Patents

Literature

2344results about How to "Reduce processing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Object detection system for vehicle

ActiveUS7038577B2Reduce processing requirementReduce possibilityImage enhancementImage analysisObject detectionEdge detection

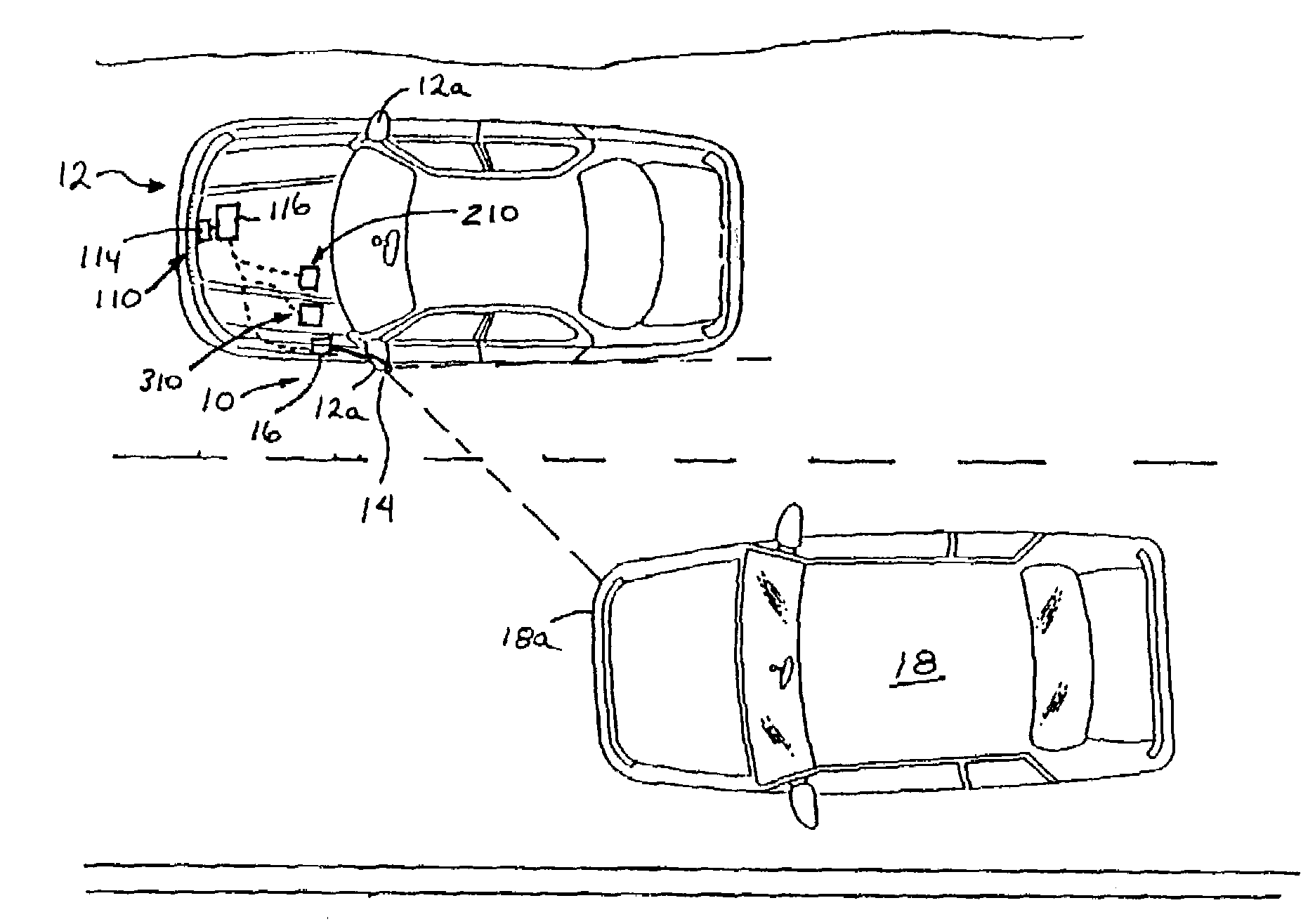

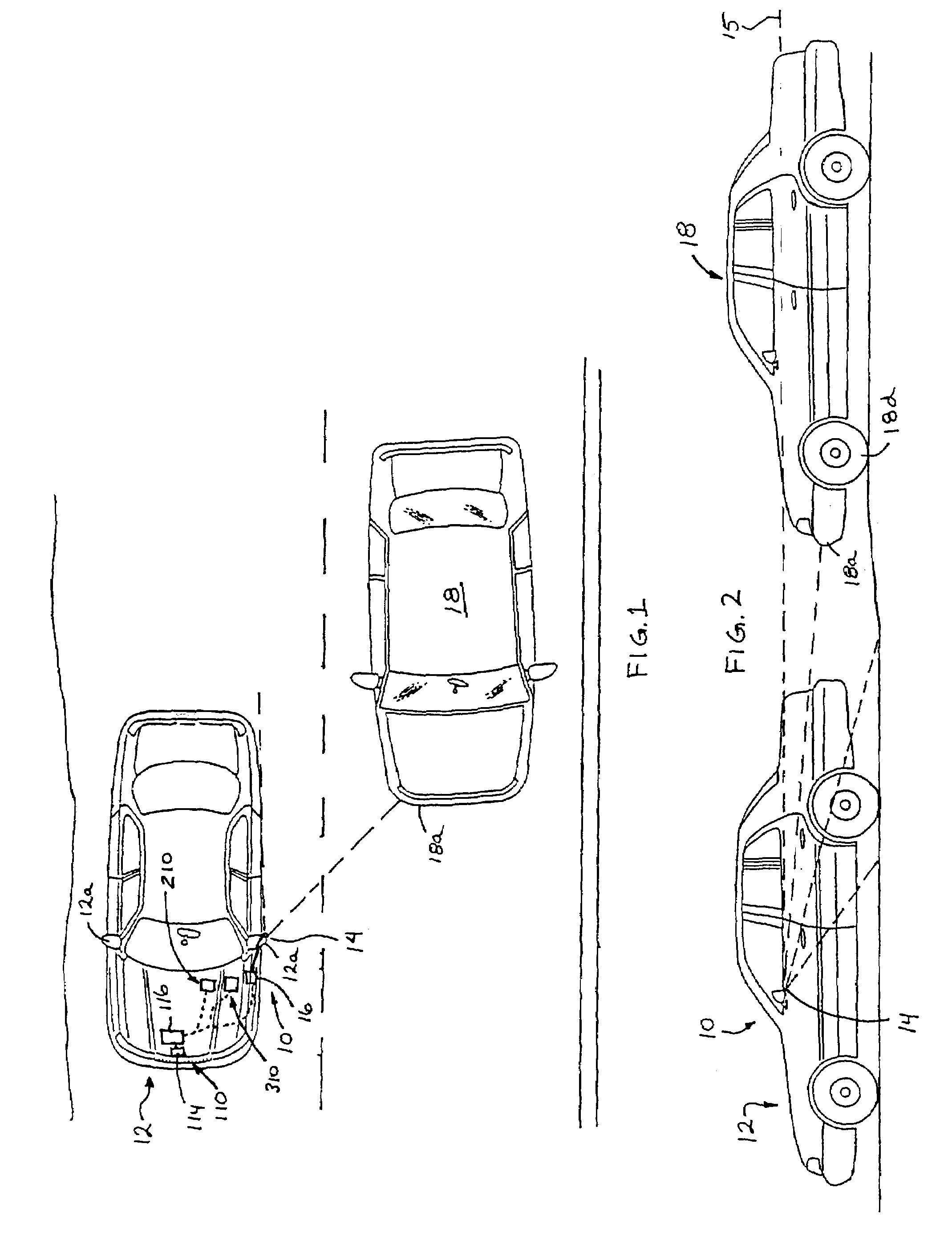

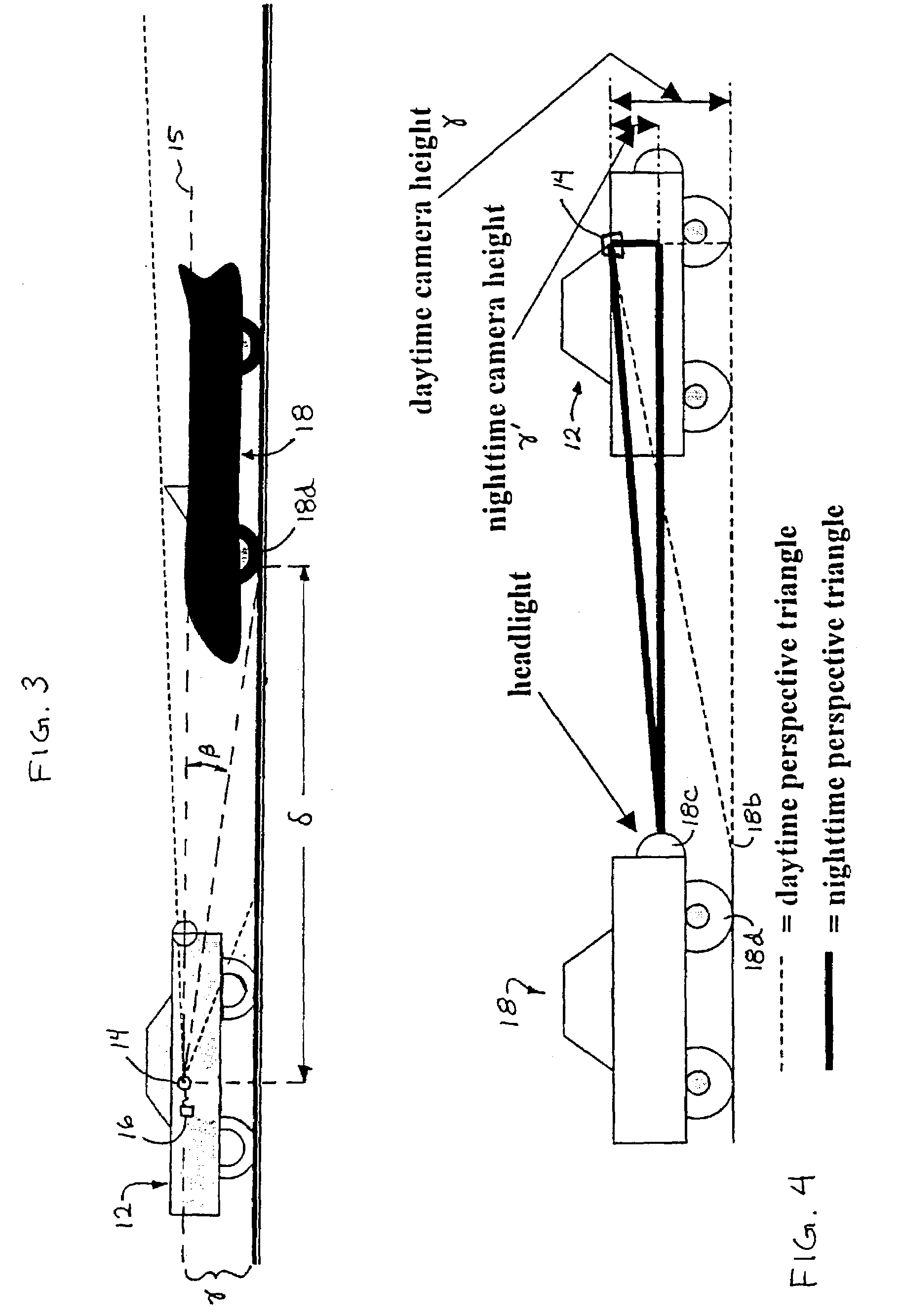

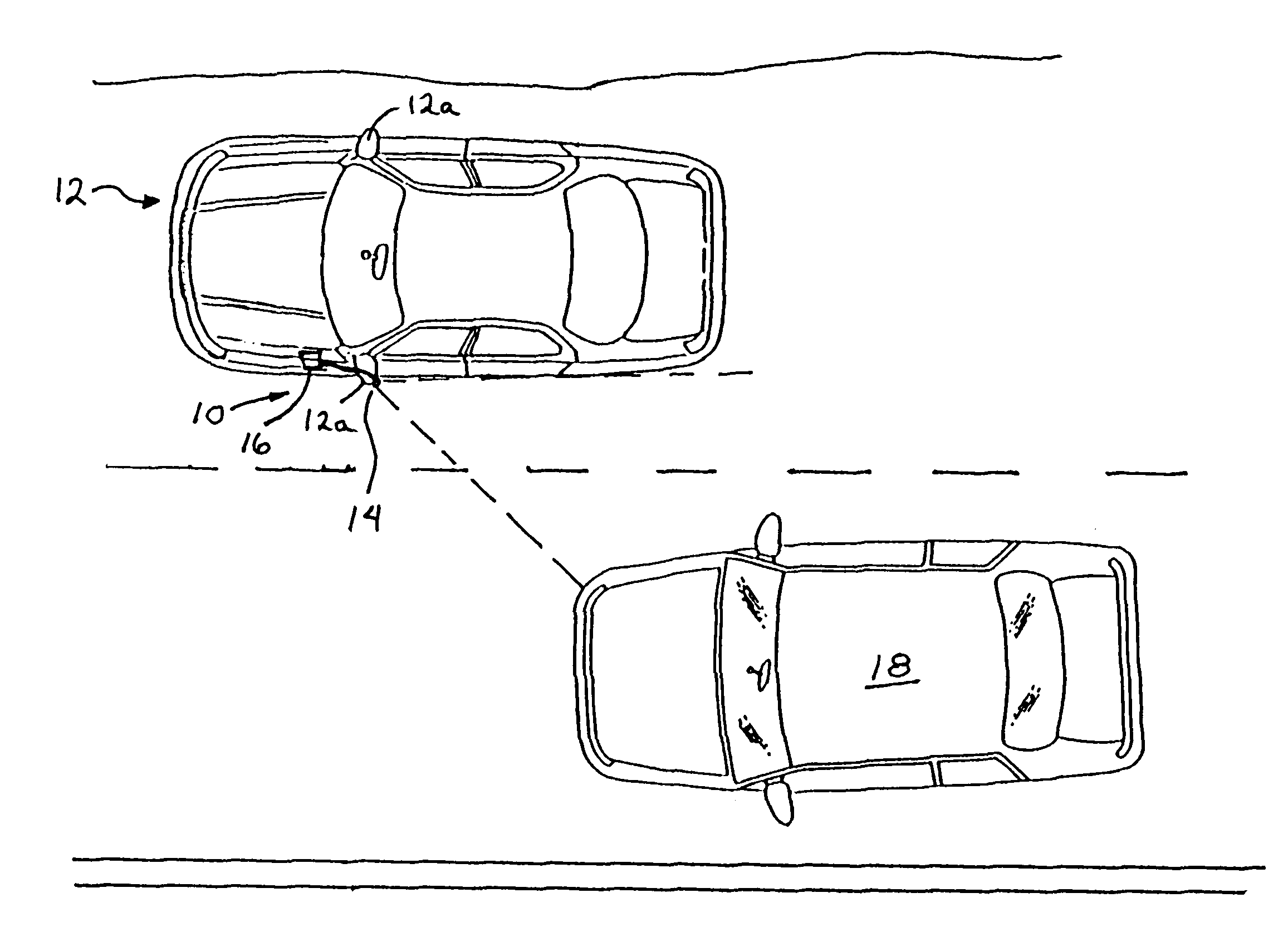

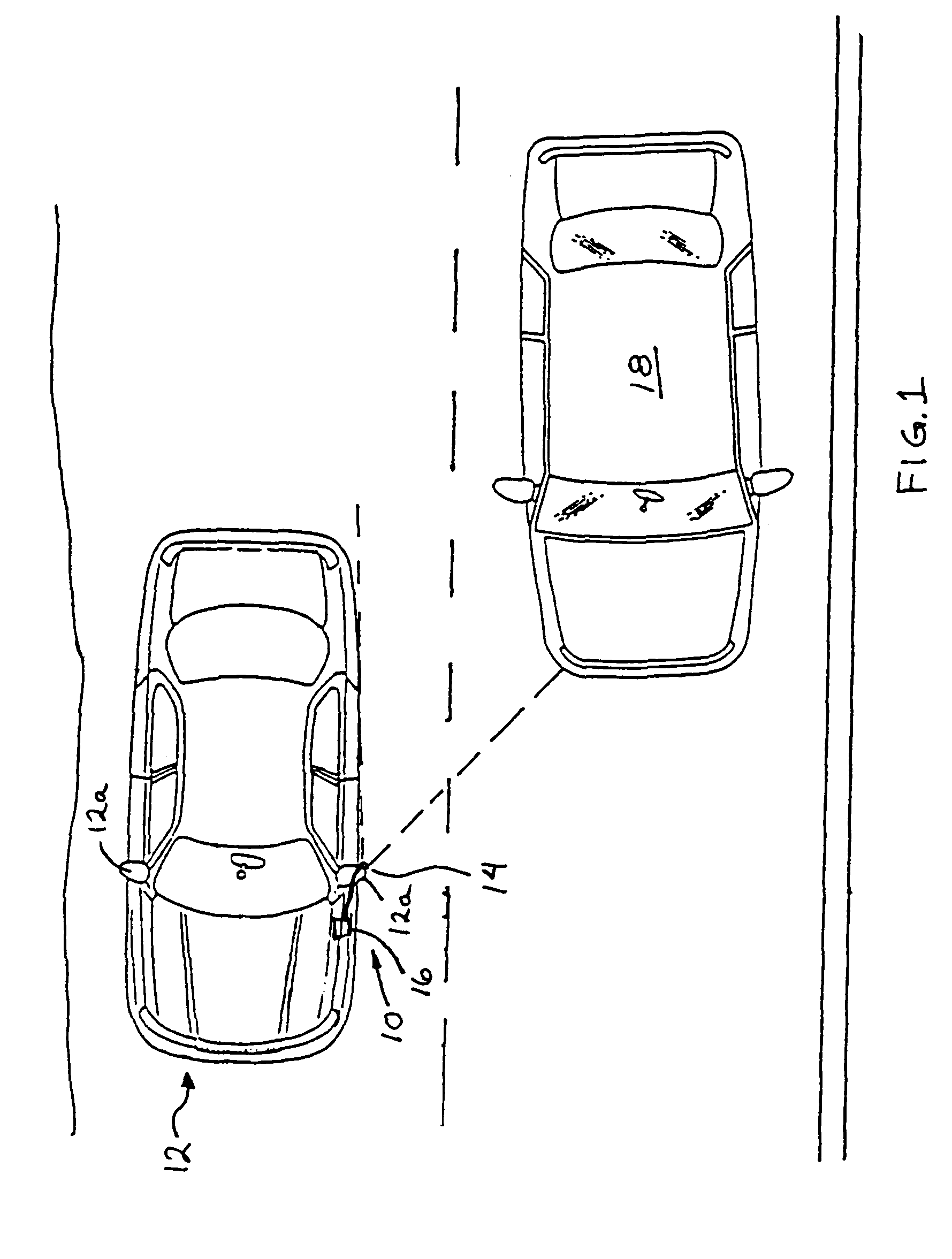

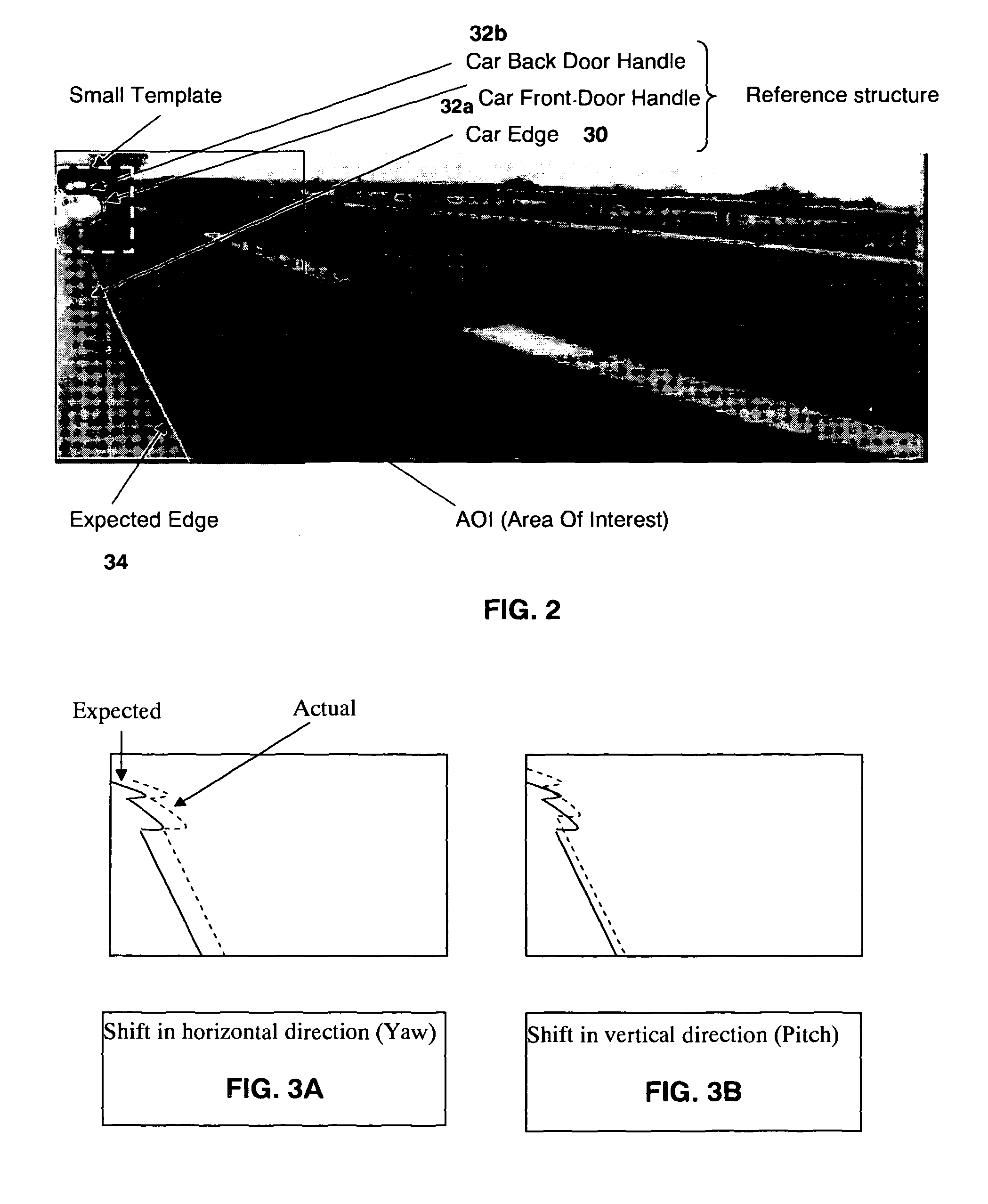

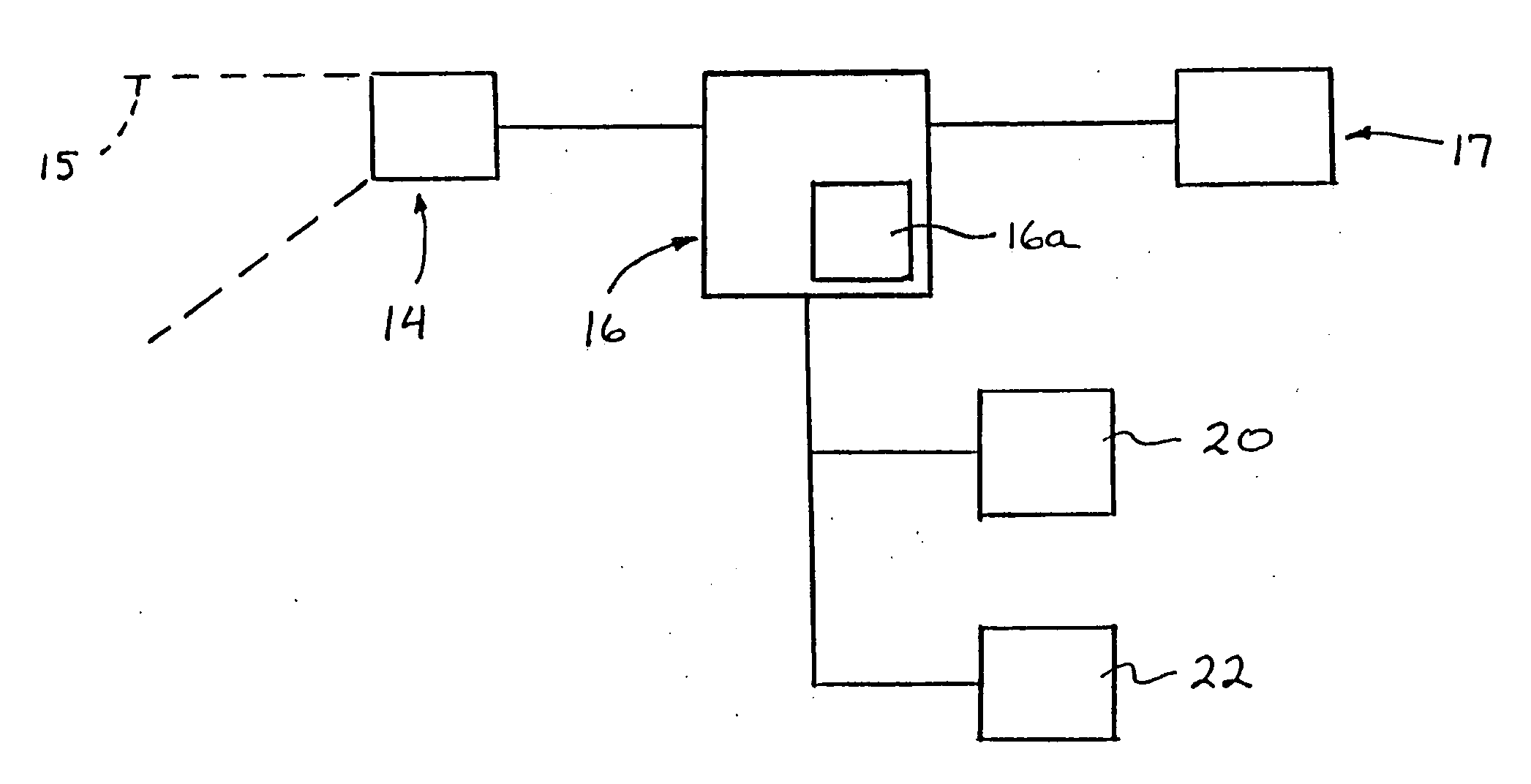

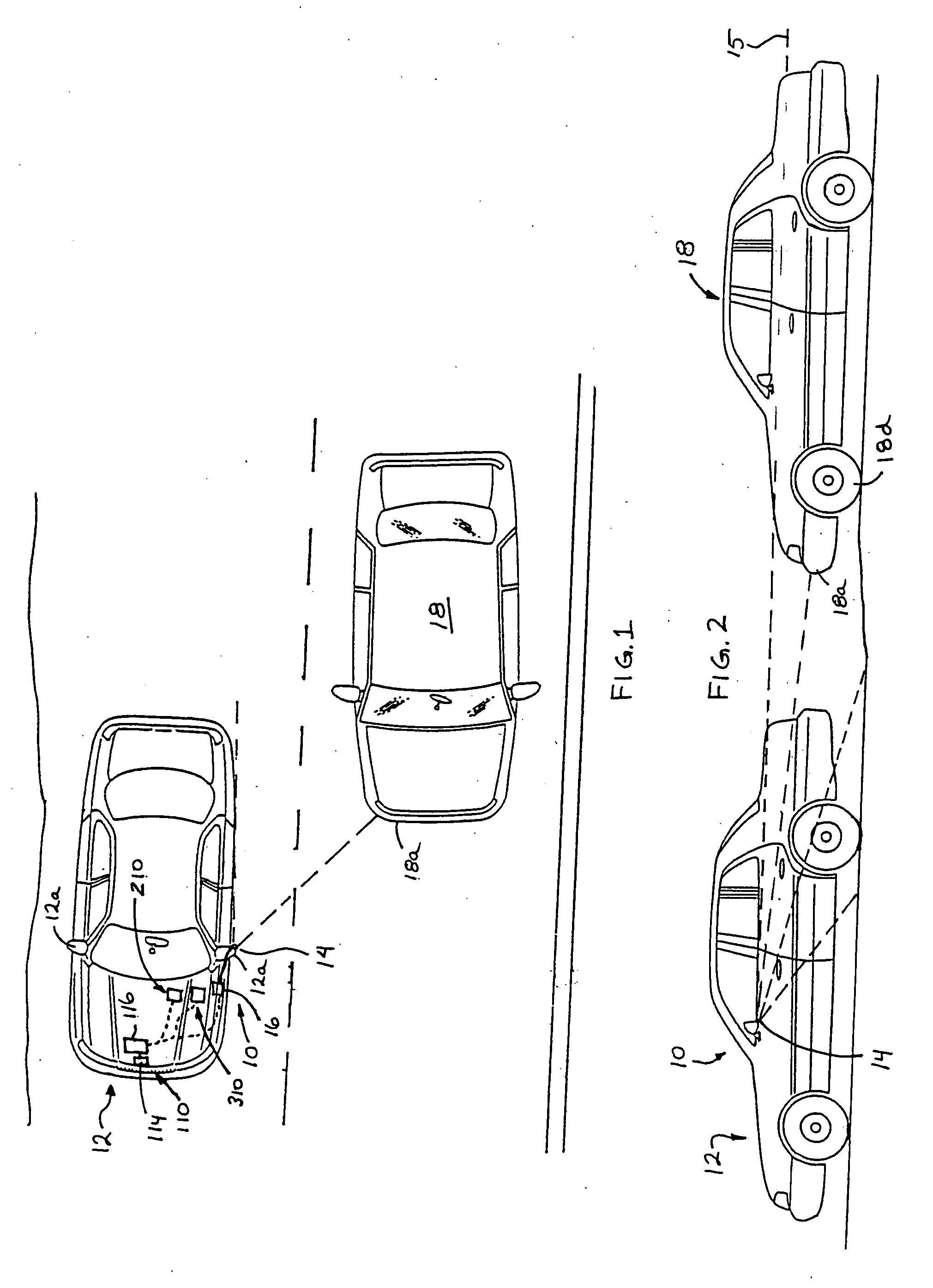

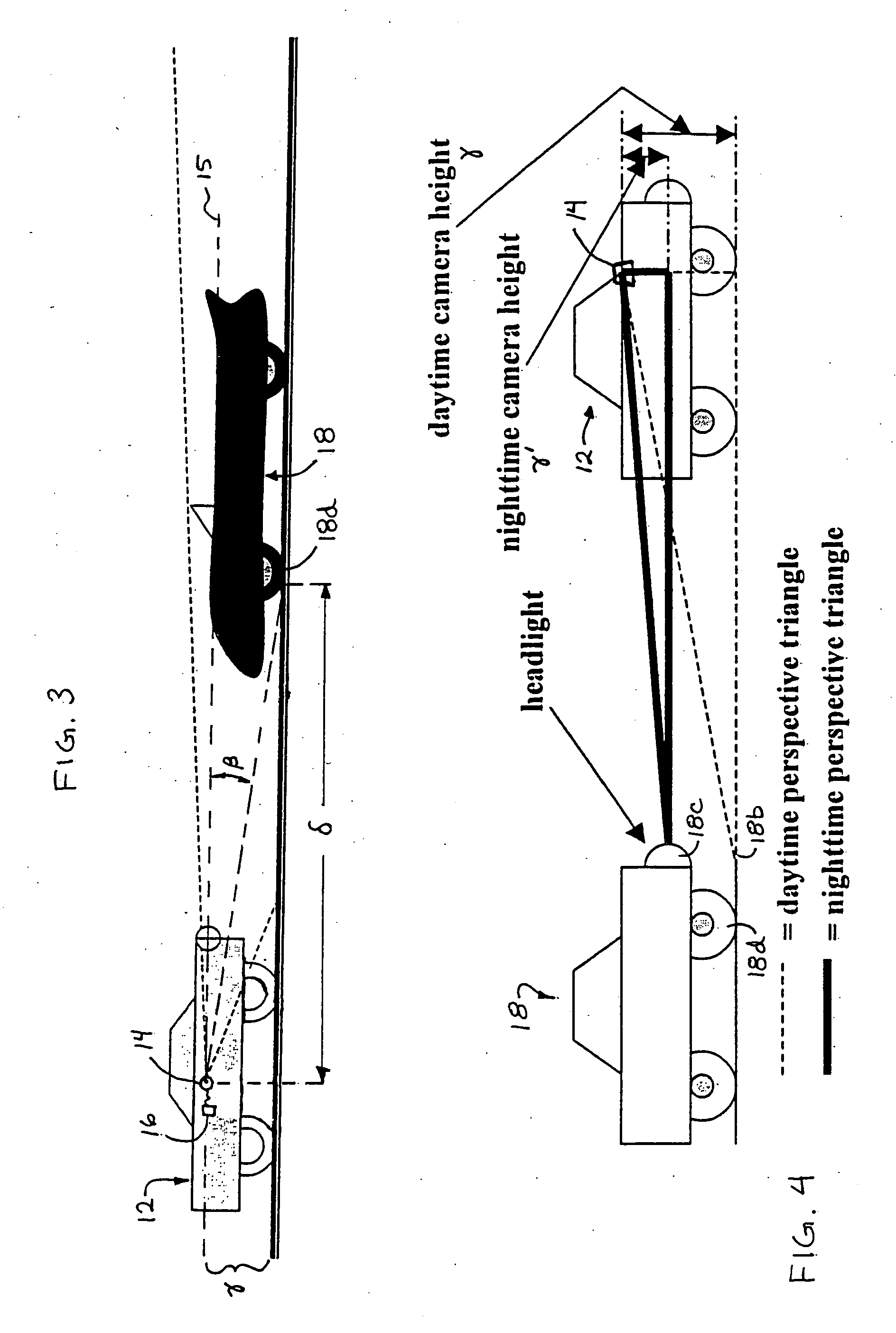

An imaging system for a vehicle includes an imaging sensor and a control. The imaging sensor is operable to capture an image of a scene occurring exteriorly of the vehicle. The control receives the captured image, which comprises an image data set representative of the exterior scene. The control may apply an edge detection algorithm to a reduced image data set of the image data set. The reduced image data set is representative of a target zone of the captured image. The control may be operable to process the reduced image data set more than other image data, which are representative of areas of the captured image outside of the target zone, to detect objects present within the target zone. The imaging system may be associated with a side object detection system, a lane change assist system, a lane departure warning system and / or the like.

Owner:MAGNA ELECTRONICS

Object detection system for vehicle

ActiveUS7720580B2Reduce processing requirementsReduce the possibilityTelevision system detailsDigital data processing detailsData setSteering angle

An imaging system for a vehicle includes an imaging array sensor and a control. The image array sensor comprises a plurality of photo-sensing pixels and is positioned at the vehicle with a field of view exteriorly of the vehicle. The imaging array sensor is operable to capture an image of a scene occurring exteriorly of the vehicle. The captured image comprises an image data set representative of the exterior scene. The control algorithmically processes the image data set to a reduced image data set of the image data set. The control processes the reduced image data set to extract information from the reduced image data set. The control selects the reduced image data set based on a steering angle of the vehicle.

Owner:MAGNA ELECTRONICS

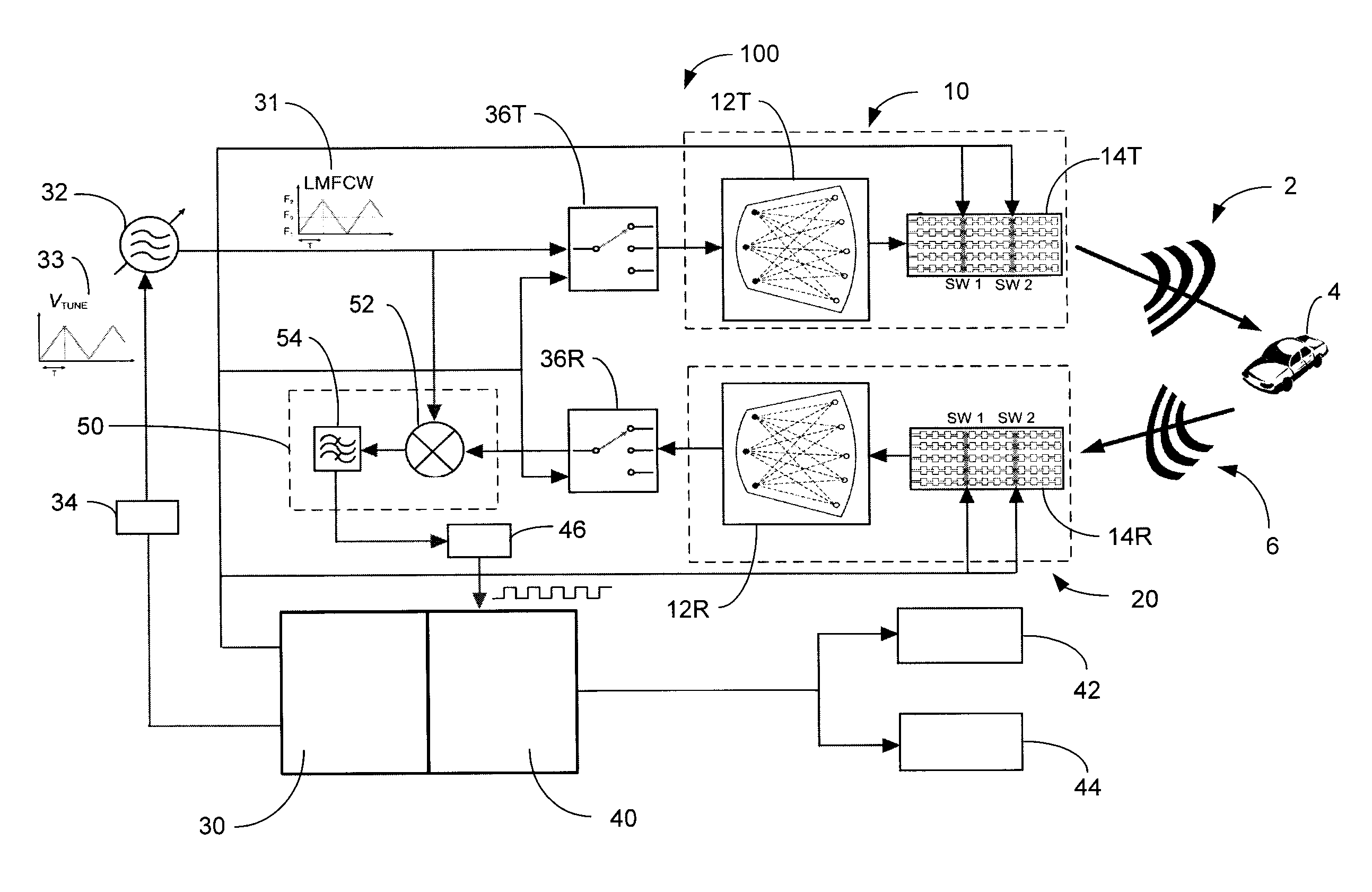

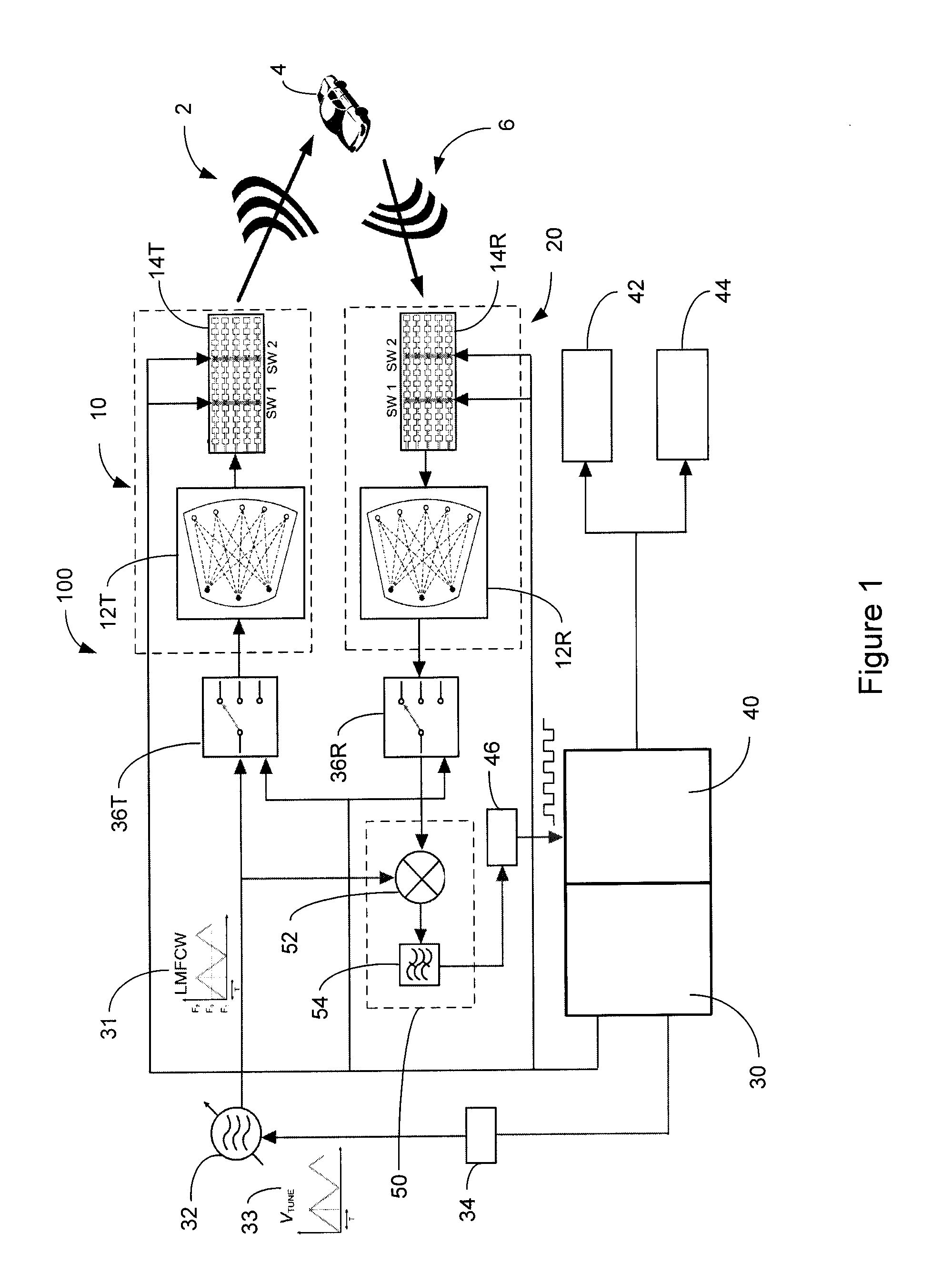

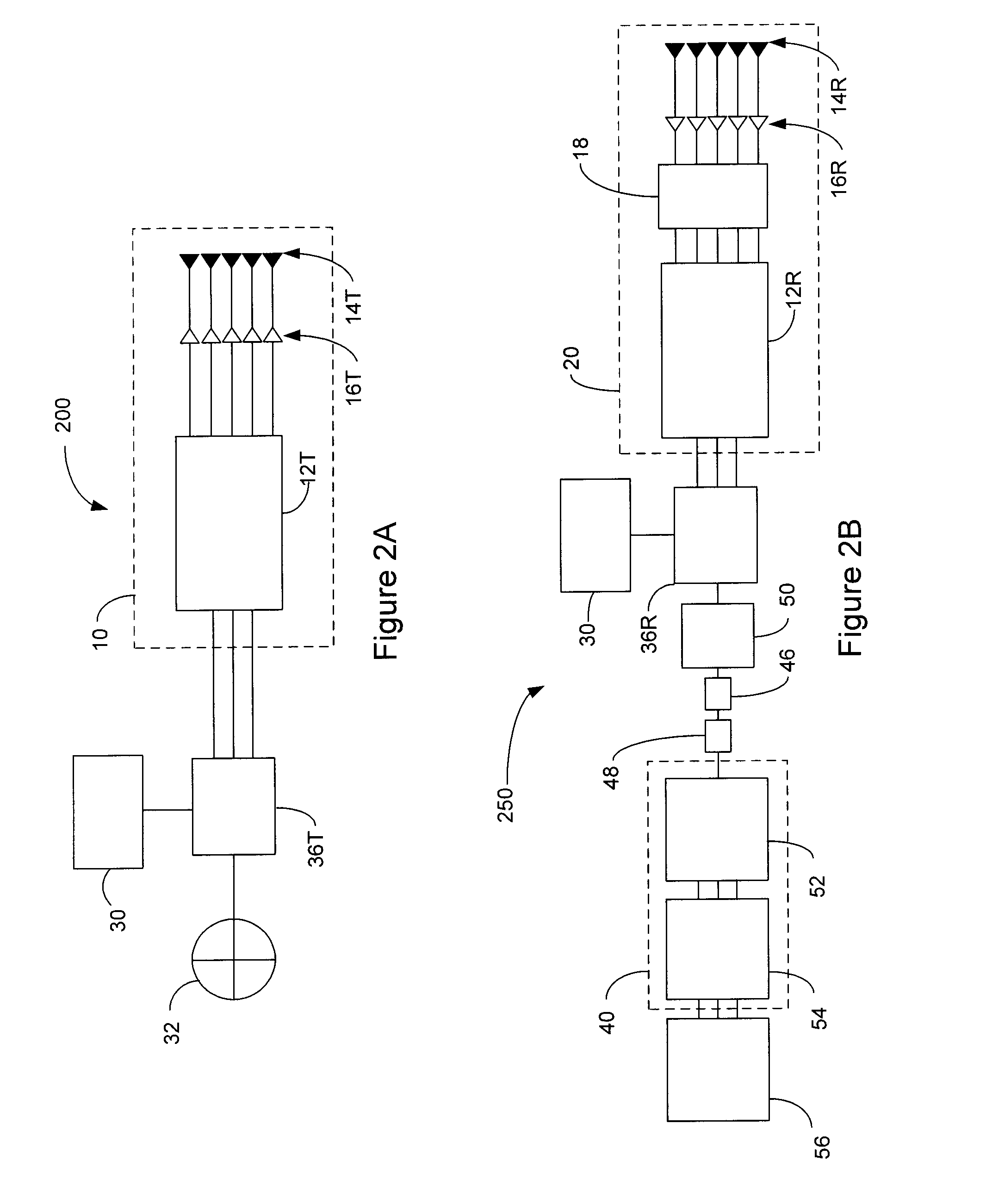

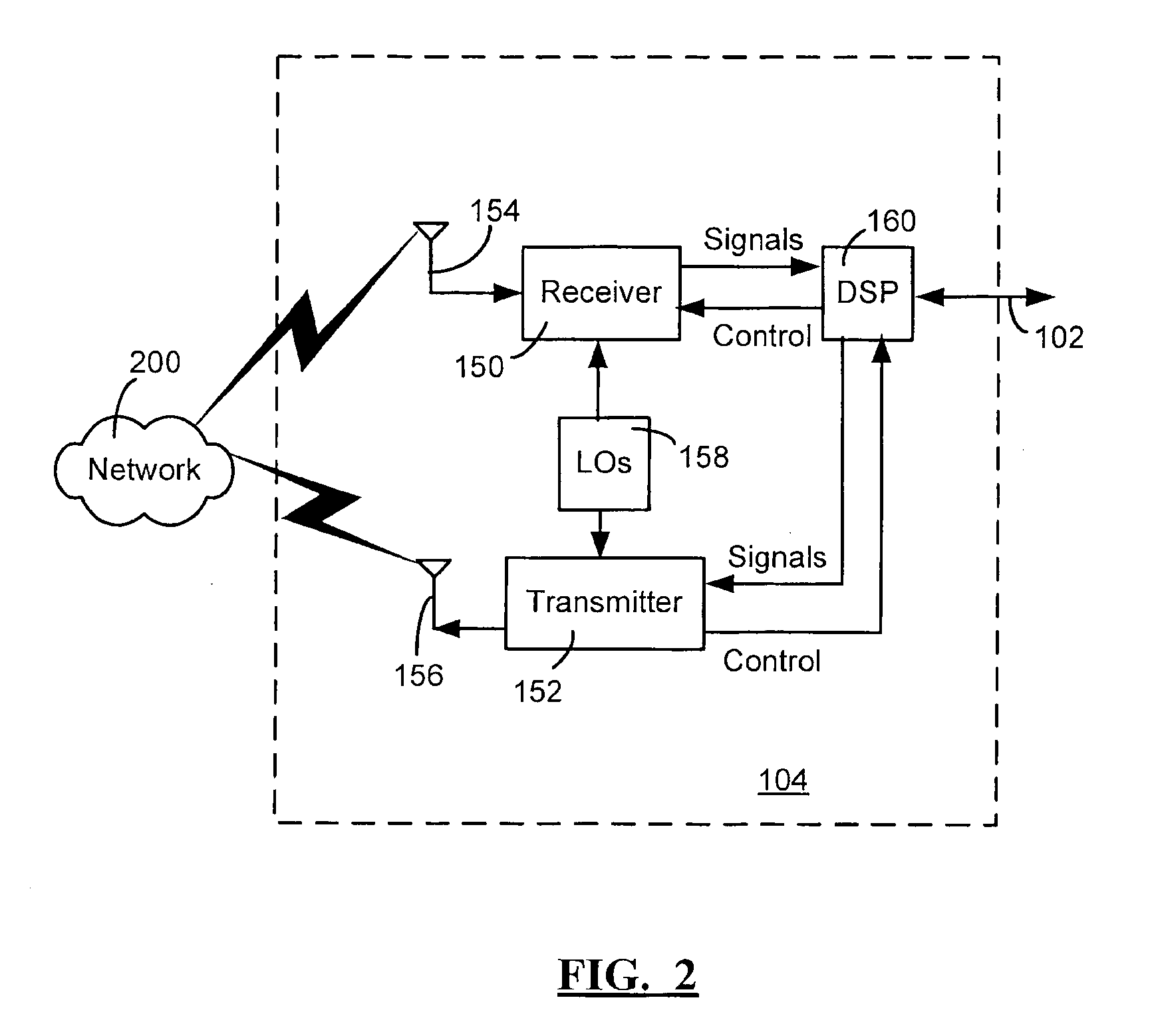

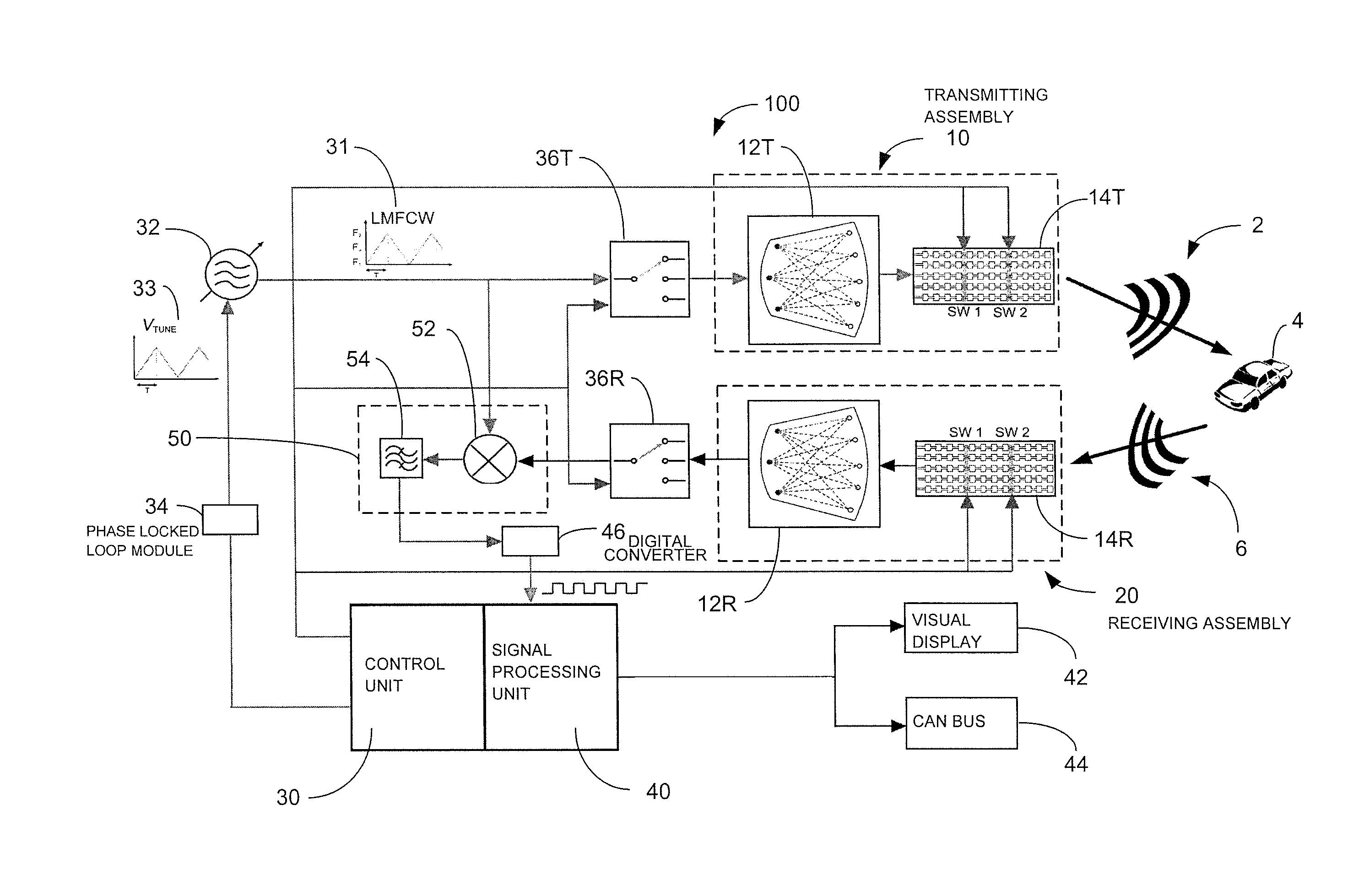

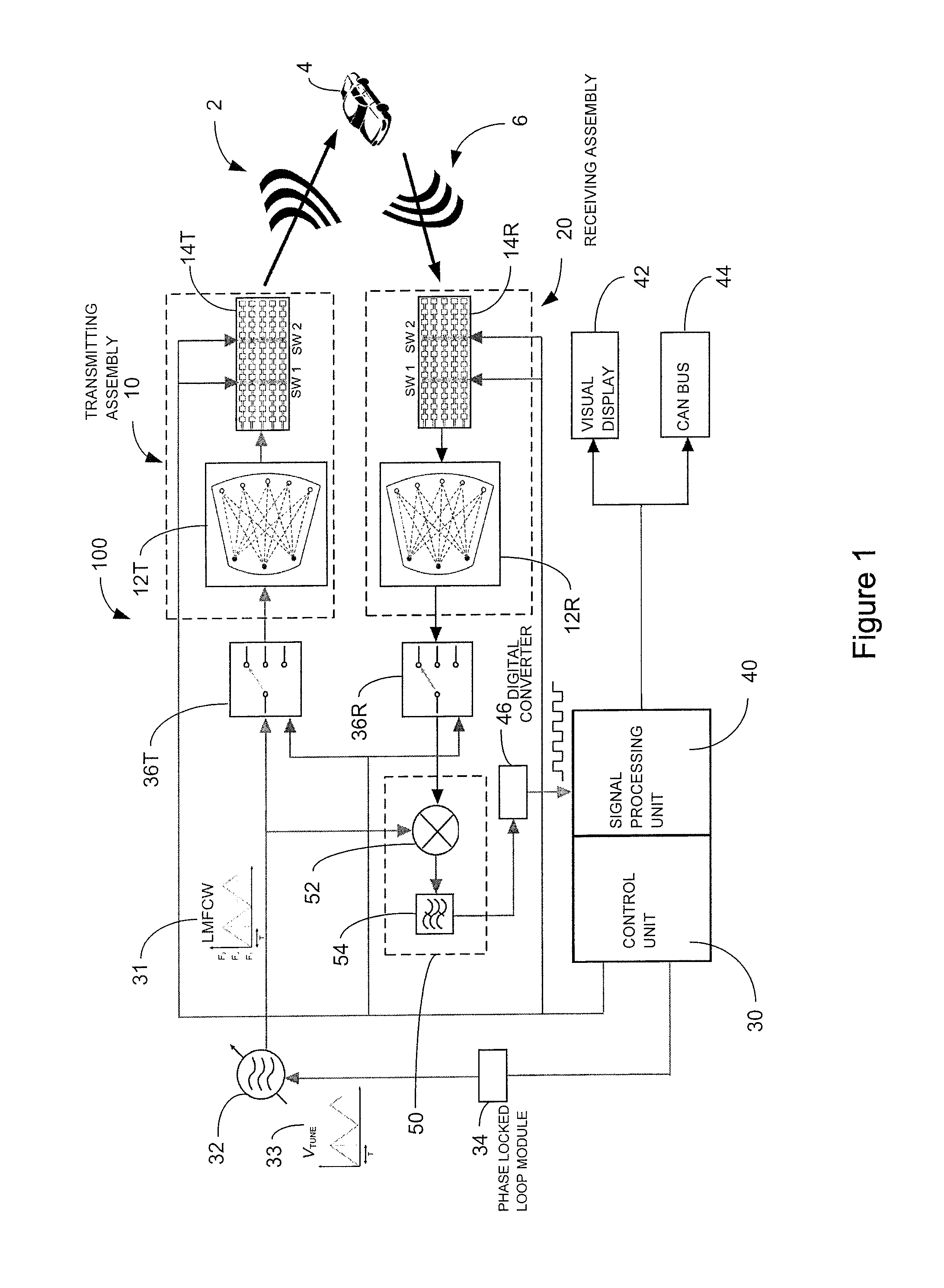

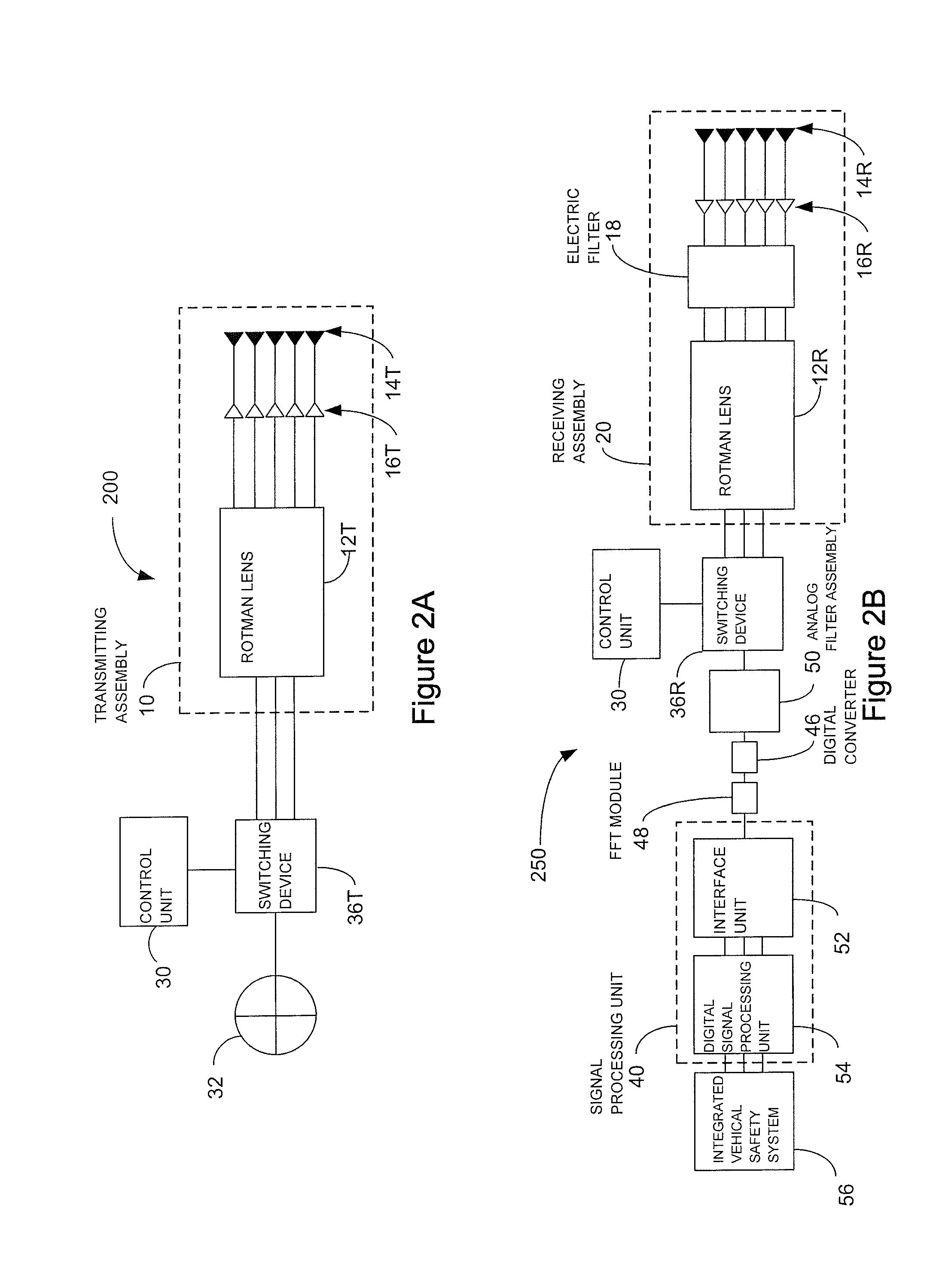

Radar system and method of manufacturing same

ActiveUS20130027240A1Increase speedThe signal is accurate and reliableAntenna adaptation in movable bodiesParallel-plate/lens fed arraysRadar systemsEngineering

A radar system (100) is described including a transmitting assembly (10), a receiving assembly (20), a control unit (30) and a signal processing unit (40). The transmitting assembly (10) receives an input signal (31) and transmits an incident radar signal (2). The transmitting assembly (10) includes a Rotman lens (12) having a lens cavity (74), a plurality of beam ports (60), a plurality of array ports (62) and a patch antenna assembly (14). The lens cavity (74) has a lens gap (h) between 10 microns to 120 microns, and preferably 40 microns to 60 microns. The patch antenna assembly (14) includes a plurality of antenna arrays (130) operable to receive a plurality of time-delayed, in-phase signals from the Rotman lens (12) and to transmit the incident radar signal (2) towards a target (4). The receiving assembly (20) receives a reflected radar signal (6) and produces an output signal. The signal processing unit (40) compares the input signal (31) to the output signal and implements an algorithm determining the range, velocity and position of the target (4).

Owner:UNIVERSITY OF WINDSOR

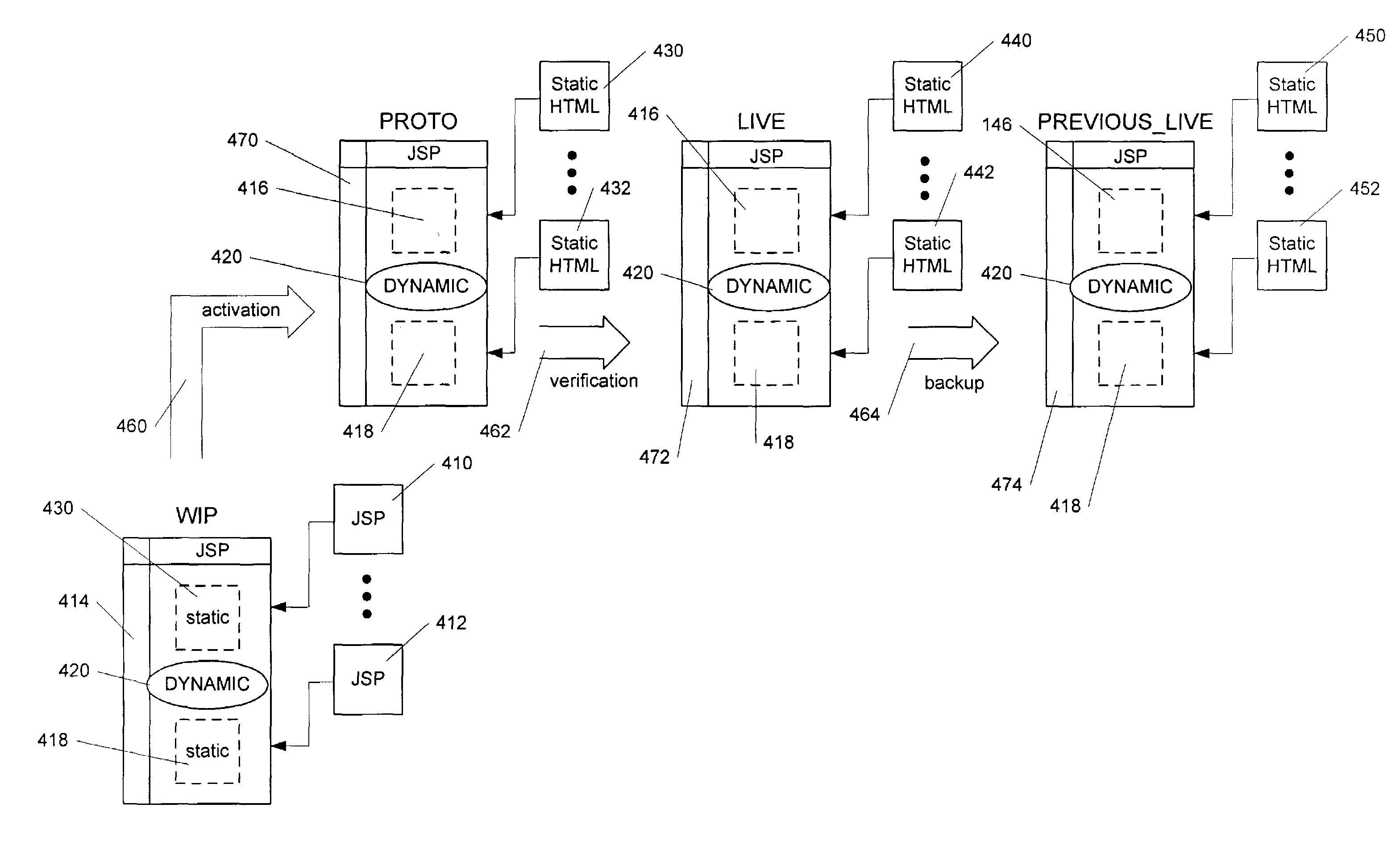

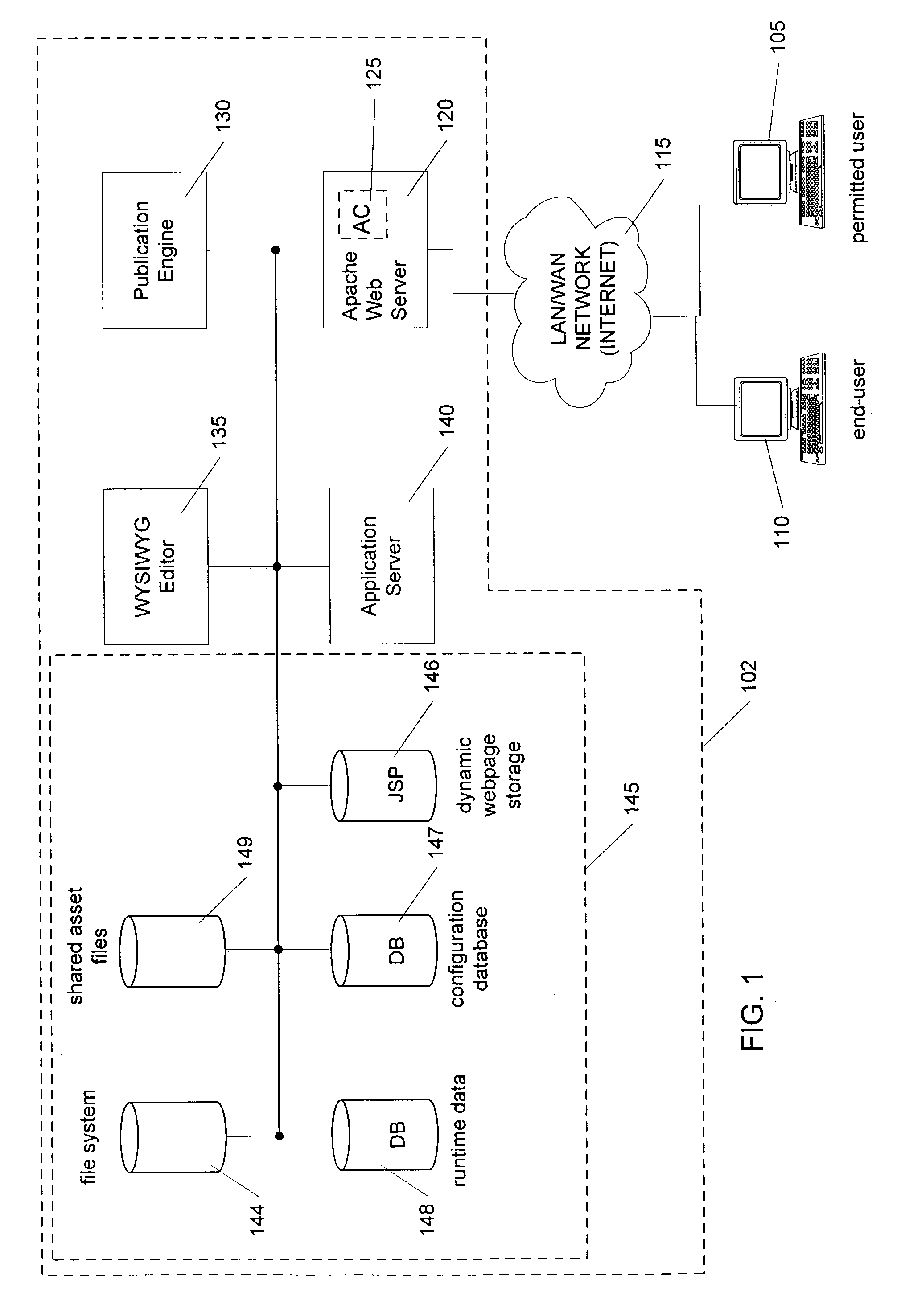

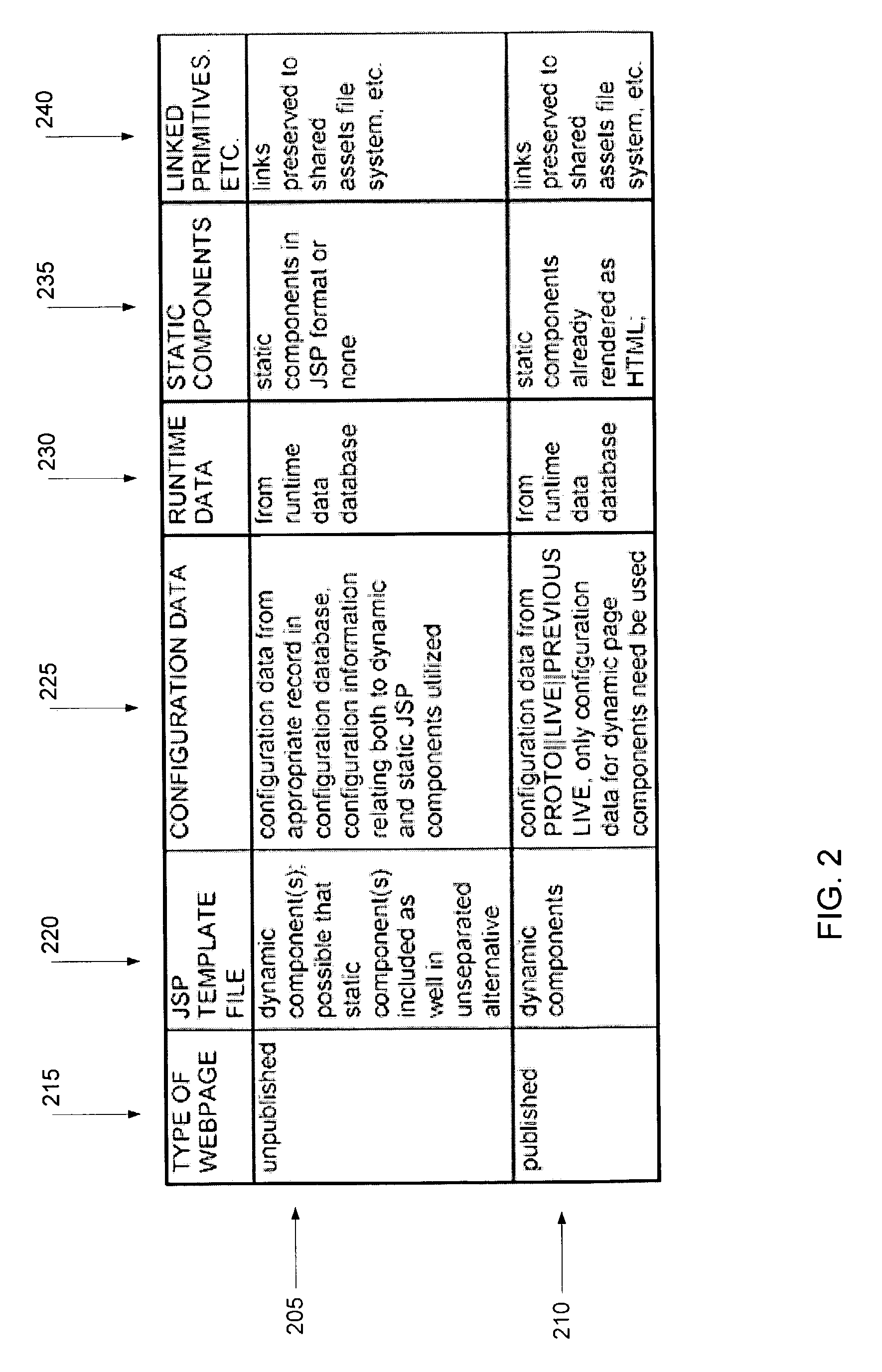

Method and apparatus for processing a dynamic webpage

InactiveUS7386786B2Reduce processing requirementsDigital computer detailsBiological modelsProgramming languageDynamic web page

A dynamic webpage processing method, including identifying a static component within a dynamic webpage, the static component comprising computer code defining at least a portion of a target webpage and configurable via first configuration data, rendering the static component as a static markup language equivalent, and returning the target webpage upon request through rendering a dynamic component within the dynamic webpage based on second configuration data is disclosed. Thus, static component(s) can be pre-rendered, leaving only the dynamic component(s) of the dynamic webpage for on-the-fly rendering when a target webpage request is made. This can greatly reduce dynamic webpage processing requirements, particularly in situations where the webpage configuration changes or evolves slowly.

Owner:SINCRO LLC

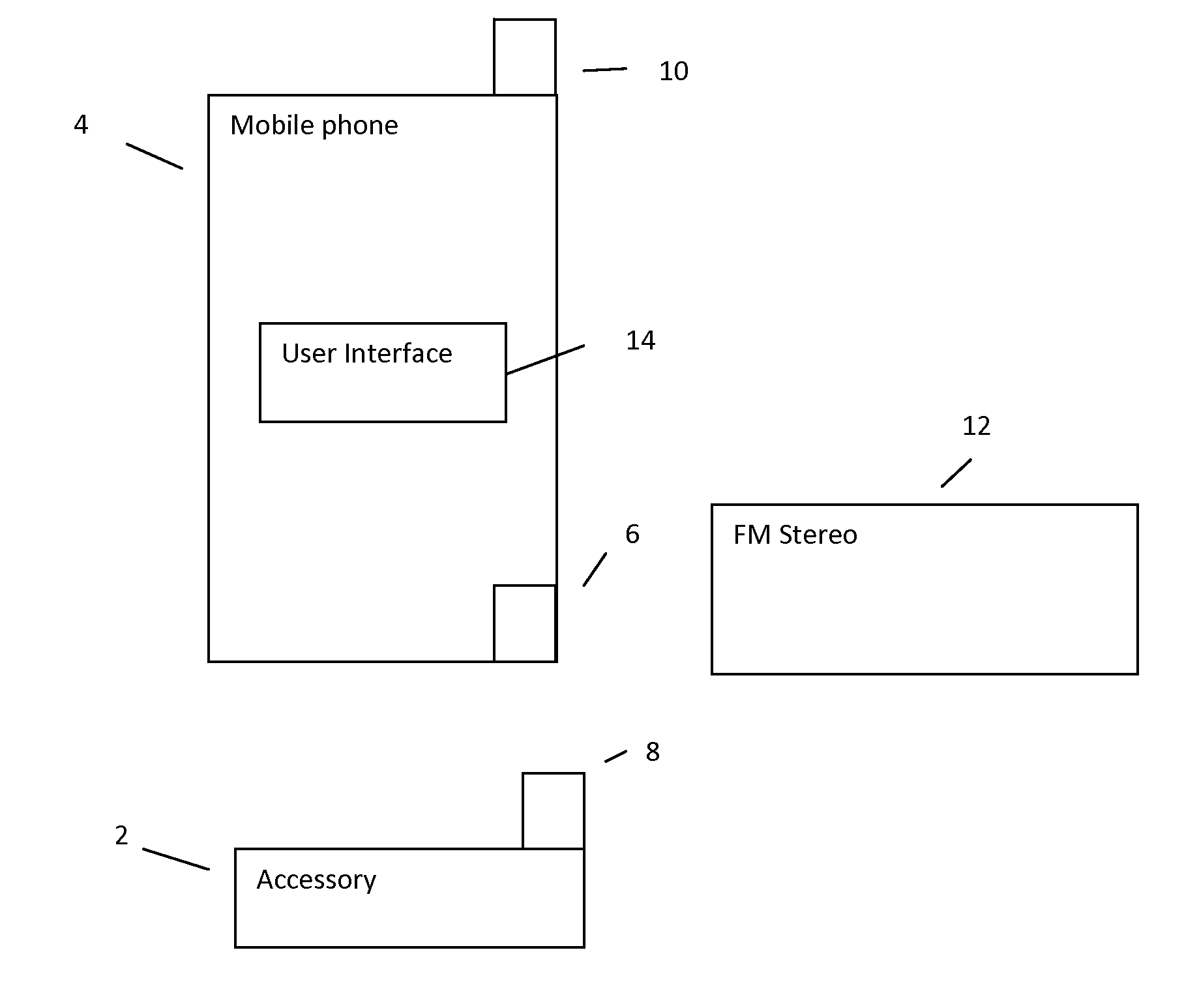

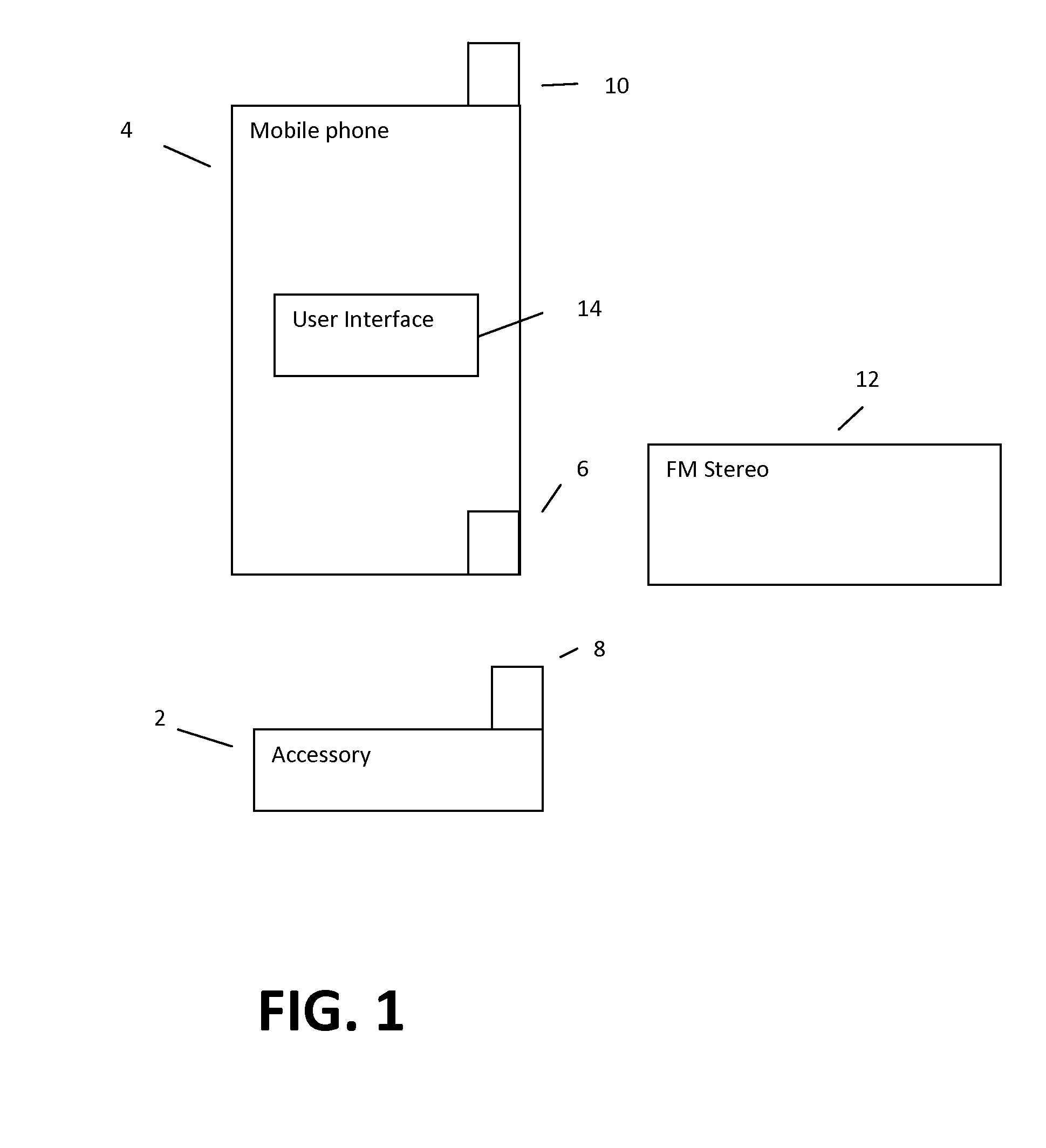

System and Apparatus for Communicating Digital Data through Audio Input/Output Ports

InactiveUS20100184479A1Improve functionalityFunction increaseSubstation equipmentTransmissionDigital dataDigital input

A system for communicating digital data between a first and second device through audio input / output ports encodes the digital data into a series of audio frequency tones. The audio frequency tones are transferred between the devices as audio inputs. Audio decoding software residing on the devices monitors the audio inputs of the devices for audio signals representing digital data and decodes the audio signals into digital data when they are detected. The audio decoding and encoding software is preferably aftermarket software that is downloaded to the device through a digital data port and executed by the device's operating system software. The system can be used to provide a low cost accessory that can communicate digital data to a device without using the device's digital input / output port or requiring any expensive digital communication circuitry in the accessory.

Owner:VINCI BRANDS LLC

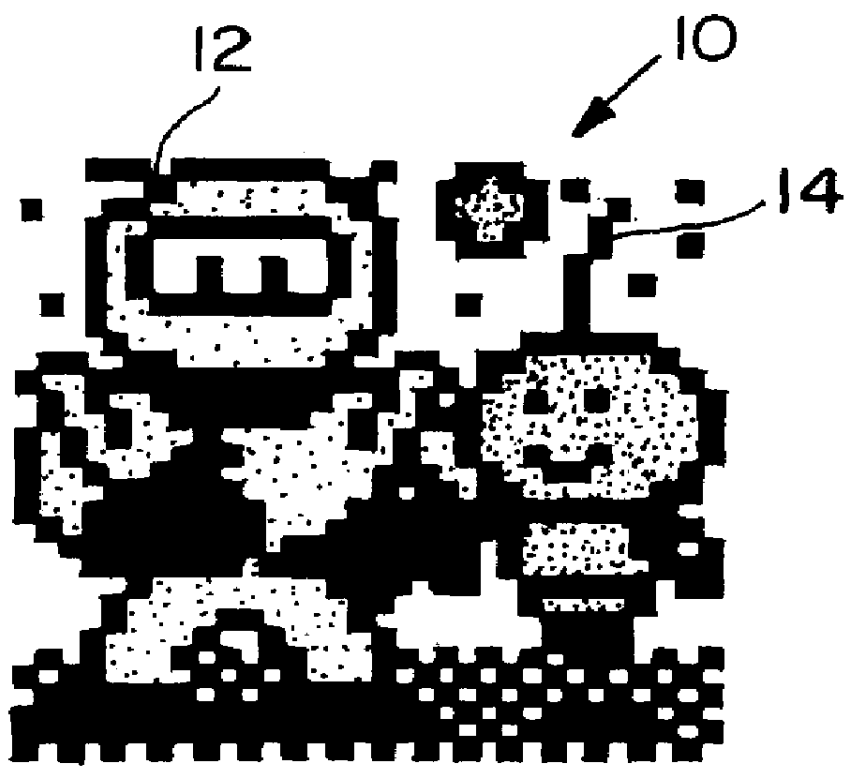

Pixel image enhancement system and method

InactiveUS6038348ALow costReduce memoryCharacter and pattern recognitionPictoral communicationDisplay deviceOutput device

A pixel image enhancement system which operates on color or monochrome source images to produce output cells the same size as the source pixels but not spatially coincident or one-to-one correspondent with them. By operating upon a set of input pixels surrounding each output cell with a set of logic operations implementing unique Boolean equations, the system generates "case numbers" characterizing inferred-edge pieces within each output cell. A rendering subsystem, responsive to the case numbers and source-pixel colors, then produces signals for driving an output device (printer or display) to display the output cells, including the inferred-edge pieces, to the best of the output device's ability and at its resolution.

Owner:CSR TECH INC

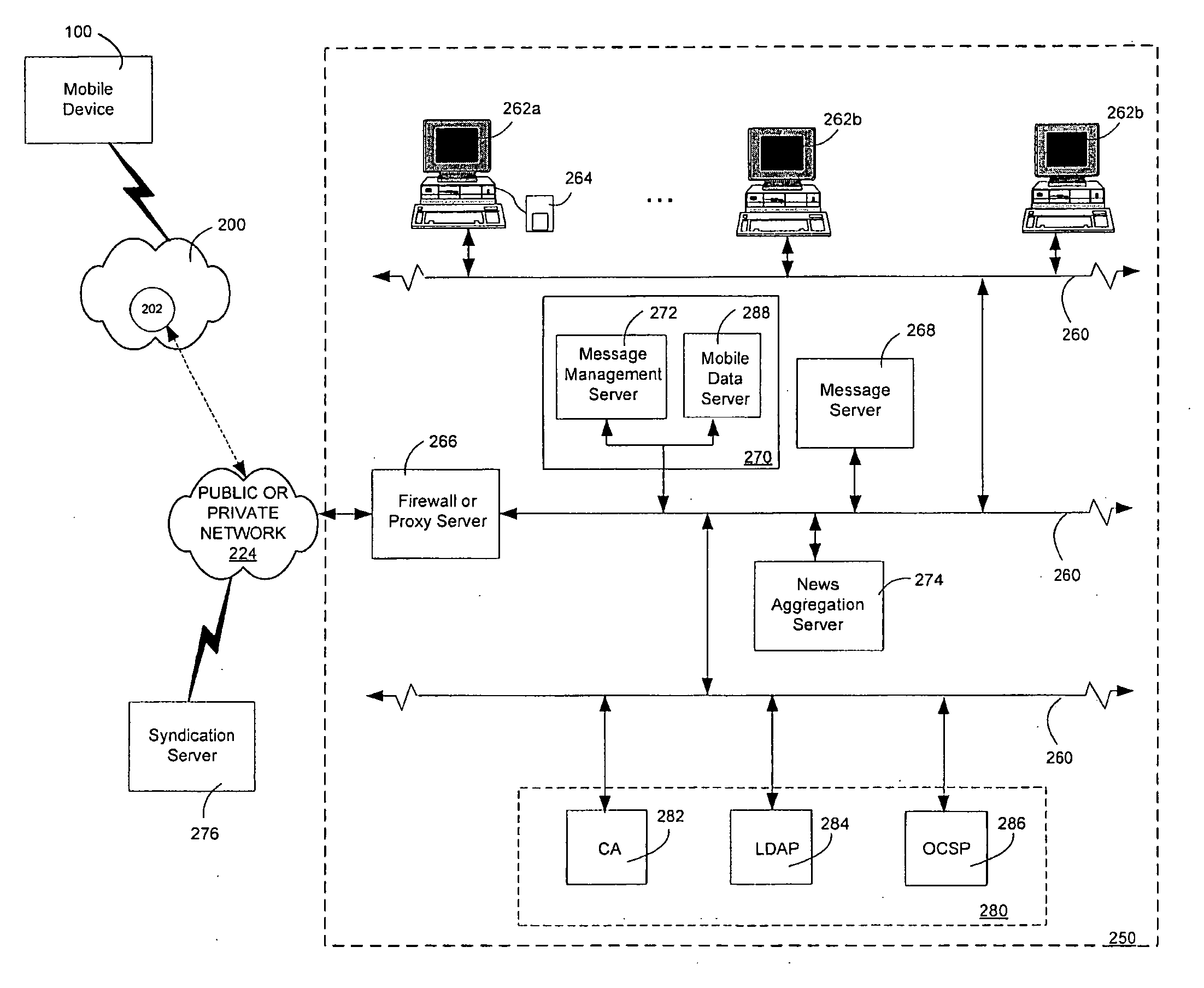

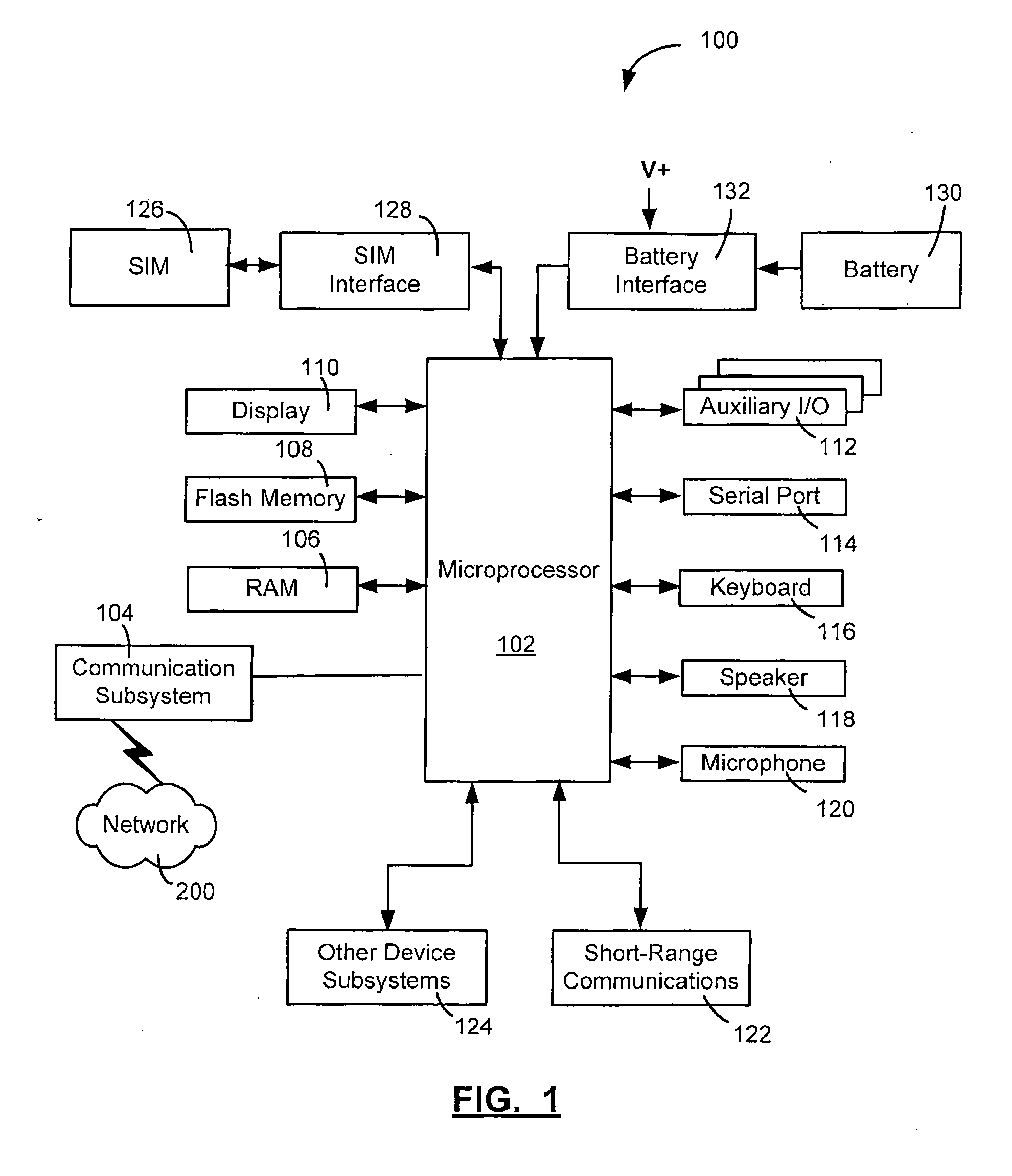

System and method for processing syndication information for a mobile device

ActiveUS20060217126A1Reduce processing requirementReadily processTelevision system detailsError preventionMobile deviceEngineering

A system and method for processing syndication information for a mobile device that includes: identifying a plurality of syndication servers to which a user of the mobile device subscribes; polling, at a first predetermined interval, the plurality of syndication servers to determine if syndication information on each the syndication server has been updated; if the syndication information has been updated, requesting and receiving updated syndication information; adapting the updated syndication information into a predetermined format, and sending the adapted syndication information to the mobile device. The sending of the adapted syndication information may also be performed at a predetermined interval. The predetermined format preferably uses less data and requires less processing than the original format.

Owner:BLACKBERRY LTD

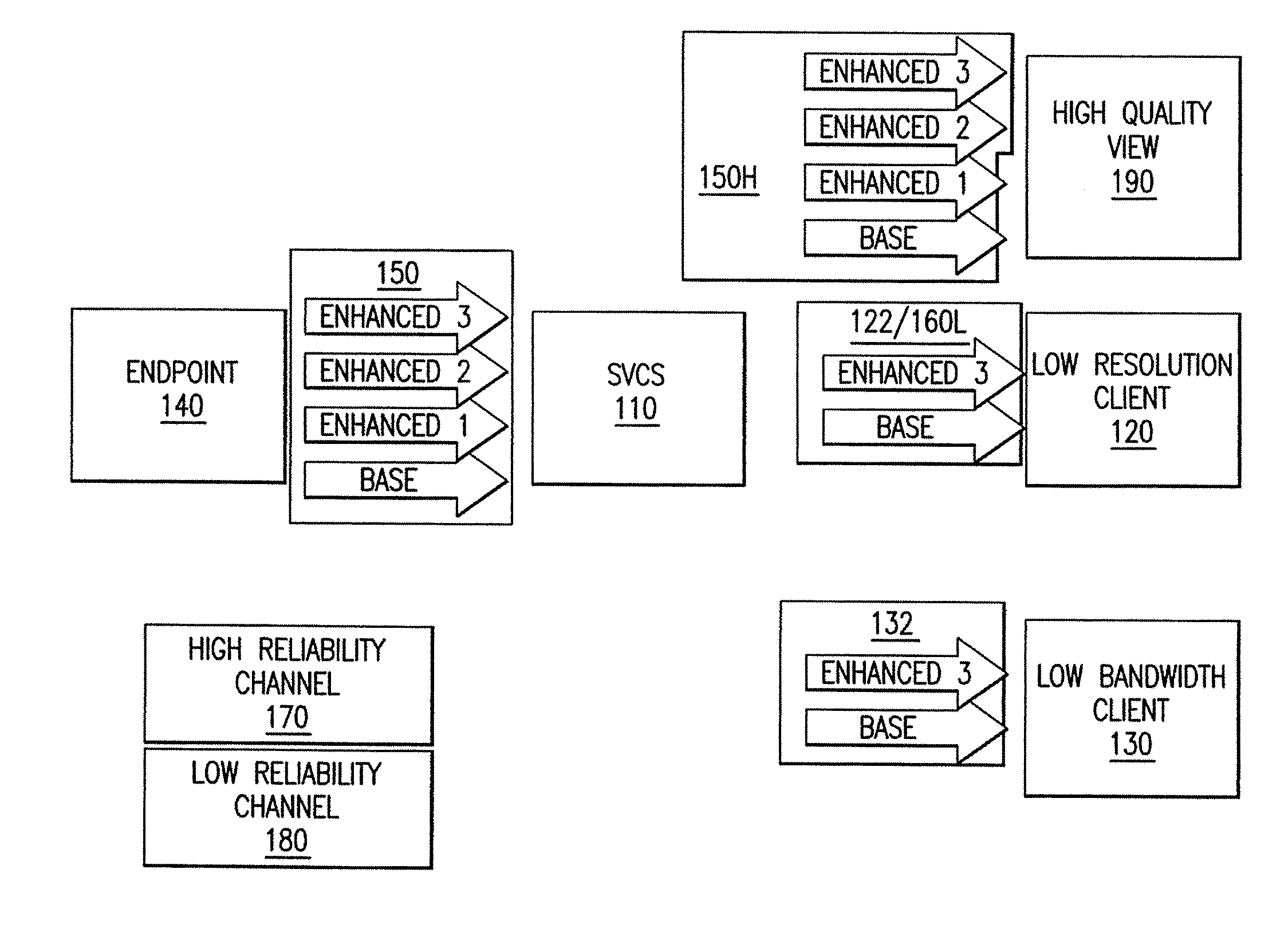

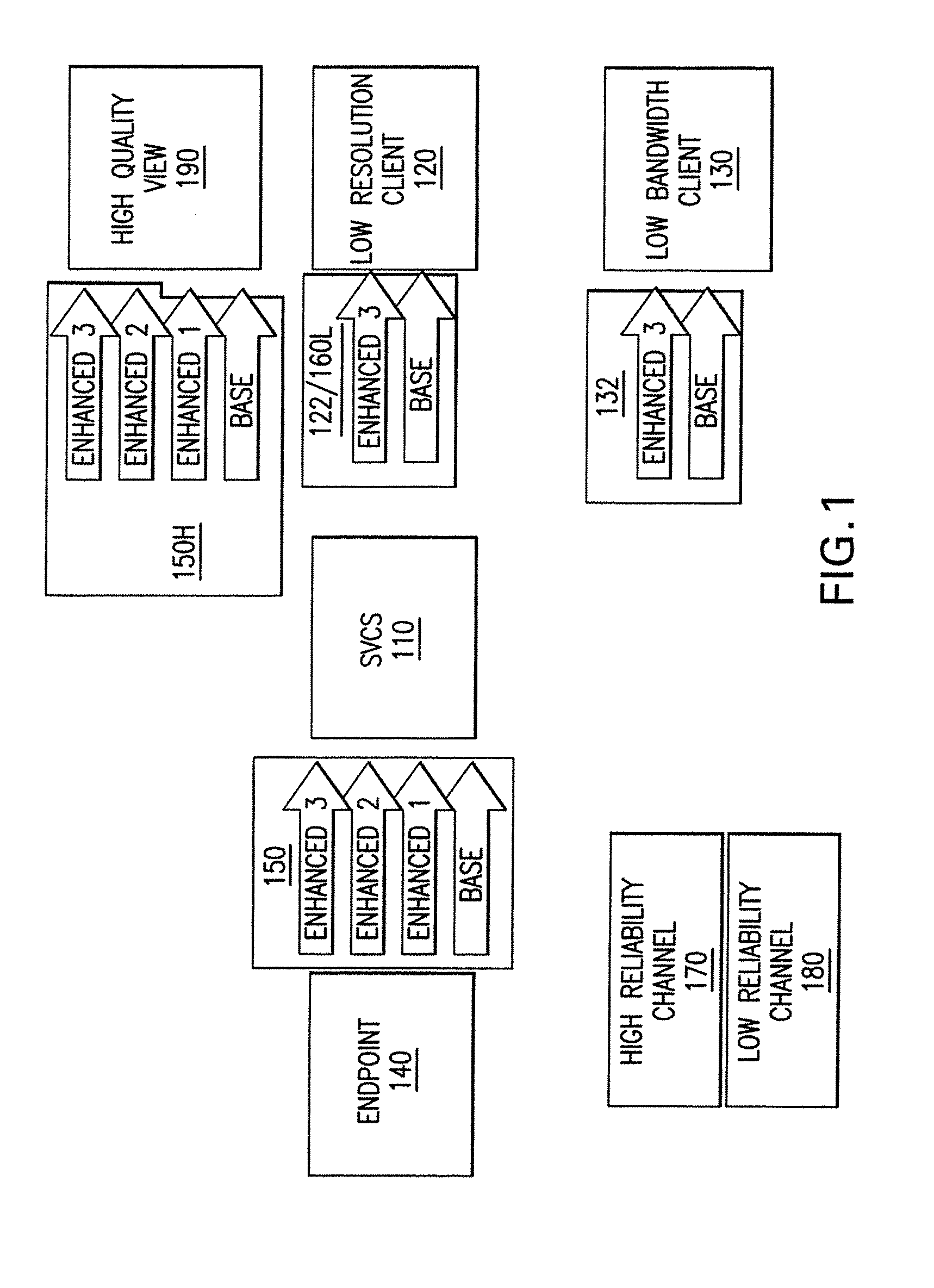

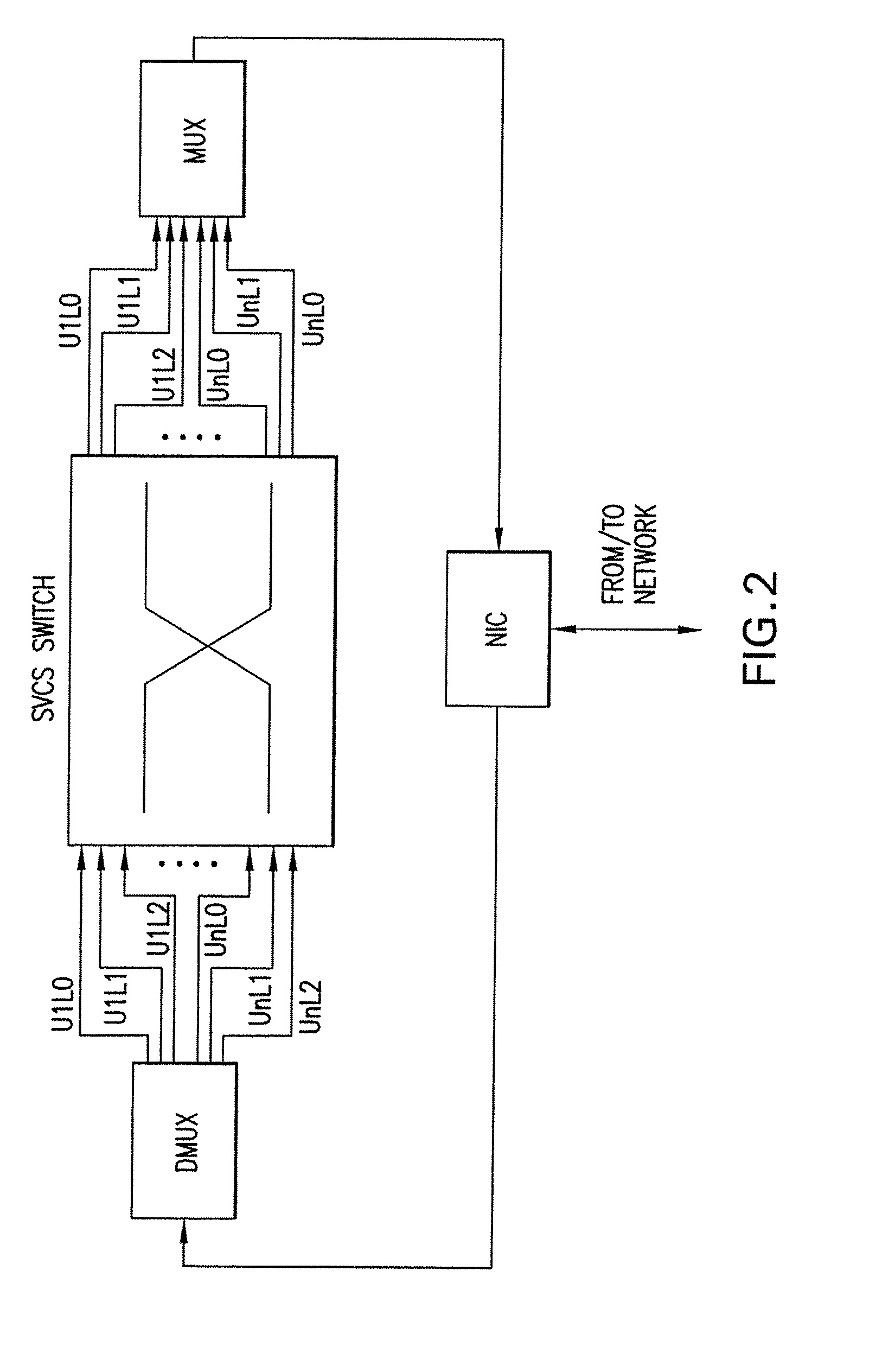

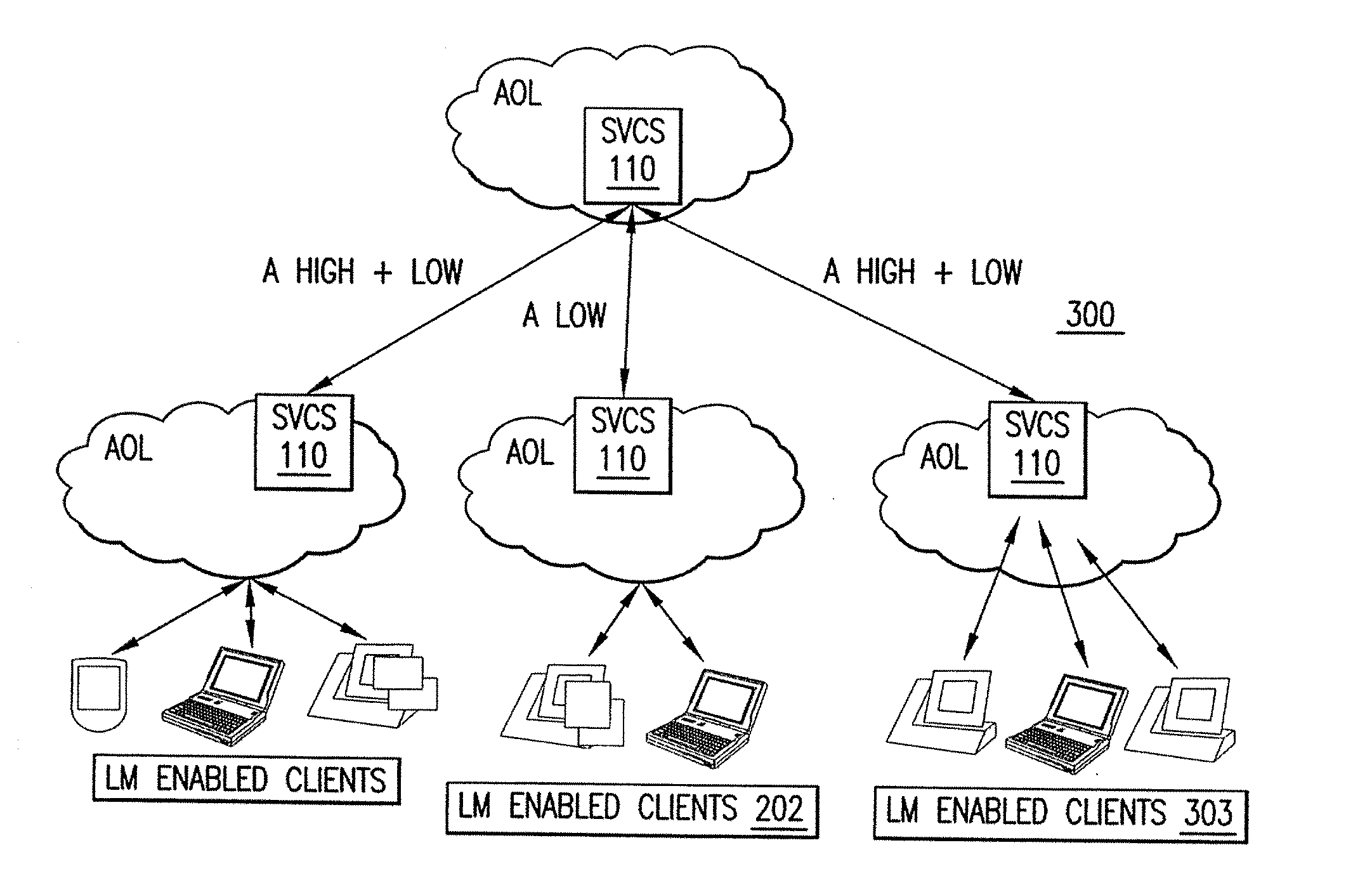

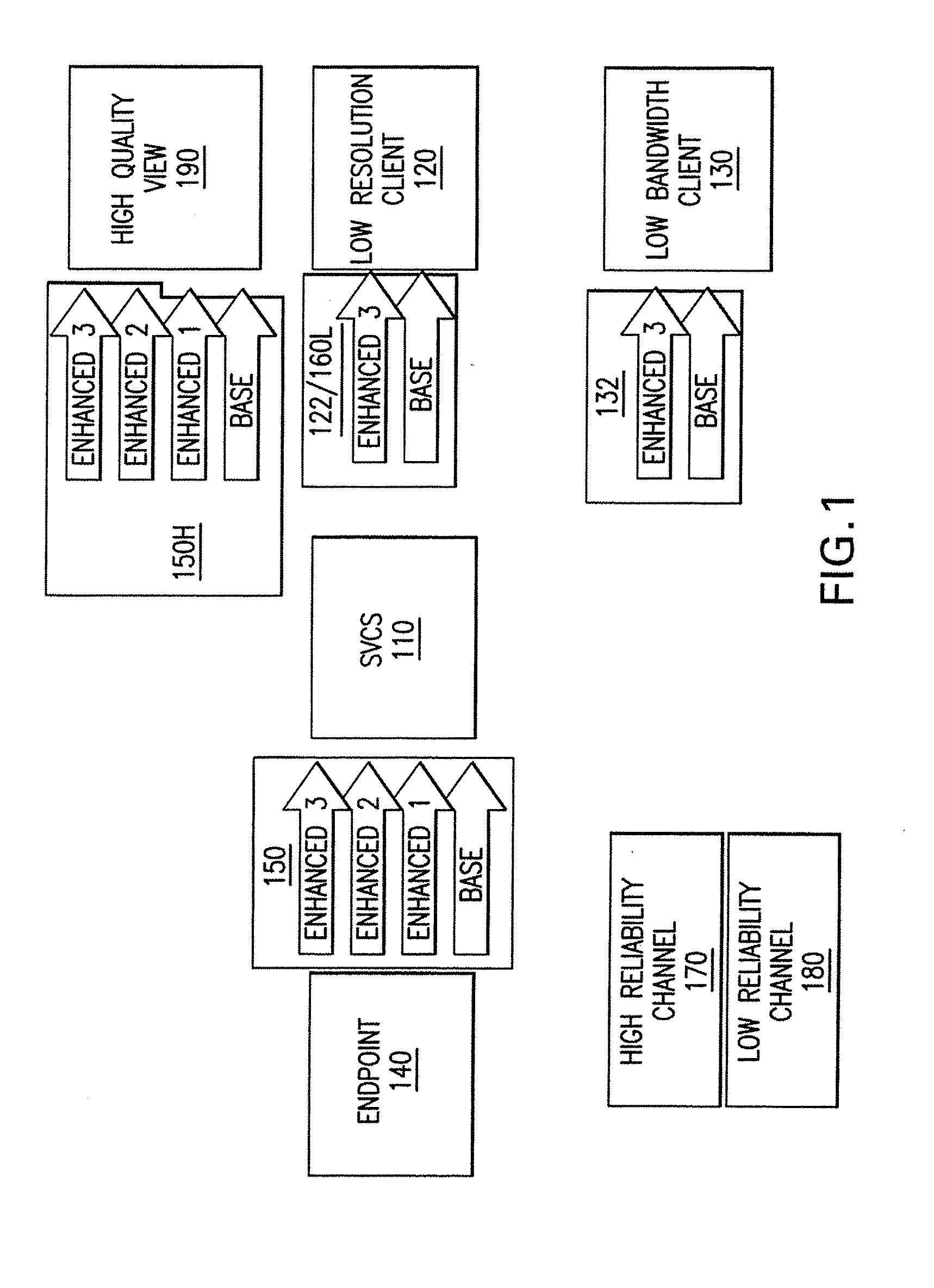

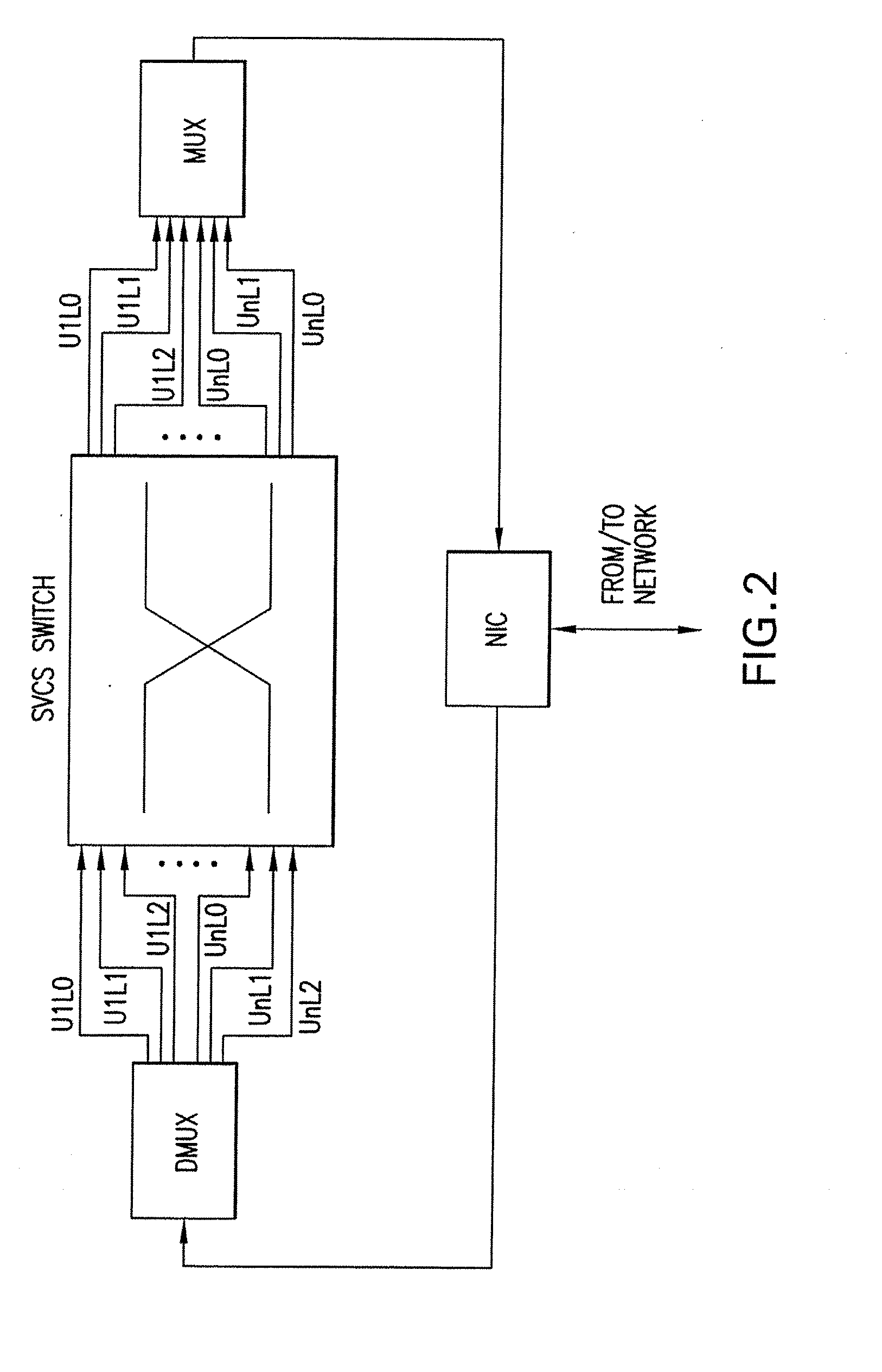

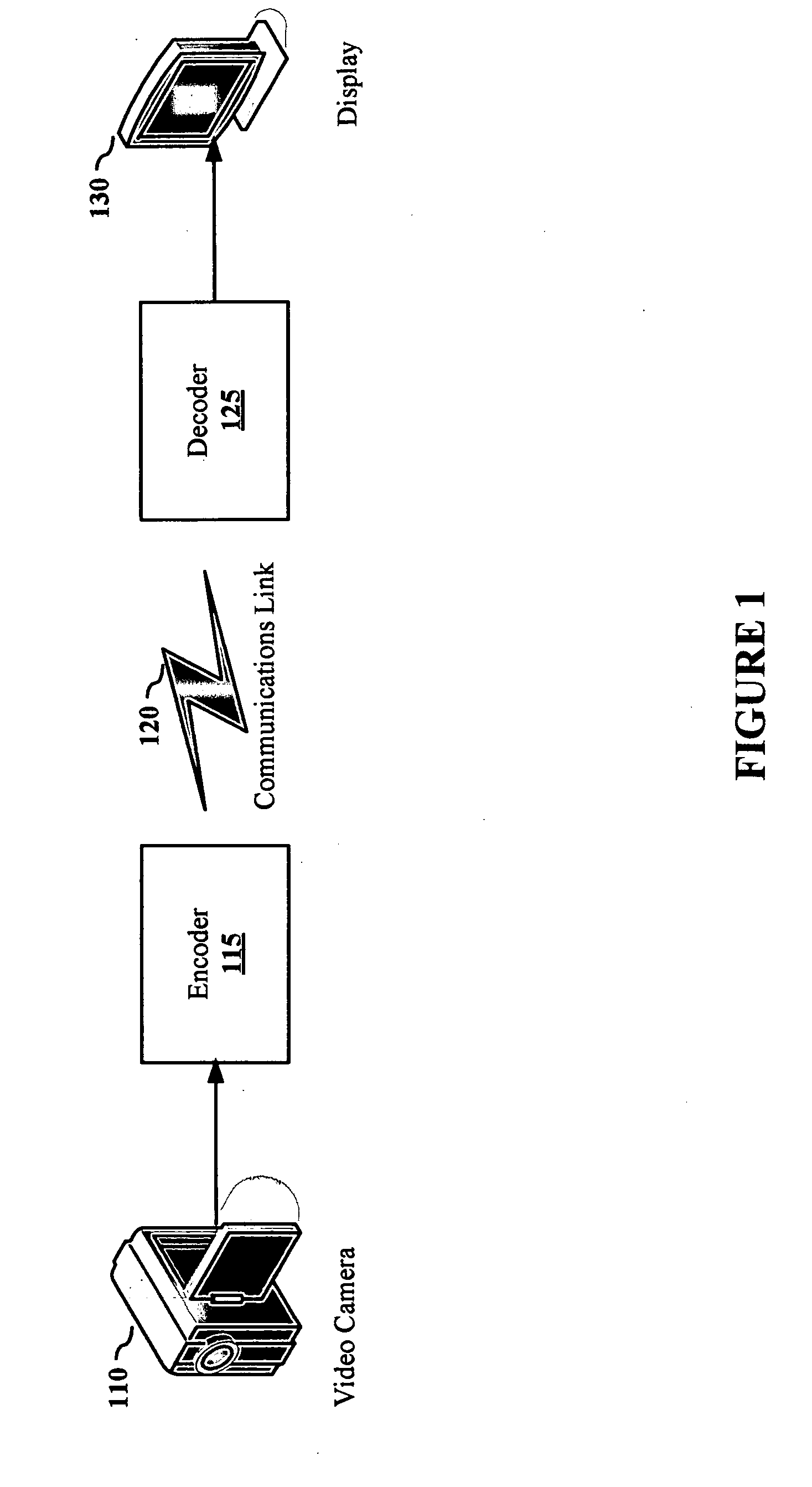

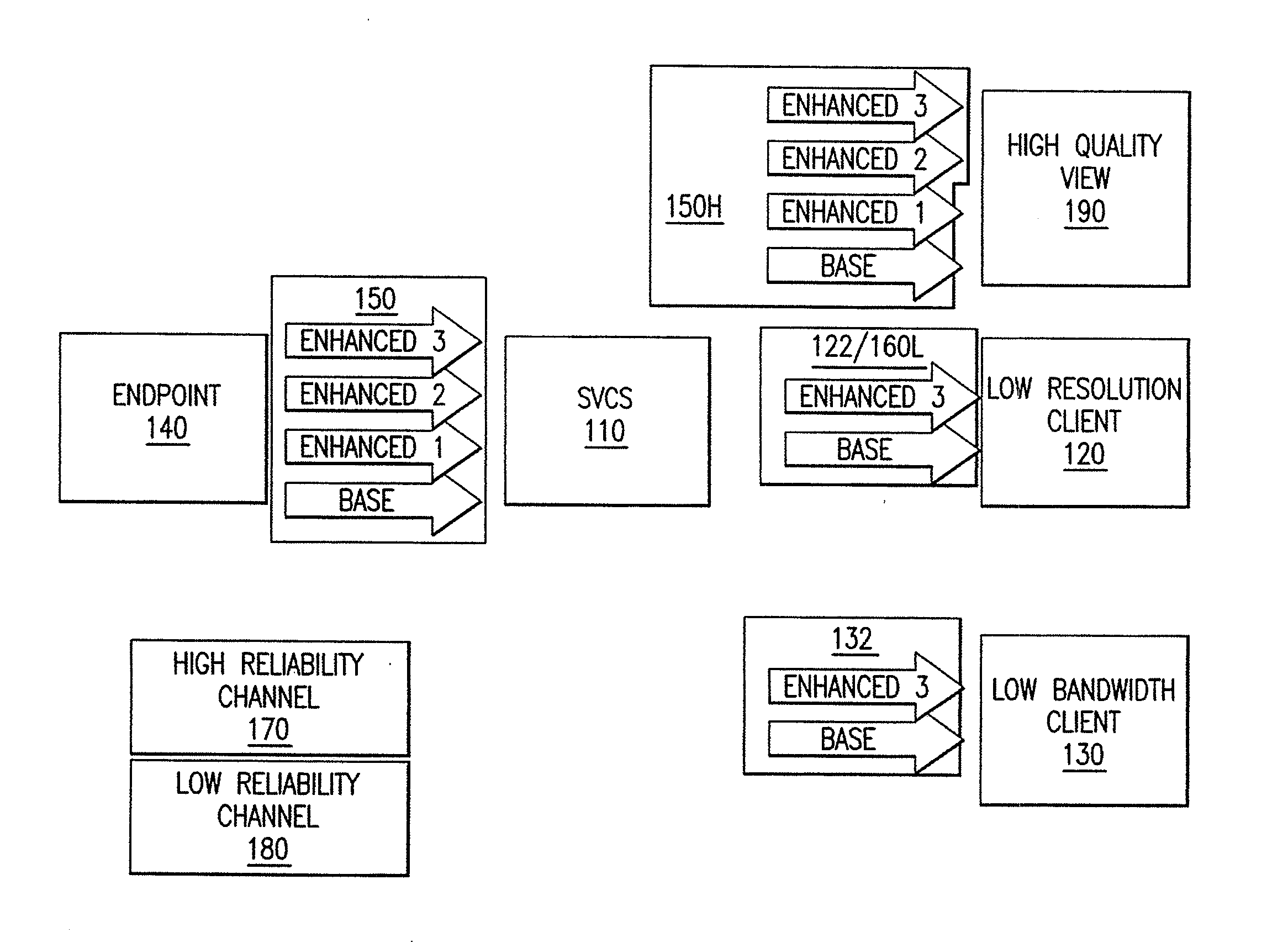

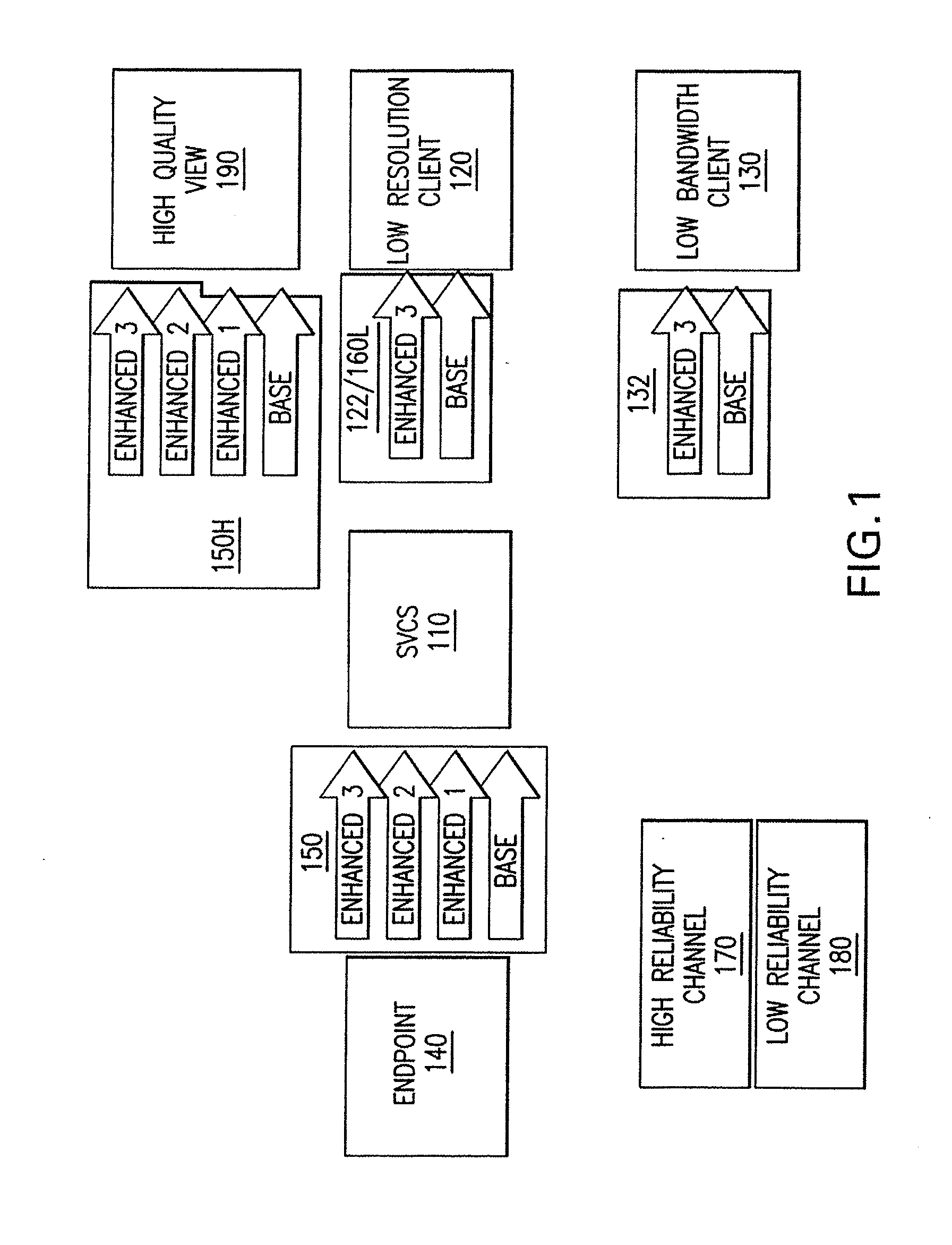

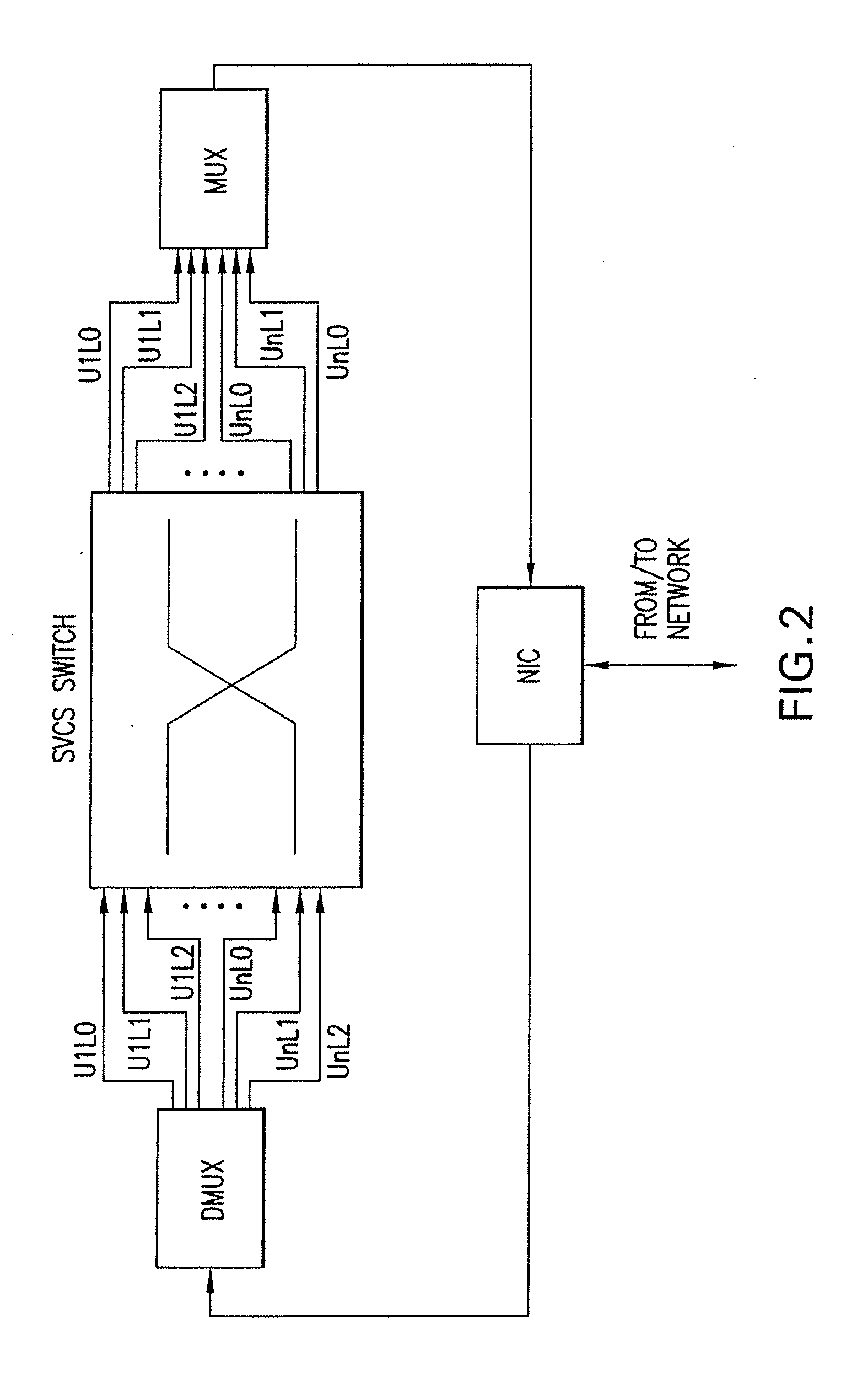

System and method for a conference server architecture for low delay and distributed conferencing applications

ActiveUS7593032B2Lower latencyImprove fault toleranceTelevision conference systemsTwo-way working systemsComputer architectureLow delay

Systems and methods for conducting a multi-endpoint video signal conference are provided. Conferencing endpoints are linked by pairs of a reliable and a less reliable communication channel. Conference video signals are scaleable coded in base layer and enhancement layers format. Video signal base layers, which correspond to a minimum picture quality, are communicated over reliable channels. The video signal enhancements layers may be communicated over the less reliable channels. A conference server mediates the switching of video layer information from transmitting endpoints to receiving endpoints without any intermediate coding or re-coding operations. The video conference can be integrated with an audio conference using either scalable coded audio signals or non-scaleable coded audio signals.

Owner:VIDYO

Object detection system for vehicle

InactiveUS20060206243A1Reduce processing requirementsReduce the possibilityImage enhancementImage analysisLane departure warning systemData set

An imaging system for a vehicle includes an imaging sensor and a control. The imaging sensor is operable to capture an image of a scene occurring exteriorly of the vehicle. The control receives the captured image, which comprises an image data set representative of the exterior scene. The control may apply an edge detection algorithm to a reduced image data set of the image data set. The reduced image data set is representative of a target zone of the captured image. The control may be operable to process the reduced image data set more than other image data, which are representative of areas of the captured image outside of the target zone, to detect objects present within the target zone. The imaging system may be associated with a side object detection system, a lane change assist system, a lane departure warning system and / or the like.

Owner:MAGNA ELECTRONICS INC

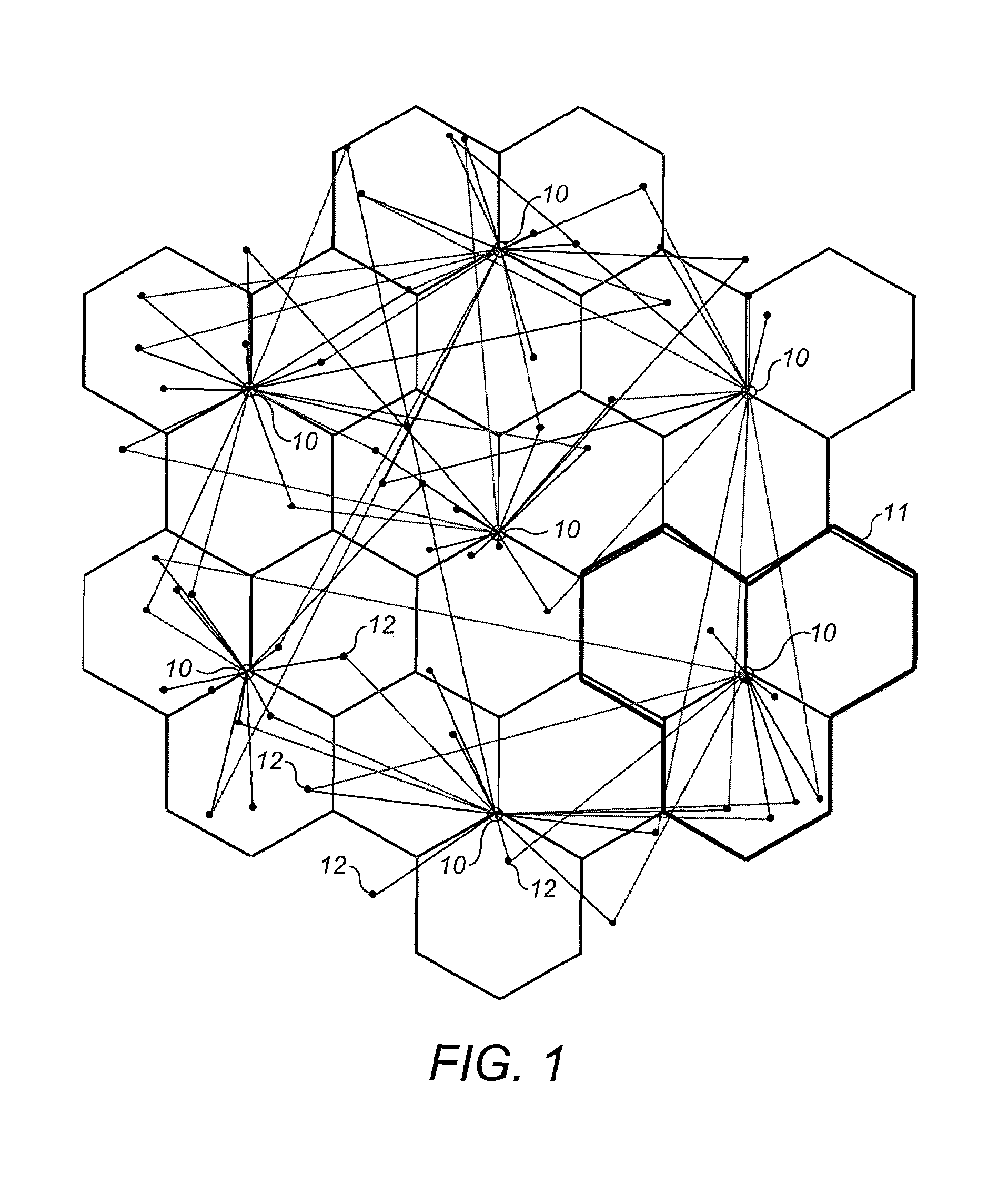

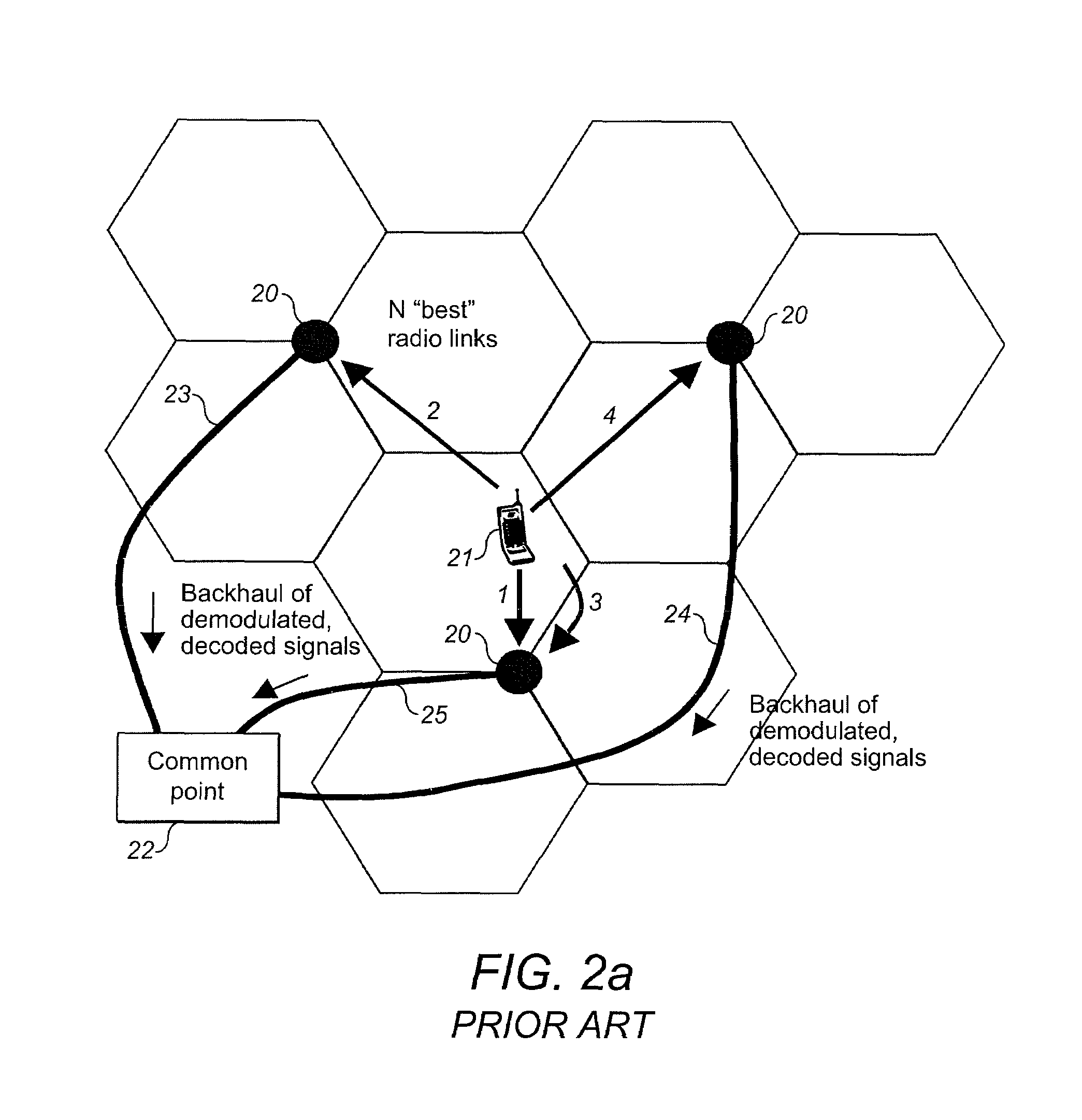

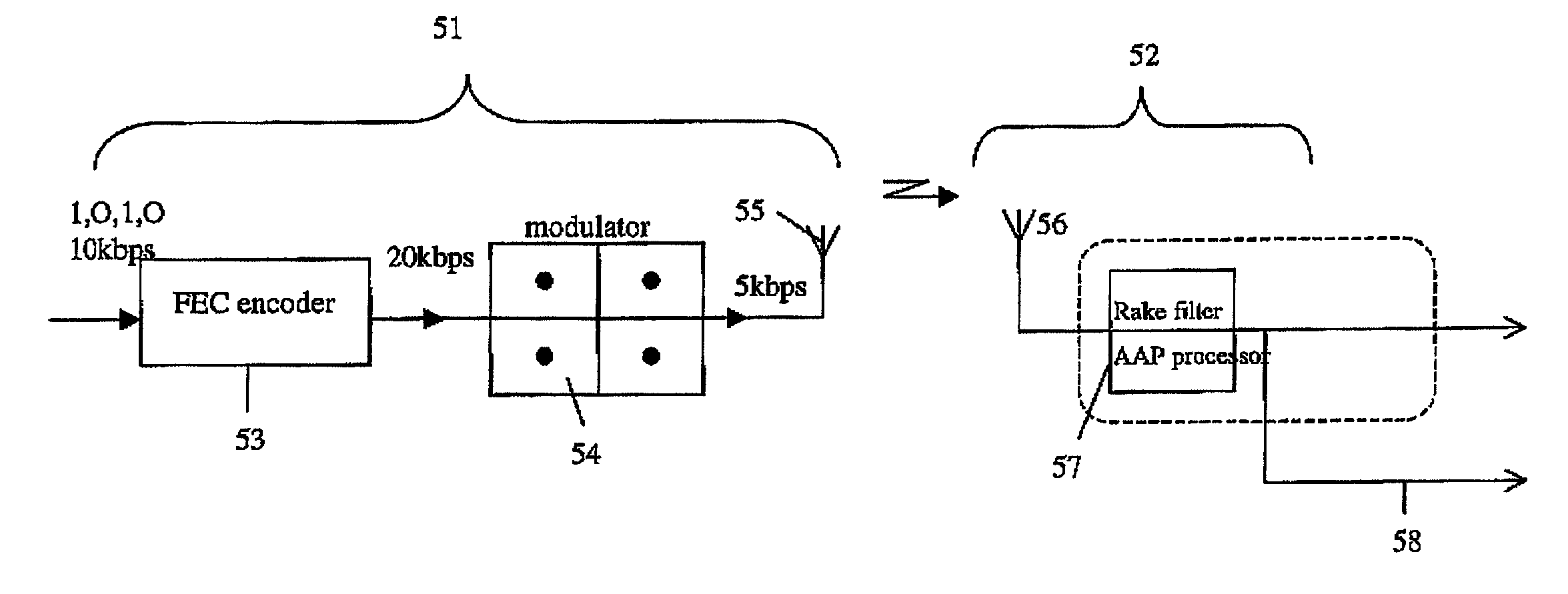

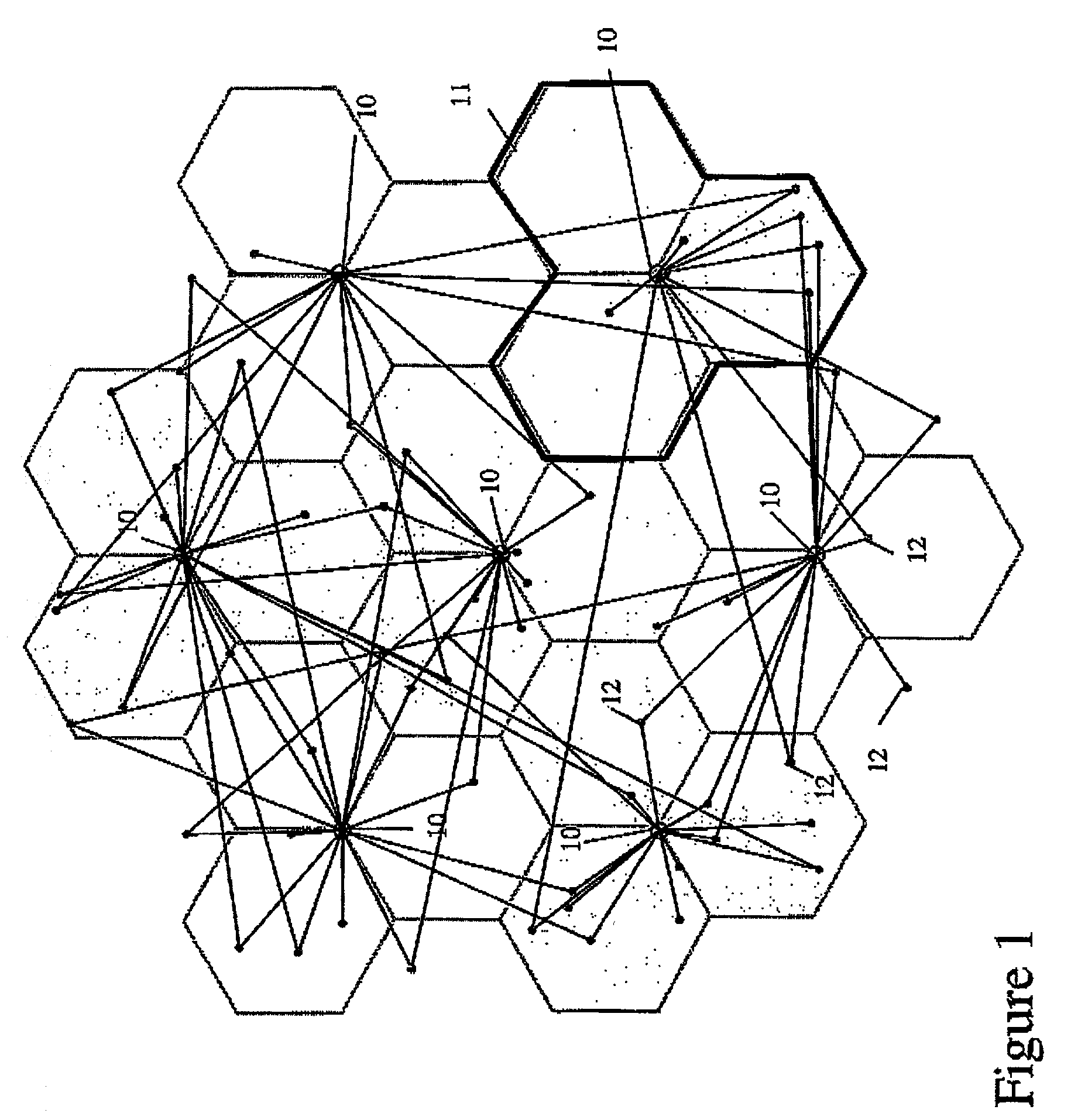

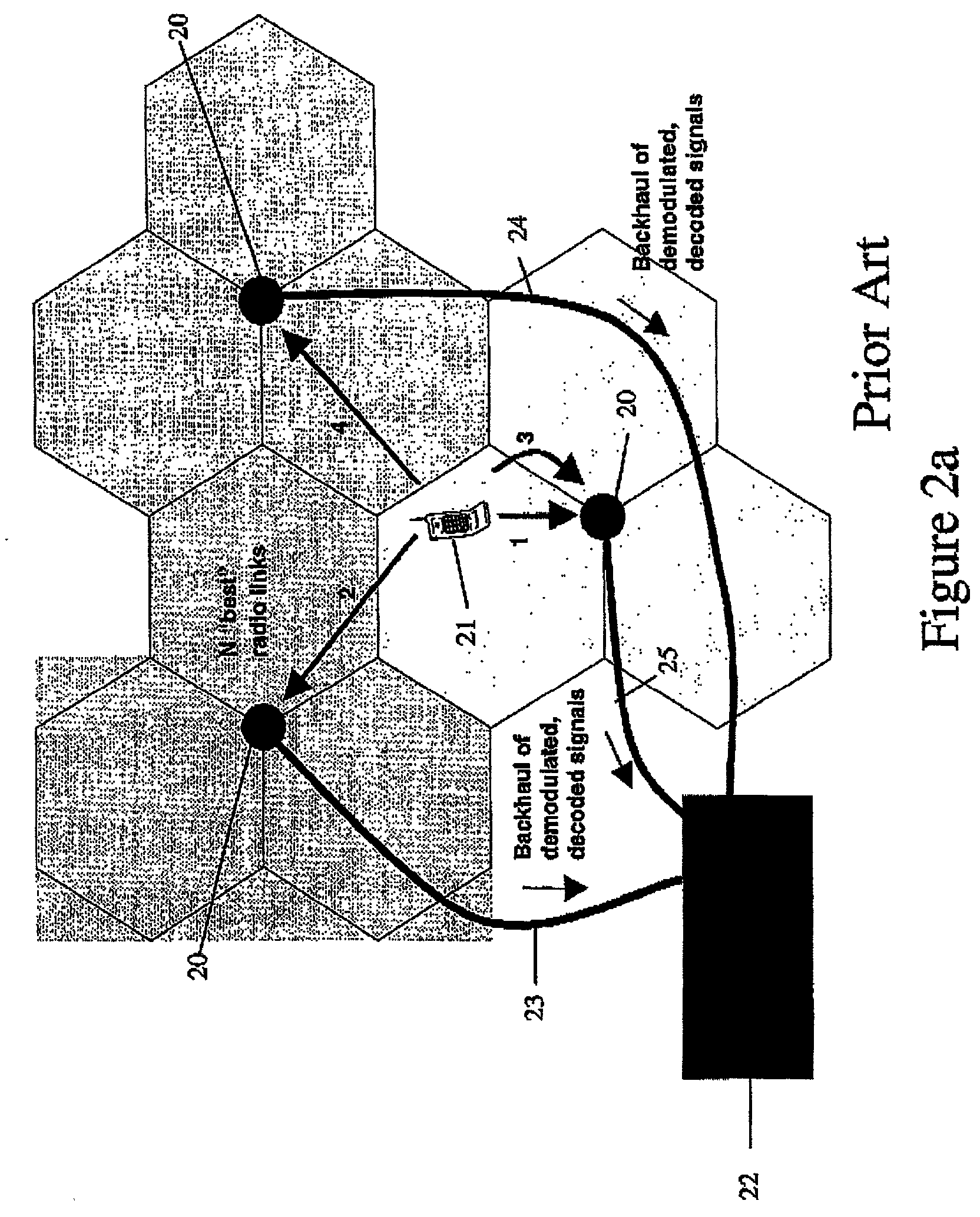

Soft handoff method for uplink wireless communications

InactiveUS7483408B2Reduce processing requirementsEnergy efficient ICTSite diversityTransmitted powerComputer science

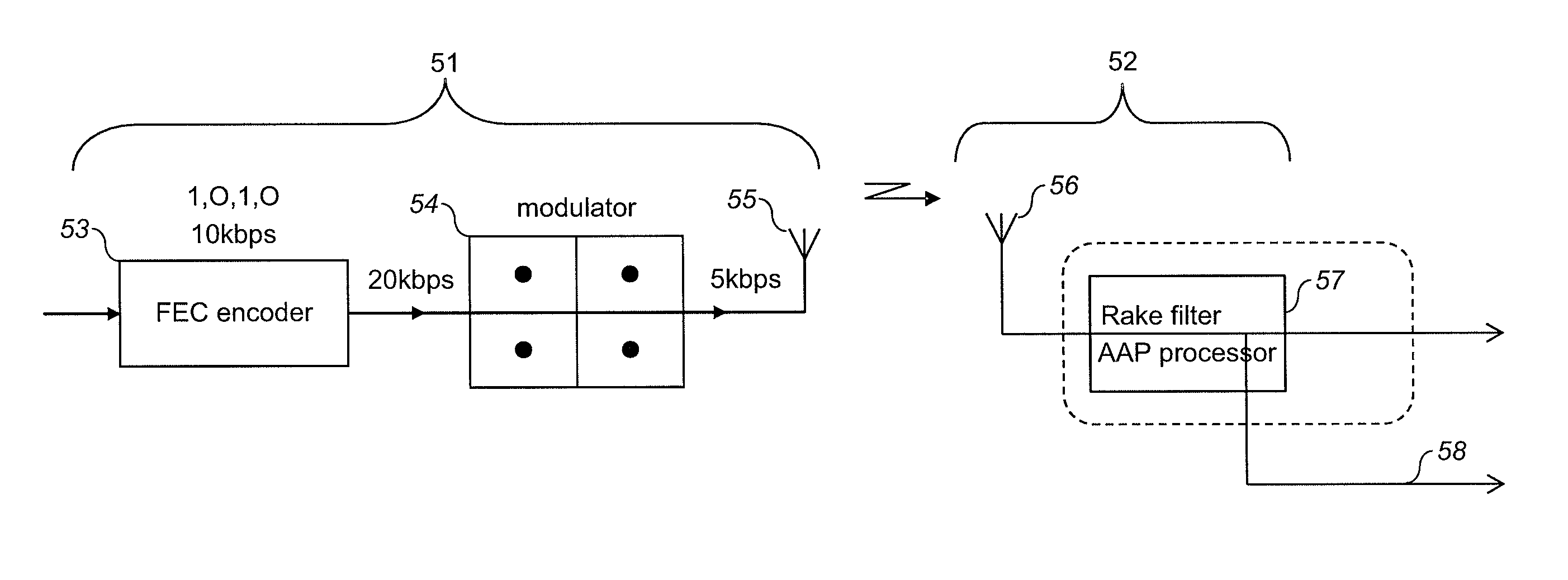

Soft-handoff methods involve receiving an uplink signal from a user equipment at more than one basestation. The uplink signals are processed at each basestation before being backhauled to a common point for use to derive a single signal from the user equipment. One problem with previous types of soft-handoff methods is that relatively complex processing is required at each basestation in order to demodulate and decode the signals. It is also desired to further increase uplink capacity as compared with known types of soft-handoff methods. This is achieved by backhauling signals without carrying out any decoding of the uplink signal at the basestation. The backhauled signals are combined at a common point using maximal ratio combining before being fully demodulated and decoded. As a result capacity is increased and required user equipment transmit power is reduced.

Owner:APPLE INC

System and method for a conference server architecture for low delay and distributed conferencing applications

ActiveUS20080158339A1Improve fault toleranceReduce processing requirementsTwo-way working systemsComputer architectureLow delay

Owner:VIDYO

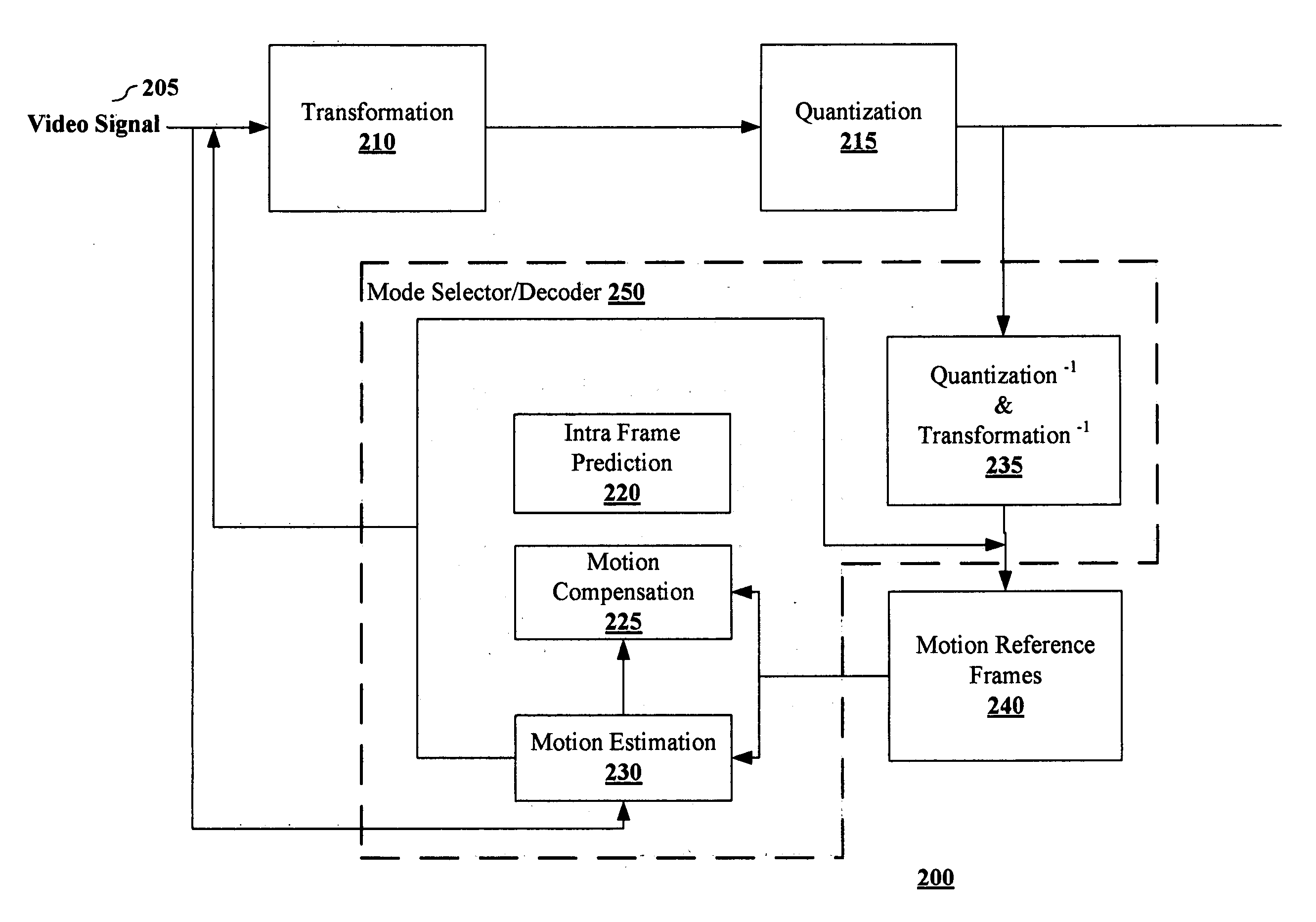

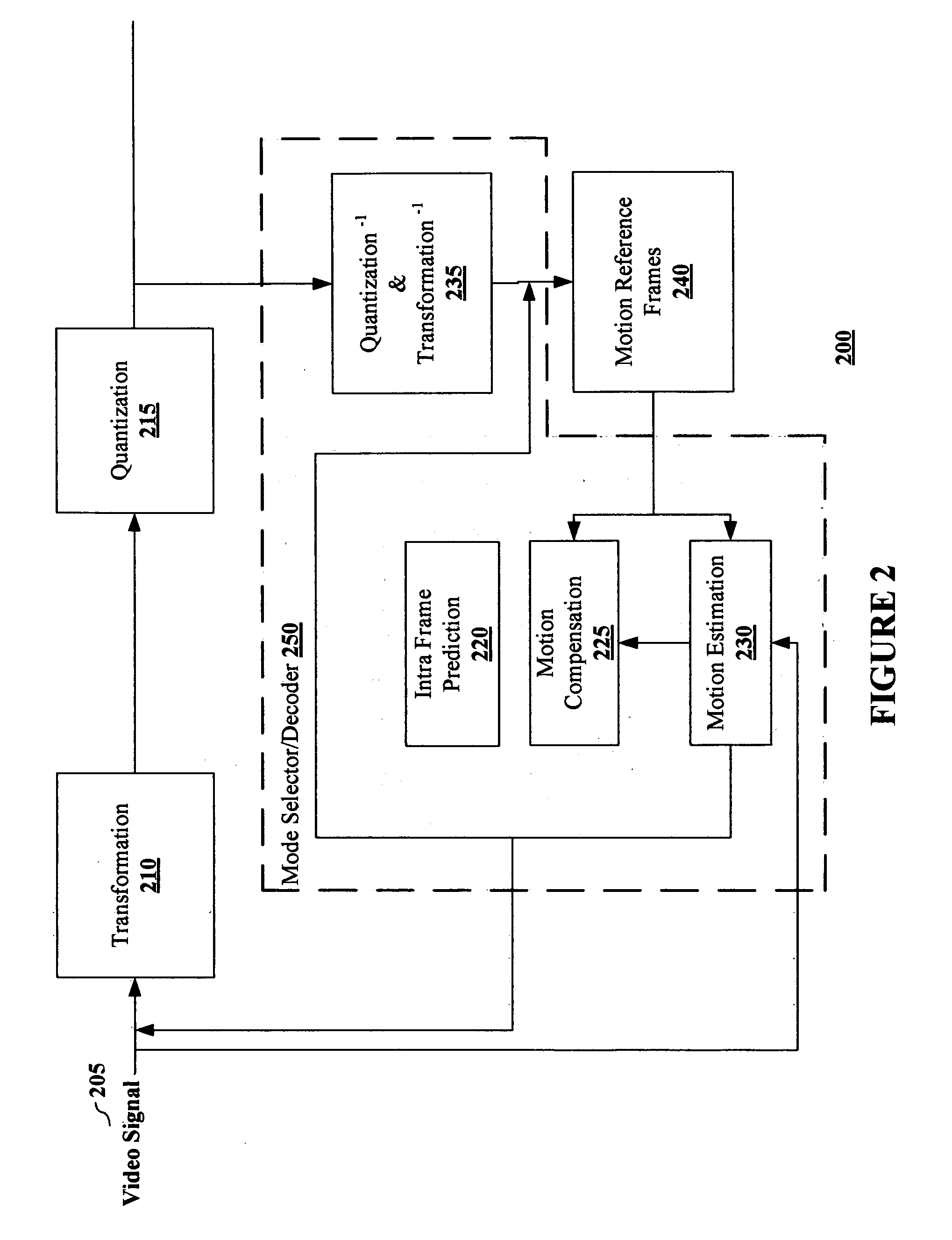

Temporal and spatial analysis of a video macroblock

InactiveUS20070140352A1Reduce processing requirementsReduce in quantityColor television with pulse code modulationColor television with bandwidth reductionRate distortionSpatial analysis

The temporal and / or spatial characteristics of a macroblock are analyzed in order to reduce the number of modes for which motion estimation and rate distortion efficiency calculations are to be performed. In one embodiment, macroblock mean and variance characteristics are analyzed to merge sub-blocks together within the macroblock. These merged sub-blocks may be used to identify both inter and intra modes for the macroblock.

Owner:SEIKO EPSON CORP

Soft handoff method for uplink wireless communications

ActiveUS20040001460A1Simple calculationReduce processing requirementsEnergy efficient ICTSite diversityTransmitted powerMaximal-ratio combining

Soft-handoff methods involve receiving an uplink signal from a user equipment at more than one basestation. The uplink signals are processed at each basestation before being backhauled to a common point for use to derive a single signal from the user equipment. One problem with previous types of soft-handoff methods is that relatively complex processing is required at each basestation in order to demodulate and decode the signals. It is also desired to further increase uplink capacity as compared with known types of soft-handoff methods. This is achieved by backhauling signals without carrying out any decoding of the uplink signal at the basestation. The backhauled signals are combined at a common point using maximal ratio combining before being fully demodulated and decoded. As a result capacity is increased and required user equipment transmit power is reduced.

Owner:APPLE INC

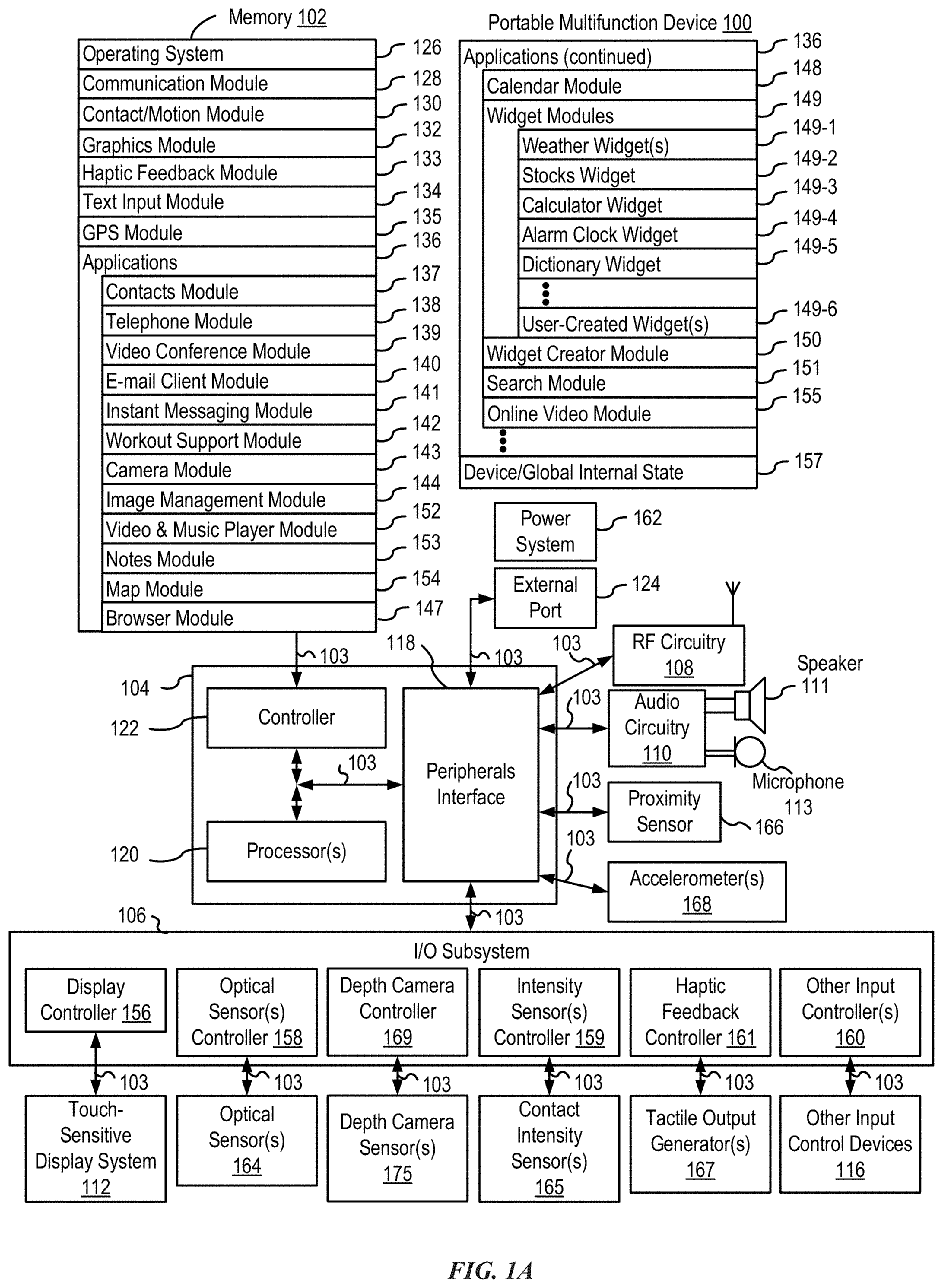

User interfaces for capturing and managing visual media

ActiveUS10645294B1Faster and efficient methodReduce cognitive loadImage enhancementTelevision system detailsMedia controlsMediaFLO

Media user interfaces are described, including user interfaces for capturing media (e.g., capturing a photo, recording a video), displaying media (e.g., displaying a photo, playing a video), editing media (e.g., modifying a photo, modifying a video), accessing media controls or settings (e.g., accessing controls or settings to capture photos or videos to capture videos), and automatically adjusting media (e.g., automatically modifying a photo, automatically modifying a video).

Owner:APPLE INC

System and method for a conference server architecture for low delay and distributed conferencing applications

ActiveUS20090295905A1Improve fault toleranceReduce processing requirementsTelevision conference systemsTwo-way working systemsComputer architectureLow delay

Systems and methods for conducting a multi-endpoint video signal conference are provided. Conferencing endpoints are linked by pairs of a reliable and a less reliable communication channel. Conference video signals are scaleable coded in base layer and enhancement layers format. Video signal base layers, which correspond to a minimum picture quality, are communicated over reliable channels. The video signal enhancements layers may be communicated over the less reliable channels. A conference server mediates the switching of video layer information from transmitting endpoints to receiving endpoints without any intermediate coding or re-coding operations. The video conference can be integrated with an audio conference using either scalable coded audio signals or non-scaleable coded audio signals.

Owner:VIDYO

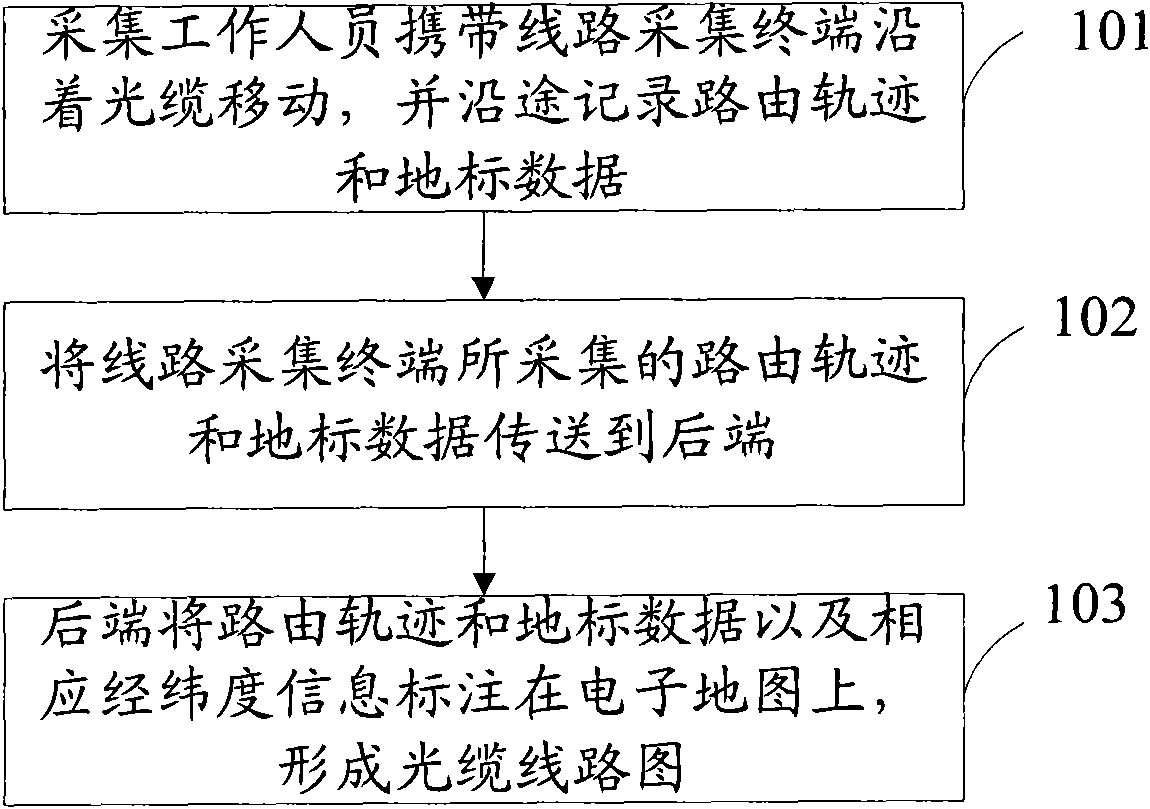

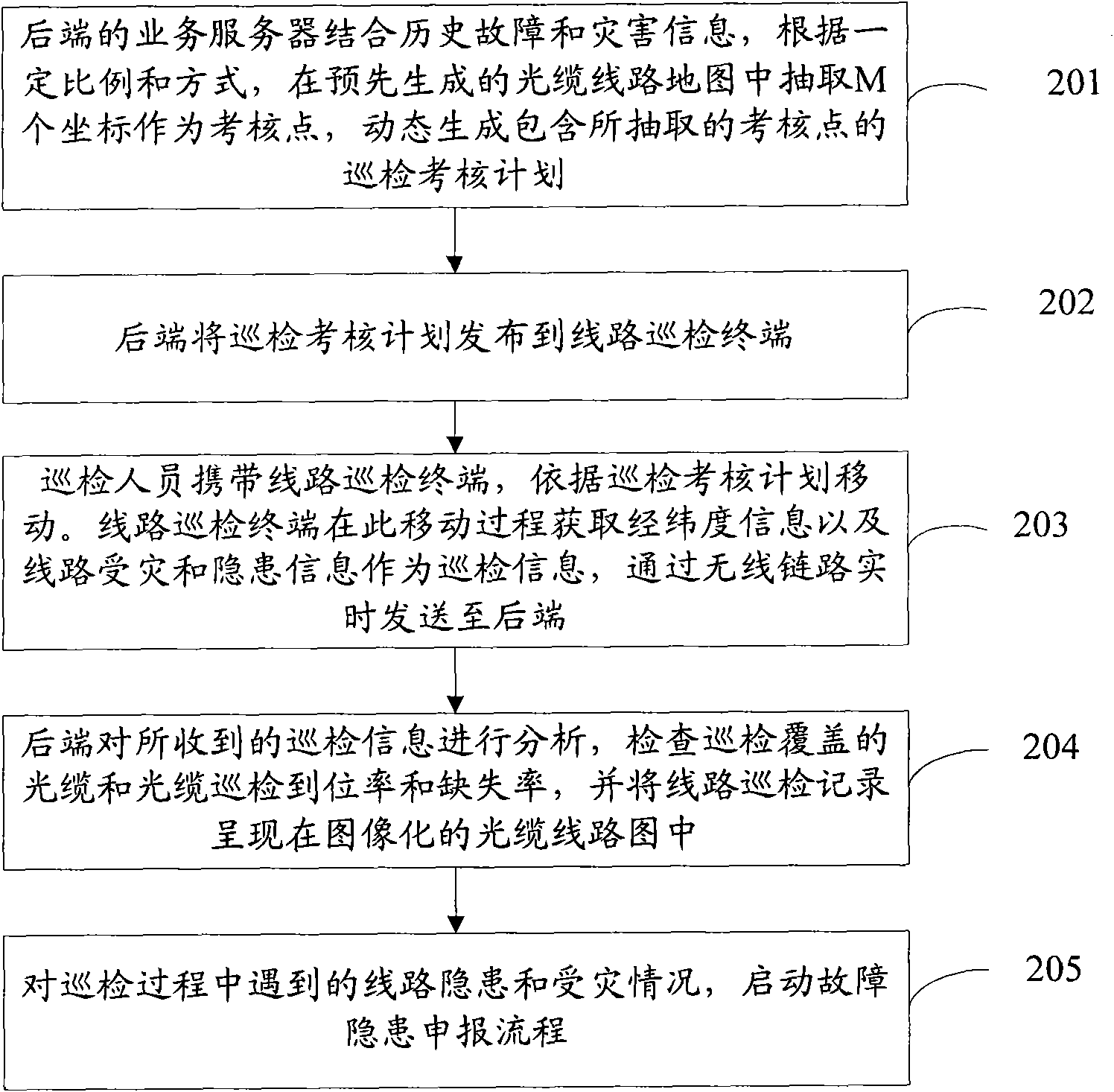

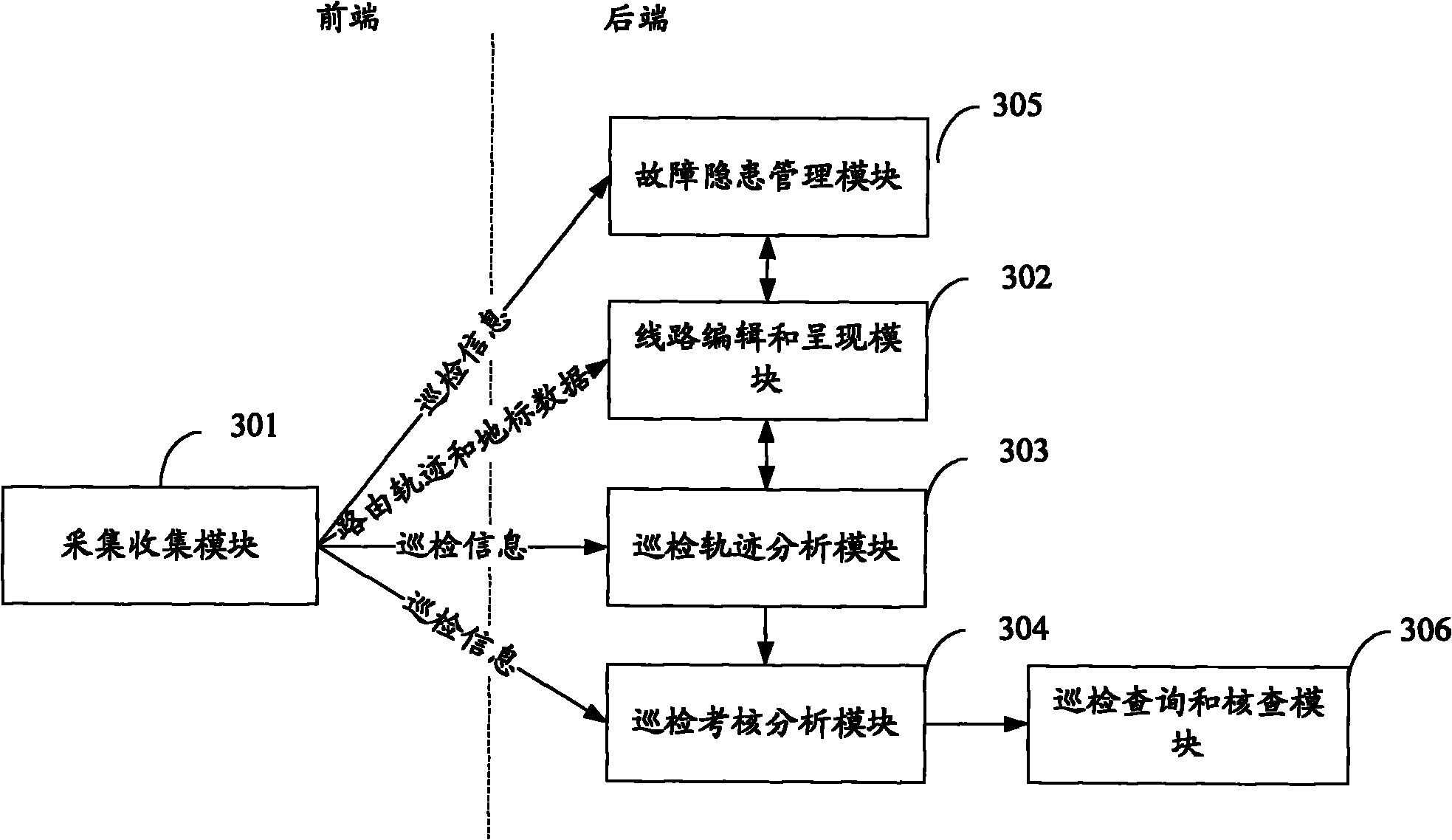

Line polling management system and method

ActiveCN102044094ALow costReduce processing requirementsChecking time patrolsFault locationComputer scienceManagement system

The invention discloses a line polling management system, which comprises an acquisition module (301), a polling locus analysis module (303) and a polling evaluation analysis module (304), wherein the acquisition module (301) is sued for acquiring polling information in a polled line, and the polling information at least comprises longitude and latitude information; the polling locus analysis module (303) is used for dividing a pre-generated line map into a plurality of grids, generating a polling locus according to the polling information acquired by the acquisition module (301), matching the polling locus and the grids and determining a candidate line to be analyzed; and the polling evaluation analysis module (304) is sued for calculating the distance between the polling locus point and the evaluation point of the candidate line and determining that the polling locus point covers the evaluation point if the distance is smaller than the preset threshold value. The invention also discloses a line polling management method. According to the scheme, the system and the method can greatly simplify the operation of polling personnel, can adapt to various environment conditions, have low cost, and are easy to popularize.

Owner:CHINA MOBILE GRP FUJIAN CO LTD

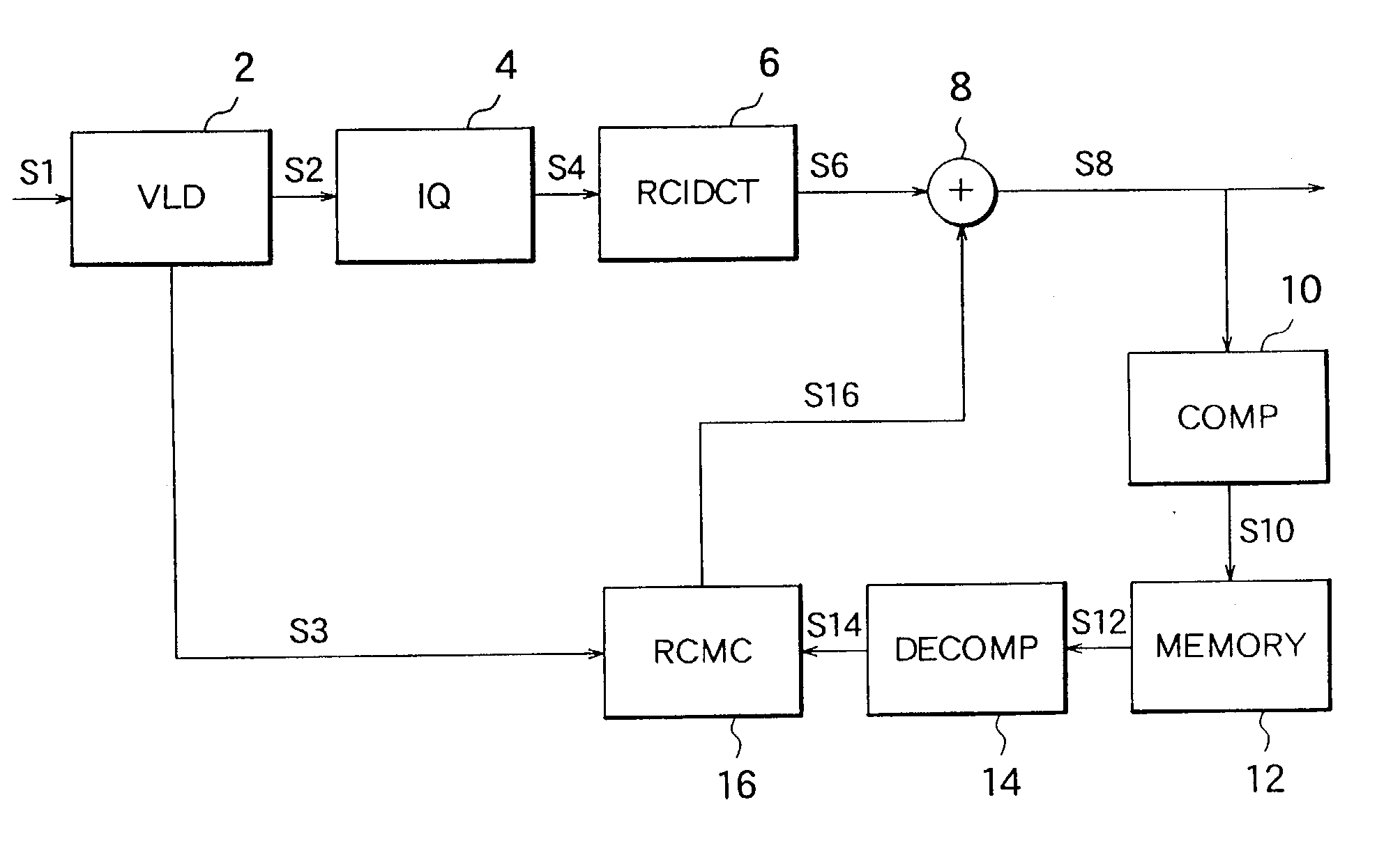

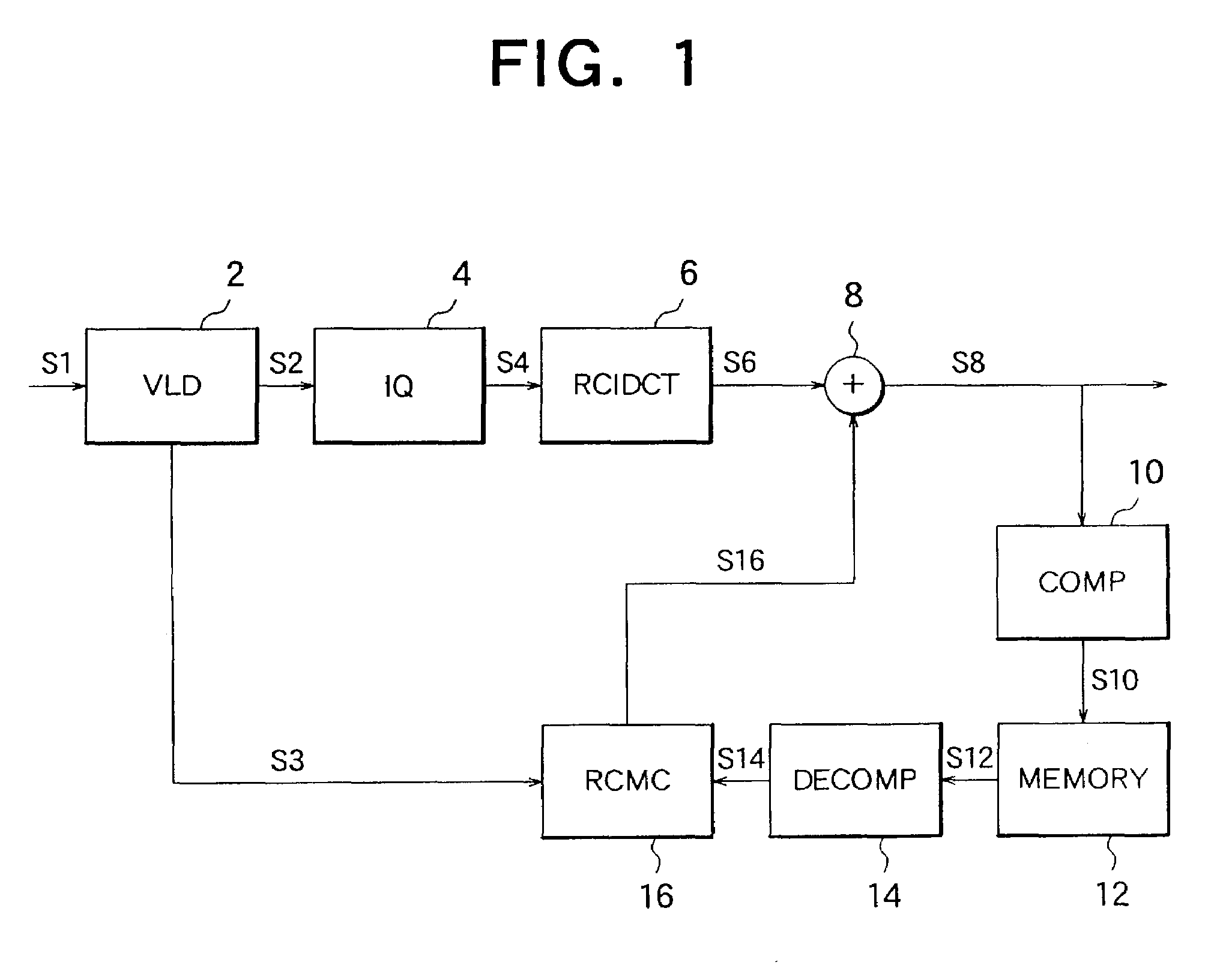

Moving-picture coding and decoding method and apparatus with reduced computational cost

InactiveUS7027507B2Reduce memory requirementsReduce processing requirementsColor television with pulse code modulationColor television with bandwidth reductionDecoding methodsImage resolution

A coded moving-picture signal is decoded by a resolution-converting motion compensation process and a resolution-converting inverse discrete cosine transform, both of which decrease the resolution of the picture, thereby reducing the amount of reference picture data that has to be stored and accessed. The reference picture data may also be stored in a compressed form. The resolution conversion and compression processes may also be used in the coding of the moving-picture signal. The resolution-converting inverse discrete cosine transform may be performed by output of intermediate results that have not been combined by addition and subtraction in a butterfly computation.

Owner:RAKUTEN GRP INC

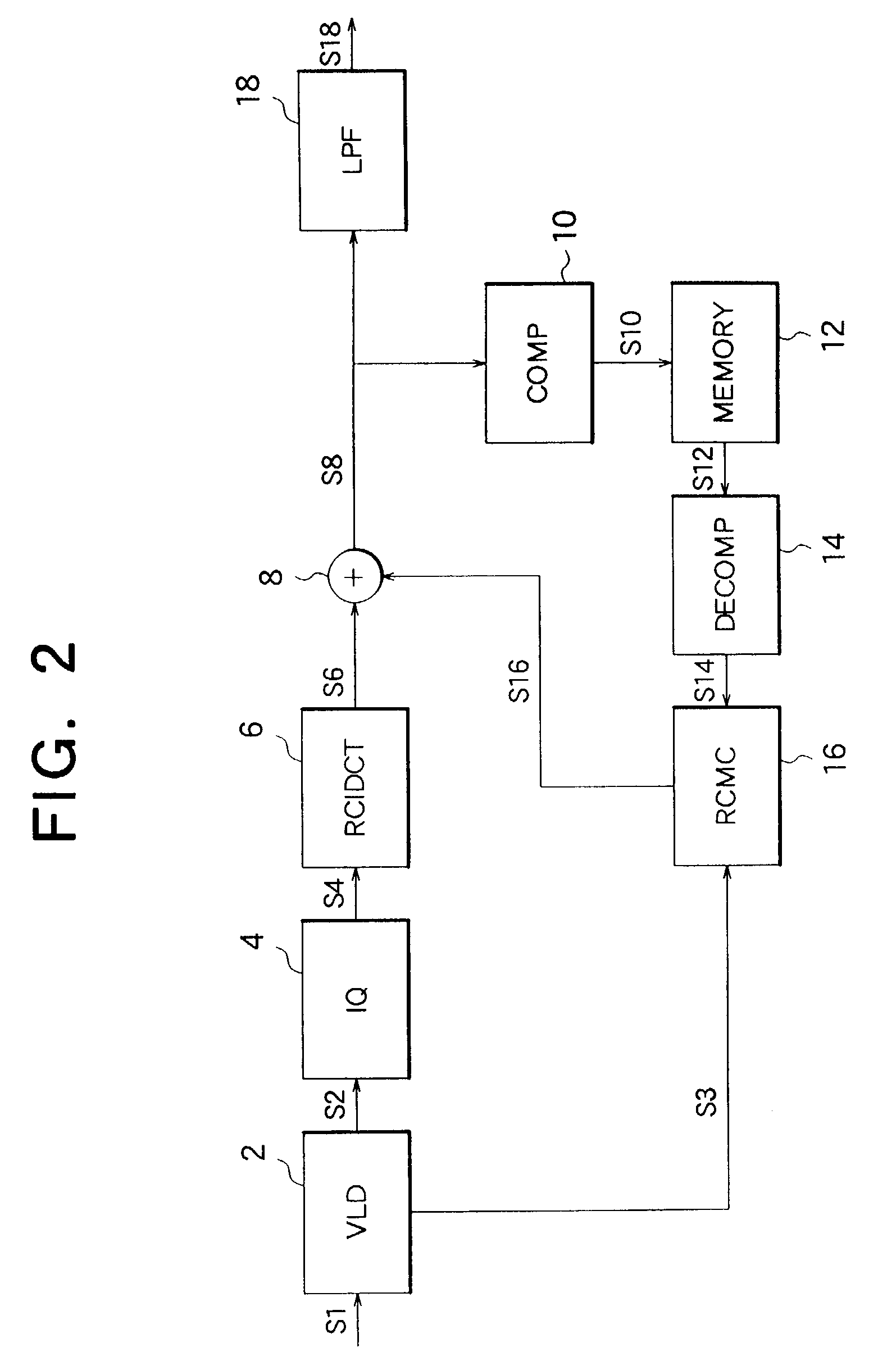

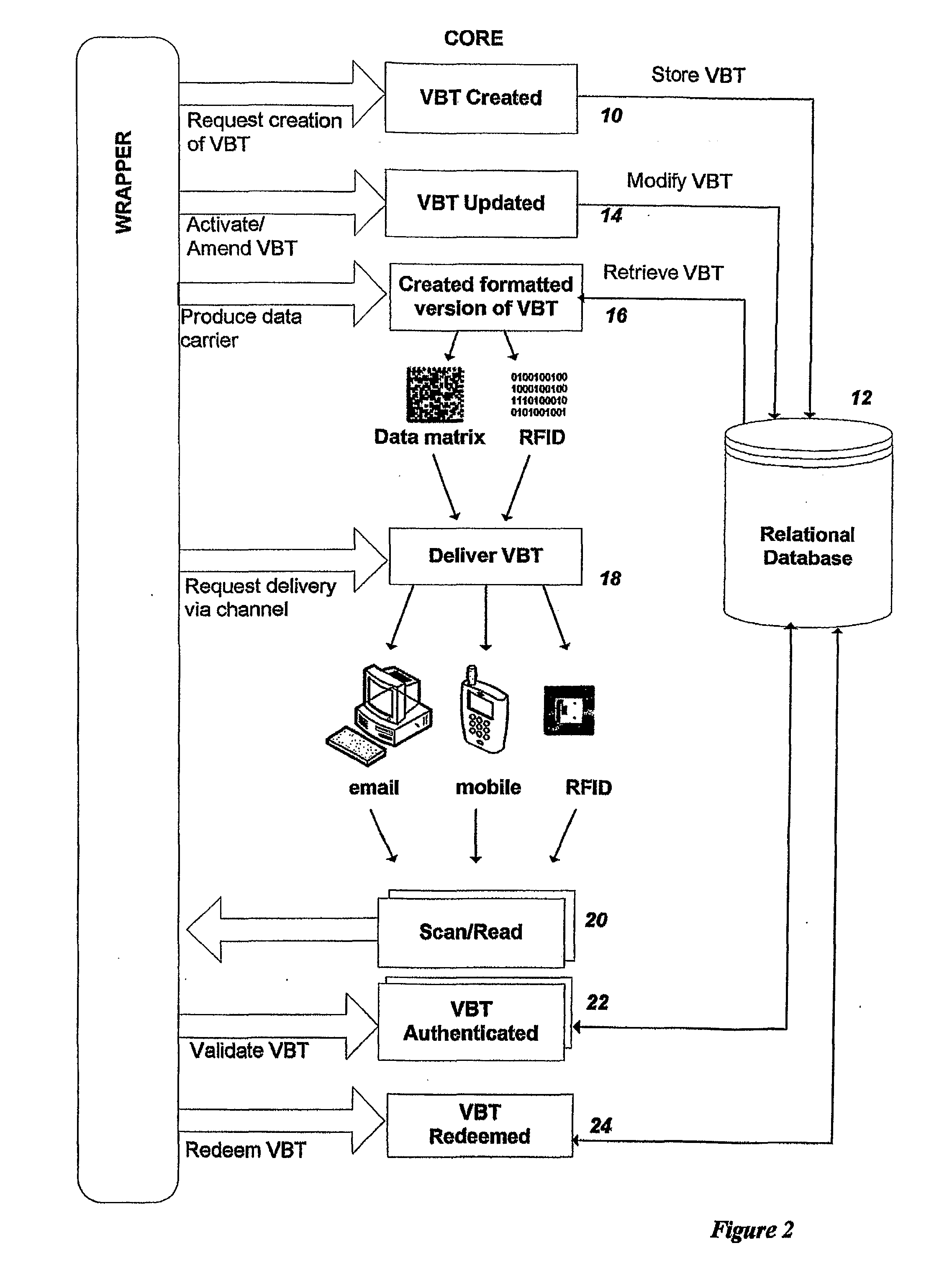

Authentication of cheques and the like

InactiveUS20090261158A1Improve securityReduce processing requirementsComplete banking machinesFinanceCore systemCheque

Value based tokens are generated for inclusion on a data carrier which may be applied to a cheque or similar document. The tokens are generated by a core system, which communicates with application specific wrappers. The wrappers supply token parameters to the core that are specific to the application and the core generates the tokens, and stores them for later authentication. The core then encodes the tokens onto a data carrier under the control of the wrapper and distributes the tokens under the control of the wrapper. The tokens are encoded onto the cheque when it is printed. When a cheque is presented for authentication, for example by at a bank, the signed cheque is imaged and the token retrieved from the encoded data carrier. It is passed back to the core by the wrapper for authentication of its identification number and other parameters. The image may be sealed by a further data carrier which may be printed on the cheque or added to the electronic image. The further data carrier may include a separate token or have a token which is related to the first token. Where the data carrier is applied to the electronic image it may replace the first data carrier. The data stored on the carrier references cheque information stored at a database which is compared with cheque information retrieved from the cheque.

Owner:FIRST ONDEMAND

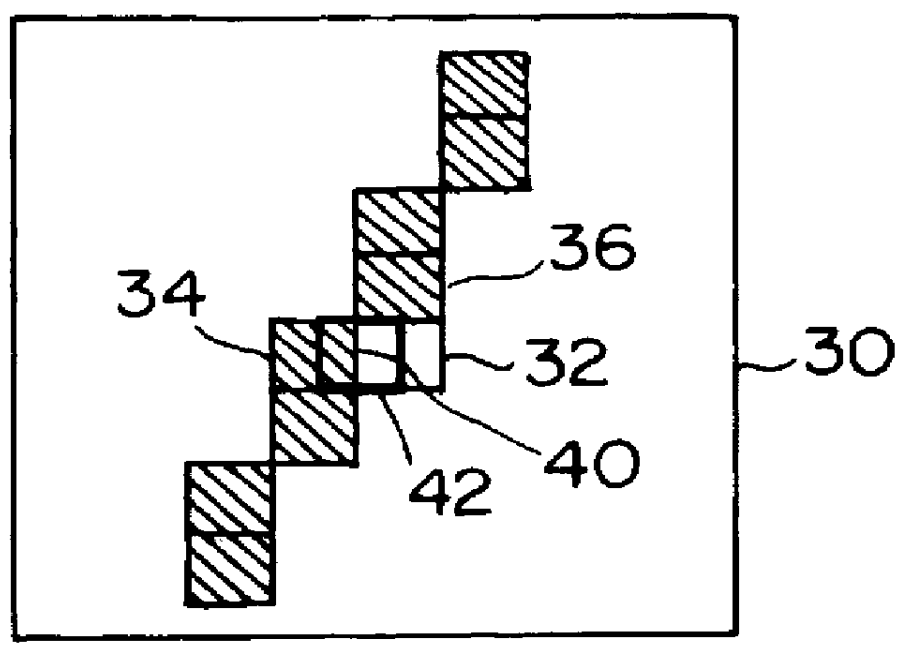

Pathfinding system

InactiveUS20070198178A1Improve experienceSpeed up the processInstruments for road network navigationRoad vehicles traffic controlVirtual worldCo ordinate

A computer system is arranged to automatically calculate a path along nodes in a virtual world. After the co-ordinates for the virtual world environment have been initially defined (40), including nodes along which a path may travel, the system automatically increases the density of nodes in the environment up to a desired density. New nodes are added between each pair of nodes which have line of sight to each other (44 to 47), dramatically increasing the number of available links and nodes. This is repeated until a sufficient density of nodes is reached and no more nodes are being added (48 and 49).

Owner:BRITISH TELECOMM PLC

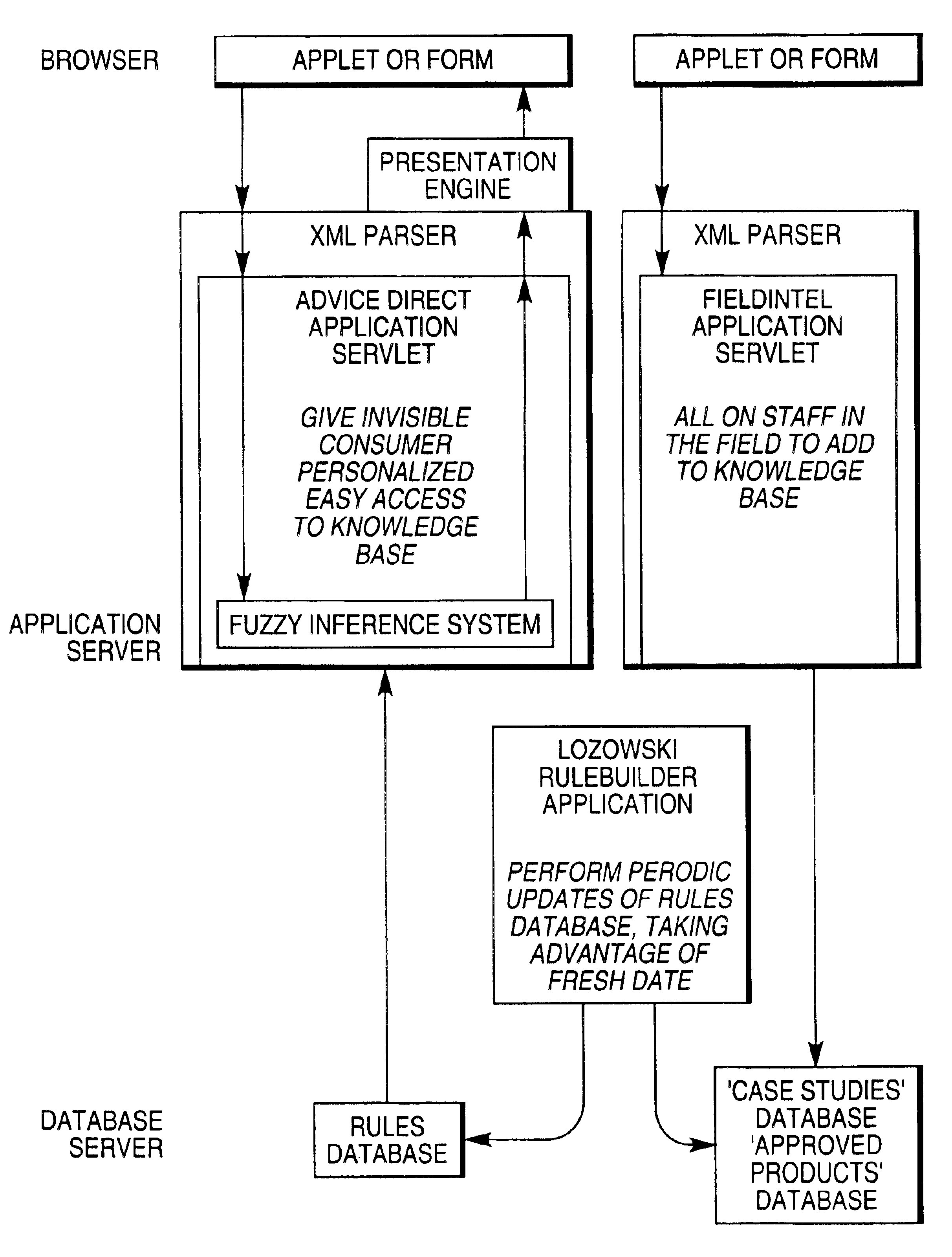

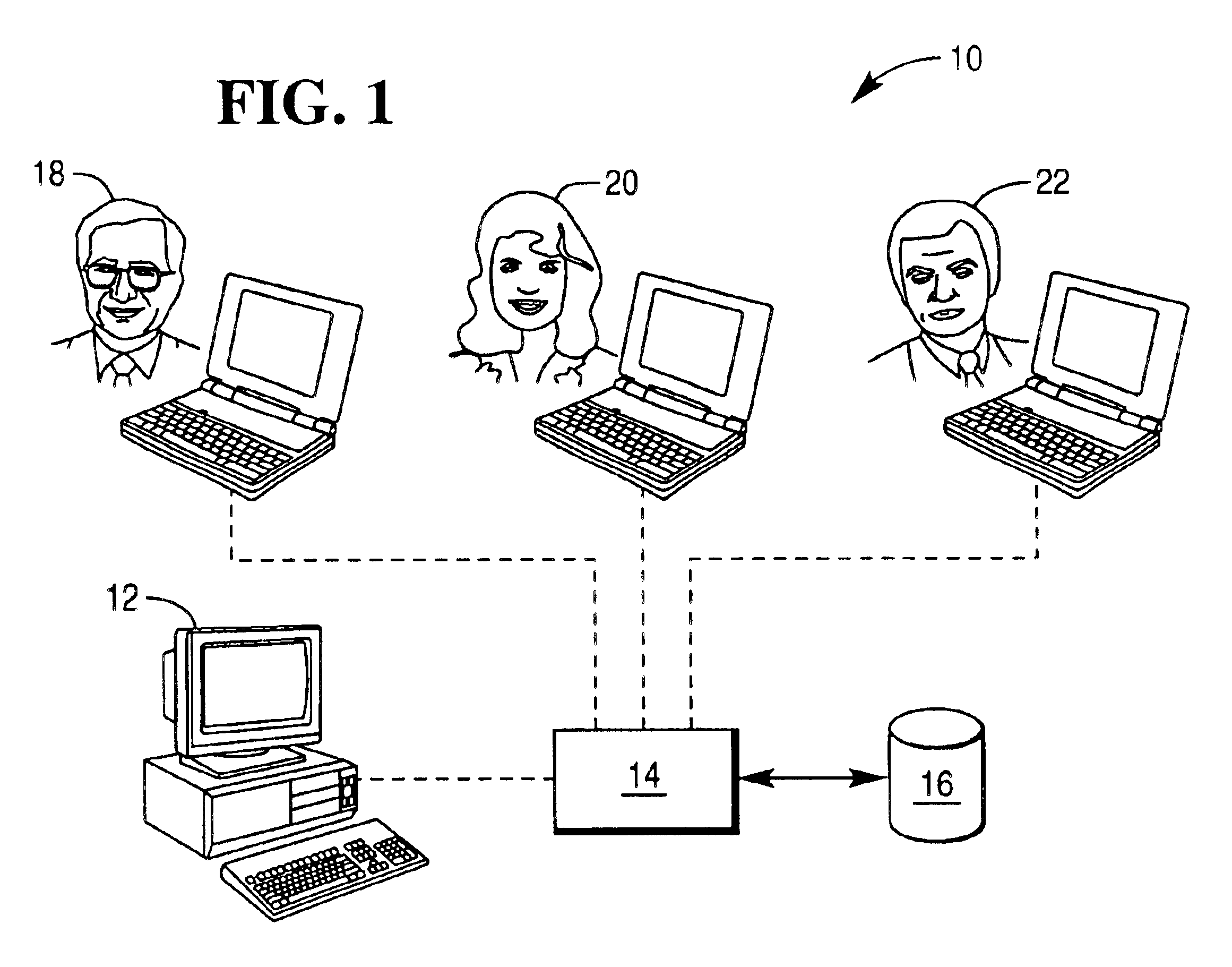

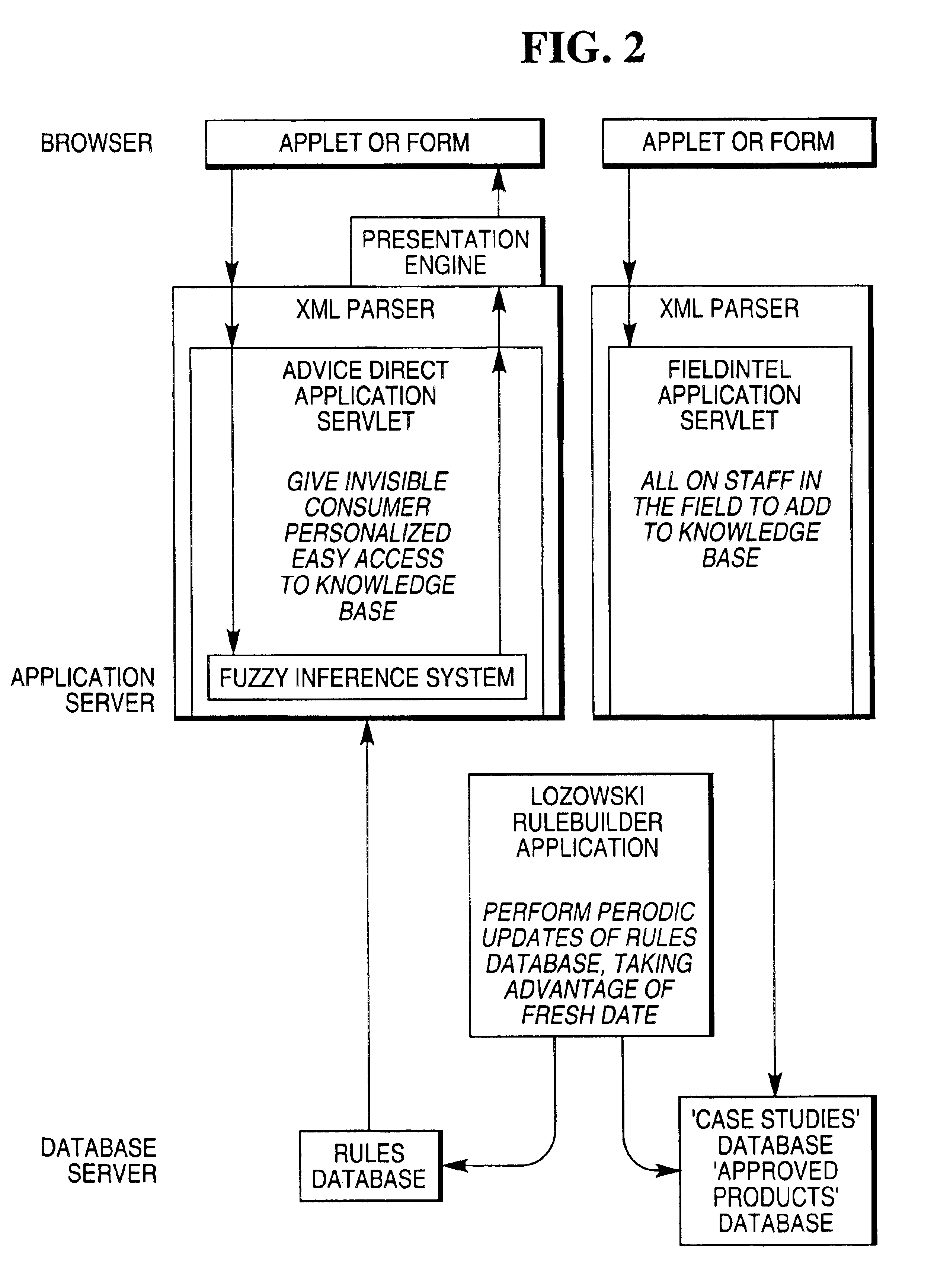

Expert system

InactiveUS6850923B1Reduce memoryReduce processing requirementsFinanceFuzzy logic based systemsHuman interactionComputer science

An expert system and a method of providing automated advice are described. The system is regularly updated by advice (or diagnosis, recommendation etc.) given by practitioners in the relevant field. The combination of the underlying facts and the consequent (human) advice is used to update a ruleset that is then used to provide automated advice.An example of financial advice is given. A database contains the details for the customers of a financial institution together with advice and recommendations given previously by the institution's human advisors. This database is used to derive a ruleset which is then applied to a subsequent customer's details in an automated manner, possibly at the user's own PC via the World Wide Web. Frequent updating using data from the human advisors' work means that the database (and hence the ruleset) are kept up to date. Consistent advice can thus be provided with minimum human interaction.

Owner:NCR CORP

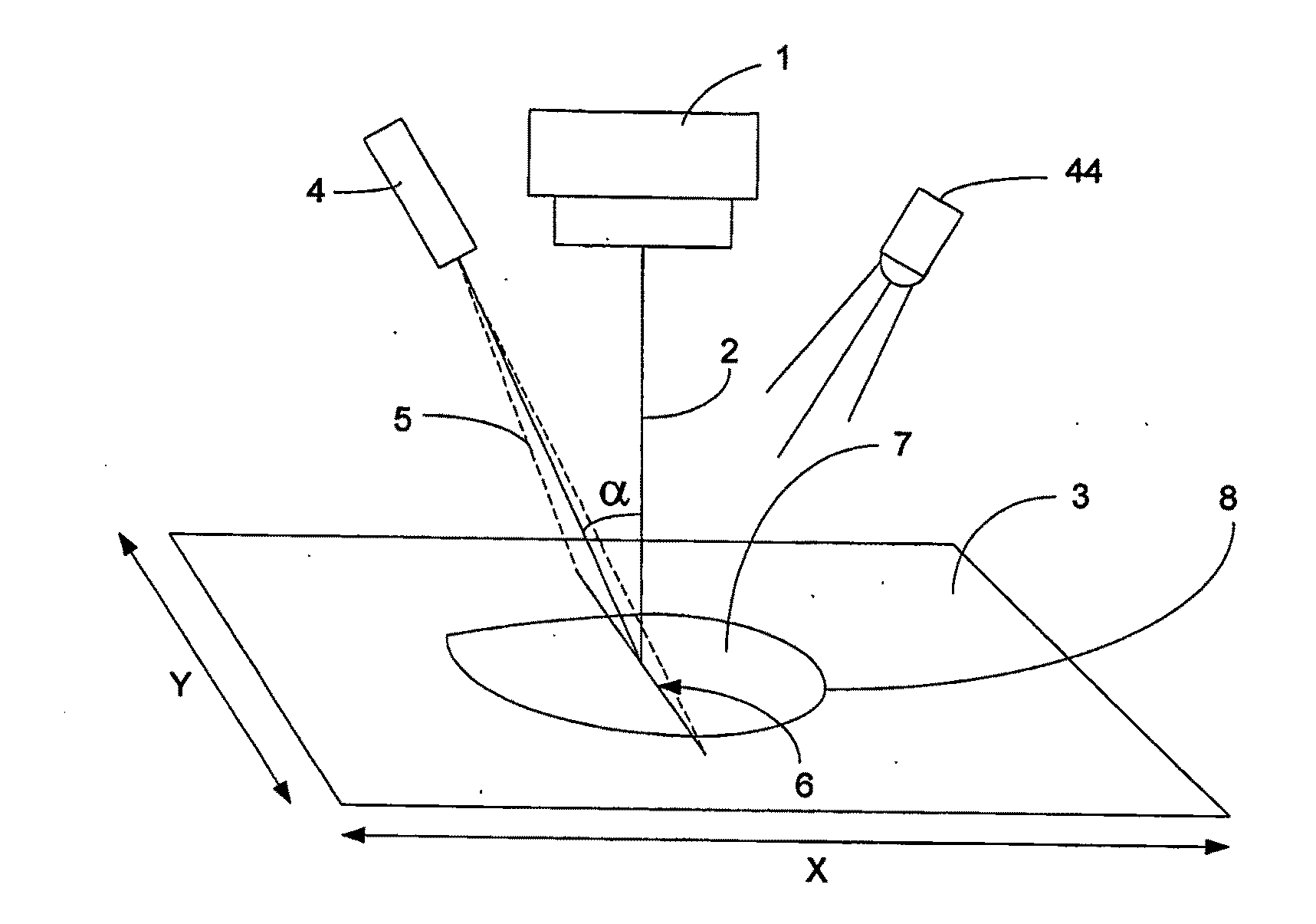

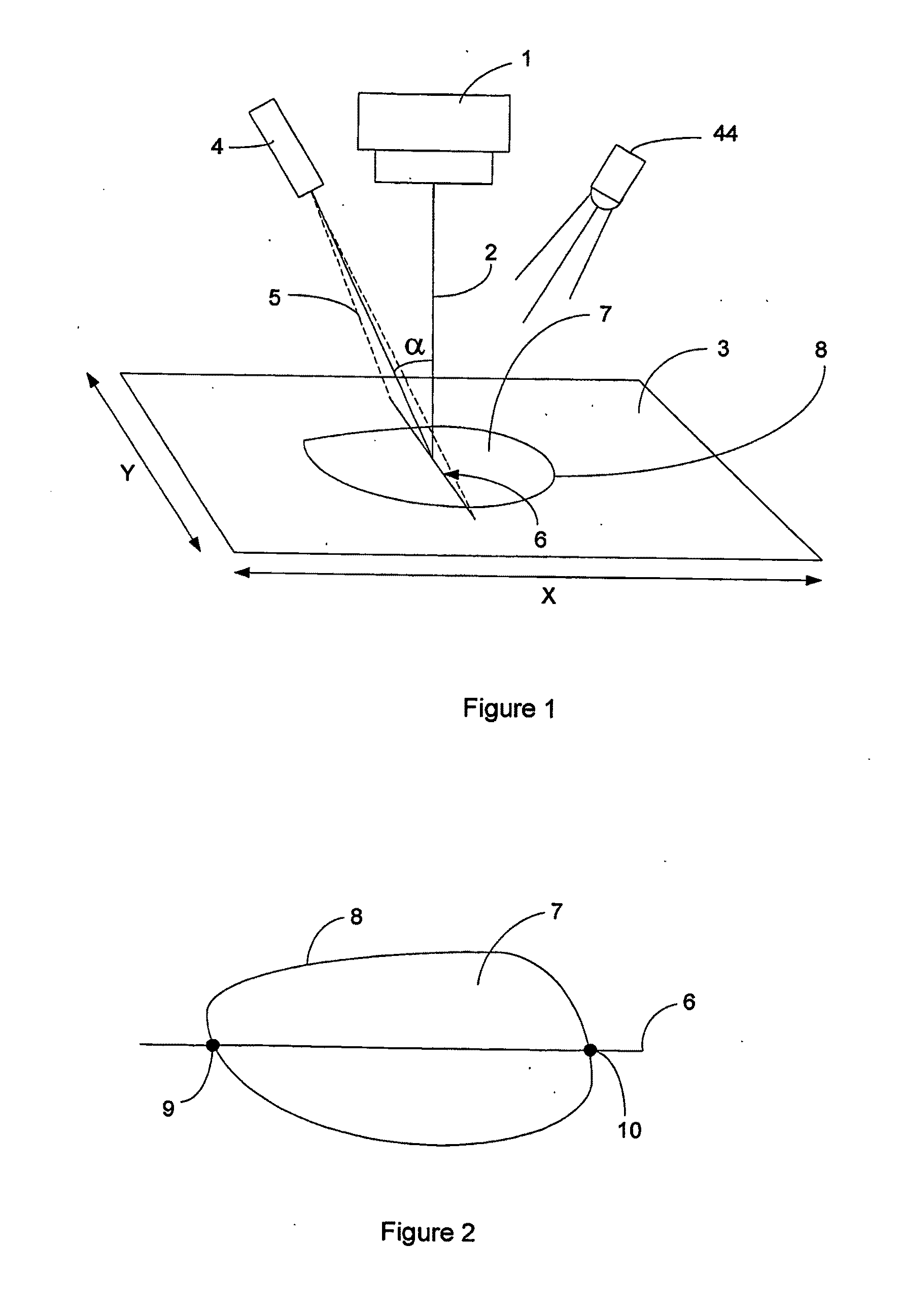

Method of Monitoring a Surface Feature and Apparatus Therefor

ActiveUS20090213213A1Minimise processing requirementSimple and inexpensiveUltrasonic/sonic/infrasonic diagnosticsImage enhancementStructured lightComputer science

Dimensions of a surface feature are determined by capturing an image of the surface feature and determining a scale associated with the image. Structured light may be projected onto the surface, such that the position of structured light in the captured image allows determination of scale. A non-planar surface may be unwrapped. The surface may alternatively be projected into a plane to correct for the scene being tilted with respect to the camera axis. A border of the surface feature may be input manually by a user. An apparatus and system for implementing the method are also disclosed.

Owner:ARANZ HEALTHCARE

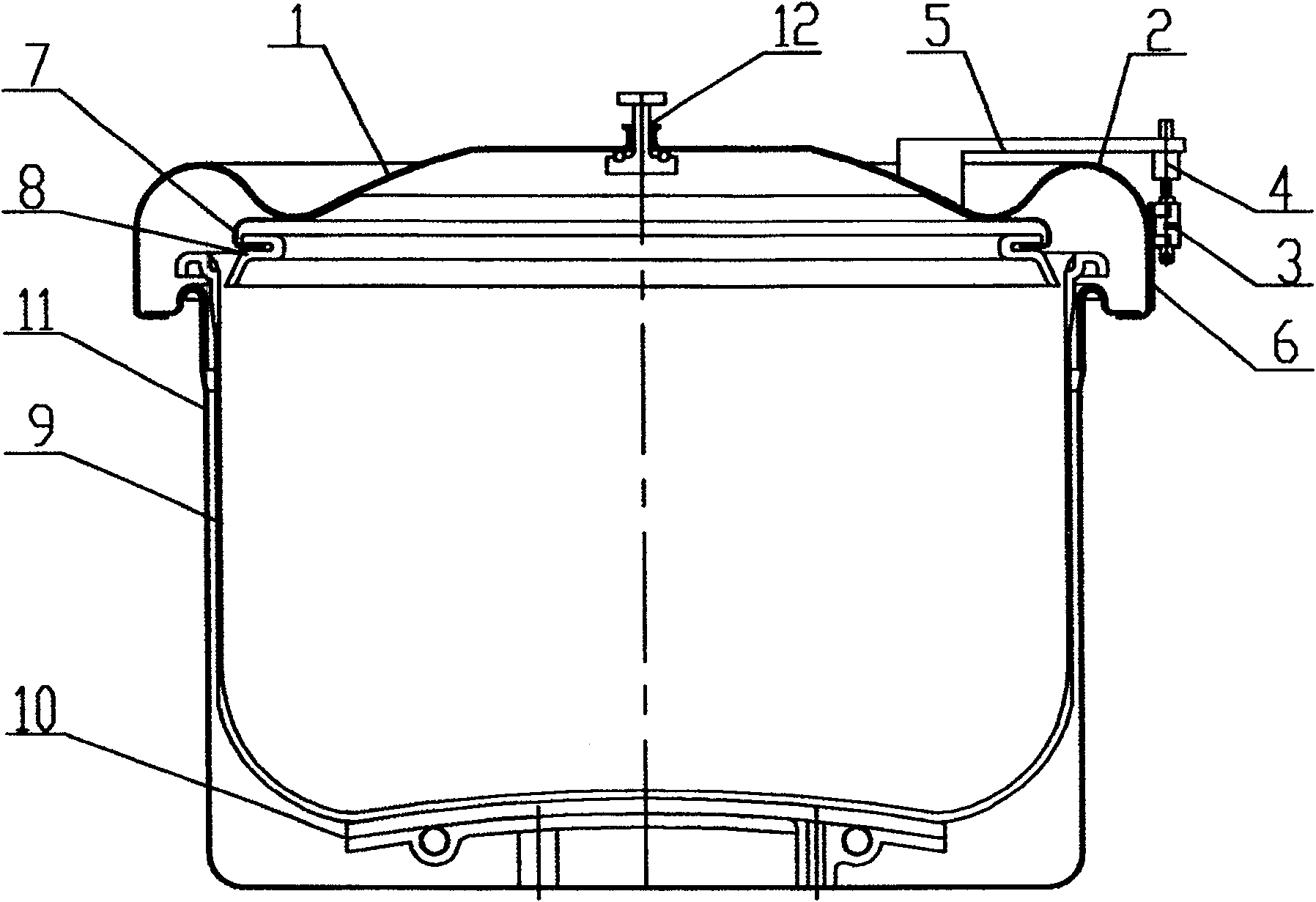

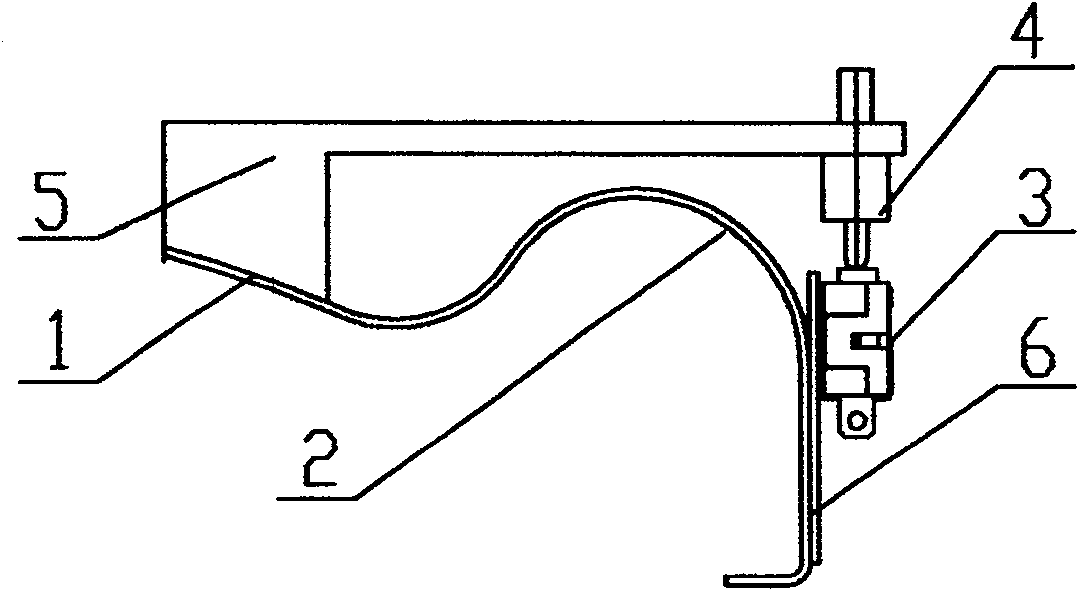

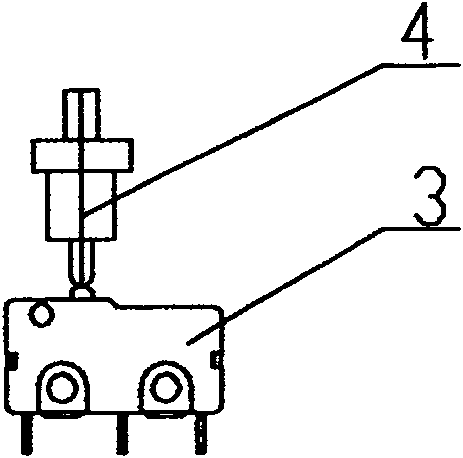

Moving-cover type electric pressure cooker

The invention relates to a movable cover electric pressure cooker, which belongs to kitchen electric appliances, and is a patented technology of electric rice cooker pressurization that controls and limits the pressure inside the cooker through an elastic cooker cover. It includes a pot cover, an elastic element, a switch, a sealing ring, an inner pot, an electric heater, and an outer pot; the edge of the inner pot sits on the edge of the outer pot; The outer pot is movable and rigidly connected; the elastic element controls the on-off of the switch by the elastic displacement generated under the pressure in the pot, and the elastic displacement is transmitted to the corresponding device through the transmission part arranged at the displacement or static position of the elastic element. on the switch. The invention can solve the problems in the integrated design and mechanical connection of the elastic element and other parts in the prior art, improve the utilization rate of materials, simplify the production process and reduce the production cost.

Owner:王永光

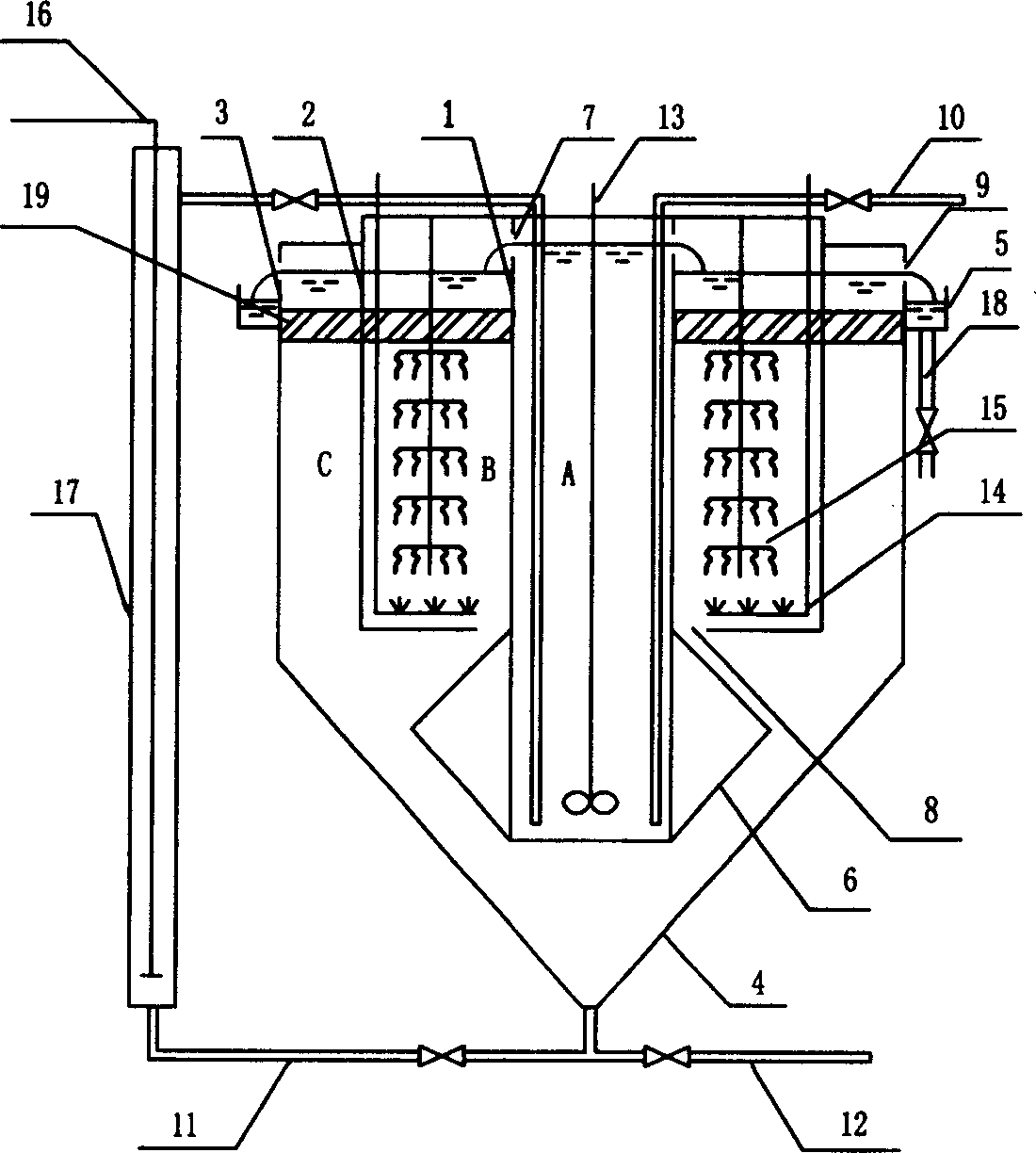

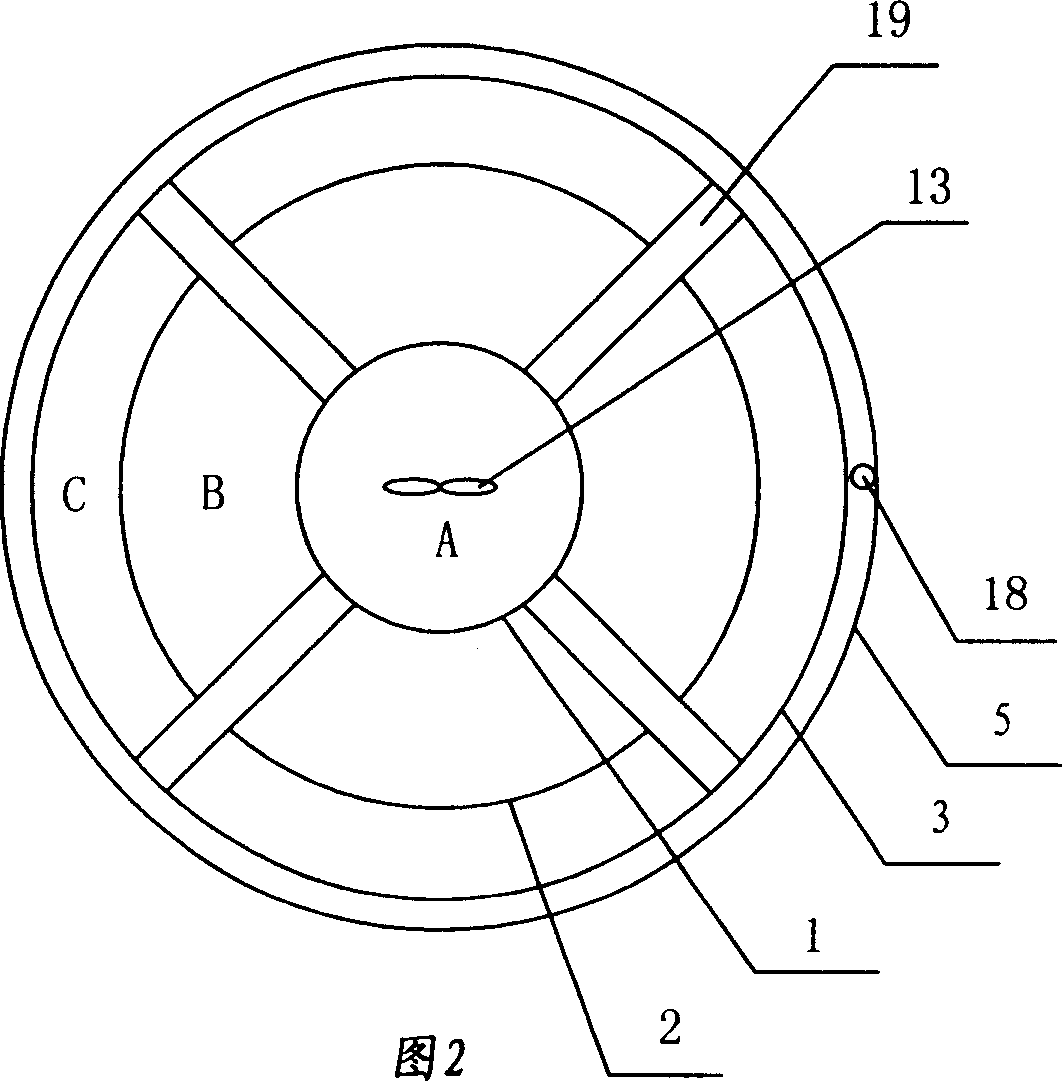

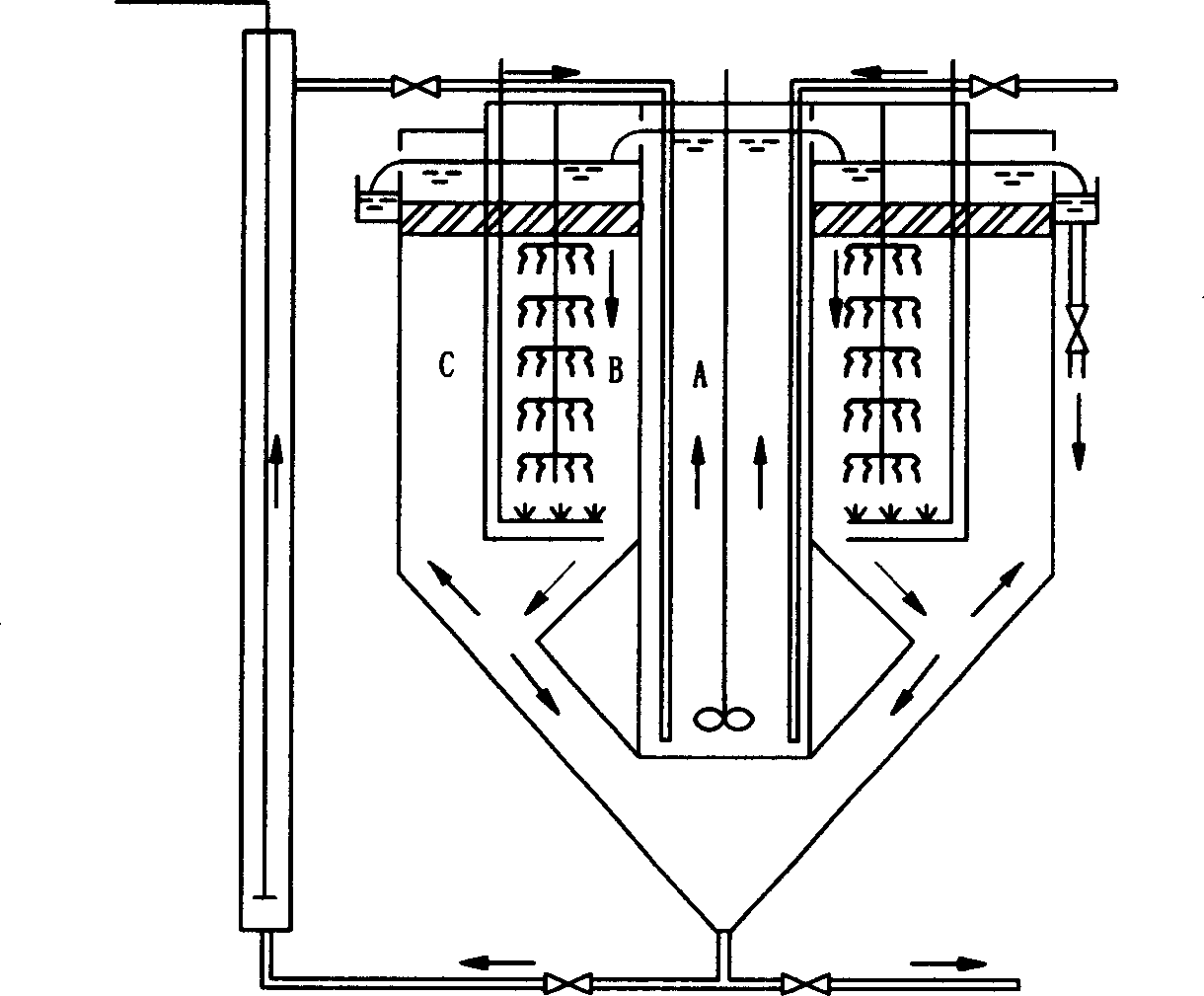

Active sludge-biomembrane compounding integral sewage treating method and apparatus

InactiveCN1887739AIncrease sludge concentrationAvoid churnTreatment with aerobic and anaerobic processesActivated sludgeEngineering

The active sludge-biomembrane compounding integral sewage treating method includes the first leading the sewage to be treated to the anoxic area through stirring for mixing sewage to be treated and active sludge, the subsequent leading the sewage to aerobic area with stuffing for aeration treatment with combined active sludge and biomembrane, and final leading the sewage to the precipitation area for natural deposition to separate sludge and water, leading out purified water, reflowing the mixed sludge liquid to the anoxic area and draining the residual sludge. The present invention also relates to the corresponding sewage treating apparatus. The present invention has the advantages of high treating capacity, resistance to impact load, simple operation, etc. and is especially suitable for use in medium and small towns.

Owner:CHONGQING UNIV

Radar system and method of manufacturing same

ActiveUS8976061B2Increase speedThe signal is accurate and reliableAntenna adaptation in movable bodiesRadiating elements structural formsRadar systemsEngineering

A radar system (100) is described including a transmitting assembly (10), a receiving assembly (20), a control unit (30) and a signal processing unit (40). The transmitting assembly (10) receives an input signal (31) and transmits an incident radar signal (2). The transmitting assembly (10) includes a Rotman lens (12) having a lens cavity (74), a plurality of beam ports (60), a plurality of array ports (62) and a patch antenna assembly (14). The lens cavity (74) has a lens gap (h) between 10 microns to 120 microns, and preferably 40 microns to 60 microns. The patch antenna assembly (14) includes a plurality of antenna arrays (130) operable to receive a plurality of time-delayed, in-phase signals from the Rotman lens (12) and to transmit the incident radar signal (2) towards a target (4). The receiving assembly (20) receives a reflected radar signal (6) and produces an output signal. The signal processing unit (40) compares the input signal (31) to the output signal and implements an algorithm determining the range, velocity and position of the target (4).

Owner:UNIVERSITY OF WINDSOR

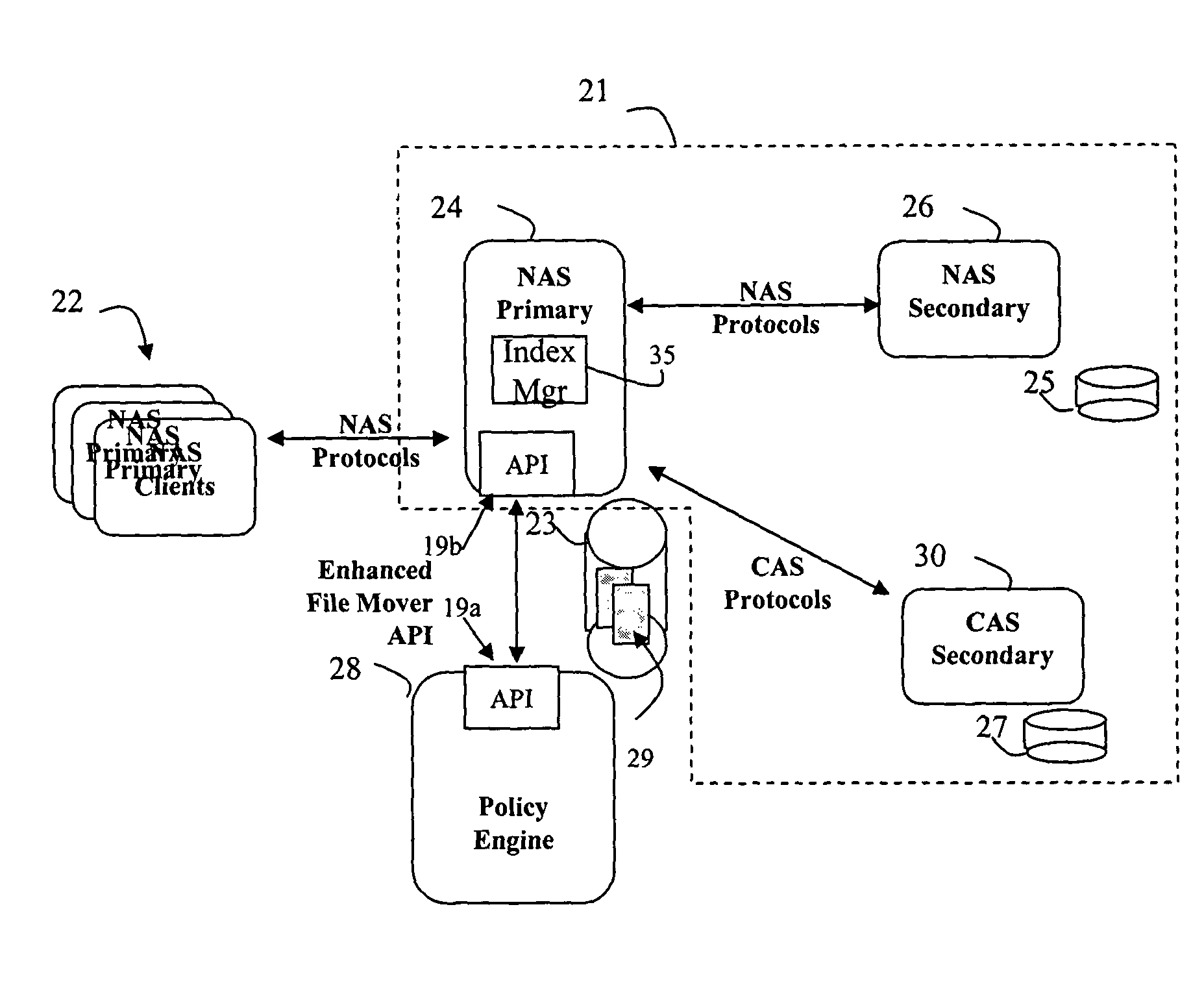

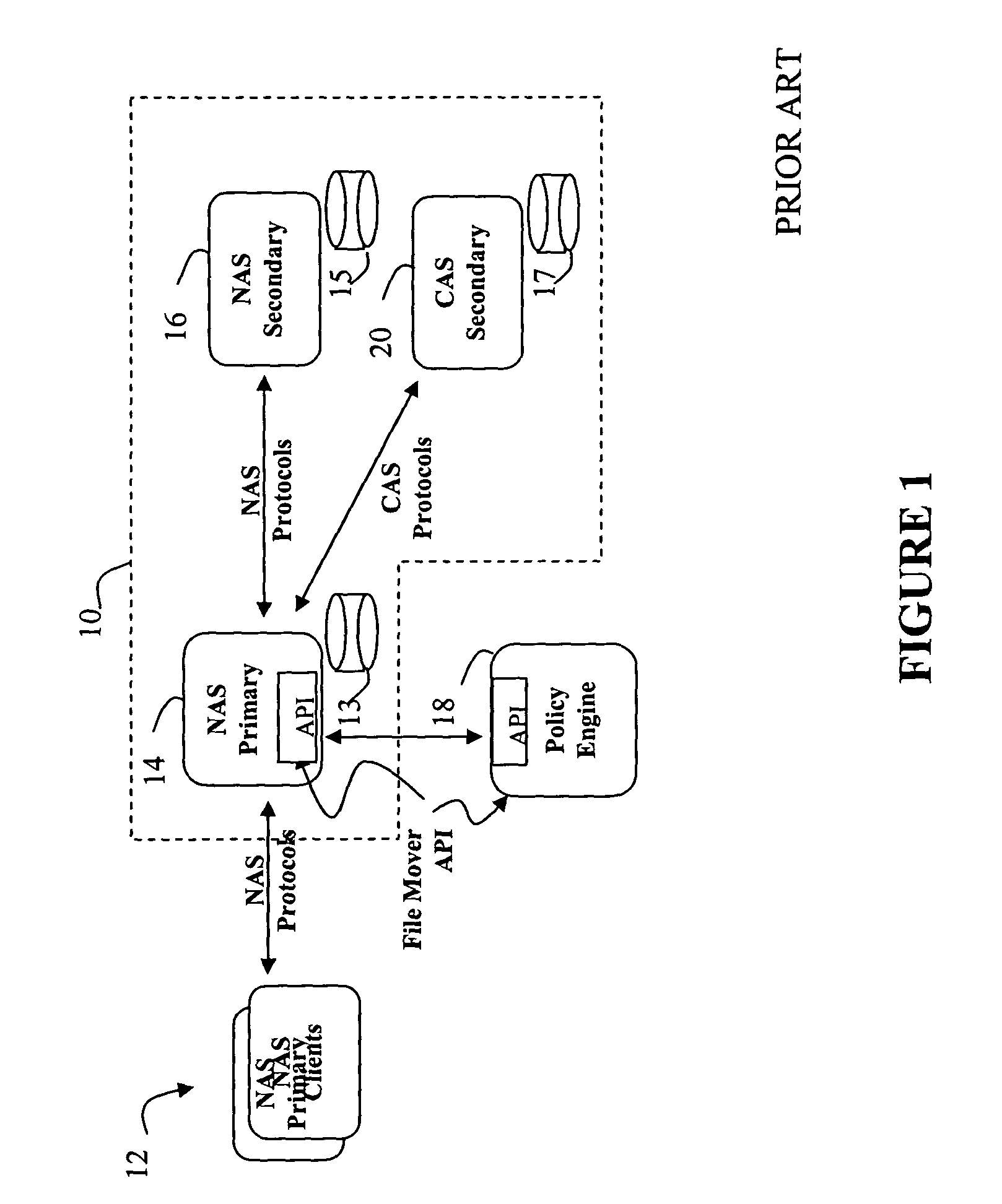

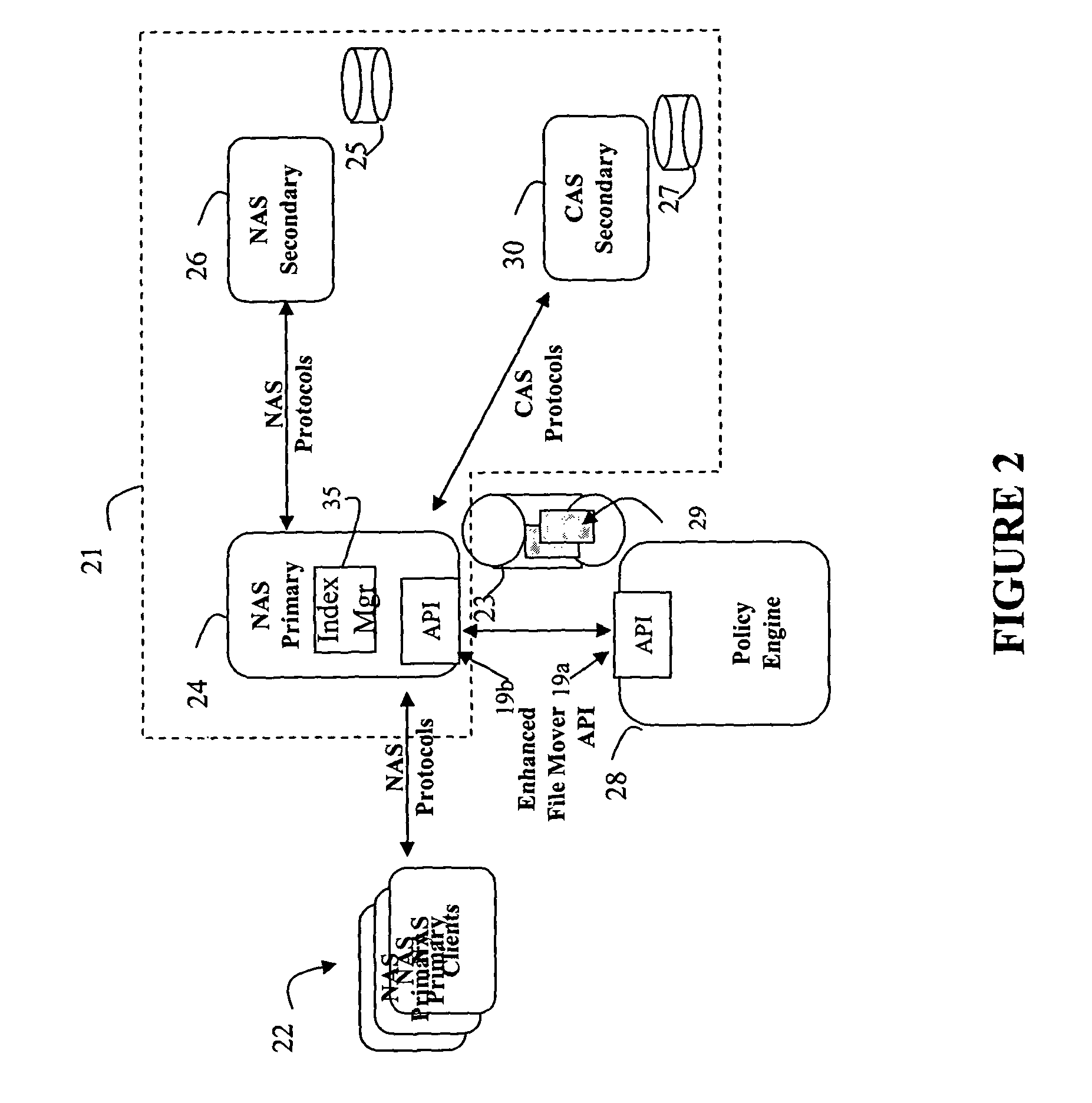

File system query and method of use

ActiveUS7805416B1Accurate identificationReduce processing requirementsDigital data processing detailsFile access structuresFile systemFile server

An improved policy enforcement architecture includes several components that improve the performance of policy enforcement in a hierarchical storage environment. A File System Query instruction permits a richer set of queries to be expressed by a policy engine, thereby permitting more complex policies to be implemented with ease. The File System result is generated at the file server, and only files of interest are forwarded to the policy engine. The file system query advantageously may be applied against a pre-generated index having one more characterizing attributes to further reduce the processing required to retrieve policy data. An Index Build instruction, added to a programming interface, allows a policy engine generate the characterizing indices in advance of use. Index maintenance techniques maintain consistency between the index and the file system to ensure that the policy can be enforced using accurate file information.

Owner:EMC IP HLDG CO LLC

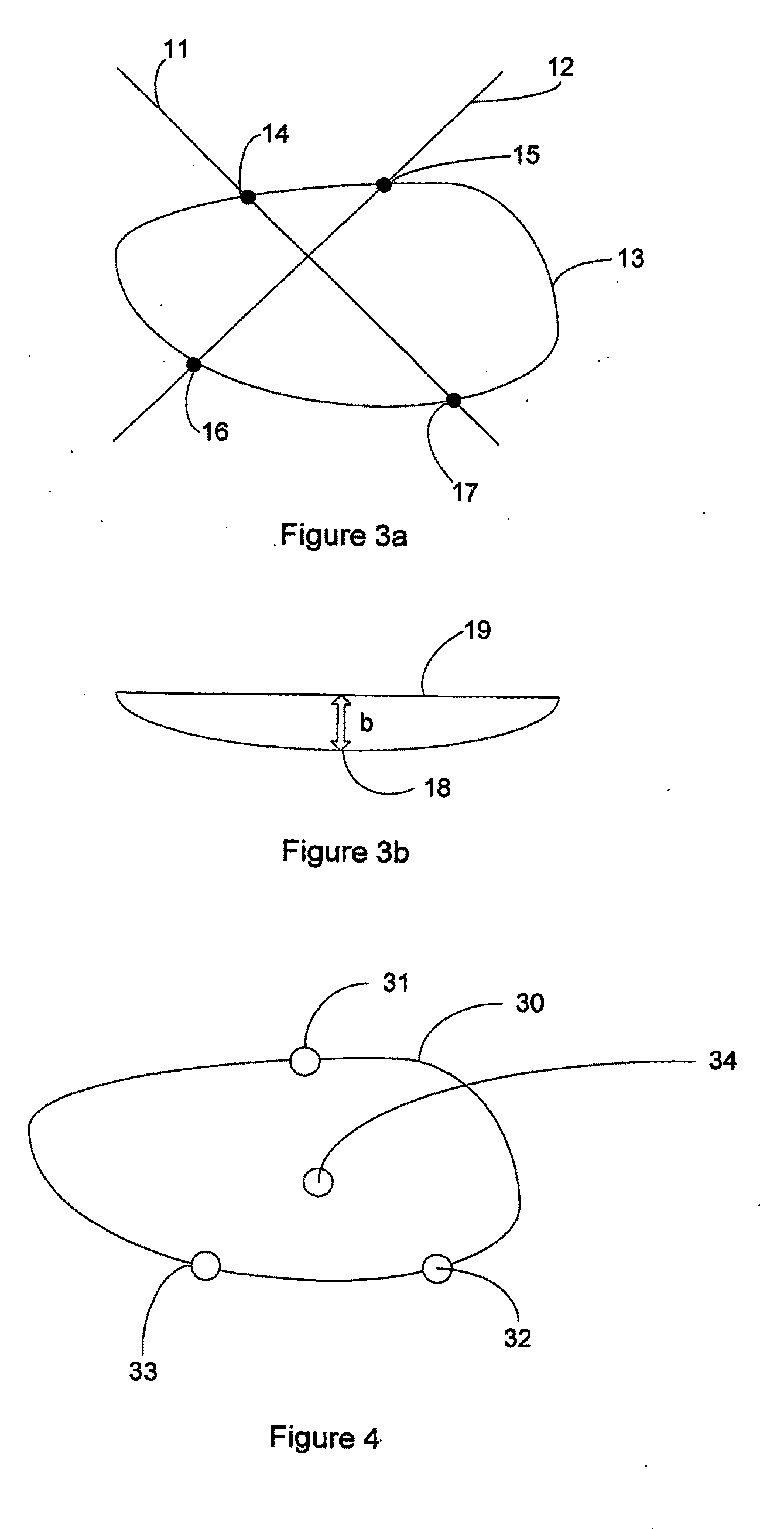

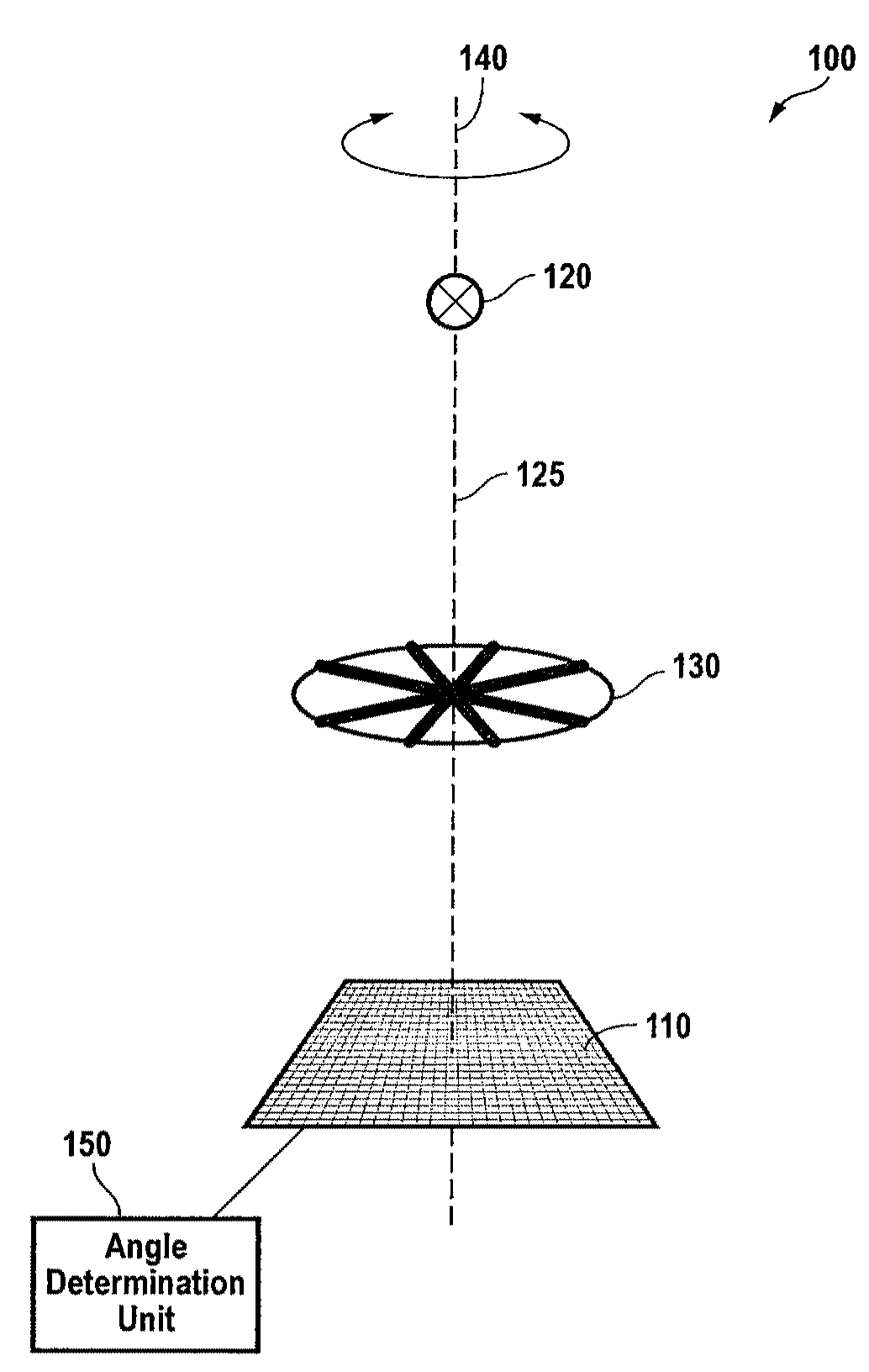

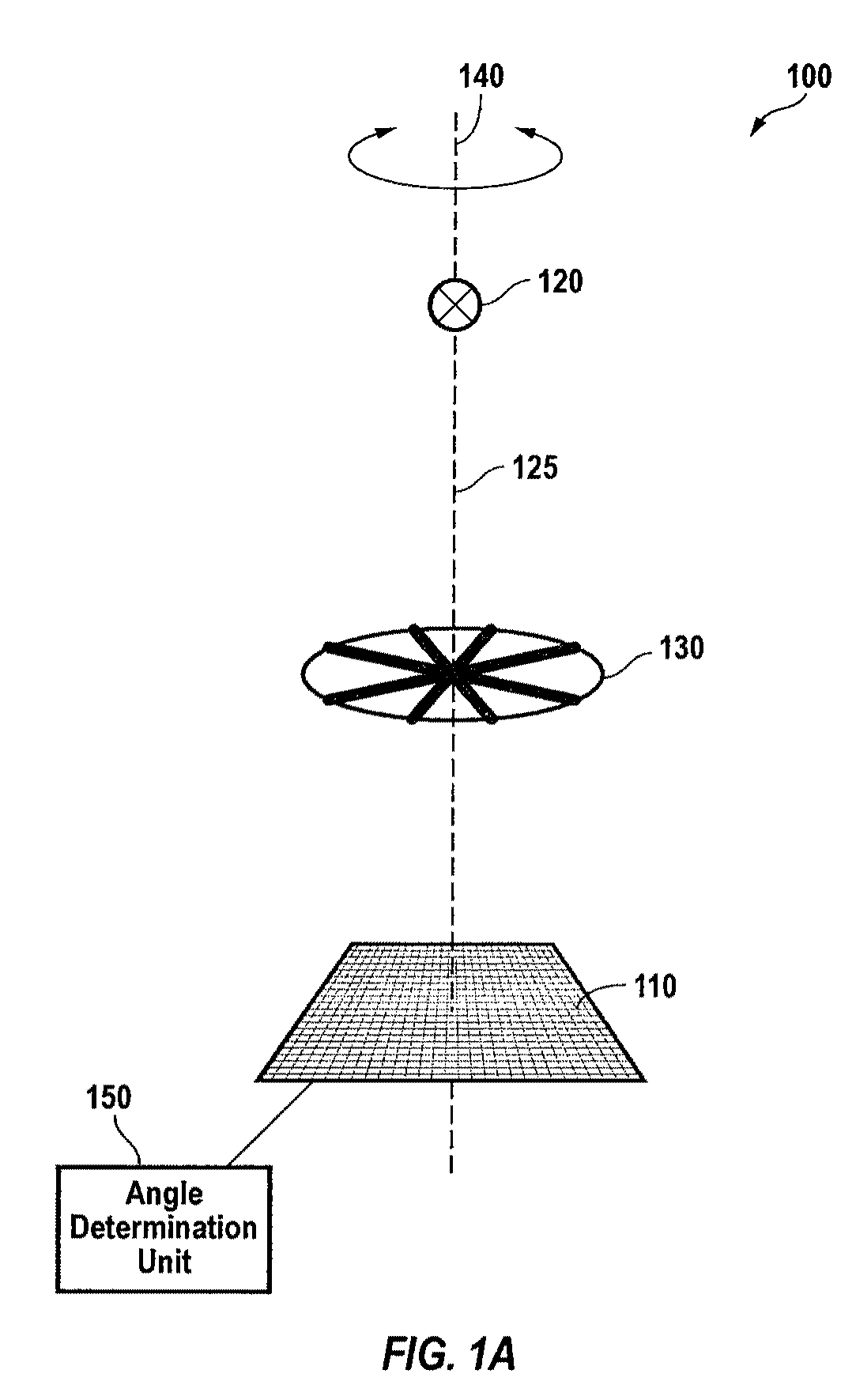

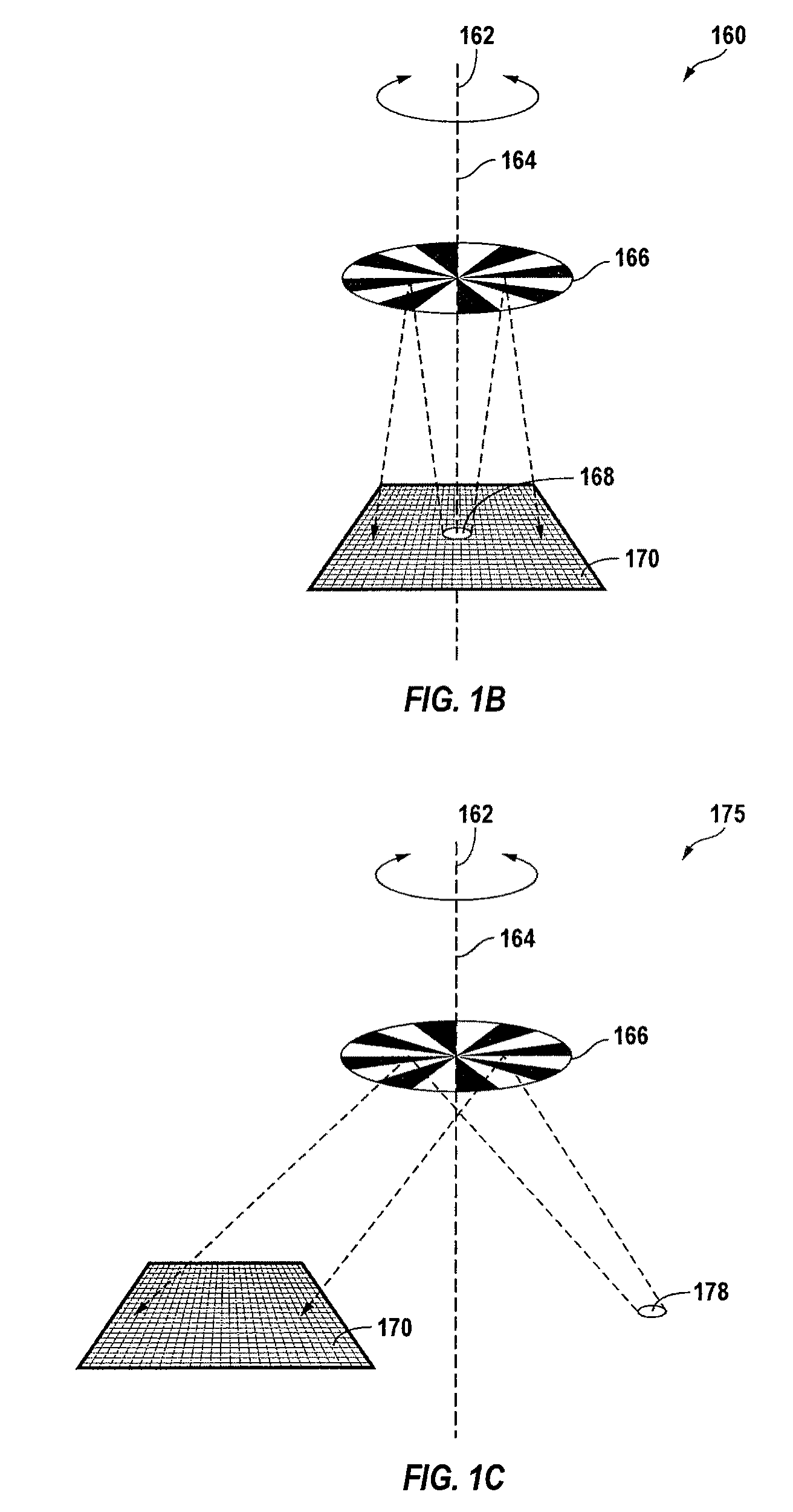

Method and system for angle measurement

ActiveUS7697127B2Improve accuracyHigh measurement accuracyAngle measurementScattering properties measurementsMeasurement deviceLight intensity

An angle measurement device includes a light source configured to emit light along an optical path and a patterned member positioned along the optical path and configured to rotate about an axis of rotation. The patterned member includes a periodic optical variation. Light passing through the patterned member provides a spatially modulated optical waveform. The angle measurement device also includes an imaging device positioned along the optical path and including a plurality of photosensitive elements disposed in an array configuration. The imaging device is configured to receive the spatially modulated optical waveform and provide a signal associated with light intensity at each of the plurality of photosensitive elements. The angle measurement device further includes an angle determination unit coupled to the imaging device and configured to compute a rotation angle of the patterned member based on a reference waveform and the provided signal.

Owner:TRIMBLE JENA

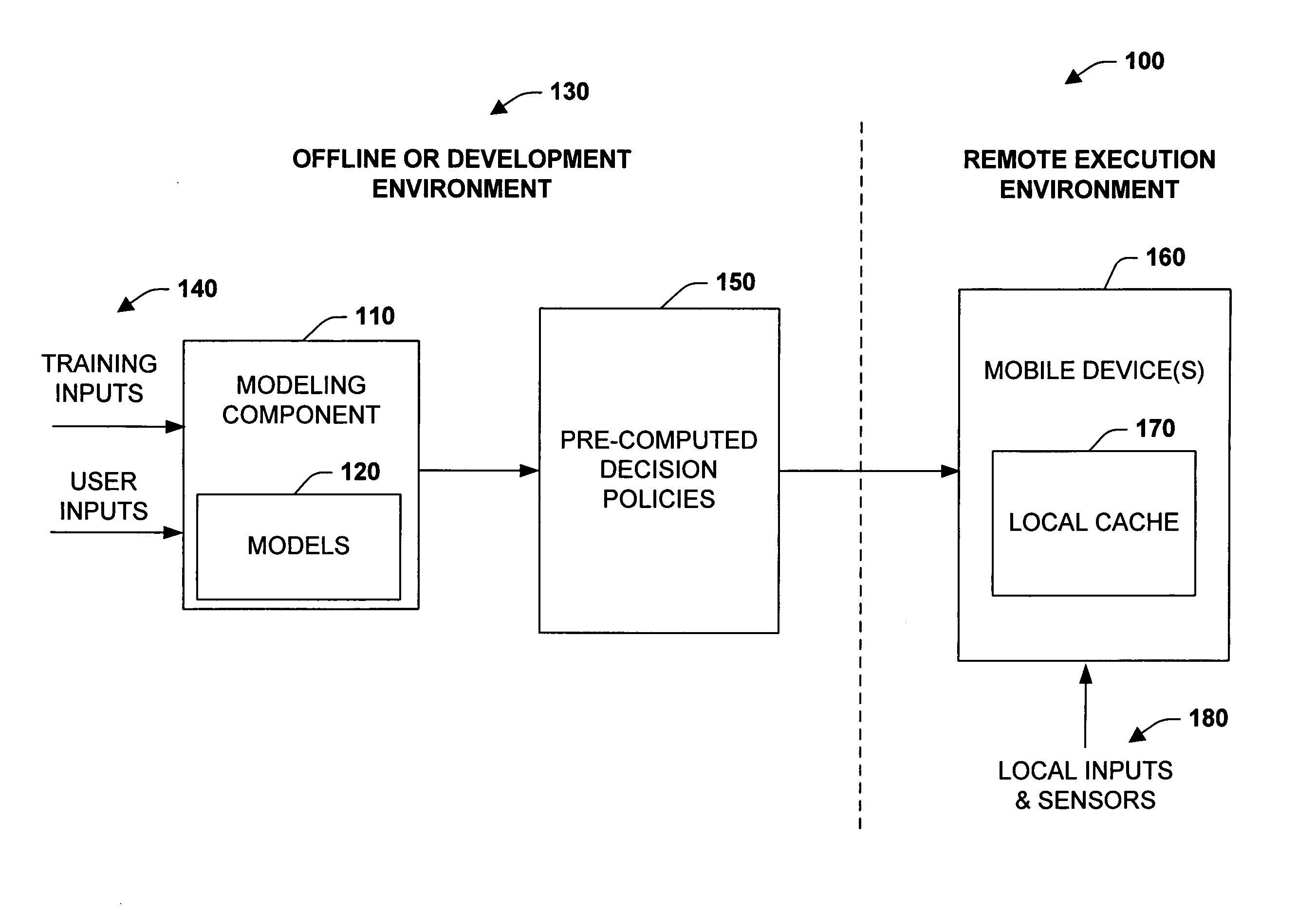

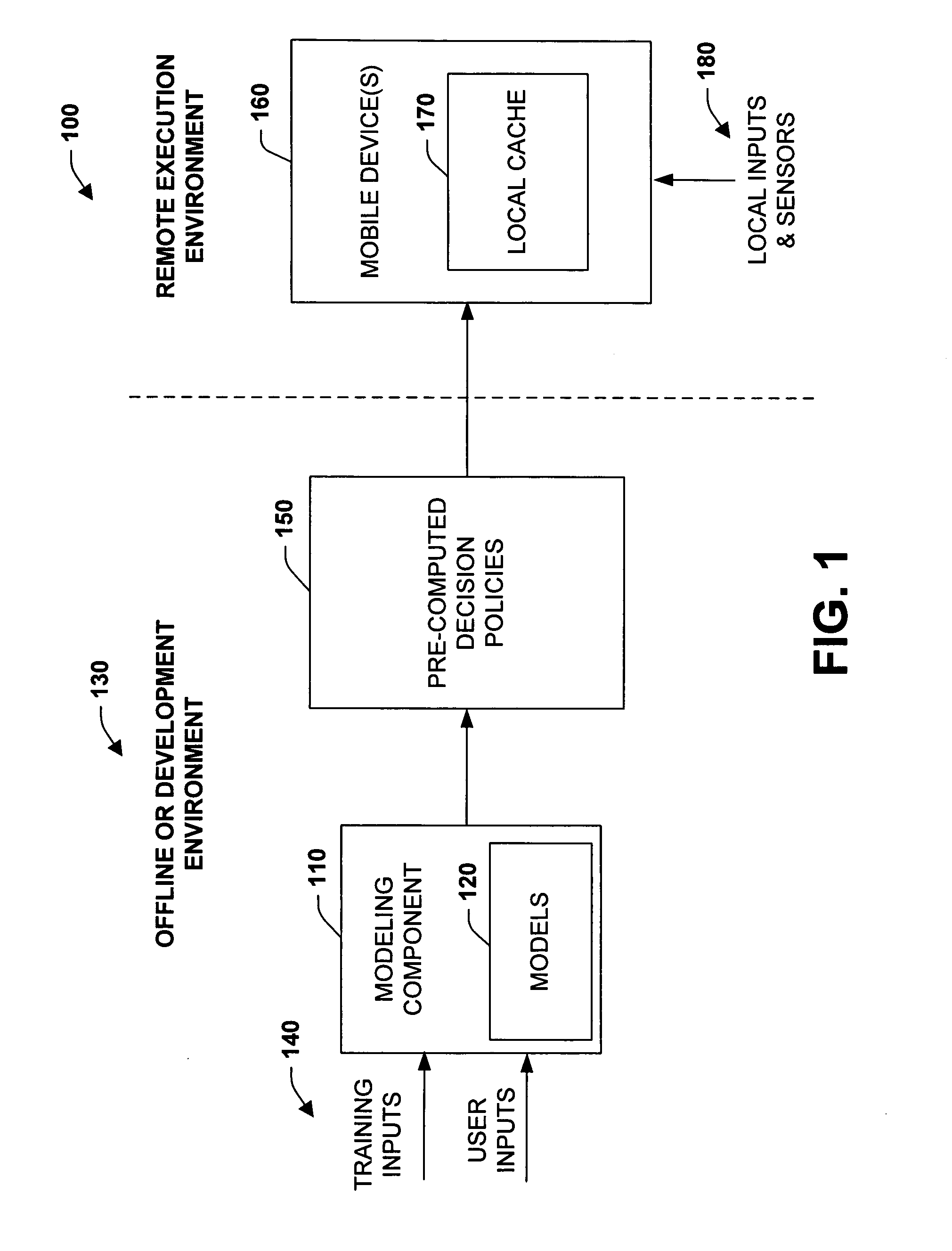

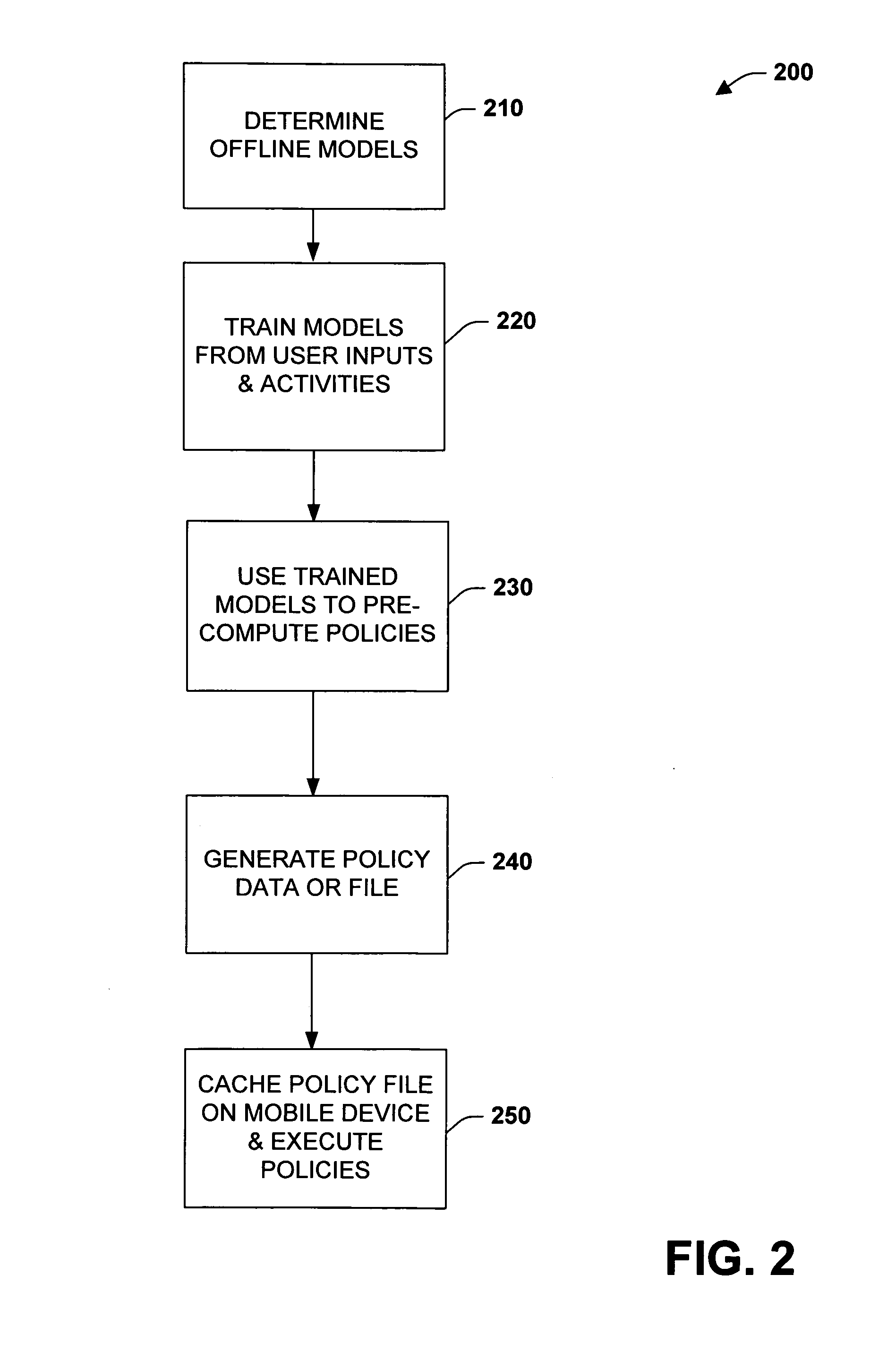

Precomputation of context-sensitive policies for automated inquiry and action under uncertainty

InactiveUS20070022075A1Enhance decision-making capability of deviceImprove device performanceProbabilistic networksFuzzy logic based systemsPrecomputationContext sensitivity

Learning, inference, and decision making with probabilistic user models, including considerations of preferences about outcomes under uncertainty, may be infeasible on portable devices. The subject invention provides systems and methods for pre-computing and storing policies based on offline preference assessment, learning, and reasoning about ideal actions and interactions, given a consideration of uncertainties, preferences, and / or future states of the world. Actions include ideal real-time inquiries about a state, using pre-computed value-of-information analyses. In one specific example, such pre-computation can be applied to automatically generate and distribute call-handling policies for cell phones. The methods can employ learning of Bayesian network user models for predicting whether users will attend meetings on their calendar and the cost of being interrupted by incoming calls should a meeting be attended.

Owner:MICROSOFT TECH LICENSING LLC

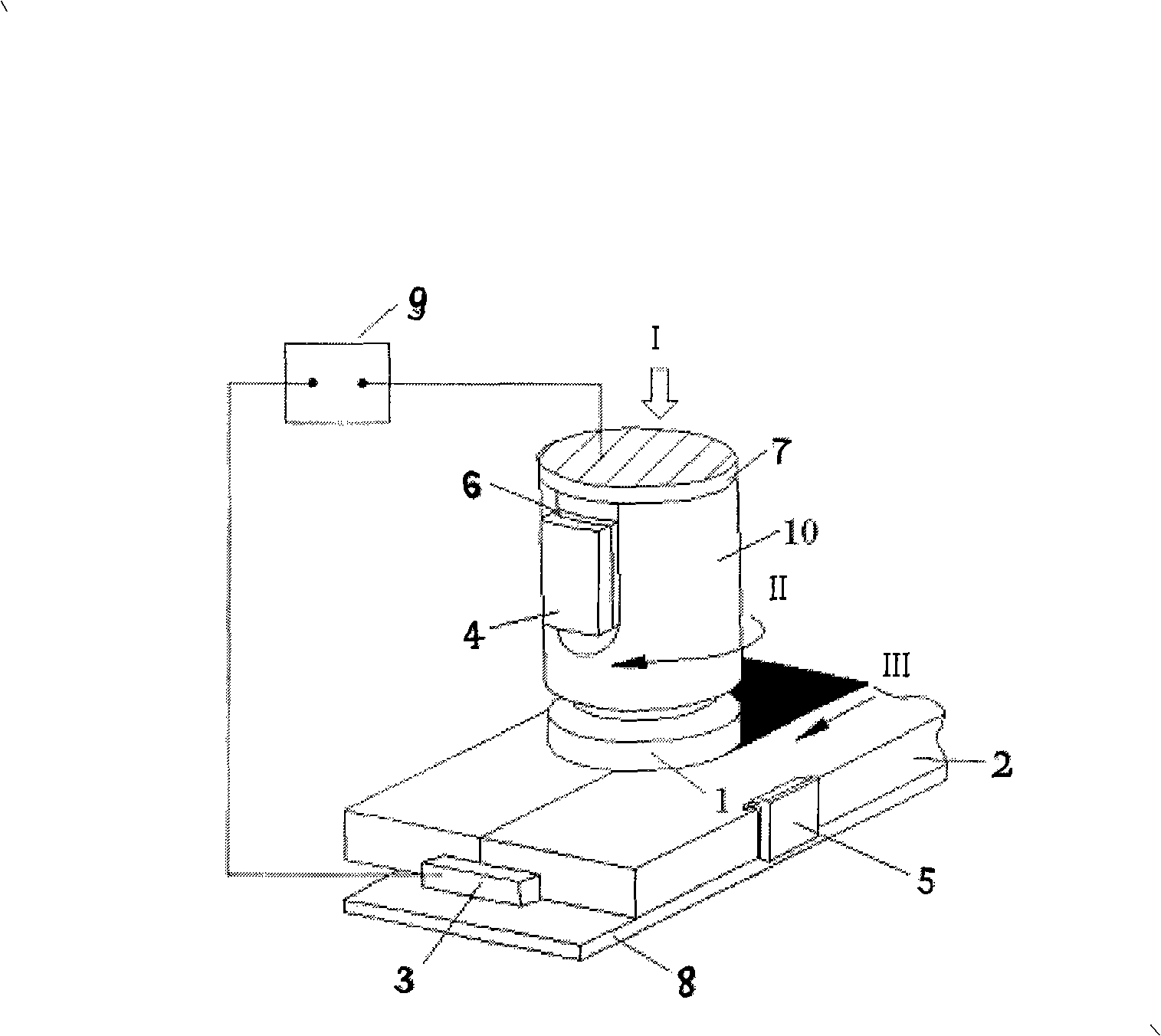

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

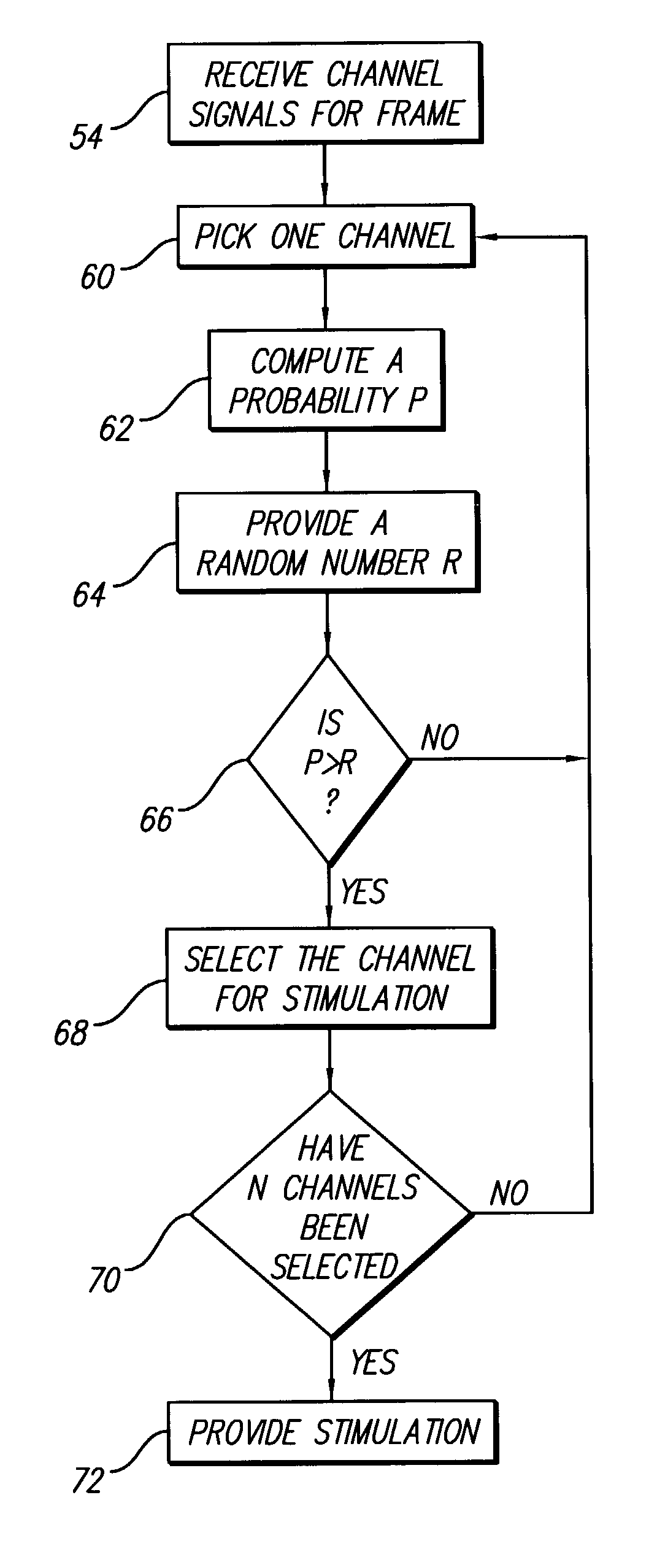

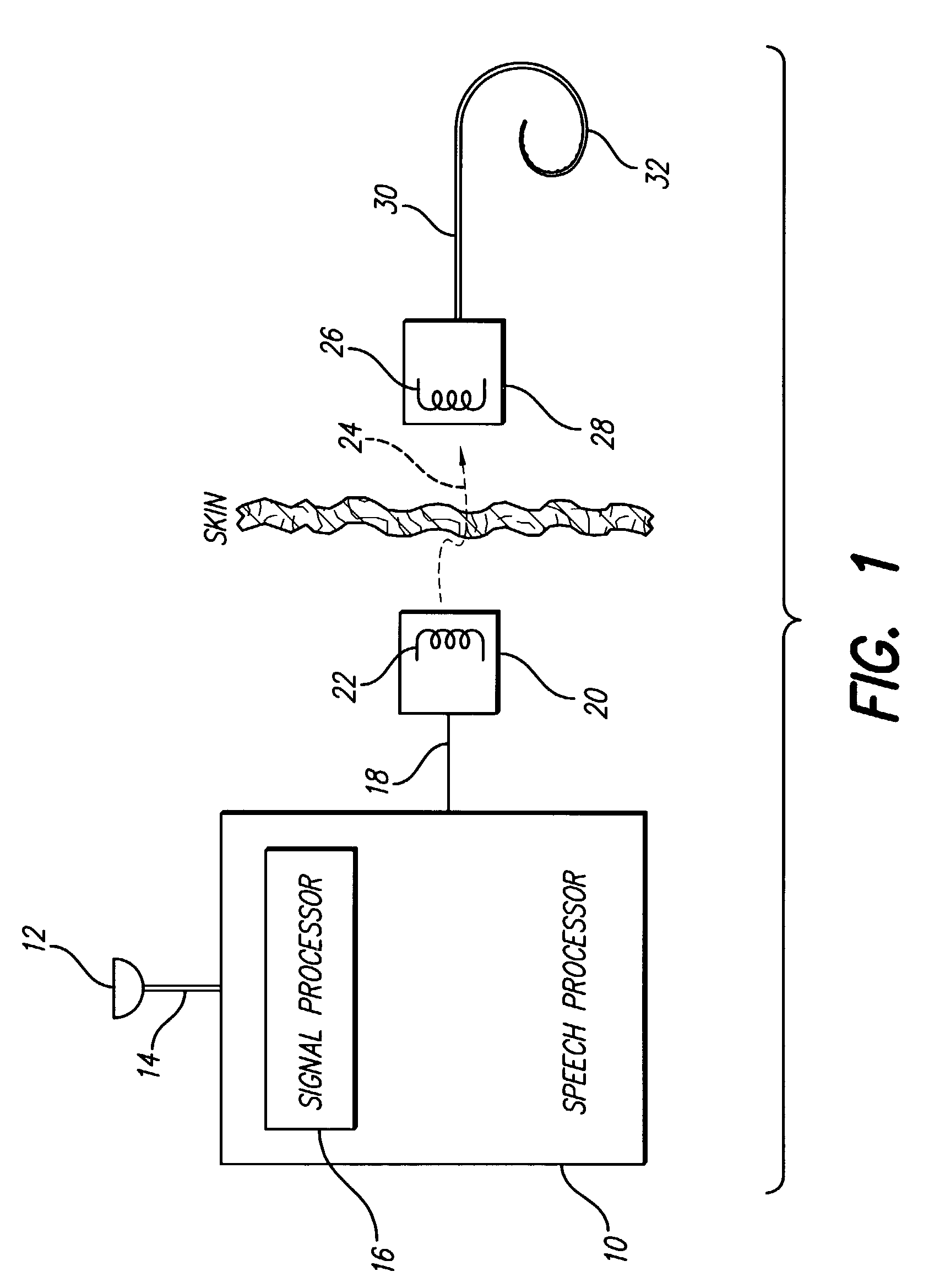

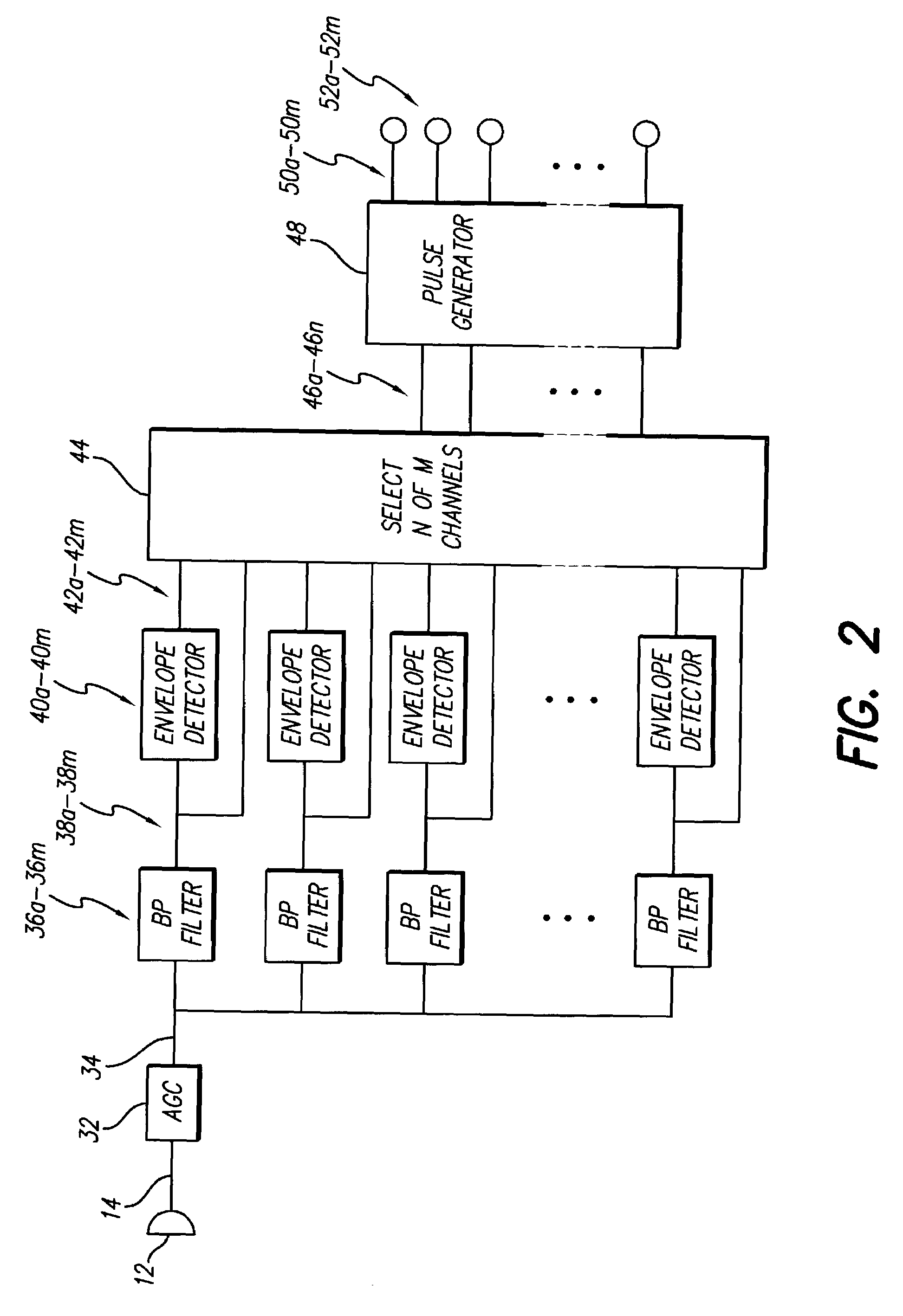

Pulse skipping strategy

InactiveUS7130694B1Reduce processing requirementsSave processor resourcesElectrotherapyBandpass filteringAcoustic energy

Improved skipping strategies for cochlear or other multi-channel neural stimulation implants selects N out of M channels for stimulation during a given stimulation frame. A microphone transduces acoustic energy into an electrical signal. The electrical signal is processed by a family of bandpass filters, or the equivalent, to produce a number of frequency channels. In a first embodiment, a probability based channel selection strategy computes a probably for each of the M channels based on the strength of each channel. N channels are probabilistically selected for stimulation based on their individual probability. The result is a randomized “stochastic” stimulus presentation to the patient. Such randomized stimulation reduces under representation of weaker channels for steady state input conditions such as vowels. In second, third and fourth embodiments, a variable threshold is adjusted to obtain the selection of N channels per frame.

Owner:ADVNACED BIONICS LLC

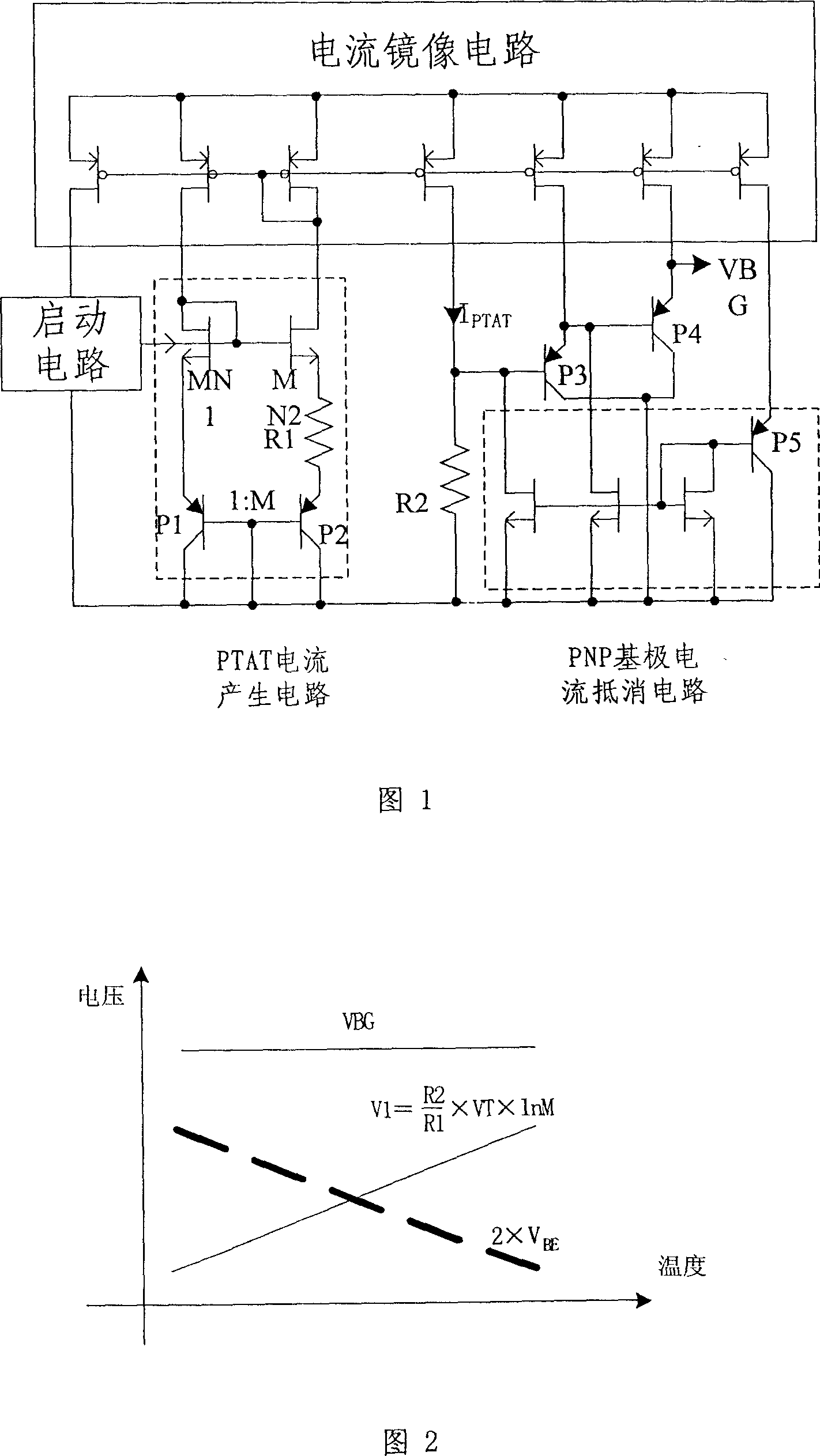

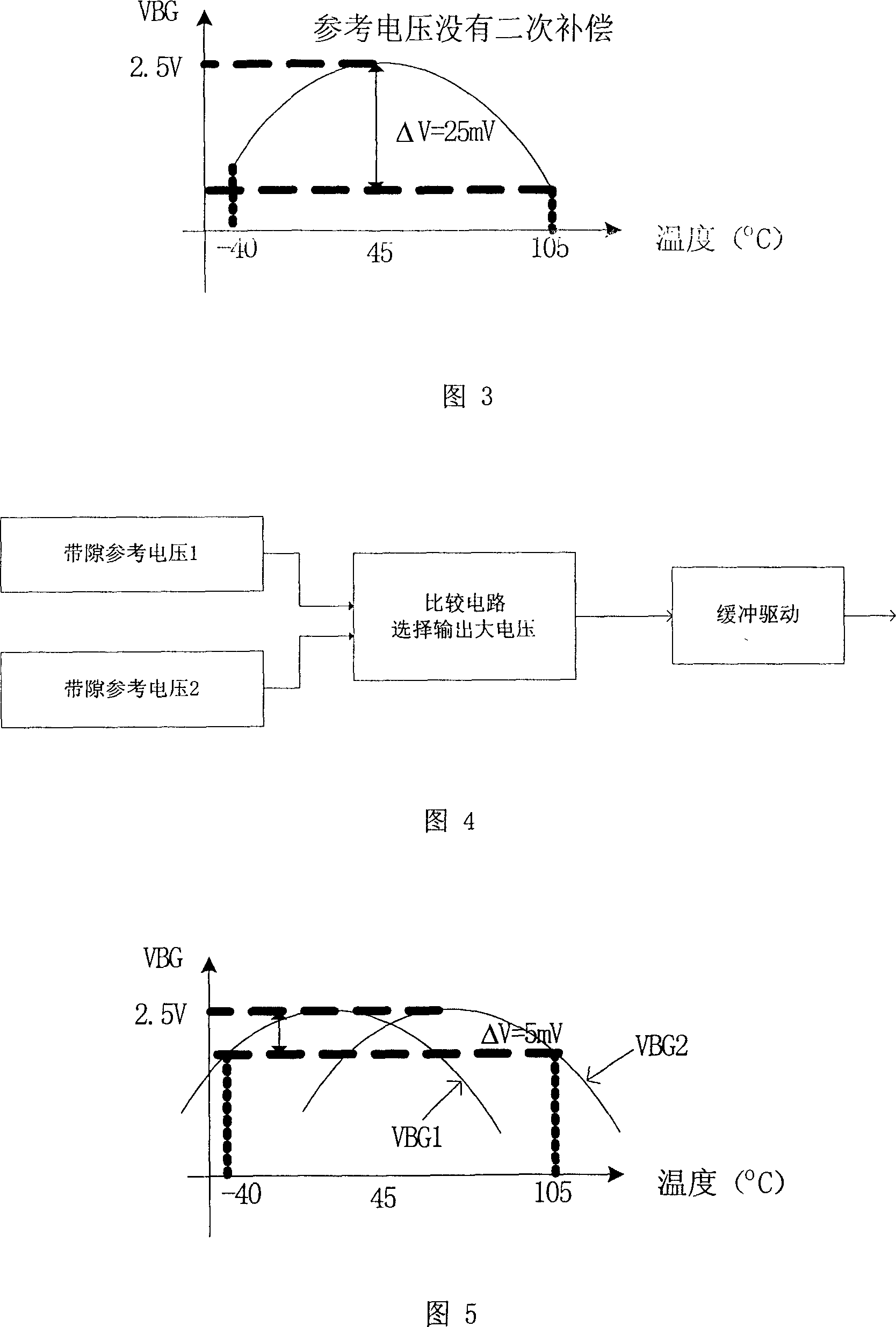

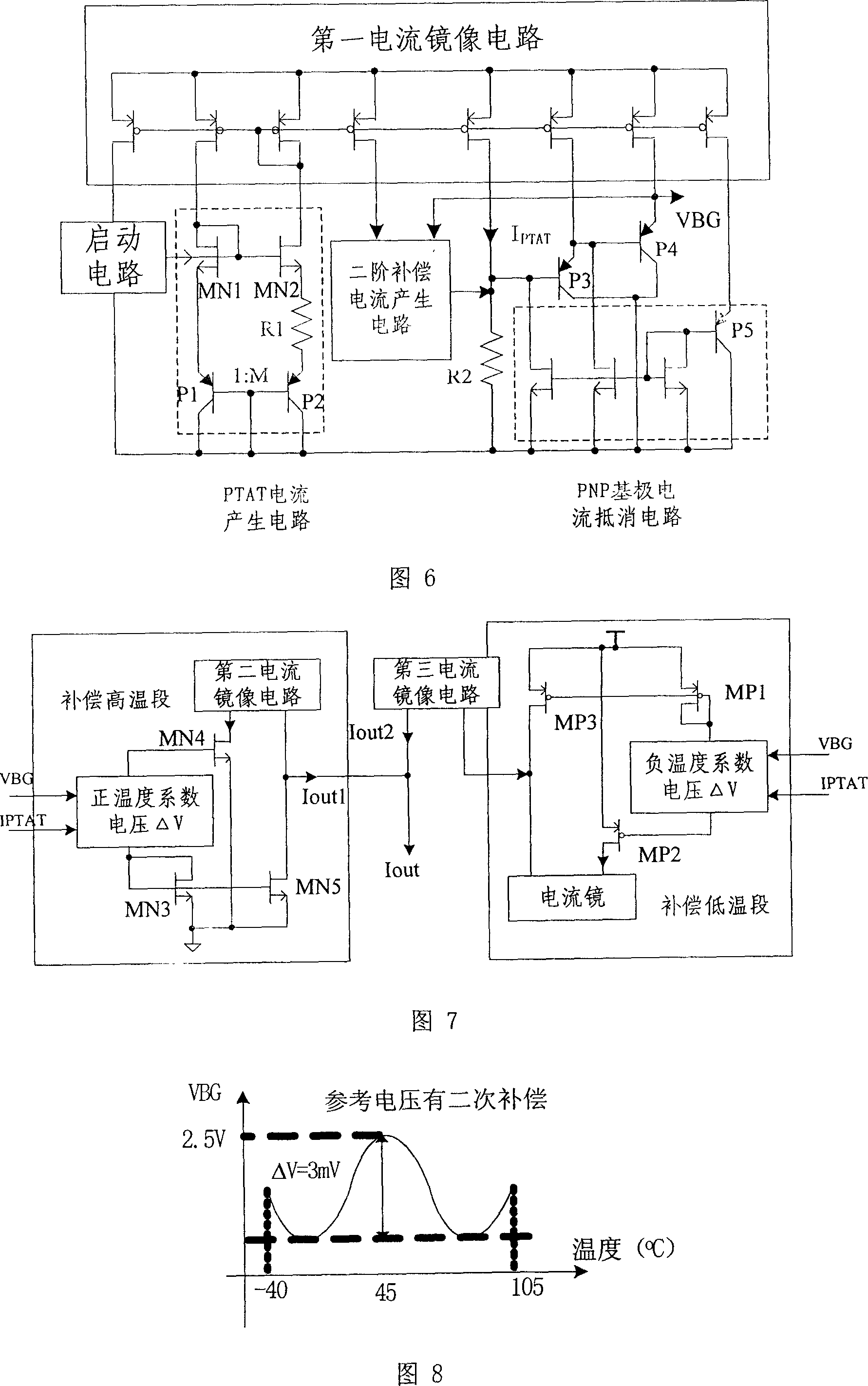

Reference voltage source for low temperature coefficient with gap

ActiveCN1987713AOvercoming the problem of high temperature coefficientSolving Temperature Compensation IssuesElectric variable regulationCMOSVoltage drop

The band-gap reference voltage (RV) source with low temperature coefficient (TC) includes PTAT current generation circuit, start circuit of RV, combiner circuit of RV, neutralization circuit of base current, mirror circuit of first current. The band-gap RV source with low TC also includes generation circuit of second order temperature compensation current, which is connected to the mirror circuit of first current, and the combiner circuit of RV. Through square relation between drain-source current and grid-source voltage drop of MOS tube, inputting PTAT current and band-gap RV generates second order compensation current. The second order compensation current is output to the combiner circuit of RV to generate second order compensation voltage to compensate second order TC of RV so as to produce RV with very low TC. The invention overcomes issue of TC on the high side in traditional band-gap RV. Using standard CMOS technique realizes band-gap RV with very low TC.

Owner:CHIPSEA TECH SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com