Patents

Literature

3017results about "Film/foil adhesives without carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electro-optic display and materials for use therein

InactiveUS7535624B2High viscosityImprove conductivityNon-macromolecular adhesive additivesStatic indicating devicesAdhesiveDisplay device

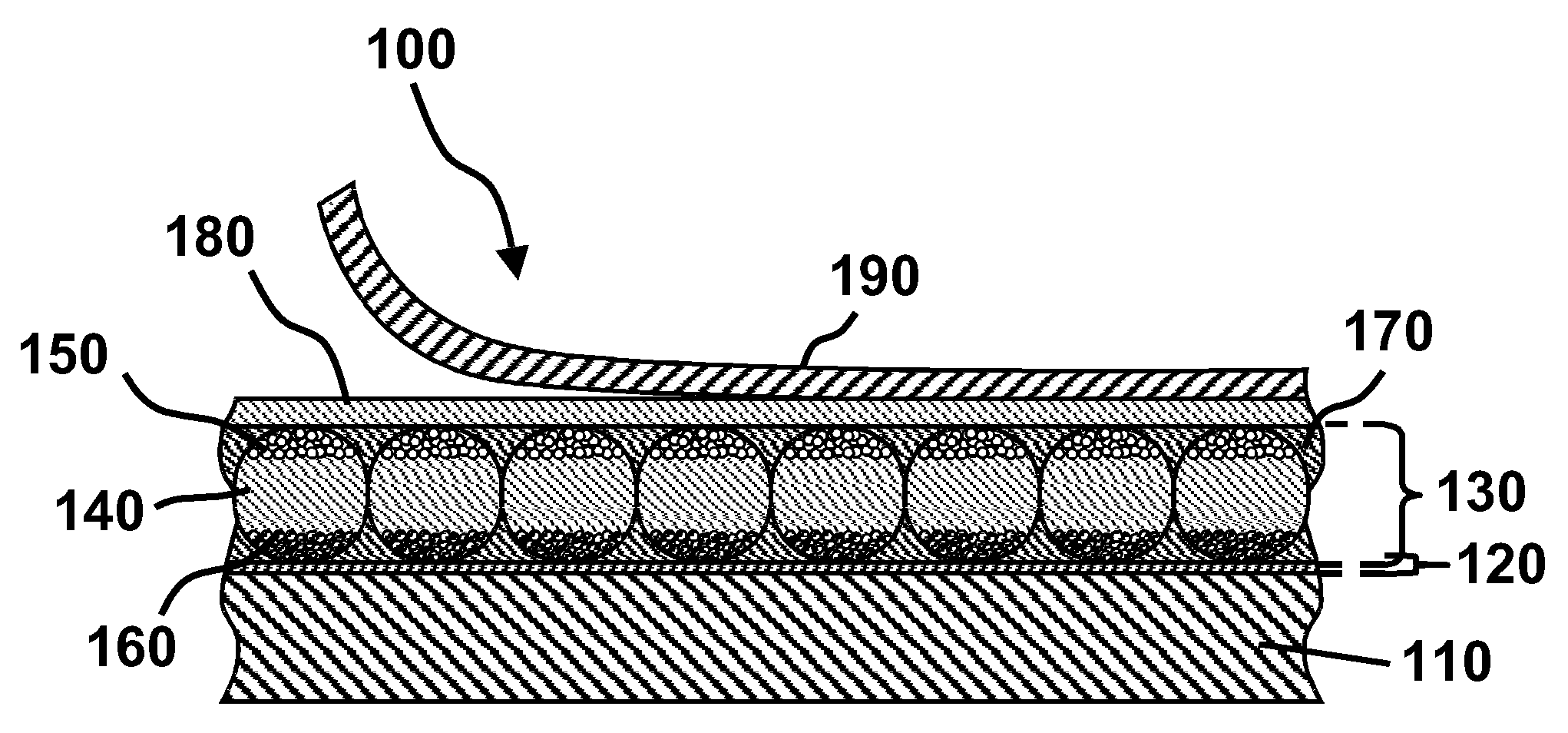

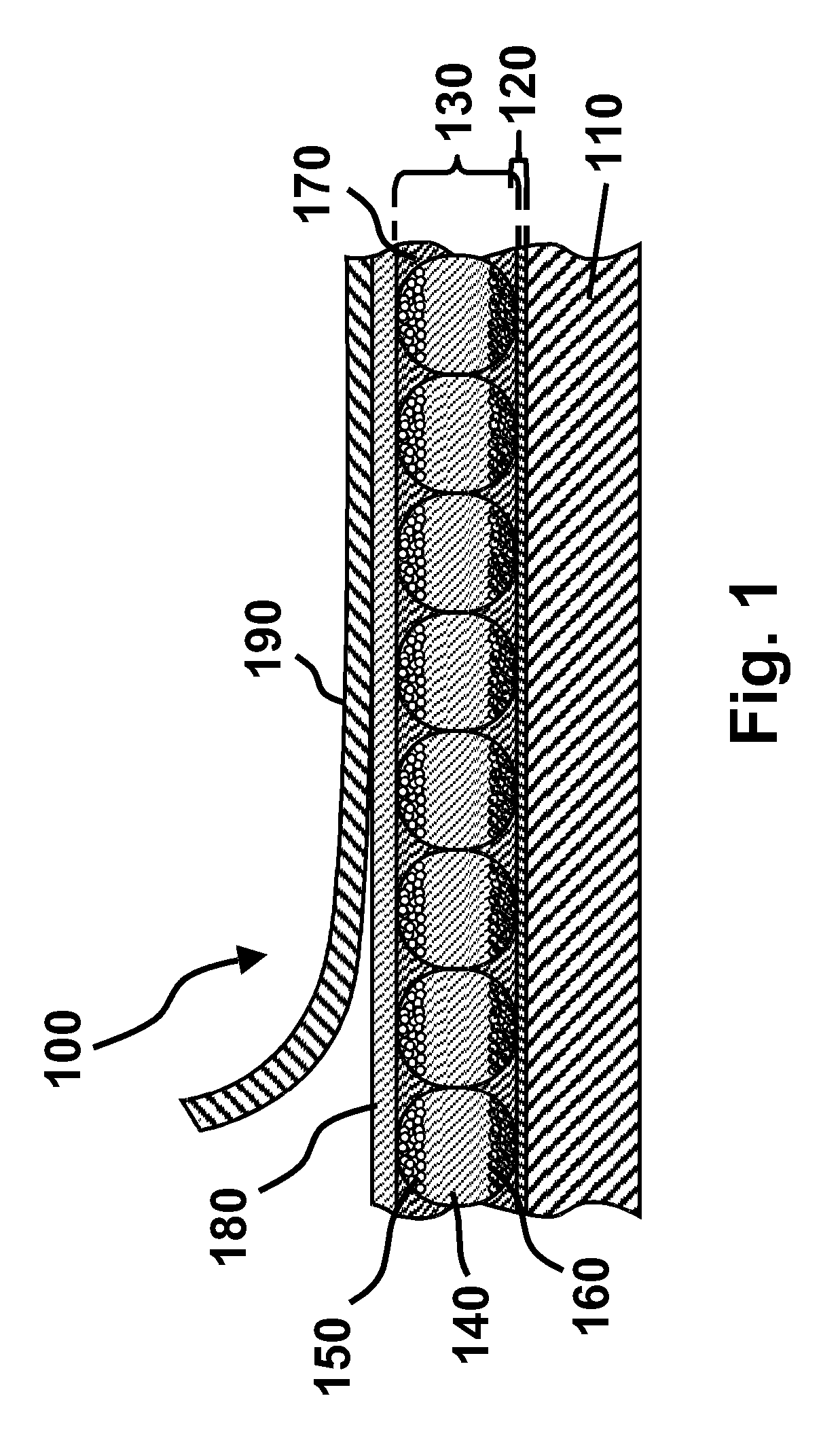

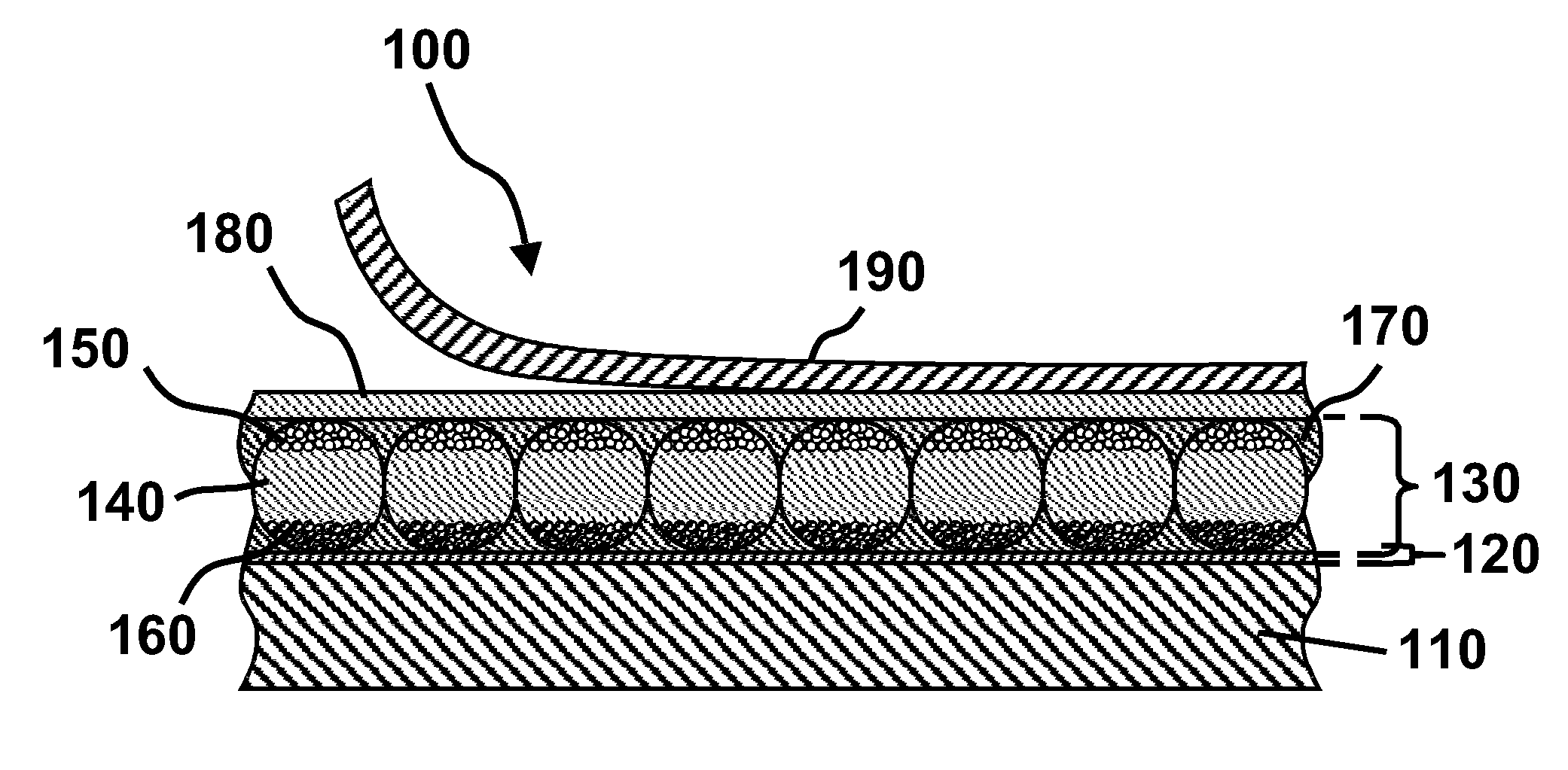

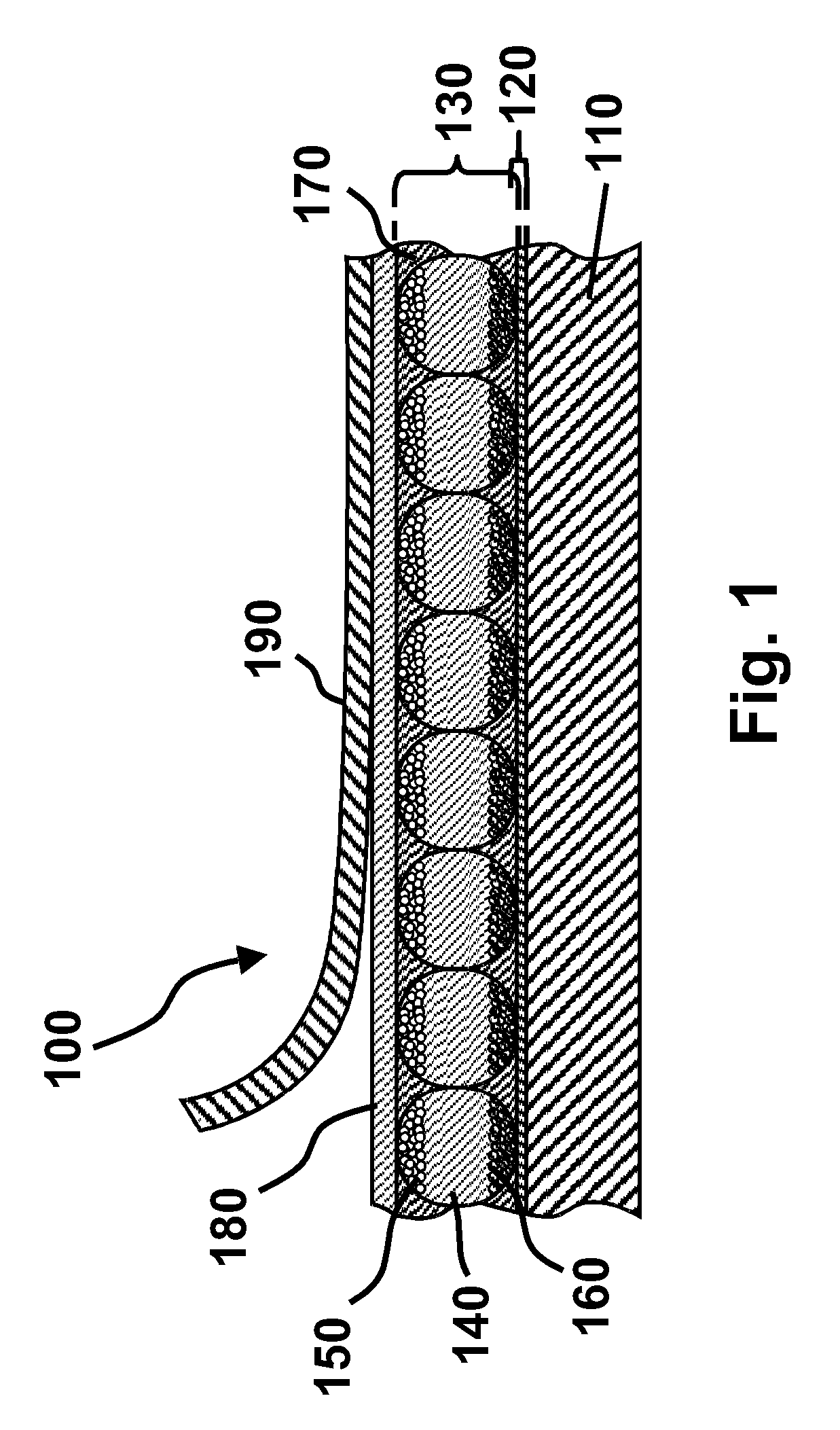

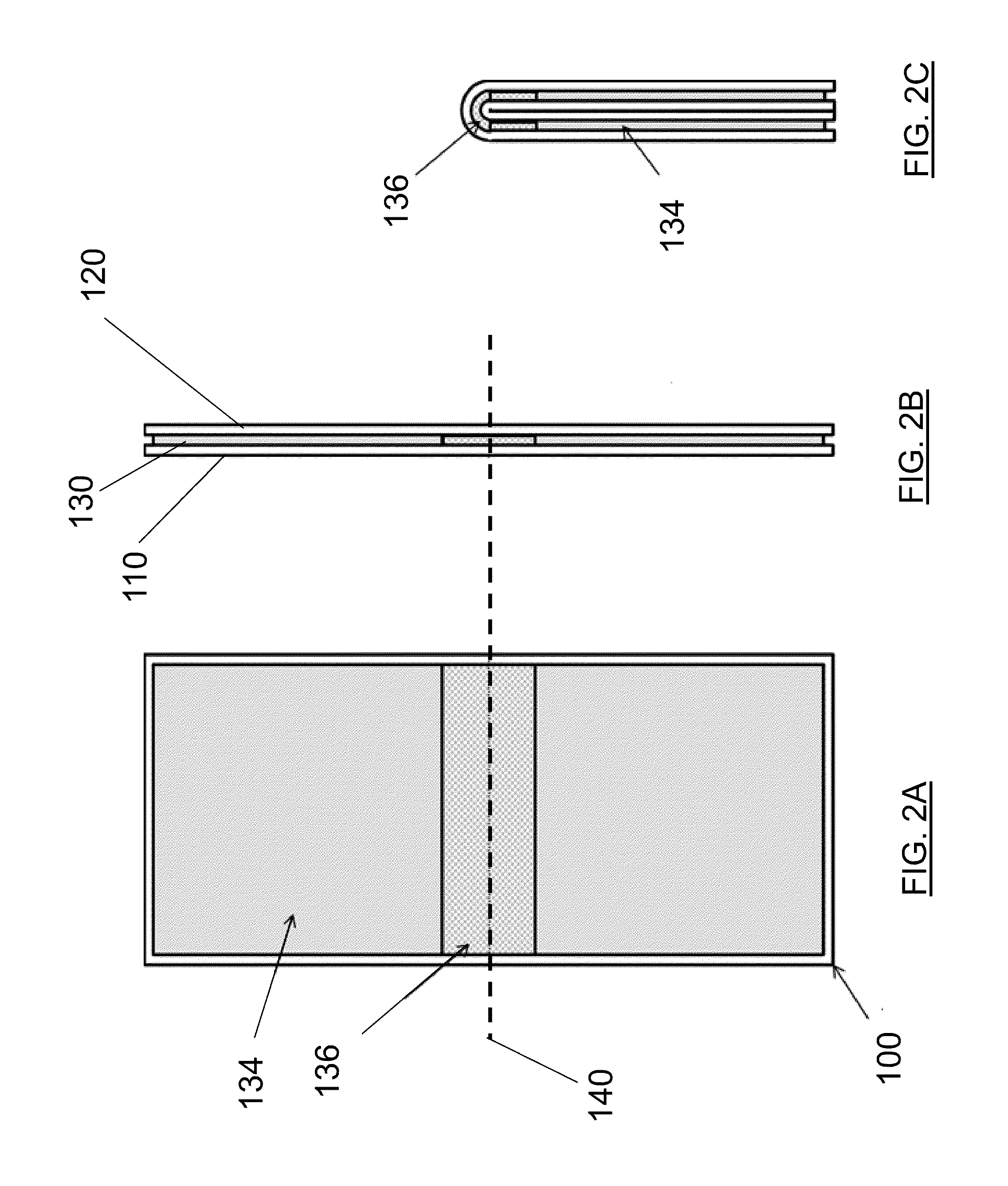

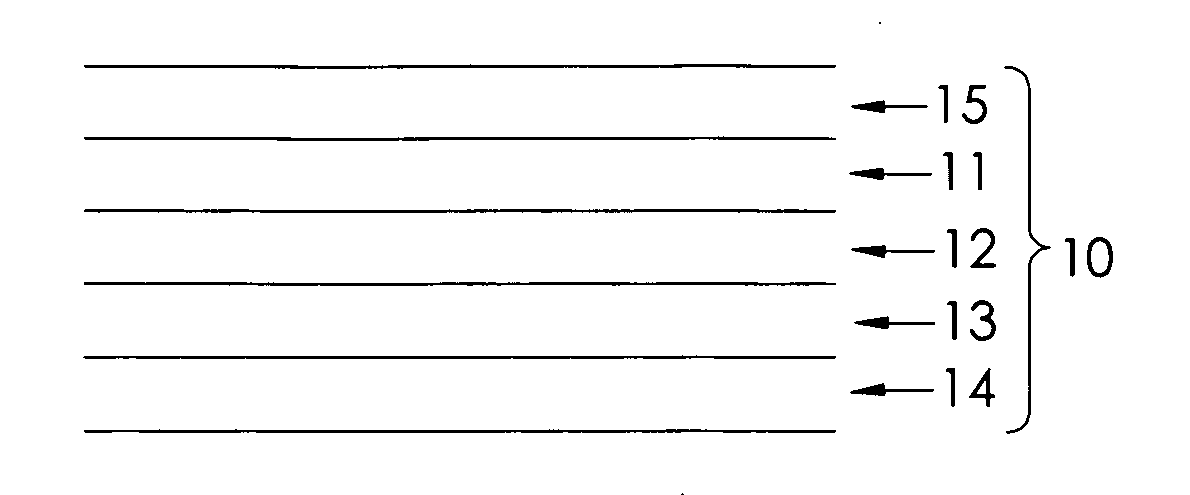

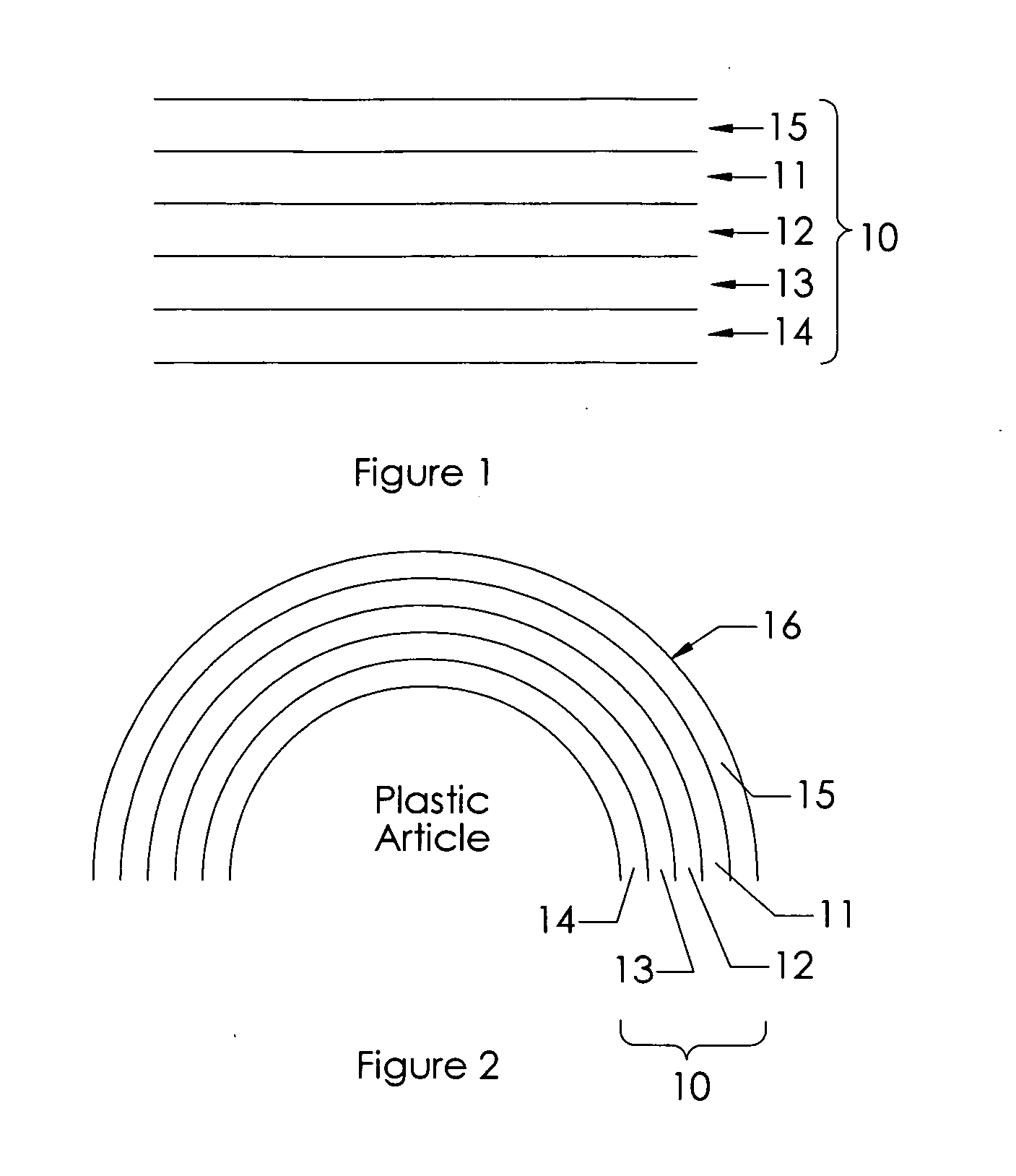

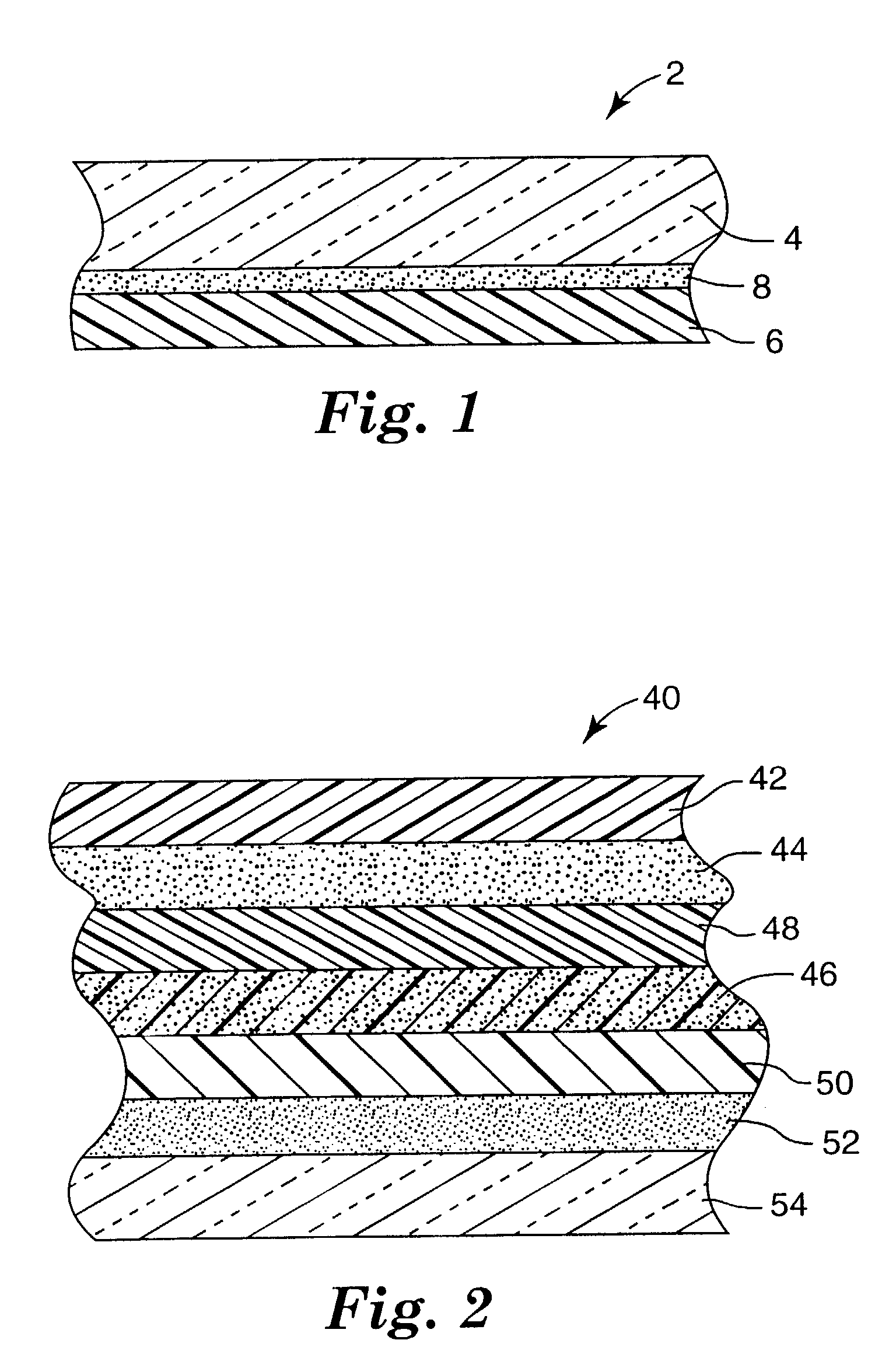

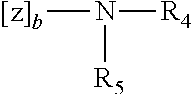

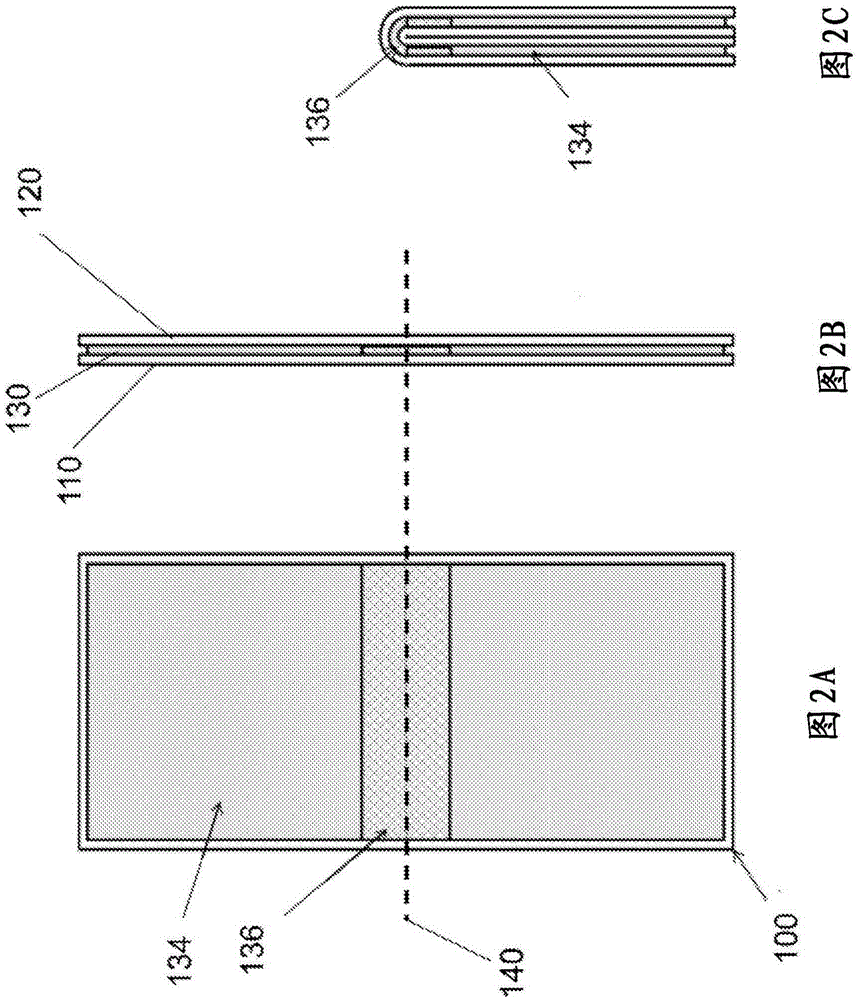

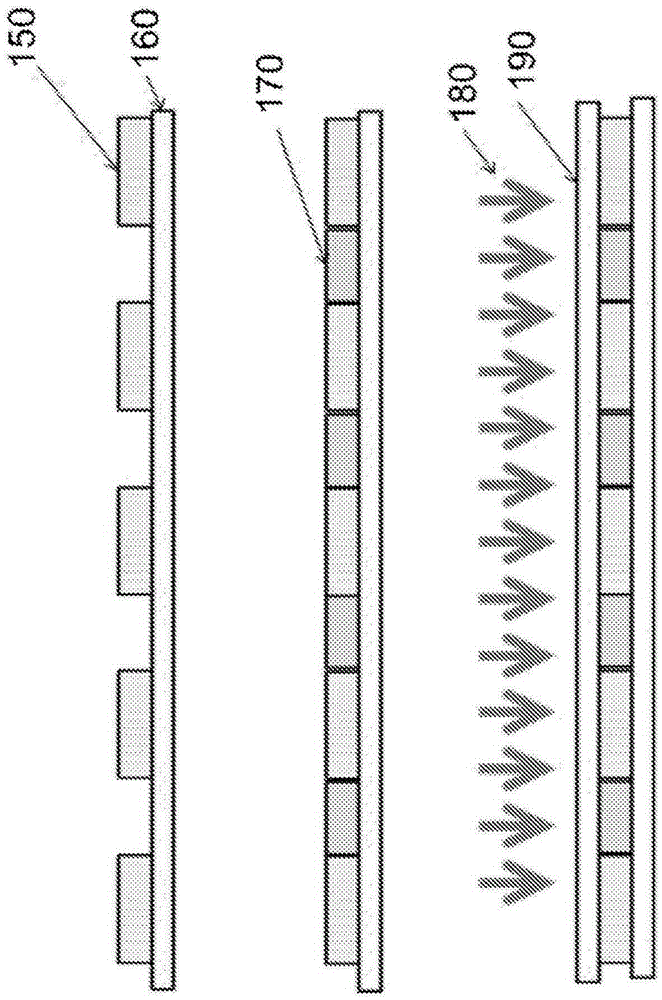

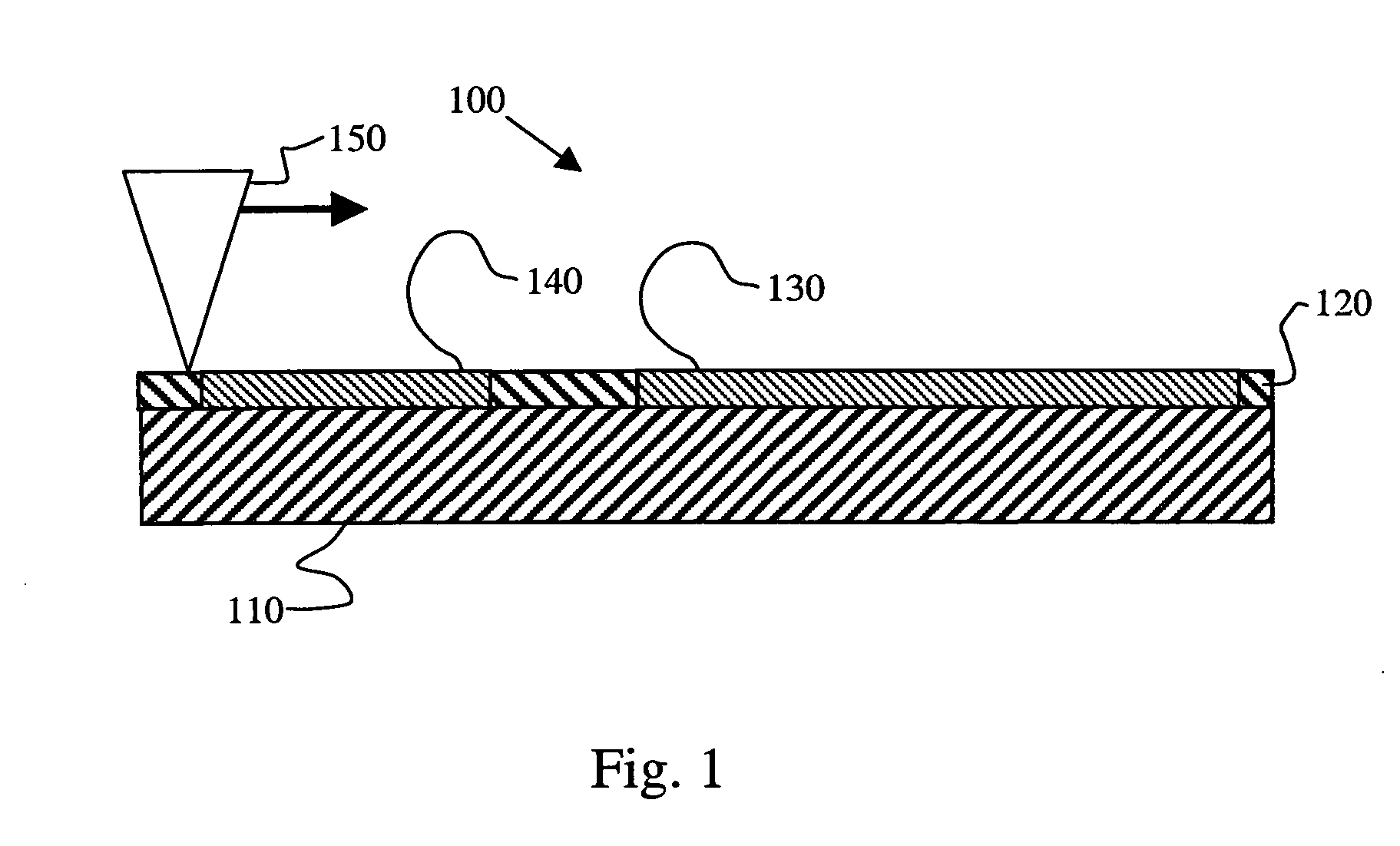

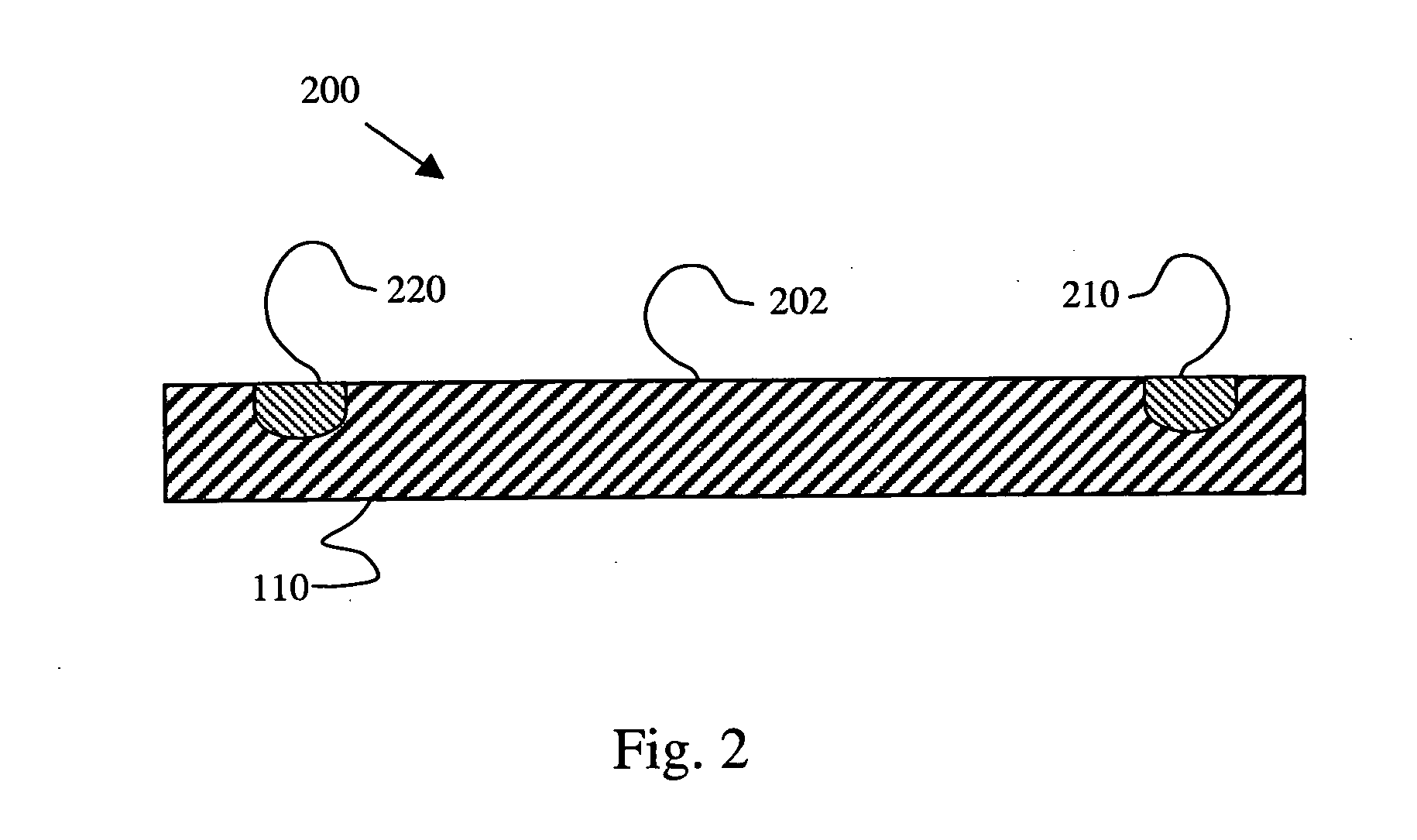

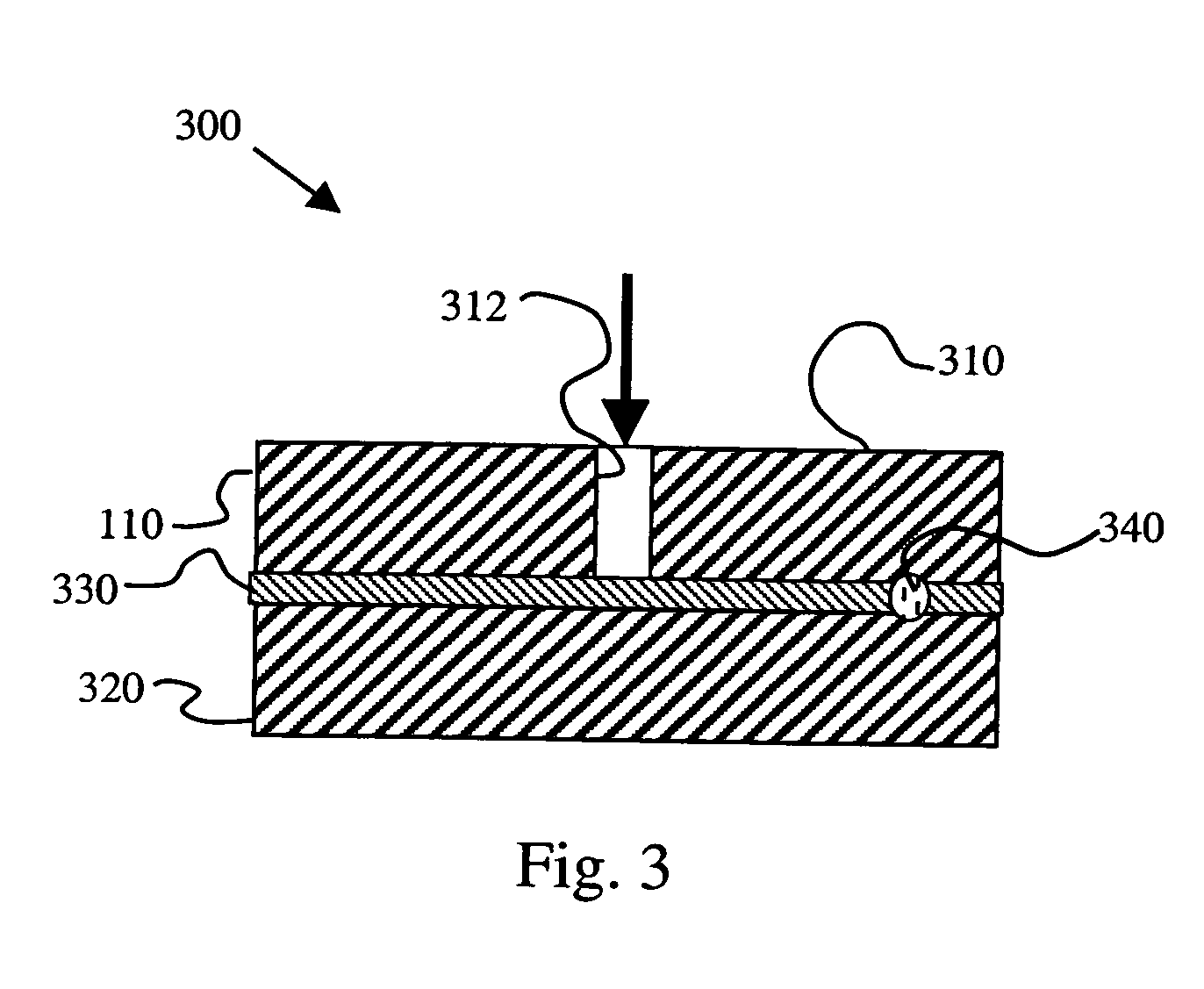

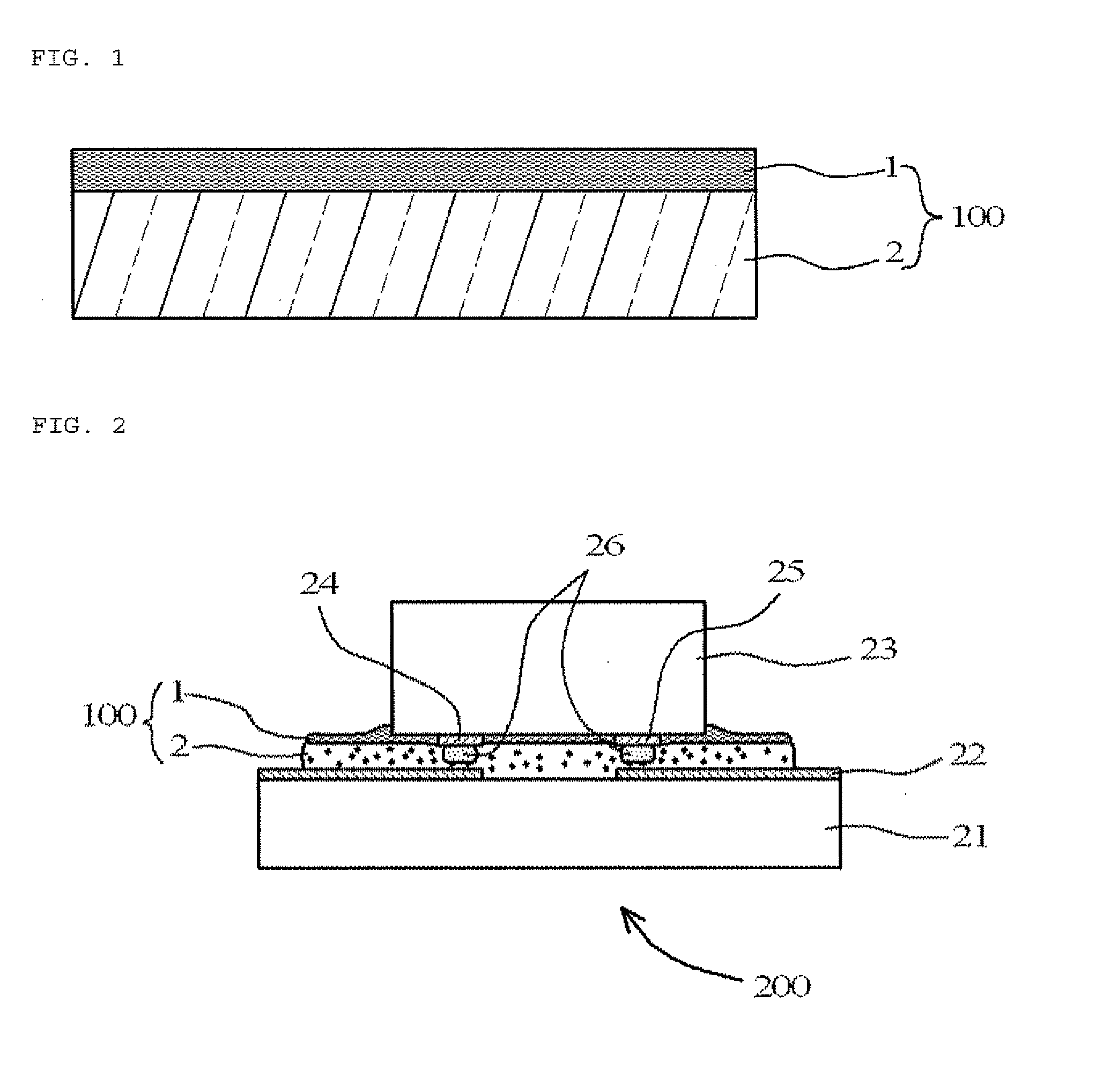

An electro-optic display comprises a layer (130) of a solid electro-optic material, at least one electrode disposed adjacent the layer (130) of electro-optic material, and a layer (180) of a lamination adhesive interposed between the layer (130) of electro-optic material and the electrode, the lamination adhesive (180) having a higher electrical conductivity in a direction perpendicular to the layer of lamination adhesive than in the plane of the layer.

Owner:E INK CORPORATION

Electro-optic display and materials for use therein

InactiveUS20070035808A1Improve conductivityHigh viscosityNon-macromolecular adhesive additivesFilm/foil adhesives without carriersAdhesiveDisplay device

An electro-optic display comprises a layer (130) of a solid electro-optic material, at least one electrode disposed adjacent the layer (130) of electro-optic material, and a layer (180) of a lamination adhesive interposed between the layer (130) of electro-optic material and the electrode, the lamination adhesive (180) having a higher electrical conductivity in a direction perpendicular to the layer of lamination adhesive than in the plane of the layer.

Owner:E INK CORPORATION

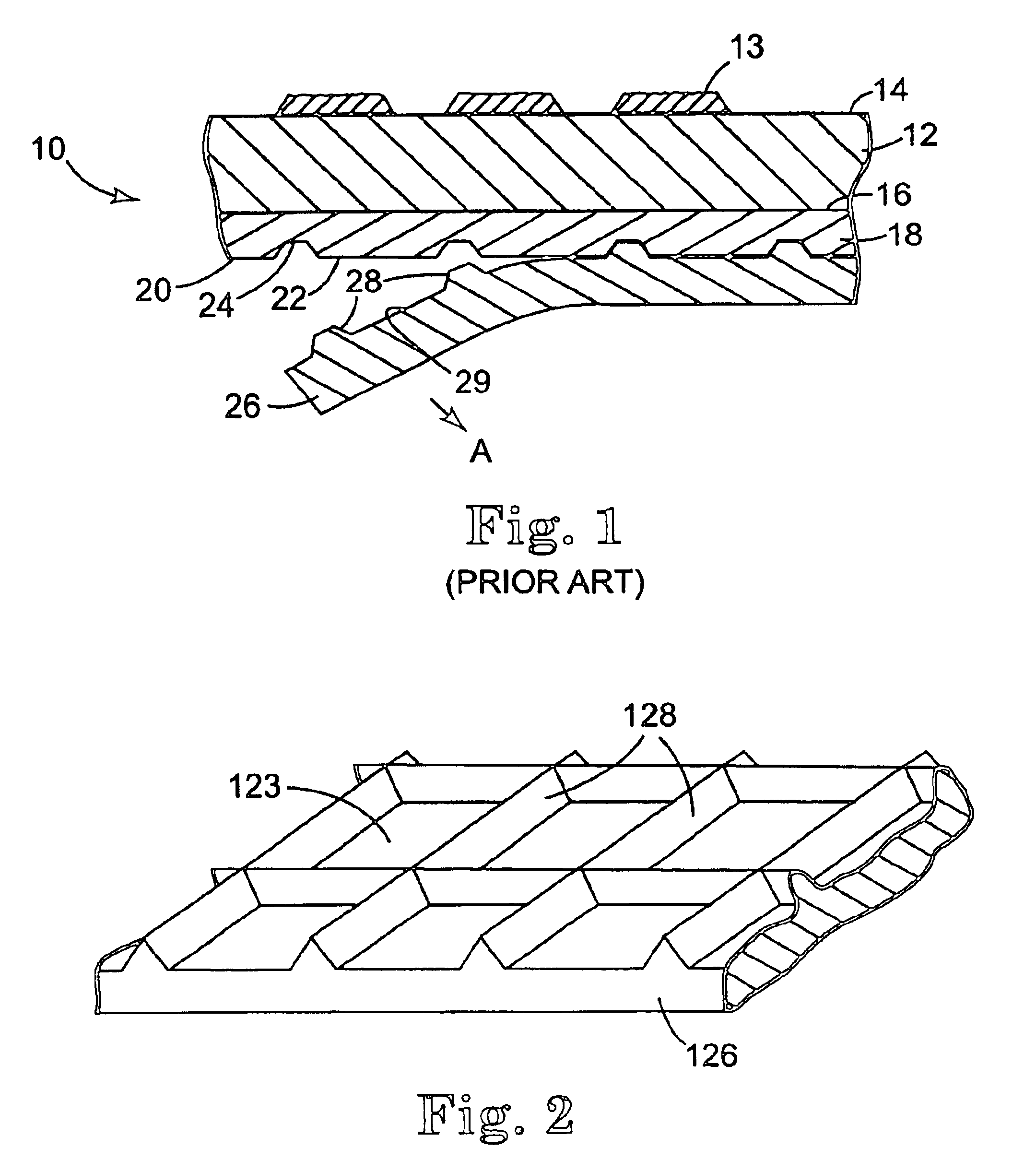

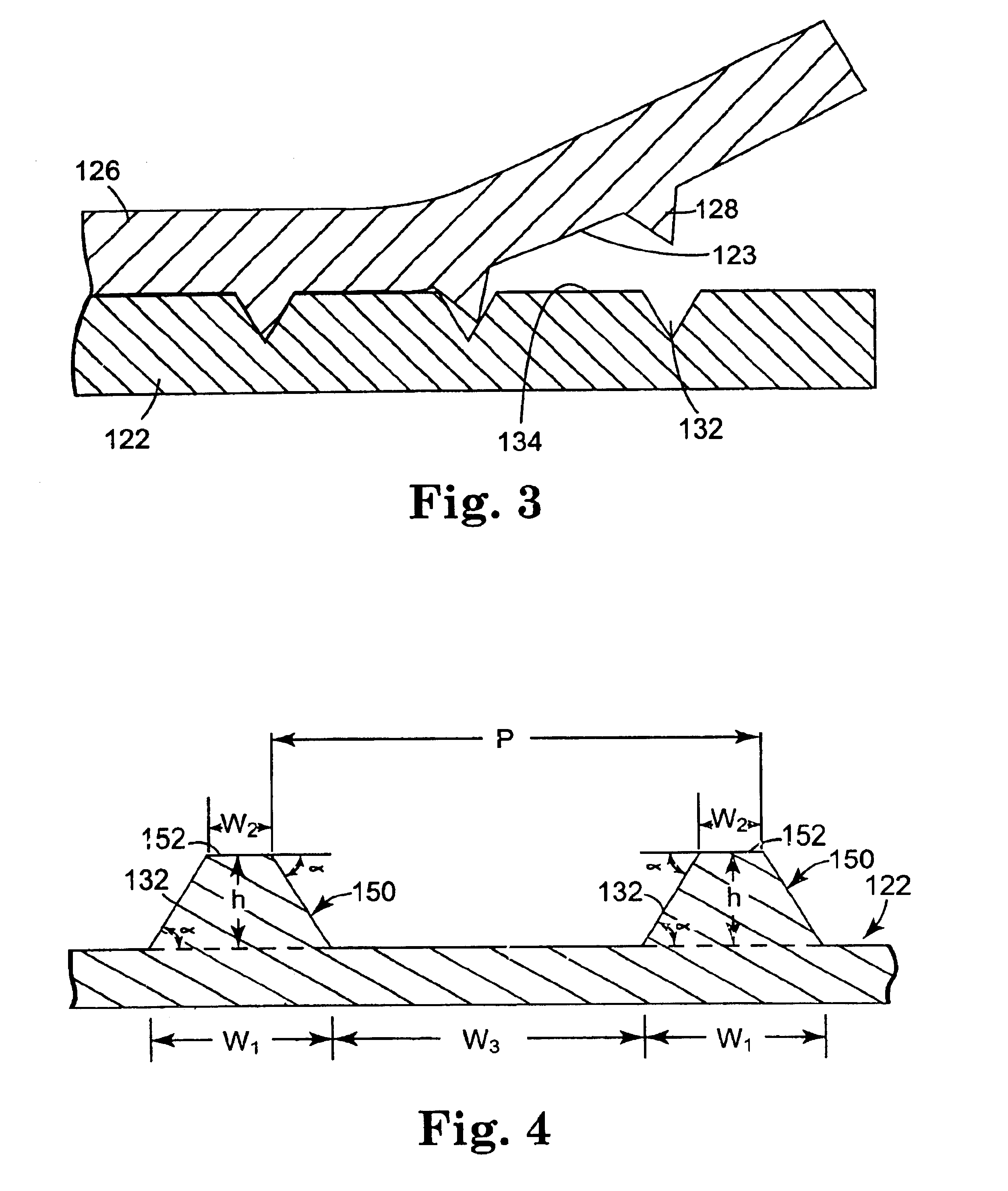

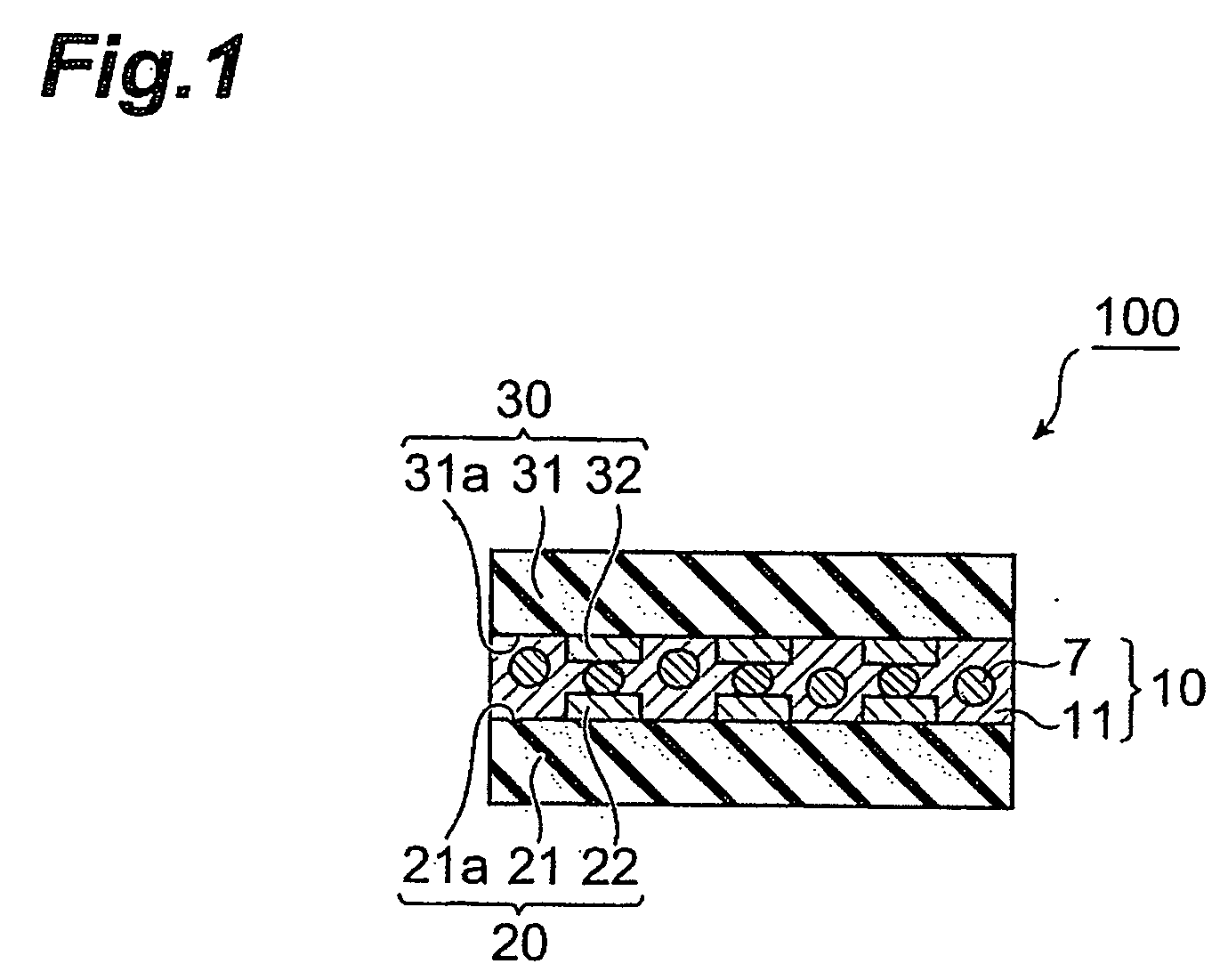

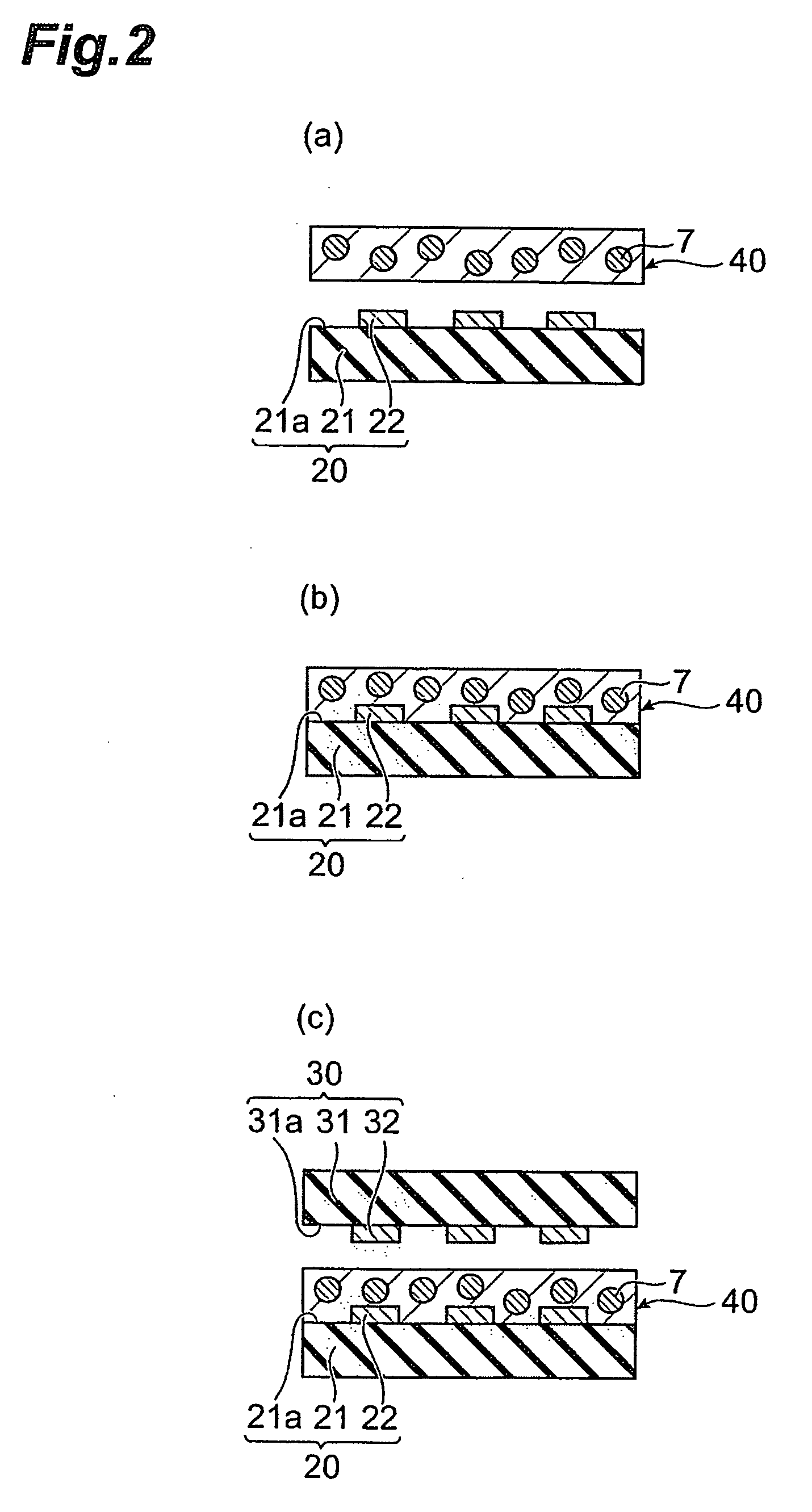

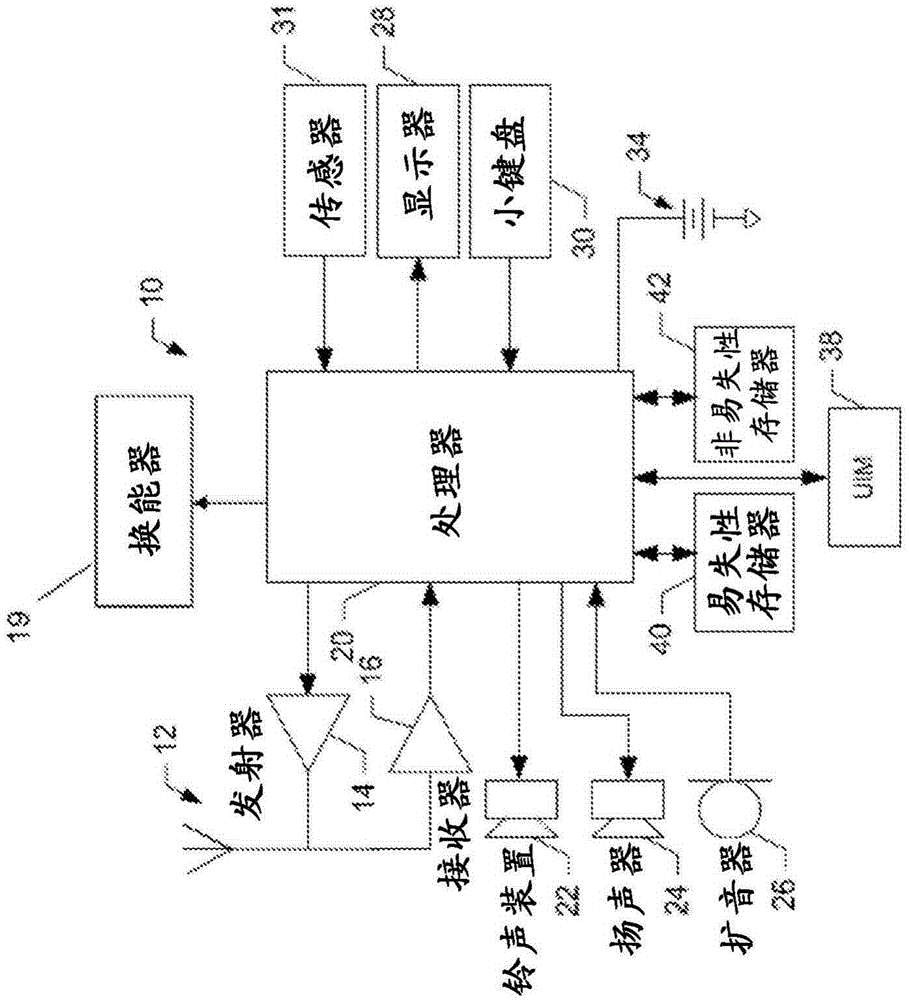

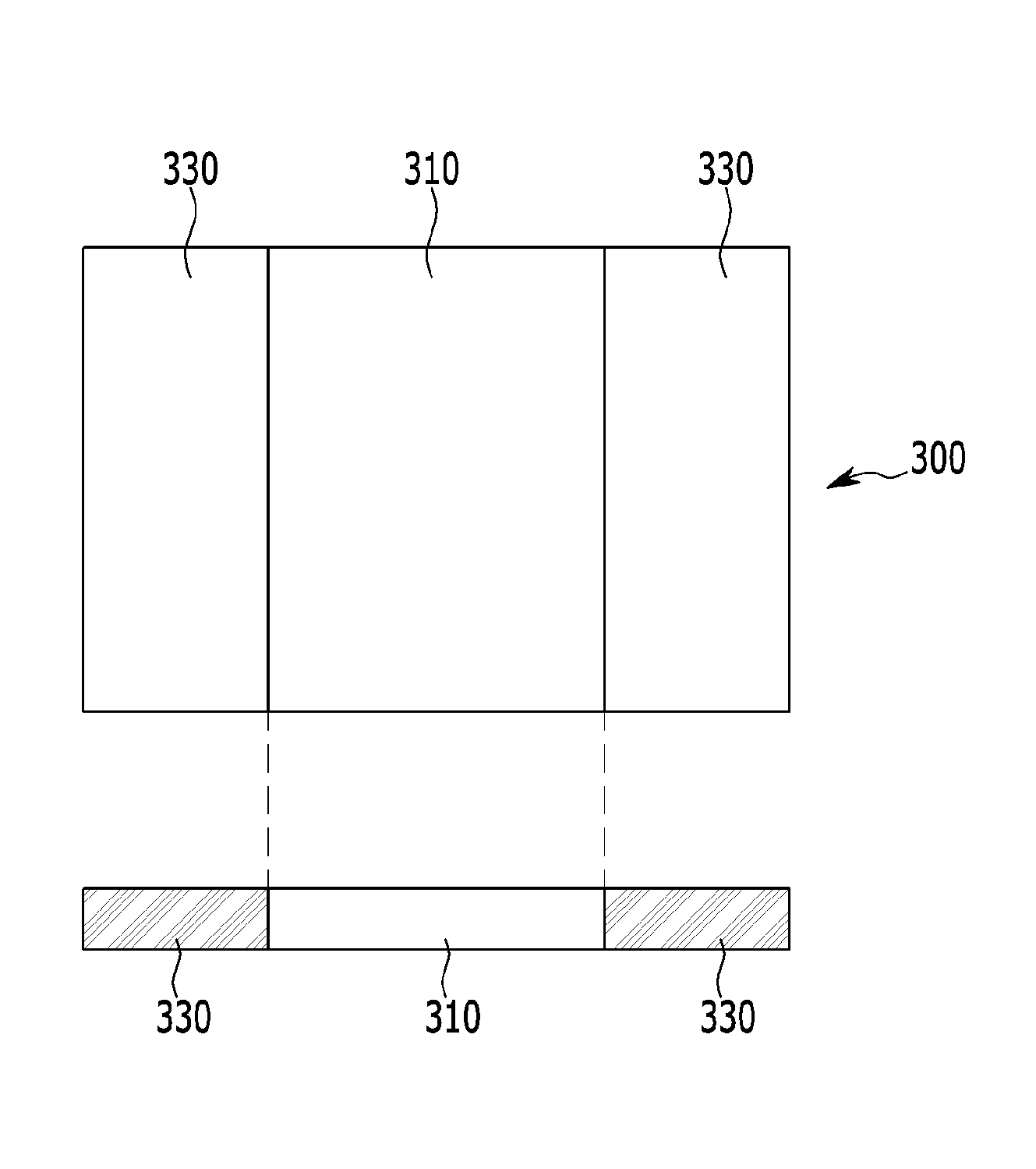

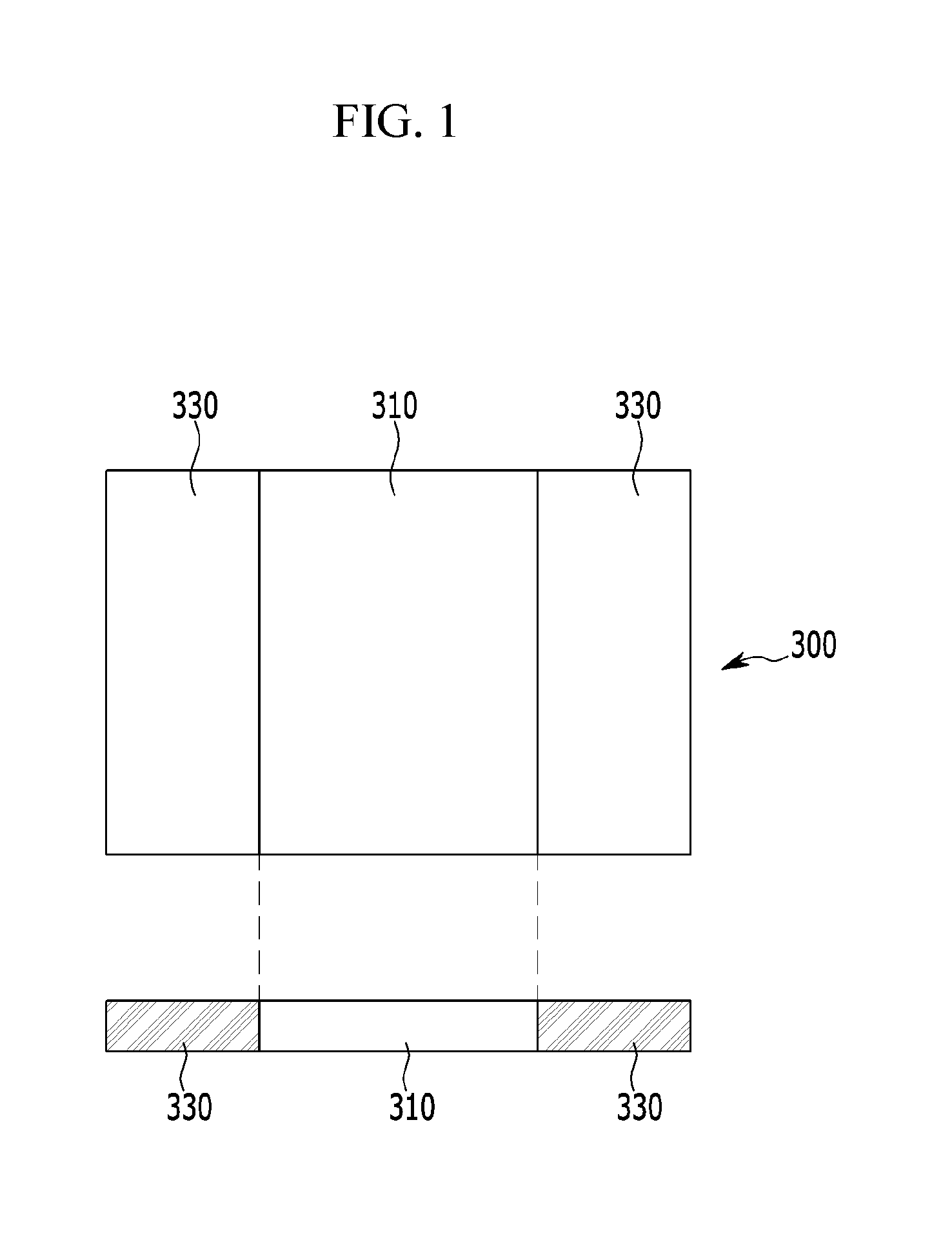

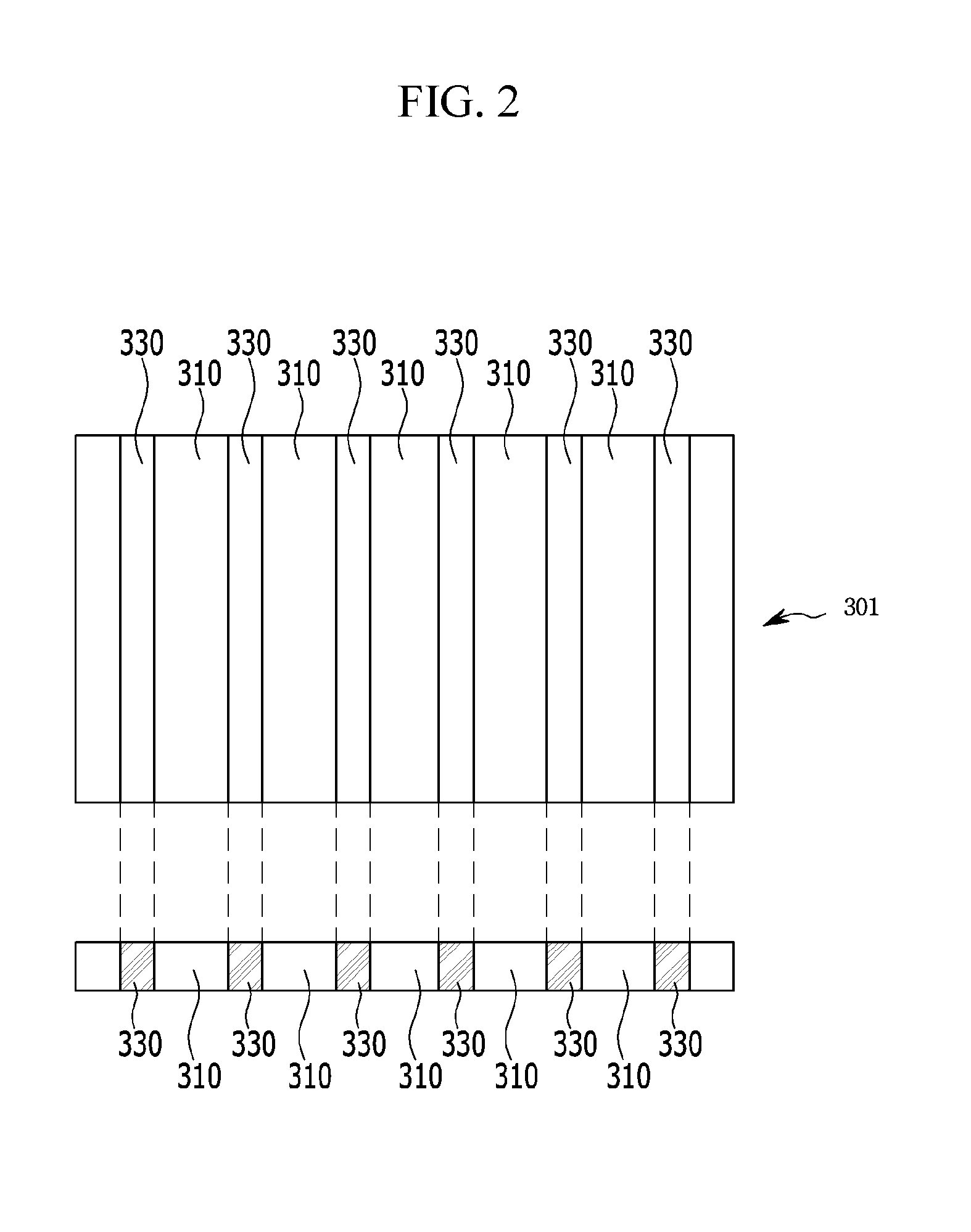

Method and apparatus for joining together multiple functional layers of a flexible display

ActiveUS20140295150A1Increase flexibilityIncrease display flexibilityFinal product manufactureFilm/foil adhesives without carriersOptical propertyAdhesive

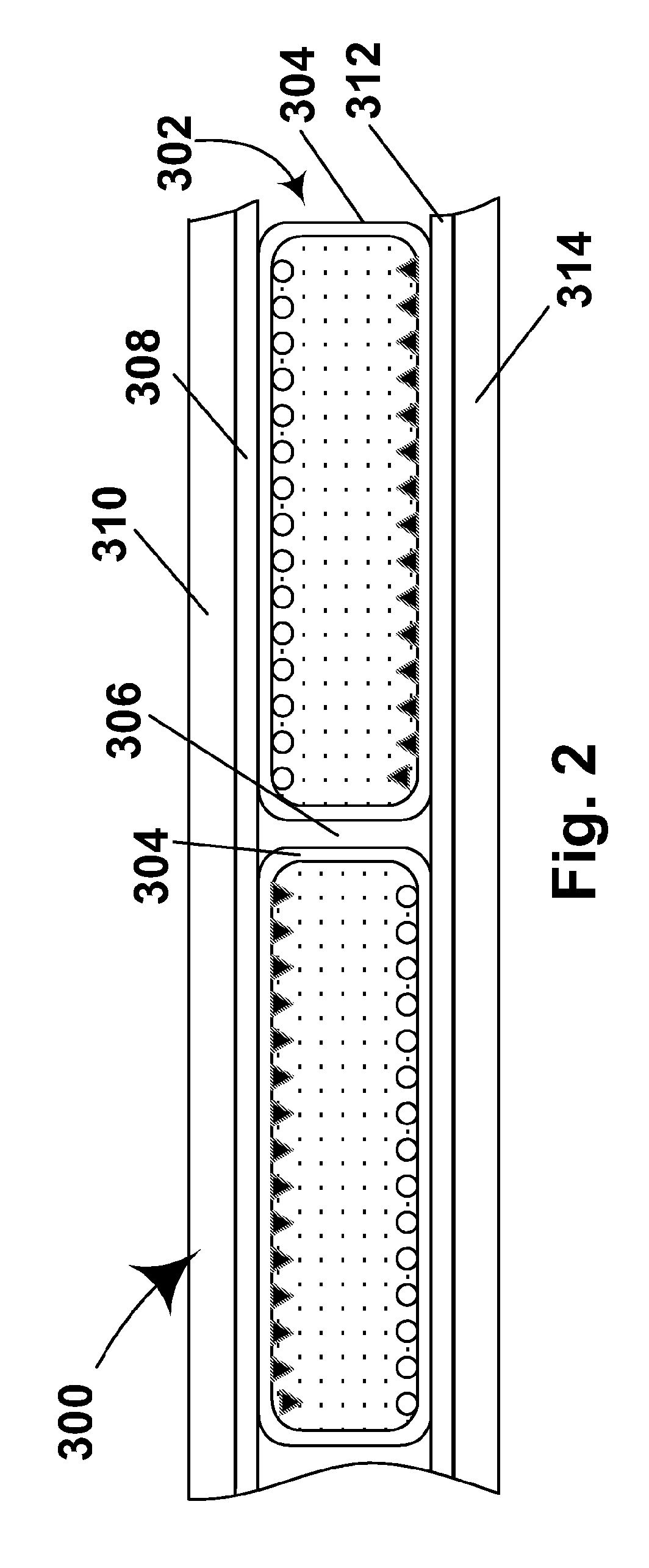

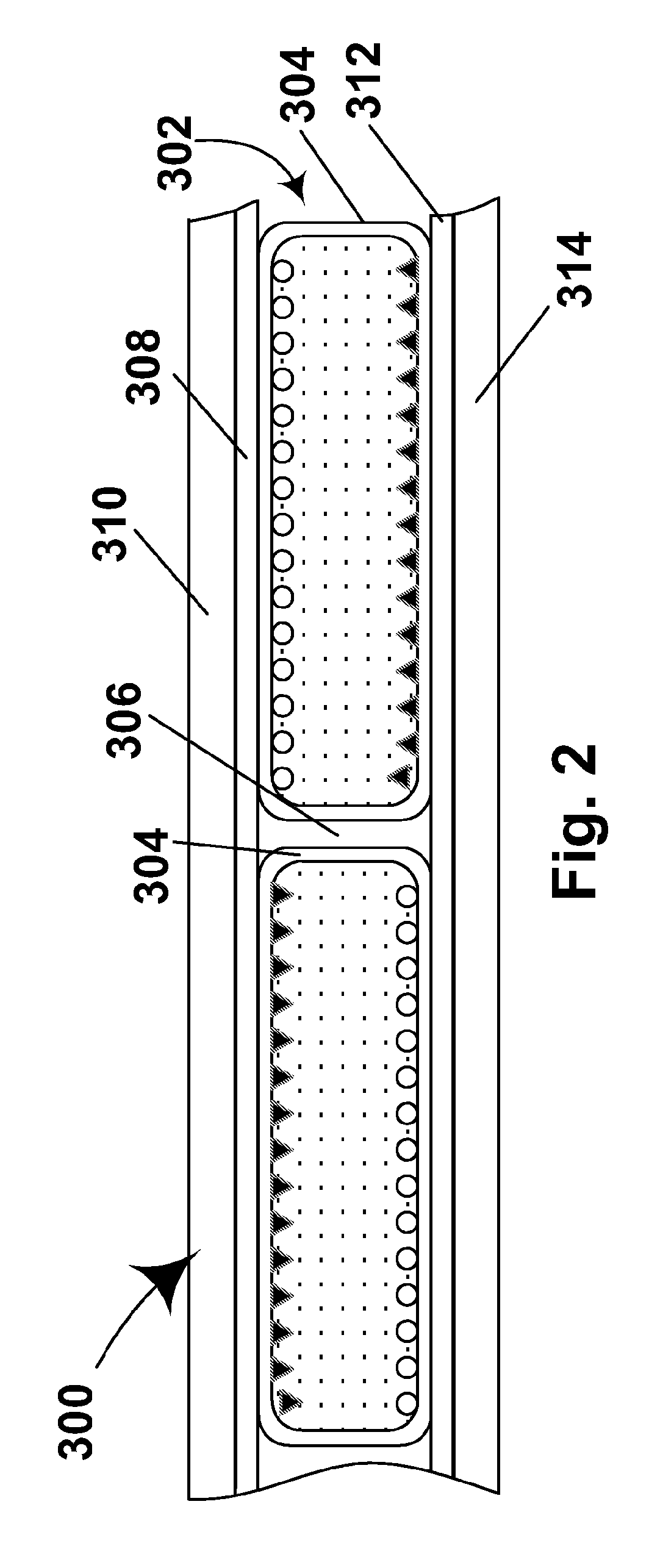

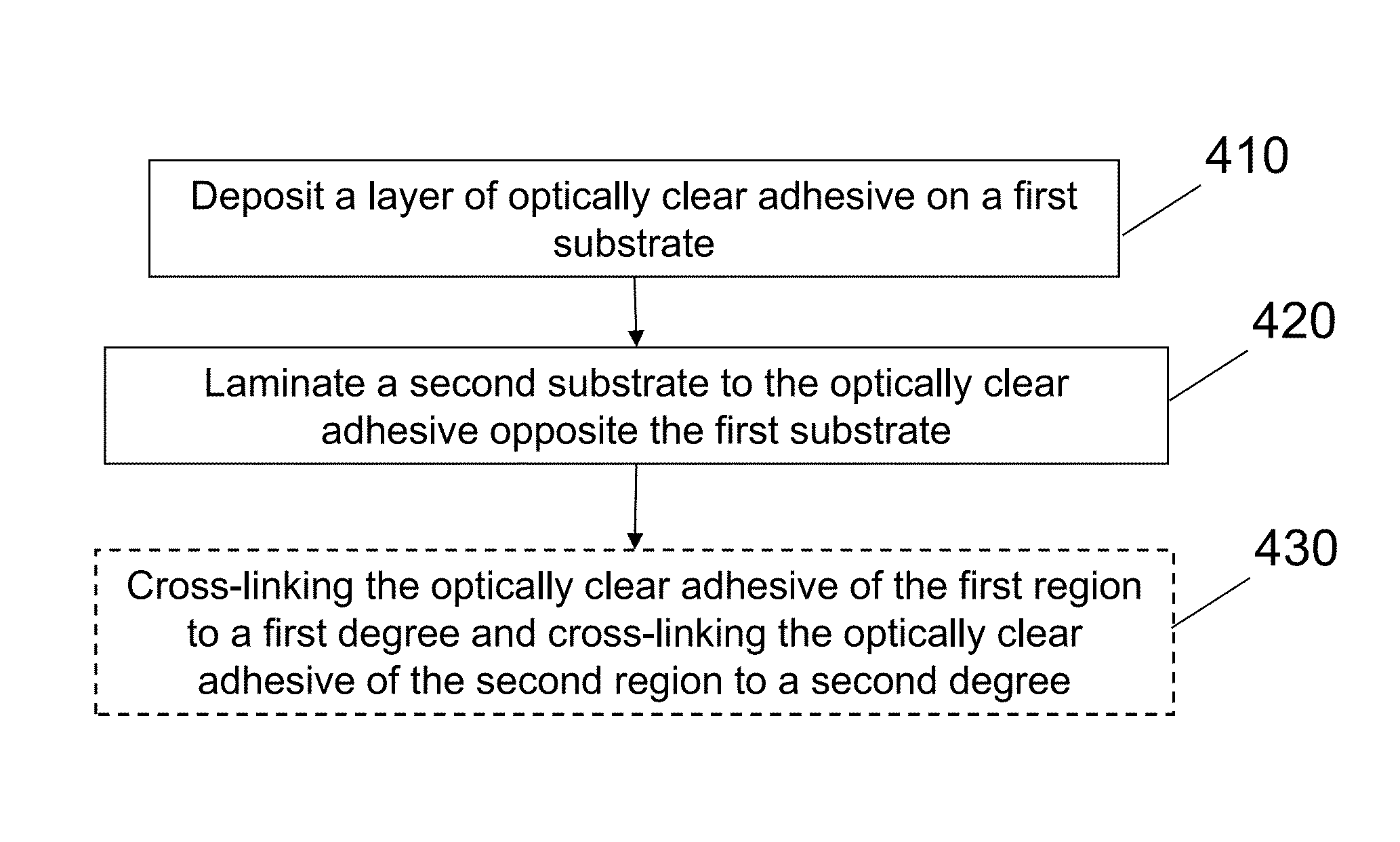

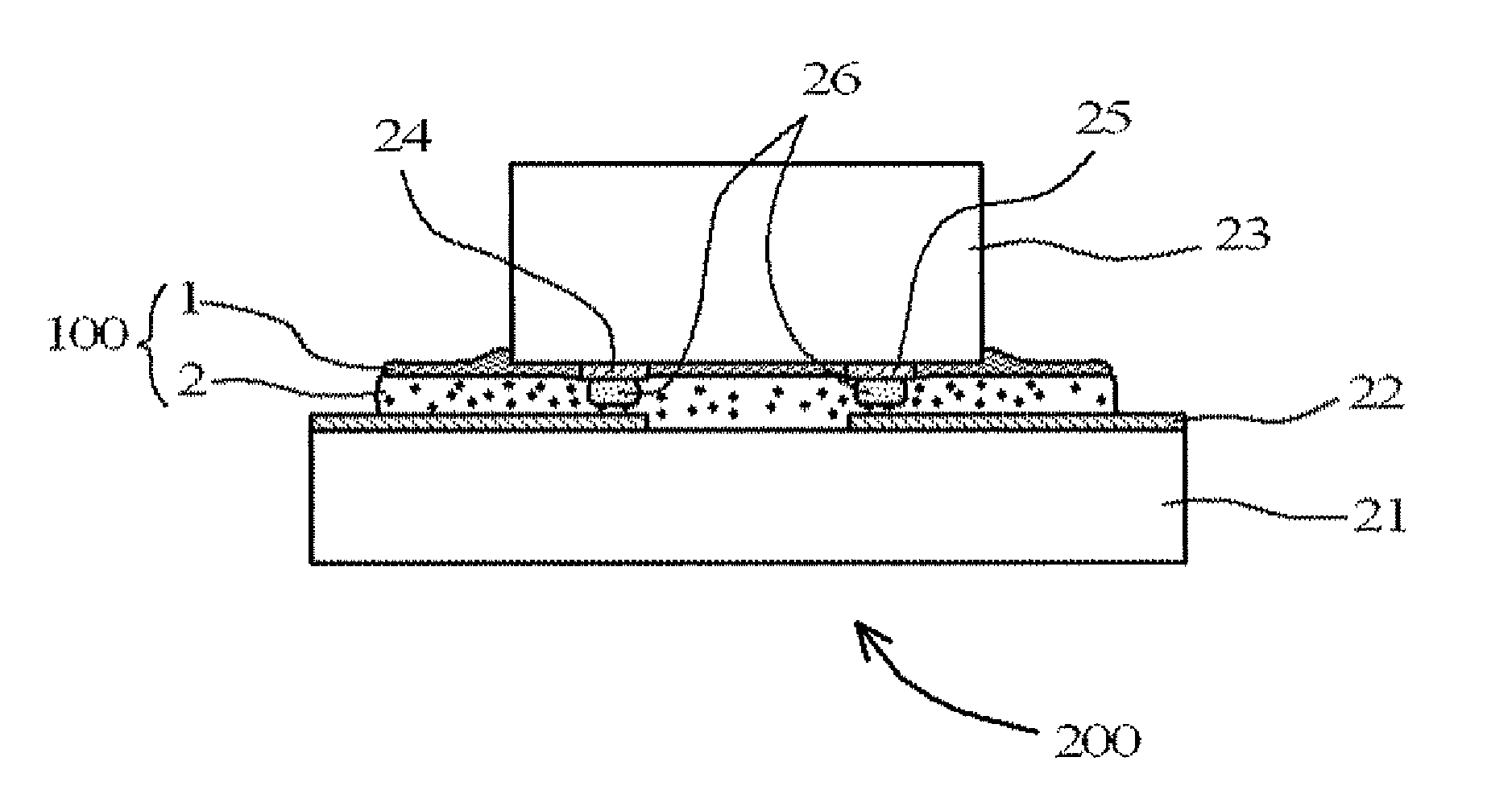

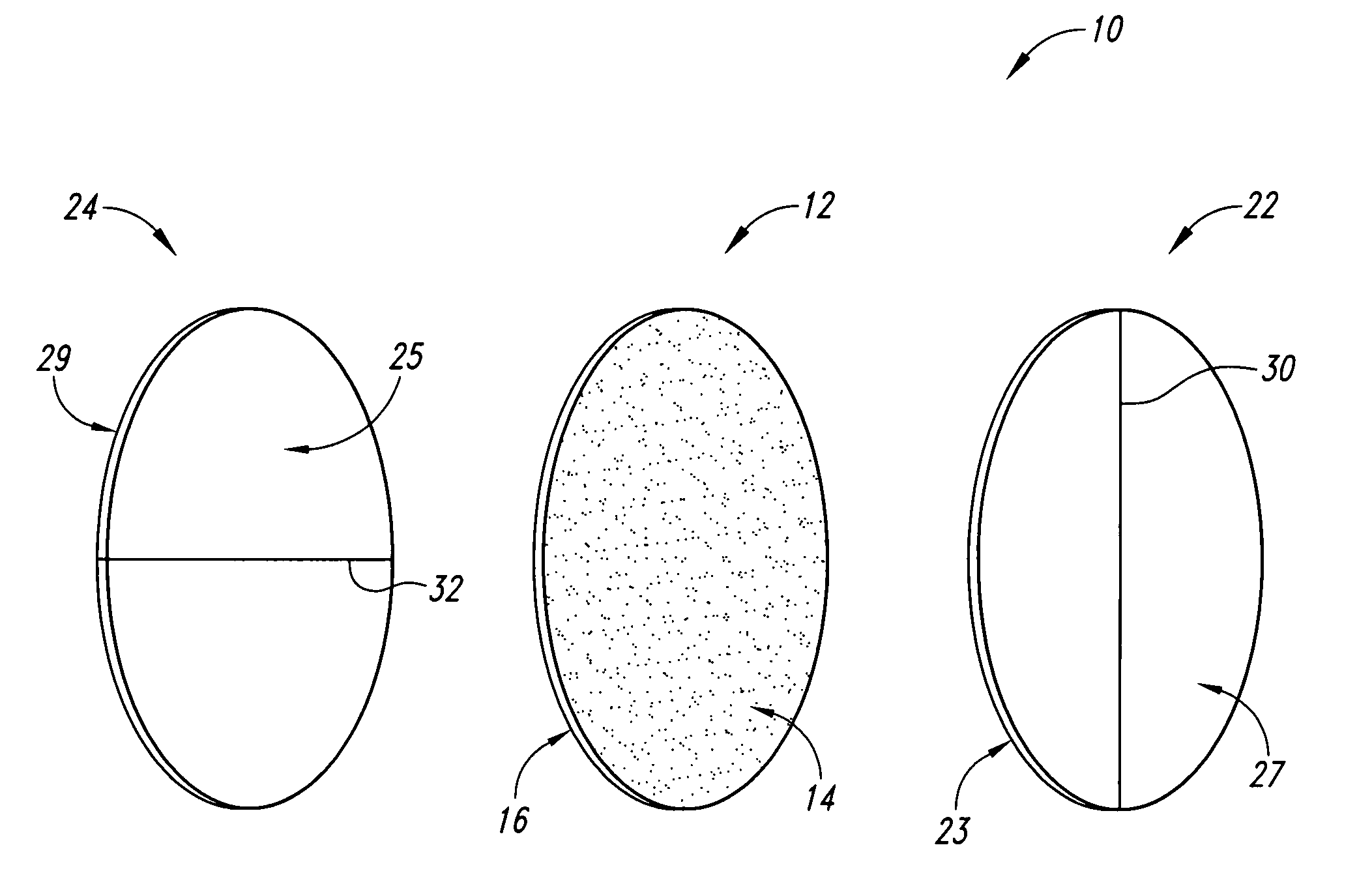

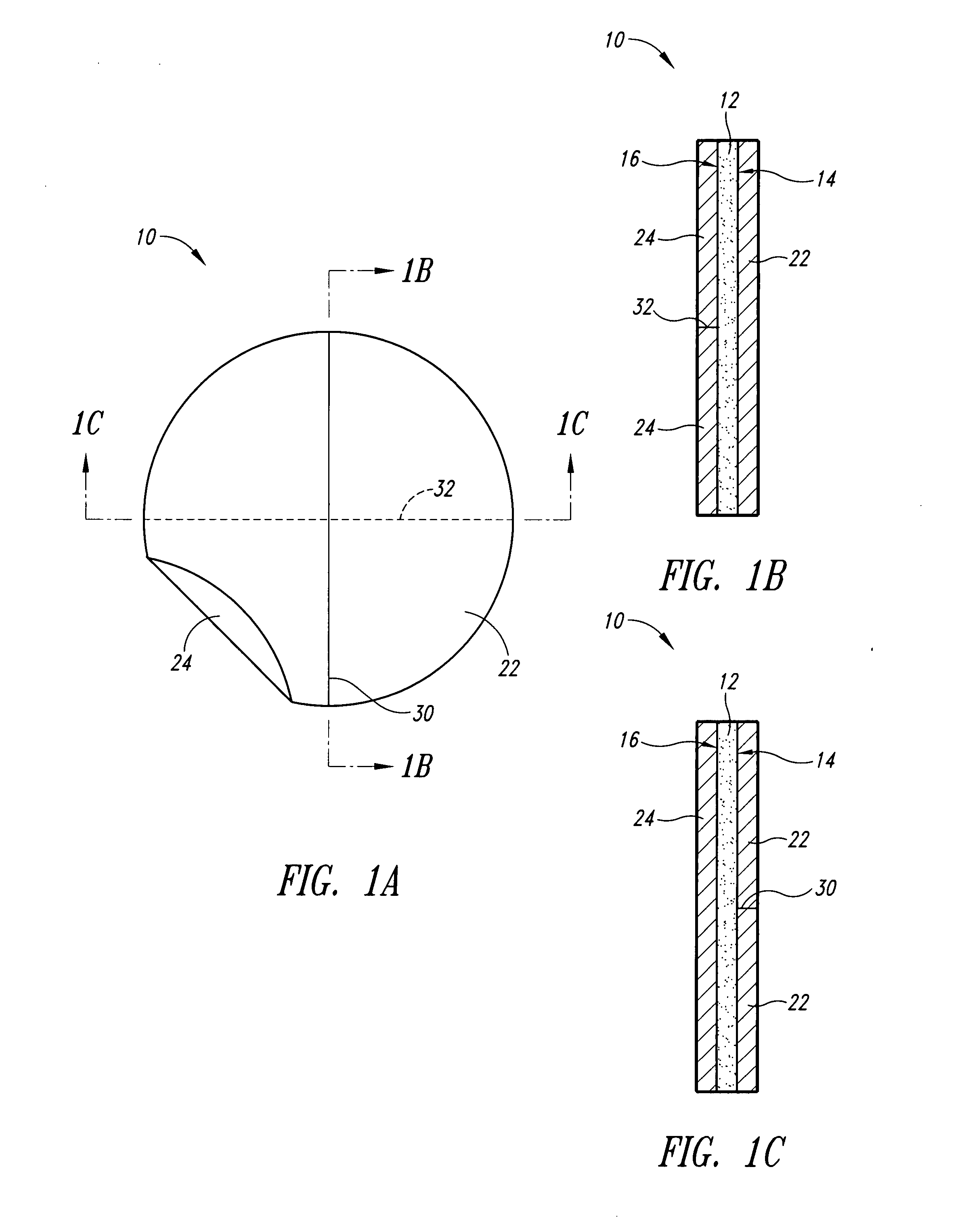

The present invention may relate to provision of a mechanism to join together the various substrate layers of a flexible display with optically clear adhesives that permit improved flexibility of the substrate layer stack and may also optically guide images to locations on a display surface that are not aligned with the display layer of a substrate layer stack. Embodiments of the present invention may provide for an improved user interface which may include enhanced flexibility and enhanced optical characteristics.

Owner:LYTEN INC

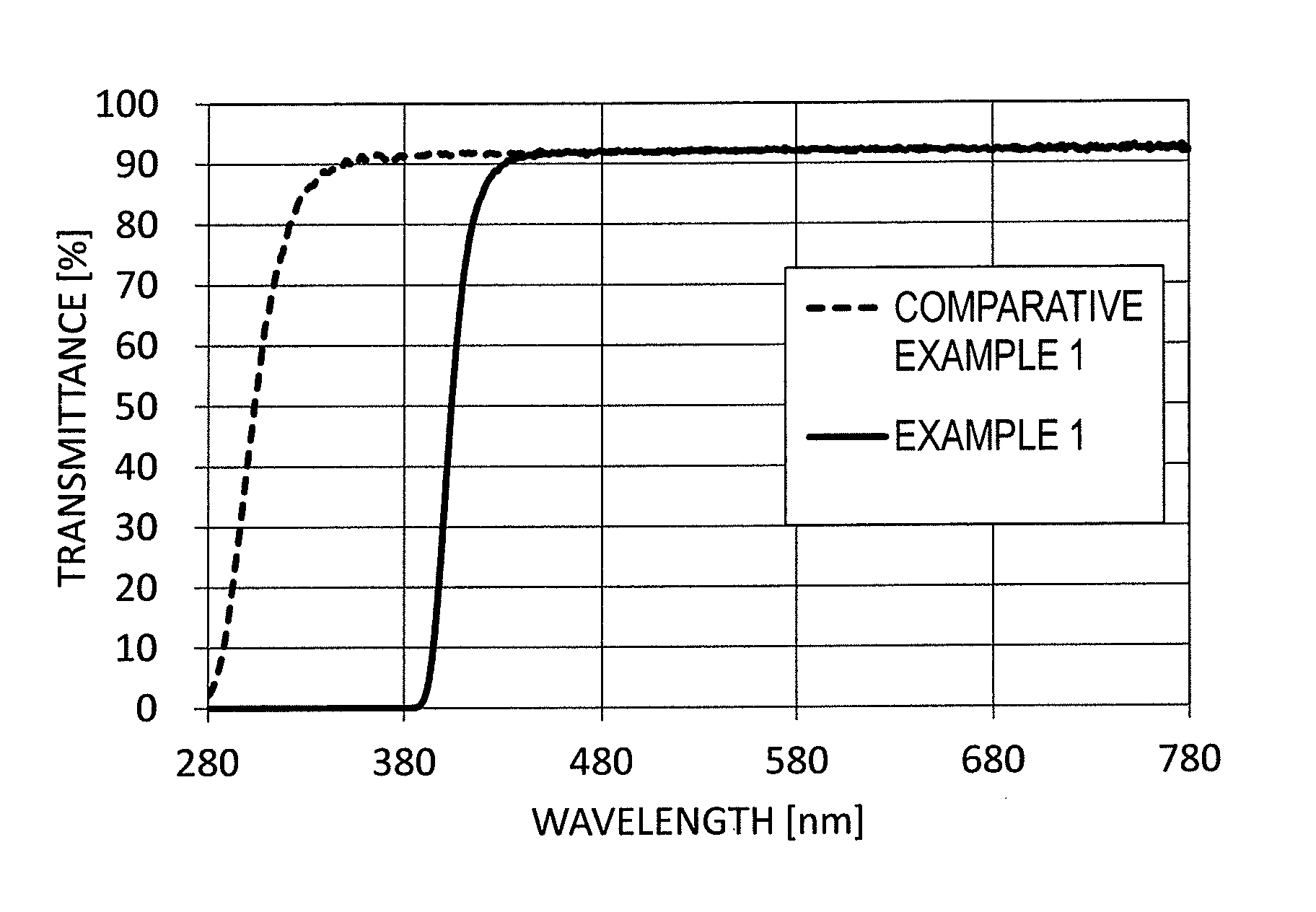

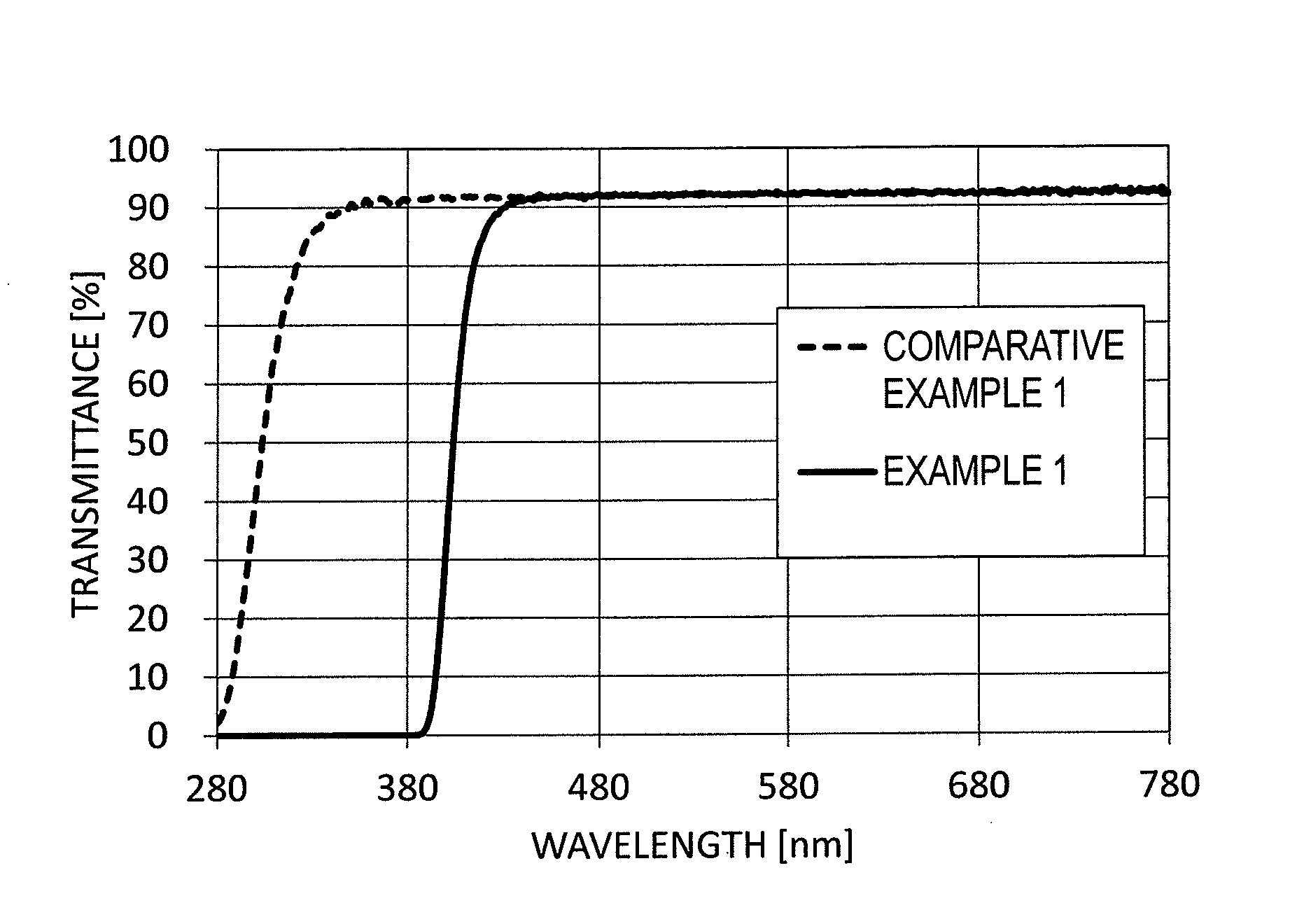

Pressure-sensitive adhesive sheet

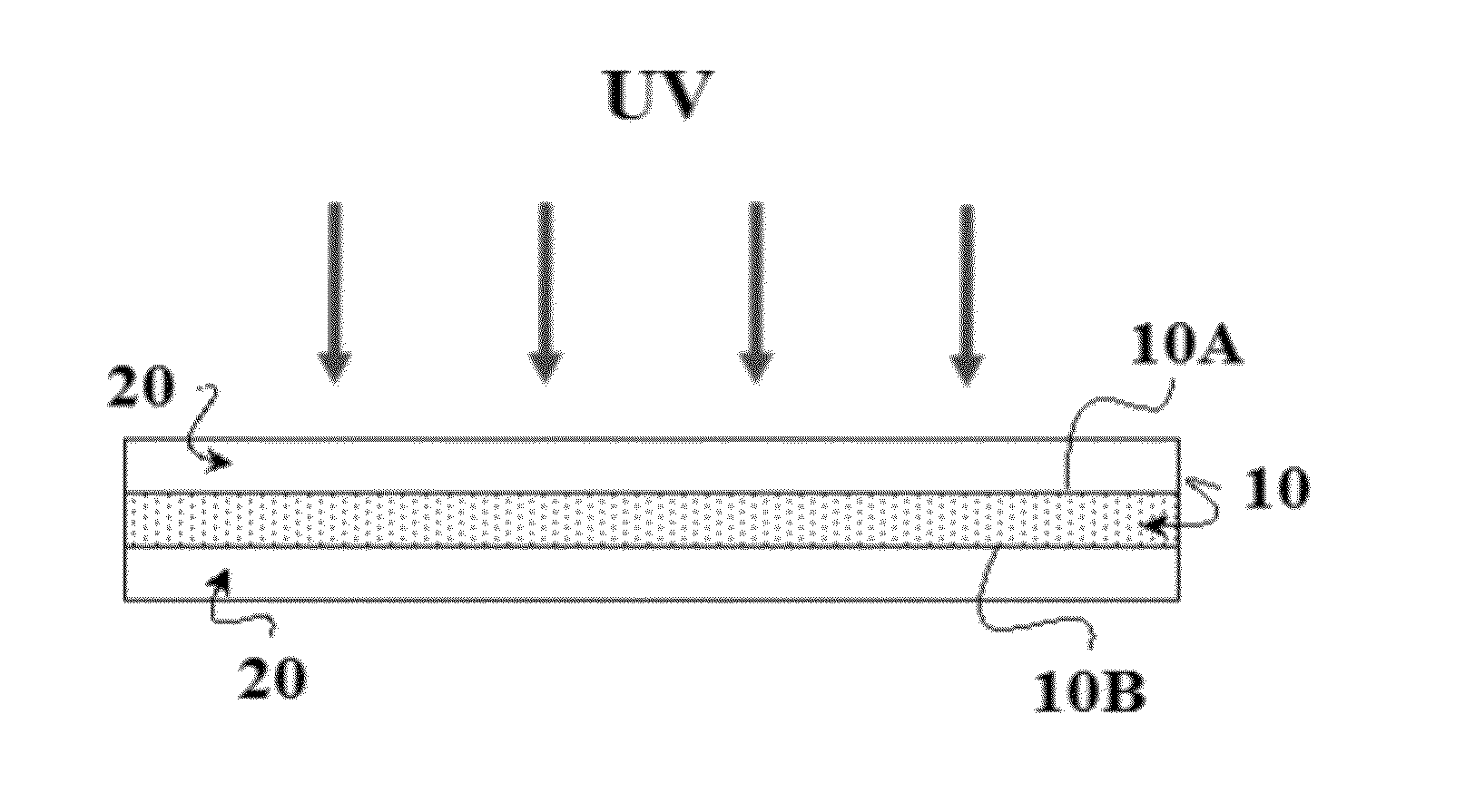

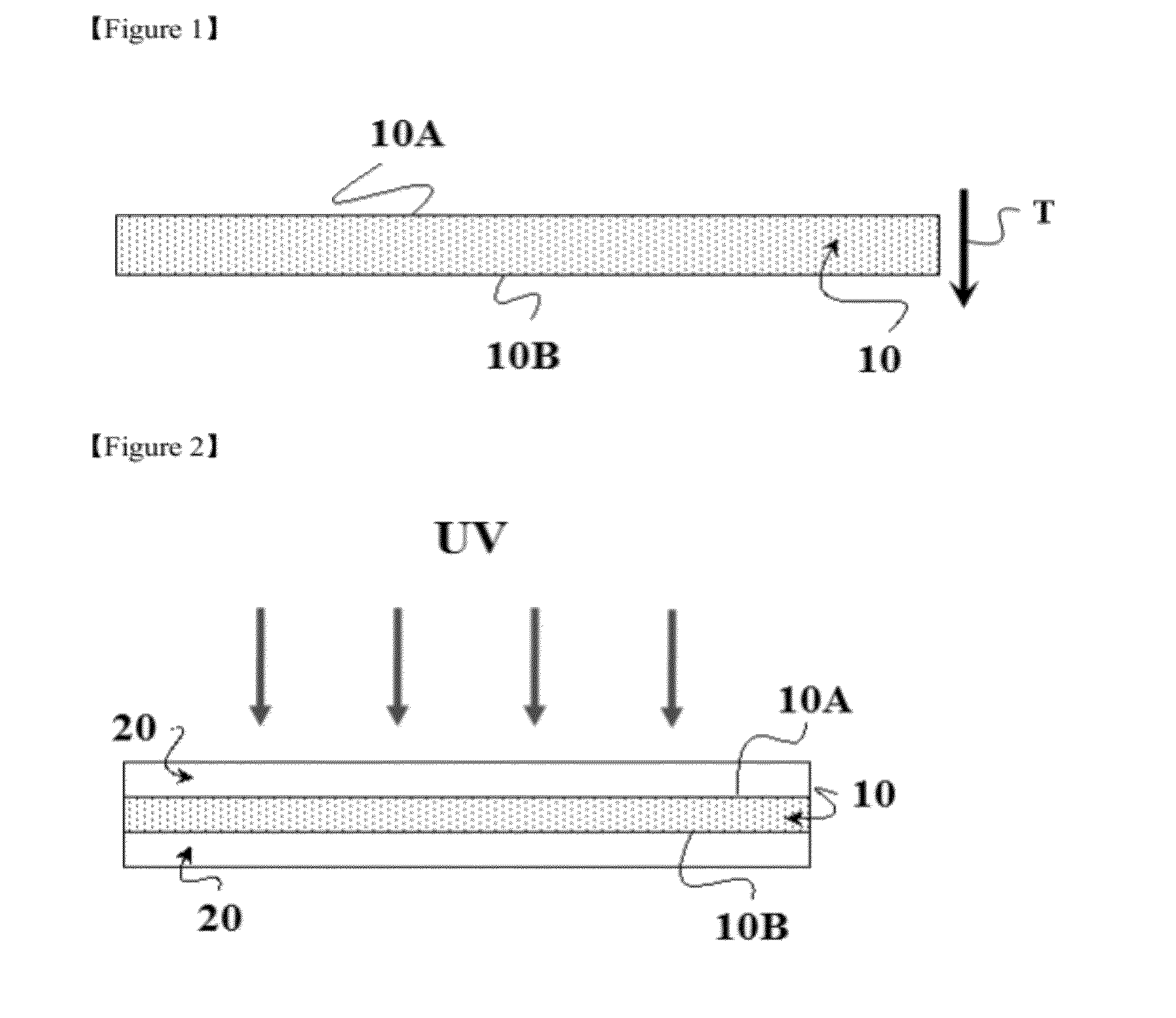

ActiveUS20130085215A1Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesEster polymer adhesivesDisplay deviceEngineering

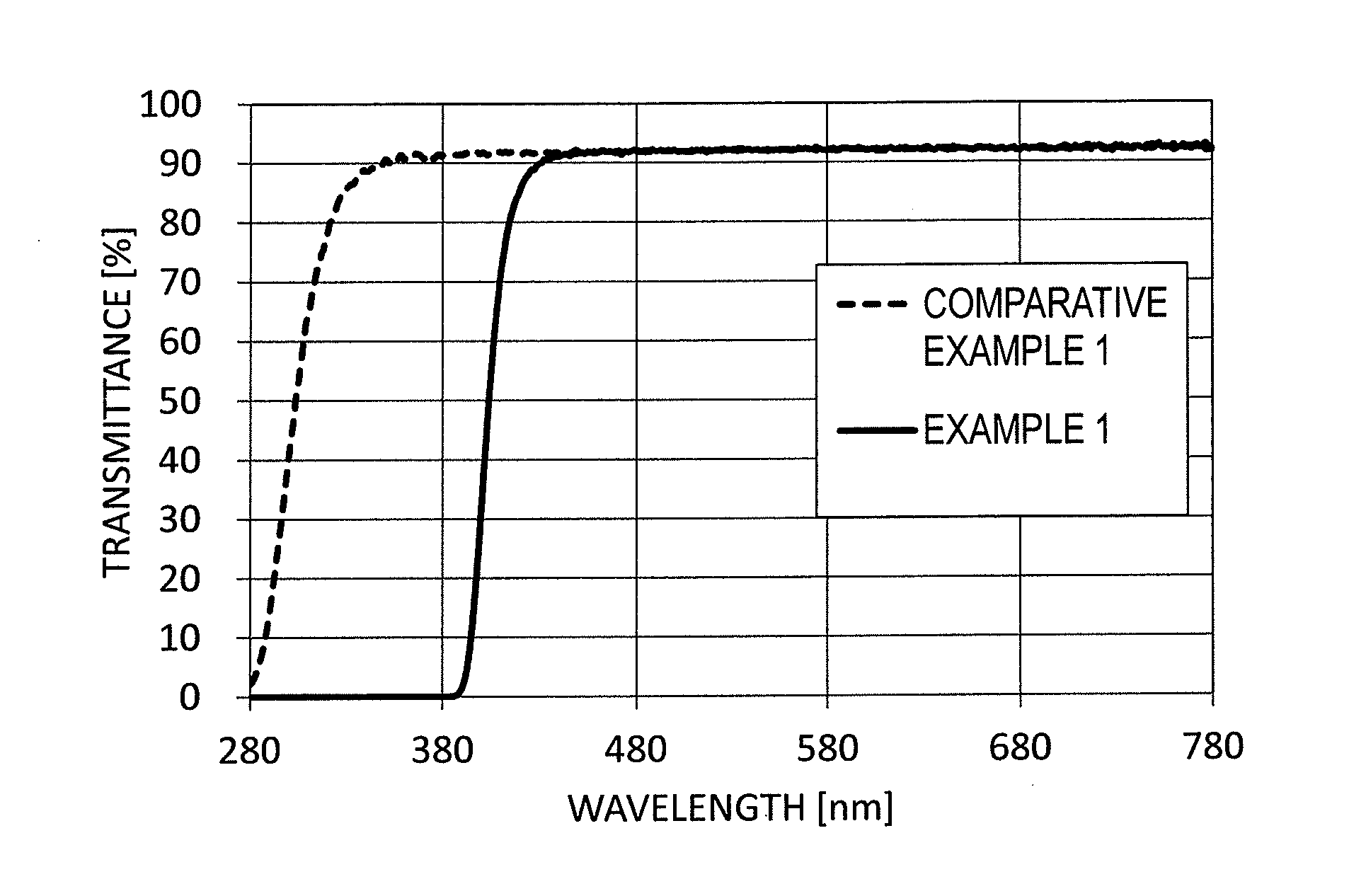

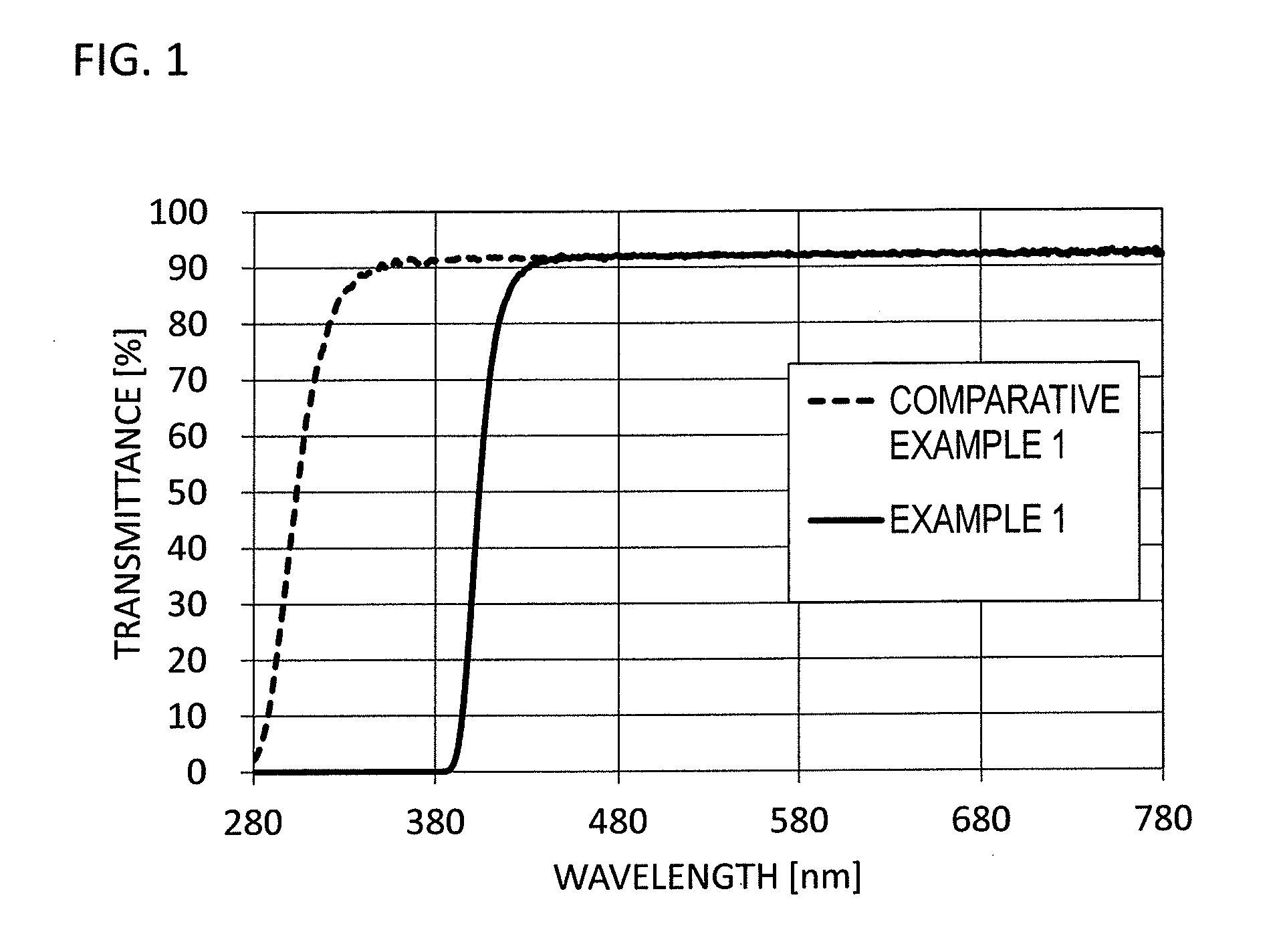

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Curing resin composition, adhesive epoxy resin paste, adhesive epoxy resin sheet, conductive connection paste, conductive connection sheet, and electronic component joined body

ActiveUS20060154078A1Adhesion reliability is highIncrease flexibilityNon-insulated conductorsSynthetic resin layered productsEpoxyHeat resistance

It is an object of the invention to provide a curable resin composition excellent in mechanical strength, heat resistance, moisture resistance, flexibility, resistance to thermal cycles, resistance to solder reflow, dimensional stability, and the like after curing and providing high adhesion reliability and conduction reliability and an adhesive epoxy resin paste, an adhesive epoxy resin sheet, a conductive connection paste, and a conductive connection sheet using the curable resin composition, and an electronic component joined body. The invention relates to a curable resin composition, which contains an epoxy resin, a solid polymer having a functional group to react with the epoxy group and a curing agent for an epoxy resin, no phase separation structure being observed in a matrix of a resin when a cured product is dyed with a heavy metal and observed with a transmission electron microscope.

Owner:SEKISUI CHEM CO LTD

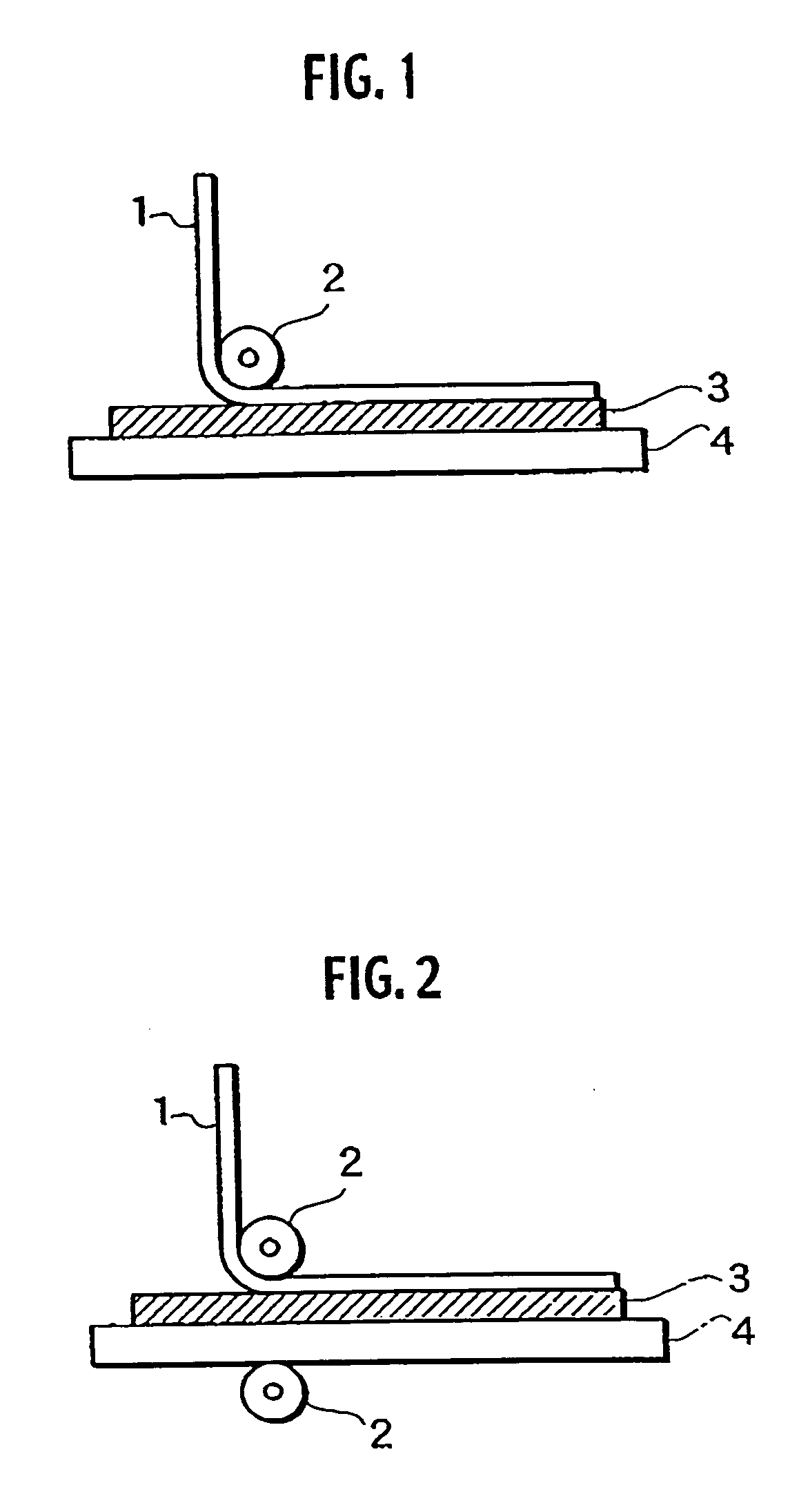

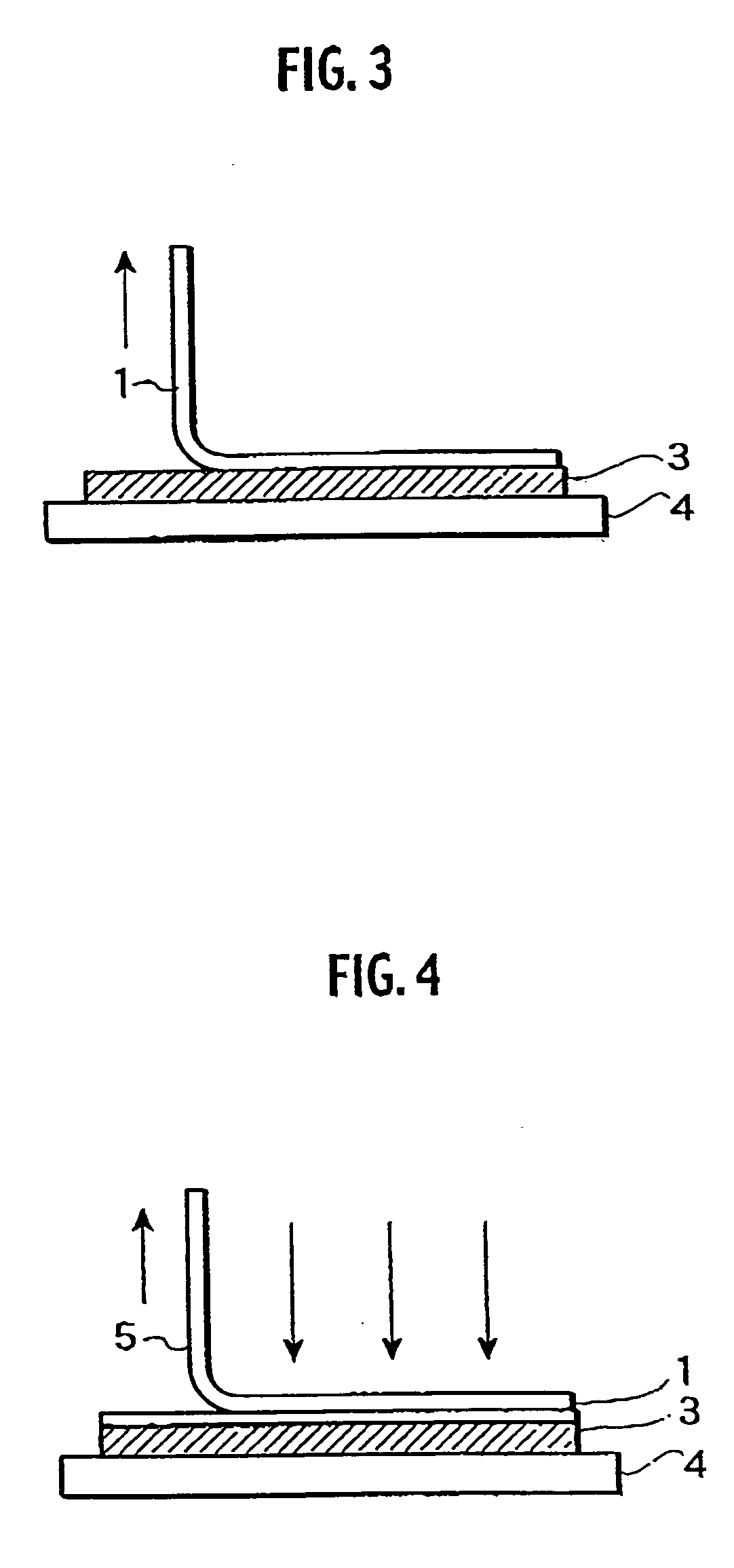

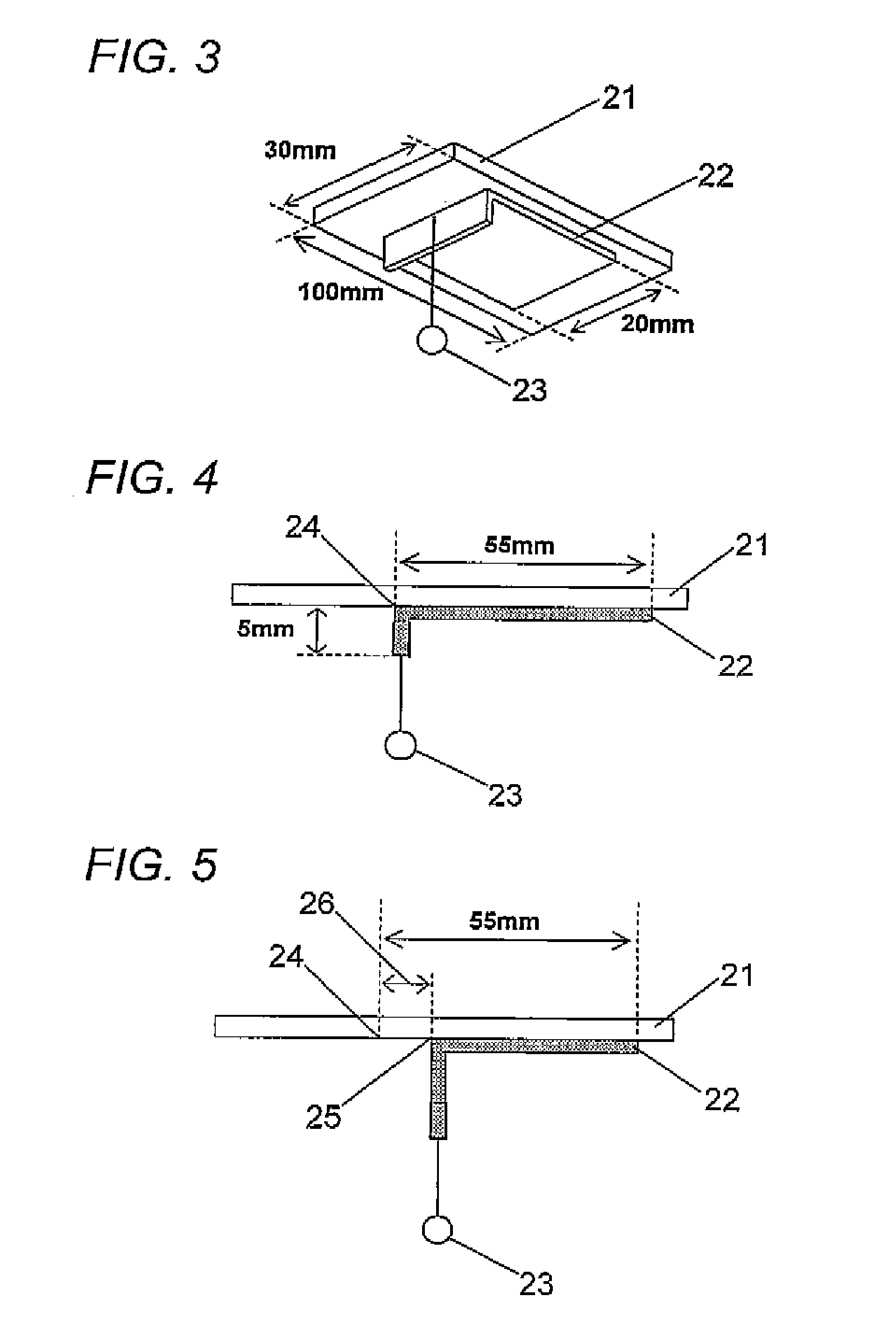

Process for the production of thinned wafer

InactiveUS20020127821A1Improve surface accuracyLittle warpingSolid-state devicesSemiconductor/solid-state device manufacturingWaferingHemt circuits

A process for the production of a thinned wafer, comprising bonding the circuit surface (surface A) of a semiconductor wafer (a) to a holding substrate (b) with an adhesive film (c), grinding and polishing the back surface (surface B) of the semiconductor wafer to thin the semiconductor wafer, carrying out the metallization of the back surface (surface B) and the like as required, and then separating the thinned wafer from the holding substrate (b), wherein a thermoplastic resin film is used as the adhesive film (c) and the above bonding of the circuit surface (surface A) of the semiconductor wafer (a) to the holding substrate (b) is carried out at a bonding temperature selected from the range of from +10.degree. C. to +120.degree. C. of glass transition point of the thermoplastic resin film or the range of from -40.degree. C. to +20.degree. C. of melting point of the thermoplastic resin film.

Owner:MITSUBISHI GAS CHEM CO INC

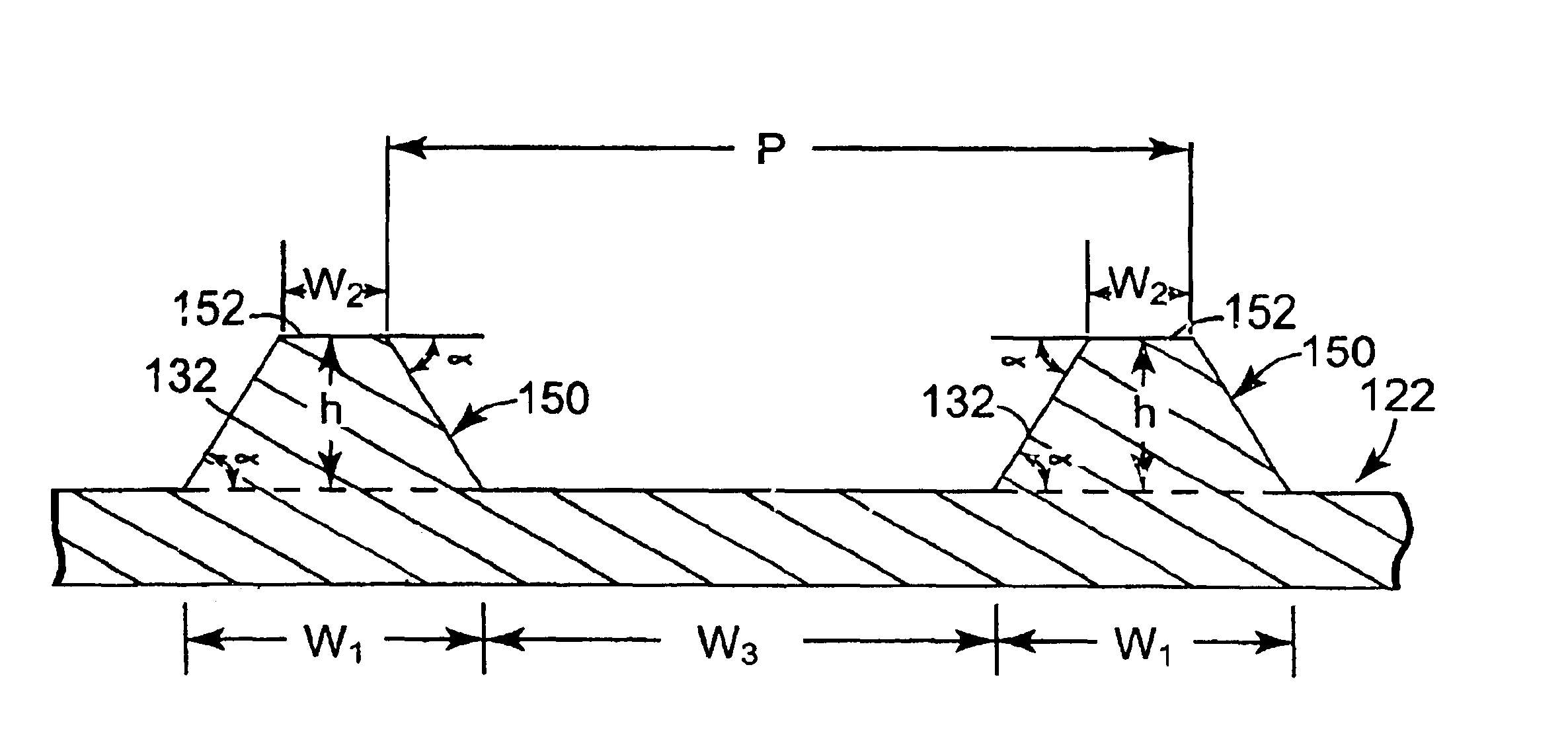

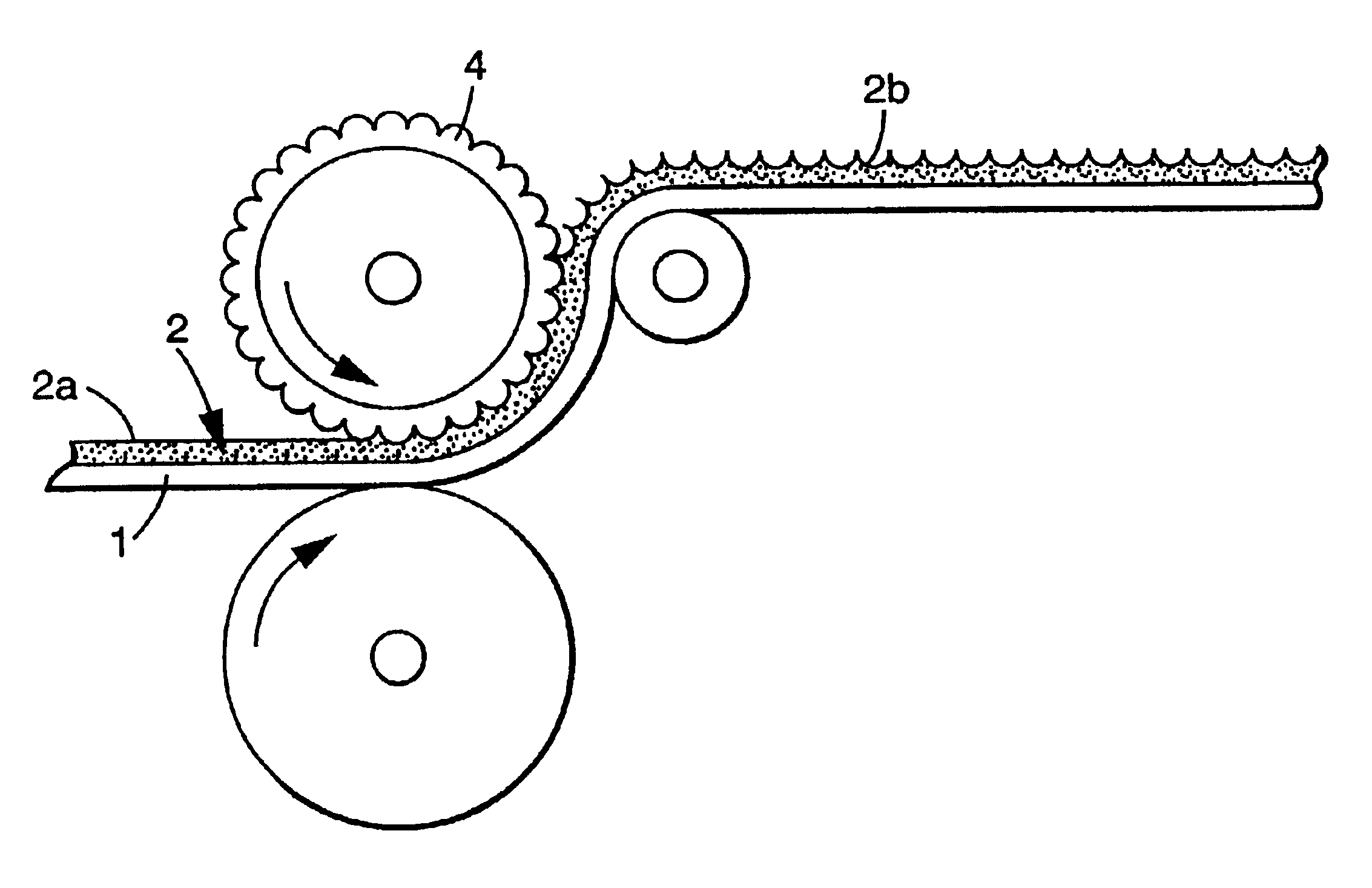

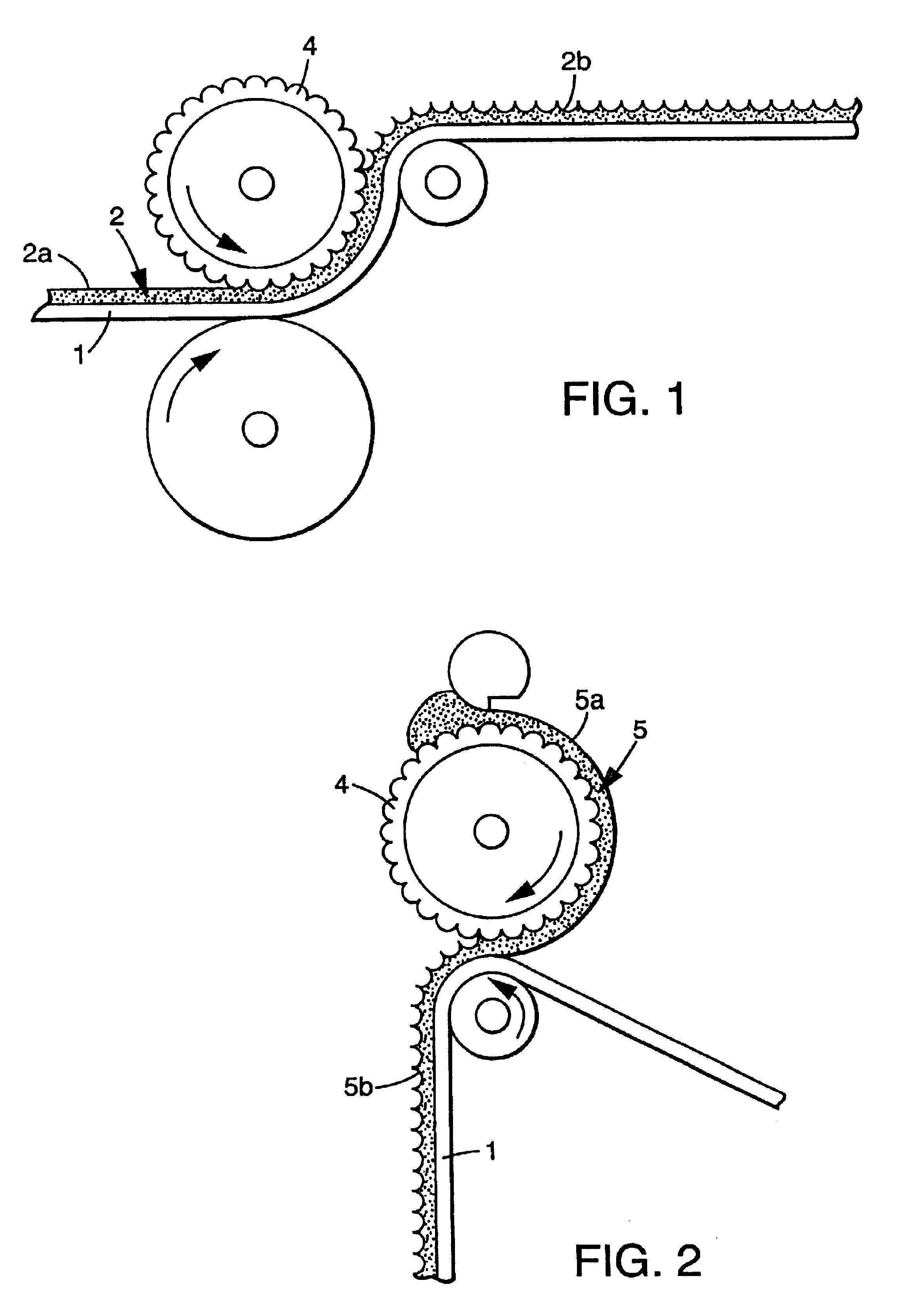

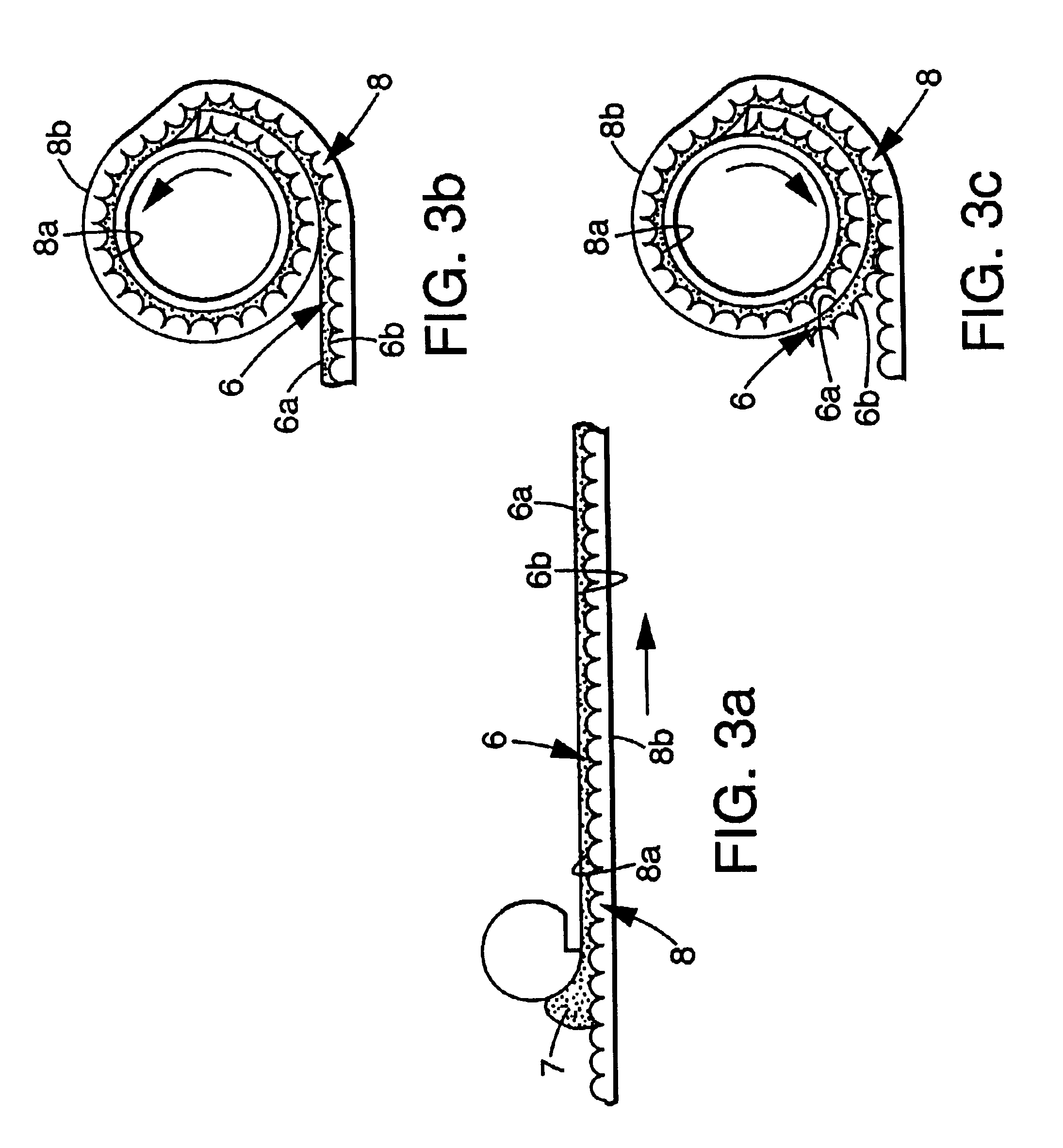

Cling films having a microreplicated topography and methods of making and using same

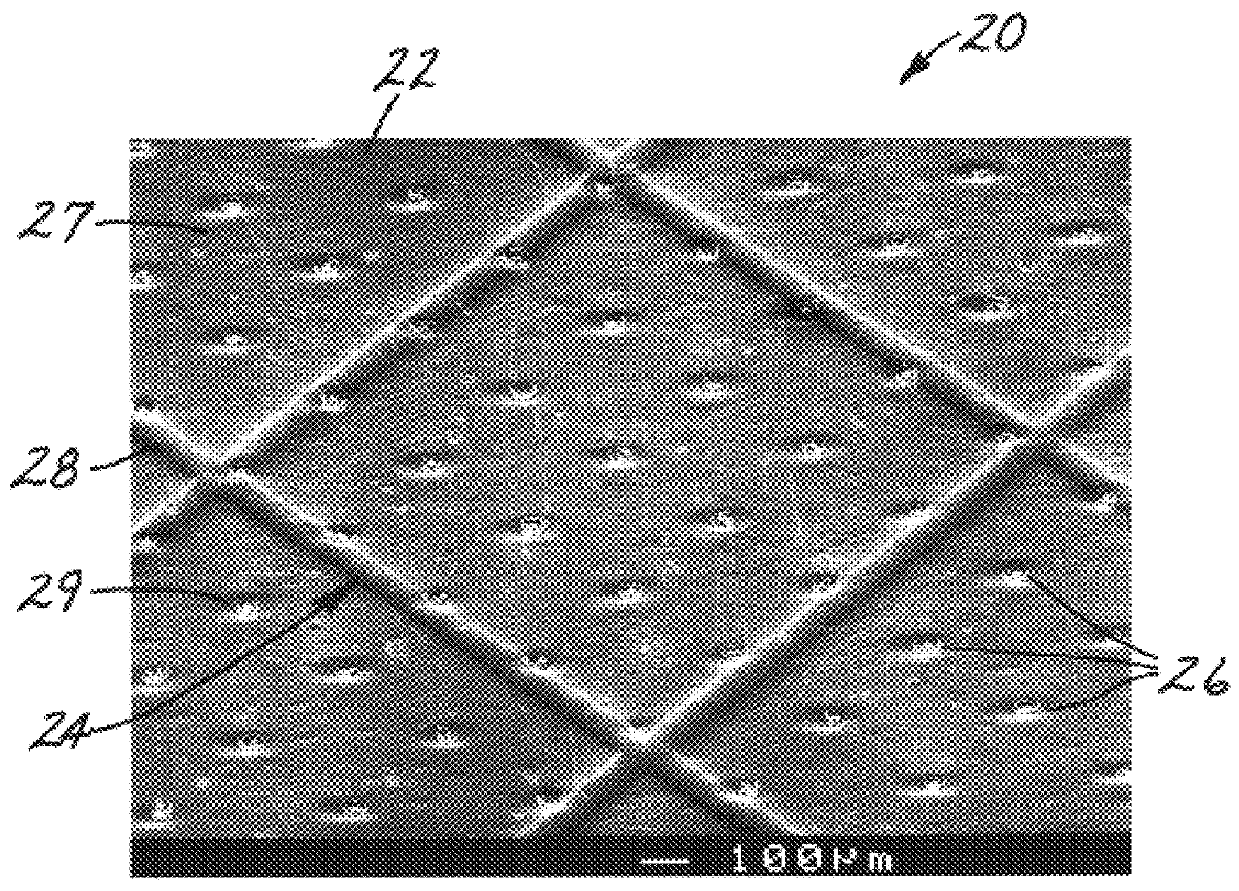

InactiveUS6203885B1Easy to disassembleChange surface propertiesAdditive manufacturing apparatusLayered productsTopographyElectrical and Electronics engineering

Films having a microreplicated topography are prepared from contacting a microembossed pattern to a layer of film. When an adhesion interface is established between the layer of film and a supporting substrate, the topography of the film surface controls the performance of the adhesion interface. Articles having microreplicated film surfaces are also disclosed that have an advantage of providing microchannels for fluid egress for an effective period of time. Multiple microembossed patterns produce microreplicated film surfaces having both microchannels for fluid egress and pegs for improved film properties.

Owner:3M INNOVATIVE PROPERTIES CO

Specular laminates

A pressure sensitive adhesive layer with a structured surface, wherein the adhesive layer is capable of being dry laminated to a substrate to form a laminate. The adhesive layer has a haze after lamination, measured according to ASTM D 1003-95, of less than about 50% of the haze of the adhesive layer before lamination. After dry lamination, the adhesive layer has a luminous transmittance of more than about 85%, a haze of less than about 25%, and an opacity of less than about 3%.

Owner:3M INNOVATIVE PROPERTIES CO

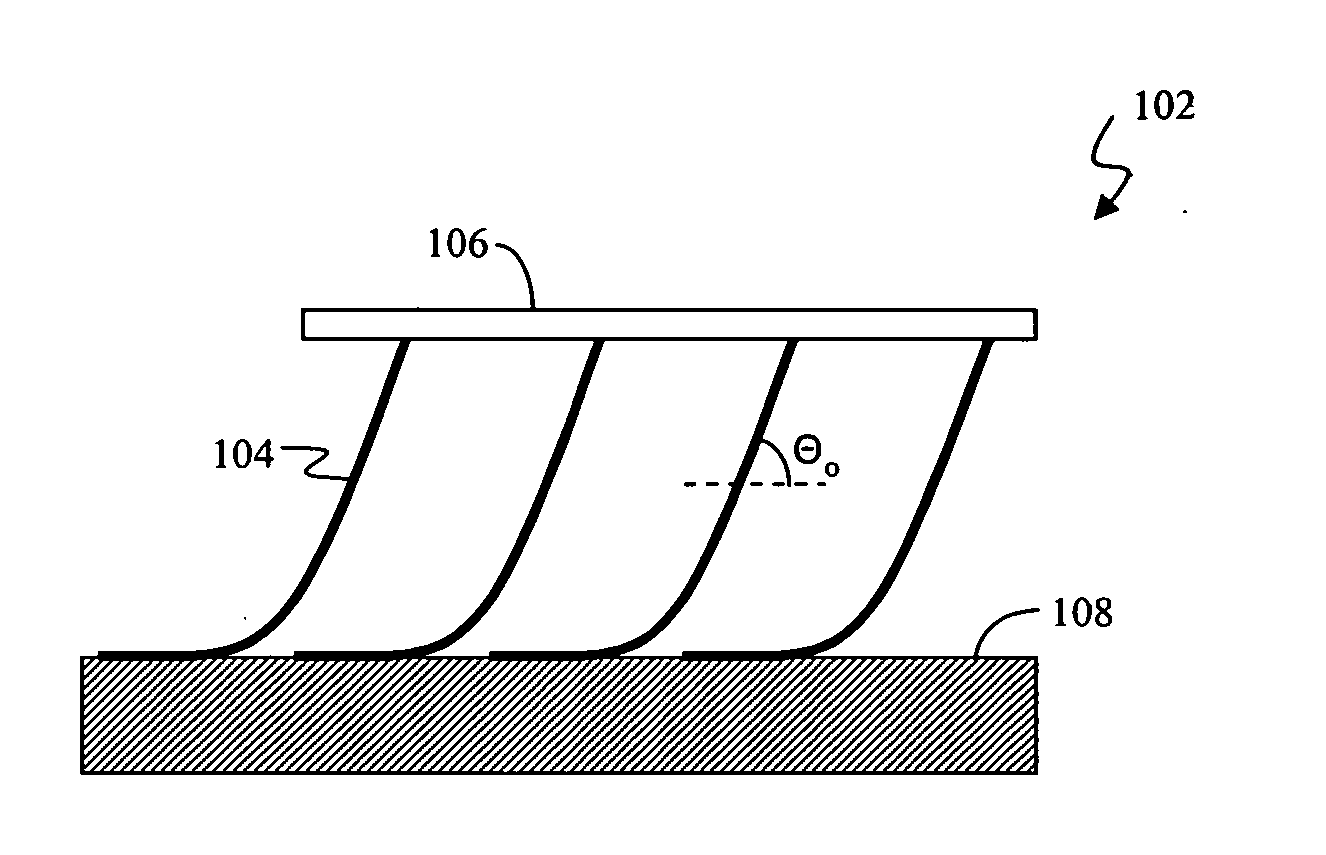

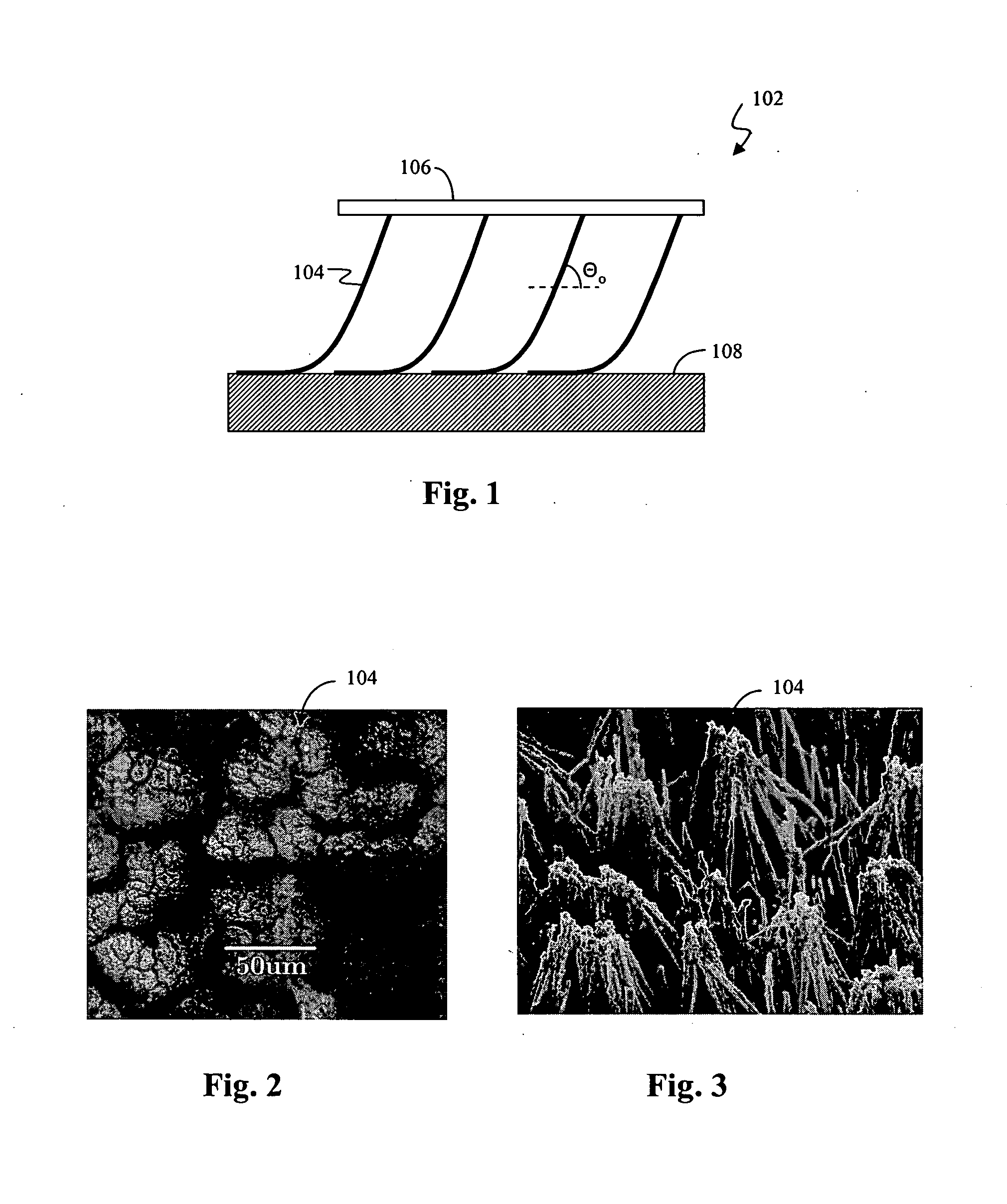

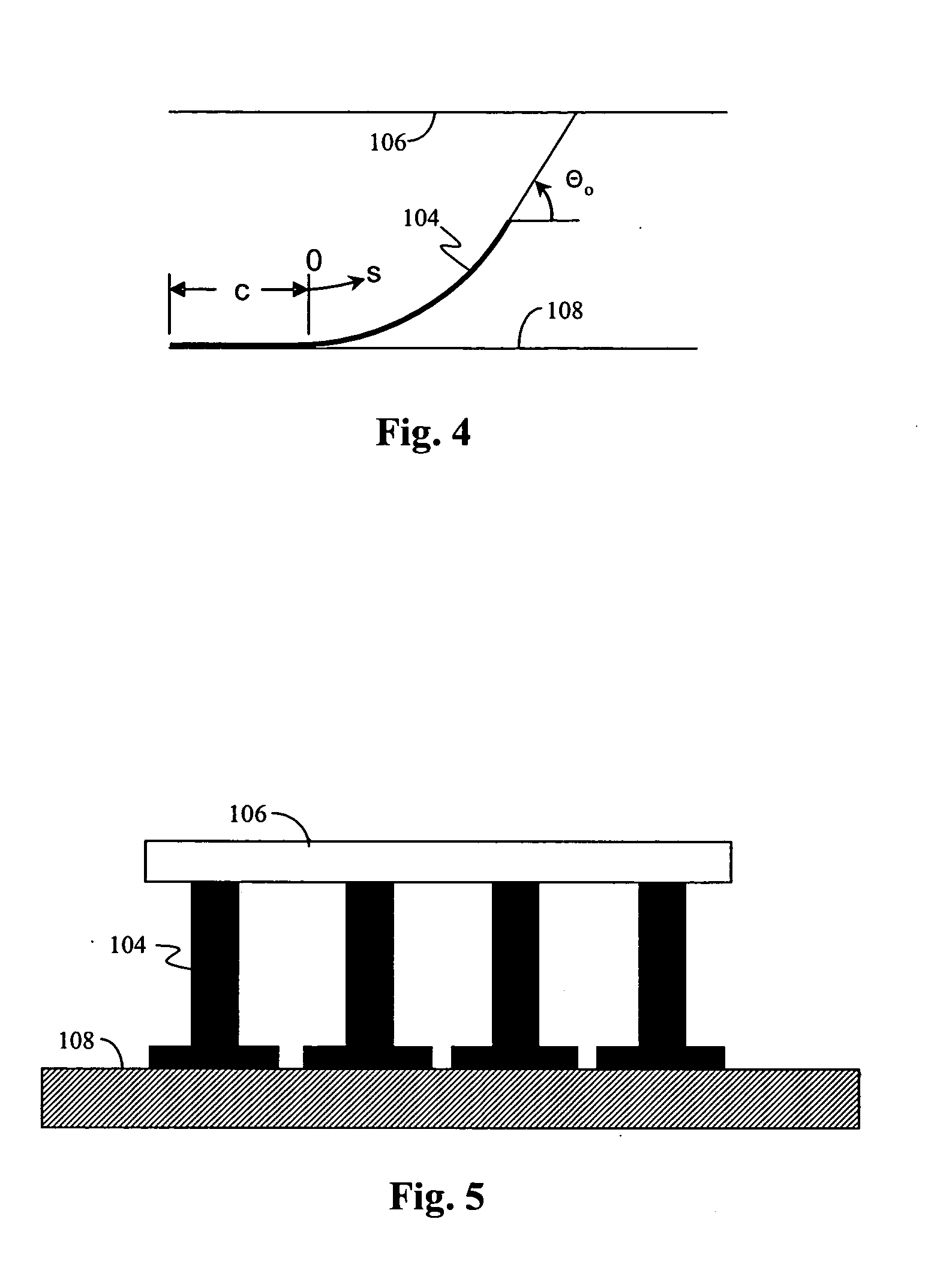

Nanostructured friction enhancement using fabricated microstructure

Described herein are fabricated microstructures to adhere in shear to a contact surface. A fabricated microstructure comprises a substrate and a plurality of nano-fibers attached to the substrate. The nano-fibers have an elasticity modulus E, an interfacial energy per unit length of contact w, a length L, a radius R, and are oriented at an angle θo relative to the substrate. The length L of the nano-fibers is greater than 0.627θo R2(E / w)1 / 2 with θo in radians. Also described herein is a method of forming a fabricated microstructure to adhere in shear to a contact surface and a method of adhering in shear a fabricated microstructure to a contact surface.

Owner:RGT UNIV OF CALIFORNIA

Pressure-sensitive adhesive sheet

ActiveUS9045670B2Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesSynthetic resin layered productsDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Adhesive layer composition for in-mold decoration

InactiveUS20060019088A1Efficient disseminationSpread the wordNon-macromolecular adhesive additivesLayered productsChemistry

This invention relates to compositions suitable for the formation of an adhesive layer used for in-mold decoration.

Owner:WANG XIAOJIA +4

Pressure-sensitive adhesives having microstructured surfaces

InactiveUS6838150B2Reduced constantReduce adhesionAdhesive articlesRecord information storagePressure sensitiveChemistry

The invention provides pressure-sensitive adhesive (PSA) coated articles, including tapes and transfer coatings, having microstructured surfaces and methods of making pressure-sensitive adhesive articles bearing such microstructured surfaces. The performance properties of the pressure-sensitive adhesive articles can be tailored by independently varying the microstructure and the rheological properties of the pressure-sensitive adhesive.

Owner:3M INNOVATIVE PROPERTIES CO

Pressure-sensitive adhesive sheet for optical use

InactiveUS20120094037A1Not adversely affectAvoid misuseLiquid crystal compositionsEster polymer adhesivesCapacitanceDielectric loss

Provided is a pressure-sensitive adhesive sheet for optical use which less suffers from a misoperation-causing change in capacitance upon application to an optical member.The pressure-sensitive adhesive sheet for optical use includes a pressure-sensitive adhesive layer and has a dielectric constant of from 2 to 8 at a frequency of 1 MHz and a dielectric loss tangent of more than 0 and 0.2 or less at a frequency of 1 MHz. The pressure-sensitive adhesive sheet for optical use preferably has a dielectric constant at a frequency of 1.0×106 Hz being 60% or more of that at a frequency of 1.0×104 Hz. In addition, the pressure-sensitive adhesive sheet for optical use preferably has an absolute value of difference between the dielectric loss tangent at a frequency of 1.0×106 Hz and that at a frequency of 1.0×104 Hz of 0.15 or less.

Owner:NITTO DENKO CORP

Adhesive film for circuit connection, and circuit connection structure

InactiveUS20050151271A1Excellent connection processabilityImprove productivityNon-insulated conductorsCeilingsElectricityEngineering

The present invention provides an adhesive film for circuit connection which is to be interposed between circuit electrodes facing each other and used for electrically connecting the circuit electrodes to each other, which comprises a curing agent to generate free radicals with heating, a radically polymerizable substance, and a film-forming polymer, and in which a temporary fixing power to a flexible substrate having the circuit electrode is 40-180 N / m.

Owner:HITACHI CHEM CO LTD

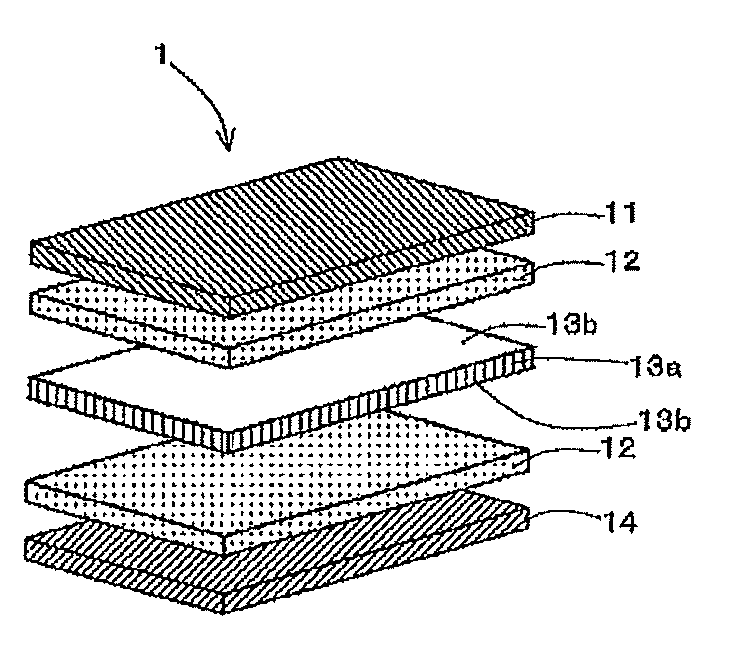

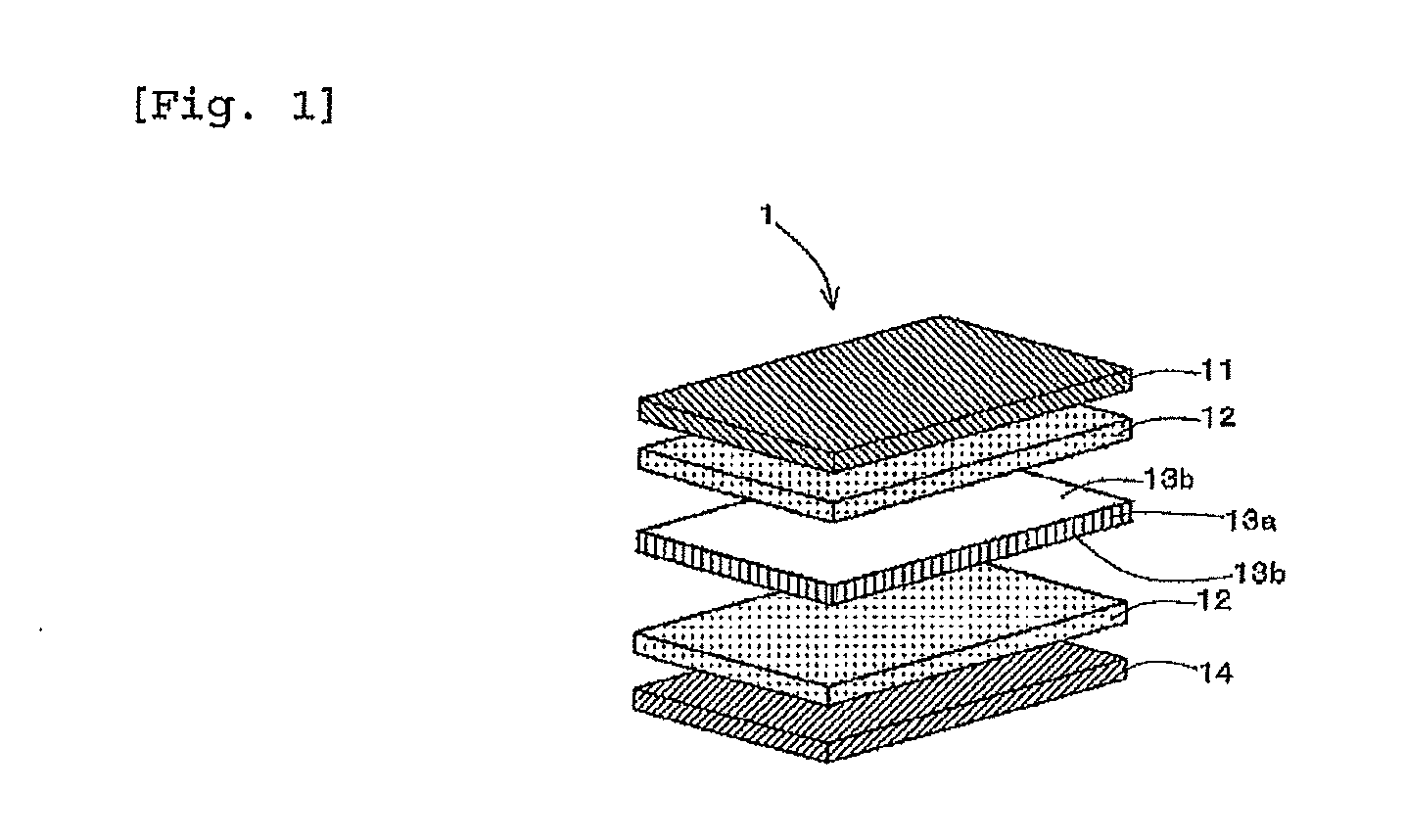

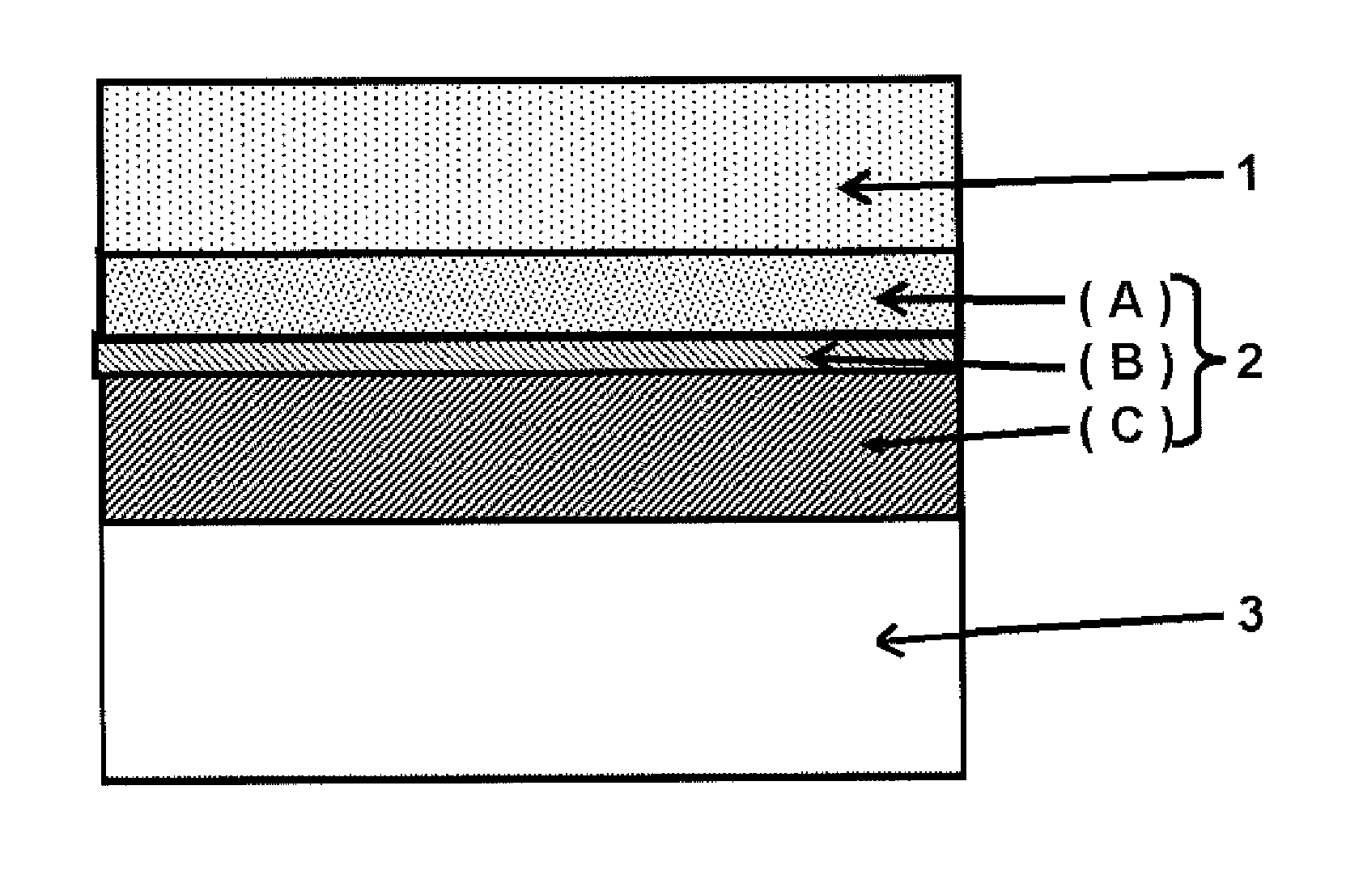

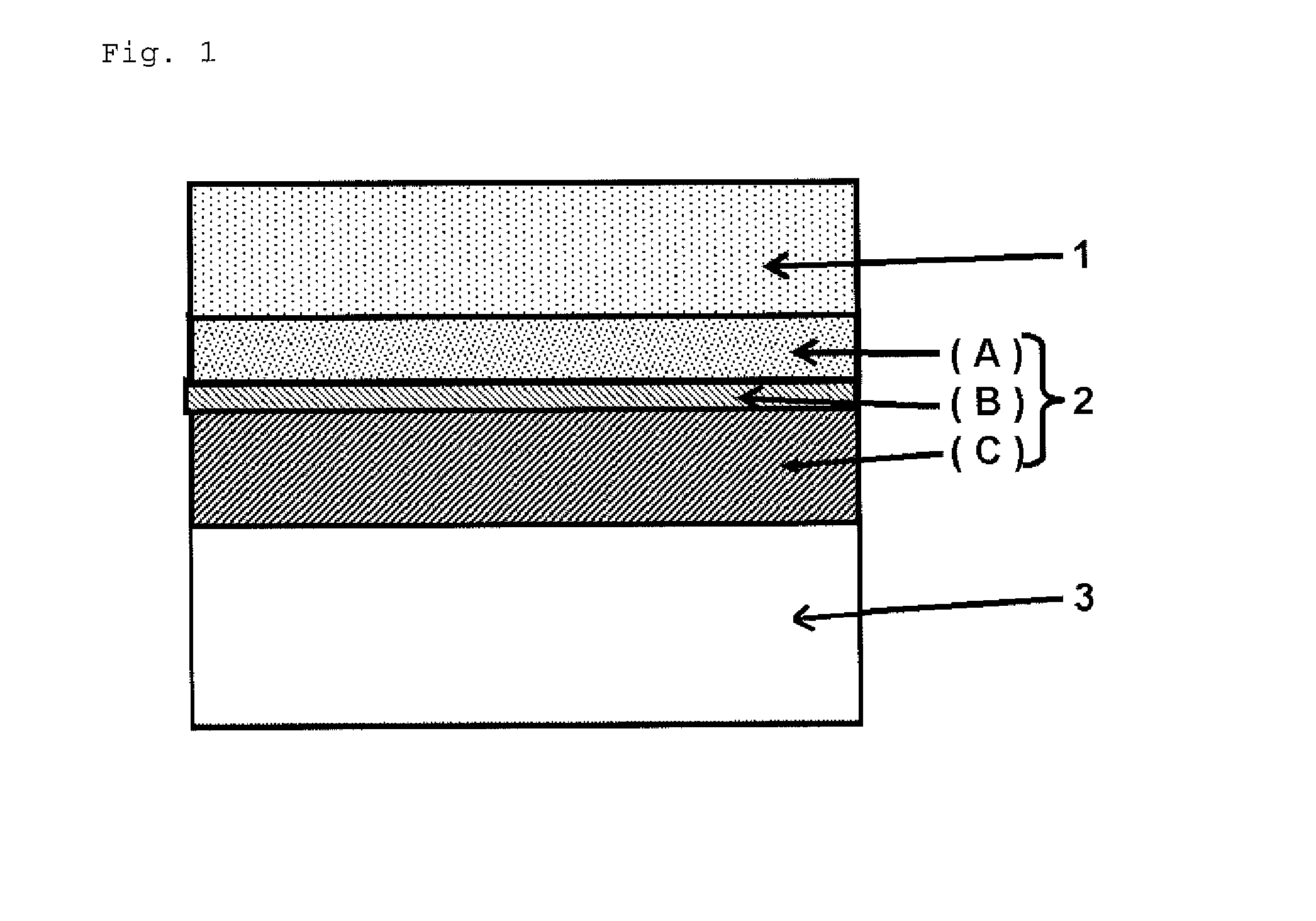

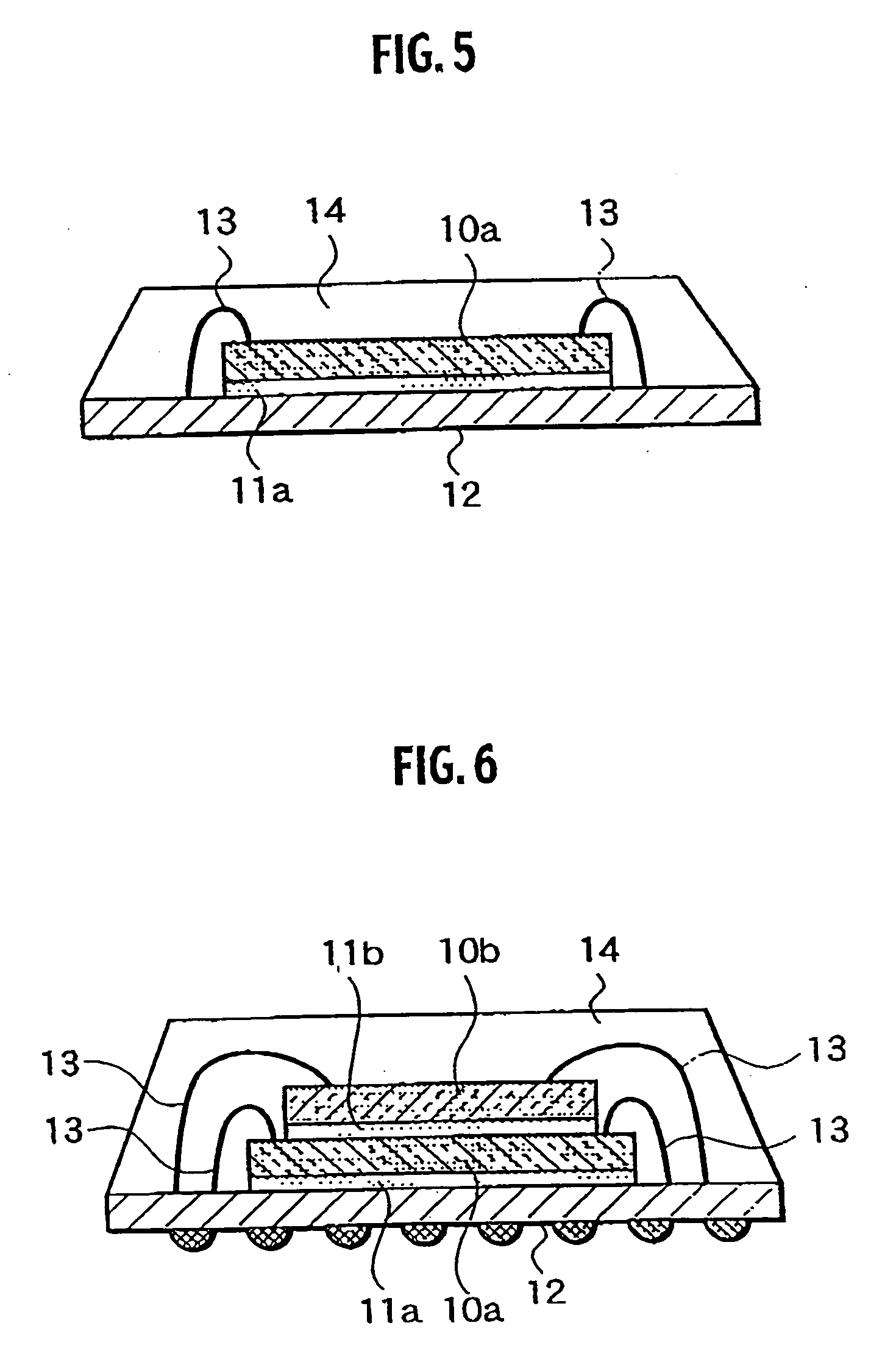

Wafer processing laminate, wafer processing member, temporary adhering material for processing wafer, and manufacturing method of thin wafer

ActiveUS20140154868A1Easy to manufactureImprove heat resistanceLayered productsSolid-state devicesEngineeringMechanical engineering

A wafer processing laminate, a wafer processing member, a temporary adhering material for processing a wafer, and a method for manufacturing a thin wafer, which facilitates to establish a temporary adhering the wafer and the support, enables to form a layer of uniform thickness on a heavily stepped substrate, and is compatible with the TSV formation and wafer back surface interconnect forming steps, and the wafer processing laminate includes a support, a temporary adhesive material layer formed thereon and a wafer laminated on the temporary adhesive material layer, where the wafer has a circuit-forming front surface and a back surface to be processed, wherein the temporary adhesive material layer includes a three-layered structure composite temporary adhesive material layer.

Owner:SHIN ETSU CHEM IND CO LTD

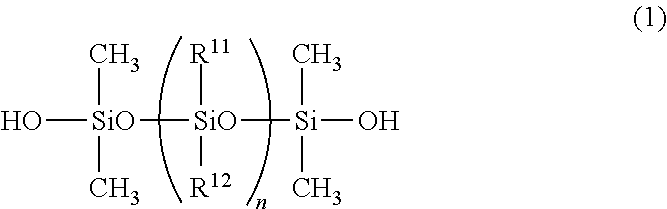

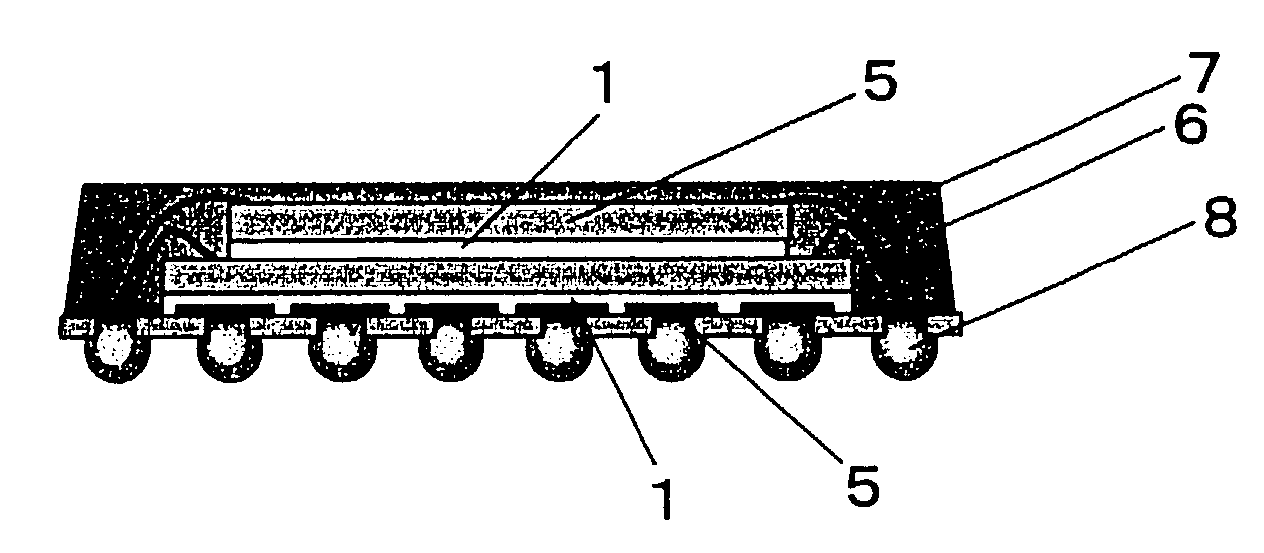

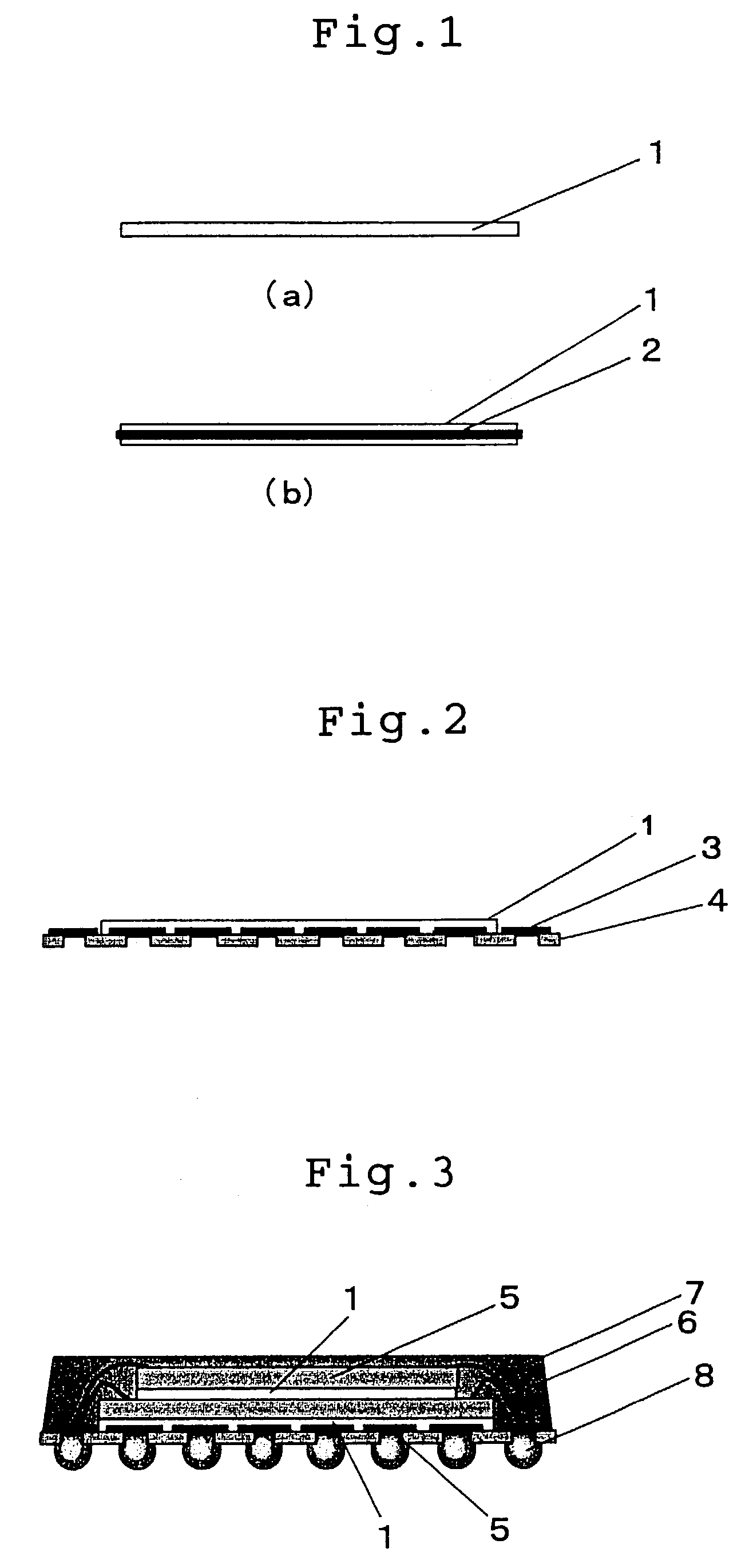

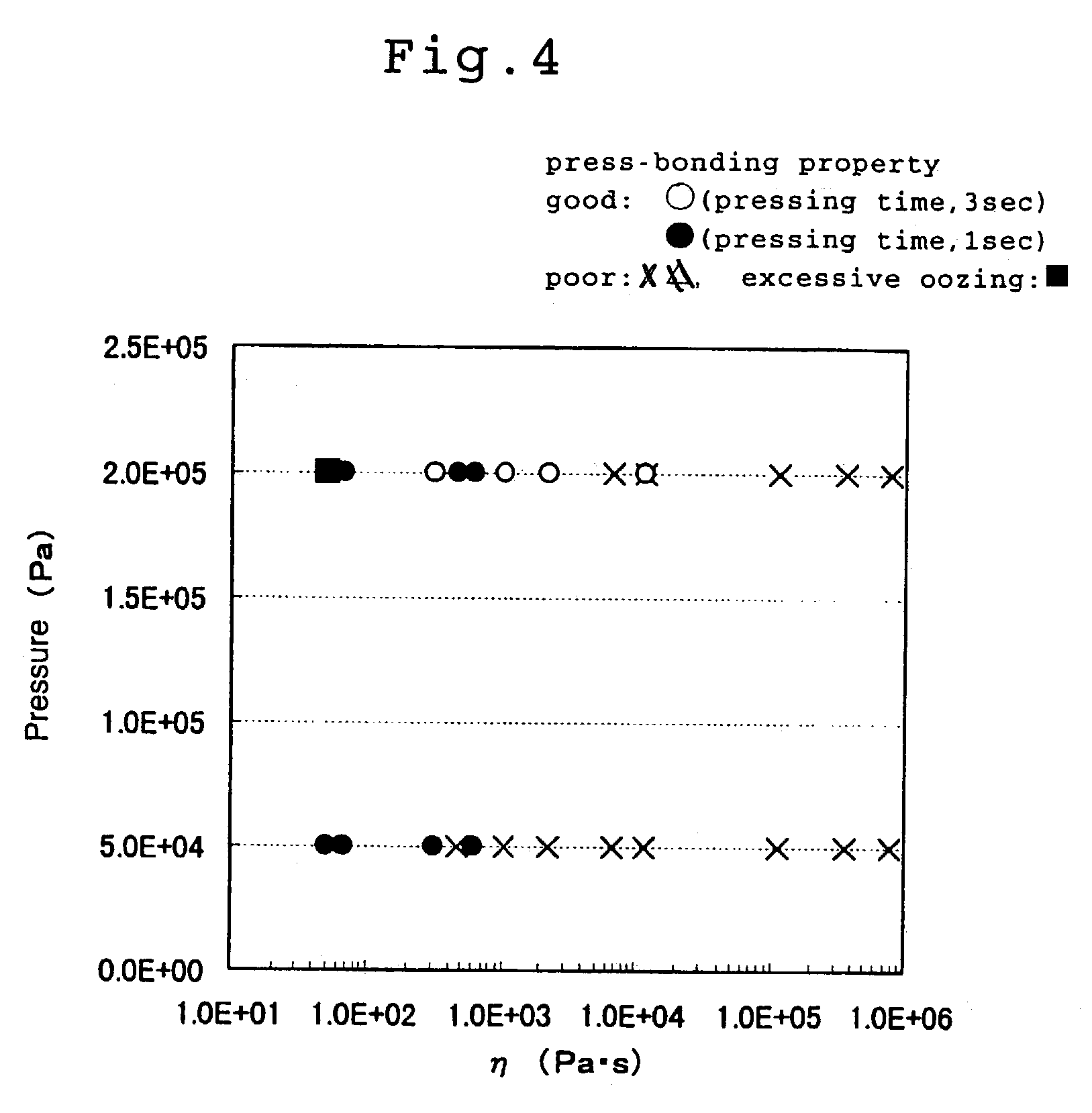

Adhesive composition, method for preparing the same, adhesive film using the same, substrate for carrying semiconductor and semiconductor device

There are disclosed an adhesive composition comprising: (a) an epoxy resin, (b) a curing agent and (c) a polymer compound with a weight average molecular weight of 100,000 or more, wherein a ratio of A / B exceeds 1 and is 10 or less, where A represents the total weight of (a) the epoxy resin and (b) the curing agent and B represents a weight of (c) the polymer compound; an adhesive composition, whose compositions are separated into a sea phase and an island phase, when viewed at a section in a cured state, and a ratio X / Y is in a range of 0.1 to 1.0, where X is an area of the sea phase and Y is an area of the island phase; a process for producing said adhesive composition; an adhesive film wherein said adhesive composition is formed into a film form; an adhesive film for bonding a semiconductor chip and a wiring board for mounting a semiconductor or for bonding semiconductor chips themselves, wherein the adhesive film can perform bonding by heat-pressing with a pressure of 0.01 to 0.5 MPa; a wiring board for mounting a semiconductor equipped with said adhesive film on a surface for mounting a semiconductor chip; and a semiconductor device using said adhesive film or said wiring board for mounting a semiconductor.

Owner:HITACHI CHEM CO LTD

Adhesive blends, articles, and methods

Described are adhesive compositions containing a mixture of a pressure sensitive adhesive, a high Tg polymer, and a crosslinker to form a compatibilized blend that is optically clear. Methods of using the adhesive compositions, and multilayer assemblies such as optical elements prepared using the adhesives, are also provided.

Owner:3M INNOVATIVE PROPERTIES CO

Adhesive compositions derived from highly functionalized ethylene copolymers

ActiveUS20060025527A1Adhesive compositionAdhesive articlesSynthetic resin layered productsEthyl hydrogen maleateHigh pressure

Disclosed are adhesive compositions comprising nonfunctionalized base resins and functionalized ethylene copolymers such as ethylene / maleic anhydride (E / MAH) or ethylene / ethyl hydrogen maleate (E / MAME) copolymer, which are synthesized directly in a high pressure autoclave. These adhesive compositions can be applied as self-supporting films or can be co-extruded or extrusion coated onto a substrate. Also disclosed are multilayer structures, films, pipe coatings and building panels comprising these compositions.

Owner:DOW GLOBAL TECH LLC

PRESSURE SENSITIVE ADHESIVE COMPOSITION (As Amended)

ActiveUS20120328800A1Improve wettabilityReduction in peel forceLiquid crystal compositionsEster polymer adhesivesPeel forcePressure sensitive

The present invention relates to a pressure sensitive adhesive composition. The present invention may effectively provide a pressure sensitive adhesive where peel forces for both sides are different and an modulus differs along the thickness direction. By applying the pressure sensitive adhesive as above, the present invention may provide, for example, an optical element, such as a polarizing plate, which can effectively inhibit light leakage and shows excellent durability, while being formed to have a thin thickness as well.

Owner:LG CHEM LTD

Adhesive article with improved air egress

This invention relates to an adhesive article which provides air egress. Air egress is provided by supplying a mute, such as areas of no initial adhesion for the air to flow out from under the construction. The invention relates to an adhesive article comprising a facestock having a front surface and a back surface, a continuous layer of adhesive having an upper surface and a lower surface wherein the upper surface of the adhesive layer is adhered to the back surface of the facestock, and a plurality of spaced-apart non-adhesive material which is in contact with the lower surface of the adhesive layer wherein the lower surface of the adhesive layer has a Sheffield roughness of at least about 10 and the adhesive article provides air egress. The invention also relates to methods of preparing the adhesive articles, These articles have usefulness as industrial graphics images, as well as decorative coverings, etc. The articles provide air egress and optionally repositionability and slideability.

Owner:AVERY DENNISON CORP

Adhesive film and process for preparing the same as well as adhesive sheet and semiconductor device

InactiveUS20070098995A1Improve workabilityLow heating temperatureNon-macromolecular adhesive additivesSynthetic resin layered productsHeat resistanceDicing tape

An object of the present invention is to provide a die-adhering adhesive film which can be laminated on a back of a wafer at a temperature lower than a softening temperature of a protecting tape for an ultra-thin wafer, or a dicing tape to be laminated, can reduce a thermal stress such as warpage of a wafer, can simplify a step of manufacturing a semiconductor device, and is excellent in heat resistance and humidity resistance reliance, an adhesive sheet in which the adhesive film and a dicing tape are laminated, as well as a semiconductor device.

Owner:HITACHI CHEM CO LTD

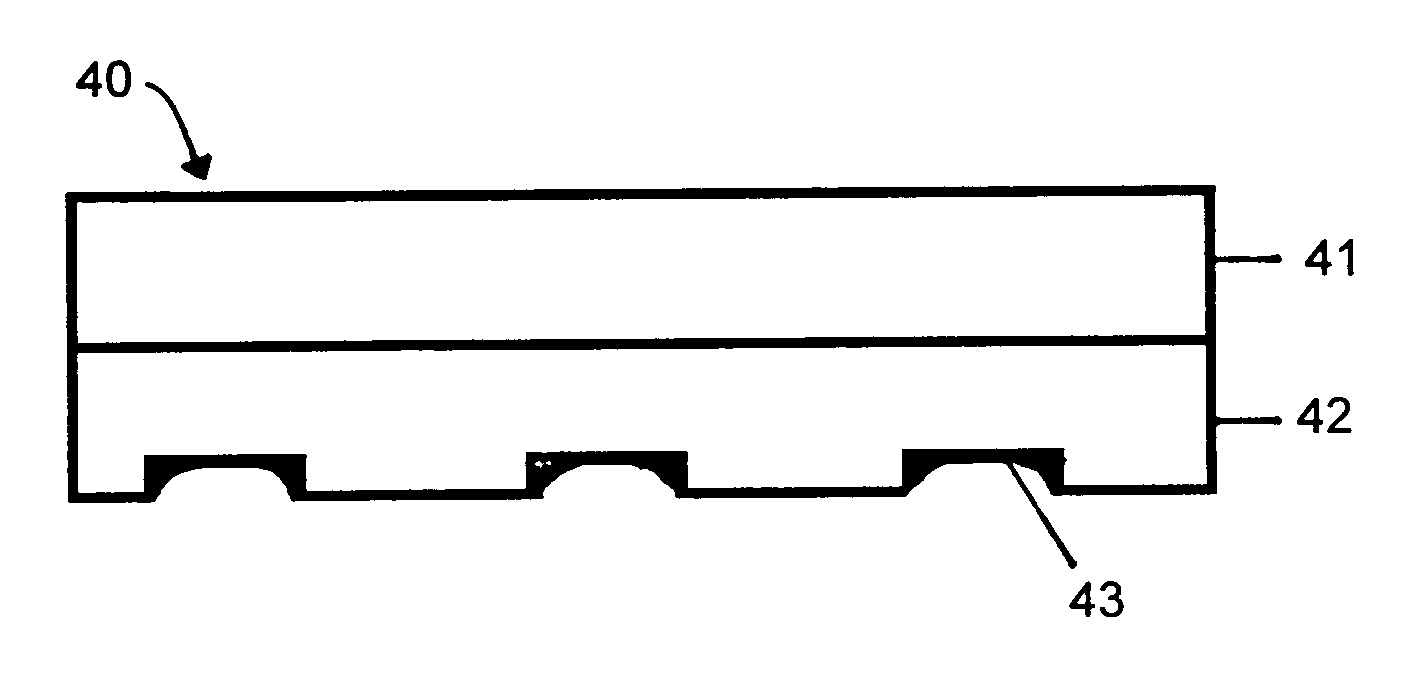

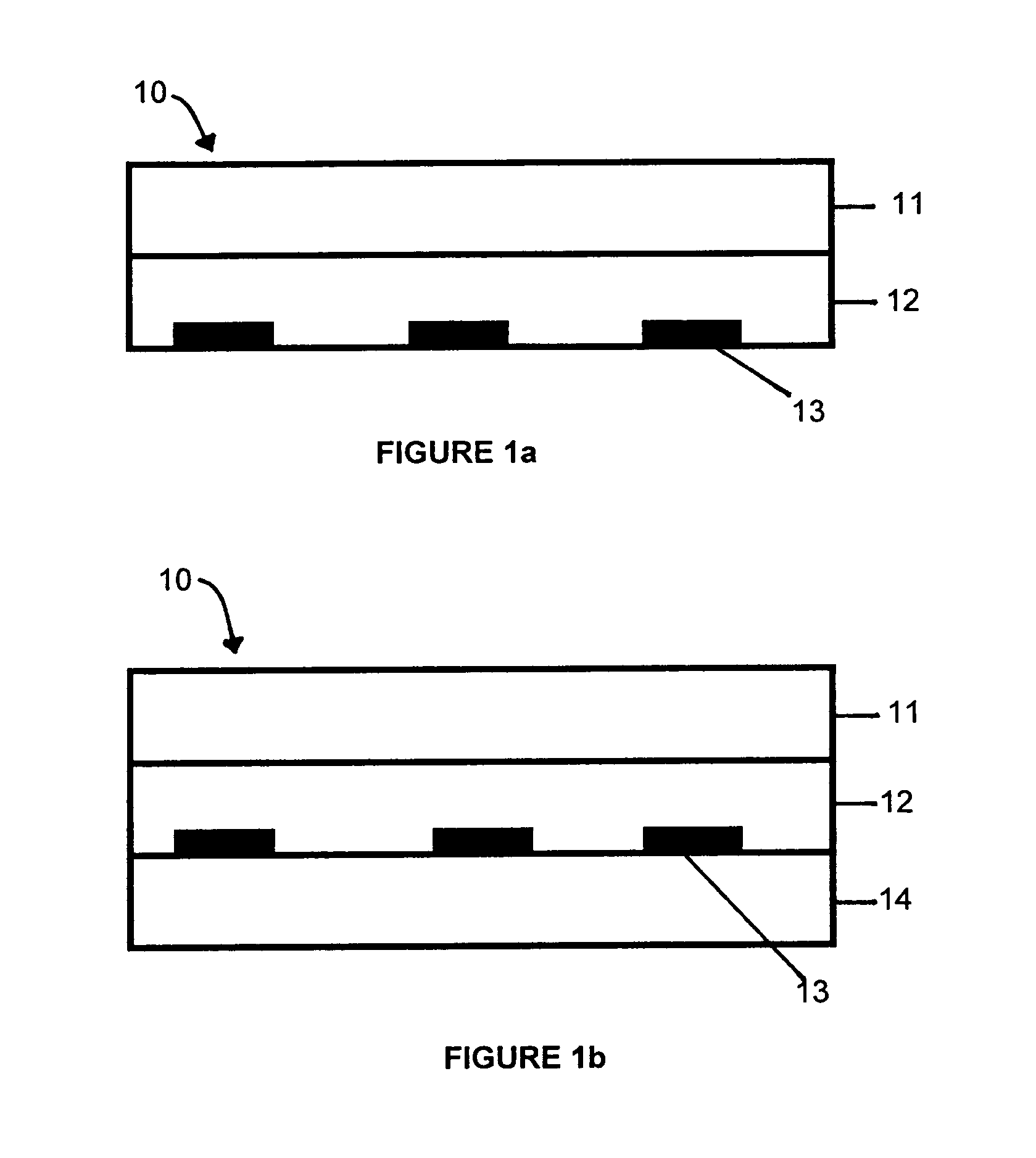

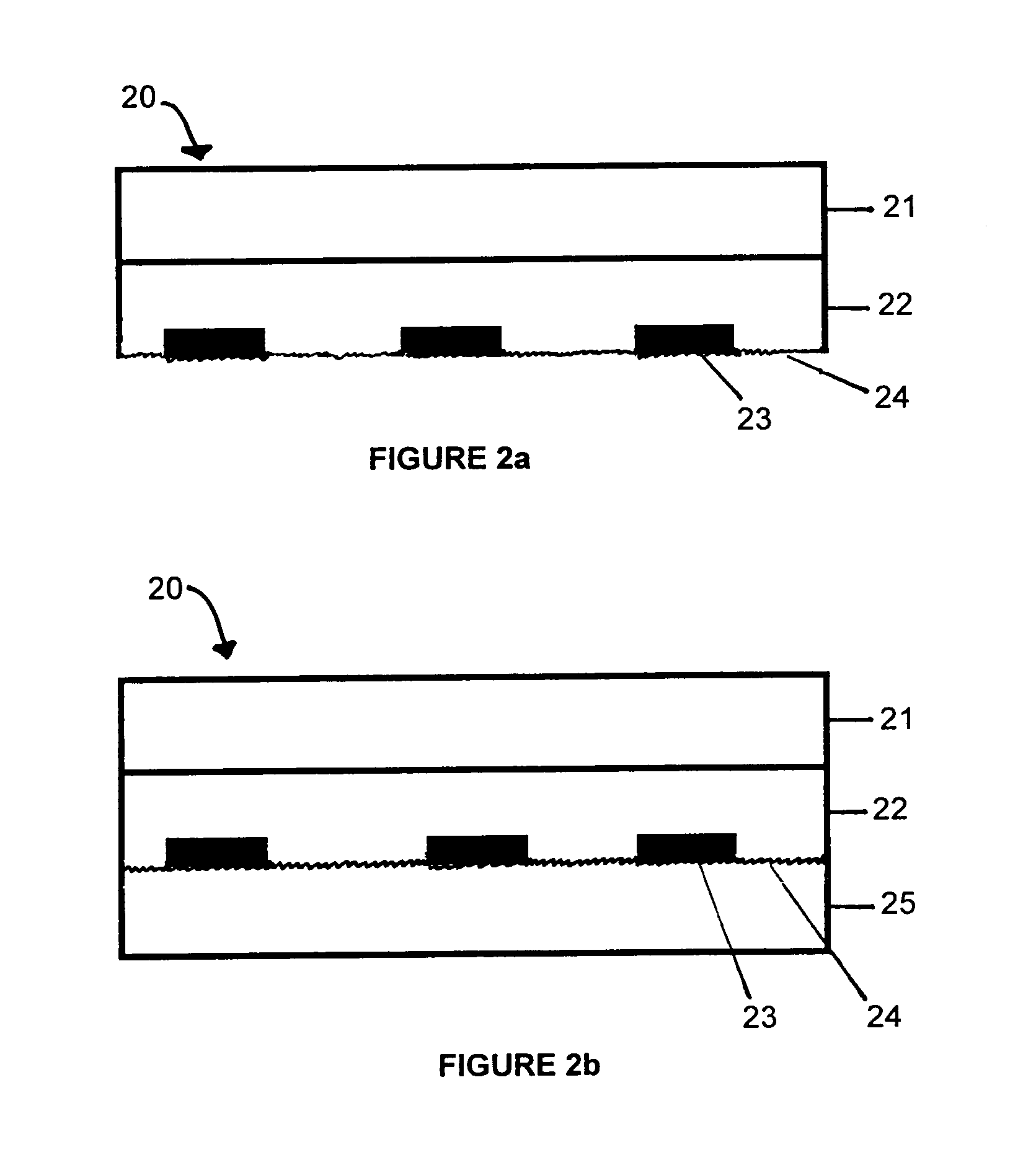

Method and apparatus for joining together multiple functional layers of a flexible display

The present invention may relate to provision of a mechanism to join together the various substrate layers of a flexible display with optically clear adhesives that permit improved flexibility of the substrate layer stack and may also optically guide images to locations on a display surface that are not aligned with the display layer of a substrate layer stack. Embodiments of the present invention may provide for an improved user interface which may include enhanced flexibility and enhanced optical characteristics.

Owner:NOKIA TECH OY

Optical-use pressure-sensitive adhesive sheet

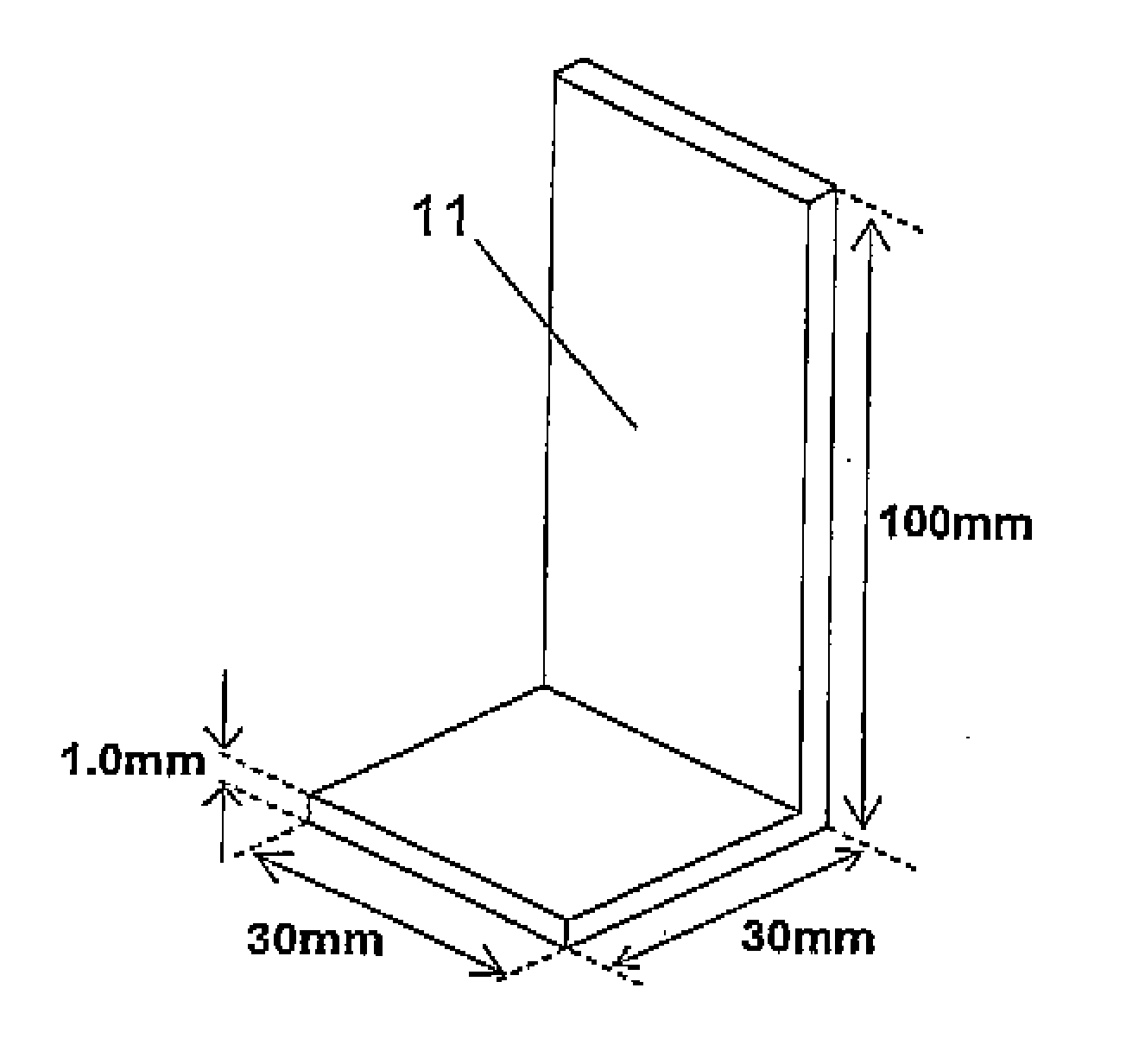

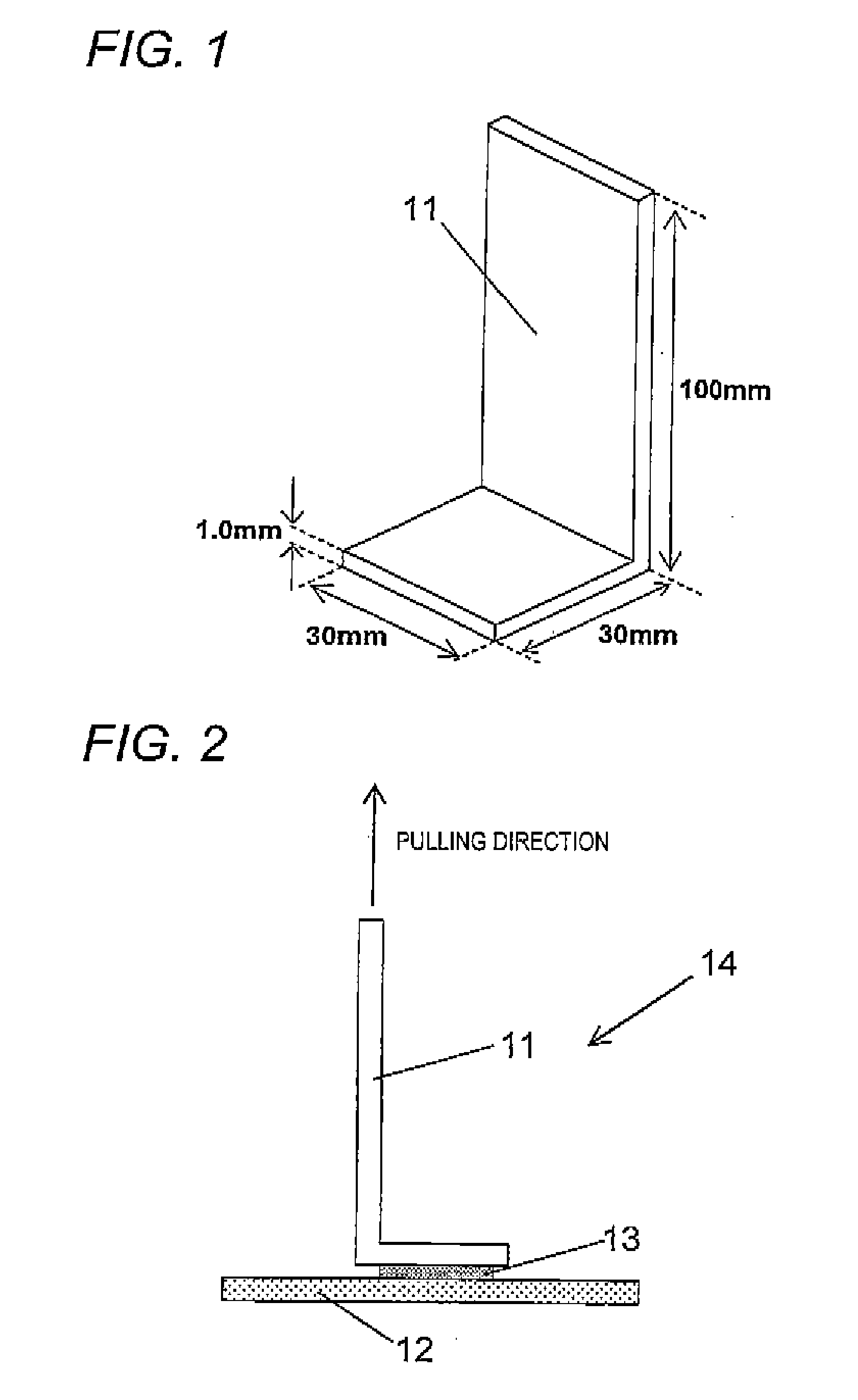

InactiveUS20110111220A1Improve adhesionExcellent in twist-proof adhesivenessMonocarboxylic acid ester polymer adhesivesOpticsConstant loadDynamic viscoelasticity

The present invention provides an optical-use pressure-sensitive adhesive sheet including a pressure-sensitive adhesive layer having, as measured through dynamic viscoelastometry, a storage elastic modulus at 80° C. of at least 2.0×104 Pa and a loss elastic modulus at 80° C. of at least 1.0×104 Pa, in which the pressure-sensitive adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test (under a load of 100 gf for 3 hours), of at most 50 mm.

Owner:NITTO DENKO CORP

Adhesive film and manufacturing method of the same, and display device including the adhesive film

ActiveUS20150144913A1Absorbing and dispersing stressAvoid crackingAdhesive processesDecorative surface effectsDisplay deviceEngineering

Owner:SAMSUNG DISPLAY CO LTD

B-stageable film, electronic device, and associated process

InactiveUS20060275608A1Semiconductor/solid-state device detailsSynthetic resin layered productsThermal energyCross-link

A B-stageable film that includes a thermal interface material is provided. The film may secure a heat-generating device to a heat-dissipating component, may further cross-link, and may conduct thermal energy from the heat-generating device to the heat-dissipating component. A method of making and using the film is provided, as well as a device that incorporates the film.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

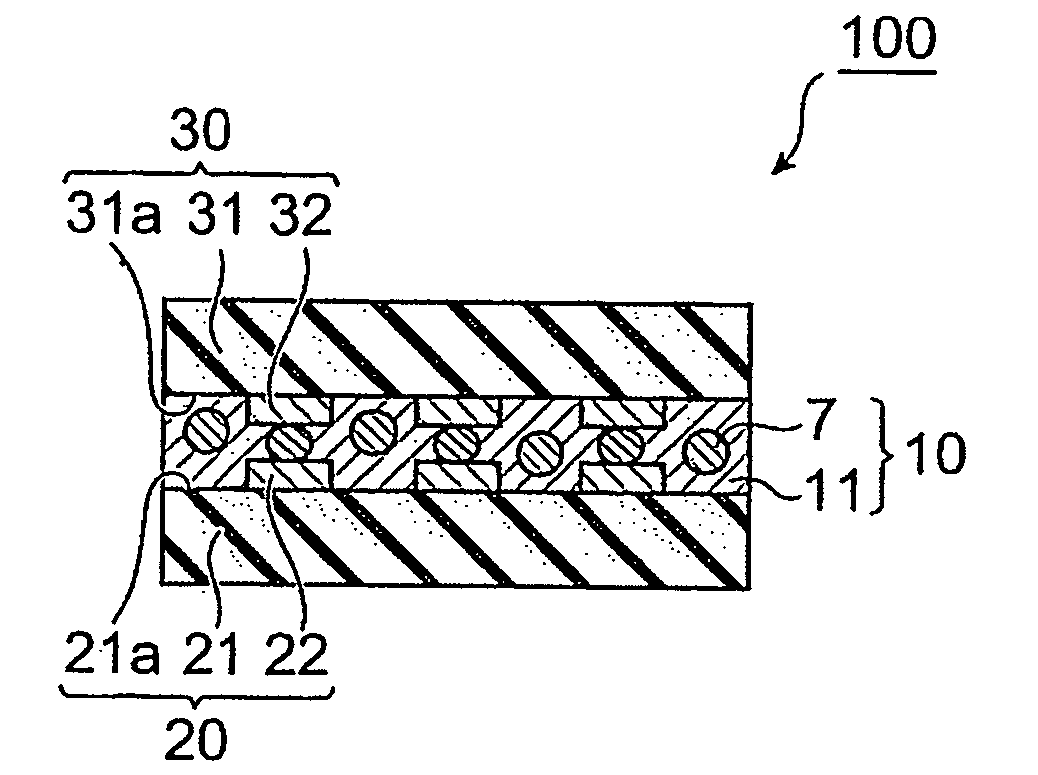

Anisotropic conductive film and light emitting device

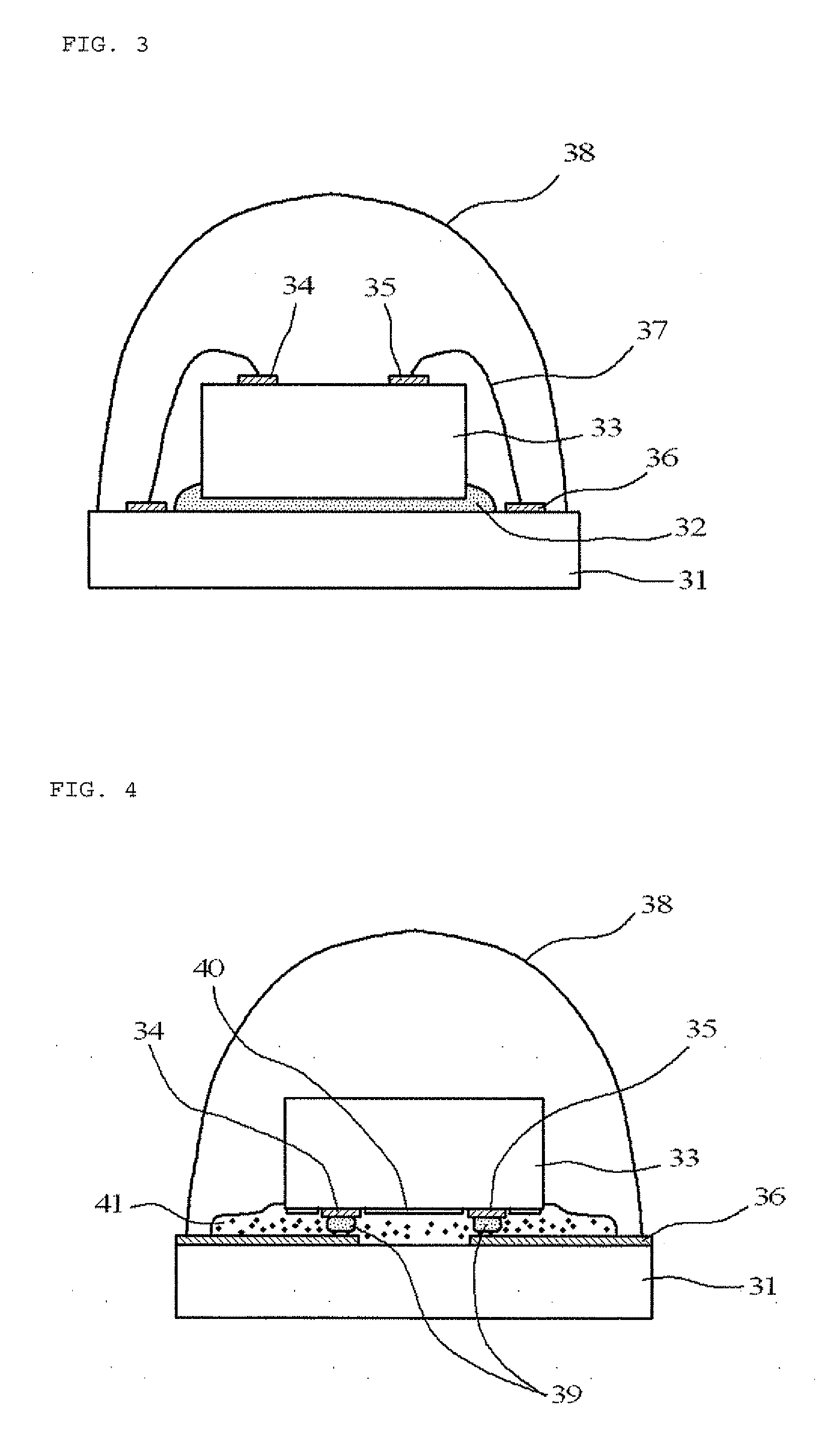

InactiveUS20110266578A1Emission efficiency of the light emitting device does not deteriorateNon-macromolecular adhesive additivesPrinted circuit aspectsAnisotropic conductive filmAnisotropic conductive adhesive

An anisotropic conductive film is provided that does not have a light-reflecting layer on a light emitting diode element which causes costs to increase when a light emitting device that uses an LED element is flip-chip mounted, and that does not cause emission efficiency to deteriorate. Further, a light emitting device that uses such an anisotropic conductive film is provided. This anisotropic conductive film has a structure in which a light-reflecting insulating adhesive layer and an anisotropic conductive adhesive layer are laminated, wherein the light-reflecting insulating adhesive layer has a structure in which light-reflecting particles are dispersed in an insulating adhesive. The light emitting device has a structure in which a light emitting diode element is flip-chip-mounted on a substrate, with this anisotropic conductive film provided between a connection terminal on the substrate and a bump for connection of the light emitting diode element.

Owner:DEXERIALS CORP

Weatherstrip tape and method for producing the same

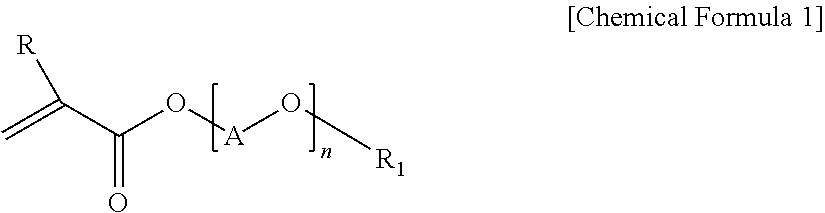

InactiveUS7217455B2Reduce stickingReliably used in bondingFilm/foil adhesives without carriersSpecial surfacesMonomerPressure sensitive

The present invention relates to an adhesive tape and to a method for its manufacture, the tape comprising: (A) a heat-activatable adhesive resin layer, wherein the resin is a polymer of one or more monomers selected from the group consisting of olefins, and (B) a pressure-sensitive adhesive layer, comprising an acrylic-type pressure sensitive adhesive, wherein said pressure sensitive adhesive layer is permanently and directly bonded to a first major surface of said heat-activatable adhesive layer. The present invention also relates to an intermediate article comprising the heat-activatable adhesive resin layer (A) releasably bonded to a support layer, to a composite article comprising the adhesive tape and a rubber article bonded to the second major surface of the heat-activatable layer (A), and to a vehicle comprising the composite article.

Owner:3M INNOVATIVE PROPERTIES CO

Label adhesive and activation method for polymeric label

InactiveUS7943714B2Accelerates the removal of moistureSufficient resistanceStampsLiquid surface applicatorsWater basedActivation method

A water activated adhesive system is described that is particularly suited for applying non-paper polymeric labels to surfaces which have low moisture permeability. The adhesive system is characterized by a dry non-tacky surface that becomes tacky in less than one second when contacted with a water-based activator. While it is a water activated adhesive, it is also characterized after aging bonded to a substrate by resistance to adhesive failure during 72 hours of immersion in ice / water mixture. The adhesive is beneficial to allow use of existing paper labeling equipment with polymeric labels.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Adhesive for circuit connection , circuit connection method using the same, and circuit connection structure

InactiveUS20030141014A1Printed circuit assemblingSemiconductor/solid-state device detailsVitrificationElectricity

There are provided an adhesive for connecting a circuit to be interposed between substrates having circuit electrodes thereon opposed to each other and to electrically connect the circuit electrodes on the substrates opposed to each other to the pressurizing direction under pressure, wherein the adhesive contains a compound having an acid equivalent of 5 to 500 KOH mg / g, and an adhesive for connecting a circuit to be interposed between substrates having circuit electrodes opposed to each other and to electrically connect the electrodes on the substrate opposed to each other to the pressurizing direction under pressure, wherein the adhesive comprises a first adhesive layer and a second adhesive layer, and a glass transition temperature of the first adhesive layer after pressure connection is higher than the glass transition temperature of the second adhesive layer after pressure connection.

Owner:HITACHI CHEM CO LTD

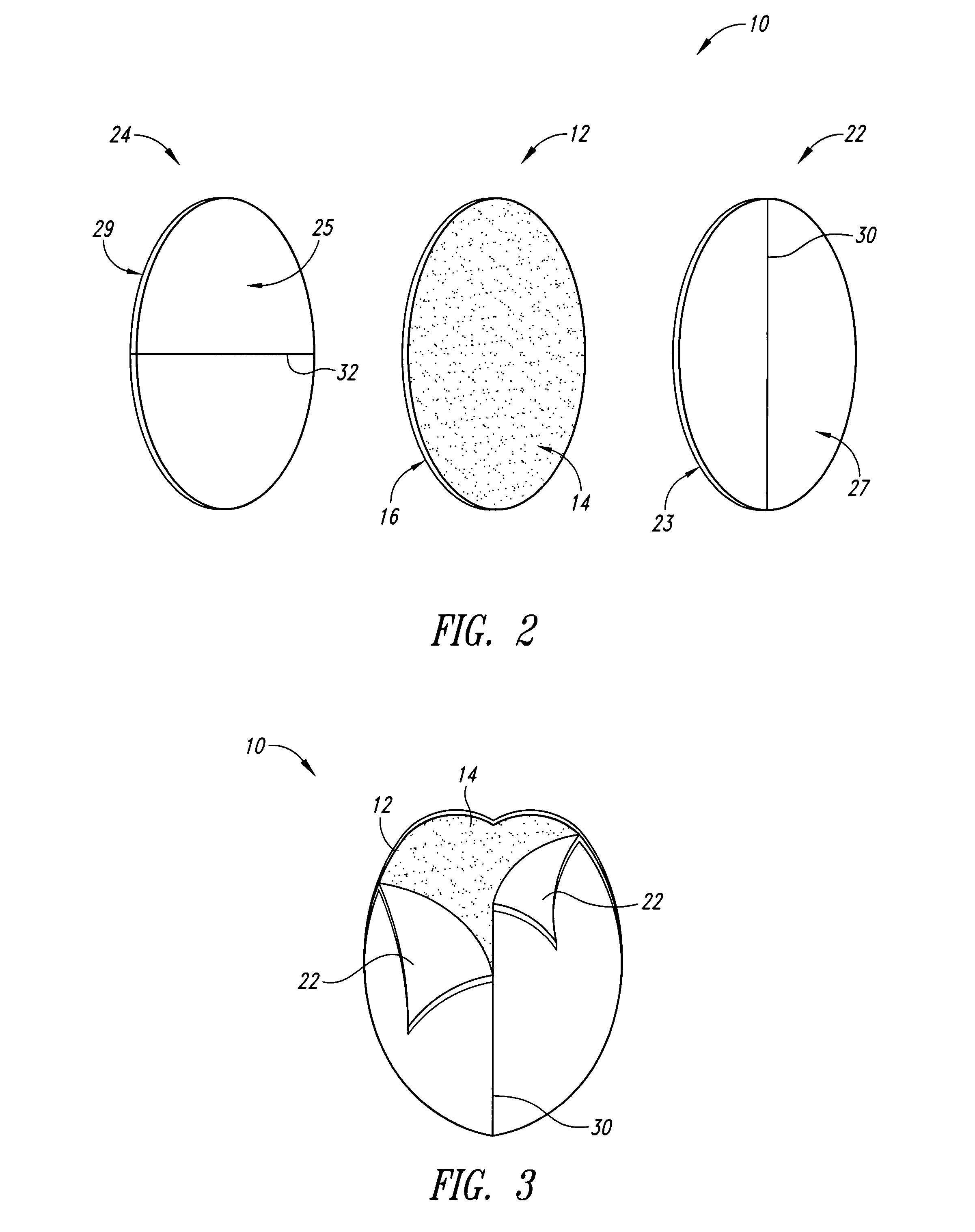

Adhesive cutout

An adhesive cutout includes an adhesive layer having a first surface and an opposing second surface, the first and the second surfaces at least partially covered by a first release liner and a second release liner, respectively. The first release liner includes first removal means for facilitating removal of the first release liner from the first surface of the adhesive layer. The second release liner includes second removal means for facilitating removal of the second release liner from the second surface of the adhesive layer.

Owner:BADGE MAGIC

Popular searches

Printed circuit manufacture Electrographic processes using charge pattern Pressure sensitive film/foil adhesives Non-linear optics Electrically-conducting adhesives Optical elements Glass/slag layered products Adhesive processes involving welding Photovoltaic energy generation Thin material handling

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com