Sensing optical cable for synchronously monitoring temperature and pressure in oil well tubing in distribution mode

A distributed monitoring and sensing optical cable technology, which is applied in the real-time monitoring of pressure and temperature in the oil pipe, can solve the problems of low pressure value accuracy, high temperature resistance, corrosion resistance and poor mechanical strength, etc., to achieve convenient collection and strong The effect of compatibility and structural symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

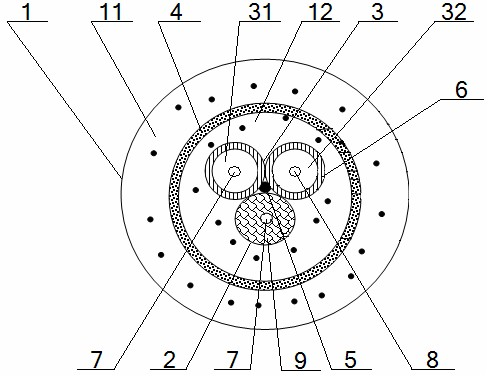

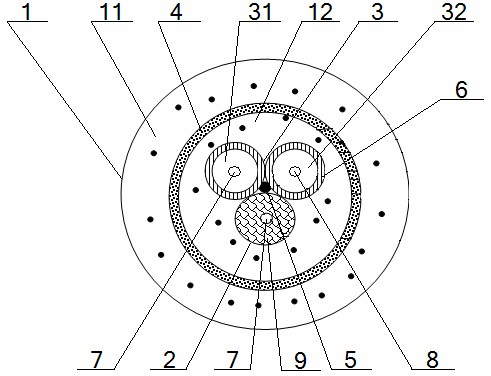

[0041] Sensing optical cable for simultaneous distributed monitoring of temperature and pressure in oil well tubing, including a circular cross-section high-strength high-temperature-resistant and corrosion-resistant material layer 1 and ring-shaped metal steel strips 4 and metal steel strips 4 set inside The high-strength, high-temperature-resistant and corrosion-resistant material layer 1 is divided into an outer protective buffer layer 11 and an inner protective buffer layer 12. The interior of the inner protective buffer layer 12 is arranged in the shape of a character. There are No. 1 high-temperature-resistant armored loose-tube optical fiber 31, and No. 2 resistant High-temperature armored loose-buffered optical fiber 32 and high-temperature-resistant and corrosion-resistant tight-buffered optical fiber 2, and among the first high-temperature-resistant armored loose-buffered optical fiber 31, the second high-temperature-resistant armored loose-buffered optical fiber 32, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com