Patents

Literature

3637 results about "Release liner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A release liner is a paper or plastic-based film sheet (usually applied during the manufacturing process) used to prevent a sticky surface from prematurely adhering. It is coated on one or both sides with a release agent, which provides a release effect against any type of a sticky material such as an adhesive or a mastic. Release liners are available in different colors, with or without printing under the low surface energy coating or on the backside of the liner. Release is separation of the liner from a sticky material; liner is the carrier for the release agent.

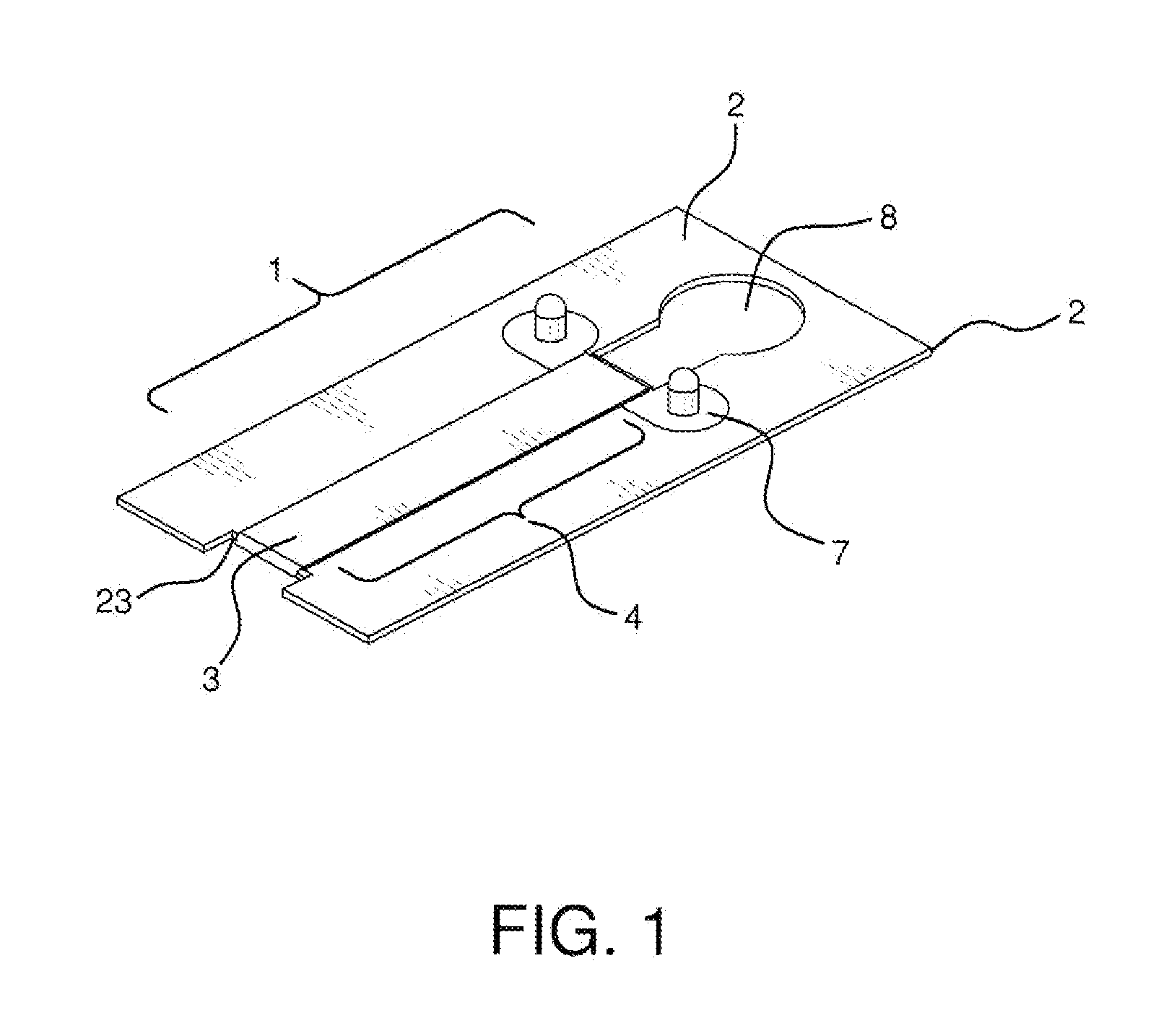

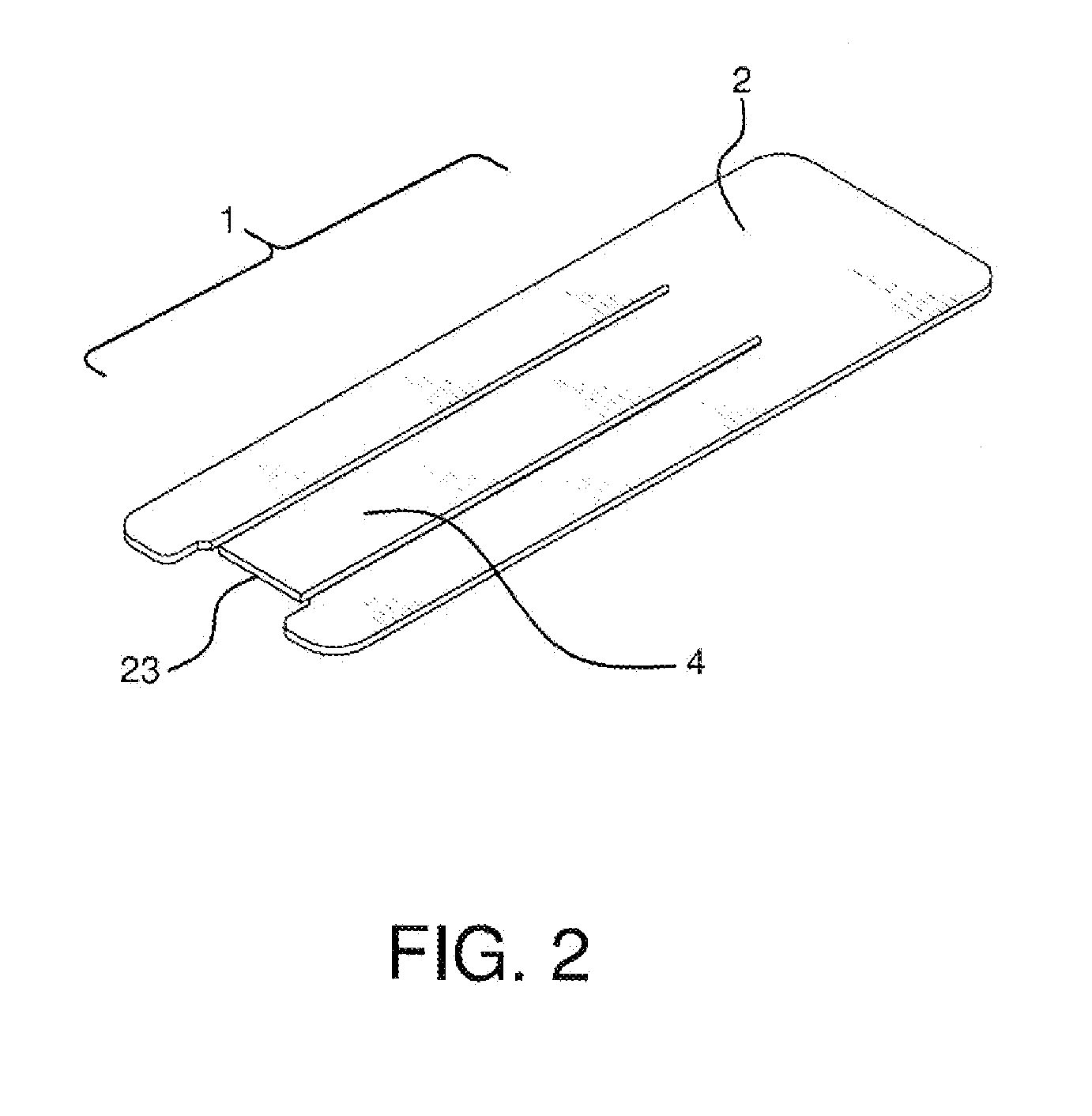

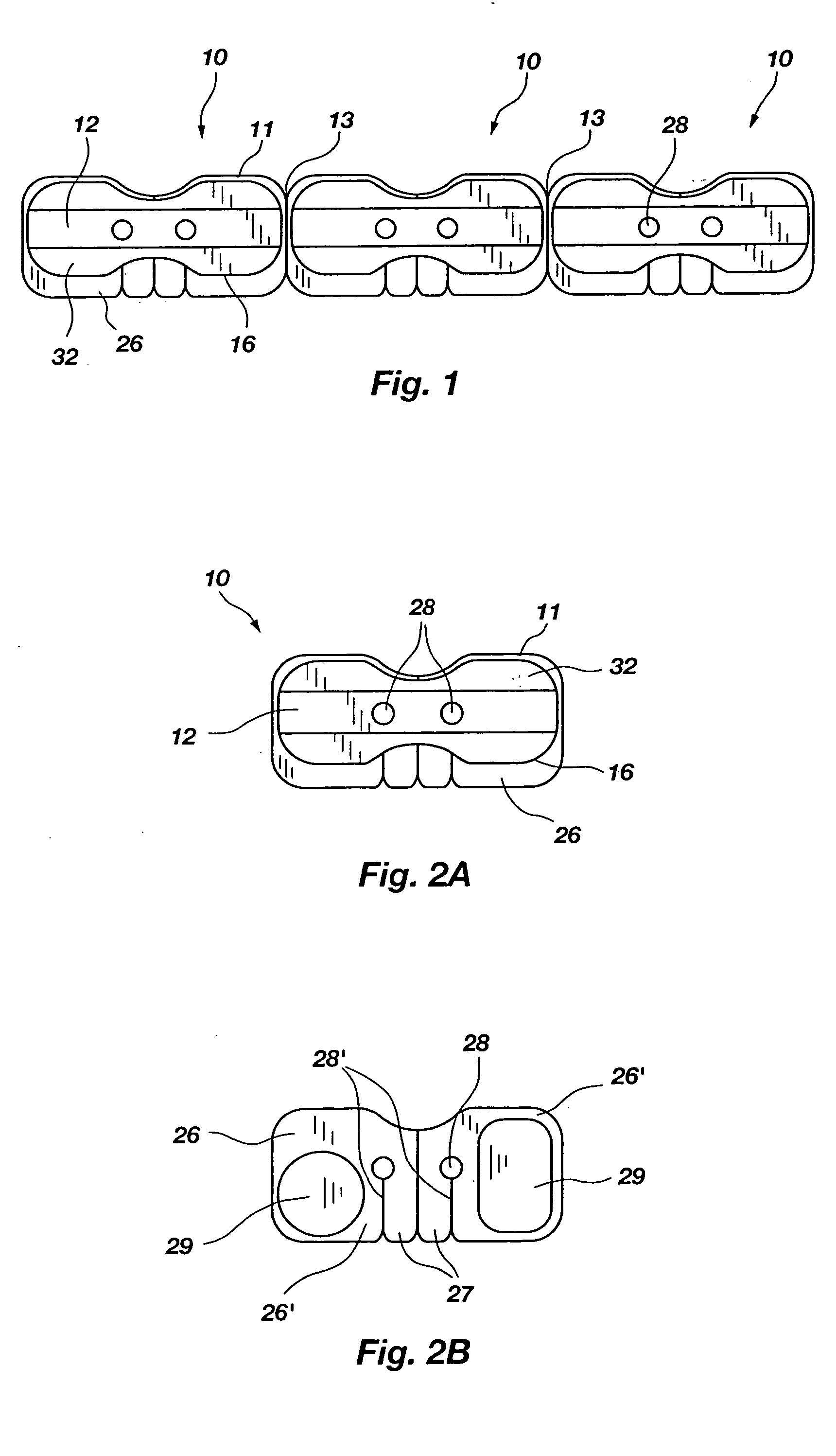

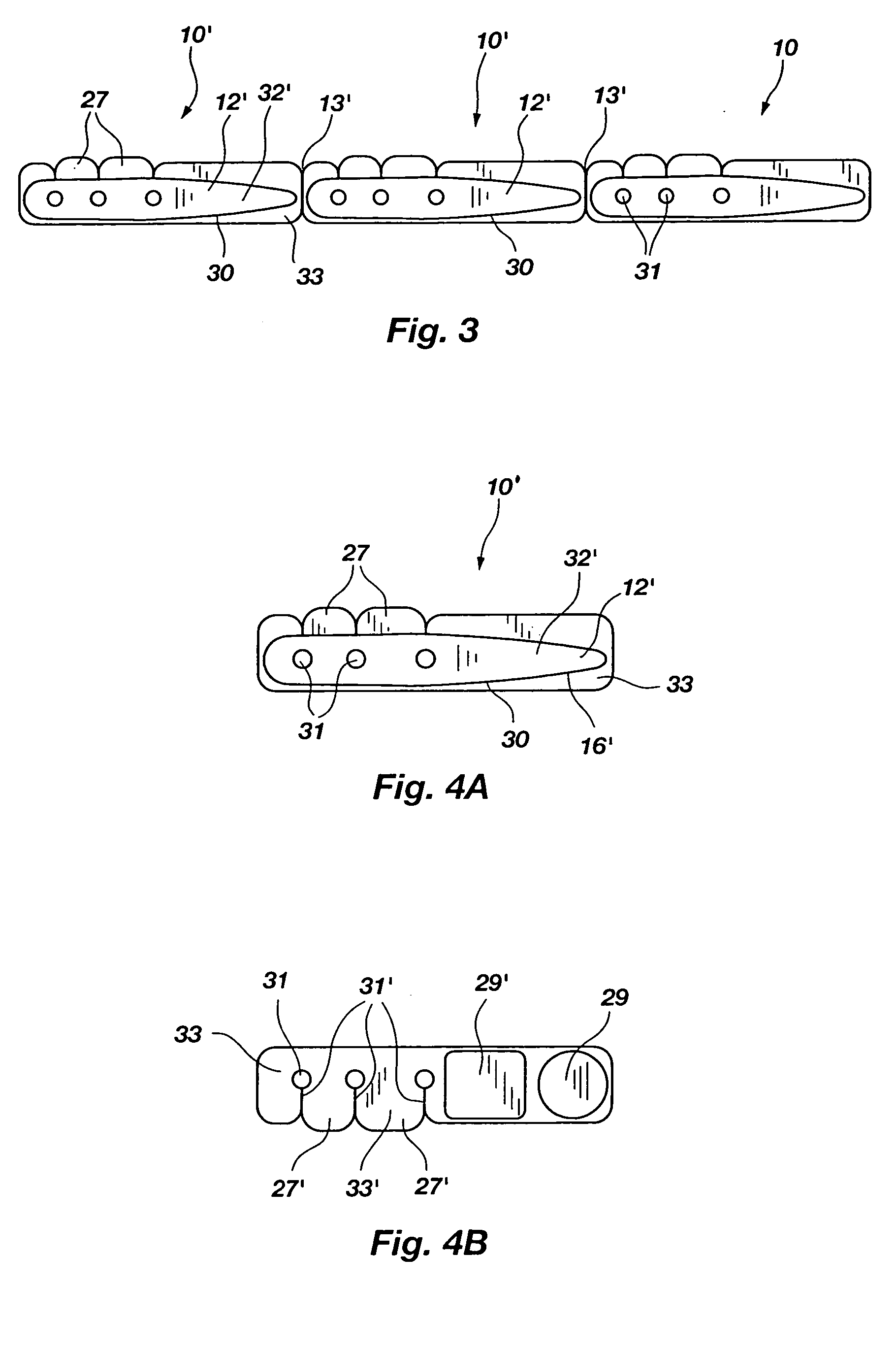

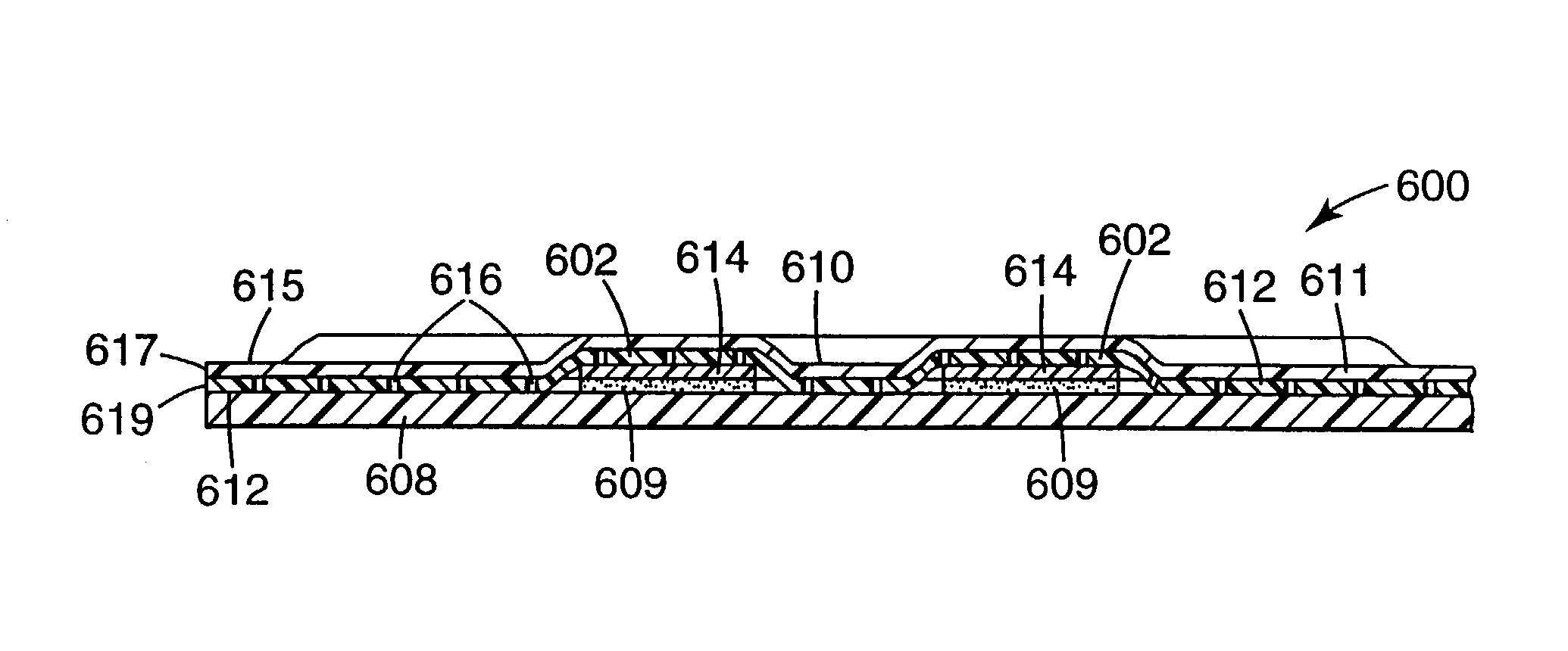

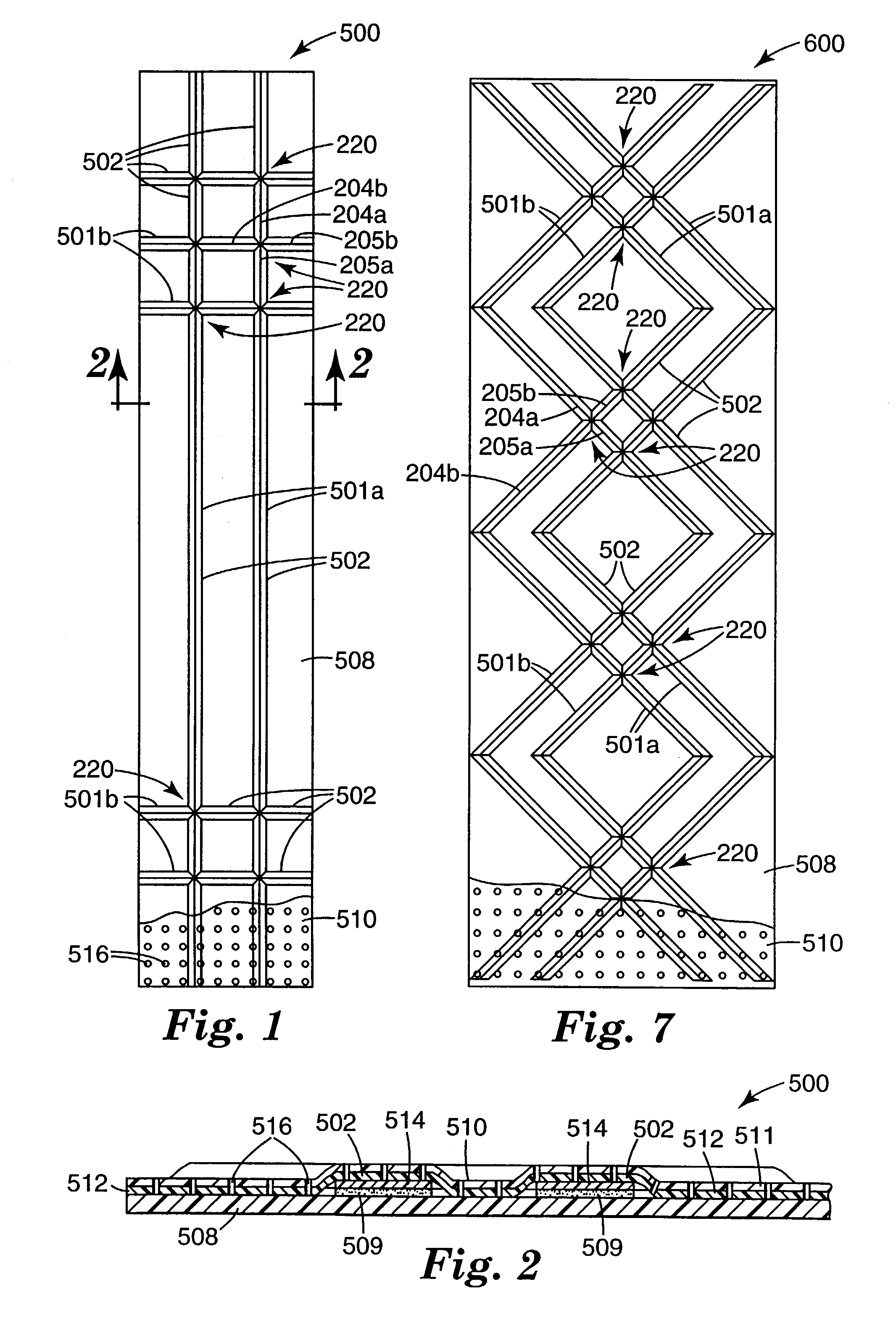

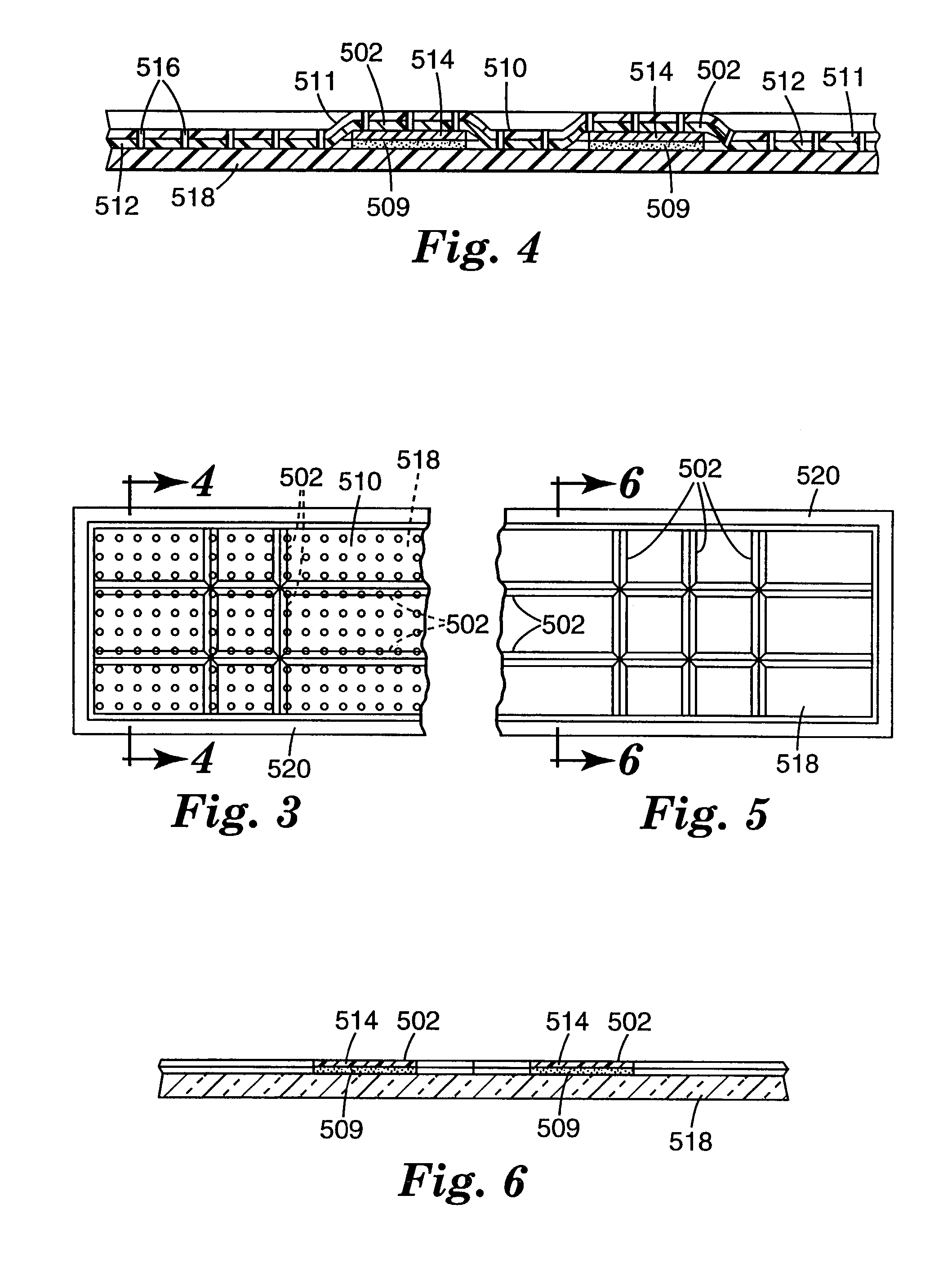

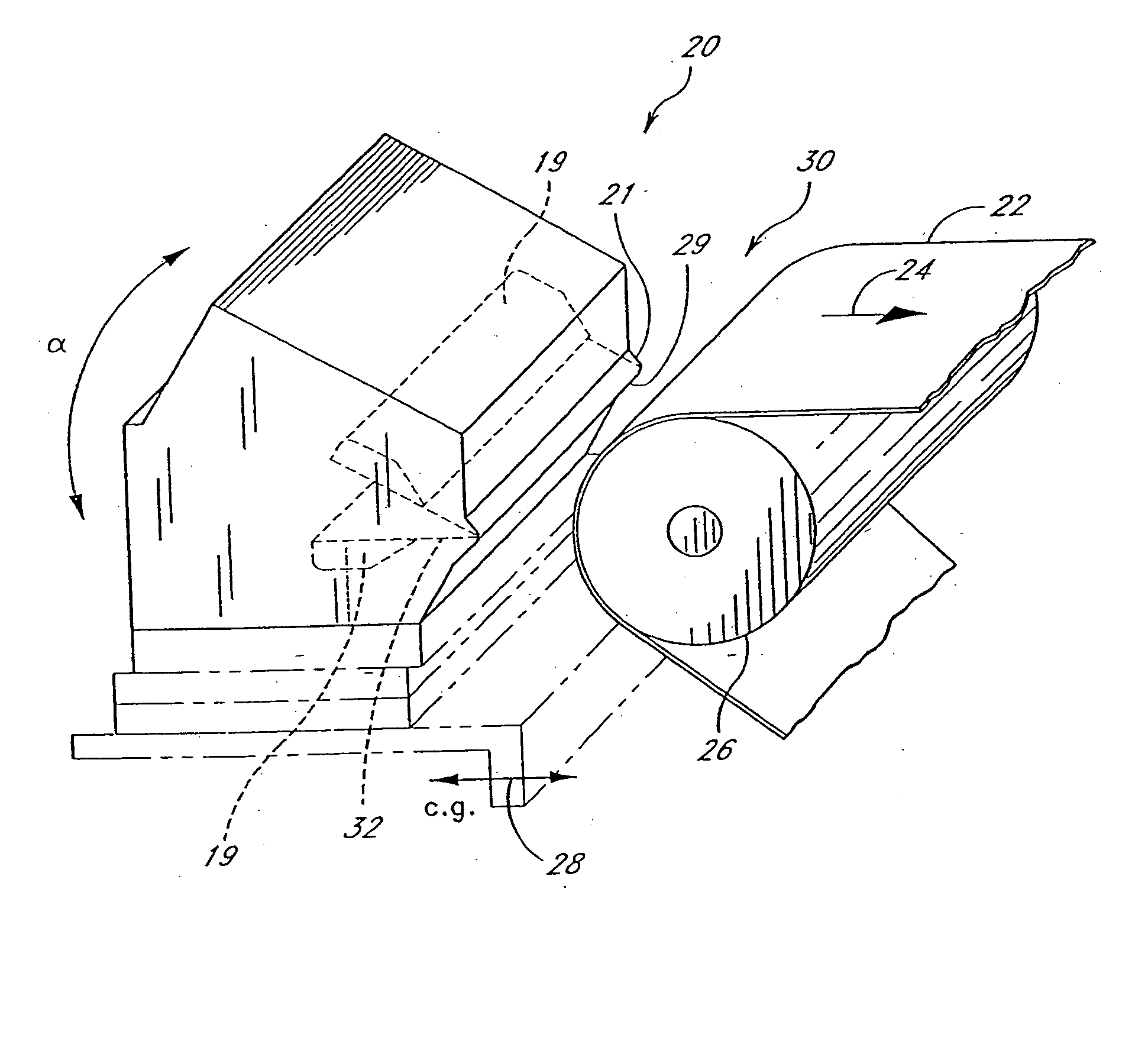

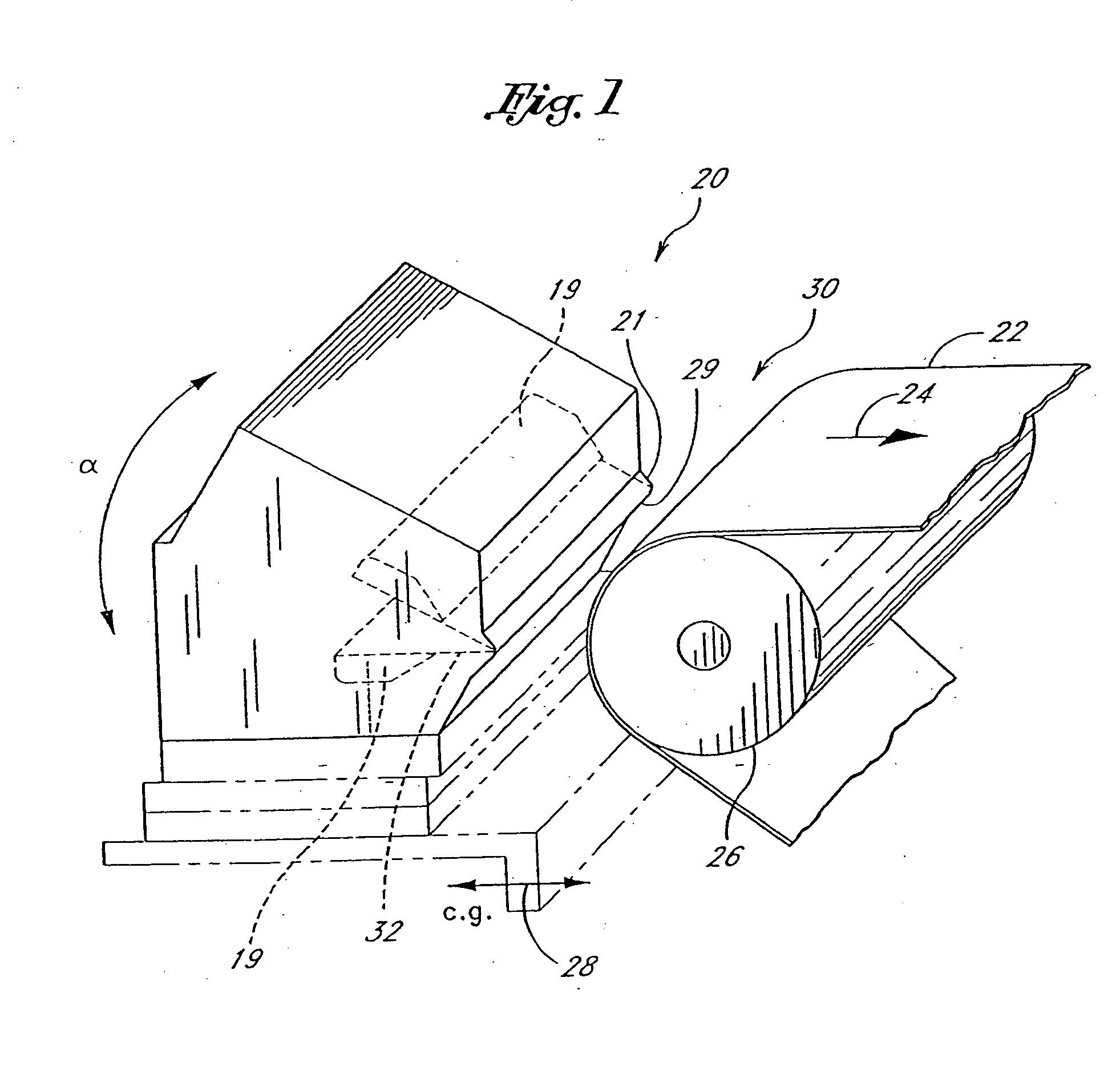

Apparatus for supplying surgical staple line reinforcement

InactiveUS8453904B2Accurately and successfully positionedMaintain strengthSuture equipmentsStapling toolsSurgical stapleBiomedical engineering

An apparatus for supplying surgical buttress material to a surgical stapler is provided. The apparatus has a pivotable area for attaching surgical buttress material. The apparatus may also have an adhesive and a release liner disposed over the buttress material.

Owner:WL GORE & ASSOC INC

Apparatus for Supplying Surgical Staple Line Reinforcement

InactiveUS20120289979A1Accurately and successfully positionedMaintain strengthSurgical staplesWound clampsSurgical stapleMaterial supply

An apparatus for supplying surgical buttress material to a surgical stapler is provided. The apparatus has a pivotable area for attaching surgical buttress material. The apparatus may also have an adhesive and a release liner disposed over the buttress material.

Owner:WL GORE & ASSOC INC

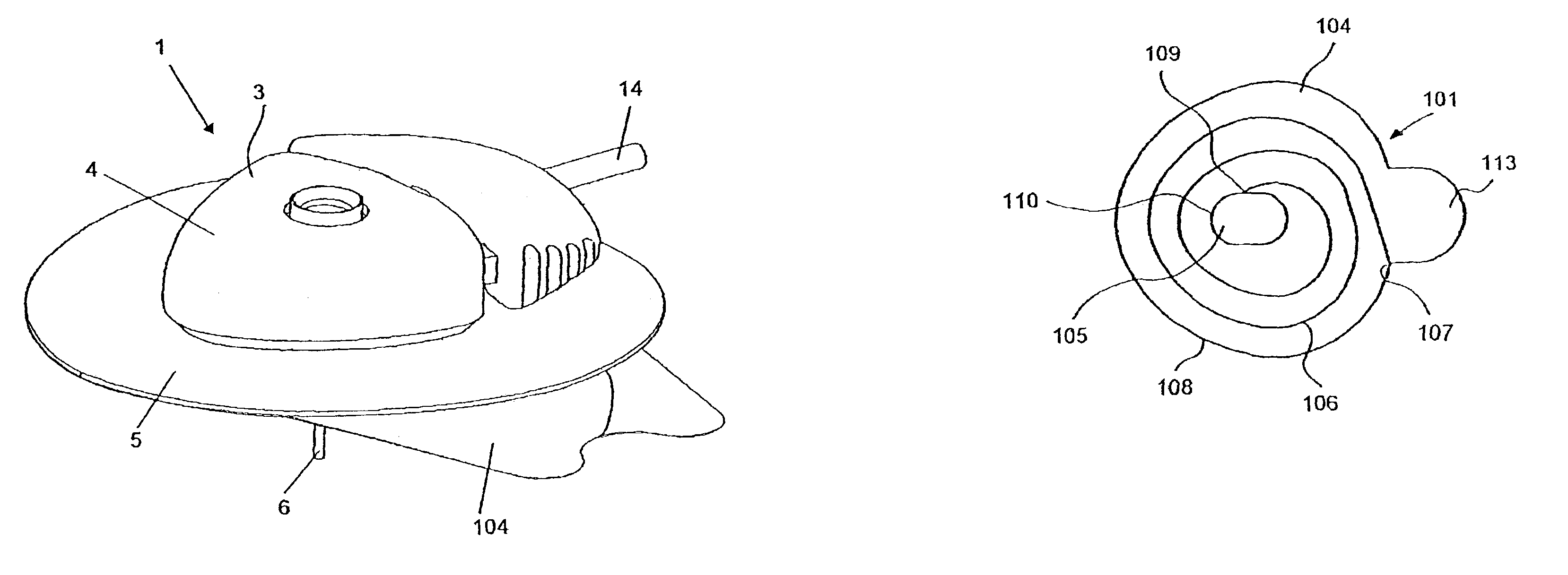

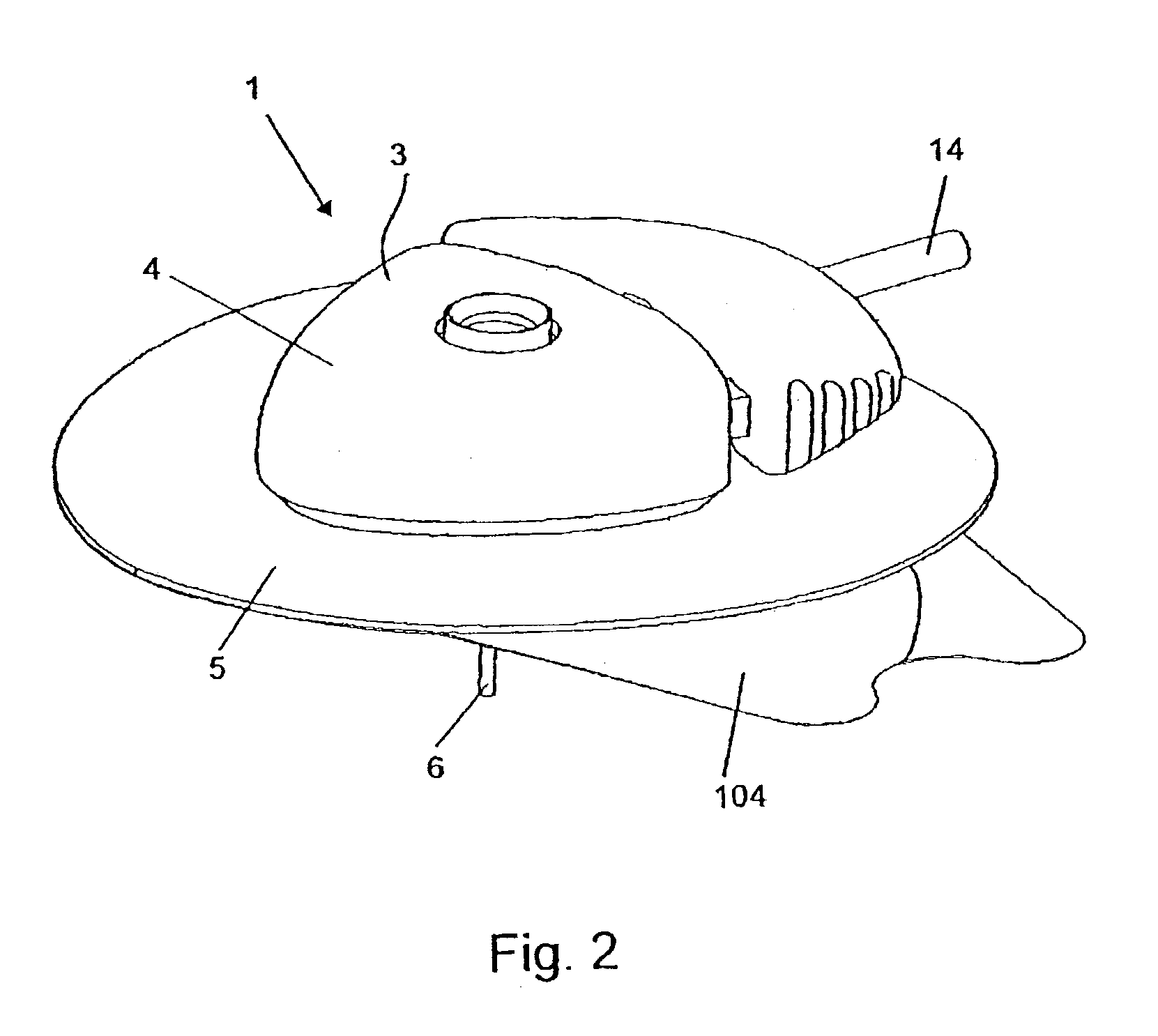

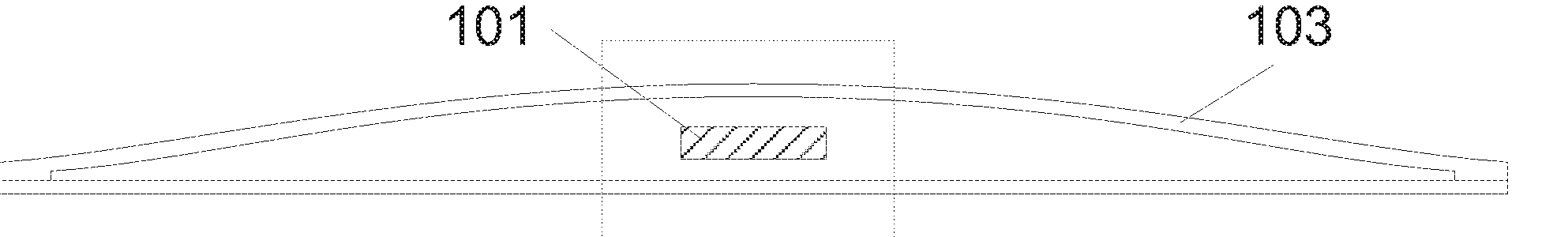

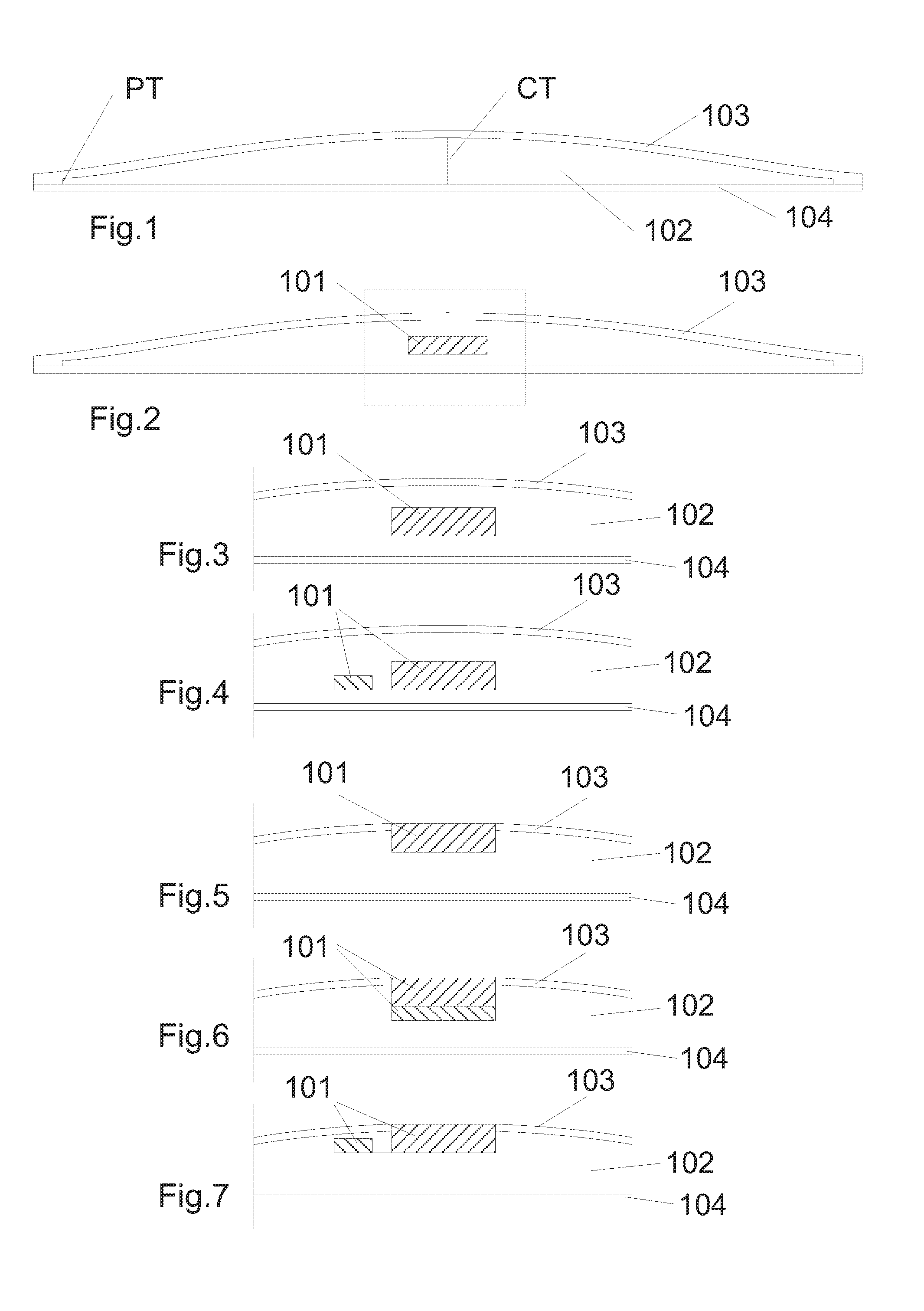

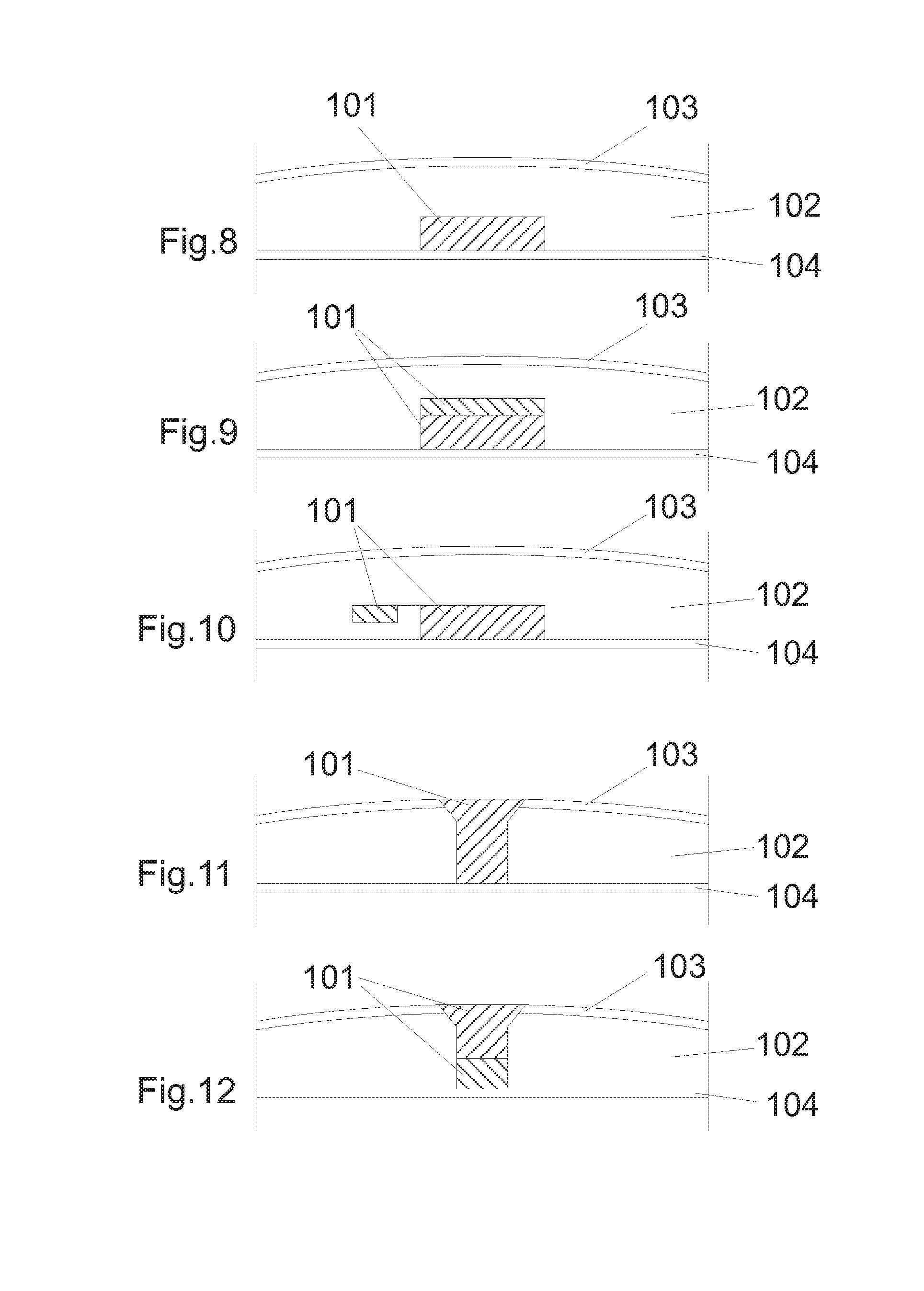

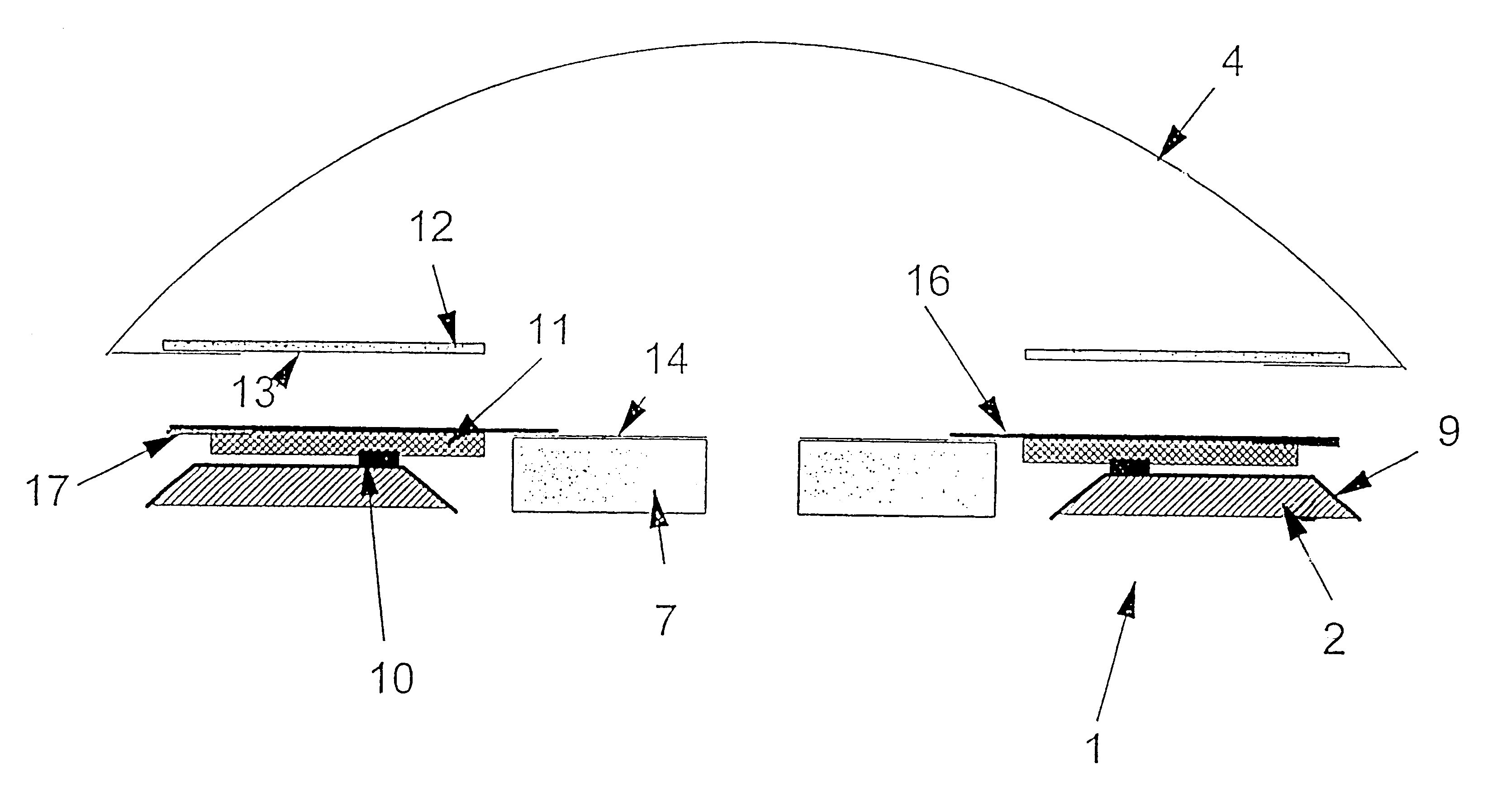

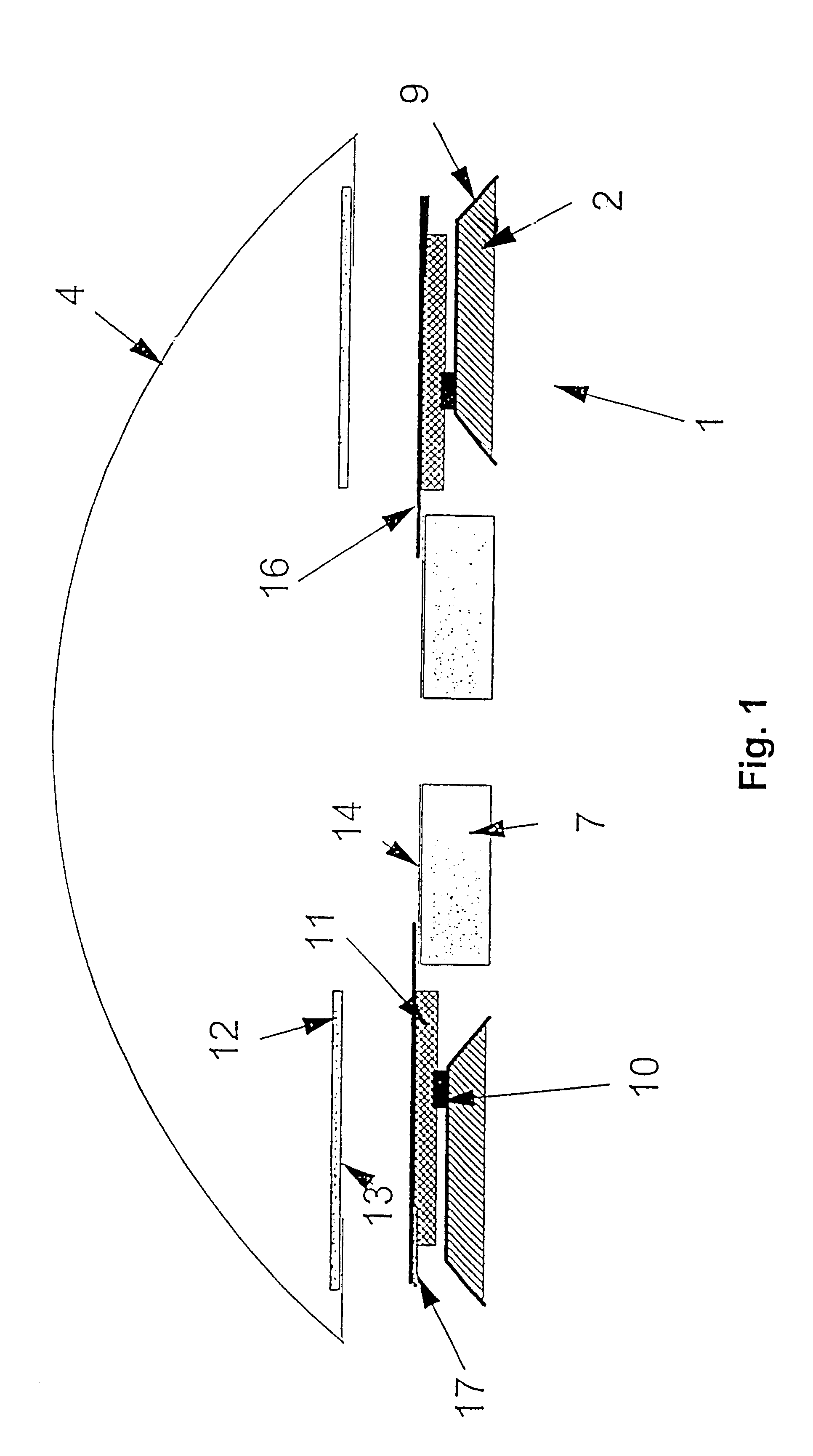

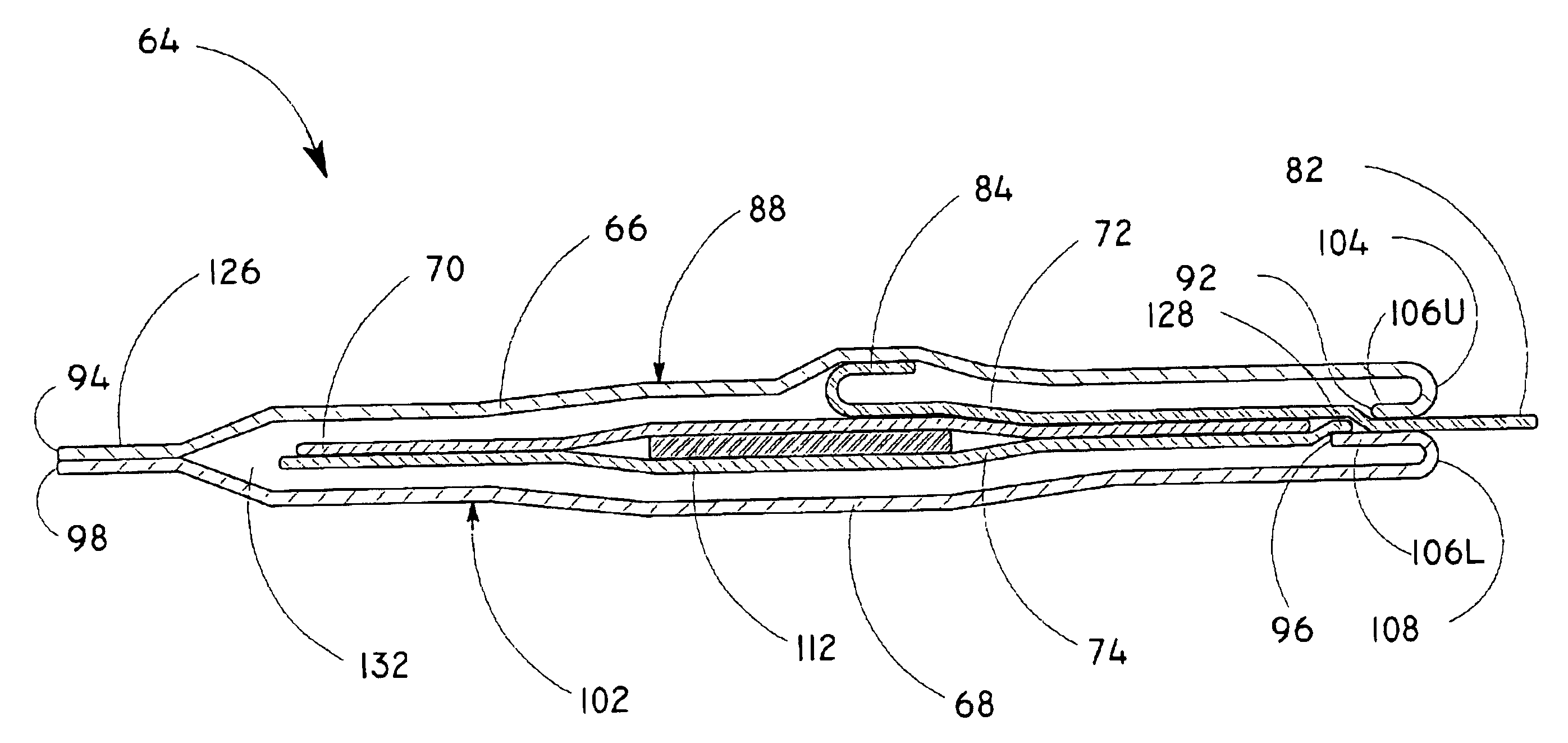

Infusion device and an adhesive sheet material and a release liner

ActiveUS7070580B2Easy to handleForce is smallPressure infusionInfusion needlesLower faceBiomedical engineering

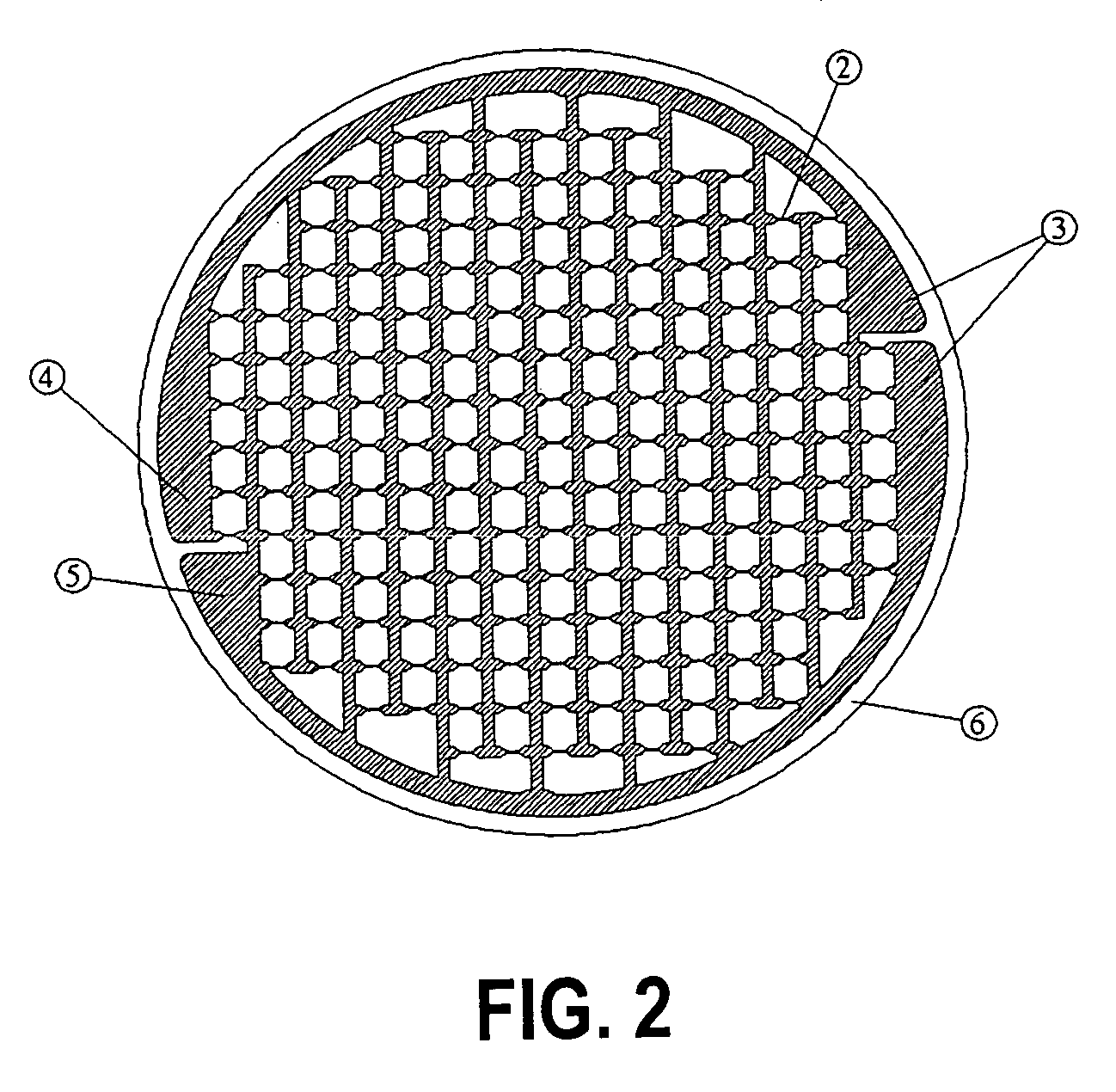

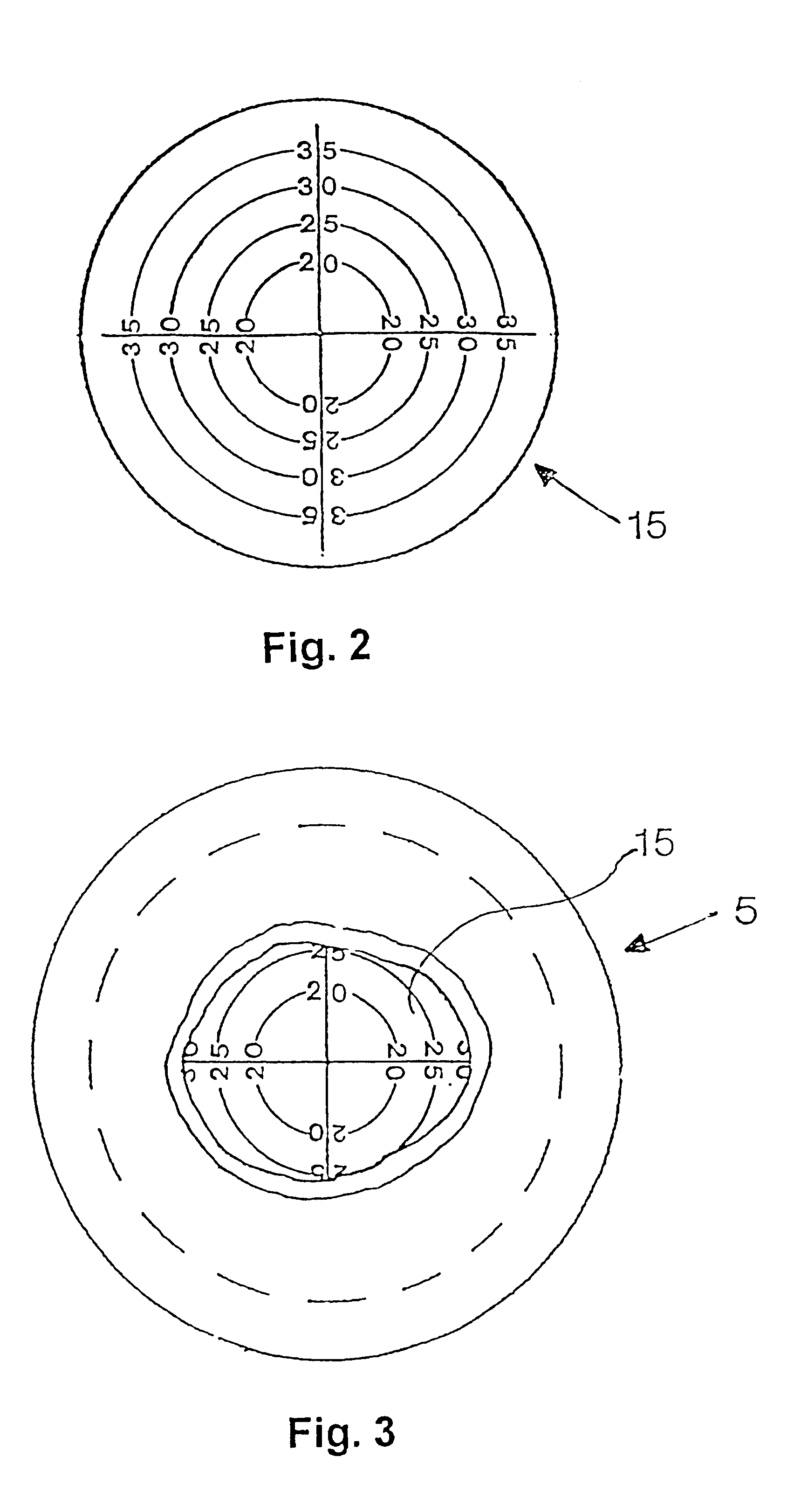

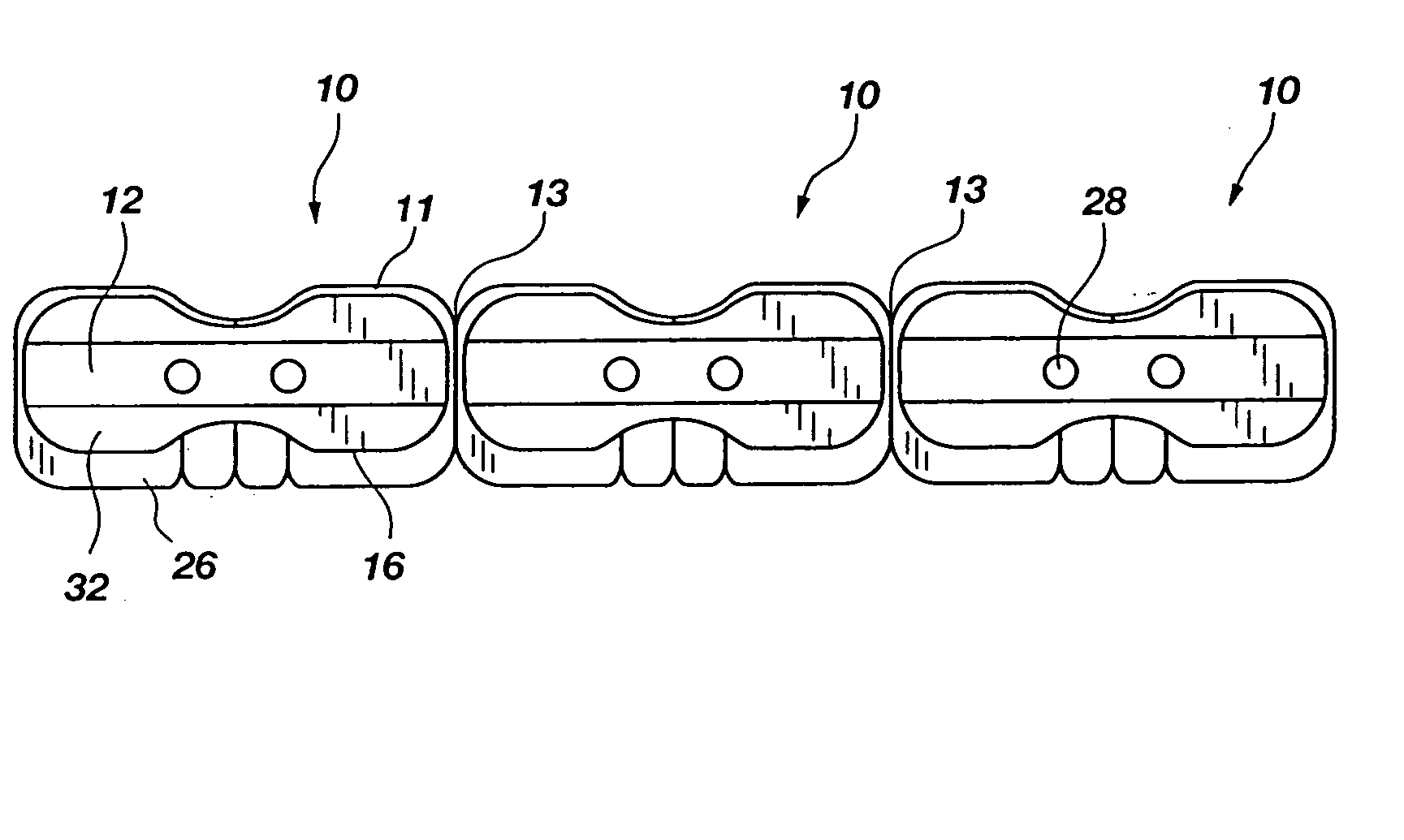

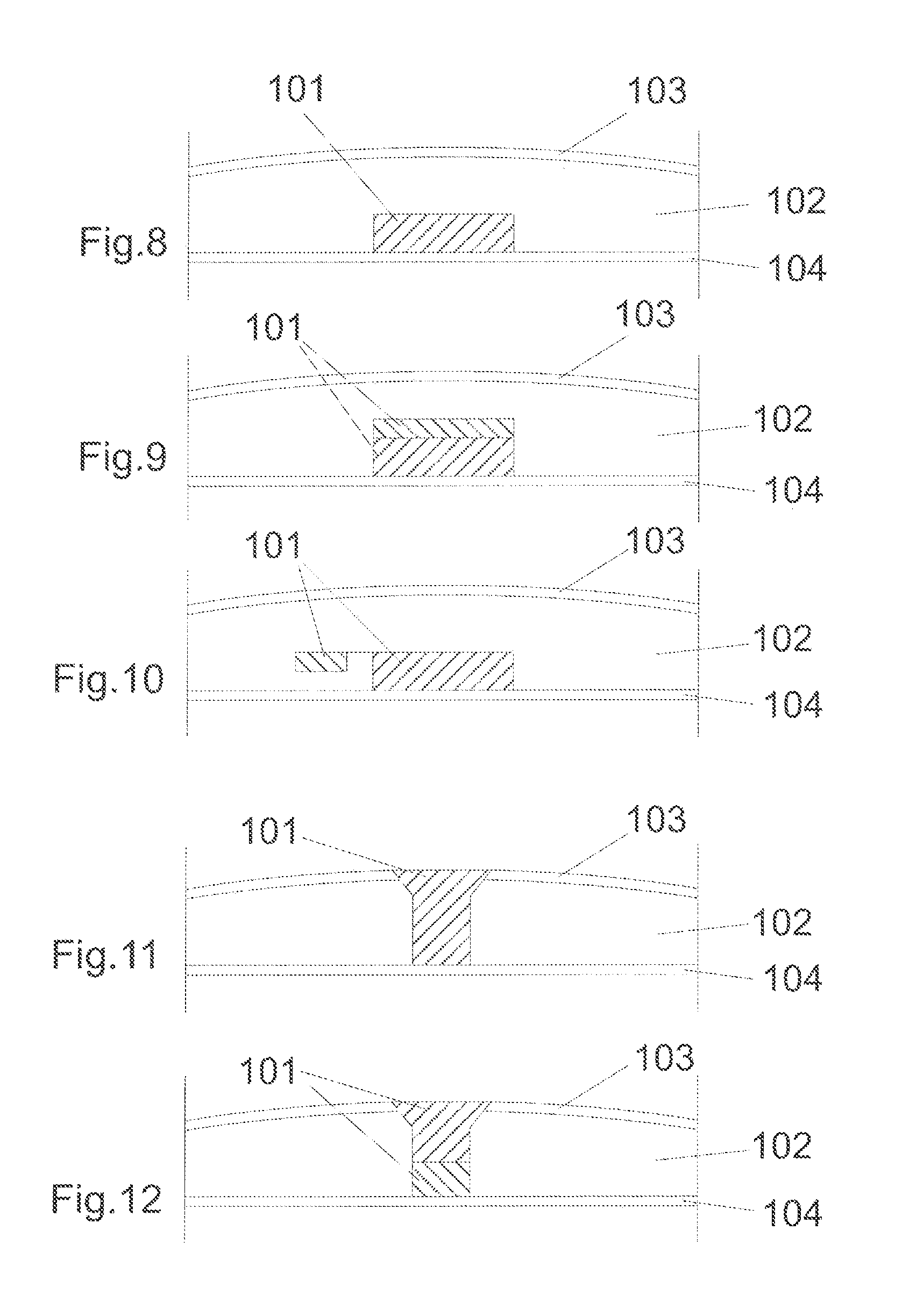

An infusion device (1) comprising a housing (3) with an upper face plate (4) and a lower face plate (5) and an adhesive sheet material (101) placed on the lower face plate (5) for securing the infusion device (1) to the skin, the adhesive sheet material (101) comprising a backing layer (102) which has an adhesive layer (103) on one surface, the adhesive layer (103) being covered by a removable release liner (104), and wherein the release liner (104) comprising at least one score line (106) comprising a spiral or helix, wherein the starting point (107) for the score line (106) is placed in the periphery (108) of the release liner (104) and wherein the score line (106) continues to an end point placed on the border of the periphery (110) of a central aperture (105) of the release liner.

Owner:UNOMEDICAL AS

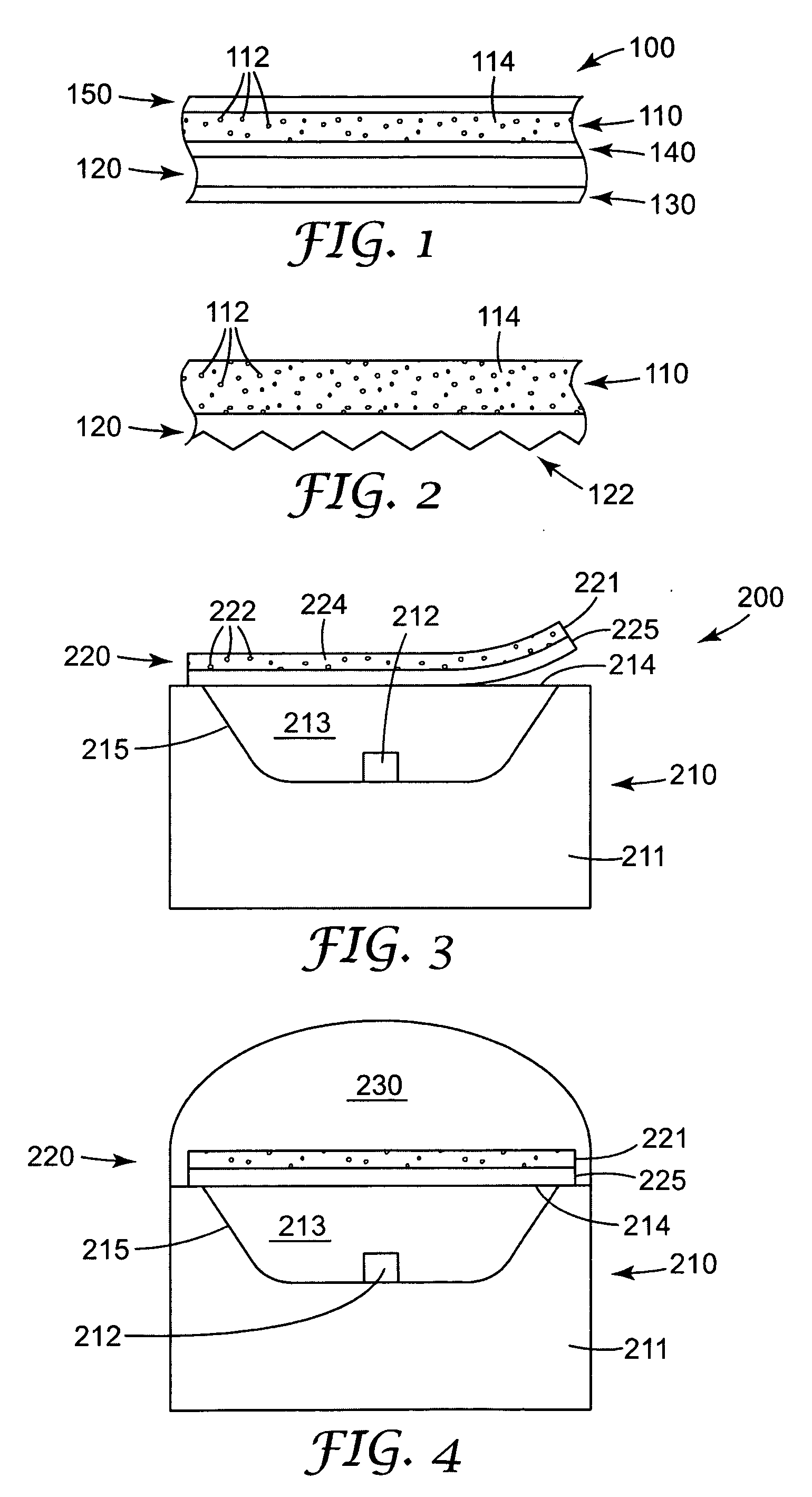

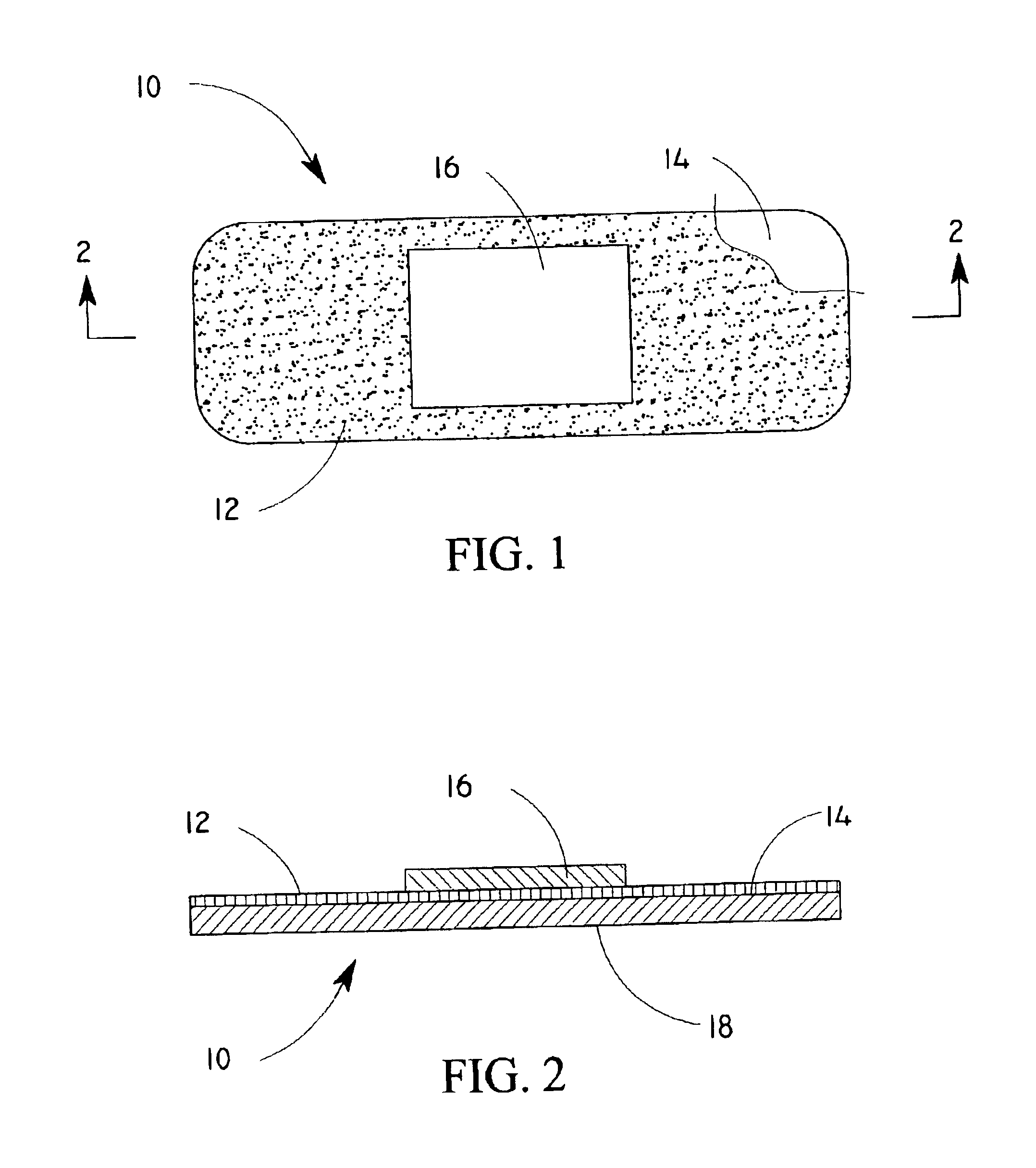

Three-Dimensional Adhesive Device Having a Microelectronic System Embedded Therein

InactiveUS20080275327A1Simple and inexpensive wayModerate viscosityWave amplification devicesLayered productsCapacitanceElectronic systems

Accordingly, the present invention relates to a three-dimensional adhesive device to be attached to the body surface of a mammal comprising a microelectronic sensing system characterized by(a) a three-dimensional adhesive body made of a pressure sensitive adhesive having an upper surface and a bottom surface;(b) a microelectronic system embedded in the body of the pressure sensitive adhesive;(c) one or more cover layer(s) attached to the upper surface; and(d) optionally a release liner releasable attached to the bottom surface of the adhesive device.Suitably the microelectronic system is a microelectronic sensing system capable of sensing physical input such as pressure, vibration, sound, electrical activity (e.g. from muscle activity), tension, blood-flow, moisture, temperature, enzyme activity, bacteria, pH, blood sugar, conductivity, resistance, capacitance, inductance or other chemical, biochemical, biological, mechanical or electrical properties.

Owner:BRAEMAR MFG +2

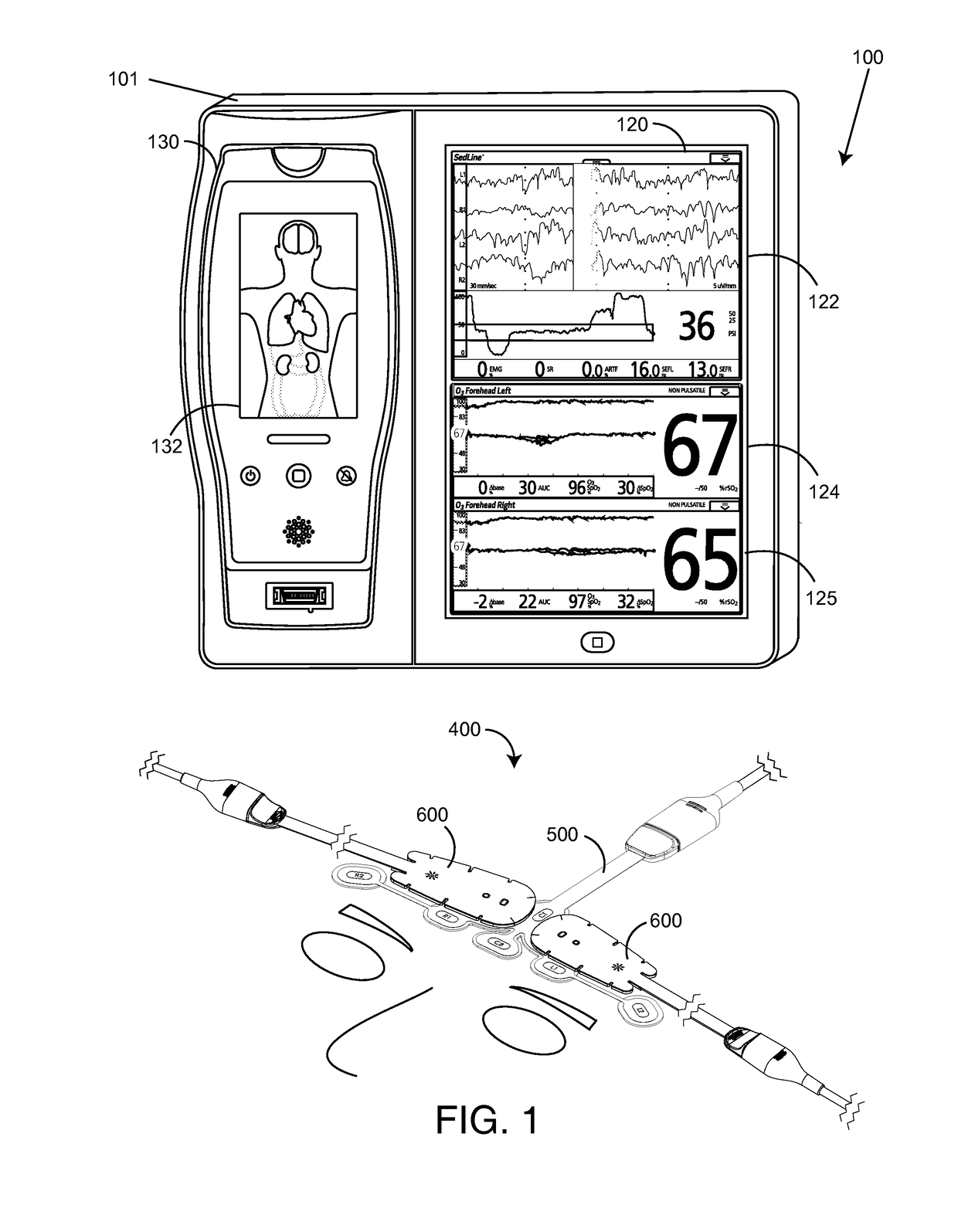

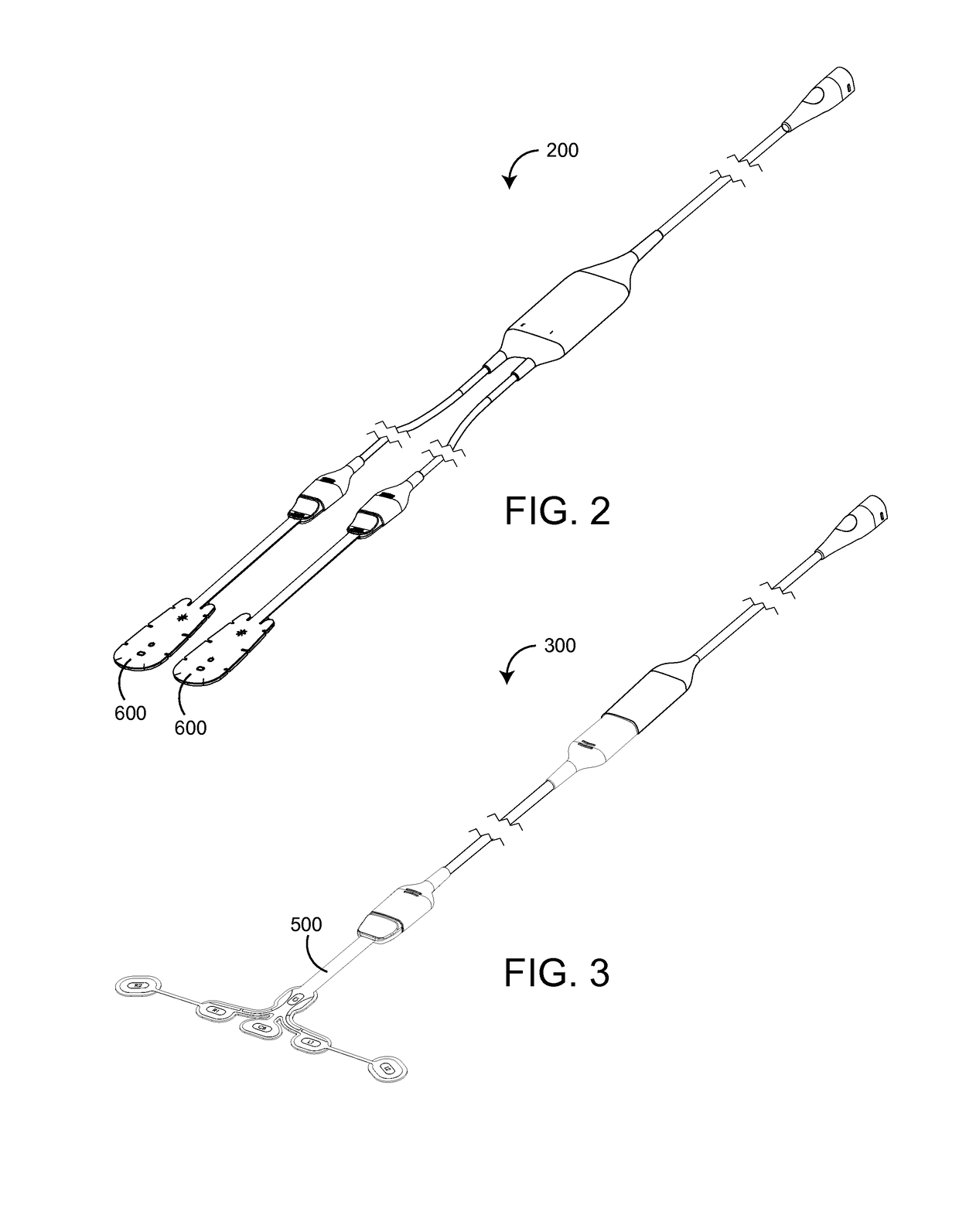

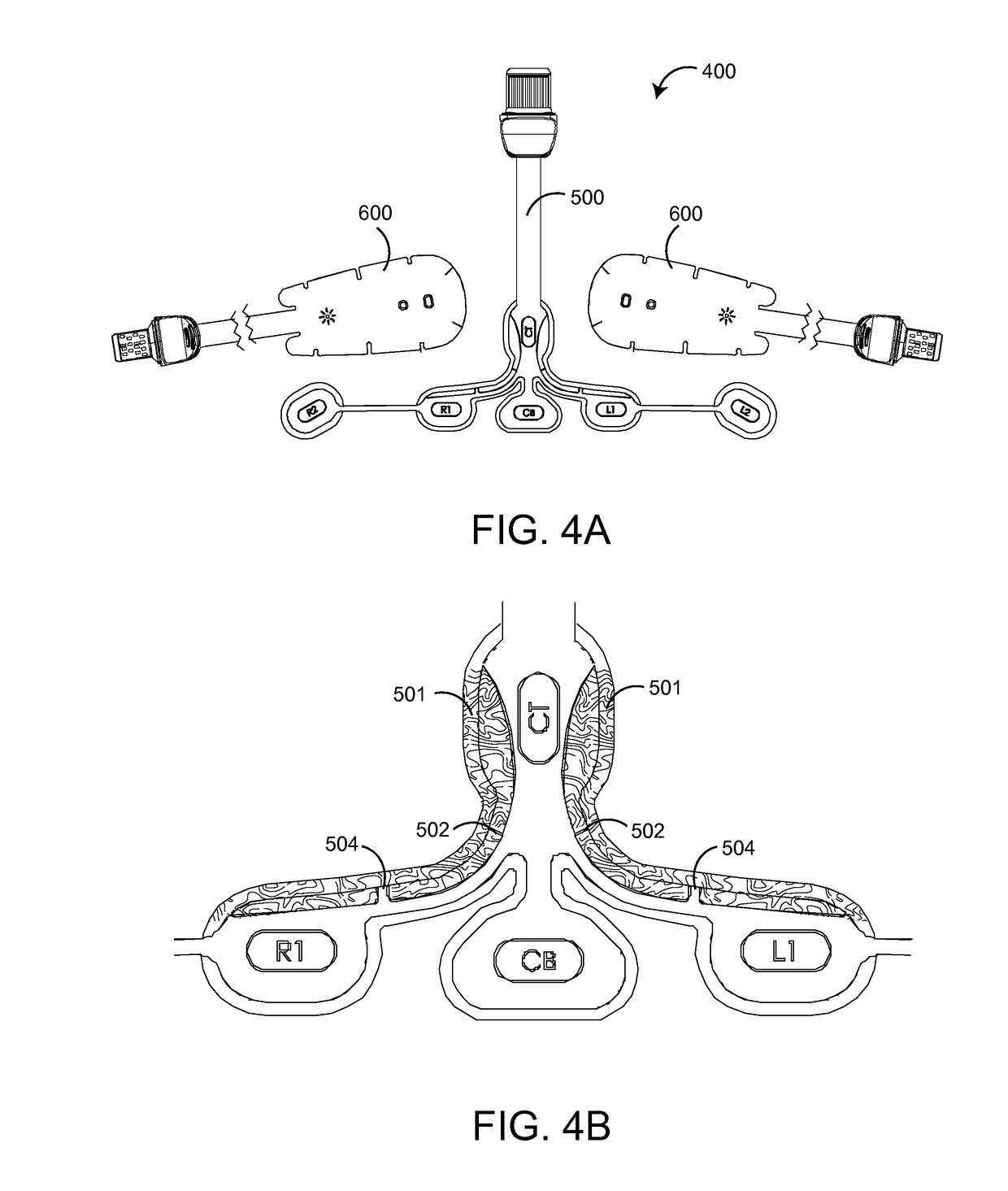

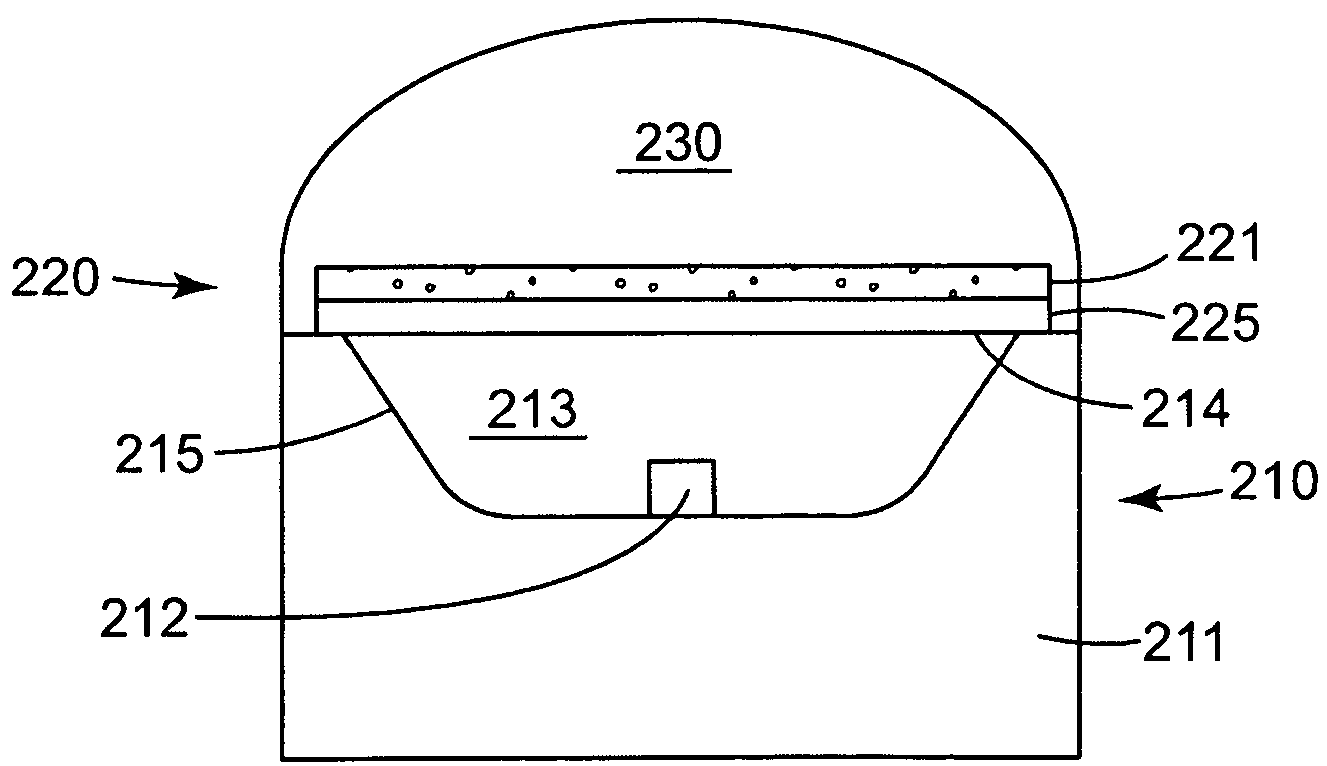

Modular physiological sensors

ActiveUS10154815B2Accurate operationAutomate analysisElectroencephalographySensorsModularityEngineering

Modular physiological sensors that are physically and / or electrically configured to share a measurement site for the comfort of the patient and / or to ensure proper operation of the sensors without interference from the other sensors. The modular aspect is realized by providing outer housing shapes that generally conform to other physiological sensors; mounting areas for attachment of one sensor to another sensor; providing release liners on the overlapping sensor attachment areas; and / or providing notches, tabs or other mechanical features that provide for the proper placement and interaction of the sensors.

Owner:MASIMO CORP

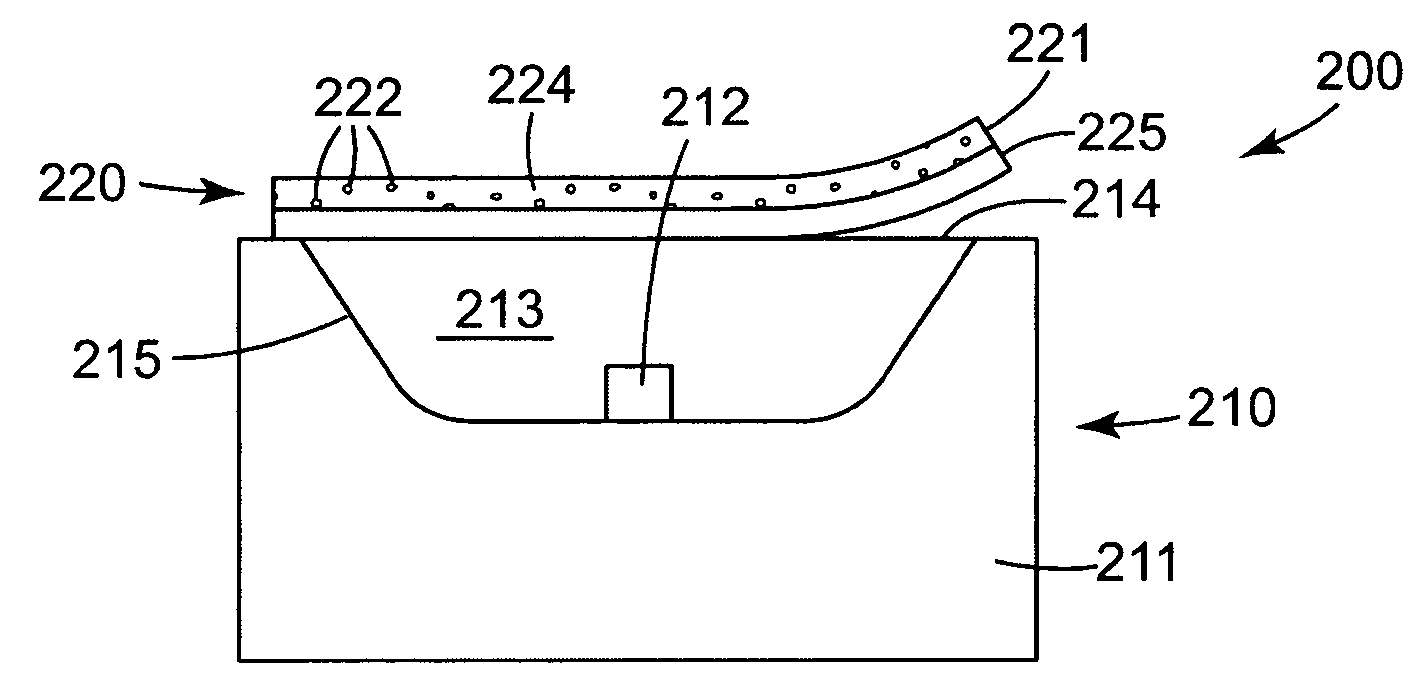

Phosphor tape article

InactiveUS7294861B2Improve consistencyImprove predictabilitySolid-state devicesSemiconductor/solid-state device manufacturingPhosphorLight emitting device

Owner:3M INNOVATIVE PROPERTIES CO

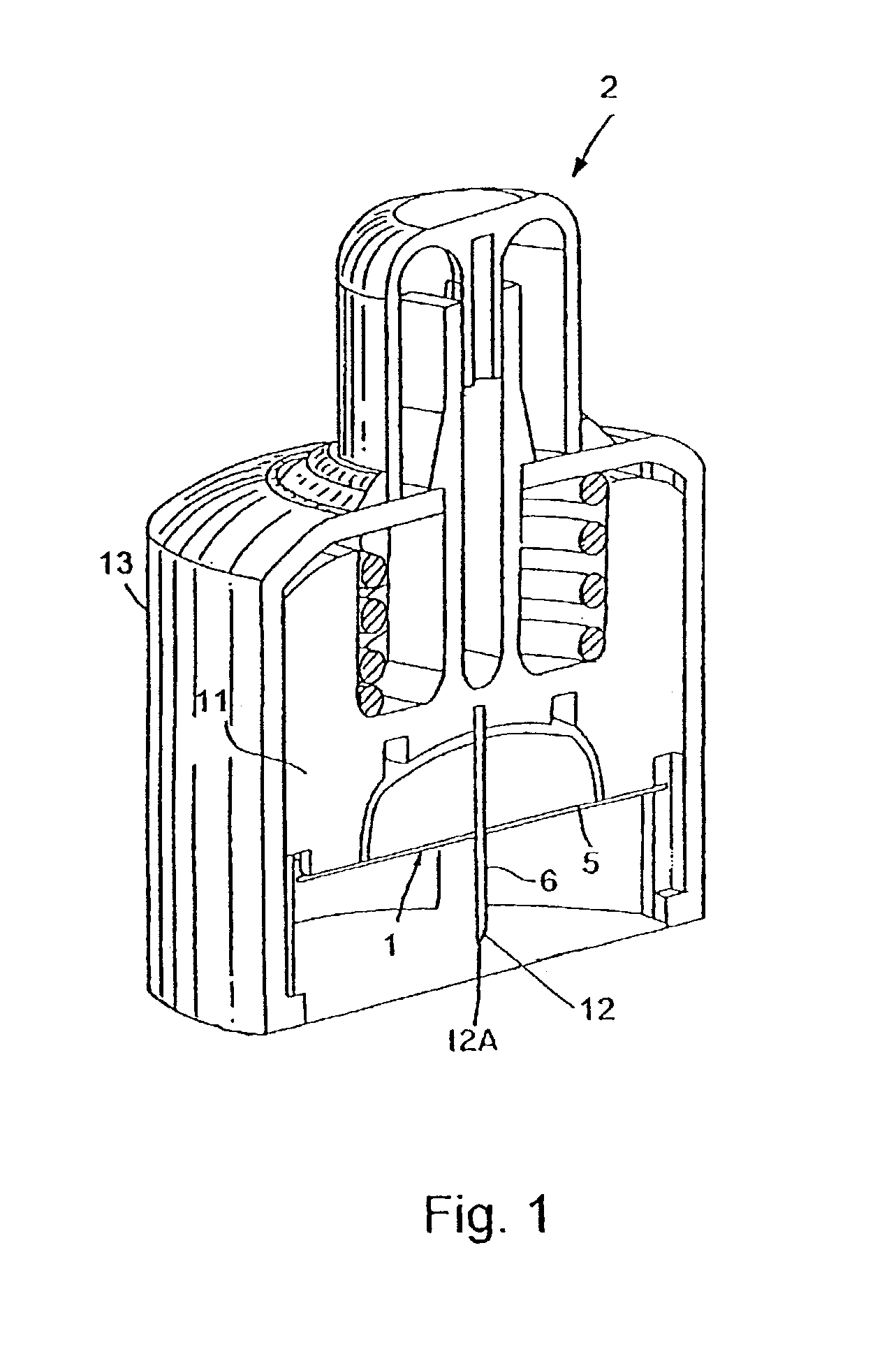

Transdermal drug delivery patch system, method of making same and method of using same

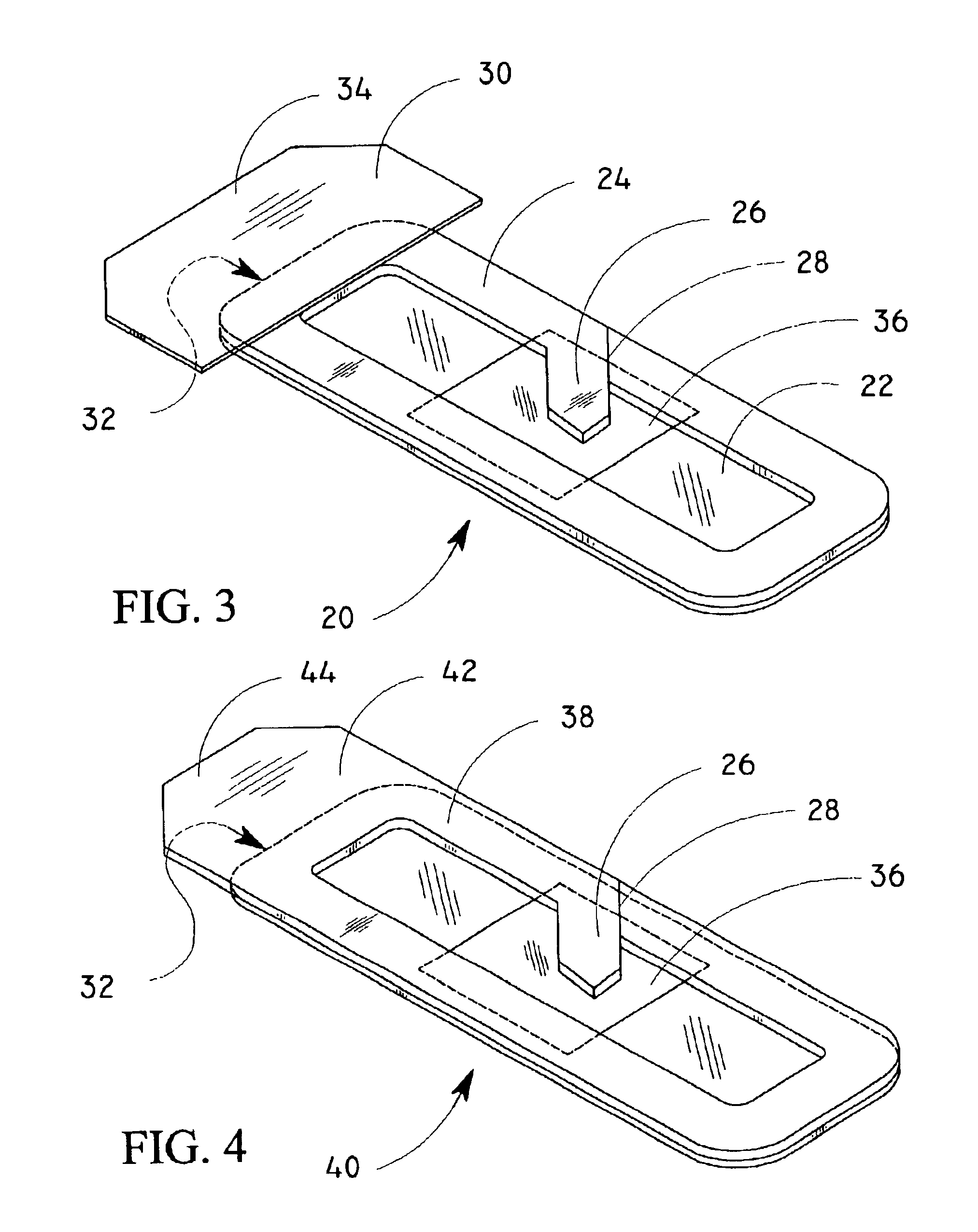

The invention provides for a transdermal drug delivery device for forming a drug delivery patch system comprising:a) an actuator comprising:i) an outer body defining a top of the actuator, the outer body containing a cavity;ii) a controller board comprising driving electronics and a battery, the controller board being positioned within the cavity; andiii) an interface connection port for receiving a porator array, the interface connection port containing an anode and a cathode;b) the porator array comprising:i) a top surface, with a removable adhesive attached to the top surface, the top surface containing two concentric electrical contact rings for contacting the interface connection port at the anode and the cathode upon removal of the adhesive layer;ii) a bottom surface comprising a tissue interface membrane, the tissue interface membrane further comprising a substrate with at least one porator contained on or within the substrate, the bottom surface further comprising an adhesive layer for attaching the porator array to a tissue membrane; andiii) an extension tab laterally and removably attached to the bottom surface, the extension tab including an adhesive applied on the bottom thereof, thereby allowing the extension tab to remain on the tissue membrane upon removal of the porator array; andiv) a release liner removably attached to the bottom surface; andc) a reservoir patch attached to the extension tab, the reservoir patch being applied to the microporated area of the tissue membrane after poration.The invention also provides for methods of making and methods of using the same.

Owner:PASSPORT TECH +1

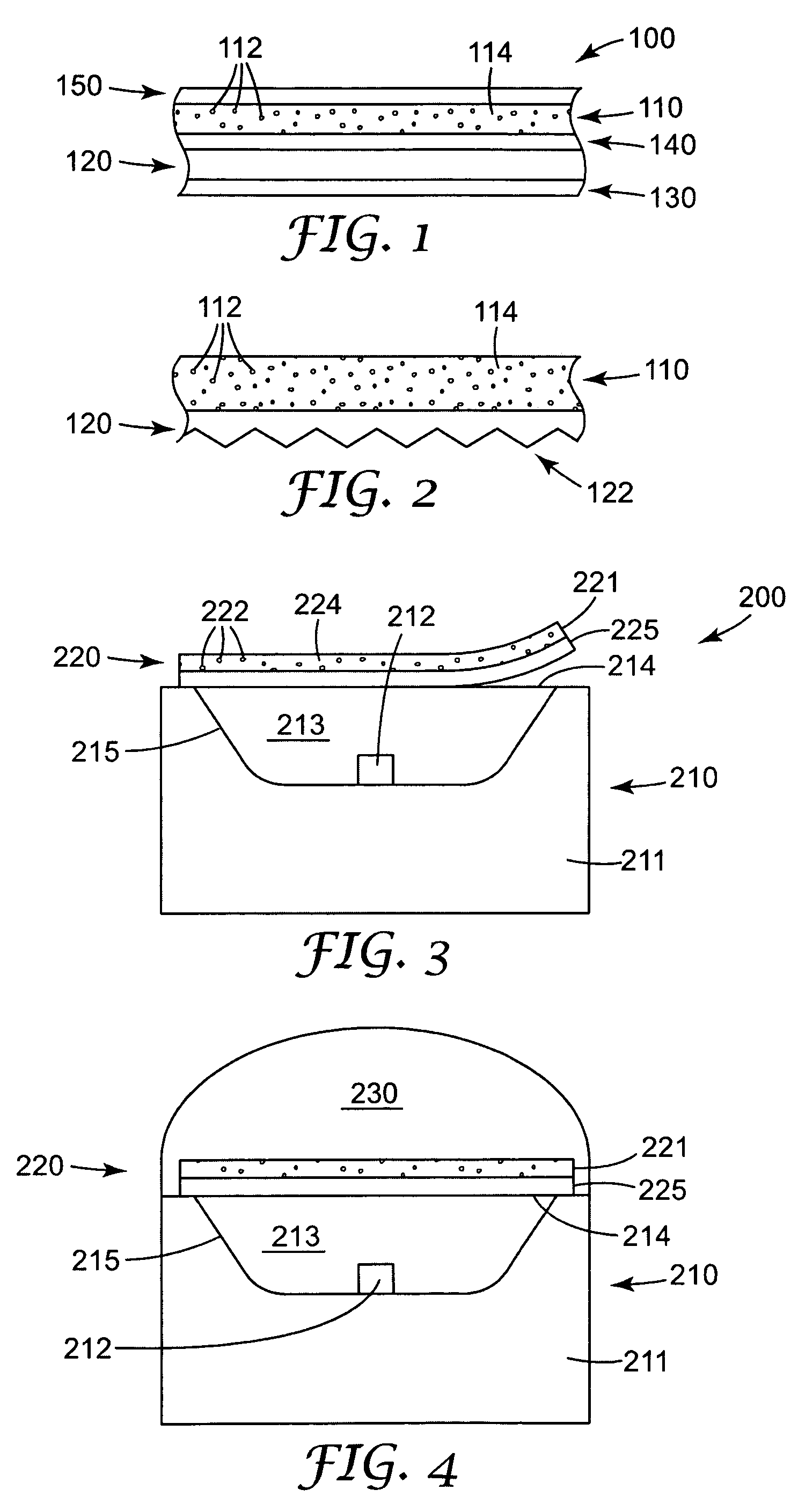

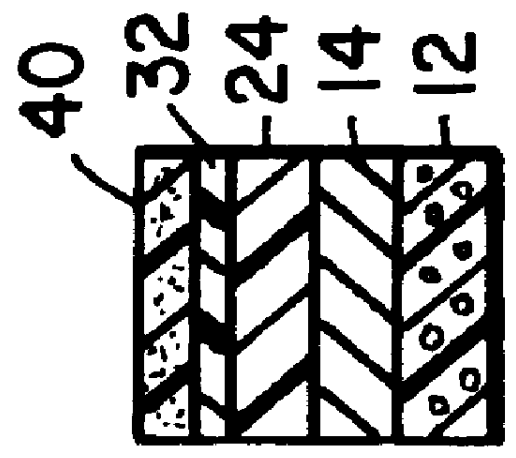

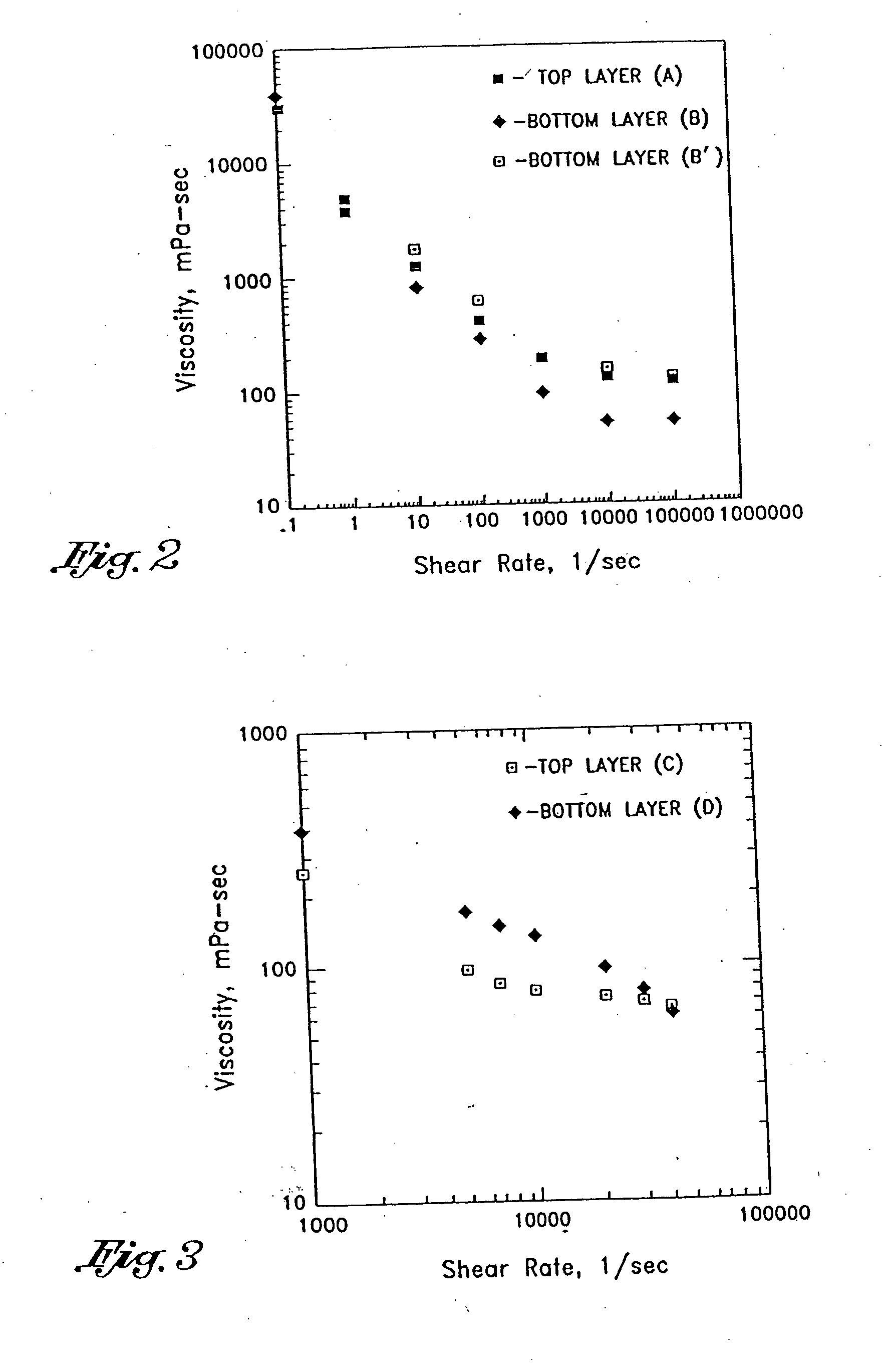

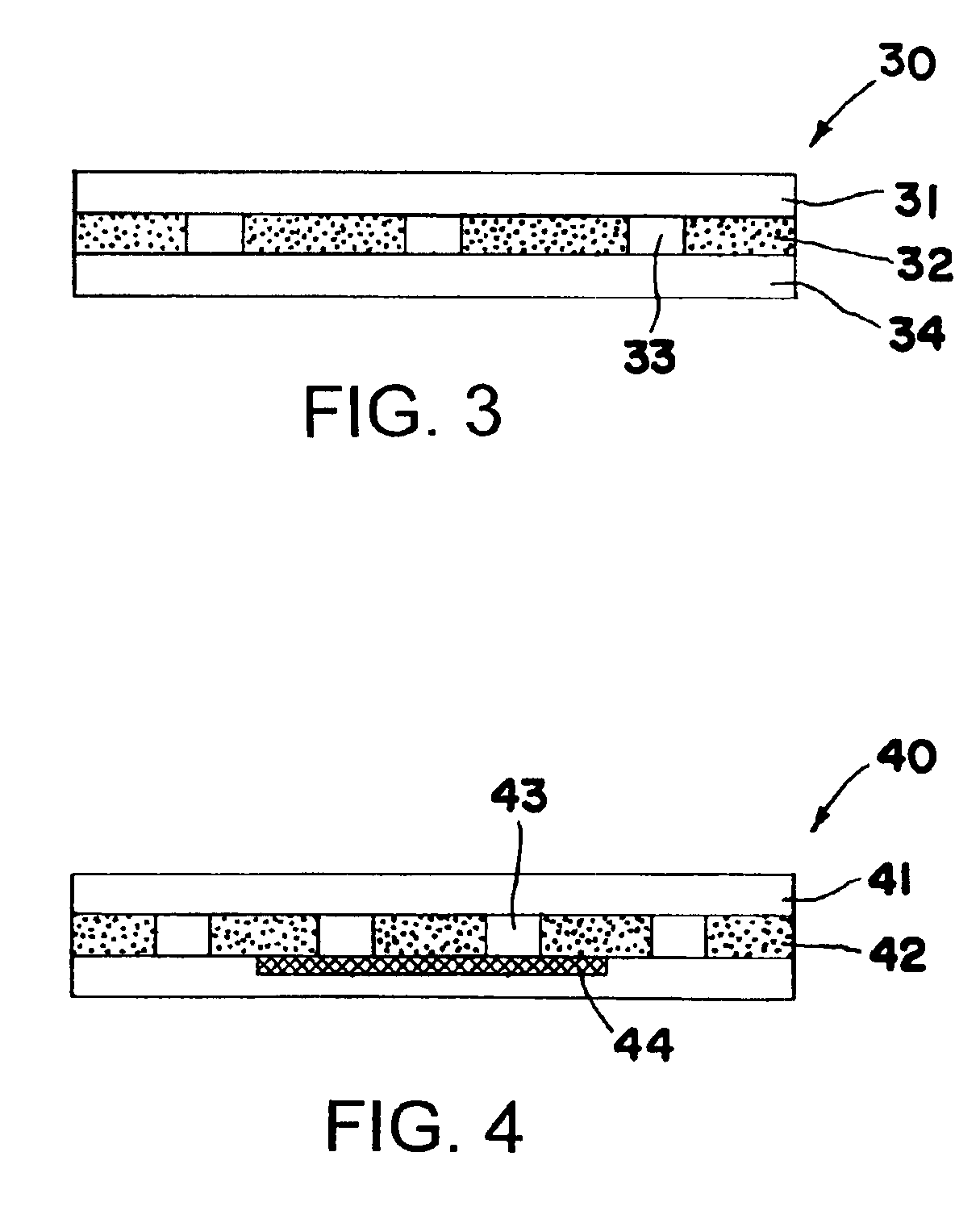

Thermal interface material having a zone-coated release linear

InactiveUS6644395B1Reduce generationIncrease physical strengthFilm/foil adhesivesSemiconductor/solid-state device detailsEngineeringConductive materials

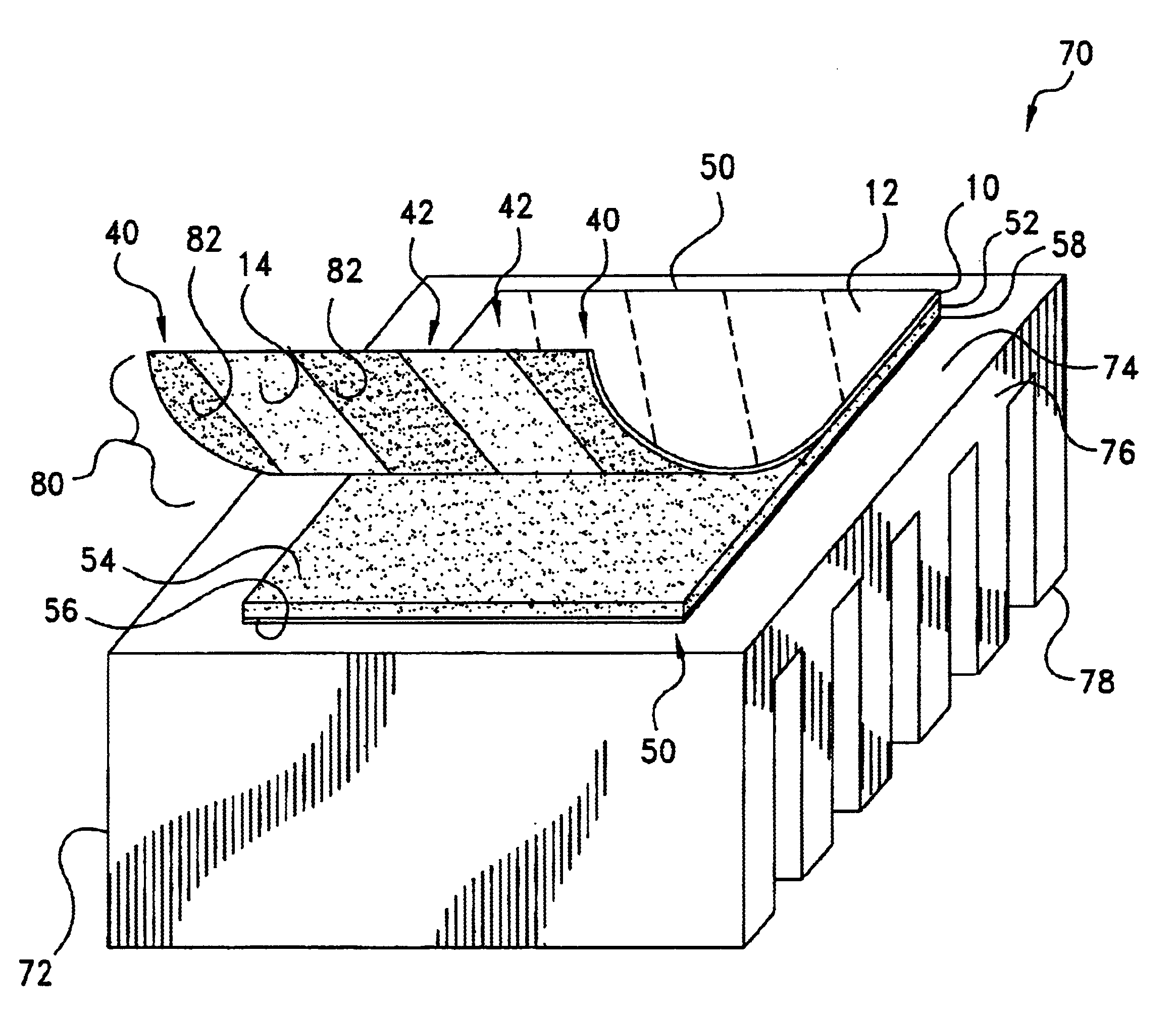

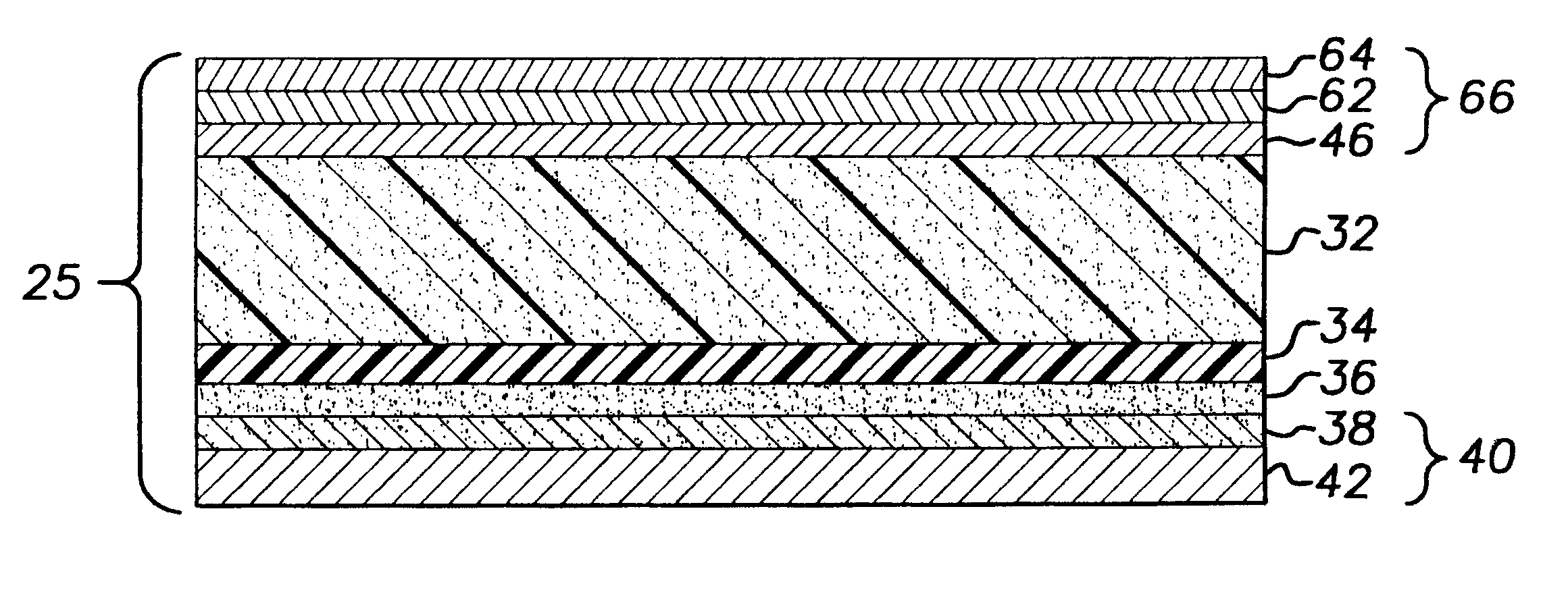

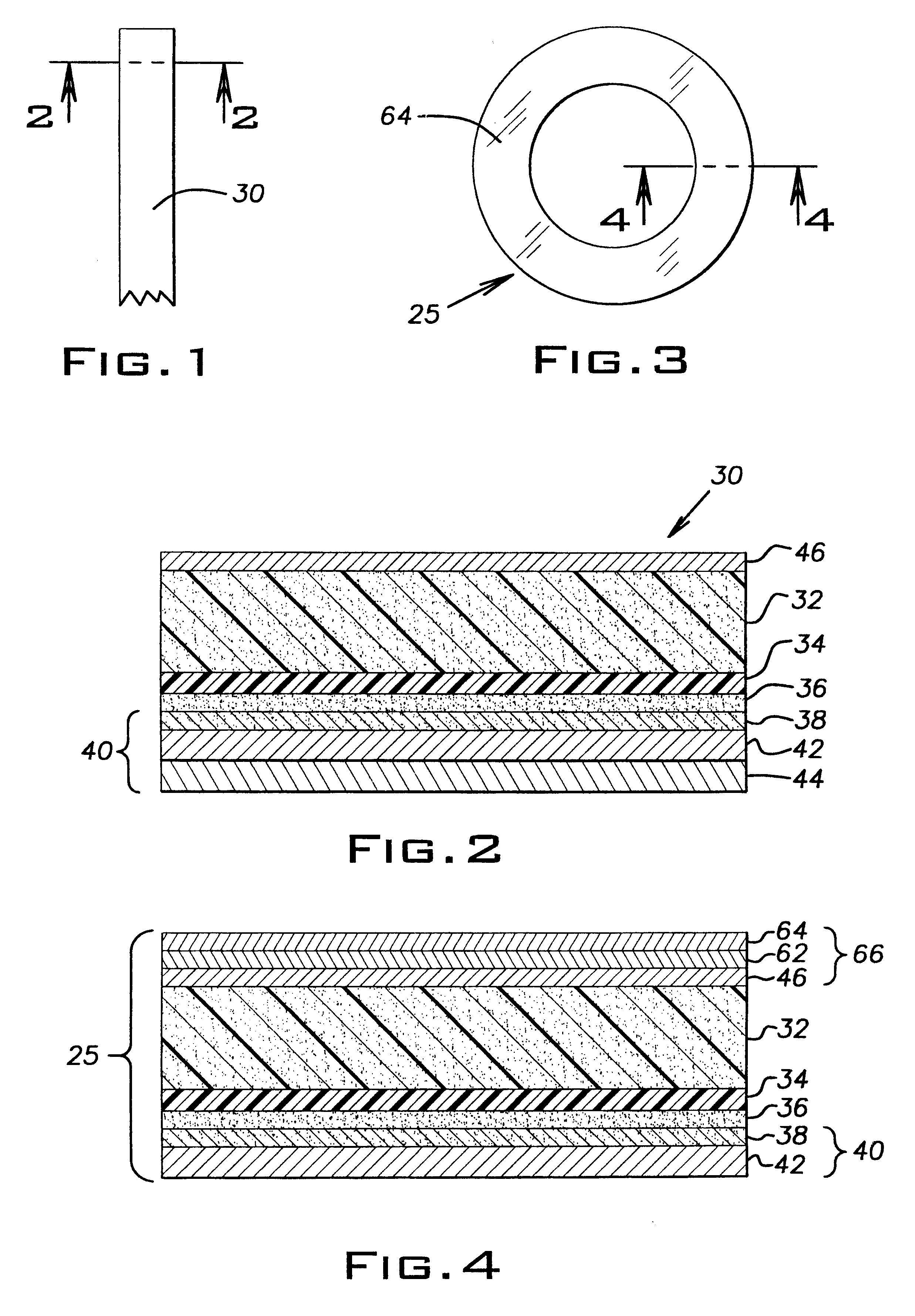

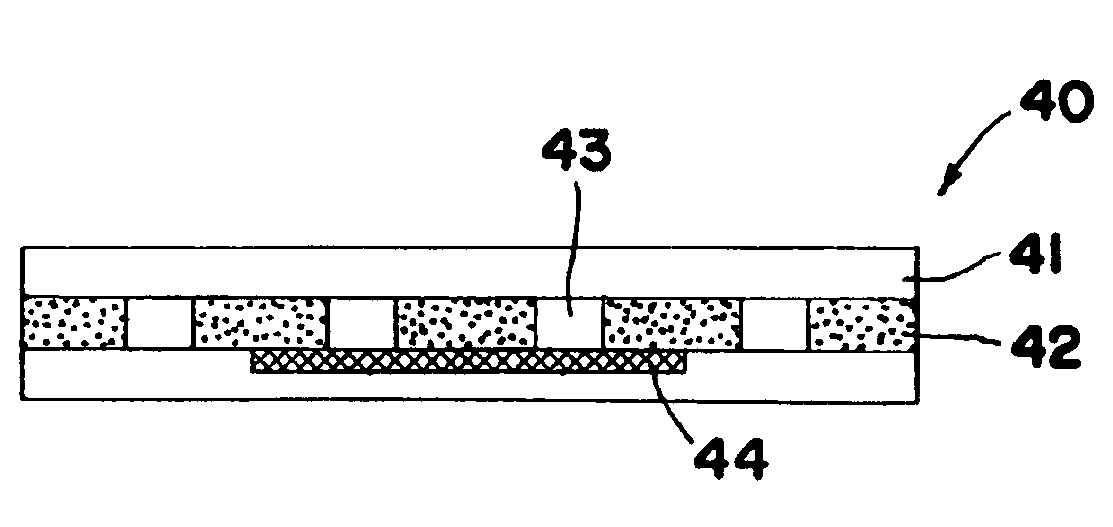

A release liner particularly adapted for use with a layer of a thermal interface material having a first surface and a second surface which is bondable to the heat transfer surface of a thermal dissipation member. The liner has an exterior surface and an interior surface disposable in adhering contact with the first surface of the thermally-conductive material. The liner interior surface has one or more first zones defined thereon which exhibit a first release value relative to the first surface of the thermally-conductive material, and one or more second zones bordered by the first zones which exhibit a second release value relative to the first surface of the thermally-conductive material which is lower than the first release value of the first zones. With the second surface of the thermally-conductive material being bonded to the heat transfer surface of the thermal dissipation member, the release liner is removable from the first surface of the thermally-conductive material without substantial cohesive or adhesive failure thereof.

Owner:PARKER HANNIFIN CORP

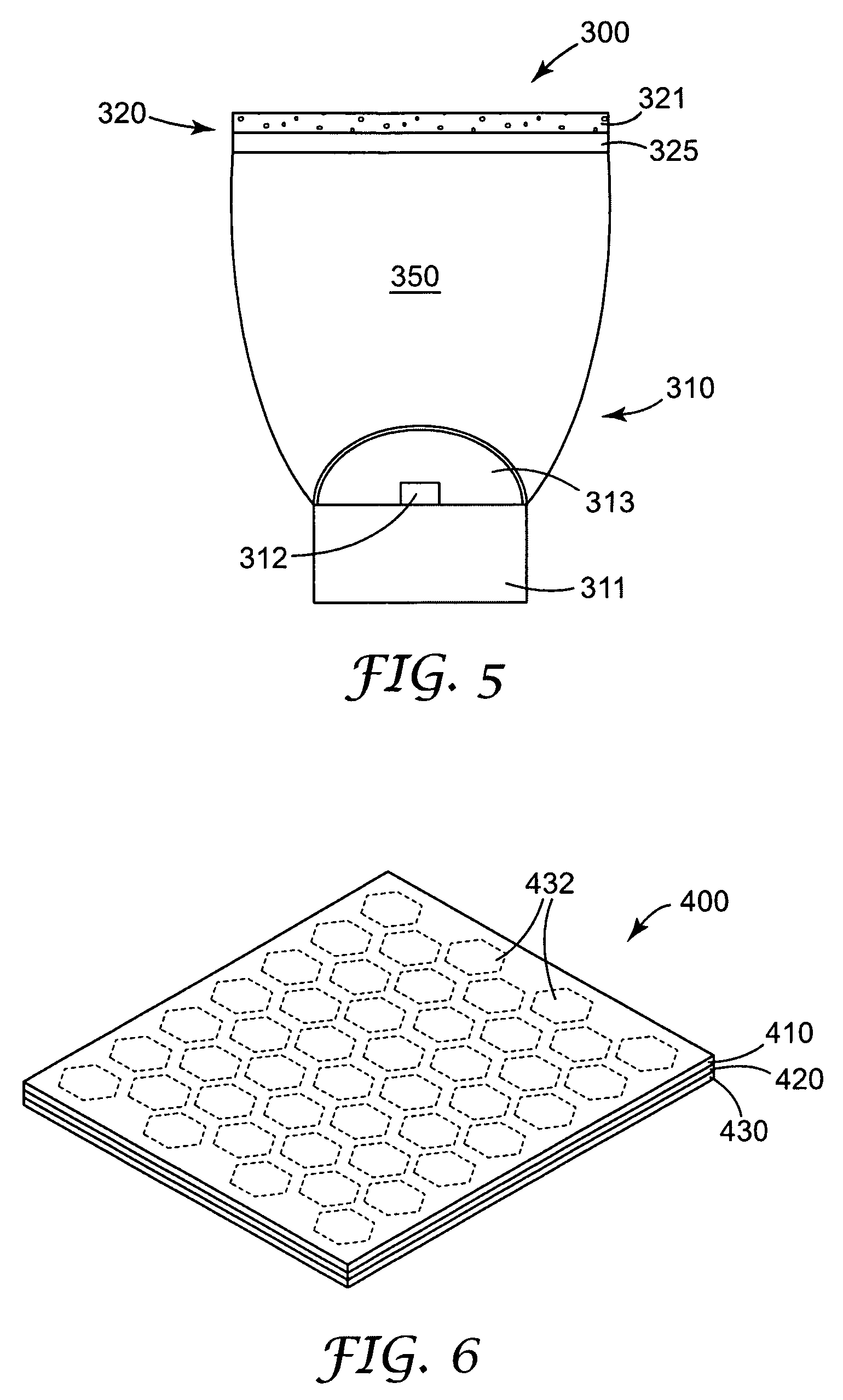

Phosphor tape article

InactiveUS20070004065A1Good color consistencyImprove predictabilitySolid-state devicesSemiconductor/solid-state device manufacturingPhosphorLight emitting device

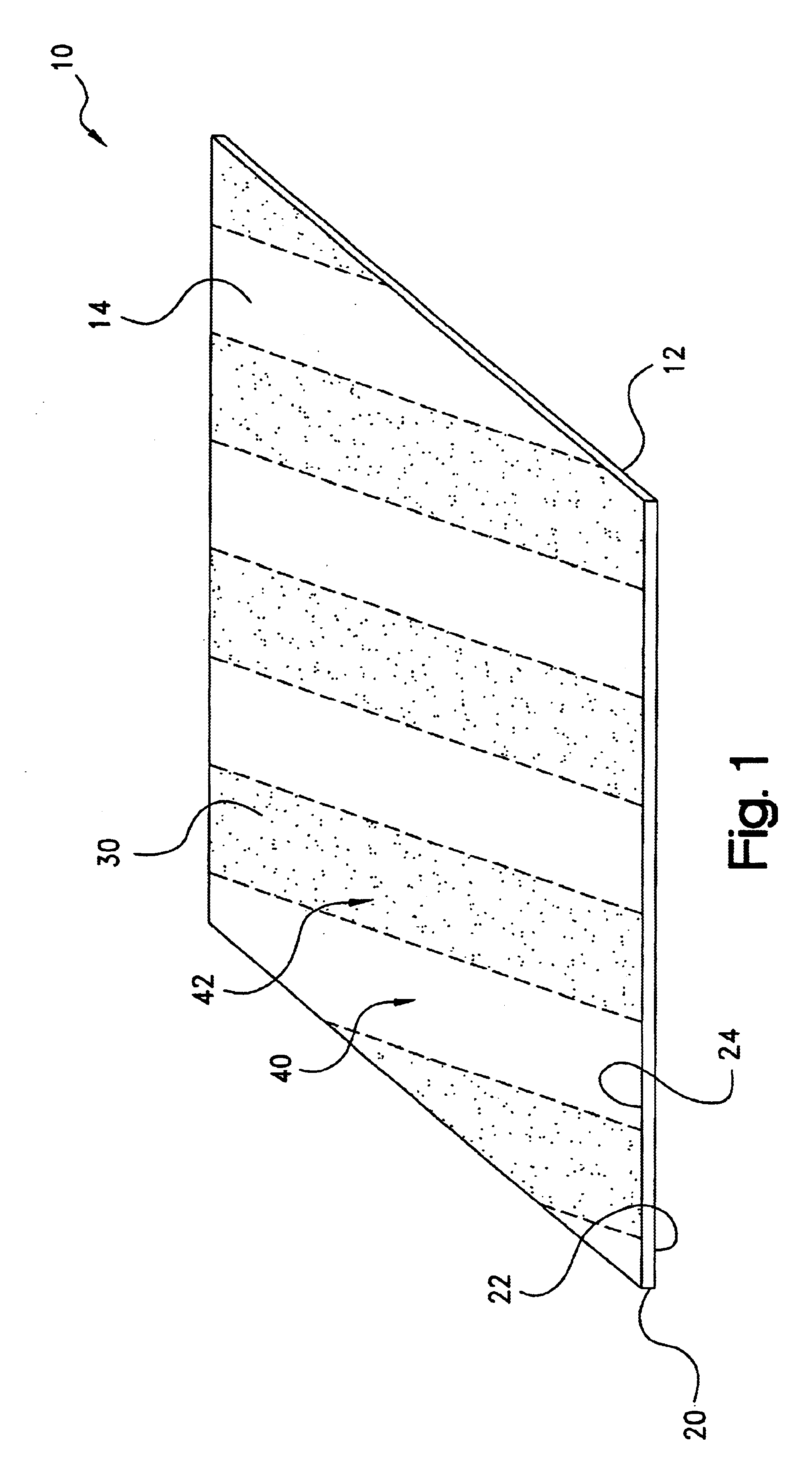

A phosphor tape article includes a phosphor layer having a phosphor and a polymeric binder material, a pressure sensitive adhesive layer disposed adjacent the phosphor layer such that light transmitted through the pressure sensitive adhesive layer is received by the phosphor layer, and a release liner disposed on the pressure sensitive adhesive layer. The pressure sensitive adhesive layer is disposed between the release liner and the phosphor layer. The phosphor is suitable for excitation by UV or blue LED light, and the phosphor emission has a characteristic decay rate of less than 1 second. Light emitting devices including pieces of phosphor tape, and methods of making such devices, are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Identification bracelet with sealable window

ActiveUS20060230661A1Reliable and accurate readingAccurate and reliable readingStampsPerson identificationEngineeringWeakness

An identification bracelet for mounting about a person's wrist or the like incorporates a sealable window to protect wearer-related information against contact with moisture and the like. The bracelet includes a flexible band defining an information-bearing zone, in combination with an overlying adhesive-backed transparent cover strip. In an initial state, the cover strip has opposite ends securely adhered to the band, and a central window segment separated from the band by a peel-off release film. The window segment is adapted for lift-away separation from the band as by tearing along a line of weakness line at one end thereof to expose the information-bearing zone for receiving wearer-related information, and for facilitated peel-off removal of the release film, followed by adhesively seating the strip central window segment onto the band in a manner defining a sealed perimeter overlying and protecting the wearer-related information.

Owner:PRECISION DYNAMICS CORPORATION

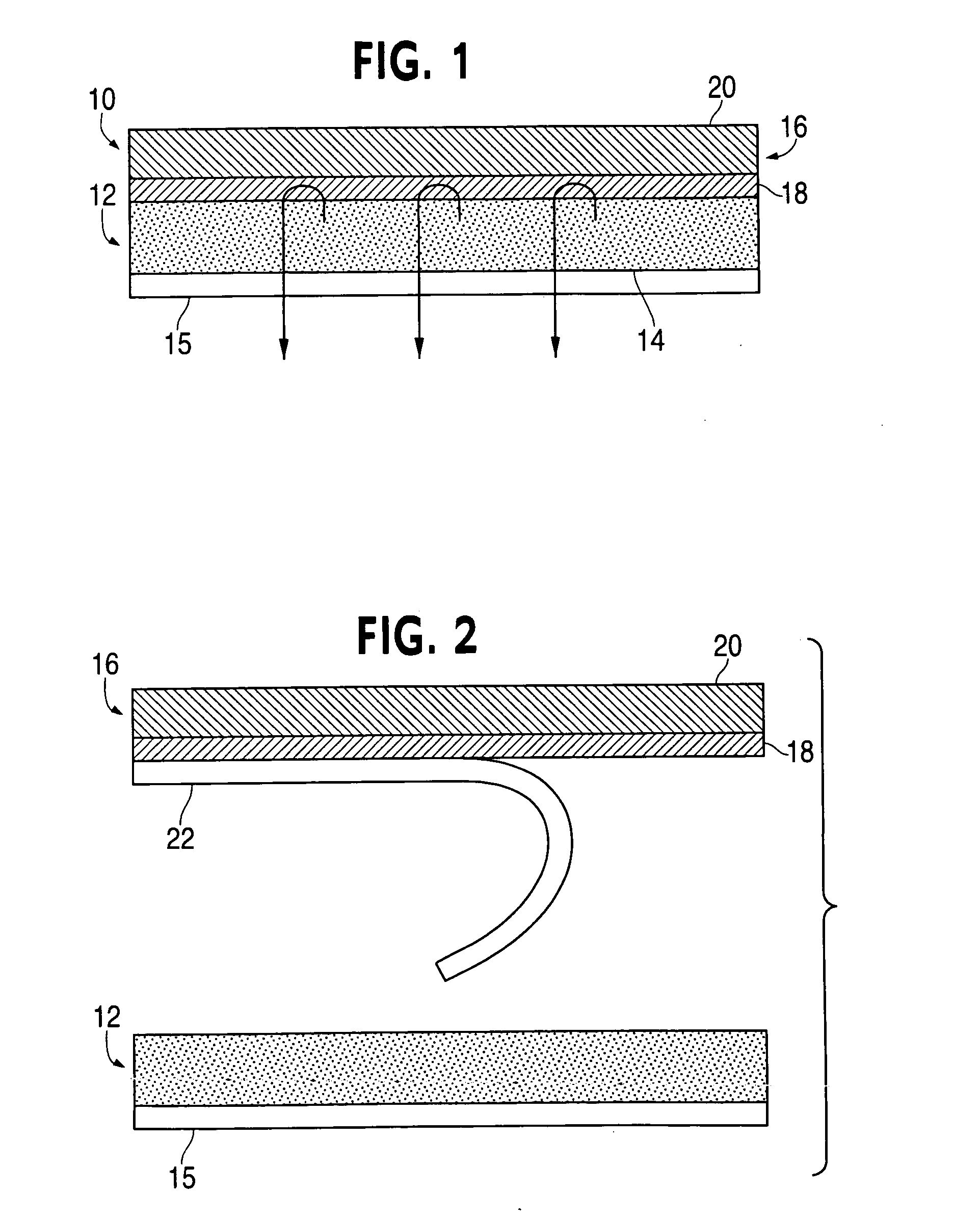

Amorphous drug transdermal systems, manufacturing methods, and stabilization

The present invention refers to a transdermal delivery device comprising a backing layer, an adhesive matrix layer comprising a supersaturated concentration of an active agent substantially in amorphous form within the adhesive matrix, and a release liner. The present invention also refers to a method of preparing an adhesive matrix containing at least one supersaturated active agent substantially in amorphous form. Further, the present invention refers to a method to stabilize and a method to reestablish the meta-stable amorphous-drug transdermal system during its manufacturing, storing, shipping and handling process.

Owner:MYLAN TECH INC

Ostomy appliance

The invention relates to an ostomy appliance comprising a body side member comprising an adhesive wafer or pad for securing the appliance to the user's skin, said wafer or pad having a hole for receiving a stoma, and an optionally separately exchangeable receiving member or bag secured to the body side ostomy member for receiving secretions from the ostomy, said ostomy appliance further comprising a sealing member disposed in the hole of the wafer or pad surrounding the stoma wherein the sealing member disposed in the hole of the wafer or pad surrounding the stoma, said sealing member having a hole for accommodating the stoma and said sealing member having balanced plastic and elastic properties allowing an adaptation of the hole of the ostomy appliance to a stoma by a temporary enlarging the hole by everting or rolling up the inner rim of the hole for accommodating the stoma. When the ostomy appliance of the invention has been placed over and around the stoma the adhesive sealing member may recover essentially to the original form to fit snugly to the stoma. Preferably at least the area of a release liner covering the separate sealing member is provided with a guide for adaptation of the hole of an ostomy appliance to the size of an ostomy, said guide being visible from the side of the release liner facing the sealing member.

Owner:COLOPLAST AS

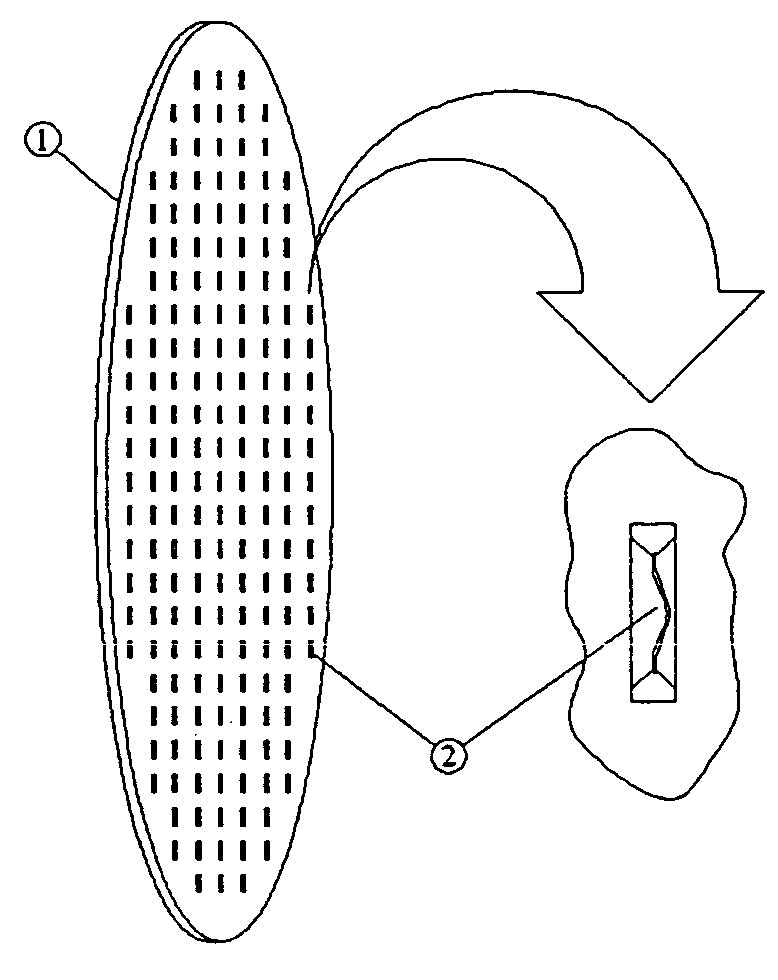

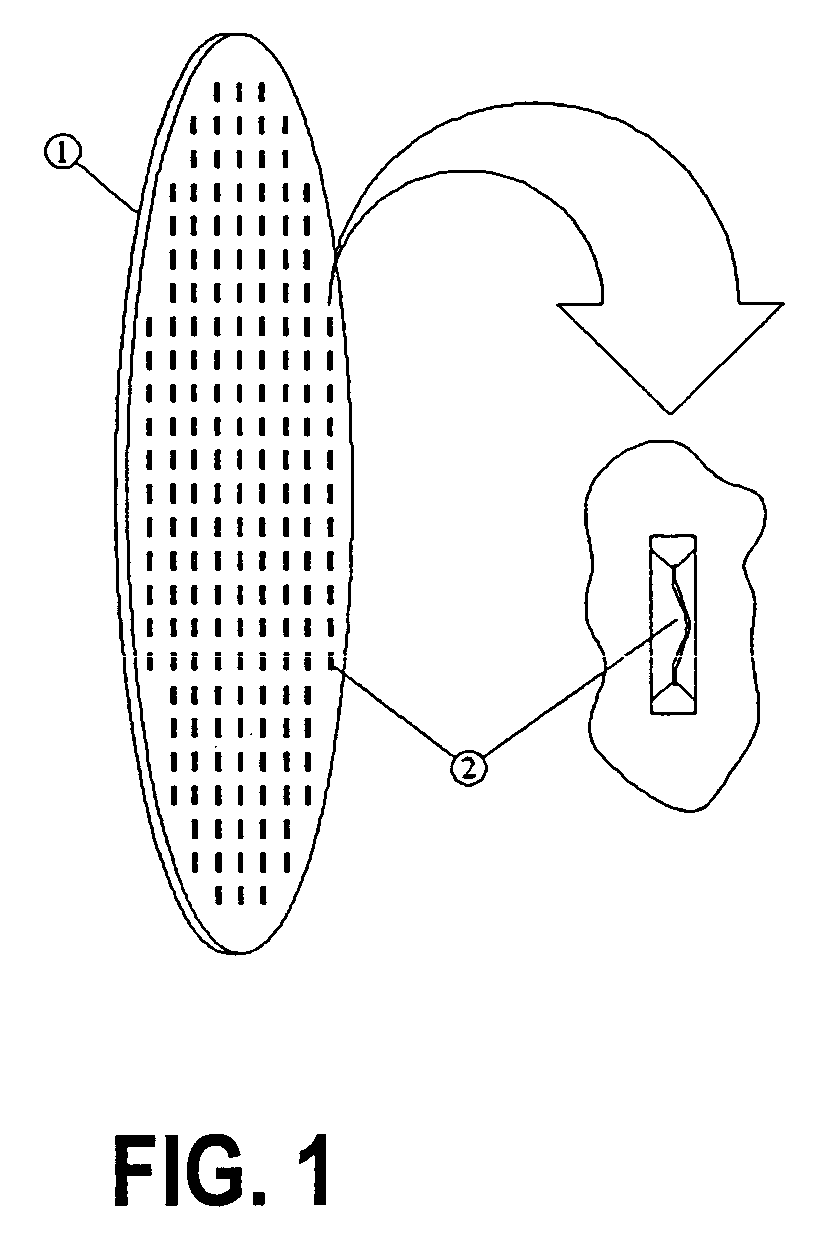

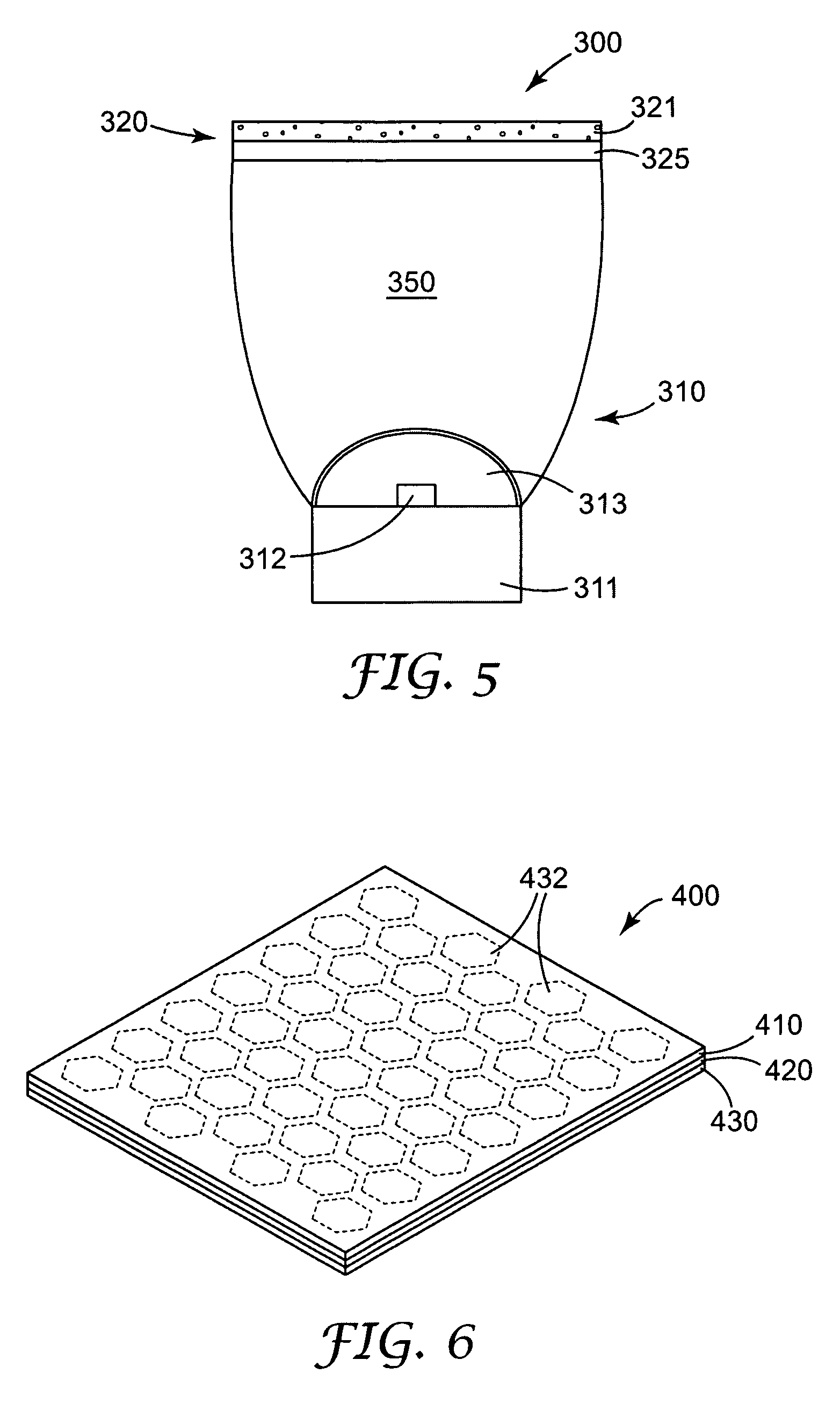

Pulse oximetry sensor and dispensing method

An oximetry sensor that can be easily applied and attached to a portion of the body of a patient in a noninvasive manner is provided. The oximetry sensor of the present invention includes an adhesive wrap member for use with reusable pulse oximetry sensor electronics (e.g., an LED assembly and a photodiode coupled with a cable) to retain the sensor in the desired position comfortably on a patient. The adhesive member includes a release liner thereover which may include an appliqué or other member thereon, for example, instructions for use. The release liner is configured for removal from the adhesive member in at least one release liner portion subsequent to attaching of the pulse oximetry sensor electronics without disturbing such positioning.

Owner:PHILIPS ELECTRONICS NORTH AMERICA

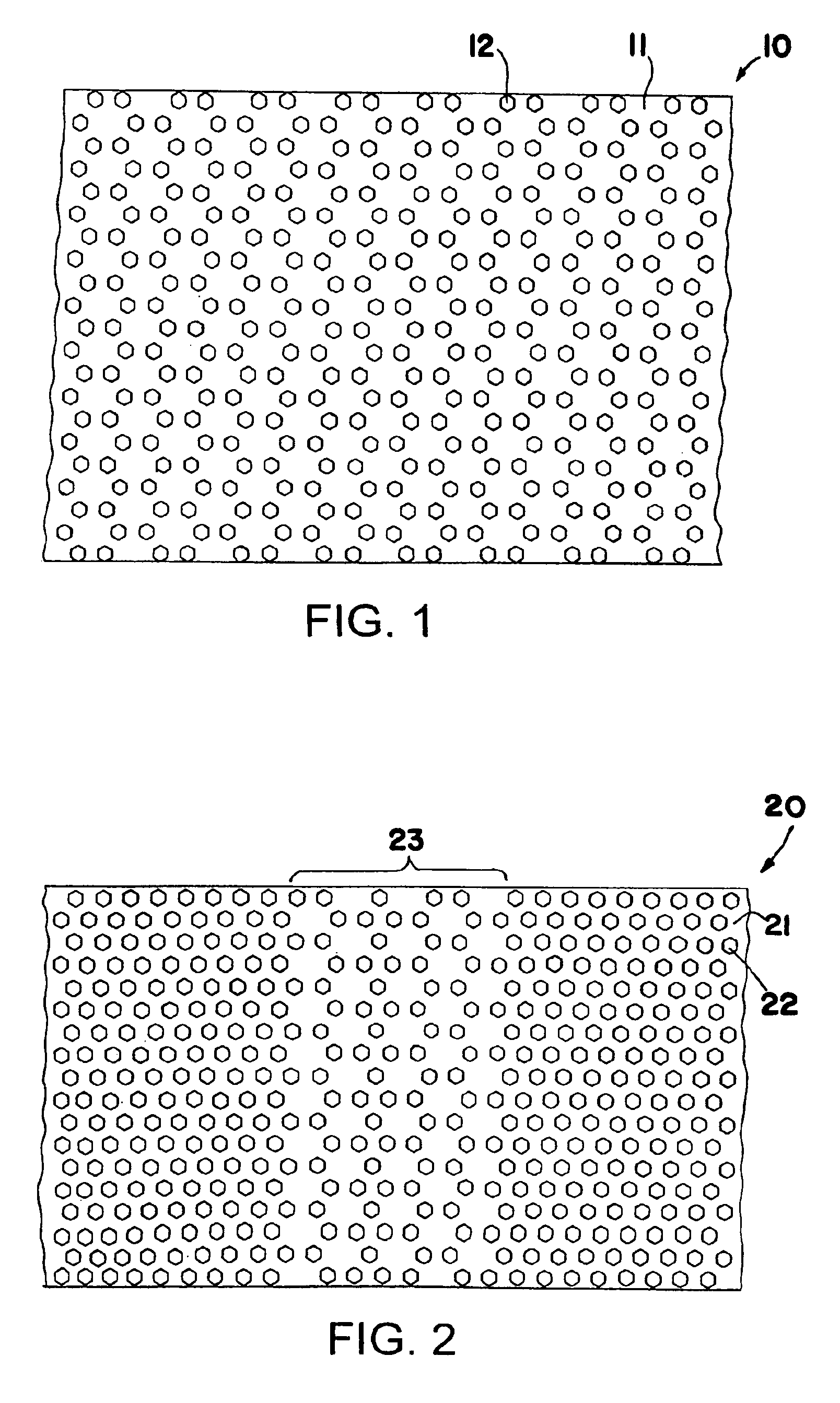

Laminate from which decorative films can be applied to a substrate

InactiveUS6984429B2Precise applicationLamination ancillary operationsDecorative surface effectsEngineeringMechanical engineering

A laminate from which decorative films can be precisely applied to a substrate. The laminate includes a polymeric cover sheet having opposite outer and inner major surfaces. A layer of structured pressure sensitive adhesive is adhered to the inner major surface of the cover sheet. The structured pressure sensitive adhesive has a plurality of spaced passageways extending to at least one edge of the layer of structured pressure sensitive adhesive. A decorative film is adhered to the structured pressure sensitive adhesive. A second layer of pressure sensitive adhesive is adhered to the major surfaces of the decorative film opposite the layer of structured pressure sensitive adhesive. A release liner extends substantially across the second layer of pressure sensitive adhesive and a portion of the structured pressure sensitive adhesive.

Owner:3M INNOVATIVE PROPERTIES CO

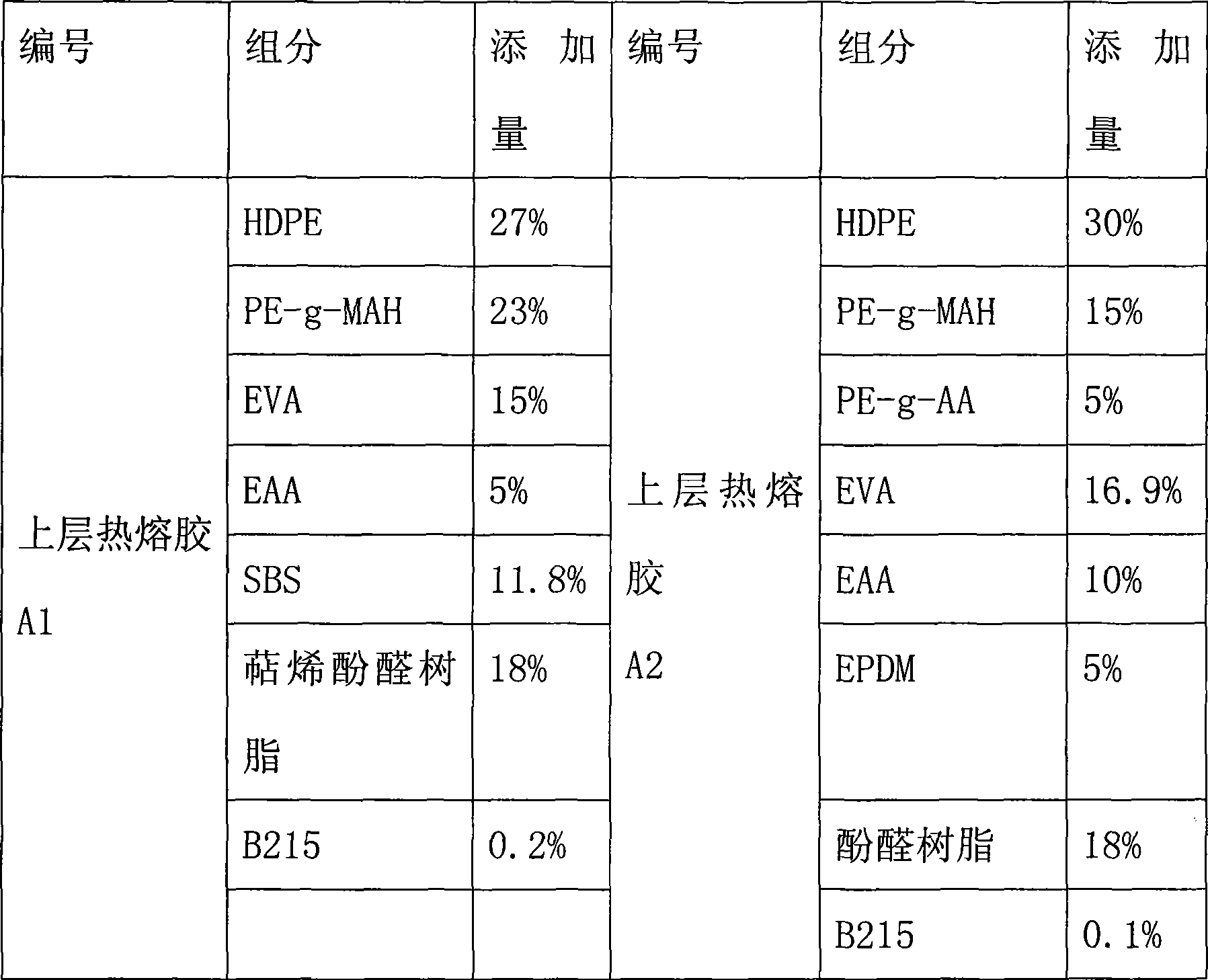

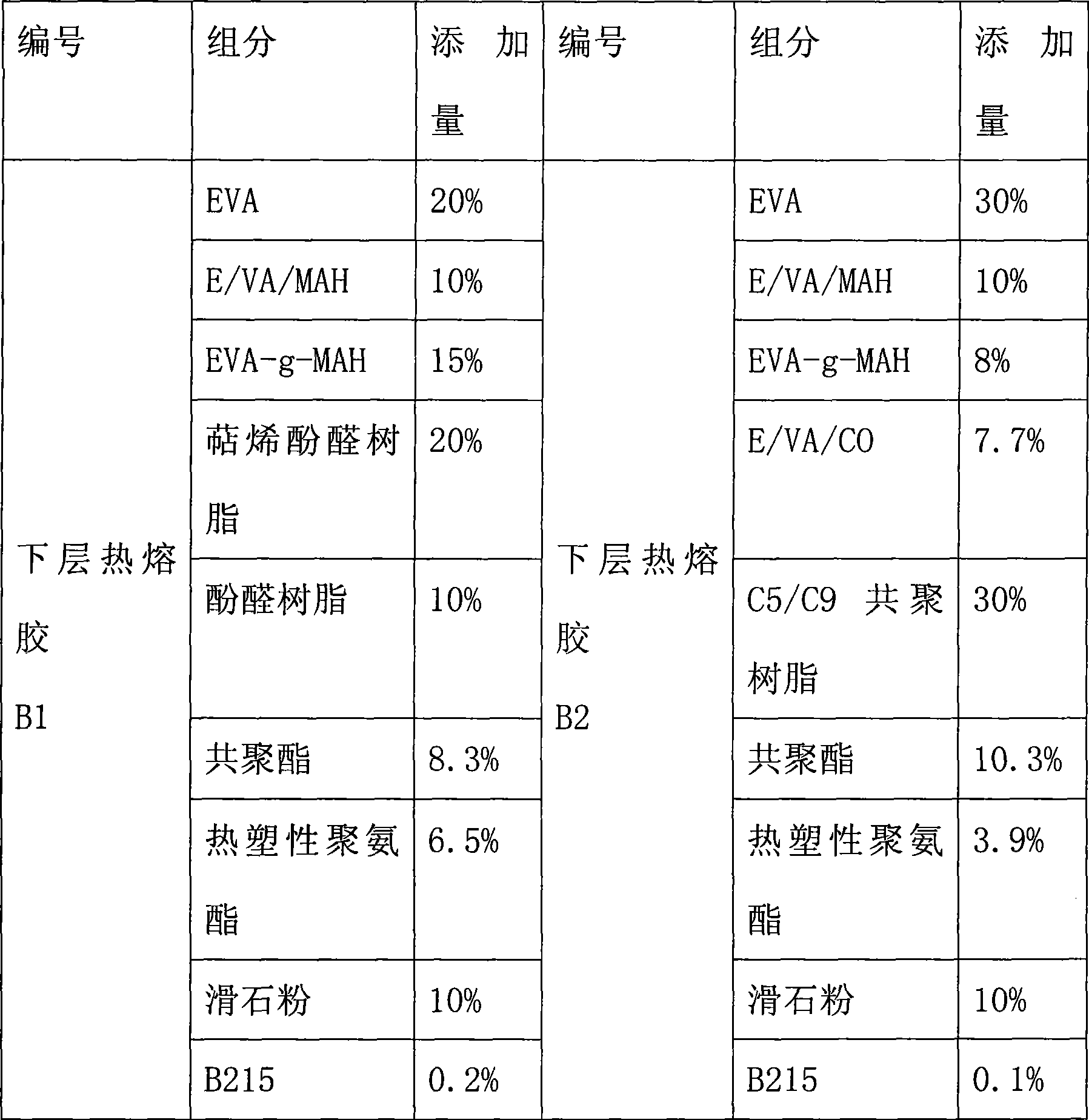

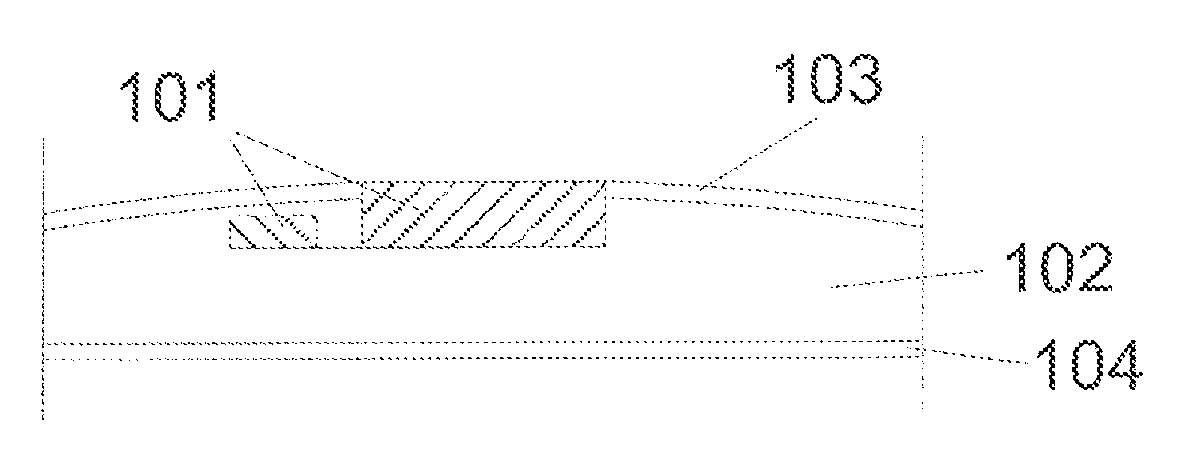

Double-layer composite hot melt adhesive film for bonding metal and plastic

The invention discloses a double-layer composite hot melt adhesive film adhering metal and plastic, which is formed by compounding an upper adhesive film layer and a lower adhesive film layer, wherein the lower adhesive film layer is attached to a piece of release paper, the thickness of the composite adhesive film is 0.05 to 0.20 millimeter, the upper adhesive film layer is a hot melt adhesive layer adhered with the metal, the thickness of the upper adhesive film layer is 30 to 60 percent of the thickness of the composite film, the lower adhesive film layer is a hot melt adhesive layer adhered with the plastic, the thickness of the lower adhesive film layer is 40 to 70 percent of the thickness of the composite film, and the lower adhesive film layer is attached to a piece of glassine release paper. The double-layer composite hot melt adhesive film directly compounds two modified hot melt adhesives with different adhesive properties, is adhered with the release paper to prevent rolling from adhering and the adhesive film from being damaged, reduces application of a middle isolating layer, reduces the thickness of the composite adhesive film, and is prepared by once casting through coextrusion casting equipment or twice casting through common coextrusion casting equipment. The double-layer composite hot melt adhesive film can be used for composite adhesion of metallic materials such as aluminum, stainless steel and the like and plastic such as ABS, PVC, PET and the like, is particularly suitable for mutual adhesion between sheets, plates and films of the metal and the plastic, and has simple and convenient operation and no pollution.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Three-dimensional adhesive device having a microelectronic system embedded therein

InactiveUS20140288381A1Simple and inexpensive wayModerate viscosityCatheterSensorsCapacitanceBlood sugar

A three-dimensional adhesive device to be attached to the body surface of a mammal including a microelectronic sensing system. The system includes (a) a three-dimensional adhesive body made of a pressure sensitive adhesive having an upper surface and a bottom surface; (b) a microelectronic system embedded in the body of the pressure sensitive adhesive; (c) one or more cover layer(s) attached to the upper surface; and (d) optionally a release liner releasably attached to the bottom surface. Suitably the microelectronic system is capable of sensing physical input such as pressure, vibration, sound, electrical activity (e.g. from muscle activity), tension, blood-flow, moisture, temperature, enzyme activity, bacteria, pH, blood sugar, conductivity, resistance, capacitance, inductance or other chemical, biochemical, biological, mechanical or electrical purposes.

Owner:BRAEMAR MFG +1

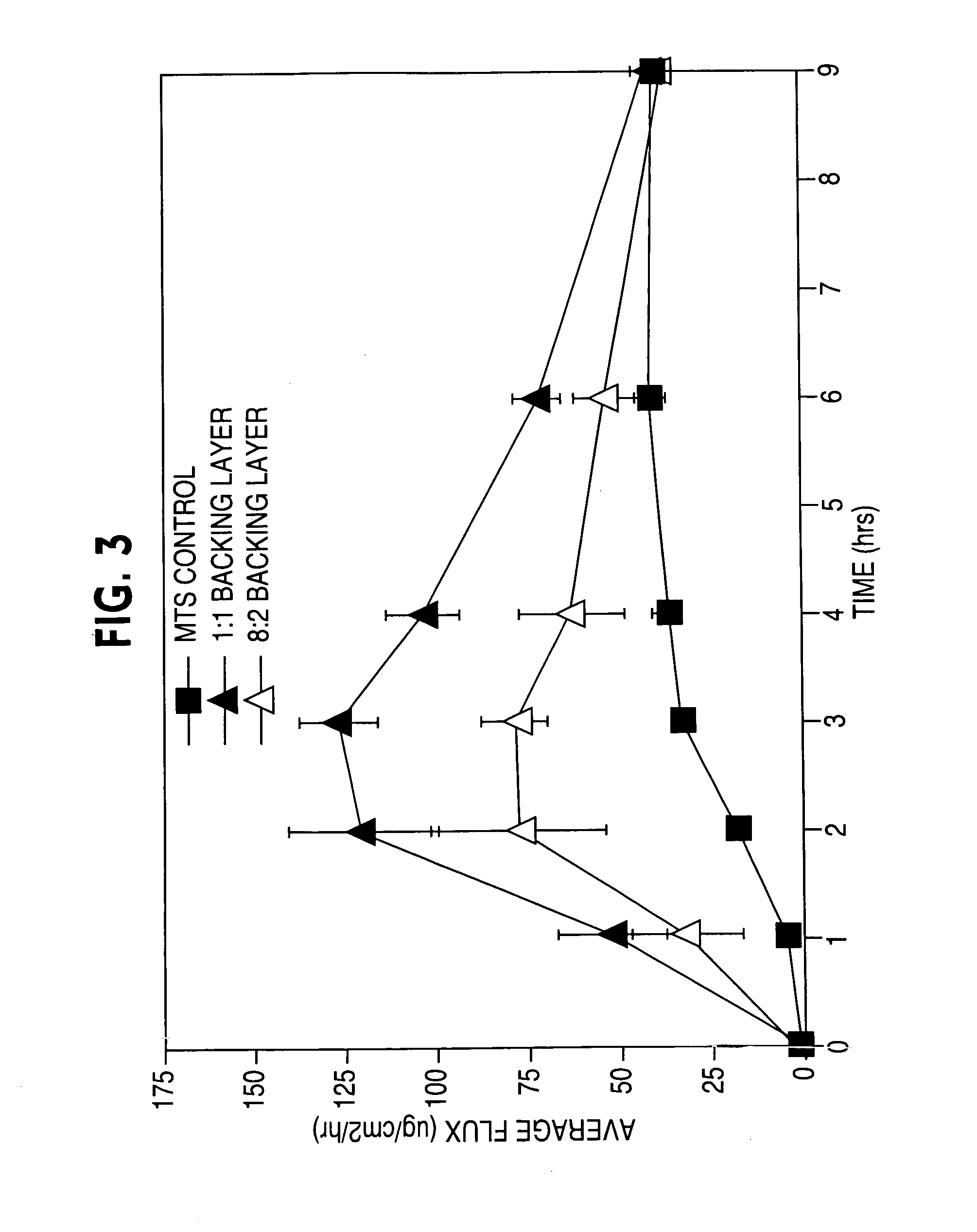

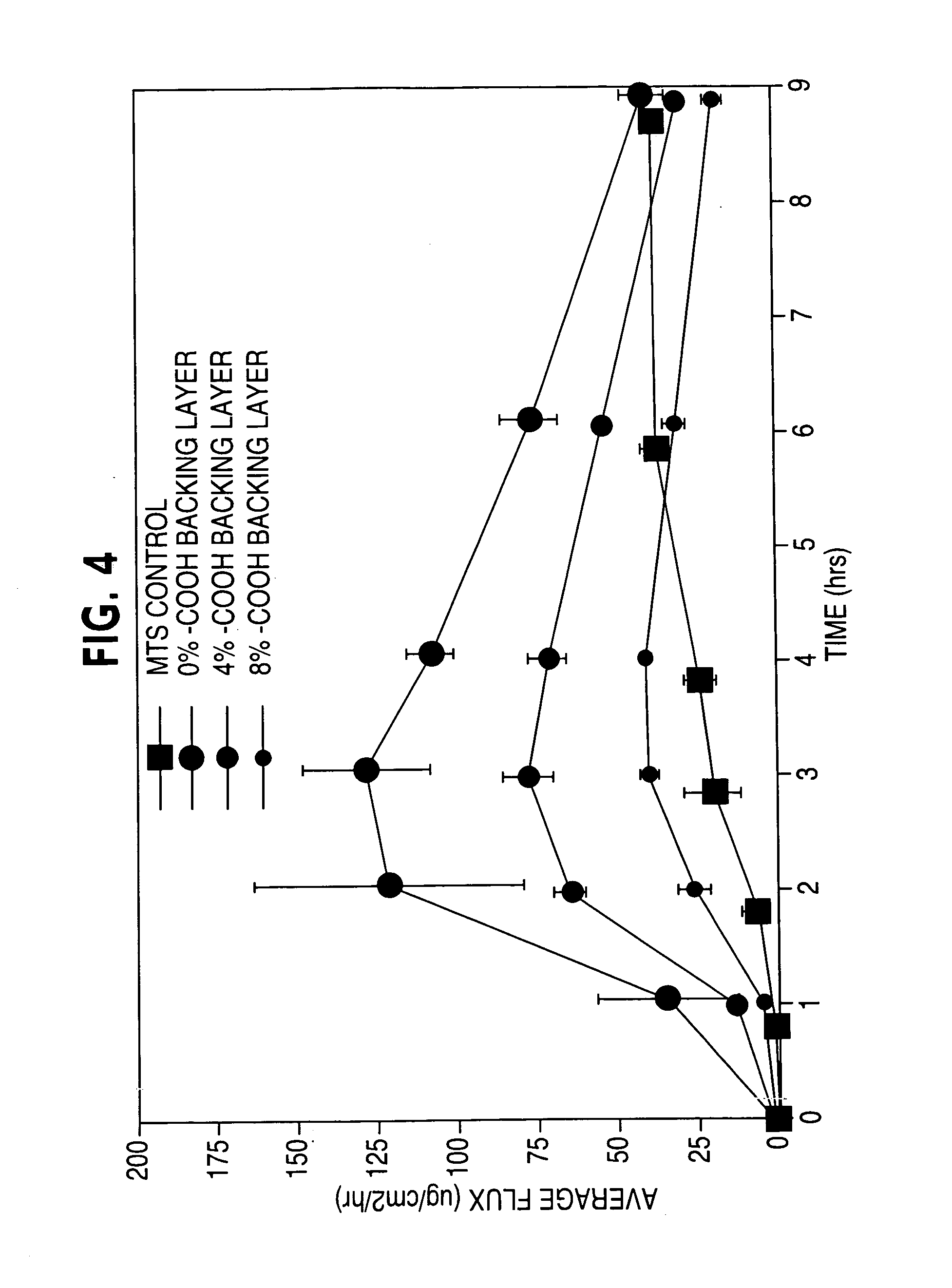

Compositions and methods for controlling drug loss and delivery in transdermal drug delivery systems

ActiveUS20050169977A1Simple and inexpensive to manufacturePreventing and minimizing drug lossOrganic active ingredientsMedical devicesActive agentDelivery system

A transdermal delivery system is provided for the topical application of one or more active agents contained in one or more polymeric and / or adhesive carrier layers, proximate to a non-drug containing polymeric and / or adhesive coating that is applied to either the transdermal system's backing or release liner. The transdermal delivery device is manufactured to optimize drug loading while providing desirable adhesion to skin or mucosa as well as providing modulation of the drug delivery and profile.

Owner:NOVEN PHARMA

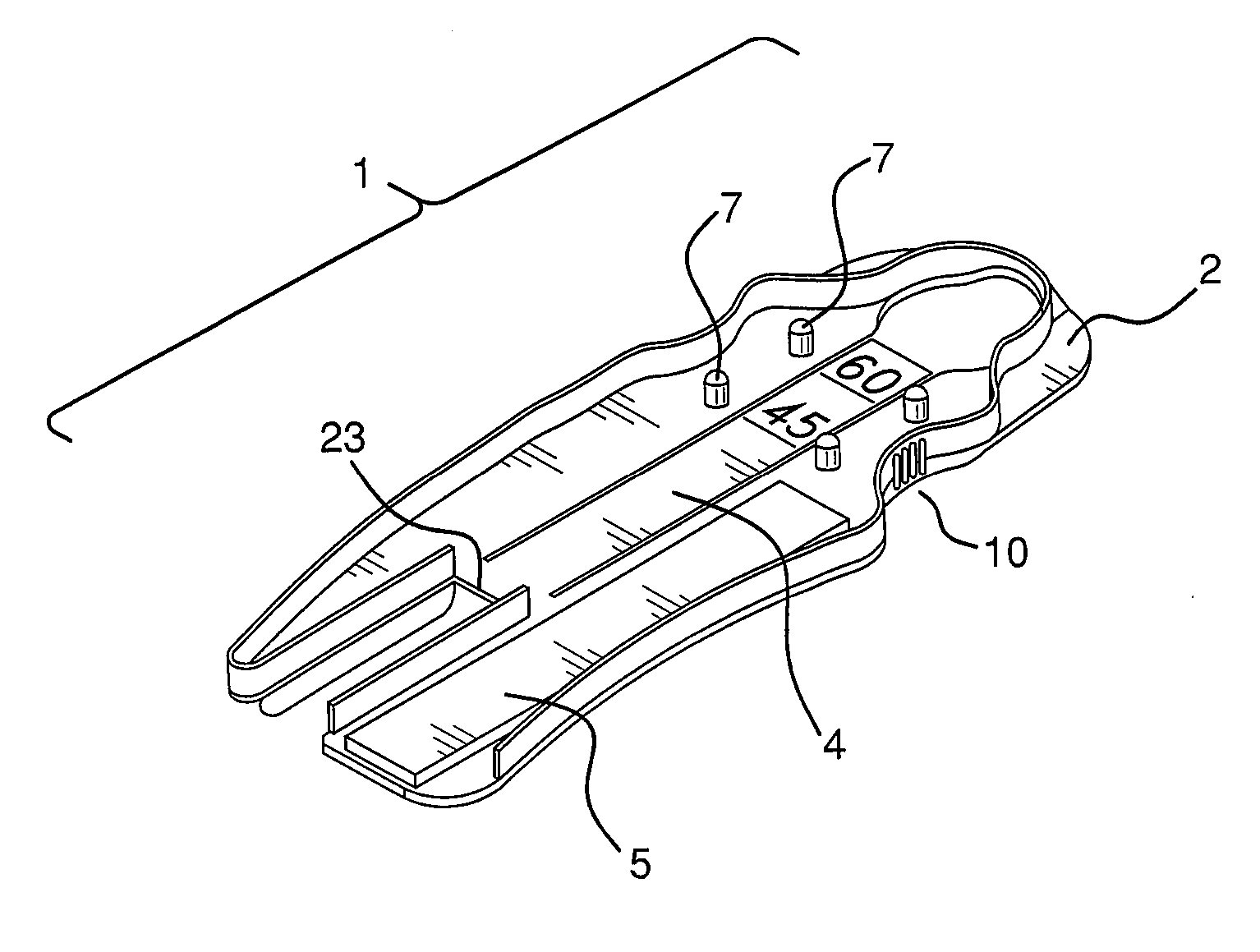

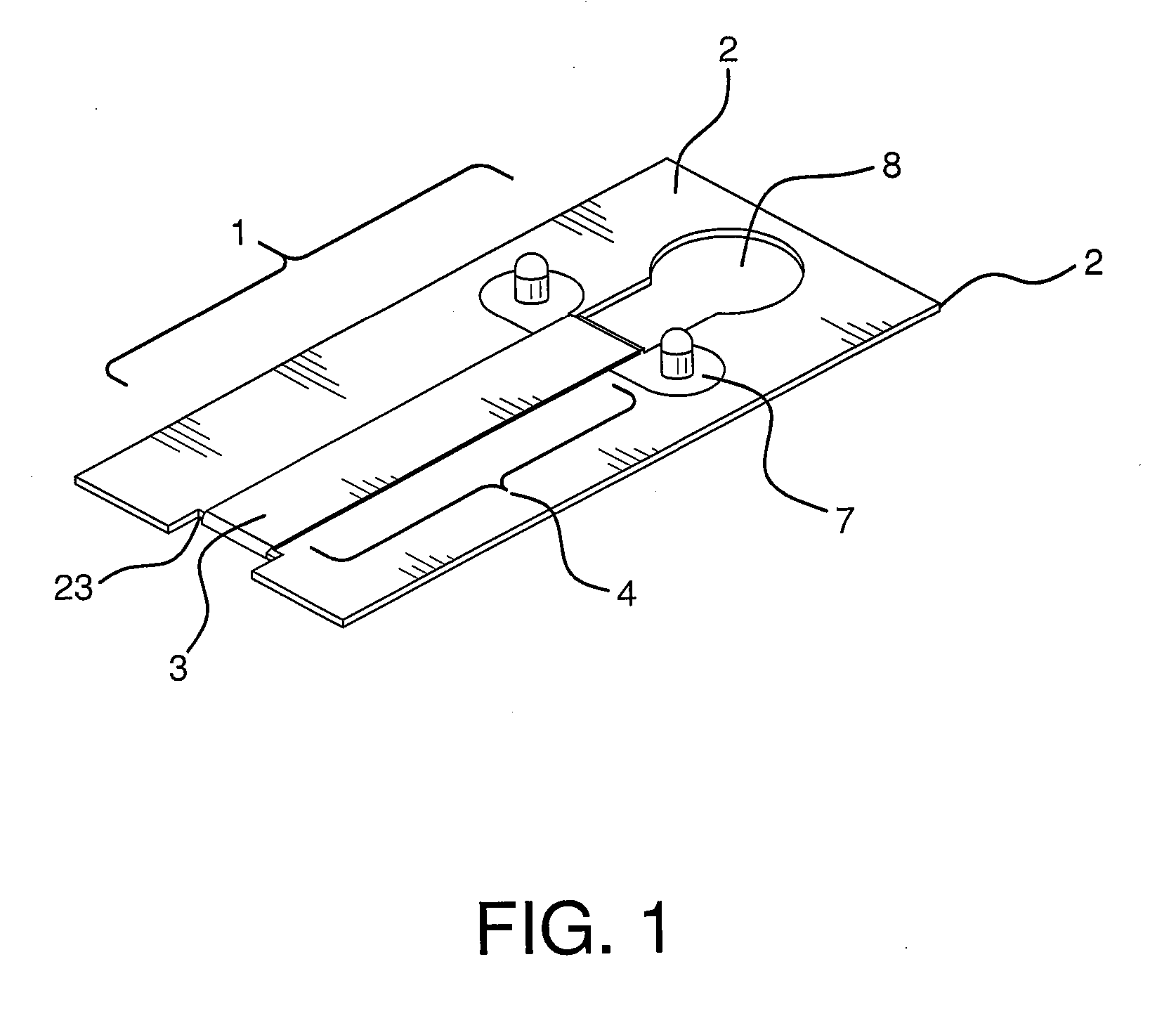

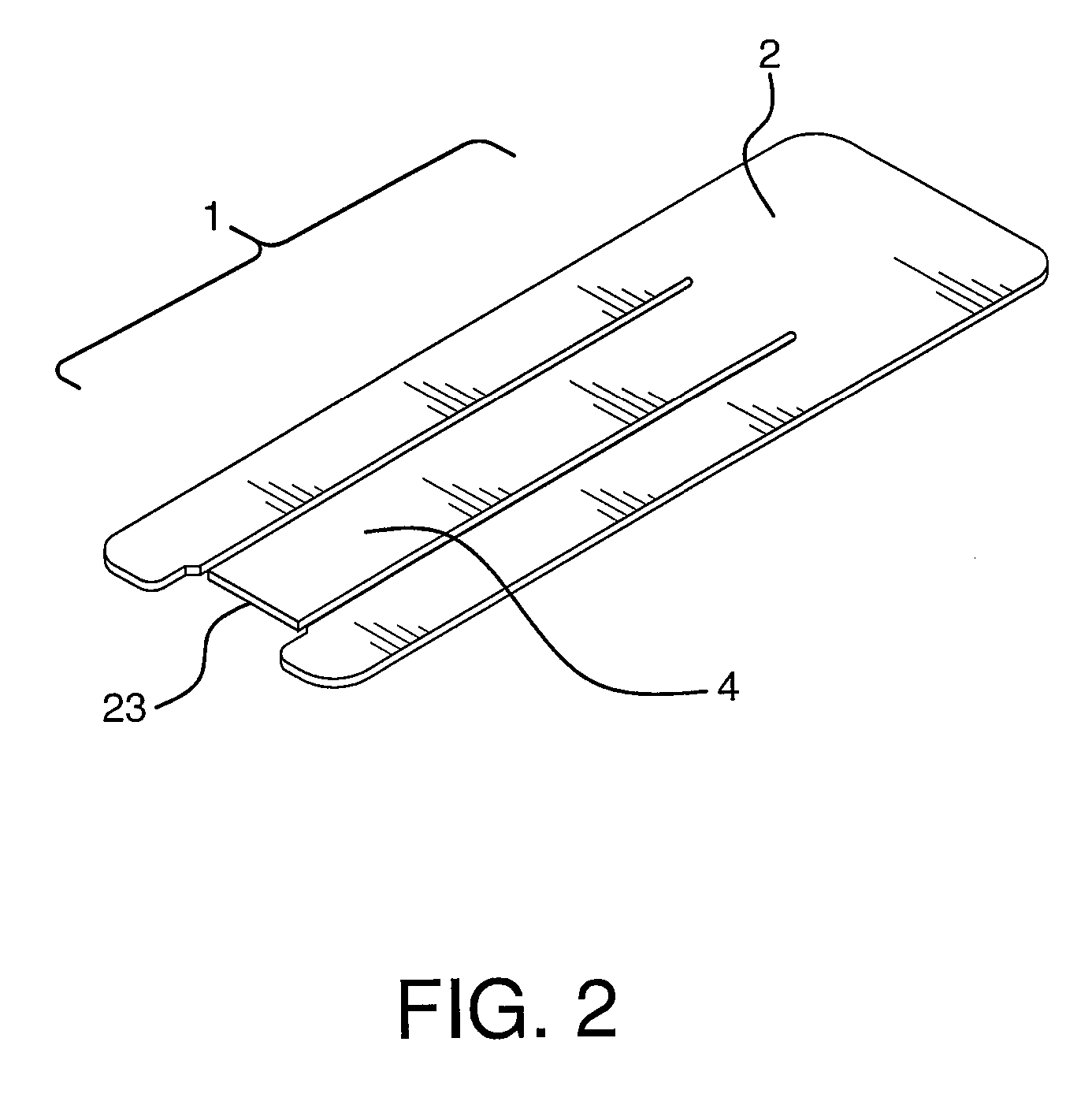

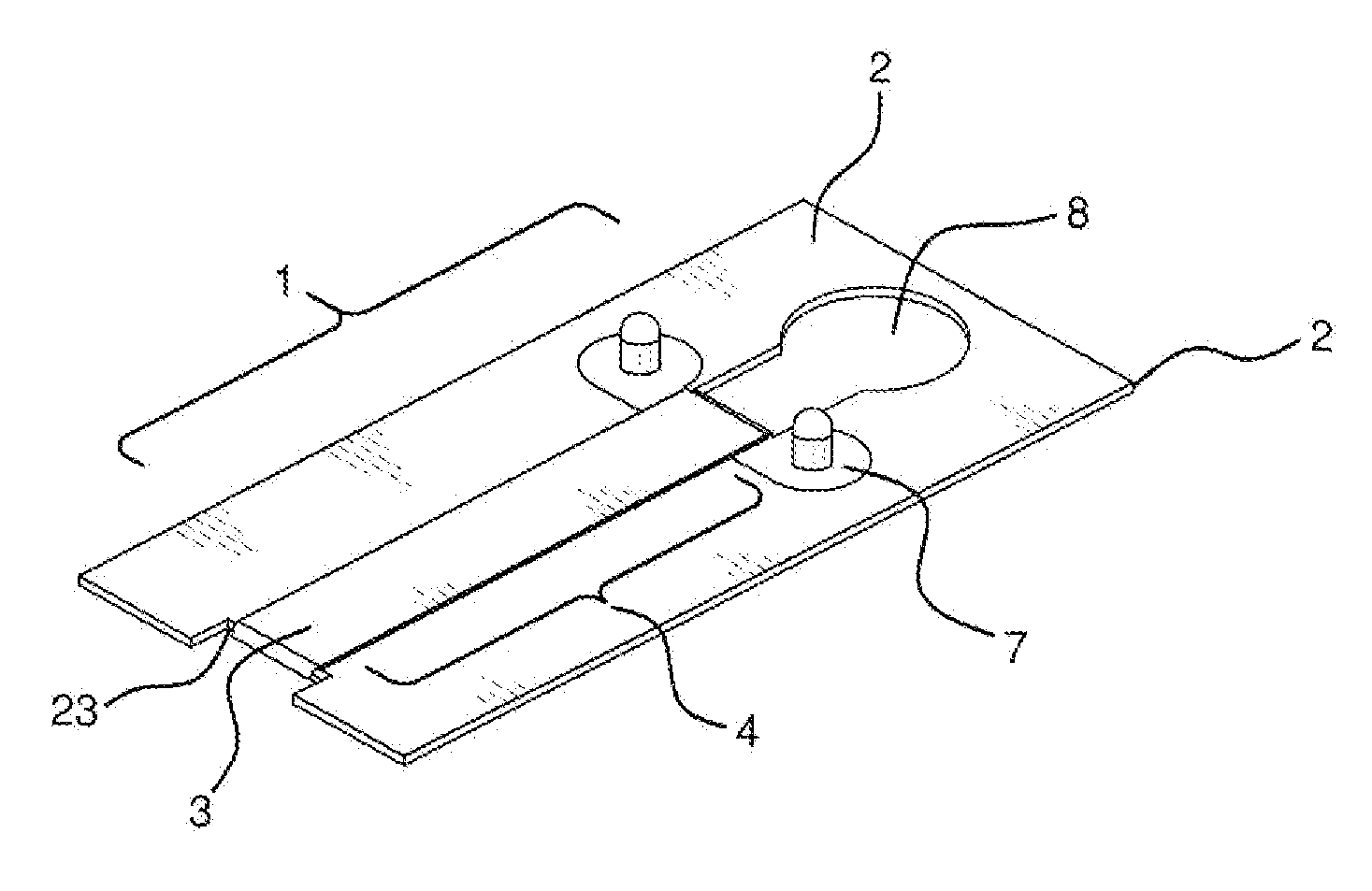

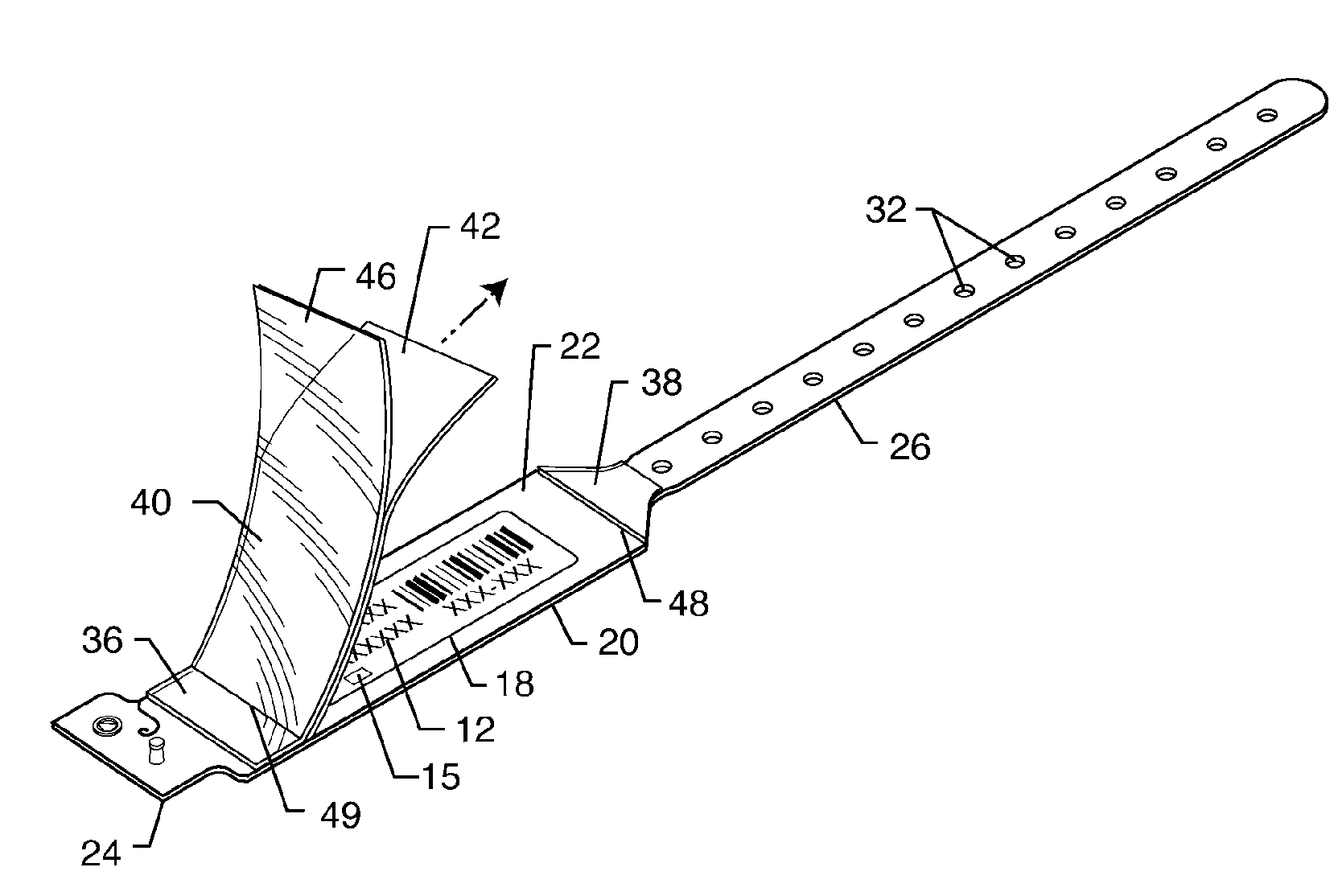

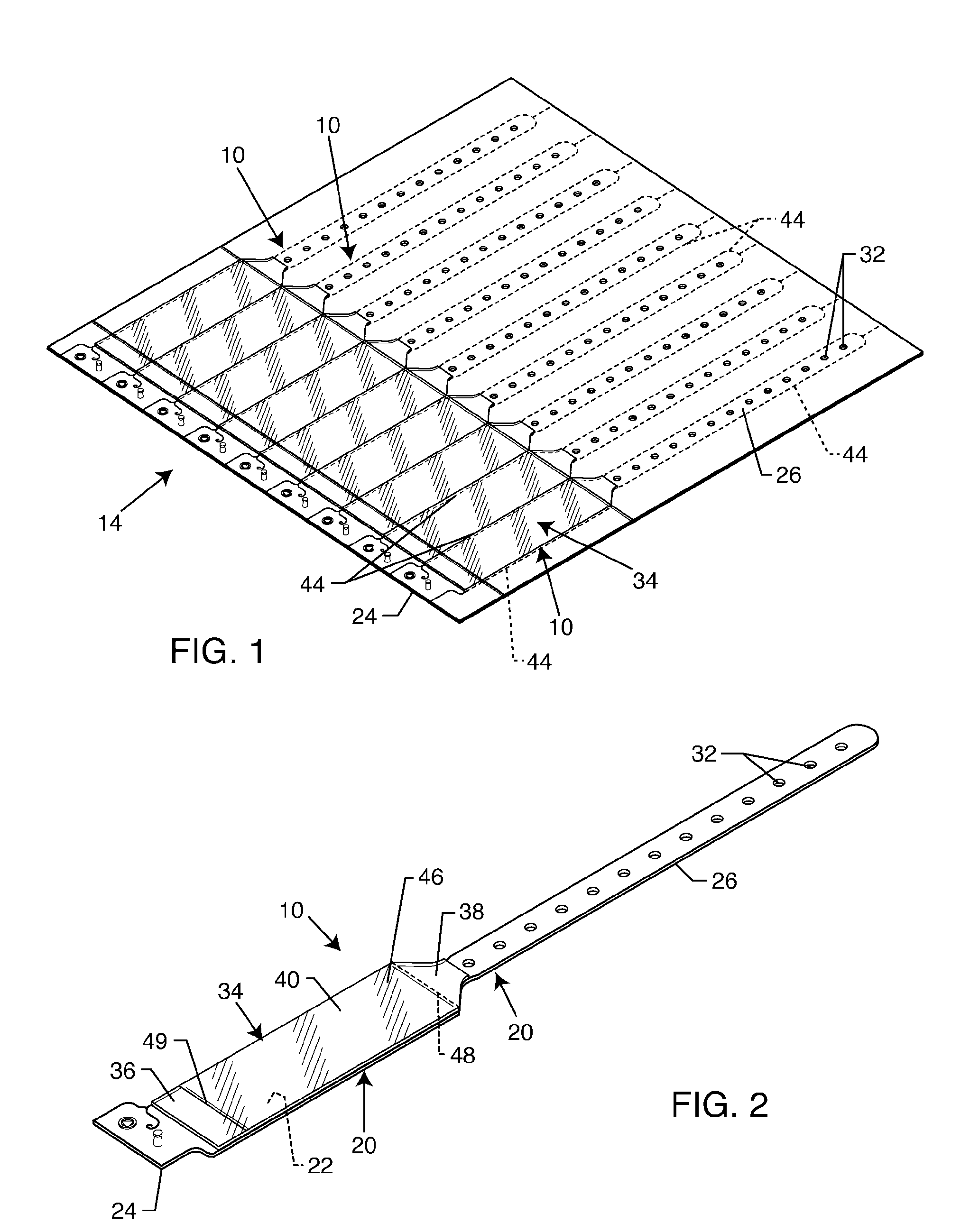

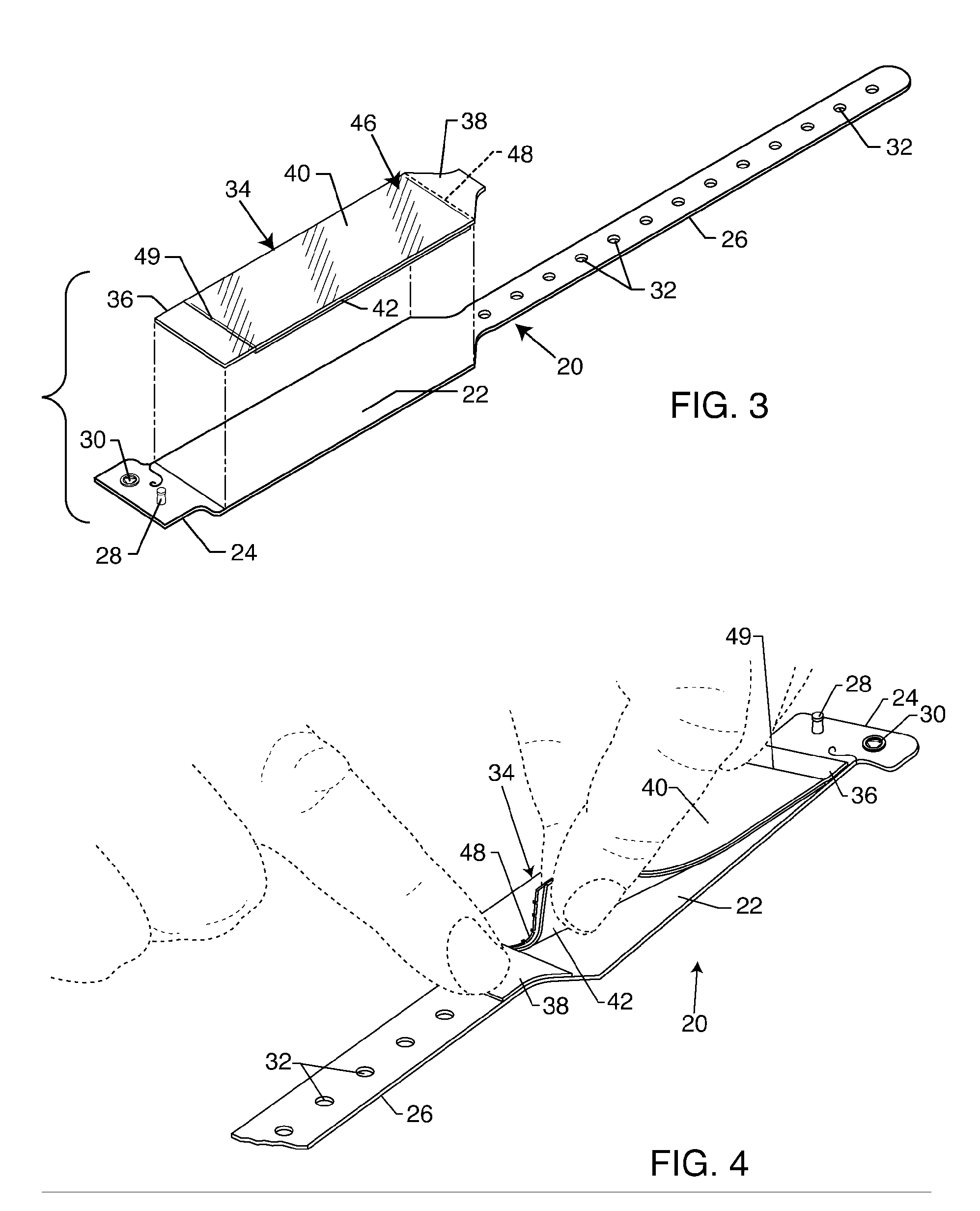

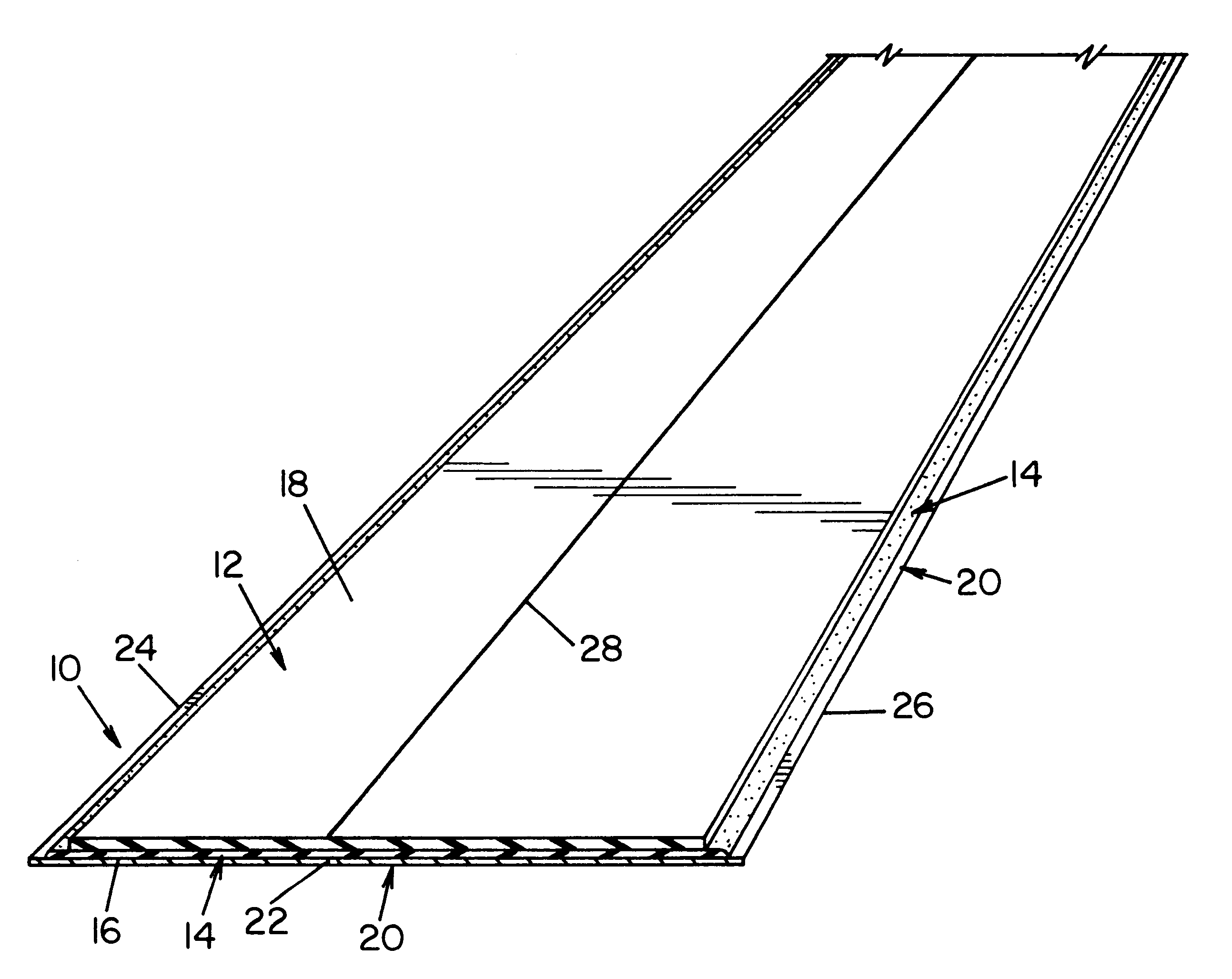

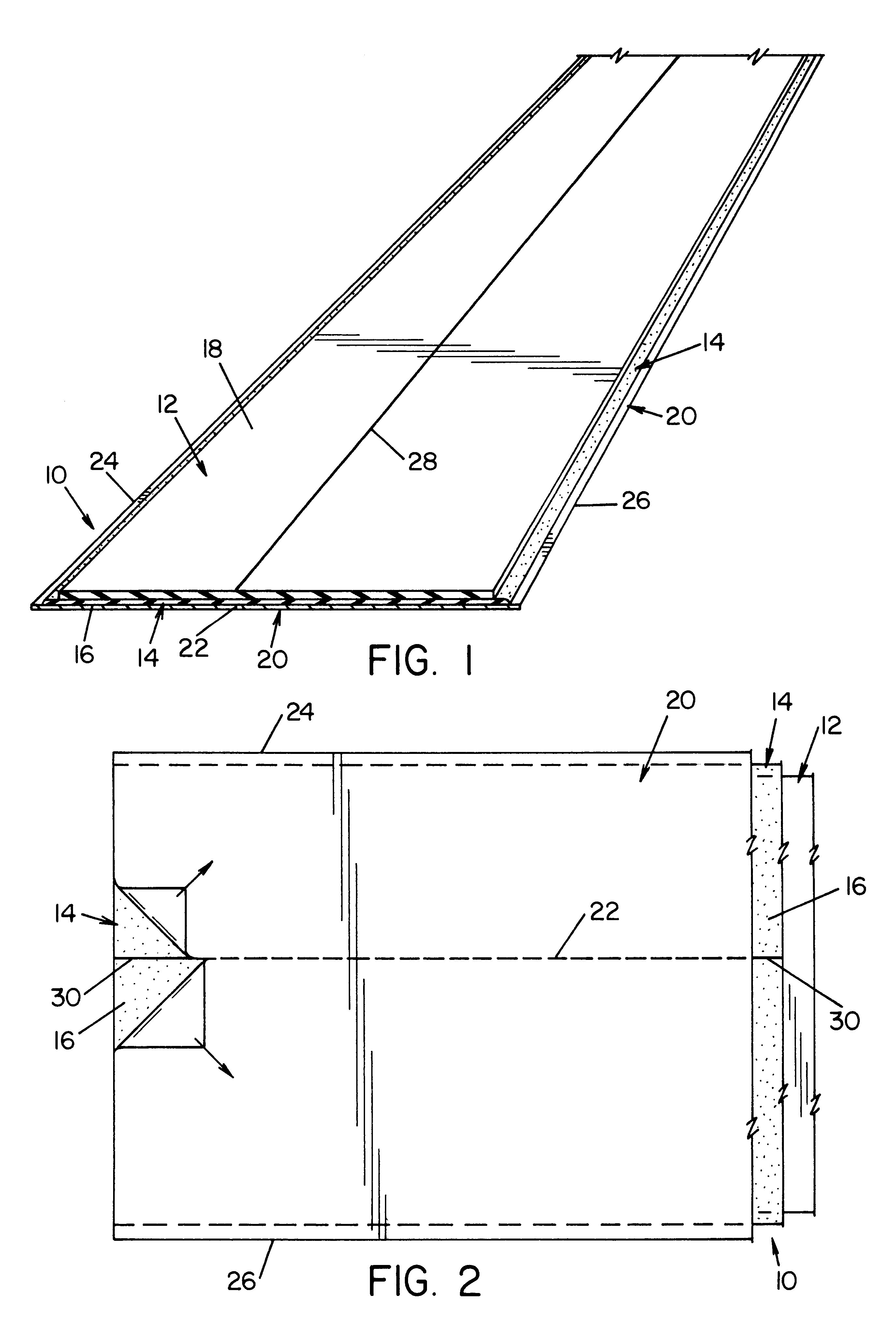

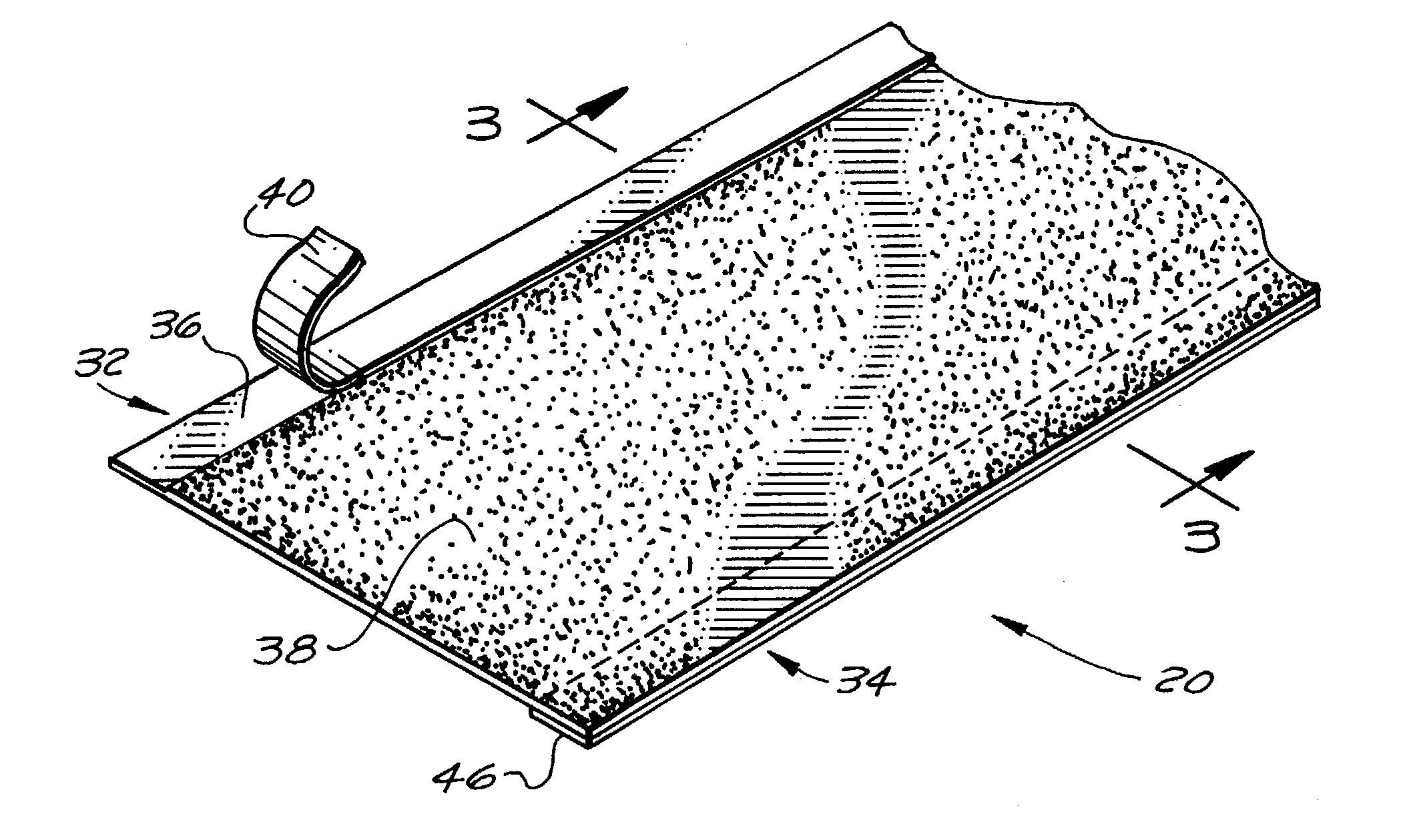

Adhesive rubber article having scored released liner and guide to facilitate field application and related methods

An adhesive rubber article of the type having a release liner covering its tacky, adhesive surface to prevent the adhesive rubber article from adhering to various substrates or to itself prior to its intended use includes an impression or mark presented on one or more surfaces for facilitating the alignment and application of the adhesive rubber article on one or more substrates. The release liner has been scored, perforated or otherwise cut in a longitudinal direction of the article such that the scoring of the release liner further produces a visual guide on the adhesive rubber article. Thus, upon removal of the release paper, the guide may be used to align and apply the adhesive rubber article to the various substrates. These adhesive rubber articles are particularly useful within the roofing industry for bonding panels of rubber membranes together or for use as flashing.

Owner:FIRESTONE BUILDING PRODS

Release liners for pressure sensitive adhesive labels

InactiveUS6110552AReduce thicknessEasy transferCoatings with pigmentsSynthetic resin layered productsEngineeringFacial tissue

A release liner for use with face stocks for pressure sensitive labels, tapes, decals and other products formed from sheet and roll stock. A filled polymer is laminated to one side of a paper web. An extrudate is laminated to the other side of the paper substrate to form a release liner. The filled polymer has paper-like properties and replaces paper tissue back liners.

Owner:FLEXCON

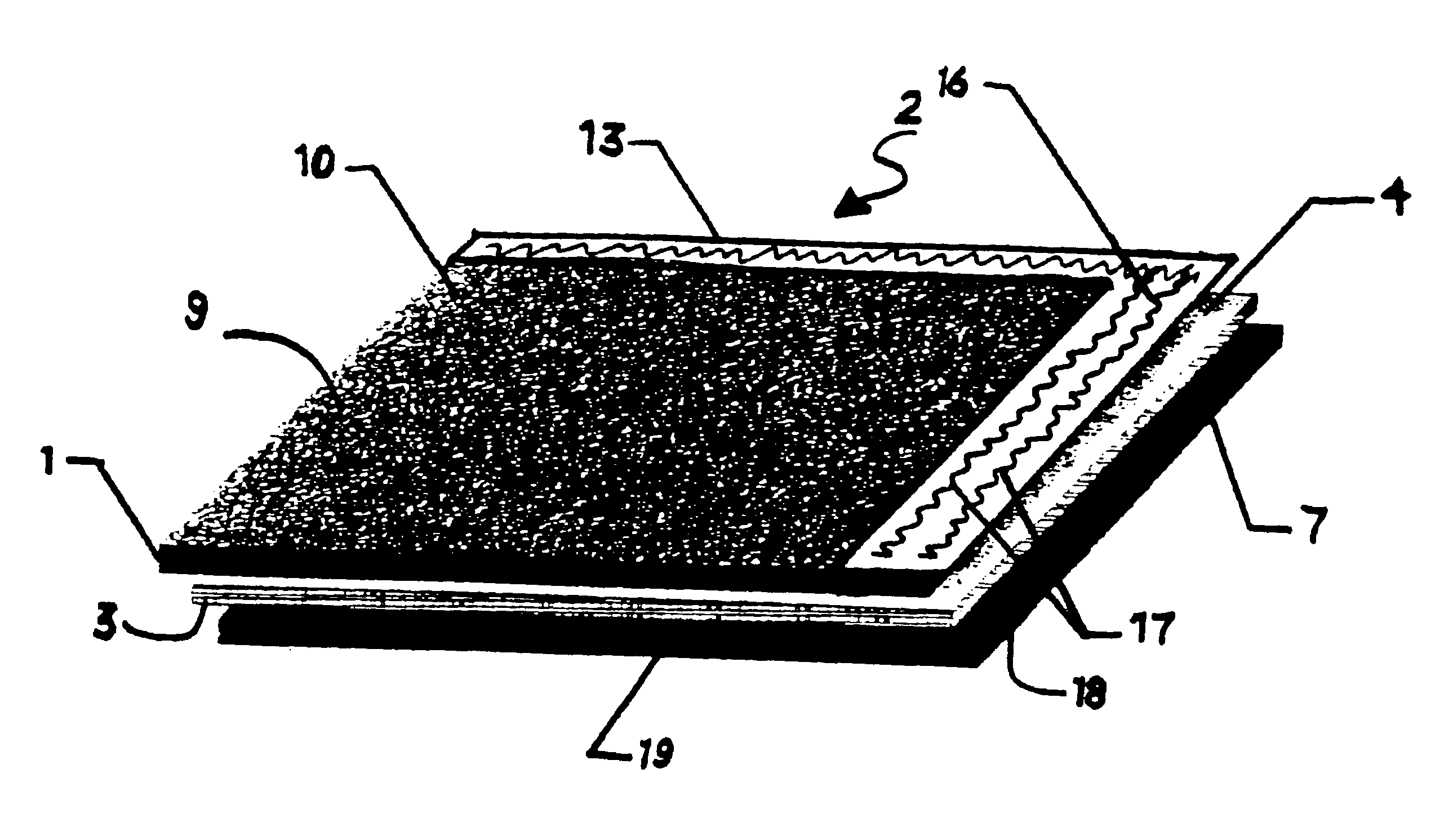

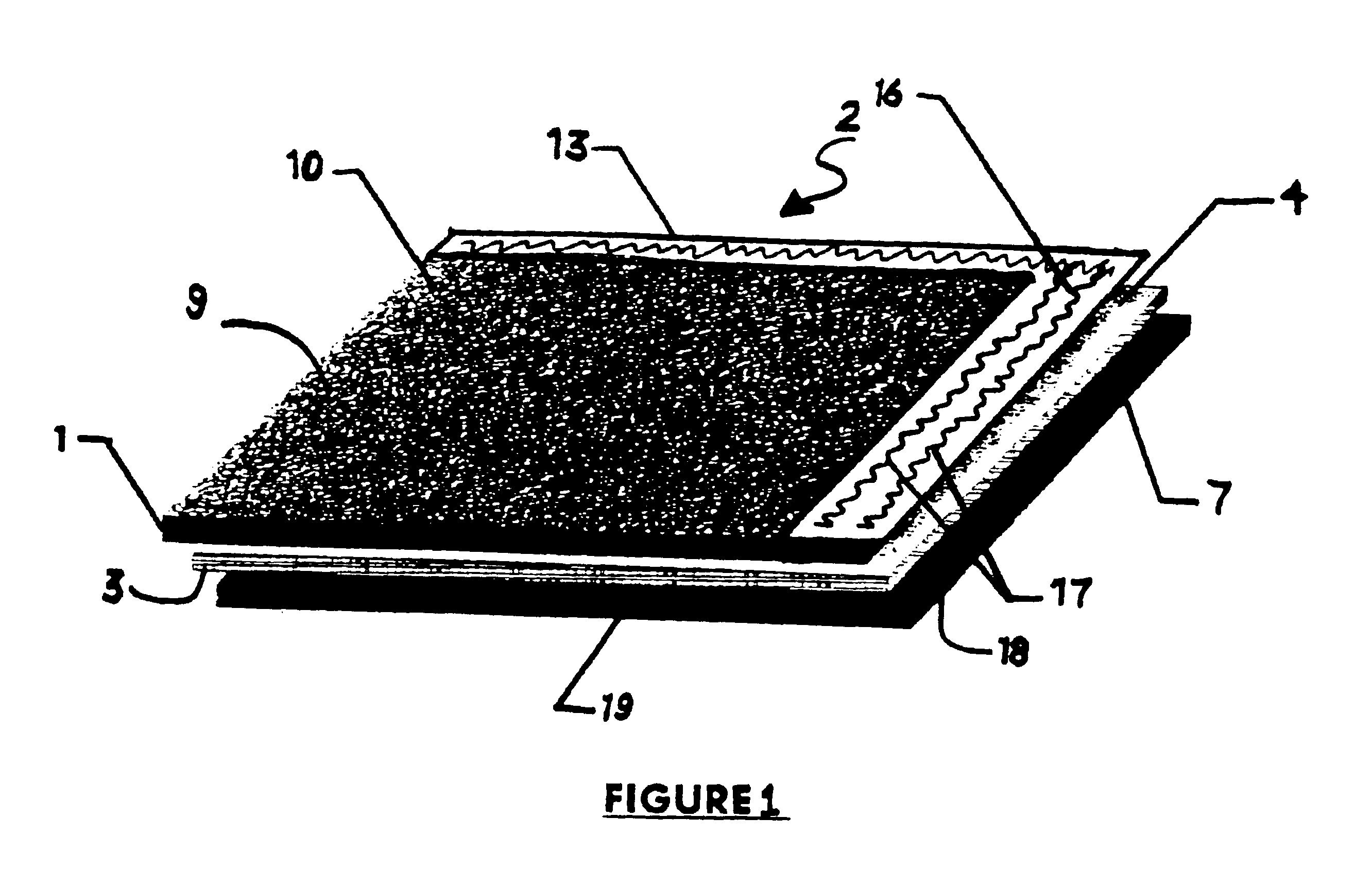

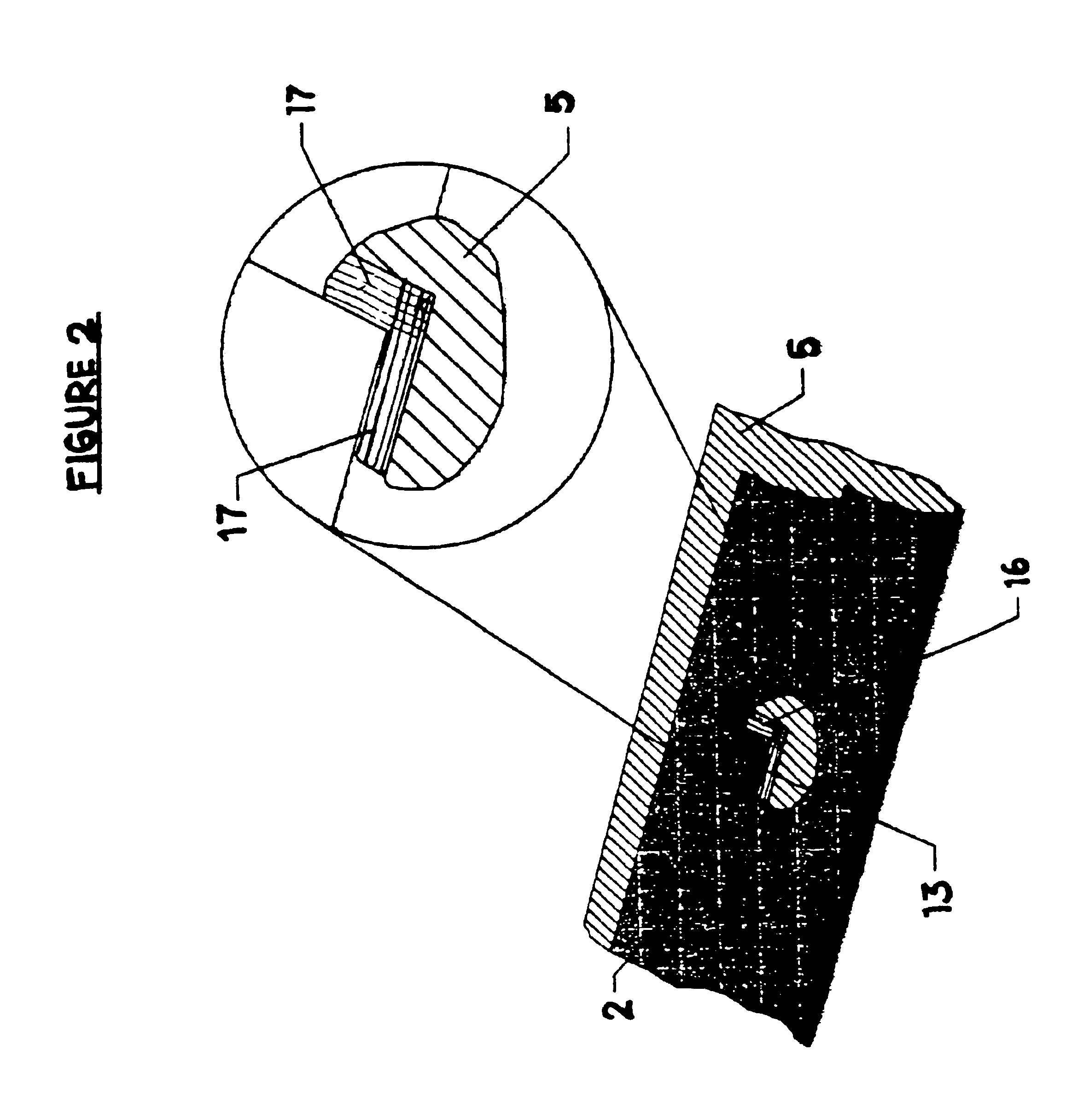

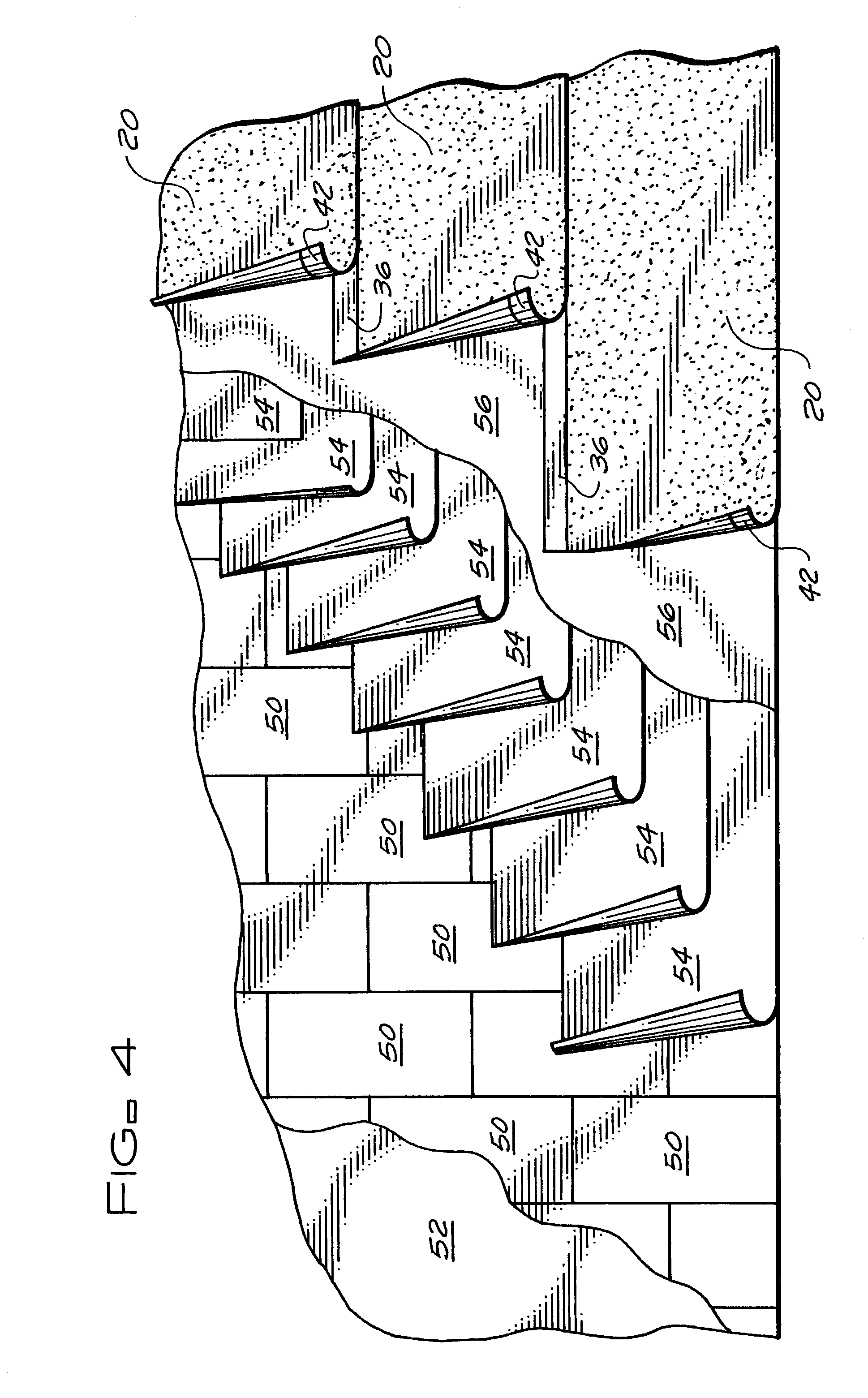

Modified bitumen roofing membrane with enhanced sealability

InactiveUS6924015B2Reduce the possibilityImprove the noise reduction effectTreadsRoof covering using flexible materialsThermoplasticEngineering

A self-adhering modified bituminous roof covering composite that comprises a thermoplastic (APP), elastomeric (SBS) or TPO modified bitumen compound on the front side, and a factory-applied self-adhesive compound on the back side of a reinforcement carrier sheet, with factory-applied tracts of adhesive on the side lap and end lap sections of each roll to enhance adhesion. A method of manufacturing such composite comprising coating an APP or SBS or TPO compound on the upper surface and affixing a self-adhesive compound to the lower surface of a reinforcement carrier support sheet, coating an adhesive on the side lap and end lap areas, applying a release liner to the tacky self-adhesive layer, and applying release films to the side and end laps during manufacture, stripping the release liner, selvage release film and end lap film from the membrane immediately prior to use, subsequently placing the exposed self-adhesive side of the membrane directly on to the end lap areas and side lap areas of adjacent rolls and applying force directly to the sheet to enhance the bond between the two sheets, resulting in a continuous roof covering. The present invention relates generally to residential and commercial roofing membranes.

Owner:POLYGLASS

Nanostructure Films

InactiveUS20090169819A1Improve propertiesGood light transmissionMaterial nanotechnologyLayered productsOptical transparencyCompound (substance)

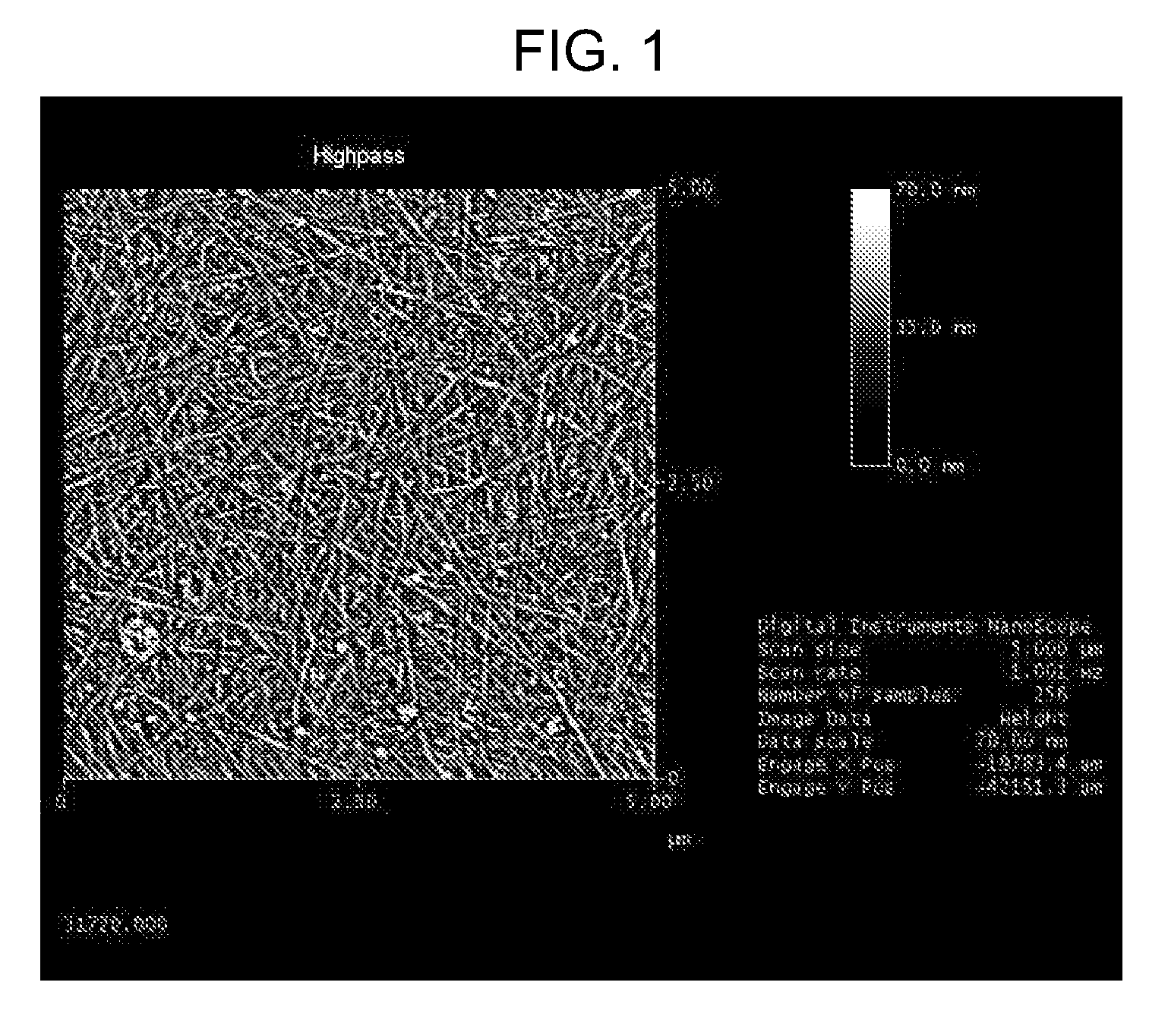

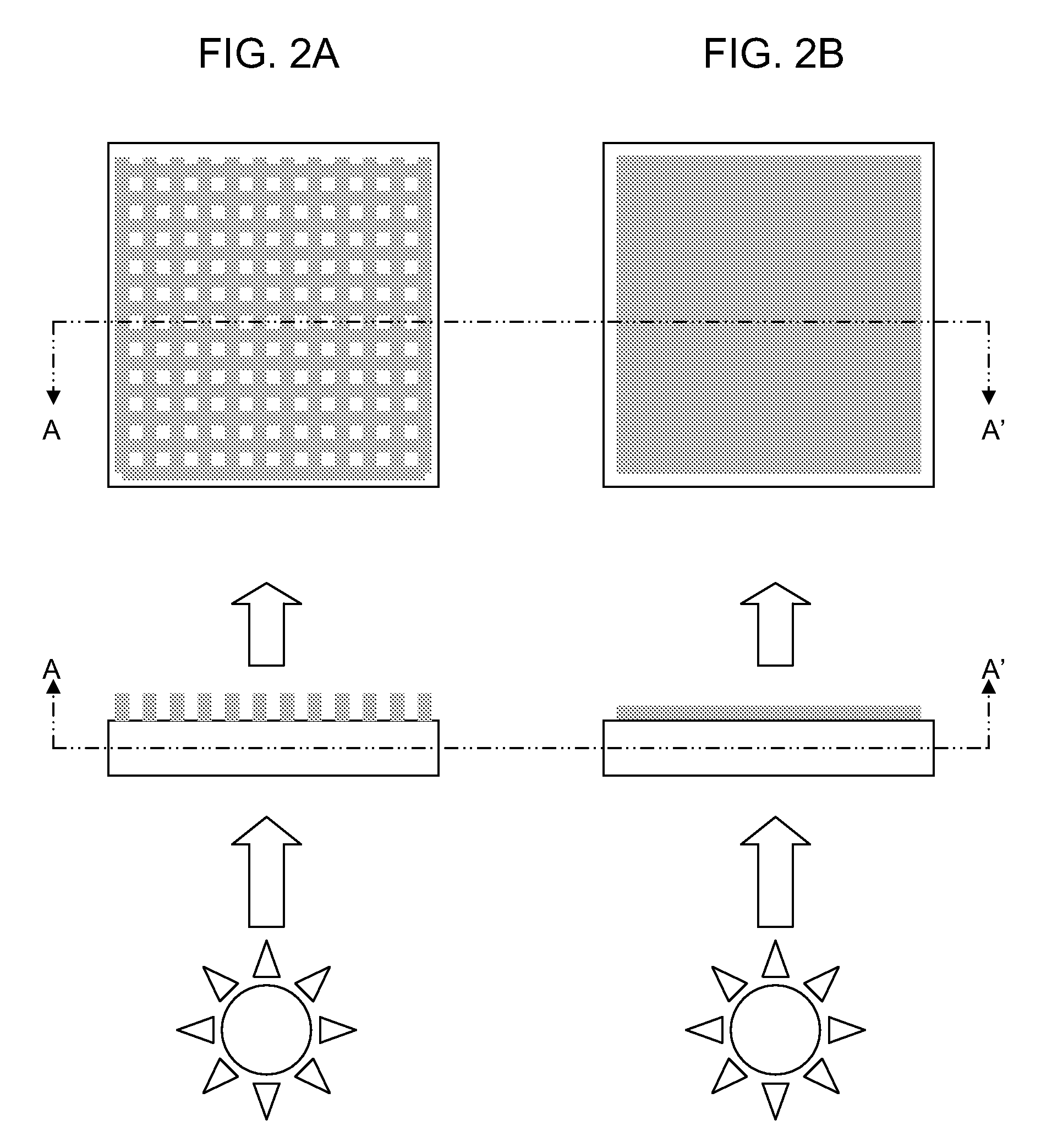

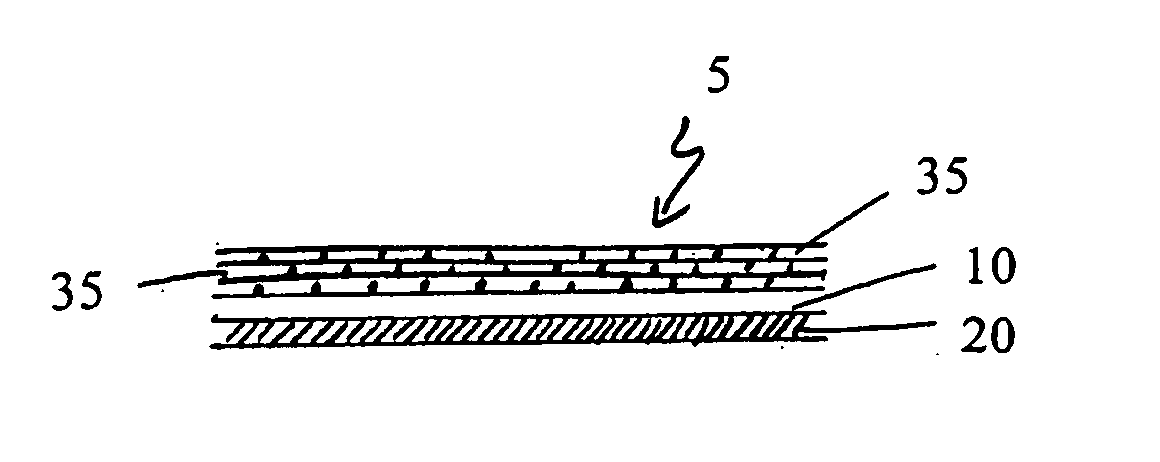

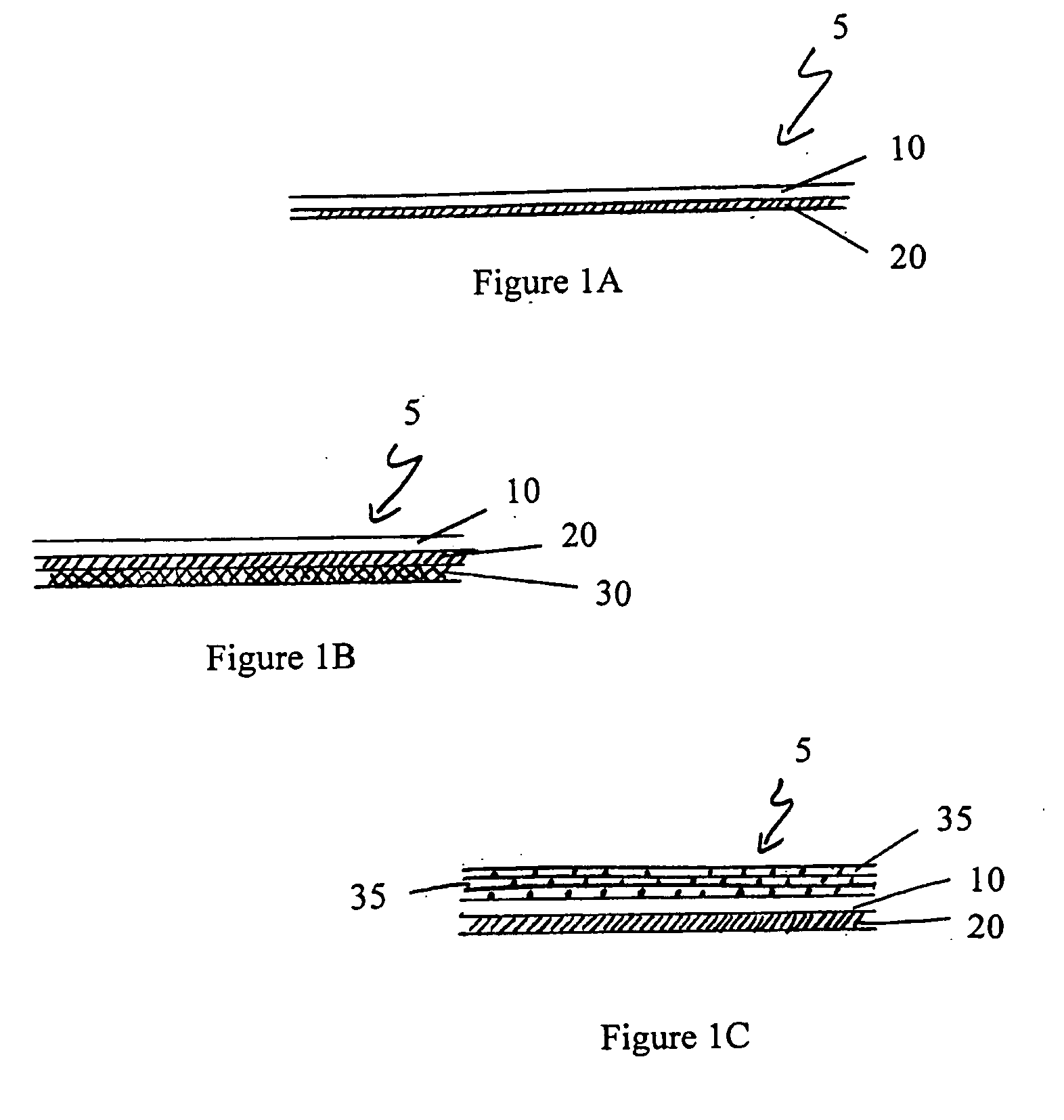

A nanostructure film, comprising at least one interconnected network of nanostructures, wherein the nanostructure film is optically transparent and electrically conductive. A method for improving the optoelectronic properties of a nanostructure film, comprising: forming a nanostructure film having a thickness that, if uniform, would result in a first optical transparency and a first sheet resistance that are lower than desired; and patterning holes in the nanostructure film, such that a desired higher second optical transparency and a second sheet resistance are achieved. A method for depositing a nanostructure film on a rigid substrate comprises: depositing the nanostructure film on a flexible substrate; and transferring the nanostructure film from the flexible substrate to a rigid substrate, wherein the flexible substrate comprises at least one of a release liner and a heat- or chemical-sensitive adhesive layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Protective cover for electronic device

ActiveUS20050116334A1Semiconductor/solid-state device detailsSolid-state devicesSurface layerEngineering

A protective cover for an electronic device including a) a surface layer including vinyl, plastic, silicone, acrylic, rubber or a combination thereof and b) an adhesive layer for affixing the protective cover to the electronic device. The protective cover may further include a release liner to prevent the adhesive layer from engaging surfaces when the protective cover is not in use, for example, when the protective cover is not affixed to an electronic device.

Owner:SKINIT ACQUISITION LLC

Release liner for pressure sensitive adhesives

InactiveUS6982107B1Imparts thermal stabilityNot likely to significantly decompose and meltSynthetic resin layered productsWater-setting substance layered productPolymer chemistryRelease liner

A release liner for use with a pressure sensitive adhesive. The release liner includes a film of a thermoplastic elastomeric olefin.

Owner:3M INNOVATIVE PROPERTIES CO

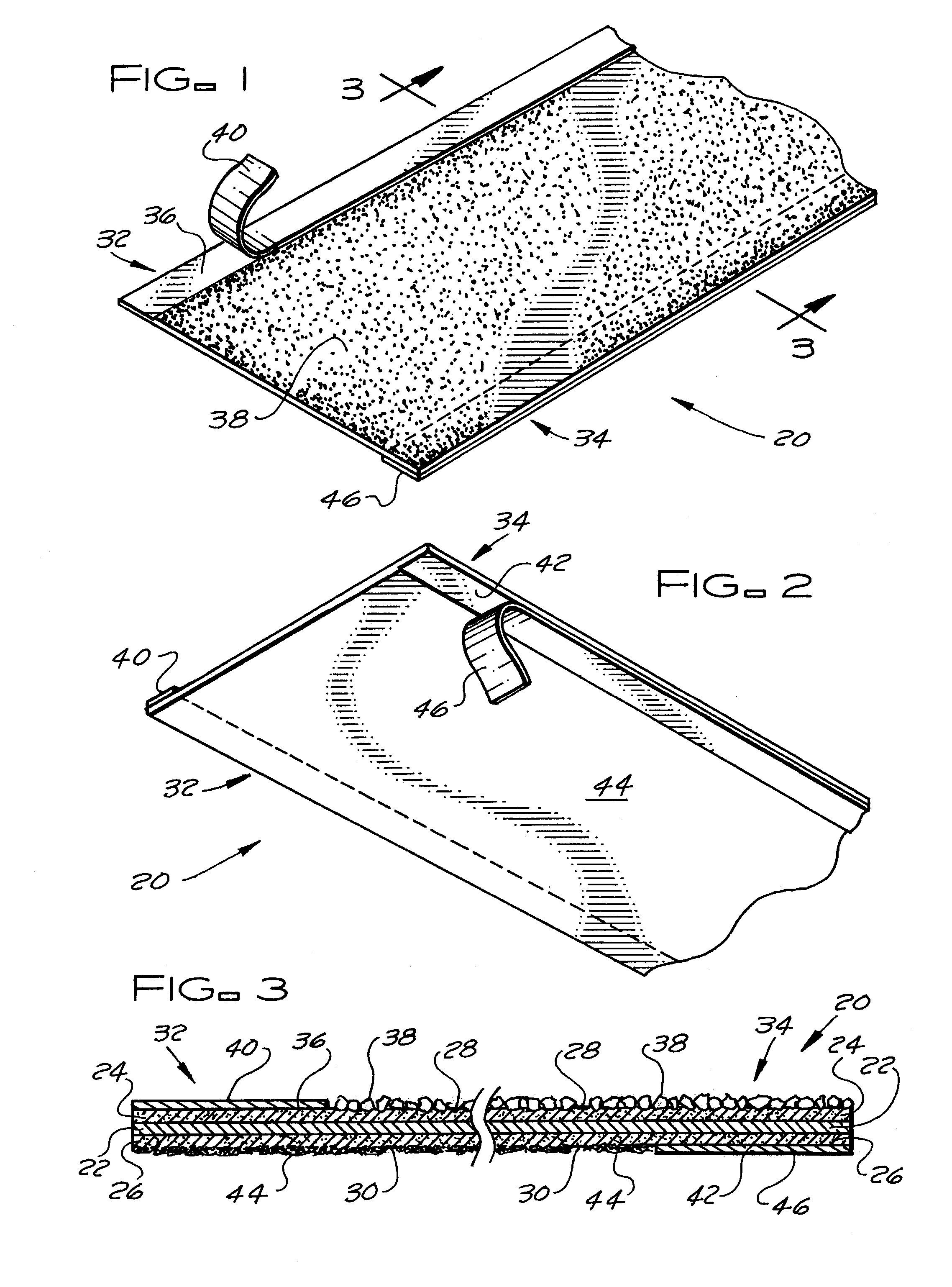

Cap sheet, roofing installation, and method

ActiveUS7146771B2Reduce the amount of adhesionEffective combinationRoof covering using tiles/slatesRoof covering using flexible materialsEngineeringMechanical engineering

A cap sheet for cold-applied adhesive roof installations includes a reinforcement mat saturated with and encapsulated within SBS modified bitumen. Bitumen layers above and beneath the mat have top and bottom major surfaces. The top surface of the top bituminous layer has a first edge portion extending inward from and along a first lateral edge. The bottom surface of the bottom bituminous layer has a second edge portion extending inward from and along a second lateral edge. The bitumen in the edge portions is a pressure-sensitive adhesive that is covered by release liners for protection prior to installation. When the cap sheets are installed, the release liners are removed from the edge portions and overlapping edge portions of the cap sheets are pressed and adhesively bonded together to immediately form effective watertight, weather-secure seams.

Owner:JOHNS MANVILLE INT INC

A kind of insulating and heat-conducting double-sided adhesive tape and preparation method thereof

InactiveCN102260466AImprove thermal conductivityGood thermal conductivity and electrical insulationFilm/foil adhesivesPolyureas/polyurethane adhesivesThermal insulationRoom temperature

The invention provides an insulating and heat-conducting double-sided adhesive tape and a preparation method thereof. In the insulating and heat-conducting double-sided adhesive tape, the outer layers on both sides are release paper, and a single layer of insulating and heat-conducting adhesive is arranged between the two layers of release paper. Or the outer layers on both sides are release paper, a single-layer substrate is arranged between the two layers of release paper, and an insulating and heat-conducting adhesive is arranged between the substrate and the release paper. The preparation method is as follows: mixing heat-conducting medium and solvent, adding insulating heat-conducting glue, stirring, coating and drying, and the preparation is completed. The adhesive tape of the invention has the advantages of good thermal conductivity, electrical insulation, stability at room temperature, easy die-cutting, reworkable characteristics, and easy operation.

Owner:ZHONGSHAN KINGLABEL ADHESIVE PRODS

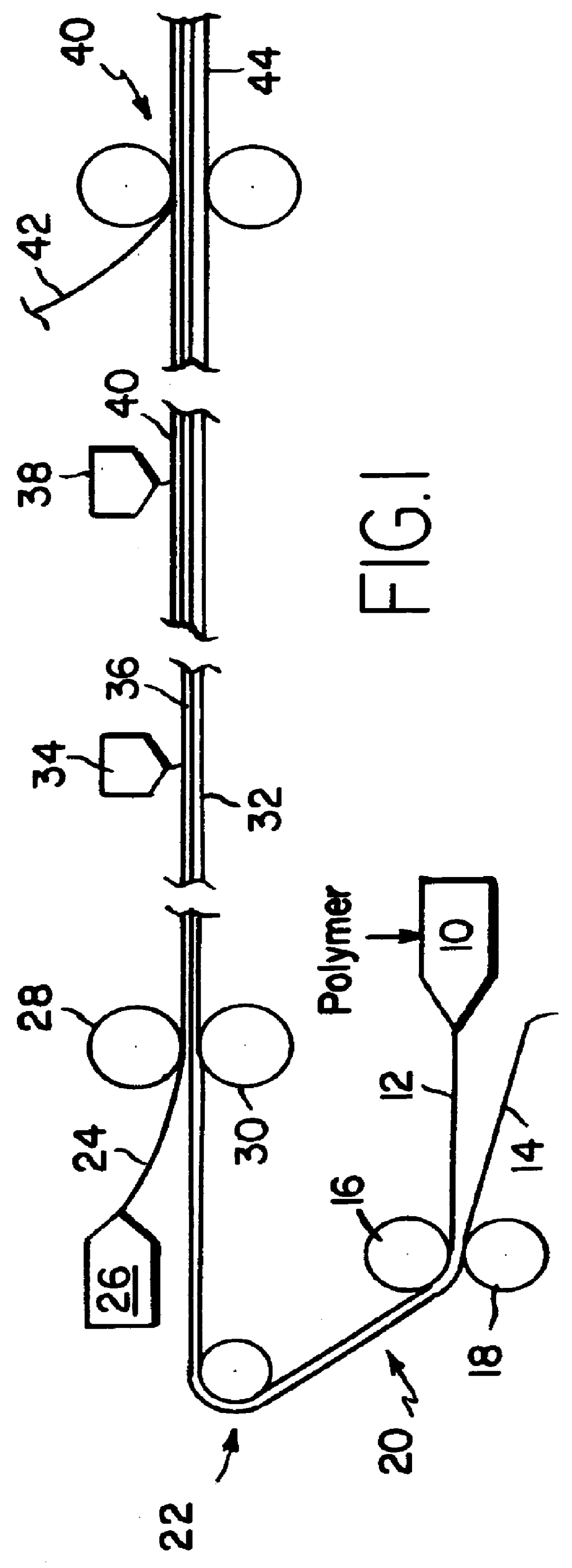

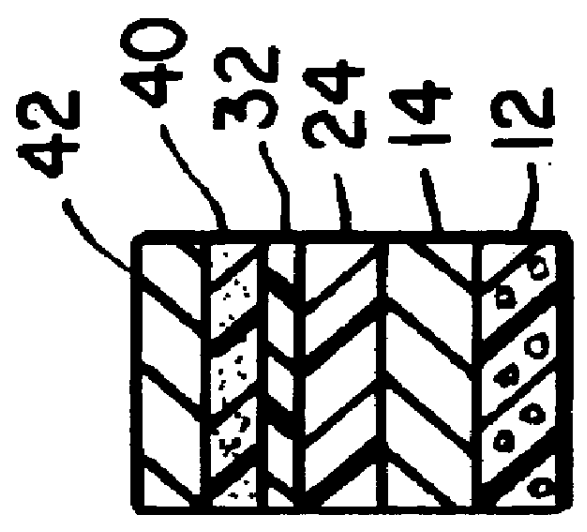

Method for forming multilayer release liners and liners formed thereby

InactiveUS20050074549A1Easy to optimizeLow costFilm/foil adhesivesLayered productsBiomedical engineeringRelease liner

Disclosed herein is a multilayer silicone release surface comprising a backing, a support layer on the backing, and a silicone layer of the support layer. The various layers of the multilayer release surface are deposited substantially simultaneously, as for example by a dual die or using curtain coating techniques.

Owner:AVERY DENNISON CORP

Bandage package and dispenser

InactiveUS6923320B2Simplifies and expedites bandage application processImprove gripDiagnosticsSurgical needlesEngineeringBandage

An element dispensing package suitable for dispensing adhesive strips or bandages. Each element is contained within an envelope formed by opposed upper and lower sheets. The lower sheet has a release liner secured thereto to protect the element while it is within the dispenser. The element is releasably secured to a pull cover and is separated from the lower sheet and release liner when the envelope is opened. The pull cover has one or more gripping means to facilitate dispensing of the element contained within the package. Additionally, the lower sheet and upper sheet have optional gripping means to facilitate dispensing of the element contained within the package.

Owner:GROSSMAN VICTOR A

Double-sided self-adhesive reinforced foam tape

A double-sided self-adhesive reinforced foam tape comprising a release liner having upper and lower surfaces which are release surfaces, a first layer of pressure sensitive adhesive applied to the upper release surface, a layer of flexible polymeric film, preferably polyester film, applied to the first pressure sensitive adhesive layer, a layer of flexible foam, preferably closed cell PVC flexible foam, thermally bonded to the flexible polymeric film layer, and a second layer of pressure sensitive adhesive applied to the flexible foam layer. A length of material for use as a double-sided tape is provided, along with a method of making the length of material. An alternative embodiment, suitable for die-cutting, including a second release liner applied to the second pressure sensitive adhesive layer is provided. The tape may be used in automobiles and other applications.

Owner:SYLVESTER MICHAEL S

Pattern coated adhesive article

InactiveUS6953602B2Promote healingImprove breathabilityMedical devicesPretreated surfacesWater vaporRelease liner

The invention relates to a adhesive article comprising at least one backing layer with a first and second surface and a pressure sensitive adhesive layer adhered first surface of the backing layer in a pattern, wherein the pattern of the adhesive layer has an adhesive free area of less than about 25% and wherein the adhesive article has a water vapor transmission rate of greater than about 2000 g / m2 / 24 hour. The invention also relates to a method of forming an adhesive article comprising (a) providing a release liner, (b) applying pressure sensitive adhesive in a pattern wherein the free adhesive area is less than 25%, and (c) applying a backing layer to the pressure sensitive adhesive.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

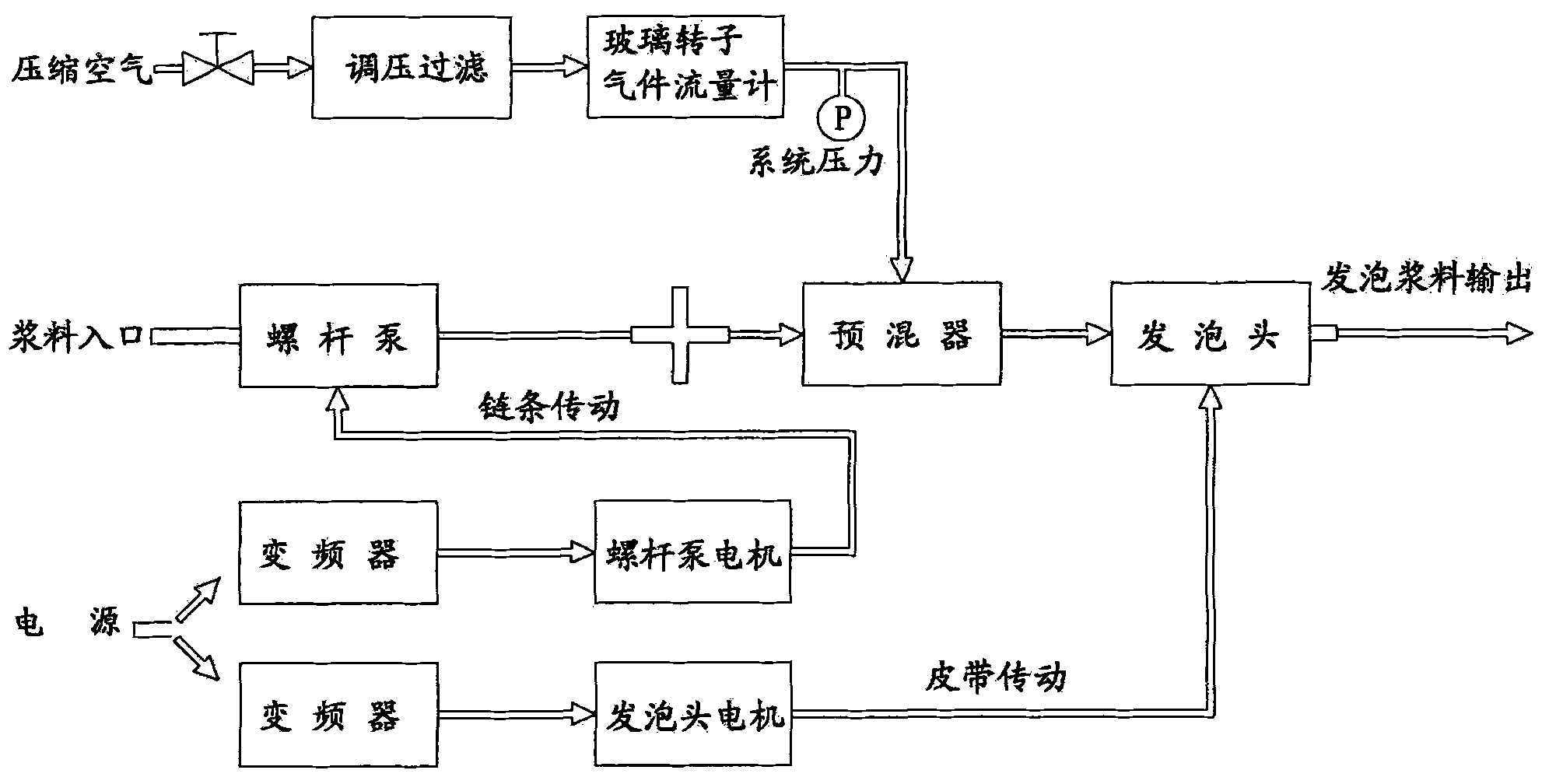

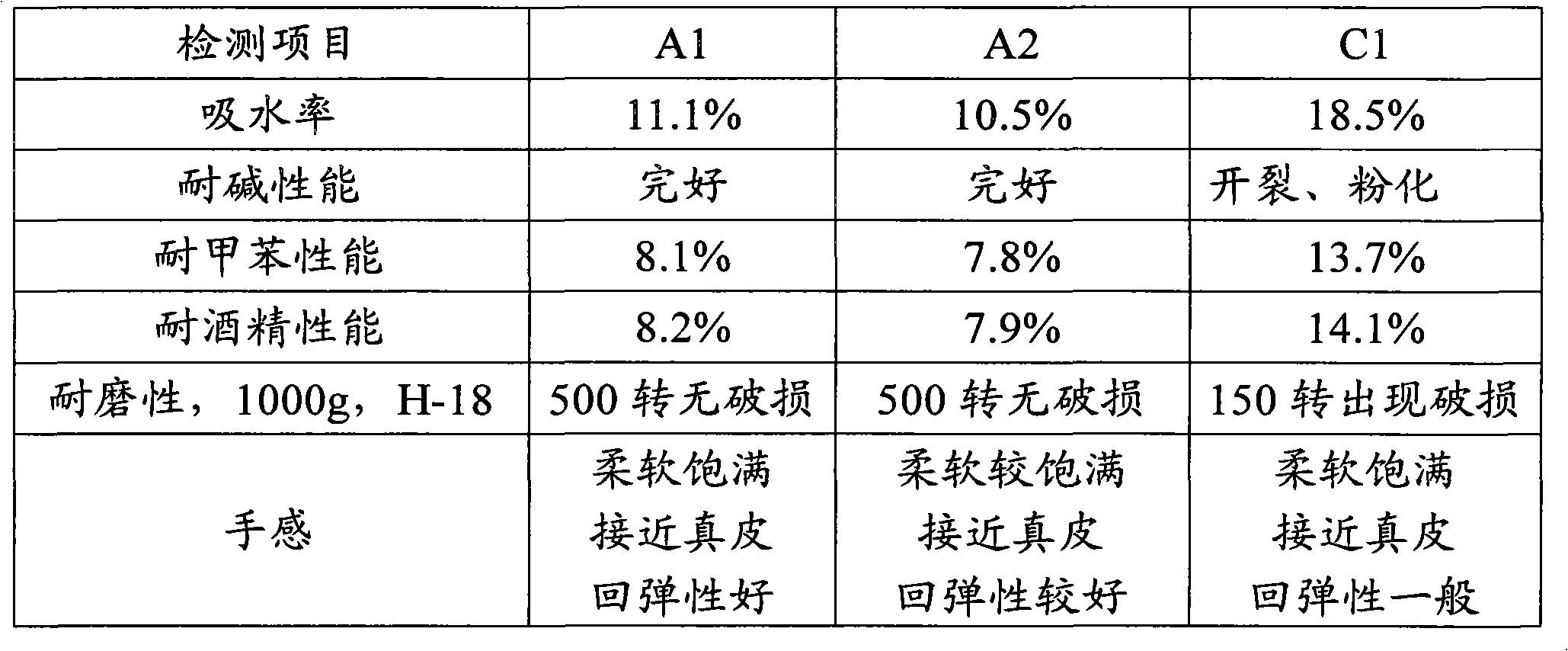

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com