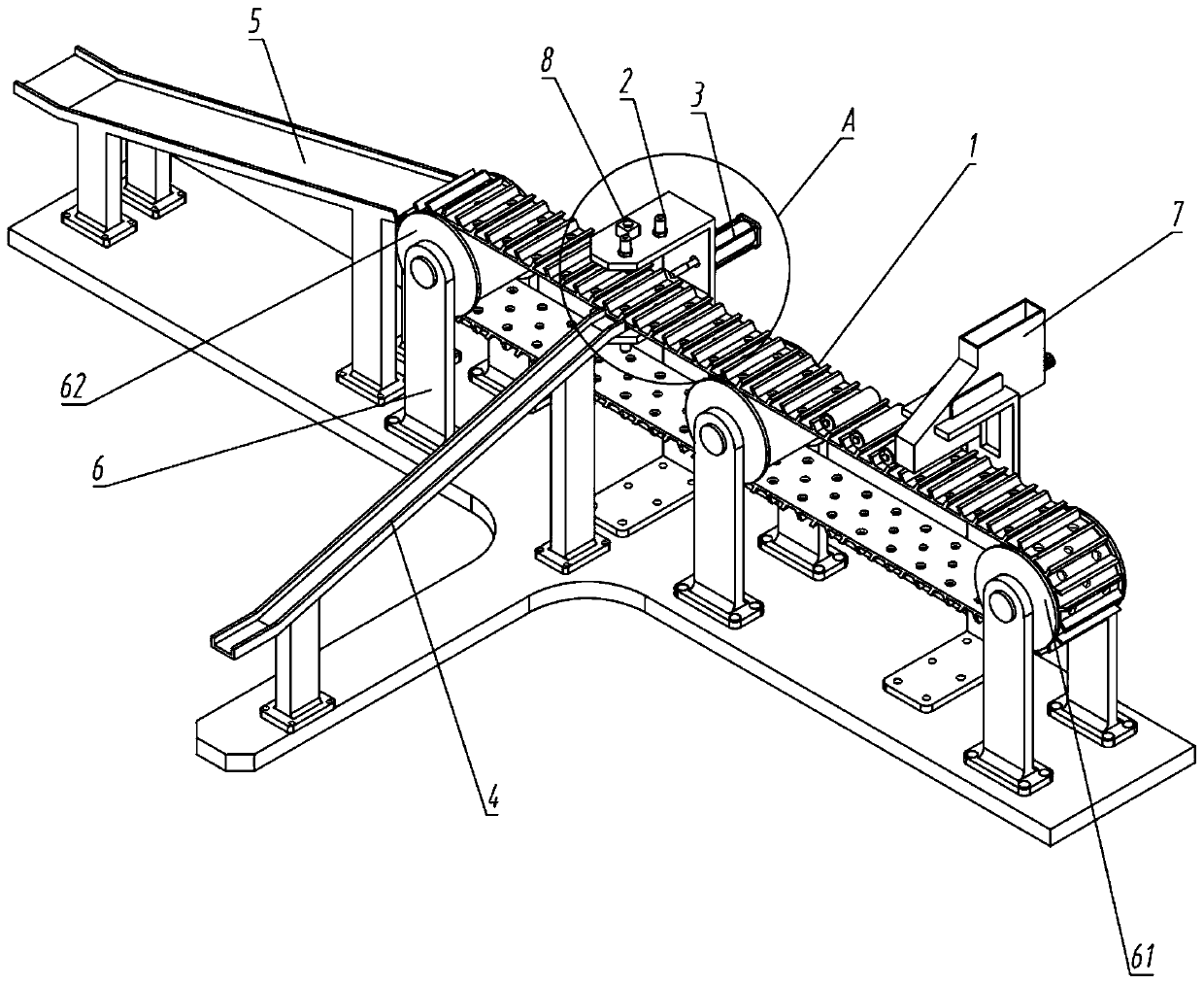

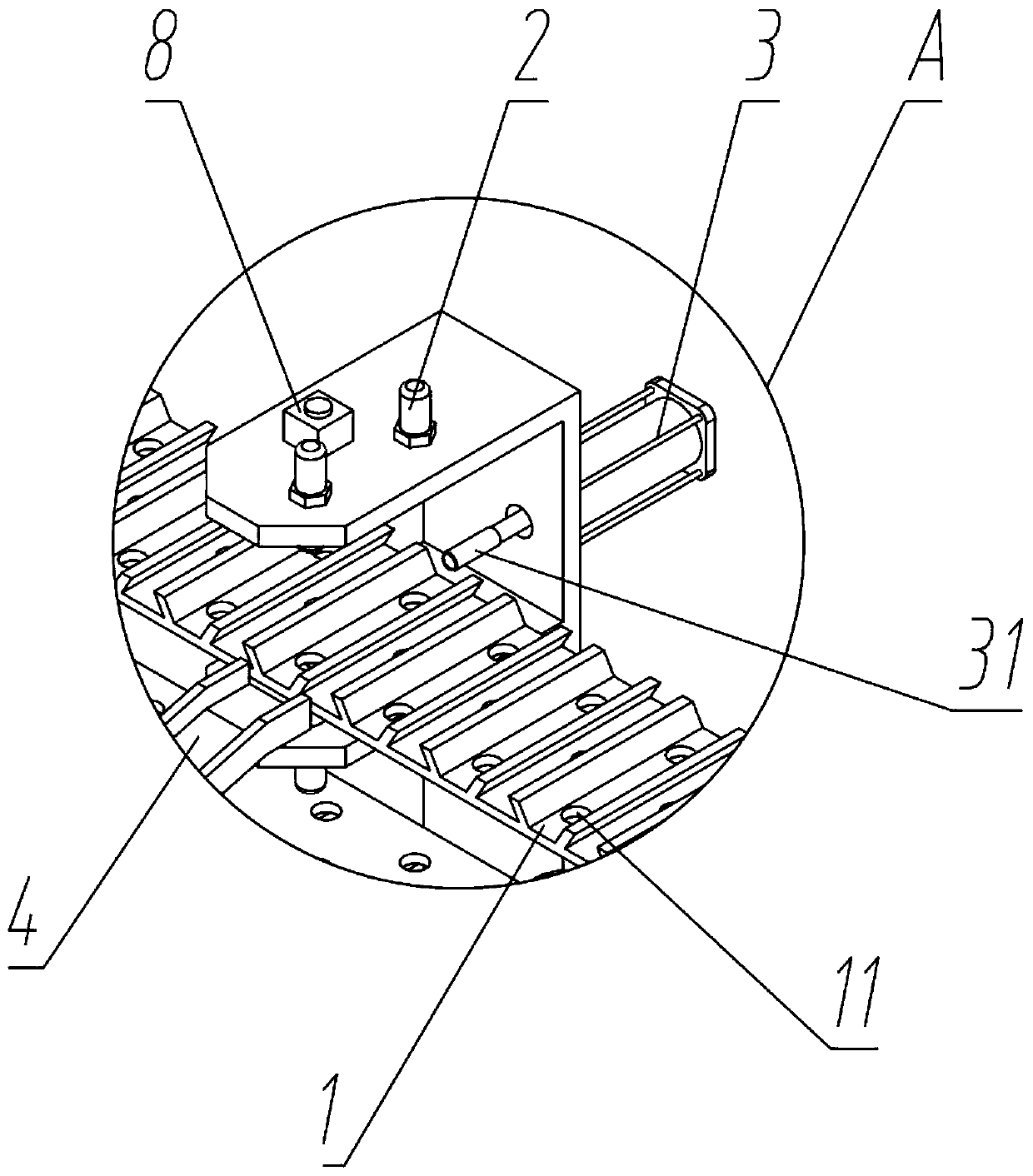

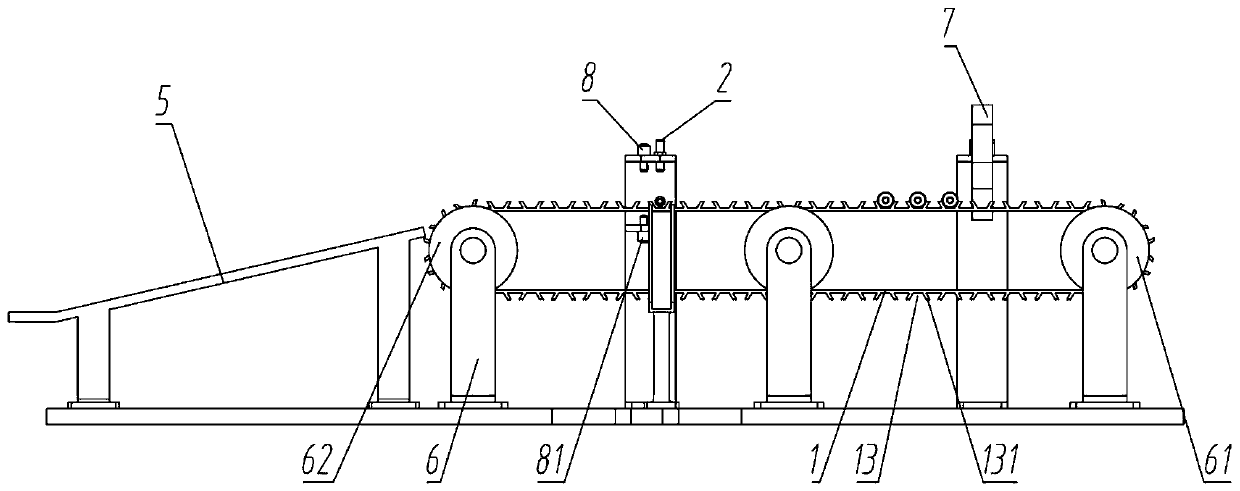

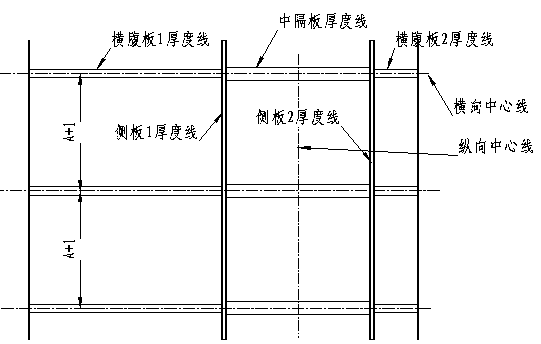

Processing method of miniature spherical or aspherical lens array

The invention relates to a processing method of a miniature spherical or aspherical lens array. A grinding wheel with a plurality of groove grinding edges is utilized to respectively grind transverse and vertical grooves which are perpendicular to each other on a glass substrate to form a rectangular cylinder array with the end face as a square. The rectangular cylinder is ground into a spherical or aspherical miniature lens base body through a grinding head with a recessed grinding edge in rotating mode. A miniature grinding head with the same structure and smaller granularity is used for conducting fine grinding on the miniature lens base body, and a miniature polishing head is used for conducting polishing on the miniature lens base body receiving fine grinding. Grinding agents are required to be added continuously during the polishing process, and the granularity of the grinding agents needs to be replaced continuously from coarse to fine till the smooth and clean degree achieves the design requirements.

Owner:吉林省钜鸿智能技术有限公司

Method for utilizing nickel flash smelting water-quenched slag

InactiveCN103114198AAvoid negative effectsChange grain structureProcess efficiency improvementCokeFlash smelting

The invention relates to a method for utilizing nickel flash smelting water-quenched slag. The method comprises the following steps of: sequentially preparing materials, mixing and sintering, and is characterized by the following steps: performing high-pressure rolling preprocessing on the nickel flash smelting water-quenched slag, preparing and mixing with other sintering feed, sintering and producing sintered ore. The method is characterized by comprising the following steps: I, performing high-pressure rolling preprocessing on the nickel flash smelting water-quenched slag, so that the ratio of -0.074mm is over 40 percent; II, the specific formula during material preparation comprises 5-15 parts of nickel flash smelting water-quenched slag, 10-40 parts of Australia ore powder, 10-40 parts of Shanxi Daixian ore powder, 10-20 parts of blast furnace ore return powder, 2-6 parts of limestone flour, 5-10 parts of dolomite dust, 3-9 parts of lime and 4-10 parts of coke powder; III, uniformly mixing through a two-section mixer, adding water, thus obtaining a mixture; and IV sintering. According to the sintered ore manufactured by the method, the nickel flash smelting water-quenched slag can be highly efficiently utilized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Cylindrical battery sorting machine

PendingCN111036564AImprove sorting efficiencyReduce production and processing costsSortingStructural engineeringDistance sensors

The invention discloses a cylindrical battery sorting machine. Placing grooves are formed in the outer surface of a conveying belt at intervals in the conveying direction of the conveying belt; each cylindrical battery is laid flat in each placing groove; a pushing mechanism is arranged on one side in the width direction of the conveying belt and is used for pushing the cylindrical battery locatedin one of the placing grooves to move towards the other side in the width direction of the conveying belt; an outer diameter measuring device comprises first distance sensors and second distance sensors, wherein the first distance sensors are arranged above the outer side of the conveying belt and the second distance sensors are arranged on the inner side of the conveying belt; the first distancesensors and the second distance sensors are oppositely arranged up and down; the bottom surface of each placing groove on the conveying belt is provided with a first through hole; and when the outerdiameter measuring device is in the measuring state, the emitting ends of the second distance sensors correspond to one of the first through holes. According to the cylindrical battery sorting machine, the cylindrical batteries with unqualified outer diameter can be automatically selected, the sorting efficiency of the cylindrical batteries is high, and the production and processing cost of the batteries can be effectively reduced.

Owner:苏州雄钜电子科技有限公司

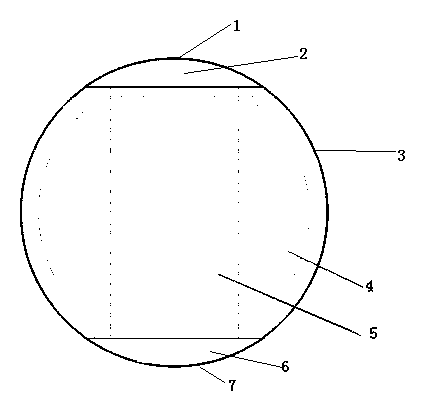

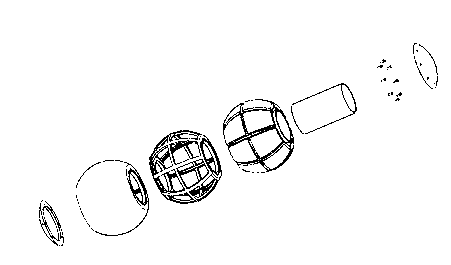

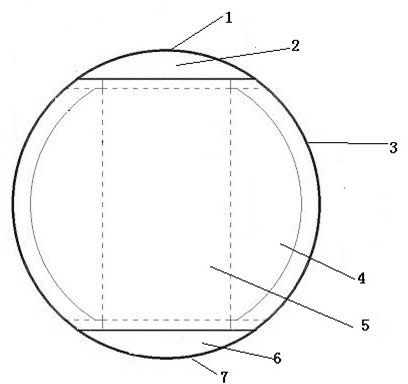

Spherical buoy and manufacturing method thereof

InactiveCN102700684AReduce non-uniform impactImprove and ensure posture stabilityWaterborne vesselsBuoysEngineeringBuoy

The invention discloses a spherical buoy and a manufacturing method thereof. The spherical buoy comprises a spherical buoy body. The spherical buoy is characterized in that the periphery of the spherical buoy body is smooth, the spherical buoy body is provided with an upper top cover and a lower bottom cover, the upper top cover, the lower bottom cover and the spherical buoy body form three cavities from top to bottom, i.e. a first cavity, a spherical buoy body cavity and a second cavity, the spherical buoy body cavity is a cylindrical cavity, and a foam body is arranged at the periphery of the cylindrical cavity. The spherical buoy has the advantages of good gesture stability, simple structure and low cost.

Owner:周涛

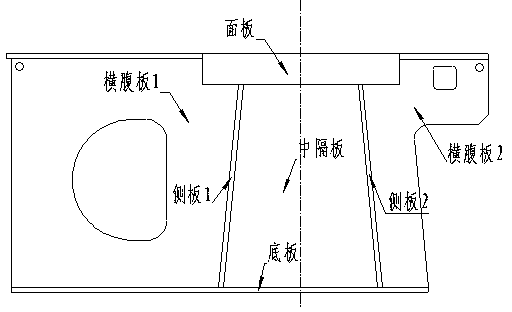

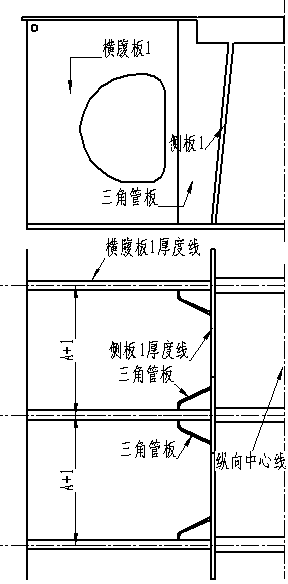

Manufacturing method of welding type cylinder block of marine diesel engine

InactiveCN103506763AReduce scrap rateReduce the amount of machiningWelding/cutting auxillary devicesAuxillary welding devicesPulp and paper industryCylinder block

The invention discloses a manufacturing method of a welding type cylinder block of a marine diesel engine. The method comprises the steps of (1) drawing lines on a platform, (2) assembling a box body of the cylinder block, (3) assembling a triangular tube plate, and (4) assembling a scavenging device. According to the manufacturing method of the welding type cylinder block of the marine diesel engine, production cost is reduced; due to the fact that the structure of the welding type cylinder block is a combination of a cylinder block body and a scavenging collecting pipe, the machining amount of the cylinder block and the scavenging pipe is greatly reduced, the workload for secondary assembly is greatly reduced, assembly errors are reduced, the defect that cold cracks appear easily during casting is overcome, defect repairing is easy, and the discarding rate of cylinder blocks is reduced.

Owner:HUDONG HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com