360-degree lighting bulb and processing method thereof

A technology of light bulbs and light-emitting chips, which is applied to semiconductor devices of light-emitting elements, optical elements used to change the spectral characteristics of emitted light, light sources, etc. Low efficiency and other problems, to achieve the effect of good color consistency, uniform luminescence, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

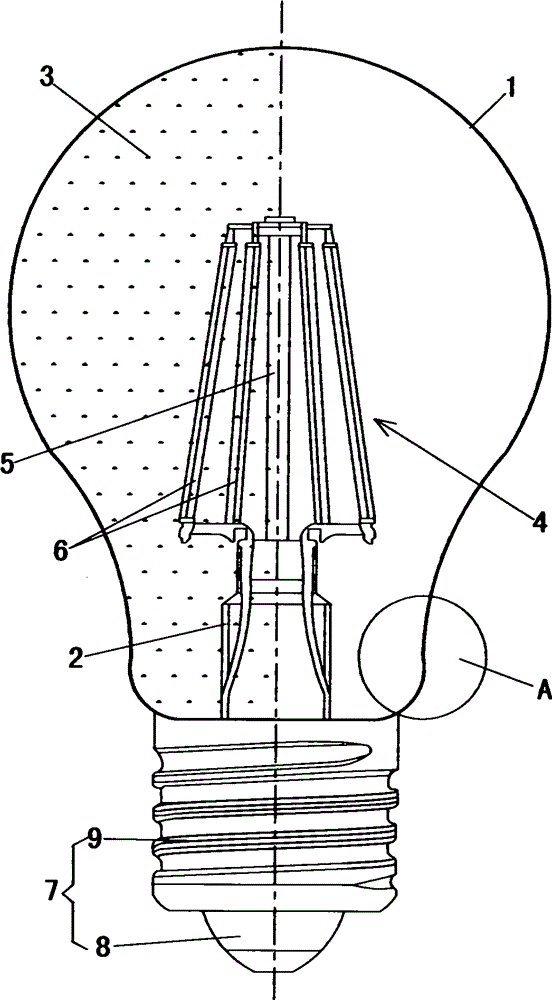

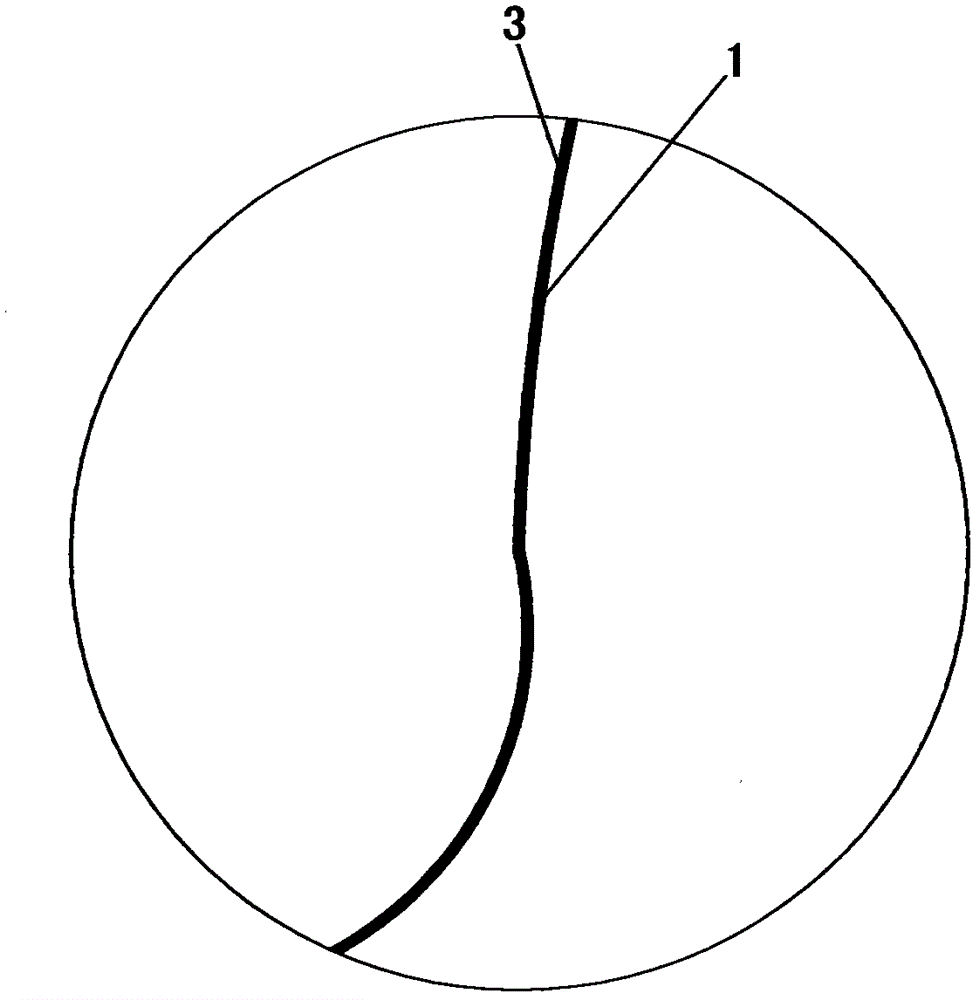

[0024] Such as figure 1 As shown, the 360° light-emitting bulb of the present invention includes a glass cover 1 and a stem 2 with a bell mouth and conductive lead wires. The glass cover 1 is one of a transparent cover, an opalescent cover, a dyed cover, a reflective cover, a frosted cover, a lens type cover or a water chestnut cover. The shape of the glass cover 1 is one of candle shape, T shape, A shape, G shape, BR shape or PAR shape, and this embodiment chooses candle shape. The mouth of the glass cover 1 is welded to the bell mouth of the stem 2 to form a vacuum sealed cavity. The vacuum sealed chamber is filled with heat dissipation gas, which may contain hydrogen, helium, nitrogen, or a gas with heat dissipation effect or a mixed gas with heat dissipation effect. combine figure 2 As shown, the inner wall of the glass cover 1 is coated with a phosphor layer 3, and a 360° light-emitting element 4 is arranged inside the glass cover 1. The 360° light-emitting element 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com