Patents

Literature

16080results about "Electrical equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

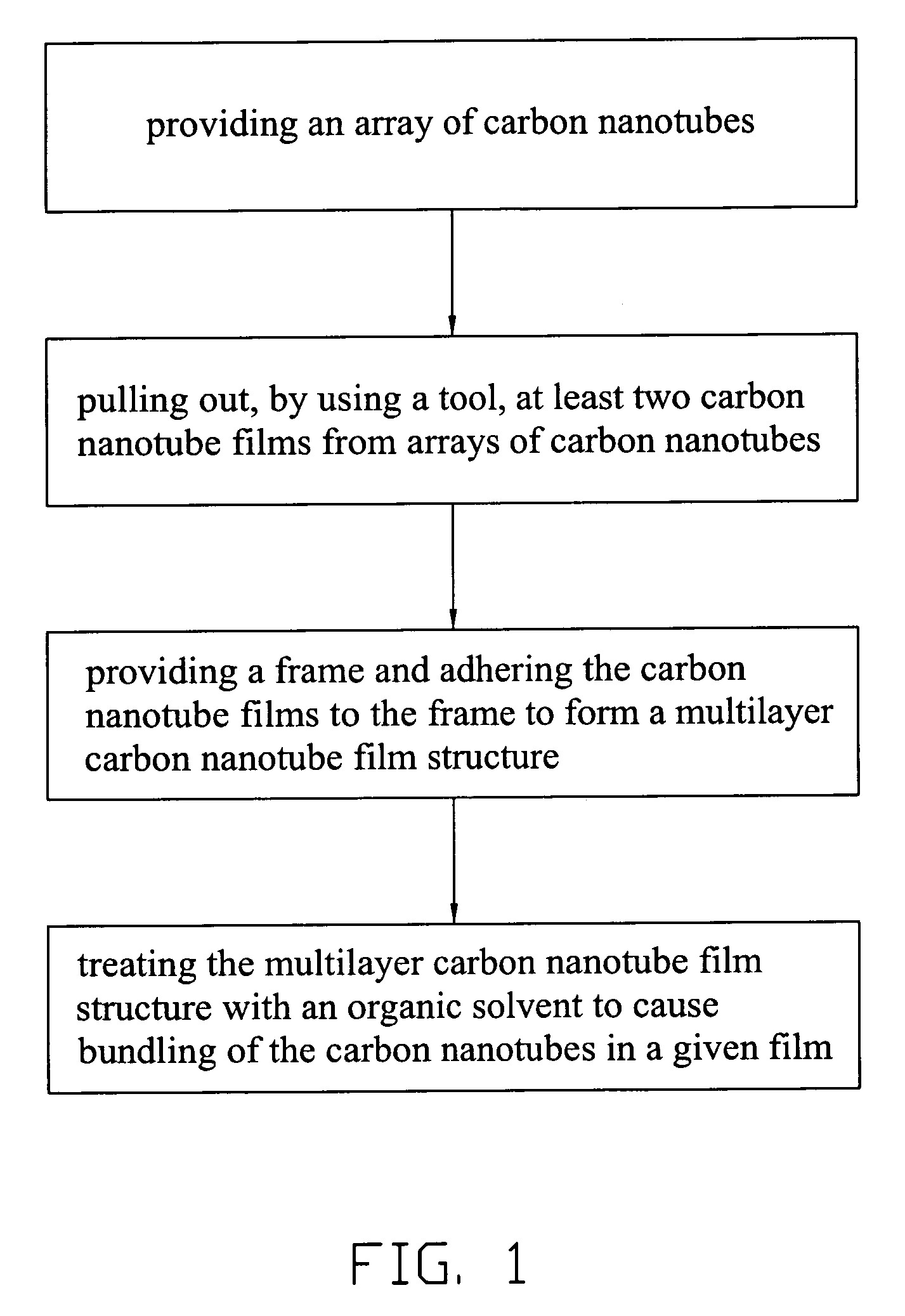

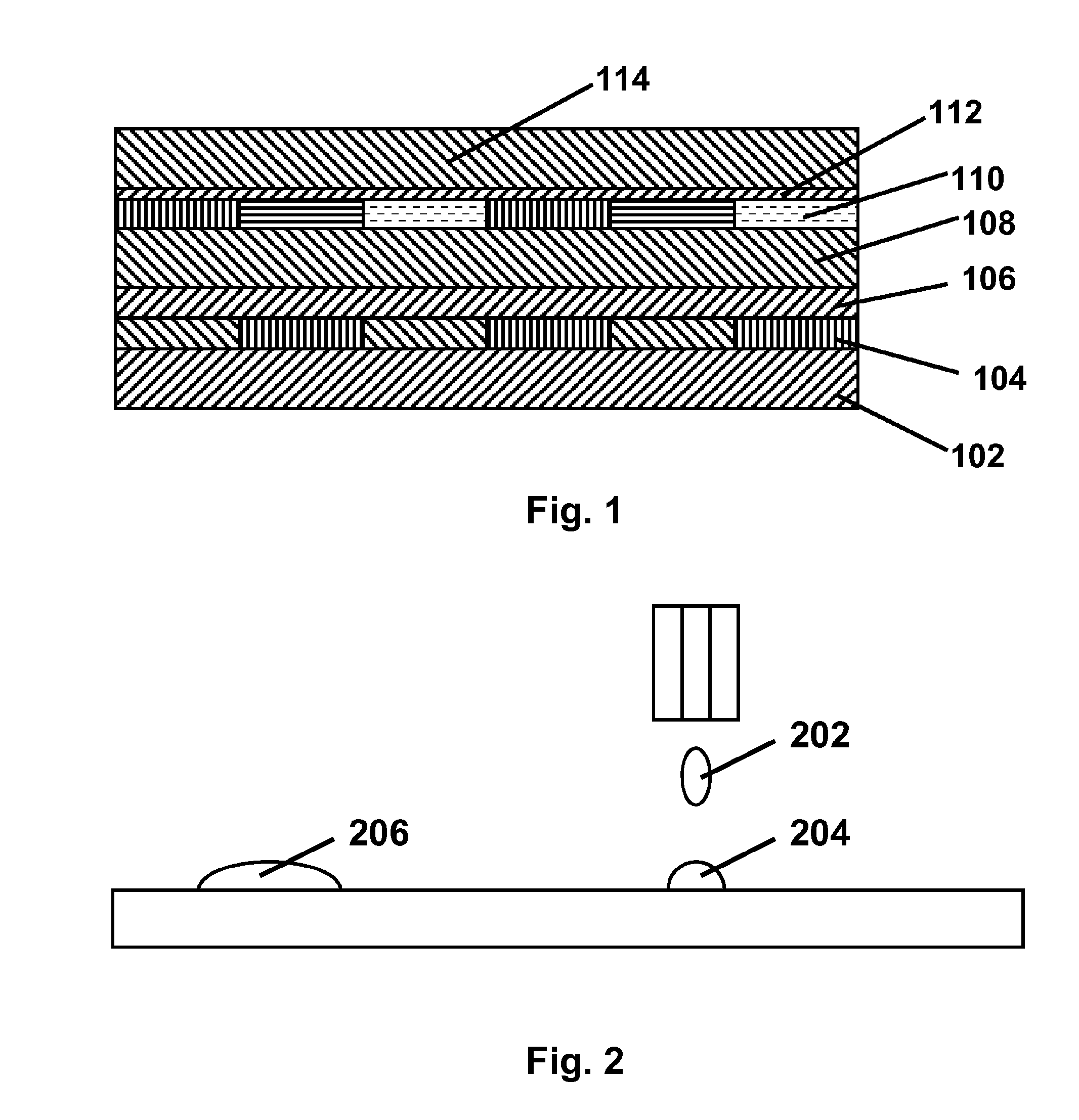

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

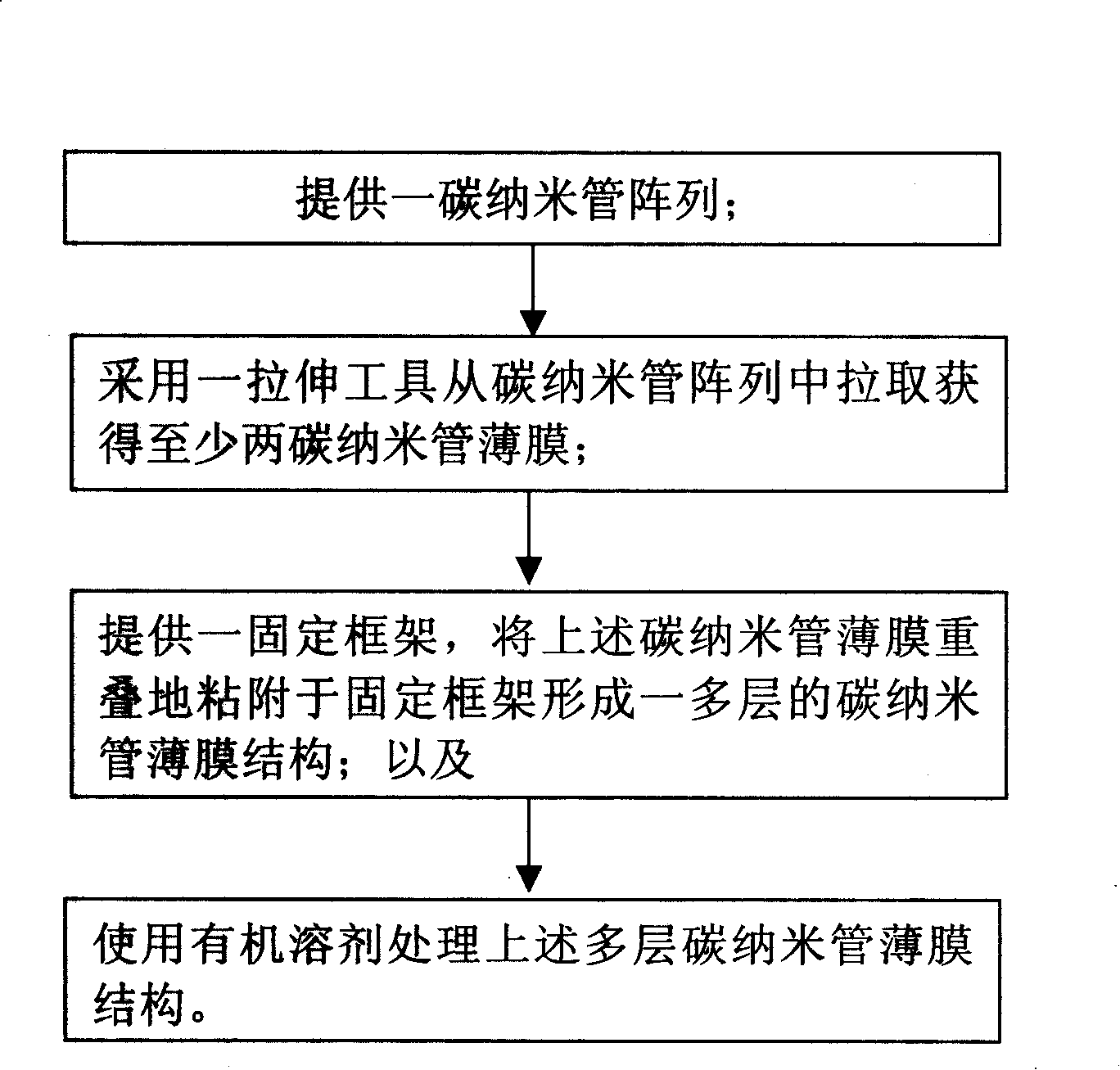

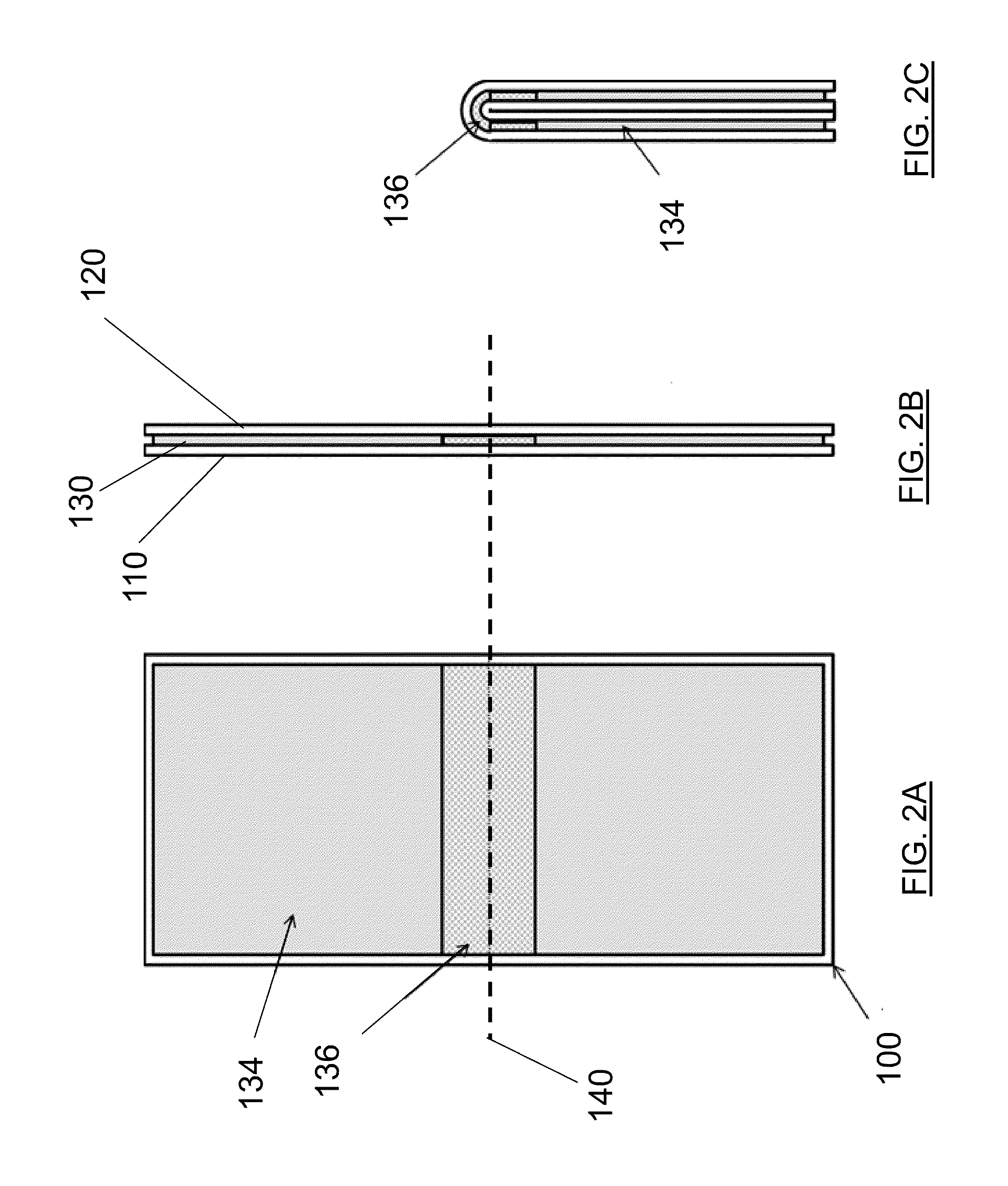

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

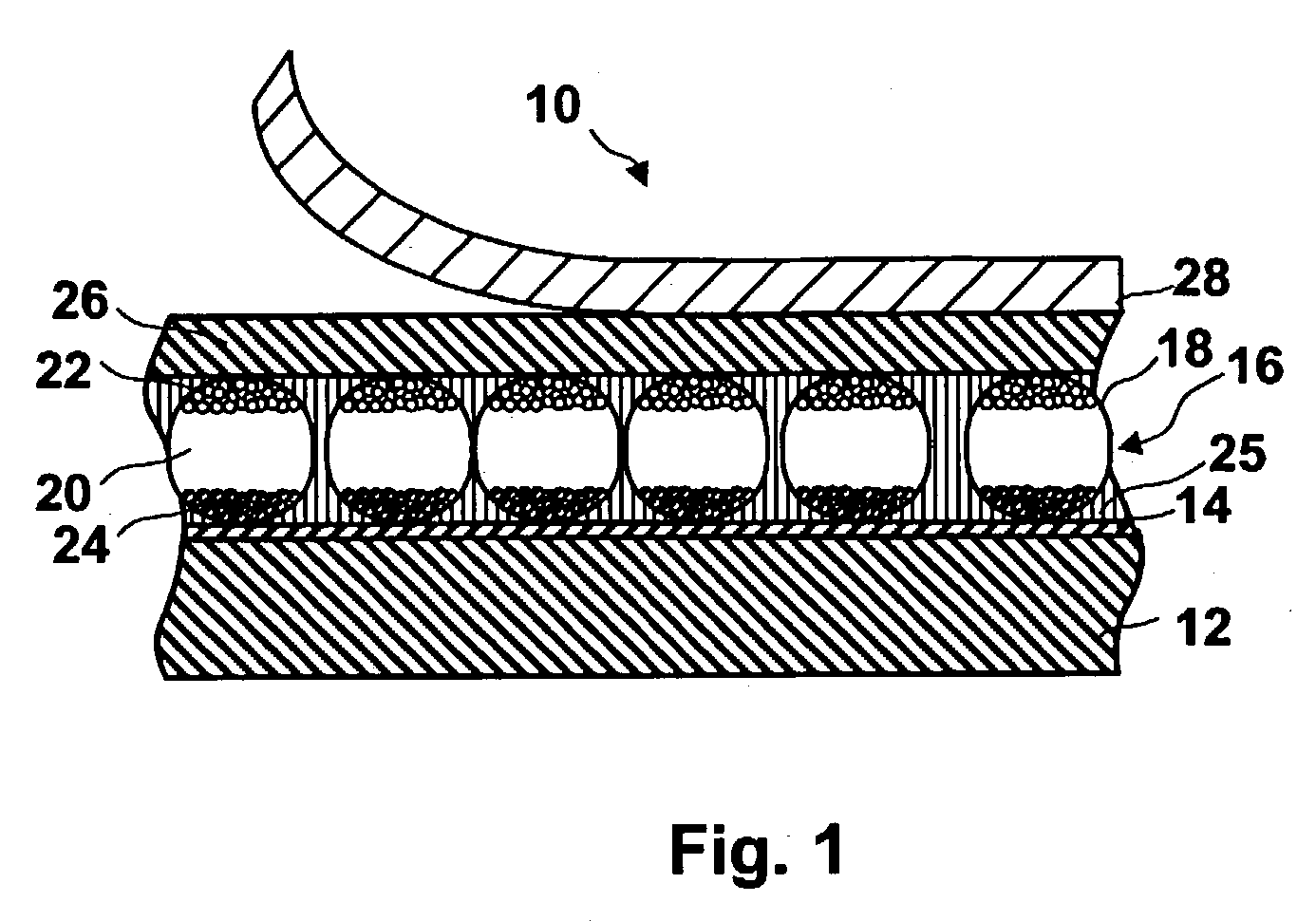

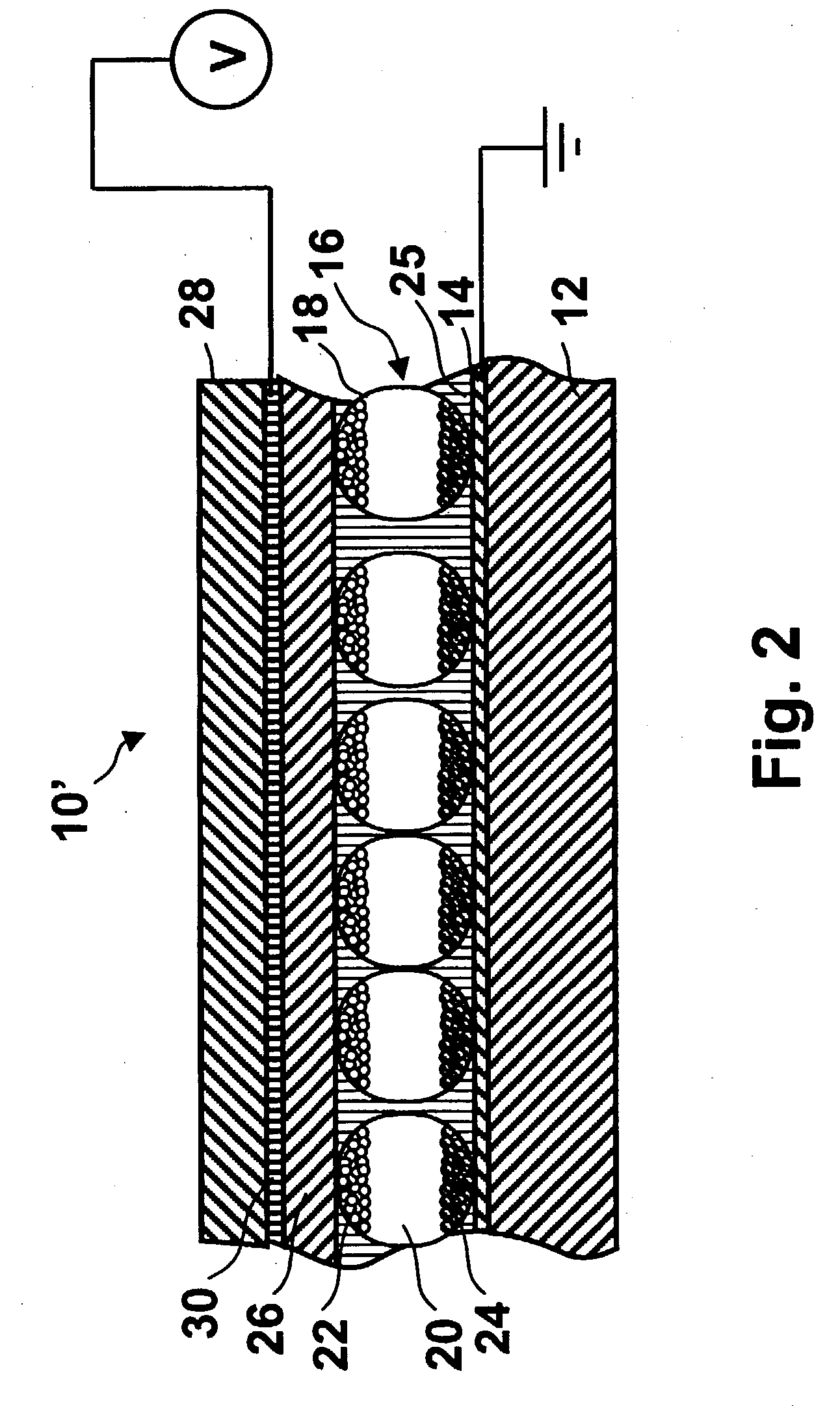

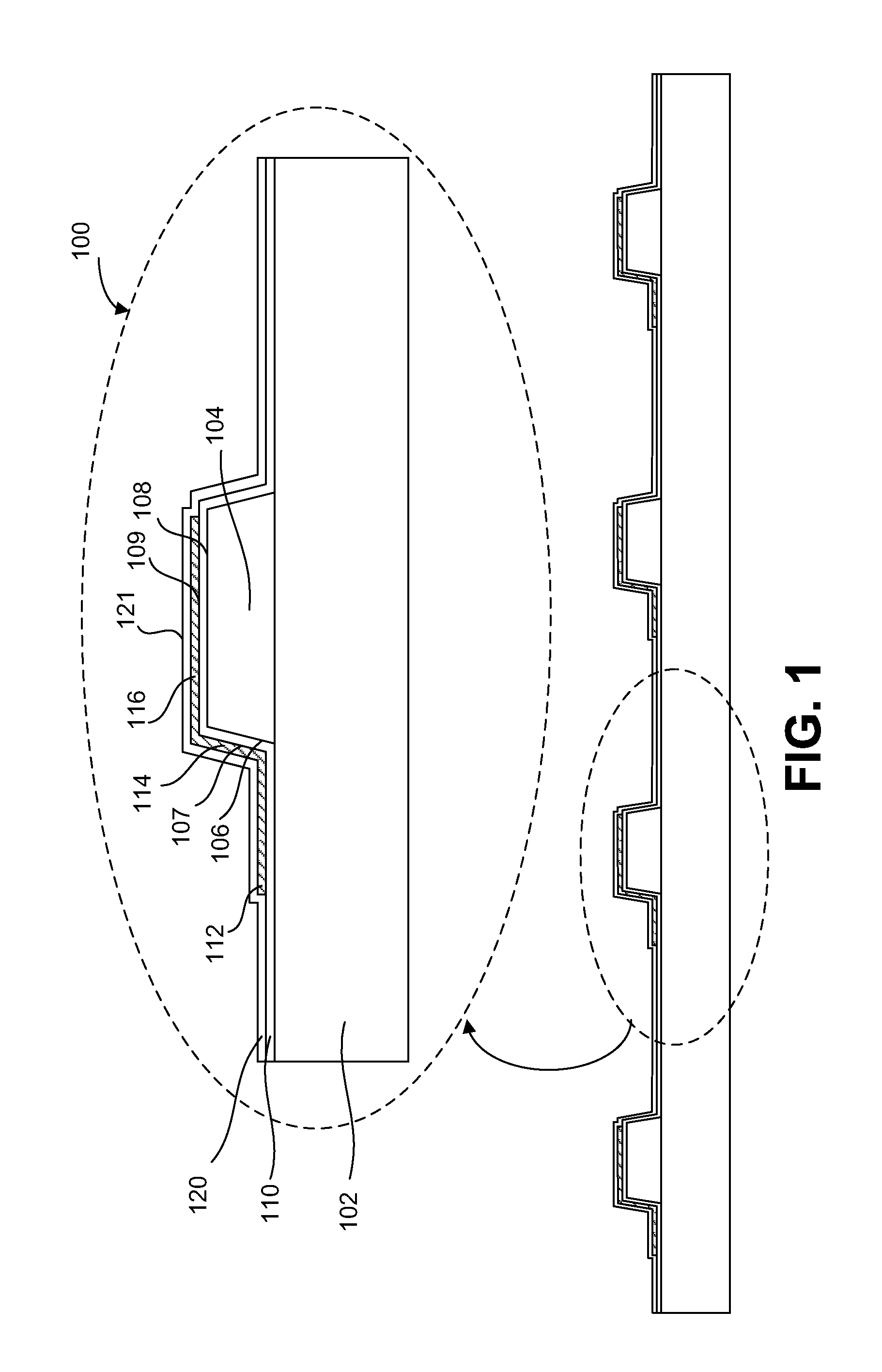

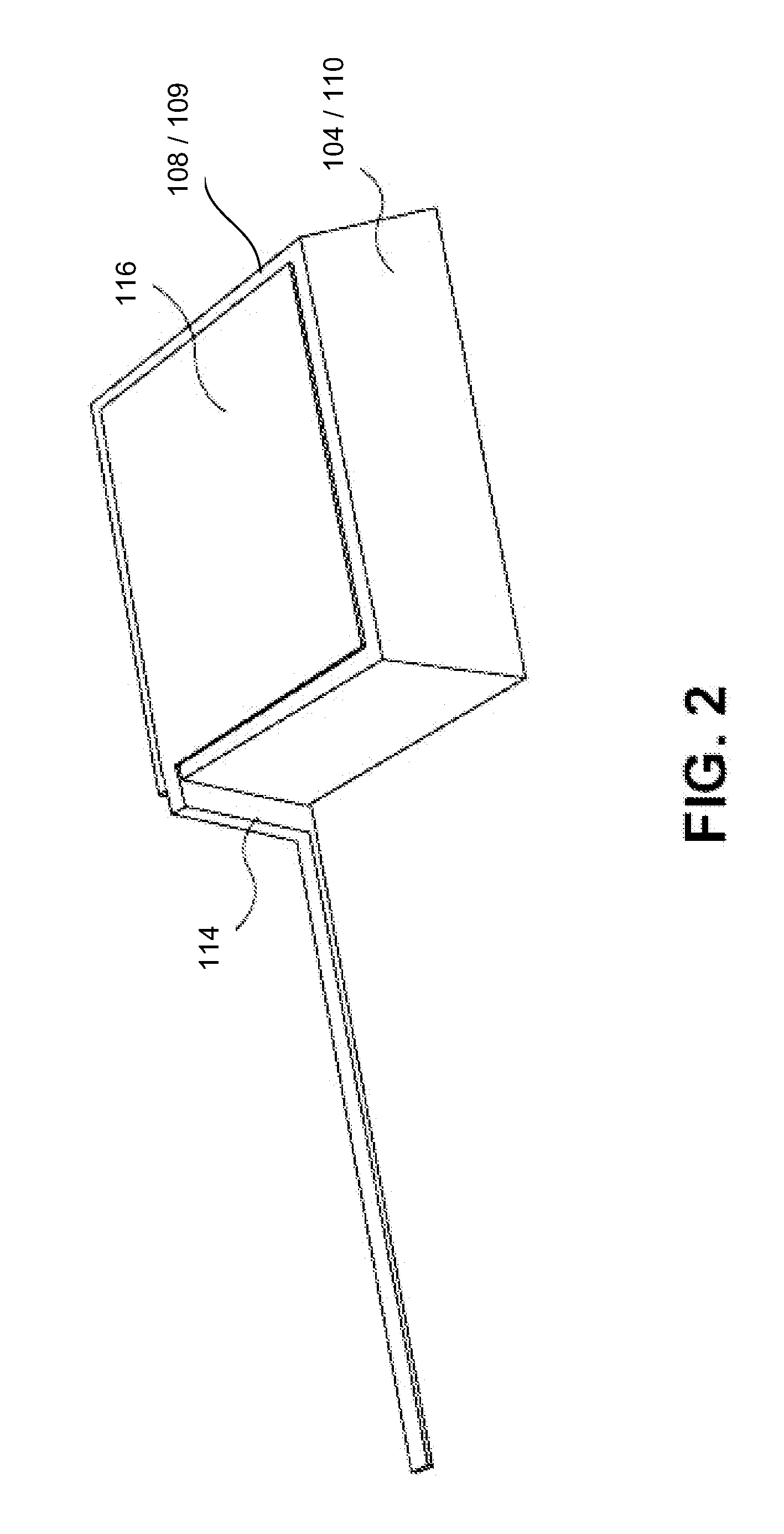

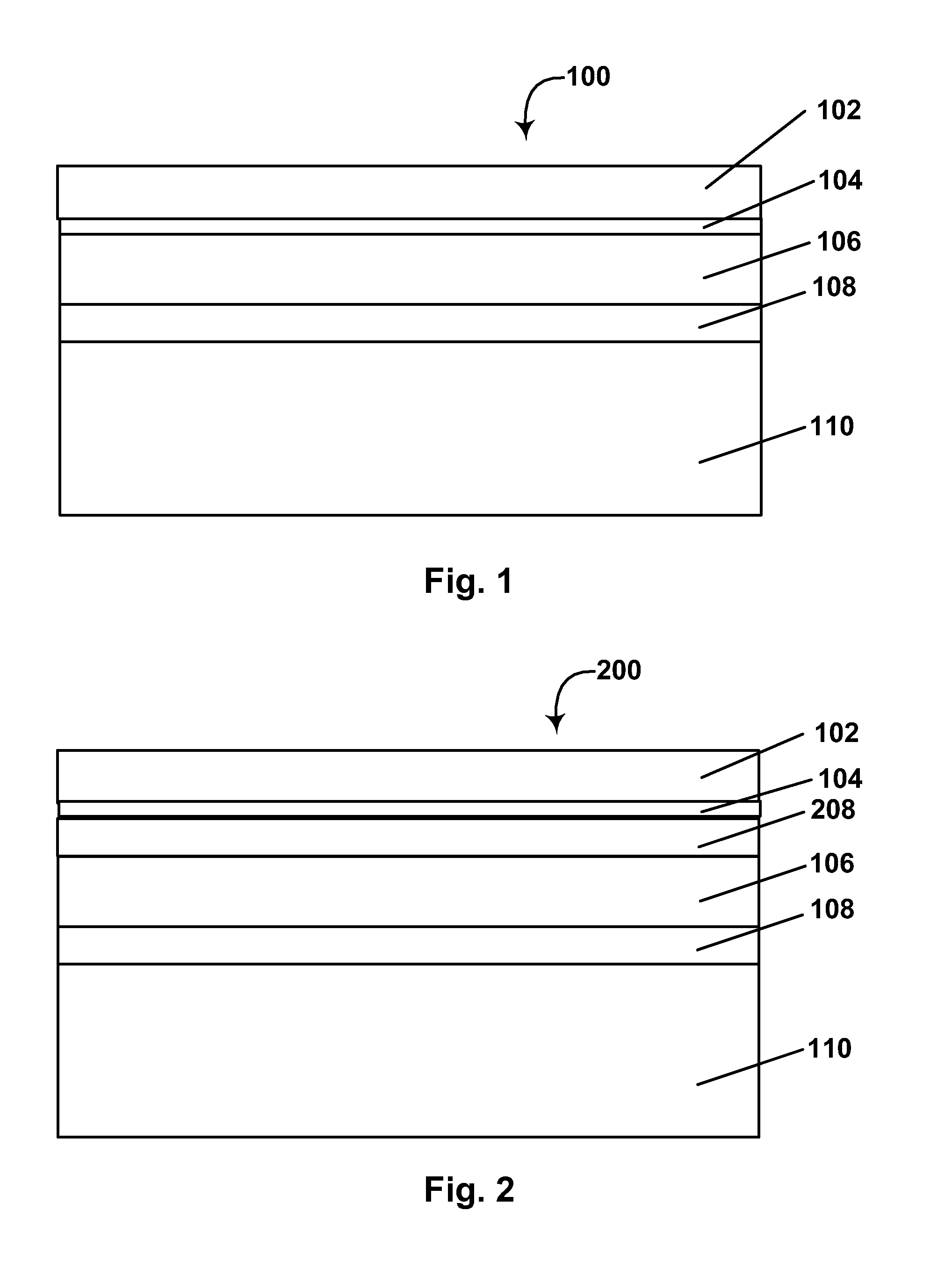

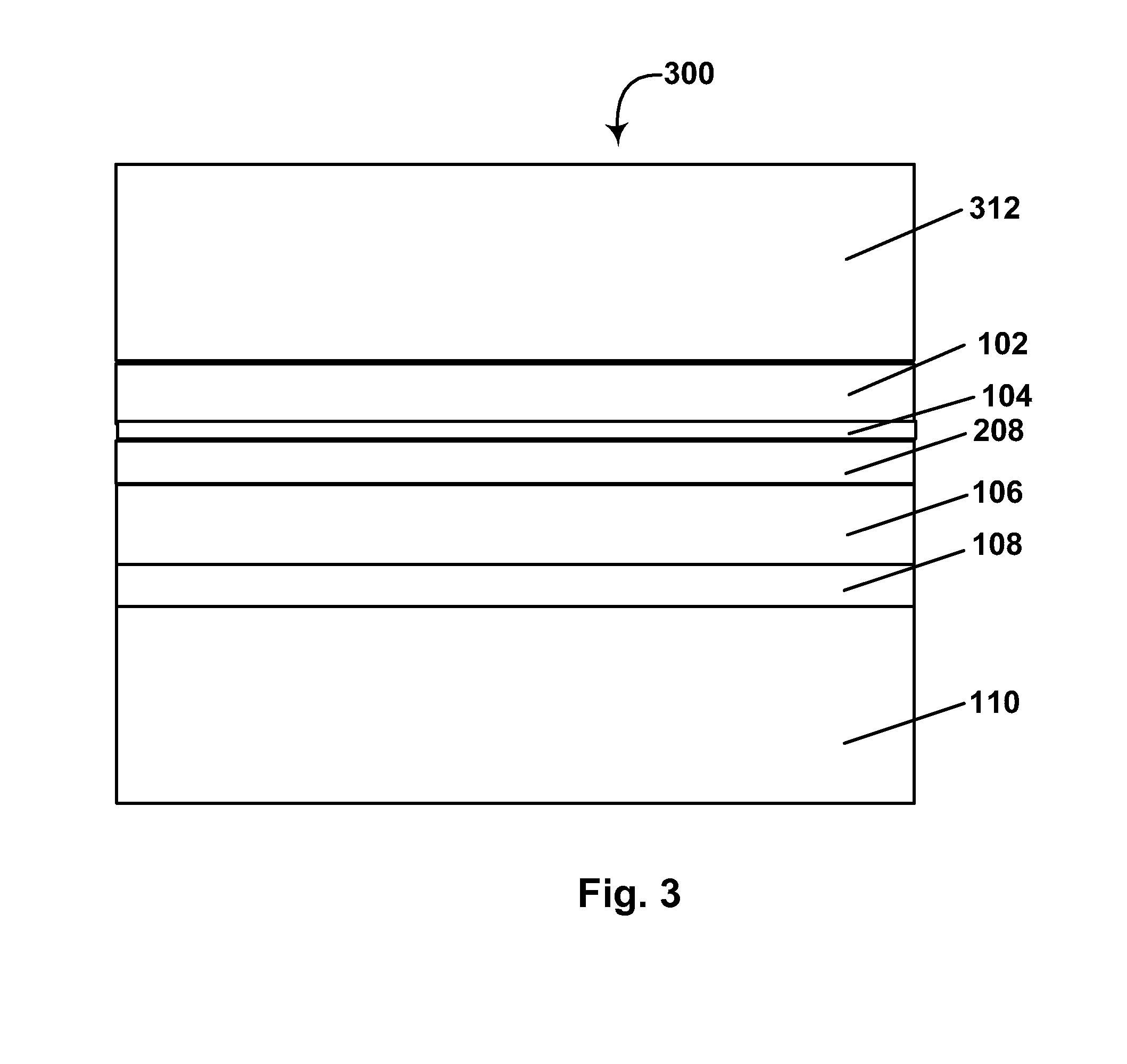

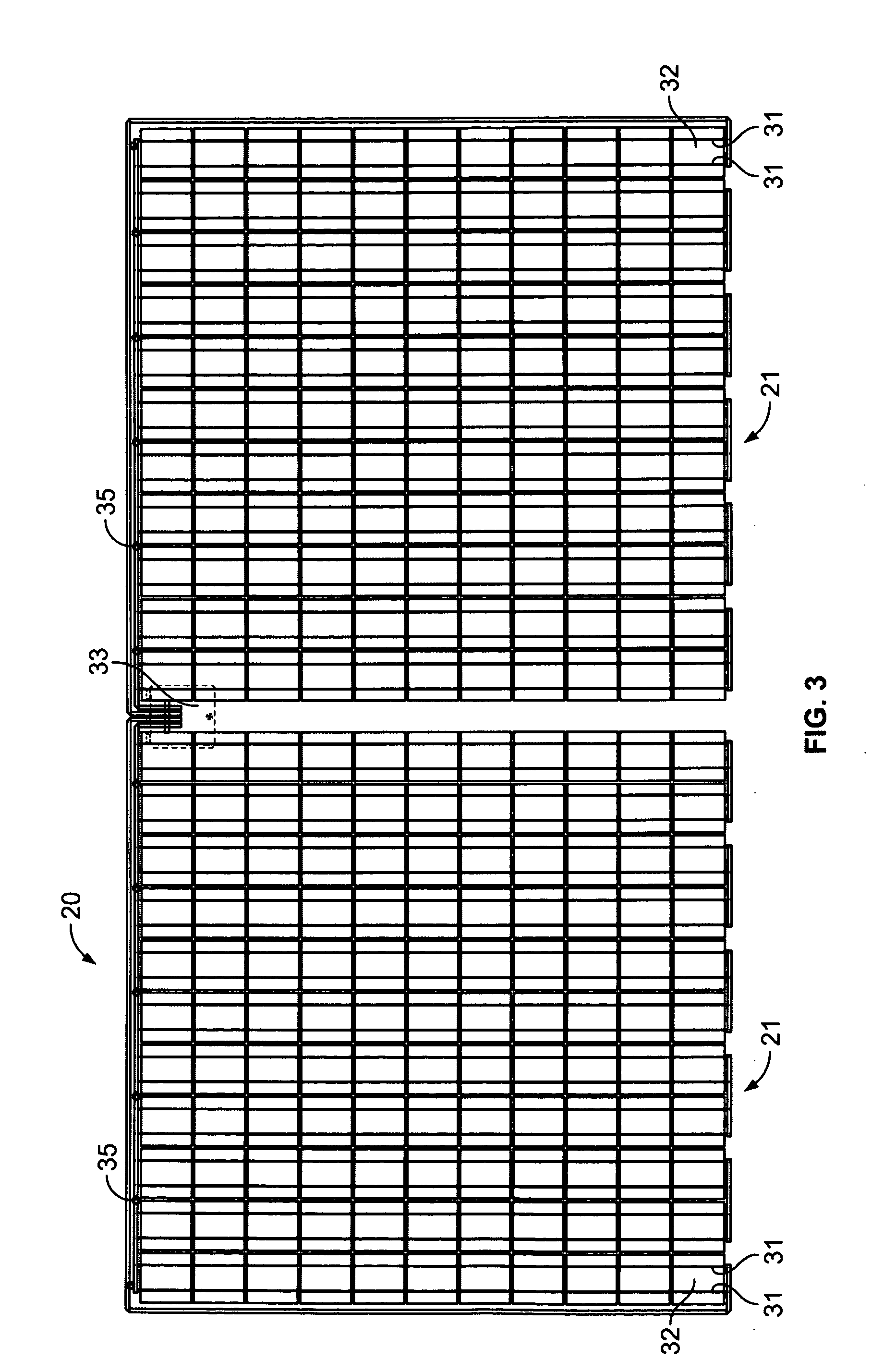

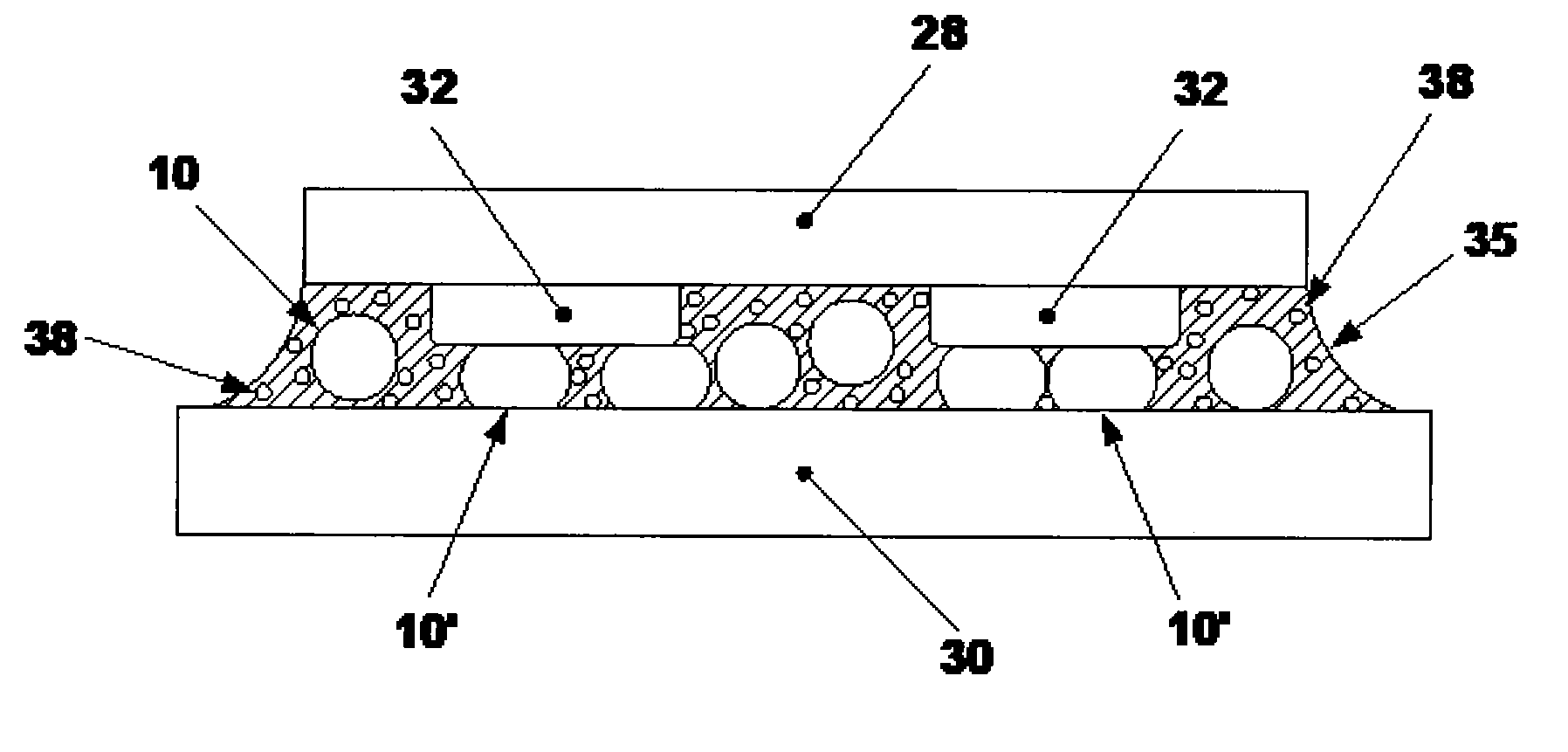

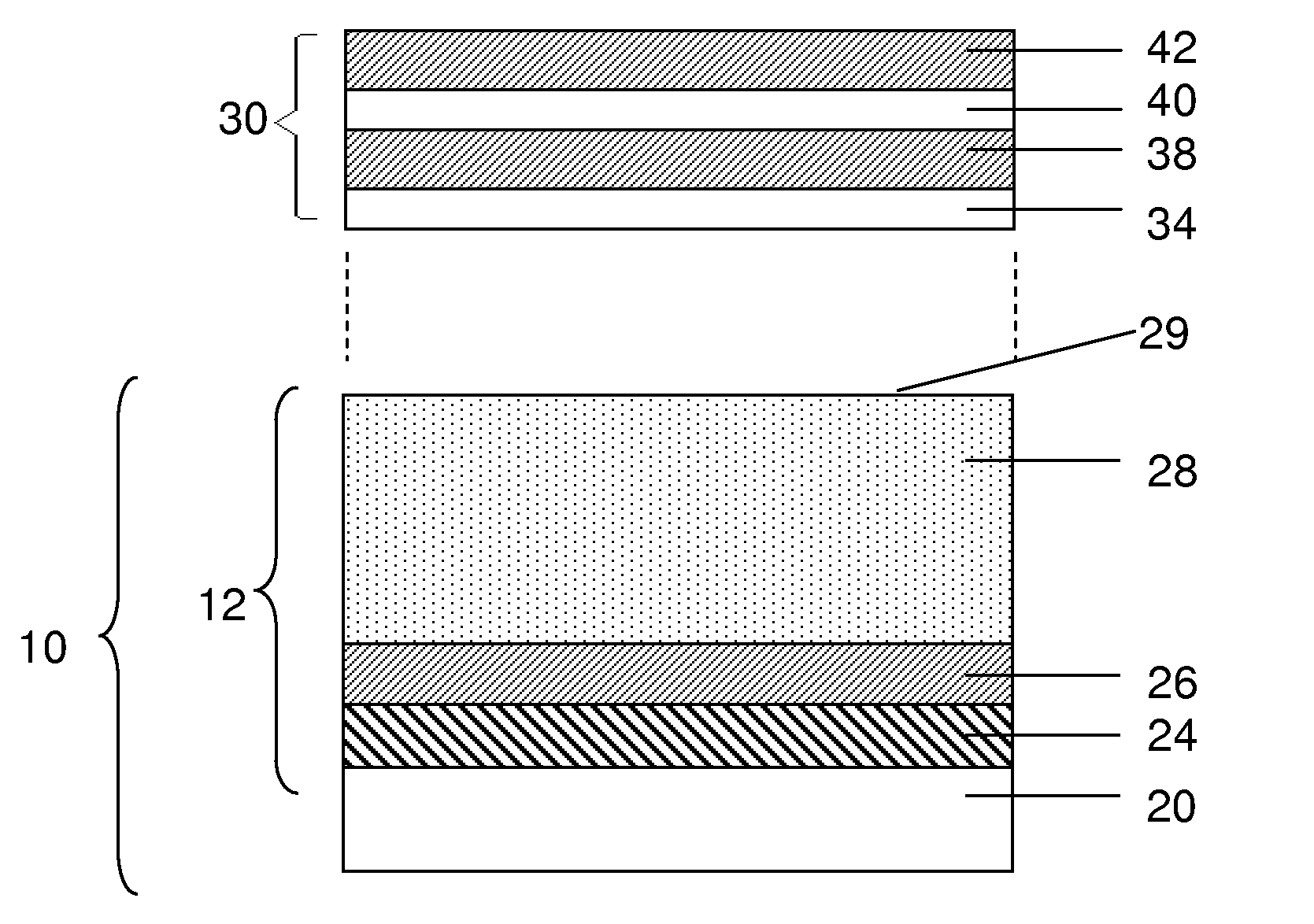

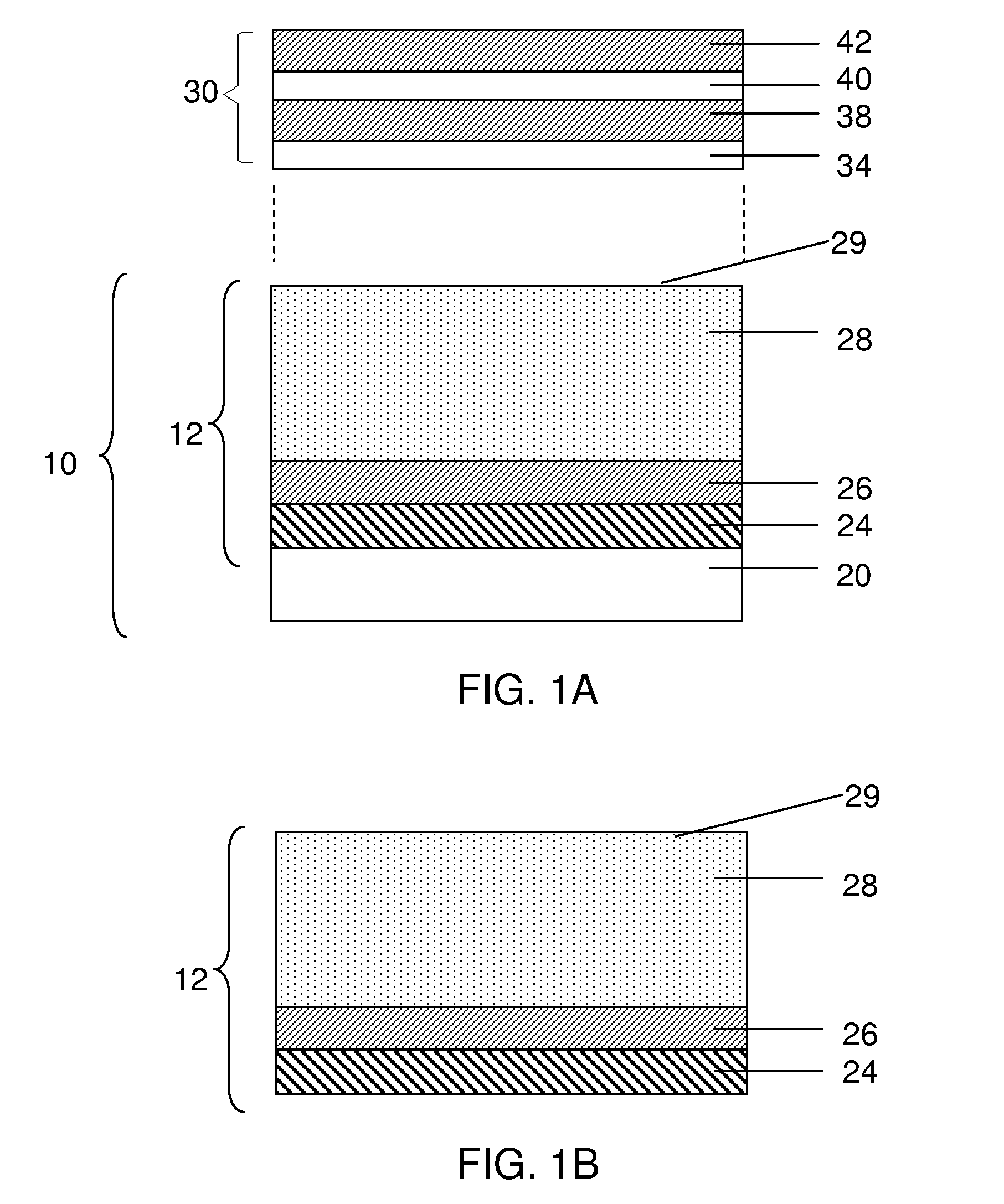

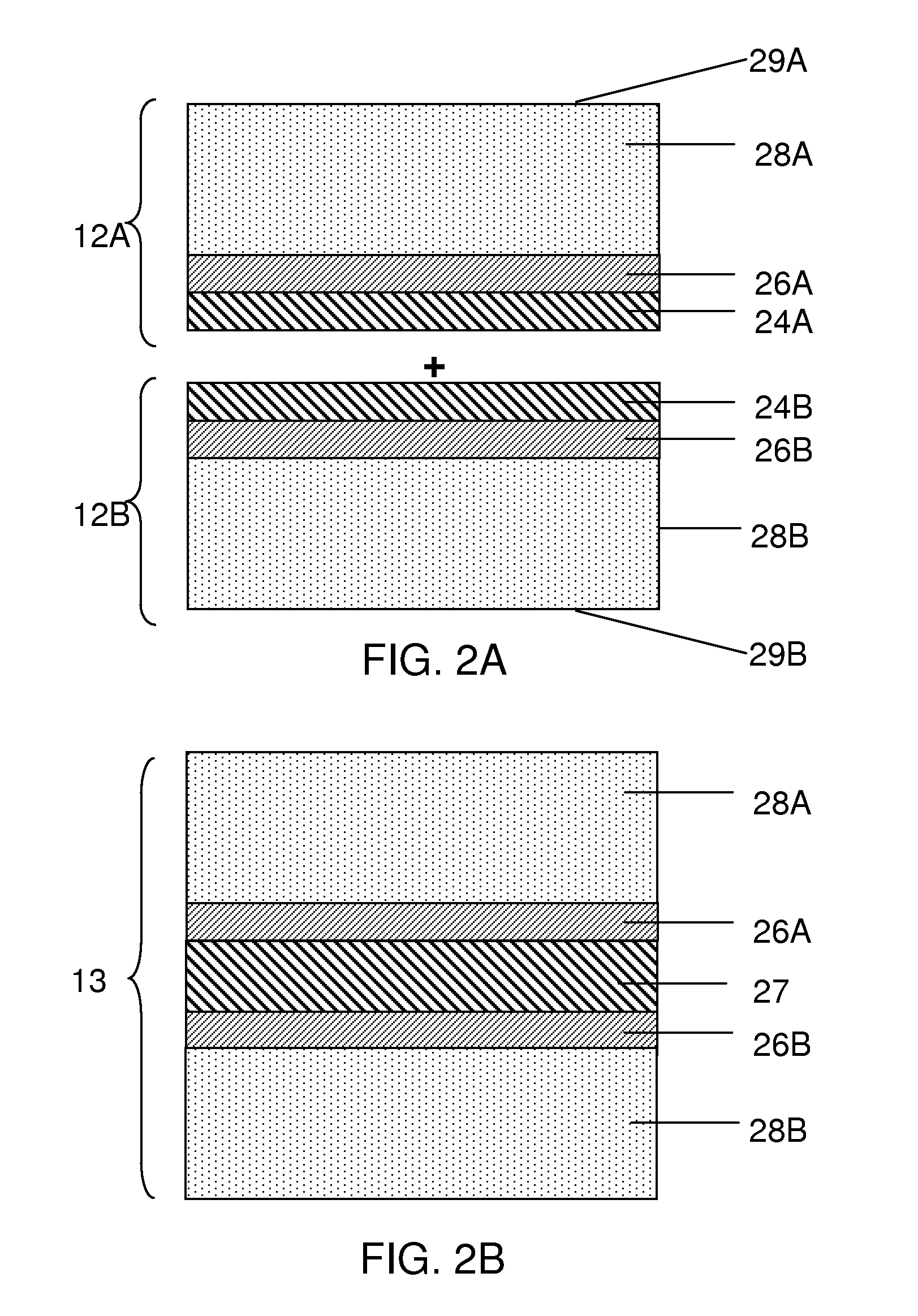

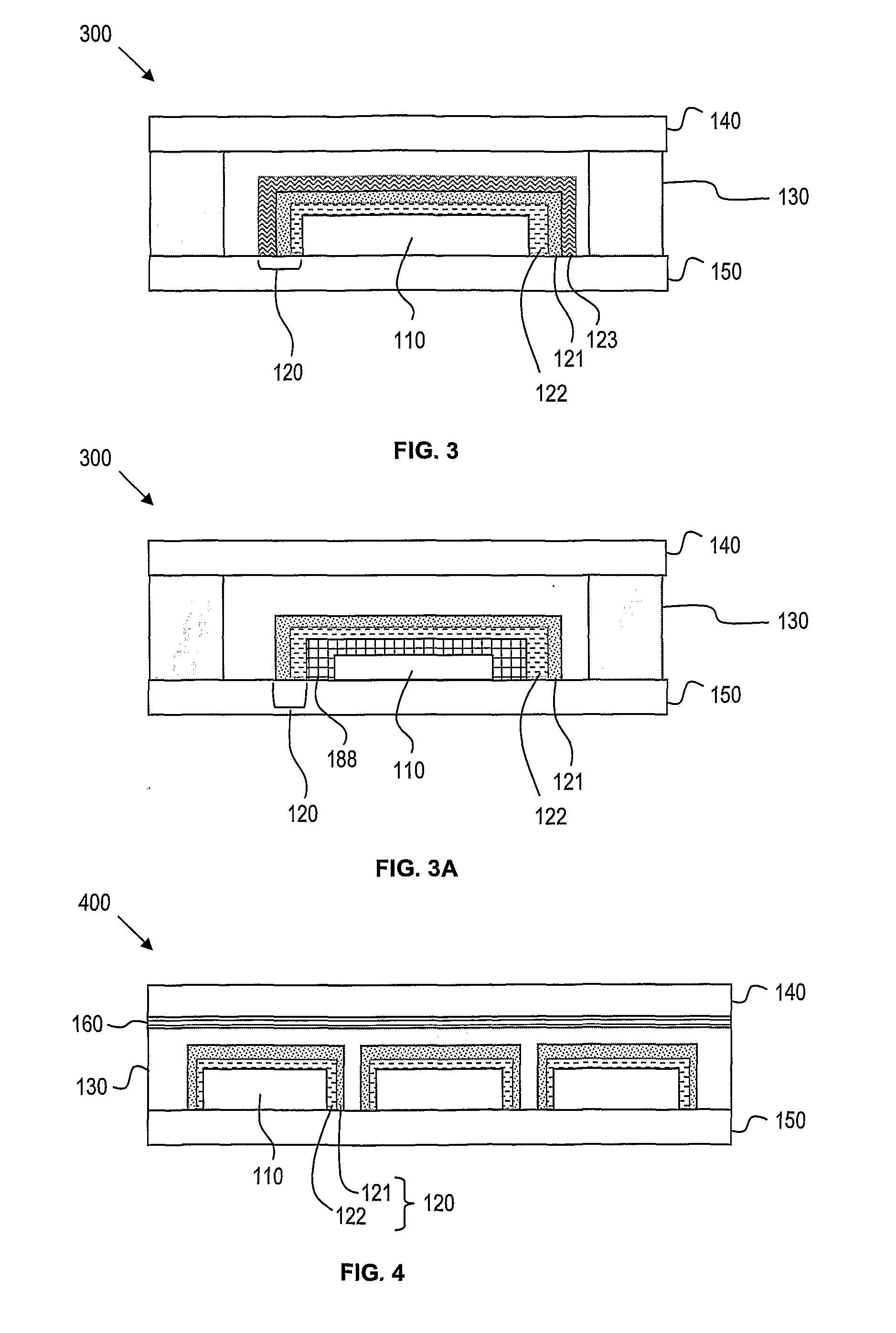

Components and methods for use in electro-optic displays

ActiveUS20040027327A1Avoid problemsLiquid surface applicatorsStatic indicating devicesElectricityDisplay device

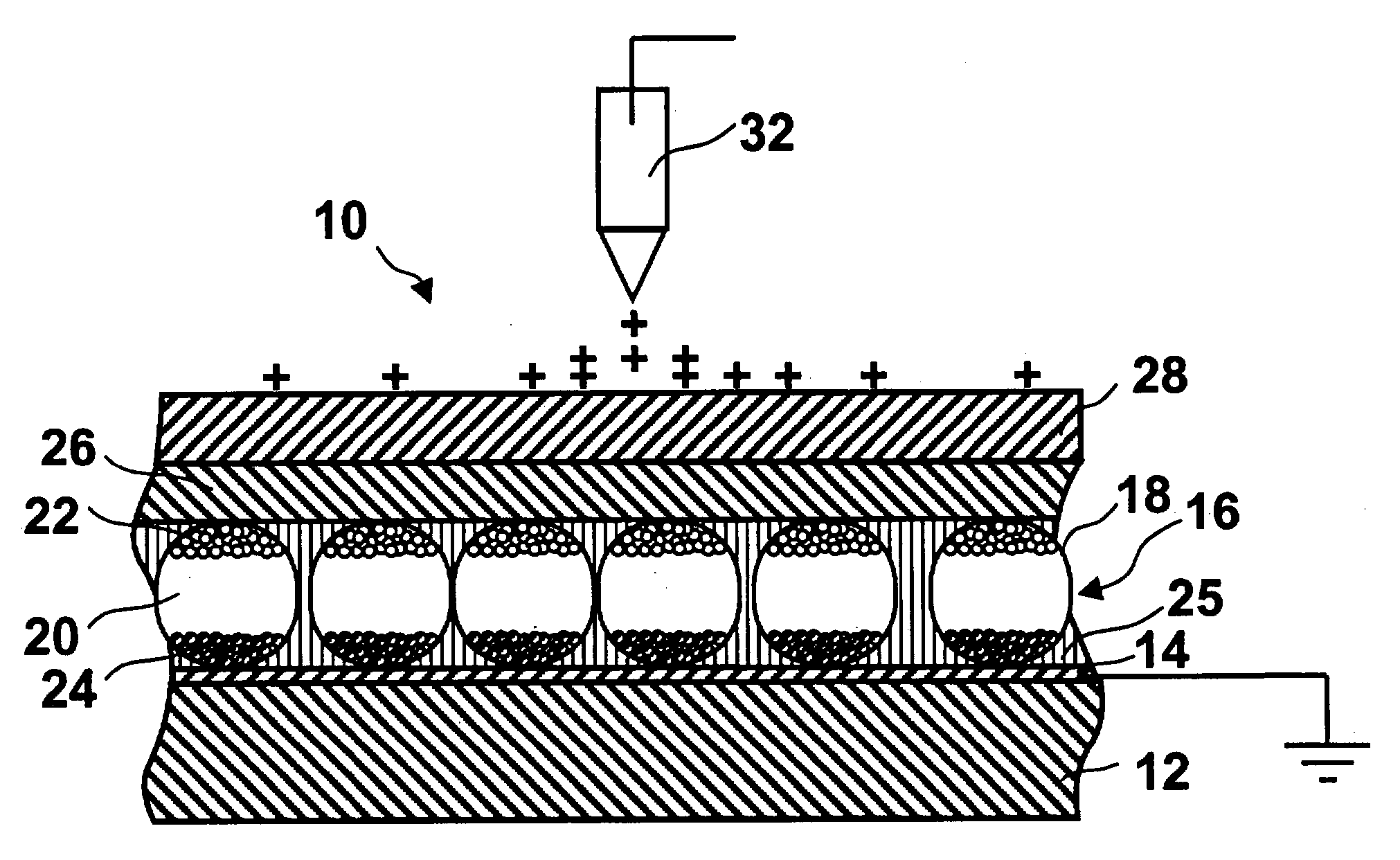

A front plane laminate useful in the manufacture of electro-optic displays comprises, in order, a light-transmissive electrically-conductive layer, a layer of an electro-optic medium in electrical contact with the electrically-conductive layer, an adhesive layer and a release sheet. This front plane laminate can be prepared as a continuous web, cut to size, the release sheet removed and the laminate laminated to a backplane to form a display. Methods for providing conductive vias through the electro-optic medium and for testing the front plane laminate are also described.

Owner:E INK CORPORATION

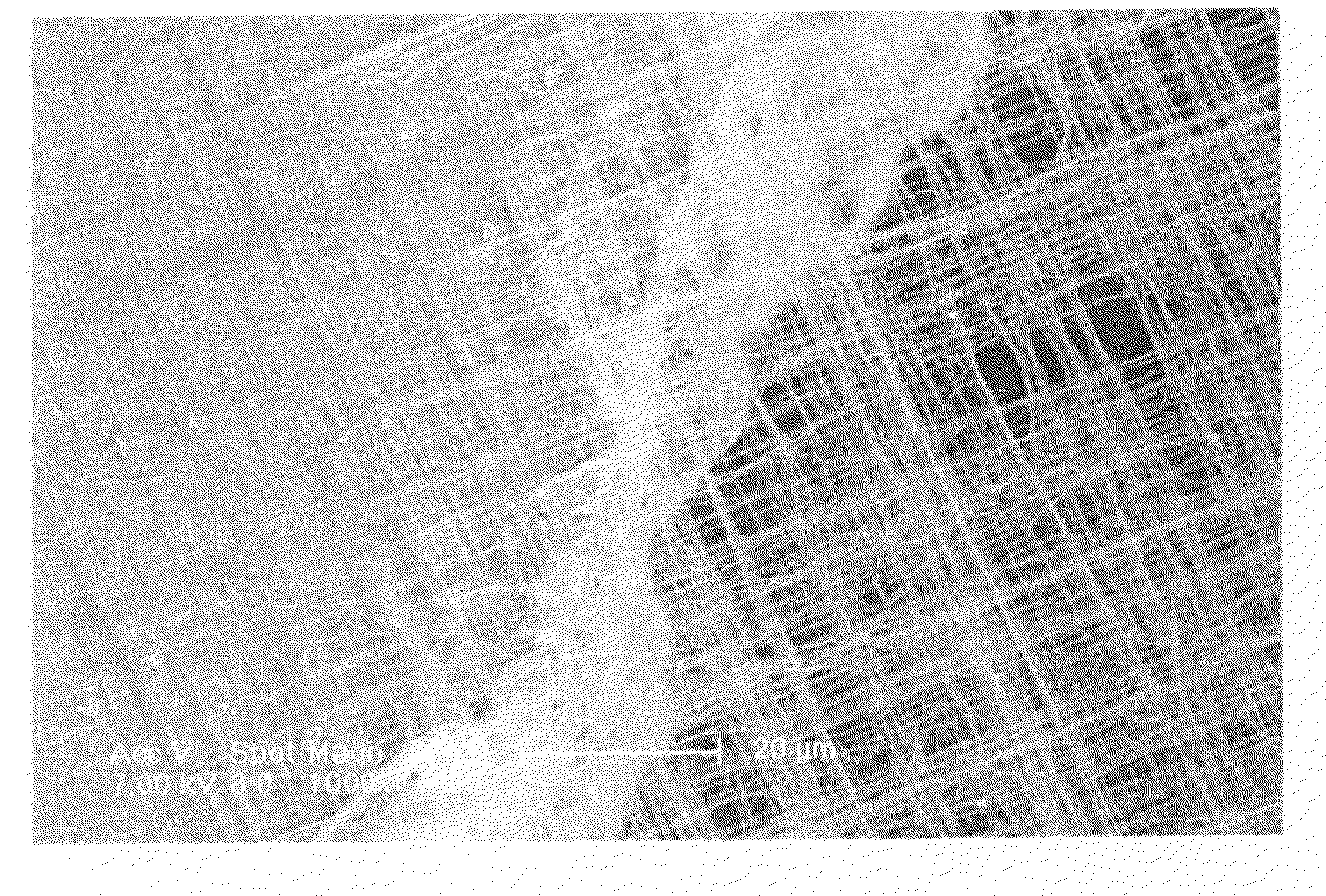

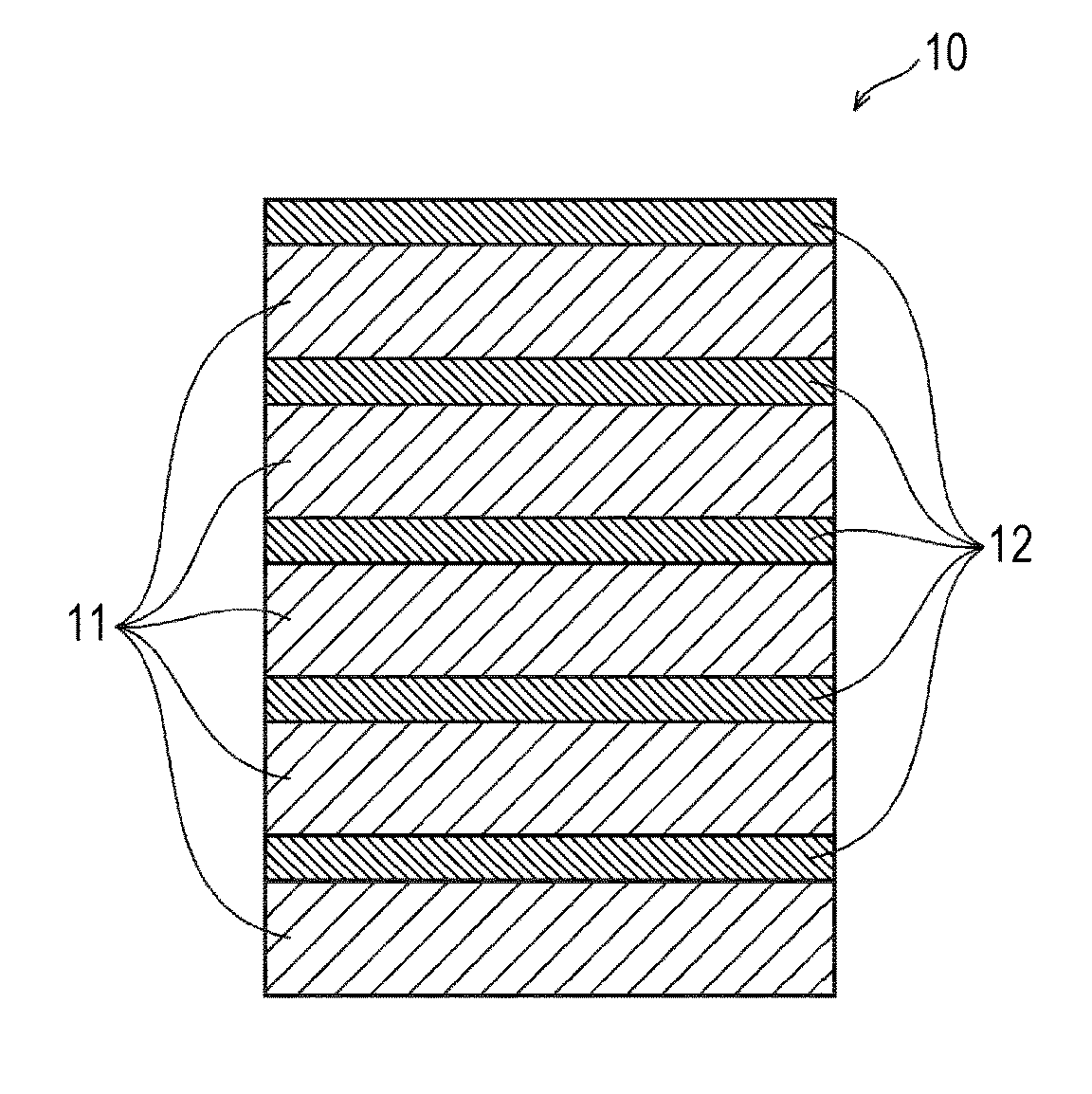

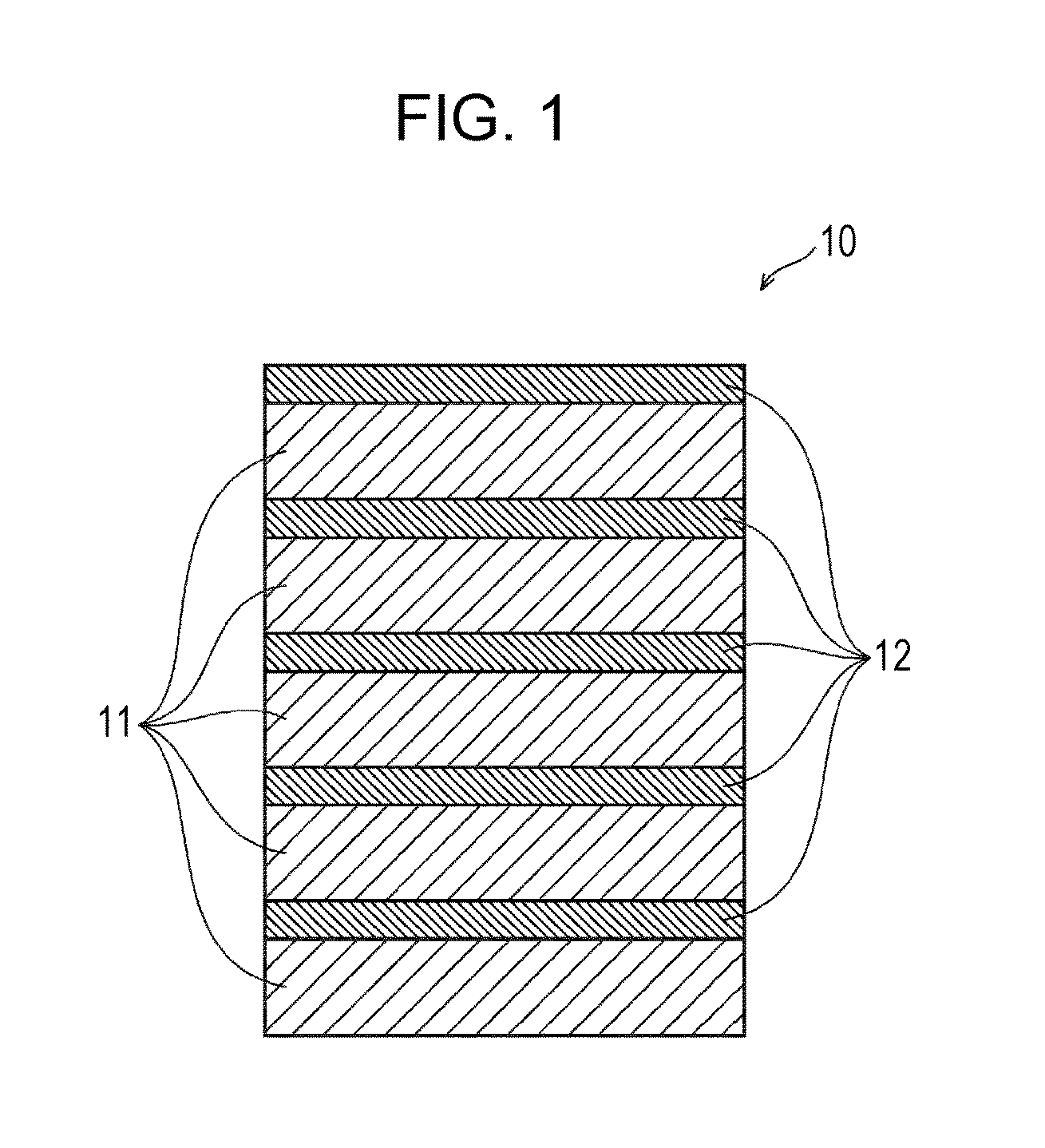

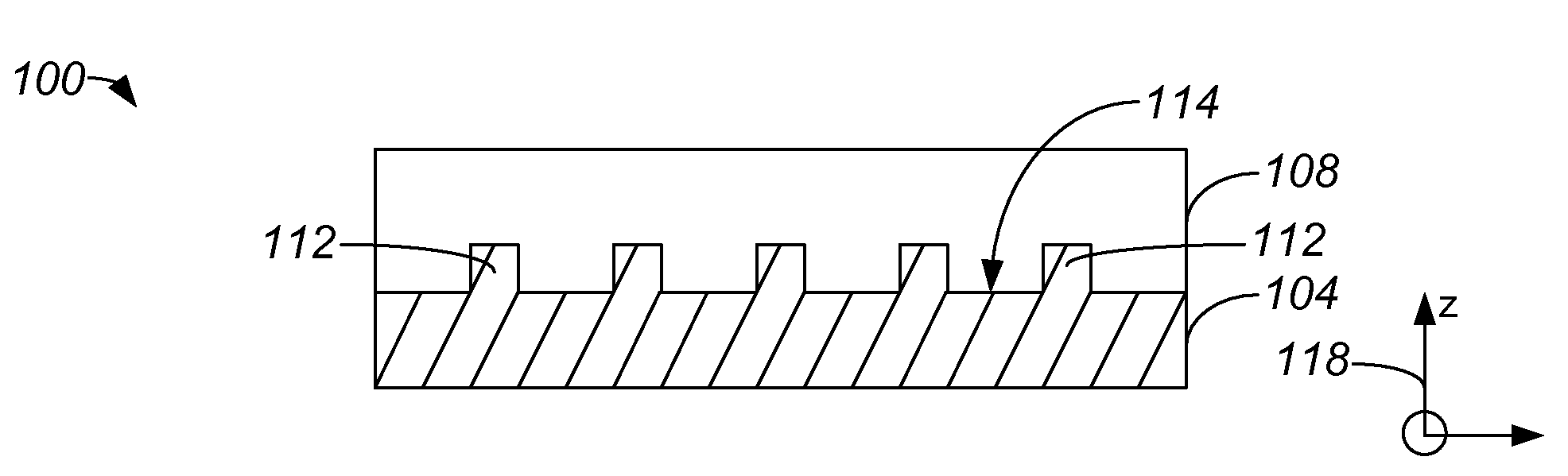

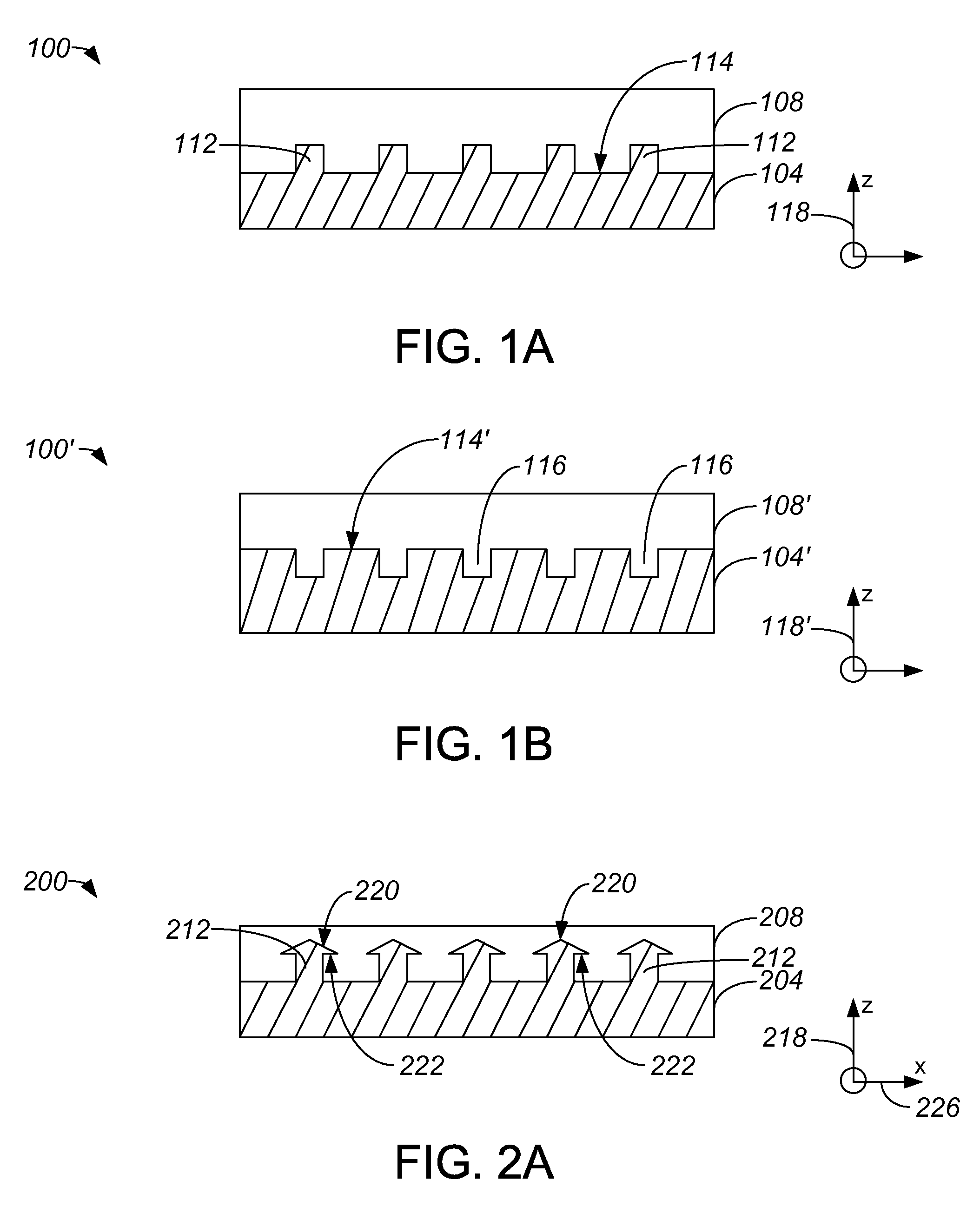

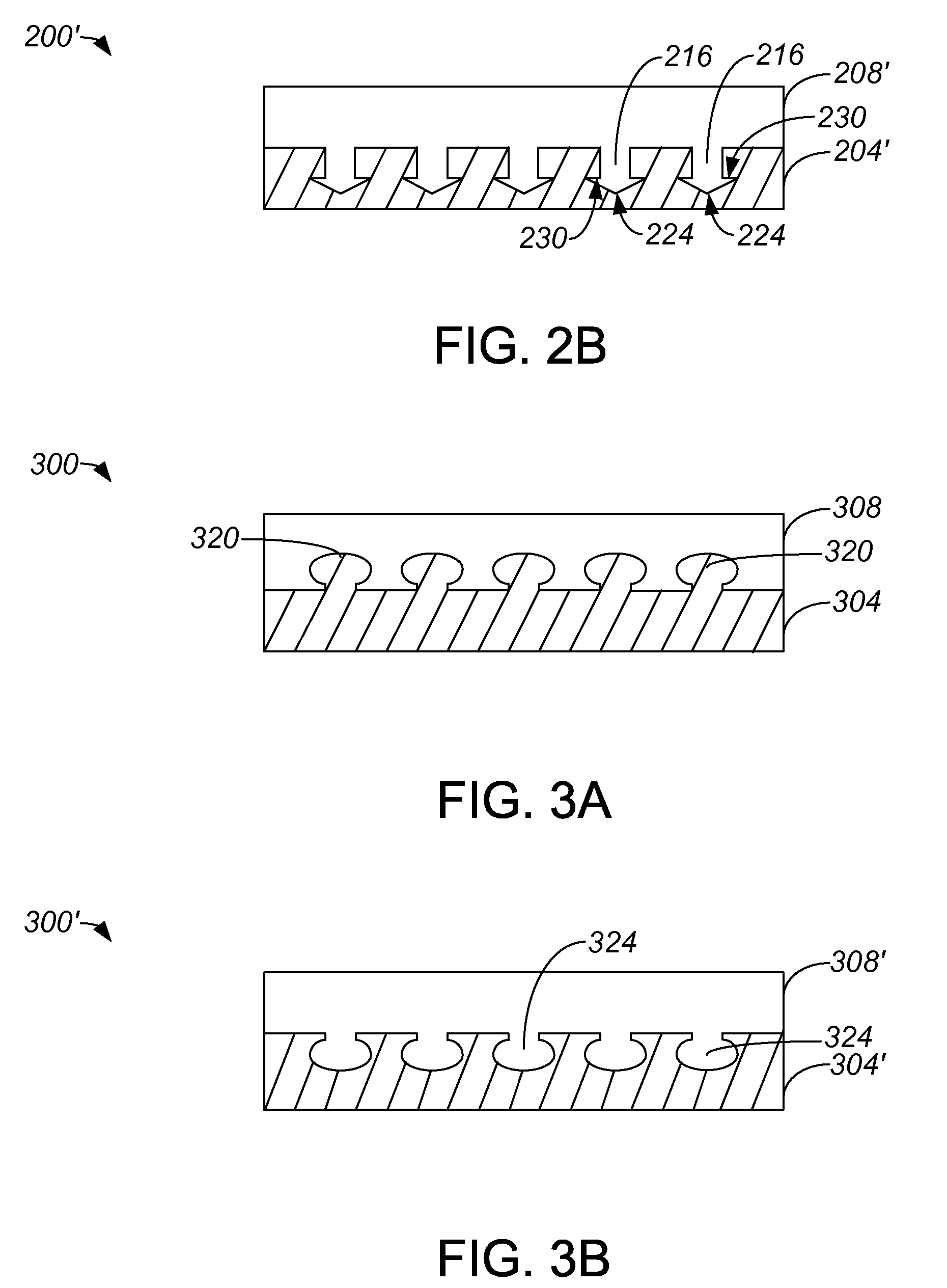

Carbon nanotube film structure and method for fabricating the same

A carbon nanotube film structure includes at least two overlapped carbon nanotube films, with adjoining films being aligned in different directions. Each carbon nanotube film includes a plurality of successive carbon nanotube bundles aligned in the same direction. The carbon nanotube structure further includes a plurality of micropores formed by / between the adjoining carbon nanotube bundles. A method for fabricating the carbon nanotube film structure includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, using a tool, one carbon nanotube film from the array of carbon nanotubes; (c) providing a frame and adhering the carbon nanotube film to the frame; (d) repeating steps (b) and (c), depositing each successive film on a preceding film, thereby achieving at least a two-layer carbon nanotube film; and (e) peeling the carbon nanotube film off the frame to achieve the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

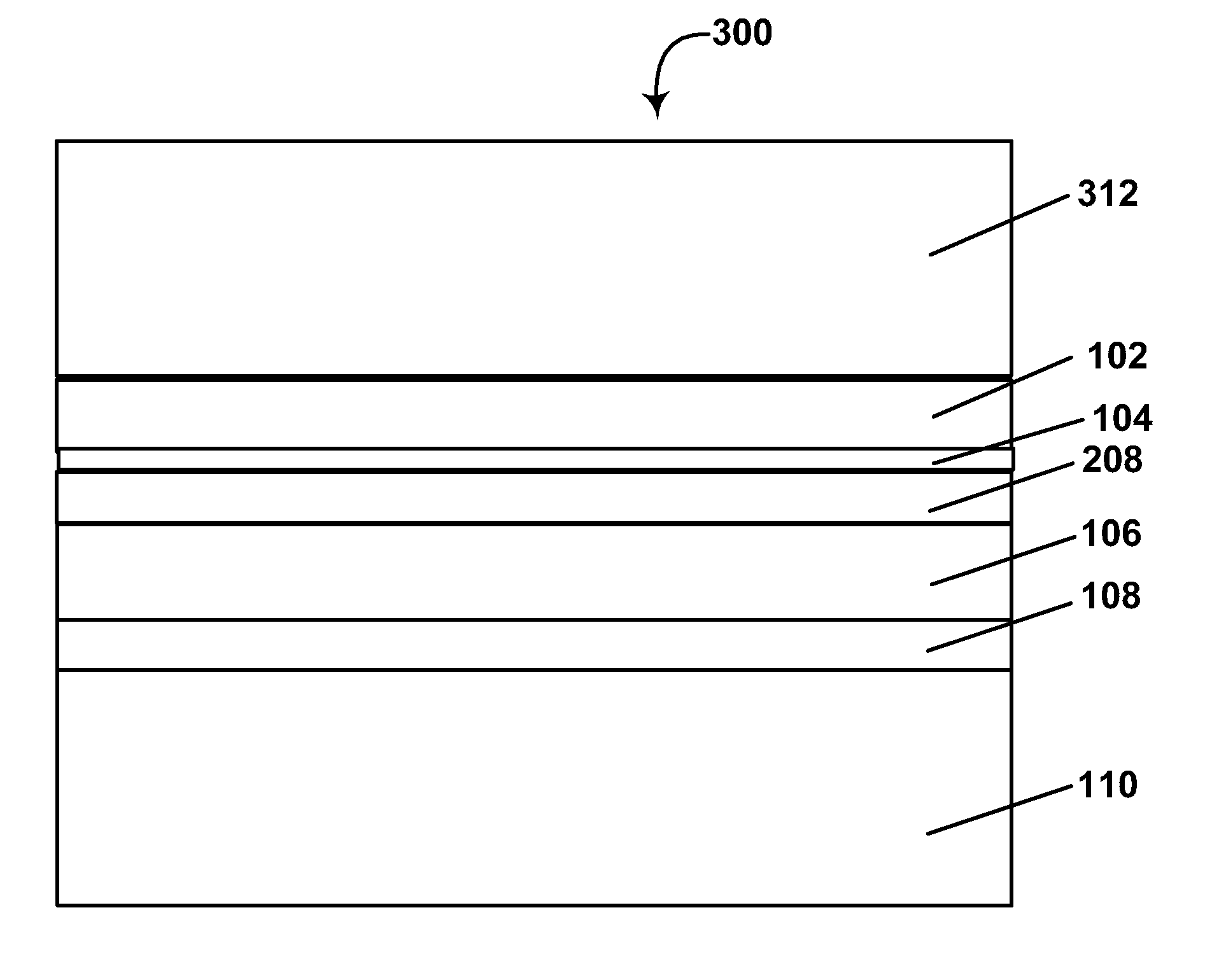

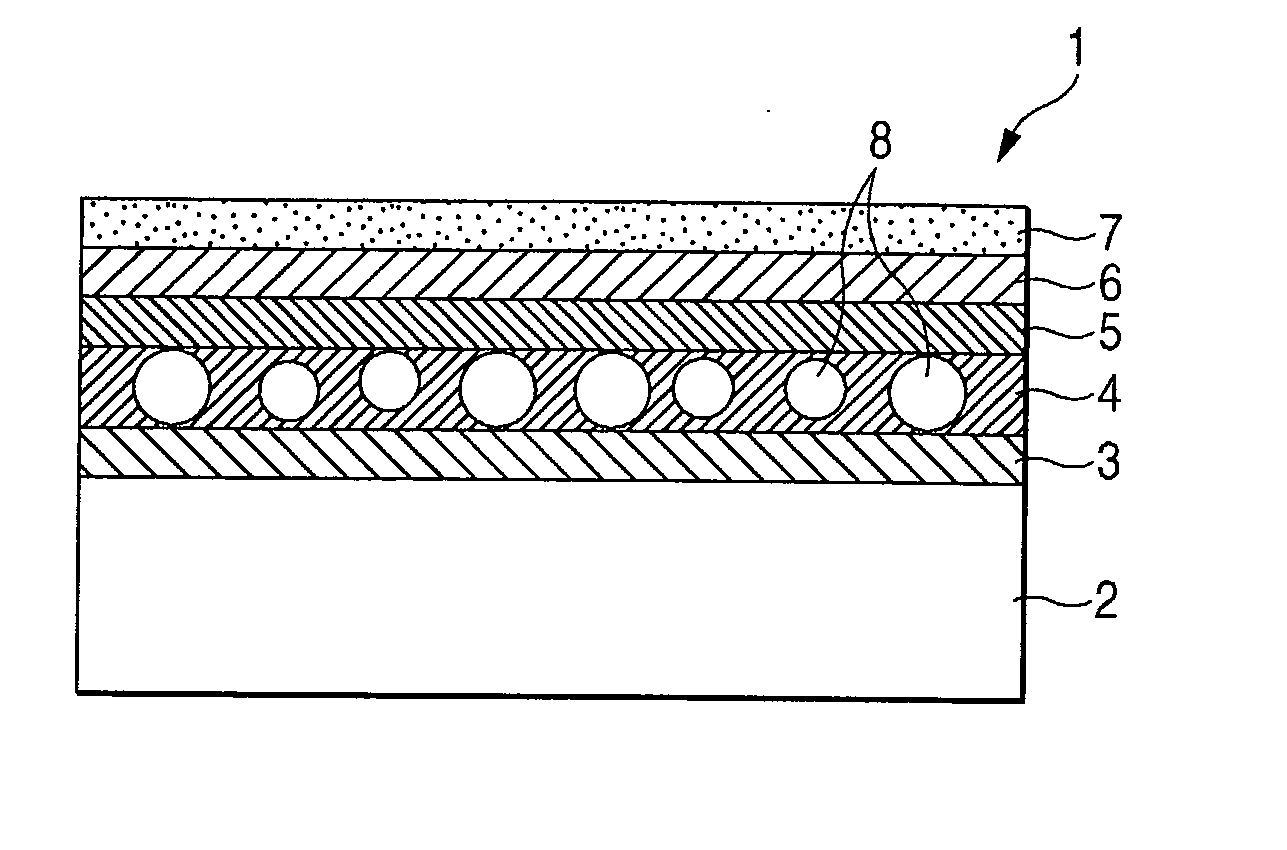

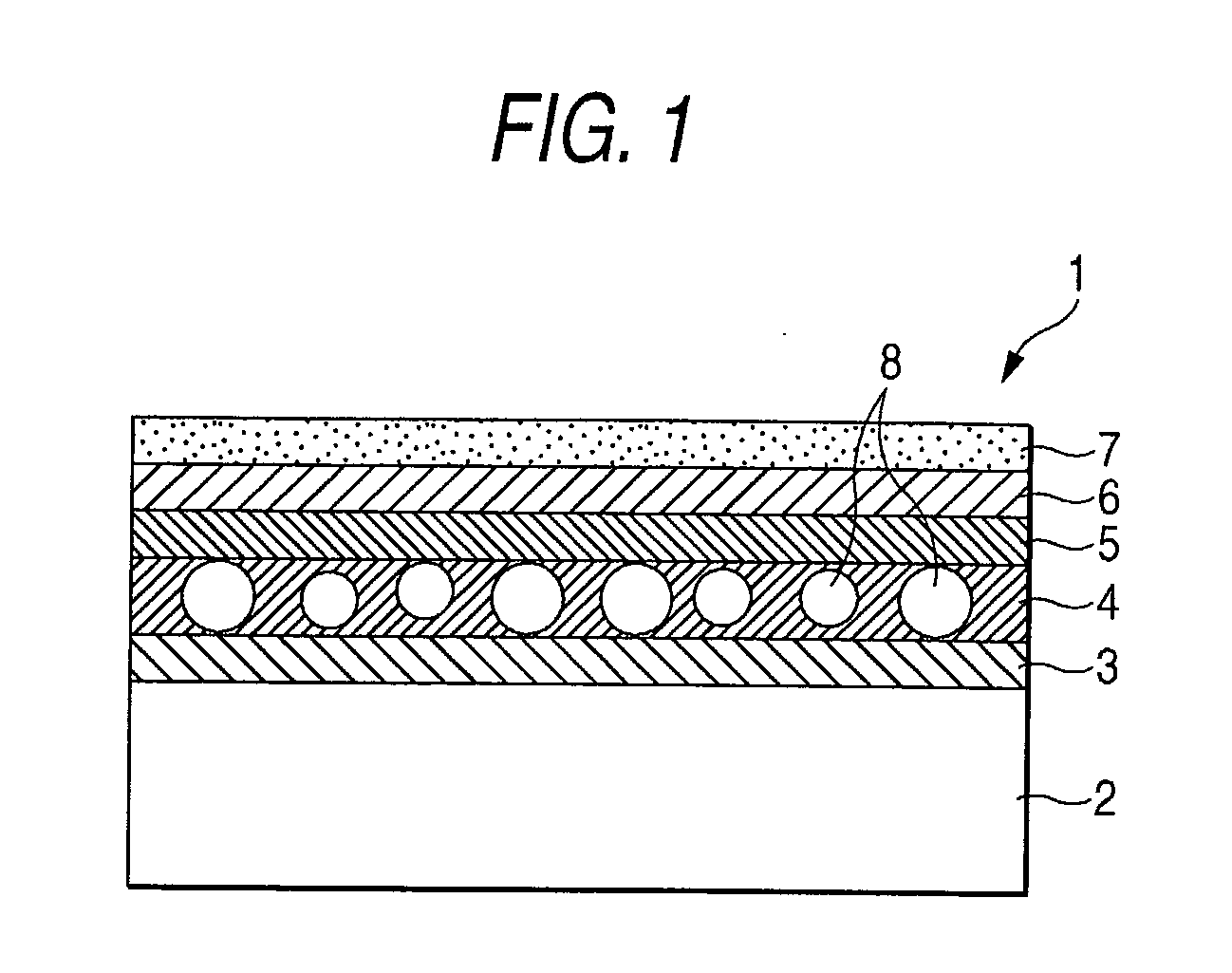

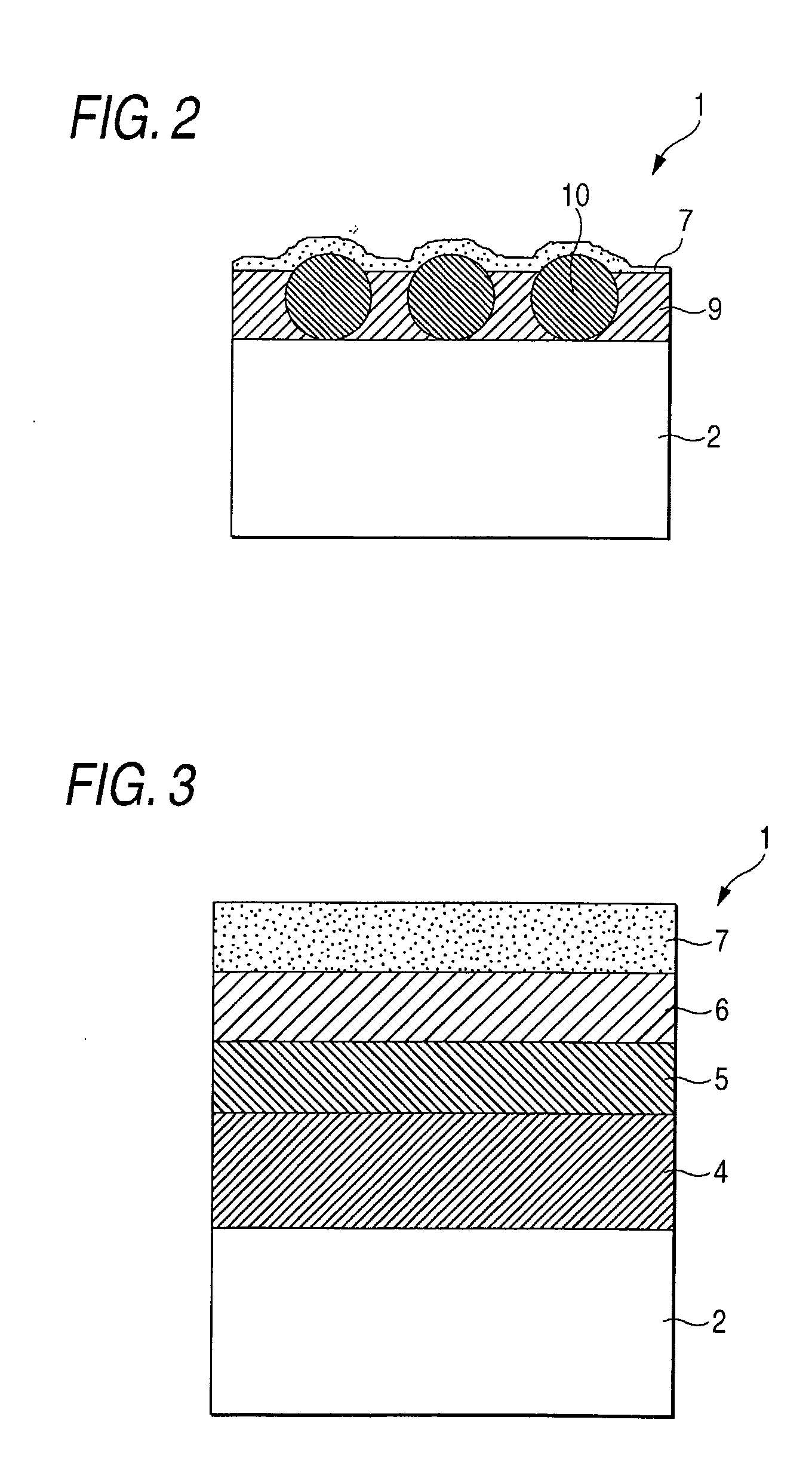

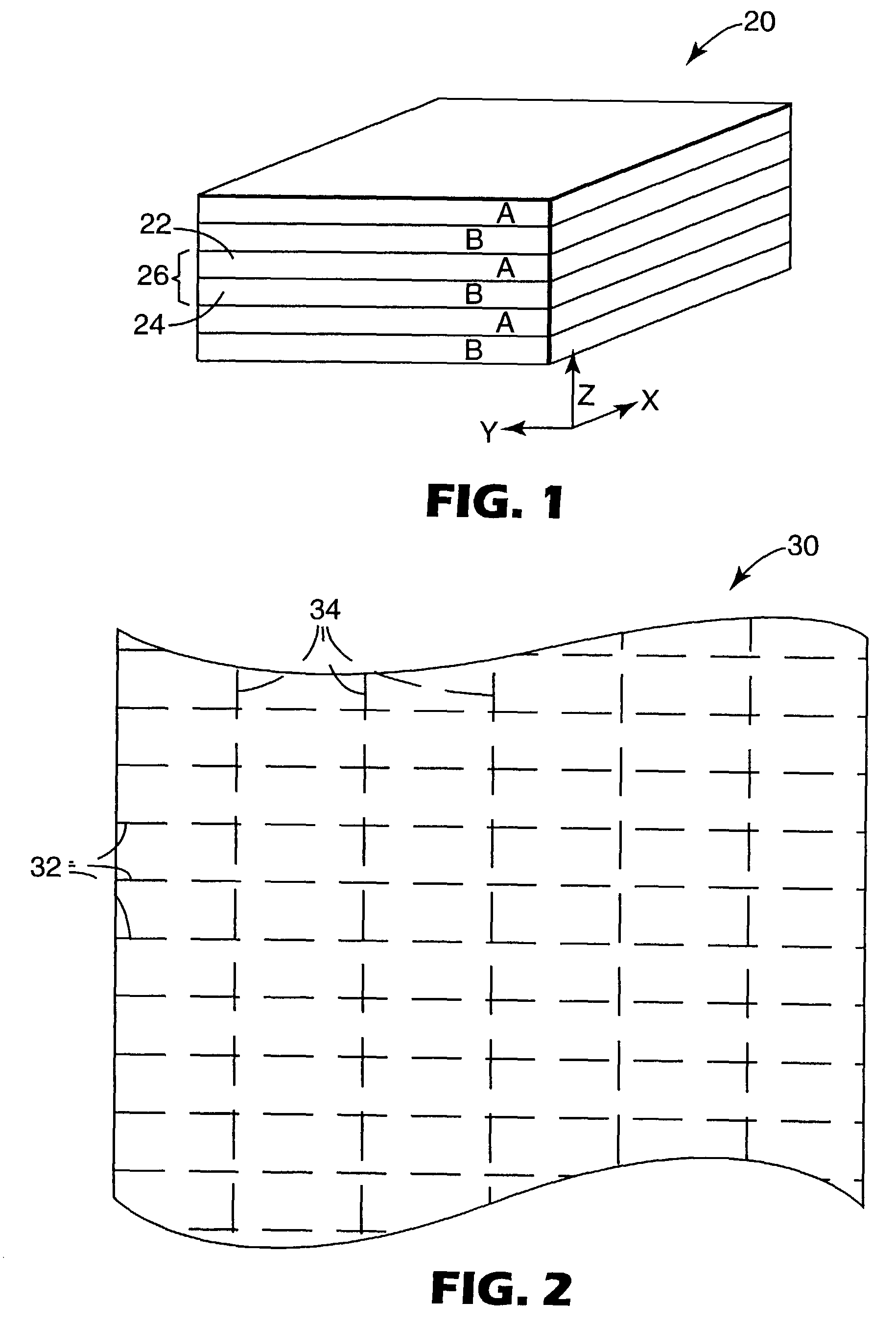

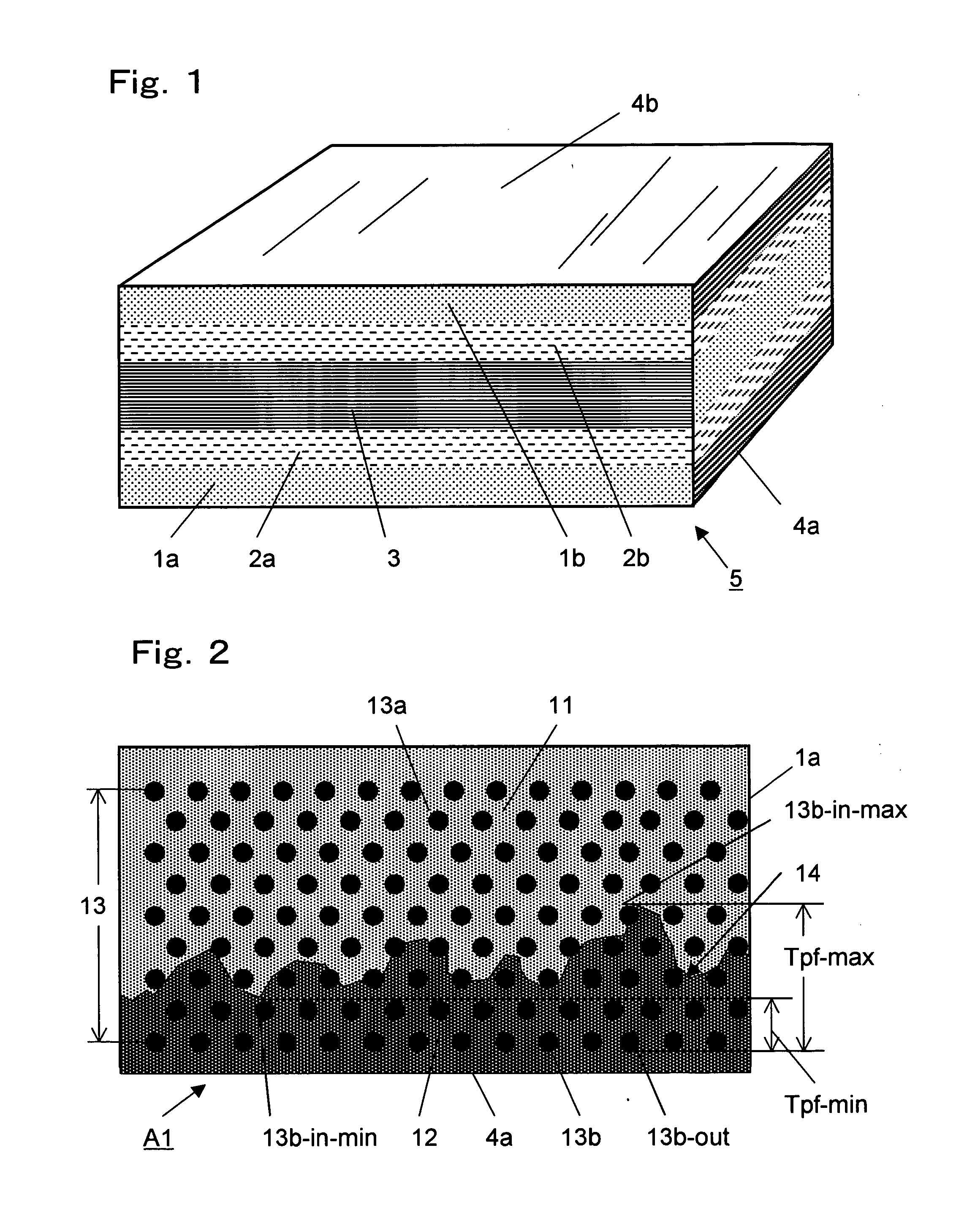

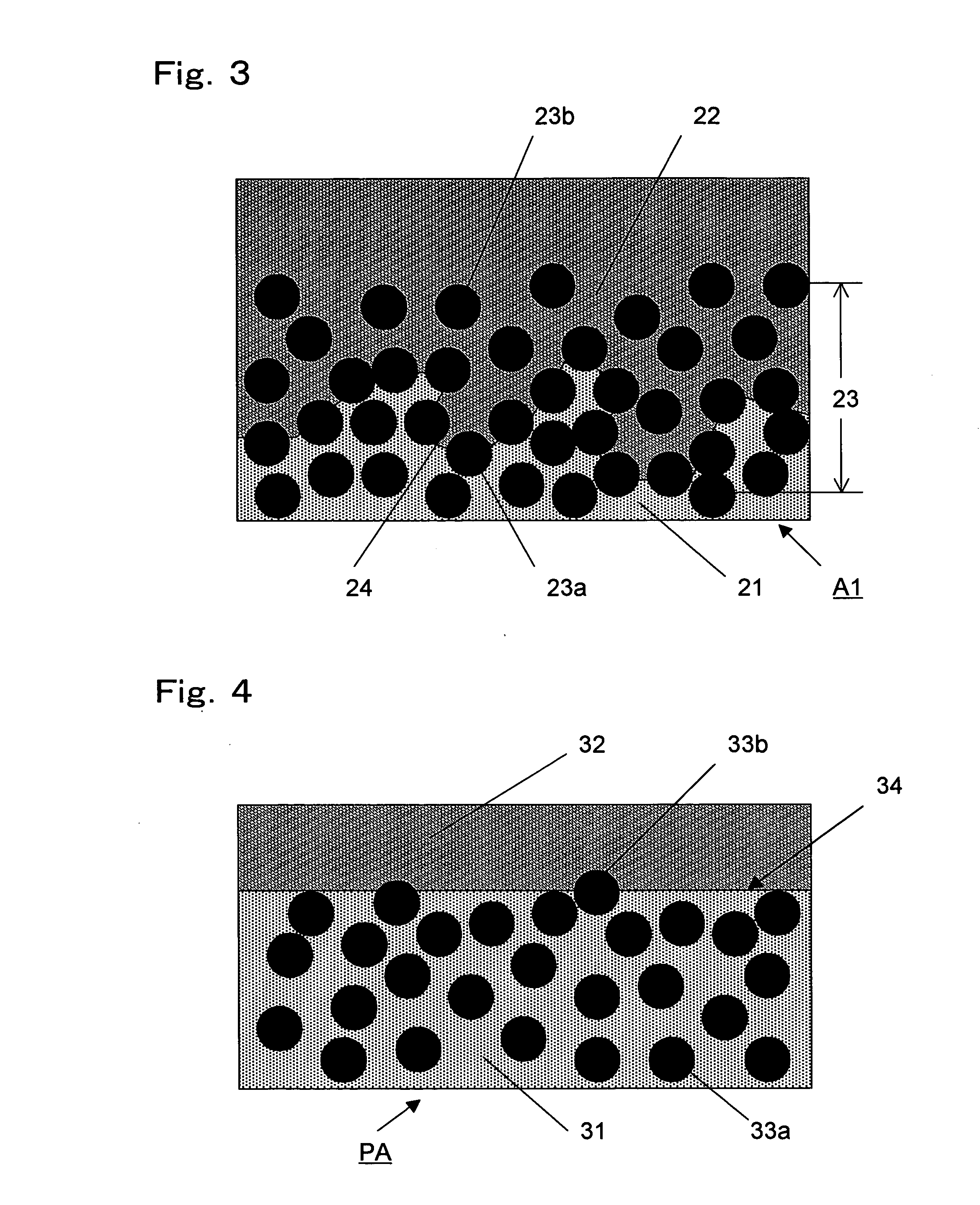

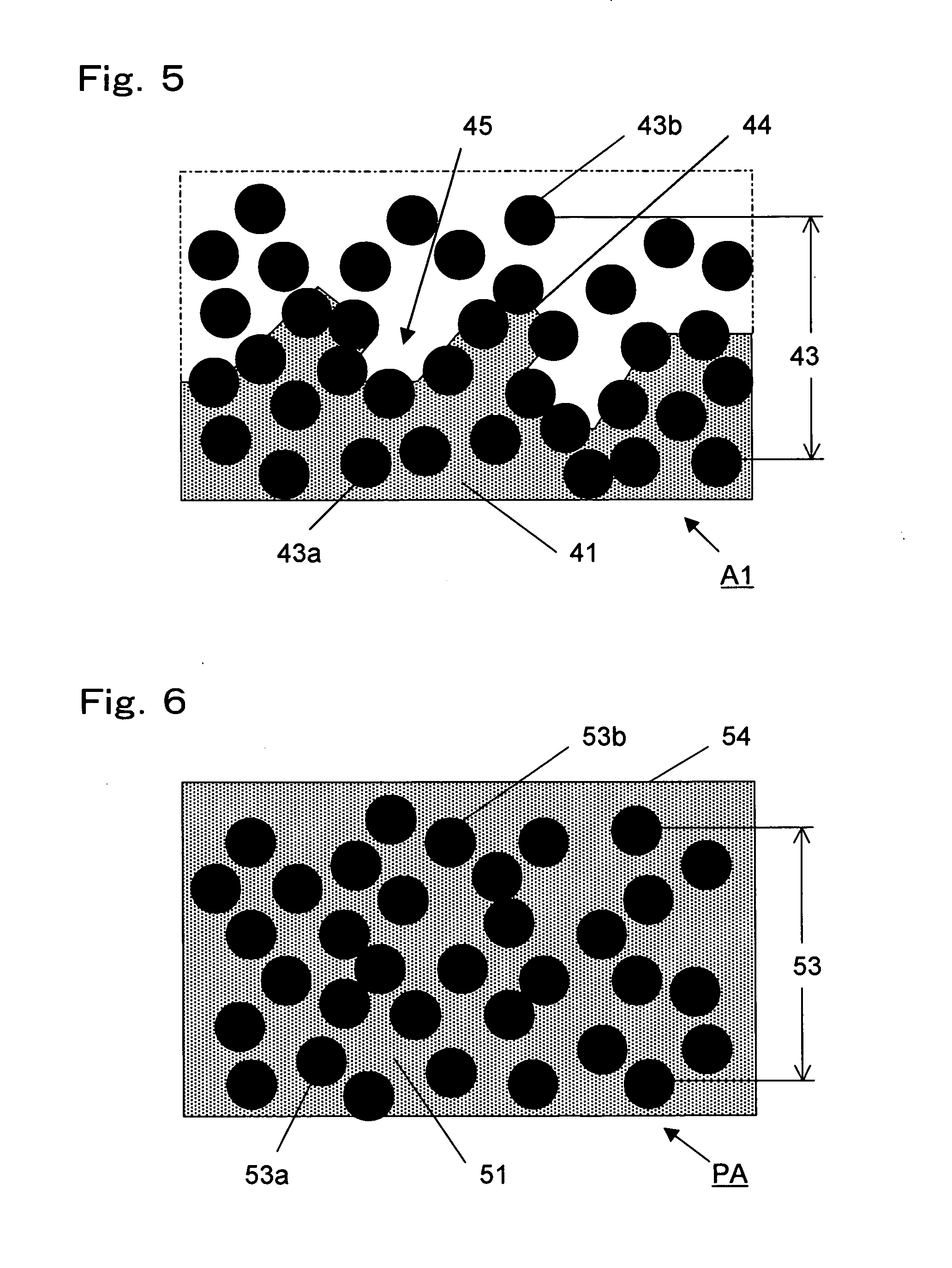

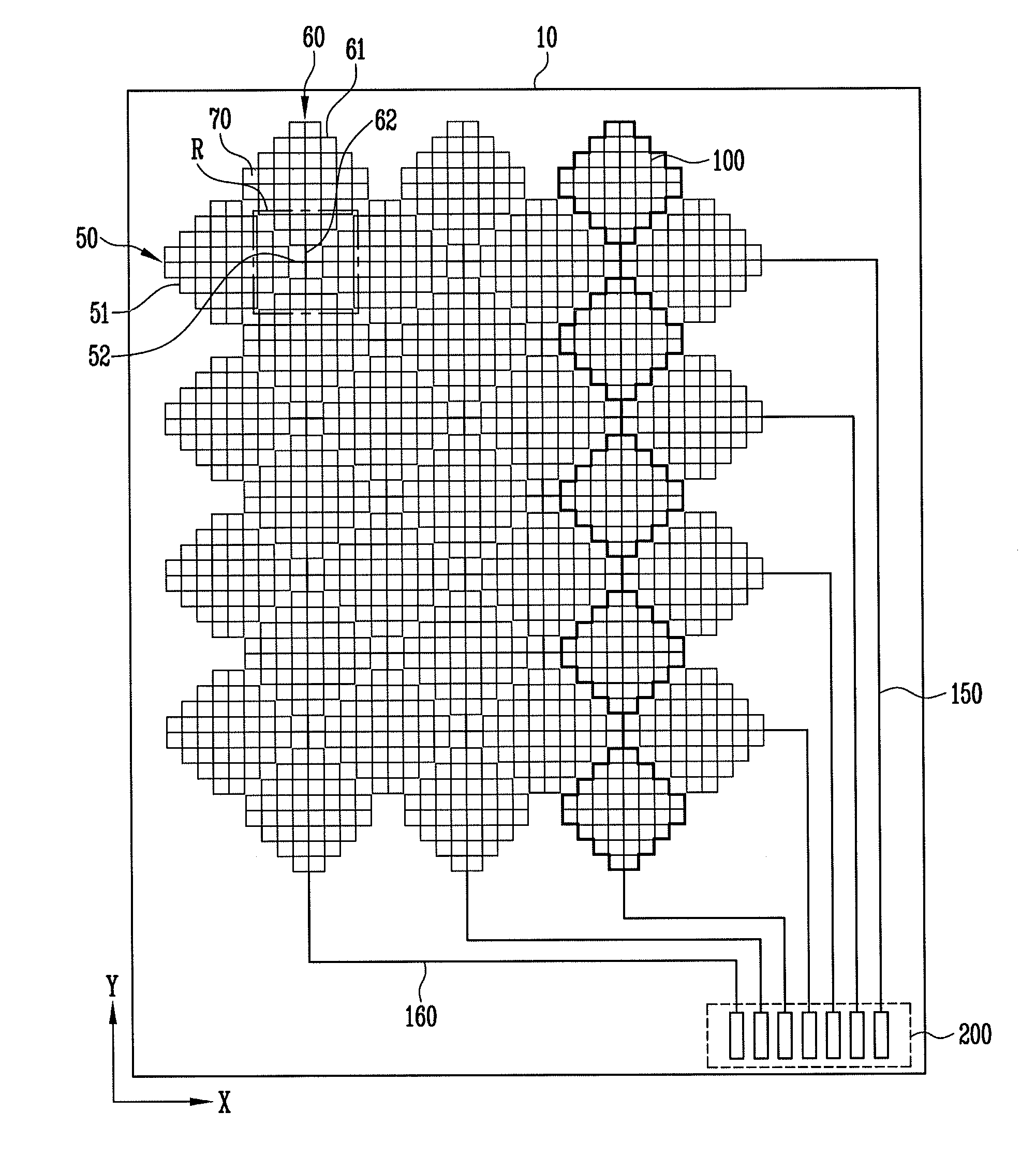

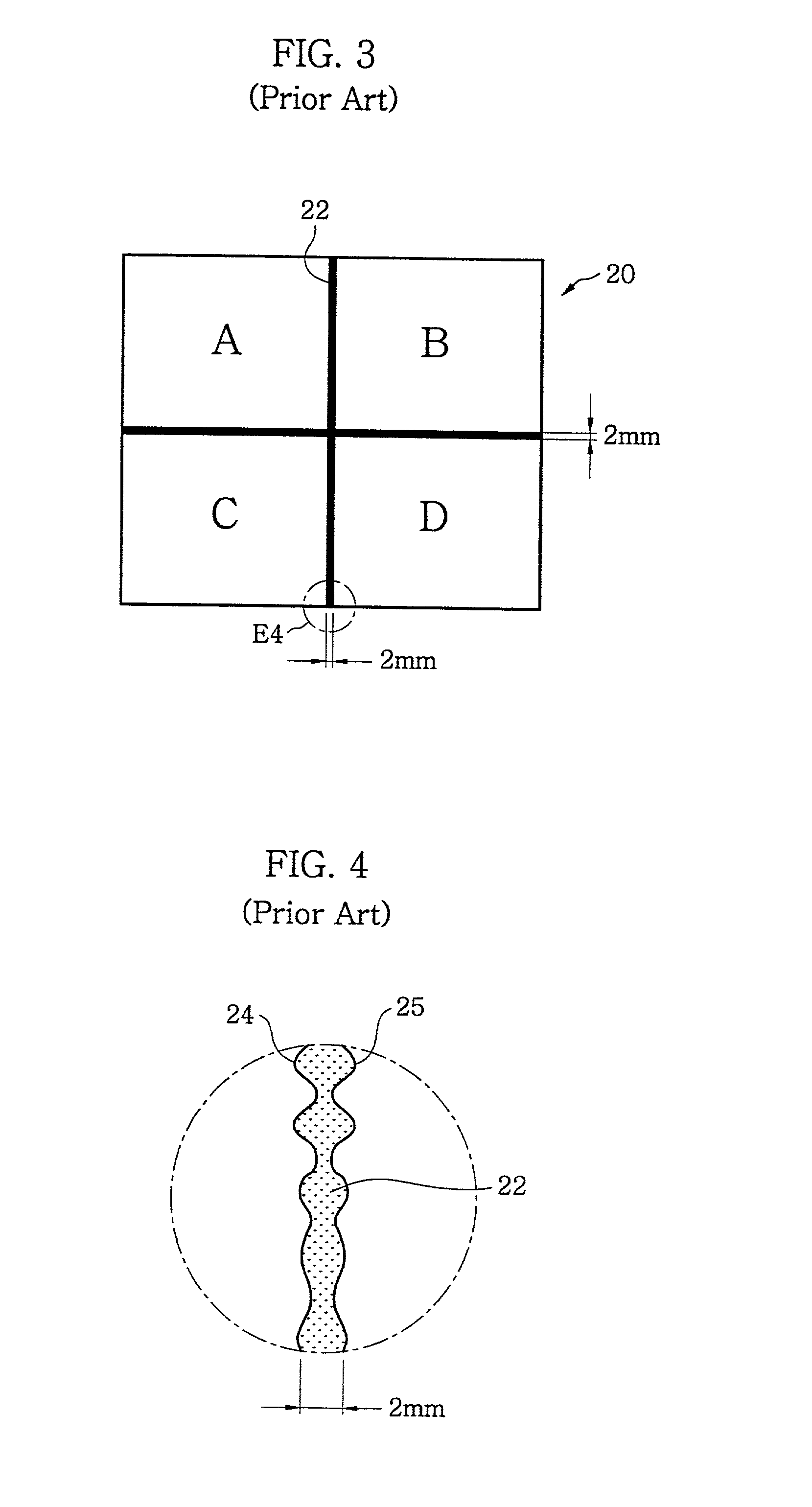

Gas barrier film, film substrate provided with gas barrier film, and electronic device including the film substrate

ActiveUS20150343741A1Excellent gas barrier performanceIncrease resistanceLayered productsRecord information storageThin membraneElectric devices

A gas barrier film includes two or more first barrier layers each made of a first inorganic material and one or more second barrier layers each made of a second inorganic material different from the first inorganic material. Each of the two or more first barrier layers and each of the one or more second barrier layers are alternately stacked. The first inorganic material comprises aluminum oxide. Each of the two or more first barrier layers has a thickness of 3 nm or more. The total thickness of the two or more first barrier layers is 20 nm or less. The two or more first barrier layers and the one or more second barrier layers are formed by atomic layer deposition.

Owner:SAMSUNG DISPLAY CO LTD

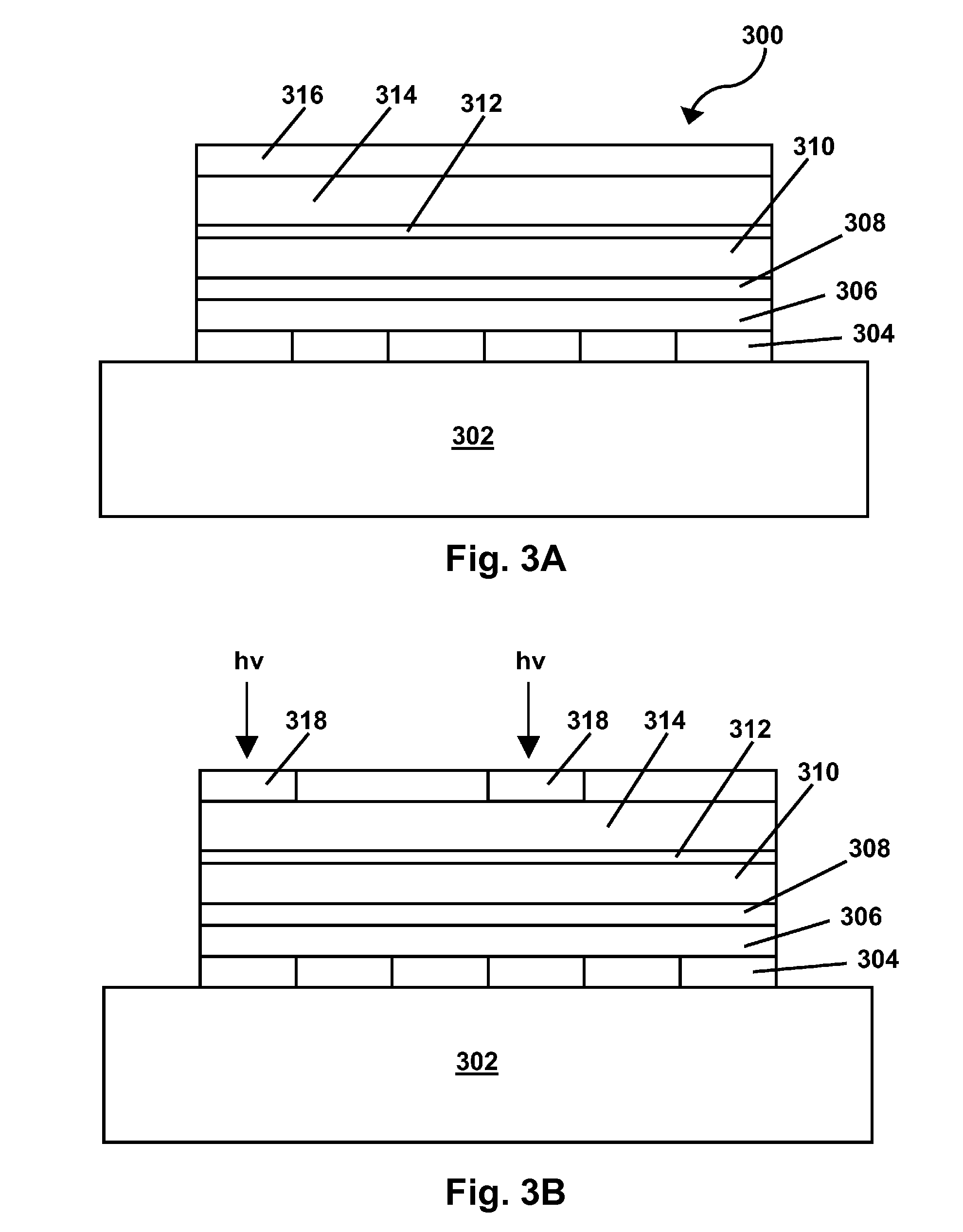

Method of transferring a micro device

A micro device transfer head and head array are disclosed. In an embodiment, the micro device transfer head includes a base substrate, a mesa structure with sidewalls, an electrode formed over the mesa structure, and a dielectric layer covering the electrode. A voltage can be applied to the micro device transfer head and head array to pick up a micro device from a carrier substrate and release the micro device onto a receiving substrate.

Owner:APPLE INC

Electro-optic displays, and color filters for use therein

ActiveUS8098418B2Solve the lack of adhesionEliminate needLayered product treatmentStatic indicating devicesDisplay deviceColor filter array

A process for producing a color electro-optic display uses an electro-optic sub-assembly comprising an electro-optic layer and a light-transmissive electrically-conductive layer. This sub-assembly is laminated to a backplane comprising a plurality of electrodes with the electro-optic layer disposed between the backplane and the electrically-conductive layer. A flowable material is placed over the sub-assembly and a color filter array is placed over the electrically-conductive layer and aligned with the electrodes of the backplane to form the color electro-optic display.

Owner:E INK CORPORATION

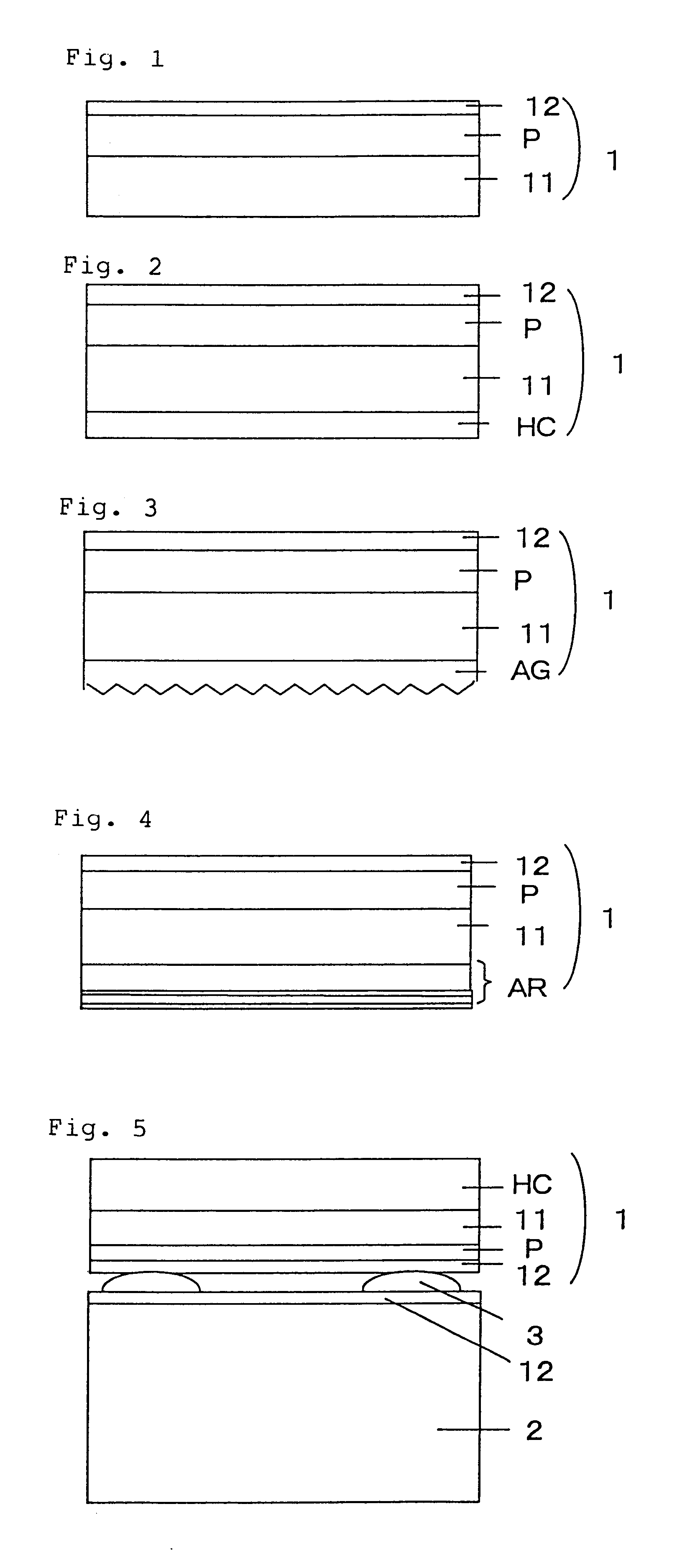

Antireflection film, polarizing plate, method for producing them, liquid cryatal display element, liquid crystal display device, and image display device

ActiveUS20070146887A1Reduce weightLow costLiquid crystal compositionsSynthetic resin layered productsSilica particleLiquid-crystal display

To provide an antireflection film which is easily and inexpensively producible and which has an antireflection property, a scratch resistance and a stain resistance in a sufficient level, and a polarizing plate and a liquid crystal display device utilizing the antireflection film of such excellent ability, the antireflection film includs a transparent support and a low-refractive index layer having a lower refractive index than the transparent support, wherein the low-refractive index layer is an outermost layer, and the low-refractive index layer contains a hollow silica particle and a compound that reduces a surface free energy of the outermost layer.

Owner:FUJIFILM CORP

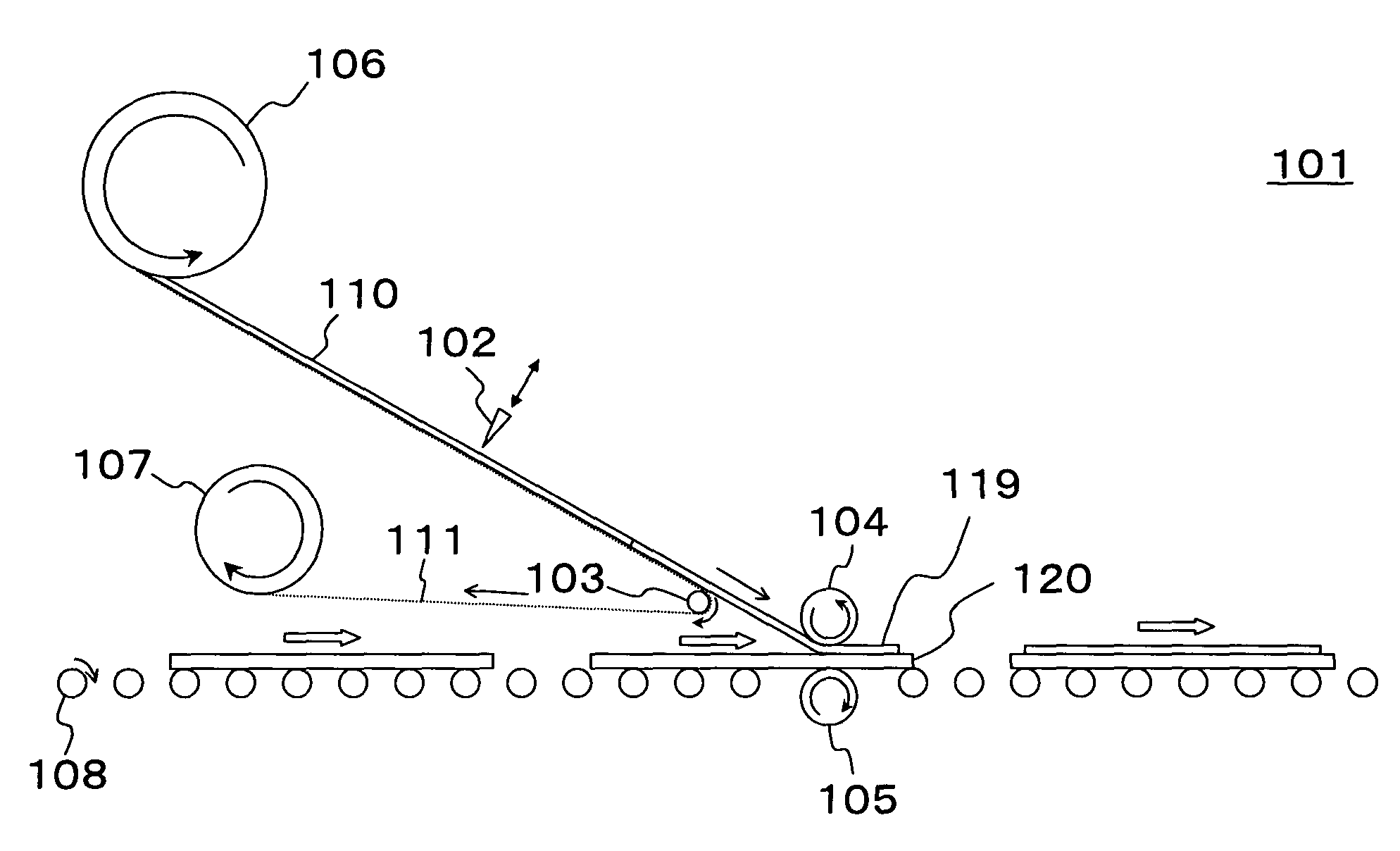

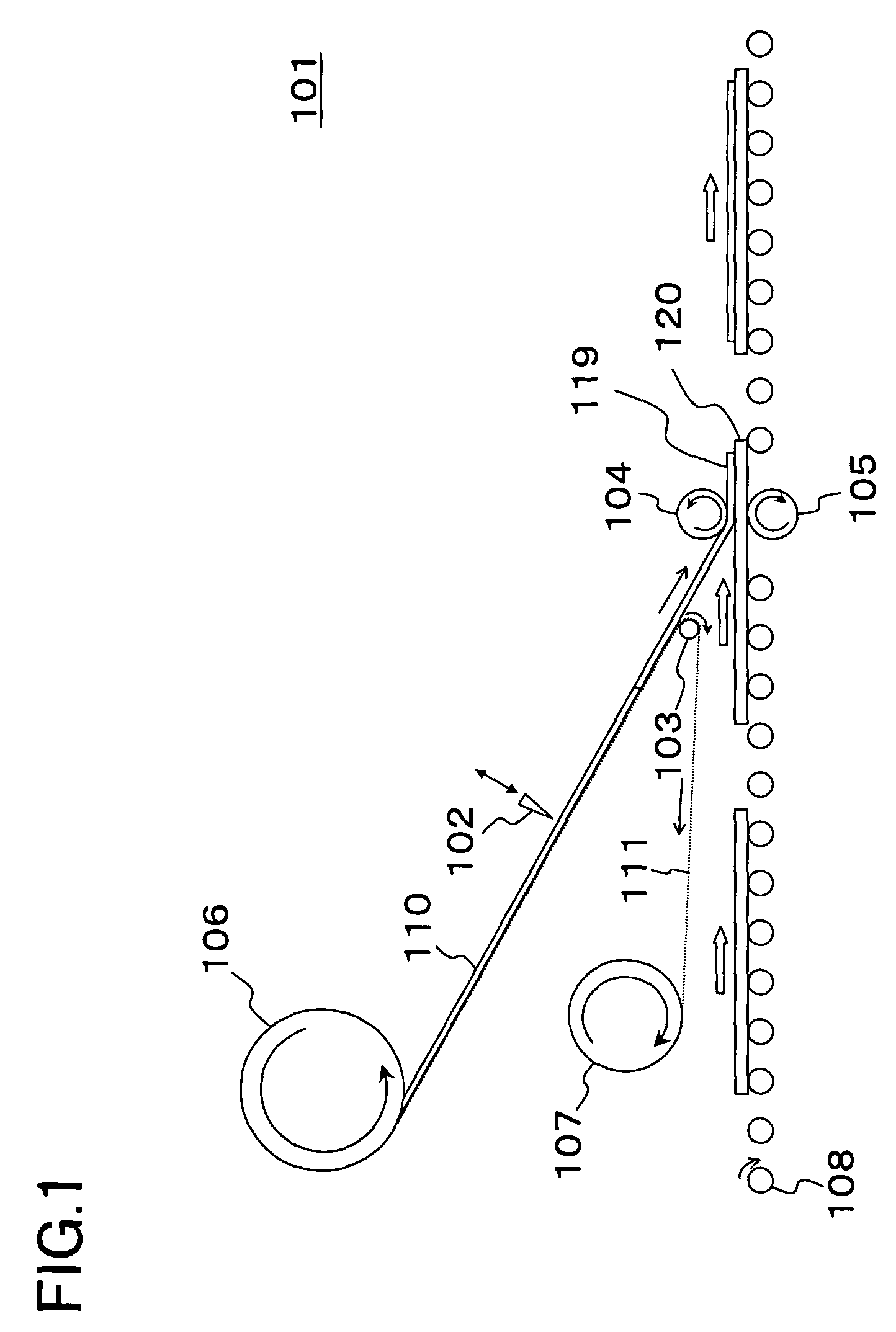

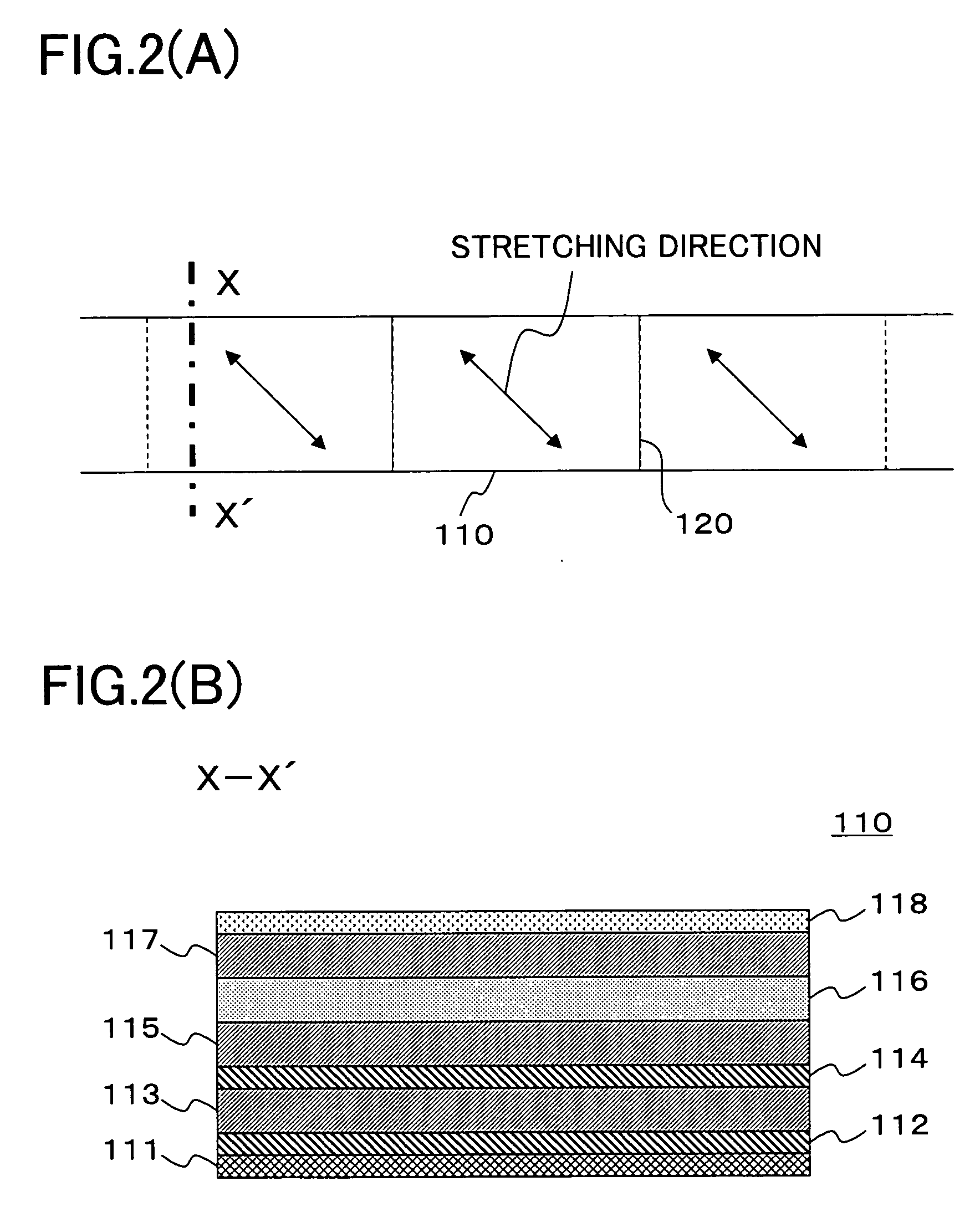

Method and apparatus for bonding polarizing plate

ActiveUS20050016670A1Easy to controlProhibit stop markLamination ancillary operationsDecorative surface effectsPolarizerEngineering

Owner:FUJIFILM CORP +1

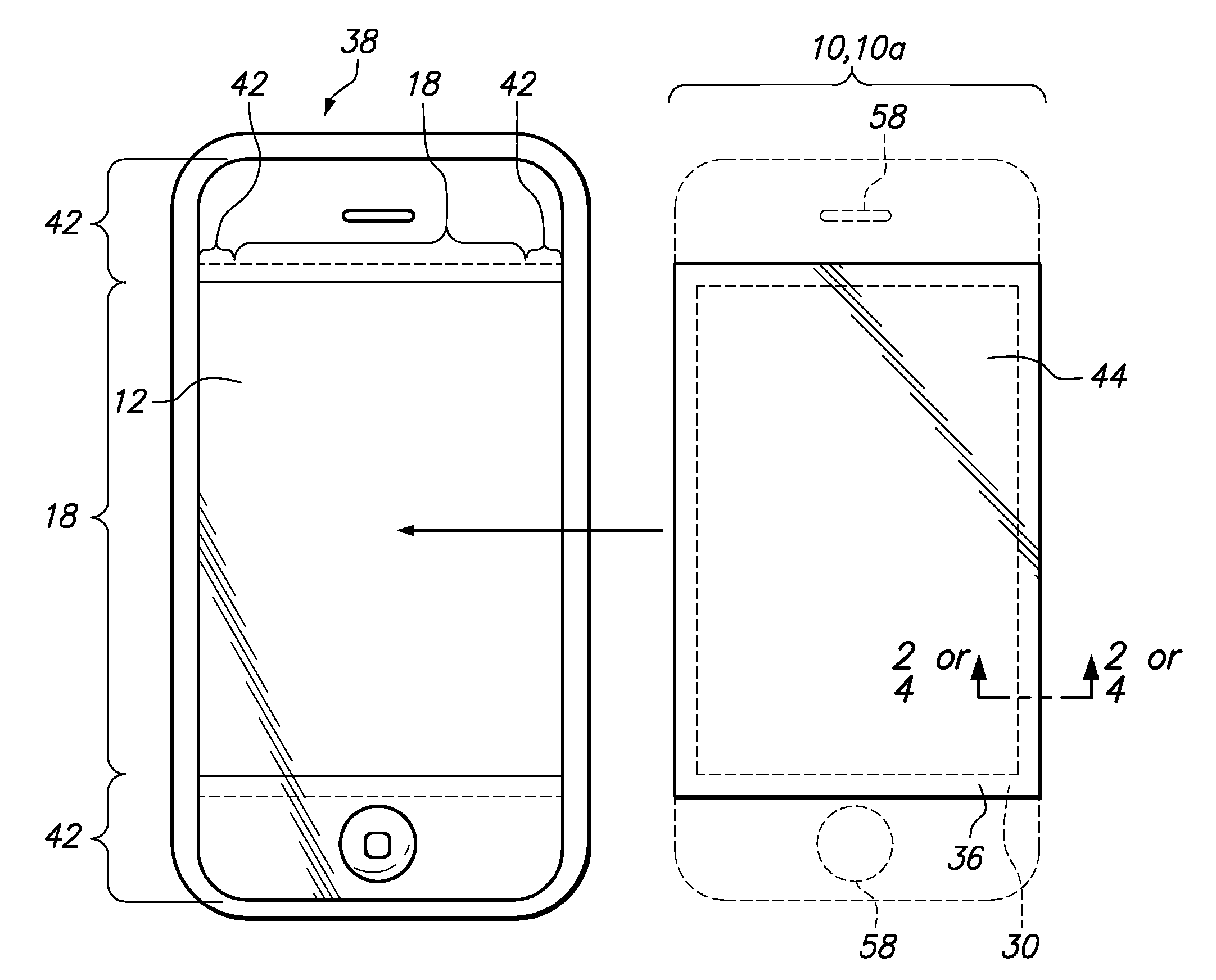

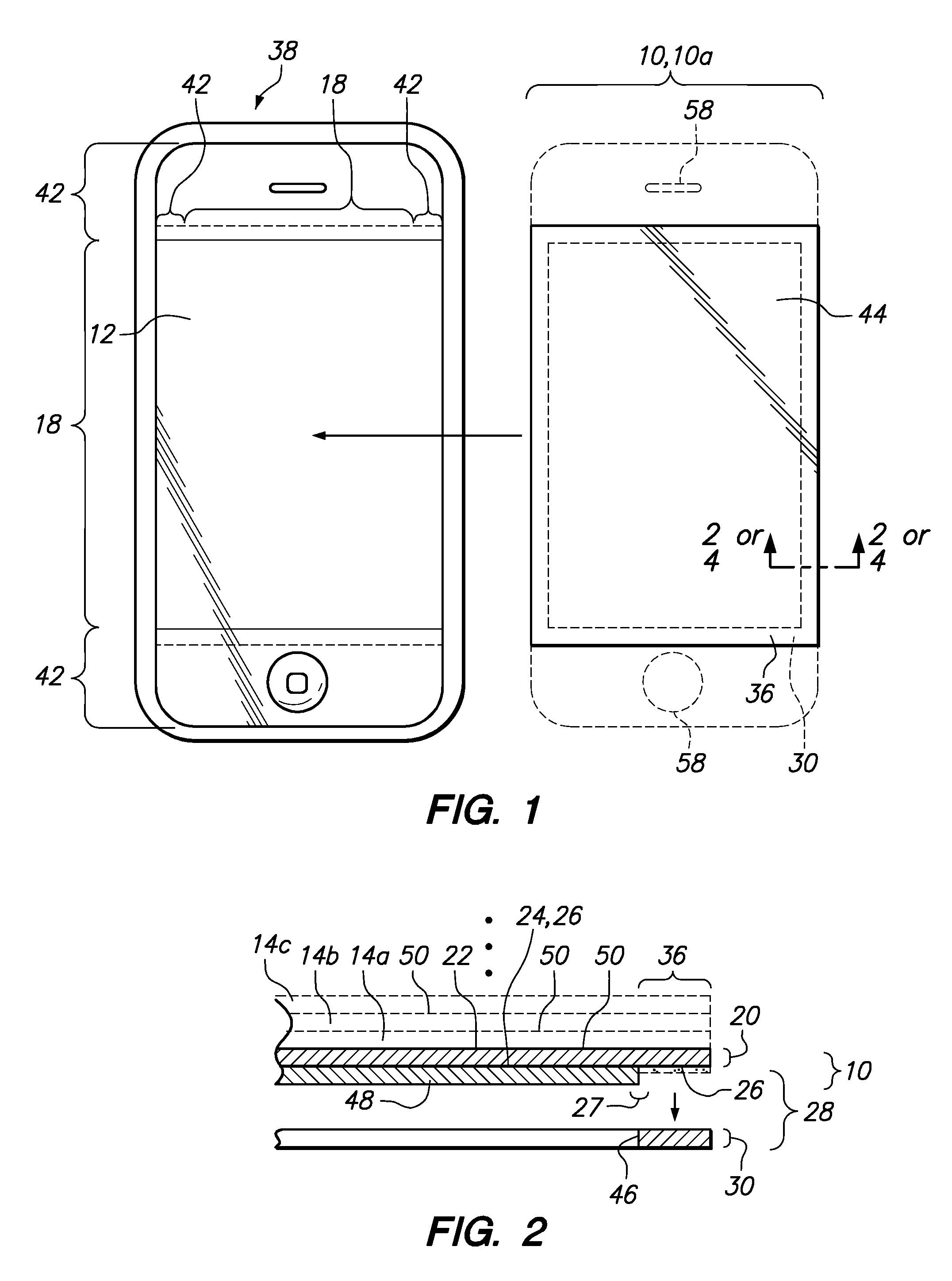

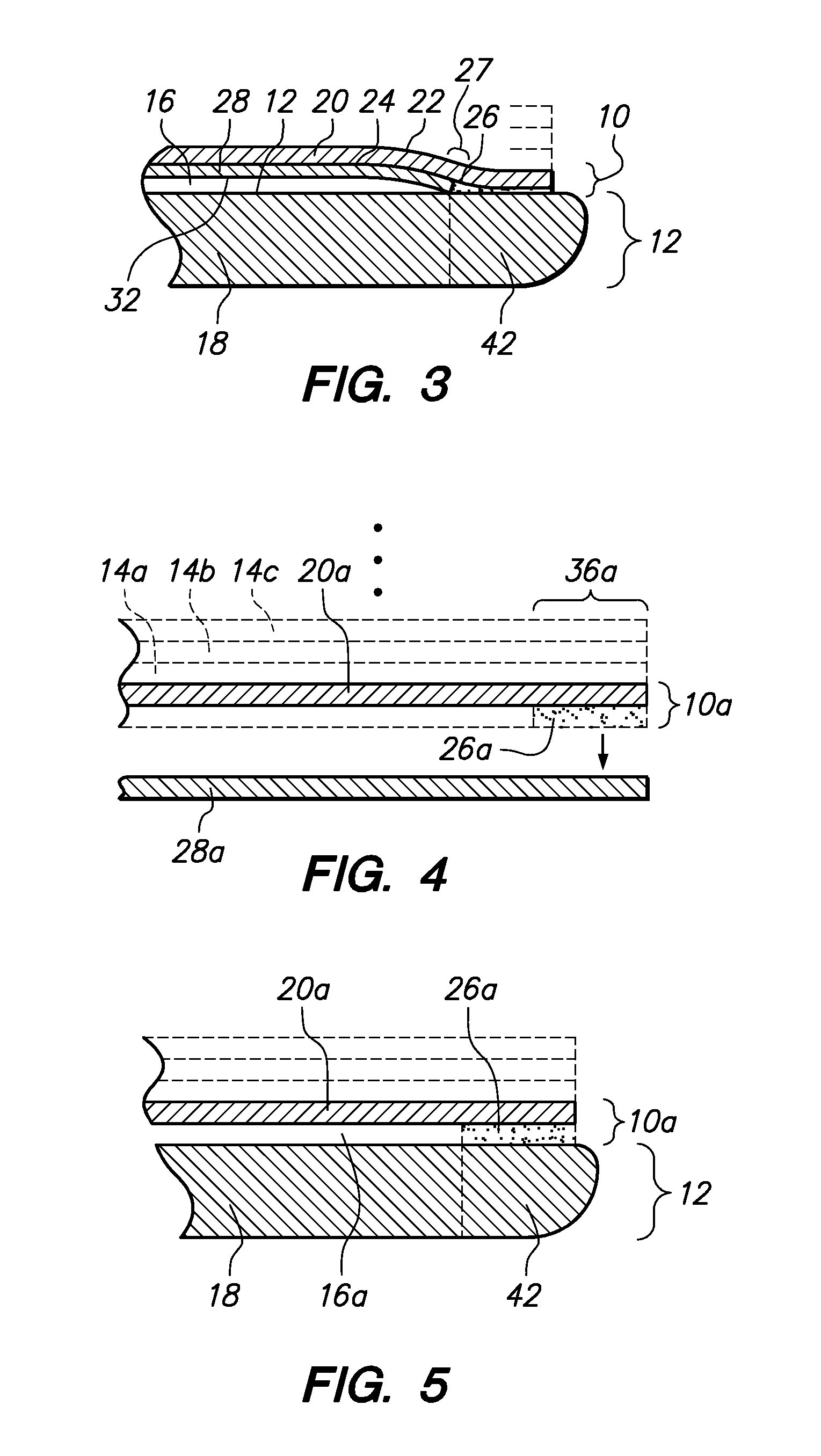

Touch Screen Shield

ActiveUS20110279383A1Promote formationStay flexibleLamination ancillary operationsProtective equipmentEngineeringTouchscreen

A shield that is attachable to a touch sensitive screen is disclosed. The shield may be attached to the touch sensitive screen only at its outer peripheral portion. An air gap is enclosed between the shield and the touch sensitive screen to form a planar air bearing. The shield preferably does not touch the active area of the touch sensitive screen when the user is not touching the shield but only viewing the touch sensitive screen through the shield. This mitigates unwanted optical artifacts such as trapped air bubbles, Newton rings and chromatic interference while maintaining the sensitivity of the touch sensitive screen.

Owner:RACING OPTICS

Polarizing film, optical film and liquid crystal display using polarizing film

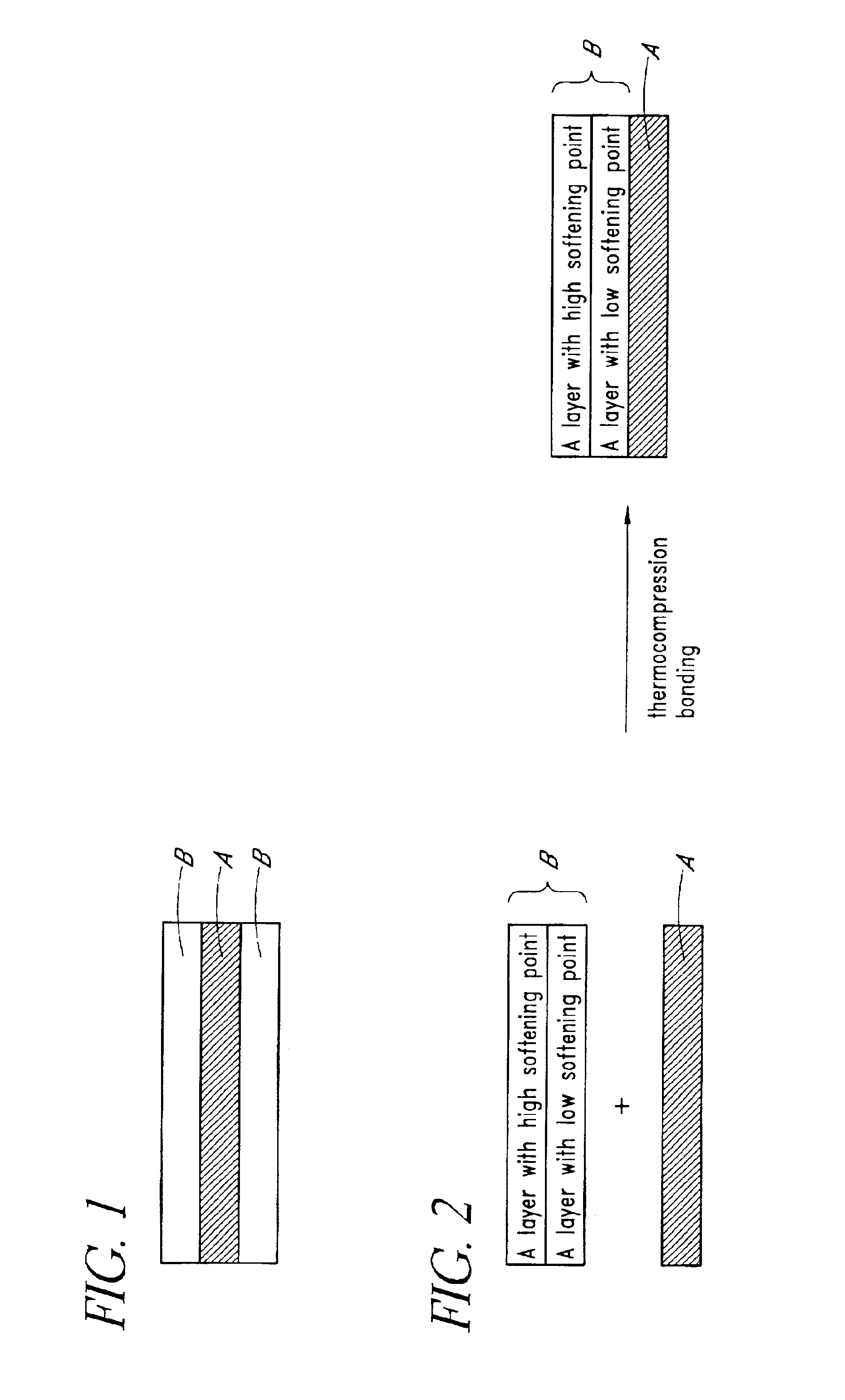

InactiveUS6961178B2Solve the real problemImprove adhesionSynthetic resin layered productsLaminationTectorial membraneLiquid-crystal display

Owner:NITTO DENKO CORP

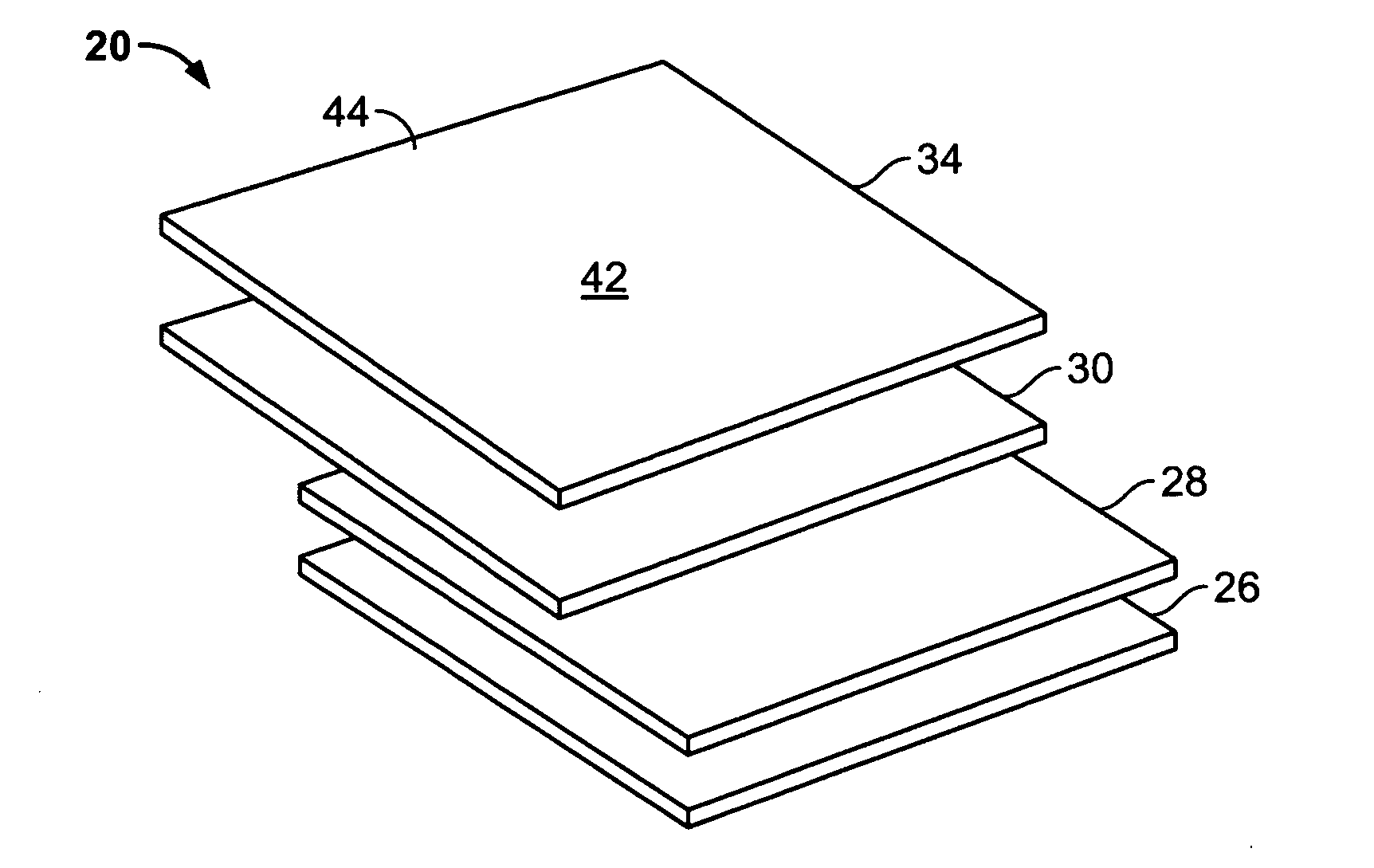

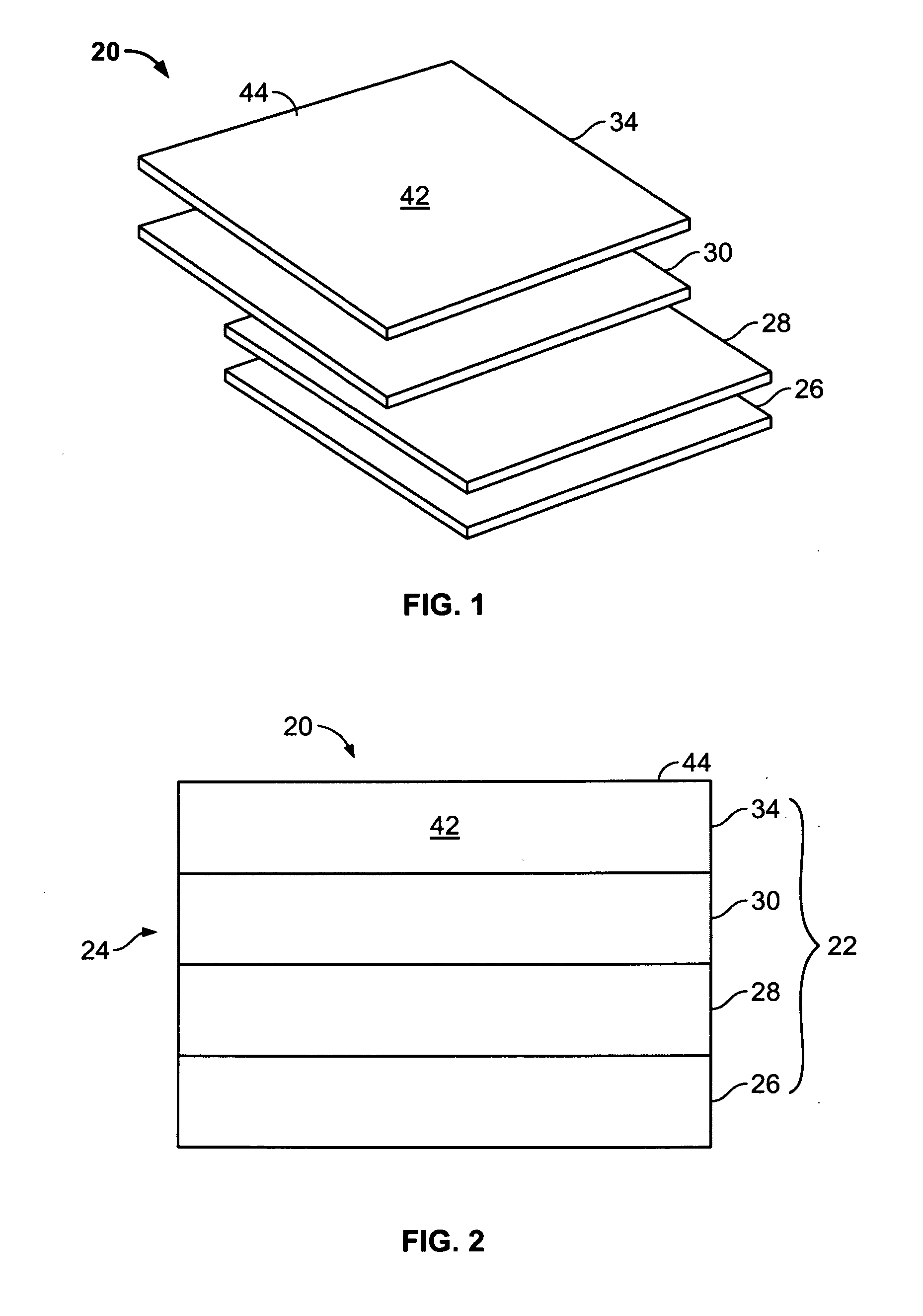

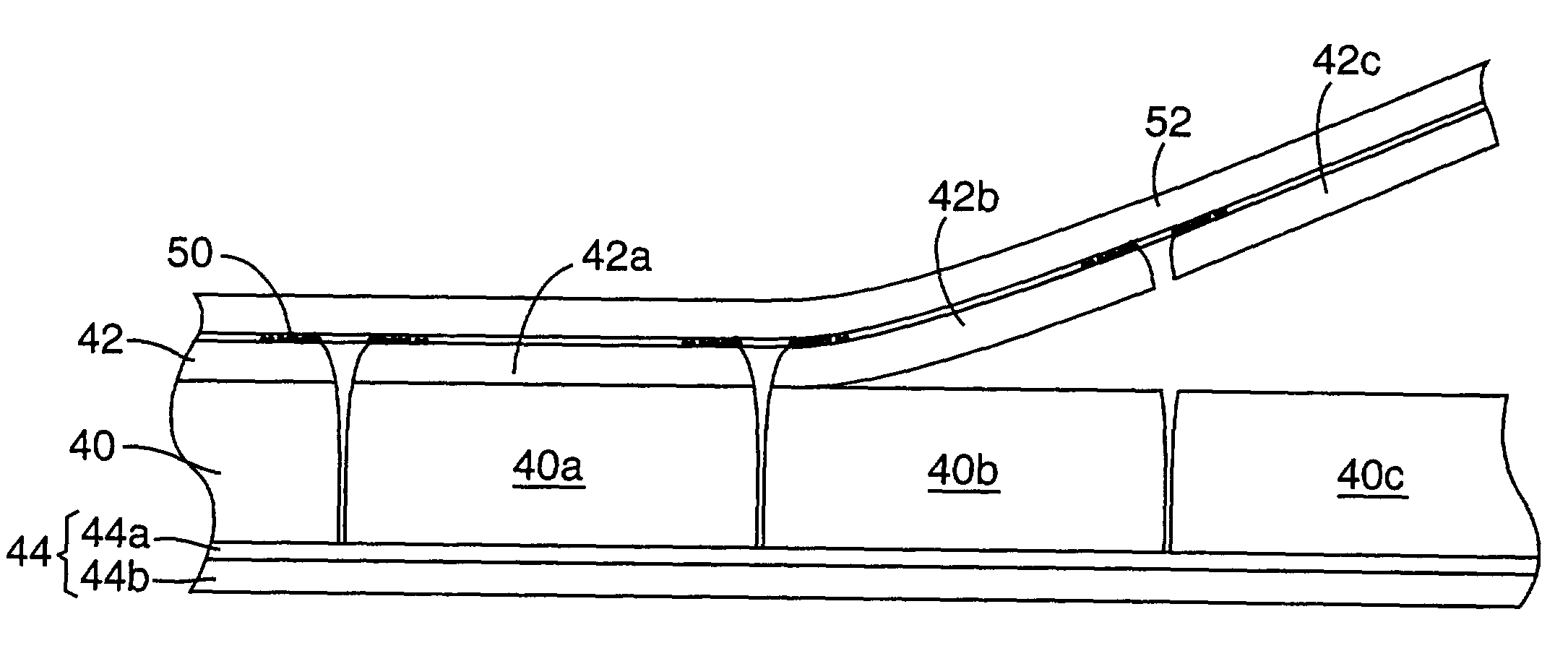

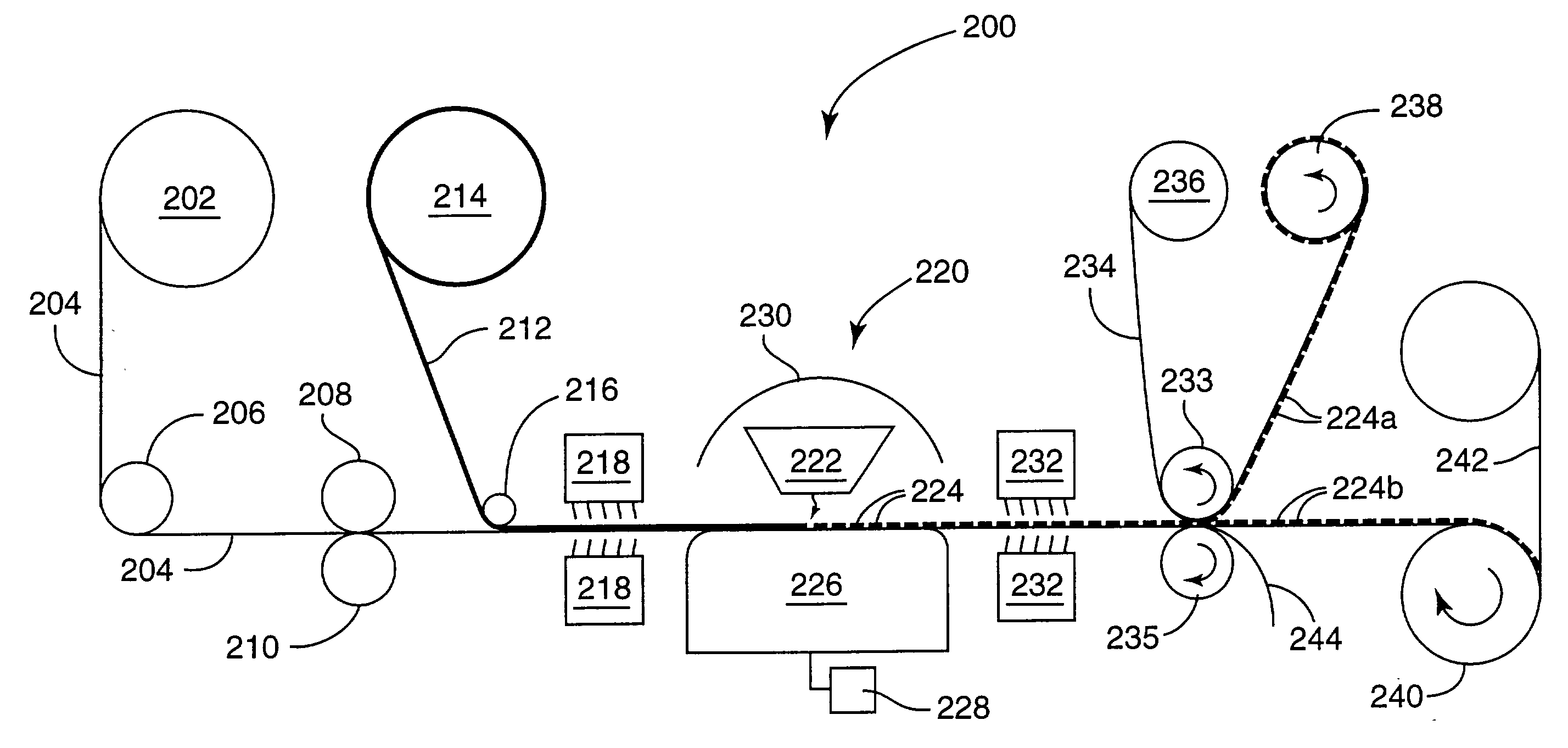

Photovoltaic system and method of making same

The present invention relates to a photovoltaic system and methods of making same. The photovoltaic system has a plurality of layers attached to each other to form a unitary structure. More specifically, the photovoltaic system includes: a base, flexible membrane layer; a photovoltaic layer having at least one photovoltaic cell associated therewith; a semi-rigid layer for supporting the photovoltaic layer and imparting rigidity thereto; and a top, transparent, protective layer for protecting the base, flexible membrane layer, the semi-rigid layer and the photovoltaic layer from exposure to the environment. The photovoltaic layer and the semi-rigid layer are disposed between the base, flexible membrane layer and the top, protective layer. Additional layers of adhesive may be disposed between the various layers to facilitate bonding thereof.

Owner:OPEN ENERGY CORP

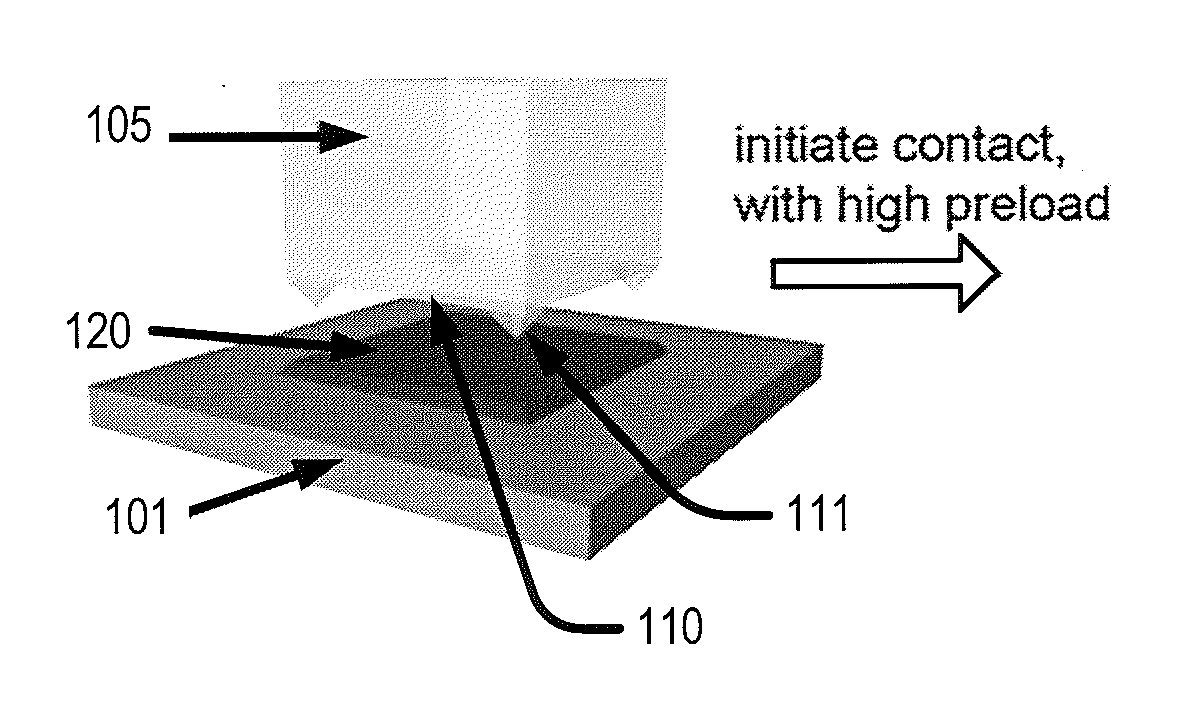

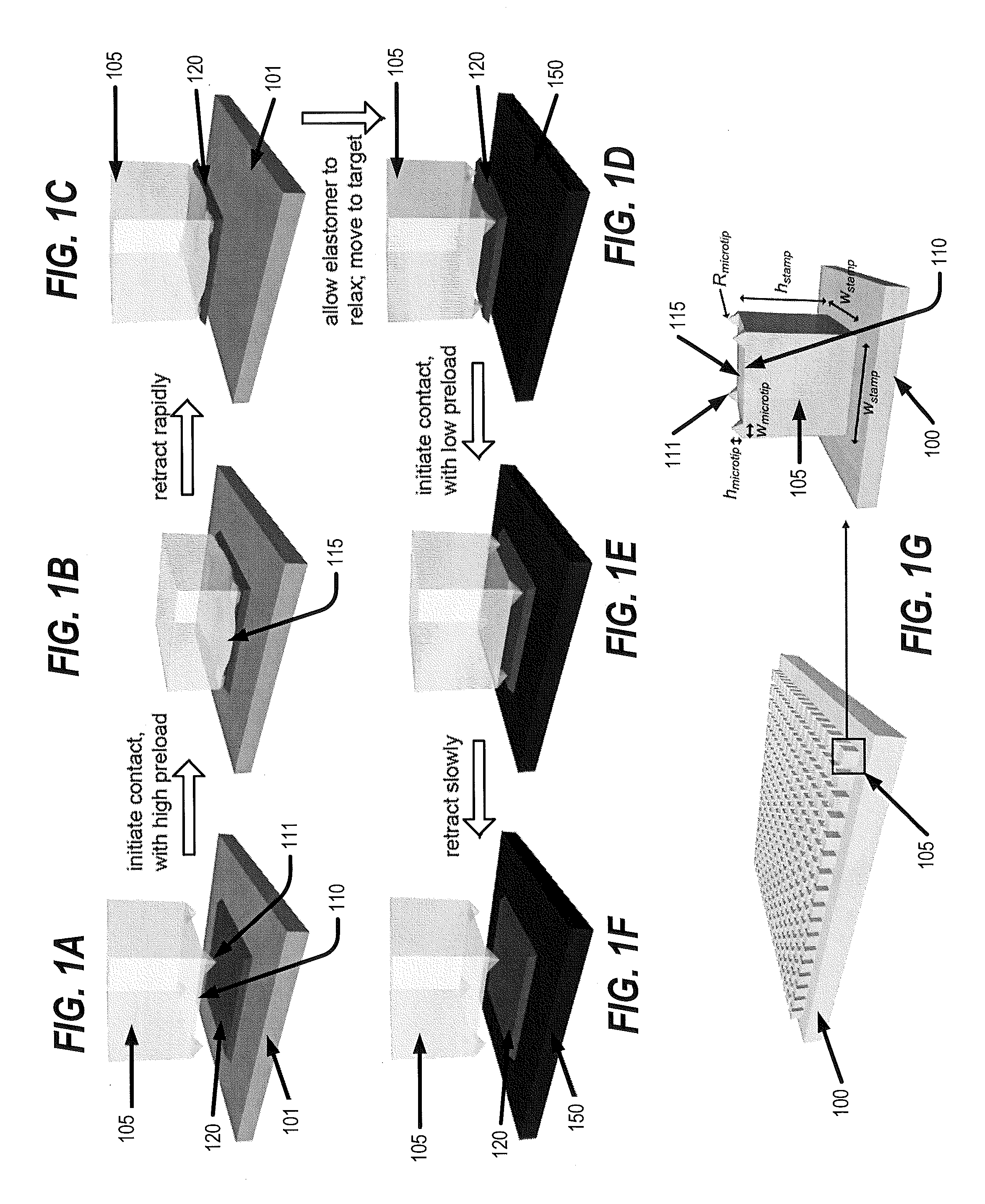

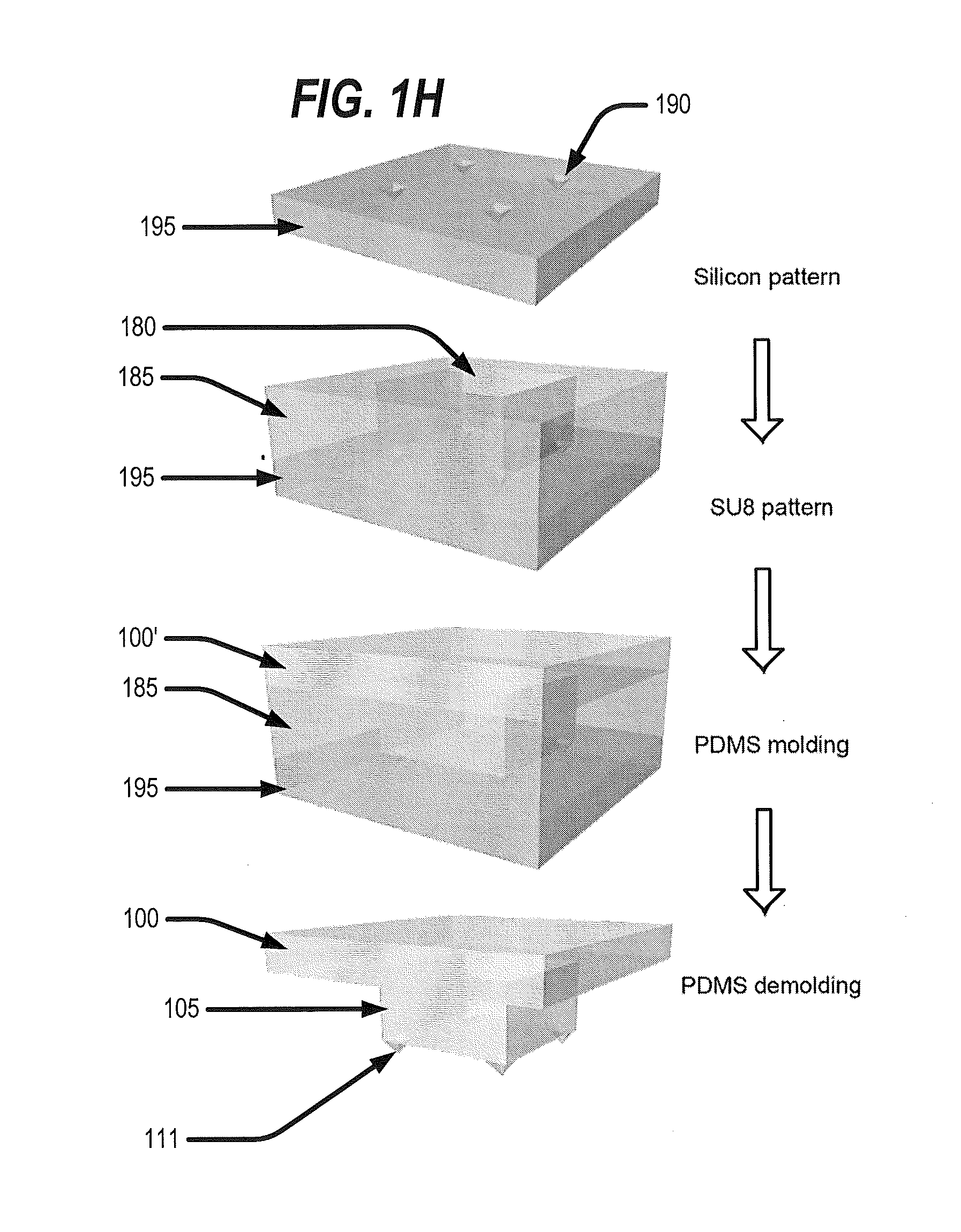

Printing transferable components using microstructured elastomeric surfaces with pressure modulated reversible adhesion

ActiveUS20130069275A1Extra featureSolve the lack of adhesionTransfer printingSemiconductor/solid-state device detailsElastomerReversible adhesion

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

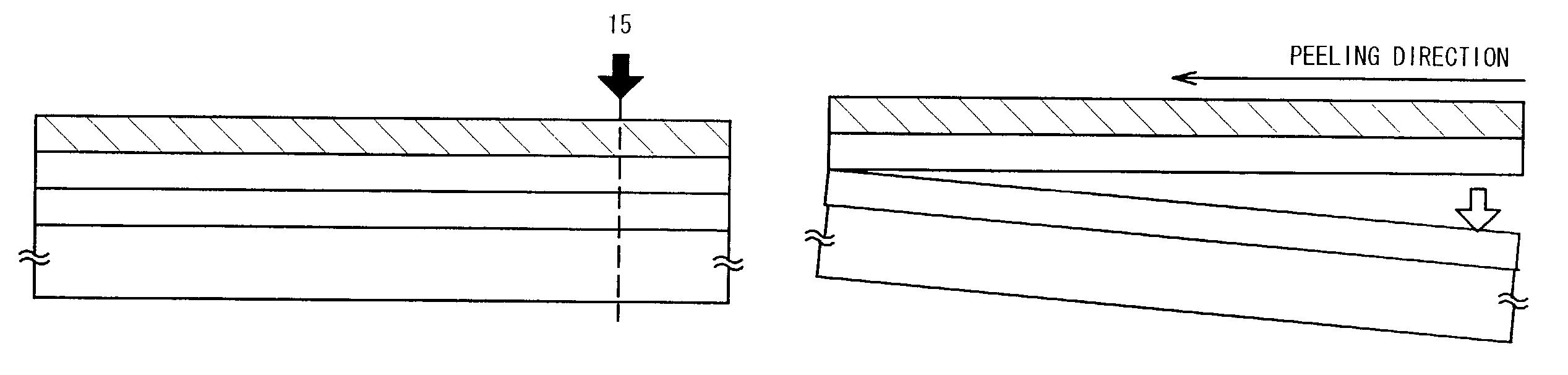

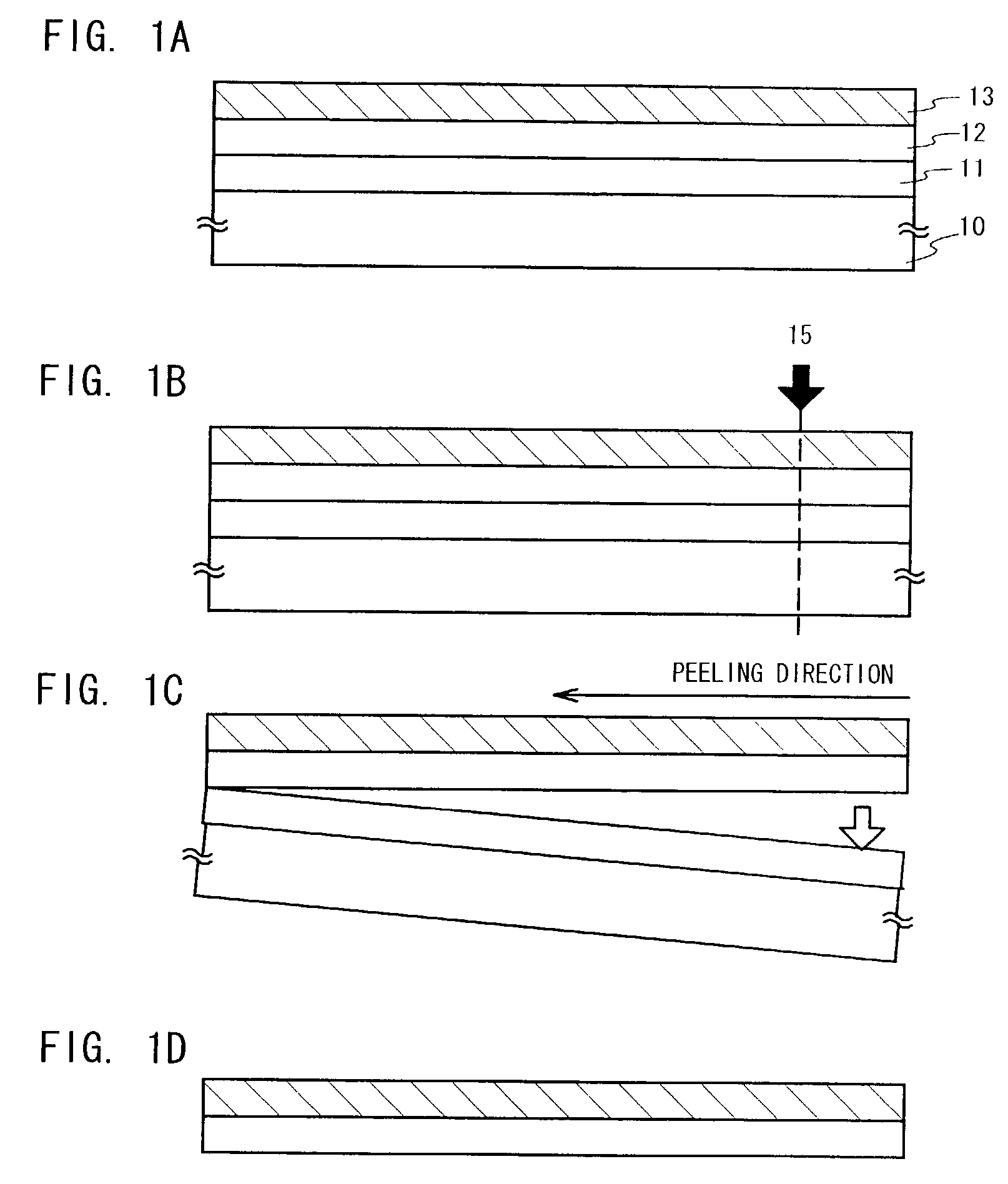

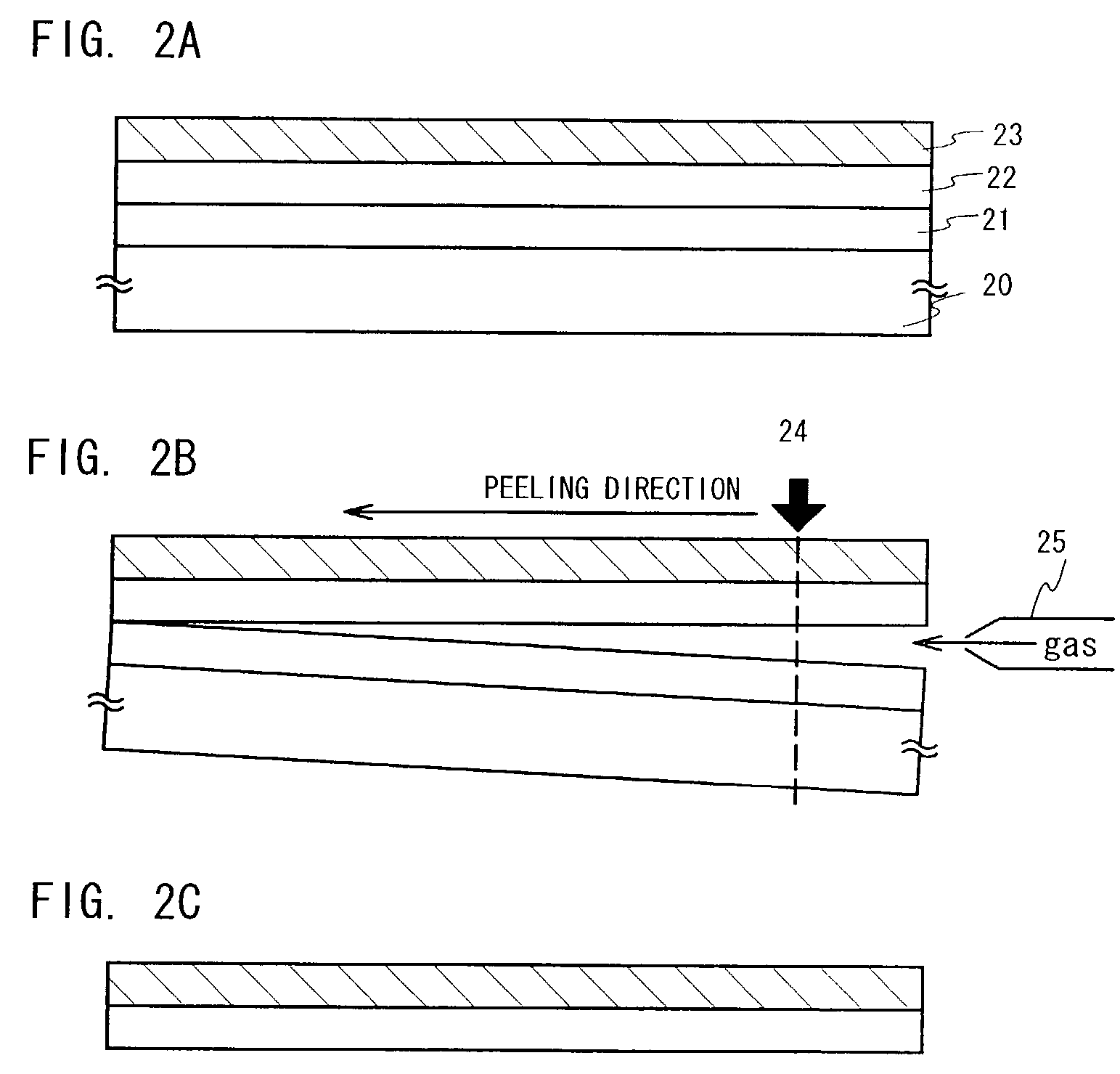

Peeling method and method of manufacturing semiconductor device

InactiveUS7351300B2Not to damageFinal product manufactureDecorative surface effectsLaser lightIrradiation

There is provided a peeling method capable of preventing a damage to a layer to be peeled. Thus, not only a layer to be peeled having a small area but also a layer to be peeled having a large area can be peeled over the entire surface at a high yield. Processing for partially reducing contact property between a first material layer (11) and a second material layer (12) (laser light irradiation, pressure application, or the like) is performed before peeling, and then peeling is conducted by physical means. Therefore, sufficient separation can be easily conducted in an inner portion of the second material layer (12) or an interface thereof.

Owner:SEMICON ENERGY LAB CO LTD

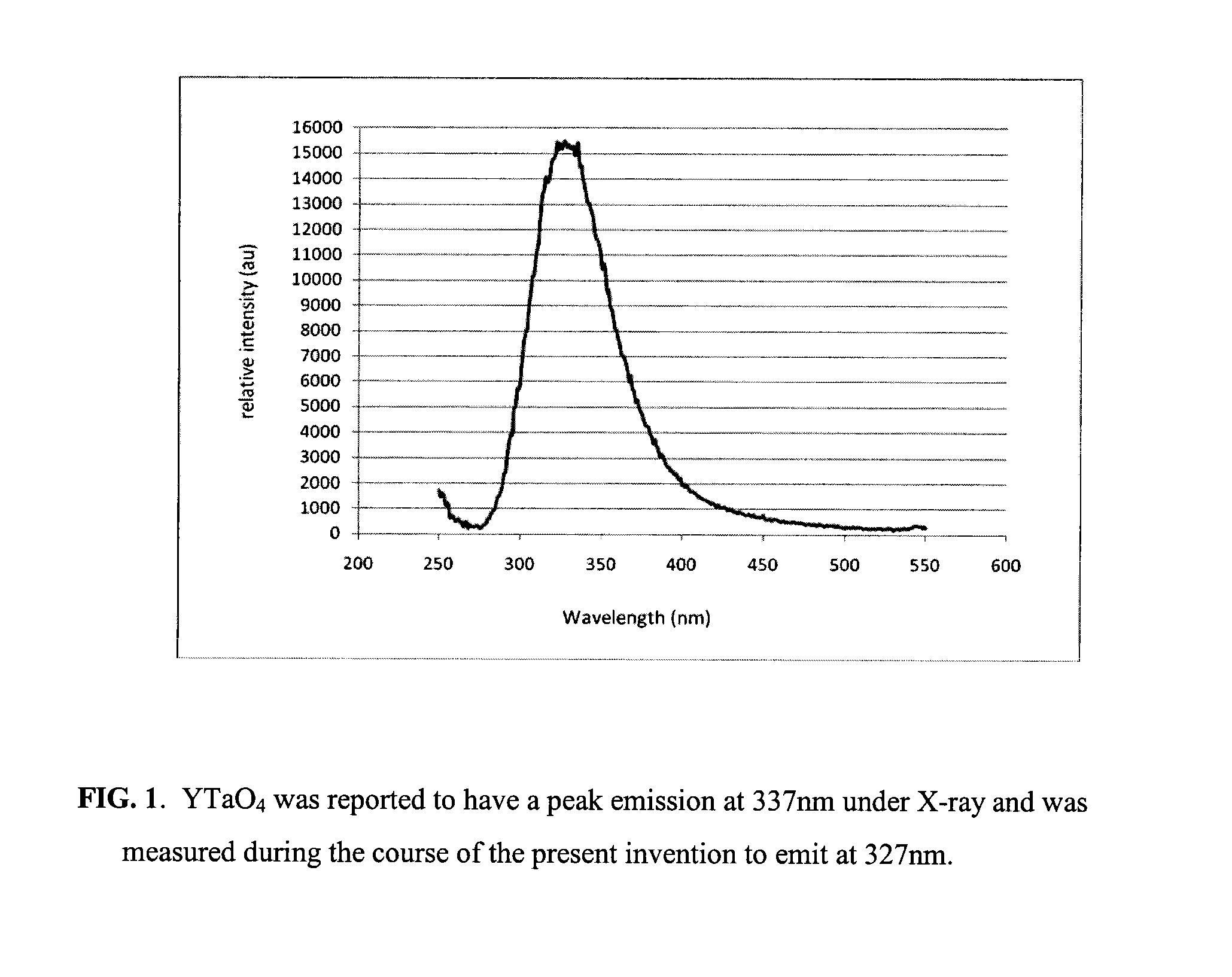

Adhesive bonding composition and method of use

A polymerizable composition includes at least one monomer, a photoinitiator capable of initiating polymerization of the monomer when exposed to light, and a phosphor capable of producing light when exposed to radiation (typically X-rays). The material is particularly suitable for bonding components at ambient temperature in situations where the bond joint is not accessible to an external light source. An associated method includes: placing a polymerizable adhesive composition, including a photoinitiator and energy converting material, such as a down-converting phosphor, in contact with at least two components to be bonded to form an assembly; and, irradiating the assembly with radiation at a first wavelength, capable of conversion (down-conversion by the phosphor) to a second wavelength capable of activating the photoinitiator, to prepare items such as inkjet cartridges, wafer-to-wafer assemblies, semiconductors, integrated circuits, and the like.

Owner:IMMUNOLIGTHT LLC +1

Prelithiated current collector and secondary lithium cells containing same

ActiveUS20130045427A1Reduce capacityMaterial nanotechnologyHybrid capacitorsLithium metalLithium sulfur

The present invention provides a battery or supercapacitor current collector which is prelithiated. The prelithiated current collector comprises: (a) an electrically conductive substrate having two opposed primary surfaces, and (b) a mixture layer of carbon (and / or other stabilizing element, such as B, Al, Ga, In, C, Si, Ge, Sn, Pb, As, Sb, Bi, Te, or a combination thereof) and lithium or lithium alloy coated on at least one of the primary surfaces, wherein lithium element is present in an amount of 1% to 99% by weight of the mixture layer. This current collector serves as an effective and safe lithium source for a wide variety of electrochemical energy storage cells, including the rechargeable lithium cell (e.g. lithium-metal, lithium-ion, lithium-sulfur, lithium-air, lithium-graphene, lithium-carbon, and lithium-carbon nanotube cell) and the lithium ion based supercapacitor cell (e.g, symmetric ultracapacitor, asymmetric ultracapacitor, hybrid supercapacitor-battery, or lithium-ion capacitor).

Owner:GLOBAL GRAPHENE GRP INC

Release system for electrochemical cells

InactiveUS20110068001A1Active material electrodesElectrical-based machining electrodesEngineeringElectrochemical cell

Electrochemical cells, and more specifically, release systems for the fabrication of electrochemical cells are described. In particular, release layer arrangements, assemblies, methods and compositions that facilitate the fabrication of electrochemical cell components, such as electrodes, are presented. In some embodiments, methods of fabricating an electrode involve the use of a release layer to separate portions of the electrode from a carrier substrate on which the electrode was fabricated. For example, an intermediate electrode assembly may include, in sequence, an electroactive material layer, a current collector layer, a release layer, and a carrier substrate. The carrier substrate can facilitate handling of the electrode during fabrication and / or assembly, but may be released from the electrode prior to commercial use.

Owner:SION POWER CORP

Method of Manufacturing a Display Device and Bonding Method

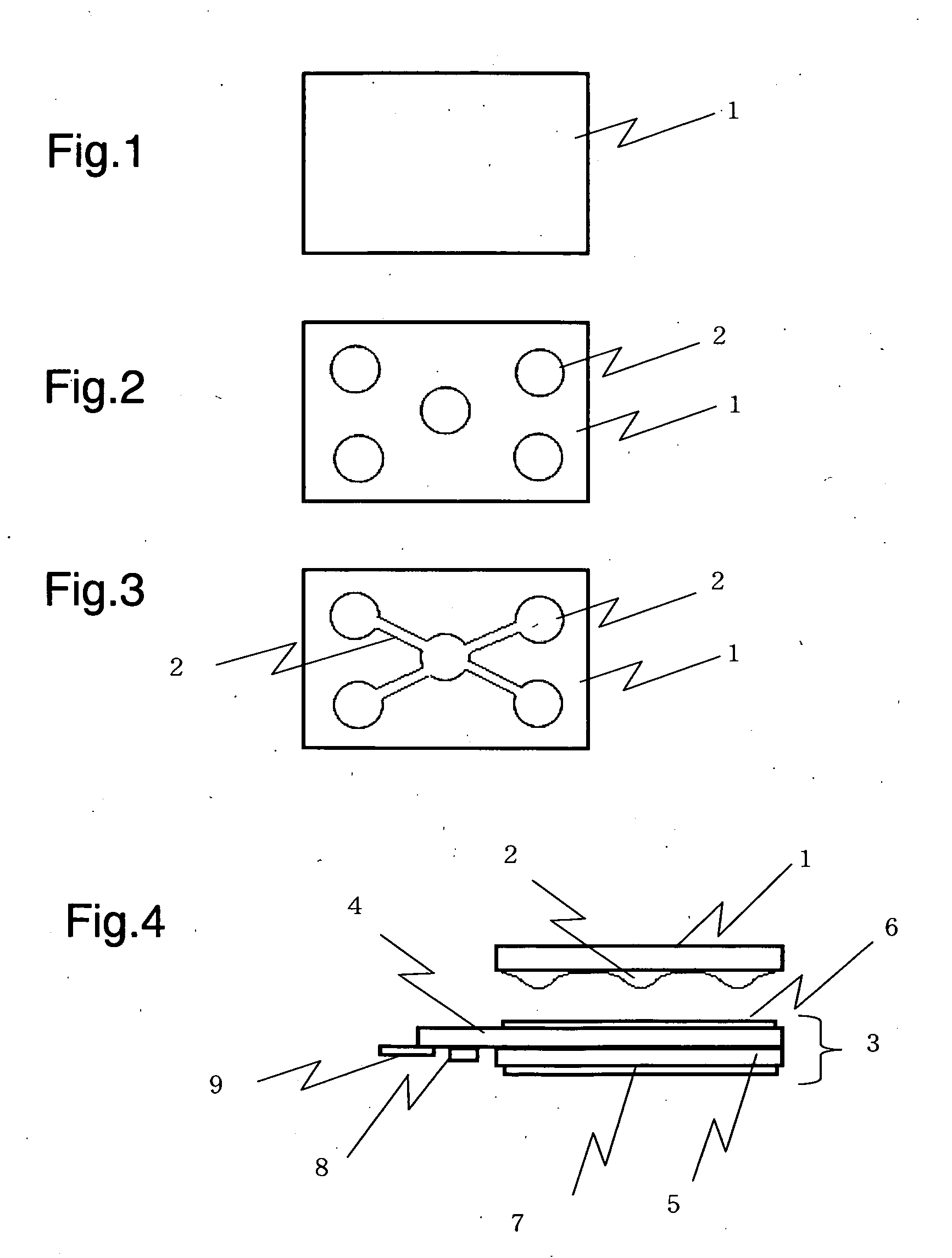

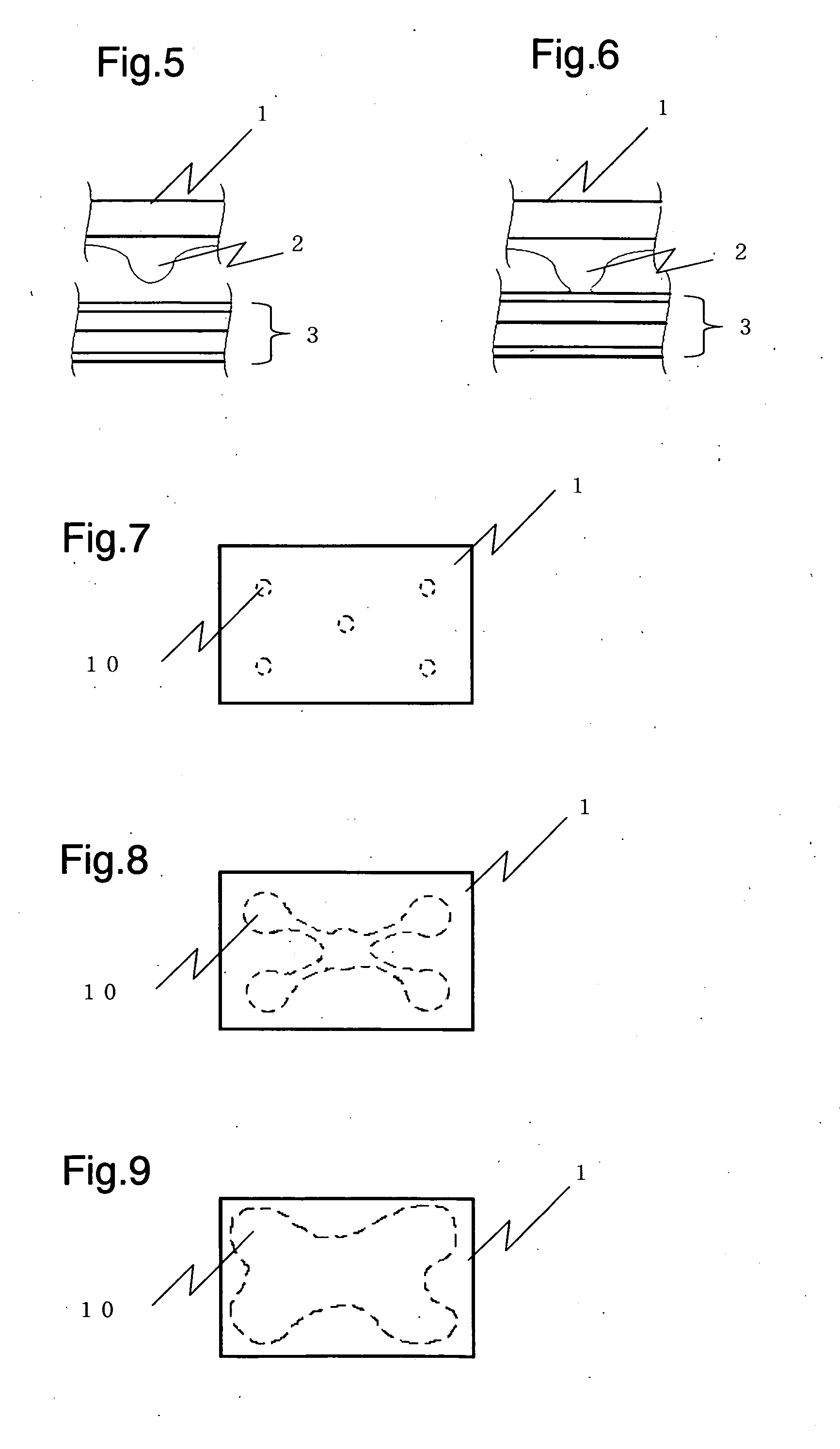

Provided is a method of bonding a transparent plate or a touch panel to a flat display without allowing air bubbles to form. A fixed amount of liquid adhesive is applied in dots to a bonding surface around corners and at the center. More adhesive is applied to connect the dots of applied adhesive with lines. The bonding surface is then reversed, causing the adhesive to drip, and the dripping adhesive is brought into contact with an opposite bonding surface to fill a gap between the bonding surfaces with the adhesive. The adhesive is cured by irradiation with light incident from a transparent plate side. In short, after dots of adhesive are brought into contact with the opposite bonding surface and the adhesive flows into a pattern that does not let in air bubbles, the gap between the bonding surfaces is filled with the adhesive.

Owner:SEIKO INSTR INC

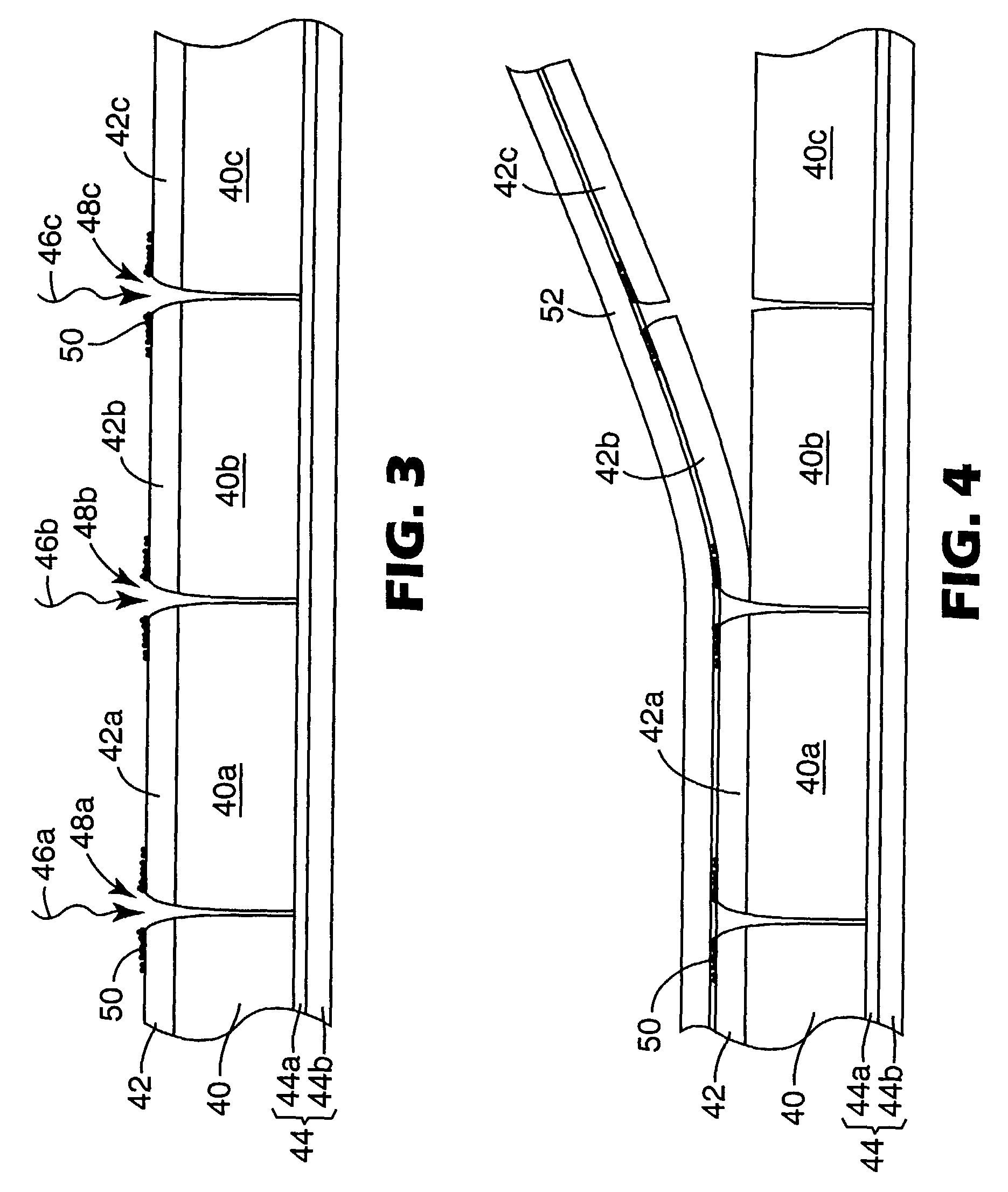

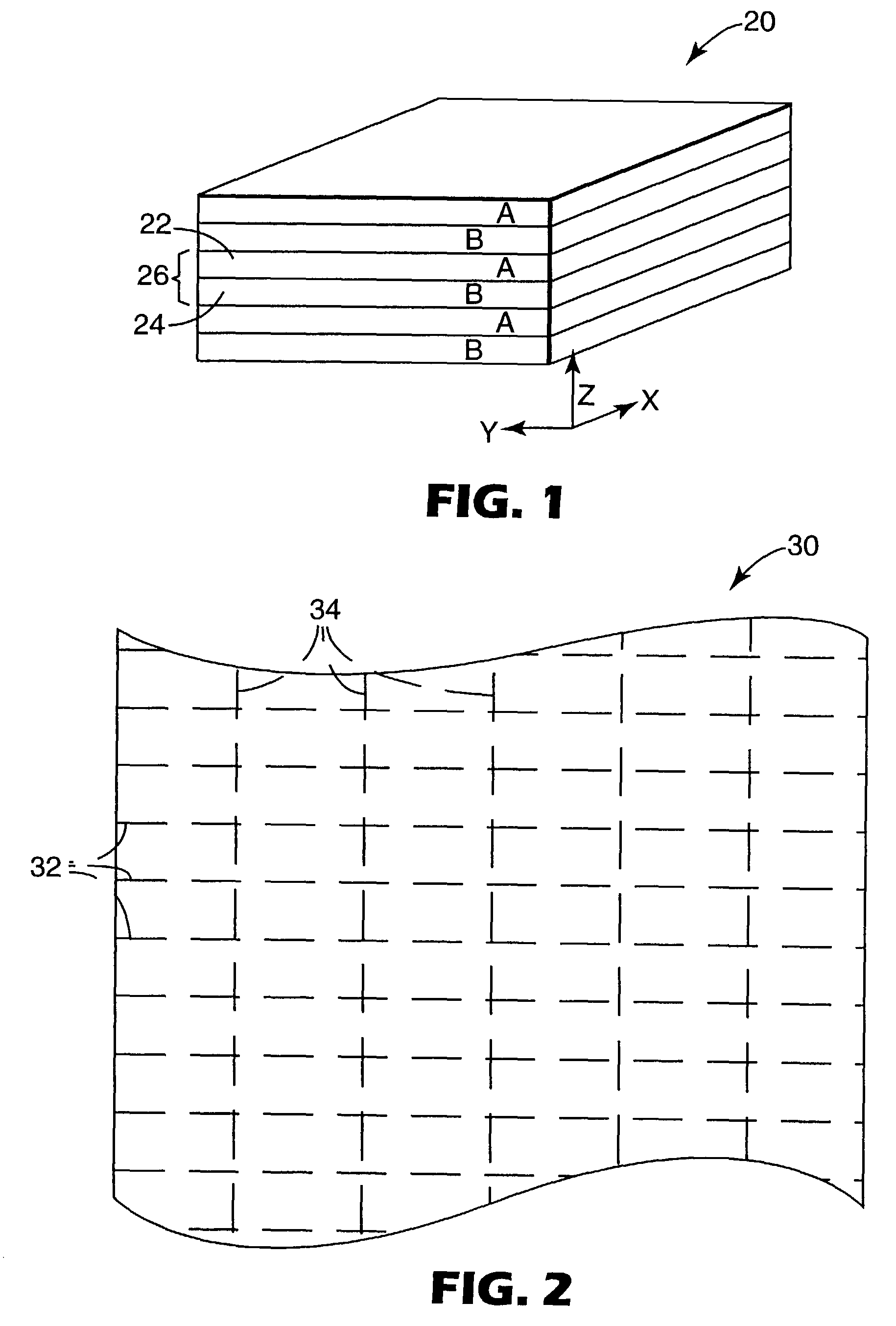

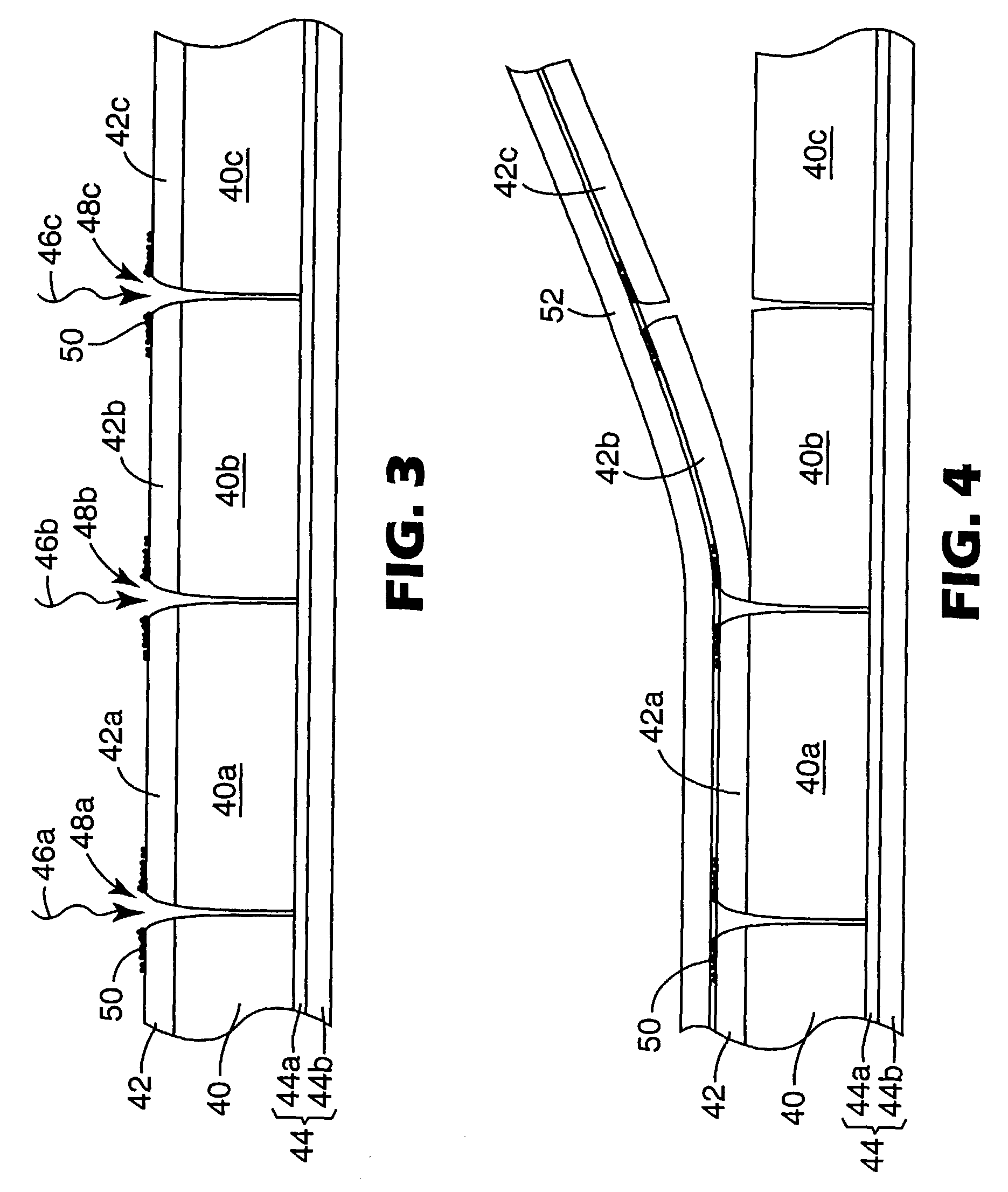

Method for subdividing multilayer optical film cleanly and rapidly

InactiveUS6991695B2Reduce electrostatic attractionPaper/cardboard articlesOptical articlesPolymerLaser

Owner:3M INNOVATIVE PROPERTIES CO

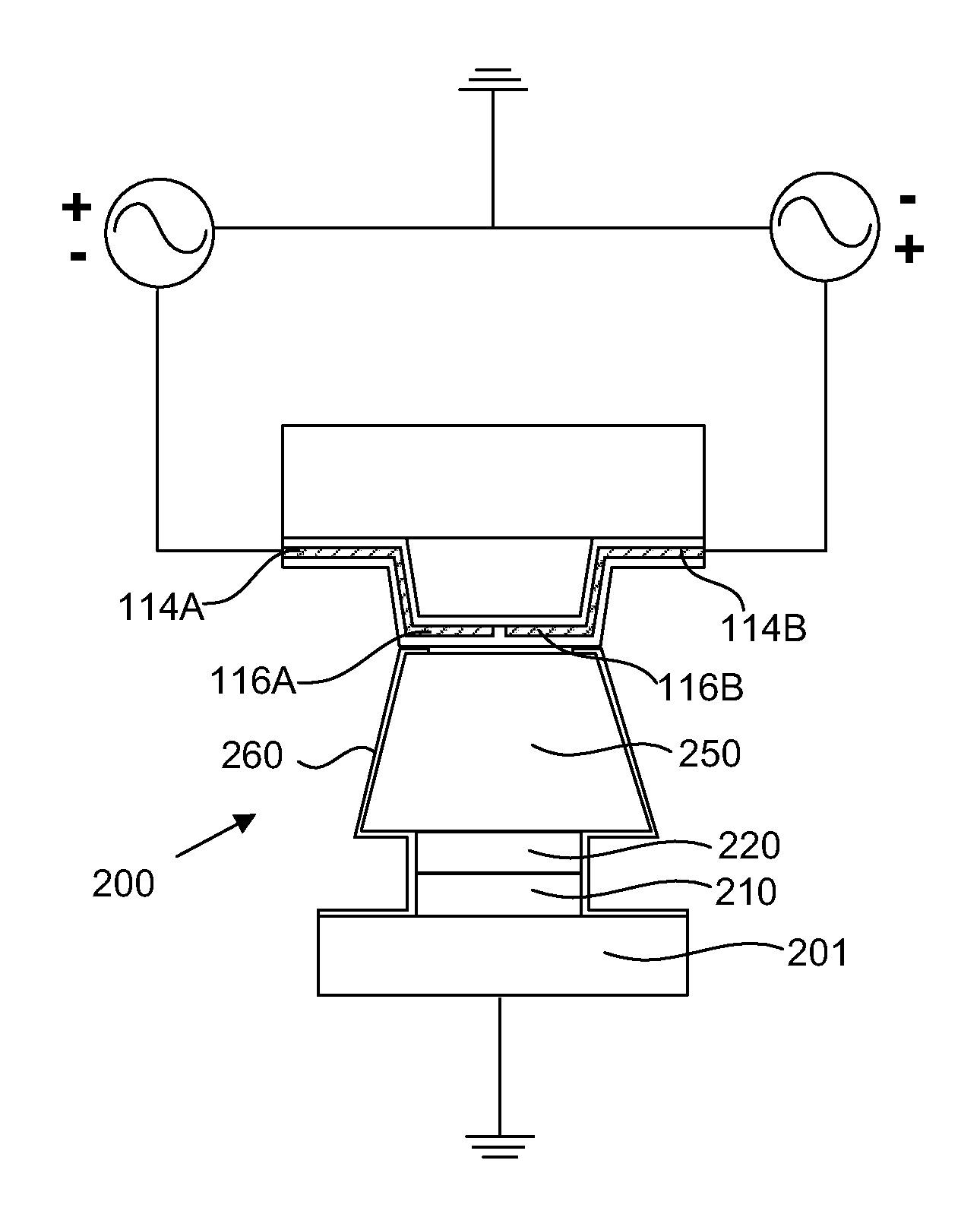

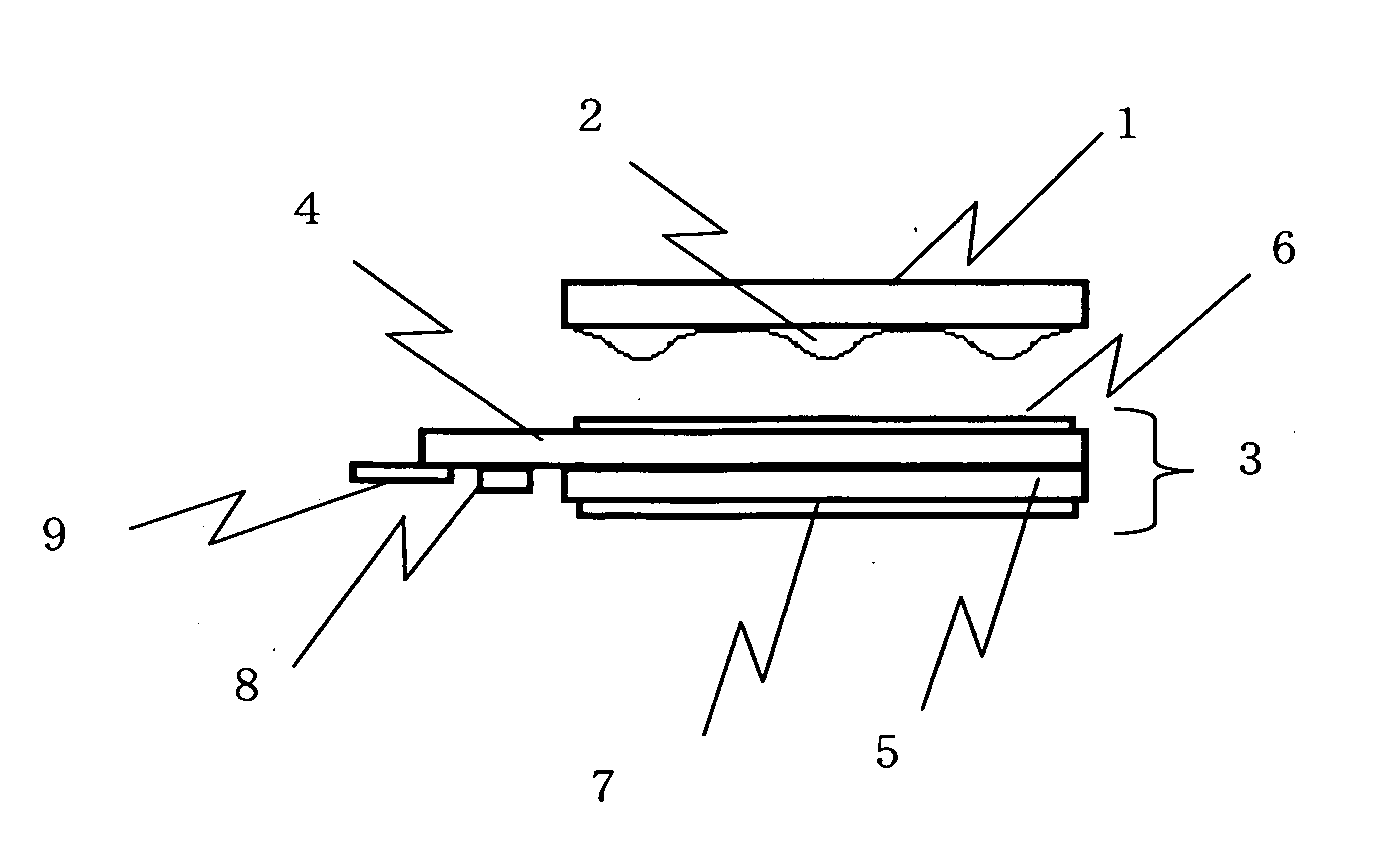

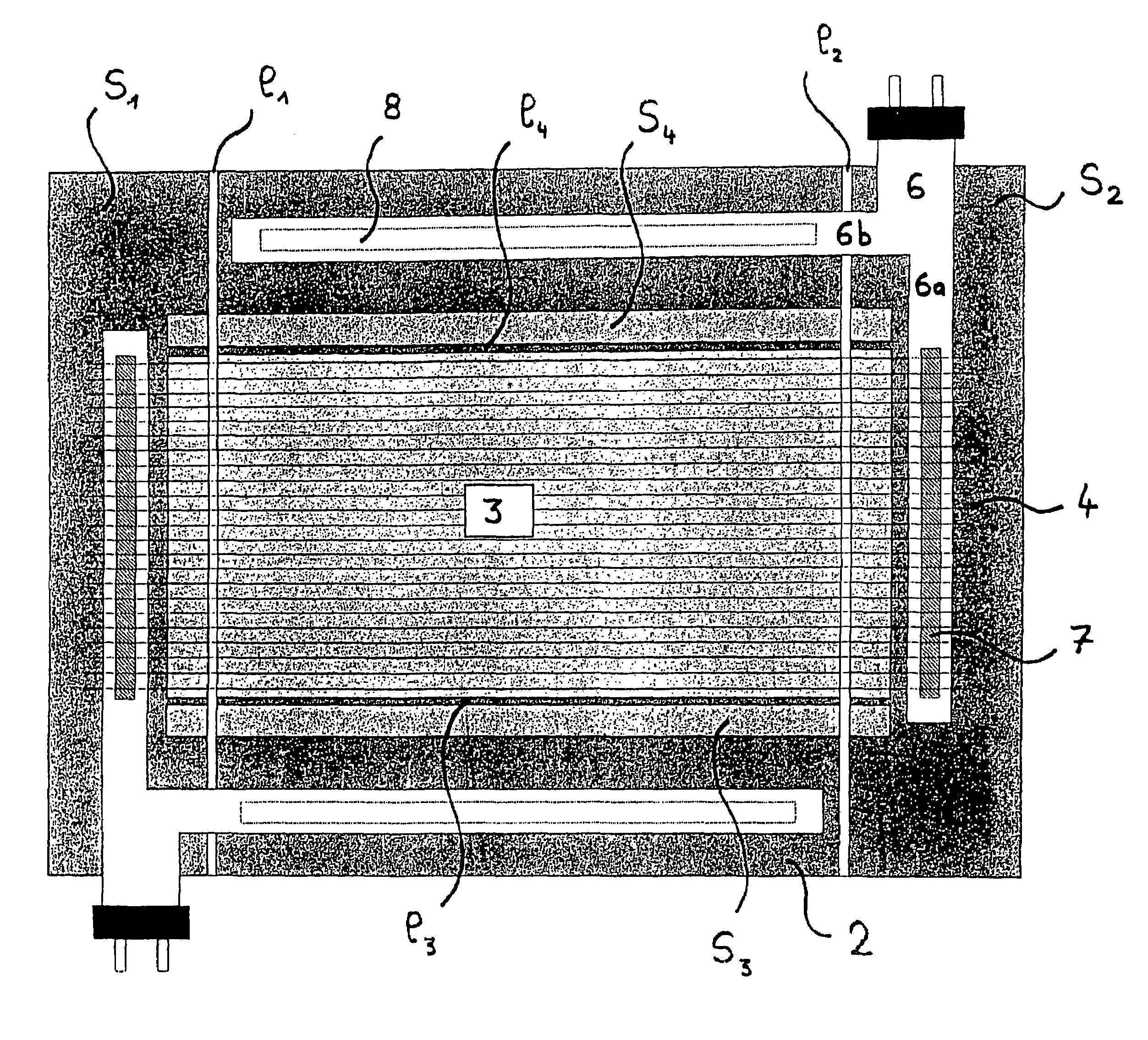

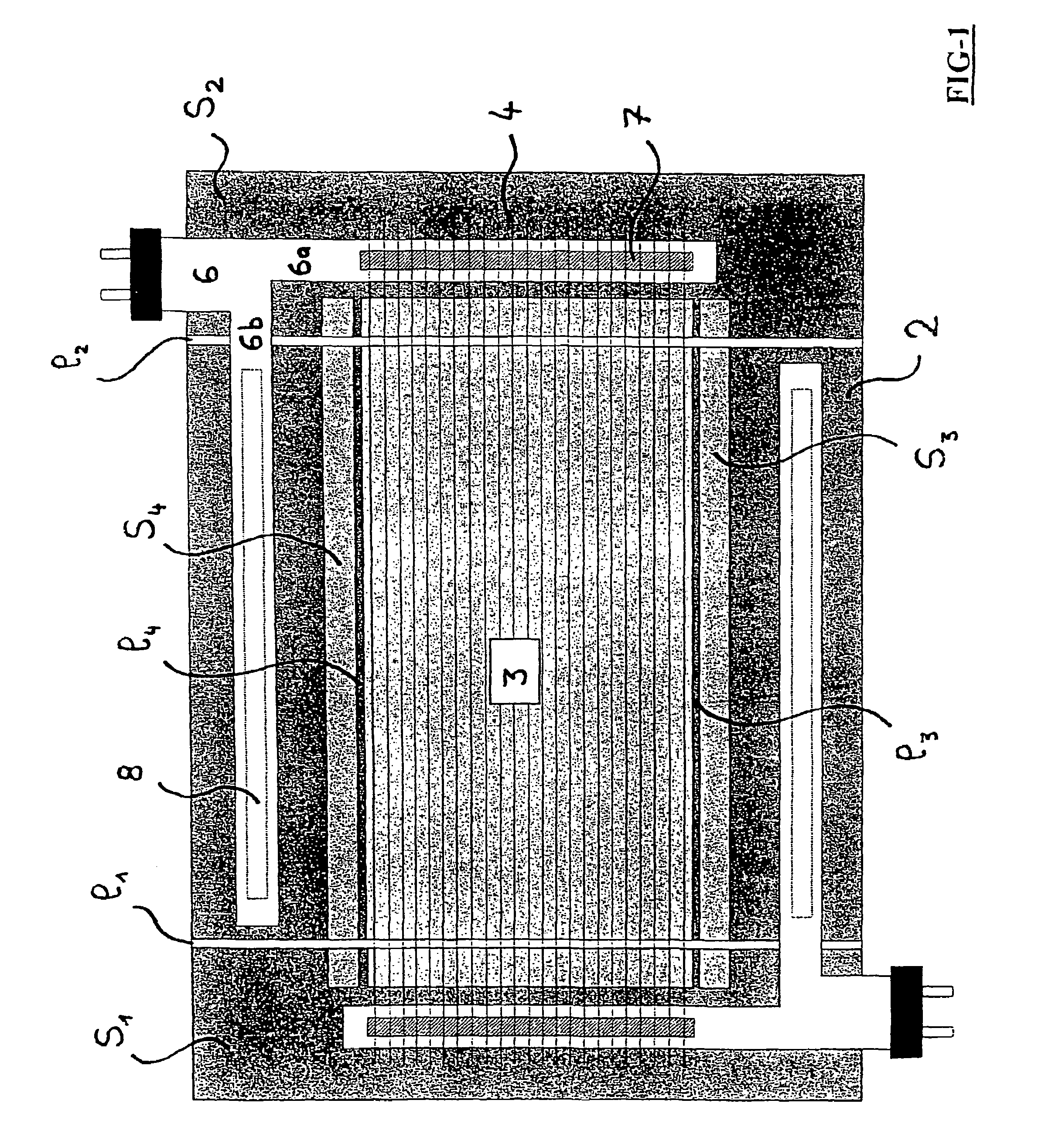

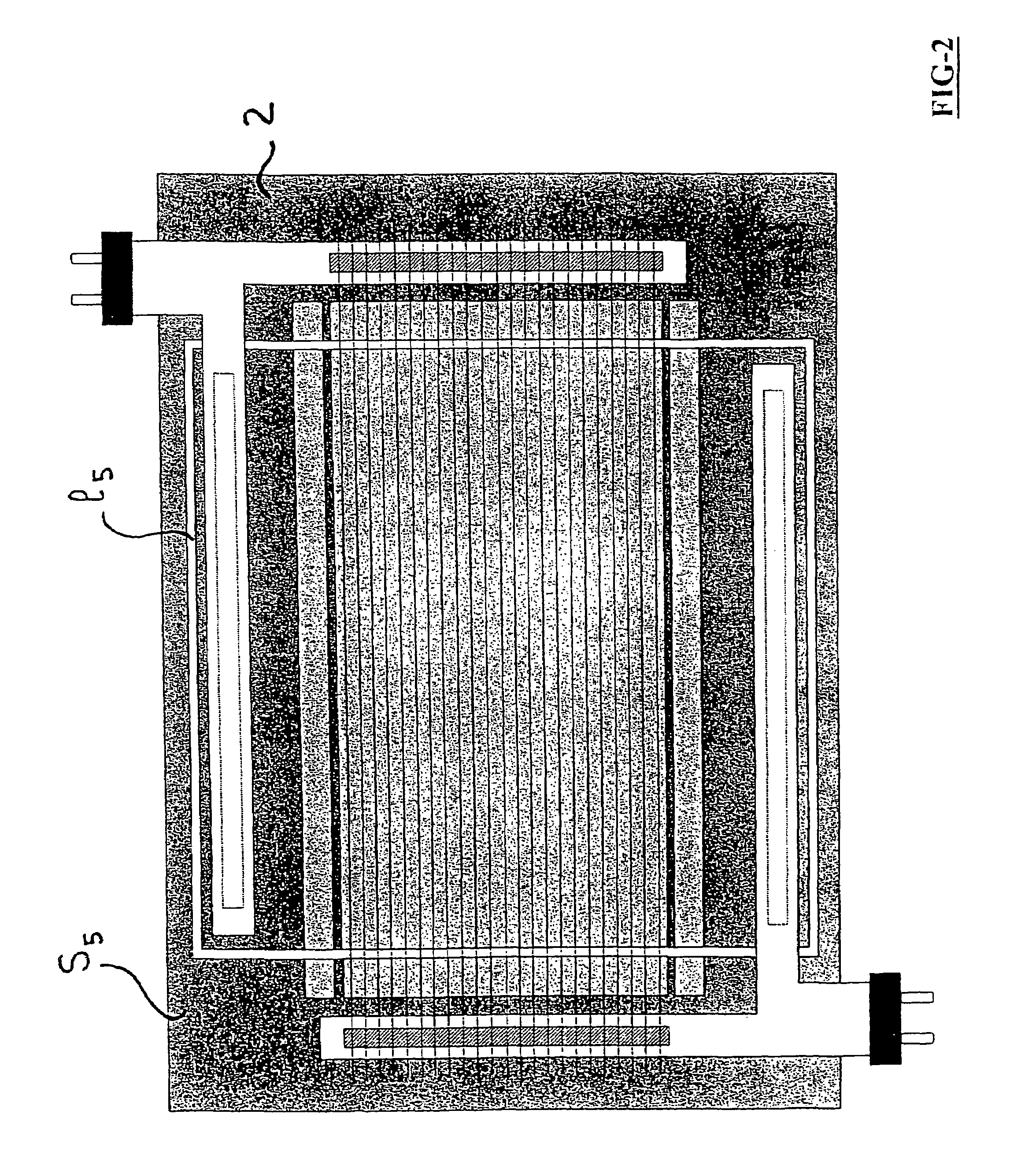

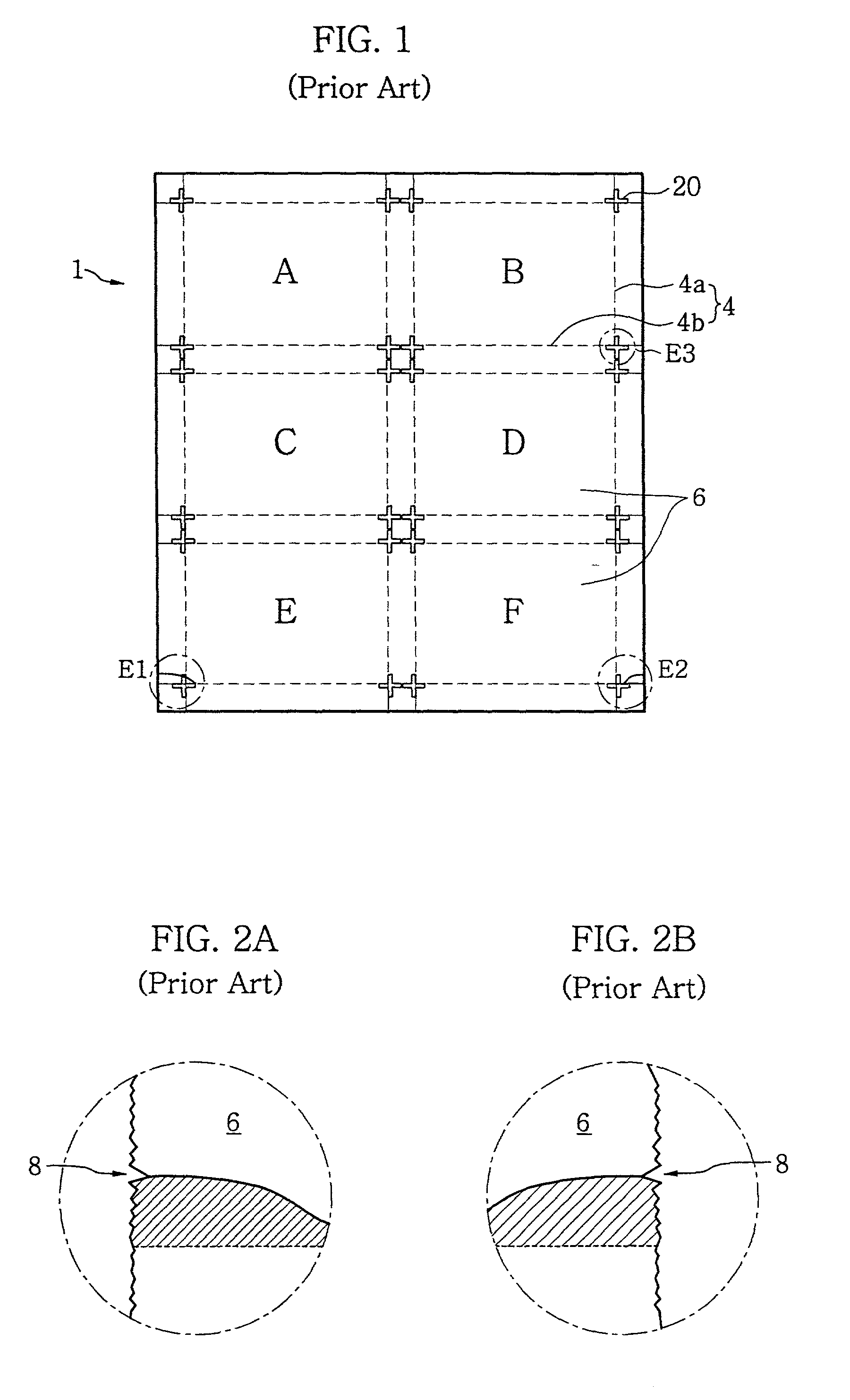

Electrochemical device such as electrochromic or photovoltaic device and electrical connection means thereof

InactiveUS7230748B2Smooth connectionSimple and flexible implementationElectrode carriers/collectorsSecondary cellsElectricityOptical property

An electrochemical device, especially an electrically controllable system with variable energy and / or optical properties or a photovoltaic device, including at least one substrate carrying an electroactive stack of layers arranged between a lower electrode and an upper electrode. Each electrode includes at least one electroconductive layer in electrical contact with at least one current lead. The current leads are arranged outside the region of the carrier substrate that is covered by the stack of electroactive layers.

Owner:SAINT-GOBAIN GLASS FRANCE

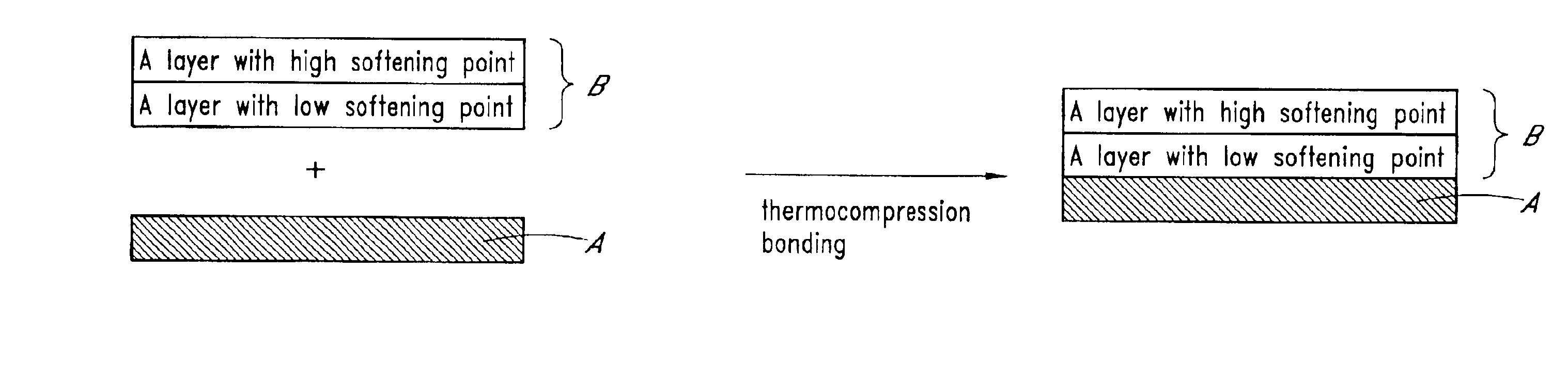

Layered product, electromagnetic-shielding molded object, and processes for producing these

ActiveUS20060110599A1Reduce thicknessReduce weightShielding materialsSynthetic resin layered productsFiberElectromagnetic shielding

A layered product which is a molded object comprising a thermoset resin layer, a thermoplastic resin layer, and reinforcing fibers comprising many continuous filaments, wherein the thremoset resin layer has been united with the thermoplastic resin layer at the interface between these layers, the resin of the thermoset resin layer and the resin of the thermoplastic resin layer each having an irregular surface shape at the interface, and a group of filaments among the reinforcing fibers are in contact with at least the resin of the thermoset resin layer and the other group of filaments among the reinforcing fibers are in contact with at least the resin of the thermoplastic resin layer, that side of the thermoplastic resin layer which is opposite to the interface being a surface of the molded object.

Owner:TORAY IND INC

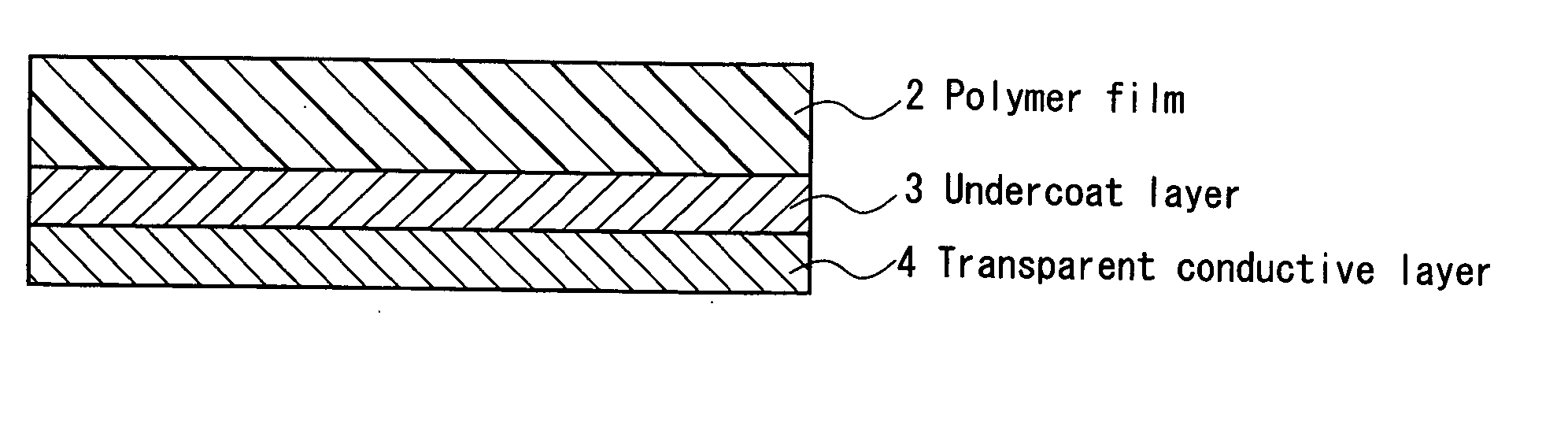

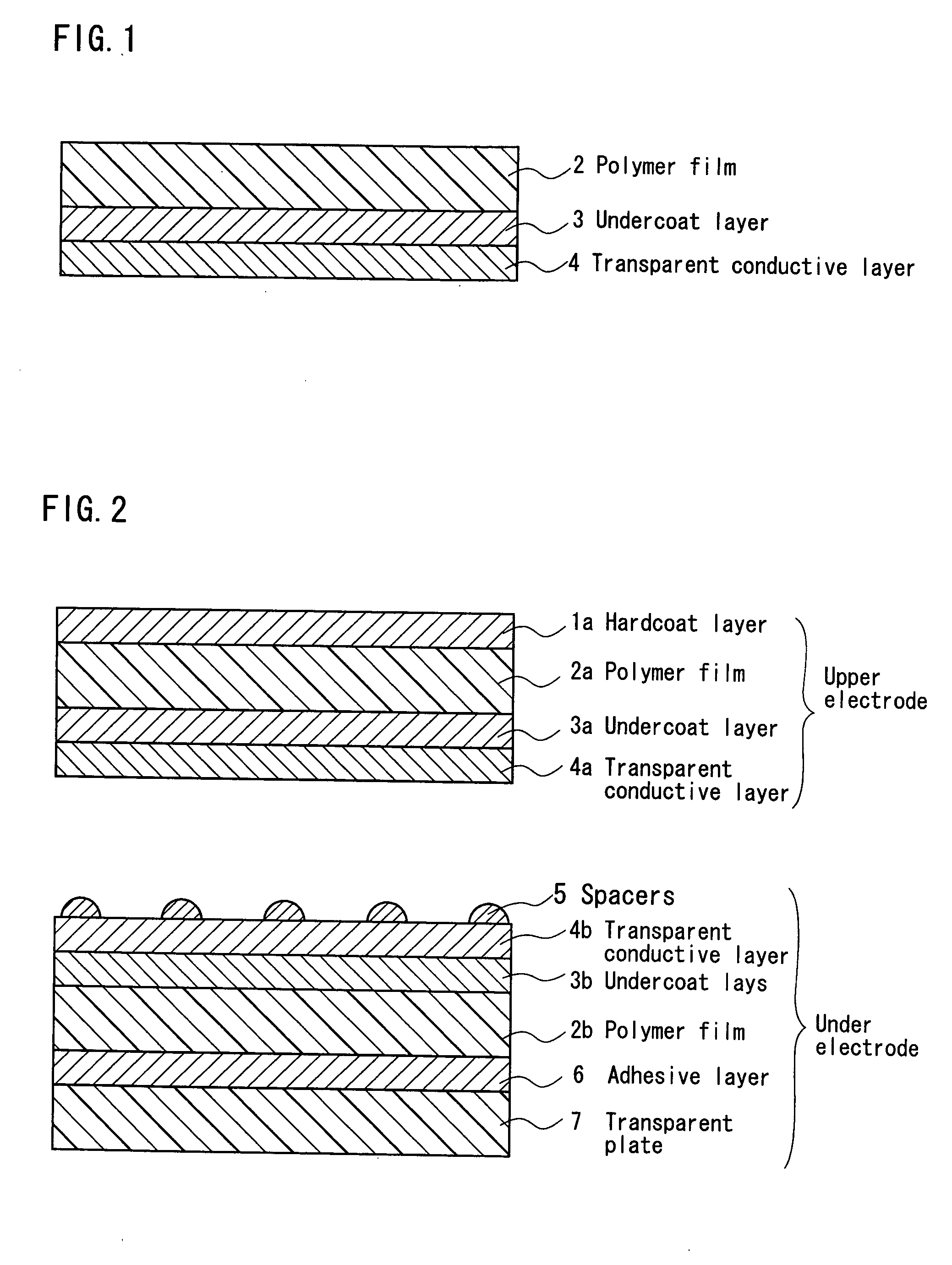

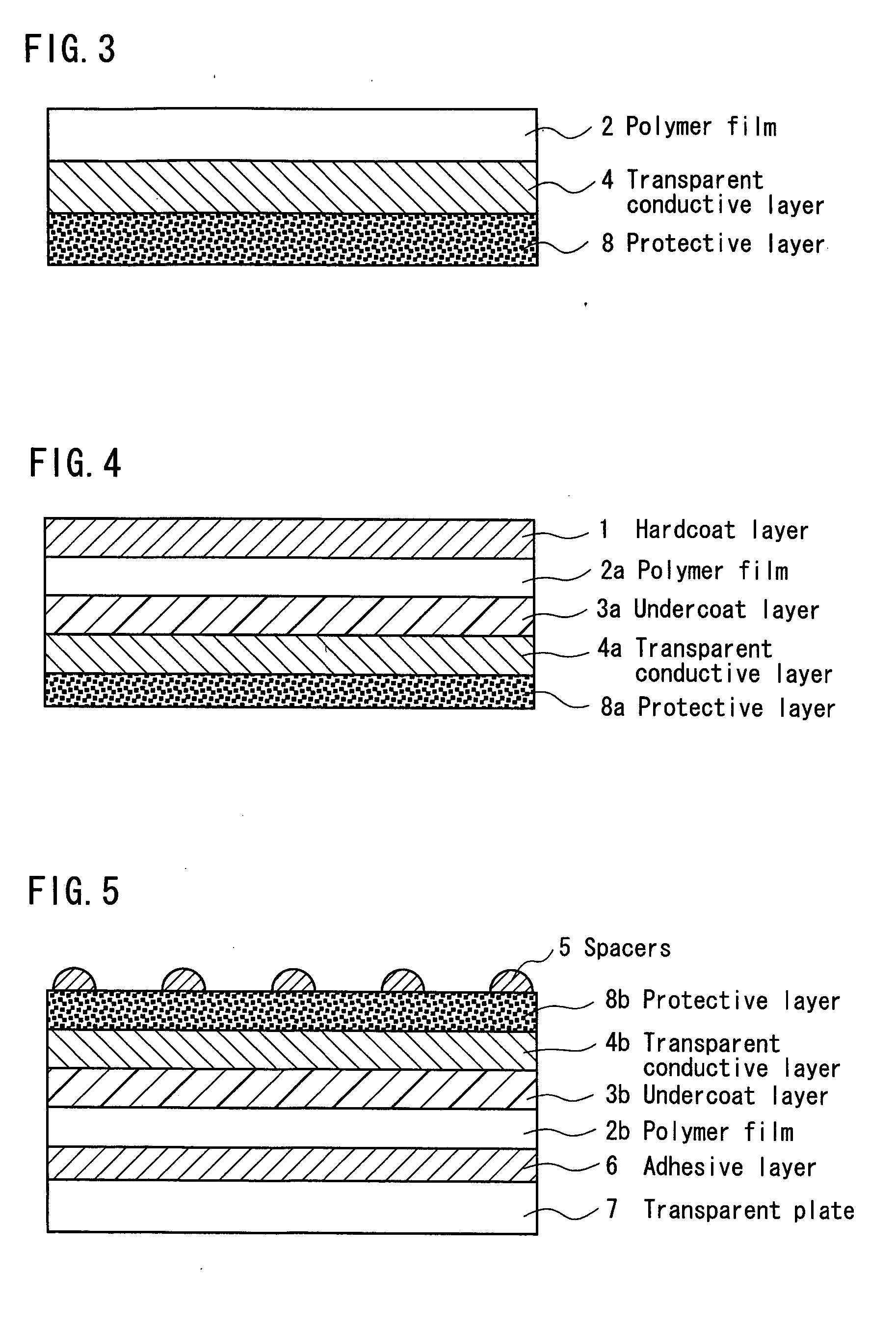

Transparent electroconductive film, method for manufacture thereof, and touch panel

InactiveUS20040265602A1Easy to prepareIncreased durabilityConductive layers on insulating-supportsContact surface shape/structurePhosphoric acidTransparent conducting film

A transparent conductive film comprising a polymer film and a transparent conductive layer provided thereon, especially a transparent conductive film improved in durability and mechanical and electrical properties, a process for the preparation thereof, and a touch panel provided with the transparent conductive film, as well as transparent conductive plate and the process for the preparation thereof. The transparent conductive film comprising a polymer film, an undercoat layer and a transparent conductive layer which are superposed in this order, and the undercoat layer contains a compound having at least one selected from an amino group and a phosphoric acid group.

Owner:BRIDGESTONE CORP

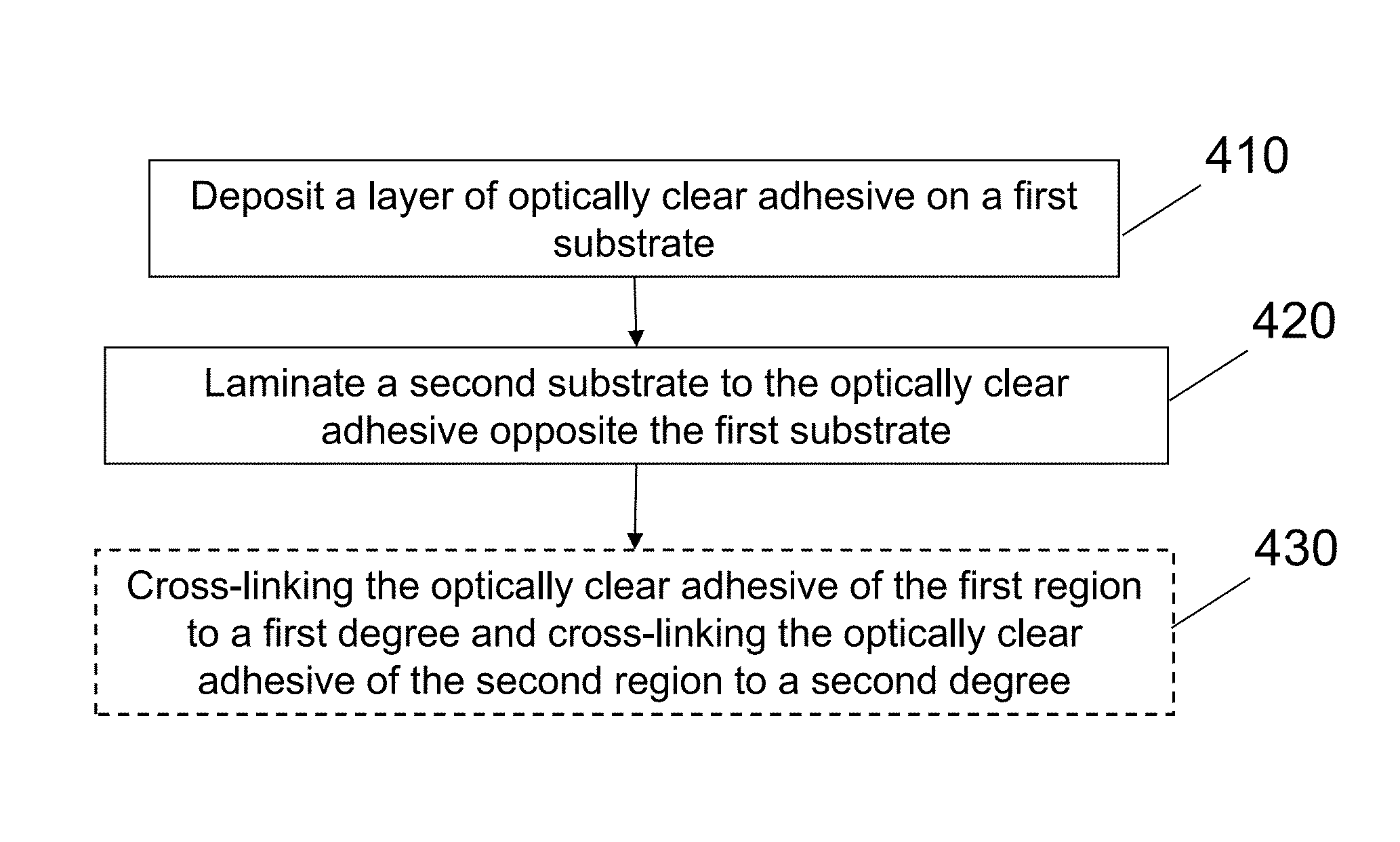

Method and apparatus for joining together multiple functional layers of a flexible display

ActiveUS20140295150A1Increase flexibilityIncrease display flexibilityFinal product manufactureFilm/foil adhesives without carriersOptical propertyAdhesive

The present invention may relate to provision of a mechanism to join together the various substrate layers of a flexible display with optically clear adhesives that permit improved flexibility of the substrate layer stack and may also optically guide images to locations on a display surface that are not aligned with the display layer of a substrate layer stack. Embodiments of the present invention may provide for an improved user interface which may include enhanced flexibility and enhanced optical characteristics.

Owner:LYTEN INC

Method for subdividing multilayer optical film cleanly and rapidly

Polymeric multilayer optical films, and laminate bodies that include such films, are cut or subdivided into one or more discrete pieces by removably applying a first and second liner to opposed major surfaces of the multilayer optical film. Laser radiation is then directed at the multilayer optical film through the first liner in such a way as to produce cut lines that define a plurality of pieces of the first liner and of the multilayer optical film. Thereafter, the plurality of pieces of the first liner are removed from the plurality of pieces of the multilayer optical film while the pieces of multilayer optical film are supported by the second liner. Application of the first liner to the multilayer optical film can be accomplished with electrostatics.

Owner:3M INNOVATIVE PROPERTIES CO

Methods and systems for forming a dual layer housing

ActiveUS20090017242A1Envelopes/bags making machinerySynthetic resin layered productsShell moldingMaterials science

Methods and apparatus for applying internal features or complex mechanical structures to a surface of a metal part are disclosed. According to one aspect of the present invention, a method for creating an assembly that includes a substrate and a molded piece involves obtaining the substrate, and forming at least one binding feature on a surface of the substrate. The method also includes molding on a surface of the binding feature and the surface of the substrate. Molding on the surface of the binding feature and the surface of the substrate mechanically binds the molded piece to the substrate.

Owner:APPLE INC

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS20090004442A1Decorative surface effectsPhotomechanical apparatusRadiative transferEngineering

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

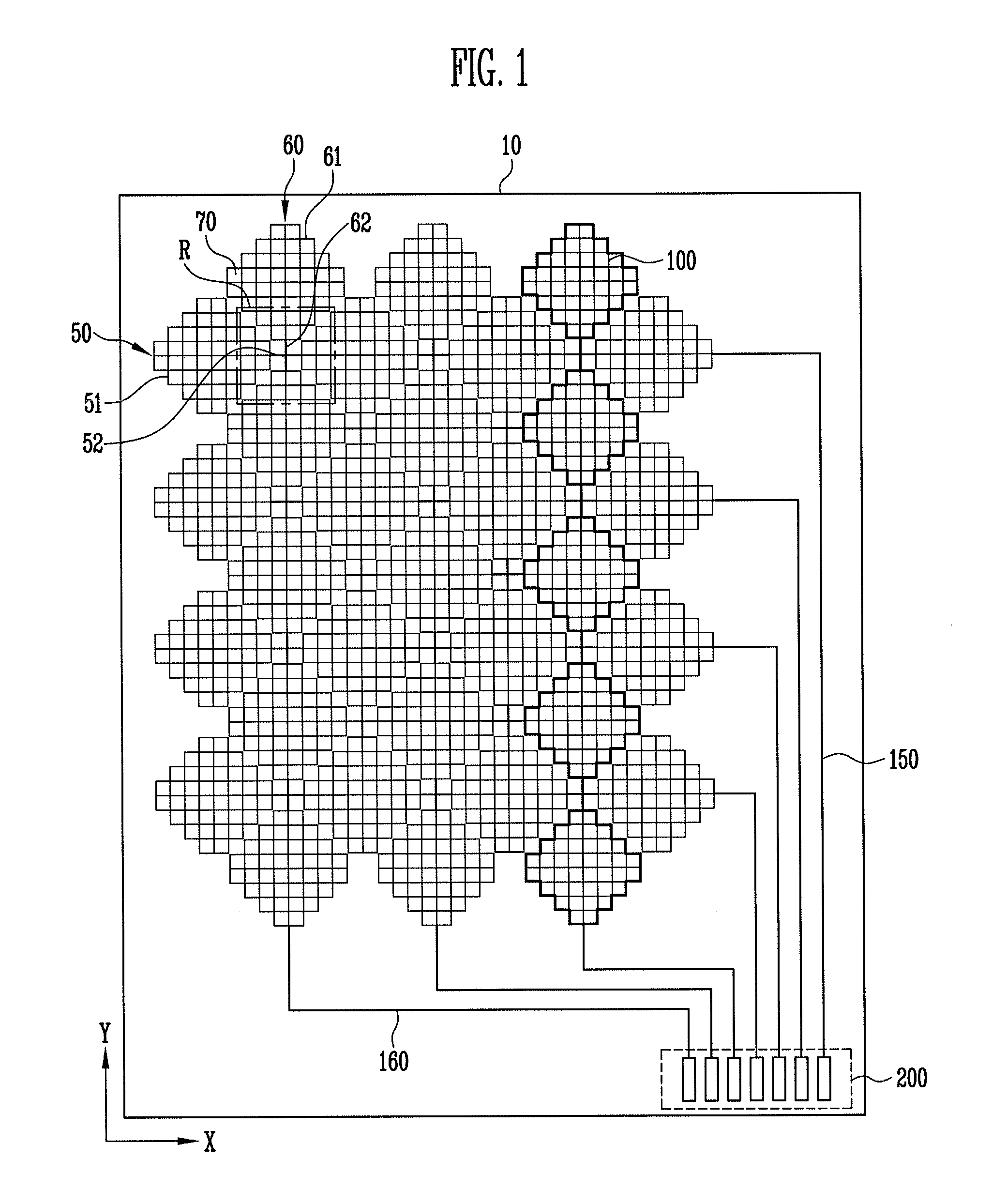

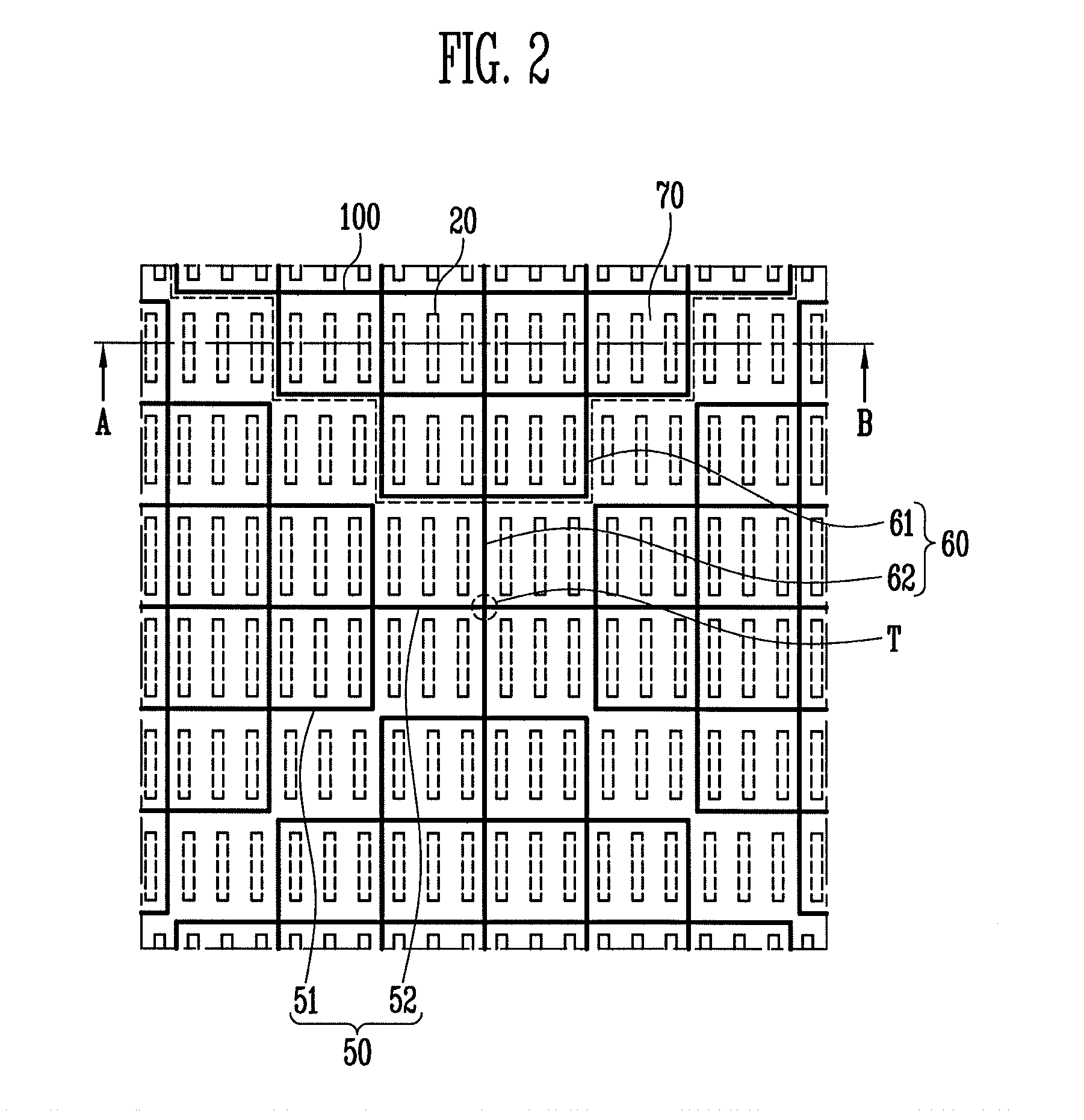

Touch screen panel

ActiveUS20130278513A1Avoid damageIncrease awarenessLayered productsElectrical equipmentEngineeringElectrical and Electronics engineering

Owner:SAMSUNG DISPLAY CO LTD

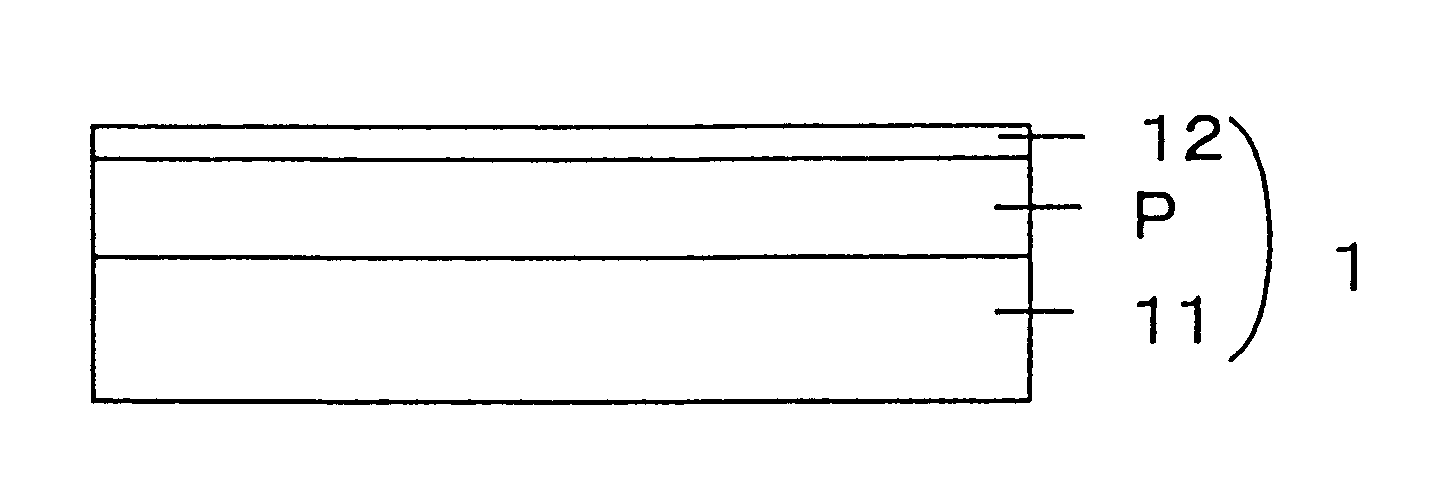

Transparent conductive film and touch panel

InactiveUS6629833B1Increased durabilityImprove adhesionLiquid surface applicatorsConductive layers on insulating-supportsCross-linkTouchpad

A transparent conductive film (1) having a transparent plastic film (11) and a transparent conductive thin film (12) formed on at least one side thereof, characterized in that a resin layer (P) containing an ionic group in the range of 20 to 1000 eq / ton is provided between the transparent plastic film and the transparent conductive thin film and the ionic group containing resin has a cross-linked structure. The transparent conductive film has excellent adhesion to other conductive thin films and therefore exhibits excellent durability to input with a pen when used in touch panels.

Owner:TOYO TOYOBO CO LTD

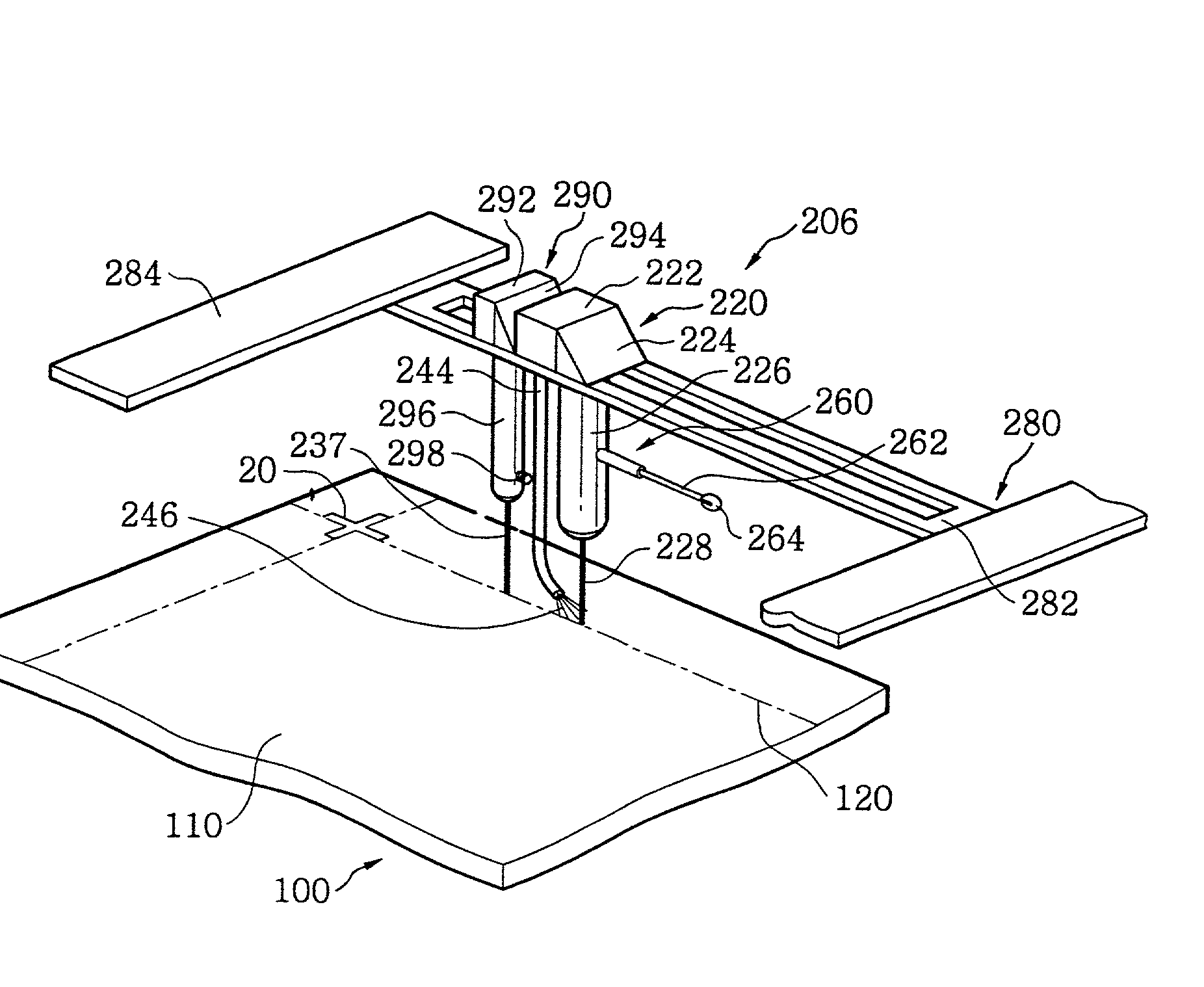

Laser cutting apparatus and method

The present invention disclose a laser cutter for cutting an object being cut such as a two glasses-attached panel for LCD using a laser beam. The laser cutter includes a laser unit for irradiating a laser beam with a specific wavelength along a marked cutting line of the object, a pre-scriber for forming a pre-cut groove at starting edge of the marked cutting line, and a cooling unit for cooling the cutting line which said laser beam has been irradiated.

Owner:SAMSUNG DISPLAY CO LTD

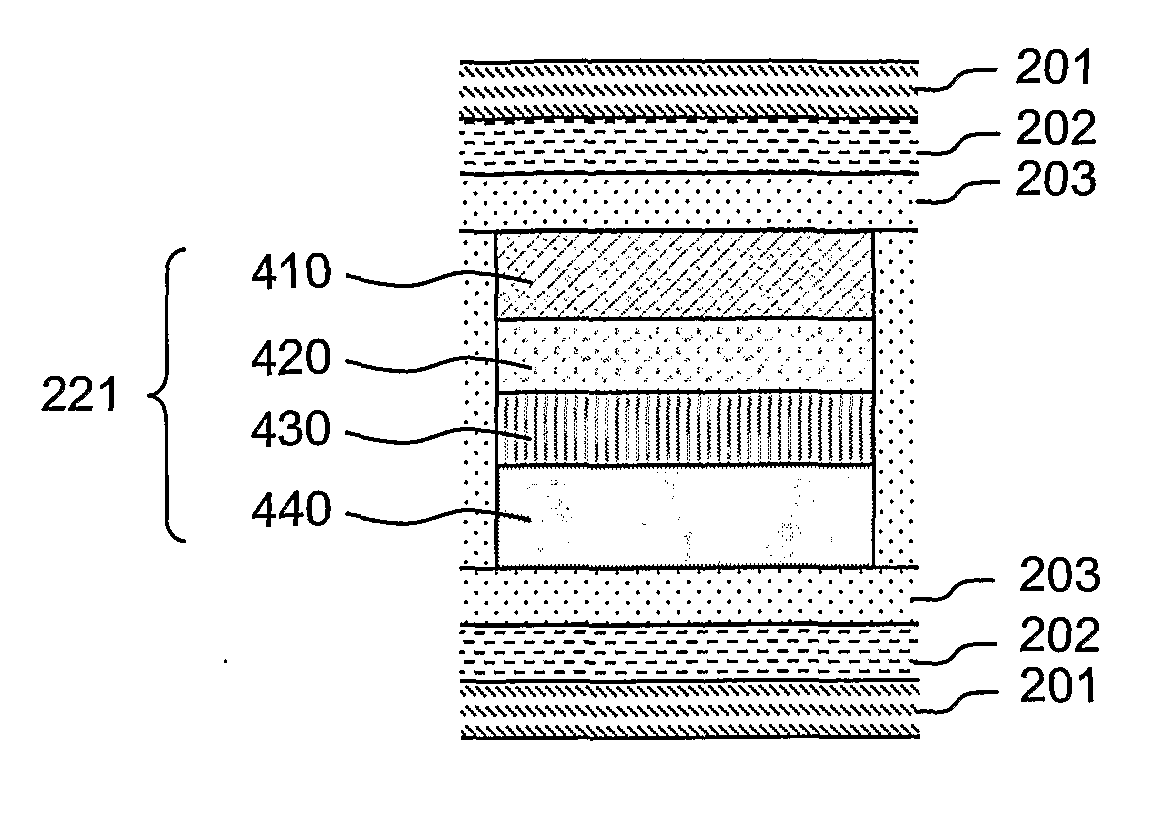

Multilayer film for encapsulating oxygen and/or moisture sensitive electronic devices

ActiveUS20110132449A1Excellent gas barrier performanceLow gas permeabilityMaterial nanotechnologyNanostructure manufactureNanoparticleUltraviolet lights

The present invention refers to a multilayer barrier film capable of encapsulating a moisture and / or oxygen sensitive electronic or optoelectronic device, the barrier film comprises at least one nanostructured layer comprising reactive nanoparticles capable of interacting with moisture and / or oxygen, the reactive nanoparticles being distributed within a polymeric binder, and at least one ultraviolet light neutralizing layer comprising a material capable of absorbing ultraviolet light, thereby limiting the transmission of ultraviolet light through the barrier film

Owner:AGENCY FOR SCI TECH & RES

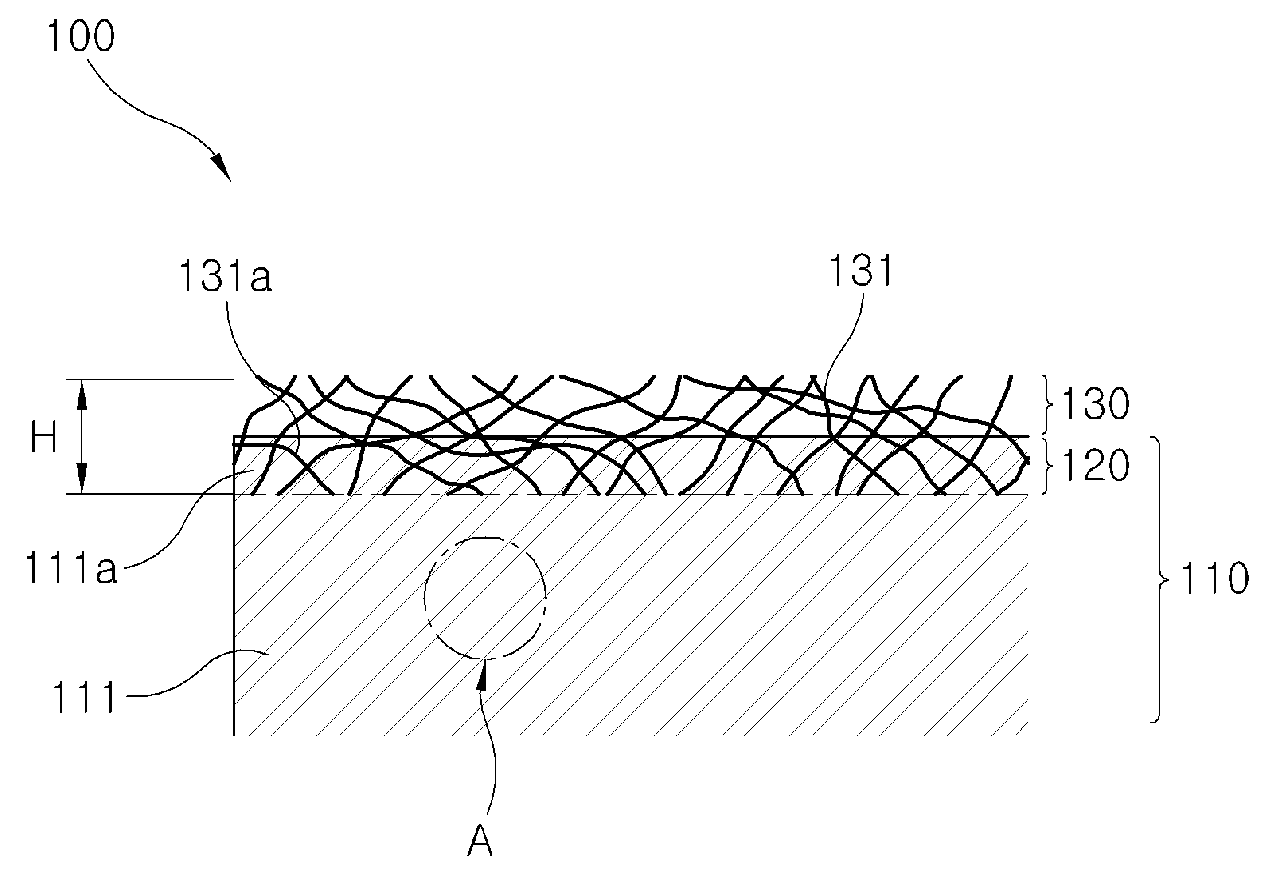

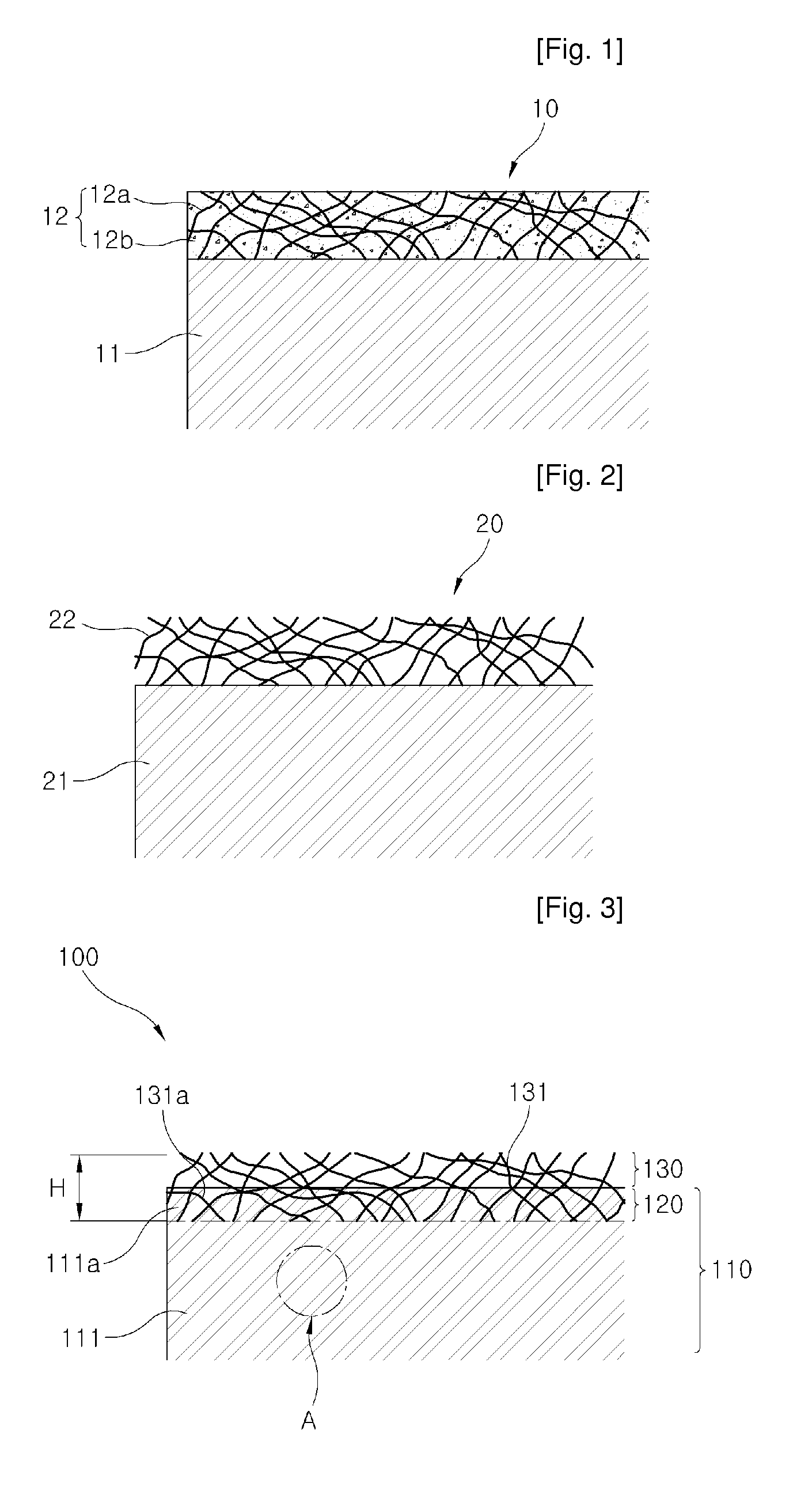

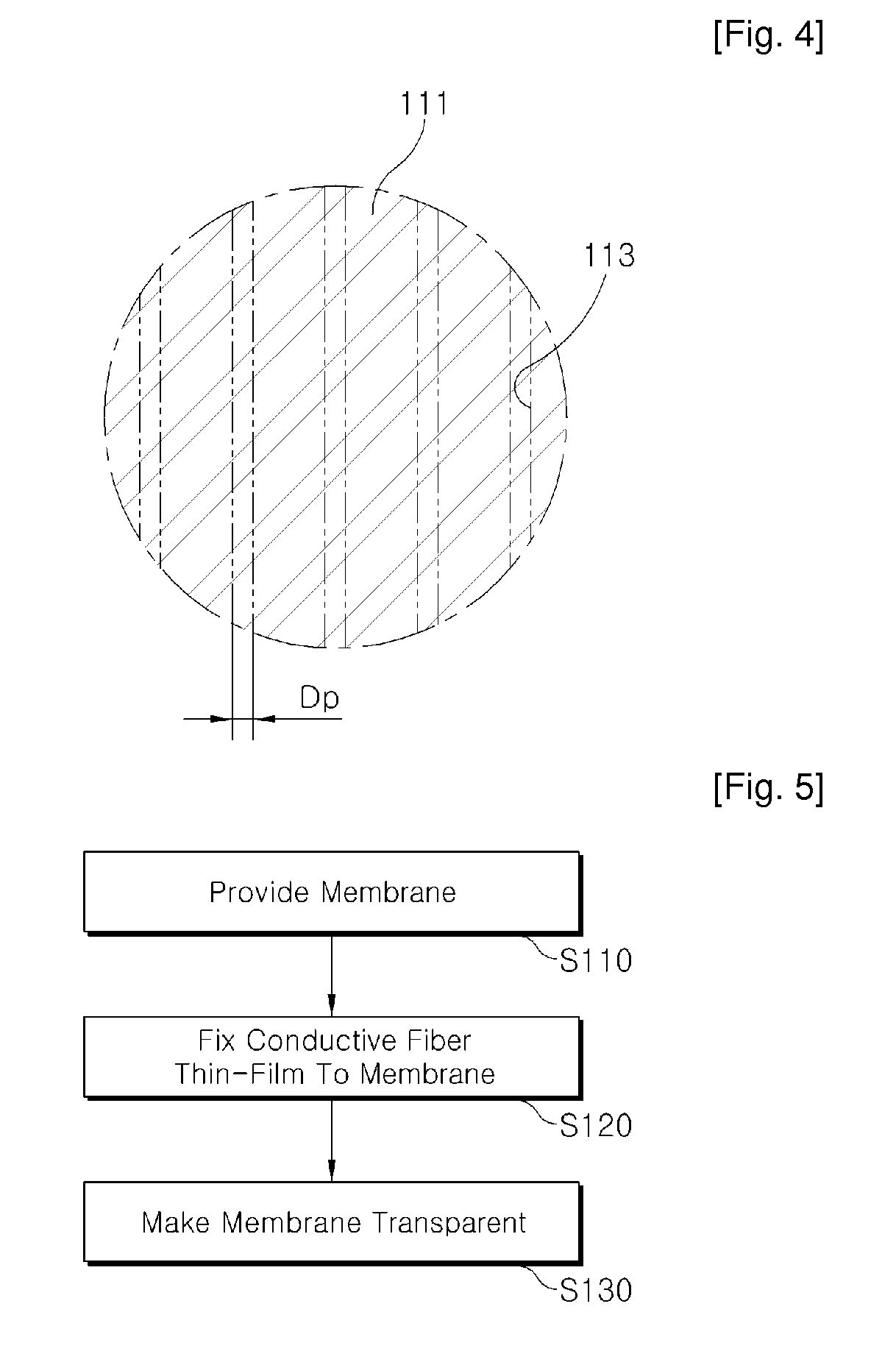

Method for manufacturing conductive composite material

InactiveUS20090056854A1Reduce thicknessHigh transparencyCathodes manufactureElectric discharge tubesFiberOptoelectronics

A conductive composite material is provided, including: a base layer; a conductive fiber thin-film made of conductive fiber and formed on the base layer; and a mixture layer in which part of the conductive fiber is inserted into part of the base layer.

Owner:TOPNANOSIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com