One-face two-pin precise positioning system and control method thereof

A precise positioning and one-sided technology, applied in the field of mechanical processing, can solve problems such as reducing processing efficiency and quality, affecting processing accuracy, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

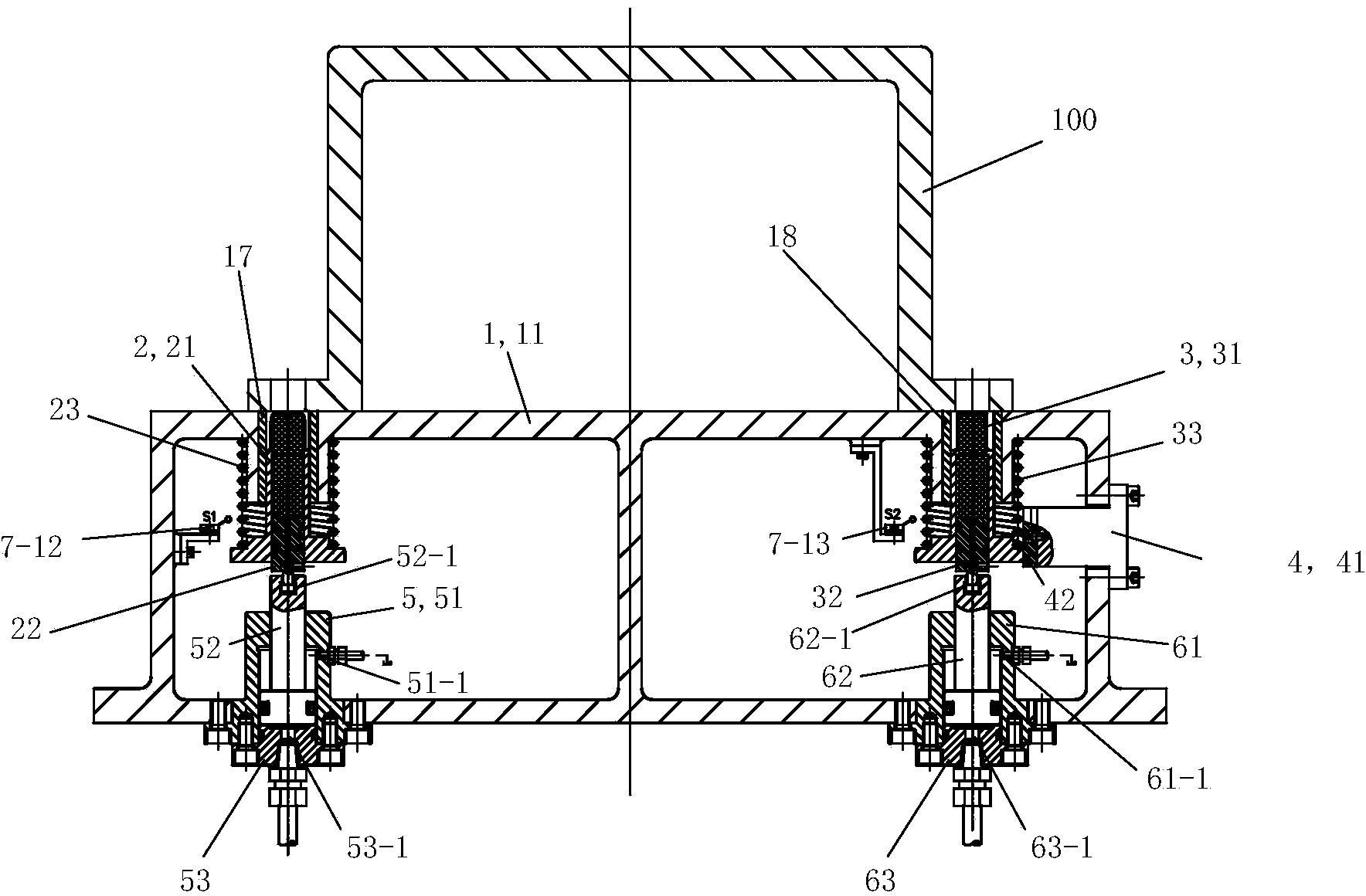

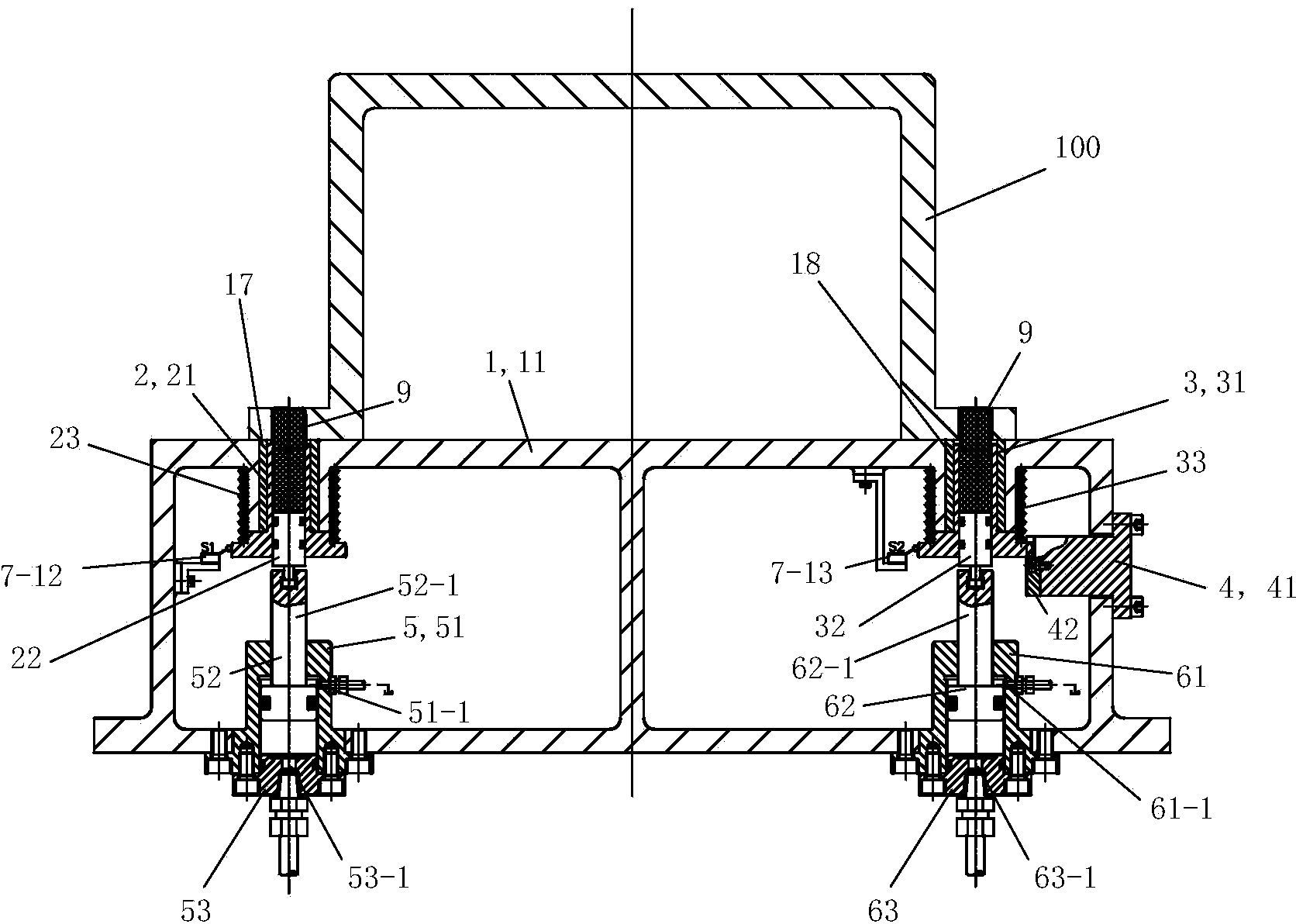

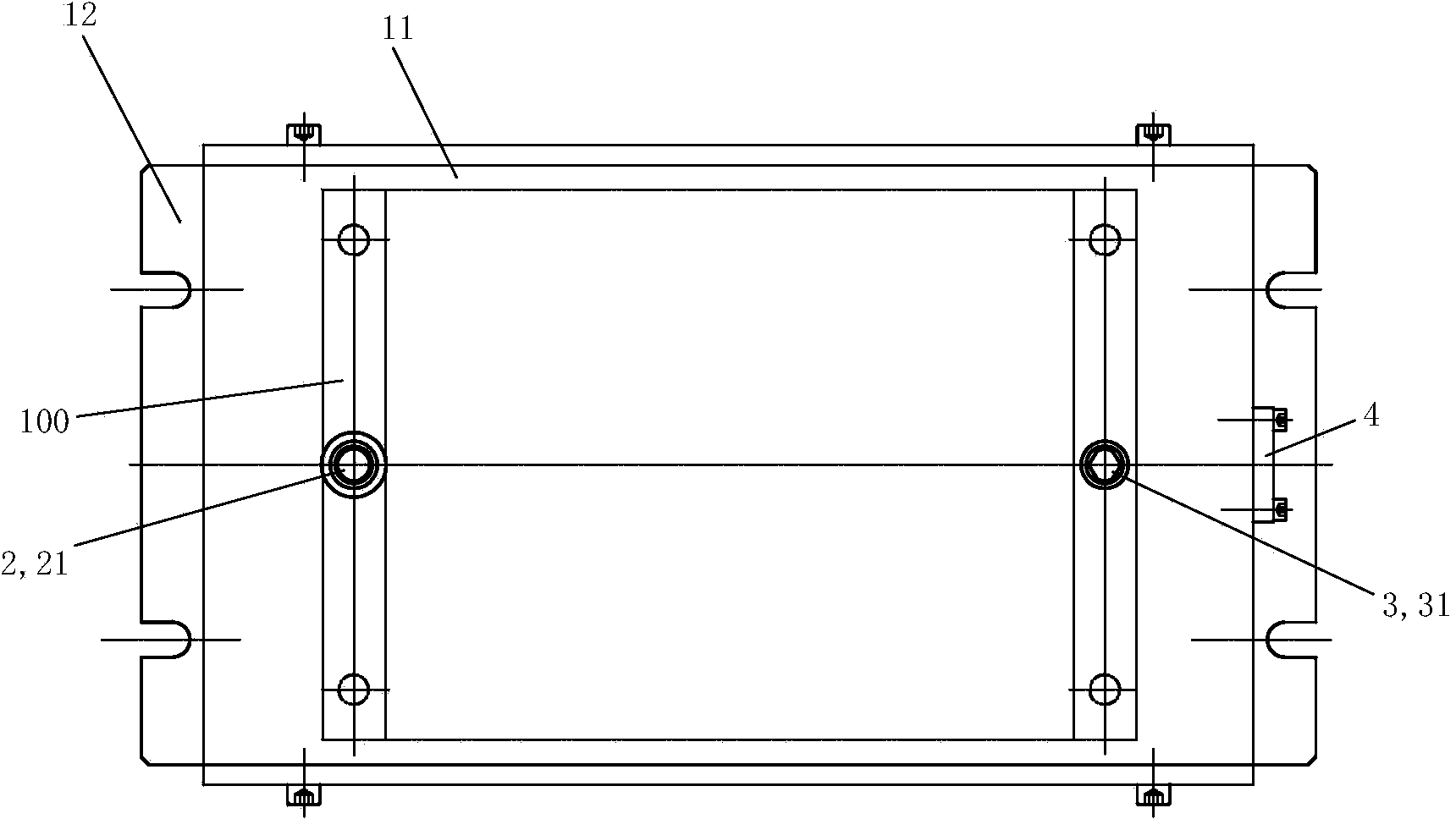

[0097] See Figure 1 to Figure 3 and Figure 12 , The precise positioning system of two pins on one side of the present invention includes a workbench 1, a cylindrical pin positioning device 2, a diamond pin positioning device 3, a guide device 4 and a control system.

[0098] See Figure 1 to Figure 3 and Figure 10 , The workbench 1 includes a main box body, a front sealing plate and a rear sealing plate. The main box body is a casting integral piece, and the main box body includes an upper panel 11 , a lower bottom panel 12 , a left side panel 13 , a right side panel 14 and a middle stiffener panel 15 . The upper panel 11 , the left side panel 13 , the lower bottom panel 12 and the right side panel 14 are sequentially connected to each other to form a main box with a rectangular section and a cavity 16 . The middle rib plate 15 is vertically arranged between the middle part of the upper panel 11 and the middle part of the lower bottom plate 12 along the front and back d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com