Patents

Literature

62results about How to "Compact profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

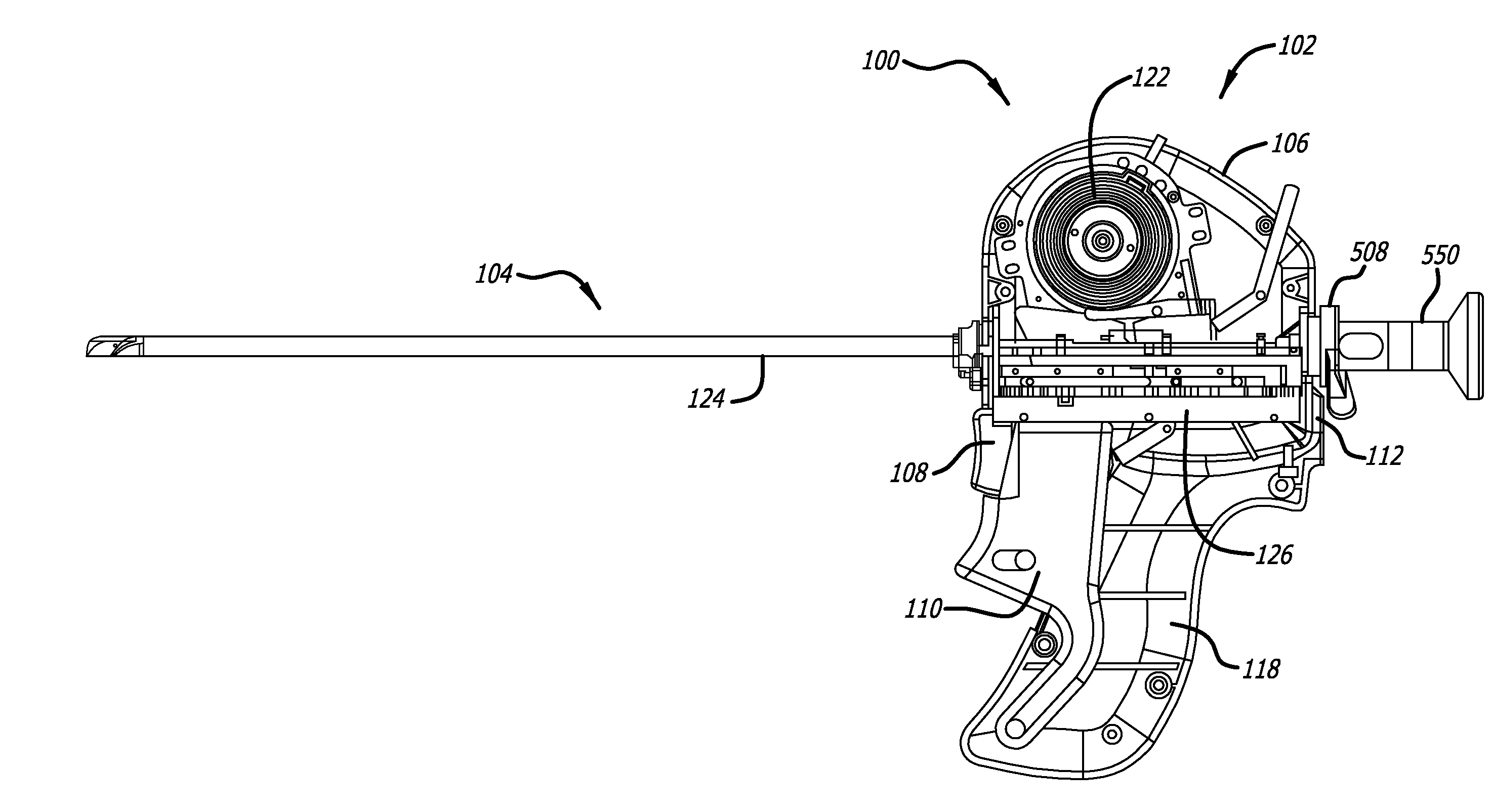

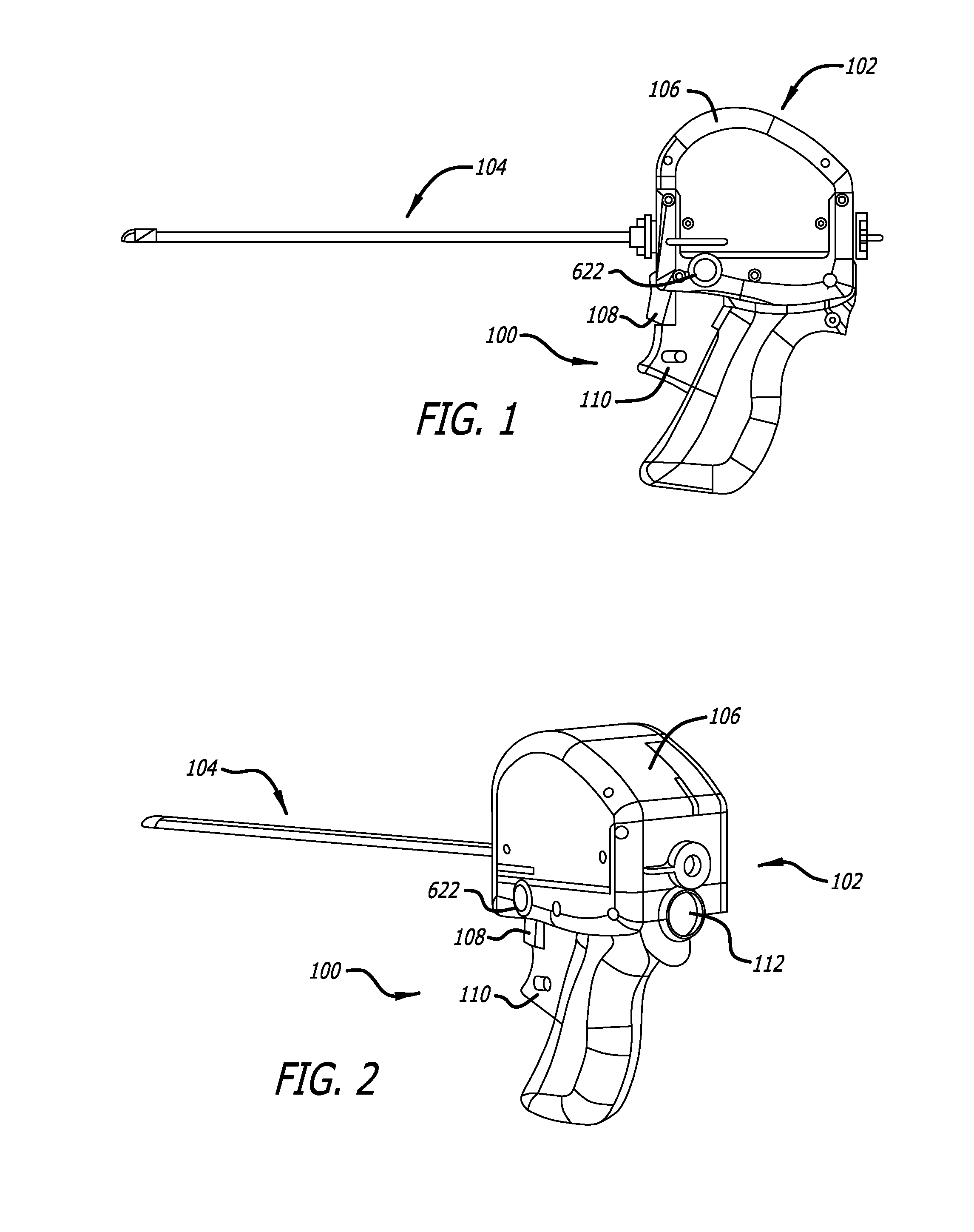

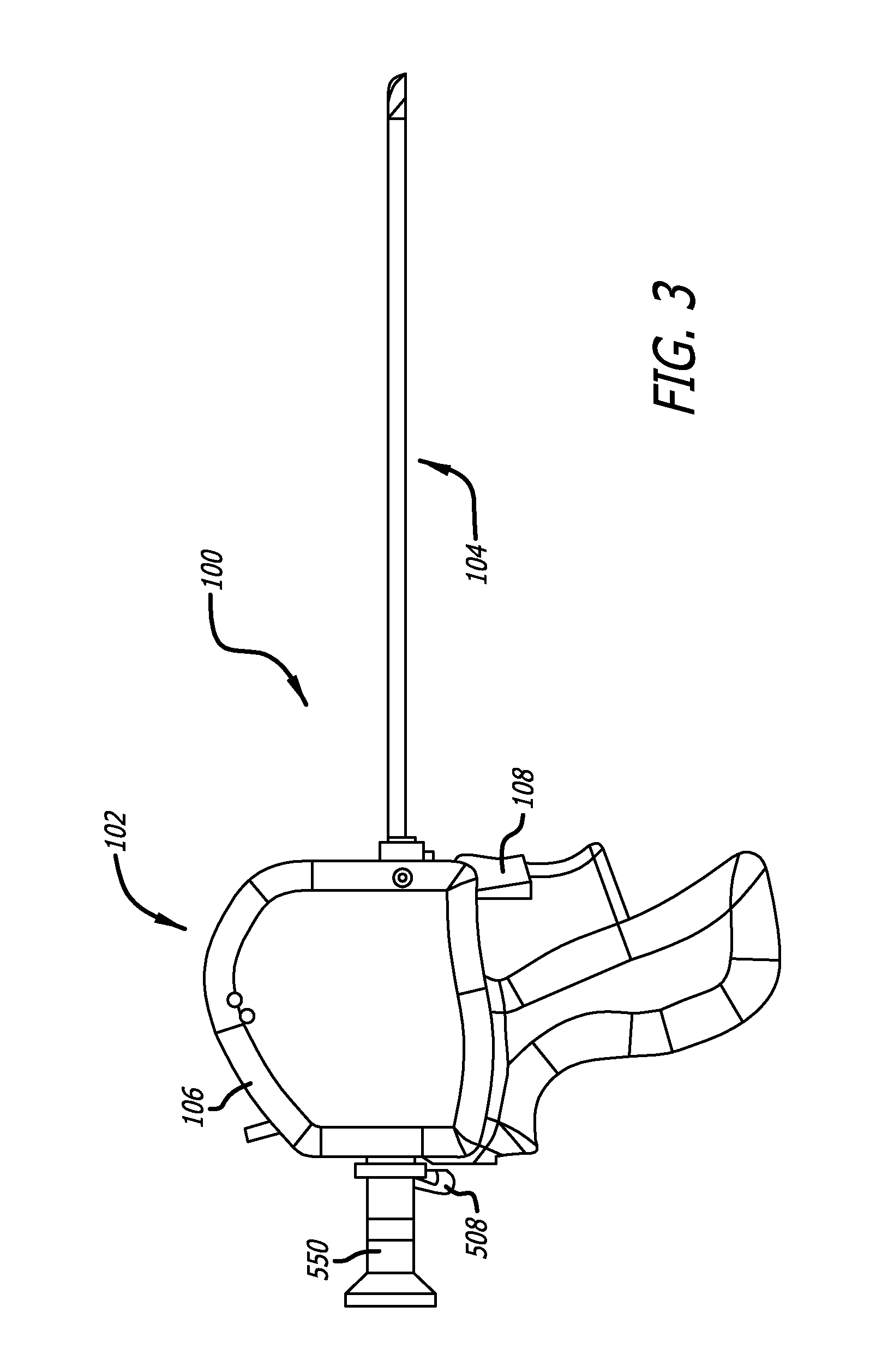

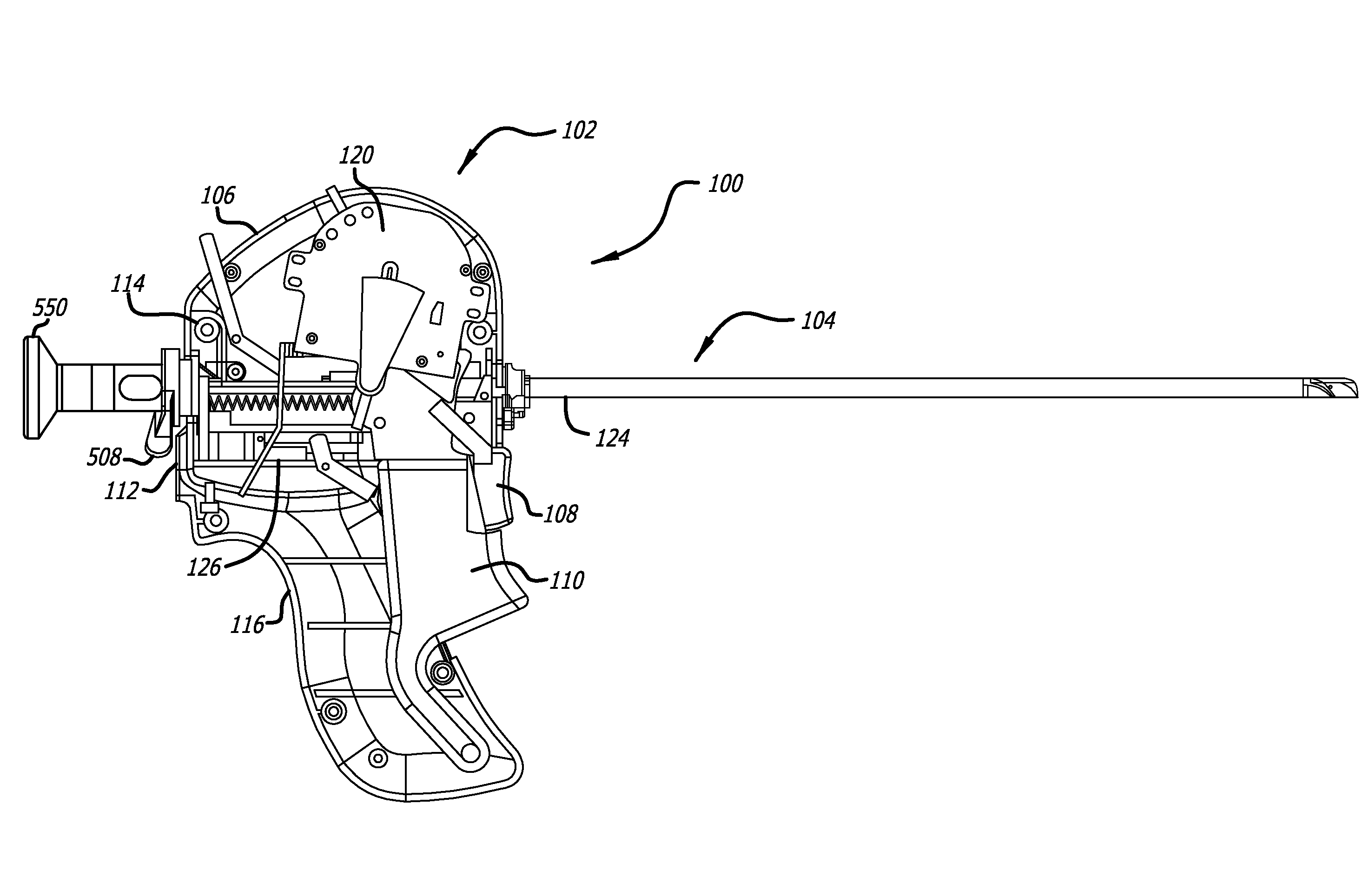

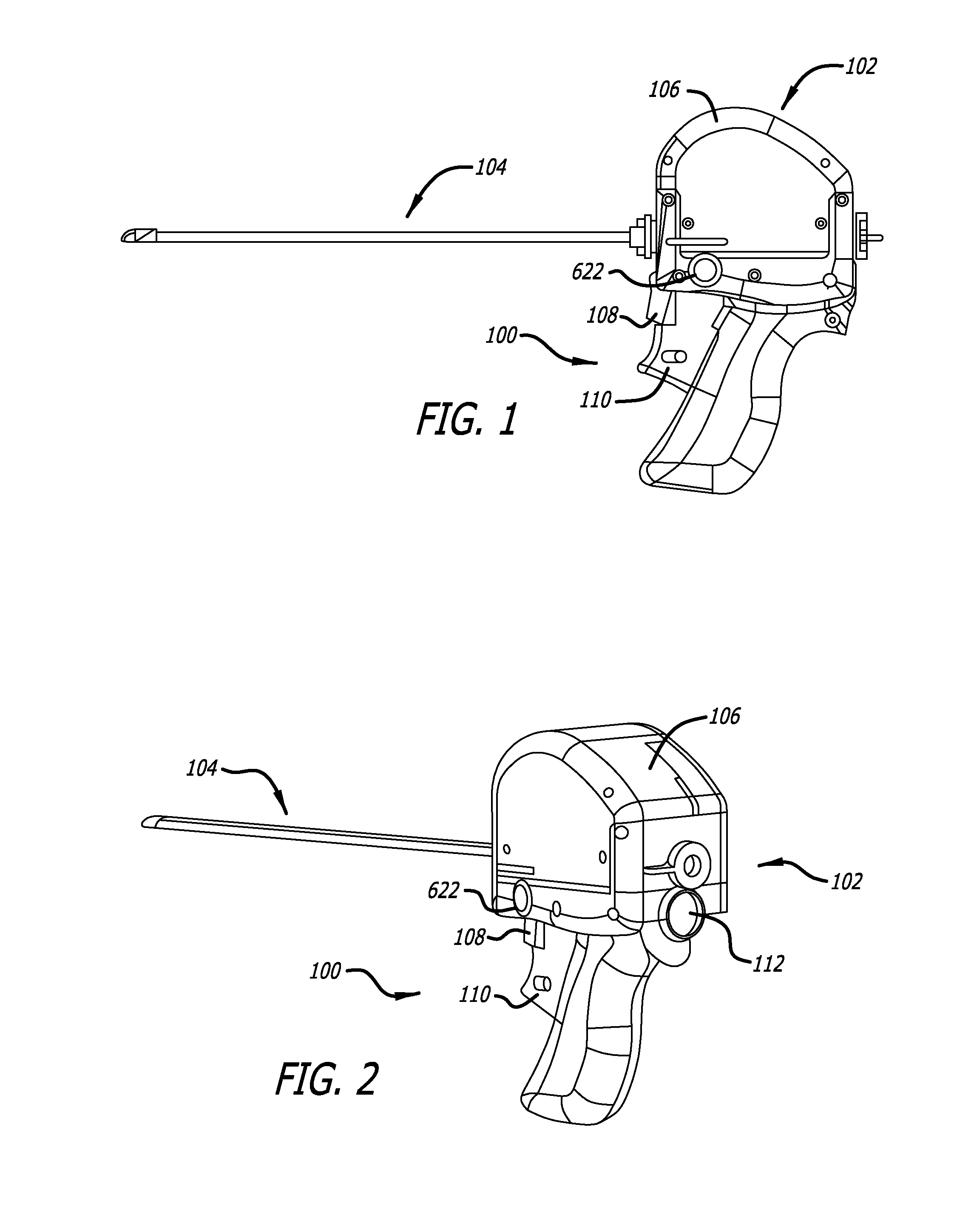

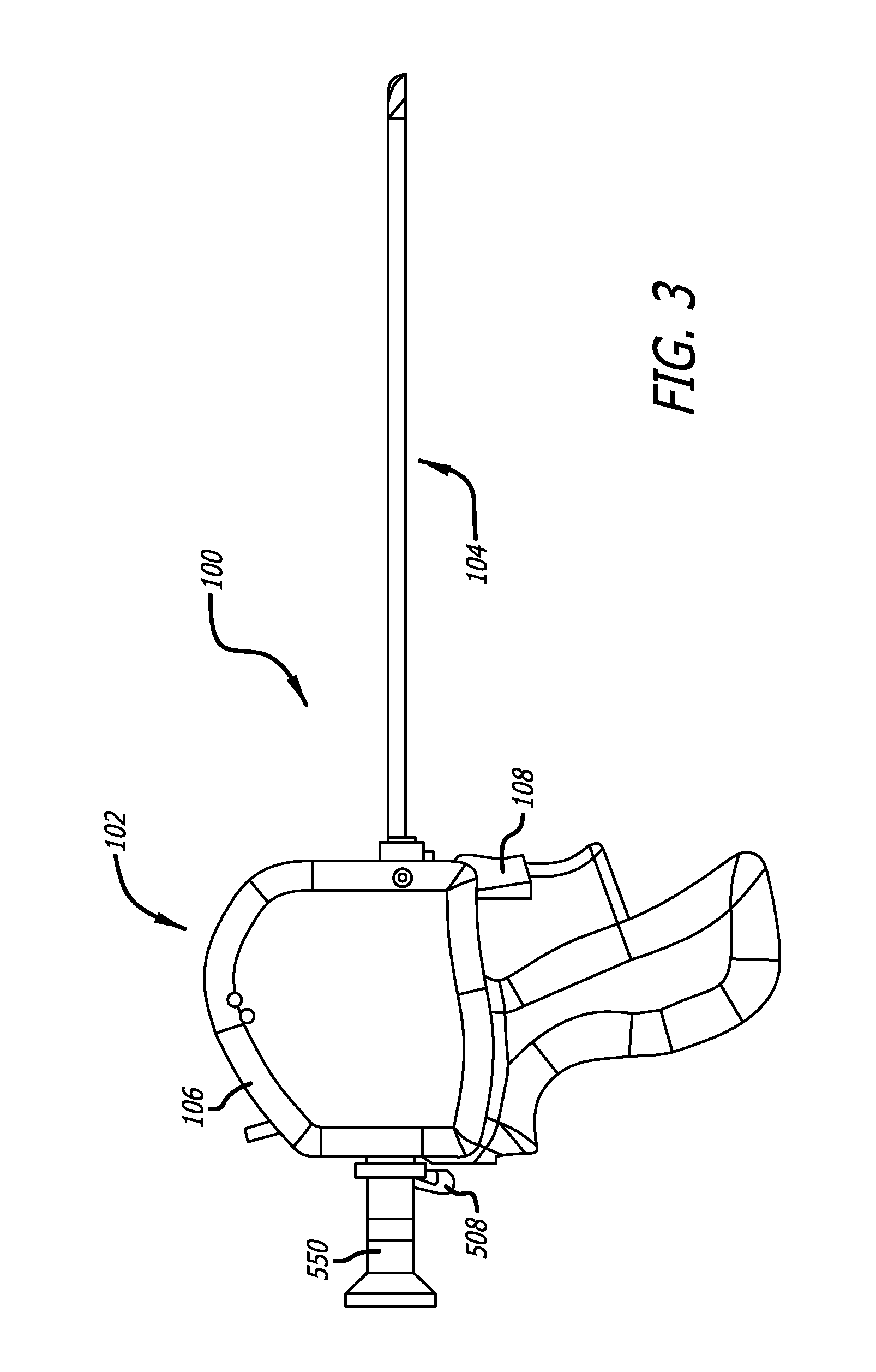

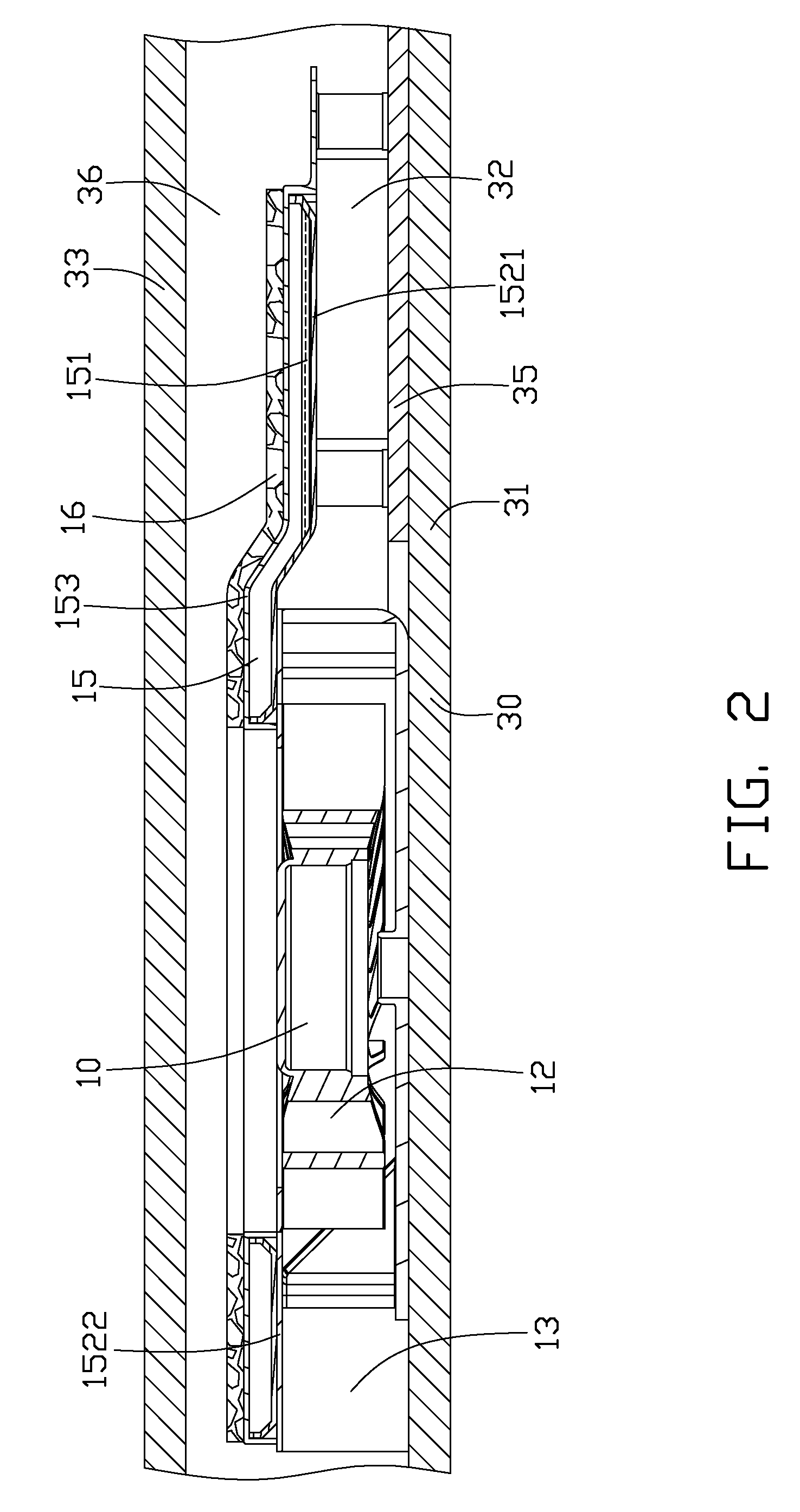

Anchor delivery system with replaceable cartridge

ActiveUS20100030262A1Convenience to mergeSufficient visibilitySuture equipmentsSurgical needlesDiseaseDelivery system

A system and associated method for manipulating tissues and anatomical or other structures in medical applications for the purpose of treating diseases or disorders or other purposes. In one aspect, the system includes a delivery device configured to deploy and implant anchor devices for such purposes.

Owner:TELEFLEX LIFE SCI LTD

Anchor delivery system with replaceable cartridge

ActiveUS8216254B2Convenience to mergeSufficient visibilitySuture equipmentsSurgical needlesDiseaseDelivery system

A system and associated method for manipulating tissues and anatomical or other structures in medical applications for the purpose of treating diseases or disorders or other purposes. In one aspect, the system includes a delivery device configured to deploy and implant anchor devices for such purposes.

Owner:TELEFLEX LIFE SCI LTD

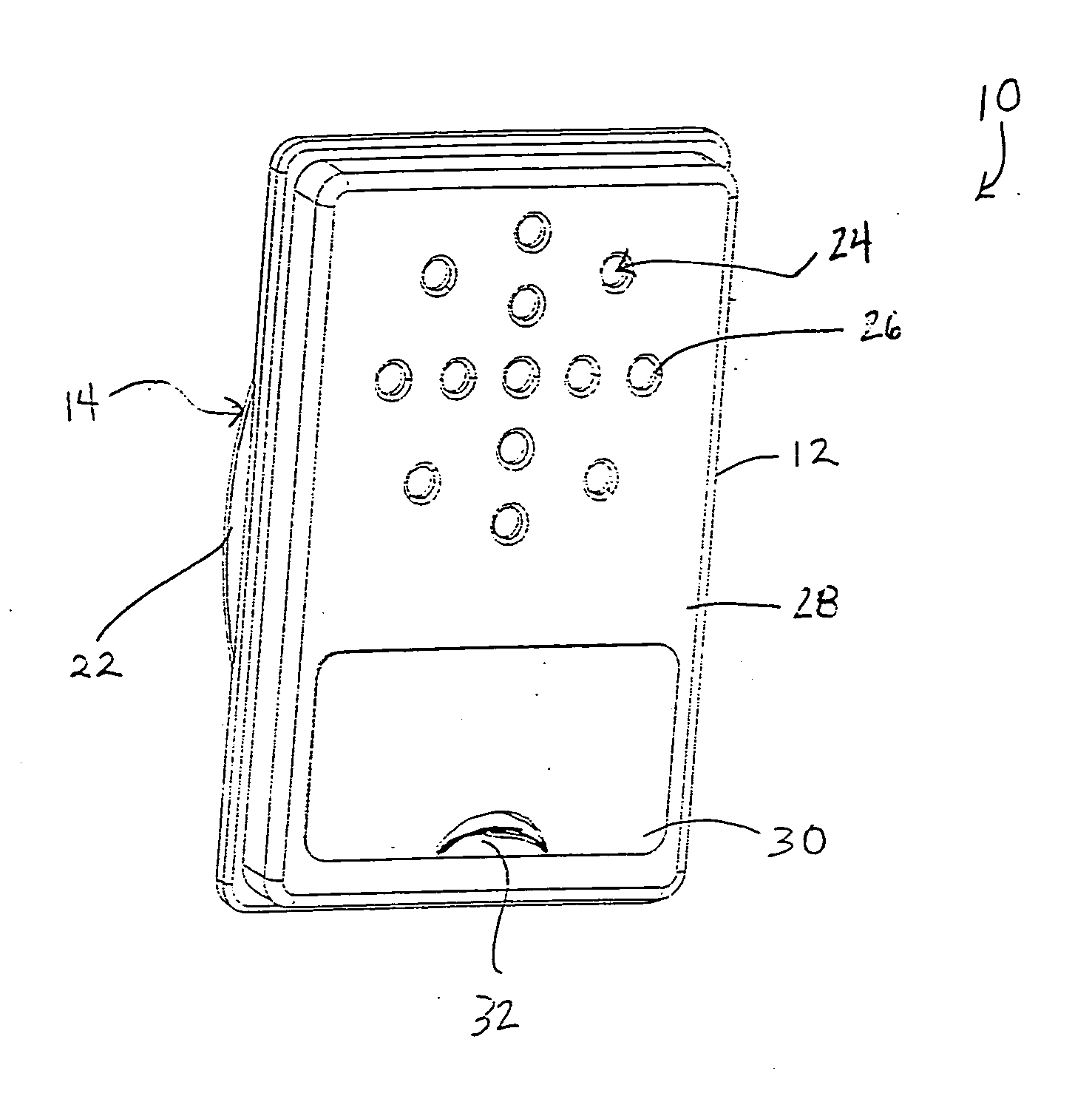

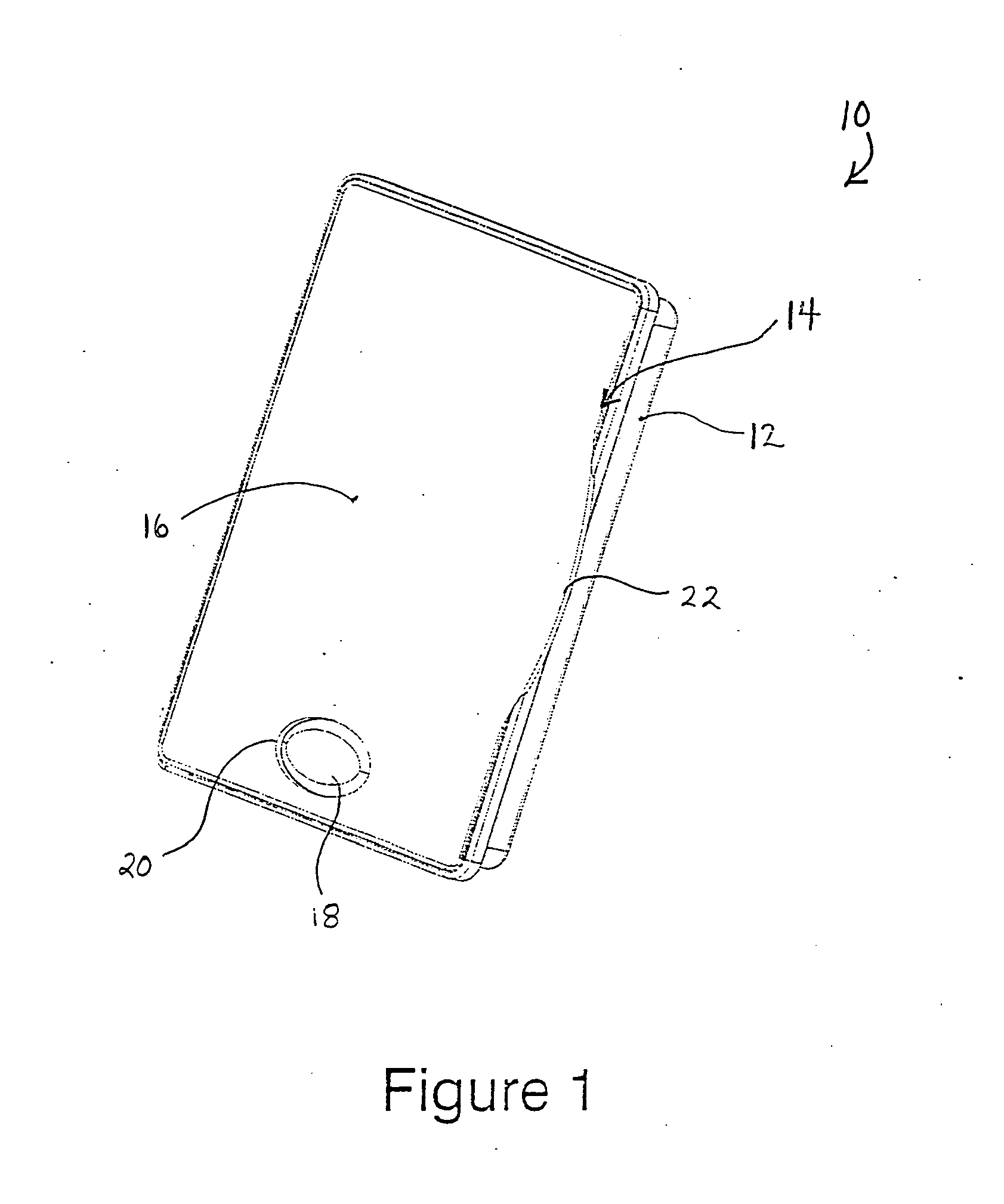

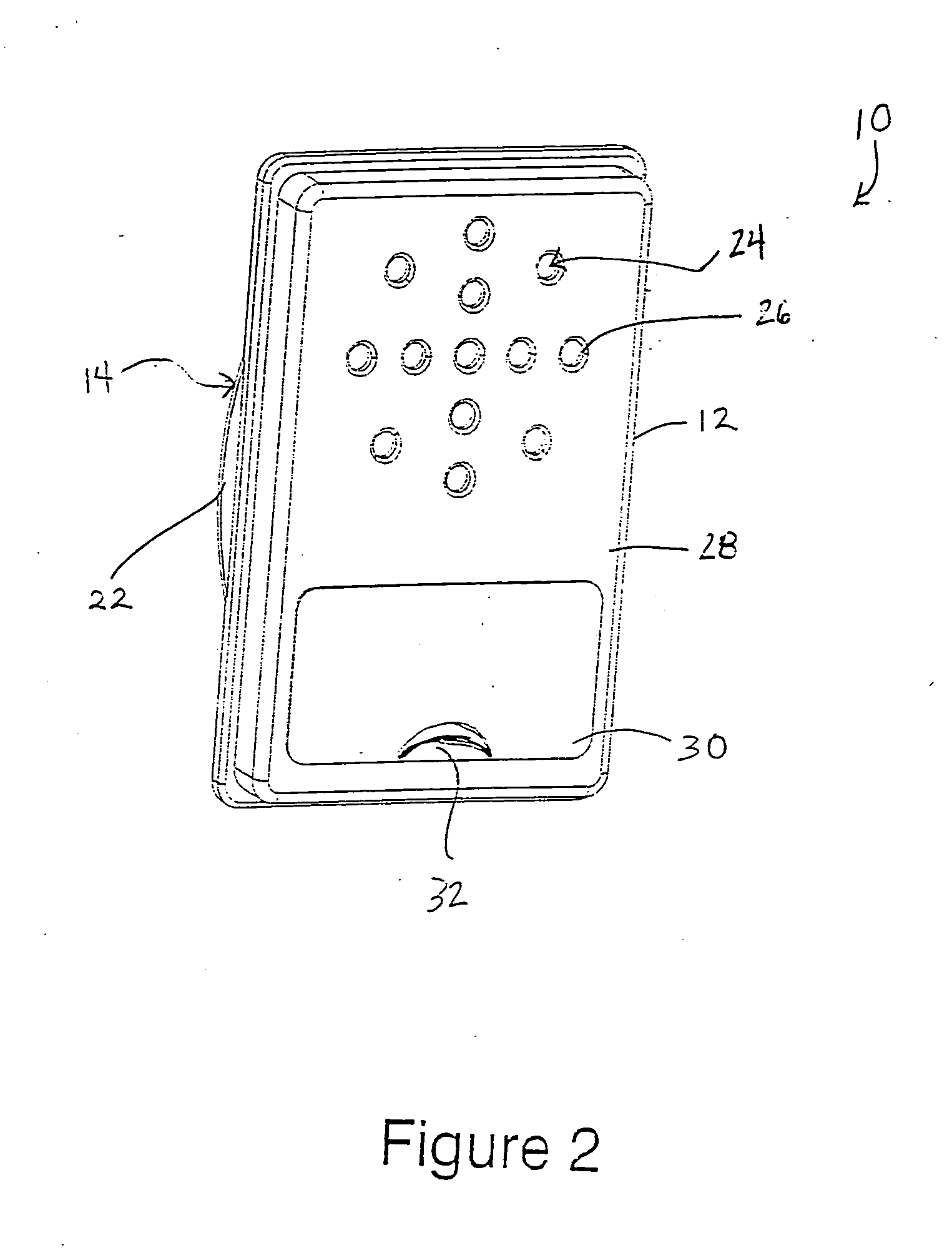

Pocket-size talking card or pamphlet device and packages containing the same

InactiveUS20070210147A1Patient compliance is goodEasy to packData processing applicationsDrug and medicationsElectricityElectronic form

A talking card device includes a support member comprising a printed portion viewable by the consumer, an electronic storage element operatively engaged to the support member, wherein the electronic storage element is adapted to store an audio communication relating to the article of manufacture in an electronic form, and an audio assembly component electronically connected to the storage element, and configured to receive the electronic form of the audio communication upon actuation of a consumer operable switch, wherein electronic form of the audio communication is converted into an audio form for the consumer to hear. The printed information and audio communication may be coordinated to provide comprehensive information to the consumer about the article of manufacturer.

Owner:PHARMADESIGN INC

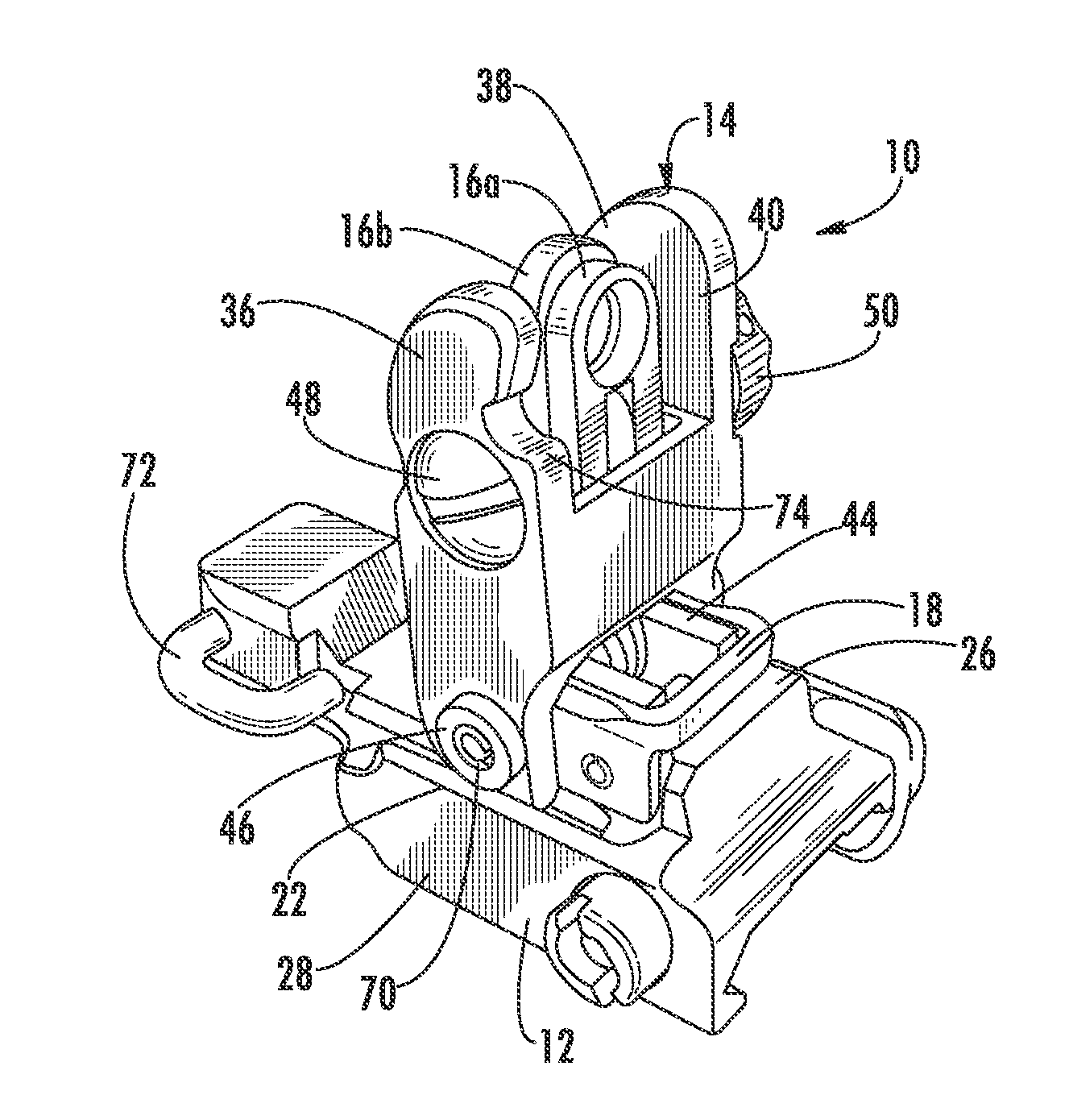

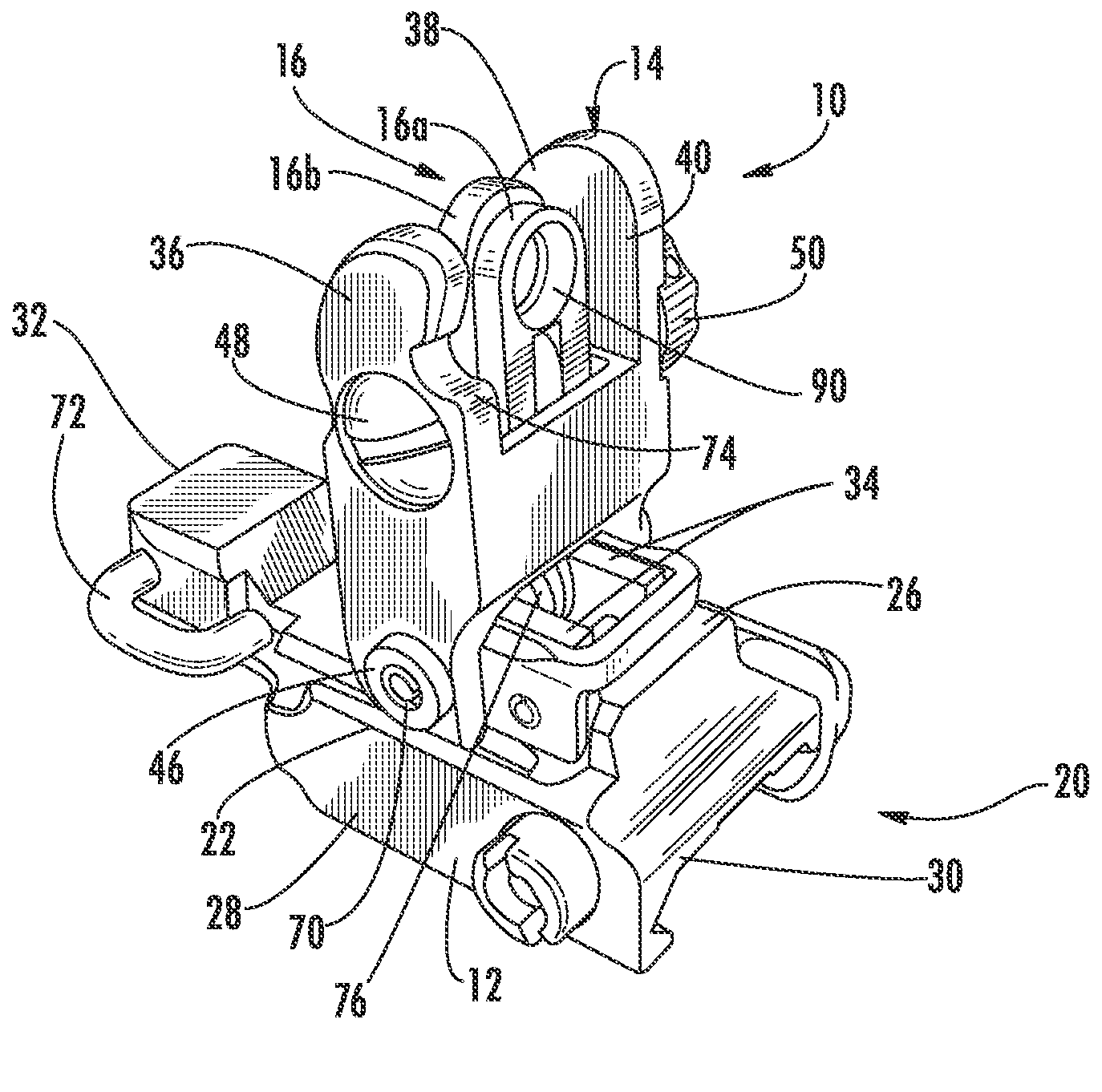

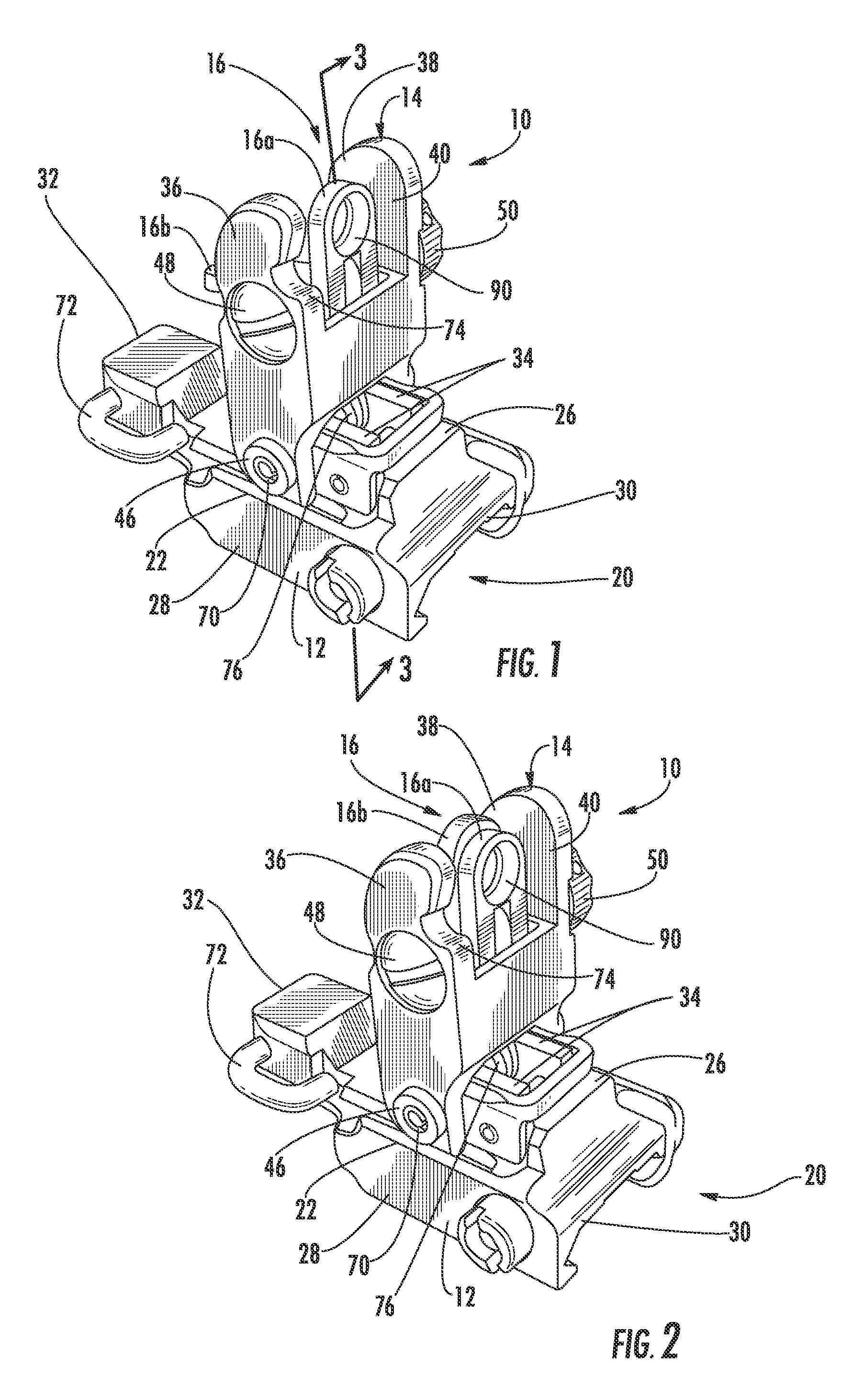

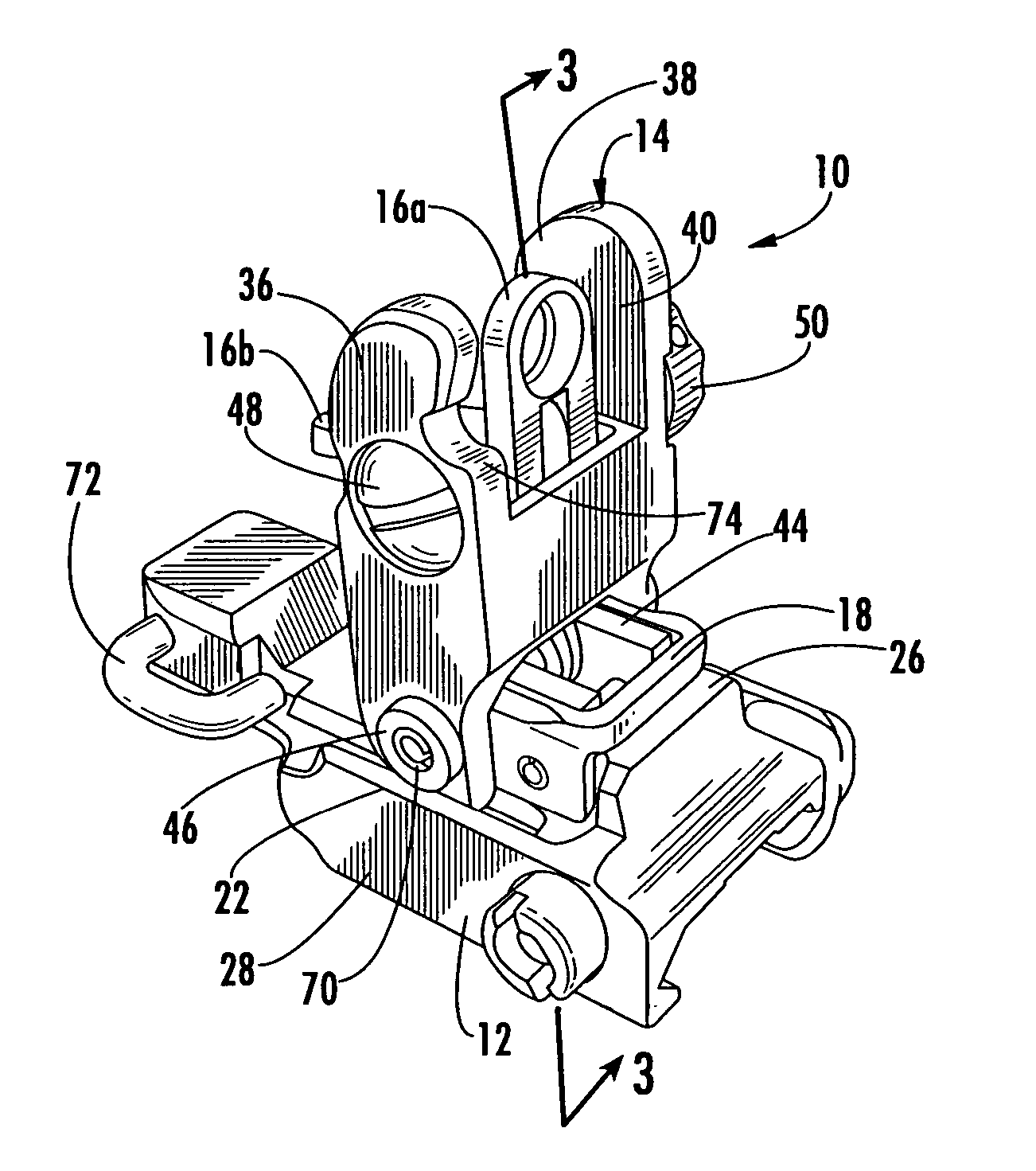

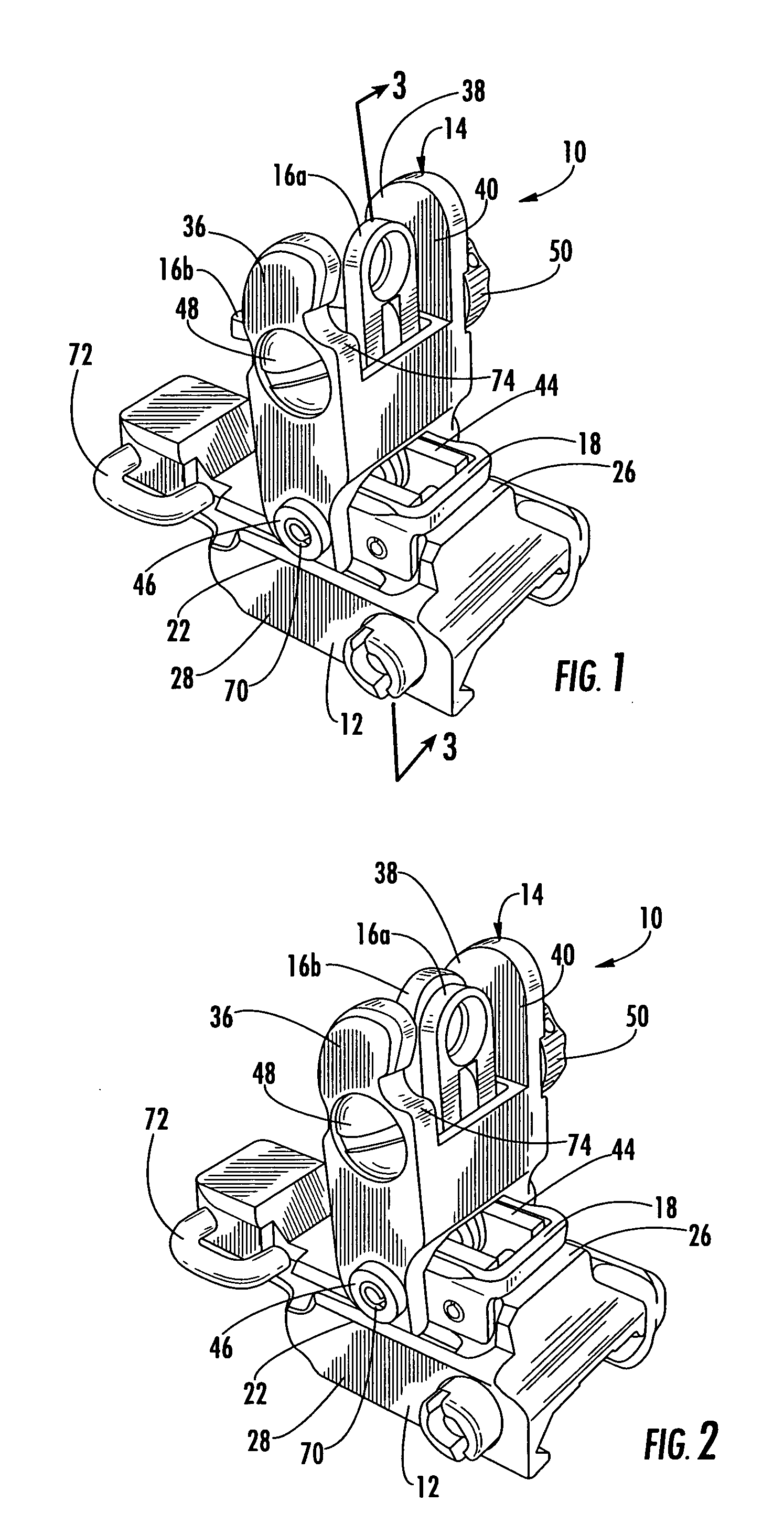

Low profile flip up site

ActiveUS7356962B2Streamlining profileSimple finger movementCartridge extractorsSighting devicesEngineeringMechanical engineering

A low profile, self-aligning, flip-up mechanism for aiming devices used with firearms. The mechanism folds the aiming device into the contour of the firearm during non-use. The mechanism is spring-loaded and flips into a vertical operational position with a simple movement of a finger or thumb. The mechanism includes at least two separate aiming elements that are mounted in a fashion that allows them to rotate relative to one another thereby facilitating a smaller storage profile. The mechanism also causes the aiming device to self-align itself as it moves into an operational position assuring vertical position repeatability.

Owner:SWAN RICHARD E

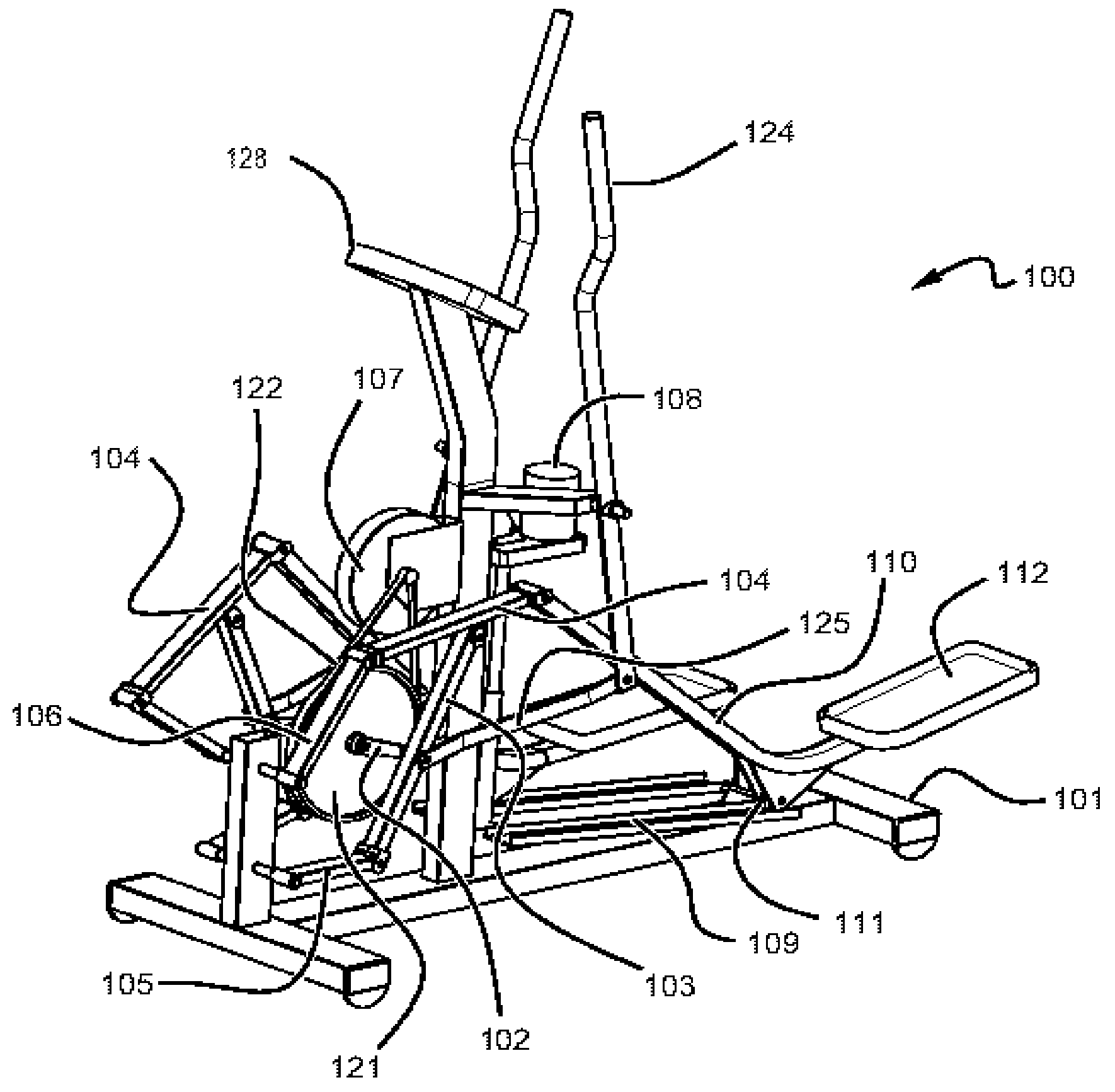

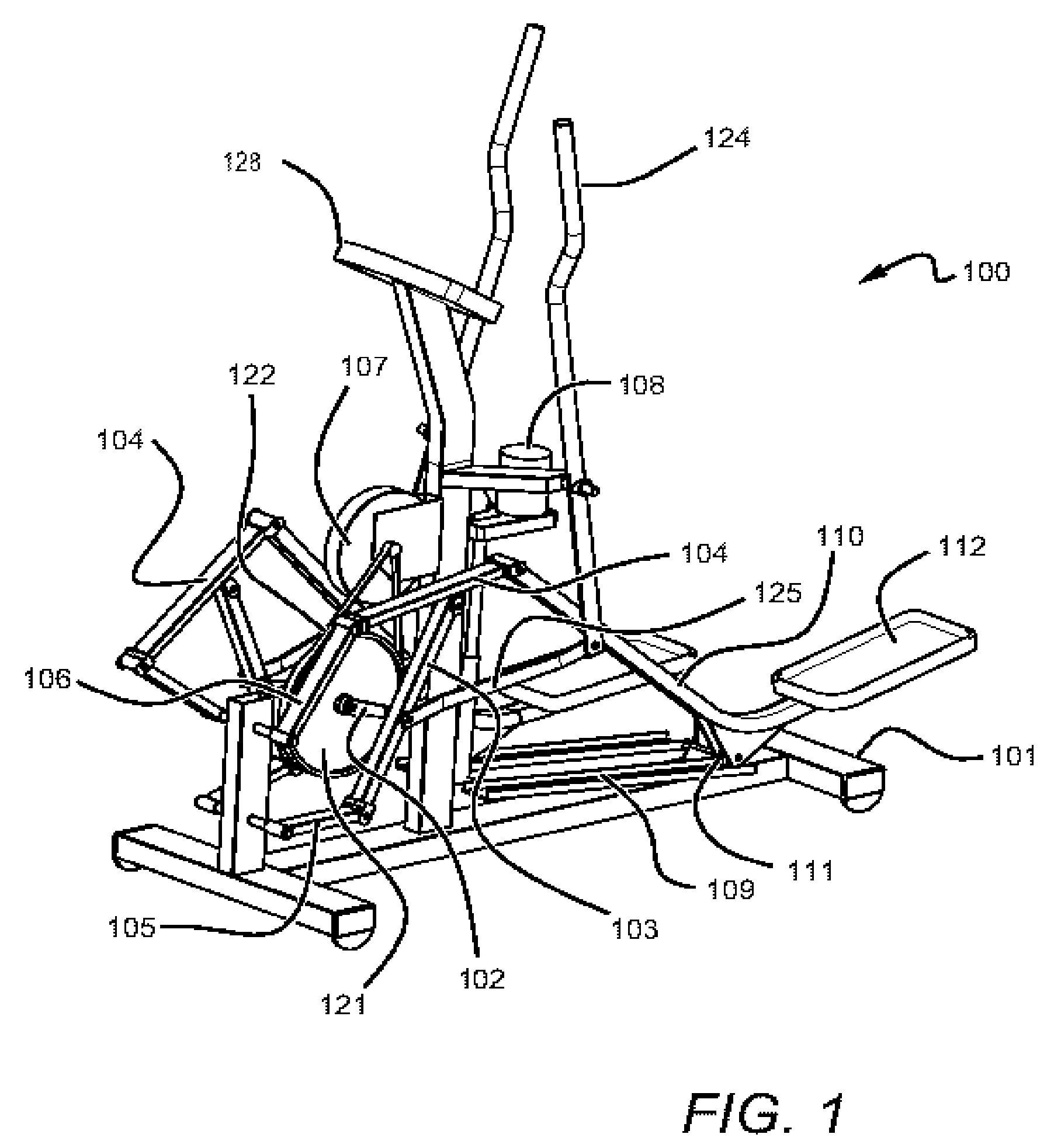

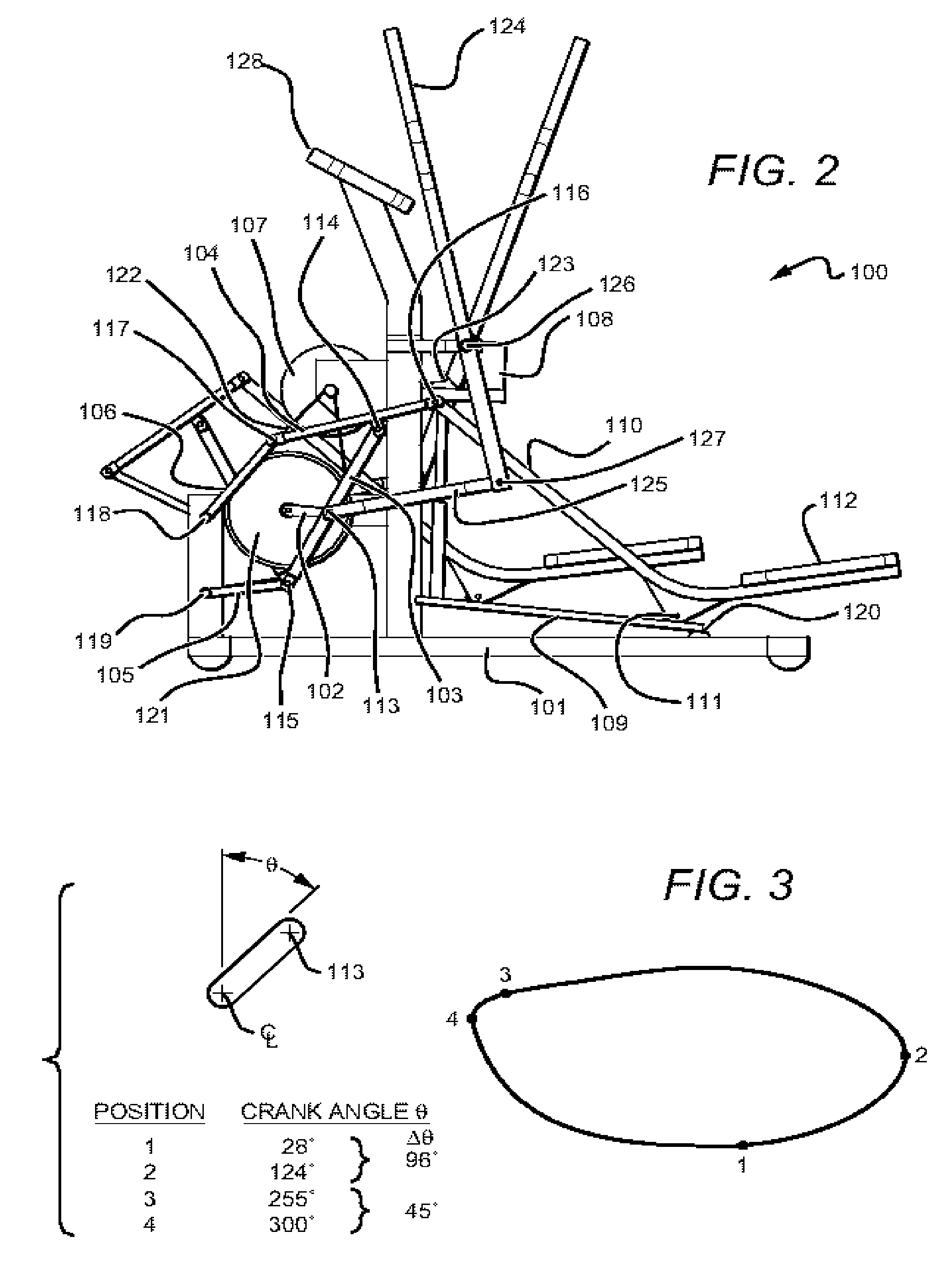

Exercise device

InactiveUS7060005B2Stored or moved more efficientlyCompact profileMovement coordination devicesCardiovascular exercising devicesMuscle groupBiomechanics

An exercise apparatus having a pair of support pedals that, when a user steps upon both pedals, can be moved by the user in a closed path that is designed to be complimentary in motion to that of the user's natural stride. The pedals are operably connected by a linkage that facilitates this natural motion. Moreover, this linkage can be adjusted thereby altering the shape of the closed path traveled by the pedals. The closed path can thus be altered to conform to the optimal biomechanics of each individual user or, it can be altered to form a closed path designed for more of a striding type of exercise or for more of a climbing exercise, thereby allowing different muscle groups to be exercised on the same machine.

Owner:CONGRESS FINANCIAL CORP WESTERN

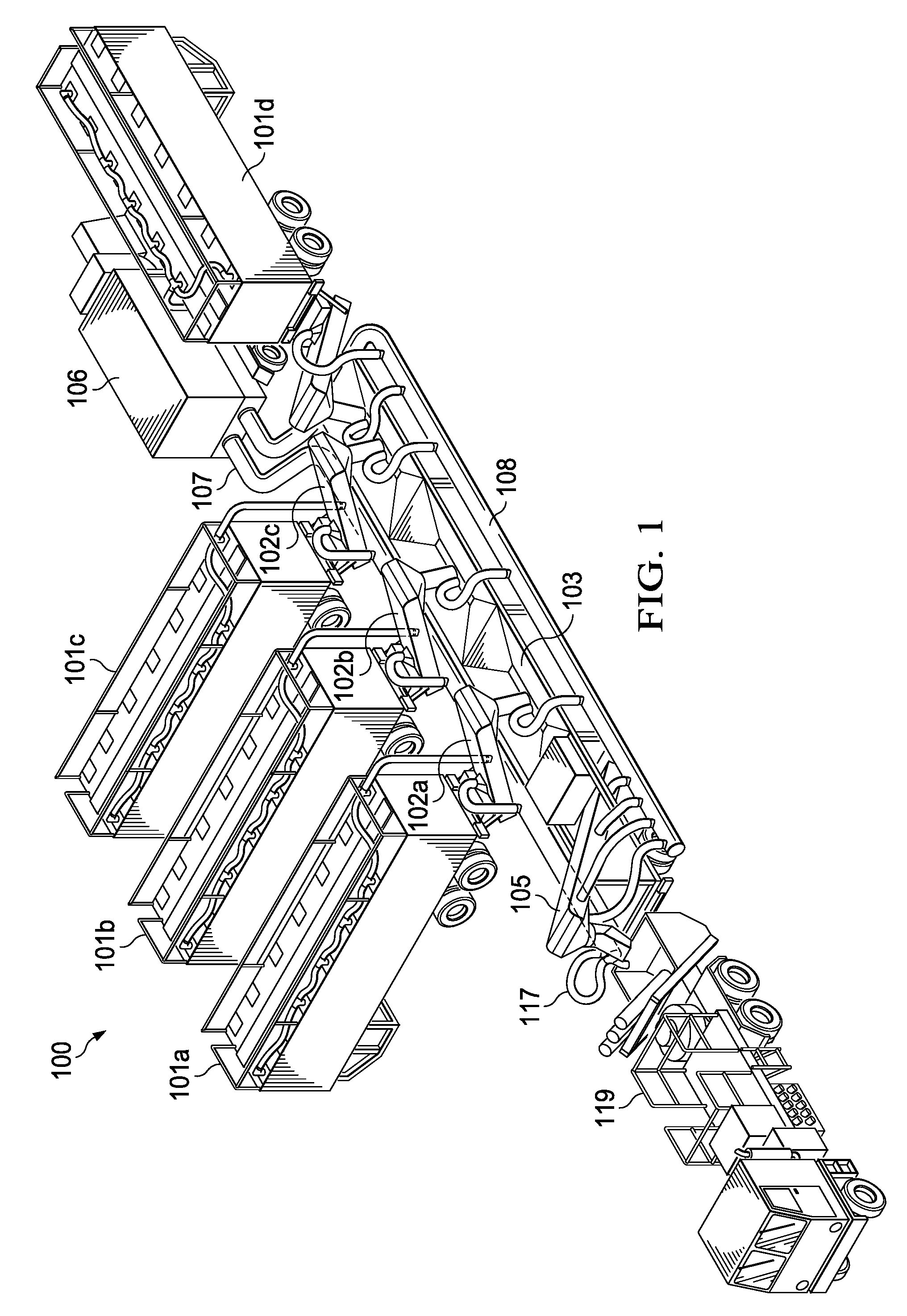

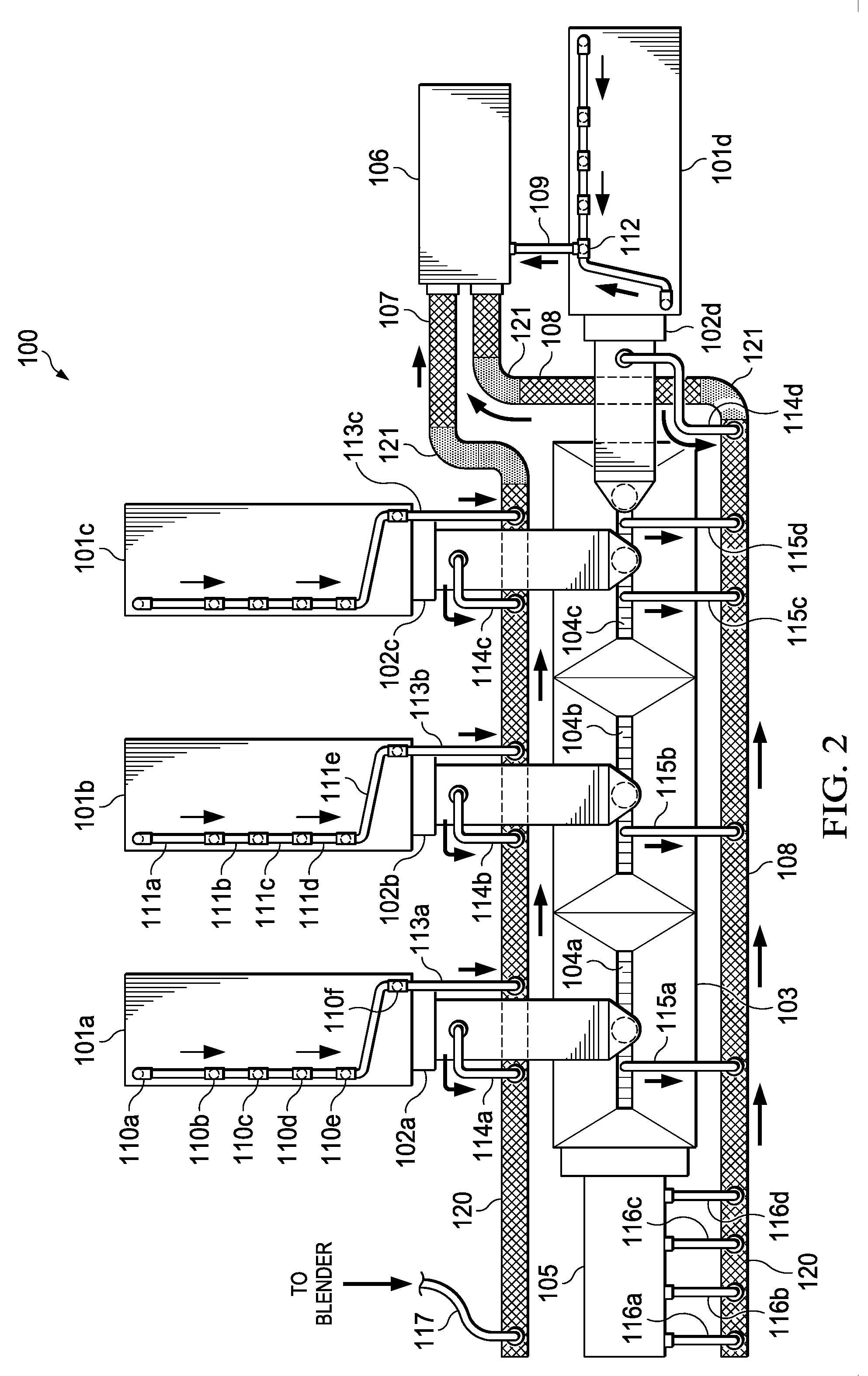

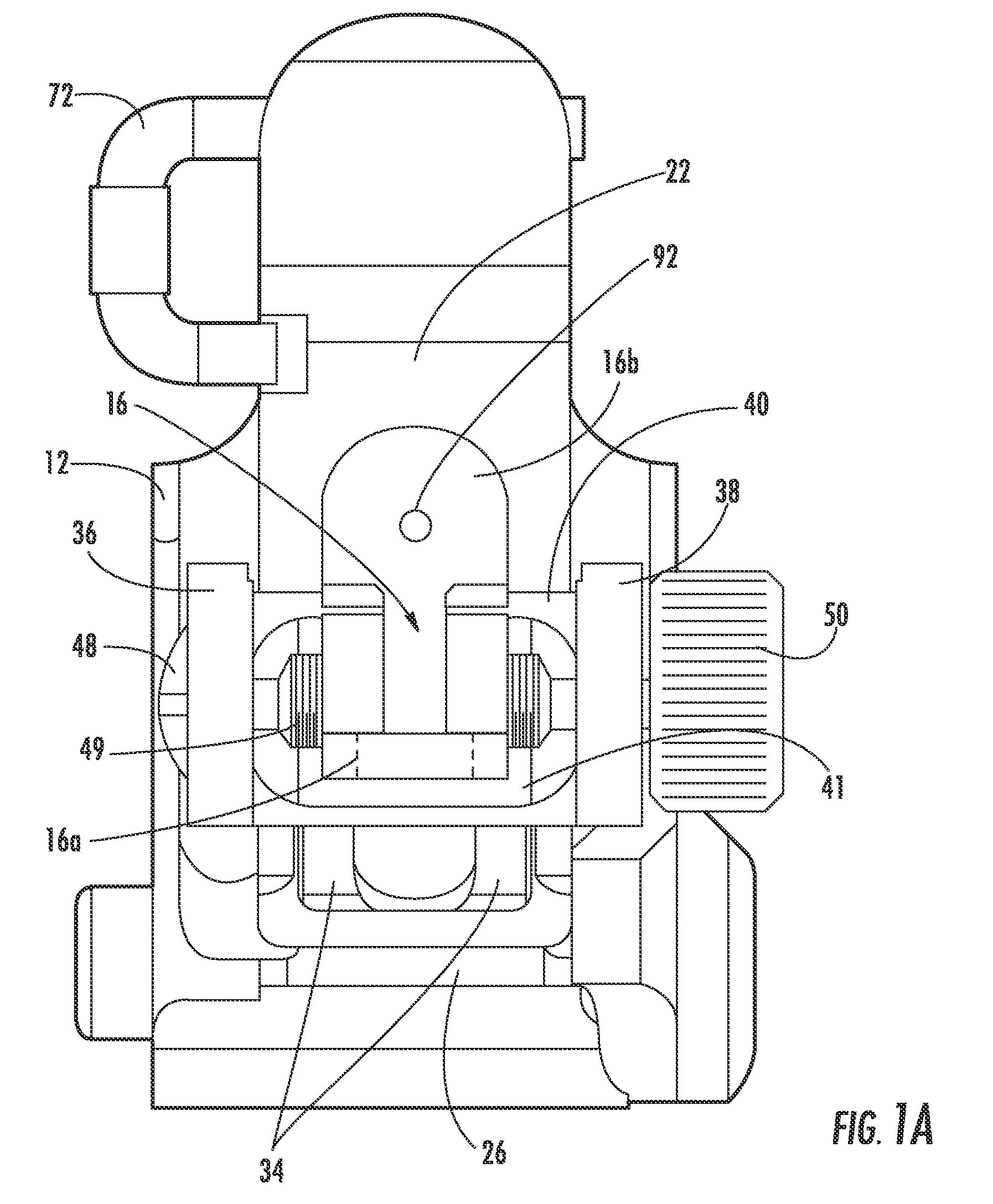

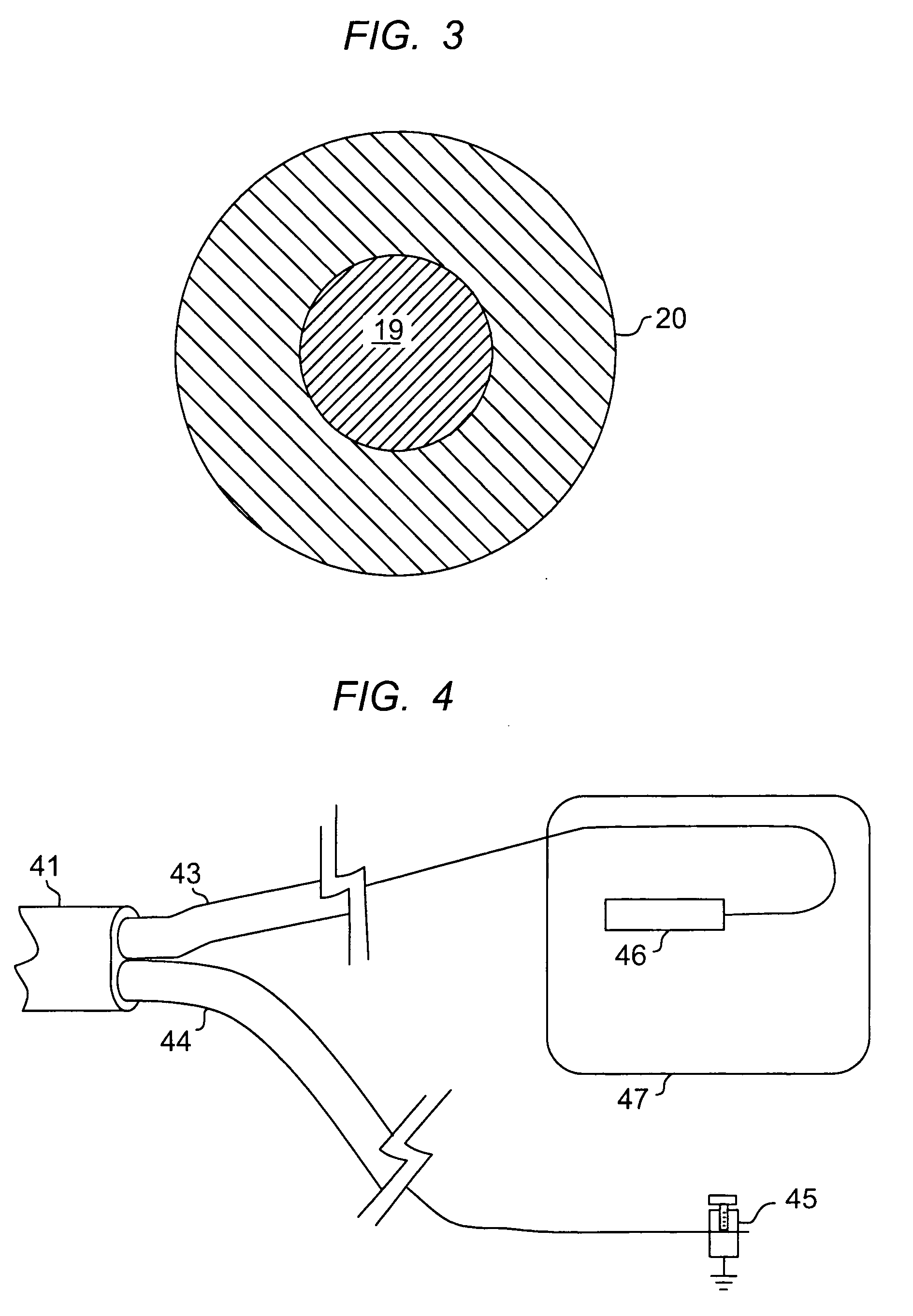

Systems and methods for controlling silica dust during hydraulic fracturing operations using an improved manifold

ActiveUS20160280480A1Simple apertureImprove efficiencyFouling preventionFluid removalHydraulic fracturingSilicon dioxide

A system for controlling dust during hydraulic fracturing operations includes a manifold having a plurality of ports for capturing dust when negative air pressure is applied to the manifold. A support frame positions the manifold above a piece of hydraulic fracturing equipment receiving sand from a sand source.

Owner:SIERRA DUST CONTROL

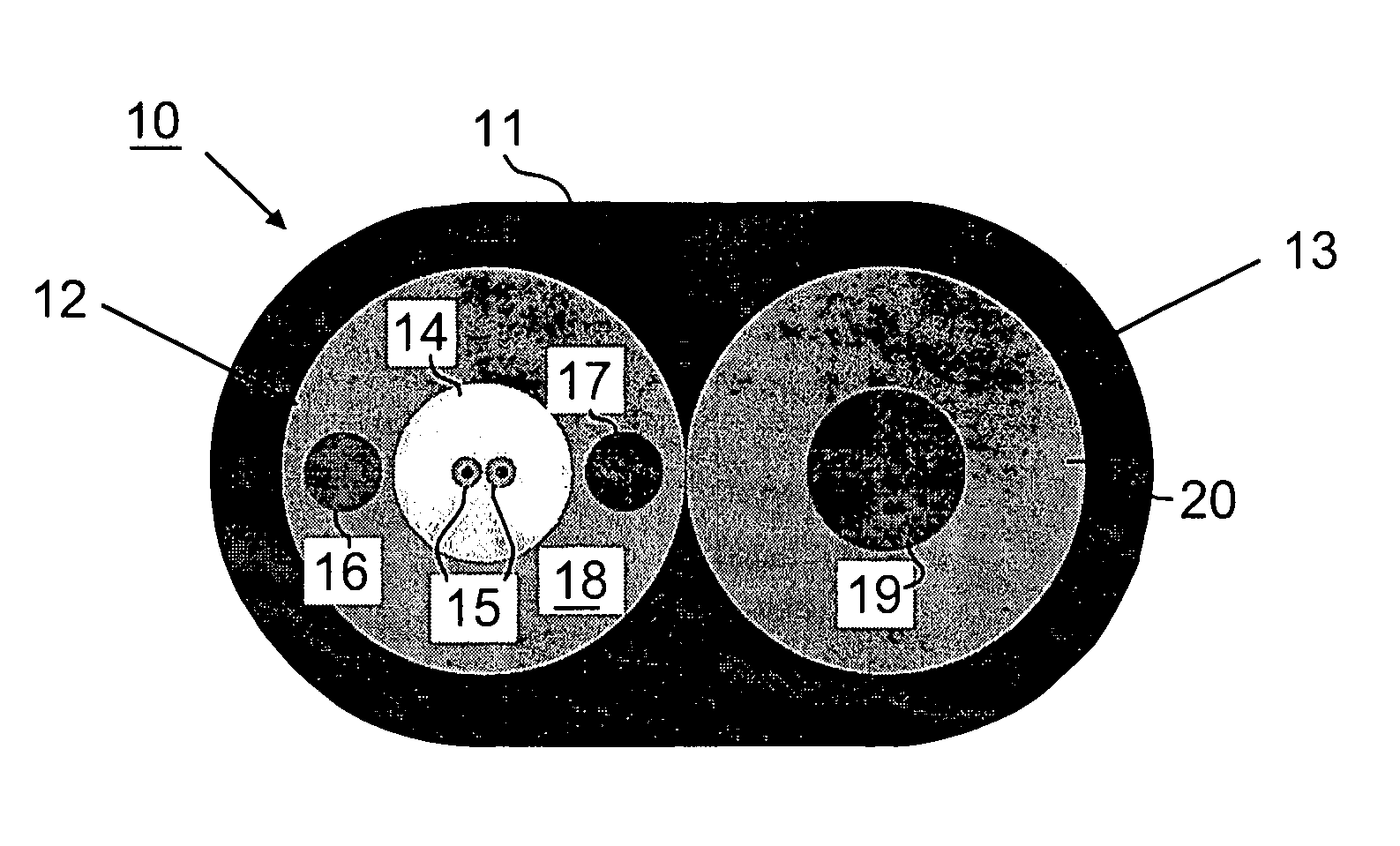

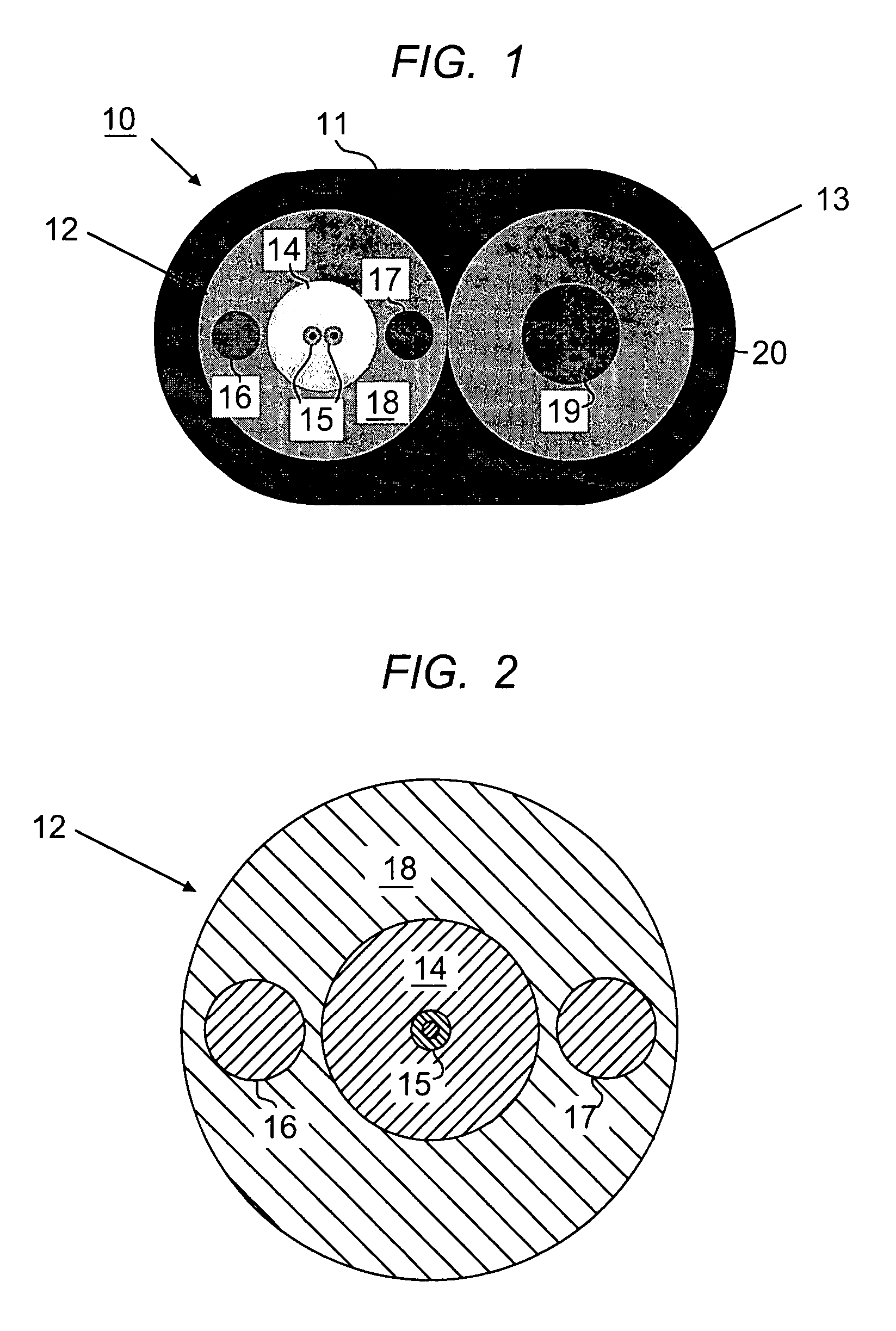

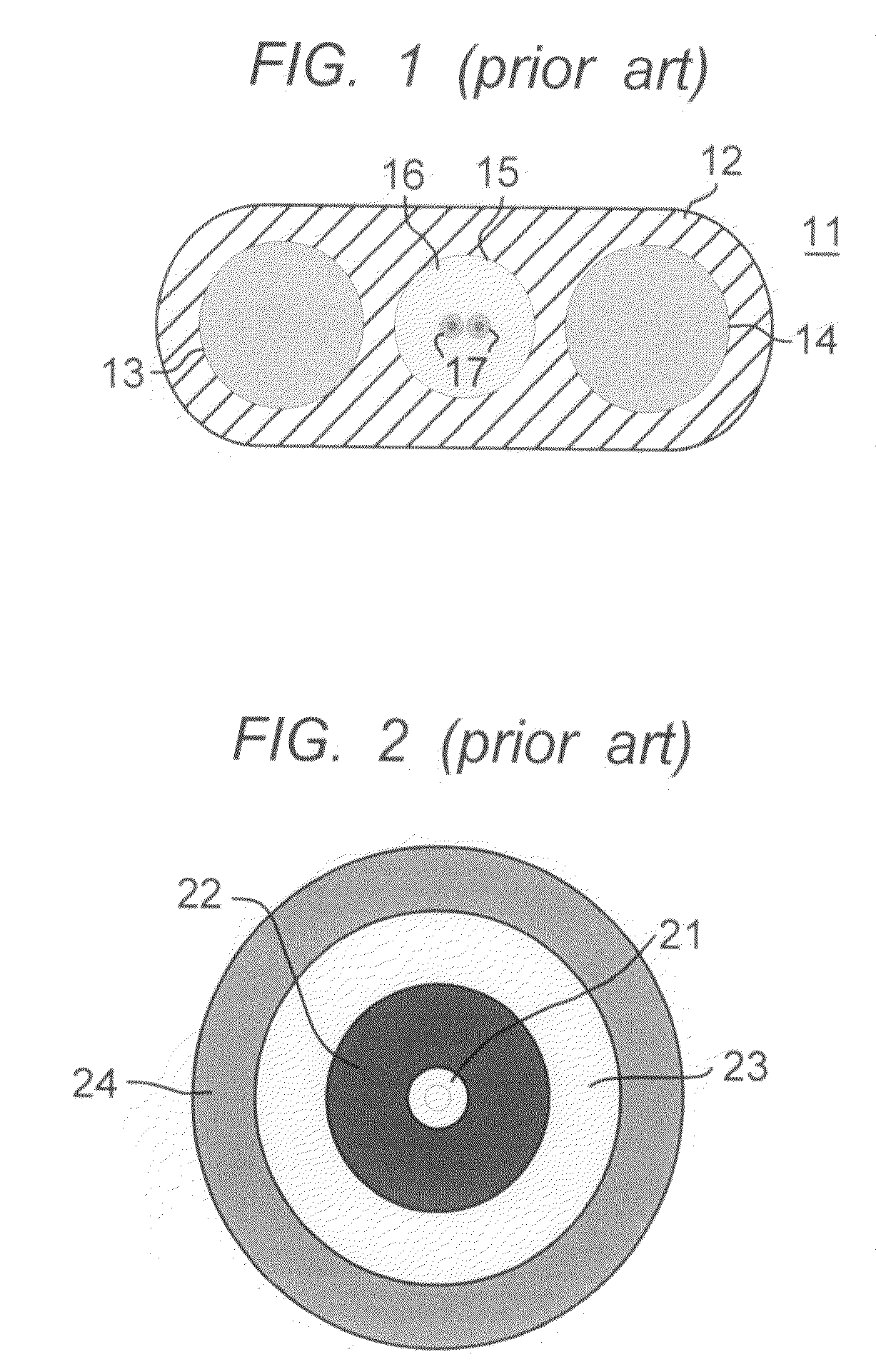

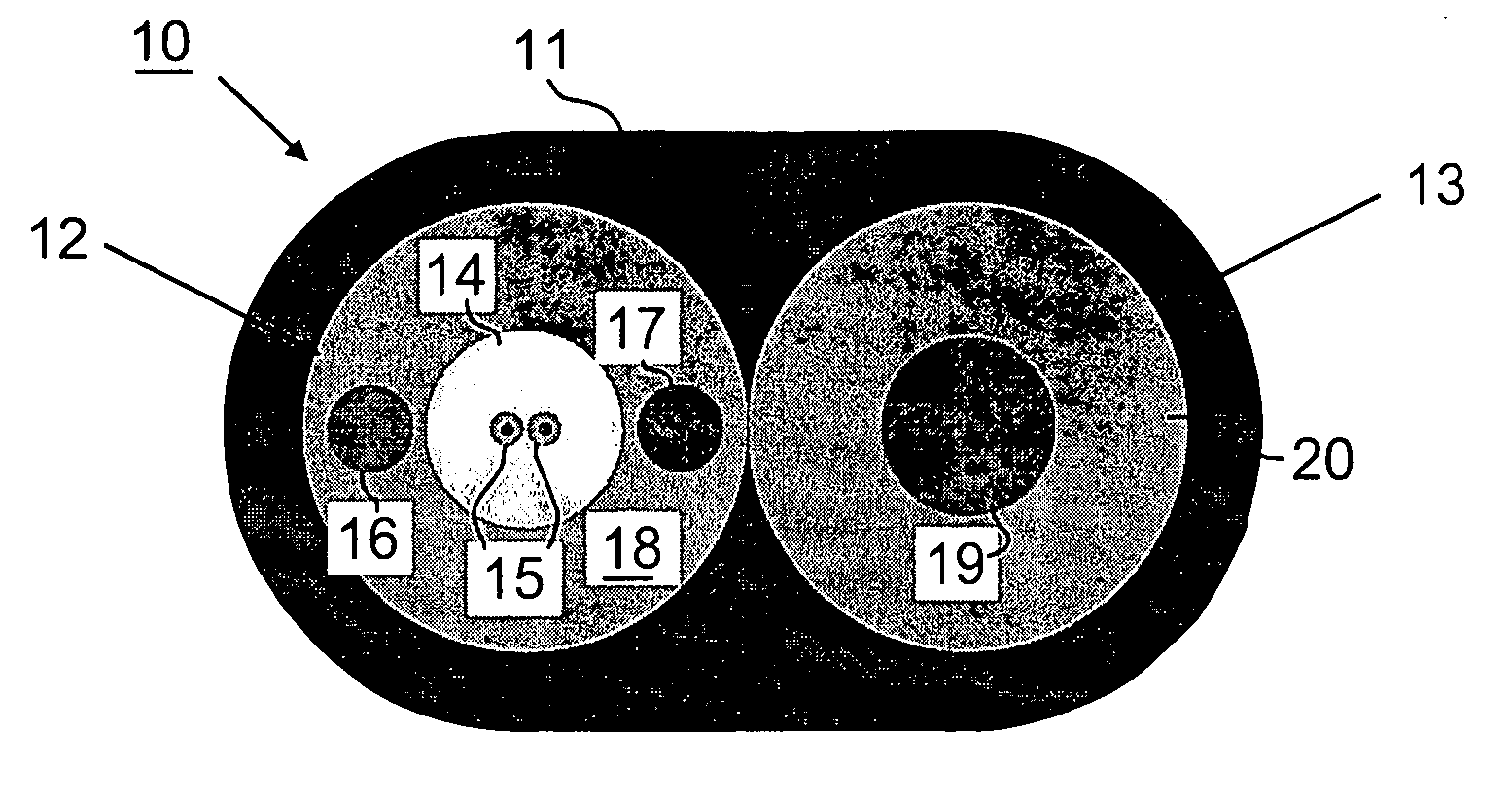

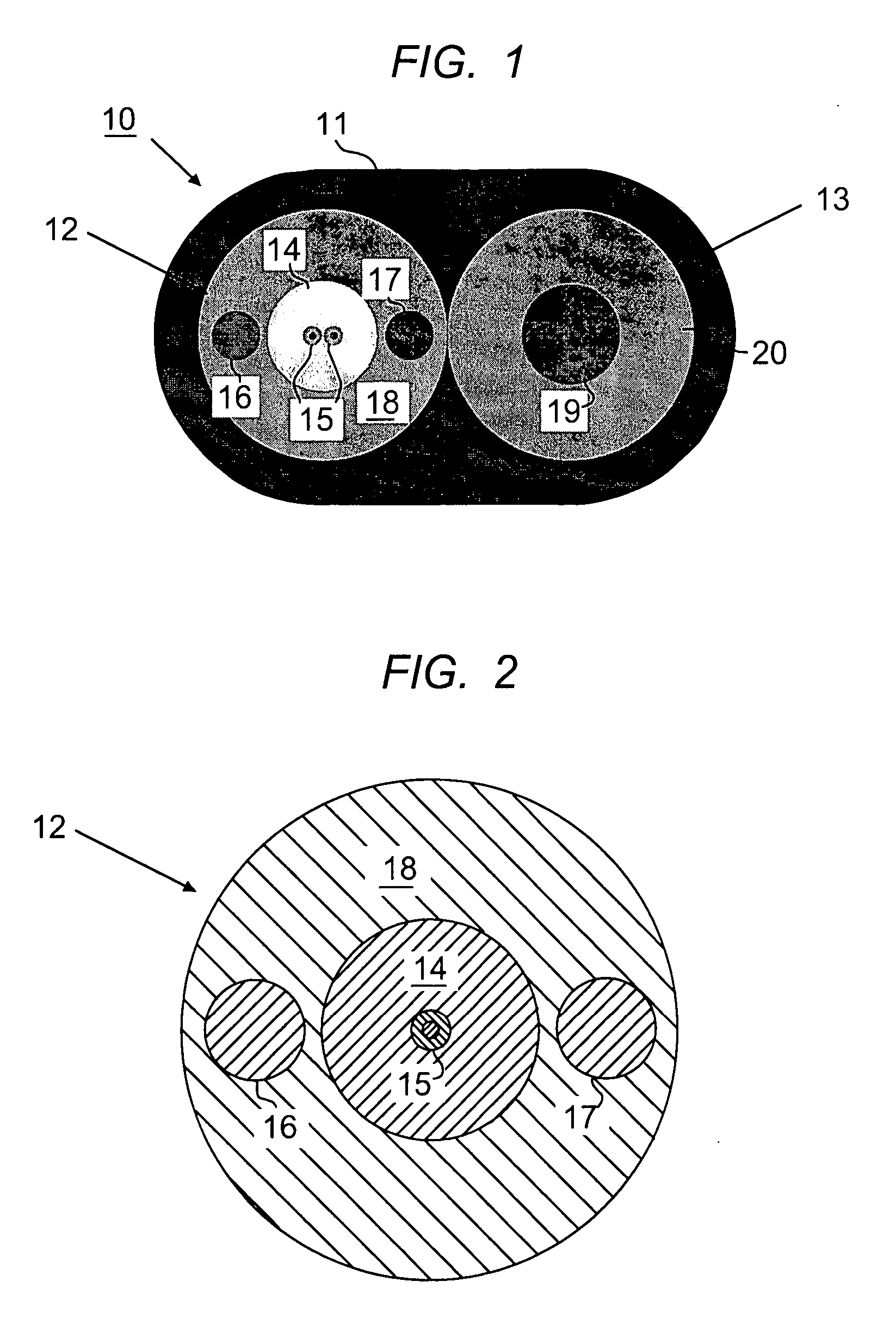

Optical fiber cables

ActiveUS7218821B2Compact profileResistant to fiber retractionOptical fibre/cable installationFibre mechanical structuresEngineeringUltimate tensile strength

The specification describes an optical fiber drop cable with a flat configuration and having two side-by-side subunits. One of the subunits contains a cable strength member, e.g. a steel wire or stranded wire. The other subunit is an optical fiber subunit, which contains the optical fiber(s), and also contains one or more additional strength members. In a preferred embodiment, the cable is dry, and has conformal encasements that couple the optical fiber(s) to the outer cable sheath.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

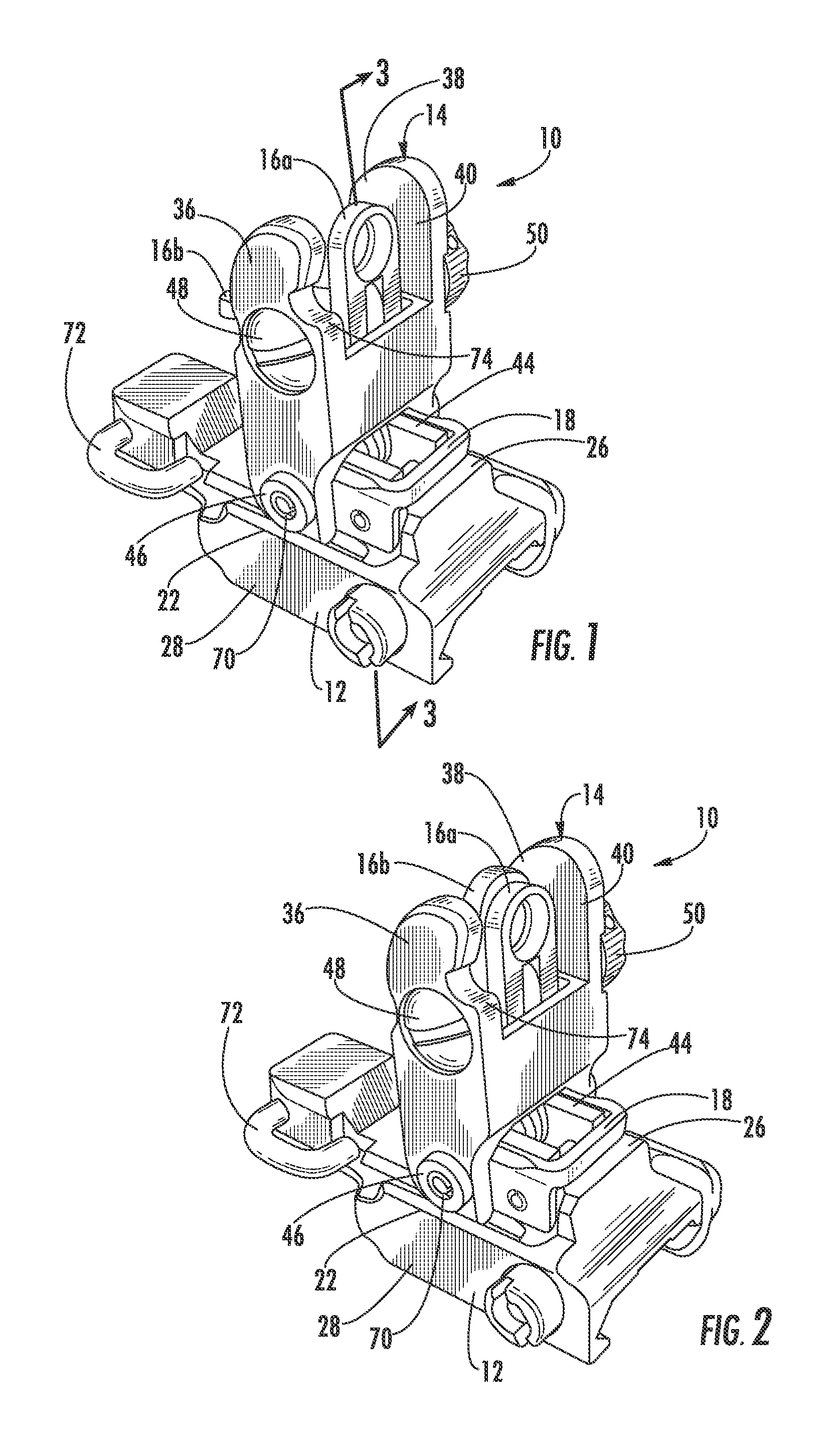

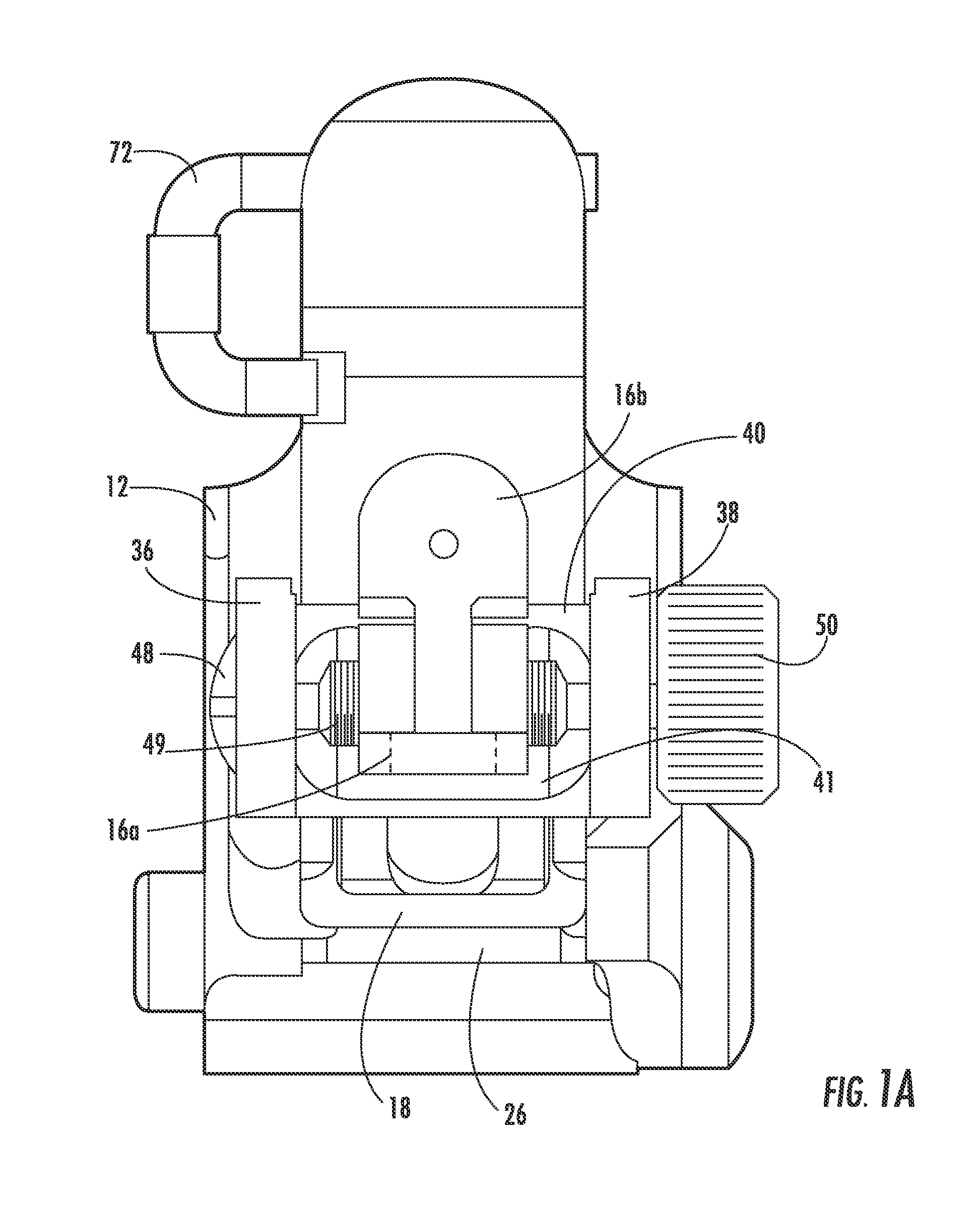

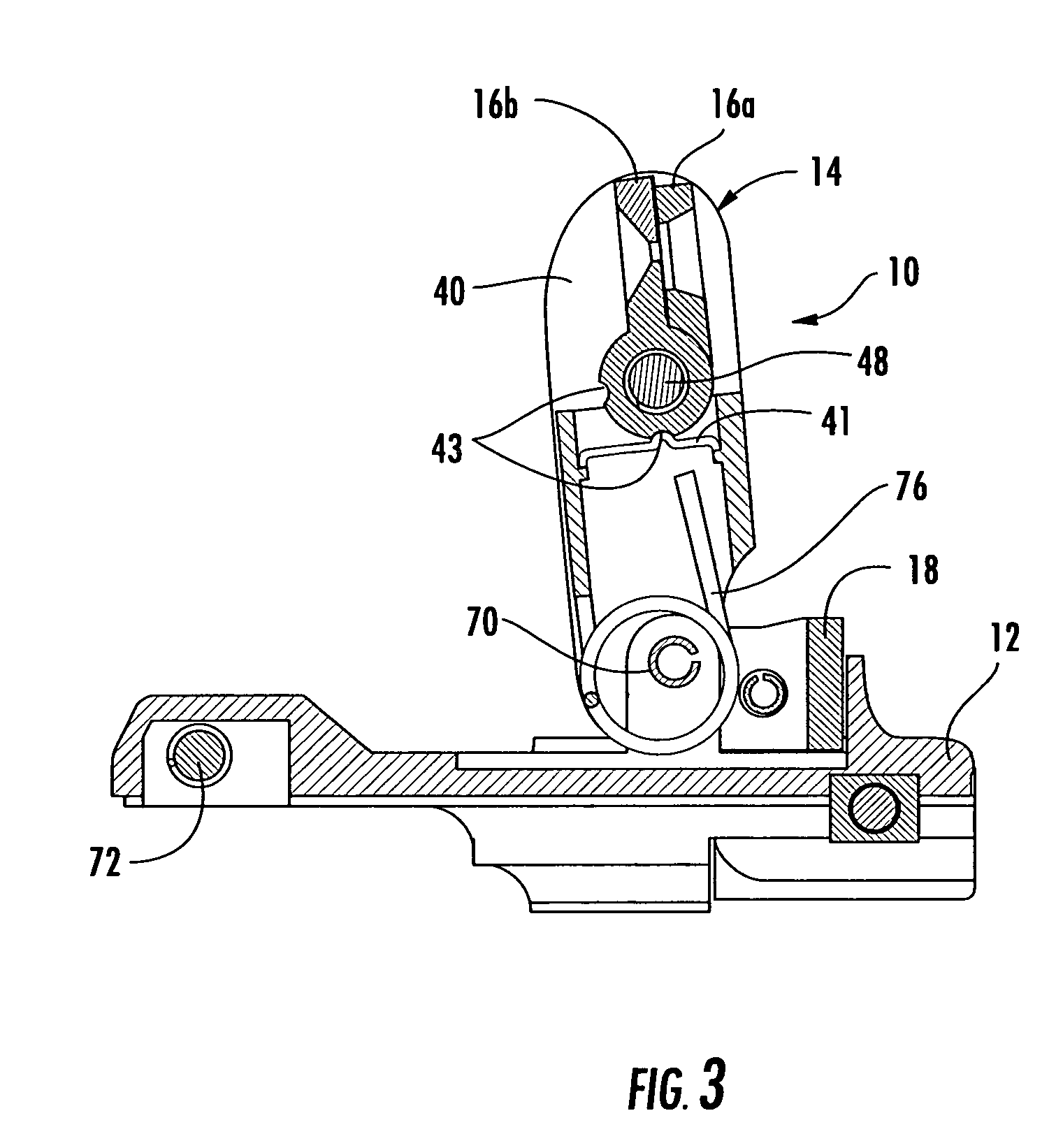

Folding rear sight with dual purpose sighting elements

ActiveUS8015744B1Store tightlyQuickly and easily deployableCartridge extractorsSighting devicesDual purposeEngineering

A folding rear sight includes a base member and a spring-loaded sight housing that deploys into an operational position with a simple release lever. The sight includes two separate dual-purpose aiming elements, one fixed, and one that rotates between an inactive position and an active position in front of the fixed element. The top aiming end of the fixed aiming element includes a large diameter close quarter battle (CQB) aperture and an vertically extending sighting notch configured and arranged above the large CQB aperture. The top aiming end of the rotatable aiming element includes a smaller, long-range sighting aperture and an elongated vertically extending sighting notch configured and arranged above the smaller sighting aperture. The dual-purpose aiming elements provide standard aperture sights for situations where the soldier has reasonable time to aim the weapon. The notched sights above the apertures provide a larger, open sighting window, which is easier to align in stressful close combat situations, as well as long range sighting.

Owner:SWAN RICHARD E

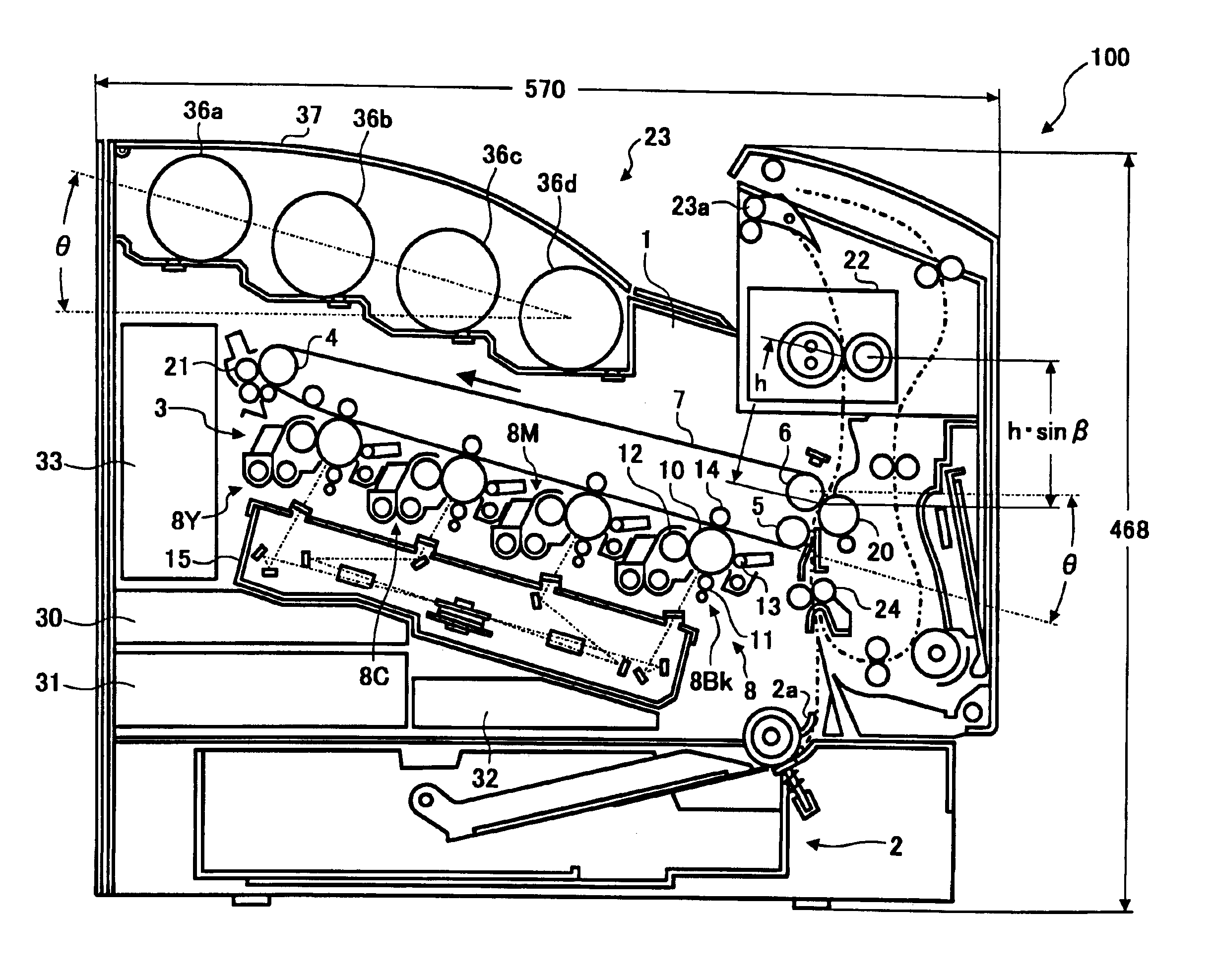

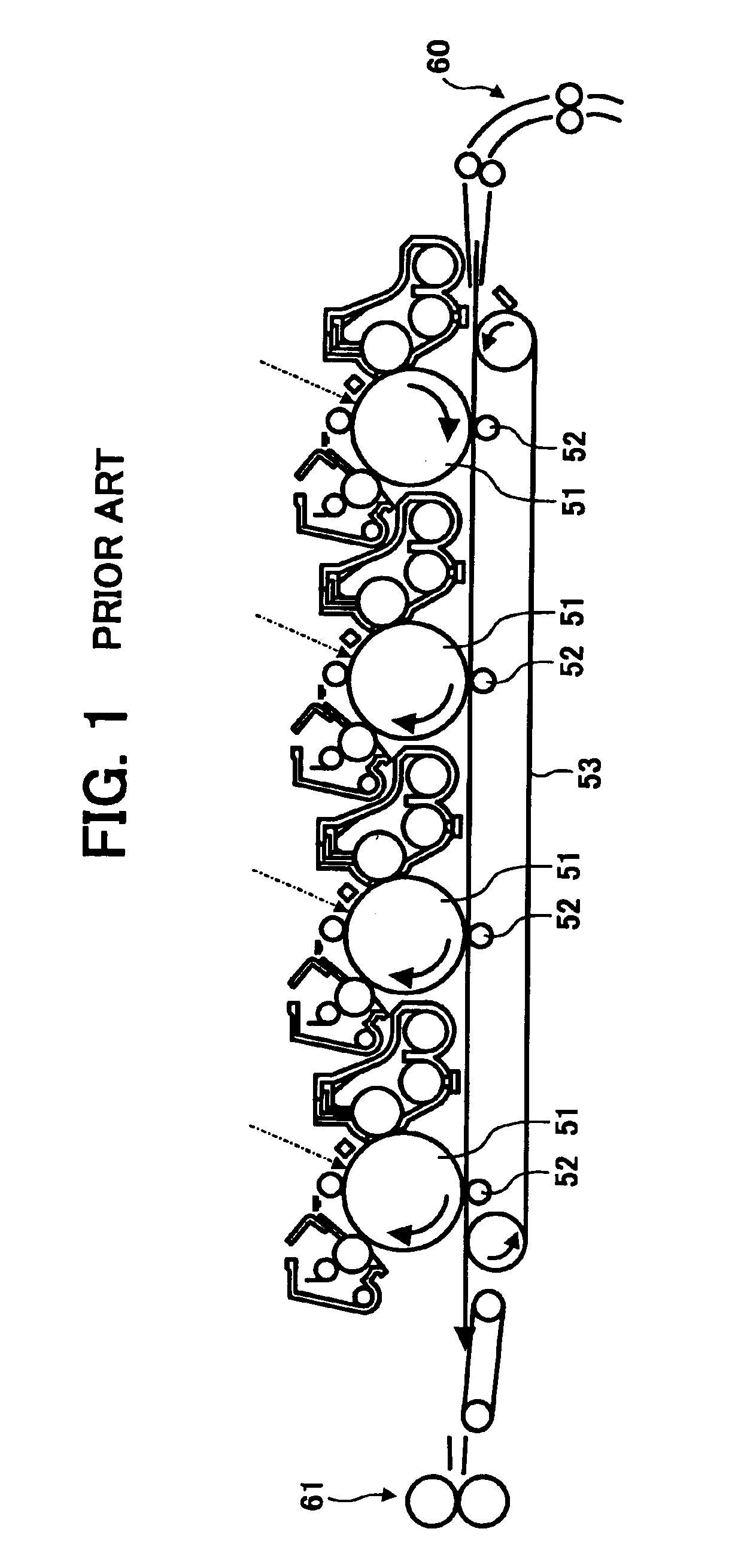

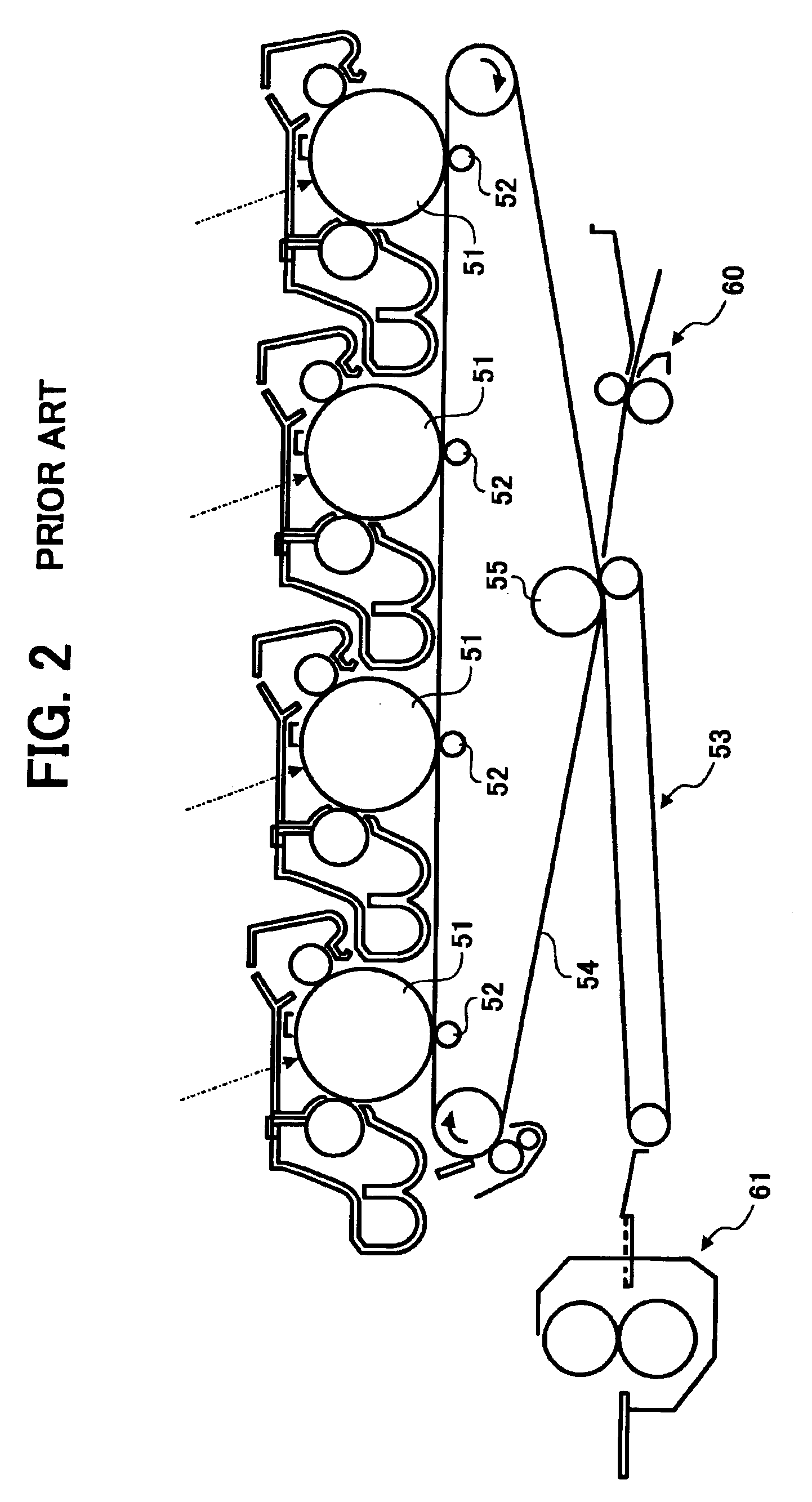

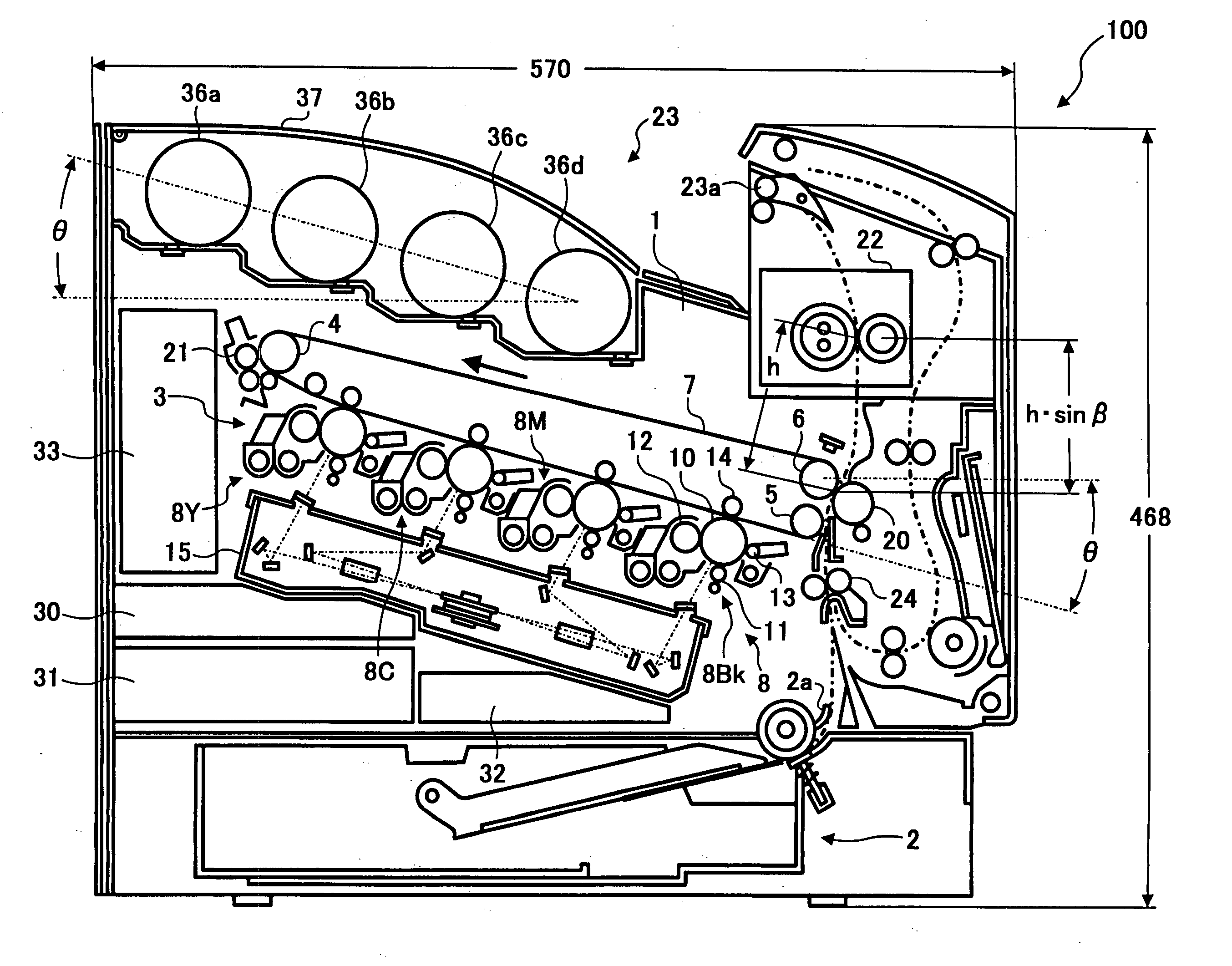

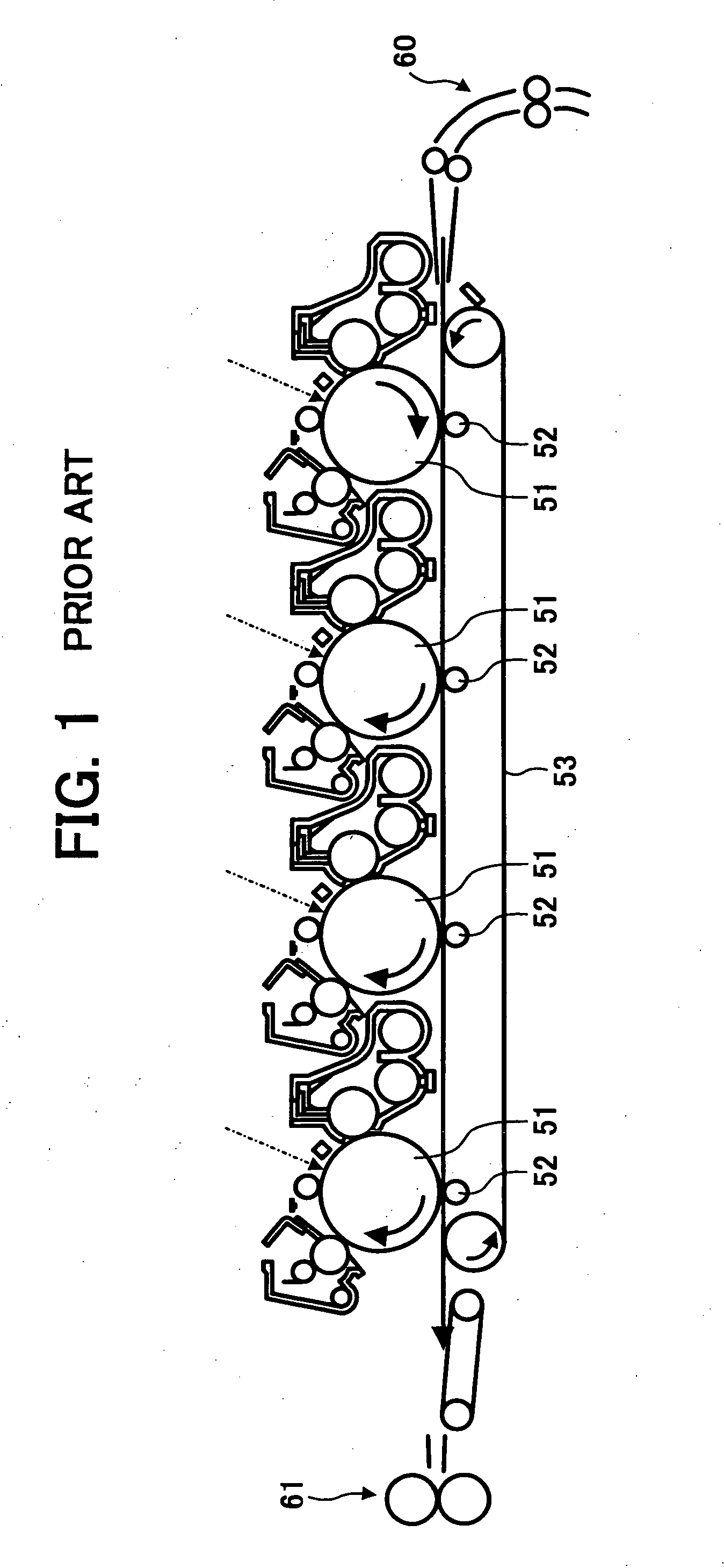

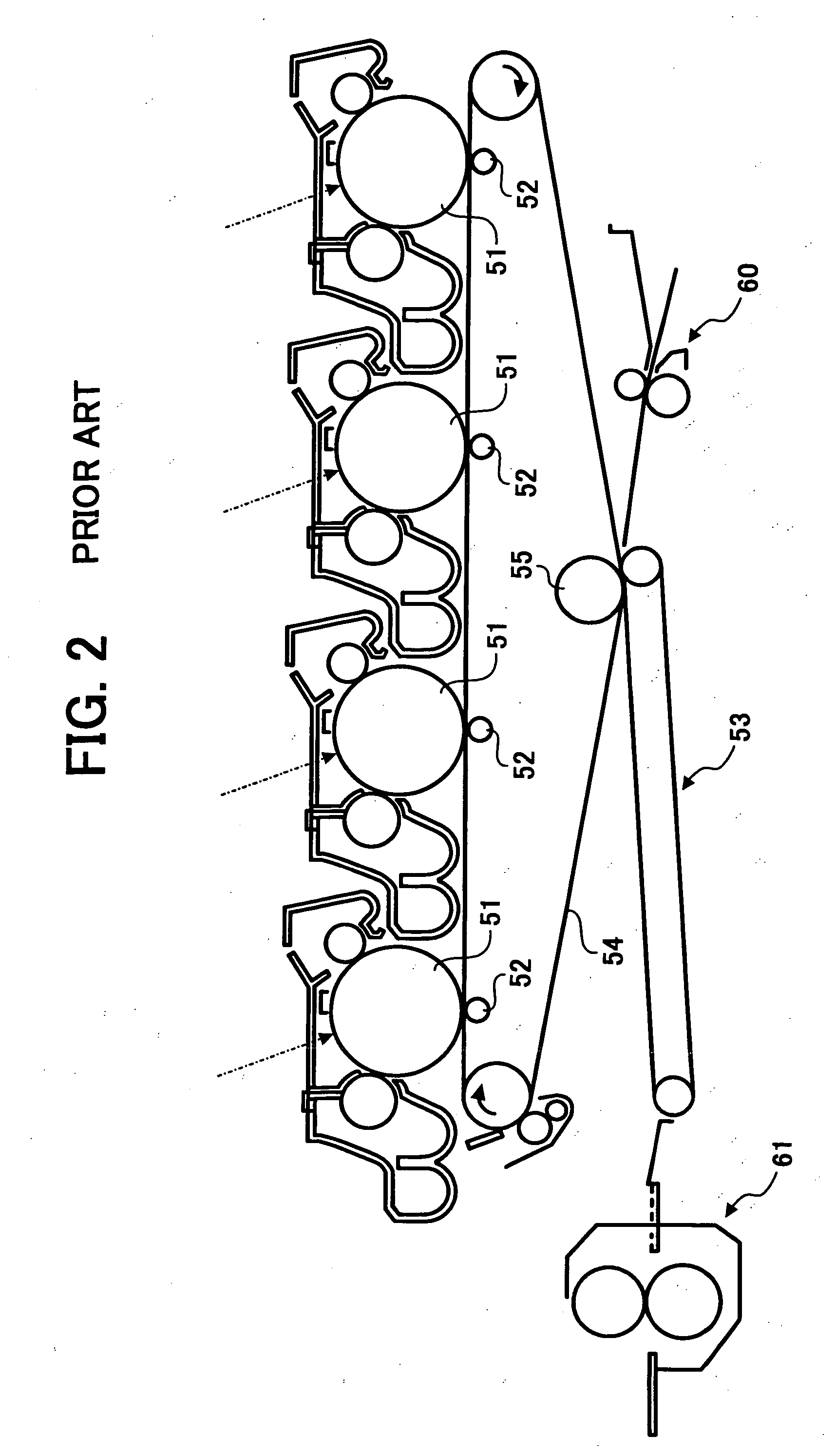

Desktop color image forming apparatus and method of making the same

ActiveUS6898407B2Compact profileAvoid insufficient lengthElectrographic process apparatusColor imageIntermediate image

The present invention relates to an electrophotographic color image forming apparatus using a tandem-drum development, an indirect image-transfer method, and a vertical sheet supply path. An intermediate image-transfer member is angled relative to a horizontal line such that a rear side of the intermediate image-transfer member away from a recording sheet is lifted and a front side of the intermediate image-transfer member closer to the recording sheet is lowered. Further, image creating mechanisms of the tandem-drum development are aligned and arranged in parallel to a moving image transfer bed of the intermediate image-transfer member, such that one of the image creating mechanisms firstly forming an image faces the rear side of the moving image transfer bed and another one of the image creating mechanisms lastly forming an image faces the front side.

Owner:RICOH KK

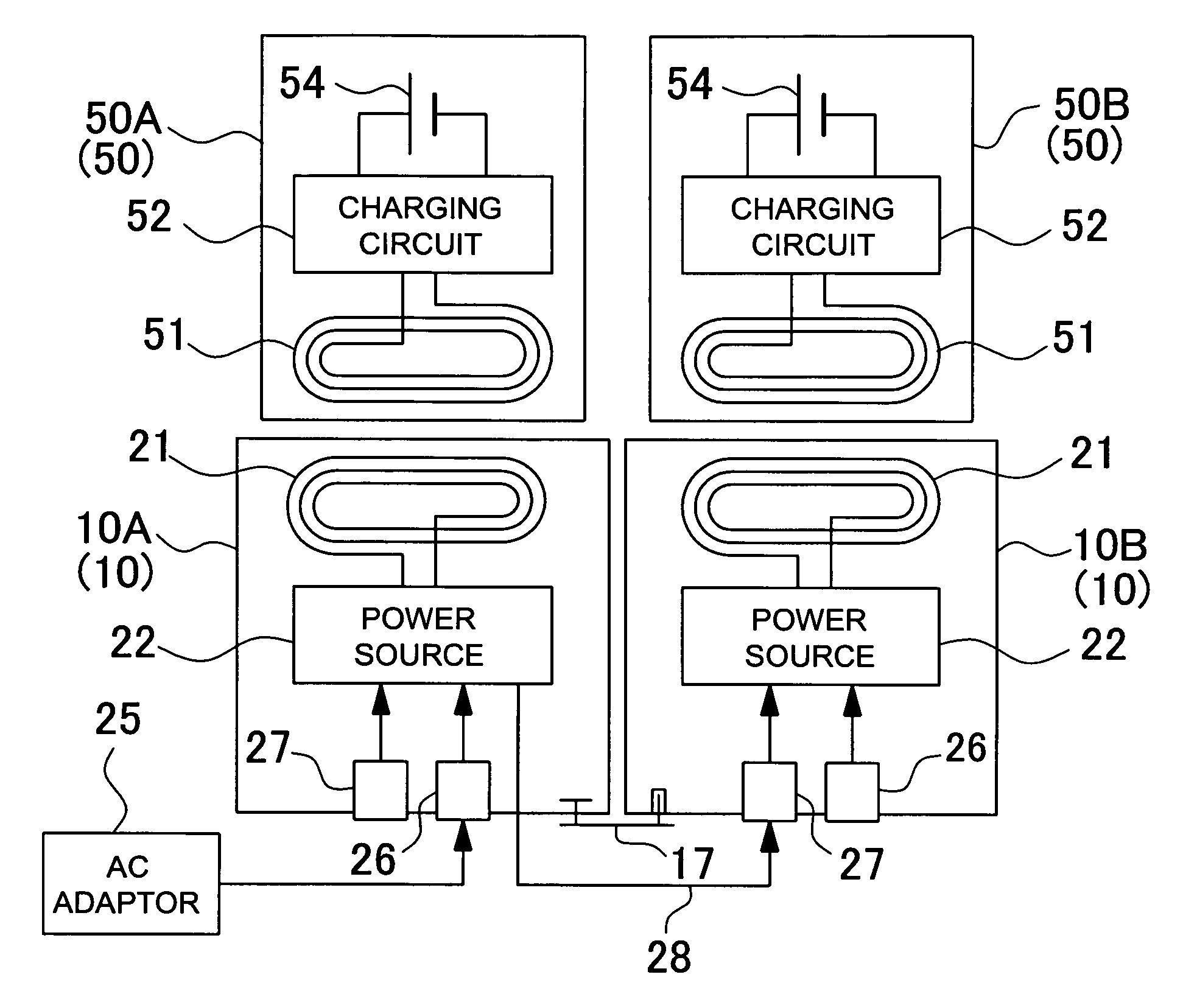

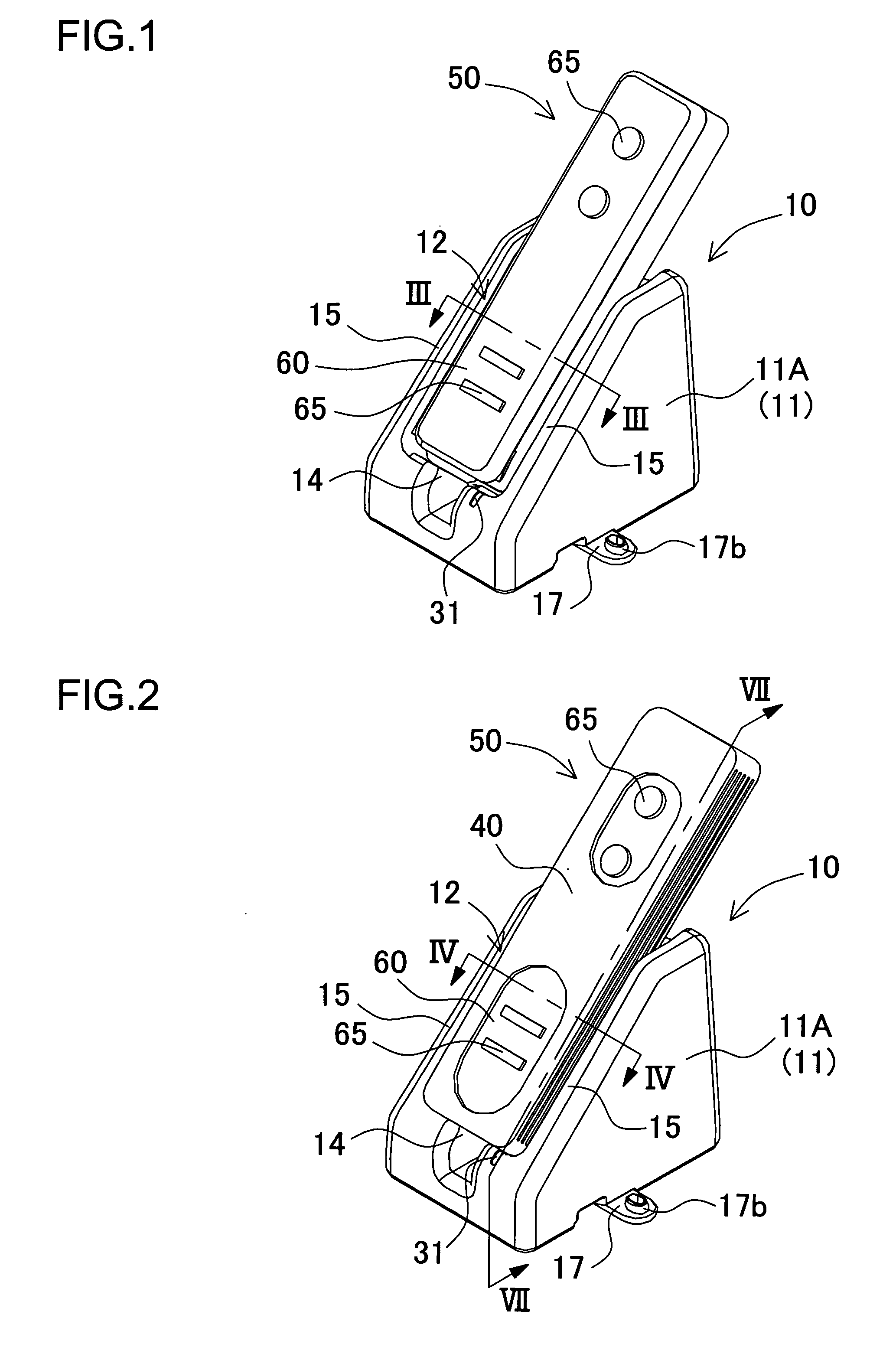

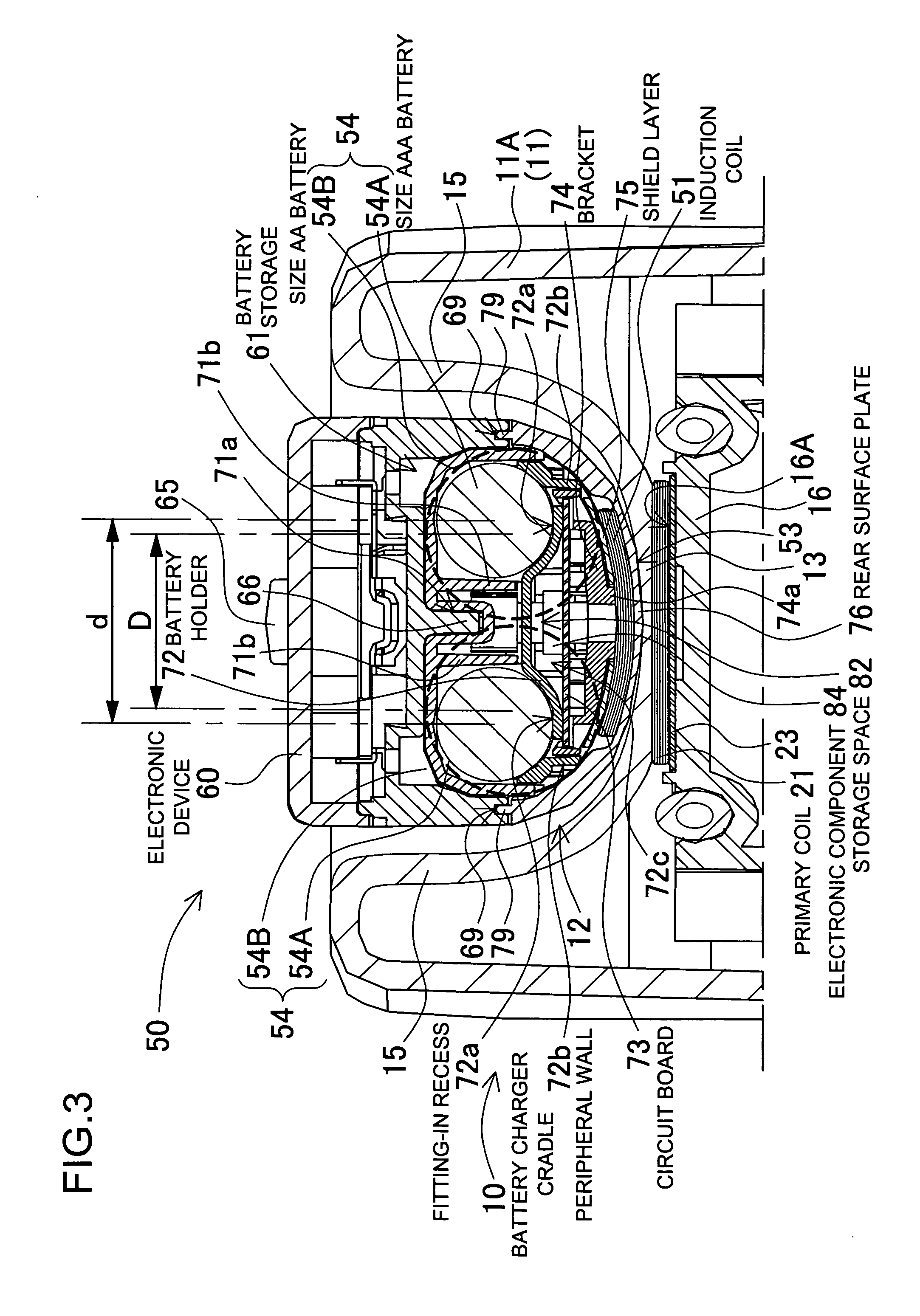

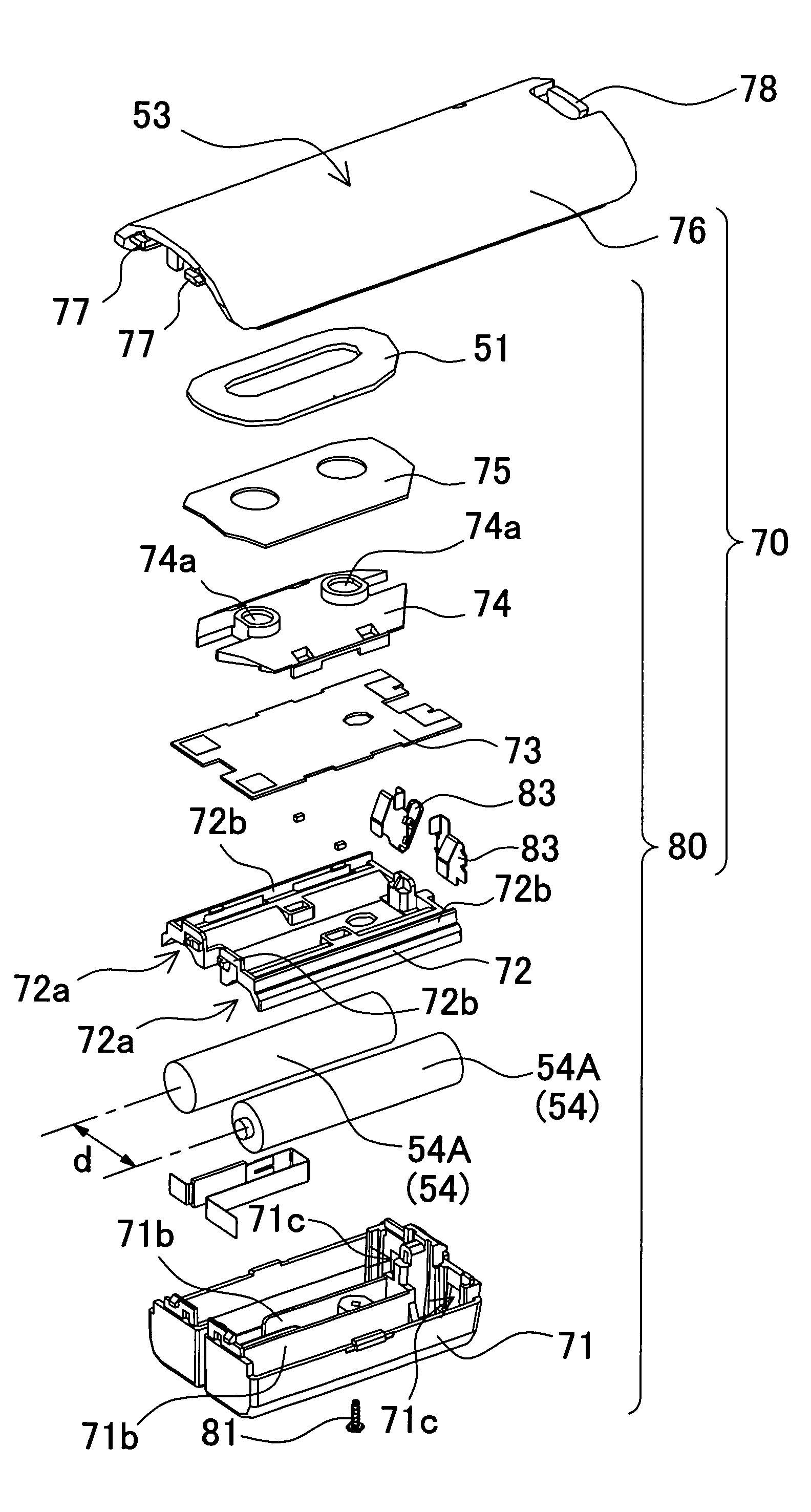

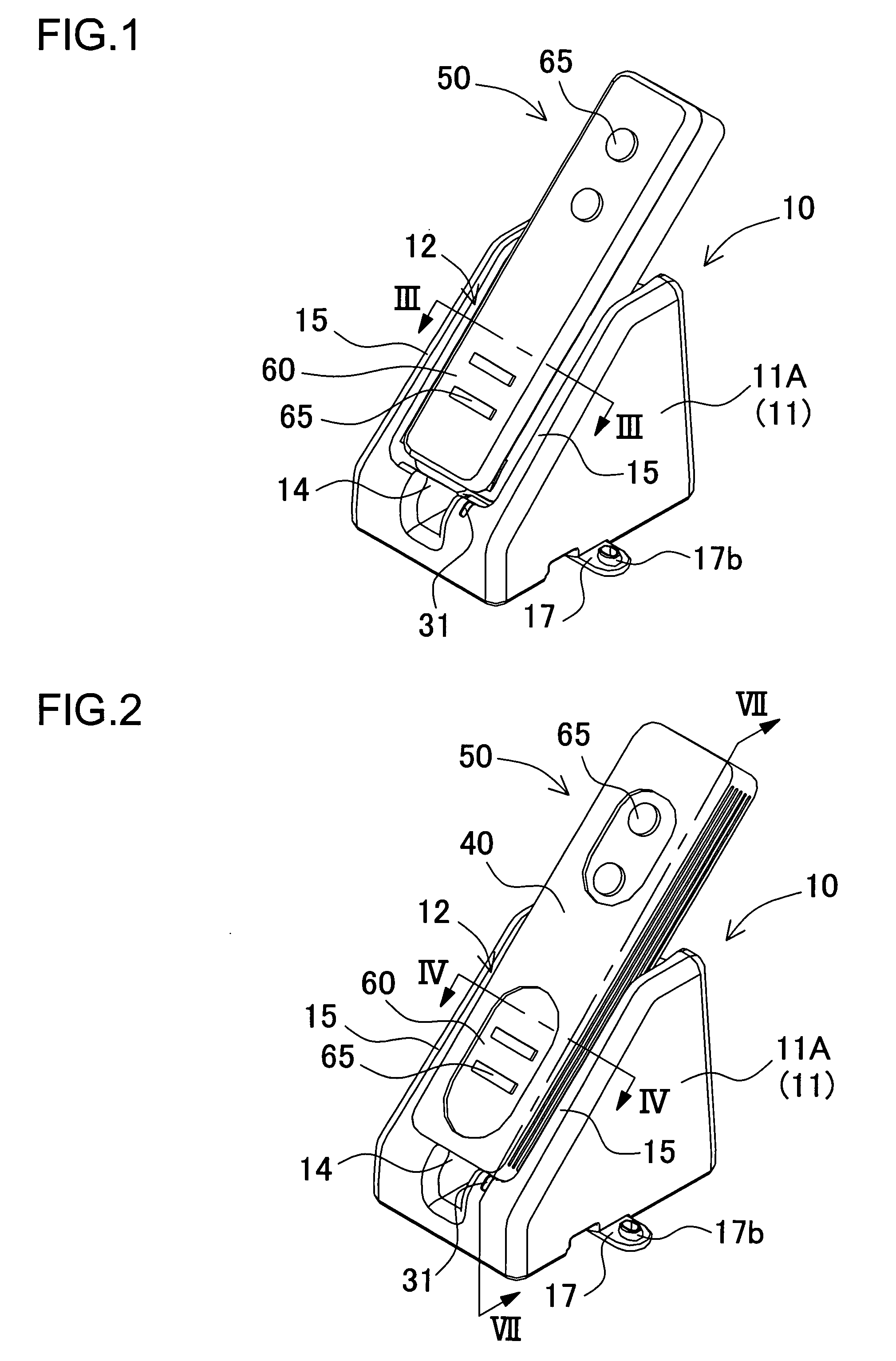

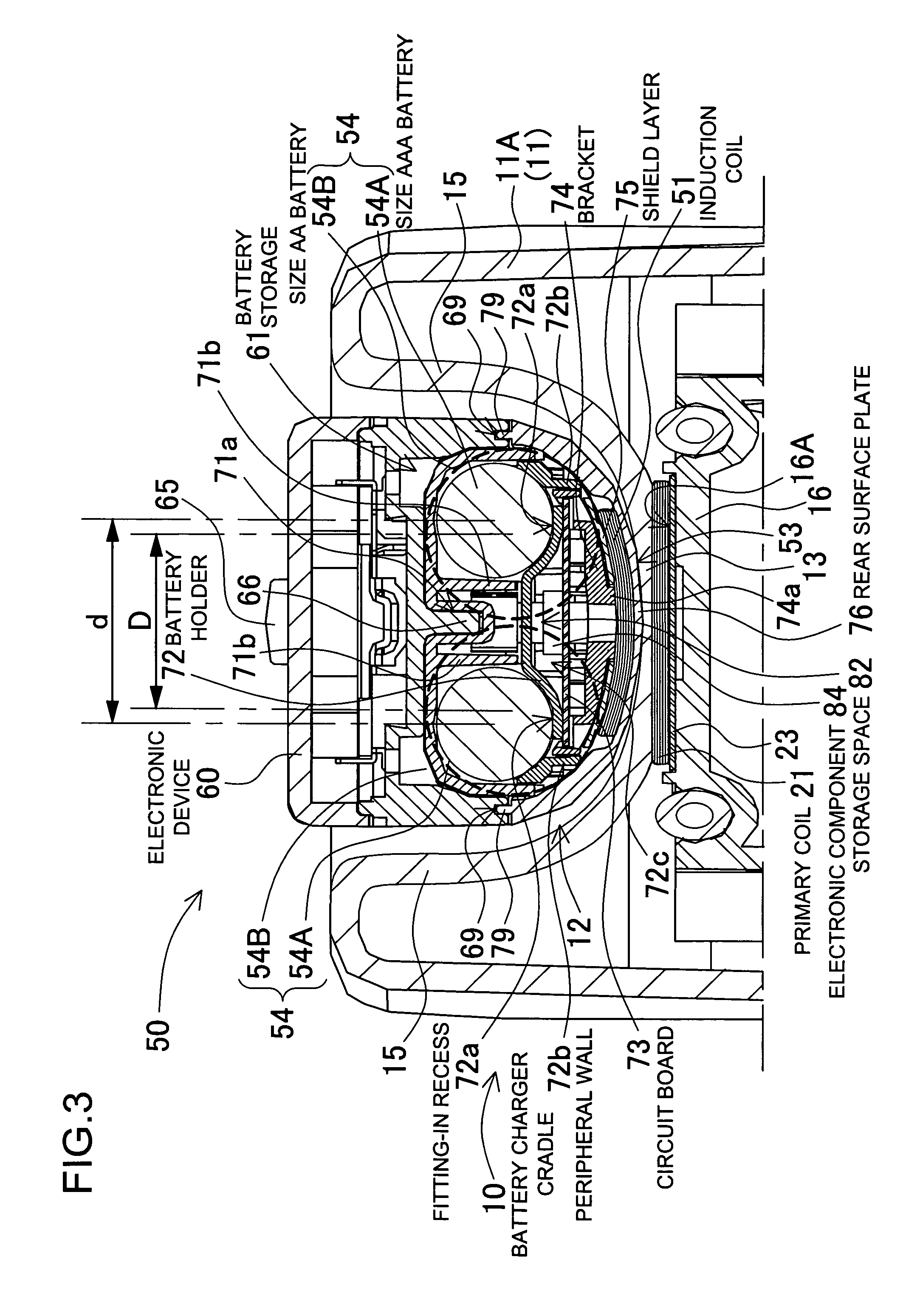

Battery pack

InactiveUS20090267560A1Large charge capacityLong-term useBatteries circuit arrangementsCells structural combinationElectronic componentBattery storage

The battery pack instead of the size AA battery is loaded in a battery storage of an electronic device. The battery pack includes a battery casing, a plurality of size AAA batteries, a battery holder, a circuit board, and an induction coil electromagnetically connected to a primary coil of a battery charger cradle. The size AAA batteries are accommodated in the battery casing in a spaced-apart manner where a distance between longitudinal axes of the size AAA batteries is larger than a distance between longitudinal axes of the size AA batteries loaded in the battery storage, and a storage space is defined between the adjacent size AAA batteries. With an electronic component, mounted on the circuit board, being disposed in the storage space, the battery pack accommodates the size AAA batteries, the battery holder, the circuit board, and the induction coil in a mutually layered state in the battery casing.

Owner:SANYO ELECTRIC CO LTD

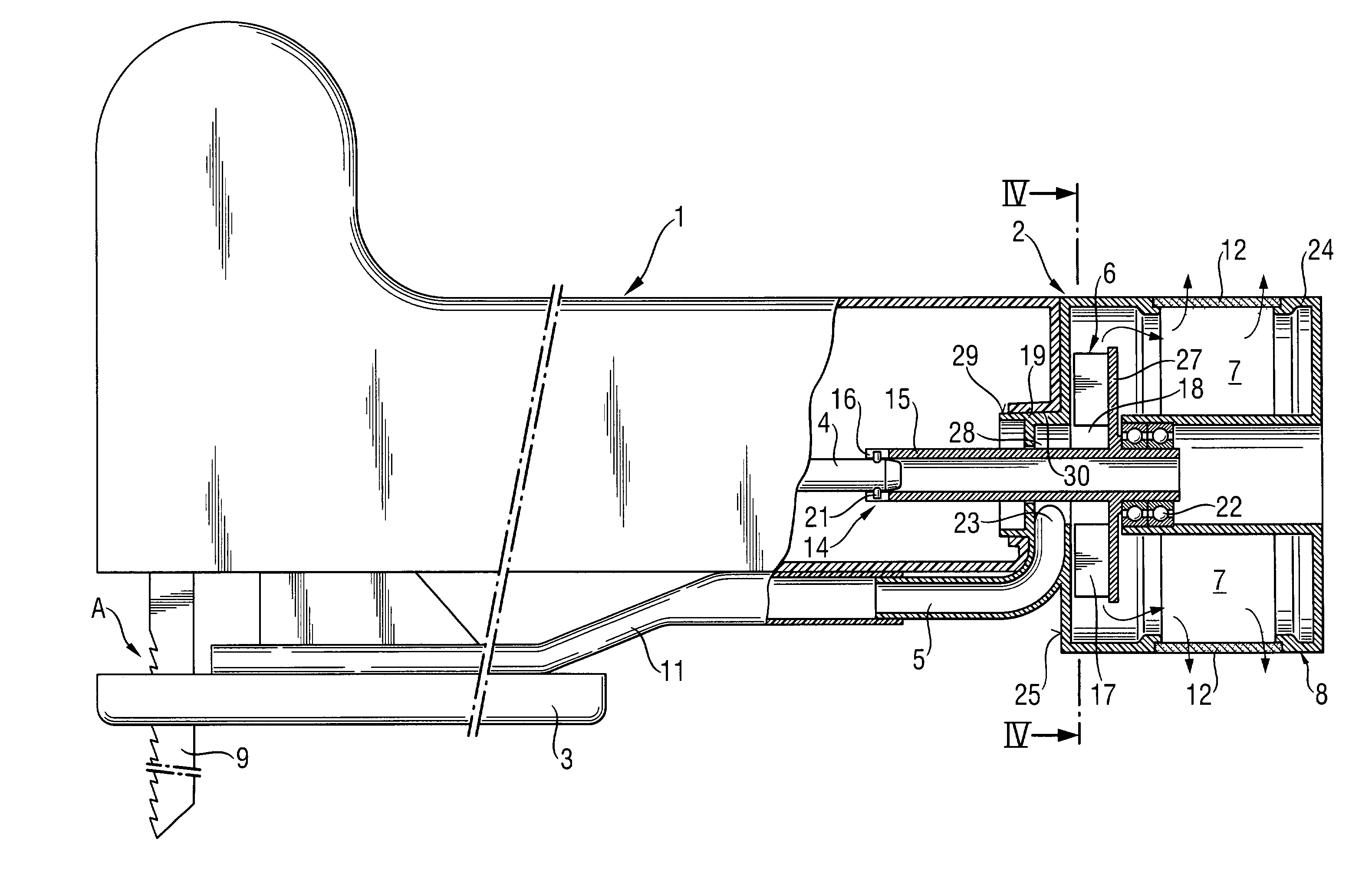

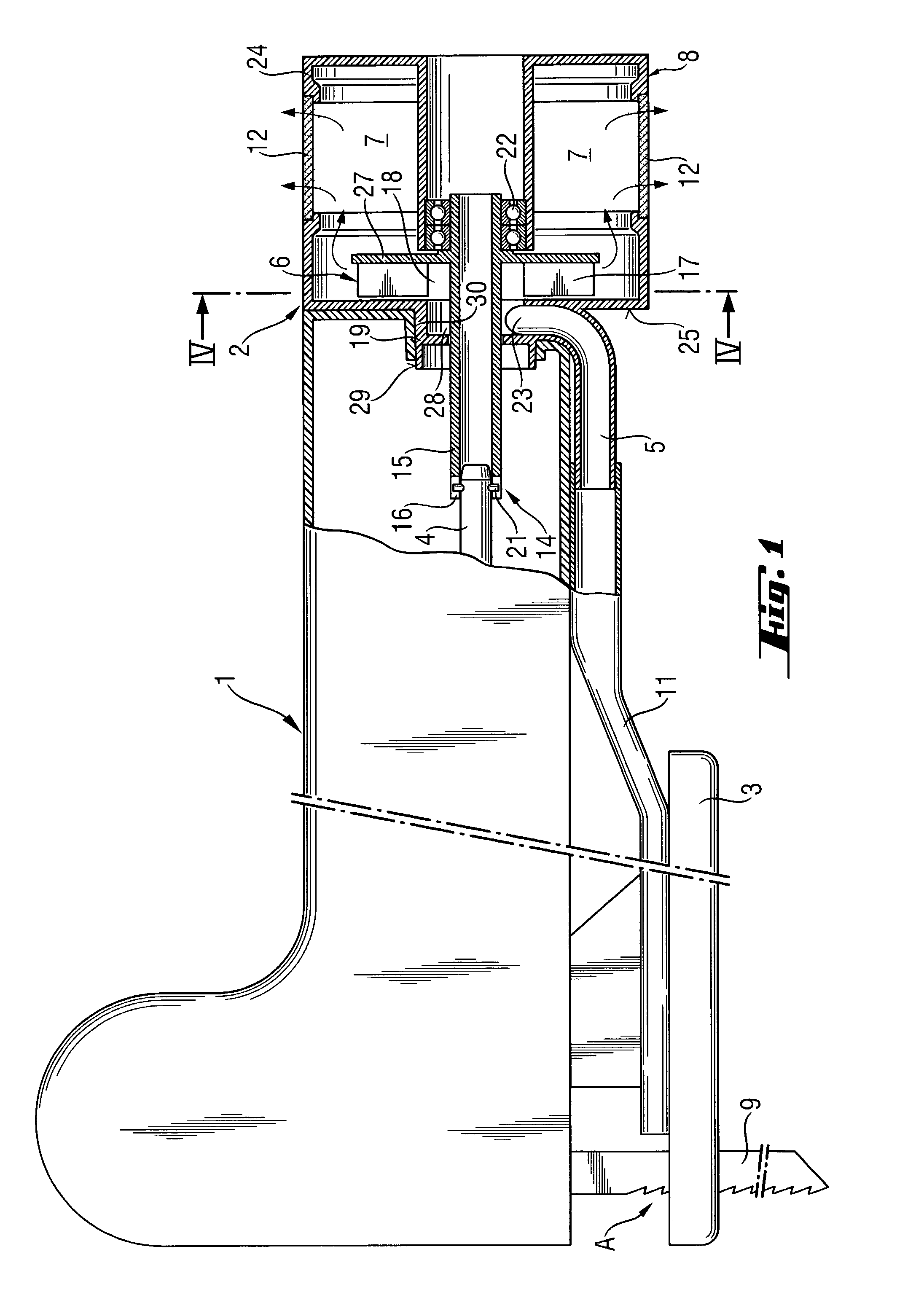

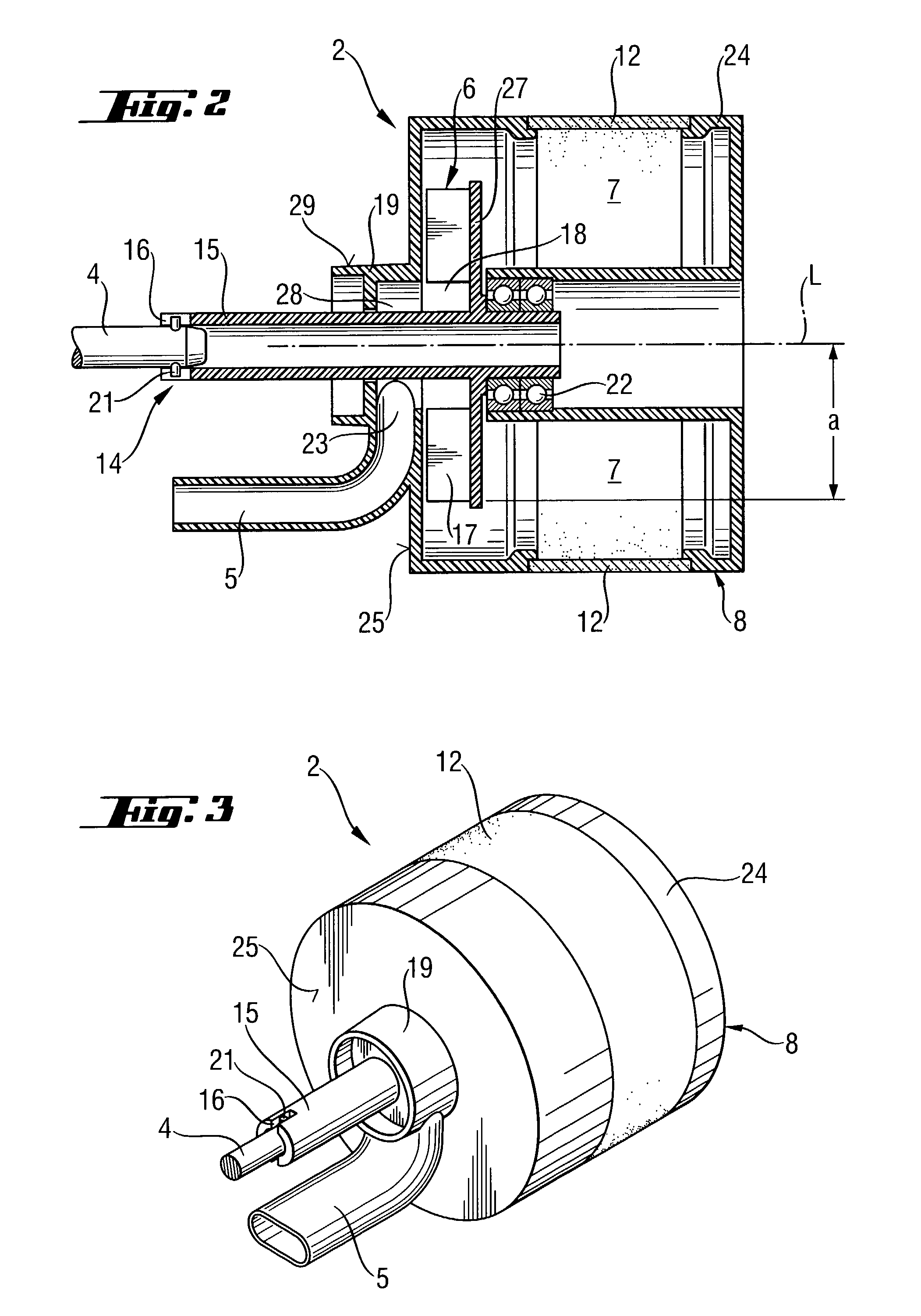

Hand-held power tool with a suction device

ActiveUS7047647B1Easily doLarge surfaceMetal sawing devicesMetal sawing accessoriesPower toolImpeller

A hand-held power tool inclLldes motor-driven drive shaft (4) for driving a working tool (9) and located in the tool housing (1), and a suction device (2) formed as a modular unit releasably connectable wYith the tool housing (1) and having a suction conduit (5), a receiving chamber (7), a precipitation device (8) located in the receiving chamber (7), and an impeller (6) driven by the drive shaft (4) of the power tool and located between the suction conduit (5) and the precipitation device (8).

Owner:HILTI AG

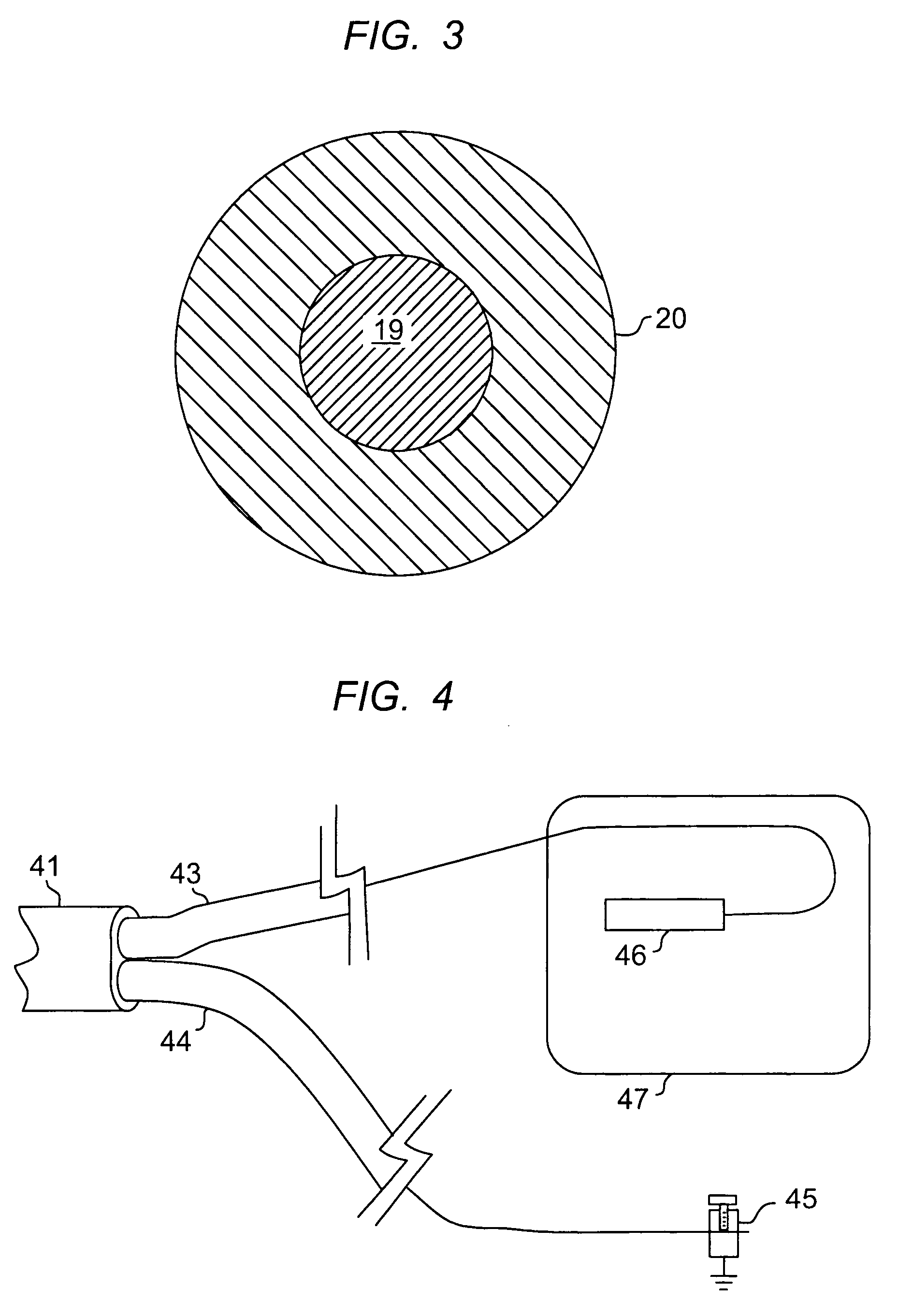

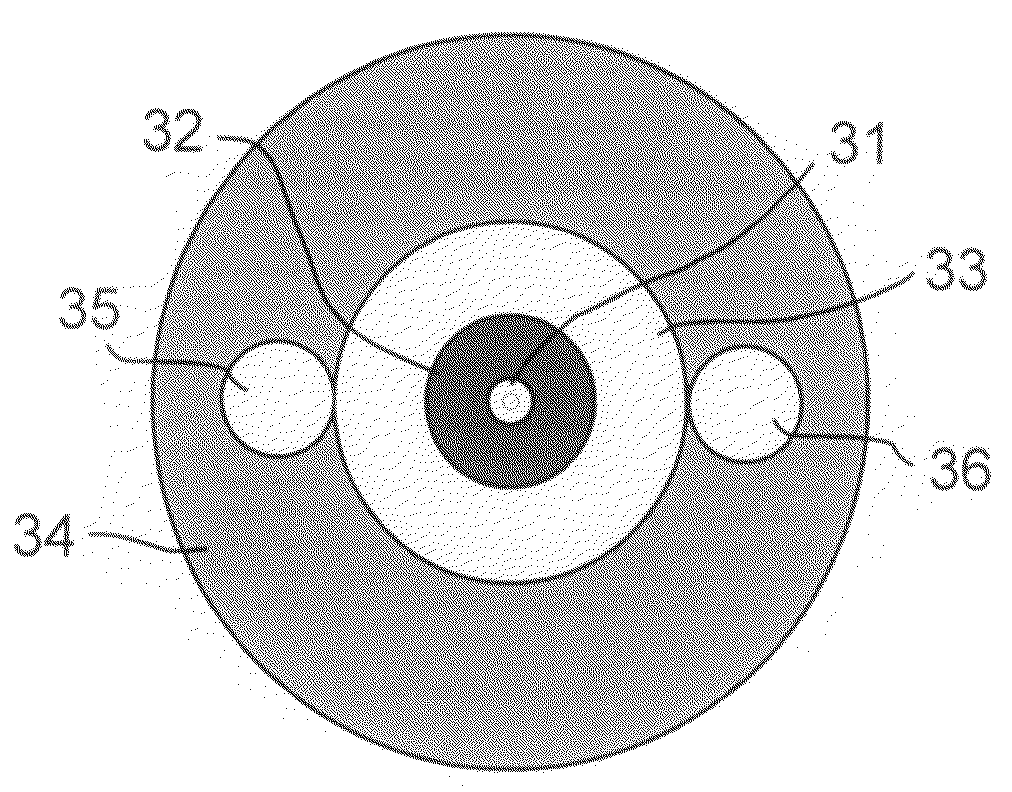

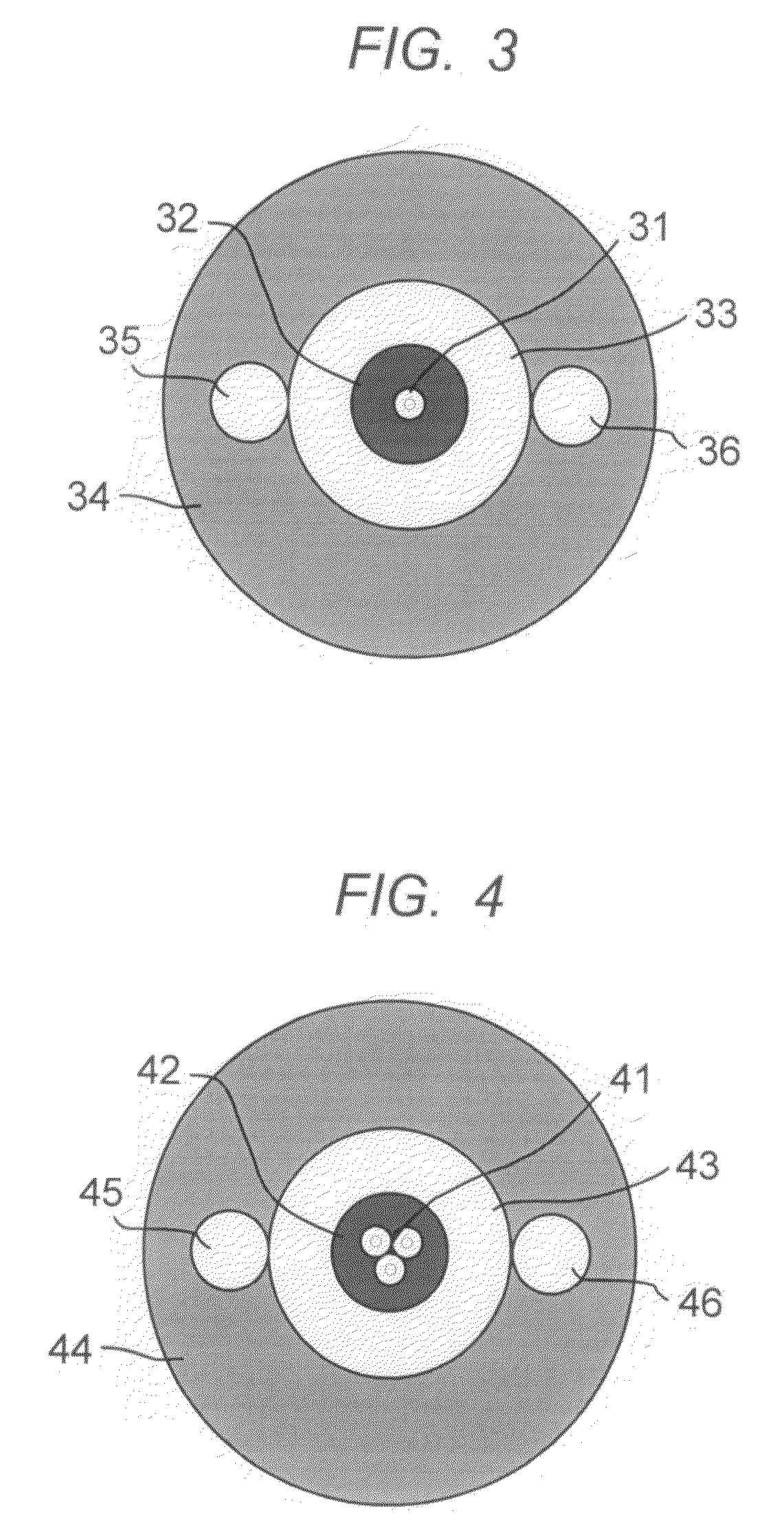

Optical fiber cables

InactiveUS20080273845A1Quick connectionEasy to installFibre mechanical structuresFiberOptical Module

Described is an optical fiber cable designed for drop cable applications that has a compact profile, and is suitable for both the indoor and outdoor portions of the installation. The new design has three functional units, an optical fiber subunit, and two strength members arranged side-by side on either side of the optical fiber. The overall cable cross section round. In a preferred embodiment, the optical fiber module of the cable has a coupled fiber design.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Desktop color image forming apparatus and method of making the same

ActiveUS20050169653A1Compact profileAvoid insufficient lengthElectrographic process apparatusColor imageIntermediate image

The present invention relates to an electrophotographic color image forming apparatus using a tandem-drum development, an indirect image-transfer method, and a vertical sheet supply path. An intermediate image-transfer member is angled relative to a horizontal line such that a rear side of the intermediate image-transfer member away from a recording sheet is lifted and a front side of the intermediate image-transfer member closer to the recording sheet is lowered. Further, image creating mechanisms of the tandem-drum development are aligned and arranged in parallel to a moving image transfer bed of the intermediate image-transfer member, such that one of the image creating mechanisms firstly forming an image faces the rear side of the moving image transfer bed and another one of the image creating mechanisms lastly forming an image faces the front side.

Owner:RICOH KK

Substitute battery pack including a case to accommodate a smaller battery type with an induction coil to facilitate charging

InactiveUS8436576B2Easy to useCompact profileBatteries circuit arrangementsCells structural combinationElectronic componentElectron

A battery pack, instead of size AA batteries, is loaded in a battery storage compartment of an electronic device. The battery pack includes a battery casing, a plurality of size AAA batteries, a battery holder, a circuit board, and an induction coil electromagnetically connected to a primary coil of a battery charger cradle. The size AAA batteries are accommodated in the battery casing in a spaced-apart manner where a distance between longitudinal axes of the size AAA batteries is larger than a distance between longitudinal axes of the size AA batteries loaded in the battery storage compartment, and a storage space is defined between the adjacent size AAA batteries. With an electronic component, mounted on the circuit board, being disposed in the storage space, the battery pack accommodates the size AAA batteries, the battery holder, the circuit board, and the induction coil in a mutually layered state in the battery casing.

Owner:SANYO ELECTRIC CO LTD

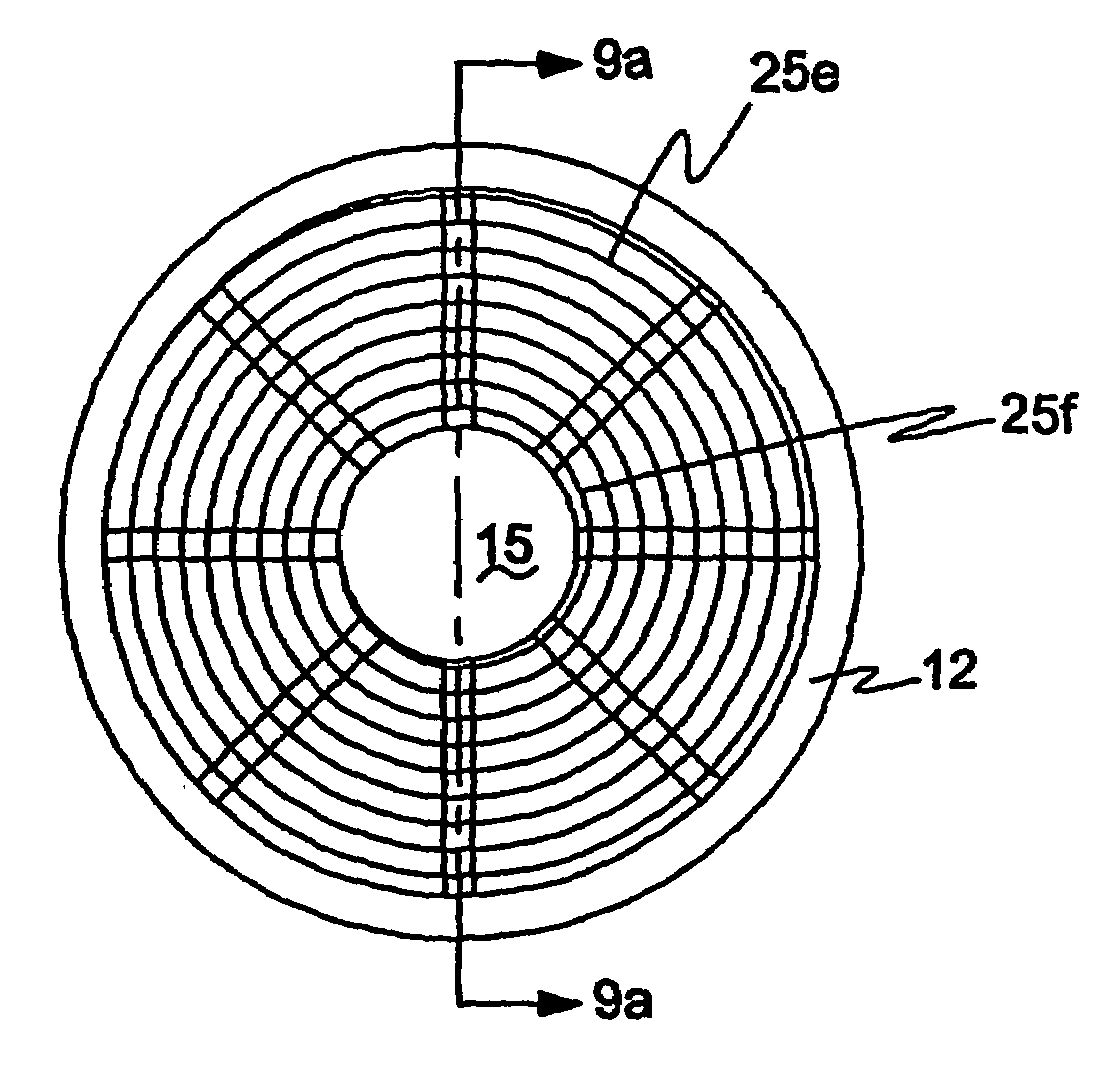

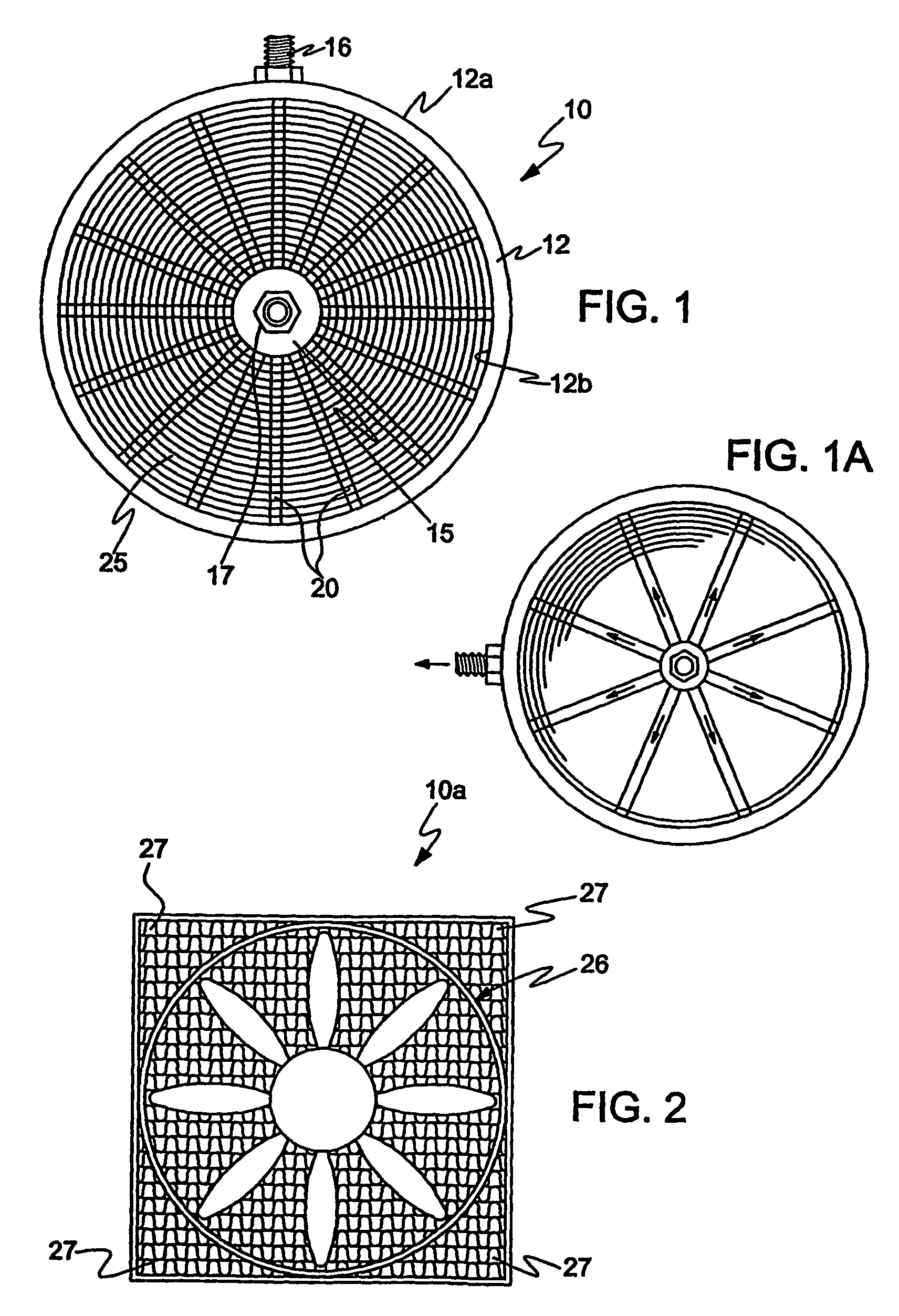

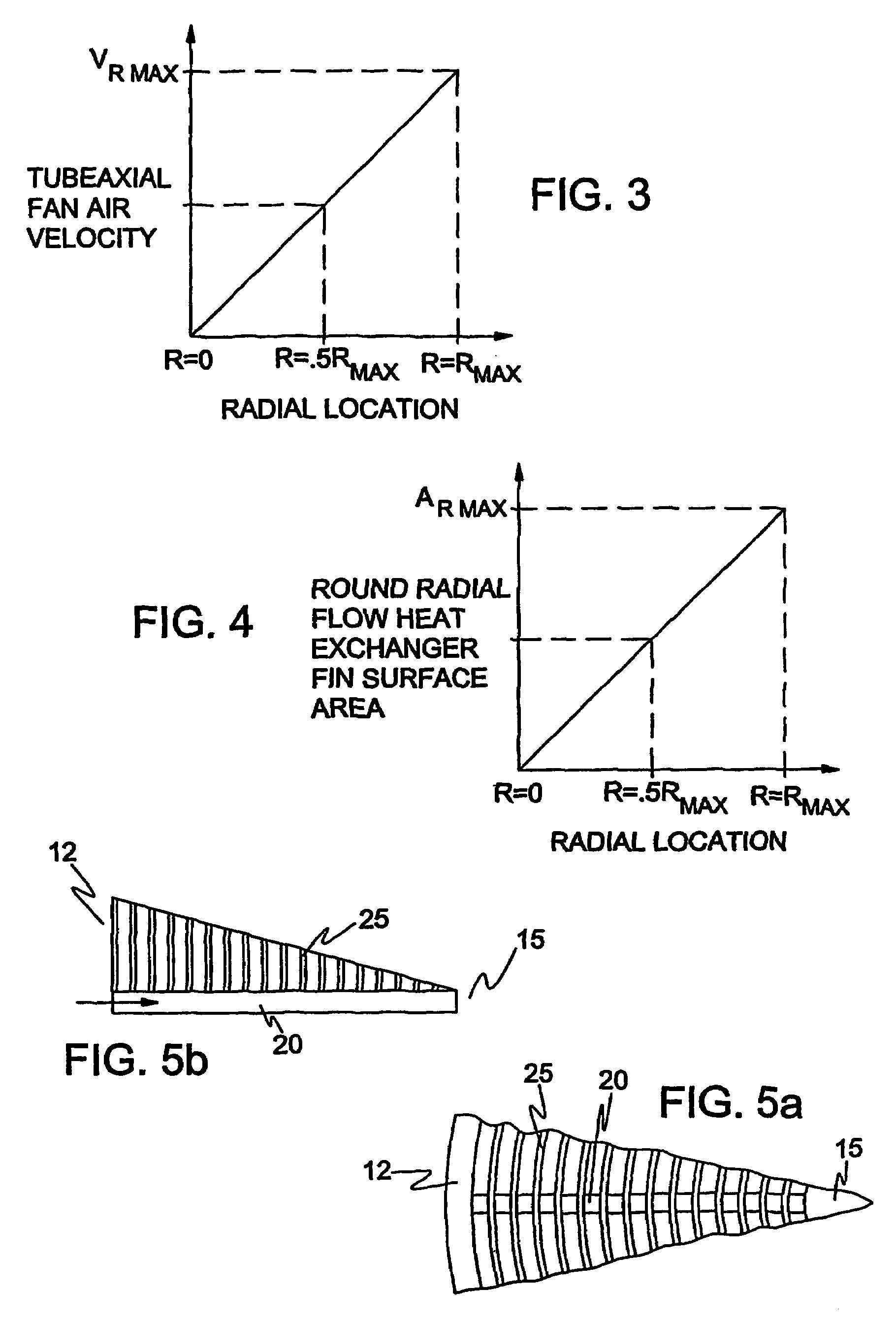

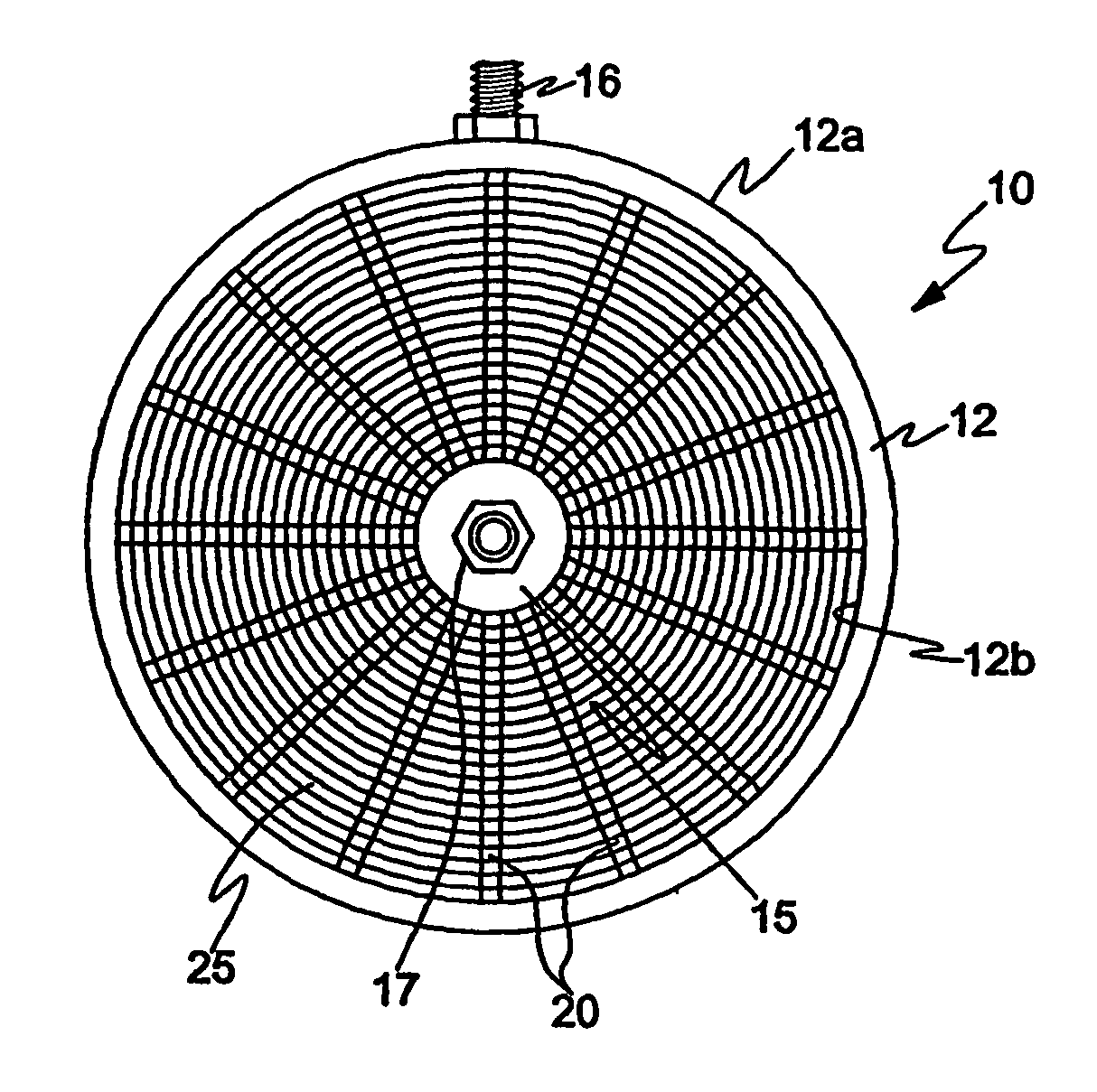

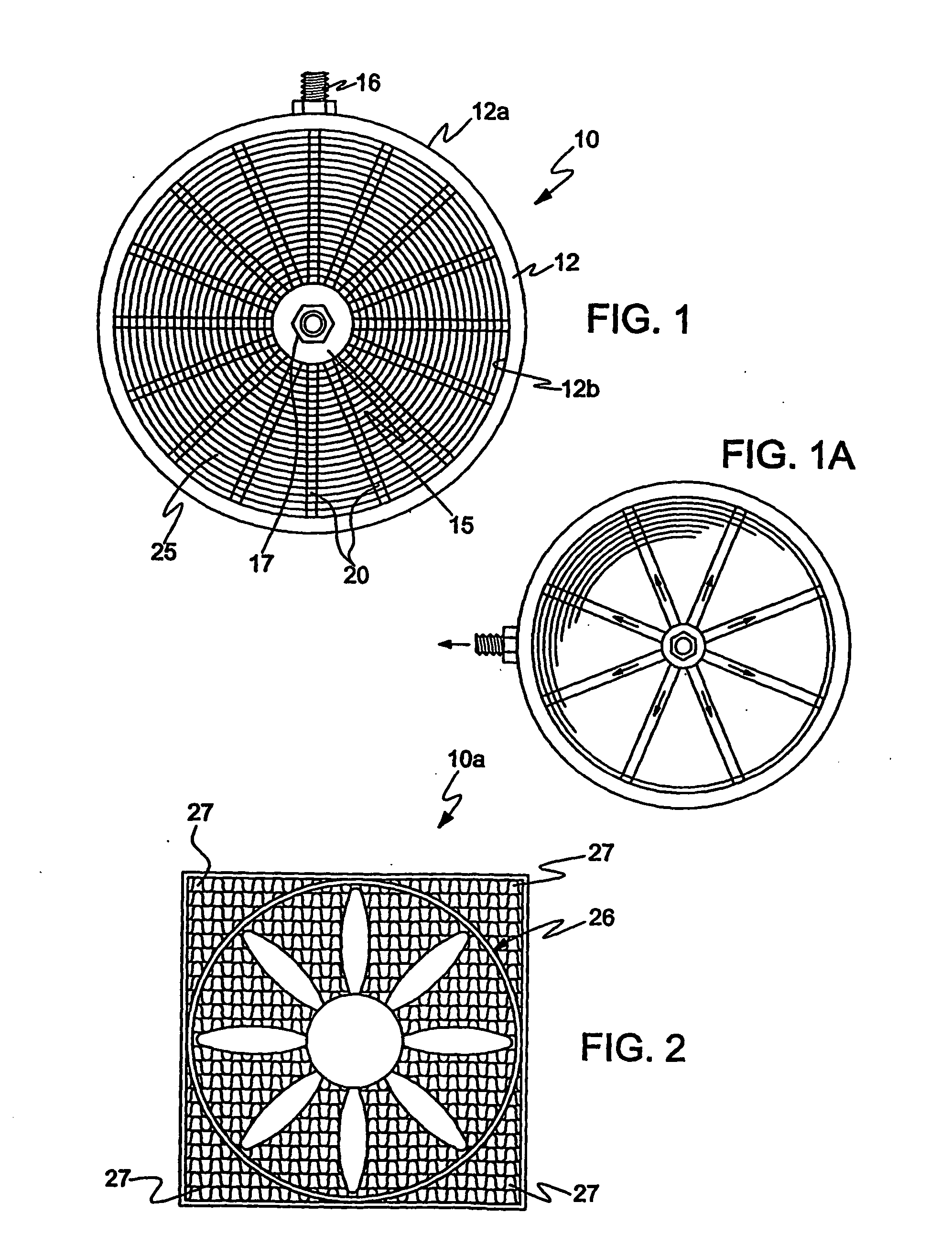

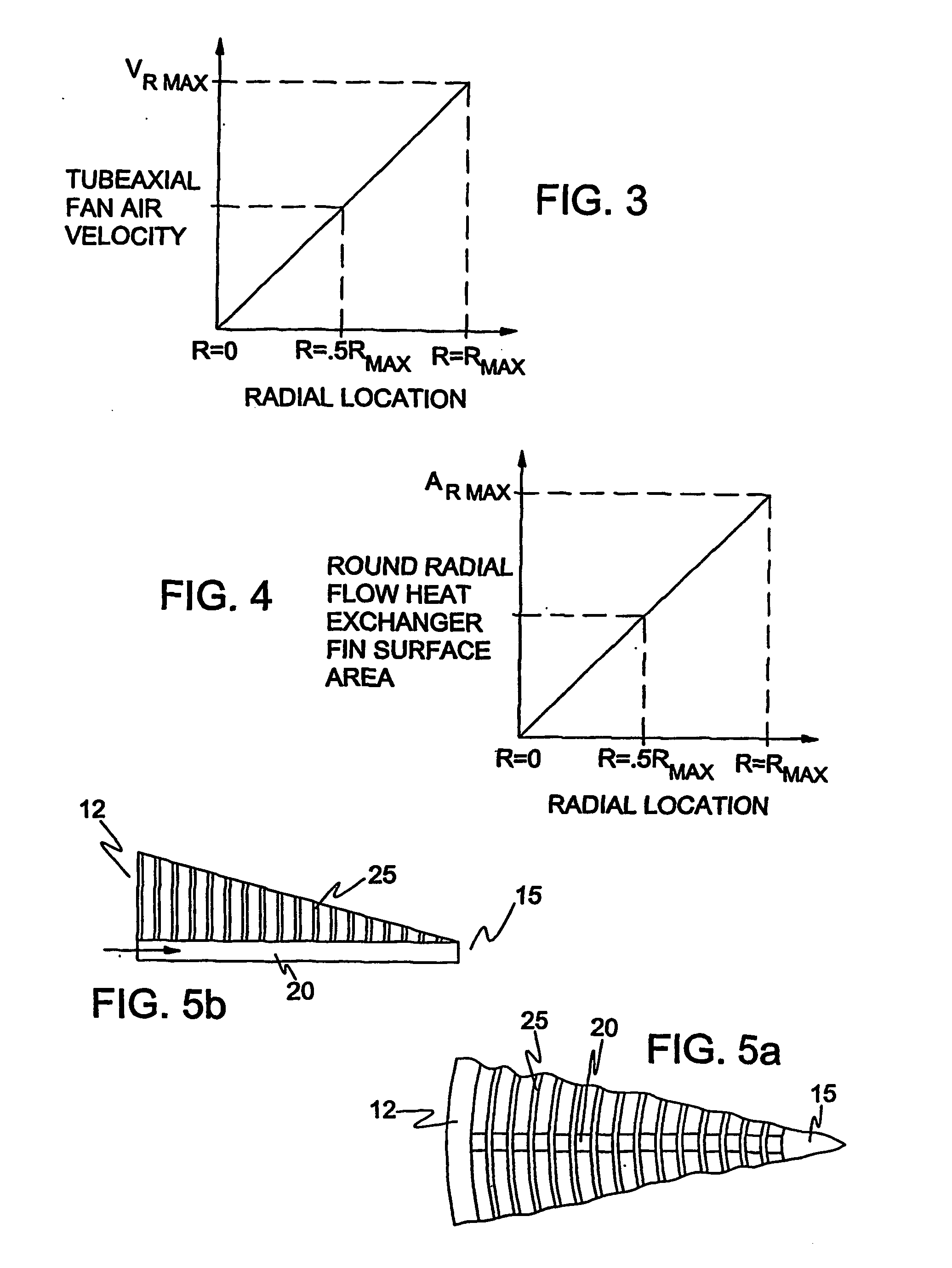

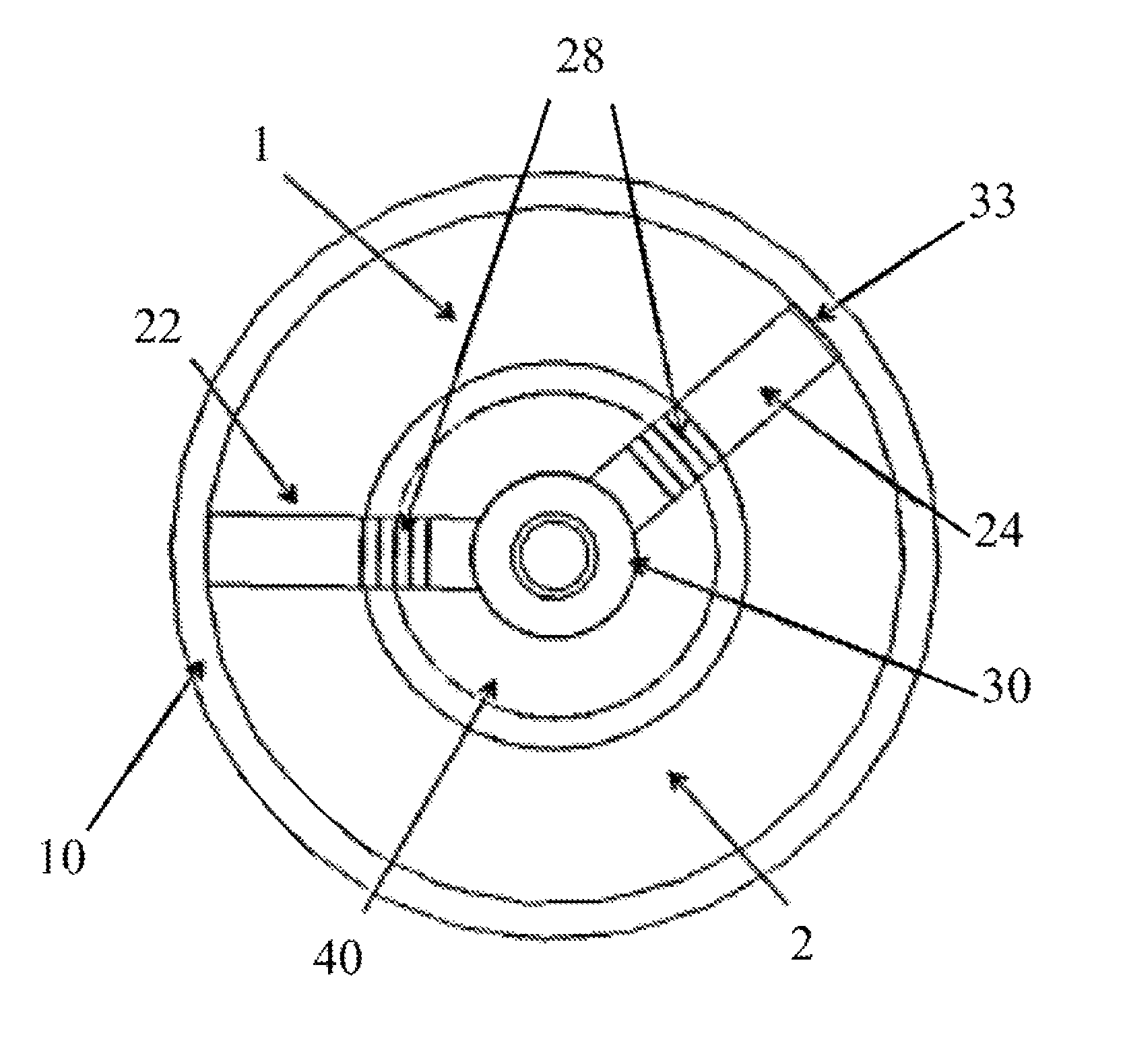

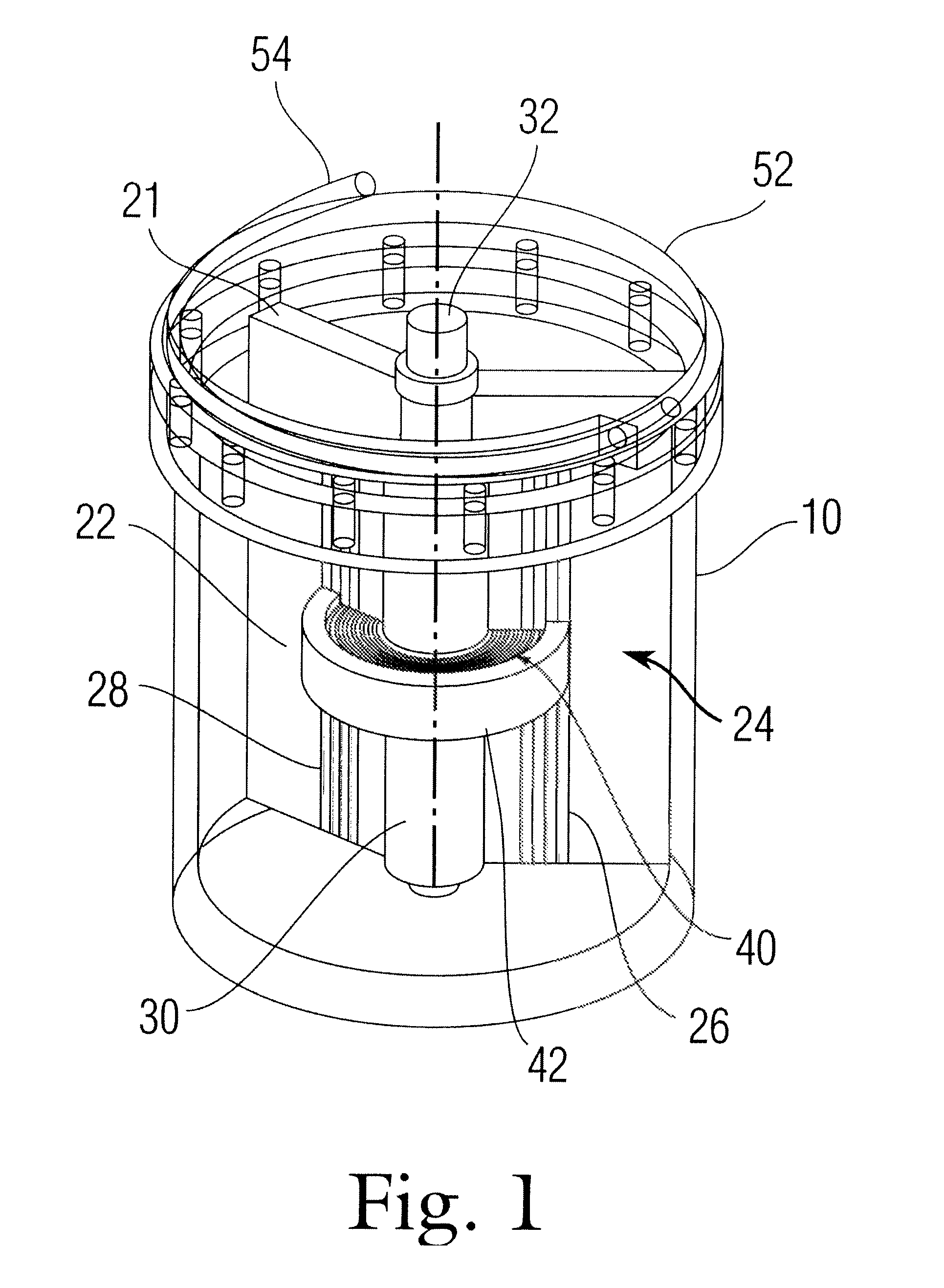

Radial flow heat exchanger

InactiveUS7128136B2Compact profileEasy to manufactureMetal-working apparatusStationary conduit assembliesHeat conductingHeat exchanger

A radial flow heat exchanger for heating or cooling a fluid includes a sealed fluid manifold for passage of fluid. A sealed fluid receiving hub is spaced interiorly of the interior peripheral portion of the manifold and includes a passageway for passage of fluid into or out of the heat exchanger. A plurality of separate and spaced fluid flow tubes are disposed between the manifold and the hub. Each of the tubes are in sealed fluid communication with the manifold at one end and the other end is in sealed fluid communication with the hub. A fin assembly is positioned between the manifold and the hub and includes a heat conducting material arranged at spaced intervals between the manifold and the hub, the heat conducting material including a plurality of spaced apertures through which tubes pass. The heat conducting material is in intimate heat conducting contact with the tubes whereby fluid flowing between the manifold and the hub flows into each of the tubes in a radial direction between the manifold and the hub and wherein the heat conducting material of the fin assembly operates to give up or pick up heat from the fluid through the wall of the tubes.

Owner:GREGORY CHRISTIAN T

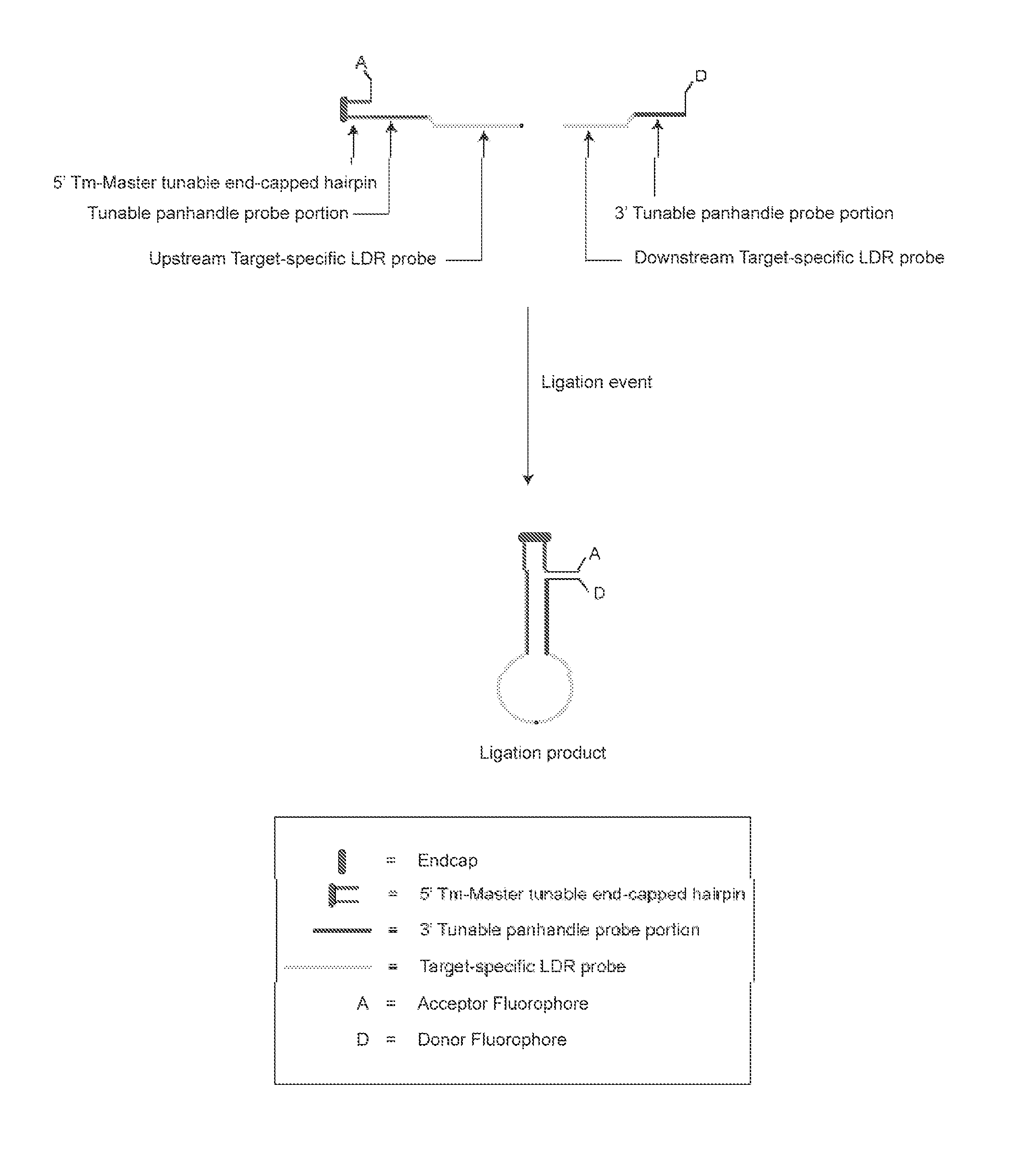

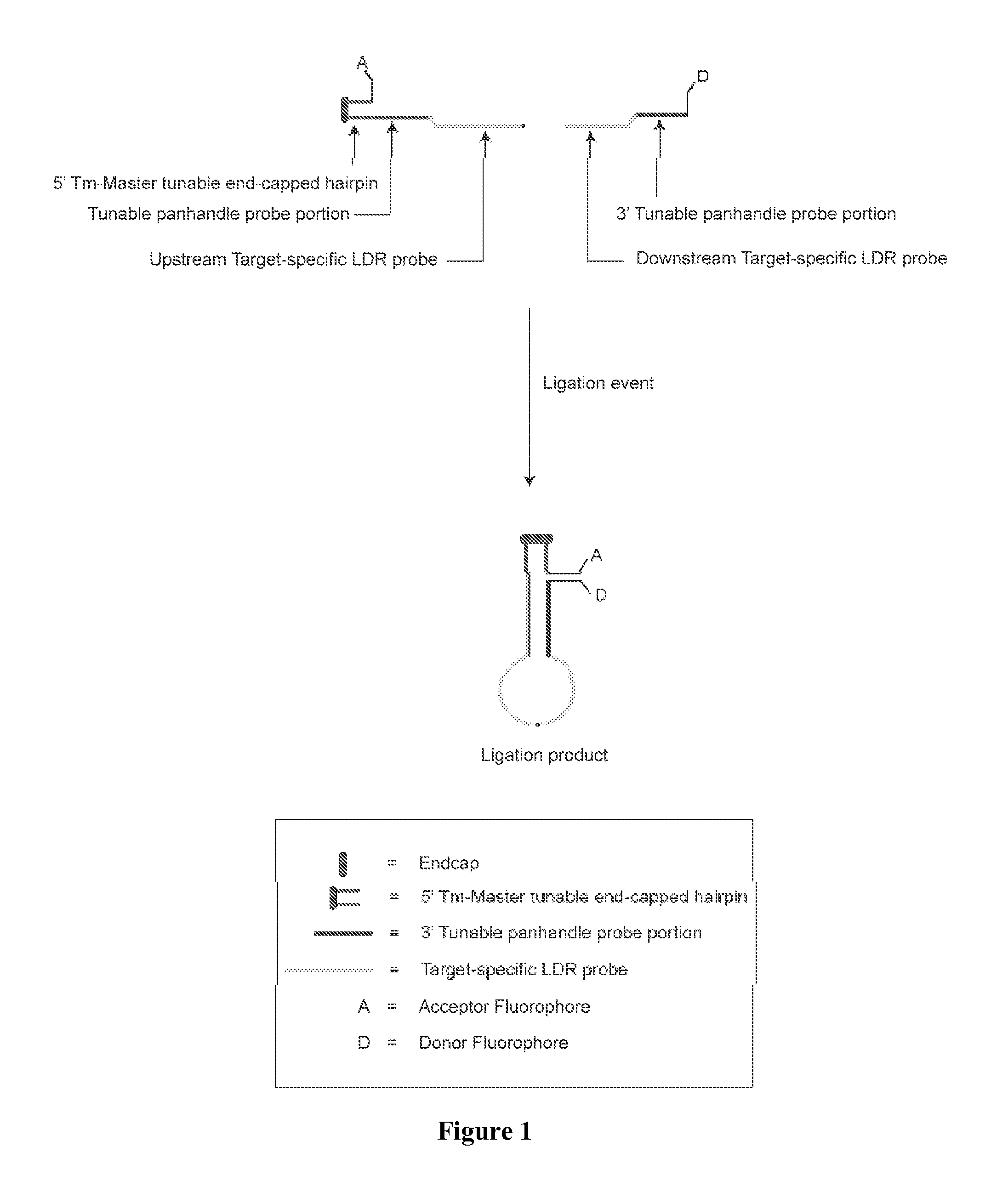

Detection of target nucleic acid sequences using fluorescence resonance energy transfer

InactiveUS20110136116A1Overcome deficienciesEasy to distinguishMicrobiological testing/measurementBiological testingNucleotideNucleic acid sequencing

A method for identifying a plurality of target nucleic acid molecules in a sample. The method provides a plurality of oligonucleotide probe sets. Each set comprises a first and a second probe, each having a target-specific portion and a tunable portion with an acceptor or a donor group. The first probe further comprises an endcapped hairpin. A reaction comprises a denaturation and hybridization cycle. Under the hybridization, the set of probes hybridize in a base-specific manner to their respective target nucleotide sequences, and ligate to one another to form a ligation product. Under conditions that permit hybridization of the tunable portions of the ligation product to one another, an internally hybridized ligation product formed, which allows the detection of the fluorescence resonance energy transfer (FRET). A method comprising PCR amplification is also disclosed.

Owner:PURDUE RES FOUND INC +1

Low profile flip up site

ActiveUS20050188602A1Streamlining profileSimple finger movementSighting devicesEngineeringRepeatability

A low profile, self-aligning, flip-up mechanism for aiming devices used with firearms. The mechanism folds the aiming device into the contour of the firearm during non-use. The mechanism is spring-loaded and flips into a vertical operational position with a simple movement of a finger or thumb. The mechanism includes at least two separate aiming elements that are mounted in a fashion that allows them to rotate relative to one another thereby facilitating a smaller storage profile. The mechanism also causes the aiming device to self-align itself as it moves into an operational position assuring vertical position repeatability.

Owner:SWAN RICHARD E

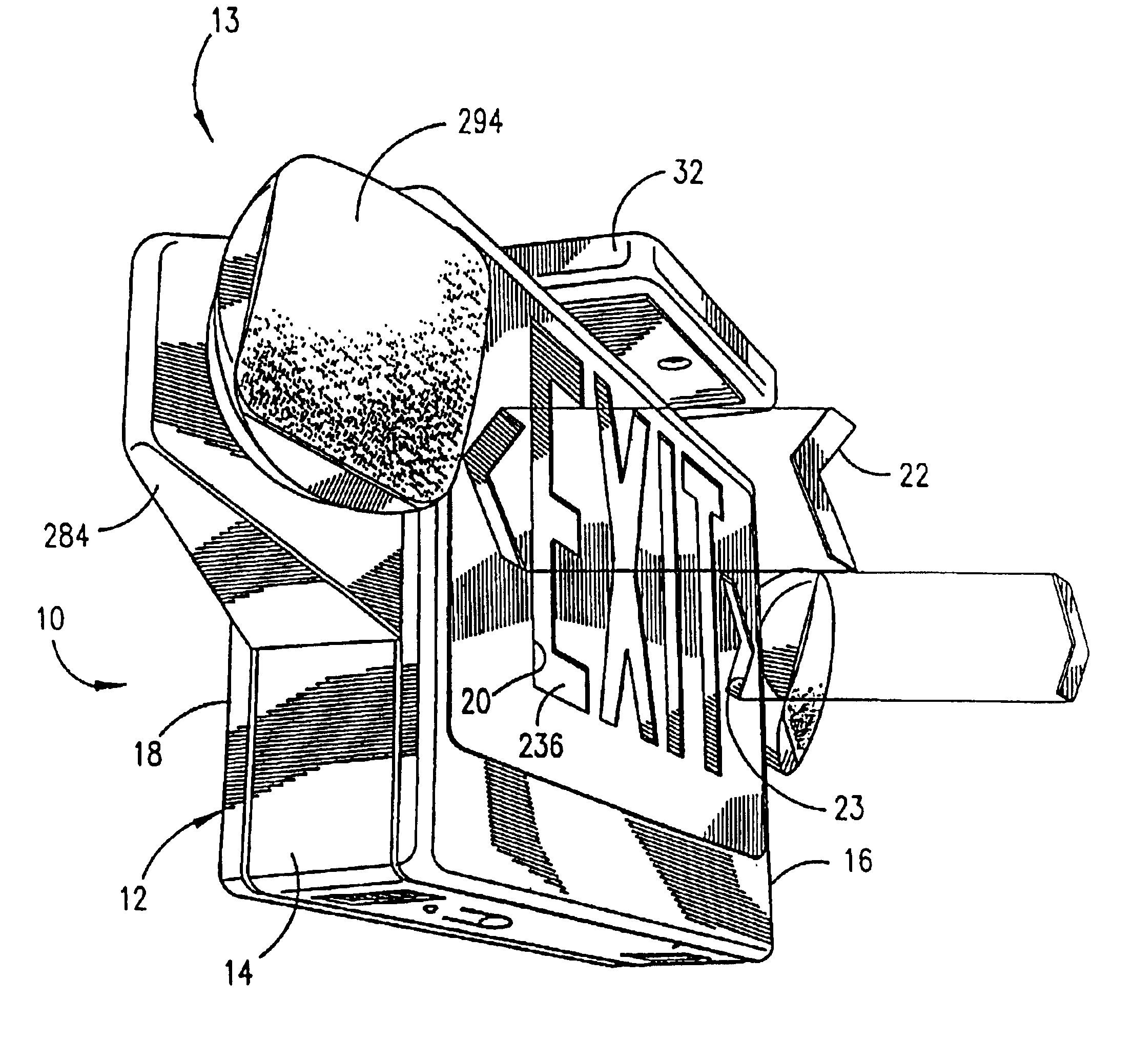

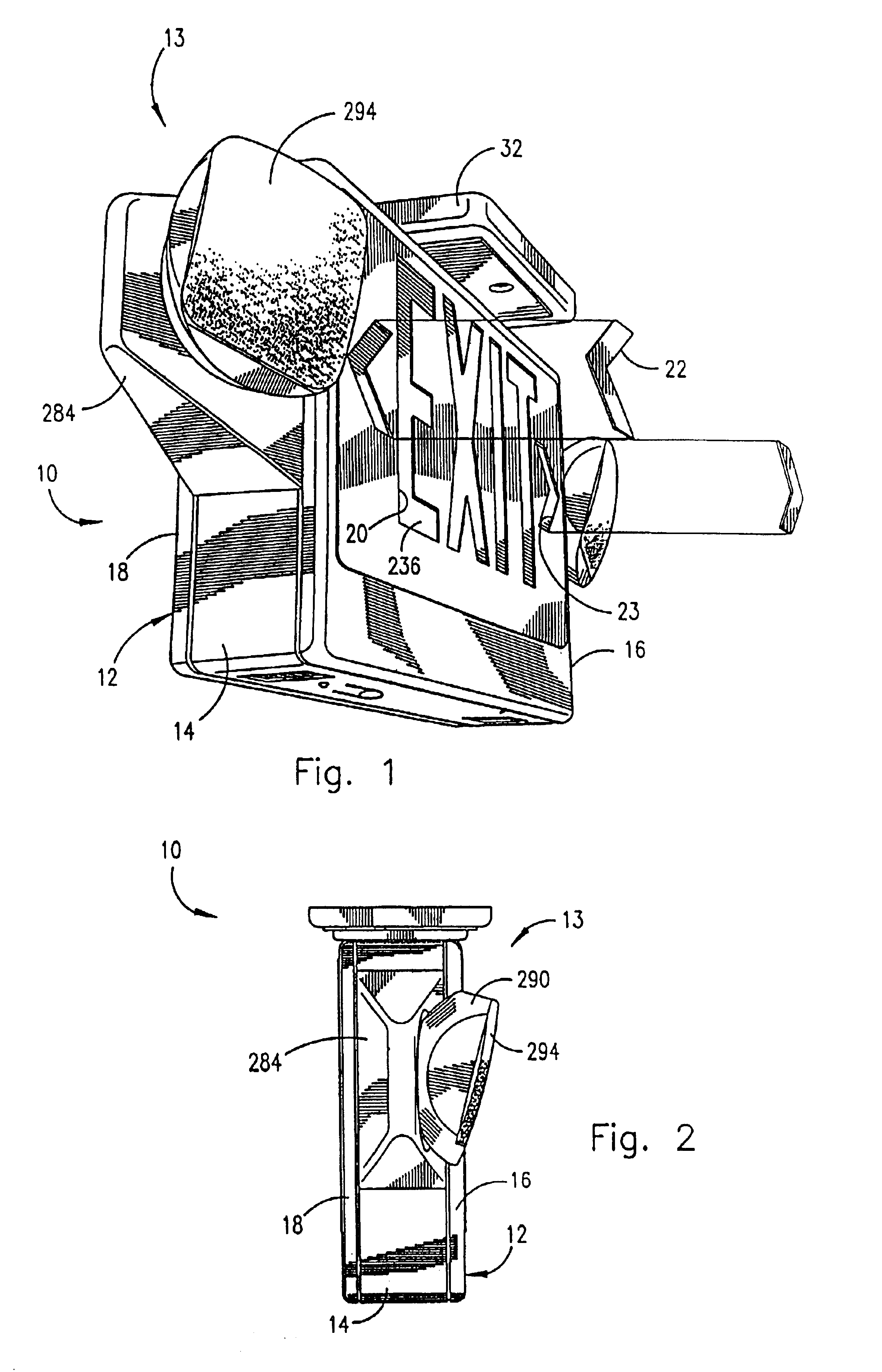

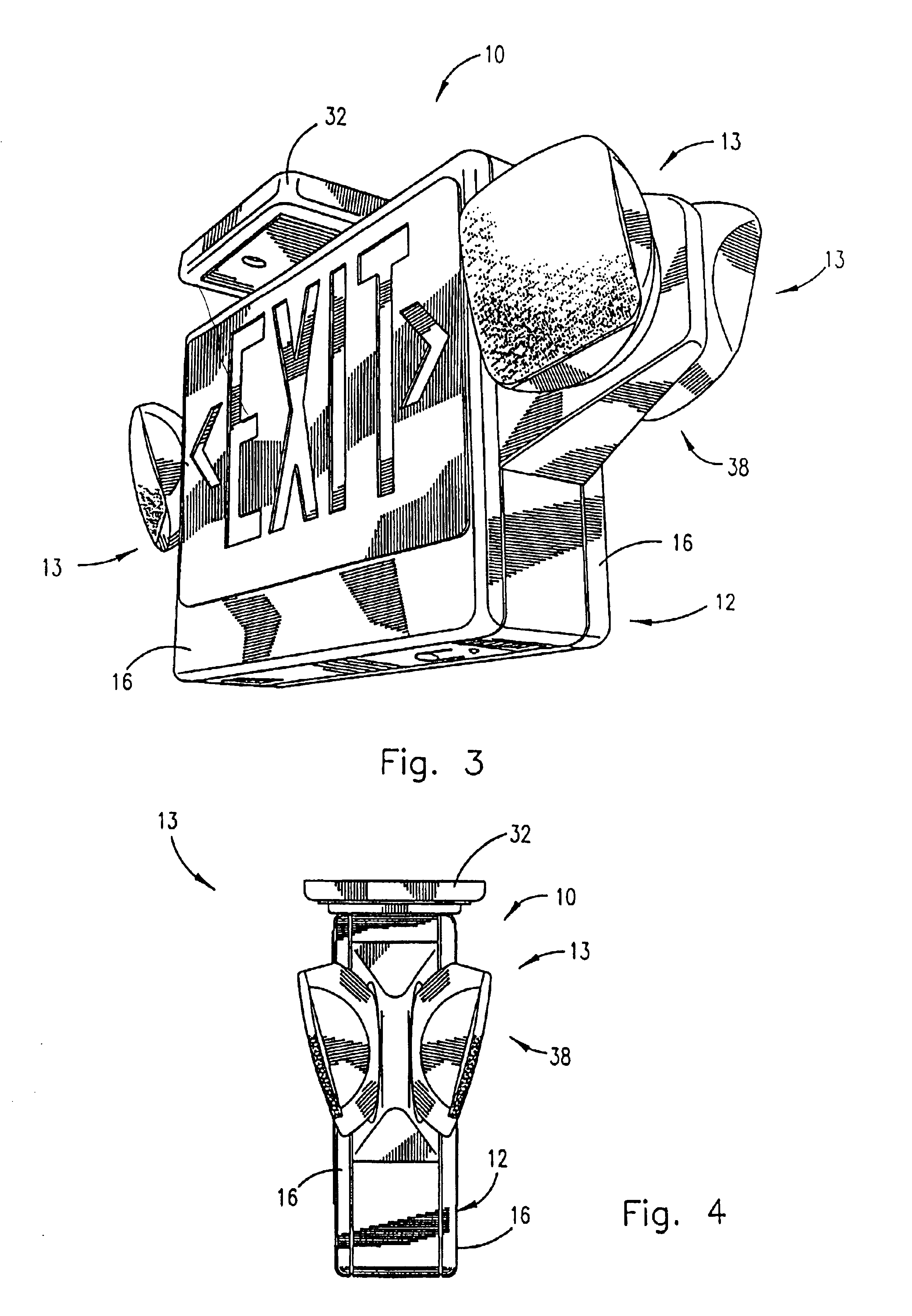

Emergency lighting unit/exit sign combination

InactiveUS6848798B1Extraordinary flexibilityEasy to assembleLighting support devicesVehicle interior lightingEffect lightEngineering

An emergency lighting fixture combining the functions of an illuminated sign such as an exit sign and an emergency lighting unit integrated into one housing onto which one or more emergency lights can be mounted at predetermined locations of the housing, the combined emergency lighting structure providing both exit location information and ambient emergency lighting in a single cooperatively operating device.

Owner:ABL IP HLDG

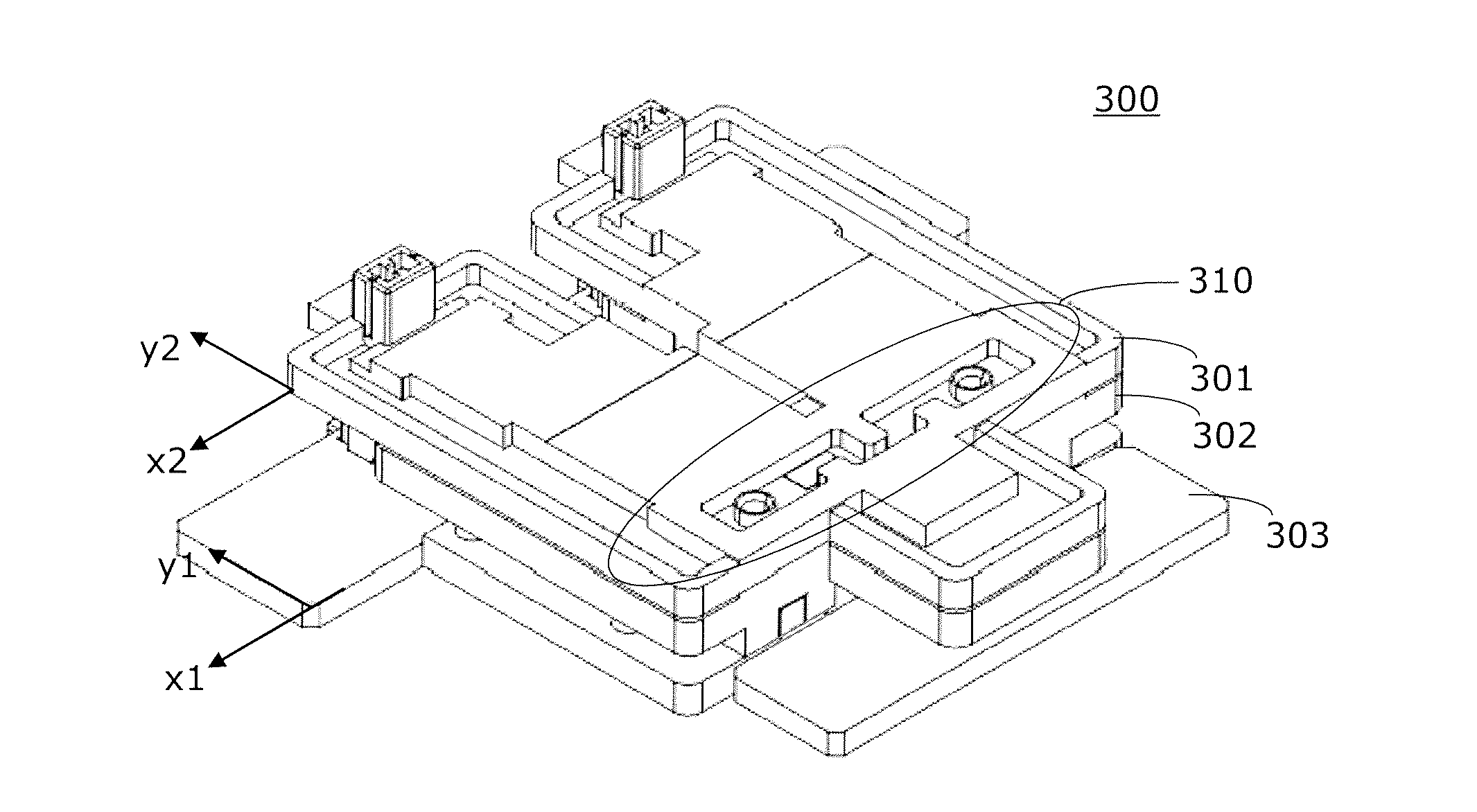

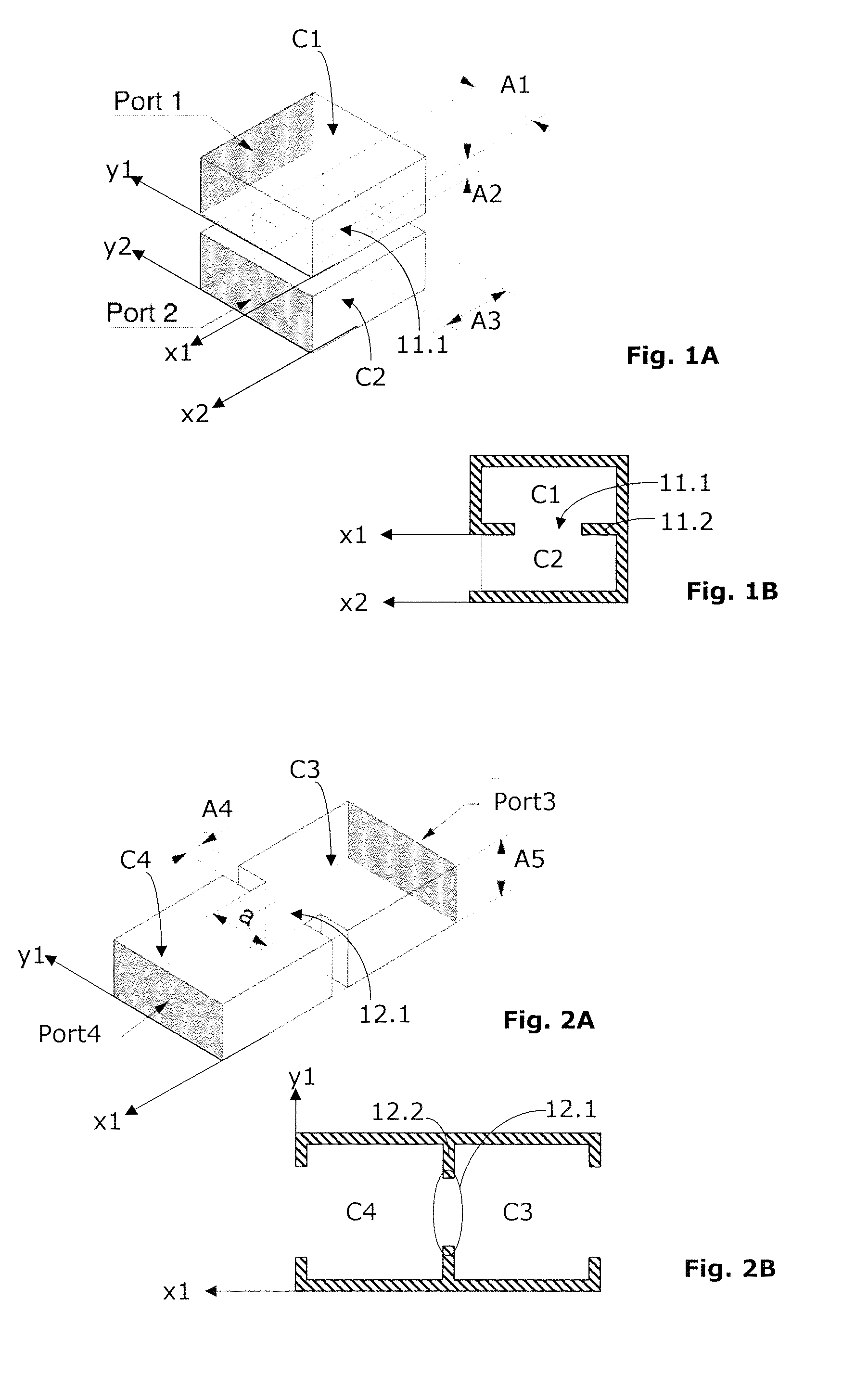

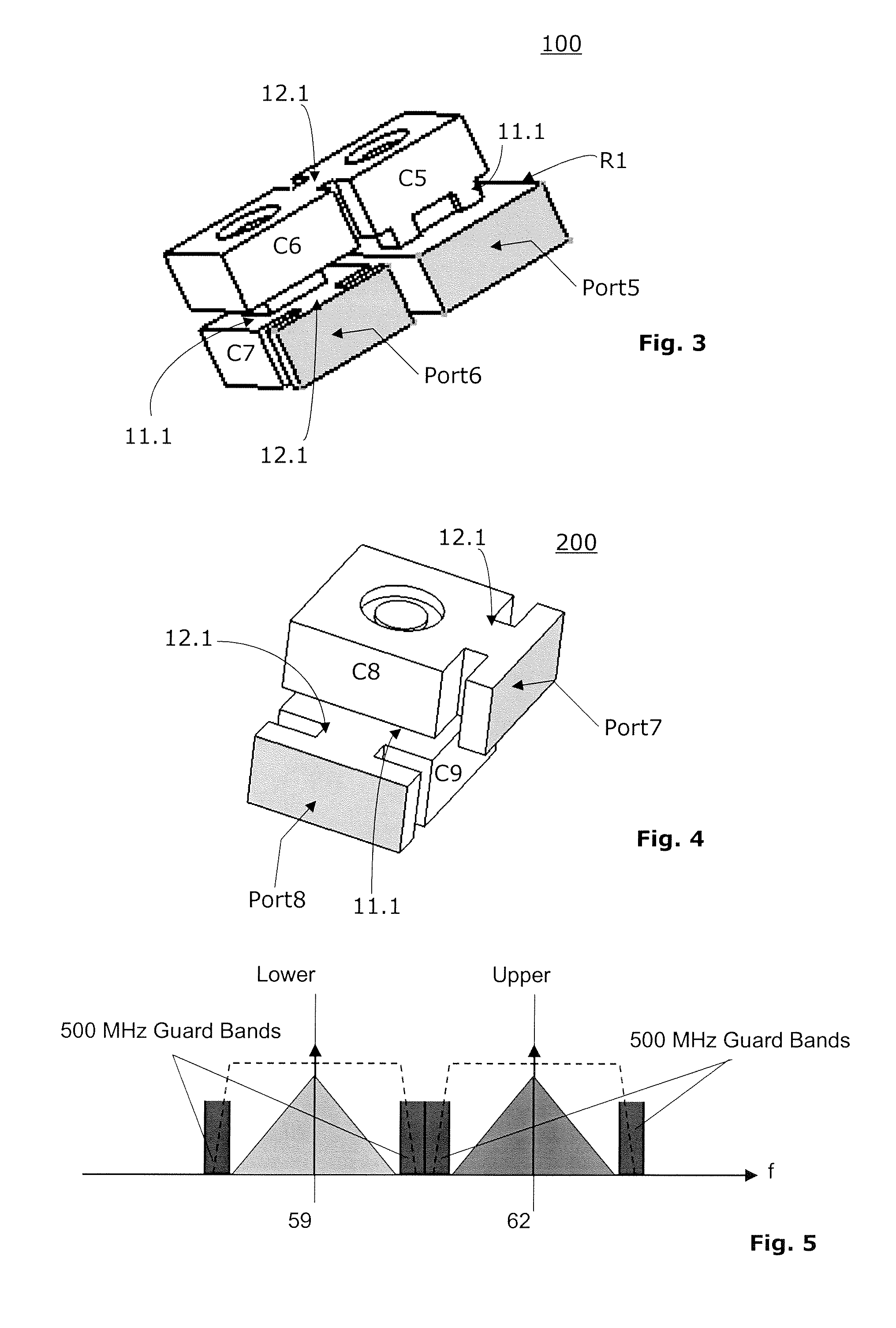

Filter assemblies and communication systems based thereon

A filter assembly (300) with a plurality of cavities serving as said waveguide resonators is presented. The cavities are arranged at least on two levels (x1, y1; x2, y2) of said filter assembly (300). Two or three molded filter parts (301, 302, 303) define the cavities, when the filter parts (301, 302, 303) are assembled. A first opening in a wall between a first and a second of cavity is provided. Said opening serves as capacitive junction between said first cavity and said second cavity. A second opening is provided in another wall between a third cavity and a fourth cavity, said opening serving as inductive junction. The filter parts (301, 302, 303) are at least partially covered by a metal layer.

Owner:HUBERSUHNER AG

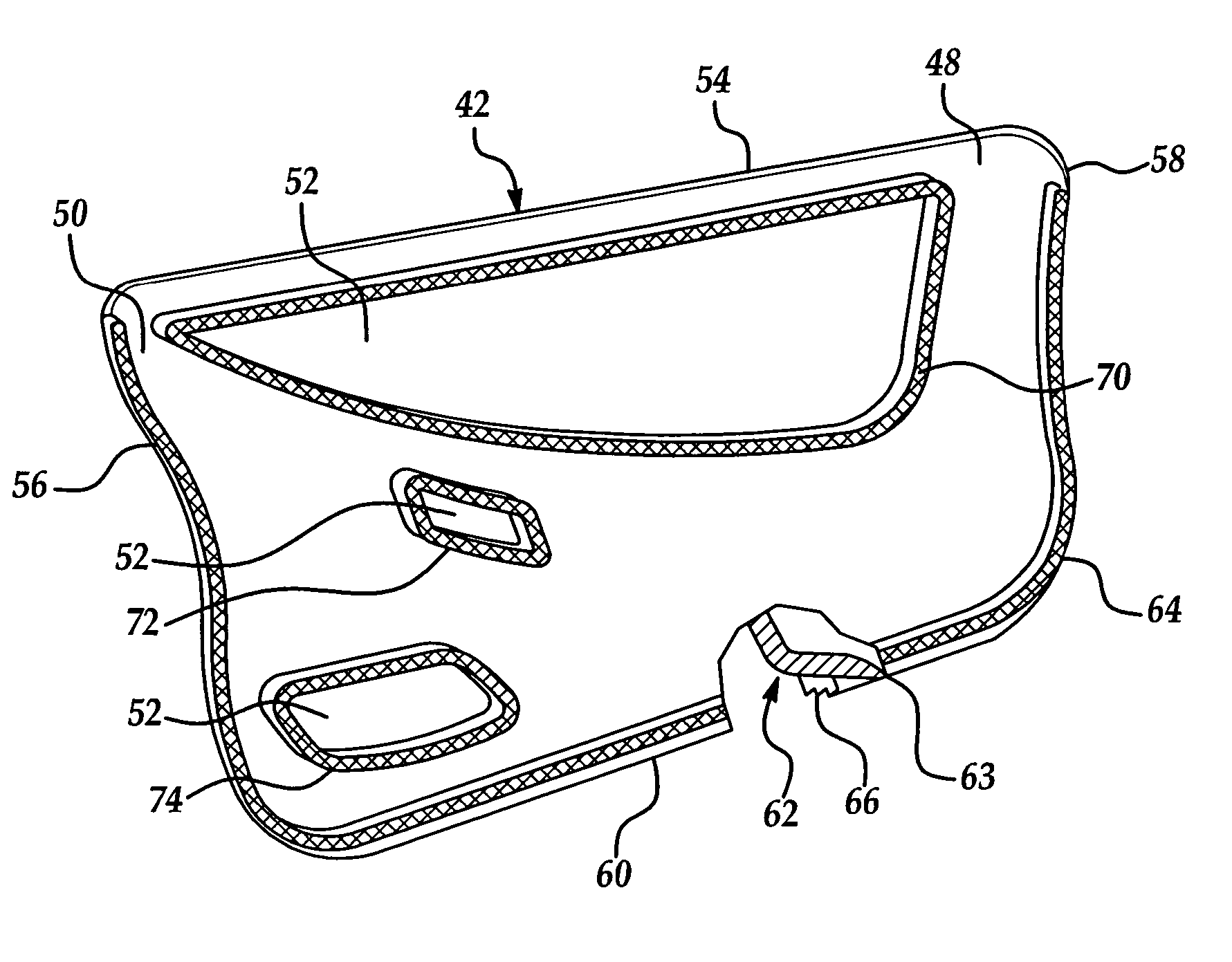

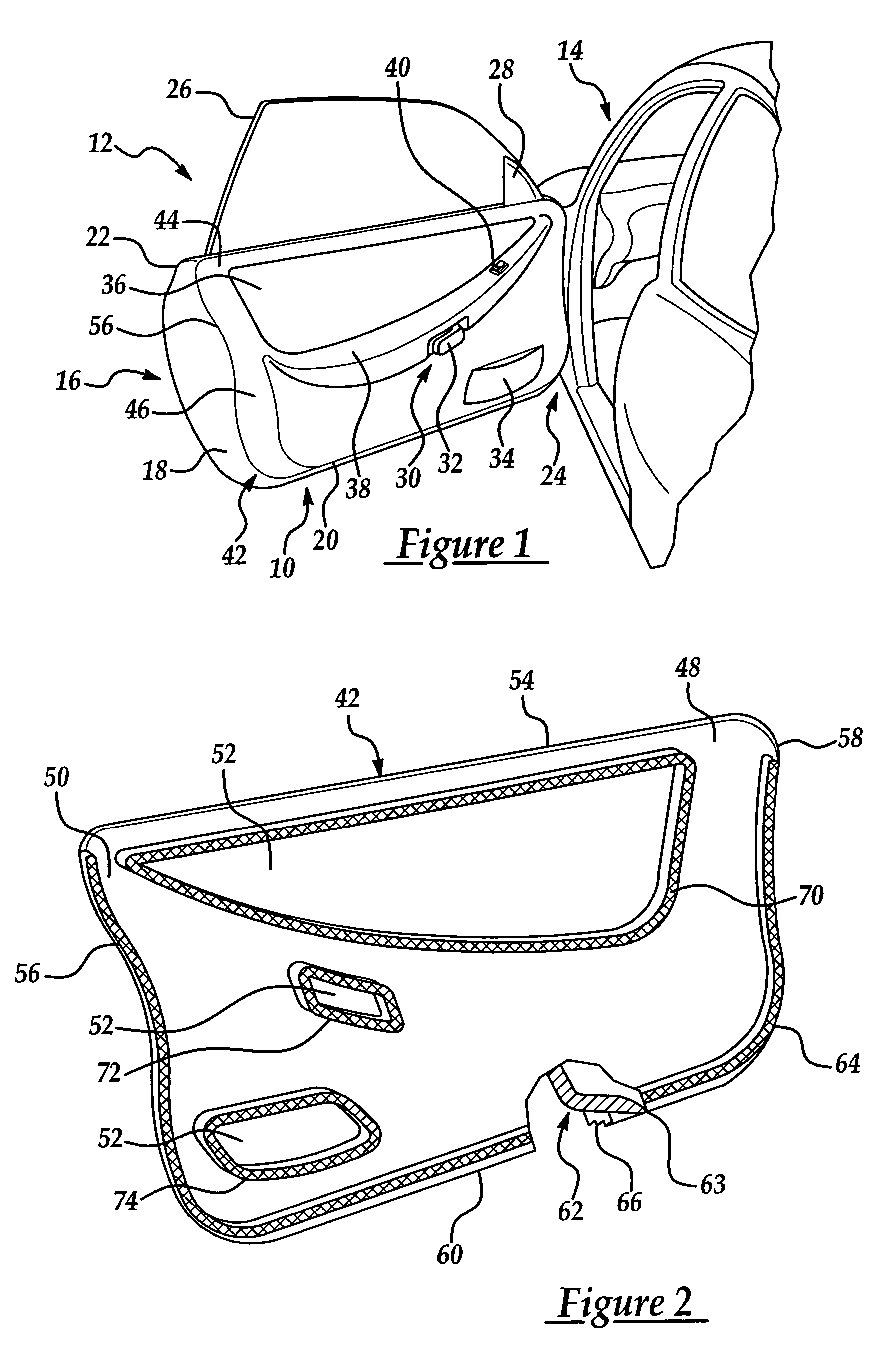

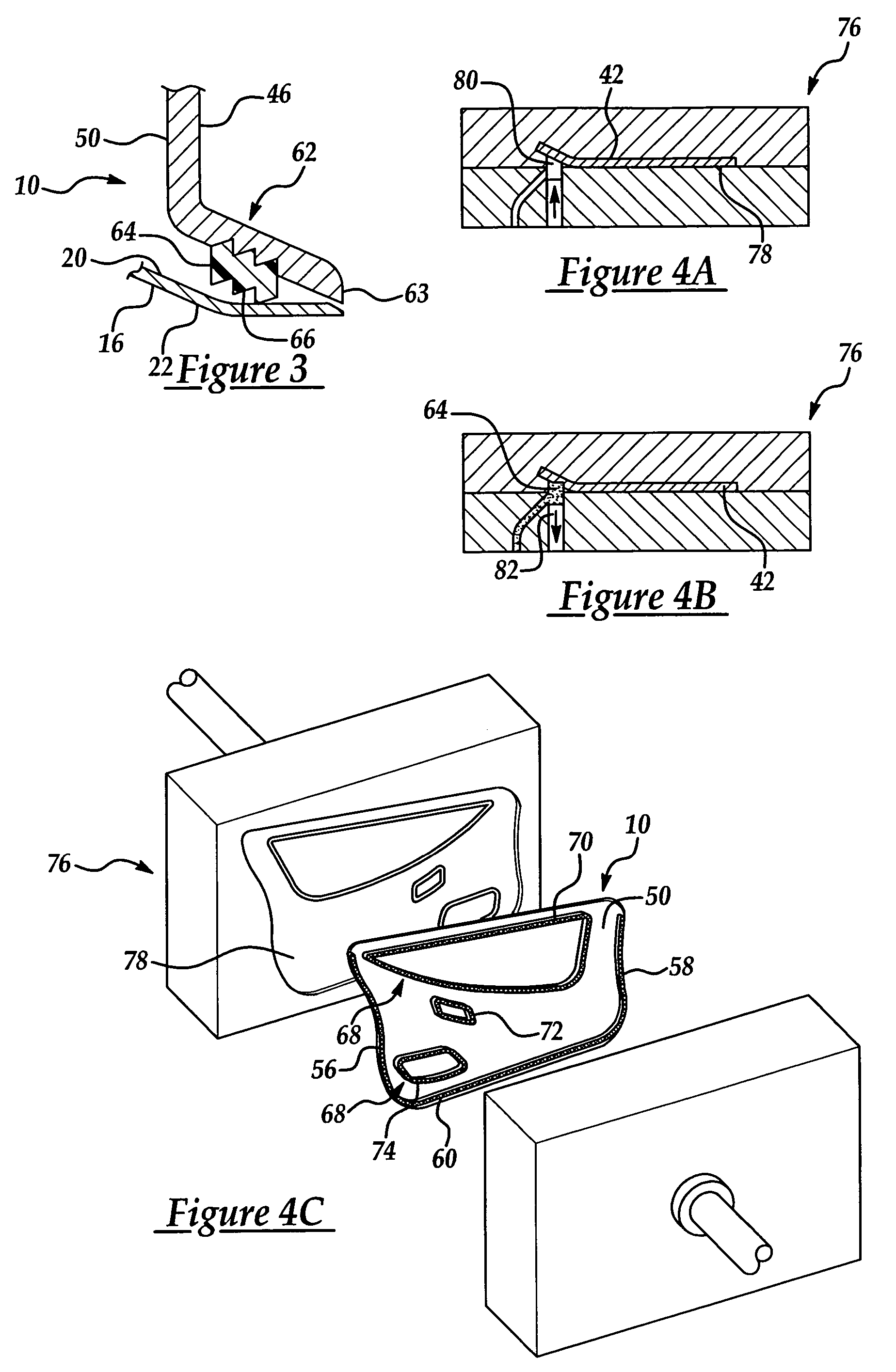

Modular door trim panel assembly having an integrated seal and method of manufacturing same

InactiveUS6997505B2Reduce needEliminate needSuperstructure subunitsMonocoque constructionsTrim tabEngineering

The present invention relates to a modular door trim panel assembly having an integrated seal for use in an automotive interior including a molded substrate having a first side defining an A-side surface visible from the interior of vehicle and a second side opposite the first side defining a B-side surface. The substrate includes a pair of side terminal edges and a lower terminal edge extending therebetween. The modular door trim panel assembly further includes at least one seal co-molded while the substrate is formed and bonded to the B-side of the substrate. The seal extends substantially parallel to the pair of side terminal edges and the lower terminal edge of the substrate and prevents the entry of moisture between the B-side of the substrate and the vehicle door. The present invention also relates to a method of molding the modular door trim panel assembly having an integrated seal.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Radial flow heat exchanger

InactiveUS20050056408A1Improve heat transfer performanceEfficient heat transferStationary conduit assembliesHeat exchanger casingsHeat conductingBiomedical engineering

A radial flow heat exchanger for heating or cooling a fluid includes a sealed fluid manifold for passage of fluid. A sealed fluid receiving hub is spaced interiorly of the interior peripheral portion of the manifold and includes a passageway for passage of fluid into or out of the heat exchanger. A plurality of separate and spaced fluid flow tubes are disposed between the manifold and the hub. Each of the tubes are in sealed fluid communication with the manifold at one end and the other end is in sealed fluid communication with the hub. A fin assembly is positioned between the manifold and the hub and includes a heat conducting material arranged at spaced intervals between the manifold and the hub, the heat conducting material including a plurality of spaced apertures through which tubes pass. The heat conducting material is in intimate heat conducting contact with the tubes whereby fluid flowing between the manifold and the hub flows into each of the tubes in a radial direction between the manifold and the hub and wherein the heat conducting material of the fin assembly operates to give up or pick up heat from the fluid through the wall of the tubes.

Owner:GREGORY CHRISTIAN T

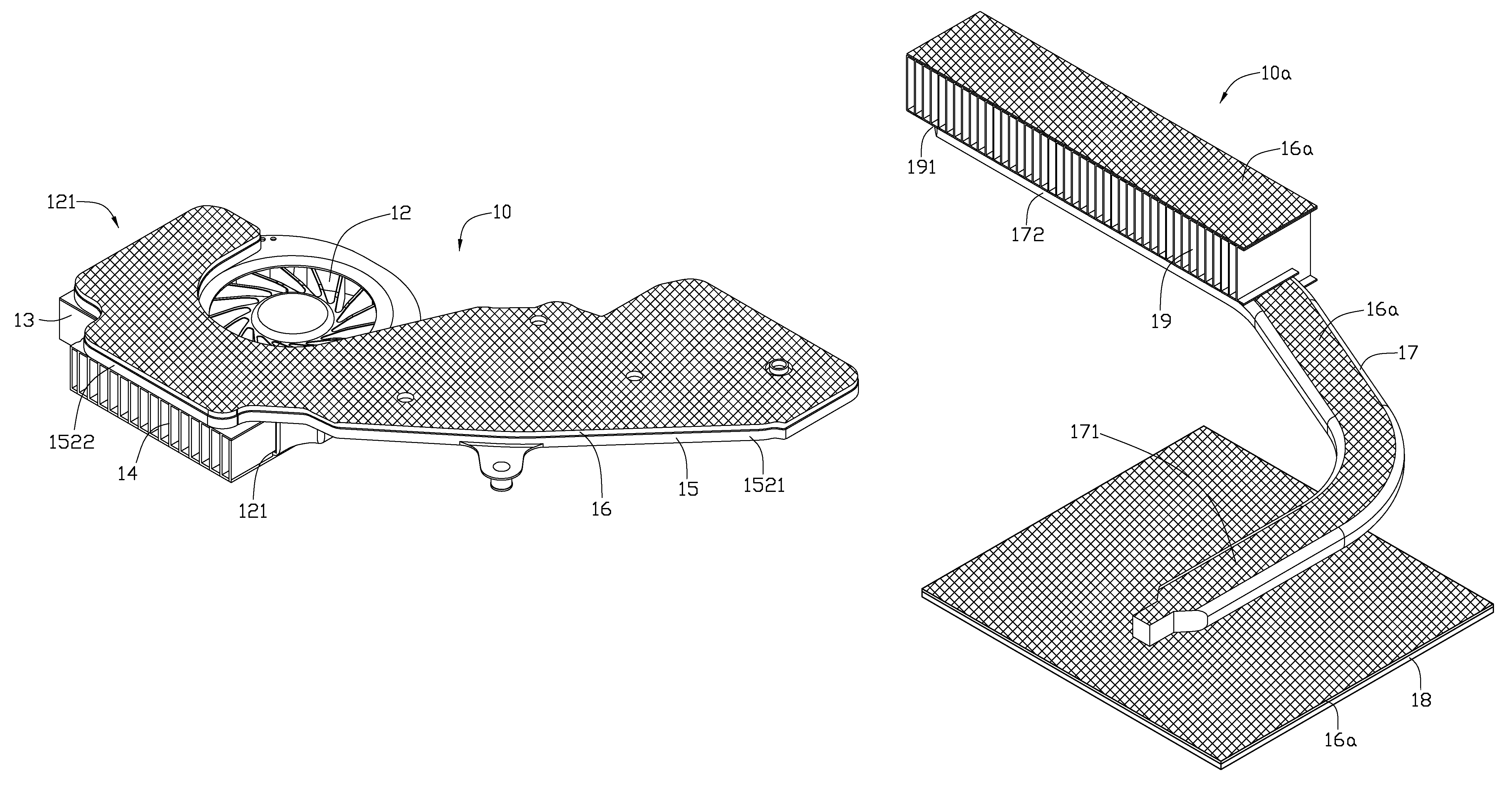

Heat dissipation device and computer using same

InactiveUS7839630B2Light weightSmall spacingDigital data processing detailsSemiconductor/solid-state device detailsIsolation layerEngineering

A heat dissipation device includes a fin unit, a heat spreader and a heat isolation layer. The heat spreader contacts the fin unit and transfers heat to the fin unit for dissipation. The heat isolation layer is coated on an outer surface of the heat dissipation device. The heat isolation layer is polyurethane foam.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

Heat dissipation device and computer using same

InactiveUS20100073864A1Light weightSmall spacingDigital data processing detailsSemiconductor/solid-state device detailsIsolation layerEngineering

A heat dissipation device includes a fin unit, a heat spreader and a heat isolation layer. The heat spreader contacts the fin unit and transfers heat to the fin unit for dissipation. The heat isolation layer is coated on an outer surface of the heat dissipation device. The heat isolation layer is polyurethane foam.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

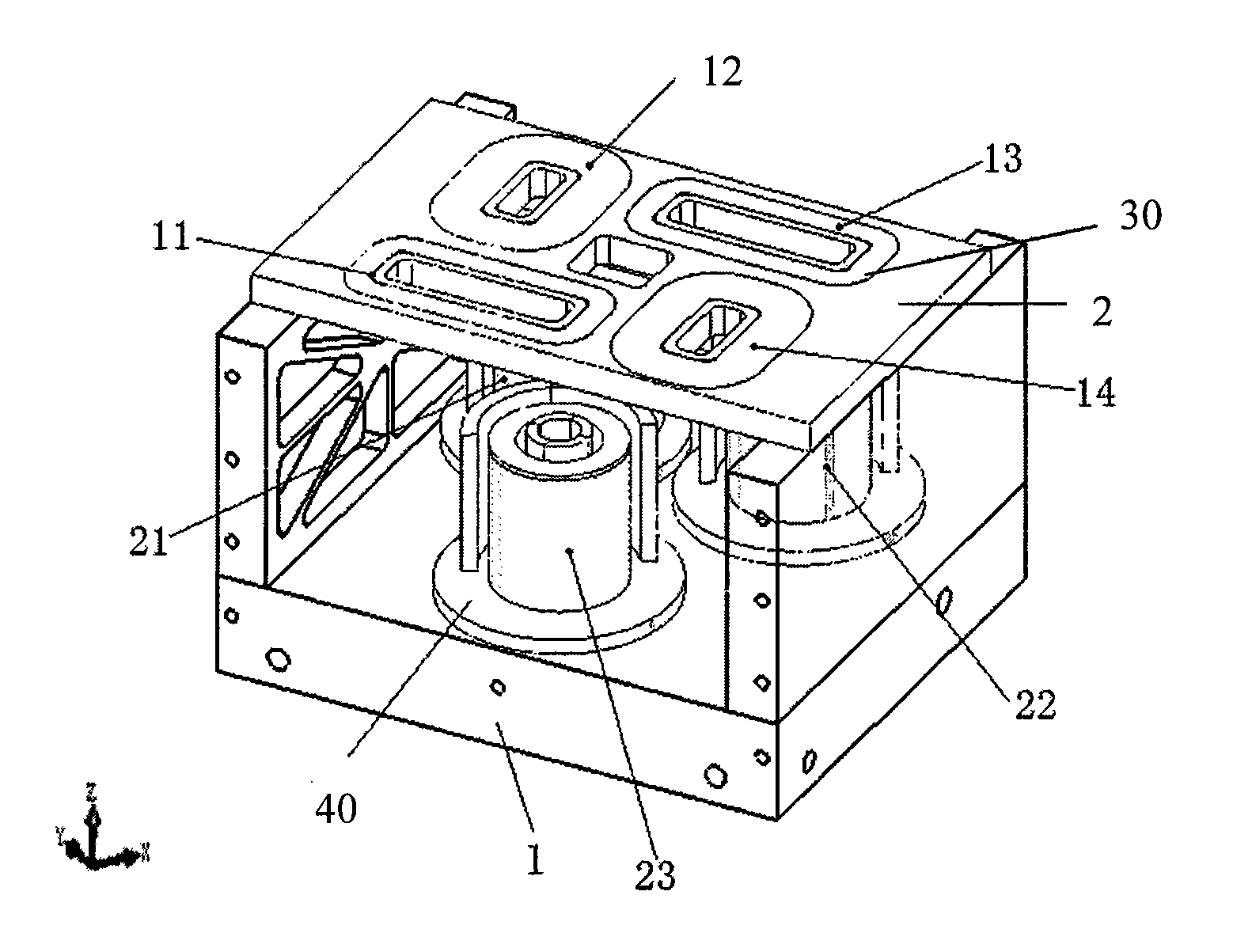

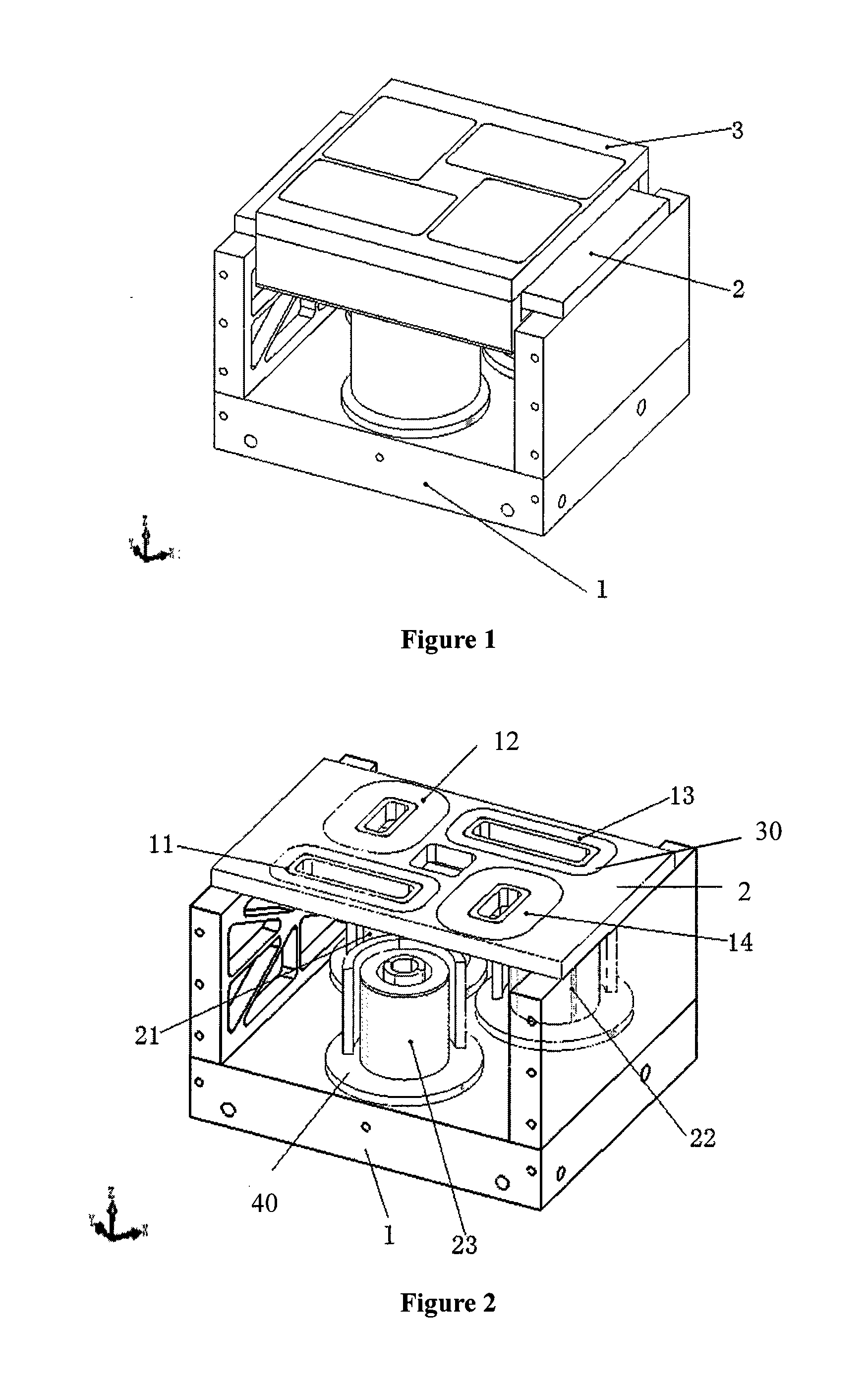

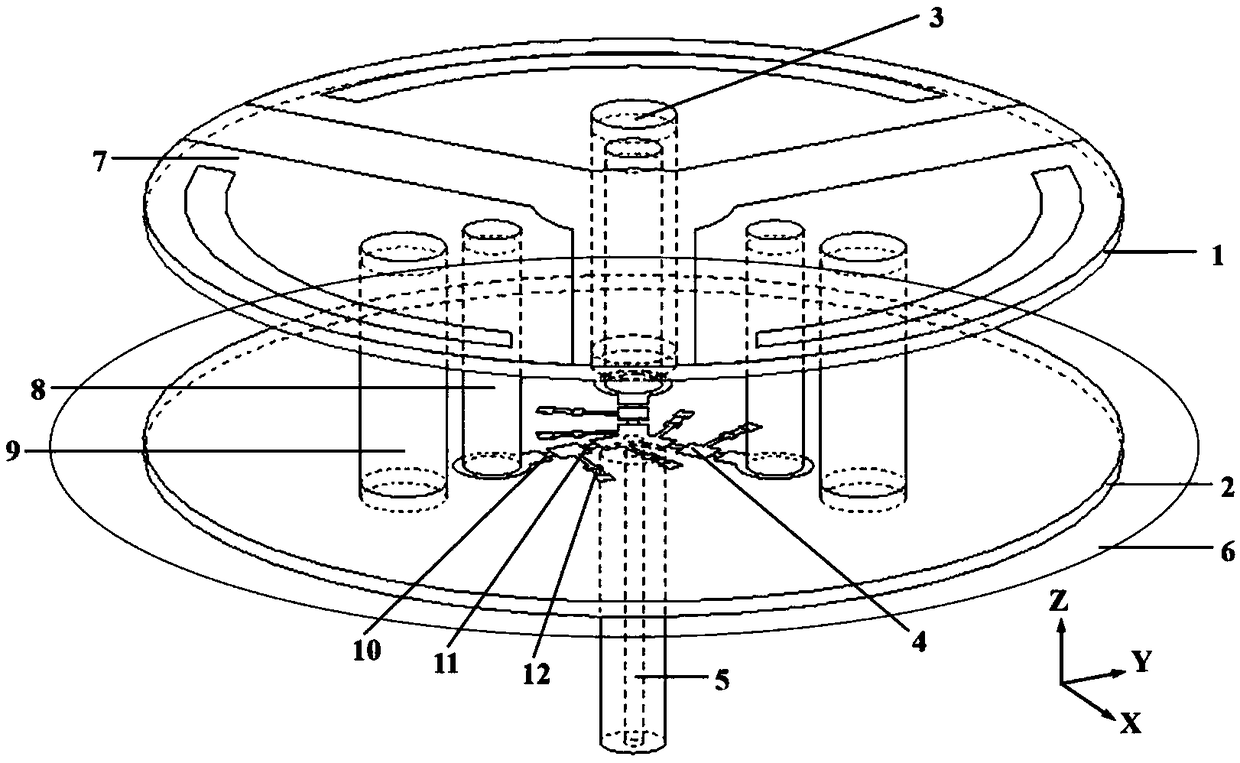

Micro stage with 6 degrees of freedom

ActiveUS20100187917A1Simple structureCompact profilePhotomechanical apparatusPropulsion systemsDegrees of freedomGravity center

A micro stage with 6 degrees of freedom used in super-precise processing and sensing equipment filed is disclosed. The micro stage has three sets of electromagnetic driving units arranged in a horizontal plane for driving the micro stage to obtain movements within the horizontal plane with 3 degrees of freedom in X, Y and θz directions and three electromagnetic driving units arranged in a vertical direction for driving the micro stage to obtain additional movements with 3 degrees of freedom in Z, θx and θy directions. Direct driving by electromagnetic force is used in the invention, resulting in advantages over stacked structures of having a simple structure, a compact profile, a low driven weight center, low stator inertia, etc. Thus, there is no mechanical friction and damping, and high displacement resolution can be provided. The positioning error of a wafer table of a lithographic machine can be compensated, and the leveling and focusing of the lithographic machine can be achieved. The invention is also applicable in super-precise processing and sensing fields for achieving 6 degree-of-freedom motions. The micro stage, which operates on the basis of Lorentz Law, provides a linear relation between the output pushing force and the input electrical current, and thus the movement control technique for it can be well established.

Owner:TSINGHUA UNIV

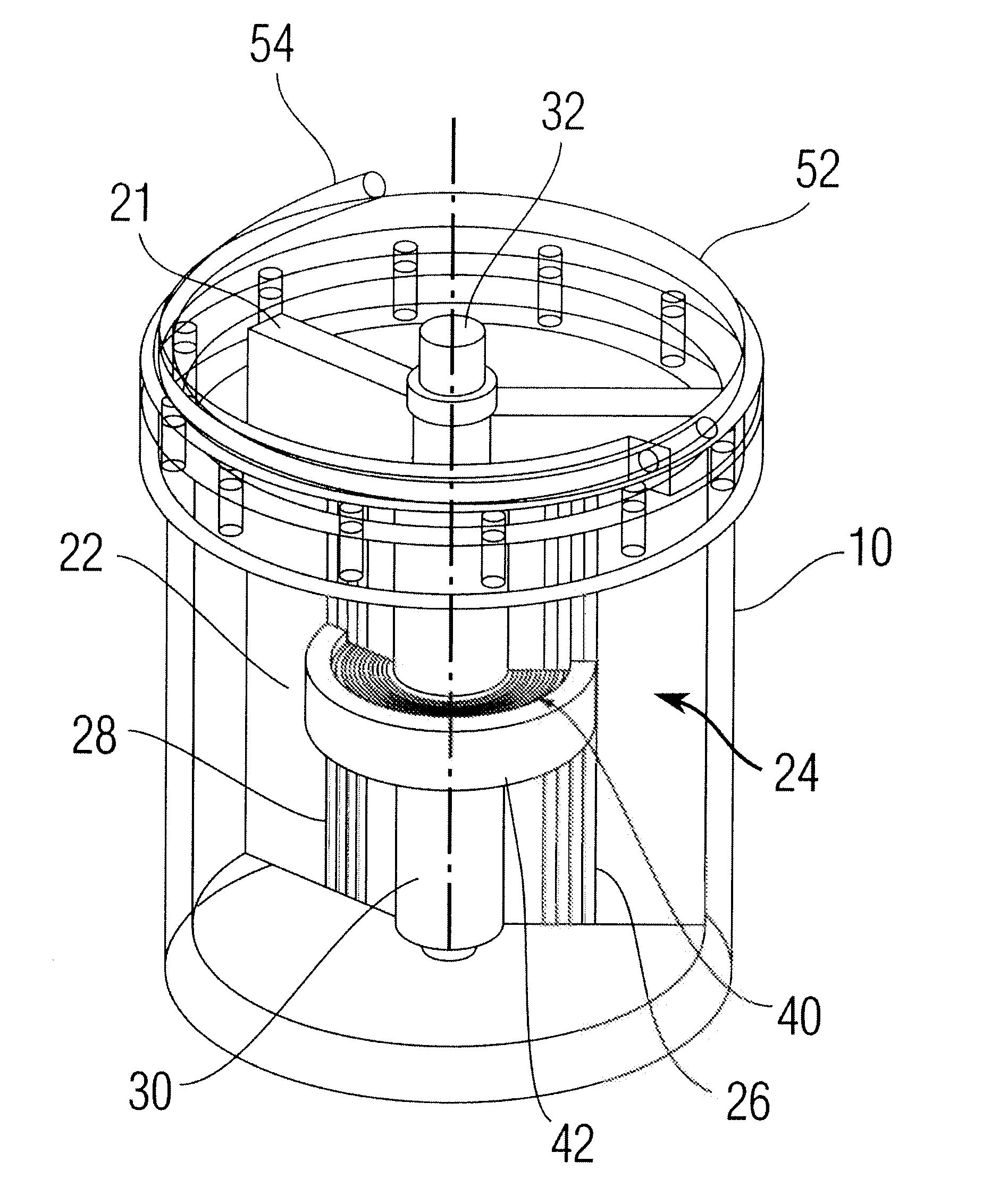

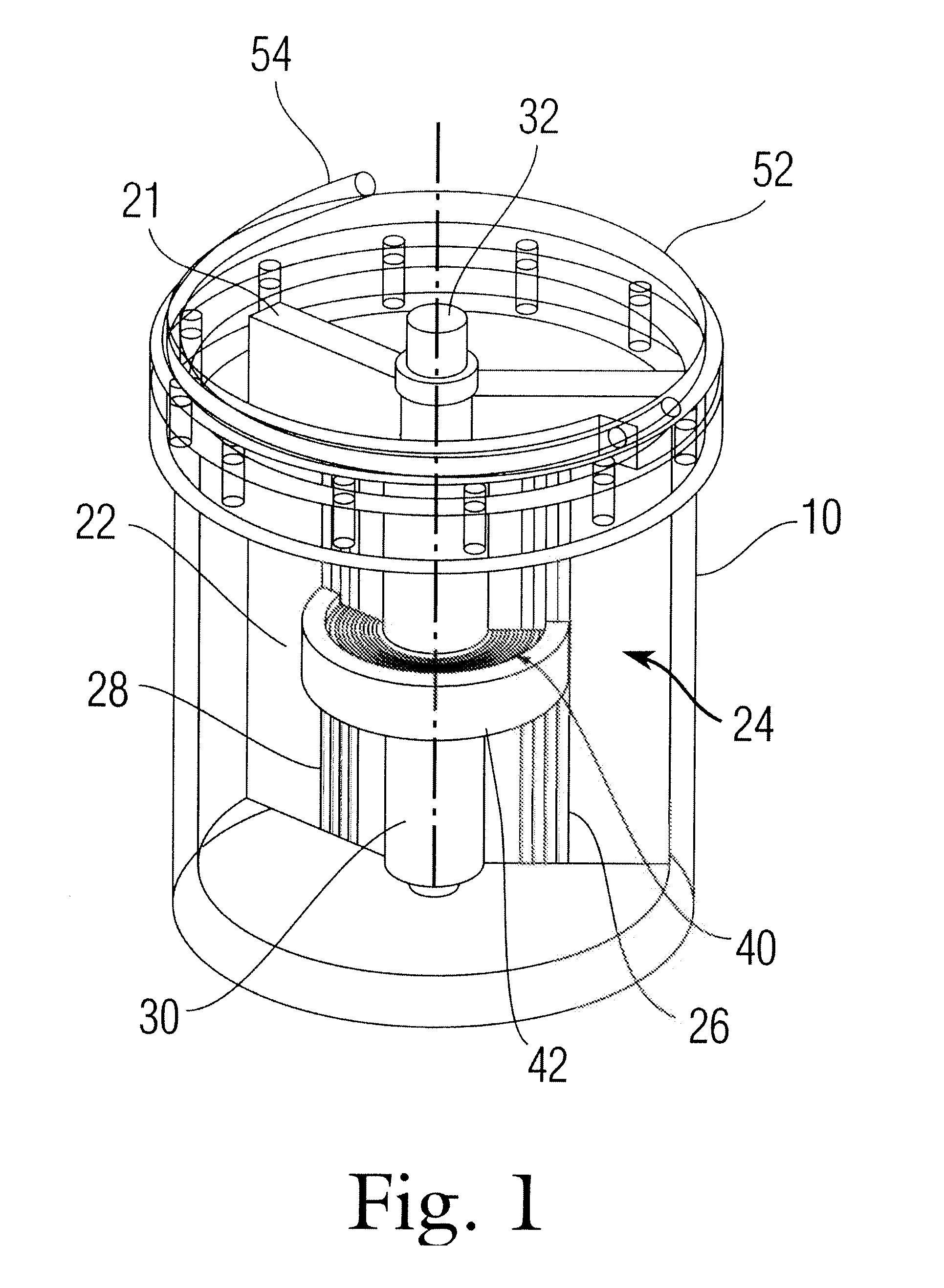

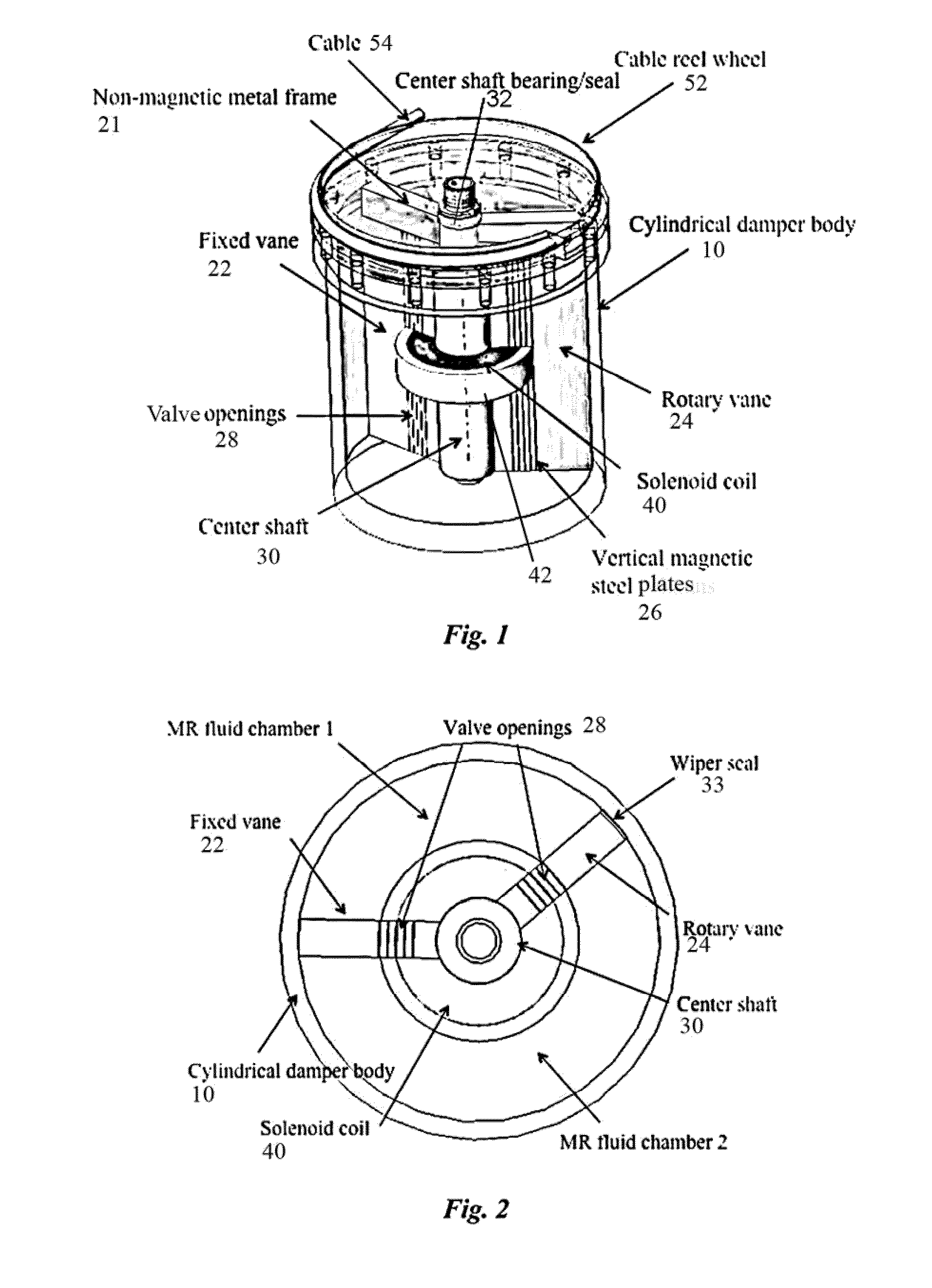

Rotary vane magnetorheological (MR) energy absorber

ActiveUS20100300819A1Increase damper strokeCompact profileLiquid resistance brakesSpringsLinear motionMagnetorheological fluid

A rotary vane magnetorheological energy absorber, which enables a longer stroke capability in a more compact configuration than conventional magnetorheological devices, is disclosed. This novel device design is attractive for applications where long stroking capability, high force dynamic range, device size, and device weight are important. The improved magnetorheological energy absorber comprises an internal or external flow valve and a hollow body enclosing fixed and rotary vanes as well as magnetorheological fluid. Fluid flow in the valve is restricted as a solenoid is activated, thus adjusting the capability of the device to react torque. Various flow valve configurations are disclosed, as well as various motion translation mechanisms for translating linear motion to rotary motion for use of the rotary vane magnetorheological energy absorber. The improved design minimizes the amount of magnetorheological fluid required as compared to conventional linear stroke energy absorbers, thus minimizing device weight.

Owner:INNOVITAL LLC +1

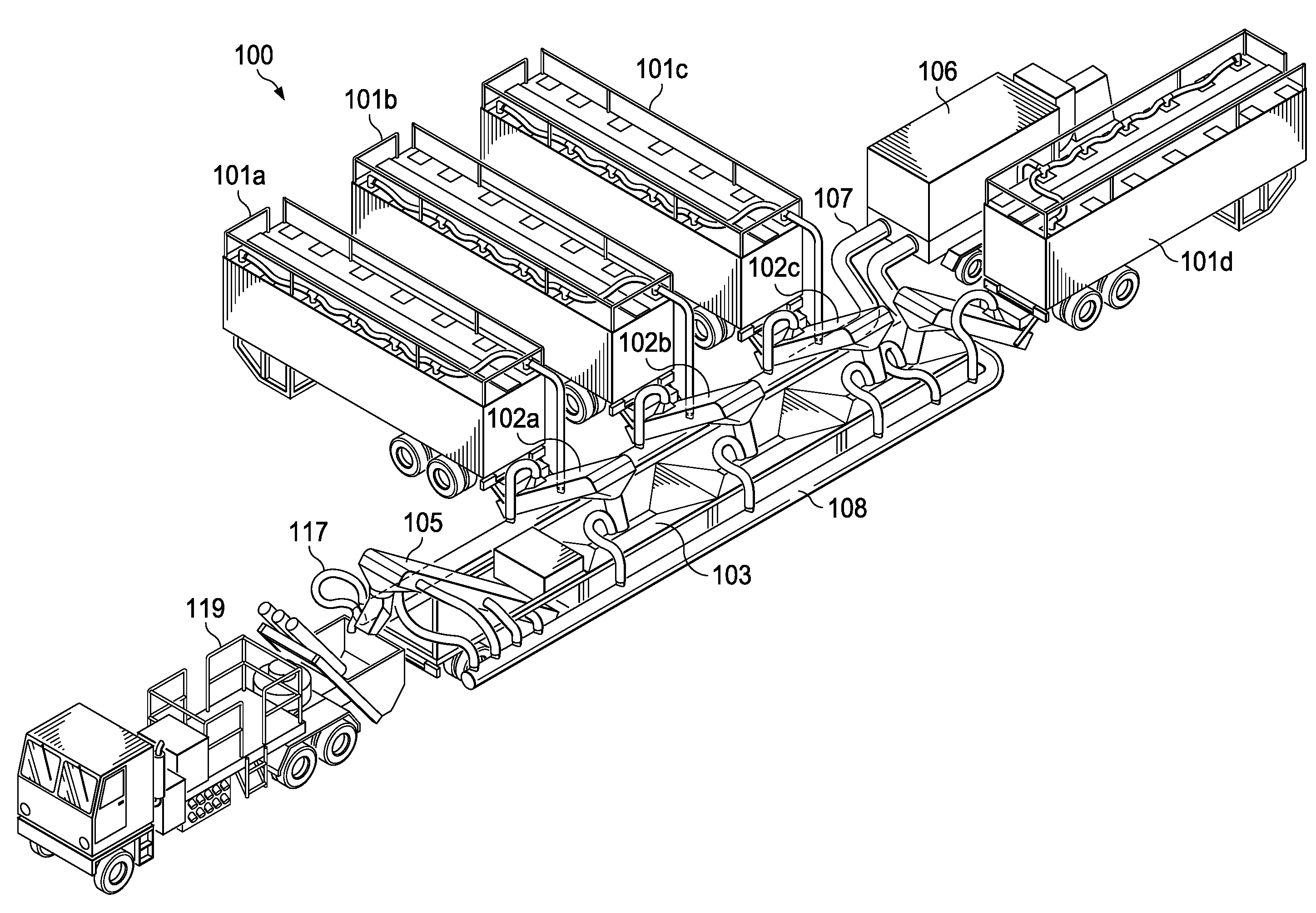

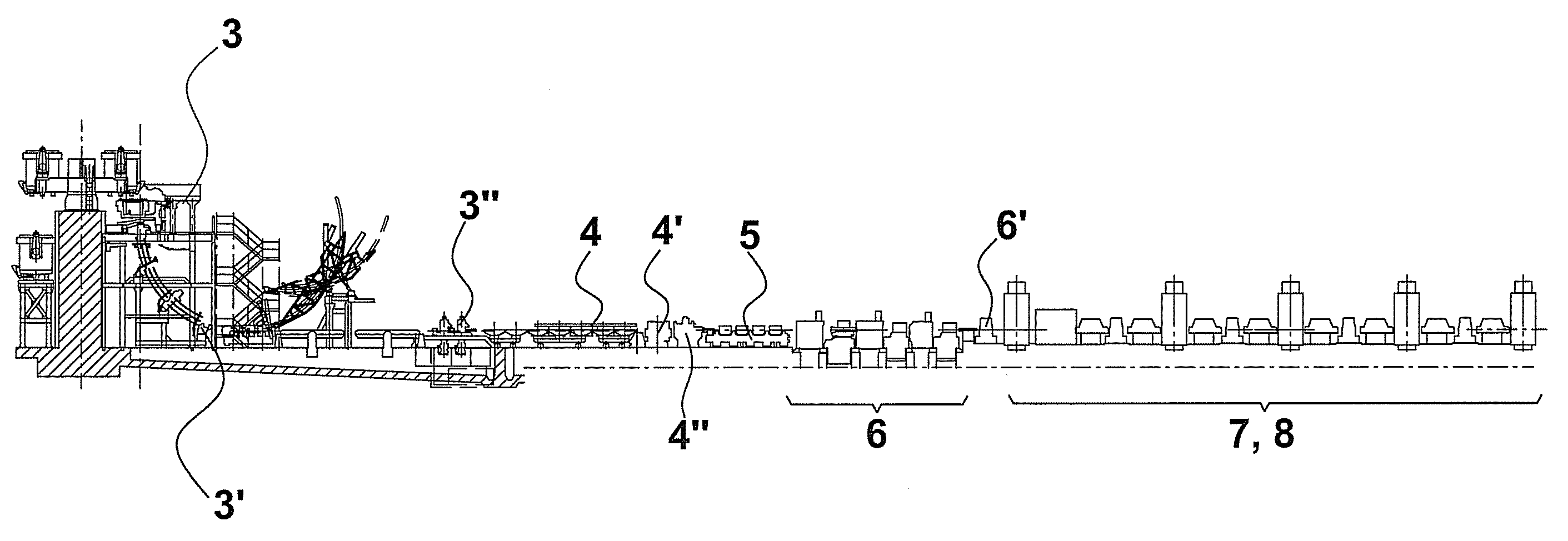

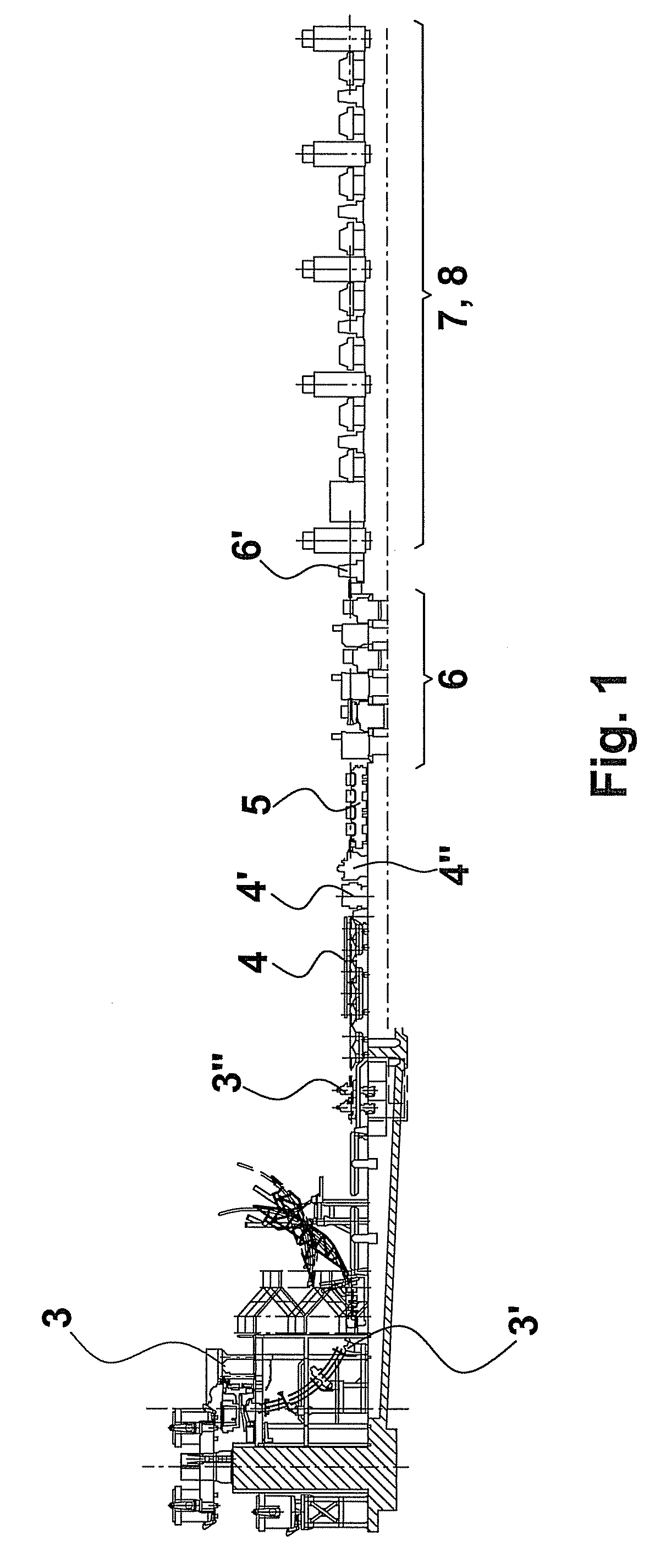

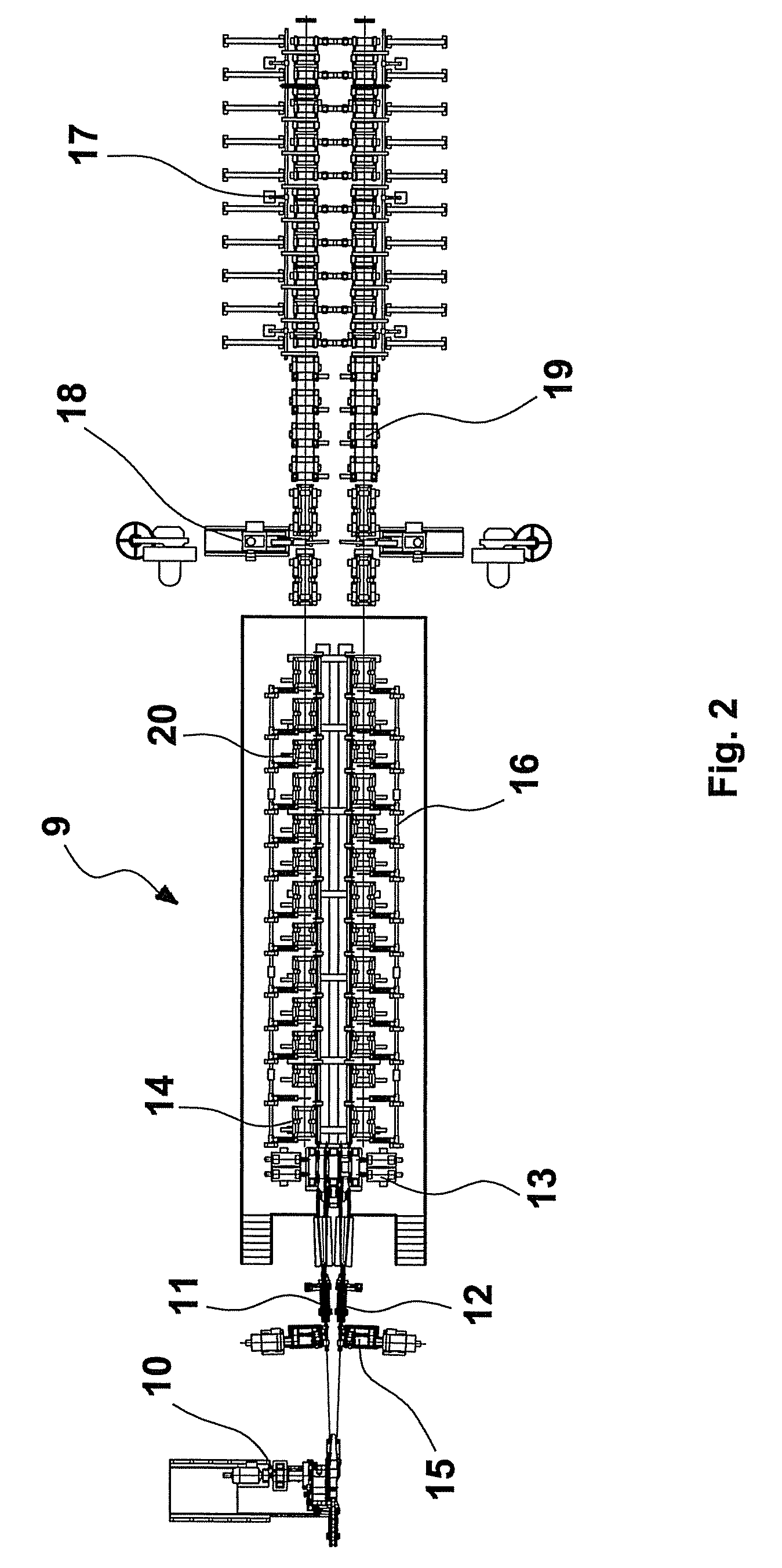

Compact Plant for Continuous Production of Bars and/or Profiles

ActiveUS20080196236A1Low investment costShorten production timeMetal rolling stand detailsGuiding/positioning/aligning arrangementsTO-18Rebar

Compact plant for making steel bars and profiles with which, starting from the scrap, it is possible to obtain the finished product, for example bars with commercial length from 6 to 18 meters, pre-packed, packaged and ready for sale, with all the stations placed in line and operating continuously. All the stations are arranged in reduced spaces, thereby reducing both investment costs and plant management costs, and decreasing production times. Advantageously, the plant of the invention incorporates an extremely compact bar packaging apparatus which, through an innovative arrangement and innovative operating method of the components thereof, allows a further reduction in length.

Owner:DANIELI & C OFF MEC SPA

Rotary vane magnetorheological (MR) energy absorber

ActiveUS8424656B2Suppress energyCompact profileLiquid resistance brakesSpringsLinear motionMagnetorheological fluid

Owner:INNOVITAL LLC +1

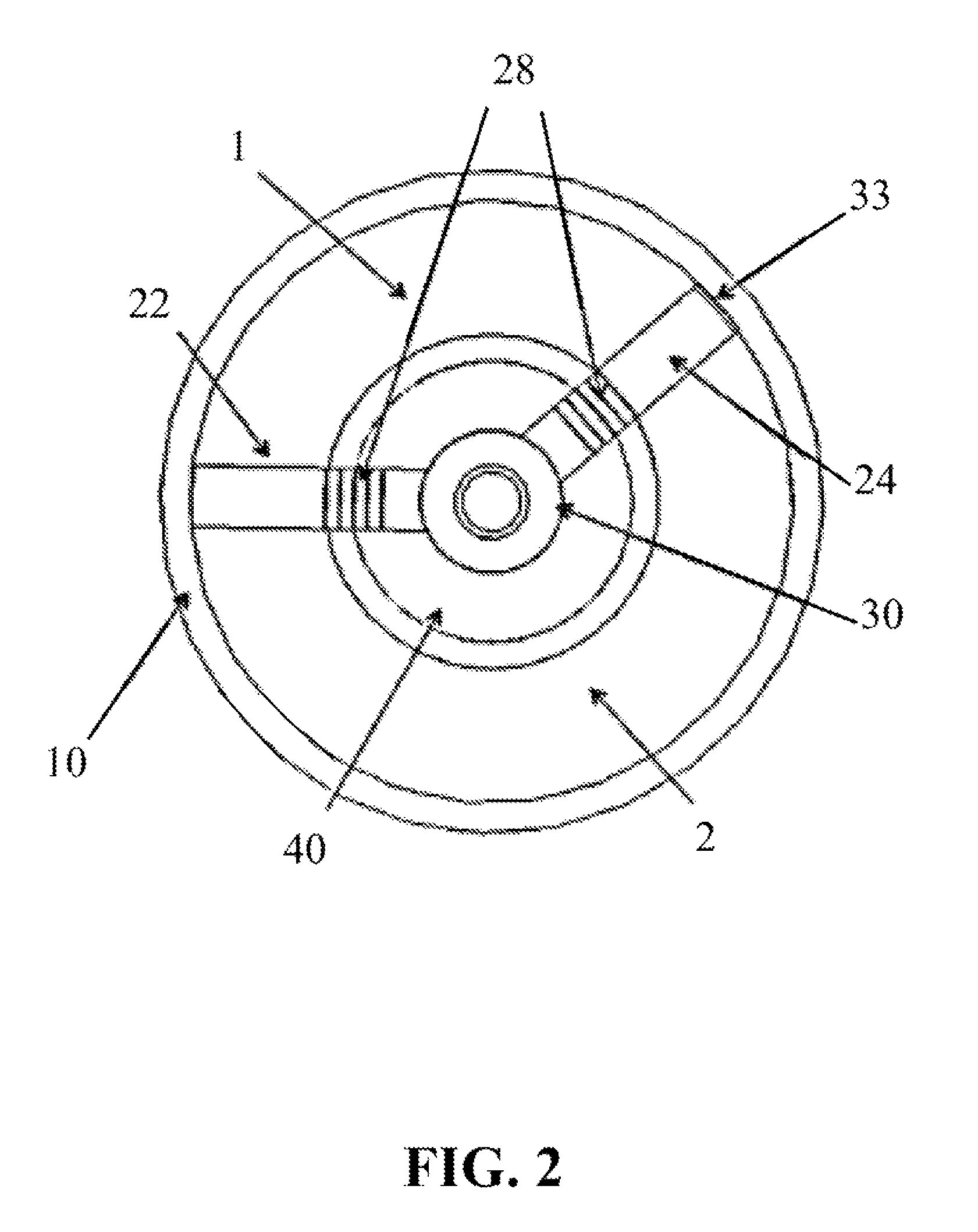

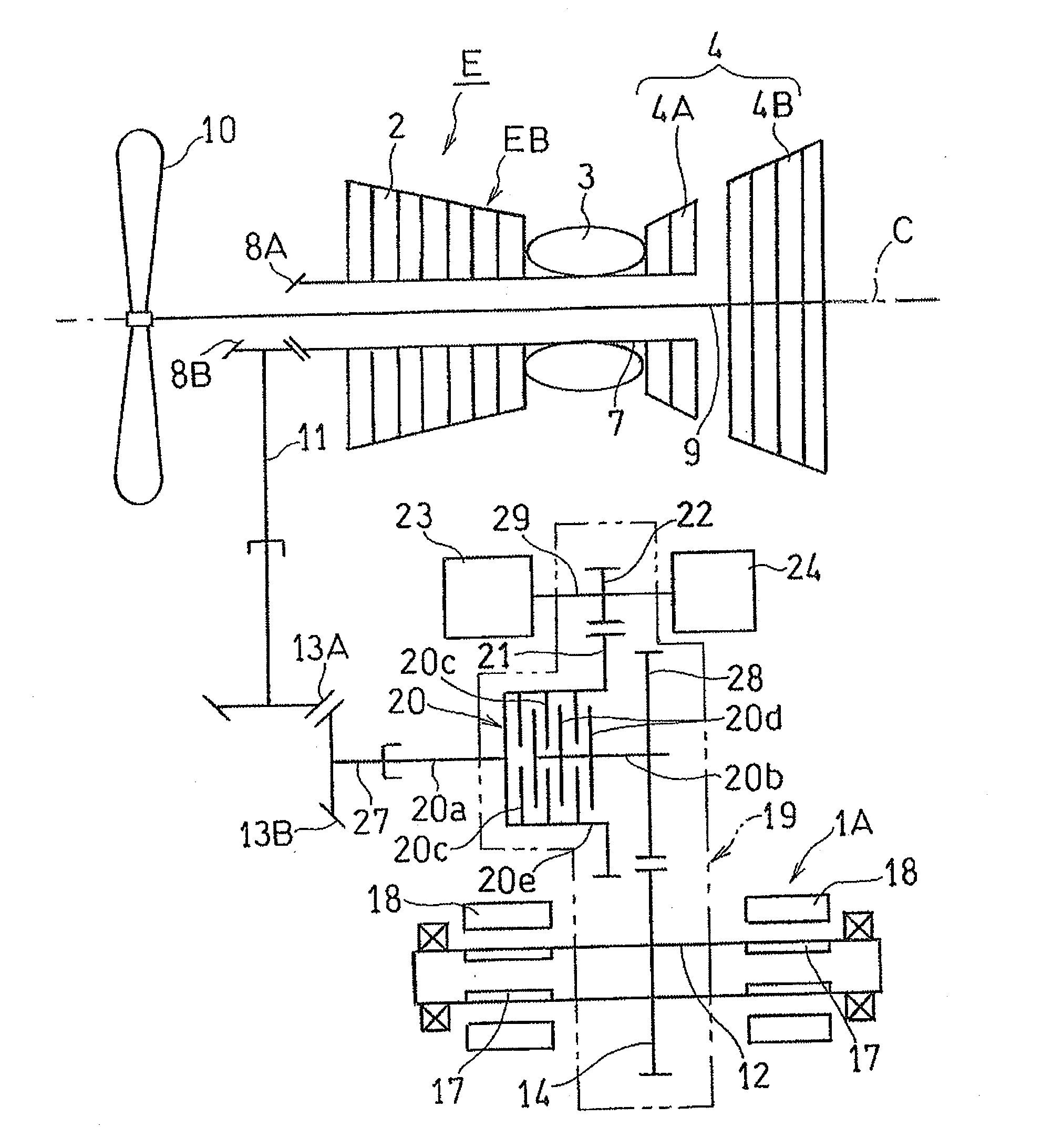

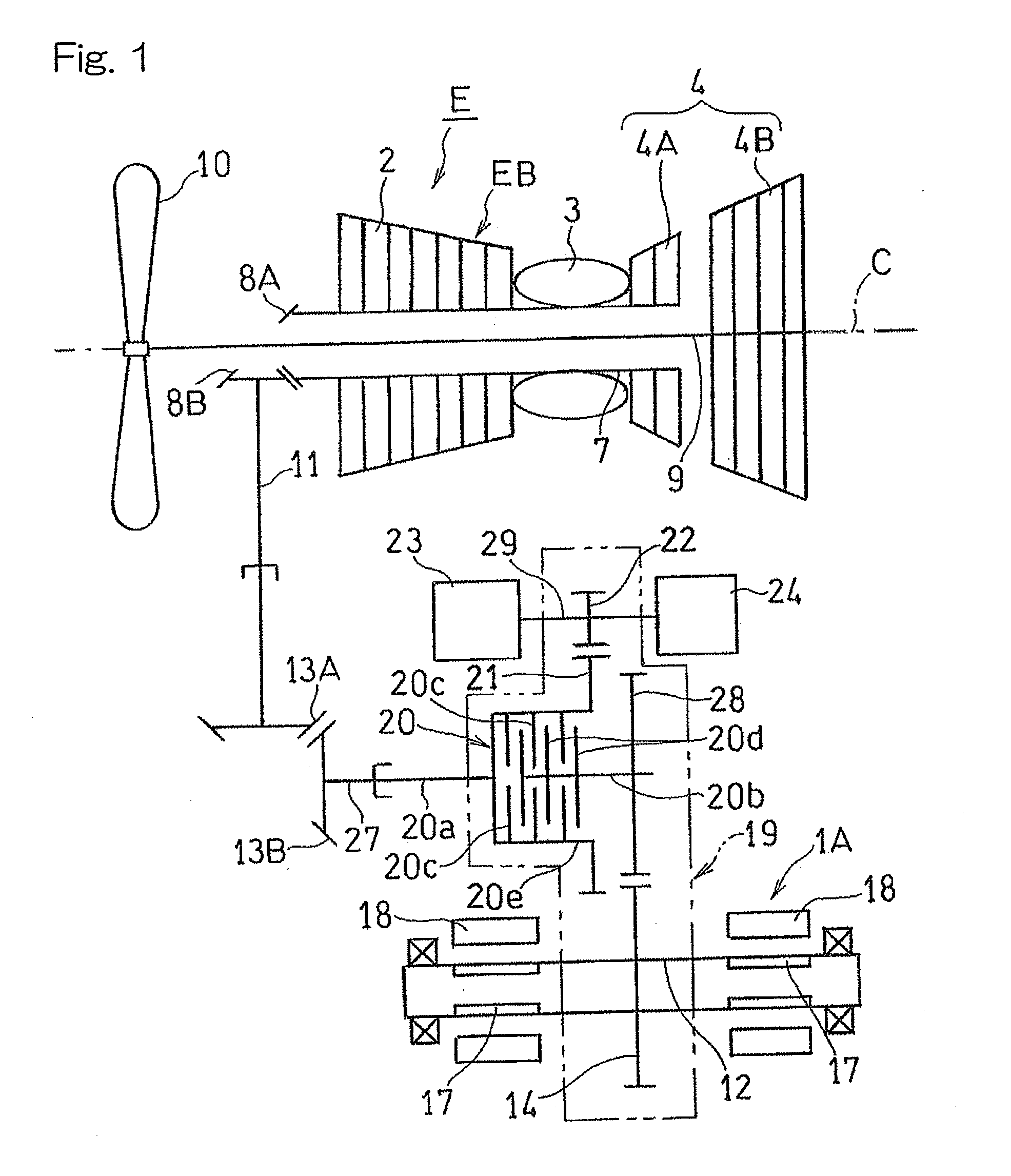

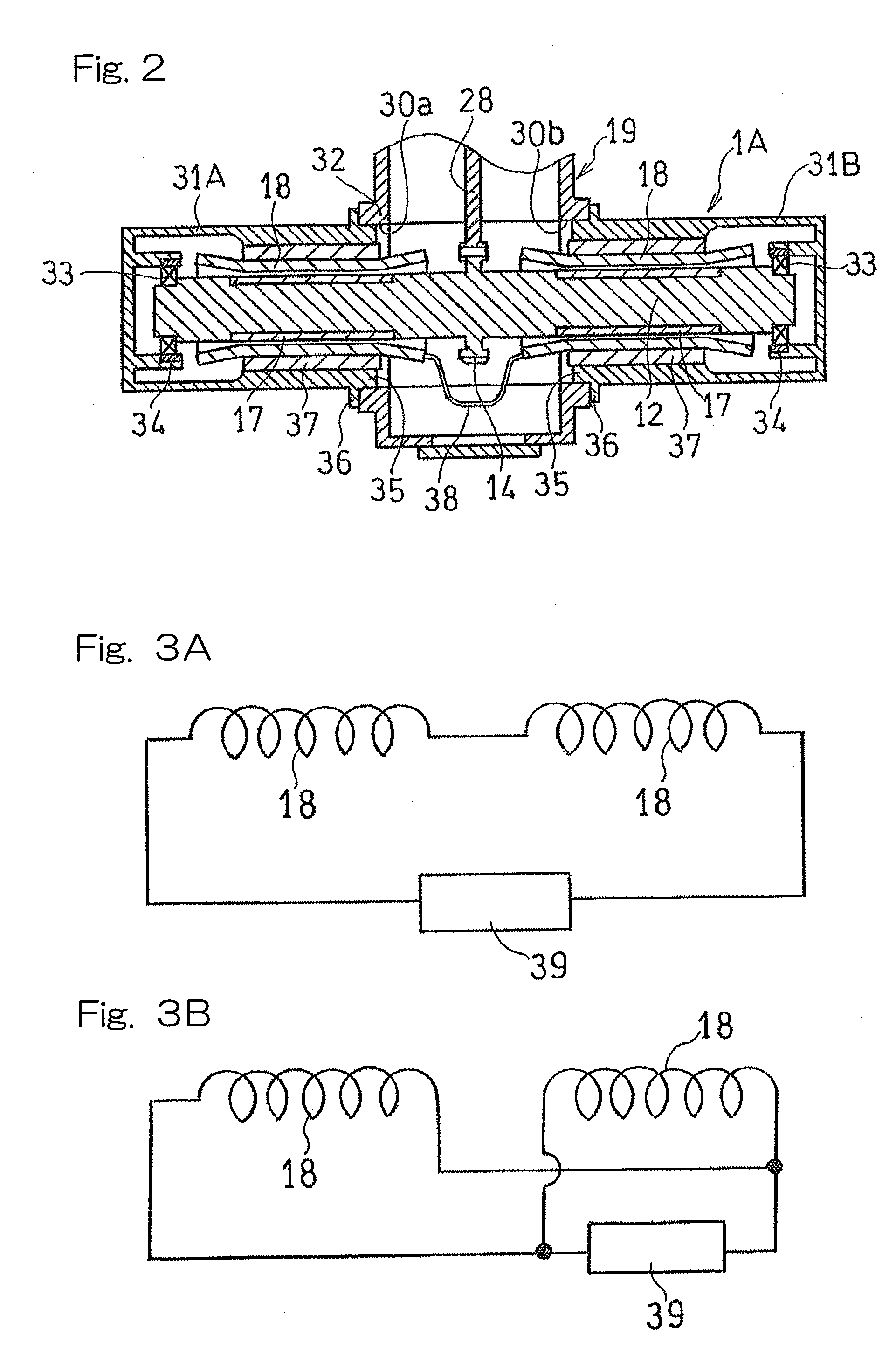

Power generation unit of integrated gearbox design for aircraft engine

ActiveUS20150311770A1Undesirable increase of be suppressReduce vibrationEngine fuctionsGas turbine plantsAirplaneMagnet

A power generation unit is connected with an engine rotary shaft via an accessory gearbox. A rotor extends through the accessory gearbox and a drive gear is disposed at an intermediate portion of the rotor for driving the latter. Permanent magnet elements are mounted on opposite side portions with the intermediate portion intervening therebetween, and stator coils are disposed so as to confront respective outer peripheries of the permanent magnet elements.

Owner:KAWASAKI HEAVY IND LTD

Optical fiber cables

ActiveUS20060039659A1Compact profileResistant to fiber retractionOptical fibre/cable installationFibre mechanical structuresUltimate tensile strengthElectric cables

The specification describes an optical fiber drop cable with a flat configuration and having two side-by-side subunits. One of the subunits contains a cable strength member, e.g. a steel wire or stranded wire. The other subunit is an optical fiber subunit, which contains the optical fiber(s), and also contains one or more additional strength members. In a preferred embodiment, the cable is dry, and has conformal encasements that couple the optical fiber(s) to the outer cable sheath.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

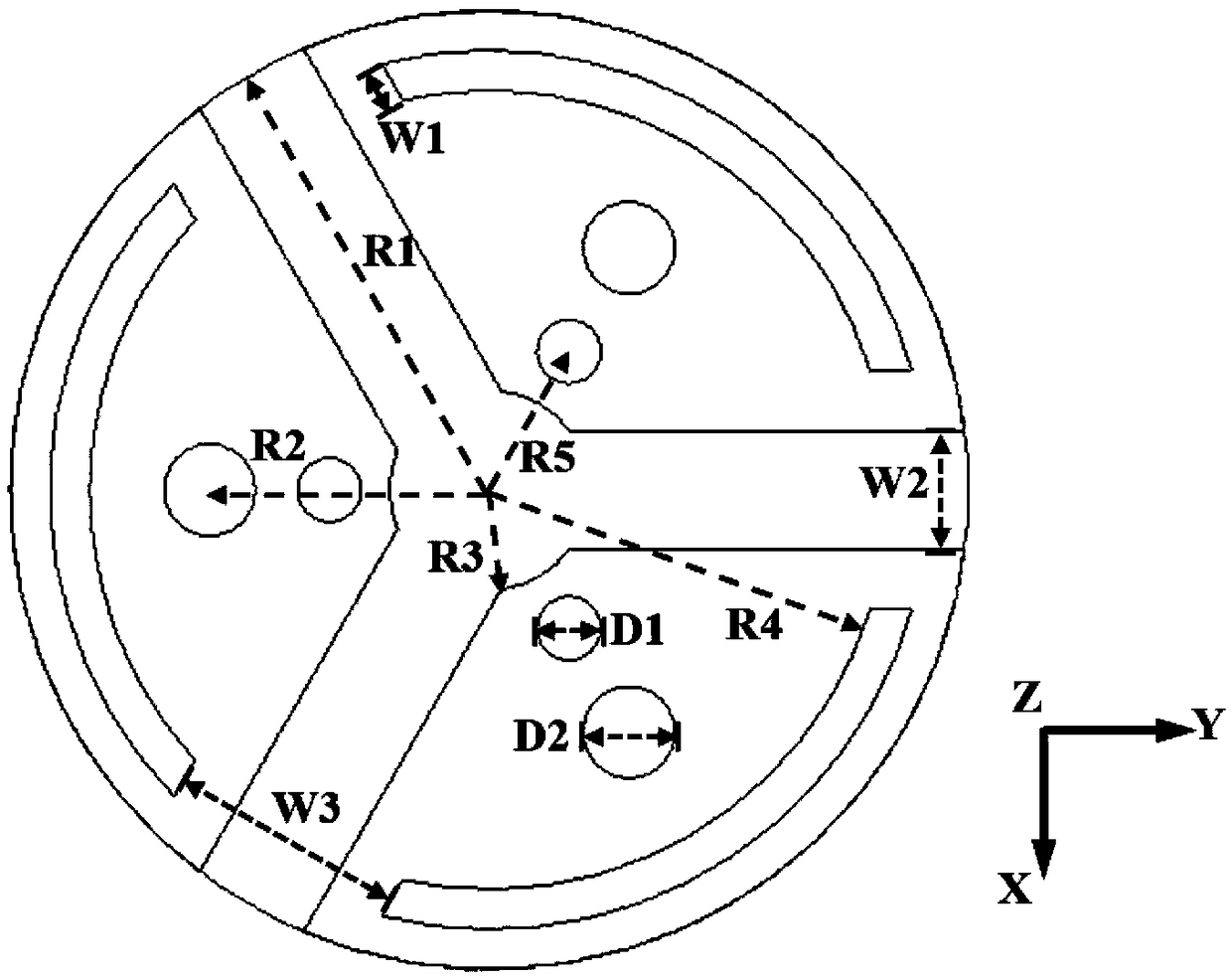

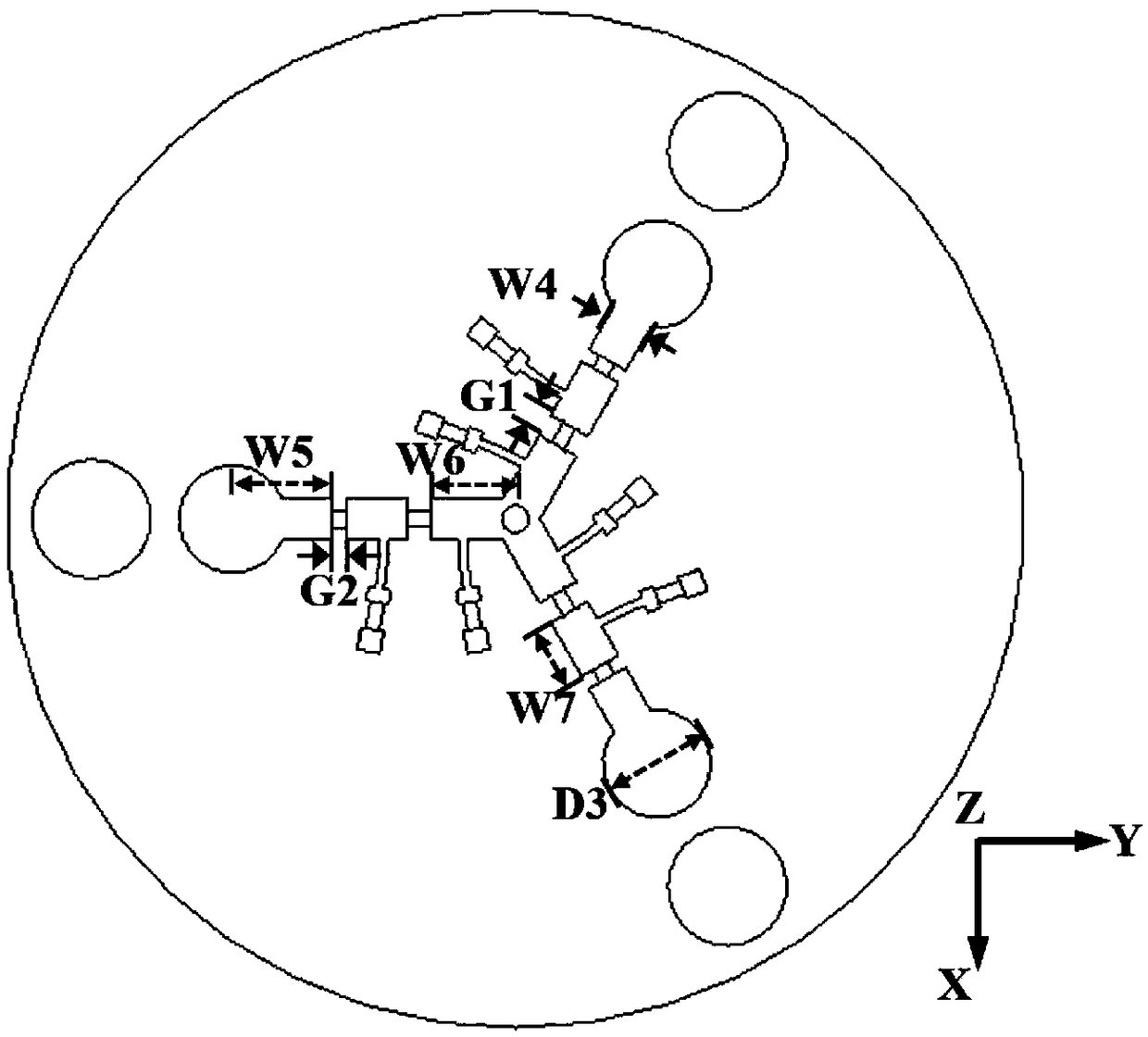

Low profile compact vertical polarization antenna with reconfigurable directional pattern

InactiveCN109494458ALow profileCompact profileRadiating elements structural formsAntenna earthingsDielectric substrateEngineering

The invention relates to a low profile compact vertical polarization antenna with a reconfigurable directional pattern, and belongs to the field of antenna design. The antenna comprises an upper dielectric substrate, a lower dielectric substrate, three identical top loaded folded monopoles, a feed structure, a coaxial cable and a metal floor. According to the invention, top loaded patches are rationally designed into the shape of a fan, so that the patches can be integrated on the same dielectric substrate to reduce the antenna size; then a curved groove is etched on each fan-shaped patch to further reduce the size of a monopole unit; and finally, three PIN switching diodes are skillfully utilized, so that the monopoles are alternately used as excitation oscillators and parasitic oscillators, and the directional pattern of the antenna can be reconstructed. The alternate working mode greatly reduces the antenna size. According to the invention, the designed vertical polarization antennahas three reconfigurable directional pattern modes, can realize 360-degree scanning in the horizontal direction, and has the advantages of low profile and compact structure.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com