Patents

Literature

4114 results about "Temperature coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A temperature coefficient describes the relative change of a physical property that is associated with a given change in temperature. For a property R that changes when the temperature changes by dT, the temperature coefficient α is defined by the following equation: dR/R=α dT Here α has the dimension of an inverse temperature and can be expressed e.g. in 1/K or K⁻¹. If the temperature coefficient itself does not vary too much with temperature and αΔT≪1, a linear approximation will be useful in estimating the value R of a property at a temperature T, given its value R₀ at a reference temperature T₀: R(T)=R(T₀)(1+αΔT), where ΔT is the difference between T and T₀.

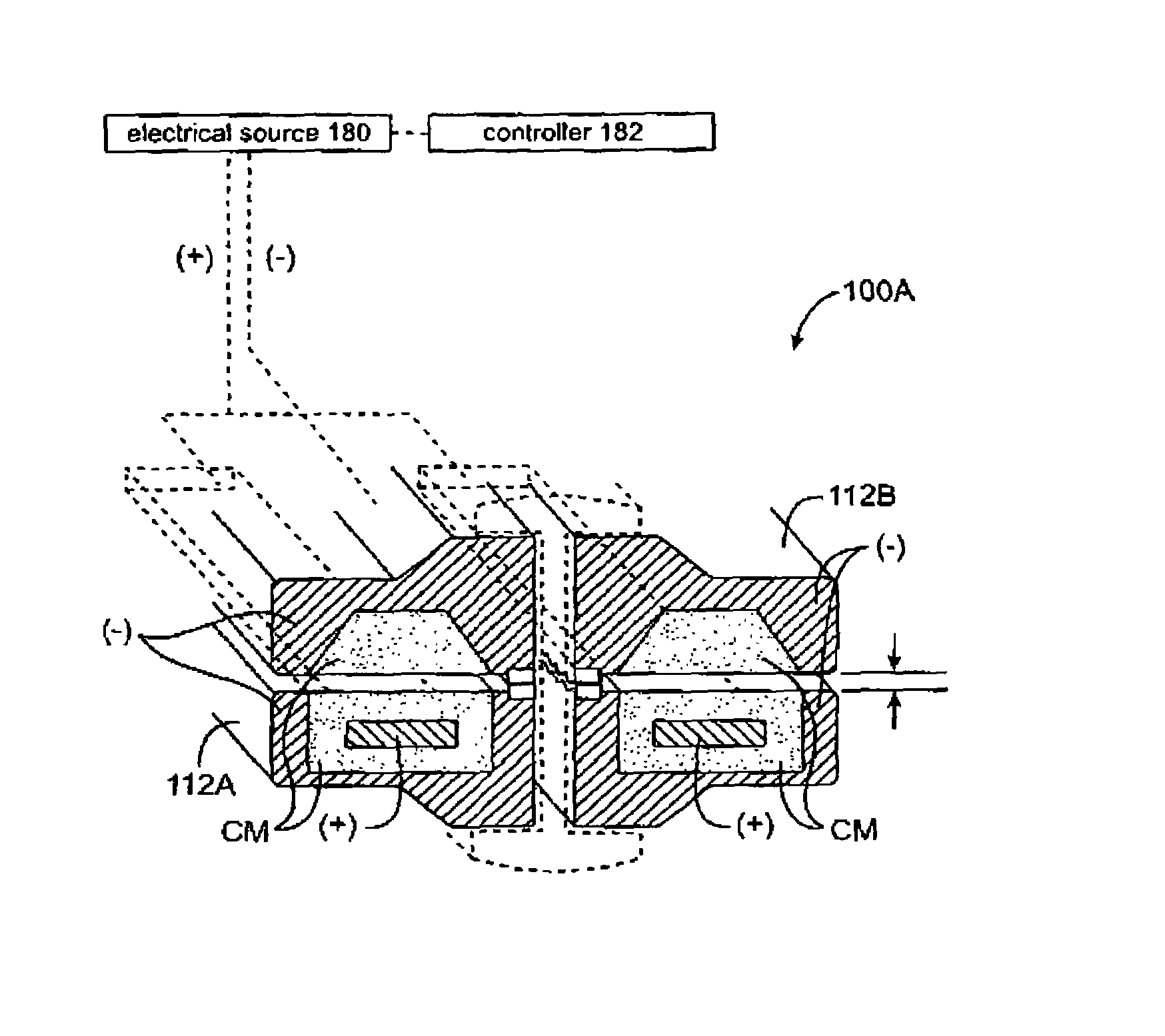

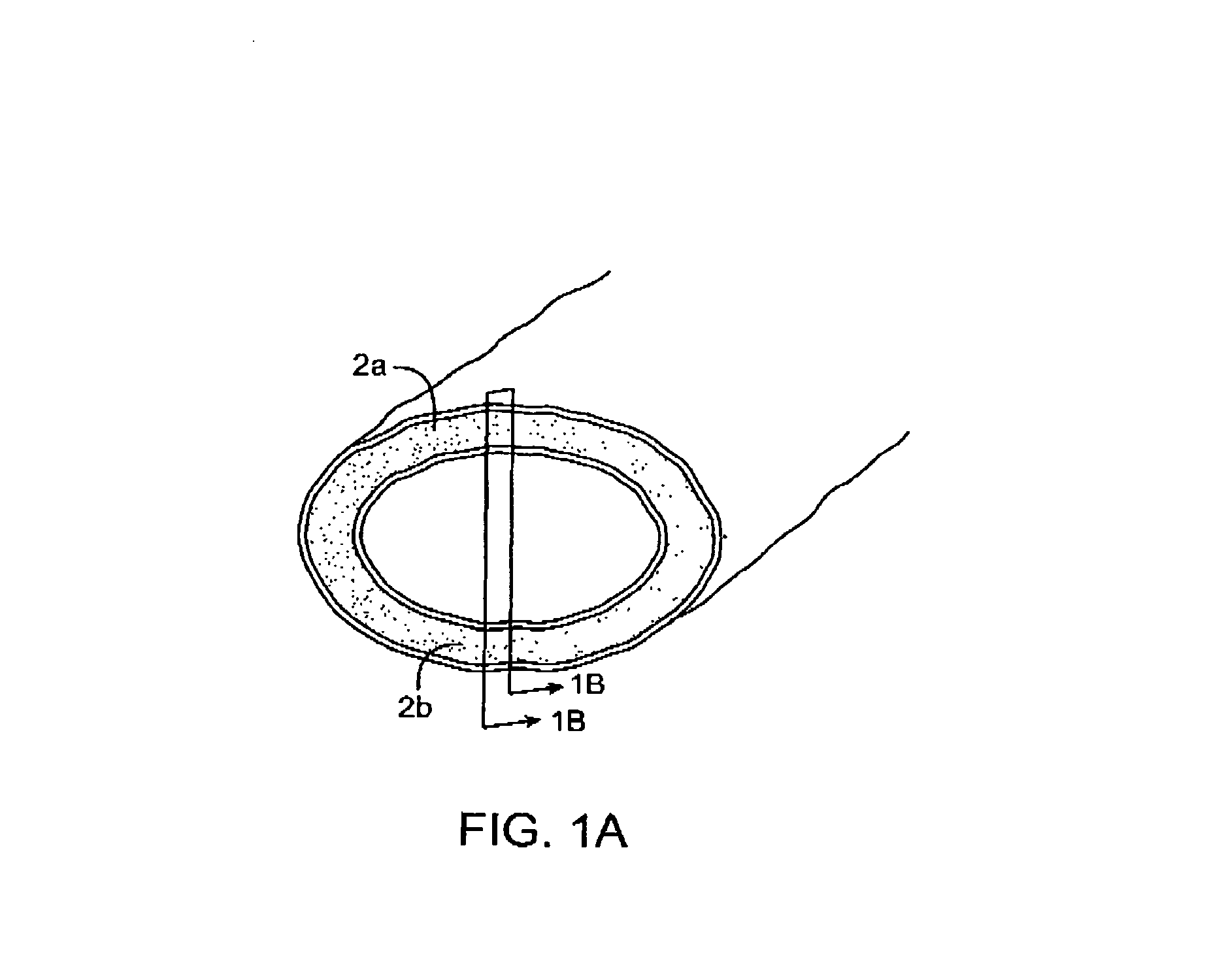

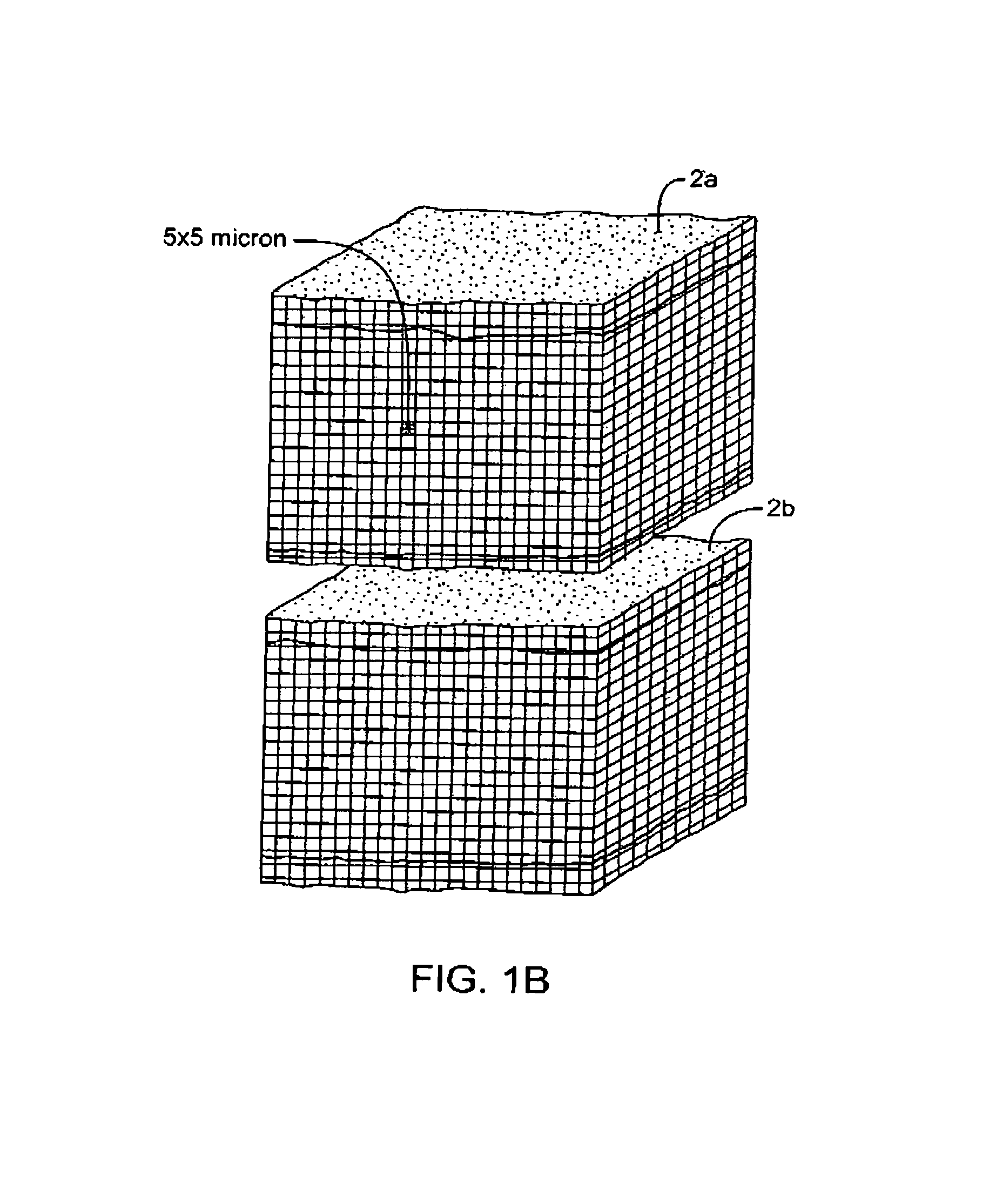

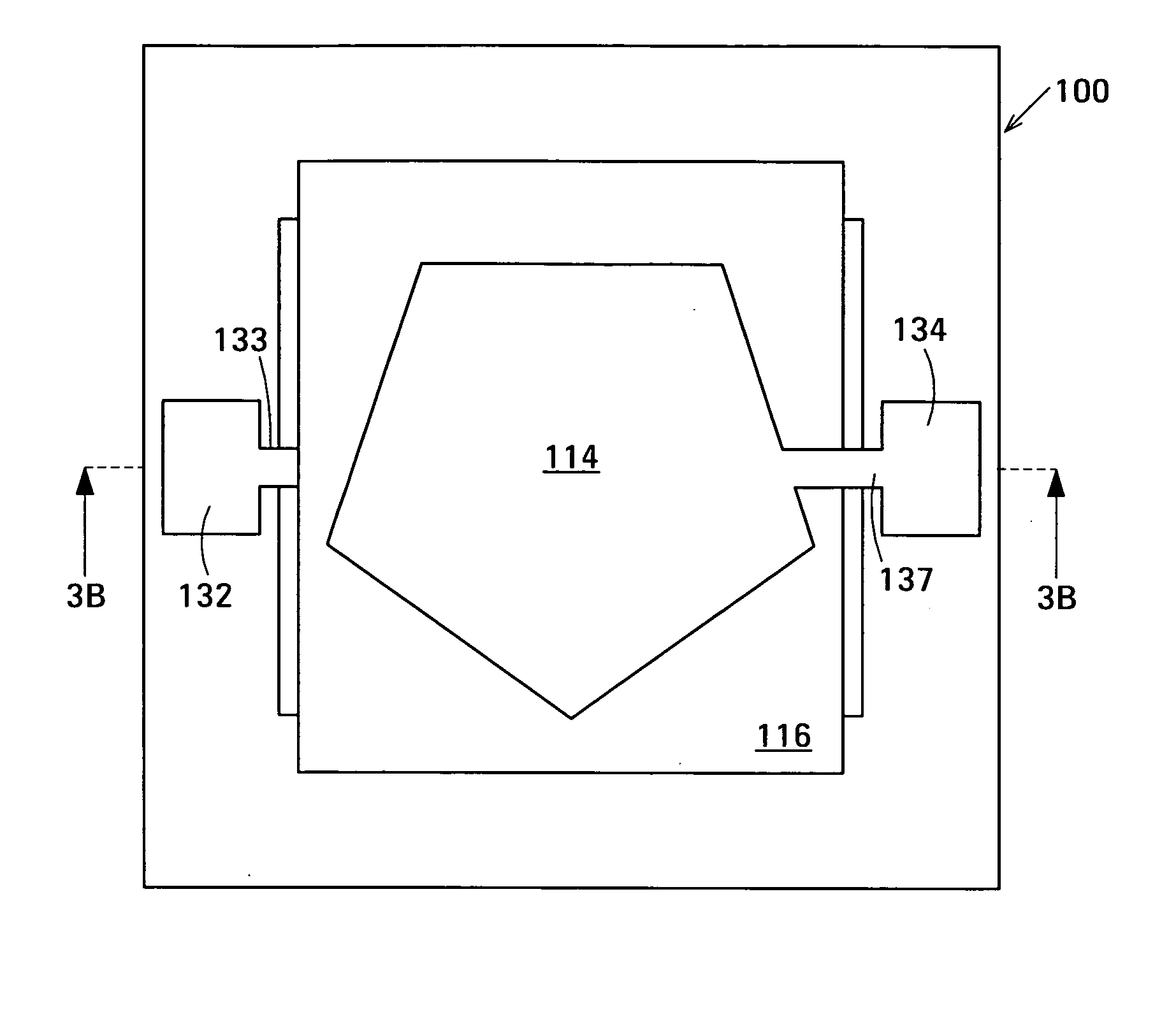

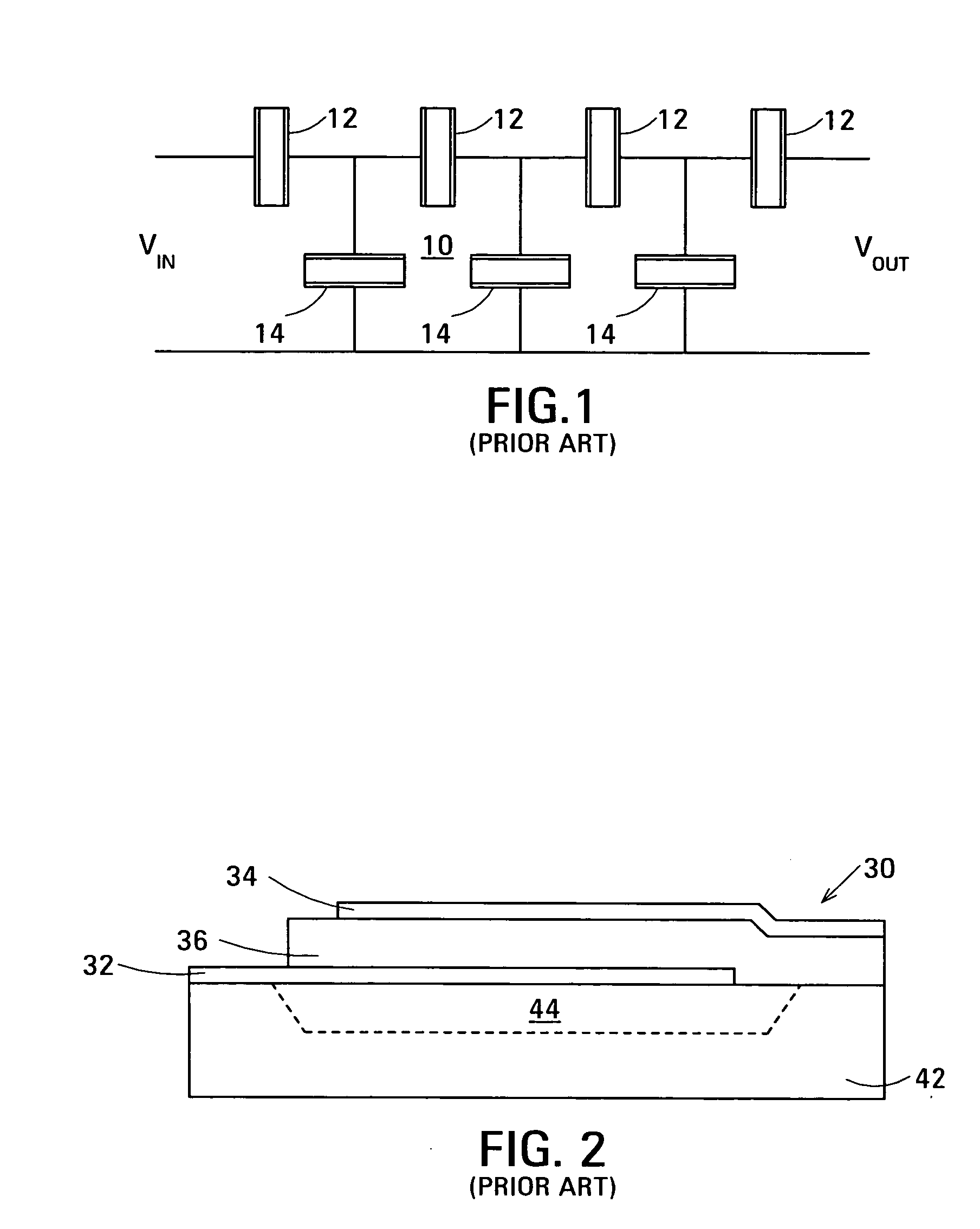

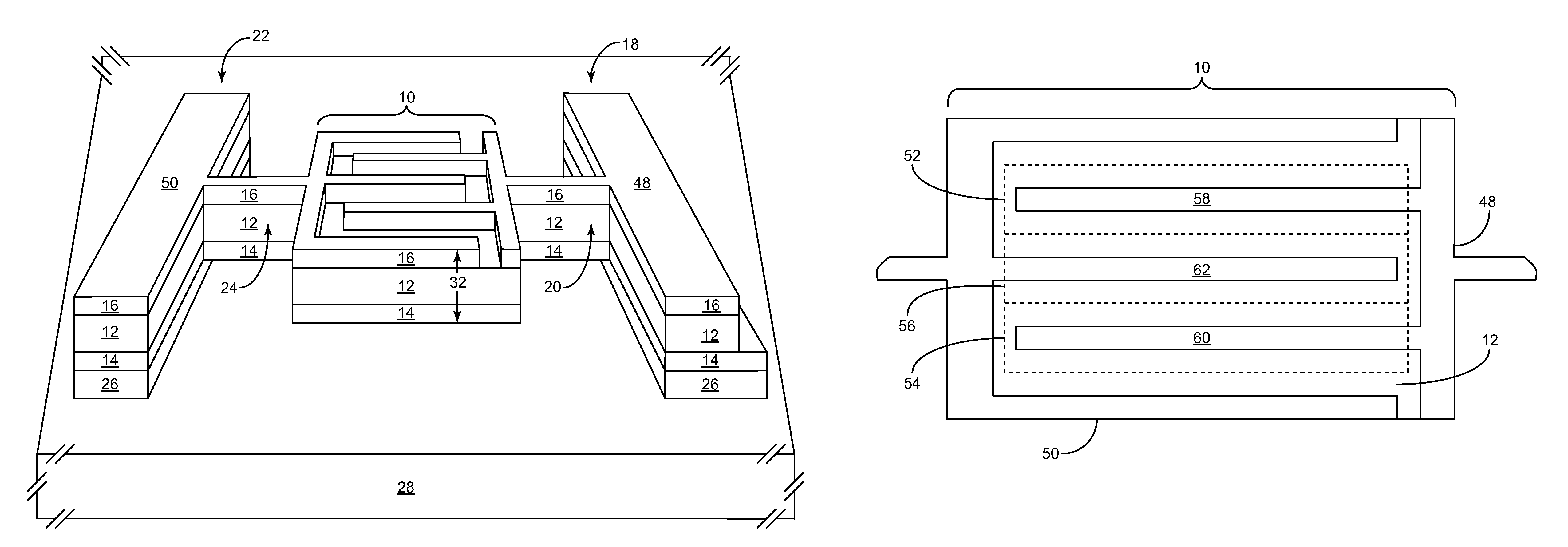

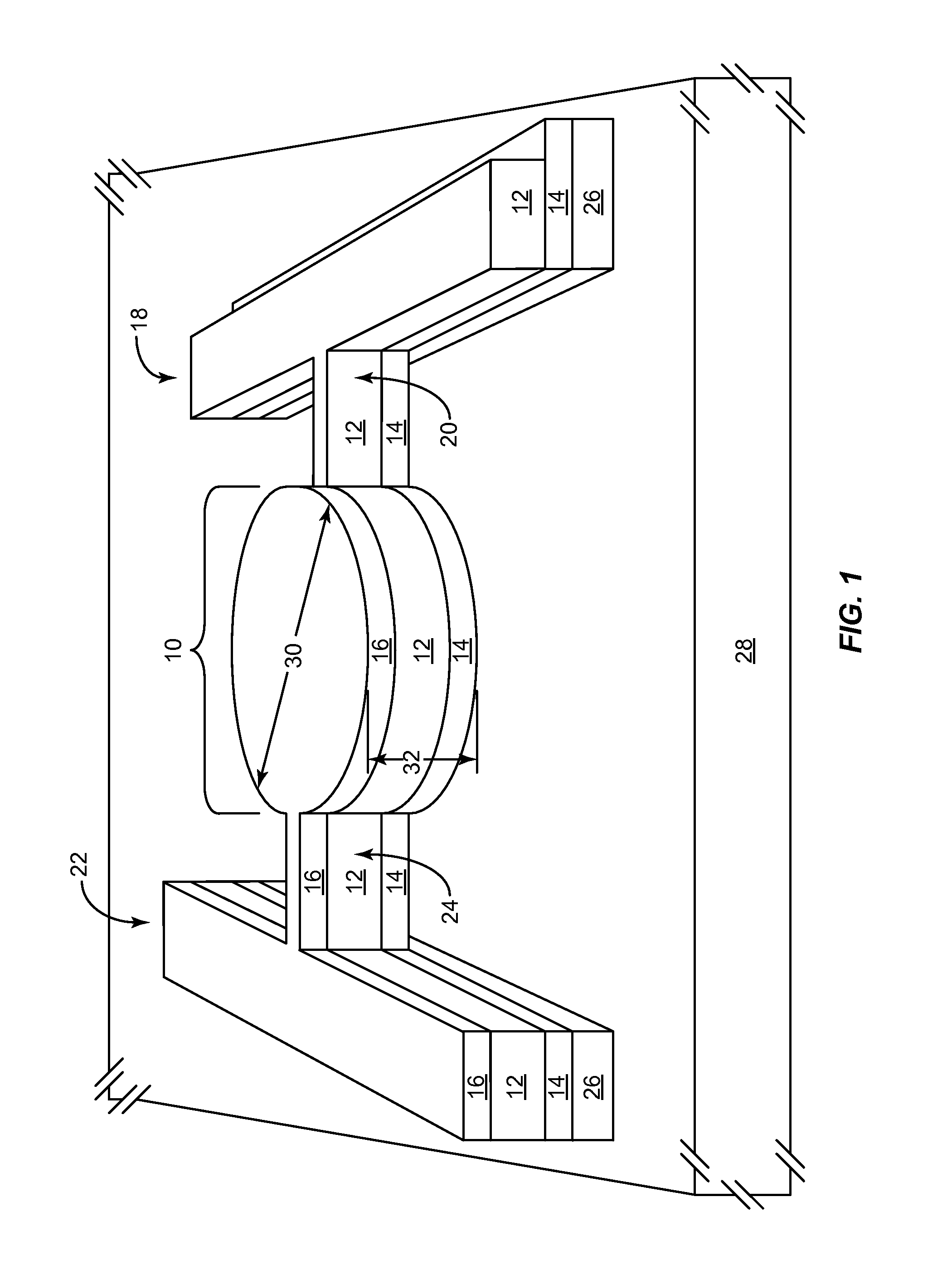

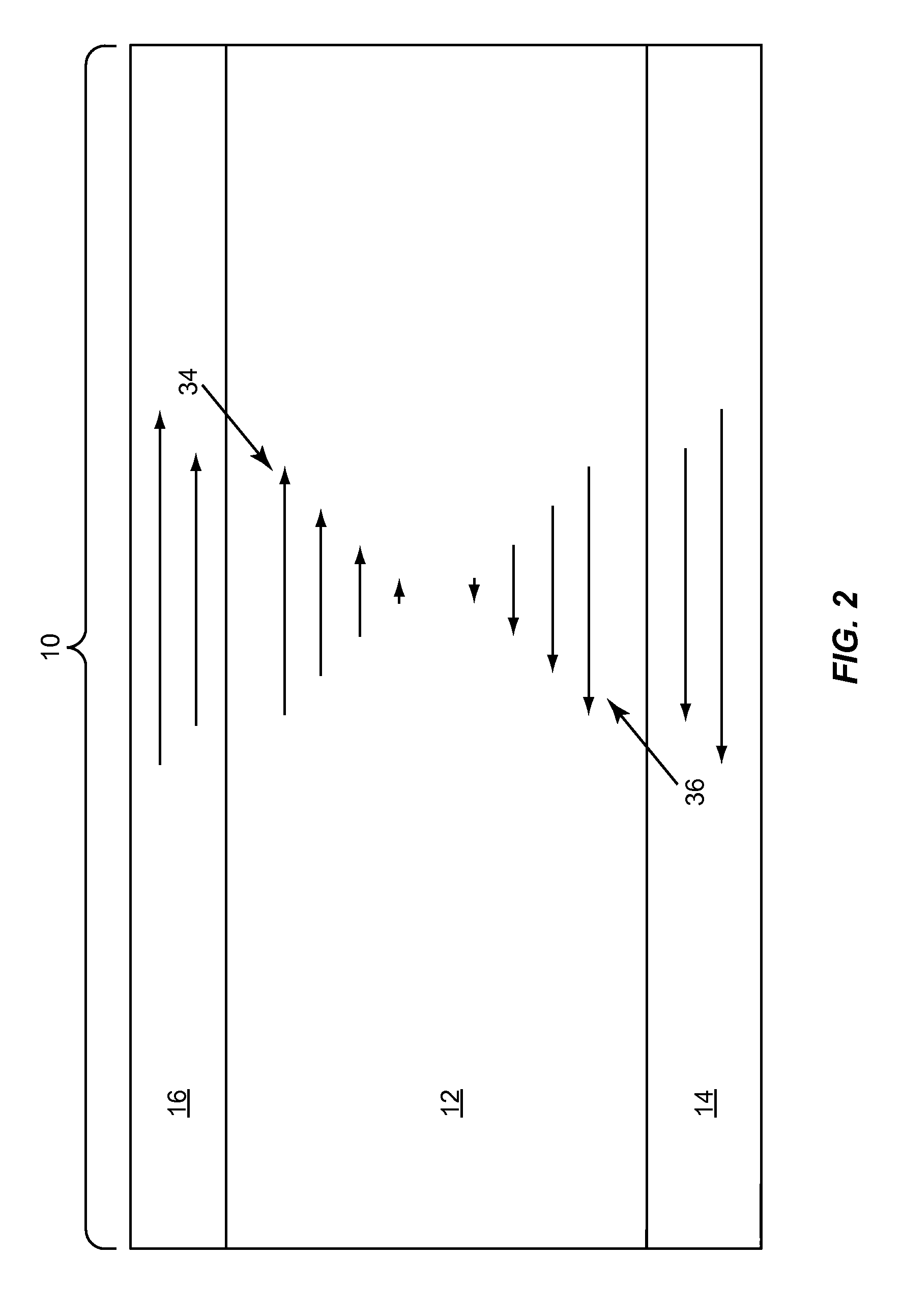

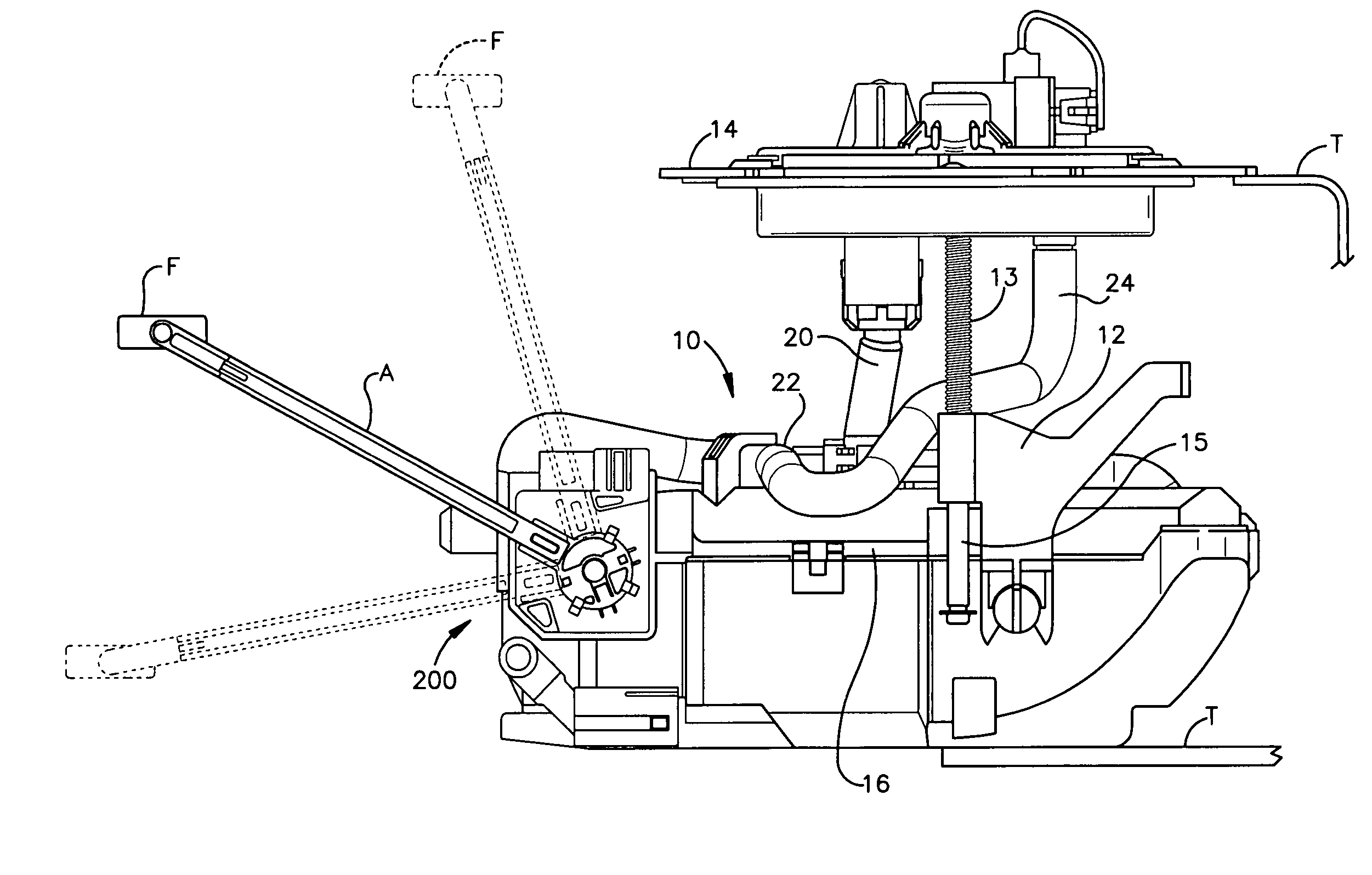

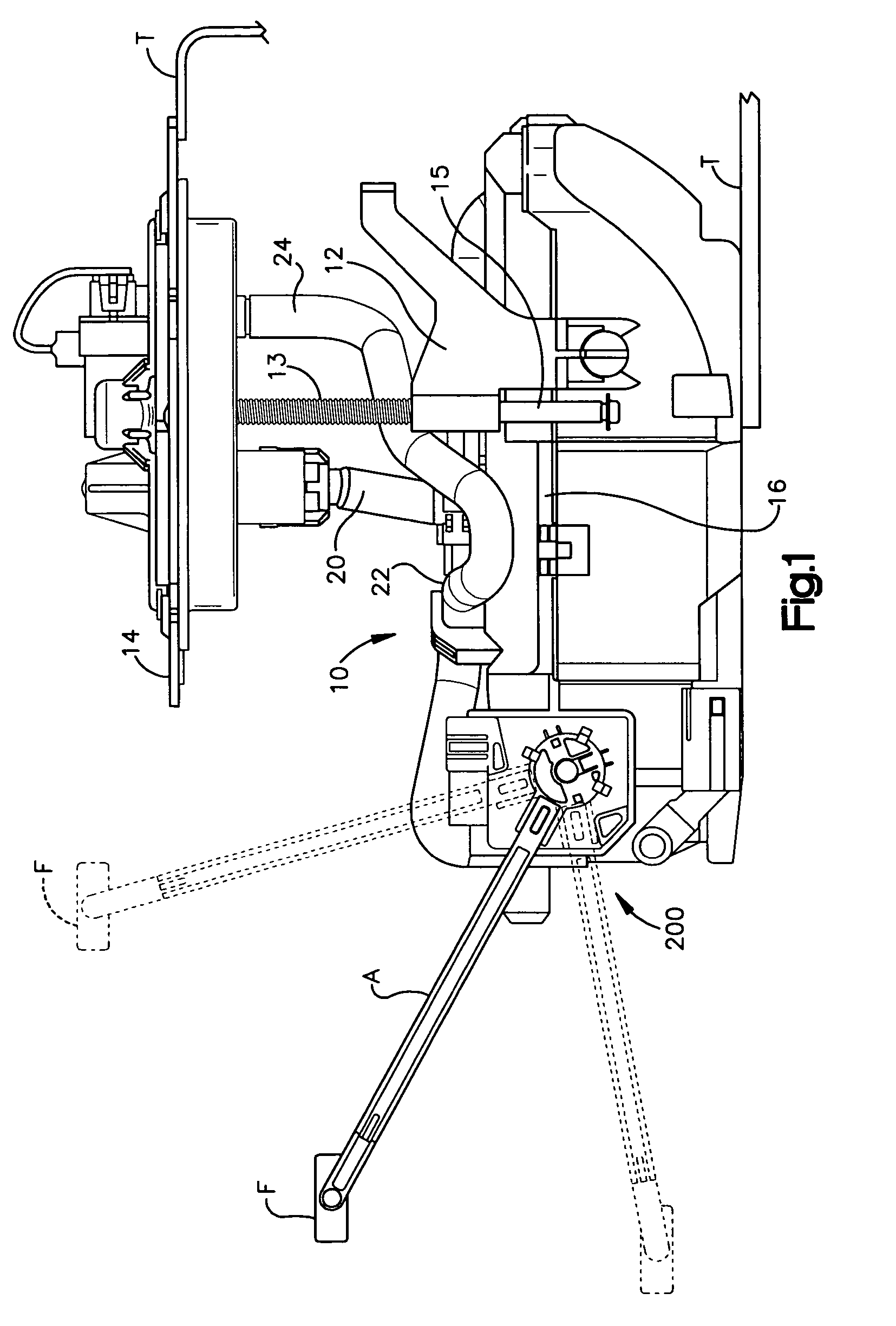

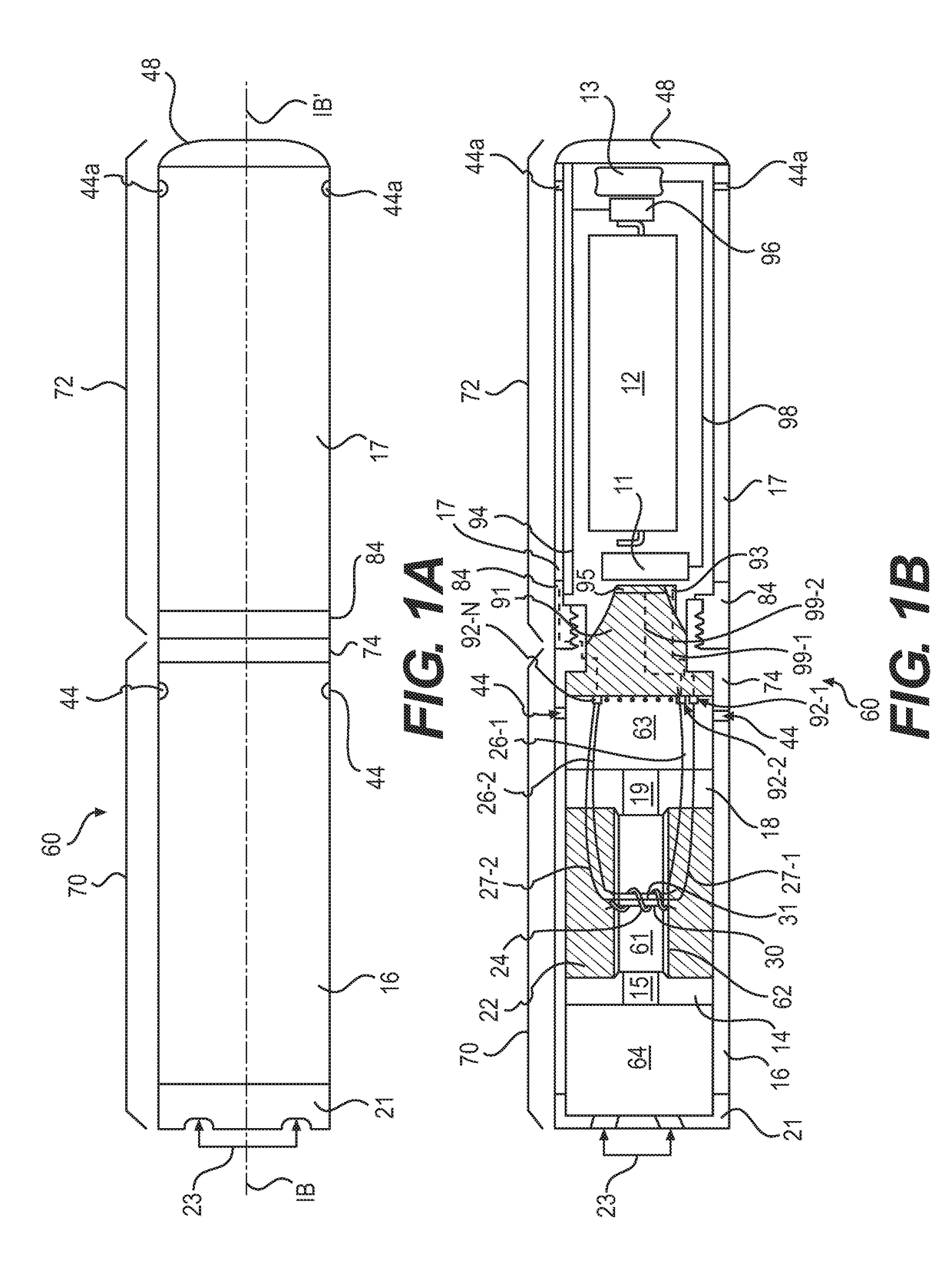

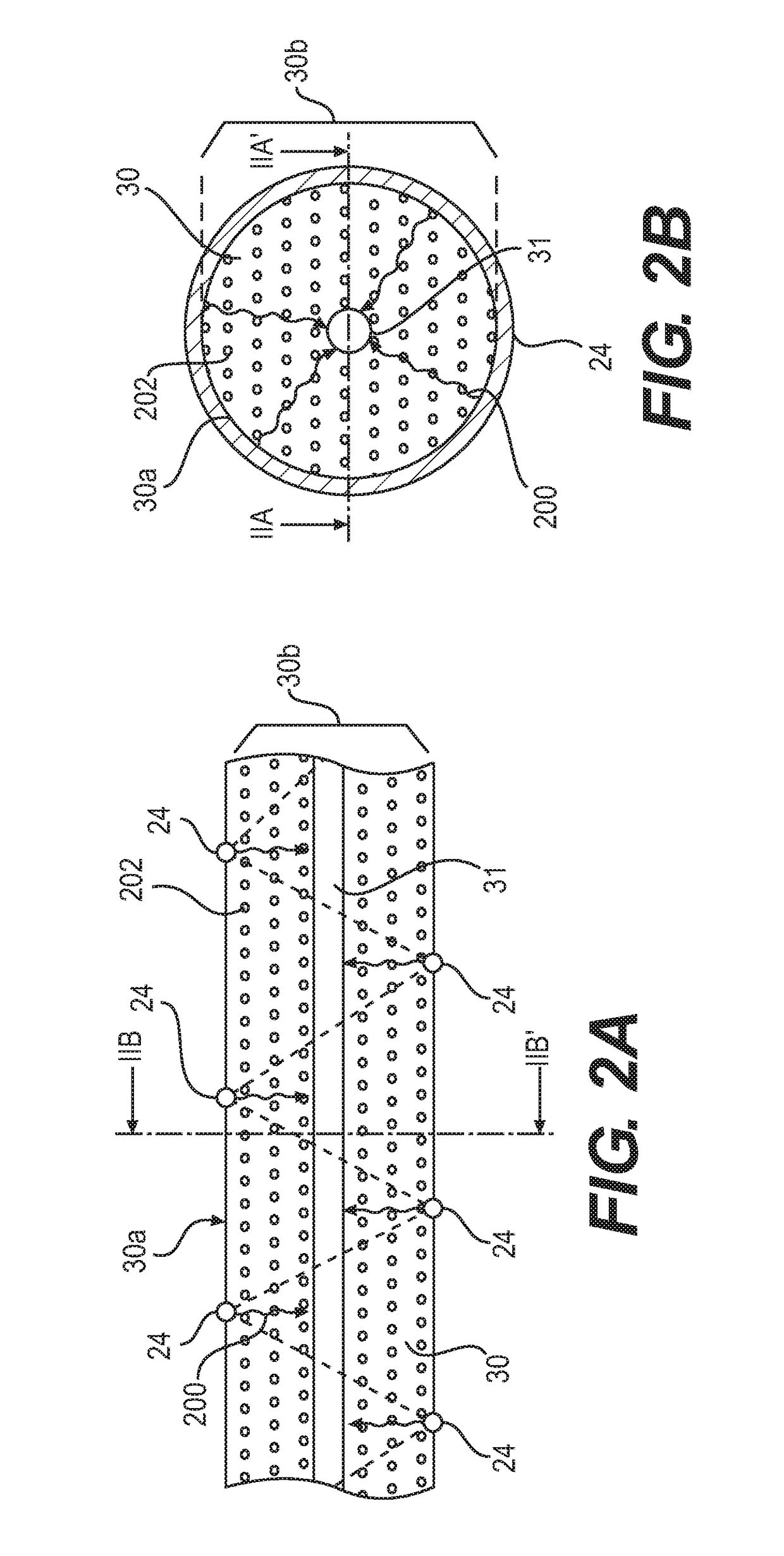

Electrosurgical instrument and method of use

InactiveUS7311709B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleSpatial positioning

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a variable resistive body of a positive temperature coefficient material that has a selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The variable resistive body can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application across micron-scale portions of the engagement surface. In another mode of operation, a variable resistive body will focus conductive heating in a selected portion of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

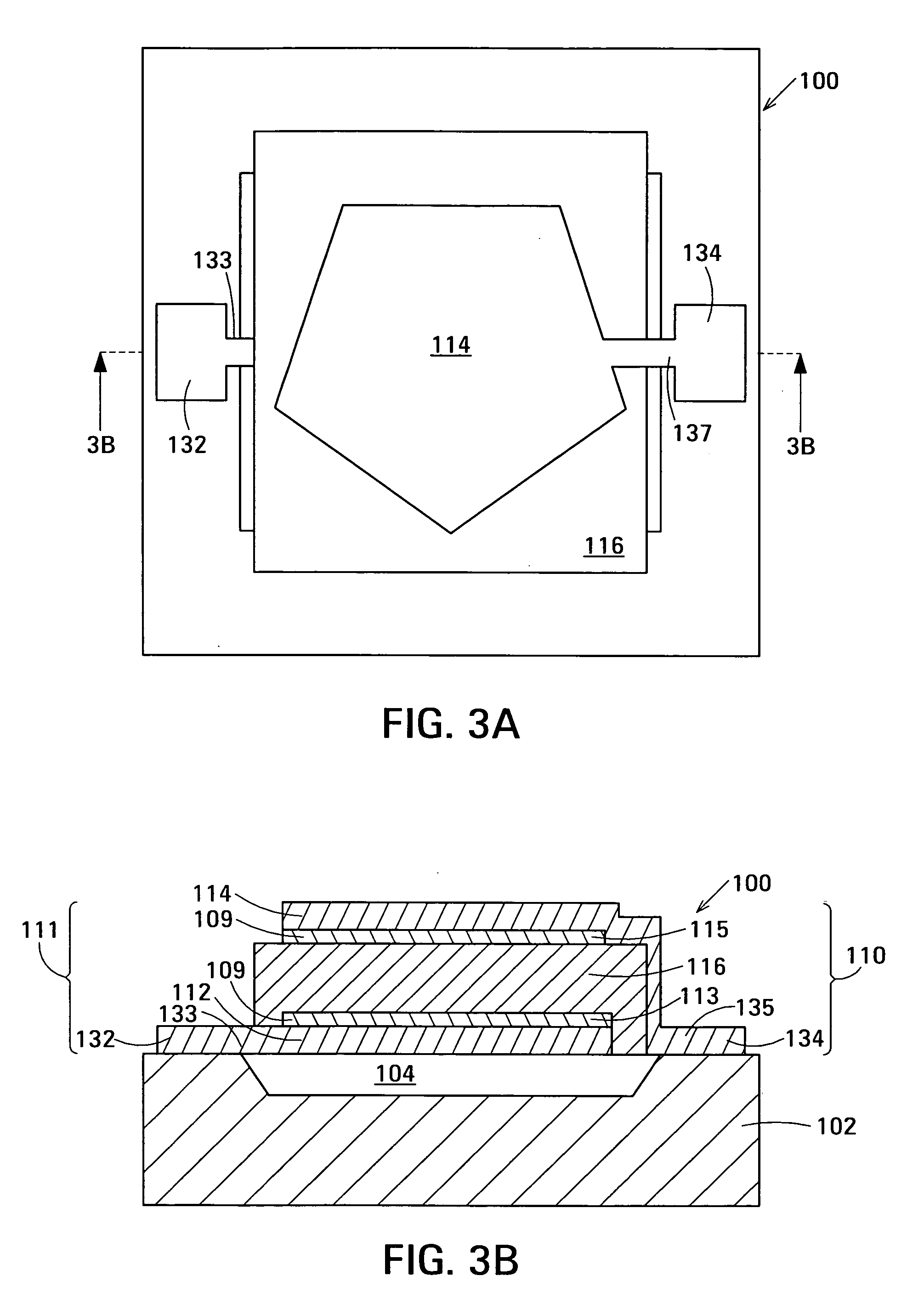

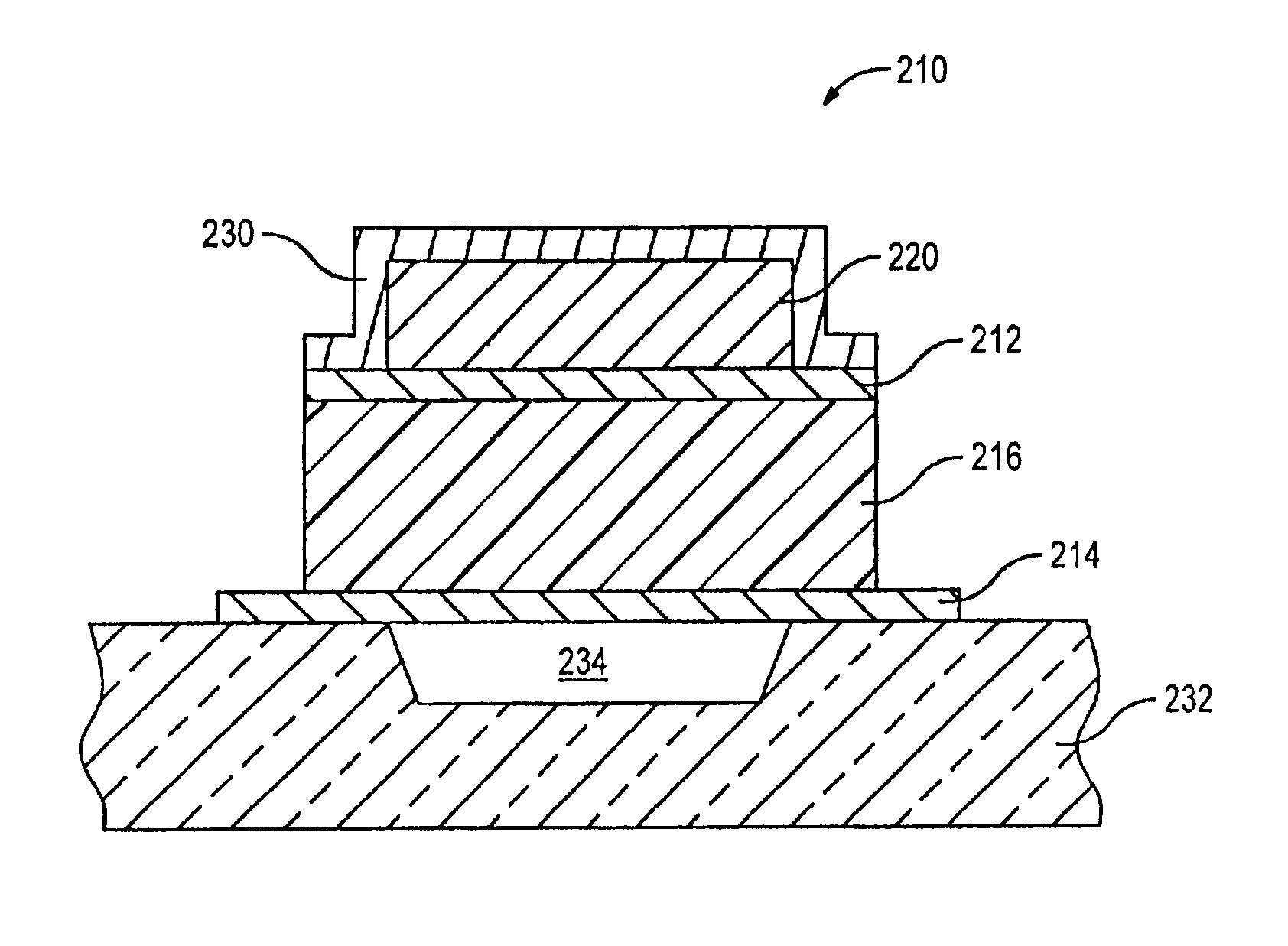

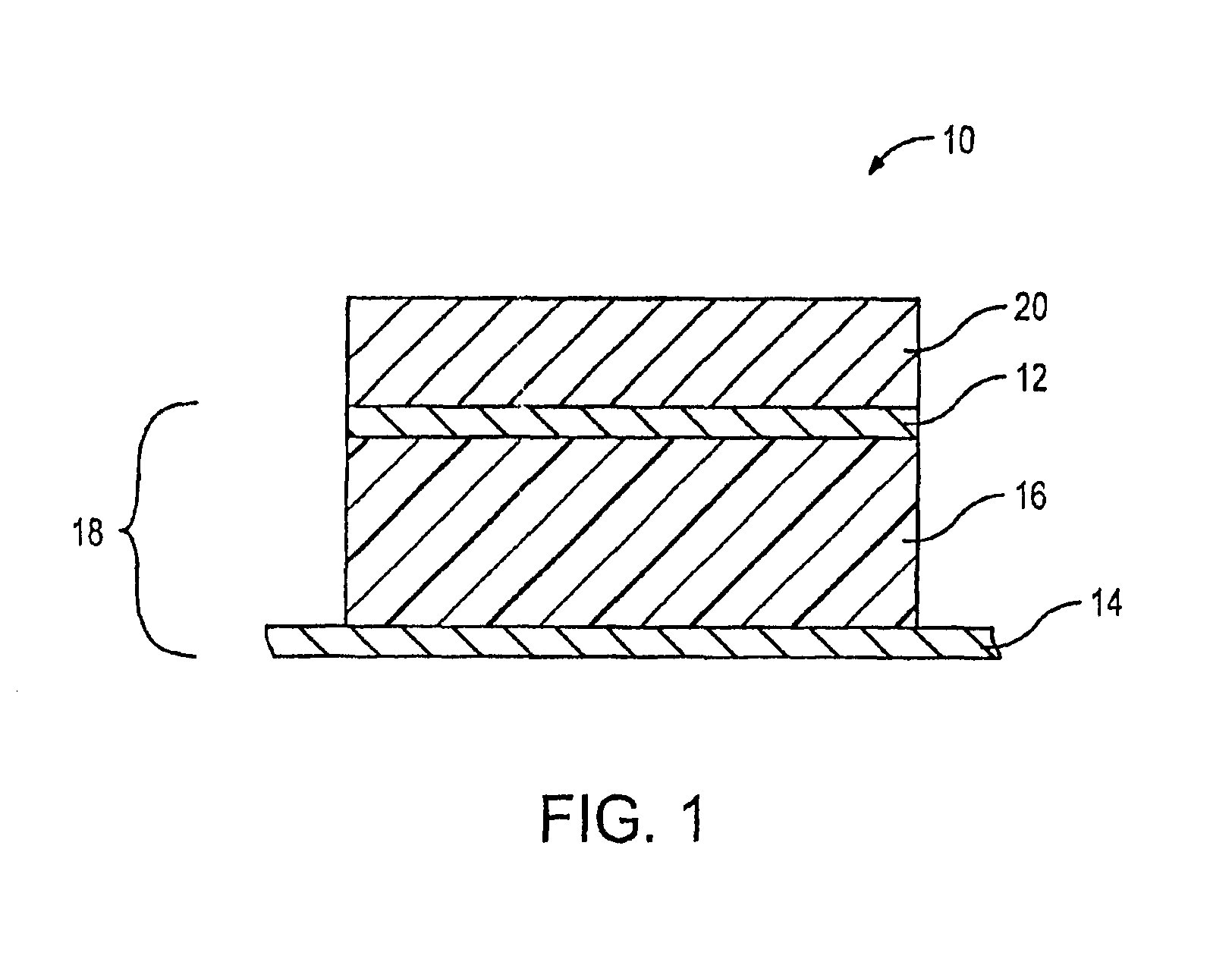

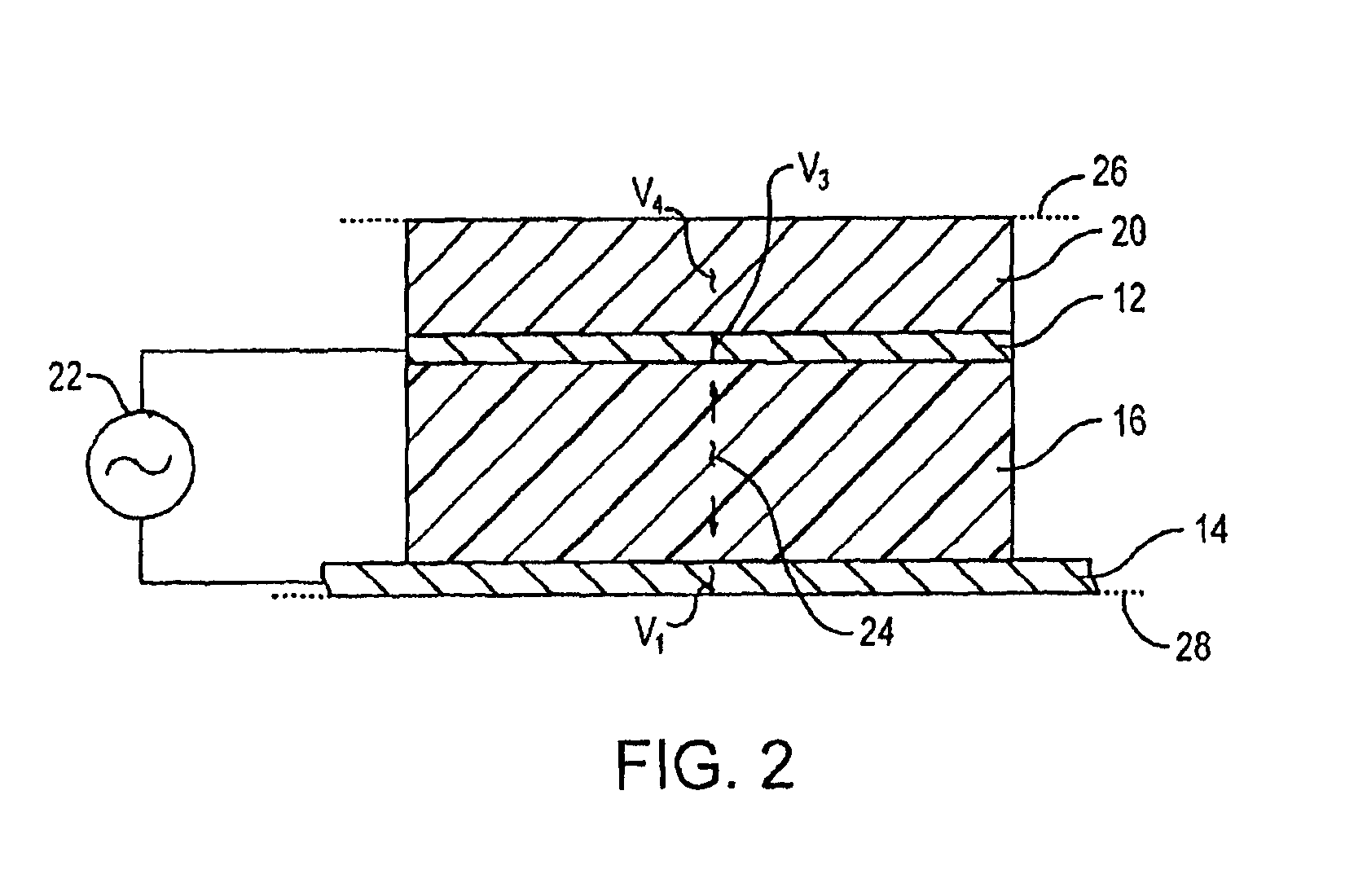

Temperature-compensated film bulk acoustic resonator (FBAR) devices

InactiveUS20050110598A1Reduce impactPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPlanar electrodeThin-film bulk acoustic resonator

The temperature-compensated film bulk acoustic resonator (FBAR) device comprises an FBAR stack. The FBAR stack comprises an FBAR and a temperature-compensating element. The FBAR is characterized by a resonant frequency having a temperature coefficient, and comprises opposed planar electrodes and a piezoelectric element between the electrodes. The piezoelectric element has a temperature coefficient on which the temperature coefficient of the resonant frequency depends at least in part. The temperature-compensating element has a temperature coefficient opposite in sign to the temperature coefficient of the piezoelectric element.

Owner:AVAGO TECH INT SALES PTE LTD

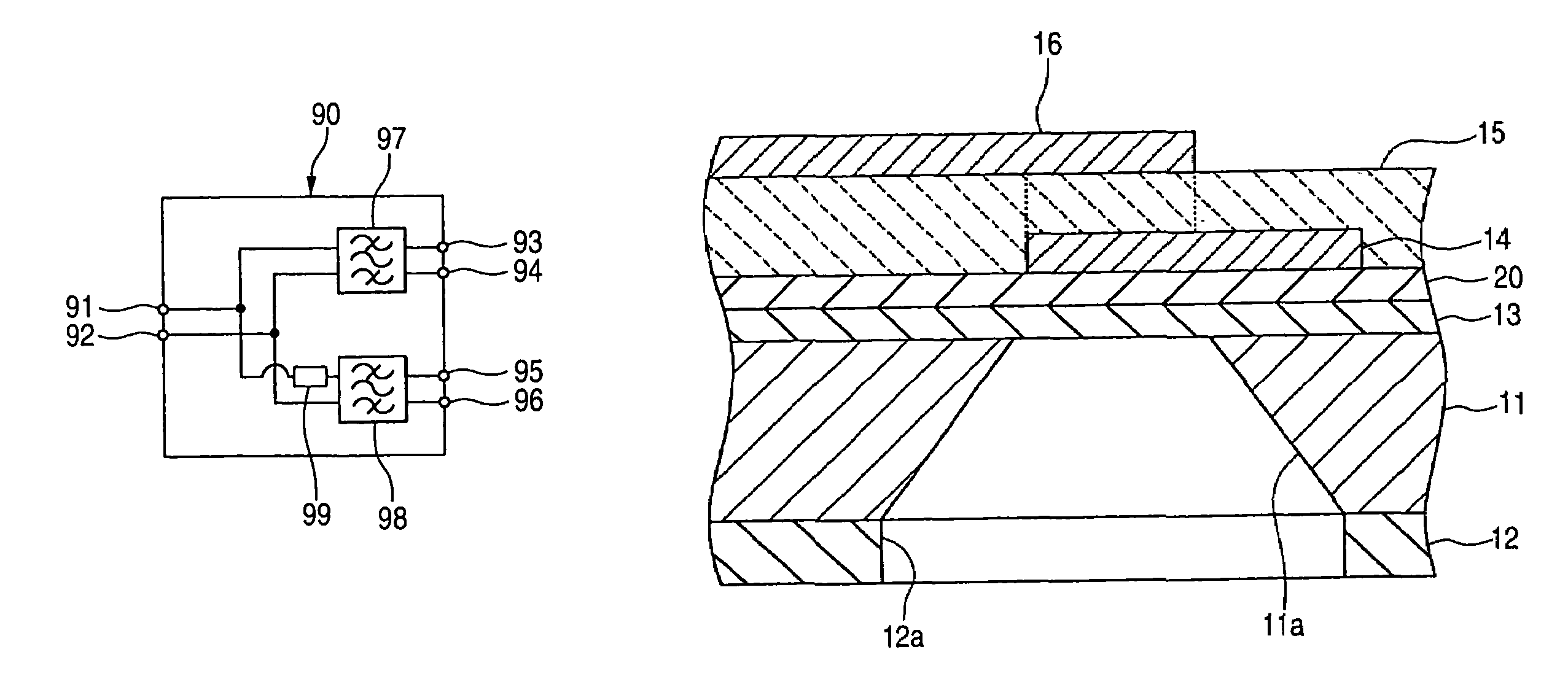

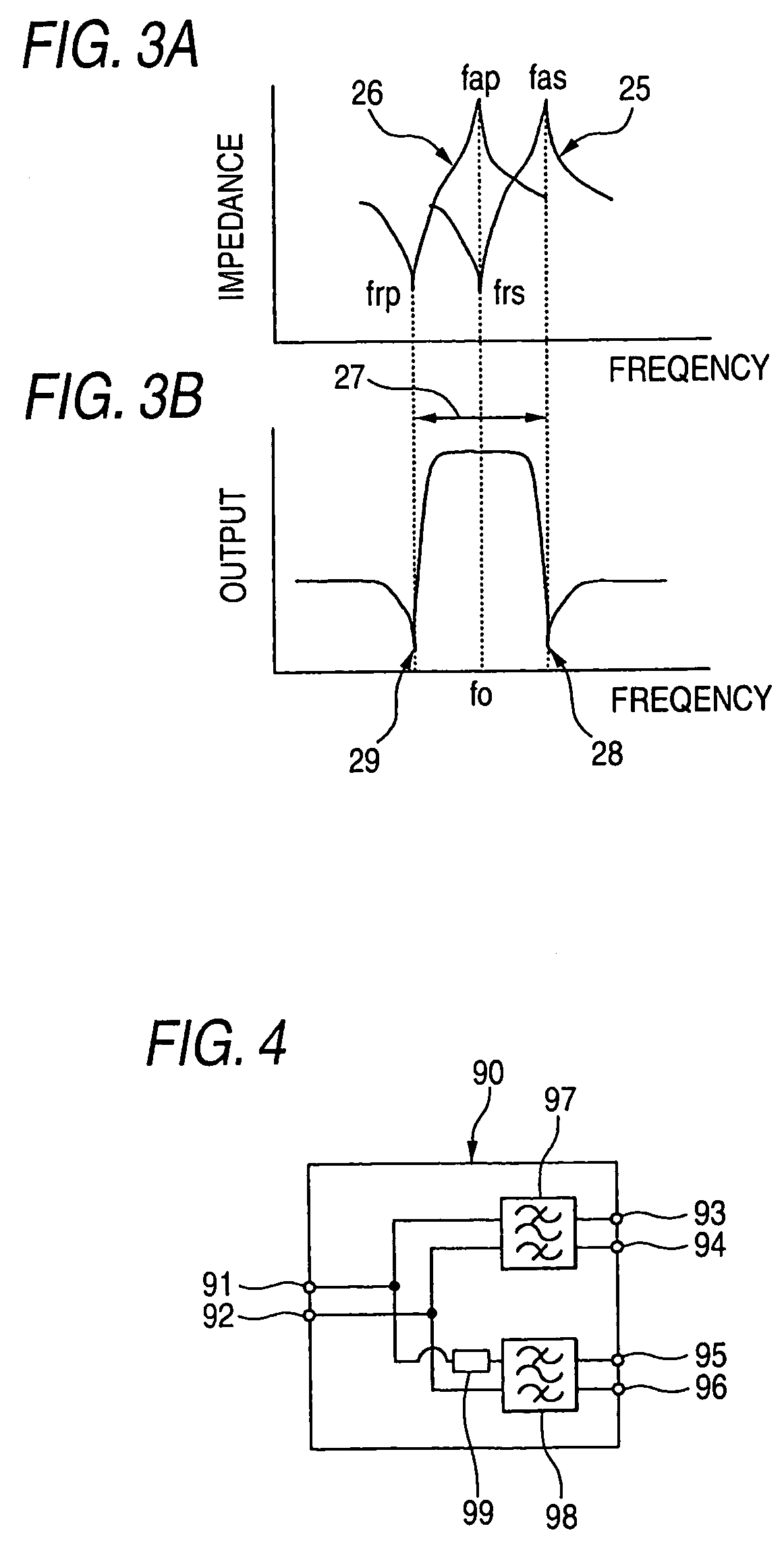

Piezoelectric resonant filter and duplexer

ActiveUS6989723B2Reduction in width can be suppressedAvoid disadvantagesImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesResonant filterTemperature coefficient

A piezoelectric resonant filter includes a group of series resonators and a group of parallel resonators for forming a ladder-type filter circuit. Each of the resonators has a piezoelectric thin film having piezoelectric characteristic, and lower and upper electrodes disposed on opposite surfaces of the piezoelectric thin film for applying an excitation voltage to the piezoelectric thin film. The group of the parallel resonators exhibits a low frequency side attenuation extremum in the filter whereas the group of the series resonators exhibits a high frequency side attenuation extremum in the filter. At least one of the group of the series resonators and the group of the parallel resonators has a temperature compensating layer for bringing the temperature coefficient of the resonant frequency close to zero.

Owner:SNAPTRACK

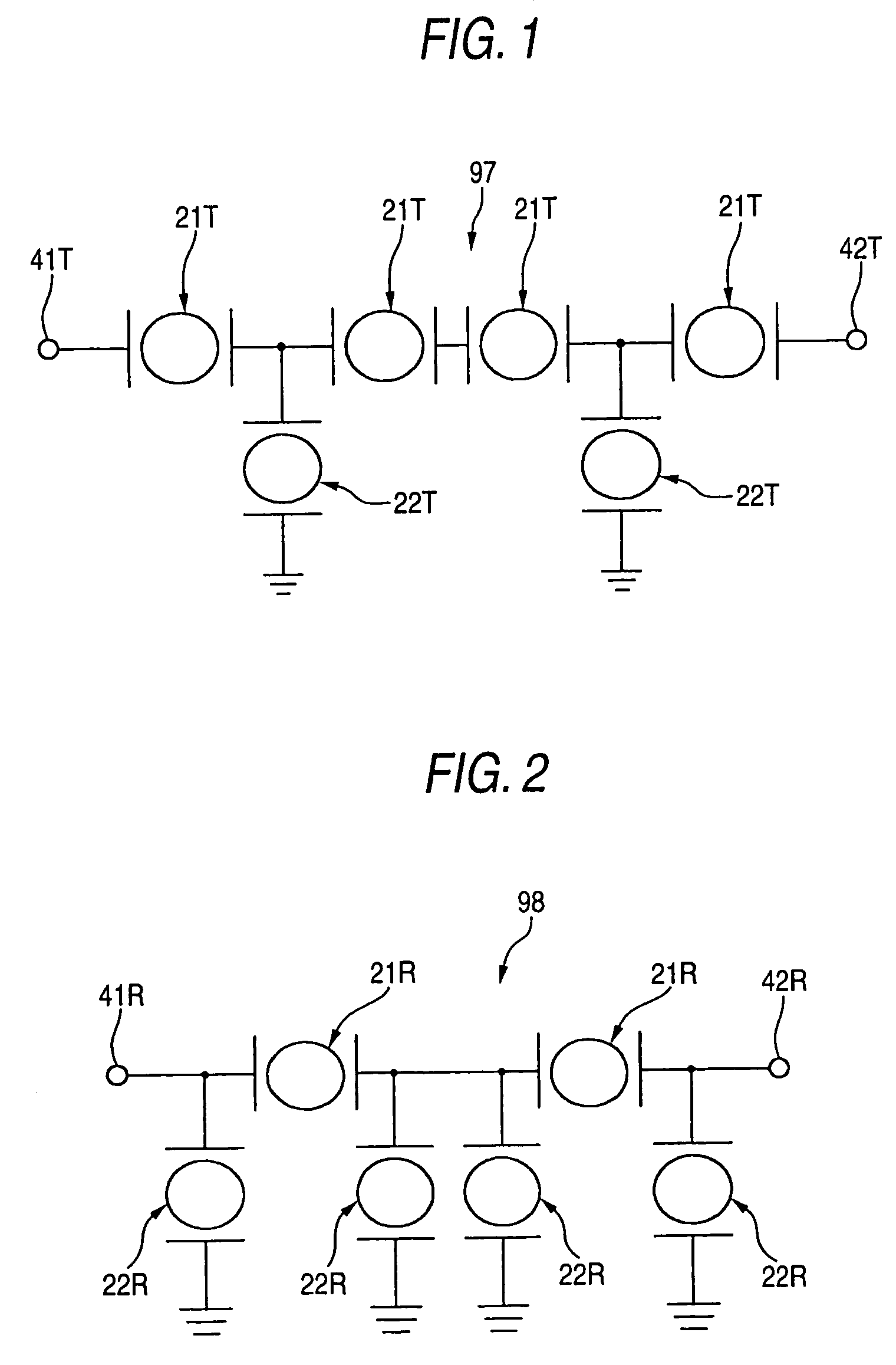

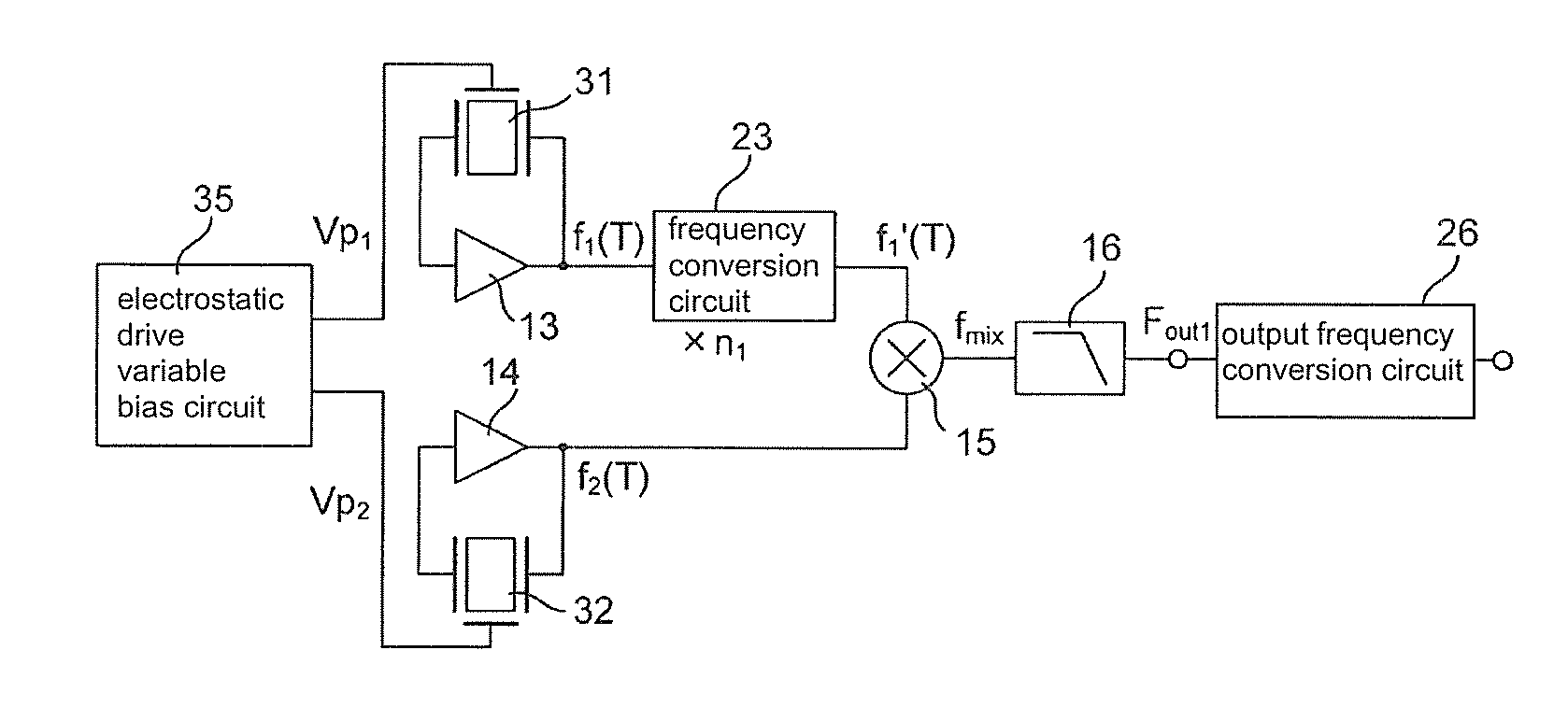

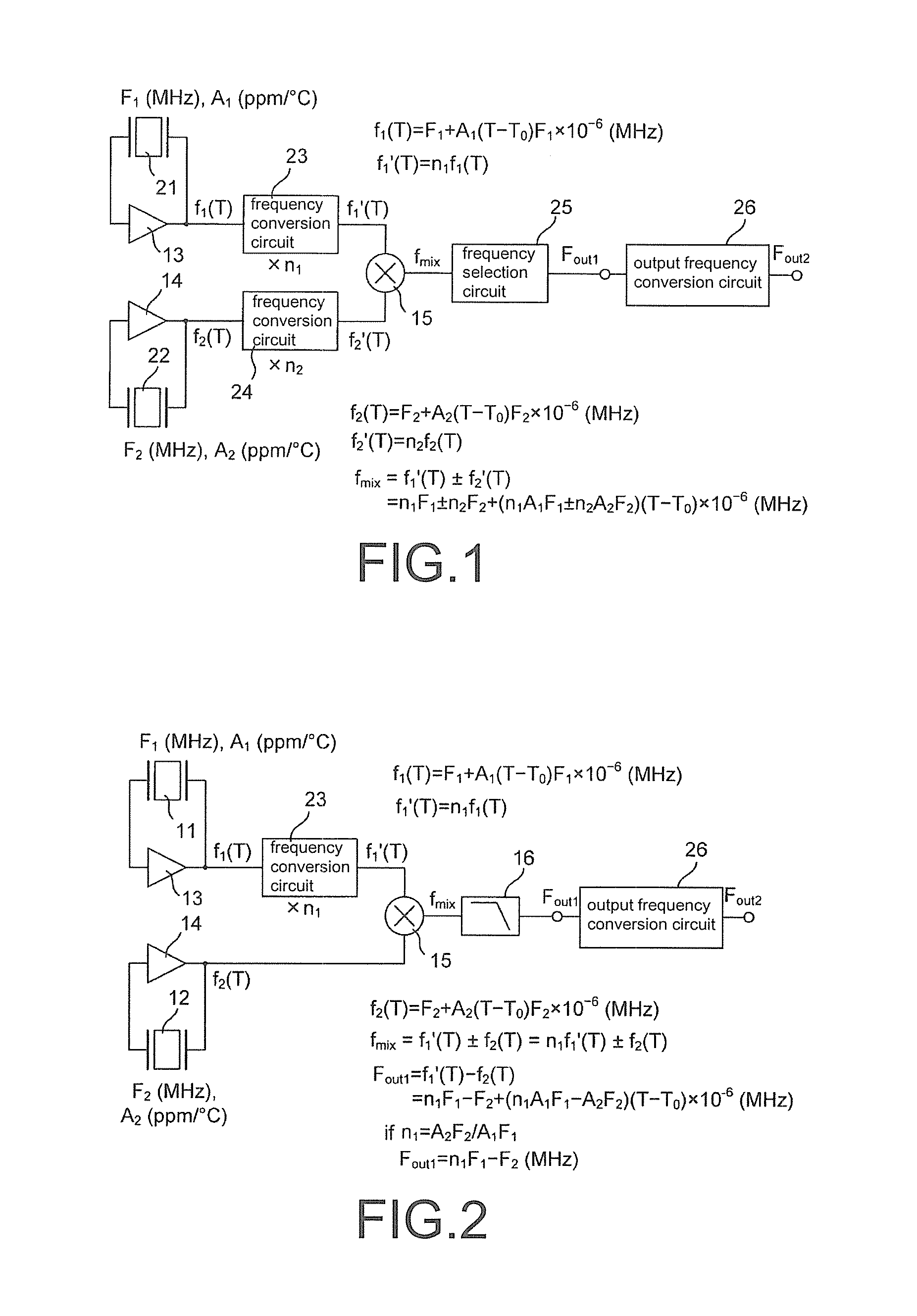

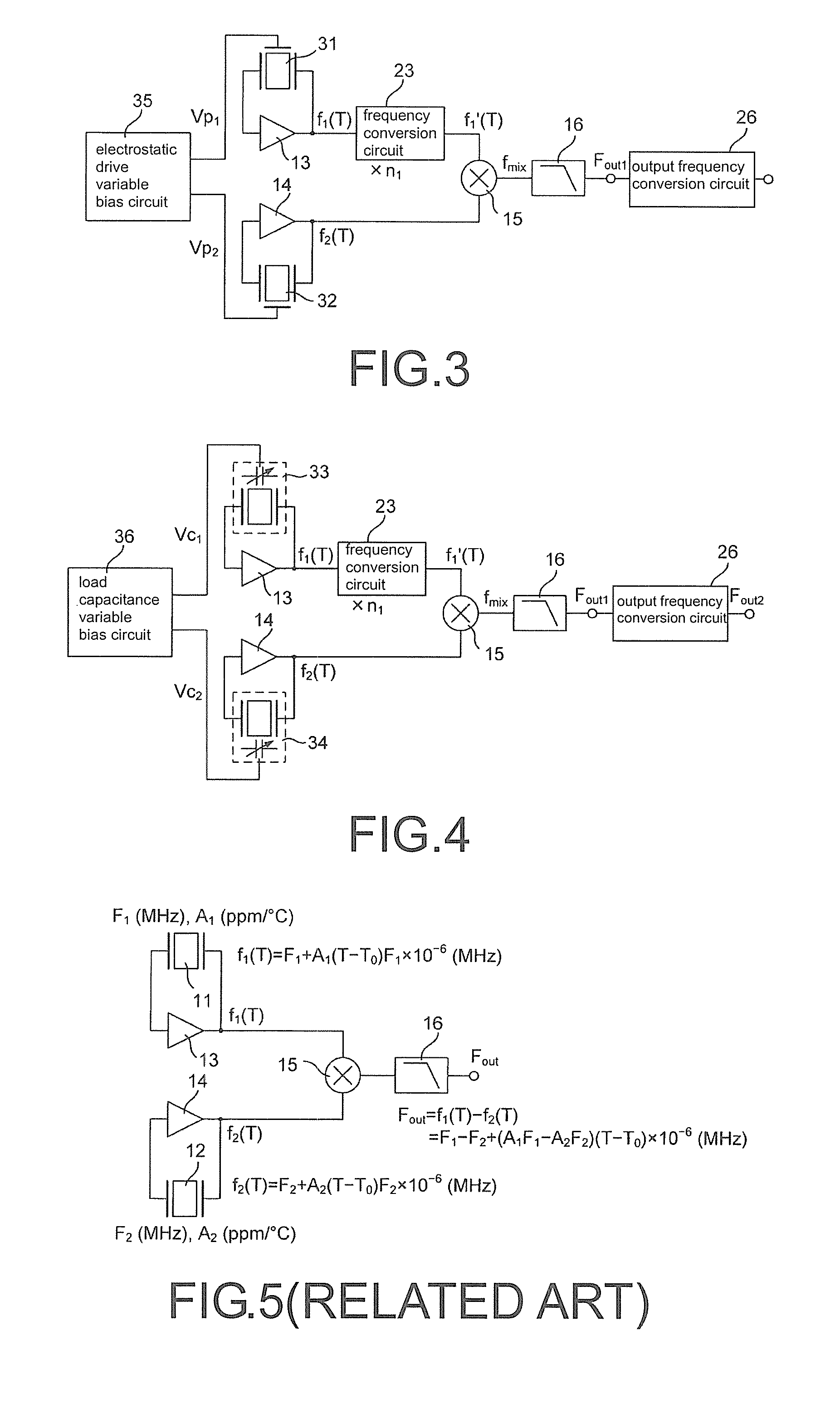

Temperature compensation type oscillator

An oscillator includes a first crystal resonator, a second crystal resonator, a first amplifier circuit for oscillation, a second amplifier circuit for oscillation, a mixer circuit, a frequency selection circuit, and a first frequency conversion circuit. Assuming that resonance frequencies of the first and the second crystal resonators at a reference temperature are respectively F1 and F2, and temperature coefficients expressed as a rate of change corresponding to temperatures of the resonance frequencies of the first and the second crystal resonators are respectively A1 and A2, the relationship of F2 / F1≠|A1 / A2| is satisfied. A signal with a temperature compensated frequency is obtained from the frequency selection circuit.

Owner:NIHON DEMPA KOGYO CO LTD

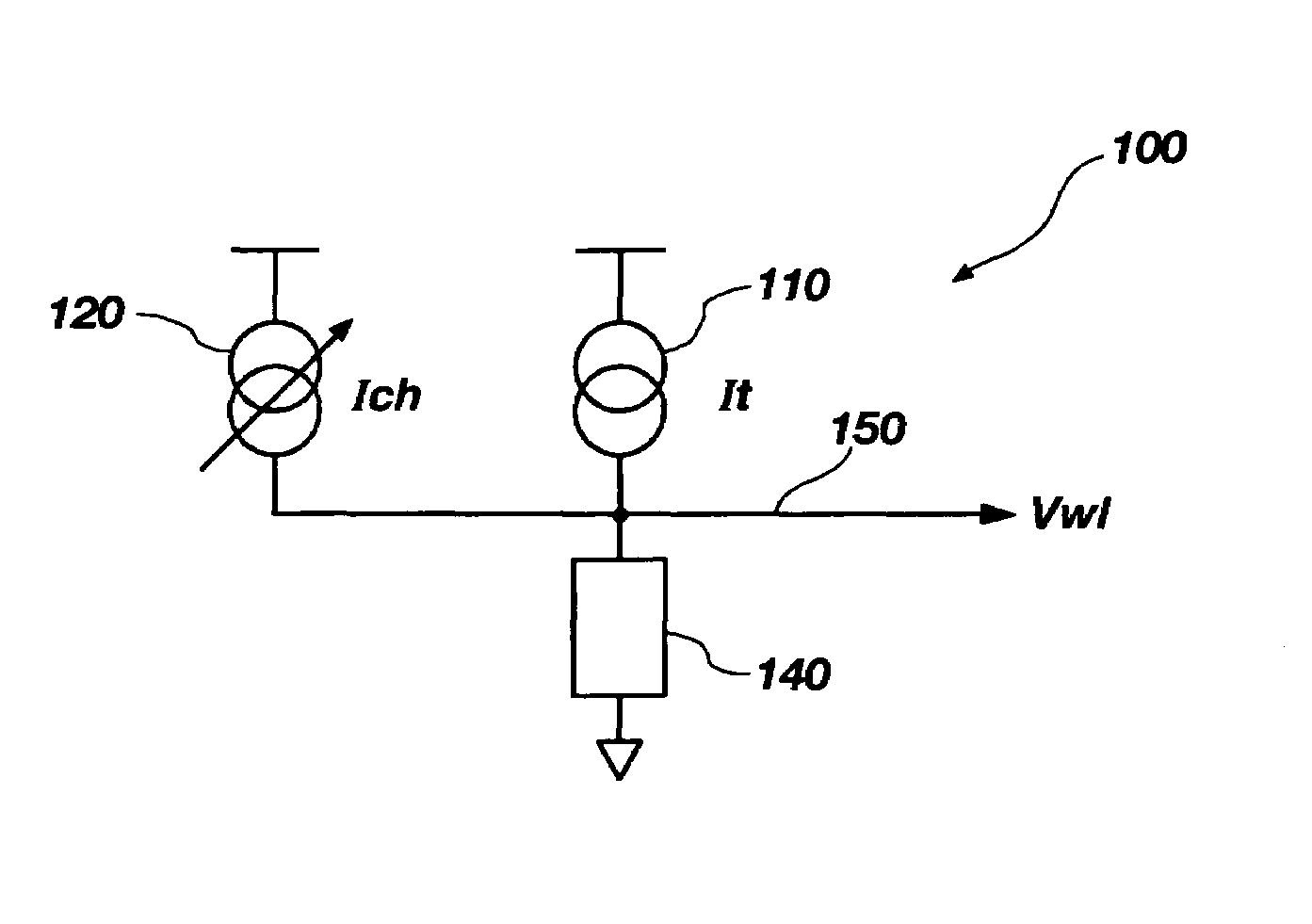

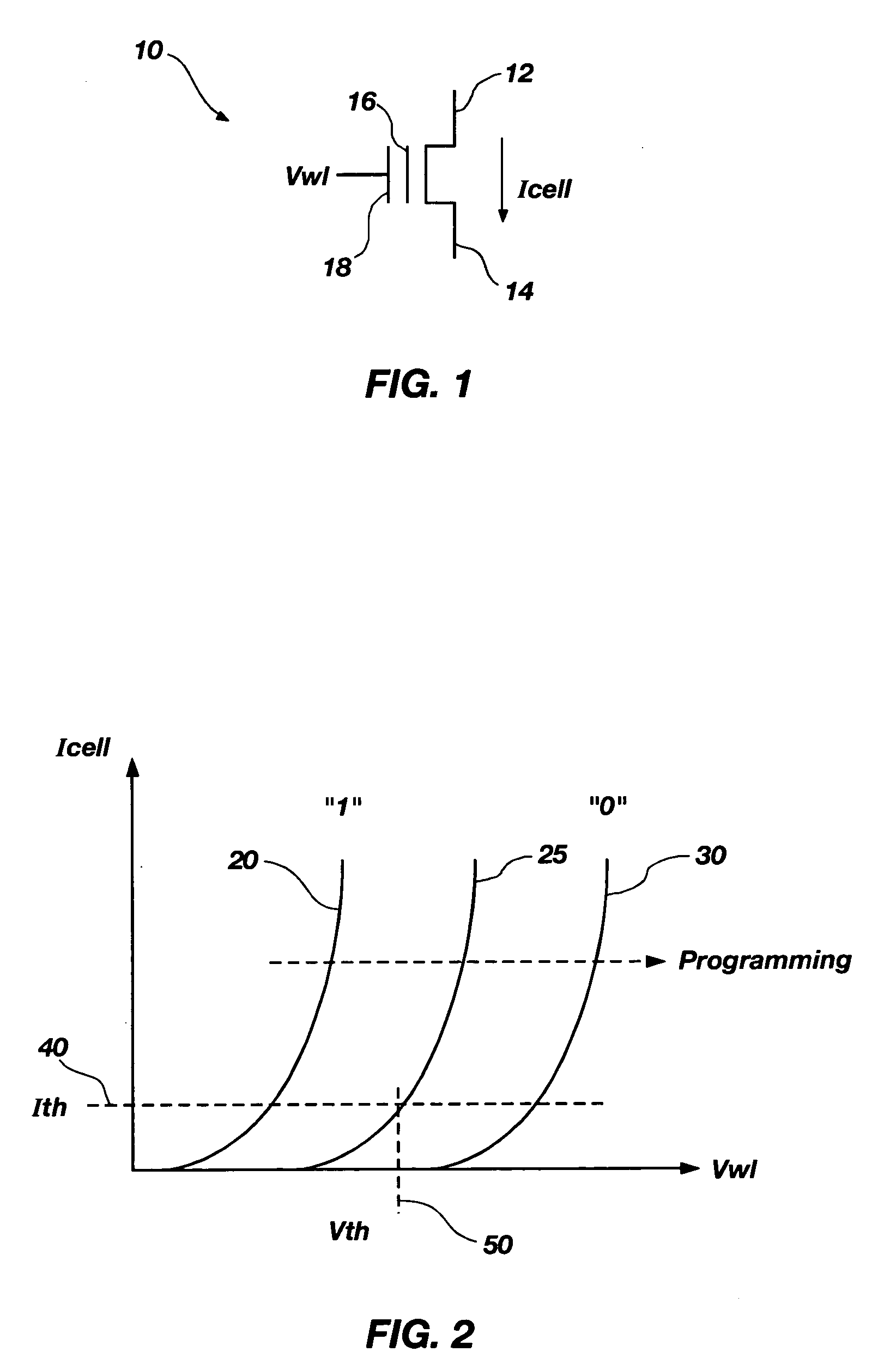

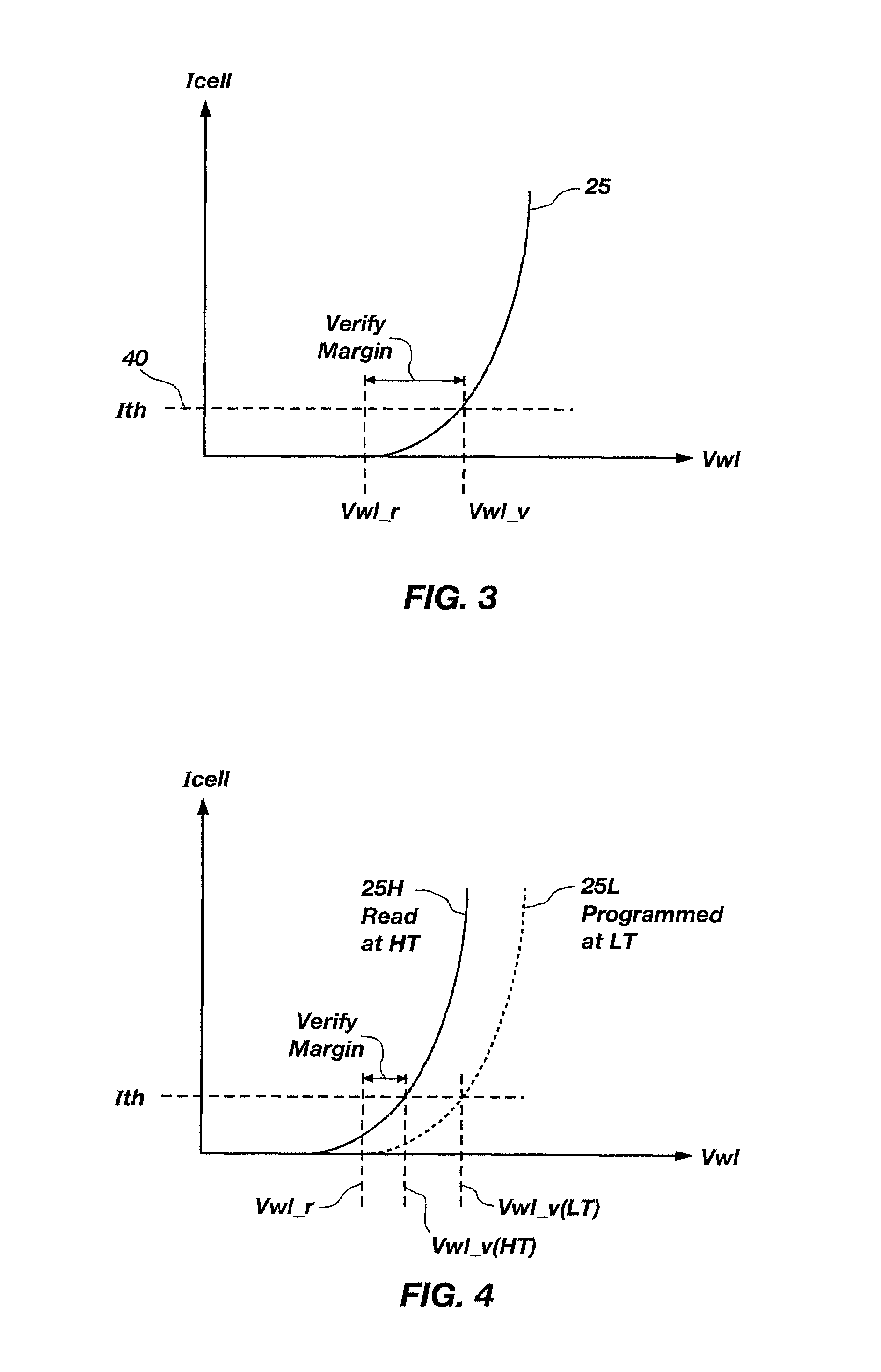

Method and apparatus for generating temperature-compensated read and verify operations in flash memories

Methods and an apparatuses for generating a word-line voltage are disclosed. A word-line voltage generator includes a first current source, an adjustable current source, adjustable current sink, and a voltage converter, all operably coupled to a current sum node. The first current source generates a first current having a temperature coefficient substantially equal to a temperature coefficient of at least one bit cell. The adjustable current source generates a second current that is substantially independent of a temperature change. The adjustable current sink sinks a third current that is substantially independent of a temperature change. The voltage converter is configured for generating a word-line signal having a word-line voltage proportional to a reference current, wherein the reference current comprises the first current, plus the second current, and minus the third current.

Owner:MICRON TECH INC

Method of making an acoustic wave resonator

InactiveUS6874212B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceAcoustic wave

Owner:AVAGO TECH INT SALES PTE LTD

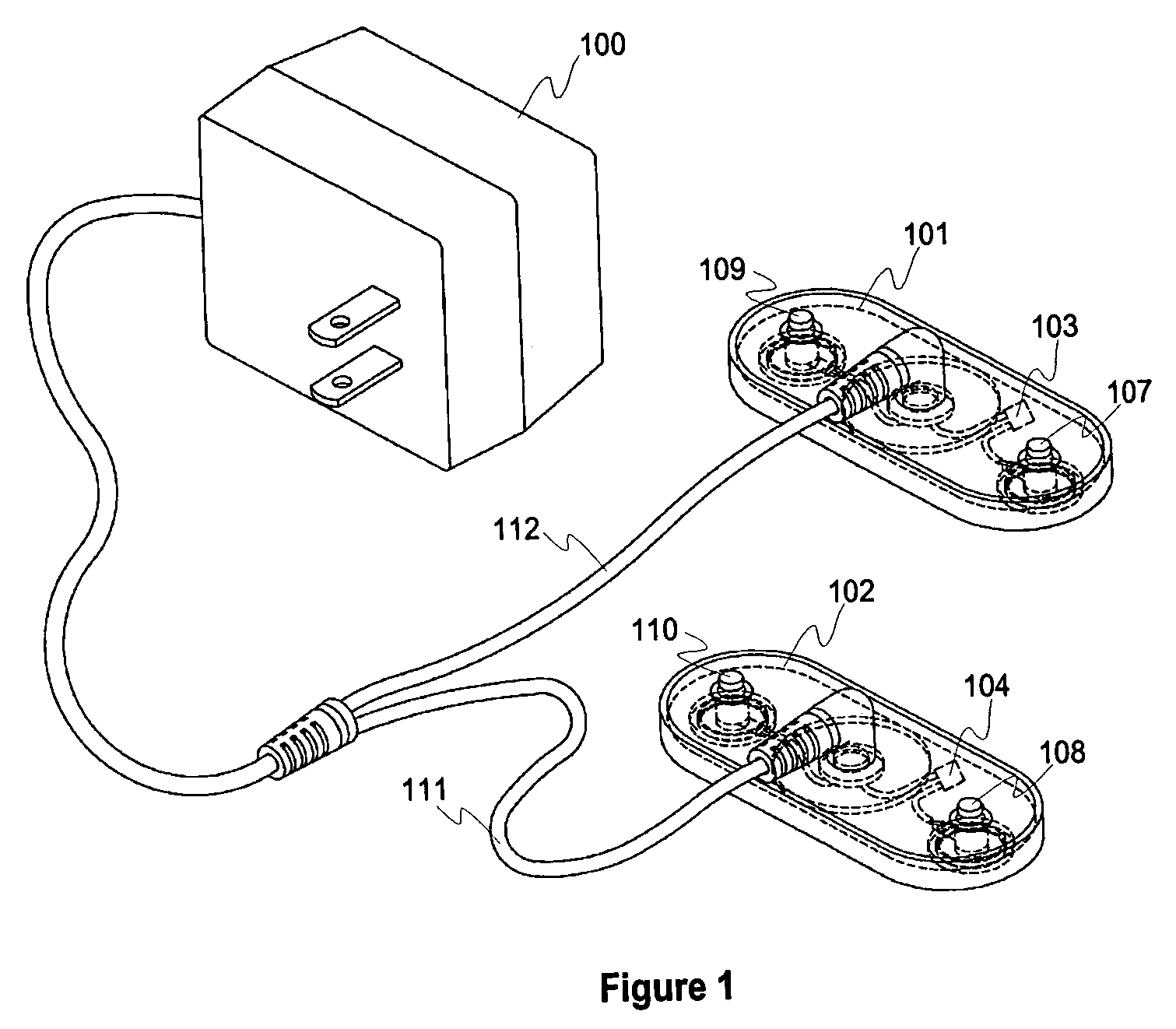

Electronic toy and teaching aid safety devices

ActiveUS7144255B2Limited amountAvoid damageSubstation/switching arrangement detailsCoupling device detailsElectronic componentPositive temperature

A battery holder containing positive temperature coefficient (PTC) resetable fuse to electronically limit the maximum current that can be drawn from circuits built using reusable electronic component housings. A power supply with similar housing to reusable battery holders, also designed to limit maximum current and perform electrically equivalent to two or more battery holders. A reusable electronic housing with means for attaching any two leaded electronic component for insertion into quick connect assembly system. This housing also contains a positive temperature coefficient (PTC) resetable fuse to electroniclly limit the maximum current that can be sent through the attached two leaded component.

Owner:ELENCO ELECTRONICS LLC

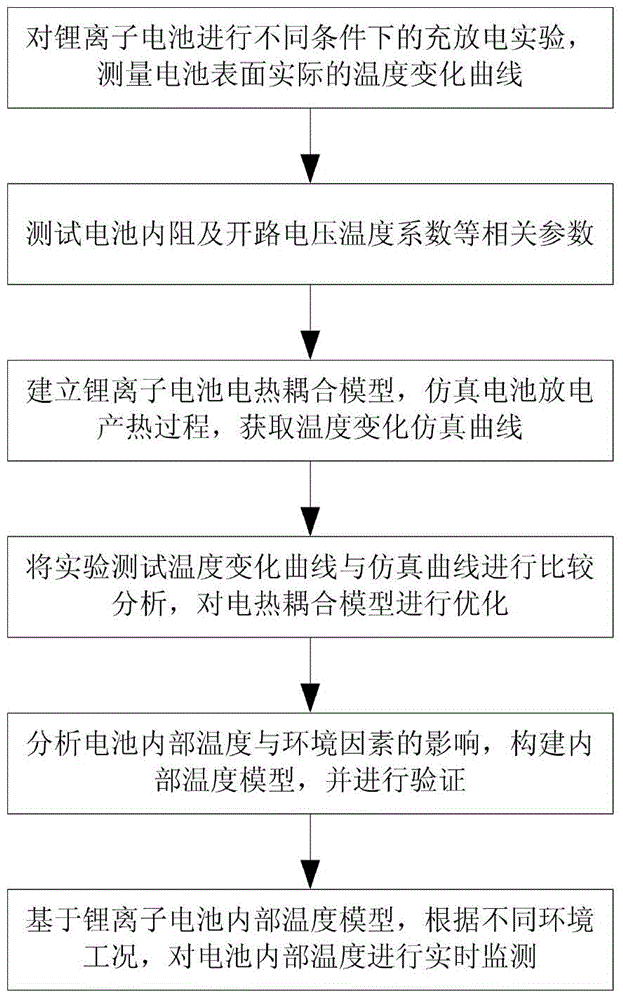

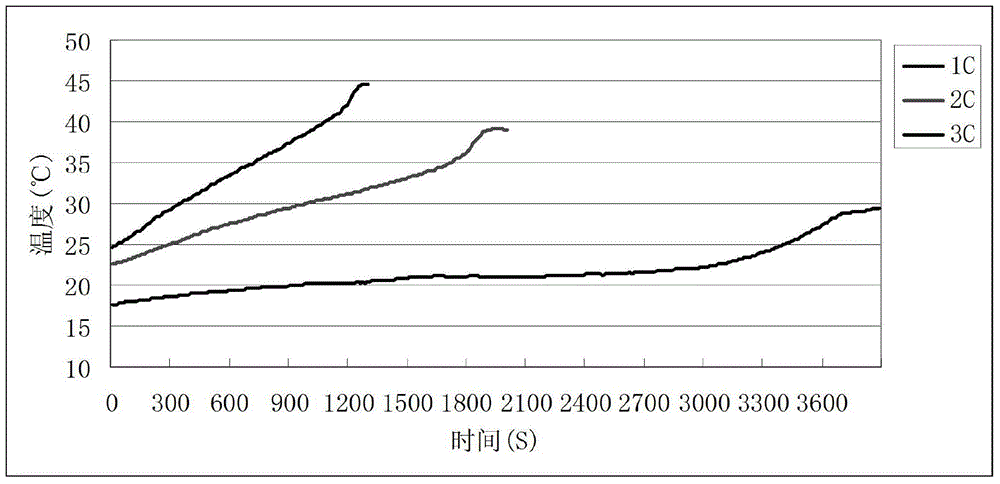

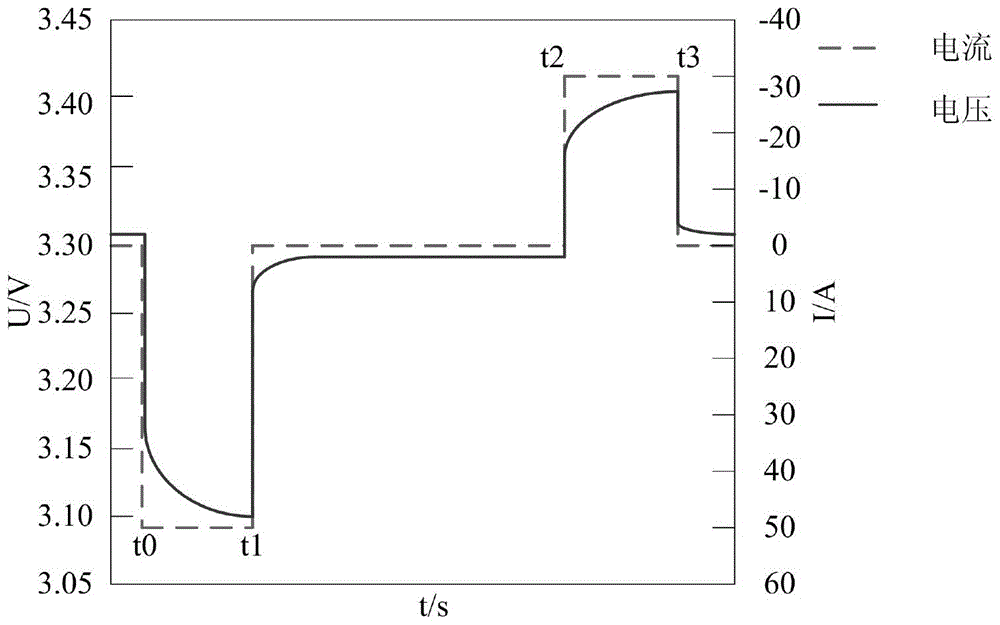

Lithium ion battery internal temperature monitoring method

InactiveCN105206888AGuaranteed accuracyReal-time measurementSecondary cellsInternal resistanceCharge discharge

The invention discloses a lithium ion battery internal temperature monitoring method. The monitoring method includes the following steps that a charge-discharge tester is used for carrying out charge-discharge tests on a lithium ion battery on different environment conditions to obtain a battery surface temperature change curve; related parameters such as battery internal resistance and an open-circuit voltage temperature coefficient are tested, and a lithium ion battery electric heating coupling model based on a variable heat production rate is set up; the temperature rise change of the discharge process of the battery is simulated to obtain a temperature change simulation curve; the experiment test temperature change curve and the simulation curve are analyzed and compared to optimize and verify the electric heating coupling model; the influence between the battery internal temperature and the battery surface temperature as well as the influence between the discharge currents and the discharge depth are analyzed, and a lithium ion battery internal temperature model is constructed; the battery internal temperature is monitored in real time according to the model. The lithium ion battery internal temperature monitoring method is simple and easy to implement, small in estimation error and capable of well meeting the requirement for monitoring the battery internal temperature in real time.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

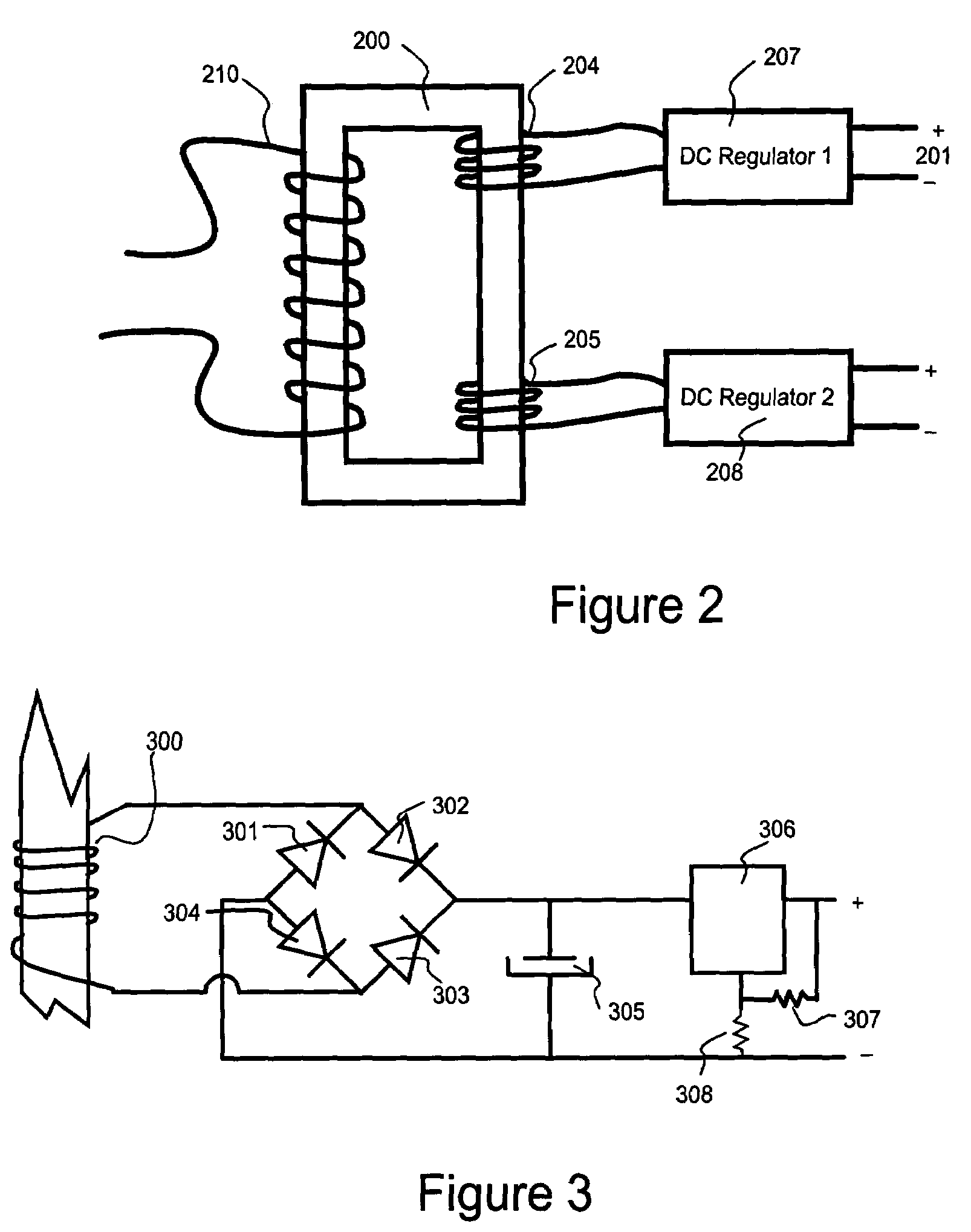

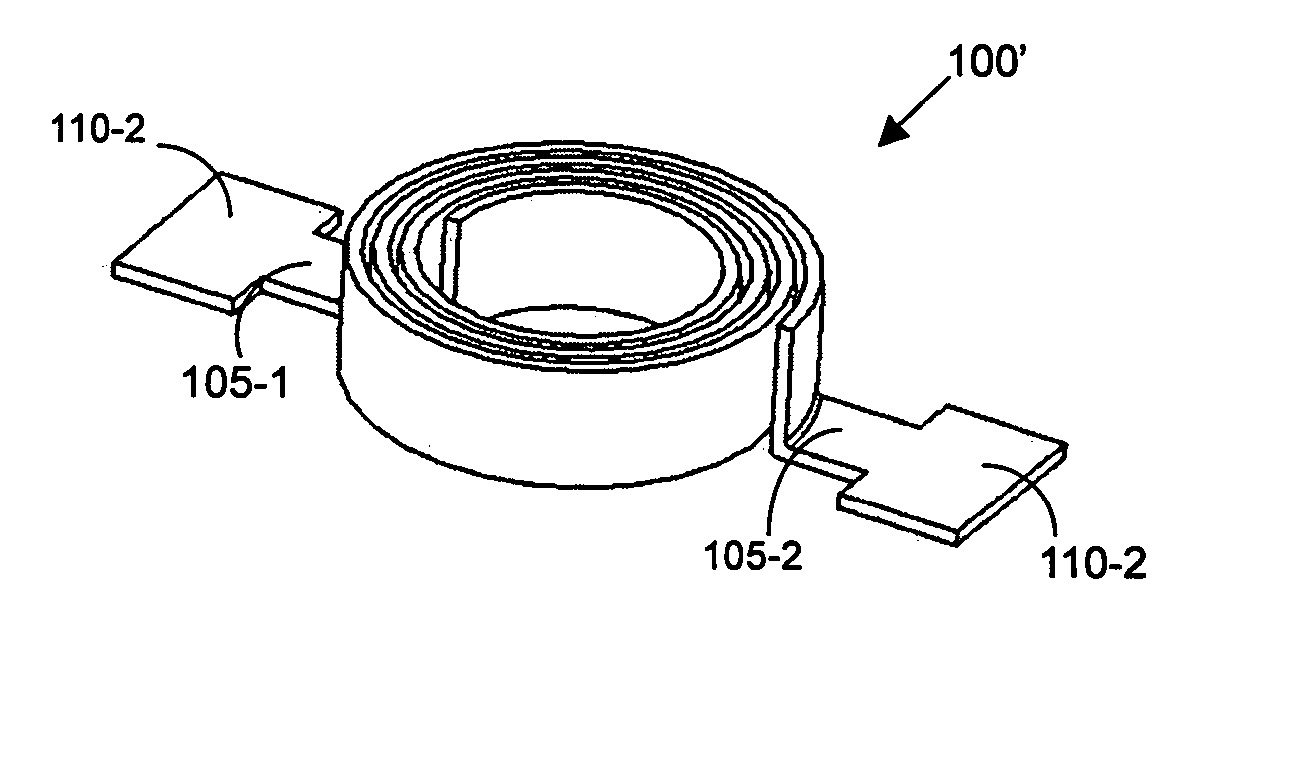

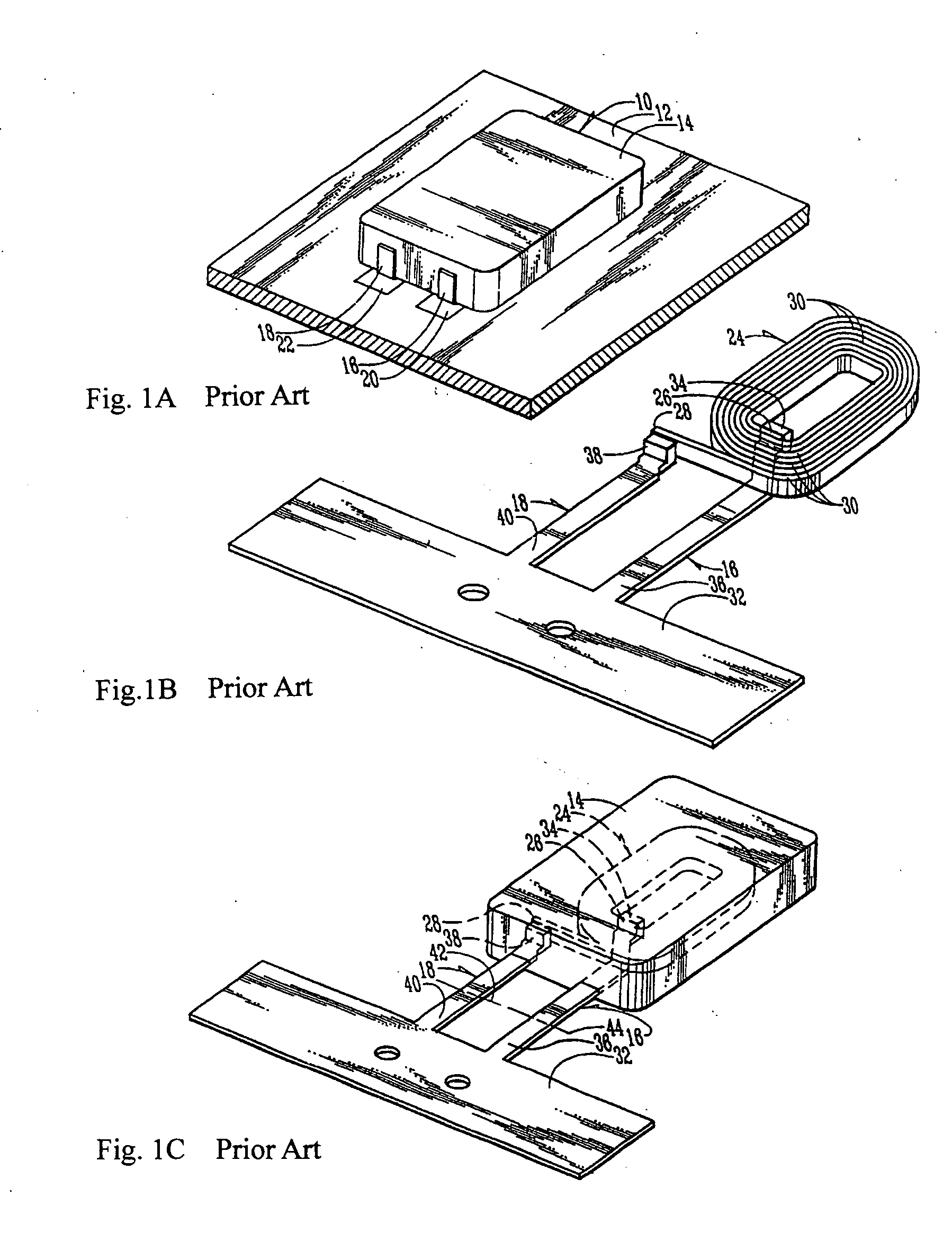

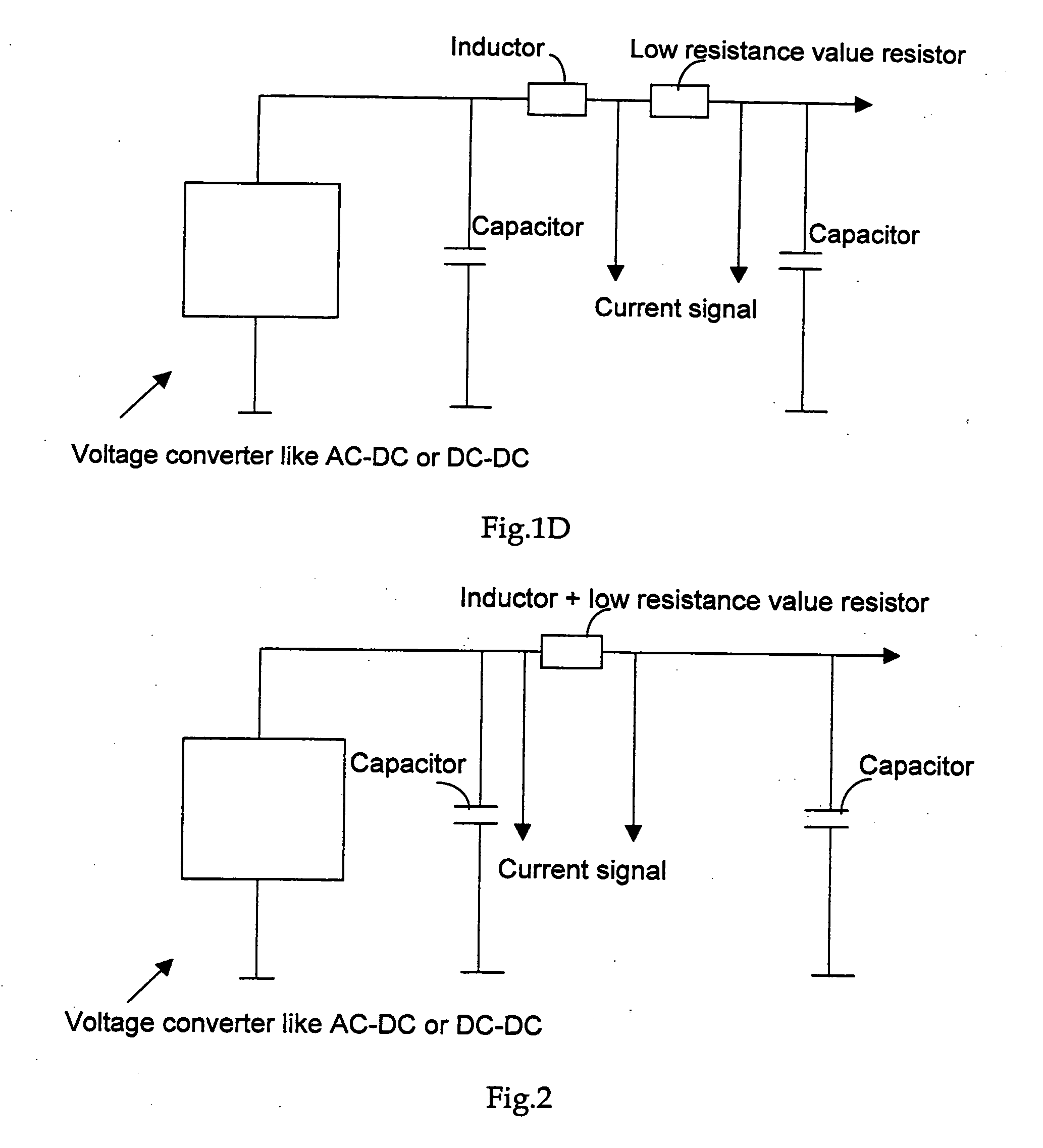

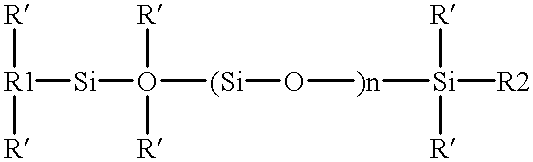

Current measurement using inductor coil with compact configuration and low TCR alloys

ActiveUS20060049907A1Simple manufacturing processSmall heightTransformers/inductances detailsInductance with magnetic coreElectrical resistance and conductanceCelsius Degree

This invention discloses an inductor that includes a conducting wire composed of an alloy having temperature coefficients of resistance (TCR) approximately 0.0002 milliohm per Celsius degree or is lower. The inductive coil has a winding configuration provided for enclosure in a substantially rectangular box with a mid-plane extended along an elongated direction of the rectangular box wherein the conducting wire interesting at least twice near said mid-plane.

Owner:CYNTEC

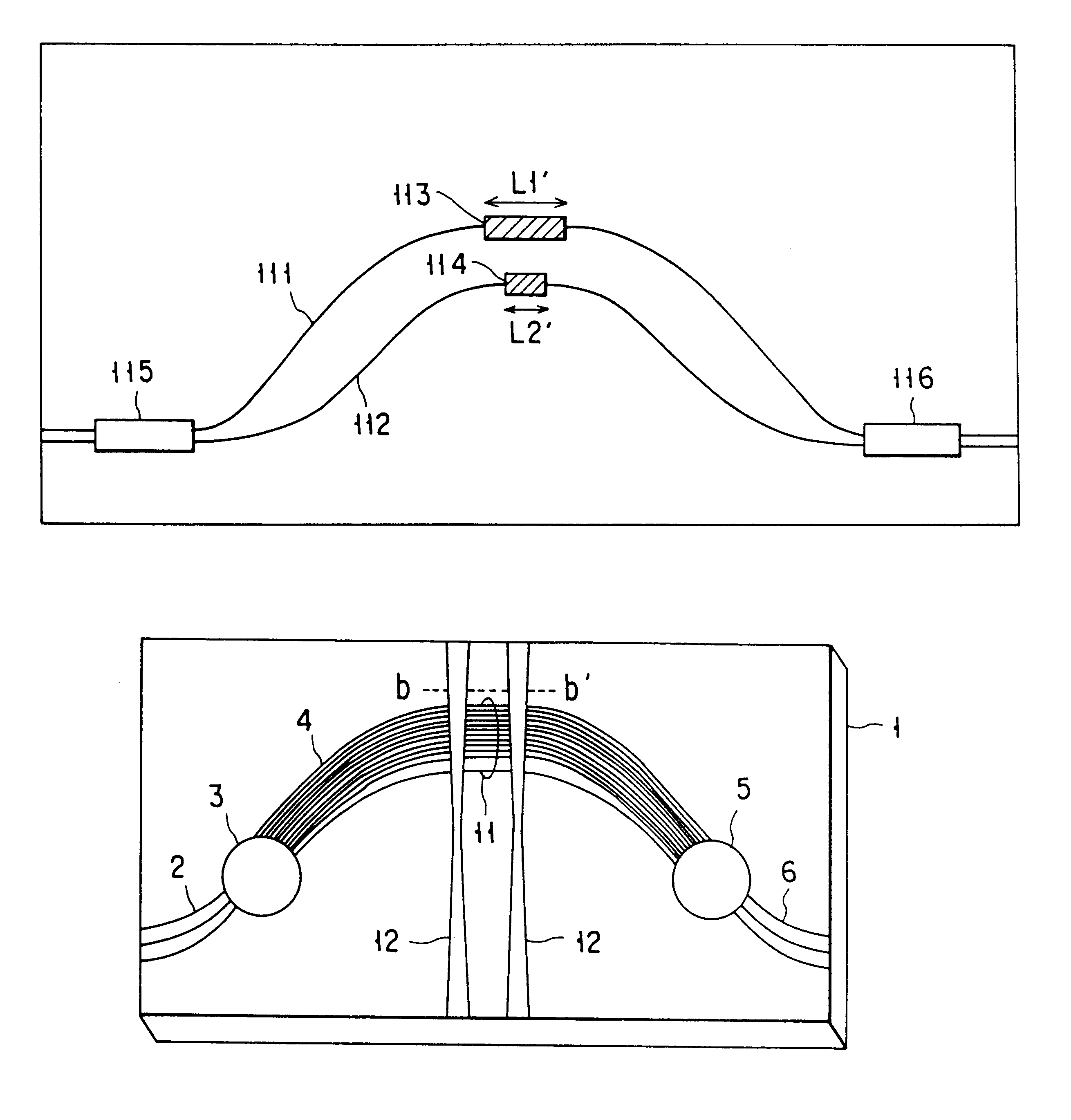

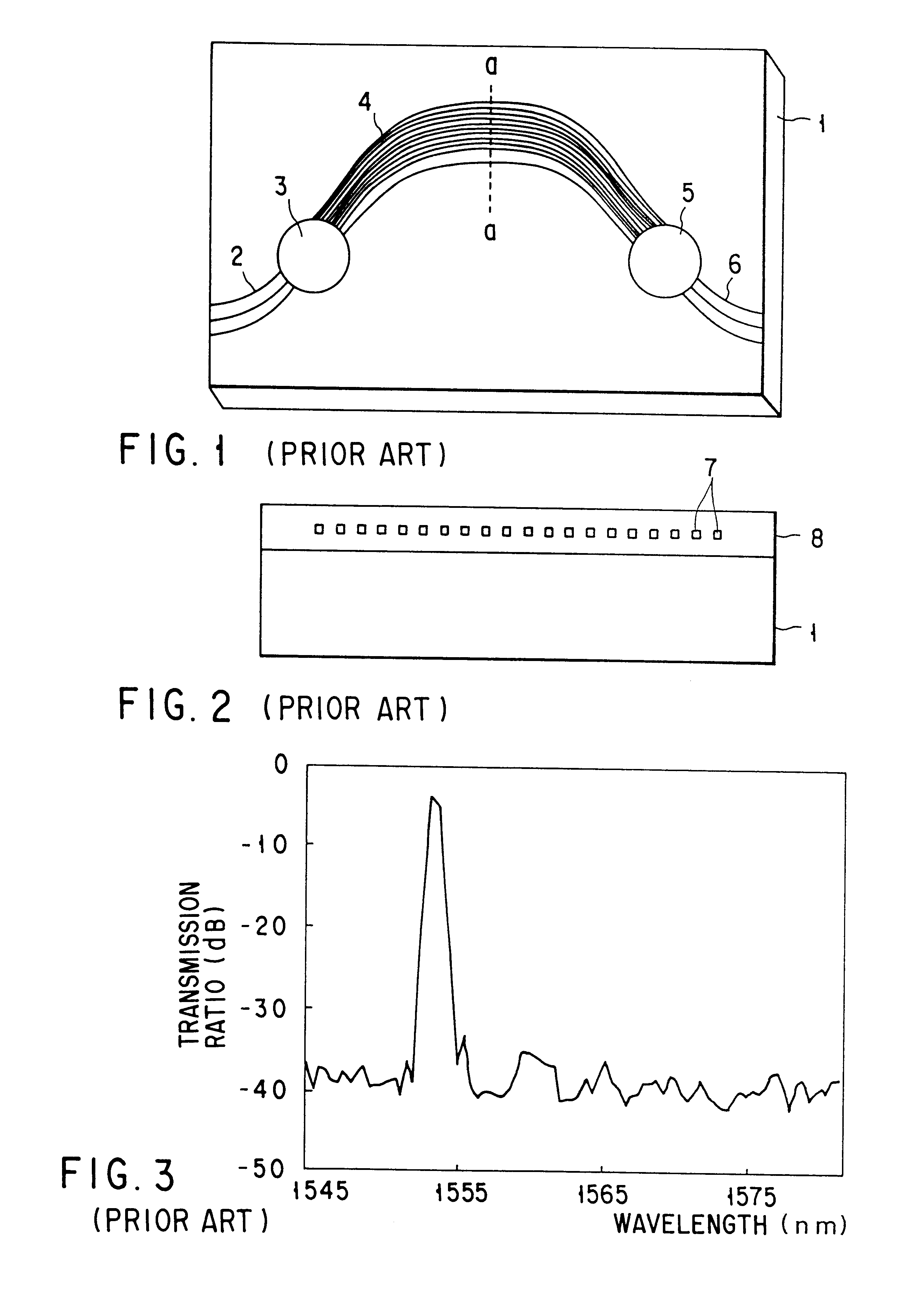

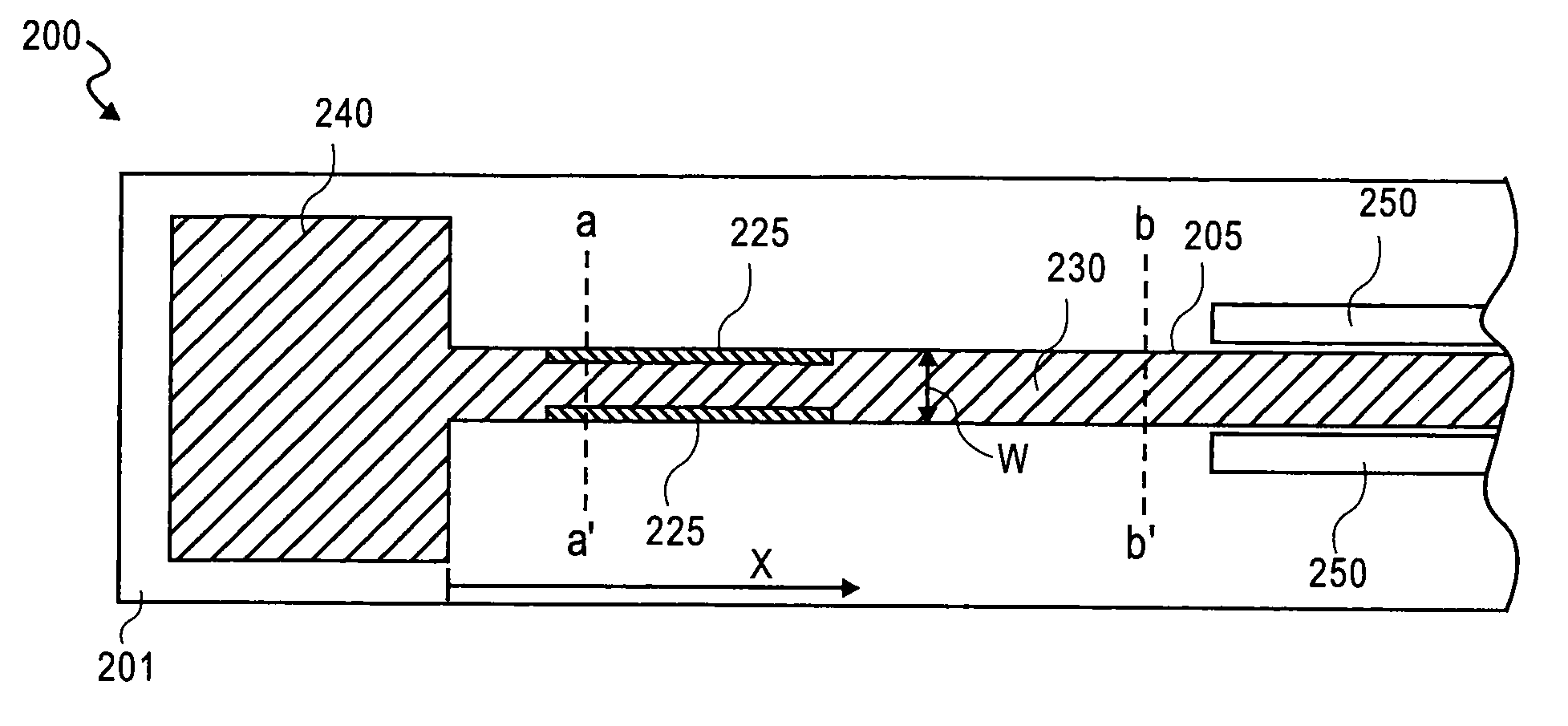

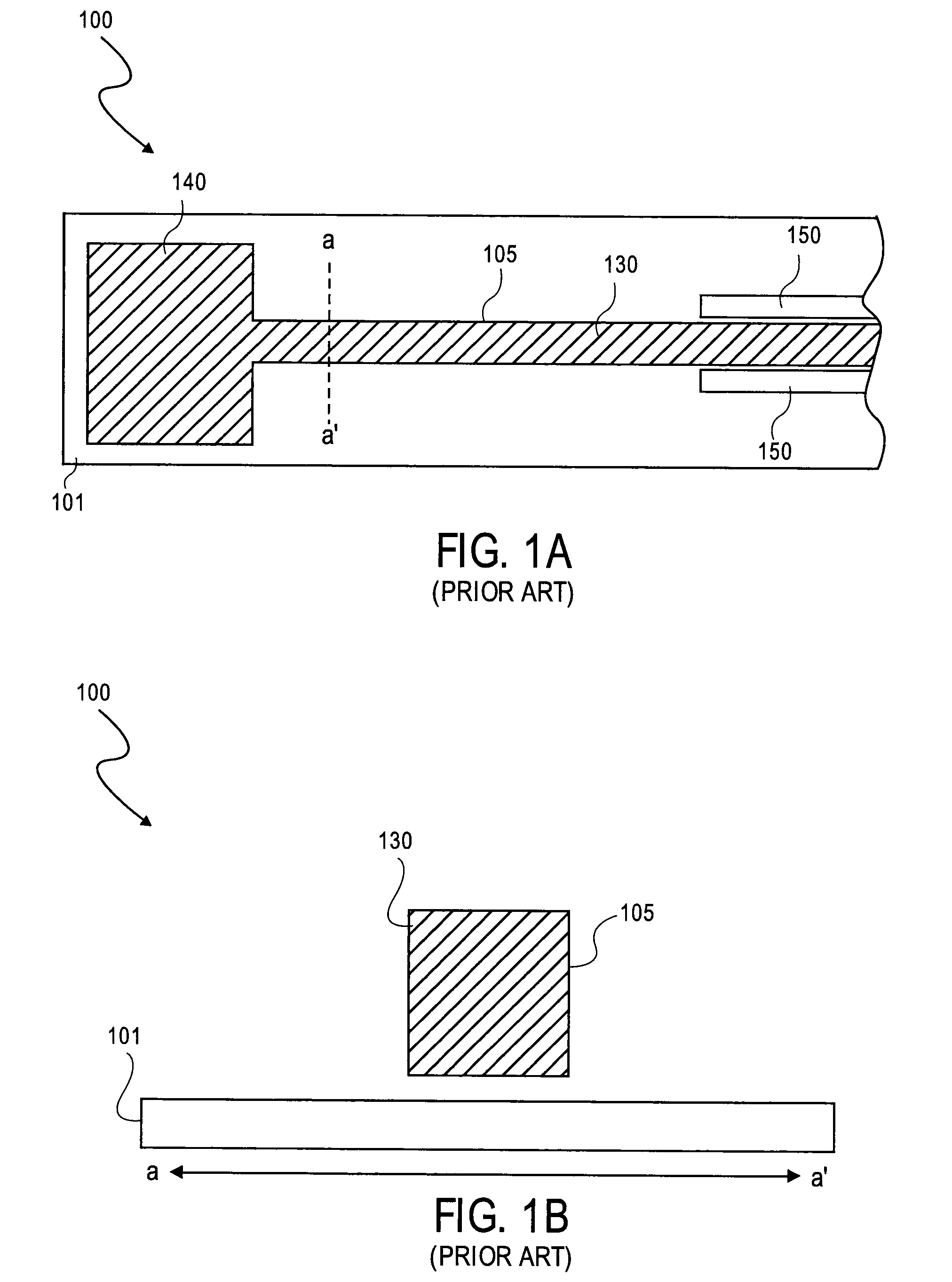

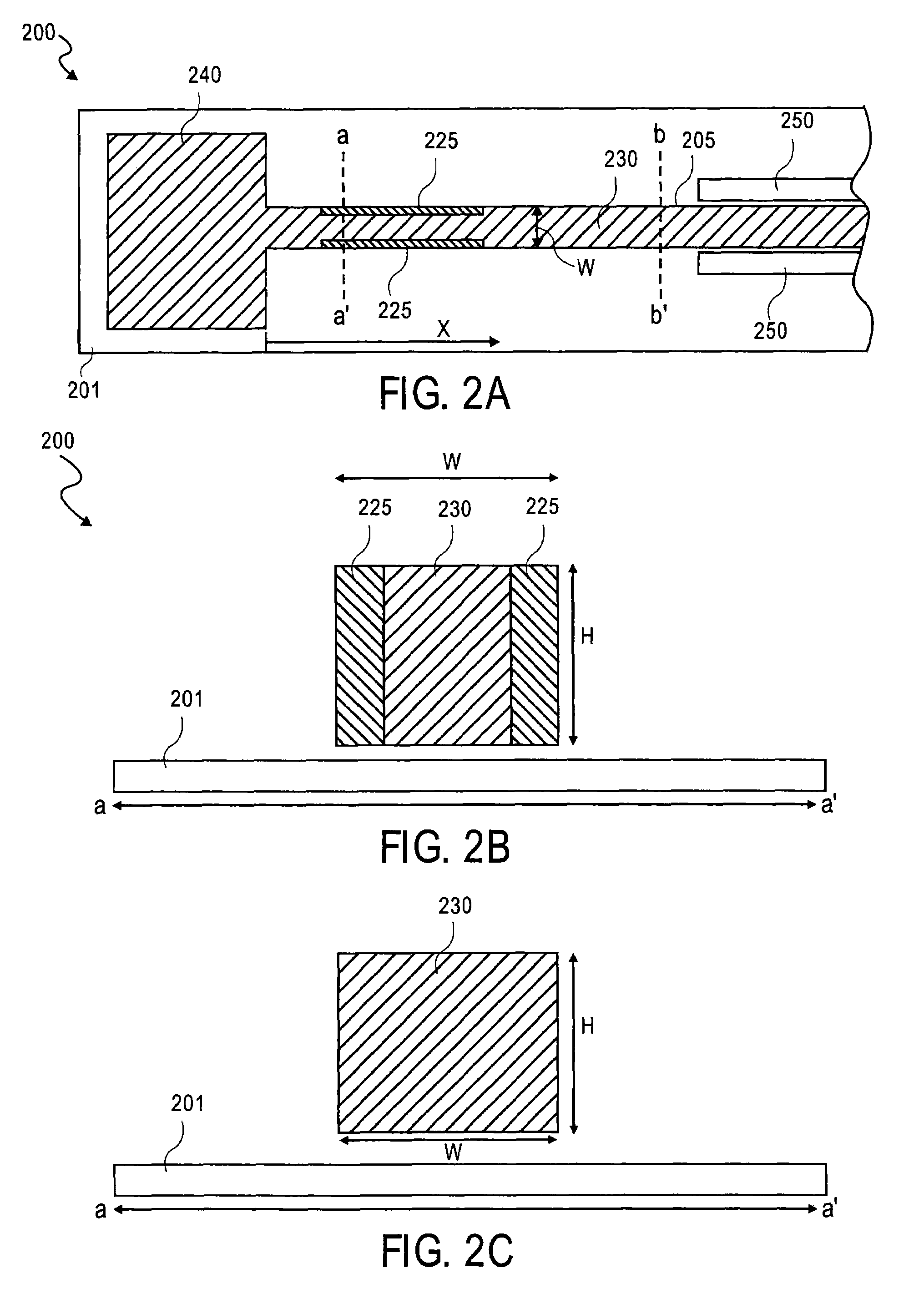

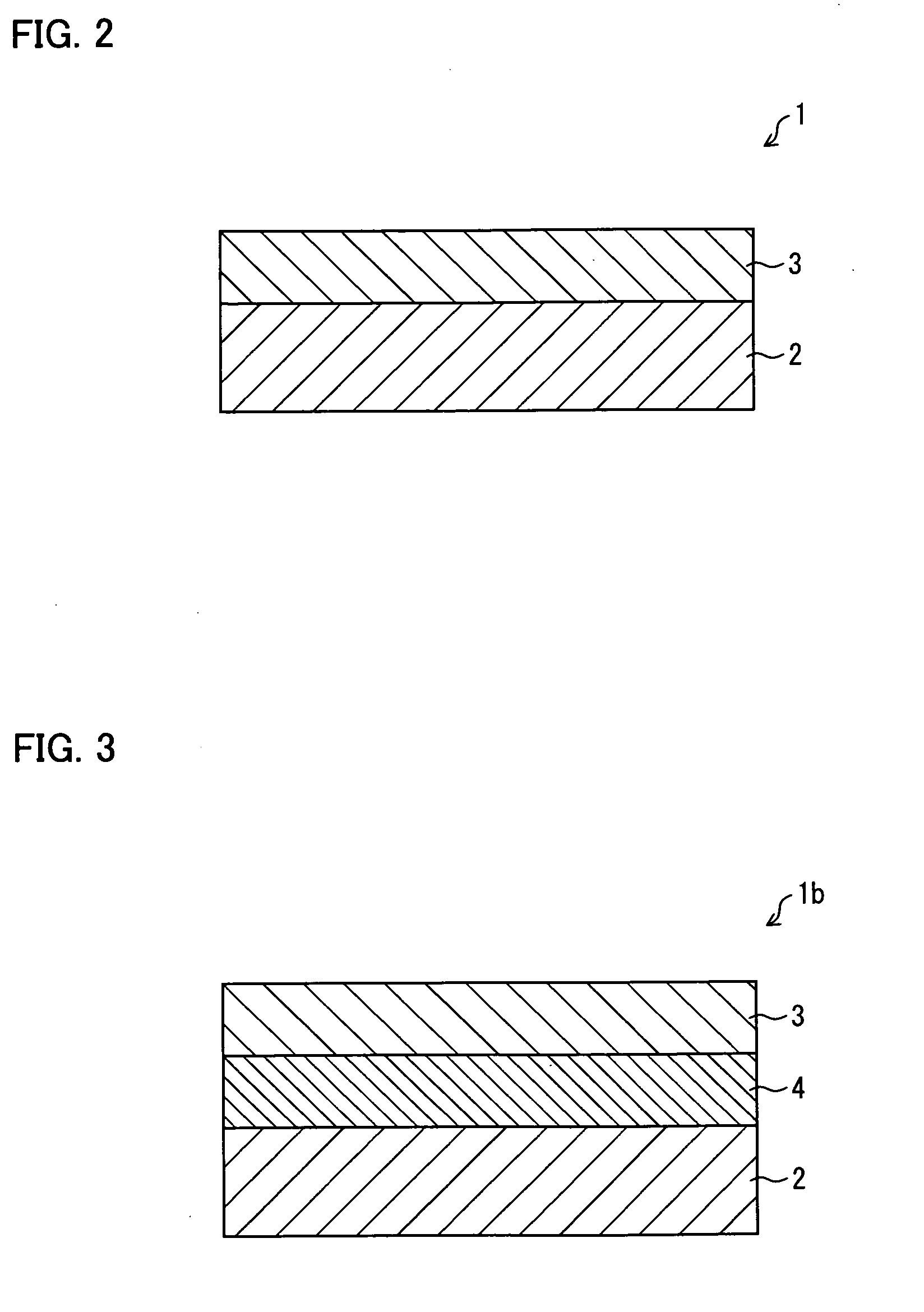

Optical waveguide circuit, its manufacturing method and optical waveguide module having the optical waveguide circuit

InactiveUS6304687B1Coupling light guidesOptical waveguide light guideTemperature coefficientEffective refractive index

In a light waveguide circuit including a plurality of waveguides having different length, a material (10) having a temperature coefficient of a refractive index including a symbol different from that of a temperature coefficient of an effective refractive index of the waveguide (4) is charged into a groove (12) formed by removing the upper clad and the core from the waveguide (4), or a groove (12) formed by removing the upper clad, the core and the lower clad from the waveguide (4). A difference in length of the removed portions between adjacent waveguides is proportional to a difference in length of the waveguides which were not removed and remained.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP +1

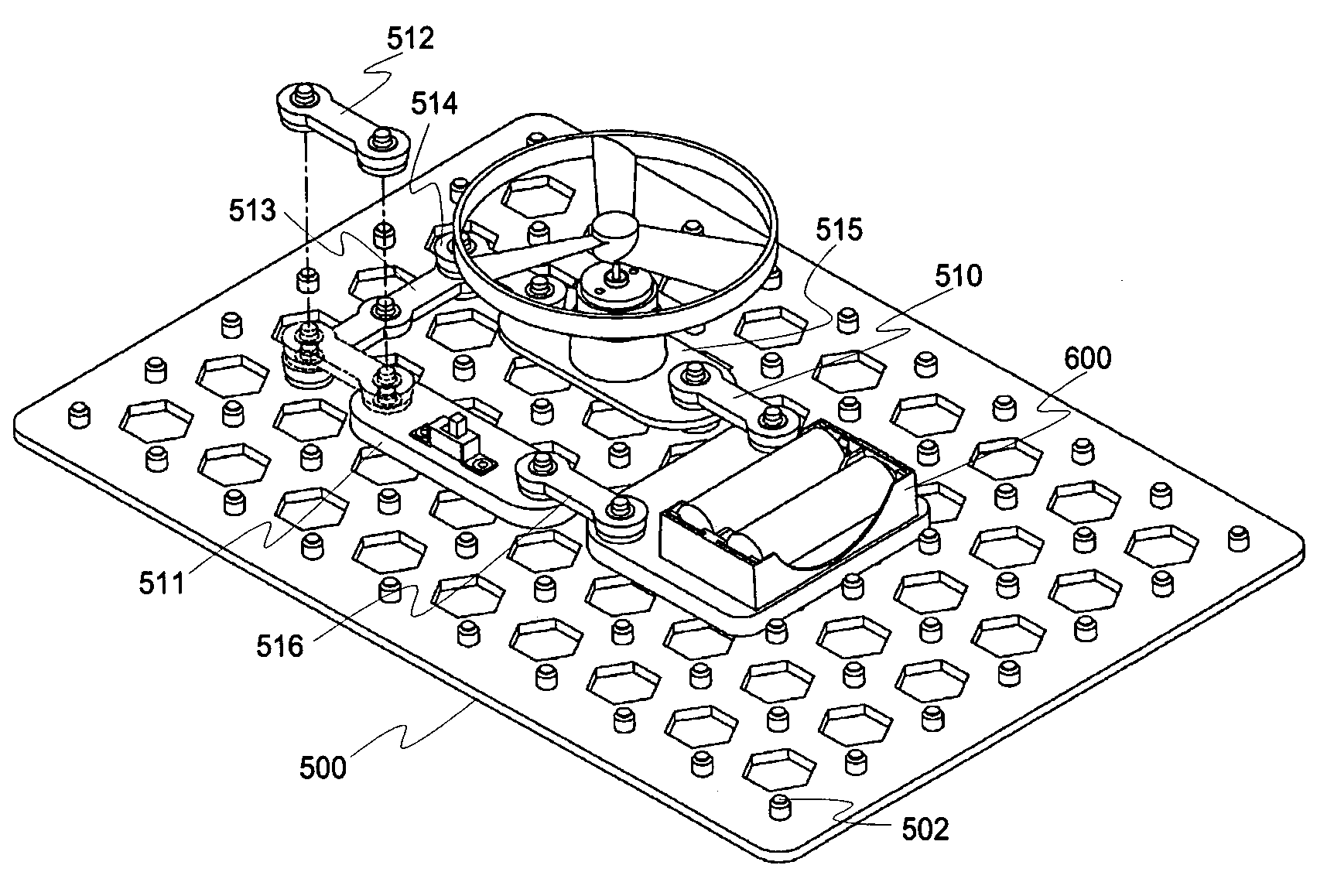

Method for temperature compensation in MEMS resonators with isolated regions of distinct material

MEMS resonators containing a first material and a second material to tailor the resonator's temperature coefficient of frequency (TCF). The first material has a different Young's modulus temperature coefficient than the second material. In one embodiment, the first material has a negative Young's modulus temperature coefficient and the second material has a positive Young's modulus temperature coefficient. In one such embodiment, the first material is a semiconductor and the second material is a dielectric. In a further embodiment, the quantity and location of the second material in the resonator is tailored to meet the resonator TCF specifications for a particular application. In an embodiment, the second material is isolated to a region of the resonator proximate to a point of maximum stress within the resonator. In a particular embodiment, the resonator includes a first material with a trench containing the second material. In a specific embodiment, the shape, dimensions, location and arrangement of a second material comprising silicon dioxide is tailored so that the resonator comprising a first material of SiGe will have a TCF of a much lower magnitude than that of either a homogeneous SiGe or homogeneous silicon dioxide resonator.

Owner:SEMICON MFG INT (SHANGHAI) CORP

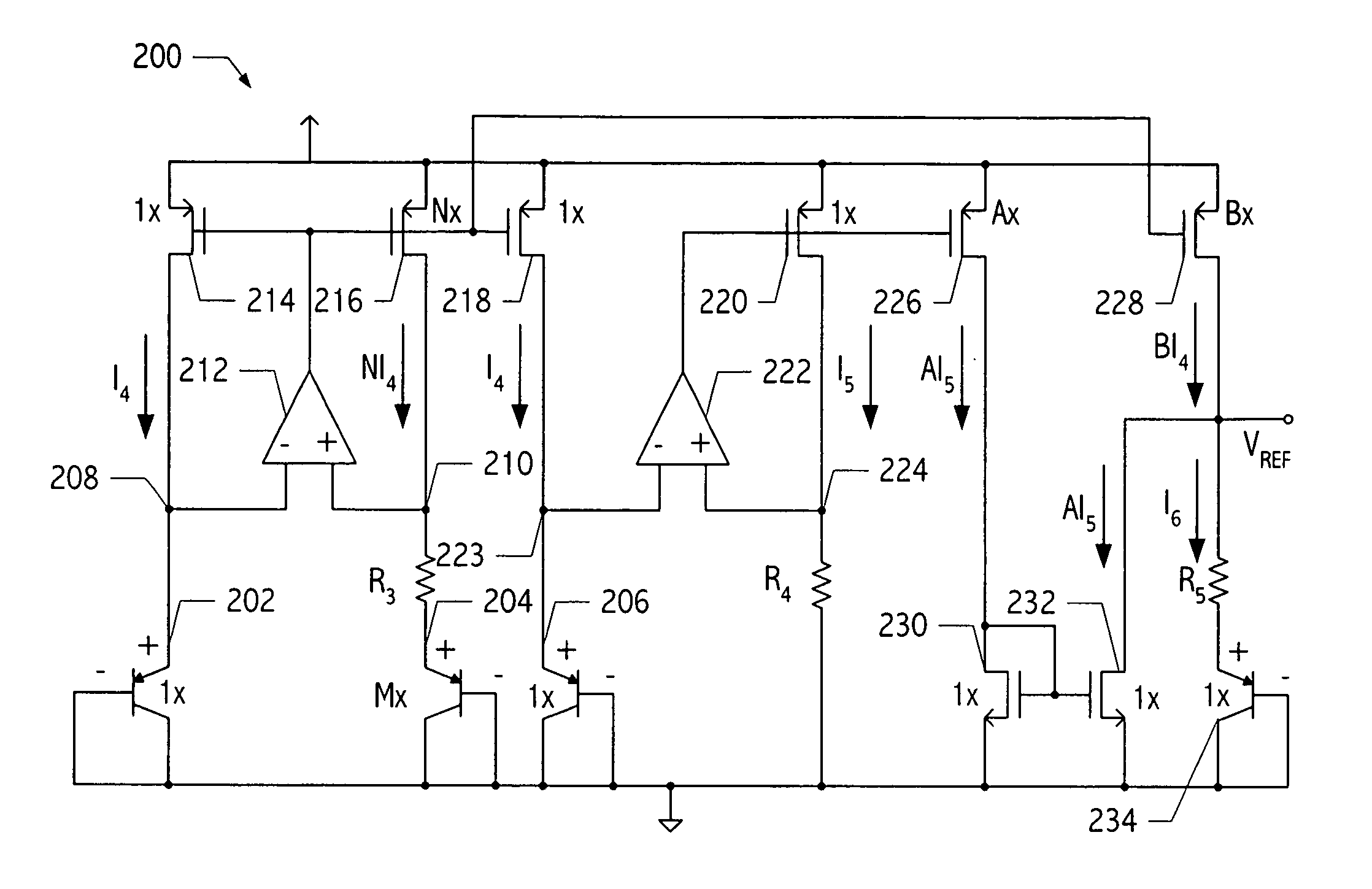

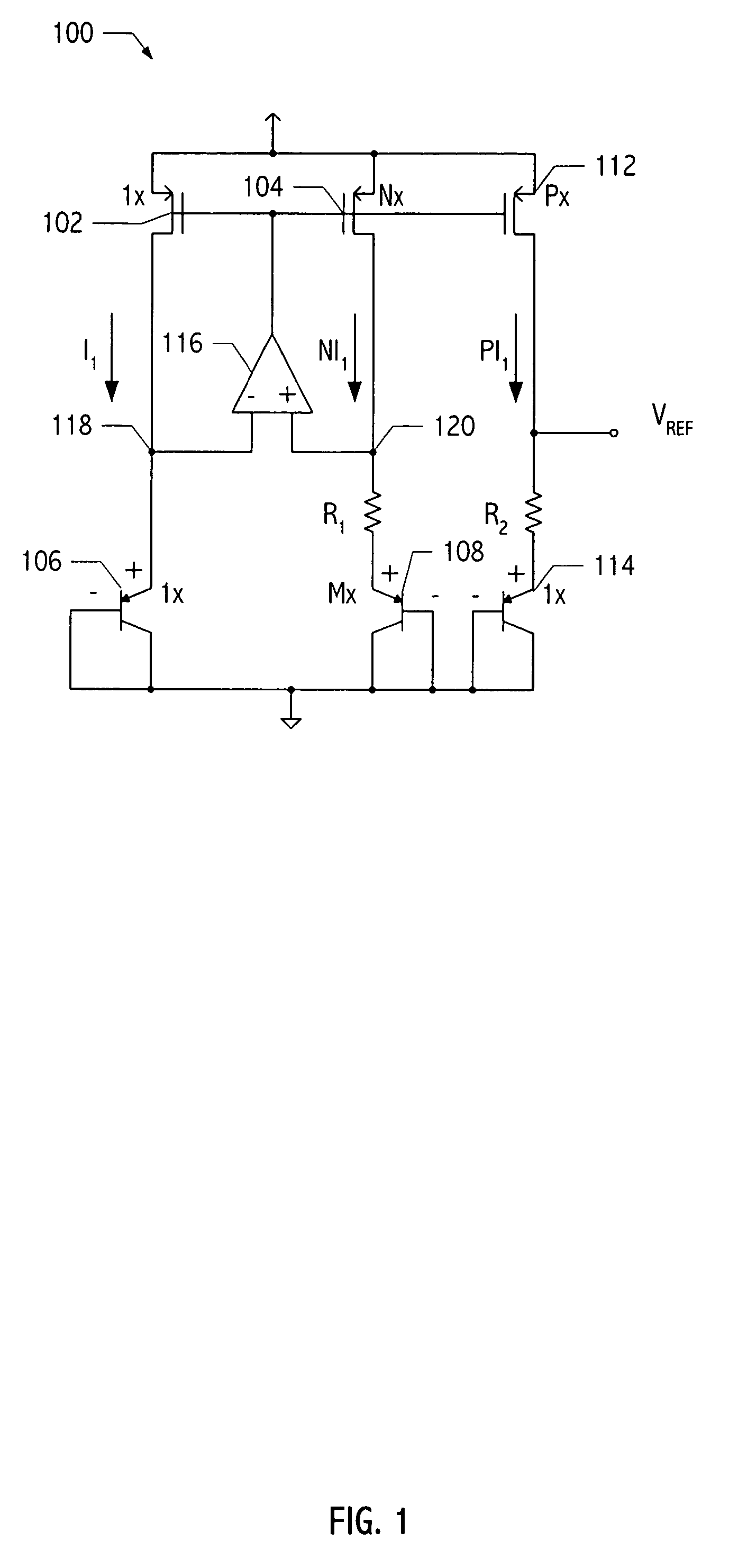

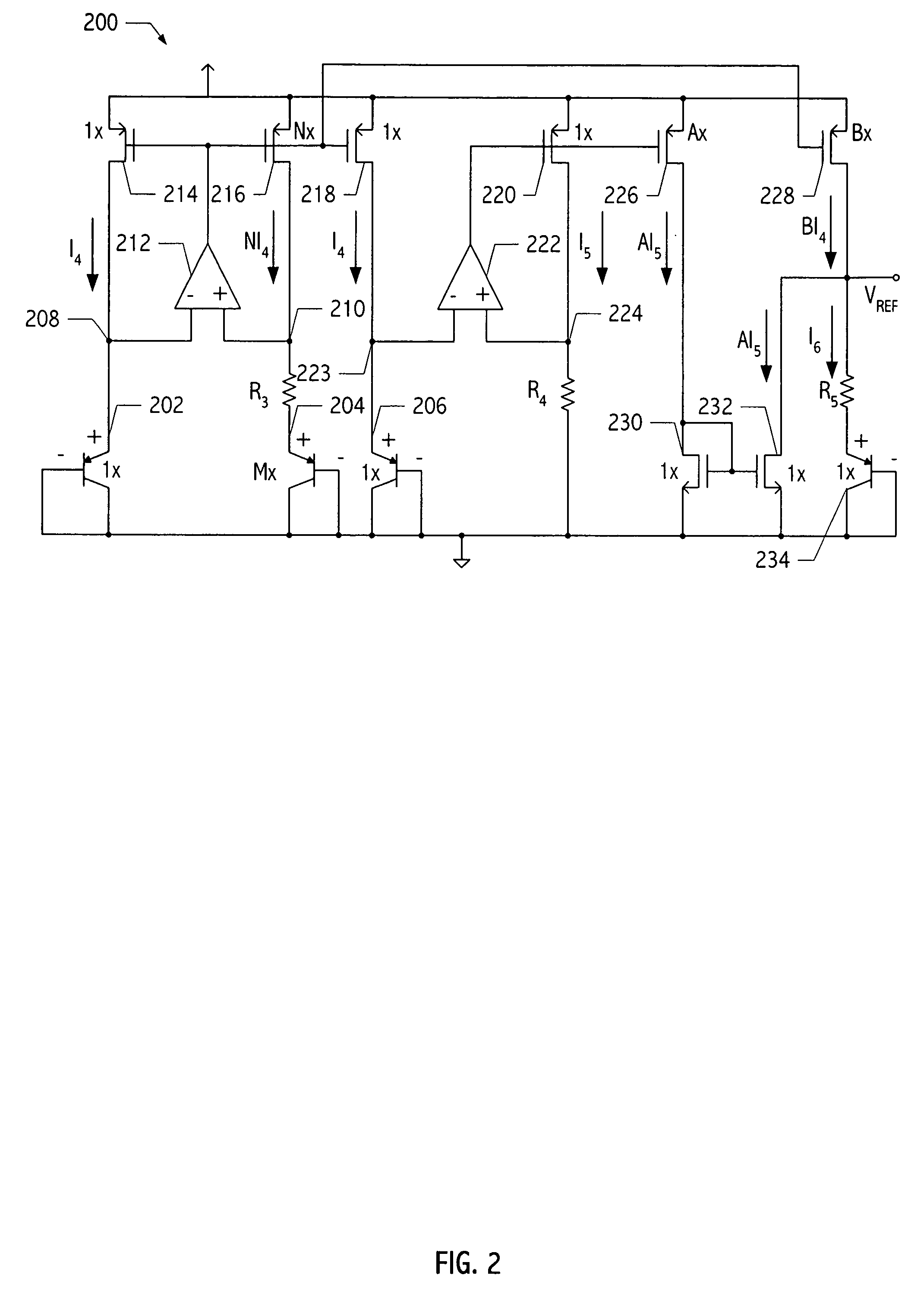

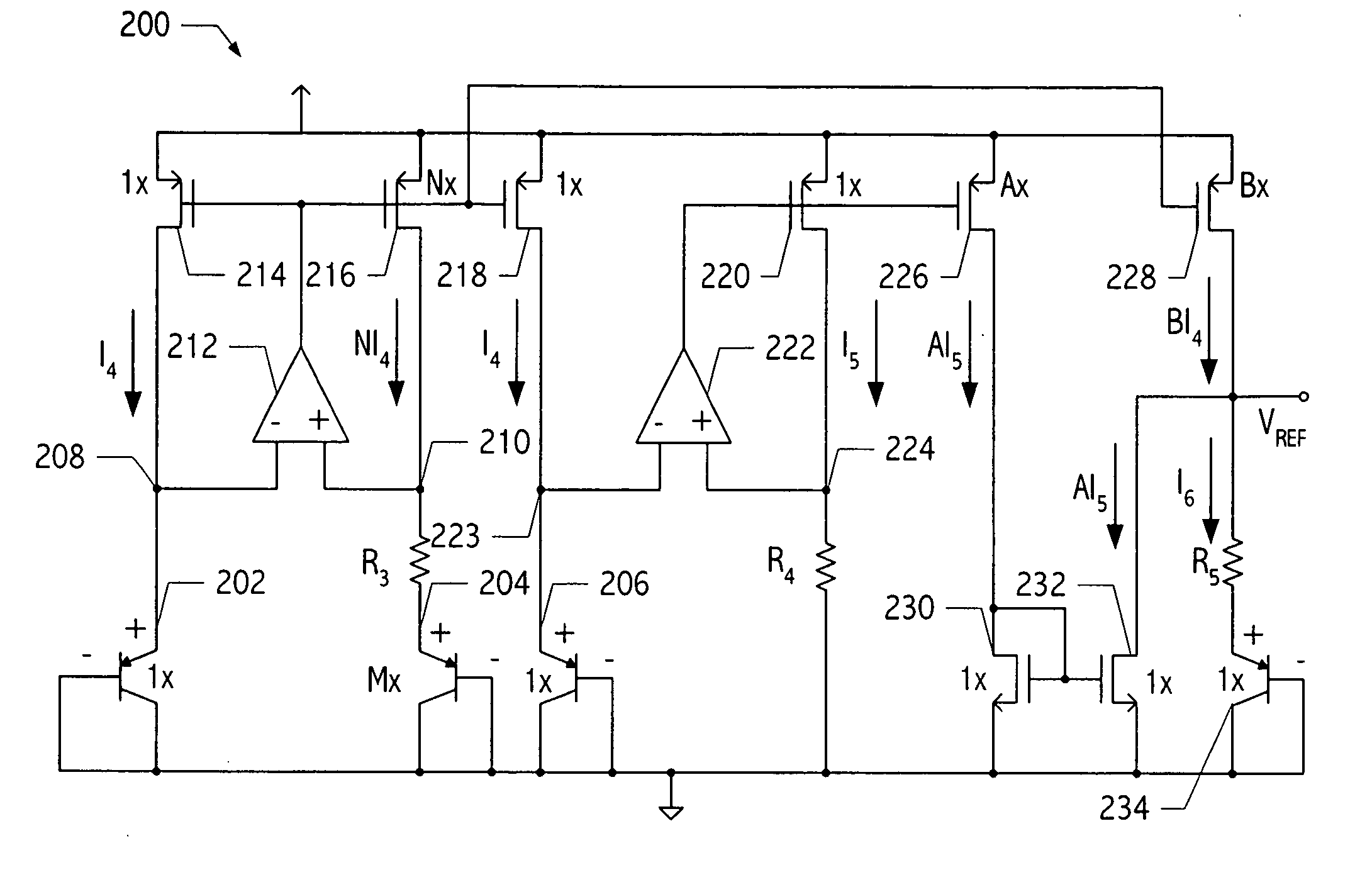

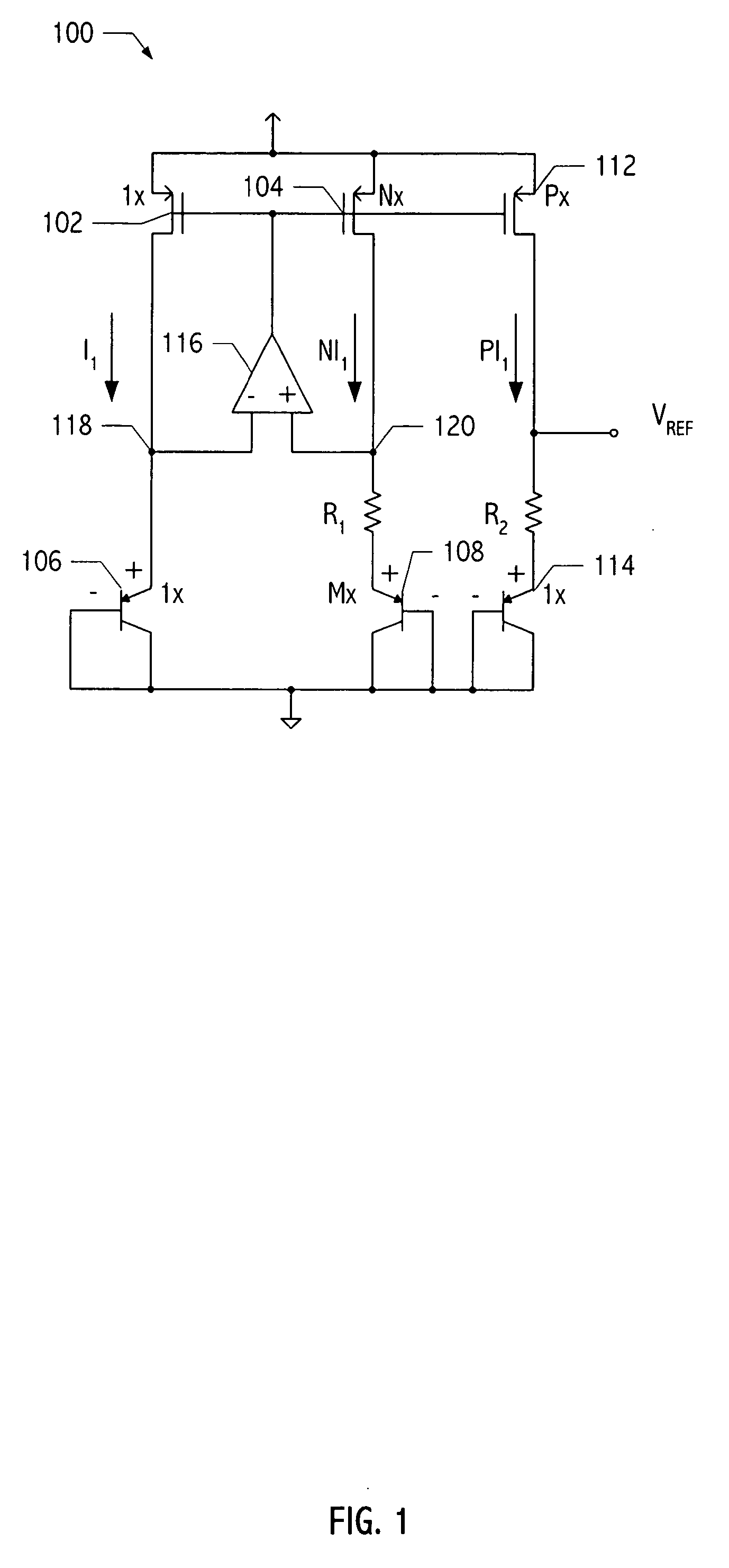

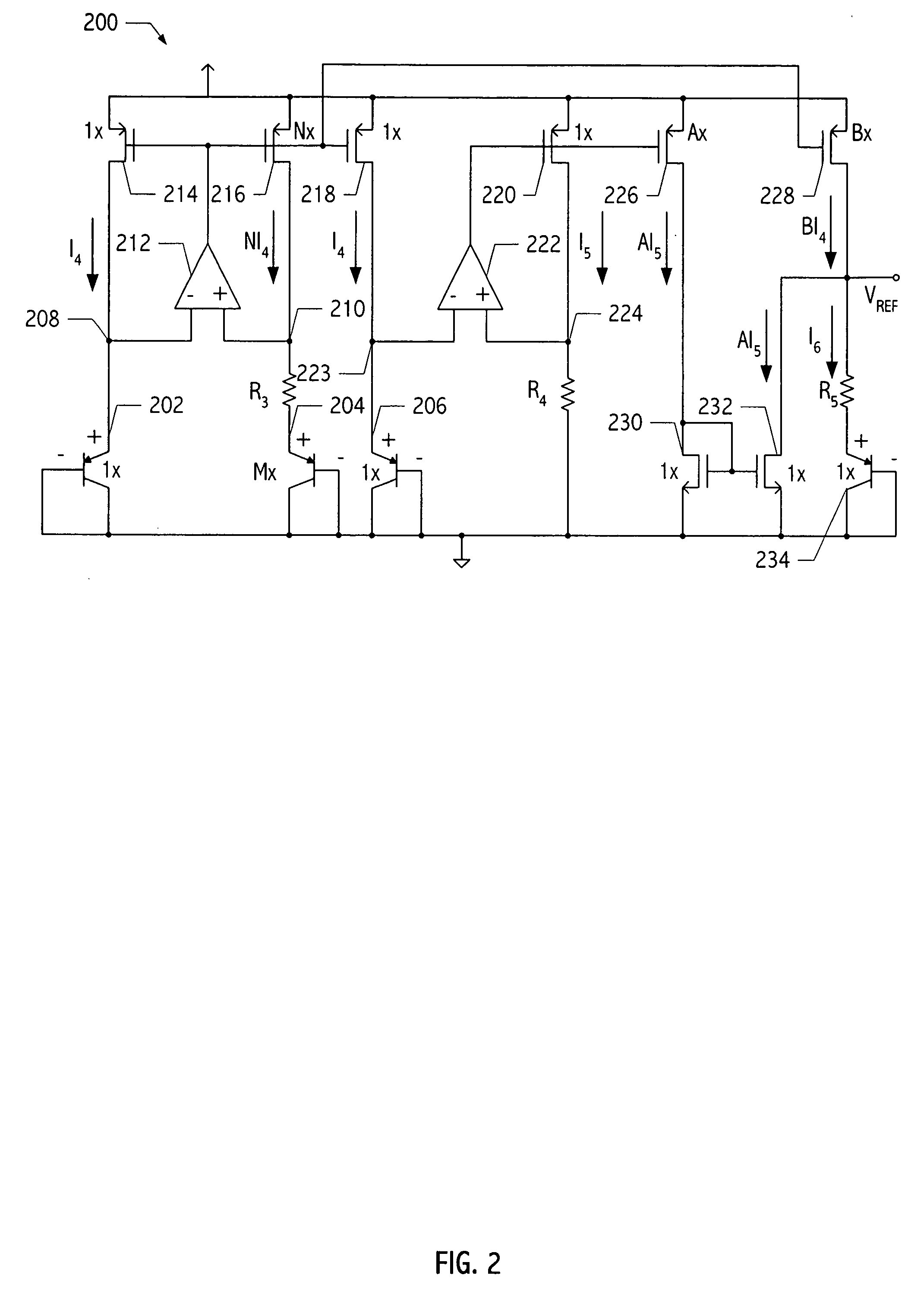

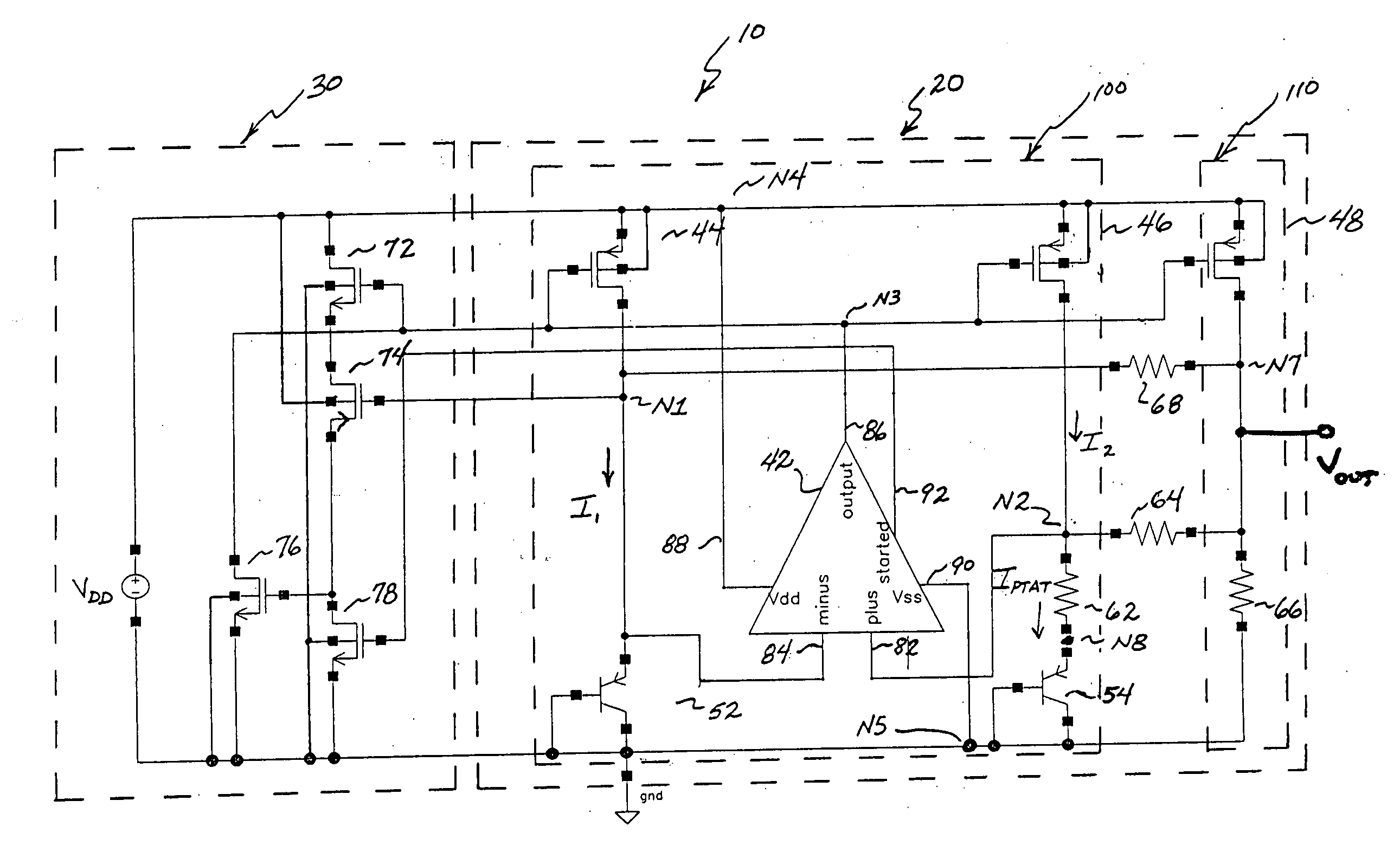

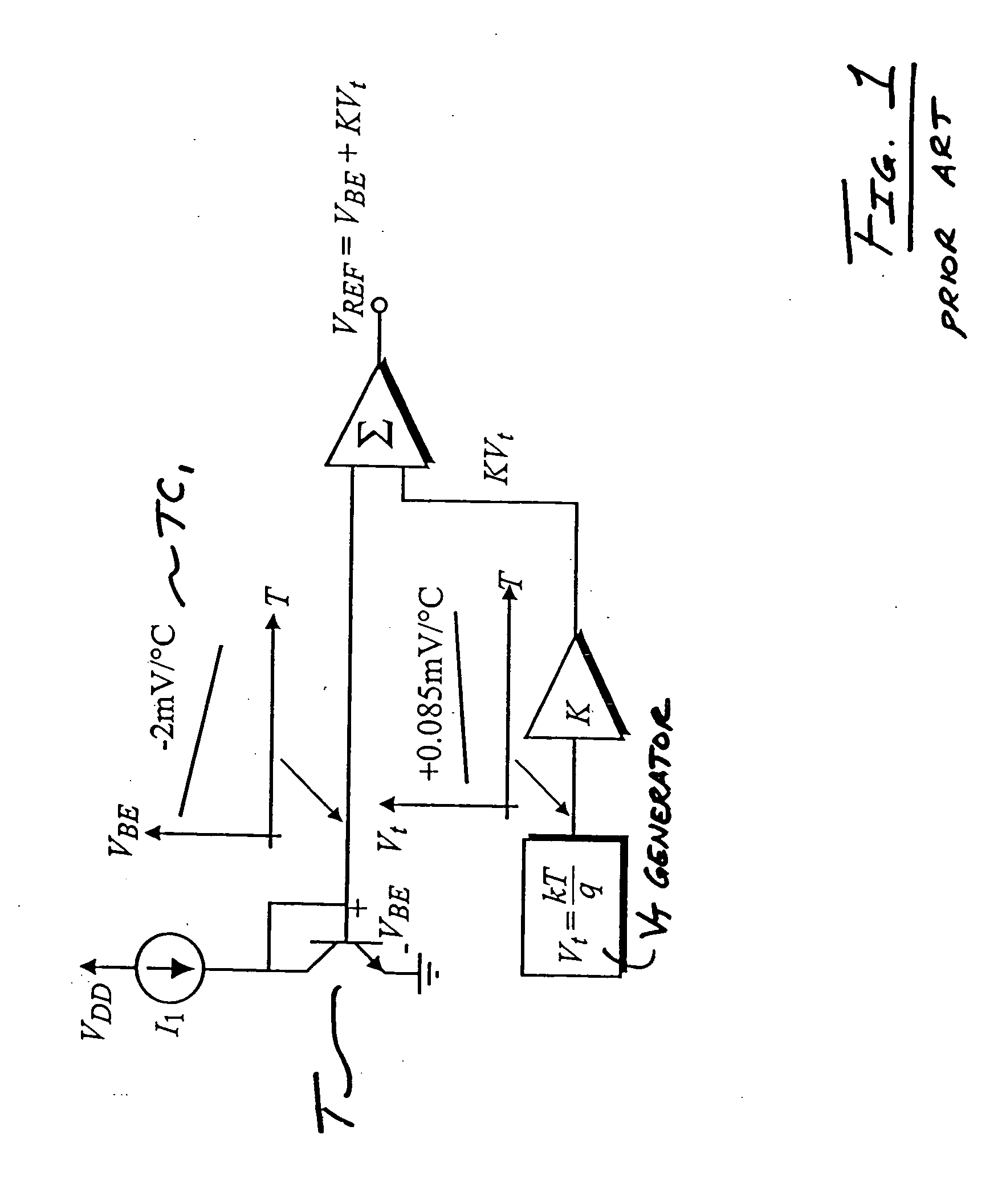

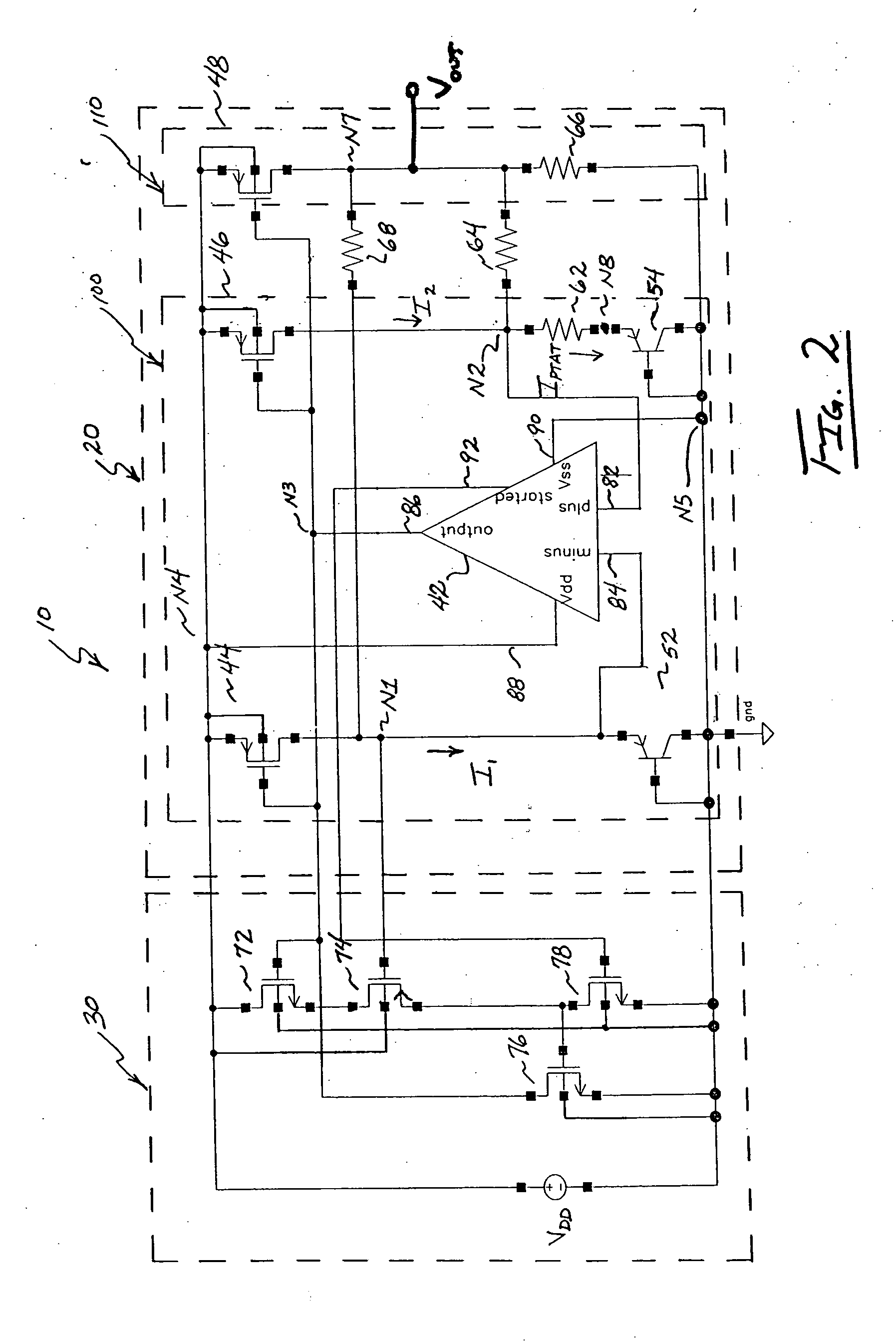

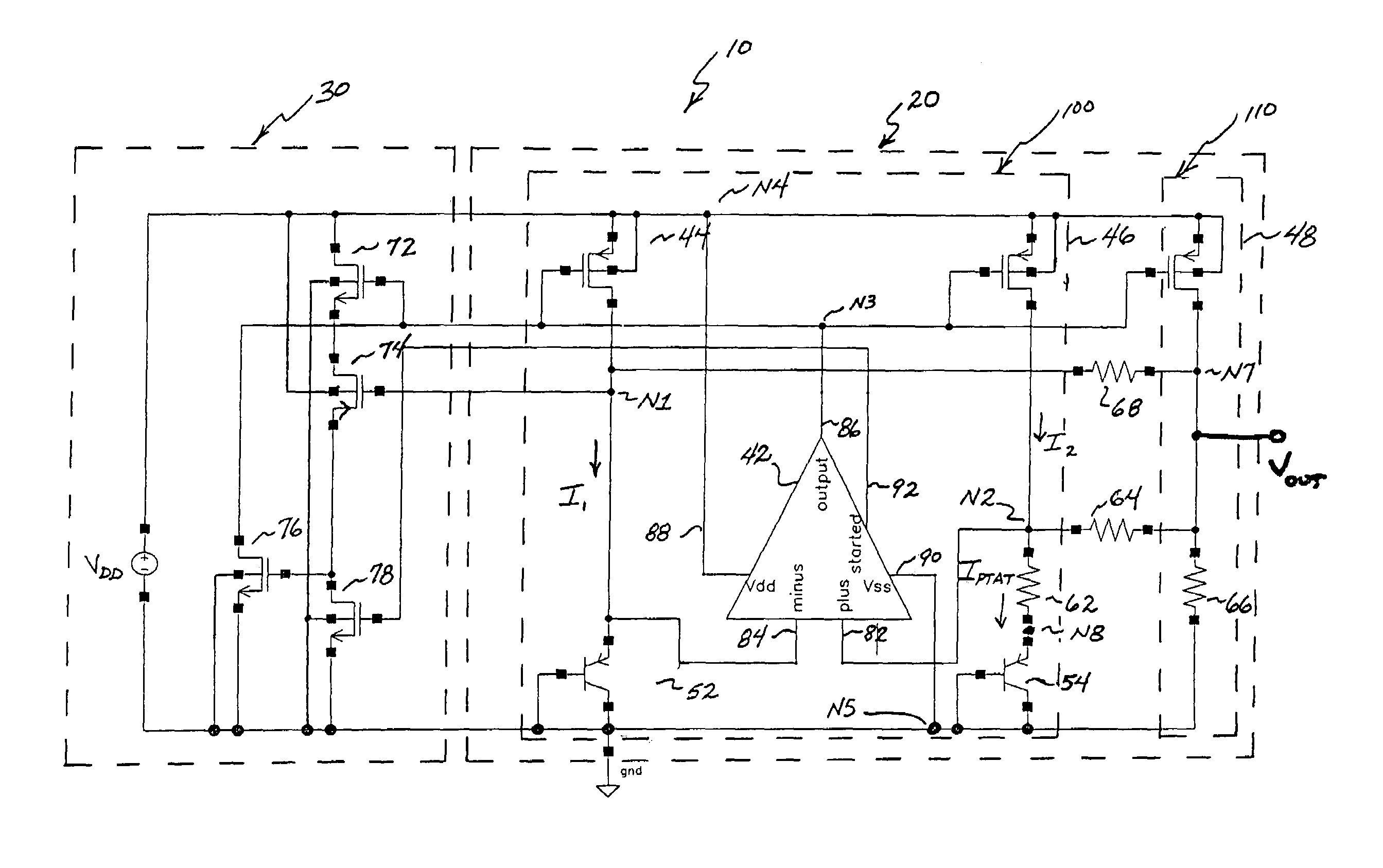

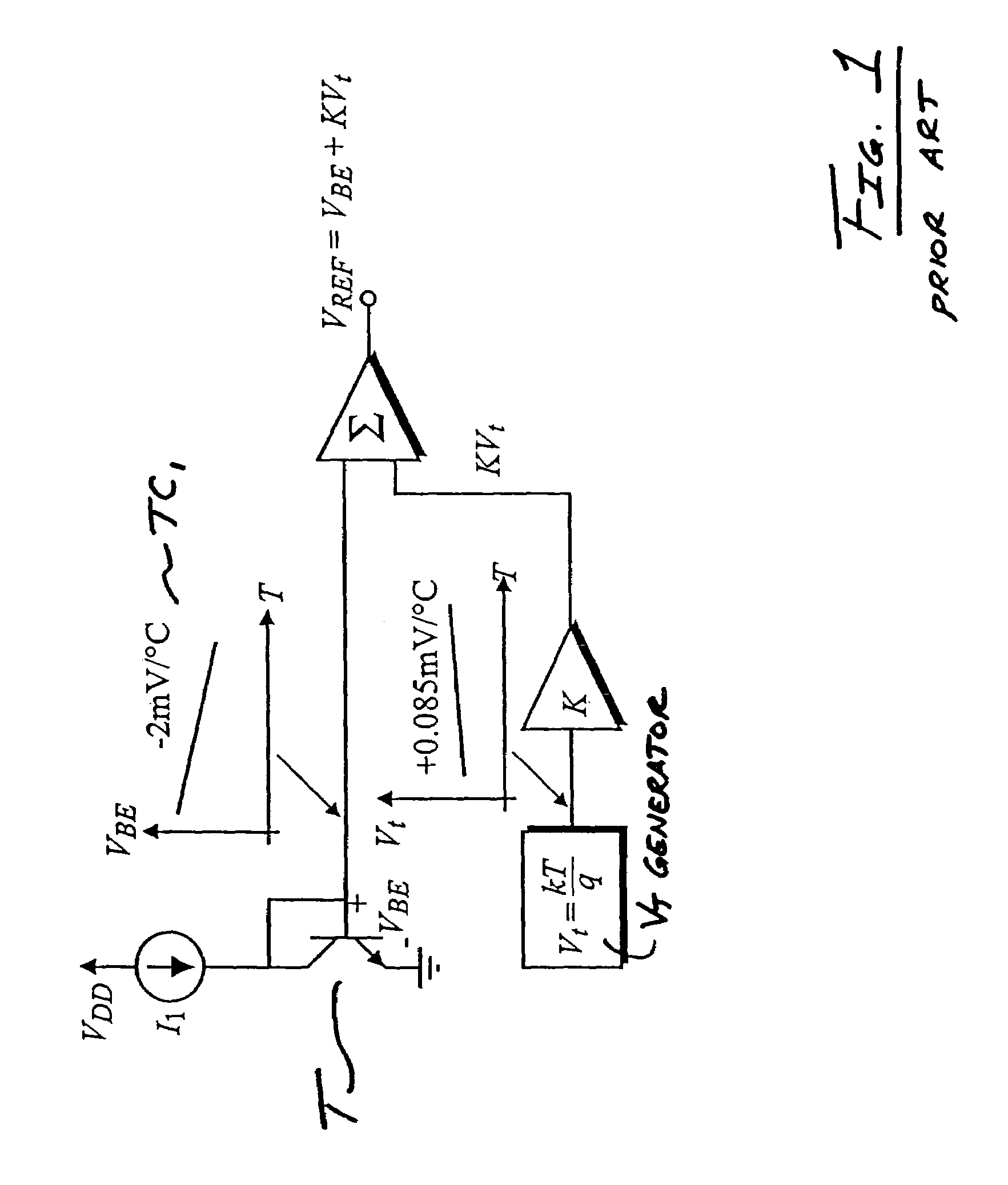

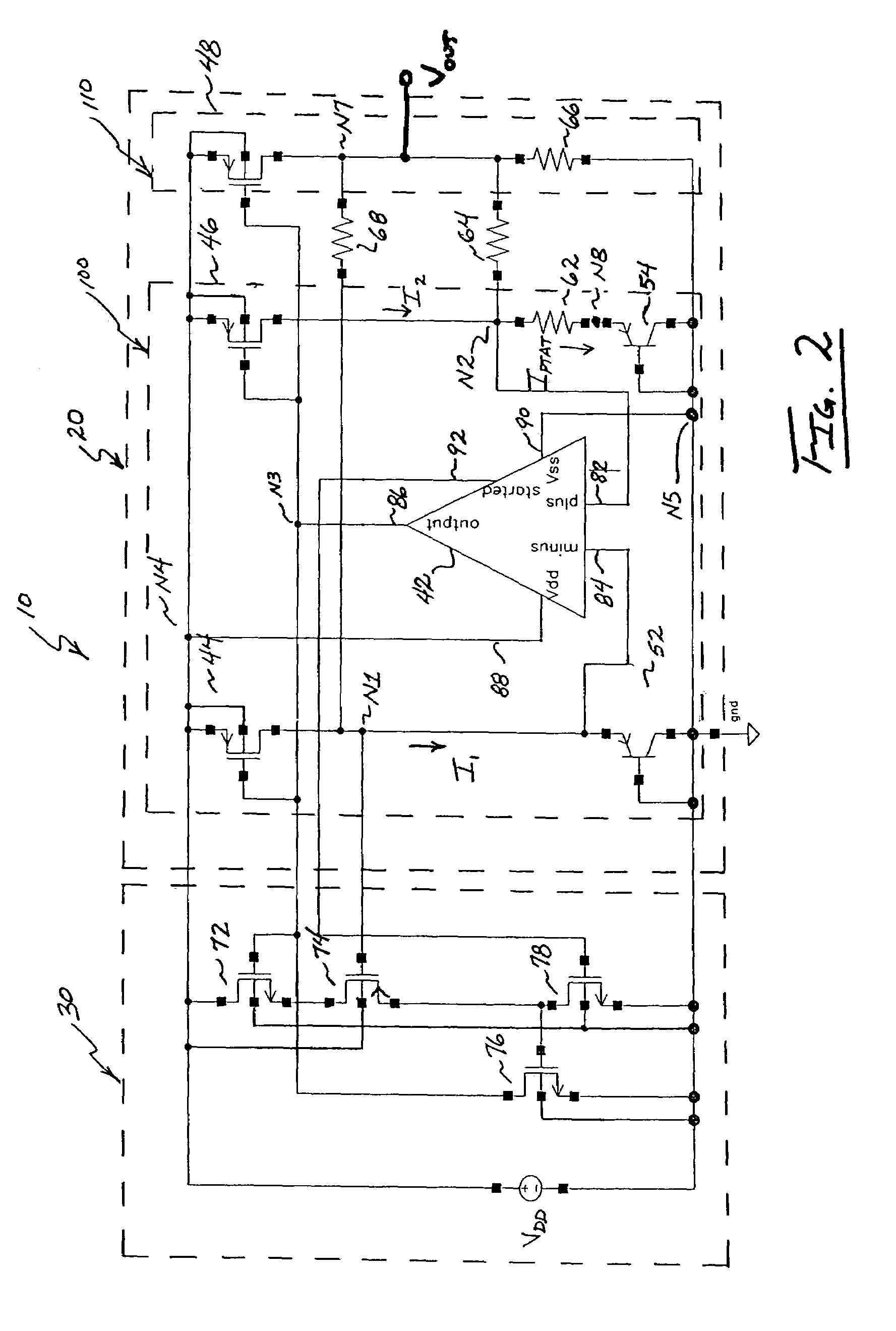

Voltage reference generator circuit subtracting CTAT current from PTAT current

ActiveUS7224210B2Dc network circuit arrangementsElectric variable regulationEngineeringVoltage reference

A voltage reference generator generates a stable reference voltage that is less than the bandgap voltage of silicon for power supply voltages less than 2V, yet provides sufficient voltage headroom to operate a current mirror. In one embodiment, the voltage reference generator has a power supply rejection ratio of at least 60 dB and has comparable noise performance as compared to traditional bandgap cirucits. These advantages are achieved by subtracting a current proportional to a complement of an absolute temperature from a current proportional to the absolute temperature to generate a voltage having a positive temperature coefficient, which is then added to a voltage that is a complement of the absolute temperature to achieve a voltage that has a low temperature coefficient.

Owner:SKYWORKS SOLUTIONS INC

Method for manufacturing a vibrating MEMS circuit

ActiveUS9369105B1Low temperature coefficientAccurate shapePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectromechanical coupling coefficientCrystal orientation

A method for making a micro-electro-mechanical systems (MEMS) vibrating structure is disclosed. The MEMS is supported by a MEMS anchor system and includes a single-crystal piezoelectric thin-film layer that has a specific non-standard crystal orientation, which may be selected to increase an electromechanical coupling coefficient, decrease a temperature coefficient of frequency, or both. The MEMS vibrating structure may have dominant lateral vibrations or dominant thickness vibrations. The single-crystal piezoelectric thin-film layer may include Lithium Tantalate or Lithium Niobate, and may provide MEMS vibrating structures with precise sizes and shapes, which may provide high accuracy and enable fabrication of multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

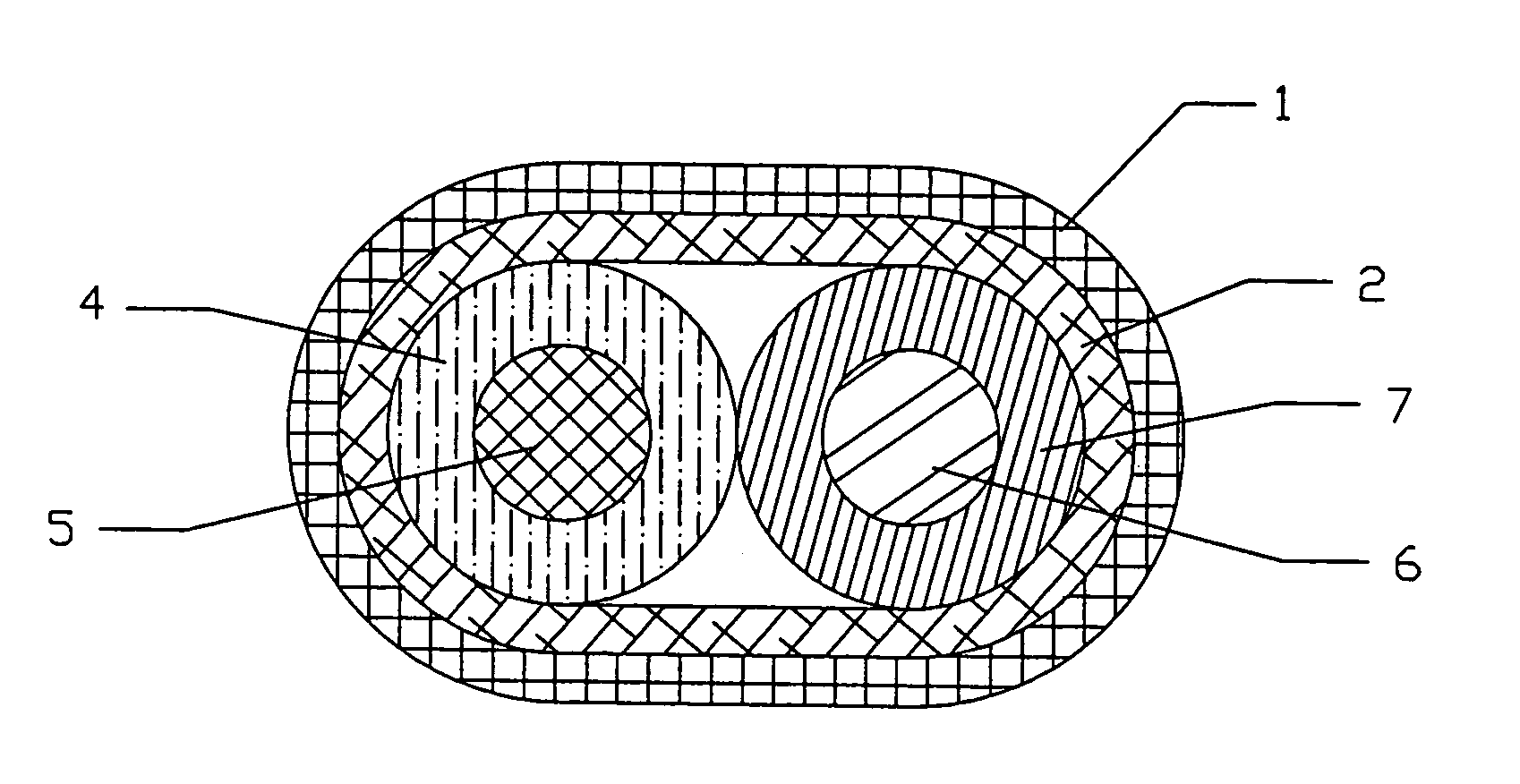

Heater with simultaneous hot spot and mechanical intrusion protection

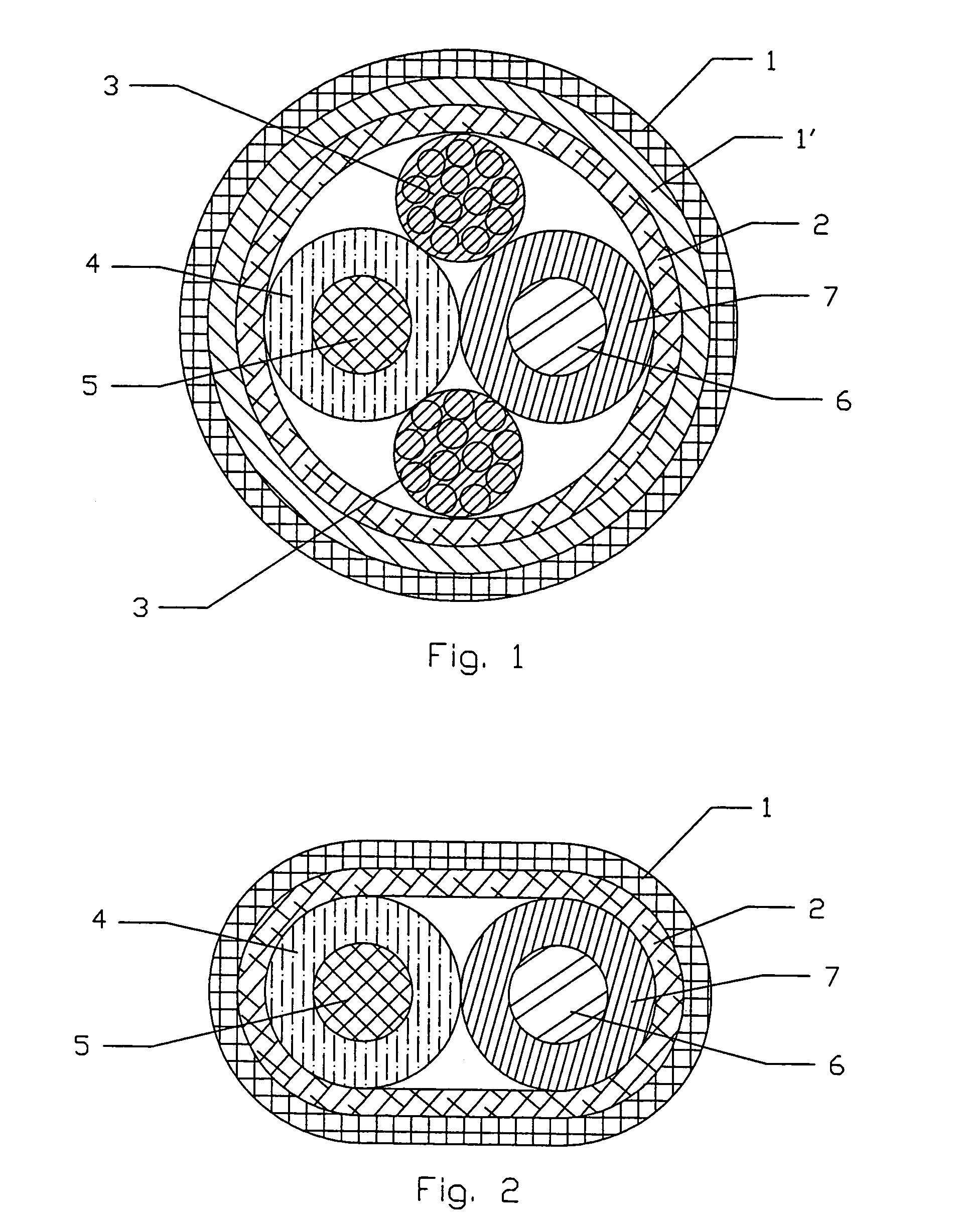

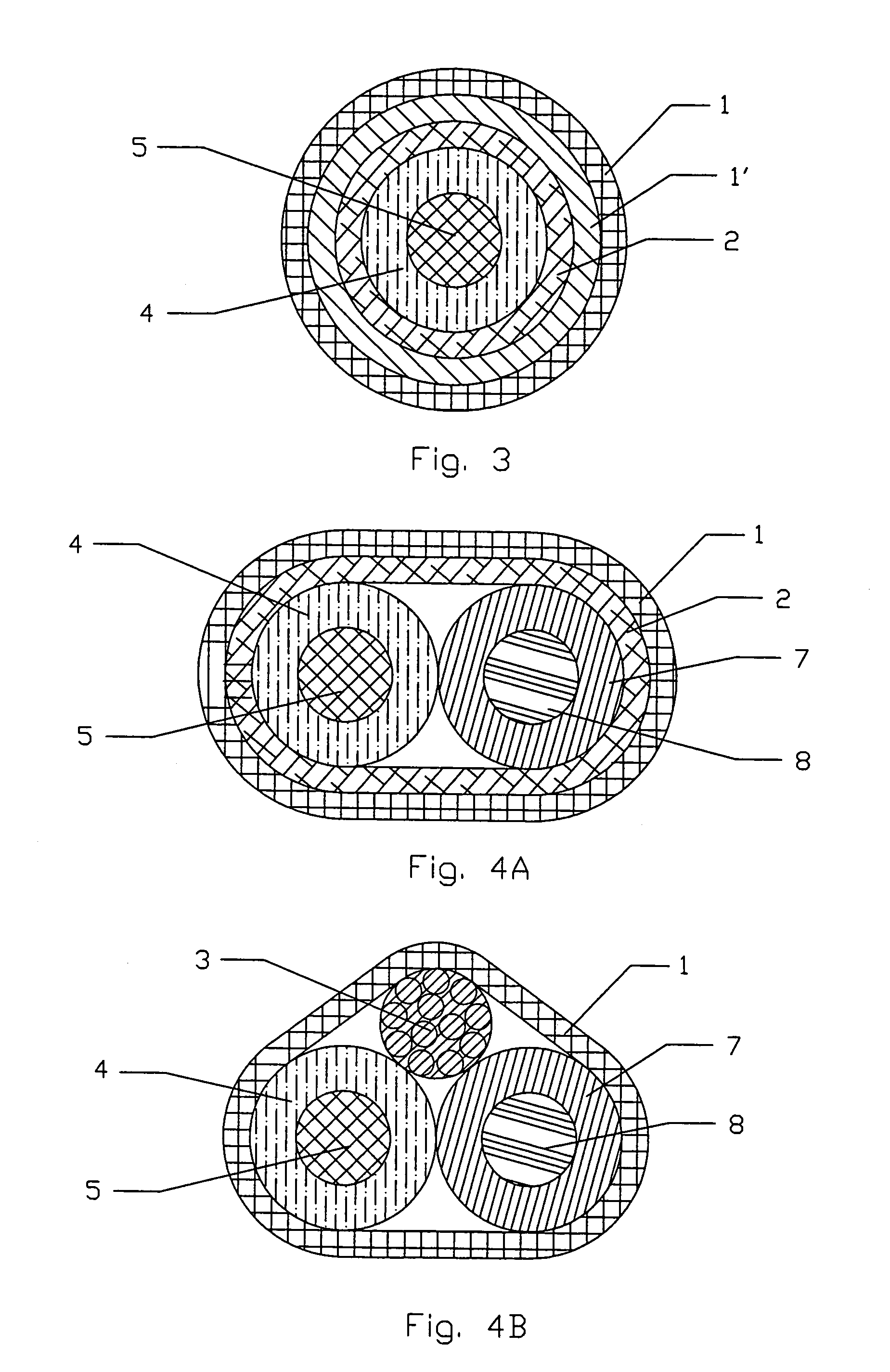

InactiveUS6958463B1Excellent dielectric propertiesPreventing and minimizing current leakageHeating element shapesFiberElectrical conductor

An electrical heater utilizes negative temperature coefficient material (NTC) and current imbalance between live and neutral ends of the heater to simultaneously protect the heater from the hot spot and mechanical intrusion into the heating cable. The NTC layer, separating the heating wire and current leakage conductor, becomes electrically conductive at the temperatures above 60° C., thus “leaking” the current to earth. The hot spot is detected by measuring the current imbalance between line and neutral connections of the heating cable. The mechanical intrusion into the heater, such as cable or insulation damage, water or sharp metal object penetration, is also simultaneously measured by the same current imbalance measuring system such as Ground Fault Circuit Interrupter (GFCI). The optional return conductor and metal foil / mesh hot spot detection shields cancel electromagnetic field. The heater may contain positive temperature coefficient (PTC) continuous sensor to control the temperature in the heater. Such PTC sensor can be made of electrically conductive fibers and / or metal wires.

Owner:THERMOSOFT INT

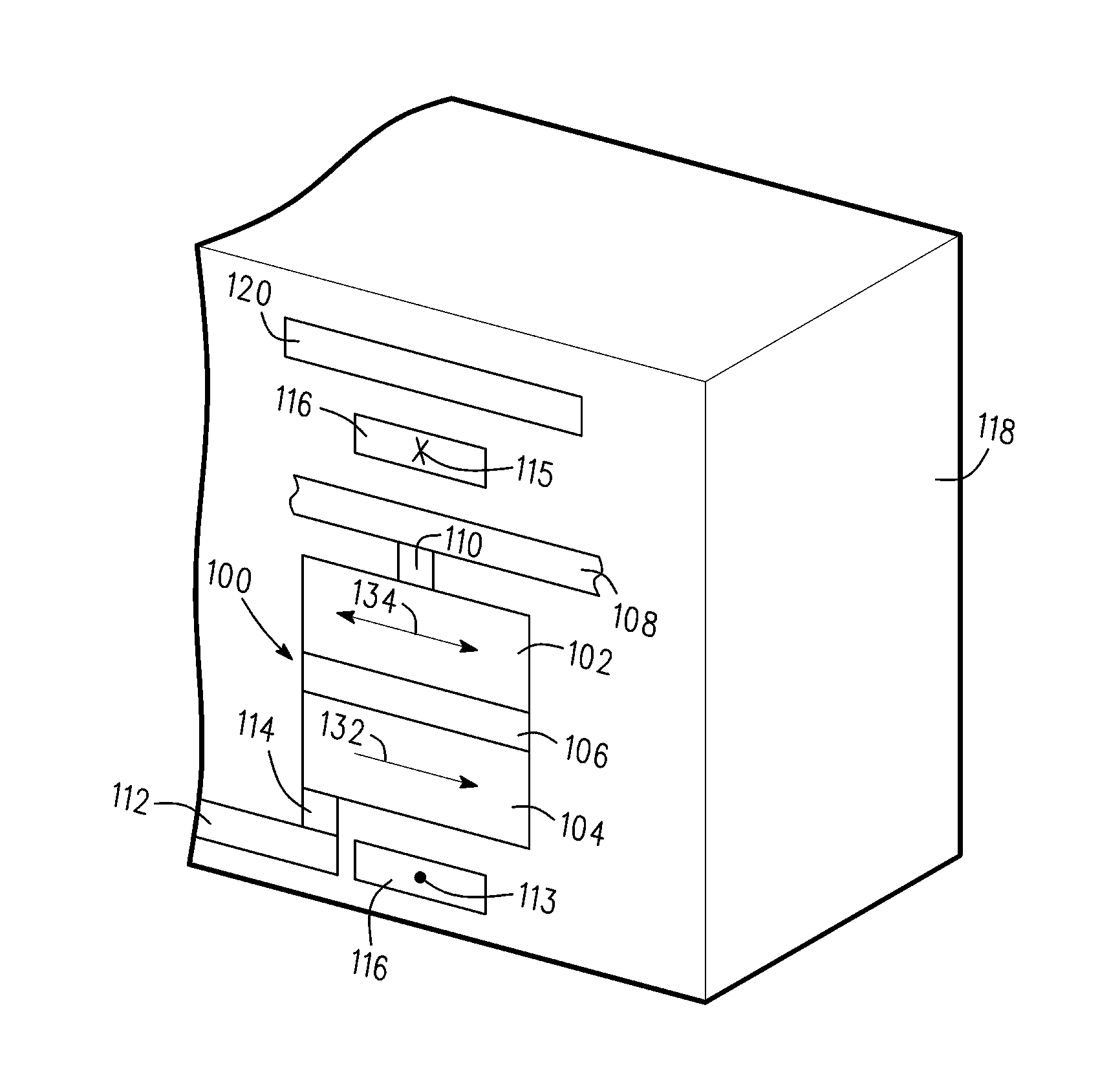

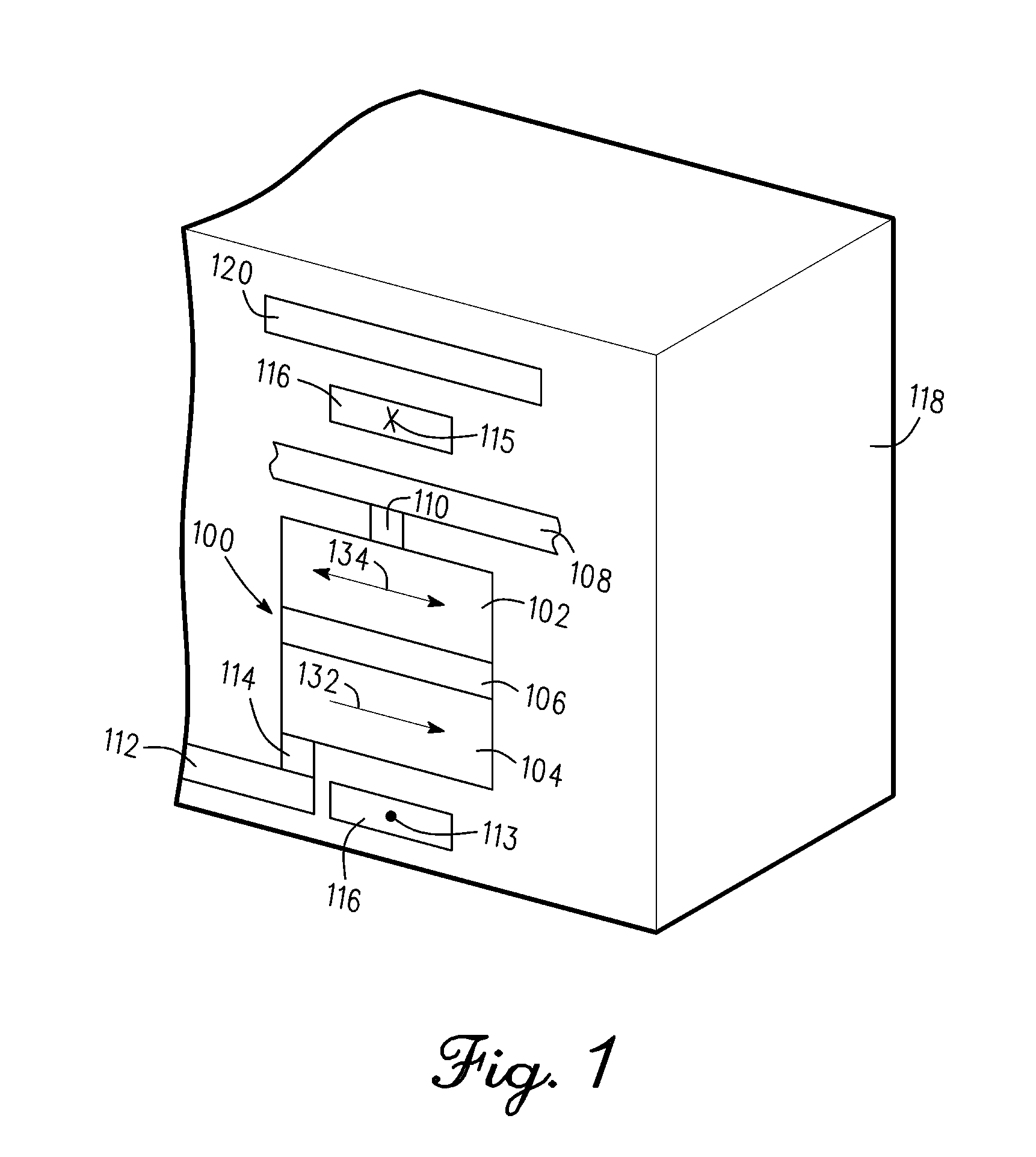

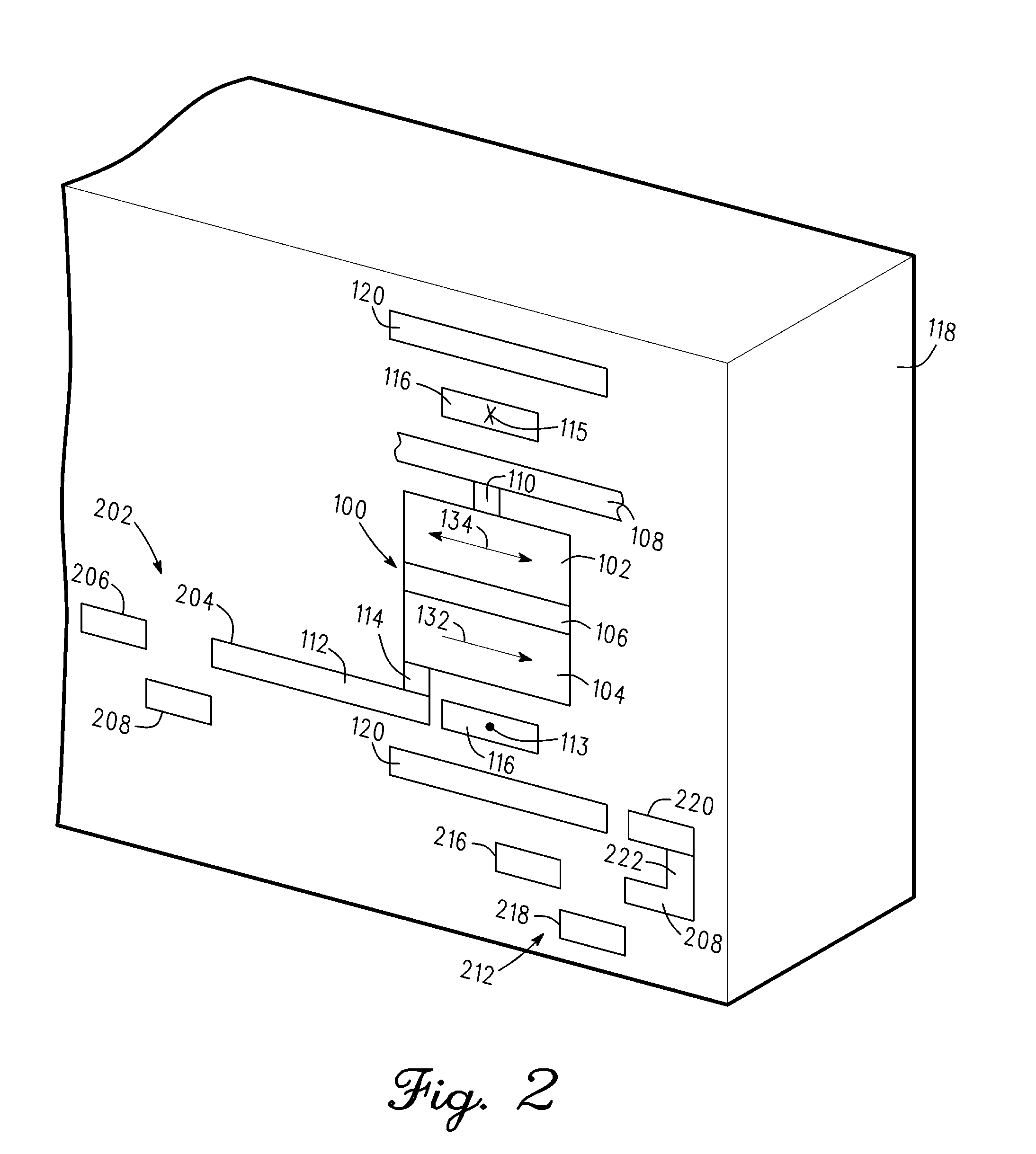

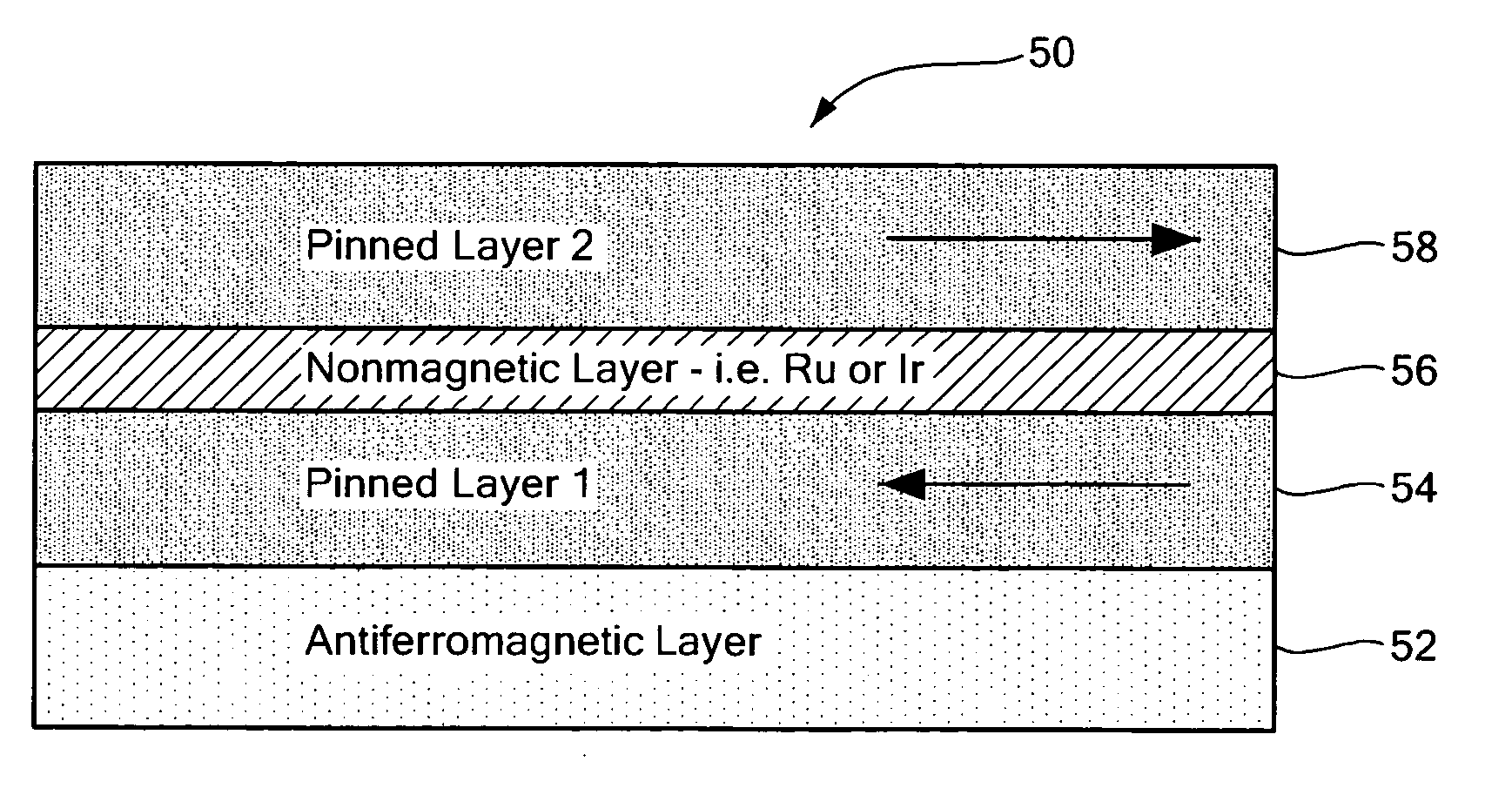

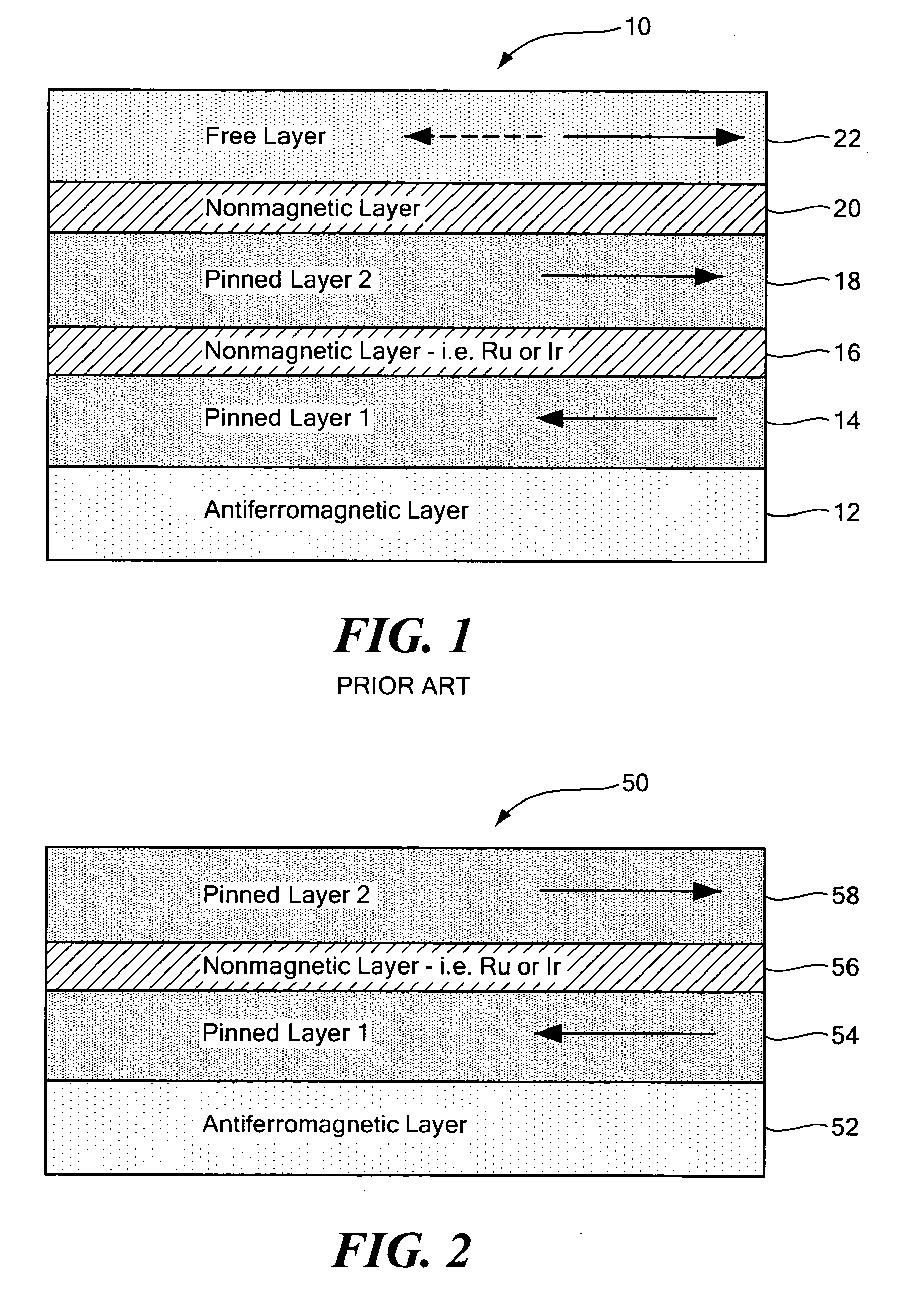

Method and structure for testing and calibrating magnetic field sensing device

A method of sensing a magnetic field including at least one magnetoresistive sensing element (100) in a circuit (101) includes supplying (702) a first plurality of currents to a stabilization line (116) disposed adjacent the magnetoresistive sensing element (100), applying (704) a second plurality of currents to a self test line (120) disposed adjacent the magnetic tunnel junction (100), one each of the first plurality of currents being supplied during one each of the second plurality of currents. Values sensed by the magnetic tunnel junction sensing element (100) in response to the supplying (702) of the first plurality of currents and the applying (704) of the second plurality of currents are sampled (706) and the sensitivity of the magnetic tunnel junction sensor (100) and electrical and magnetic offset are determined (708) from the sampled values. The temperature coefficient of offset may also be determined.

Owner:EVERSPIN TECHNOLOGIES

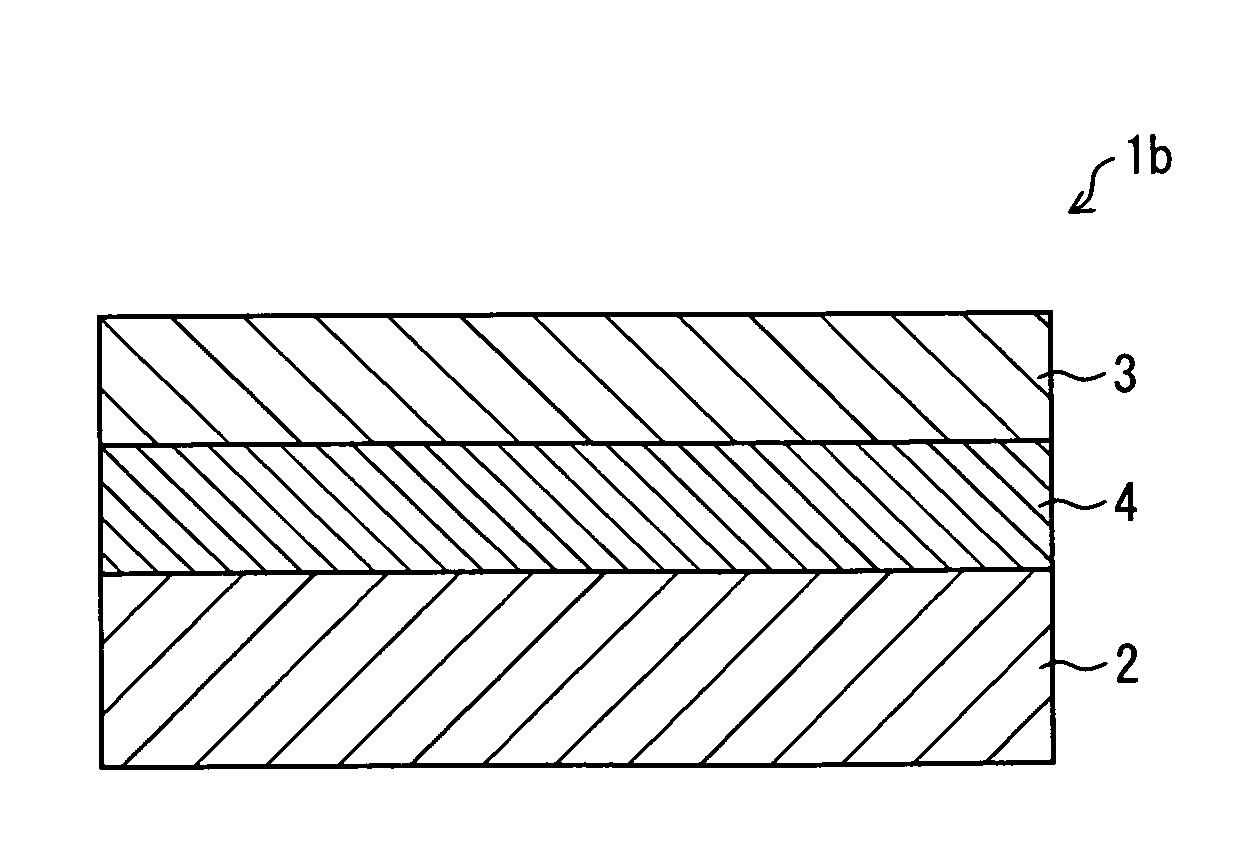

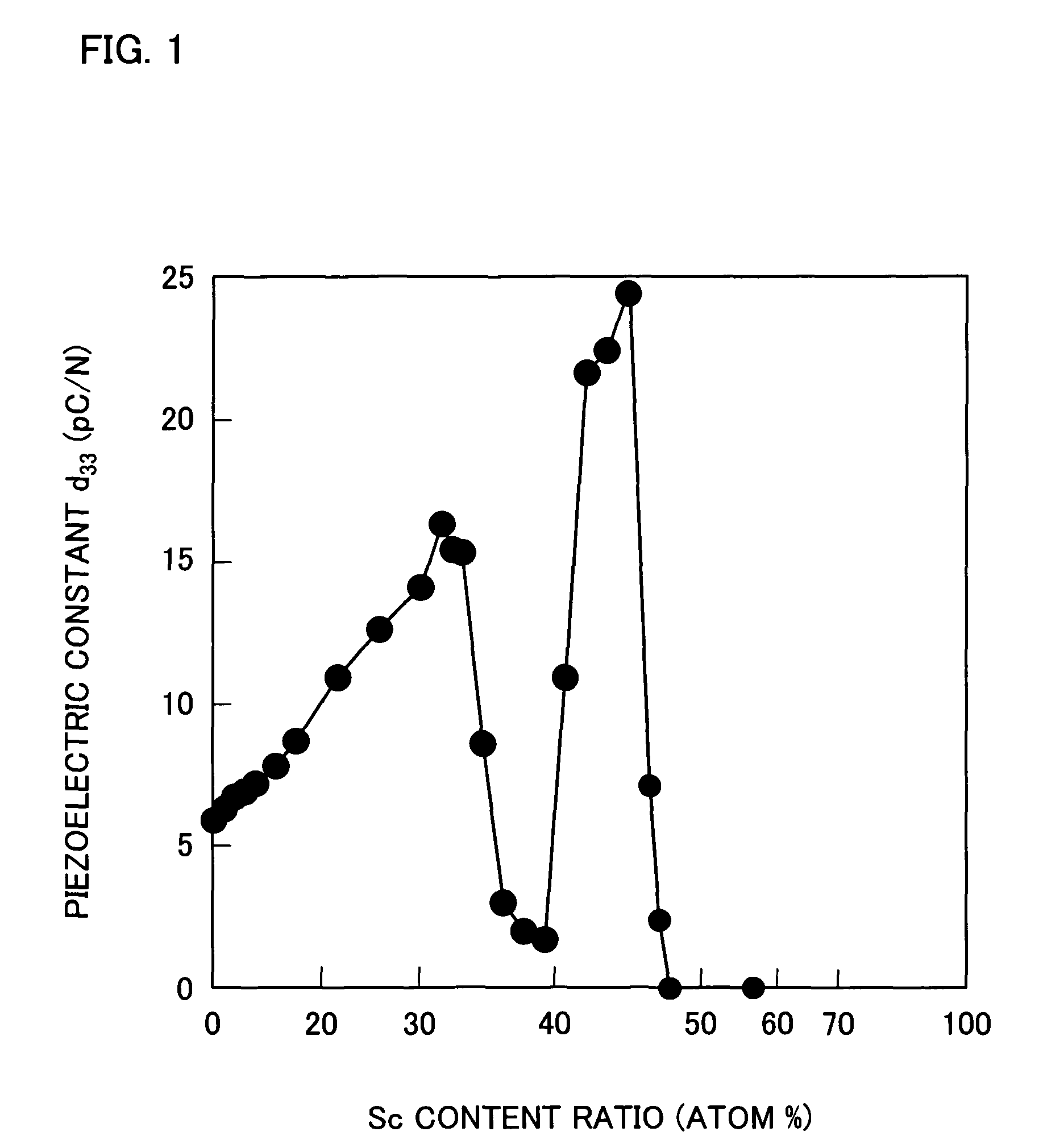

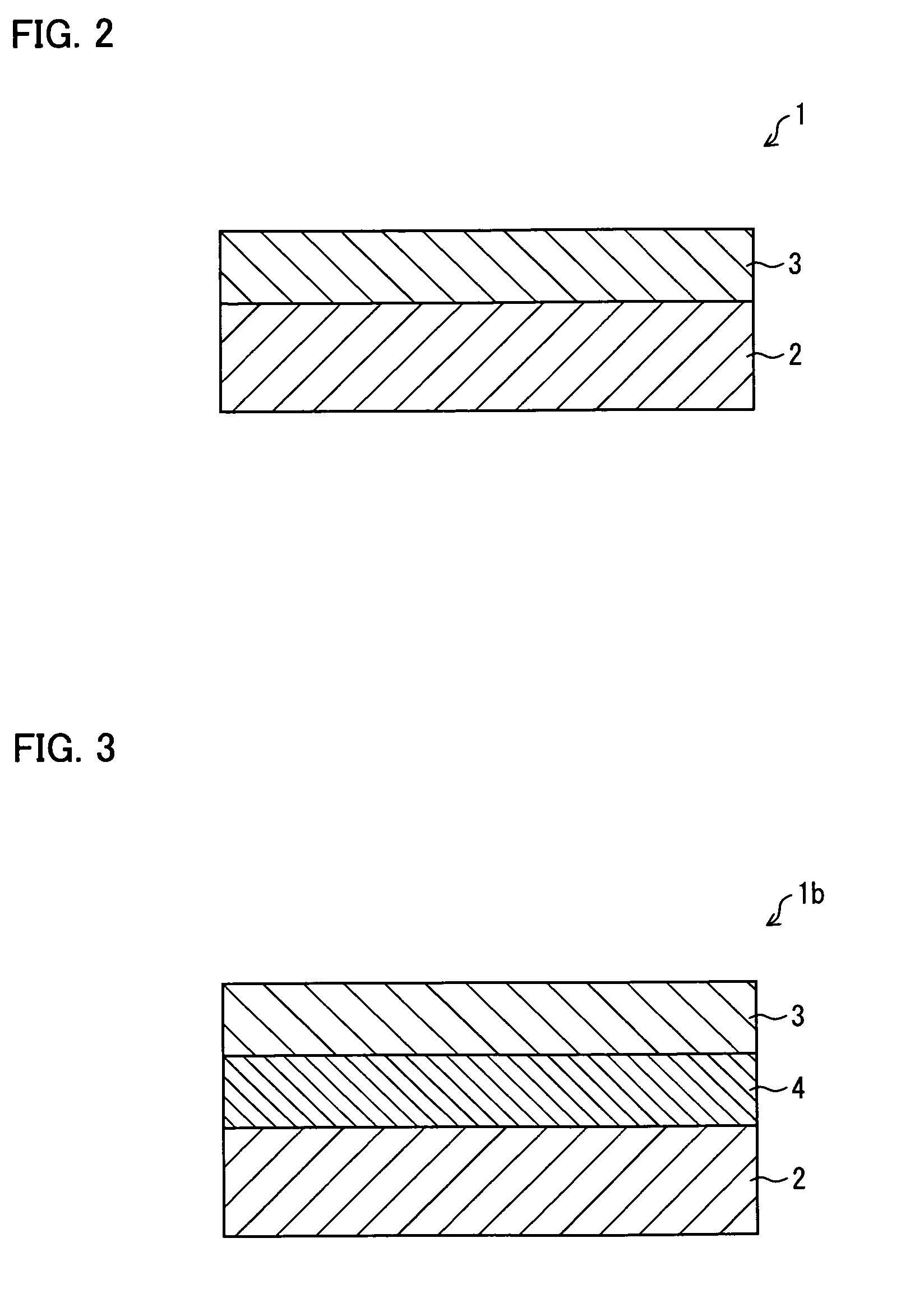

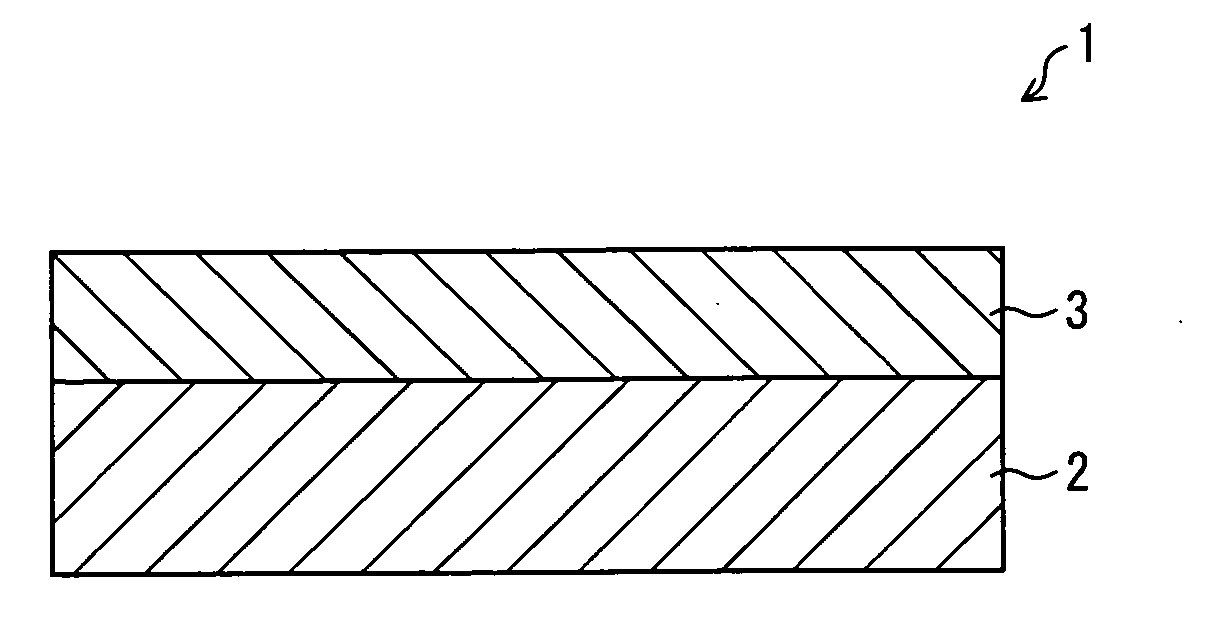

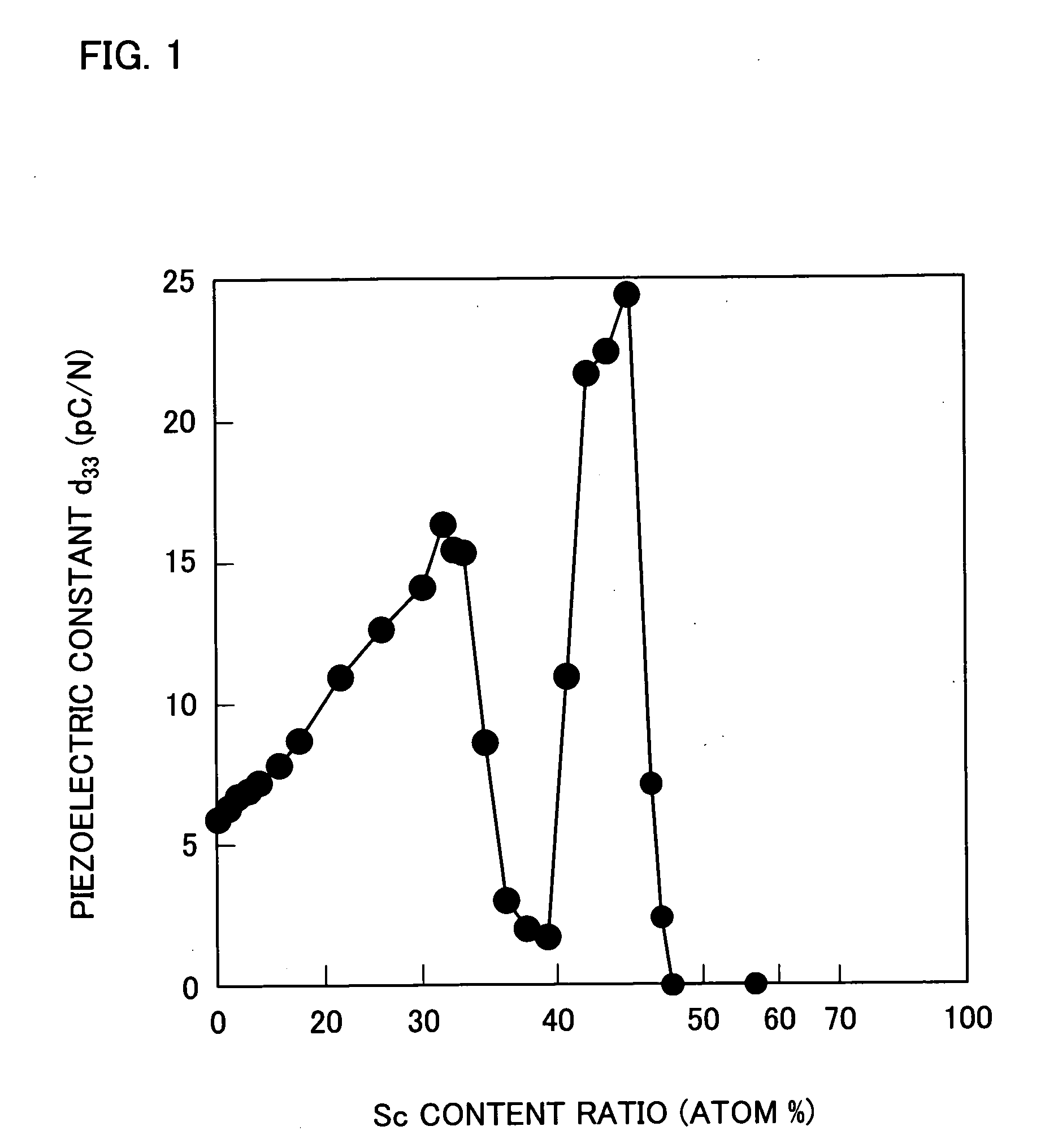

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS7758979B2Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksNatural mineral layered productsActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

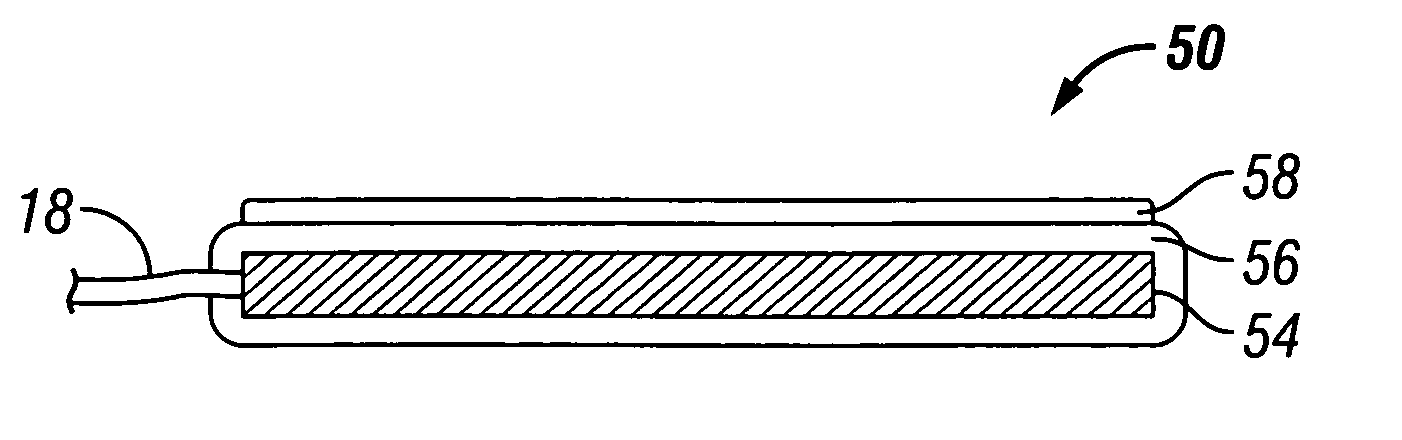

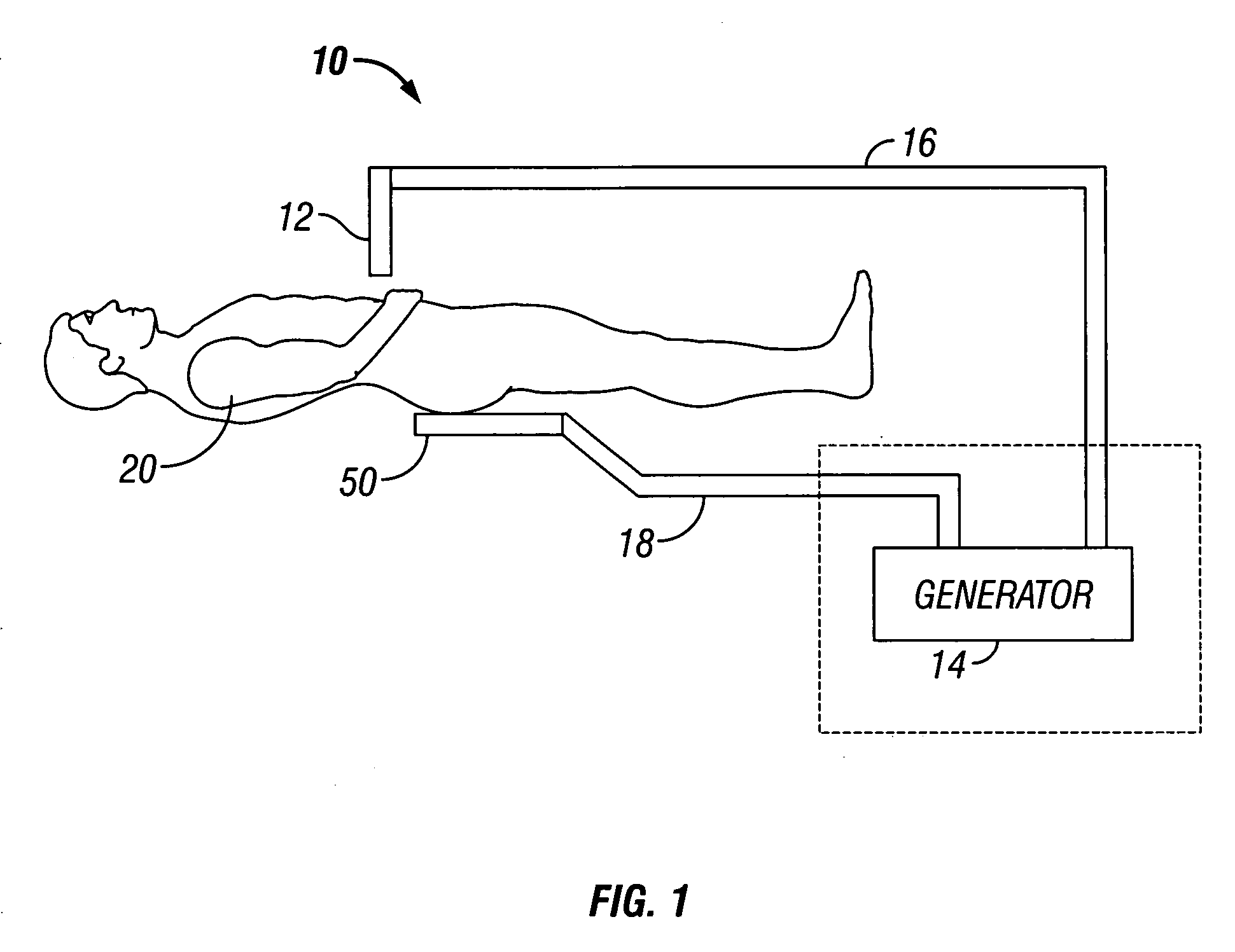

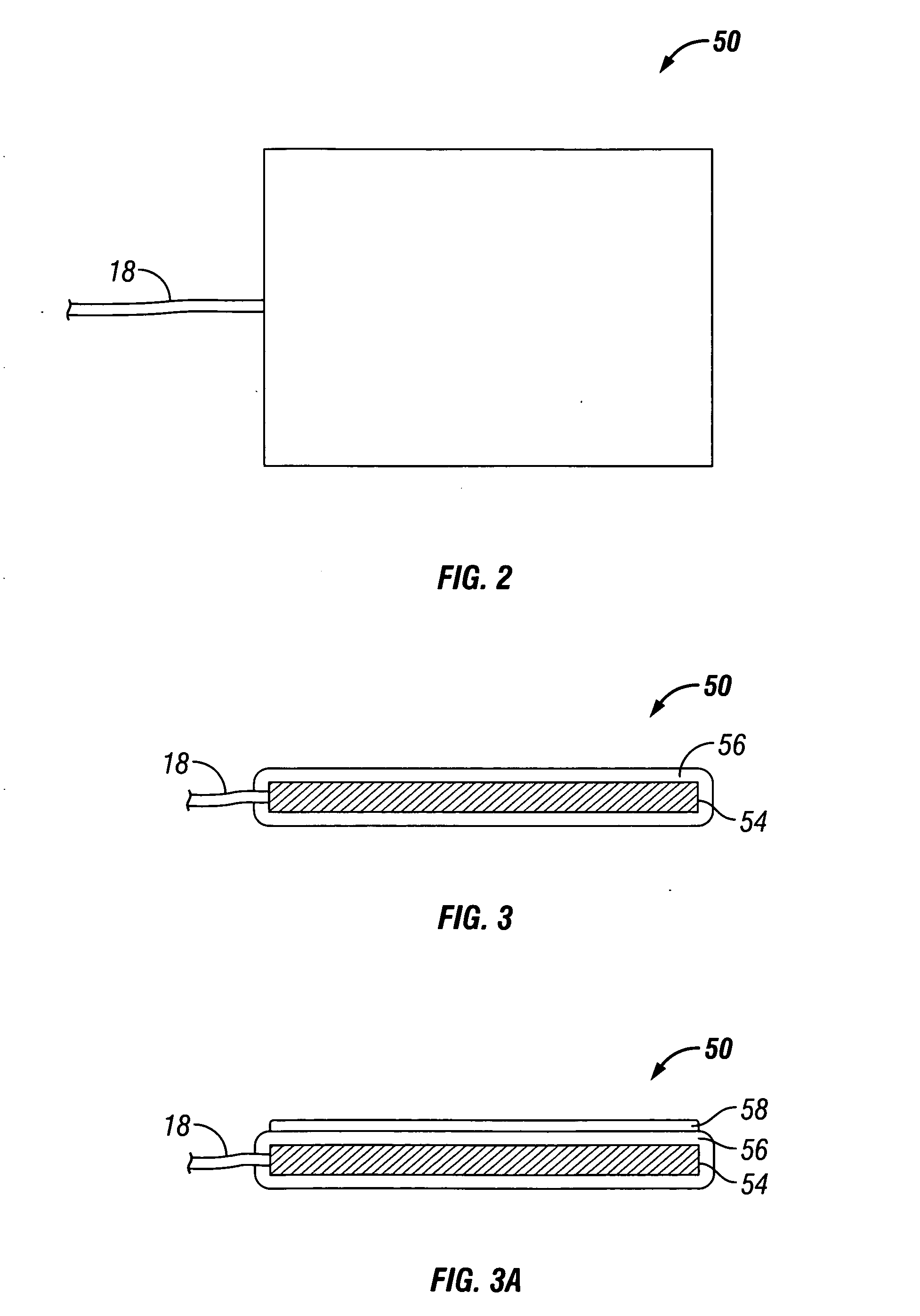

Temperature regulating patient return electrode and return electrode monitoring system

ActiveUS20060224150A1Reduce probabilityImprove the immunityElectrotherapyDiagnostic recording/measuringElectrical resistance and conductancePower flow

A temperature regulating patient return electrode and return electrode monitoring system for use in monopolar surgery, includes a positive temperature coefficient (PTC) material disposed on its surface. The PTC material responds to local increases in temperature by increasing local resistance. This quality decreases the probability of a patient burn as a result of monopolar surgery. The return electrode monitoring system includes a generator for generating current; an active electrode coupled to the generator for supplying the current to a patient; and a return electrode coupled to the generator with a surface for receiving the current from the patient and returning the current to the generator. A positive temperature coefficient (PTC) material is disposed on the return electrode for regulating the temperature over the surface of the return electrode.

Owner:COVIDIEN AG

High polymer-based graphene composite material with positive resistance temperature coefficient and preparation method

InactiveCN102532669AReduce dosageImprove conductivityState of artElectrical resistance and conductance

The invention relates to a high polymer-based graphene composite material with positive resistance temperature coefficient, and a preparation method of the material. The composite material comprises a base body and conductive filler; the content of conductive material is 0.01-10wt%; all components are mixed uniformly and are formed through mold-pressing or extrusion / injection molding; and the formed material is irradiated after being dried, so that the high polymer-based graphene composite material with positive resistance temperature coefficient can be obtained. Compared with the prior art, the graphene composite material and the preparation method have the advantages that the manufacturing process is simple, less influence is caused to the performance of base material, oxidation is unlikely to occur, the resistivity is more stable, the circulation stability of the material is better, and NTC (Negative Temperature Coefficient) effect is not generated easily.

Owner:SHANGHAI JIAO TONG UNIV

Voltage reference generator circuit subtracting CTAT current from PTAT current

ActiveUS20050285666A1Dc network circuit arrangementsElectric variable regulationEngineeringVoltage reference

A voltage reference generator generates a stable reference voltage that is less than the bandgap voltage of silicon for power supply voltages less than 2V, yet provides sufficient voltage headroom to operate a current mirror. In one embodiment, the voltage reference generator has a power supply rejection ratio of at least 60 dB and has comparable noise performance as compared to traditional bandgap cirucits. These advantages are achieved by subtracting a current proportional to a complement of an absolute temperature from a current proportional to the absolute temperature to generate a voltage having a positive temperature coefficient, which is then added to a voltage that is a complement of the absolute temperature to achieve a voltage that has a low temperature coefficient.

Owner:SKYWORKS SOLUTIONS INC

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS20080296529A1Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksPiezoelectric/electrostrictive device material selectionActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

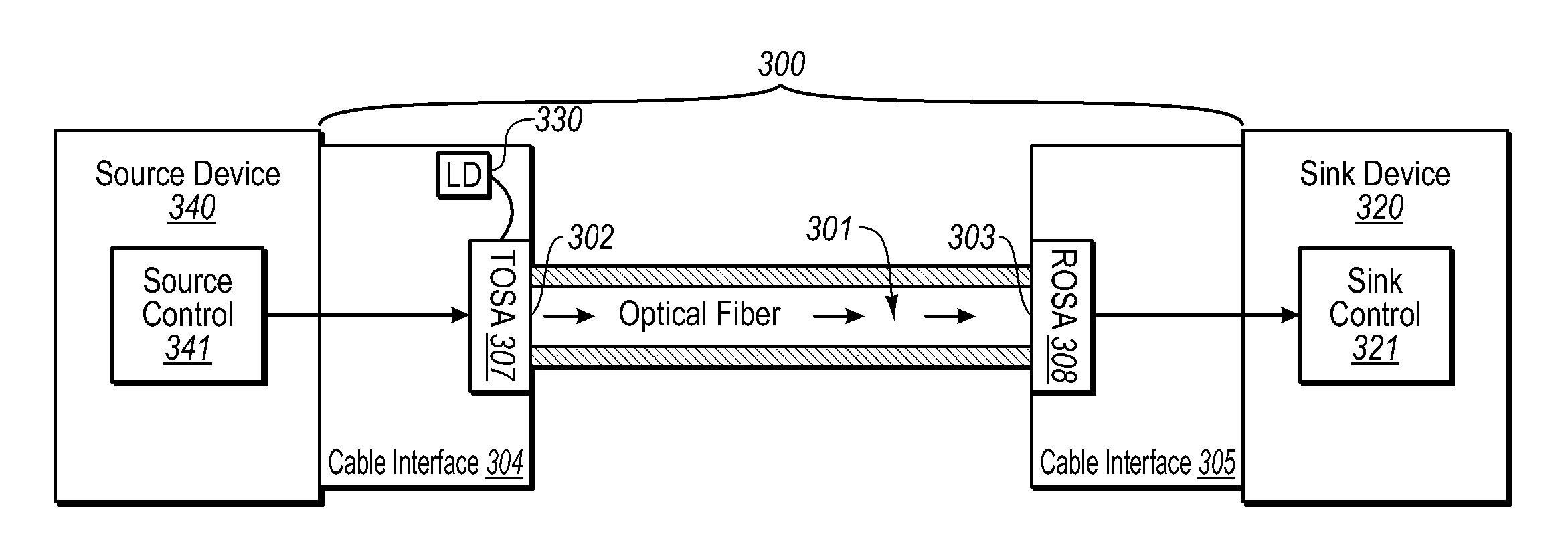

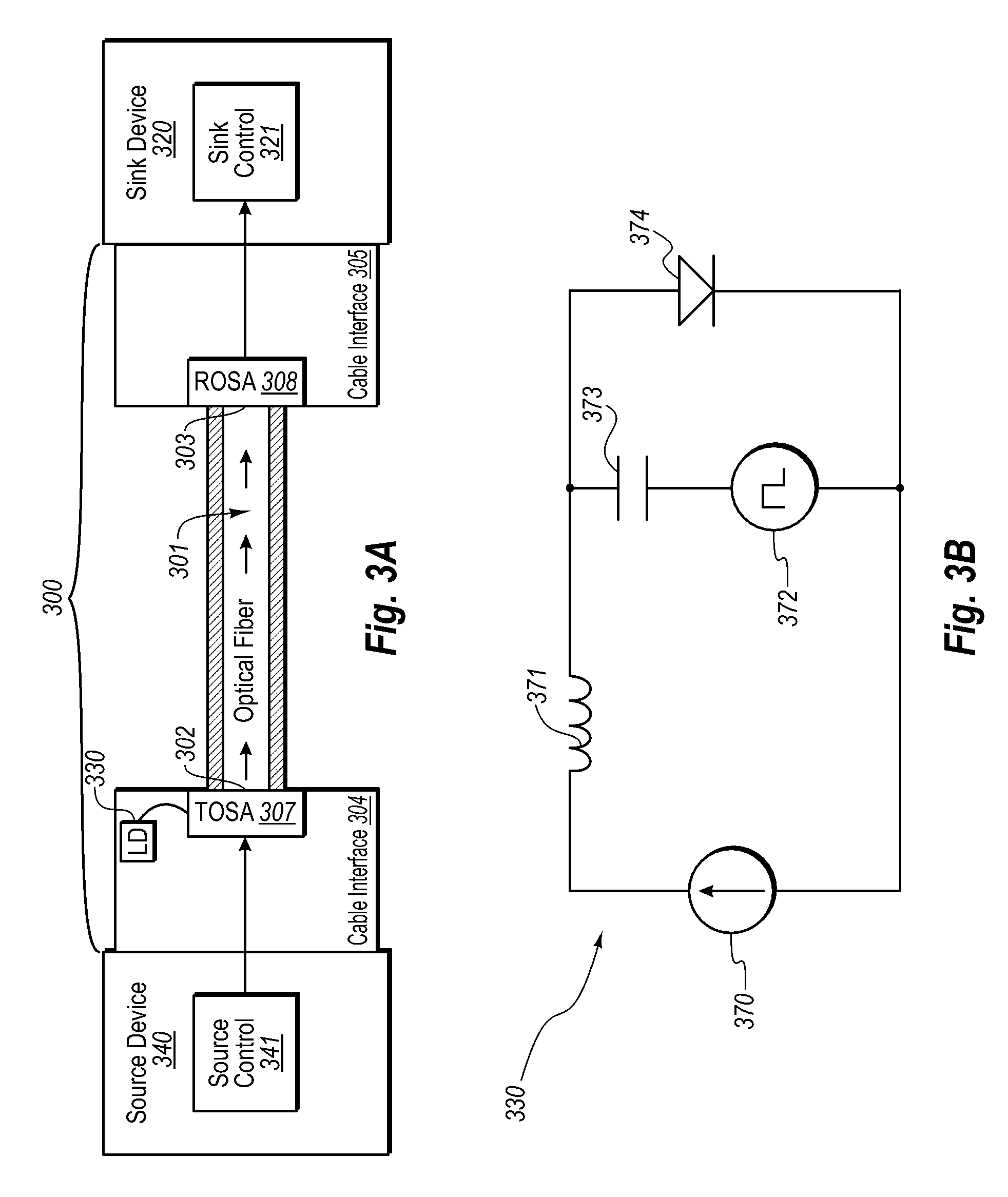

Laser drivers for closed path optical cables

InactiveUS7860398B2Time-division optical multiplex systemsSemiconductor laser structural detailsOptical communicationTemperature coefficient

Simplified laser drivers for closed path digital optical cables and digital optical cables including the simplified laser drivers. The laser driver can include less transistors than conventional laser drivers for optical communication cables. The laser can include a bias source and modulation source. The bias source can have a single constant current bias point for all laser diodes. The modulation current source can have a single temperature coefficient for all laser diodes. The laser driver can exclude, for example, any one of or combination of temperature compensation of the modulation or bias current sources, external programming of the modulation or bias current sources, power control based on output of the laser diode, and / or control based on feedback received from a monitor device or other sensor within the cables.

Owner:II VI DELAWARE INC

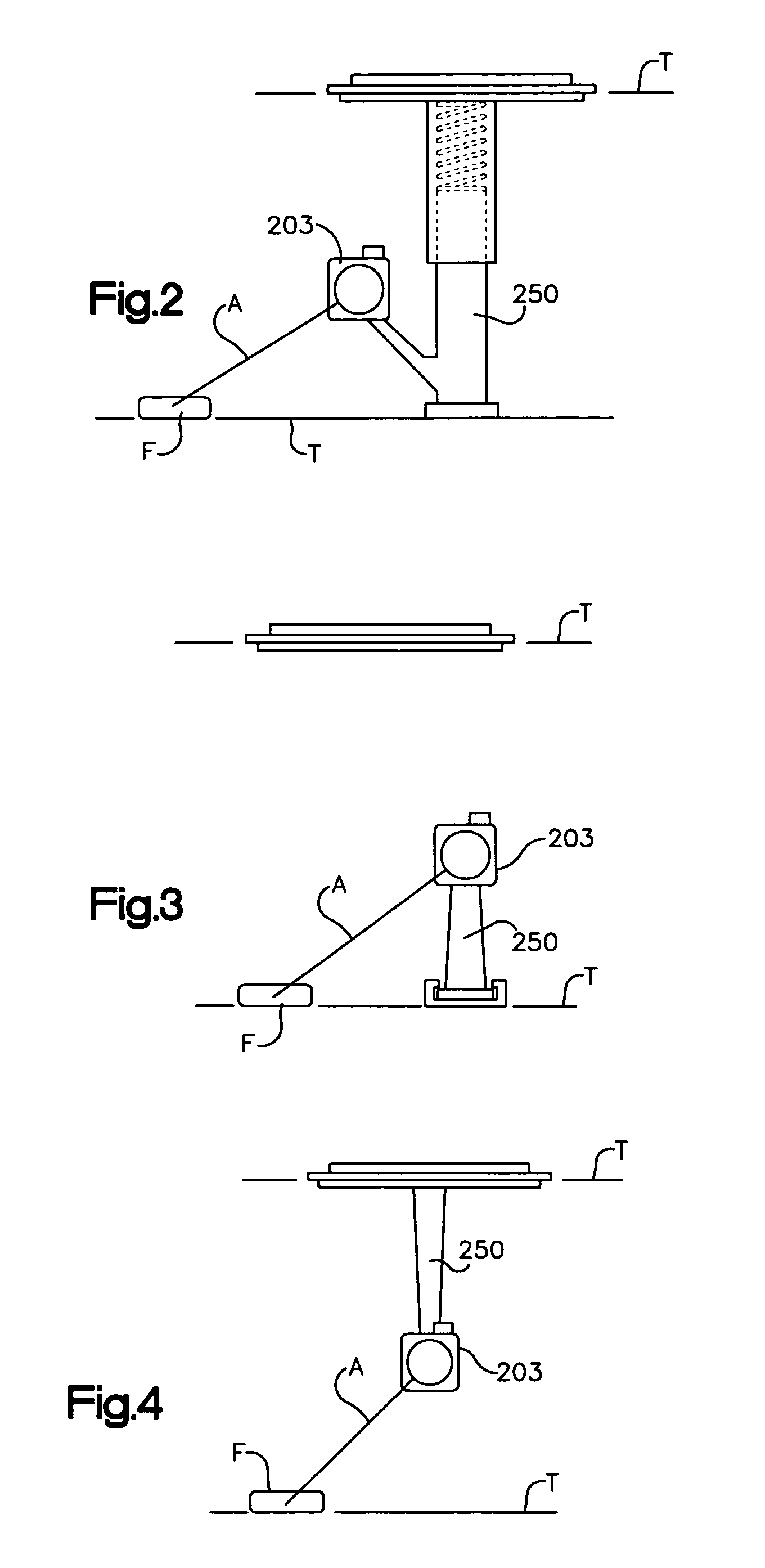

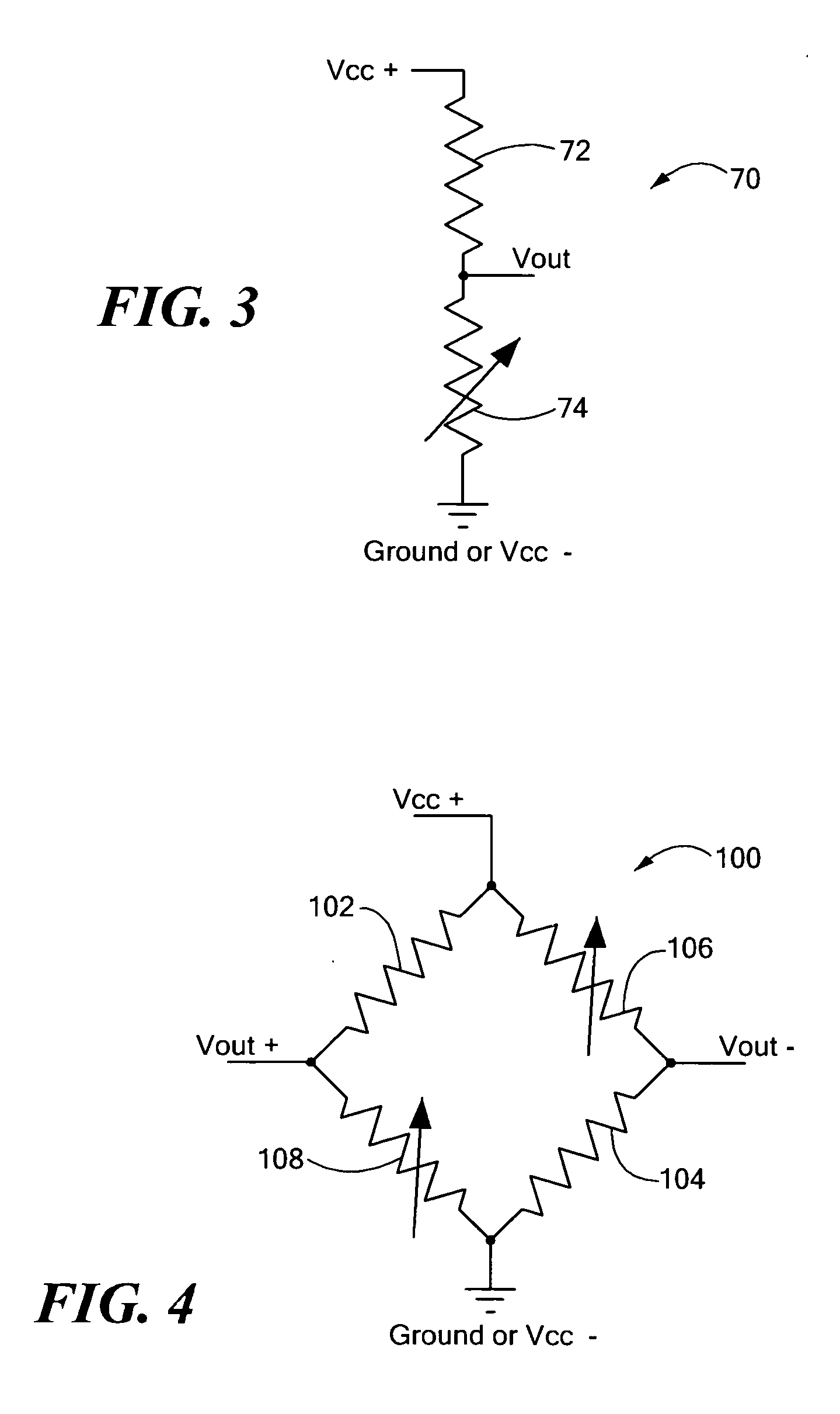

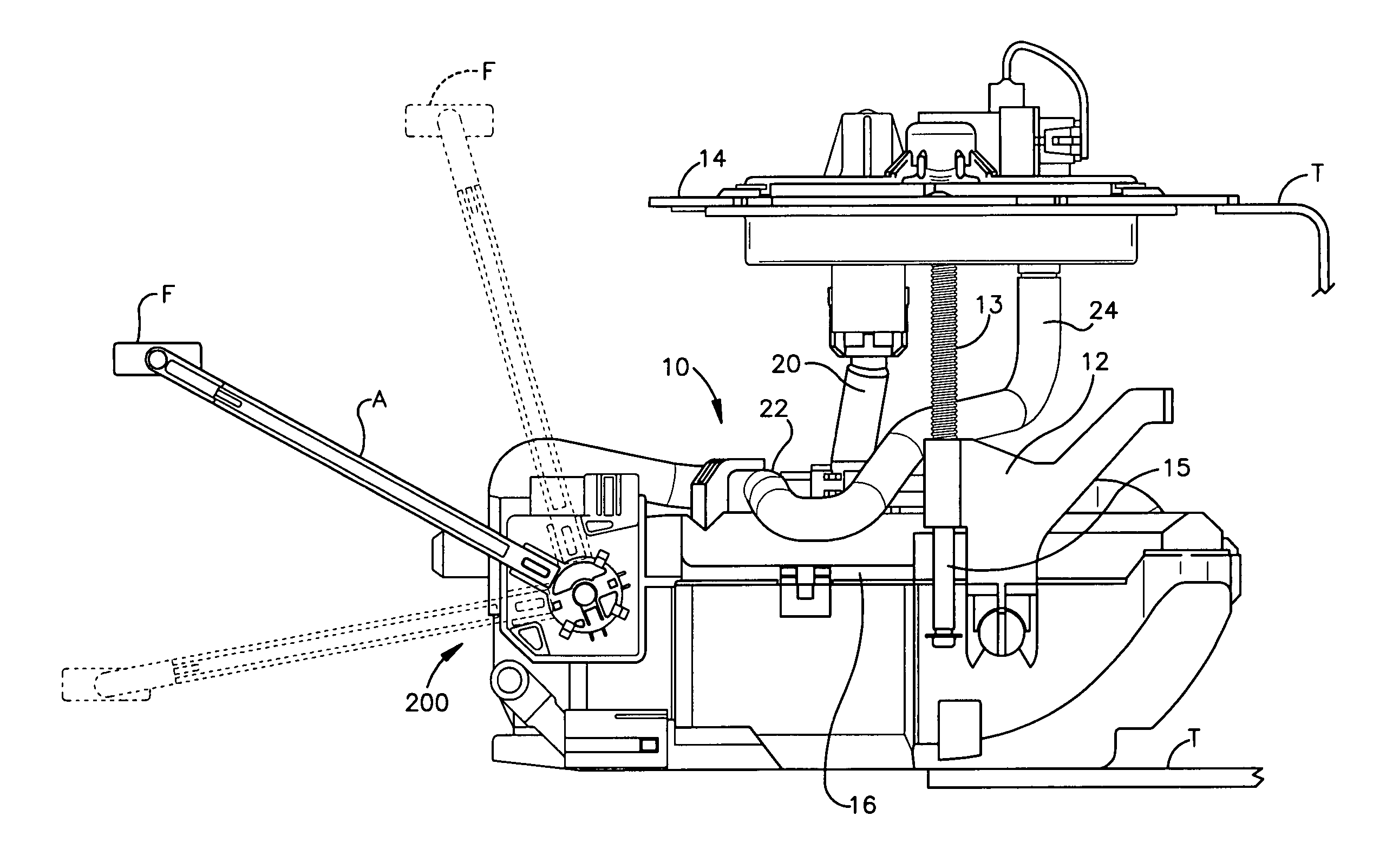

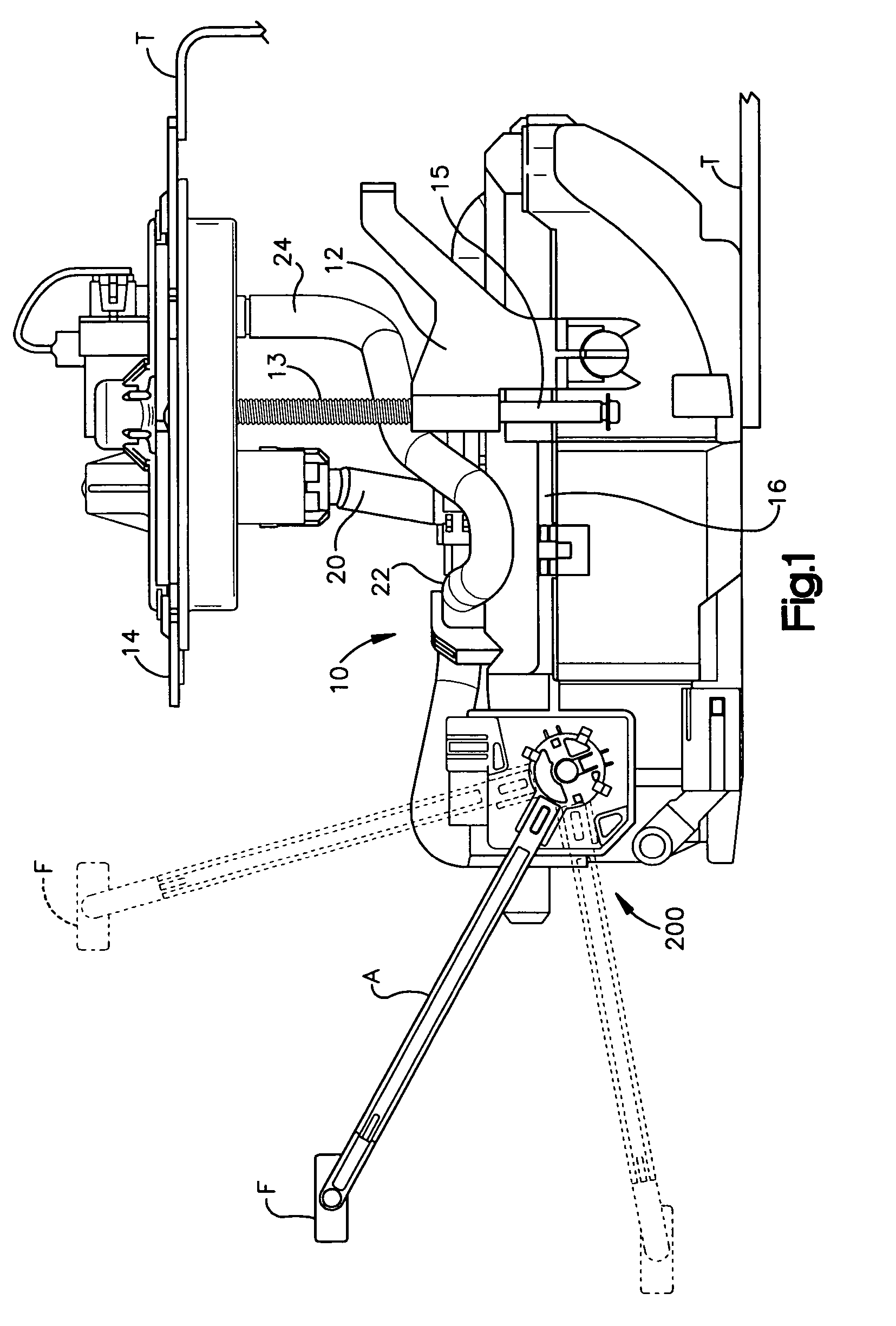

Fuel level sensor

InactiveUS20050103103A1Easy to installEasy to adaptMachines/enginesLubrication indication devicesFuel tankResistor

A fuel level sensor for sensing and monitoring the level of remaining fluid in a container such as a fuel tank for a motorized vehicle is disclosed. The fuel level sensor incorporates an improved float and pivot arm member attached to a hub that rotates about a pivot base. The conventional resistor card technology, commonly found in automotive applications for translating the position of the float into an electrical signal, is replaced by a more reliable non-contact magnetic flux sensing circuit. The fuel level sensor incorporates a magnetic sensor and magnetic circuit in a commonly known and practiced rotational position sensor configuration for determining the angular position of a hub relative to its pivot base, where the hub is attached to a conventional float-arm member and the base remains stationary relative to the fuel container. The preferred embodiment includes a magnetic flux sensor positioned between two movable magnets. The magnetic flux sensing element is a Hall effect integrated circuit, magnetoresistor, magnetodiode, magnetotransistor, or similar magnetic flux sensing element with associated electronic circuitry having adjustable or programmable features including ratiometry, gain, offset voltage, temperature coefficient, and output signal range limiting. Critical electronic components are hermetically sealed making the fuel level sensor fully submersible in fuel for long term fuel exposure.

Owner:UUSI

Low-voltage bandgap voltage reference circuit

A bandgap reference voltage generating circuit includes a proportional to absolute temperature (PTAT) voltage generating means generating a PTAT voltage. A complementary to absolute temperature (CTAT) voltage generating means generates a CTAT voltage. A temperature coefficient determining means interconnects the PTAT voltage generating means and the CTAT voltage generating means.

Owner:RAUM TECH CORP

Resistor having a predetermined temperature coefficient

ActiveUS20060077598A1NanomagnetismSolid-state devicesElectrical resistance and conductanceMagnetic reluctance

A material stack has an electrical resistance generally the same in the presence of a magnetic field and in the presence of no magnetic field. The electrical resistance of the material stack has a temperature coefficient generally the same as a magnetoresistance element.

Owner:ALLEGRO MICROSYSTEMS INC

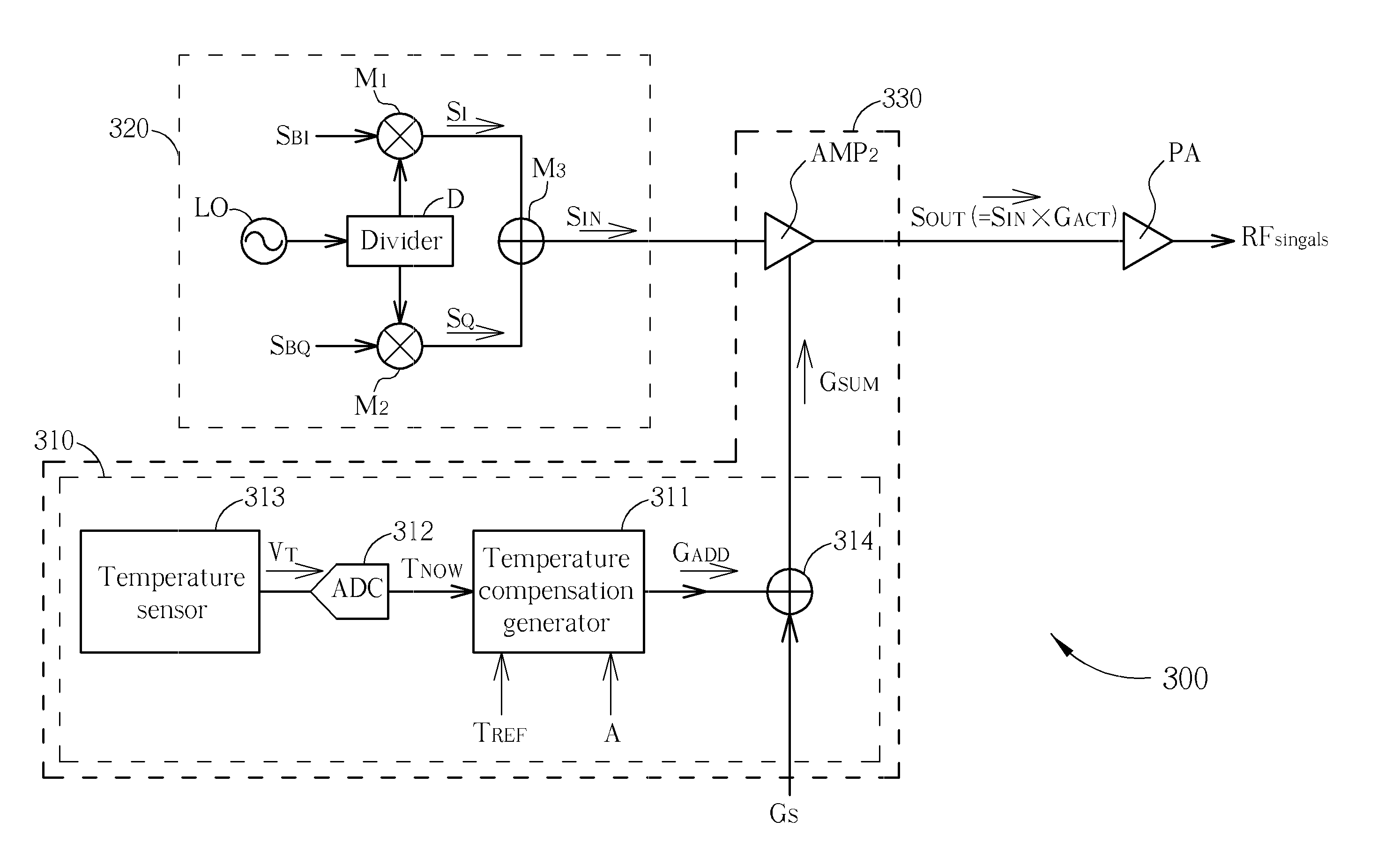

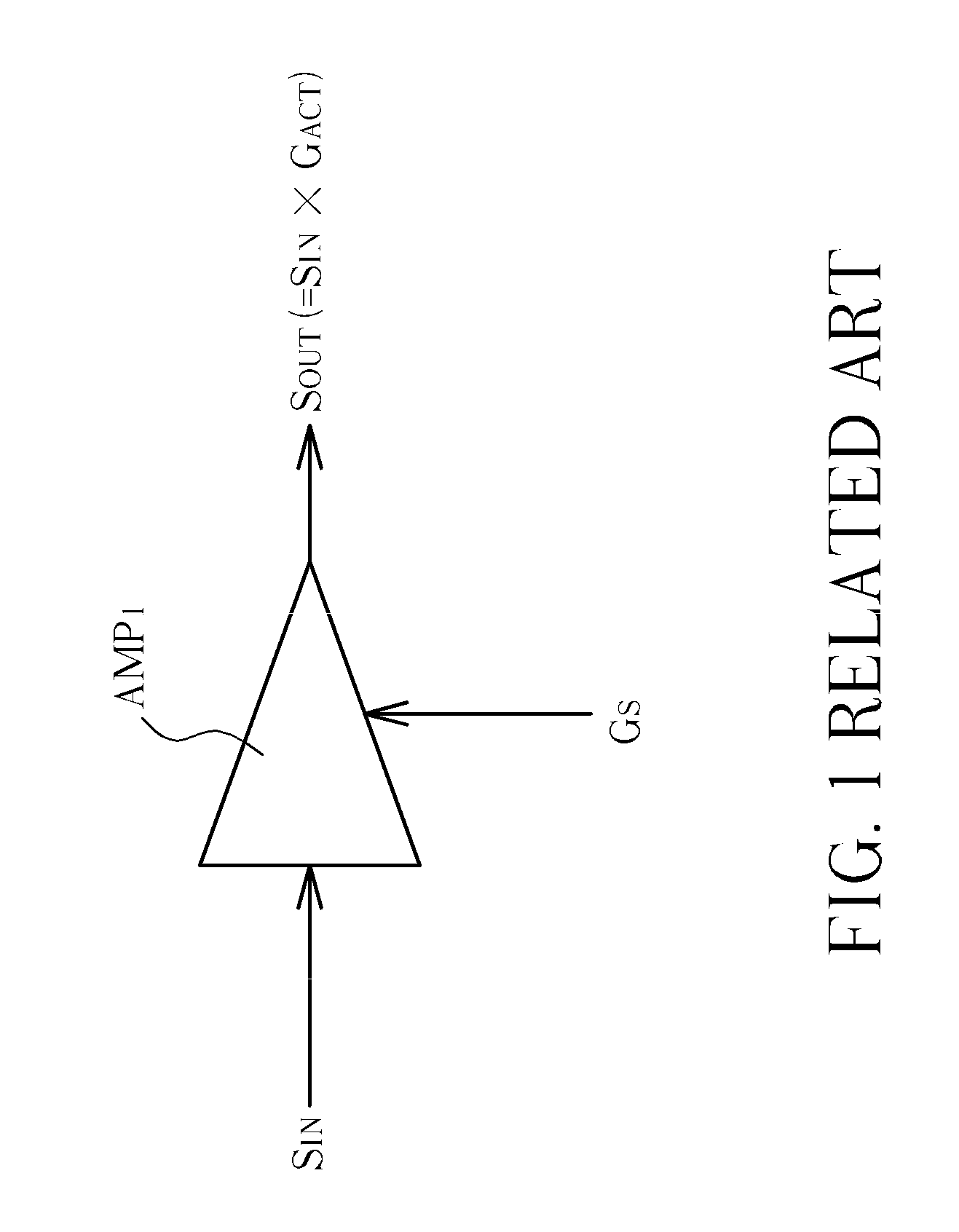

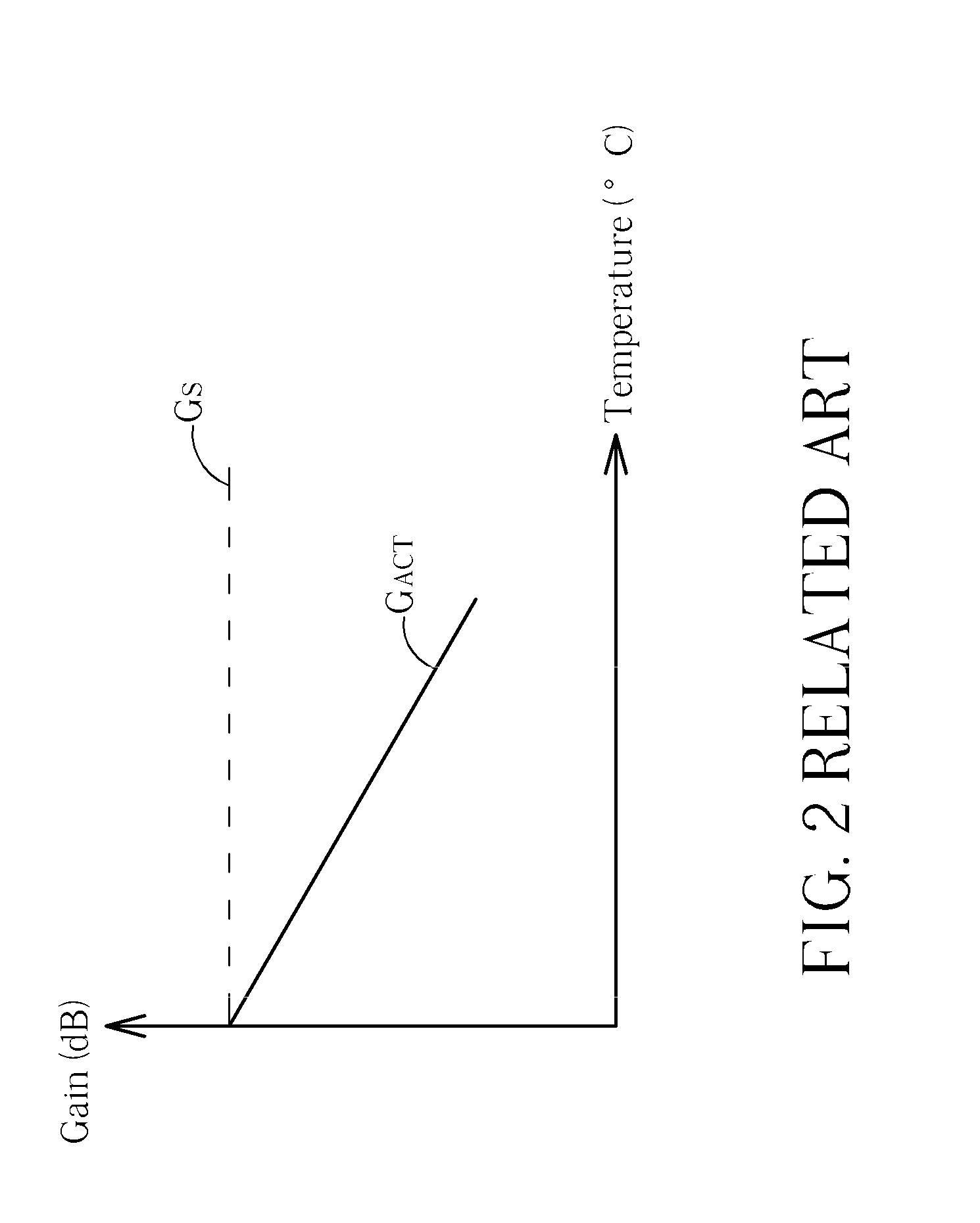

Gain compensation device over temperature and method thereof

InactiveUS20100311362A1Resonant long antennasHigh frequency amplifiersAudio power amplifierSignal on

A gain compensation device for adjusting gain of an amplifier over temperature is disclosed. The gain of the amplifier is controlled by signals on a gain control end of the amplifier. The gain compensation device comprises a temperature compensation generator, an adder, and a temperature sensor. The temperature compensation generator is for generating an additional gain parameter according to a reference temperature, a current temperature, and a temperature coefficient. The adder comprises a first input end, coupled to the temperature compensation generator for receiving the additional gain parameter, a second input end for receiving a default gain parameter, and an output end coupled to the gain control end of the amplifier for outputting sum of the additional gain parameter and the default gain parameter. The temperature sensor is for providing the current temperature.

Owner:MEDIATEK INC

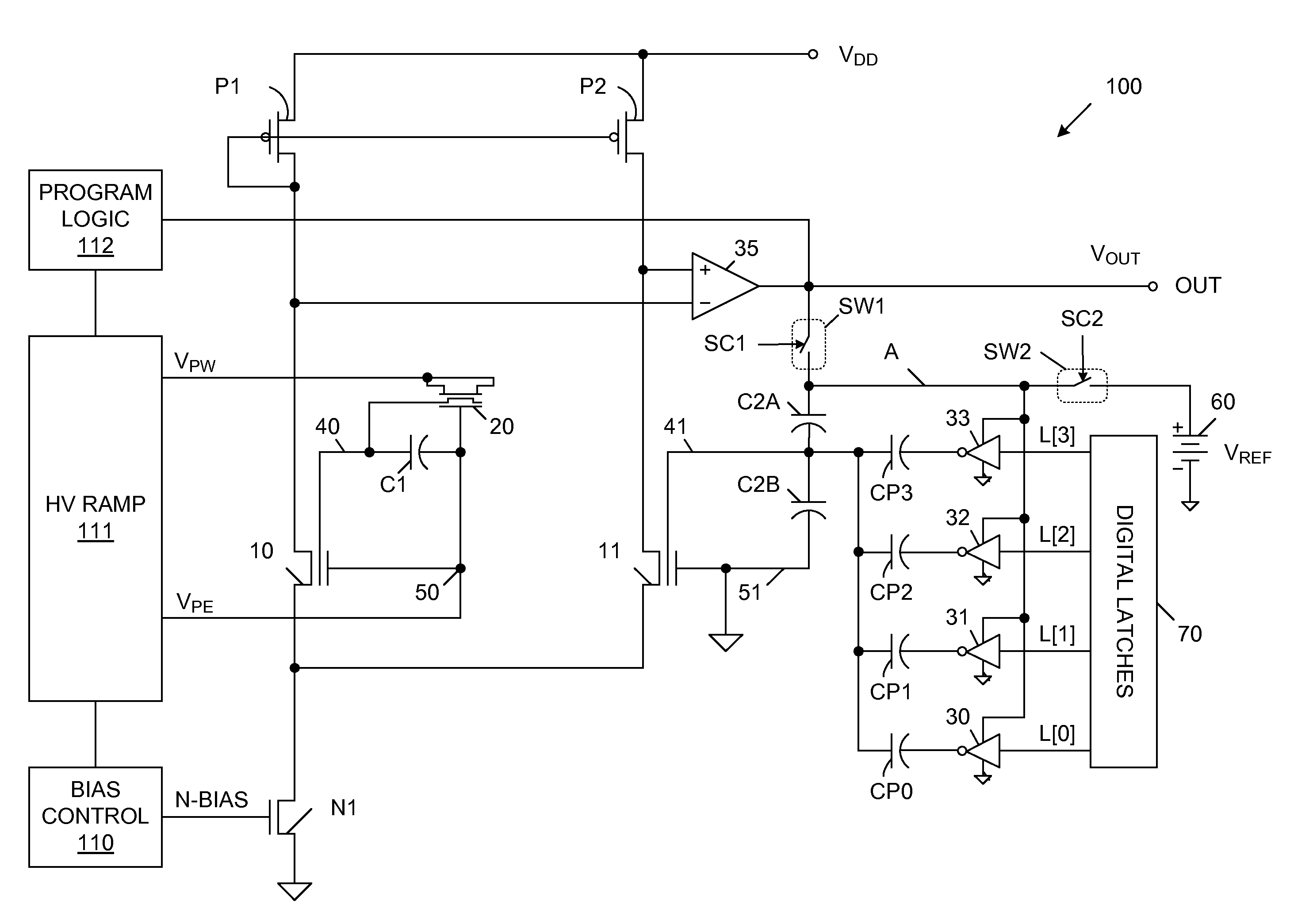

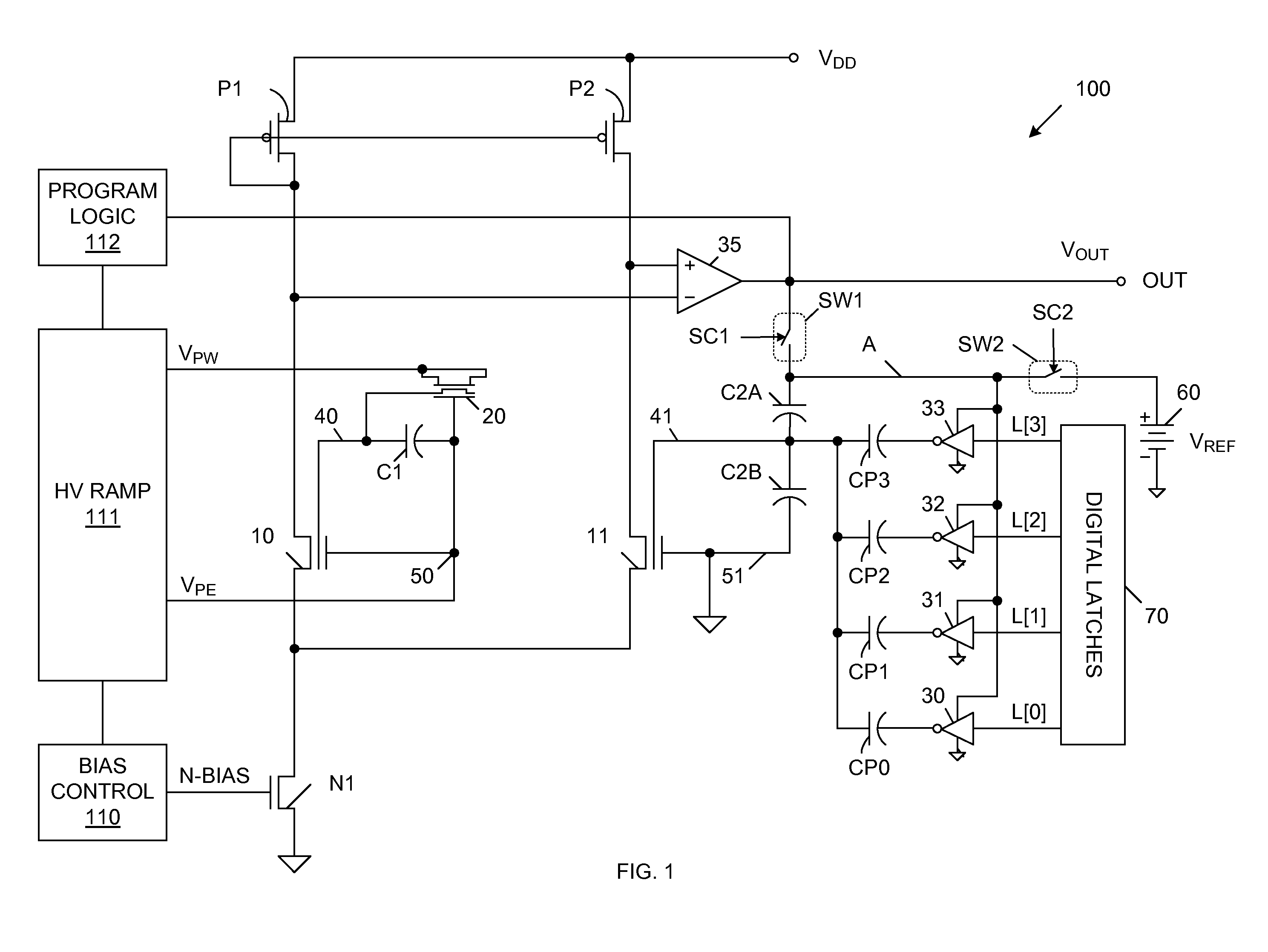

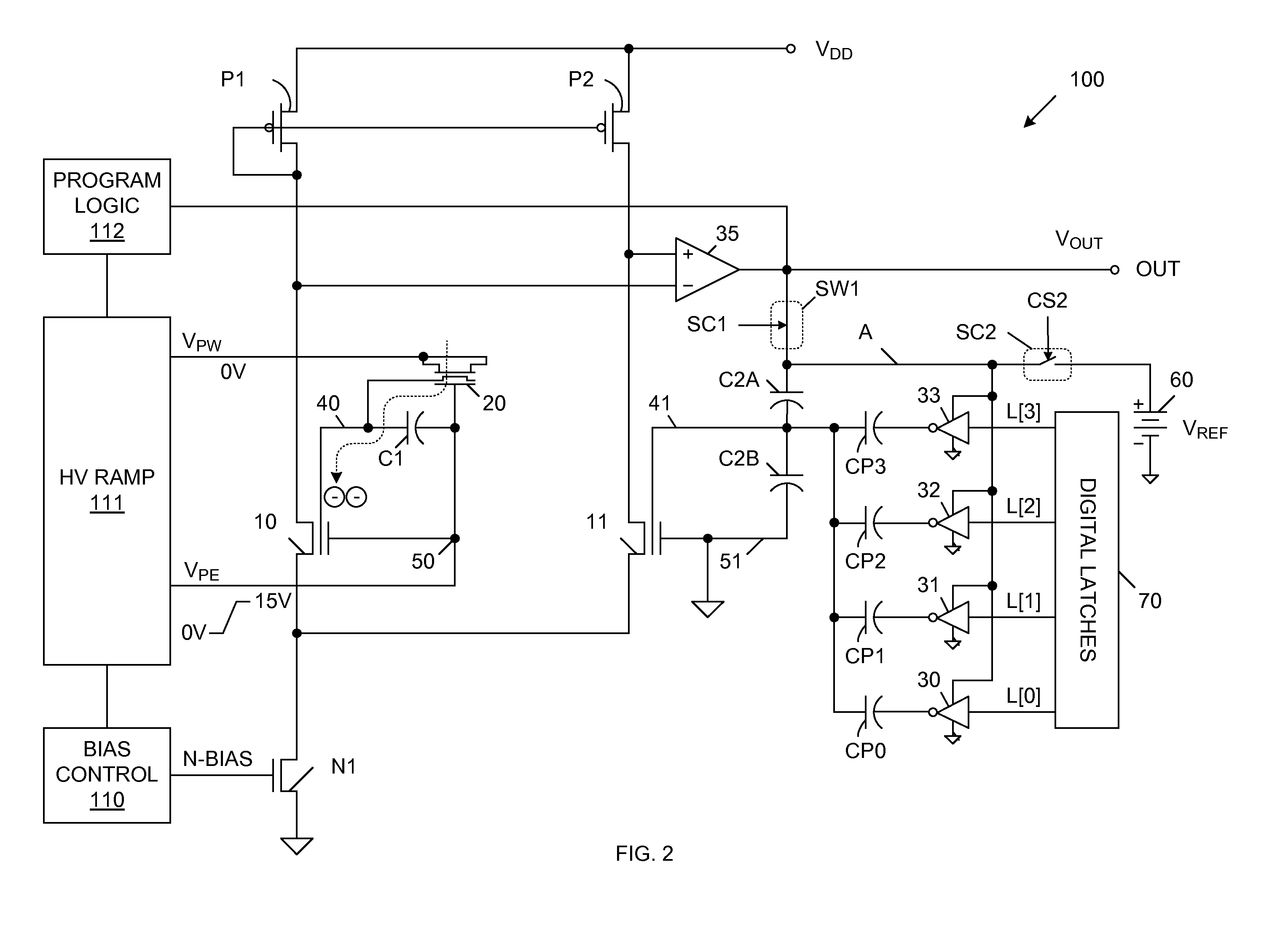

Method for trimming the temperature coefficient of a floating gate voltage reference

ActiveUS7324380B2Easy to controlGood precisionRead-only memoriesDigital storageHemt circuitsEngineering

A voltage reference circuit provides a reference voltage that can be precisely programmed. The threshold voltage of a first non-volatile memory (NVM) transistor is programmed while coupled in parallel with a second NVM transistor. During programming, one or more capacitors are connected between the floating gate of the first NVM transistor and ground, and one or more capacitors are connected between the floating gate of the second NVM transistor and ground. The first and second NVM transistors are then coupled to a differential amplifier, which is used to generate a single-ended reference voltage in response to the programmed threshold voltage of the first NVM transistor. Bipolar transistors are selectively switched between the various capacitors and ground, thereby providing precise adjustment of the temperature coefficient of the voltage reference circuit.

Owner:SEMICON COMPONENTS IND LLC

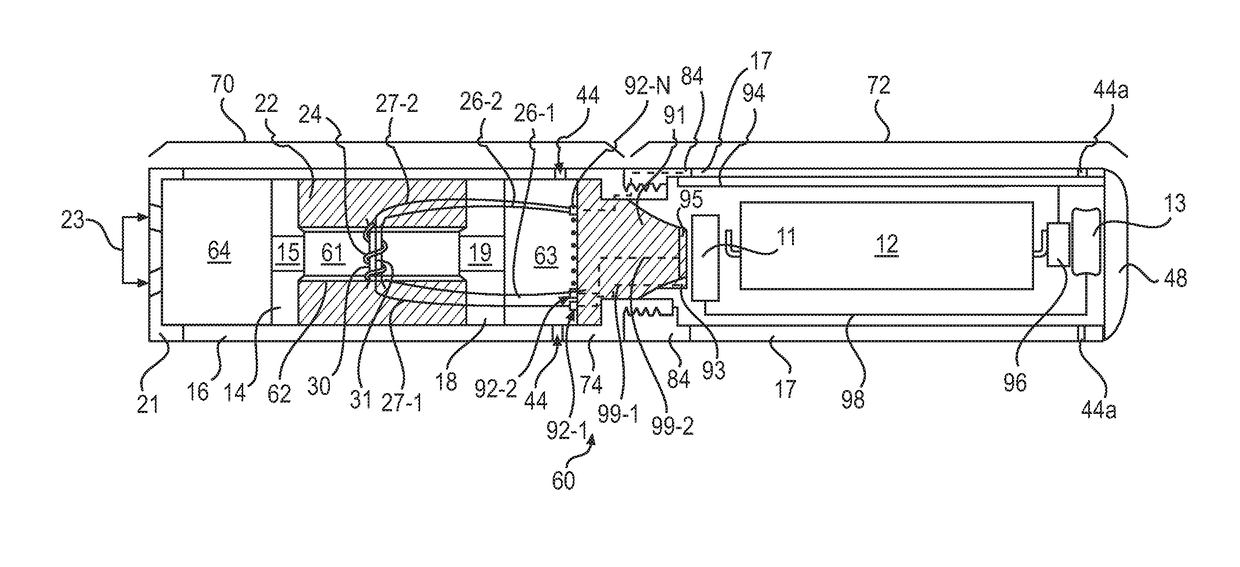

E-vaping device cartridge with internal conductive element

A cartridge for an e-vaping device includes a conductive element extending through an interior of a dispensing interface to which a heating element is coupled. The conductive element may have a greater temperature coefficient of electrical resistivity than the heating element. The dispensing interface may include a fibrous wicking material, and the conductive element may be woven through an interior of the fibrous wicking material. A temperature of the dispensing interface may be determined based on monitoring an electrical resistance of the conductive element. An amount of pre-vapor formulation may be determined based on an electrical resistance of the bridge electrical circuit to an electrical signal between the heating element and the conductive element through the dispensing interface.

Owner:AKRIA CLIENT SERVICES LLC

Fuel level sensor

InactiveUS7093485B2Easy to installEasy to adaptMachines/enginesLubrication indication devicesFuel tankEngineering

Owner:UUSI

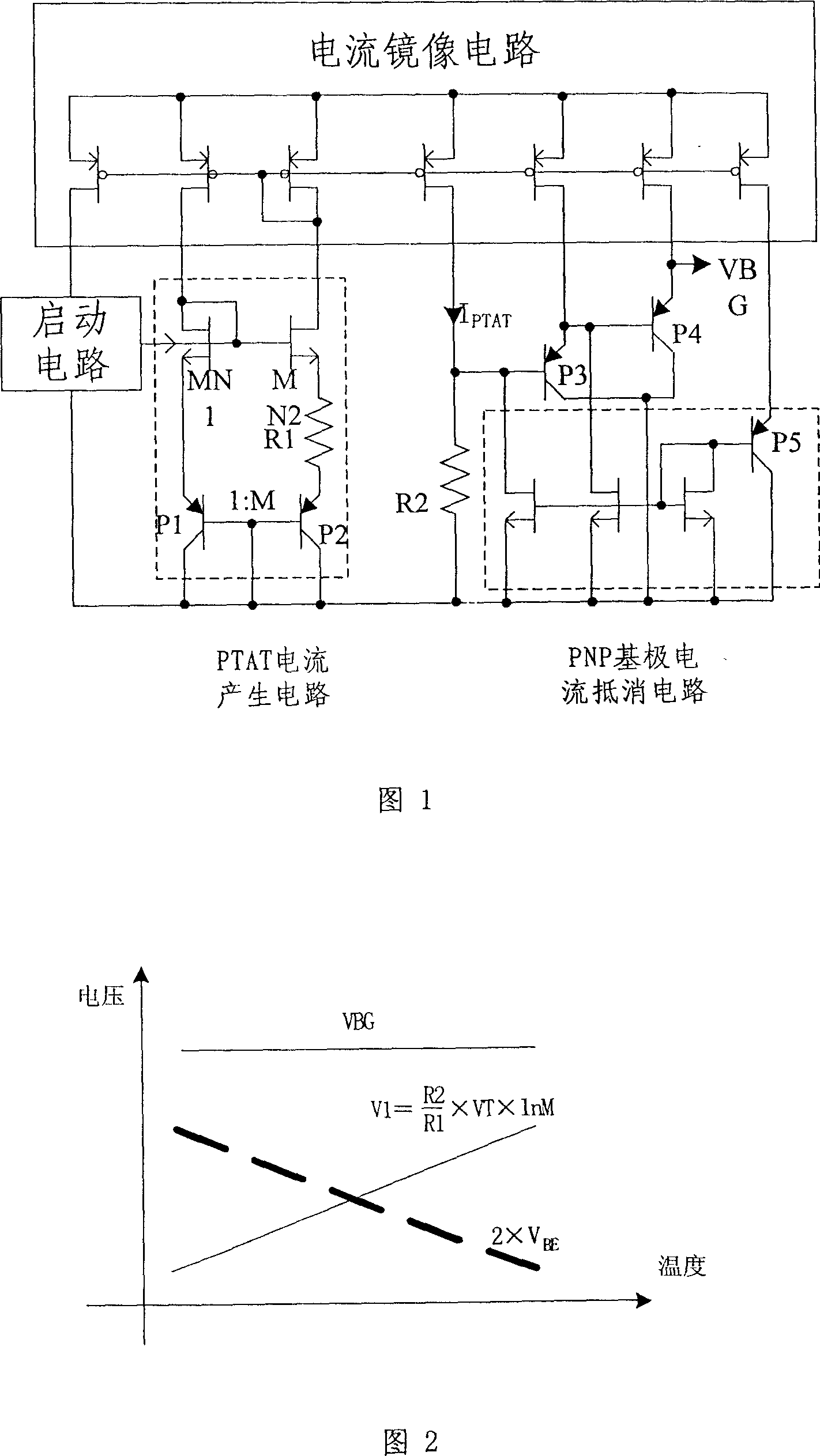

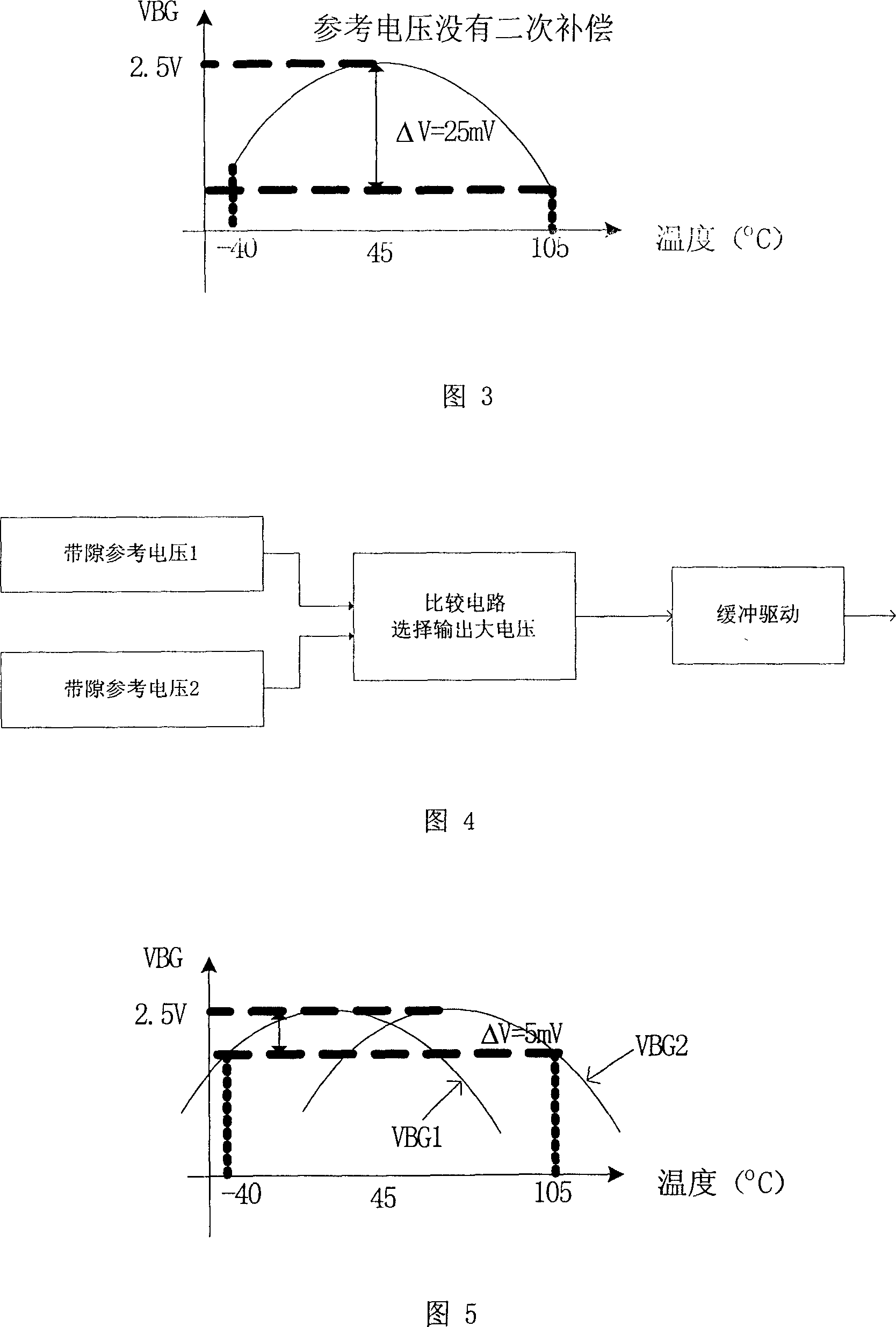

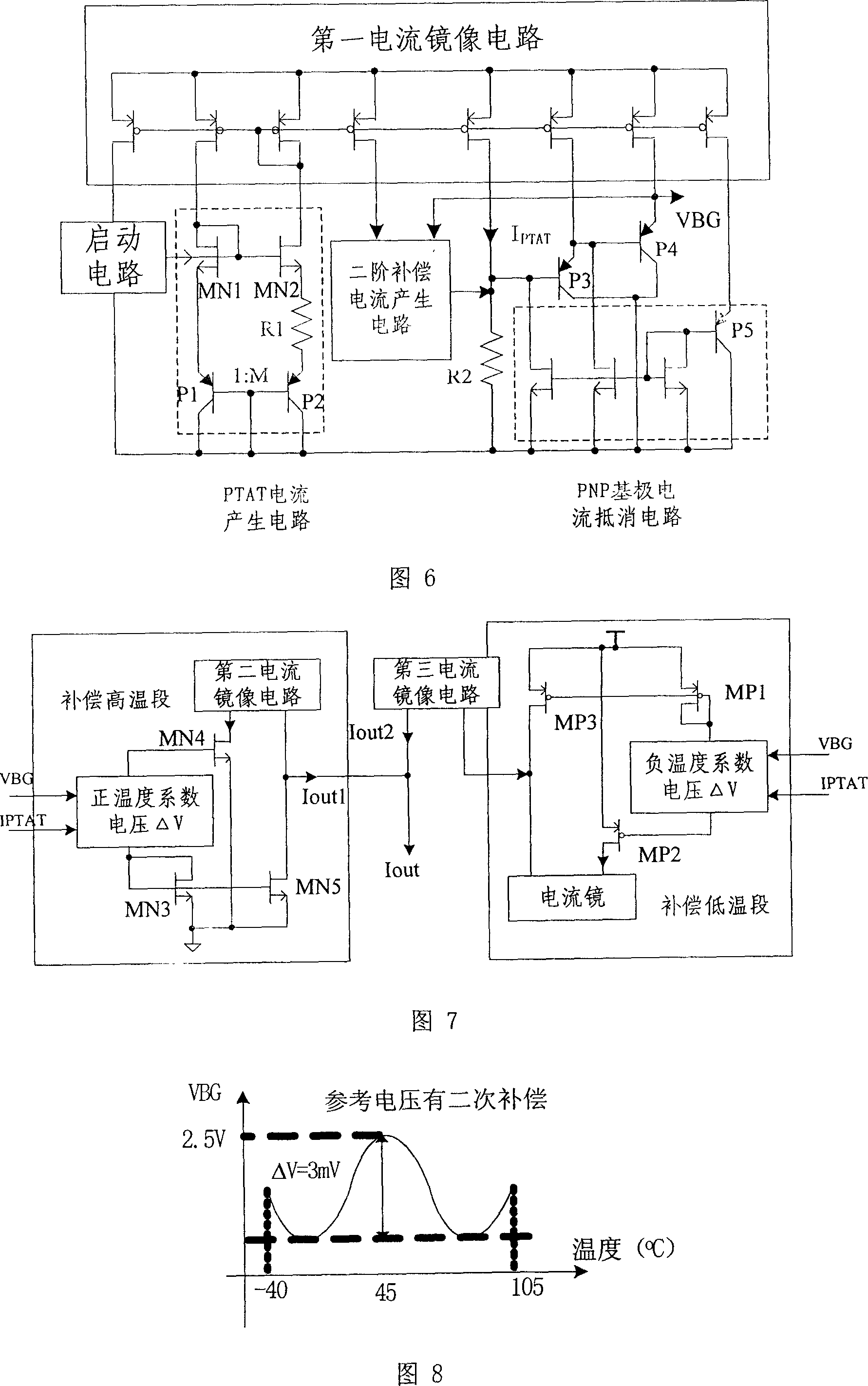

Reference voltage source for low temperature coefficient with gap

ActiveCN1987713AOvercoming the problem of high temperature coefficientSolving Temperature Compensation IssuesElectric variable regulationCMOSVoltage drop

The band-gap reference voltage (RV) source with low temperature coefficient (TC) includes PTAT current generation circuit, start circuit of RV, combiner circuit of RV, neutralization circuit of base current, mirror circuit of first current. The band-gap RV source with low TC also includes generation circuit of second order temperature compensation current, which is connected to the mirror circuit of first current, and the combiner circuit of RV. Through square relation between drain-source current and grid-source voltage drop of MOS tube, inputting PTAT current and band-gap RV generates second order compensation current. The second order compensation current is output to the combiner circuit of RV to generate second order compensation voltage to compensate second order TC of RV so as to produce RV with very low TC. The invention overcomes issue of TC on the high side in traditional band-gap RV. Using standard CMOS technique realizes band-gap RV with very low TC.

Owner:CHIPSEA TECH SHENZHEN CO LTD

Low-voltage bandgap voltage reference circuit

A bandgap reference voltage generating circuit includes a proportional to absolute temperature (PTAT) voltage generating means generating a PTAT voltage. A complementary to absolute temperature (CTAT) voltage generating means generates a CTAT voltage. A temperature coefficient determining means interconnects the PTAT voltage generating means and the CTAT voltage generating means.

Owner:RAUM TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com