Patents

Literature

11731results about How to "Improve buffering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

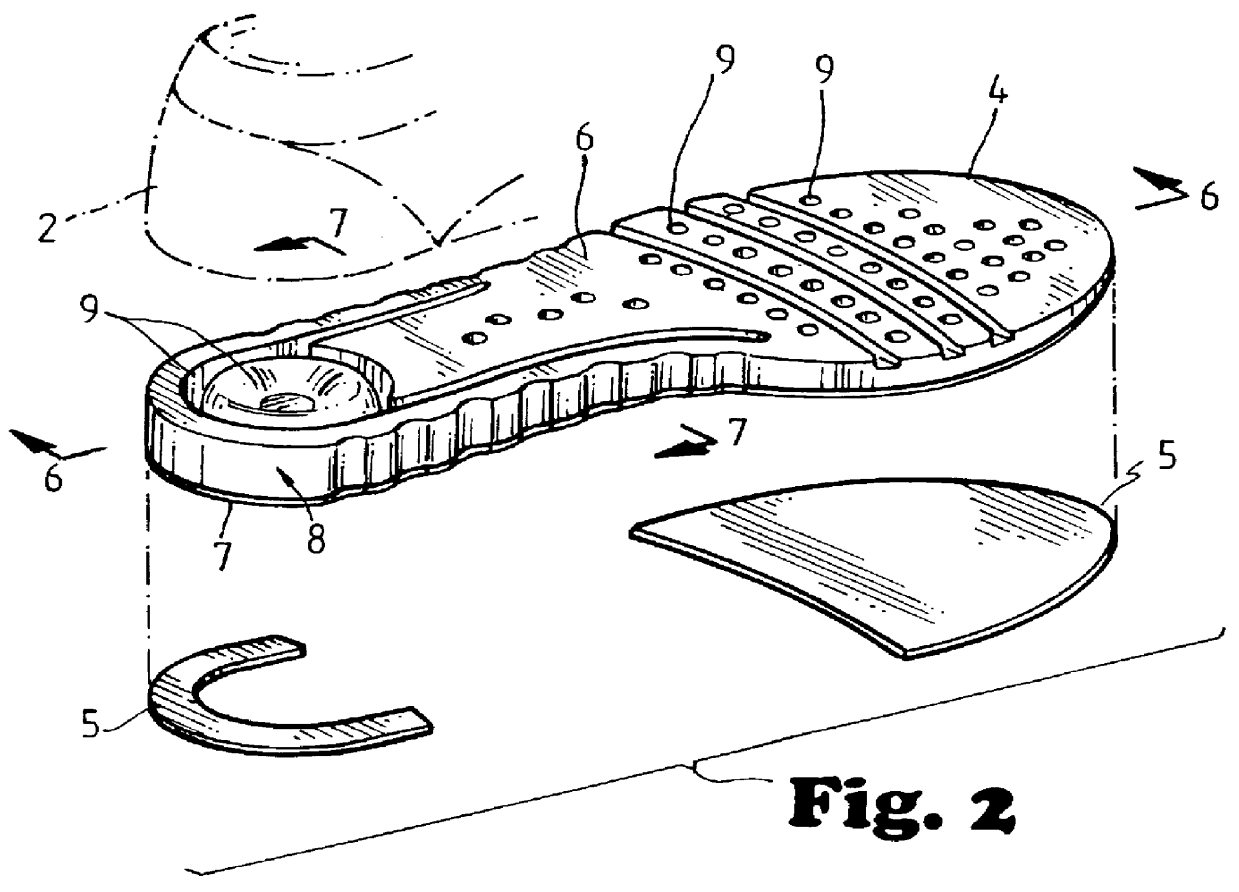

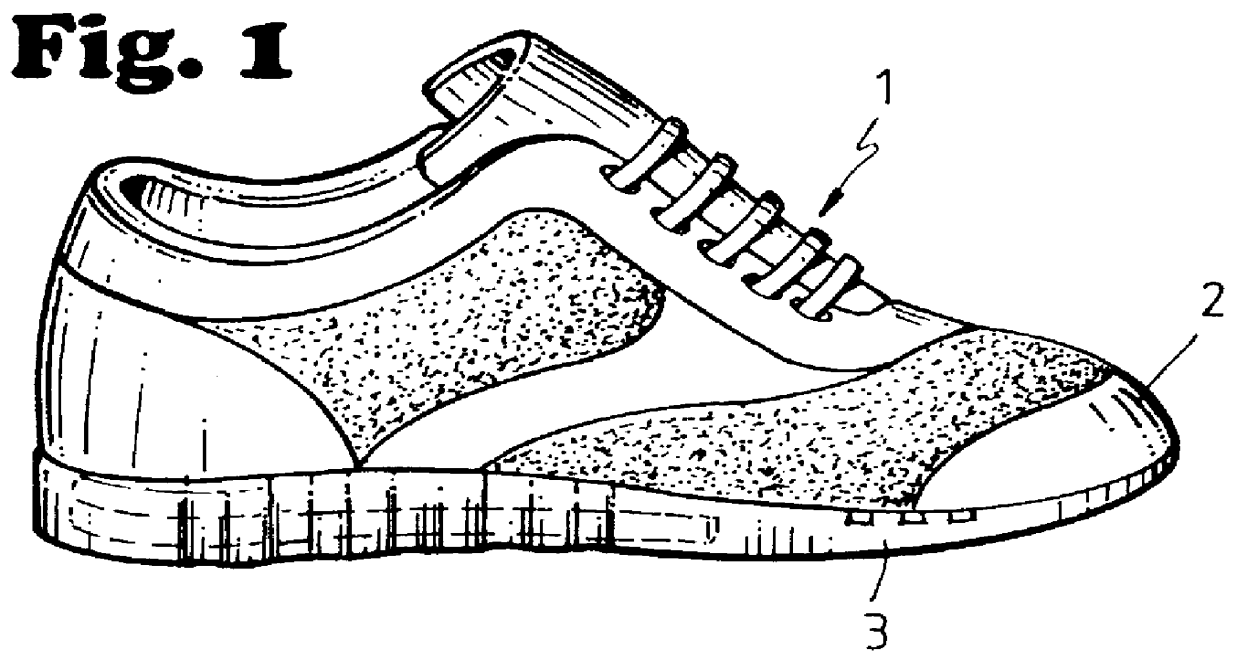

Shoe sole component and shoe sole component construction method

A high polymer resin material is configured into a shoe sole component having a plurality of inwardly extending indentations in one or both of the top and bottom members of the component. The indentations extend into the interval between the members and adjacent to the opposite member to provide support members for the sole component. The sole component can be constructed by molding upper and lower sole component halves wherein the molds are configured to provide indentations in the top and bottom members. The upper and lower sole component halves are then joined to complete the sole component.

Owner:LIESENFELD MARY C +1

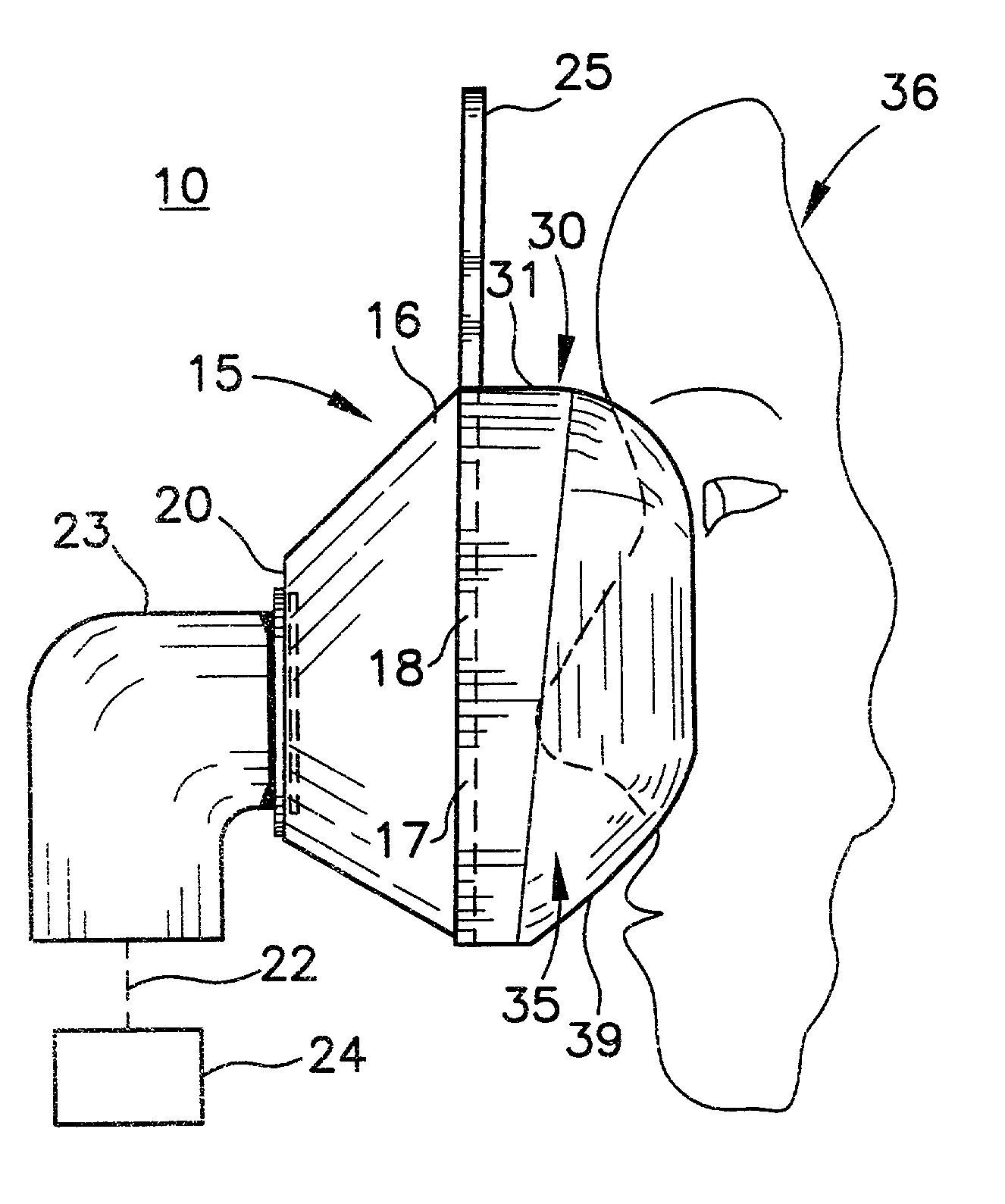

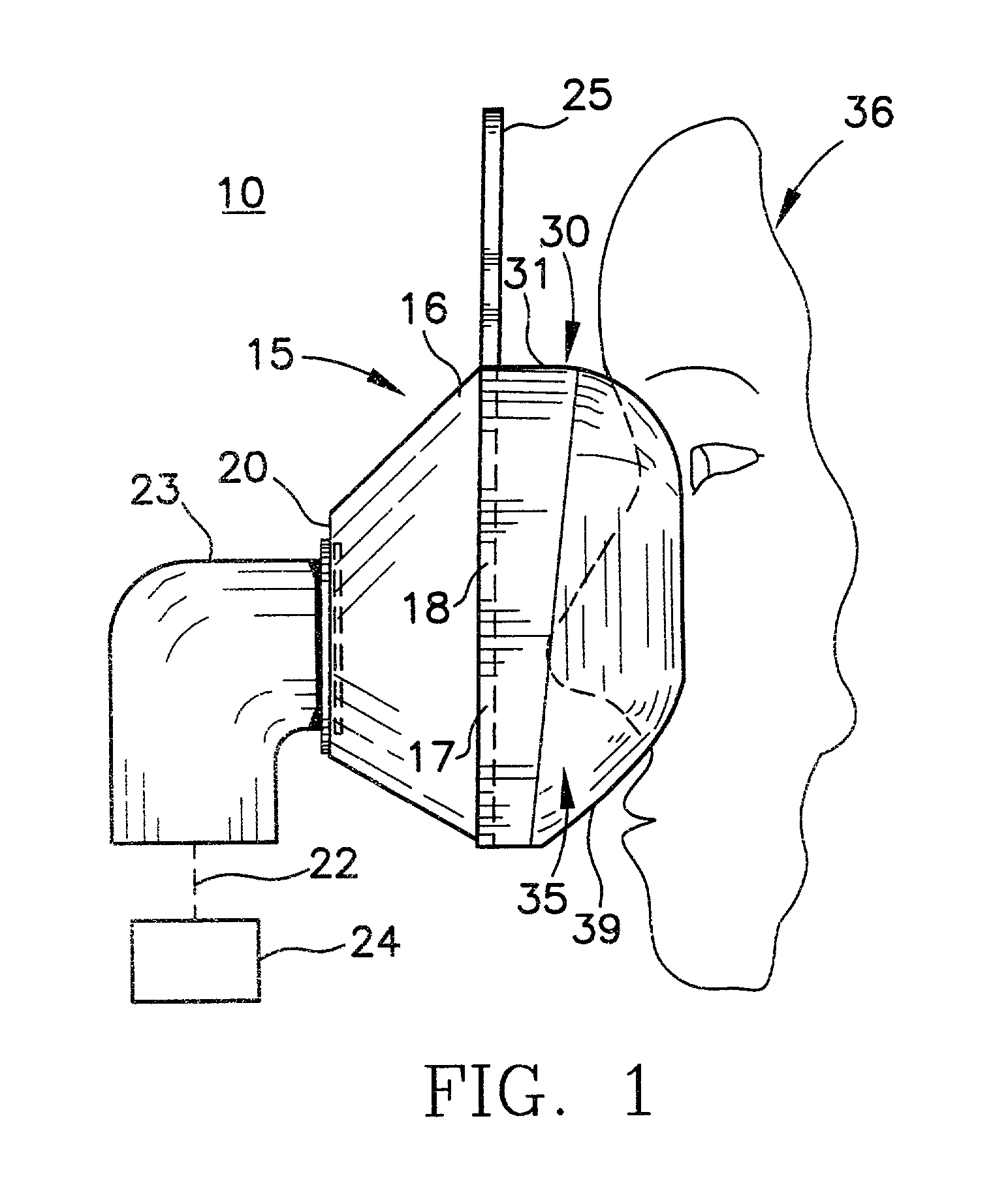

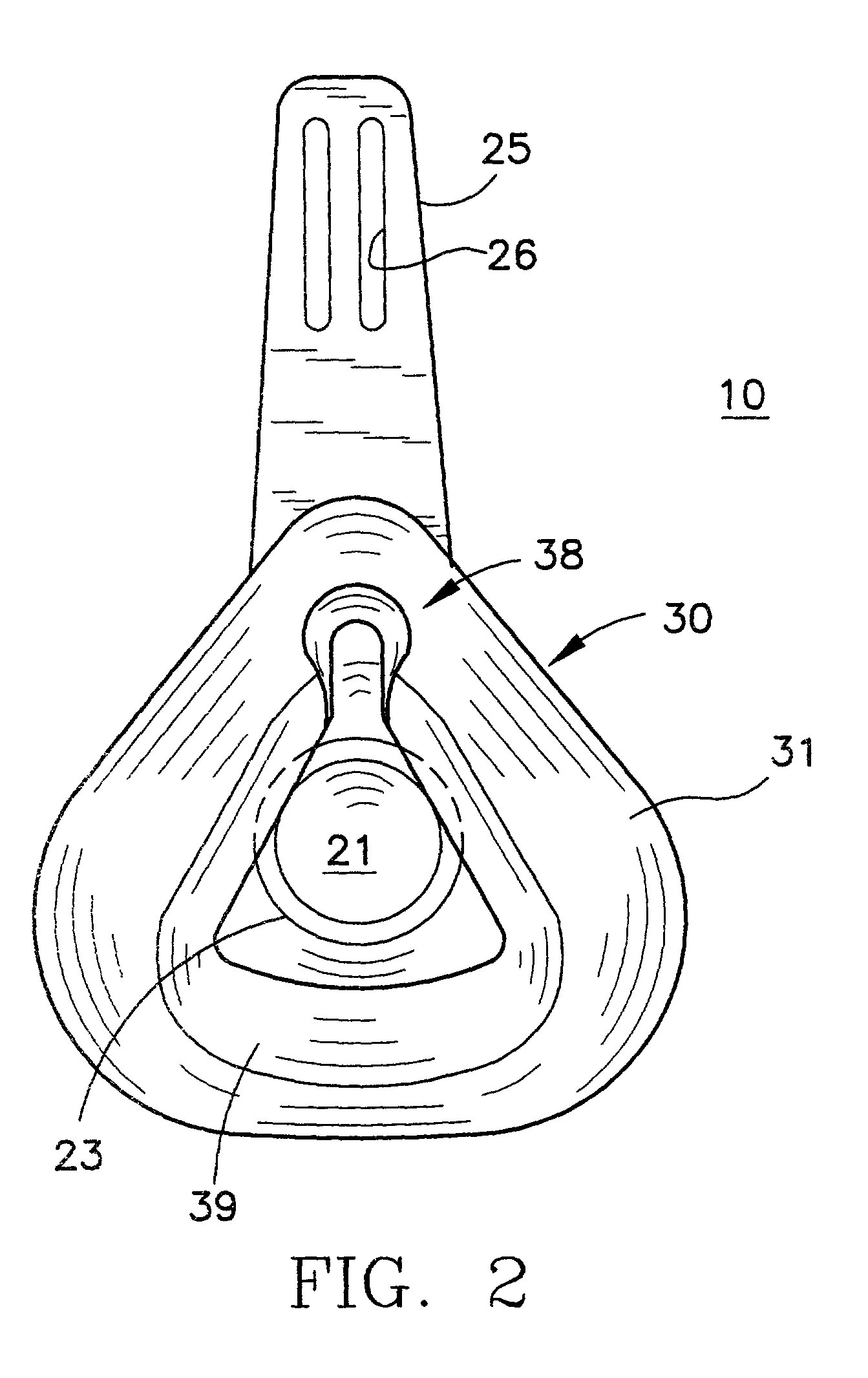

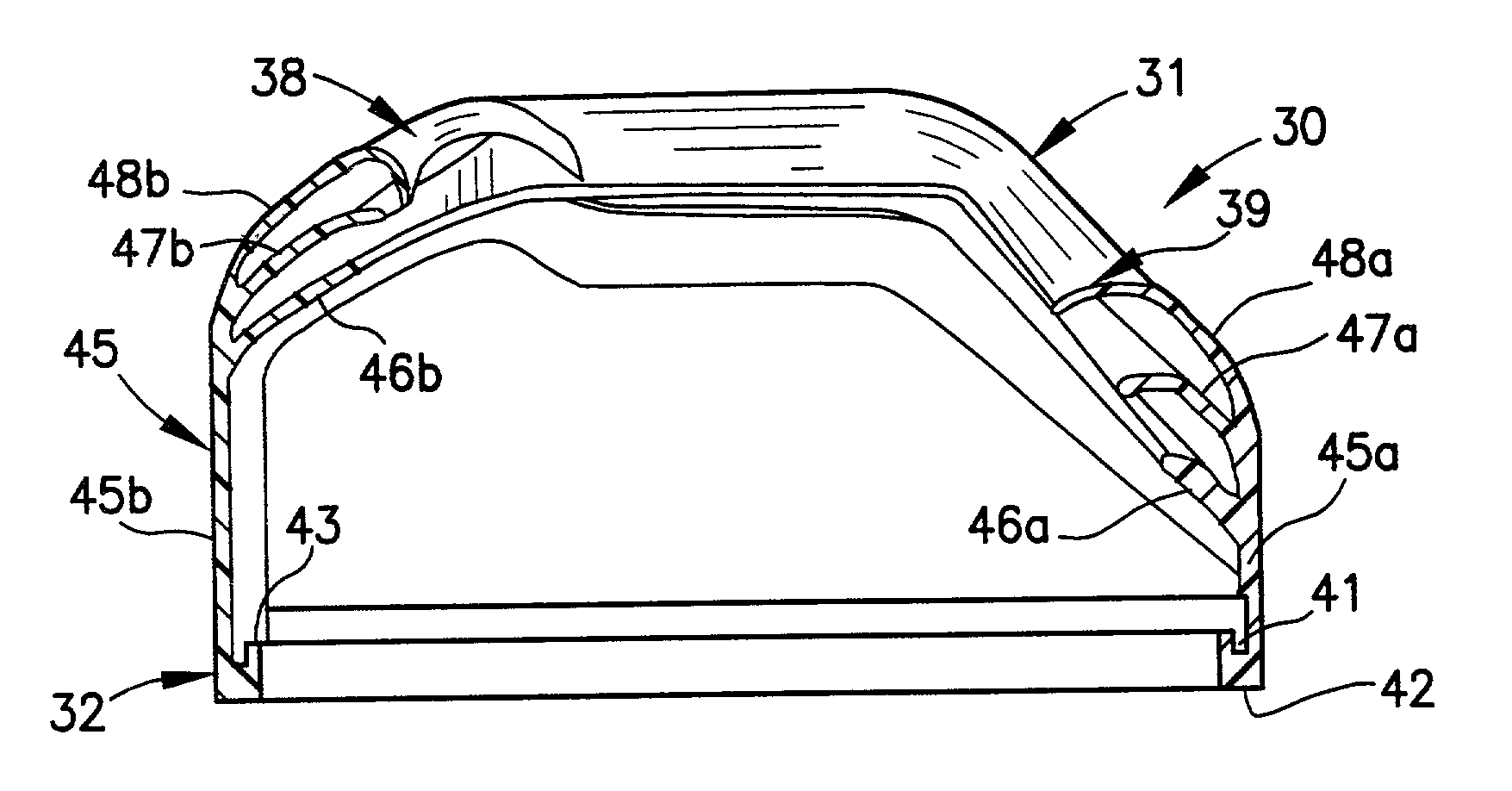

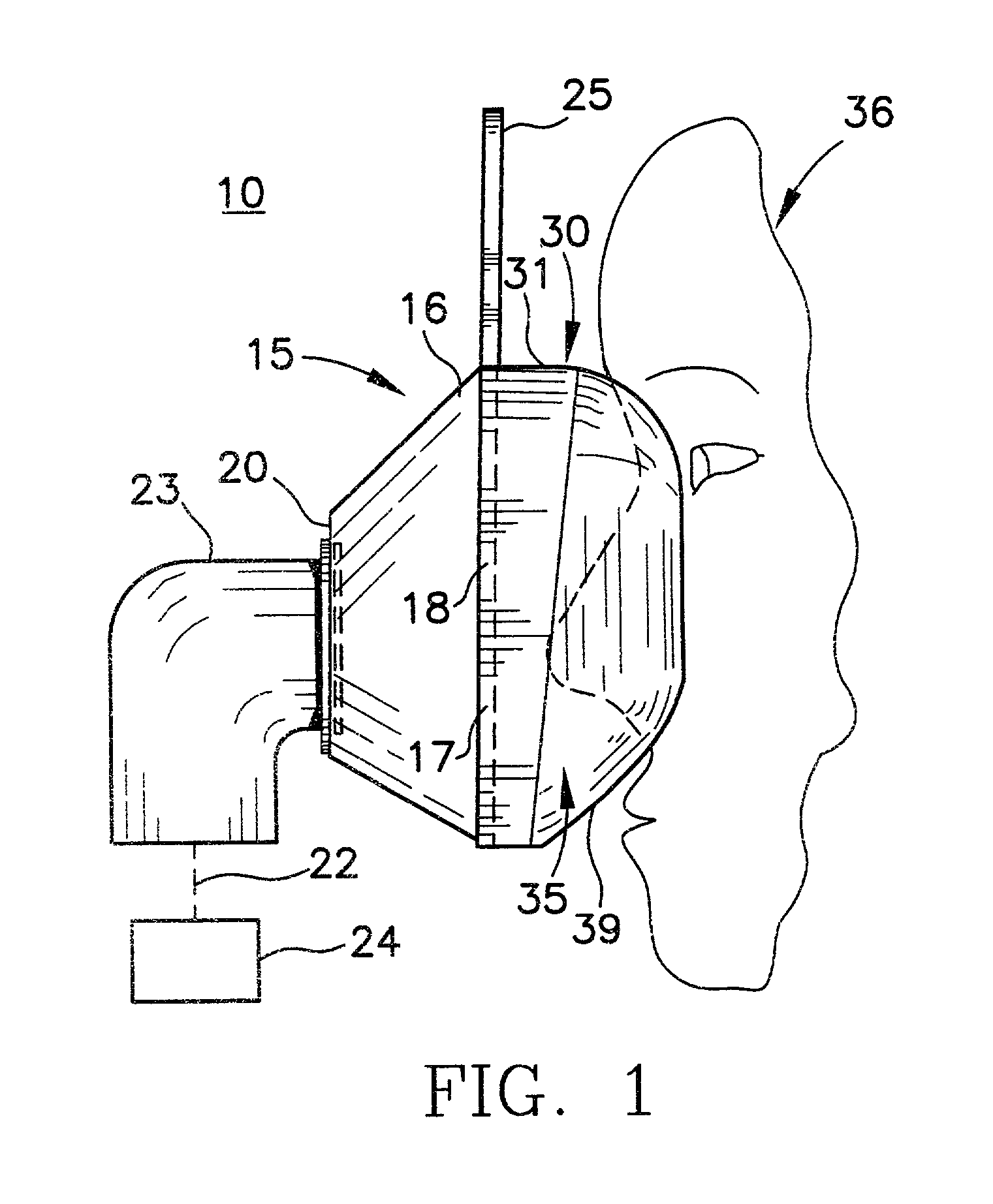

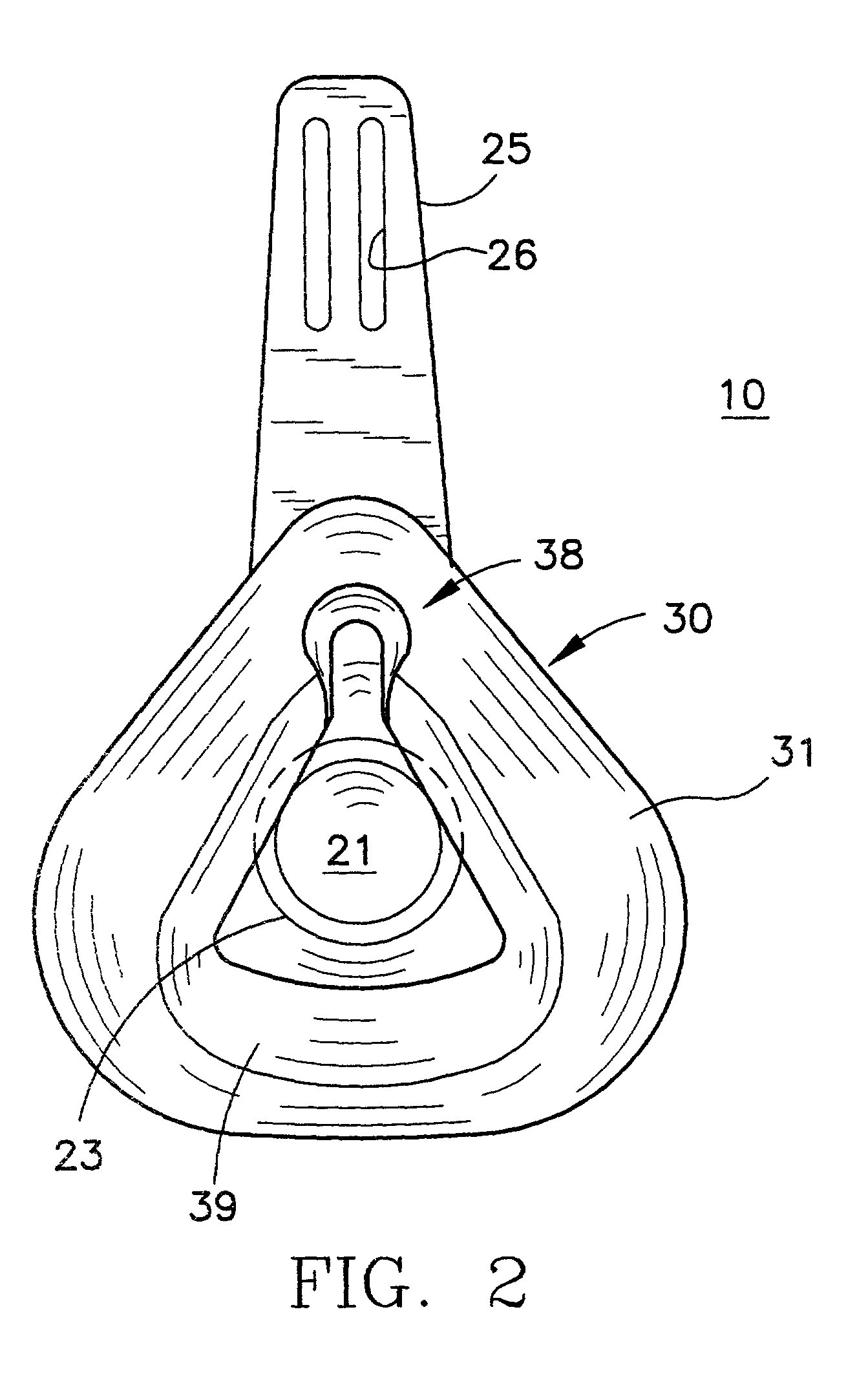

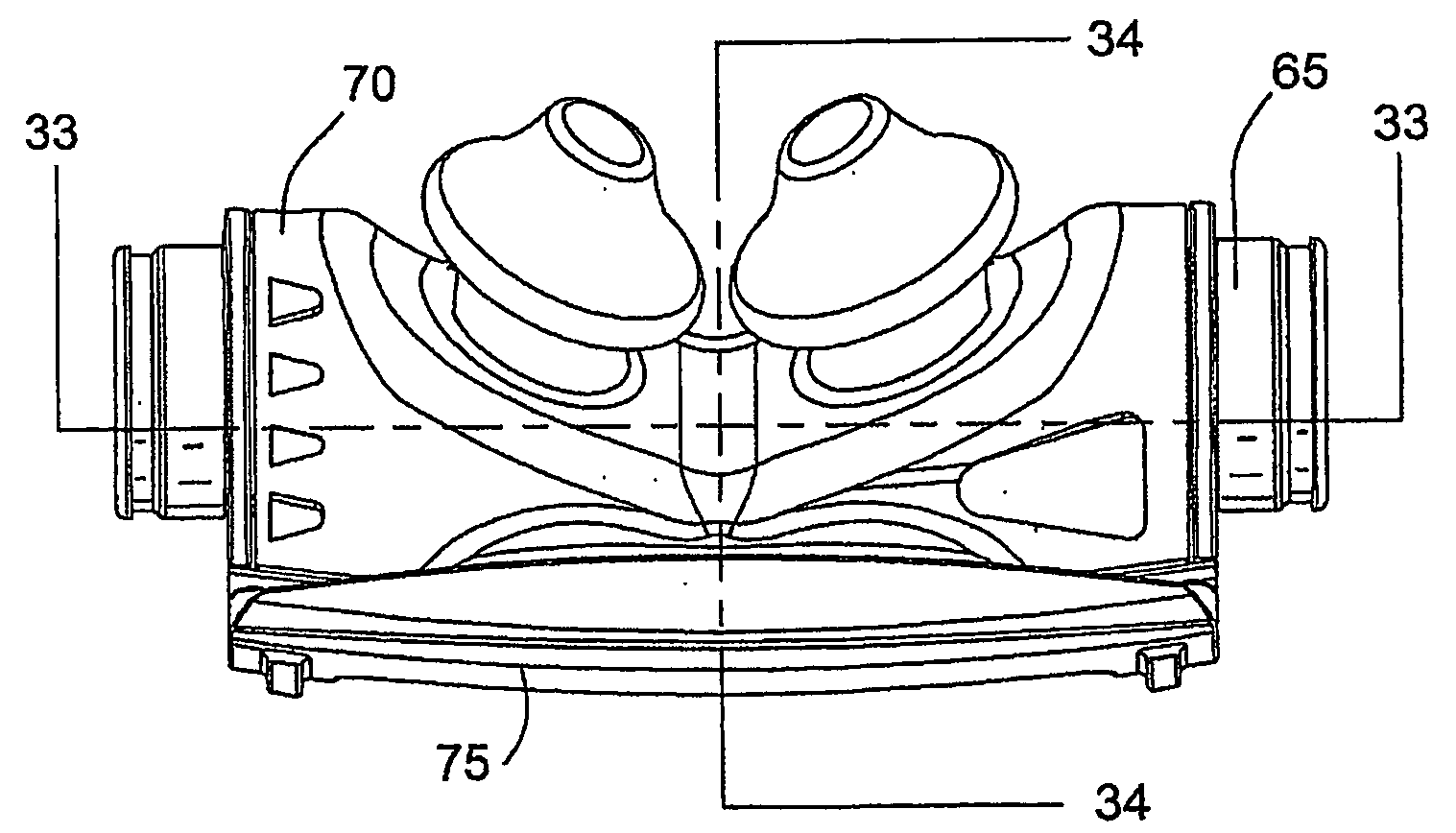

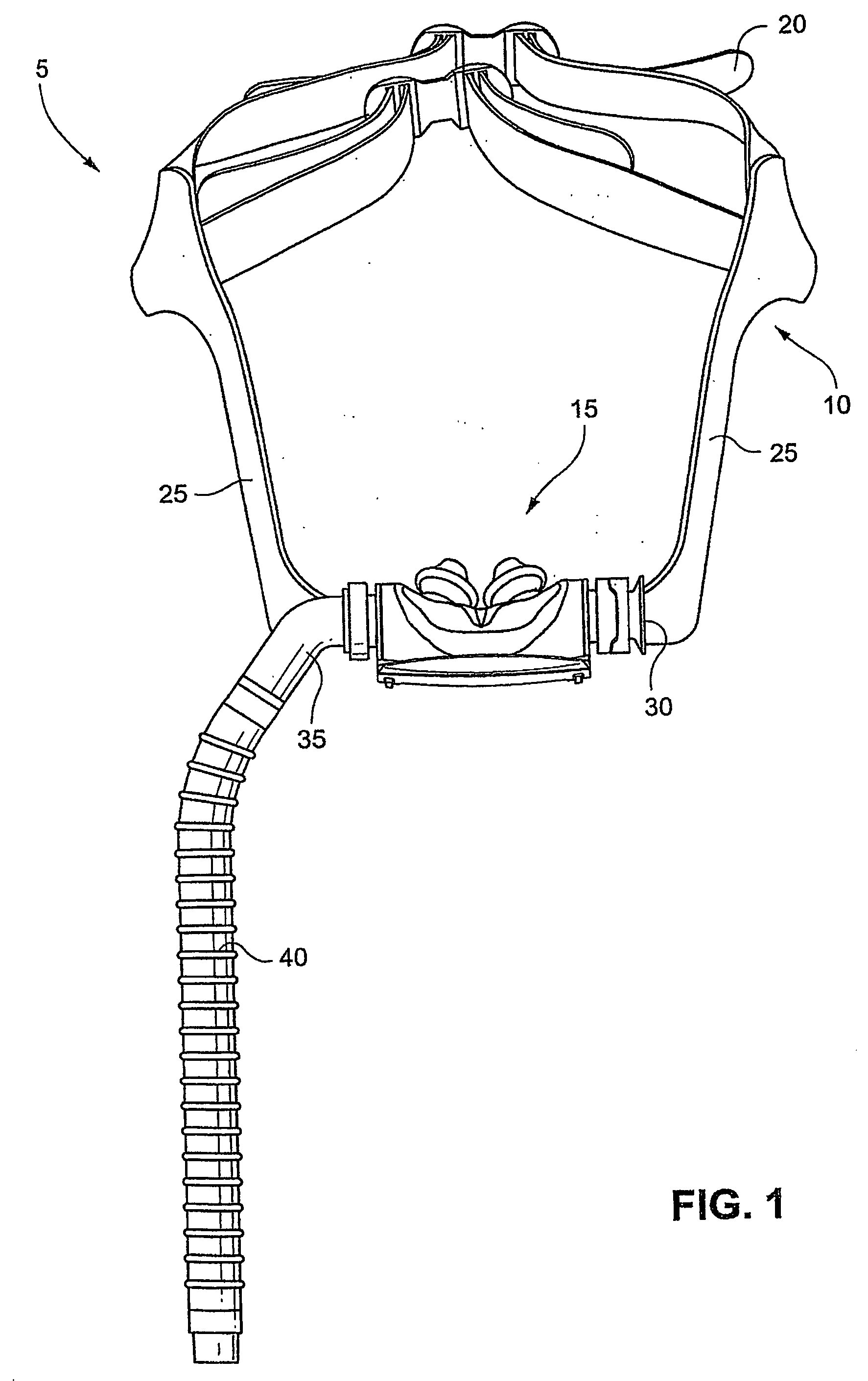

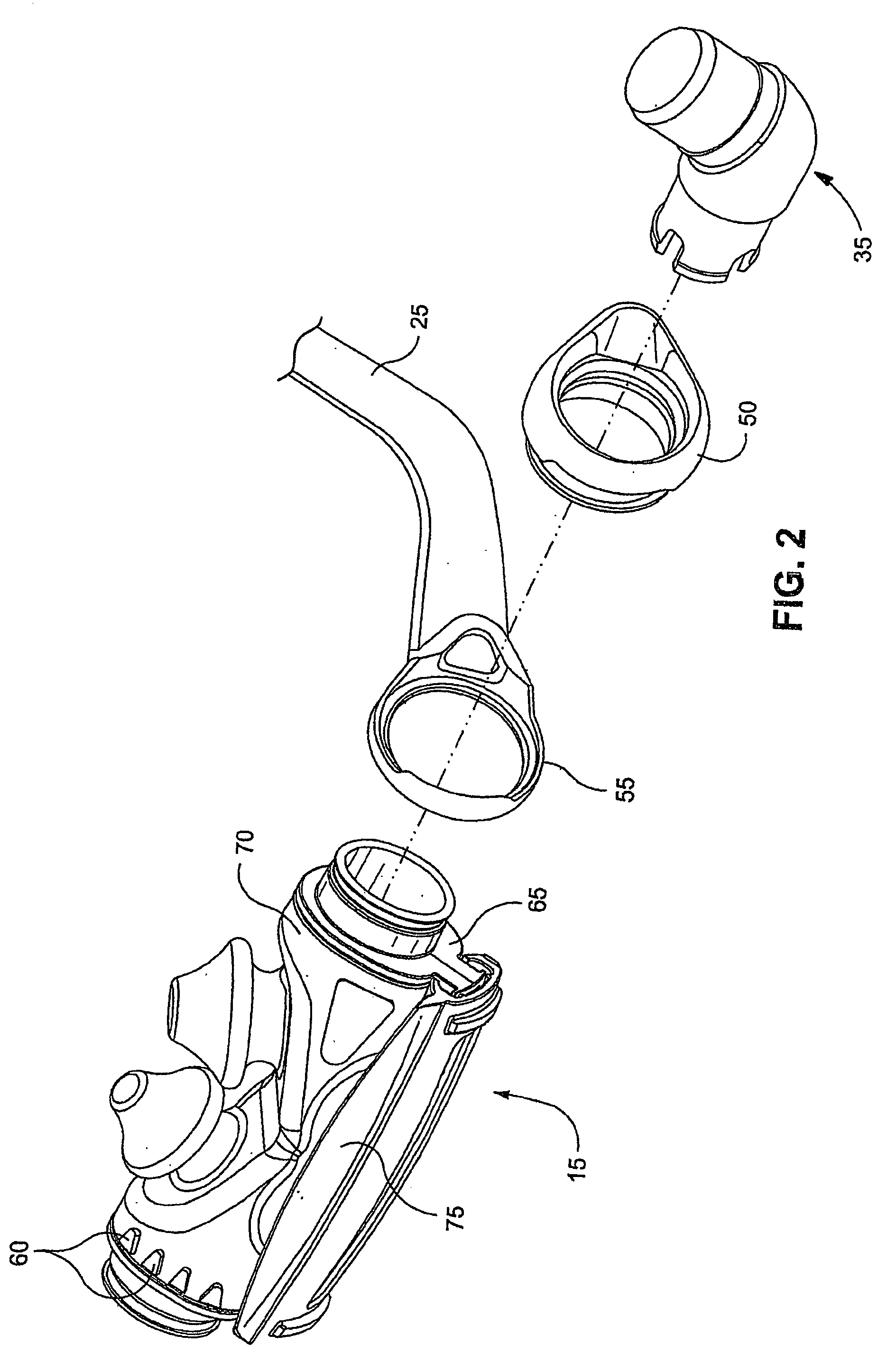

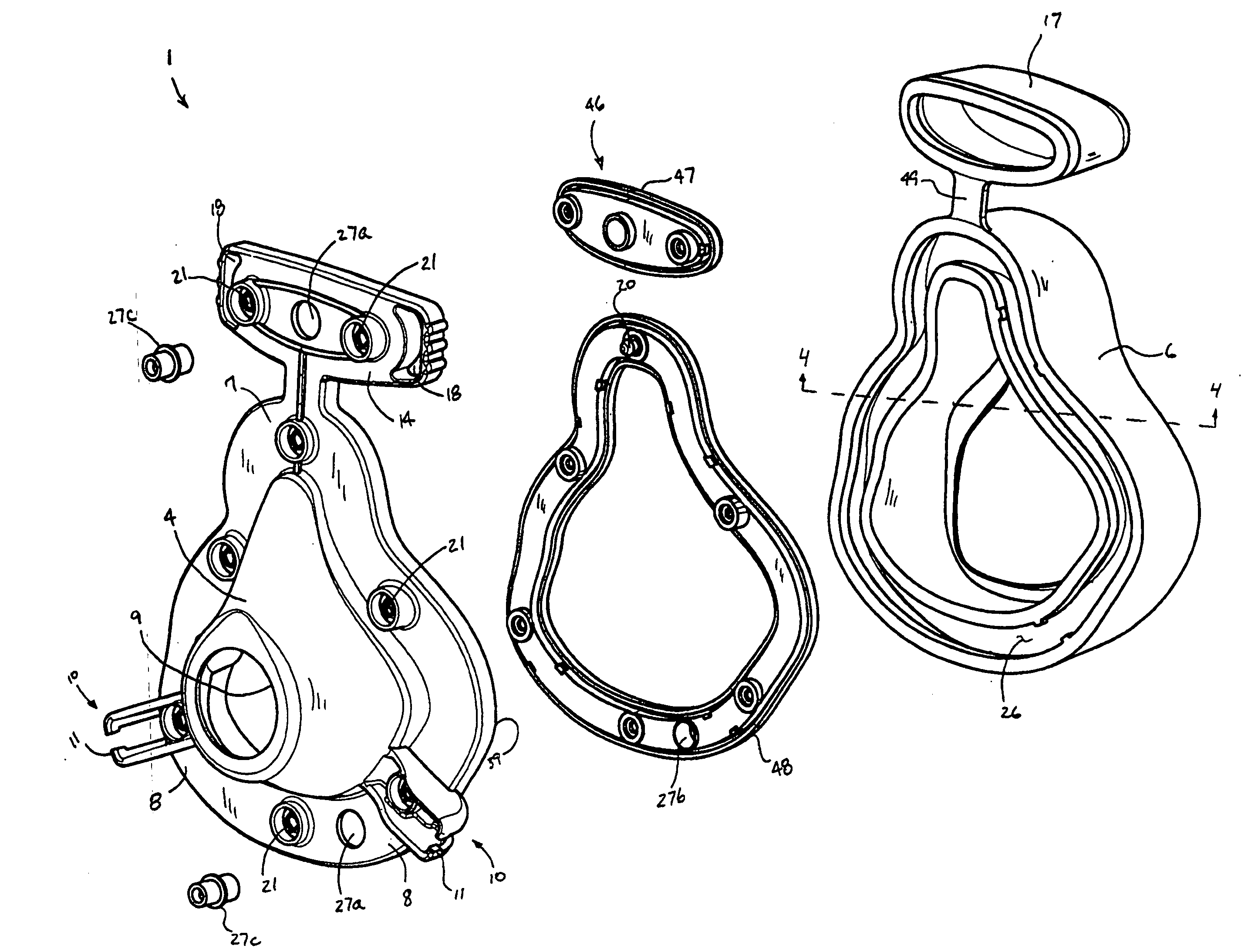

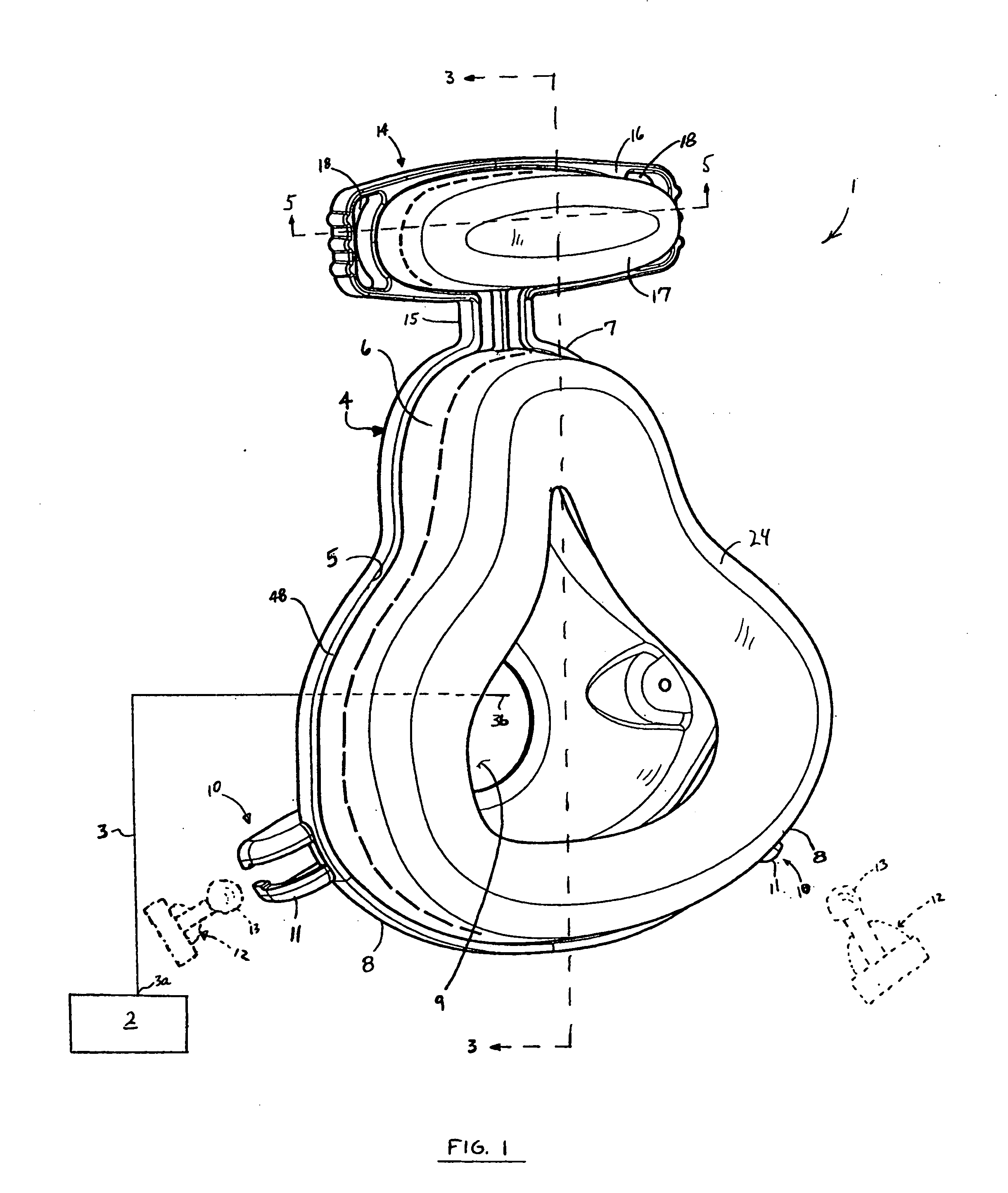

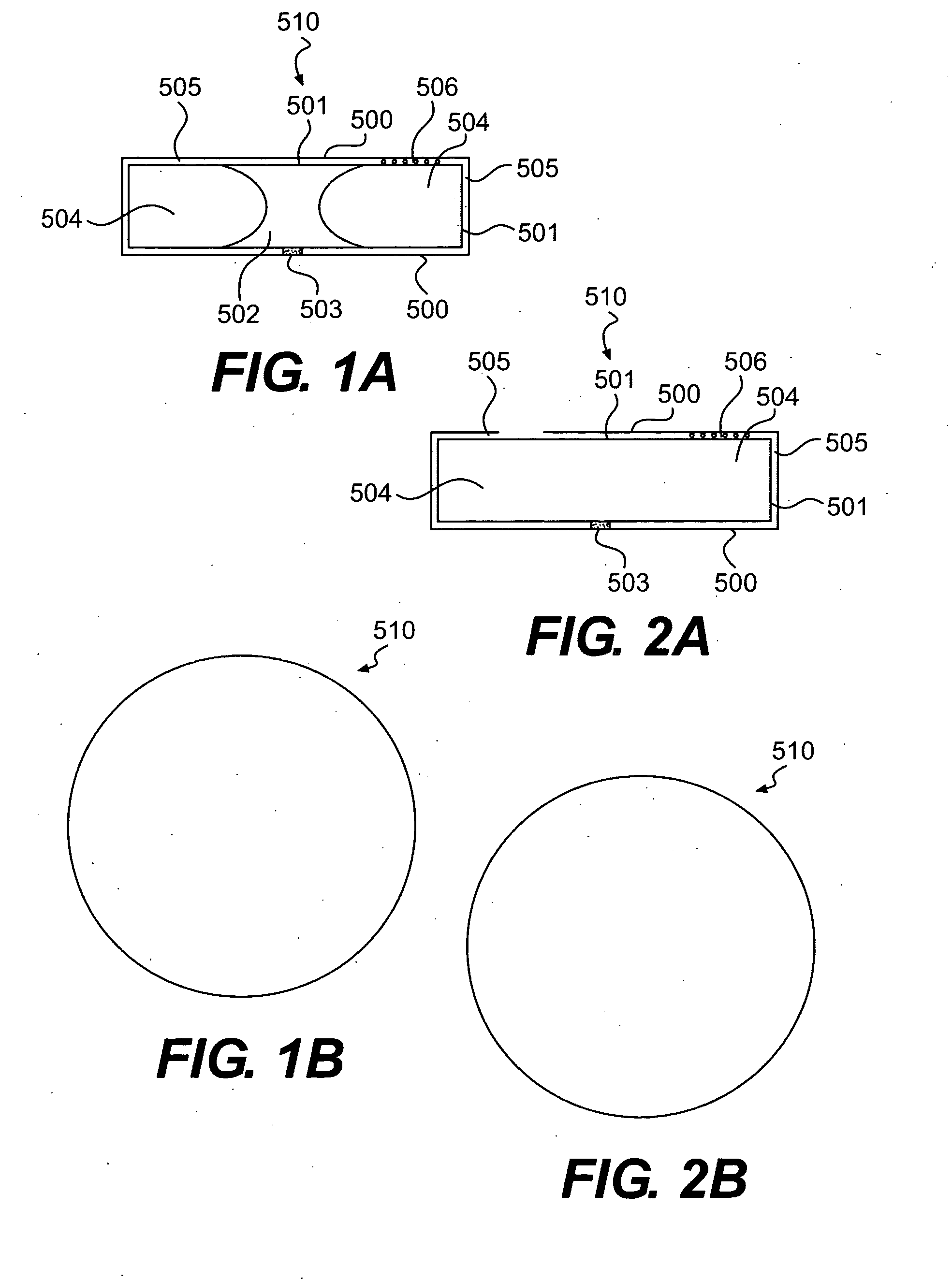

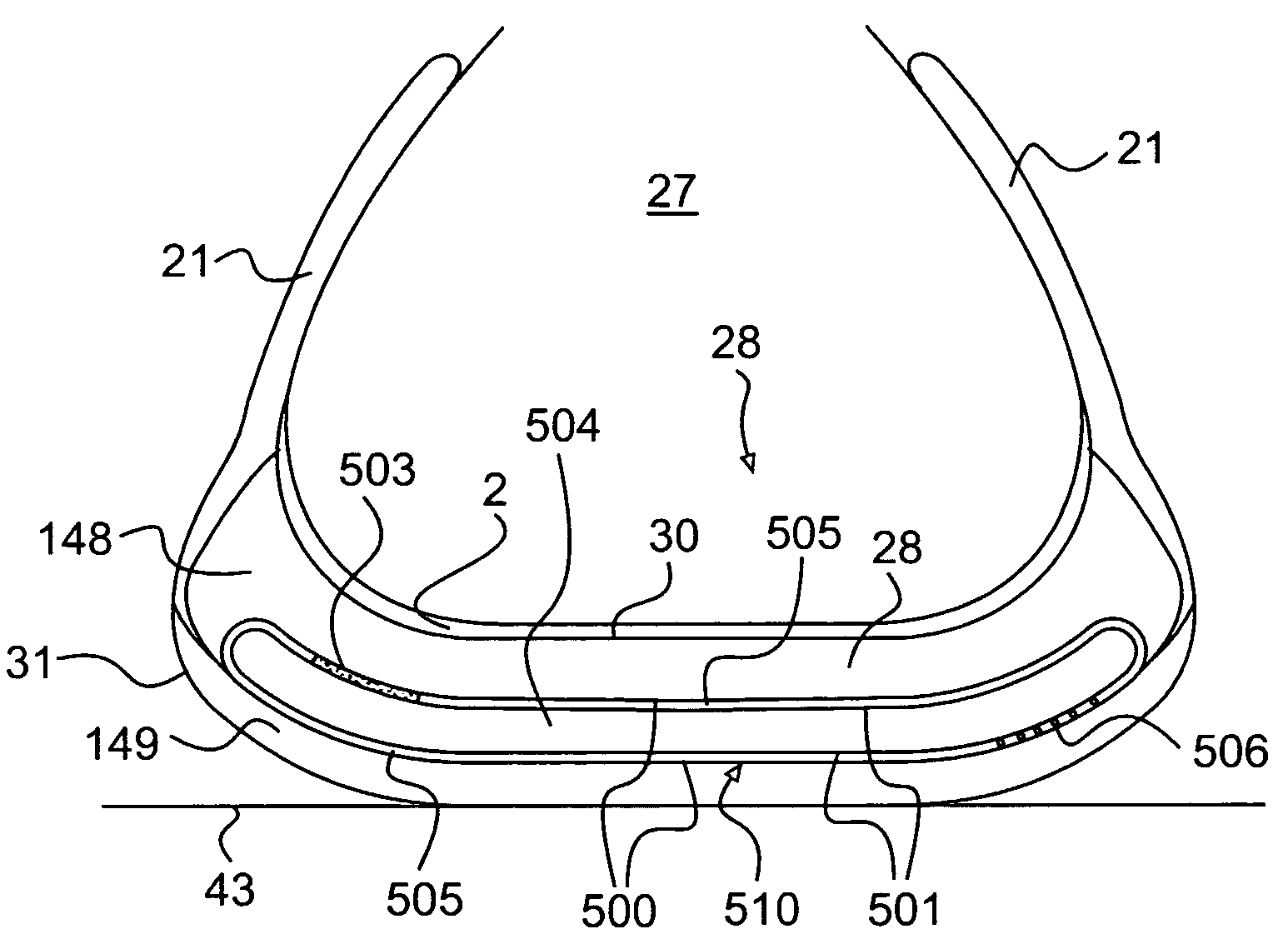

Mask cushion and method of using same

ActiveUS20030019495A1Minimizing head strap tensionImprove sealing propertiesBreathing masksRespiratory masksNasal bridgeNasal cpap

A nasal CPAP treatment apparatus is disclosed with a flow generator coupled to a nasal mask. The mask has a nasal cushion forming a nose-receiving cavity. The cushion has a triangularly-shaped frame of resilient material with a mask engaging portion connected by a side wall to a face engaging portion which has a nasal bridge region, a cheek region and a lip region. The cushion may have a portion of the side wall in the nasal bridge region being other than straight to provide an improved sealing in the nasal bridge region. A plurality of membranes, preferably three, of resilient material extend substantially around the triangularly-shaped frame. Some of the membranes are thicker in the lip region than in the nasal bridge region to improve fit of the cushion in use.

Owner:VYAIRE MEDICAL CAPITAL LLC

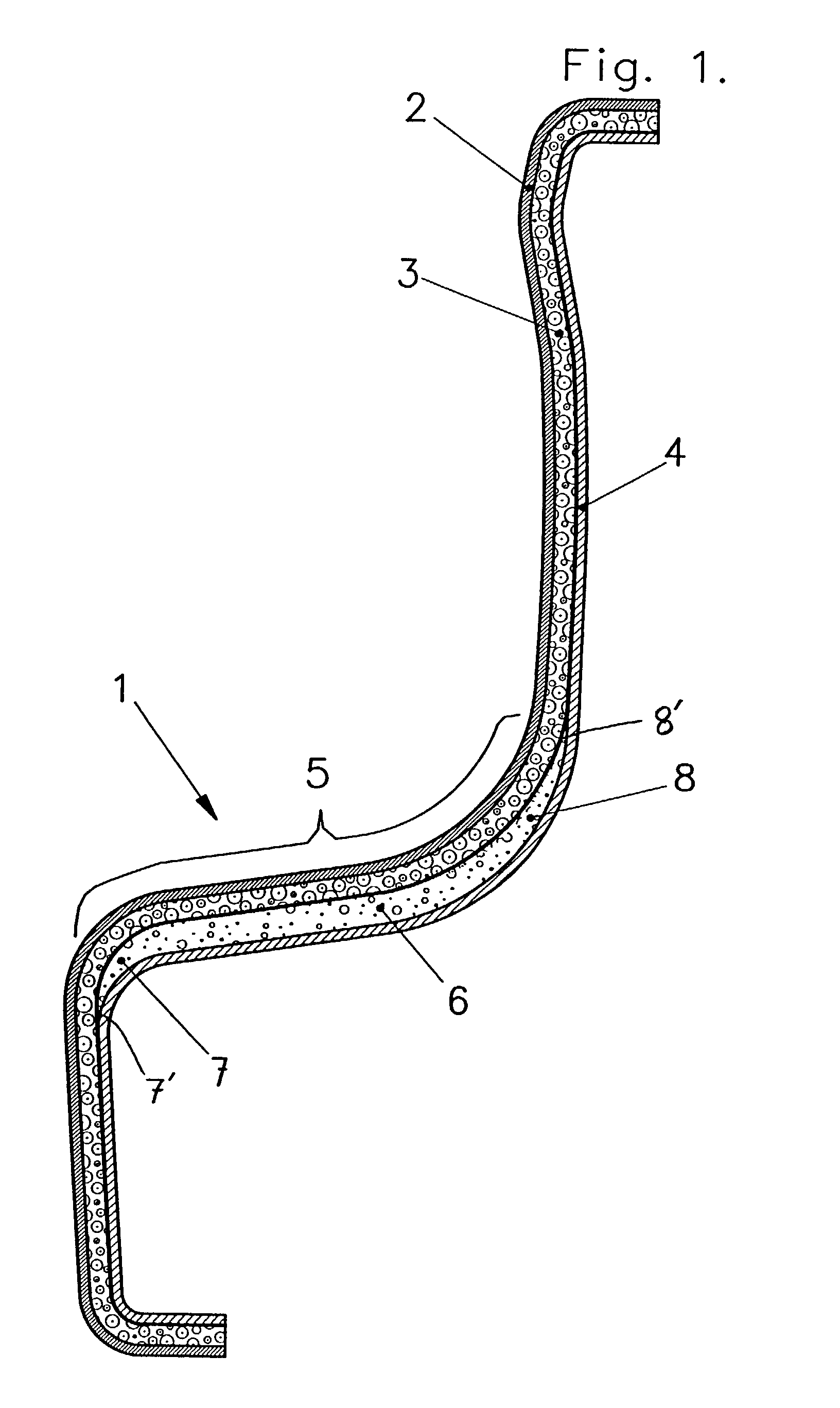

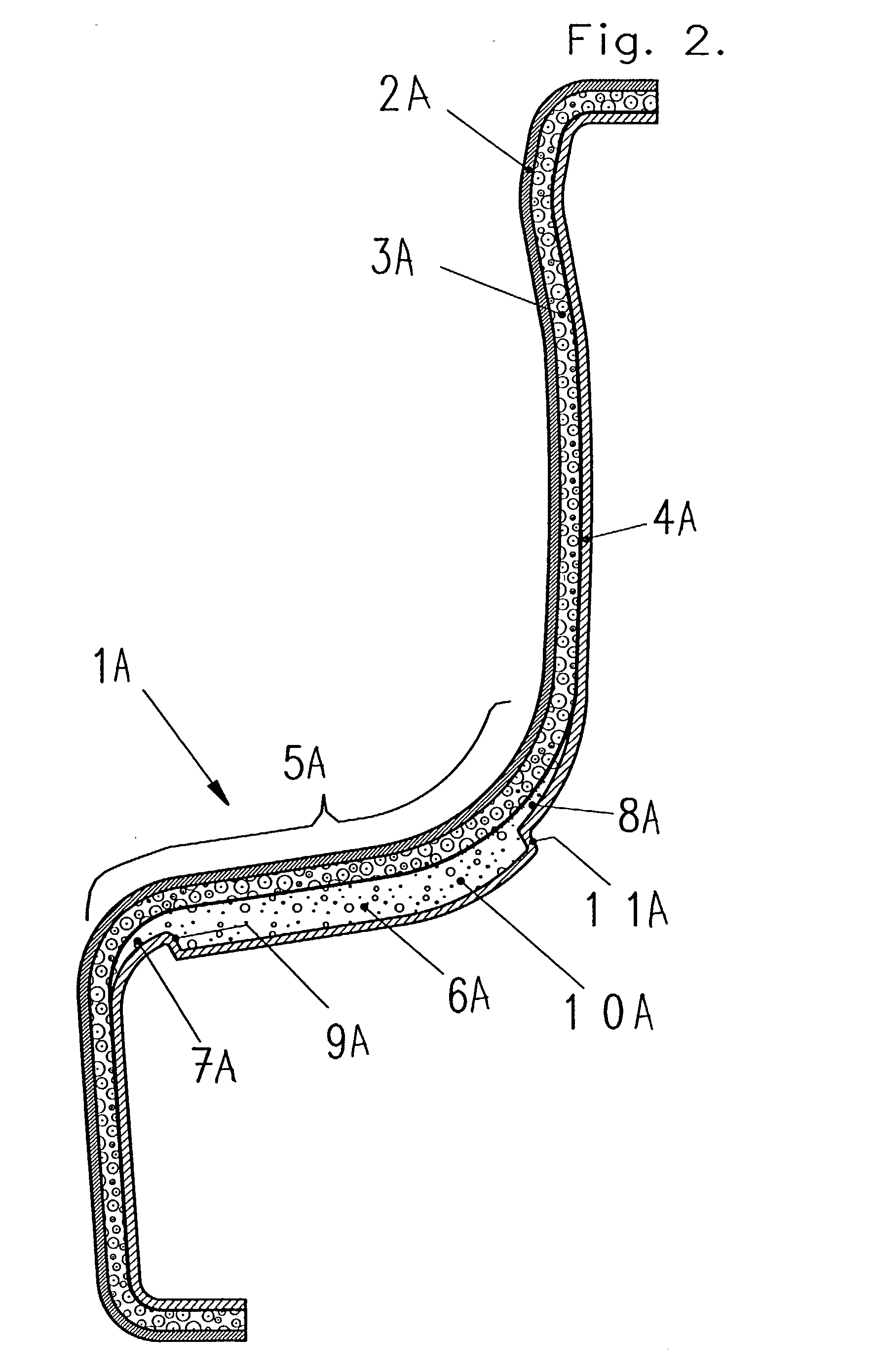

Mask cushion and method of using same

ActiveUS7007696B2Improve buffering effectImprove sealingRespiratory masksBreathing masksNasal bridgeNasal cpap

Owner:VYAIRE MEDICAL CAPITAL LLC

Nasal Assembly

InactiveUS20090151729A1Reduce noiseImproved componentRespiratory masksBreathing masksNasal cavityBreathing gas

A nasal assembly for delivering breathable gas to a patient includes a frame having lateral connector, a cushion with a pair of nozzles, and a clip to secure the cushion to the frame. The frame includes a vent channel and a plurality of vent holes. The frame / cushion includes structure (lugs / cut outs) to prevent the assembly of an unvented frame with an unvented cushion, for safety purposes. The frame includes cored portions that interface with corner lugs provided on the cushion. A patient interface includes a frame, a cushion (nasal mask, nasal-oro mask, nozzles, etc.) and a vent assembly including a pattern of vent holes including at least two rows.

Owner:RESMED LTD

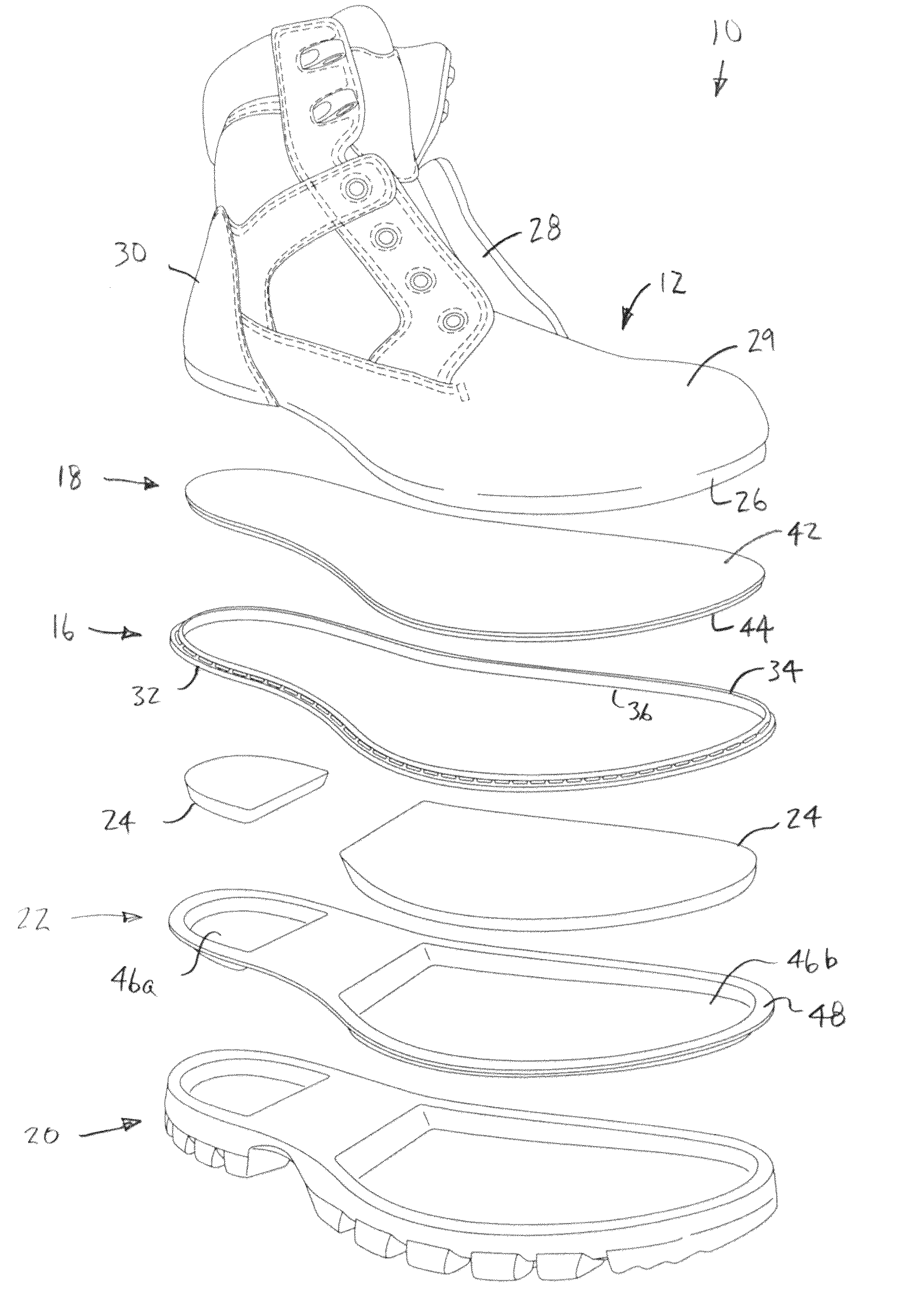

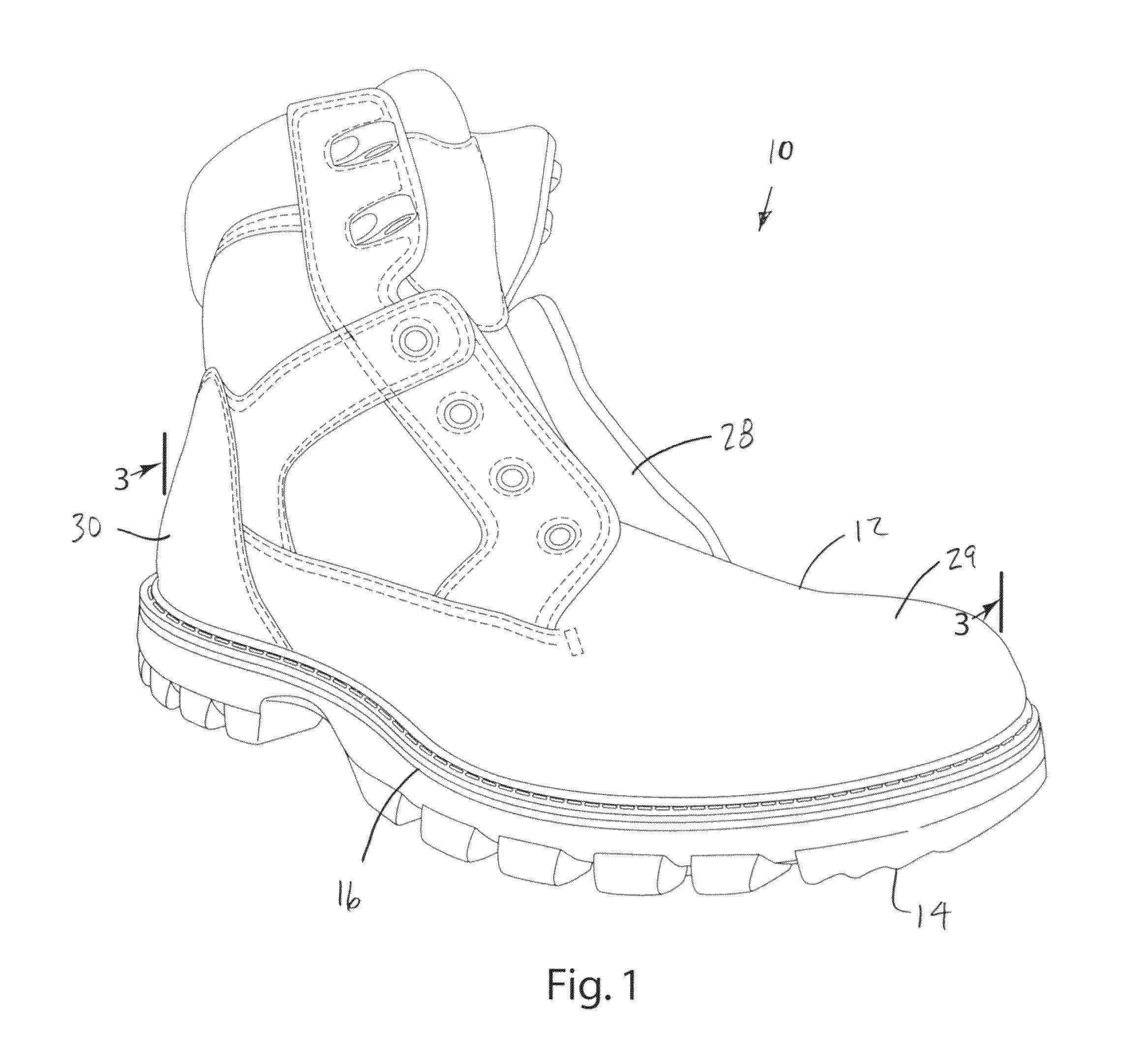

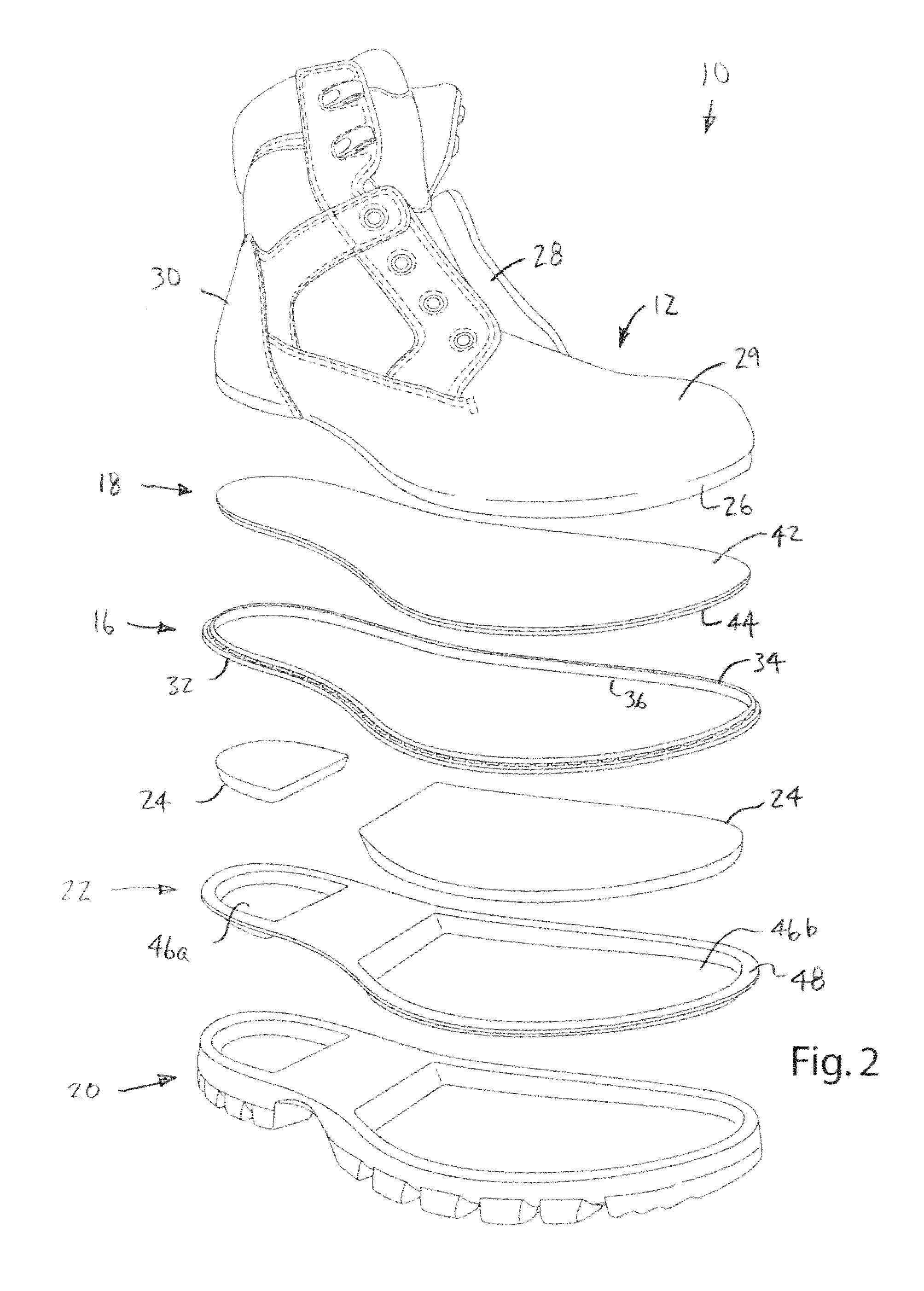

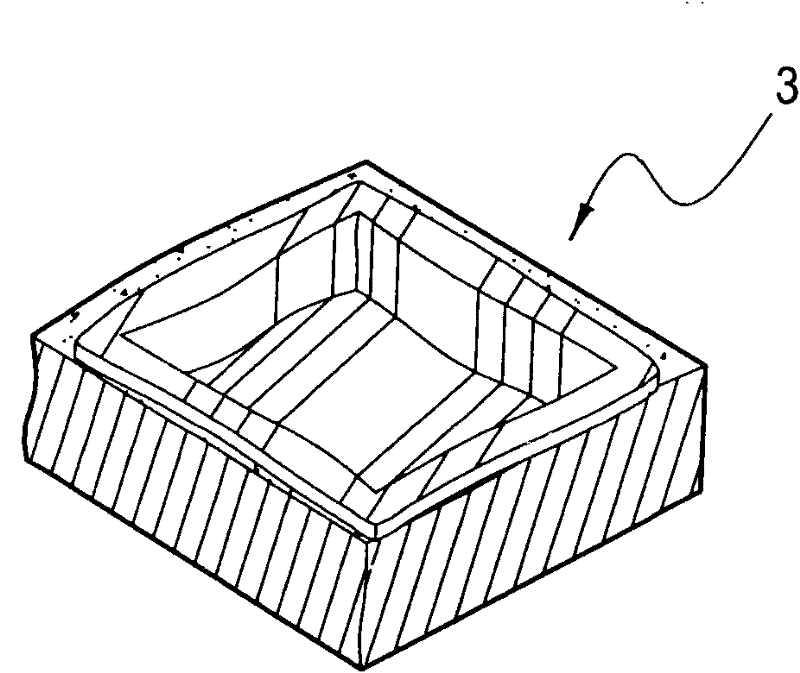

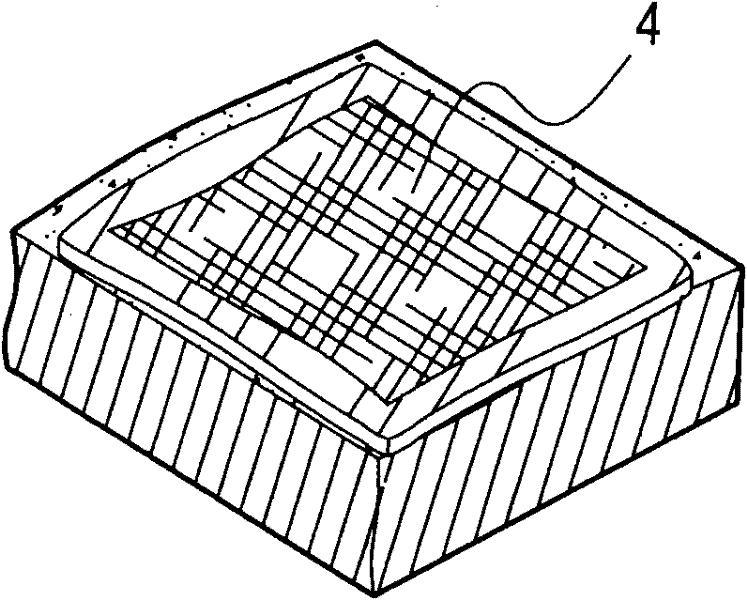

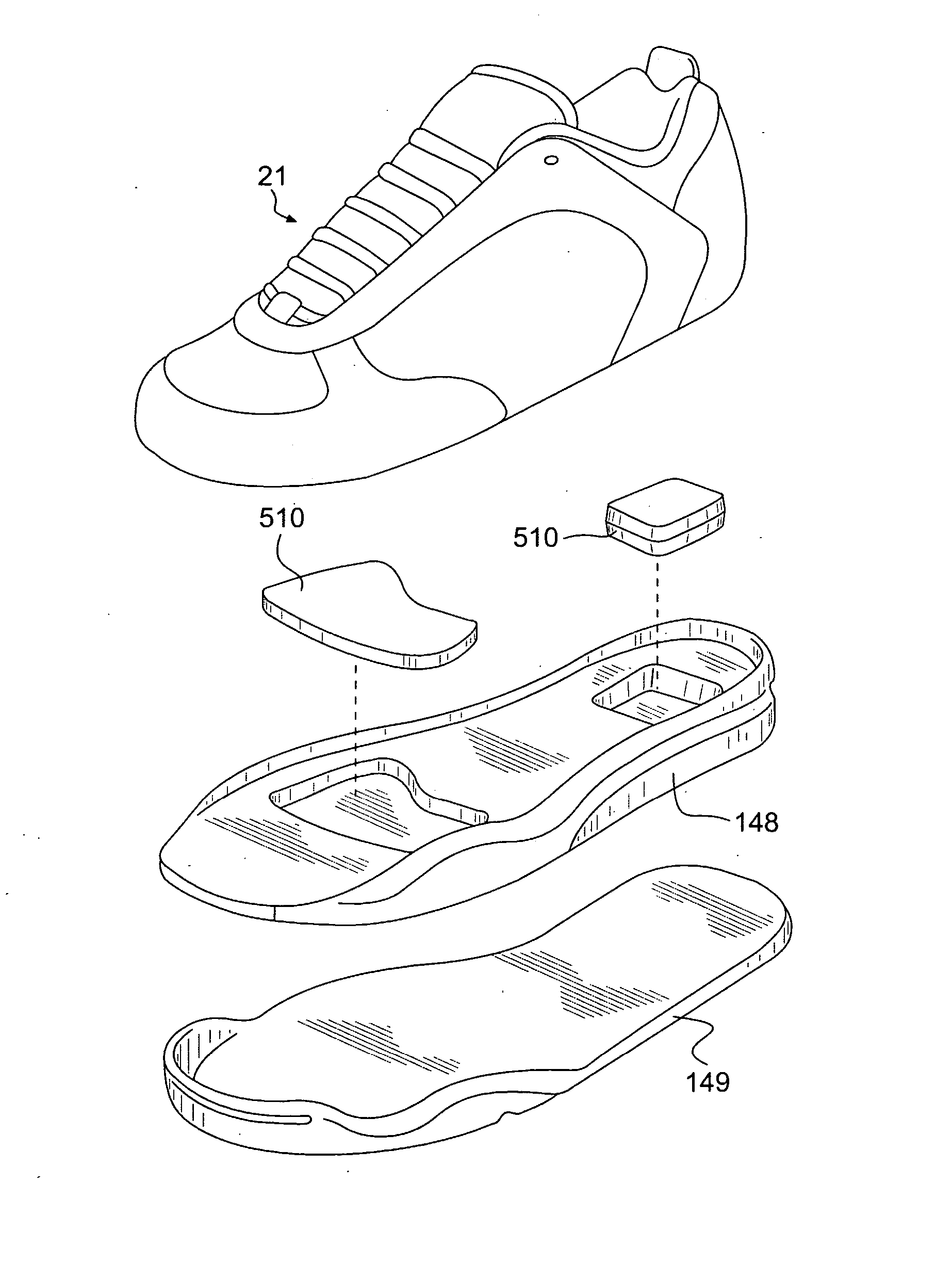

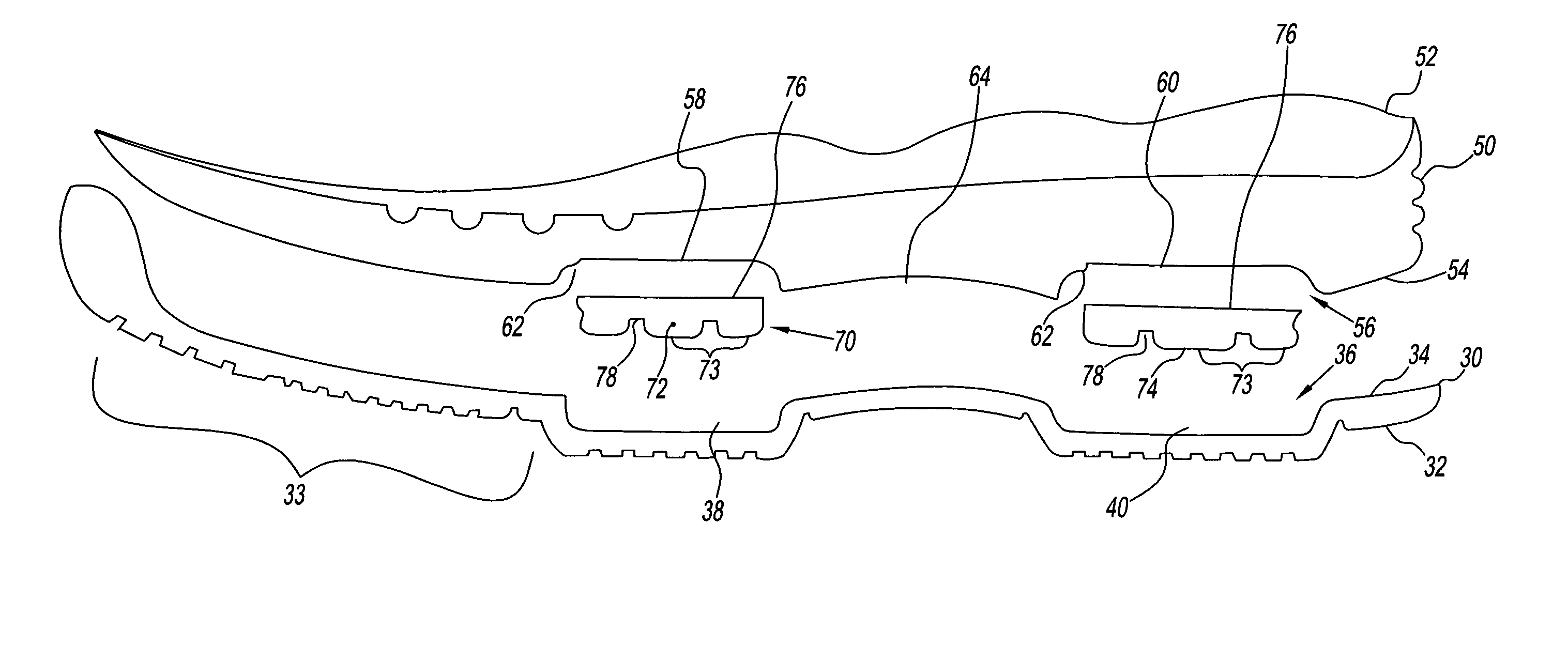

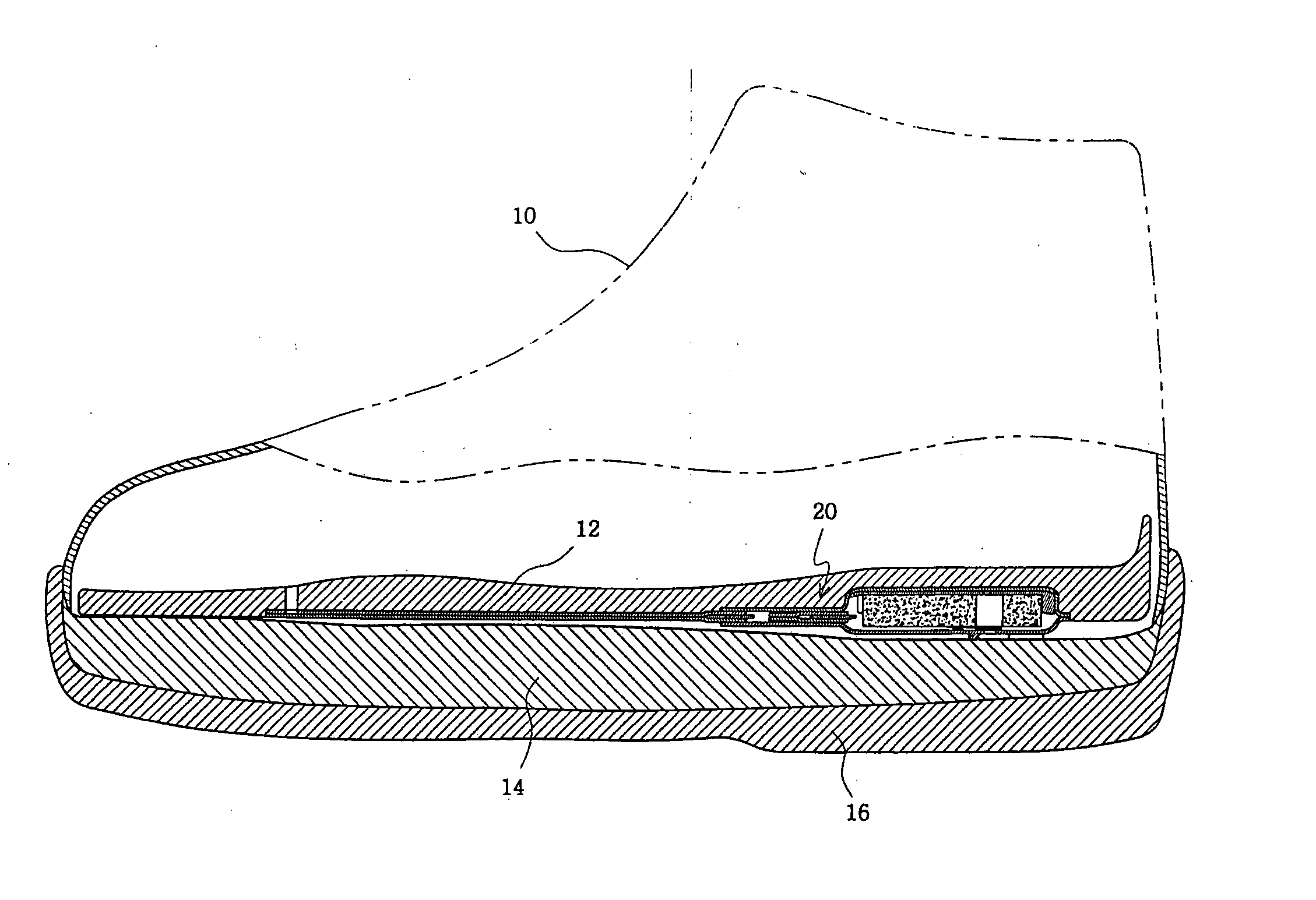

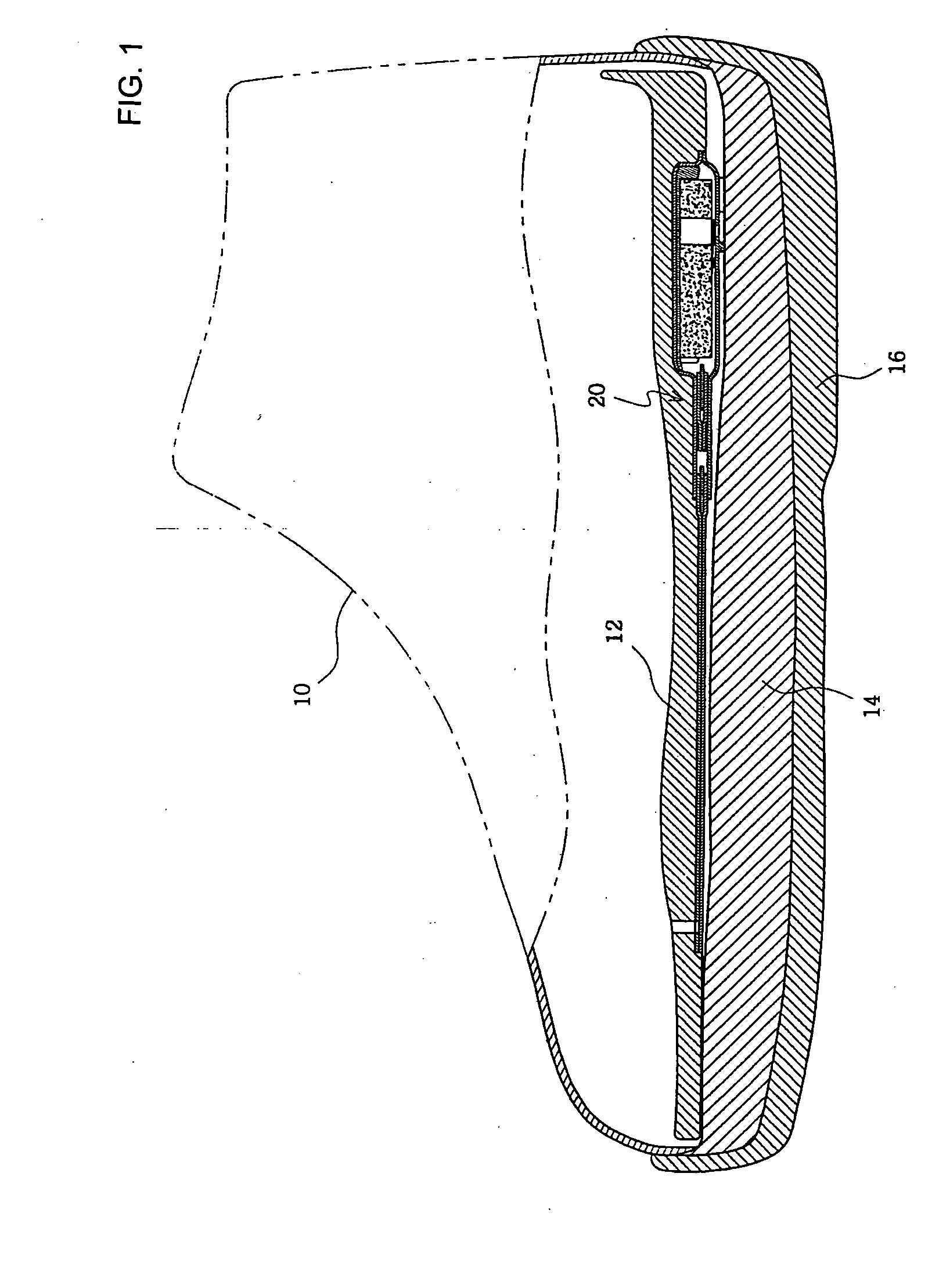

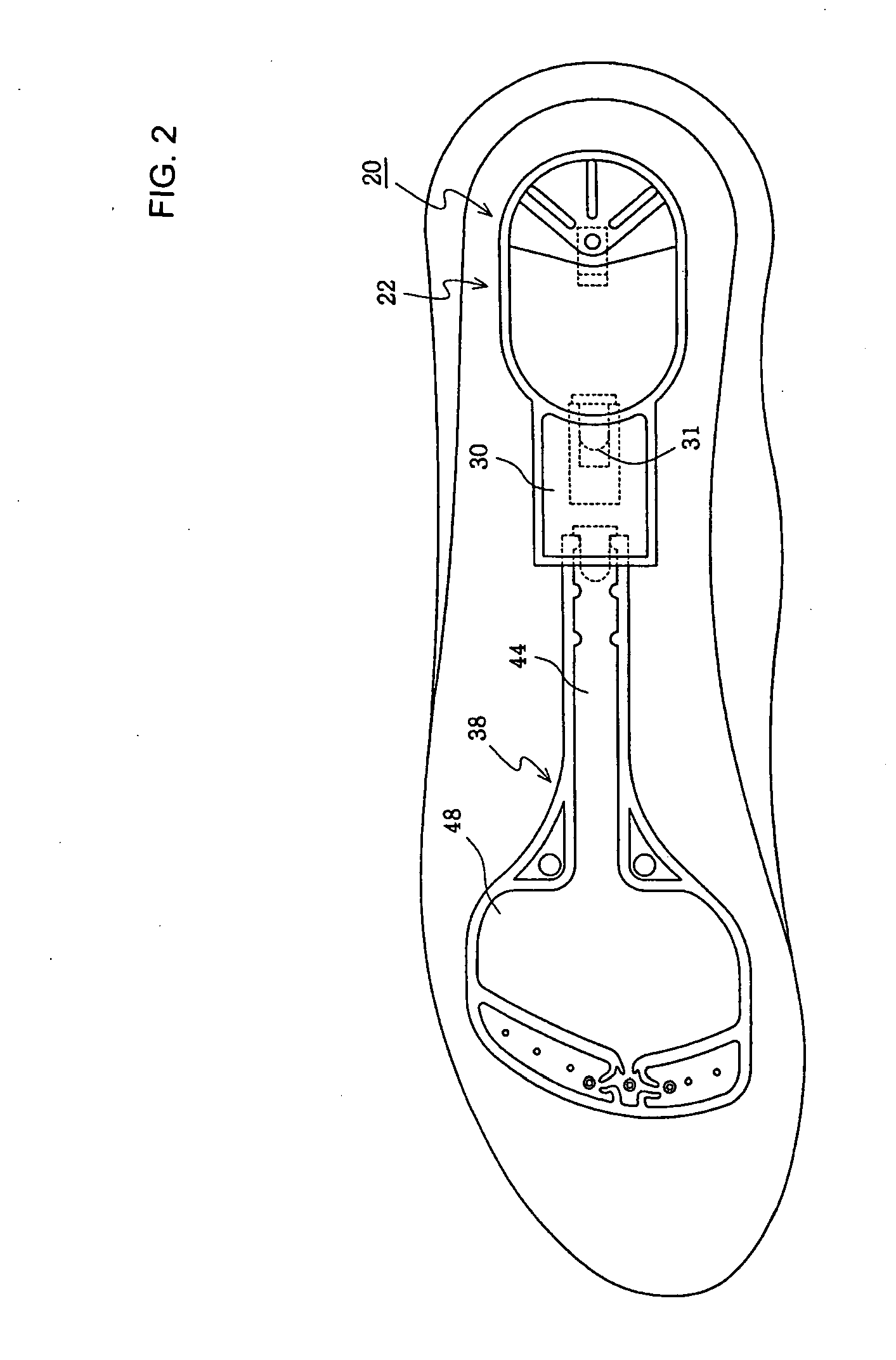

Footwear construction

A welted footwear construction with a direct-attach outsole and an internal tray containing a low density cushioning material. The welt may be secured to the upper and insole by one line of stitching and to the tray by a second line of stitching. The tray may include separate heel and forefoot cavities, each containing a low density cushioning material. The tray may be manufactured from thermoplastic urethane (“TPU”) and may contain low-density polyurethane (“PU”). The low-density PU may be molded in place within the cavities in the tray. The outsole may be directly attached to the undersurface of the tray, and may be manufactured from high-density PU.

Owner:WOLVERINE OUTDOORS

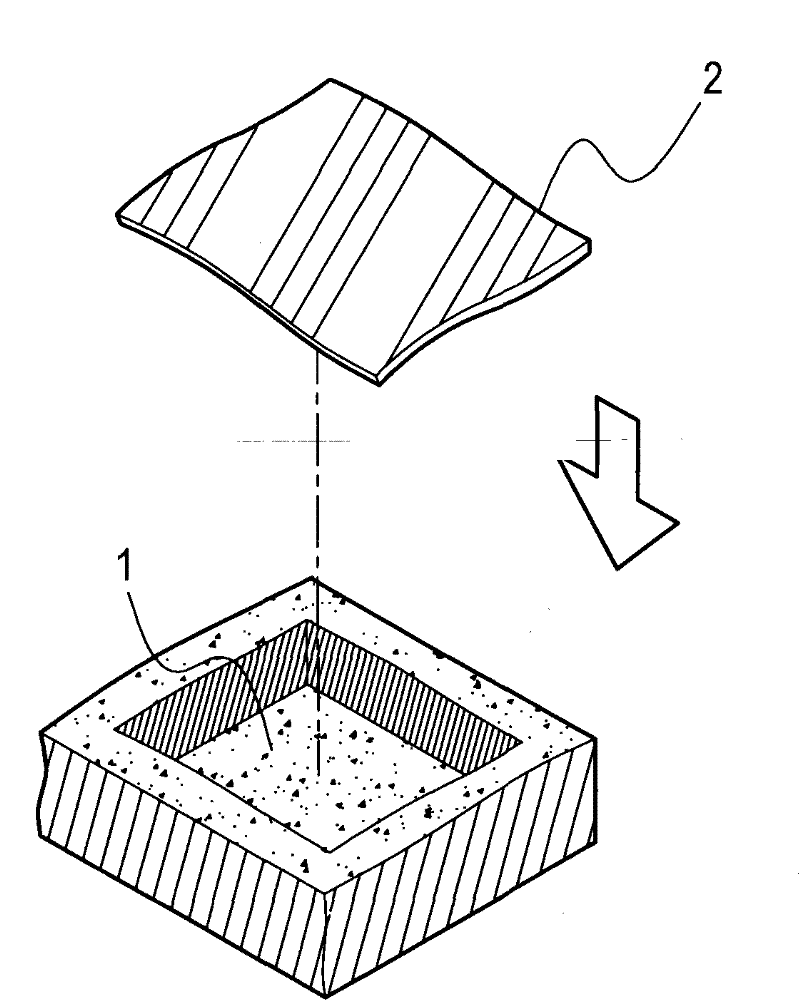

Organic cultivation medium and application method thereof

InactiveCN102217469ARefined grain structurePromote proliferationPlant cultivationCultivating equipmentsRoot growthSludge

The invention discloses an organic cultivation medium and an application method thereof. The organic cultivation medium is formed by fermenting a mixture comprising organic wastes (comprising straws, animal manures and organic garbage), sludge soil (urban sludge and substrate sludge of rivers and lakes) and composite soil microorganism preparations. The organic cultivation medium can be applied to plant and crop planting, and can be mixed with microelements, water-retaining agents and root-growth accelerants according to proportions in accordance with the nutrition requirement characteristics of plants and crops to form organic soil with common soil, and then the organic soil can be arranged in a manual anti-leakage cultivation slot or a specific container cultivation system to cultivate crops, vegetables and fruits, flowers or Chinese herbal medicine plants, etc.

Owner:陆振冈 +1

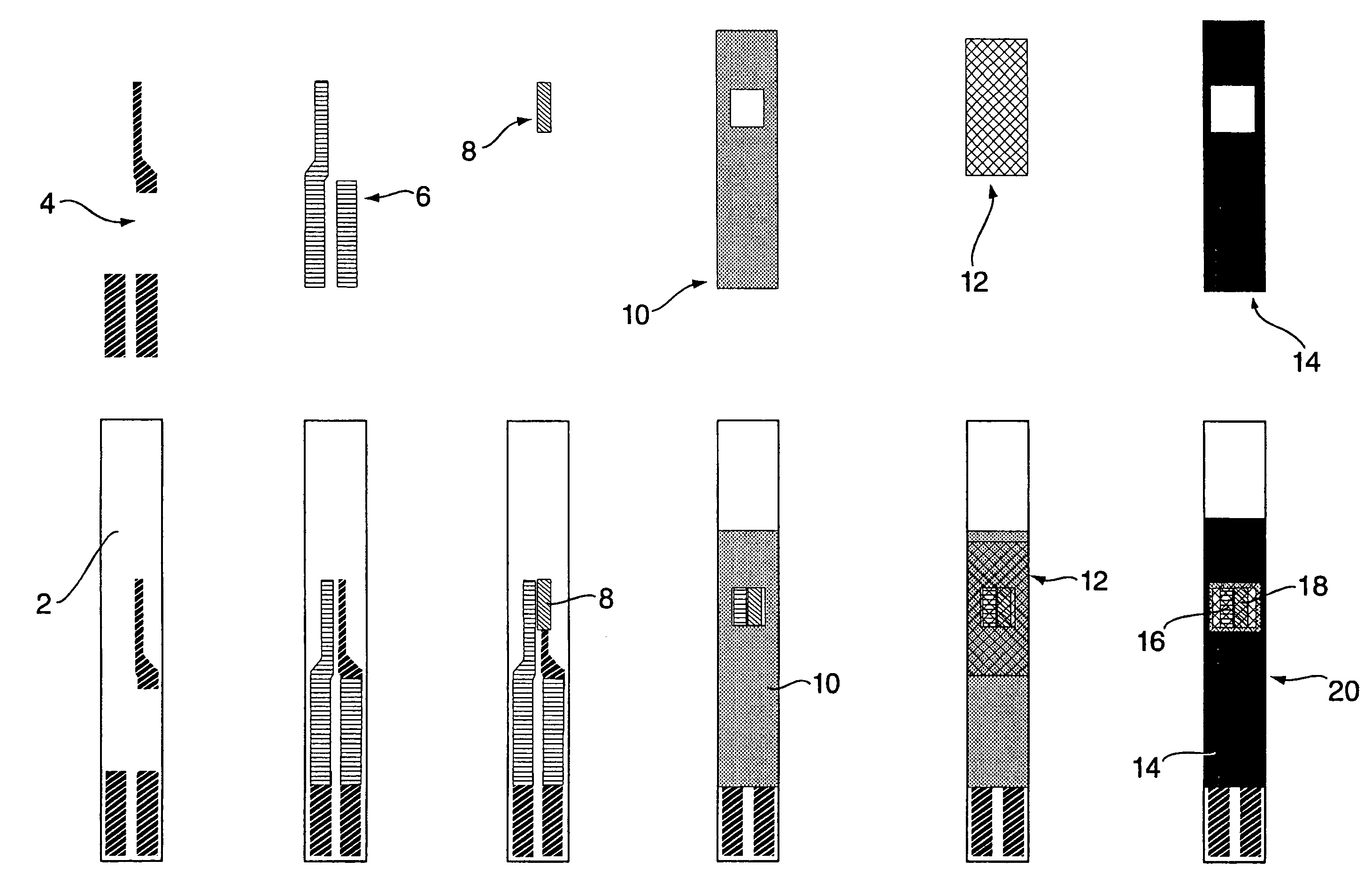

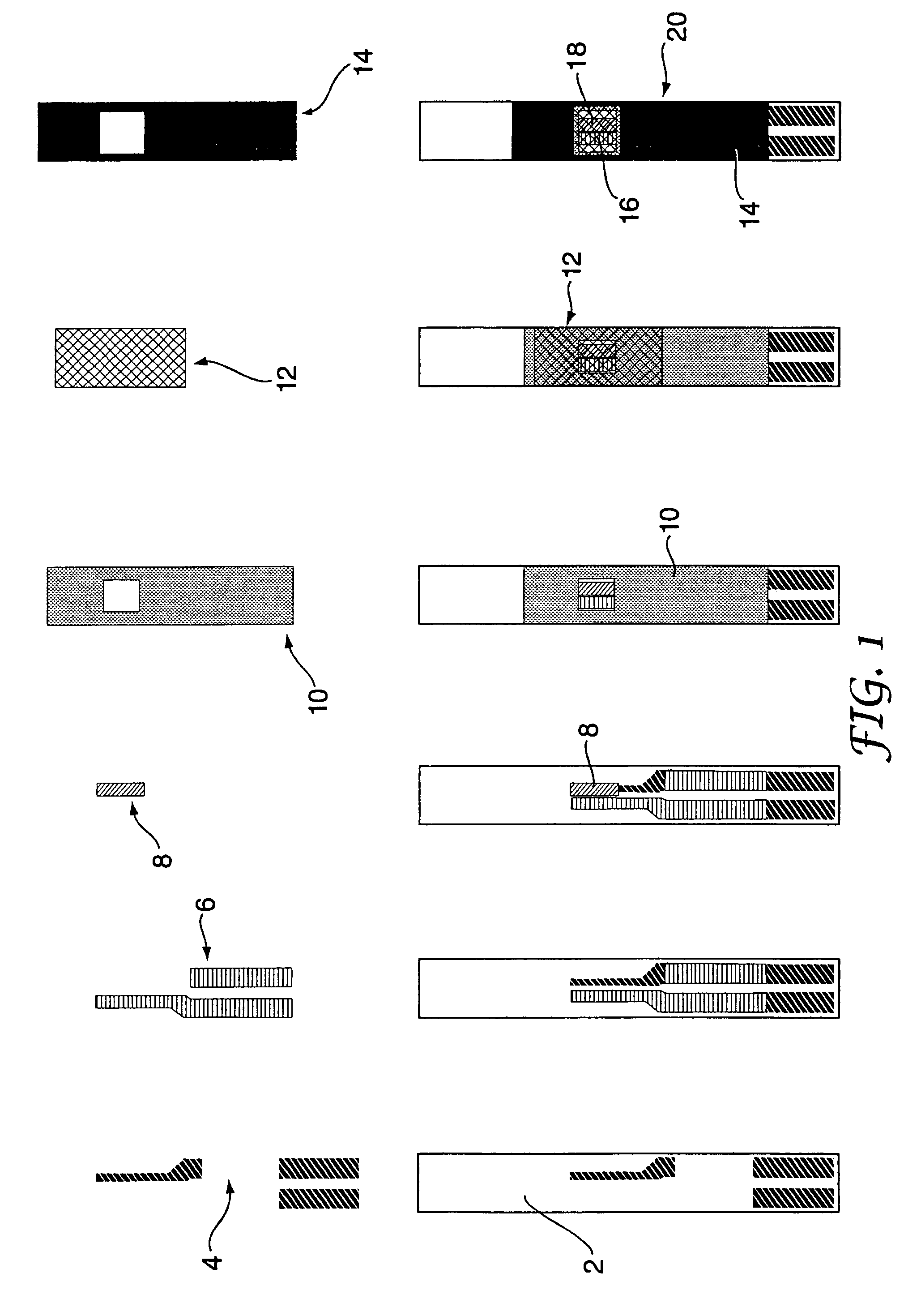

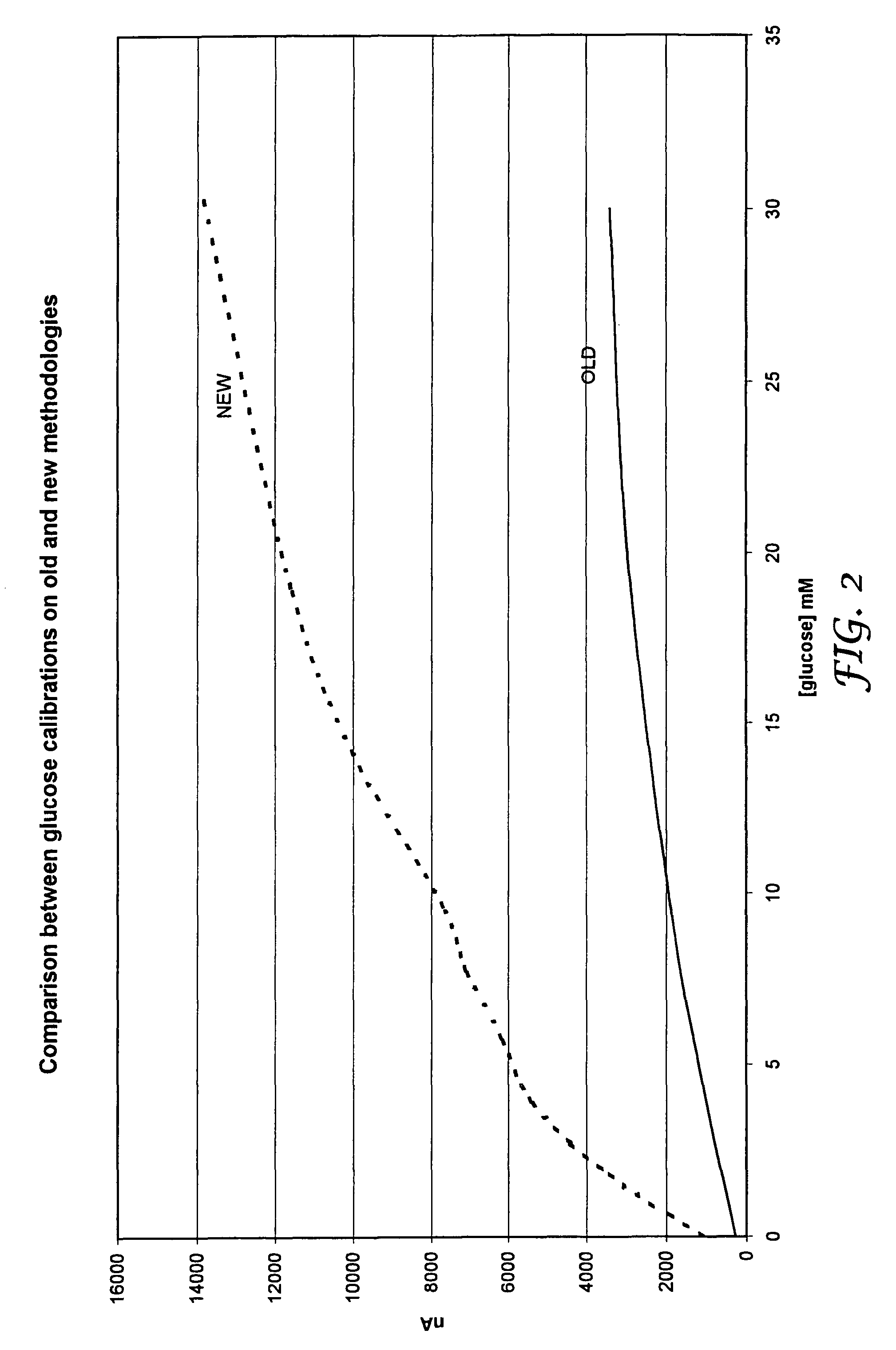

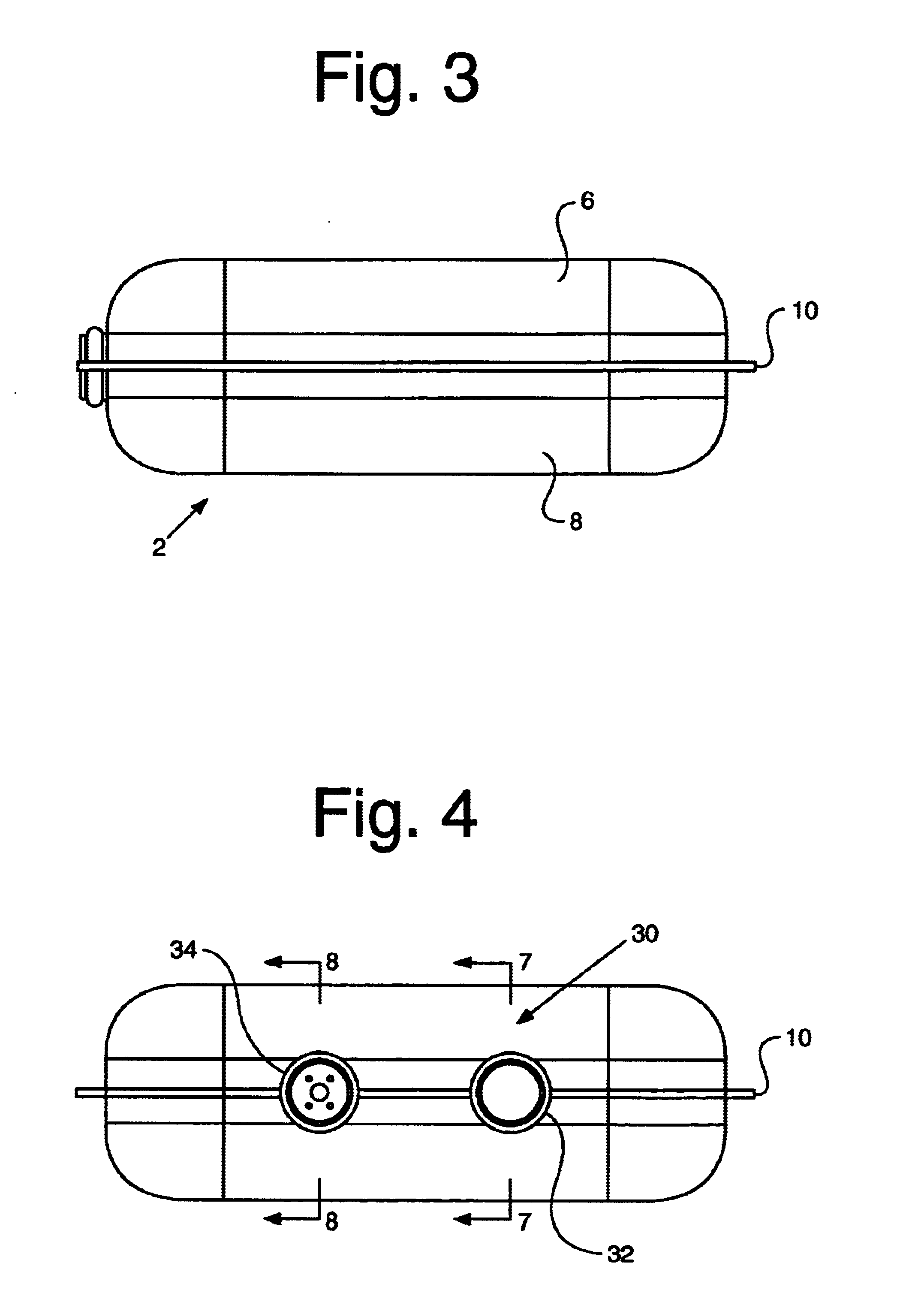

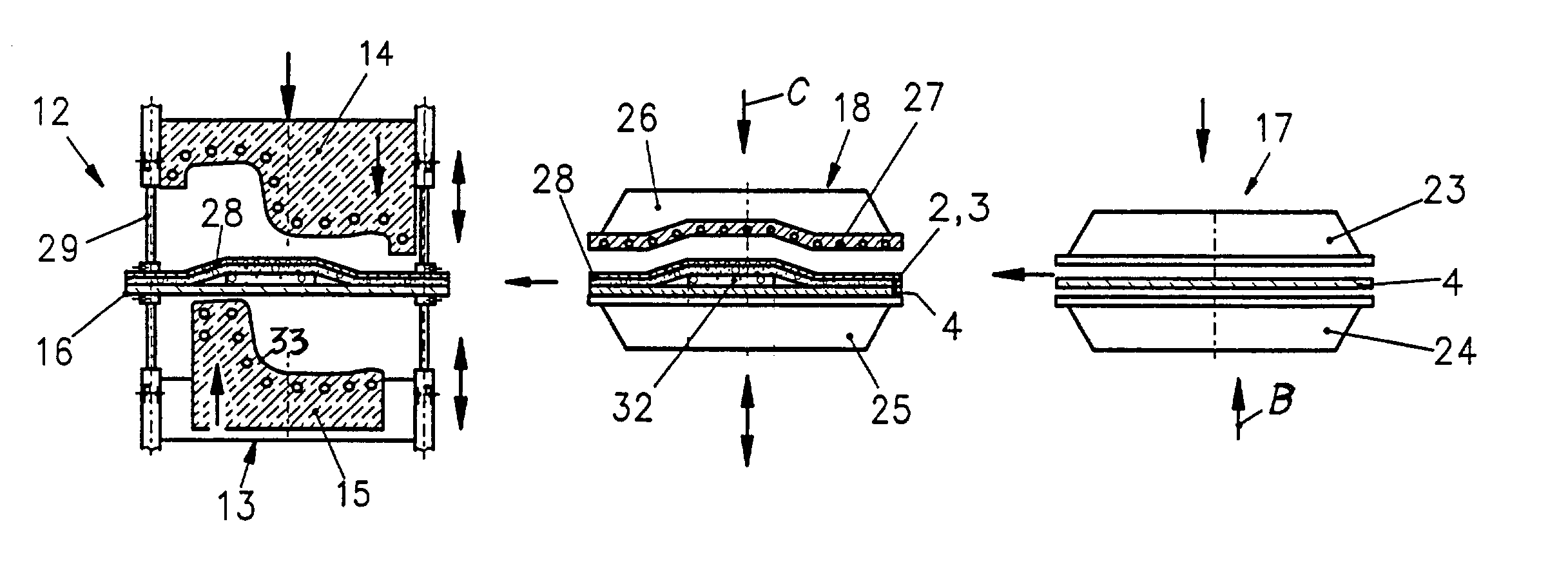

Enzyme electrodes and method of manufacture

ActiveUS7250095B2Easy to adjustStabilise enzymeImmobilised enzymesBioreactor/fermenter combinationsEnzyme electrodeEnzyme

A non-mediated enzyme electrode comprises a base substrate (2) on which is provided an electrically conductive base layer (8) comprising finely divided platinum group metal or oxide bonded together by a resin; a top layer on the base layer (8), the top layer comprising a buffer. A catalytically active quantity of an oxidoreductase enzyme is provided in at least one of the base layer and the top layer. The invention also provides a biosensor (20) which includes an enzyme electrode, and methods of manufacturing the enzyme electrode and biosensor.

Owner:ARKRAY INC

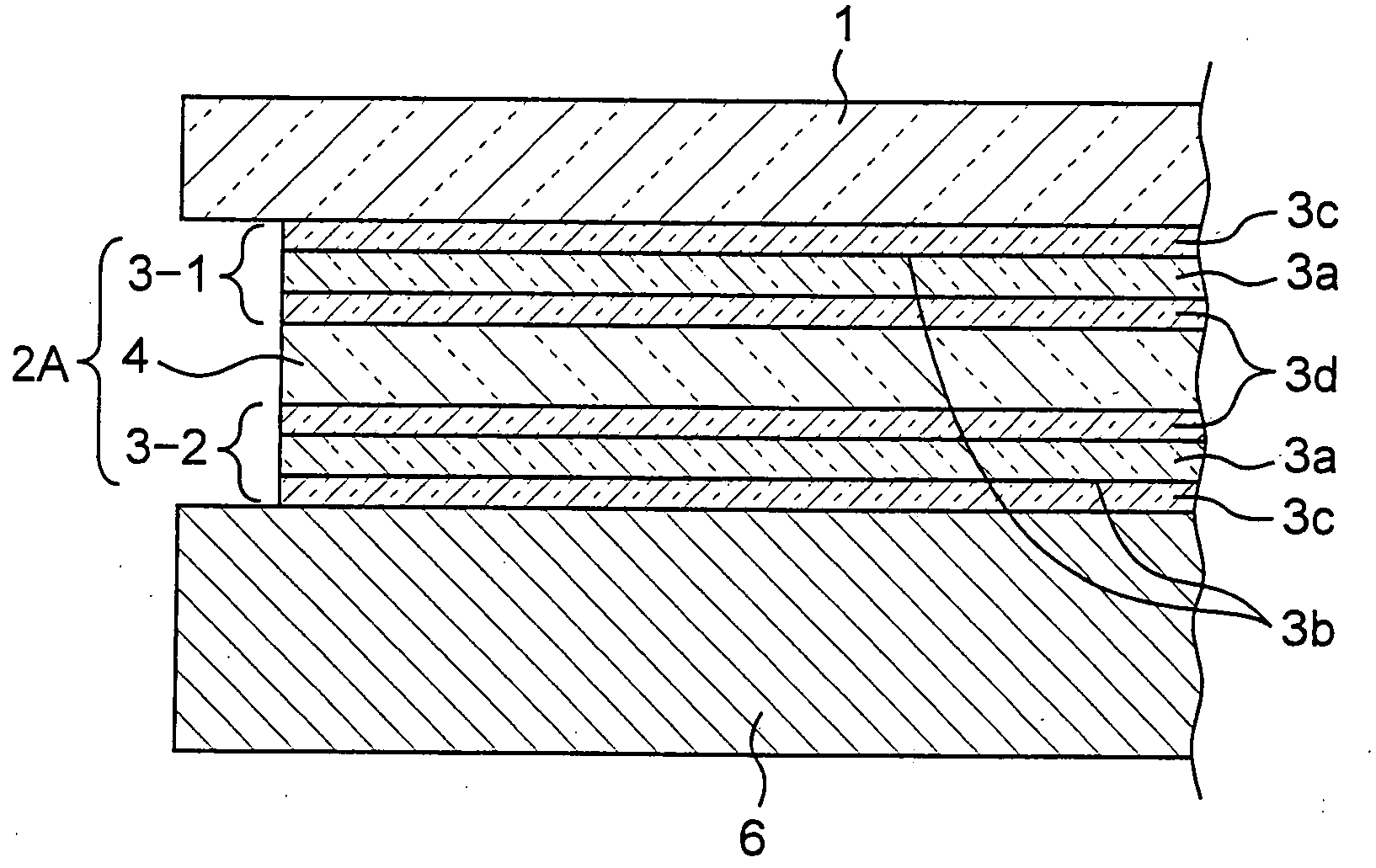

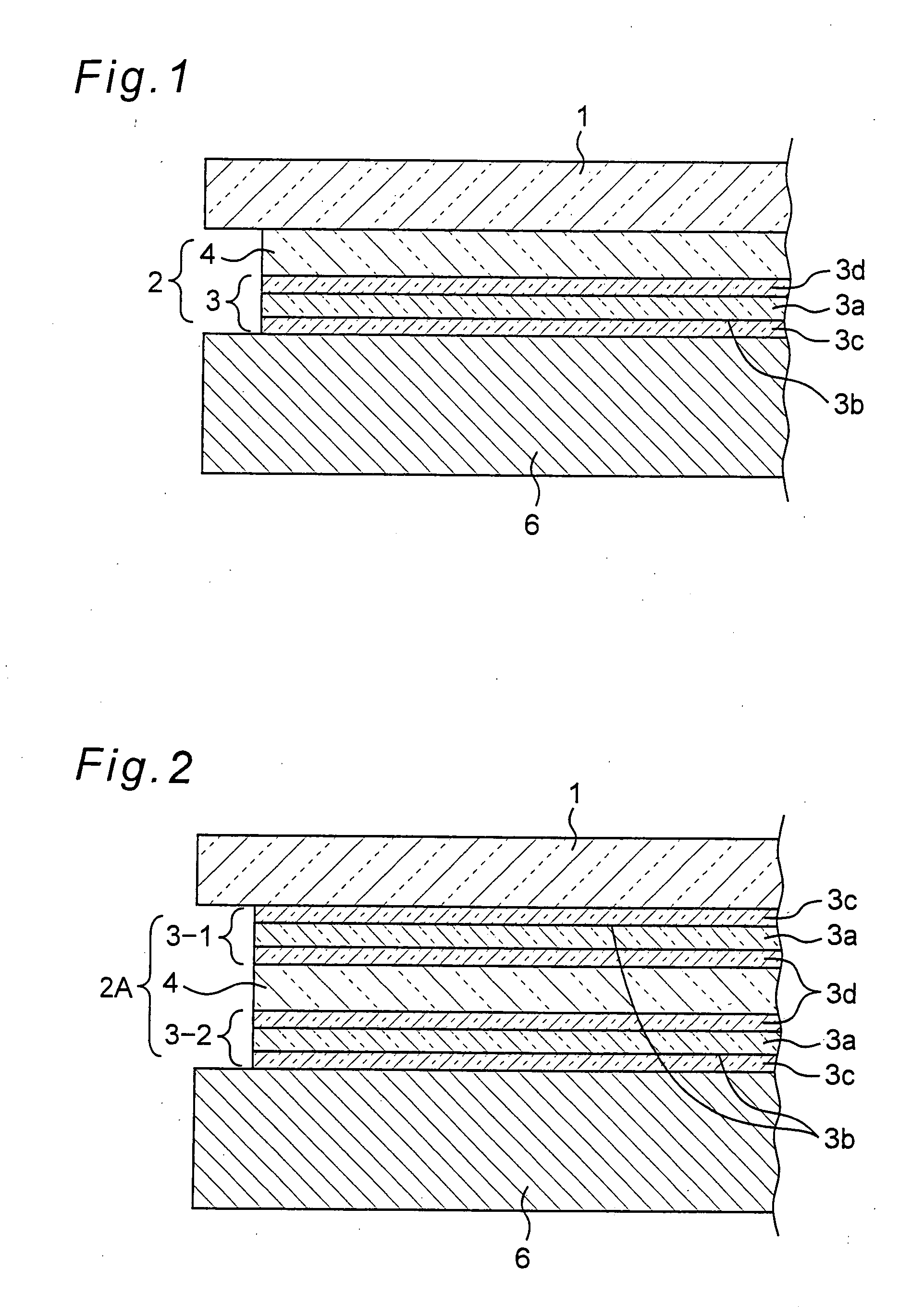

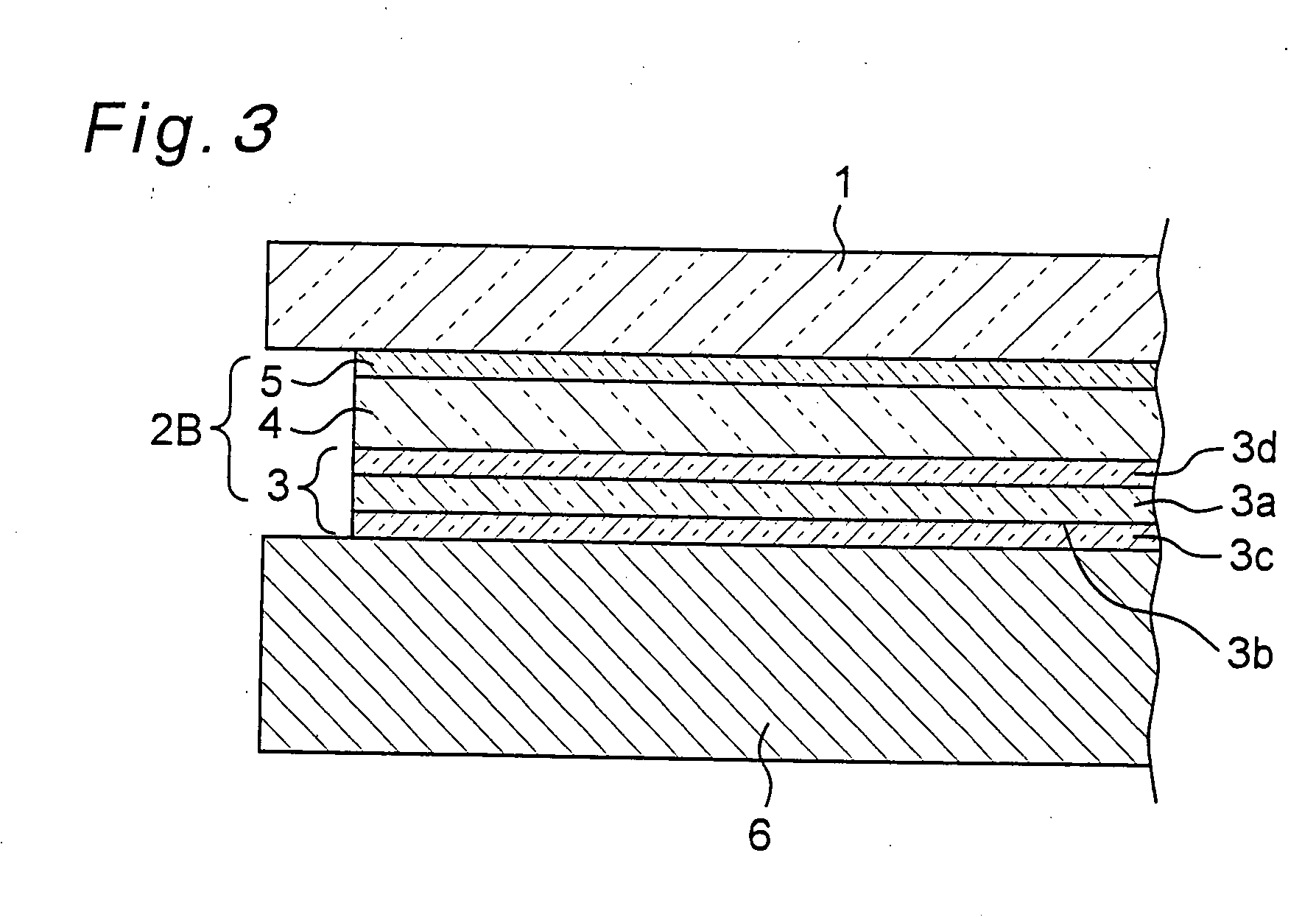

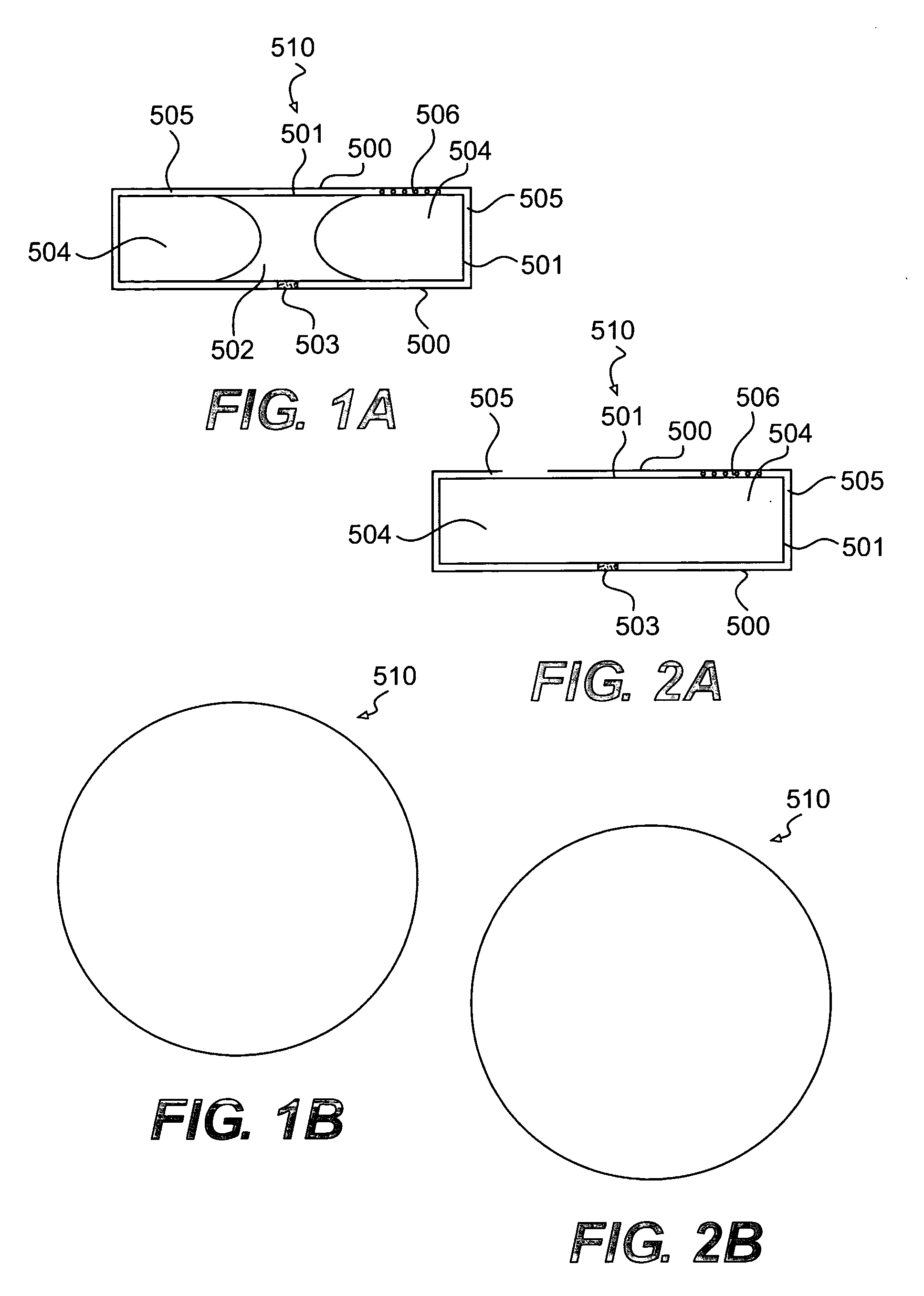

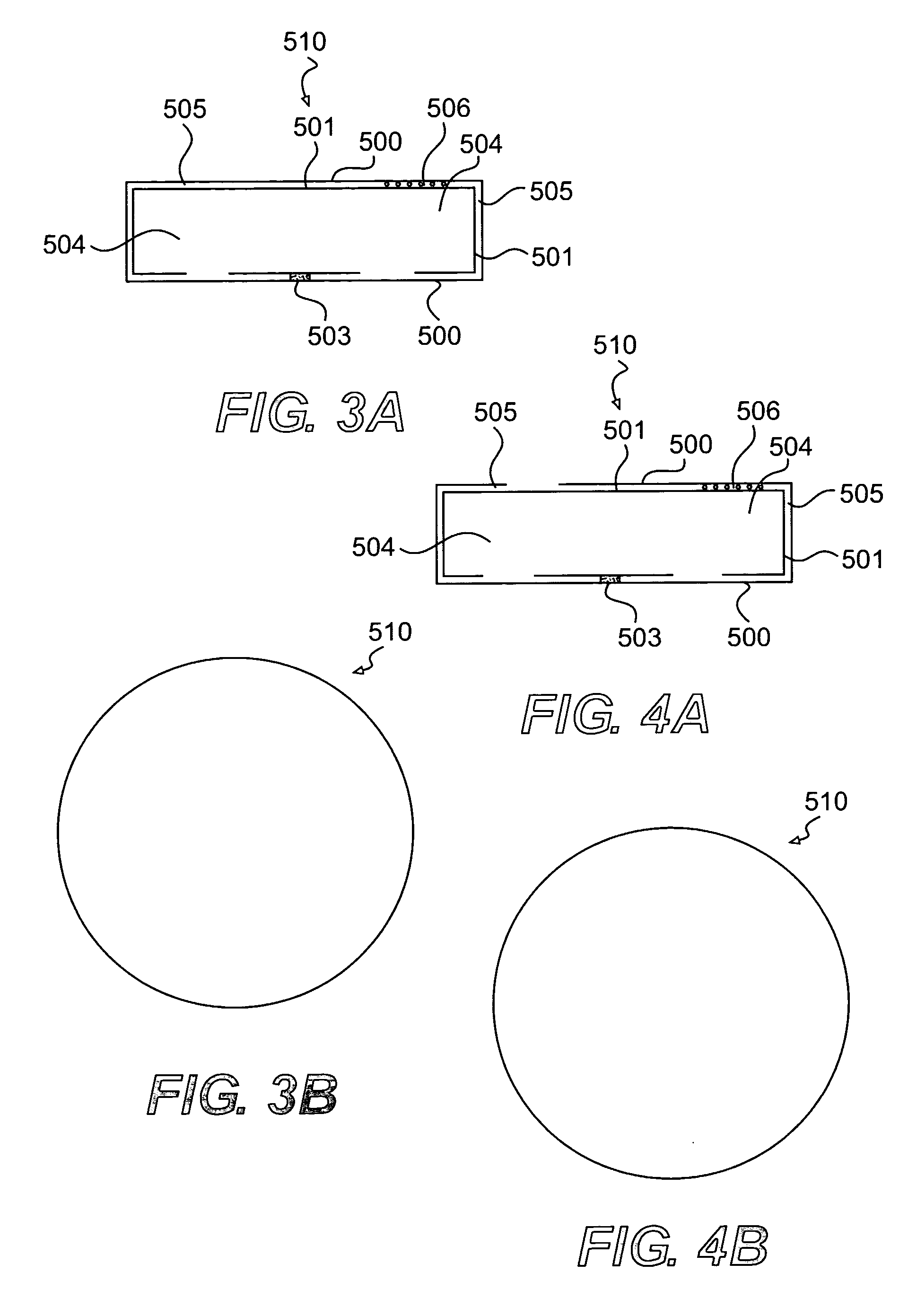

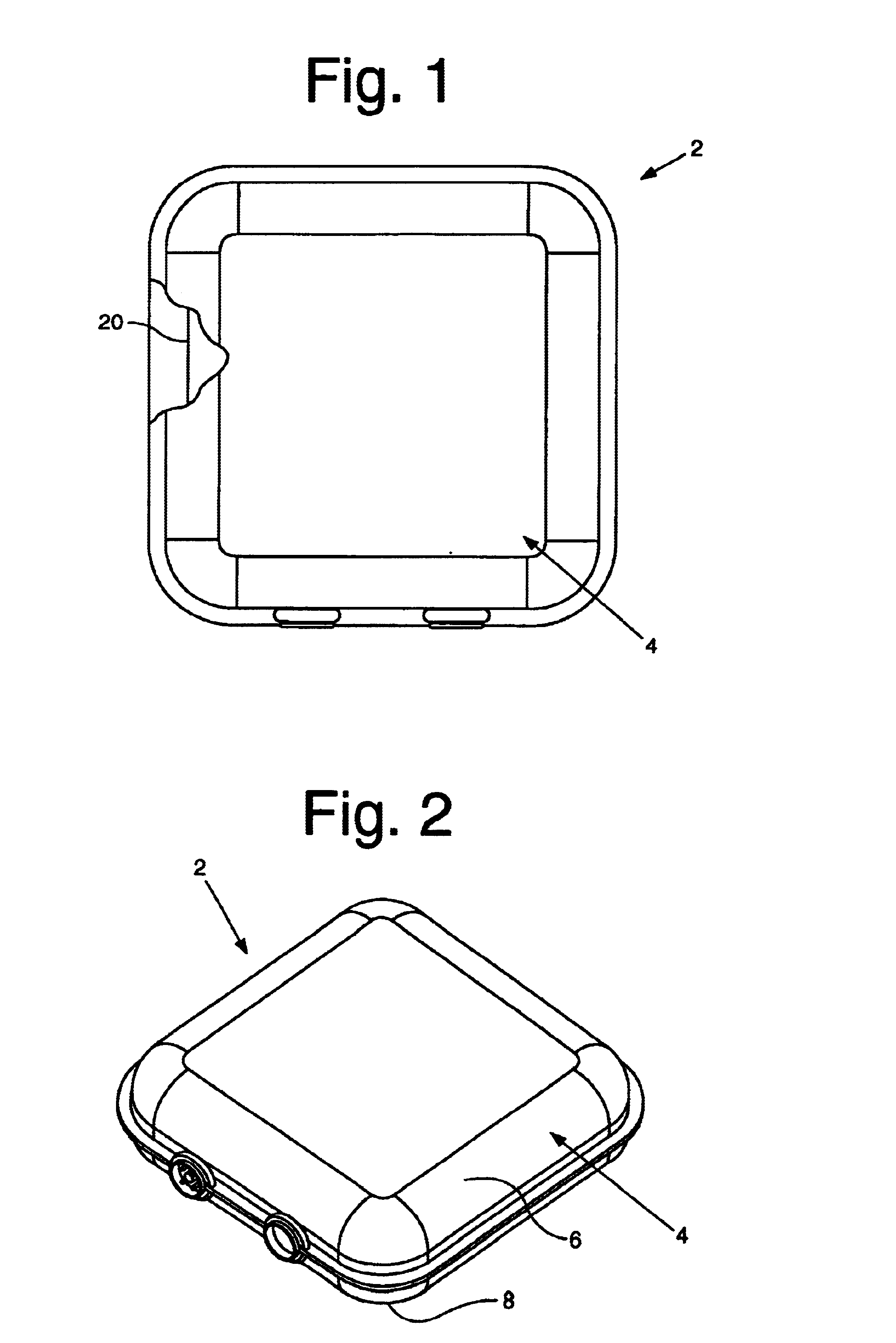

Mounting structure of re-peelable protective panel and mounting sheet using the same

InactiveUS20090087655A1Improve buffering effectAvoid elevationDetails for portable computersElectrical equipmentDisplay deviceEngineering

A transparent mounting sheet has a structure in which a one-sided re-peelable sheet, provided with a core member of a plastic film, a silicone rubber sheet that is laminated on a primer treated surface formed by one surface of the core member having been subjected to a primer treatment, and an acrylic adhesive agent layer that is laminated on the other surface of the core member, is bonded to at least one of surfaces of a gel sheet by the acrylic adhesive agent layer, and this transparent mounting sheet is used so that a protective panel for an electronic apparatus display window is mounted on a surface of a display in a manner so as to be re-peelable.

Owner:NISSHA PRINTING COMPANY

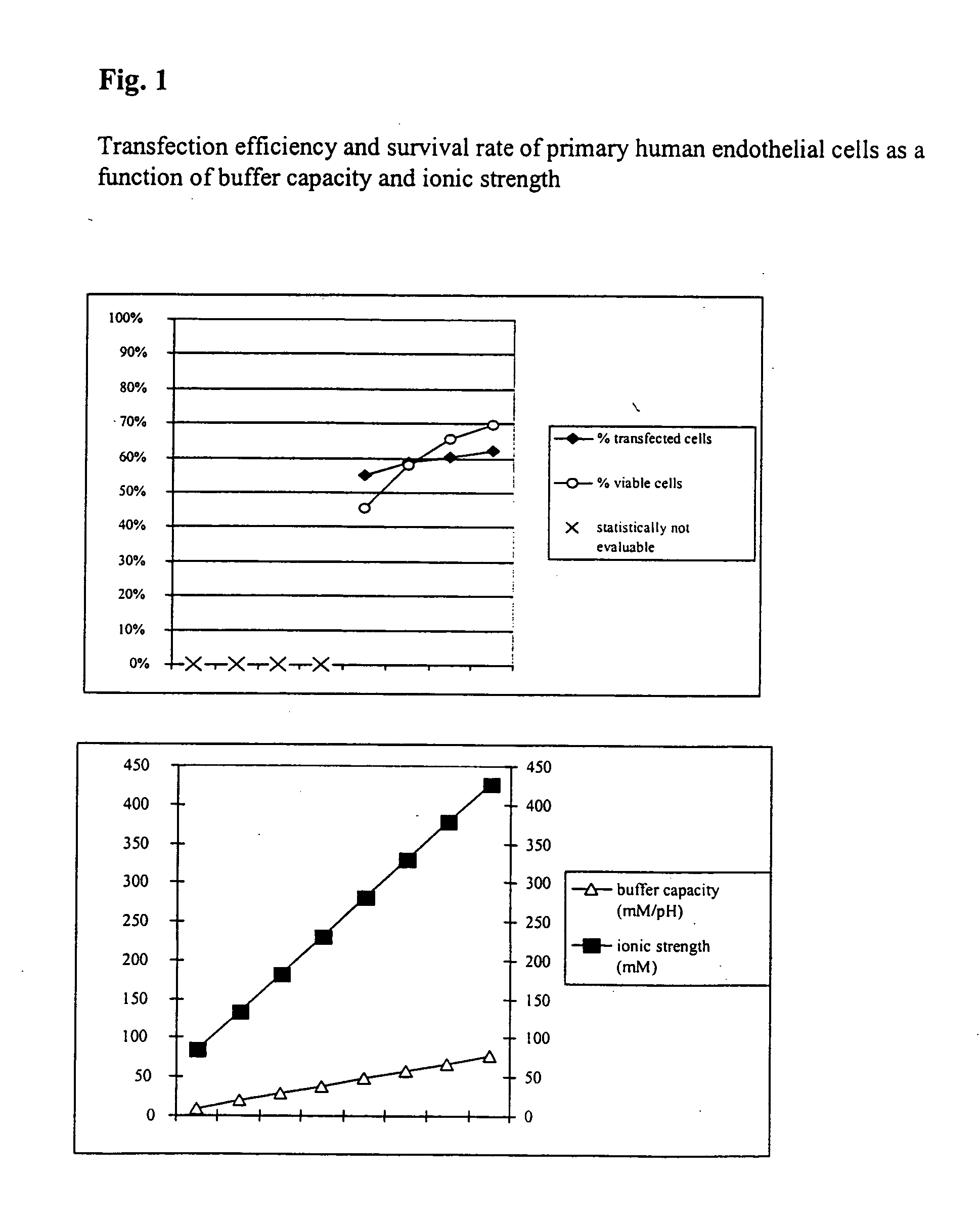

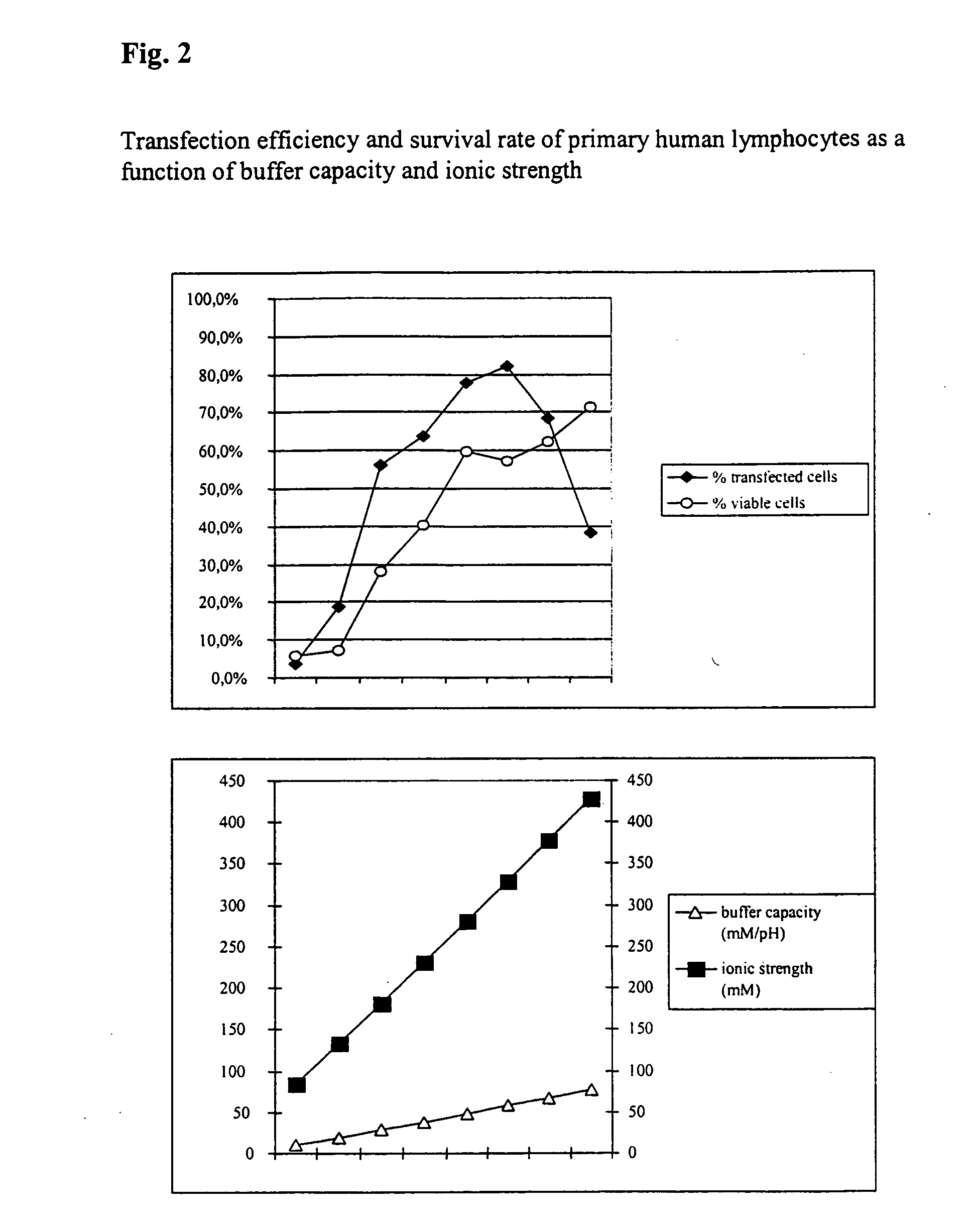

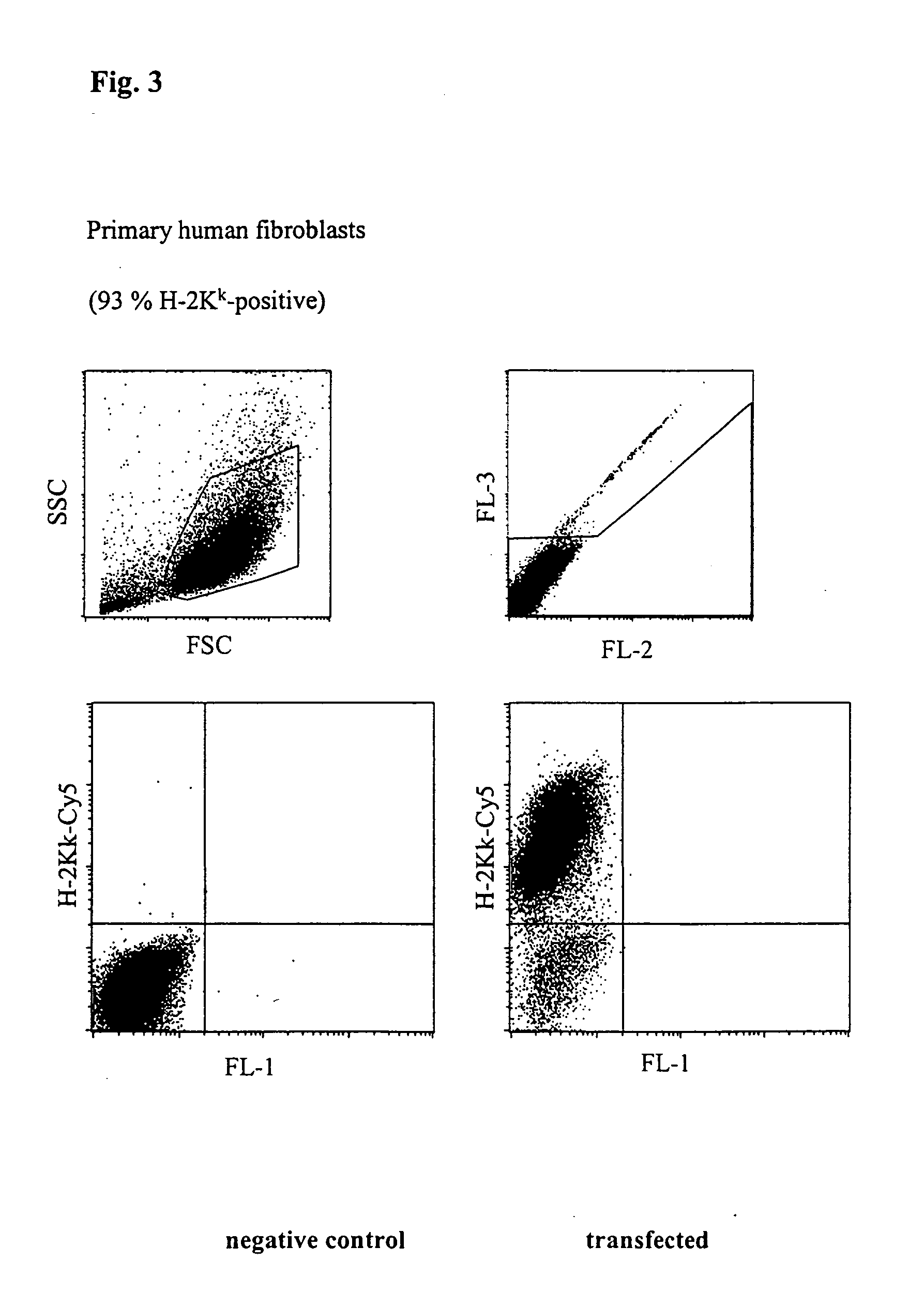

Buffer solution for electroporation and a method comprising the use of the same

InactiveUS20050064596A1High transfection efficiencyReduce cell deathPeptide/protein ingredientsGenetic material ingredientsElectroporationIon

The invention relates to a buffer solution for suspending animal or human cells and for dissolving biologically active molecules in order to introduce said biologically active molecules into the cells using an electric current and to a method for introducing biologically active molecules into animal or human cells using an electric current and a buffer solution. The inventive buffer solution has a buffering capacity of at least 20 mmol*I−1*pH−1 and an ionic strength of at least 200 mmol*I−1 during a change to the pH value from pH 7 to pH 8 and at a temperature of 25° C. The use of a buffer solution of this type in the corresponding method allows biologically active molecules to be introduced into animal and human cells with a high degree of transfection efficiency and at the same time a low cell mortality. Different cell types, in particular dormant and actively dividing cells of low activity, can be successfully transfected in said buffer solution.

Owner:LONZA COLOGNE

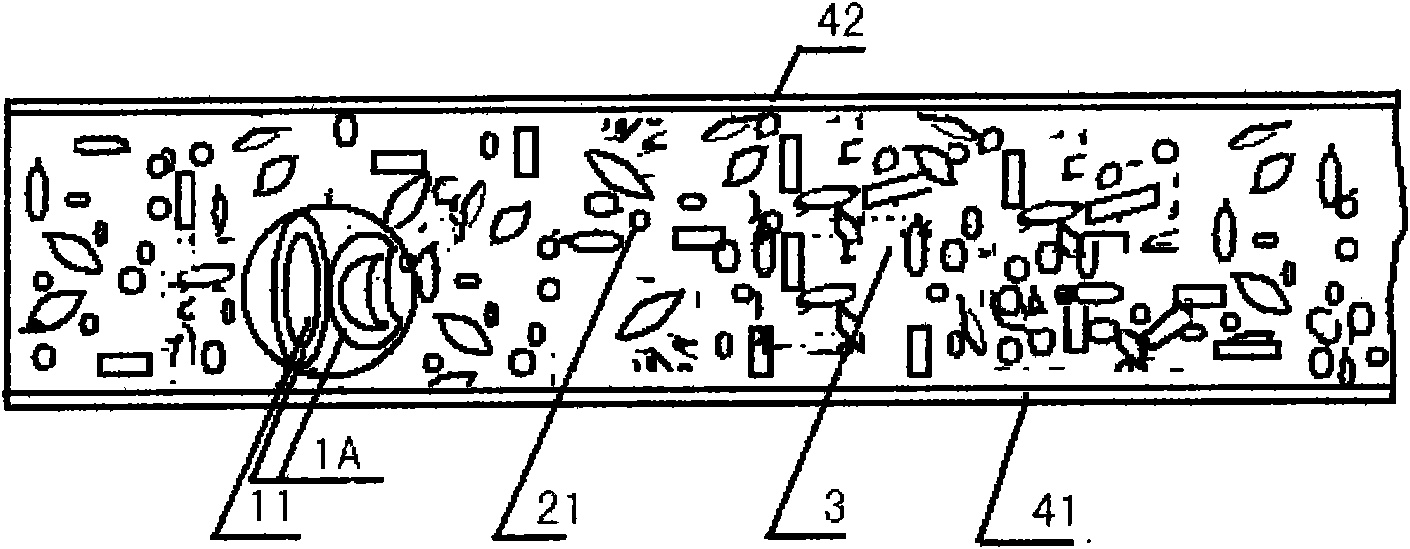

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

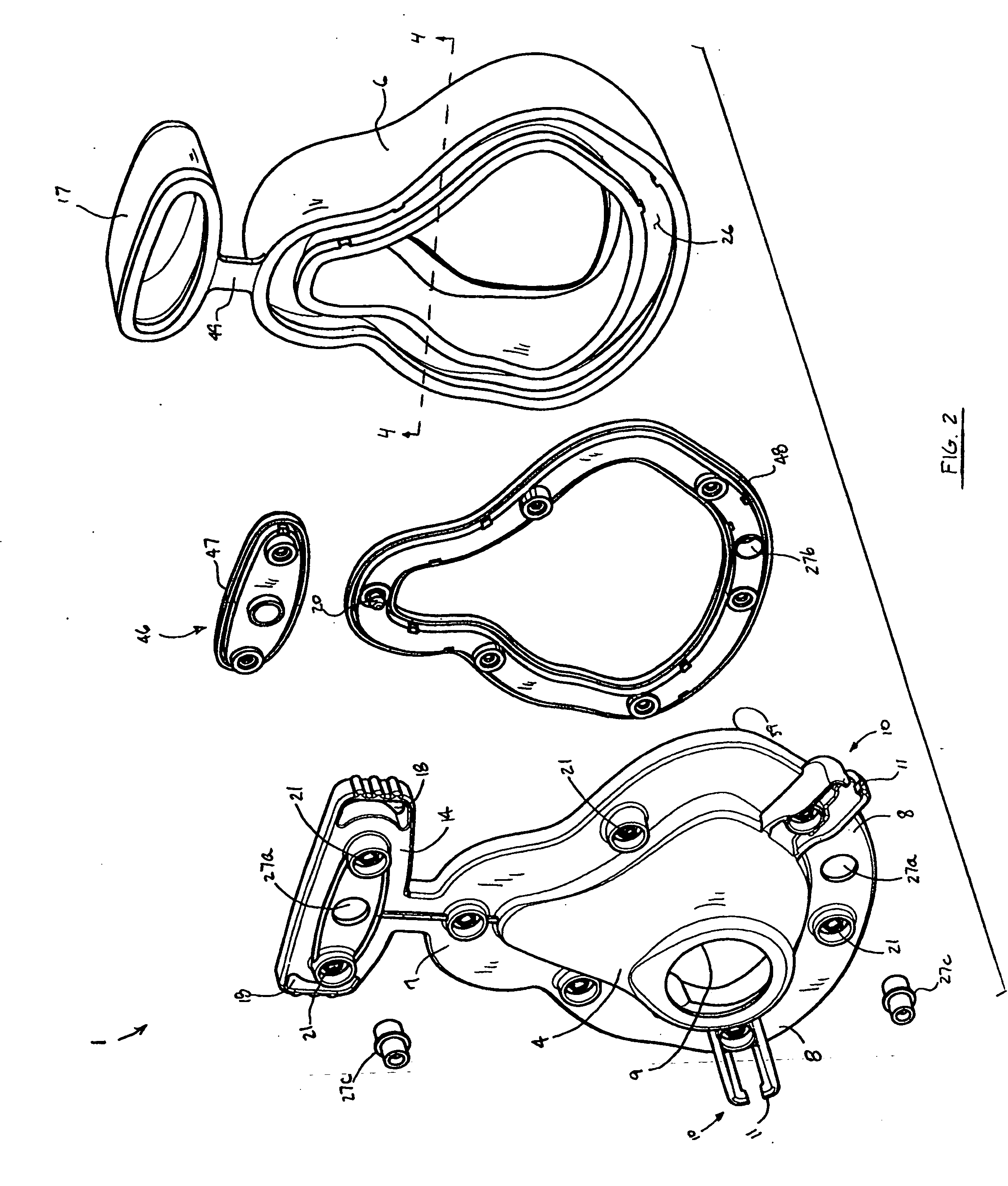

Patient interface device with dampening cushion

A cushion for use with a patient interface device includes a first end portion, which typically contacts the patient's face when the patient interface device is worn, a second end and / or opposite the first end, which is typically coupled to a portion of the patient interface device, a chamber, which is typically disposed between the first and second end portions, and an orifice. The chamber is structured to receive and store a dampening medium therein; and the orifice, which is in operative communication with the chamber, controls the passage of the dampening medium into and / or out of the chamber. A patient interface device including a mask shell and the cushion is also described.

Owner:RIC INVESTMENTS LLC

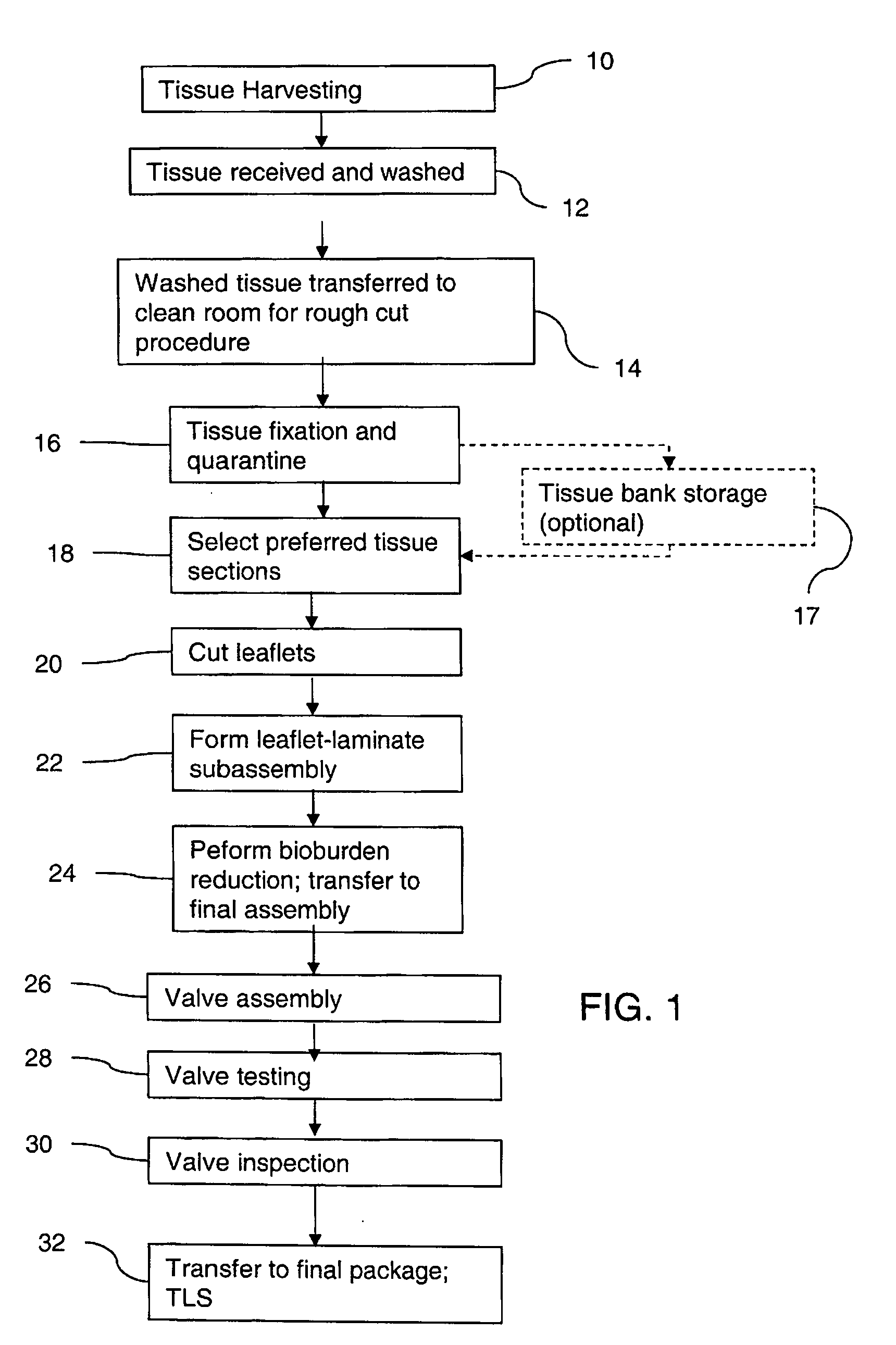

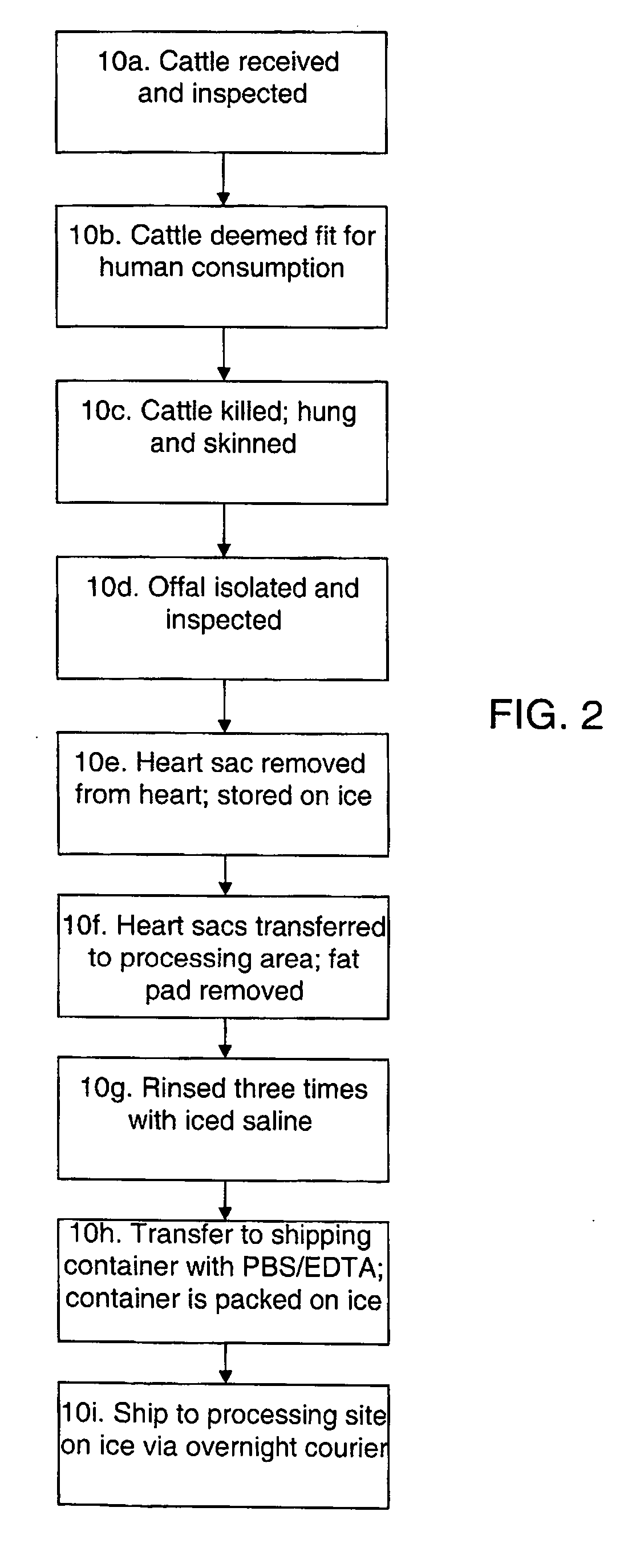

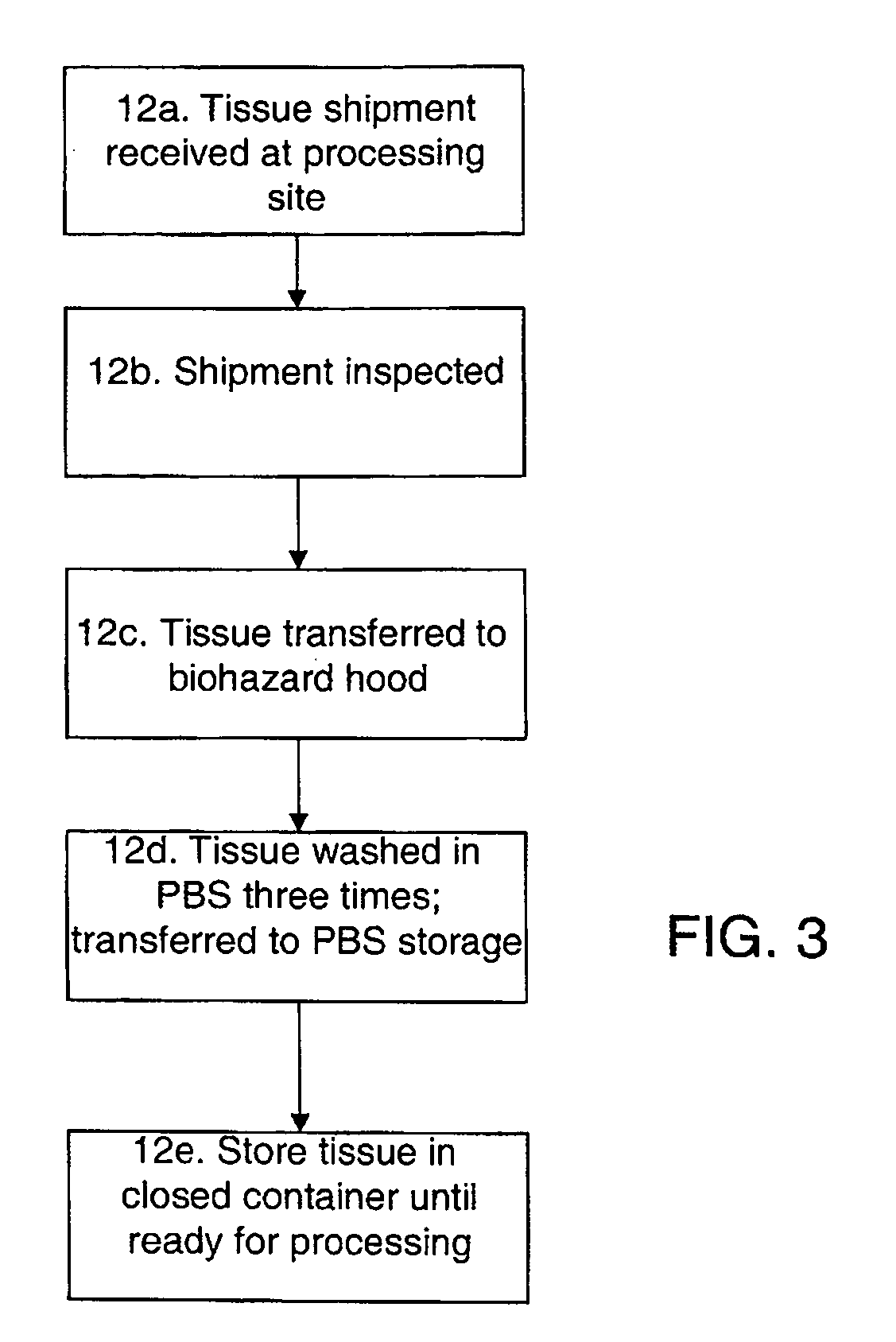

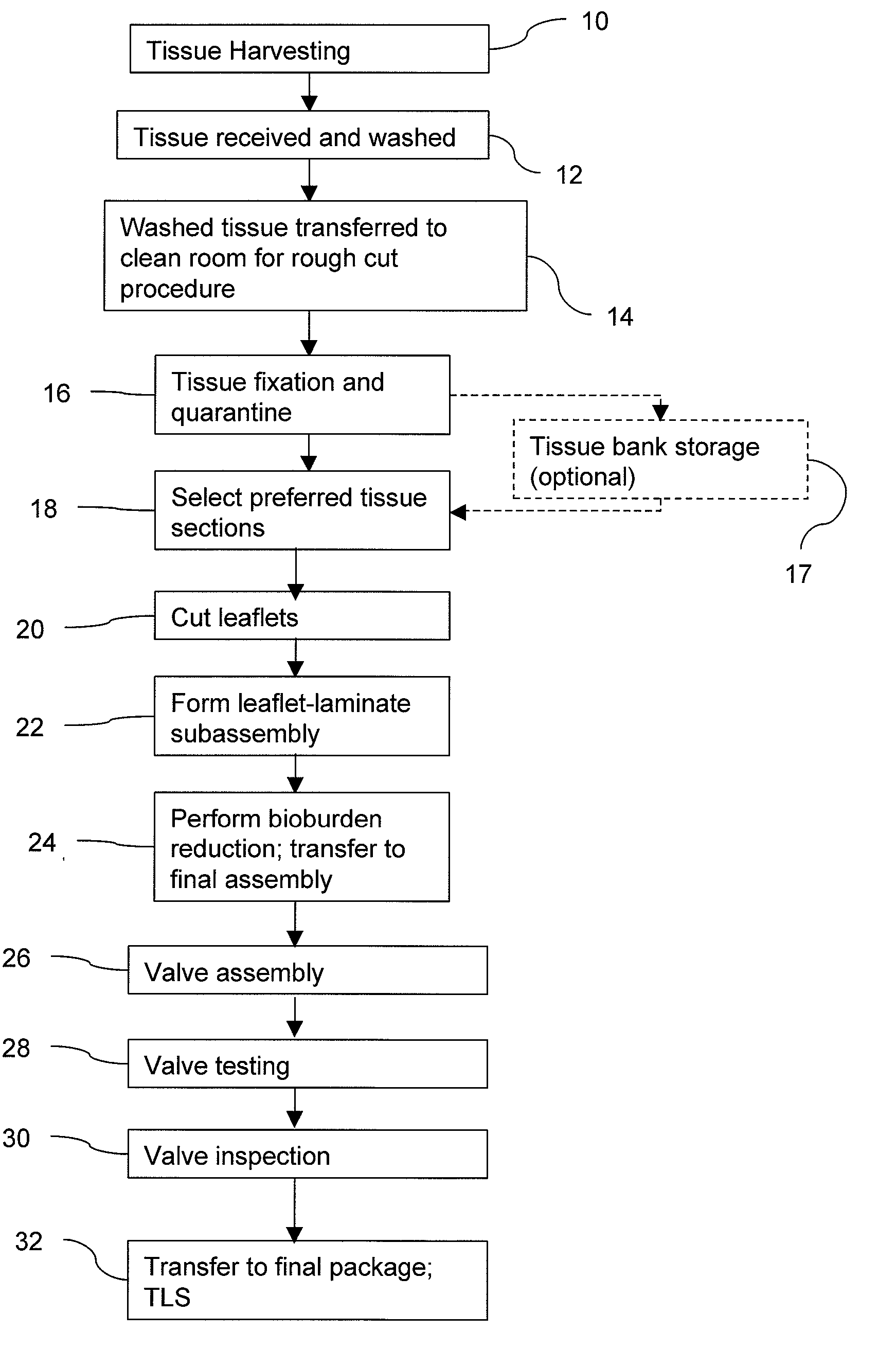

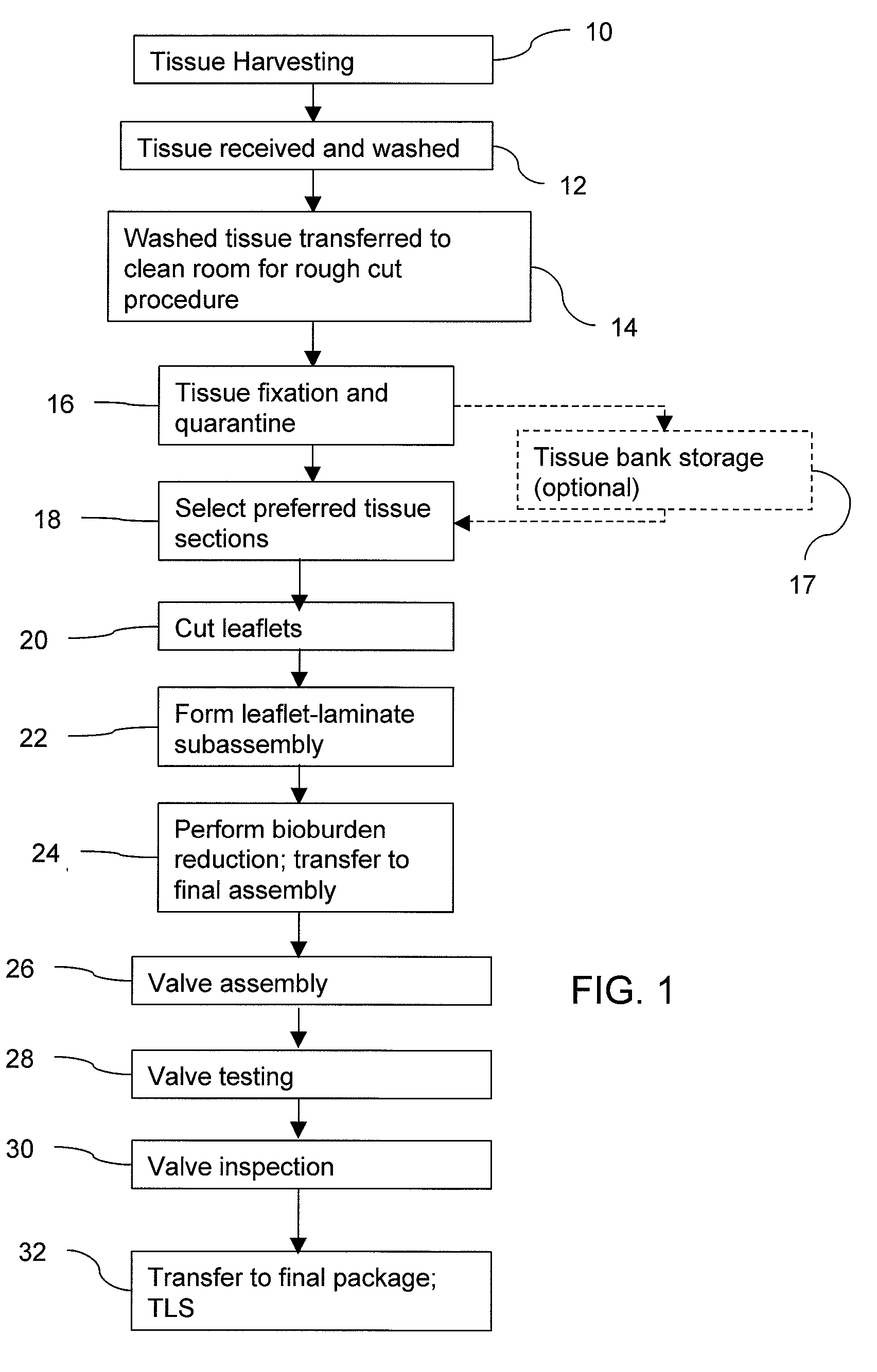

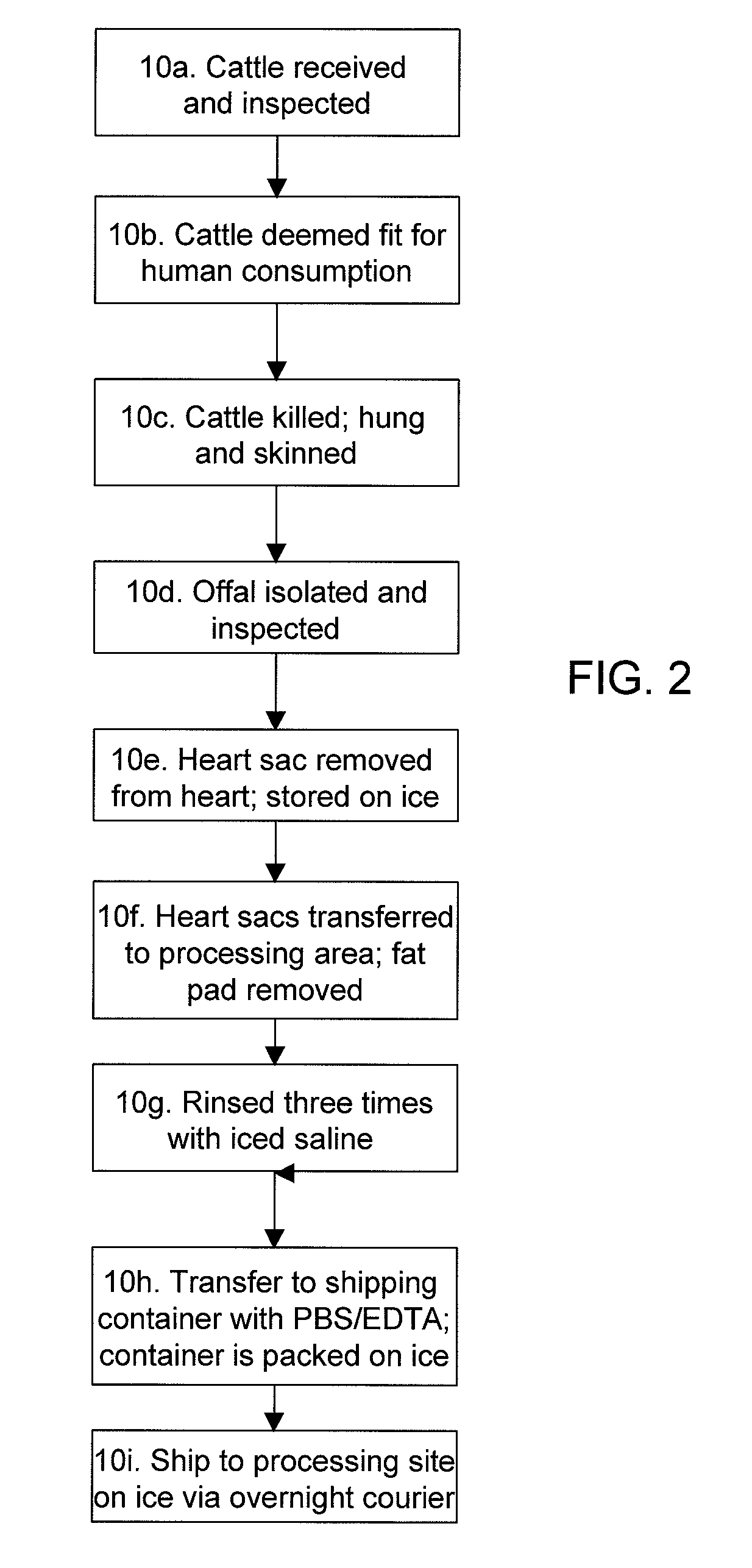

Methods for processing biological tissue

ActiveUS20060154230A1Remove background levelAvoid degradationDead animal preservationPhosphateCalcification

A method for processing biological tissue used in biological prostheses includes providing a tissue procurement solution formed from a phosphate buffered saline (PBS) solution and a chelating agent. The tissue is transferred from the tissue procurement solution and undergoes chemical fixation. The fixed tissue is then immersed in a series of fresh bioburden reduction process (BRP) solutions to extract phospholipids. The tissue procurement solution reduces the bioburden on the stored tissue and preserves tissue architecture by minimizing tissue swelling. The tissue procurement solution further reduces calcium from the incoming water and / or tissue, and inhibits enzymes that digest the collagen matrix. The serial immersion of the tissue in the fresh bioburden solutions ensures optimal extraction of phospholipids thereby mitigating subsequent calcification of the tissue.

Owner:MEDTRONIC INC

Methods for processing biological tissue

ActiveUS20060207031A1Remove background levelAvoid degradationSuture equipmentsDead animal preservationCalcificationPhospholipid

A method for processing biological tissue used in biological prostheses includes providing a tissue procurement solution formed from a phosphate buffered saline (PBS) solution and a chelating agent. The tissue is transferred from the tissue procurement solution and undergoes chemical fixation. The fixed tissue is then immersed in a series of fresh bioburden reduction process (BRP) solutions to extract phospholipids. The tissue procurement solution reduces the bioburden on the stored tissue and preserves tissue architecture by minimizing tissue swelling. The tissue procurement solution further reduces calcium from the incoming water and / or tissue, and inhibits enzymes that digest the collagen matrix. The serial immersion of the tissue in the fresh bioburden solutions ensures optimal extraction of phospholipids thereby mitigating subsequent calcification of the tissue.

Owner:MEDTRONIC INC

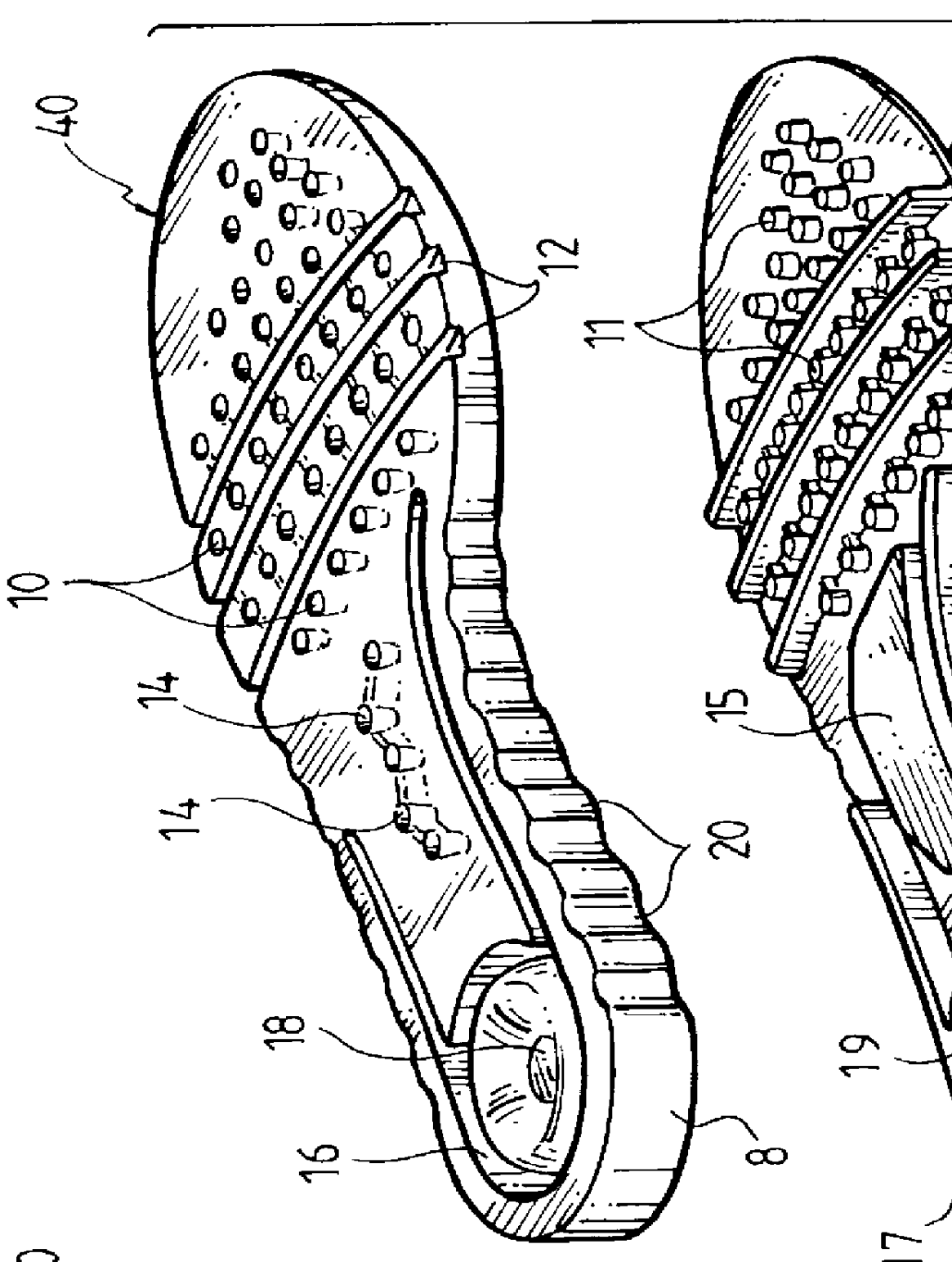

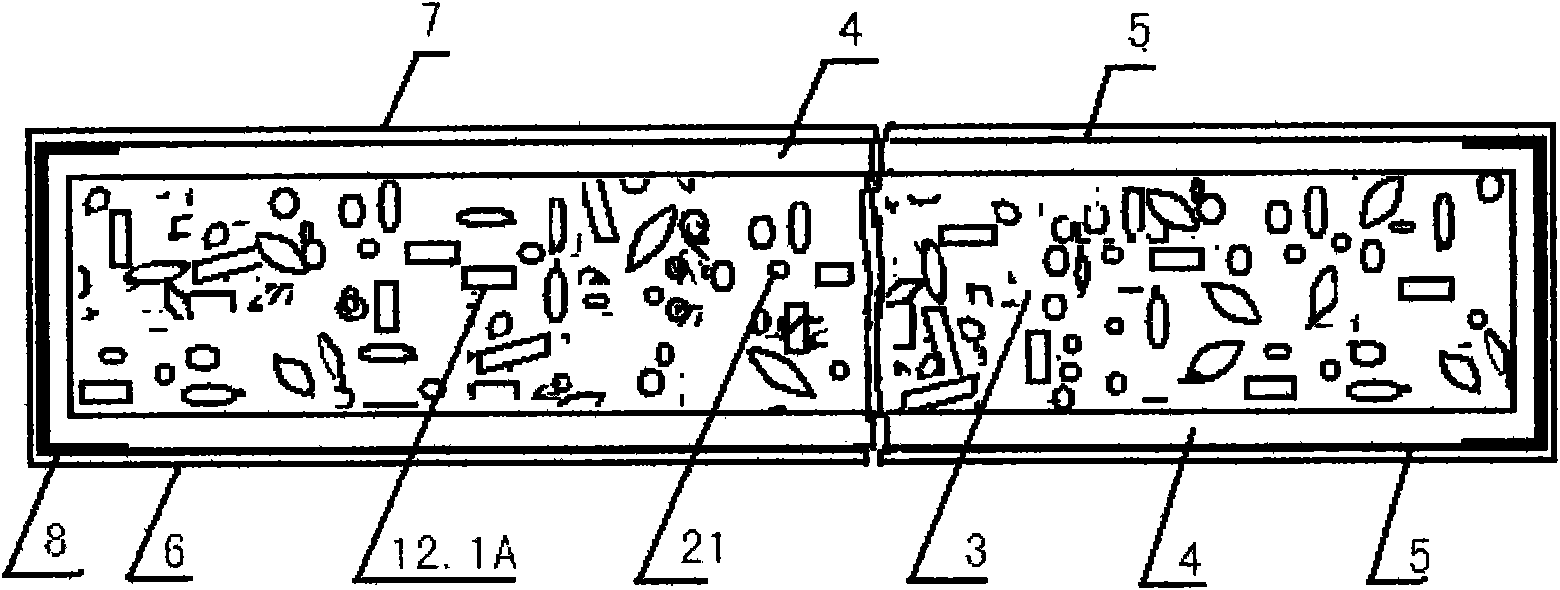

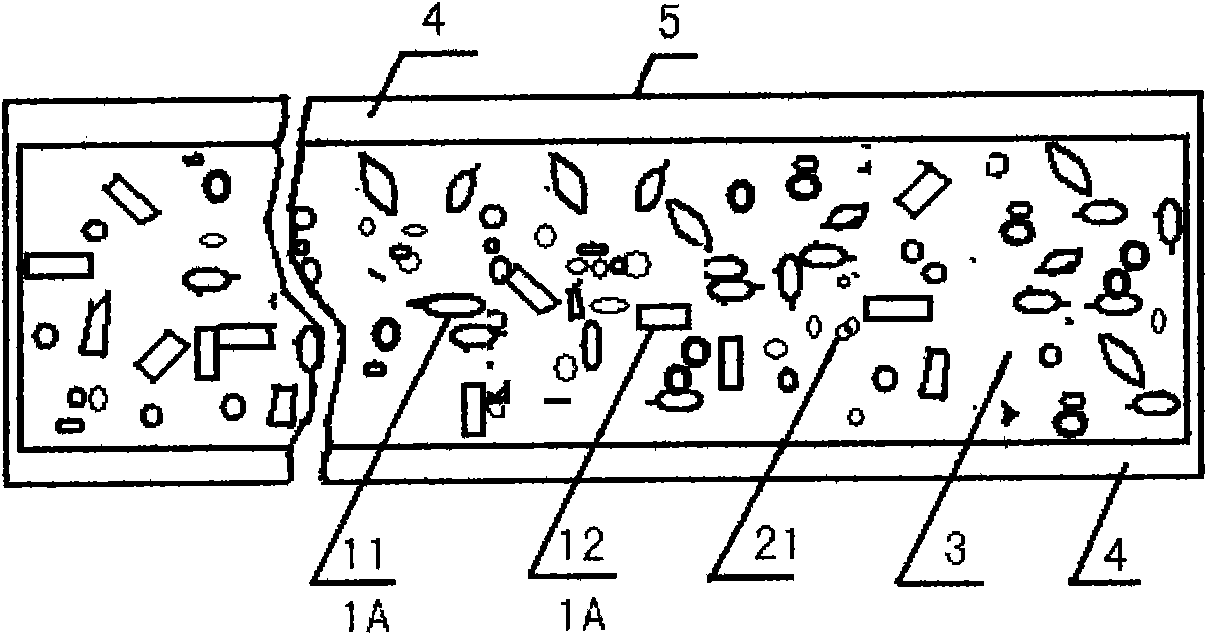

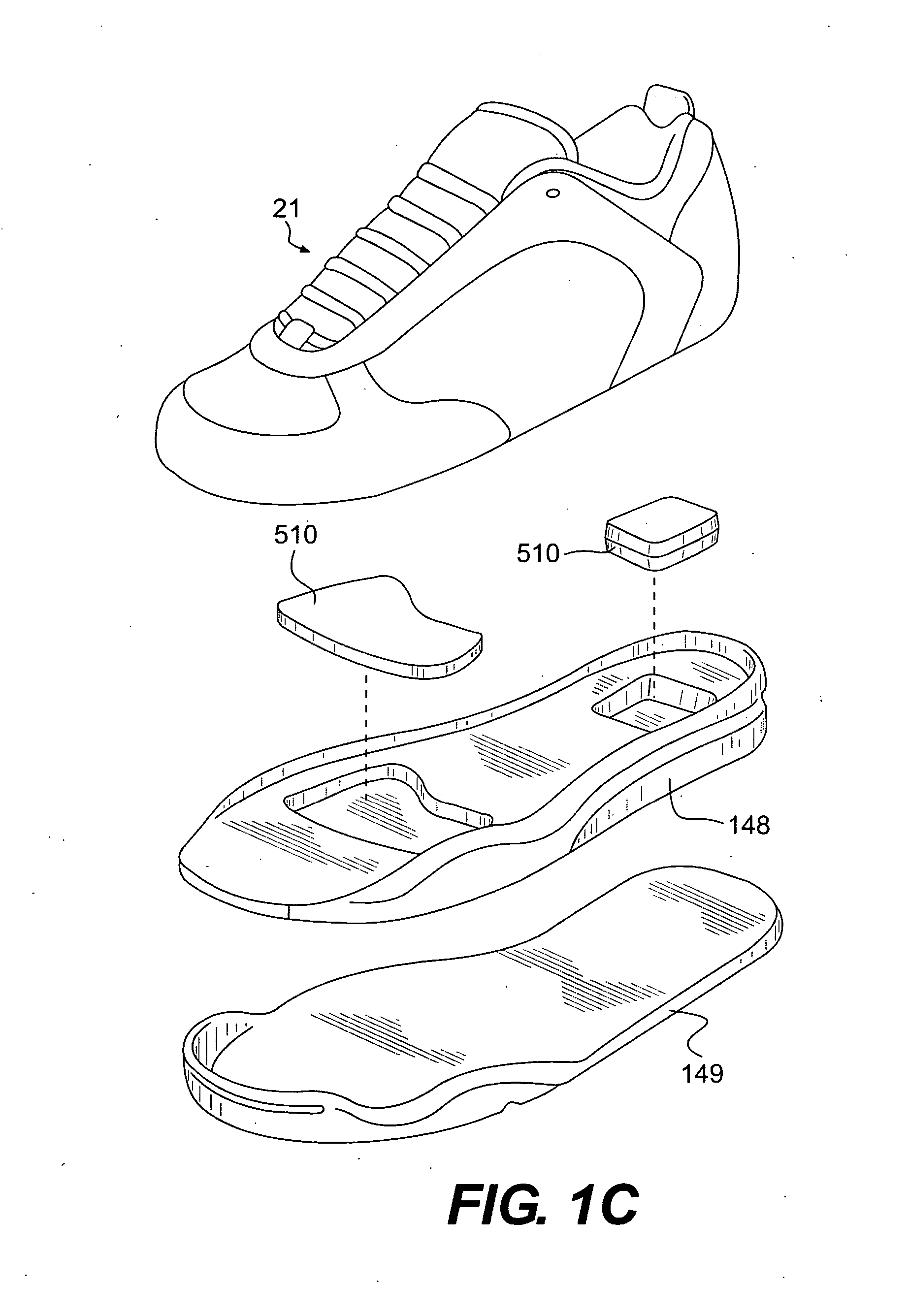

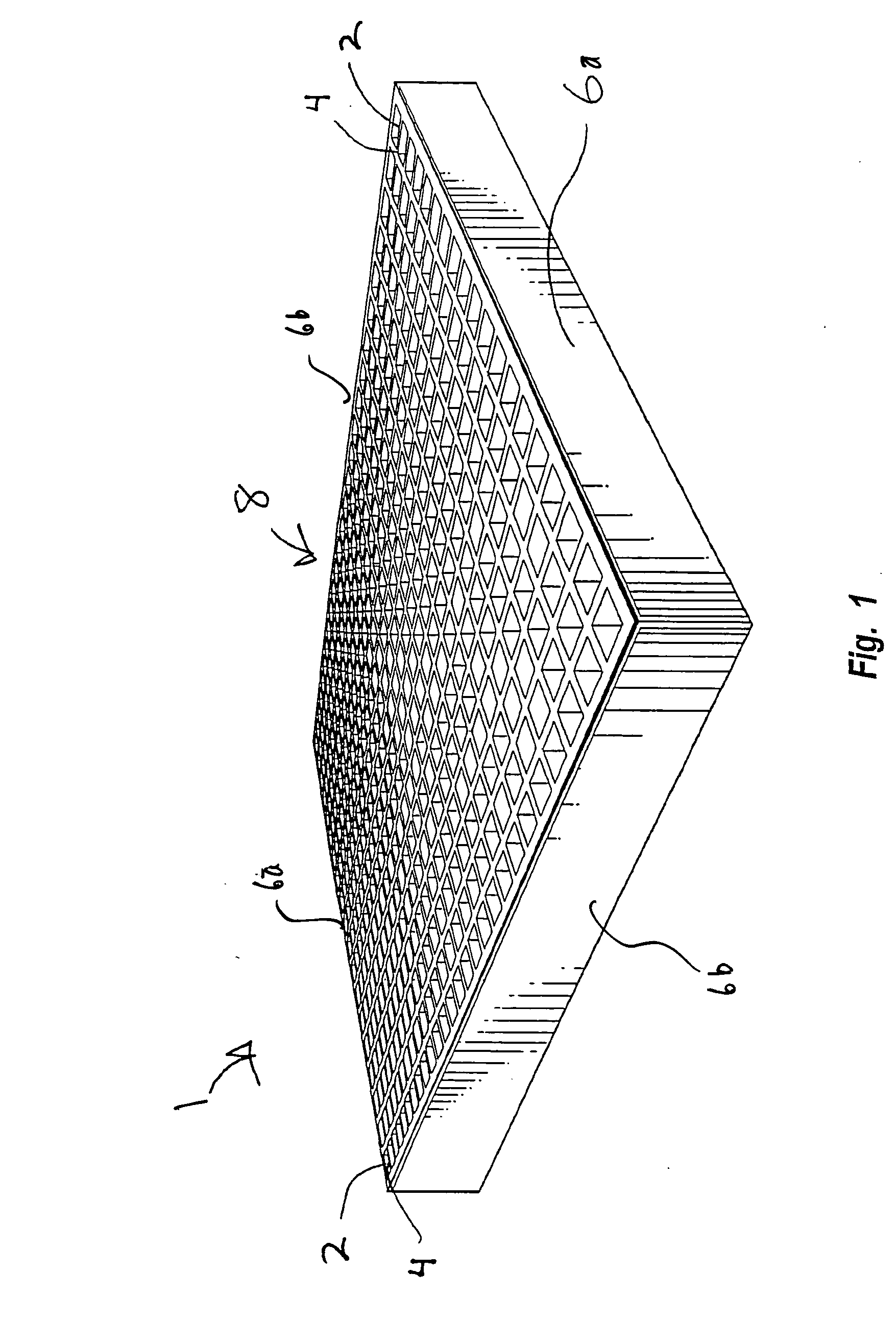

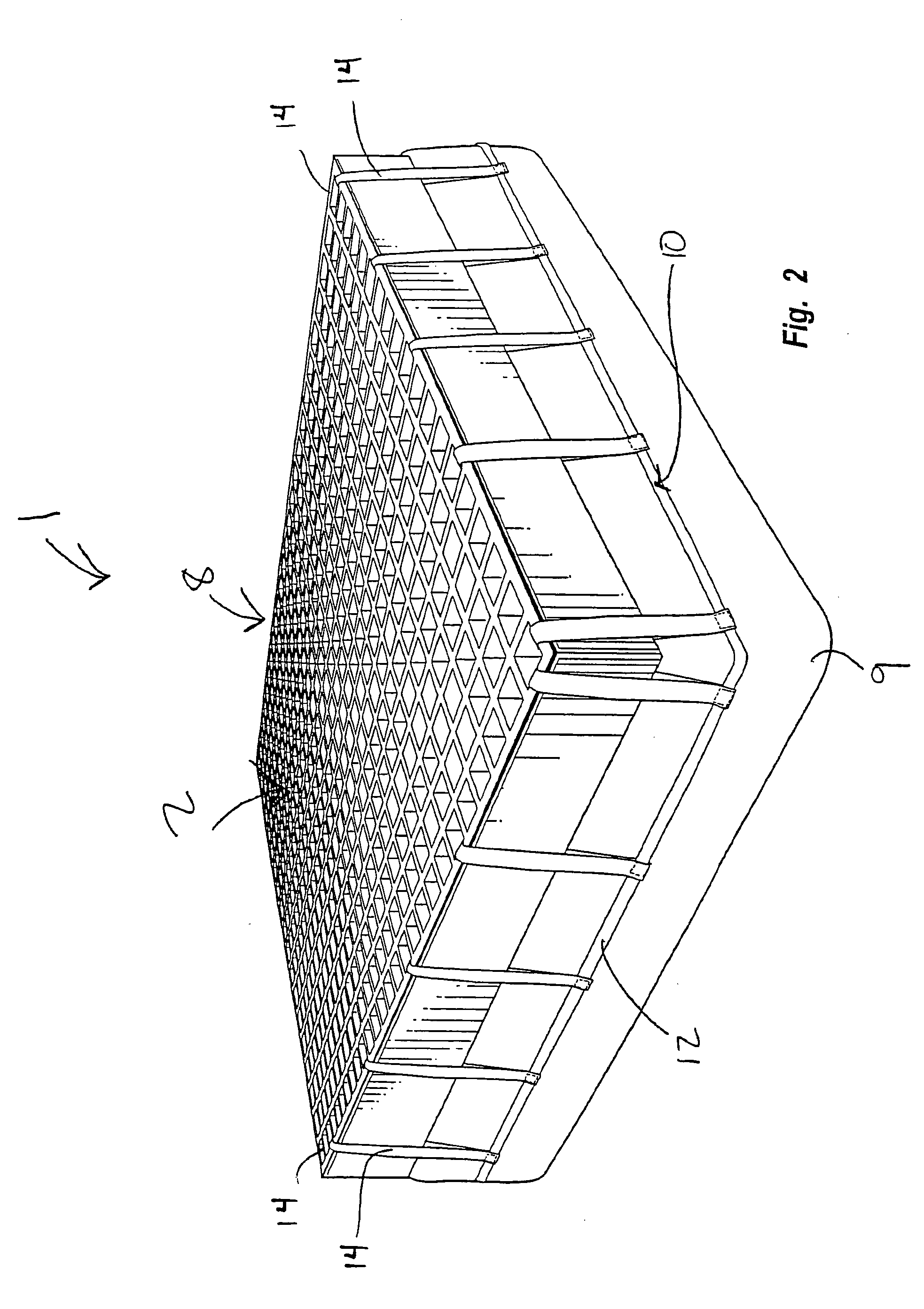

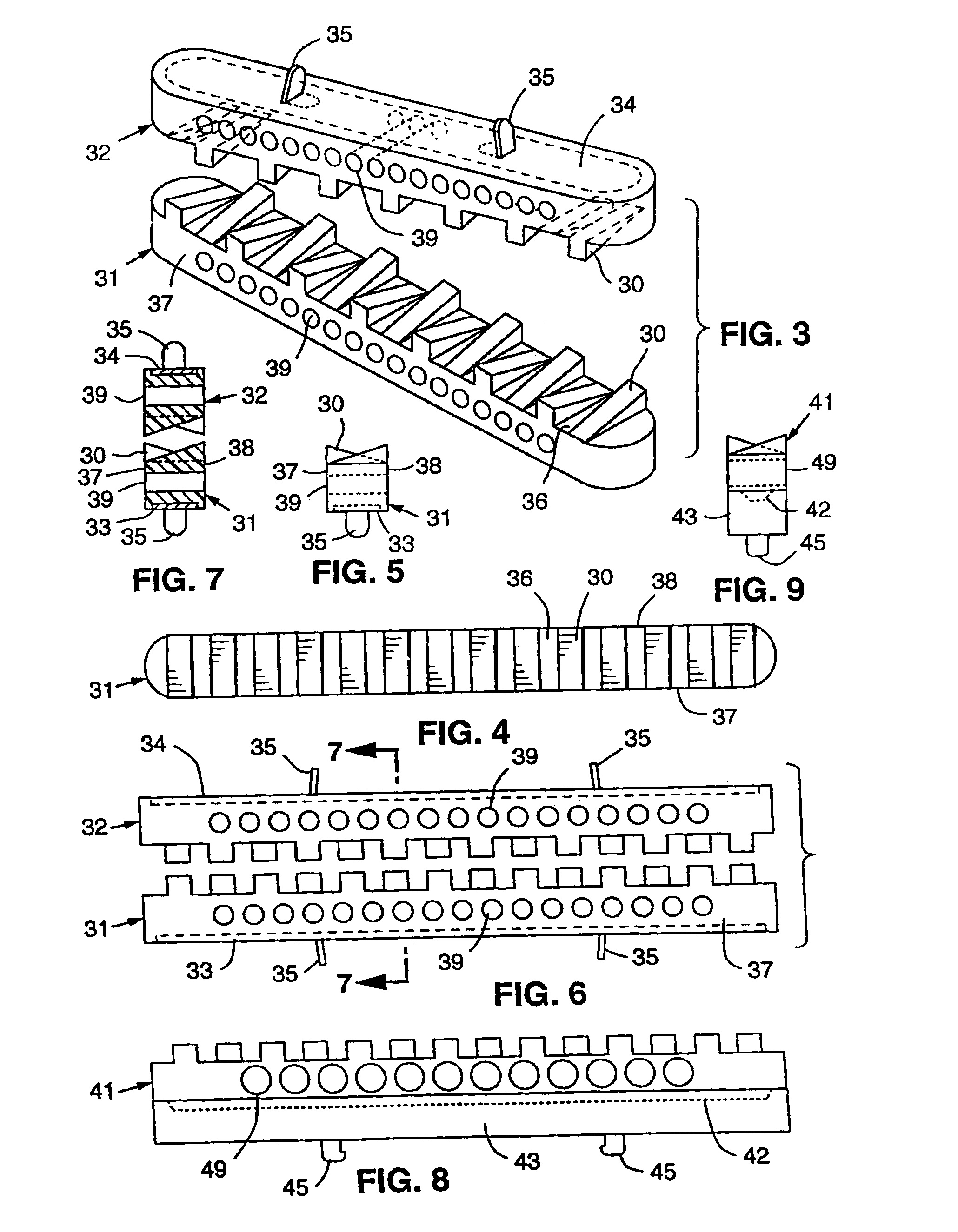

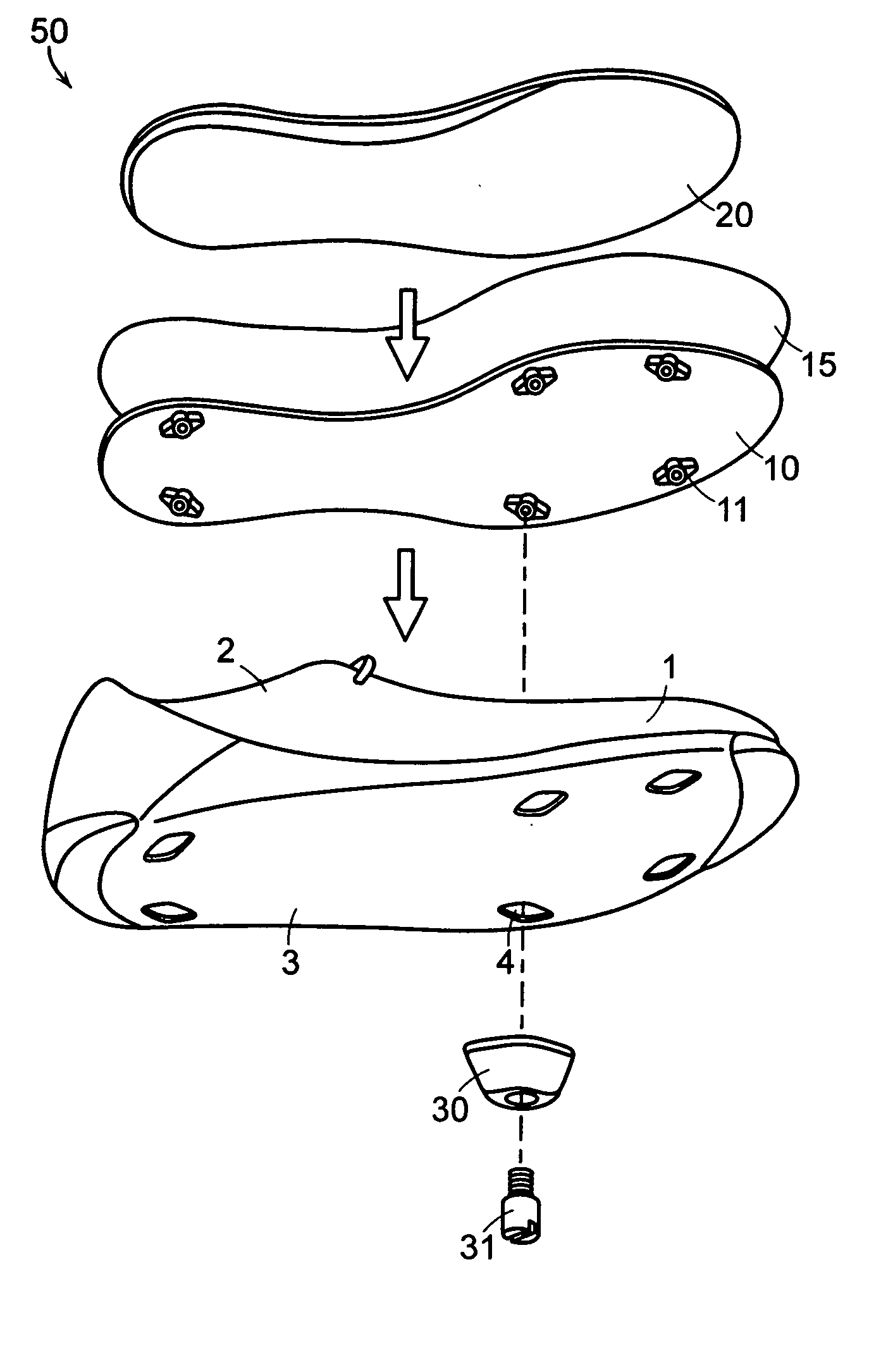

Devices with internal flexibility sipes, including siped chambers for footwear

ActiveUS20080086916A1Increase flexibilityImprove buffering effectSolesLayered productsBiomedical engineeringCushioning

Devices with internal flexibility sipes, such as slits, provide improved flexibility, improved cushioning to absorb shock and / or shear forces, and improved stability of support. Siped devices can be used in any existing product that provides or utilizes cushioning and stability. These products include human and other footwear, both soles and uppers, as well as orthotics; athletic, occupational and medical equipment and apparel; padding or cushioning, such as for equipment or tool handles, as well as furniture; balls; tires; and any other structural or support elements in a mechanical, architectural, or any other product.

Owner:ELIIS FRAMPTON E

Footwear system

Owner:TRANSFORM SR BRANDS LLC

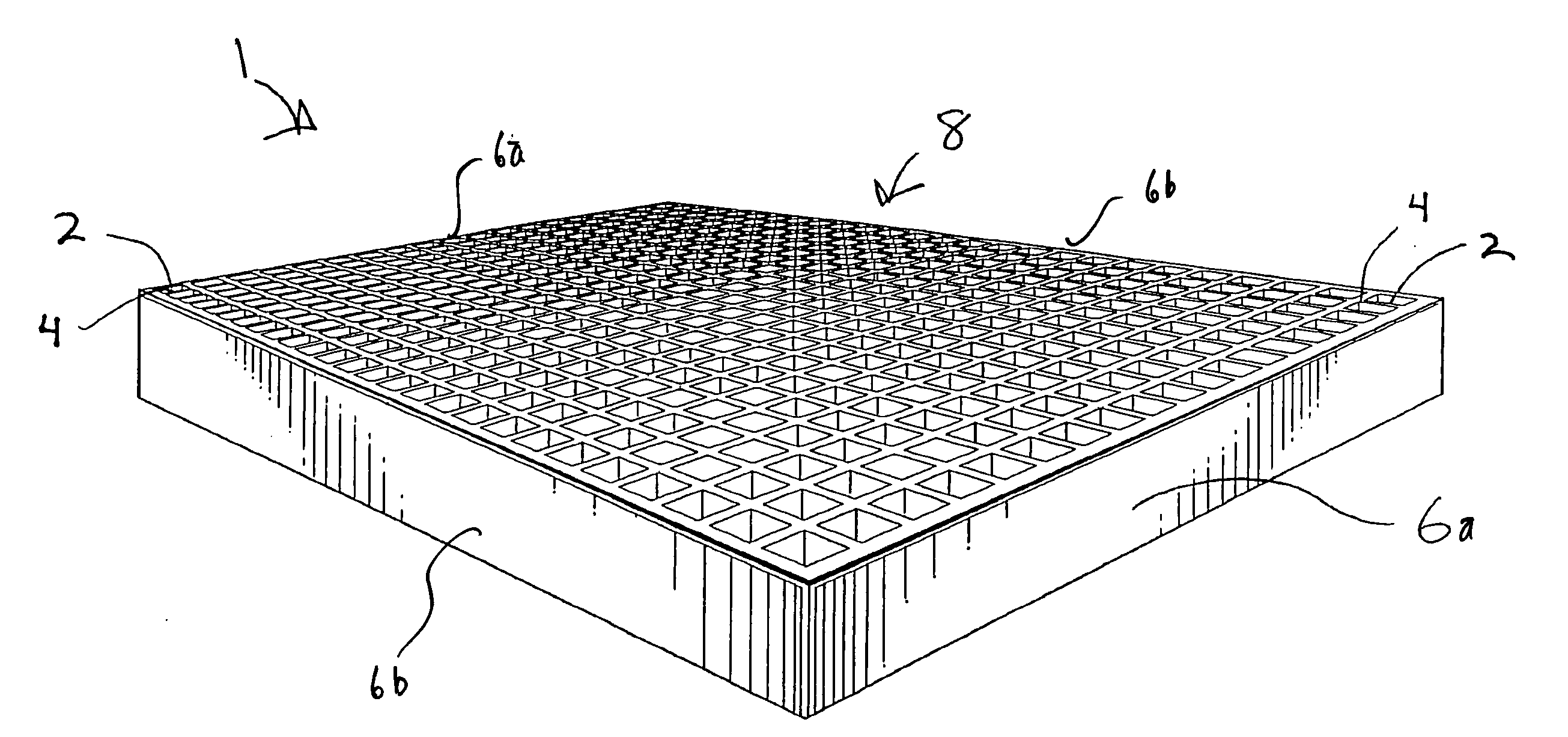

Cushioned apparatus

InactiveUS20050223667A1Easy to optimizeEliminate pointStuffed mattressesSpring mattressesCushioningThermoplastic

The present invention relates to cushioning apparatus having a plurality of intersecting columns, the columns being formed from a thermoplastic, silicone, two-part, or other gel material. The cushioning apparatus are extremely strong and durable yet provide an improved cushioning apparatus. The intersecting columnar configuration of the cushioning apparatus allow for weight to be shared with neighboring column walls. When force is exerted on the columns, the column walls are designed to buckle in the areas of greatest pressure. The column buckling diffuses energy from the areas of highest pressure effectively eliminating pressure points. As the polymer gel collapses within the column walls, the column walls essentially collapse at least partially in a lateral direction allowing pressure to flow away from the areas of greatest pressure to areas of lesser pressure. This provides an improved cushioning surface on which a user can sit, sleep, or other types of cushioning can be provided.

Owner:MCCANN BARRY +1

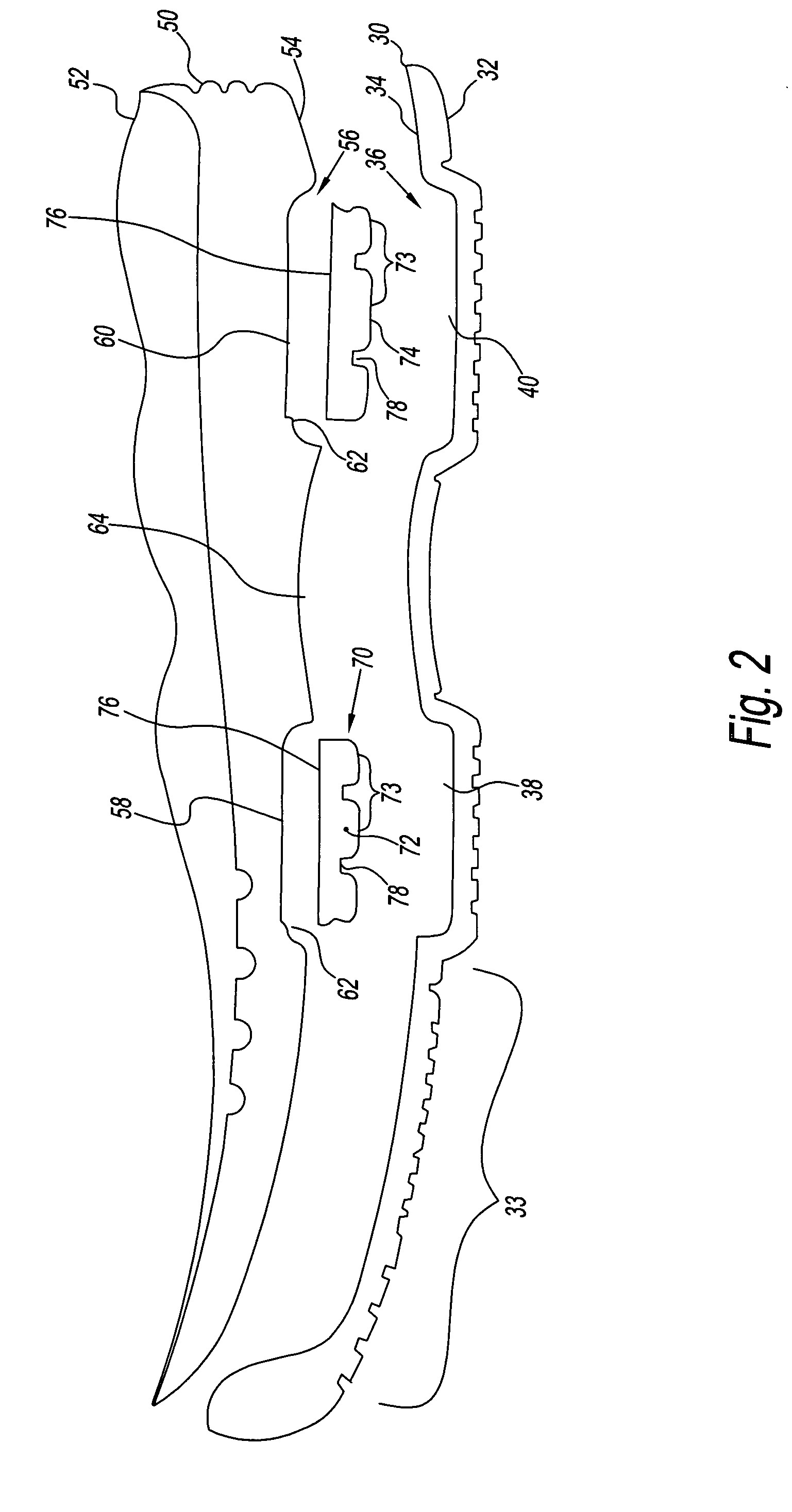

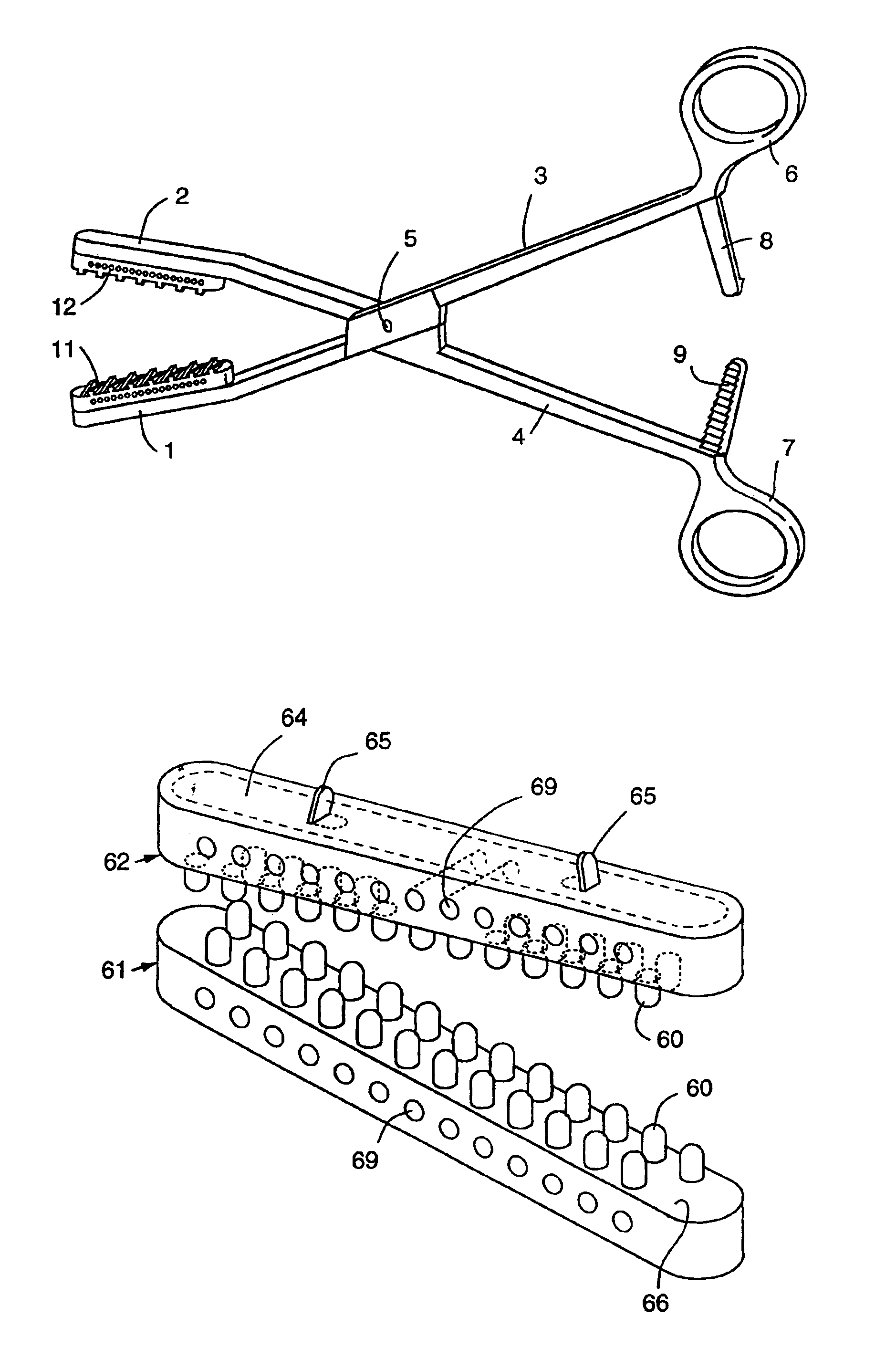

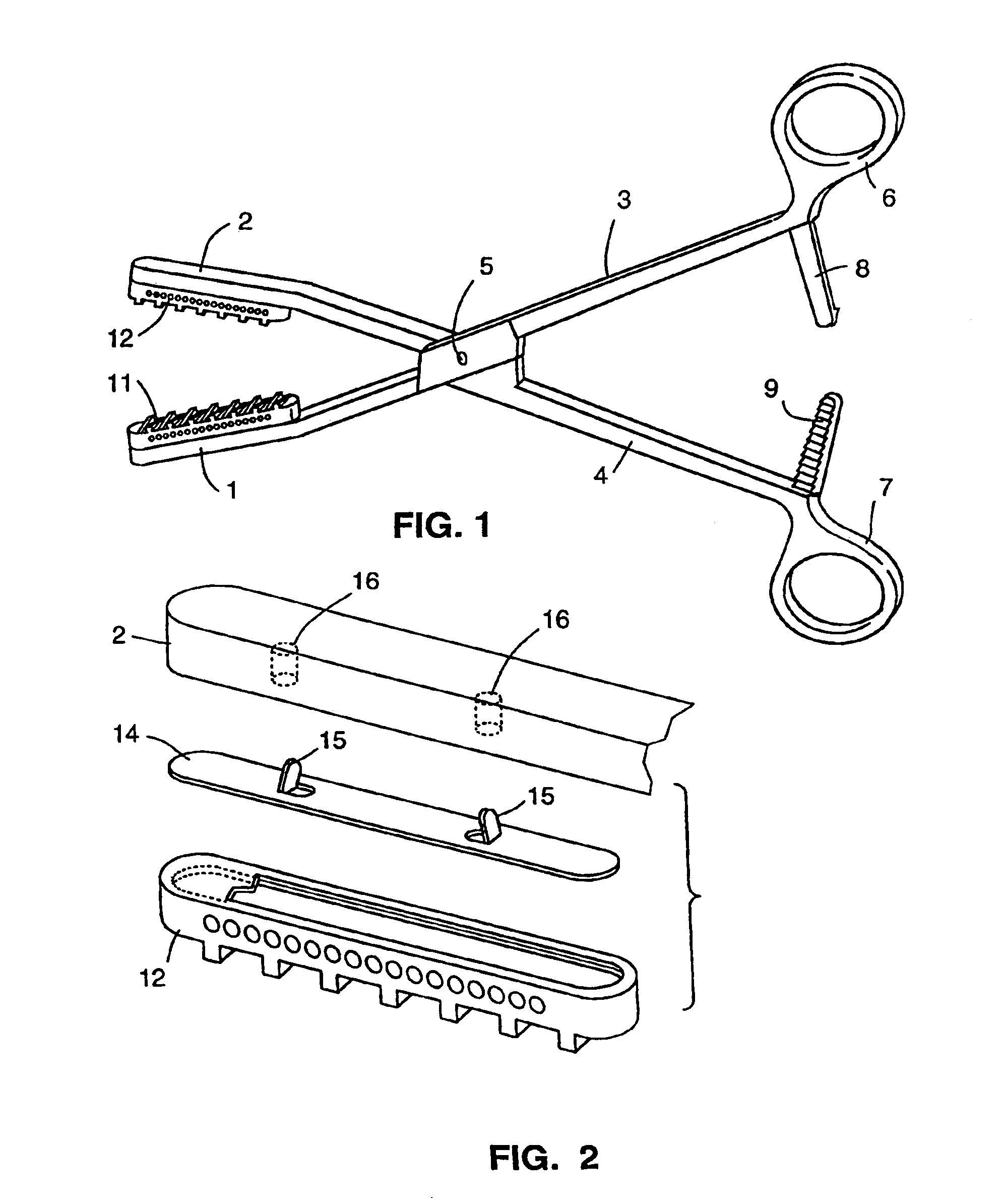

Surgical clamp pad with interdigitating teeth

InactiveUS6989017B2Improve gripGreat tractionSurgical forcepsWound clampsSurgical ClampsSurgical department

Opposable surgical clamp members having opposable resilient pads with wedge-shaped and cylindrical protrusions extending from the surfaces of the pads and the use of such members for occluding vessels and other tubular body structures are described. The protrusions are arranged such that when the members are moved toward one another, the protrusions of one pad interdigitate with the protrusions of the other pad. Upon engagement with a vessel, portions of the vessel are forced into the interdigital spaces providing for improved gripping of the vessel. The protrusions also resist lateral or transverse movement of a clamped vessel relative to the pads. The existence of through holes under the pad surface alters the relative resiliency of the pad, allowing for an overall pad resiliency that minimizes trauma to a clamped vessel while allowing the local resiliency of the protrusions themselves to be of a hardness to avoid excessive deflection and retain the desired shape and gripping ability.

Owner:VITALTEC INT

Bio-organic compound fertilizer

InactiveCN101781149AImprove fat retention capacityImprove buffering effectFertilizer mixturesPotassiumOrganic compound

The invention relates to a bio-organic compound fertilizer, which comprises the following components in part by weight: 10 to 30 parts of organic matter, 2 to 10 parts of compound microbial inoculants, 5 to 20 parts of humic acid, 5 to 20 parts of amino acid, 4 to 10 parts of chitin, 1 to 5 parts of polypeptide, 530 parts of nitrogen, phosphorus and potassium, 5 to 10 parts of secondary and trace elements, 5 to 15 parts of algae fertilizer, 5 to 10 parts of zeolite powder and 1 to 5 parts of synergistic agent. Through the scientific and rational formula, the bio-organic compound fertilizer achieves nutritive equilibrium and can satisfy the need of crop growth in nutrient. The microbial inoculants are added to quickly degrade natural macromolecular organic compounds into the organic fertilizer and decompose organic pollutants, which effectively improves the capacity of crops in the absorption of nutrient components, reduces the waste of the fertilizer and reduces the damage of the chemical fertilizer to soil to further achieve the nutritive equilibrium, satisfy the need of the crop growth in the nutrient, achieve the aims of low investment and high output value, improve the quality of the crops and improve the economic benefit brought by the crops.

Owner:张钧

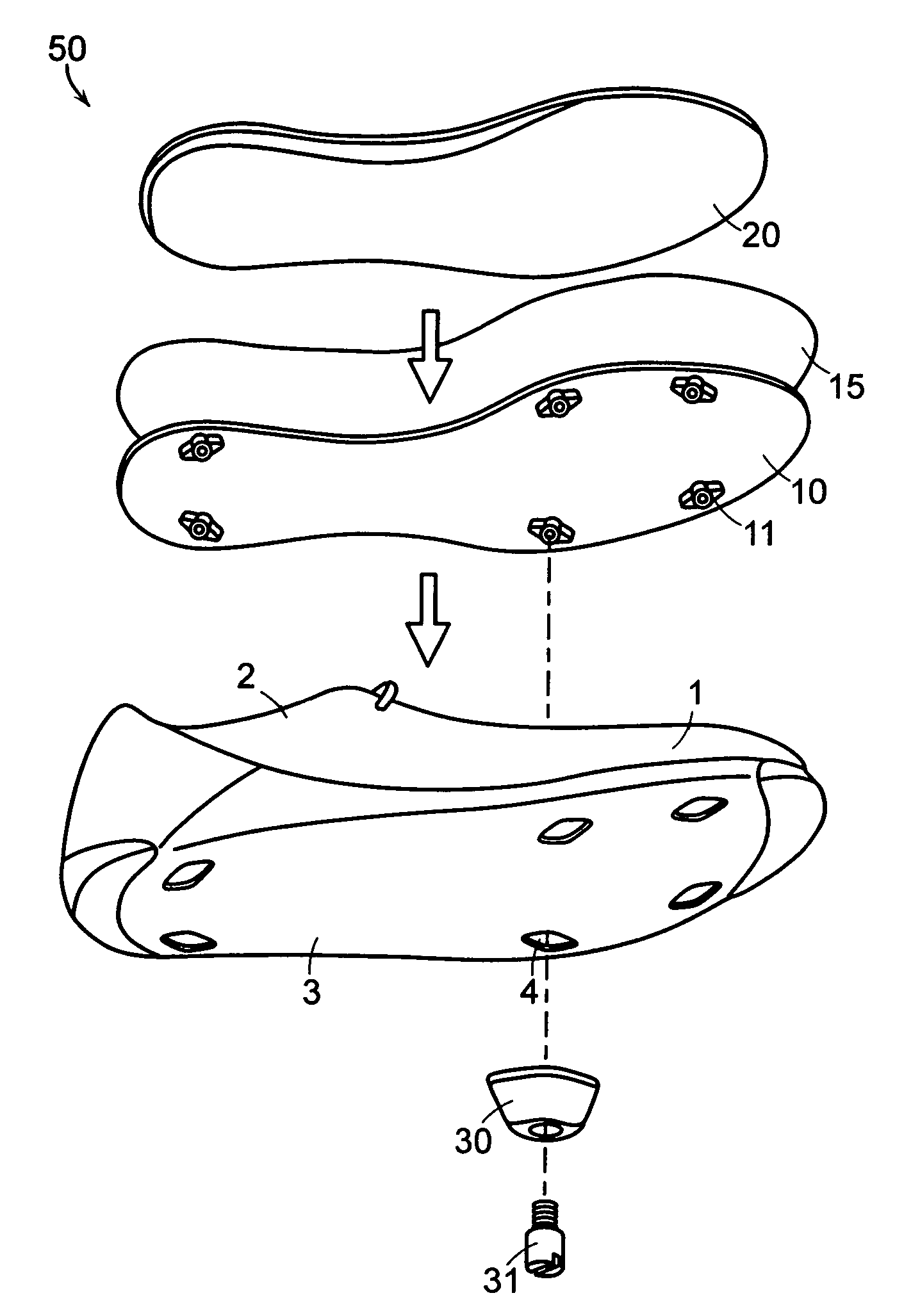

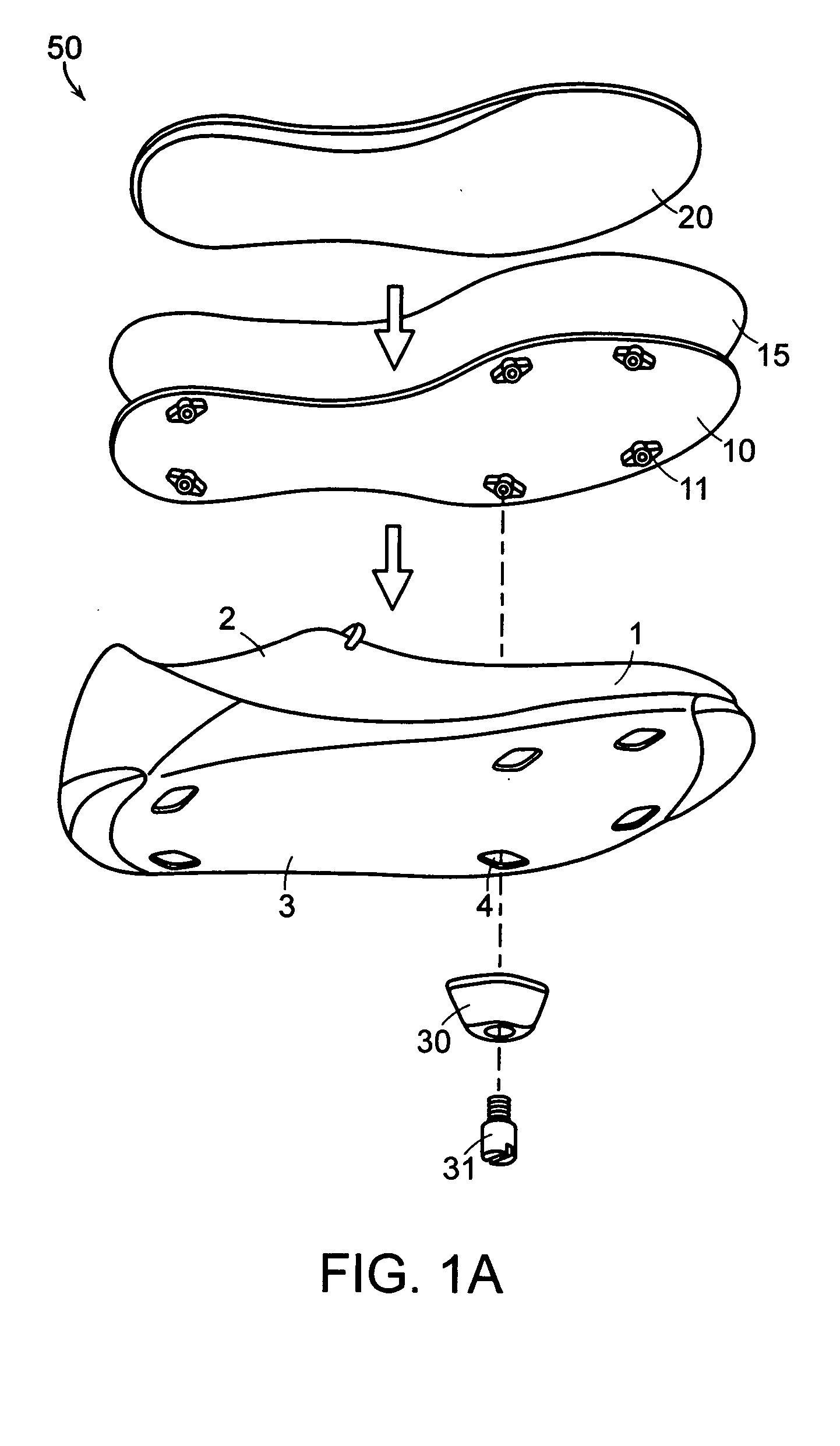

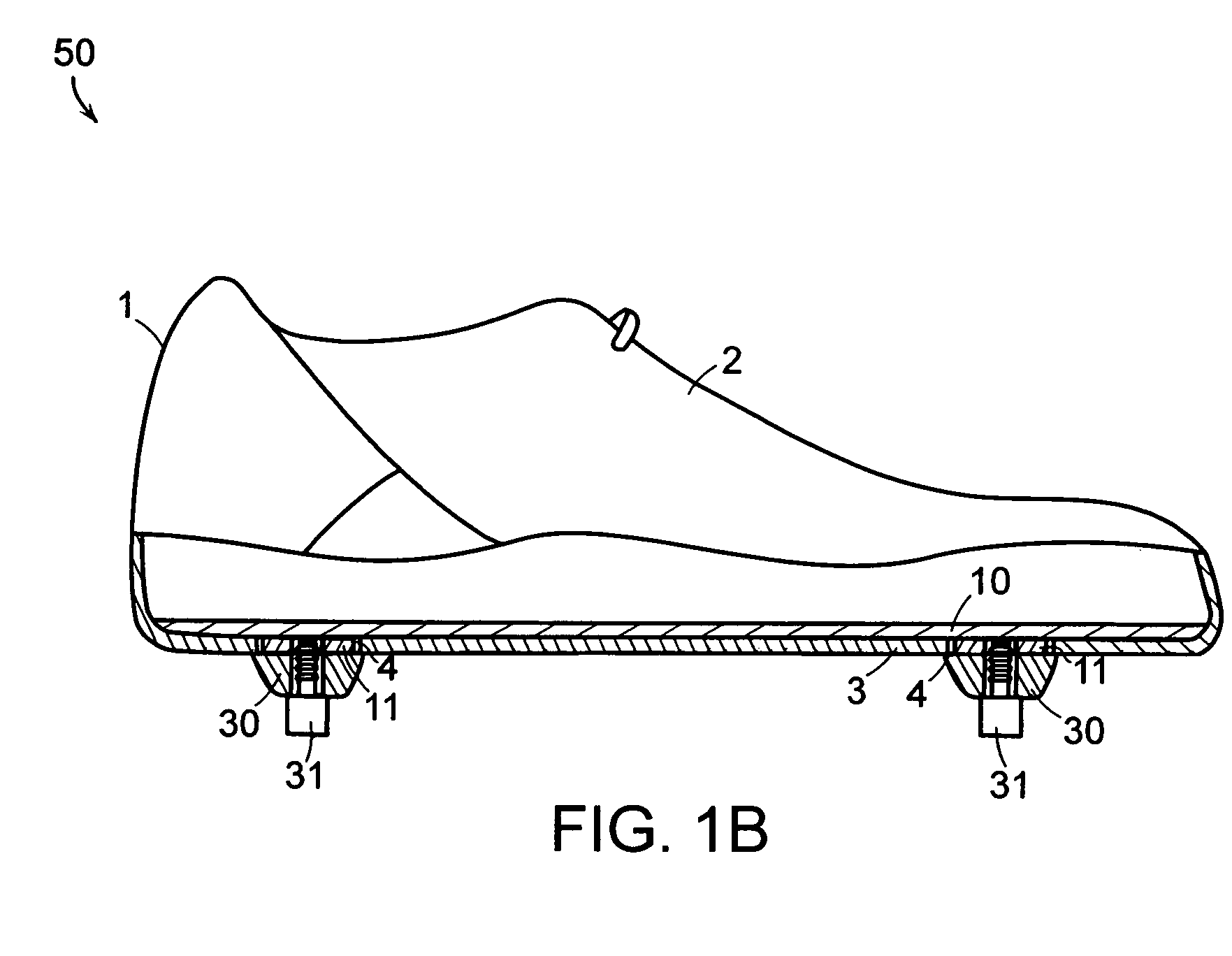

Modular shoe

Owner:ADIDAS

Process for preparing liquid seaweed fertilizer through enzymolysis and fermentation

ActiveCN104262008AEnlarged vascular cellsPromotes plant cell divisionOrganic fertilisersFertilizer mixturesMacromolecular SubstancesSeaweed food

The invention discloses a process for preparing a liquid seaweed fertilizer through enzymolysis and fermentation. The process disclosed by the invention can be used for generating a large quantity of soil beneficial bacteria and multiple special-effect metabolites by degrading macromolecular substances which are contained in seaweeds and difficult to utilize into micromolecular polysaccharide, monosaccharide and a nitrogen-containing compound in compound enzymolysis and multi-strain co-fermentation modes, thereby enhancing the biological activity of a seaweed fertilizer, preventing the destruction of strong base, high temperature and high pressure in the production process of the seaweed fertilizer and completely retaining abundant nutrient substances contained in the seaweeds. According to the process, the content of a product, namely alginic acid, is 40-60 g / L and is increased by more than 30% compared with that prepared from an enzymolysis method, an alkaline hydrolysis method, an acid hydrolysis method and a simple microbe fermentation method, and the effective viable count is more than or equal to 2 billion / mL; the product integrates natural nutrient components, antibiotic substances and plant hormones, combines the efficacy of three fertilizers, namely an organic fertilizer, a microbe fertilizer and a trace element fertilizer and has a wide application prospect.

Owner:JIANGMEN ZHIHU IND CO LTD

Shoe with cushion and ventilation device

Provided is a shoe with a cushion and ventilation device. The cushion and ventilation device includes an air pump having an air discharge tube provided at its one side, and an air tube having a connection pipe connecting to the air discharge tube of the air pump, and an air chamber, wherein the air pump is provided by placing an upper sheet having a cavity on a lower sheet having an intake hole, and thermally bonding circumference surfaces of the upper and lower sheets using microwave, and wherein the upper and lower sheets further comprise a sponge having contraction and restoring forces therein.

Owner:CHO JONG SOO +1

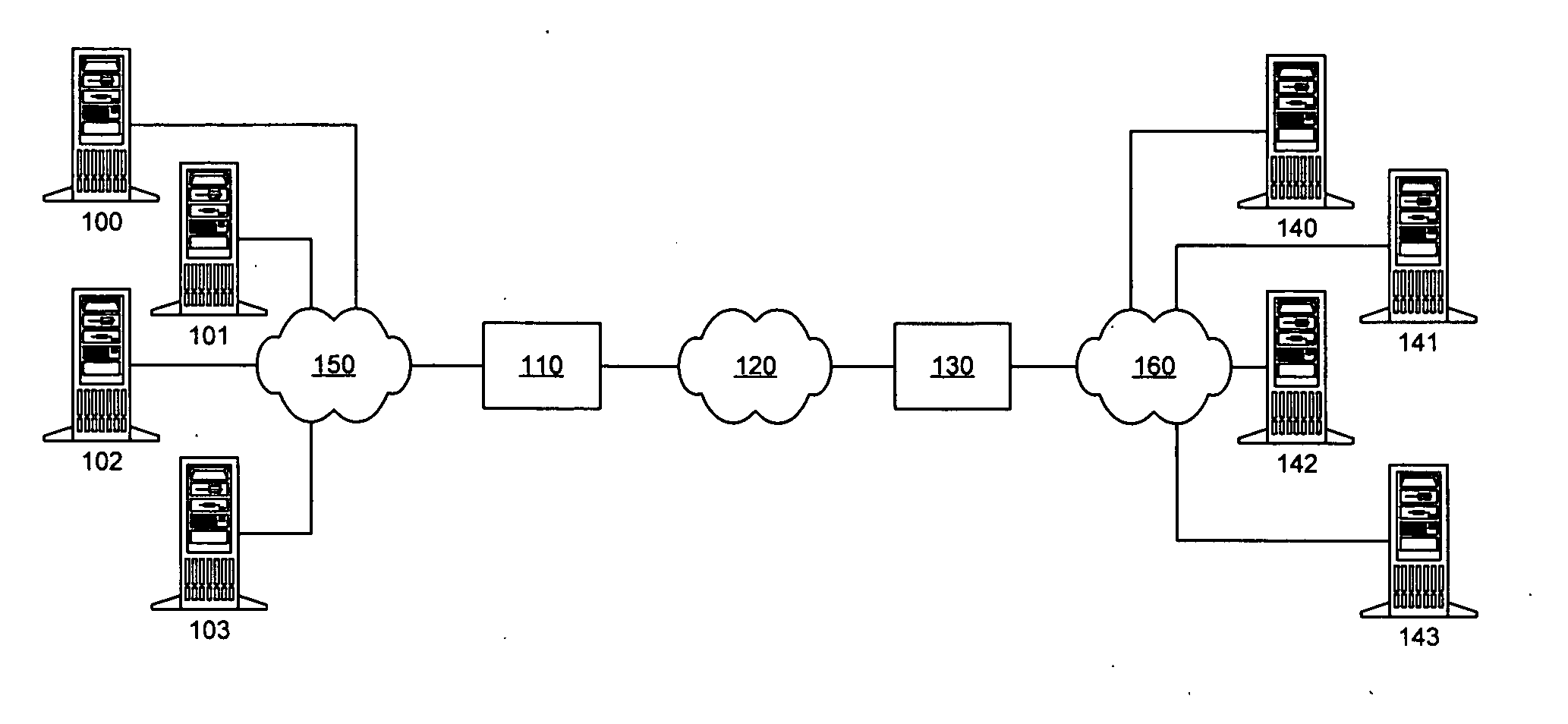

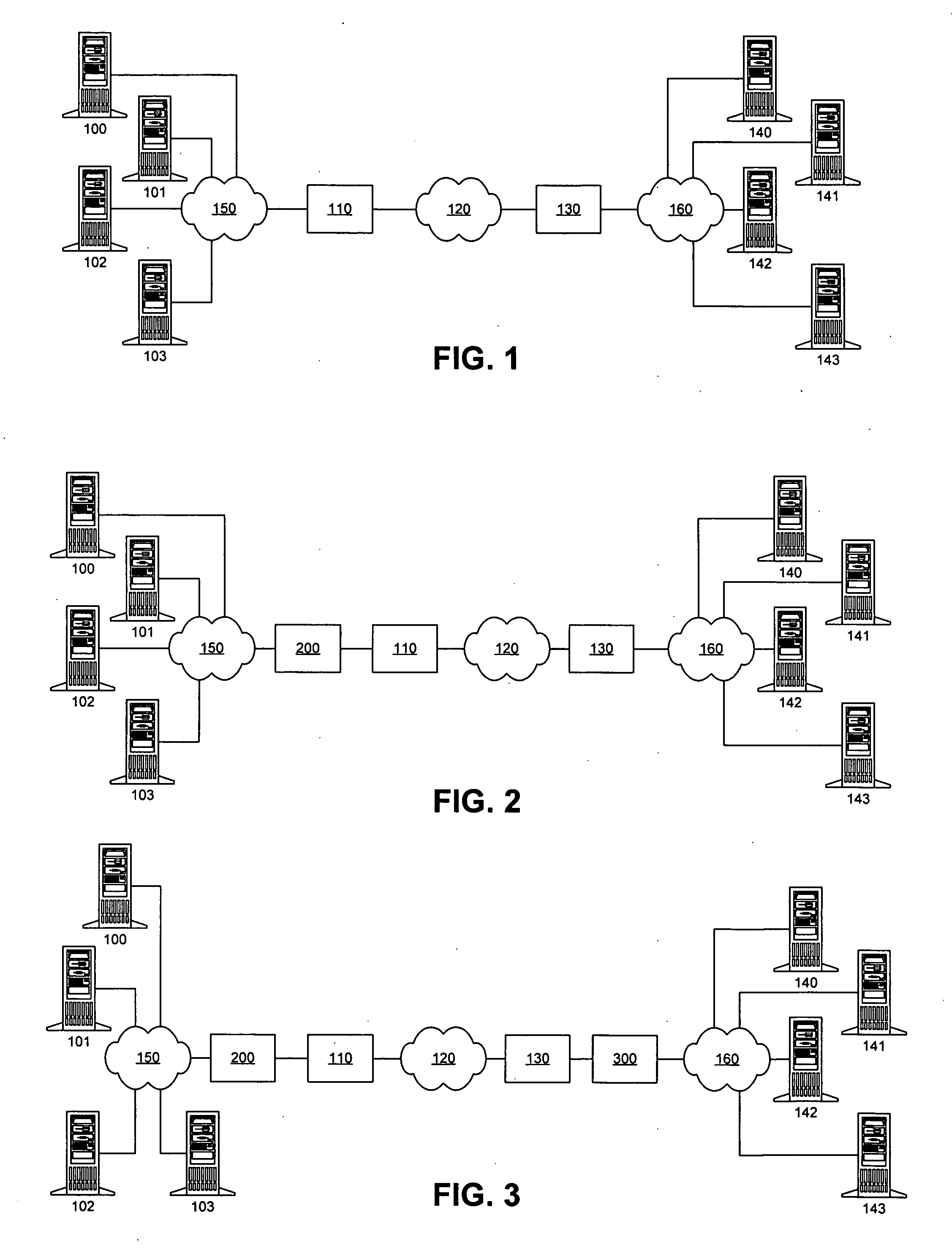

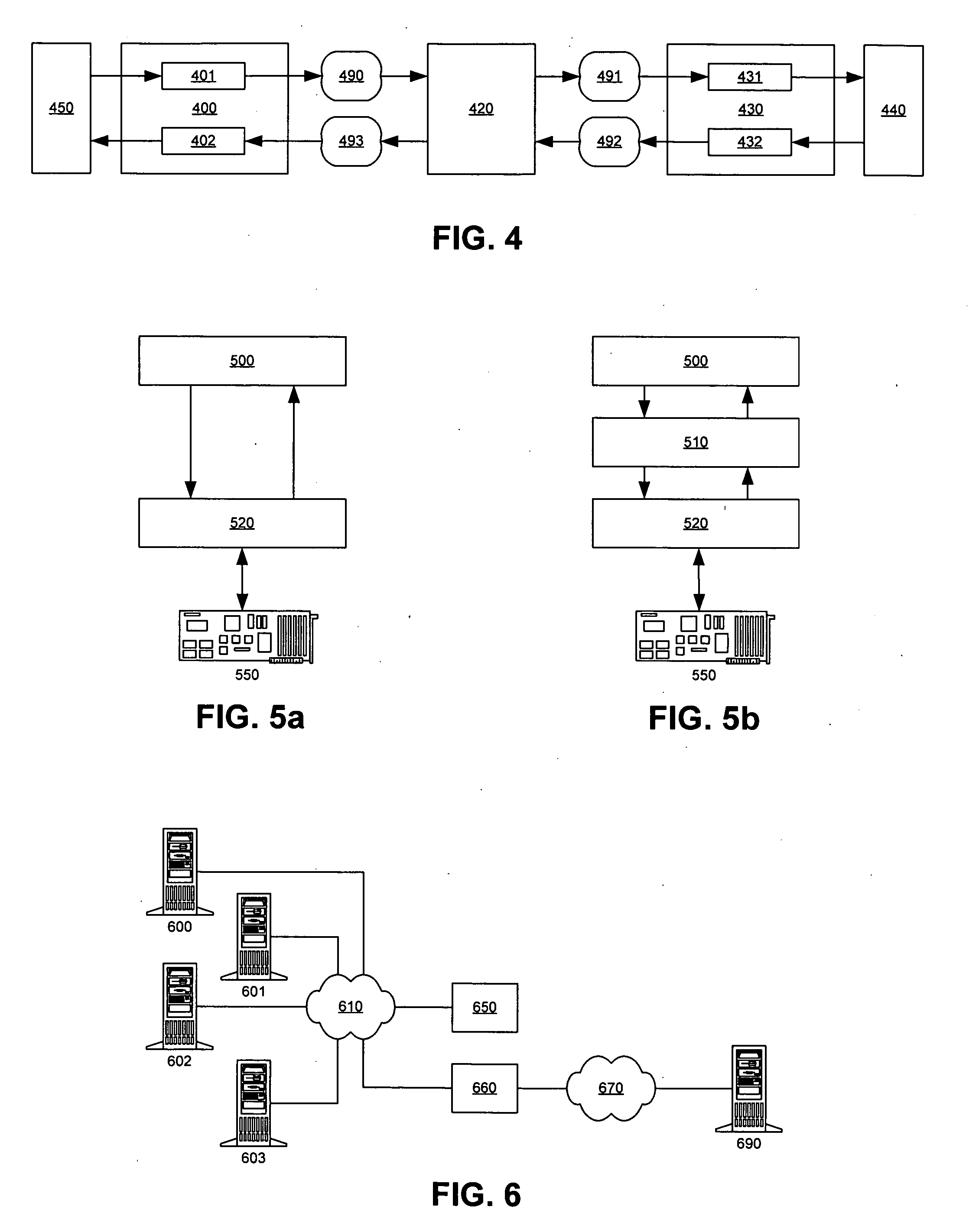

Automatic detection and window virtualization for flow control

ActiveUS20050063302A1Increasing data buffering capabilityImprove data throughputError preventionTransmission systemsVirtualizationNetwork connection

One or more flow control modules, implemented on various types of network topologies, provide a number of functionalities for controlling the flow of IP packets (such as TCP / IP packets) over a network connection. The flow control modules may be implemented within a sender and / or receiver or may be deployed into a network as a separate device without requiring significant additional resources.

Owner:CITRIX SYST INC

Devices with internal flexibility sipes, including siped chambers for footwear

InactiveUS20090183387A1Increase flexibilityImprove buffering effectSolesHollow inflatable ballsCushioningOrthotic device

Devices with internal flexibility sipes, such as slits, provide improved flexibility, improved cushioning to absorb shock and / or shear forces, and improved stability of support. Siped devices can be used in any existing product that provides or utilizes cushioning and stability. These products include human and other footwear, both soles and uppers, as well as orthotics; athletic, occupational and medical equipment and apparel; padding or cushioning, such as for equipment or tool handles, as well as furniture; balls; tires; and any other structural or support elements in a mechanical, architectural, or any other product.

Owner:ELLIS

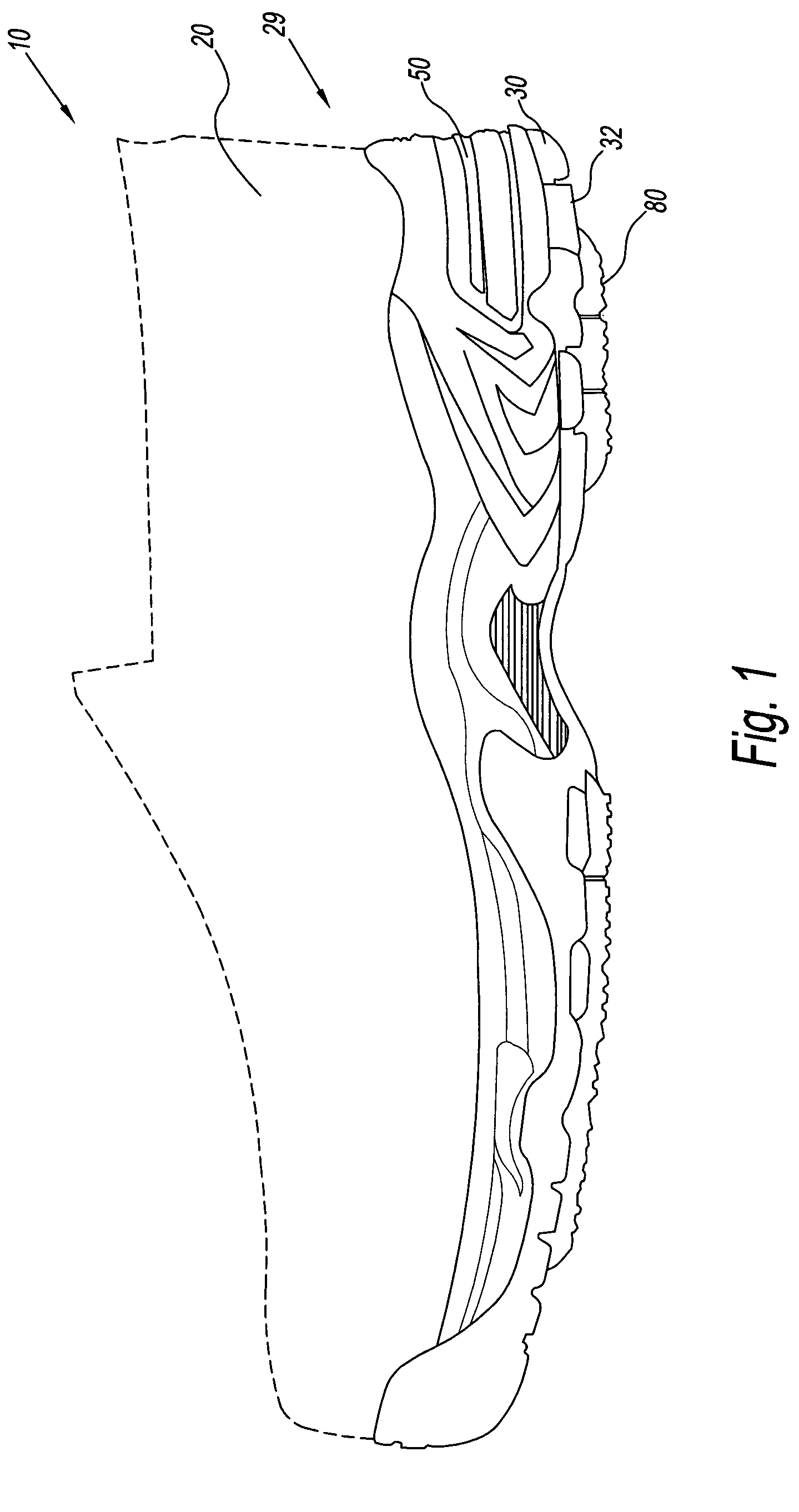

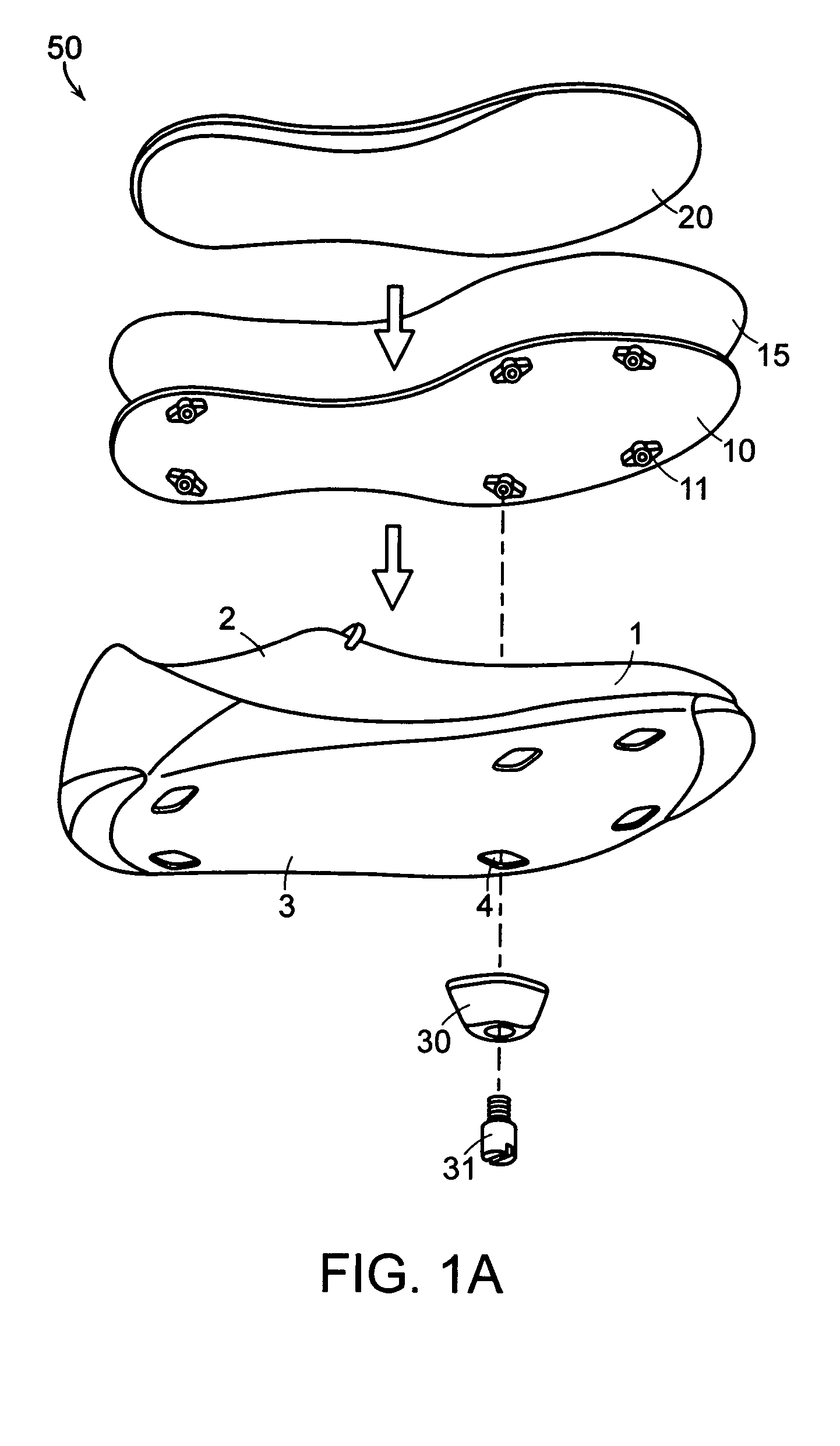

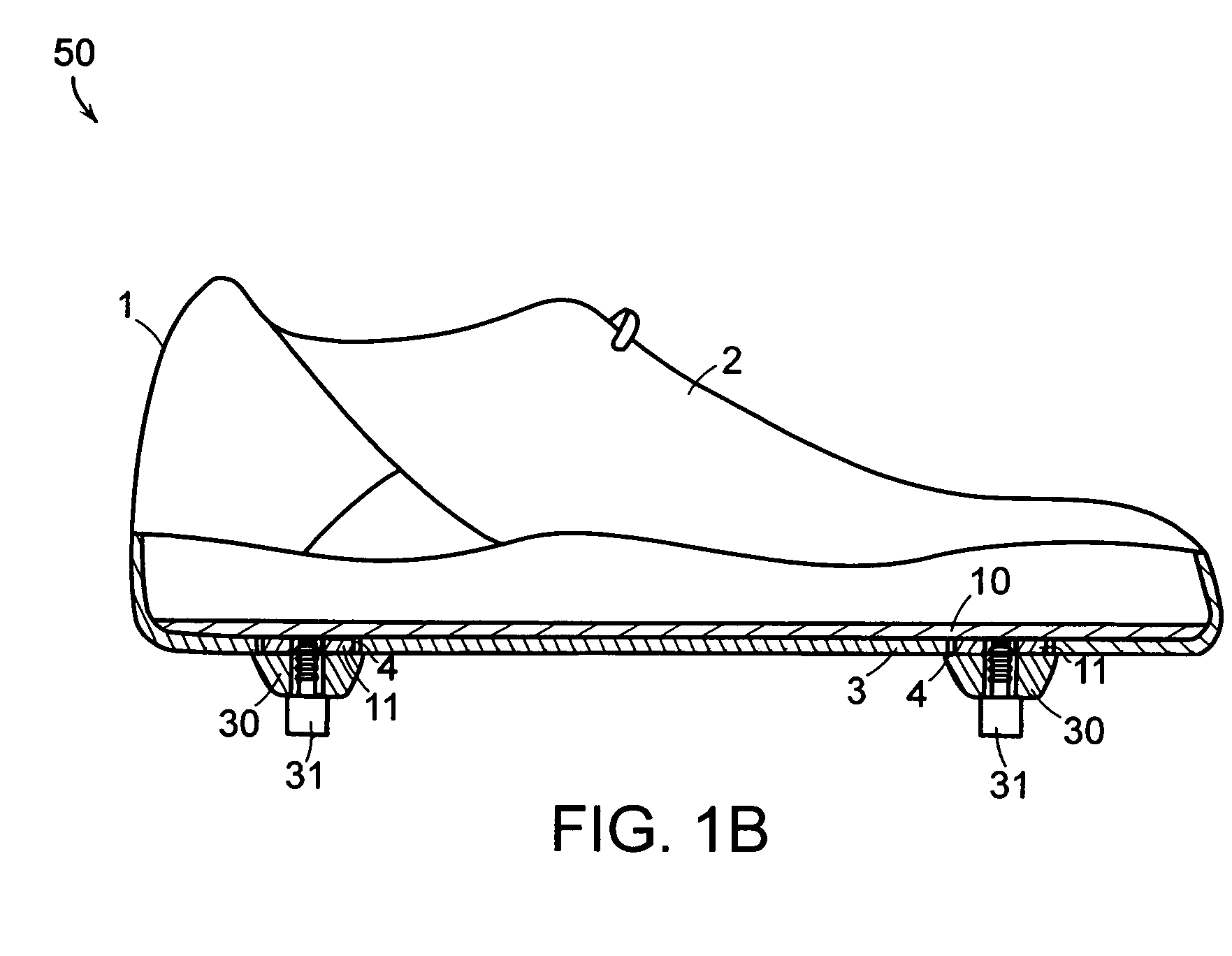

Modular shoe

A modular shoe includes an upper with an upper side and a lower side, a chassis releasably arranged in an interior of the upper, and a plurality of studs. Each stud is releasably attached to the chassis through the lower side of the upper. The lower side of the upper is clamped between the chassis and at least one of the attached studs. The invention also relates to the various components used in a modular shoe in accordance with the invention.

Owner:ADIDAS

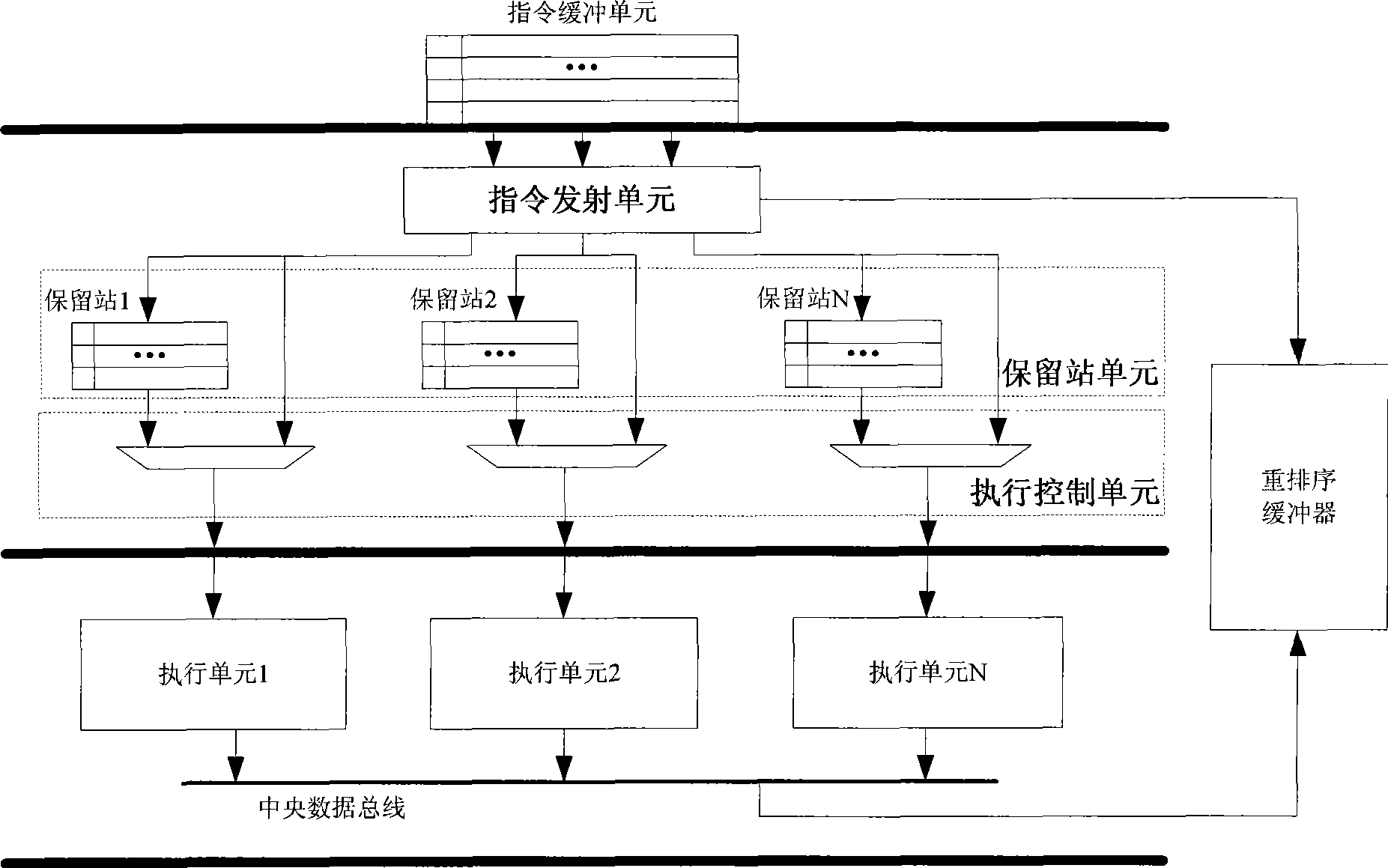

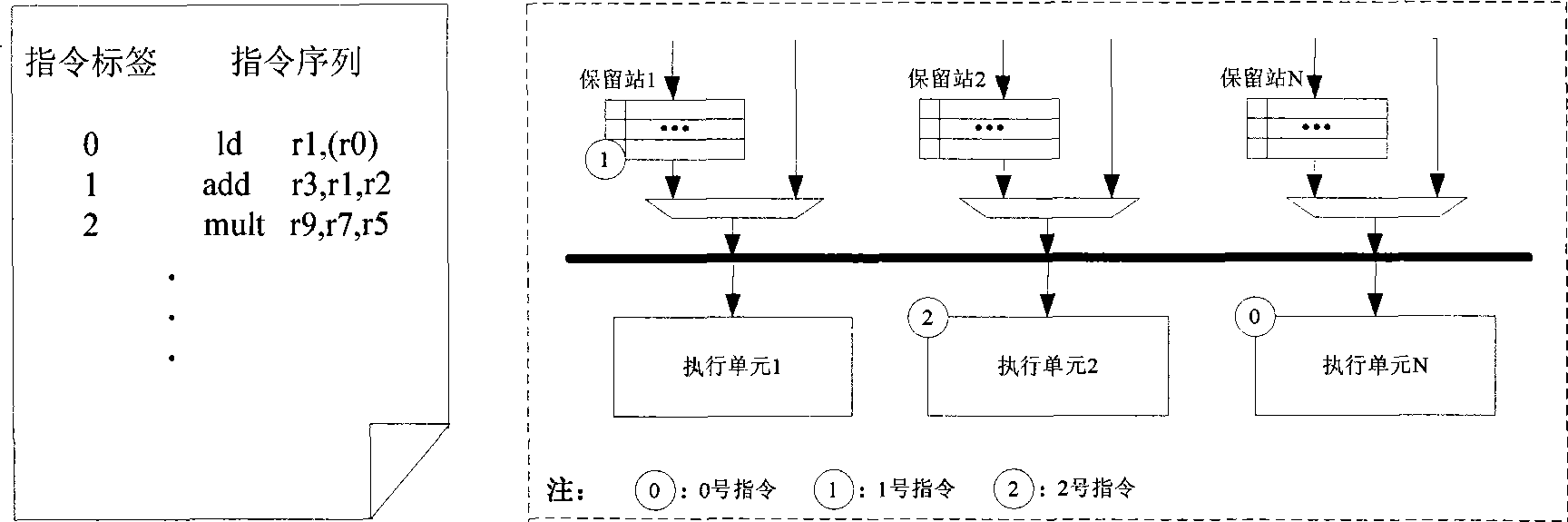

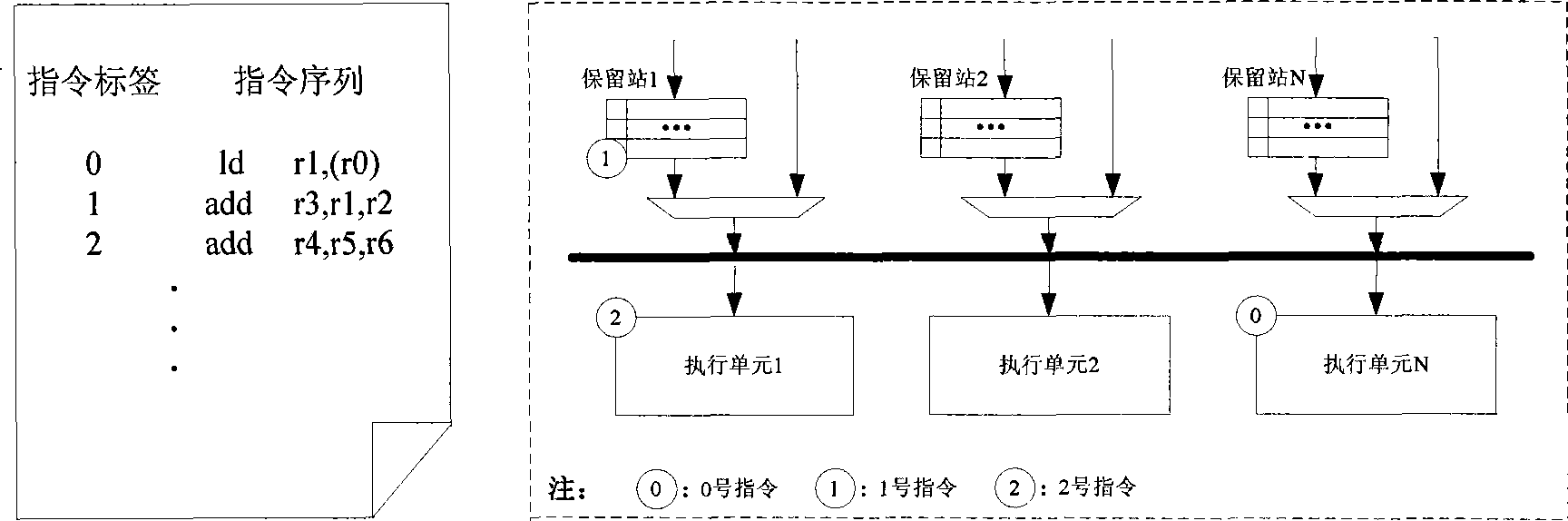

Out-of-order execution control device of built-in processor

InactiveCN101477454AImprove performanceSimplify Bypass LogicConcurrent instruction executionReservation stationProcessor register

The invention relates to a device of an embedded processor, which can control the out-of-order execution. The device comprises a transmit unit, a reservation station register unit and an execution control unit. The transmit unit is used for storing a decoded instruction on a pipeline register, and sending an instruction in a single-clock-cycle manner; the reservation station register unit is used for temporarily storing an instruction for generating for generating a pause when the sent instruction generates a pause because of the related conflict of write / read data, and conducting the bypass monitoring on operands; the execution control unit is used for monitoring the working condition of each execution unit in a real time manner, and dynamically distributing the instruction in the reservation station register unit or the current transmitted instruction according to the information returned by each execution unit. The invention has the advantages of simple design, easy realization and remarkable promotion of the performance of the embedded processor.

Owner:ZHEJIANG UNIV

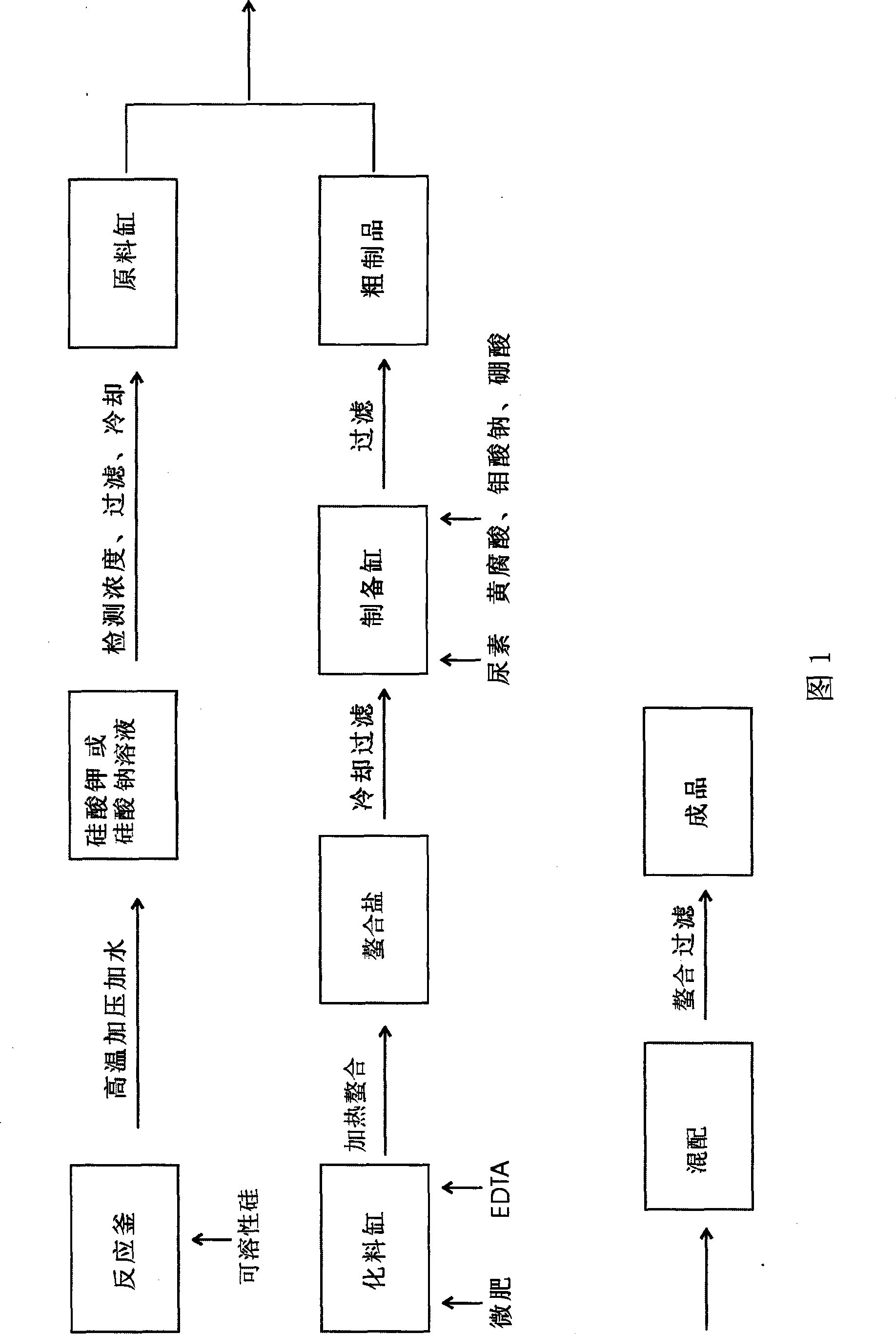

Liquid silicon fertilizer and technique for producing the same

InactiveCN101440001APromote growthIncrease resistanceOrganic fertilisersUrea compound fertilisersMetasilicateSilicic acid

The invention relates to a liquid silicon fertilizer and a production technique thereof, and belongs to the technical field of fertilizer. The liquid silicon fertilizer is characterized in that raw materials comprise soluble silicon, urea, trace elements, chelate and fulvic acid, which are prepared into the balanced compound fertilizer. The production technique comprises the following steps: 1, dissolving solid potassium metasilicate; 2, dissolving sulfate of the trace elements in water, and adding EDTA into the mixture to obtain the chelate of the EDTA trace elements; and adding boric acid, ammonium molybdate, the urea and the fulvic acid into the mixture after cooling and filtration; and 3, blending the chelate into the mixture to obtain the liquid silicon fertilizer. The production technique is characterized in that (1) the production technique uses water glass and the fulvic acid chelate, has better buffer action for alkali, and can effectively improve stability of SiO3; and (2) the trace elements are chelated twice by using the EDTA and the fulvic acid to form chelated metal ions, so as to prevent silicic acid radicals and the metal ions reacting to form silicate difficult to be dissolved in water, and influence utilization rate of silicon element. The production technique uses the liquid potassium metasilicate and large amount of elements, trace elements and organic substances to establish a balanced compound system, and can effectively improve utilization rate of the silicon element and various nutrient elements for the crops.

Owner:于春开

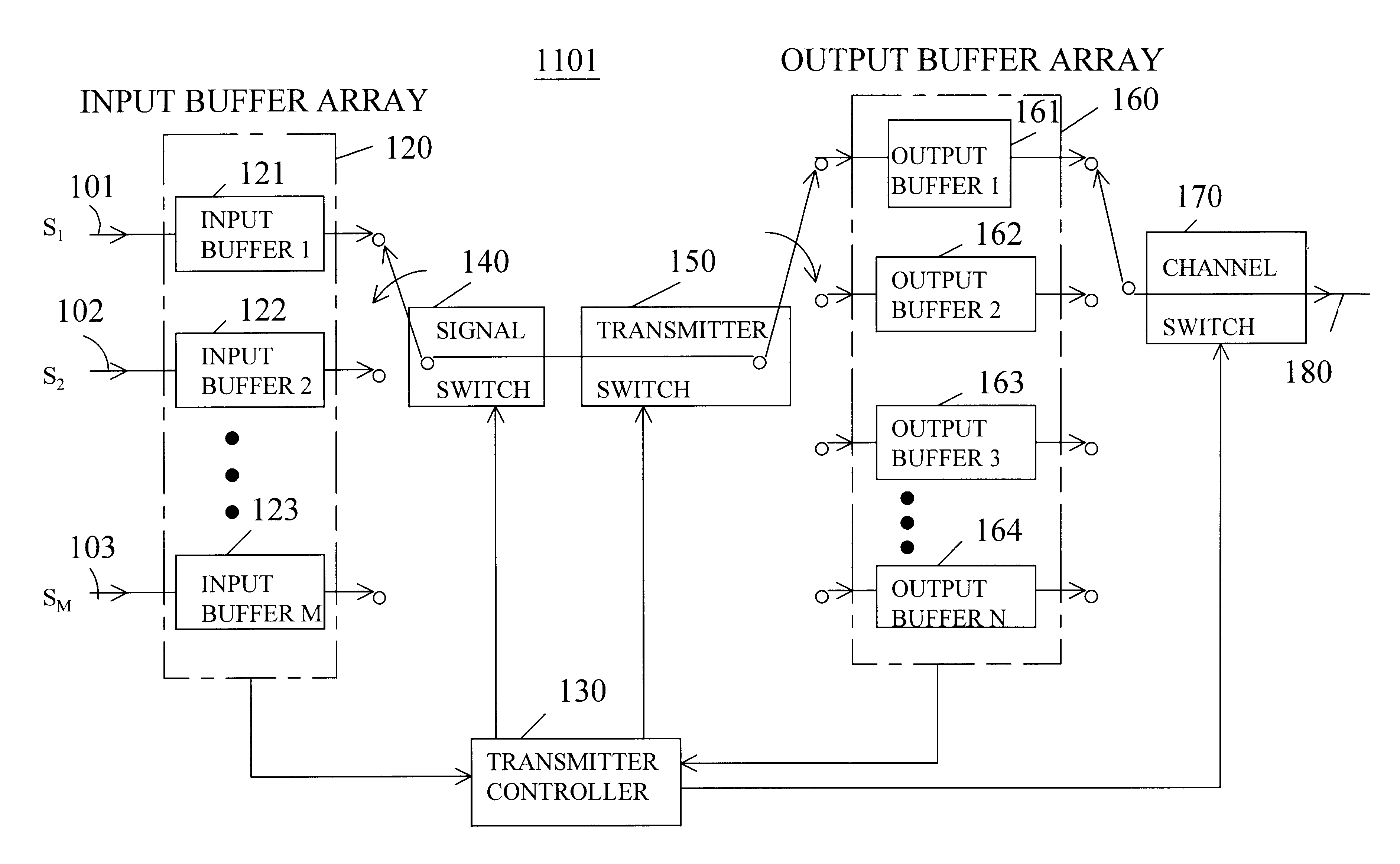

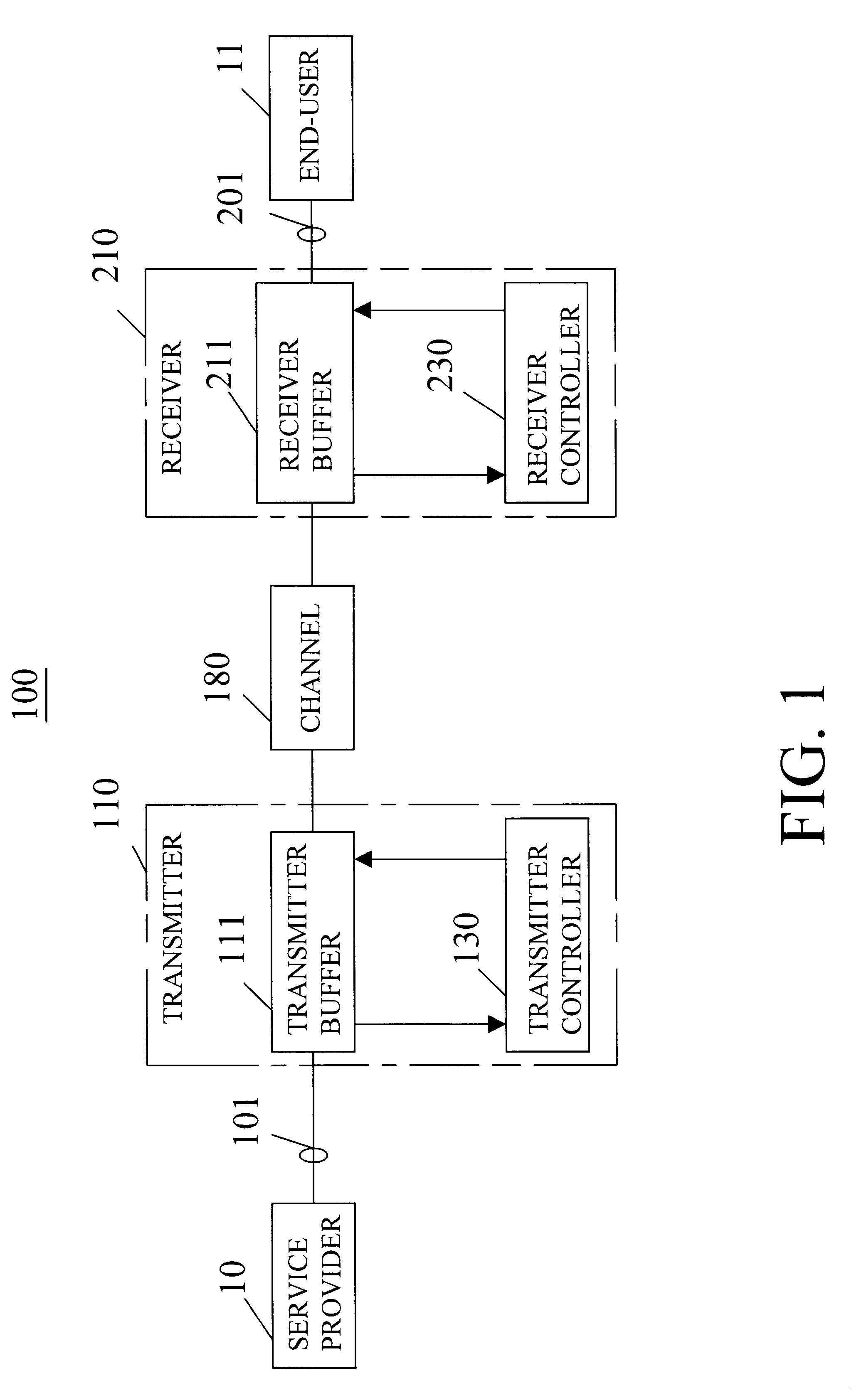

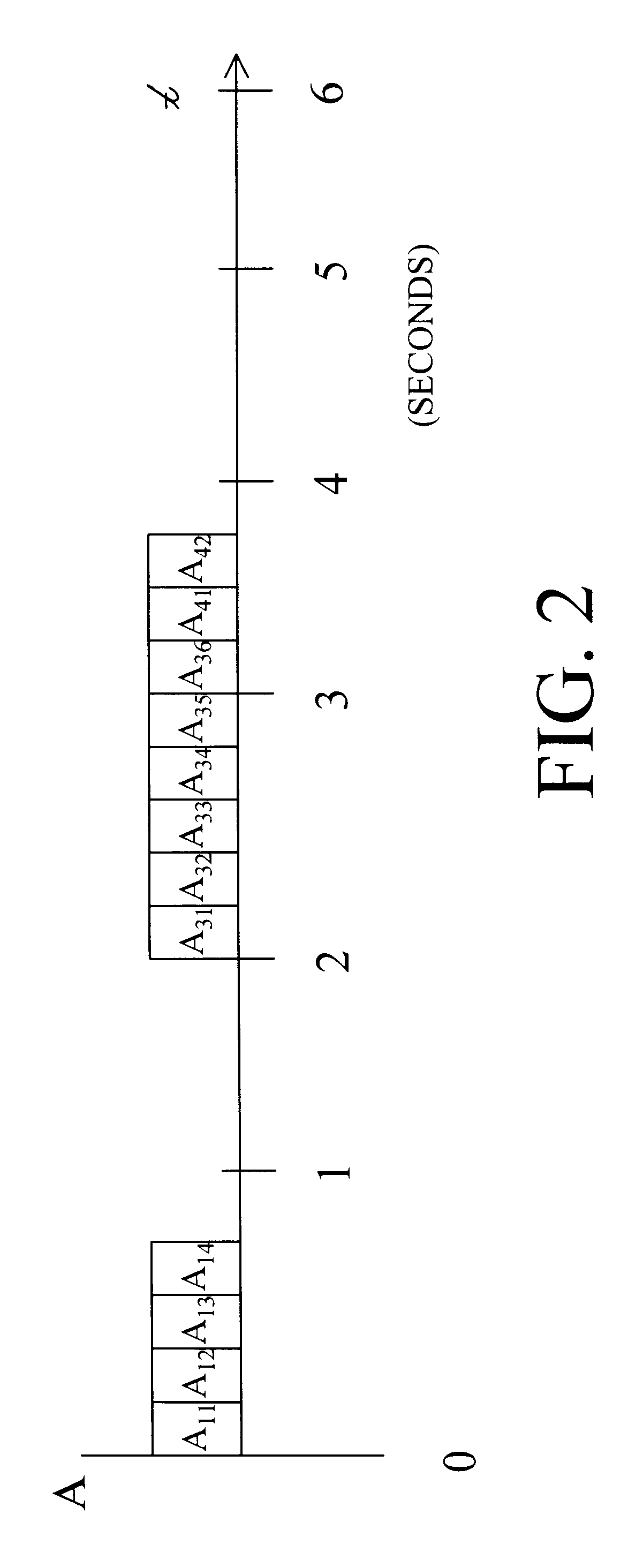

Reducing the variability of the data rates of high-rate data streams in order to communicate such streams over a low-rate channel of fixed capacity

InactiveUS6359883B1Low costReduce decreaseTime-division multiplexData switching by path configurationMultiplexingData stream

Techniques whereby a transmitter / receiver pair are cooperatively arranged to buffer incoming data to both the transmitter and the receiver. The transmitter and receiver of the pair are coupled, generically, by pre-existing channel which has a known, fixed capacity. The transmitter / receiver pair exploits whatever delay is permissible, as determined by end-users of the data, for the data stream or streams that are using the channel for the purpose of accommodating periods of excessive instantaneous aggregate data transfer demands. The matched transmitter / receiver pair thereby permits (i) the transmission of a variable rate stream over a channel with capacity less than the peak rate of the stream, or (ii) the multiplexing of variable and / or fixed rate data streams.

Owner:THE KOHL GROUP

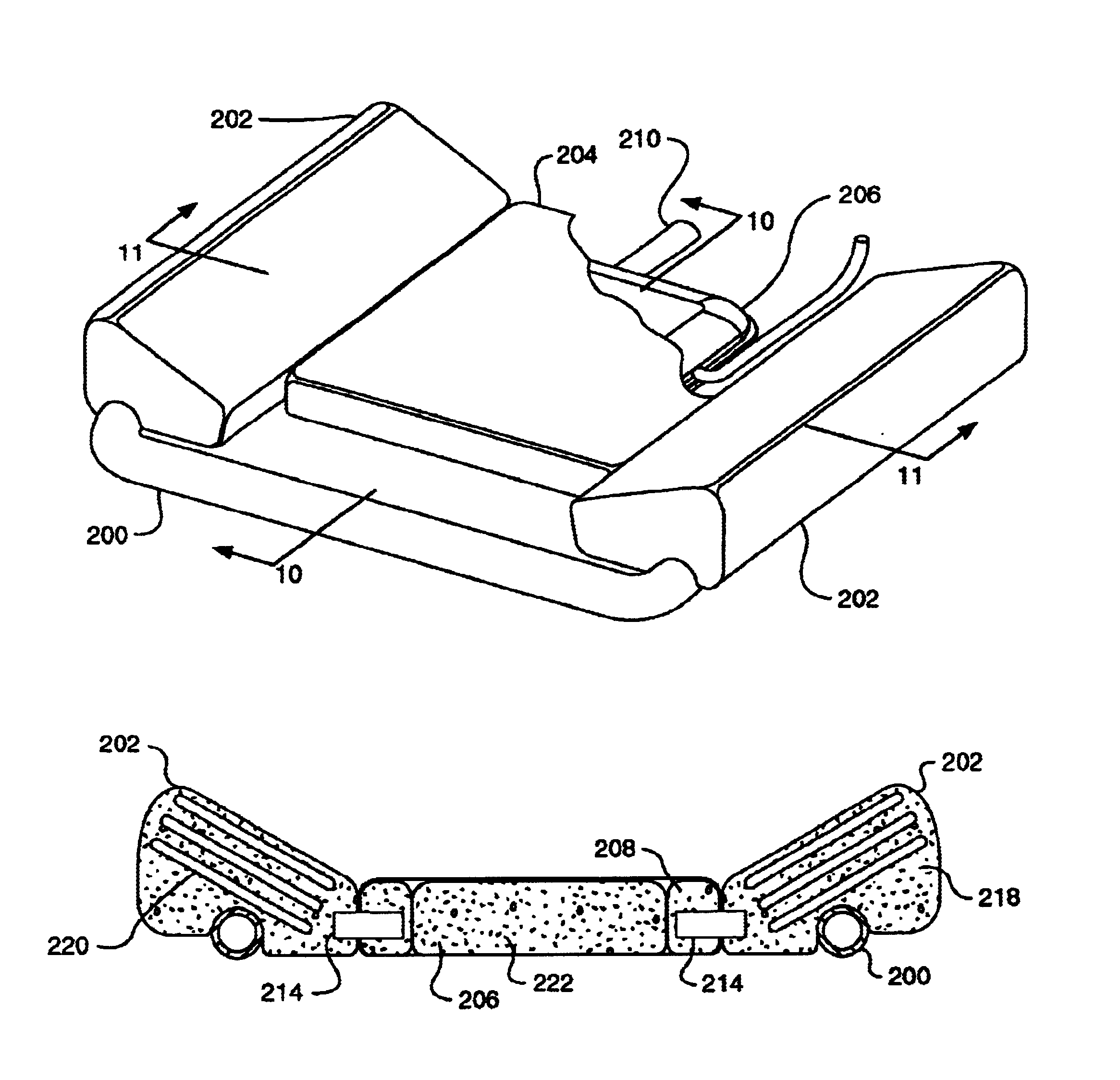

Self inflating pneumatic seat cushion apparatus and method

ActiveUS6912748B2Reduce the cushioning forceImprove buffering effectVehicle seatsStuffed mattressesExhaust valvePump chamber

A self inflating pneumatic seat cushion, especially for automobile seats, has foam filled bladders and bolsters. A pneumatic pumping chamber intakes air through an inlet and distributes air to the cushion bladders and bolsters through outlet tubes. The motion of a seat occupant against the pneumatic pumping chamber bladder operates to let air in through the inlet and distribute it through the outlet tubes. A collapsible seat has an exhaust valve for compressing the bladders in a stowed position. The exhaust valve may have an adjustable pressure release.

Owner:L & P PROPERTY MANAGEMENT CO

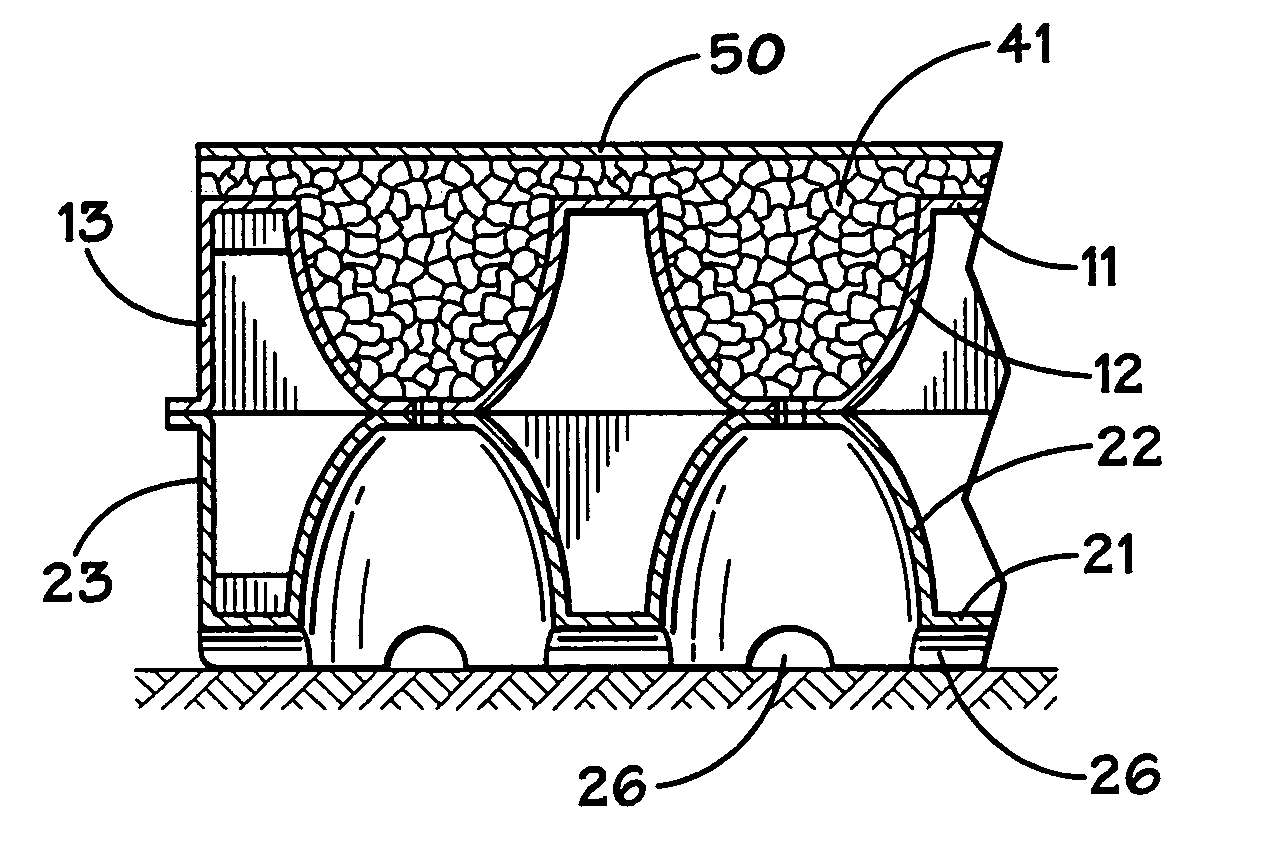

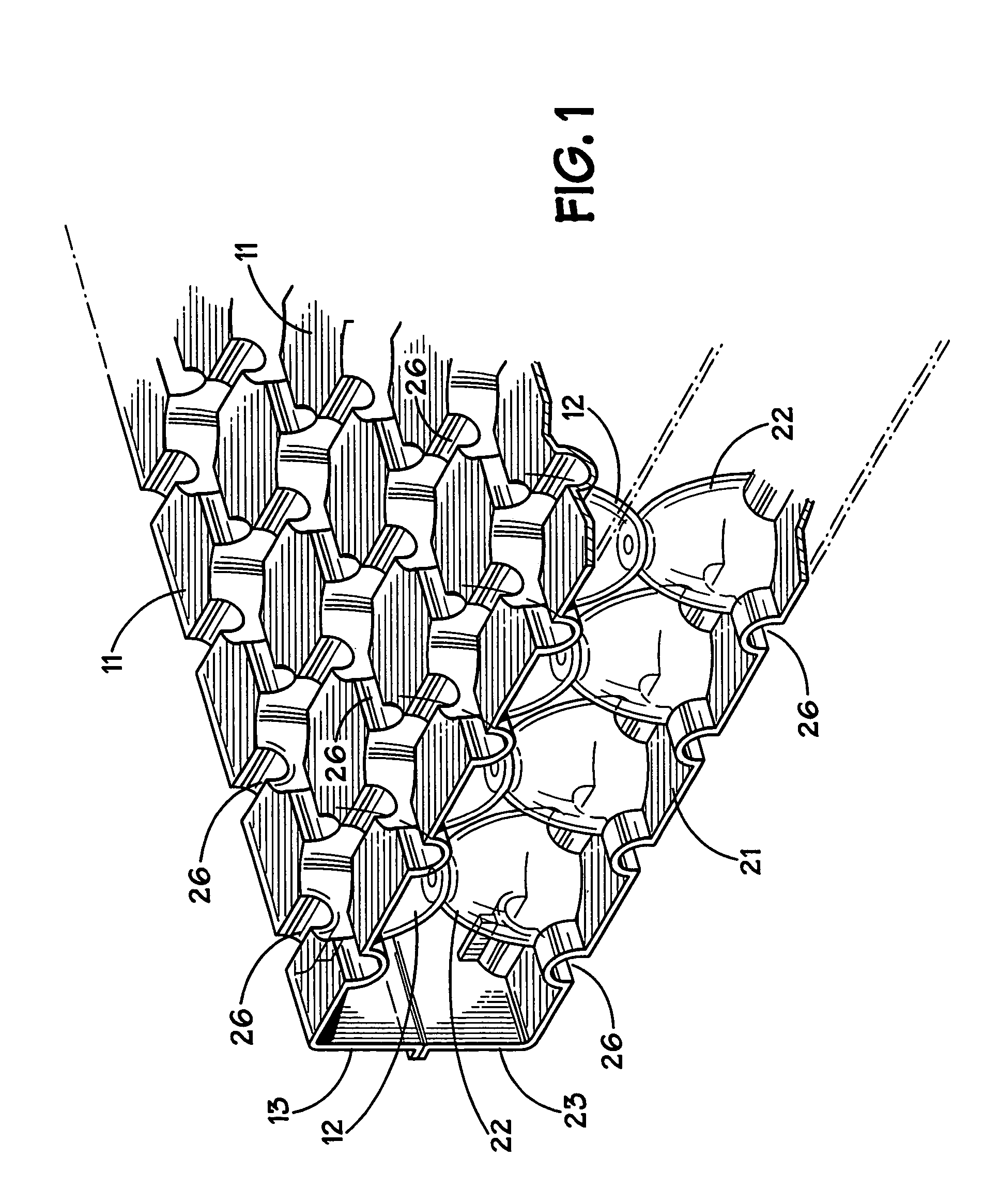

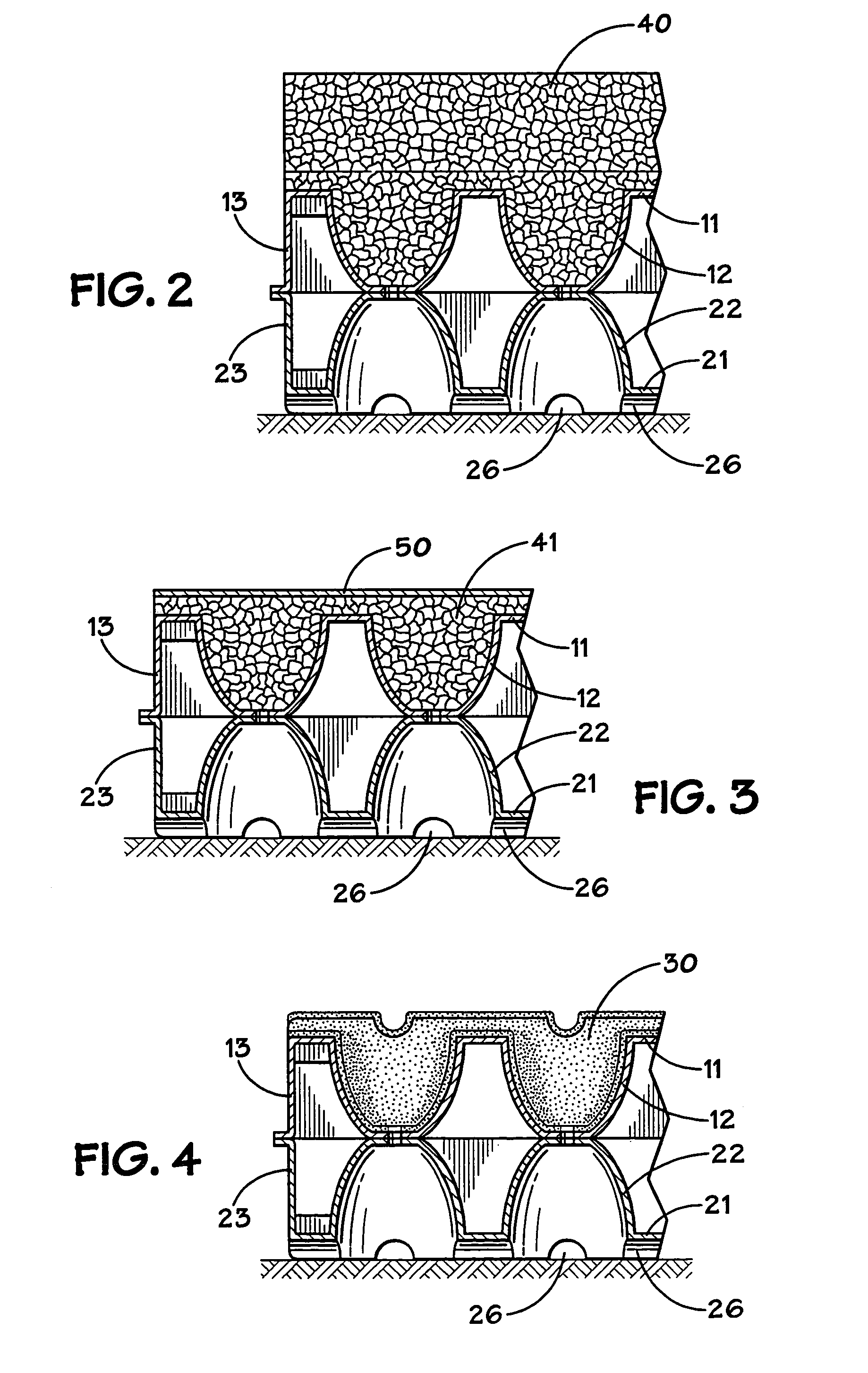

Cushioning structure for floor and ground surfaces

InactiveUS7033666B2Less laborImprove buffering effectLayered productsMultiple spring combinationsThermoplasticParticulates

Owner:SKYDEX TECH INC

Method and apparatus for making a trim component with a foam core having a smoothly varying thickness

InactiveUS20030041955A1Guaranteed shock absorptionSoftness shockAdhesive processesEngine sealsThermoplasticPolymer science

A trim component includes a foam backing layer and a foam pad insert laminated between a cover material and a substrate. The foam pad insert provides an area of enhanced cushioning, and has smoothly tapered edges to ensure a smooth surface contour without a visible edge transition on the cover material. The foam pad insert has a lower melting temperature than the foam backing layer, both of which are thermoplastics. A foam pad insert is positioned and fixed on the back surface of the foam backing layer. A substrate material is heated and then laminated and molded with the foam and the cover material. The heat from the substrate partially softens and melts the foam backing layer and the foam pad insert. The partially melted foam pad insert is viscously deformed to form the tapered edges, as dictated by the smoothly varying mold gap spacing of the forming tools.

Owner:HERBERT OLBRICH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com