Patents

Literature

178results about How to "Good color consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium nitride ceramics material and preparation method thereof

ActiveCN101386539ADoes not significantly affect colloidal propertiesGood dispersion propertiesAluminium acetylacetonateNano al2o3

The invention discloses an aluminium nitride ceramic material and a preparation method thereof. The method is to add nano-alumina to raw materials in the prior preparation method for preparation according to the prior preparation process. In-situ growing nano-alumina can be obtained directly through adding the nano-alumina, or indirectly through adding organic aluminum, such as aluminium secondary butylate, aluminium isopropoxide or aluminium acetylacetonate, and by means of low-temperature decomposition of the organic alumina. The method can be applied to dry pressing and tape casting shaping, can obtain slurry with good dispersing characteristic and even mixing of the aluminium nitride and the nano-alumina by the ceramic preparation process, such as normal pressure, hot pressed sintering or the like, and is favorable for the improvement of sintering activity of materials, the reduction of sintering temperature, the improvement of luster uniformity, planeness and roughness for a ceramic substrate, and the reduction of production cost. The aluminium nitride ceramic material and the preparation method thereof can be widely applied to the field of aluminium nitride ceramic production.

Owner:无锡海古德新技术有限公司

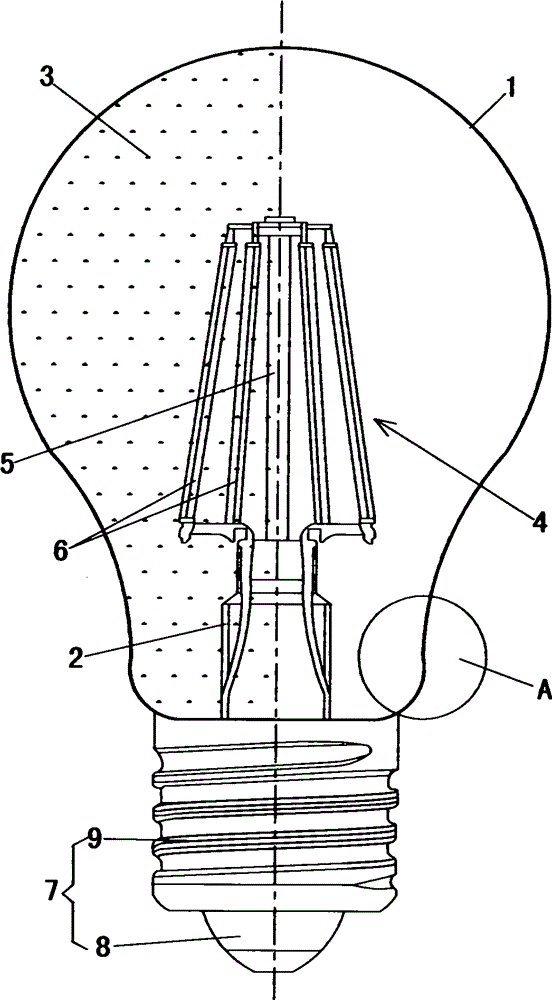

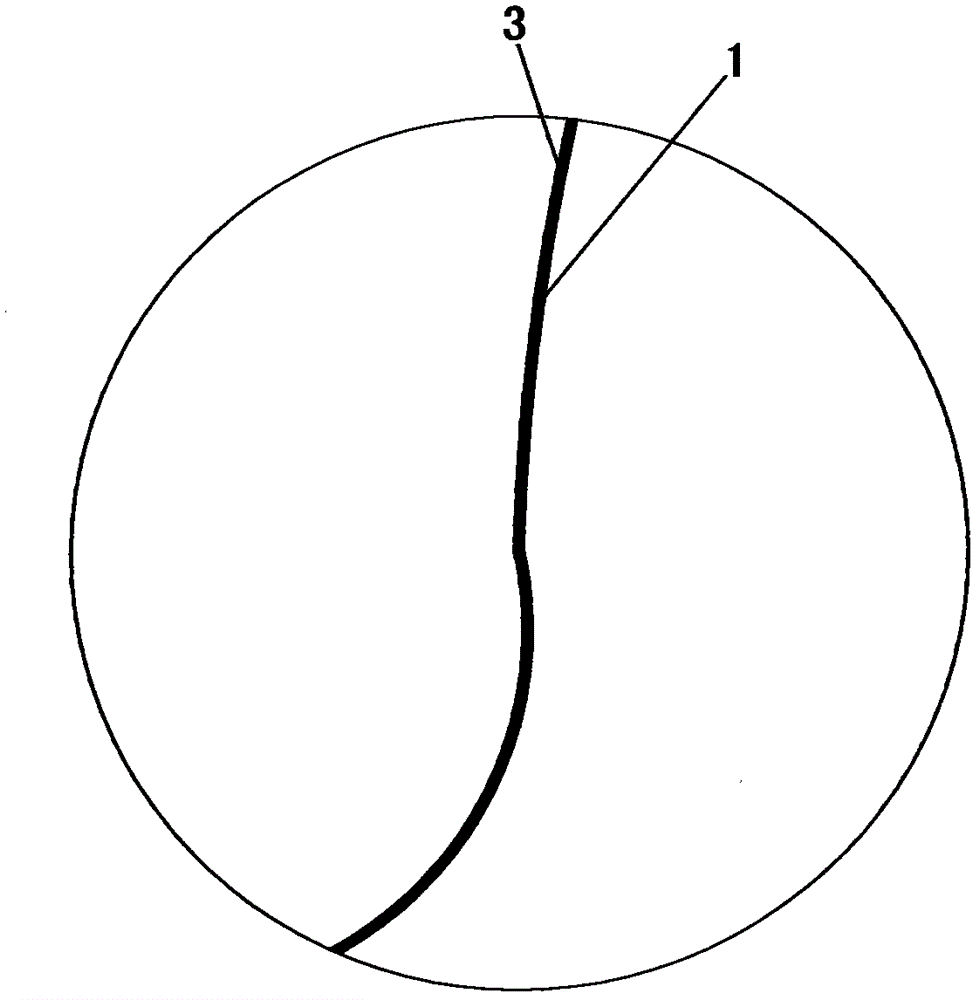

360-degree lighting bulb and processing method thereof

InactiveCN105042354AGood color consistencyThere is no color difference problemPoint-like light sourceElectric circuit arrangementsEffect lightEngineering

A 360-degree lighting bulb and a processing method thereof are provided; the bulb comprises a glass shield and a core rod; a glass shield port and a core rod bell mouth are fused to form a vacuum seal cavity filled with heat radiation gas; an inner wall of the glass shield is coated with a phosphor layer; a 360-degree lighting element is arranged in the glass shield, and comprises a rack arranged on the core rod; the rack is connected with a plurality of LED lighting chips; electrodes of each LED lighting chip are connected with conduction pins on the rack through metal wires according to polarity characteristics, thus forming more than one loop; the rack having the plurality of LED lighting chips is coated with a glue layer; the conduction pins on the rack are welded with conduction lead wires on the core column according to polarity characteristics; the glass shield is connected with a lamp holder. The lighting bulb uses the LED lighting chips of the 360-degree lighting element to illuminate, and glue mutual reflection (refraction) characteristic can excite the phosphor layer on the surface of the glass shield, so the bulb is uniform in lighting, good in color consistency, has no color difference, is high in yield rate, low in cost, and simple in technology.

Owner:王志根

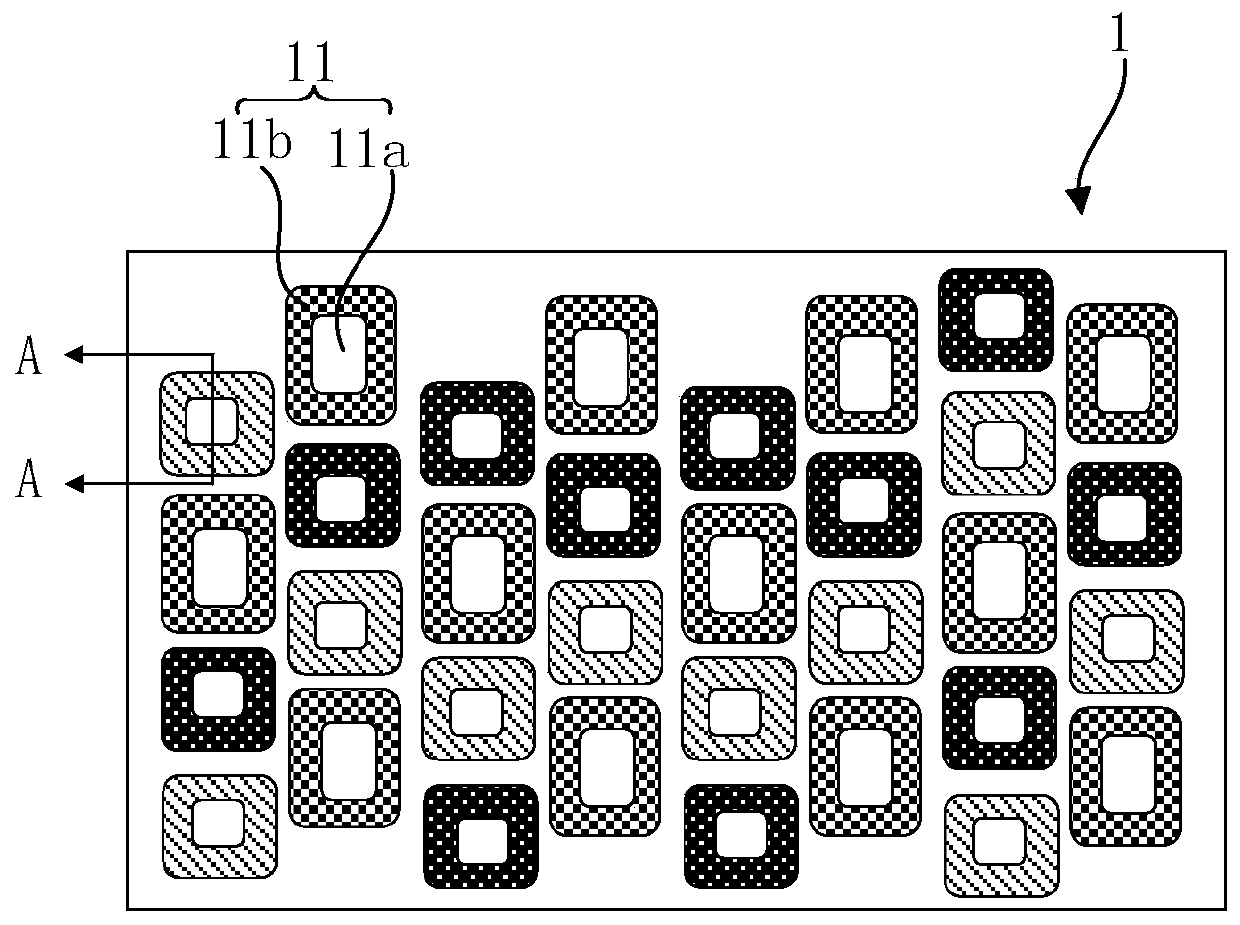

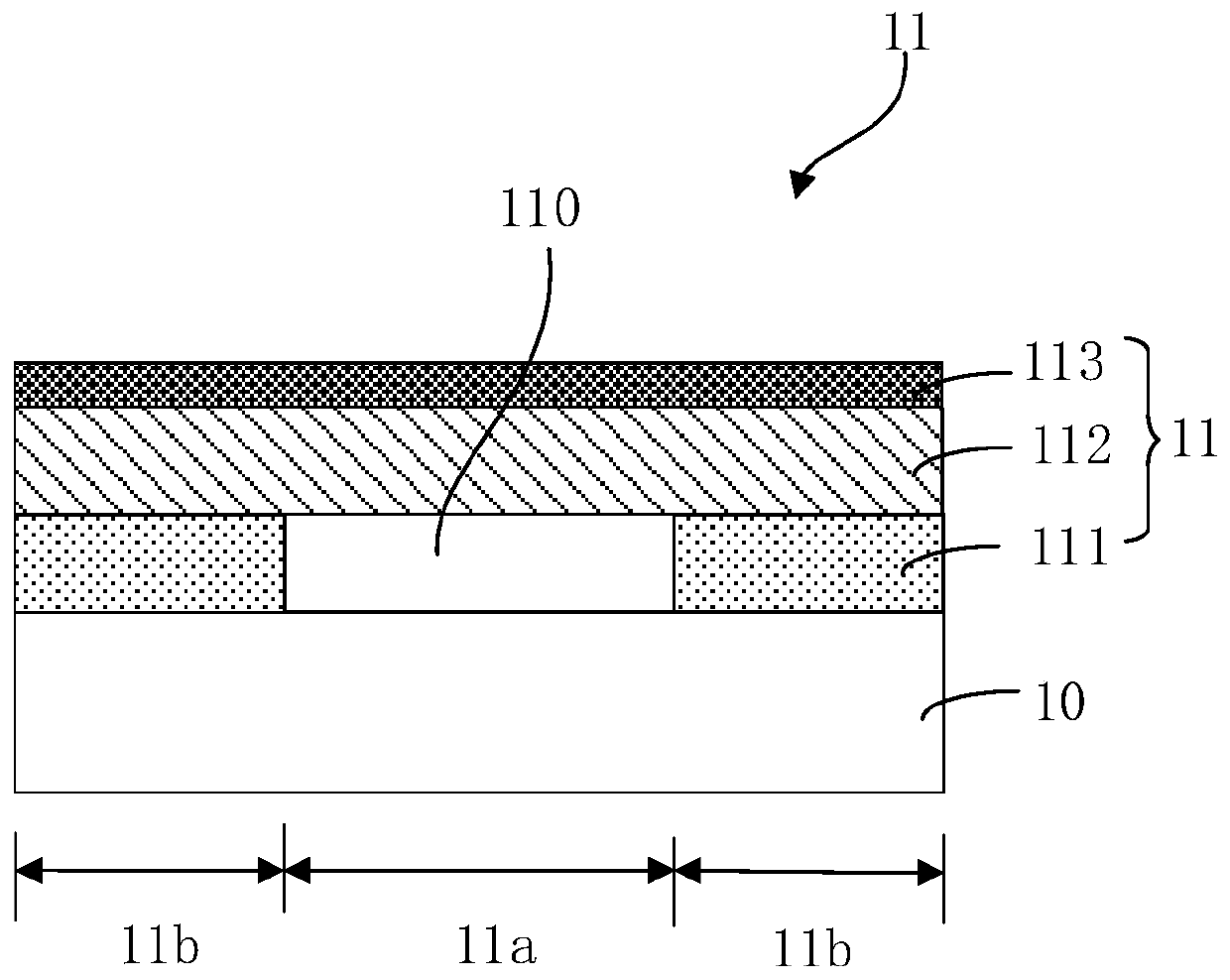

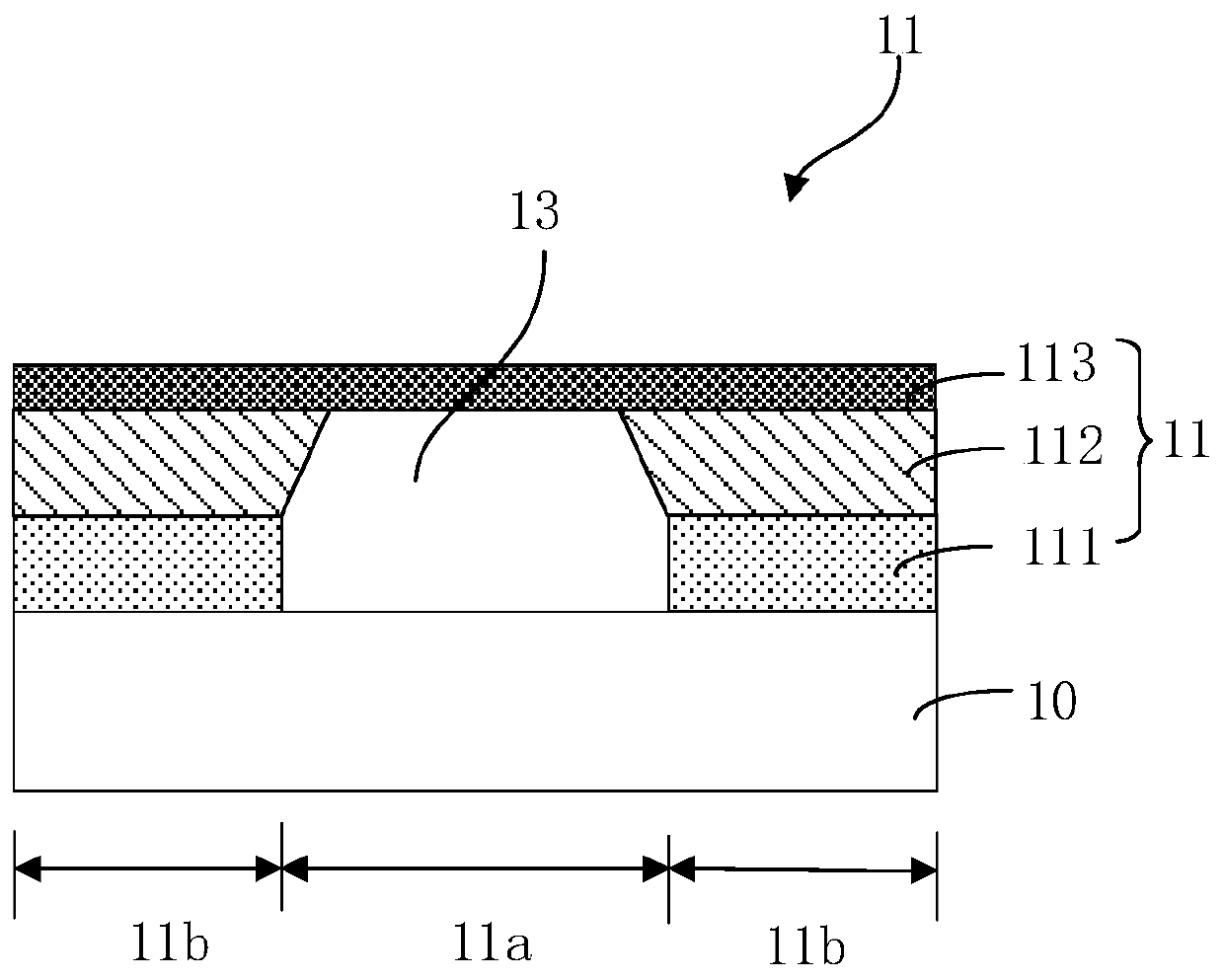

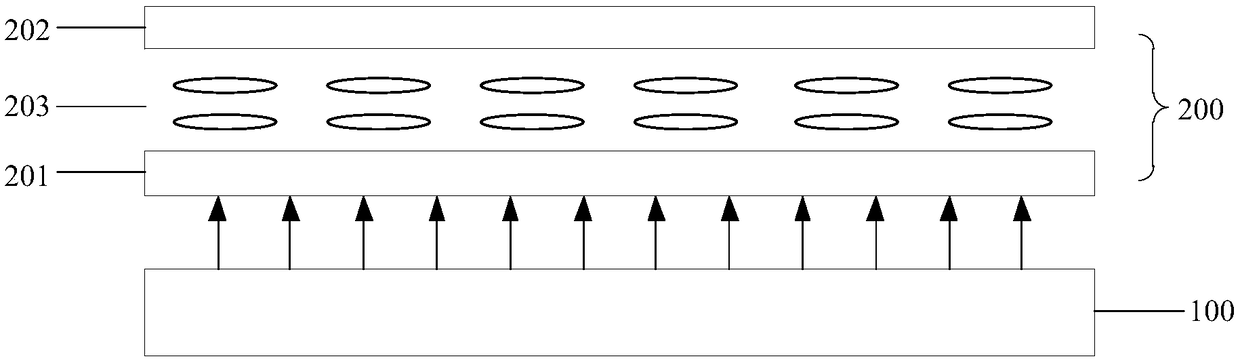

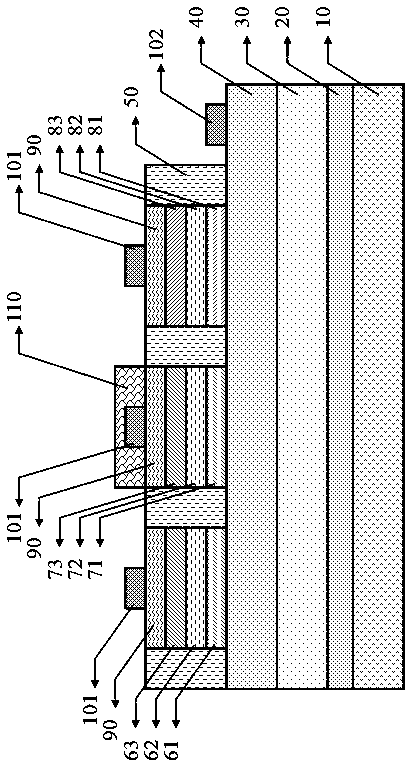

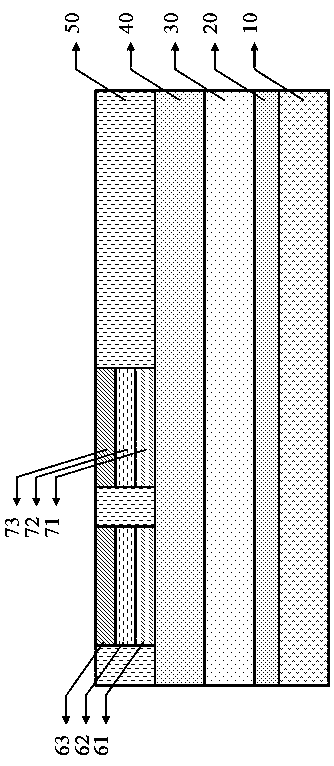

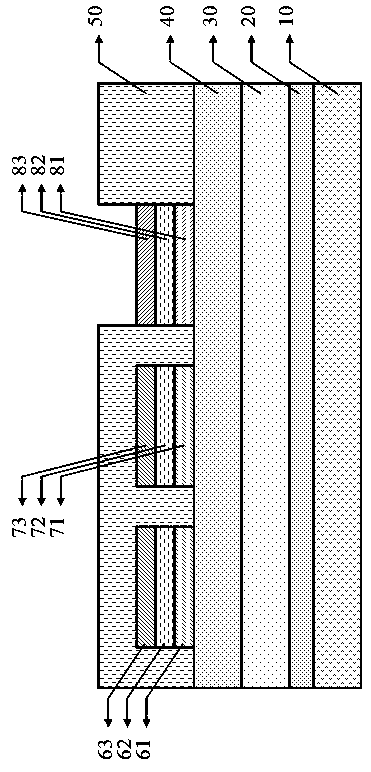

Display device, display panel thereof, and transparent display panel

ActiveCN110289298AImprove display qualityGood color consistencySolid-state devicesSemiconductor/solid-state device manufacturingFrequency spectrumDisplay device

The invention provides a display device, a display panel thereof, and a transparent display panel. A first sub-pixel of the transparent display panel is arranged to comprise a light-transmitting area and a non-light-transmitting area, wherein the non-light-transmitting area is provided with a first light reflecting anode, a first light-emitting structure layer and a first cathode in a stacked mode, and the light-transmitting area completely wraps the non-light-transmitting area, or the non-light-transmitting area completely wraps the light-transmitting area. The light emitted by the first light-emitting structure layer can be reflected back and forth between the first light-reflecting anode and the first cathode for multiple times to form a microcavity effect, so that the light-emitting efficiency is enhanced, the frequency spectrum is narrowed, and the display quality of the transparent display panel is improved; when the full screen displays, the color coordinates of the light-transmitting display area and the non-light-transmitting display area are basically consistent, and deviation is avoided. The non-light-transmitting area is completely wrapped by the light-transmitting area, or the non-light-transmitting area is completely wrapped by the light-transmitting area, so that light emitted by one first sub-pixel can be uniformly diffused to all pixels around, the color coordinate offset is reduced, and the color rendering consistency under different visual angles is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Trivalent chromic rainbow color passivating agent for galvanizing and its production

ActiveCN1584117ANo pollutionLarge operating rangeMetallic material coating processesRainbowNitrogen dioxide

A trivalent chromic ion iridescent passivating agent for galvanizing and its preparing method are disclosed. It consists of trivalent chromic salt, chelating agent, oxidant, the mol ration is 1:1:2.5-1:2:5.5, the trivalent chromic ion concentration in passivating groove liquid is 2.5-25g / L. It is prepared by adding the components into reactor, heating, mixing and chelating reacting, boiling and back-flowing to remove nitrogen dioxide after reacting, adding water and adjusting to obtain passivating agent concentrate with Cr3+ ionic concentration 30-80g / l after discharging. It achieves no pollution and wide range.

Owner:江西伟邦化工有限公司

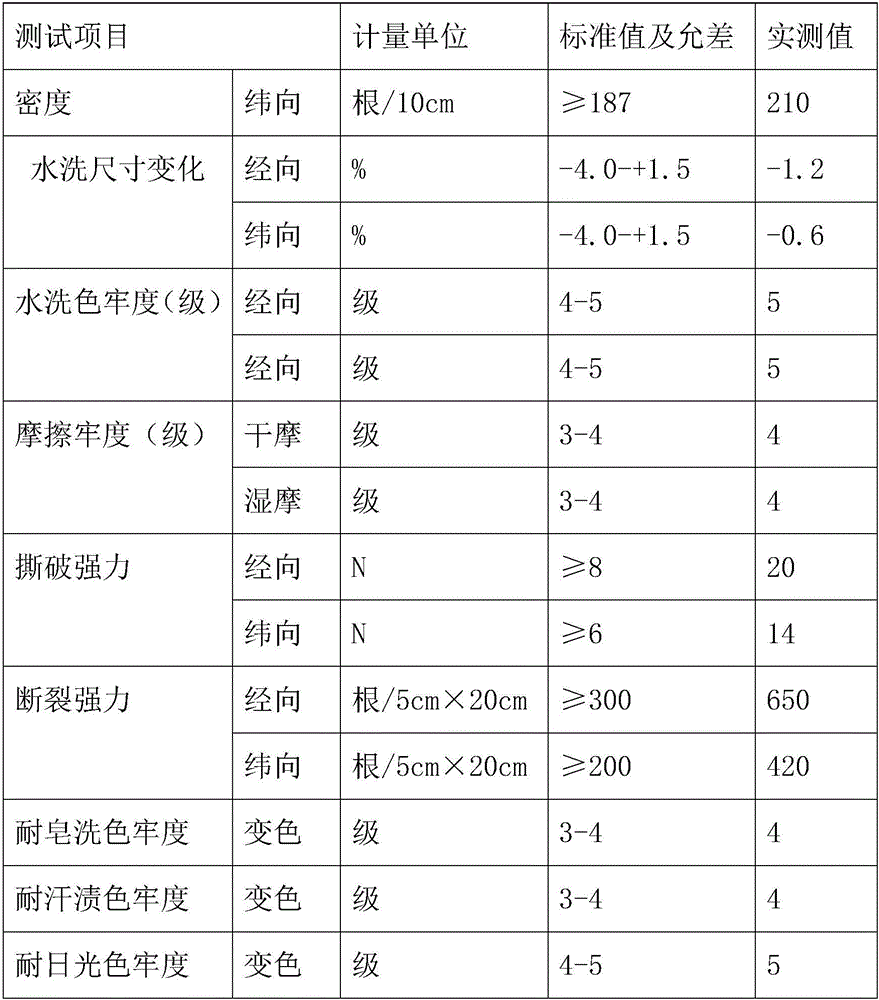

Anti-infrared military camouflage fabric and printing and dyeing process thereof

ActiveCN106049092AImprove friction resistanceImprove tensile strength at breakMercerising of indefinite length fabricsSingeingDisperse dyeColour fastness

The invention discloses anti-infrared military camouflage fabric and a printing and dyeing process thereof. Warp and weft yarns of the camouflage fabric use cotton polyester blended yarns; the cotton polyester blended yarns are formed by blending 40 to 60 weight percent of cotton fiber, 30 to 50 weight percent of polyester fiber, 5 to 10 weight percent of polyamide fiber and 5 to 10 weight percent of spun silk fiber. The printing and dyeing process of the anti-infrared military camouflage fabric comprises the following steps of S1, a pretreatment process; S2, a dyeing process; S3, a printing process; S4, tentering sorting, wherein the dyeing process uses disperse bath process dyeing of reduced dye and disperse dye; the printing process uses printing of reduced dye and disperse dye in one paste. According to the anti-infrared military camouflage fabric and the printing and dyeing process of the anti-infrared military camouflage fabric, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness of all items, full color and luster and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

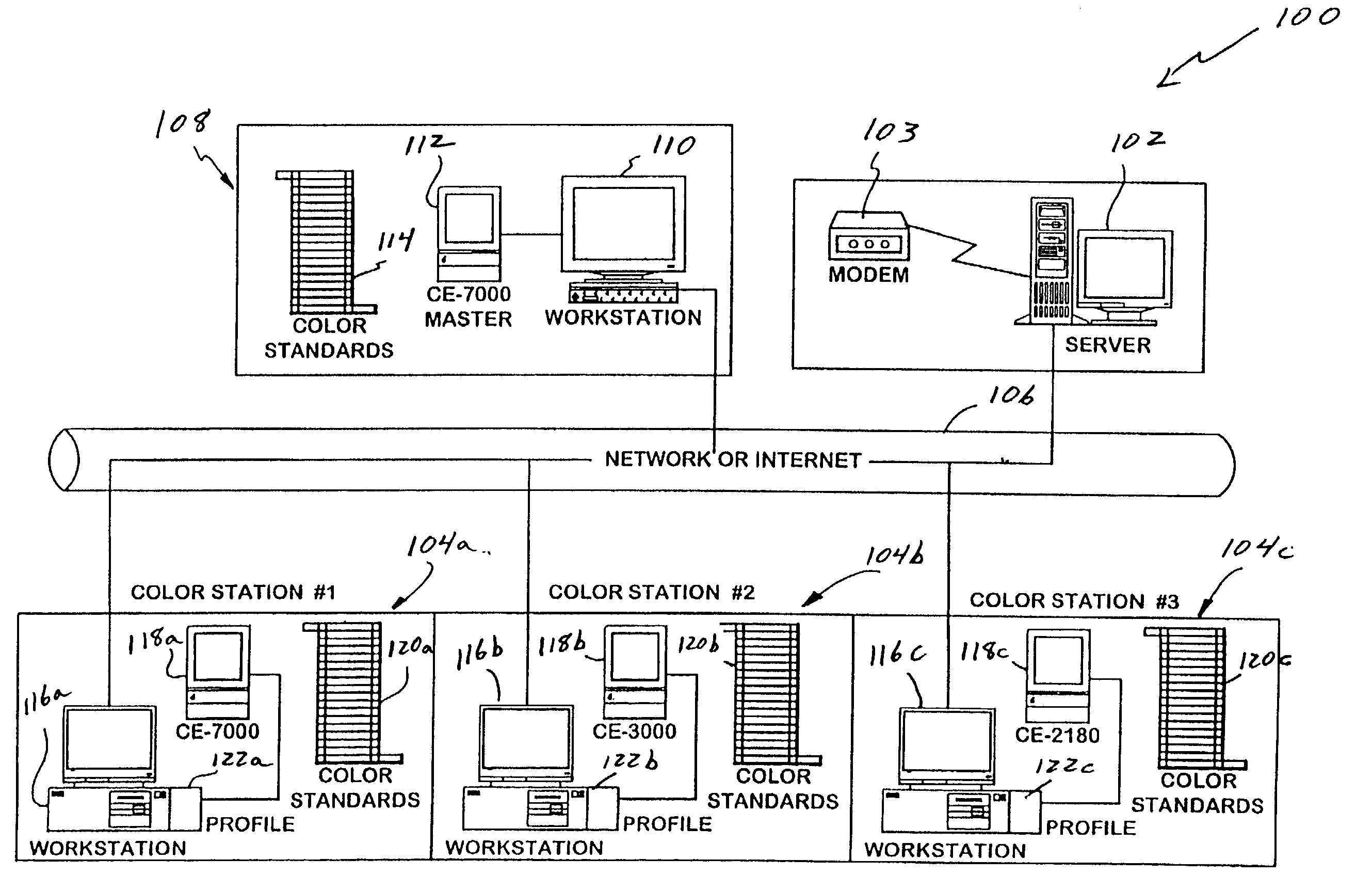

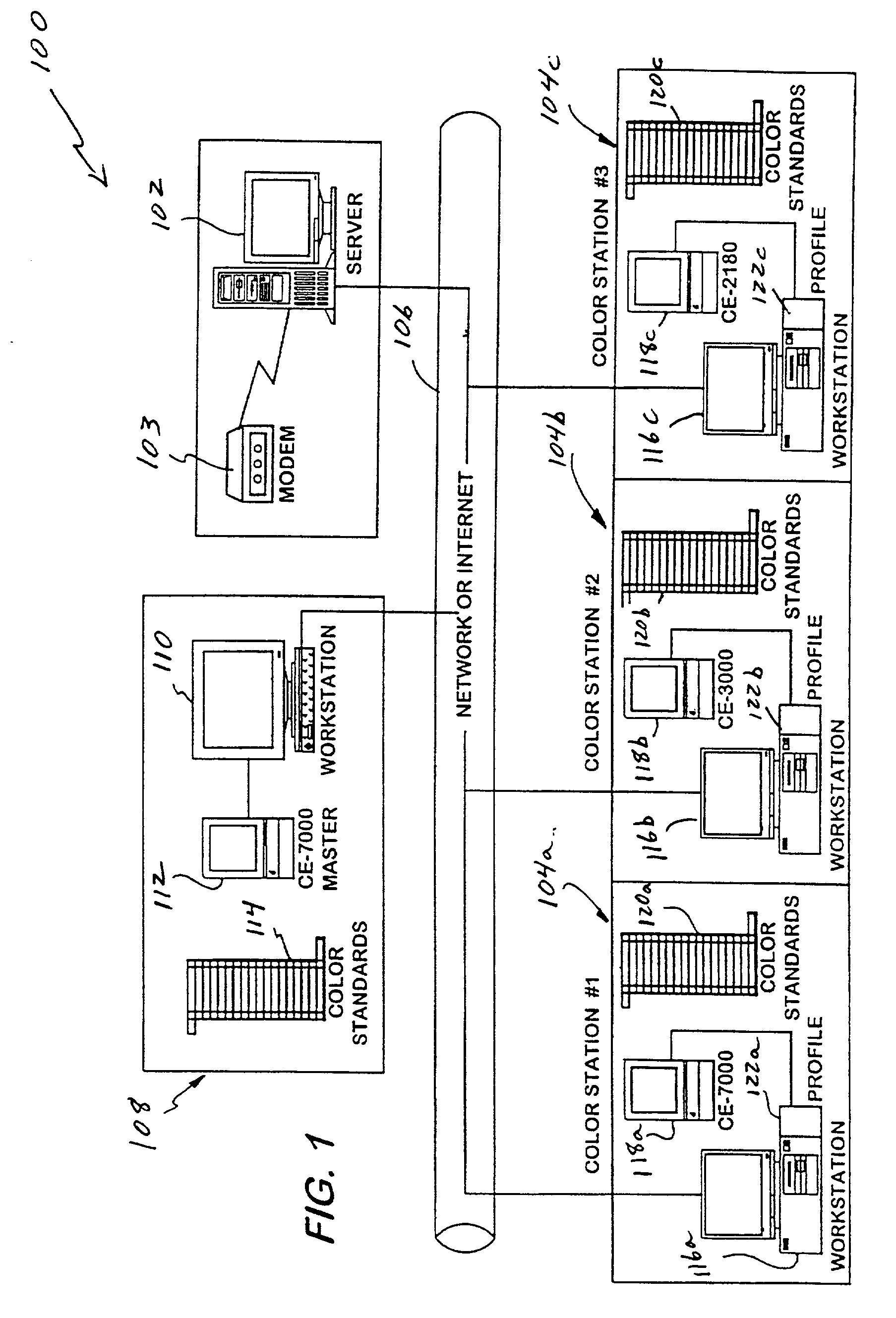

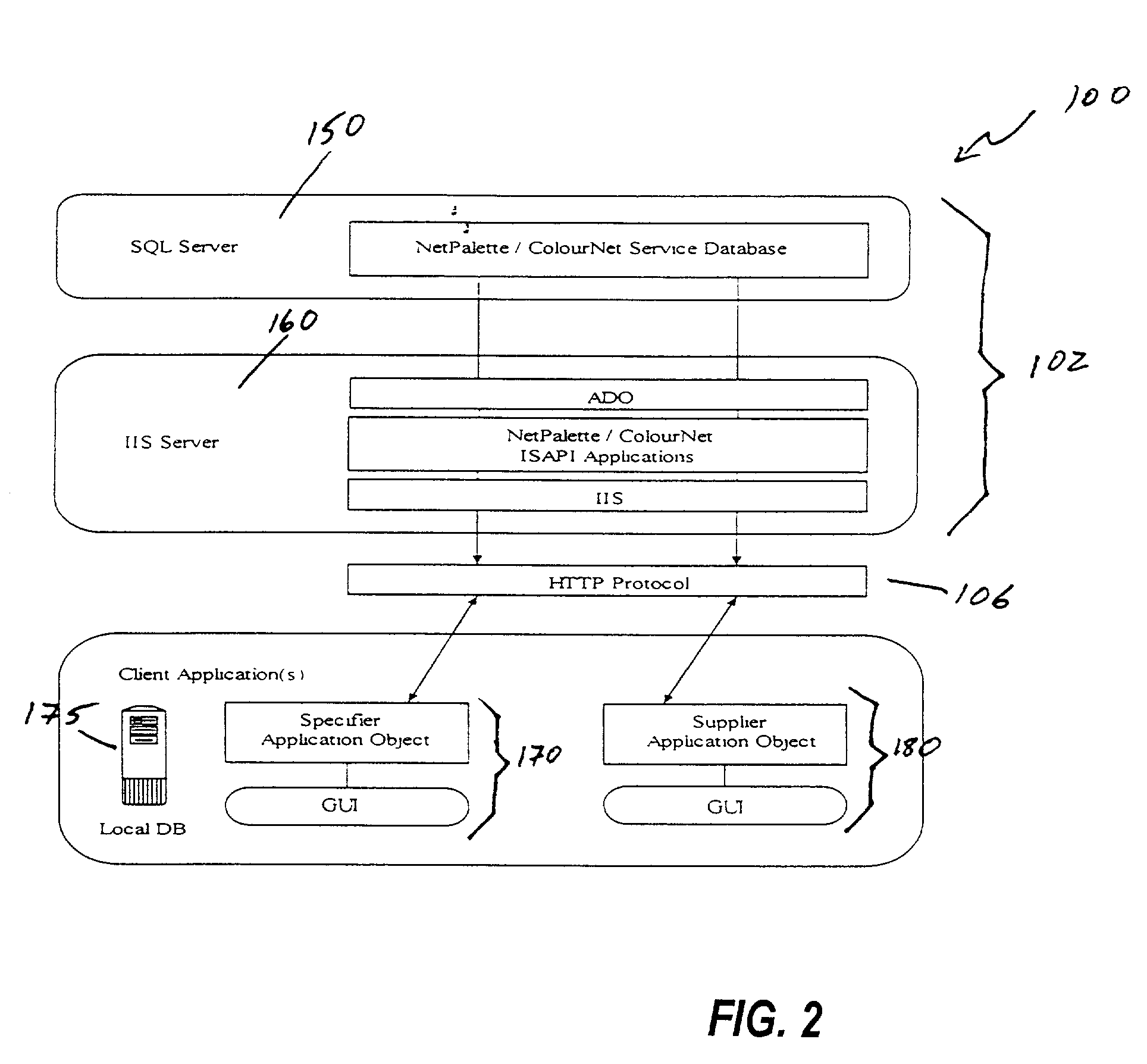

System and method for facilitating specifier and supplier communications

InactiveUS20030078794A1Facilitate communicationGood color consistencyRadiation pyrometrySpectrum investigationComputer scienceFacilitated communication

Owner:GRETAGMACBETH LLC

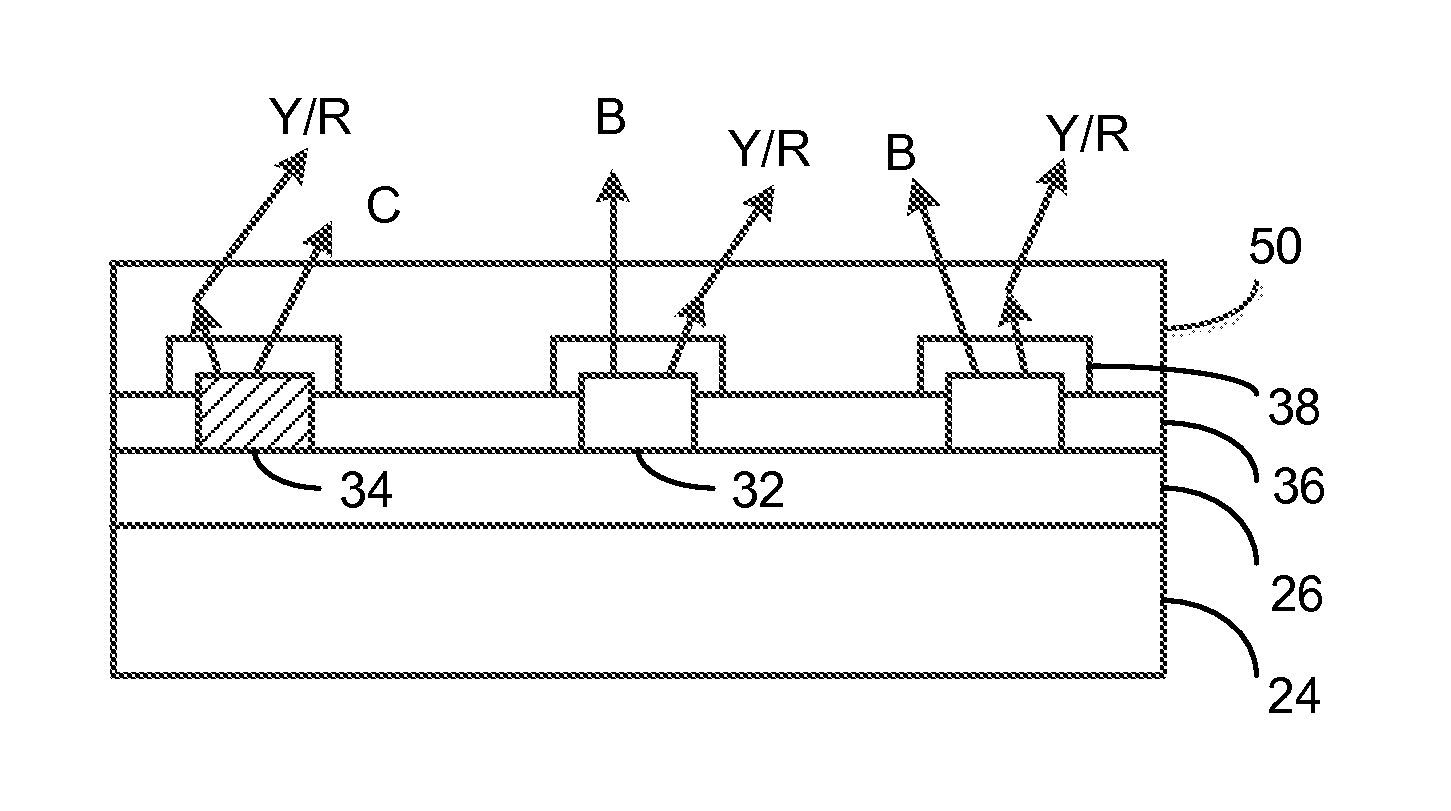

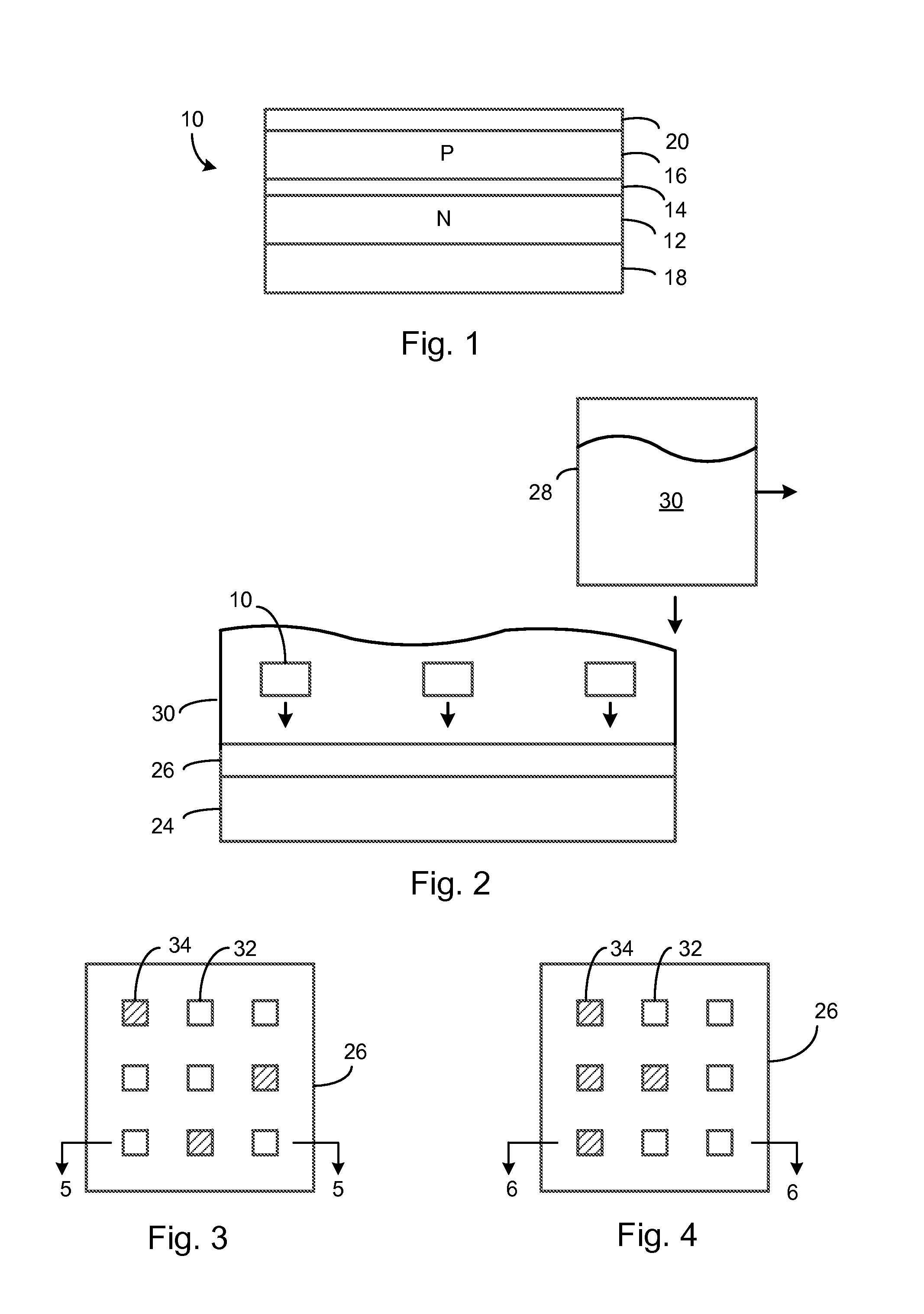

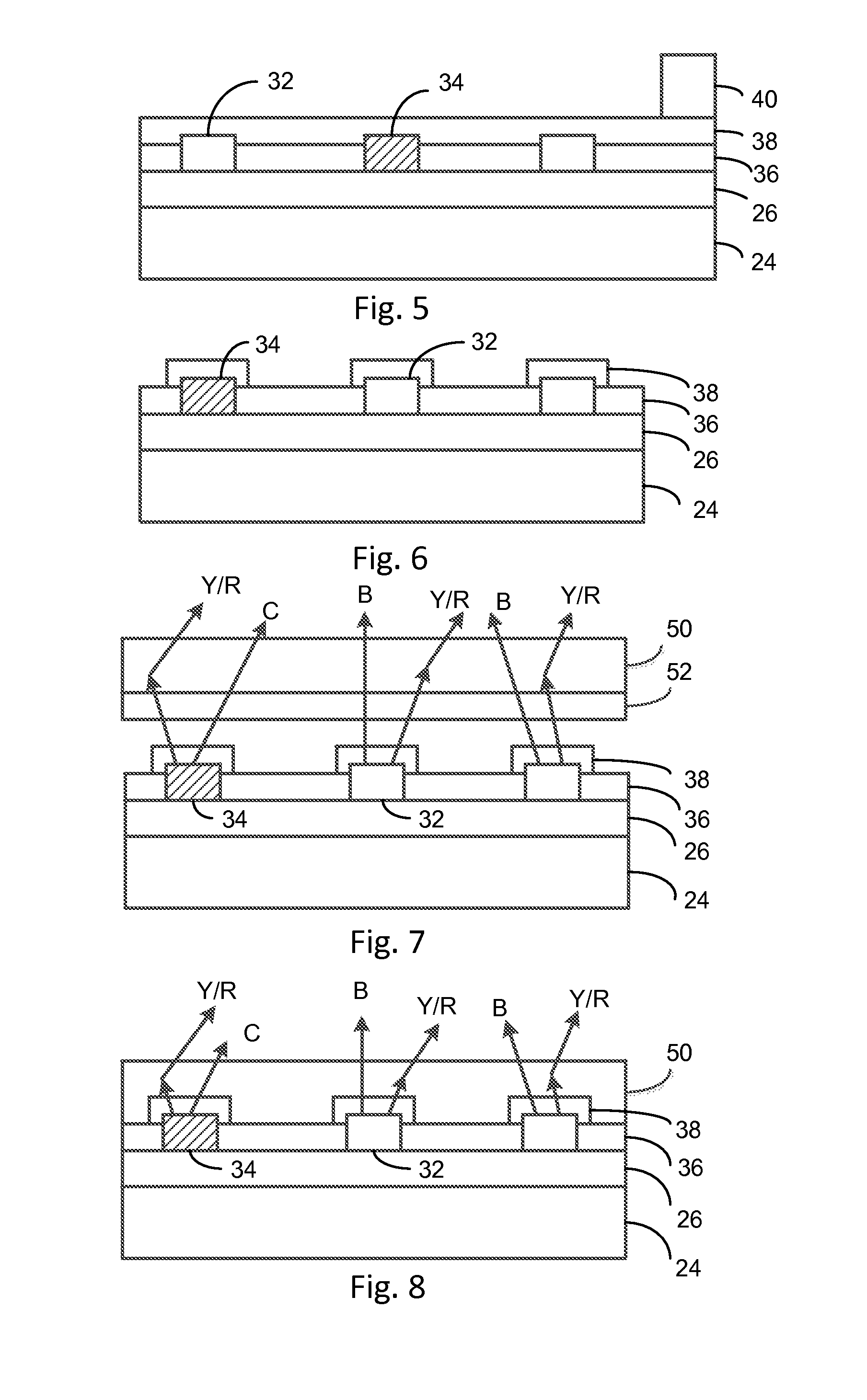

LED lamp using blue and cyan LEDs and a phosphor

ActiveUS8906713B2Efficient excitationHigh color rendering indexSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorWavelength

Many thousands of micro-LEDs (e.g., 25 microns per side) are deposited on a substrate. Some of the LEDs are formed to emit a peak wavelength of 450 nm (blue), and some are formed to emit a peak wavelength of 490 nm (cyan). A YAG (yellow) phosphor is then deposited on the LEDs, or a remote YAG layer is used. YAG phosphor is most efficiently excited at 450 nm and has a very weak emission at 490 nm. The two types of LEDs are GaN based and can be driven at the same current. The ratio of the two types of LEDs is controlled to achieve the desired overall color emission of the LED lamp. The blue LEDs optimally excite the YAG phosphor to produce white light having blue and yellow components, and the cyan LEDs broaden the emission spectrum to increase the CRI of the lamp while improving luminous efficiency. Other embodiments are described.

Owner:NTHDEGREE TECH WORLDWIDE

Super-high-density LED display device and manufacturing method thereof

PendingCN105206642APrevent light diffusionHigh resolutionSolid-state devicesIdentification meansHigh densityLED display

The invention discloses a super-high-density LED display device which comprises a substrate and an LED chip array packaged on the substrate. The chip array comprises a plurality of LED chips distributed evenly at intervals. By means of the Fan-Out Wafer-Level Package (FOWLP) process, the packaging area is narrowed, and the resolution ratio of an LED display screen is increased; all the LED chips are the same in structure, light-emitting wave band and type, the LED chips emit red light, green light and blue light after being coated with red light fluorescent powder, green light fluorescent powder and blue light fluorescent powder in a chip light-emitting curing mode respectively, and therefore it is ensured that the LED chips are consistent in light attenuation in the use process, and the development performance of the display screen is improved; pixel point distances can be smaller than 1 mm and even smaller than 0.1 mm, better performance such as high integrity, high resolution and consistent light color of the LED display device is achieved, and the super-high-density LED display device is importantly applied to indoor high-density display screens, projection devices and wearable display devices.

Owner:NANJING UNIV

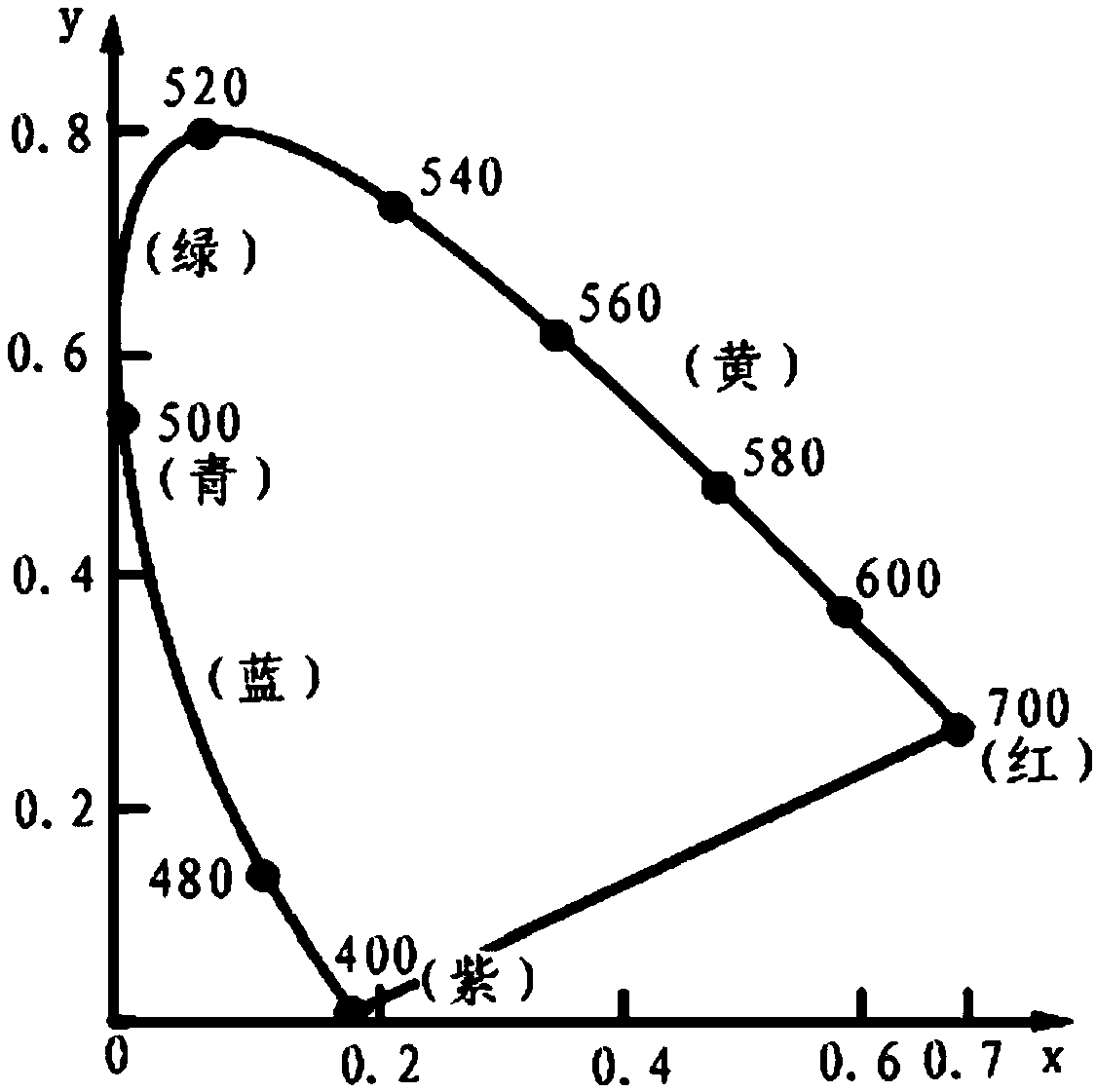

Chroma adjustment method and device of display panels

The invention discloses a chroma adjustment method and device of display panels. Present white point color coordinate values of the different display panels are measured, and a target white point color coordinate value is determined according to the measured white point color coordinate values of the different display panels; and according to the present white point color coordinate values of different display panels and the target white point color coordinate value, initial data voltages of different color sub-pixels of the display panels are adjusted successively, so that the difference between each adjusted white point color coordinate value of the display panel and the target white point color coordinate value is lower than a preset value, and the data voltage after adjustment serves as a standard data voltage of the color sub-pixels of the display panels. The data voltages of the different color sub-pixels of the display panels are adjusted, so that the chroma of the display panels after adjustment basically equals the target white point color coordinate value, and the chroma of the display panels is more consistent.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

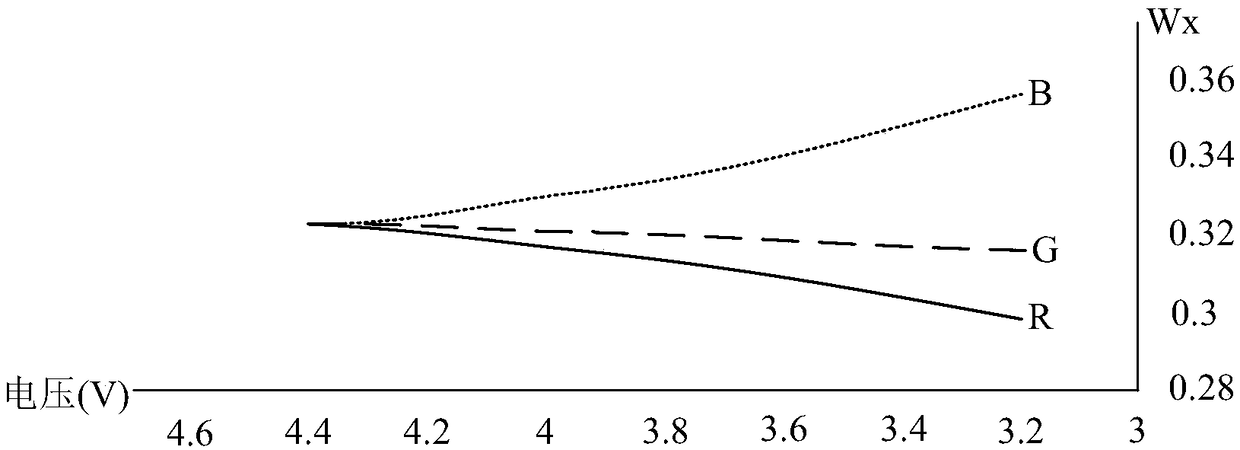

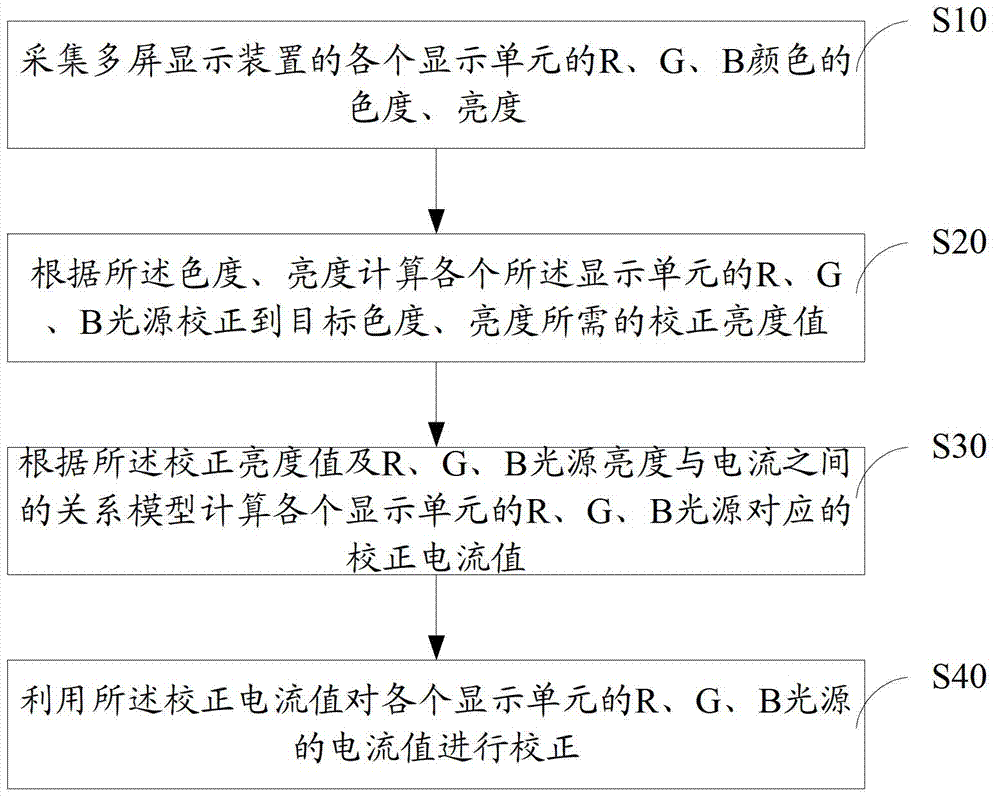

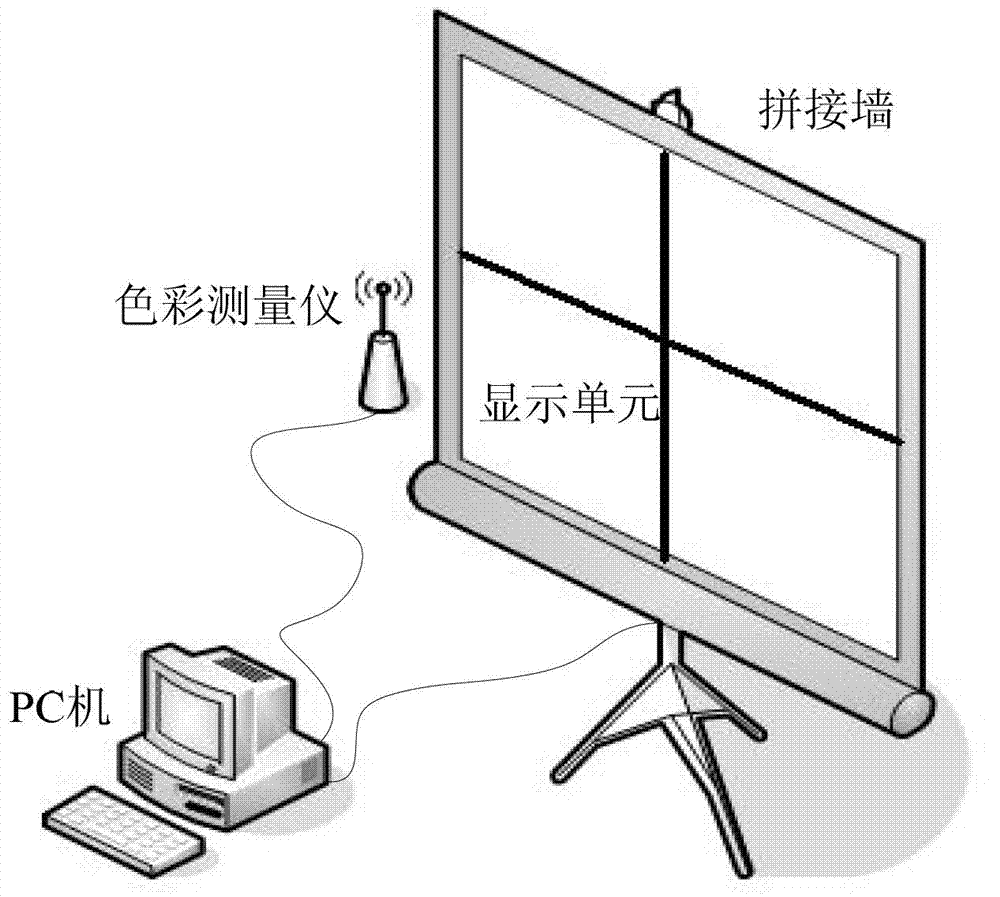

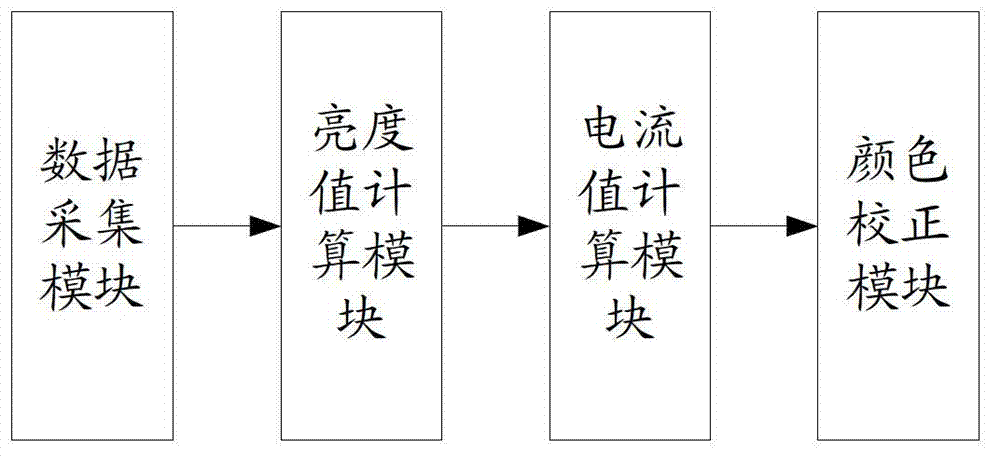

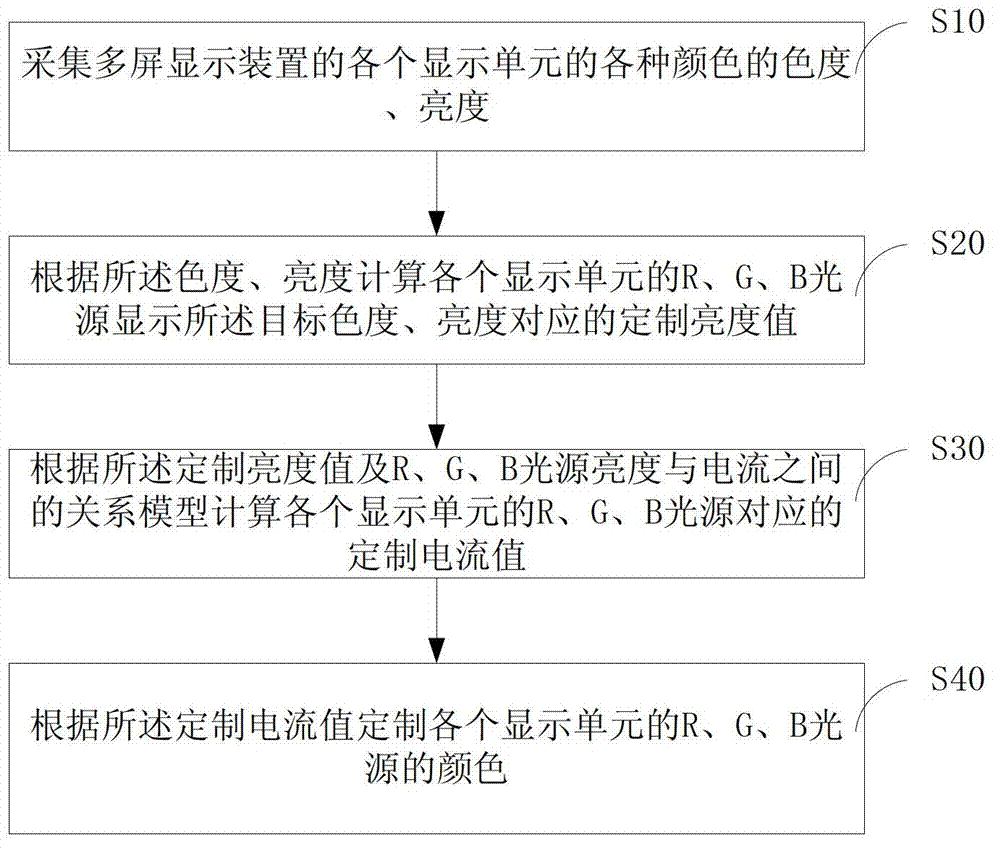

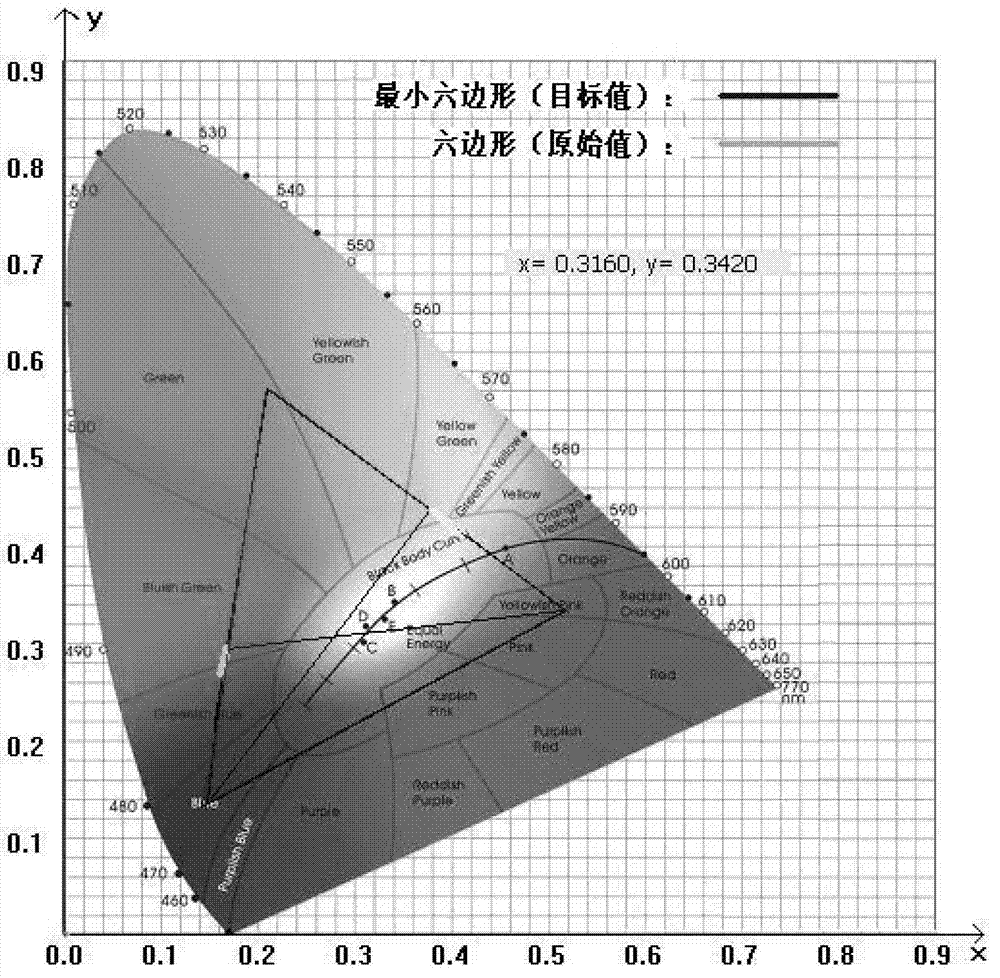

Color correction method and system for multi-screen display device

InactiveCN103050109AColor Correction ImplementationMaintain color hierarchyCathode-ray tube indicatorsRelational modelColor correction

The invention discloses a color correction method and a color correction system for a multi-screen display device. The method comprises the following steps: acquiring chroma and brightness of red, green and blue (R, G and B) of each display unit of the multi-screen display device; calculating corrected brightness values required by correcting R, G and B light sources of each display unit to reach the target chroma and brightness according to the chroma and brightness; calculating corrected current values corresponding to the R, G and B light sources of each display unit according to the corrected brightness value and a relation model between the brightness of the R, G and B light sources and current; and correcting current values of the R, G and B light sources of each display unit according to the corrected current values. After the multi-screen display device is corrected, the color consistence of each display unit of the multi-screen display device is good; and compared with the traditional signal compression correction method, a current value correction method can keep the color layering among display units and has better display effect.

Owner:GUANGDONG VTRON TECH CO LTD

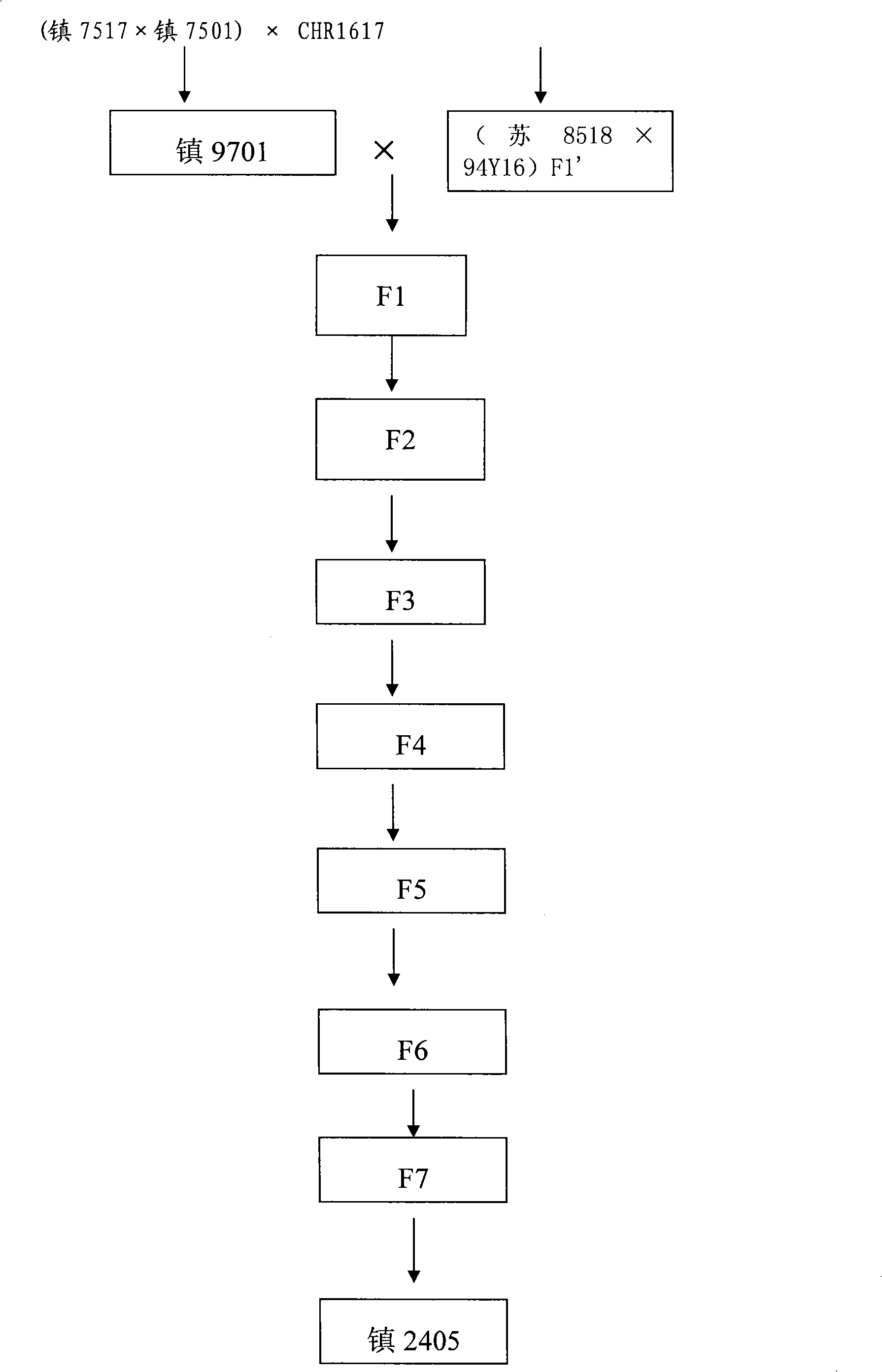

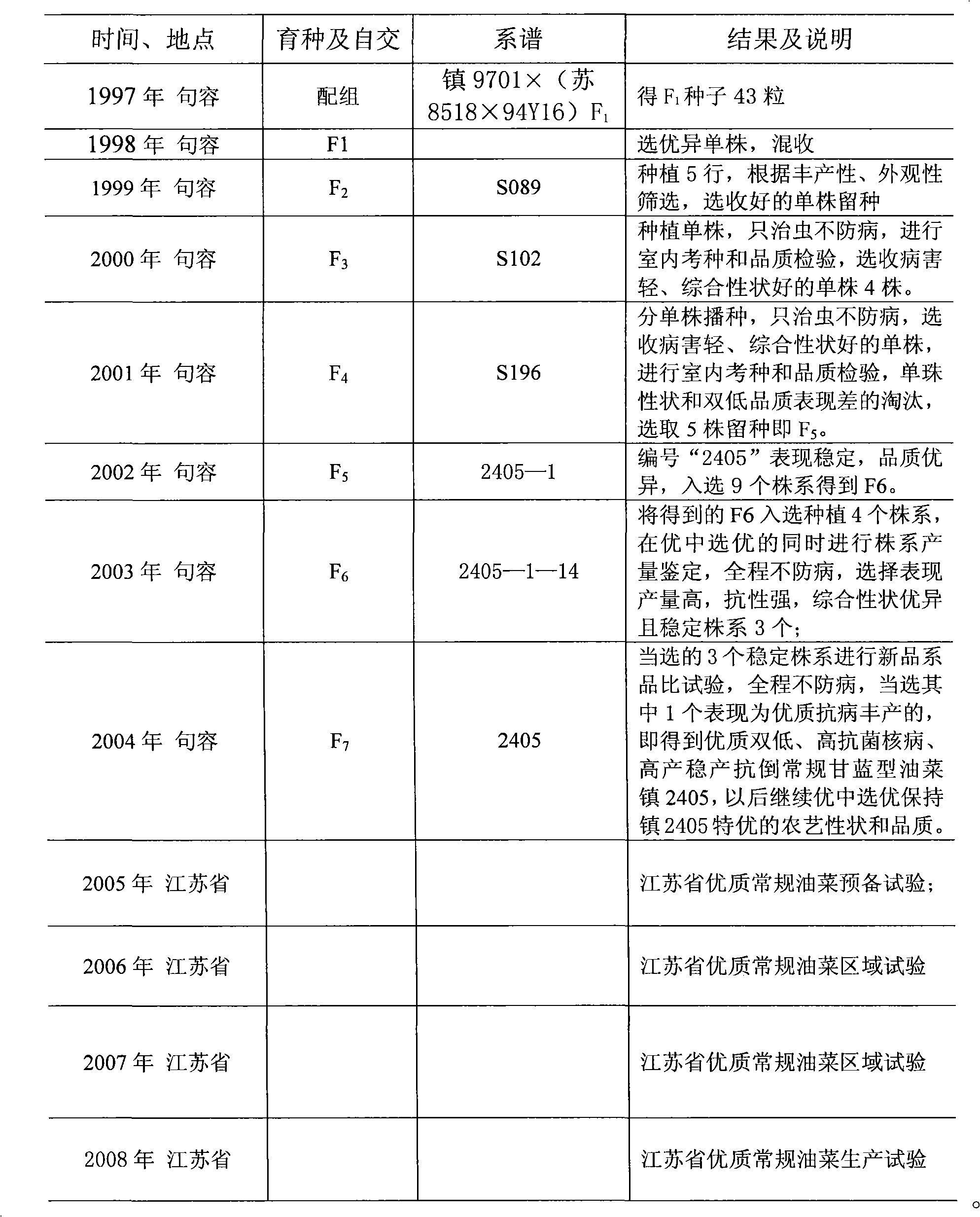

Breeding method of good quality, double-low, disease-resistant, high yield, lodging-resistant rape

InactiveCN101336611AExcellent and stable qualityQuality improvementPlant genotype modificationAngiosperms/flowering plantsDiseaseHigh resistance

The invention discloses a breeding method of high-quality double-low disease-resistant high-yield lodging-resistant rape cultivar 'Zhen 2405'. The bred high-quality double-low rape cultivar has the advantages of full and round seed grain, heavy thousand grain weight, black seed grain, good marketability, excellent disease resistance, stable yield, good lodging resistance, good plant-type trait, good maturity performance, consistent maturity and suitability for the mechanized harvest. The method comprises the following steps: A) selecting the early-mature high-yield rapeseed line 'Zhen 9701' as the maternal plant, which has high resistance to Sclerotinia sclerotiorum and lodging and has compact plant-type trait, selecting rape line F1 as the male parent, which has good agronomic characters and high-yield trait, and cross-breeding to obtain a rape line F0; and B) sowing the rape line F0, sowing the excellent individual plants after the two-row sowing of the rape line F0, and self-inbreeding for 6 generations to obtain the high-quality double-low high-yield rape cultivar (Brassica napus) 'Zhen 2405' with excellent resistance to Sclerotinia sclerotiorum and lodging.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Nylon camouflage fabric preparation process

ActiveCN103541232AGood color consistencyHigh color fastnessDyeing processTextile printerCooking & baking

The invention relates to a textile printing and dyeing process, and especially relates to a nylon camouflage fabric preparation process. The process comprises the steps of original cloth stitching, pretreatment, styling, bottom dyeing, printing, baking, steaming, post-finish tentering, and inspecting. The formula of the printing material is that: every 100kg of a colorant comprises 0.6-1.8kg of a dispersing material, 0.01-5.0kg of an acidic material, and 0.02-0.5kg of paint. In the baking step, a moving speed is 35+ / 1m / min, and a temperature is 165-170 DEG C. in the steaming step, the moving speed is 10+ / 1m / min, the temperature is 101-105 DEG C, and the time is 30min. In the post-finish step, different auxiliary agents are used, such that waterproof, air-permeating, oil-repelling, and antistatic functions are made compatible. The process has the advantages of short production process, good color phase consistency, good color fastness, bright color, and low cost. The method mainly adopts environment-friendly dyes, and is especially suitable for high-grade products in anti-infrared camouflage product fabrics.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

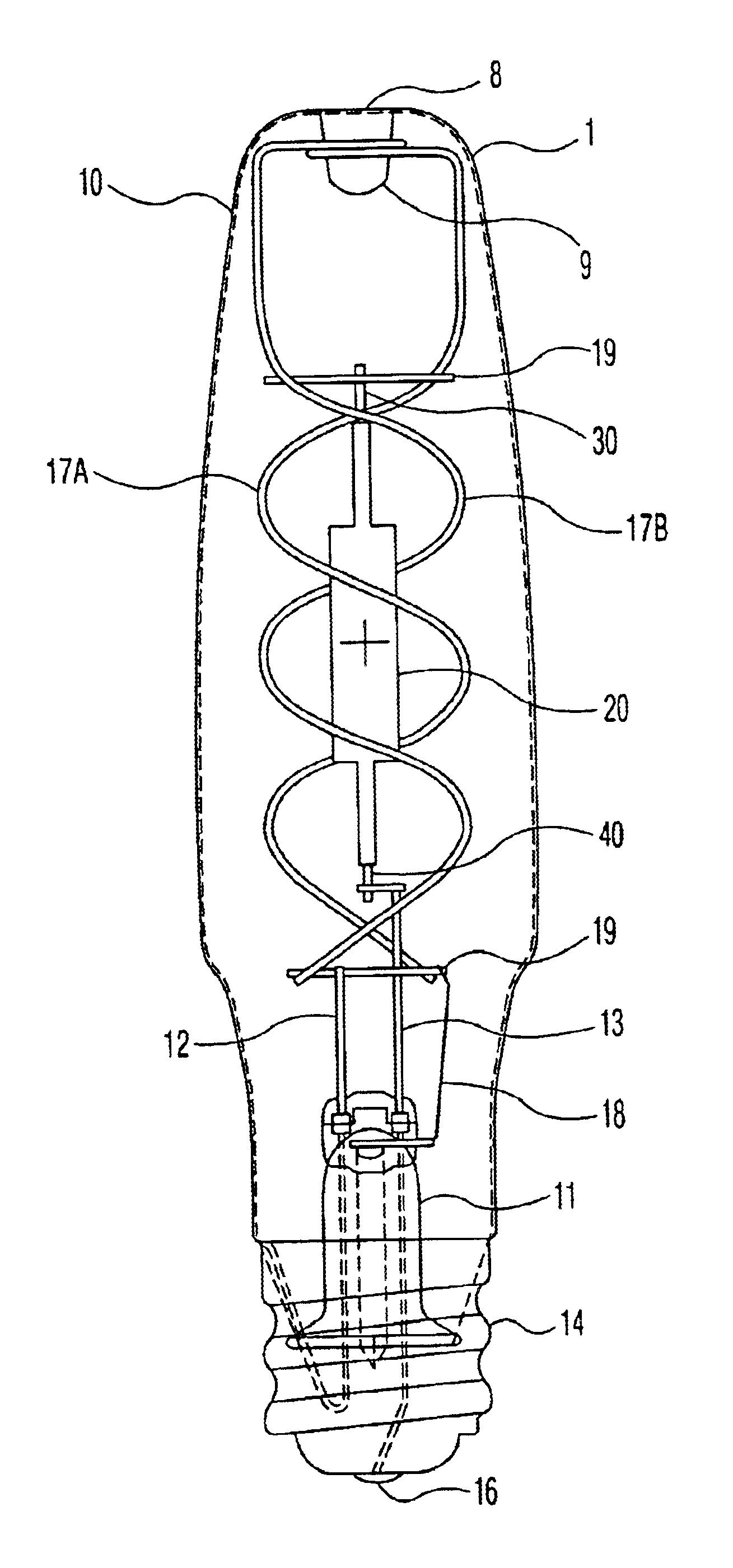

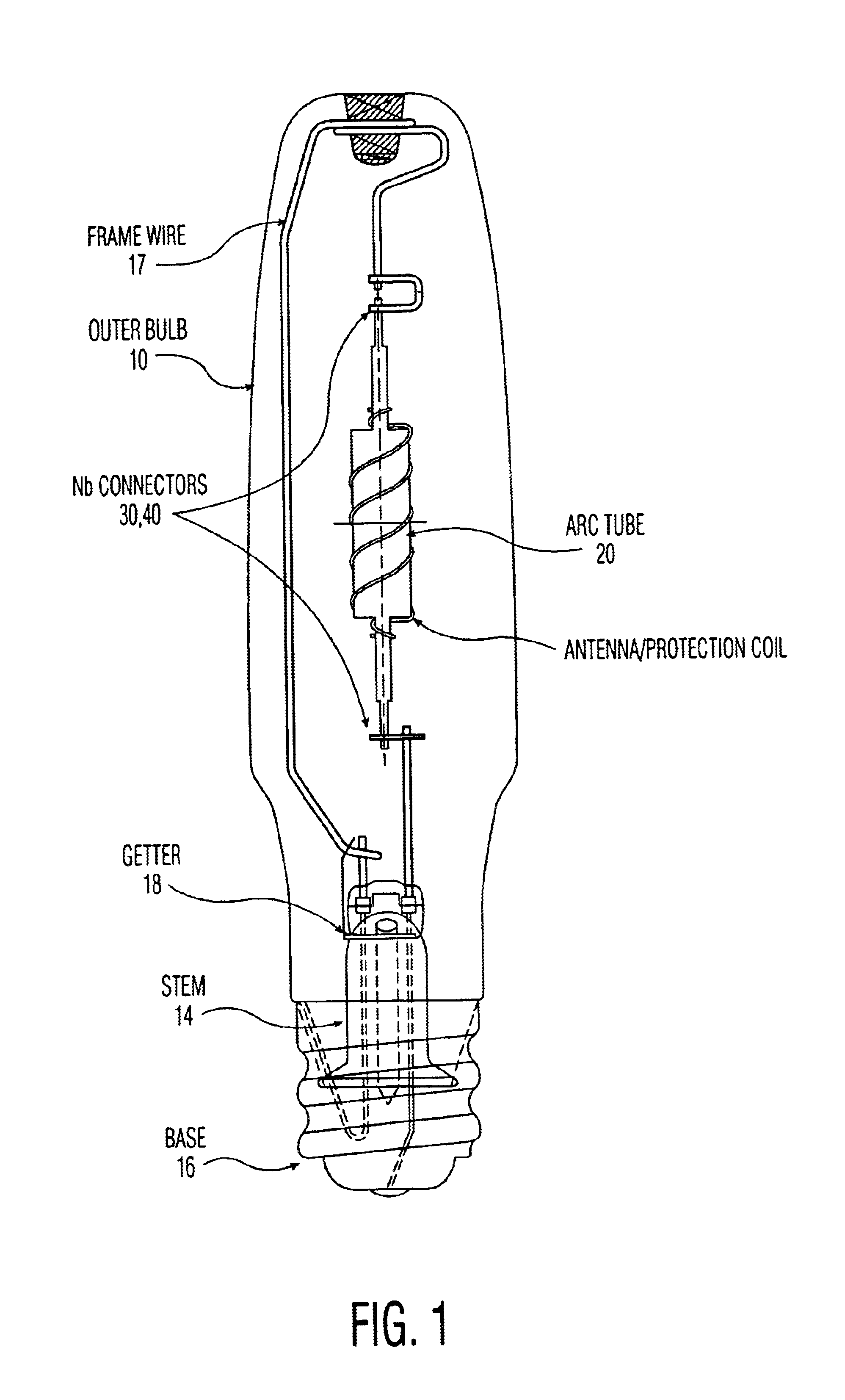

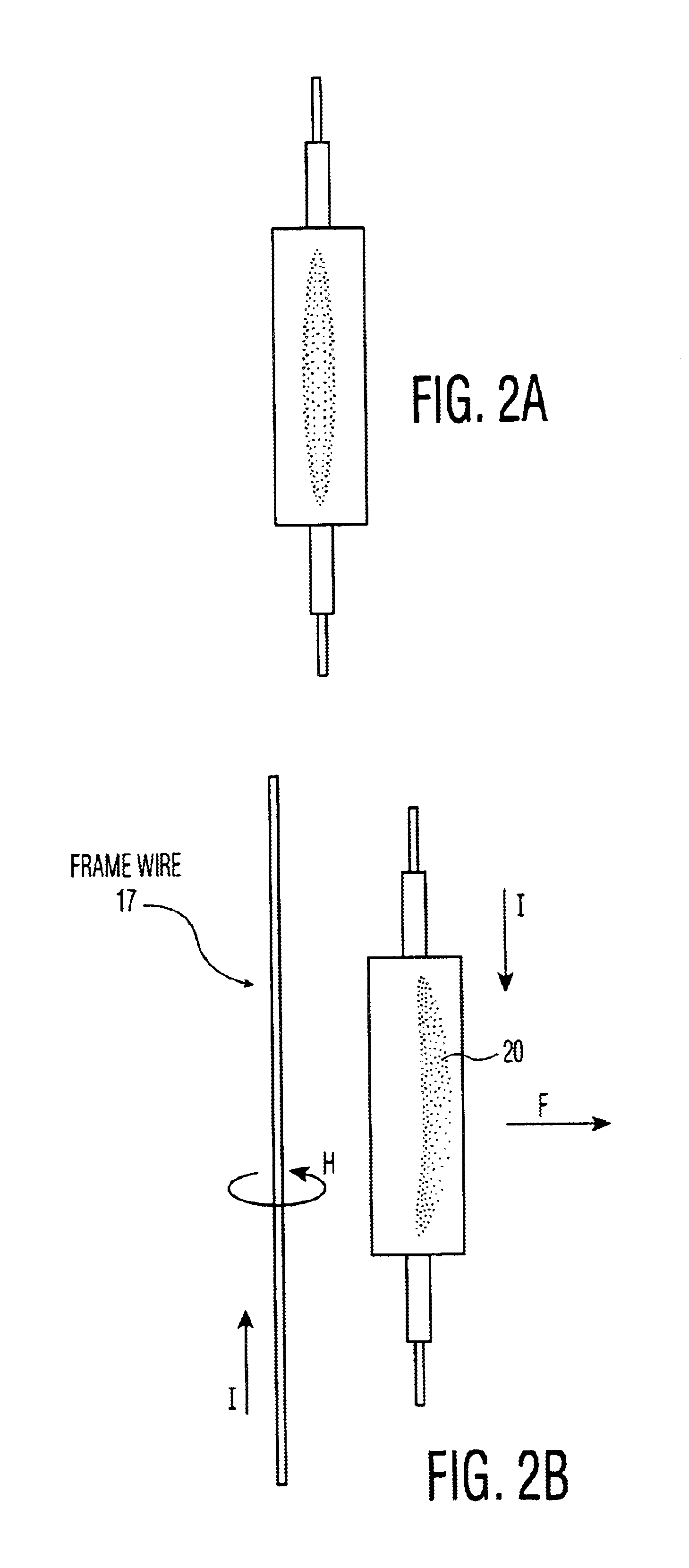

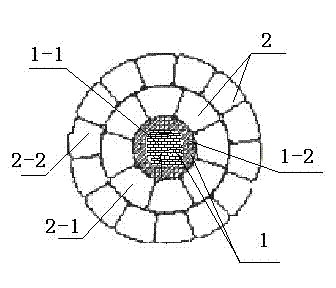

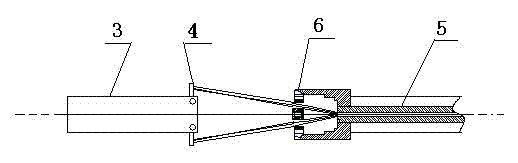

Ceramic HID lamp with special frame wire for stabilizing the arc

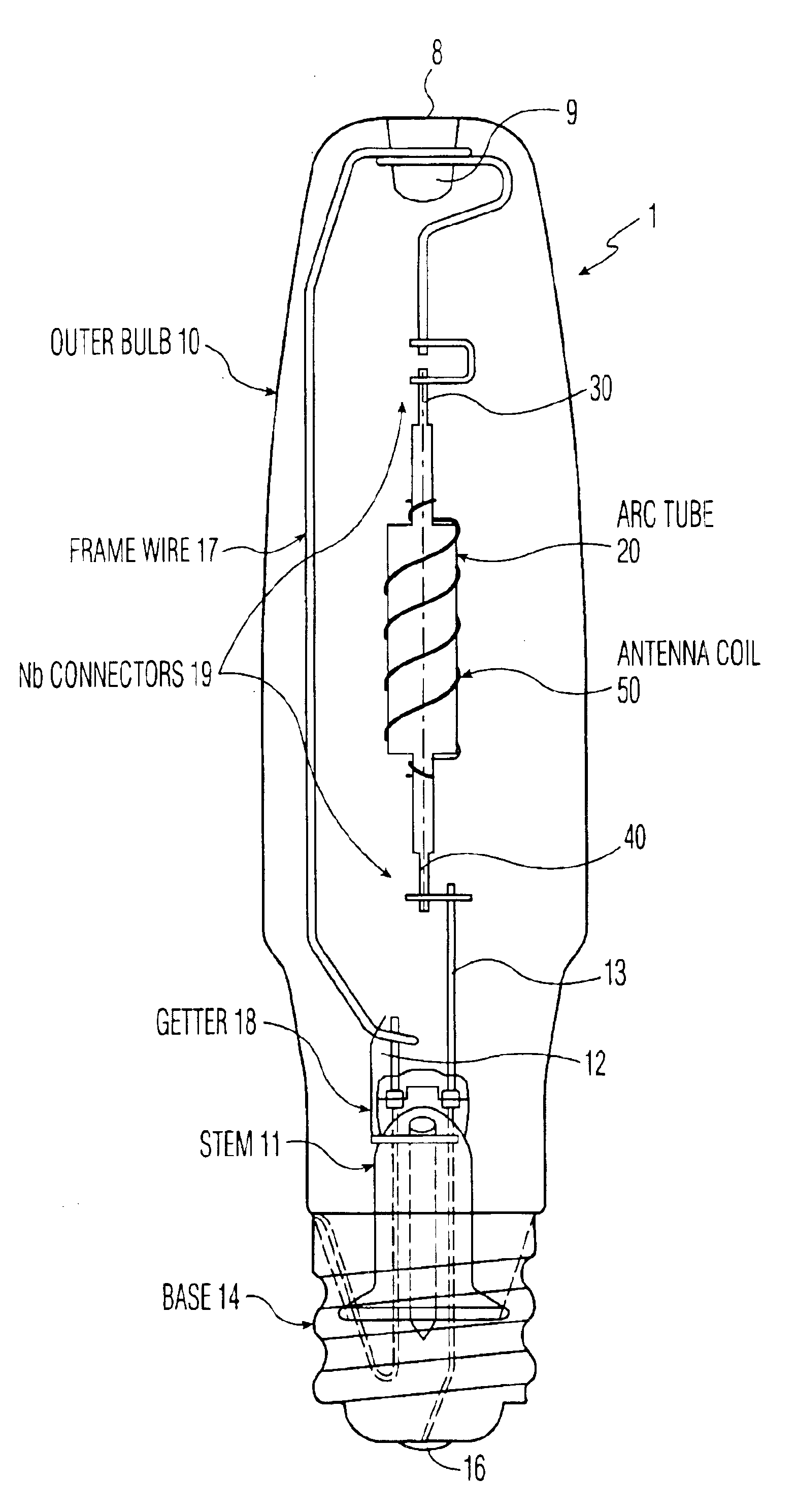

InactiveUS6844676B2Eliminate the problemIncrease heightSolid cathodesGas discharge lamp detailsElectrical conductorHigh pressure

A high-pressure discharge lamp of the ceramic metal halide type having power ranges of about 150 W to about 1000 W. Such lamps have outer bulb enclosing a cylindrical ceramic discharge vessel enclosing a discharge space. The discharge vessel includes an ionizable material containing a metal halide; a first and second discharge electrode feedthrough; and a first and second current conductor connected to the first and second discharge electrode feedthrough, respectively. A frame wire structure includes at least one frame wire, connected to the current conductors, through a conductor. The frame wire structure extends between the ceramic discharge vessel and the glass bulb, and is effective to reduce arc bending, regardless of the orientation of the lamp during operation in a fixture and regardless of the relative position of the frame wire to the arc tube.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

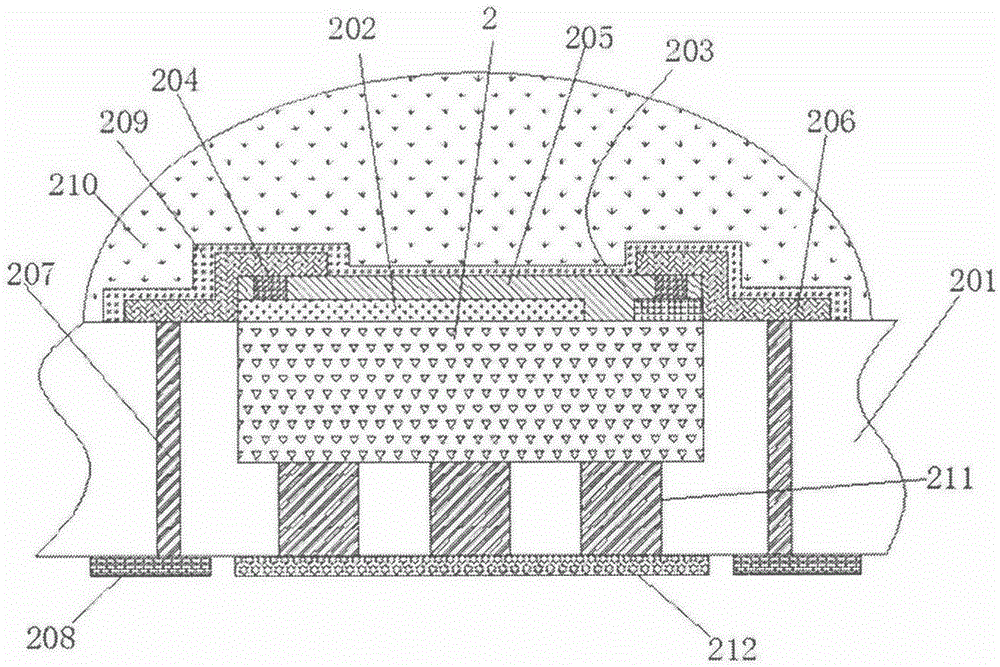

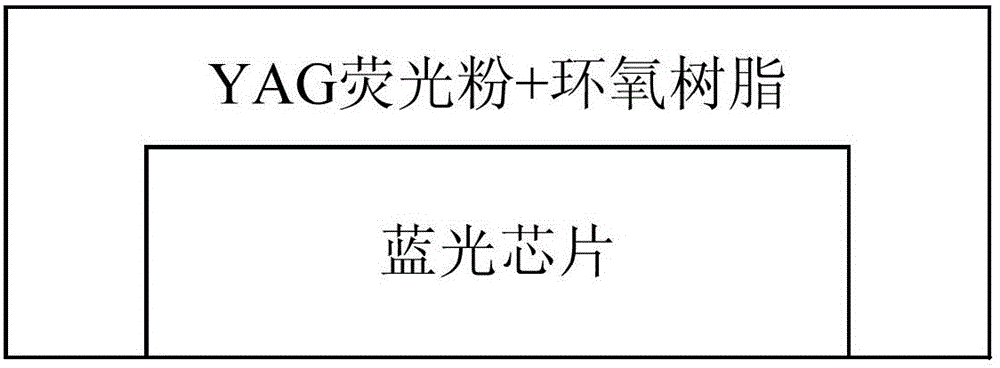

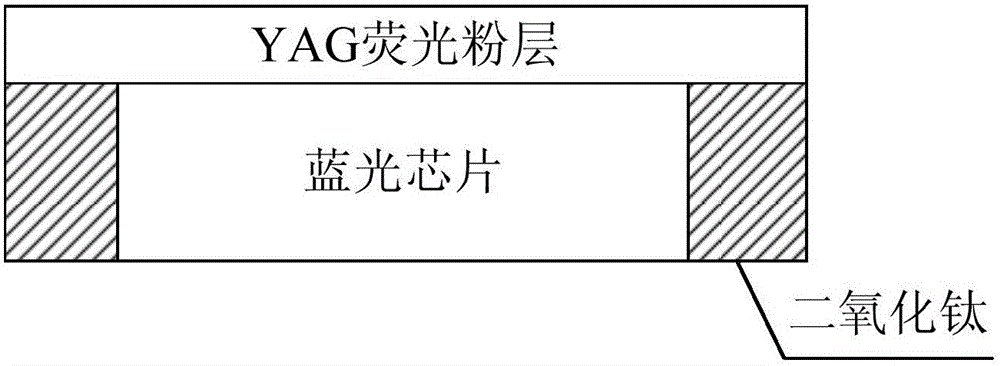

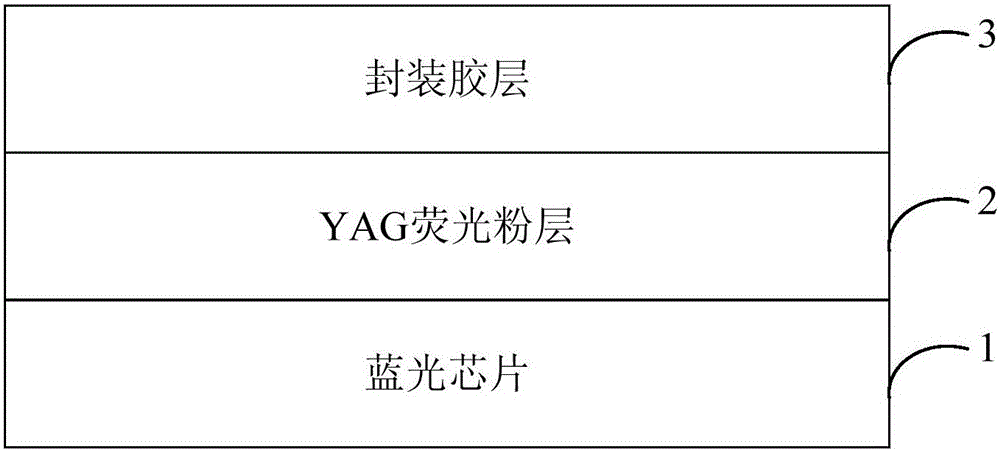

Light-emitting diode (LED), LED packaging method, straight down type backlight module and liquid crystal display television

ActiveCN105895787AImprove removal efficiencyGood color consistencyNon-linear opticsSemiconductor devicesFluorescenceRefractive index

The invention provides a light-emitting diode (LED), an LED packaging method, a straight down type backlight module and a liquid crystal display television. An LED packaging structure is achieved by the following steps of first covering the surface of a blue-light chip with a yttrium aluminum garnet (YAG) fluorescent powder layer; and then attaching a packaging glue layer to the surface of the YAG fluorescent powder layer, wherein the packaging glue layer is formed by light diffusion particles and a packaging glue. The refractive index of the YAG fluorescent powder layer is greater than the refractive index of the blue-light chip, so that the blue-light extraction efficiency is improved; the refractive indexes of the light diffusion particles and the packaging glue in the packaging glue layer are different, so that blue light and yellow light can be fully mixed after being refracted in the packaging glue for many times, the chrominance consistency of an LED light emergent surface is improved, and the chromaticity consistency of the straight down type backlight module is further improved.

Owner:HISENSE VISUAL TECH CO LTD

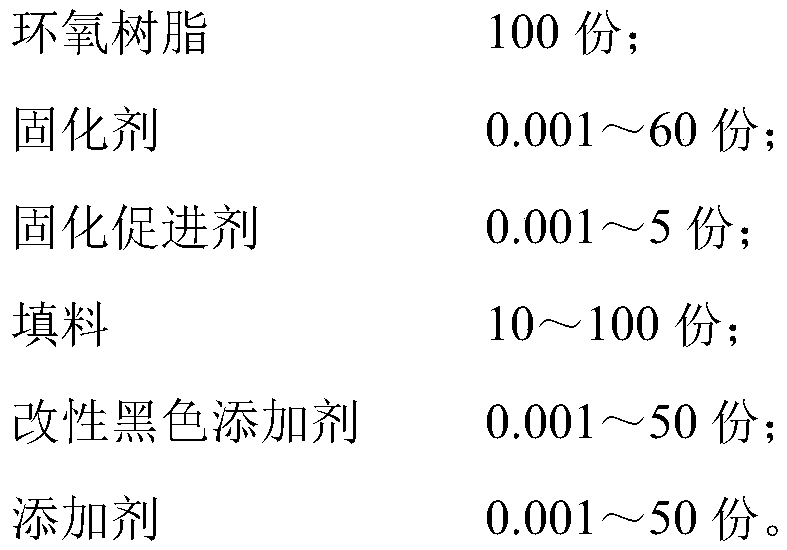

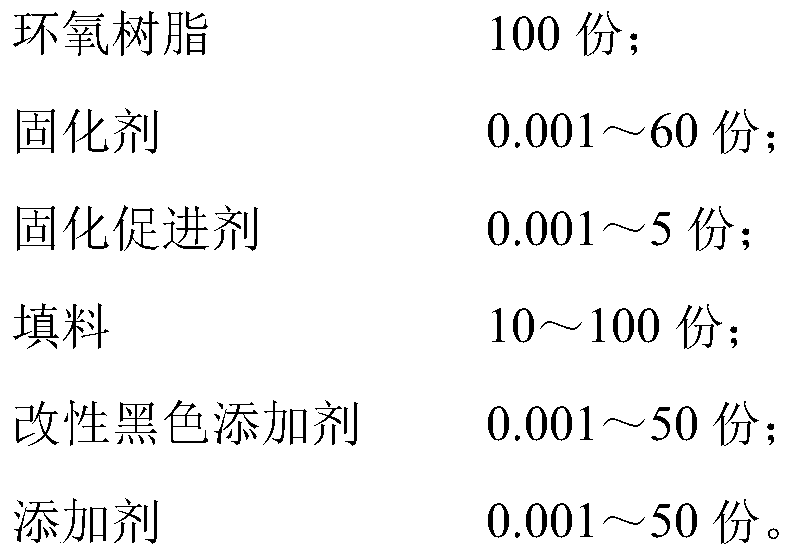

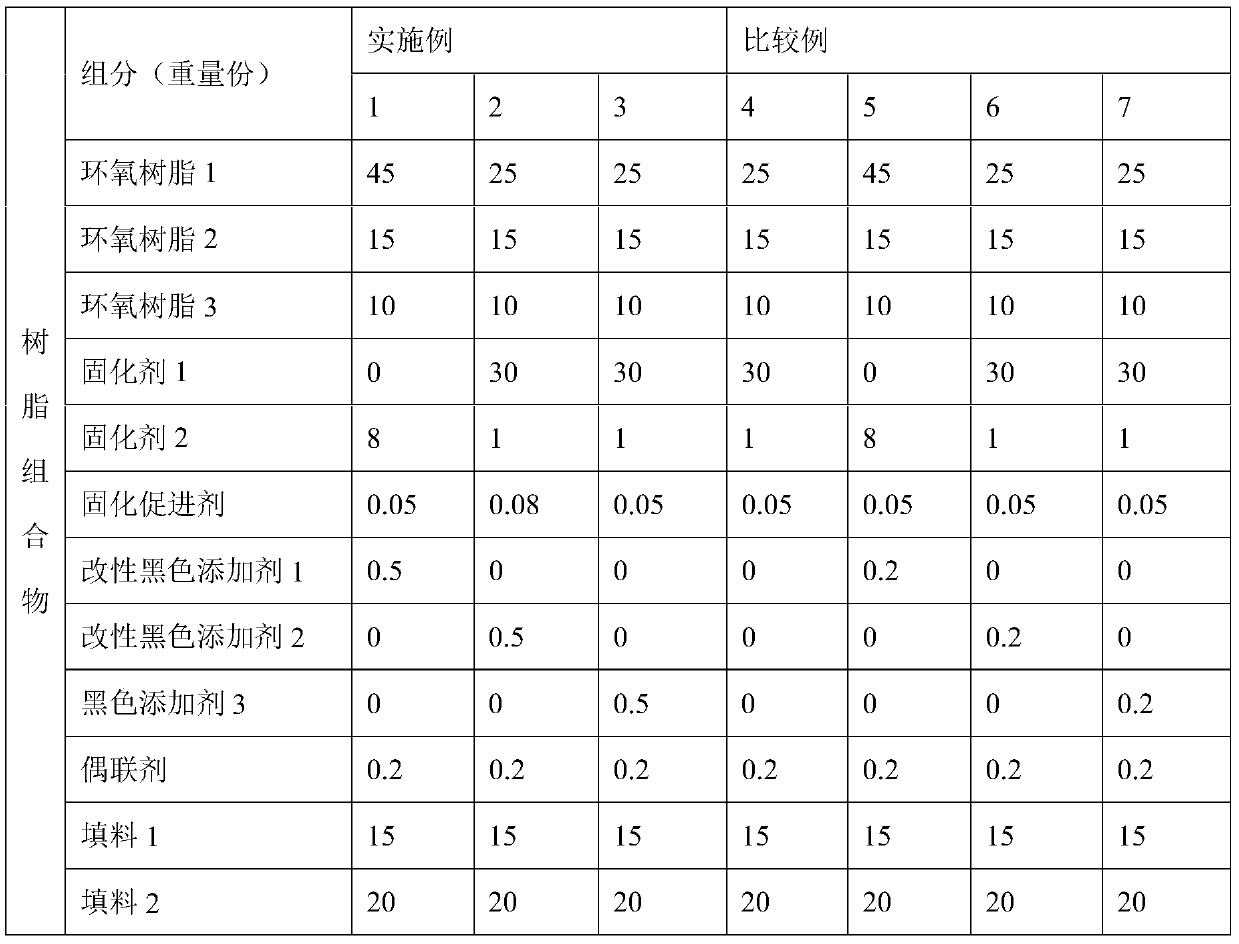

Black resin composition, prepreg and laminated plate

InactiveCN110305445AImprove Difficult DispersionHigh strengthSynthetic resin layered productsElectrical equipmentEpoxyPrinted circuit board

The invention belongs to the field of resin materials for printed circuit boards, in particular to a black resin composition, a prepreg and a laminated plate, wherein the black resin composition comprises the following components in parts by weight: 100 parts of epoxy resin; 0.001-60 parts of curing agents; 0.001-5 parts of curing accelerators; 10-100 parts of fillers; 0.001-50 parts of modified black additives; and 0.001-50 parts of additives. The resin composition improves the defects of difficult dispersion of the resin system, weak light shielding strength of the prepreg and the laminatedplate and large dust adsorption by modifying the black additive, and has good processability.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

LED light assembly and associated method

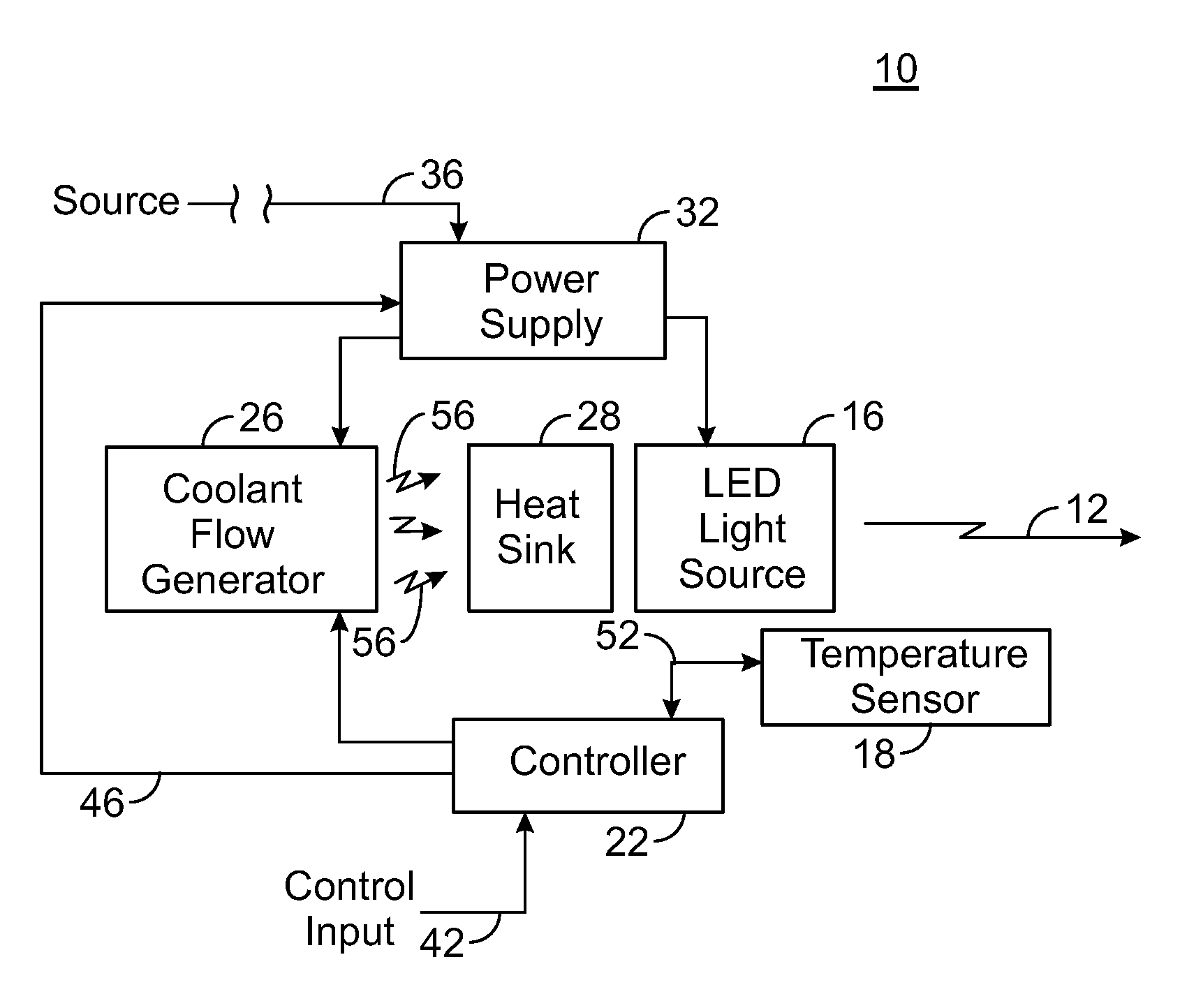

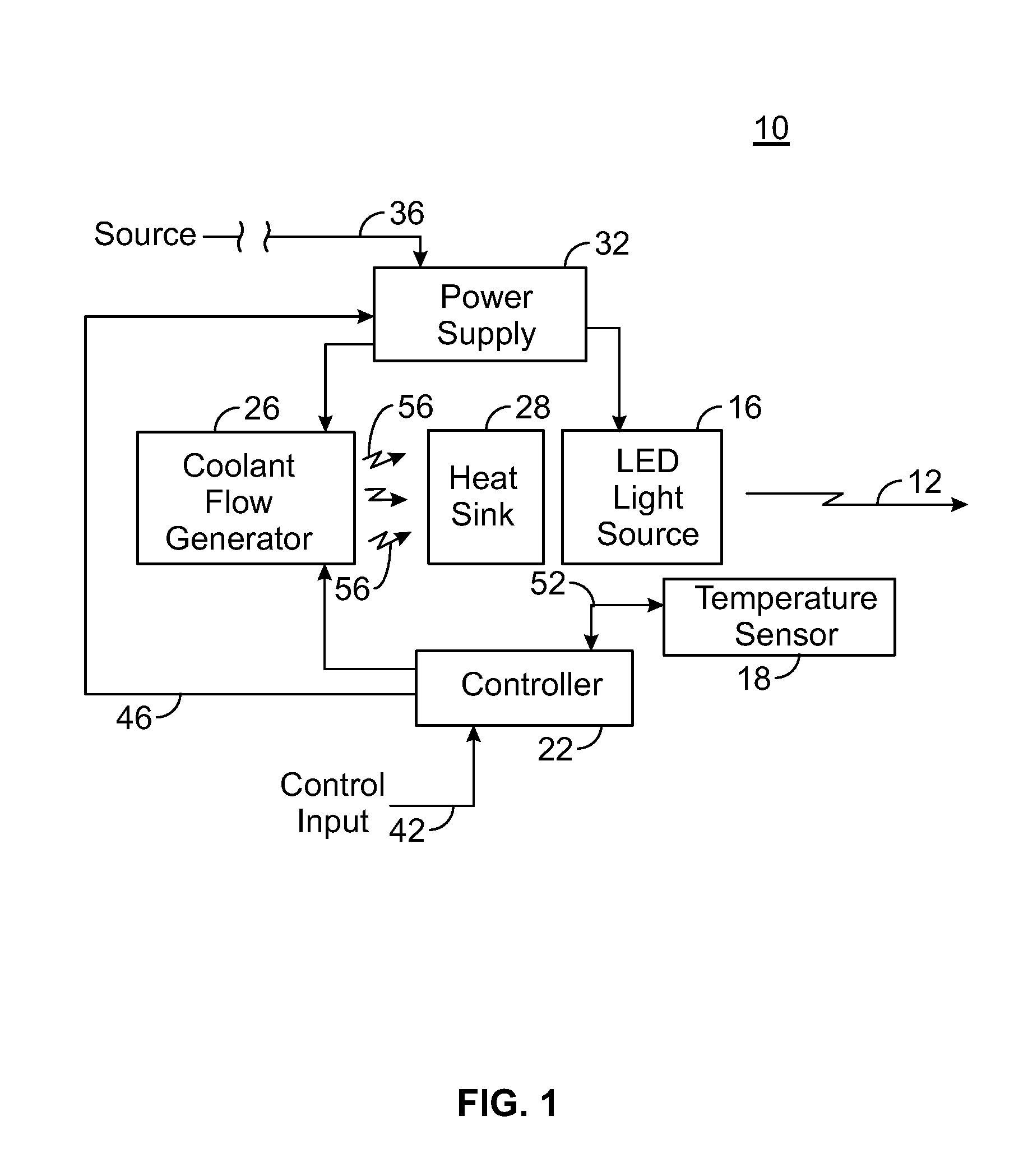

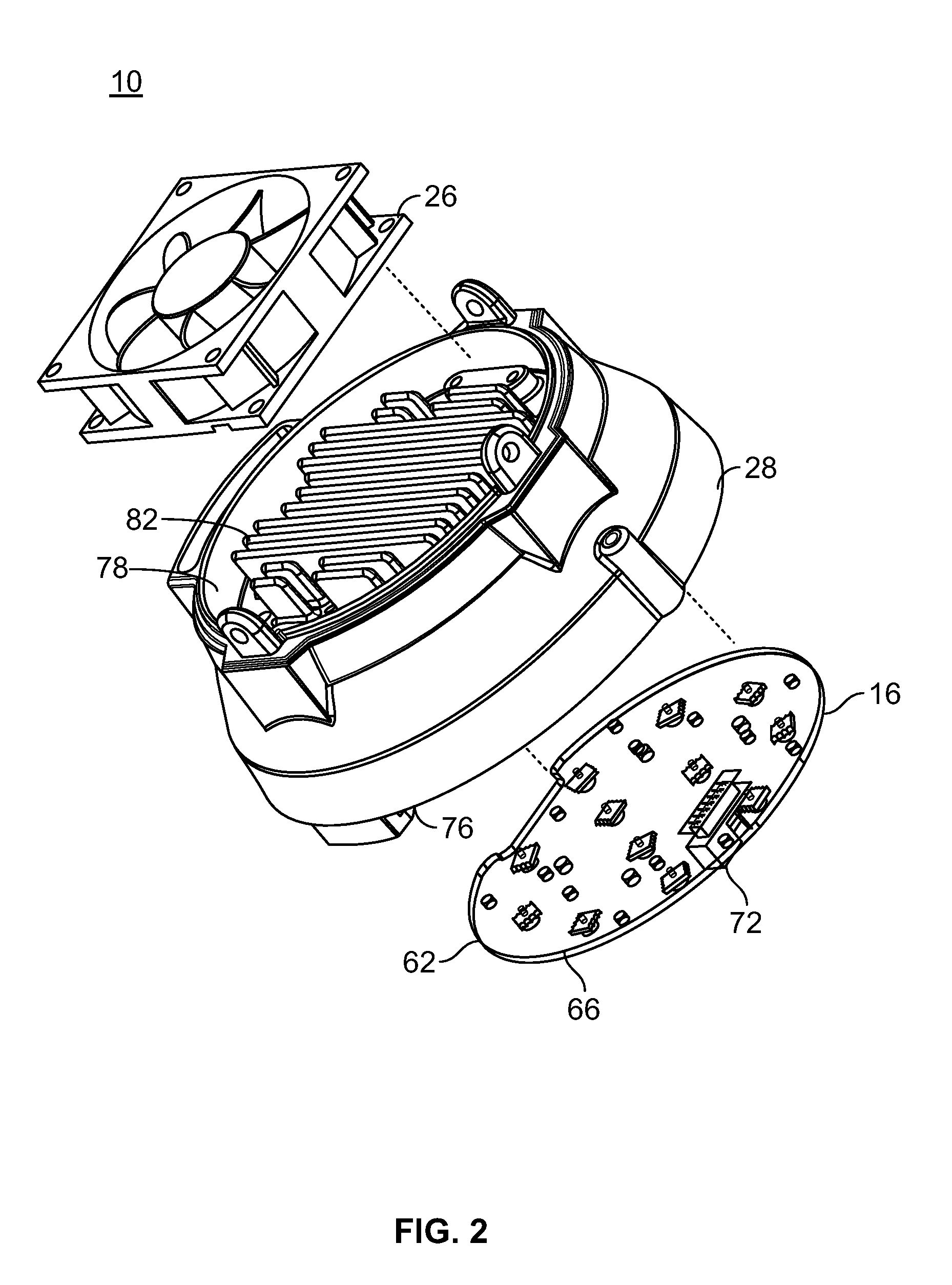

InactiveUS20120098434A1Cool buildingPrevent buildupPlanar light sourcesLight source combinationsThermal energyCoolant flow

A light assembly, and an associated method, provides color-mixed light generated by light emitter diode elements. A temperature sensor is position to sense temperature levels proximate to the LED light-emitter elements. And, a coolant flow generator is configured in a feedback arrangement to generate coolant fluid to dissipate thermal energy generated during operation of the LED elements to maintain the temperature levels at a constant temperature or within an allowable range.

Owner:WYBRON

Method for preparing rolled copper foil

InactiveCN1709596AImprove thickness uniformityImprove consistencyMetal rolling arrangementsCopper foilAlloy

This present invention discloses a method of rolling copper foil. It comprises that heat roll alloy copper, alternately repeat cold roll and anneal until the copper foil is 0.01mm thin and tolerance is 0.0005.The copper foil made by this method has the virtues of even thickness, good coherence. The product of this invention can be widely used to construction, craftwork, calendar, goldleaf painting, frame, costume and so on.

Owner:SHANGHAI XINGYI METAL MATERIAL

Coil antenna/protection for ceramic metal halide lamps

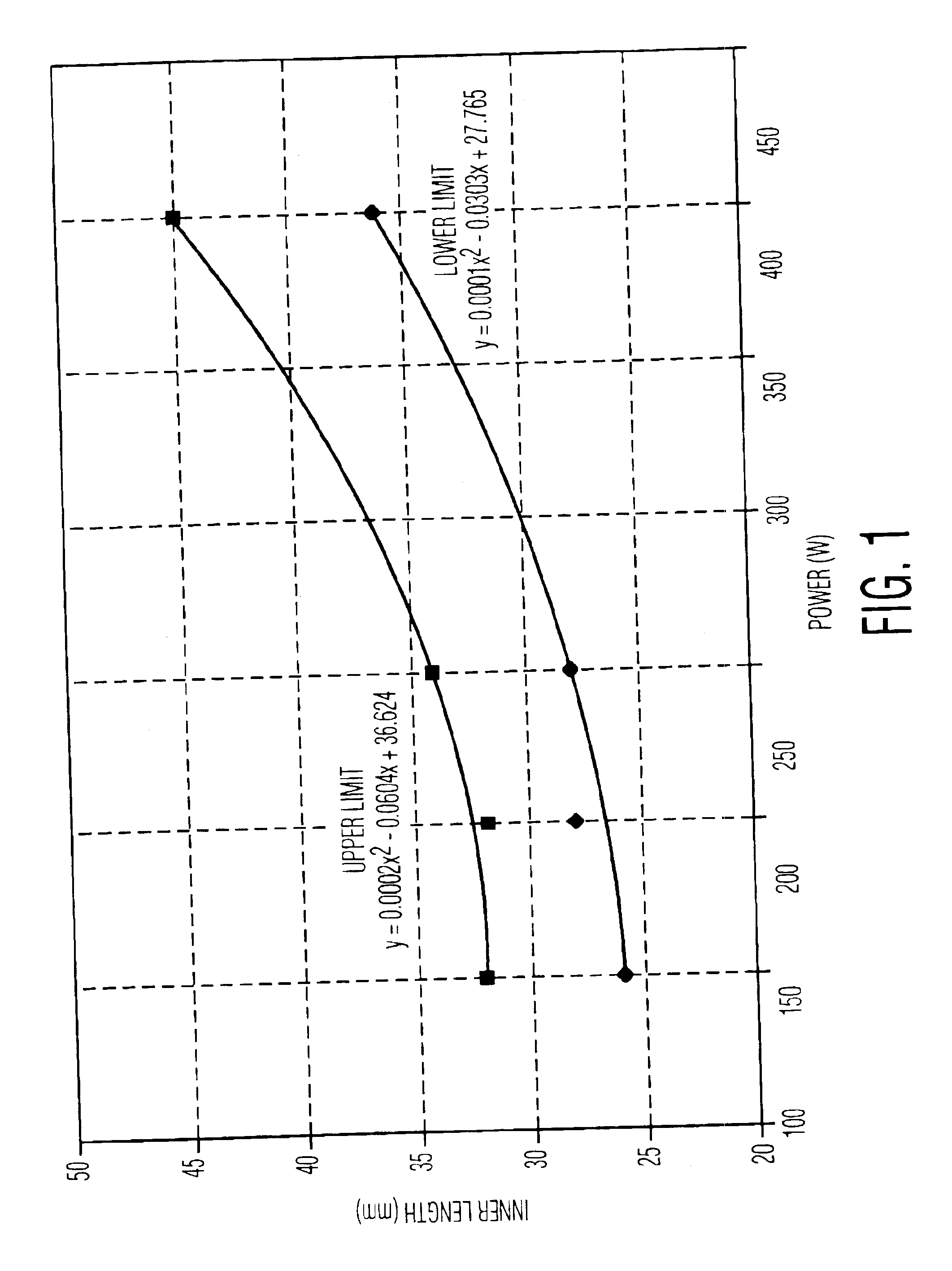

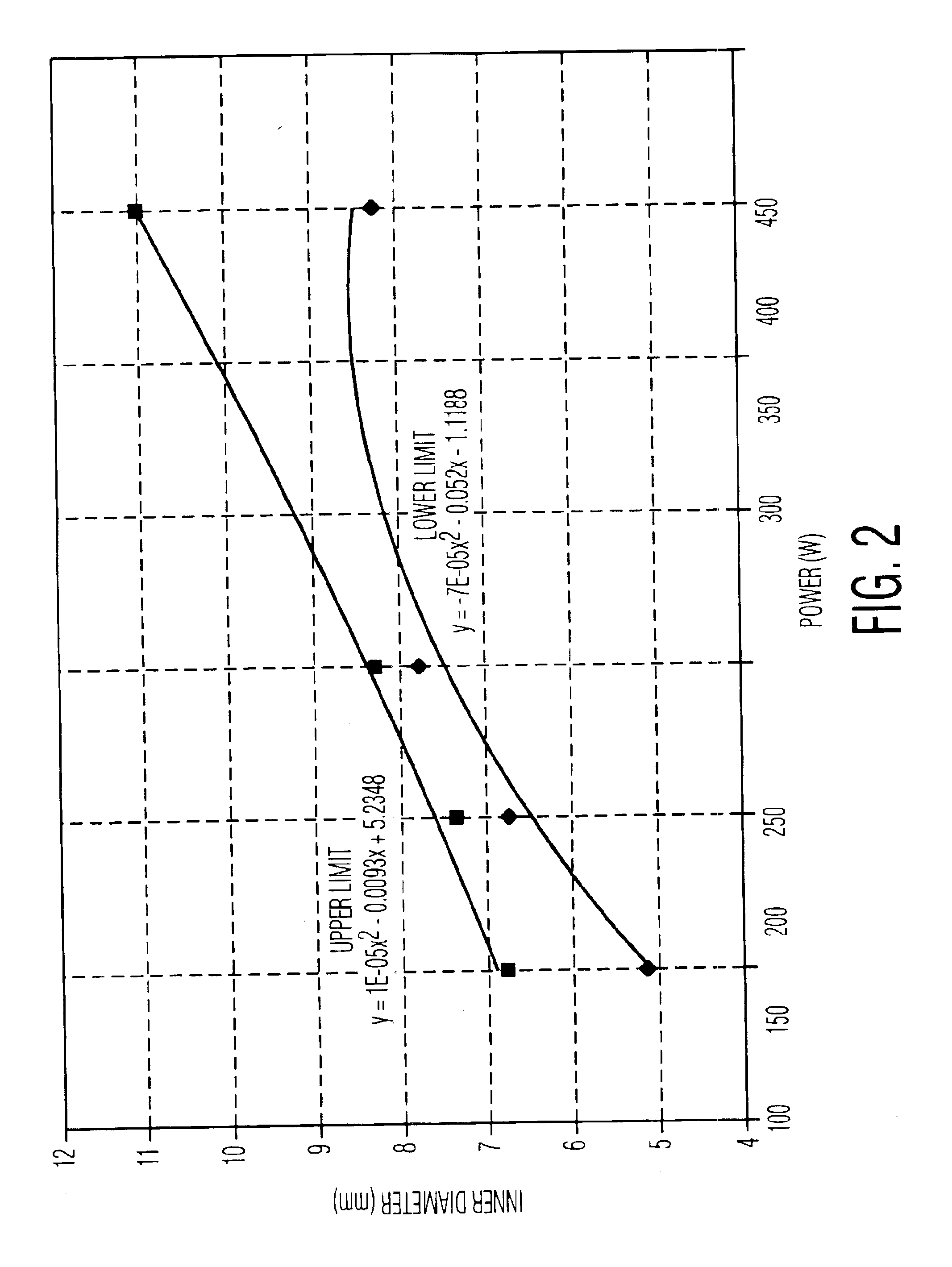

InactiveUS6861805B2Good color consistencyImprove stabilitySolid cathode detailsStructural circuit elementsColor rendering indexLumen maintenance

The invention relates to a high-pressure discharge lamp of the ceramic metal halide type of the Philips MasterColor series having a molybdenum coil wrapped around the discharge vessel and at least a portion of the electrode feed through means, and having power ranges of about 150 W to about 1000 W. Such lamps are provided with a discharge vessel which encloses a discharge space. The discharge vessel has a ceramic wall and is closed by a ceramic plug. An electrode which is located inside the discharge space is connected to an electric conductor by way of a leadthrough element. The leadthrough element projects through the ceramic plug with a close fit and is connected thereto in a gastight manner by way of a sealing ceramic. The leadthrough element has a first part which is formed by a cermet at the area of the gastight connection. In addition, the lamps display one or more and most preferably all of the following properties: a CCT (correlated color temperature) of about 3800 to about 4500K, a CRI (color rendering index) of about 70 to about 95, a MPCD (mean perceptible color difference) of about ±10, and a luminous efficacy up to about 85-95 lumens / watt, a lumen maintenance of >80%, color temperature shift <200K from 100 to 8000, and lifetime of about 10,000 hours to about 25,000 hours. The invention also relates to design spaces for the design and construction of high power lamps and methods for construction of such lamps using the design spaces.

Owner:KONINK PHILIPS ELECTRONICS NV

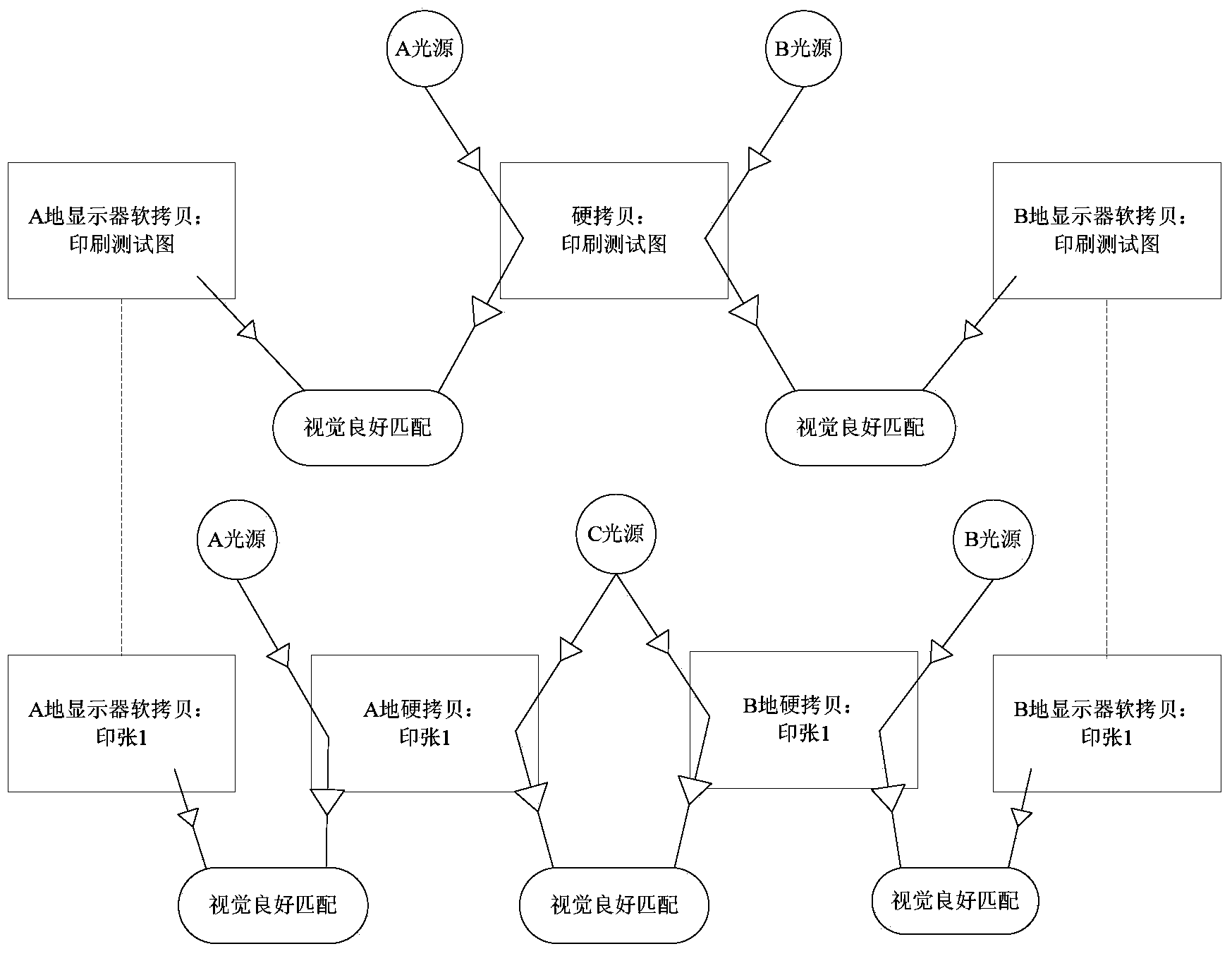

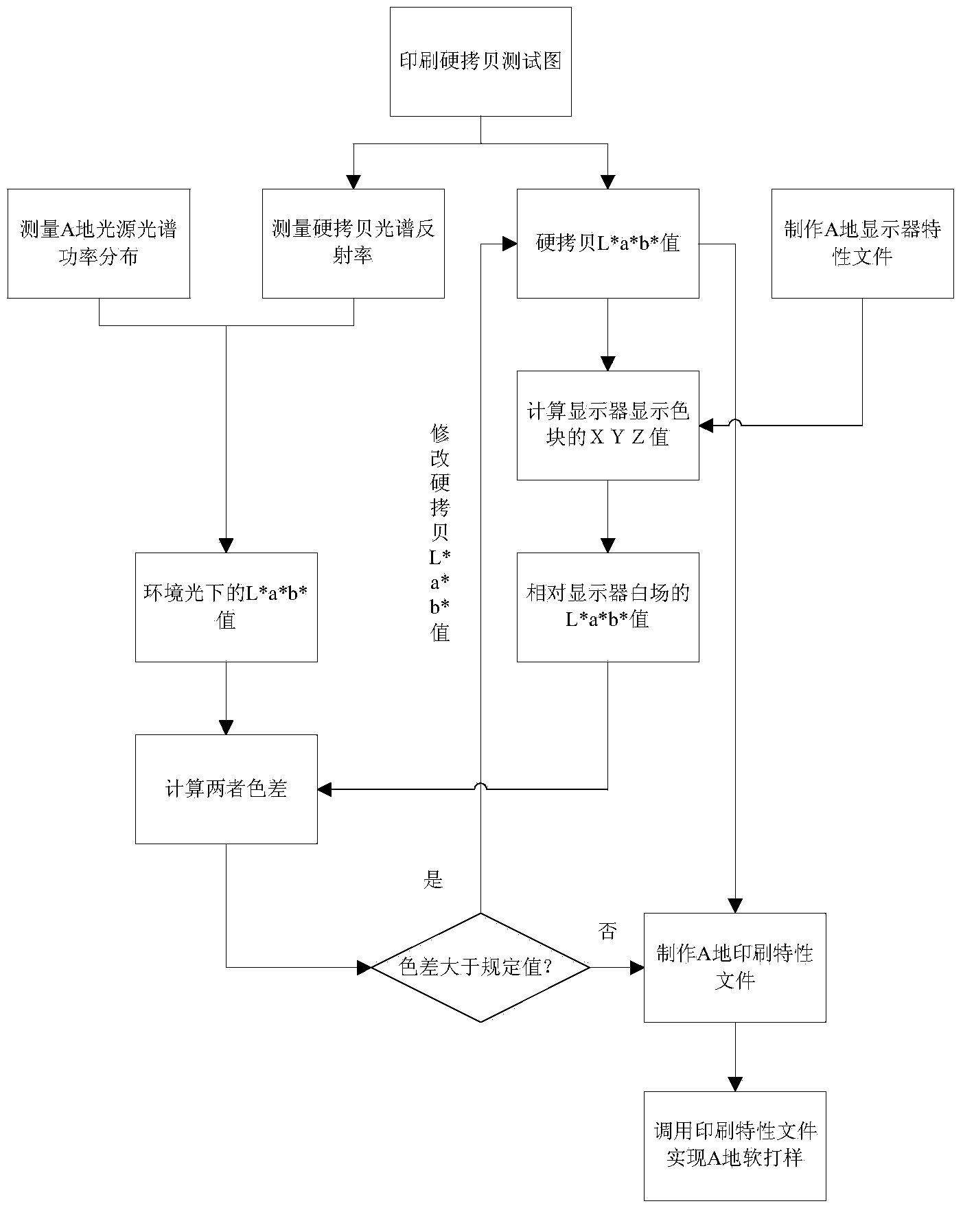

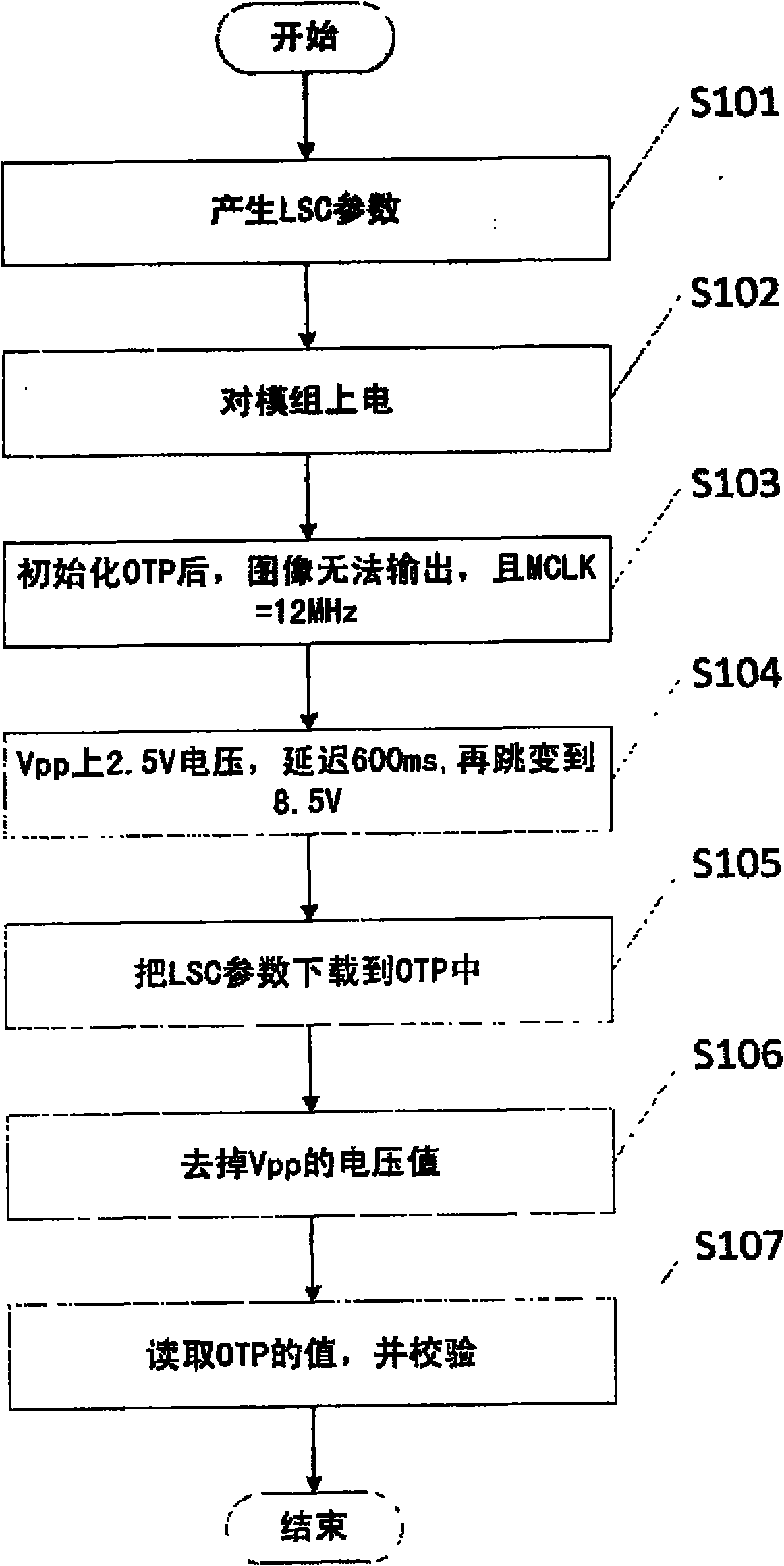

Method for achieving newspaper printing soft-proofing color consistency

ActiveCN104301580AGood color consistencyPictoral communicationComputer graphics (images)Display device

The invention discloses a method for achieving newspaper printing soft-proofing color consistency. According to the method, a hard copy of a representative printing test chart is used, visual perception L*a*b* values of the hard copy under various region light source environments are calculated through detection, then L*a*b* values of the hard copy L*a*b* values which are displayed by displayers under a D50 illuminating body are calculated, the difference values of the hard copy vision L*a*b* values and the L*a*b* values displayed by the displayers are compared, the hard copy L*a*b* values are corrected until the difference values of the hard copy vision L*a*b* values and the L*a*b* values displayed by the displayers are smaller than the specified tolerance, the corrected L*a*b* values of the hard copy are used for making printing characteristic files, the corrected L*a*b* values are assigned to opened image files by application software, and accordingly the color of the same hard copy and the colors of the displayers at various region can be matched with each other in visual perception. Hence, printing enterprises which are distributed at different regions can conduct printing by referring to the same soft-proofing color approximately, and the color consistency of newspapers printed at various regions can be facilitated.

Owner:泰安易捷数字印刷有限公司

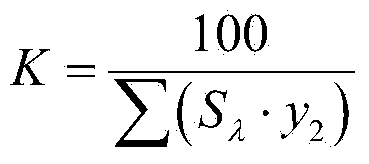

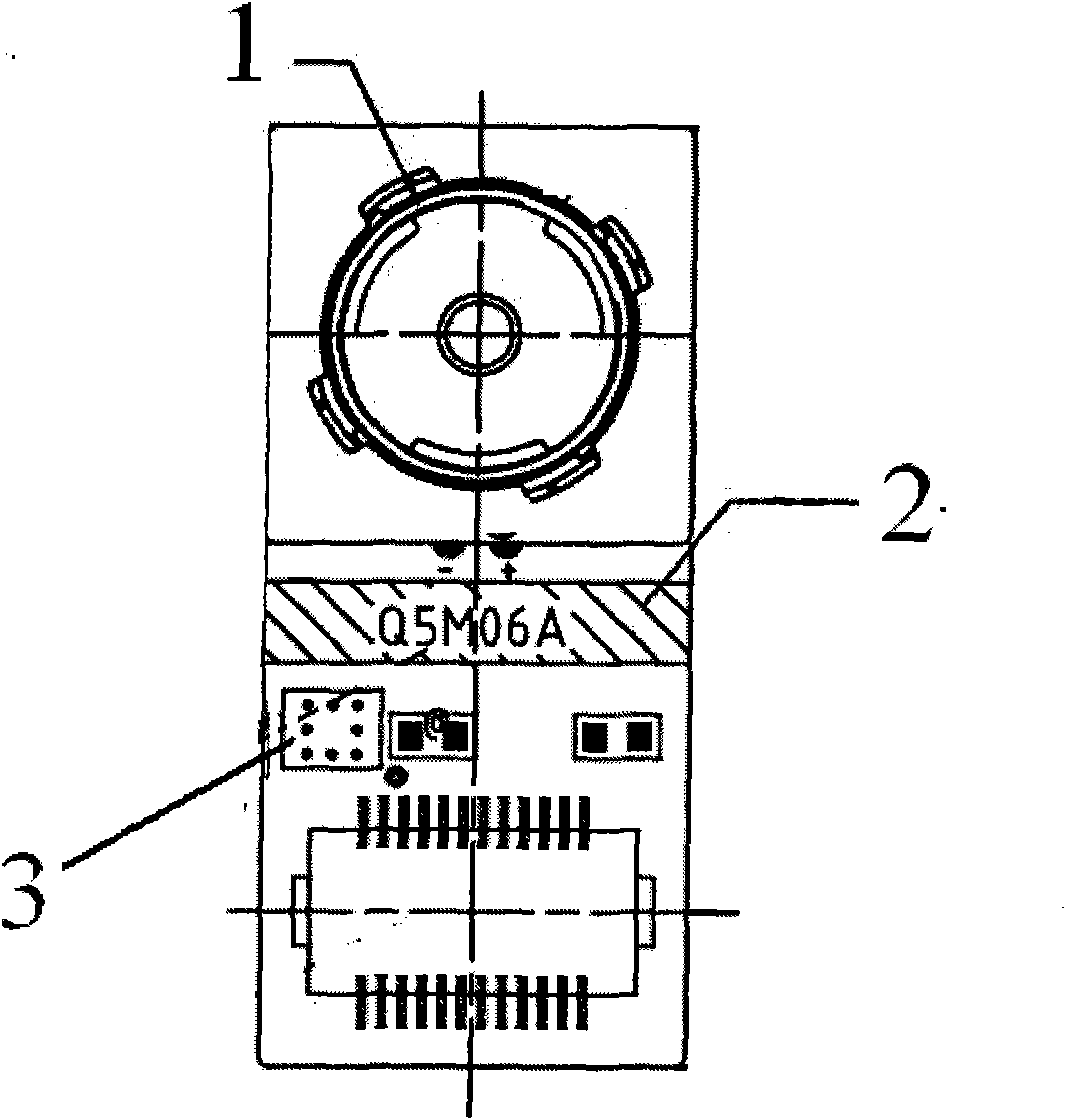

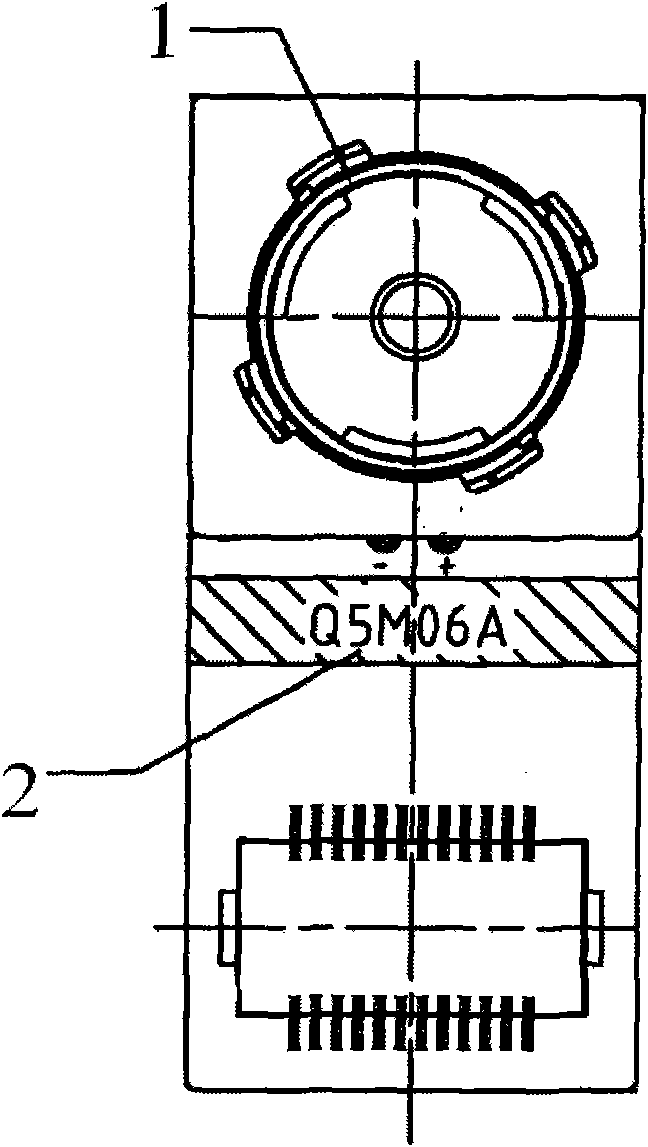

High-pixel photographic module and burning method for chip

ActiveCN102158589ASmall sizeImprove accuracyTelevision system detailsColor television detailsOne time programmableComputer science

The invention discloses a high-pixel photographic module, which comprises an optical detection element, a programmable chip and a circuit board for fixing the optical detection element and the programmable chip. The high-pixel photographic module is characterized in that: the programmable chip is a one-time programmable chip; moreover, the photosensitive optical detection element is integrated with the chip; a camera consistence compensation parameter of the optical detection element is burnt in the chip; and mobile phone software reads the parameter by a preset format so as to correct the optical accuracy of the optical detection element. Compared with the conventional high-pixel photographic module structure, the invention reduces the size of the whole module, widens the application range of the module, simultaneously can increase the yield and improve the production efficiency in module batch production, shortens the time and achieves technical advantages and good technical effects. In addition, the invention also discloses a burning method for the chip of the high-pixel photographic module.

Owner:NINGBO SUNNY OPOTECH CO LTD

Nylon 56 flame-retardant infrared-resistant camouflage ribbon

InactiveCN110747666AGood color consistencyInfrared reflectivity is stableHeat resistant fibresDyeing processTextile printerInfrared reflectivity

The invention provides a nylon 56 flame-retardant infrared-resistant camouflage ribbon relates to the technical field of camouflage ribbon production; a production technique of the nylon 56 flame-retardant infrared-resistant camouflage ribbon comprises rinsing, deoiling, dyeing with ground color, printing, post-treating, carrying out flame-retardant treatment and other steps, wherein the flame-retardant treatment includes soaking a ribbon in a flame-retardant liquid for 45 minutes for the first time before rolling the ribbon for the first time, transferring the ribbon subjected to first rolling to the flame-retardant liquid again for second soaking for 15 minutes, then rolling for the second time, and pre-baking the double-dipped and double-rolled ribbon at 100 DEG C for 3 min, and at 130DEG C for 5 min. The nylon 56 flame-retardant infrared-resistant camouflage ribbon has the advantages that the preparation steps are short, the prepared nylon 56 flame-retardant anti-infrared camouflage ribbon is good in color phase consistency, stable in infrared reflectivity and low in cost, especially when an organic nitrogen flame retardant and a phosphorus flame retardant are used together, the synergistic effect can be achieved, and the flame retardant property of the camouflage ribbon is better.

Owner:四川鑫敬业化纤织带有限公司

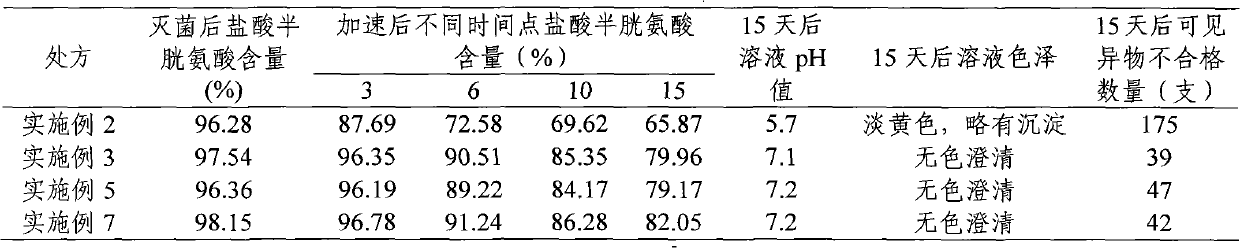

Compound glycyrrhizin injection preparation

InactiveCN101766641AImprove stabilityGood color consistencyPowder deliveryOrganic active ingredientsGlycineCysteine Hydrochloride

The invention relates to a compound glycyrrhizin injection preparation which is prepared by glycyrrhizin (or monoammonium glycyrrhizinate), glycine, cysteine hydrochloride, basic amino acid, a pH buffer system and an isotonic regulator. The injection prepared by the prescription has the advantages of stable quality and high safety and can avoid the use of sodium bisulfite and other substances which are easy to produce potential safety hazard.

Owner:BEIJING KAWIN TECH SHARE HLDG

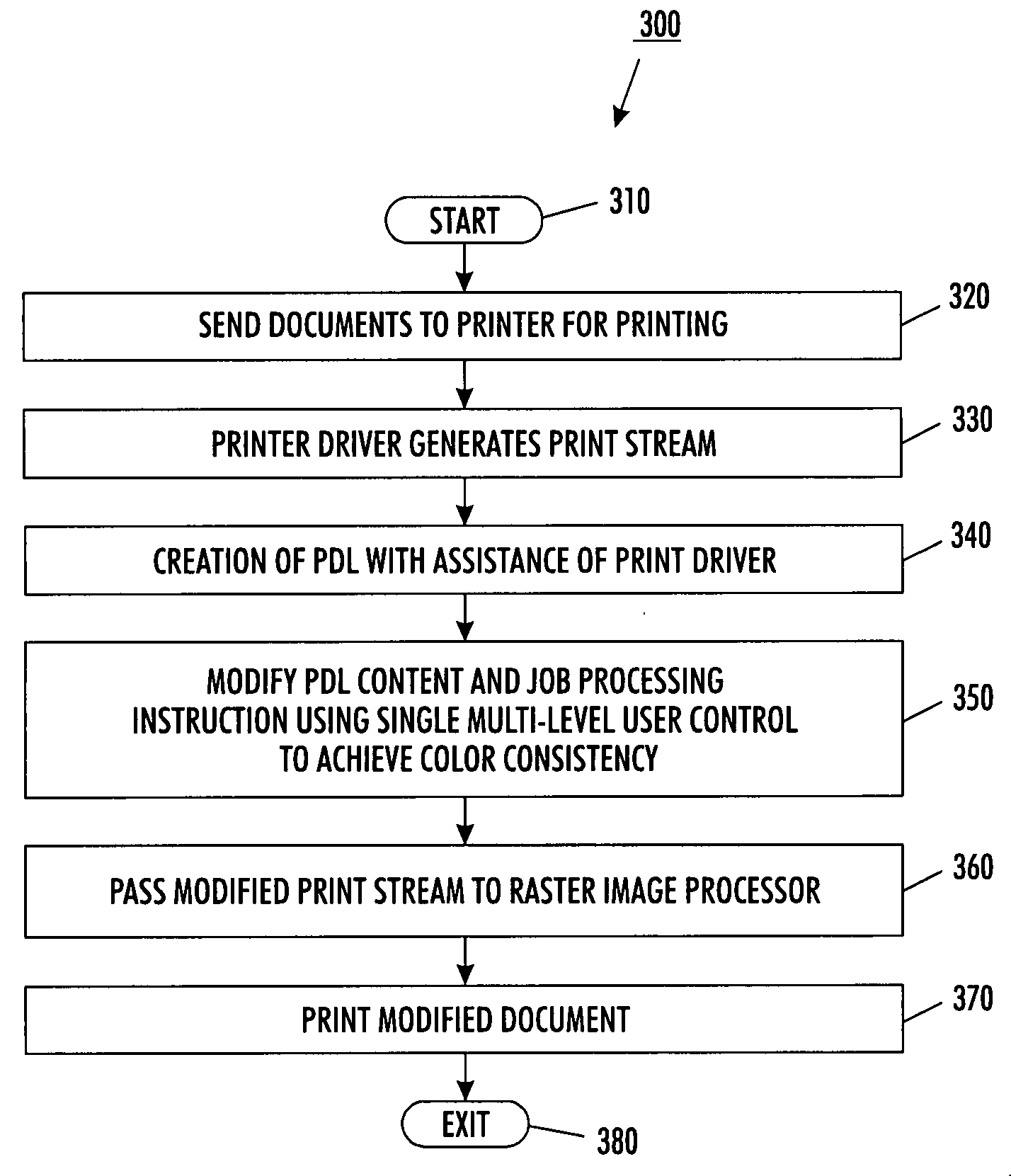

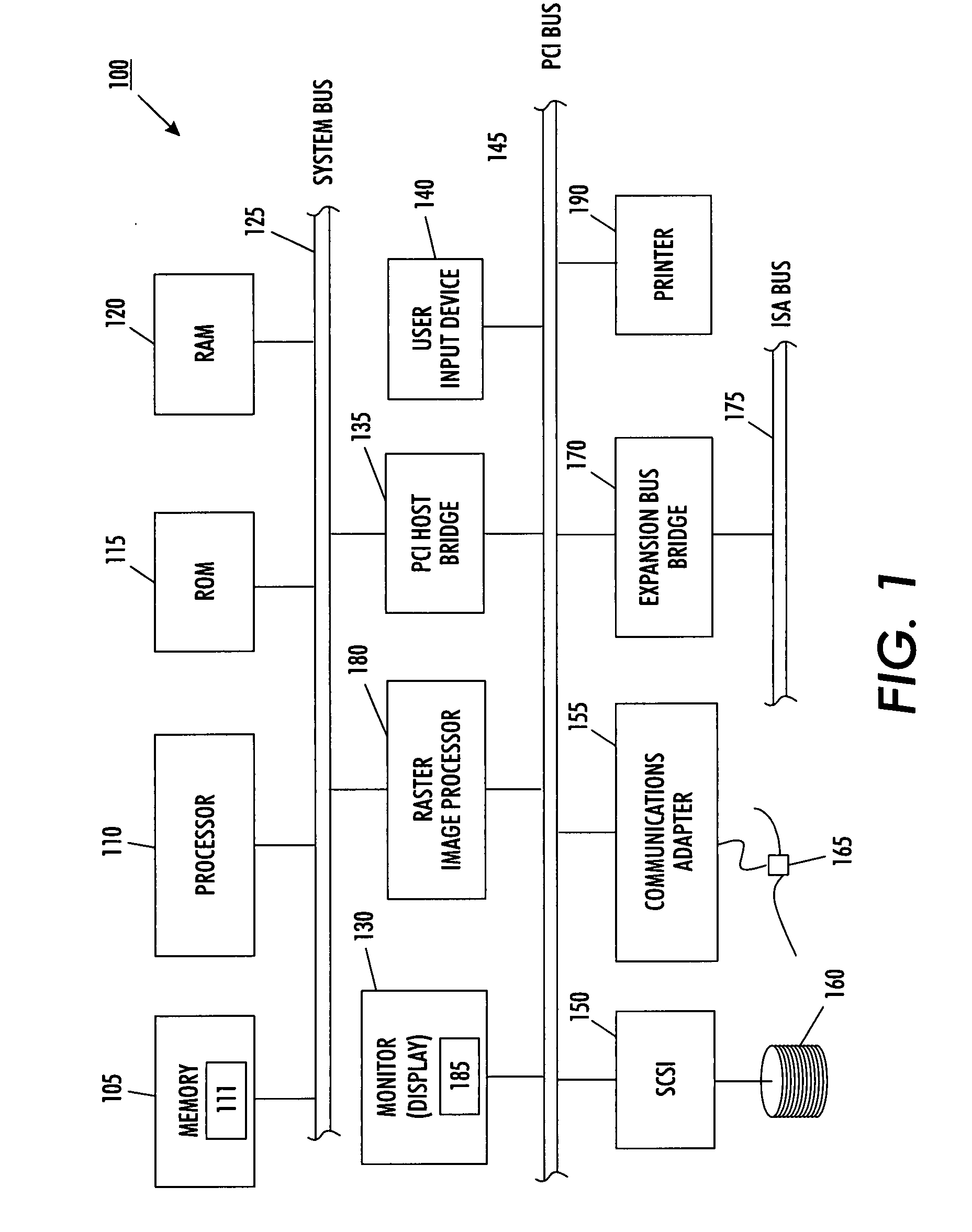

Method and system for consistent color control

InactiveUS20080259401A1Good color consistencyHiding the complexity from the userVisual presentationInput/output processes for data processingRaster image processorProcessing Instruction

A method and system for achieving consistent color control by integrating multiple color management and rendering techniques using single multi-level user control. Page Description Language (PDL) data and job processing instructions can be modified upstream of the Raster Image Processor (RIP). The processing operations associated with processing a print job comprising of at least one page include at least one of: flattening all objects on the at least one page into a single layer; removing overprint commands from the print job; converting all objects on the at least one page into a common colorspace; removing embedded tone reproduction curves and halftone screens from the print job.

Owner:XEROX CORP

Zinc plating deactivation liquid

InactiveCN101041900AGood color consistencyColor saturationMetallic material coating processesSulfuric acidZinc

The invention discloses an inactivating liquid of zinc coating, which comprises the following parts: (200-220) g / L chromic anhydride, (24-28) ml / L nitric acid, (12-18) ml / L sulfuric acid, (6-8) g / L ferrous sulfate, (8-12) g / L iron trichloride, 5-8ml / L acetic acid and water. The produce surface displays good consistency inactivated by inactivating liquid, which possesses even brightness and gloss.

Owner:攀枝花钢城集团恒升实业有限公司

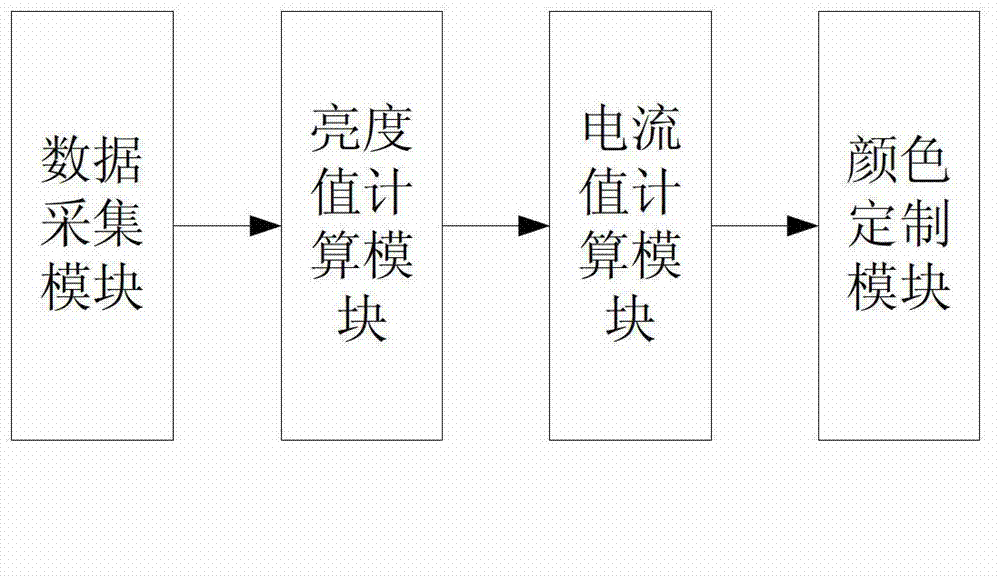

Light source color custom method and light source color custom system

ActiveCN103093739ACustom implementationImprove the display effectCathode-ray tube indicatorsComputer scienceBrightness perception

The invention discloses a light source color custom method and a light source color custom system. The light source color custom method includes the following steps: the chromaticity and the brightness of each color of each display unit of a multi-screen display unit are acquired; custom brightness values corresponding to target chromaticity and brightness displayed by light sources of R, G and B of each display unit are calculated according to the chromaticity and the brightness; custom current values corresponding to the light sources of R, G and B of each display unit are calculated according to the custom brightness values and a relation model between the brightness of the light sources of R, G and B and current; and colors of the light sources of R, G and B of each display unit are customized according to the custom current values. Due to the technologies, the custom of the colors of the light sources of the multi-screen display unit is achieved, color uniformity of each display unit is improved, and the display effect of the multi-screen display unit is promoted.

Owner:GUANGDONG VTRON TECH CO LTD

Integrated light-emitting Micro LED chip and manufacturing method thereof

PendingCN110534542AImprove luminous efficiencySmall temperature driftSolid-state devicesSemiconductor devicesPhotoluminescenceGreen-light

The invention provides an integrated light-emitting Micro LED chip and a manufacturing method thereof, which belong to the field of semiconductor optoelectronic technologies. A buffer layer, an unintentionally doped GaN layer and an n-type doped GaN layer epitaxially grow on the same side of a substrate. First and second blue light electroluminescence structure layers and a green light electroluminescence structure layer are etched laterally at intervals by depositing an insulating dielectric mask layer twice, and corresponding light-emitting structure layers are manufactured in correspondingly formed etching areas. Blue light emitted by the second blue light electroluminescence structure layer is converted into red light by a red light photoluminescence conversion layer. According to theinvention, GaN-based blue and green electroluminescence and red light photoluminescence technologies are integrated to produce red, green and blue three-primary-colour MicroLED LED light-emitting units; red, green and blue three-primary-colour light-emitting units are laterally deposited on the n-type doped GaN layer at intervals and are connected through the n-type doped GaN layer.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

Carbon fiber composite material cable and preparation method of cable core thereof

ActiveCN102810346AImprove straightnessGuaranteed tensionNon-insulated conductorsPower cablesFiberGlass fiber

The invention discloses a carbon fiber composite material cable and a preparation method of a cable core of the carbon fiber composite material cable. The preparation method comprises the following steps: testing and adjusting the tensile forces of carbon fibers and glass fibers; dewatering; pulling the carbon fibers into a procuring die (3) by infiltrating adhesive in a constant temperature adhesive groove; operating the glass fibers to pass through a rectangular splitting plate (4); pulling the carbon fibers into a curing die (5); feeding the glass fibers through a planar guide plate (6), and then puling into the curing die (5) so as to wrap the surrounding parts of the carbon fibers with the glass fibers, thus obtaining the carbon fiber composite material cable core. The method provided by the invention has high operability and relatively high production efficiency, can saves large amount of manpower and materials, and has low cost of production; and the carbon fiber composite material cable core prepared by the method has relatively high linearity, high roundness, no eccentricity, no bending, and high consistency in color; and as the detecting results shown, the carbon fiber composite material cable core has the advantages of high temperature resistance, lower energy consumption, long service life, no eccentricity, and good performance.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

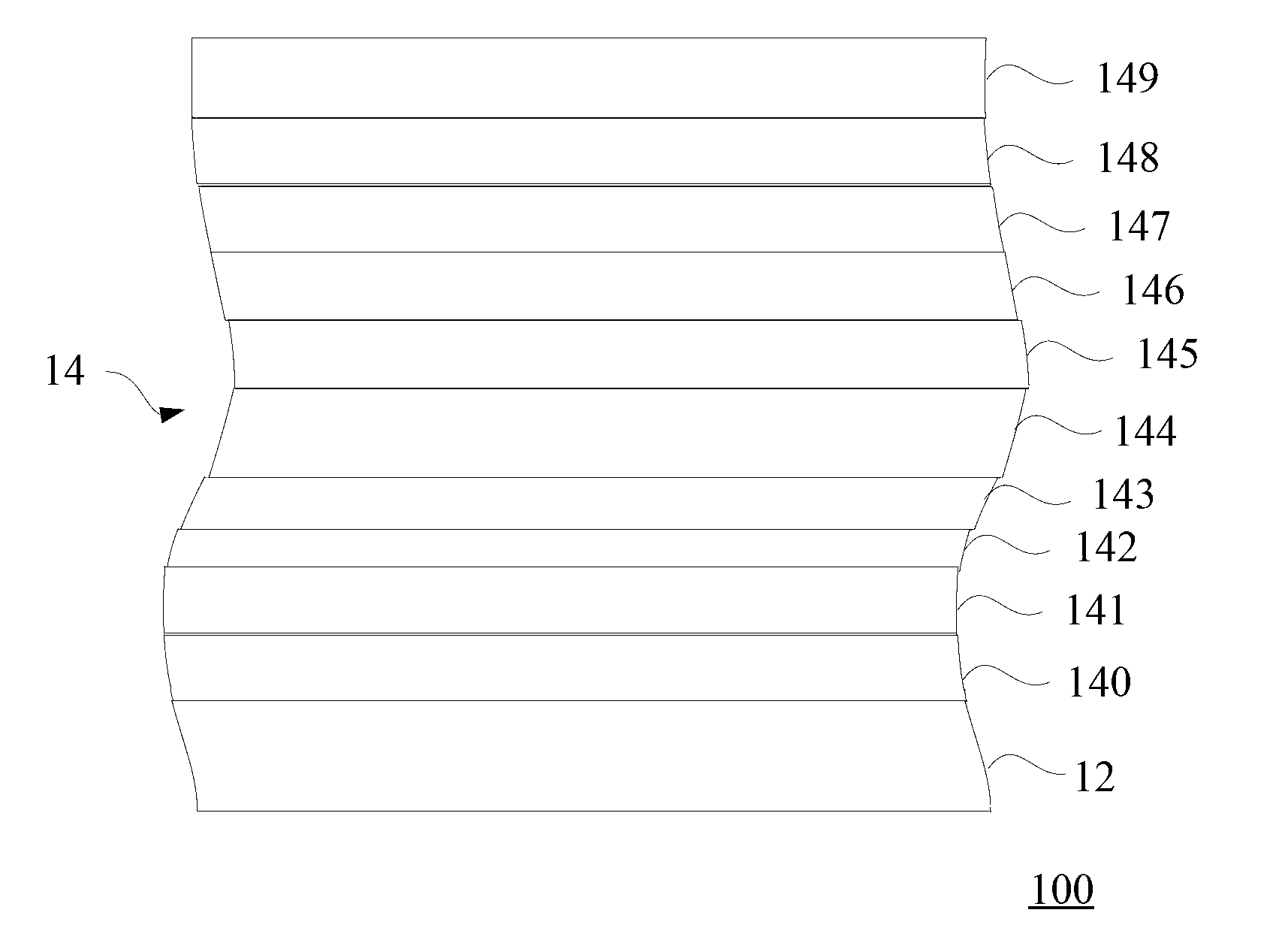

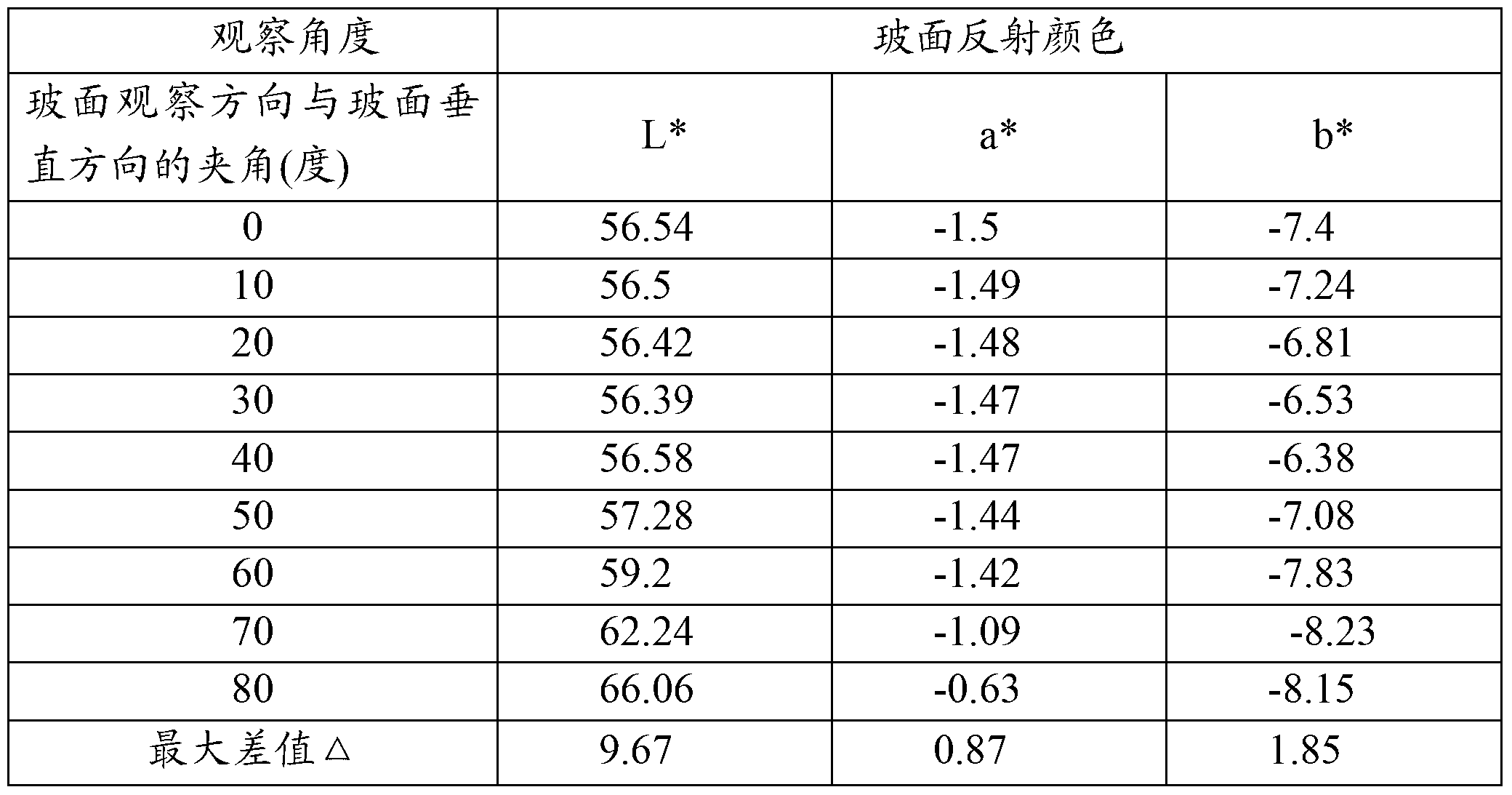

Infrared ray shielding glass with front surface and side surface having consistent reflection hues

The invention relates to a piece of infrared ray shielding glass with a front surface and a side surface having consistent reflection hues. The infrared ray shielding glass comprises a glass substrate and an infrared ray shielding film structure formed on the surface of the glass substrate, wherein the film structure sequentially comprises a first composite medium layer, a bottom infrared ray shielding layer, a first protective layer, a second composite medium layer, an infrared ray shielding mixing layer, a second protective layer, a third composite dielectric layer, a top infrared ray shielding layer, a third protective layer and a fourth composite dielectric layer from the glass substrate to the outside, wherein the thickness of the bottom infrared ray shielding layer is less than that of the top infrared ray shielding layer, and the thickness of the top infrared ray shielding layer is less than that of the infrared ray shielding mixing layer. The infrared ray shielding glass has an excellent infrared ray shielding performance and also has the advantages that the front surface and the side surface of the glass have the consistent reflection hues.

Owner:CSG HOLDING

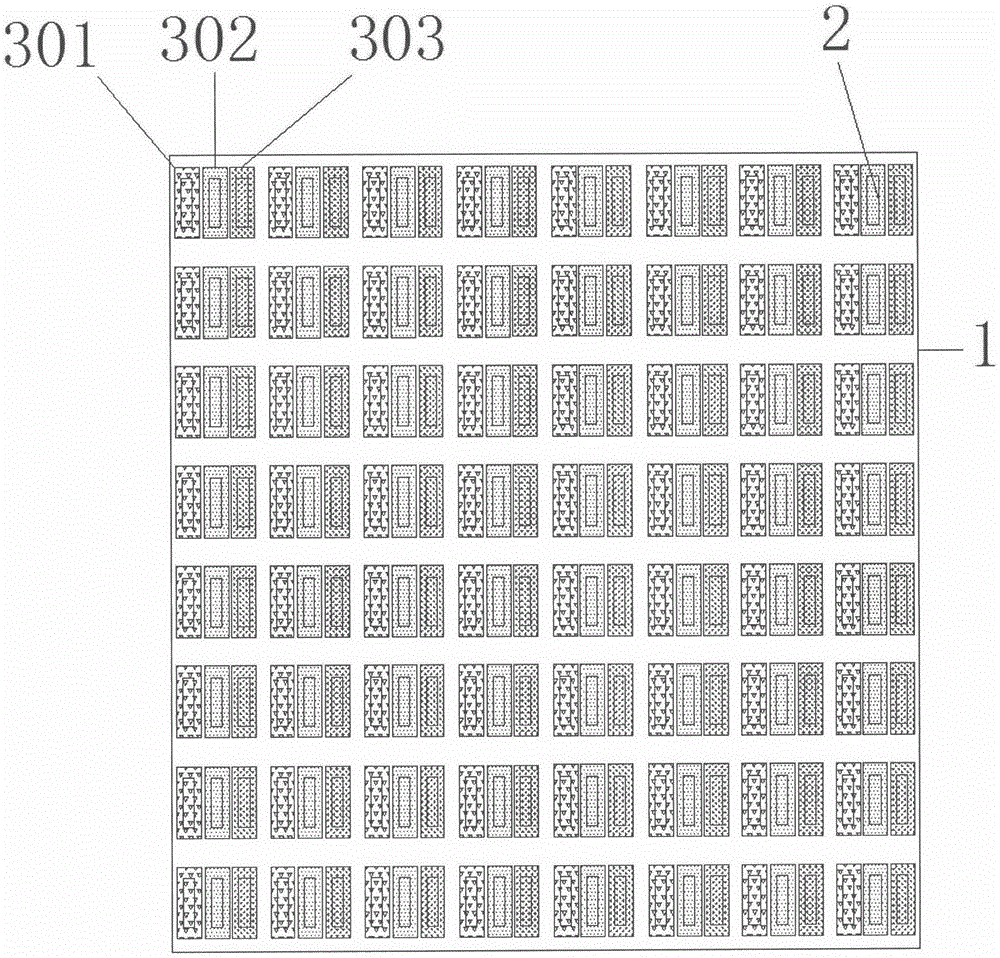

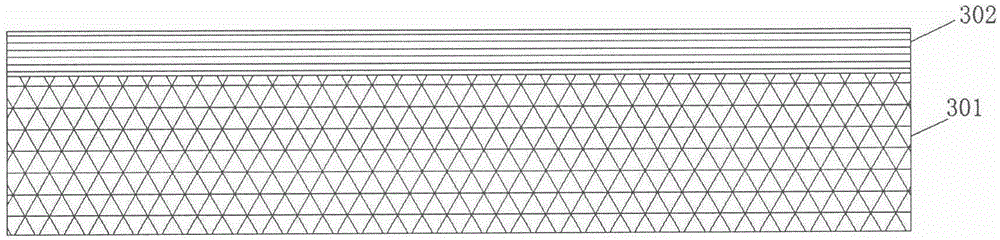

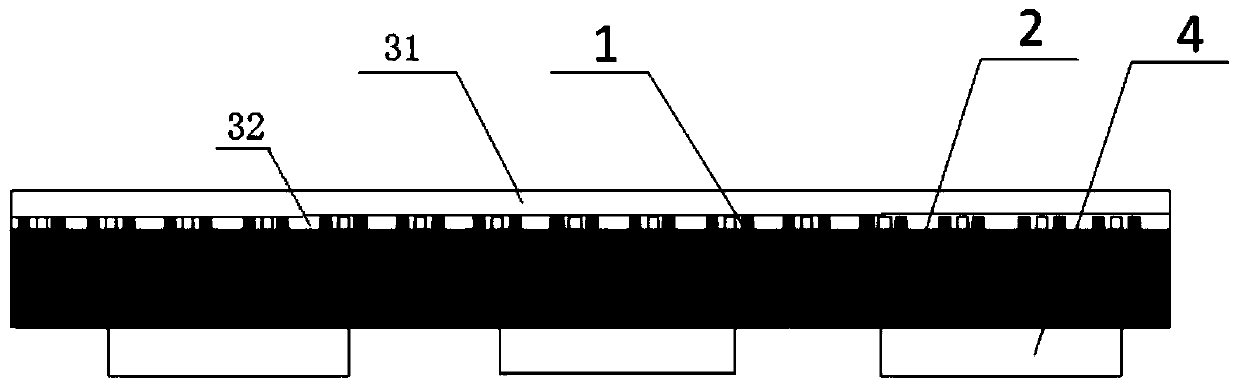

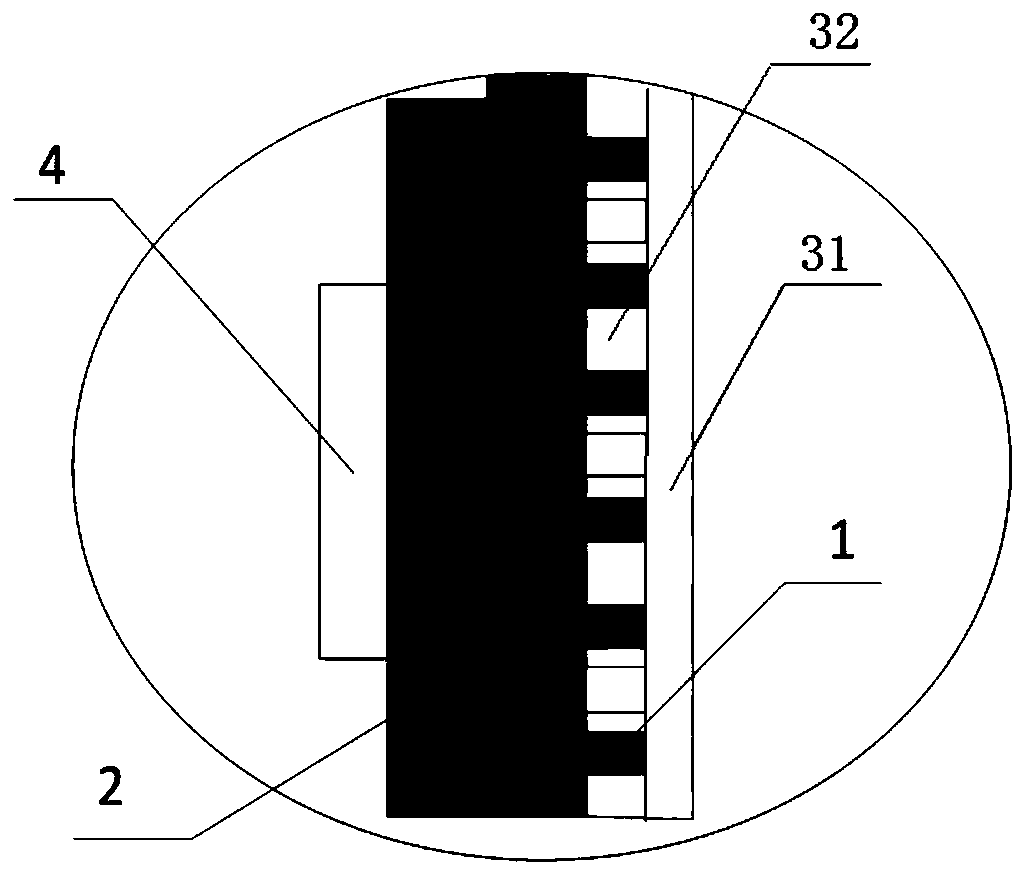

Thin film packaged LED display array module

The invention relates to a thin film packaged LED display array module. The module is formed by splicing a plurality of LED display modules, wherein the LED display module comprises a driving IC, a display substrate and an LED wafer; the driving IC is welded to the rear surface of the display substrate; the LED wafer is fixed on the front surface of the display substrate; at least one layer of thin film is further packaged on the front surface of the display substrate; and the total thickness of the thin film is 0.1-0.8 mm. The LED display array module has the advantages of large visual angleand high color consistency, meanwhile, a traditional glue filling or die pressing packaging process is omitted, a production process is simplified, the cost is reduced, and meanwhile, a splicing gap is favorably further reduced.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

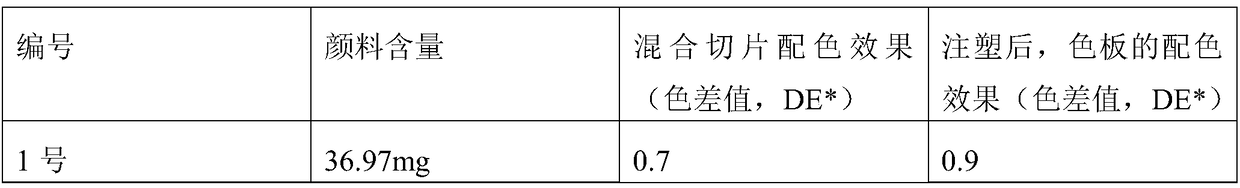

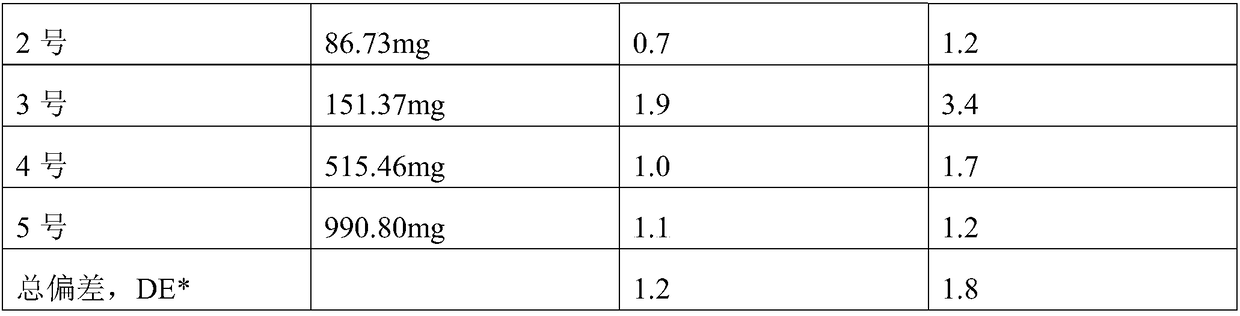

Plastic color matching process

The invention discloses a plastic color matching process, which comprises the following steps: (1) weighing plastic particles, adding the plastic particles into a high mixing machine, adding a dispersant and a pigment, and uniformly mixing the particles, the dispersant and the pigment; (2) at least setting four groups according to the process in Step (1), wherein the concentrations of the dispersants of the groups are the same, and the concentrations of the pigments of the groups are different; (3) respectively detecting the mixing uniformity of each group of test sample with a color measuringand matching instrument, wherein each test sample is detected for at least three times to obtain a corresponding color difference value; (4) performing automatic color matching fitting on each groupof test sample with color matching software of the color measuring and matching instrument to obtain a fitted color difference value; (5) performing injection molding: performing injection molding oneach group of test sample with the fitted color difference value less than or equal to 2; and (6) performing automatic color matching fitting on an injection molding color plate with the color matching software, thus obtaining a total color difference value. The process disclosed by the invention can save the time and the raw material cost, and guarantees the color matching quality.

Owner:GUANGDONG XINHUI MEIDA NYLON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com