Optical fiber cables

a technology of optical fiber cables and fiber optic cables, applied in the field of optical fiber cables, can solve the problems of time-consuming installation and repair of gel filled cables, expensive gel removal, cosmetic or other problems, etc., and achieve the effects of convenient installation, convenient installation and maintenance, and convenient installation and maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

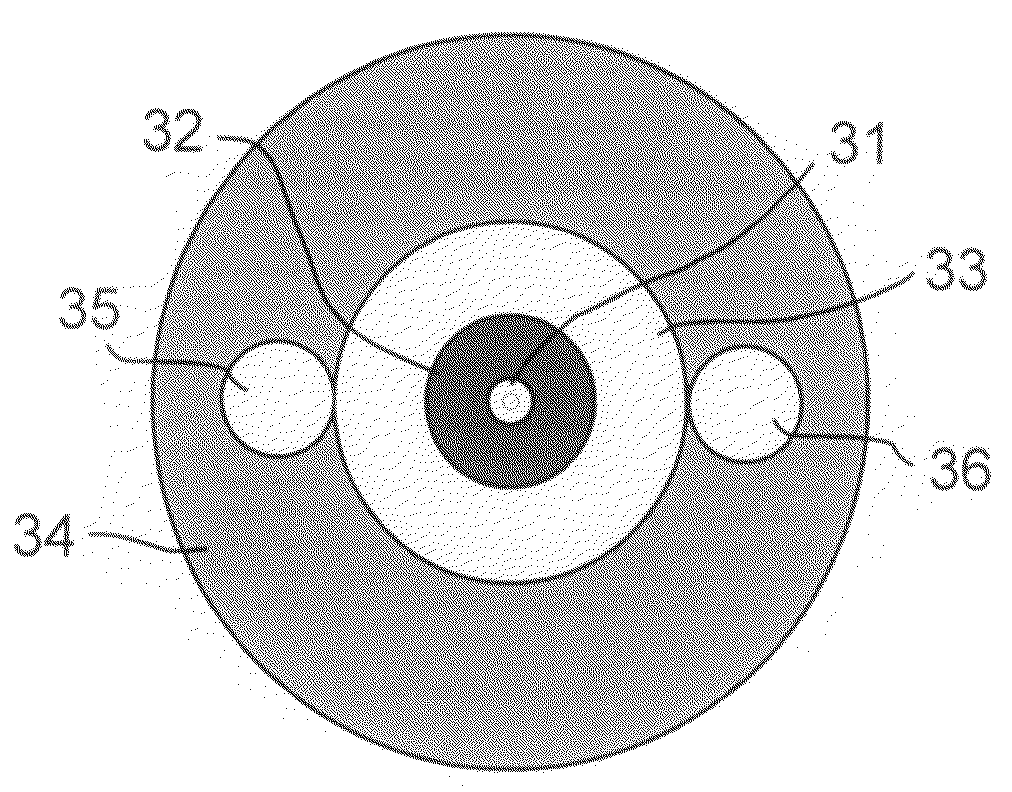

[0024]Referring to FIG. 1, a flat optical fiber drop cable 11 is shown with optical fiber module 15 and strength members 13 and 14. The optical fiber tube 15 comprises two optical fibers 18, an extruded plastic buffer tube 17, and a gelled filling compound 16. The strength members 13 and 14 are typically glass fibers bonded and encased in a rigid thermoset resin, forming a rod structure. The three modules are encased in a common outer jacket or encasement 12, with the centers of the optical fiber module and the centers of the strength members in-line. The strength members 13 and 14 are preferably approximately the same size, as shown, which imparts symmetry to the cable cross section.

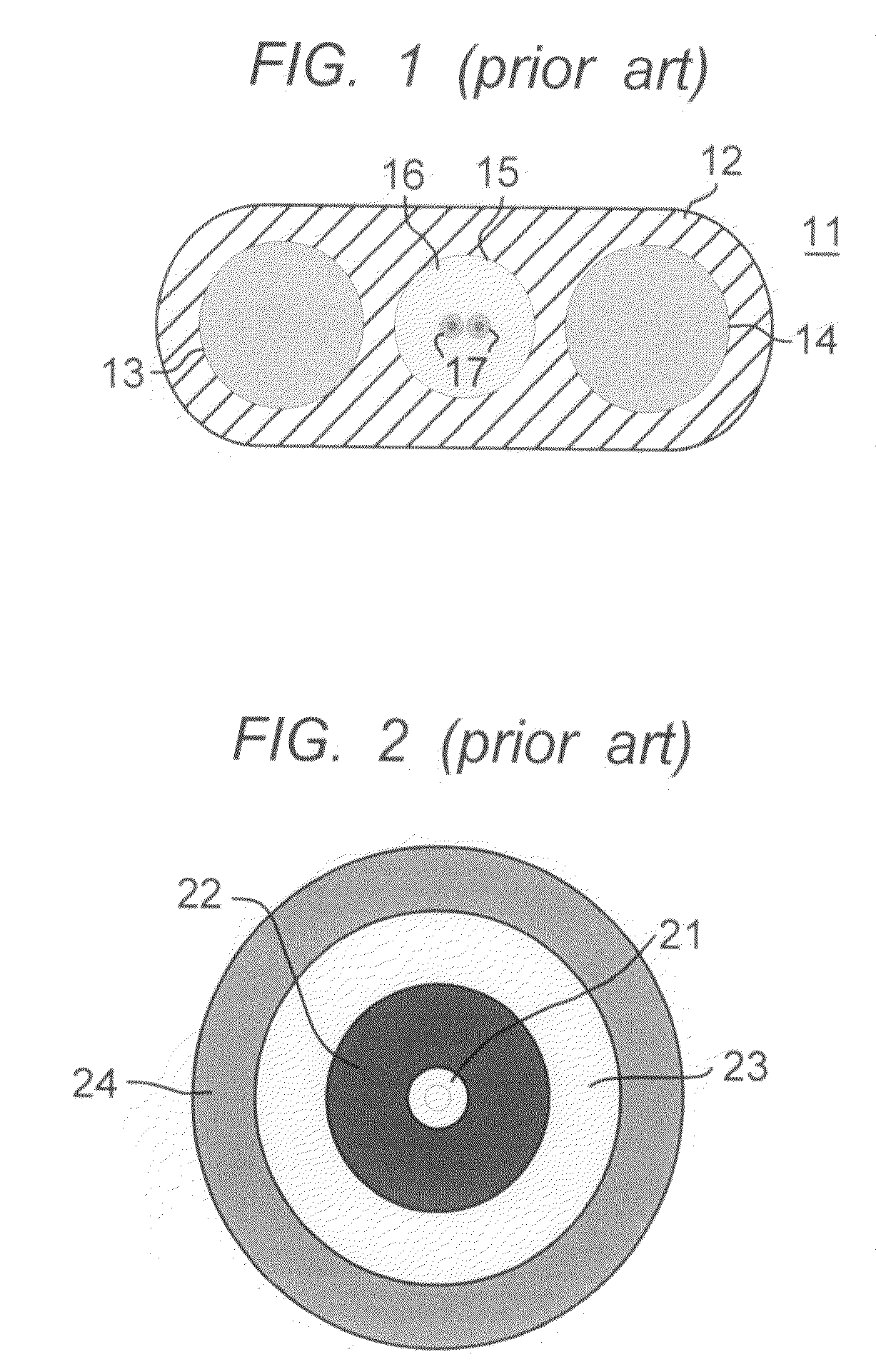

[0025]FIG. 2 shows an optional cable design with strength members omitted. The cable has optical fiber 21 with a conformal tight buffer 22, an aramid protective layer 23, and outer sheath 24. This design allows for a very flexible cable with a small form factor. The overall size typically may be 2-4 mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com