Patents

Literature

216 results about "Cable design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

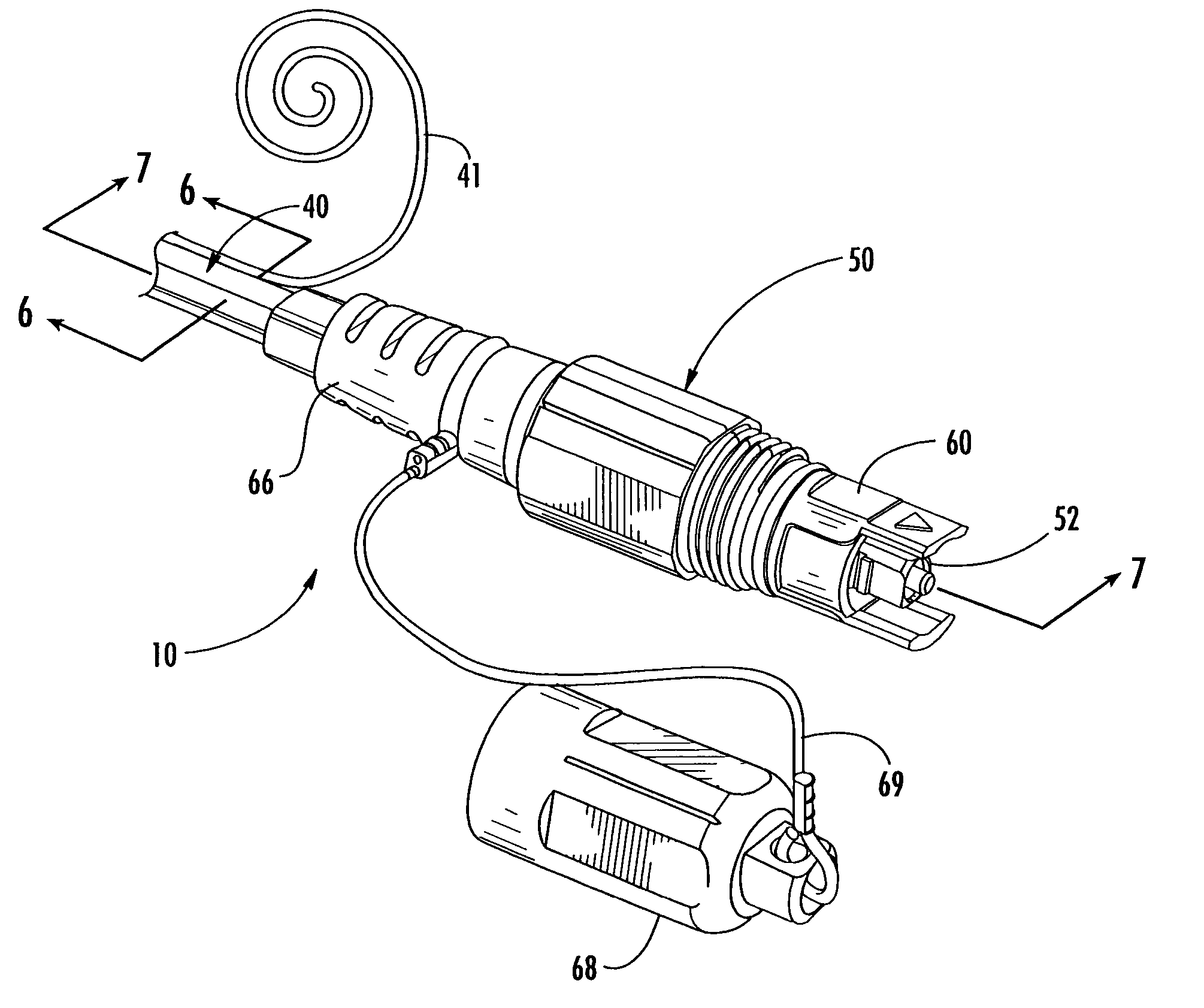

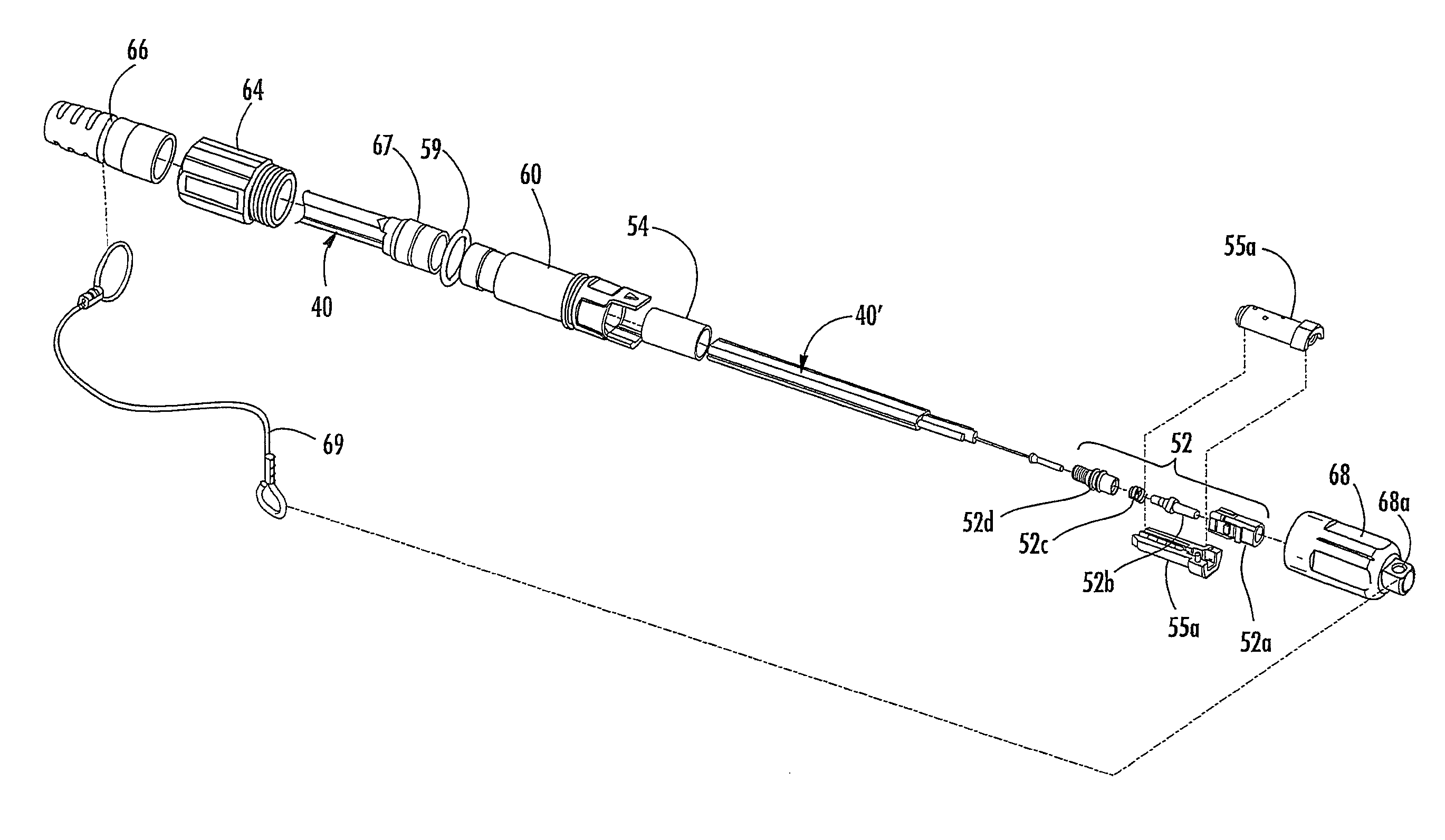

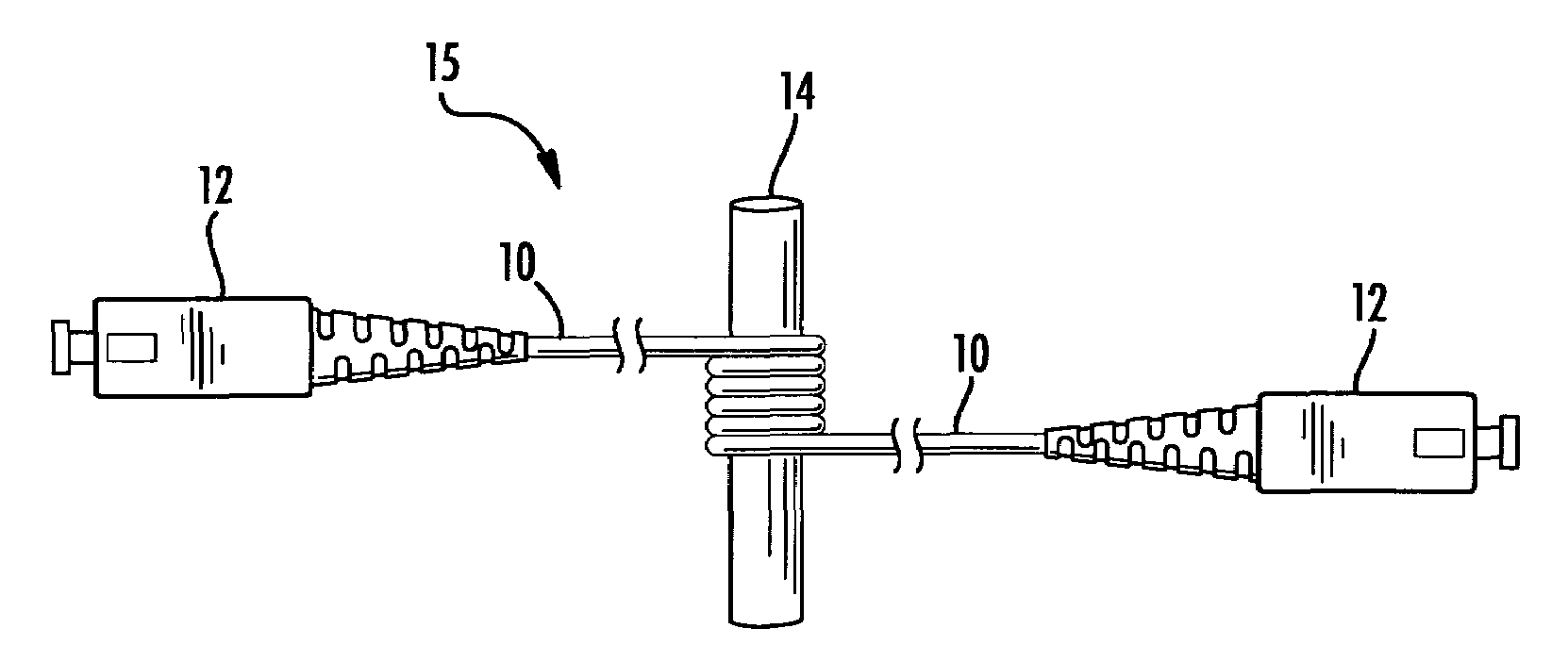

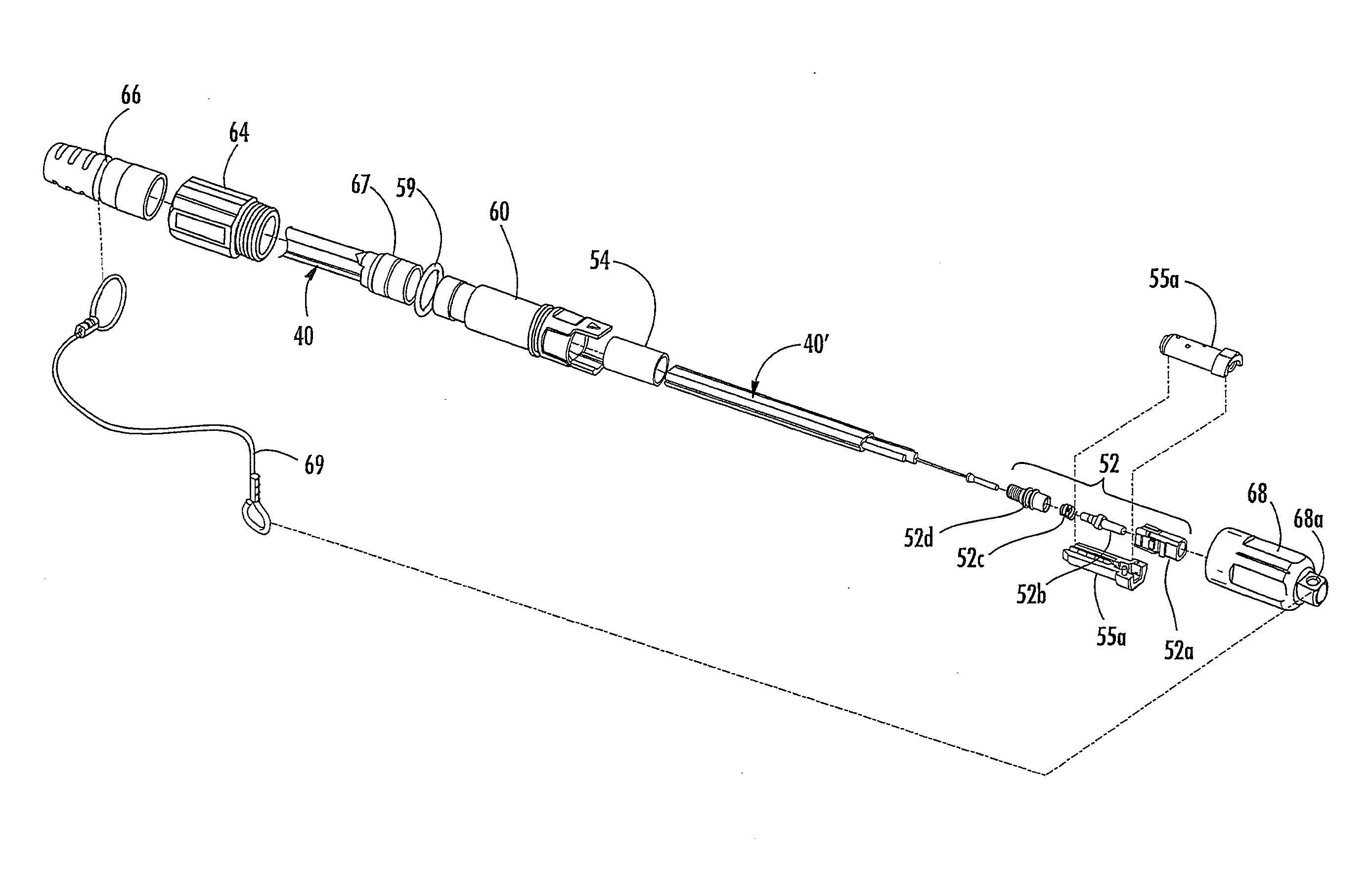

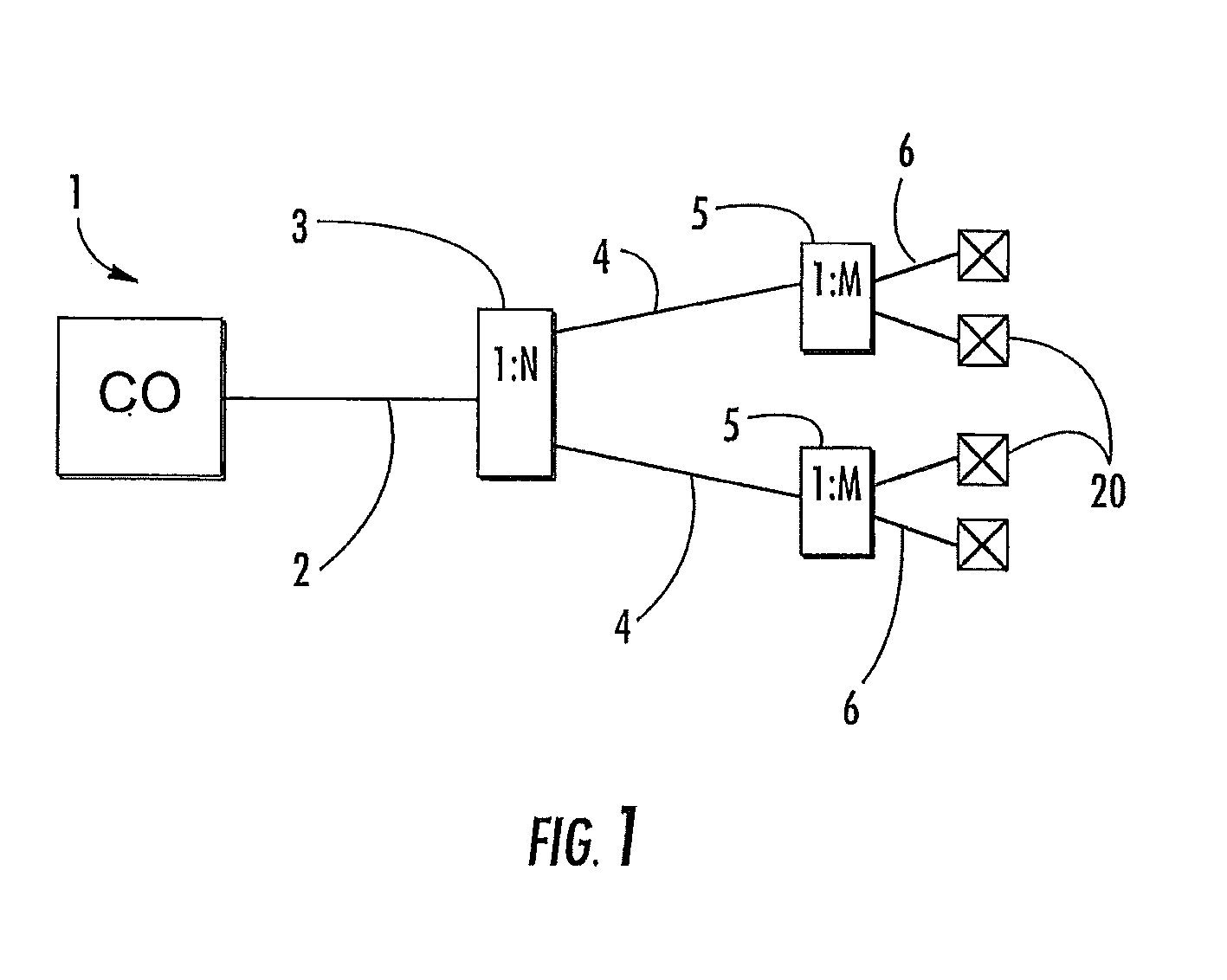

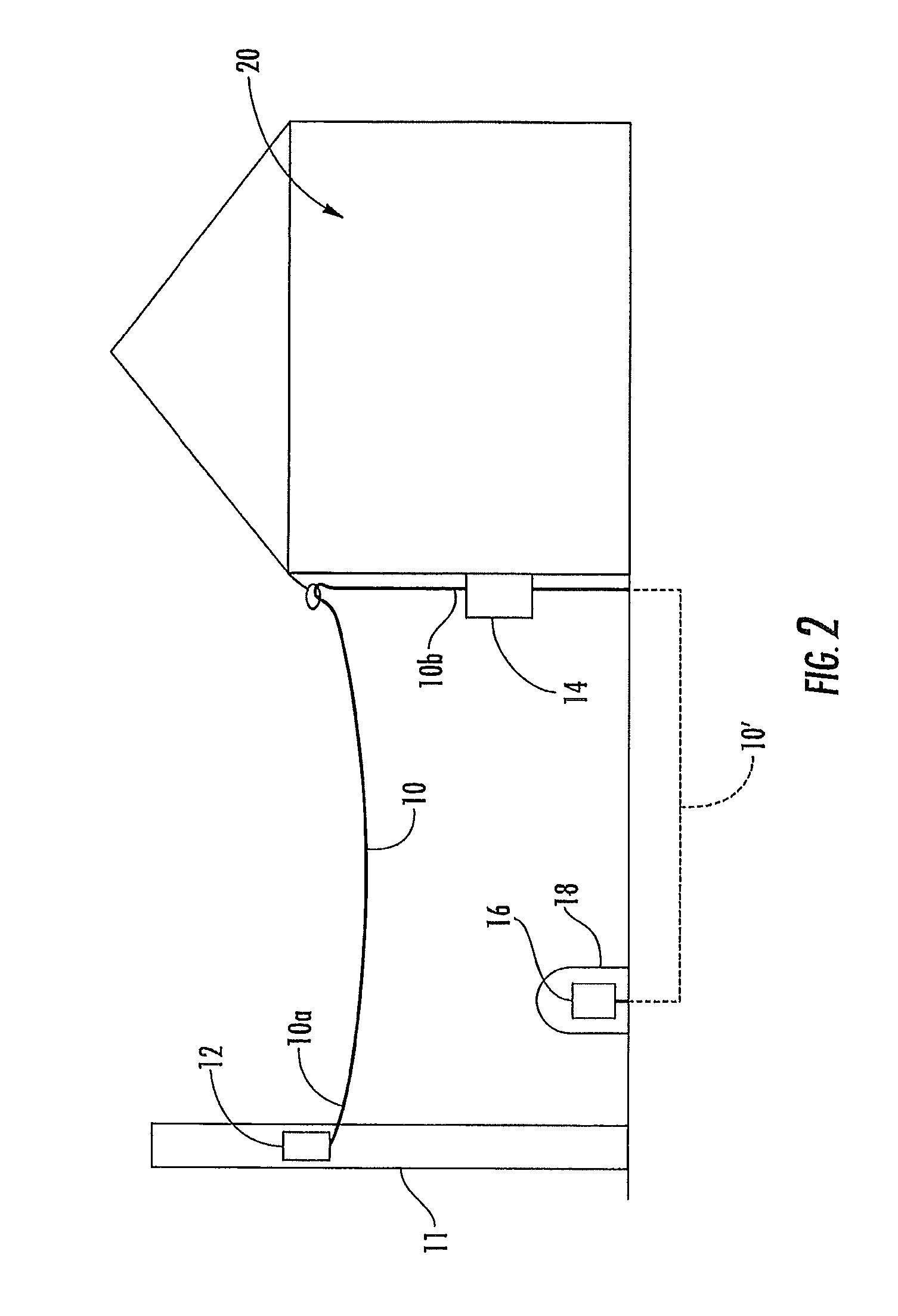

Preconnectorized fiber optic drop cables and assemblies

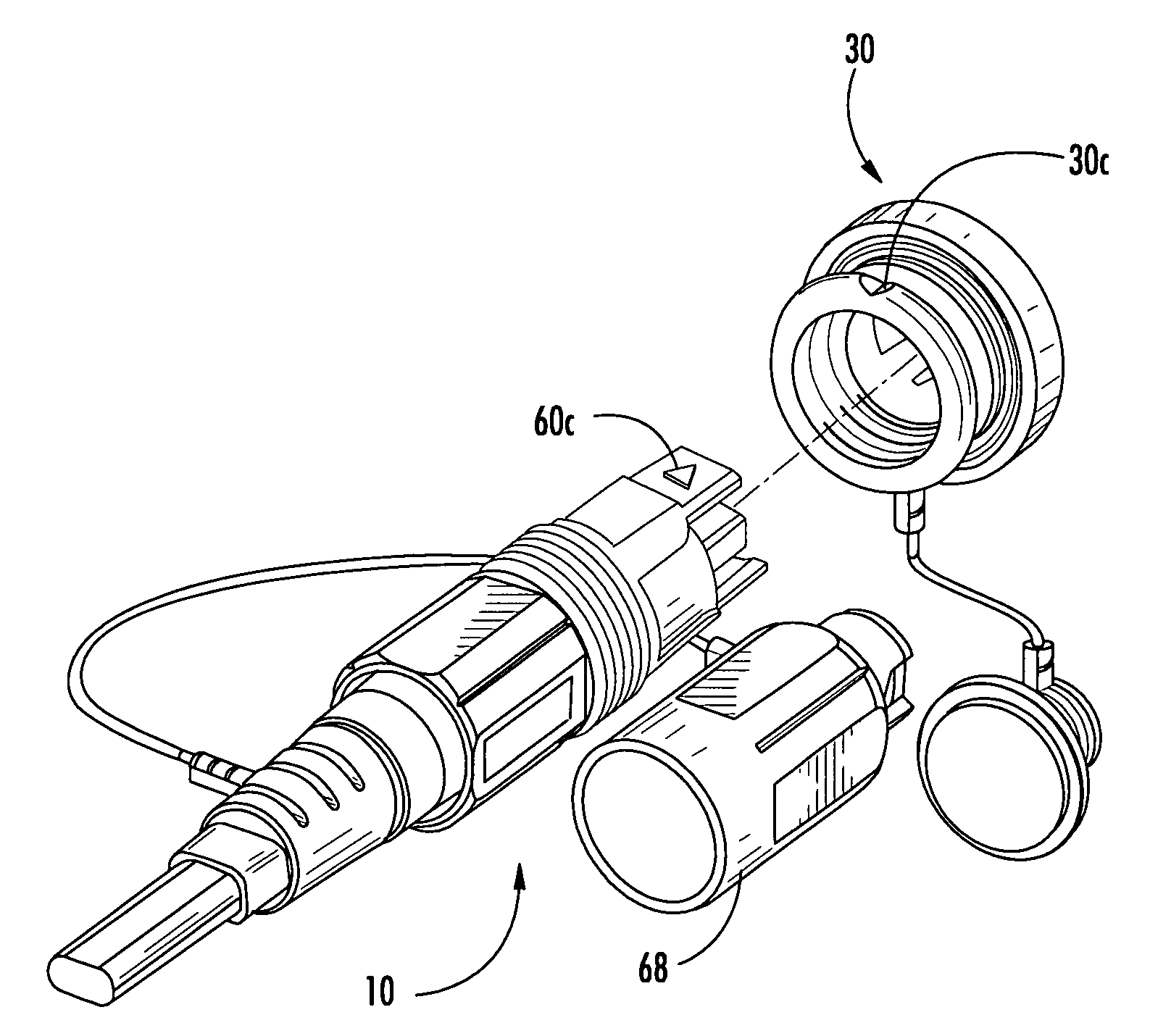

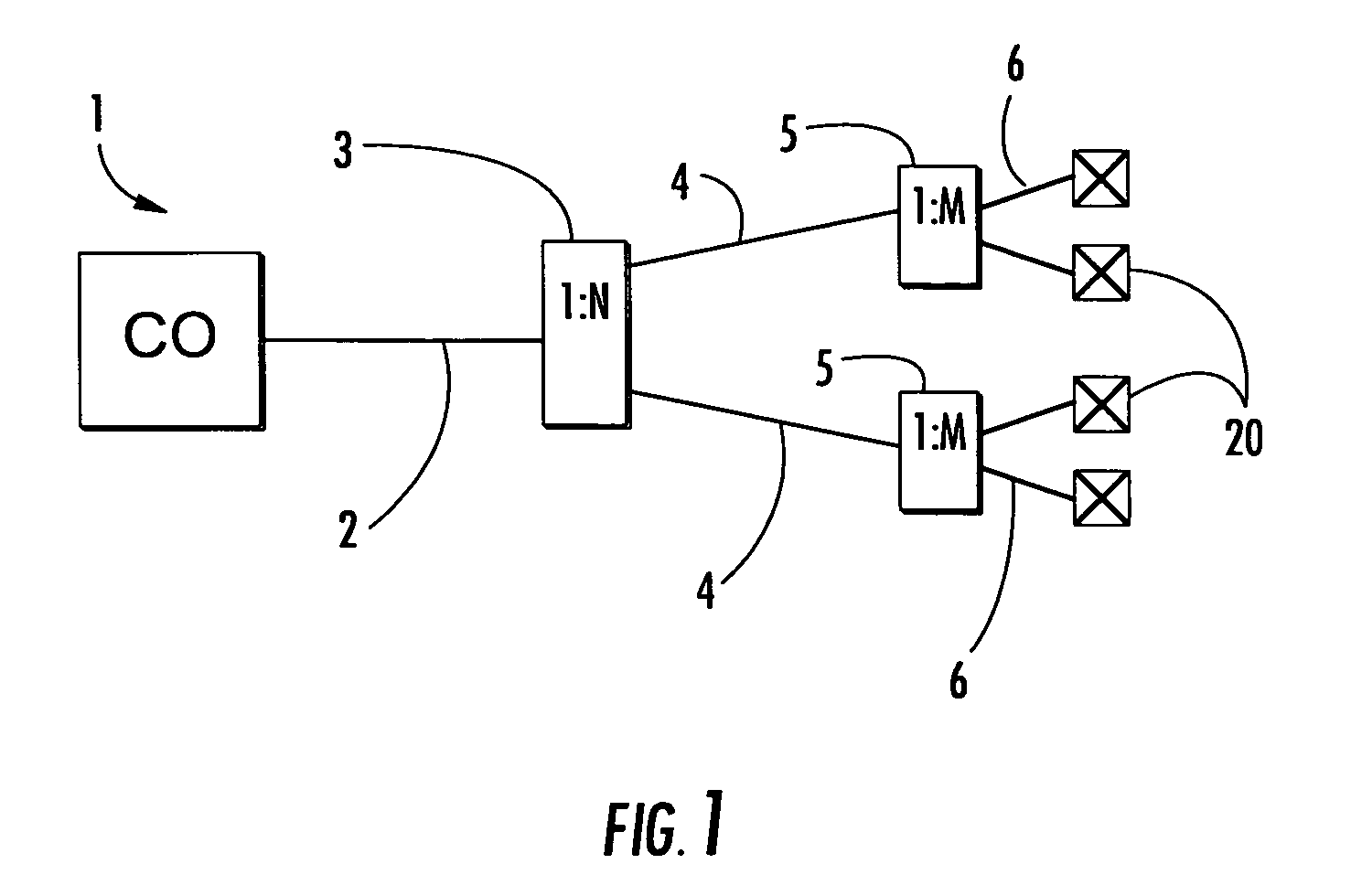

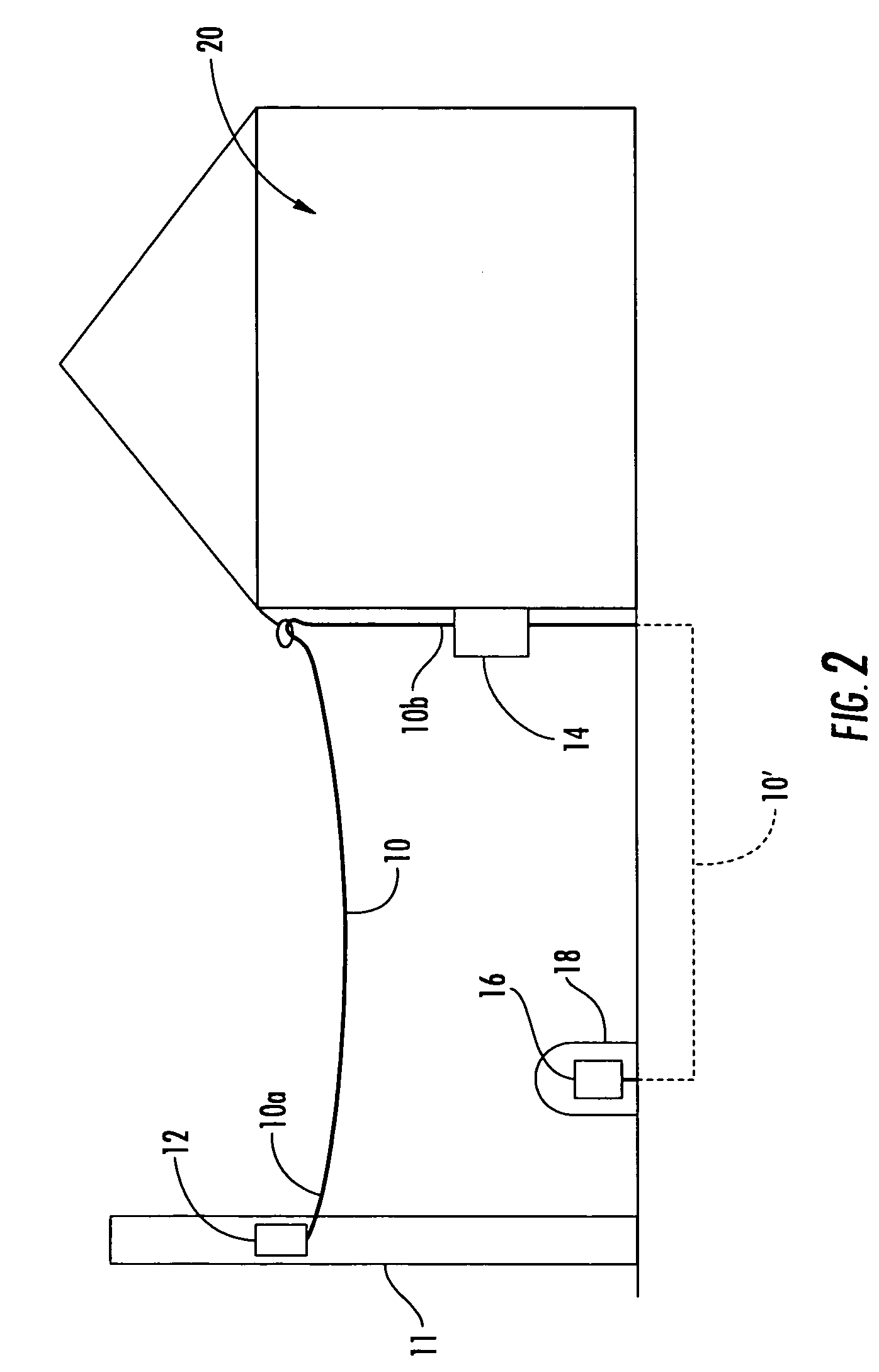

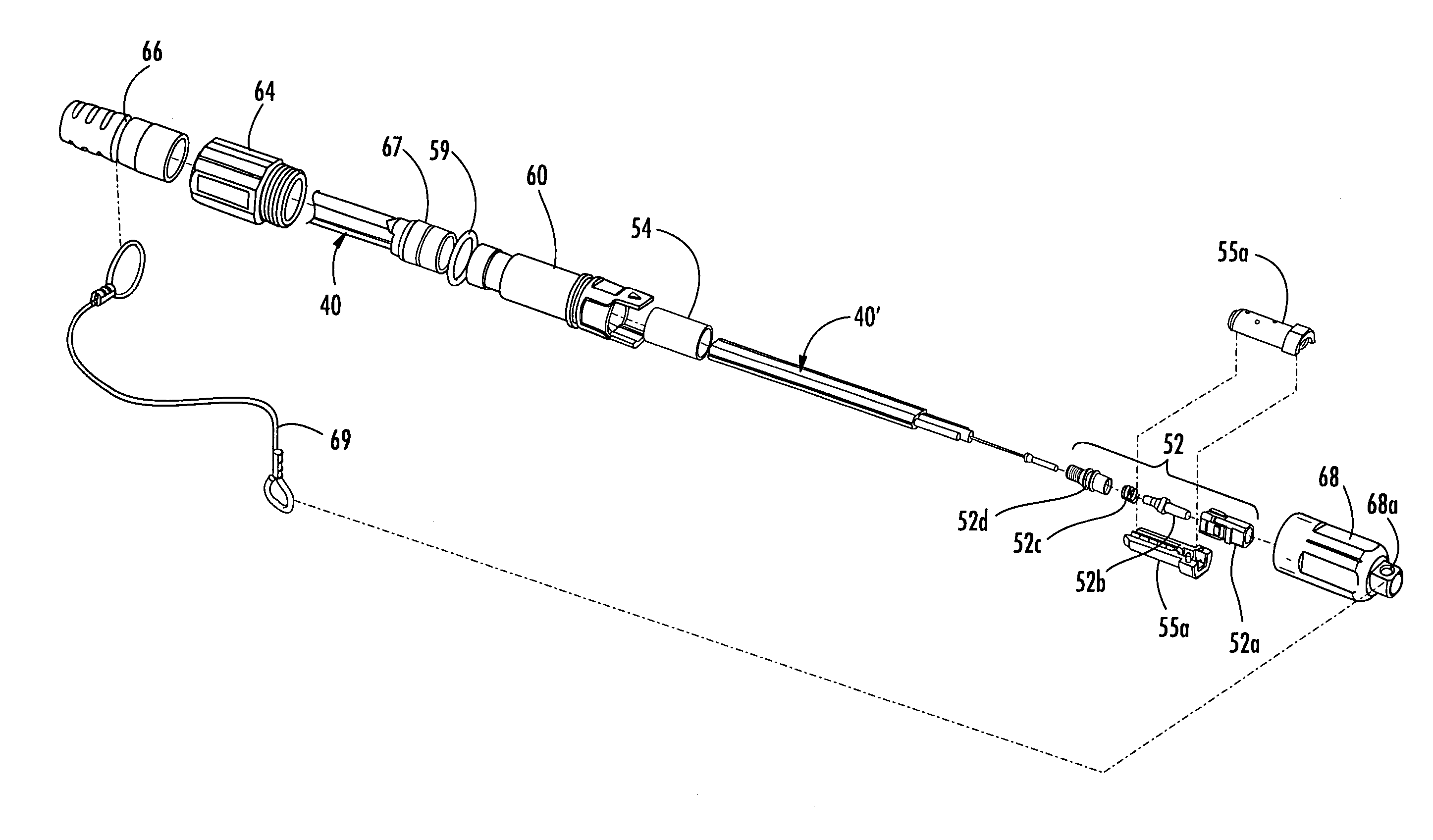

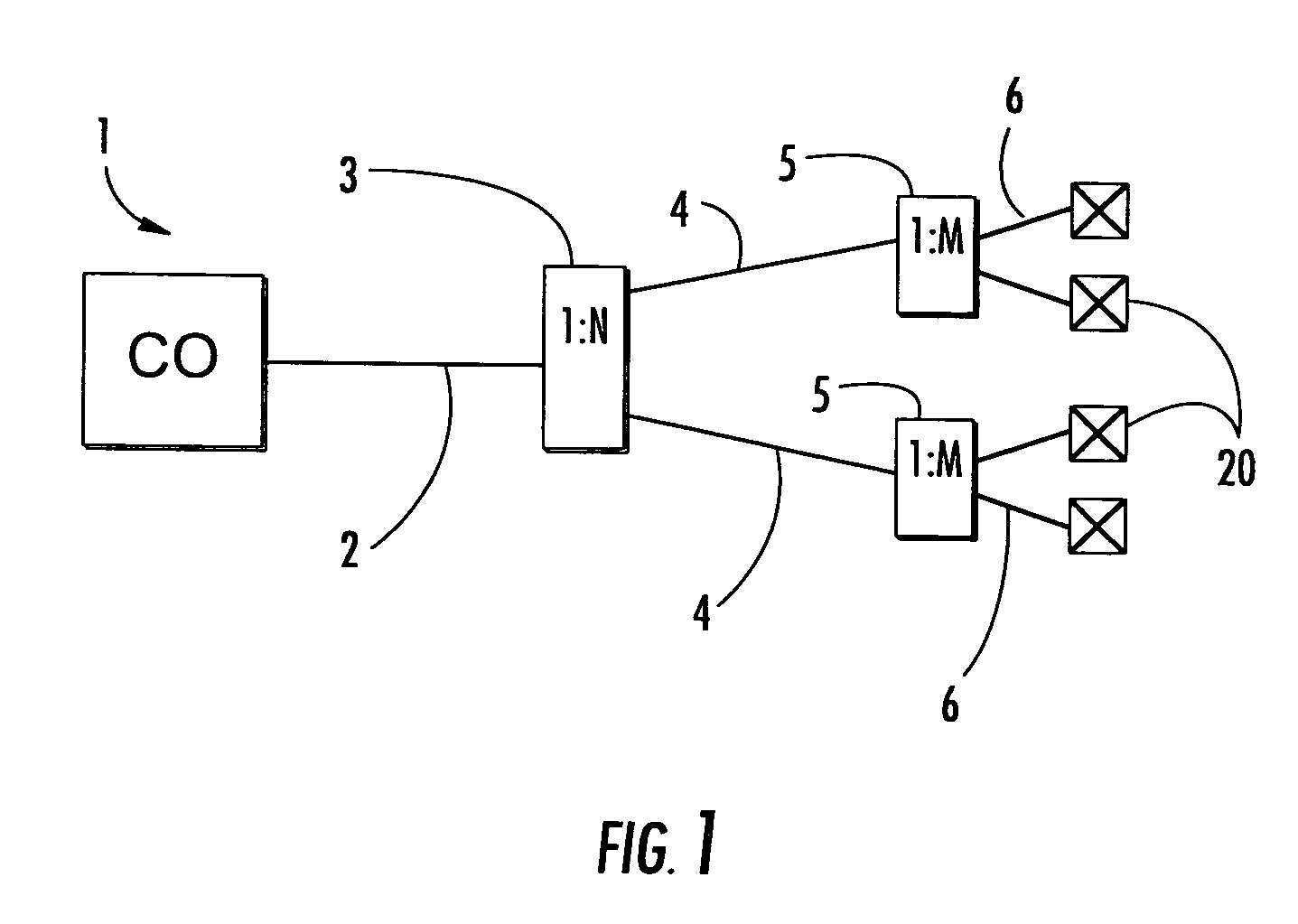

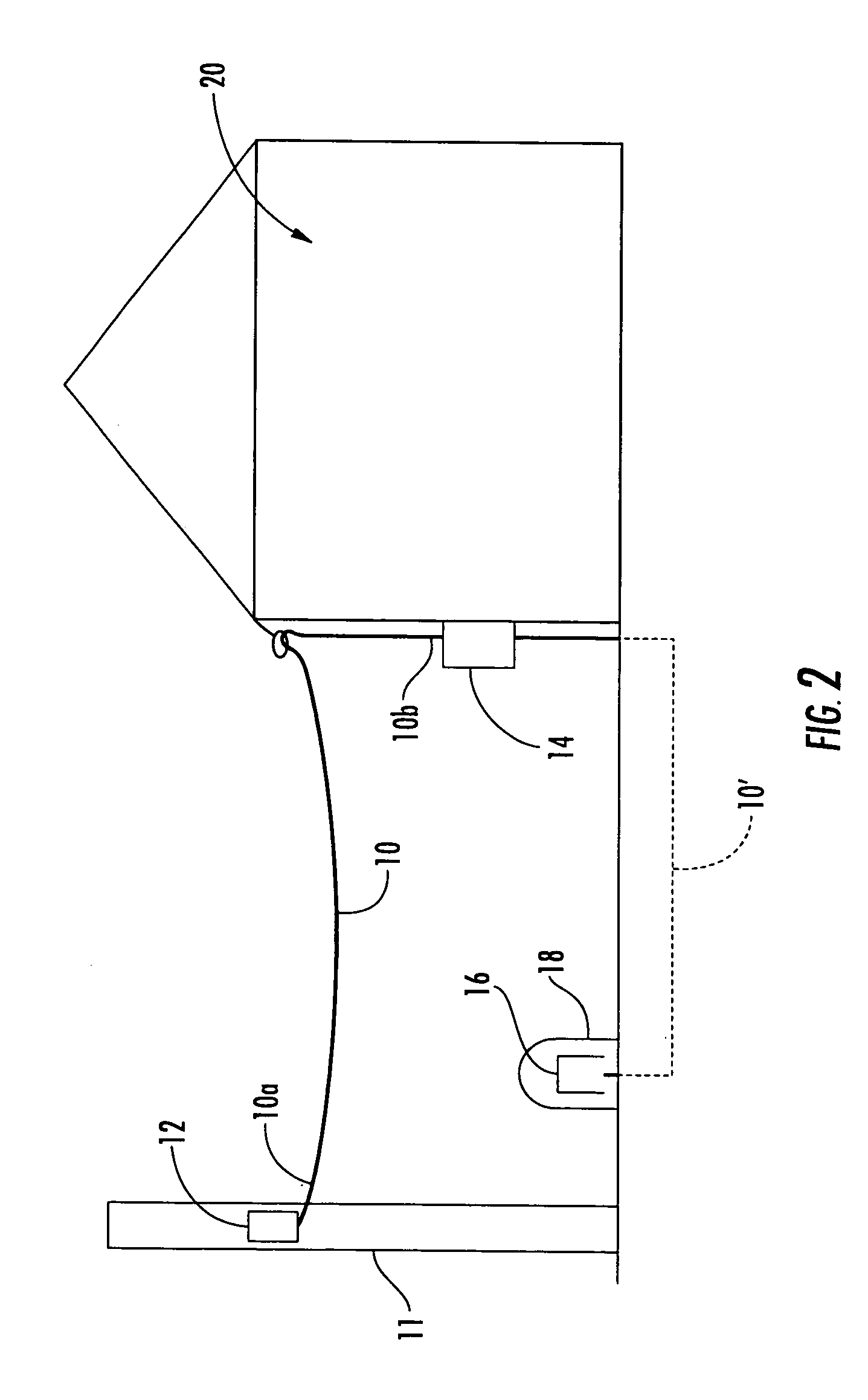

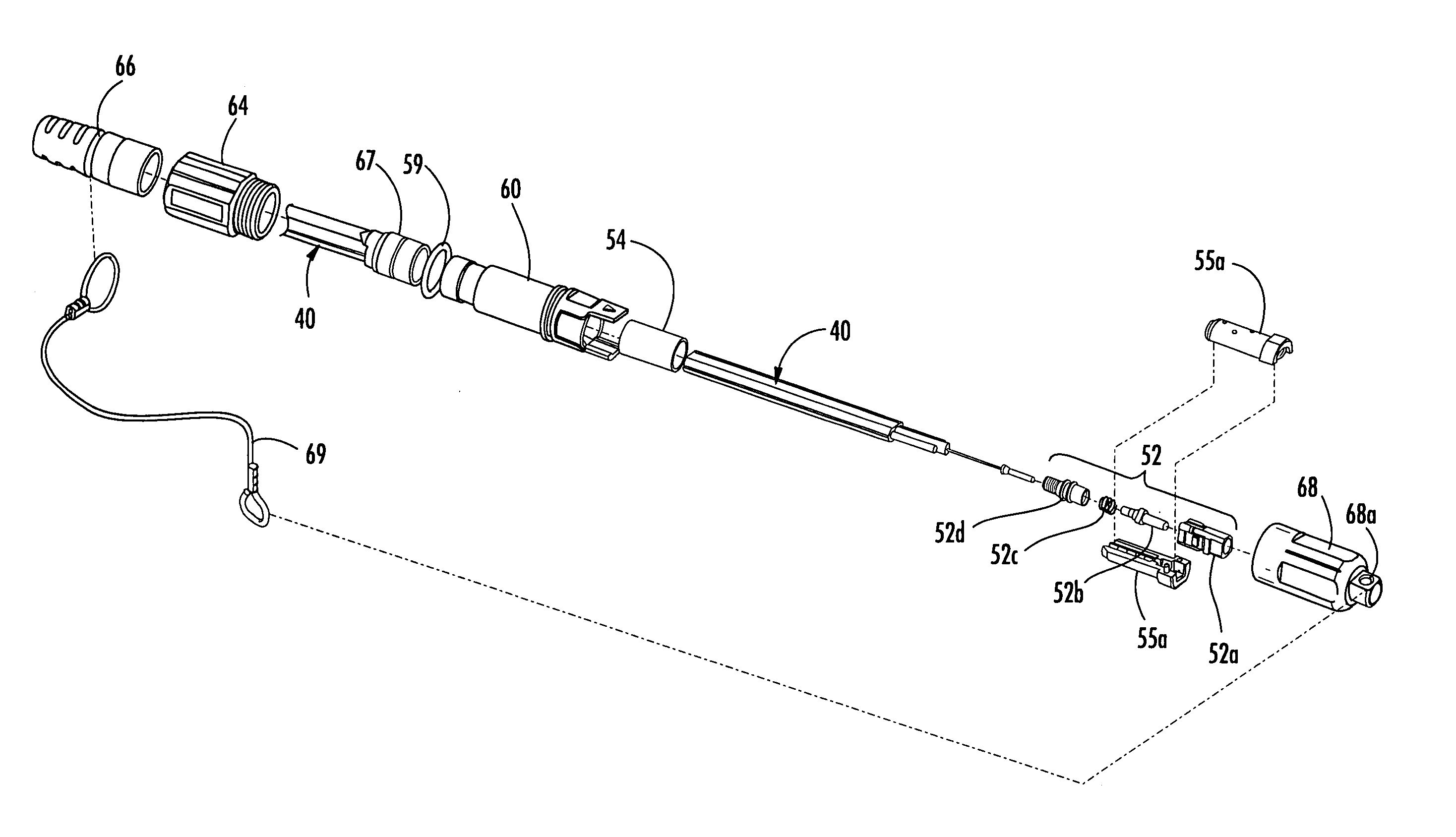

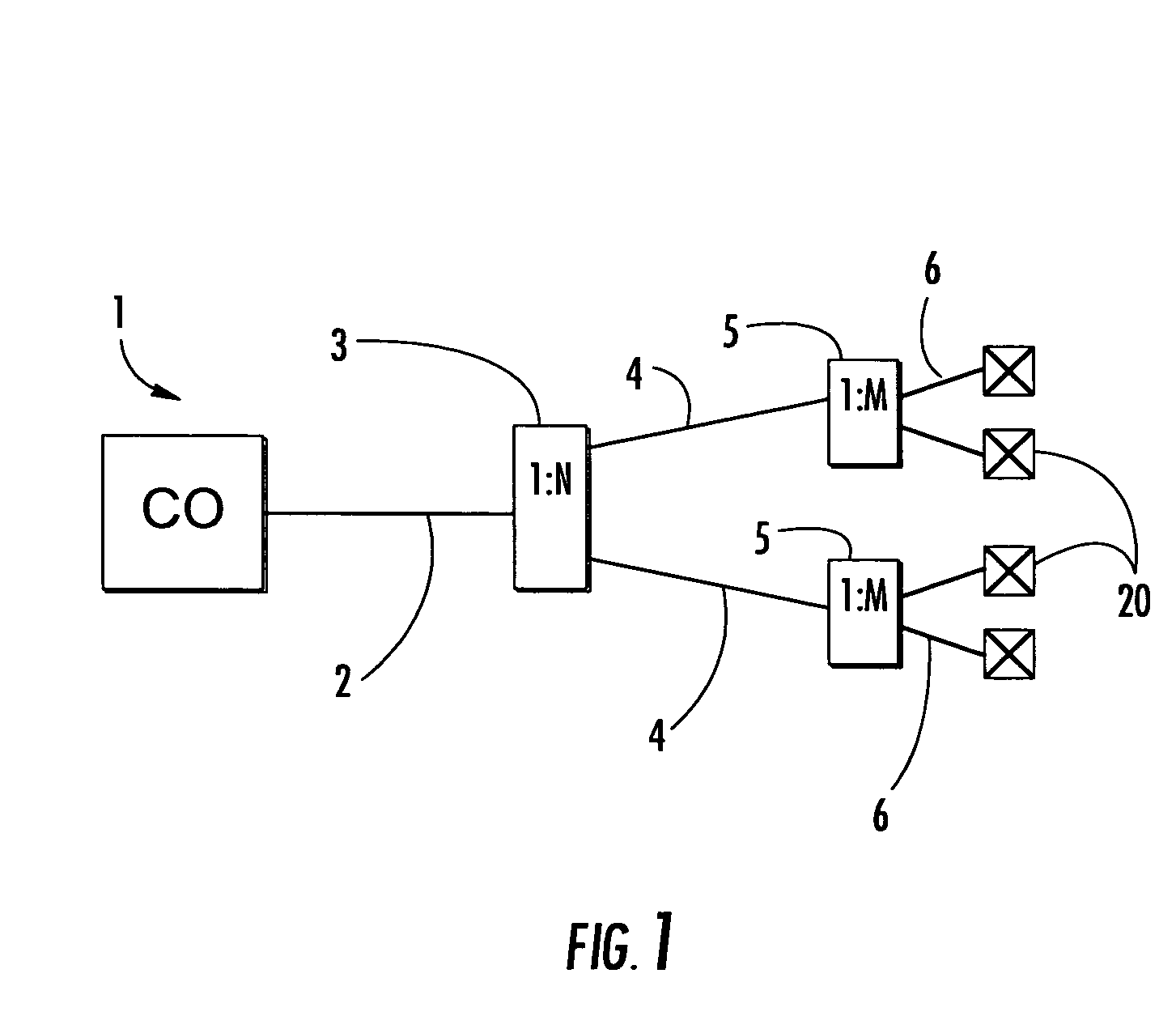

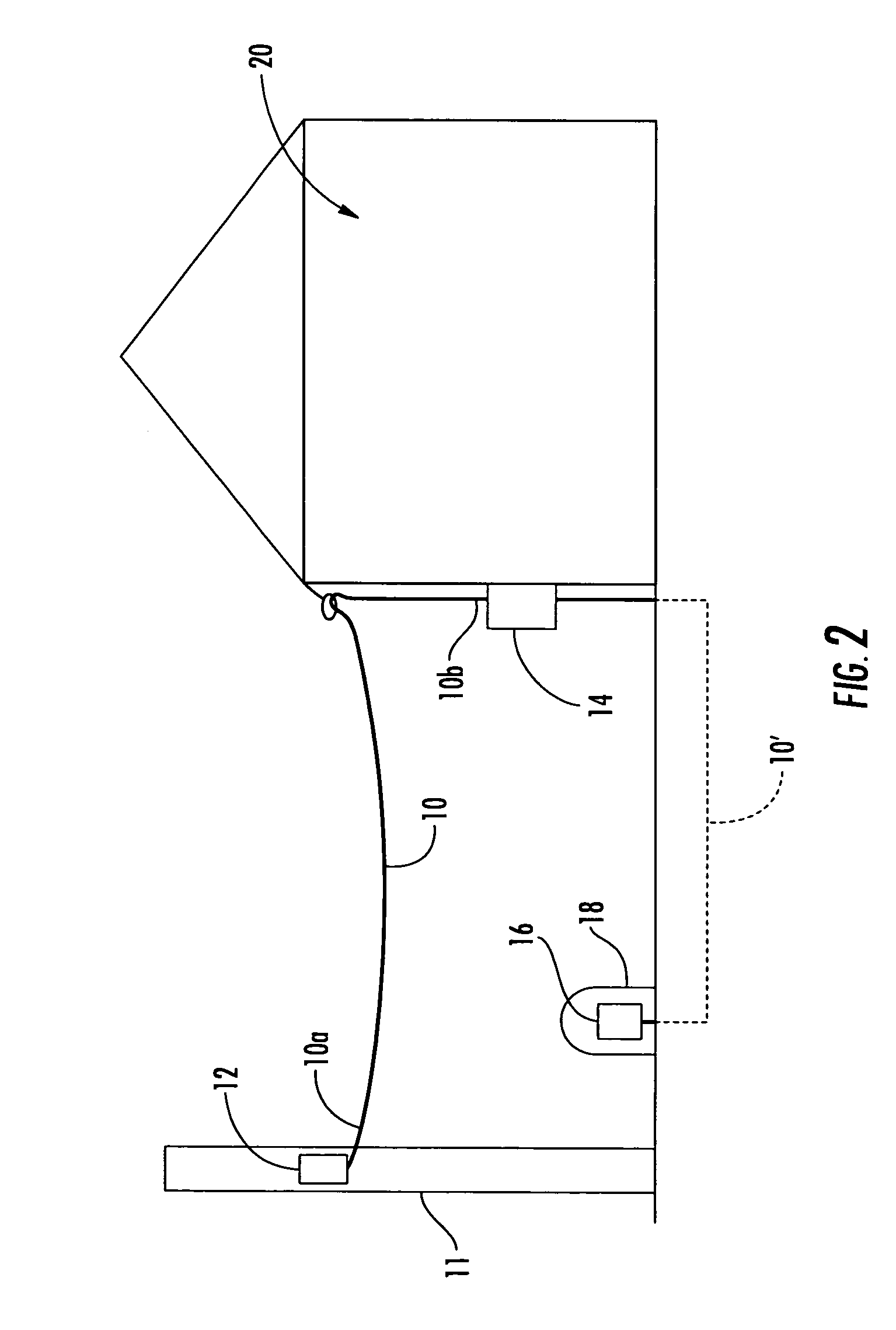

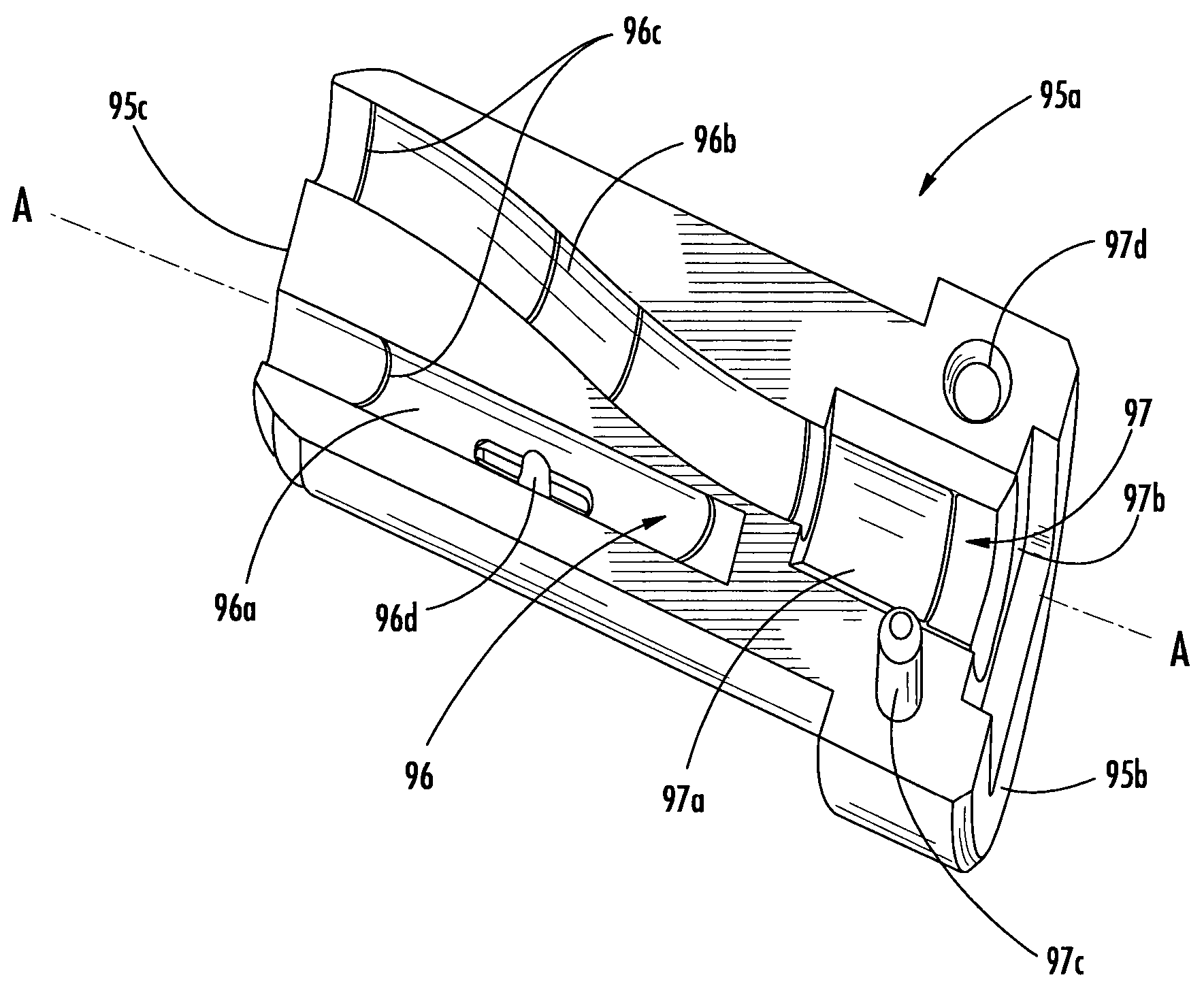

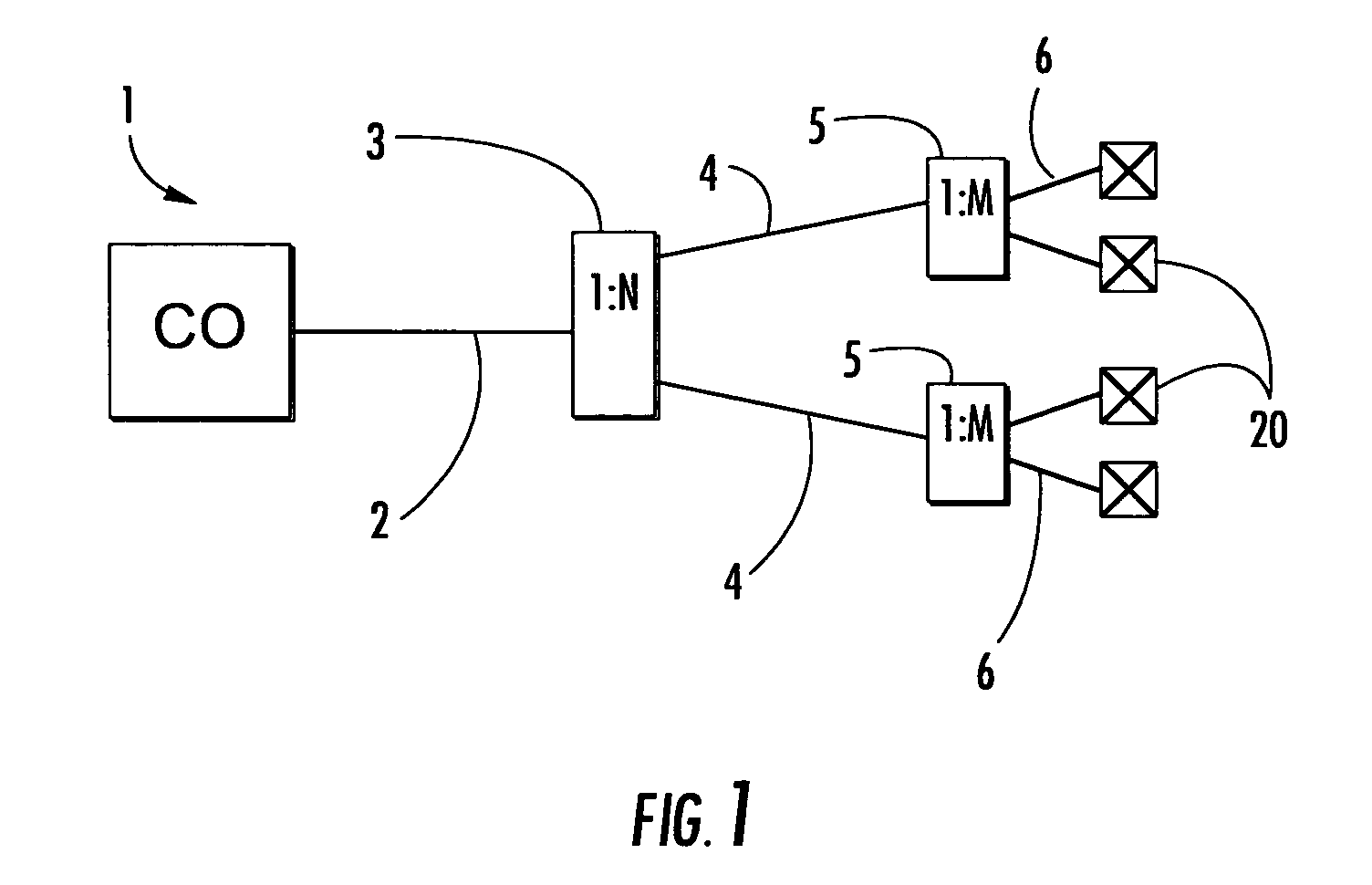

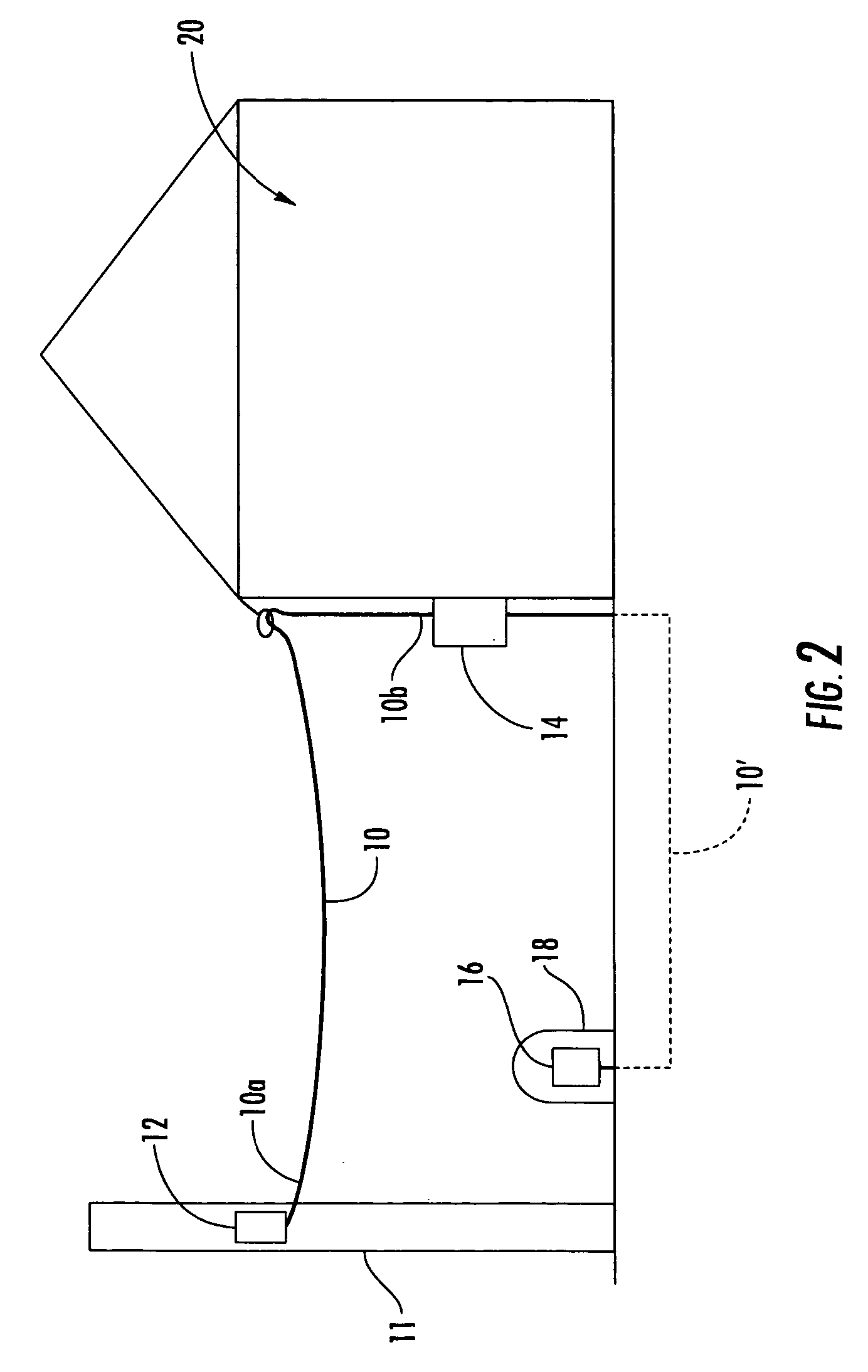

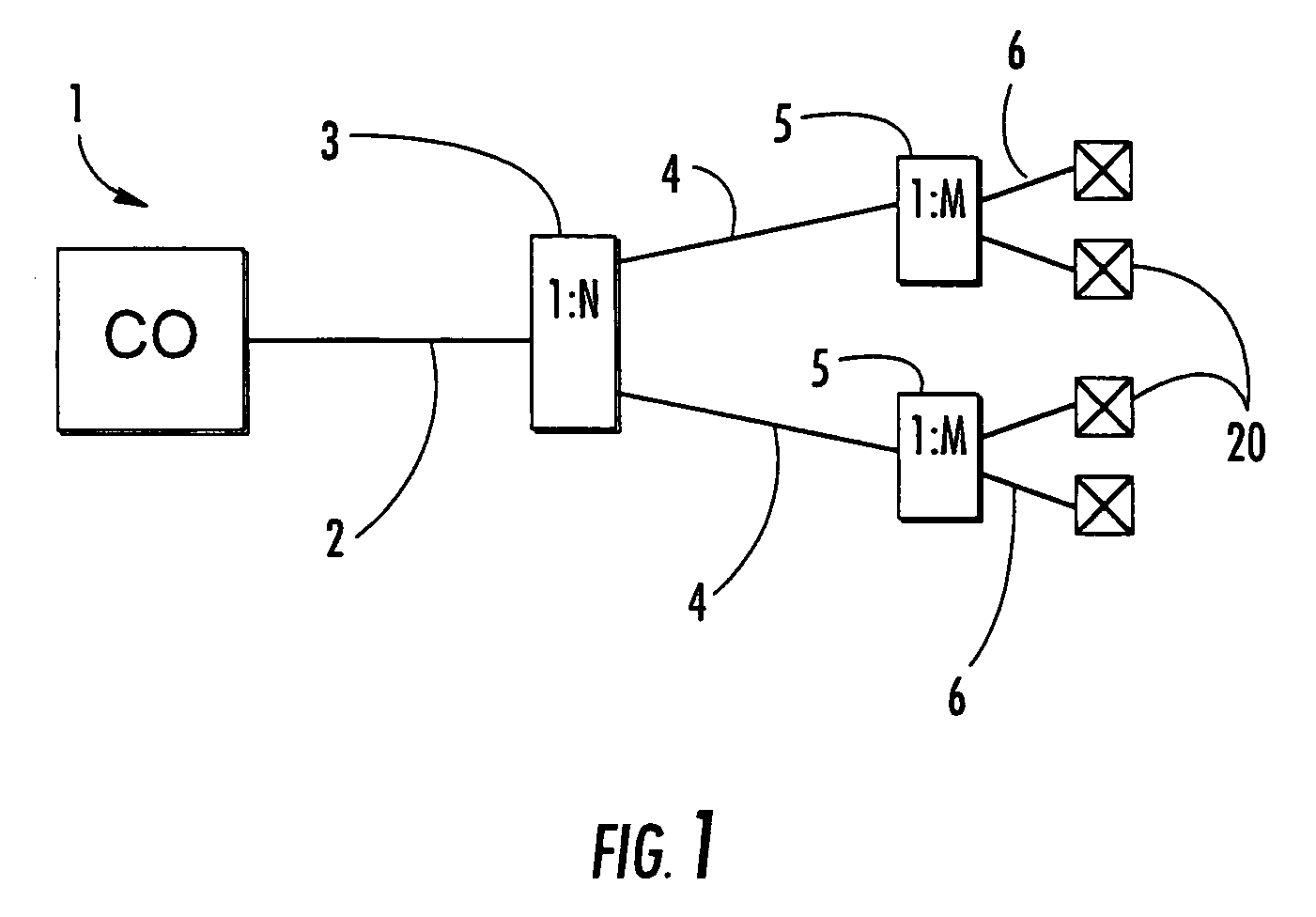

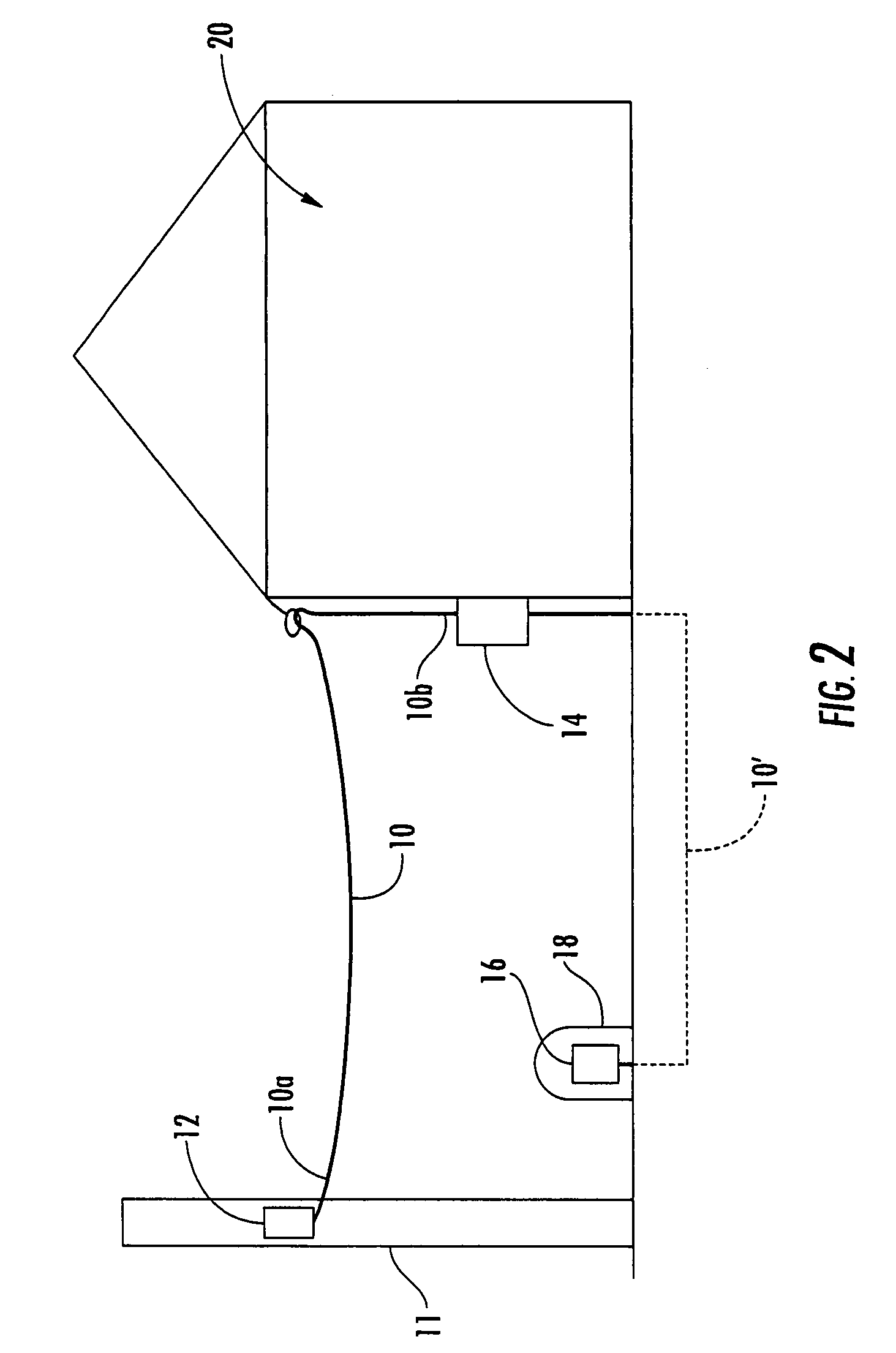

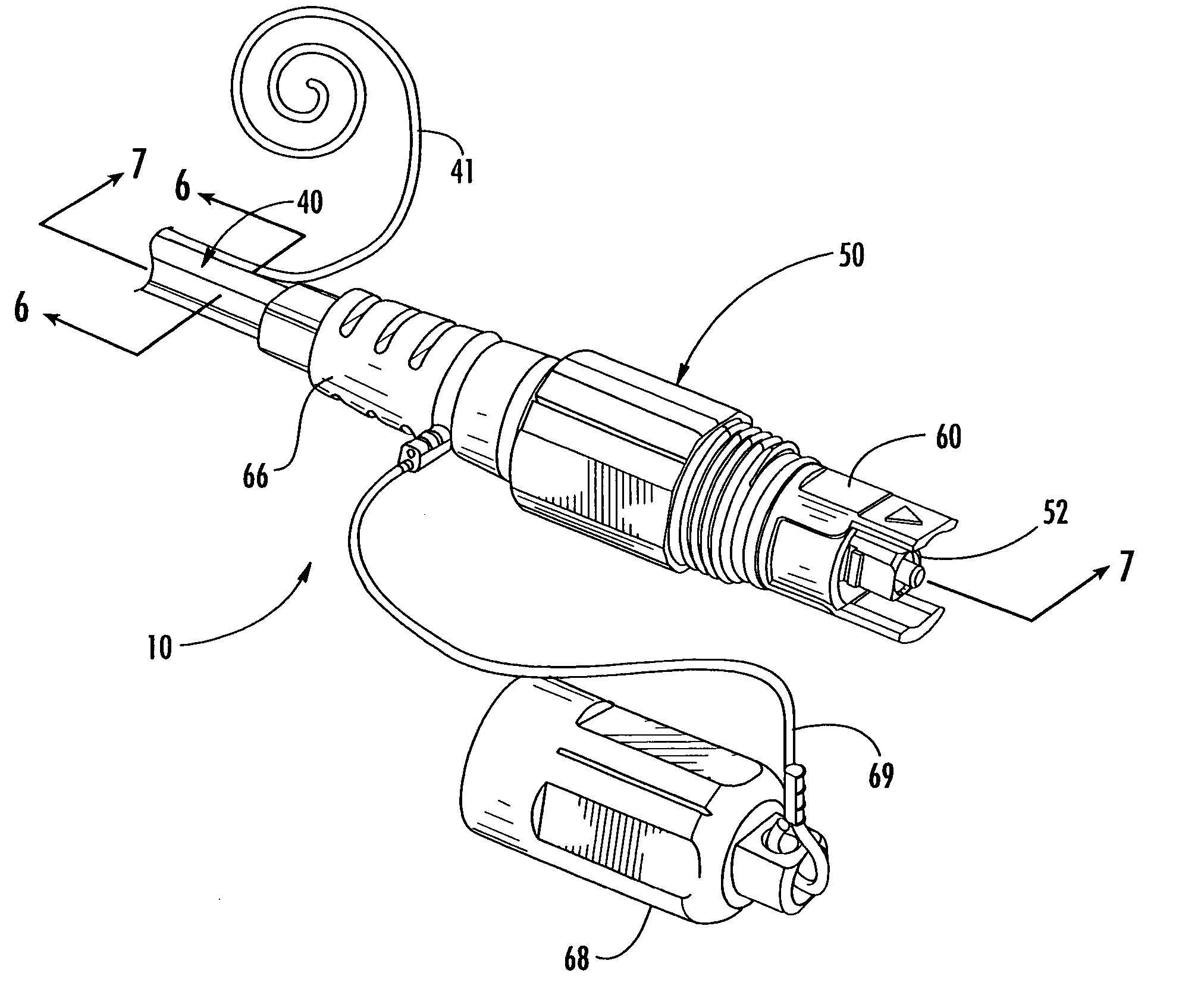

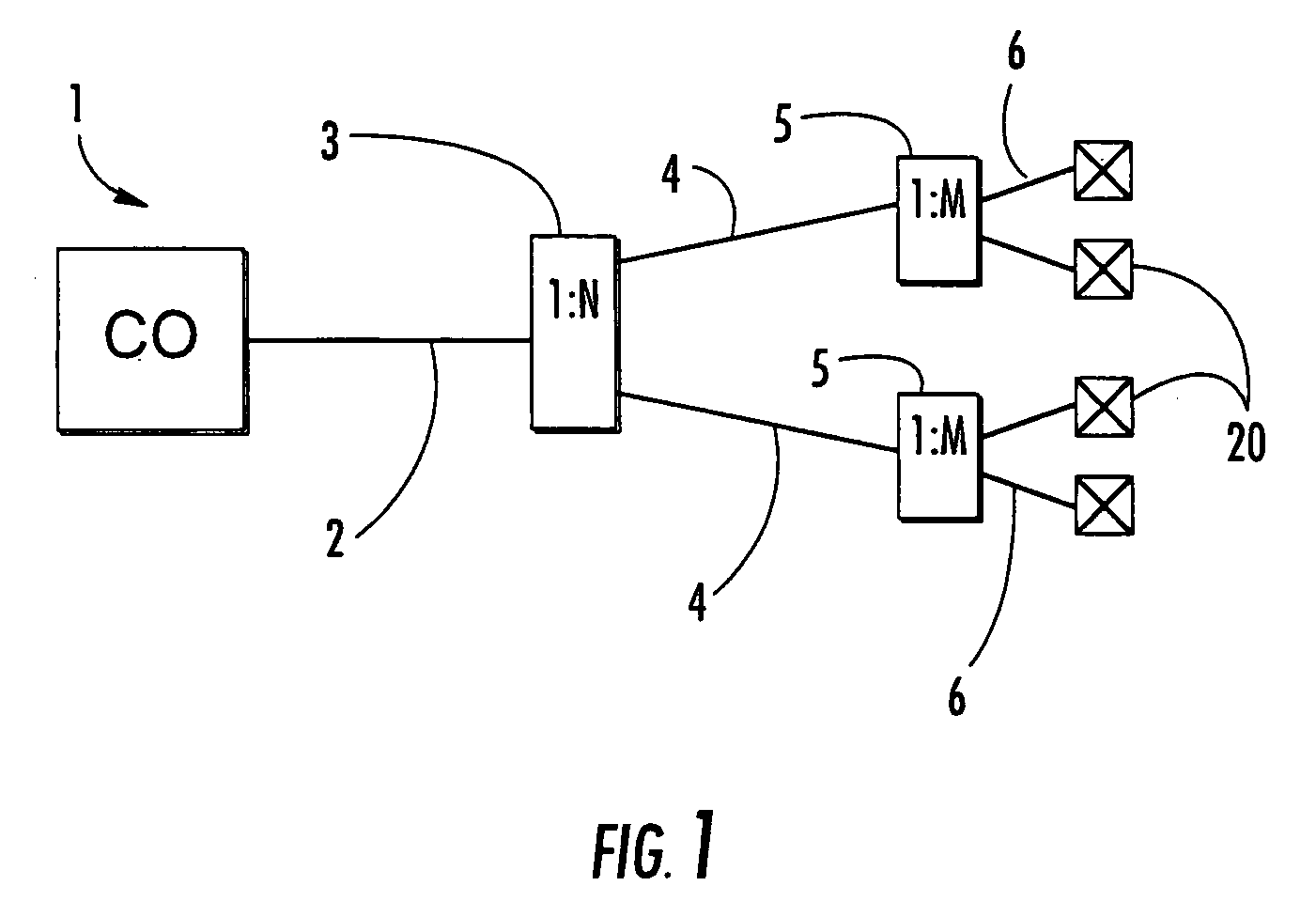

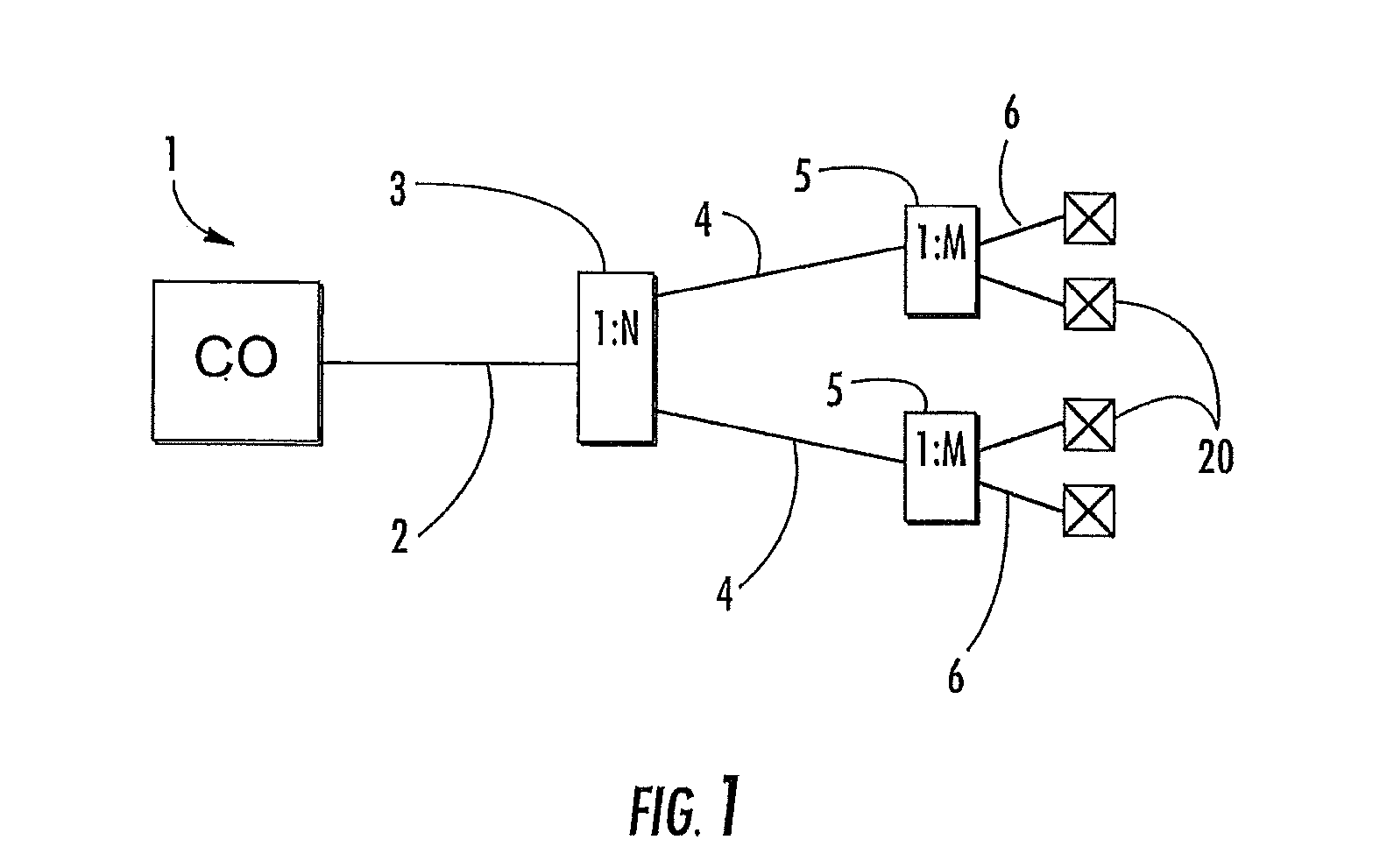

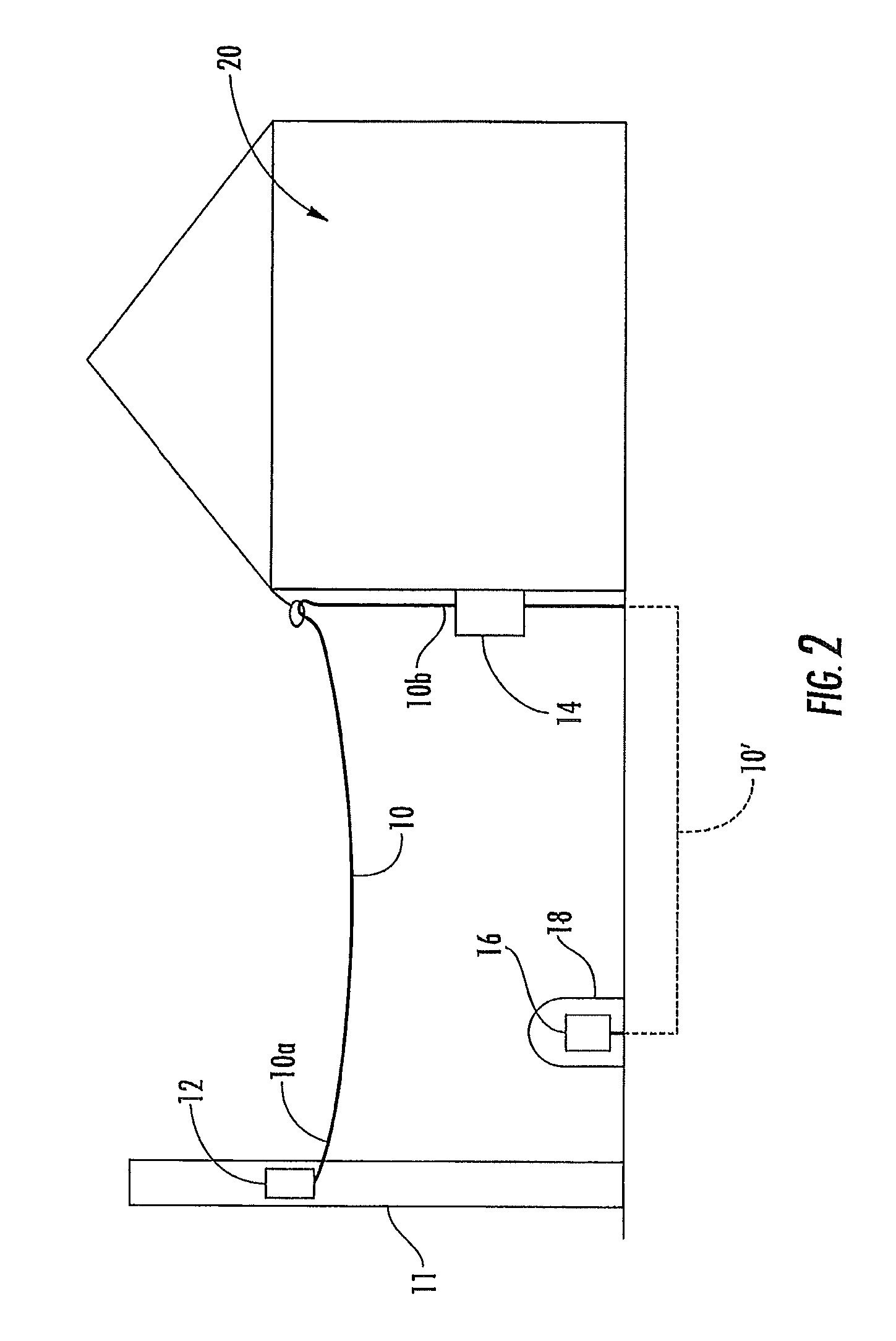

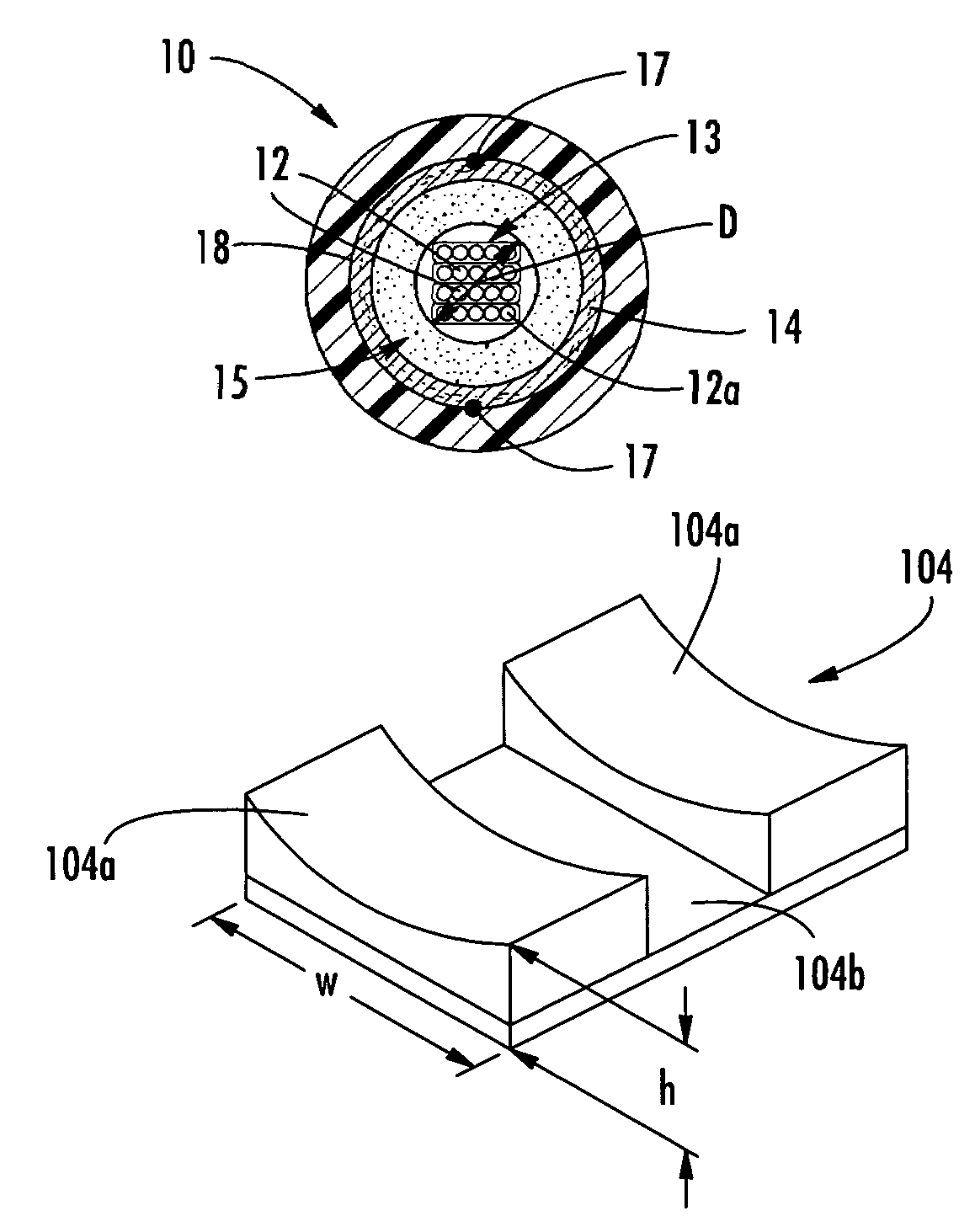

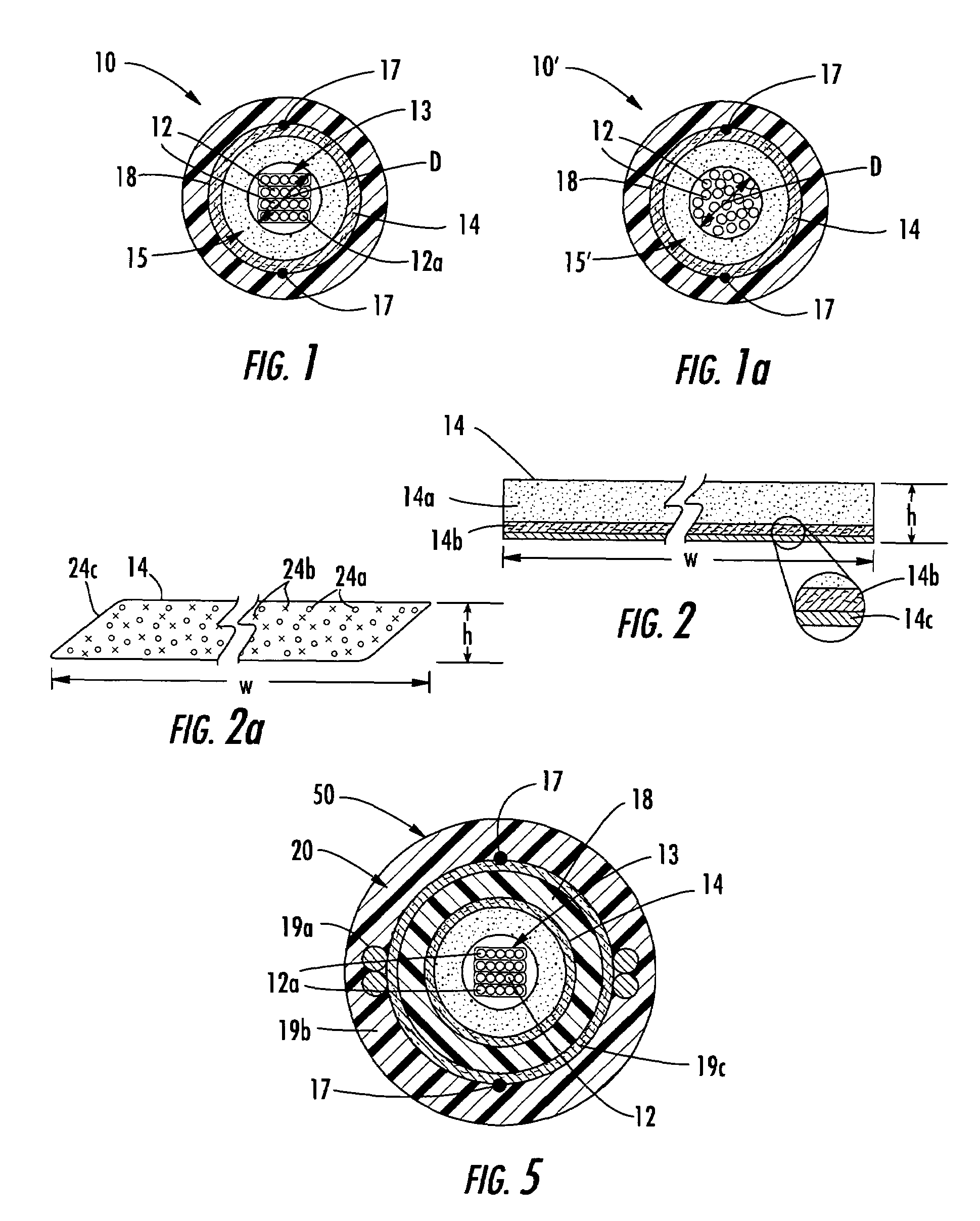

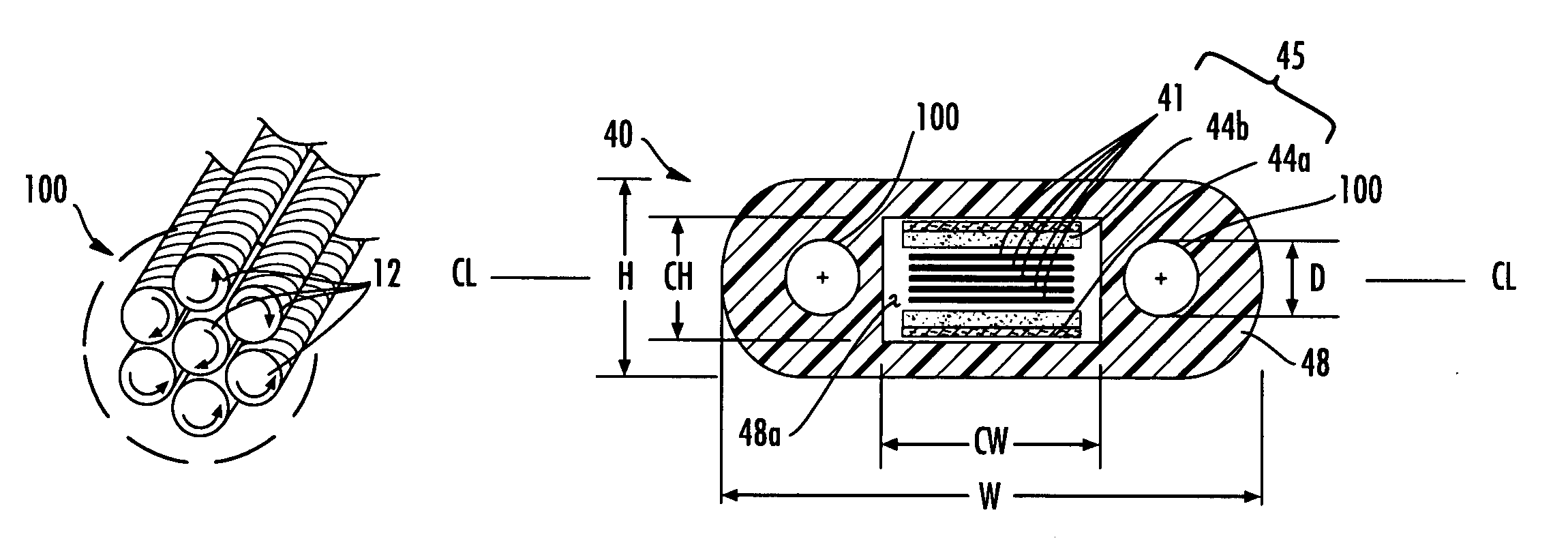

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of a optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

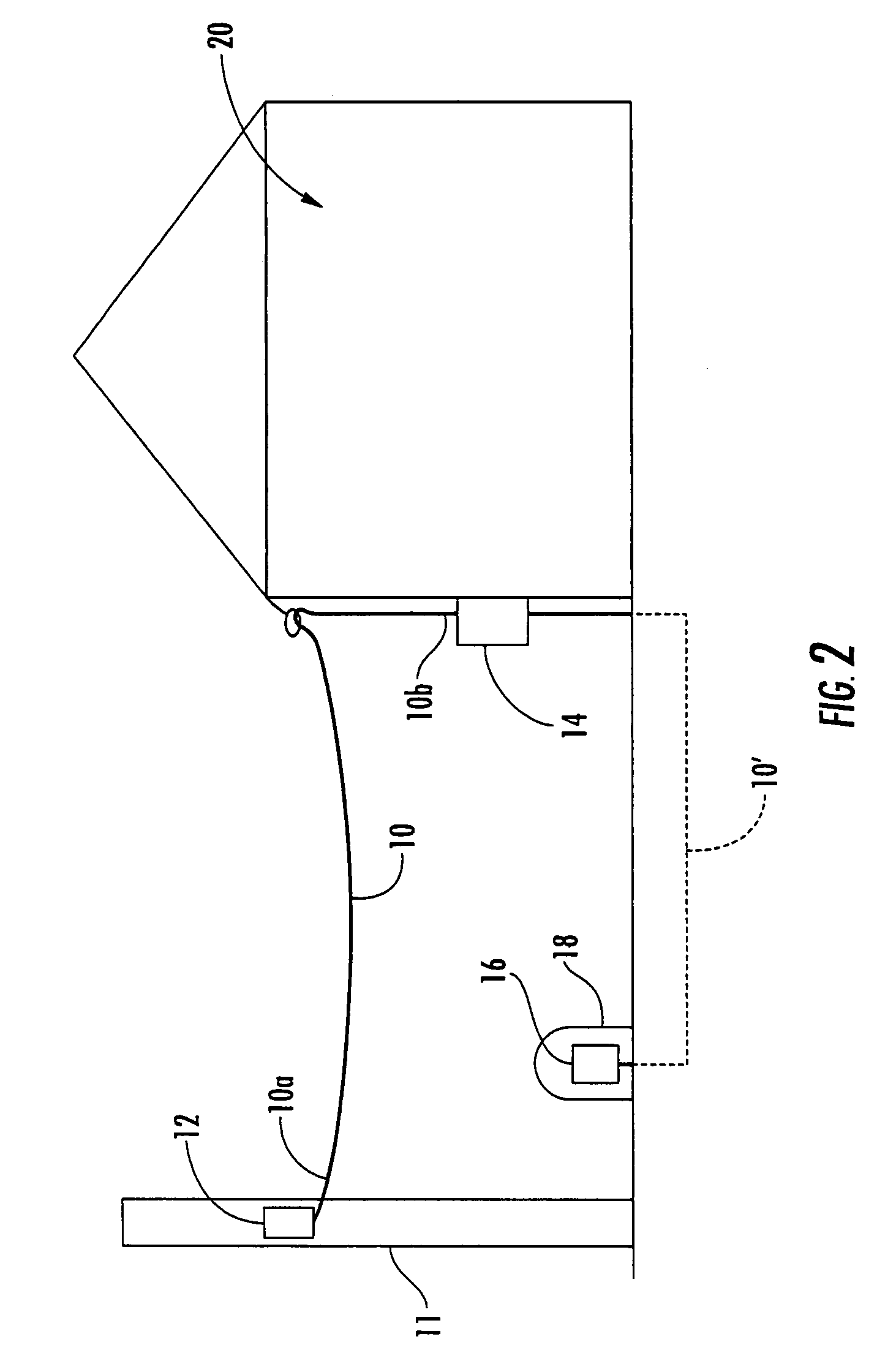

Fiber optic drop cables and preconnectorized assemblies having toning portions

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of an optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

Preconnectorized fiber optic drop cables and assemblies for efficient deployment

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of a optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

Figure-eight preconnectorized fiber optic drop cables and assemblies

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of a optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

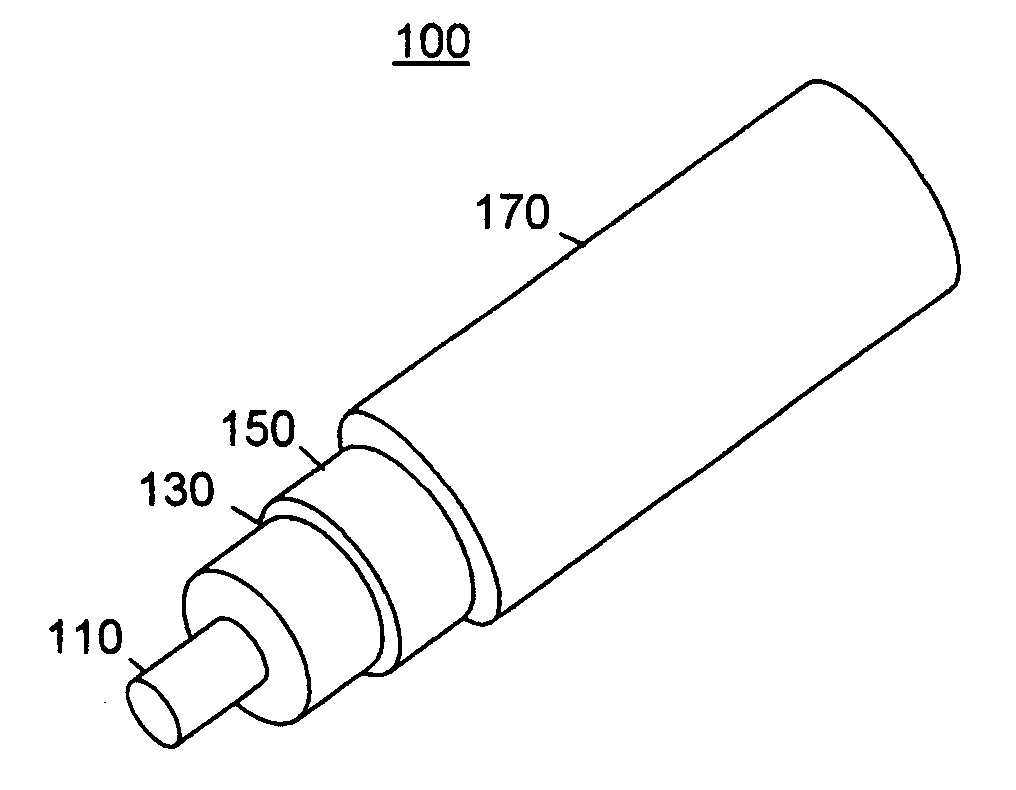

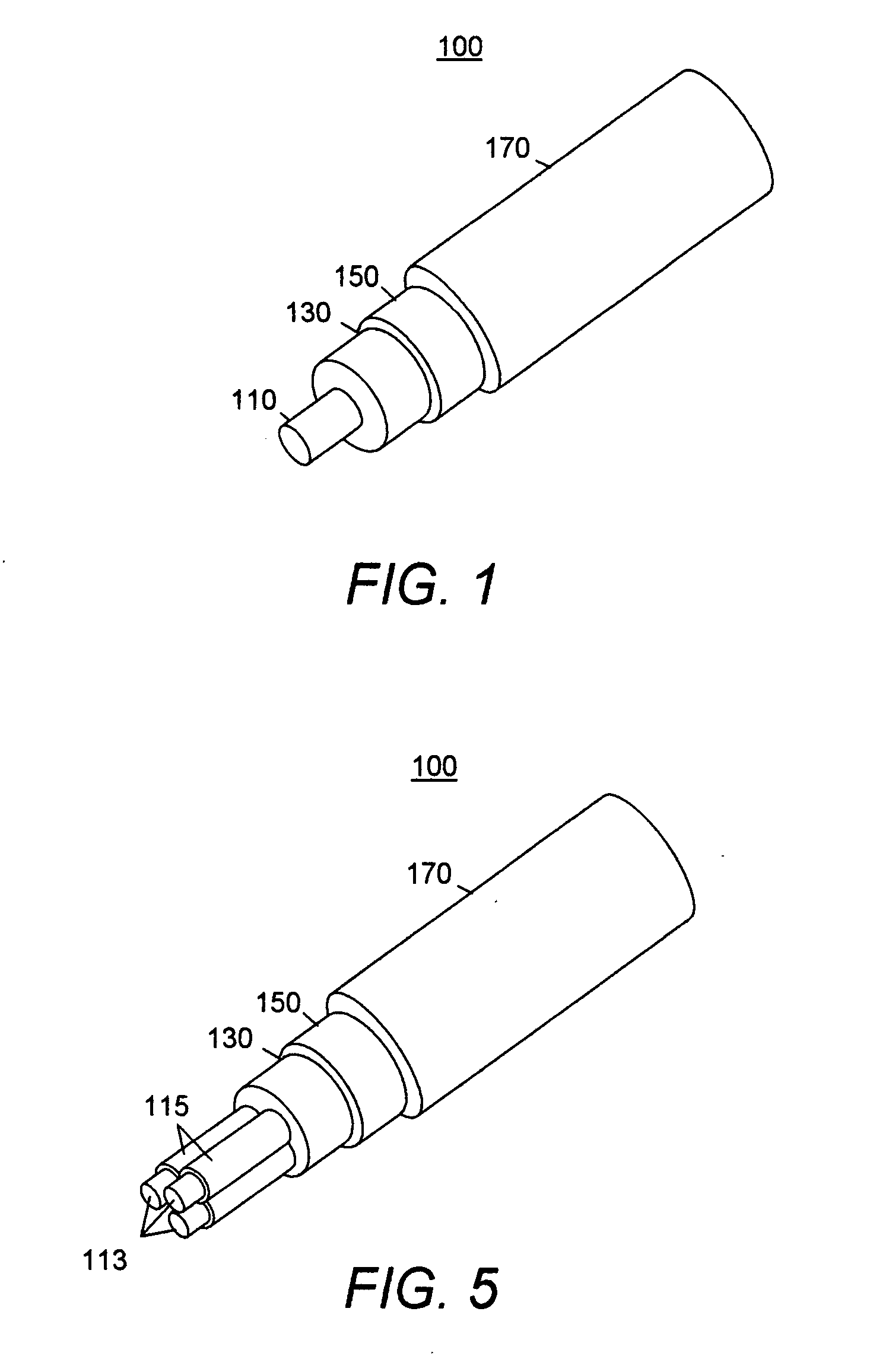

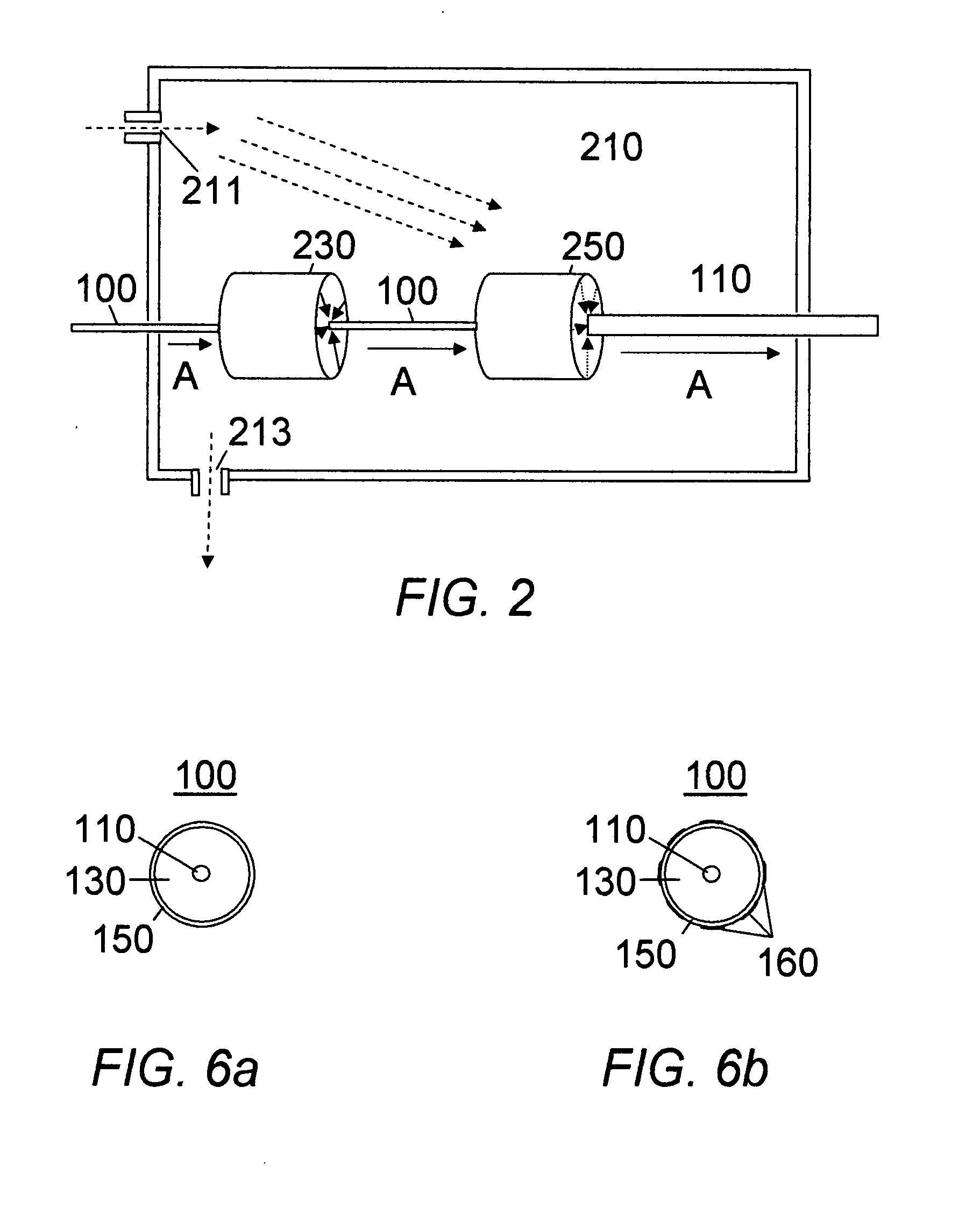

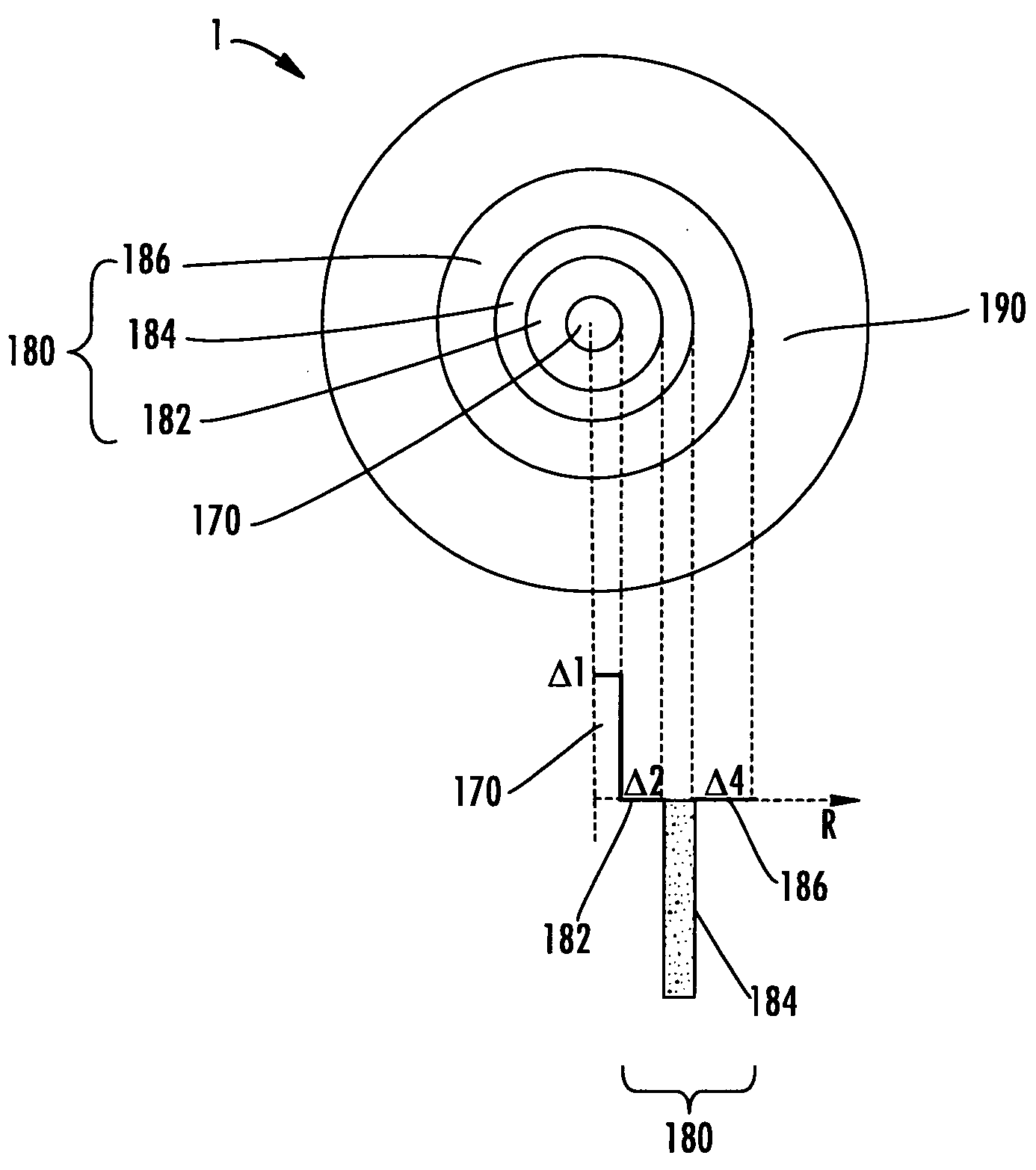

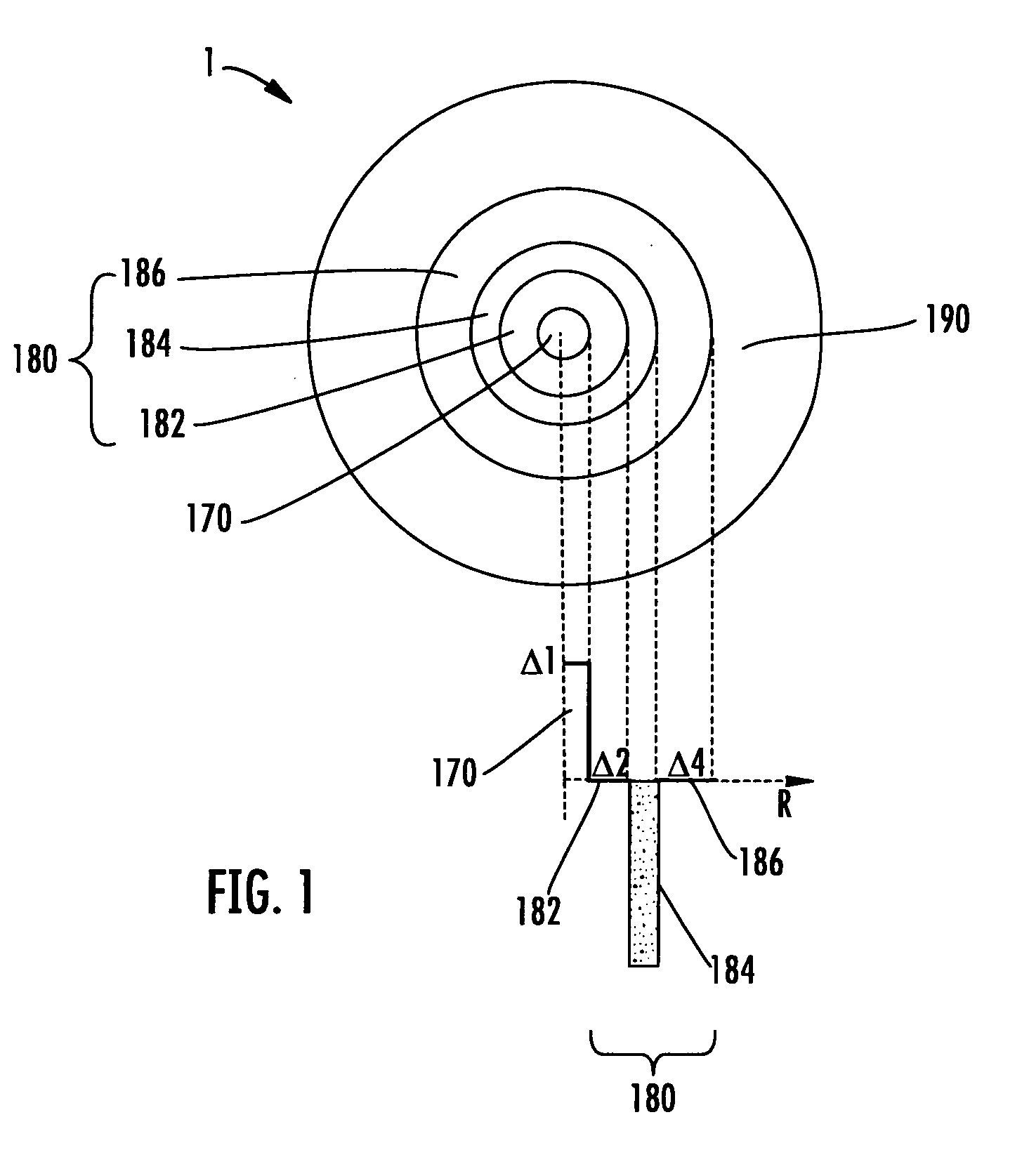

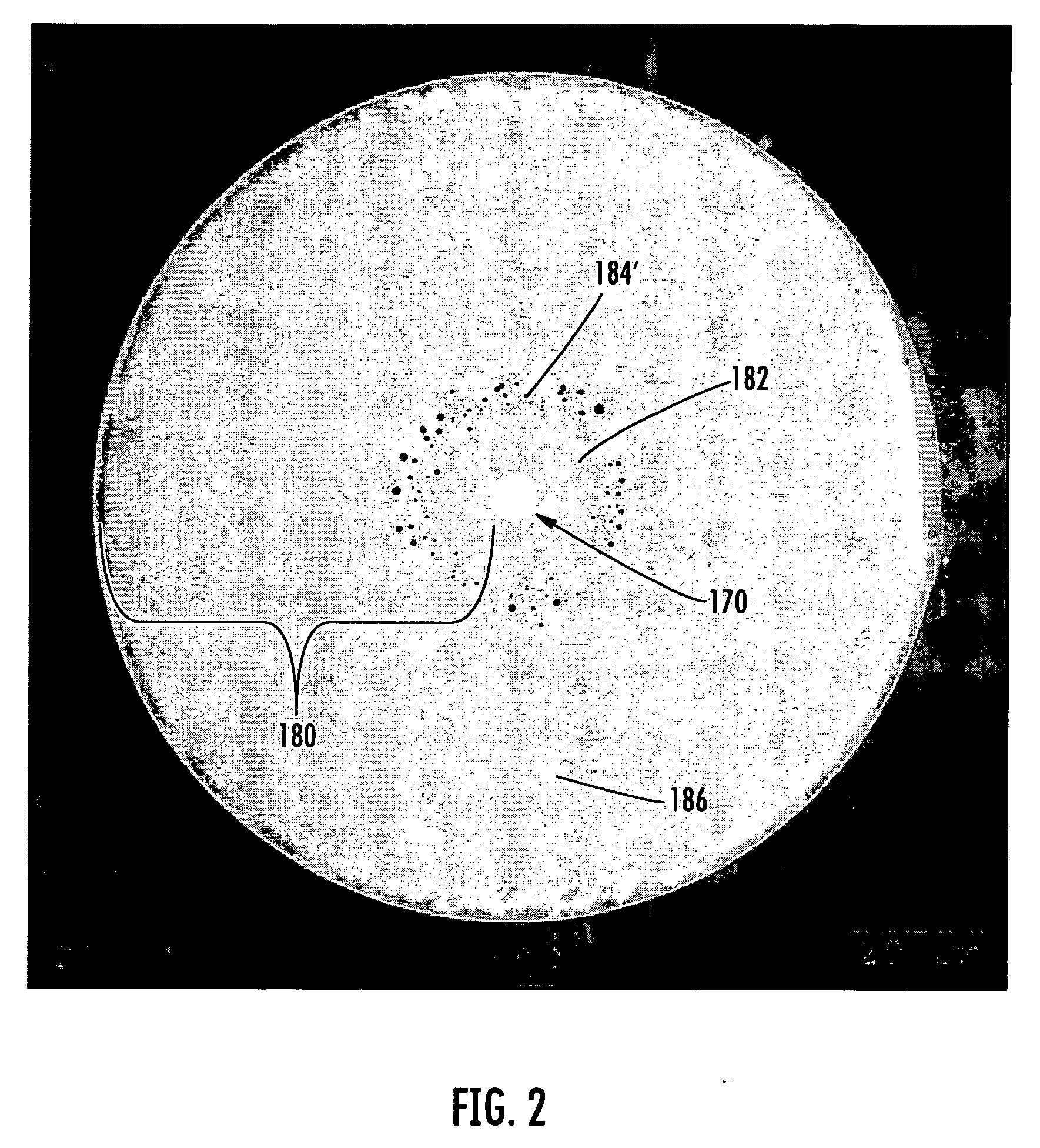

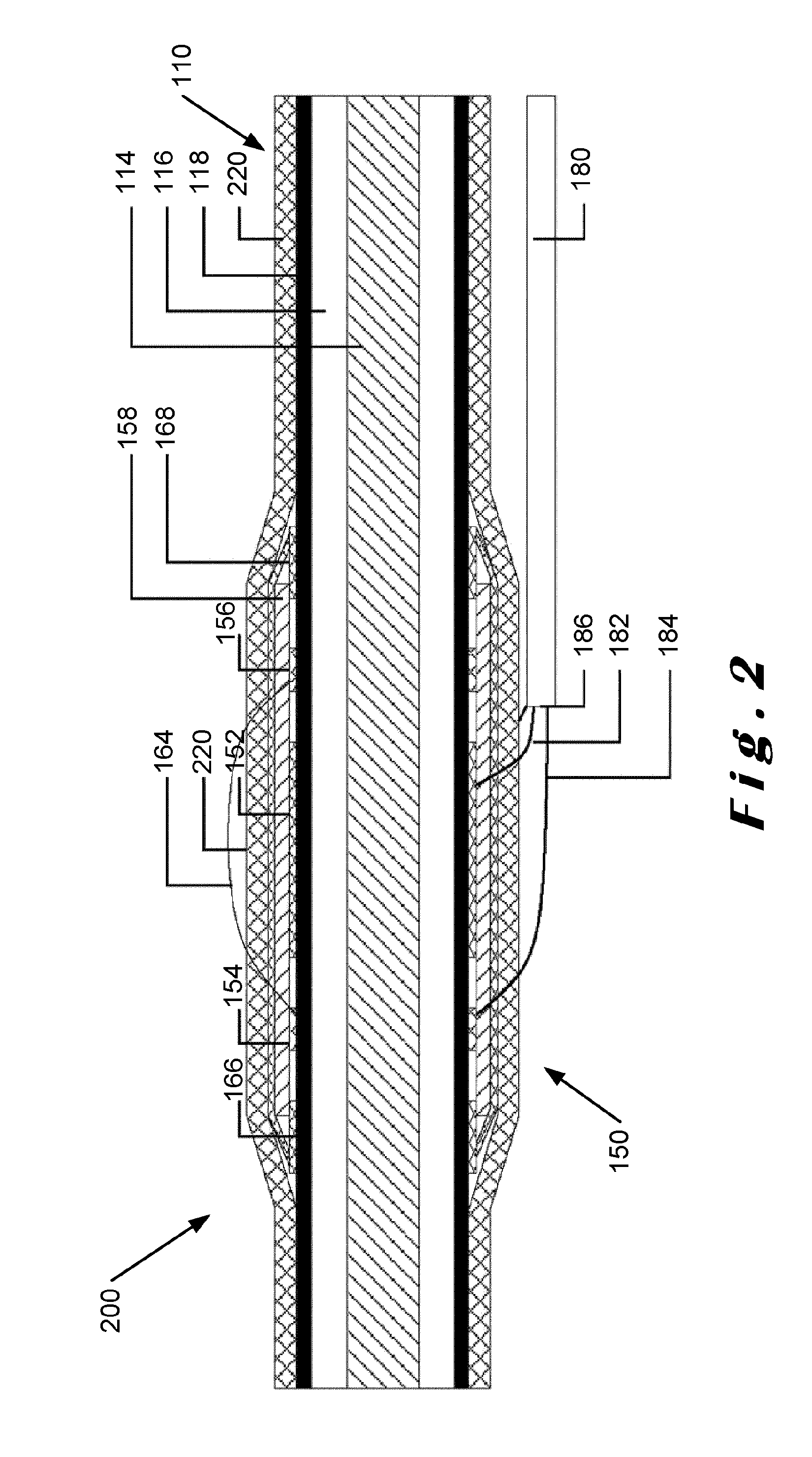

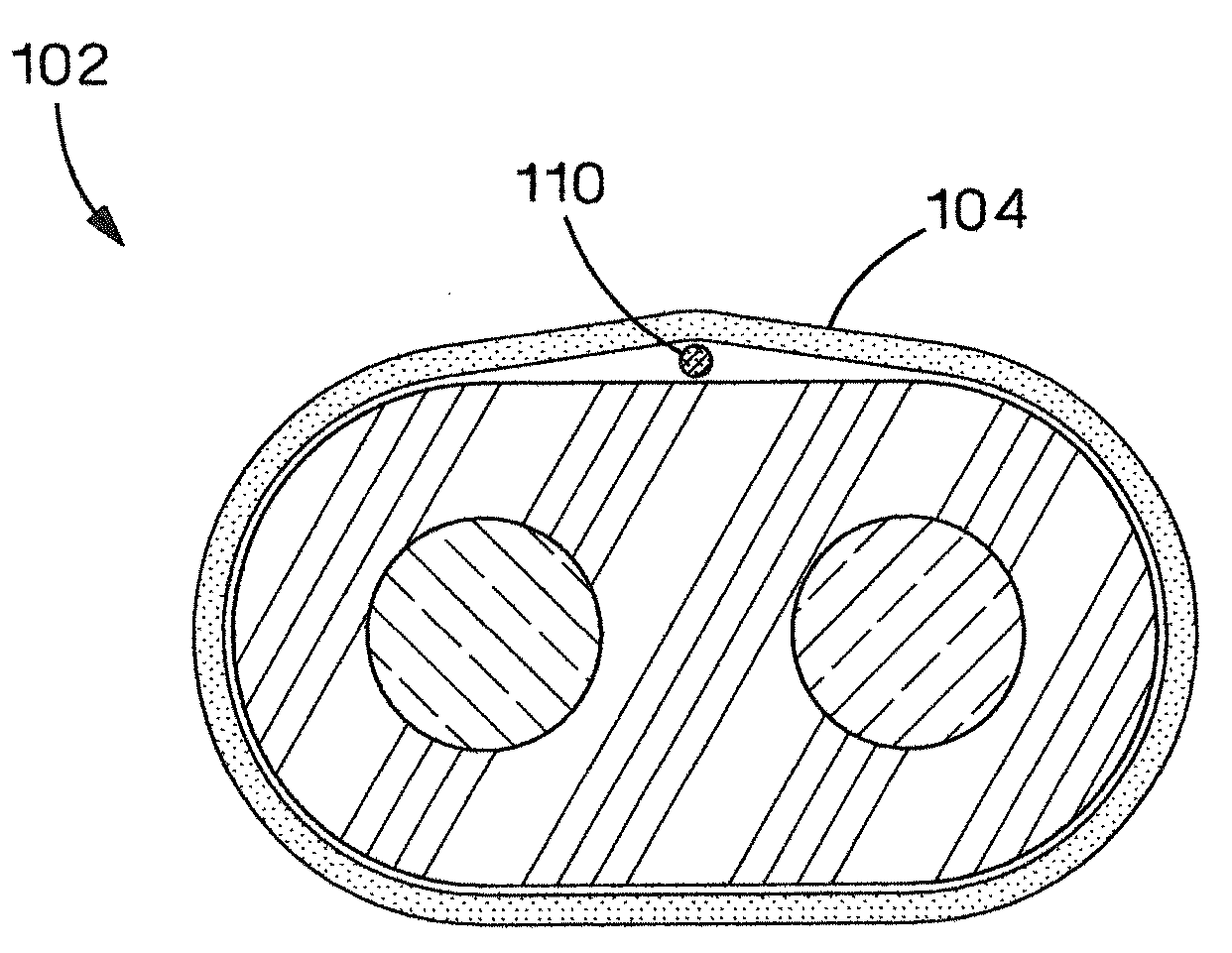

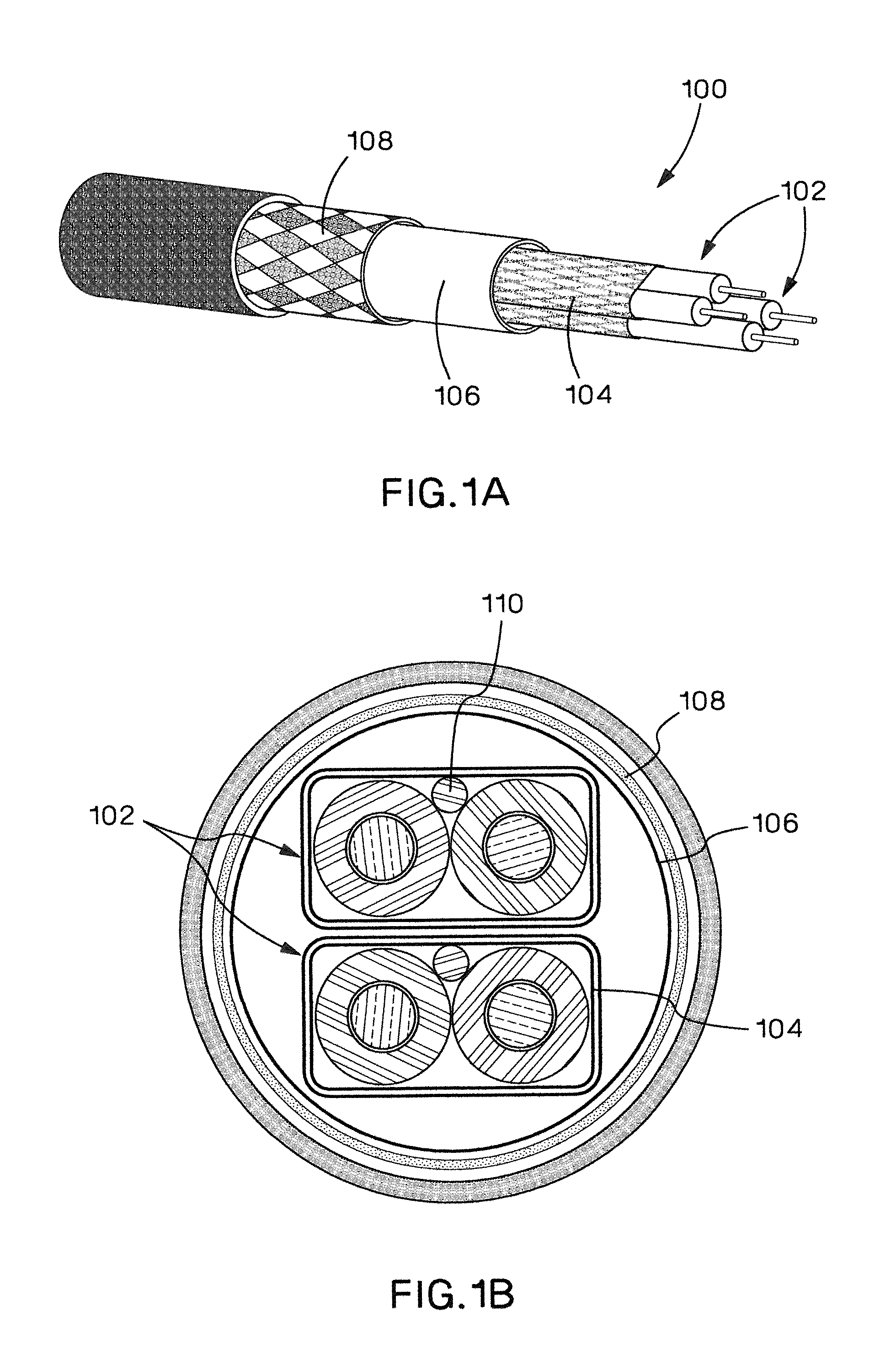

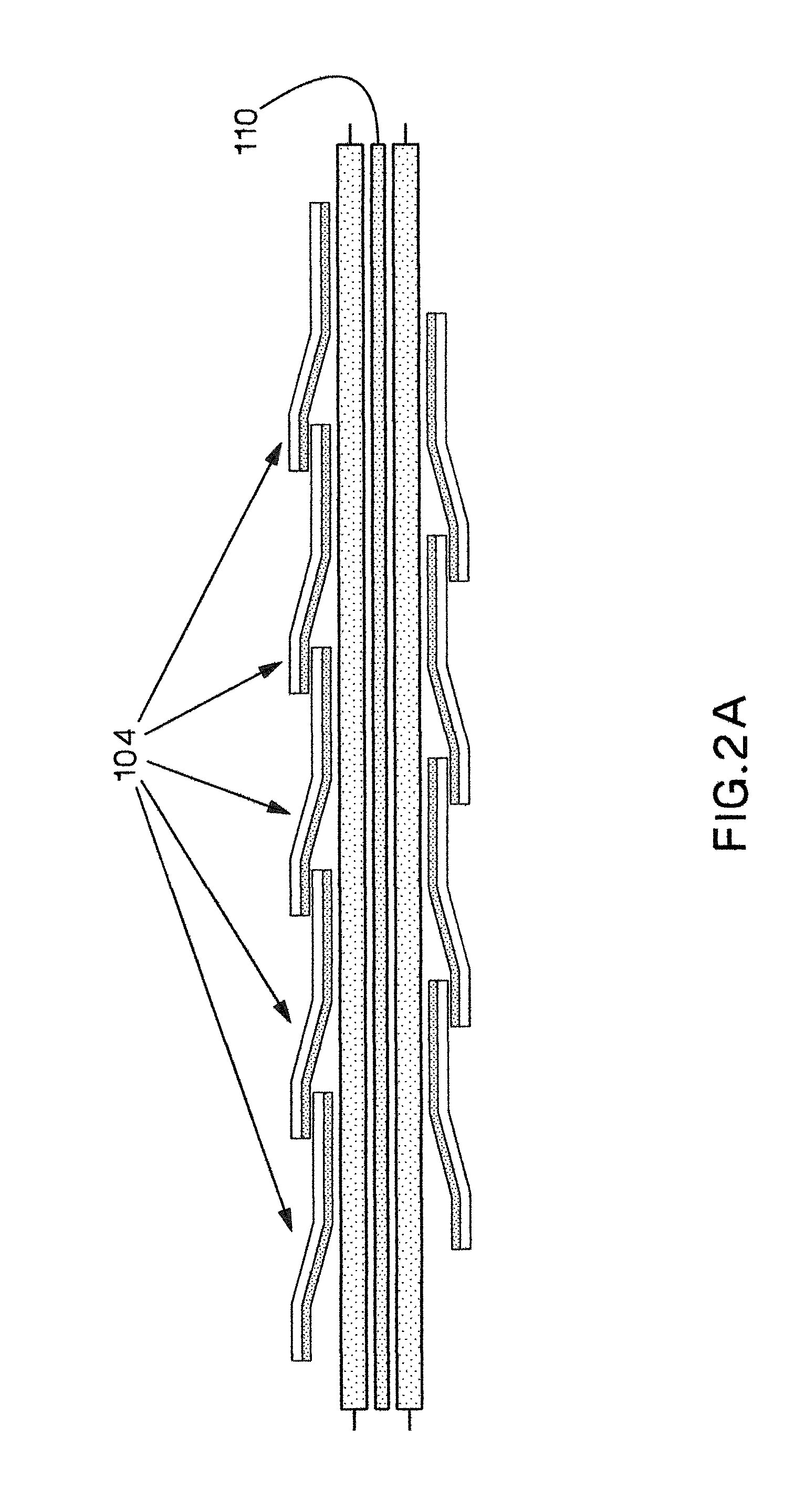

Multi-layer cable design and method of manufacture

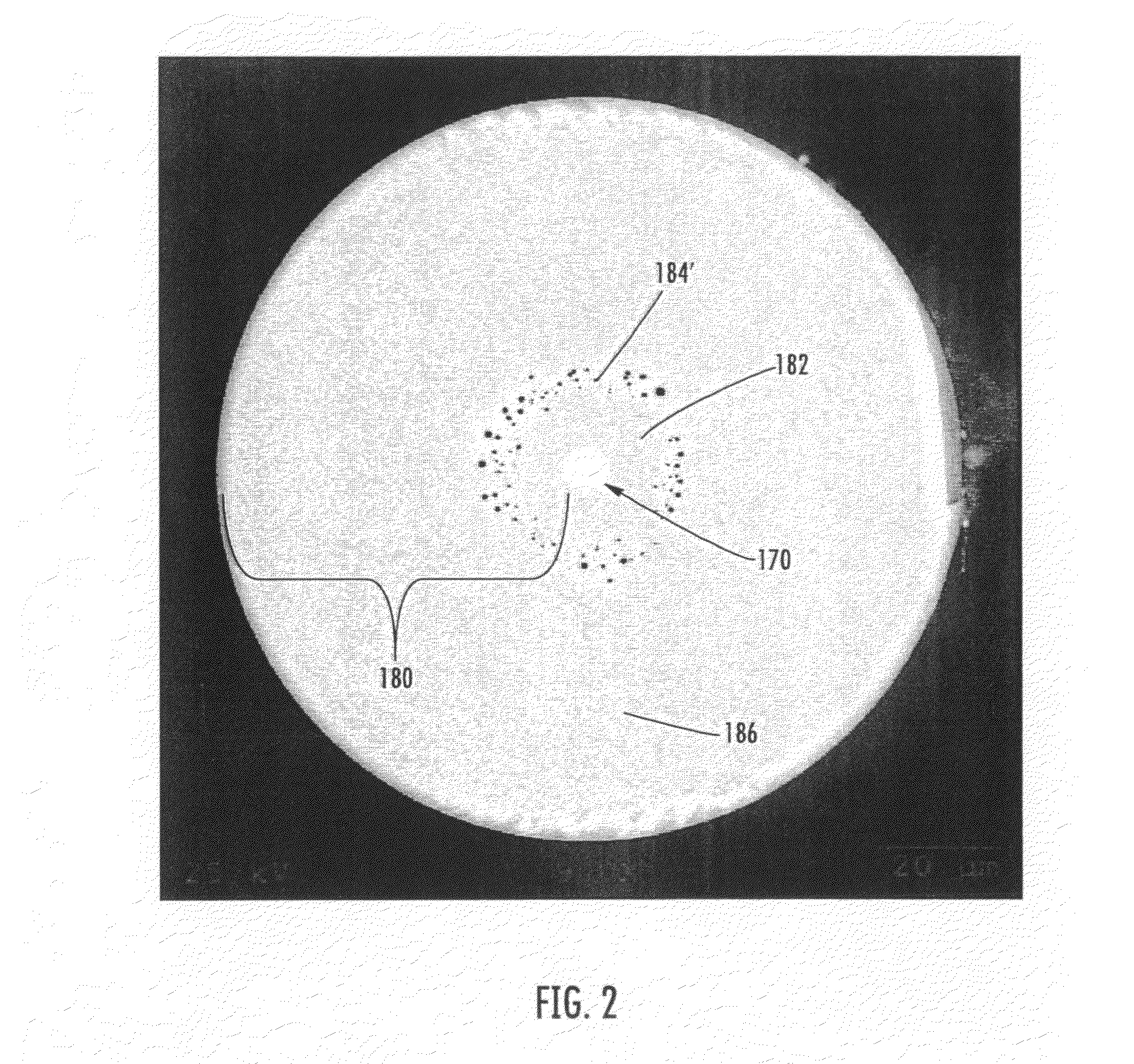

InactiveUS20080060832A1Economically manufacturedVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsCathodic arc depositionFiber

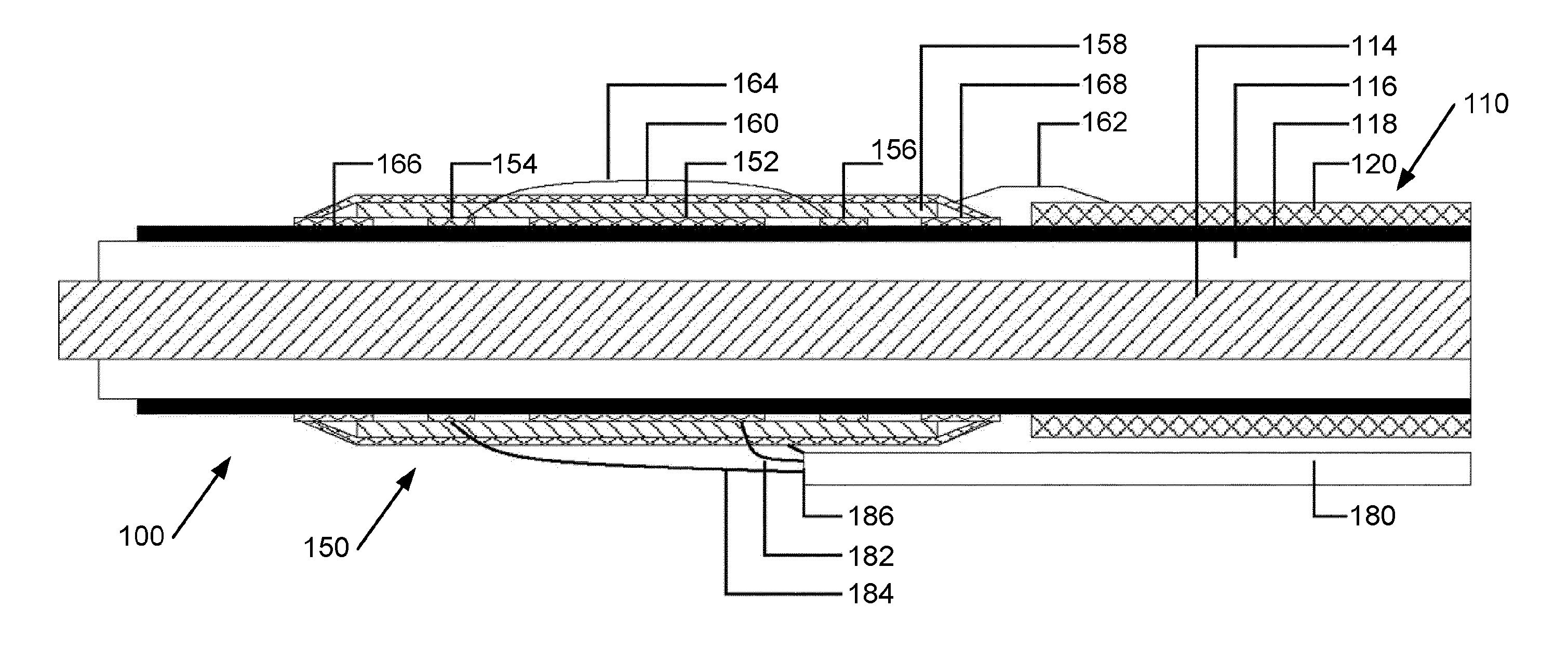

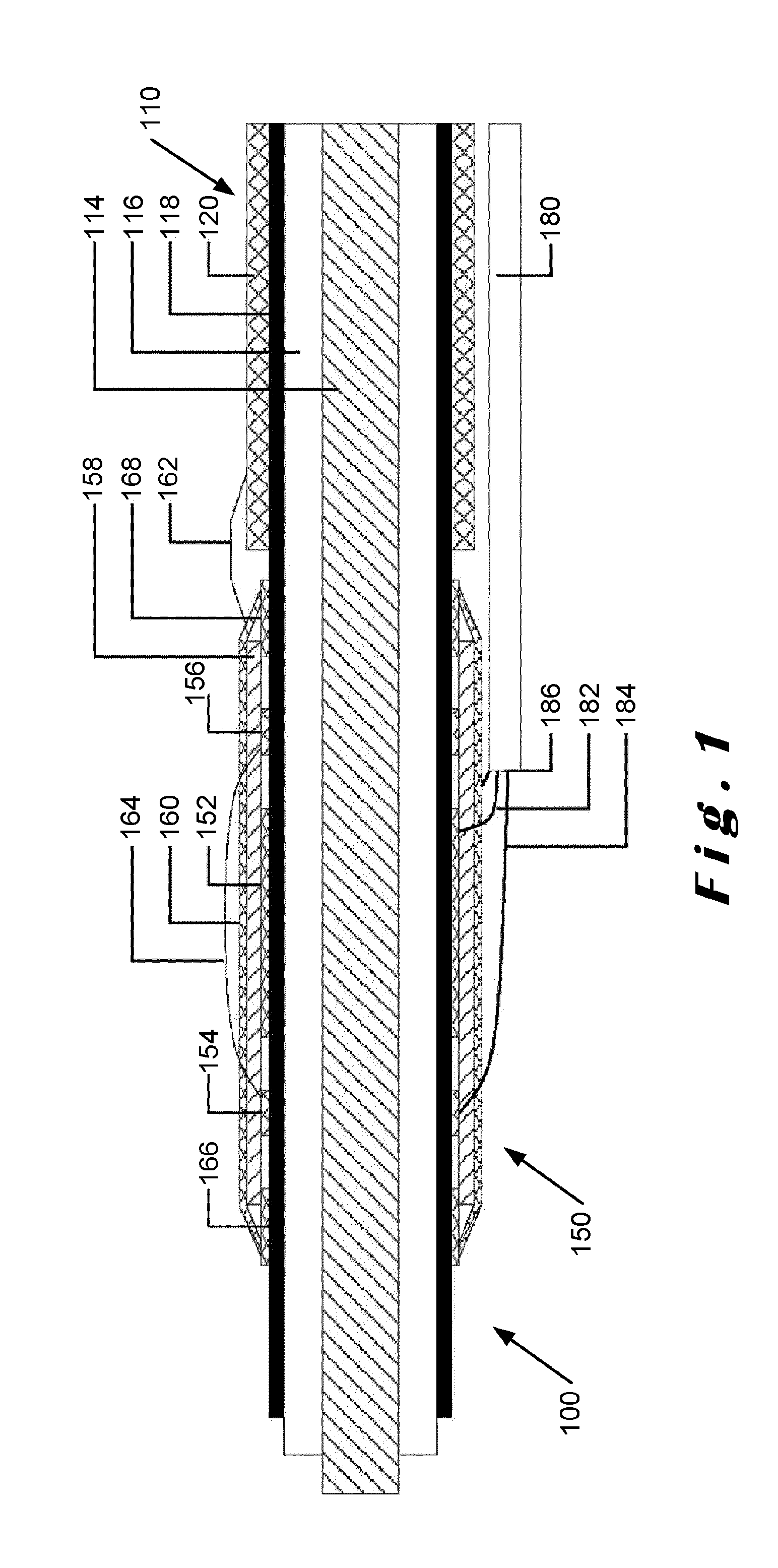

A novel method of designing and fabricating flexible and lightweight cable [100] having a central conductor [110], a dielectric layer [130], an outer conductor [150] and an insulation coating [170] using thin film technology is disclosed. The dielectric layer [130] is ‘grown’ on dielectric layer [130] using electrophoretic deposition to a specified thickness, based upon its intended use. It may include nano-diamonds. Ion beam assisted deposition is used to metalize the cable dielectric layer [130]. This may be ion beam assisted sputtering, ion beam assisted evaporative deposition or ion beam assisted cathodic arc deposition. In an alternative embodiment, the outer conductor may be etched to provide greater flexibility, or to add a piezoelectric layer. The central conductor [110] may be created from dielectric fibers [113] which are metalized as described above. The piezoelectric layer added to create ultrasonic transducer cables.

Owner:RAZAVI ALI

Fiber optic drop cables and preconnectorized assemblies

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of an optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

Fiber optic drop cables and preconnectorized assemblies having toning portions

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of an optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

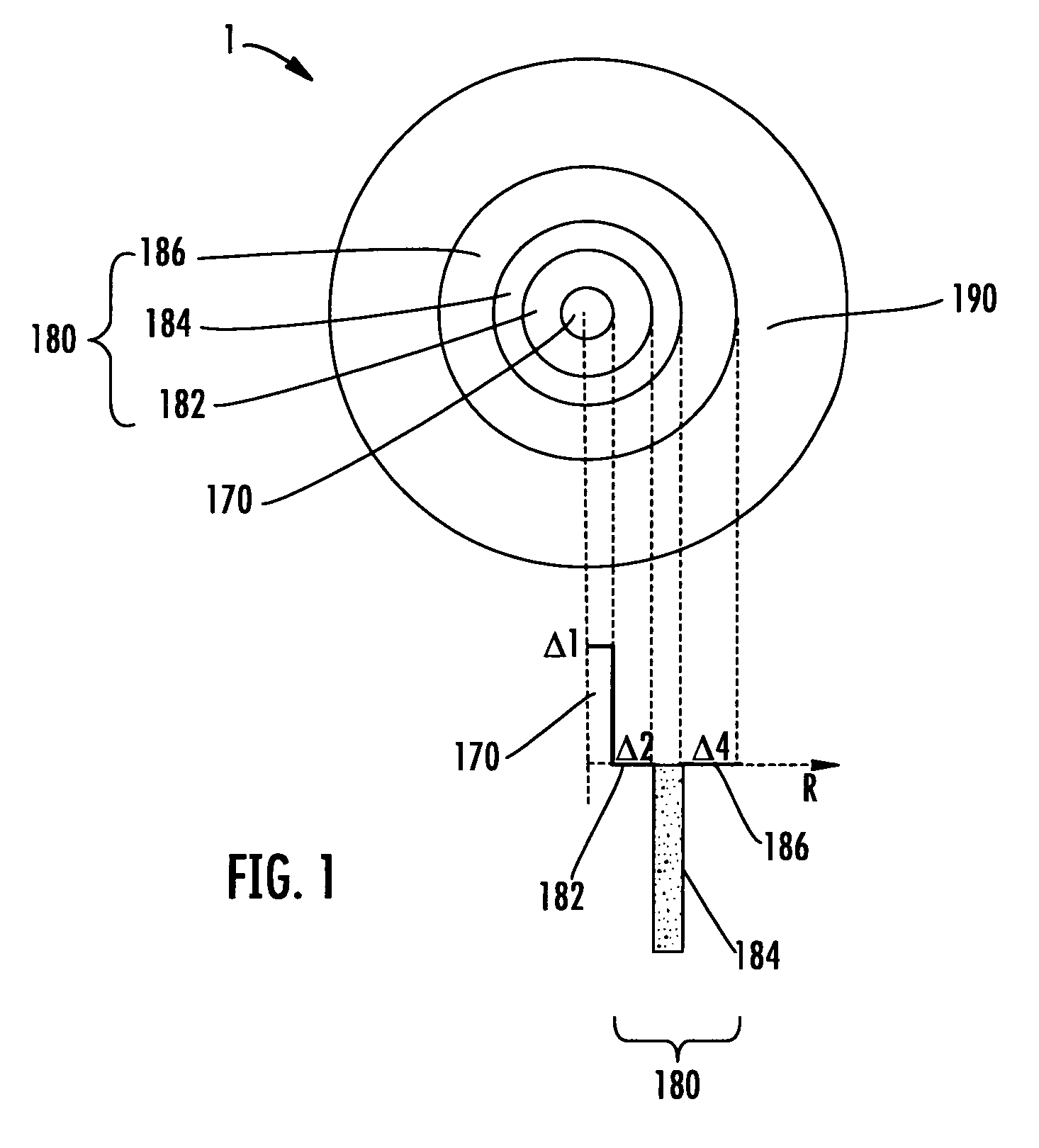

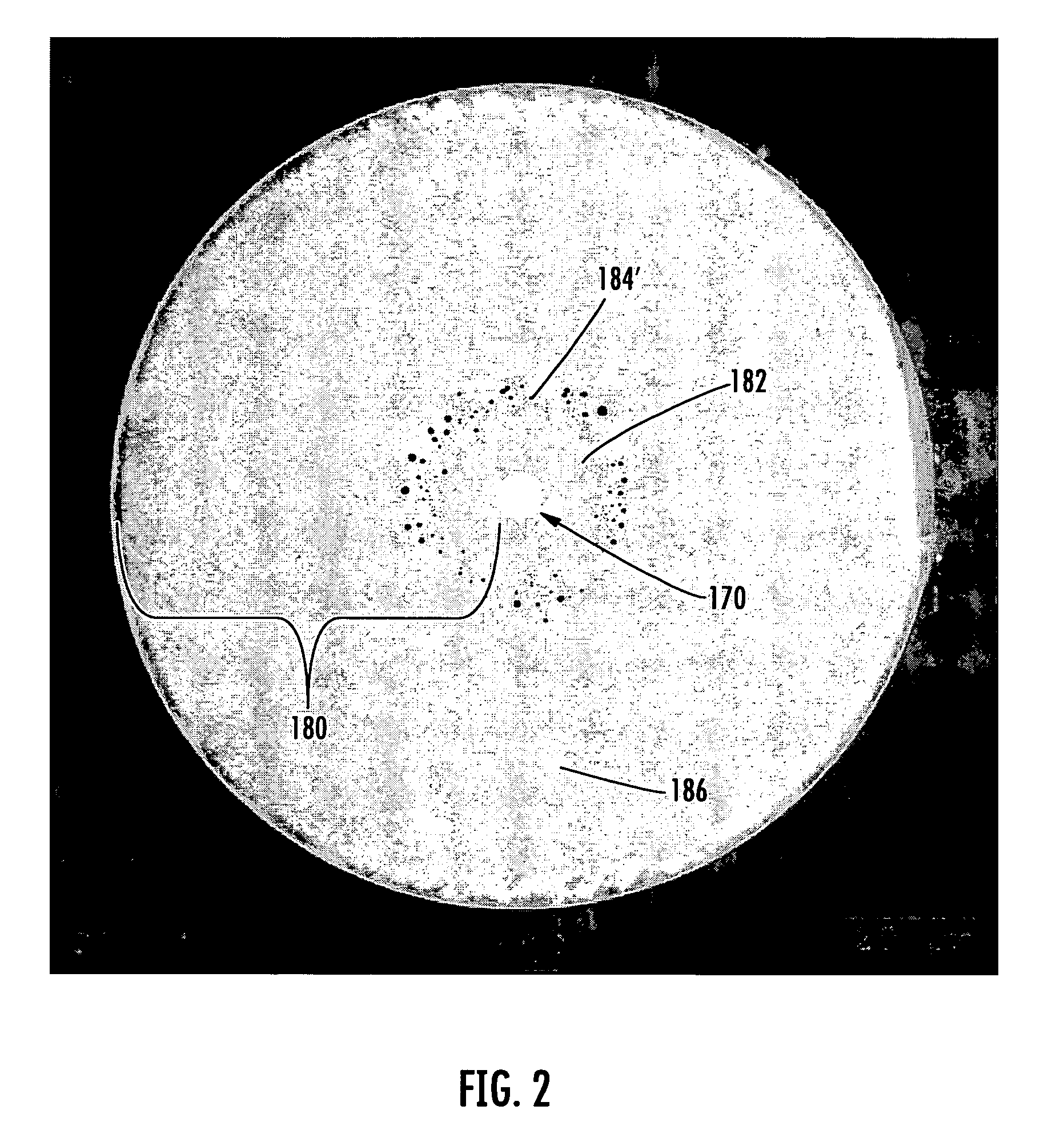

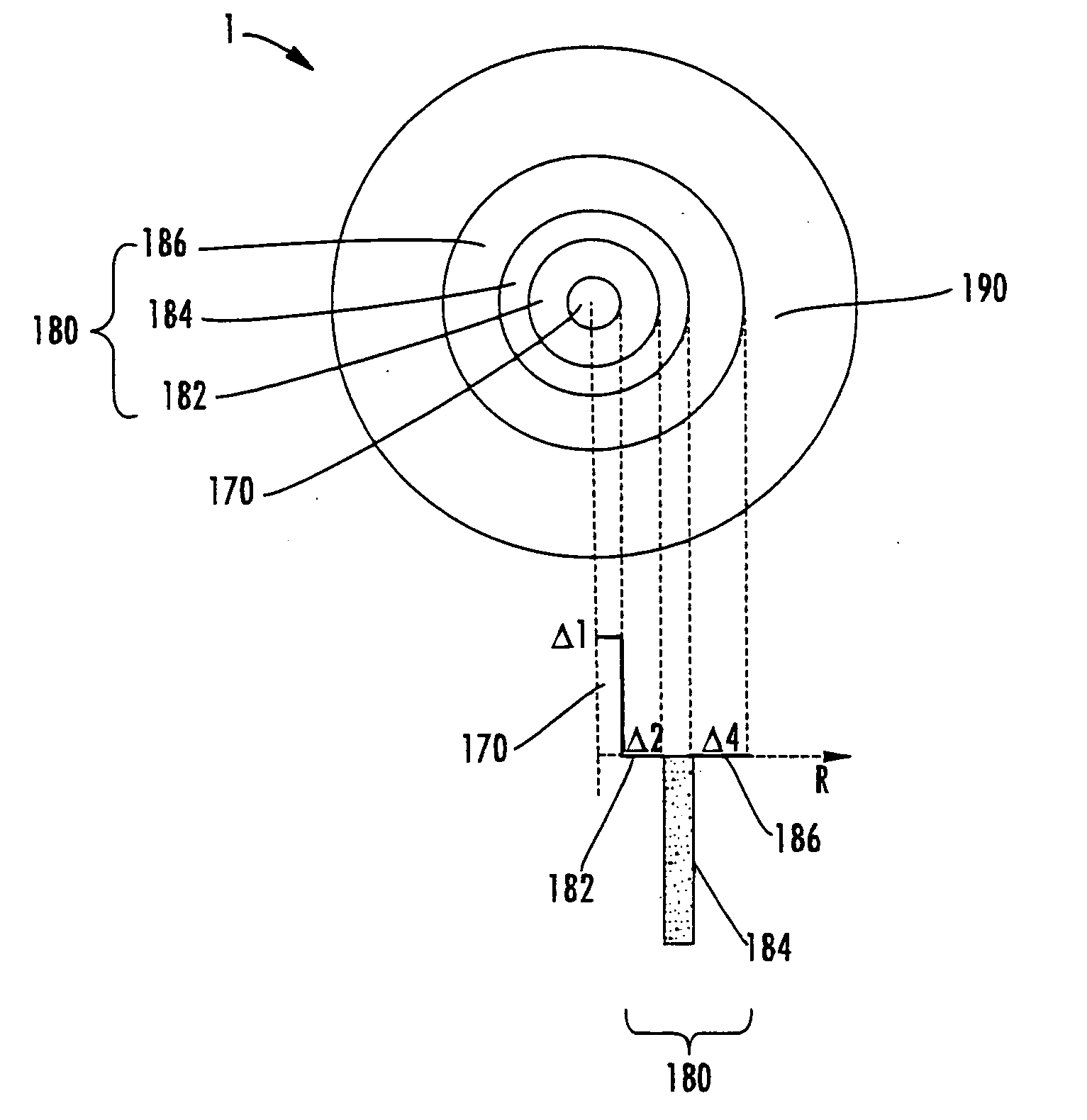

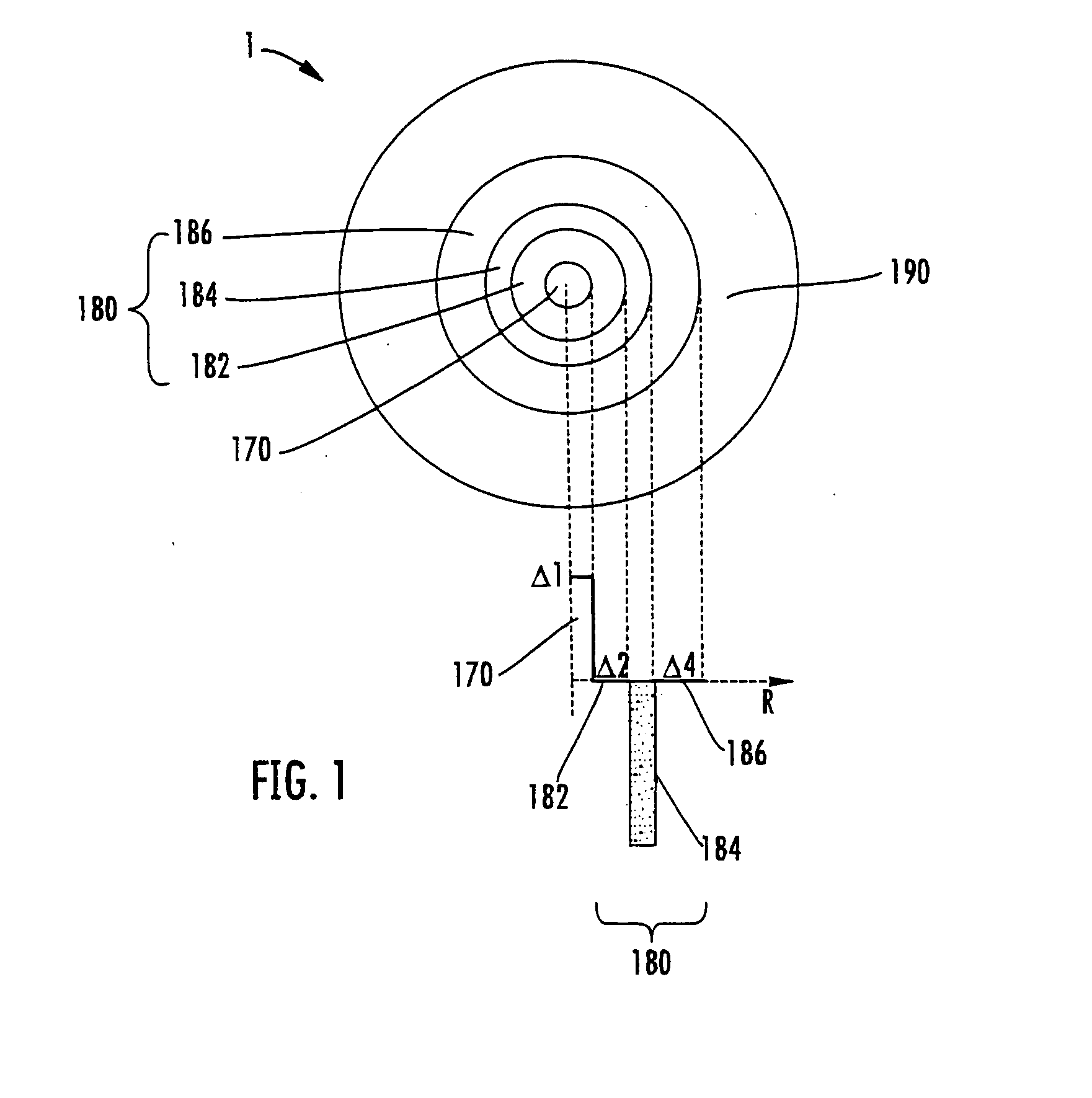

Fiber optic cables and assemblies and the performance thereof

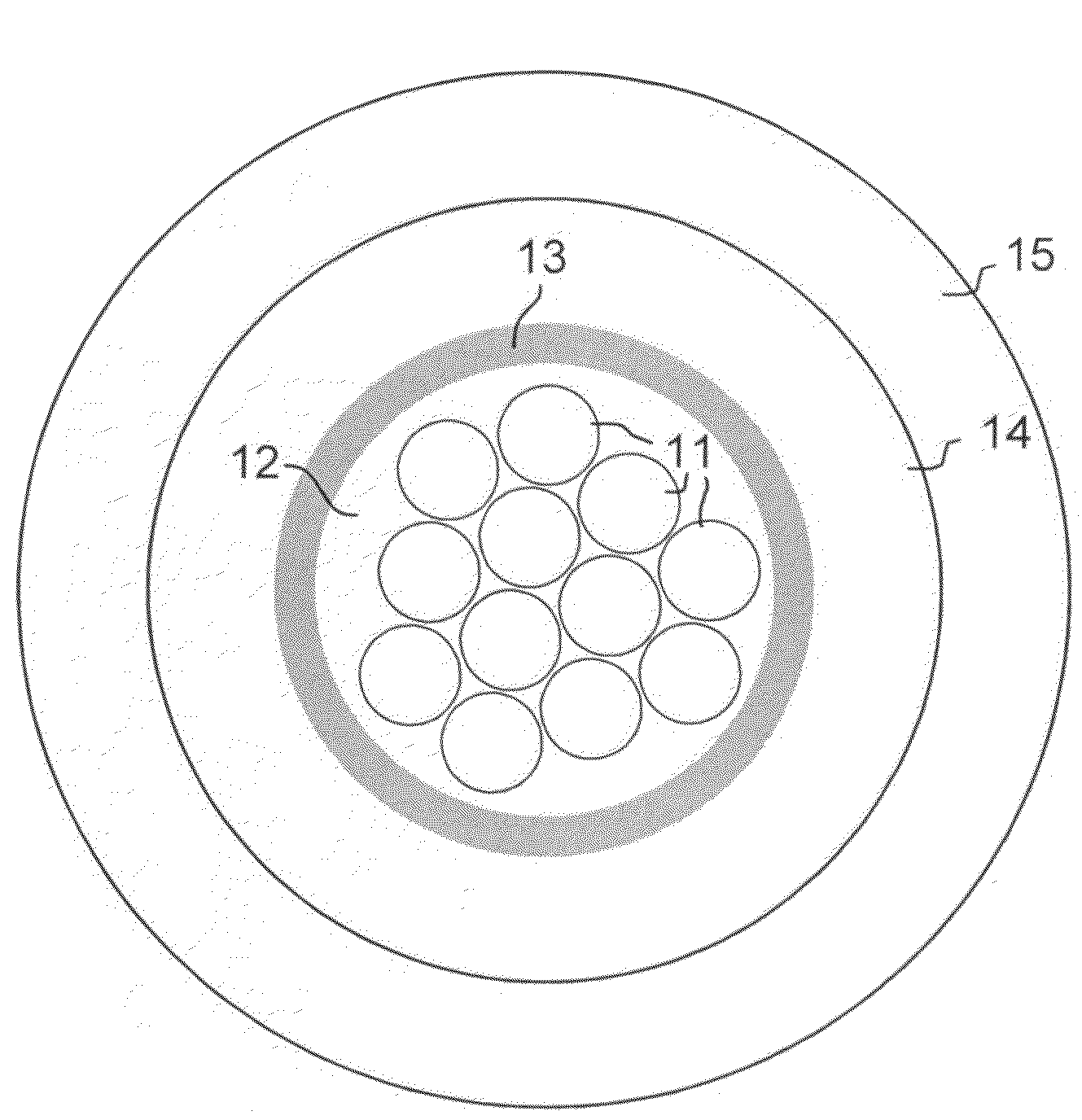

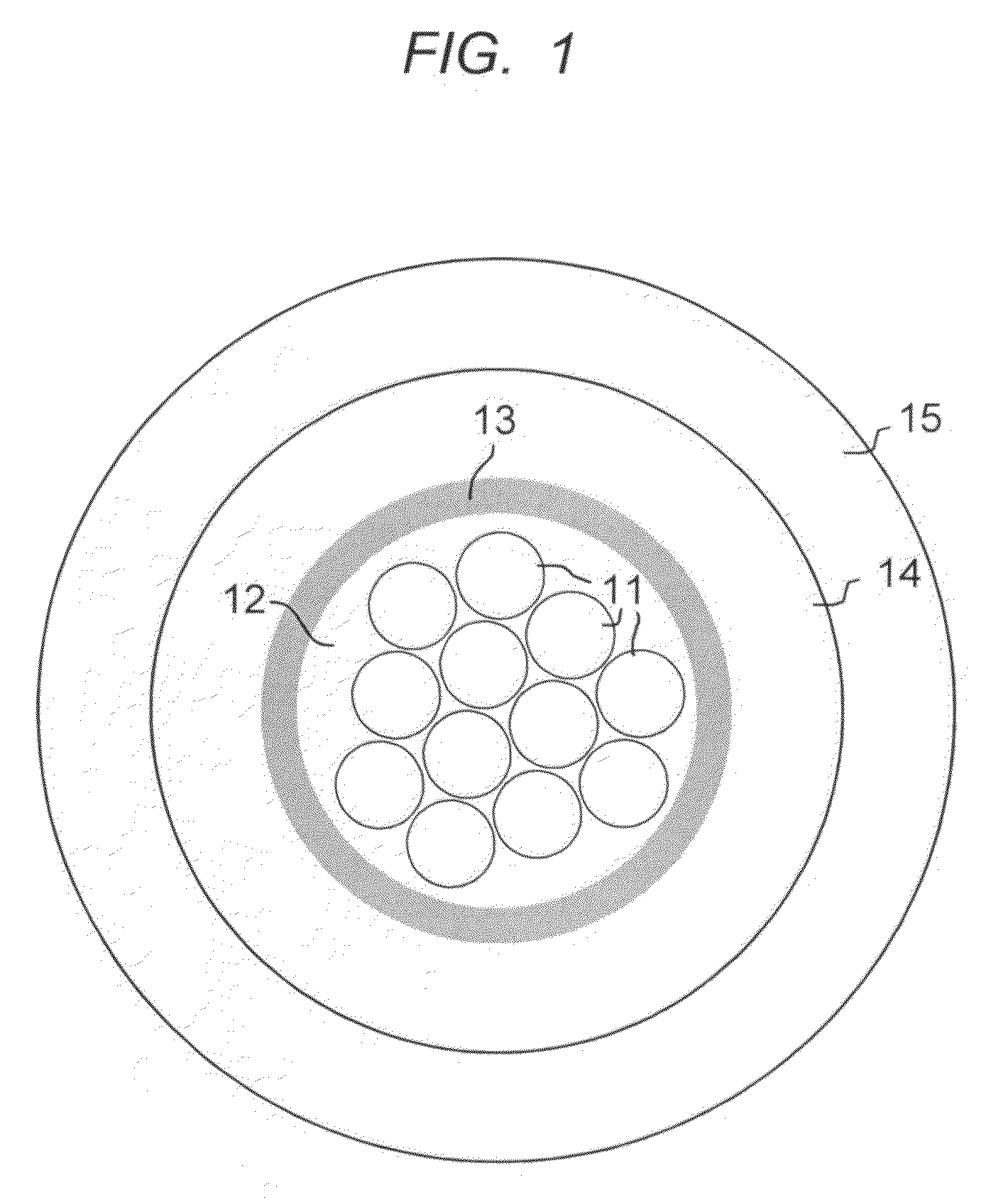

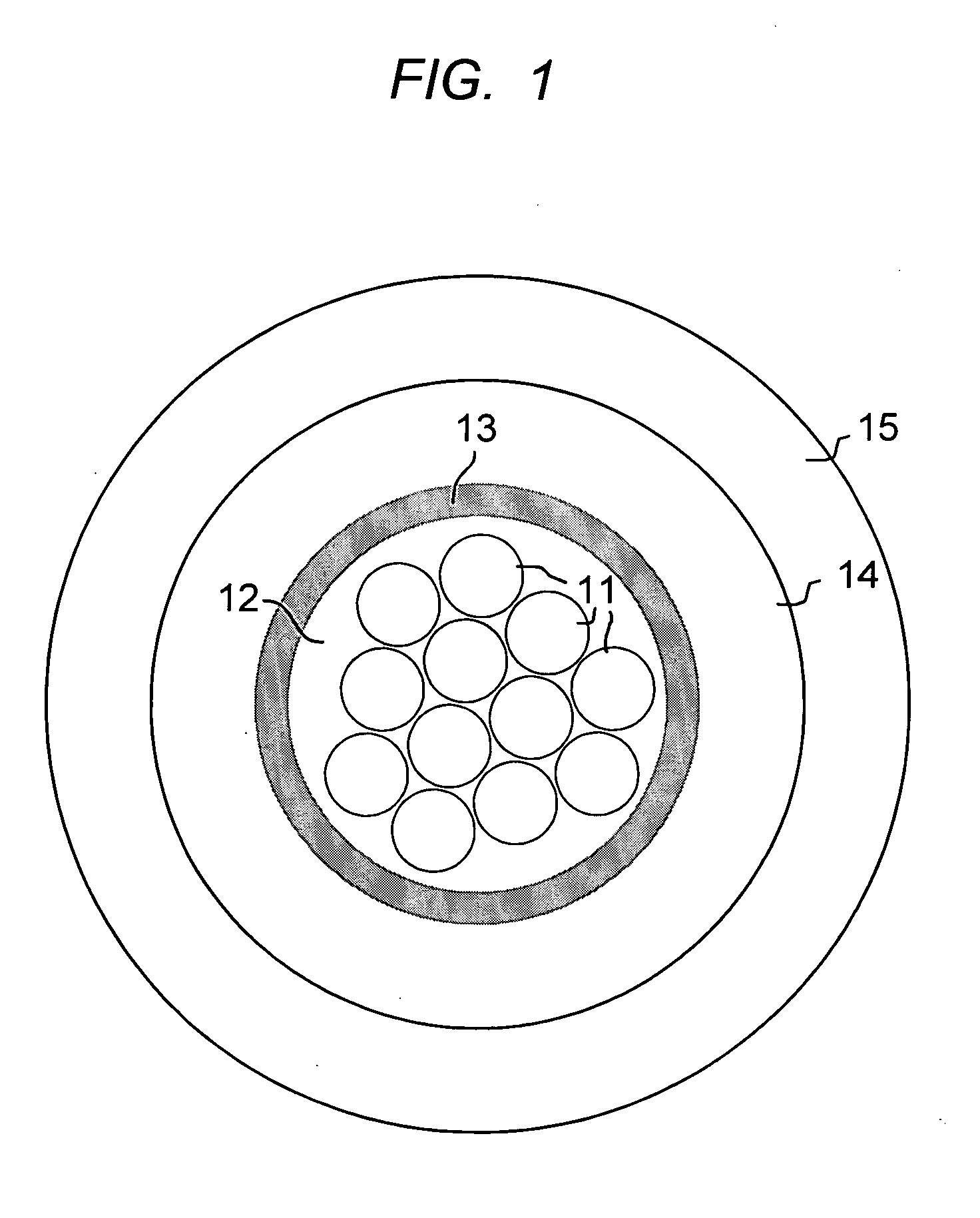

ActiveUS20080145011A1Small component sizeTight bend radiusOptical fibre with multilayer core/claddingFibre mechanical structuresUltrasound attenuationFiber

A fiber optic cable having at least one optical fiber such as a microstructured bend performance optical fiber disposed within a protective covering. The protective covering is highly flexible and the fiber optic cable has extremely low delta attenuation when aggressively bent compared with the conventional fiber optic cable designs. By way of example, the delta attenuation of one fiber optic cable design is about 0.33 dB or less when wrapped 3 turns about a 7.5 millimeter mandrel at a reference wavelength of 1625 nanometers. Other variations of the present invention include a connector attached to the fiber optic cable.

Owner:CORNING OPTICAL COMM LLC

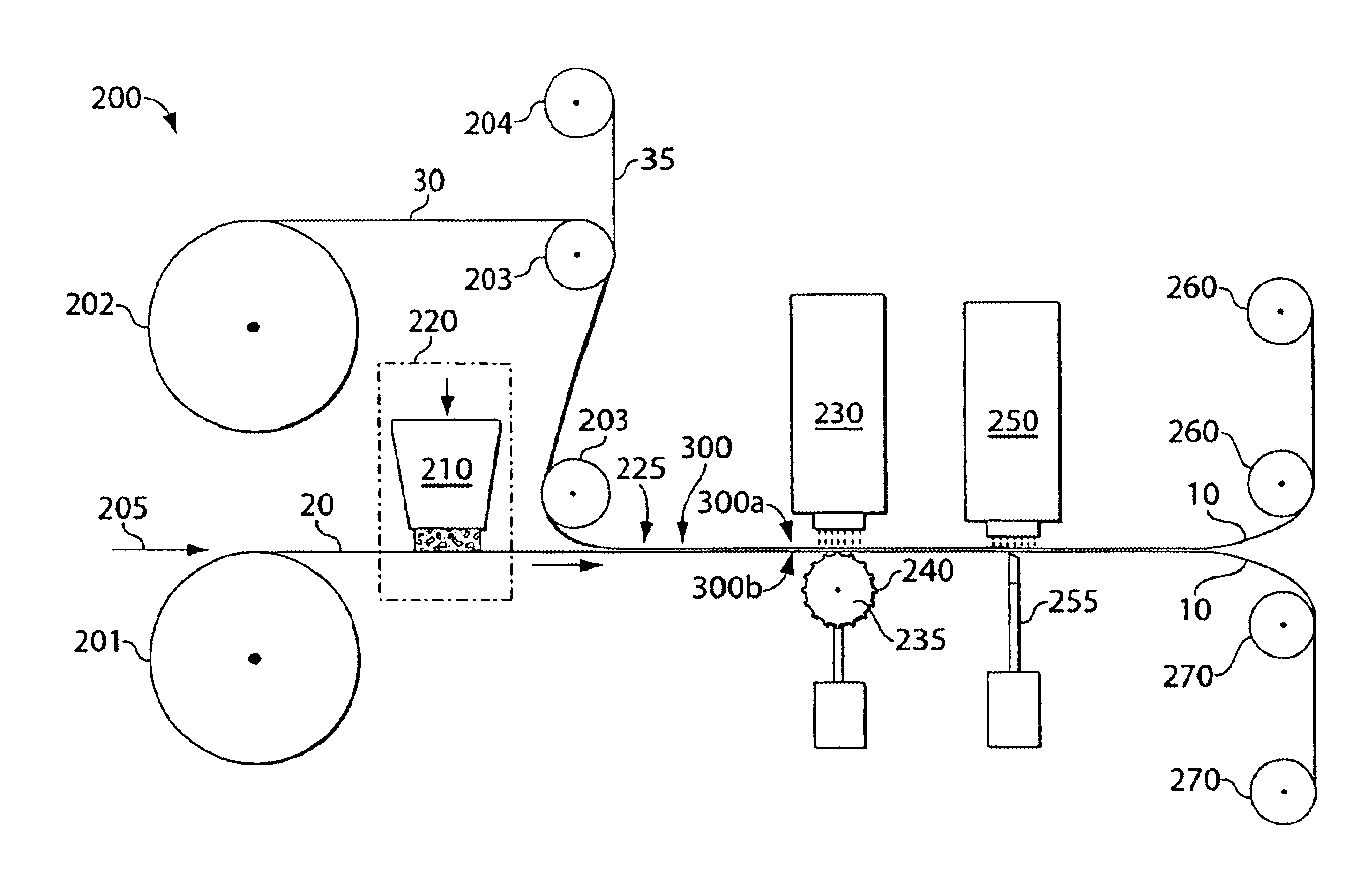

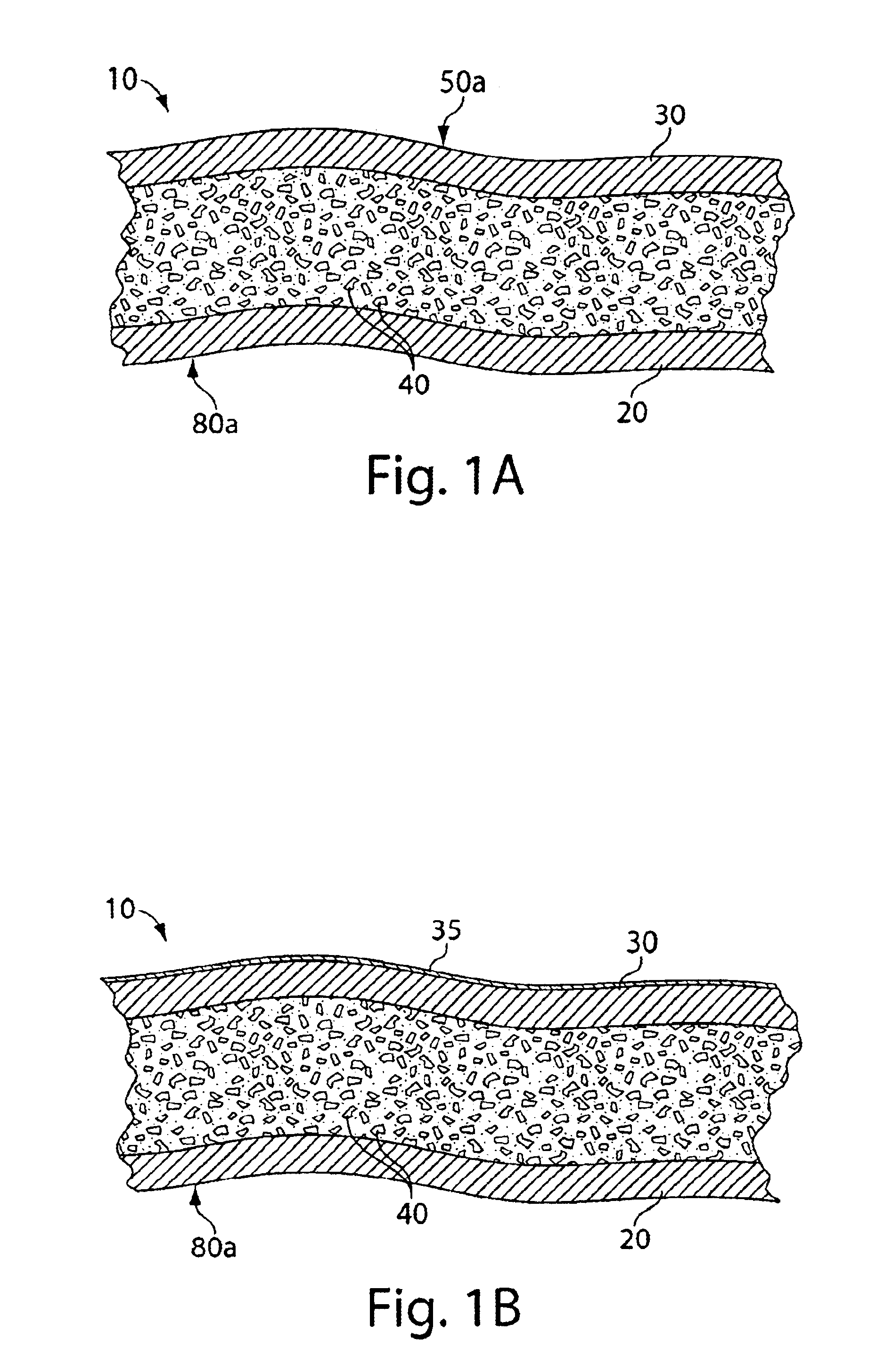

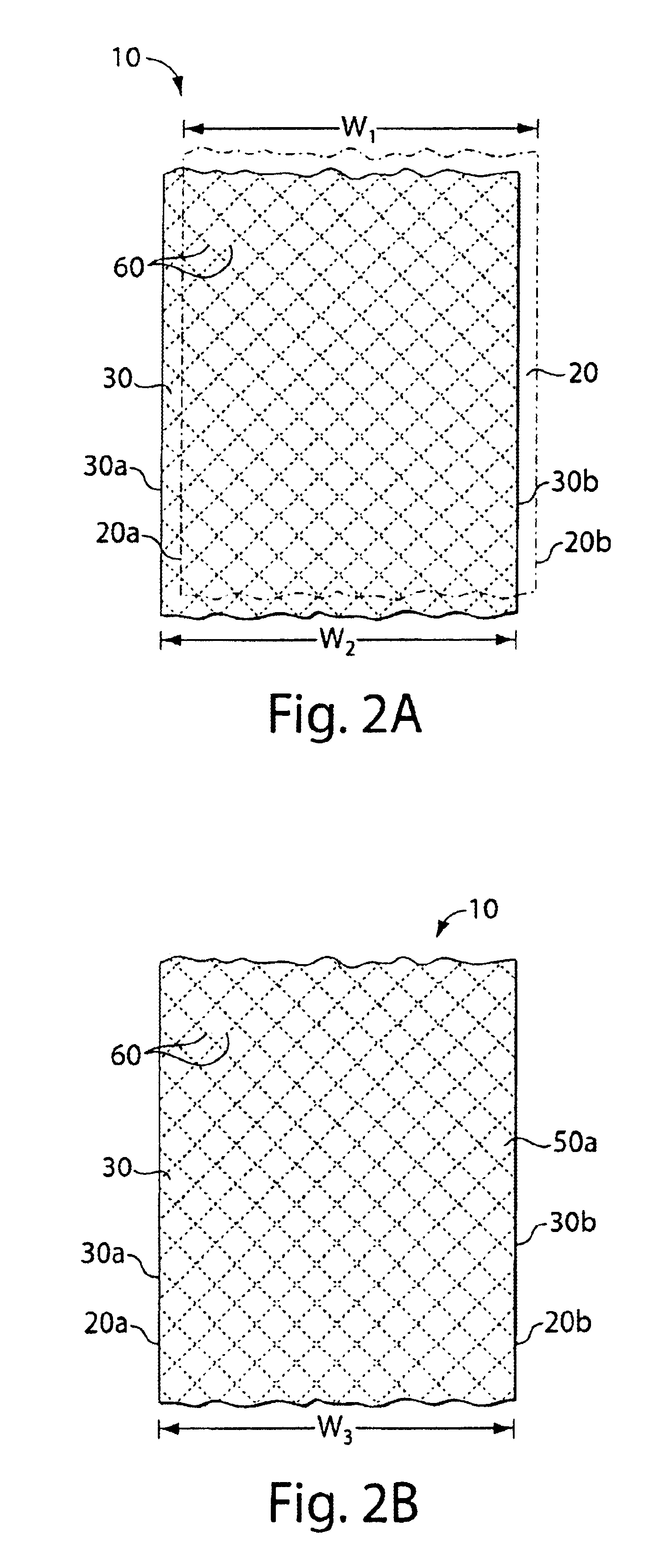

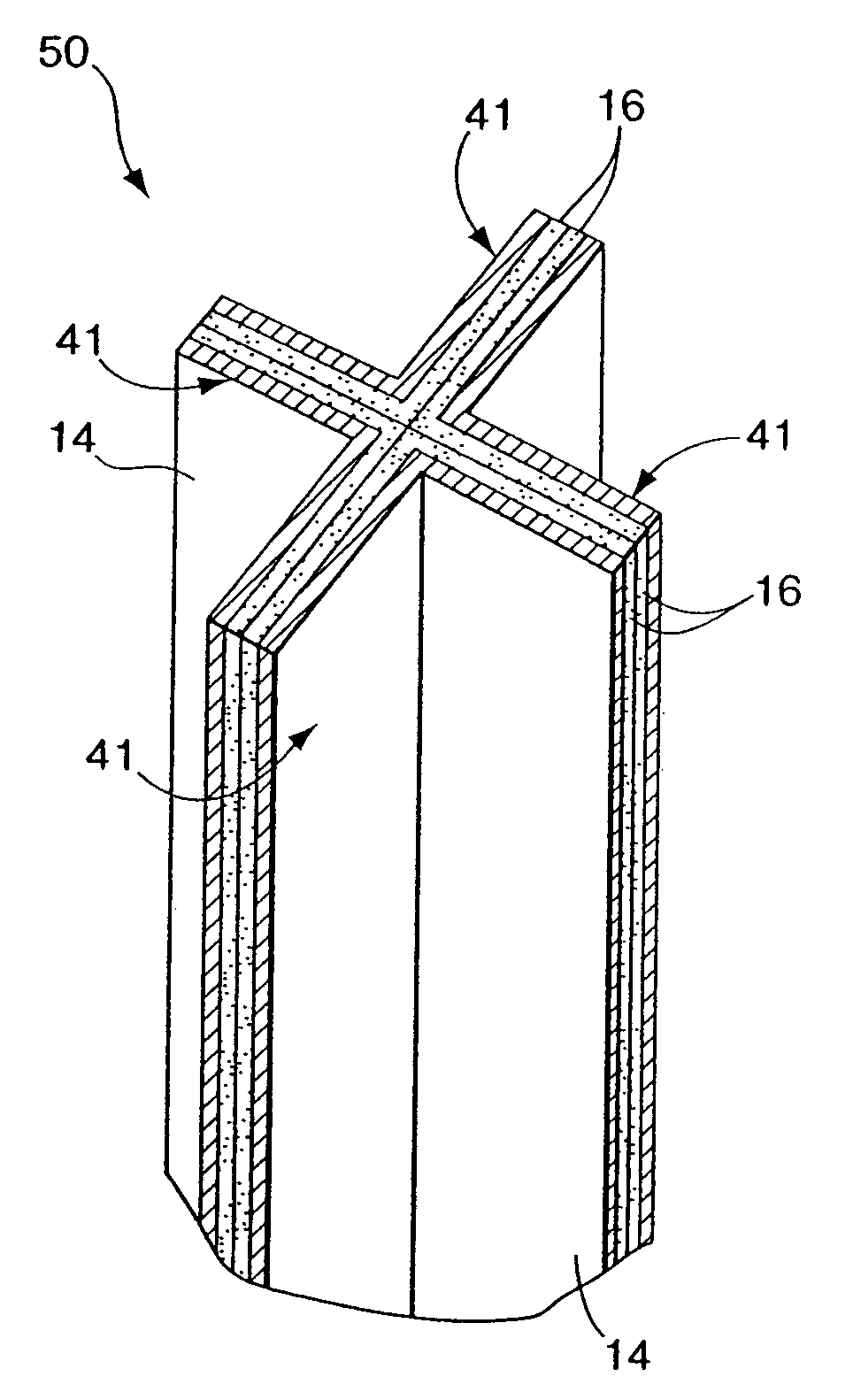

Water blocking cable tape and methods for making same

The invention provides a water blocking tape for use in a variety of cable designs, such as power cable, data communications cable and telecommunications cable. A water blocking tape according to the invention includes layers of lightweight nonwoven fabric with one or more swellable water blocking compounds, such as water absorbent polymers, disposed between the layers. The nonwoven fabric layers are bonded in a pattern using an ultrasonic bonding technique. The bonding pattern helps to contain and to restrain movement of the water blocking compounds between the layers. The bonding pattern compartmentalizes the water blocking compounds to prevent pooling of the compounds and to facilitate a substantially consistent distribution of the compounds between the layers such that when a tape contacts water, the tape achieves a substantially consistent swell height. A substantially consistent swell height permits a tape to serve as a reliable water barrier to prevent damage and degradation of a cable and its components. Ultrasonic bonding of the multilayer tape eliminates the need and use of adhesives and bonding agents to form the tape that can have inhibiting effects on a swelling action of the tape.

Owner:NEPTCO

Fiber optic drop cables and preconnectorized assemblies having toning portions

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of an optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

High voltage measurement systems

InactiveUS20140021965A1Good overvoltage protectionEnsure mechanical stabilityResistance/reactance/impedenceVoltage/current isolationHigh pressureElectric cables

Owner:EANDIS +1

Fiber optic cables and assemblies and the performance thereof

ActiveUS7397991B1Small component sizeTight toleranceOptical fibre with multilayer core/claddingFibre mechanical structuresUltrasound attenuationFiber

A fiber optic cable having at least one optical fiber such as a microstructured bend performance optical fiber disposed within a protective covering. The protective covering is highly flexible and the fiber optic cable has extremely low delta attenuation when aggressively bent compared with the conventional fiber optic cable designs. By way of example, the delta attenuation of one fiber optic cable design is about 0.33 dB or less when wrapped 3 turns about a 7.5 millimeter mandrel at a reference wavelength of 1625 nanometers. Other variations of the present invention include a connector attached to the fiber optic cable.

Owner:CORNING OPTICAL COMM LLC

Fiber optic drop cables and preconnectorized assemblies having toning portions

A preconnectorized outdoor cable streamlines the deployment of optical waveguides into the last mile of an optical network. The preconnectorized outdoor cable includes a cable and at least one plug connector. The plug connector is attached to a first end of the cable, thereby connectorizing at least one optical waveguide. The cable has at least one optical waveguide, at least one tensile element, and a cable jacket. Various cable designs such as figure-eight or flat cables may be used with the plug connector. In preferred embodiments, the plug connector includes a crimp assembly having a crimp housing and a crimp band. The crimp housing has two half-shells being held together by the crimp band for securing the at least one tensile element. When fully assembled, the crimp housing fits into a shroud of the preconnectorized cable. The shroud aides in mating the preconnectorized cable with a complimentary receptacle.

Owner:CORNING OPTICAL COMM LLC

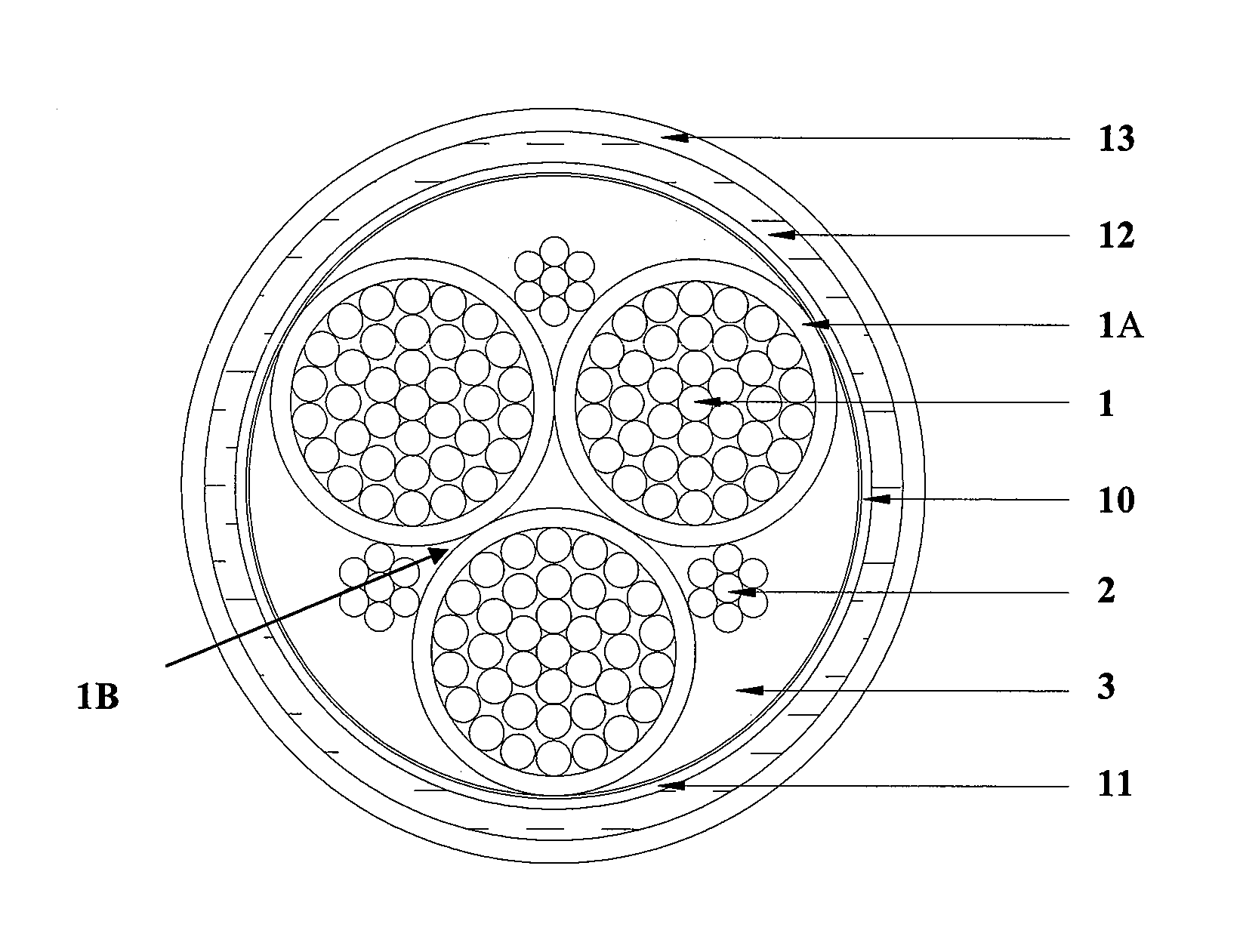

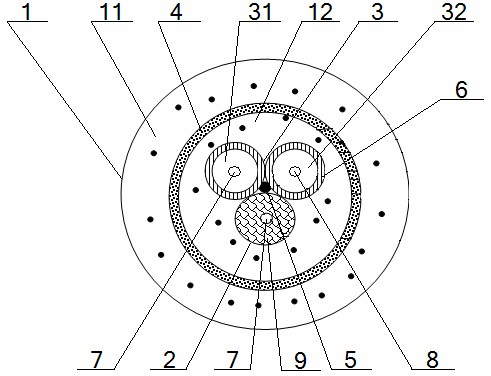

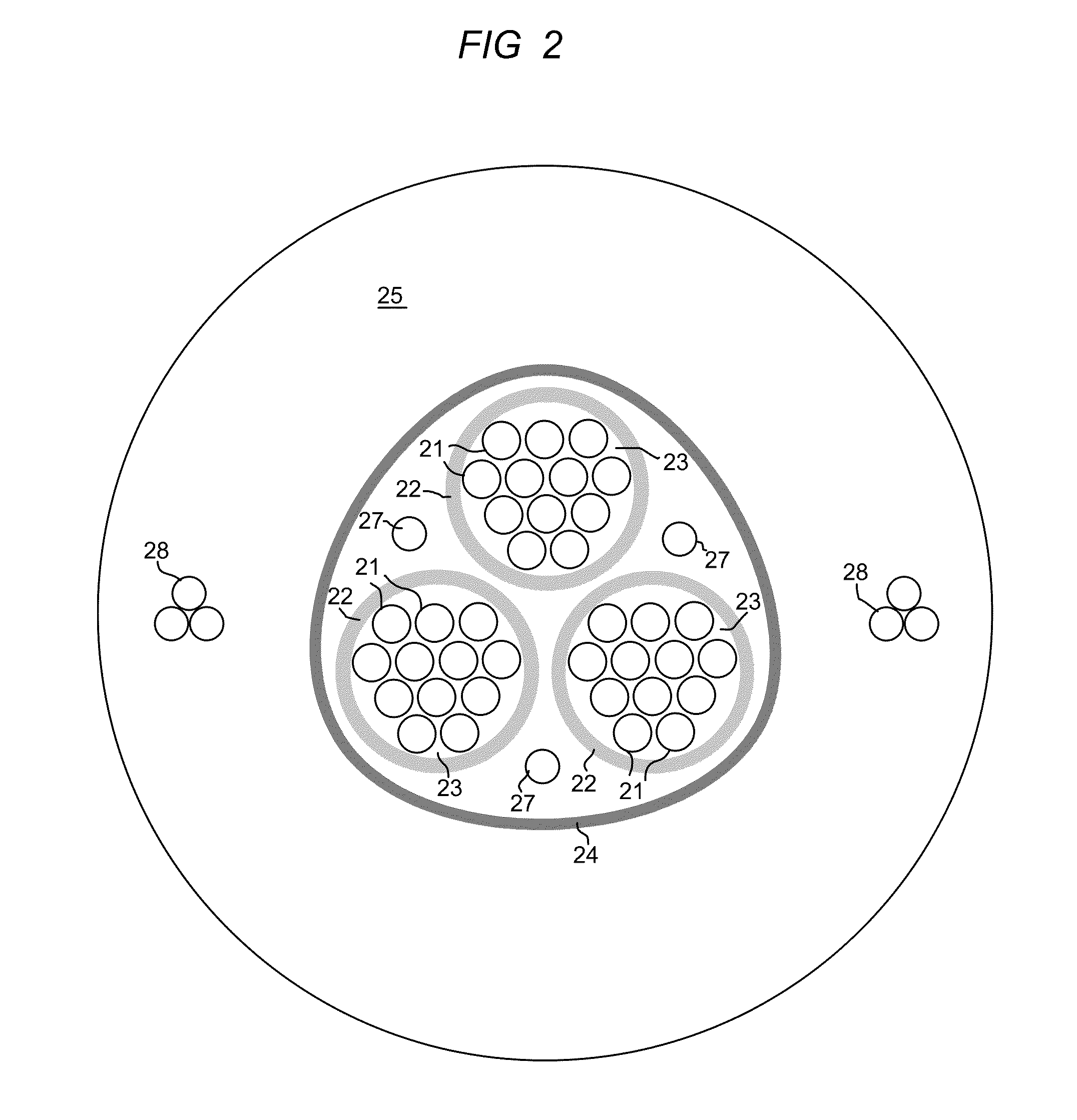

Adjustable Speed Drive Cable and Shield Termination

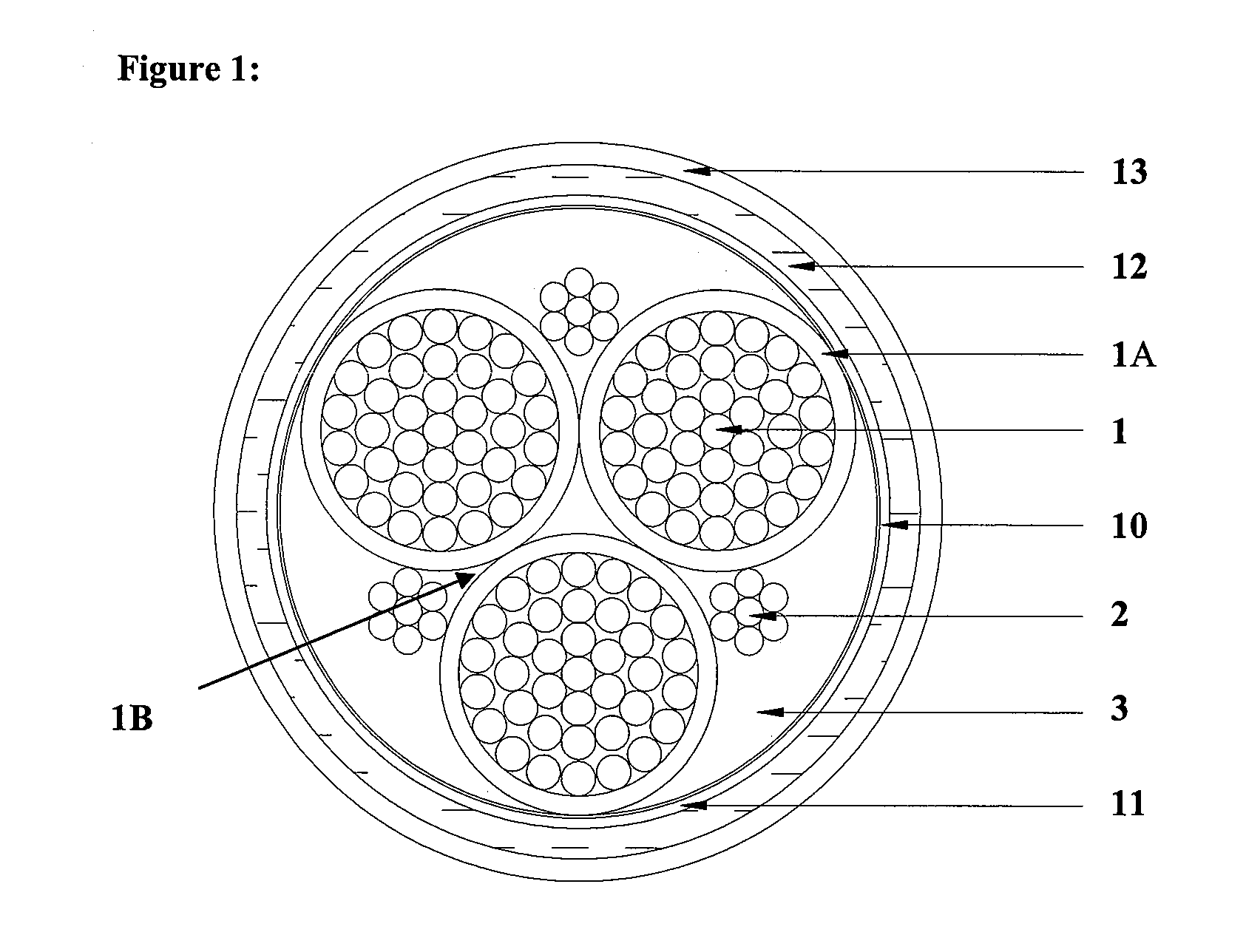

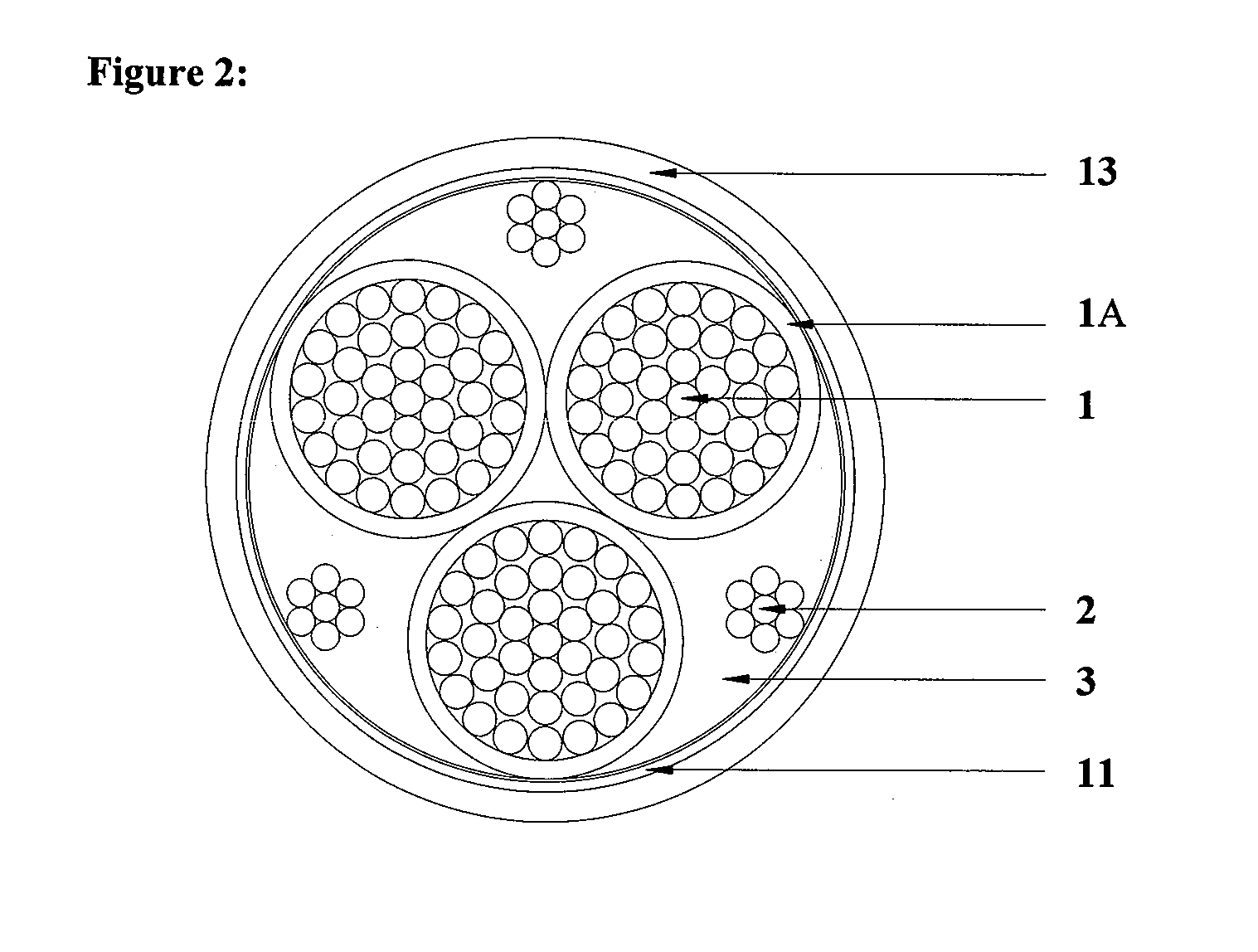

ActiveUS20070107921A1Power cables with screens/conductive layersInsulated cablesThree-phaseAdjustable-speed drive

The product of the present invention comprises flexible tray cables and metal-clad cables designed for use with adjustable speed drives, and terminations coupled therewith. The cables comprise, generally, three phase conductors, three ground conductors and fillers, and are wrapped with copper tape and other elements. The terminations comprise a plurality of connectors and a plurality of flexible, tinned-copper braids acting as the shield termination for the copper tape. More detailed and other embodiments of the present invention are disclosed in the specification hereof.

Owner:SERVICE WIRE

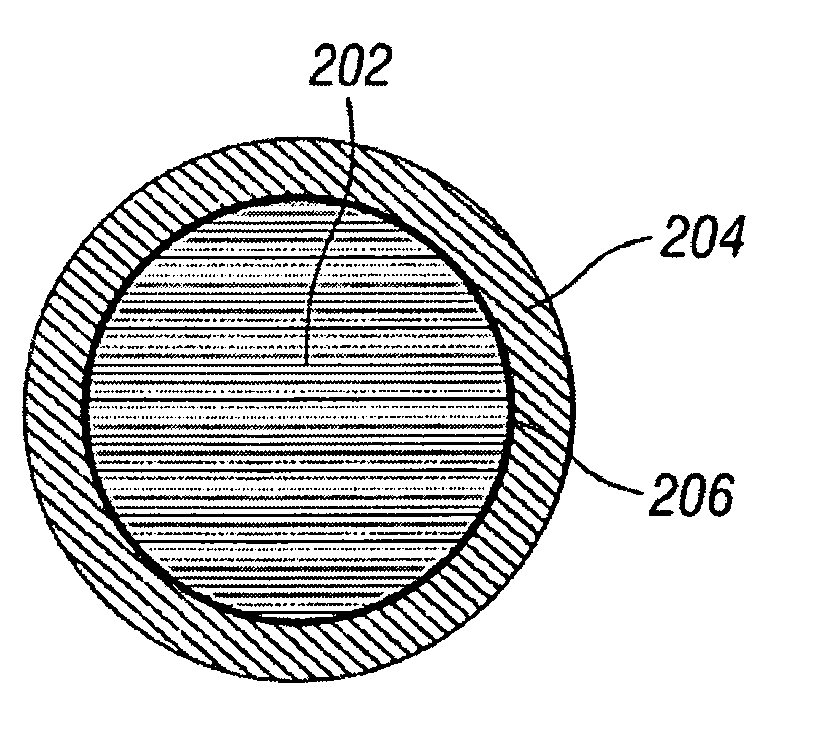

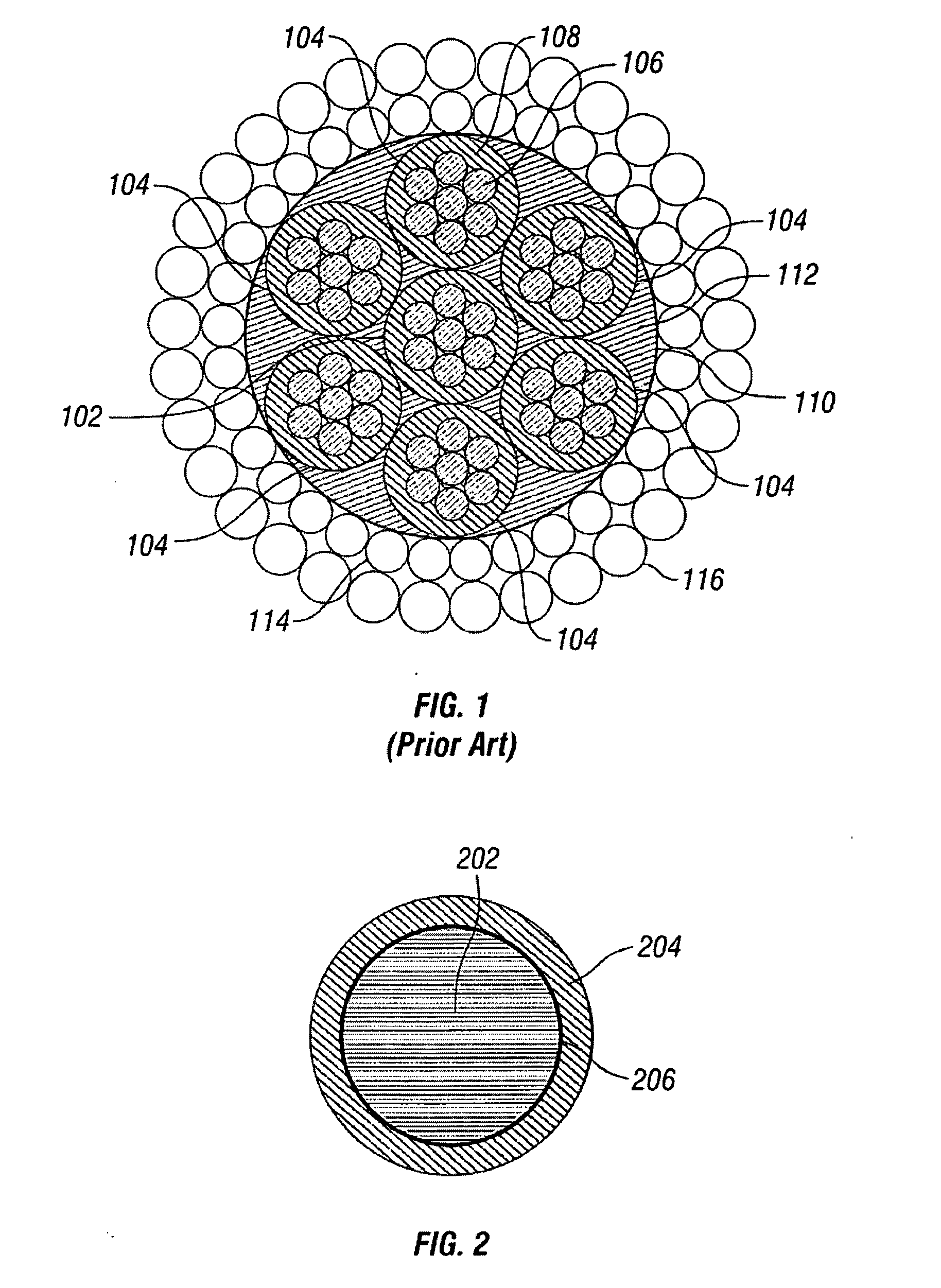

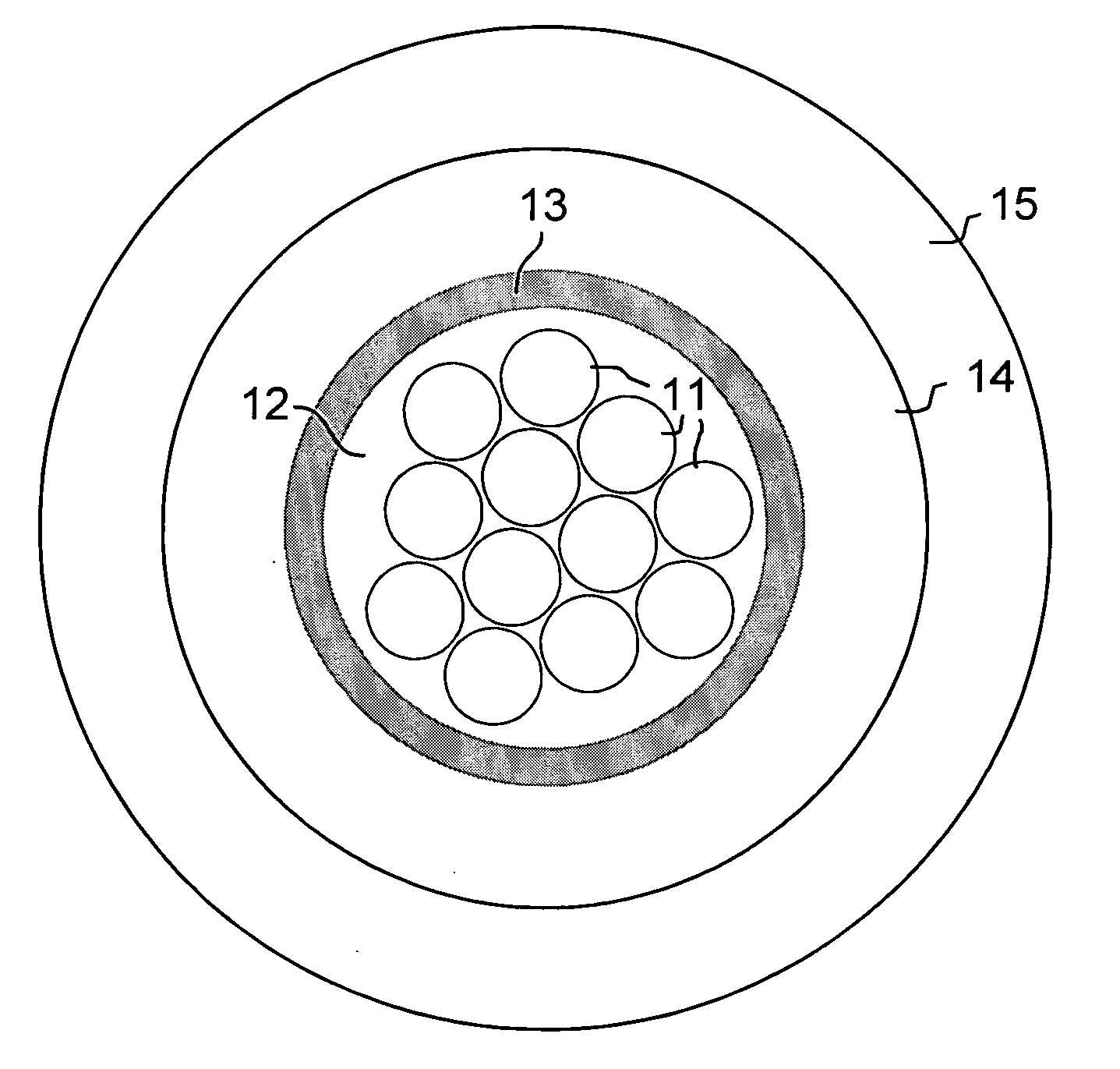

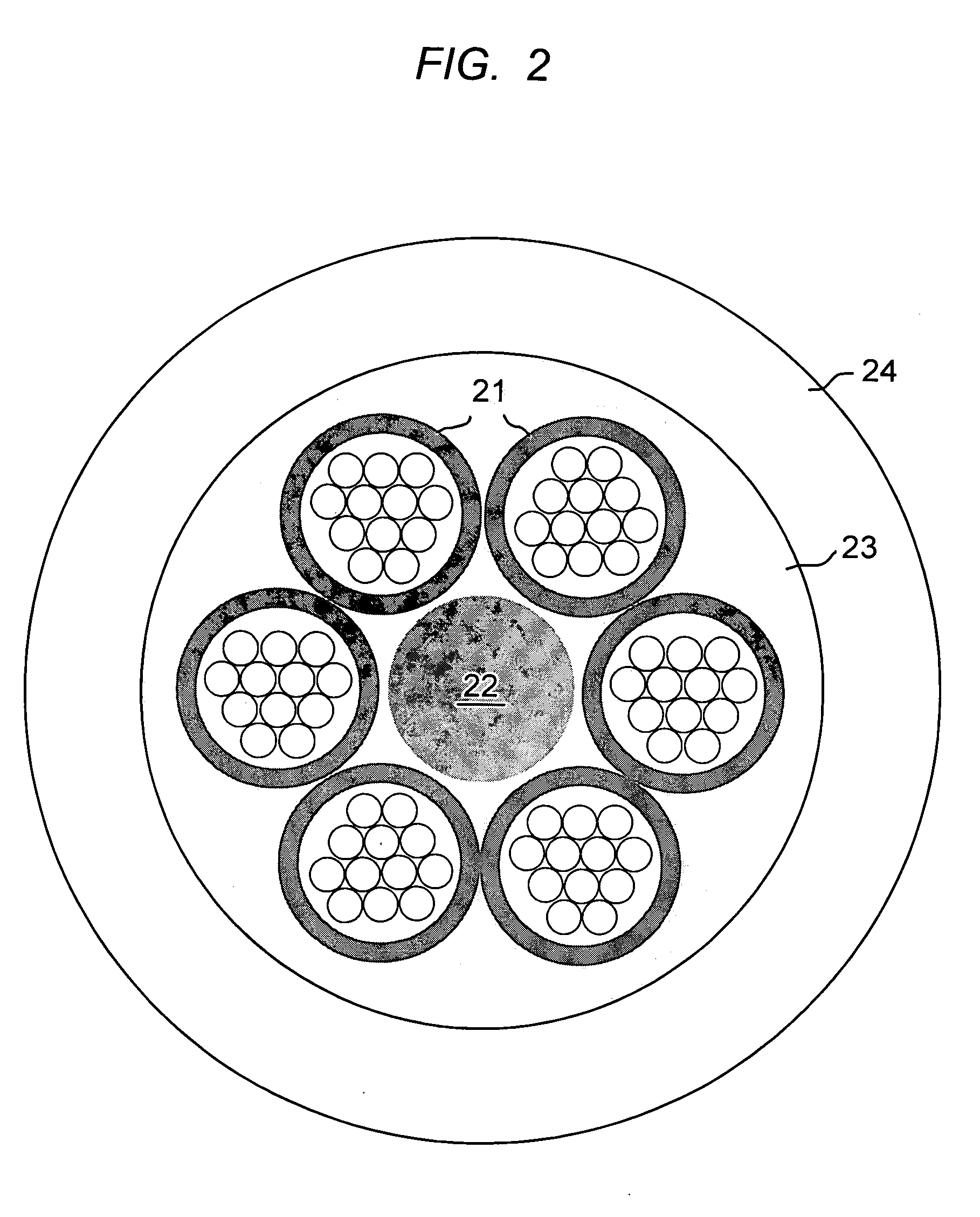

Lightweight armor wires for electrical cables

ActiveUS20070158095A1Simple designHigh strengthNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorTitanium alloy

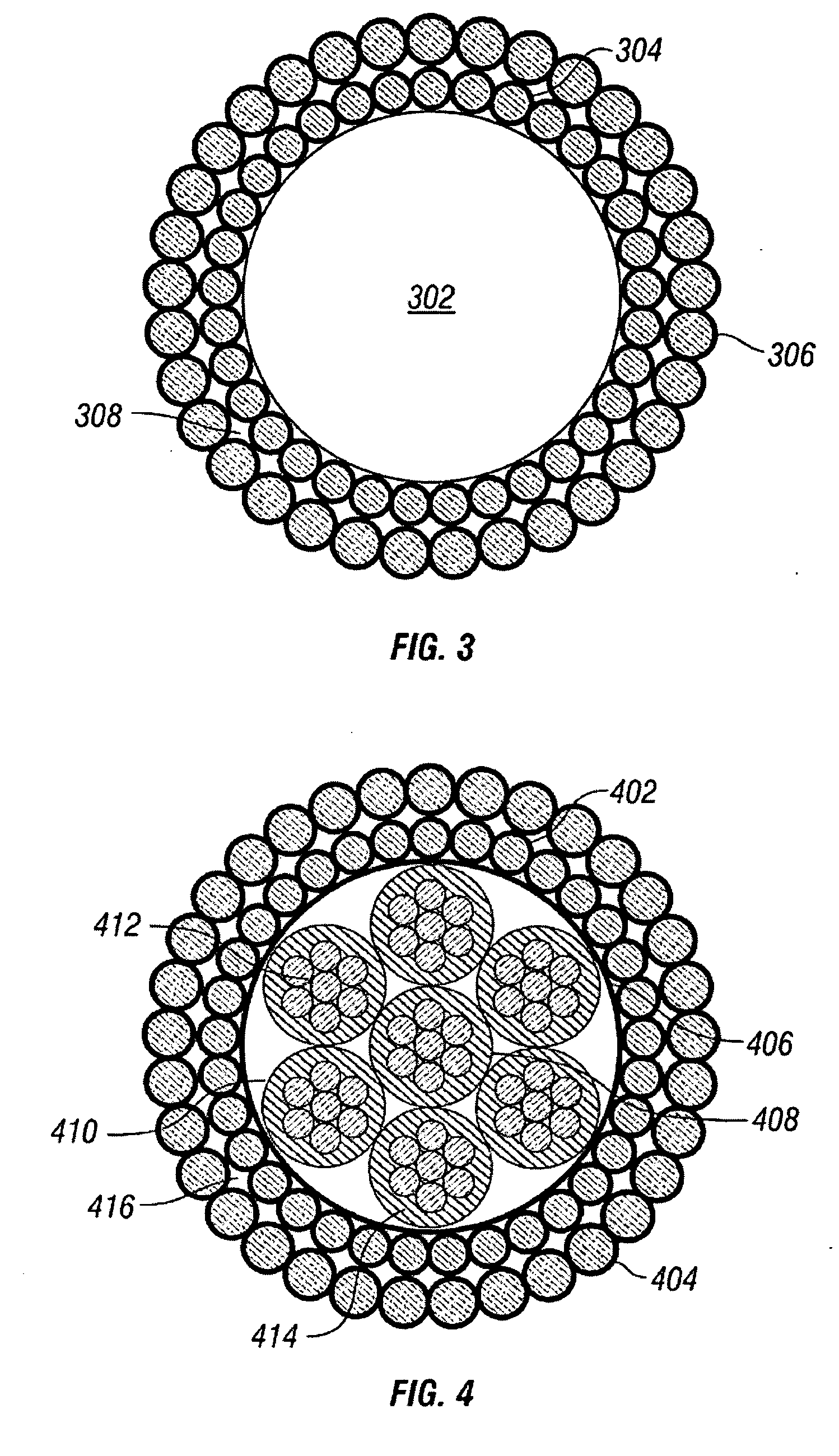

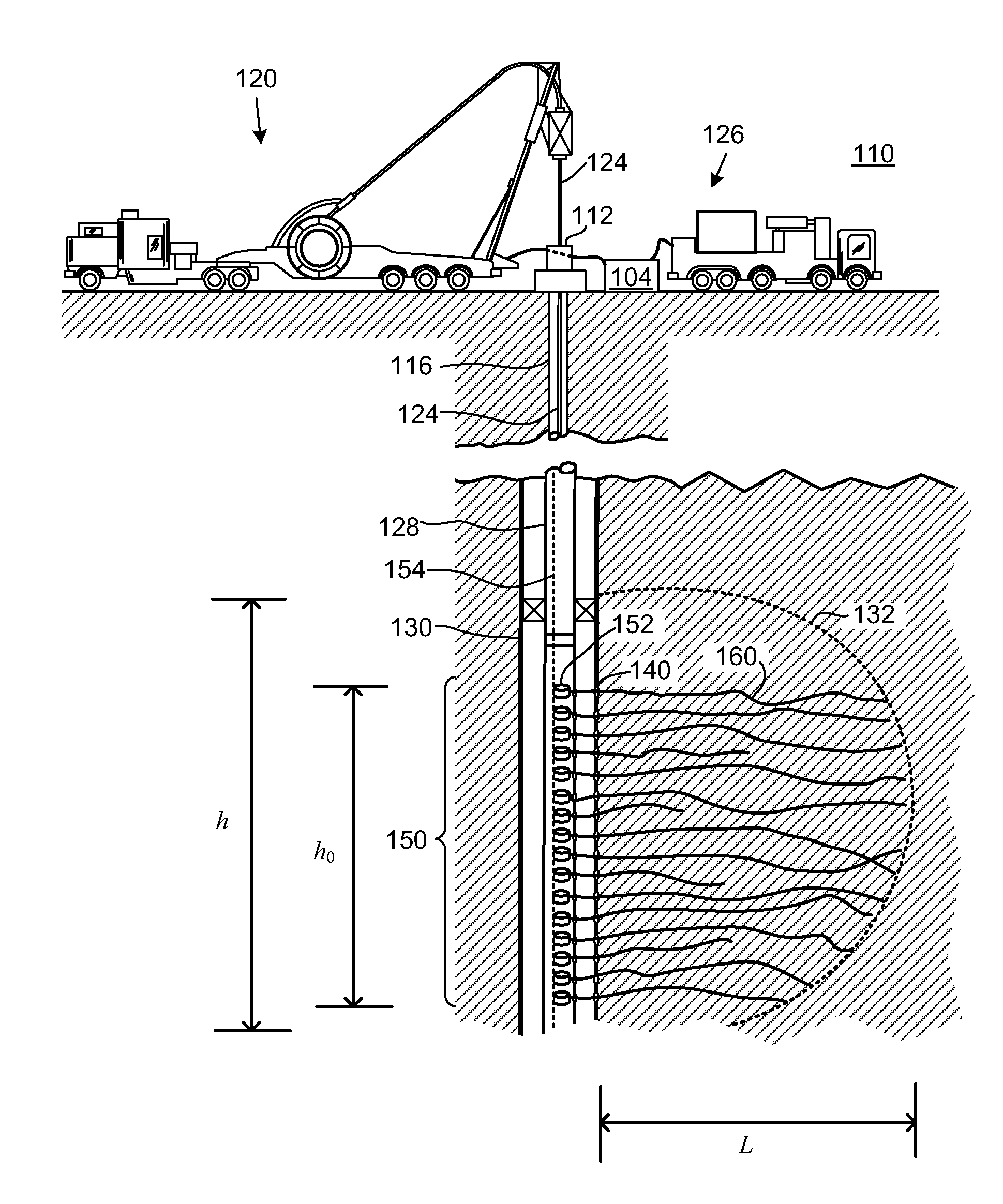

Disclosed are electric cables with improved armor wires used with wellbore devices to analyze geologic formations adjacent a wellbore. The cables include at least one insulated conductor, and one or more armor wires surrounding the insulated conductor. The armor wires include a low density core surrounded by a corrosion resistant alloy clad, where the alloy clad includes such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The low density core may be based upon titanium or titanium alloys. The cables of the invention may be any useful electric cable design, including monocables, quadcables, heptacables, quadcables, slickline cables, multiline cables, coaxial cables, or seismic cables.

Owner:SCHLUMBERGER TECH CORP

Fiber optic cable for distributed acoustic sensing with increased acoustic sensitivity

Owner:WEATHERFORD TECH HLDG LLC

Optical fiber cables

InactiveUS20090087154A1Minimize stress transferredFibre mechanical structuresOptical waveguide light guideYarnFiber

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Twinax Cable Design for Improved Electrical Performance

ActiveUS20120145429A1Coaxial cables/analogue cablesMagnetic/electric field screeningElectrical performanceTwinaxial cabling

Owner:PANDUIT

Fiber optic cables and assemblies and the performance thereof

ActiveUS20080273846A1Small component sizeTight toleranceFibre mechanical structuresUltrasound attenuationFiber

Owner:CORNING OPTICAL COMM LLC

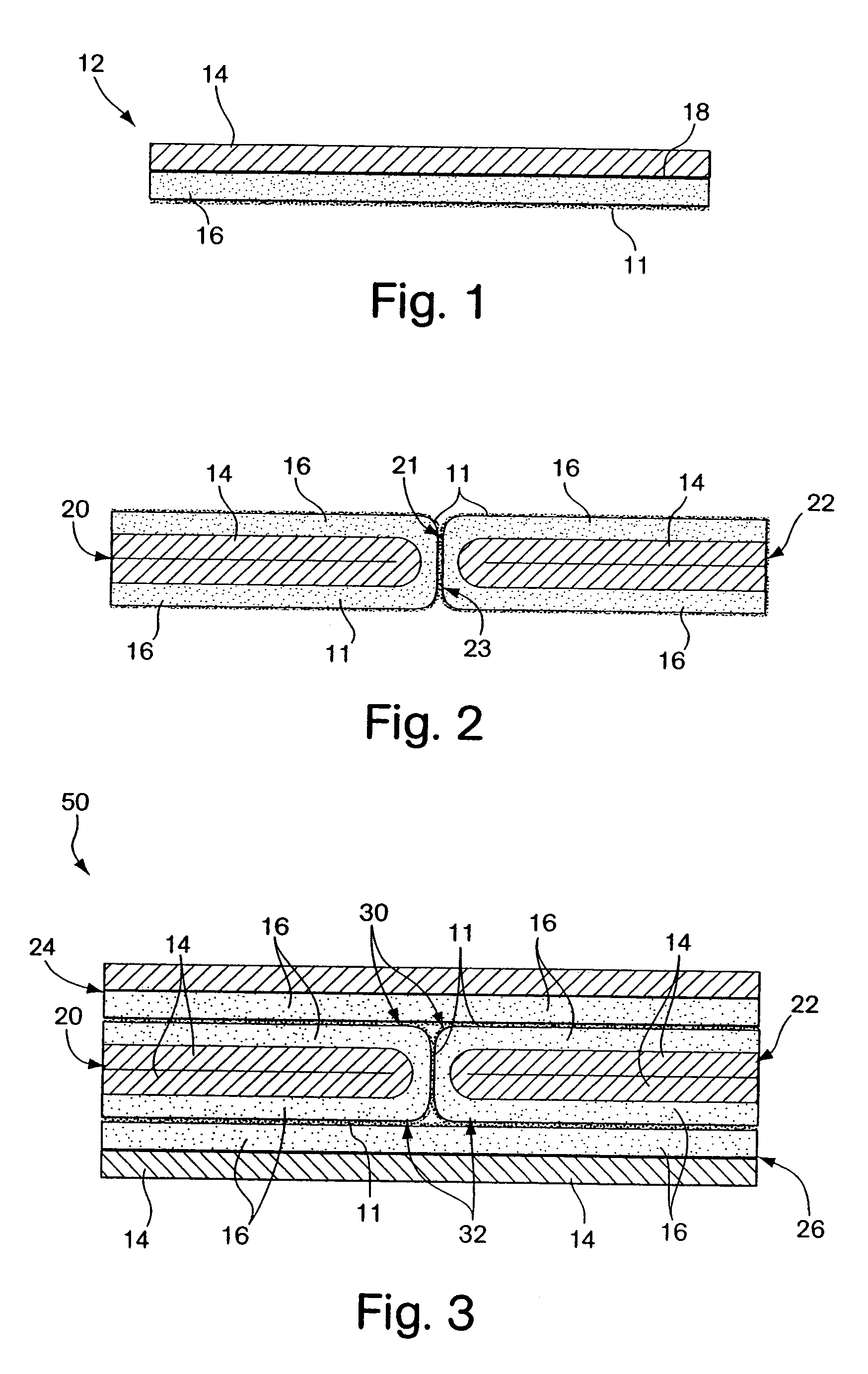

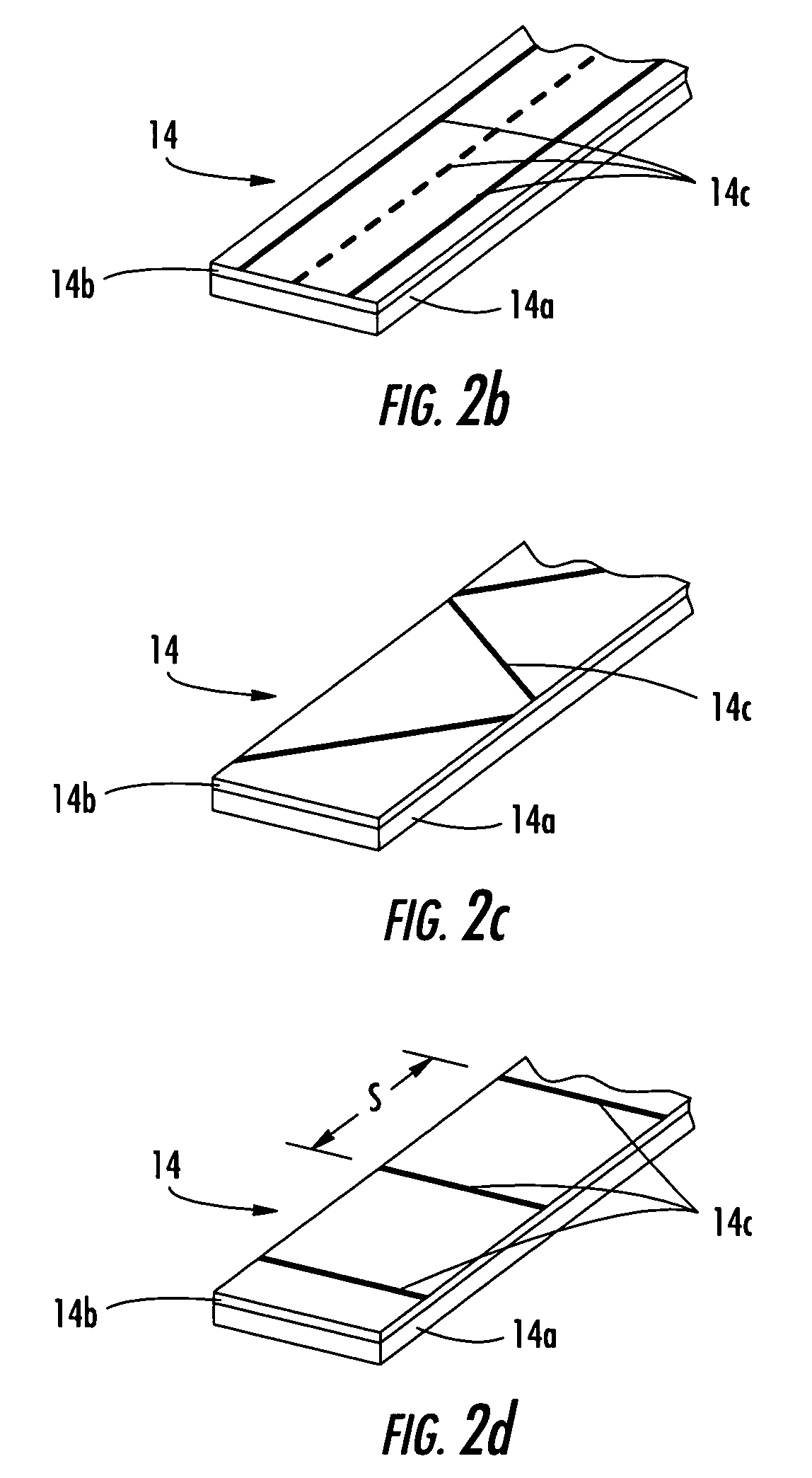

Multifolded composite tape for use in cable manufacture and methods for making same

InactiveUS6974913B2Improve isolationGood data transmissionFlat/ribbon cablesInsulated conductorsElectrical conductorCrosstalk

The invention provides a composite wrapping and shielding tape for use in cable manufacture. Embodiments of the composite tape comprise a single tape configuration to separate and shield individual pairs of insulated conductors housed within a cable such as a high-speed data communications cable. The single tape configurations of the invention are multifolded and assembled from foil / film laminates to form a plurality of longitudinal channels or grooves to accommodate one or more pairs of insulated conductors and a variety of cable designs. During cable manufacture, one or more pairs of insulated conductors is wrapped within a continuous shield provided by each longitudinal channel or groove, thereby separating and shielding each pair of insulated conductors and, hence, isolating or at least substantially reducing crosstalk between pairs of insulated conductors contained within the cable. The invention also provides methods for making a multifolded composite tape. The invention further provides a communications cable comprising a multifolded composite tape to separate and shield insulated conductors.

Owner:NEPTCO +1

Optical tube assembly having a dry insert and methods of making the same

An optical tube assembly having at least one optical waveguide, at least one dry insert, and a tube. The at least one optical waveguide is disposed within the tube and generally surrounds the at least one optical waveguide. In one embodiment, the dry insert has a first layer comprising a felt having at least one type of non-continuous filament. The dry insert may also include a plurality of water-swellable filaments. In another embodiment, a dry insert has a first layer, a second layer, and a plurality of water-swellable filaments. The first and second layers are attached together at least along the longitudinal edges thereof, thereby forming at least one compartment between the first and second layers and the plurality of water-swellable filaments are generally disposed in the at least one compartment. The dry insert also is advantageous in tubeless cable designs.

Owner:CORNING OPTICAL COMM LLC

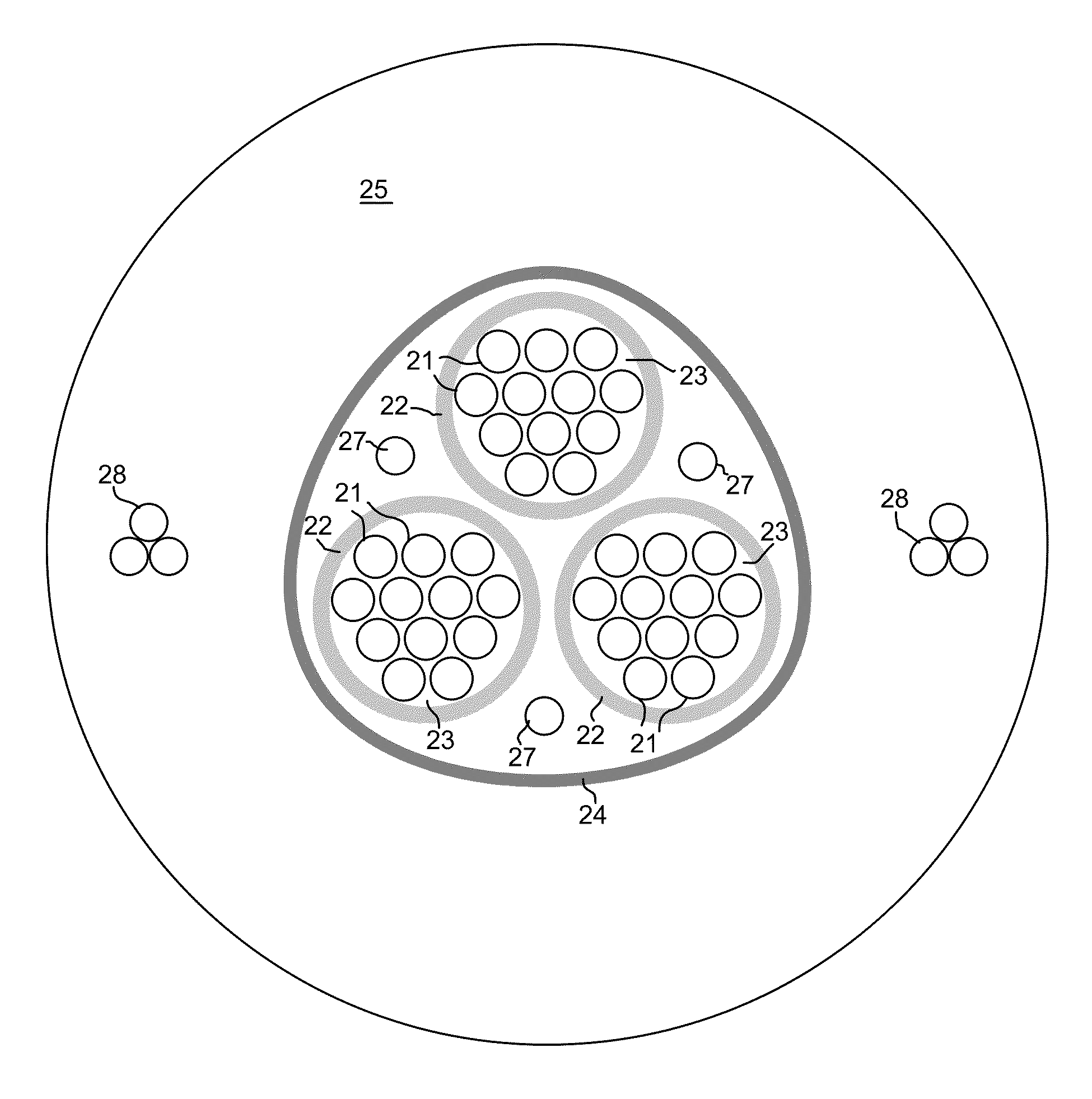

Optical fiber cables

Described are new cable designs for indoor installations wherein the cable comprises a dual-layer optical fiber buffer encasement of acrylate resin. The buffer encasement has an acrylate compliant inner layer that protects the fiber and minimizes stress transfer to the fiber; and a hard, tough acrylate outer layer that provides crush resistance. The dual-layer optical fiber buffer encasement is wrapped with reinforcing yarn and encased in an outer protective jacket. A dual jacket embodiment adapted for indoor / outdoor installations is also described.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Tubeless fiber optic cables having strength members and methods therefor

ActiveUS7397992B1Avoid distortionInhibiting distortion of cross-sectional shapeFibre mechanical structuresFiberEngineering

Disclosed are tubeless fiber optic cables having strength members, methods of making the cables, and methods for making strength members. Specifically, the concepts of the invention inhibit the distortion and / or influence the cross-sectional shape of the tubeless fiber optic cables due to torsional forces from the strength members. For instance, one tubeless fiber optic cable of the invention uses strength members with a dead-lay construction for inhibiting distortion of the same. Another tubeless fiber optic cable design uses strength members on opposite sides of the cavity where the torsional forces from the strength members are in opposite directions for influencing the cross-sectional shape of the same. Other aspects of the invention are directed to methods for making the tubeless fiber optic cables.

Owner:CORNING OPTICAL COMM LLC

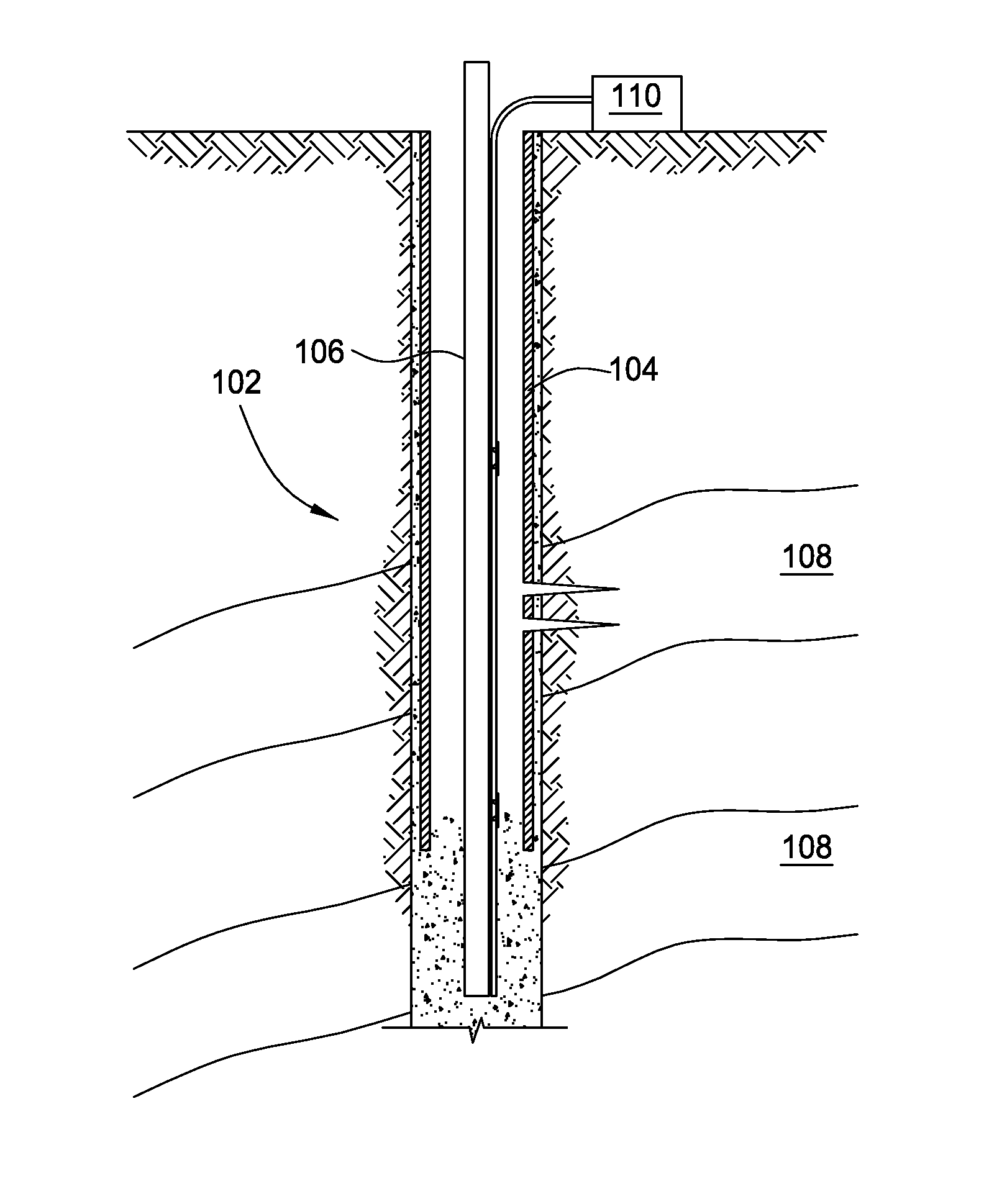

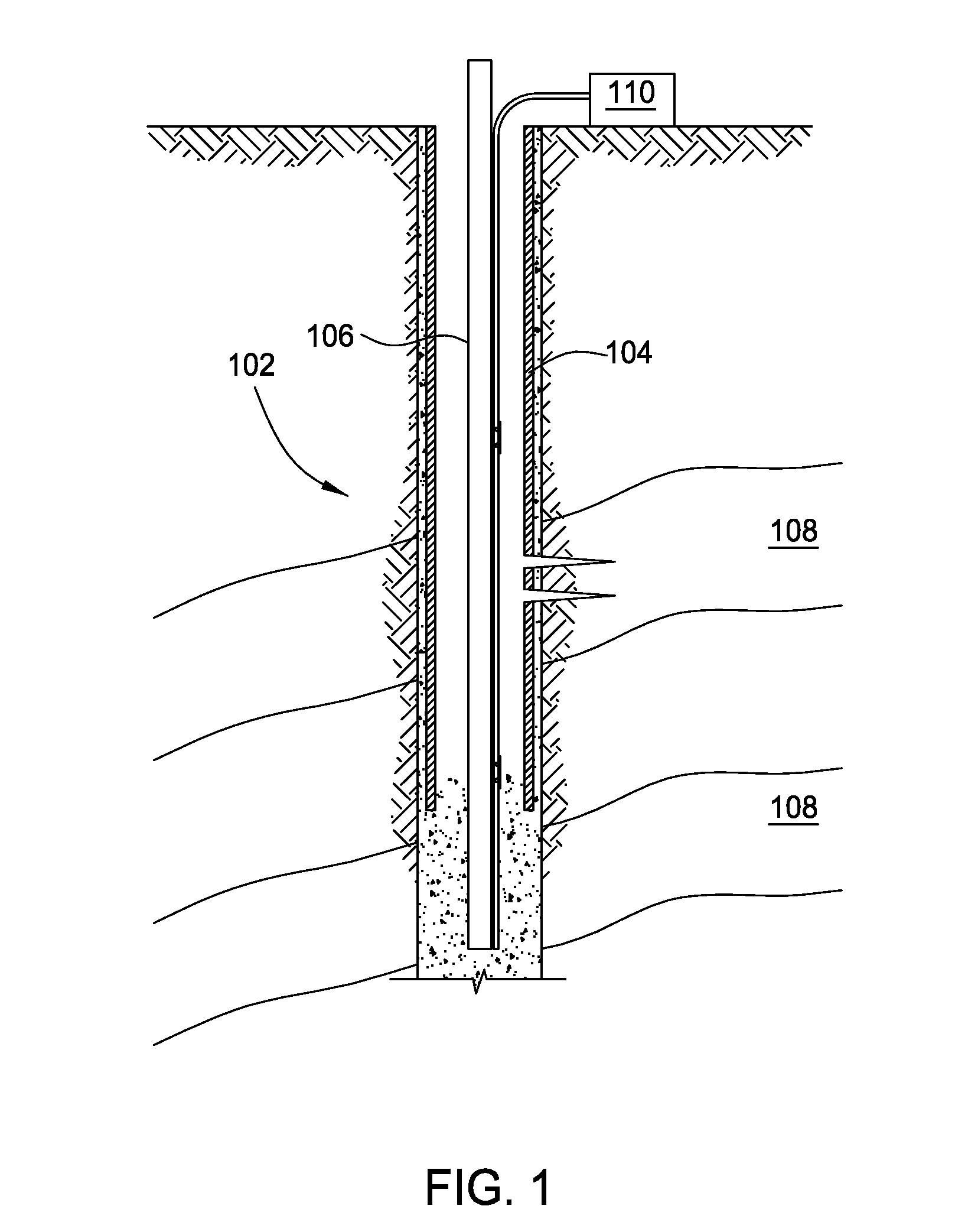

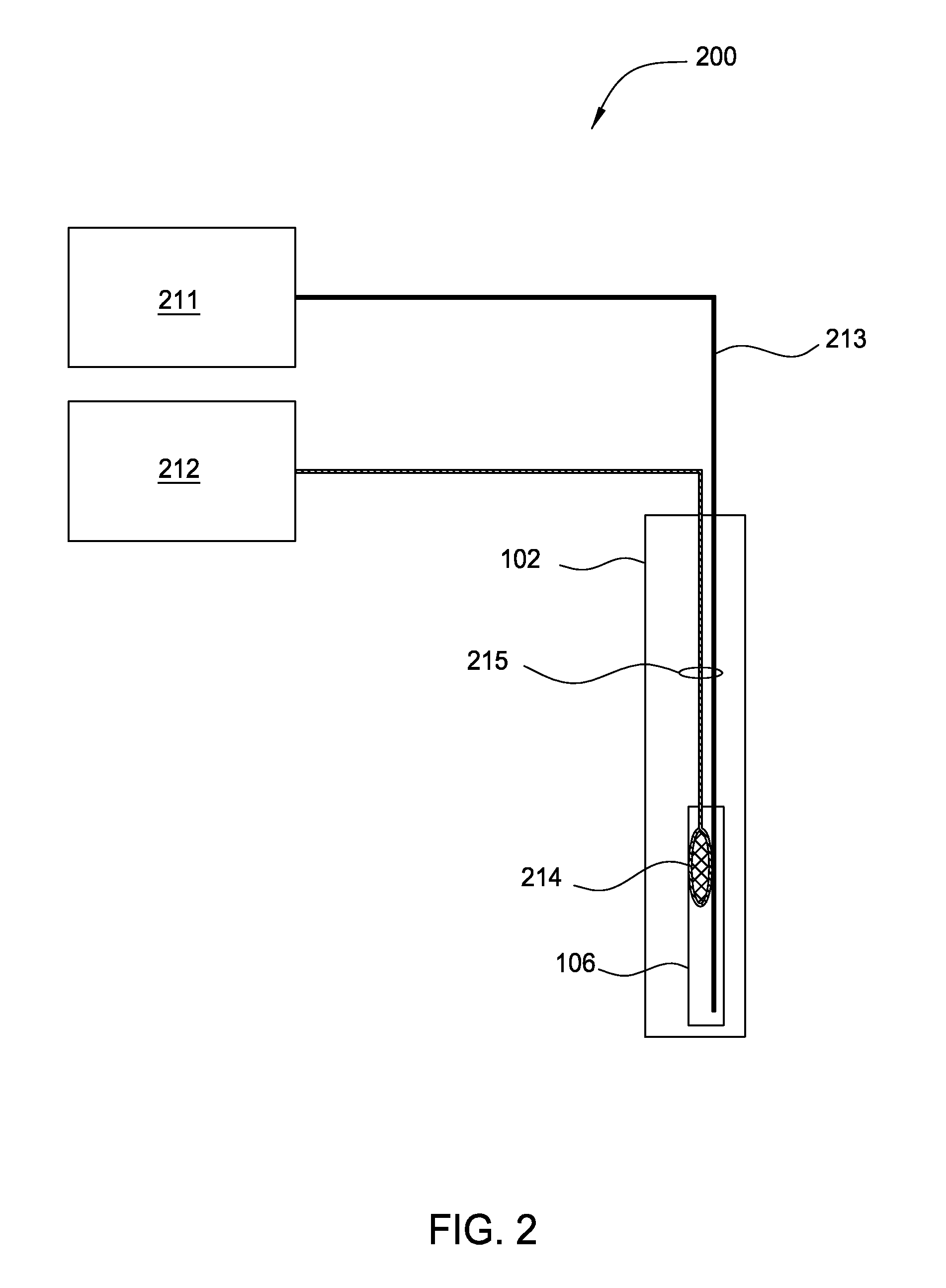

Sensing and monitoring of elongated structures

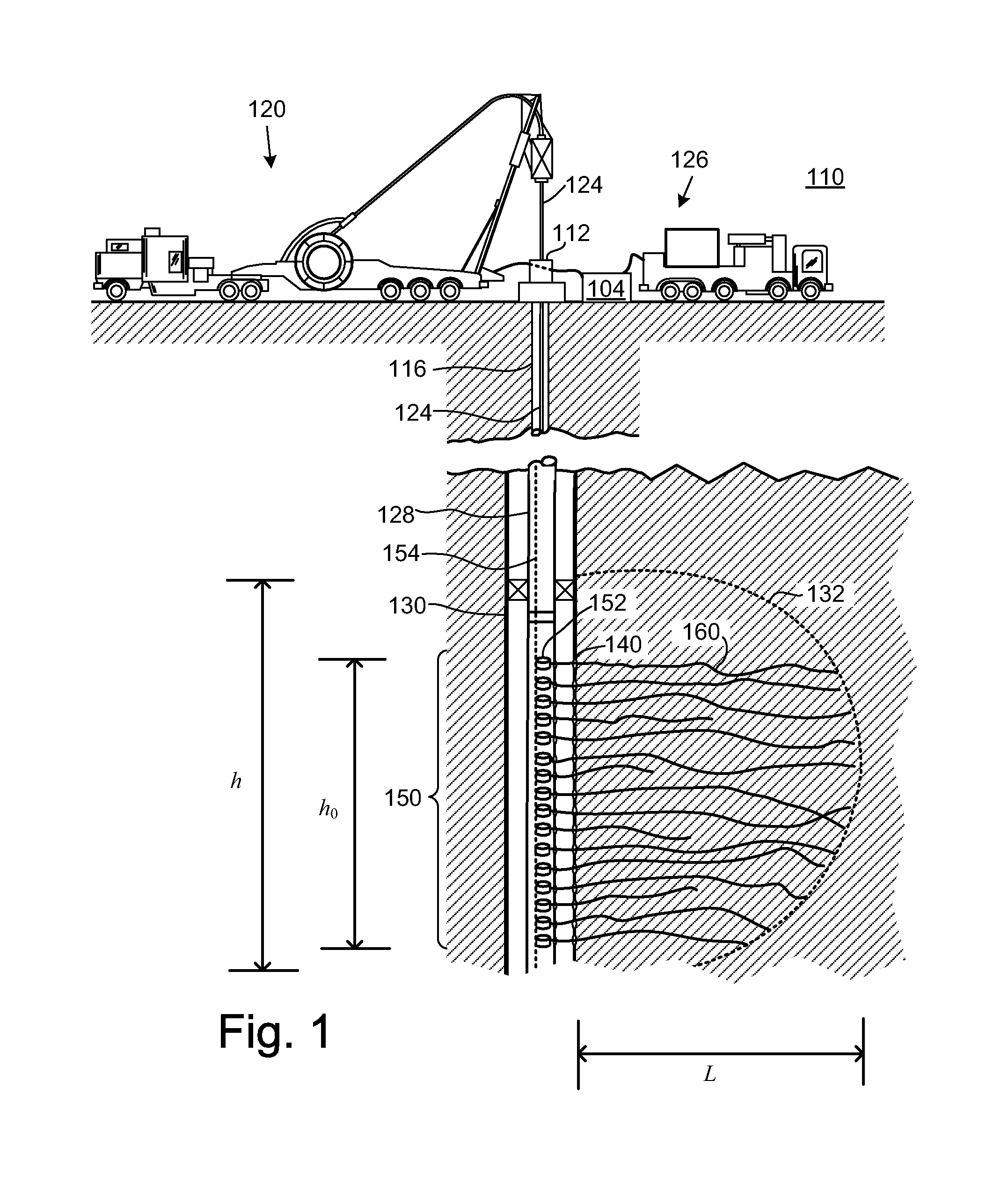

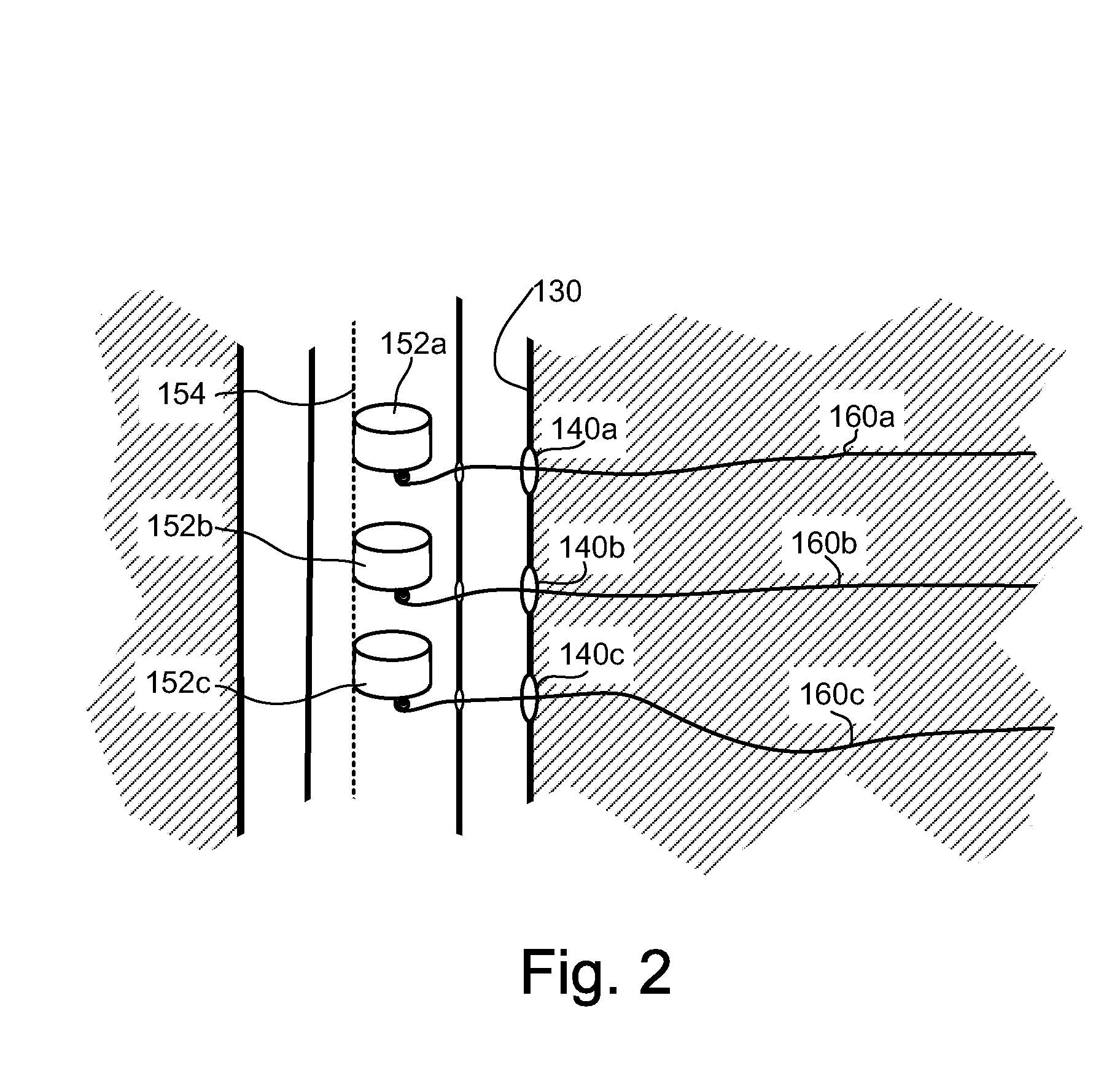

Methods and related systems are described for use with a wireline tool system including a wireline cable designed to deploy a wireline tool into a wellbore from the surface, the wireline cable having one or more conducting members for communication between the wireline tool and the surface; and a plurality of sensing elements located on the wireline cable in a spaced apart fashion along substantially the entire length of the wireline cable, each sensing element being in communication with one or more adjacent sensing elements.

Owner:SCHLUMBERGER TECH CORP

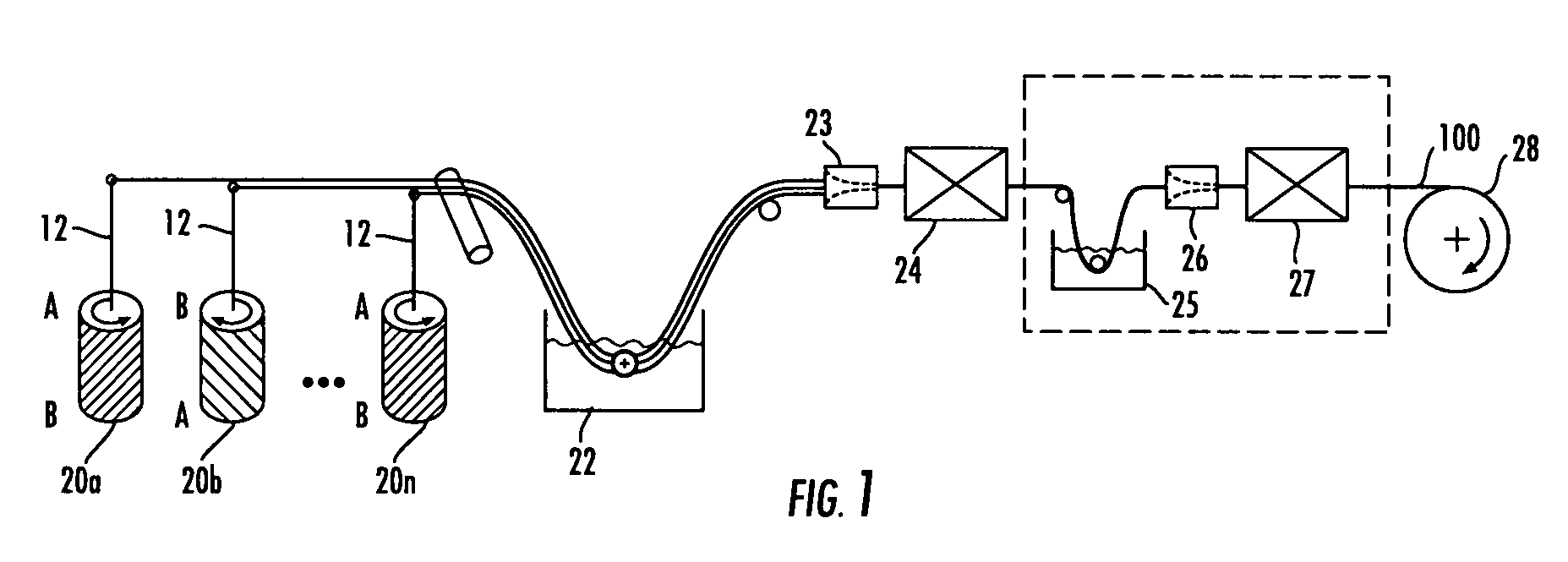

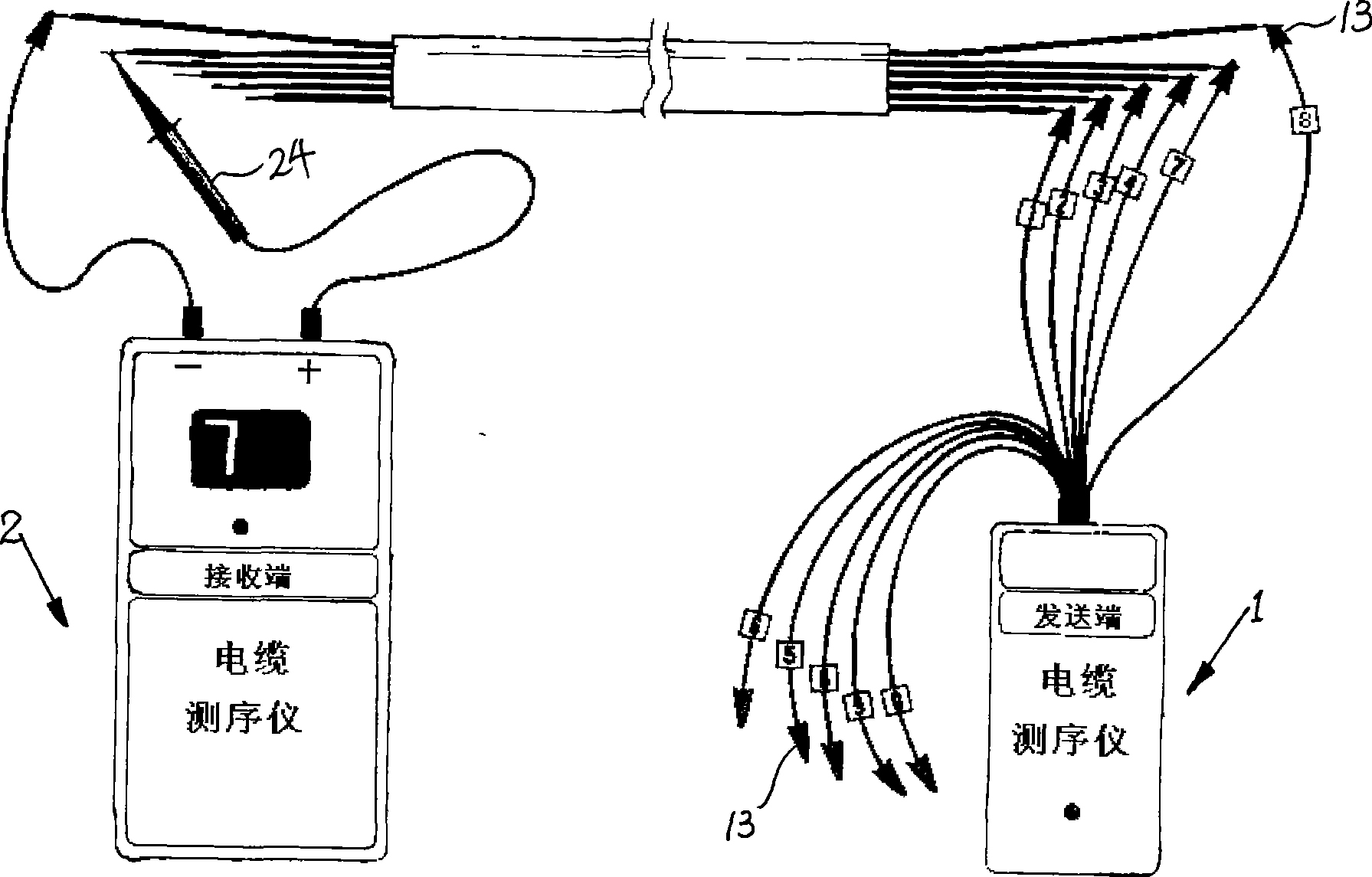

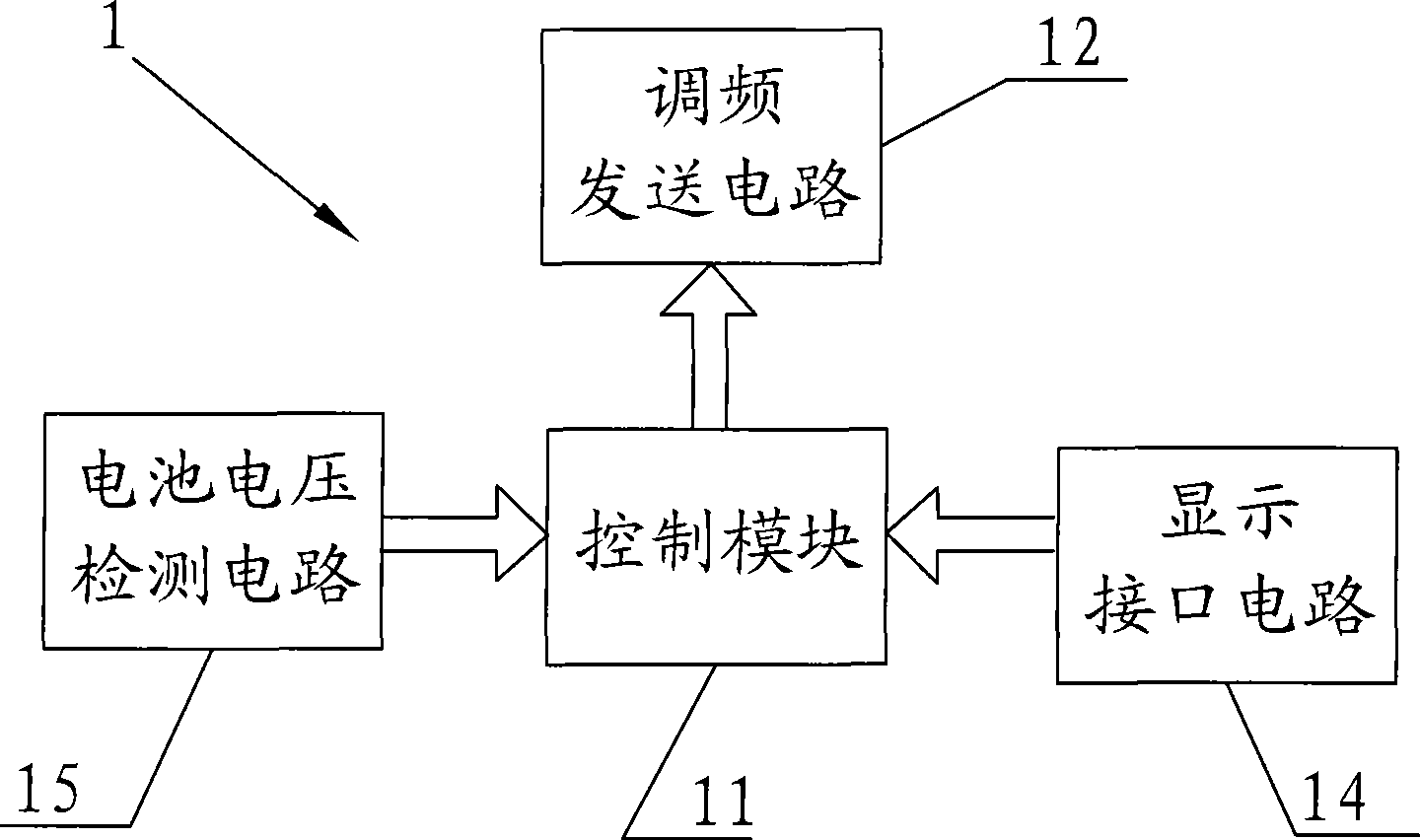

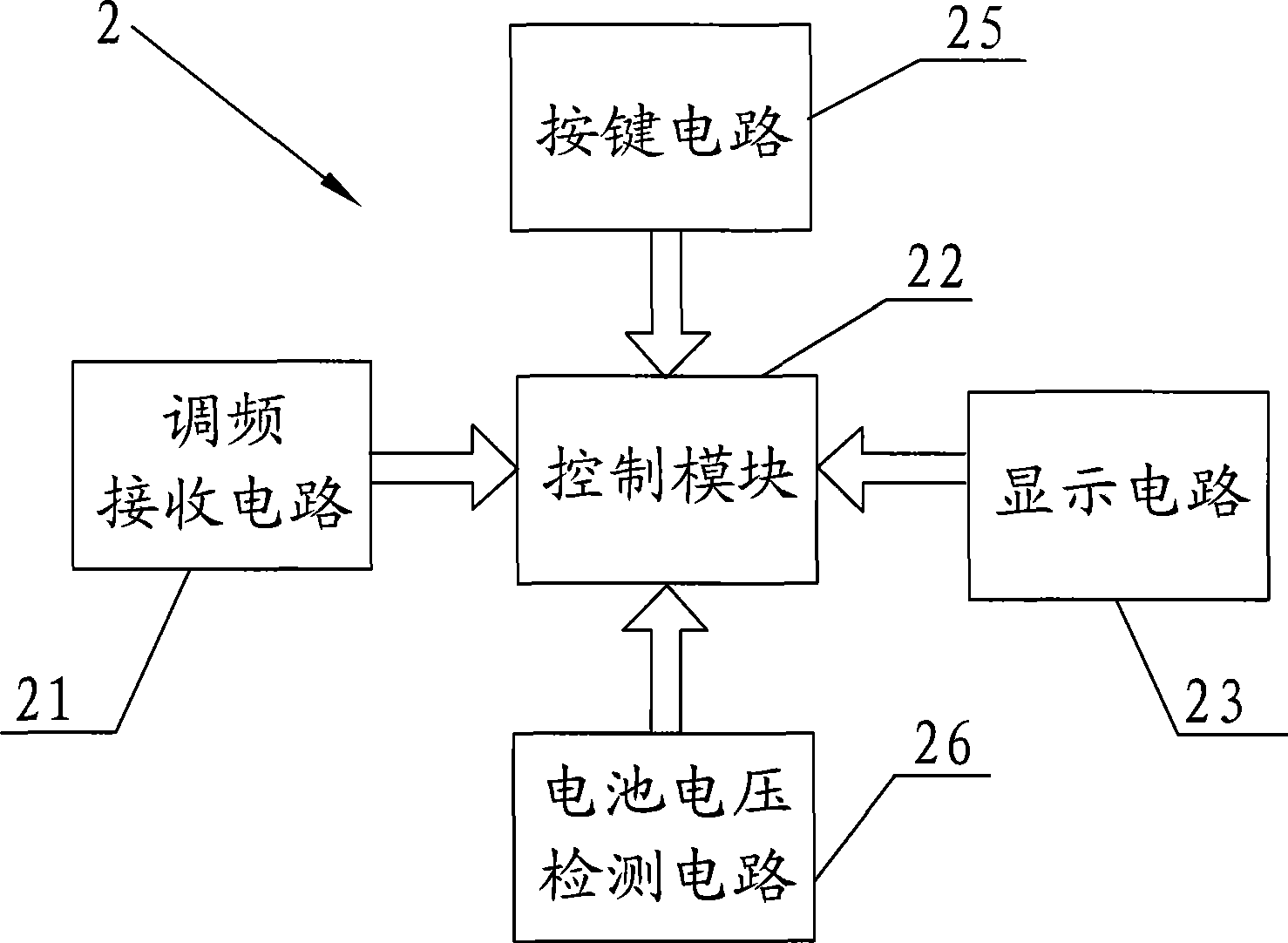

Multi-core cable sequence measuring method based on frequency modulation digital code and apparatus thereof

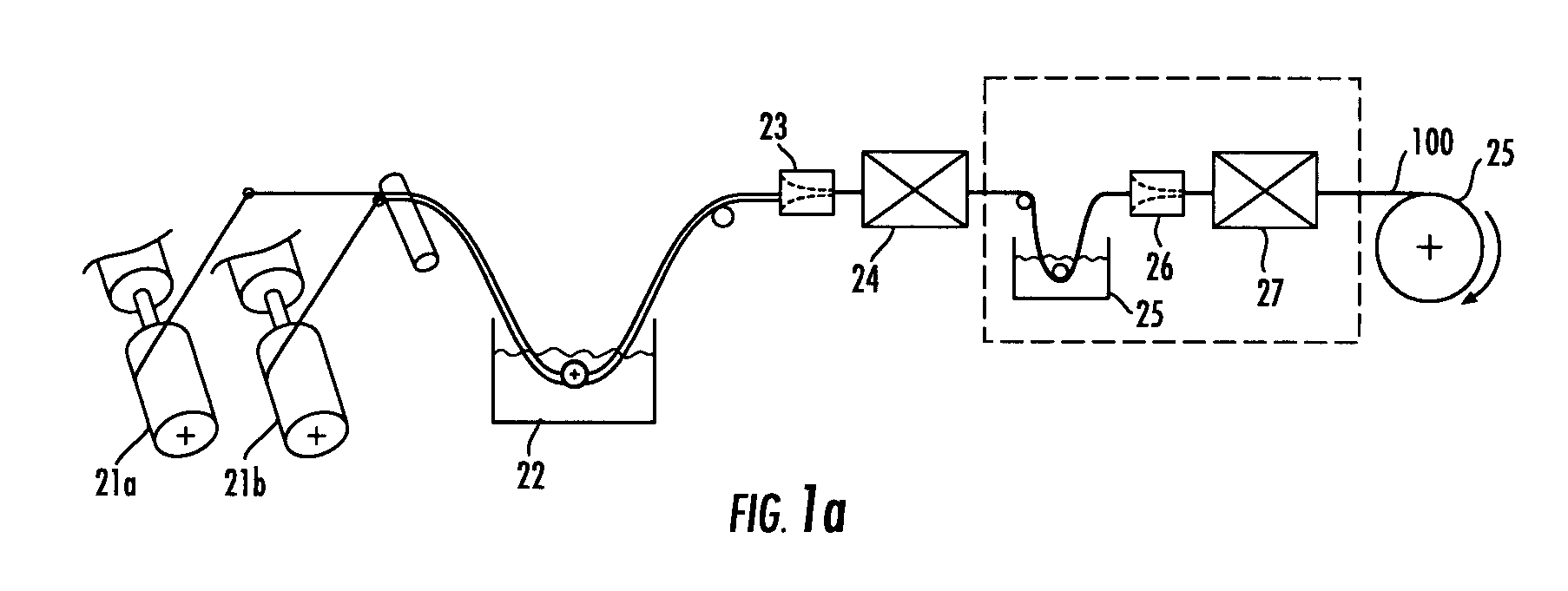

The invention relates to a polycore cable sequencing method based on digital frequency-modulation encoding and a device thereof. The device consists of a transmitter and a receiver, which are connected with the two ends of a polycore cable to be detected; during measurement, the transmitter designs digital encoded signals for each cable to be detected and sends the encoded signals to the cable to be detected after frequency modulation; a receiving end connects any two cables by a measuring probe, the received signals of the two cables obtain effective received signals of the cable marked as 'plus' end through a difference circuit; the effective received signals are modulated, thus obtaining the sequence numbers of connected cables and displaying the result. The measuring device adopting the measuring method of the invention has quite small volume is convenient for being used on site. No public reference lines are needed to during measurement, In addition, the adoption of the measuring method of the invention ensures higher reliability of the measurement and long-distance test.

Owner:SUZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

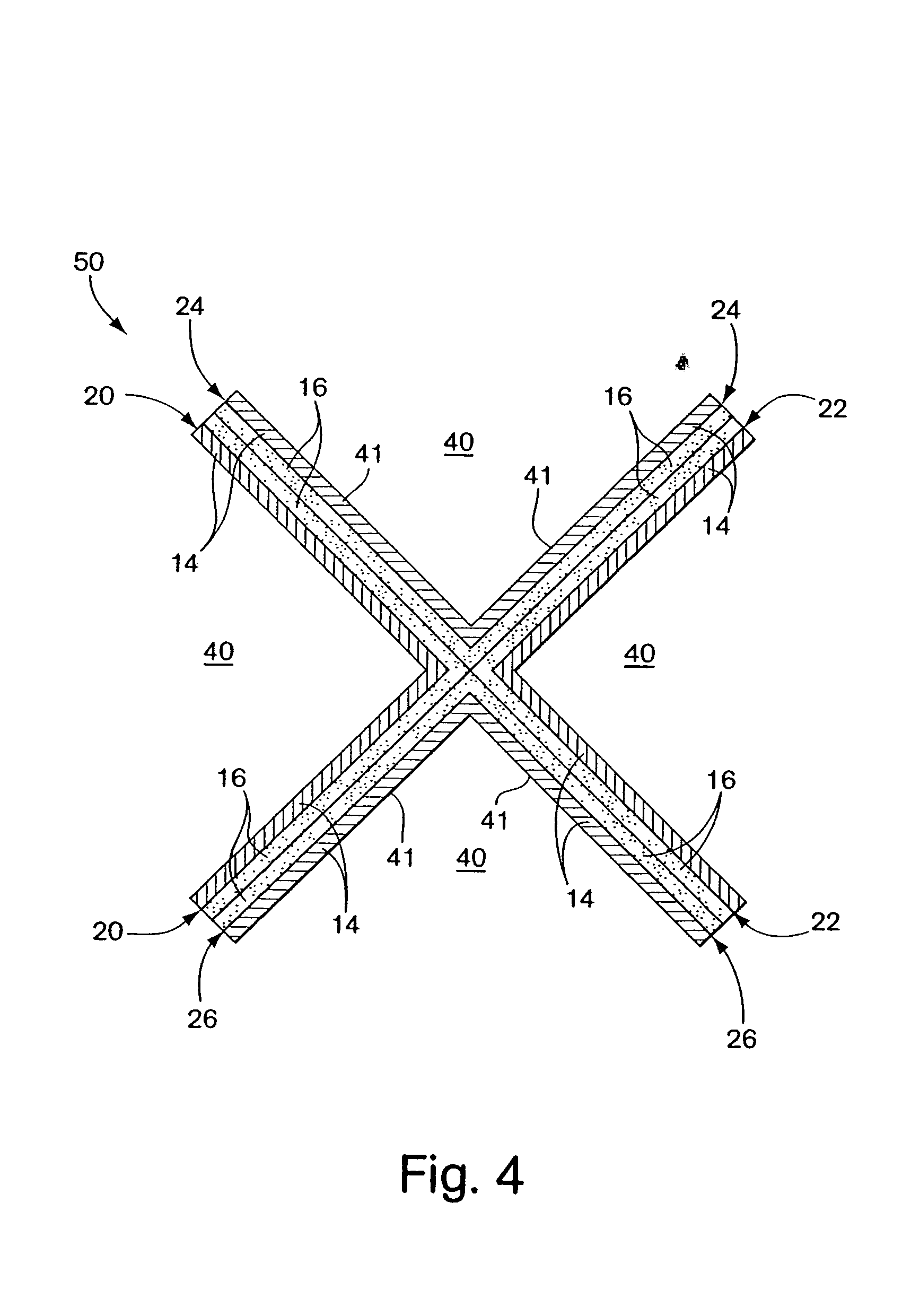

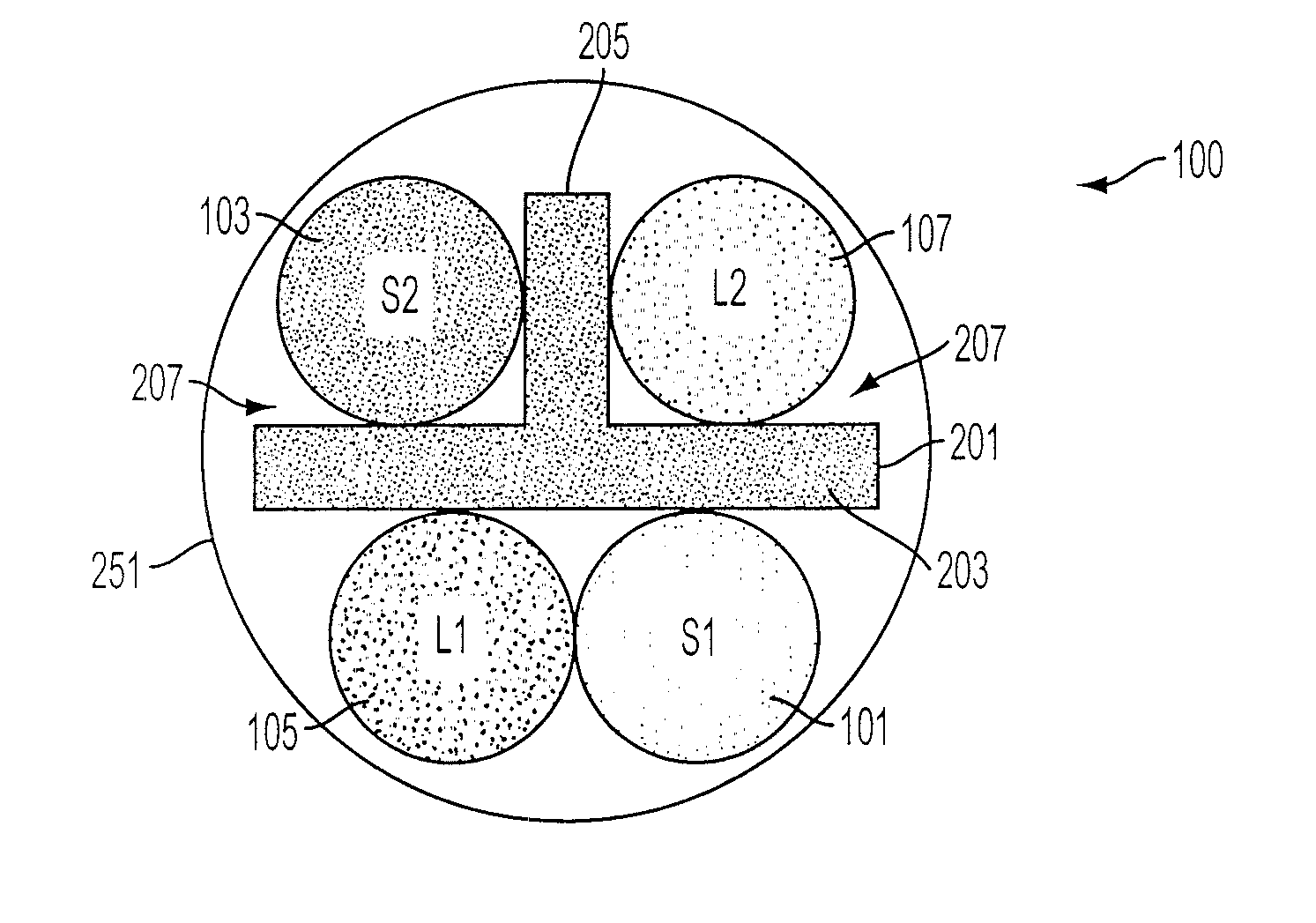

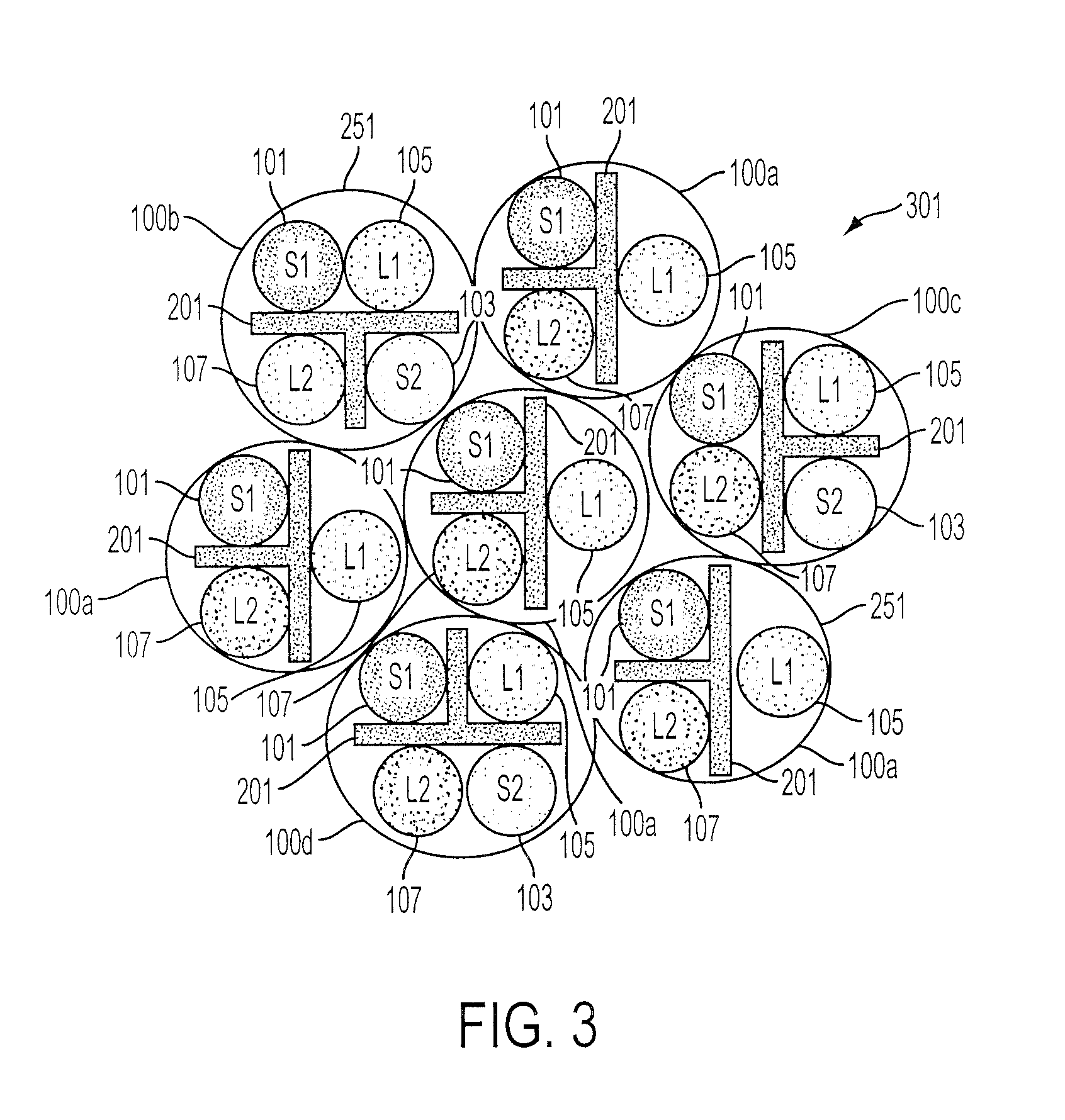

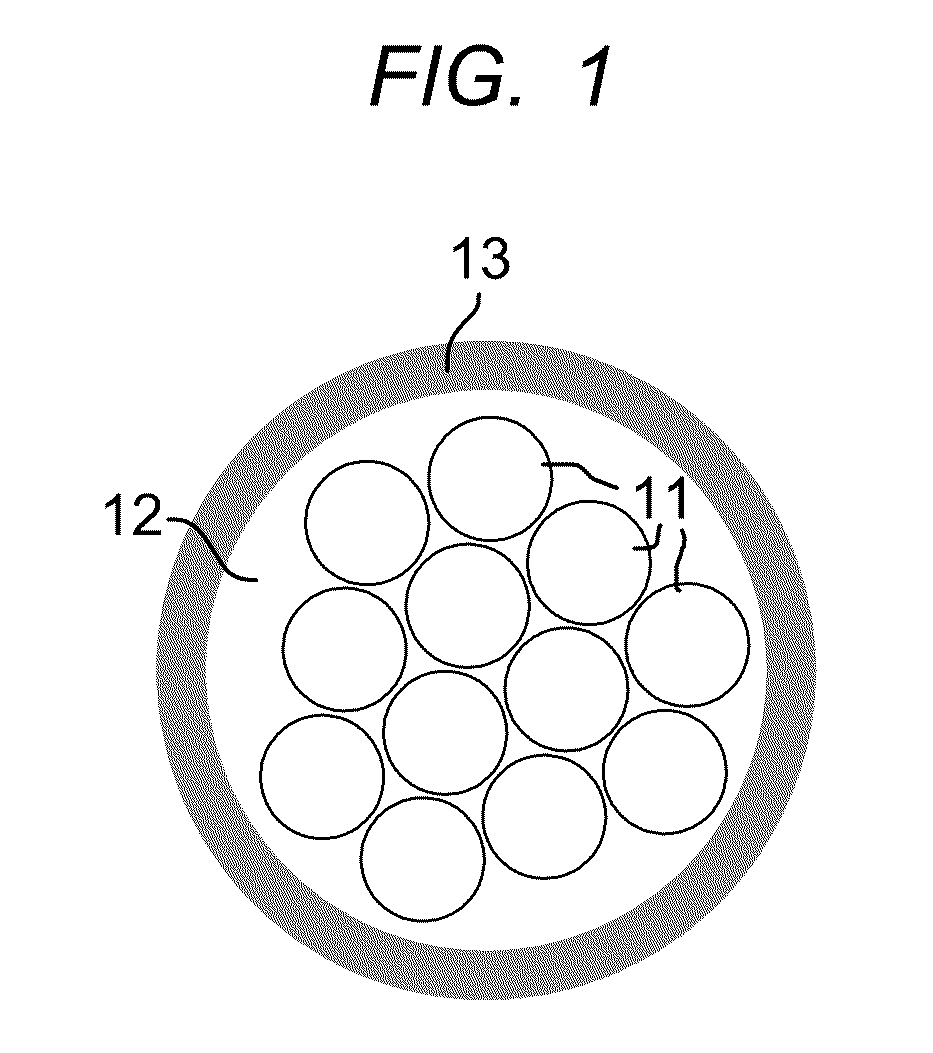

Separator spline and cables using same

ActiveUS7897875B2Less materialEasy constructionCables with twisted pairs/quadsEngineeringBuilding construction

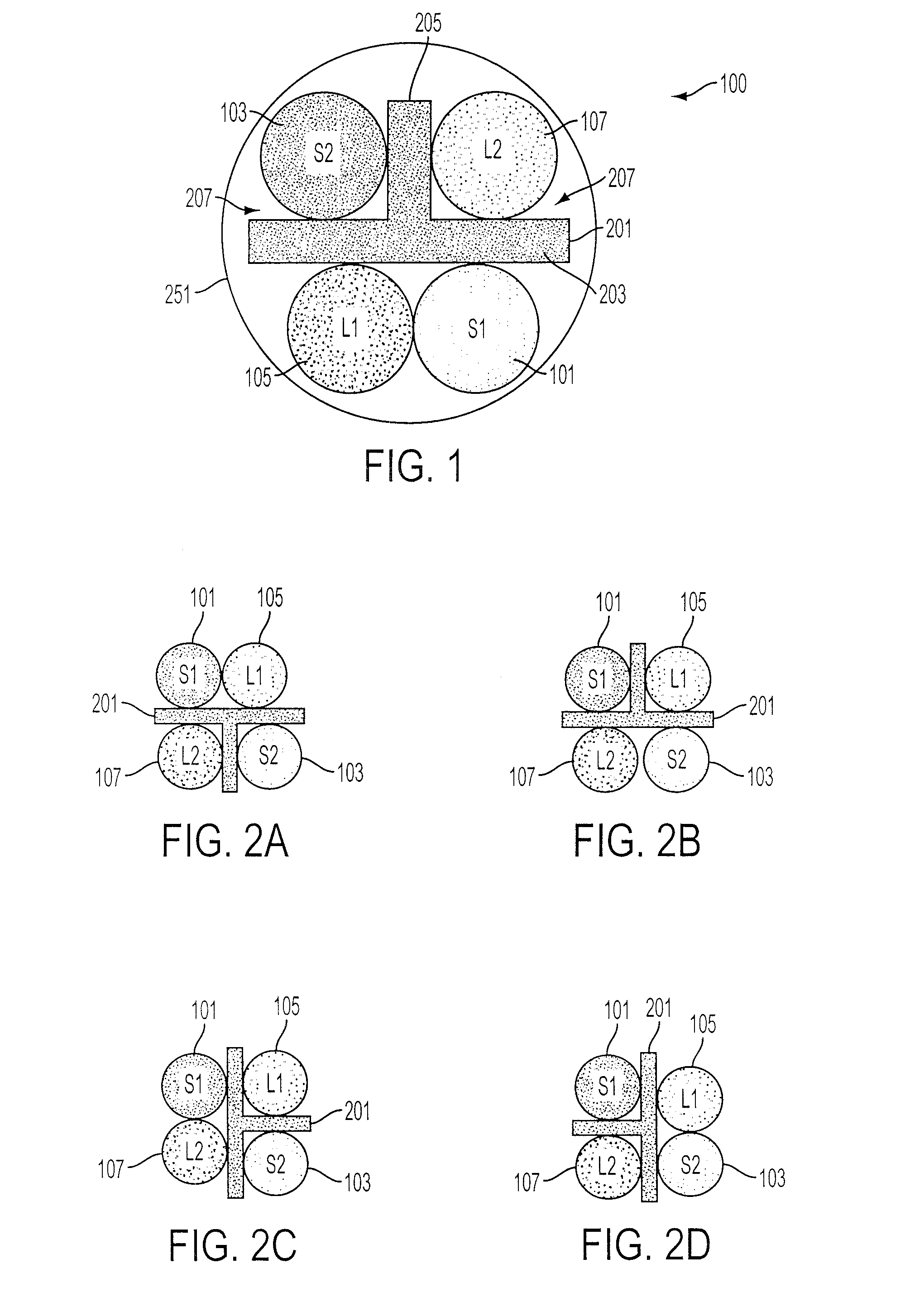

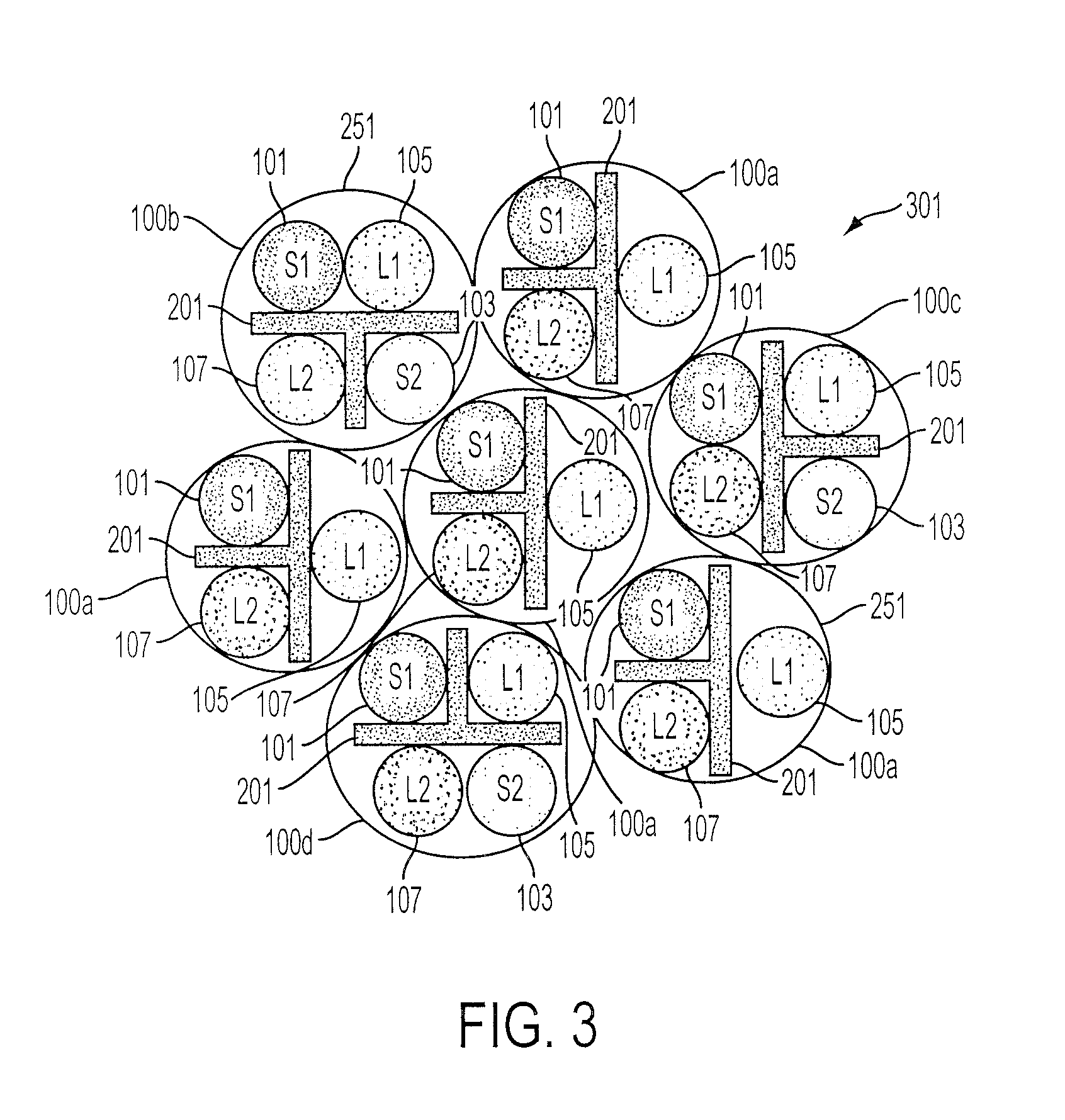

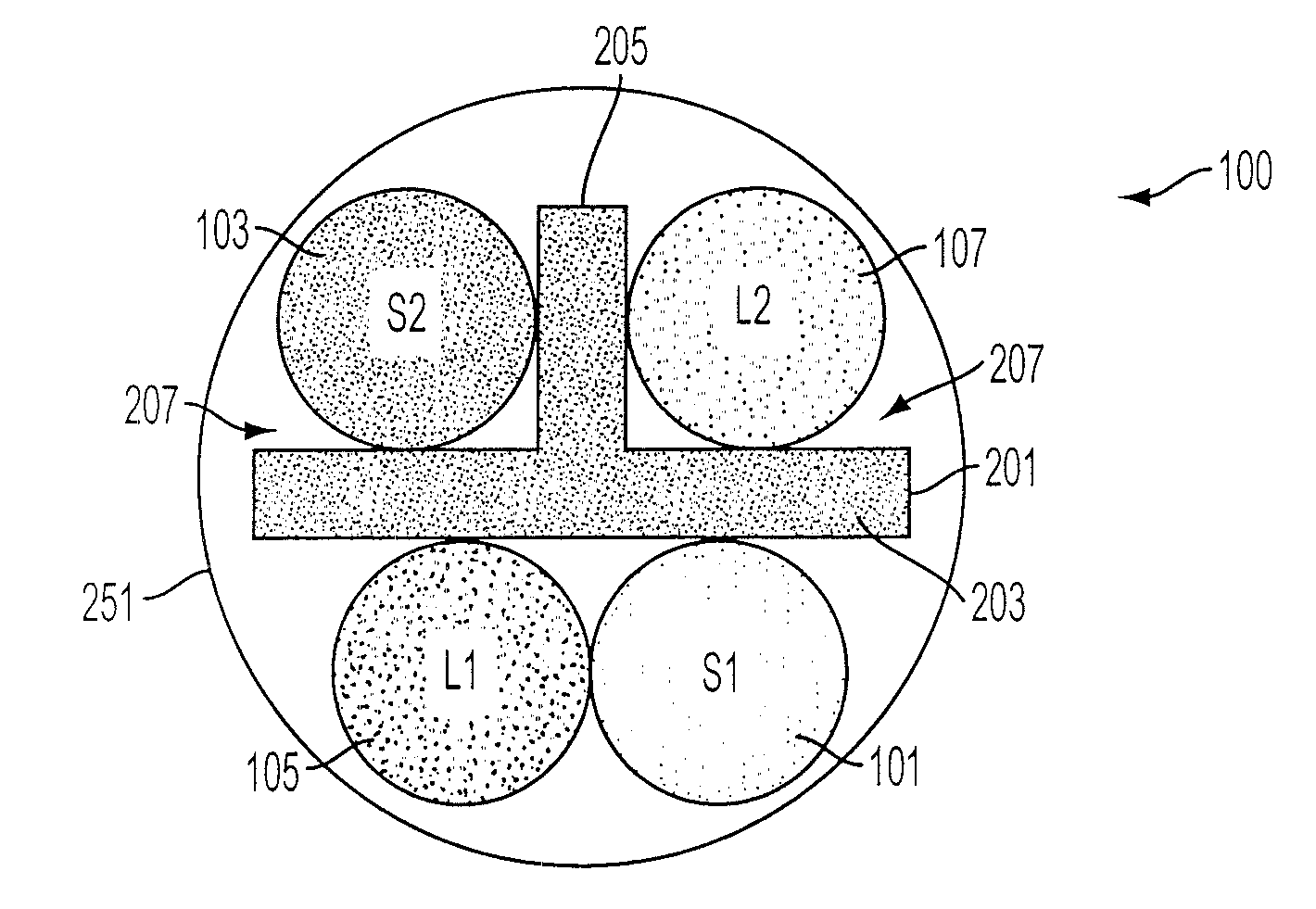

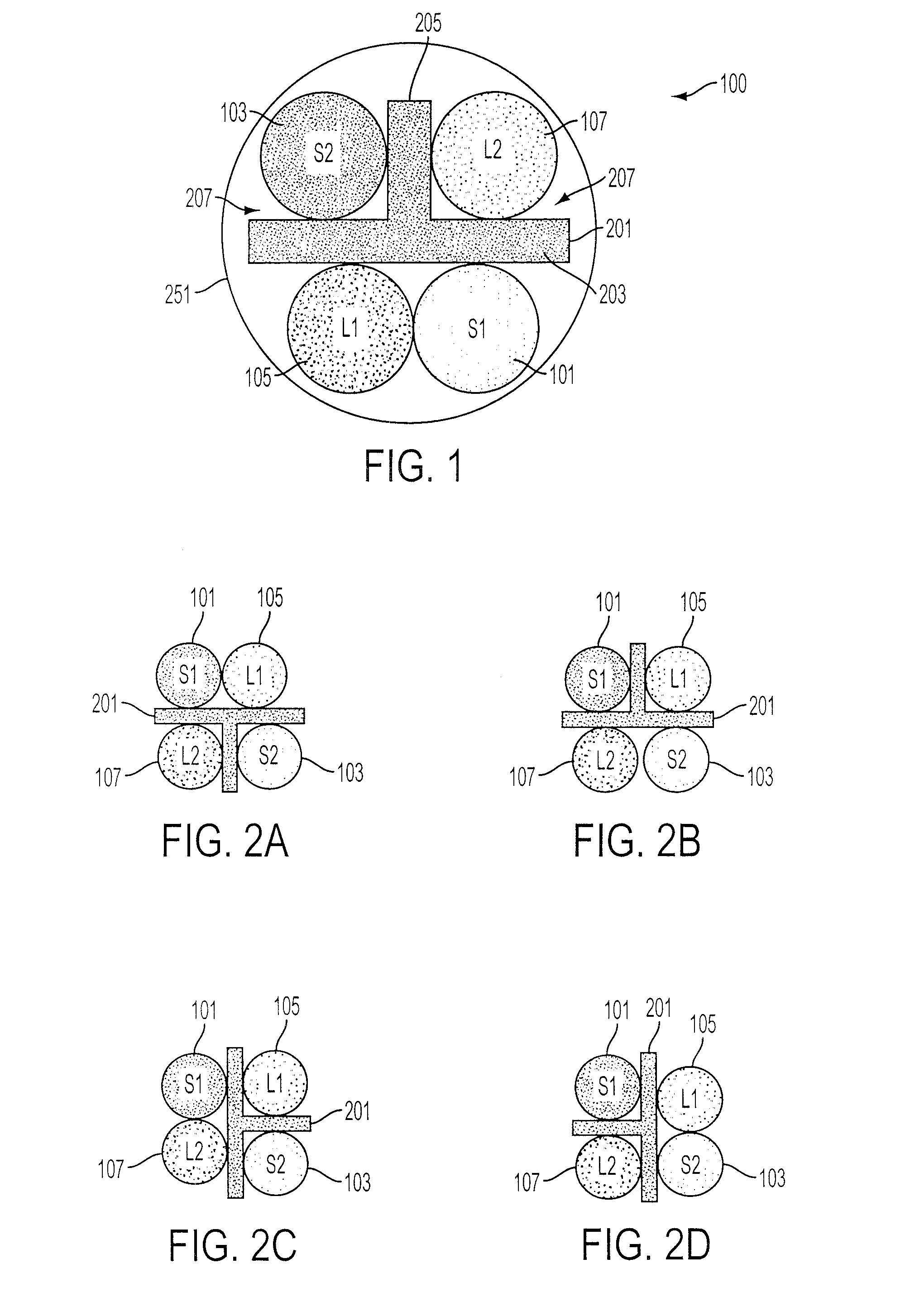

A cable, specifically a data cable, which utilizes a T-shaped spline to separate four internal data cables. This cable is a specific form of a more general cable which utilizes a central spline which is designed to separate all but one pair of component cables to provide for material savings in cable construction which still sufficiently reducing cross-talk to meet data cable design specifications.

Owner:BELDEN INC

Separator Spline and Cables Using Same

ActiveUS20090173514A1Less materialEasy constructionInsulated cablesInsulated conductorsEngineeringBuilding construction

A cable, specifically a data cable, which utilizes a T-shaped spline to separate four internal data cables. This cable is a specific form of a more general cable which utilizes a central spline which is designed to separate all but one pair of component cables to provide for material savings in cable construction which still sufficiently reducing cross-talk to meet data cable design specifications.

Owner:BELDEN INC

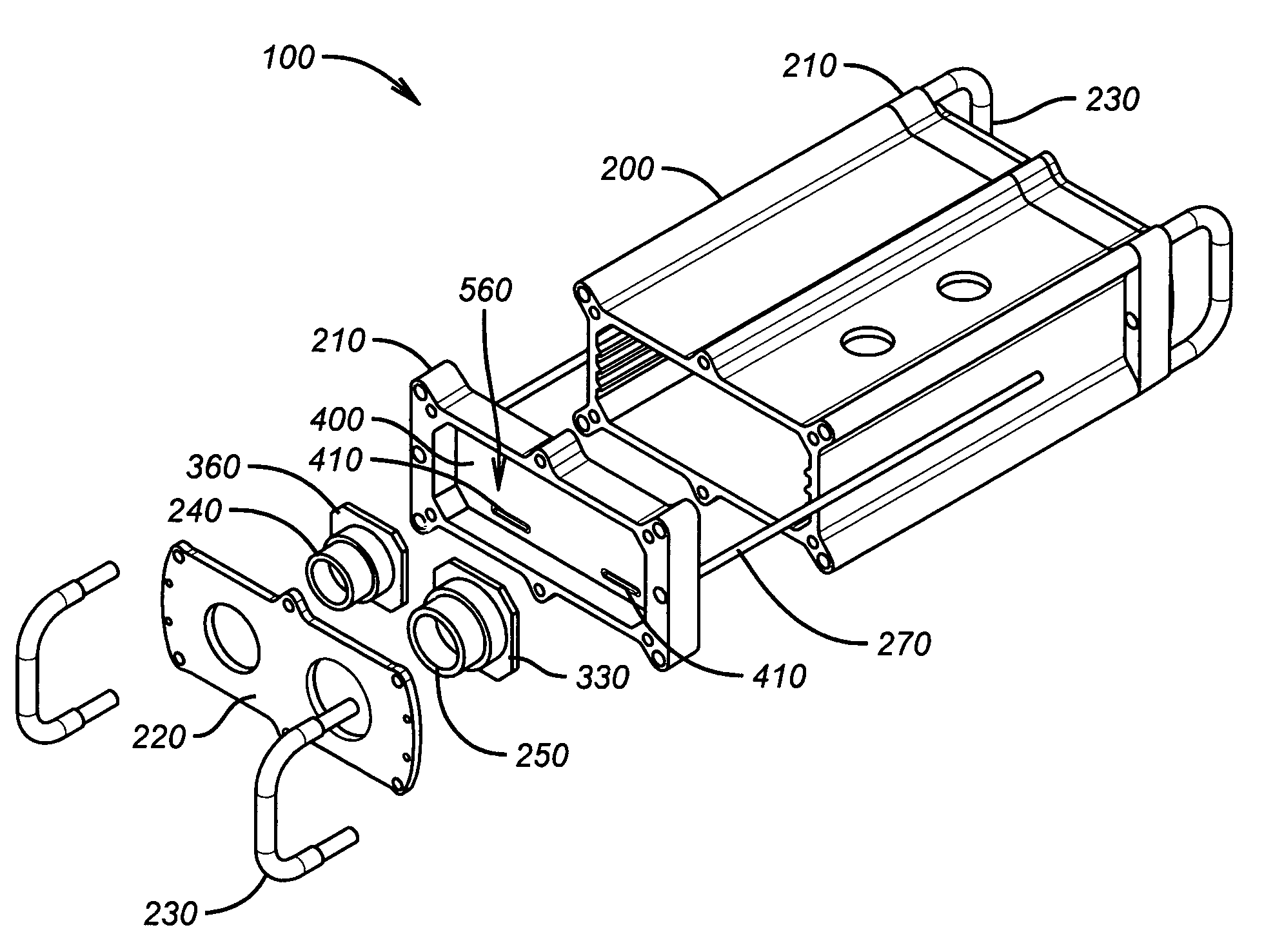

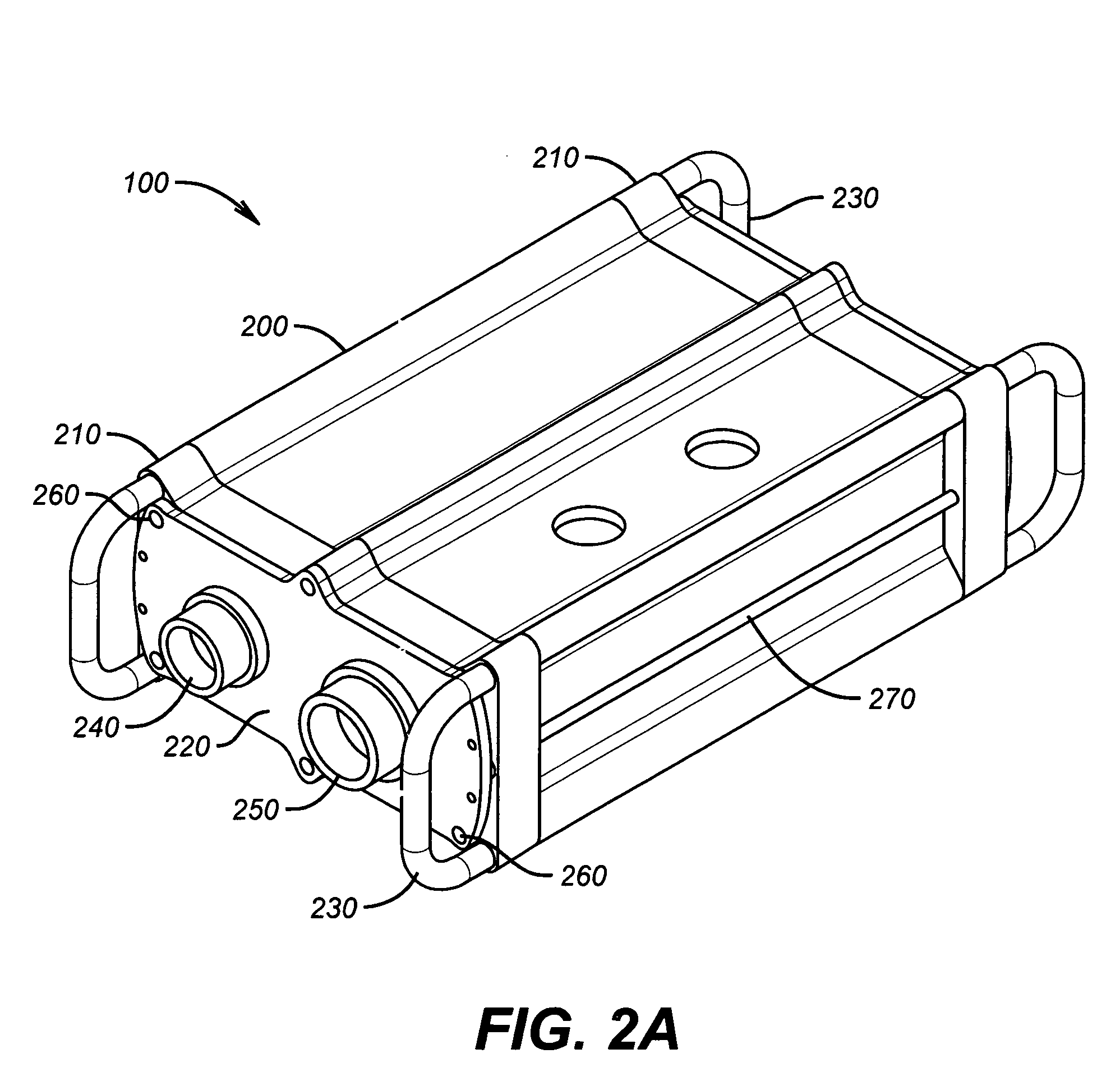

Universal seismic data acquisition module

ActiveUS7078619B2Easy to disassemblePromote exchangeSubstation/switching arrangement detailsCouplings bases/casesSignal processing circuitsComputer module

A universal seismic data acquisition module includes independent environmental isolation chambers for essential signal processing circuitry and for cable connection unions. Cable connection unions are rapidly replaced without opening the main protective chamber. Different connector types required for the many data transmission cable designs needed to service a wide range of survey conditions are more easily accommodated than in conventional single chamber designs. The module is rugged and suitable for operating in a wide range of physical environments including lake or sea immersion to substantial water depths, desert, arctic and others. Need for investment in multiple module types for varying survey conditions is thereby reduced without compromising capacity.

Owner:INOVA SYST CORP

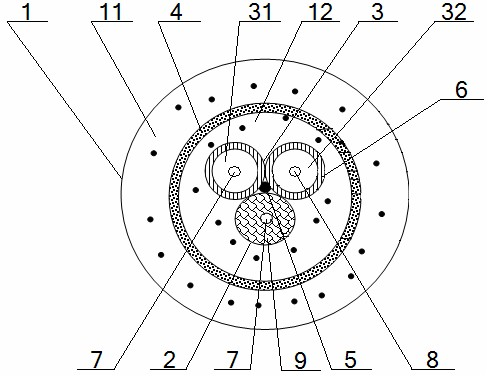

Sensing optical cable for synchronously monitoring temperature and pressure in oil well tubing in distribution mode

ActiveCN102305965AAvoid errorsEasy to collectMeasurement devicesFibre mechanical structuresFiberMaterials science

The invention provides a sensing optical cable for synchronously monitoring the temperature and pressure in oil well tubing in a distribution mode, which comprises a high-strength heat-resistant corrosion-resistant material layer which is divided into an outer protective buffer layer and an inner protective buffer layer by a metal steel strip, wherein a first heat-resistant armored loose tube optical fiber, a second heat-resistant armored loose tube optical fiber and a heat-resistant corrosion-resistant tight tube optical fiber are distributed in the Chinese character of 'Pin' in the inner protective buffer layer; metal strengthened cores are respectively arranged in the middle parts of the first heat-resistant armored loose tube optical fiber, the second heat-resistant armored loose tubeoptical fiber and the heat-resistant corrosion-resistant tight tube optical fiber; and a heat-resistant singlemode optical fiber is arranged in the first heat-resistant armored loose tube optical fiber, a heat-resistant multimode optical fiber is arranged in the second heat-resistant armored loose tube optical fiber, and a heat-resistant singlemode optical fiber is arranged in the heat-resistant corrosion-resistant tight tube optical fiber. The sensing optical cable designed by the invention has the advantages of higher accuracy of finally-obtained pressure value, higher heat resistance and corrosion resistance, high mechanical strength, high safety and unified lattice performance and is convenient to manufacture and construct.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

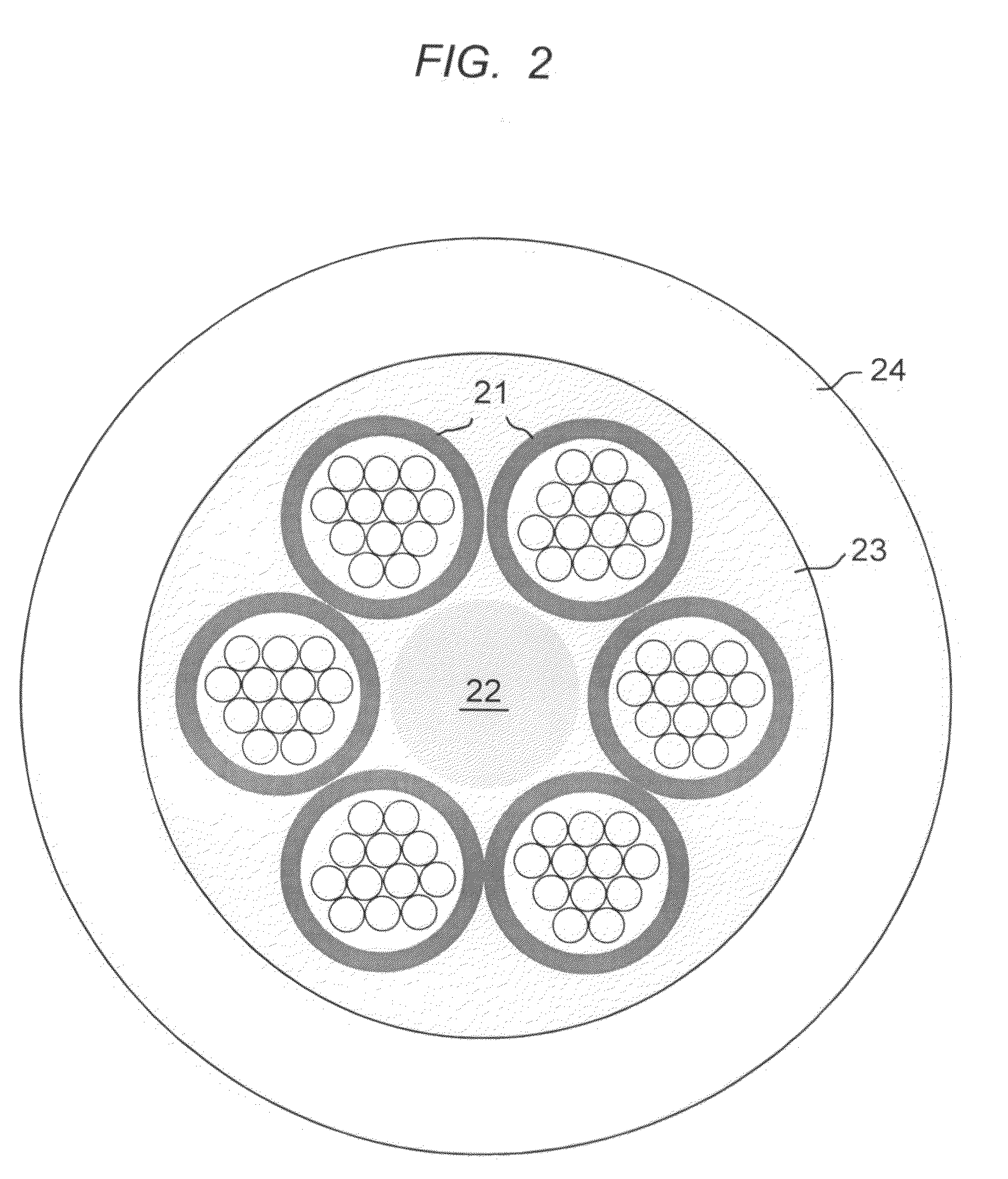

Aerial optical fiber cables

ActiveUS20150049996A1Increase fiber countEasy to operateFibre mechanical structuresFiberThinning skin

Described are cable designs adapted for aerial installations wherein the cable comprises a bundle of multifiber tight buffer encasement units, with a conformal thin skin containment layer surrounding the bundle. The multifiber tight buffer encasement units have an acrylate compliant inner layer that protects the fiber and minimizes stress transfer to the fiber; and a hard, tough acrylate outer layer that provides crush resistance. The thin skin containment layer provides cable integrity with a minimum of added size and weight. The thin skin containment layer encasement is encased in an outer protective jacket.

Owner:OFS FITEL LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com