Patents

Literature

489 results about "Closed path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

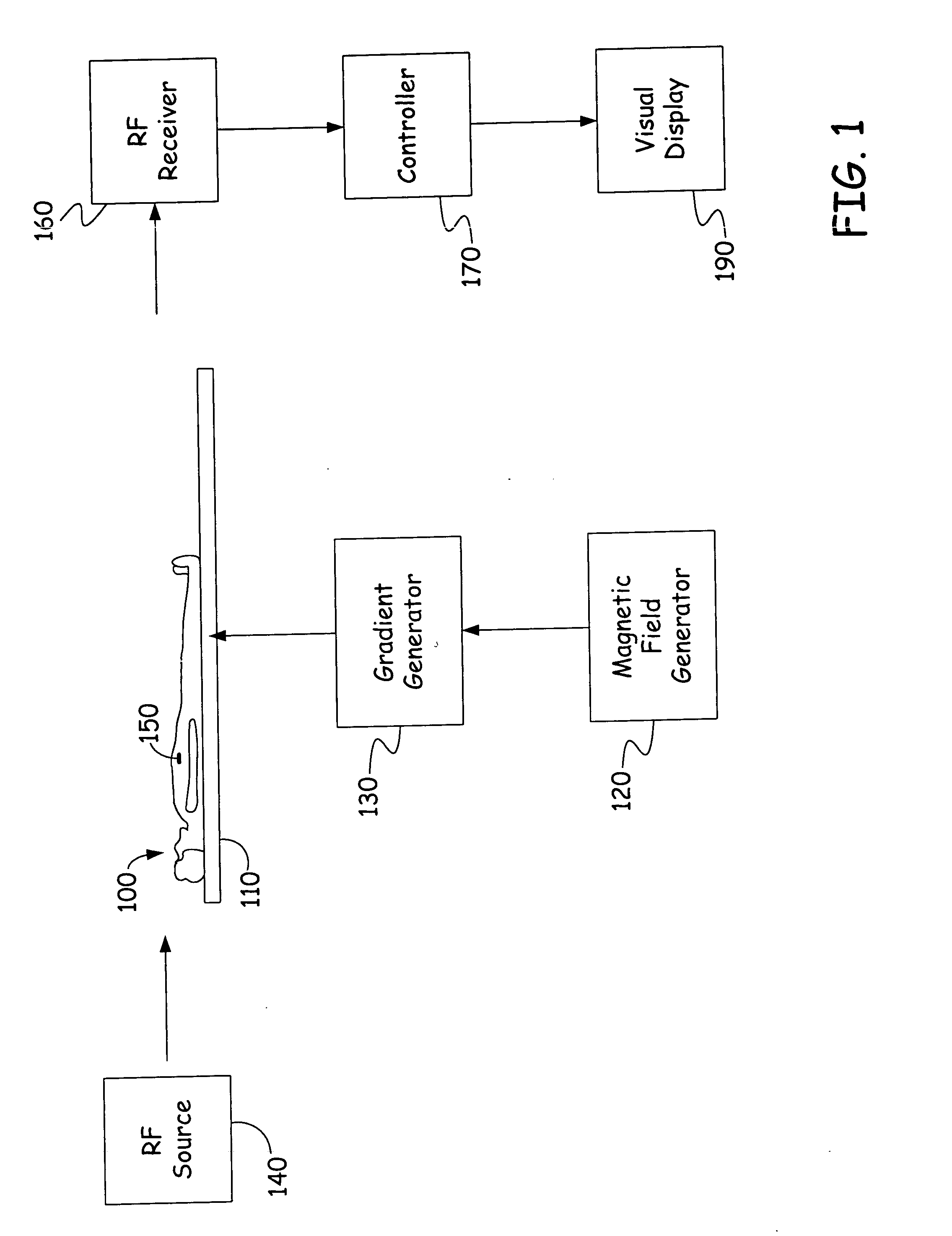

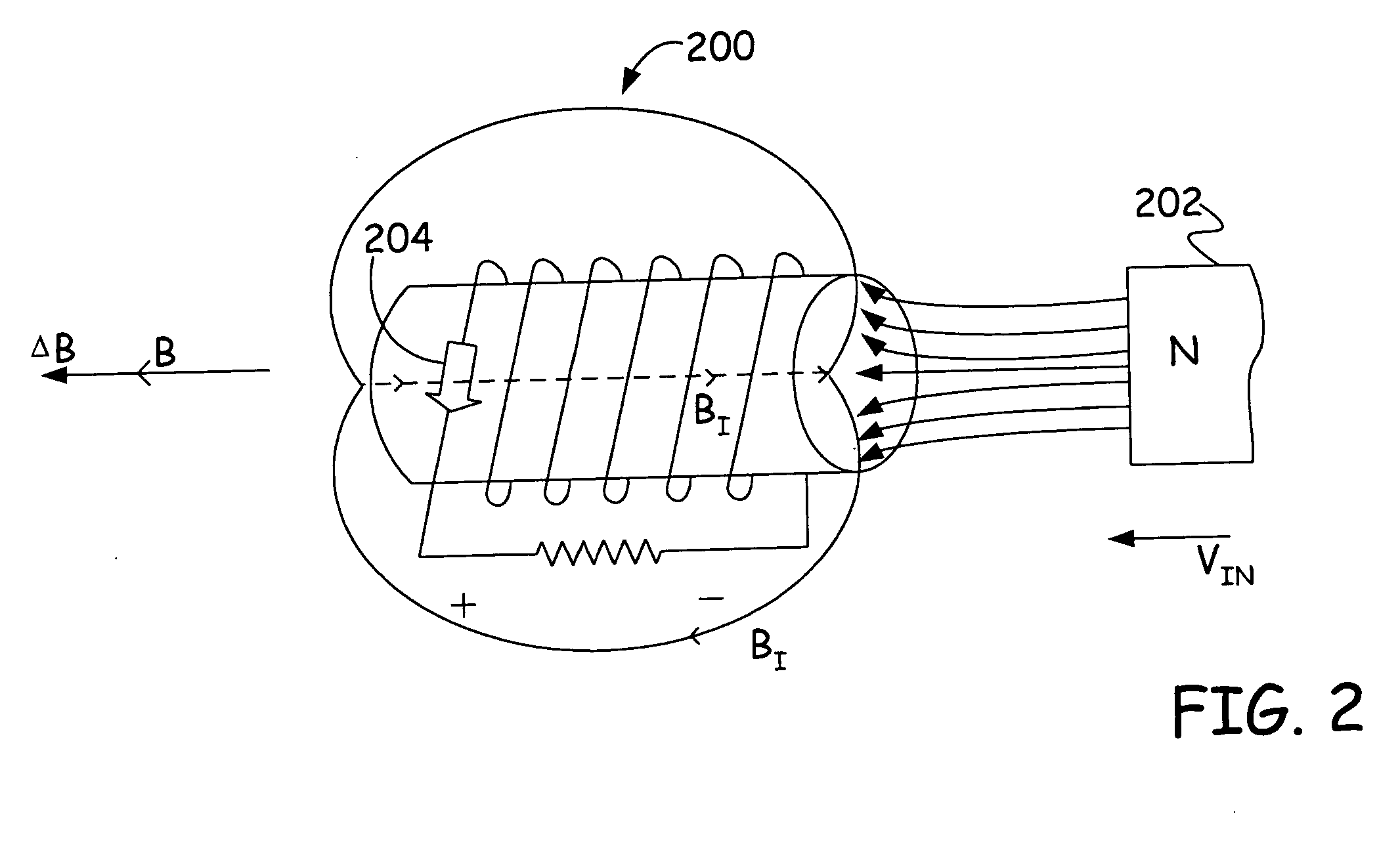

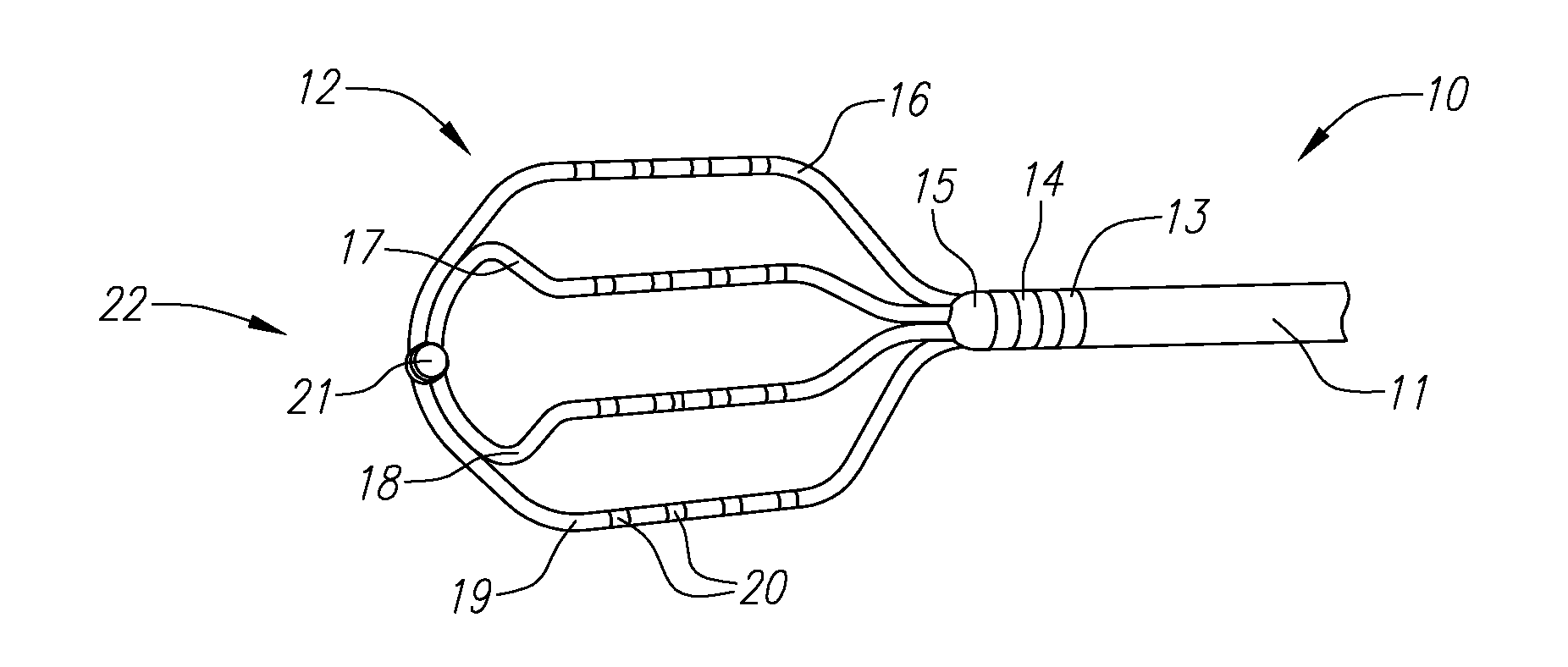

Stent designs which enable the visibility of the inside of the stent during MRI

InactiveUS20050033407A1Reduce distortion problemsIncrease awarenessStentsBlood vesselsVisibilityProximate

Owner:BOSTON SCI SCIMED INC

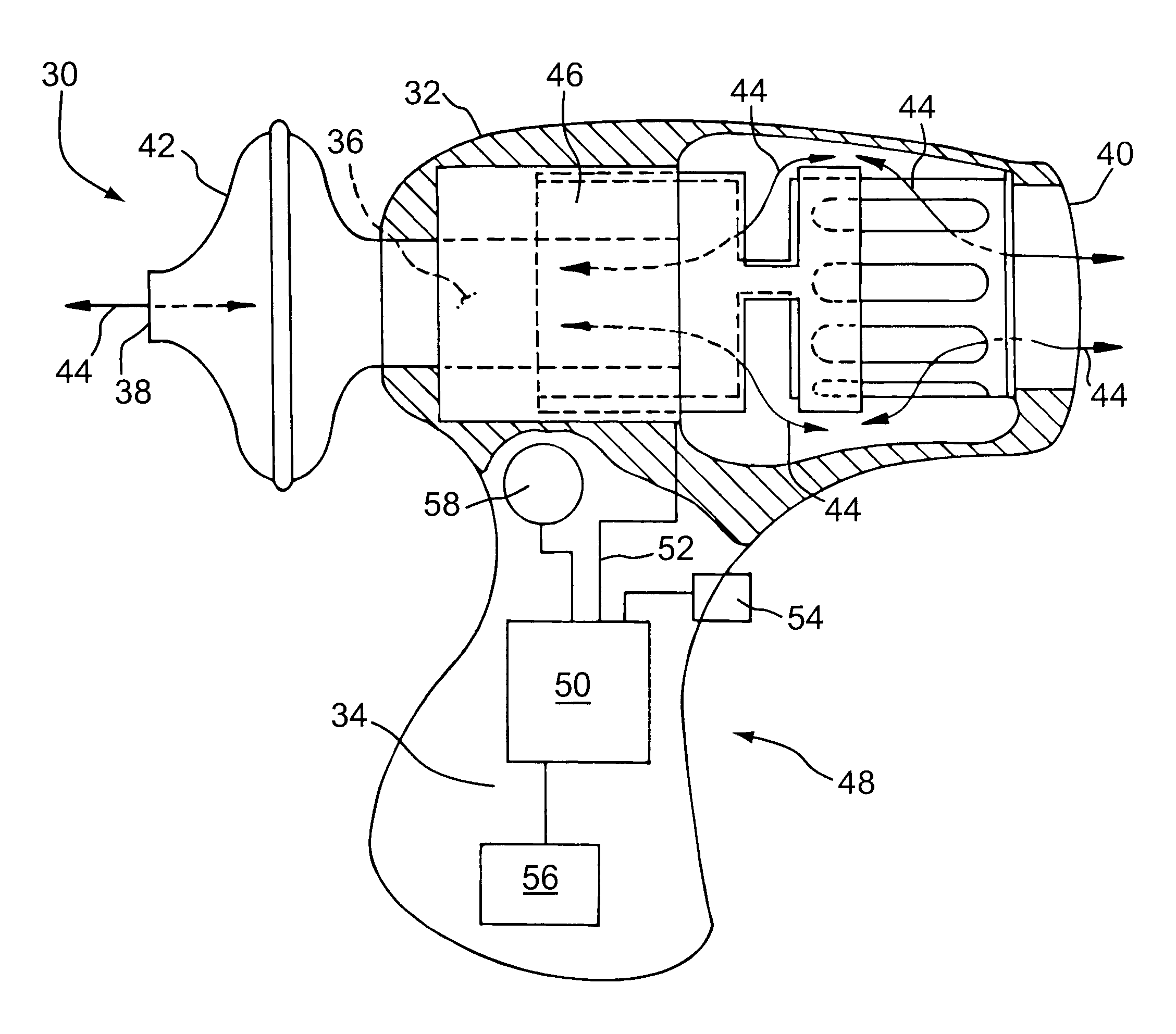

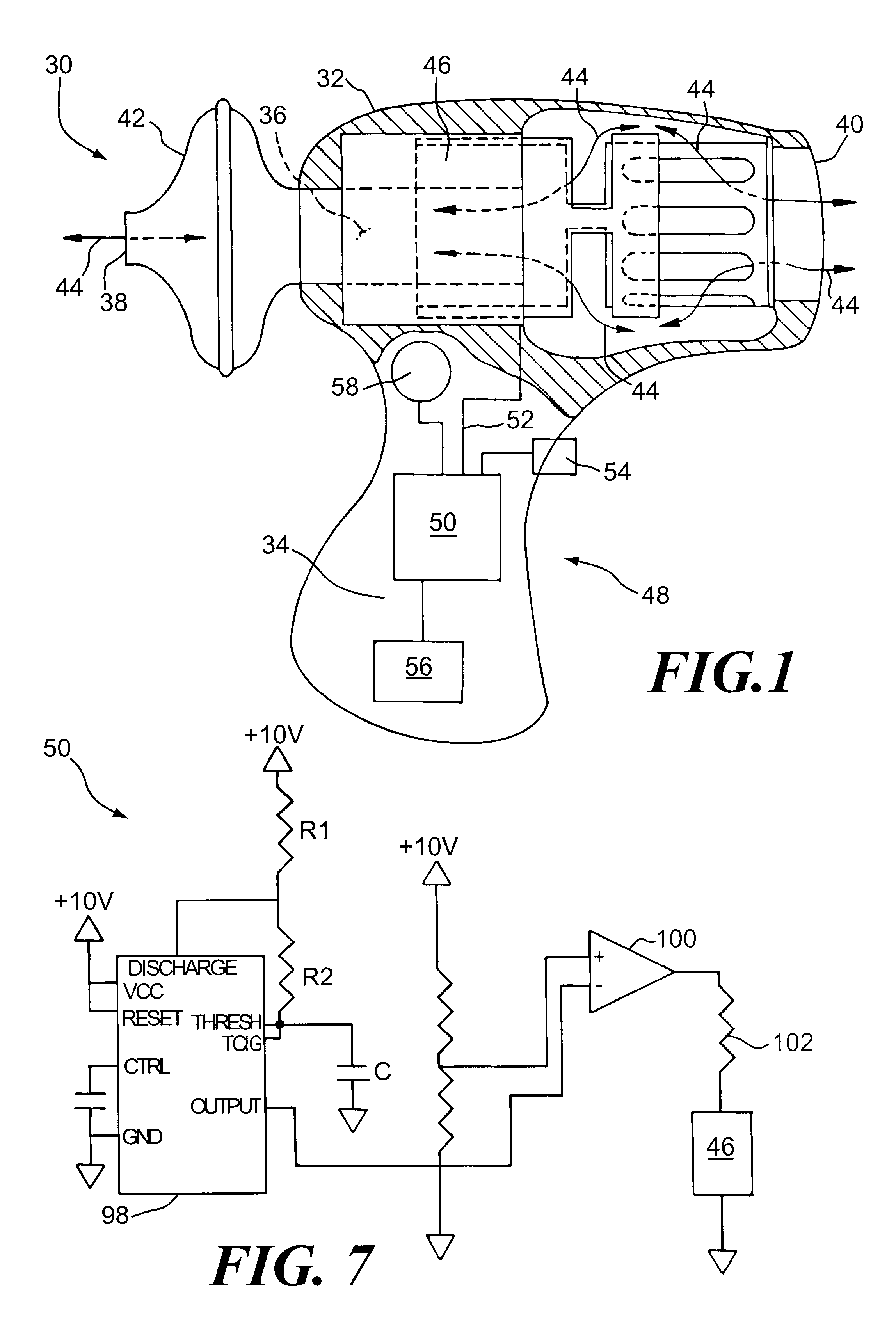

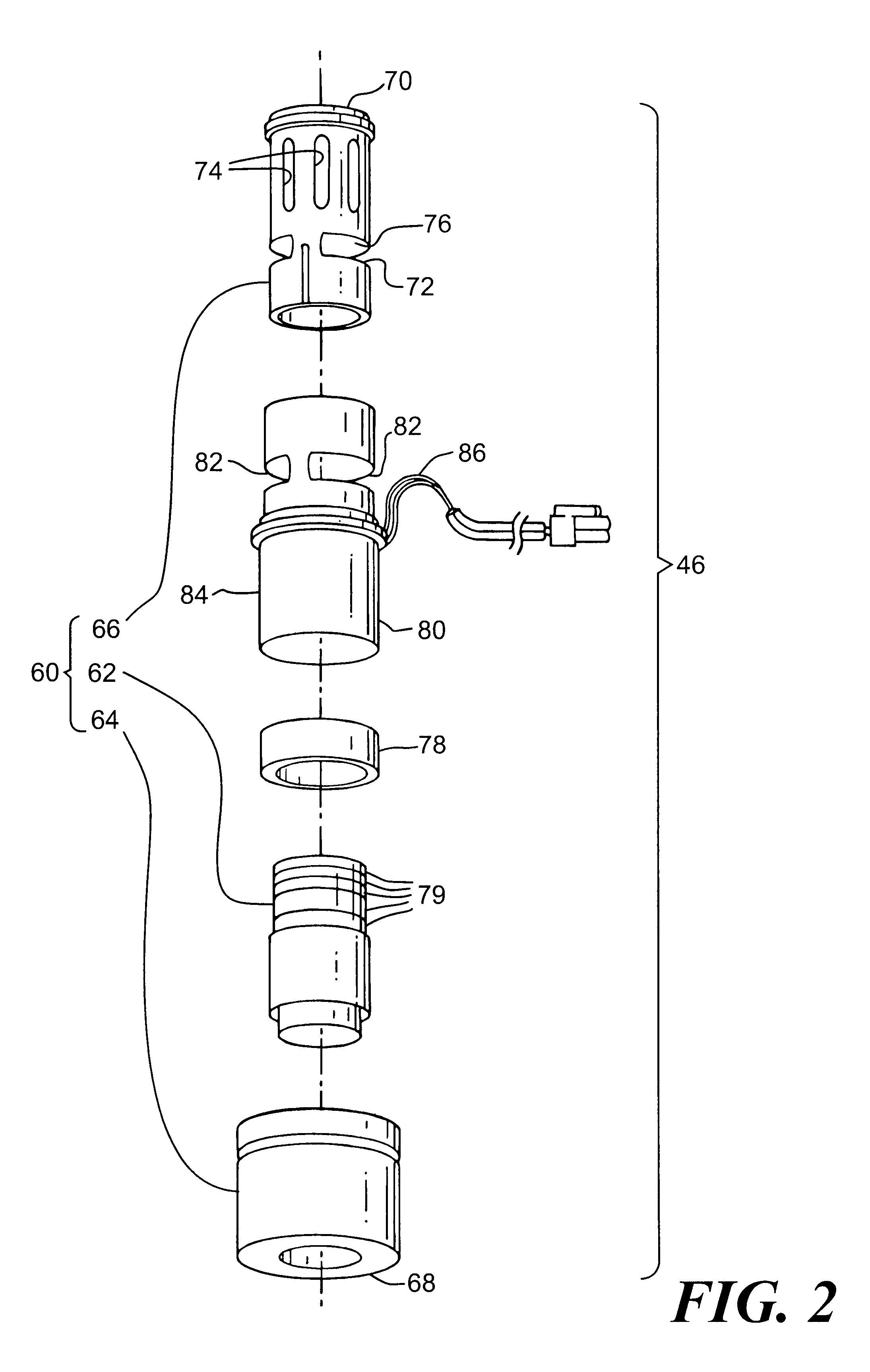

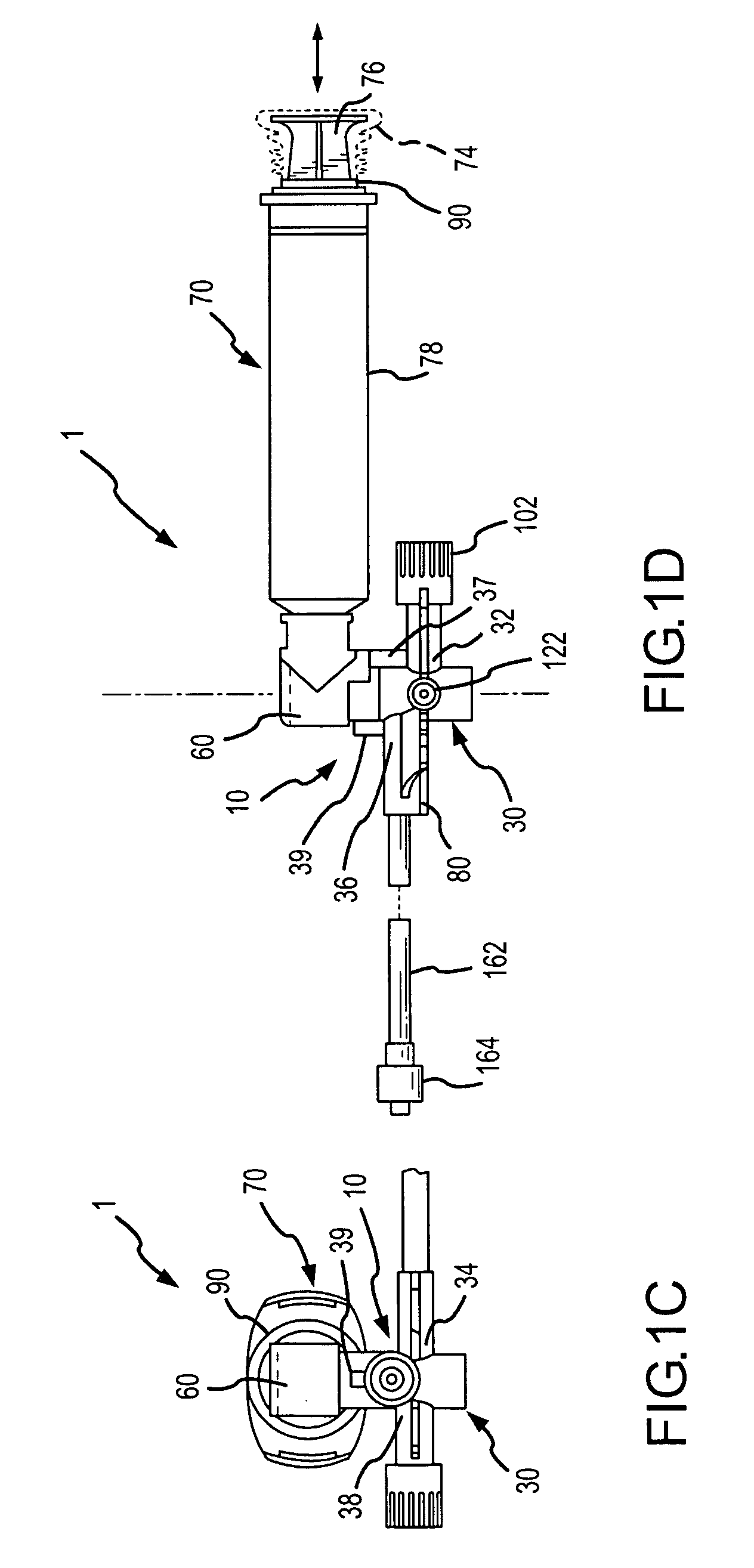

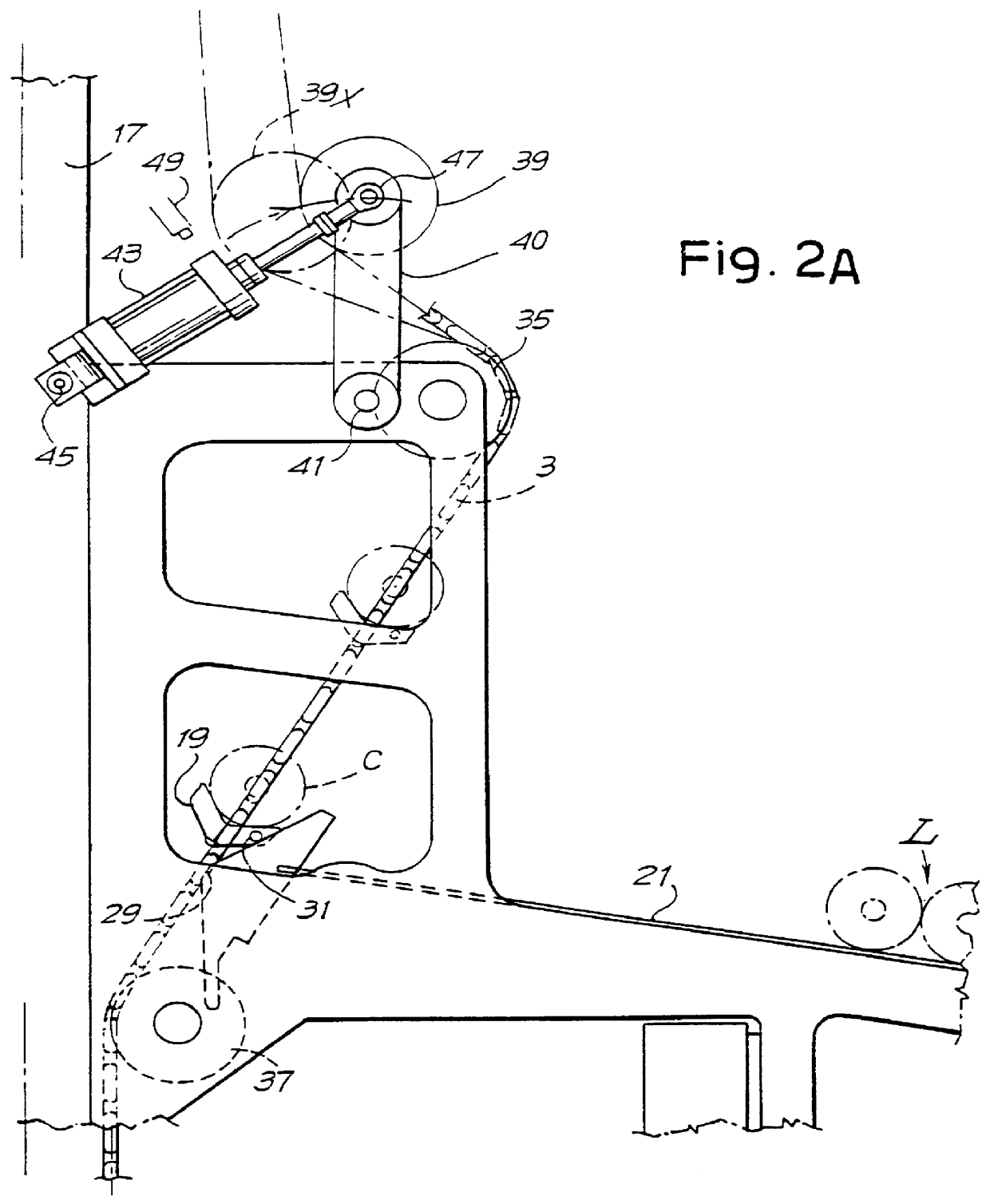

Apparatus and method of providing high frequency variable pressure to a patient

InactiveUS6581596B1Facilitates loosening and removalRespiratorsOperating means/releasing devices for valvesBreathing gasSecretion

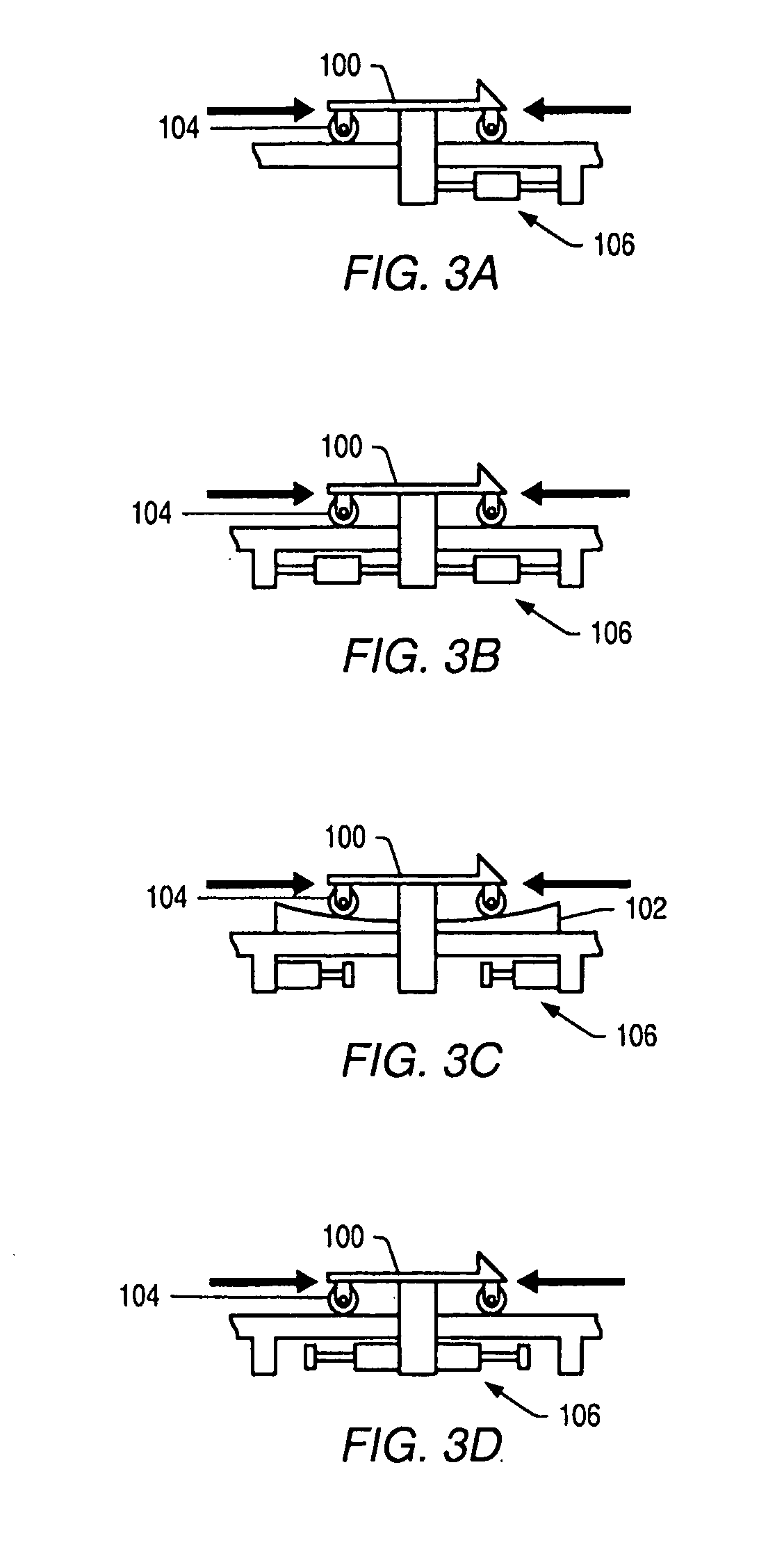

A high frequency pressure oscillation device that selective restricts the flow of breathing gas to or from a patient to produce pressure spikes in the patient's airway that facilitate clearing secretions from the patient's airway. The device includes a patient circuit that defines a closed path between a source of breathing gas and the patient's airway. A valve is disposed in the patient circuit such that in an open position the path between the source of breathing gas and the airway of the patient is substantially unobstructed. When the valve is in a closed position, the path between the source of breathing gas and the patient's airway is at least partially obstructed to create the pressure spikes. An actuating system associated with the valve alternatively places the valve in the open position and in the closed position at a predetermined oscillation rate that is independent of patient effort.

Owner:RIC INVESTMENTS LLC

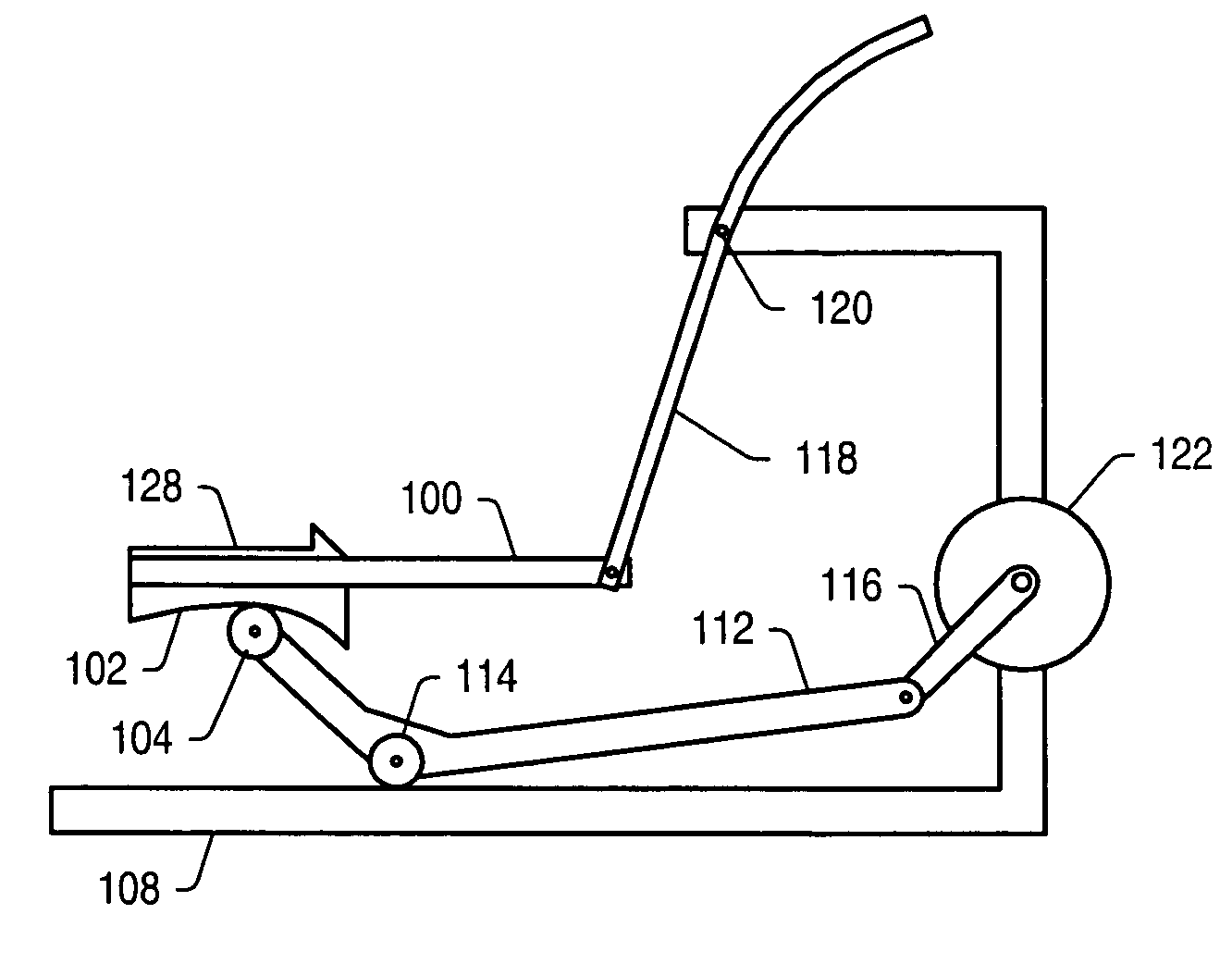

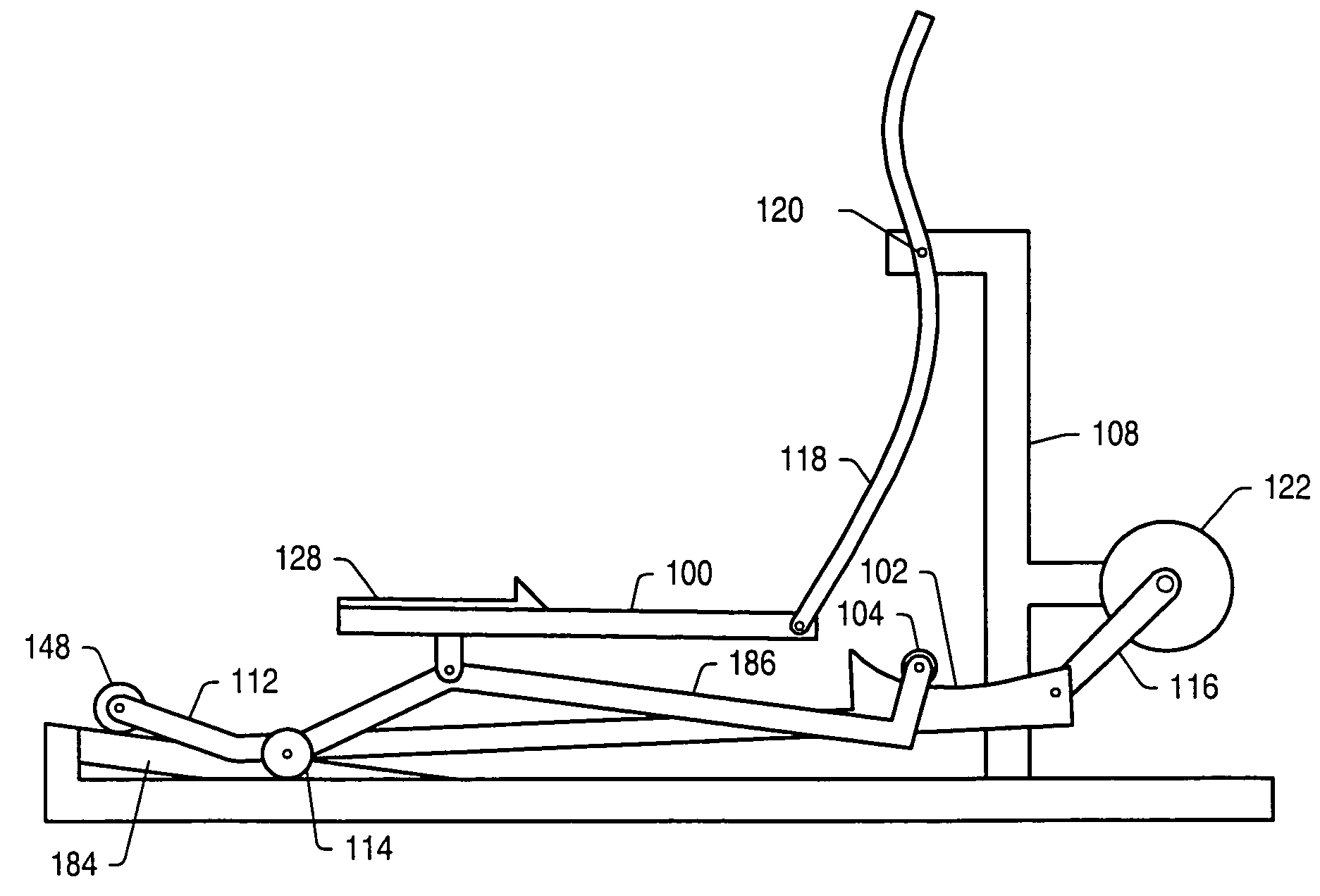

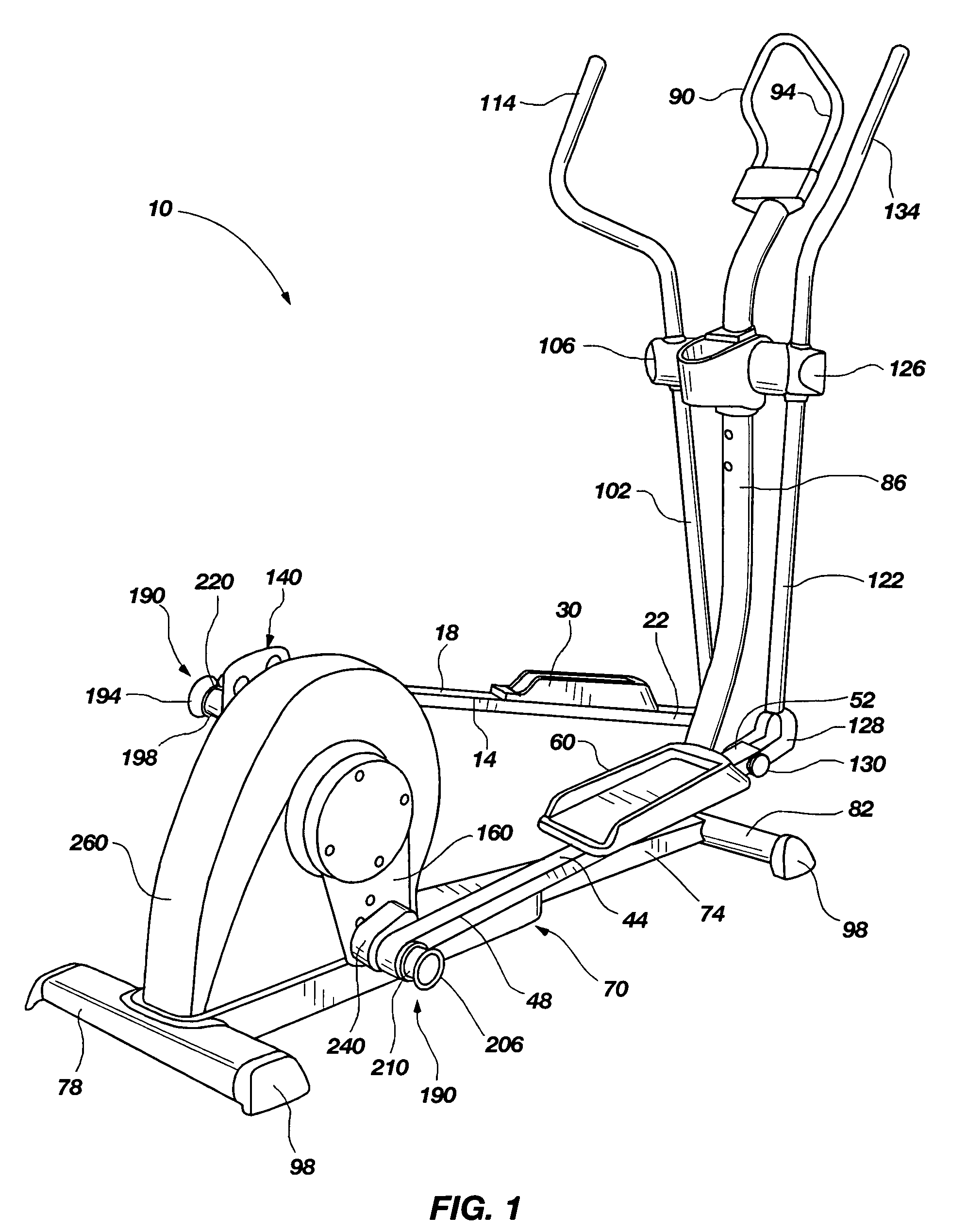

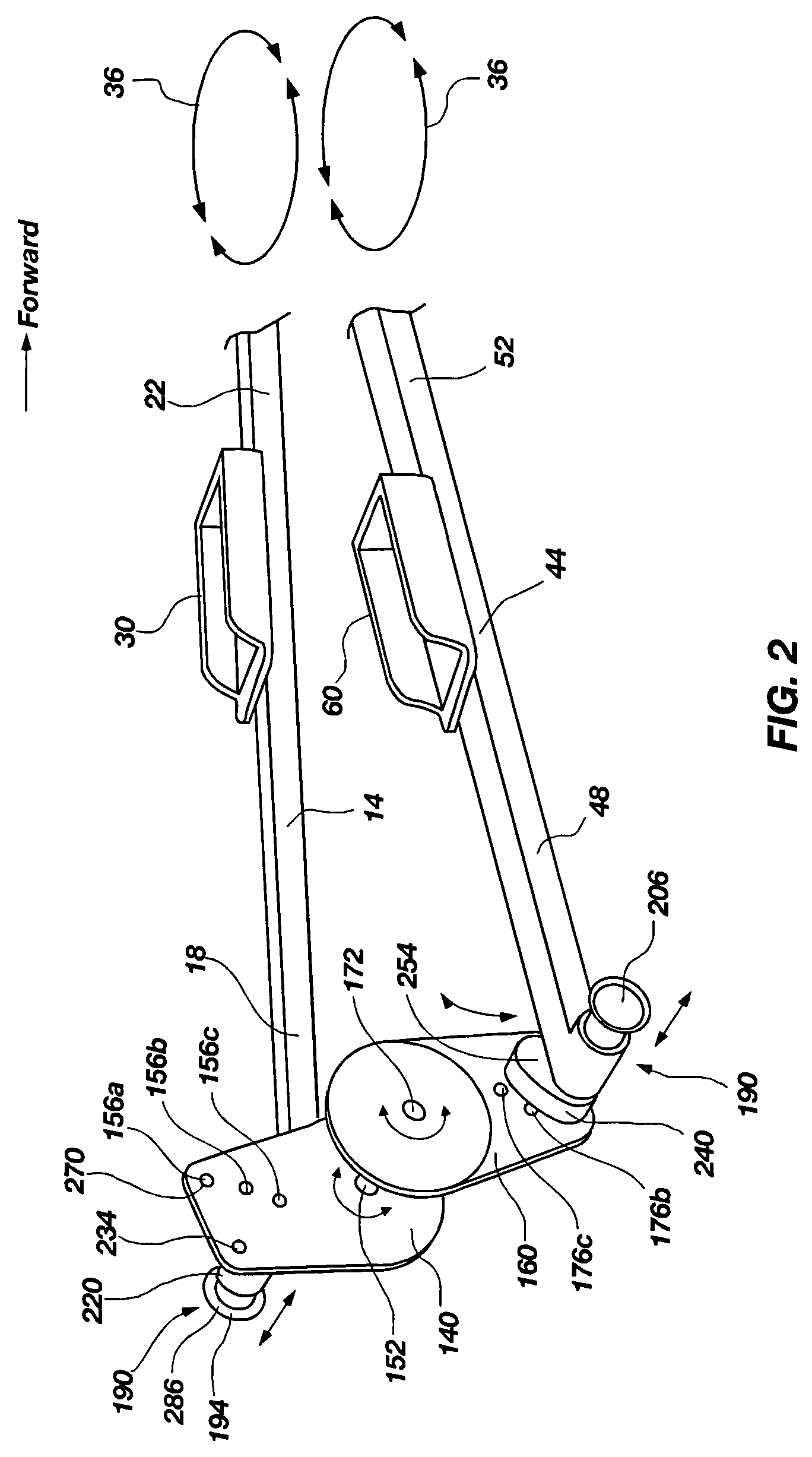

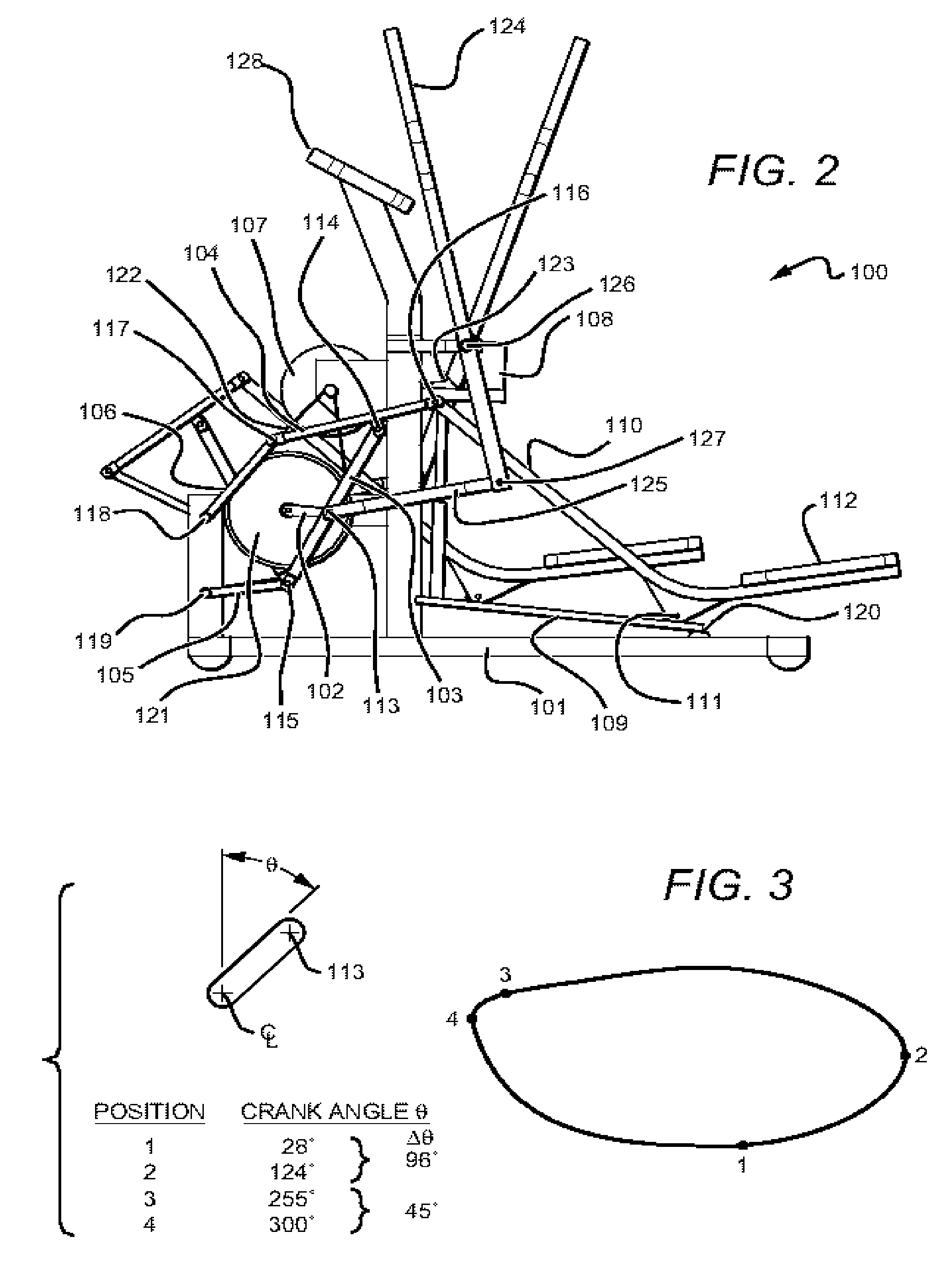

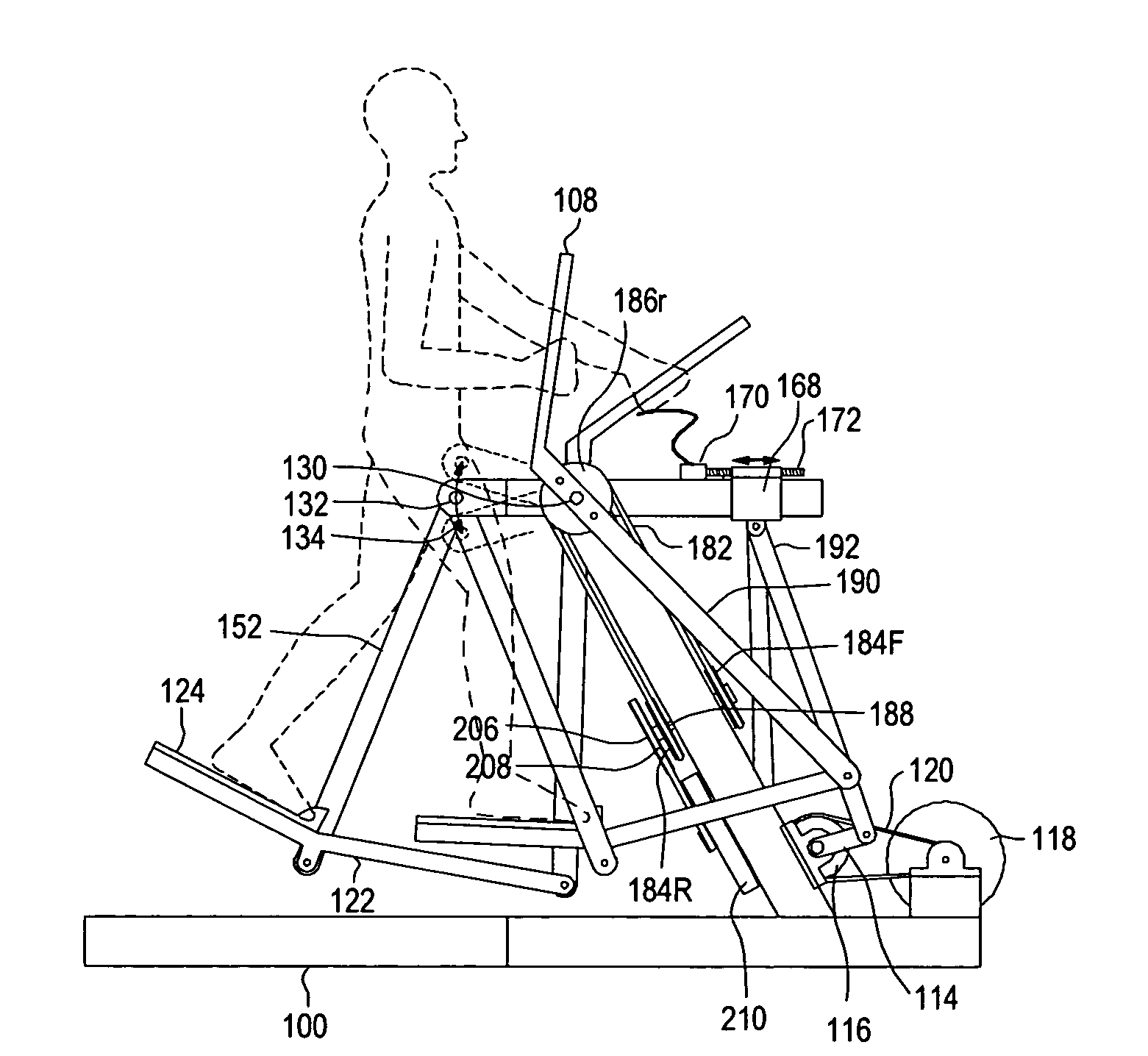

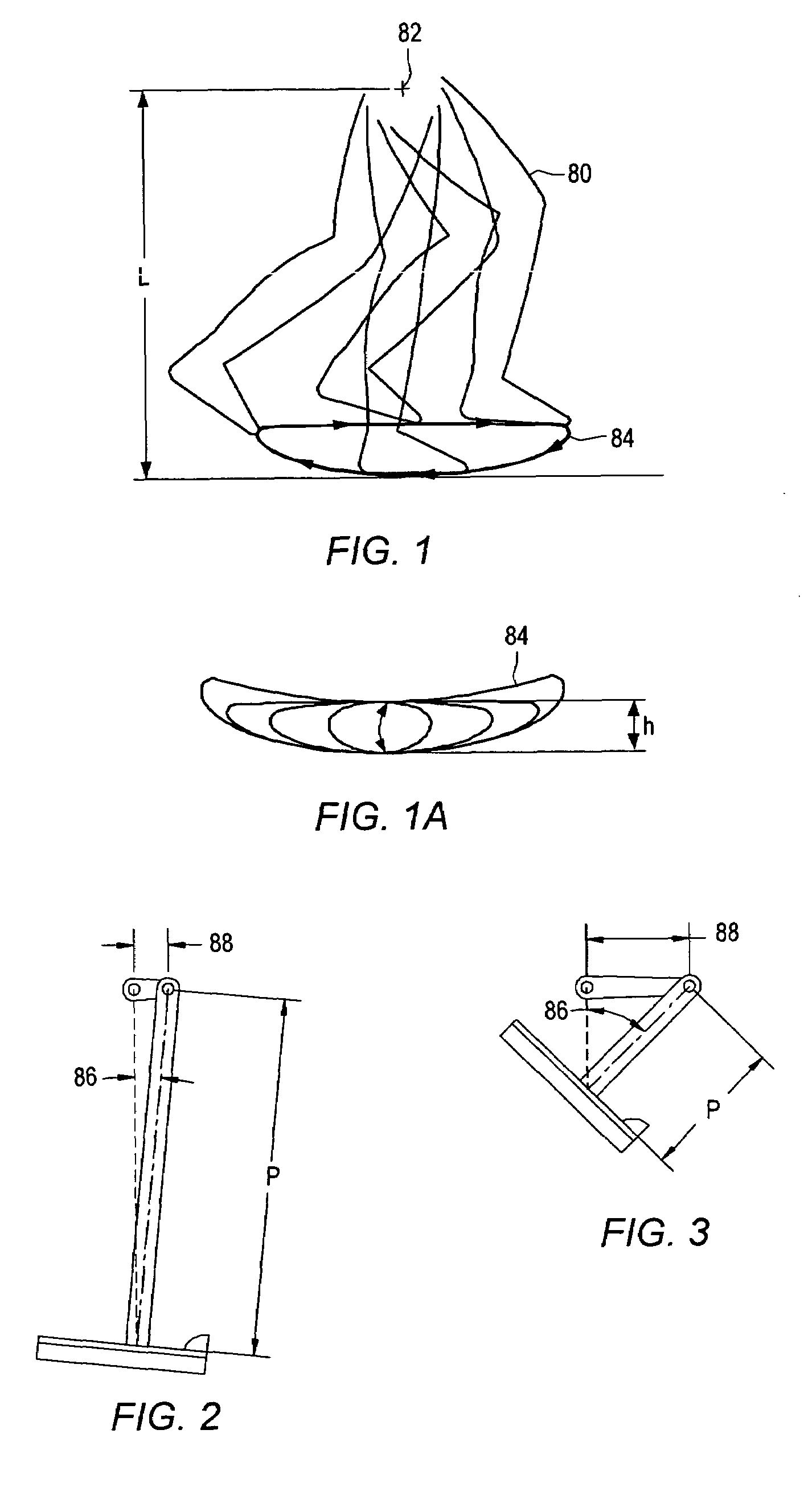

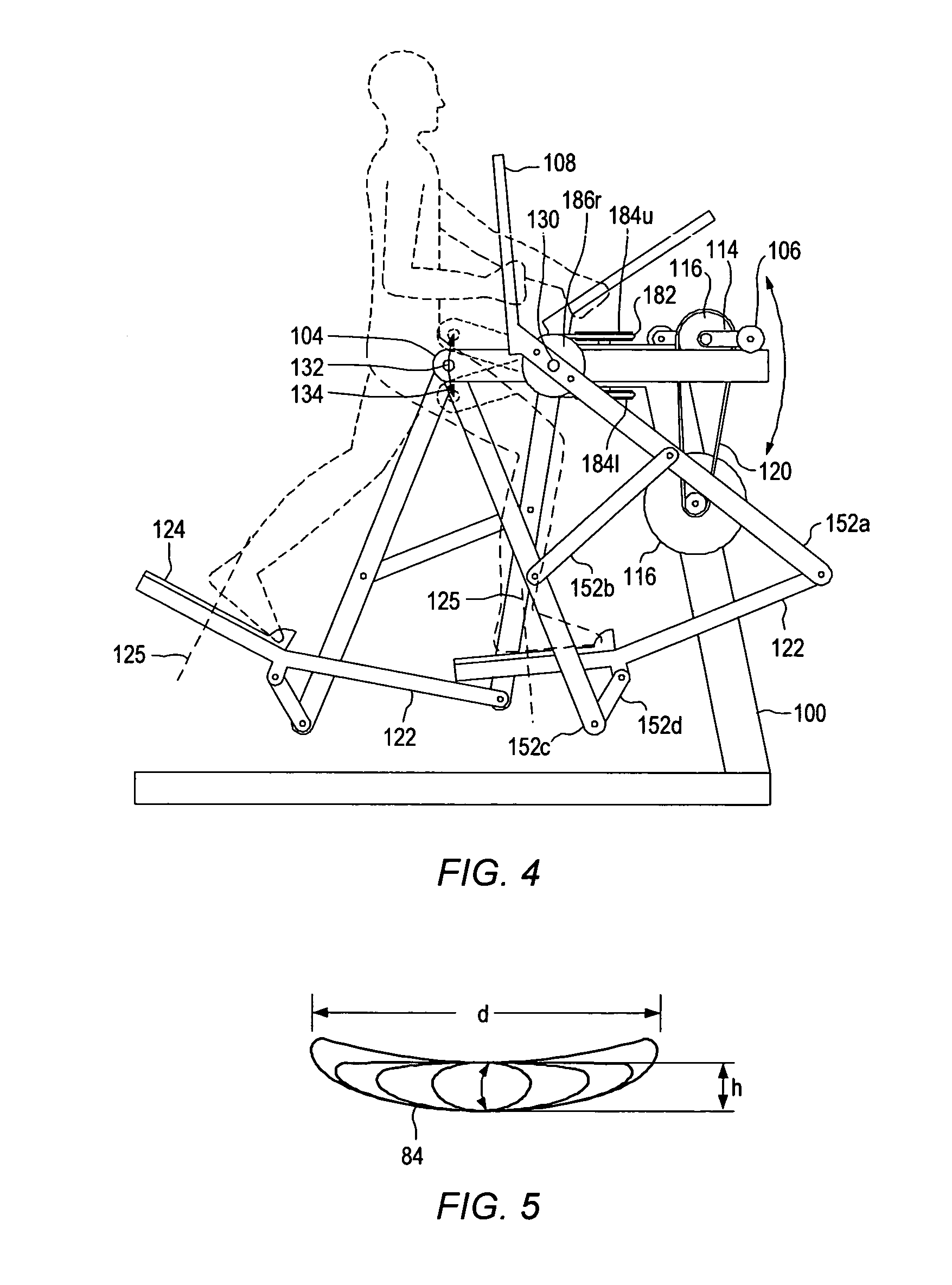

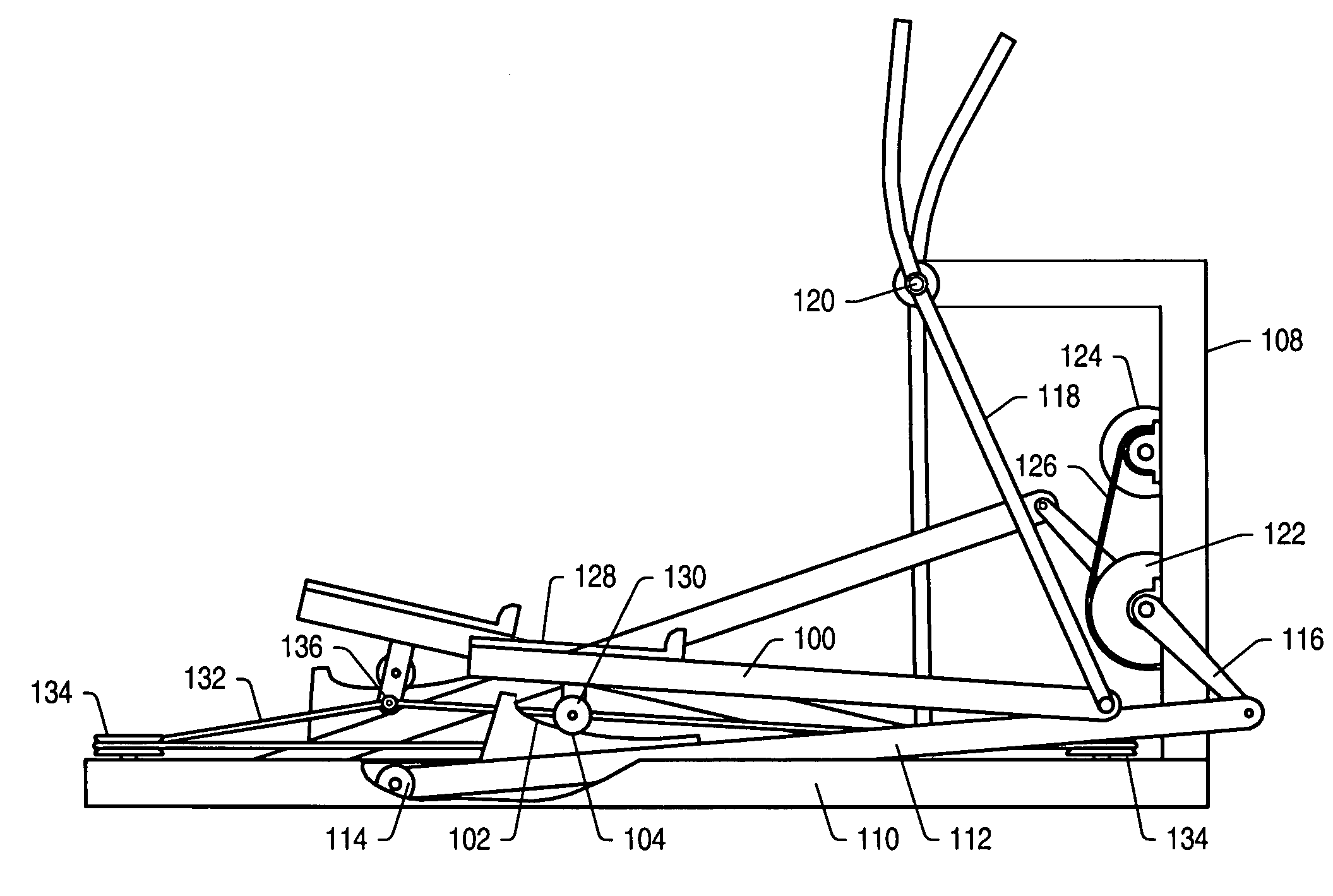

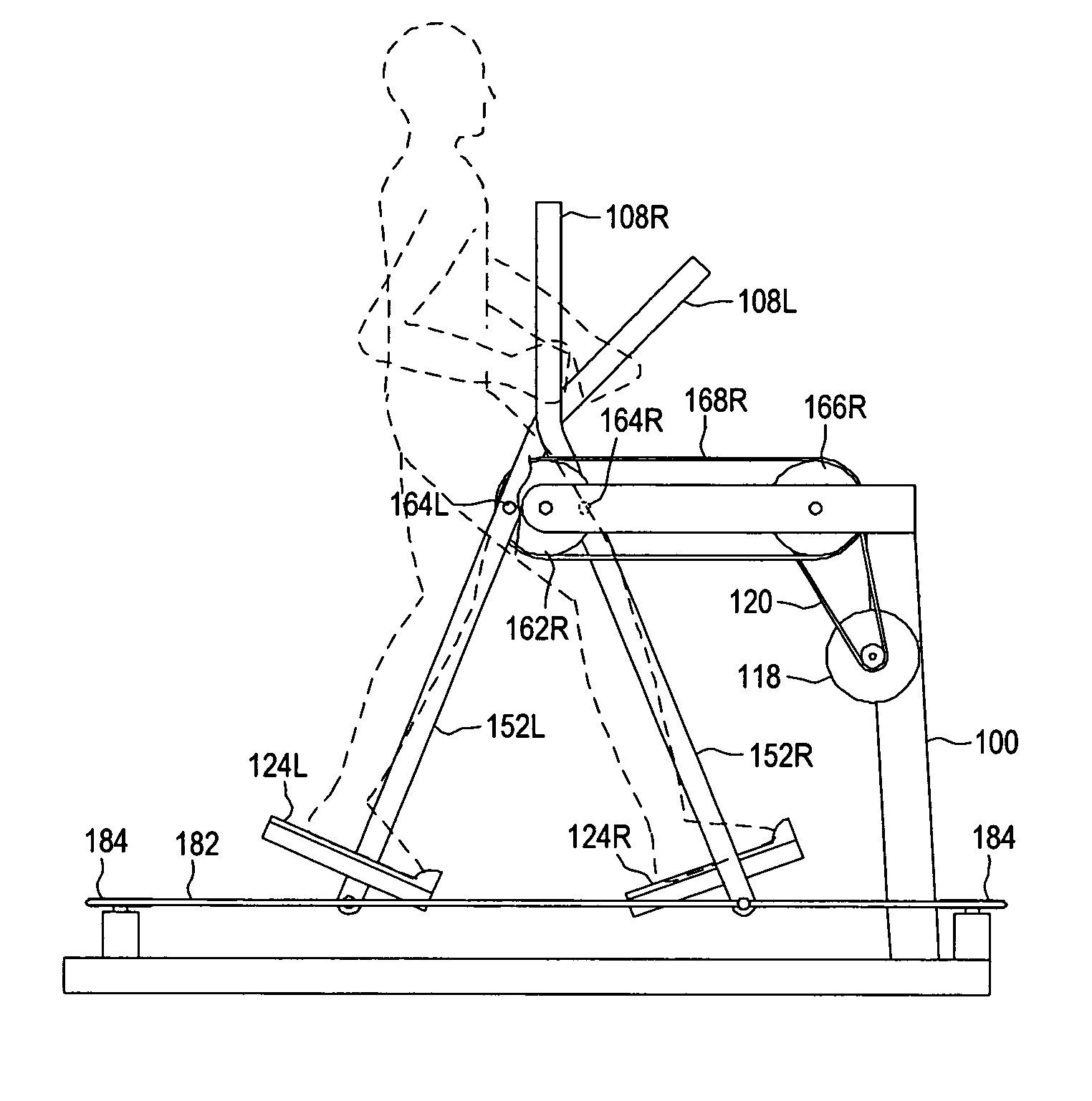

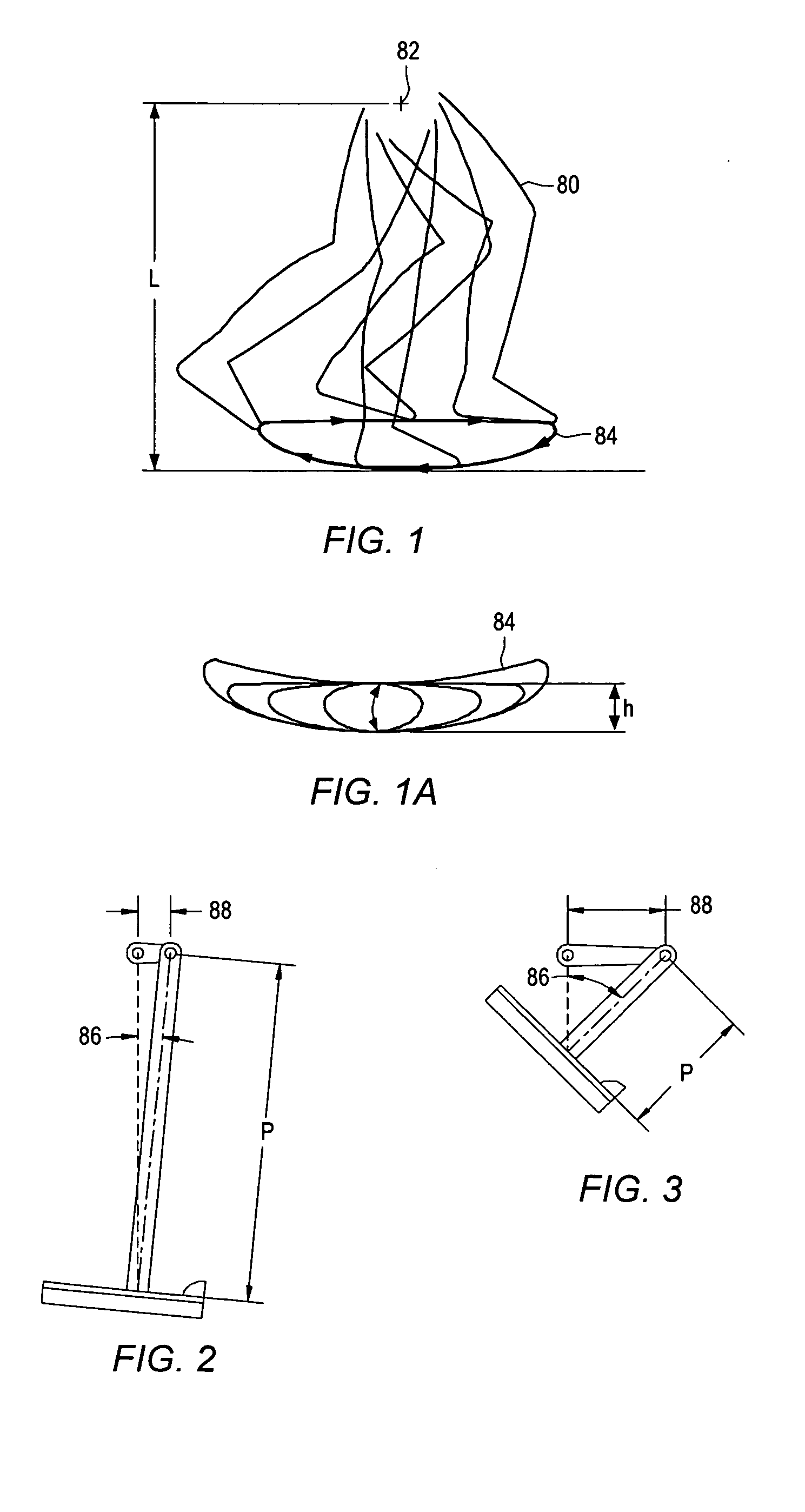

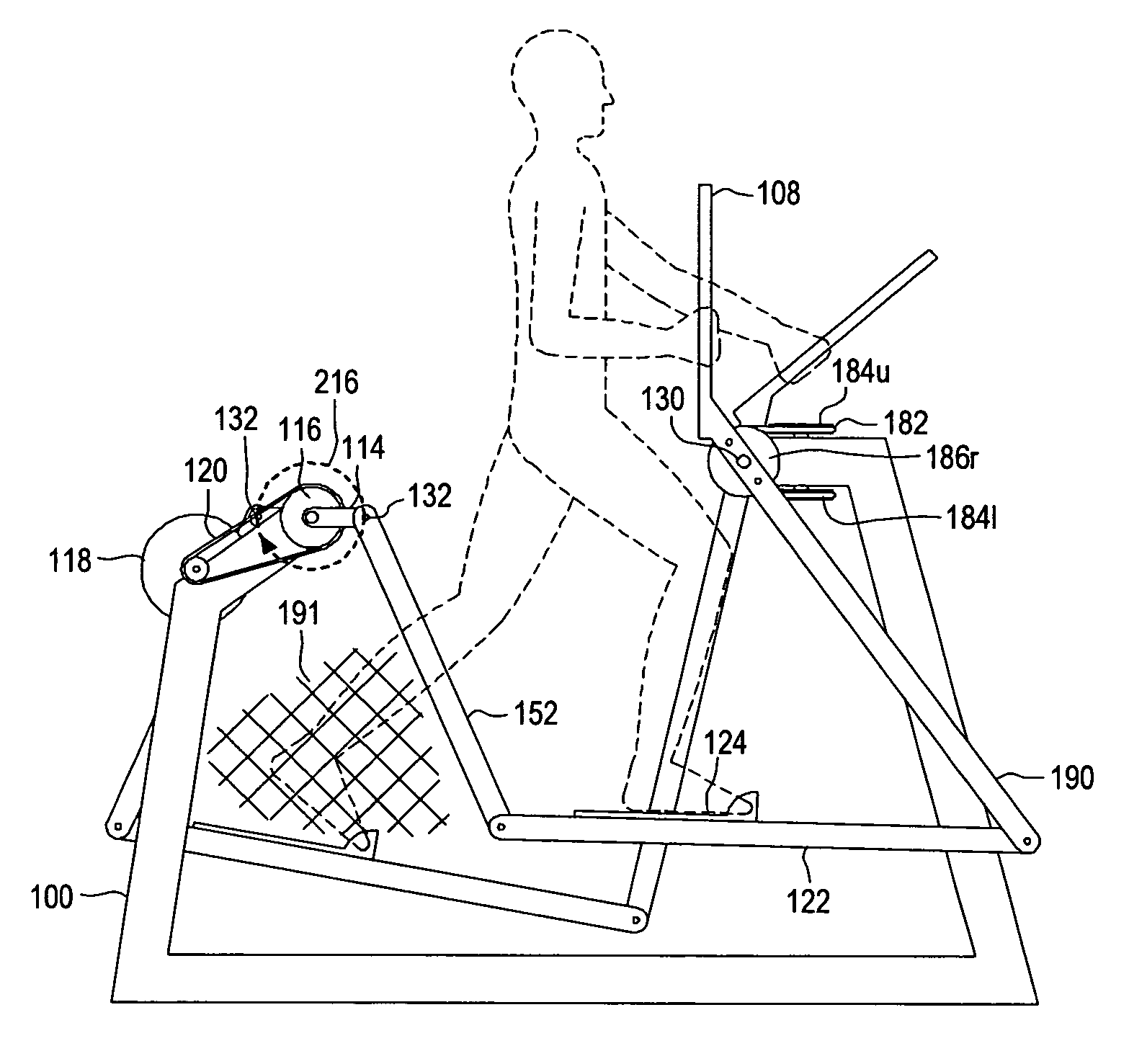

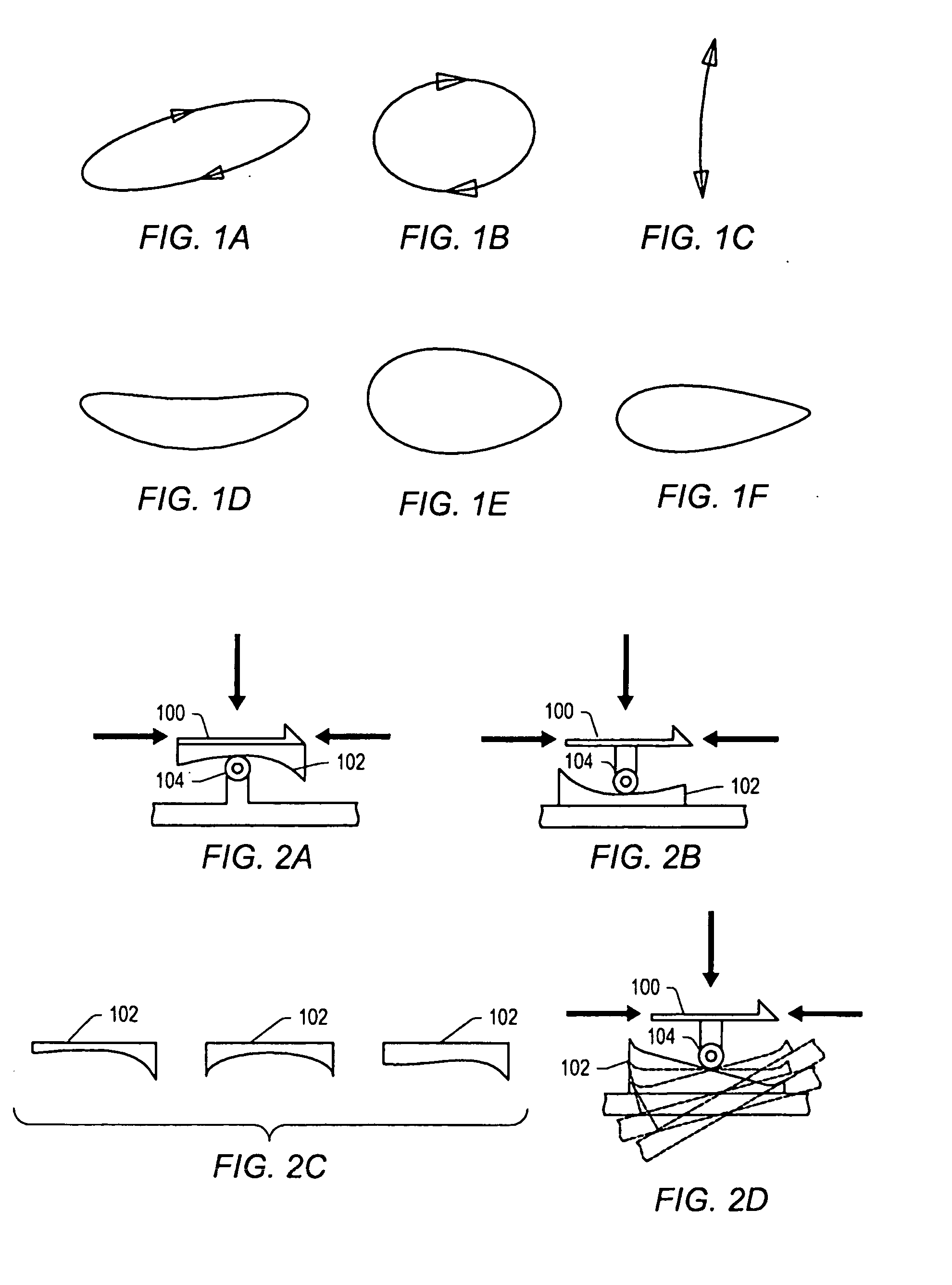

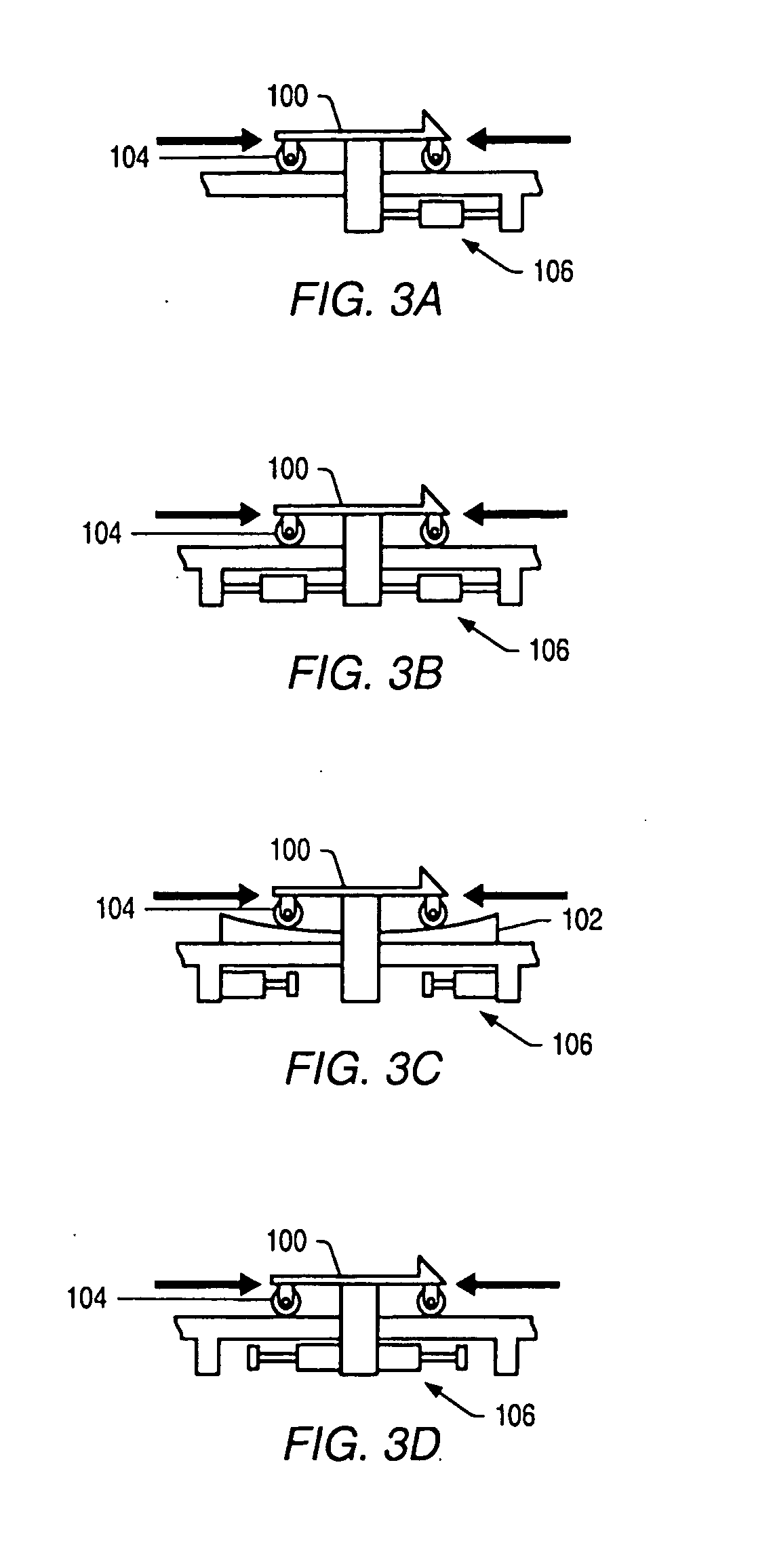

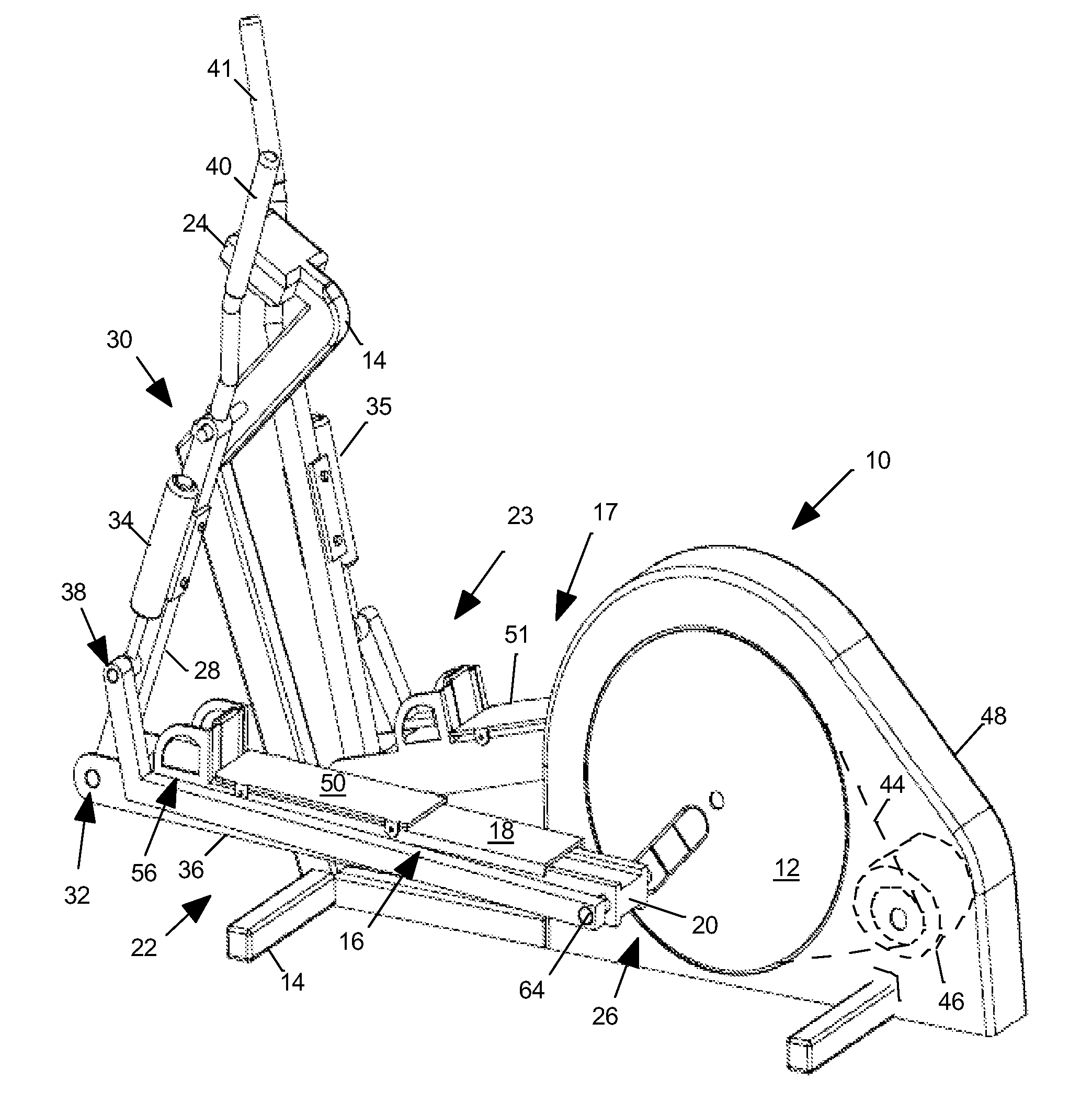

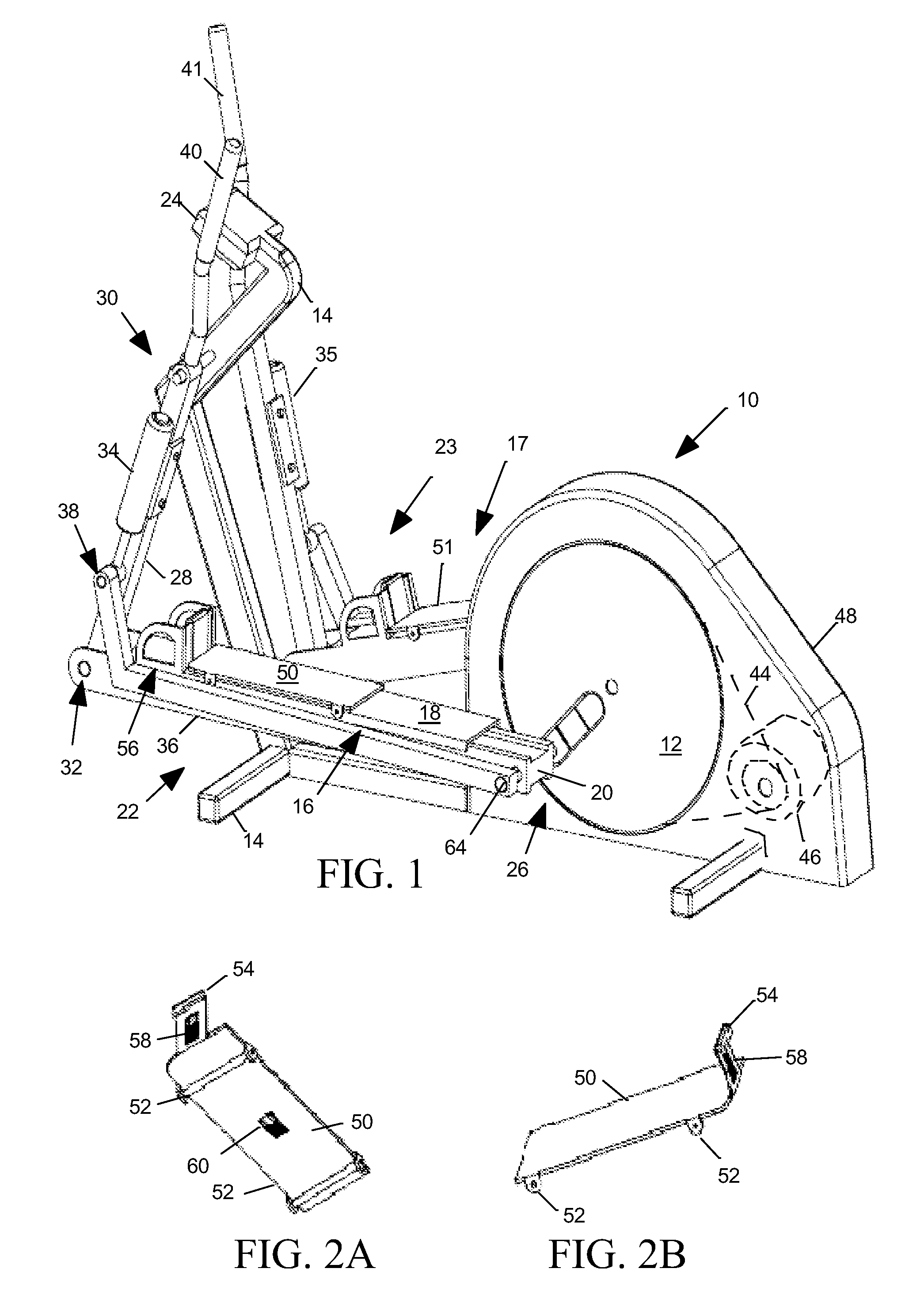

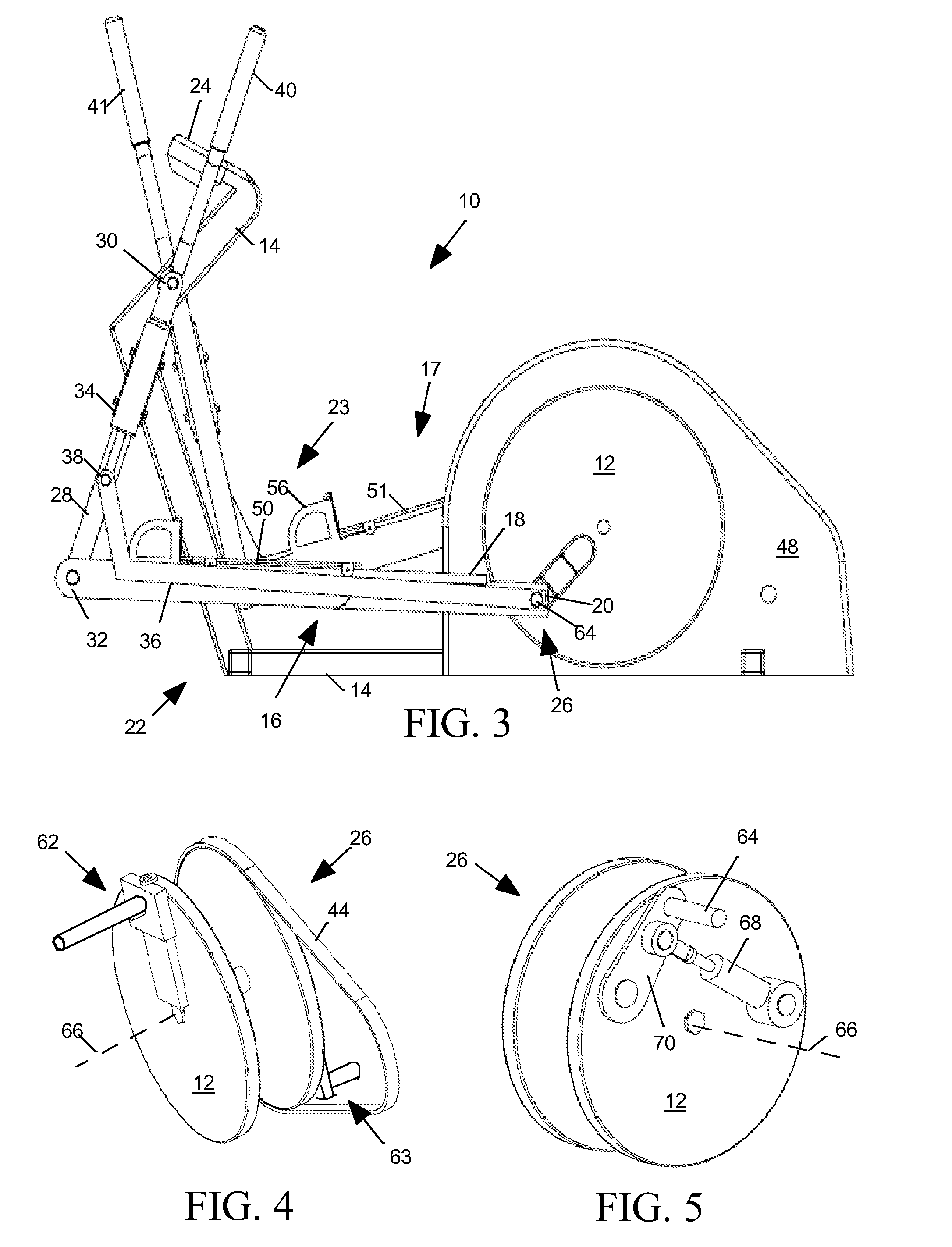

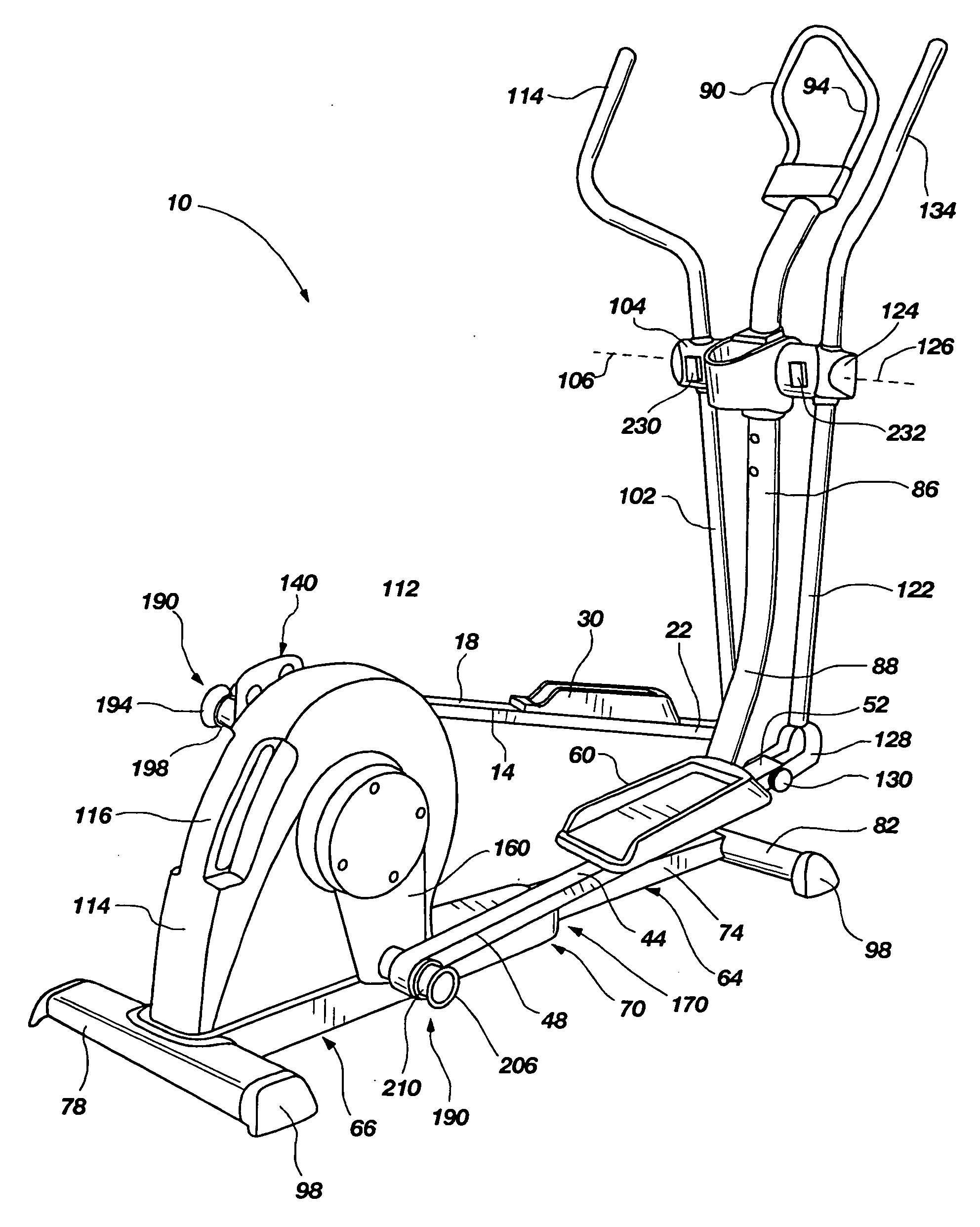

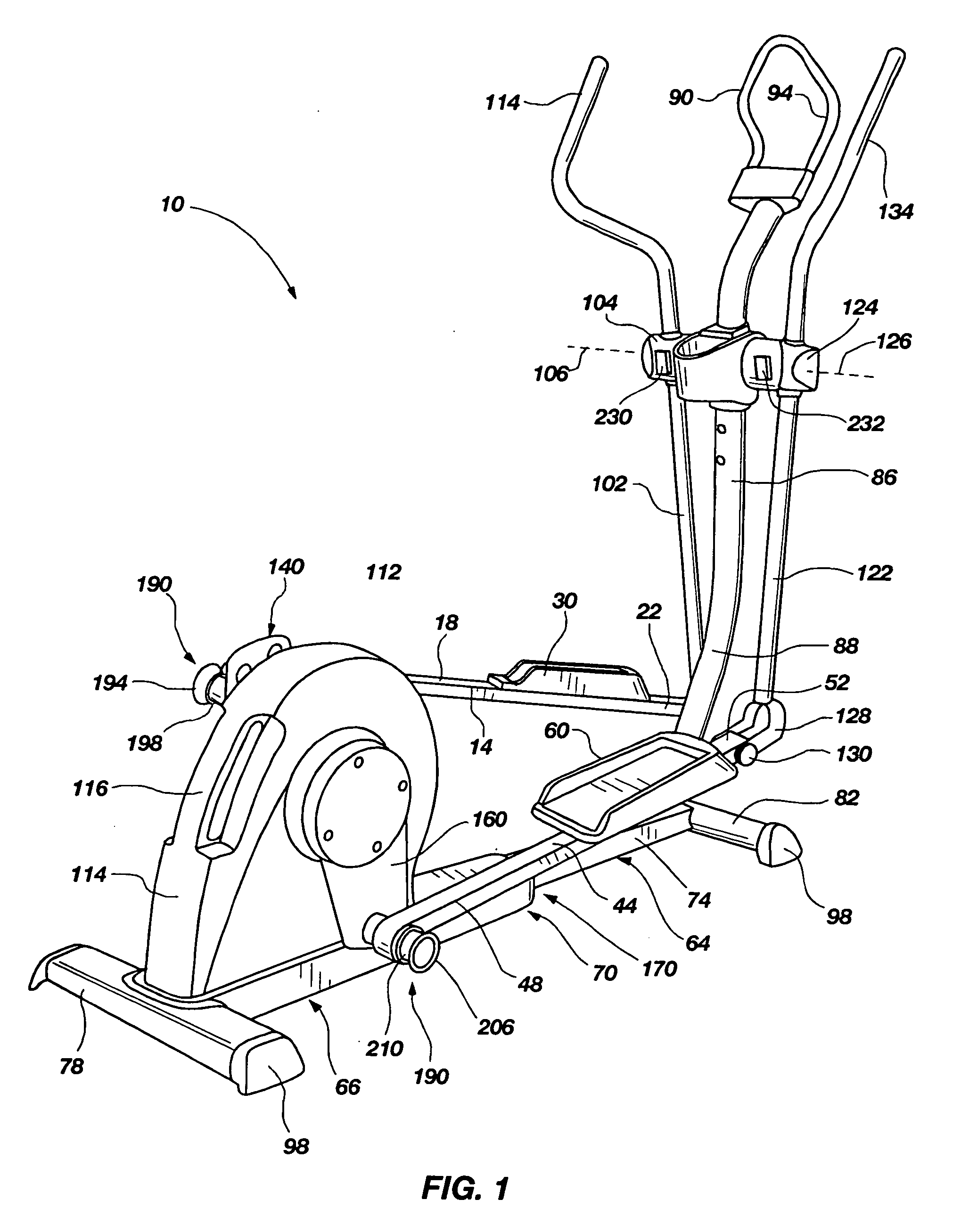

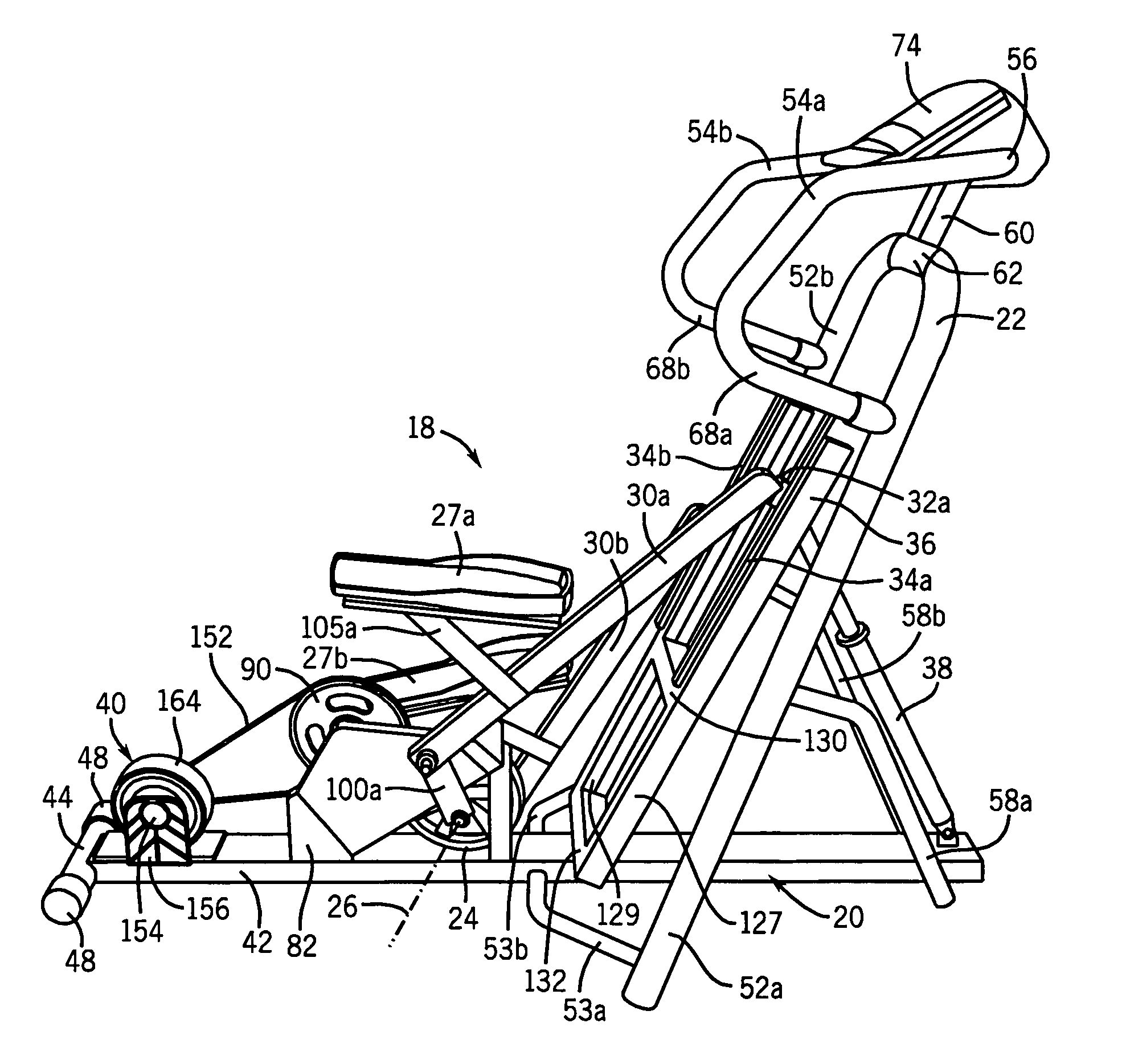

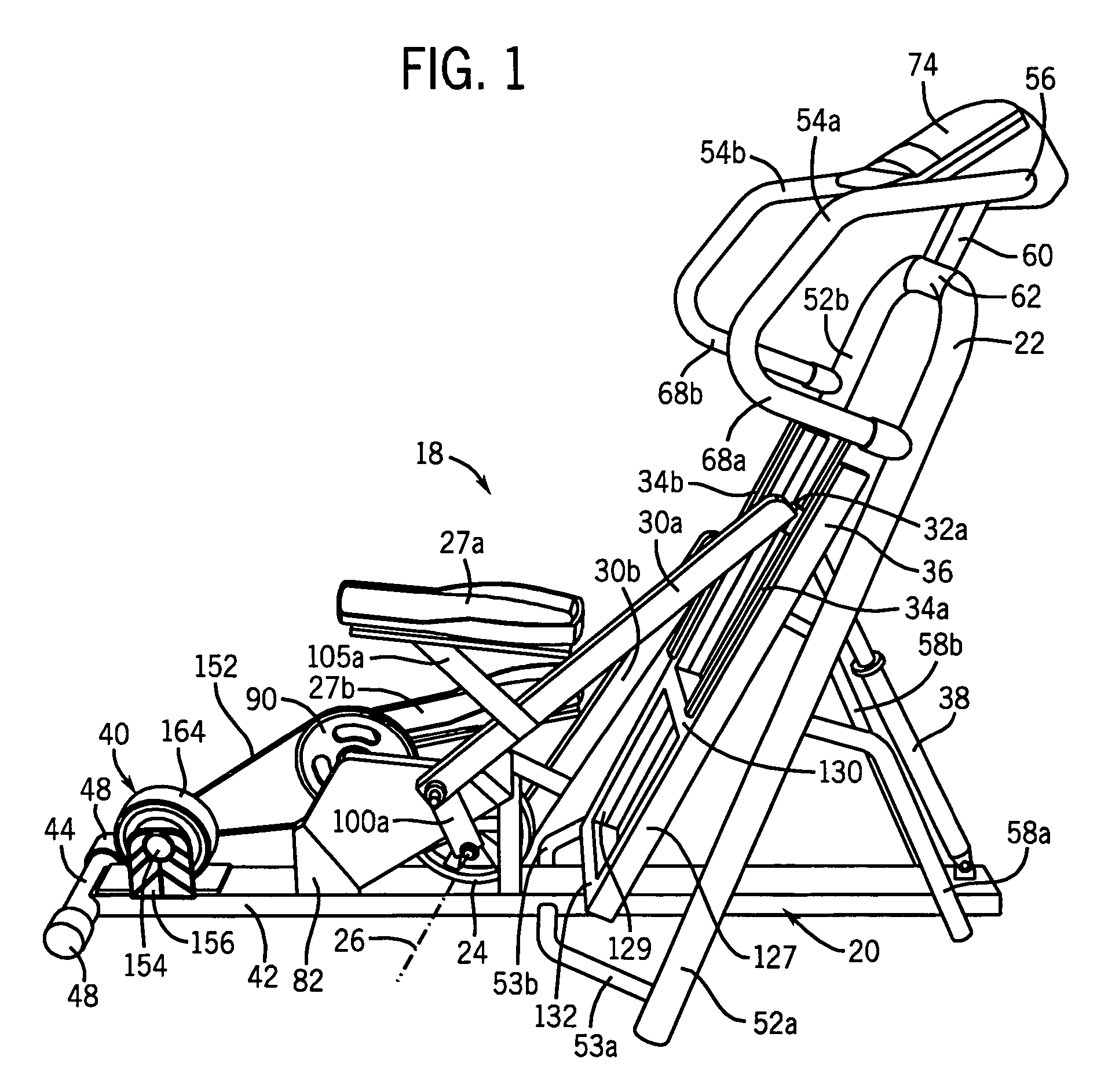

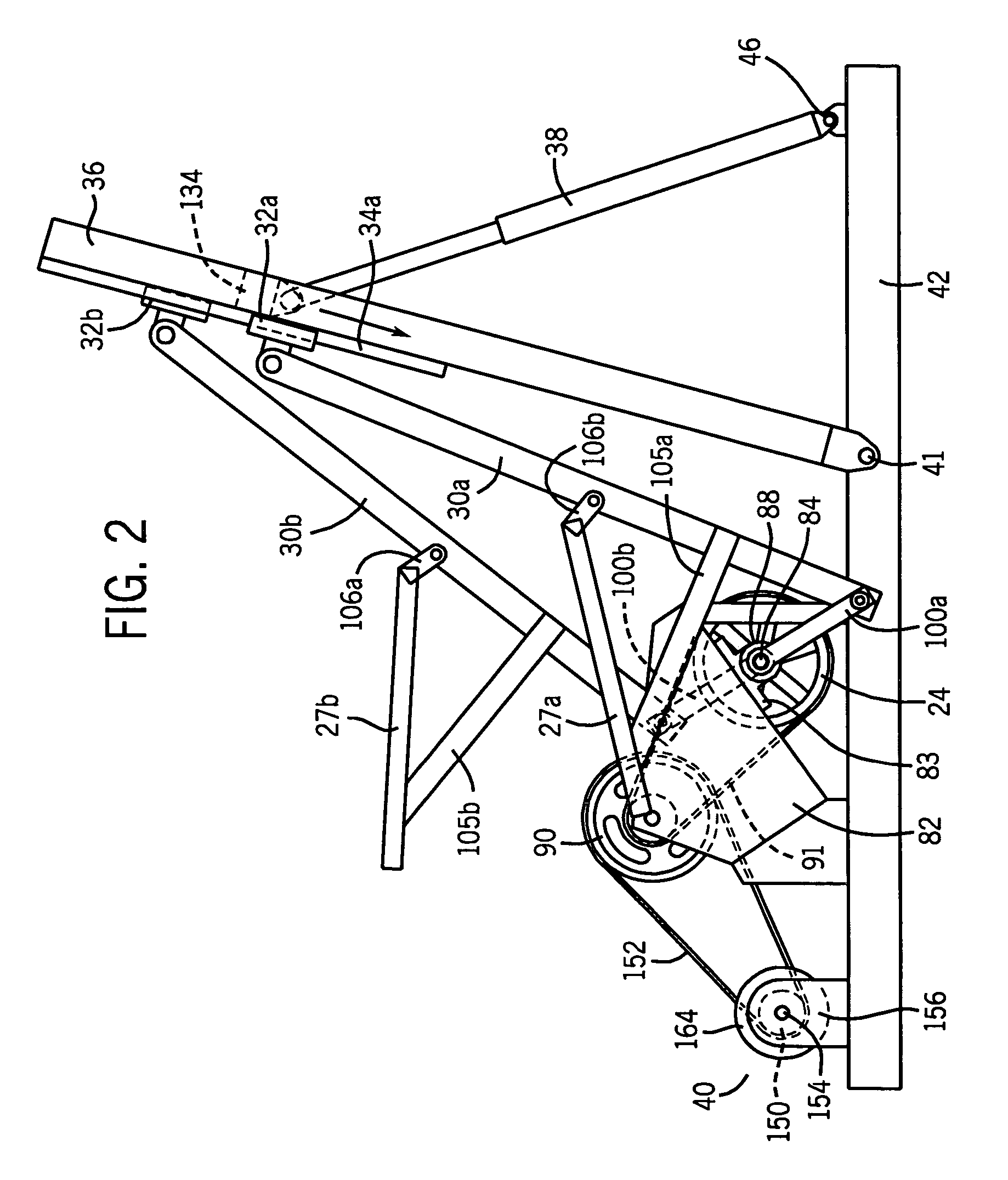

Exercise apparatus that allows user varied stride length

ActiveUS7244217B2Length of may varyMovement coordination devicesCardiovascular exercising devicesStride lengthEngineering

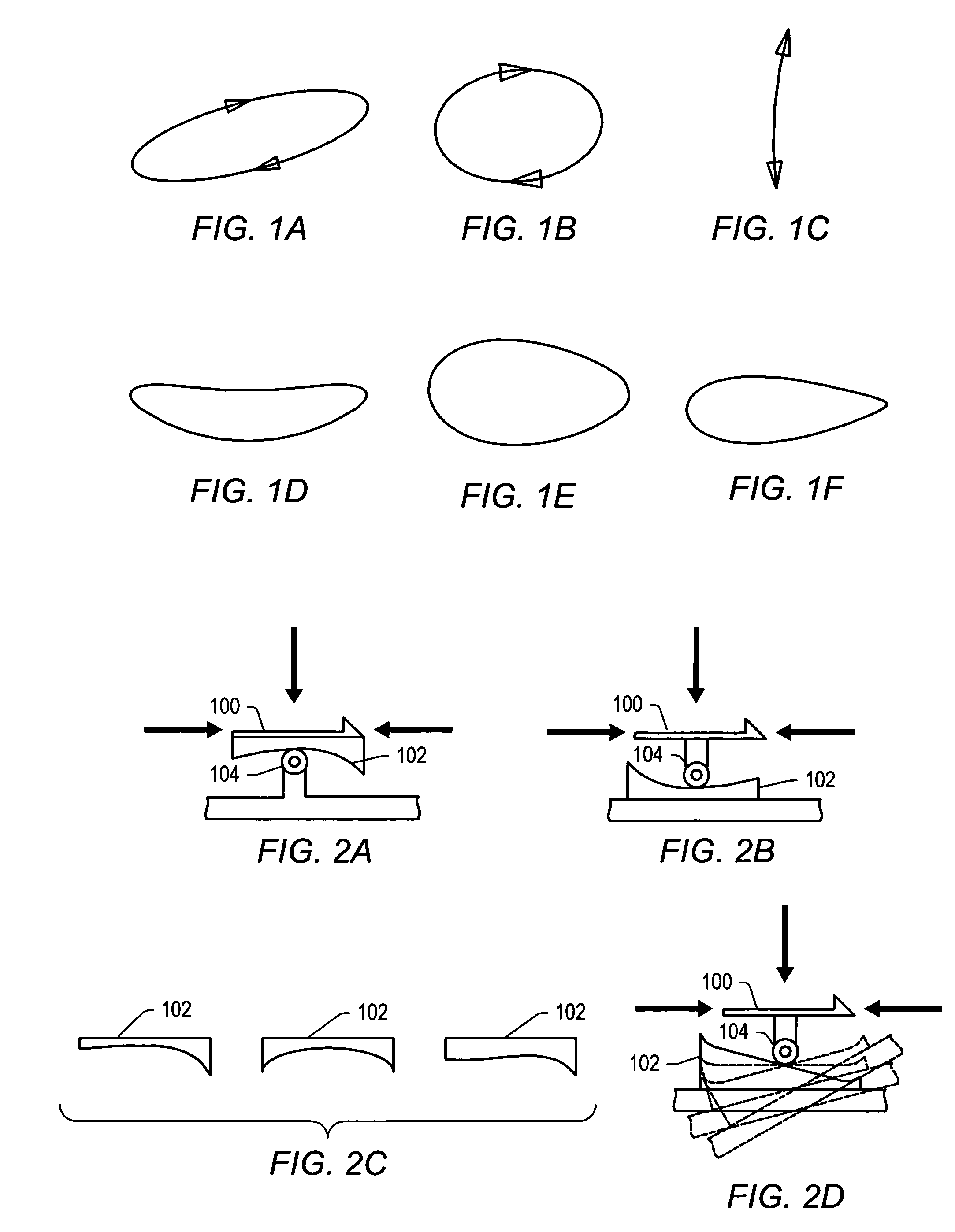

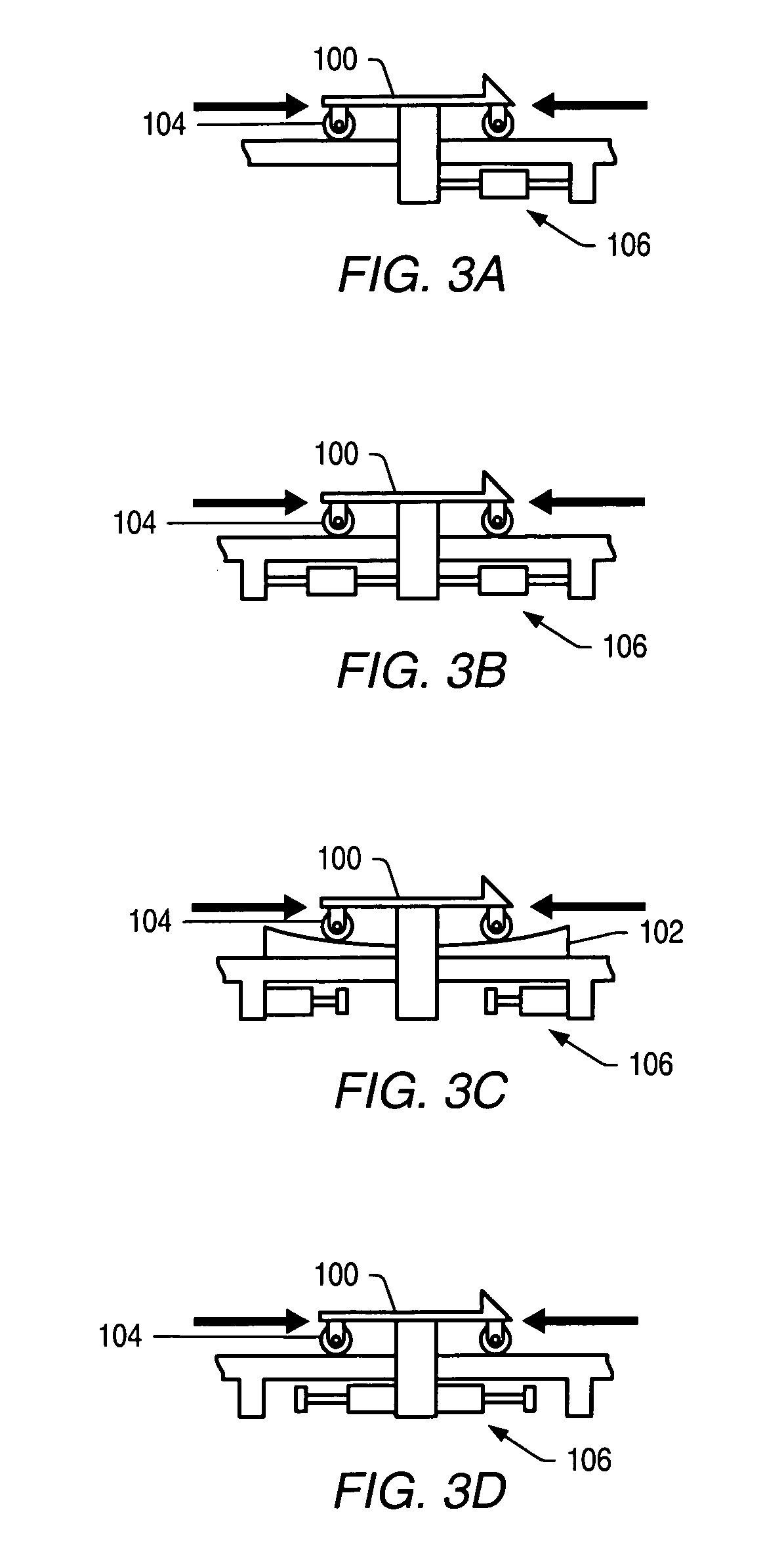

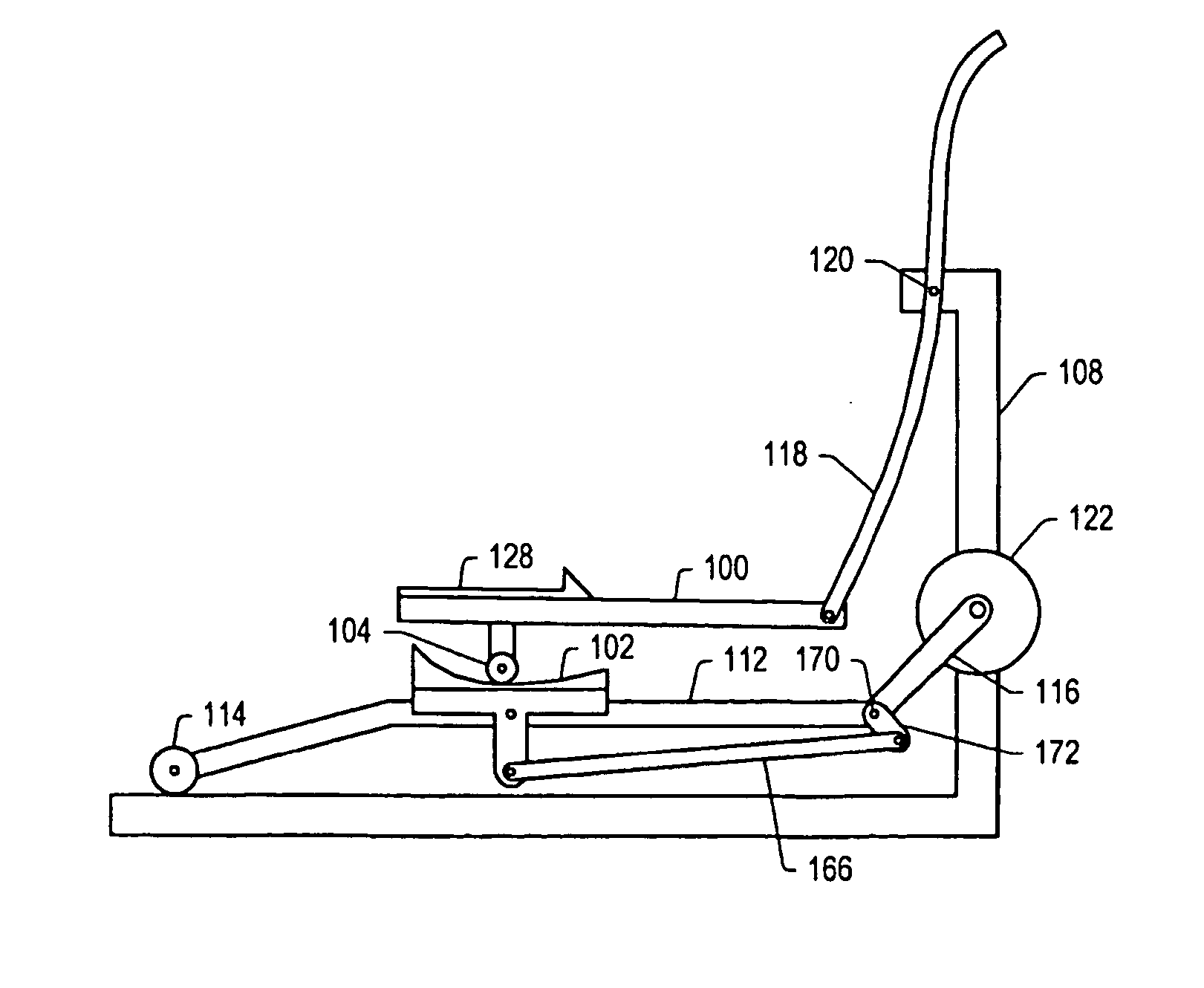

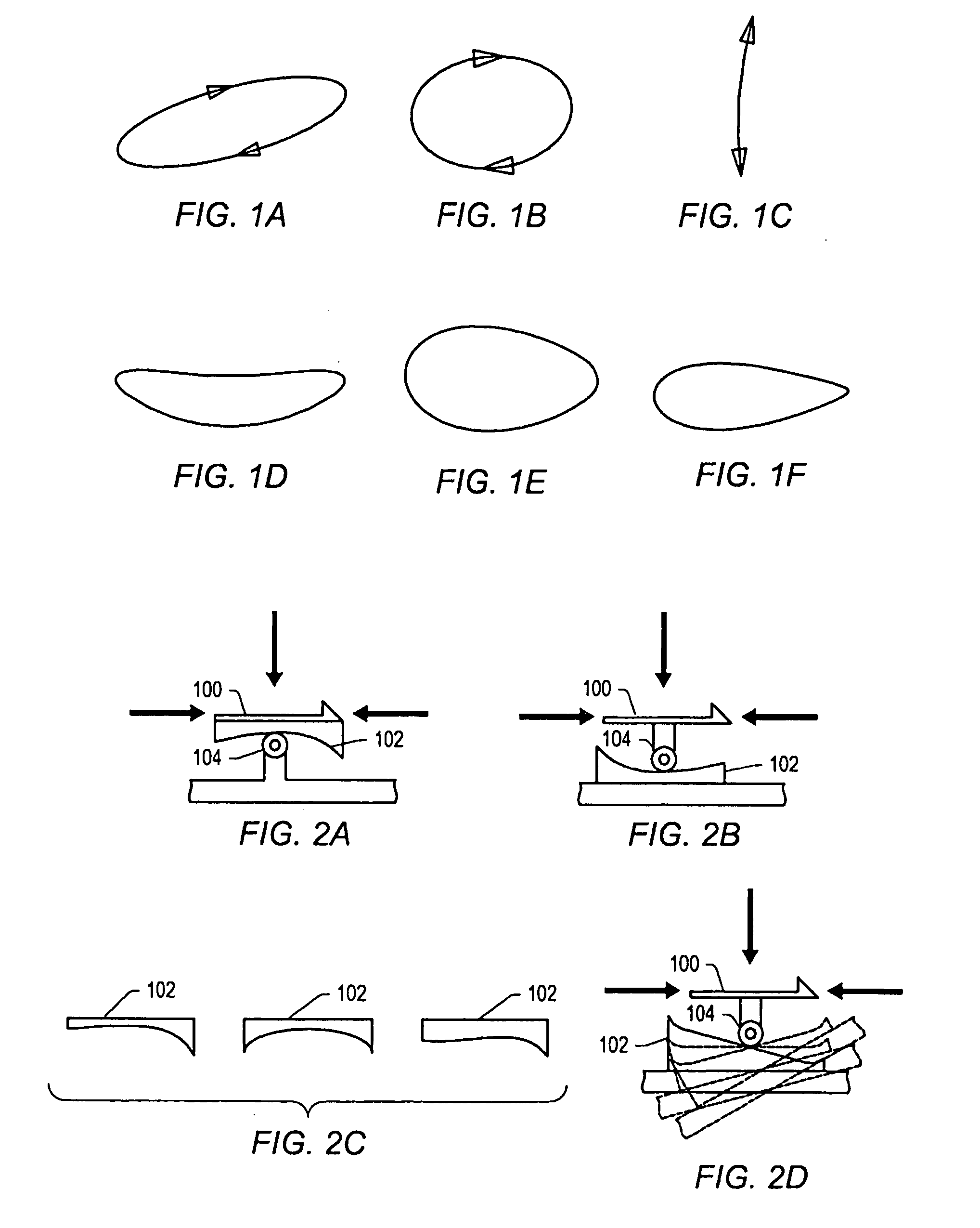

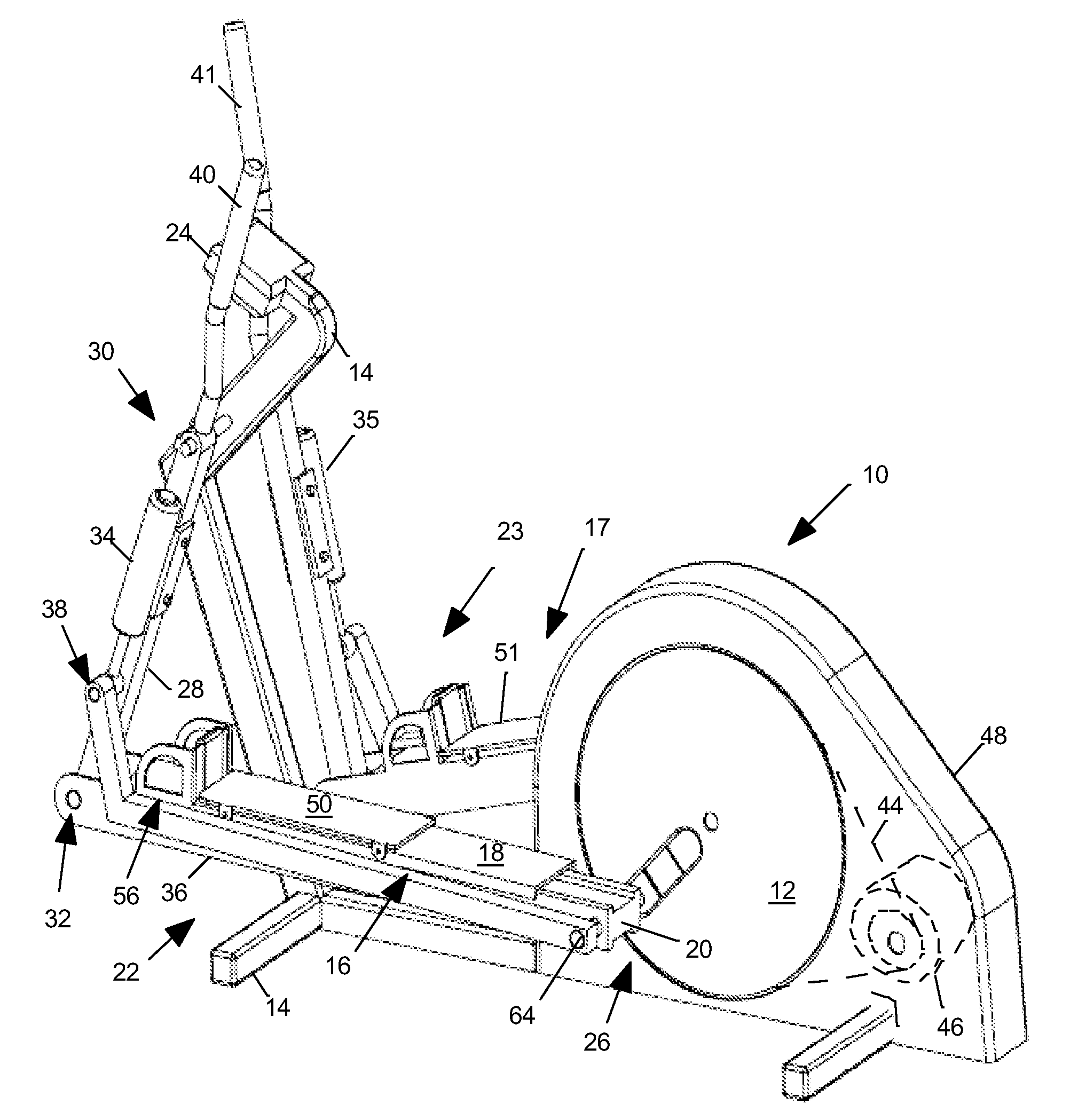

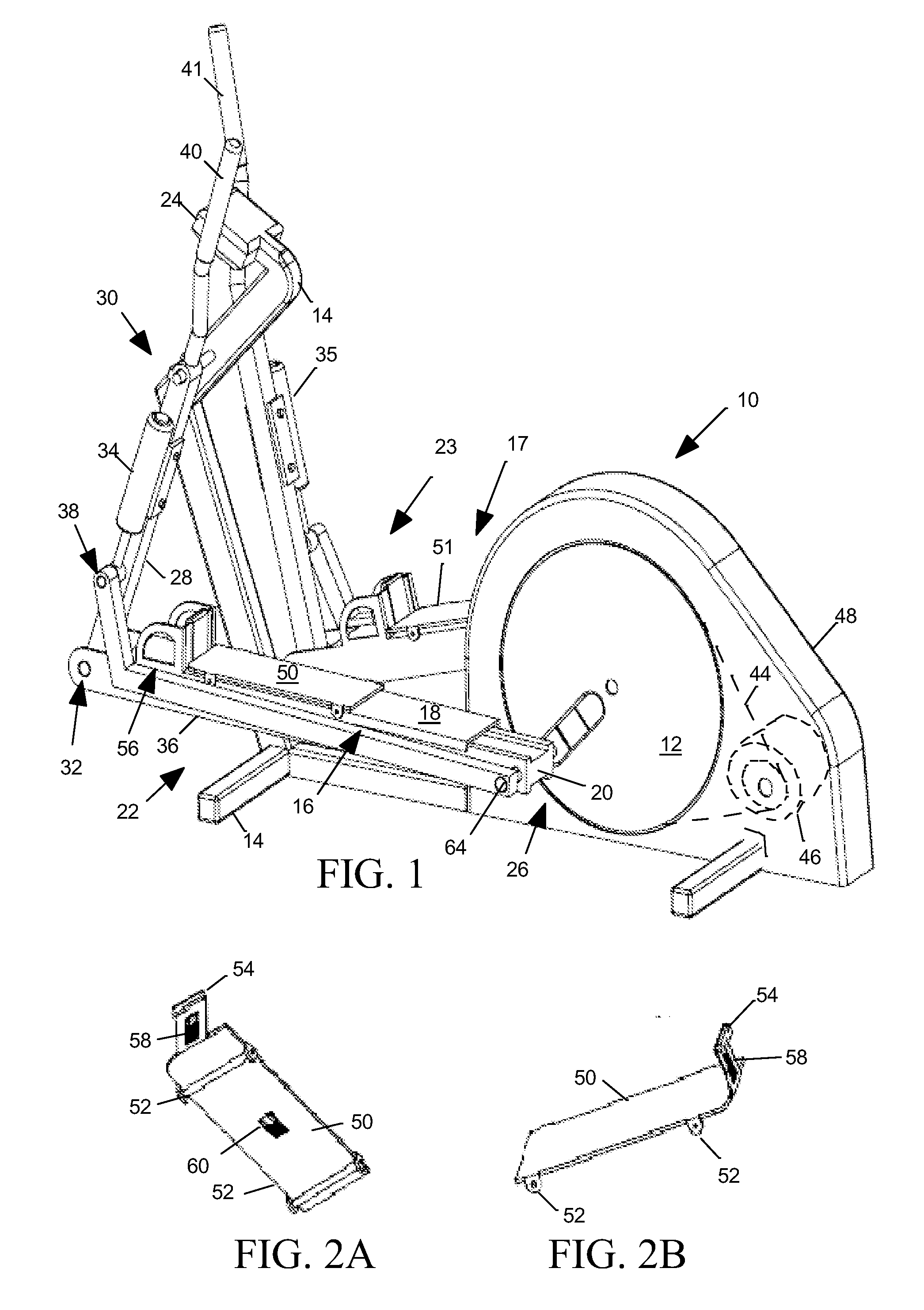

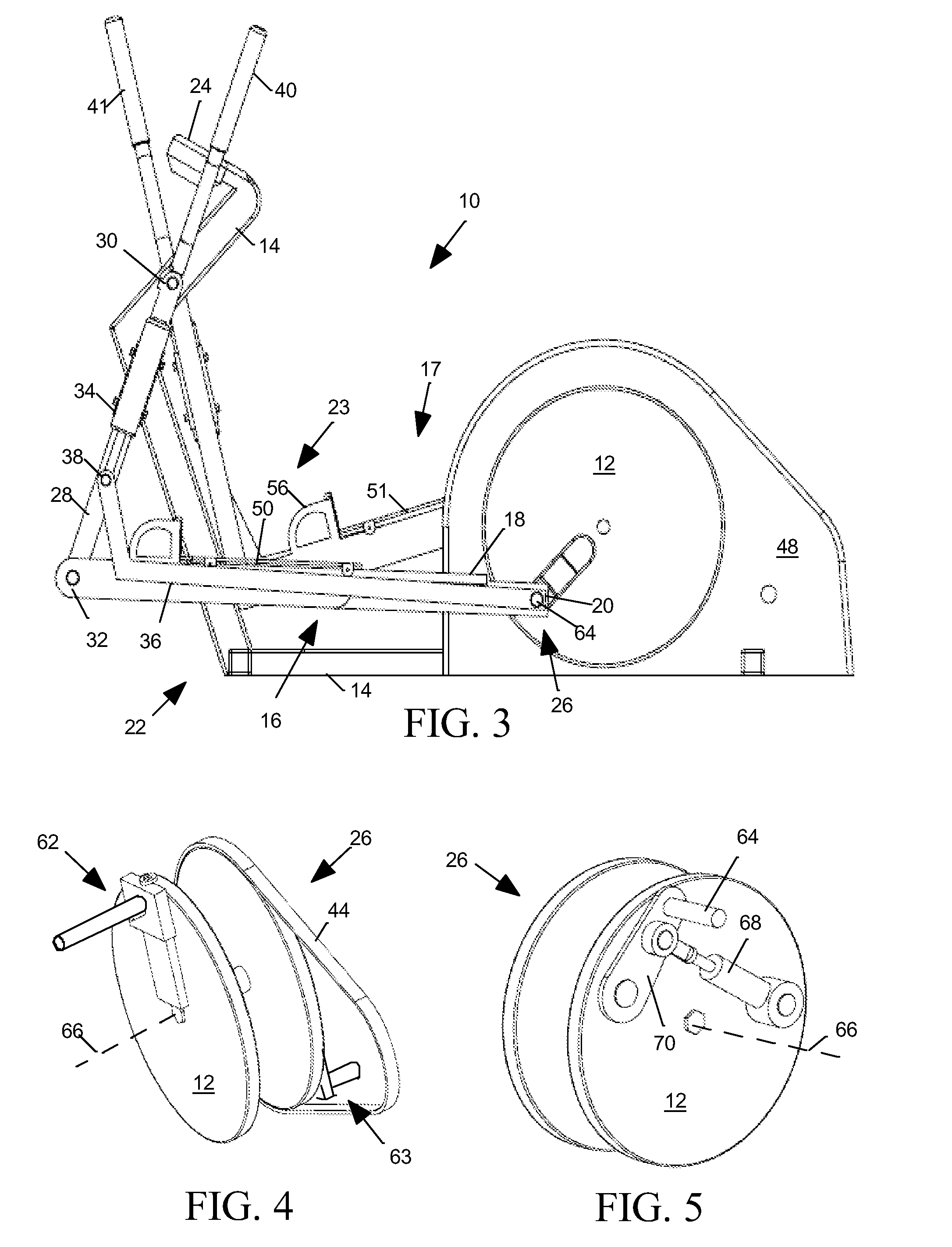

A variable stride exercise apparatus is described. A variable stride exercise apparatus may include a frame having a first end and a second end. A crank system may be coupled to the frame. A foot member may be coupled to the crank system. The foot member may include a footpad. A variable stride system may be coupled to the foot member. The variable stride system may be located closer to the second end of the frame than the first end of the frame. The variable stride system may allow a user of the apparatus to vary the length of the user's stride during use of the apparatus. The foot of the user may travel in a substantially closed path during use of the apparatus. At least a portion of the apparatus may remain substantially stationary during use.

Owner:RODGERS JR ROBERT E

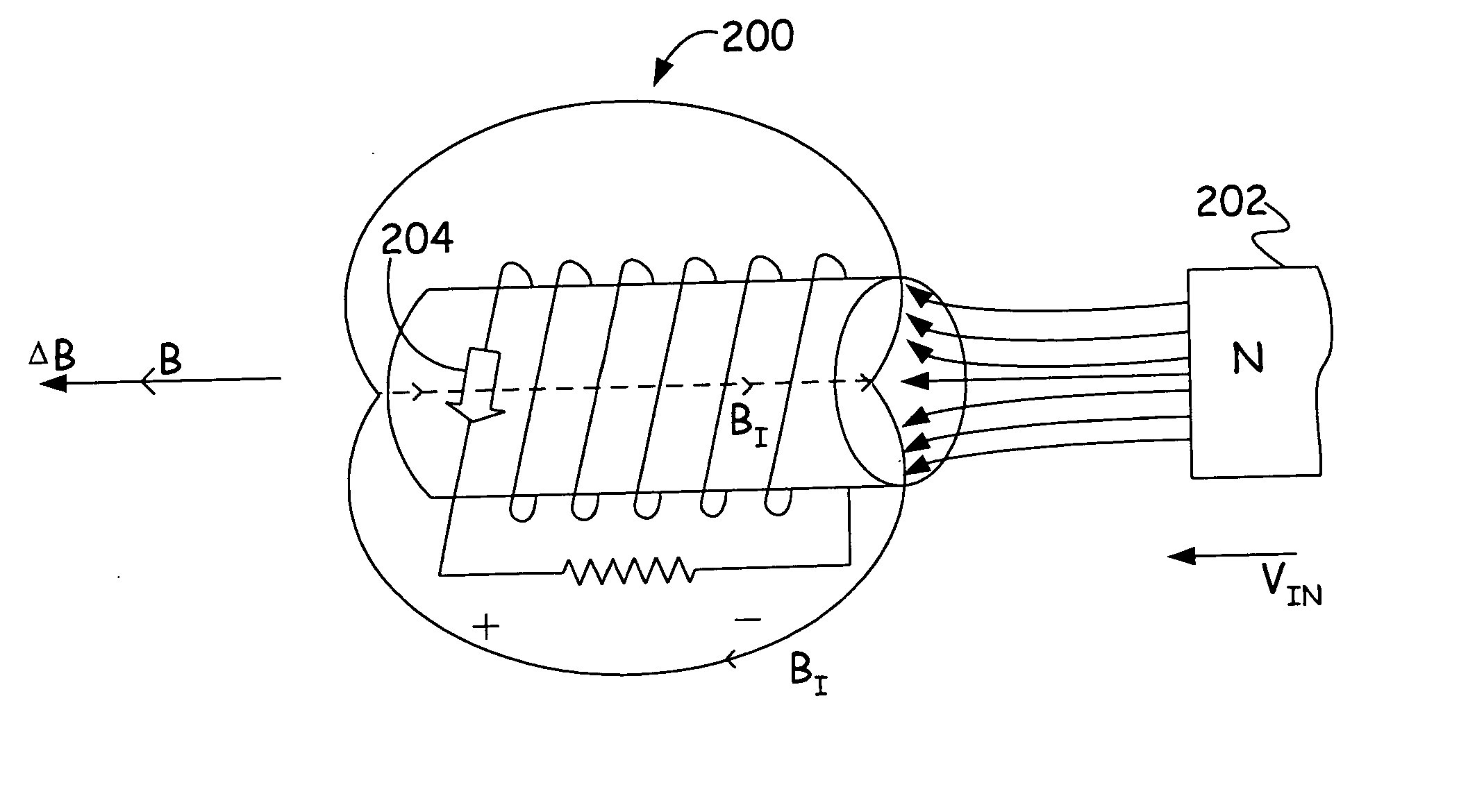

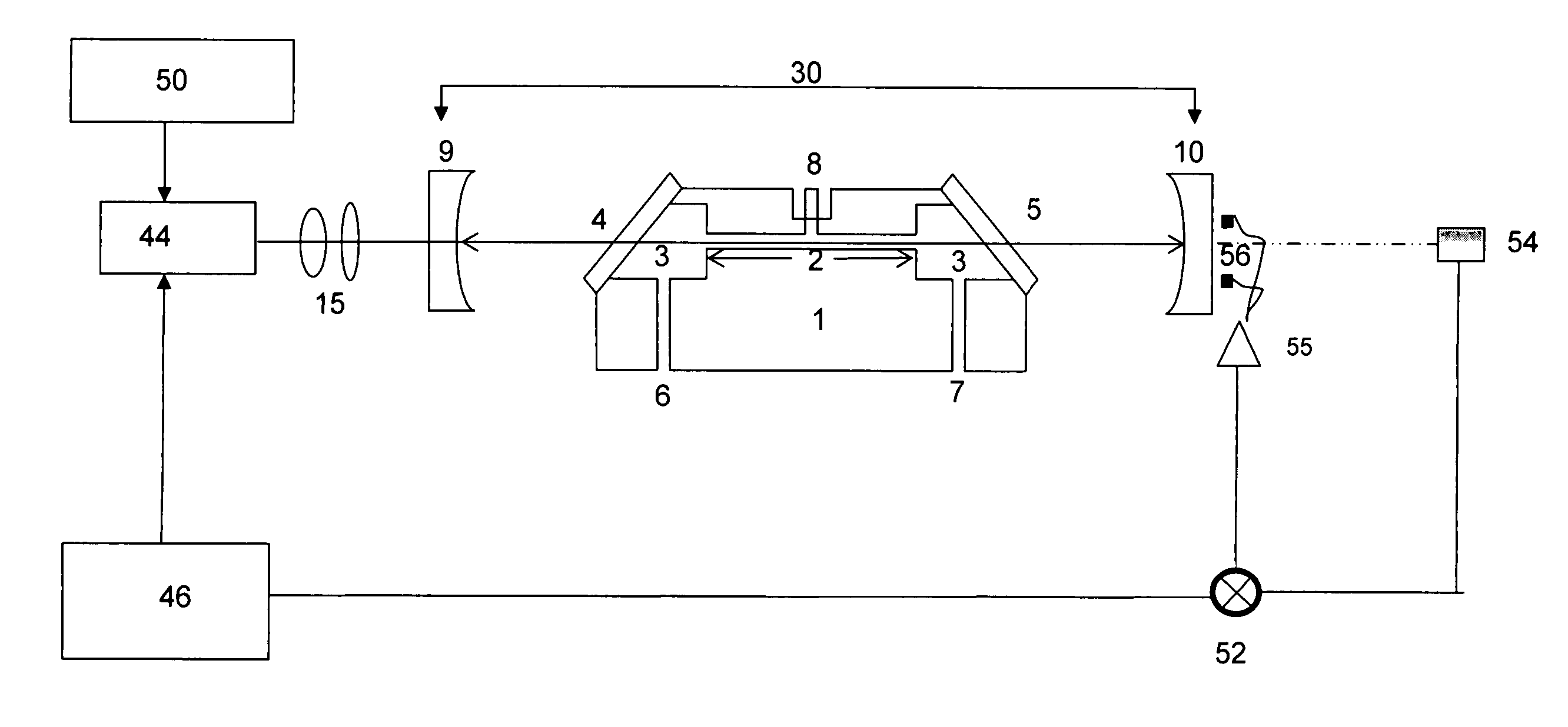

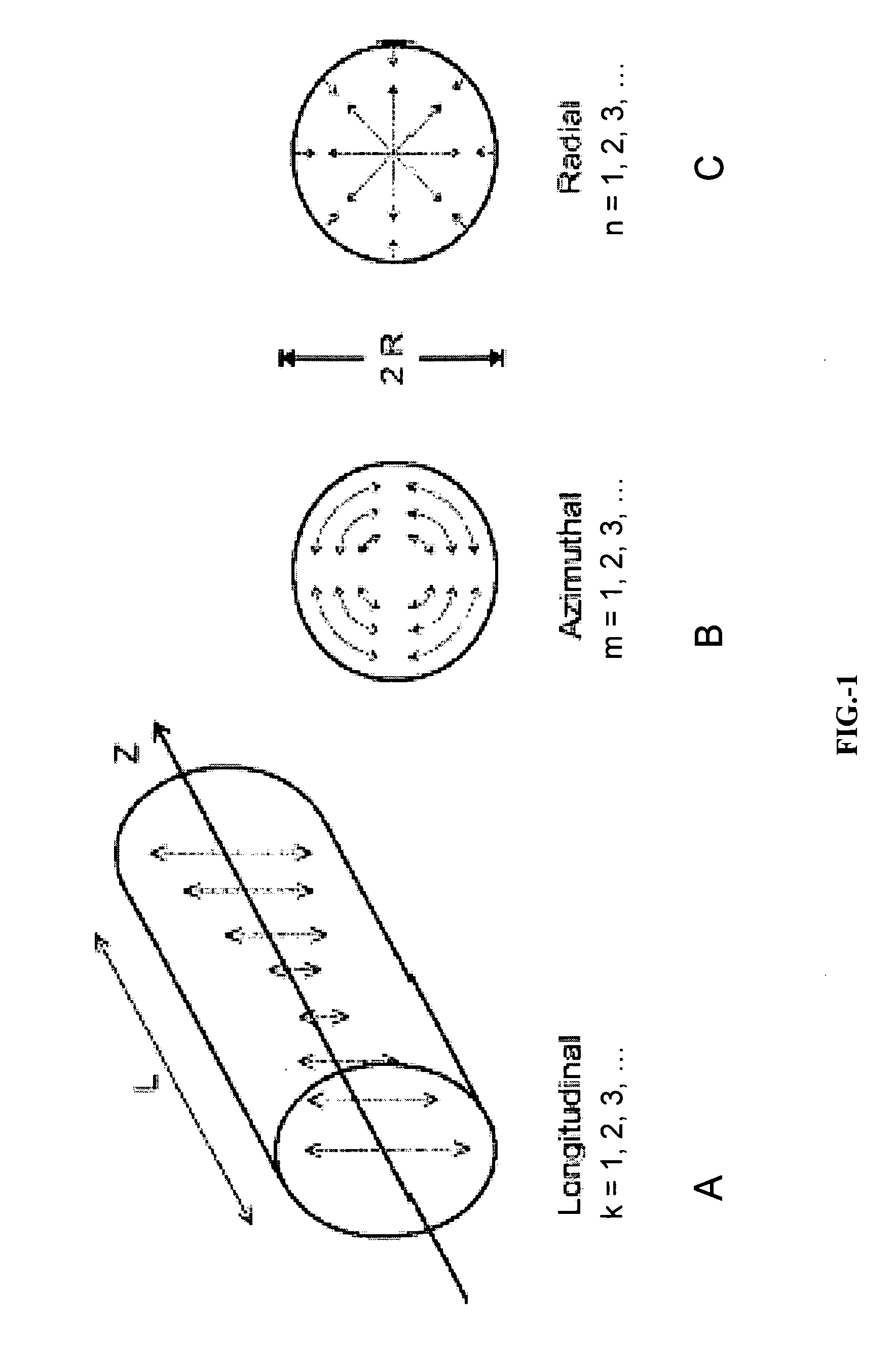

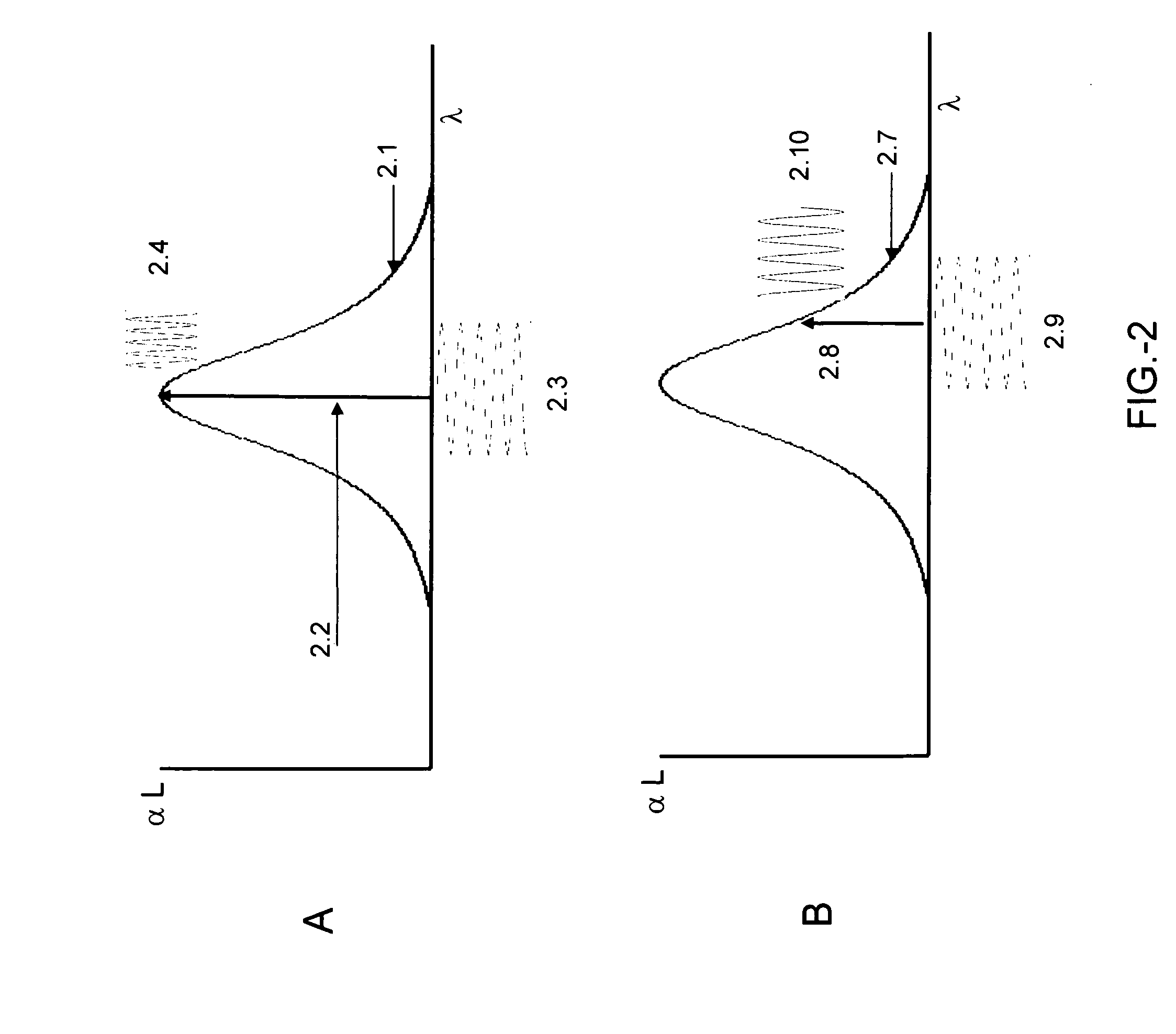

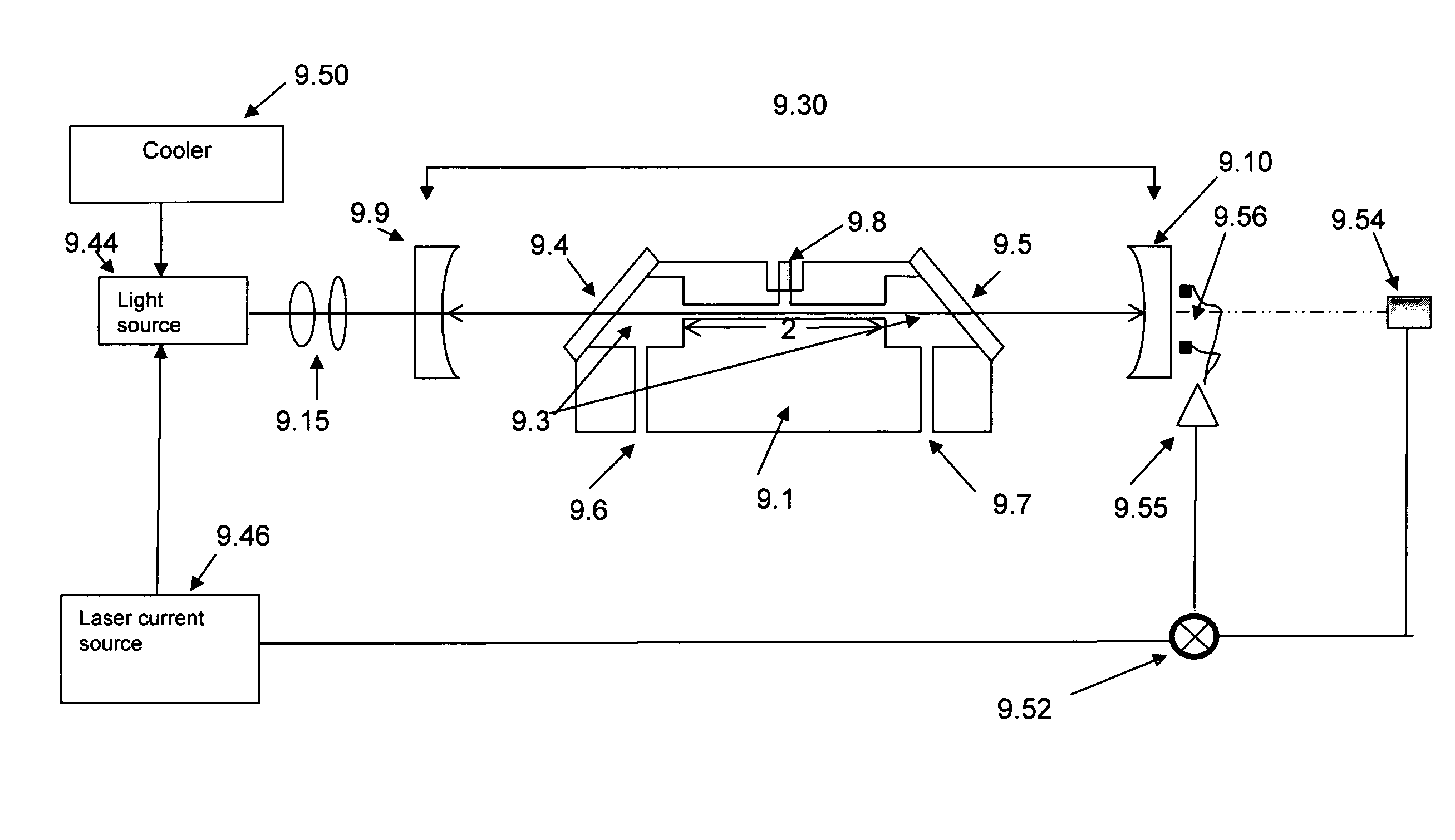

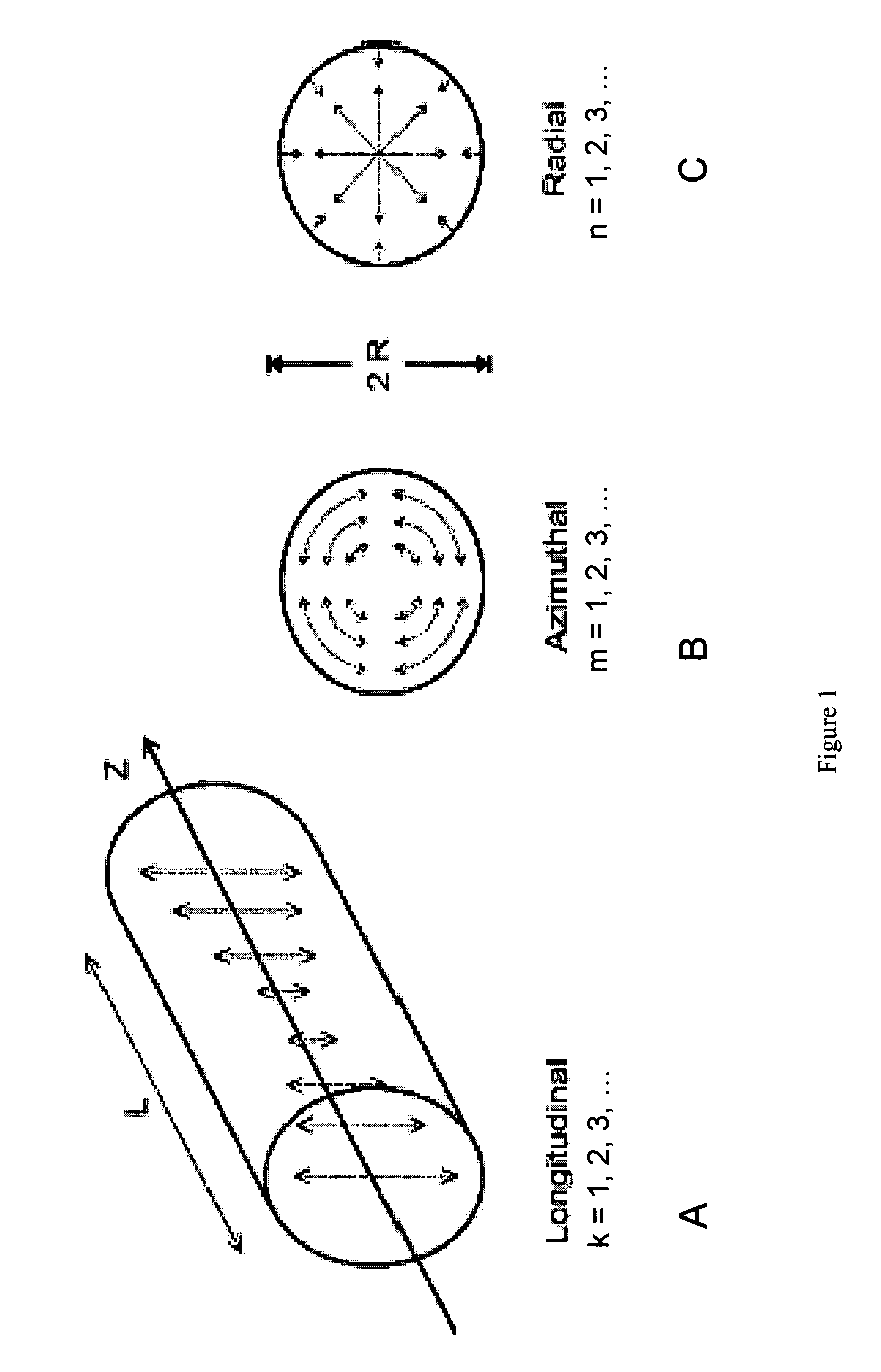

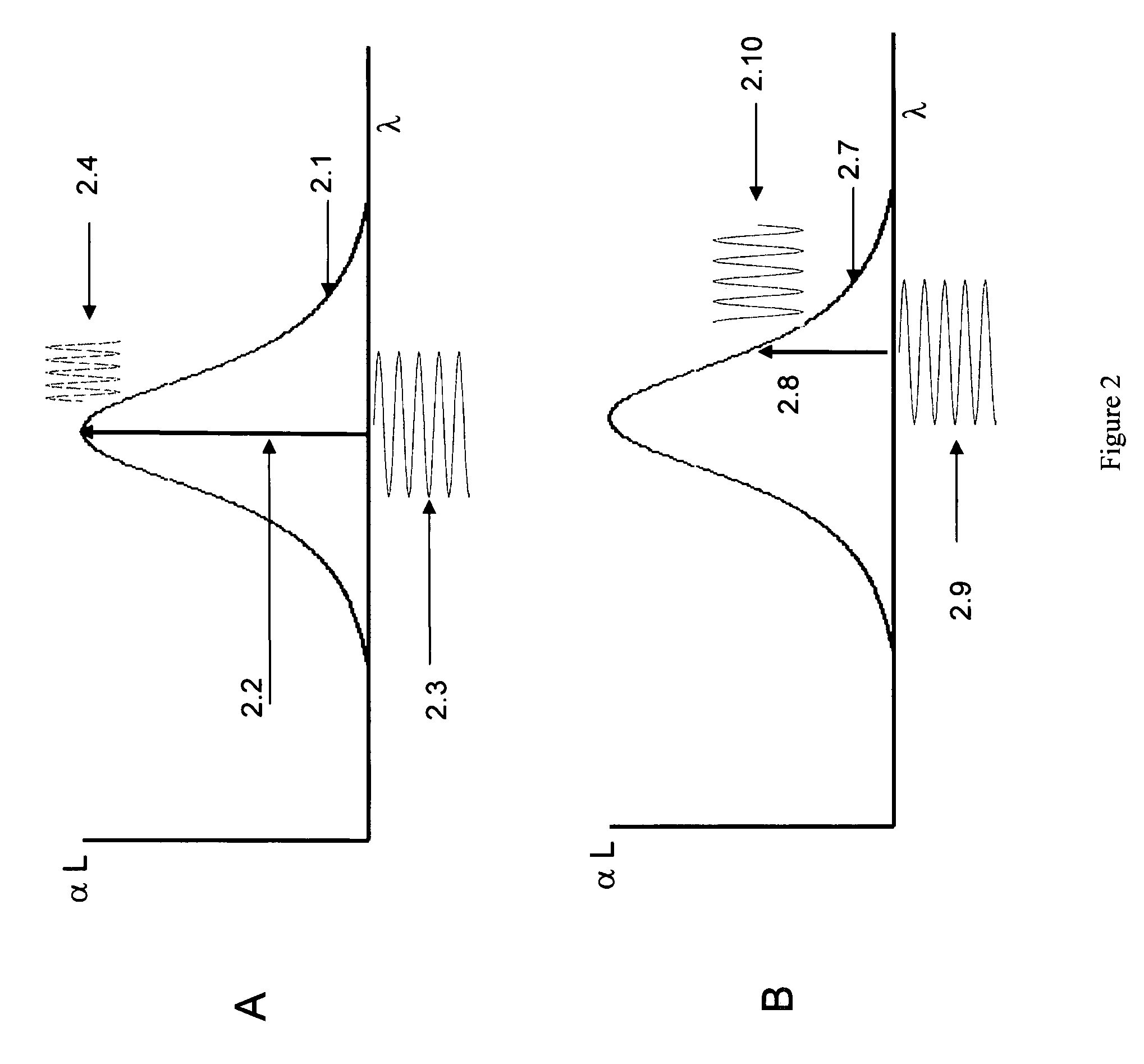

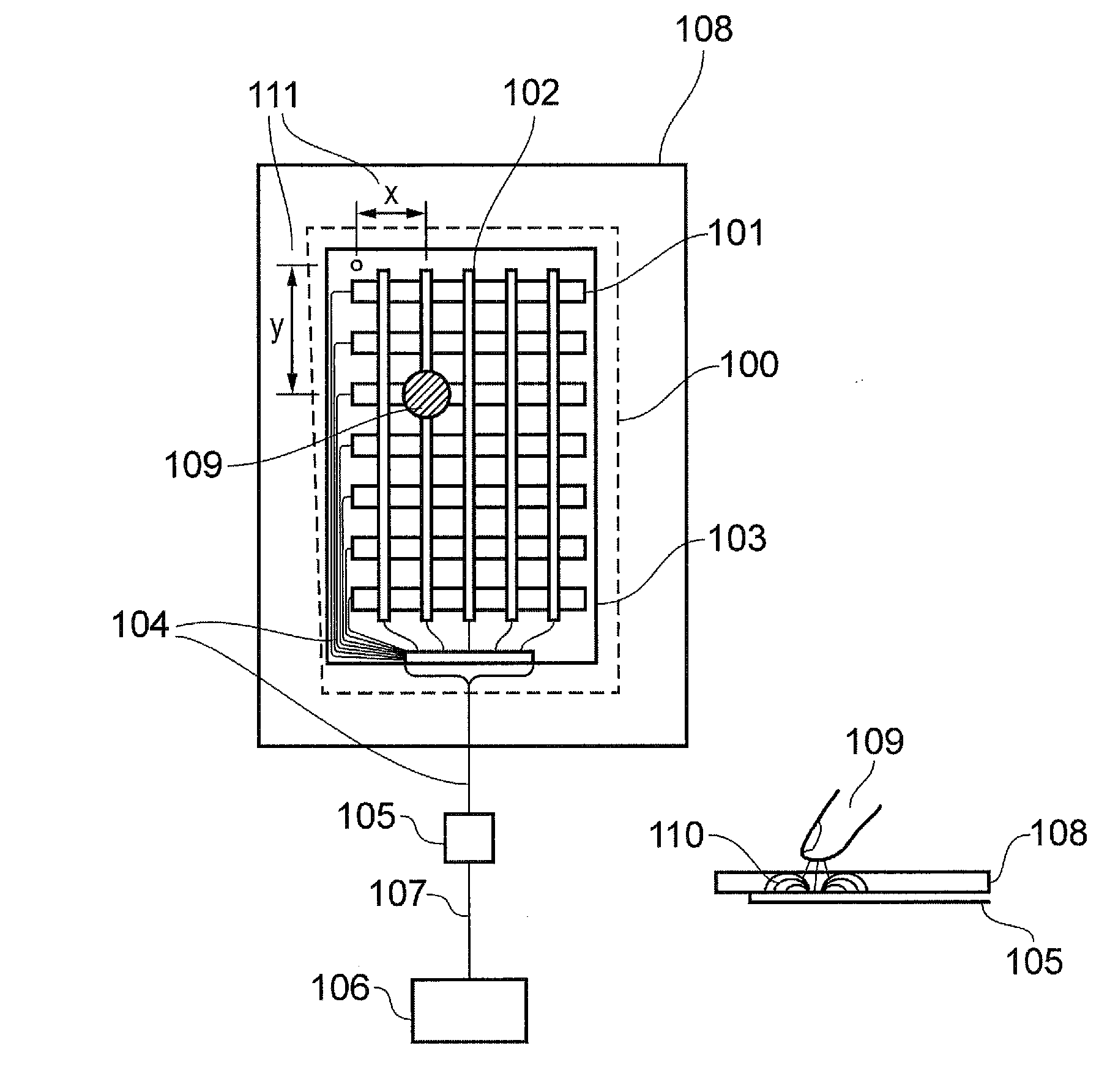

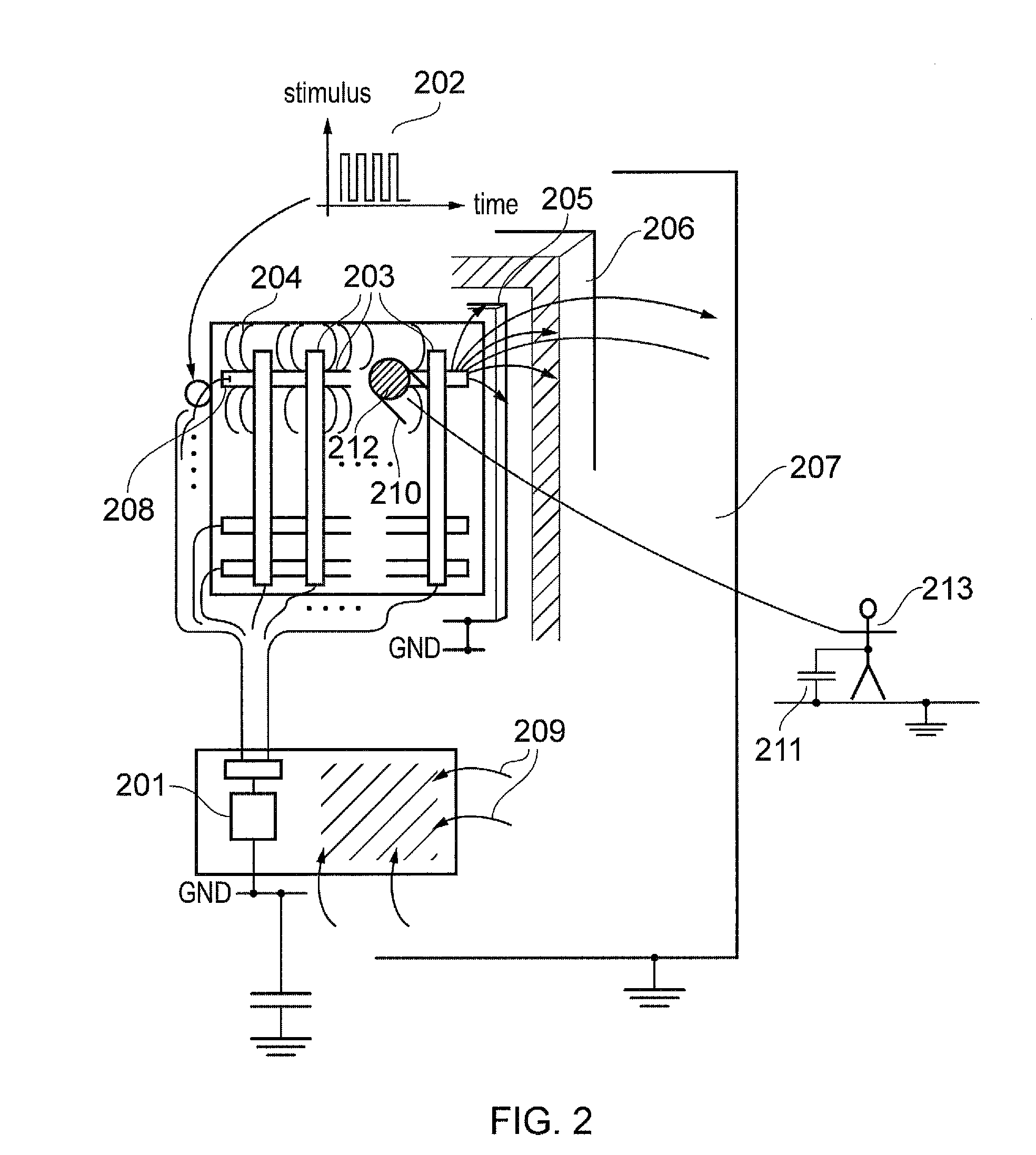

System and method for gas analysis using doubly resonant photoacoustic spectroscopy

ActiveUS20060123884A1Increase productionReduce equipment downtimeMaterial analysis using wave/particle radiationMaterial analysis using microwave meansGas analysisGas detector

A method for analyzing gas concentration using doubly resonant photoacoustic spectroscopy, and a doubly resonant photaoacoustic gas detector comprising: i) a continuous wave light beam whose wavelength coincides with an absorption wavelength of a gaseous analyte; ii) a closed path optical cavity having at least two reflective surfaces; iii) an acoustic resonator chamber contained within said optical cavity, and comprising an acoustic sensor for detecting sound waves generated by a gaseous analyte present within said chamber, the light beam passing sequentially into, through and out of said chamber, and being repeatedly reflected back and forth through said chamber, and being modulated at a frequency which is equal to or equal to one-half of an acoustic resonance frequency of said acoustic resonator chamber.

Owner:LI COR

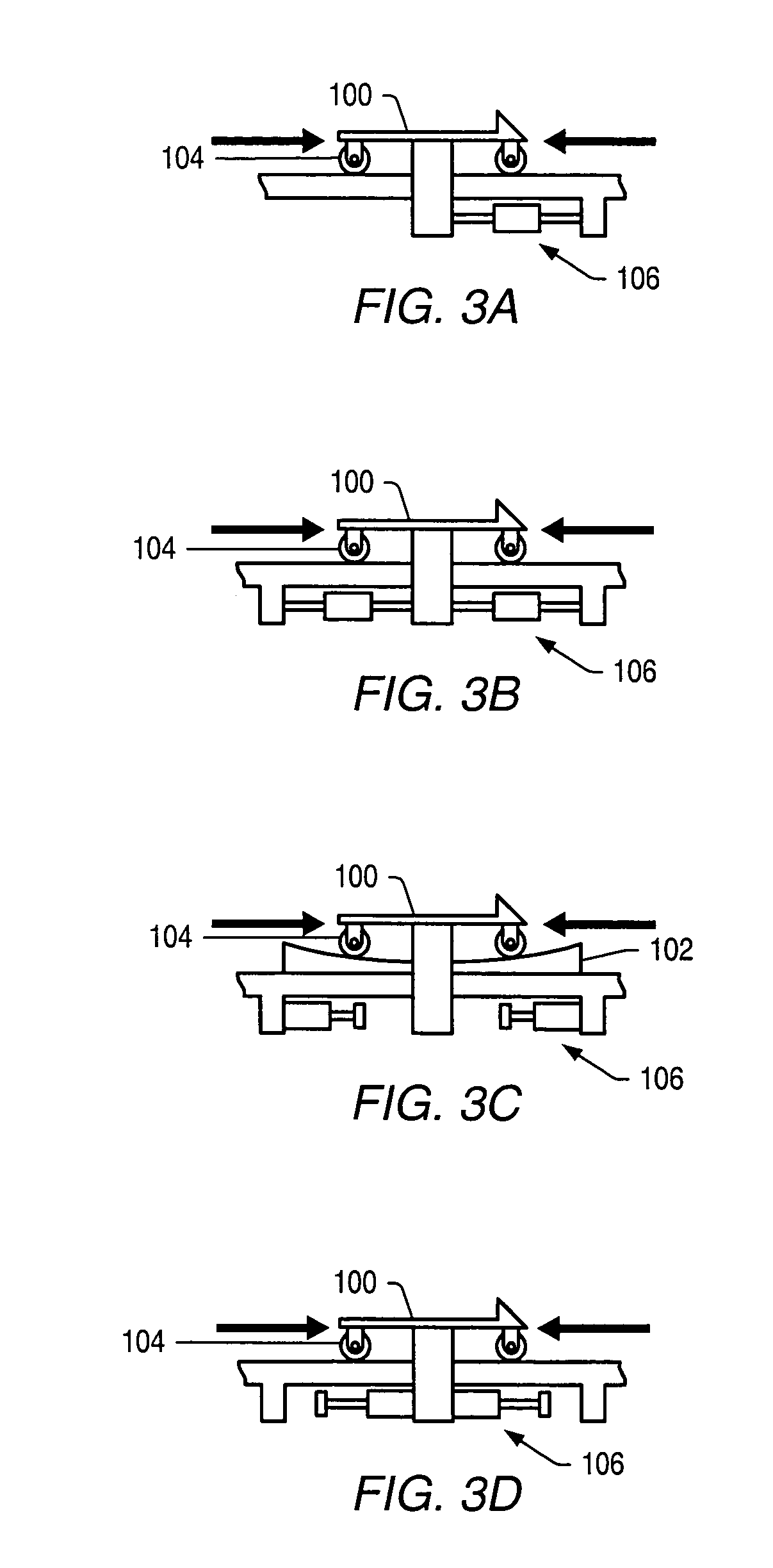

Exercise apparatus with a variable stride system

ActiveUS7201705B2Length of may varyMovement coordination devicesCardiovascular exercising devicesEngineeringClosed path

A variable stride exercise apparatus is described. A variable stride exercise apparatus may include a frame. A crank system may be coupled to the frame. A foot member may be coupled to the crank system. The foot member may include a footpad. A variable stride system may be coupled to the foot member. The variable stride system and the foot member may be coupled at a location between the footpad and the crank system. The variable stride system may allow a user of the apparatus to vary the length of the user's stride during use of the apparatus. The foot of the user may travel in a substantially closed path during use of the apparatus. At least a portion of the apparatus may remain substantially stationary during use.

Owner:RODGERS JR ROBERT E

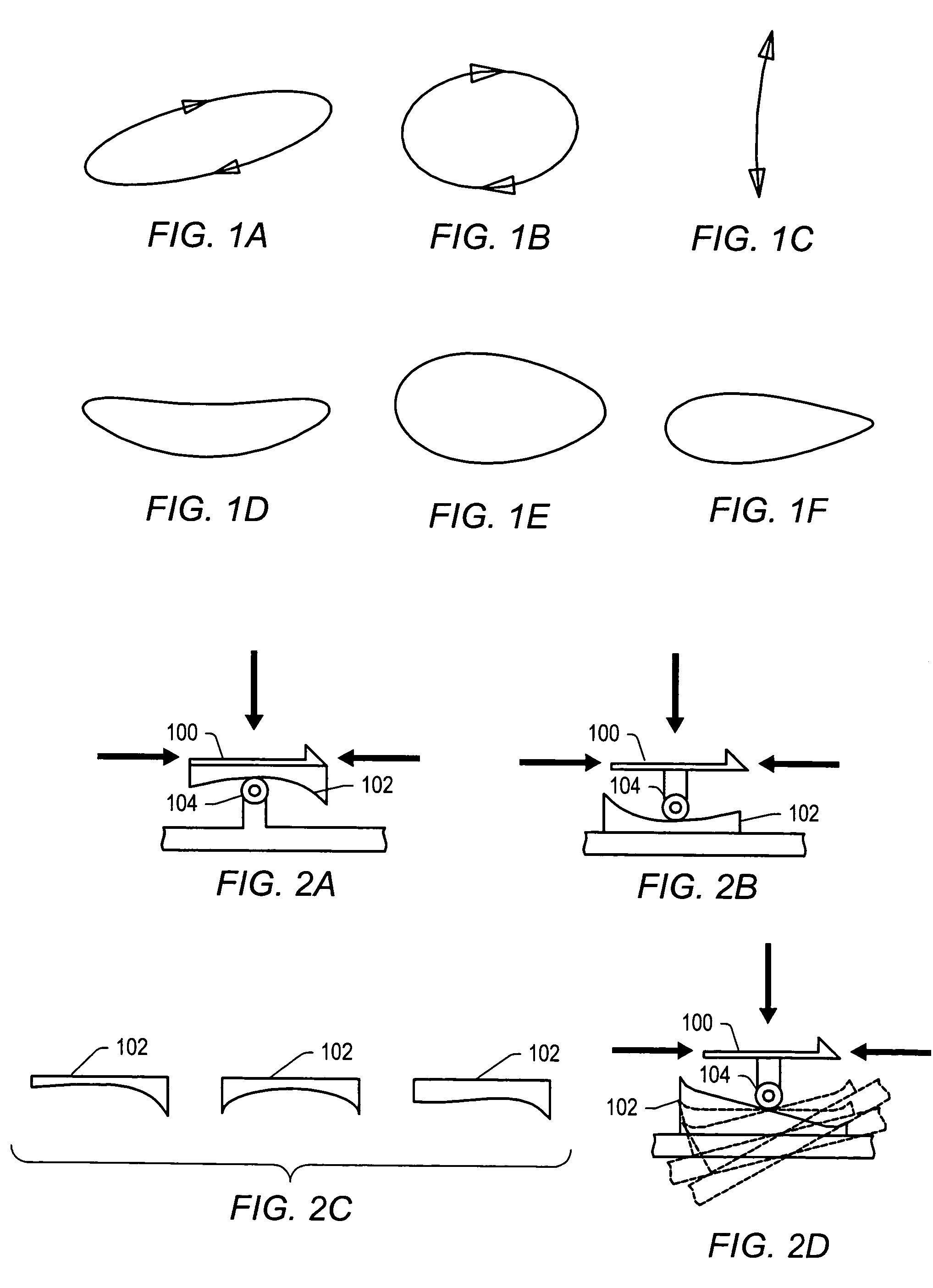

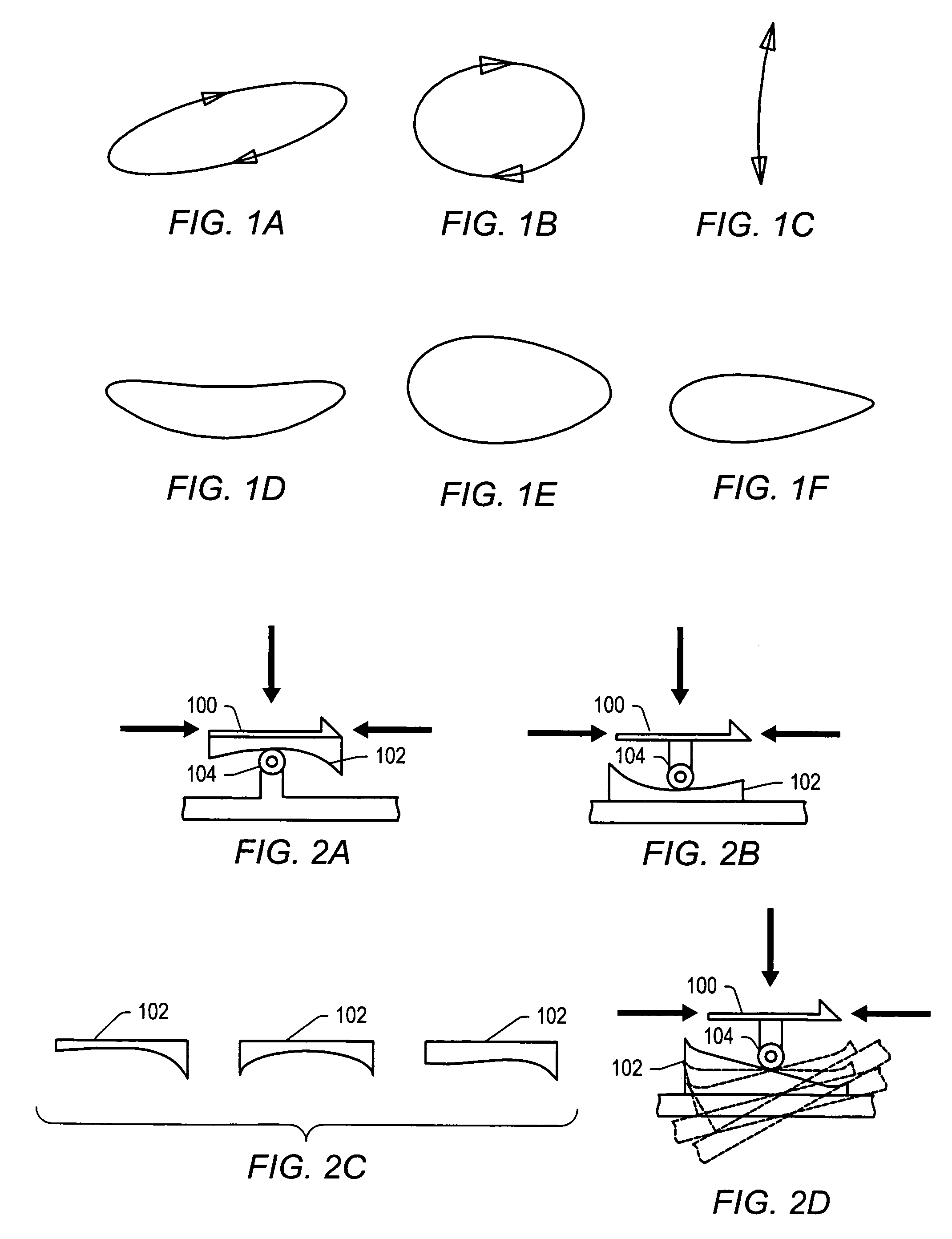

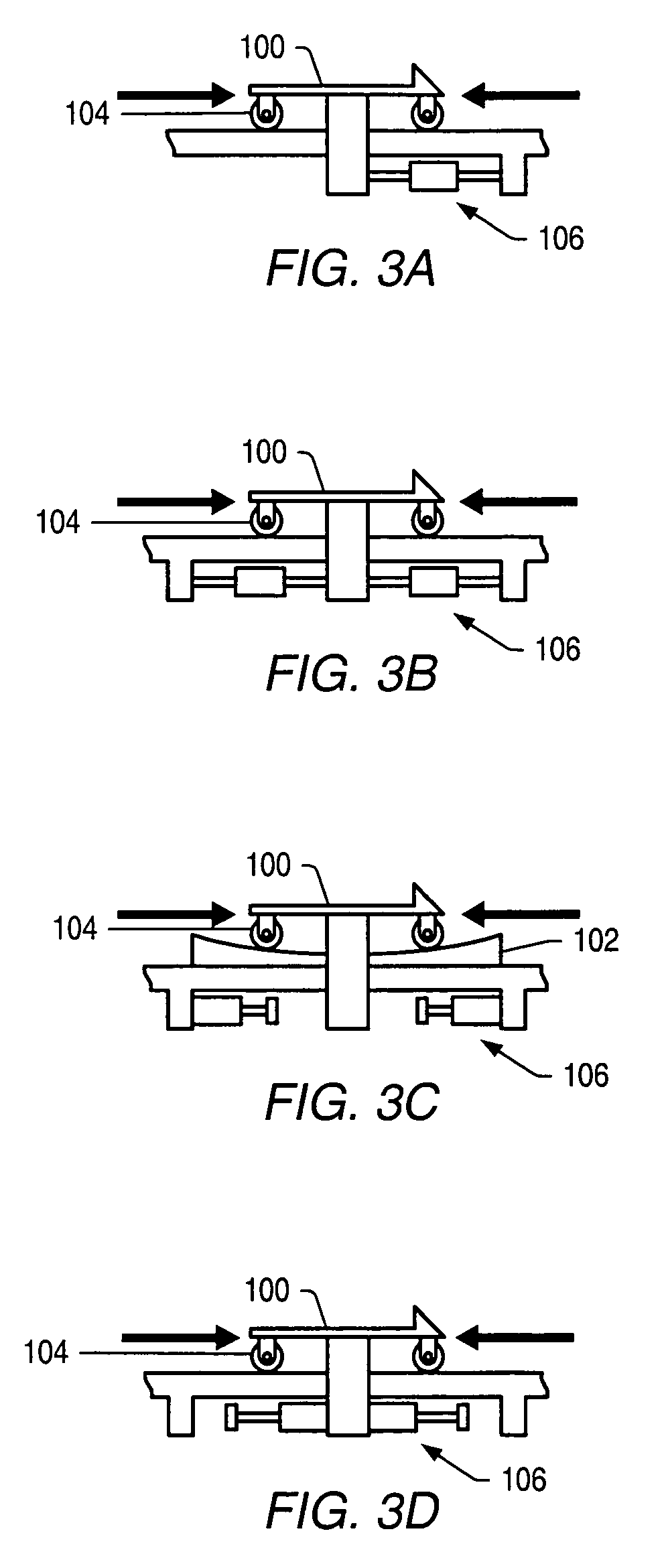

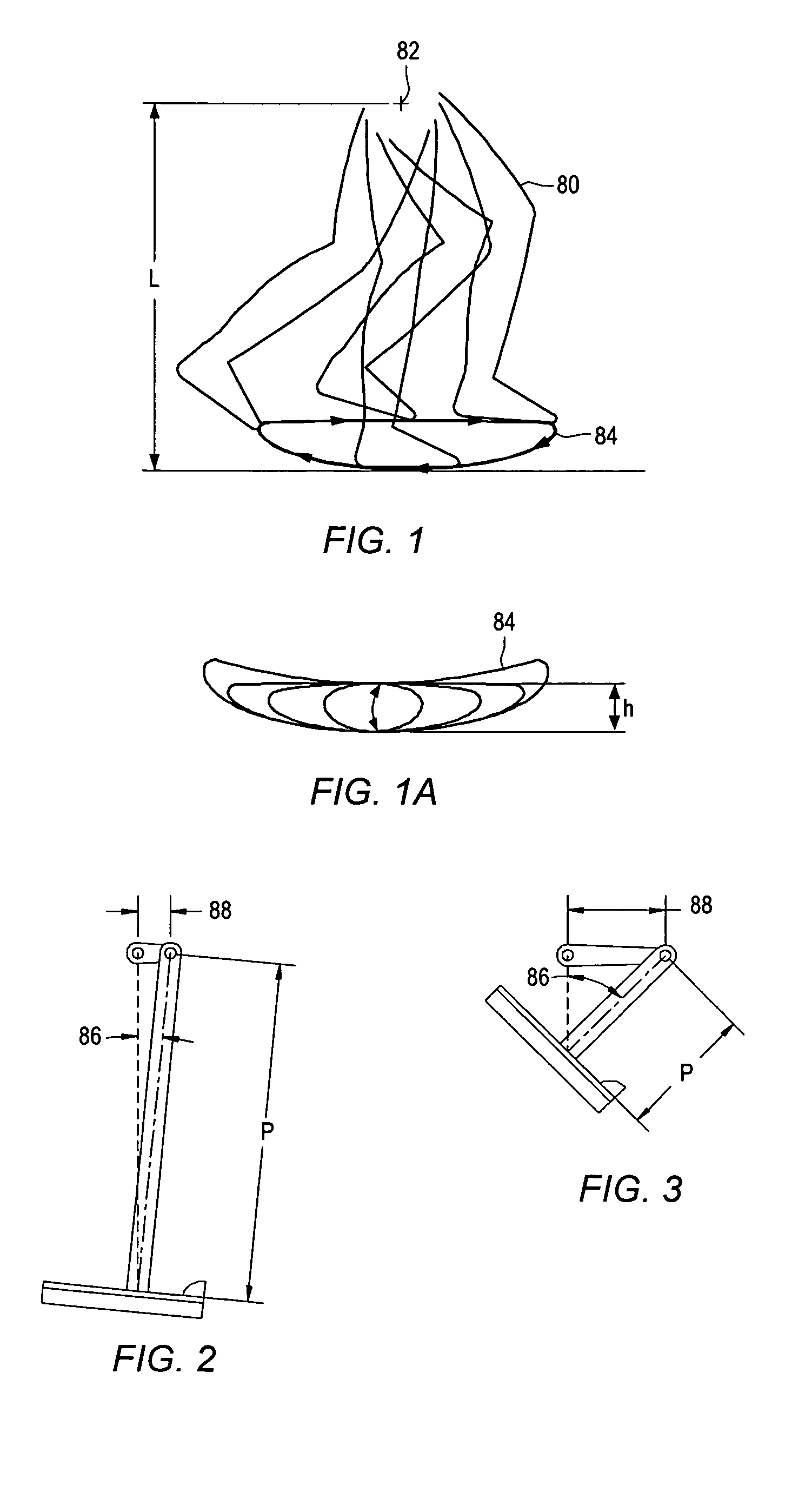

Method and system for varying stride in an elliptical exercise machine

ActiveUS7604573B2Movement coordination devicesCardiovascular exercising devicesClassical mechanicsStride length

Disclosed is an exercise machine, and particularly a front or rear mount elliptical or elliptical-type machine, comprising: (a) a support structure; (b) a drive component pivotally coupled to the support structure and configured to rotate about a first pivot axis; (c) a reciprocating foot support configured to travel about a closed path having a stride length upon rotation of the drive component; (d) a coupling configuration configured to support the reciprocating foot support about the drive component at a position radially offset from the first pivot axis, the coupling configuration pivotally coupled to the drive component about a second pivot axis; and (e) an adjustment mechanism configured to enable the coupling configuration to pivot about the second pivot axis between at least two adjustment positions to vary the radial offset of the reciprocating foot support with respect to the first pivot axis.

Owner:IFIT INC

Exercise device

InactiveUS7060005B2Stored or moved more efficientlyCompact profileMovement coordination devicesCardiovascular exercising devicesMuscle groupBiomechanics

An exercise apparatus having a pair of support pedals that, when a user steps upon both pedals, can be moved by the user in a closed path that is designed to be complimentary in motion to that of the user's natural stride. The pedals are operably connected by a linkage that facilitates this natural motion. Moreover, this linkage can be adjusted thereby altering the shape of the closed path traveled by the pedals. The closed path can thus be altered to conform to the optimal biomechanics of each individual user or, it can be altered to form a closed path designed for more of a striding type of exercise or for more of a climbing exercise, thereby allowing different muscle groups to be exercised on the same machine.

Owner:CONGRESS FINANCIAL CORP WESTERN

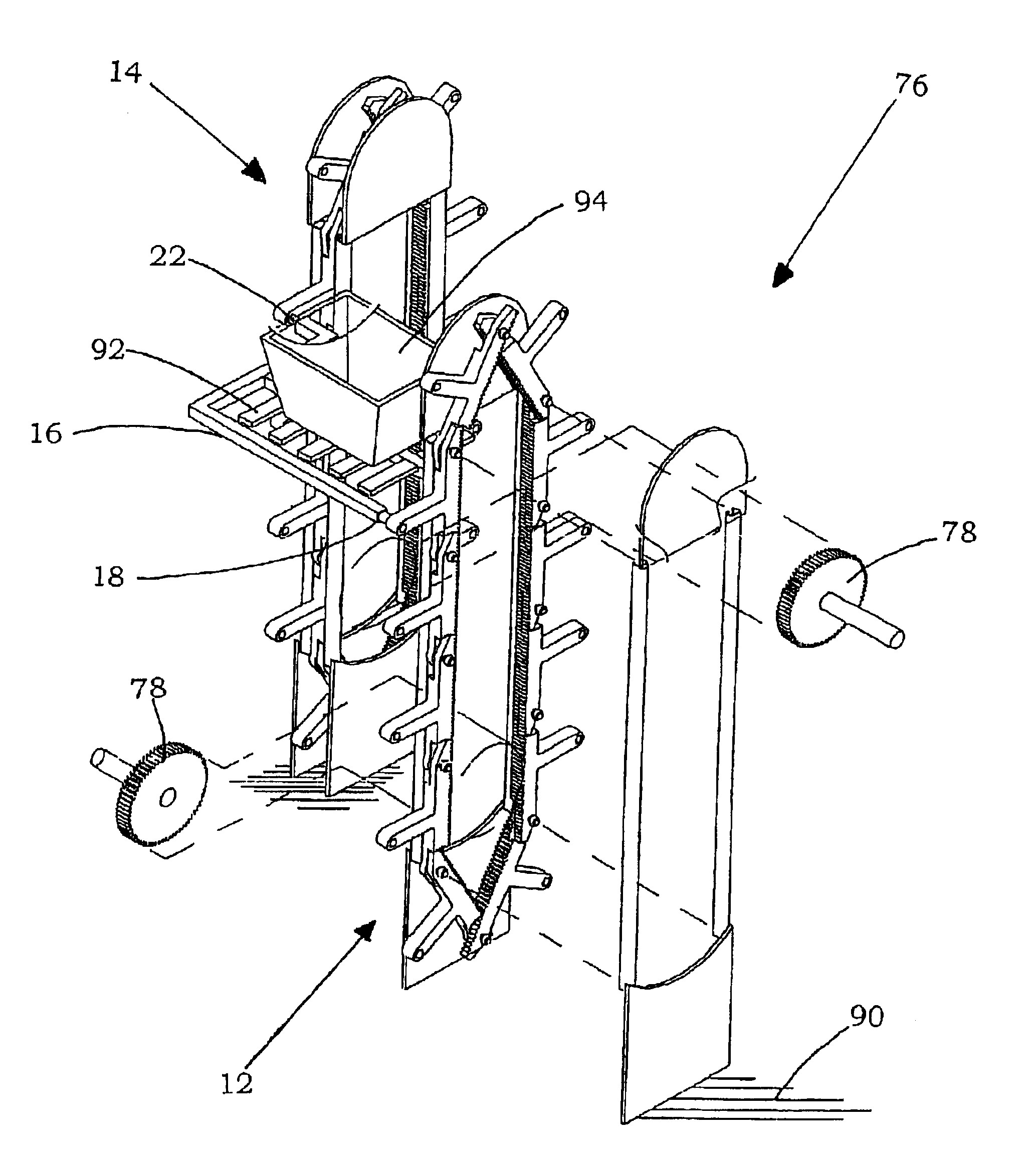

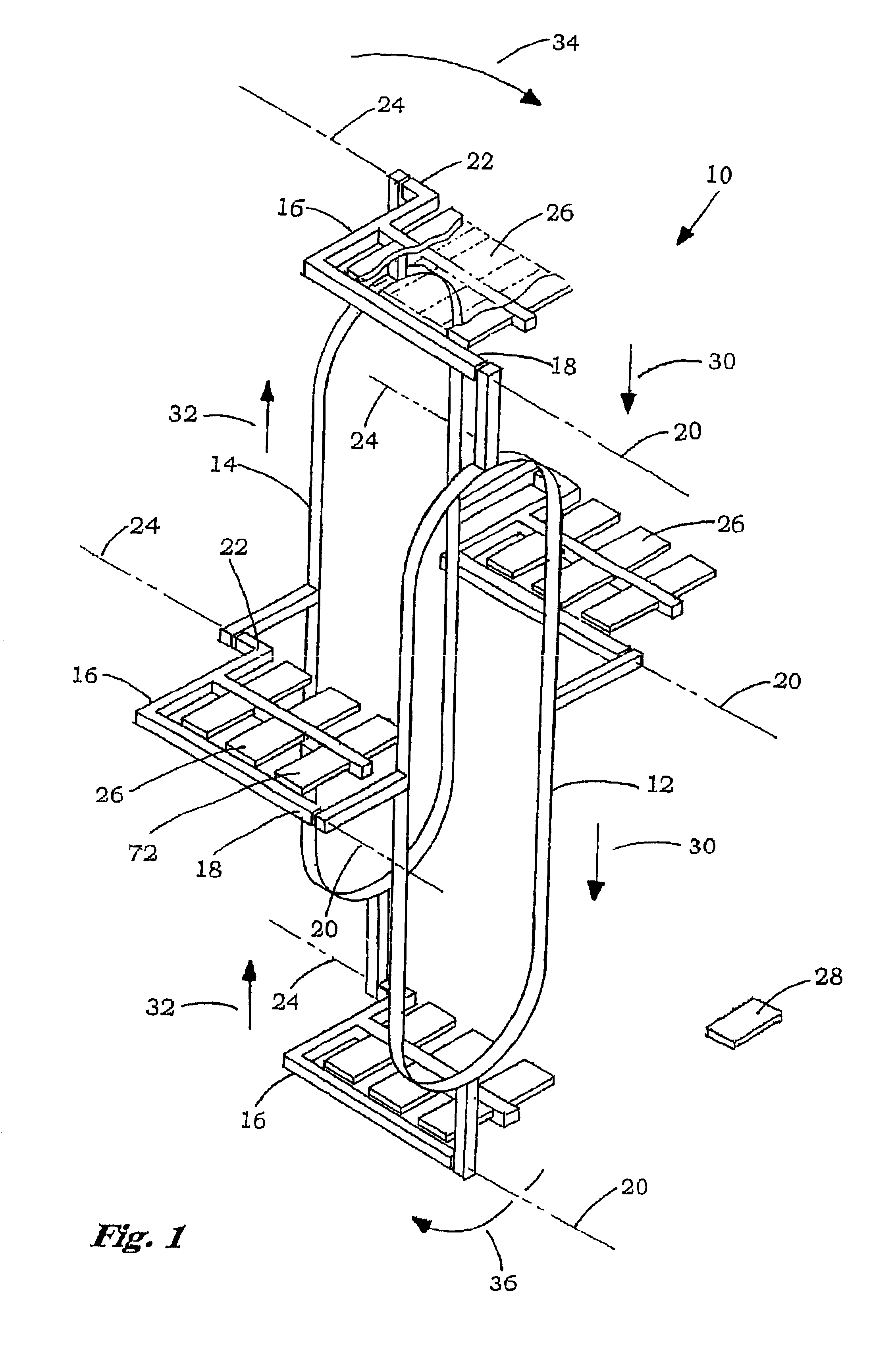

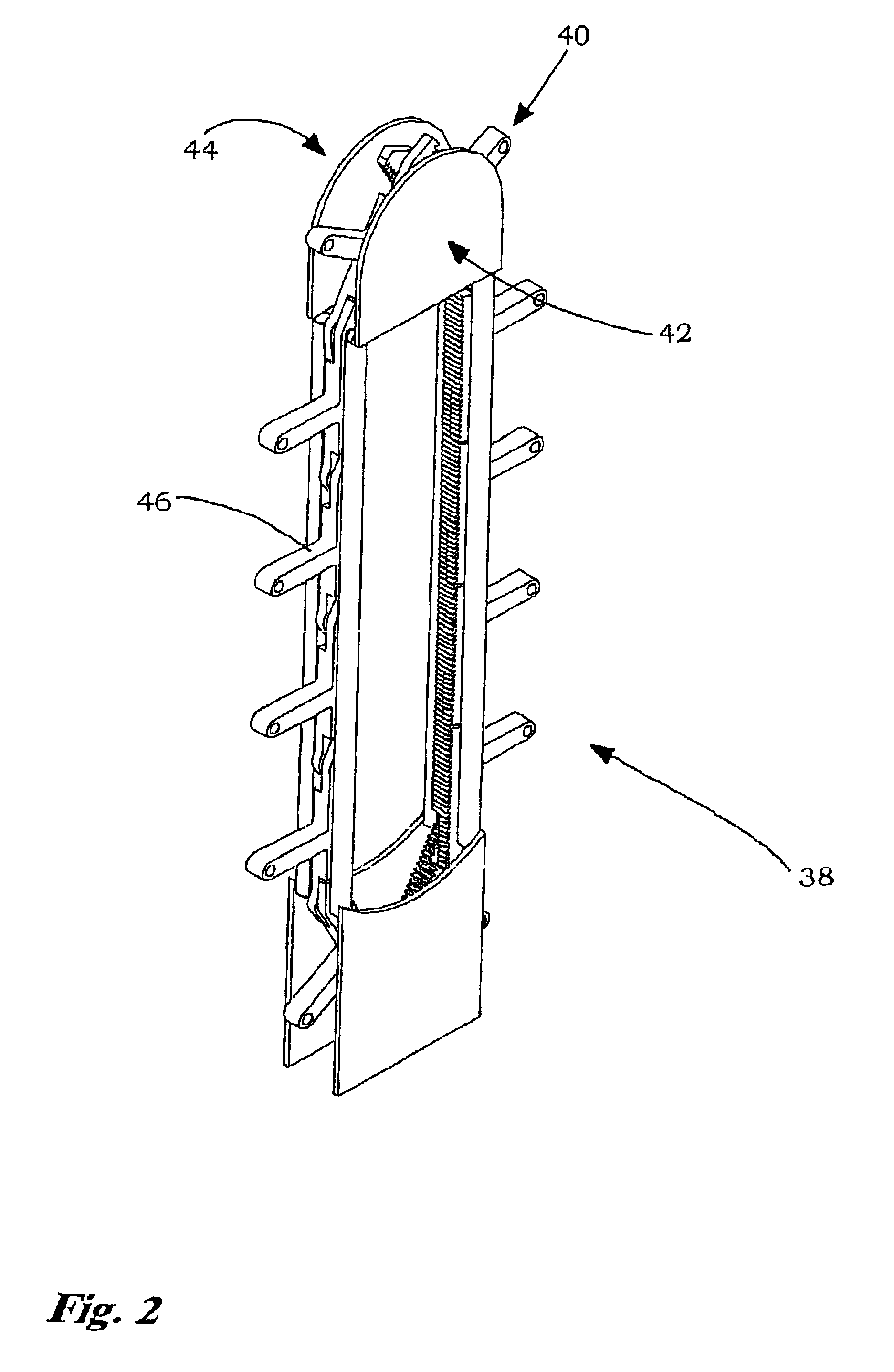

Moving crank mechanism

InactiveUS7025191B2Improve efficiencyIncrease flexibilityStorage devicesConveyor partsClosed loopEngineering

A moving crank mechanism that is particularly adapted for use in a conveyor system. A moving crank remains in a substantially parallel position with respect to a fixed reference plane as the crank member is driven by its offset opposed ends along an endless loop. The closed loop vertical lift unit is adapted for use in an automated high-speed storage system. The vertical lift unit is adapted to be used as a primary storage location or as a lift for carrying objects in transit between levels in a storage system. The vertical lift unit includes a plurality of crank members with generally rigidly mounted shelves that are adapted to carry objects continuously and indefinitely as the shelves travel through a vertically oriented closed path. While traveling along the vertically oriented closed path the shelves remain parallel to a fixed horizontal plane so objects can be carried on the shelves while the shelves transition between the up and down reaches of the vertical lift mechanism. The opposed ends of the crank member are journaled in carriage members that are mounted to carry the respective ends of the crank member around the closed loop. The respective ends are carried around the closed loop at about the same rate. The closed loops are offset from one another by the amount of the crank offset. Shelf stabilizing mechanisms can also be employed.

Owner:LICHTI ROBERT D +1

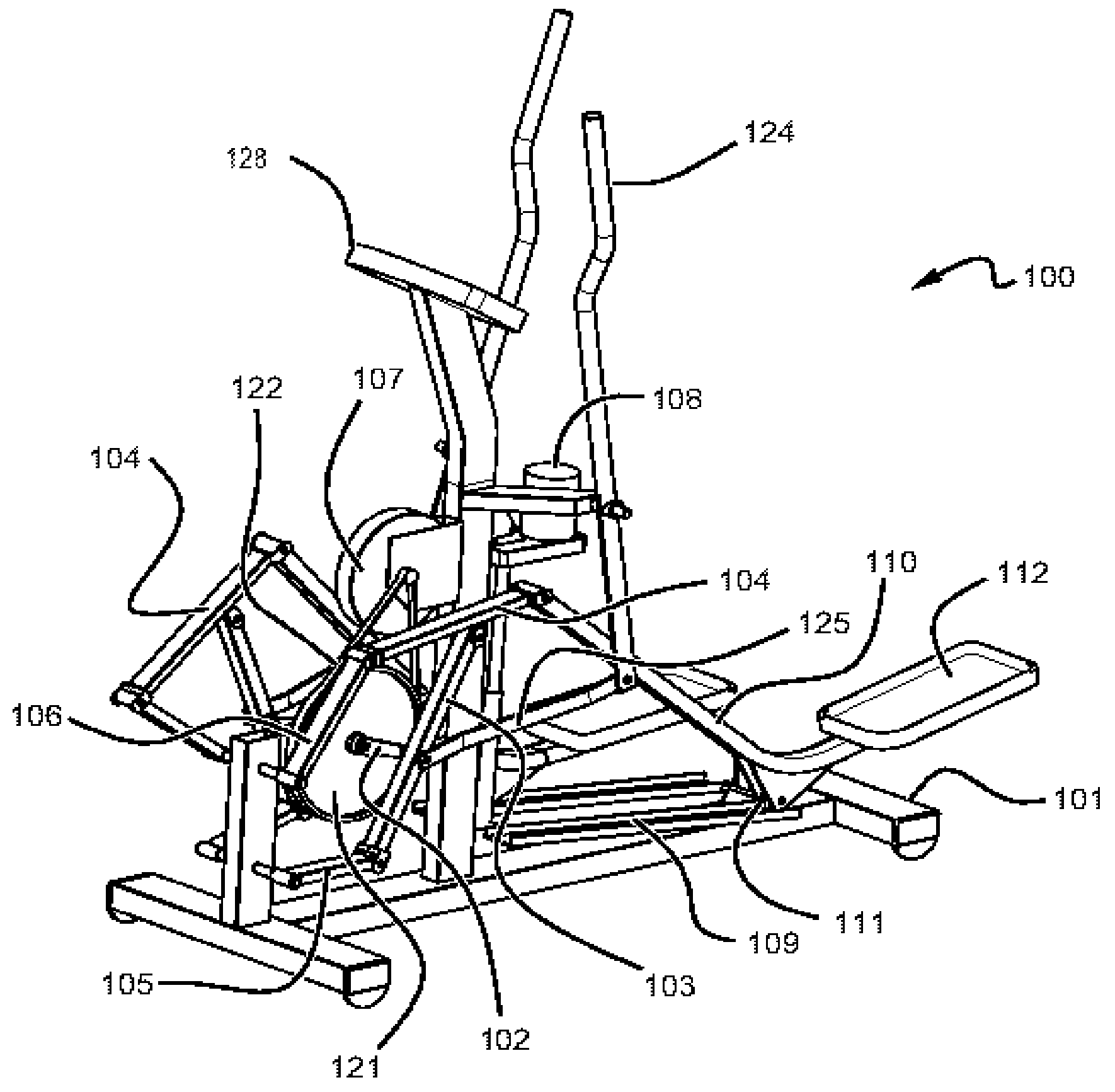

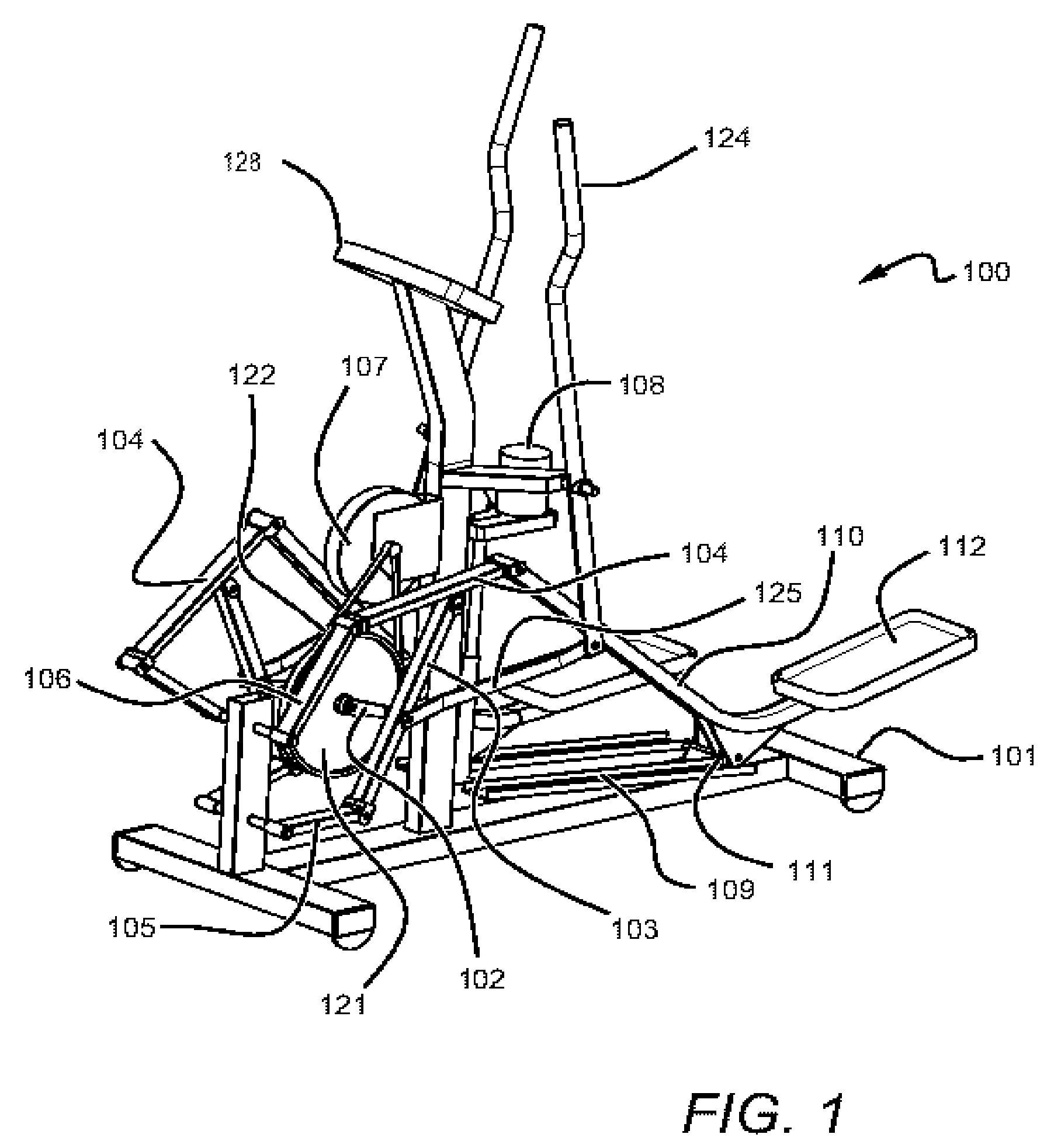

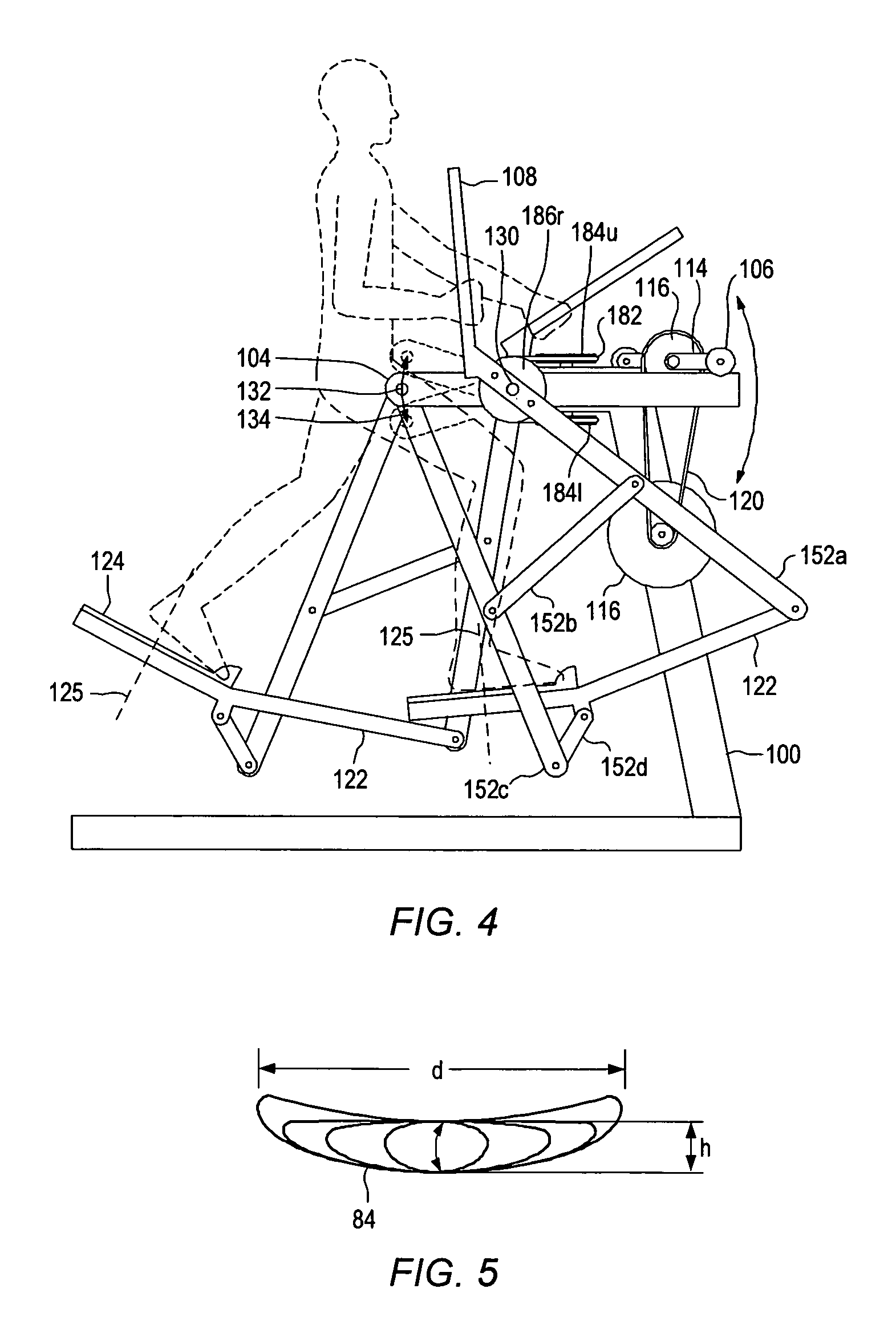

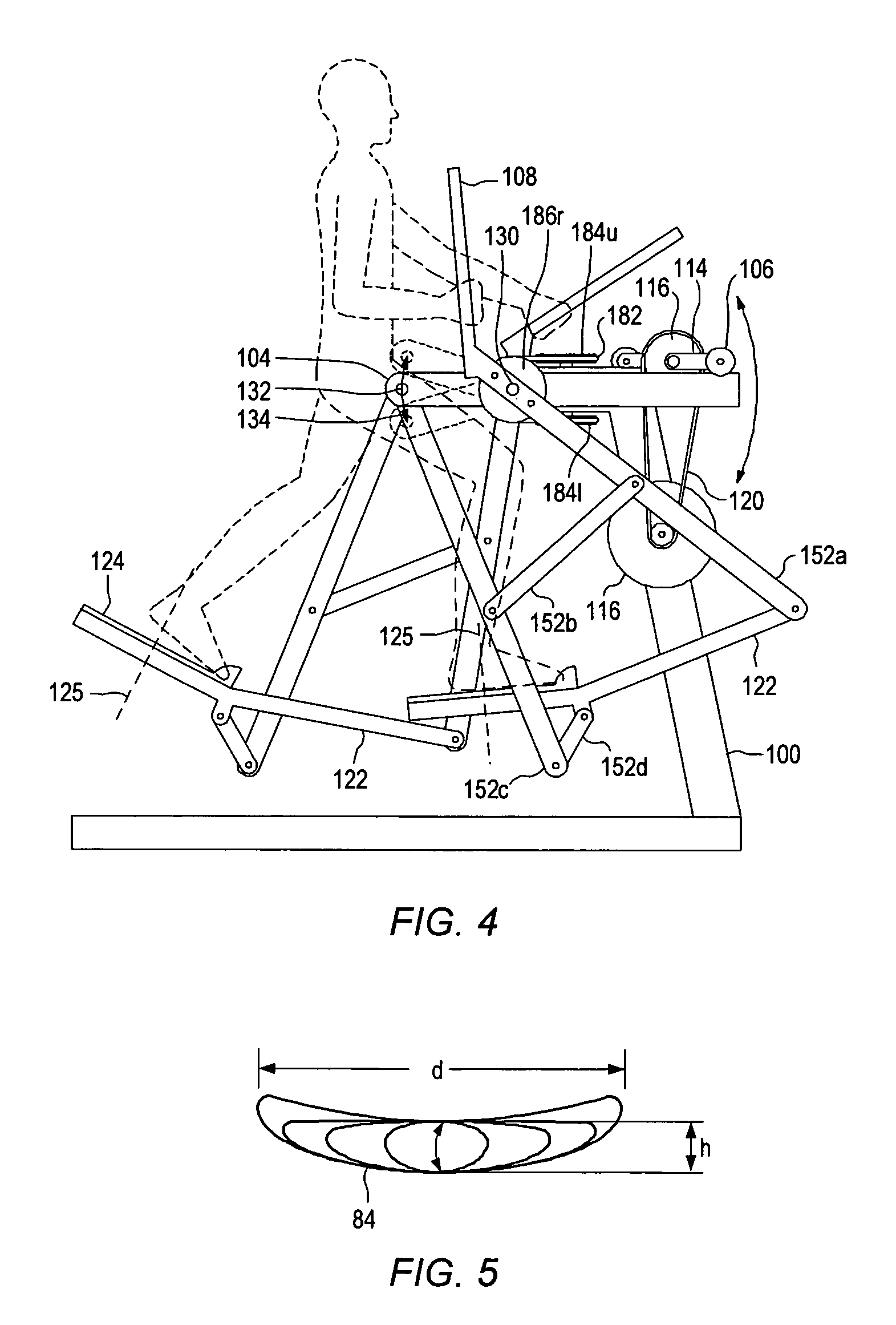

Pendulum striding exercise apparatus

An exercise apparatus may include a frame. A crank system may be coupled to the frame. A brake / inertia device may be coupled to the crank system. A pivotal linkage pendulum system may be coupled to the crank system. The pivotal linkage pendulum system may include one or more link members. An upper pivot point of at least one of the link members may be coupled to the crank system. In some embodiments, the upper pivot point of the at least one of the link members may be coupled to the crank system through a movable member. The upper pivot point may move in a back and forth path of motion or in a closed path motion. A foot member may be coupled to one or more of the link members. The foot member may include a footpad.

Owner:RODGERS JR ROBERT E

Variable stride exercise apparatus

ActiveUS7172531B2Length of may varyMovement coordination devicesCardiovascular exercising devicesEngineeringClosed path

A variable stride exercise apparatus is described. A variable stride exercise apparatus may include a frame. A crank system may be coupled to the frame. A foot member may be coupled to the crank system. The foot member may include a footpad. A variable stride system may be coupled to the foot member. The variable stride system and the foot member may be coupled such that at least a portion of the variable stride system is under at least a portion of the footpad. The variable stride system may allow a user of the apparatus to vary the length of the user's stride during use of the apparatus. The foot of the user may travel in a substantially closed path during use of the apparatus. At least a portion of the apparatus may remain substantially stationary during use.

Owner:RODGERS JR ROBERT E

Variable stride exercise device using spring damper assembly

InactiveUS20070087907A1Length of may varyMuscle exercising devicesMovement coordination devicesEngineeringClosed path

A variable stride exercise apparatus is described. A variable stride exercise apparatus may include a frame. A crank system may be coupled to the frame. A foot member may be coupled to the crank system. The foot member may include a footpad. A variable stride system may be coupled to the foot member. The variable stride system and the foot member may be coupled such that at least a portion of the variable stride system is under at least a portion of the footpad. The variable stride system may allow a user of the apparatus to vary the length of the user's stride during use of the apparatus. The foot of the user may travel in a substantially closed path during use of the apparatus. At least a portion of the apparatus may remain substantially stationary during use.

Owner:RODGERS ROBERT E JR

Exercise apparatus with automatically adjustable foot motion

An elliptical exercise apparatus includes a frame, a pair of footpads, and a linkage coupling the footpads to the frame and for guiding the footpads in closed paths when a user's feet apply forces to the footpads. The linkage, which includes a rotatable member having an angular position indicative of the positions of the footpads within their closed paths, responds to input control signals by adjusting length and height dimensions of the closed paths. A control system senses the angular position of the rotatable member, senses the forces the user applies to the footpads, and generates the control signals to increase or decrease the path dimensions when it senses particular combinations of angular position and user forces, thereby permitting the user to control the path dimensions by controlling the forces applied to the footpads.

Owner:MARESH JOSEPH D +1

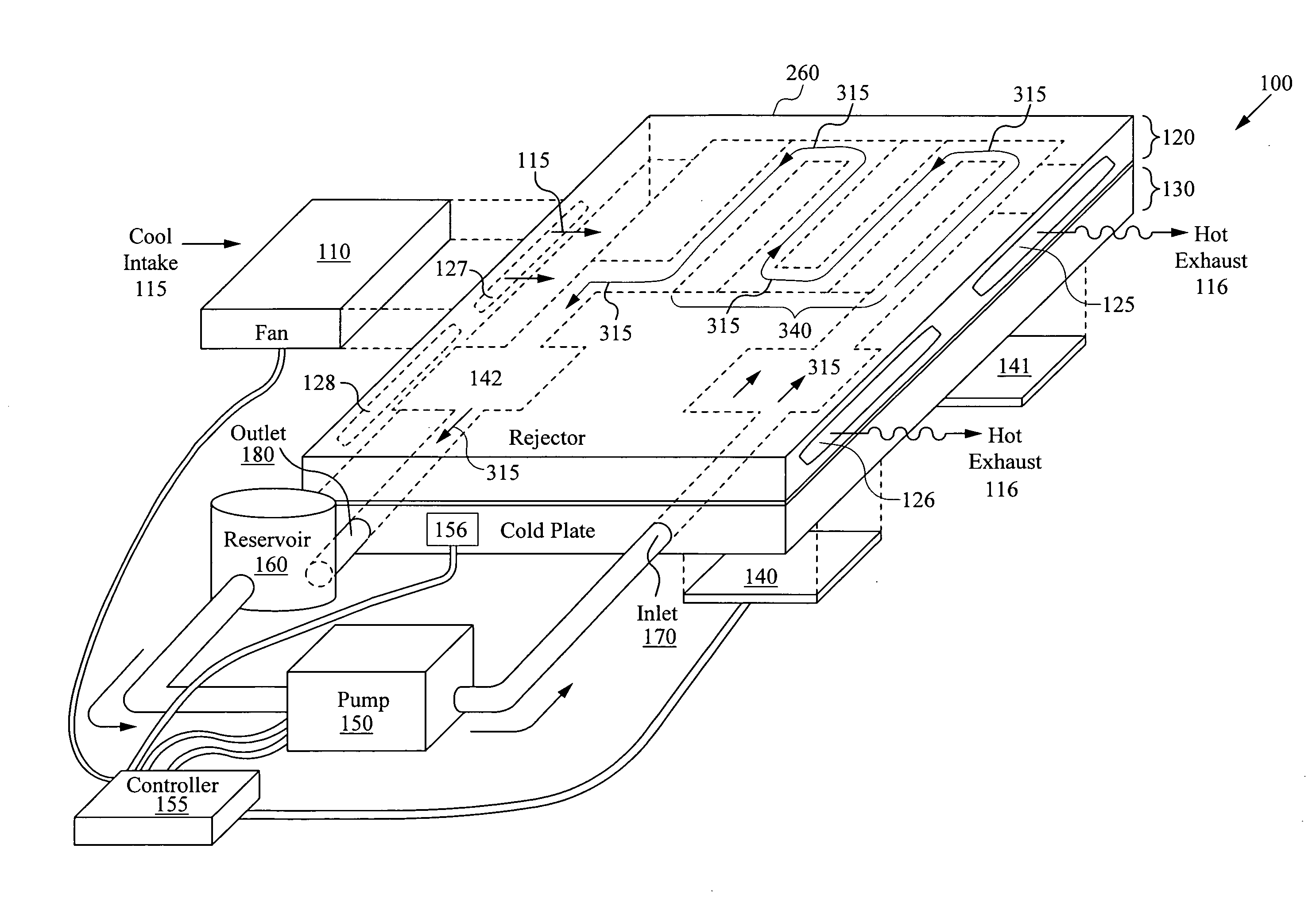

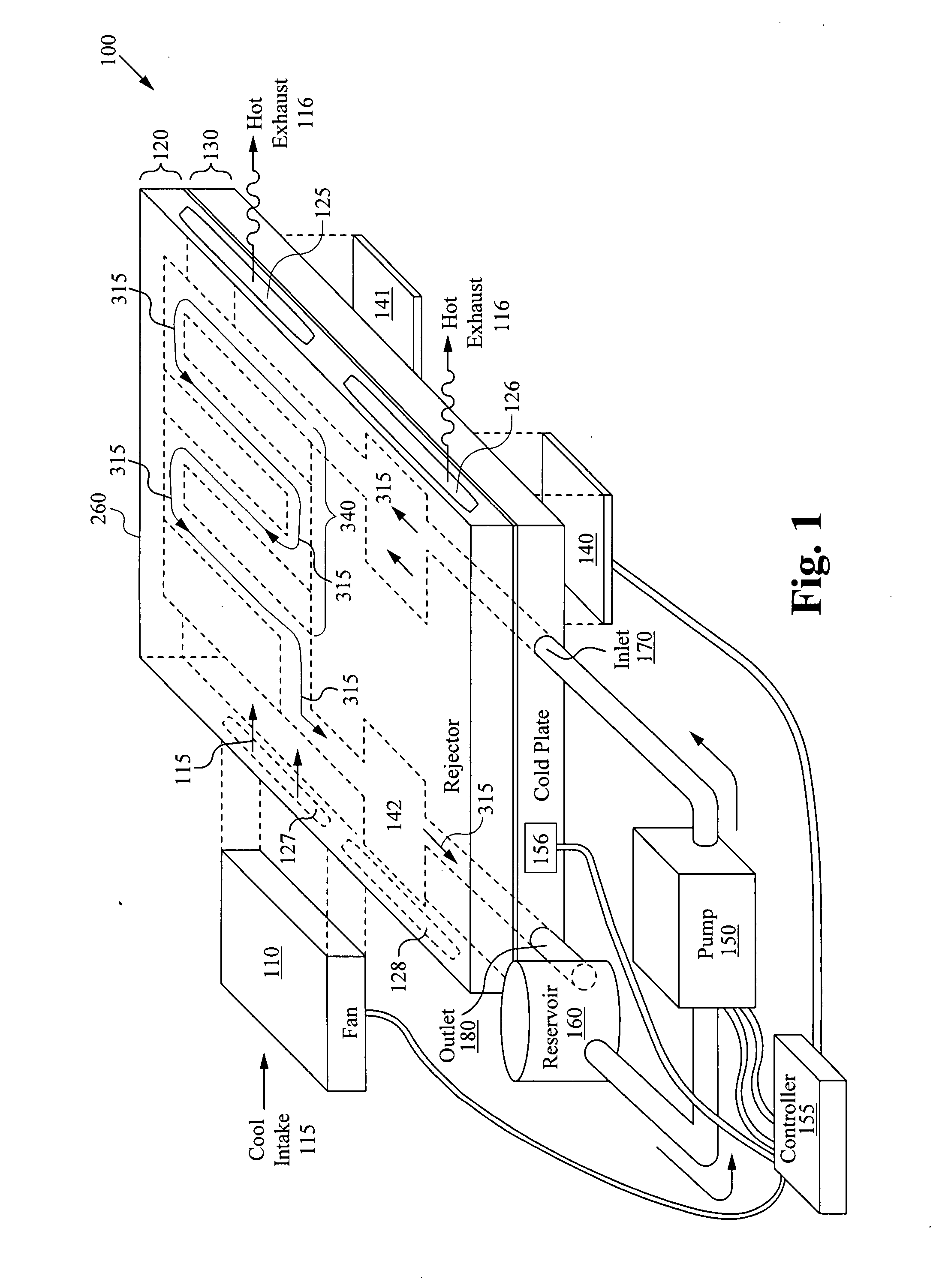

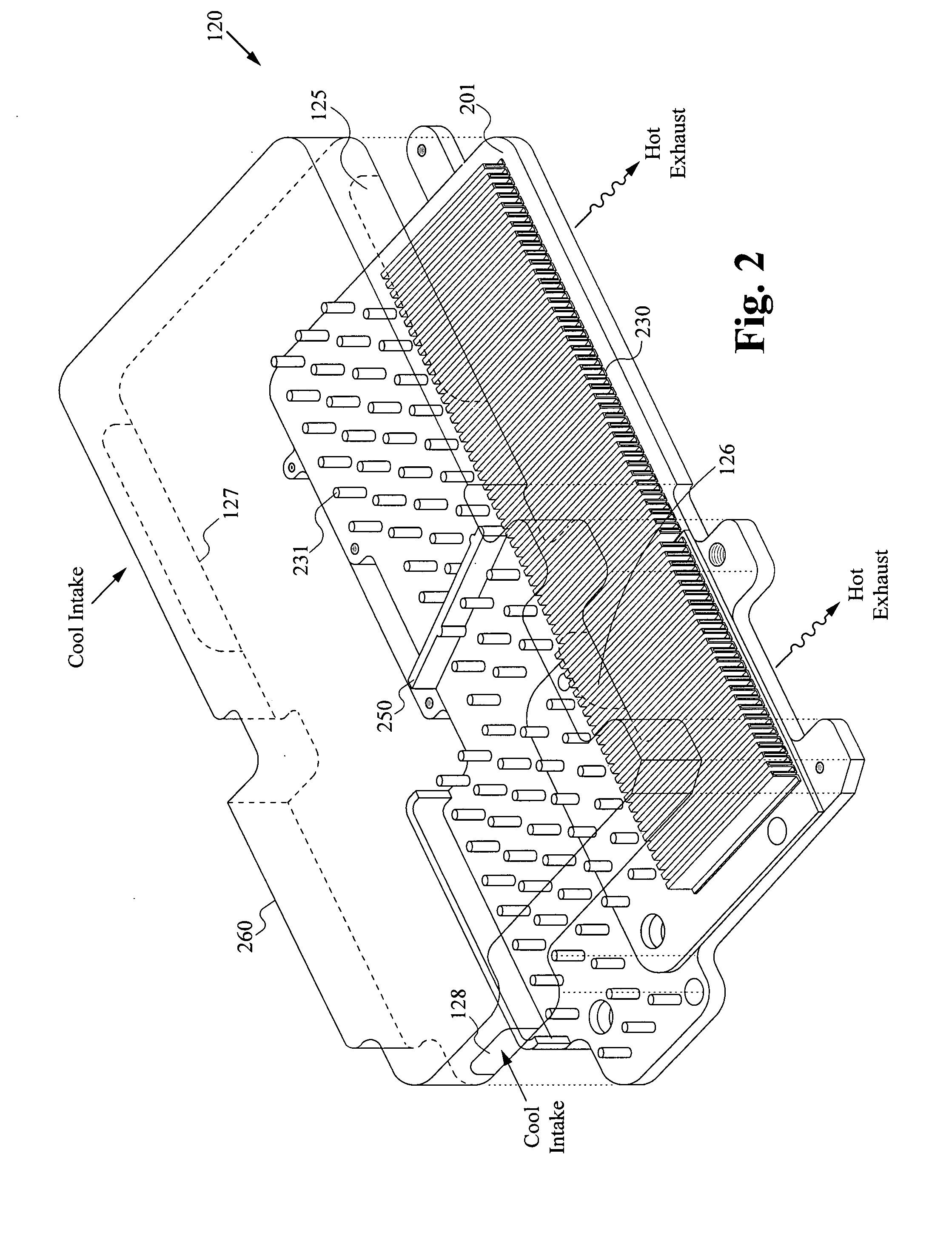

Integrated liquid to air conduction module

ActiveUS20070227708A1Increase the areaMaximizes timeSpace heating and ventilation safety systemsSpace heating and ventilation control systemsGraphic cardCounter flow

An integrated cooling system for cooling systems such as laptops or subsystems such as a graphics card is disclosed. An integrated cooling system includes a first layer having a contact area configured for coupling to a heat source, wherein the first layer has a fluid path passes adjacent to the contact area where the heat source is in thermal contact with first layer. Coupled to the first layer is a second layer to which a number of air fins are attached. The invention includes a pump that is connected to the fluid path forming a closed path for circulating a fluid through the first layer. Within the first layer, the fluid path will contain a plurality of fluid fins which control the flow of a fluid within the fluid path. Within the fluid path, a structure providing a double-counter flow adjacent to one or more electronic devices. Additionally the fluid path can include a microchannel plate structure. The system can include a includes a programmable controller connect the an air-mover, pump and temperature sensing device. A reservoir can be connected to the fluid path.

Owner:VERTIV CORP

Pendulum striding exercise devices

ActiveUS20050124467A1Muscle exercising devicesMovement coordination devicesEngineeringPendulum system

An exercise apparatus may include a frame. A crank system may be coupled to the frame. A brake / inertia device may be coupled to the crank system. A pivotal linkage pendulum system may be coupled to the crank system. The pivotal linkage pendulum system may include one or more link members. An upper pivot point of at least one of the link members may be coupled to the crank system. In some embodiments, the upper pivot point of the at least one of the link members may be coupled to the crank system through a movable member. The upper pivot point may move in a closed path motion. A foot member may be coupled to one or more of the link members. The foot member may include a footpad. A majority of a path of motion of the footpad may be below the closed path during use.

Owner:RODGERS JR ROBERT E

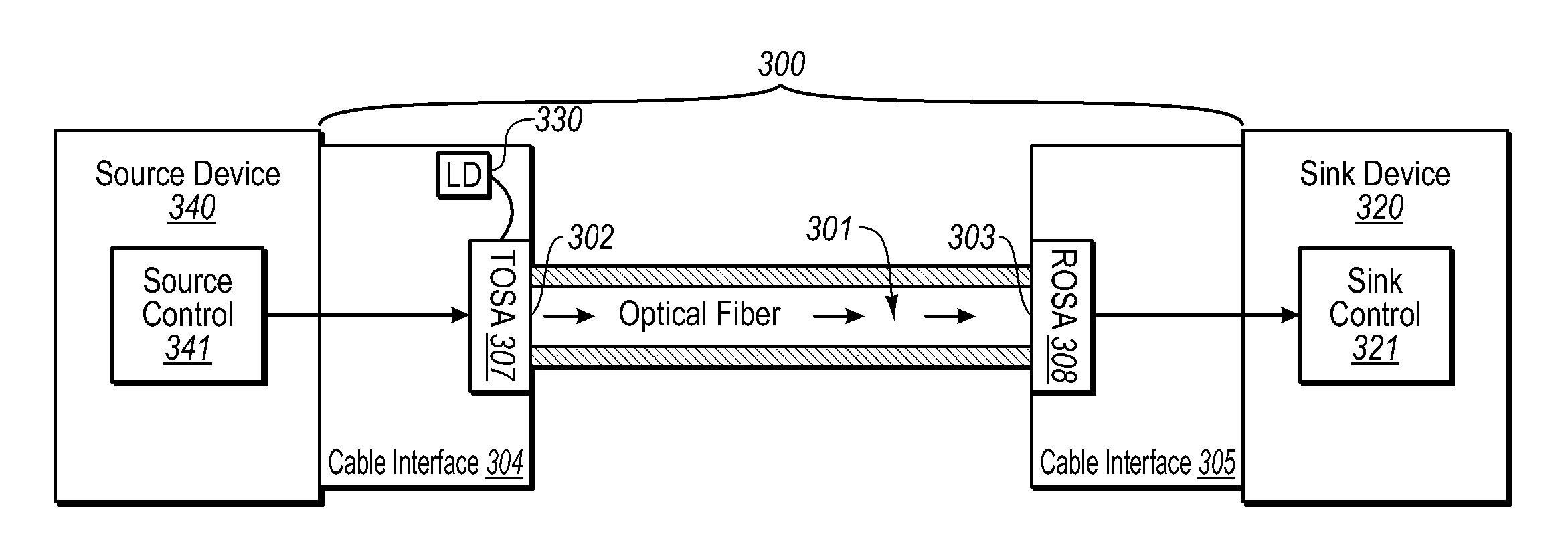

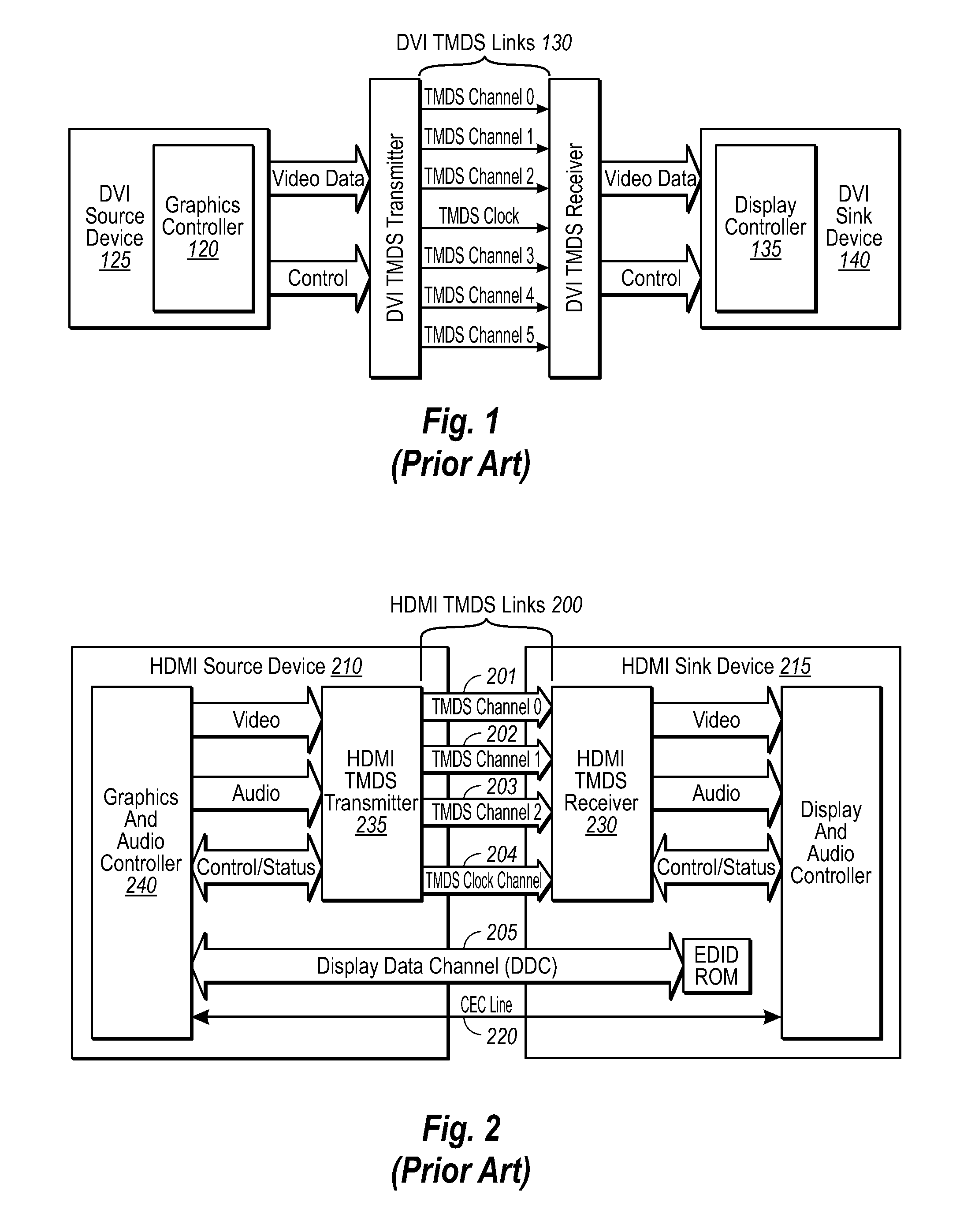

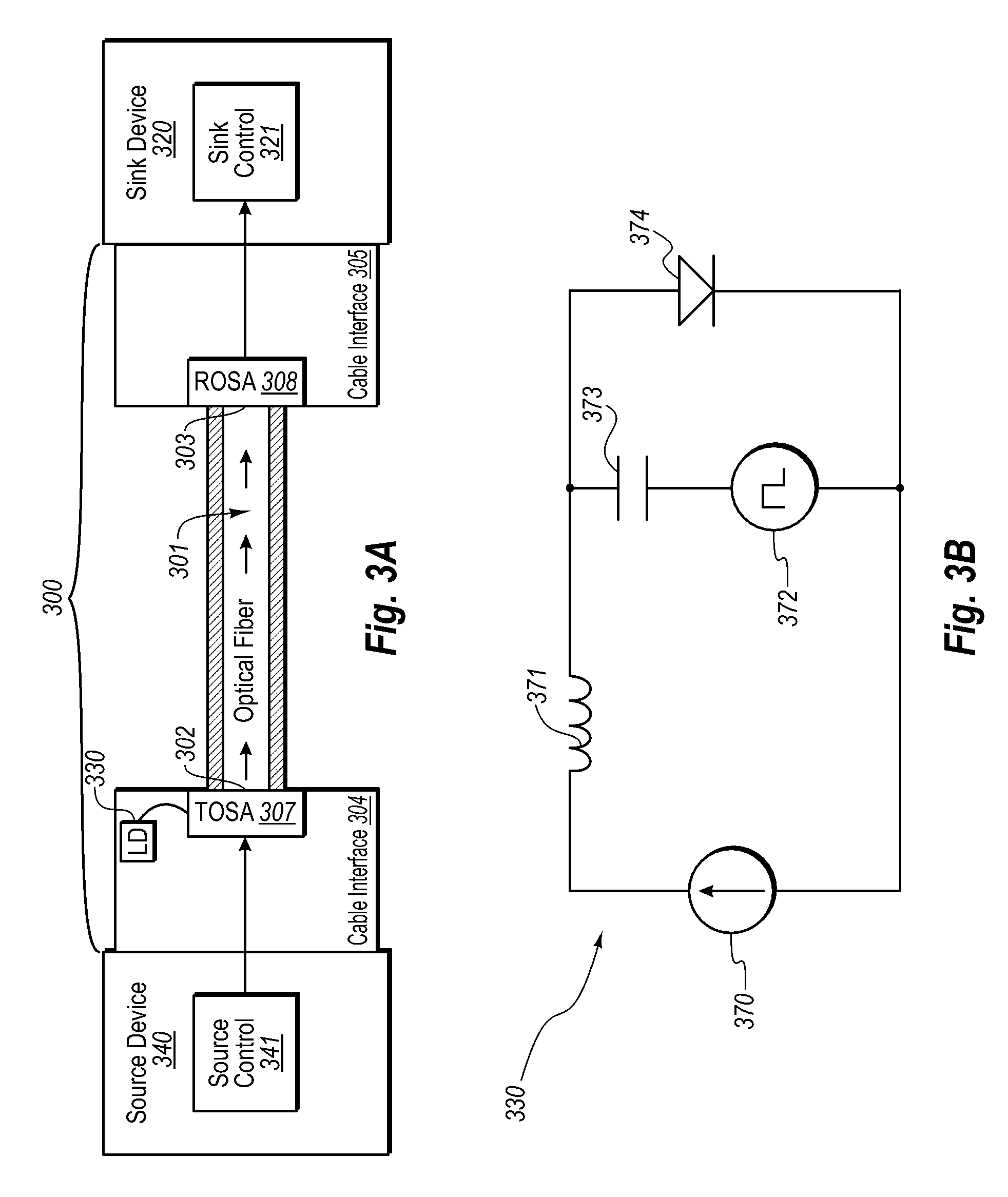

Laser drivers for closed path optical cables

InactiveUS7860398B2Time-division optical multiplex systemsSemiconductor laser structural detailsOptical communicationTemperature coefficient

Simplified laser drivers for closed path digital optical cables and digital optical cables including the simplified laser drivers. The laser driver can include less transistors than conventional laser drivers for optical communication cables. The laser can include a bias source and modulation source. The bias source can have a single constant current bias point for all laser diodes. The modulation current source can have a single temperature coefficient for all laser diodes. The laser driver can exclude, for example, any one of or combination of temperature compensation of the modulation or bias current sources, external programming of the modulation or bias current sources, power control based on output of the laser diode, and / or control based on feedback received from a monitor device or other sensor within the cables.

Owner:II VI DELAWARE INC

Pendulum striding exercise devices

Owner:RODGERS JR ROBERT E

System and method for gas analysis using doubly resonant photoacoustic spectroscopy

ActiveUS7263871B2High frequencyLow costAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationGas analysisGas detector

A method for analyzing gas concentration using doubly resonant photoacoustic spectroscopy, and a doubly resonant photaoacoustic gas detector comprising:i) a continuous wave light beam whose wavelength coincides with an absorption wavelength of a gaseous analyte;ii) a closed path optical cavity having at least two reflective surfaces;iii) an acoustic resonator chamber contained within said optical cavity, and comprising an acoustic sensor for detecting sound waves generated by a gaseous analyte present within said chamber, the light beam passing sequentially into, through and out of said chamber, and being repeatedly reflected back and forth through said chamber, and being modulated at a frequency which is equal to or equal to one-half of an acoustic resonance frequency of said acoustic resonator chamber.

Owner:LI COR

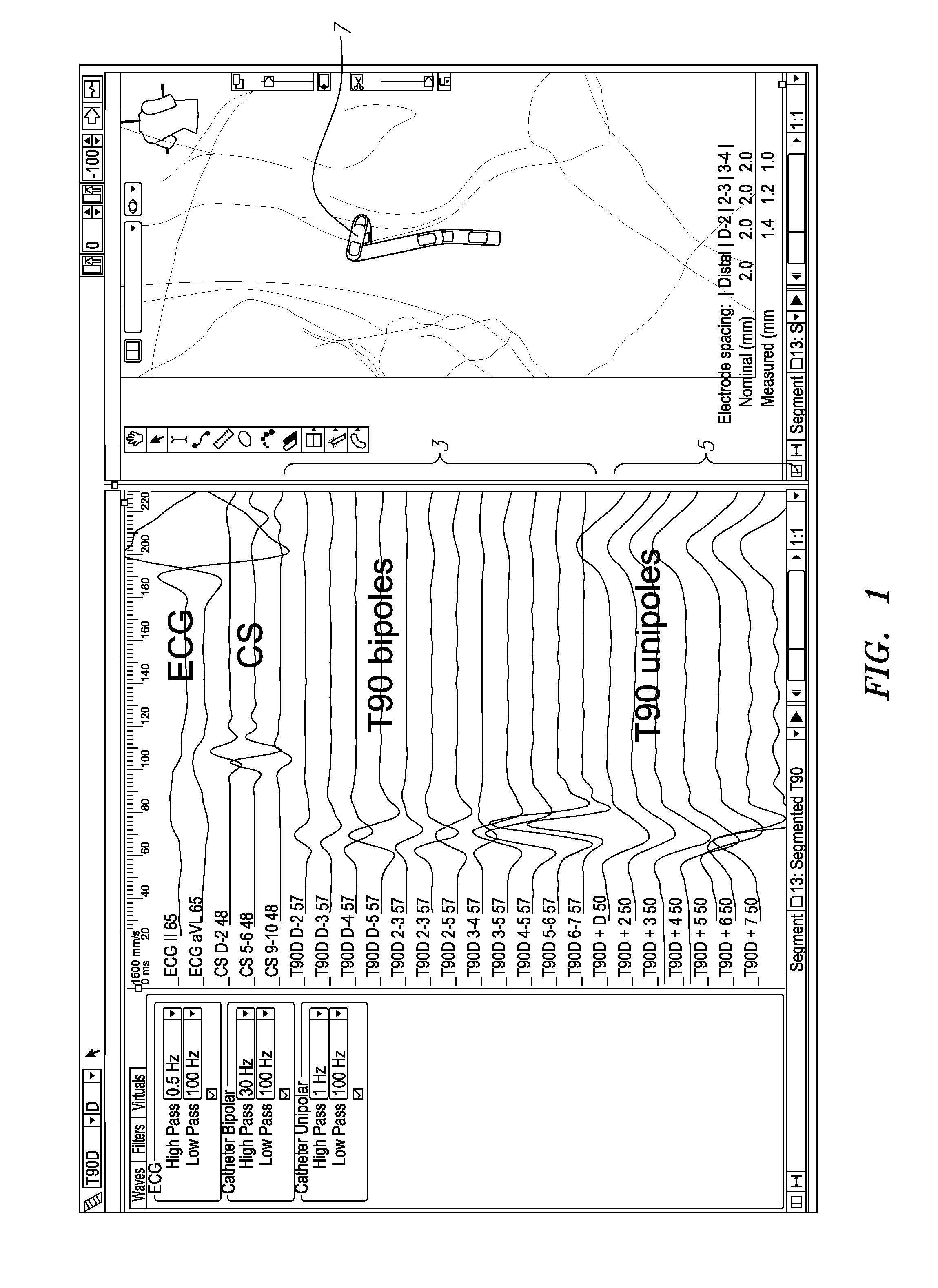

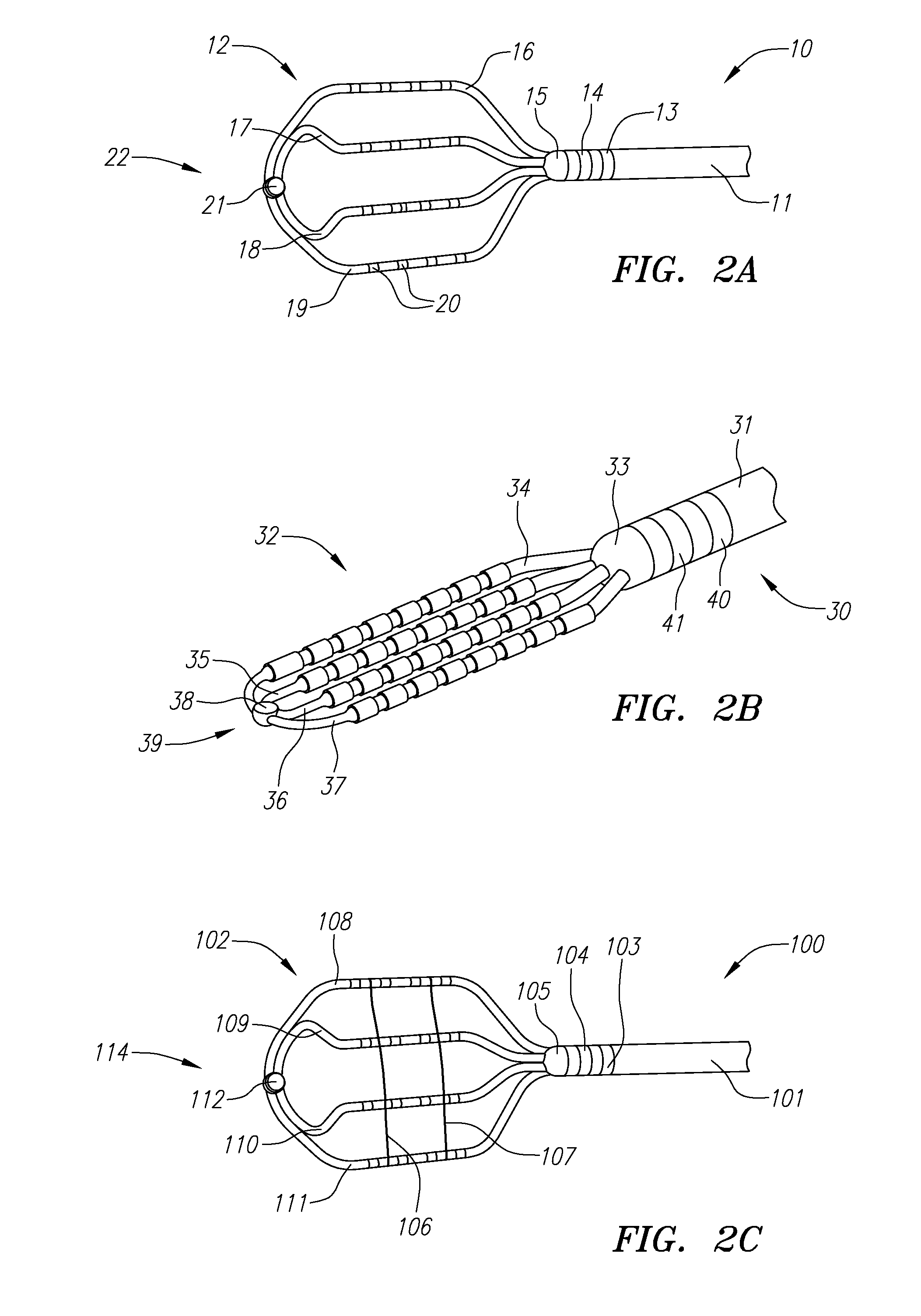

Systems and methods for using electrophysiology properties for classifying arrhythmia sources

ActiveUS20170049348A1Easy to identifyDiagnostic signal processingElectrocardiographyVelocity conductionCell electrophysiology

A method for determining electrophysiology properties of tissue comprising acquiring electrical signal data from a plurality of electrodes (130) of one or more catheters, determining at least one electrode clique from the plurality of adjacent electrodes (136), computing local conduction velocity vectors for the at least one electrode clique (138), determining at least one catheter orientation independent indicator from which to classify an arrhythmia source based on one or more of an angular dependence parameter associated with a flow field of the local velocity conduction vectors, an eccentricity parameter reflecting the uniformity of local conduction velocity, and divergence and curl-like sums or closed path integral parameters associated with the local velocity vectors, and displaying a rhythm classification responsive to catheter movement thereby facilitating identification of types and causes of arrhythmia disorders.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

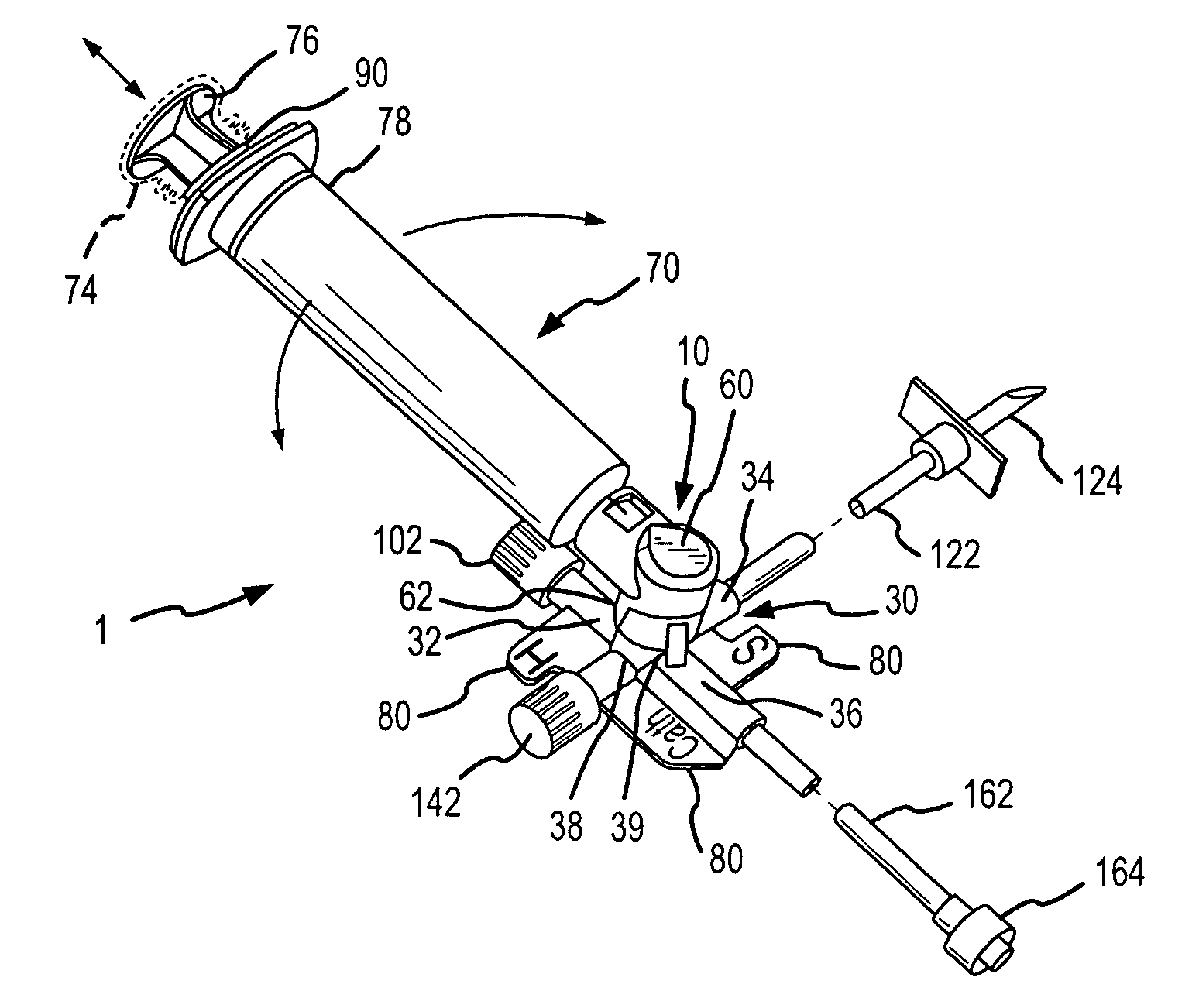

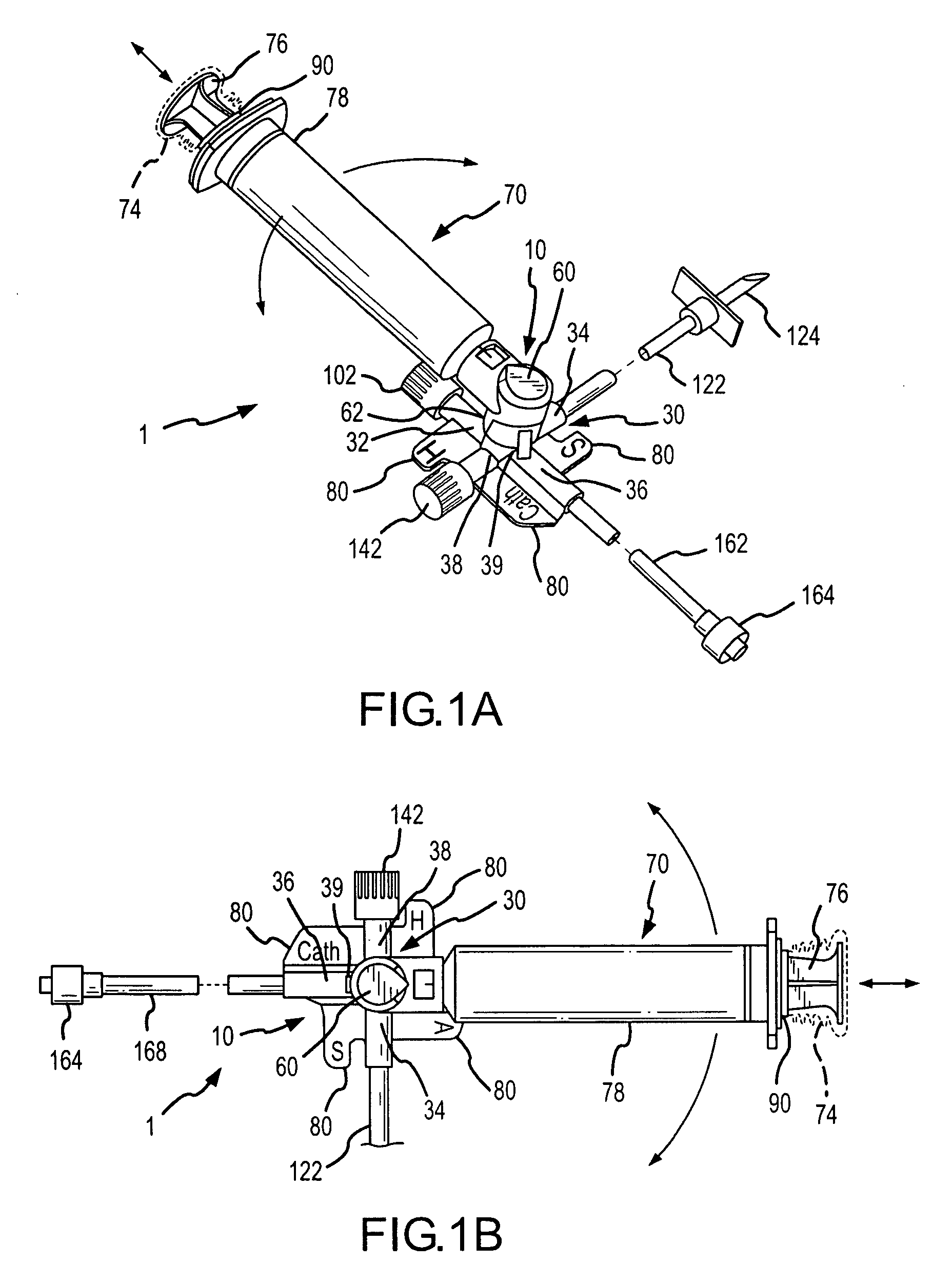

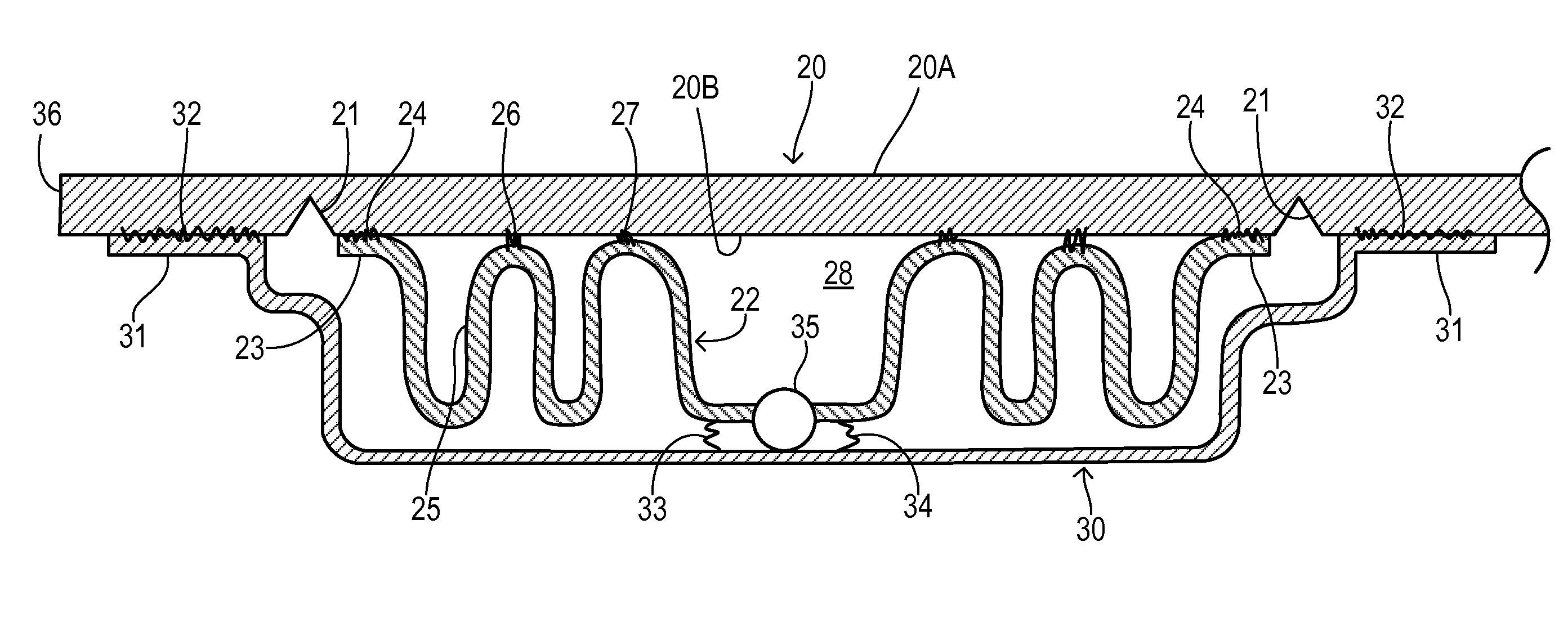

Apparatus and method for administration of IV liquid medication and IV flush solutions

InactiveUS20050245883A1Reduce the numberShorten the timeDiaphragm valvesEngine diaphragmsInterconnectionSurgery

The present invention provides a medical liquid administration apparatus and administration method that are particularly apt for intravenous (IV) applications. More particularly, the administration apparatus and method may be employed in conjunction with the administration of liquid medication and one or more flush solutions from multi-dose sources, wherein fluid interconnections between at least one flush solution source and the administration apparatus may be established a single time at the outset of a given procedure. The administration apparatus may include a valve having a control member selectively positionable to provide any selected one of a plurality of closed flow paths through the valve, and a syringe interconnected to the control member for clockwise / counterclockwise co-rotation therewith (e.g. to establish the selected flow path). The valve may include a valve housing have a plurality of ports, wherein in one arrangement at least two of the ports have corresponding center axes lying in offset first and second planes. Correspondingly, the control member may include an internal passageway extending between a plurality of apertures, wherein at least two of the apertures have center axes lying in said offset first and second planes. By selectively rotating the control member, different fluid paths may be established between different ones of the valve housing ports, thereby facilitating closed-path passage of a liquid medication and one or more flush solutions therethrough. In particular, the flush solution(s) and liquid medication may be passed sequentially into the interconnected syringe for subsequent manual administration by medical personnel.

Owner:BAXA CORP

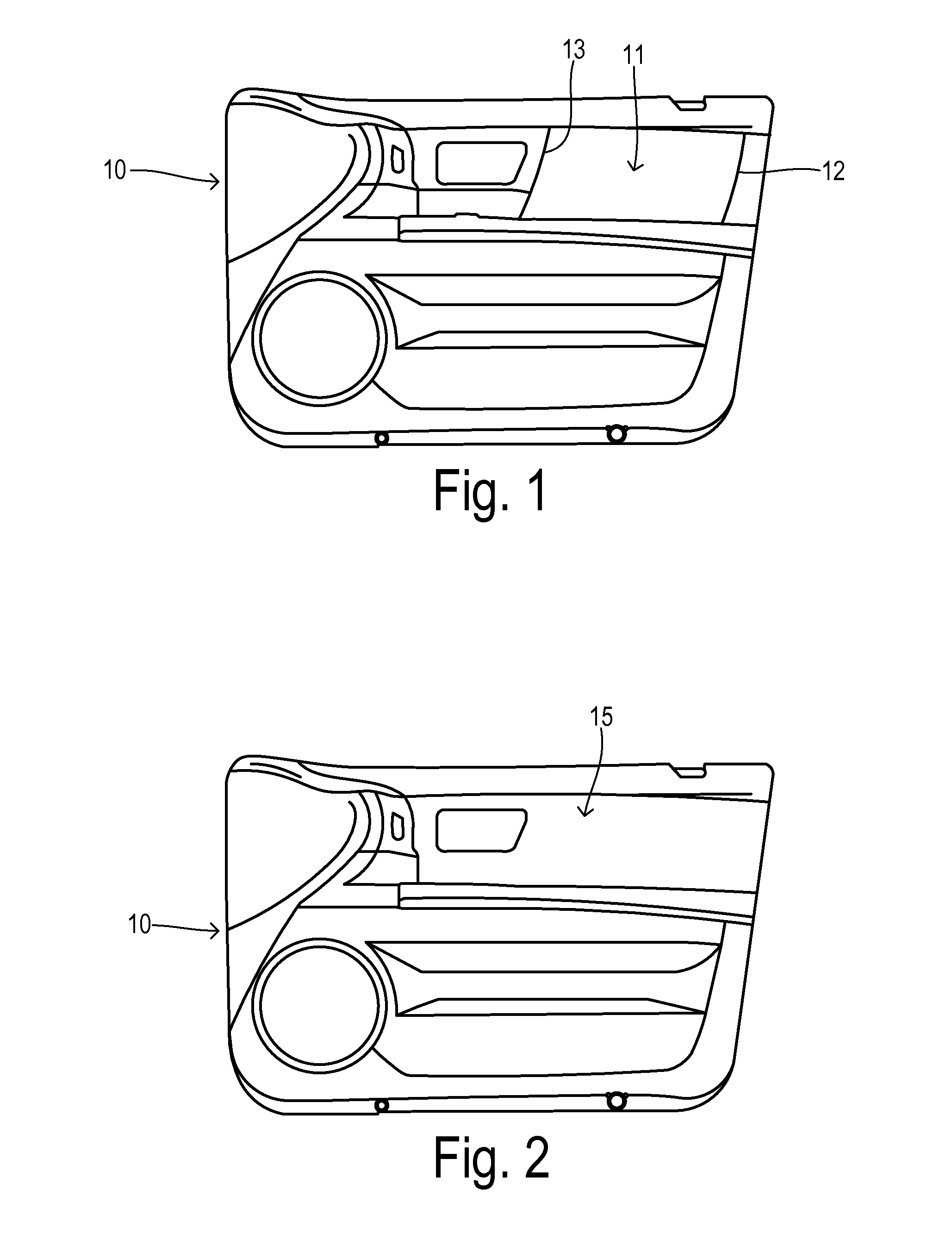

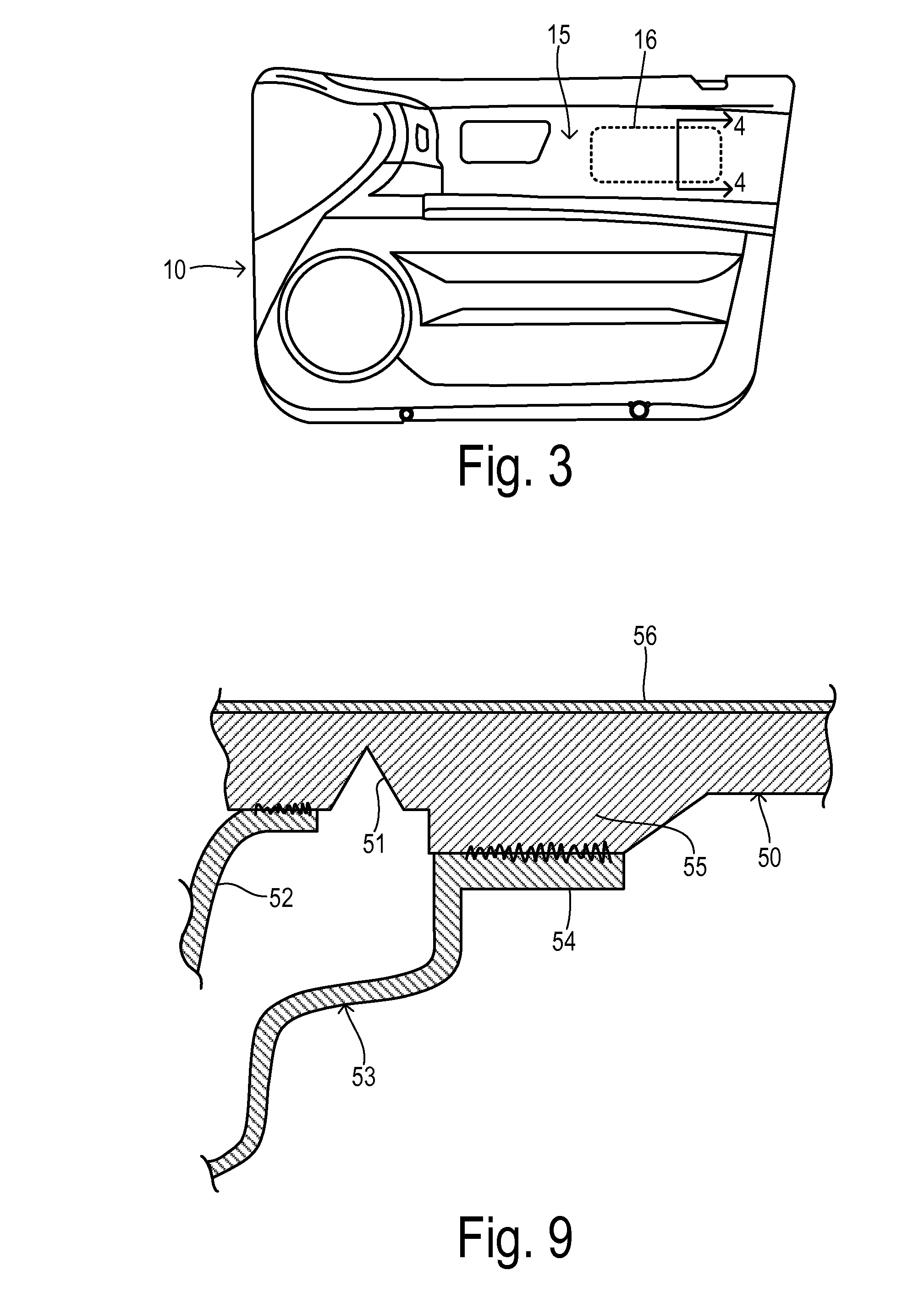

Active bolster with integrated tear seam

An active bolster is provided on an generally-planar interior trim panel. An invisible tear seam in the panel follows a closed path that is spaced away from a peripheral edge of the panel. An inflatable bladder has a rim bonded to the panel along an inward edge of the tear seam. A bowl-shaped reaction frame has a cavity receiving the inflatable bladder and has a rim bonded to the panel along an outward edge of the tear seam, so that the inflatable bladder is contained between the reaction frame and the interior trim panel. Inflation of the inflatable bladder causes the interior trim panel to tear at the tear seam causing the portion of the interior trim panel within the closed path to separate and expand away from the reaction frame into the passenger compartment.

Owner:FORD GLOBAL TECH LLC

Variable stride exercise apparatus

InactiveUS20070087906A1Length of may varyMuscle exercising devicesMovement coordination devicesEngineeringClosed path

A variable stride exercise apparatus is described. A variable stride exercise apparatus may include a frame. A crank system may be coupled to the frame. A foot member may be coupled to the crank system. The foot member may include a footpad. A variable stride system may be coupled to the foot member. The variable stride system and the foot member may be coupled such that at least a portion of the variable stride system is under at least a portion of the footpad. The variable stride system may allow a user of the apparatus to vary the length of the user's stride during use of the apparatus. The foot of the user may travel in a substantially closed path during use of the apparatus. At least a portion of the apparatus may remain substantially stationary during use.

Owner:RODGERS ROBERT E JR

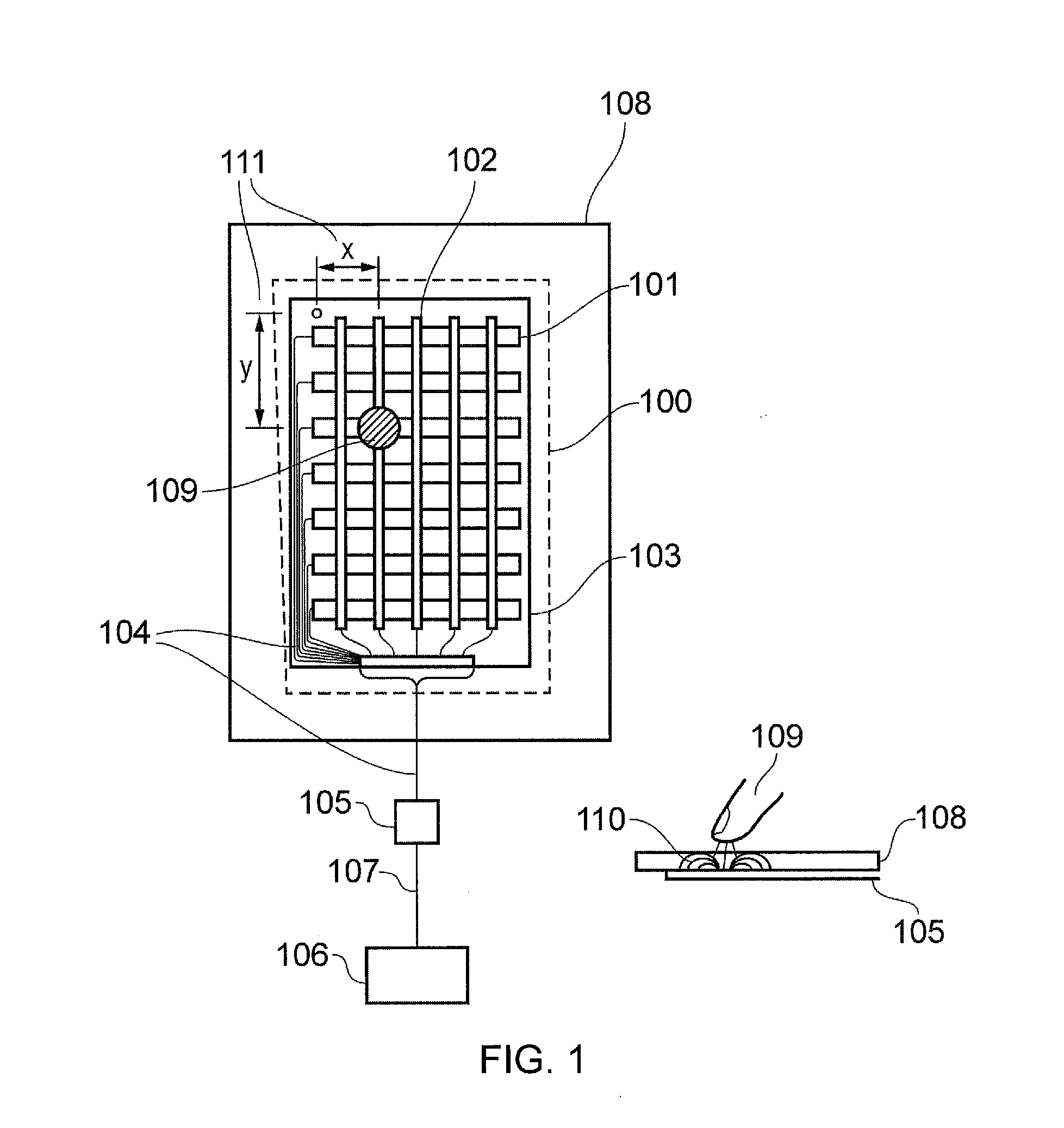

Touch sensors and touch sensing methods

ActiveUS20150242028A1Cathode-ray tube indicatorsInput/output processes for data processingElectrical resistance and conductanceCapacitance

A touch-sensitive position sensor is disclosed. The sensor comprises an array of first electrodes and an array of second electrodes arranged to cross one another in a pattern to define a sensing surface. The sensing surface has a rectangular shape which is formed into a cylinder such that first and second opposing edges of the sensing surface are adjacent one another. A controller is coupled to respective ones of the first electrodes and the second electrodes and arranged to measure changes in an electrical parameter, e.g. capacitance or resistance, associated with the first and second electrodes caused by the presence of the object adjacent the sensing surface. The controller is further operable to determine a reported position for the object from these measurements in a coordinate system defined relative to the electrodes. At least some of the electrodes are arranged to follow paths which are non-linear within the sensing surface such that object positions along a straight line between the first and second opposing edges on the sensing surface correspond with reported positions along a closed curve in the coordinate system defined relative to the electrodes. Thus, a continuous movement around a circumference of the cylindrical sensing surface is reported as a continuous movement around a closed path in the coordinate system defined relative to the electrodes.

Owner:TOUCHNETIX

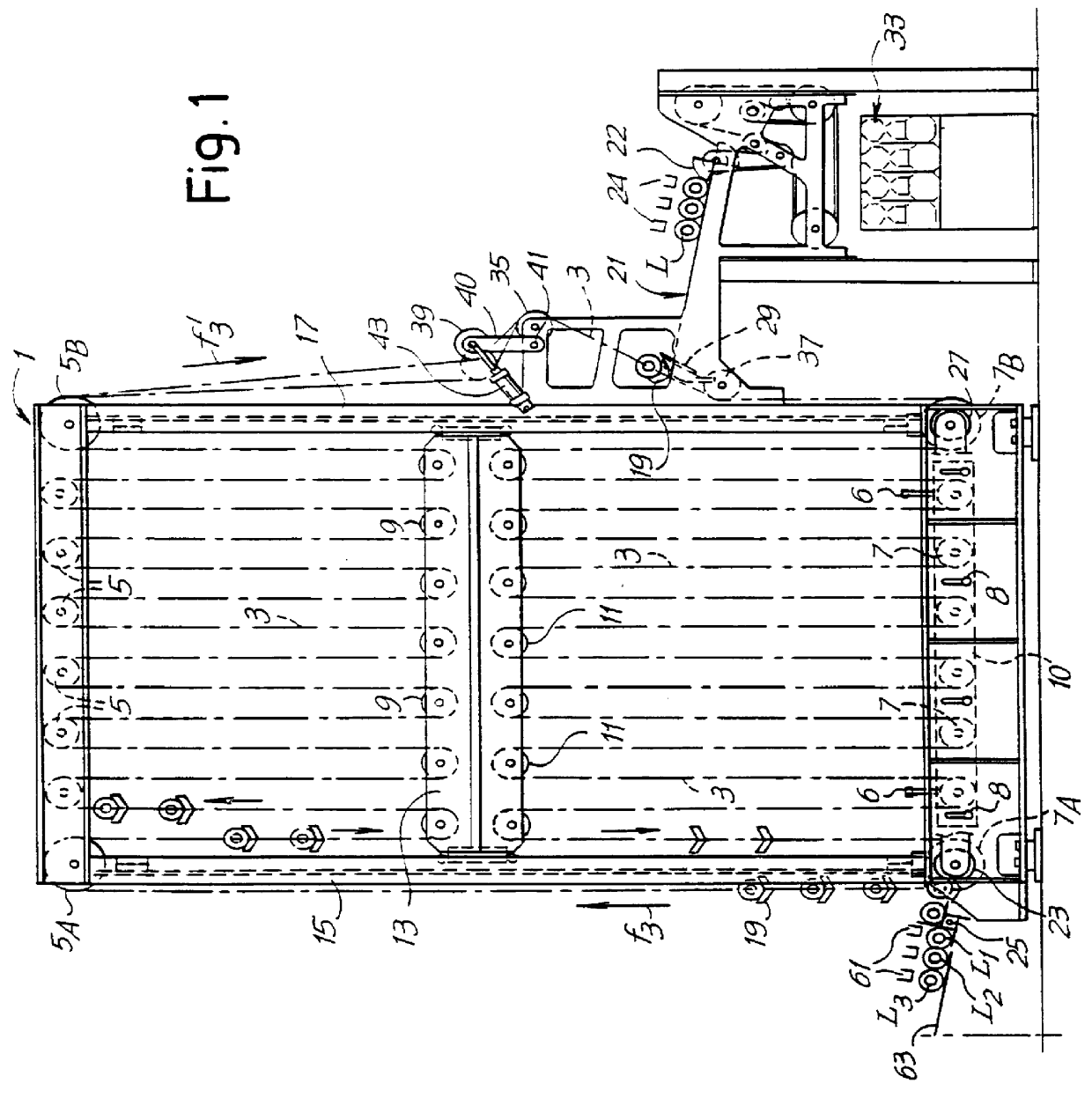

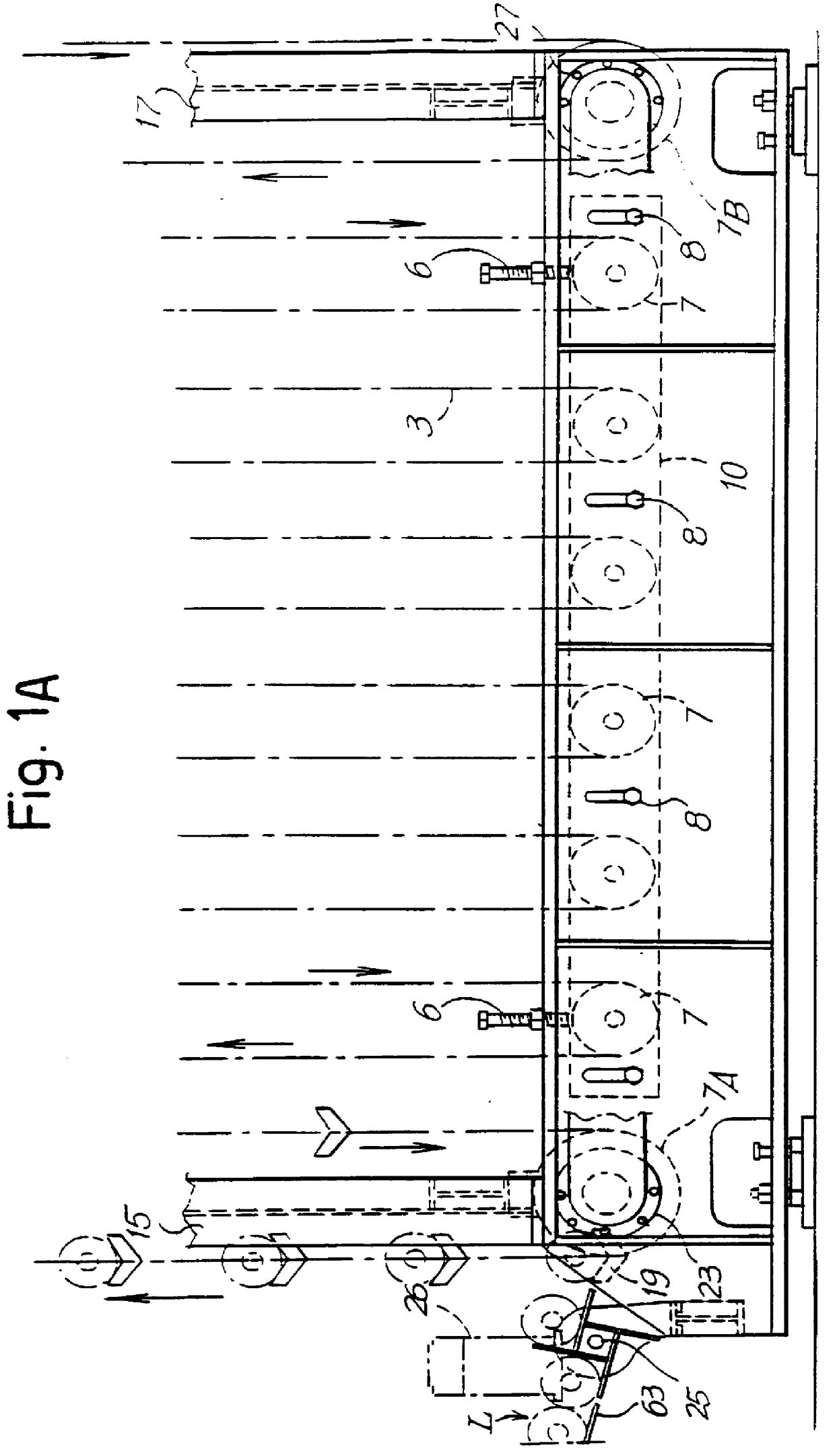

Storage unit with rates of advance dependent on upstream and downstream rates

InactiveUS6053304AReduce mechanical stressEliminate disadvantagesControl devices for conveyorsStorage devicesProduction lineEngineering

PCT No. PCT / IT96 / 00075 Sec. 371 Date Oct. 8, 1997 Sec. 102(e) Date Oct. 8, 1997 PCT Filed Apr. 16, 1996 PCT Pub. No. WO96 / 33114 PCT Pub. Date Oct. 24, 1996A storage unit for the temporary storage of rolls, arranged between a first section and a second section of a production line, is described which includes an endless flexible member defining a closed path within the storage unit and bearing a plurality of seats for the rolls, the seats being subdivided into a first group of empty seats and a second group of full seats; an input feeder for controlled distribution of rolls arriving from the first section to the seats of the first group; an output feeder for controlled discharge of rolls from the seats of the second group toward the second section; a first motor for advancing the seats of the first group toward the input feeder and; a second motor for advancing the seats of the second group toward the output feeder. The first and second motors have first and second independently adjustable continuous speeds, respectively. Further, the first and second motors move the flexible member at a continuous but variable speed. The first and second speeds are dependent on the rate of roll arrival from the first section and the rate of roll request from the second section, respectively.

Owner:FABIO PERINI SPA

Exercise apparatus with automatically adjustable foot motion

An elliptical exercise apparatus includes a frame, a pair of footpads, and a linkage coupling the footpads to the frame and for guiding the footpads in closed paths when a user's feet apply forces to the footpads. The linkage, which includes a rotatable member having an angular position indicative of the positions of the footpads within their closed paths, responds to input control signals by adjusting length and height dimensions of the closed paths. A control system senses the angular position of the rotatable member, senses the forces the user applies to the footpads, and generates the control signals to increase or decrease the path dimensions when it senses particular combinations of angular position and user forces, thereby permitting the user to control the path dimensions by controlling the forces applied to the footpads.

Owner:MARESH JOSEPH D +1

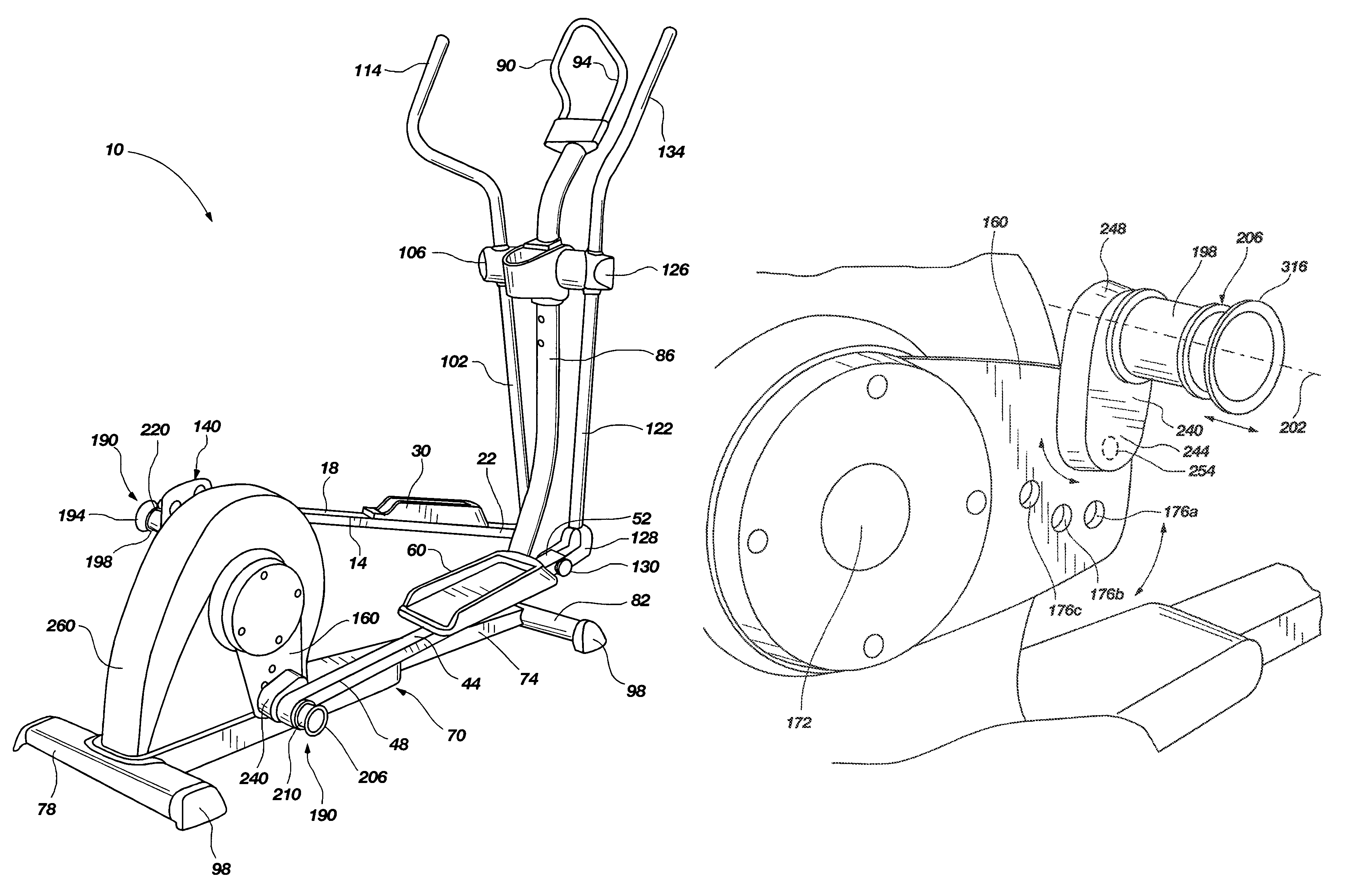

Foldable elliptical exercise machine

ActiveUS20060287161A1Easy to foldSpace saving gamesMovement coordination devicesEllipseFoot supports

An elliptical exercise machine comprising a base support structure having a front portion, a rear portion, and a pivot joint comprising a pivot mechanism configured to pivotally connect the front and rear portions, the pivot mechanism being configured to facilitate a breakaway of the base support and an upward rotation of the rear portion with respect to the front portion, thereby enabling the elliptical exercise machine to fold into a compact configuration; an upright support structure extending upward with respect to the base support structure; a drive assembly operably supported about the rear portion of the base support structure and comprising a drive component configured to rotate about a pivot axis; and a reciprocating foot support operable with the drive assembly and configured to travel about a closed path upon rotation of the drive component and operation of the elliptical exercise machine. In a preferred embodiment, the reciprocating foot support is configured to releasably engage the drive component, thereby allowing the rear portion to fold upward and the reciprocating foot support also to be folded upward and out of the way.

Owner:IFIT INC

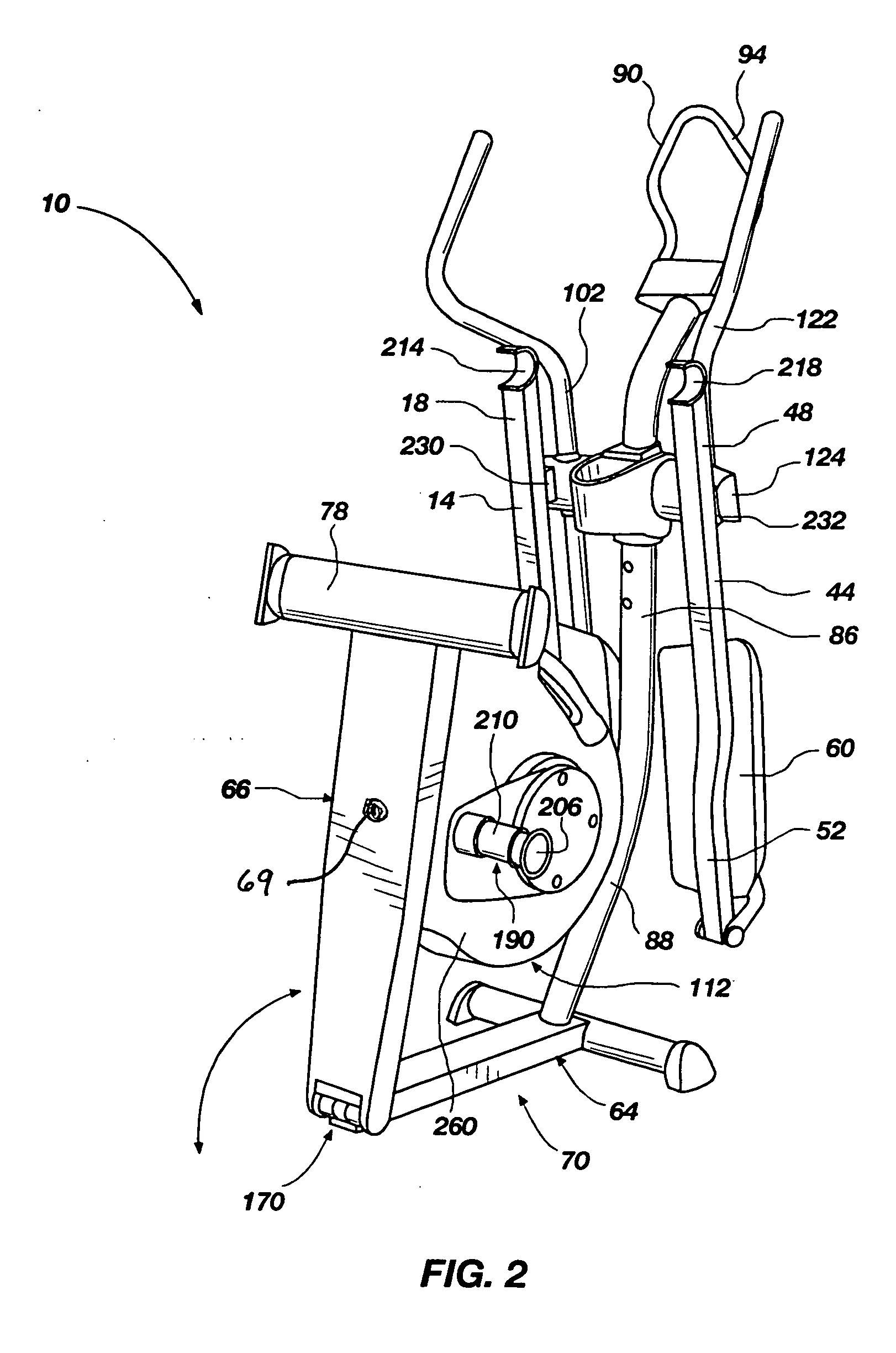

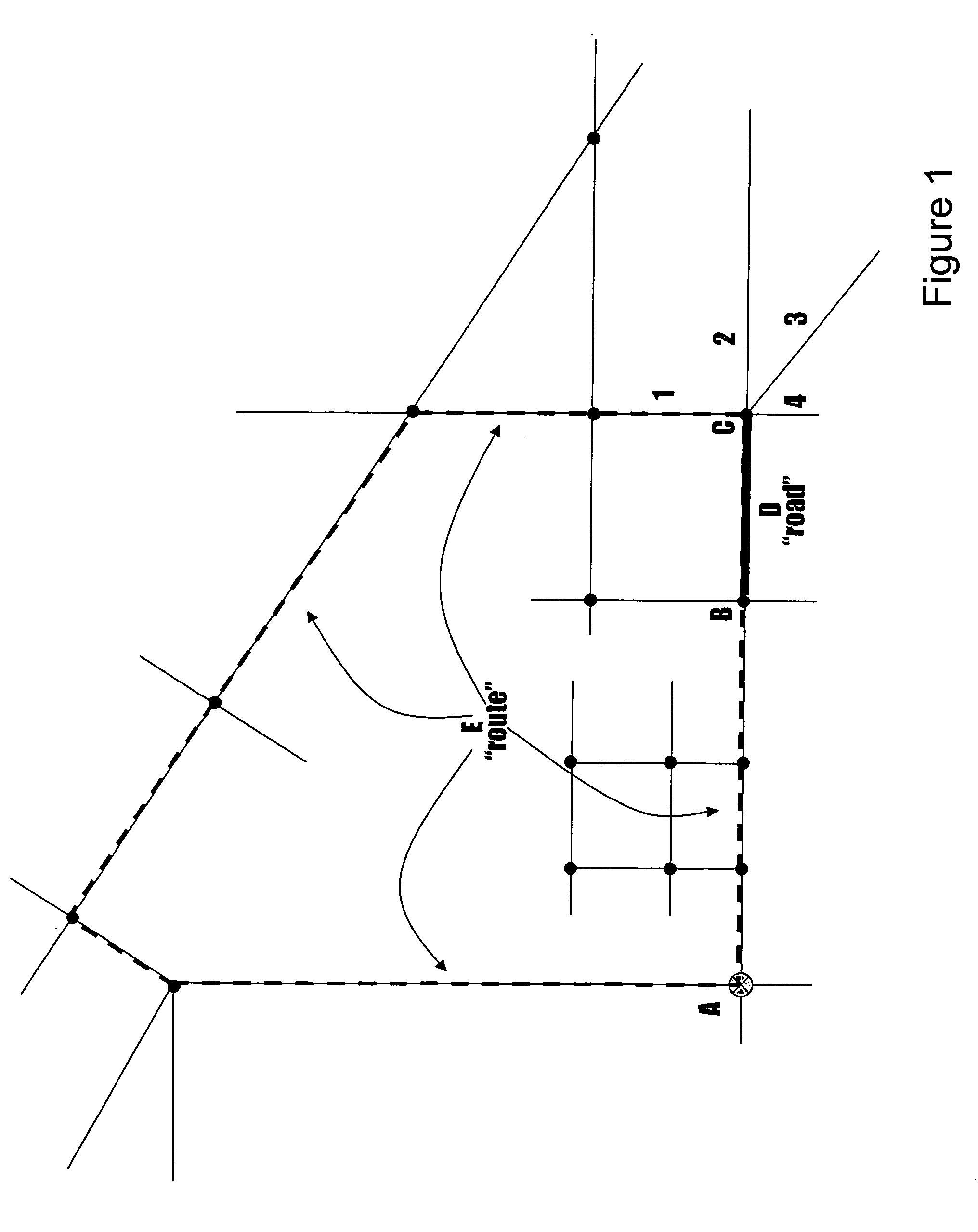

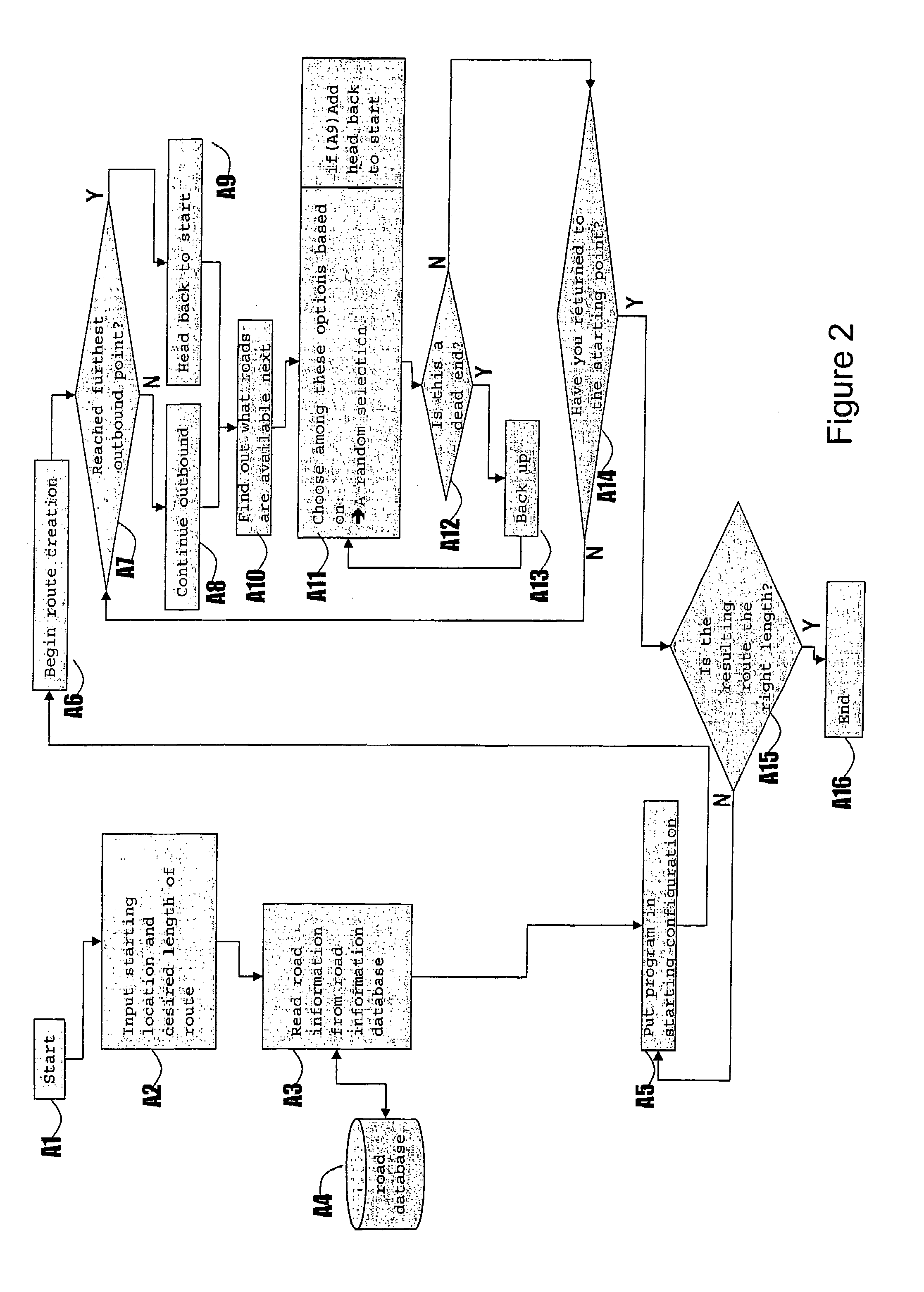

Travel route mapping

ActiveUS7162363B2Instruments for road network navigationRoad vehicles traffic controlComputer scienceGeographic information system

A method and system for providing a closed route for travel features a database having geographic information and input information including a starting point and a desired route length. The geographic information from the database and the input information are processed to define an outbound path from the starting point to a turning point, the turning point determined based on the desired route length, and to define an inbound path from the turning point to the starting point, the outbound path and the inbound path together defining the closed route. A representation of the closed route may be output as a static map, interactive map or a turn-by-turn listing.

Owner:CHINITZ LEIGH M

Start-up method for ex-situ prevulcanization secondary activity center hydrogenation catalyst

ActiveCN103773436AChange processLess investmentHydrotreatment operations starting-upHydrocarbon oil crackingNaphthaEngineering

The invention discloses a start-up method for an ex-situ prevulcanization secondary activity center hydrogenation catalyst. After resistance to air loss of a device is qualified, circulating hydrogen compressor working load is adjusted to 0-20% of a maximum load, the catalyst reacts at a low temperature to release heat; when the bed layer temperature rise to 60-150 DEG C, start-up activation oil is introduced, the circulating hydrogen compressor working load is adjusted to 60-100% of the maximum load for wetting of the catalyst; the start-up activation oil is cycled in a reaction system closed path, the catalyst bed temperature is risen to 180 to 230 DEG C by heat exchange; a proper amount of olefin-enriched naphtha is added into the start-up activation oil, the catalyst bed temperature is risen to 300-380 DEG C to complete start-up activation. The start-up method, in the premise of no influence on the use properties of the secondary activity center hydrogenation catalyst, can better use the catalyst characteristics, reduce the device energy consumption, and reduce the device investment cost, and the start-up process can be simplified.

Owner:CHINA PETROLEUM & CHEM CORP +1

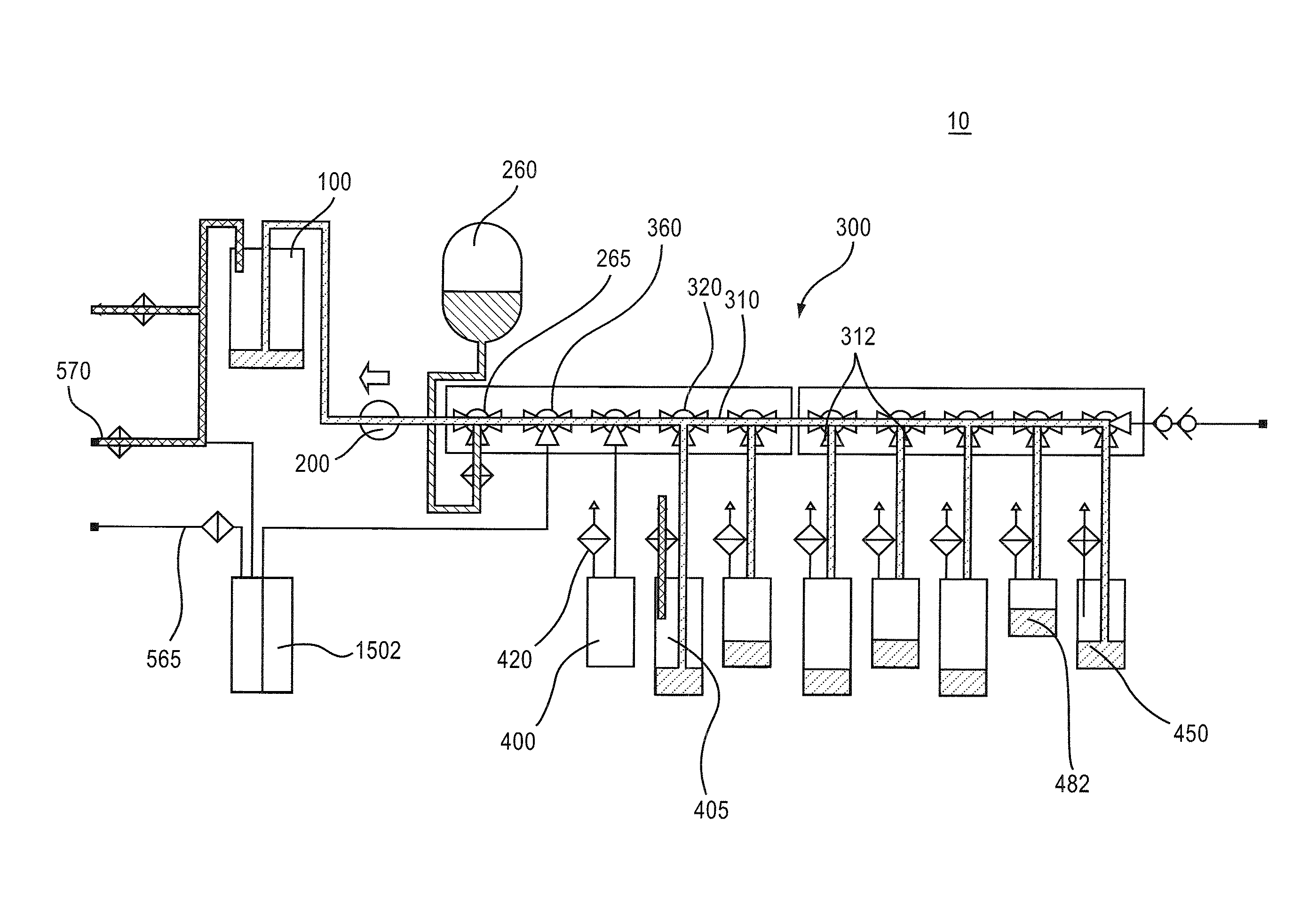

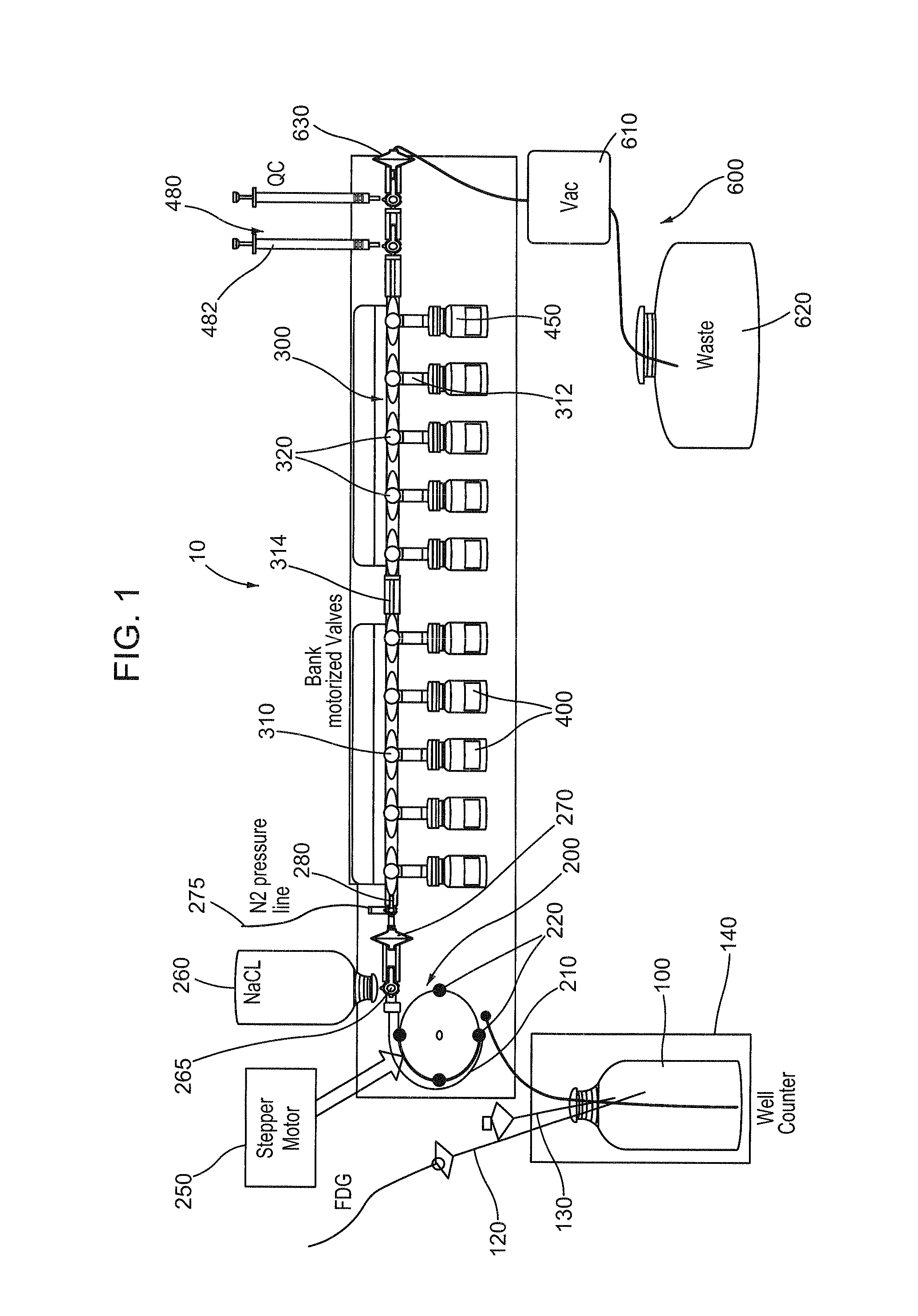

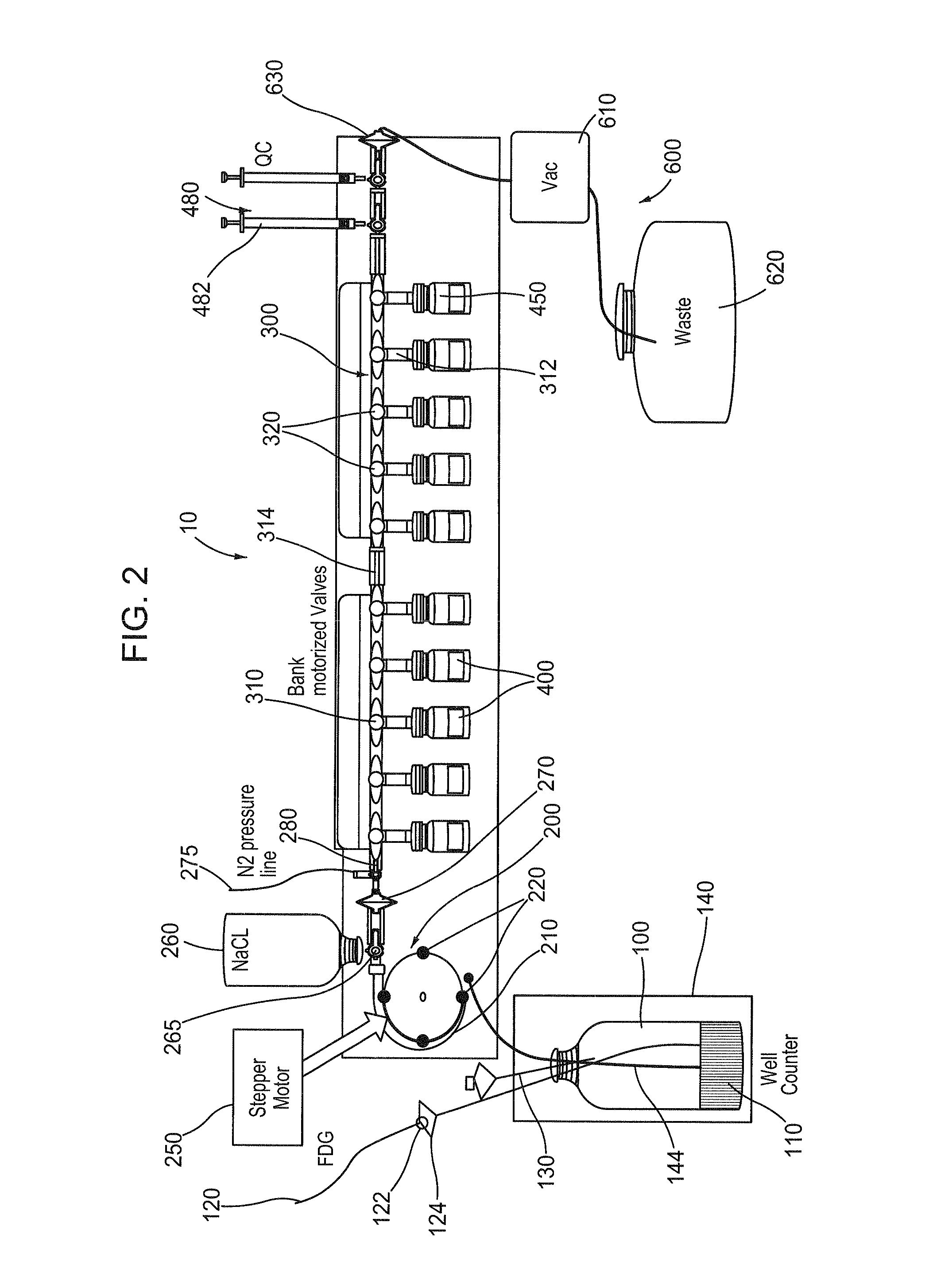

Closed vial fill system for aseptic dispensing

A closed path vial fill system includes a bulk product vial, a peristaltic pump operated by a stepper motor, a dispensing manifold assembly to which may be coupled at least one final product vial, an optional quality check station, and an optional waste collection system. A concentration, activity, and volume (CAV) sensor may be incorporated into the system to receive a radiopharmaceutical product directly from a synthesizing unit. A control system may be integrated into the system to provide automated control of various aspects of the radiopharmaceutical dispensing process. The system is used to aseptically dispense finished radiopharmaceuticals into receiving vessels, such as a Quality Control vial, a sterility vial, and / or final product vials, while providing users an efficient means for removing and discarding contaminated disposable components.

Owner:CARDINAL HEALTH INC

Cross training exercise device

InactiveUS20060281604A1Frictional force resistorsMovement coordination devicesFoot supportsEngineering

An exercise device includes a frame, first and second foot links, first and second foot supports, a coupling system and a guide system. Each foot link has a first portion and a second portion. The first and second foot supports are carried by the first and second foot links, respectively. The coupling system is associated with the first portion of each foot link for coupling the first portion to the frame so that the first portion of each foot link travels in a closed path relative to the frame. The guide system supports the second portions along a preselected reciprocating path of travel as the first portions of the respective foot links travel along their paths of travel. The guide system is selectably positionable at an angle from horizontal within the range of 45 degrees to 75 degrees.

Owner:PRECOR

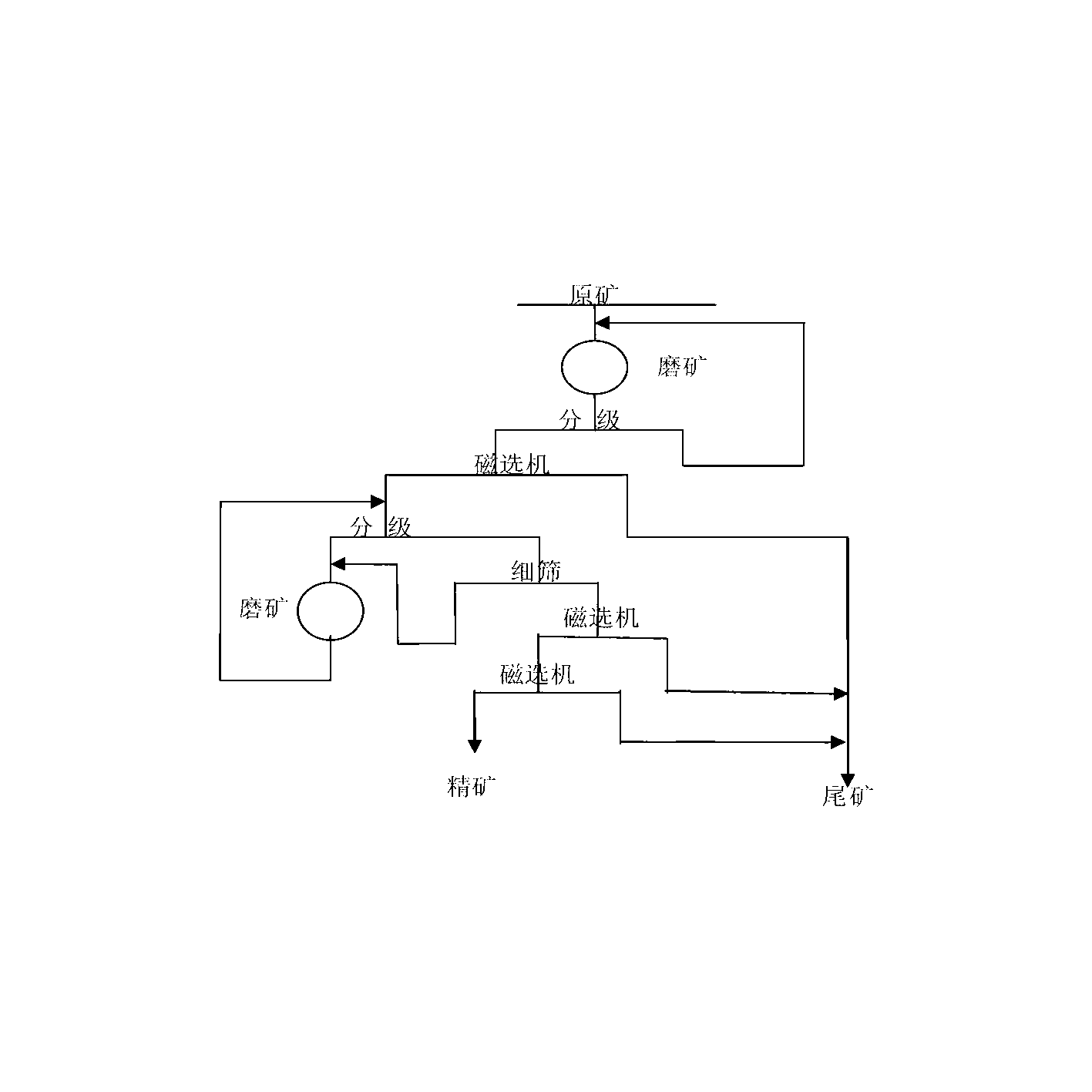

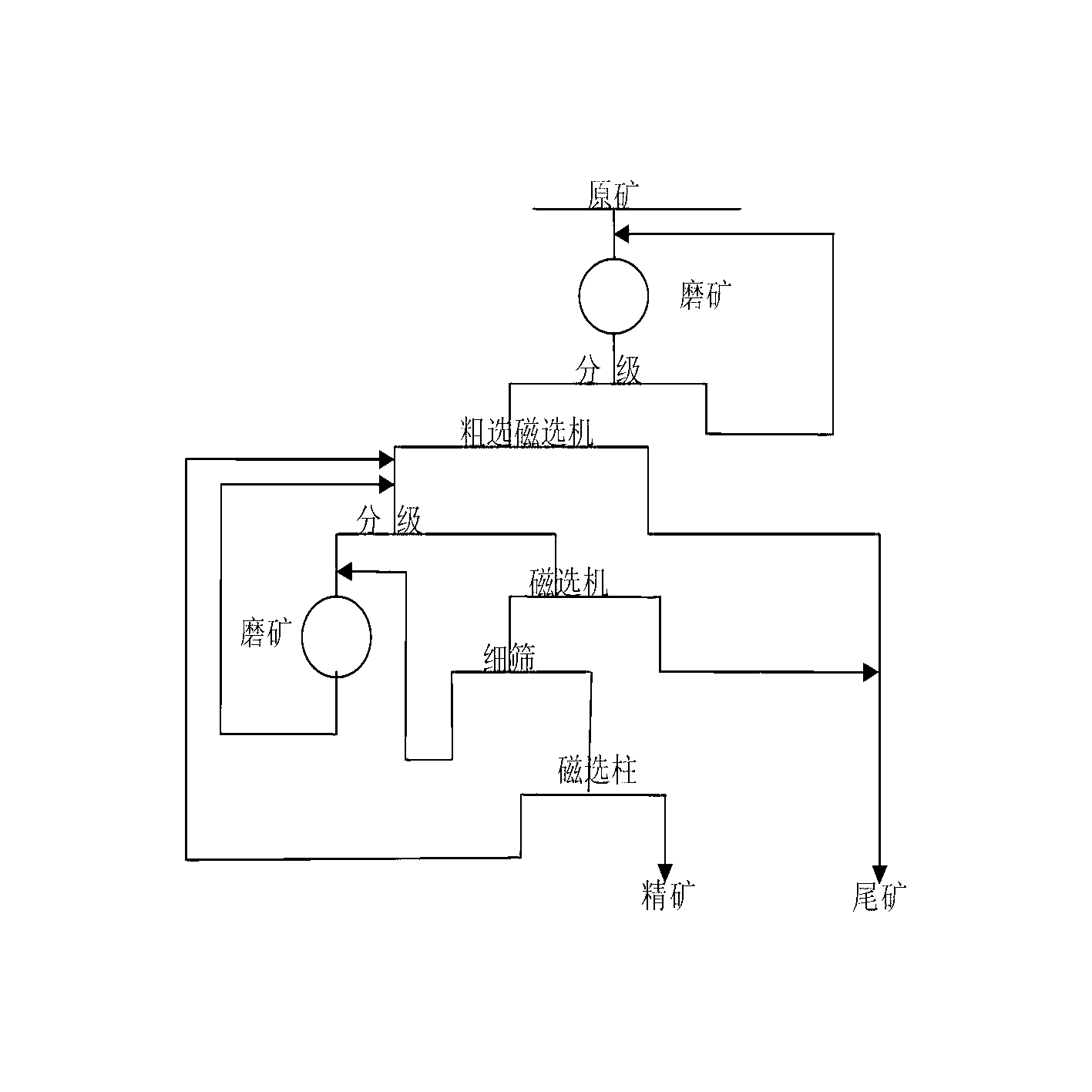

Ore dressing technology for treating vanadium titano-magnetite

ActiveCN102698871AReduce the amount of oreReduce processingMagnetic separationGrain treatmentsResource utilizationMagnetite

The invention relates to an ore dressing technology for treating vanadium titano-magnetite. The technology comprises the following steps of: feeding crushed raw ore into a ball mill in a primary milling and grading closed path, and feeding primary graded overflow containing 40 to 50 percent of milled powder with the granularity of 200 meshes into a rough magnetic separator, wherein tailings in the rough magnetic separator are final tailings; demagnetizing the concentrate in the rough magnetic separator, then feeding for secondary grading, feeding secondary graded return sand into a secondary ball mill, returning the discharged ore in the secondary ball mill for grading, and feeding secondary graded overflow containing 65 to 95 percent of milled powder with the granularity of 200 meshes into a magnetic separator, wherein the tailings in the magnetic separator are final tailings; and demagnetizing the concentrate in the magnetic separator, then feeding into a high-frequency vibrating mesh fine screen, returning the ore on the high-frequency vibrating mesh fine screen to the ball mill, feeding the powder below the fine screen into a magnetic separation column, and returning middling in the magnetic separation column for secondary grading, wherein the concentrate in the magnetic separation column is used as final concentrate. The technology has the advantages of effectively improving the grade and the recovery rate of the vanadium titano-magnetite, reducing the ore dressing energy consumption, improving the utilization rate of resources and reducing the production cost.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com